Preparation method and application of discarded tobacco leaf fermentation extract

A technology of extracts and tobacco leaves, which is applied in the field of preparation of low-order tobacco leaf fermentation extracts, can solve the problems of affecting the taste, burnt taste, etc., and achieve the effect of improving the use effect, increasing the smoke concentration and aroma, and improving the taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

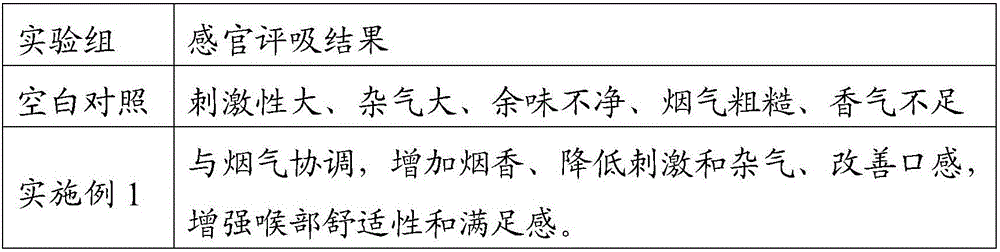

Examples

Embodiment 1

[0022] The present invention provides a kind of preparation method of low order tobacco leaf fermentation extract, comprises the following steps:

[0023] (1) Fermentation transformation of low-grade tobacco leaves: Mix low-grade tobacco leaves and water evenly at a mass ratio of 1:10, adjust the pH to 4.5 with acetic acid, and add 0.05% β- Glucosidase, stirred evenly, incubated for 12 hours to obtain tobacco biotransformation liquid;

[0024] The β-glucosidase is food grade, and the enzyme activity is 10,000 u / g.

[0025] (2) Tobacco Maillard reaction: Add 0.1% aspartic acid and 0.05% xylose, which account for the quality of low-grade tobacco leaves, and stir evenly, adjust the pH to 11 with sodium hydroxide, and pressurize the container to 0.05 MPa at 120°C. Inactivation, Maillard reaction for 3 hours to obtain natural tobacco Maillard reaction mixture;

[0026] The aspartic acid and xylose are food grade.

[0027] (3) Purification by molecular distillation: the natural t...

Embodiment 2

[0031] The present invention provides a kind of preparation method of low order tobacco leaf fermentation extract, comprises the following steps:

[0032] (1) Fermentation transformation of low-grade tobacco leaves: Mix low-grade tobacco leaves and water evenly at a mass ratio of 1:15, adjust the pH to 5.0 with acetic acid, and add 0.1% β- Glucosidase, stirred evenly, incubated for 24 hours to obtain tobacco biotransformation liquid;

[0033] The β-glucosidase is food grade, and the enzyme activity is 1000u / g.

[0034] (2) Tobacco Maillard reaction: Add 0.5% alanine and 0.05% glucose and stir evenly, and adjust the pH to 12 with sodium hydroxide. At 150° C., the pressure in the container reaches 0.07 MPa, and the enzyme is extinguished. Live, Maillard reaction 4 hours, obtain natural tobacco Maillard reaction mixture;

[0035] Both the alanine and glucose are food grade.

[0036] (3) Purification by molecular distillation: the natural tobacco Maillard reaction mixed solutio...

Embodiment 3

[0041] The present invention provides a kind of preparation method of low order tobacco leaf fermentation extract, comprises the following steps:

[0042] (1) Fermentation transformation of low-grade tobacco leaves: Mix low-grade tobacco leaves and water evenly at a mass ratio of 1:30, adjust the pH to 5.5 with acetic acid, and add 0.3% β- Glucosidase, stirred evenly, incubated for 48 hours to obtain tobacco biotransformation liquid;

[0043] The β-glucosidase is food grade, and the enzyme activity is 100u / g.

[0044] (2) Tobacco Maillard reaction: add 3% aspartic acid and 1.5% fructose that account for low quality tobacco leaves and stir evenly, adjust the pH to 14,180°C with sodium hydroxide, under pressurized conditions (the pressure in the container Reach 0.08MPa), enzyme inactivation, Maillard reaction 5 hours, obtain natural tobacco Maillard reaction mixture;

[0045] The aspartic acid and fructose are food grade.

[0046] (3) Purification by molecular distillation: t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com