Patents

Literature

479 results about "Smoke paper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

While smoking paper is not as hazardous as smoking tobacco, any type of smoke inhalation is still unhealthy. Smoking paper with ink or other chemicals on it is more hazardous than smoking untreated paper.

Smoking paper for smoking article

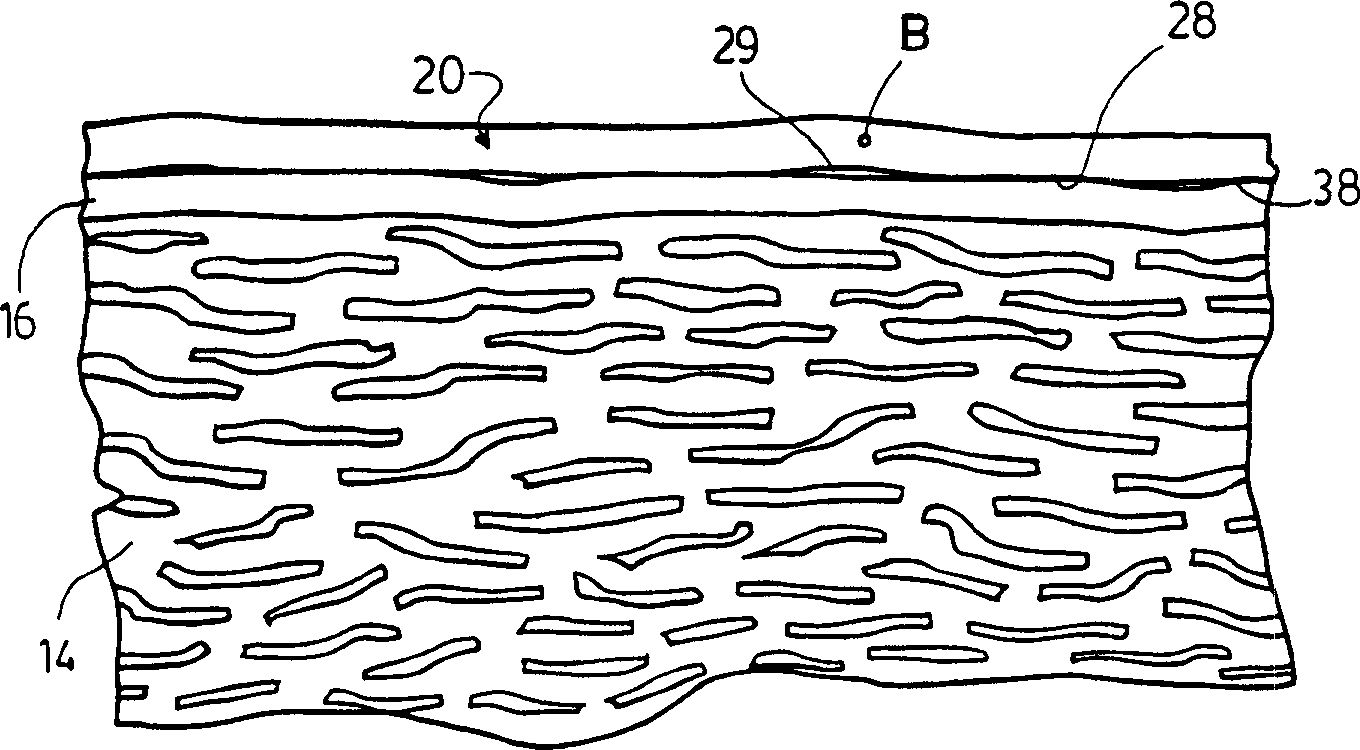

InactiveUS6138684AReduce decreaseExcellent in optical characteristicTobacco preparationNon-fibrous pulp additionPulp and paper industrySmoke paper

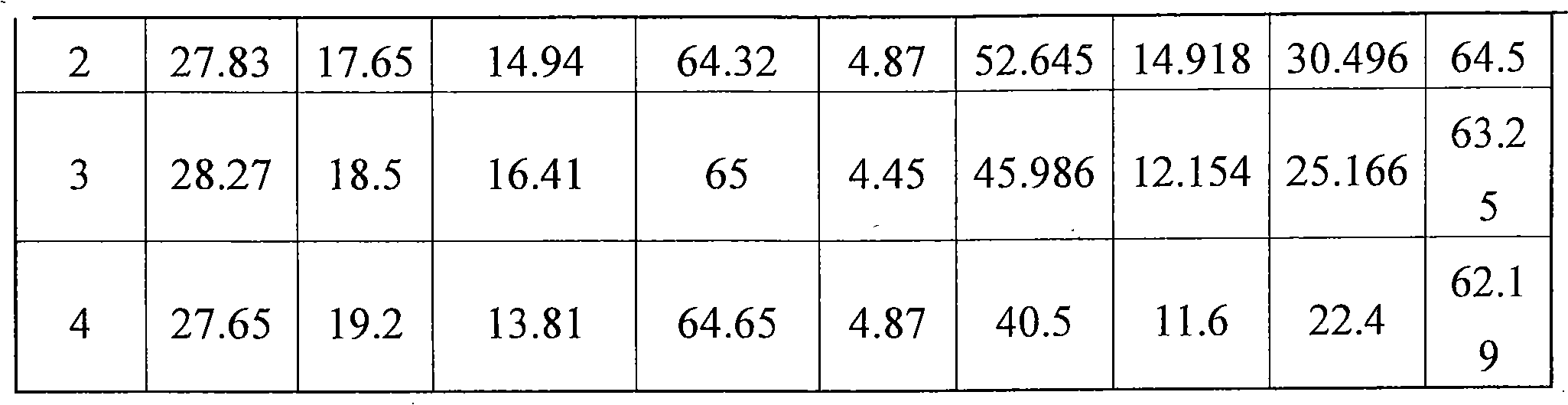

PCT No. PCT / JP96 / 01630 Sec. 371 Date May 7, 1997 Sec. 102(e) Date May 7, 1997 PCT Filed Jun. 14, 1996 PCT Pub. No. WO97 / 09483 PCT Pub. Date Mar. 13, 1997The paper for rolling a smoking article of the present invention contains particle-form calcium carbonate (30 to 60 wt %), calcined clay (5 to 30 wt %) and pulp. Furthermore, an alkaline metal salt is contained as a chemical additive. In addition, kaolin is contained in the paper. The basis weight of the paper falls within the range of 20 to 70 g / m2. Optical characteristics of the paper and the burning characteristics and ash characteristics of a cigarette are improved and the side stream smoke is reduced.

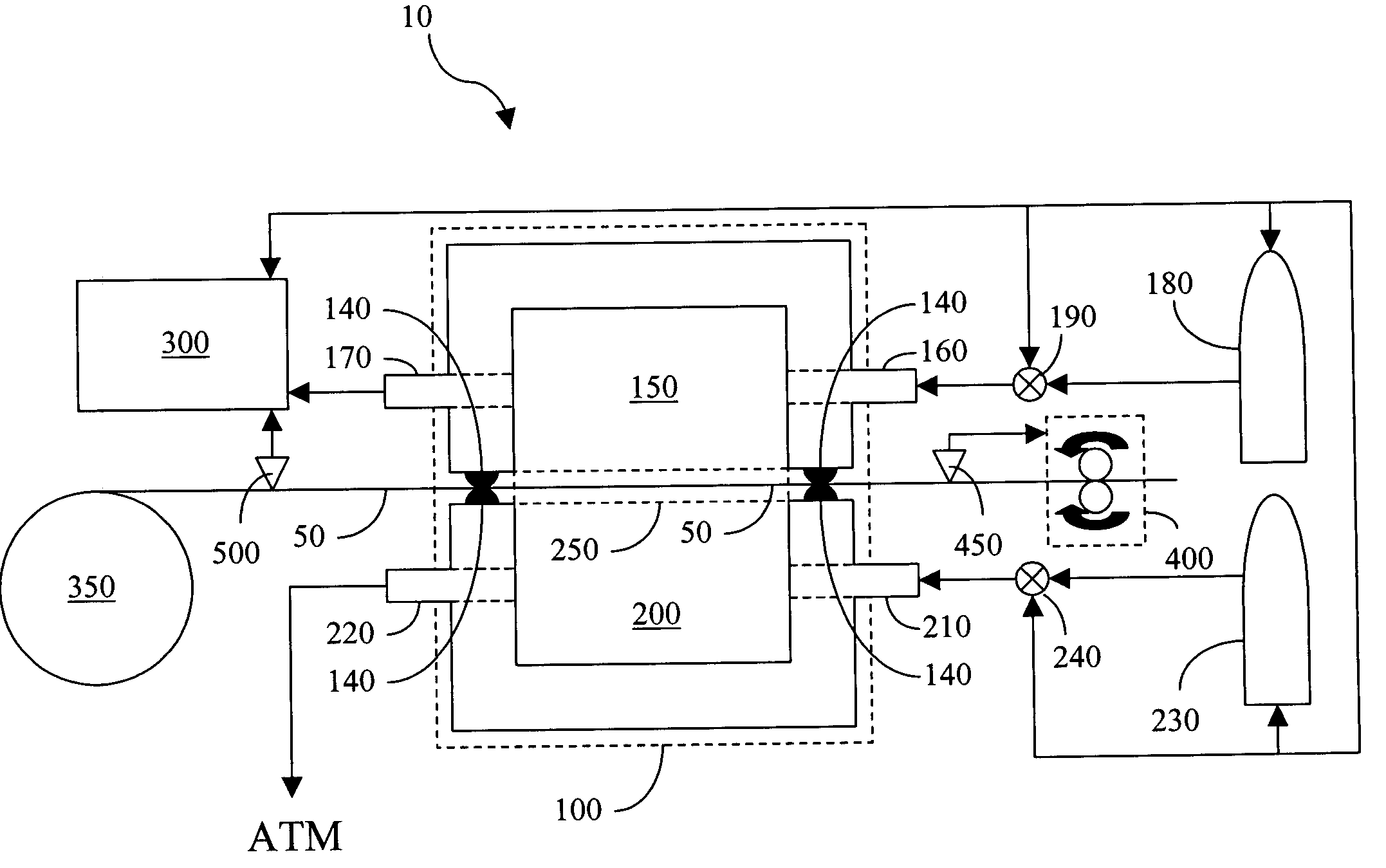

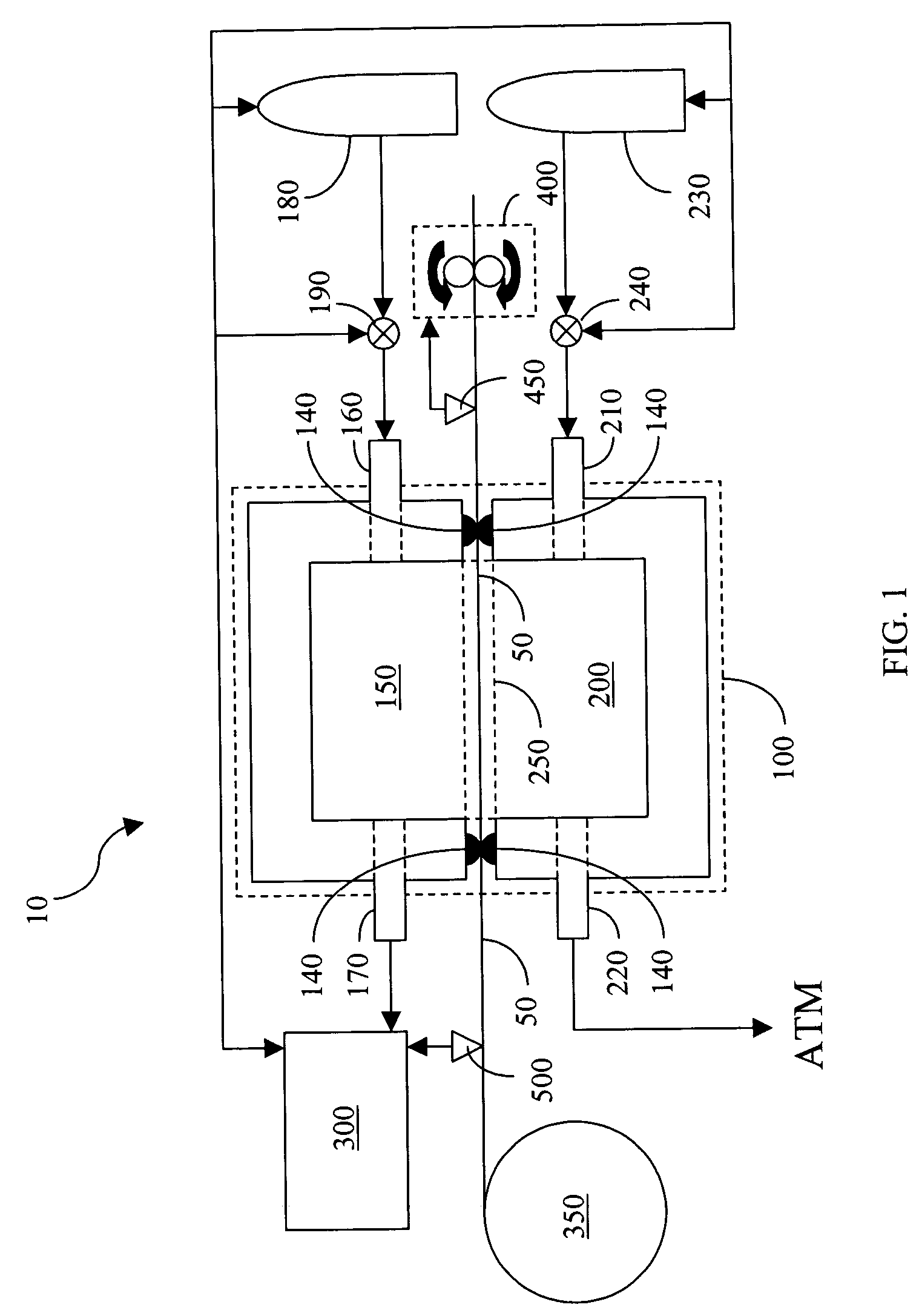

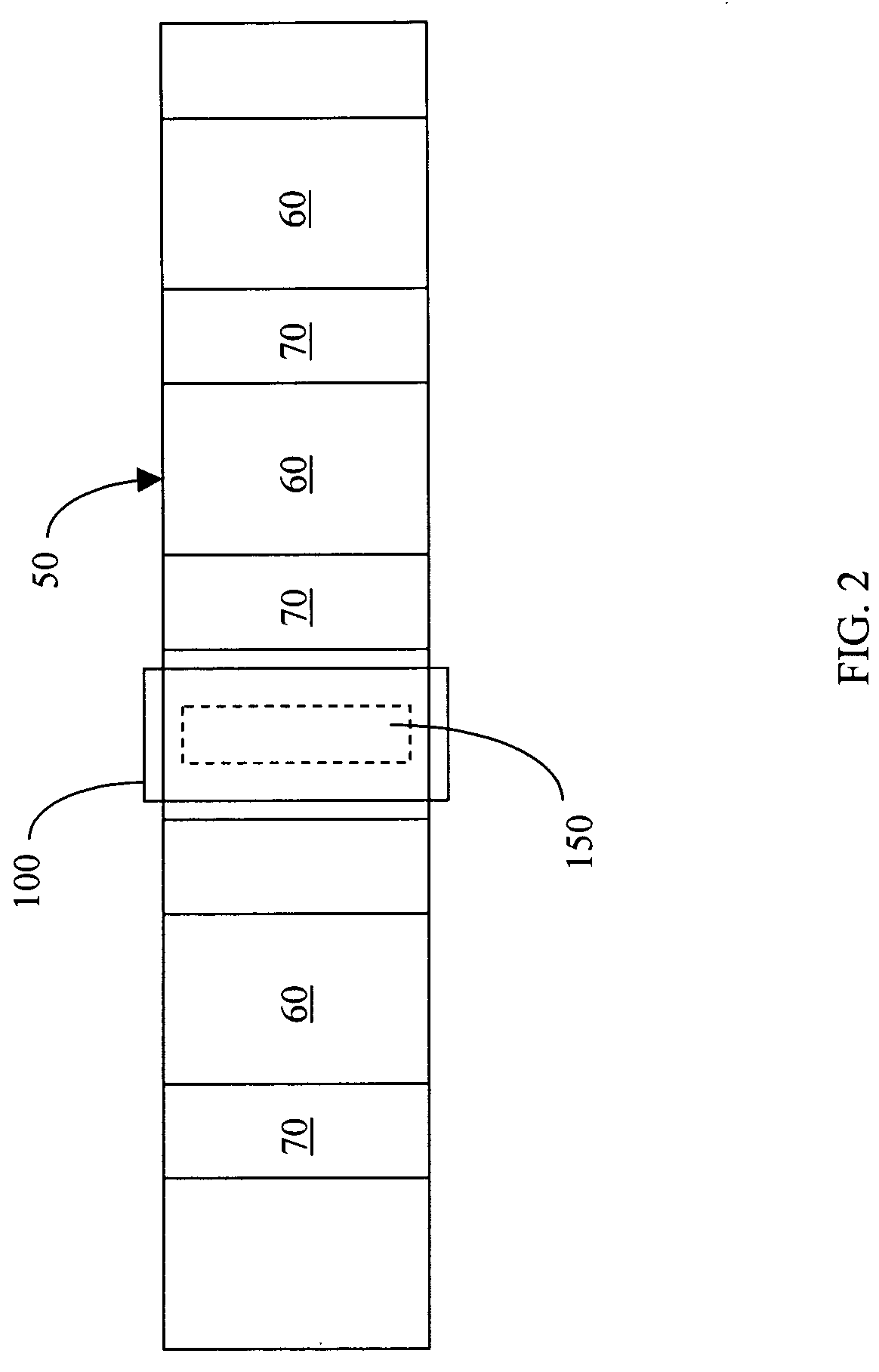

Apparatus for measuring a property of a cigarette paper wrapper and associated method

An apparatus for measuring a property of a cigarette paper wrapper is provided and includes a sampling device having a first chamber portion capable of being engaged with a corresponding second chamber portion to define a sampling area configured to receive the wrapper such that the wrapper spans the sampling area and separates the chamber portions. A first gas source supplies a carrier gas to the first chamber portion and a second gas source supplies a detectable gas to the second chamber portion. An analyzer device in communication with the first chamber portion receives a resultant gas flow that includes the carrier gas and any of the detectable gas entering the first chamber portion through the wrapper. The analyzer device is capable of determining an amount of the detectable gas in the resultant gas flow so as to thereby determine a property of the cigarette paper wrapper, such as a diffusion coefficient with respect to the detectable gas. An associated method is also provided.

