Patents

Literature

6342results about How to "Unique flavor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

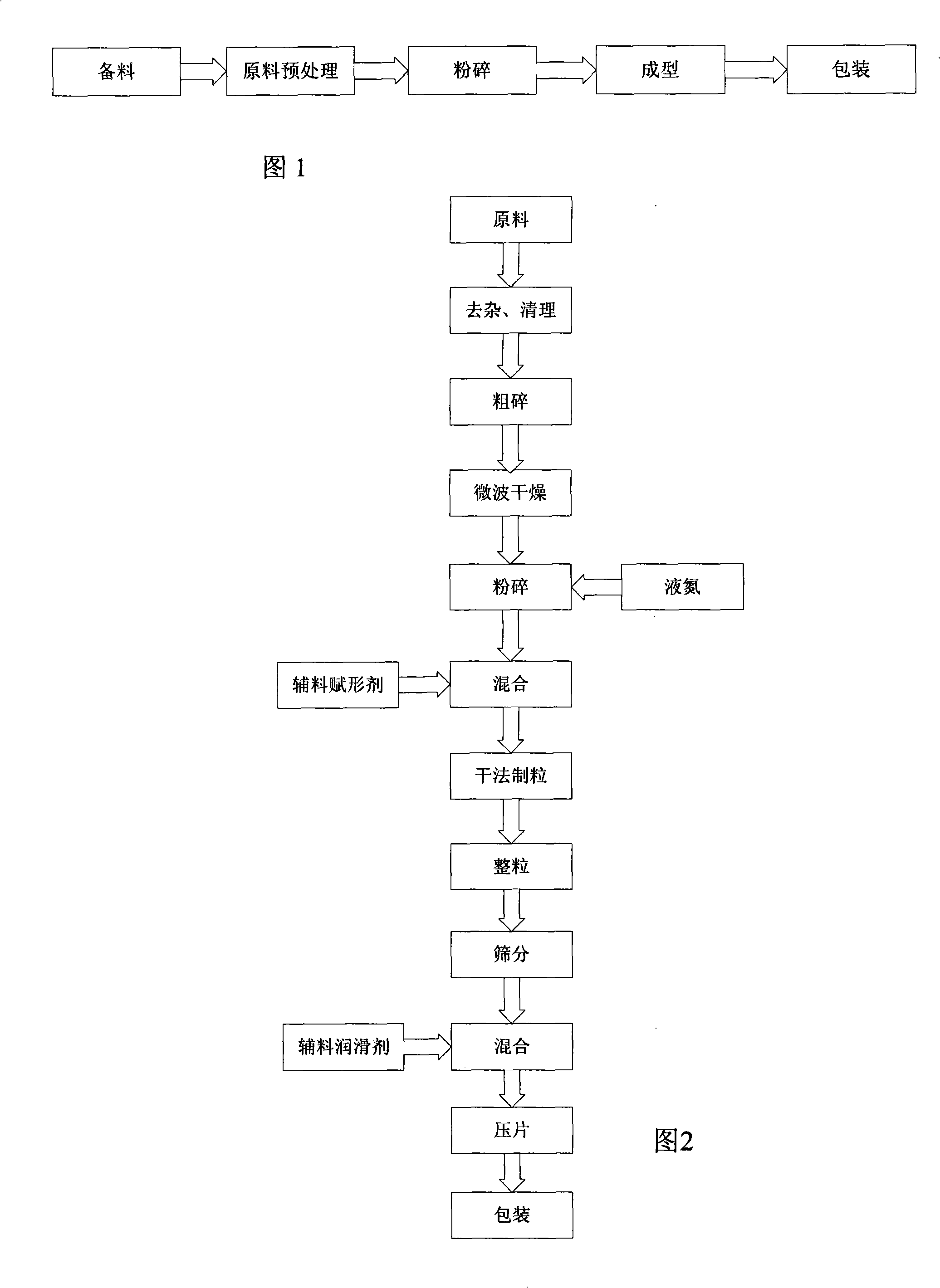

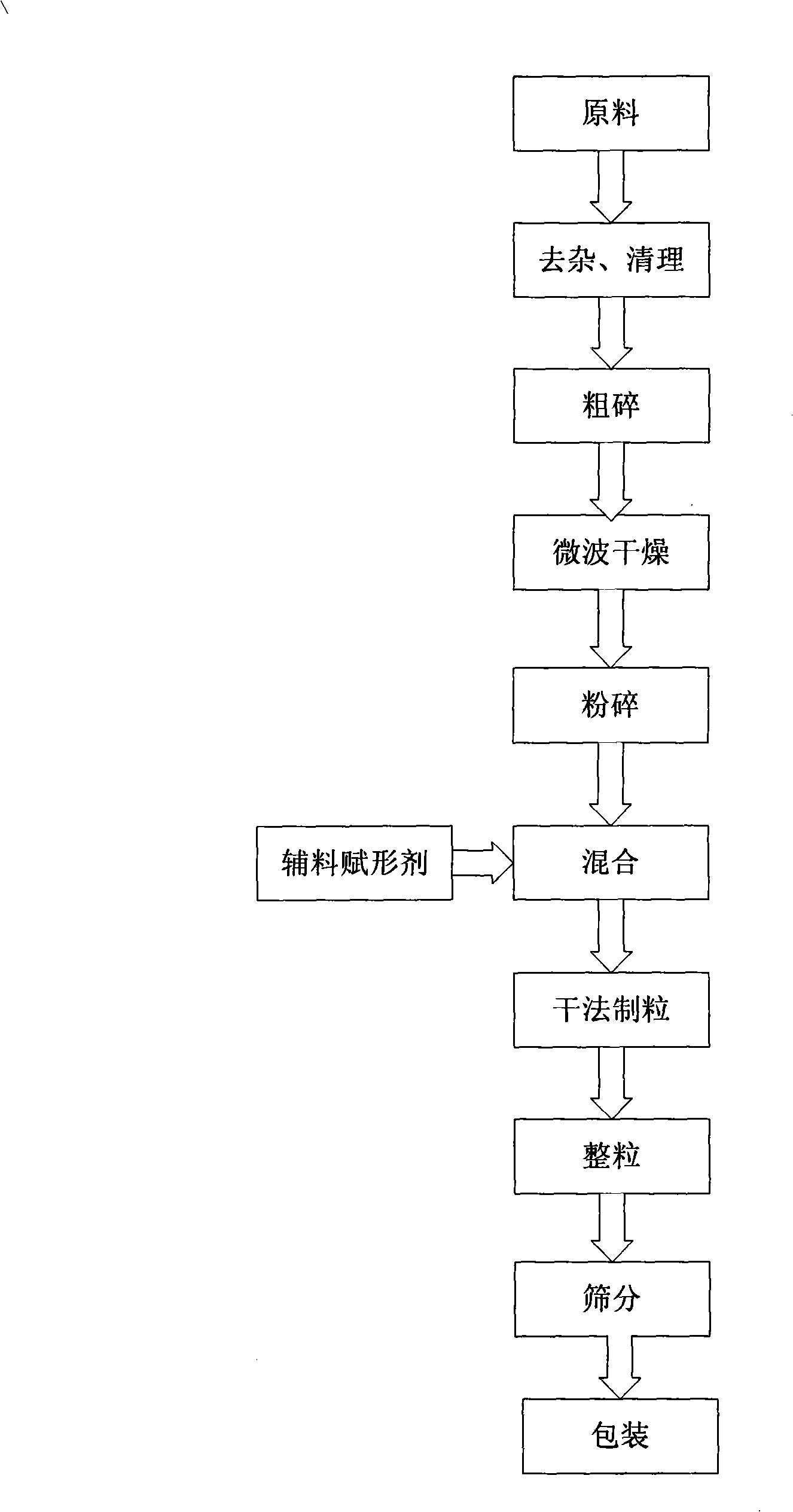

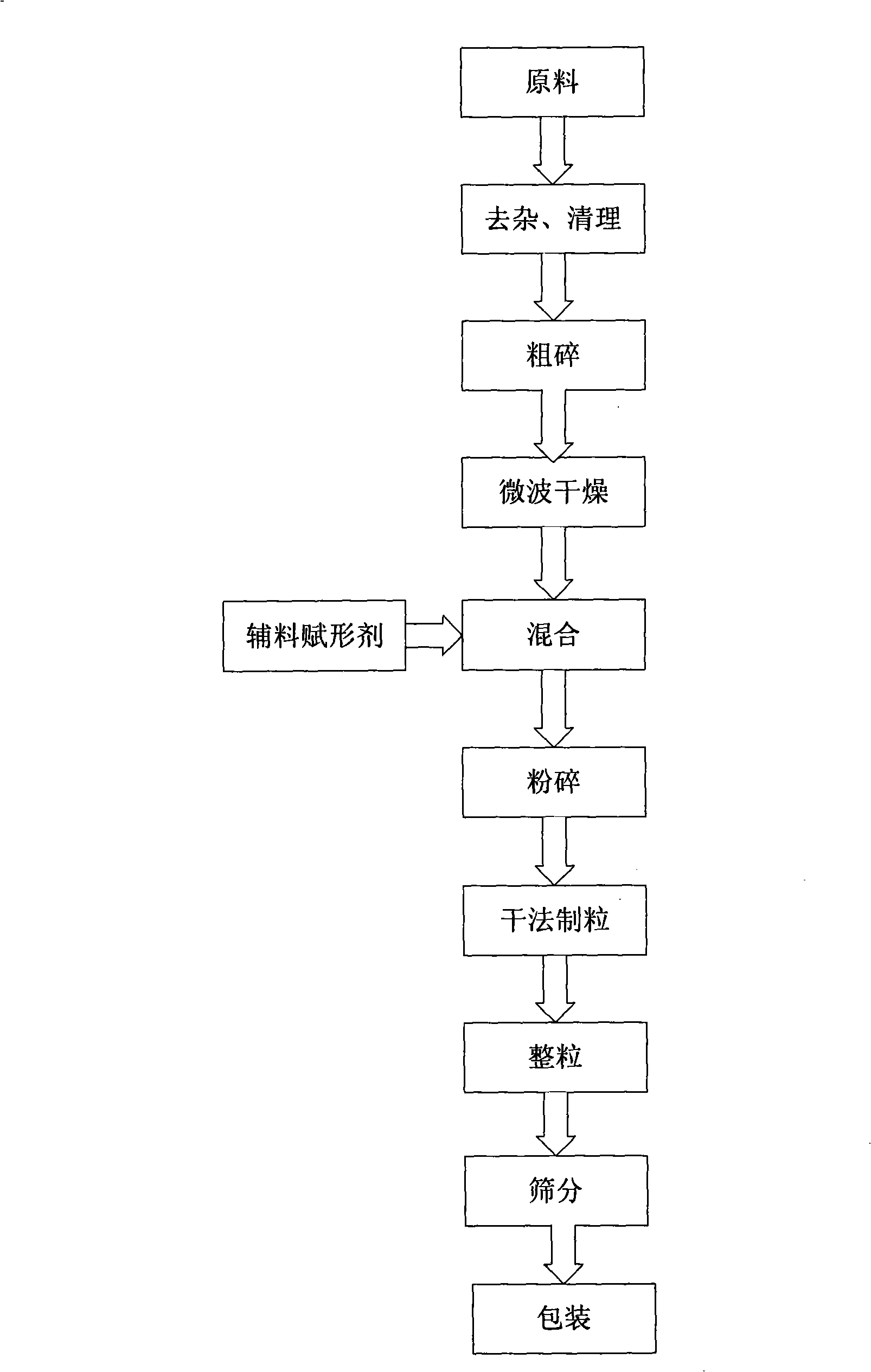

Method of preparing novel composite aromatic condiment

The invention relates to a method for manufacturing novel composite spice in the food industry technical field. The method adopts the means of effectively preserving components to thin the spice which is then manufactured into shapes such as granules, slices, blocks, balls, ellipses, cylinders, triangles, prisms and so on; and the components are preserved as possible during the preparation process, the shelf life and the use period of the spice through the method, thereby the integrity and the maximization of the 'original' flavor are achieved. The method adopts the 'complete method technique' to achieve the aim of making the best use of things. The method utilizes spice resource to the maximum degree, and has great significance on improving the added value of spice agricultural products,the product quality, and the standardization and industrialization degree and reducing the resource waste.

Owner:山东龙脉中医药科技有限公司

Marine product meat sausage and making method thereof

