Fermentation treatment method and device of an organic waste

An organic waste and treatment method technology, applied in the field of fermentation treatment devices, can solve the problems of insufficient dehydration, unsuitable for large-scale, increased facility cost, etc., to prevent bridging phenomenon, reduce drying burden, and low moisture content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

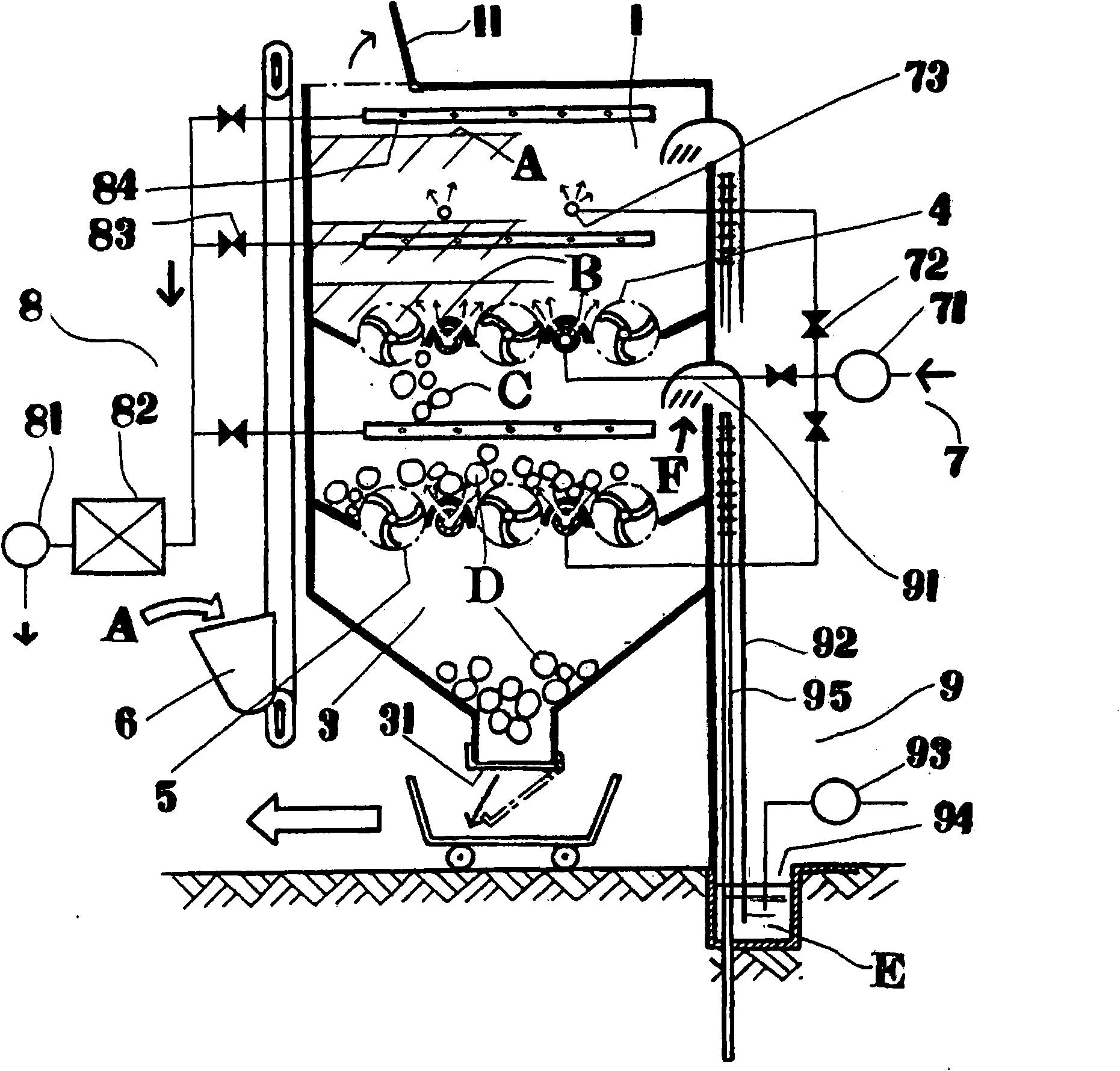

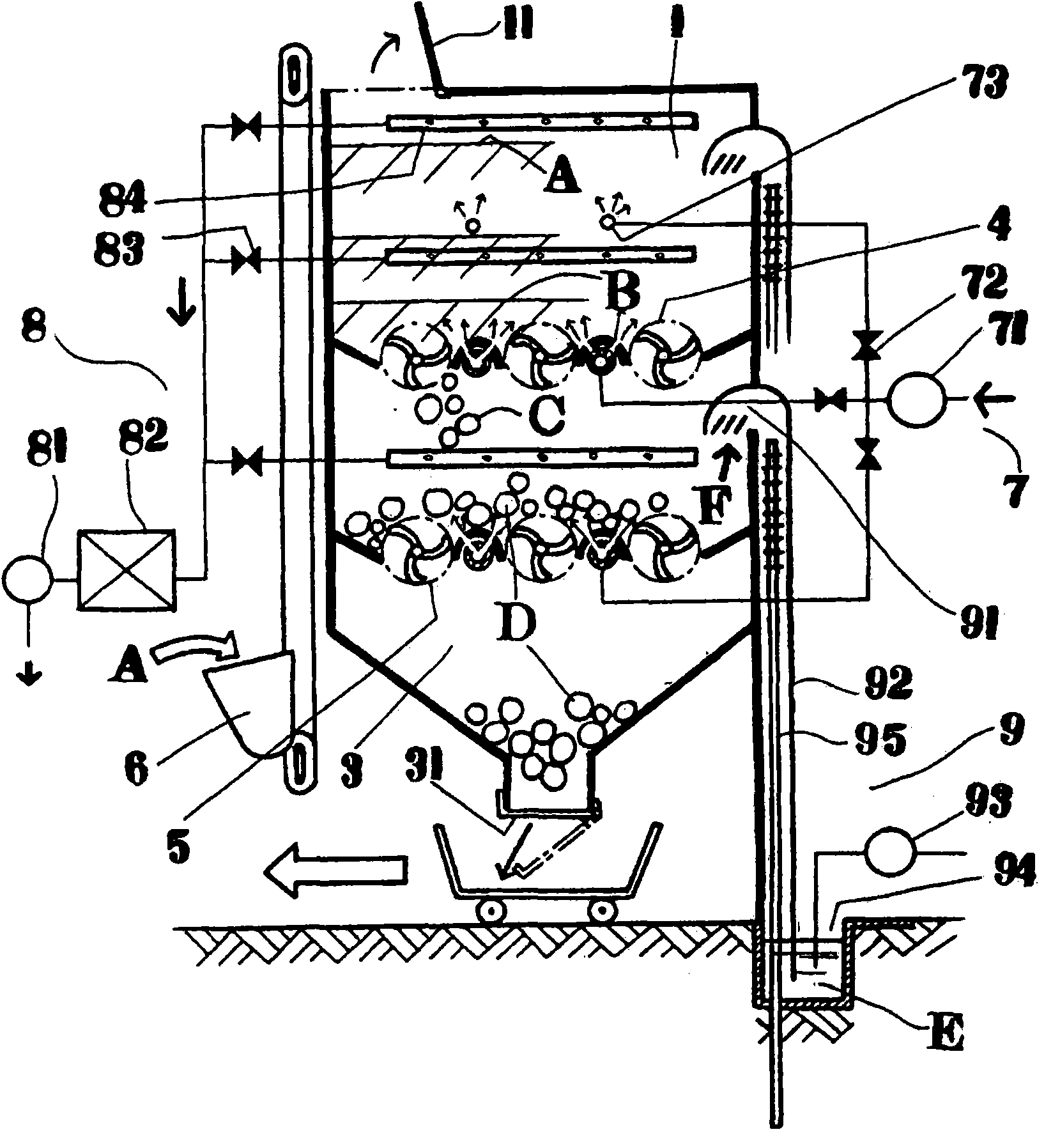

[0036] Next, embodiments of the present invention will be described. The organic waste fermentation treatment device shown in the embodiment is formed by assembling various mechanism parts in the main body of the multi-stage fermentation tank elongated in the longitudinal direction. The fermentation tank will form the first fermentation chamber 1, the second fermentation chamber 2, And the discharge chamber 3, the stirring transfer mechanism 4 is provided between the first fermentation chamber 1 and the second fermentation chamber 2, and the transfer mechanism 5 is provided between the second fermentation chamber 2 and the discharge chamber 3.

[0037] In addition, a supply mechanism part 6 for supplying the fermentation object A to the first fermentation chamber 1 of the fermentation tank main body, an air supply mechanism part 7 for supplying fermentation air, and an exhaust mechanism part for exhausting air from the fermentation tank are attached. 8. And liquid fertilizer m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com