Owner:SODIM INSTR

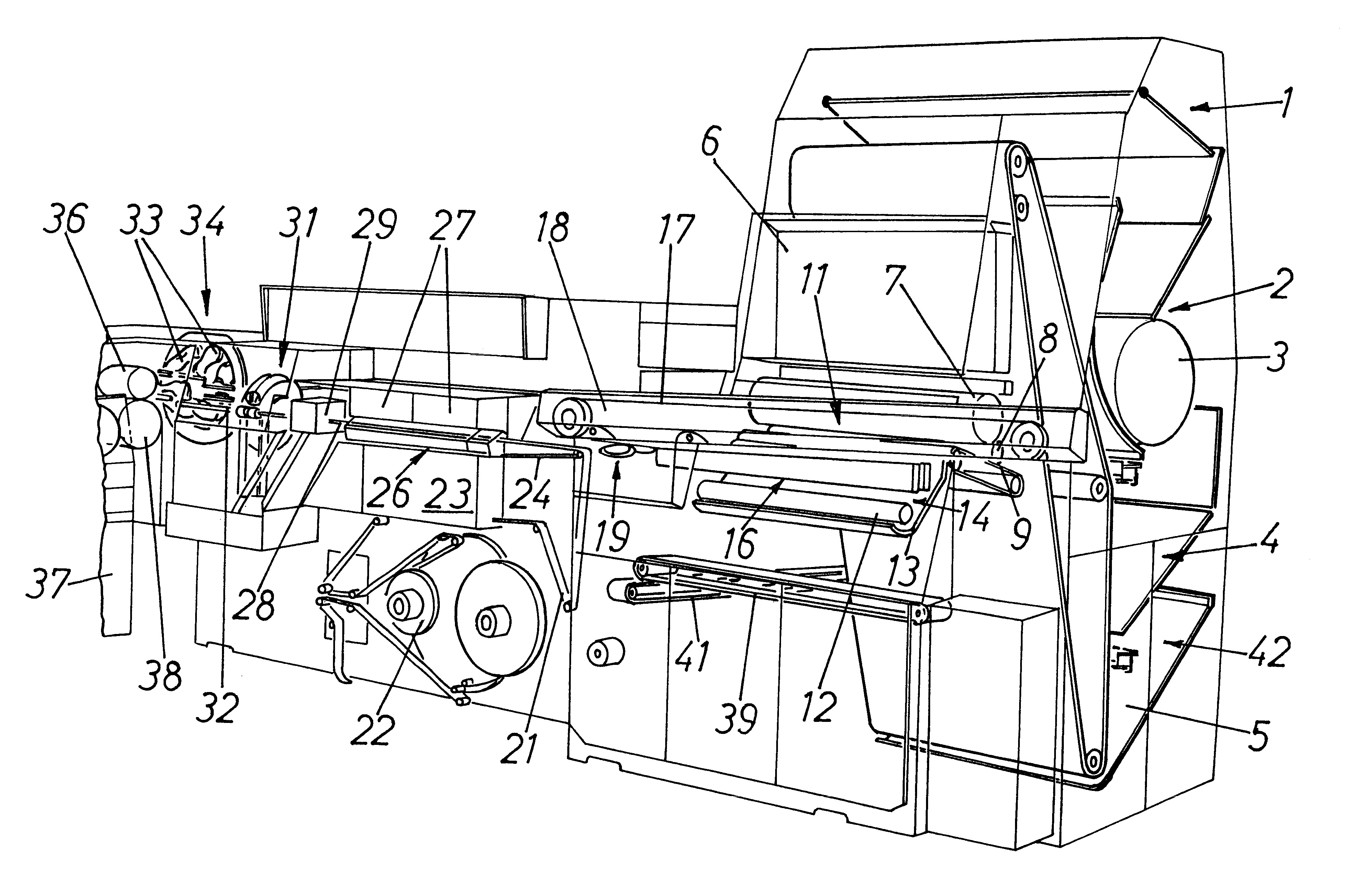

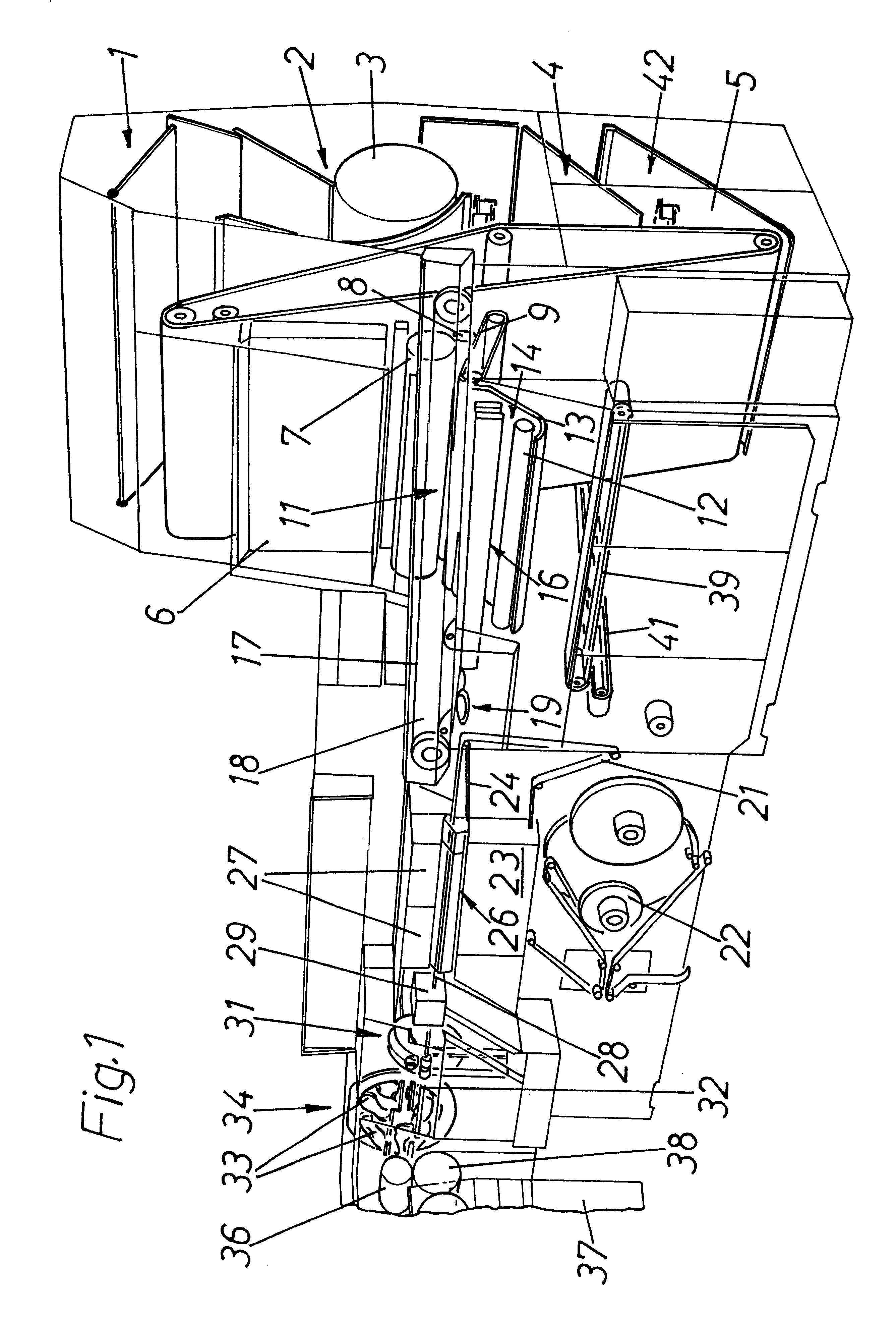

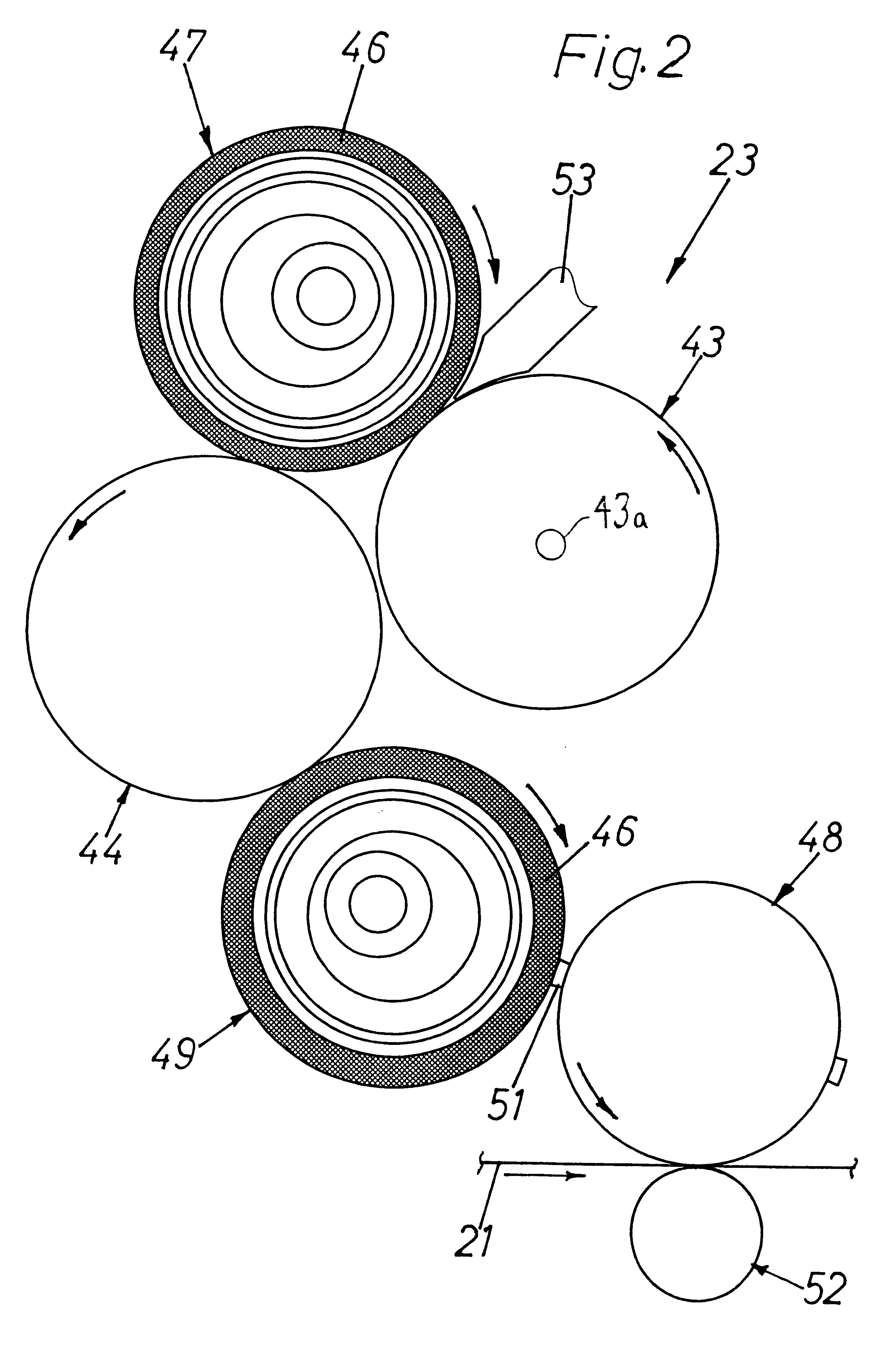

Apparatus for applying printed matter to webs of wrapping material for smokers' products

Owner:HAUNI MASCHINENBAU AG

Colorized cigarette paper and preparation method

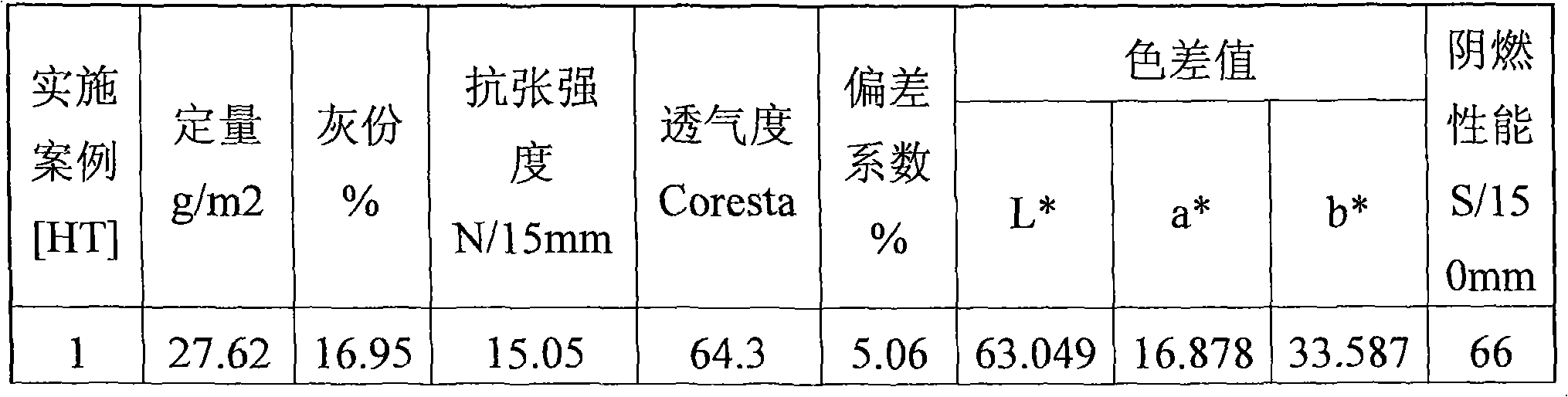

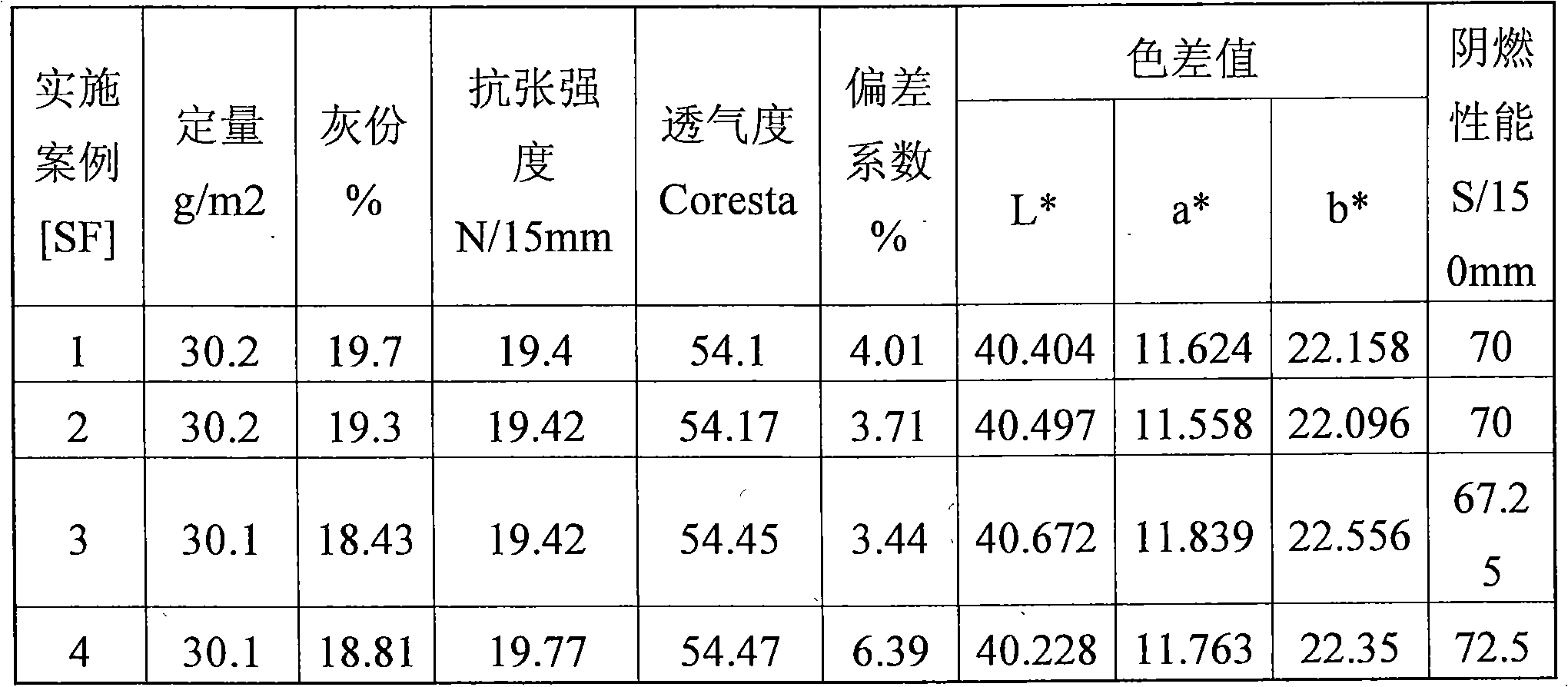

The invention discloses colorized cigarette paper, which mainly comprises the following components in part by weight: 55 to 70 parts of fiber, 30 to 45 parts of filler, 0.5 to 8 parts of combustion improver and 0.5 to 30 parts of cigarette paste, wherein the cigarette paste comprises the following components in part by weight: 1 to 8 parts of tobacco extract, 0.05 to 4.0 parts of natural extract, 0.001 to 0.05 part of edible pigment and the balance of water. The invention also discloses a preparation method for the colorized cigarette paper, which comprises the following steps of: (1) preparing combustion improver solution; (2) preparing dyeing solution; and (3) respectively adding the combustion improver solution and the dyeing solution prepared in the steps (2) and (3) into the cigarette paper by using a sizing machine for dyeing. The colorized cigarette paper and the preparation method thereof have the advantages that: the color of the cigarette paper is close to the original color of tobacco, so that the colorized cigarette paper has a more natural feel; and the preparation method can be used for production without any change of the production process for the conventional cigarette paper production equipment.

