Patents

Literature

560results about How to "Prevent bridging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

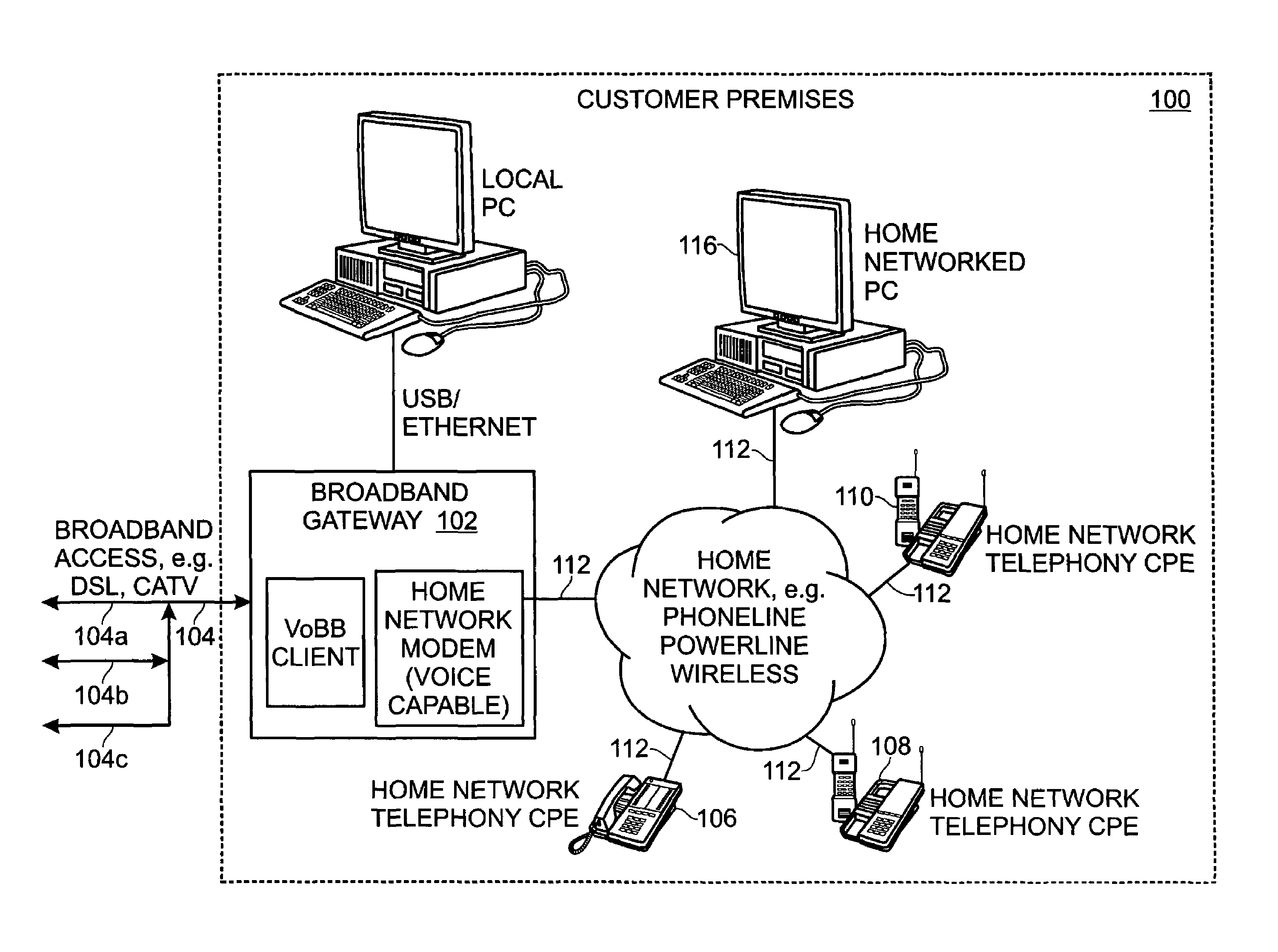

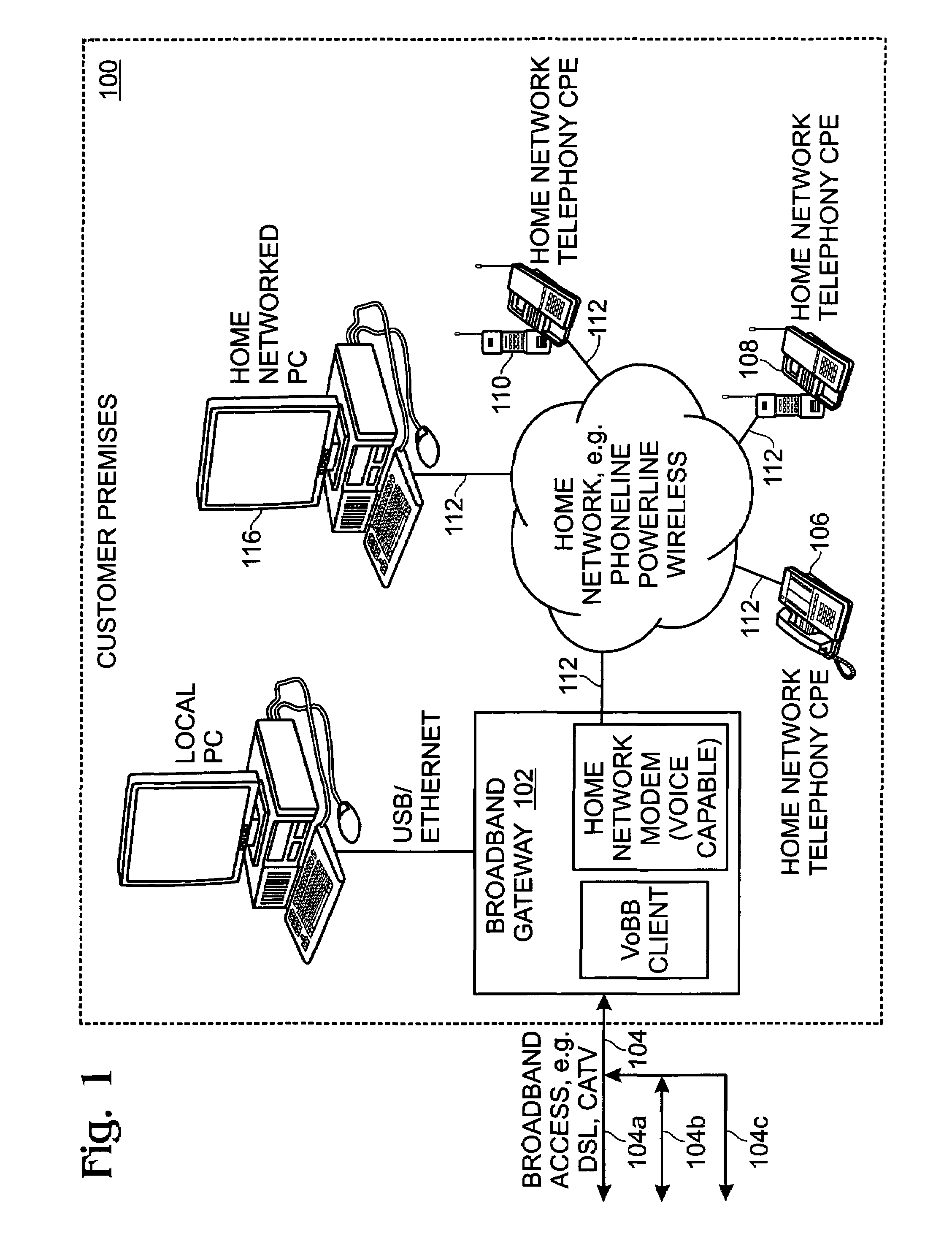

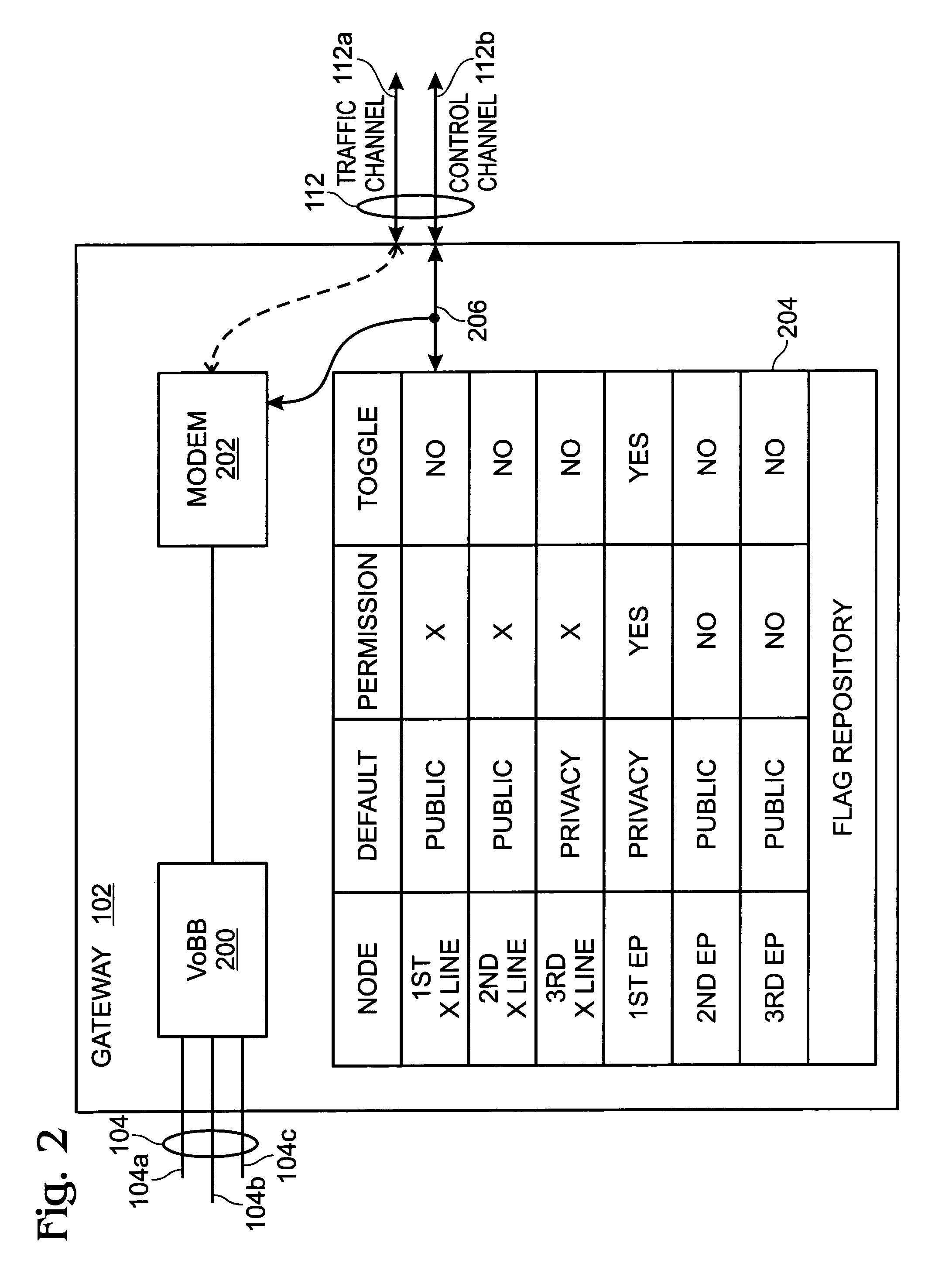

Privacy mode system and method for home network telephone

InactiveUS7023975B2Prevent bridgingInterconnection arrangementsSubstation speech amplifiersOperation modeFamily network

A system and method are provided for controlling communications privacy in a Home Network telephone system. The method comprises: using a gateway to send and receive calls on at least one external telephone line; supplying privacy and public mode bridging options; and, selectively excluding bridges between external telephone lines and a plurality of Home Network endpoints. In response to the privacy mode being selected, the gateway bridges a call between a first external telephone line and a first endpoint, and prevents bridges between the first external telephone line and other endpoints in the system. Alternately, when the public mode is selected, the gateway bridges a call between the first external telephone line and the first endpoint; and permits bridges between the first external telephone line and other endpoints in the system. That is, while the call is bridged to the first endpoint, a bridge is added between the first telephone line and the second endpoint. The privacy and public mode bridging options are selected with respect to nodes. A node can be an external telephone line or an endpoint. That is, a privacy or public mode of operation can be selected for a first external telephone line, whether calls are received or originated through the Home Network telephone system. Likewise, a privacy or public mode of operation can be selected for a particular endpoint, regardless of whether the endpoint receives or originates the call.

