Patents

Literature

63results about How to "Reduce drying load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

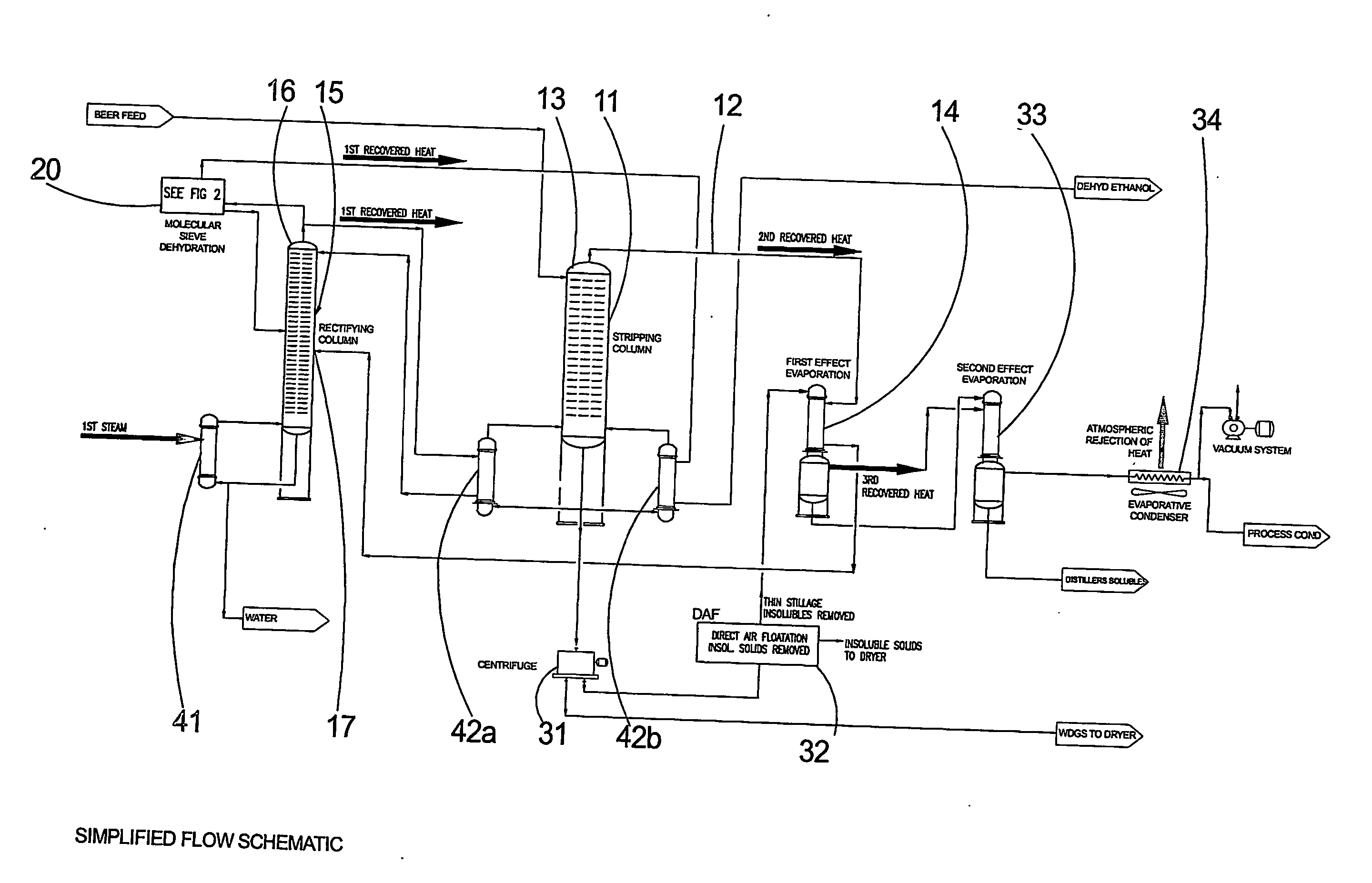

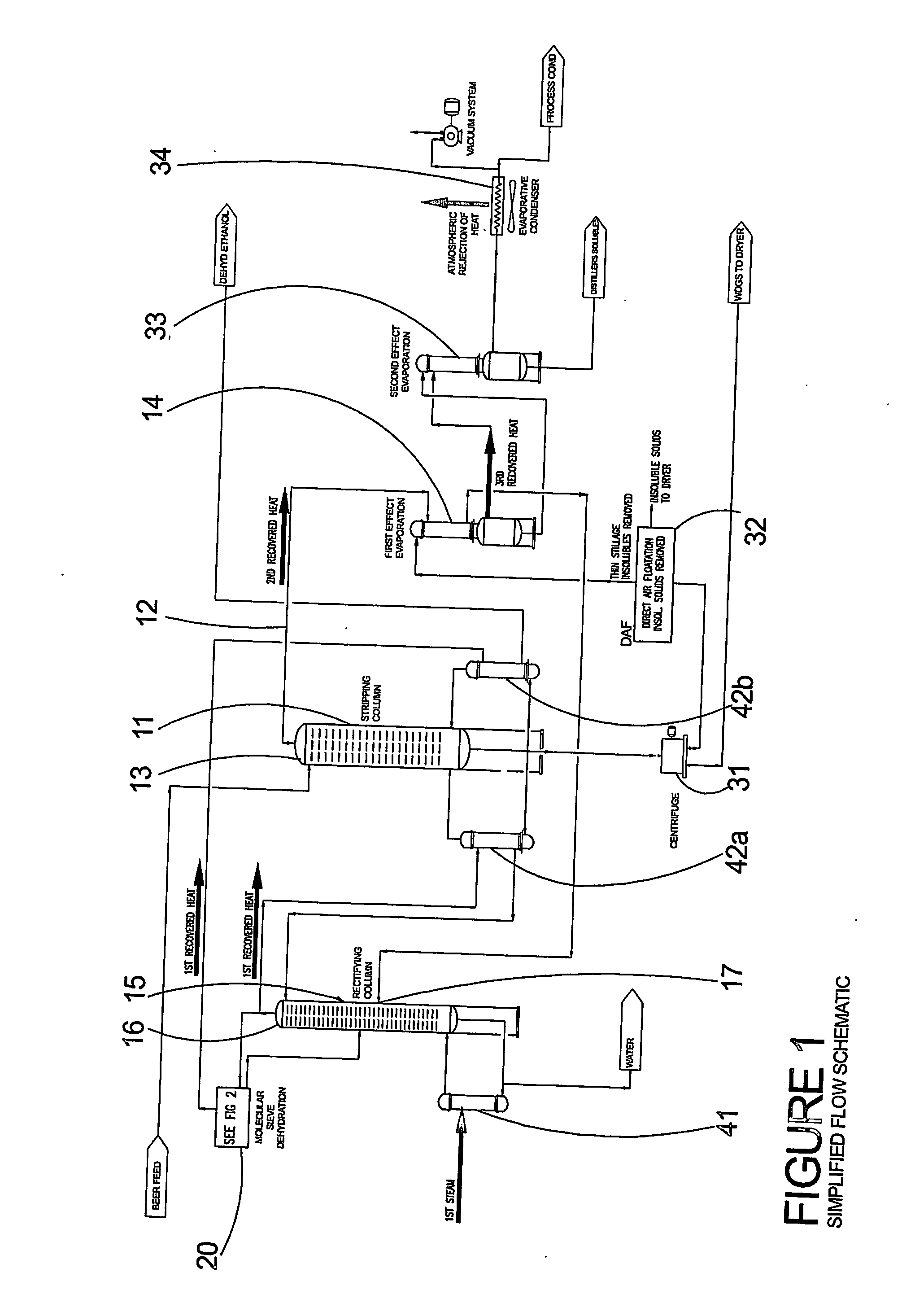

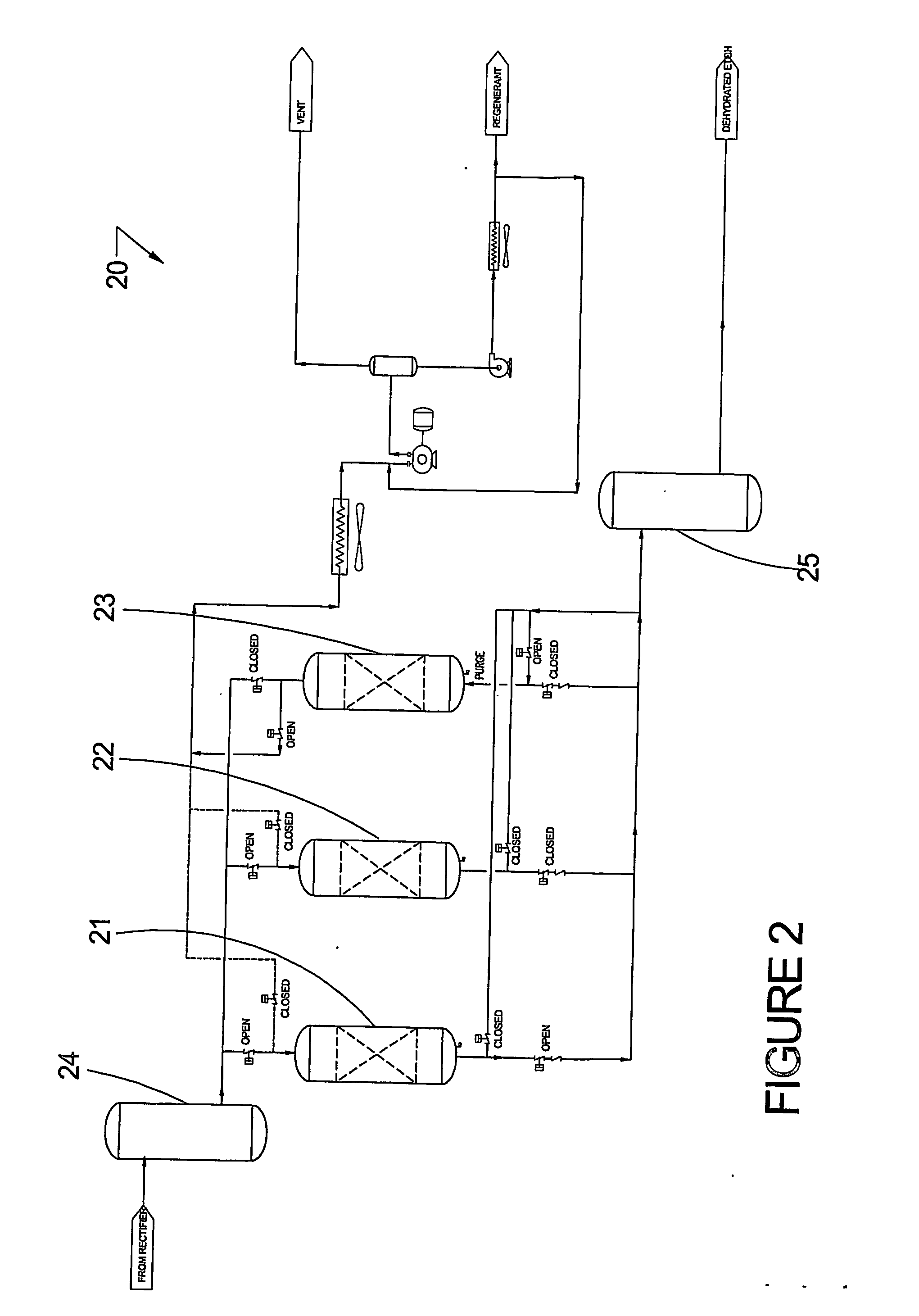

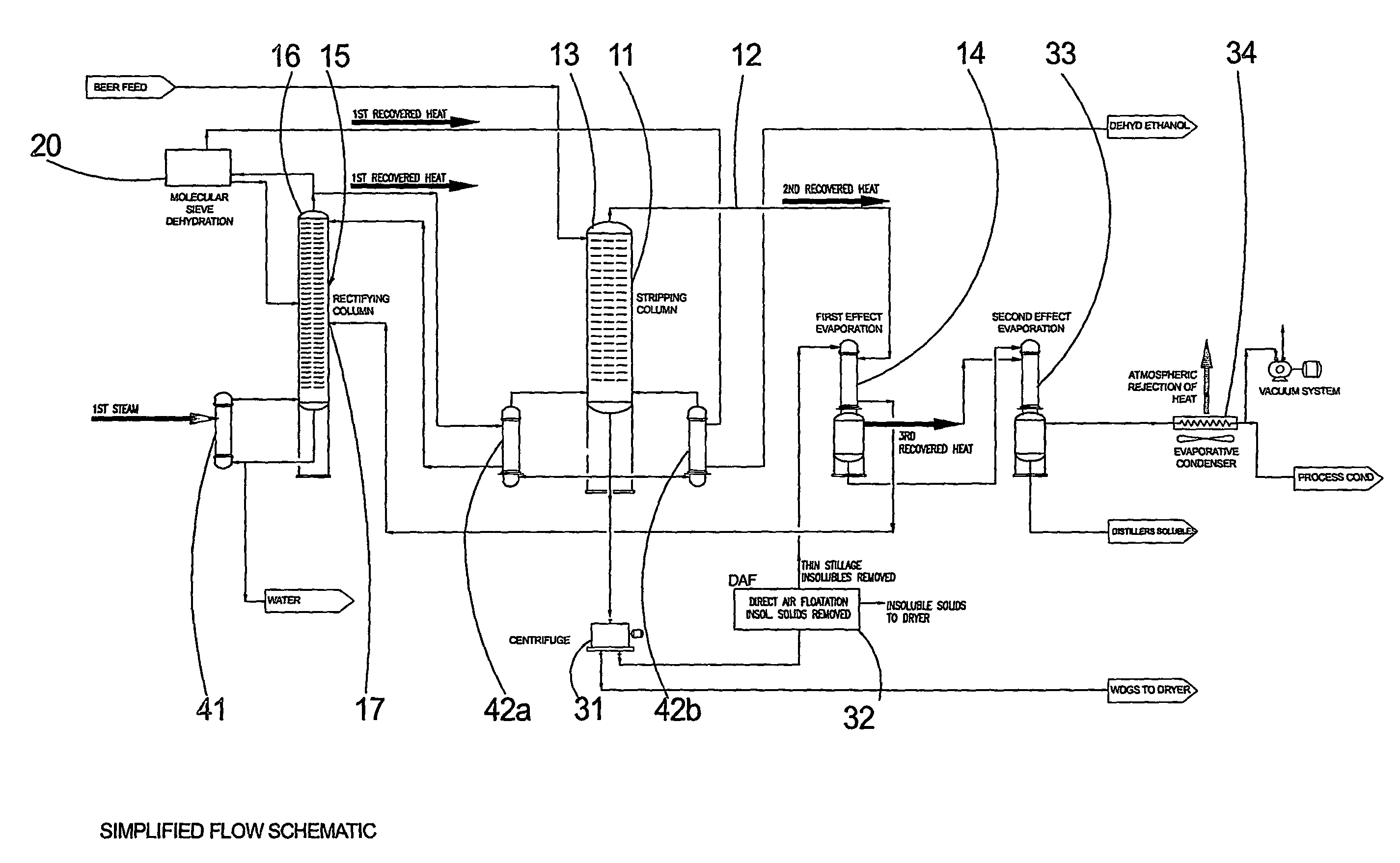

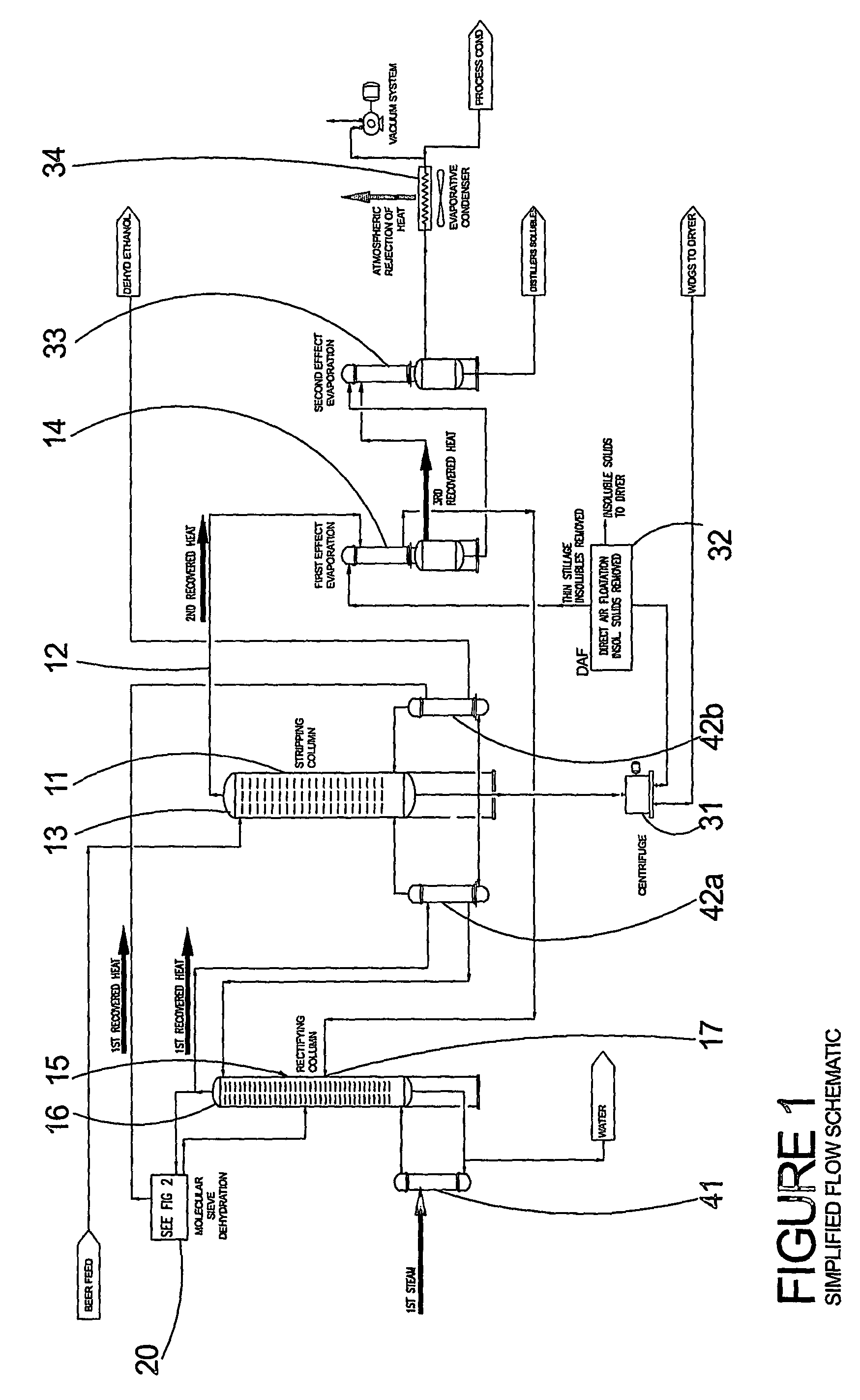

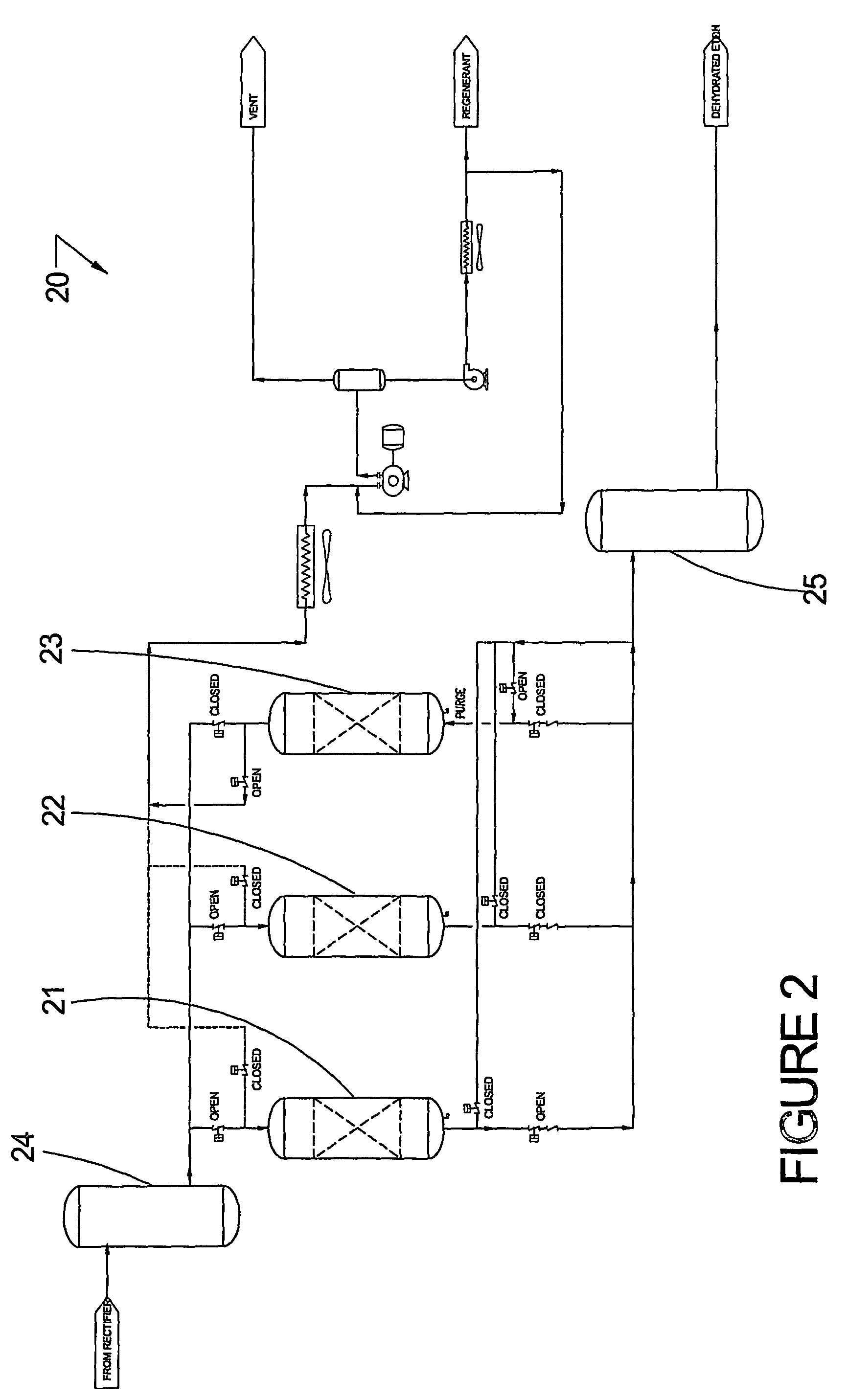

Ethanol distillation with distillers soluble solids recovery apparatus

ActiveUS20070000769A1High operating temperatureReduce drying loadDistillation regulation/controlBiofuelsMolecular sieveAnhydrous ethanol

The present invention relates to a system for producing ethanol from an organic source and that operates to purify and dry ethanol from a beer source. The system for producing substantially anhydrous ethanol comprises: (a) a first distillation stripping column that operates between 160 to 220 degrees F.; (b) a second distillation rectifying column having a higher operating temperature than said stripping column; (c) a molecular sieve dehydration means in fluid communication with said rectifying column; and (d) an energy control means.

Owner:RCM TECH USA INC

Ethanol distillation with distillers soluble solids recovery apparatus

ActiveUS7867365B2Reduce energy useIncrease concentrationDrying using combination processesDistillation regulation/controlMolecular sieveAnhydrous ethanol

The present invention relates to a system for producing ethanol from an organic source and that operates to purify and dry ethanol from a beer source. The system for producing substantially anhydrous ethanol comprises: (a) a first distillation stripping column; (b) a second distillation rectifying column having a higher operating temperature than said stripping column; (c) a molecular sieve dehydration means in fluid communication with said rectifying column. Heat from the overhead of the second distillation rectifying column and the molecular sieve dehydration are used to heat the first distillation stripping column.

Owner:RCM TECH USA INC

Former hot blast and latter vacuum microwave combining drying process of producing crisp fruit and vegetable grains

InactiveCN1672531AReduce drying loadReduced moisture removal requirementsFruits/vegetable preservation by dehydrationWater contentFood processing