Owner:云南红塔蓝鹰纸业有限公司

Method for tobacco slice cigarette paper coloring by adopting Millard reaction

Disclosed is a method for tobacco slice cigarette paper coloring with Millard reaction. The method comprises the following steps: (1) tobacco patches or stems are put into hot water with temperatures from 40 degrees to 70 degrees and extracted for 20 minutes-40 minutes, and extract liquor is obtained. (2) The extracted tobacco patches or the stems are put into the hot water with 1 to 3 times total weight of the tobacco patches or the stems after being shoved initially by a shoving machine. The temperature of the hot water is controlled at 45 DEG C + / - 5 DEG C. The tobacco patches or the stems are extracted for 20 minutes. The tobacco patches or the stems are pulped from 25 degrees SR to 40 degrees SR by the pulping machine after the tobacco patches or the stems are shoved, thus tobacco syrup is obtained. (3) Additional fibers are pulped by the pulping machine to 40 degrees SR to 75 degrees SR. Cigarette paper is mixtured by mixturing the additional fibers and the tobacco syrup. (4) Extracted liquors are concentrated after the extracted liquors are combined. Sylvite, compound Millard reaction liquid and spices are added to the concentrated extracted liquors and made into coating liquid. The coating liquid is coated on the cigarette paper with the way of coating. (5) The coated cigarette paper is put under temperature condition of from 70 DEG C to 130 DEG C to conduct the Millard reaction.

Owner:HUBEI XINYE TOBACCO SLICE DEV +1

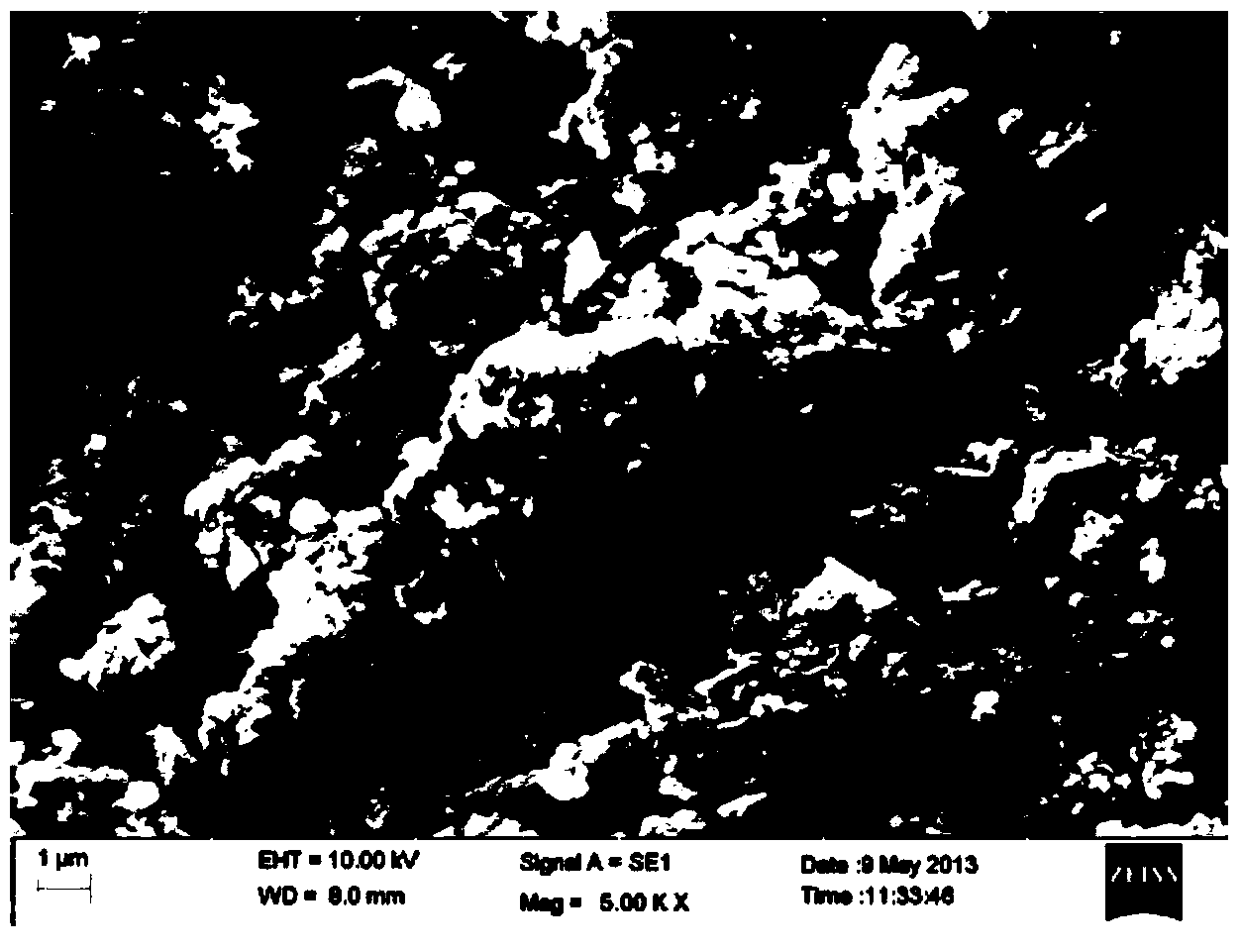

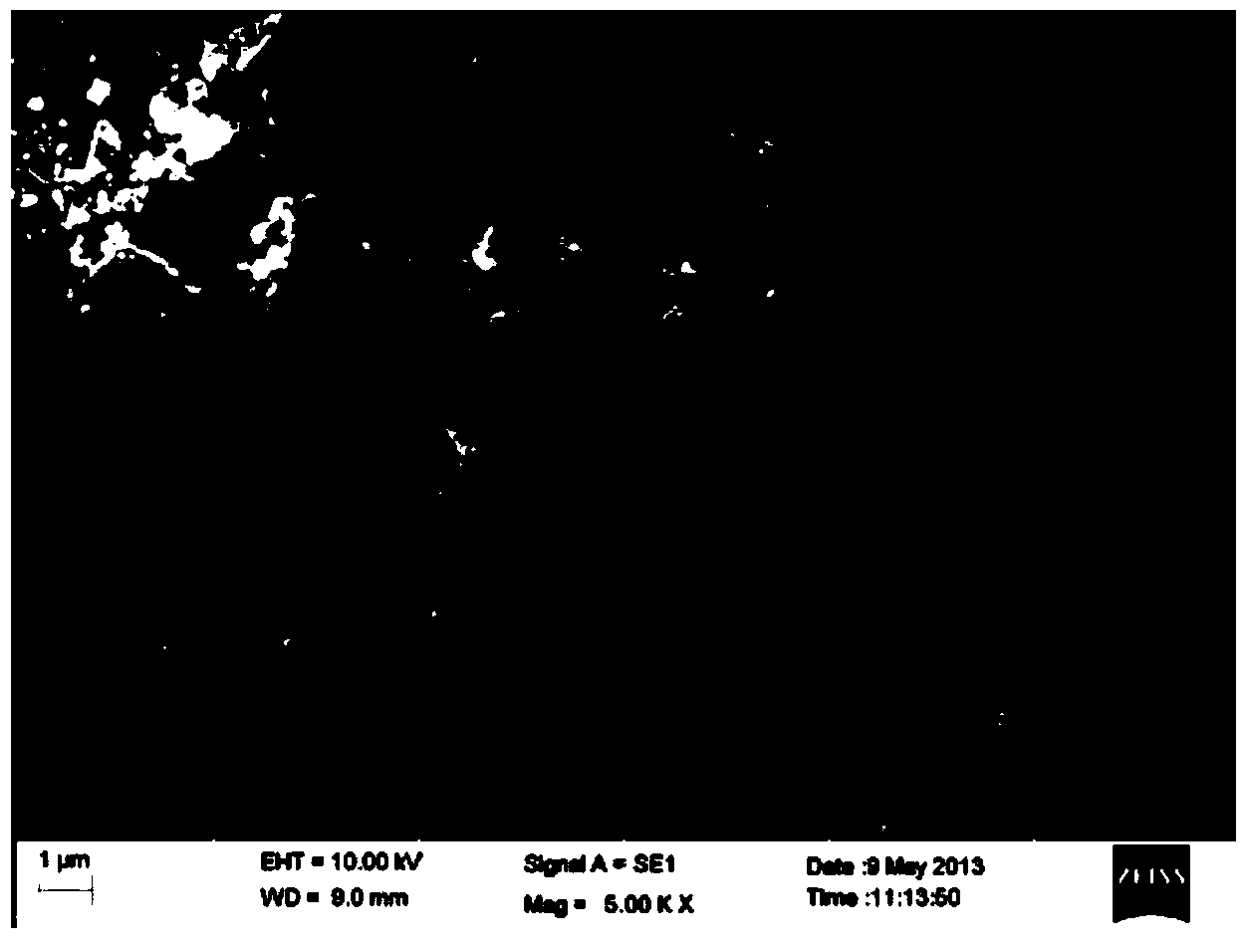

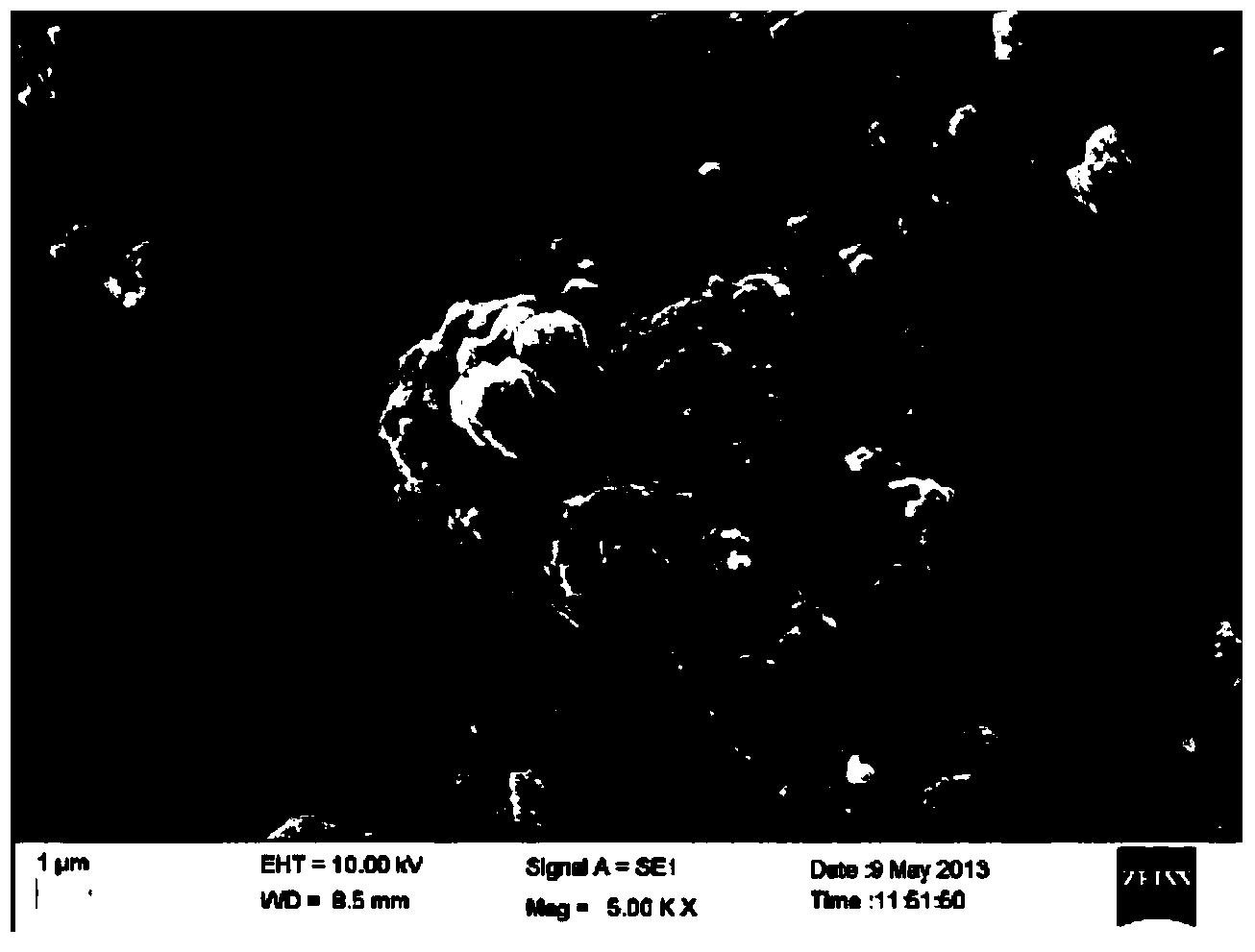

Cationization modification method for nano-crystalline cellulose and preparation method of high-strength cigarette paper

ActiveCN102180979ALess investmentHigh strengthReinforcing agents additionPaper/cardboardFiberReaction temperature

The invention belongs to the field of production of special paper, and in particular relates to a cationization modification method of nano-crystalline cellulose and a method for preparing high-strength cigarette paper from the modified nano-crystalline cellulose. Specific to the characteristic of high specific surface area of nano-crystalline cellulose, KOH and a method for adding an etherification reaction accelerant are adopted, the reaction temperature is lowered below 50 DEG C, cationization modification is performed on the nano-crystalline cellulose, and the modified nano-crystalline cellulose has the characteristics of retention and enhancement, so that the modified nano-crystalline cellulose has a wider application prospect; in the method for preparing cigarette paper, softwood pulp is not used, and higher natural air permeability and higher bonding strength of a product are ensured under the condition of reducing broadleaf wood fiber devillicate and fibrillation, so that energy consumption in the production process of paper, in particular in the pulping process, is remarkably lowered, equipment investment of a paper mill is reduced, high-strength cigarette paper is manufactured, the page quality is improved, higher strength and air permeability of the product are achieved, and the requirements on energy conservation and emission reduction are met.