The invention discloses a marine product meat sausage and a making method thereof. The marine product meat sausage is characterized by comprising the following raw materials proportioning by weight: 30-85 portions of marine product, 0-30 portions of edible meat, 10-30 portions of edible water, 1-12 portions of edible vegetable oil, 2-6 portions of soybean protein isolate, 0.5-1.6 portions of saltand 2.0-7.5 portions of starch; the marine product meat sausage is prepared according to the steps of raw material processing, twisting, chopping, stirring, filling, sterilizing and packaging. The invention is prepared by adopting the marine products (scallop muscle, oyster meat, sleeve-fish meat, salmon meat, shrimp meat, trepang, abalone, yellow croaker meat, hairtail meat, fish seeds, ling meat, waste fish meat and the like) or adding the edible meat (chicken, pork, mutton, beef and the like) as the main raw materials, has abundant and balanced nutrition, meets the requirement of a consumeron the marine products and increases the appetite, and the product has strong seafood taste and unique flavor, does not contain nitrite, is beneficial to health, is packaged in vacuum, has unique appearance and is ready to be enjoyed when a bag is opened.

Owner:青岛农博农食品科技有限公司

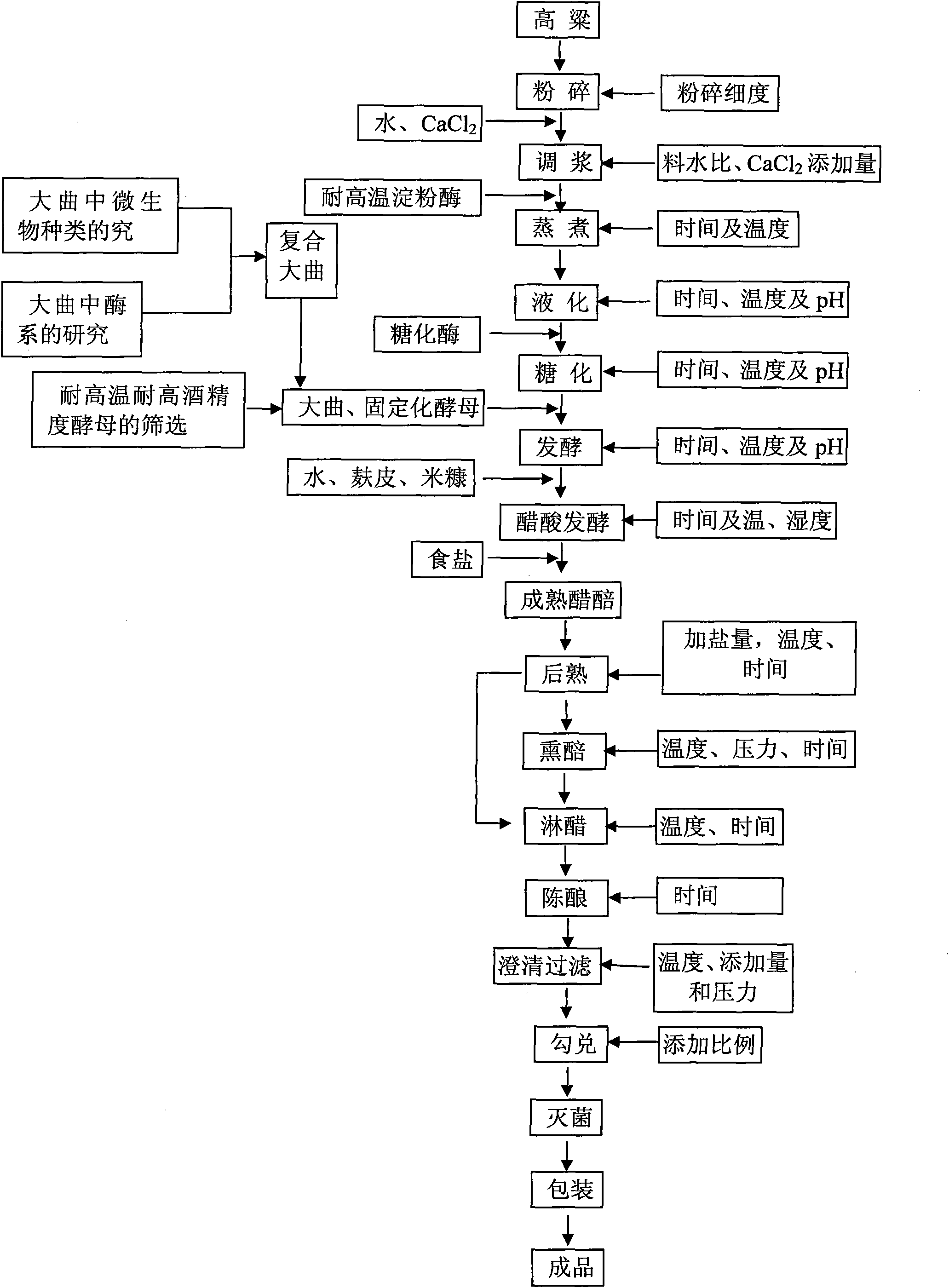

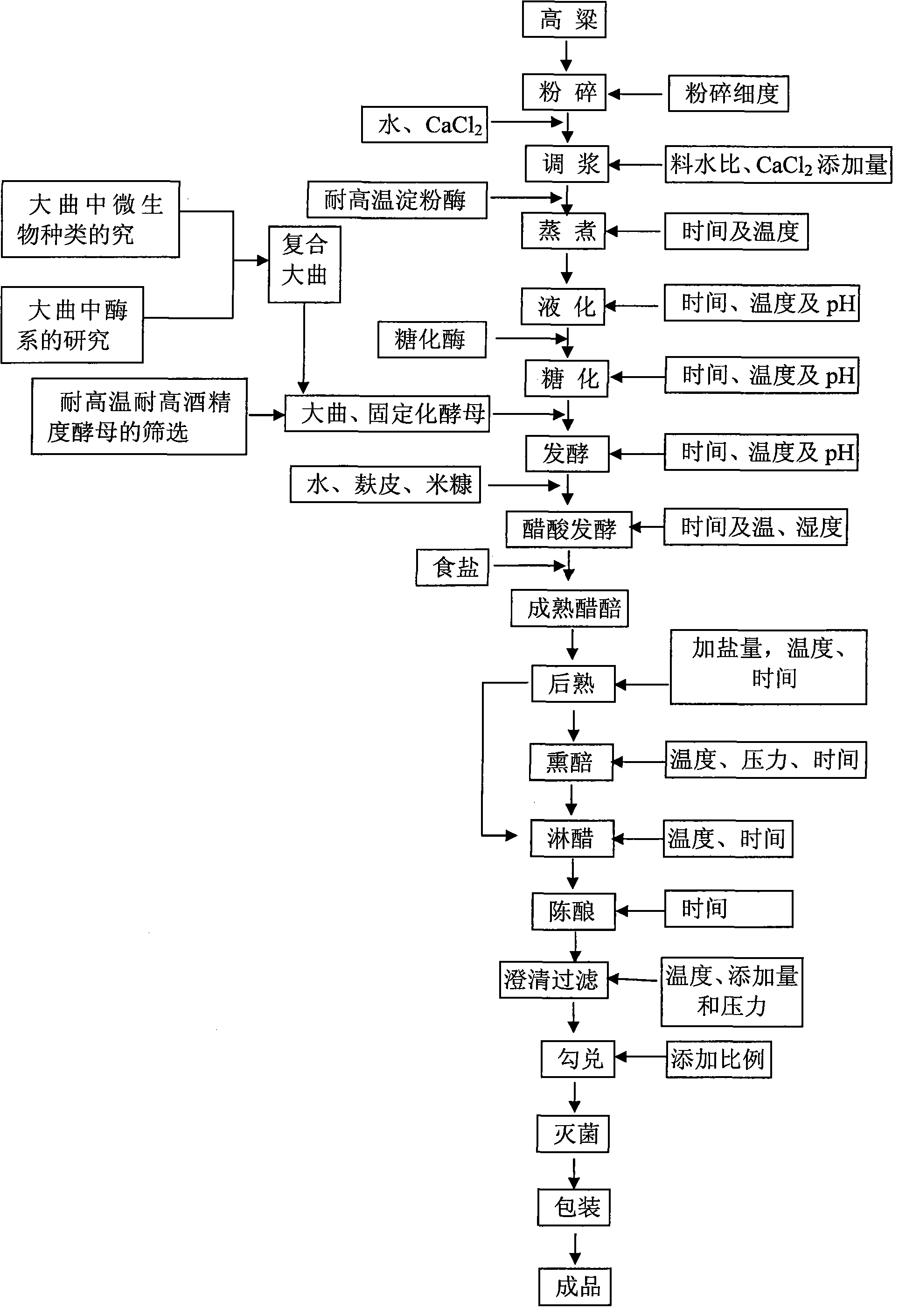

Standardized and industrialized production process for Shanxi mature vinegar

ActiveCN101857833ASystematization of processHigh technology contentMicroorganism based processesVinegar preparationMaterials processingSaccharomyces