The present invention is former hot blast and latter vacuum microwave combining drying process of producing fruit and vegetable grains, and belongs to the field of fruit and vegetable food processing technology. The drying process includes the steps of: washing fruit and vegetable material, dicing, scalding to killing enzyme, cooling in flow water, draining, optional fast freezing and defrosting, soaking with seasoning, draining, pre-dewatering with hot blast to obtain semi-finished product with water content of 40-60 %, and final vacuum microwave drying to obtain product with water content of 2-5 %. The said process has the nutritious components and color well maintained, crisp product, short production period, low cost, high product quality and other features.

Owner:JIANGNAN UNIV

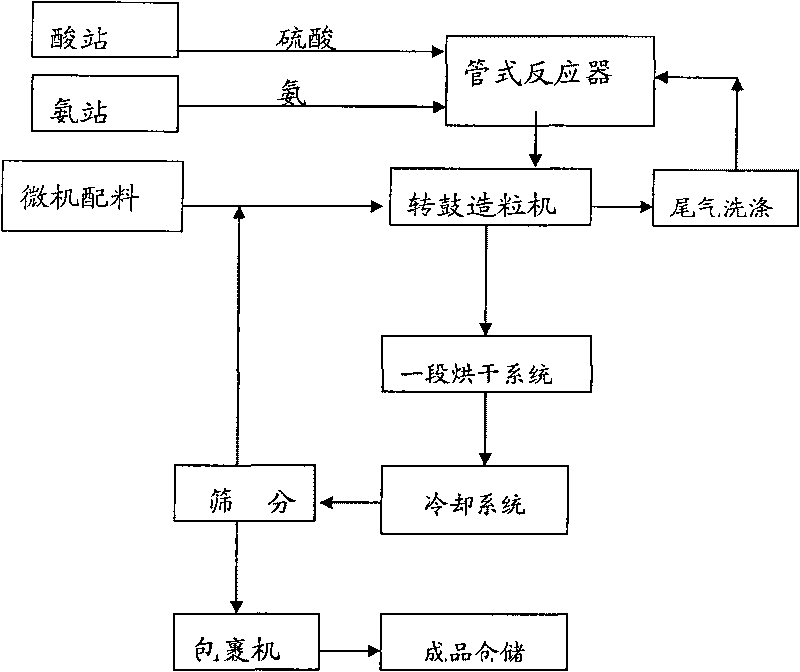

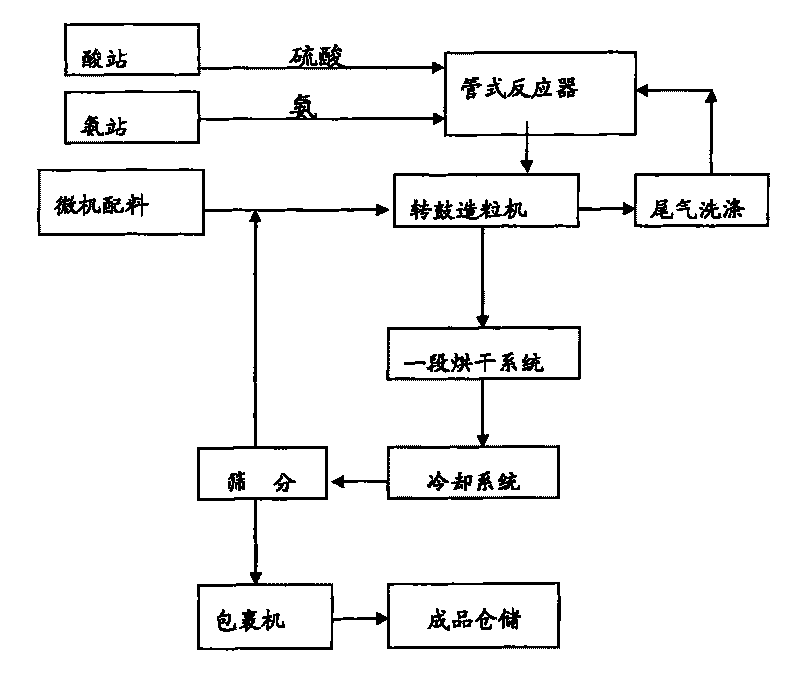

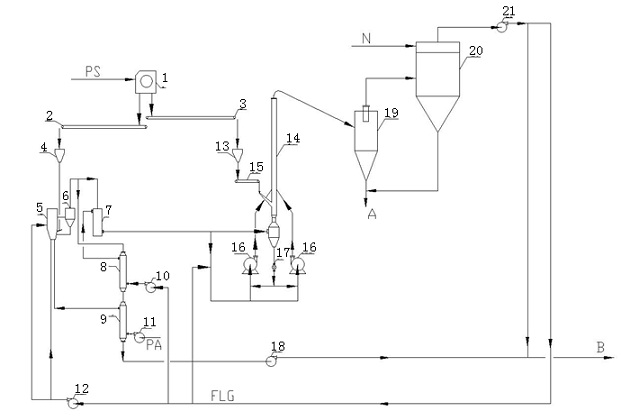

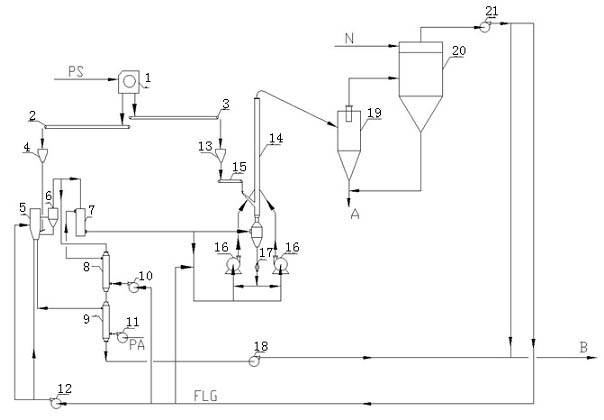

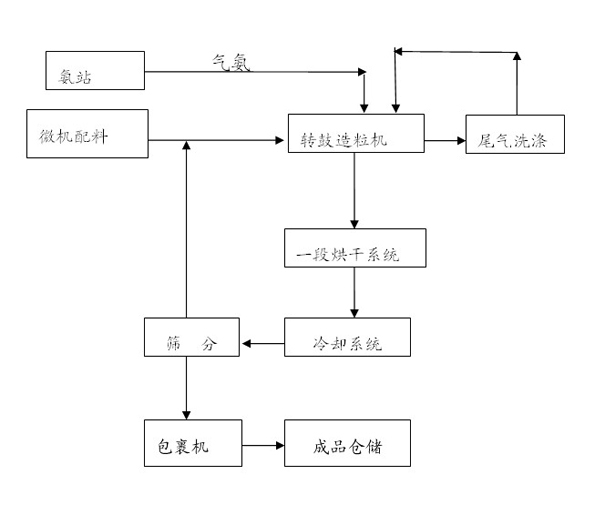

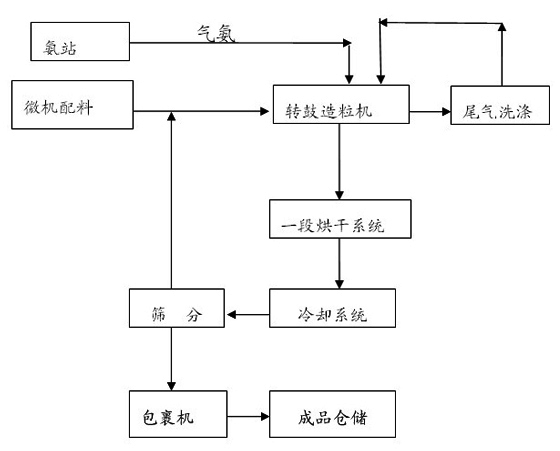

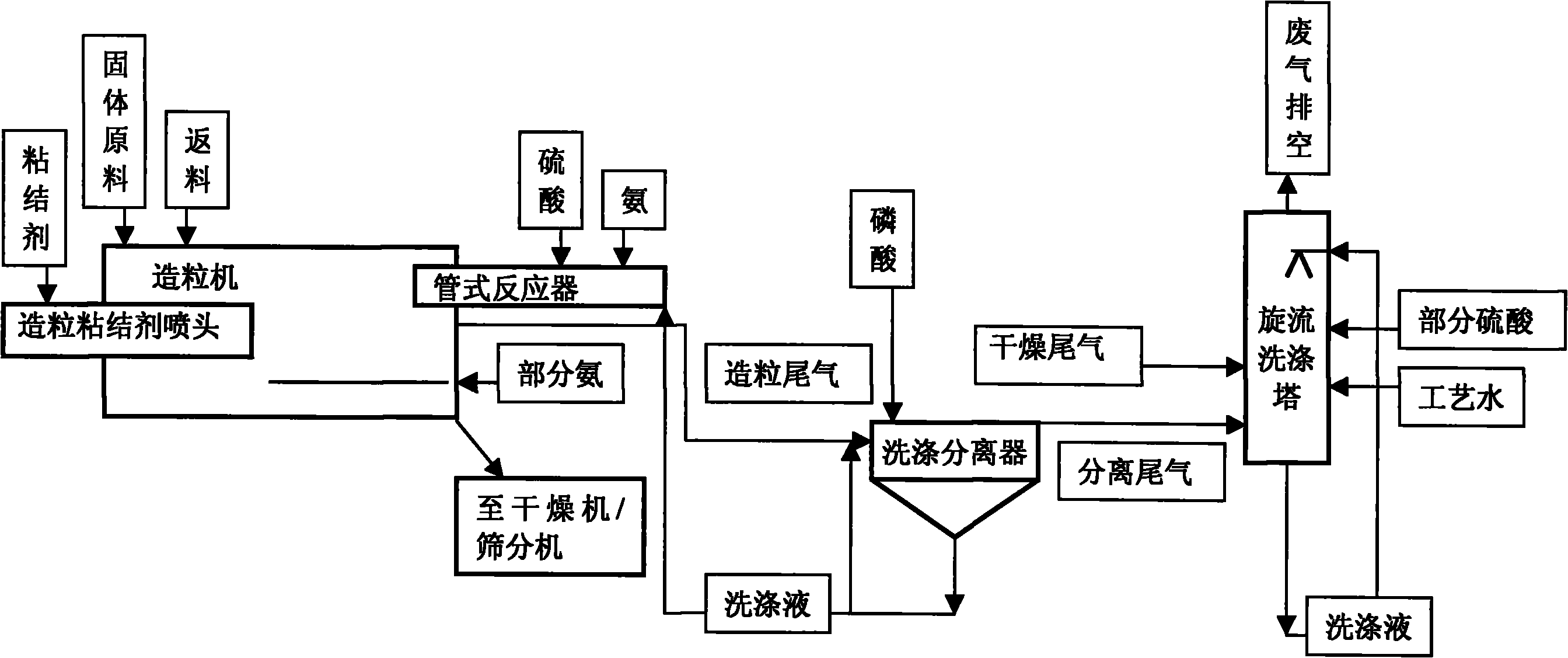

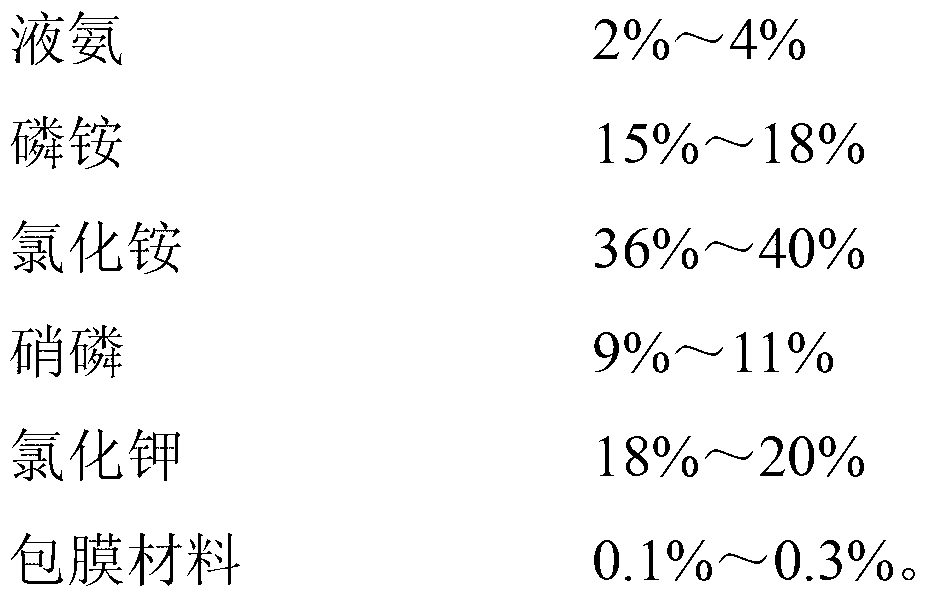

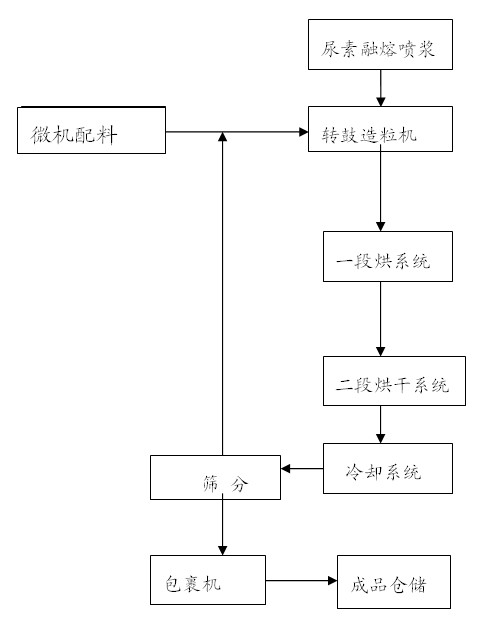

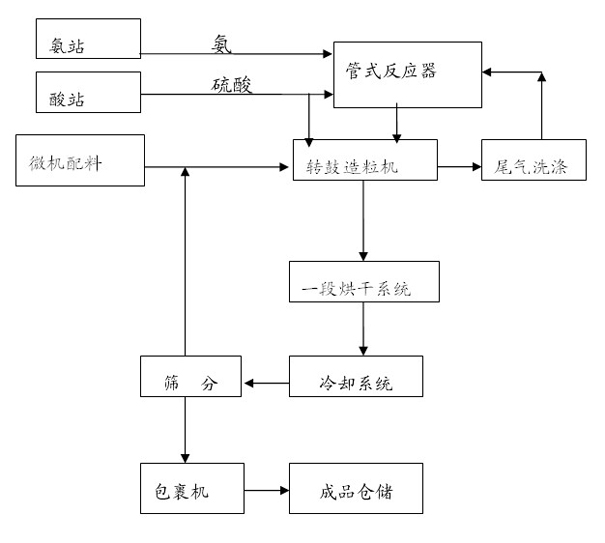

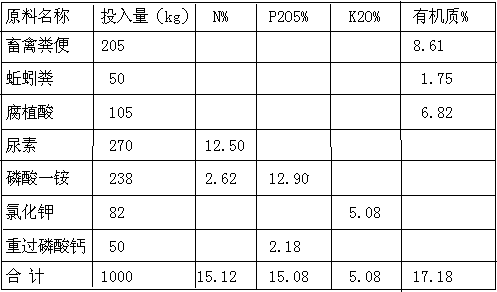

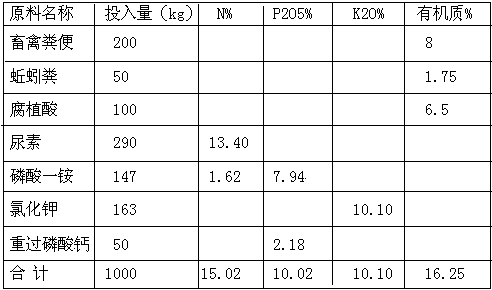

Method for producing Nitrogen-Phosphorus-Potassium compound fertilizer by ammonia and acid tubular reactor

The invention discloses a method for producing a Nitrogen-Phosphorus-Potassium compound fertilizer by using an ammonia and acid tubular reactor. The method comprises the following steps of: preparing an ammonium sulfate solution at 180-220 DEG C by concentrated sulfuric acid, ammonia and water; controlling the reaction heat of ammonia and acid by the addition amount of the water; spraying in a granulator to granulate with other base fertilizers containing nitrogen, phosphorus and potassium; drying; cooling; screening; and filming to obtain a nitrogen-phosphorus-potassium compound fertilizer. The reaction heat of the ammonia and the acid is fully utilized, the ammonium sulfate solution generated by the reaction is in liquid phase and viscosity, the balling rate is high, the moisture of granulation materials is obviously reduced, the drying load is lowered, the production need can be satisfied by changing two-section drying into one-section drying, and the equipment investment and great energy consumption are saved.