Owner:MUDANJIANG HENGFENG PAPER CO LTD

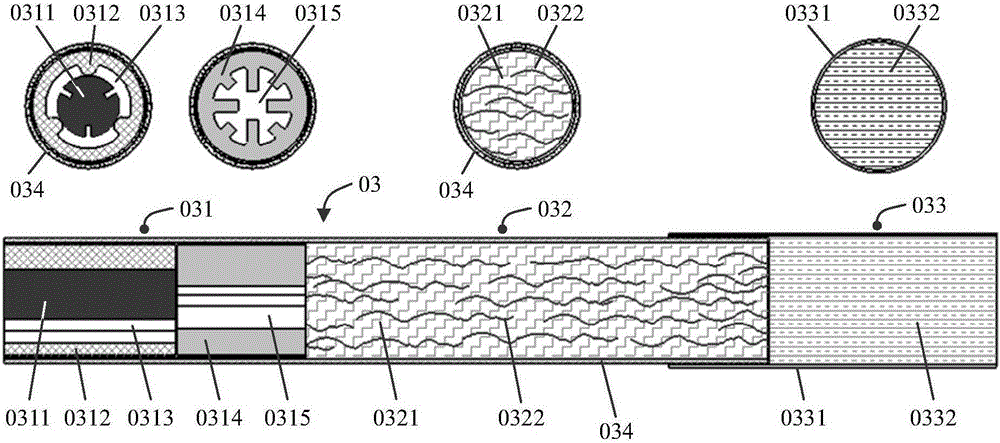

Non-combustion type low temperature cigarette product based on phase change temperature-controlled fuel assembly and preparation method of aerosol generating section

InactiveCN105167182AAvoid conduction heatingLow conduction heatingCigar manufactureFiberProduct base

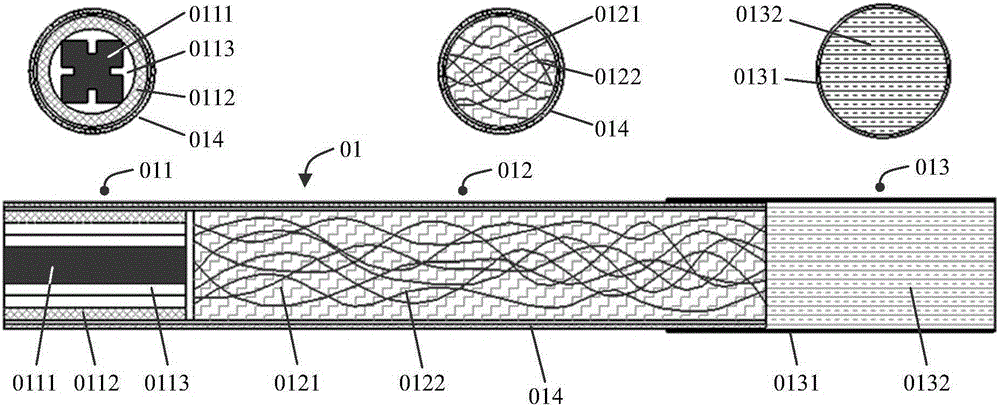

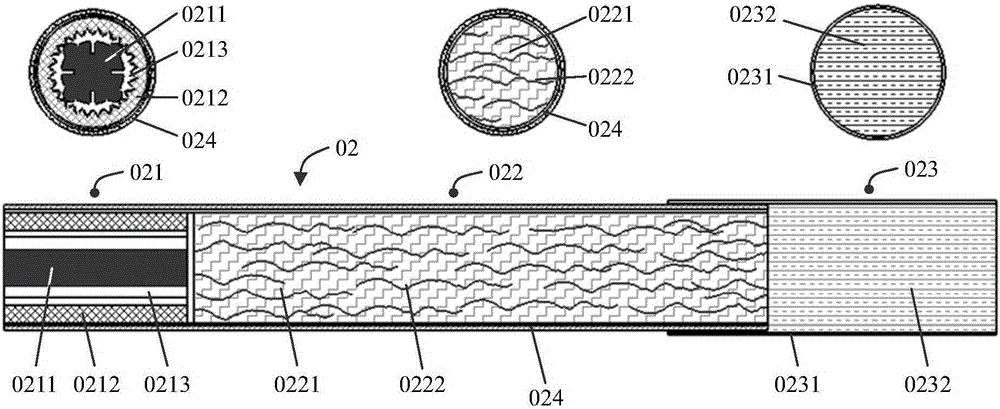

The invention relates to a non-combustion type low temperature cigarette product based on a phase change temperature-controlled fuel assembly. The cigarette product comprises a phase change temperature-controlled fuel assembly section, an aerosol generating section and a filter section which are sequentially connected. Energy released in a combustion process is transmitted to the aerosol generating section through mainstream smoke, and under the action of a phase change heat storage material, adsorbing purification and oxidation catalysis on CO are achieved, so that unexpected pyrolysis on a smoke matrix due to excessive temperature is avoided. The aerosol generating section is prepared by uniformly blending and mixing the smoke matrix and high-thermal-conductivity MPCF carbon fiber long filaments or short filaments, so that the temperature of an aerosol generating system is reduced in a gradient mode in the axial direction of the cigarette and the entire aerosol generating section is uniformly heated; therefore, a smoking experience is prevented from being rapidly decreased with increase in smoking times. The phase change temperature-controlled fuel assembly section and the aerosol generating section are integrally covered and rolled by virtue of heat-insulating cigarette paper, so that consumption of heat energy is reduced, and effective thermal excitation of the smoke matrix is achieved under relatively low heat distribution.

Owner:叶菁 +2

Composite additive for reducing harmful constituents in cigarette smoke gas and use thereof

InactiveCN101015391ASimple processEasy to manufactureTobacco treatmentNitriteComponents of crude oil

The invention discloses a composite additive and application, which is composed of tobacco extract, alkaline metal salt and metal hydroxide to reduce harmful component such as amine nitrite, condensed-nuclei aromatics and carbon monoxide. The composite additive is fit for cigarette, which can modify and improve the quality of cigarette.

Owner:YUNNAN RES INST OF TOBACCO SCI +1

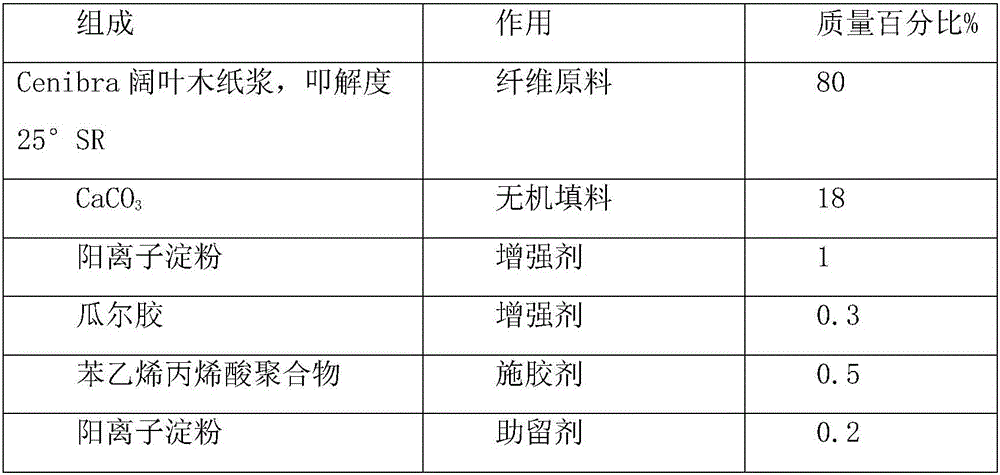

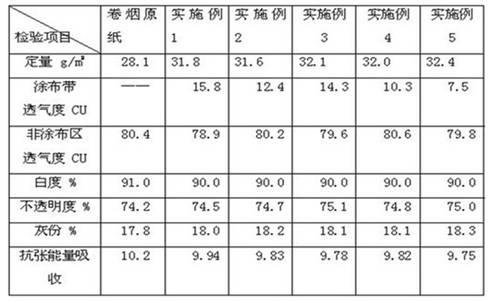

A kind of production method of tobacco sheet cigarette paper

ActiveCN102277780AImprove taste qualityReduce woodinessNon-fibrous pulp additionCoated paper substrateFiberIrritation

The invention relates to a production method of tobacco sheet cigarette paper. The method comprises the following steps of: (1) adding tobacco leaf pieces or tobacco stems into hot water, and extracting at 40-70 DEG C for 20-40 minutes, wherein the adding amount of the hot water is 3-5 times of the weight of the tobacco pieces; (2) primarily extruding the extracted tobacco leaf pieces or tobacco stems with a pulp extrusion machine, then adding hot water of which the amount is 1-3 times of the total weight of the tobacco leaf pieces or tobacco stems, extracting at 45+ / -5 DEG C for 20 minutes, extruding again, and then pulping with a pulping machine until the SR (Schopper-Riegler) degree reaches 25-40; (3) pulping applied fibers with the pulping machine until the SR degree reaches 40-75, mixing with the tobacco pulp, and making cigarette paper, wherein the adding amount of the applied fibers is 0.25-0.5 time of the total weight of the tobacco leaf pieces or tobacco stems; and (4) mixingthe two extraction liquids, then concentrating until the relative density reaches 1.02-1.2 g / cm<3>, adding potassium salts, food pigments and spices, mixing to obtain a coating liquid, and spreading the coating liquid on the cigarette paper. The method provided by the invention can improve the cigarette quality, can reduce the woody smoke of cigarettes and reduce the irritation, and makes naturalsweet taste of tobaccos more predominant.

Owner:HUBEI CHINA TOBACCO IND +1

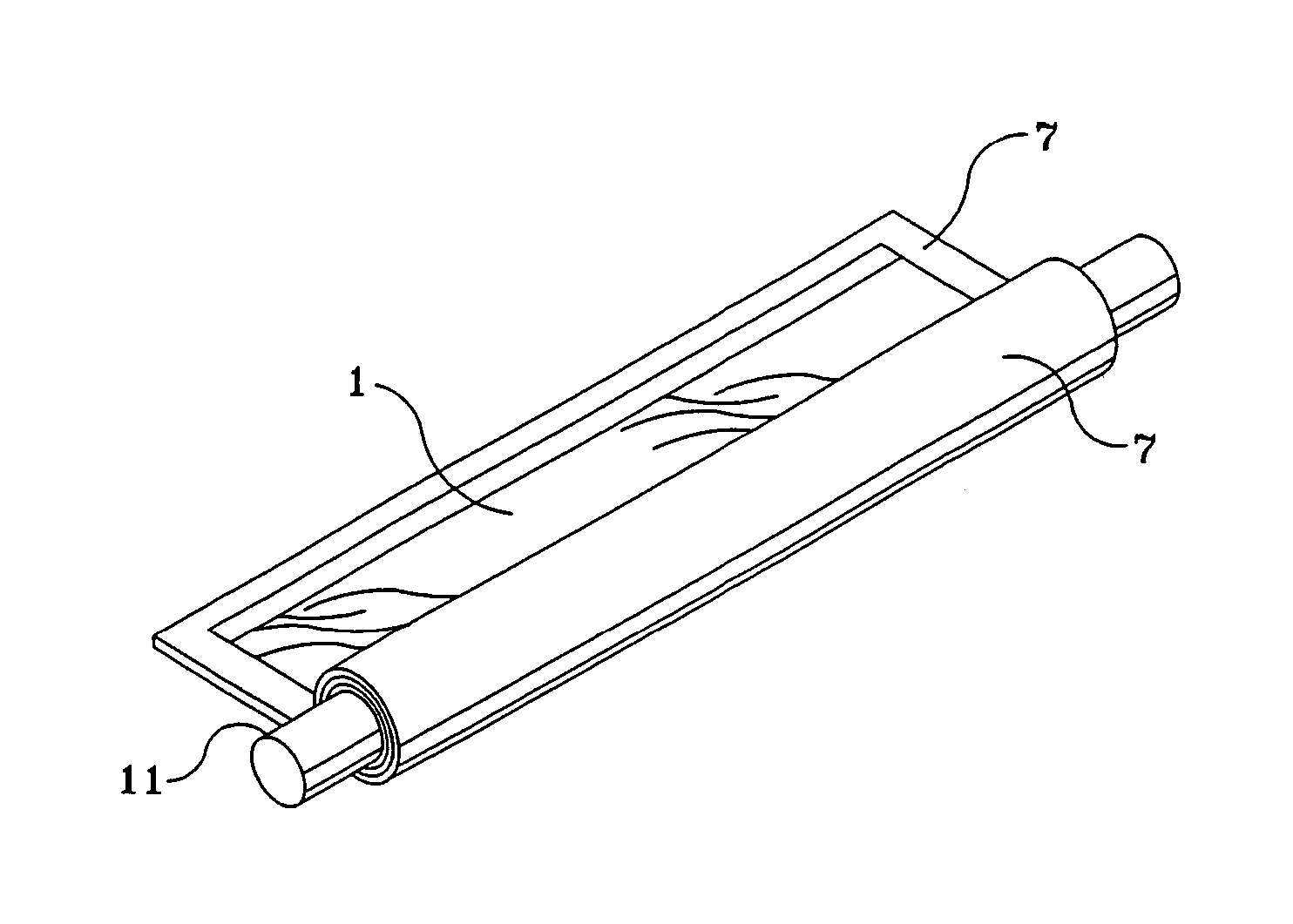

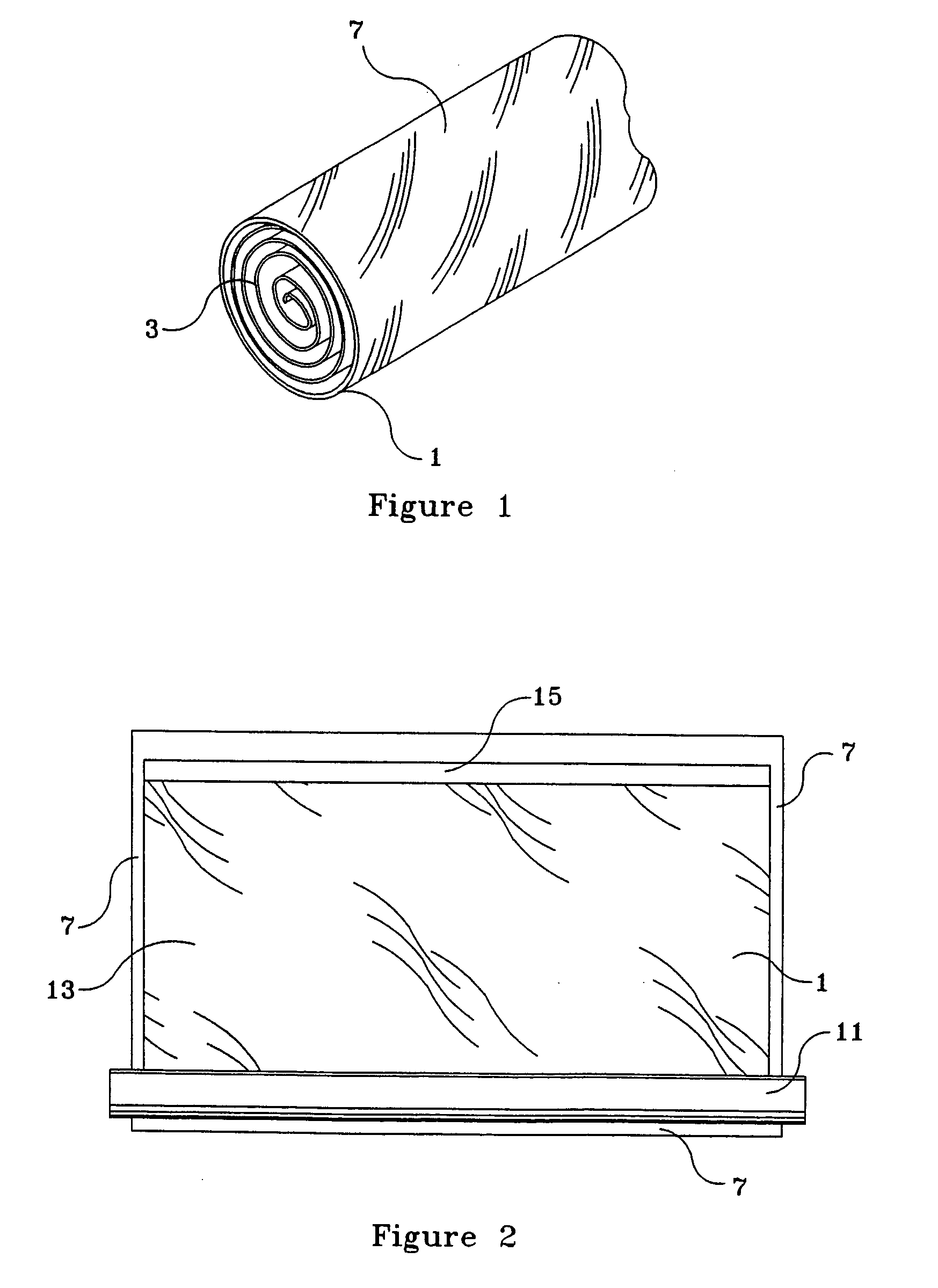

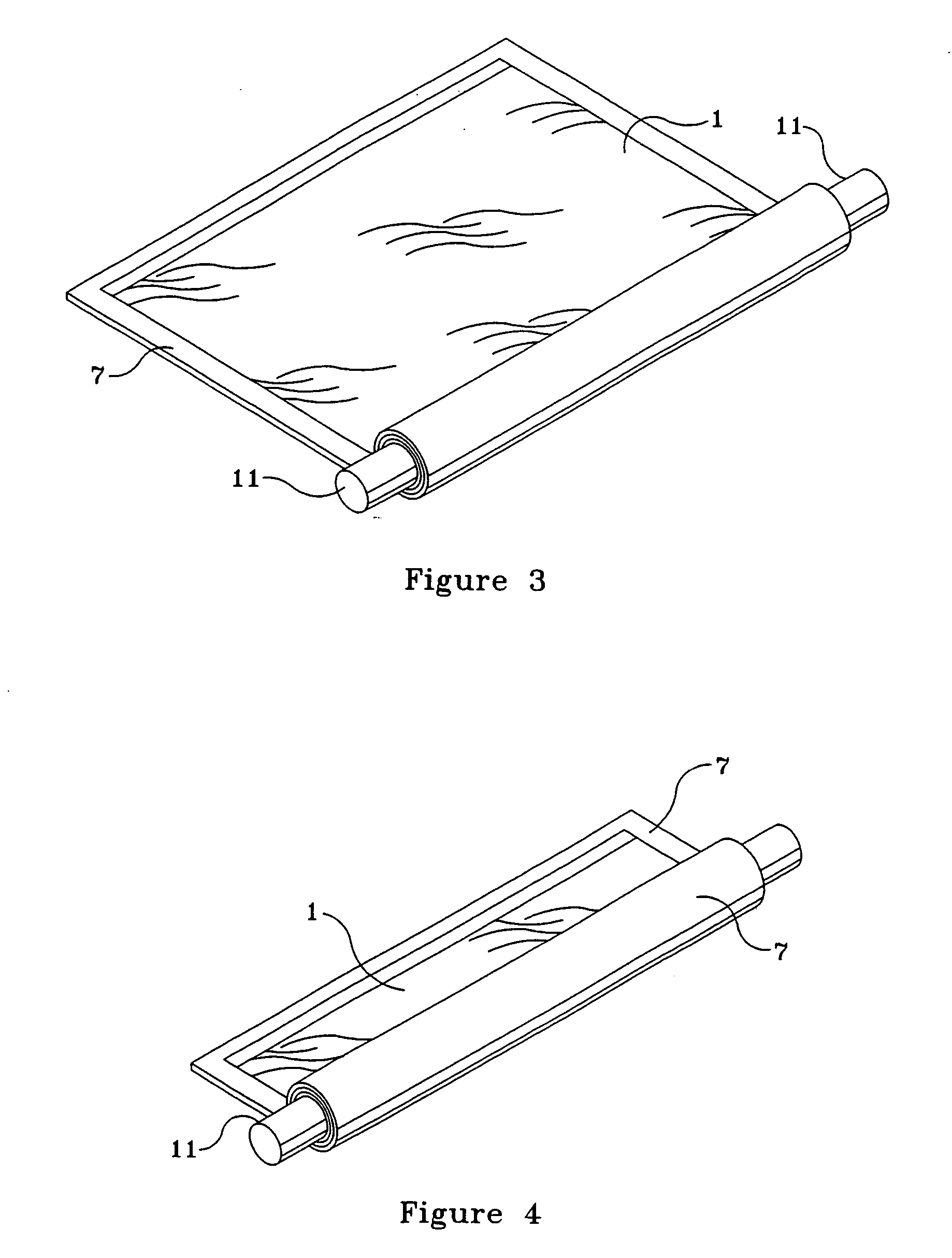

Cigar tobacco paper and a method for packaging the same

A cigar tobacco paper and a method for packaging the same is provided. The cigar tobacco paper is packaged with an enveloping means to hold a cylindrical shape. The cigar tobacco paper is rolled into cylindrical shape and placed within an enveloping means. The tobacco paper is wrapped into cylindrical form causing the cigar tobacco paper to form a plurality of layers in cylindrical form. The rolled tobacco paper is then placed inside a enveloping means having a diameter larger than the diameter of the rolled cigar tobacco paper. The encased tobacco paper within the enveloping means allows for the tobacco paper to keep a cylindrical shape until delivered and used by a consumer. The enveloping means may maintain the moisture and the flavor of the cigar tobacco paper prior to delivery to a consumer.