Owner:SHARP KK

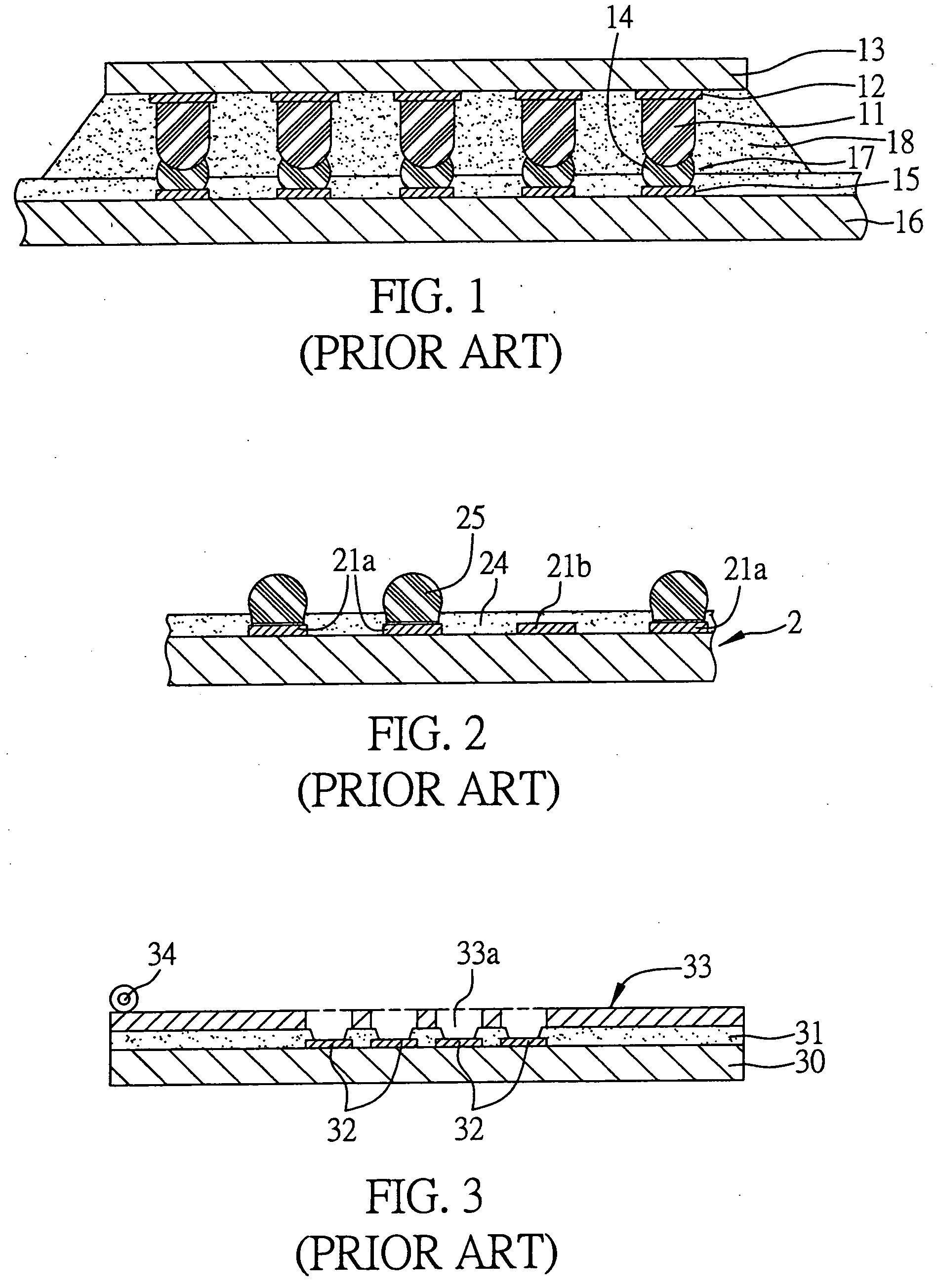

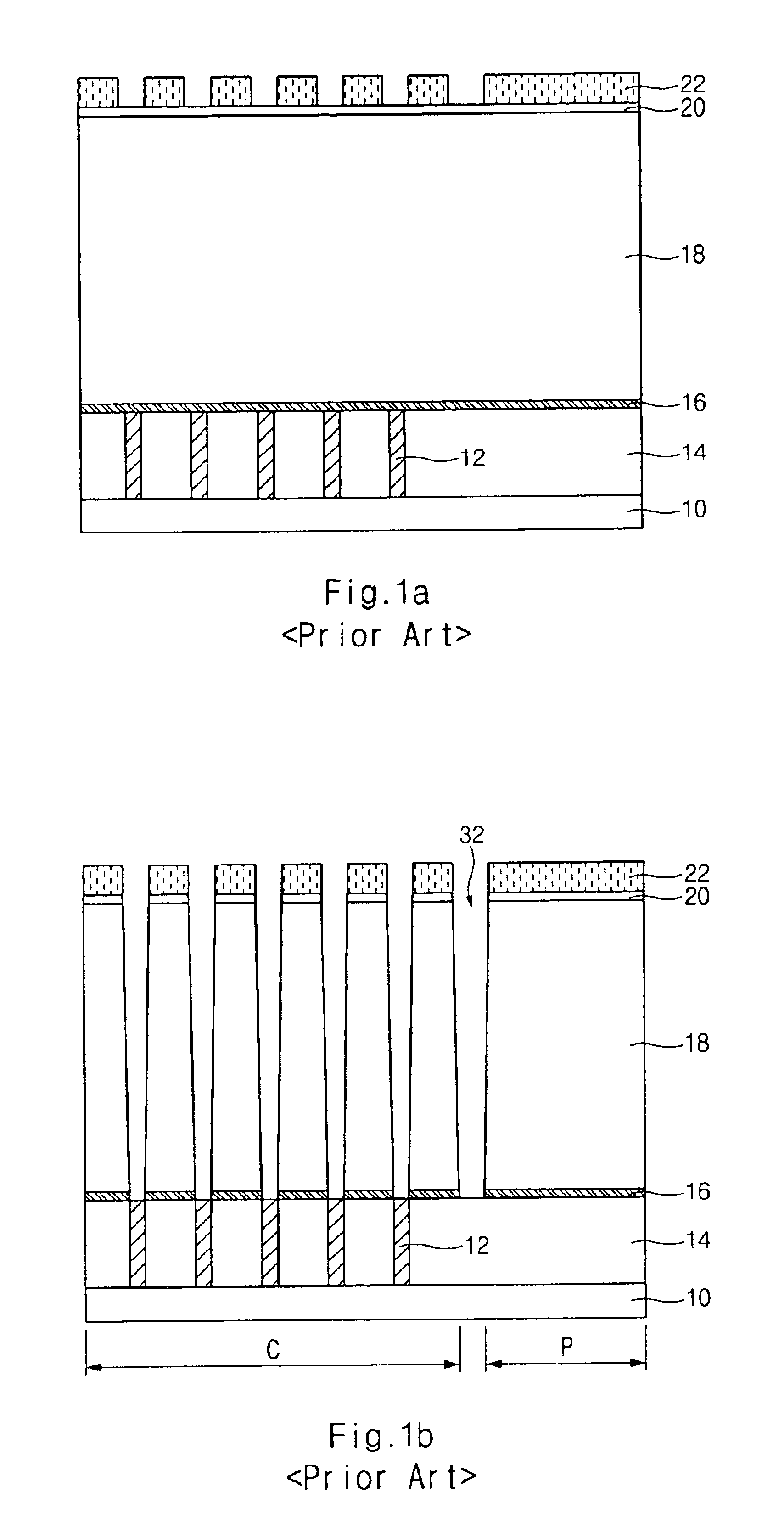

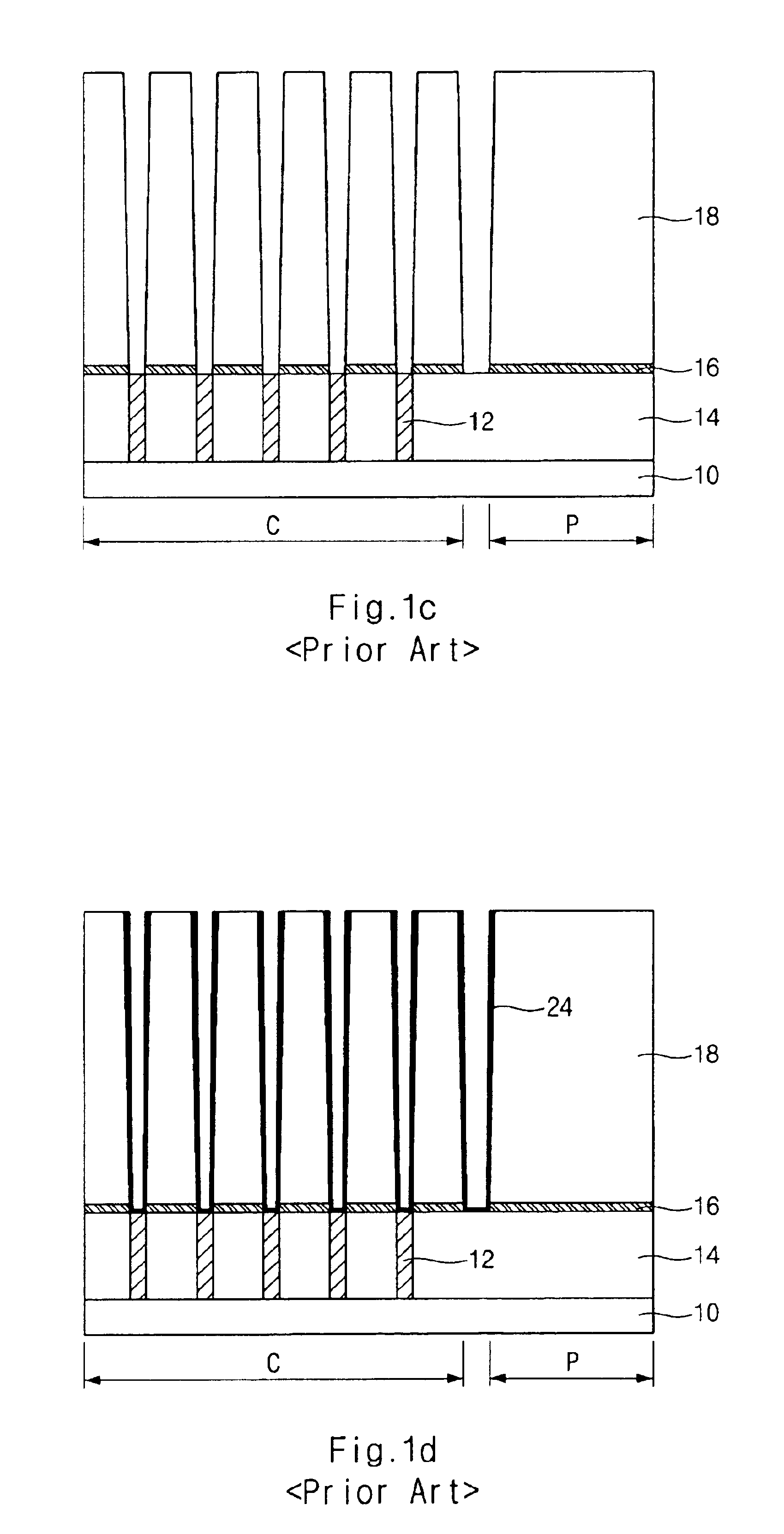

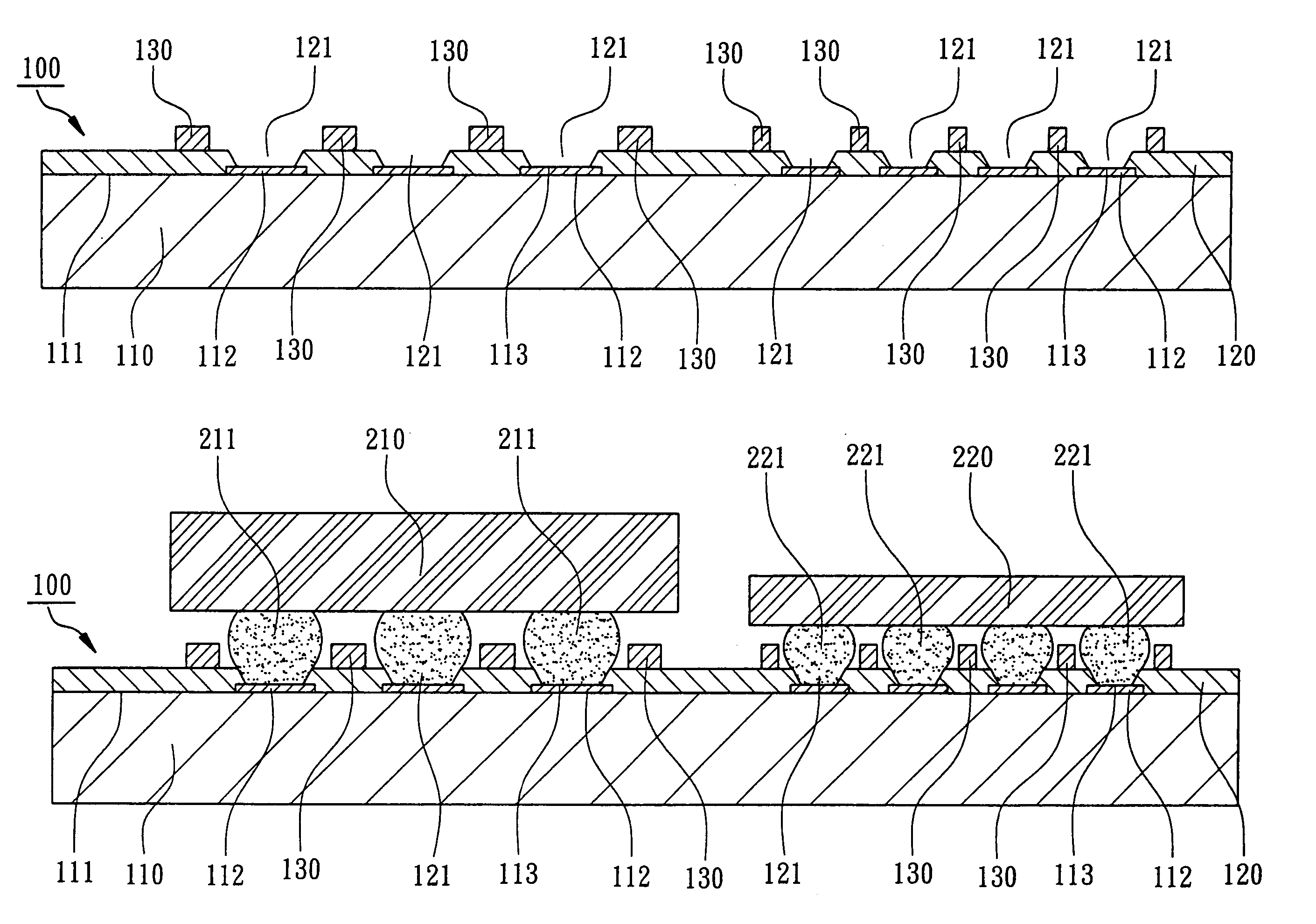

Pre-solder structure on semiconductor package substrate and method for fabricating the same

InactiveUS20050167830A1Pad pitchFabrication cost is increasedPrinted circuit assemblingSemiconductor/solid-state device detailsResistSemiconductor package

A pre-solder structure on a semiconductor package substrate and a method for fabricating the same are proposed. A plurality of conductive pads are formed on the substrate, and a protective layer having a plurality of openings for exposing the conductive pads is formed over the substrate. A conductive seed layer is deposited over the protective layer and openings. A patterned resist layer is formed on the seed layer and has openings corresponding in position to the conductive pads. A plurality of conductive pillars and a solder material are deposited in sequence in each of the openings. The resist layer and the seed layer not covered by the conductive pillars and the solder material are removed. The solder material is subject to a reflow-soldering process to form pre-solder bumps covering the conductive pillars.

Owner:PHOENIX PRECISION TECH CORP

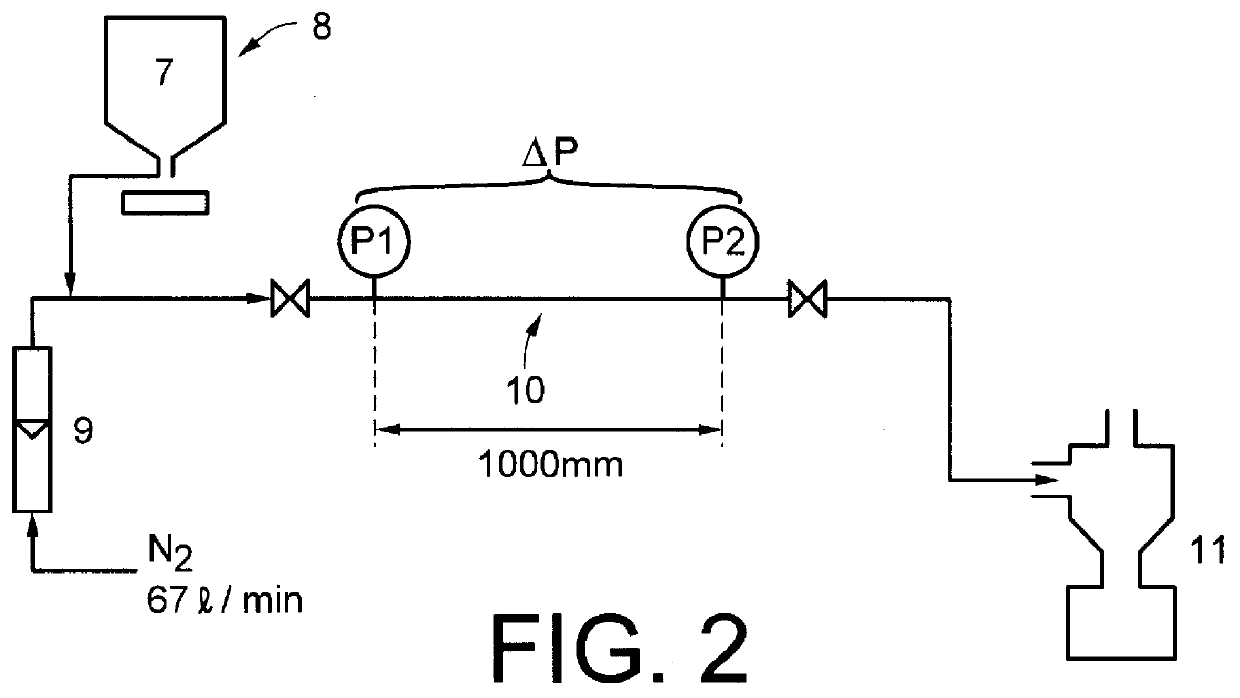

Pulverized coal carriability improver

InactiveUS6083289AGreat varietyImprove liquiditySolid fuel pretreatmentSolid fuelsInorganic saltsCombustion

PCT No. PCT / JP97 / 00668 Sec. 371 Date Sep. 25, 1998 Sec. 102(e) Date Sep. 25, 1998 PCT Filed Mar. 5, 1997 PCT Pub. No. WO97 / 36009 PCT Pub. Date Oct. 2, 1997The use of pulverized coal as the fuel to be injected into metallurgical or combustion furnace becomes possible enabled by improving the transportability thereof. Further, a pulverized coal is provided, which is inhibiting from bridging or channeling in a hopper, or piping choking. A water-soluble inorganic salt having a polar group is made to adhere to pulverized coal which is prepared from raw coal having an average HGI of 30 or above and which is in a dry state at the injection port of a metallurgical or combustion furnace, The inorganic salt is selected from among BaCl2, CaCl2, Ca(NO2)2, Ca(NO3)2, Ca(ClO)2, K2CO3, KCl, MgCl2, MgSO4, NH4BF4, NH4Cl, (NH4)2SO4, Na2CO3, NaCl, NaClO3, NaNO2, NaNO3, NaOH, Na2S2O3, Na2S2O5, HNO3, H2SO4, H2CO3, and HCl.

Owner:KAO CORP

Method for manufacturing semiconductor device

Owner:SK HYNIX INC

Belt type filter press

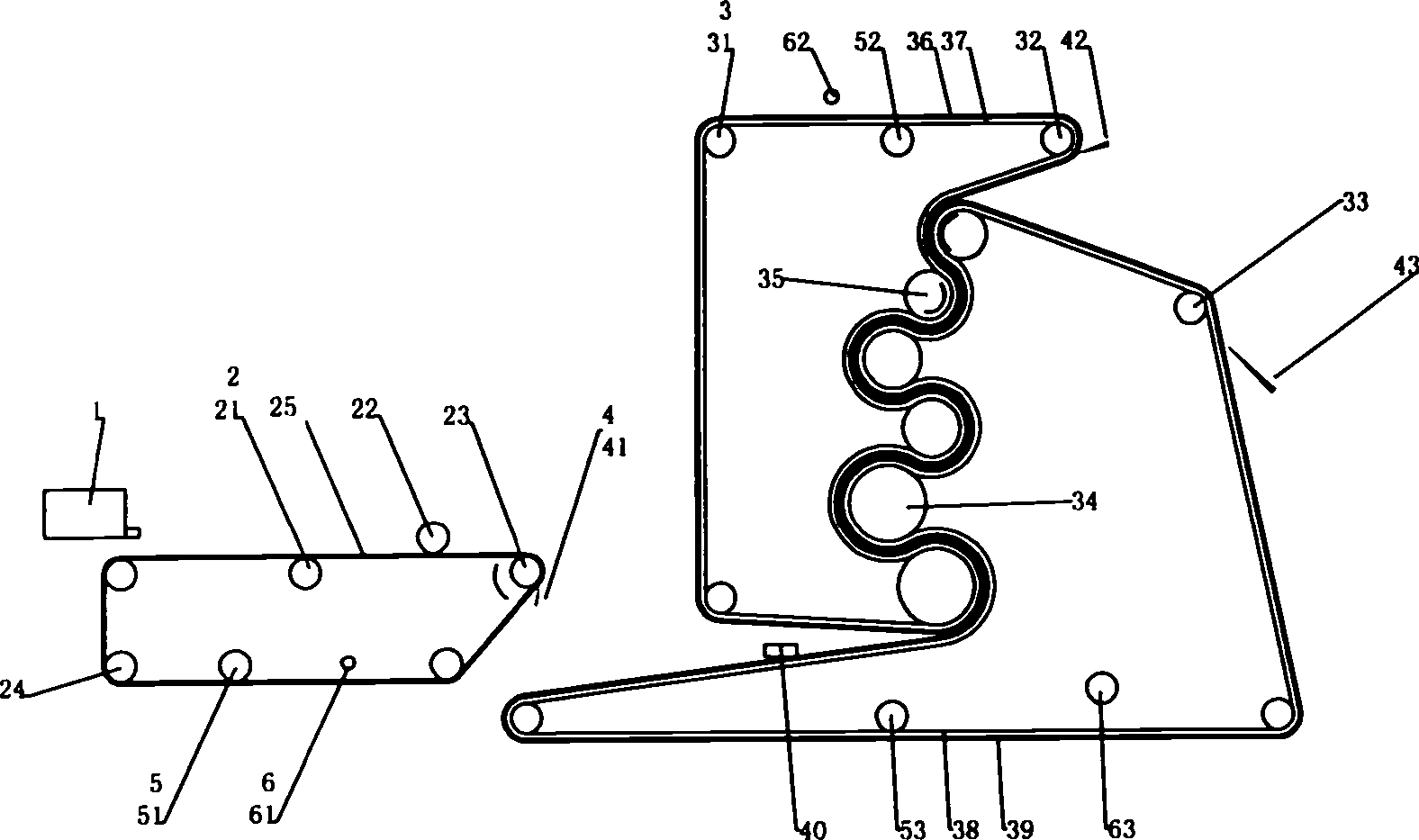

ActiveCN1879932AHigh filtration pressureHigh filter pressureMoving filtering element filtersEngineeringFilter press

The invention relates to a belt compress filter for dewatering the micro grains, wherein it is formed by a frame, a driver, a feeding device, a compress area and an auxiliary device; said compress area comprises a compress filtering roller and a filtering belt; the driver comprises a motor and a gear box; the auxiliary device comprises a tension roller, a scrape device, a water collector, a corrector, and a filter belt washer. The invention is characterized in that: the back of filter belt is lined with steel compress belt; the compress filtering rollers are compacted arranged. The invention can improve the filter pressure of compress filter to improve the balance point between the filter pressure and the filter resistance, to overcome the defects of present technique, while it can improve the dewatering efficiency and the yield.

Owner:ZHEJIANG HUAZHANG TECH

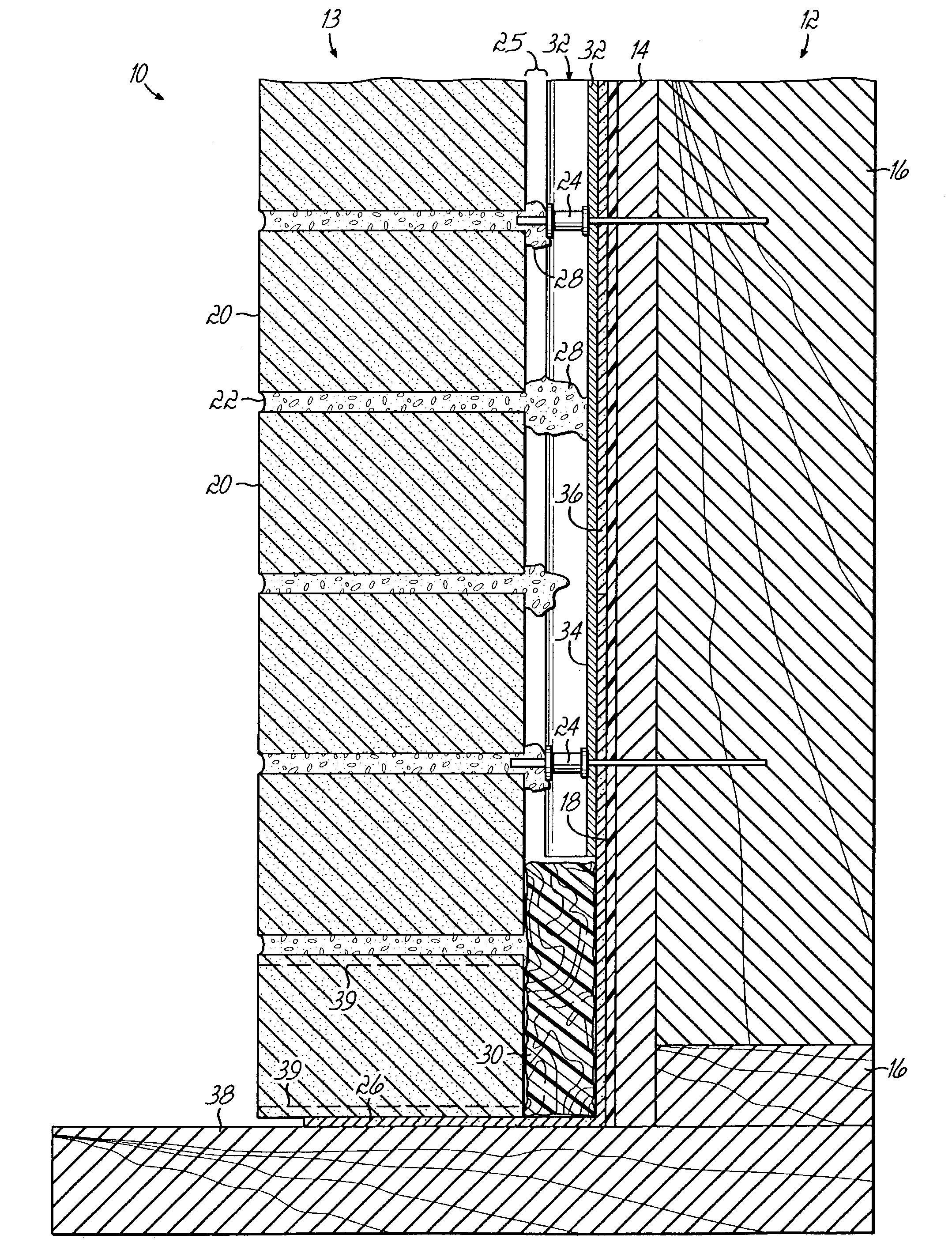

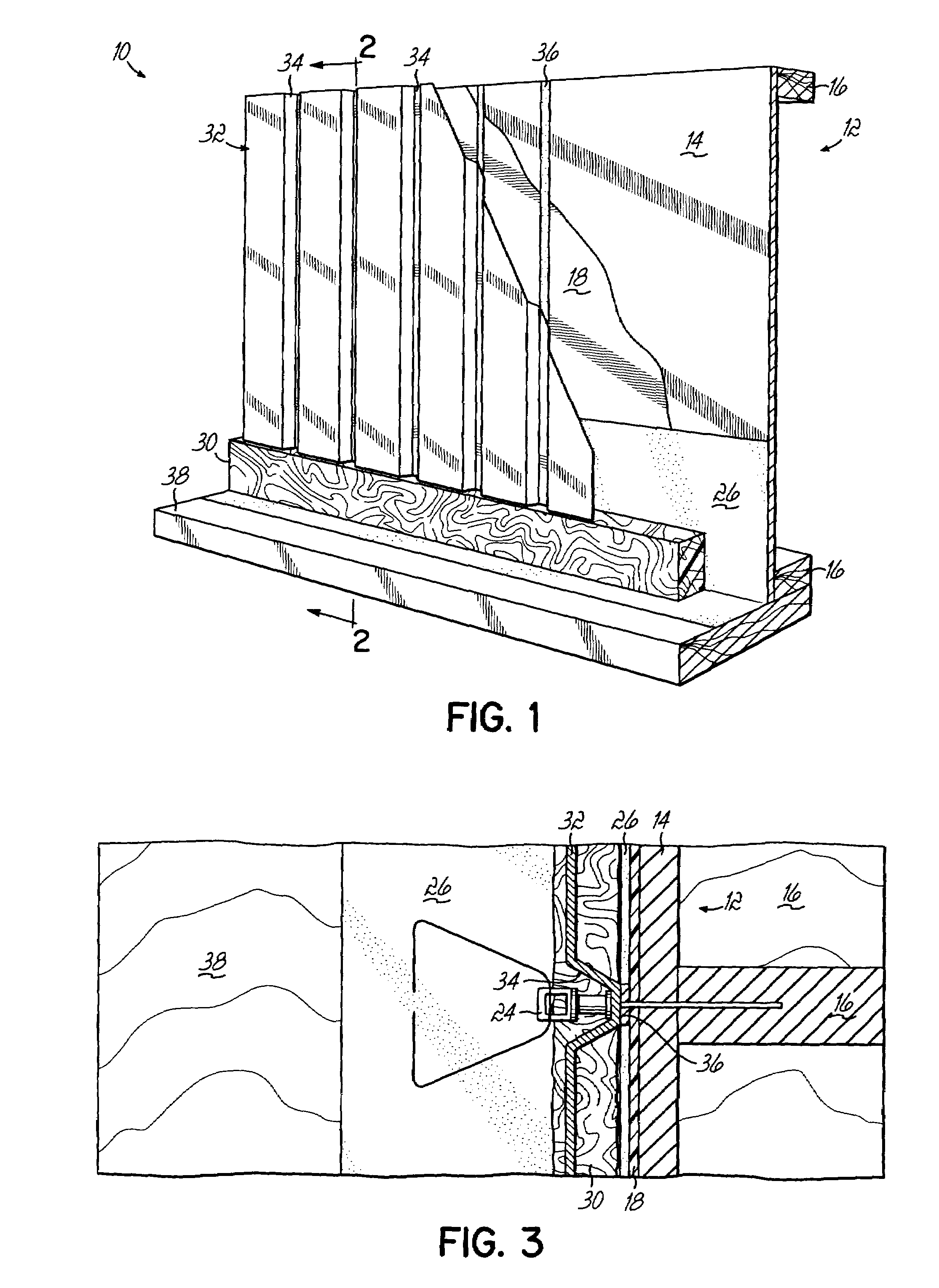

Air circulation board for cavity wall construction

A corrugated board is secured to the inner wall of a cavity wall construction to establish a defined spacing between the inner and outer walls and prevent excess mortar from bridging to the inner wall. The corrugated board has a series of spaced channels, furrows or grooves into which an anchor projects into the studs of the inner wall to secure the outer wall. The corrugated board is installed prior to the construction of the outer wall and establishes a minimum spacing or gap between the walls based upon the thickness of the board. The outer wall is constructed immediately adjacent to the outer face of the corrugated board. The grooves or channels of the corrugated board create a chamber for vapor and air circulation. The board eliminates bridging by the mortar and provides an air conduit to exhaust even the minimal amounts of vapor that will occur in the cavity.