Owner:天津达汇丰生物科技有限公司

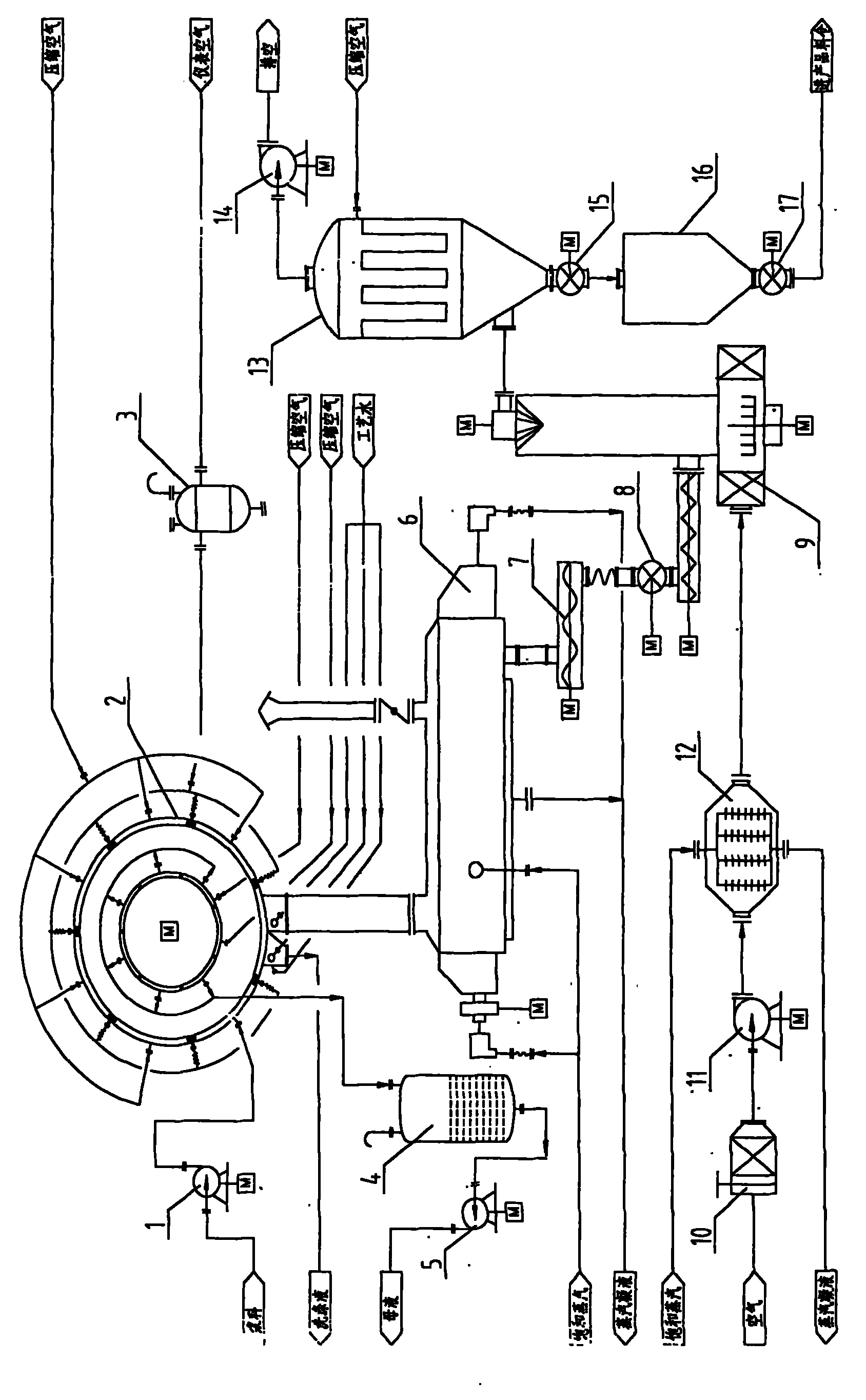

Process for carrying out strengthening circulation, stage grinding and quality improvement on lignite by utilizing superheated steam and system thereof

ActiveCN101870897AOptimize energy distributionMaximize energy utilizationCombination devicesDrying solid materials with heatFlue gasProcess engineering

The invention relates to a process for carrying out strengthening circulation, stage grinding and quality improvement on lignite by utilizing superheated steam and a system thereof. The method comprises the following steps: (1) carrying out grinding on the raw material lignite; (2) burning one part of coal blocks / powder to produce high-temperature flue gas serving as a heat source and carrying out air separation and dring on the other part of coal blocks / powder requiring to be subjected to quality improvement; (3) in the process of air separation, adopting the high-temperature flue gas from the step (2), carrying out drying, separation and dust removal on the qualified coal blocks / powder conforming to the standard grain diameter after air separation, collecting the qualified coal blocks / powder, sending the qualified coal blocks / powder to the forming process, making the unqualified coal blocks / powder drop in a grinding ventilating device to carry out grinding and drying, then continuously completing deep drying by air separation and repeating the steps, wherein the oxygen content in the flue gas is less than 8 percent; and (4) sending one path of waste gas subjected to air separation and drying to the washing process and returning the other path of waste gas serving as a return tail gas part to the step (2) so as to prepare the high-temperature flue gas and carry out air separation. The process has the advantages of safety, energy saving, environment protection, high efficiency, stability and the like.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

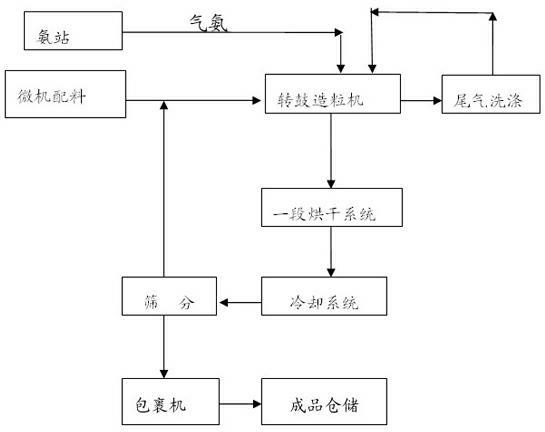

Method for producing chlorine-based high phosphorus compound fertilizer by ammoniation method

The invention discloses a method for producing a chlorine-based high phosphorus compound fertilizer by an ammoniation method. The method is characterized by directly introducing gas ammonia to a material layer of a rotary drum granulator to increase the neutralization degree of monoammonium phosphate, granulating gas ammonia with other powdered fundamental fertilizers containing nitrogen, phosphorus and potassium and obtaining the compound fertilizer containing nitrogen, phosphorus and potassium through drying, cooling, screening and enveloping after granulation. The method has the following advantages: the heat producing reaction between the gas ammonia and double superphosphate and heat of neutralization generated by the reaction between the gas ammonia and the monoammonium phosphate are fully used of to maintain the temperature of the materials, and the solubility of ammonium phosphate salt is improved to satisfy the liquid phase quantity needed by granulation; the higher granulation rate can be ensured without adding other adhesives, thus lowering the input cost of the materials; and the moisture of the materials to be granulated is obviously reduced, thus reducing the drying load and saving plenty of energy.

Owner:天津芦阳肥业股份有限公司

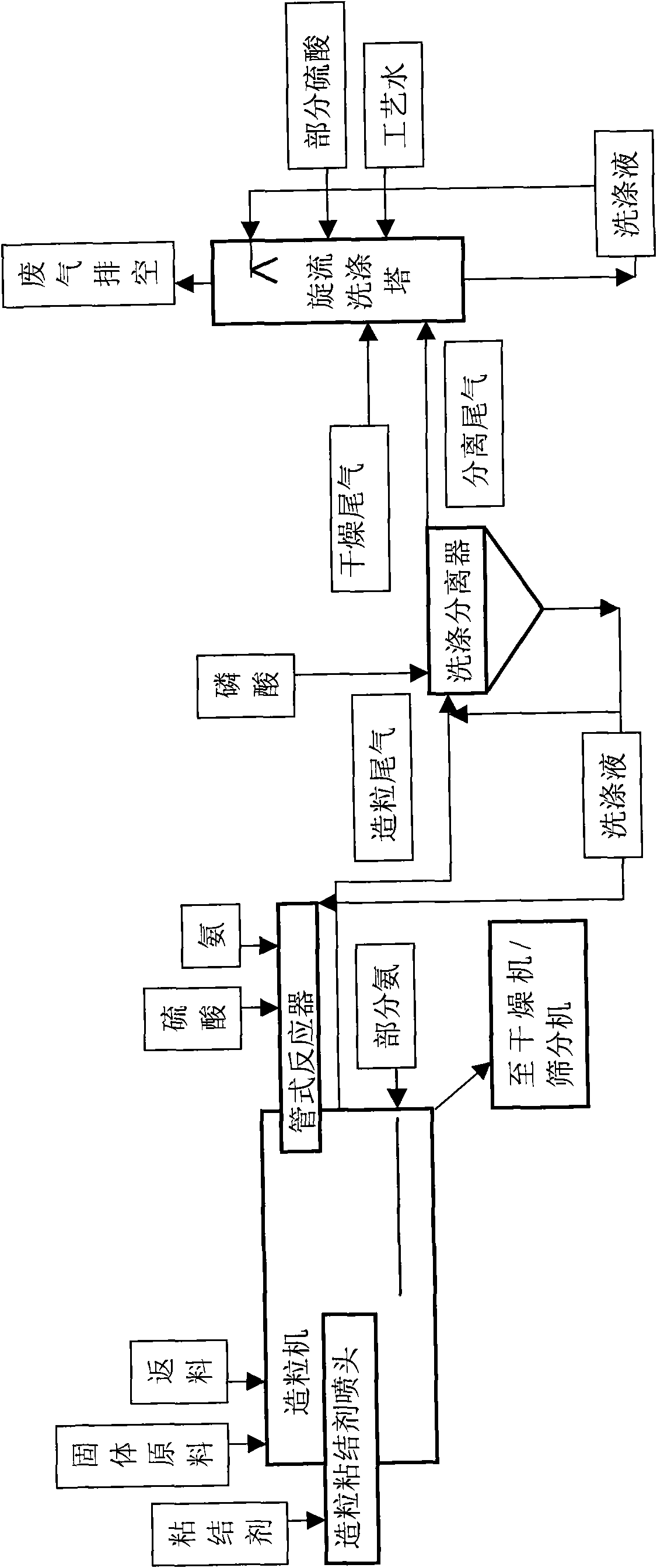

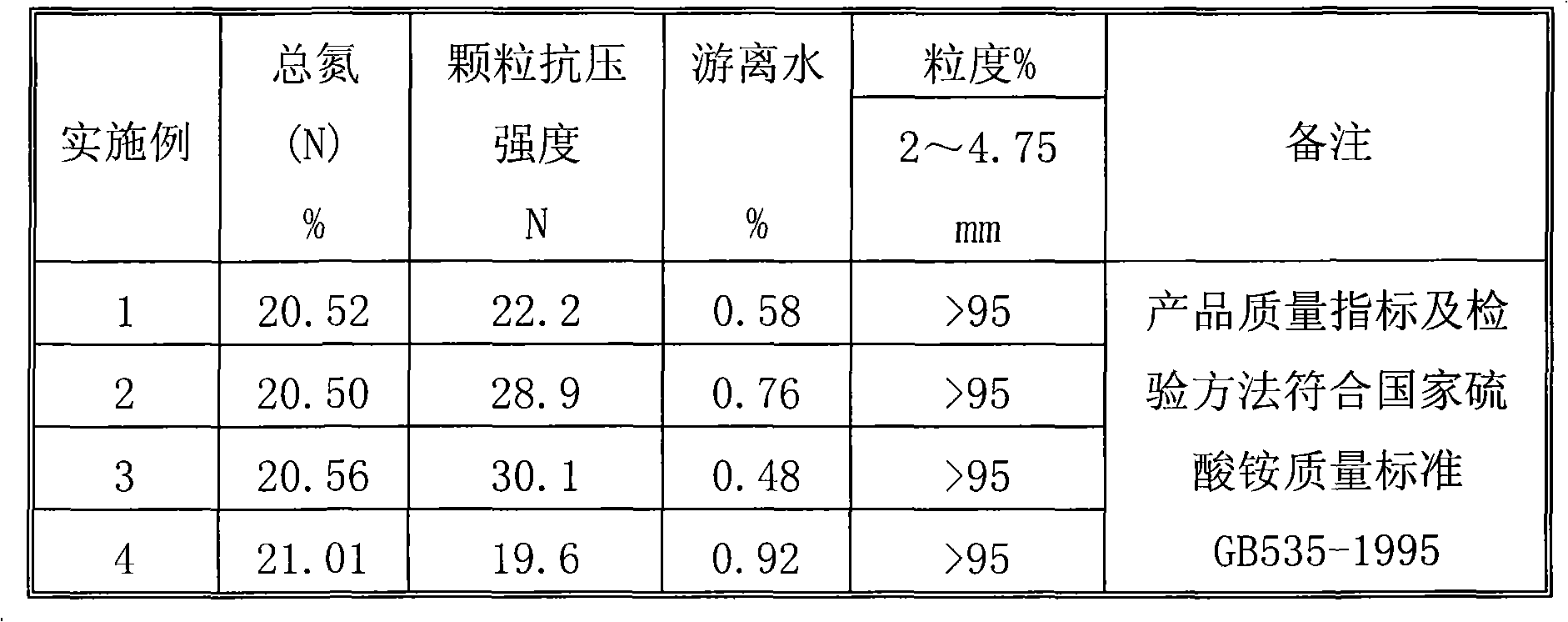

Preparation method of large-particle ammonium sulfate

InactiveCN101850989AReduce reaction loadControl water balanceAmmonium salt fertilisersAmmonia compoundsSlurryWater balance

The invention relates to a preparation method of large-particle nitrogenous fertilizers, in particular to a preparation method of large-particle ammonium sulfate, which comprises the following steps: firstly, adding 25-60 parts by weight of sulfuric acid, 7.6-16.5 parts by weight of ammonia and washing liquid from a gas-liquid separator to a tubular reactor for neutralization reaction; spraying high-temperature slurry formed after the reaction into a pelletizer; wherein, simultaneously, a solid material bed which comprises 20-70 parts by weight of solid material and rolls together with returns in the pelletizer can be installed in the pelletizer; spraying a pelleting binder through a spray nozzle and spraying the ammonium through an ammonium spraying shaft for pelleting to form wet solid material; fractionating the dried material after entering a sieving machine to sieve qualified particles and then cooling the particles to obtain the product. The invention reduces the reaction load of the tubular reactor; the system returns ratio is reduced, and the water balance is easier to control; simultaneously, the production cost is reduced, and recycling and the high-value utilization of industrial byproducts are realized by utilizing by-product powdery ammonium sulfate.

Owner:河北天人化工股份有限公司

Production method of readily available and controlled release composite fertilizer containing three nitrogen elements

The invention discloses a production method of a readily available and controlled release composite fertilizer containing three nitrogen elements. The production method is as follows: raw materials containing nitric nitrogen, ammonium nitrogen and amido nitrogen are added in materials; in order to prevent that urea reacts with nitro phosphate fertilizer to generate too much urea nitrate and the production can not performed, ammonia gas is introduced in the granulation process according to different proportions to ammonify nitro phosphate fertilizer, reduce the generation of urea nitrate and increase the neutralization degree of monoammonium phosphate; and powdery fundamental fertilizers containing nitrogen, phosphorous and potassium are added to granulate, and then the composite fertilizer can be obtained through drying, cooling, screening and coating. In the production method of the invention, a lot of heat generated in the thermolysis of the nitro phosphate fertilizer and the neutralization heat of the reaction of ammonia gas and monoammonium phosphate are fully utilized to heat materials and increase the granulation temperature; and the viscosity of urea nitrate is utilized, the solubility of ammonium phosphate salt is increased, the quantity of the liquid phase for granulation can be satisfied, higher granulation rate can be realized without using other adhesive, the cost is reduced, the water content of the granulation material is significantly reduced, the drying energy consumption can be reduced and a large amount of energy consumption can be saved.