The invention relates to a production process for vinegar, in particular to the standardized and industrialized production process for Shanxi mature vinegar, which solves the problems of long production process period, complex process, unstable product quality, low raw material utilization rate and the like, of the prior production process. The production process comprises the following steps of: performing material processing before alcoholic fermentation, crushing, mixing, liquefaction and saccharification; selecting high-temperature resistant and high-alcoholic strength resistant saccharomyces, and adding a composite yeast to perform alcoholic fermentation; adding the composite acetic bacteria into vinegar residue, stirring with a vinegar residue stirrer, fermenting the vinegar residue in an acetyl hydrate fermenting tank, and turning the vinegar residue with a vinegar residue turning machine; tamping the vinegar residue in the acetyl hydrate fermenting tank, covering a layer of table salt on the tamped vinegar residue, and standing the vinegar residue; fuming the vinegar residue by the combination of a vinegar residue fuming furnace and a steam vinegar residue fuming jar; pouring vinegar; ageing the vinegar; clarifying the vinegar with a crude acidic protease, and filtering the vinegar with kieselguhr; blending the vinegar and the traditional Shanxi mature vinegar; sterilizing the vinegar; and packing the vinegar. The process of the invention has the advantages of systematized flow, standardized technological parameters, scale production procedure, normalized product quality and optimized production process.

Owner:山西金龙鱼梁汾醋业有限公司

Quick preparation method for pickled vegetable containing biodiasmin

InactiveCN103120294AImprove production efficiencyIncrease productivityFood preparationVegetable processingSalt content

The invention provides a quick preparation method for a pickled vegetable containing biodiasmin. The quick preparation method comprises the following steps of: preparing biodiasmin liquor, preparing pickled vegetable fermentation liquor, preparing a seasoning fermentation liquor, pre-treating and preparing a finished pickled vegetable containing biodiasmin. According to the quick preparation method disclosed by the invention, the pickled vegetable fermentation liquor is independently prepared according to the conventional pickled vegetable production way, and the pickled vegetable fermentation liquor is treated by seasoning to form seasoning fermentation liquor; osmotic dehydration and the brittleness-keeping treatment are carried out on the fresh vegetable to obtain a semi-finished product; and the semi-finished product is pickled by the seasoning fermentation liquor, and the seasoning fermentation liquor is quickened up to permeate into the vegetable through the vacuum treatment to obtain the delicious finished pickled vegetable. The pickled vegetable is prepared by the preparation method disclosed by the invention is low in salt content, short in production time, high in calcium content and biodiasmin content and beneficial to the body health of a user; and moreover, the automation degree of the pickled vegetable processing is improved.

Owner:HEFEI UNIV

Mushroom sauce and preparation method thereof

The invention relates to the technical field of deep processing of mushroom, in particular to a mushroom sauce and a preparation method of the mushroom sauce. The invention aims to solve the problem that current homemade mushroom is poor in taste, and provides the mushroom sauce with unique flavor. The mushroom sauce comprises the following components in parts by weight: 10-15 parts of edible oil, 50-60 parts of mushroom, 5-6 parts of sweet soybean paste, 5-6 parts of fermented soya beans, 5-6 parts of bean sauce, 3-7 parts of carrot, 1-3 parts of onion, 0.1-0.3 parts of sesame, 1-3 parts of table salt, 2-4 parts of white sugar, 0.5-1 parts of monosodium glutamate and 0.8-1 parts of spice. The mushroom sauce is mellow, concentrated, and oil but not greasy, pliable and tough, spicy but not dry, fresh and tasty, and has flickering bakery spices flavor, unique spicy flavor. The mushroom sauce is a tasty food which is low in salt, healthy and convenient and light but thin in flavor.

Owner:山西沐风农林开发有限公司

Former hot blast and latter vacuum microwave combining drying process of producing crisp fruit and vegetable grains

InactiveCN1672531AReduce drying loadReduced moisture removal requirementsFruits/vegetable preservation by dehydrationWater contentFood processing

The present invention is former hot blast and latter vacuum microwave combining drying process of producing fruit and vegetable grains, and belongs to the field of fruit and vegetable food processing technology. The drying process includes the steps of: washing fruit and vegetable material, dicing, scalding to killing enzyme, cooling in flow water, draining, optional fast freezing and defrosting, soaking with seasoning, draining, pre-dewatering with hot blast to obtain semi-finished product with water content of 40-60 %, and final vacuum microwave drying to obtain product with water content of 2-5 %. The said process has the nutritious components and color well maintained, crisp product, short production period, low cost, high product quality and other features.

Owner:JIANGNAN UNIV

Cherry fruity ice cream and its preparation method

The invention discloses a cherry fruity ice cream and its preparation method. The cherry fruity ice cream is made from the following raw materials of: by weight, 40-60 parts of a cherry juice, 8-15 parts of a strawberry juice, 8-15 parts of a watermelon juice, 40-60 parts of whole milk, 10-20 parts of white sugar, 5-10 parts of cream and 30-50 parts of water. The preparation method comprises the following steps of: 1) uniformly mixing each raw material to obtain a mixture; 2) sterilizing the mixture; 3) putting the mixture into a homogenizer for homogenization; 4) rapidly cooling the mixture to minus 2-4 DEG C, and aging at the temperature; and 5) filling the aged mixture into a stirring barrel of a freezing machine, freezing at the stirring state, taking out, packaging, and quick-freezing and hardening to obtain the ice cream. The ice cream provided by the invention has a simple preparation method, contains no chemical additive, and has health-care effects of whitening, beautifying, clearing away summer heat, strengthening physique and the like.

Owner:张小钰

Potato ice cream

The invention relates to an ice cream, and specifically relates to a potato ice cream. The potato ice cream has a great taste, and abundant nutrition. A technical scheme adopted by the invention is characterized in that the potato ice cream comprises 10-50wt% of meshed potato, 13-15wt% of white granulated sugar, 2-5wt% of shortening oil, 2-10wt% of whole milk powder, 3-5wt% of a glucose syrup, 0.5wt% of an emulsification stabilizing agent, 0.1wt% of a fresh milk essence, and the balance water.

Owner:张占斌

Leisure vegetarian meat based on textured soybean protein

ActiveCN103734454ARich categoryFull of nutritionCheese manufactureVegetable proteins working-upVegetarian dietsMeat fibers

The invention discloses leisure vegetarian meat based on textured soybean protein. The vegetarian meaty food is prepared from the textured soybean protein as a raw material by the procedures of soaking and cleaning to remove beany flavor and peculiar smell, dewatering, surface oiling and sizing, imitating meat to supply flavors, sterilizing at high temperature and the like. The product is free of beany flavor, abundant in nutrient, convenient to carry, high in meat imitating degree, and moderate in saltiness and sweetness, mellow and delicious, strong in sensual appeal, and unique in flavor, has the chewing feeling of a real meat fiber and the flavor of meat, is a novel instant leisure flavor vegetarian product. Not only is the variety of the leisure bean products enriched, but also a new convenient and delicious choice is provided for vegetarian crowd.