Owner:TY DAS BUILDING PROD LLC

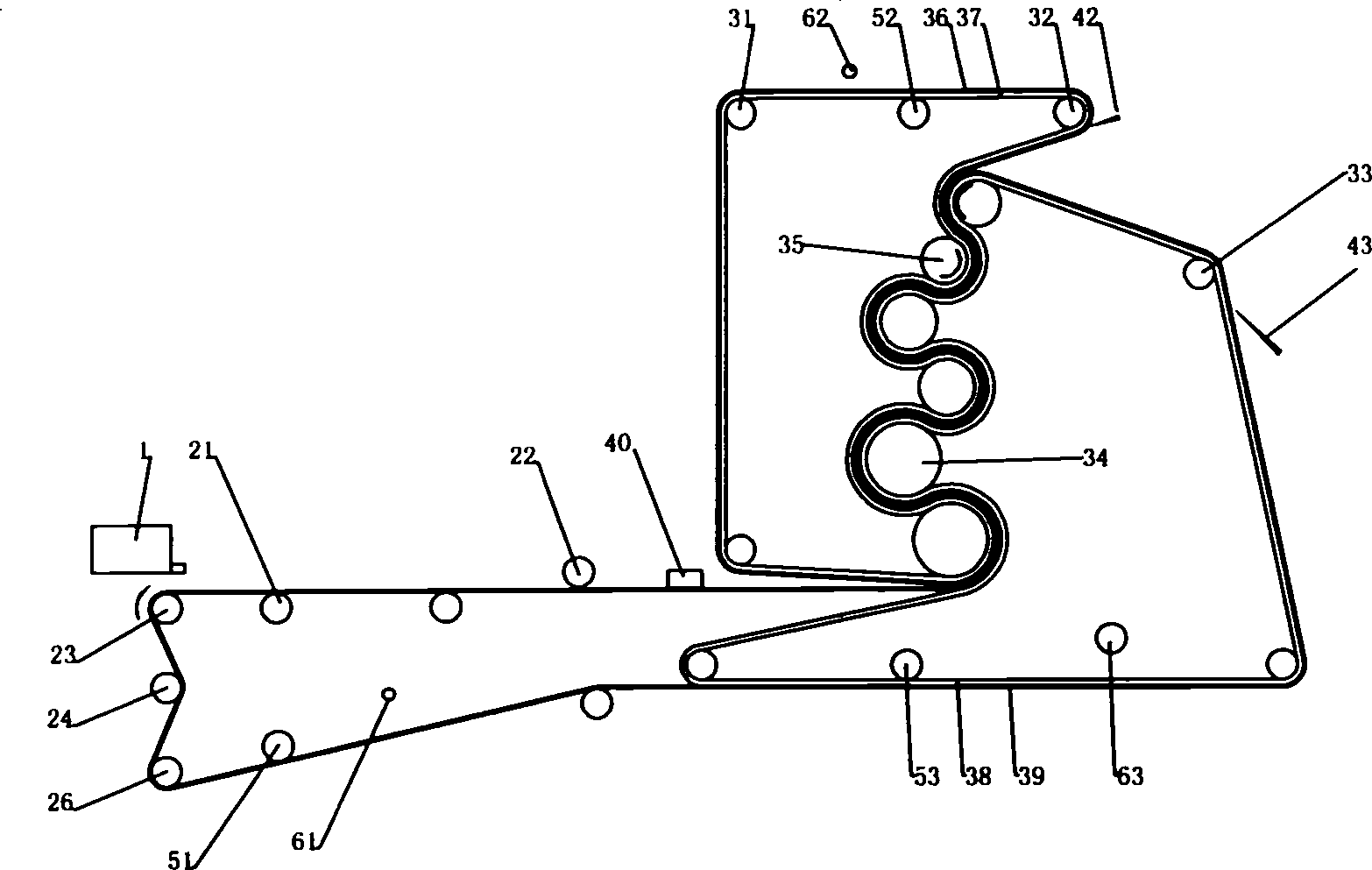

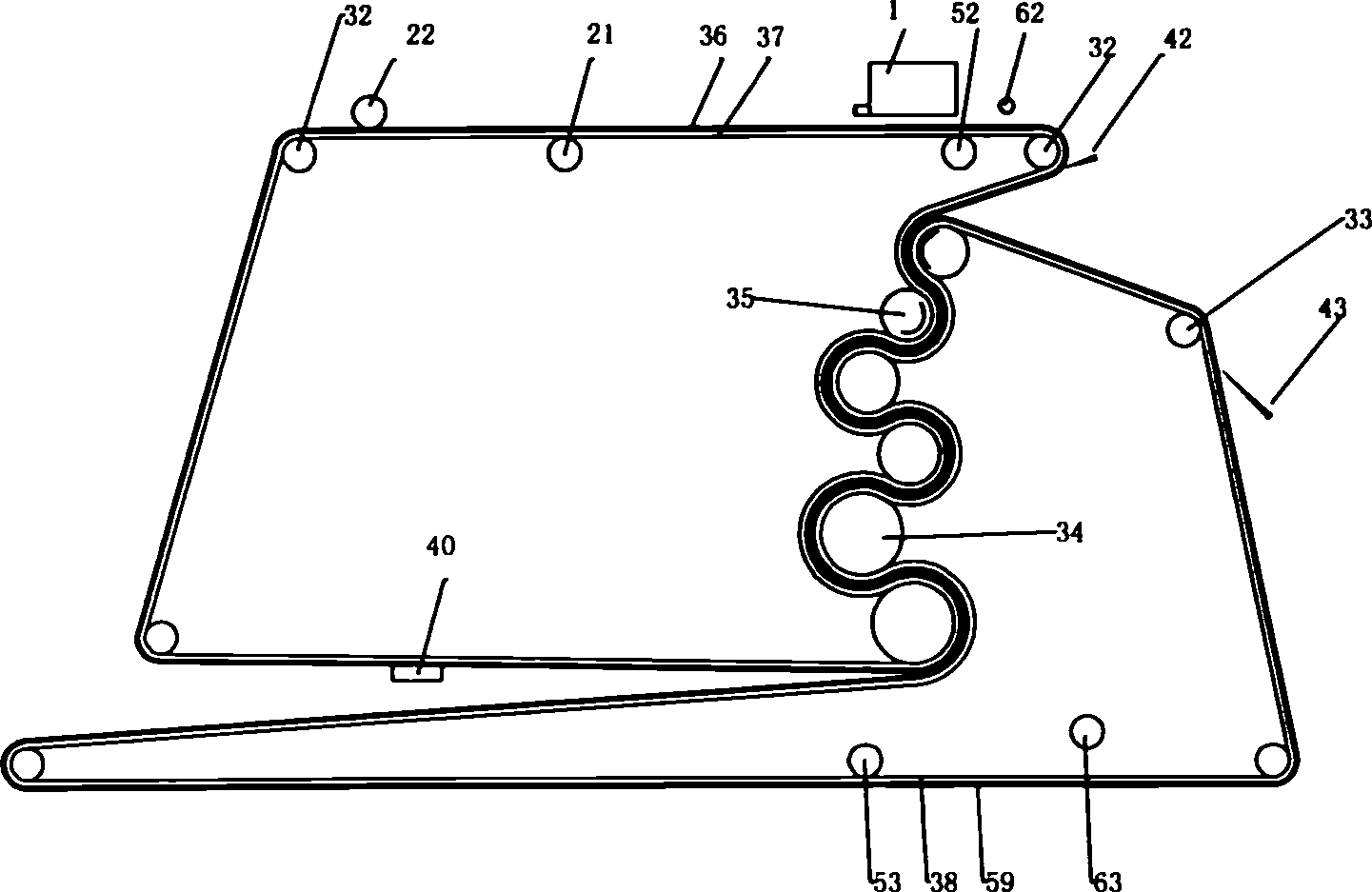

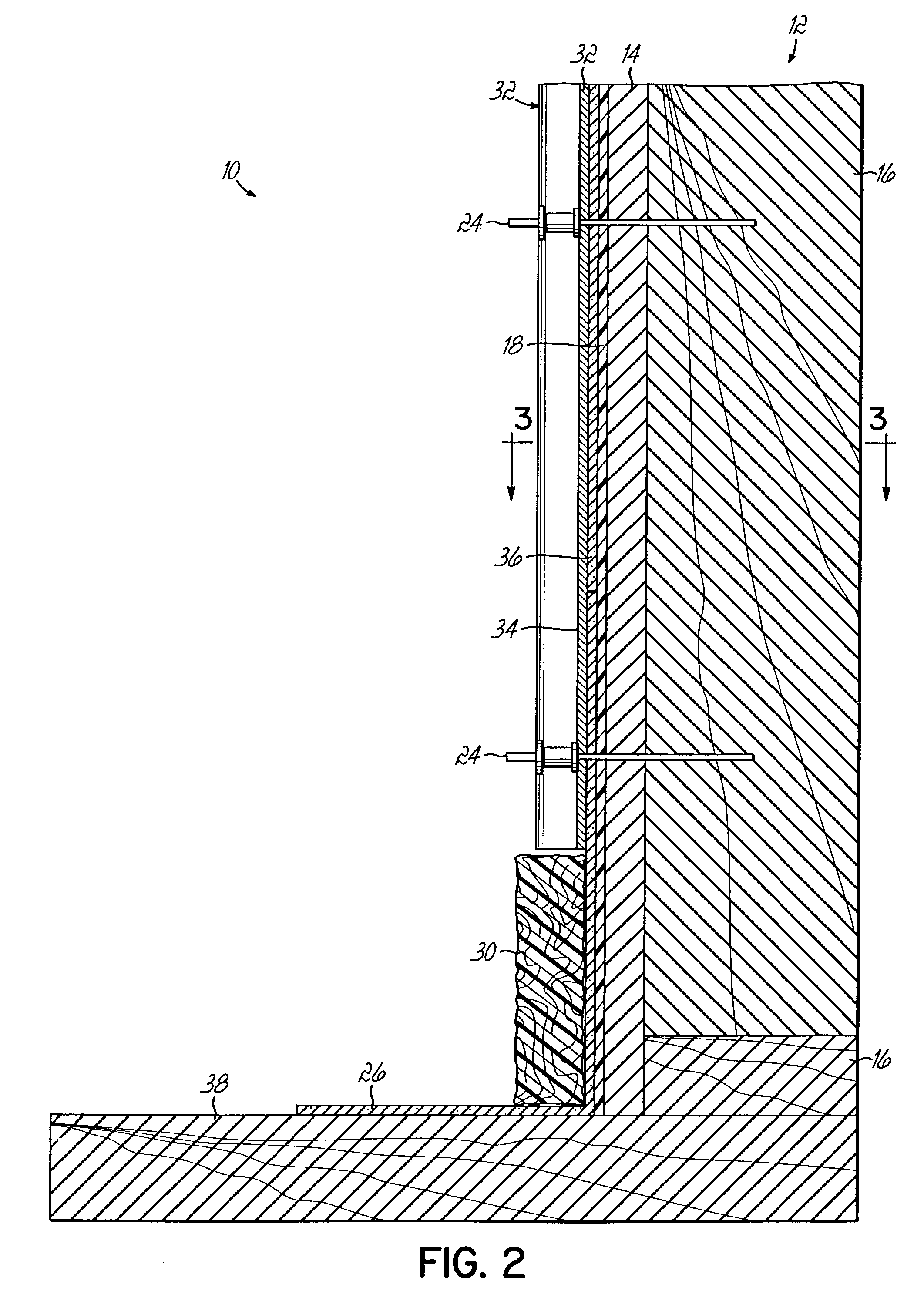

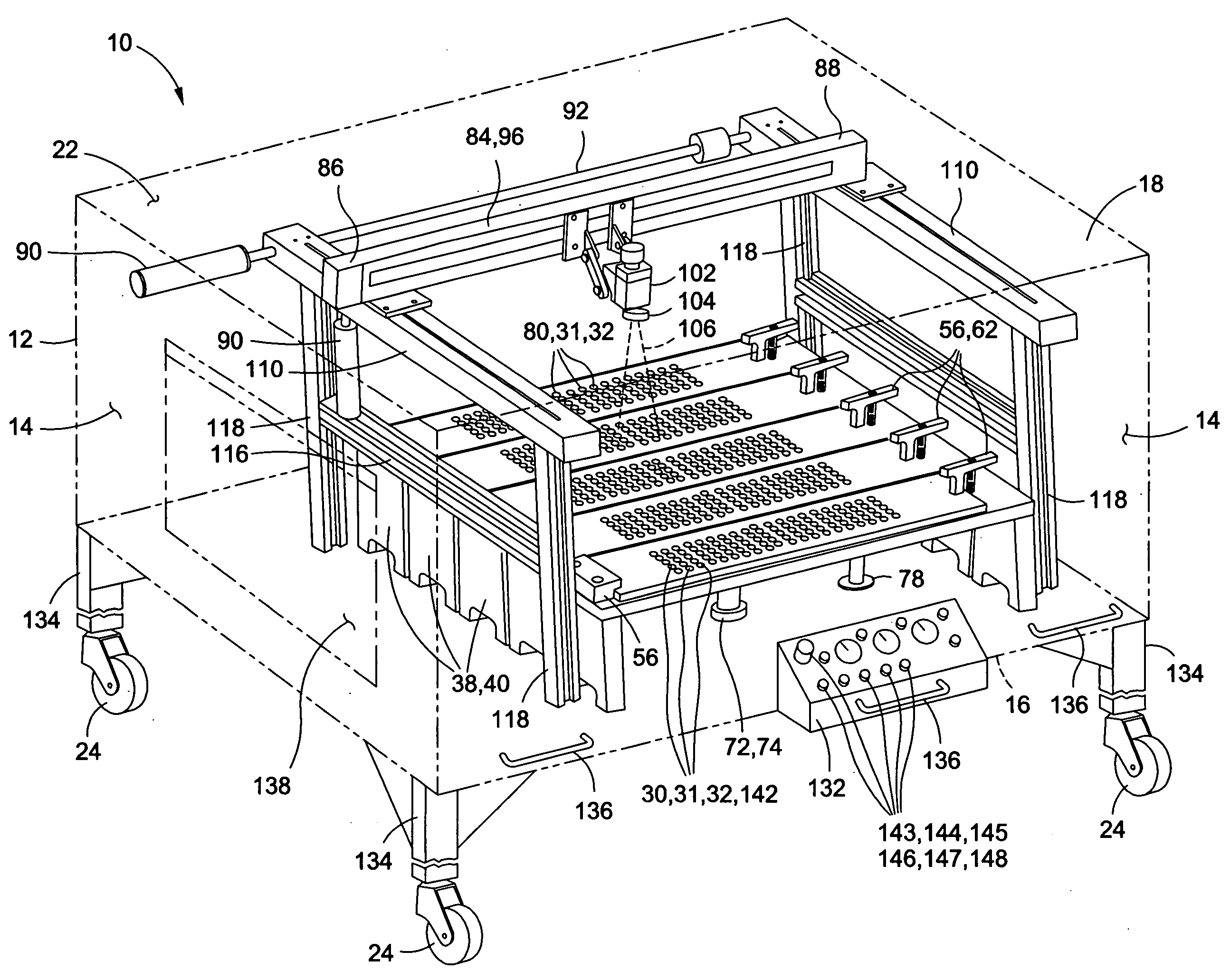

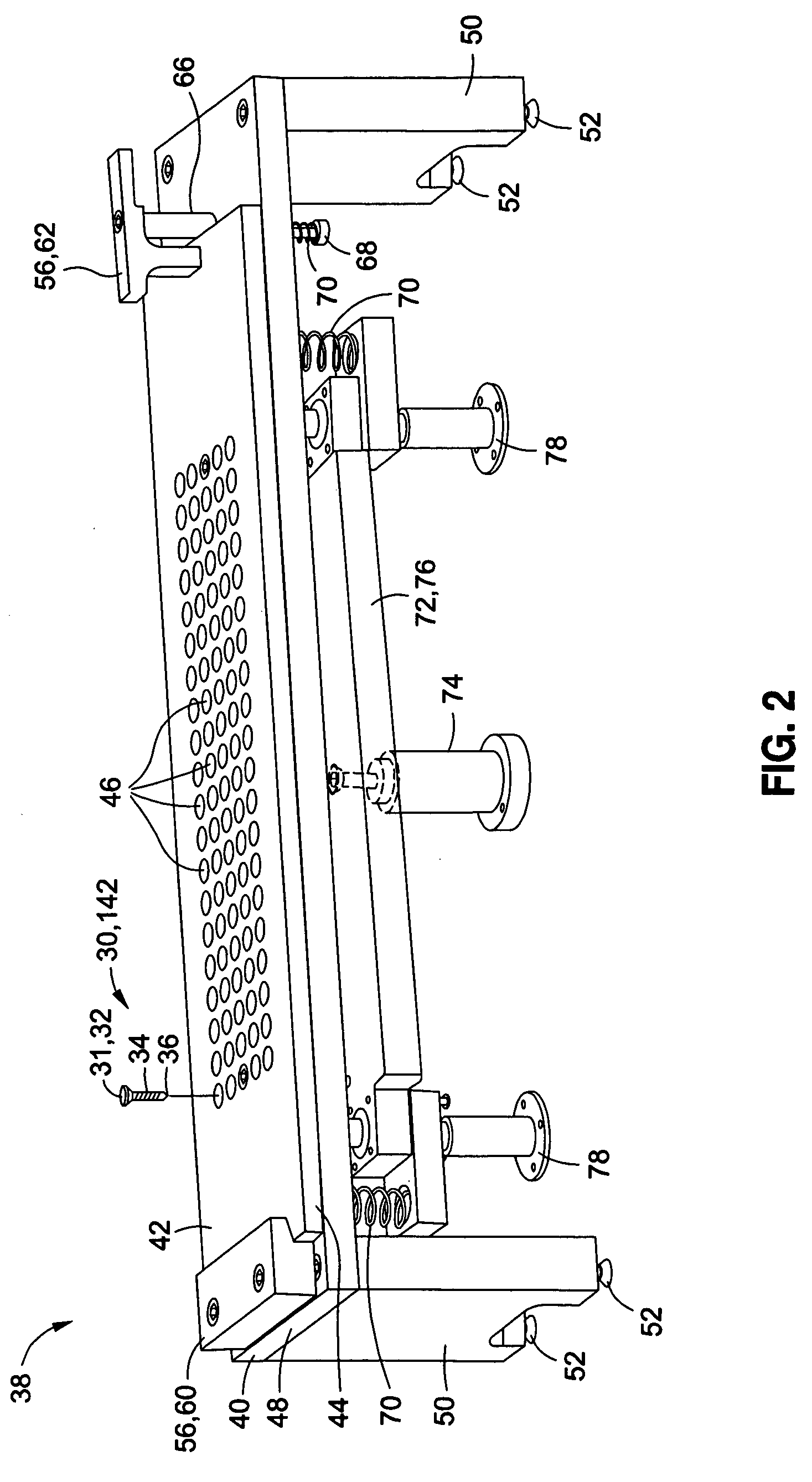

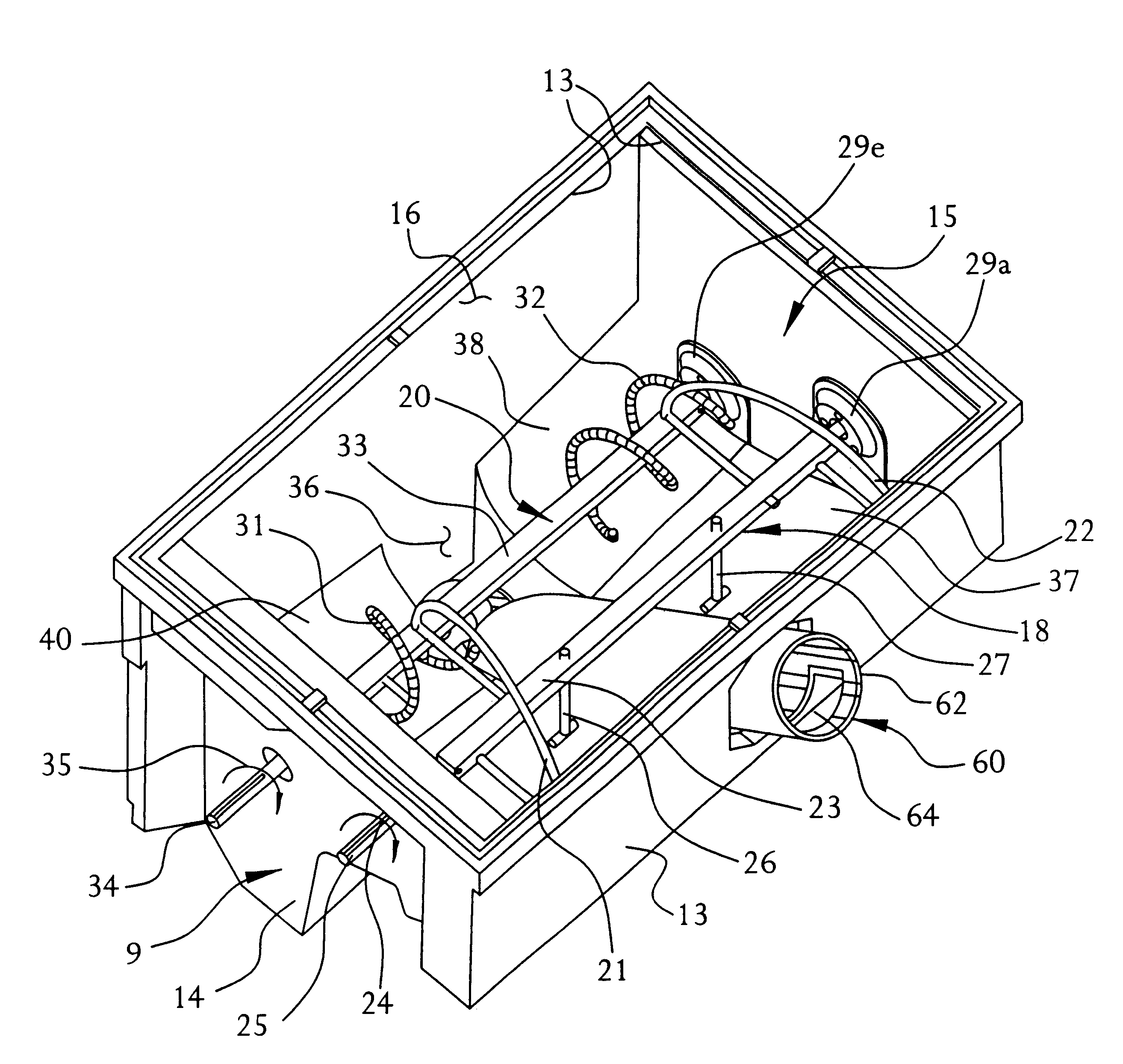

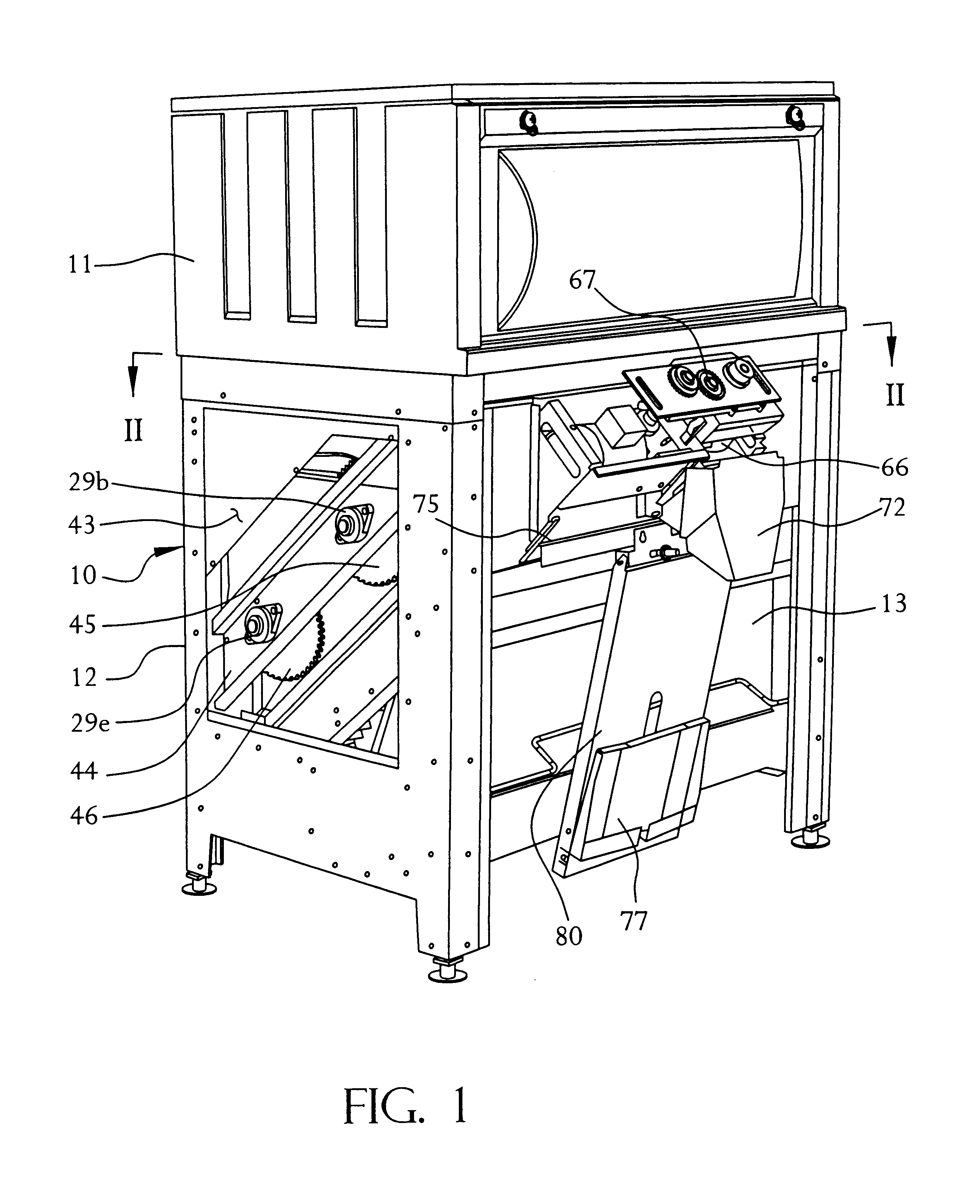

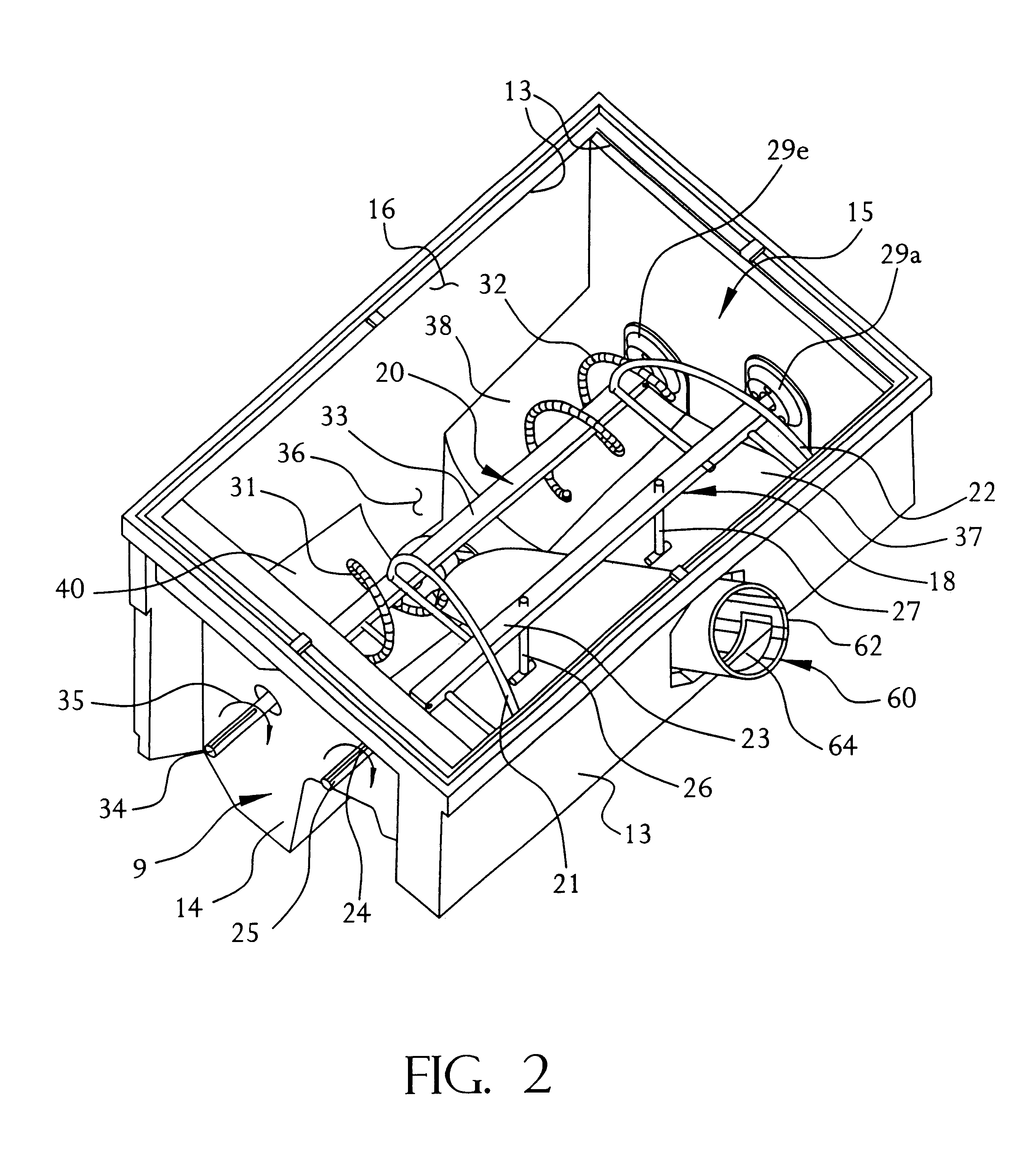

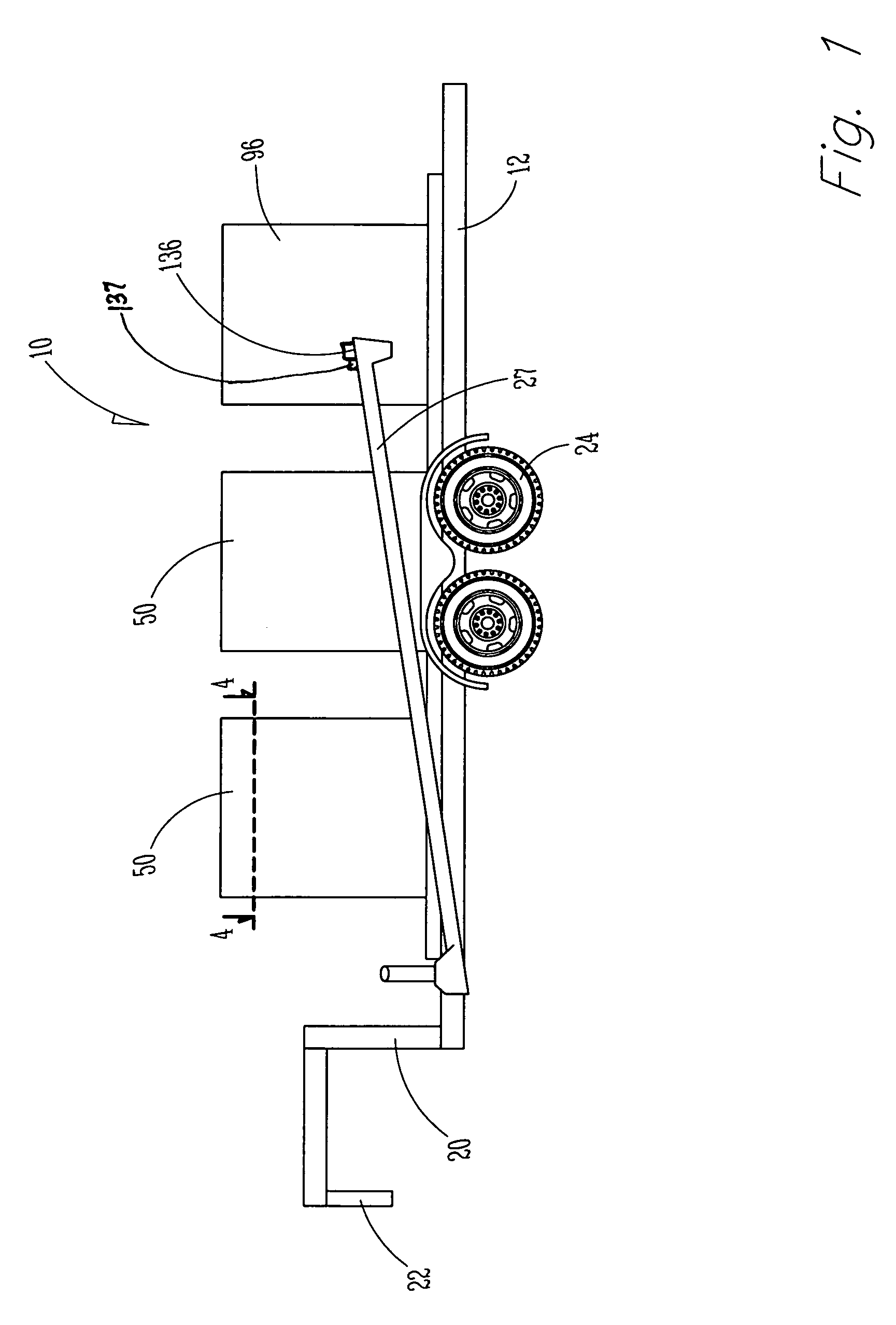

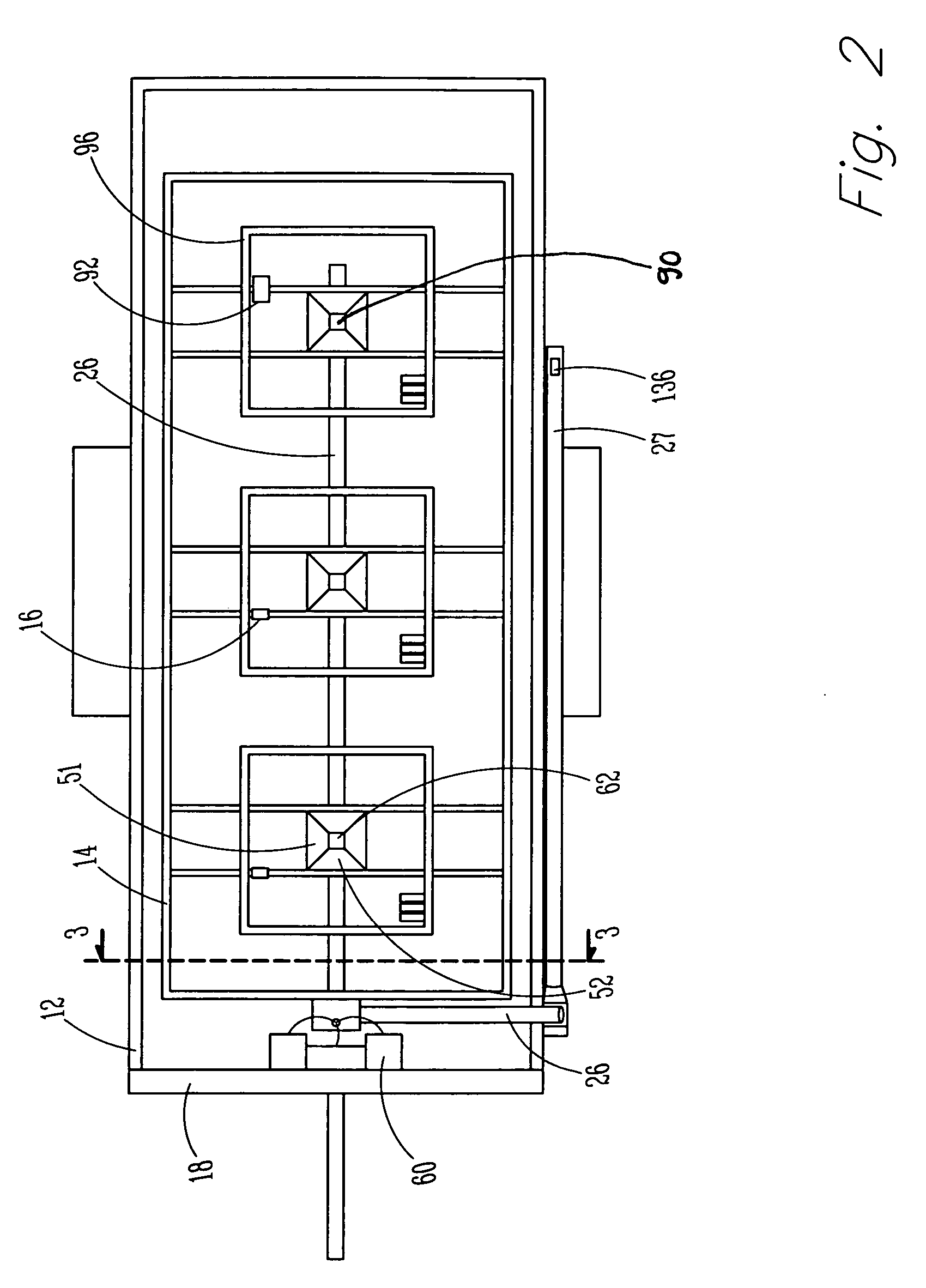

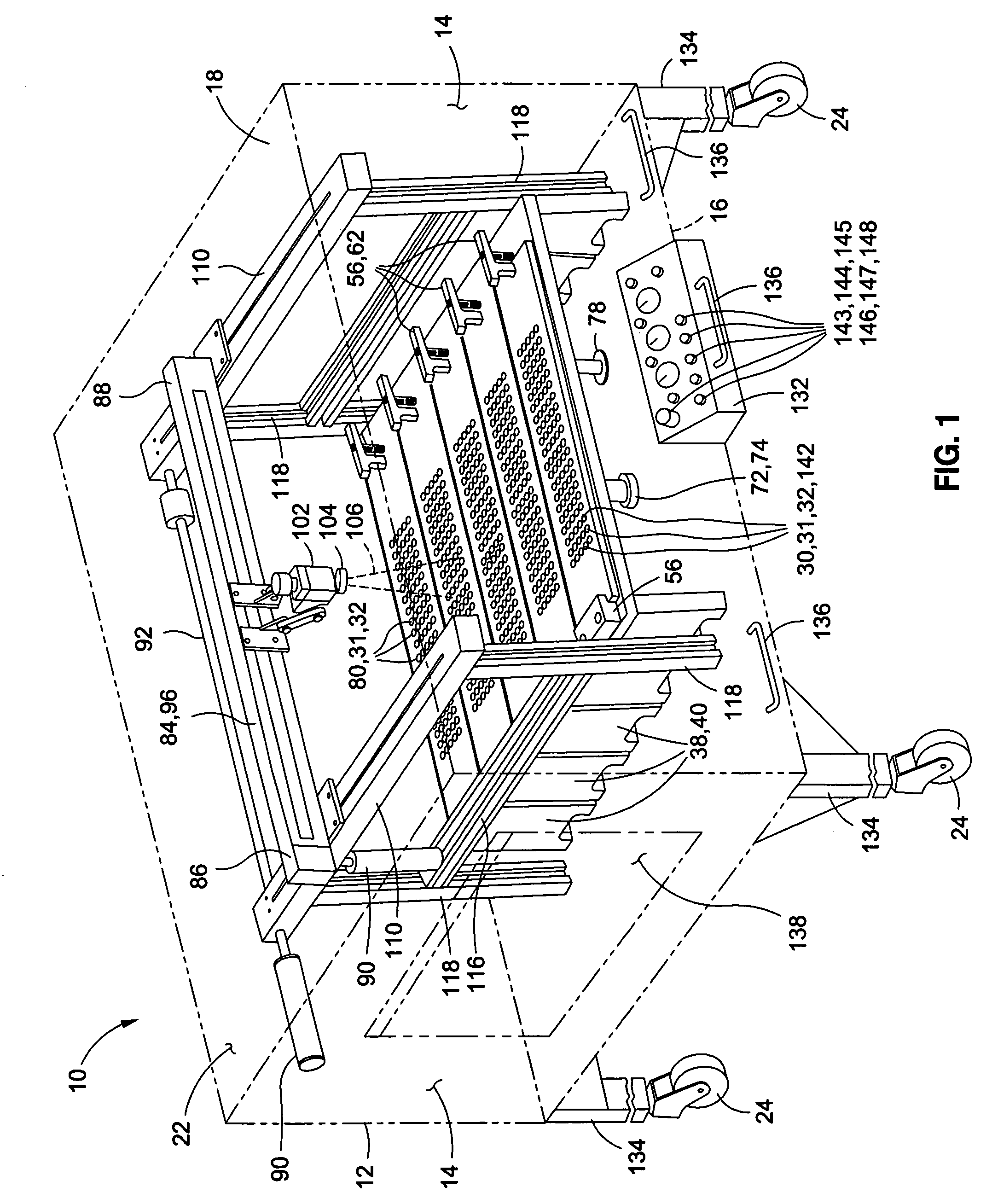

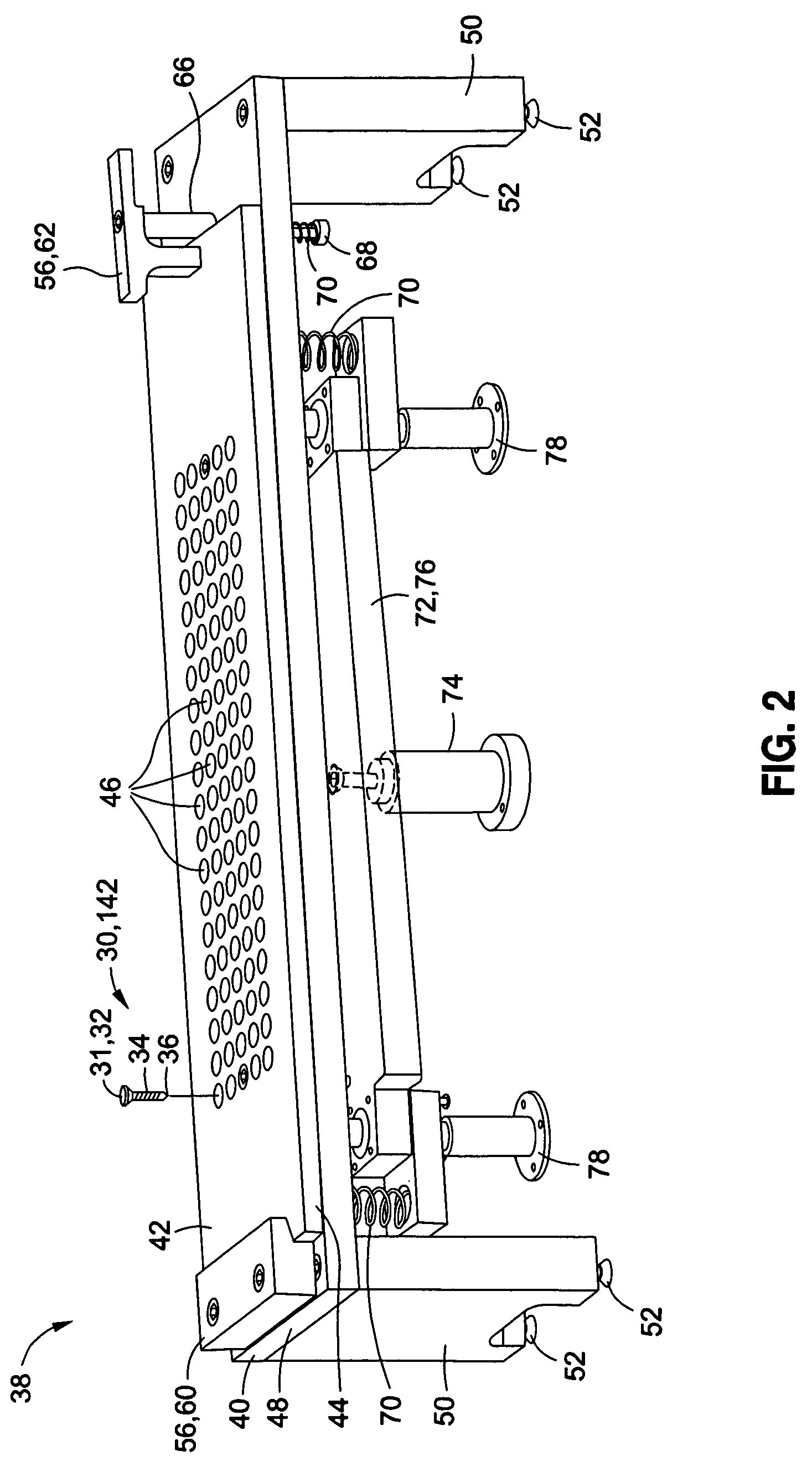

Controlled environment fastener head painting device and method

ActiveUS20100173090A1Small sizeEasy to controlWire articlesSlide fastenersEngineeringMechanical engineering

A painting apparatus for applying a coating material to a member surface of a member comprises a housing, at least one slide rail, a rack assembly, a cross beam and a spraying device. The slide rail may be mountable within the housing and may have a plurality of rack positions. The rack assembly is mountable within the housing at one of the rack positions. The rack assembly is configured to support the member such that the member surface is exposed. The cross beam may be coupled to the slide rail. The cross beam is movable along the slide rail and is positionable at the rack positions. The spraying device is mountable on the cross beam and is configured to move along the cross beam while spraying the coating material onto the member surface.