Owner:天津芦阳肥业股份有限公司

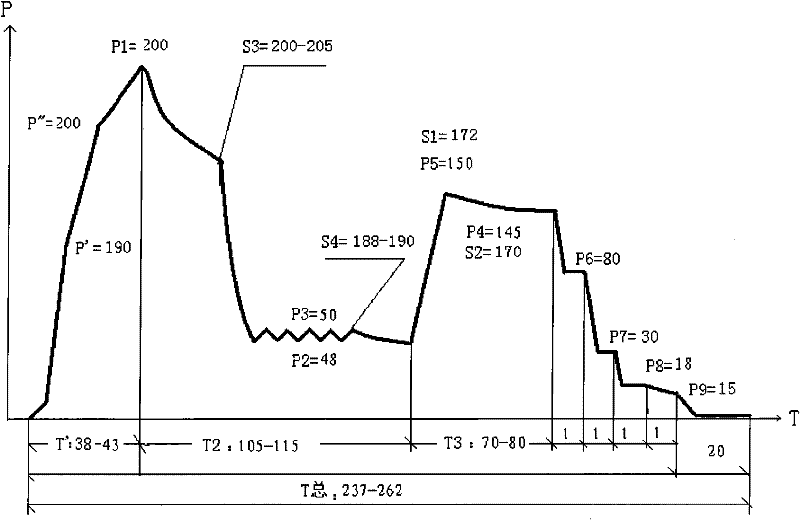

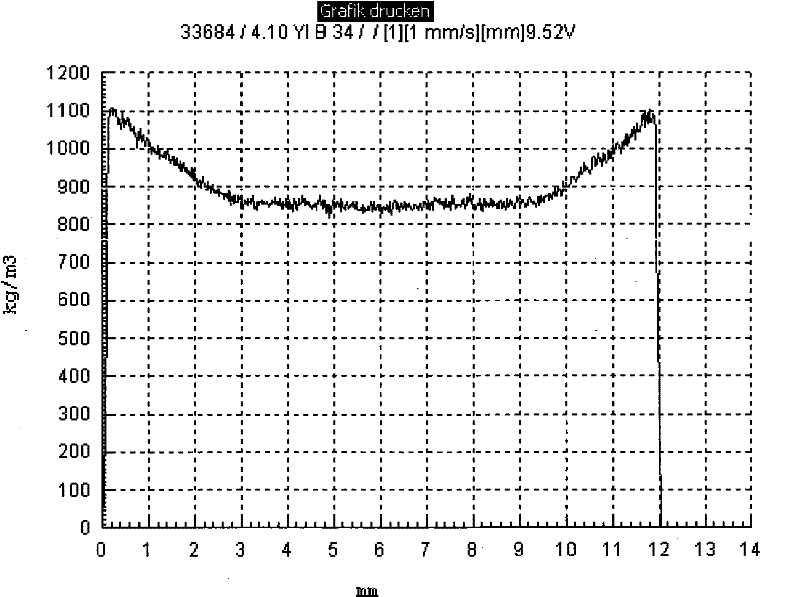

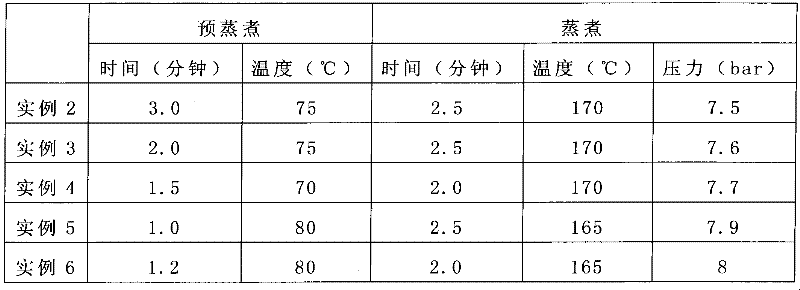

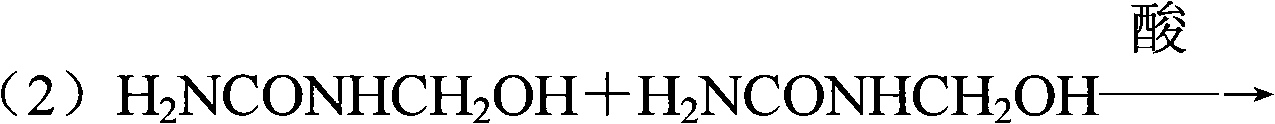

Manufacturing method of high density fiberboard for whitened type E1 grade floor substrate

InactiveCN102407553ASmall aspect ratioReduce cellulose contentWood working apparatusFlat articlesHexamethylenetetraminePhosphoric acid

The invention relates to a manufacturing method of a high density fiberboard for a whitened type E1 grade floor substrate, which comprises the steps of wood chipping and screening, pre-stewing and stewing, defibrator process for causing fiber separation, concoction of E1 grade urea formaldehyde resin glue, curing agent preparation, the application of urea-formaldehyde glue, curing agents and paraffins, drying, paving, hot pressing, cooling and tempering, and sanding and saw cutting, and is characterized in that woods are selected from major diameter cottonwoods with diameters larger than 8cm, are evenly chipped and are then placed in an outdoor storage yard to be fermented for 5 to 15 days; in the concoction process of the E1 grade urea formaldehyde resin glue, urea is added at 5 times; and the curing agents are formed by preparing phosphoric acid accounting for 3 to 5 percent of the total content, urotropin accounting for 1 to 3 percent of the total content, triethanolamine accounting for 1 to 3 percent of the total content, and ammonium sulfate accounting for 19 to 21 percent of the total content. The obtained whitened type E1 grade floor substrate has the advantages of little surface impurity, fine and smooth fiber, white color, good visual effect, reasonable density distribution and moderate intensity, and is frequently used for producing top grade indoor laminate flooring and composite floors.

Owner:DARE TECH

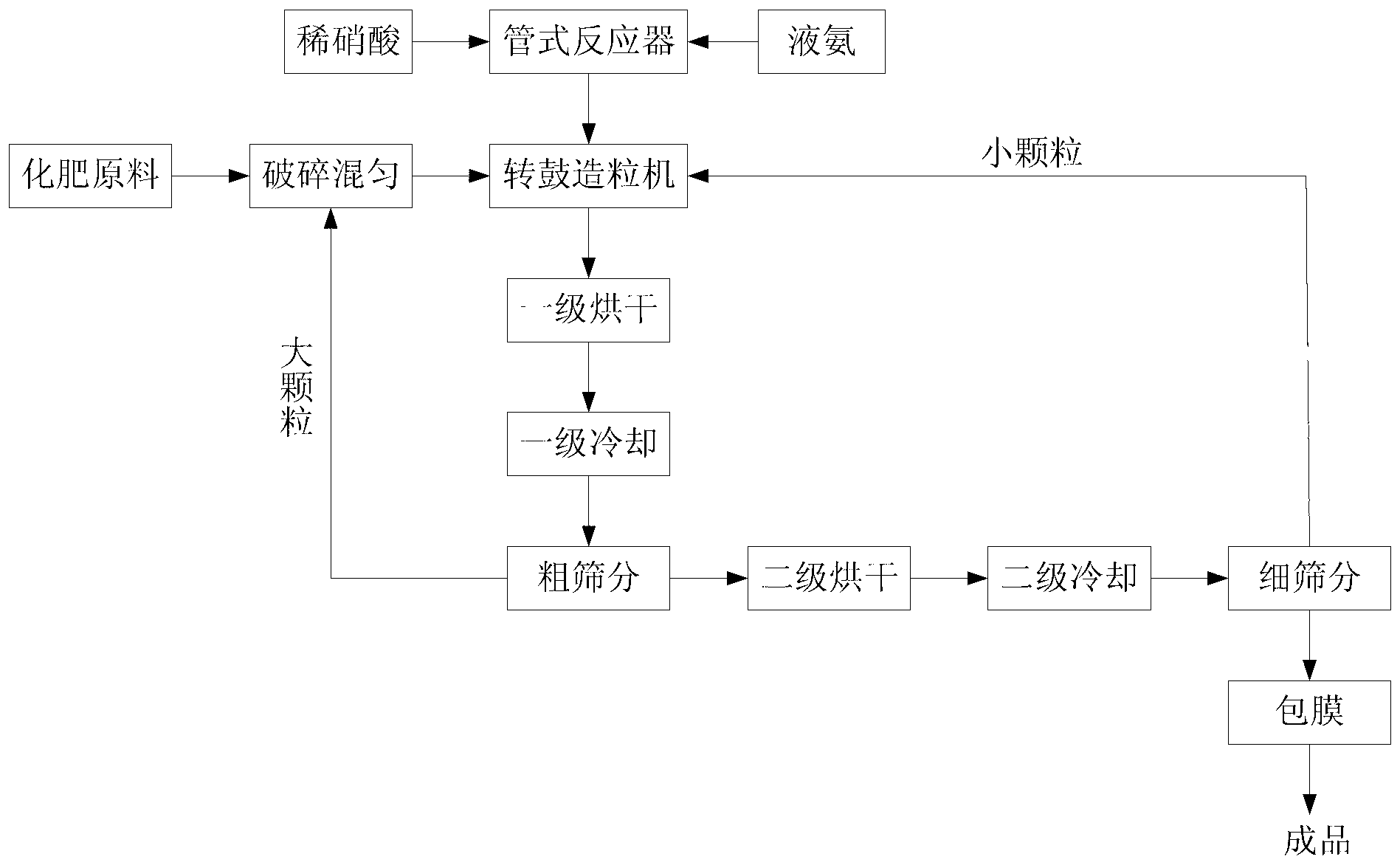

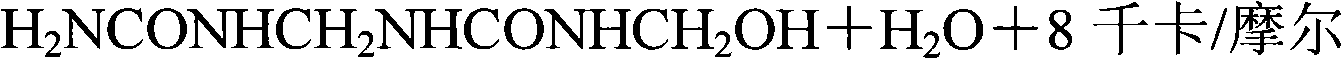

High-concentration compound fertilizer and production method thereof

ActiveCN103232293AHigh strengthImprove solubilityFertilizer mixturesHigh concentrationChemical reaction

The invention provides a high-concentration compound fertilizer and a production method thereof. The production method comprises the following steps of: smashing materials, and uniformly mixing; weighting ammonium dihydrogenphosphate, ammonium chloride, nitrophosphate, potassium chloride in a formula proportion, smashing, uniformly mixing, feeding the mixture into a rotor drum granulator; feeding liquid ammonia and dilute nitric acid into a tubular reactor for carrying out amino acid reaction; pelleting in a rotary drum, namely, after the liquid ammonia and the dilute nitric acid react in the tubular reactor, spraying into the rotor drum granulator, and pelleting by the chemical reaction of the liquid ammonia and the dilute nitric acid; drying, cooling and screening pelleted particles, wherein the particles with qualified particle size enter a coating machine, the large particles return to be smashed, and the small particles return to the granulator; coating by an anti-blocking agent; and spraying the anti-blocking agent into the coating machine for coating, thus obtaining the high-concentration compound fertilizer. According to the production method, the pelleting temperature is increased by using the chemical reaction heat between the nitric acid and ammonia, the characteristic of the material is improved, the production capacity of devices is improved, and the production cost is reduced.

Owner:嘉施利(应城)化肥有限公司

Method for preparing long-acting slow-release compound fertilizers by one-step pulp spraying granulation

InactiveCN101857513AIncrease temperatureReduce moistureFertilizer mixturesMixed materialsFORMALDEHYDE SOLUTION

The invention relates to a method for preparing long-acting slow-release compound fertilizers by one-step pulp spraying granulation, which comprises the following steps: heating and mixing urea and formaldehyde solution according to a mol ratio of (2 to 7) / 1 to be prepared into mixed material pulp with the temperature between 40 and 90 DEG C; introducing N, P and K fertilizers or filling materials and the like into a granulation device; after the mixed material pulp and ammonium sulphate are mixed in a pipeline according to a weight ratio of (5 to 30) / 1, spraying the mixture on solid materials in the granulation device for mixed granulation; simultaneously introducing ammonia for neutralization during the granulation; and obtaining the grain compound fertilizers, wherein the weight ratio of the mixed material pulp to the sulphuric acid is (5 to 30) / 1, the addition of the mixed material pulp sprayed on the solid materials accounts for 10 weight percent to 50 weight percent of the total material weight, and the quantity of the introduced ammonia accounts for 1 weight percent to 5 weight percent of the total material weight.

Owner:SHANGHAI RES INST OF CHEM IND

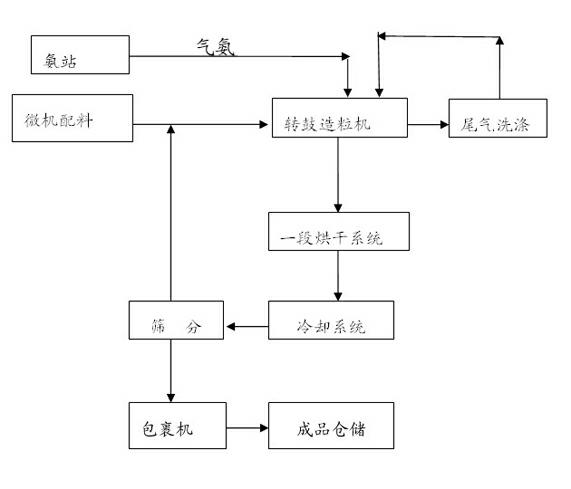

Method for producing nitrogen-fixing potassium slow-release compound fertilizer with mesh inner membrane by using ammonia-acid method

The invention discloses a method for producing nitrogen-fixing potassium slow-release compound fertilizer with mesh inner membranes by using an ammonia-acid method. The compound fertilizer comprises the following added raw materials: natural minerals capable of fixing and absorbing nutrients, and raw materials capable of forming shells with porous multiple layers of mesh inner membranes; and calcium salt is used to form a packaging skeleton and fix nutrients. The added concentrated sulfuric acid is divided into two parts, wherein one part is prepared into an ammonium sulfate solution of 180-220 DEG C with ammonia and water, amino acid reaction heat is controlled through controlling the added amount of water, and then the ammonium sulfate solution is sprayed into a granulator to granulate with powdery basic materials which contain nitrogen, phosphorus, potassium and natural minerals and are capable of forming shells with mesh inner membranes; and the other part is diluted and then directly added into the granulator to react with urea to generate thiocarbamide, and then drying, cooling, screening and enveloping are carried out on thiocarbamide after granulating to obtain the slow-release compound fertilizer containing nitrogen, phosphorus and potassium. In addition, two-section drying is changed to one-section drying, which can meet the requirements of production.

Owner:天津芦阳肥业股份有限公司

Water soluble paint for base paper surface treatment of vacuum aluminum-plated paper

InactiveCN102505562AHigh solid contentImprove friction resistanceCoatings with pigmentsCoatingsEnvironmental resistanceOrganic solvent

The invention provides water soluble paint as well as a preparation method and an application thereof. The water soluble paint for the base paper surface treatment of the vacuum aluminum-plated paper comprises a pigment, rubber latex, a dispersing agent, a rheological agent, a water-resistant agent, a defoaming agent and water, wherein the pigment is kaolin and / or calcium carbonate. The water soluble paint for the base paper surface treatment of the vacuum aluminum-plated paper can be applied to the surface treatment of cigarette lining paper. The paint for the base paper surface treatment of the vacuum aluminum-plated paper is mainly characterized in that (1) after being coated, the water soluble paint with high solid content has small drying load; (2) the defect that an organic solvent is used in the traditional paint for the surface treatment of the vacuum aluminum-plated paper is overcome, and the requirements of environmental friendliness, energy conservation and emission reduction for the paint are satisfied; (2) under the condition that a wear-resisting agent is not used, the wear resistance is better, and the cost is reduced; and (2) as a proper amount of nanometer calcium carbonate is added in the paint, the smoothness and the gloss on the surface of the paper are improved.

Owner:ZHEJIANG YONGTAI PAPER IND GROUP +1

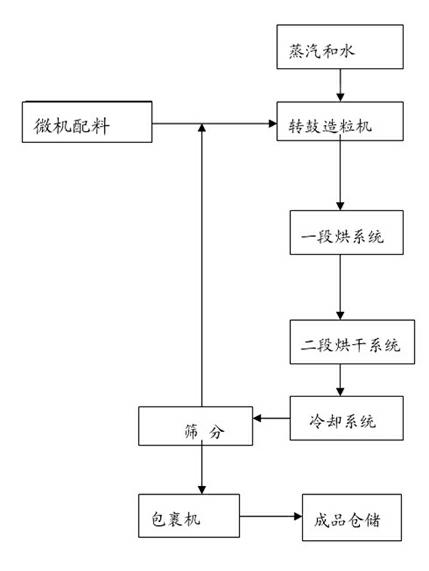

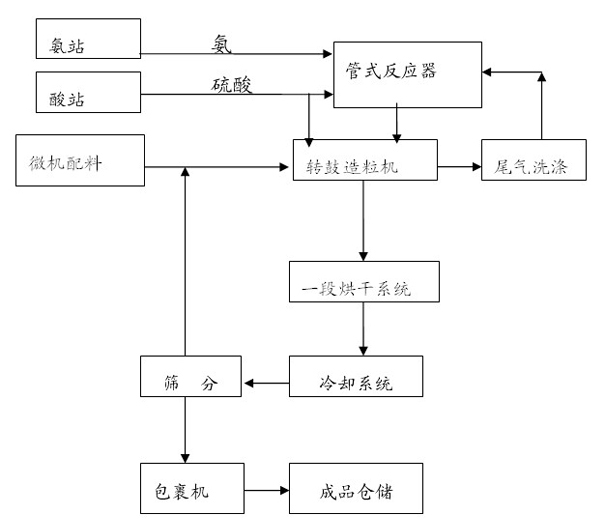

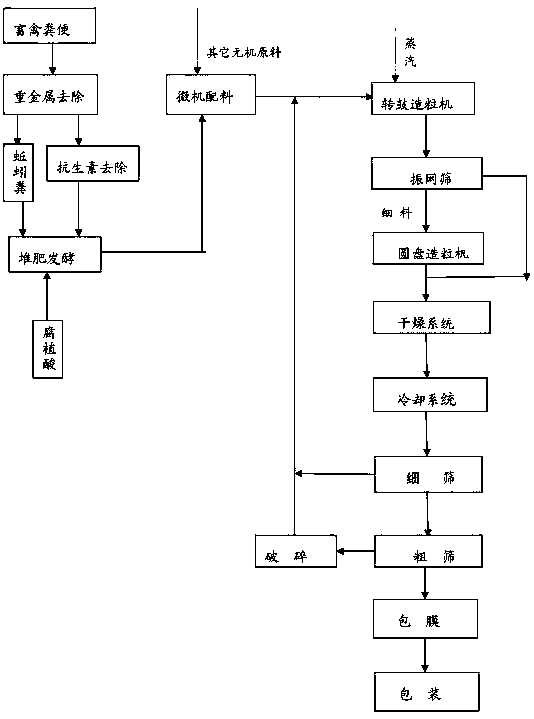

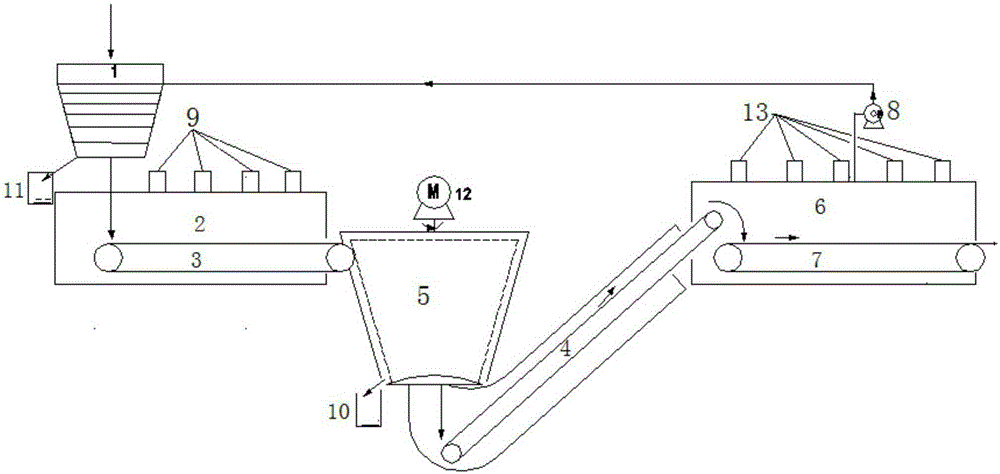

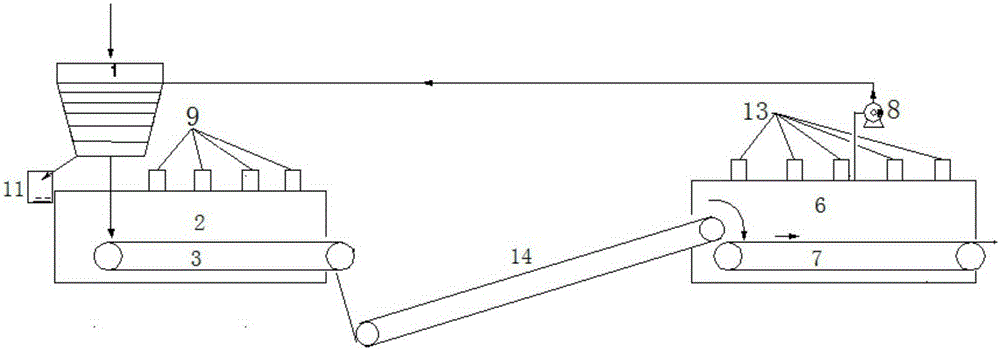

Production process of organic-inorganic compound fertilizer

InactiveCN101684051ASolve the problem of poor product appearance qualityHigh one-time ball forming rateFertiliser formsFertilizer mixturesCrusherOrganic fertilizer

A technology problem solved by the invention is to provide a production process of organic-inorganic compound fertilizer with high pelleting rate, round appearance and low moisture. The process has the steps of: fermenting organic raw materials into ecological organic fertilizer, adding inorganic raw material into a crusher; pelleting by assistantly adding water, steam and urine after crush of thematerial in the rotary drum comminutor; pelleting continuously using the material in the disk comminutor from the rotary drum comminutor; carrying out two-stage drying for the material after pelleting, and cooling the material; sieving macrobead in the cooled material; packing the sieved product after anti-blocking treatment and then delivering them out of factory. Using the technical scheme cansufficiently play the roles of the two kinds of pelleting methods, as well as solve the problems of bad appearance quality of product, and high moisture of pelleting.