Owner:ZUMING BEAN PROD

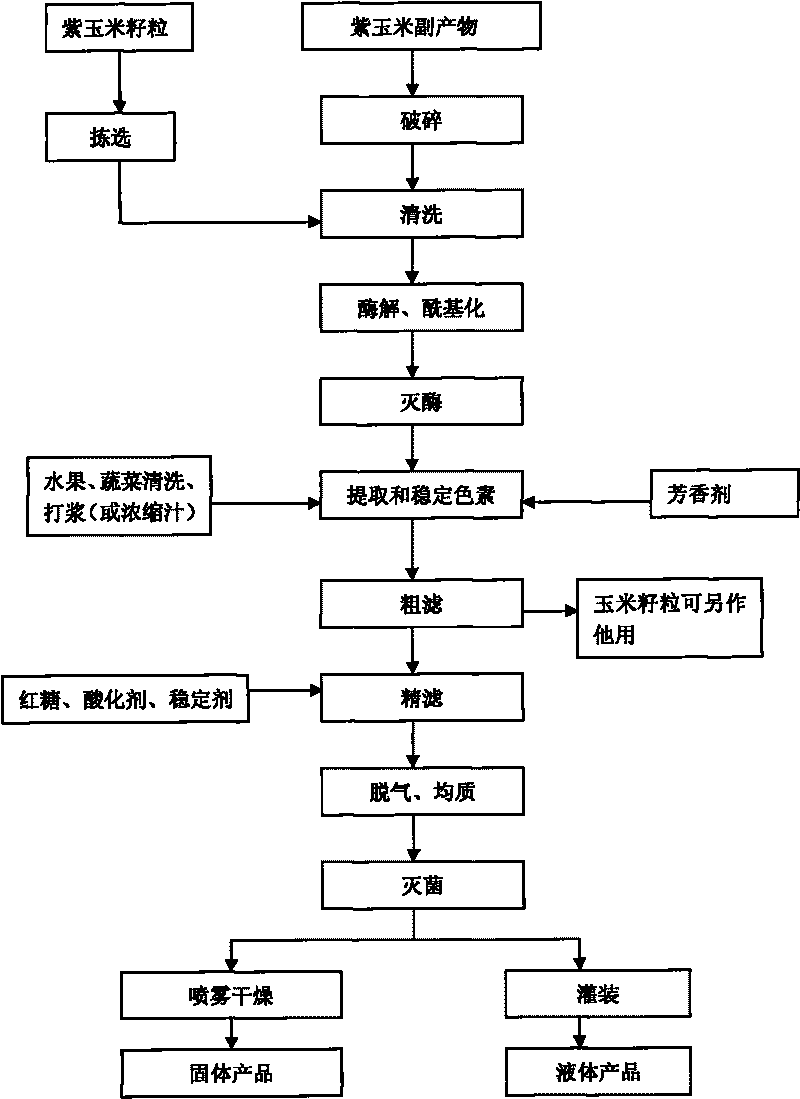

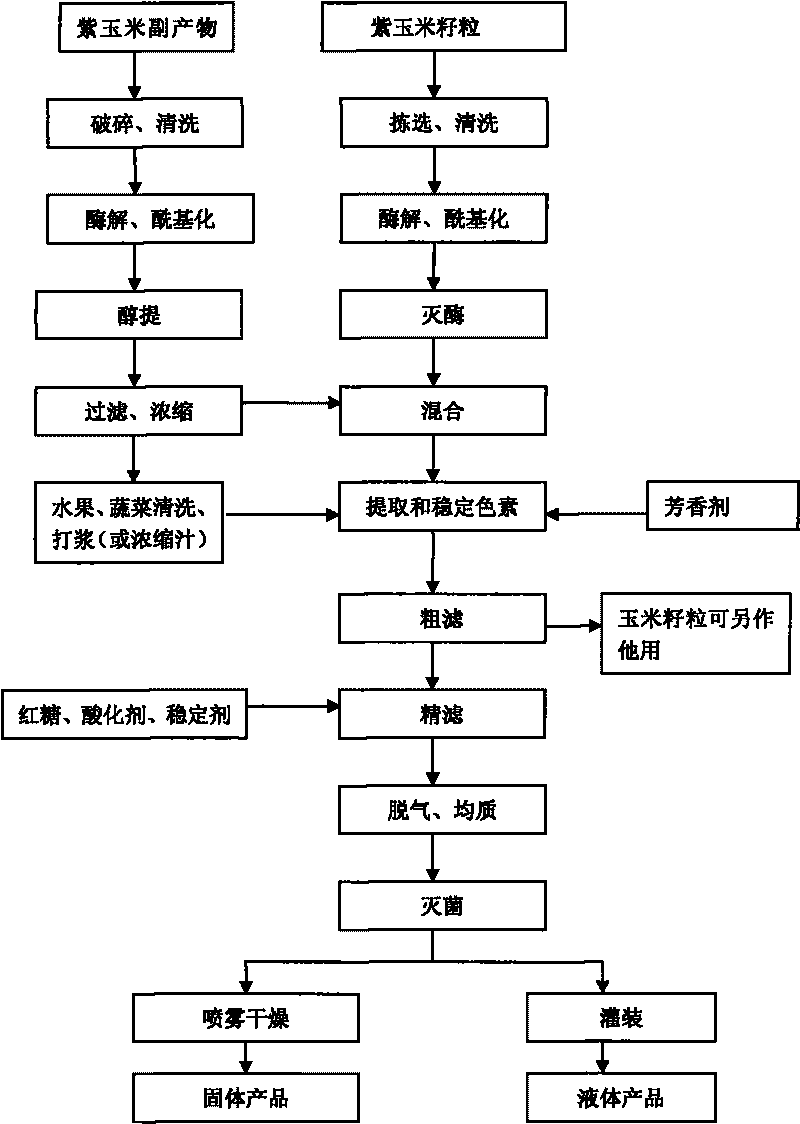

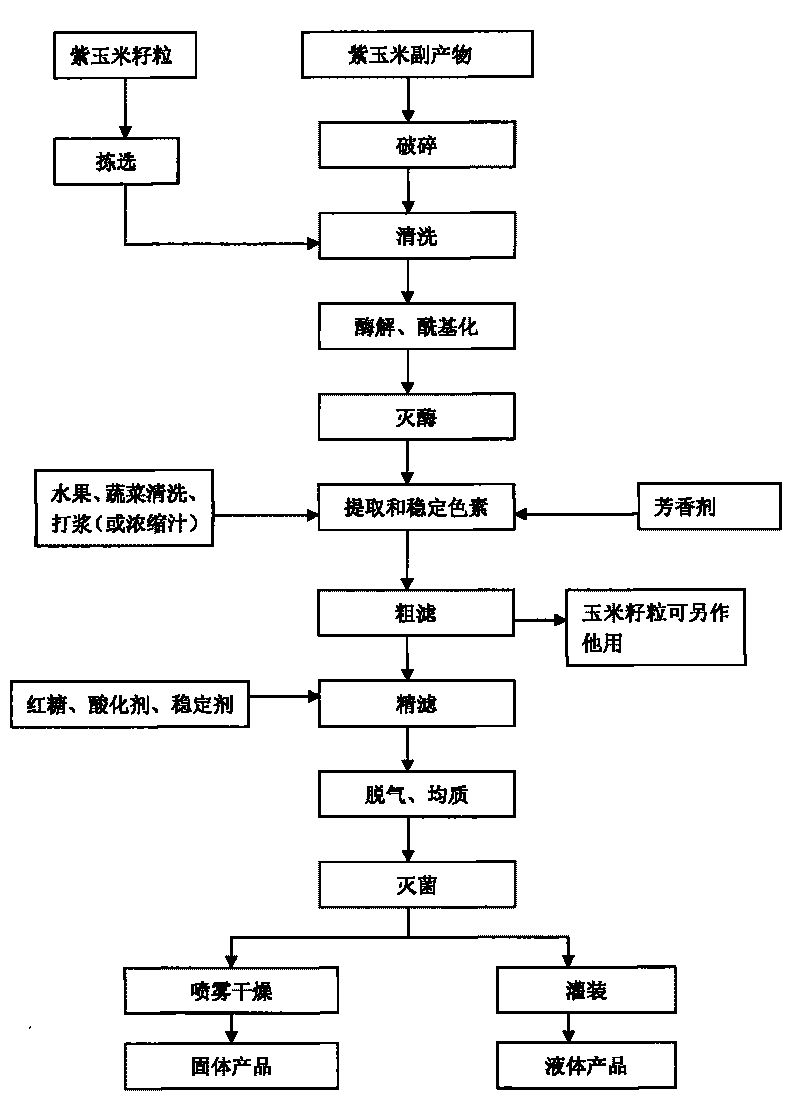

Purple corn beverage and preparation method thereof

The invention provides a purple corn beverage and a preparation method thereof. The major raw materials of the beverage are purple corn seeds and purple corn byproducts, fruit and vegetable pulp and flavorings are added to the beverage, and the beverage is treated by enzymolysis and acylation, so that cyanidin in the raw material purple corn is effectively extracted and stably stored in the beverage, thereby obtaining a purple corn beverage with rich cyanidin and unique taste.The scheme of the invention realizes the overall utilization of the purple corn plants; the cyanidin provides the function of health care, and the fruits, vegetables and flavorings not only feature the unique mouthfeel, but also boast various nutrient contents; and thus, the purple corn beverage is a novel health care beverage.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

Method for processing marinated beef with bean fragrance and marinated beef with bean fragrance

The invention provides a method for processing marinated beef with bean fragrance. The method comprises the following working procedures of marinating beef, cooking beans, mixing the beef and the beans, packaging in vacuum, sterilizing and putting a finished product into a storehouse. The marinated beef with the bean fragrance has rich nutrition; the meat is soft, tender and matured; the fragrance is rich; the taste is proper; the flavor is unique; the meat has high protein, low fat and high calcium; the marinated beef with the bean fragrance has the health protection effects of tonifying the spleen, stimulating the appetite, moistening the lung, reducing the lip, promoting the sleeping and the like and also has the effects of nourishing the body, complementing the calcium, expelling the toxin, beautifying and eliminating acne; the processing technology is scientific; and nitrite is eliminated.

Owner:ANHUI GUANGZHENG FOOD

Probiotic fruit and vegetable enzyme drink and preparation method thereof

PendingCN107348272AHigh activityHigh nutritional valueFood ingredient for microbe protectionNutritive valuesLactobacillus paracasei

The invention provides a probiotic fruit and vegetable enzyme drink and a preparation method thereof. Fruits and vegetables as well as four-in-one PPHR Lactobacillus powder (including Lactobacillus paracasei, L. plantarum, L. helveticus and L. rhamnosus) are mixed and the obtained mixture is fermented, and the obtained fermented product is the probiotic fruit and vegetable enzyme drink. Compared with the prior art, the preparation method has the advantages that the fermentation process can be shortened, the fermentation process can be simplified, the nutritional value of fruit and vegetable juice can be increased, the fruit and vegetable juice is endowed with higher oxidation resistance, and the application range of Lactobacillus in food, particularly drinks, is broadened.