Owner:THE BOEING CO

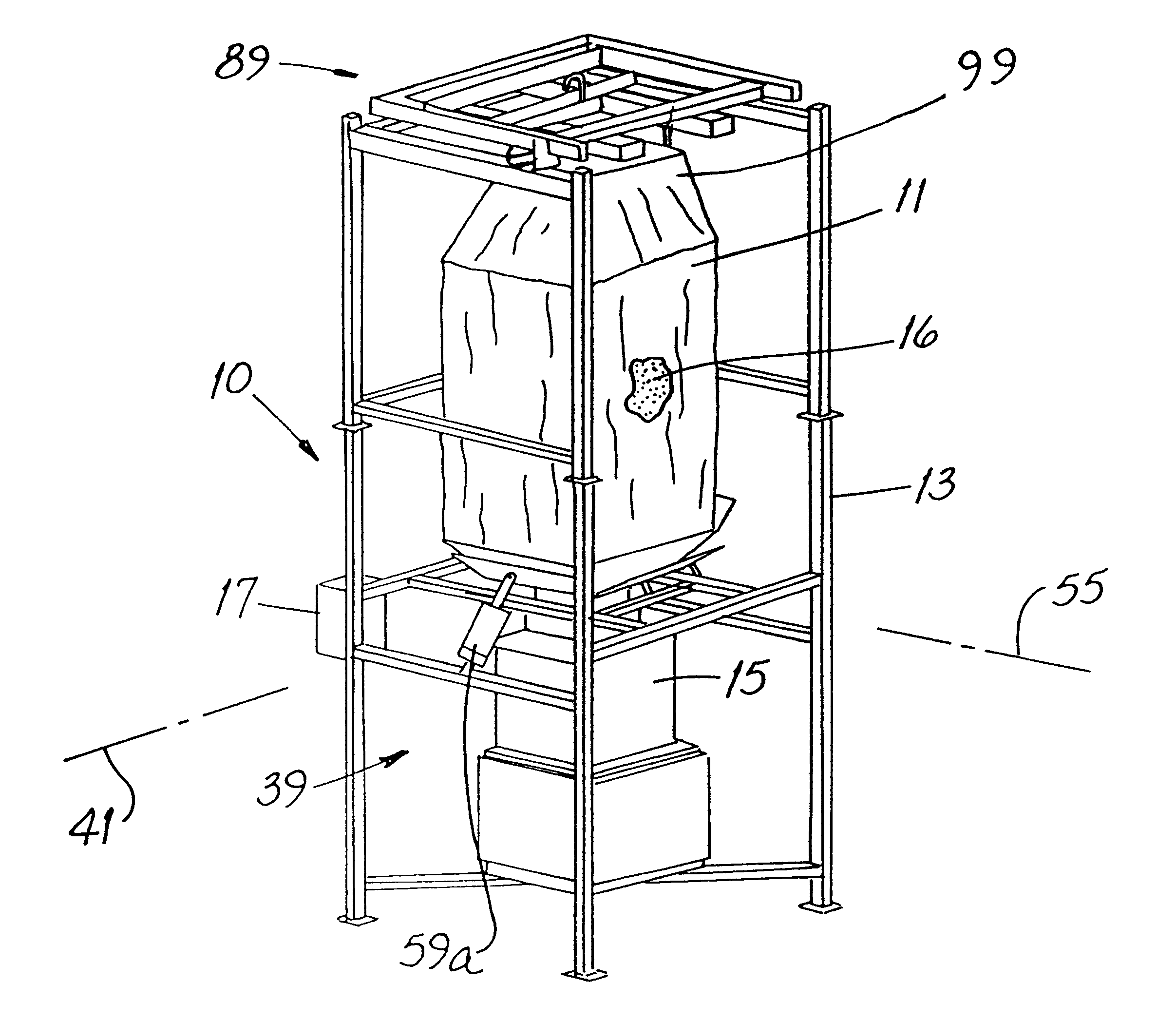

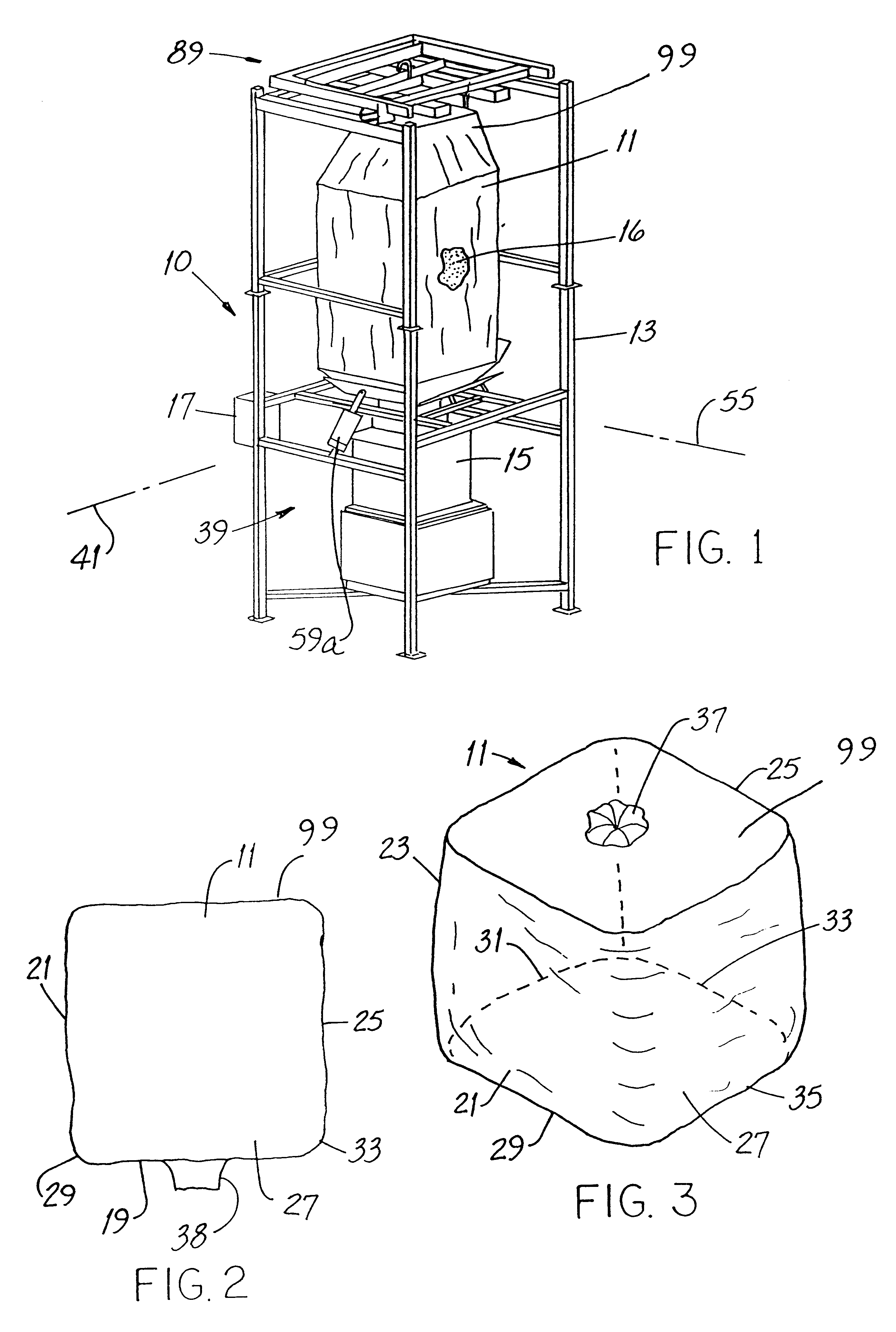

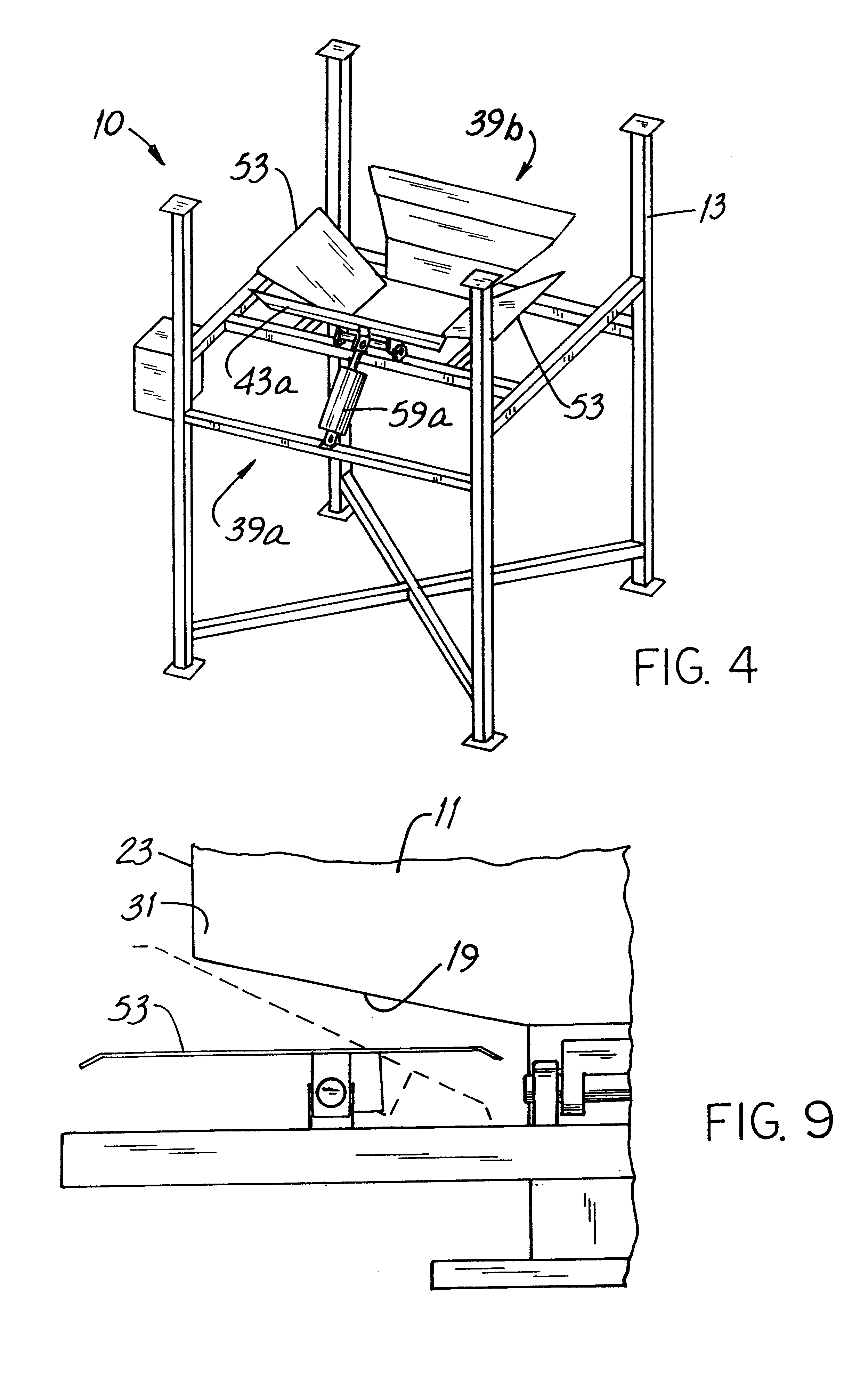

Machine and method for unloading a bulk-material bag

InactiveUS6186360B1Reduce distanceFacilitate material flowOpening closed containersBottle/container closureCompressibilityEngineering

Disclosed is a machine for unloading a bulk-material bag of the type having a bottom portion, a side portion and a transition portion between the bottom and side portions. The machine includes an apparatus aiding discharge of the material from the bag. In the improvement, the apparatus includes a tri-section panel mounted for movement on the machine, thereby configuring the panel to sequentially contact the bottom, transition and side portions of the bag. The panel has first, second and third segments angle-mounted to one another. In a specific embodiment, the segments are substantially planar. A microprocessor-based controller is coupled to the actuator and regulates its movement as a function of a process parameter, e.g., the compressibility of the bag and / or the weight of the material contained in the bag. A highly preferred embodiment of the machine also has a bag lifting mechanism above the tri-section panel. Such mechanism includes an extensible device coupled to the controller for regulating extension of such device as a function of the weight, volume or level of the material contained in the bag. A new method for unloading a bulk material bag is also disclosed.

