Quantum dot diaphragm, optical element, backlight module group and preparation method

A quantum dot film and quantum dot technology, applied in the display field, can solve problems such as difficult to control the uniformity of thickness, and achieve the effect of convenient preparation, good uniformity, and thin size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

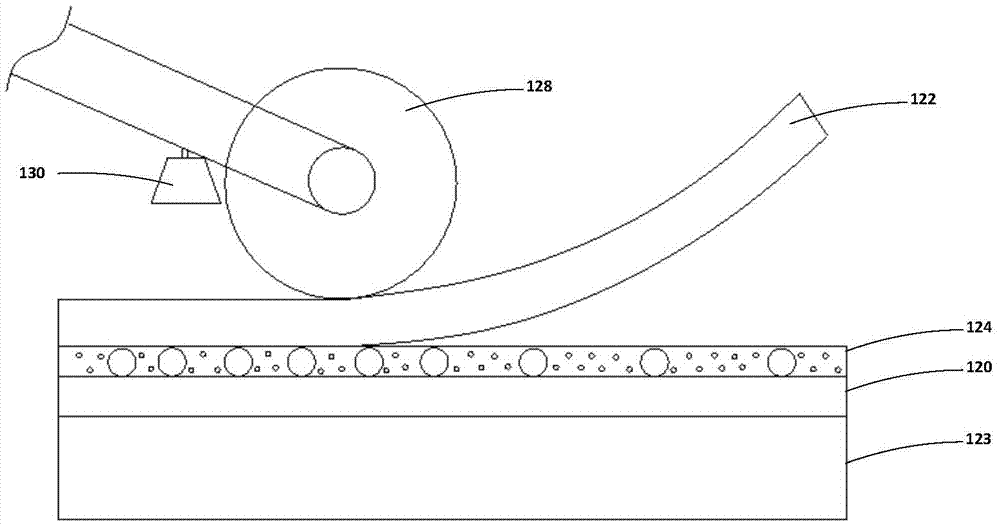

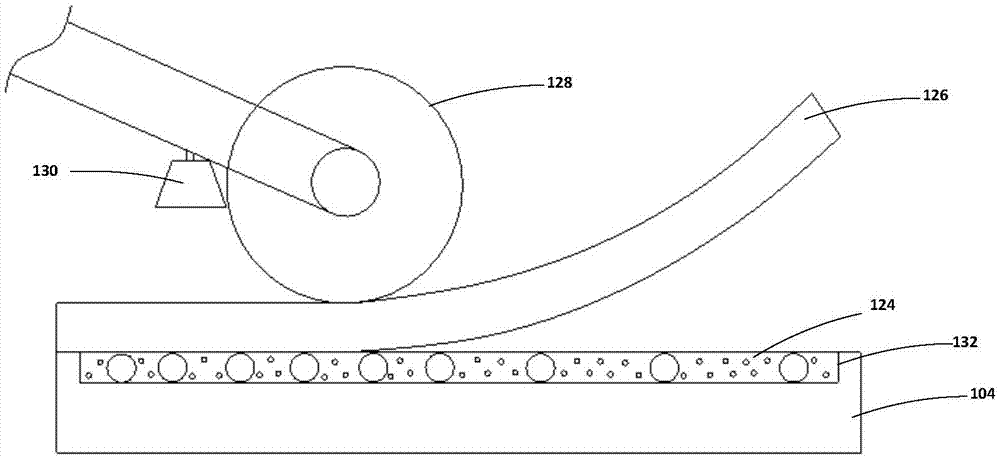

[0042] The present invention also discloses a method for preparing a quantum dot membrane 110, which includes the following steps: a) making a liquid matrix uniformly dispersed with quantum dots 116 and microstructures 118 with a predetermined particle size form a coating 124; b) utilizing the microstructure The body 118 acts as an underlayment to condition the coating 124 to a predetermined thickness and cure.

[0043] In order to disperse the microstructures 118 uniformly in the liquid matrix without affecting the dispersion of the quantum dots, the mass fraction of the microstructures 118 in the liquid matrix or the quantum dot layer 112 ranges from 0.5% to 5%.

[0044]Liquid substrates include, but are not limited to, polymer material precursors. The curing method of the liquid matrix includes at least one of light curing, heat curing, pressure curing and natural curing. In a preferred embodiment, the liquid matrix is UV glue, including but not limited to one of silicon...

Embodiment 1

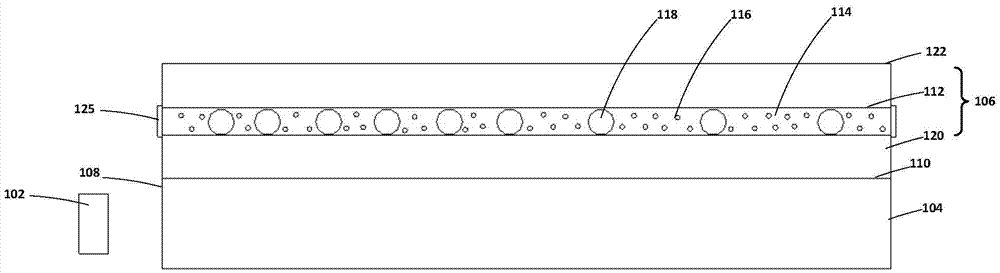

[0051] A backlight module 100 includes a light source 102 , a light guide plate 104 and a quantum dot film 106 . The light guide plate 104 includes a light incident surface 108 and a light exit surface 110 , the light source 102 is adjacent to the light incident surface 108 , and the quantum dot film 106 is adjacent to the light exit surface 110 . The quantum dot film 106 includes a first barrier film 120, a second barrier film 122 and a quantum dot layer 112 therebetween. The quantum dot layer 112 is a polyacrylic polymer material uniformly dispersed with quantum dots 116 and glass microspheres. The particle size of the glass microspheres is 20 microns, and the thickness of the quantum dot layer is 25 microns.

Embodiment 2

[0053] A preparation method with a thickness of 225 micron quantum dot film specifically comprises the following steps: 1) adding mass fraction of 20% quantum dots and 1% polystyrene microspheres to UV glue, stirring evenly, Forming a quantum dot dispersion, wherein the particle size of polystyrene is 25 microns; 2) coating the above-mentioned quantum dot dispersion on the flat surface of the first barrier film with a thickness of 100 microns to form a coating, and the coating thickness is not less than 50 microns ; 3) the second barrier film with a thickness of 100 microns is placed on the coating surface, and the second barrier film is rolled by a rolling machine, and the rolling pressure is constant; 4) an ultraviolet lamp is set on the back side of the rolling machine, At the same time, the area that has just been rolled is cured by an ultraviolet lamp; 5) The edge is sealed with a sealant to form a quantum dot membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com