Owner:DARWISH AHMAD MOHAMMAD

Heating non-combustible cigarette paper and preparation method thereof

ActiveCN106368069ANo tar spotsDoes not start carbonationInorganic fibres/flakesSpecial paperFiberBurn cigarette

The invention discloses heating non-combustible cigarette paper and a preparation method thereof. The preparation method of the heating non-burning cigarette paper comprises the following steps: 1) pulping the plant fiber with the length of 0.5 to 4mm, or adding the appropriate proportion of inorganic fiber; 2) adding the inorganic filler in the process of dilution of the pulp, wherein the addition ratio of the inorganic filler is 5 to 50% of the mass of the pulp; 3) sizing the paper to improve water and oil resistance, and cigarette paper is quantified at 50 to 120 g / m<2>. Compared with the existing heated non-combustible cigarette paper that is heated at 350 DEG C, the non-combustible cigarette paper of the present invention has very few yellow stitches, and no tar spots and carbonization, while the entire surface of the existing non-combustible cigarette paper turns yellow, with large tar penetrating and carbonized. In addition, the non-combustible cigarette paper of the present invention is rarely present broken in actual production, and there is almost no deformation and wrinkling after being sucked as the heated cigarette paper.

Owner:中烟摩迪(江门)纸业有限公司

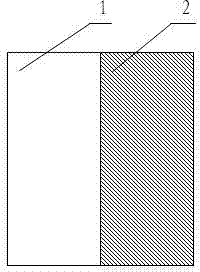

Cigarette with dobble-layer of cigarette paper

The present invention discloses cigarette with tobacco encircled with two, one inner and one outer, layers of cigarette paper. The inner layer of cigarette paper contains inorganic stuffing 20-40 wt%, combustion assistant 6-10 wt% and essence 12-18 wt%; and the outer layer of cigarette paper contains inorganic stuffing 25-35 wt% and combustion assistant 5-10 wt%. The said inorganic stuffing is calcium carbonate, magnesium hydroxide, magnesia, trihydroxyl aluminum or their mixture; the combustion assistant is the mixture of potassium citrate and sodium citrate with weight ratio between potassium ion and sodium ion of 2-4; and the essence is one of menthyl palmitate, vanillin, menthyl carbonate and beta-carotene. The present invention can reduce the side flow fume of cigarette, lower tar and reduce fragrance loss.

Owner:YUNNAN RES INST OF TOBACCO SCI

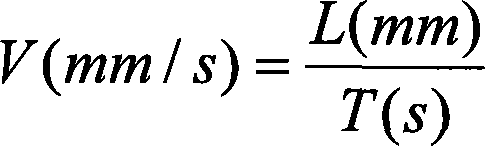

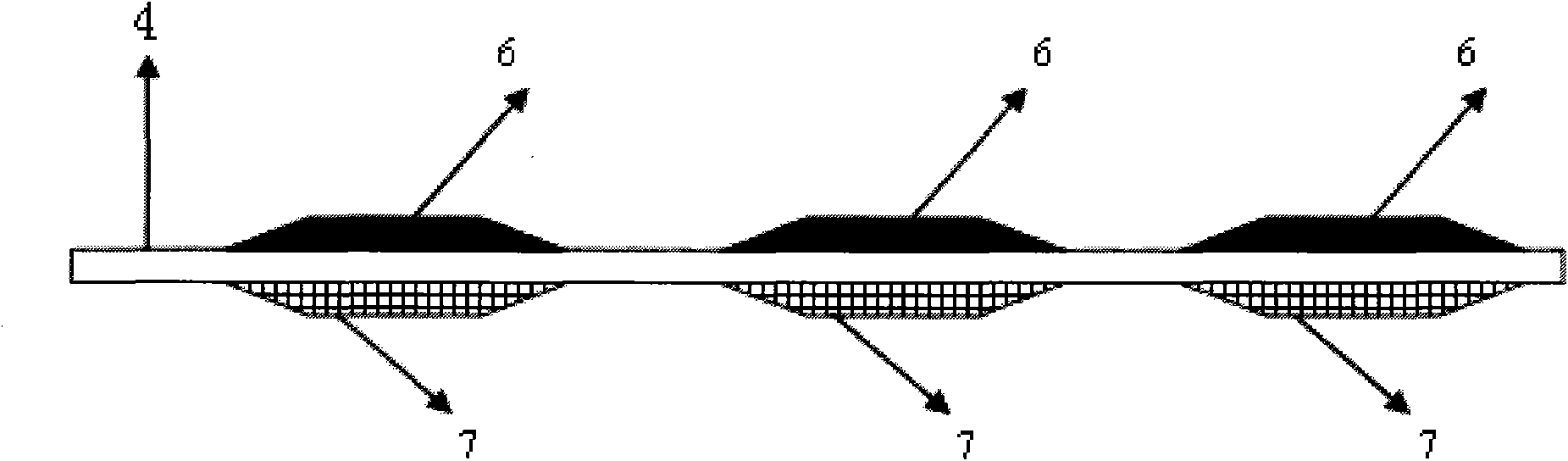

Cigarette paper with low ignition tendency and preparation method

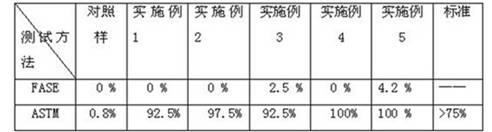

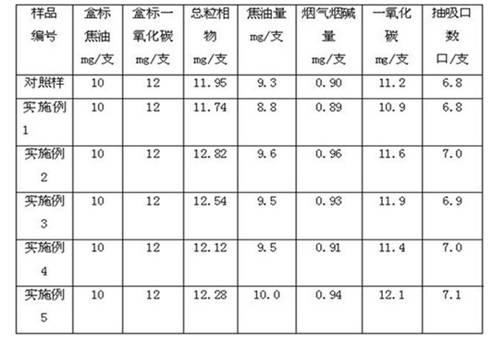

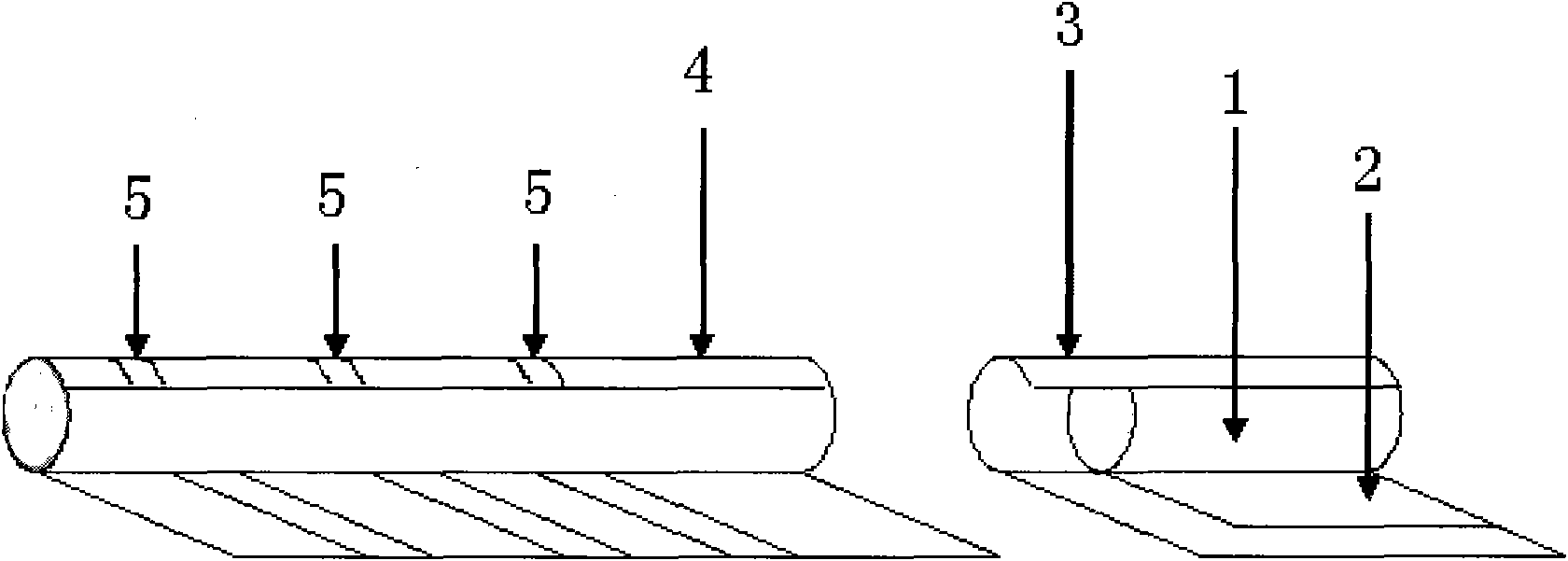

ActiveCN102199902AGuaranteed uniformitySimple and fast operationSpecial paperCigar manufacturePapermakingStandard test condition

The invention discloses cigarette paper with low ignition tendency and a preparation method. The cigarette paper comprises common cigarette paper manufactured by a papermaking process; and a coating liquid film consisting of film forming agent, viscosity regulator and filler is printed on the inner surface of the common cigarette paper. The preparation method comprises the following steps of: (1) preparing the common cigarette paper of certain specification; (2) preparing the filler into 40 to 60 percent suspension, and stirring uniformly; (3) adding the viscosity regulator component into the (2) at normal temperature to prepare 2 to 4 mass percent aqueous solution, and stirring for 10 minutes; (4) adding the film forming agent component into the (3) at normal temperature to prepare 25 to 35 mass percent aqueous solution, and stirring for 20 minutes; and (5) adding the sizing material prepared in the (4) on the surface of the cigarette paper through a silk screen in certain interval by adopting a printing and coating mode. When the cigarette paper is burnt to a coated strip in the atmospheric environment, the cigarette has low extinguishing rate and even is not extinguished; and under the standard test condition, the filter paper of contact matrix has high extinguishing rate, and meanwhile, the cigarette paper has no obvious adverse effects on the cigarette smoke and the smoking quality.

Owner:MINFENG SPECIAL PAPER

Functional cigarette paper

InactiveCN1429946AImprove combustion qualityNice appearanceNon-fibrous pulp additionAlkaline earth metalSilicon oxide

A function cigarette paper for reducing tar and improving combustion quality features that it contains the assistant composed of inorganic filler, combustion promoter and flavouring. Said inorganic filler consists of calcium carbonate, alkalimetal algate, nano-class oxide, and silicon oxide or alkali-earth metal silicate or alkali-earth metal carbonate or their mixture. Said combustion promoter is composed of alkali metal (or alkali-earth metal) carboxylate and alkali metal carbonate. Said flavouring contains cylitol or sorbitol or glocose.

Owner:YUNNAN REASCEND TOBACCO TECH GRP +1

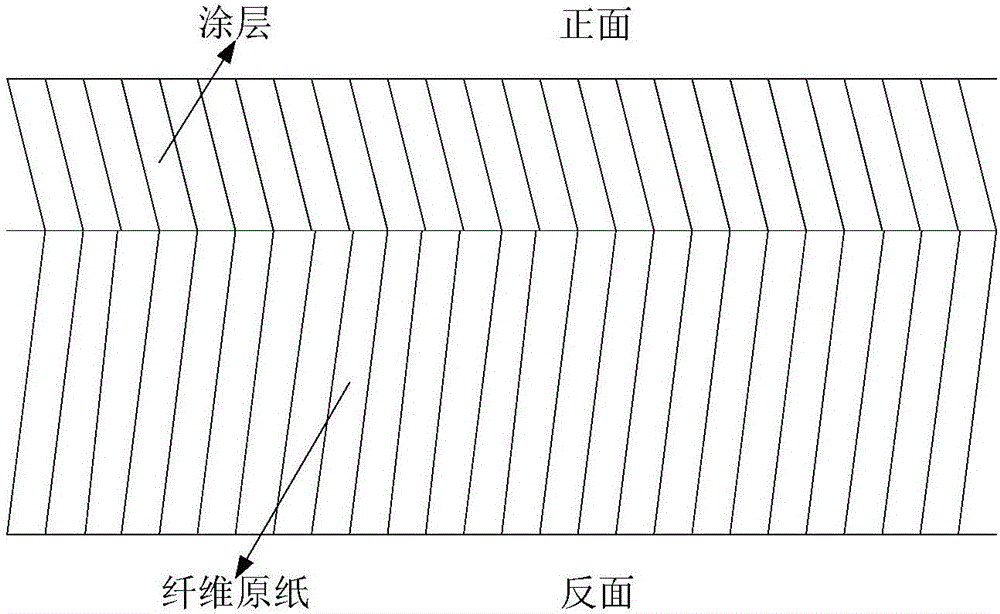

Preparation method of natural tobacco texture cigarette paper

InactiveCN103469691AIncrease the fragranceReduce mistSpecial paperPaper coatingCombustionSolid matter

The invention discloses a preparation method of natural tobacco texture cigarette paper. The method comprises the following steps: firstly weighing 5-60% of tobacco raw material and 40-95% of wood pulp by weight percentage; extracting the tobacco raw material, and separating to get a tobacco solid matter and an extraction solution; mixing the tobacco solid matter and the wood pulp to obtain mixed pulp; and preparing a cigarette paper base from the mixed pulp; concentrating the extraction solution to prepare a tobacco extract; adding 1-4% of a combustion-supporting agent, 0-4% of a natural pigment extract and 0-3% of a moisture retention agent relative to the weight of the tobacco extract into the tobacco extract to prepare a coating solution, coating the cigarette paper base with the coating solution, and directly performing embossing treatment by utilizing an embossing roller carved with tobacco textures after coating and drying to prepare the cigarette paper with the tobacco vein textures. According to the preparation method disclosed by the invention, the natural tobacco fragrance of the cigarette paper is increased, and the cigarette paper is also endowed with the tobacco characteristic appearance; the cigarette grade is upgraded; the cigarette paper miscellaneous gas during combustion is reduced, and the smoking quality is upgraded; the natural tobacco texture cigarette paper can further serve as wrappers of hand-rolled cigars.

Owner:HUBEI CHINA TOBACCO IND +1

Method for manufacturing aroma-increasing moisture retention cigarette paper

ActiveCN103711029ASimple production processLow costSpecial paperVegetable material additionPapermakingTherapeutic effect

The invention discloses a method for manufacturing aroma-increasing moisture retention cigarette paper. The method comprises the following steps: according to mass percent, firstly drying a CaCO3 filler till the moisture content of the filler is lower than 0.5%; emulsifying and modifying the dried CaCO3 filler under the effect of a stearic acid coupling agent for 0.5-3 minutes, dispersing 0.1-20% of tobacco extractive and fruit extractive relative to the mass percentage of the CaCO3 filler in an ethanol solution, loading an aroma-increasing component on the surface of the modified CaCO3 filler, and uniformly distributing the loaded and modified CaCO3 on paper by adopting a common papermaking technology, thus obtaining the aroma-increasing moisture retention cigarette paper. The method has the characteristics of good treatment effect, low cost, easy operation and the like; the produced novel aroma-increasing moisture retention cigarette paper has mellow fragrance, strong durability and improvement of quality of cigarettes; materials used in the method conform to the admittance criterion of additives for cigarette industries; and a relatively good processing effect can be obtained through the minor improvement in a production process.