Owner:河南财鑫实业化工有限责任公司

Lignocellulose material for road and method for making same

InactiveCN101096835AReduce manufacturing costImprove hydrophobicityIn situ pavingsTextile disintegration and recoveryCelluloseCardboard

The invention discloses a road wood fibre, which comprises the following steps: choosing waste newspaper as raw material; proceeding high concentration fluff; screening; deslagging; purifying slurry; stirring with mixed filling evenly; pasting; forming paper web; squeezing; drying with drying cylinder and infrared; proceeding flicking course; adding into caoline (talcum powder), active calcium carbonate filler and NaCl with dry method; getting the wood fiber product.

Owner:NANJING FORESTRY UNIV

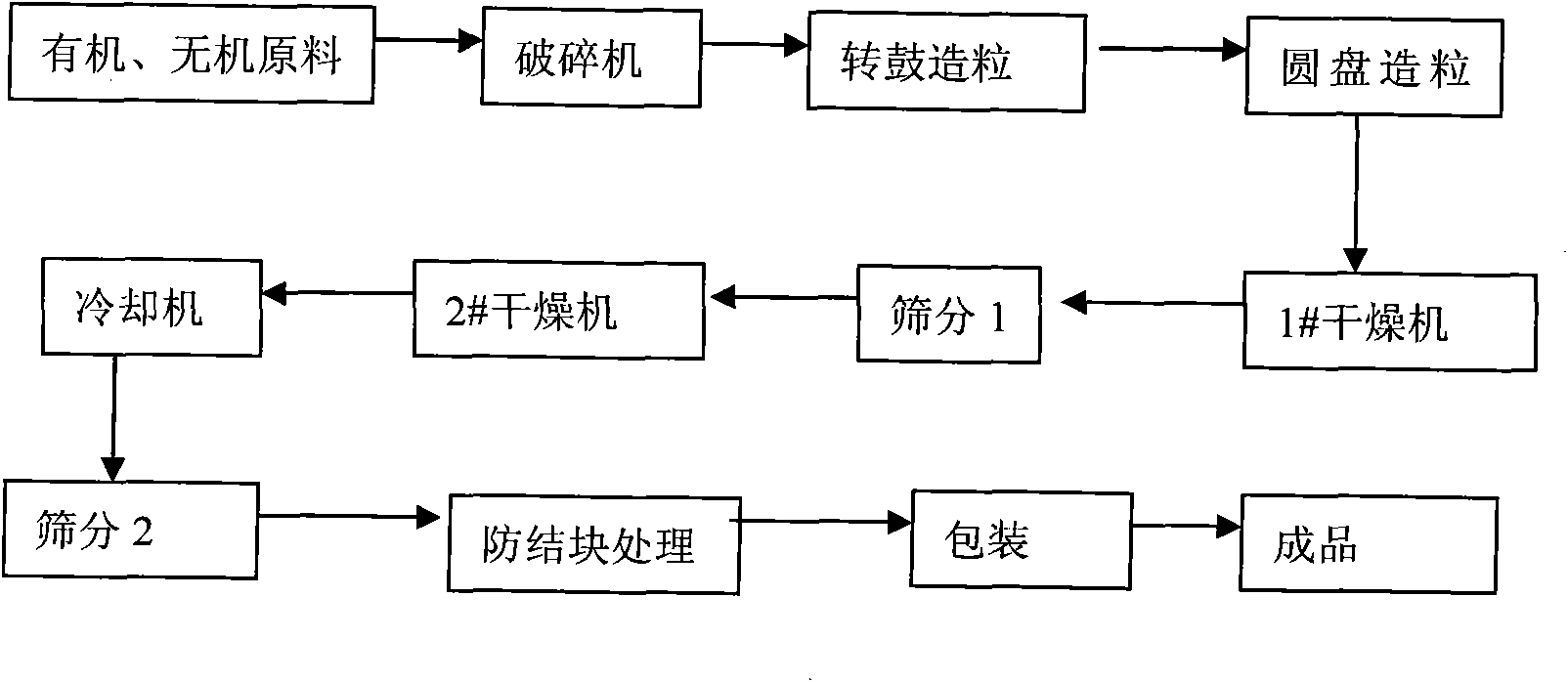

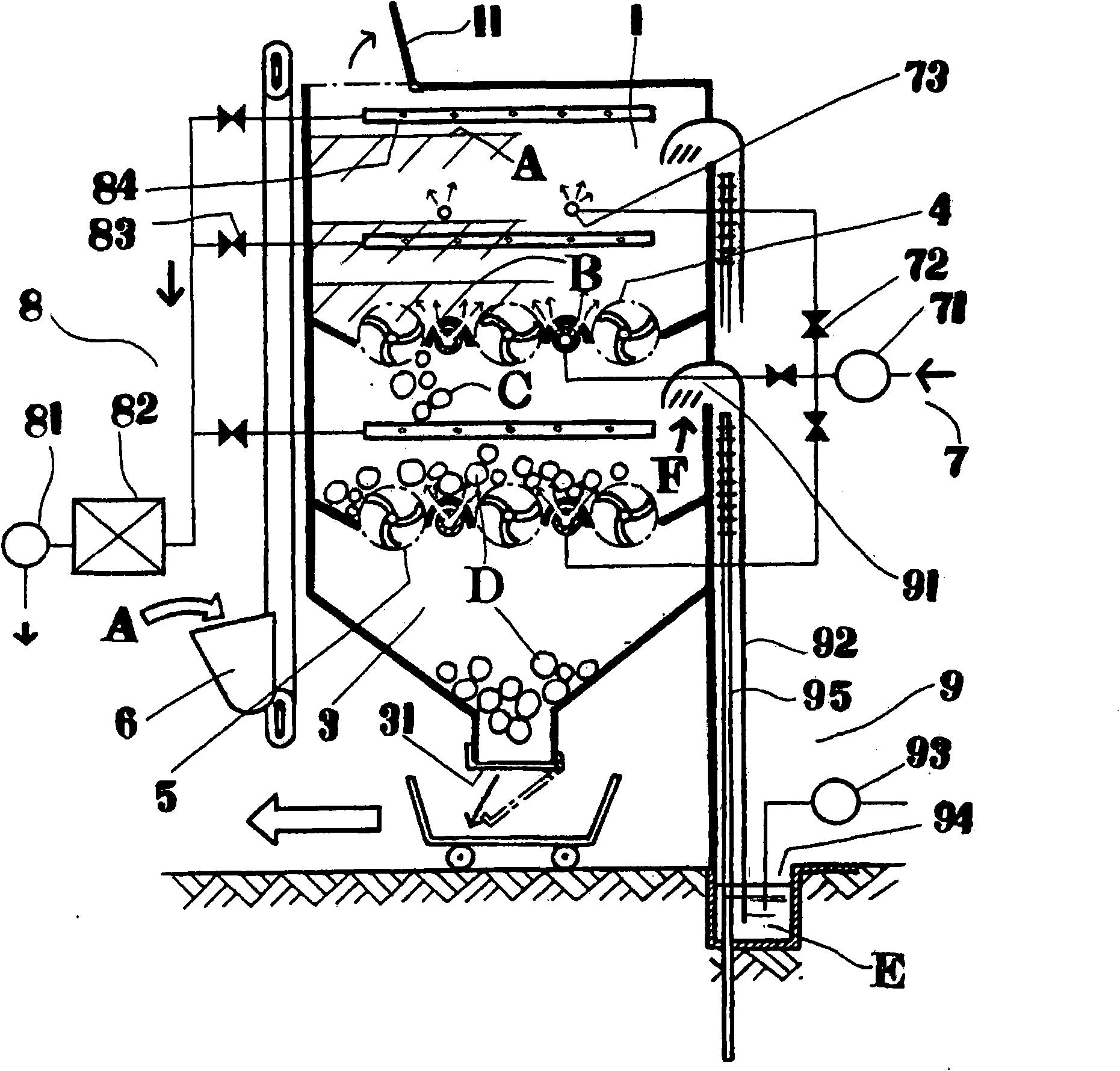

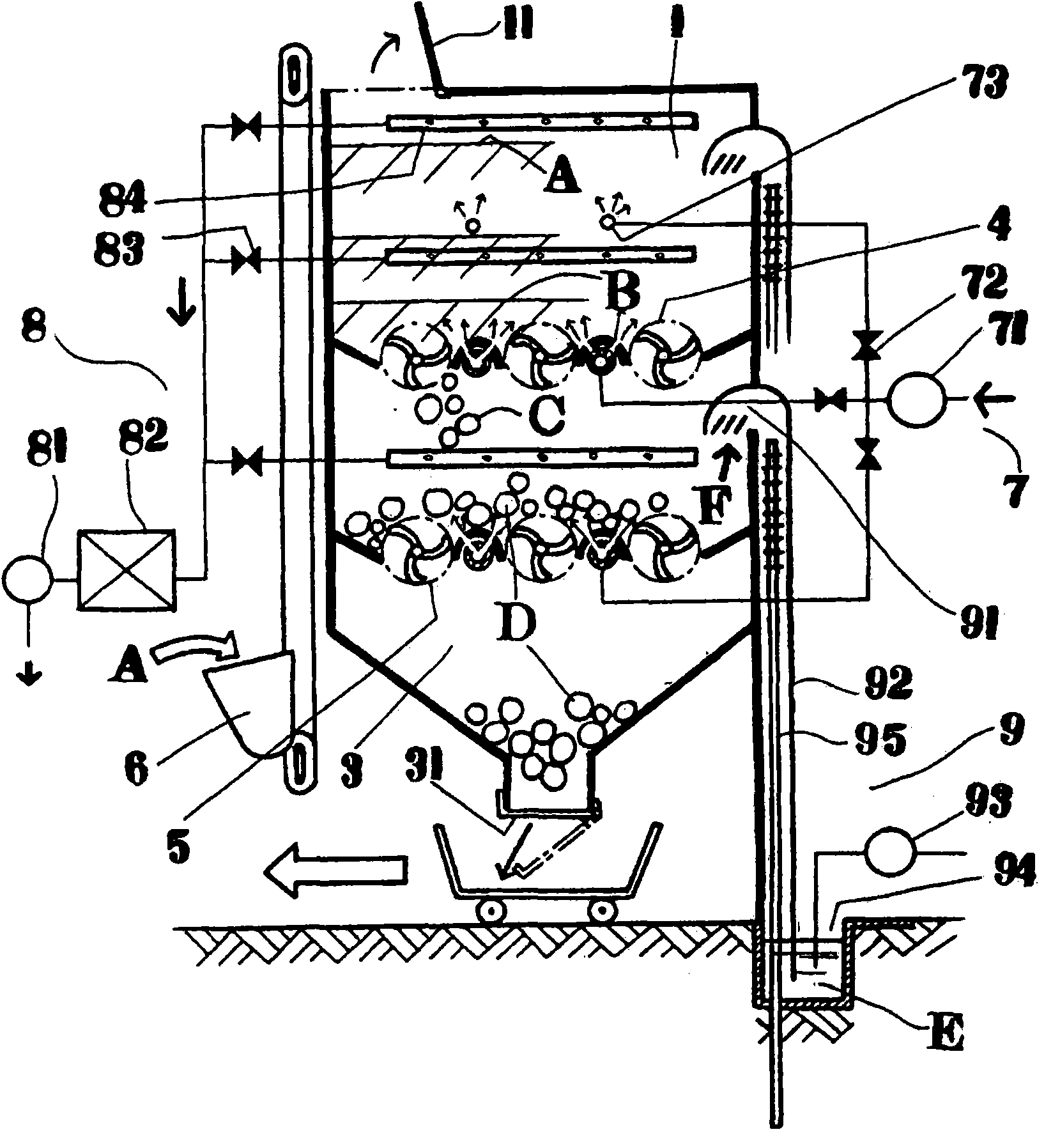

Fermentation treatment method and device of an organic waste

InactiveCN101961724AHigh temperature fermentation goes wellHigh temperature fermentation process goes wellSolid waste disposalEnergy based wastewater treatmentSludgeSlurry

The invention relates to a fermentation treatment method and a device of an organic waste. In the fermentation treatment of the organic waste (such as sludge, animal manure), high efficiency of high temperature fermentation and low moisture of a fermentation end product can be realized to make the post-treatment work (drying step) easy and perform the large batch treatment. A dehydration paper-making slurry and a cutting paper slice are mixed to be used as the auxiliary material, the high temperature fermentation treatment is high efficiency performed and after the fermentation object is subject to low-oxygen high-temperature fermentation treatment at the preset period in a first fermentation chamber (1) and the treated fermentation product is placed into a second fermentation chamber (2) and stirred up, therefore the vapor is generated by stirring up the loose fermentation product and the dehydration maturation fermentation treatment is performed in the second fermentation chamber (2) in the preset period.

Owner:岩渊健一

Manufacturing method of lithium ion battery high-compaction density pole plate

InactiveCN109473623AIncrease compaction densityLower internal resistanceElectrode rolling/calenderingSecondary cellsInternal resistanceSlurry

The invention discloses a manufacturing method of a lithium ion battery high-compaction density pole plate. The pole plate comprises a metal current collector and a conducting mixed slurry; the conductive mixed slurry is coated on the metal current collector at twice or multiple times, the pole plate is dried and rolled after the first coating, and the plate is dried and then rolled after the second coating, the coating, the drying, and the rolling are orderly performed until the conducting mixed slurry is completely coated. The thickness of the conducting mixed slurry wet coating layer through twice or multiple coating is thinner than that of once coating process, the drying load is educed, the drying time is shortened, the single rolling load is reduced, the roll coating is hard to occurunder high rolling pressure, the coating uniformity and precision are improved, the compaction density of the pole plate is increased, so that the volumetric specific energy is increased, the internal resistance of the pole plate is reduced, the polarization is reduced, the discharge capacity is increased, the battery energy density is increased, the cost is reduced, the flexibility of the pole plate is guaranteed, and the phenomena that the surface is curly uneven and even the plate is broken or crisp are avoided.