Owner:恒利康生物科技股份有限公司

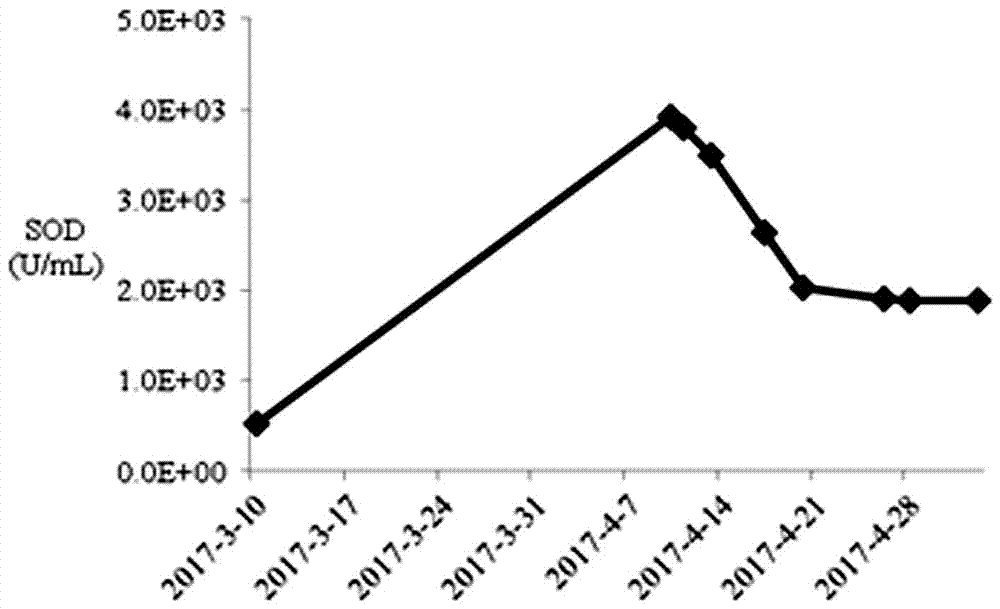

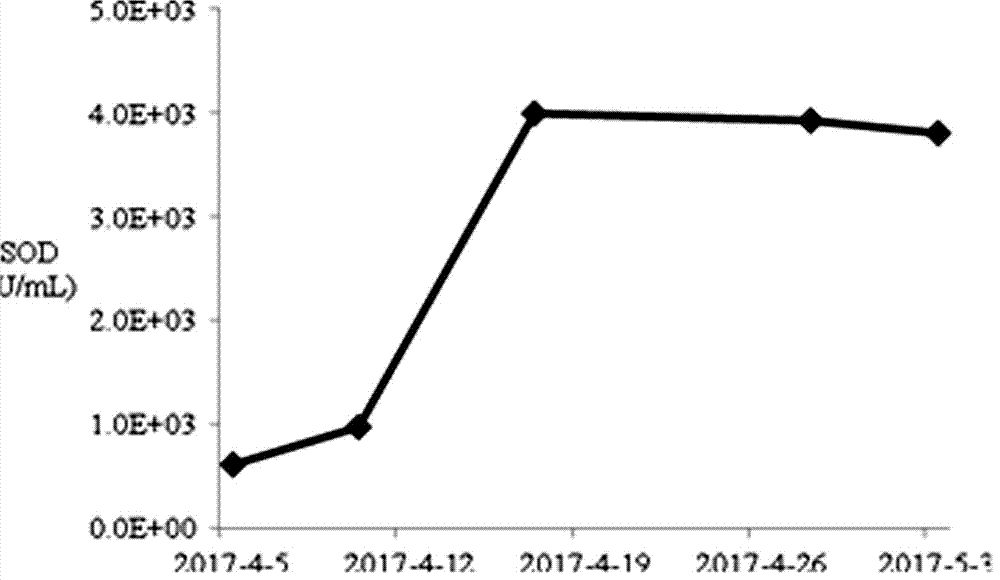

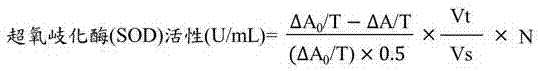

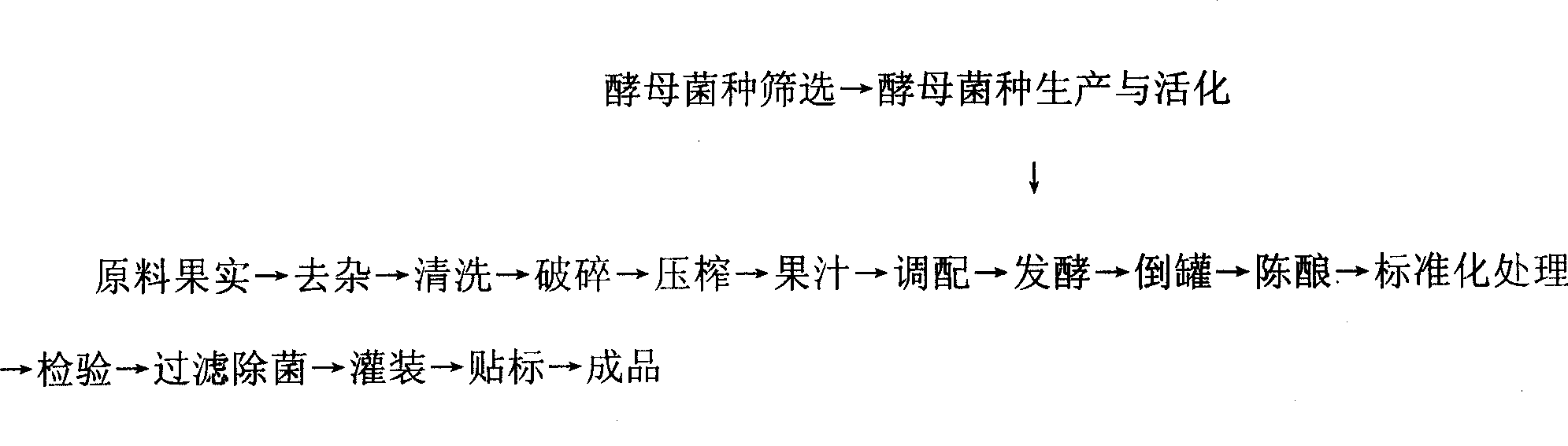

Aroniamelanocarpa fruit wine and brewing method thereof

InactiveCN101481643ARaw materials are uniqueFull of nutritionAlcoholic beverage preparationFruit juiceAntioxidant

The invention relates to an aroniamelanocarpa fruit wine and a brewing method thereof. The fruit of aroniamelanocarpa is taken as raw material and is made into fruit juice, fruit wine microzyme is selected for use and put into the fruit juice according to the proportion being 5-10% of the weight of the fruit juice, and the aroniamelanocarpa fruit wine is brewed with the alcohol content of 5-13% (v / v) and the total sugar content of 4.0-80.0g / L. The brewing technique of the invention comprises preparing the fruit juice, inoculation and fermentation, aging and store maturity, purifying wine body as well as filtration and sterilization, and the most advanced fermenting and purifying technique can be adopted by the production. The product of the invention has unique flavor, slightly acerbic and fresh taste, mellow mouthfeel, pleasing aroma and wide applicable people. The fruit wine contains multiple nutritional functional components such as anthocyanin, flavone, polyphenol active substance, vitamins antioxidant, mineral composition, polyoses, organic acid and the like which are rich in the fruit of aroniamelanocarpa, and has good effects of oxidation resistance, ageing prevention, blood pressure regulation, vessel relaxing, blood-fat reduction, anti-inflammation and detoxification, radiation resistance, etc.

Owner:辽宁省干旱地区造林研究所

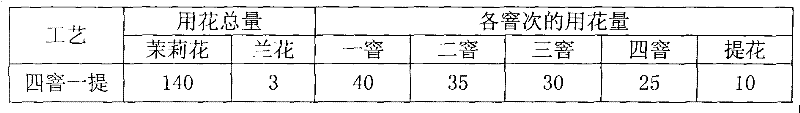

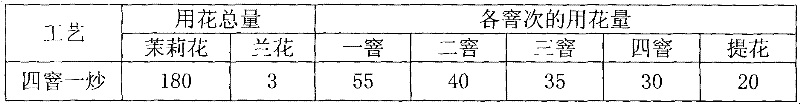

Production technology of orchid fragrance type jasmine tea

ActiveCN102450348ASolve the problem of single fragranceUnique flavorPre-extraction tea treatmentFood flavorChemistry

The invention relates to a processing technology of a scented tea, and especially relates to a production technology of an orchid fragrance type jasmine tea. The production technology of the orchid fragrance type jasmine tea, which comprises three operations of tea blank processing, fresh flower processing and scenting, allows a single fragrance problem of present scented teas to be effectively solved, a tender tea fragrance, an orchid fragrance and a jasmine fragrance to be ingeniously fused and a specific mixed fragrance to be generated. Release speeds and endurances of the orchid fragrance and the jasmine fragrance in a tea soup are different, so the fragrance of the tea soup, which has a change trend of the jasmine fragrance - the mixed fragrance - the orchid fragrance, has a unique flavor.

Owner:艾秀群

Flavored bittern fish food and preparation method thereof

The invention discloses a flavored bittern fish food and a preparation method thereof. The preparation method comprises the following steps: 100 parts of cleaned and drained block fish or meat is added with 1 part of common salt and 6 parts of cooking wine to be evenly mixed for 30-minute curing, and then the obtained mixture is taken out for 2-hour air drying, and the air-dried fish or meat is deep-fried for 10-12 minutes and added with 100 parts of bittern blending materials for 5-10 minutes of soaking, thus preparing the flavored bittern fish food. The flavored bittern fish food has the advantages of special flavor, rich nutrition, high safety and convenient eating.

Owner:武汉大汉口食品有限公司

Lactobacillus plantarum fermented milk and preparation method thereof

ActiveCN103004984ASolve the limiting factorsSolve production technical problemsMilk preparationCow milkingMicroorganism

The invention discloses Lactobacillus plantarum fermented milk and a preparation method thereof, and relates to fermented milk in the technical field of microbial fermentation. The Lactobacillus plantarum fermented milk comprises the following components in percentage by mass: 84-99.5% of cow milk, 0.035-0.7% of amino acid, 0.001-0.1% of nucleotide, 0.01-15% of sweet substance, 0.1-1% of thickening agent, 0.01-0.1% of flavoring essence and 1.0*10<6>-1.0*10<7>CFU / mL of leavening. The preparation method preferably adopts a stirring manner and a solidifying manner. According to the invention, restrictive factors of Lactobacillus plantarum grow and reproduce in the milk are overcome; the fermented milk has good mouthfeel and flavor and high Lactobacillus plantarum content, thereby obtaining greatly improved probiotic function.