Owner:SOUTH CHINA UNIV OF TECH

Tobacco and cigarette with reduced harmful components

InactiveCN1720828AReduce productionSidestream smoke reductionTobacco treatmentHazardous substancePhosphate

Disclosed is a kind of tobacco and cigarette for reducing harmful constituents, which is prepared by mixing hydroxyapatite with tobacco or attaching onto tobacco of the surface of cigarette paper, the hydroxyapatite is the common type one or calcium-loss type one, in addition, other ingredients including tricalcium phosphate and clay can also be charged. The prepared tobacco and cigarette can decrease the content of hazardous substance in the smoke.

Owner:青木 秀希

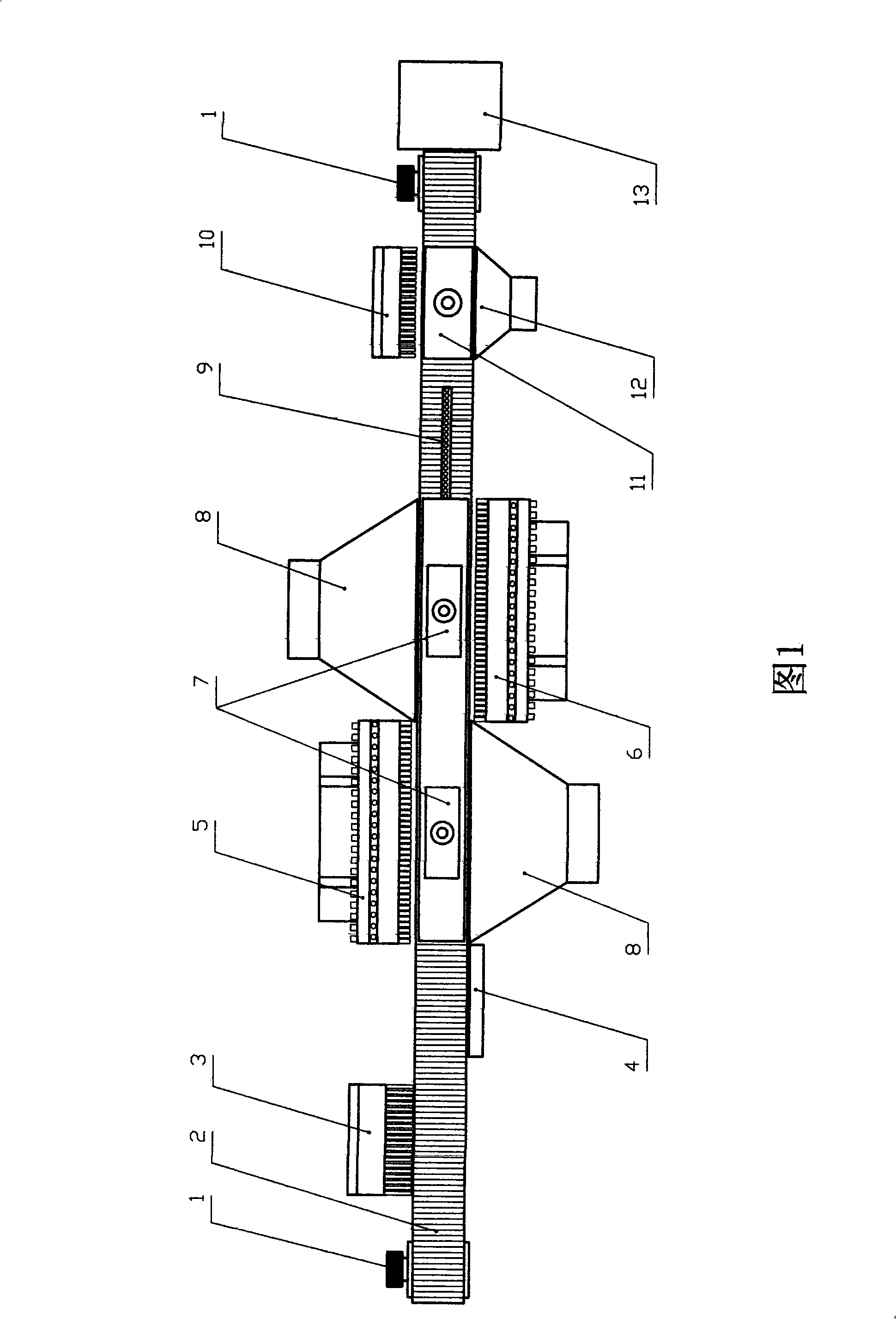

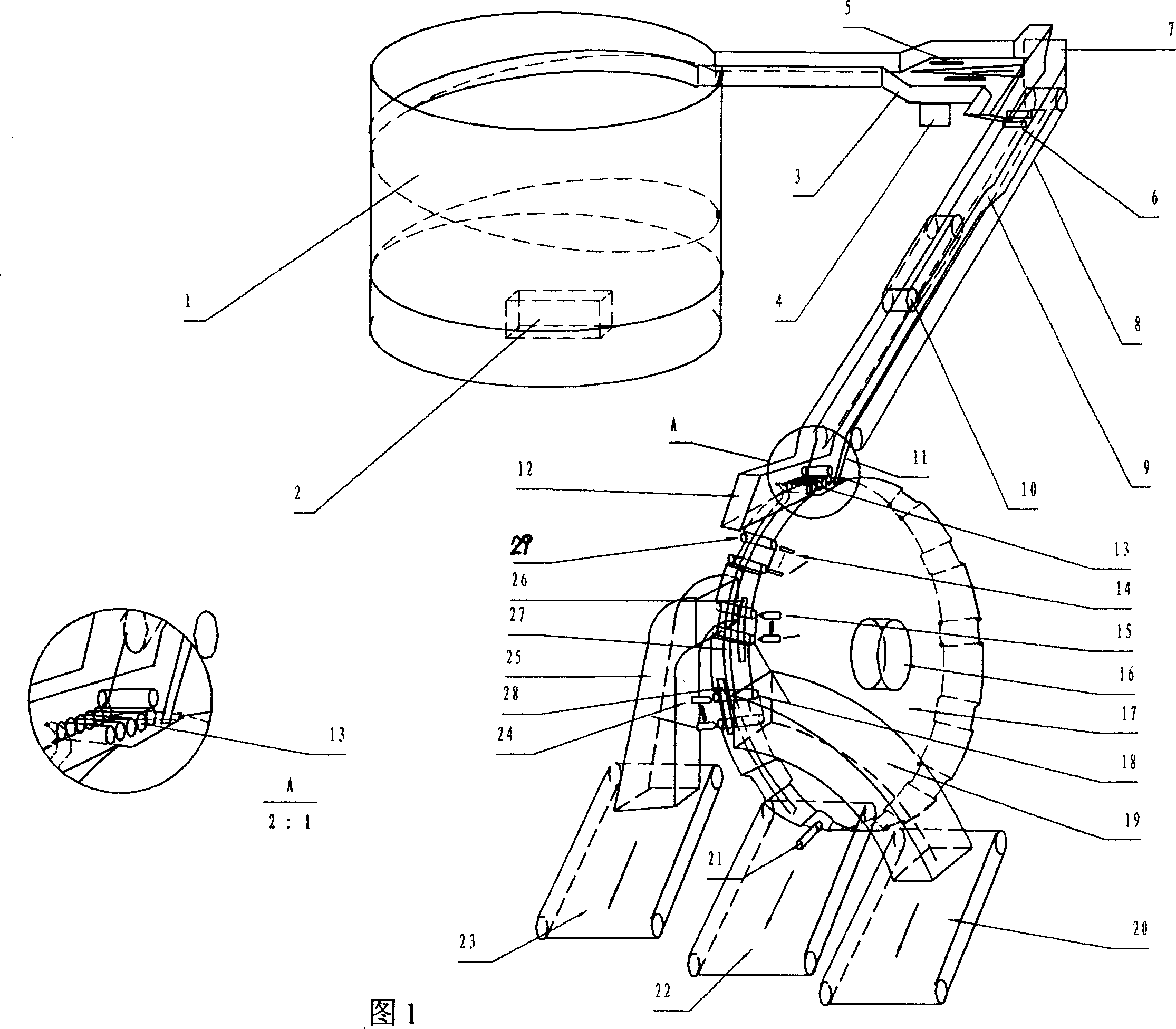

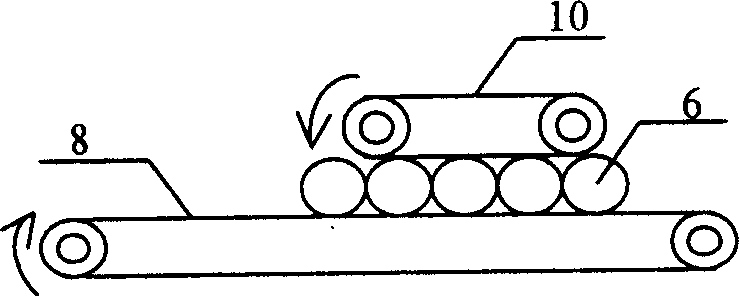

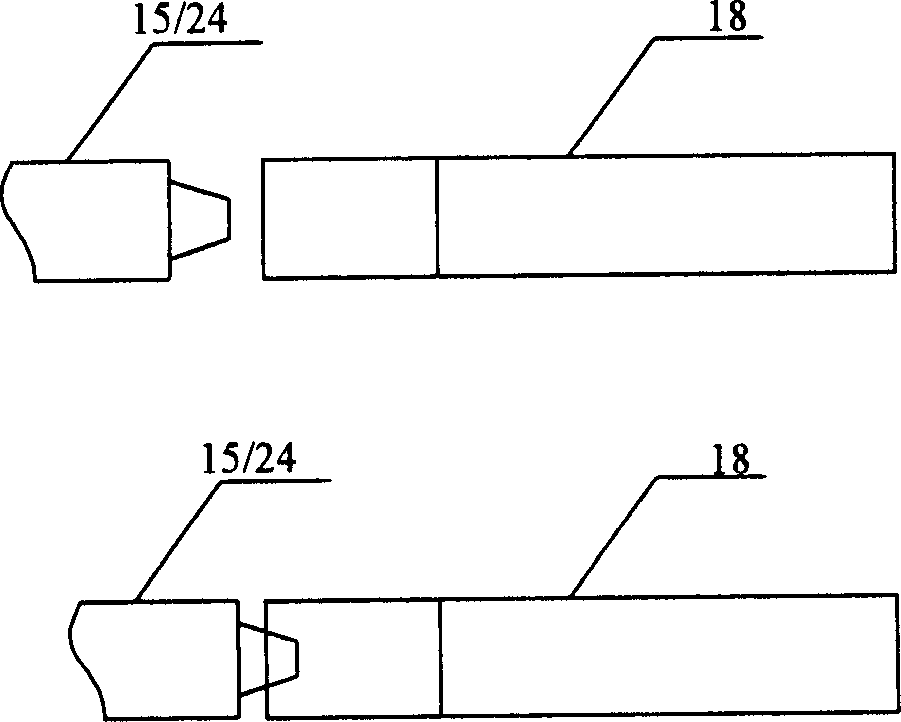

Multi-time two-sided gas blowing type recycling machine for tobacco shred of waste cigarette

ActiveCN101317694AHigh recovery rateImprove recycling effectCigarette manufactureEngineeringReclaimer

The invention discloses a multi-time double-faced air-blown reclaimer of discarding tobacco shreds consisting of a synchronous pulley, a groove conveyer belt, gas nipple set system for filter tip detection and left and right blowing, a gas nipple set system for uncleaned cigarette detection and blowing, a PLC system, etc., so as to realize the rectilinear and interstitial motion. By adopting the technology of secondary blowing for each end of the discarding cigarette and adding the uncleaned cigarette detection and blowing system, the defects of one-go blowing for a single side or for two sides can be effectively overcome so as to multiply improve the reclaiming effect of the discarding tobacco shreds. Owing to the treatment of the uncleaned cigarettes, the reliable separation of the tobacco shreds and the cigarette paper of the filter tip can be guaranteed. The reclaimer of the invention has reasonable design, simple structure, good applicability and high popularization and application value.

Owner:CHANGDE RUIHUA MFG

High-temperature-resistant non-combustion cigarette paper and preparation method thereof

ActiveCN106480773AMeet high quality requirementsTo achieve the purpose of high temperature resistanceInorganic fibres/flakesWater-repelling agents additionCombustionTar

The invention discloses high-temperature-resistant non-combustion cigarette paper and a preparation method thereof. The preparation method of the high-temperature-resistant non-combustion cigarette paper comprises the following steps: (1) glue application in pulp: a glue application agent is added into the pulp after pulping, and the solid content is controlled to be 1 to 5 percent of the specified quantity of raw paper; (2) surface glue application after papermaking; (3) single-side or two-side coating after glue application, wherein the coating quantity is 5 to 50g / m<2>; fixed quantity before paper sheet coating is 30 to 120g / m<2>. On the basis of the existing cigarette paper production process, the goal of resisting high temperature is achieved through performing glue application and coating treatment on the cigarette paper, so that the cigarette paper can be applied to the heating on non-combustion cigarettes. The high-temperature-resistant non-combustion cigarette paper obtained by the preparation method can be used at 300 to 500 DEG C; in the use process, the cigarette paper hardly generates color change, avoids tar penetration and does not deform; the high-quality requirement of heating non-combustion paper for cigarettes is met.