Owner:SCHENCK PROCESS LLC

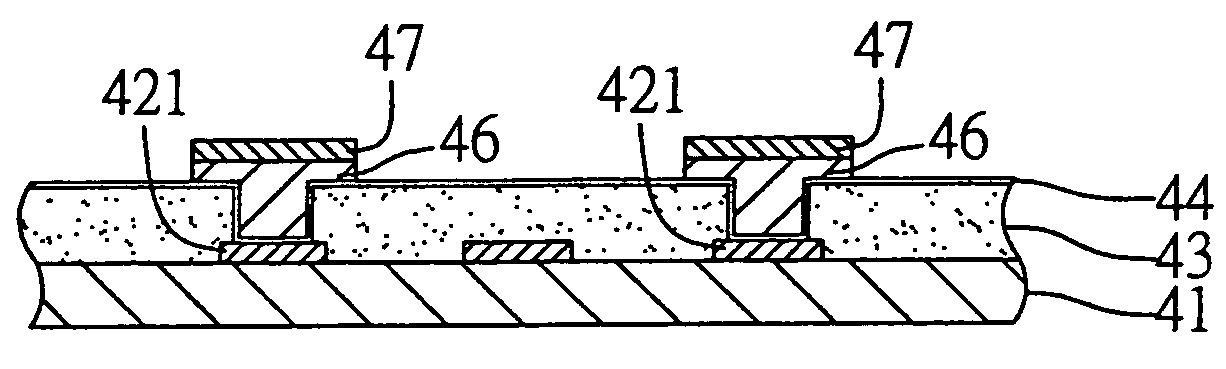

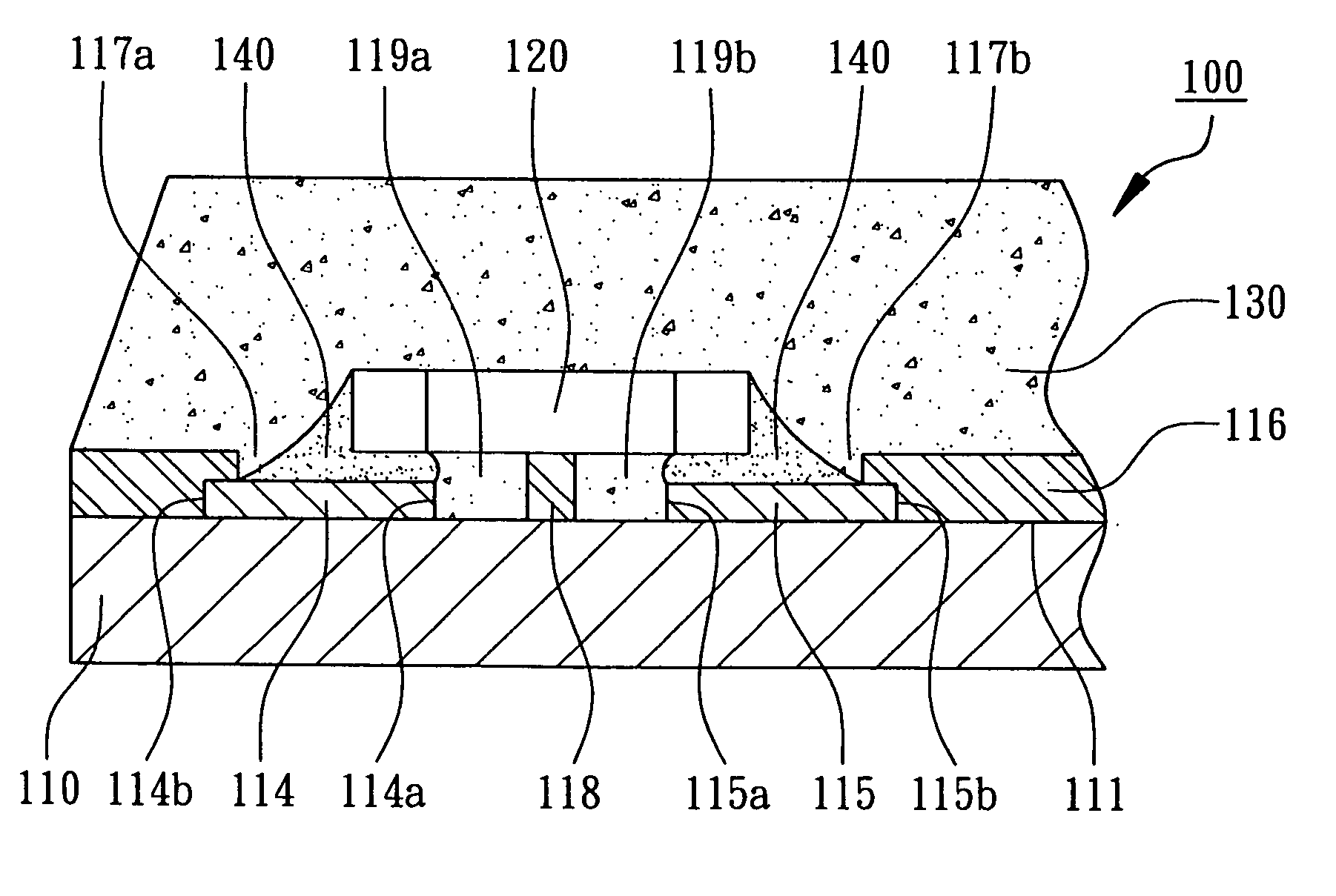

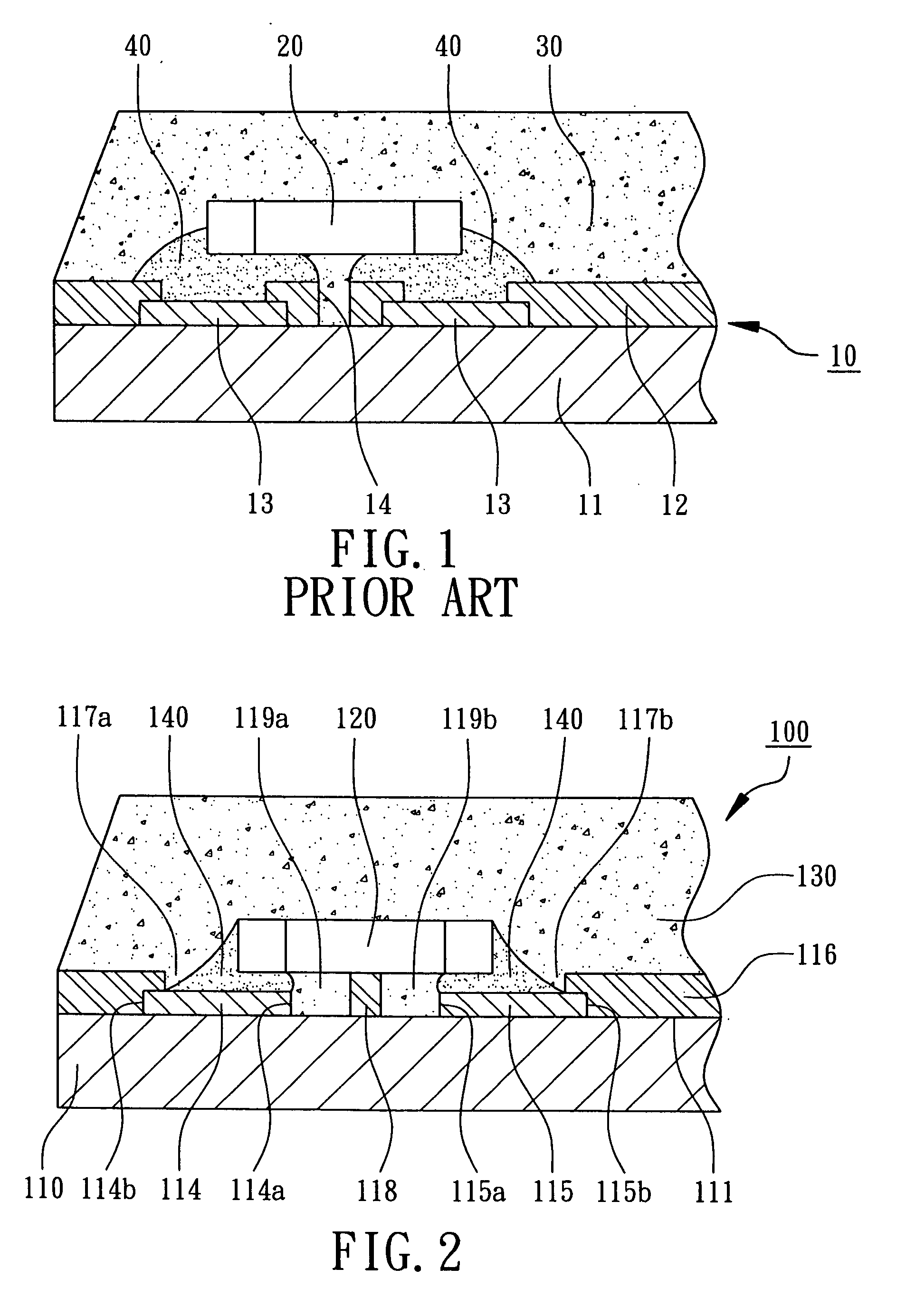

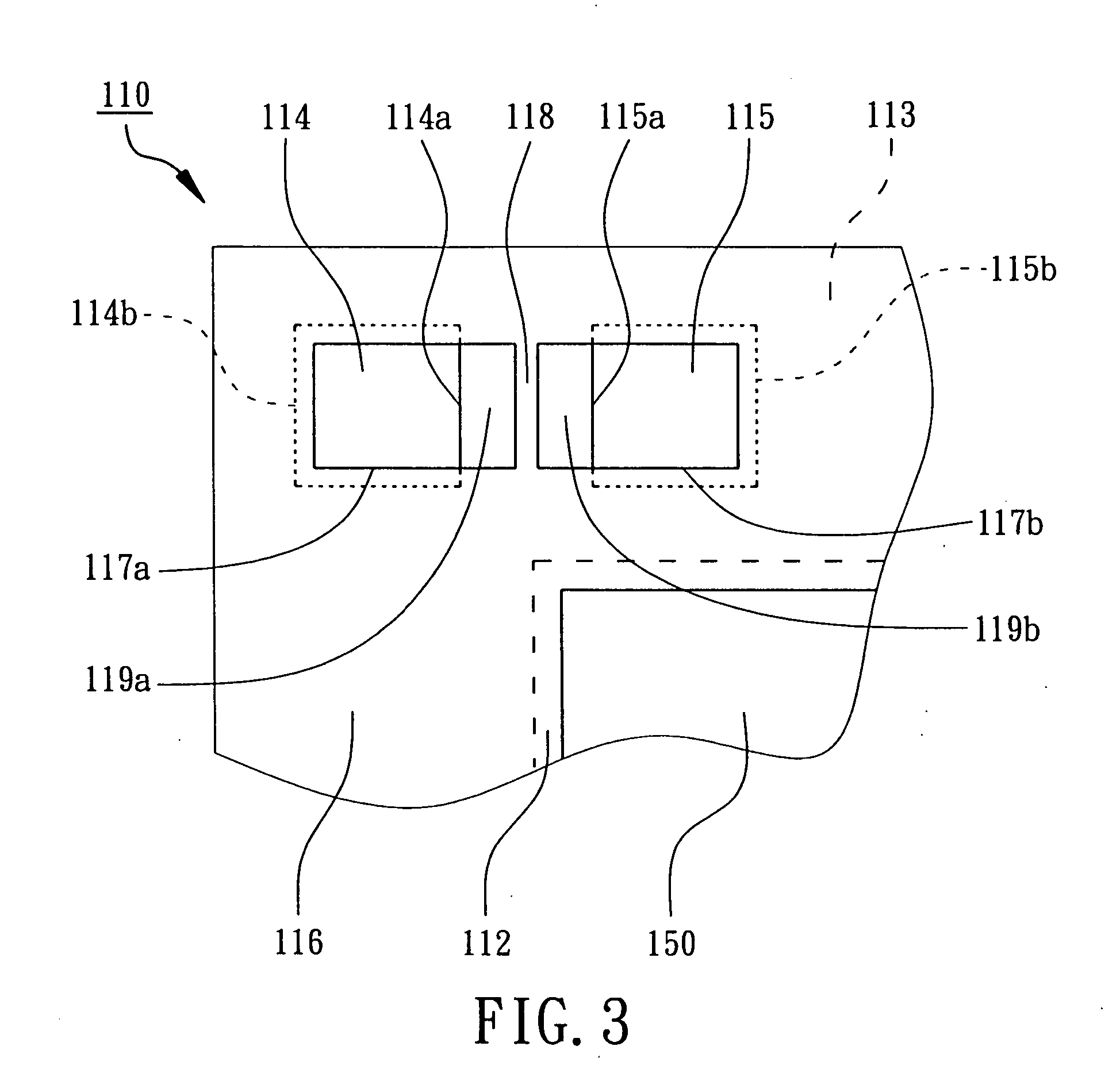

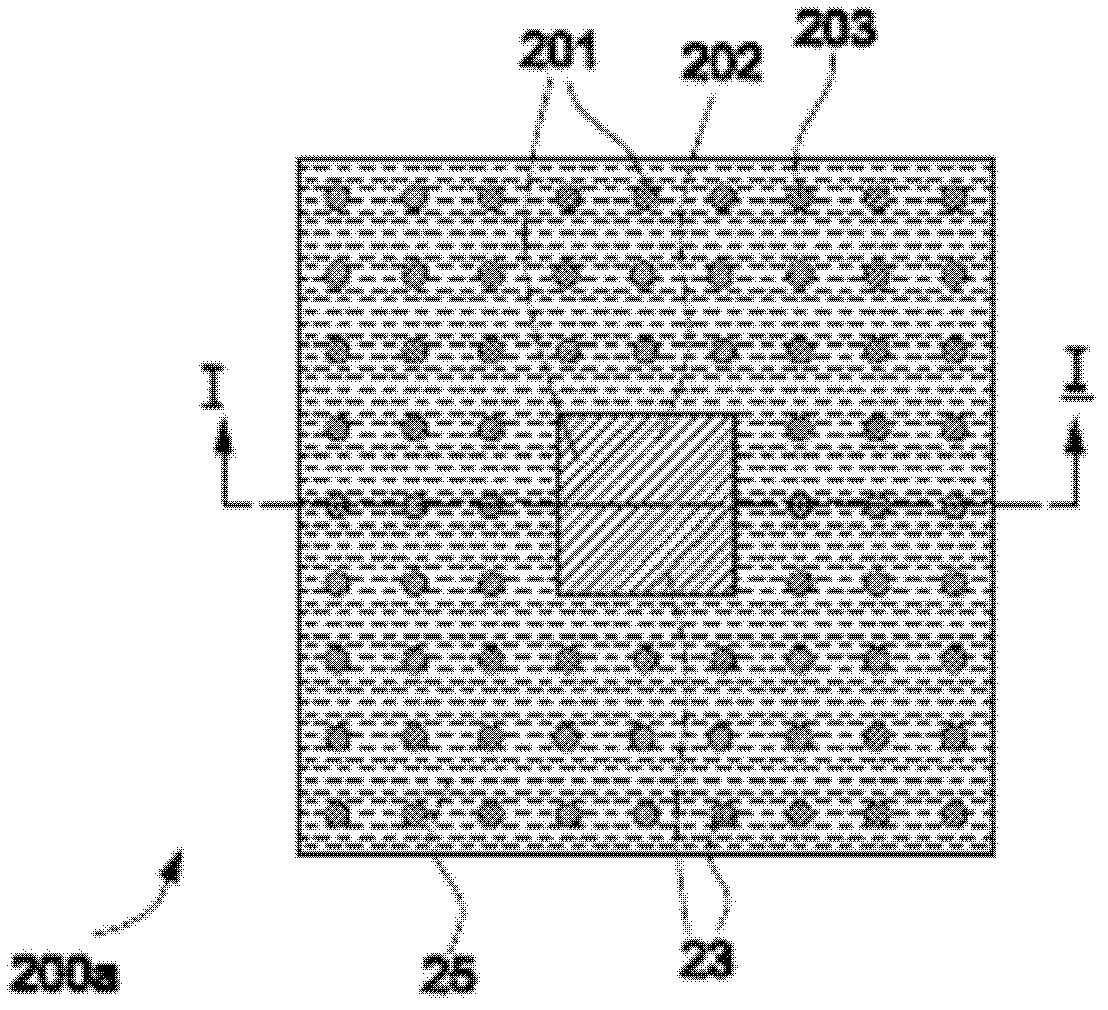

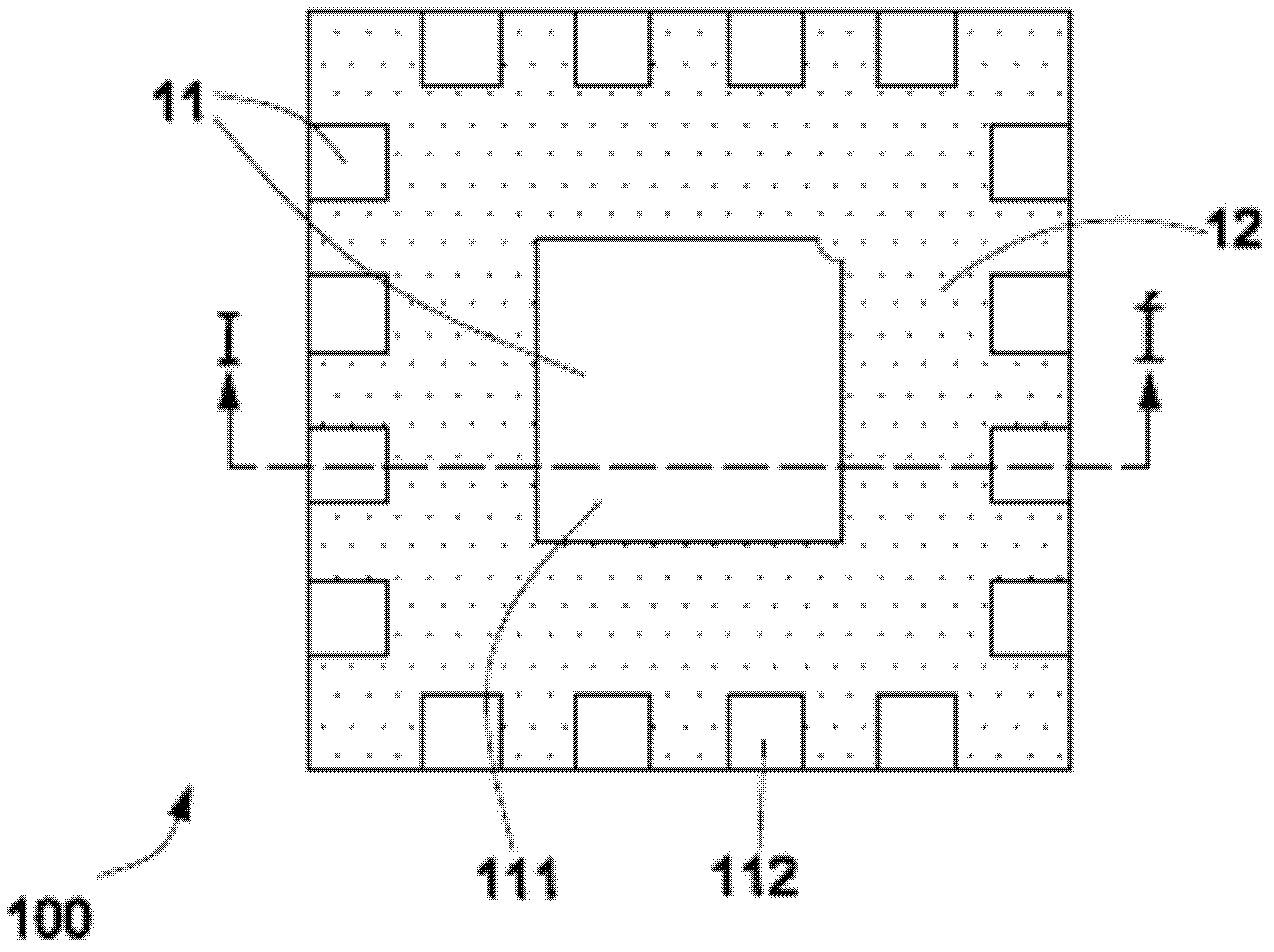

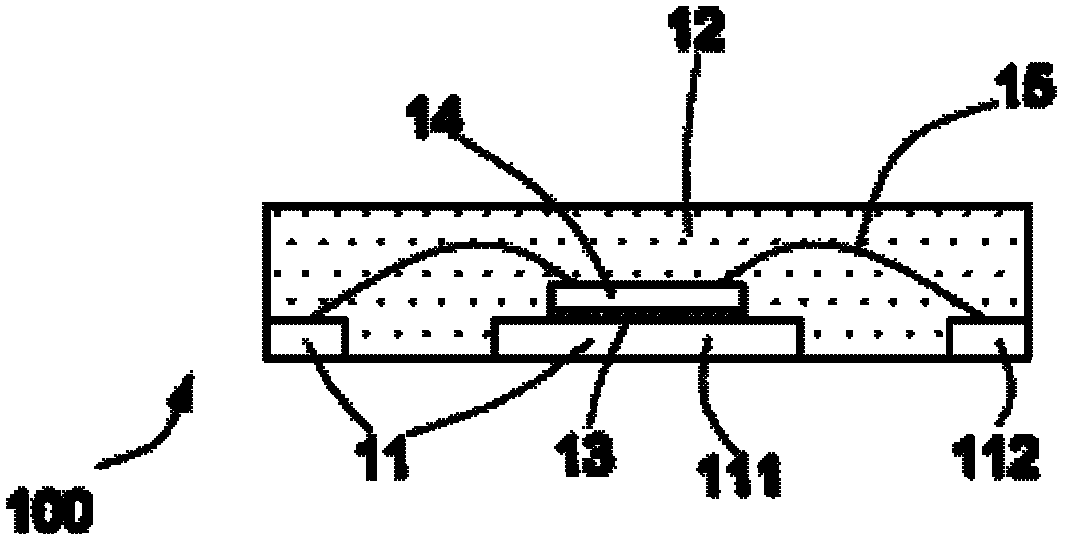

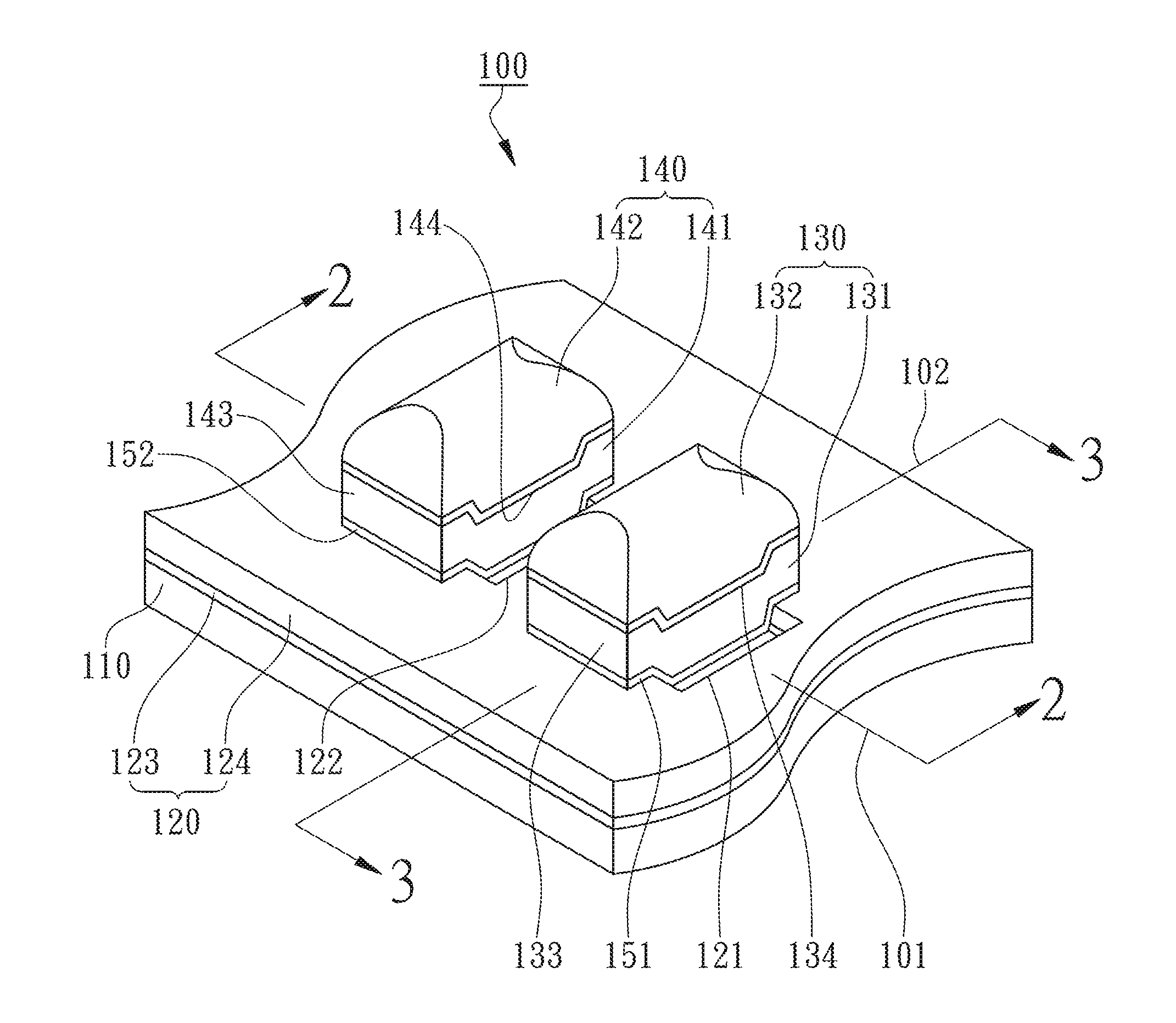

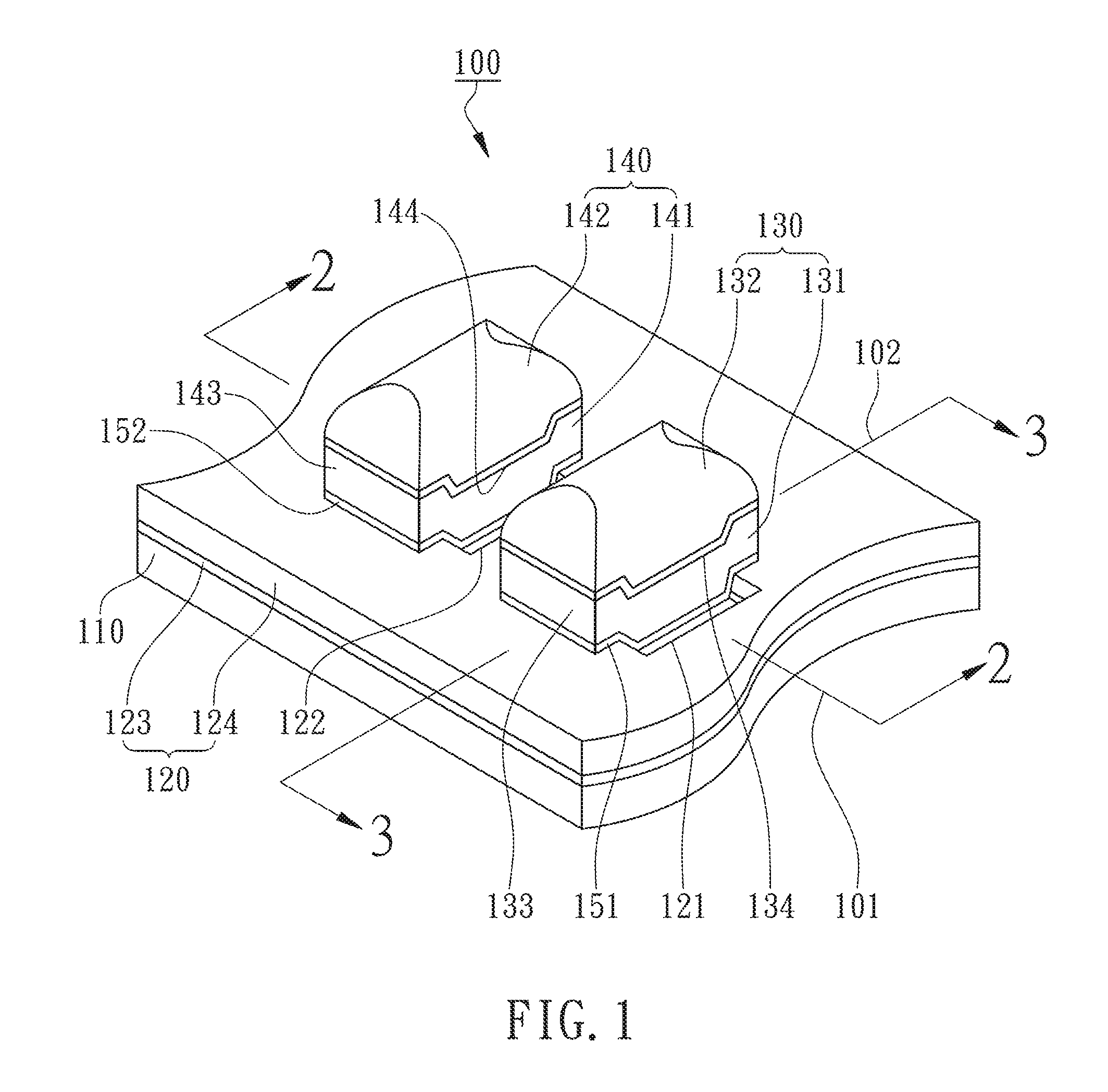

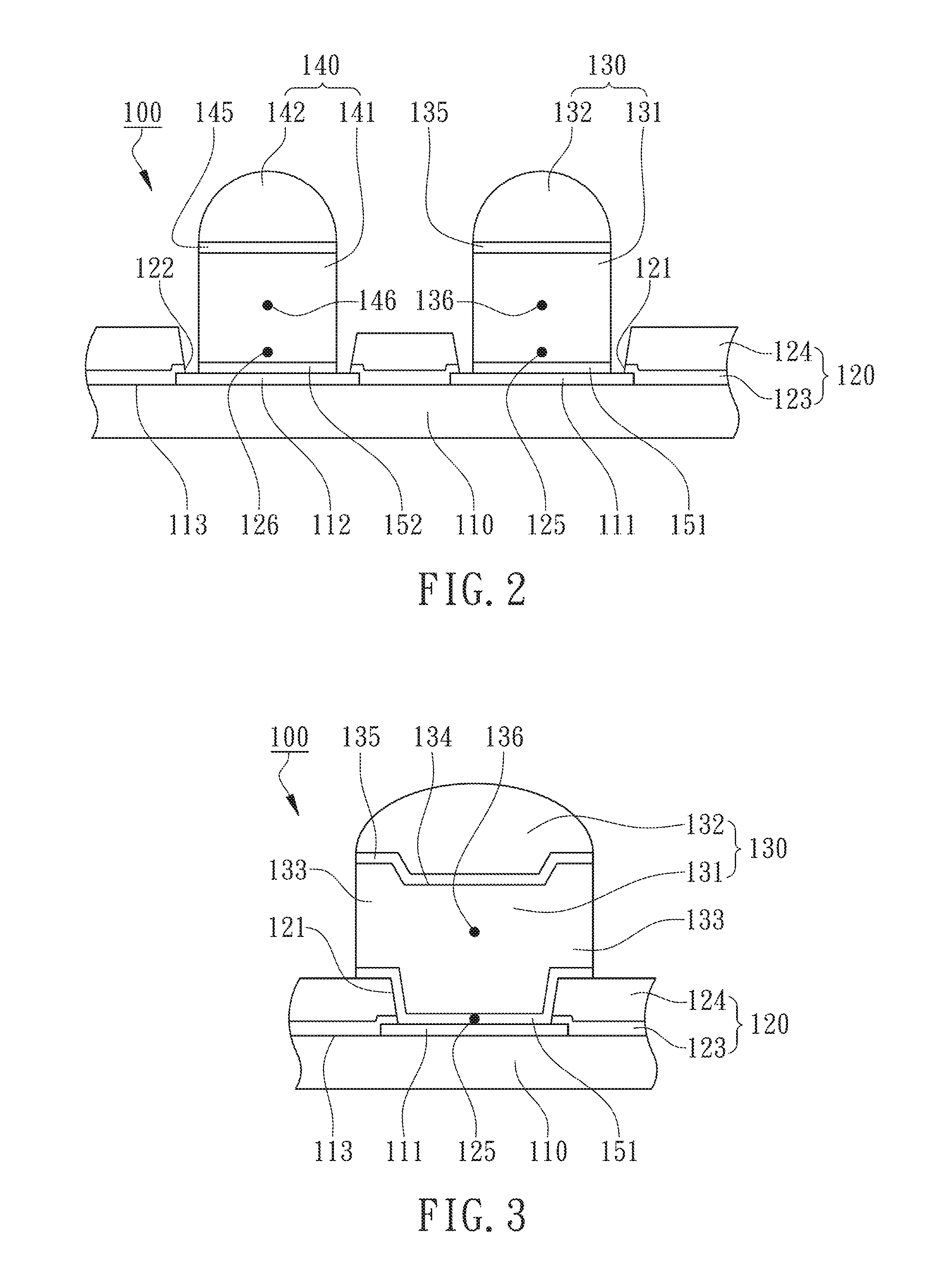

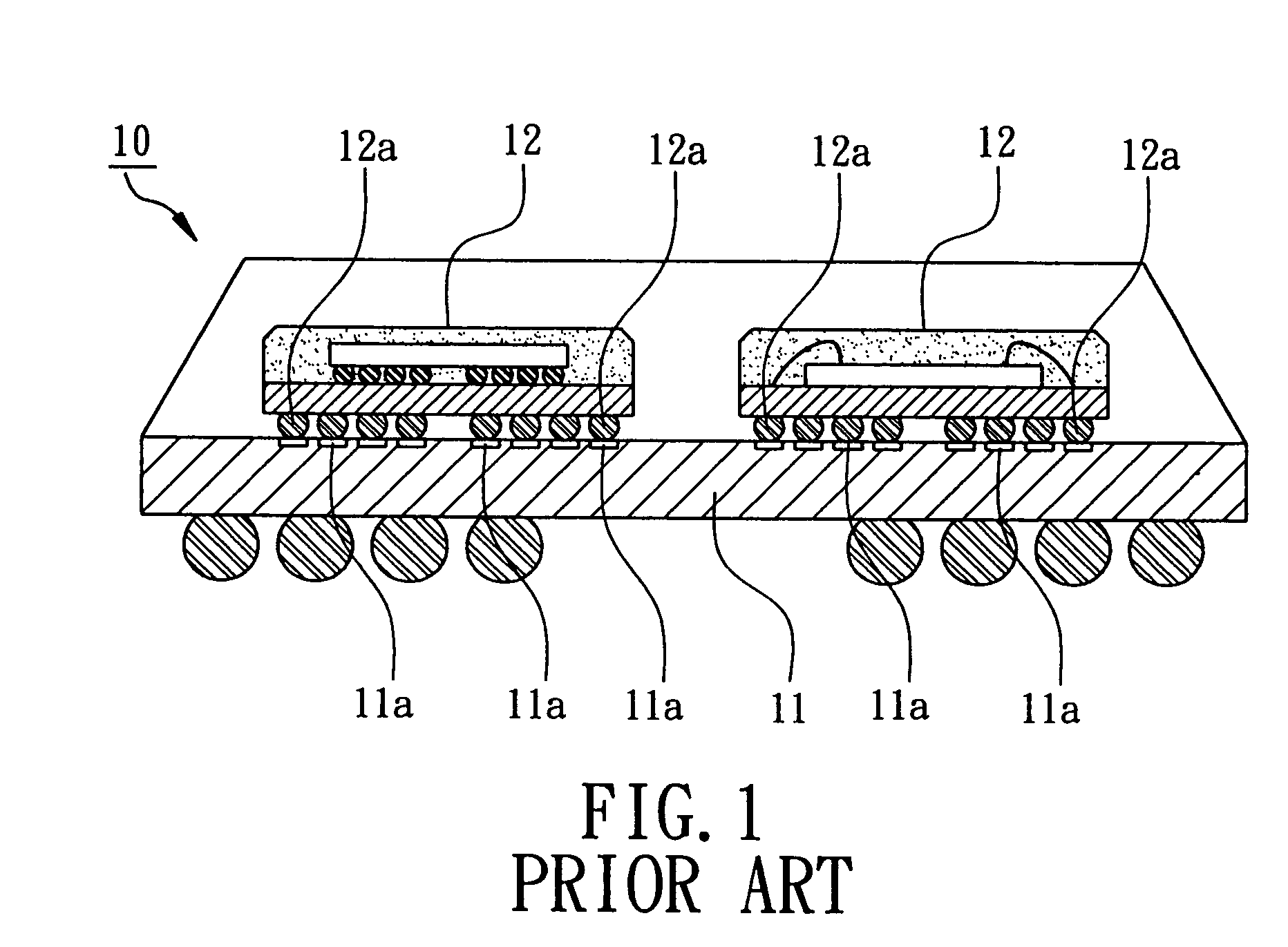

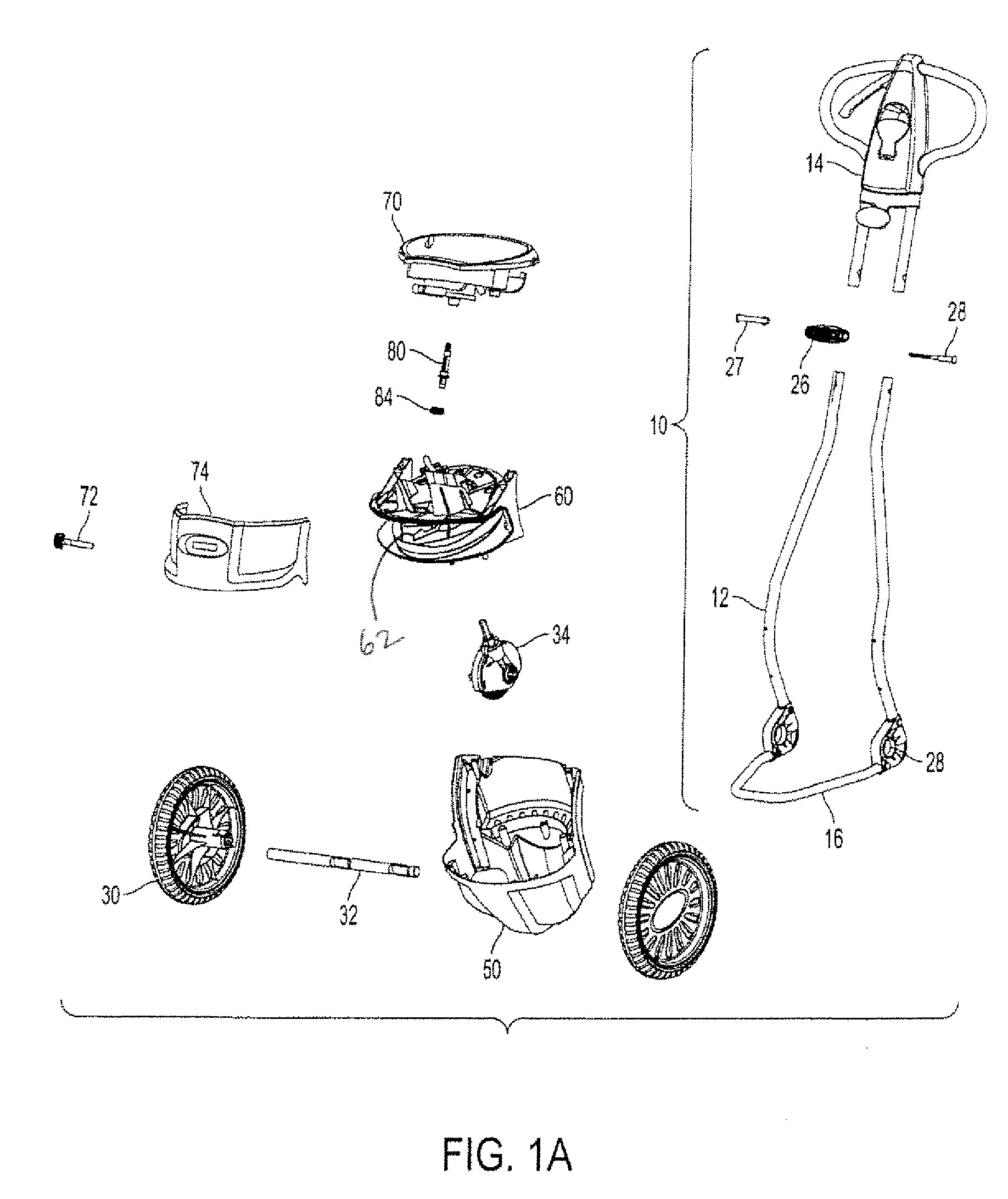

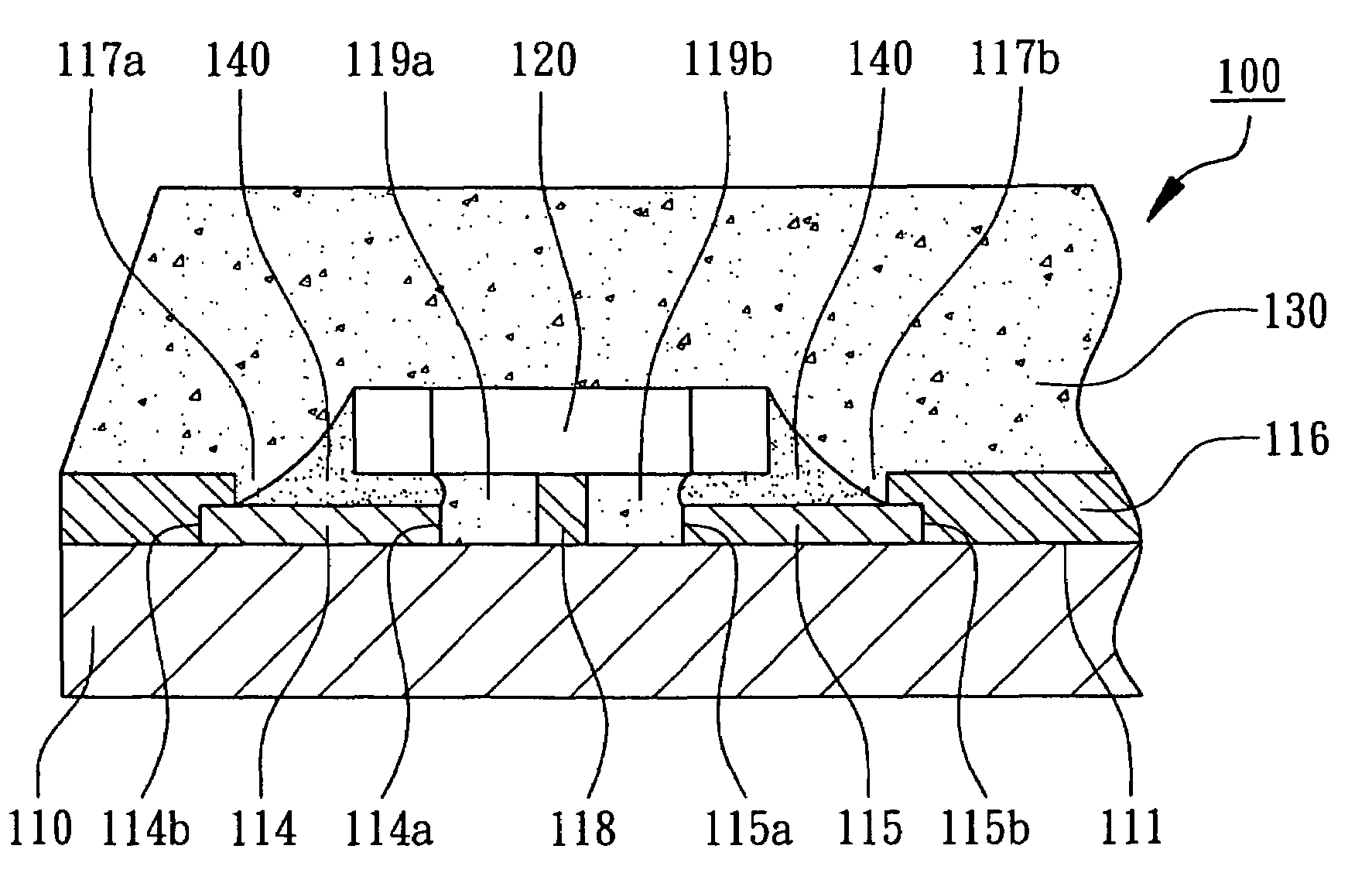

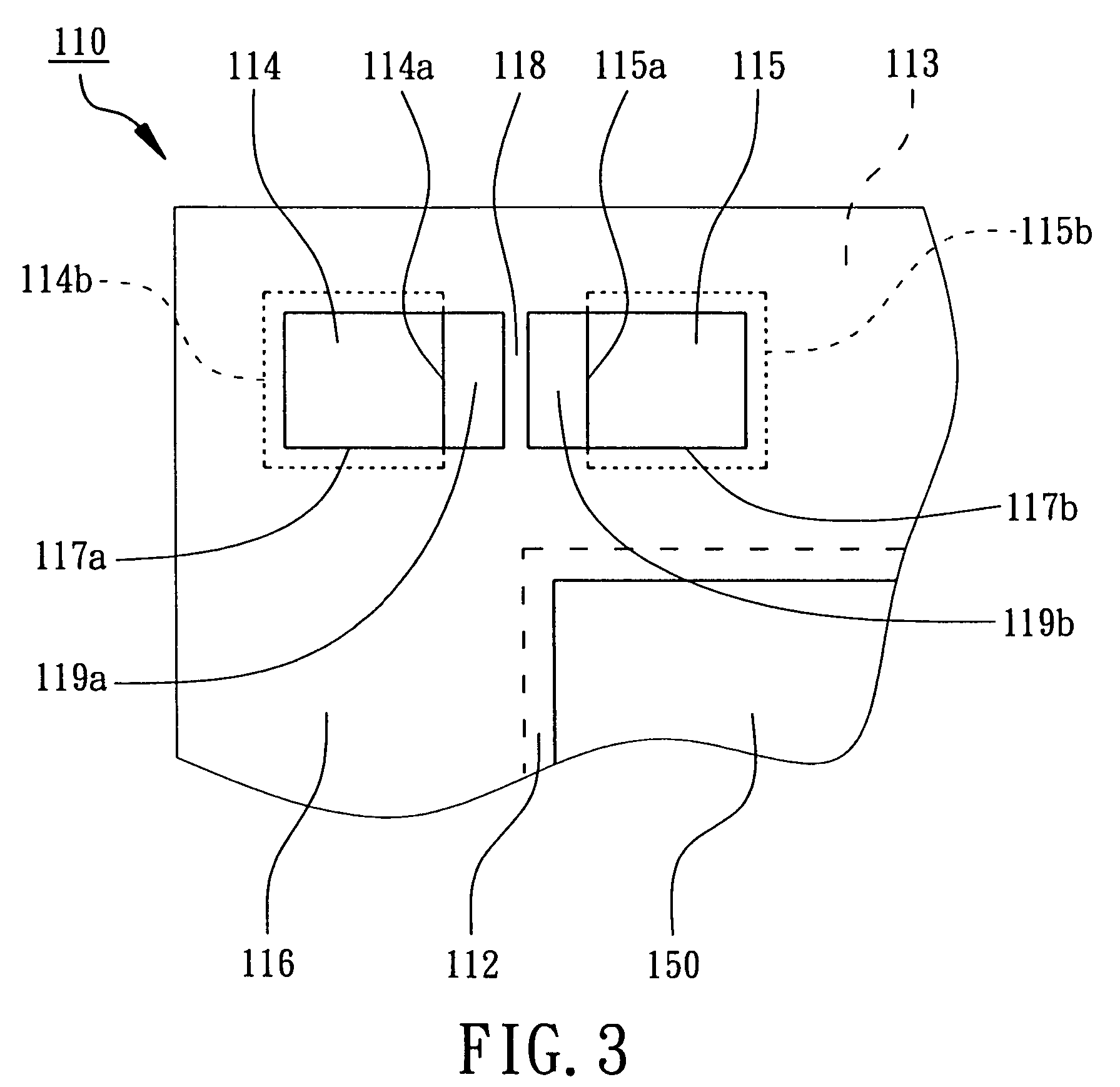

Semiconductor package with encapsulated passive component

ActiveUS20050253231A1Avoid problemsPrevent bridgingPrinted circuit assemblingFinal product manufactureSolder maskSemiconductor package

A semiconductor package with an encapsulated passive component mainly includes at least a substrate having a surface, a passive component and a molding compound. A plurality of SMD pads (Solder Mask Defined pads) and a solder mask are formed on the surface of the substrate. Each SMD pad has an exposed sidewall portion exposed out of the solder mask. A blocking bar is formed between the exposed sidewall portions of the SMD pads. There is at least a flowing channel formed between the blocking bar and the exposed sidewall portions. The passive component is mounted on the surface of the substrate and connected to the SMD pads, the flowing channel is located under the passive component. It is advantageous to fill the molding compound into the flowing channel.