Owner:HUIZHOU WES NEW ENERGY LIMITED

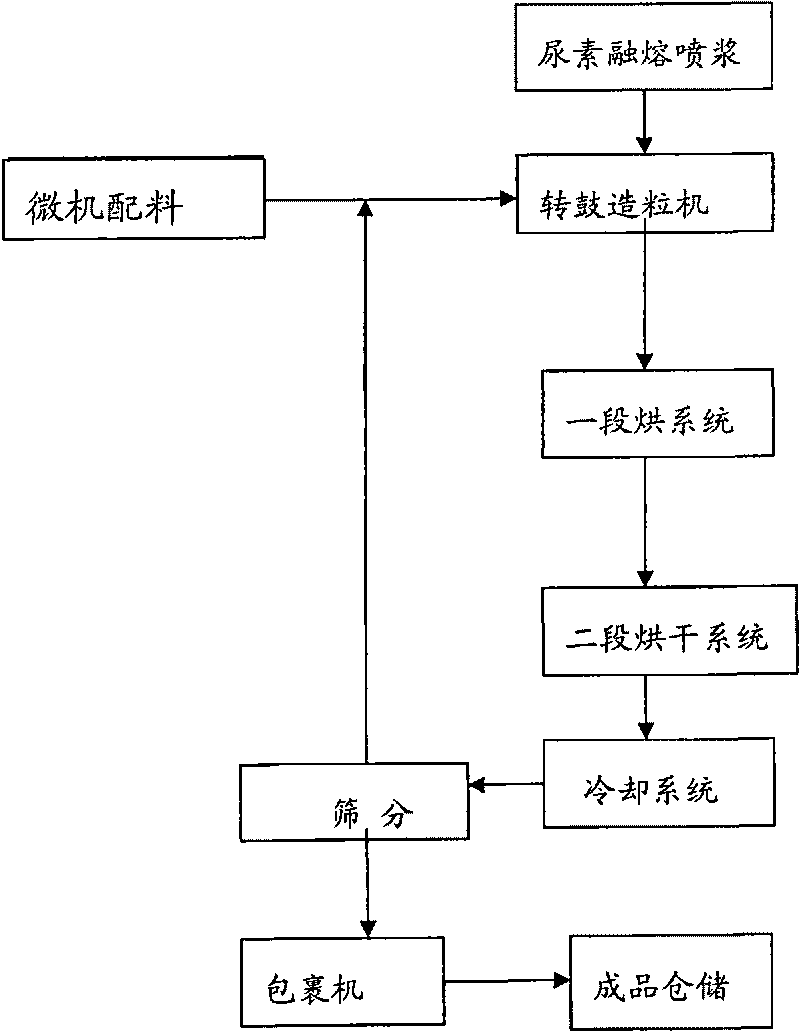

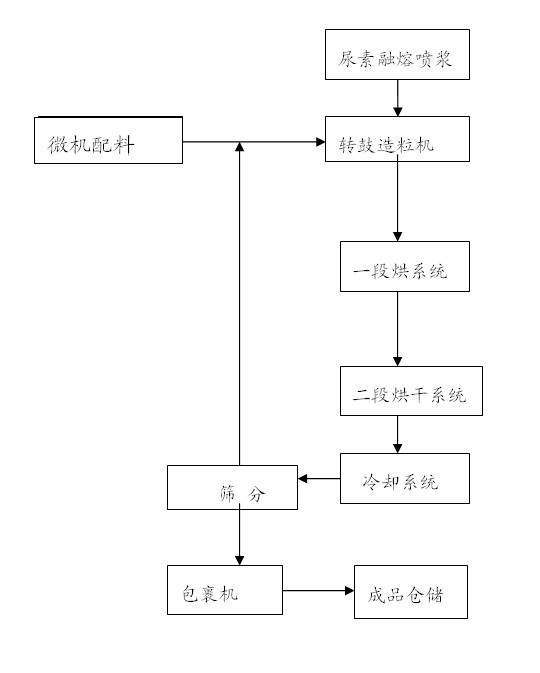

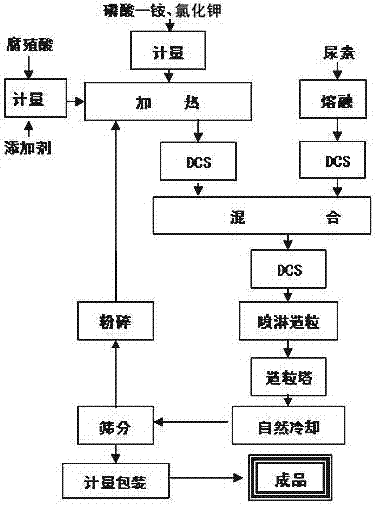

Special functional melt granulated humic acid fertilizer and production method thereof

ActiveCN102503640AAdvanced technologyRealize continuous feedingFertilizer mixturesSpray GranulationLiquid temperature

The invention discloses a special functional melt granulated humic acid fertilizer and a production method thereof. The production method comprises the following steps: proportionally weighing urea, monoammonium phosphate, potassium chloride, humic acid and additives as raw materials; adding preheated monoammonium phosphate, potassium chloride, humic acid and other powdery materials into the urea molten liquid; under the actions of molten liquid temperature and mechanical stirring, quickly compounding an eutectoid with certain flowing property; granulating by a spray granulation technique in a granulation tower; and when the sprayed drops in the falling process in the granulation tower exchange heat with ascending air flow to be quickly cooled and solidified, forming the special functional melt granulated humic acid fertilizer. The special fertilizer disclosed by the invention has the advantages of high fertilizer efficiency and environmental protection, enhances the soil activity, and conforms to the development trend of the green environmental-protection fertilizer.