Owner:武汉光明乳品有限公司

Production method for mycelium pellets of edible and medicinal fungi and products of mycelium pellets of edible and medicinal fungi

InactiveCN102550285AFull of nutritionUnique flavorHorticultureFertilizer mixturesBiotechnologyMycelium

A production method for mycelium pellets of edible and medicinal fungi uses fruit and vegetable juice as main materials obtained by liquid fermentation, and fermentation medium with pH5-8 is made of the fruit and vegetable juice 50-300ml / L, granulated sugar 5-20g / L, KH2PO4 1-5g / L, MgSO4X7H2O 1-5g / L, ZnSO4X7H2O 0-0.5g / L and CaCO3 3-7g / L by adding water to meter the volume. The mycelium pellets of edible and medicinal fungi produced by the method and products of the mycelium pellets have the colors of natural fruit and vegetable juices and functional ingredients of edible and medicinal fungi, and the products are nutritious, unique in flavor, bright and attractive, and have the health functions of coloration, fragrance and taste, and have great market potential.

Owner:YUANTUO FUZHOU BIO TECH

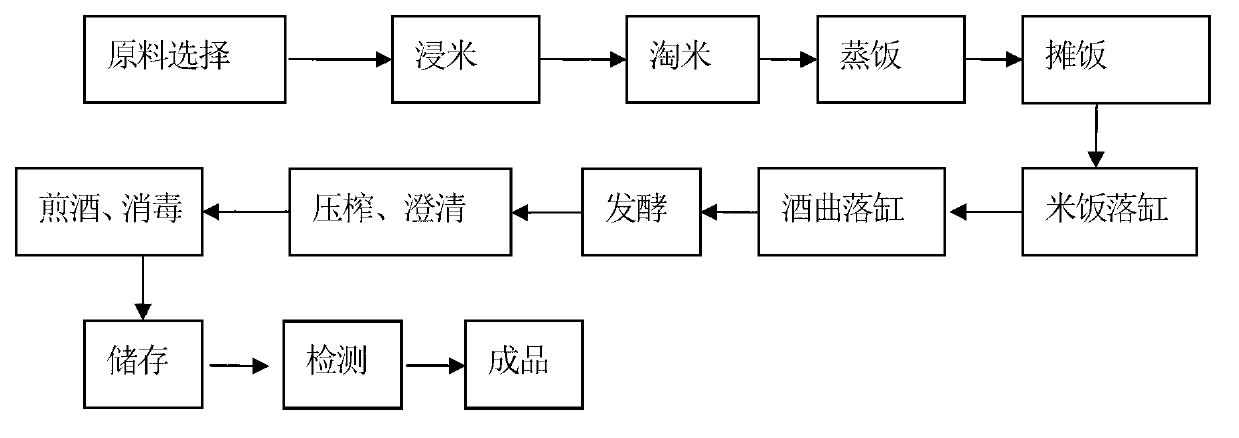

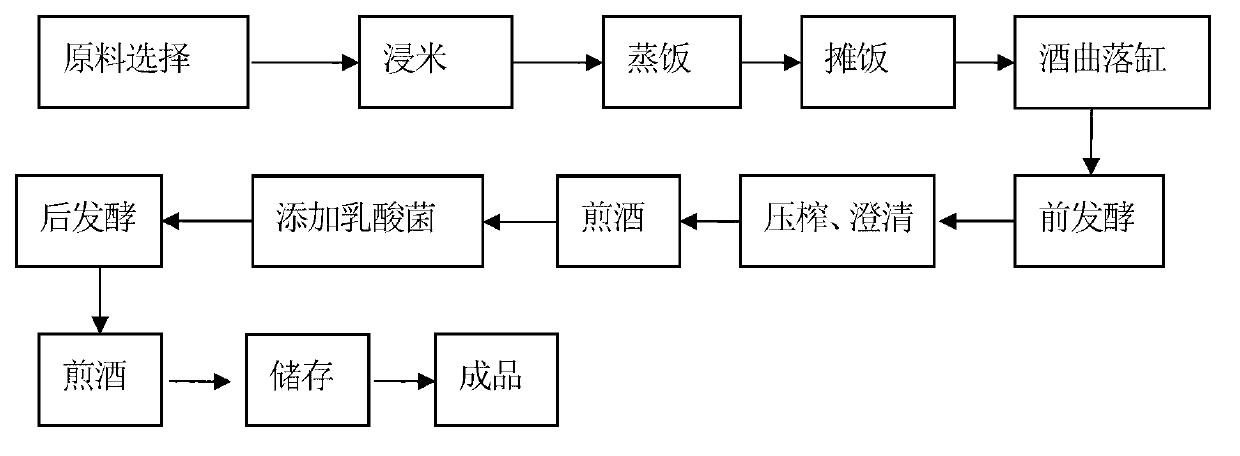

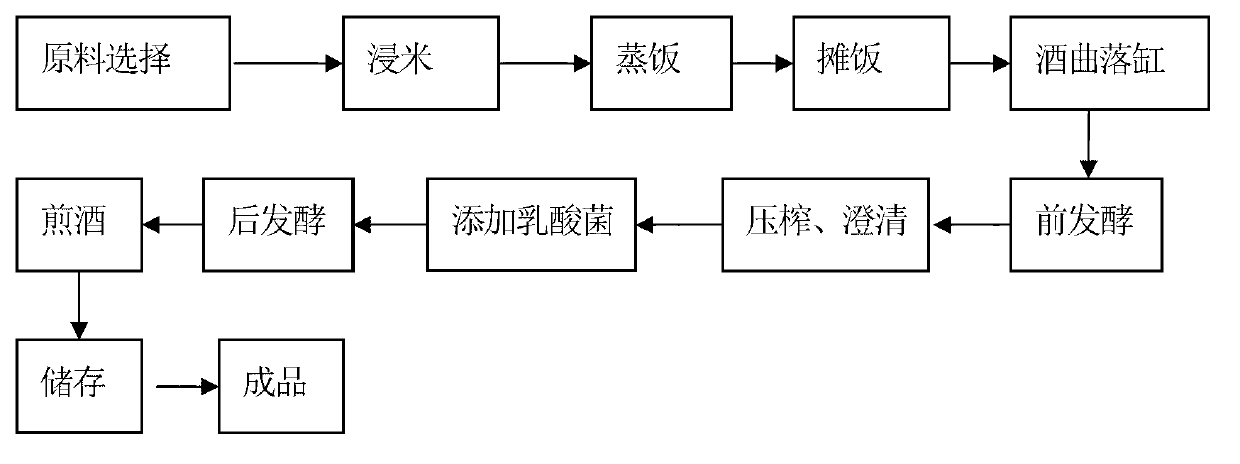

Method for producing millet wine by using lactobacillus fementation

ActiveCN102994318AUnique flavorIncrease contentAlcoholic beverage preparationMicroorganism based processesFlavorMicrobiology

The invention discloses a method for producing millet wine by using lactobacillus fementation. The method comprises steps of primary fermentation and secondary fermentation, and the secondary fermentation is that lactic acid bacteria are added in wine liquid to ferment, adding proportion of the lactic acid bacteria is 105-109CFU / mL, and the lactic acid bacteria are compositions of any one or more than two of lactic acid bacteria of oenococcus, lactic acid bacteria of lactobacillus, lactic acid bacteria of leuconostoc and lactic acid bacteria of pediococcus. The lactic acid bacteria are externally planted in the method, lactic acid and antibacterial peptide produced by the lactic acid bacteria can restrain movement of other bacteria, so that the lactic acid and the antibacterial peptide have inbibitional effects on rancidity, problems of reduced wine yield and damaged end product wine flavor of caused by rancidity are avoided, flavor of the obtained millet wine is special, and the method is favorable for product stability in an after-ripening process of the millet wine.

Owner:杜林

Method for processing bean pig trotter and bean pig trotter

The invention provides a method for processing bean pig trotter. The method comprises the following working procedures of marinating a pig trotter, cooking beans, mixing the pig trotter and the beans, packaging in vacuum, sterilizing and putting a finished product into a storehouse. The bean pig trotter manufactured by the method retains the nutrient components of the pig trotter and the beans to the maximum extent, has high protein and low fat, is rich in nutrition, spicy and delicious and rich in taste, has various effects of softening the blood vessel, moisturizing the skin and delaying aging and has rich nutrition; the meat is soft, tender and matured, has rich fragrance, proper taste and unique flavor and has health protection effects of tonifying spleen; under often use, body building can be realized, and the activity and the energy are enhanced; effects of tonifying kidney and spleen, stimulating the appetite, moistening lung, reducing sputum, reducing lip, complementing calcium and the like are achieved; the processing technology is scientific; nitrite is not produced; and the bean pig trotter is healthy.

Owner:ANHUI GUANGZHENG FOOD

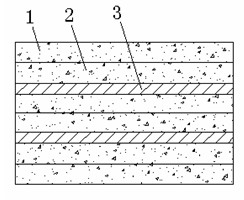

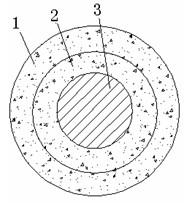

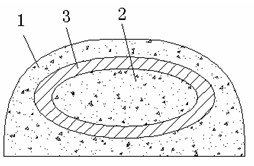

Nutrient noodle and preparation method thereof

InactiveCN102125072ASatisfy meat and vegetablesFulfil requirementsBakery productsFood preparationFlavorAdditive ingredient

The invention provides a nutrient noodle and a preparation method thereof. The invention is characterized in that coarse food noodle and fine food noodle are internally packed with a meat product to form into the meat-noodle integrated nutrient noodle, wherein the coarse food noodle and the fine food noodle comprise the following components in percentage by weight: 40-50% of wheat flour, 20-30% of corn flour, 10-15% of pumpkin flour, 5-15% of bean flour, 5-15% of potato flour, 5-8% of buckwheat flour, and 5-10% of peanut flour; and the meat product comprises the following components in percentage by weight: 60-70% of meat, 5-10% of starch, 5-10% of rice flour, 10-15% of wheat flour and 8-12% of onion. The nutrient noodle not only has the special nutrition constituents, such as the dietaryfiber, the carbohydrate, the mineral matter, the vitamin and the like, of the coarse food and the fine food, but also has the nutrients, such as the protein, the fat and the like, of the meat, thereby being a delicious food which ensures meat-vegetable and coarse-fine collocation. People can get at least three foods such as the coarse food, the fine food and the meat, so that the meat-vegetable and coarse-fine collocation requirements can be met, the nutrition constituents gotten by the people can be comprehensive and diversified, and the unique flavor and mouthfeel of the nutrient noodle canbe enjoyed simultaneously; and the nutrient noodle is free of any chemical additive, environmental-friendly and natural, so that the appetite of the people can be improved.