Owner:中烟摩迪(江门)纸业有限公司

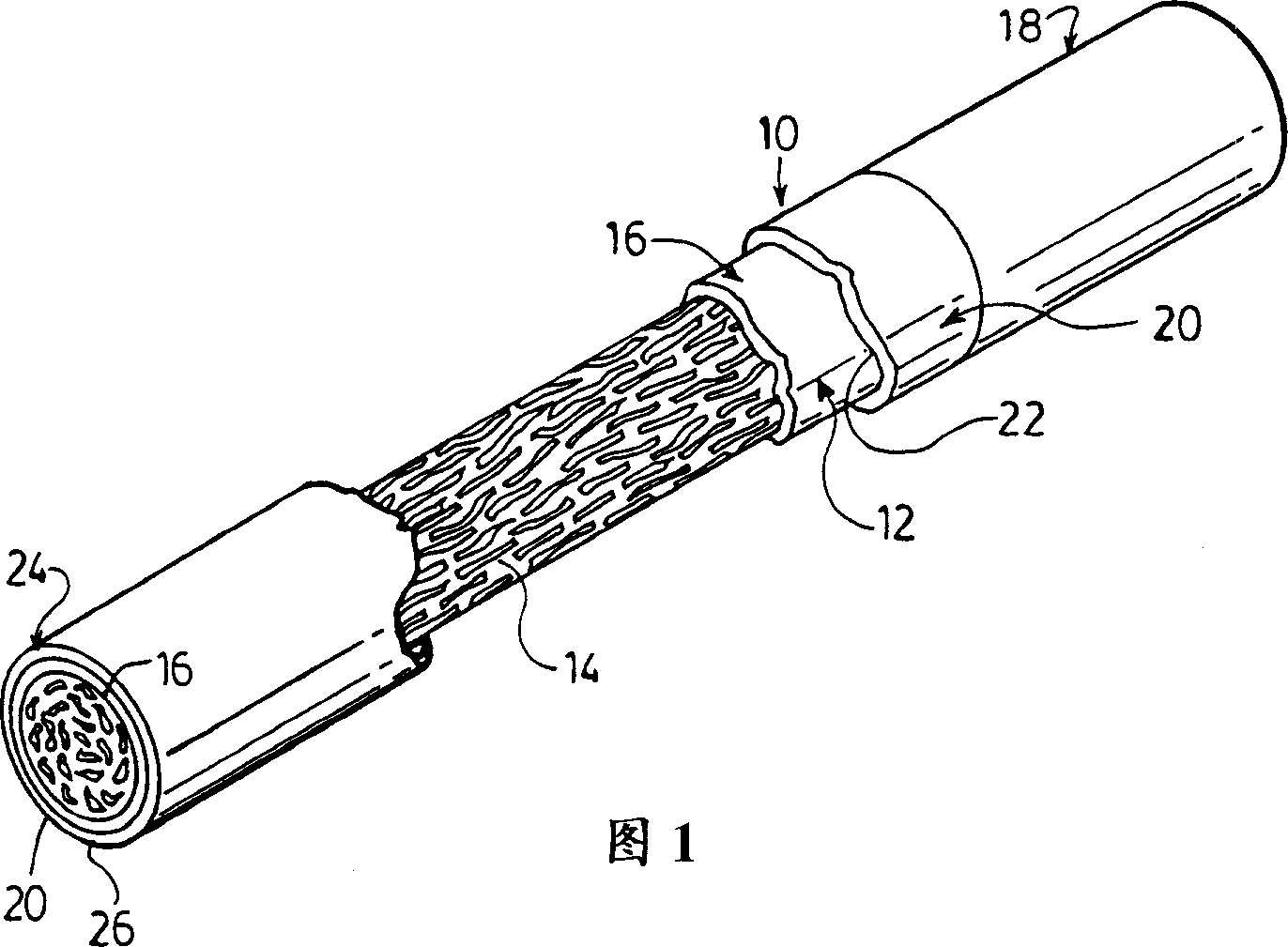

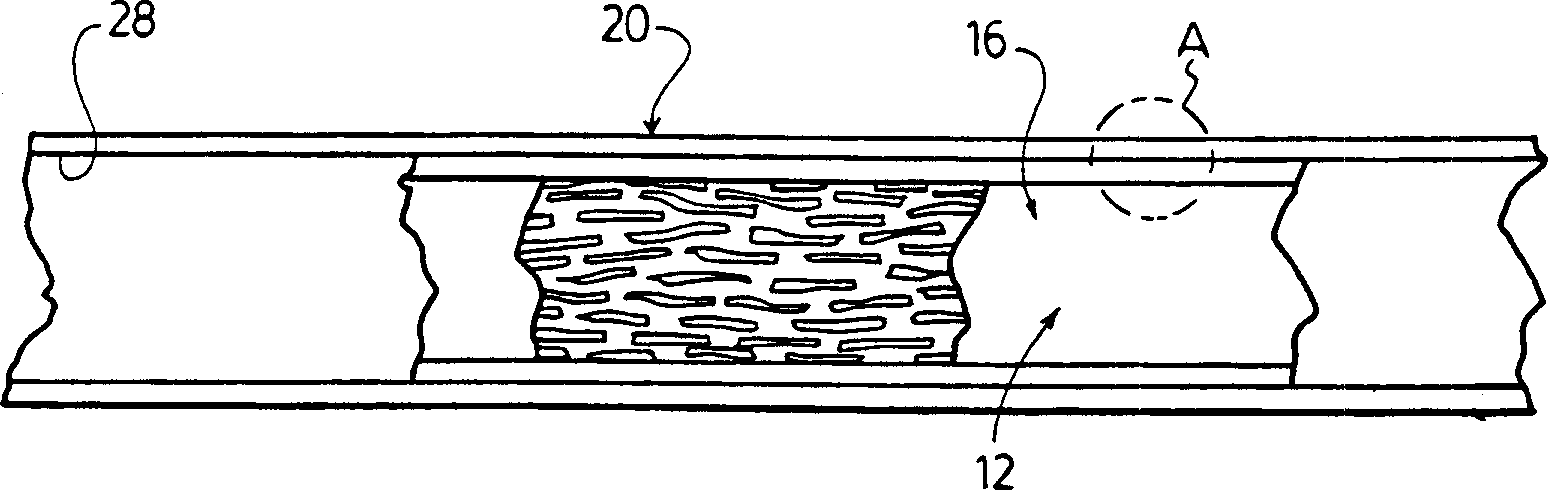

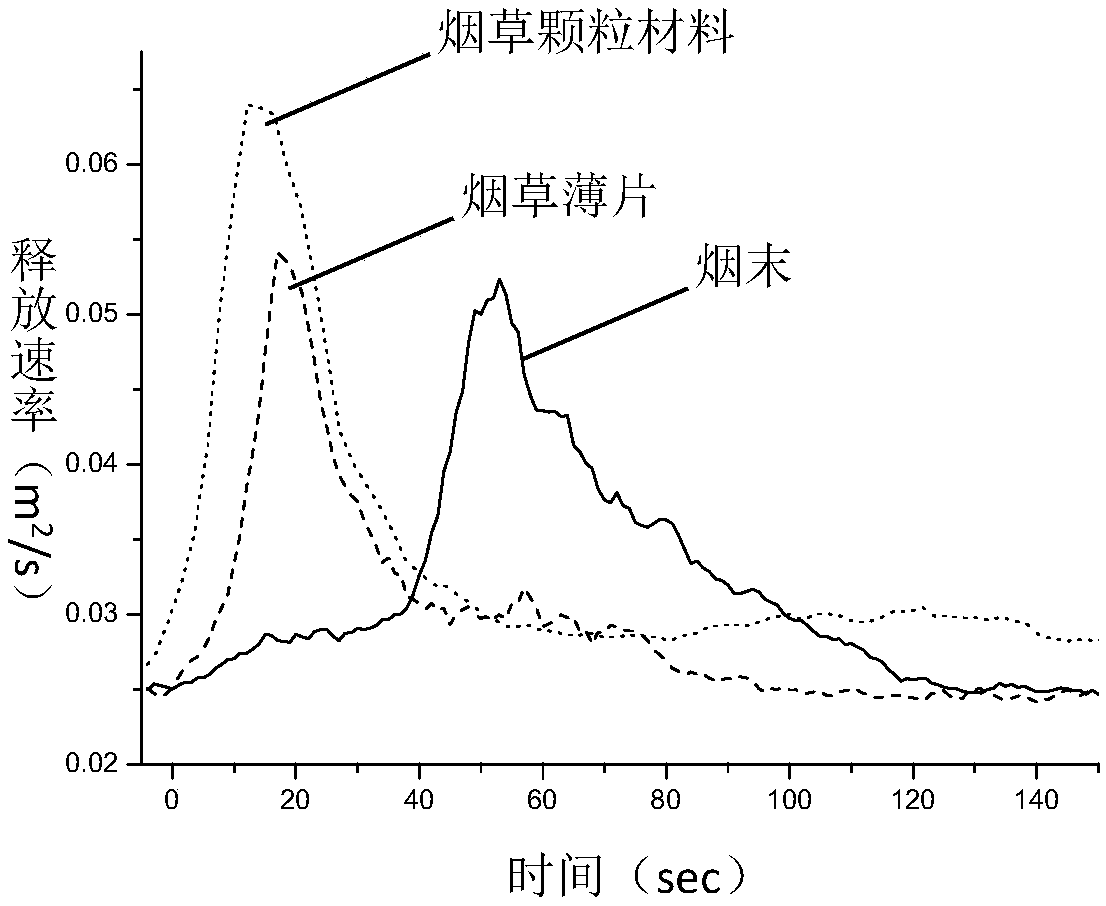

Cigarette sidestream smoke treatment material

InactiveCN1306401AWith suction resistanceTobacco preparationTobacco treatmentPorosityAdditive ingredient

A cigarette sidestream smoke treatment material made from a sheet of non-combustible active ingredients provides a porous structure for sidestream smoke treatment. The treatment material, when used in combination with conventional cigarette paper cigarettes, provides a cigarette unit that delivers low sidestream smoke. The porosity of the material facilitates the normal free burn rate of the cigarette. The material may contain an adsorbent capable of adsorbing sidestream smoke components and an oxygen storage component capable of releasing oxygen at the free burn rate temperature to ensure that the normal free burn rate is maintained and to enhance oxidation of the adsorbed non-water components. Preferably the material includes an oxidation catalyst, preferably the oxygen storage component also has dual functions as an oxidation catalyst. A particularly preferred component that performs a dual function is an oxide of cerium.

Owner:ROTHMANS BENSON & HEDGES INC CA

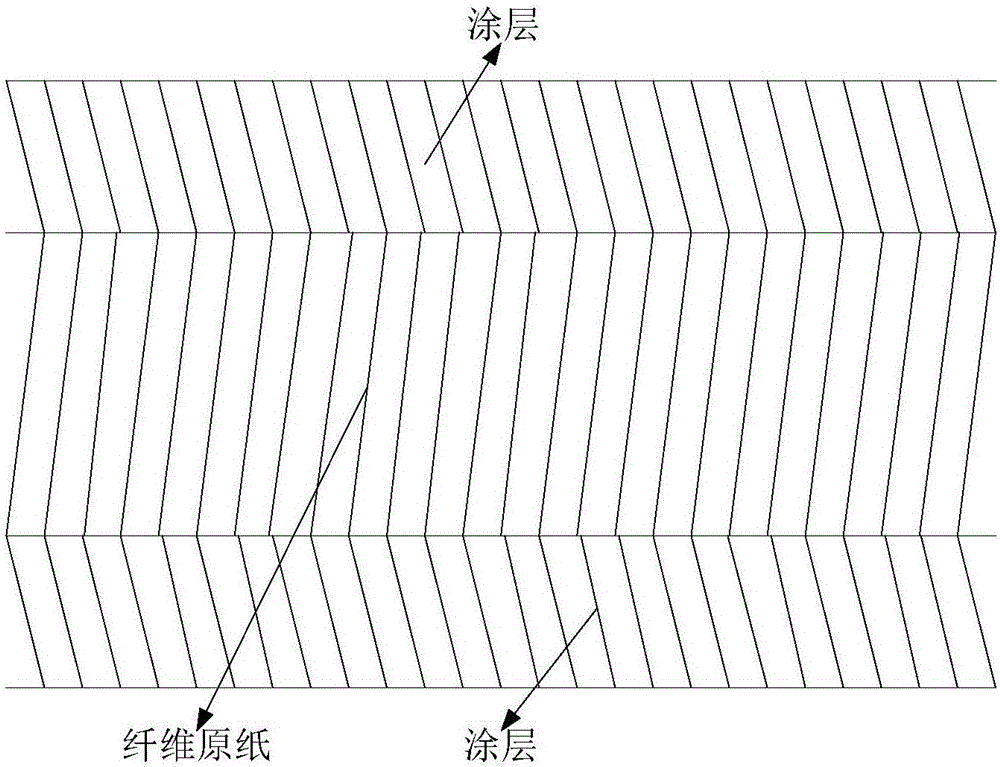

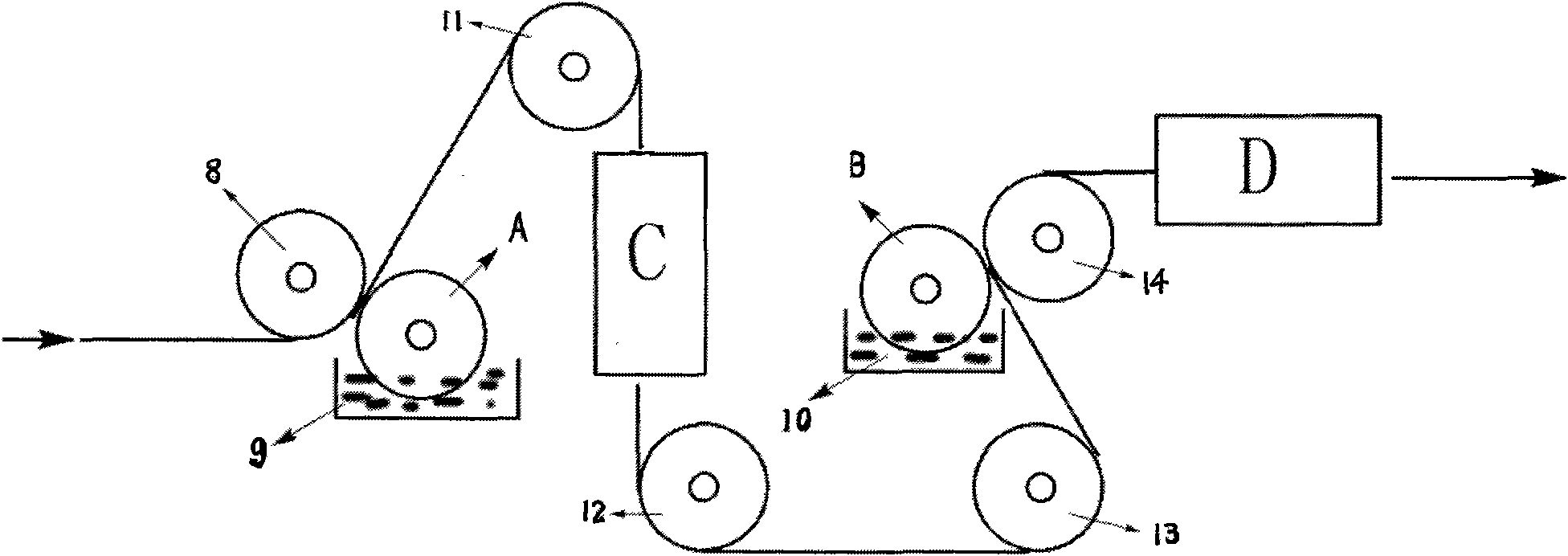

Preparation method of natural-textured cigarette paper

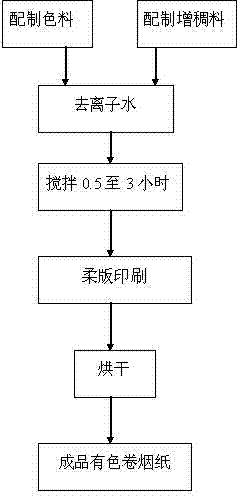

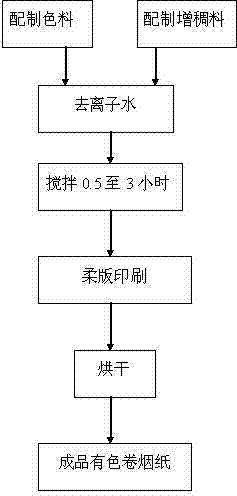

ActiveCN102409577AReduce mistWith anti-counterfeiting functionSpecial paperPaper coatingLycopenePotassium

The invention discloses a preparation method of a natural-textured cigarette paper. The method is characterized by comprising the following steps of: A, preparing as dyes by mixing one or more of caramel pigment, lycopene, anthocyanin, gardenia yellow pigment and Zimbabwe tobacco extract according to a weight ratio; B, preparing thickening agent by using one or more of potassium humate, sodium humate, sodium alginate, potassium alginate, guar gum and pectin according to a weight ratio for further use; C, uniformly mixing deionized water, dye and viscosity material according to a weight ratio for further use; D, stirring at normal temperature to obtain coating liquid; E, using the coating liquid in flexographic printing of the cigarette paper, coating the coating liquid on the single face or double faces of the cigarette paper; and obtaining the natural-textured cigarette paper and drying. The preparation method utilizes flexographic printing technology, naturally hangs liquid to print the natural-textured cigarette paper and endows the cigarette paper characteristic appearance and certain anti-fake function without modifying the sucking quality of the product.

Owner:杨涛

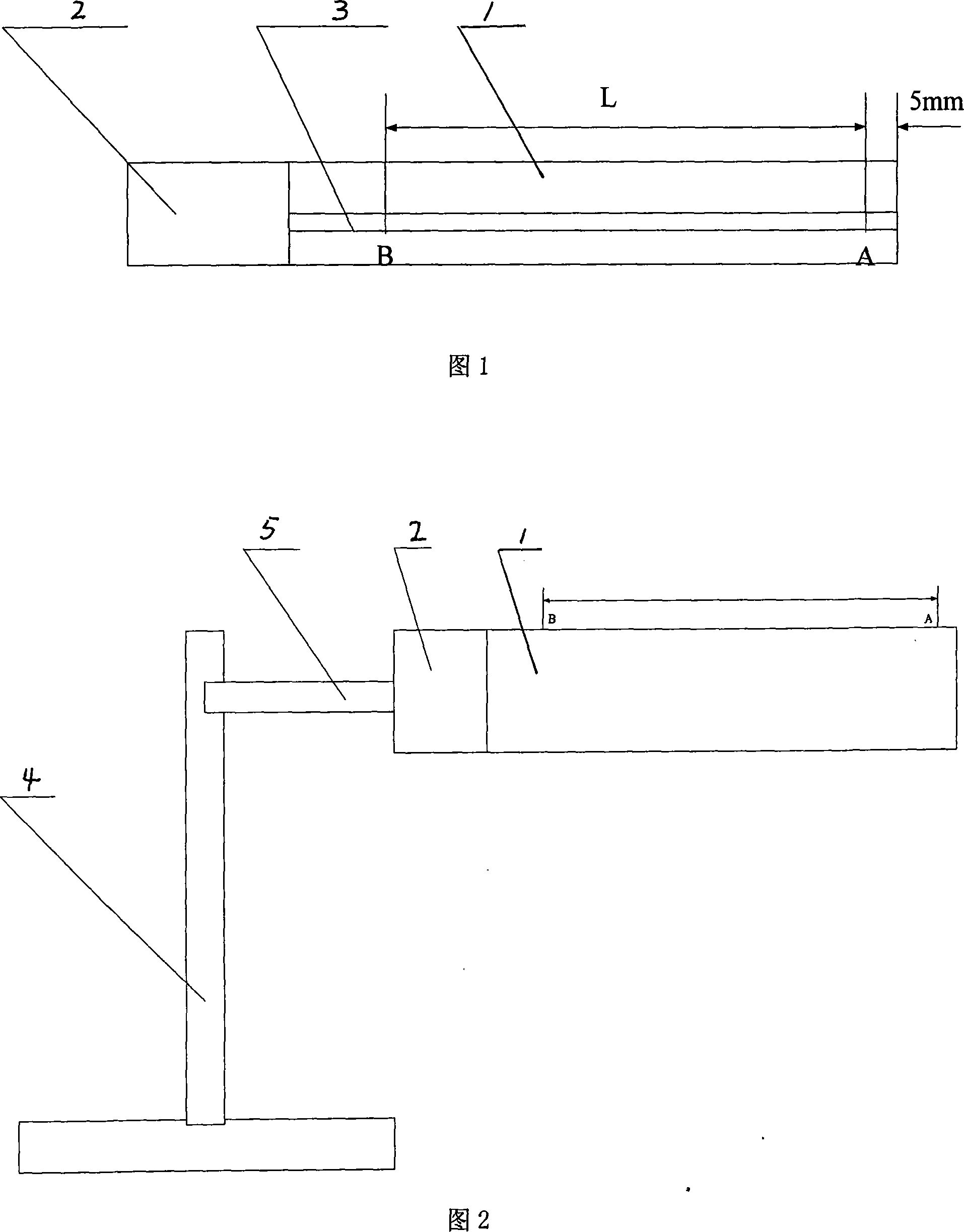

Method for determining cigarette paper smolder speed

InactiveCN101226186AGood repeatabilitySmall discreteChemical analysis using combustionPaper testingPulp and paper industrySingle level

The invention relates to a measuring method of smoldering speed of cigarette paper, which comprises a, preparing a cigarette hollow paper drum sample, b, setting relative marks, c, setting fixing method, d, setting test conditions, e, calculating out the cigarette paper smoldering speed via formula. Compared with prior three test methods, the invention has the advantages that 1, the test result has good repeatability, 2, the test result has good stability, 3, the test result can actually represent product quality, 4, the test result can represent the application character of product, 5, and the method has good operability. The test result indicates that since the cigarette paper has single-layer drum structure, is suspended and horizontally arranged and smoldered, the sample is in one small space, to make smoldering line regular, obtain the test result with good repeatability and reduce dispersion as small variation factor, thereby truly representing the quality and application character of product.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Cigarette paper for reducing harmful substance contents of carbon monoxide, oxynitride and phenols in cigarette smoke gas and preparation thereof

ActiveCN101435176ANo need to change the production processEasy to operateSpecial paperPaper/cardboardHazardous substanceCerium

The invention relates to double-layer cigarette paper formed by an inner layer of cigarette paper wrapped outside tobacco shred, and an outer layer of cigarette paper wrapped outside the inner layer of cigarette paper. The inner layer of cigarette paper can be loaded with a catalyst which comprises a metallic oxide, a metallic compound oxide, a metallic hydroxide or a metallic oxide hydroxide, concretely relates to one or a plurality of the oxides, the compound oxides, the hydroxide or the oxide hydroxide of iron, manganese, copper, zinc, titanium, aluminum, calcium, cobalt, palladium, platinum, lanthanum, strontium or cerium and the like; the mass content of the catalyst accounts for 1 to 30 percent of the mass of the inner layer of cigarette paper, preferably 3 to 10 percent of the mass of the inner layer of cigarette paper. The technique can effectively reduce the content of hazardous substances such as carbon monoxide, oxynitride and phenols and the like in the smoke of the cigarette.