Owner:STANLEY AGRI GRP CO LTD

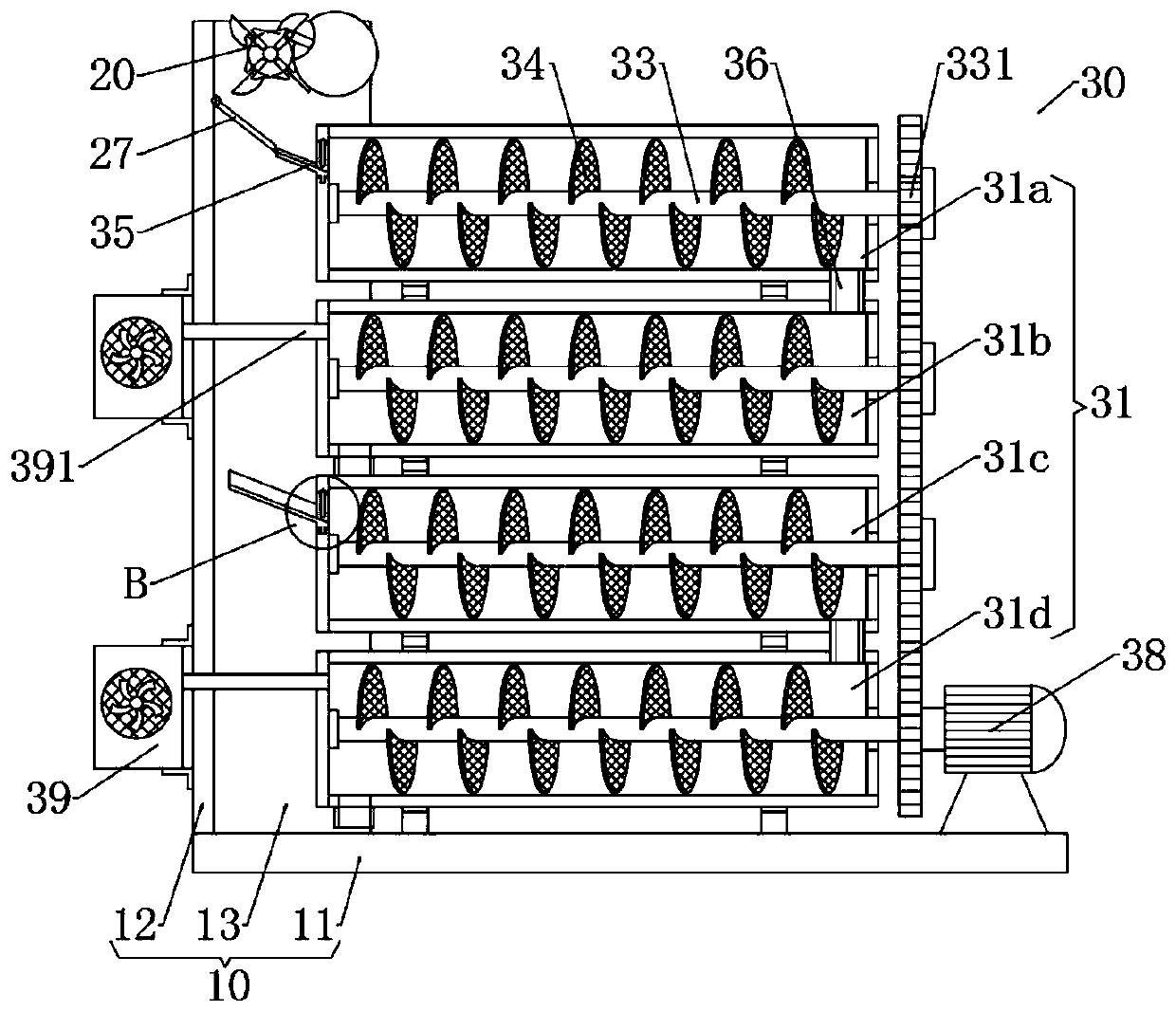

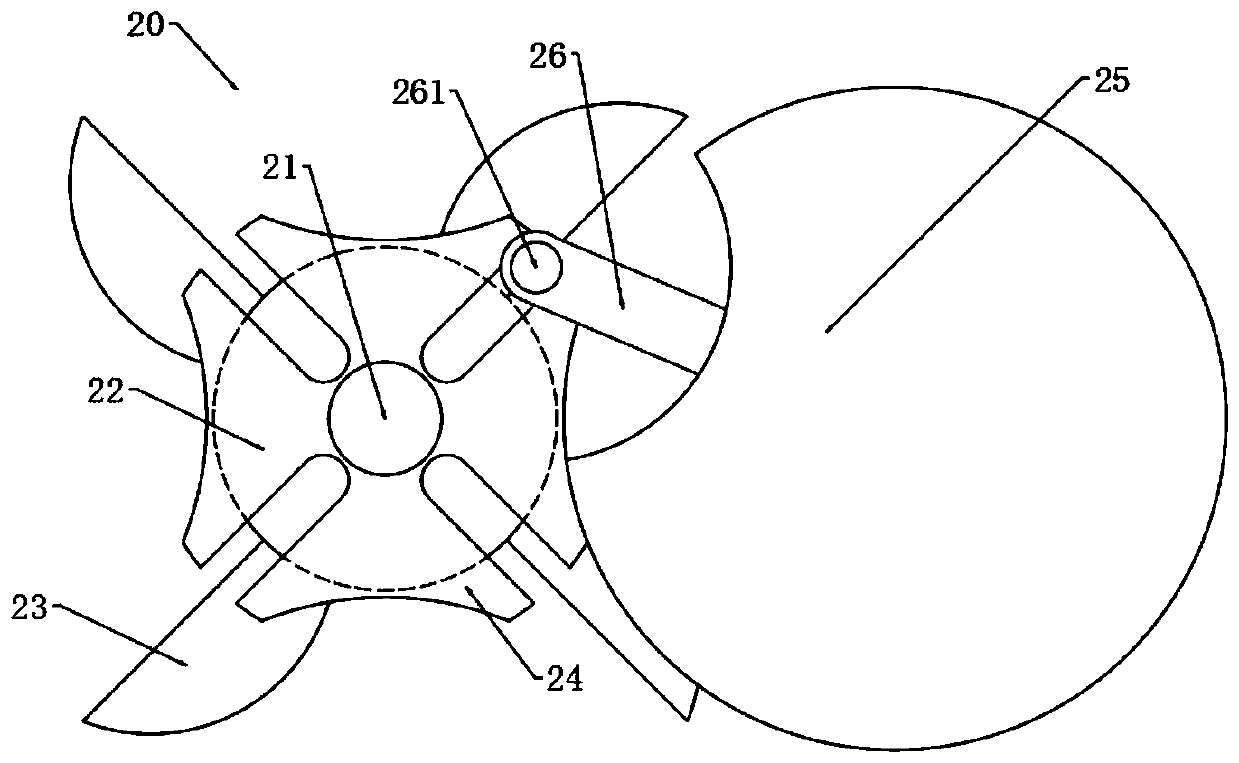

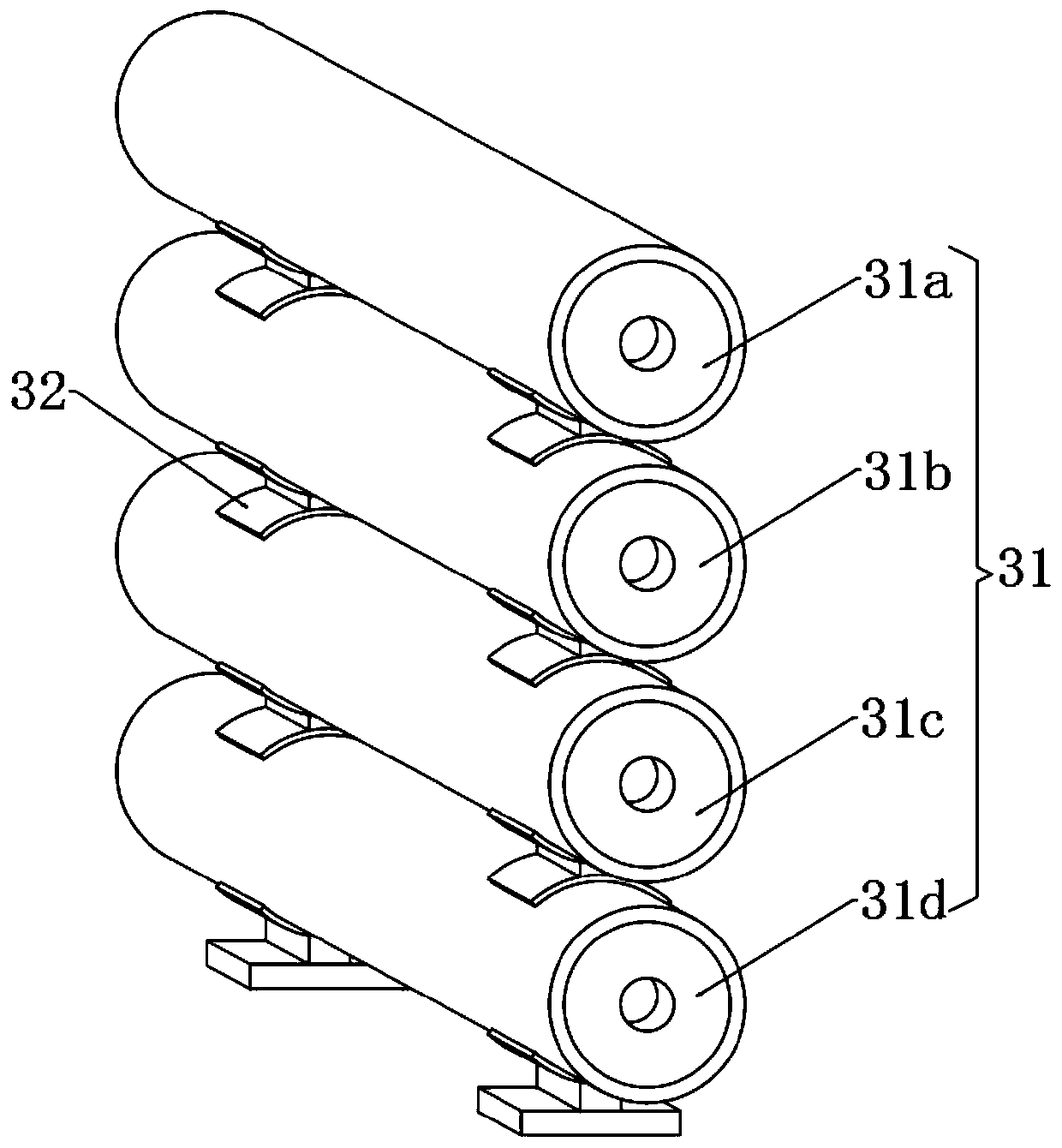

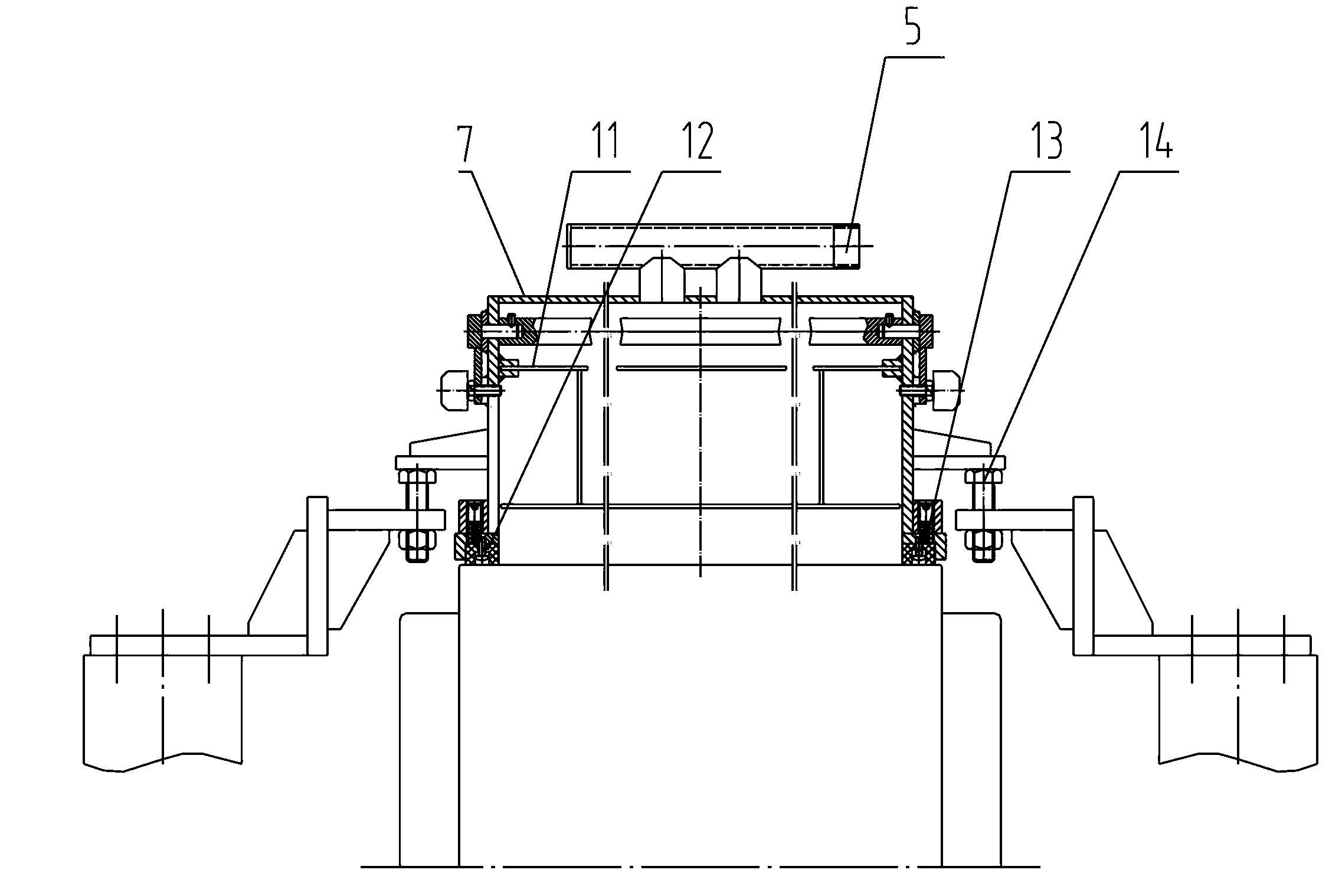

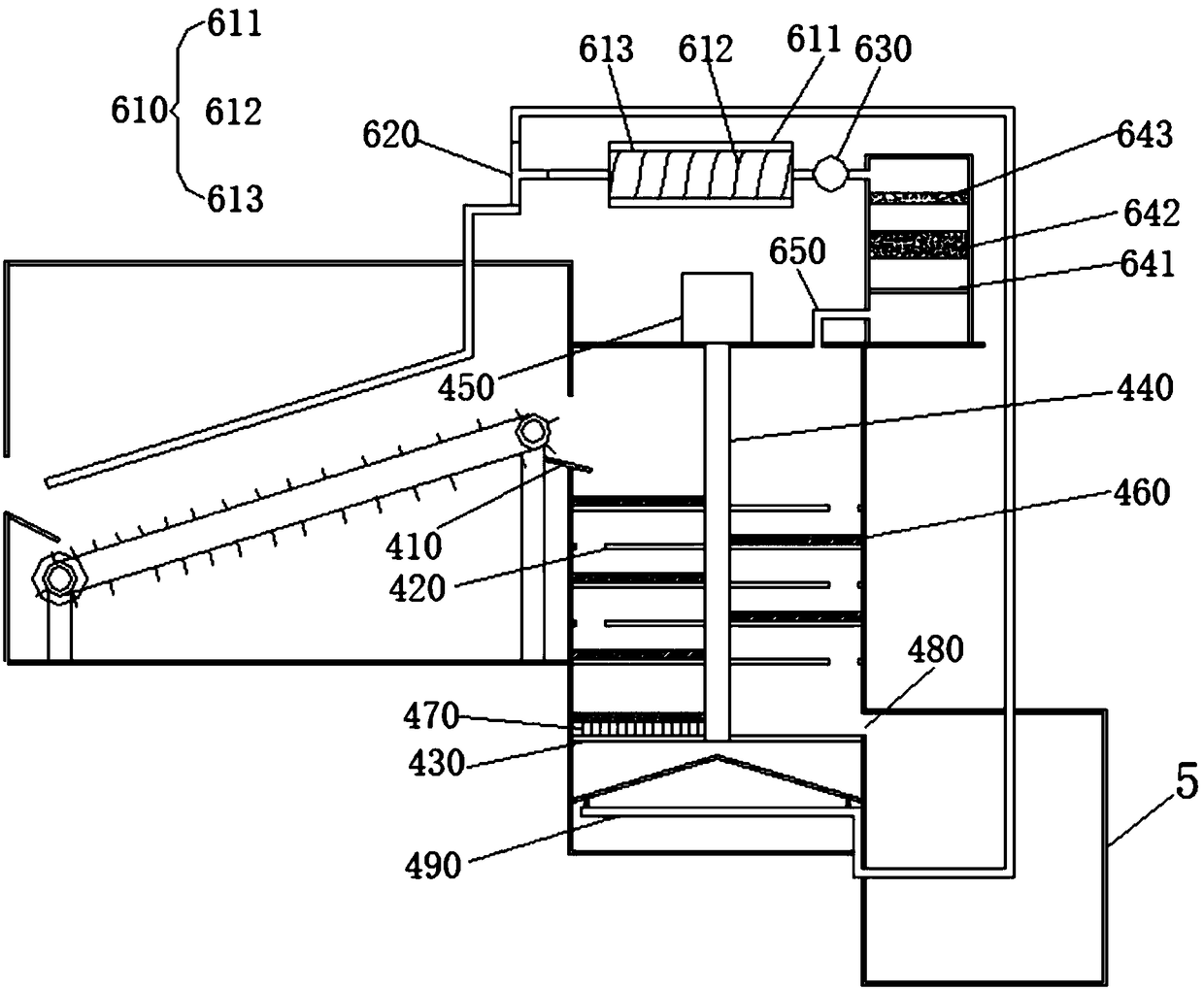

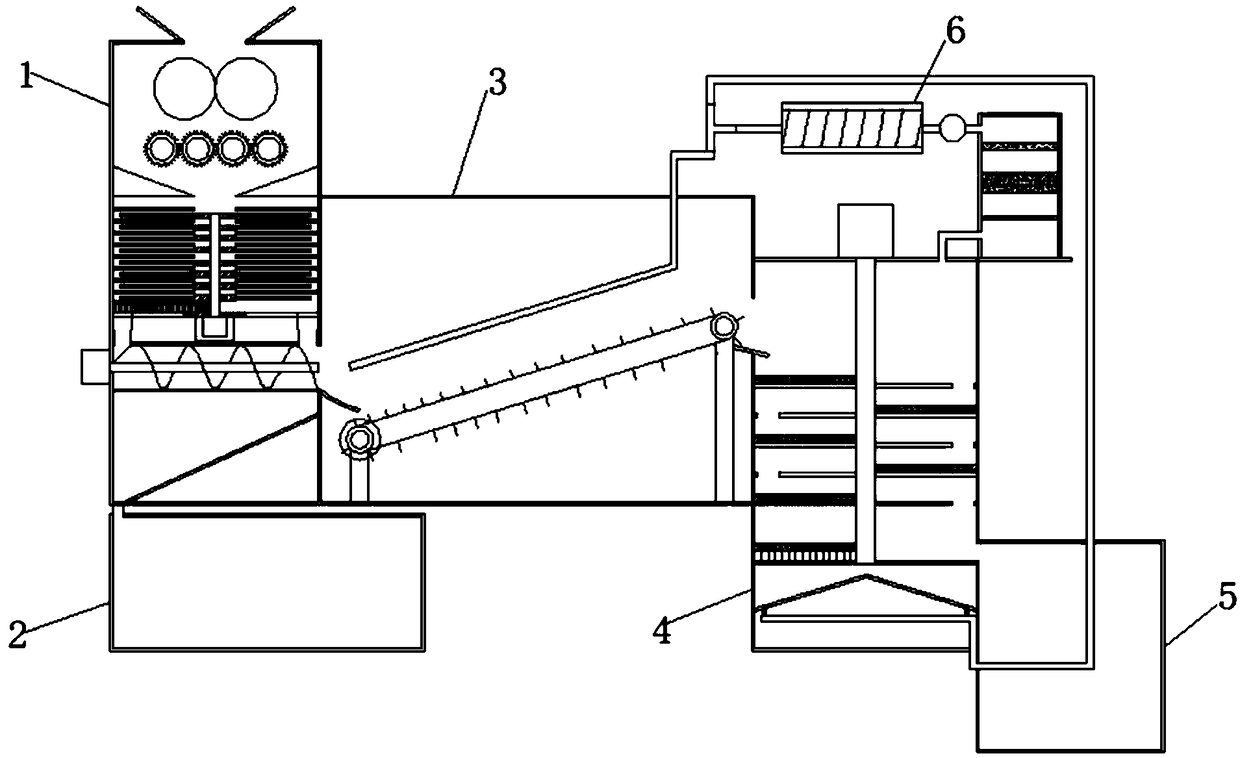

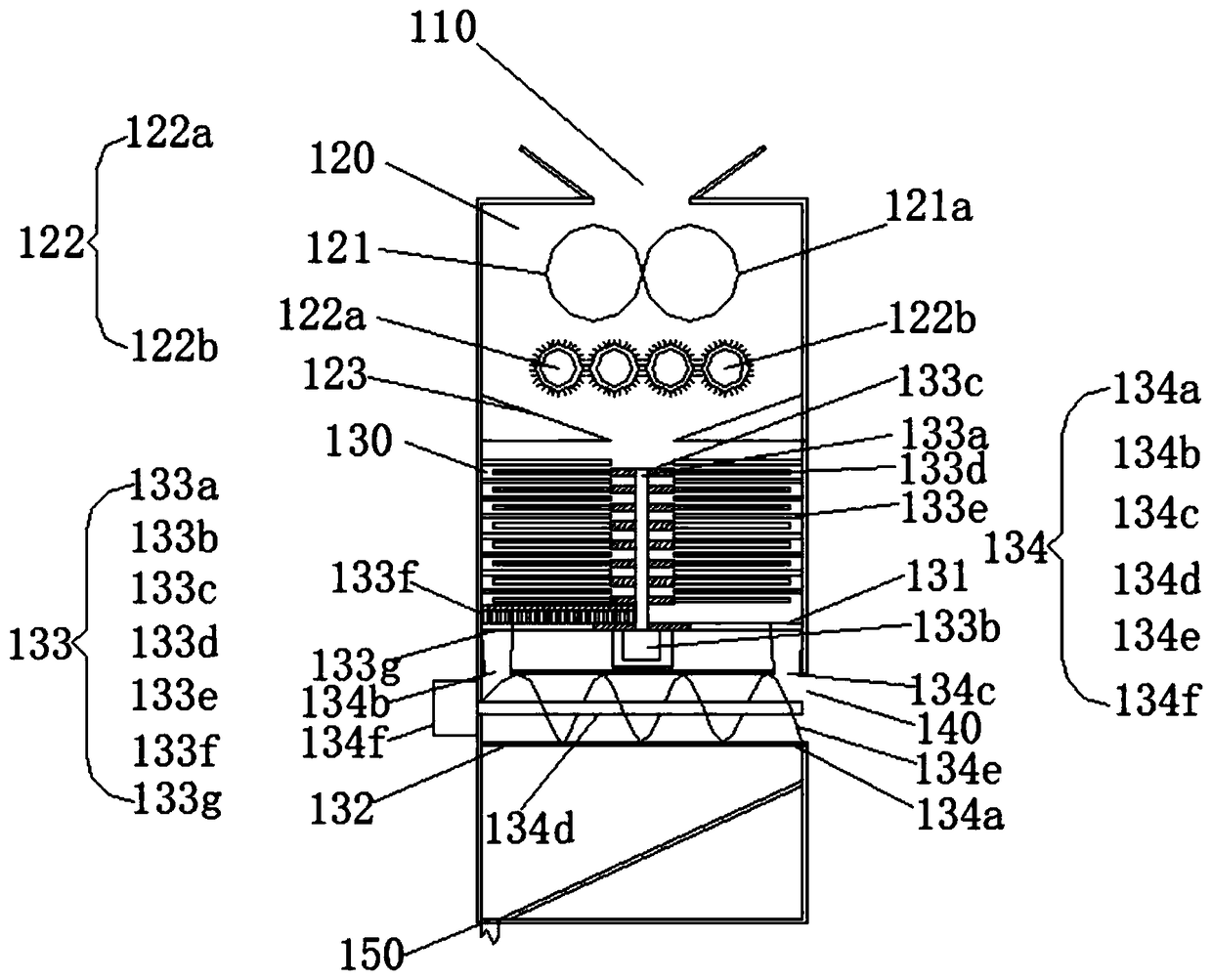

Automatic particle plastic dehumidification drying system and technology

ActiveCN111504042AReduce drying loadExtension of timeDrying solid materials without heatDrying gas arrangementsAir blowerMechanical engineering

The invention relates to an automatic particle plastic dehumidification drying system and technology. The automatic particle plastic dehumidification drying system comprises a pedestal, a material distributing device and a drying device, wherein the material distributing device and the drying device are installed on the pedestal. The drying device comprises drying cylinders which are horizontallyarranged. Rotating shafts extending in the length directions of the drying cylinders are formed in the corresponding drying cylinders. Screw blades which are distributed in the length directions of the rotating shafts are arranged on the outer walls of the rotating shafts. According to the automatic particle plastic dehumidification drying system and technology, a grooved wheel is used for drivinga material receiving groove to rotate intermittently, and plastic particles are sequentially guided into the different drying cylinders through a material guide plate; and meanwhile, the plastic particles are subjected to primary dehumidification with feeding mechanisms at feeding inlets of the drying cylinders, and drying loads of the drying device are lowered. By means of the automatic particleplastic dehumidification drying system and technology, the screw blades are used for conveying the plastic particles, the plastic particles enter the next set of the drying cylinders through a firstcommunicating pipe, the time for the plastic particles to stay in the drying cylinders is prolonged, a hot-air blower is used for blowing reverse hot air into the drying cylinders, the contact area ofthe hot air and the plastic particles is increased, the contact time of the hot air and the plastic particles is prolonged and hence drying is made more thorough.

Owner:山东华鹏高分子材料有限公司

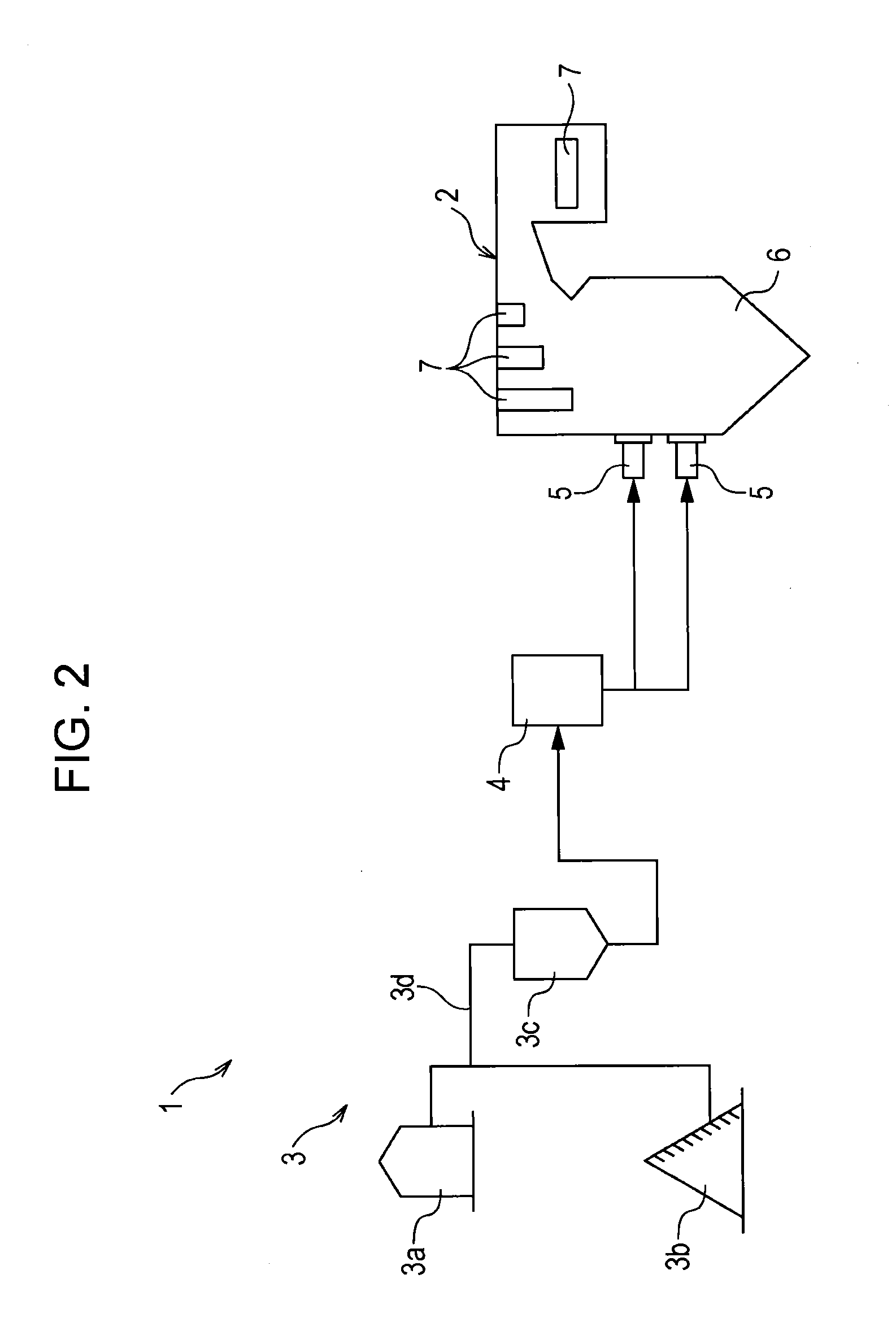

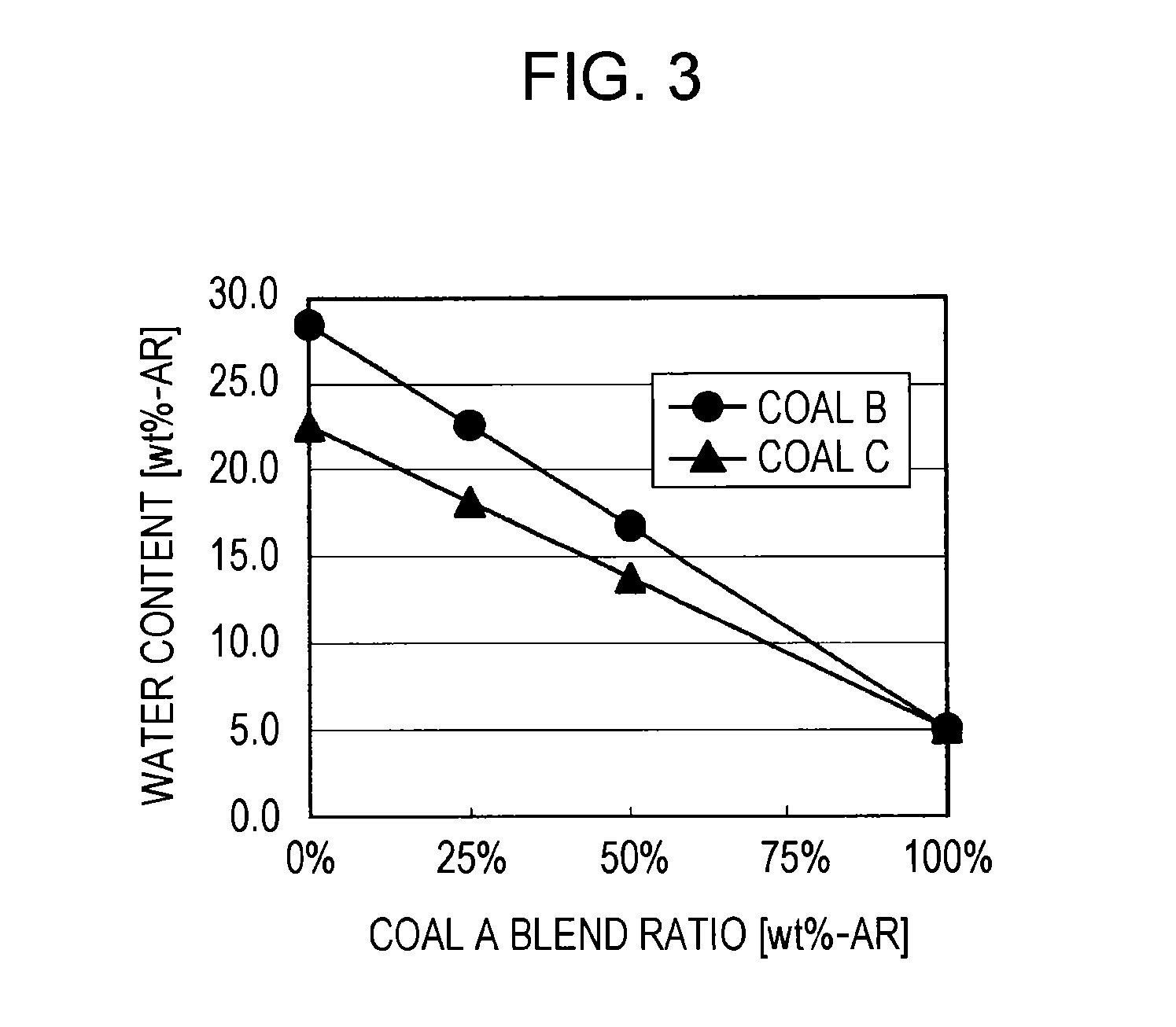

Coal-blended fuel, method for combusting the same, and coal fuel for use in coal-blended fuel

ActiveUS20140352583A1Reduce adhesionImprove efficiencySolid fuelsWaste based fuelEngineeringPulverized fuel ash

This mixed coal fuel is obtained by mixing a low-grade coal and residual coal. The residual coal is obtained by separating, through evaporation, a solvent from concentrated solids left over when a solution portion, which contains soluble coal components in solvent, is separated from a slurry obtained by mixing and heating coal and a solvent. Furthermore, the ratio (base / acid) of basic components to acidic components contained in ash of the residual coal is lower than that of the low-grade coal.