Owner:李民健

Zymolysis rice milk beverage and preparation method thereof

InactiveCN101181088AFully dispersedImprove product qualityFood preparationWater bathsCarboxymethyl cellulose

The invention discloses a fermentation rice milk drink and a preparation method thereof, which adopts fermentation rice as raw material that is processed through immersion, water bathing, cooking, fermentation, beating and pulp refining, and then the pH value of the obtained emulsion is adjusted; thermostable alpha-amylase Unikamyl HT is added according to a portion of 10 kilograms of the material being added with 3 to 5ml of thermostable alpha-amylase Unikamyl HT; then the obtained starch milk is sent into the ejector device through a flow meter; through flash cooking, the temperature of the obtained material should rise to 95 to 98 DEG C; then thermal insulation, enzyme stabilization, cooling and pH value regulation are done; efficient glucoamylase Unikase GA is added according to the portion of 10 kilograms of the material being added with 5 to 15ml of efficient glucoamylase Unikase GA; the temperature of the obtained material should rise to 100 DEG C, and the killing of enzyme is done; next, the obtained material are added with water, citric acid, xanthan and sodium carboxymethyl cellulose; the temperature raises by 55 to 60 DEG C so as to do secondary homogeneous; finally, the super-high-temperature sterilization and aseptic packing are done. The fermentation rice has specific flavor of rice wine, and is characterized by sweet and fragrant taste, light yellow or ivory color, being rich in nutrition and with the functions of health care and skin-maintaining and stable storage.

Owner:SOUTH CHINA UNIV OF TECH

Healthcare potato chip and processing method thereof

The invention discloses a healthcare potato chip and a processing method of the healthcare potato chip. The healthcare potato chip is composed of the following raw materials in percentage by weight: 72-85% of potato, 5-10% of glutinous rice flour, 2-5% of palm oil, 1-3% of Chinese herbal medicine, 0.5-2% of a condiment and the balance of water, wherein the Chinese herbal medicine is composed of 8-15 parts of liquorice, 5-11 parts of peppermint, 1-3 parts of corktree and 3-8 parts of chrysanthemum, and the Chinese herbal medicine is processed by steps of treating the raw materials, hot ironing and freezing, preparing additives, dipping, coating lining, microwave roasting and cooling, packaging, and the like. The healthcare potato chip has the characteristics of good taste, low heat and green health, the microwave roasting procedure is used for saving oil consumption and reducing the production cost, and the oil content of the chip is low, thereby capable of being stored for a long time.

Owner:王惠莹

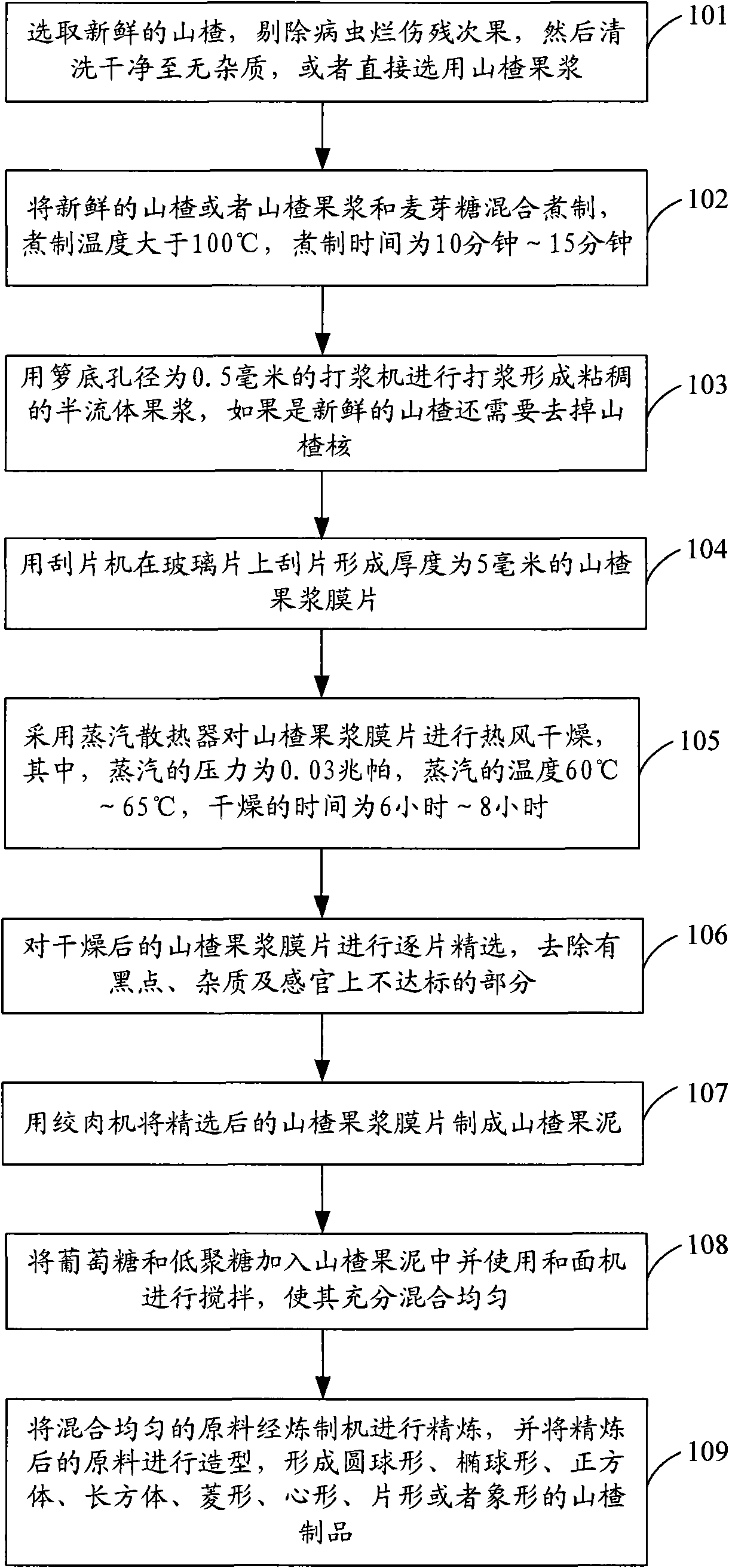

Haw product and producing method thereof

The invention relates to a haw product and a producing method thereof. The haw product includes haw, sugar component and water, the sugar component includes maltose, glucose and oligose. The haw product is diversified in flavours, healthy, suitable for old and young, thoroughly disinfected in materials, secure and sanitary, and has long shelf life, small size, convenient carrying and storing, thereby not only enriching the nutrition but also reducing the cost; has pleasant sweetness and sourness, suppleness in the mouth feel, and machine packing on the whole line, thereby not only being sanitary but also reducing the cost and increasing the efficiency.

Owner:姜云天 +1

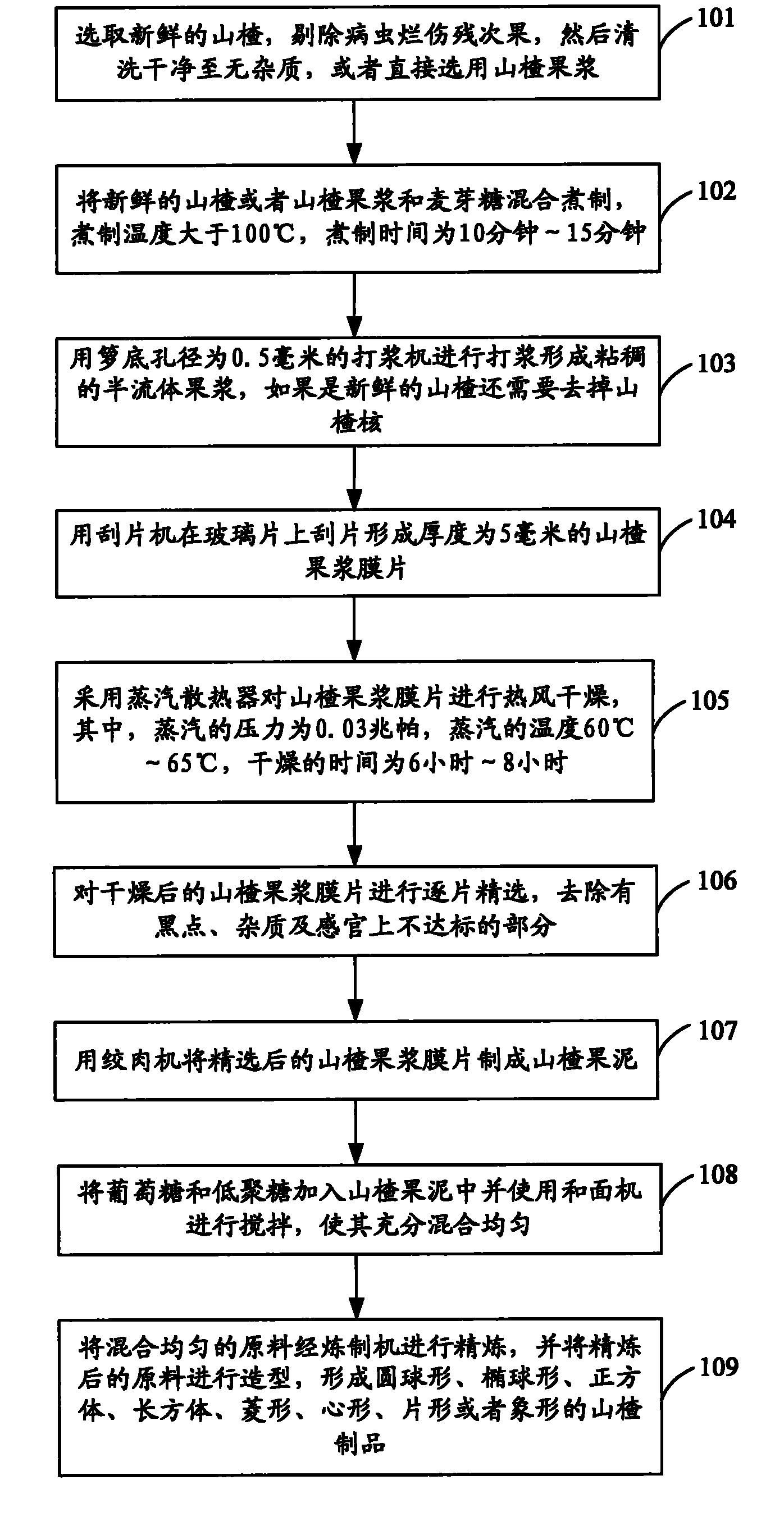

Fermentation type beef sauce and preparation method thereof

InactiveCN103478683ASpecial flavorSpecial colorYeast food ingredientsFood ingredient functionsFlavorYeast