Owner:CHINA TOBACCO HUNAN INDAL CORP

A compound addictive for lowering CO content in cigarette smoke and application thereof

InactiveCN1951240AReduce carbon monoxideImproving and improving the taste qualityTobacco treatmentPipe TobaccoAlkali metal

The invention relates to a composite additive which can reduce the carbon monoxide content of smoke gas, and relative application. Wherein, said composite additive comprises that tobacco extract, alkali metal salt, transition metal hydroxide, or metal hydroxide; the composite additive can be used in variable tobaccos as flue-cured tobacco, suncured tobacco leaf, oriental tobacco leaf, expansion pipe tobacco, etc. The inventive composite additive can be used in tobacco to reduce carbon monoxide content 1.5-3.0mg / n of smoke gas and reduce the tar content.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

Heating incombustible tobacco product containing tobacco particles and preparation method

The invention discloses a heating incombustible tobacco product containing tobacco particles. The tobacco product is formed by compounding a cooling filter stick and a compound filter stick through acigarette tipping paper, wherein the cooling filter stick and the compound filter stick are connected in sequence. The cooling filter stick is filled with a cooling material, and the compound filter stick includes a first filtering section, a cavity particle section and a second filtering section which are connected in sequence. The cavity particle section is filled with the tobacco particles, andthe first filtering section and the second filtering section are filled with a filter material. The first filtering section, the cavity particle section and the second filtering section are coated together through cigarette paper to form the compound filter stick. Compared with the prior art, the heating incombustible tobacco product has the advantages that the tobacco particles of the cavity particle section are sealed and packed between the two filtering sections, and the tobacco product is matched with a heating tobacco rod, the tobacco product can be directly taken out of the heating tobacco rod after being used, a smoke-releasing material of the tobacco product does not remain in the heating tobacco rod and does not pollute the heating tobacco rod, and thus the heating tobacco rod does not need to be cleaned.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Cigarette for generating smoke through burning or heating

PendingCN109430932ATake advantage ofPlay a role in reducing focusCigar manufactureTobacco devicesHazardous substanceSmoke Emission

The invention relates to a cigarette for generating smoke through burning or heating and relates to the technical field of cigarette processing and production. The cigarette comprises a tobacco segment, a heat insulation segment and a nozzle rod segment which are connected in sequence. The tobacco segment comprises a cigarette core material and cigarette paper, the tobacco segment is filled with the cigarette core material, and the cigarette paper wraps the tobacco segment. The cigarette is characterized in that the cigarette core material comprises tobacco shreds, tobacco slices, an additivefor the cigarette and a smoke generation agent; the cigarette can generate smoke through an ignition or heating mode. The cigarette can better adapt to the two modes including burning and heating, thesmoke concentration can also be increased, permeation deformation is prevented, the poisonous and harmful substance components are reduced, and heating is evener.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

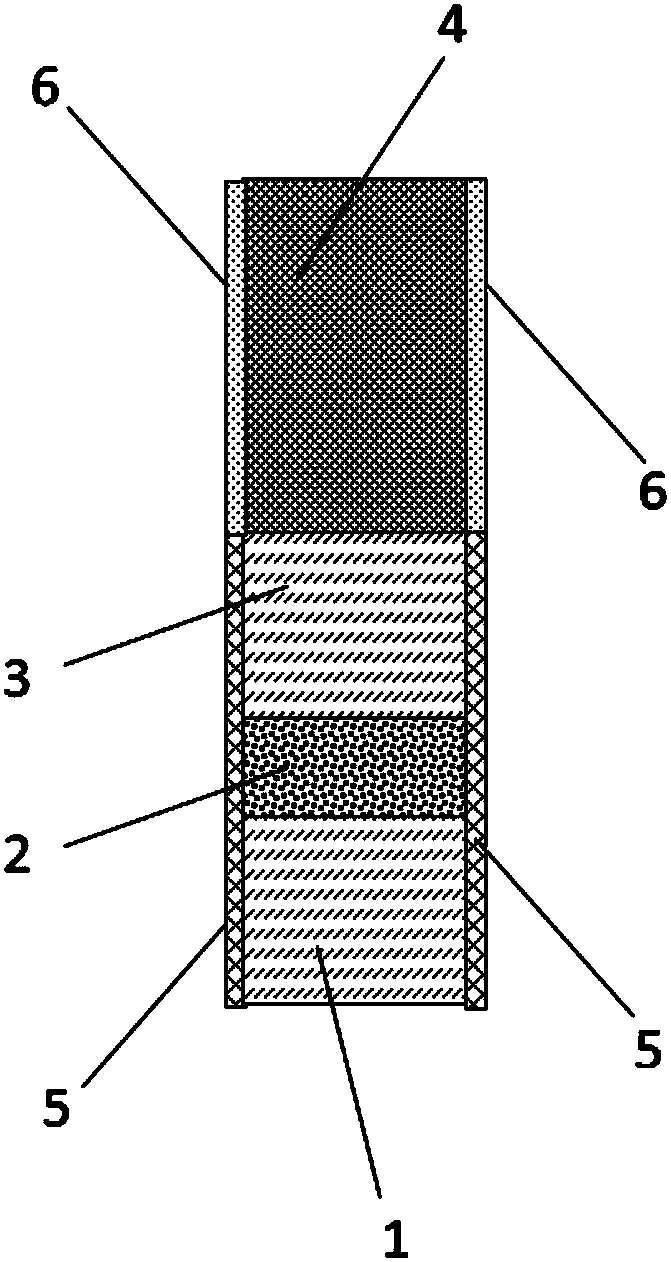

Low ignition tendency cigarette paper and preparation method thereof

ActiveCN101781867AImprove comfortImprove suction qualityNon-fibrous pulp additionFlexible coversEngineeringFire retardant

The invention discloses a low ignition tendency cigarette paper and preparation method thereof. The cigarette paper is formed by coating a retardancy strip on the outer surface of common cigarette paper, and the retardancy strip is composed of fire retardant, flavour absorbing regulator and ash content regulator. By taking cigarette finished product as mass basis, the fire retardant, flavour absorbing regulator and ash content regulator account for 7.0%, 0.3-1.0% and 0.5-1.5% of the cigarette weight respectively. Cigarette finished product is made by adopting the cigarette paper, the cigarette has better ash including effect when in suction, cigarette ash is gray-white, appearance is beautiful; when the cigarette is burned to the retardancy strip and suction is stopped, the cigarette can be automatically extinguished; and meanwhile the original suction style of the cigarette can be maintained while suction quality of the cigarette is not obviously reduced.

Owner:CHINA TOBACCO GUANGDONG IND

Tobacco thin sheet cigarette paper preparation method

ActiveCN105019294AIncrease contentProduct quality, safety and stabilityNon-fibrous pulp additionPaper/cardboardMaillard reactionPaper sheet

The present invention discloses a tobacco thin sheet cigarette paper preparation method, which comprises: extracting tobacco stem, tobacco smalls and tobacco leaf debris with water, preparing the residue into substrate paper, carrying out enzymolysis on the extraction solution, carrying out alcohol precipitation, carrying out a Maillard reaction to prepare a toner, adding a combustion additive and a perfume to the toner, uniformly mixing to prepare a coating liquid, coating the substrate paper with the coating liquid, drying, and slicing to obtain the tobacco thin sheet cigarette paper. According to the present invention, with the prepared tobacco thin sheet cigarette paper, the woody gas, the hybrid gas and the mouth irritation are effectively reduced, the aroma of the tobacco thin sheet cigarette paper is increased, the smoking effect is improved, the cigarette paper color is uniform and does not have spots, and the chrominance is close to the chrominance of the cigar.

Owner:HUBEI CHINA TOBACCO IND

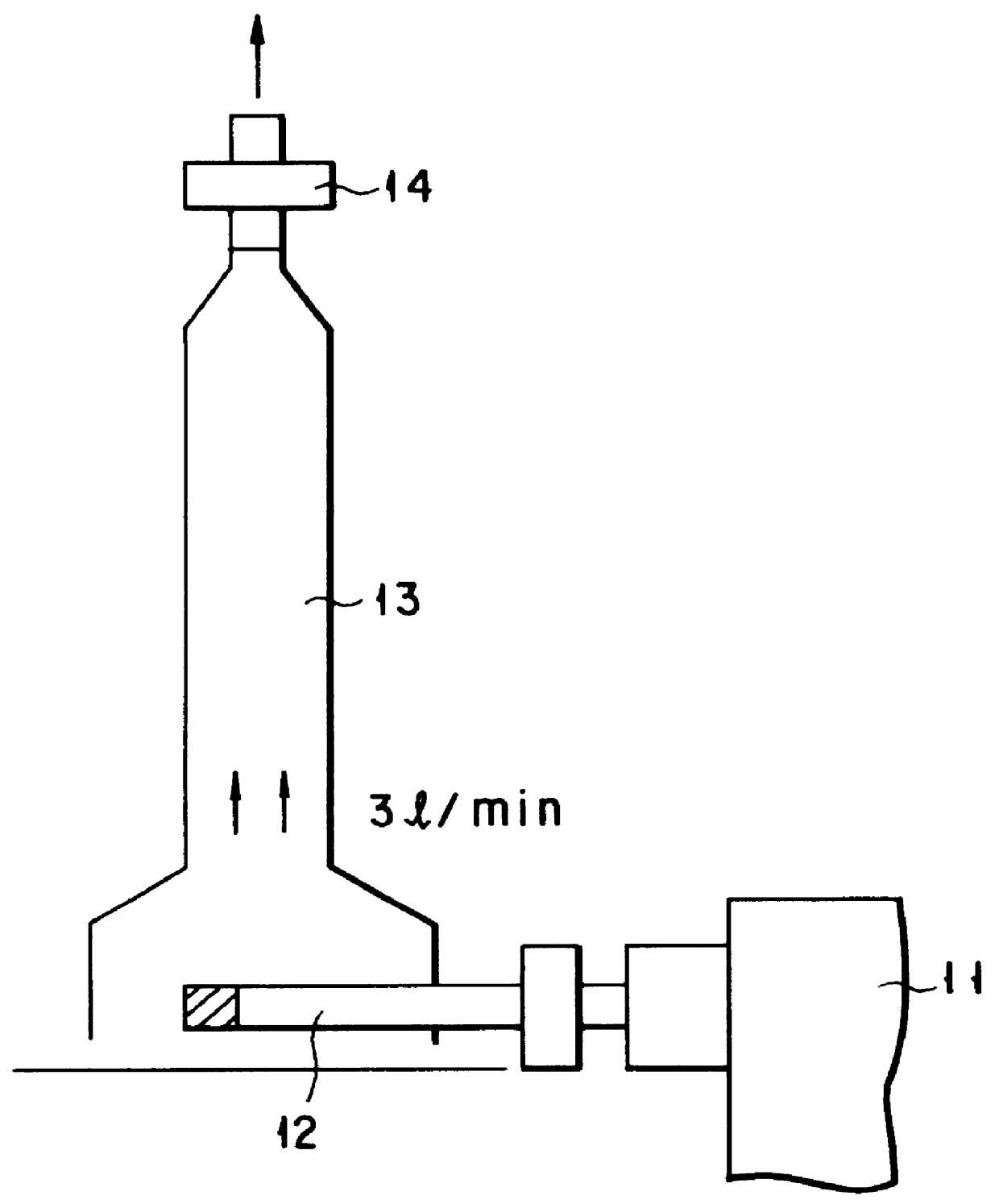

Method and apparatus for recovering inferior cigarettes and tobacco by gas separation

A method for recovering the tobacco shreds from the rejected and defective cigarettes by air separation features that the compressed air is pulsively sprayed onto the rejected and defective cigarettes to separate the tobacco shreds from paper and tip filters. Its apparatus is composed of feeding unit, shaper, conveyer, pulse spray separator, shreds recovering unit, papper and tip filter recovering unit, and electric controller.

Owner:魏积斌 +2

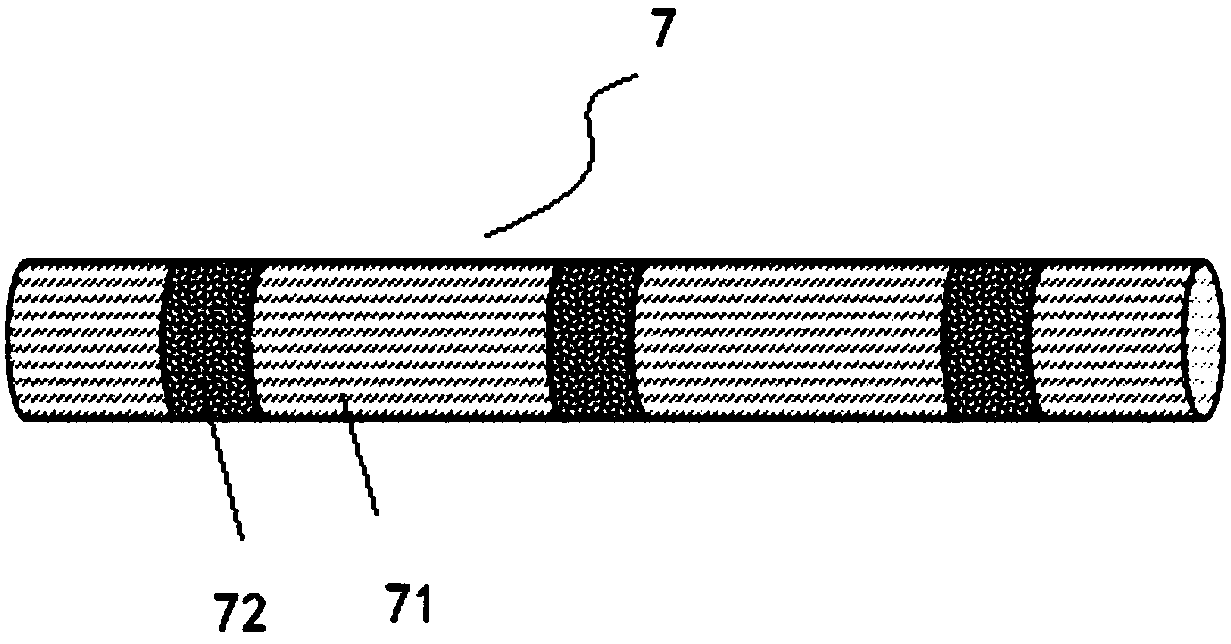

Cigarette paper with low ignition tendency and preparation method thereof

InactiveCN102094364ANon-flammableReduce the temperatureSpecial paperPaper/cardboardCombustionColloid

The invention relates to cigarette paper with low ignition tendency and a preparation method thereof. At least one thermal conductive flame retardant belt is arranged on the cigarette paper which wraps shredded tobacco; and each flame retardant belt is formed by an inner layer and an outer layer, wherein the inner layer is coated with a flame retardant colloid and the outer layer is coated with a thermal conductive flame retardant material so that the inner layer and outer layer coated thermal conductive flame retardant belt is formed. When the ignited cigarette is burnt to the flame retardant belt and makes contact with a combustible, with the presence of the inner flame retardant layer, the cigarette paper is nonflammable and the temperature is reduced; at the same time, with the presence of the outer thermal conductive layer, the temperature transferred from a cigarette combustion cone to the cigarette paper can be delivered out rapidly so that the combustion tendency of the cigarette paper is further reduced and the possibility of igniting the combustible is reduced. The flame retardant cigarette paper disclosed by the invention can satisfy the requirements of the cigarettes with low ignition tendency, is low in cost, practical and efficient, and can effectively reduce the ignition tendency of the cigarettes.

Owner:YUNNAN RES INST OF TOBACCO SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com