Owner:KOBE STEEL LTD

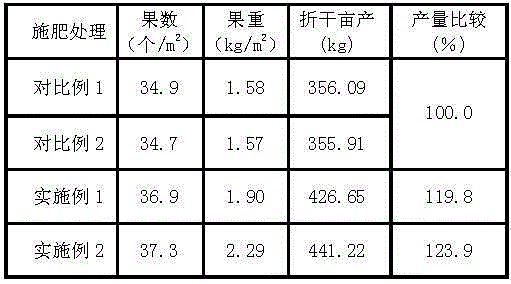

Novel high-effective bio-composite fertilizer specially used for crops and production method thereof

InactiveCN105418329AAdvanced production technologyIncrease production capacityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphatePotassium

The invention discloses a novel high-effective bio-composite fertilizer specially used for crops. The fertilizer is prepared from the following raw materials: urea, potassium chloride, monoammonium phosphate, ammonium bicarbonate, a biological additive, plant amino acids, bio-chemical fulvic acid, and EDTA-chelating medium and trace elements. The bio-composite fertilizer is advanced in production process, is improved in productivity, can save energy resource, and can promote photosynthesis, improve stress resistance of crops, improve quality of crops, improve soil and improve soil fertility.

Owner:MEISHAN JINWEITE FERTILIZER

Organic-inorganic environmentally-friendly pollution-free compound fertilizer

InactiveCN109851453AEfficient removalSolve the environmental problems of secondary pollutionBio-organic fraction processingOrganic fertiliser preparationPhosphatePhosphoric acid

The invention discloses an organic-inorganic environmentally-friendly pollution-free compound fertilizer and a preparation method thereof. The compound fertilizer comprises the following components, in percentages by mass: 20-25% of harmless livestock and poultry manure, 5-10% of earthworm excreta, 10-15% of humic acid, 25-30% of urea, 14-24% of monoammonium phosphate, 8-18% of potassium chloride,and 5-8% of calcium dihydrogenphoshate. The preparation method comprises the following steps: removing heavy metals in the livestock and poultry manure, performing harmless treatment on heavy metal ions through earthworms and preparing the high-quality organic fertilizer raw material earthworm excreta, removing antibiotics of the livestock and poultry manure by adopting physical, chemical and biological methods, wherein the above steps solve the problems that the heavy metals and the antibiotics pollute the environment and endanger human health, and performing composting fermentation, whereina secondary granulation technology is adopted to improve a granulation rate of the material, clay for promoting granulation does not need to be added, a large amount of liquid vapor or water does notneed to be supplemented, so that the problem of difficulty in granulation of an organic-inorganic fertilizer is solved. The prepared product provided by the invention has the following advantages: 1,the product has a high nutrient content, a low moisture content, good particle strength and low costs; and 2, organic matter sources of the product are the livestock and poultry manure, the earthwormexcreta and the humic acid, compared with other organic-inorganic fertilizers, the fertilizer provided by the invention has diversified and pollution-free organic matter sources, facilitates being absorbed and utilized by crops.

Owner:黑龙江金合康肥业有限公司

Method for preparing high-nitrogen sulfonyl azophoska compound fertilizer

ActiveCN101337847AIncrease profitEvenly distributedFertiliser formsFertilizer mixturesPotassiumSlurry

The invention relates to a method for producing a high-N S-based NPK compound fertilizer from an S-based NPK compound fertilizer slurry and urea. The method comprises the following steps: drying the S-based NPK compound fertilizer slurry at a low temperature in an empty tower; mixing the dried NPK basal fertilizer powder with urea powder obtained by crushing granulated urea; granulating, drying at a low temperature, polishing and sieving to obtain the high-N S-based NPK compound fertilizer. Compared with the prior S-based compound fertilizer production method, the method has the advantages of high N content in the S-based NPK compound fertilizer product, large adjusting range of N content, less N loss in the production process, long time for crops in absorbing N in the fertilizer.

Owner:贵州西洋实业有限公司

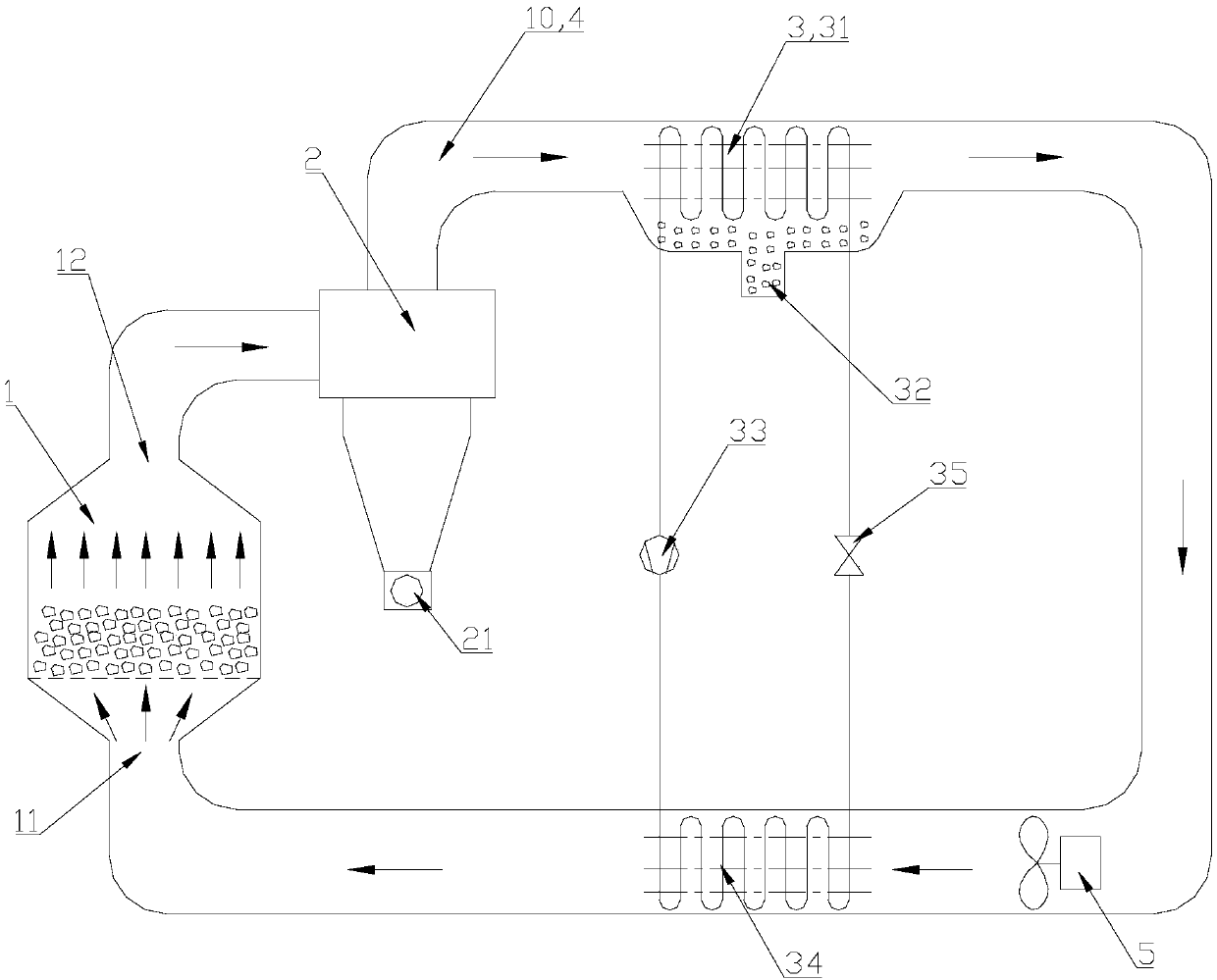

Segmented water removing and drying system for high-humidity coal and application method for segmented water removing and drying system

ActiveCN105157399AAvoid energy consumptionImprove economyDrying using combination processesDrying solid materials with heatCoalMicrowave

The invention discloses a segmented water removing and drying system for high-humidity coal and an application method for the segmented water removing and drying system. The system comprises a discharging mechanism. A first microwave drying mechanism is arranged below the discharging mechanism and internally provided with a first conveying mechanism. A solid-liquid separation mechanism is arranged at the tail end of the first conveying mechanism. A second conveying mechanism is arranged at an outlet of the solid-liquid separation mechanism. A second microwave drying mechanism is arranged at the tail end of the second conveying mechanism. The segmented water removing and drying system has the beneficial effects that a microwave heating manner and a non-heating manner are combined with the water removing and drying technology, a heat water removing manner and a non-heat water removing manner are organically combined, water in coal is removed in the form of a liquid state on the basis of low-rank coal microwave drying, and energy consumption of a microwave drying system is greatly reduced; raw coal is heated through the reutilization of residual heat and waste heat generated by the drying system, and the economical efficiency of the whole drying system is improved; and after deep drying is carried out, utilization of later finished coal is more flexible and safer, and the processing cost is reduced.

Owner:SHANDONG UNIV

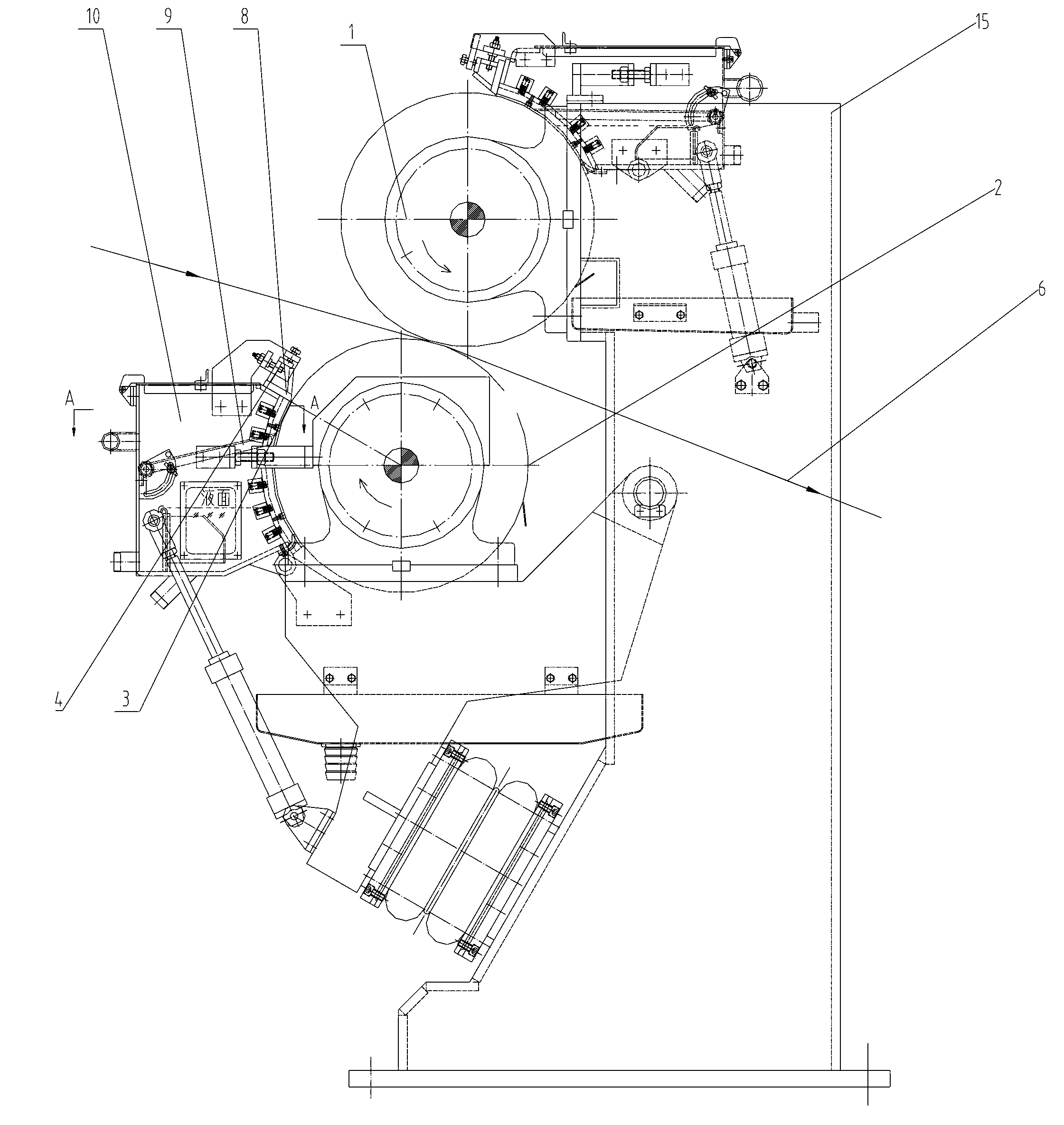

Adhesive applicator/coater

The invention provides an adhesive applicator / coater. The adhesive applicator / coater comprises a rack and two coating rollers, wherein roller surfaces of the two coating rollers are in contact with each other; a material pool is formed in each roller surface; a sealing plate is arranged on one side of the bottom of each material pool; each material pool, the corresponding roller surface and the corresponding sealing plate form a closed space; an air inlet gap is formed between each sealing plate and the corresponding roller surface; a screw regulating mechanism which is used for regulating the size of a material liquid outlet by regulating distance between each sealing plate and the corresponding roller surface is arranged on each sealing plate; a vacuum pumping hole is formed in the upper part of each material pool; a partition plate is arranged between each vacuum pumping hole and the liquid level of the corresponding material pool. The adhesive applicator / coater is used for manufacturing coating paper; according to the difference between external air flow and the internal air pressure of the closed space, redundant material liquid is blown away in the air inlet gaps, so that the material liquid is quantitatively and uniformly adhered to the roller surfaces. Furthermore, two surfaces of raw paper can be simultaneously coated by the same coatings or different coatings; the coating amount is uniform, and the smoothness and the flatness of finished paper are improved; high-solid-content coatings can be used, and a drying load is reduced.

Owner:HANGZHOU PROJECT & RES INST OF ELECTRO MECHANIC & LIGHT IND

Traditional Chinese medicine residue dehydration and recycling device

ActiveCN108759326AReasonable structural designSpread evenlyDrying using combination processesDrying solid materials without heatMedicineChinese drug

The invention provides a specific technical scheme of a traditional Chinese medicine residue dehydration and recycling device. The traditional Chinese medicine residue dehydration and recycling deviceis characterized by comprising a smashing box, a liquid collection box, a first drying box, a second drying box, a material storage box and a hot air circulating device. The traditional Chinese medicine residue dehydration and recycling device is reasonable in structural design; medicine residues are sufficiently pressed and smashed by the smashing box and thereby being convenient to dry, the drying efficiency is improved, and the drying load of the drying box is reduced; because a material feeding device and a conveying device are used in cooperation, it is avoided that medicine residues aredried incompletely because of accumulation; a plurality of baffles are arranged on a conveyer belt, so that the medicine residues are prevented from sliding off in the conveying process; a pluralityof drying plates and a plurality of material shifting plates are arranged in the second drying box, so that the medicine residues are evenly dried in the conveying process; and with the device, not only is the drying efficiency is improved, but also the drying effect is improved, the medicine residues can be conveniently dried, collected and stored, the environmental problems caused by direct discharging or burying of the medicine residues are avoided, and the device achieves the effects of energy saving, emission reduction and environmental protection.

Owner:江西天元药业有限公司

Method for lowering inorganic ultrafine powder slurry moisture content by adding rotary drum pressurizing type filtering machine

InactiveCN102976368AManual labor intensity is highReduce manual labor intensityMagnesium hydroxideFiltrationEngineering

The invention proposes a method for lowering energy consumption for drying inorganic ultrafine powder slurry by adding a rotary drum pressurizing type filtering machine. A pressurizing rotary drum filtering machine system is added in front of a conventional paddle dryer, and the inorganic ultrafine powder slurry moisture content is greatly reduced by pressure filtration. The method is characterized by continuous operation, saved energy, lowered consumption, reduced tail gas discharge quantity, and conformity with the national industrial policy of energy conservation and emission reduction.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION +2

Treatment process of salt-containing organic wastewater

InactiveCN111517549ANo pollution in the processReduce processing costsWater contaminantsMultistage water/sewage treatmentInorganic saltsWastewater

The invention discloses a treatment process of salt-containing organic wastewater. The treatment process comprises the following steps: firstly, adjusting the pH value of the wastewater to 6-10 in a pretreatment system; injecting the wastewater into a nanofiltration membrane concentration system, and concentrating the wastewater by selectively intercepting organic molecules and inorganic salt; andinjecting a concentrated solution intercepted by the nanofiltration membrane concentration system into drying equipment and concentrating the concentrated solution into blocks, sheets or powder for discharge. According to the invention, organic matters and inorganic salts in wastewater can be simultaneously treated, the process is simple, an evaporative crystallization procedure is eliminated inthe process, organic matters in the wastewater cannot be accumulated or generate mother liquor, the organic matters are thoroughly changed into dry materials through the drying equipment, the outsourcing cost is saved, the organic matters and salt in the wastewater can be selectively intercepted, the drying load is greatly reduced, the energy consumption is low, no pollution is caused to the environment, and the treatment cost of the salt-containing organic wastewater is greatly reduced.

Owner:SUZHOU ZHANQING ENVIRONMENT PROTECTION TECHCO LTD

Hot air circulation system for tobacco drying

PendingCN111174539AQuality assuranceReduce loadDrying gas arrangementsTobacco dryingThermodynamicsNicotiana tabacum

The invention discloses a hot air circulation system for tobacco drying. The system comprises a drying chamber, a circulating air duct and a heat pump system, wherein the drying chamber is provided with an air inlet and an air outlet; the circulating air duct is arranged outside the drying chamber, and two ends of the circulating air duct are connected with the air inlet and the air outlet of thedrying chamber correspondingly to form a circulating air path with the drying chamber; at least part of the heat pump system is arranged in the circulating air duct; and after materials in the dryingchamber are dried through airflow in the circulating air duct, the airflow become medium-temperature drying airflow after being dehumidified and heated through the part, located in the circulating airduct, of the heat pump system and then flows back into the drying chamber. By means of the arrangement, medium-temperature drying of the materials can be achieved, the drying quality of the materialsis guaranteed, and the system is of great significance in the speed-reducing drying stage with long drying time and relatively small drying load. Besides, a closed circulation mode of dry airflow isadopted, so that the load of air purification equipment is reduced, and the fragrance loss of the materials in the drying process is reduced.

Owner:QINHUANGDAO TOBACCO MACHINERY

Multi-element biological organic synergistic fertilizer and manufacturing method thereof

InactiveCN107973652AReasonable compositionNutrient balanceBio-organic fraction processingBacteriaMicrobial agentPhosphate

The invention discloses a multi-element biological organic synergistic fertilizer and a manufacturing method thereof. The multi-element biological organic synergistic fertilizer is prepared from the following raw materials in parts by weight: 150 parts of mushroom residues, 200 to 300 parts of tobacco residues, 40 to 60 parts of plant ash, 40 to 60 parts of wormcast, 2 to 4 parts of a compound microbial agent, 0.8 to 1.6 parts of a synergist, 80 to 120 parts of urea, 100 to 150 parts of monoammonium phosphate, 100 to 150 parts of potassium sulfate, 5 to 10 parts of a dispersing synergist and 4to 8 parts of a coating agent. The multi-element biological organic synergistic fertilizer disclosed by the invention is reasonable in components and balanced in nutrients, the utilization rate of the fertilizer is greatly improved through the synergistic effect of the components, the requirements of crops on the nutrients are sufficiently met, the fertilizer is economical, environmentally-friendly and good in fertilizer efficiency, the effect of the fertilizer is developed to the maximum extent, the yield can be improved, the quality can also be improved, and the fertilizer is an ideal biological green and environmentally fertilizer.

Owner:山东中新农业发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com