The invention relates to a preparation method of a beef sauce. According to the preparation method, raw materials comprise beef, bean pulp, flour, lentinus edodes powder, salt and water. A production process adopts a low-salt solid-state fermentation method; fermentation strains adopt aspergillus oryzae A100-8, a salt-tolerant yeast S3-2 and salt-tolerant lactobacillus. The specific steps comprise preparation of aspergillus oryzae A100-8 koji, preparation of beef sauce yeast and fermentation of the beef sauce. According to the preparation method, the beef and the bean pulp are mixed and fermented to according to different nutritional characteristics of animal proteins and plant proteins so as to prepare a sauce product with abundant nutrition and unique flavor; the beef sauce has a prominent aroma and a delicious mouth feel, and also has the nutrition supplementary effects of the animal proteins and the plant proteins; the beef sauce is favored by consumers.

Owner:TIANJIN UNIV OF SCI & TECH

Coating and suspending chocolate with sweet potato powder added

The invention relates to a coating chocolate, wherein, every 1000 weight portions of chocolate comprises raw materials of 220 to 250 weight portions of sugar, 30 to 80 weight portions of sweet potato powder, 180 to 280 weight portions of milk solid, 340 to 430 weight portions of oil, 70 to 110 weight portions of cocoa powder and 0.5 to 1 weight portion of emulsifier. The sweet potato powder is cheap, full of nutriments, rich in cellulose, pectin and protein and relatively expensive raw materials such as milk powder, whey powder, etc., are replaced in the current coating chocolate, thus guaranteeing the quality of the coating chocolate and greatly saving cost. The coating chocolate provided by the invention can be applied to producing ice cream with surface coated with particles, can improve the adhesive capacity of particles by 5 to 10 percent, thereby not only improving the flavor and taste of ice cream, but also reducing the waste of particles.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Health-protection Chinese chestnuts and making method thereof

InactiveCN103999996ASolve the problem of single health care effectNutritional diversityConfectionerySweetmeatsDiseaseFood Component

The invention belongs to the technical field of food processing, and in particular relates to health-protection Chinese chestnuts and a making method thereof. The health-protection Chinese chestnuts are prepared from Chinese chestnuts, chufa, myrtles, mulberries, brown sugar and honey. Various health-protection natural fruits and medicinal and edible food components are added into Chinese chestnut kernels, so that the made Chinese chestnut products have refreshing taste, no sweetness, low heat and complete nutrition, and have multiple health-protection effects of enhancing immunity, maintaining beauty and keeping young, tonifying spleen, nourishing stomach, tonifying kidney, benefiting qi, preventing diseases and the like; the problems that a conventional single Chinese chestnut kernel product has a single effect, tastes sweet and the like are solved; demands of different markets and people can be met.

Owner:陈国勇

Maotai-flavor peanut thick chilli sauce and its preparation method

The invention discloses a peanut butter and its preparing process, wherein the raw materials include (by weight ratio) peanut 45-55 parts, dried soybean paste 15-25 parts, refined pork 30-50 parts, fermented soybean 35-45 parts, dried pepper 10-30 parts, soaked pepper 45-55 parts, chilli-paste with broad bean 45-55 parts, sesame 10-20 parts, catsup 25-35 parts, Chinese prickly ash 3-6 parts, white sugar 15-25 parts, green onion 10-20 parts, fresh ginger 10-20 parts, garlic 10-20 parts, cooking oil 80-120 parts, water or soup 200-300 parts.

Owner:安艳涛

Method for producing tasty instant rice noodles from broken rice

The invention discloses a method for producing tasty instant rice noodles from broken rice. The formula of the starch raw material of the tasty instant rice noodles comprises 72-84% of rice meal prepared from broken rice, 4-7% of potato starch, and corn starch of which the amount is 3 times that of the potato starch, and a polysaccharide thickener and an emulsifier are added. The production process comprises the following steps: making the starch raw material into starch dough; adjusting the extrusion parameters and temperature in the process of preparing wavy noodle blocks on an instant rice noodles production line; aging and re-steaming the noodle blocks, and drying by a three-section hot air circular drying method; and finally cooling, inspecting and packing. The instant rice noodles produced by the method disclosed by the invention can not cause paste soup, seasonings in the soup can enter the rice noodles, so that the rice noodles have good taste and toughness and is easy to cook; the soaking time is long that the rice noodles are not broken after being soaked for 12 hours, and the rice noodles have smooth and tough mouthfeel, good taste, unique flavor and rich nutrition; and moreover, the comprehensive utilization rate of the broken rice is improved, the production cost is reduced, and relatively high economic and social benefits are gained.

Owner:LOUDI TONGXING RICE

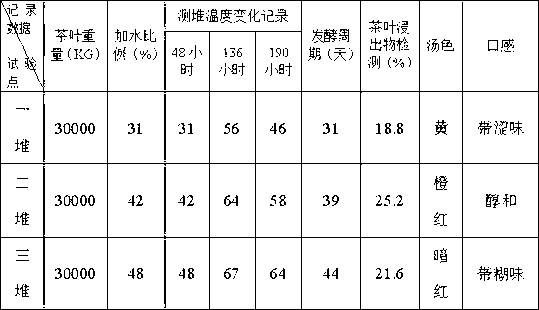

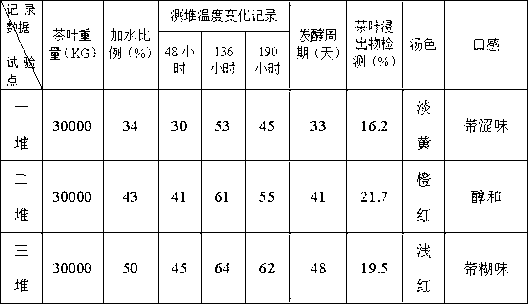

Green brick tea fermentation method

The invention provides a green brick tea fermentation method. The method comprises the following steps of: tea leaf raw material pre-processing, water adding, pile fermenting, tea turning, stacking, digging, drying and aging, wherein 1 water adding-pile fermenting: namely adding water to enable the water content of green tea to reach 32%-48%, carrying out the first pile fermenting, laying the tea into 3-4 layers with the height of 0.5m for pile fermenting, and spraying water layer by layer; and naturally fermenting the green tea in 34-48 hours after adding water into the piled tea, wherein the pile temperature is 45-69 DEG C; 2, tea turning: namely, first tea turning, second tea turning and third tea turning; 3, stacking; and 4 aging. Compared with the prior art, the method beneficial for improving the tea leave quality and extract, so that a green brick tea product has a mellow taste and red and transparent liquor color, can be quickly brewed, and has brewing and decocting durability and a unique green brick tea aged fragrance and flavor.

Owner:CHIBI ZHAOLI QIAODONGZHUANG TEA

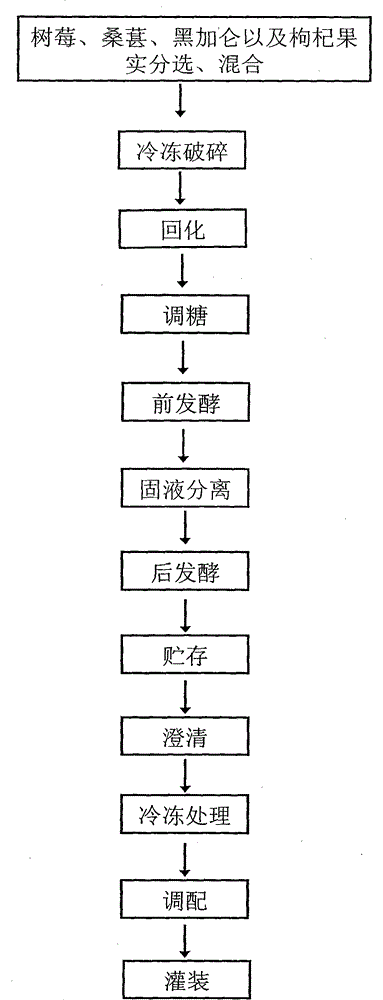

Compound raspberry wine brewing method

InactiveCN103555513ARich in nutritional valueActivate and maintain the ovaryAlcoholic beverage preparationFlavorAdditive ingredient

The invention discloses a compound raspberry wine brewing method. The compound raspberry wine brewing method comprises the following steps: mixing obtained raspberries, mulberries, blackcurrants, and medlar in a weight ratio of 16: 2: 1: 1; freezing and breaking; thawing; adjusting the sugar degree; carrying out primary fermentation; carrying out solid-liquid separation; carrying out post-fermentation; storing; clarifying; carrying out freezing treatment; blending; filling. The compound raspberry wine brewing method has the advantages that the raspberries, the mulberries, the blackcurrants and the medlar are mixed in proportions and then are subjected to compound fermentation, the chemical acid adjustment is not needed, and the acidity is adjusted by mixing the raspberries, the mulberries, the blackcurrants and the medlar in proportions so as to facilitate the maintenance of nutritional ingredients in the raspberries, the mulberries, the blackcurrants and the medlar and biological functions such as oxidation resistance and adjustment of the immunity of the organism and ensure that raspberry wine has full-bodied fruity taste and unique flavor.

Owner:山东尚美健康产业技术发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com