Preparation method of natural-textured cigarette paper

A cigarette paper and texture technology, which is applied to paper, papermaking, paper coating, etc., can solve the problems of inability to make specific textures, large amount of coloring material, single color, etc., so as to reduce the miscellaneous smell of cigarette paper and improve the quality of smoking , the effect of upgrading the grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

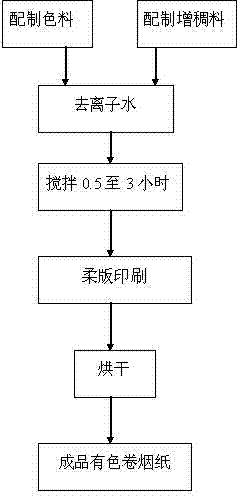

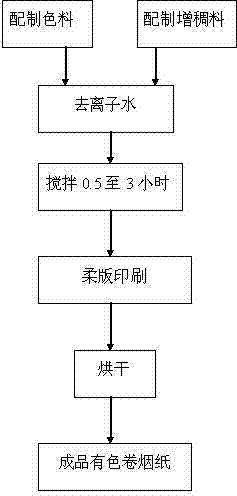

Method used

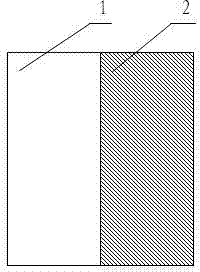

Image

Examples

Embodiment 1

[0022] A. Prepare the caramel pigment, chlorophyll, and gardenia yellow pigment at a weight ratio of 2:1:1 and prepare them as a dye for use;

[0023] B. Mix potassium alginate, guar gum, and pectin into a thickening material at a weight ratio of 5:9:2;

[0024] C. Add deionized water, coloring agent, and viscosity material at a weight ratio of 30:2:3 and mix them evenly;

[0025] D. Stir for 2h at room temperature to obtain coating liquid;

[0026] E. The coating liquid is used for flexographic printing of cigarette paper, and the control printing method is light pressure printing; the doctor blade angle is 40°; the number of printing times is monochrome; the printing width is 320mm; the printing roller is a flat roller;

[0027] F. Dry the coated cigarette paper to a moisture content of 9.7% and a drying temperature of 90°C, and print according to the above printing technical indicators to obtain a natural texture cigarette paper with stable and controllable texture;

[0028] G. Roll t...

Embodiment 2

[0030] A. Use a single caramel pigment as a coloring agent;

[0031] B. Prepare sodium alginate, guar gum, and sodium humate in a weight ratio of 5:2:7 into thickening materials for later use;

[0032] C. Mix the deionized water, coloring agent, and thickening material in sequence at a weight ratio of 30:1:1;

[0033] D. Stir at room temperature for 3 hours to obtain coating liquid;

[0034] E. The coating liquid is used for flexographic printing of cigarette paper, and the control printing method is light pressure printing; the doctor blade angle is 45°; the number of printing times is monochrome; the printing width is 1280mm; the printing roller is a flat roller;

[0035] F. Dry the coated cigarette paper to a moisture content of 8.3% and a drying temperature of 80°C, and print according to the above printing technical indicators to obtain a natural texture cigarette paper with stable and controllable texture;

[0036] G. Roll this cigarette paper into a cigarette. Use the original ci...

Embodiment 3

[0038] A. Use a single chlorophyll as a dye;

[0039] B. Prepare potassium alginate, guar gum, and potassium humate in a weight ratio of 5:5:6 to make a thickening material for later use;

[0040] C. Mix the deionized water, dye and thickener according to the weight ratio (30:2:5) evenly;

[0041] D. Stir at room temperature for 3 hours to obtain coating liquid;

[0042] E. The coating liquid is used for flexographic printing of cigarette paper, and the control printing method is light pressure printing; the doctor blade angle is 45°; the number of printing times is monochrome; the printing format is 640mm; the printing roller is a flat roller;

[0043] F. Dry the coated cigarette paper to a moisture content of 8.3% and a drying temperature of 80°C, and print according to the above printing technical indicators to obtain a natural texture cigarette paper with stable and controllable texture;

[0044] G. This cigarette paper is rolled into a cigarette, and the original cigarette paper is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com