Owner:ADVANCED SEMICON ENG INC

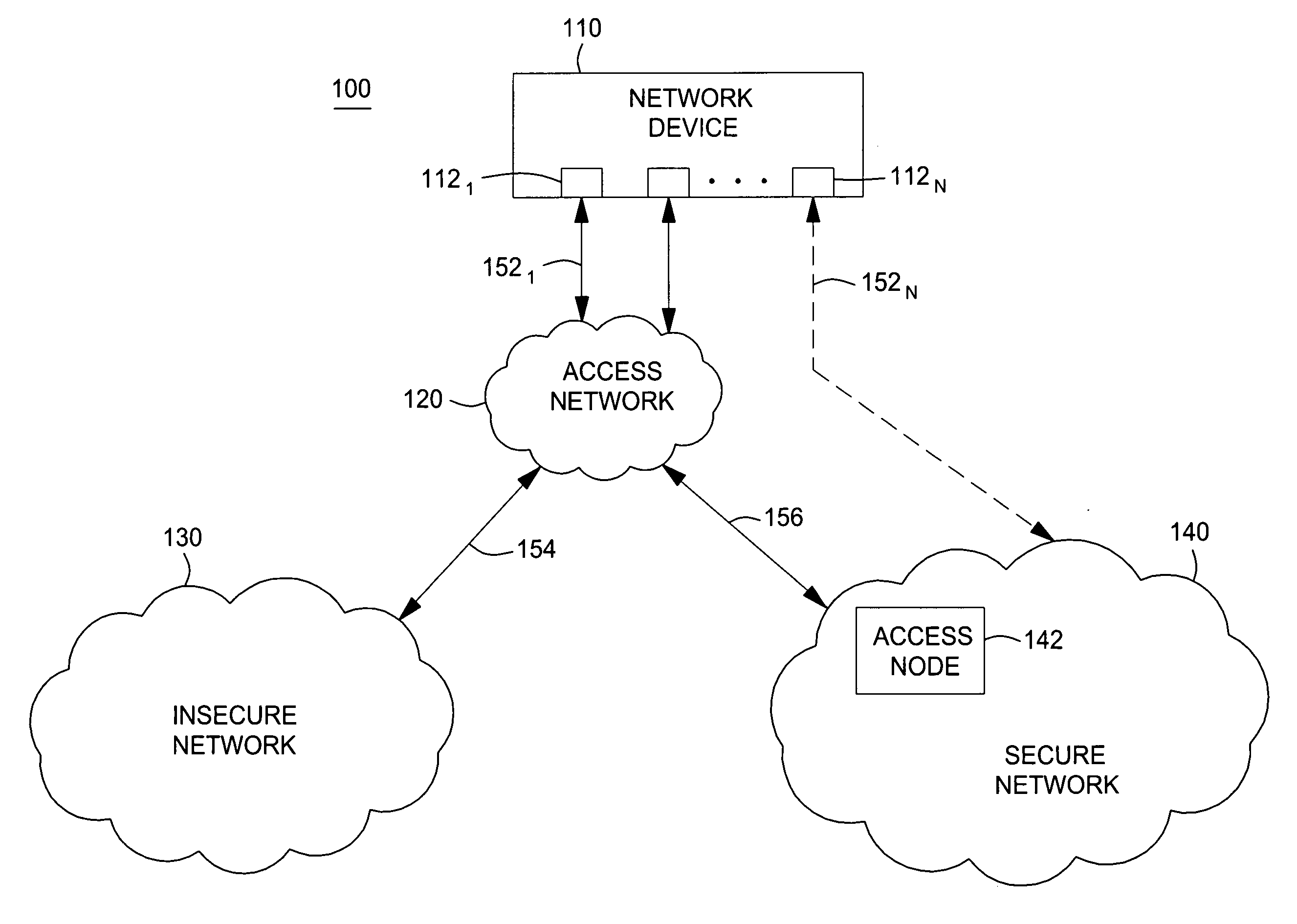

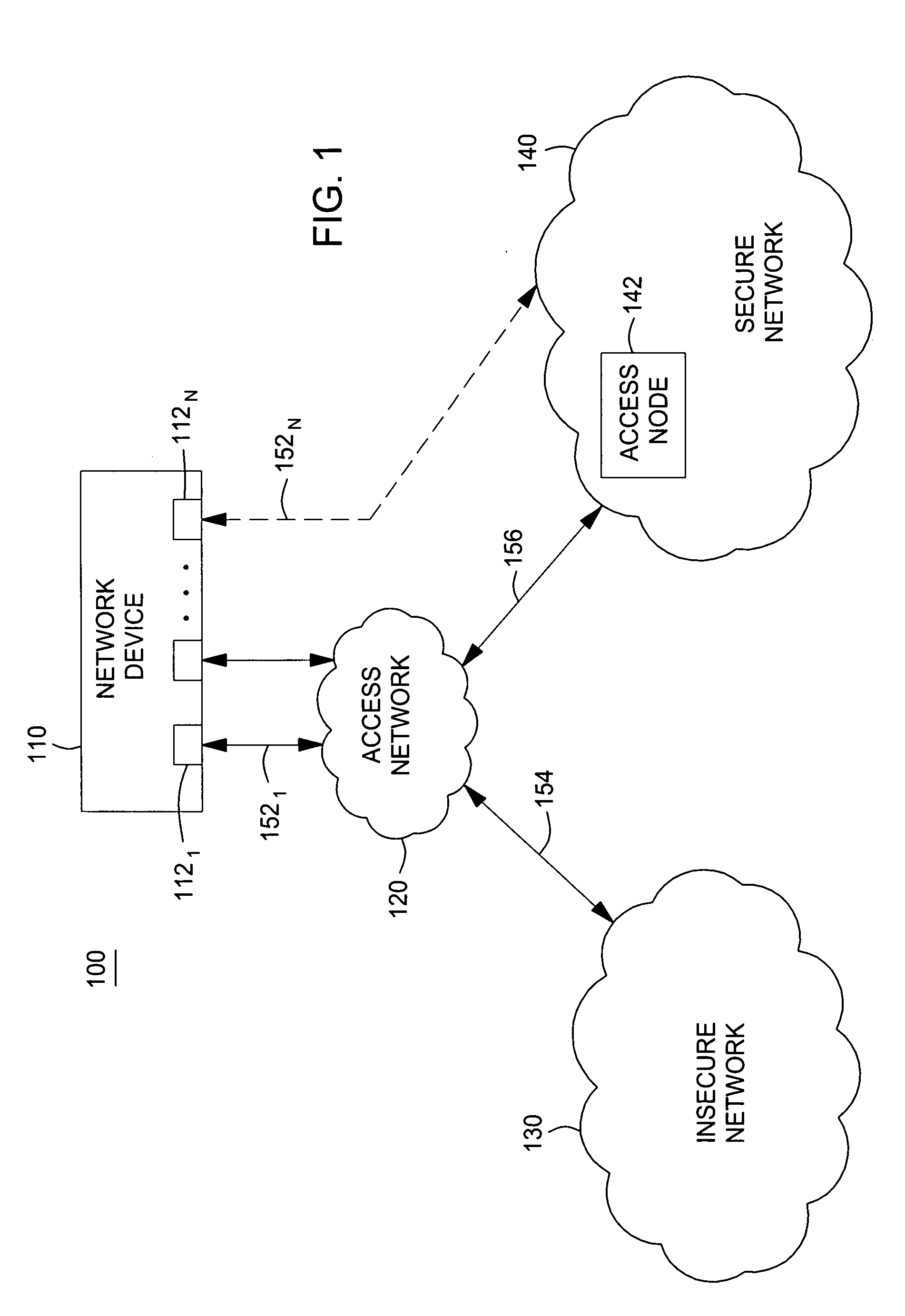

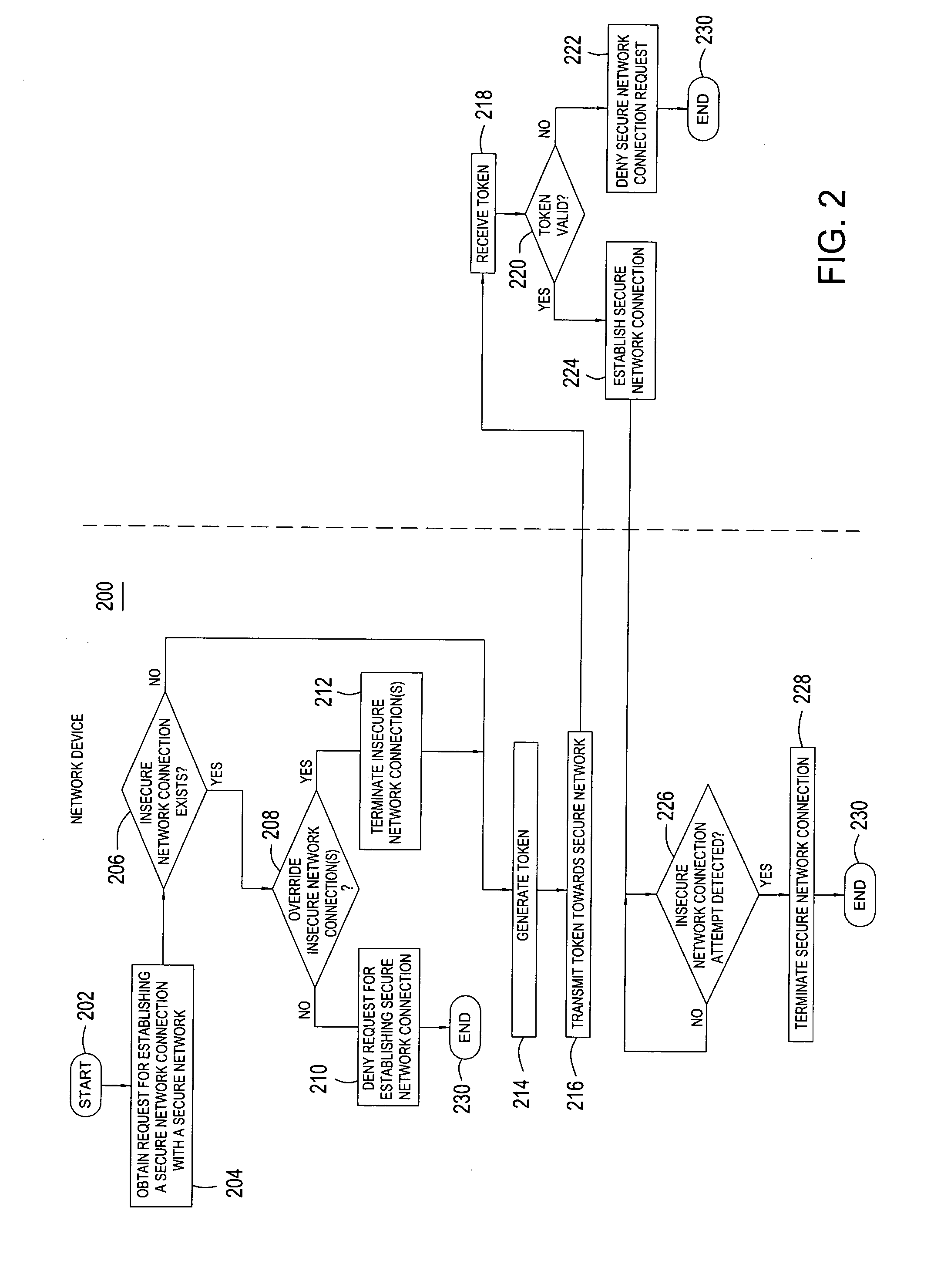

Method and apparatus for preventing bridging of secure networks and insecure networks

InactiveUS20060236093A1Prevent bridgingDigital data processing detailsMultiple digital computer combinationsNetwork connectionNetwork layer

The invention comprises a method and apparatus for preventing a bridge between a secure network and an insecure network. Specifically, the method comprises monitoring a network device supporting a secure network connection for an attempt to establish an insecure network connection, and terminating the secure network connection in response to detecting the attempt to establish the insecure network connection, where the secure network connection comprises a network layer connection.

Owner:ALCATEL-LUCENT USA INC +1

Apparatus for removal of ice from a storage bin

InactiveUS6685053B2Facilitates gravity droppingPrevent bridgingVolume measurement and fluid deliveryCoin-freed apparatus detailsMarine engineering

An apparatus for storing ice in a container and dispensing ice from the container is provided in the form of a storage bin, having ice agitating apparatus for engaging ice to loosen the same and to keep ice particles from adhering together in a common mass. An ice dispenser is provided for delivering ice from a lower to an upper end. The ice dispenser and the ice agitator are provided with separate drives.

Owner:FOLLETT PROD LLC

Package and manufacture method for thermal enhanced quad flat no-lead flip chip

InactiveCN102543907AImprove thermal conductivityImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesFilling materialsHeat conducting

The invention discloses a packaging and manufacturing method for a thermal enhanced quad flat no-lead flip chip. A thermal enhanced quad flat no-lead flip chip package piece structure comprises a lead framework, a first metal material layer, a second metal material layer, IC chips with convex points, an insulating filler material, a sticking material, radiating fins, heat conducting spacers and a plastic package material, wherein the lead framework comprises a chip carrier and a plurality of pins arranged in multiple circles around the chip carrier; the first metal material layer and the second metal material layer are respectively configured on the upper surface and the lower surface of the lead framework; the IC chips with the convex points are invertedly welded and configured at the position of the first metal material on the upper surface of the lead framework; the insulating filler material is configured below the stepped structure of the lead framework; the heat conducting spacers are configured between the IC chips and the chip carrier through the sticking material; and the radiating fins are configured on the edgeless surfaces of the IC chips through the sticking material and wrapped by the plastic package material to form a package piece. The QFN (Quad Flat No-lead) package piece structure provided by the invention has the advantages of high reliability, low cost and high I / O (Input / Output) density.

Owner:BEIJING UNIV OF TECH

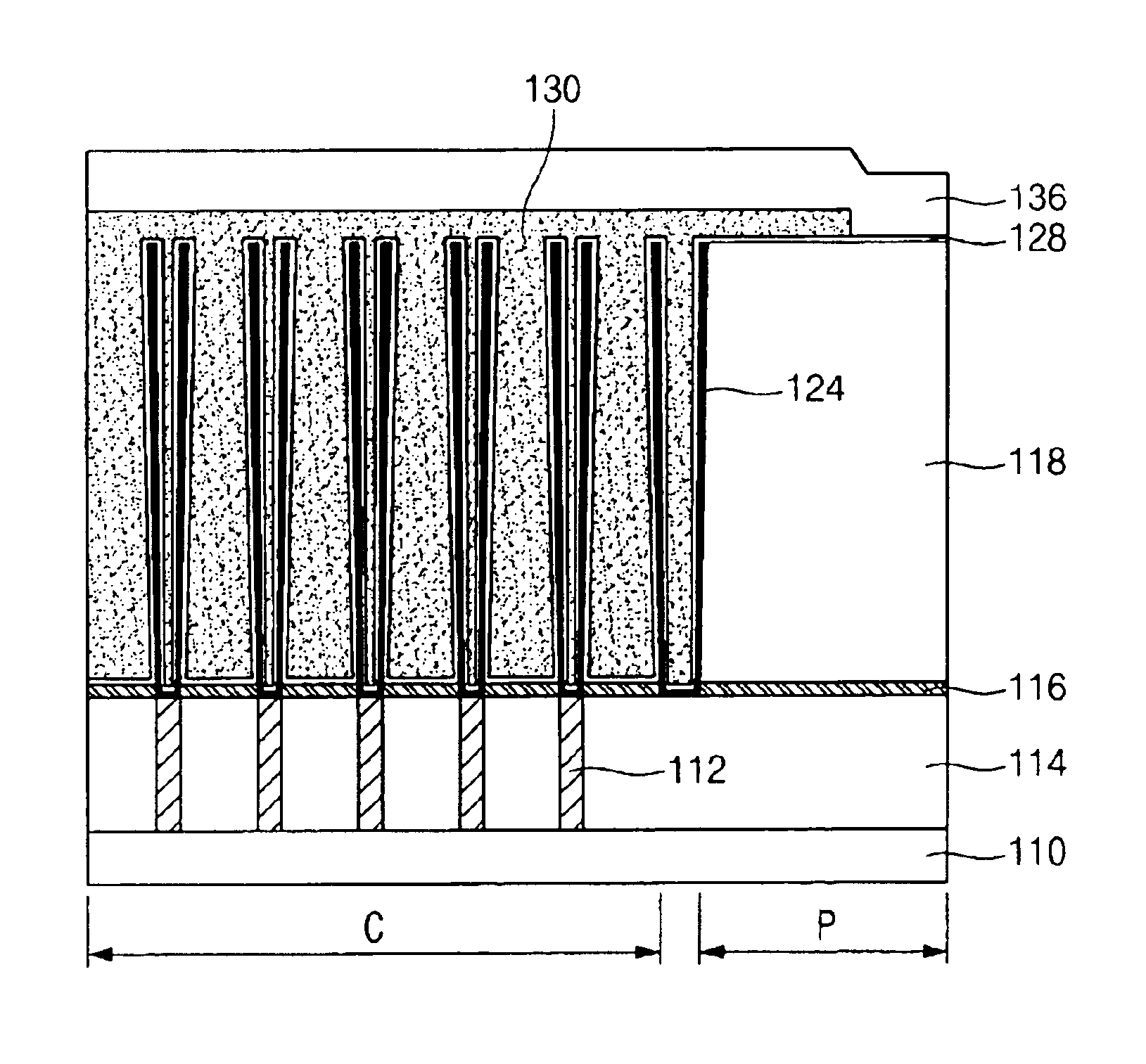

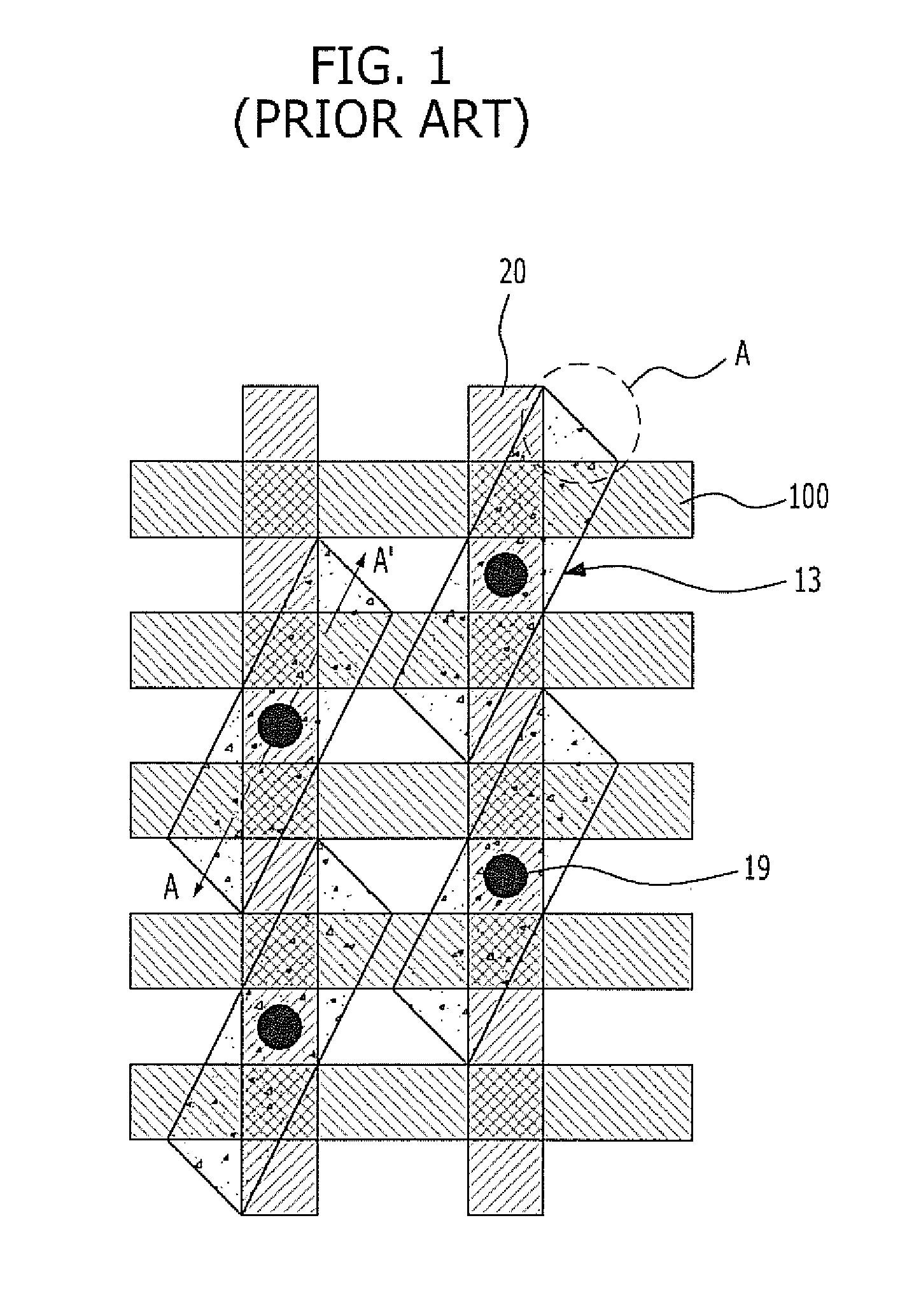

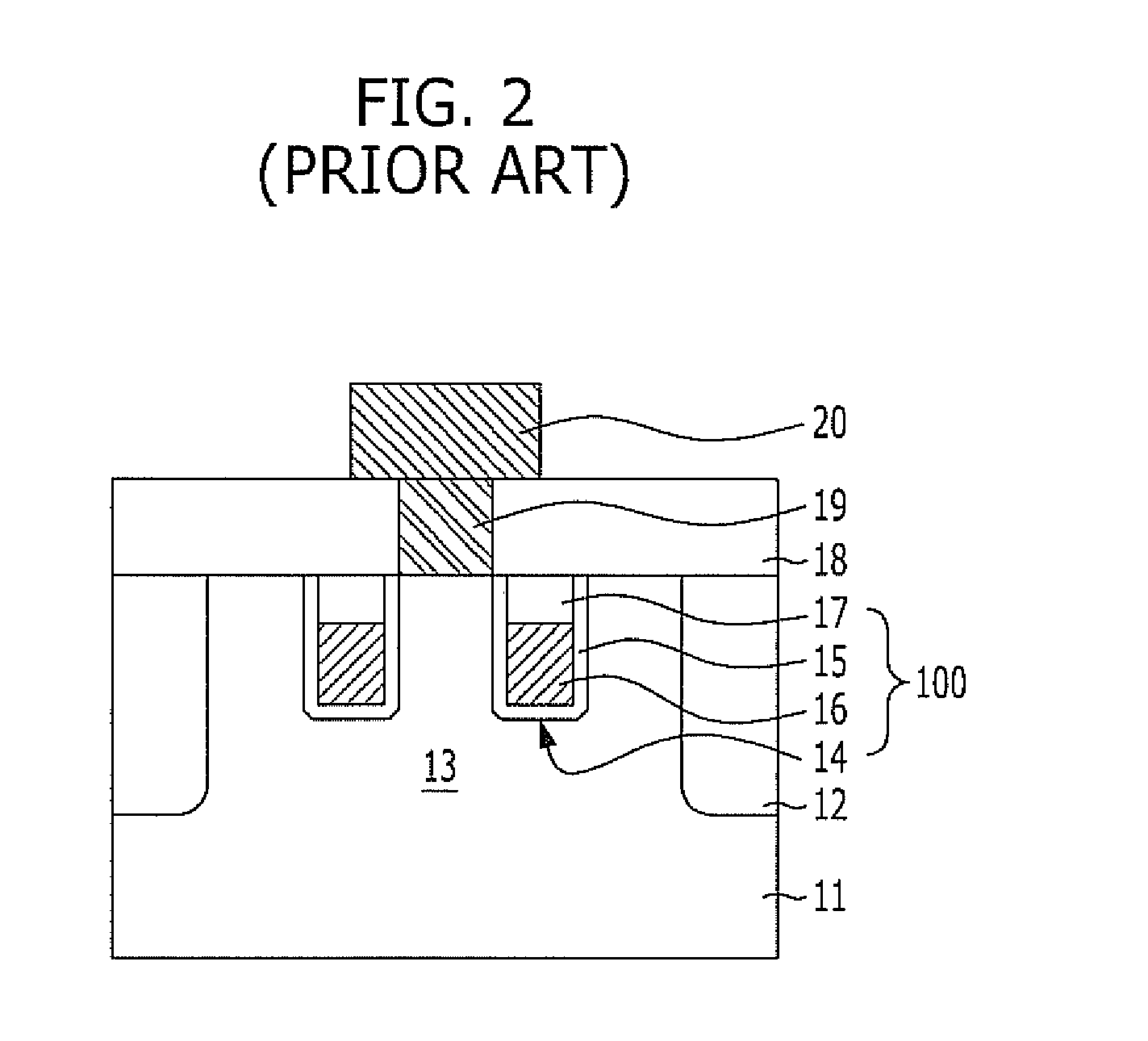

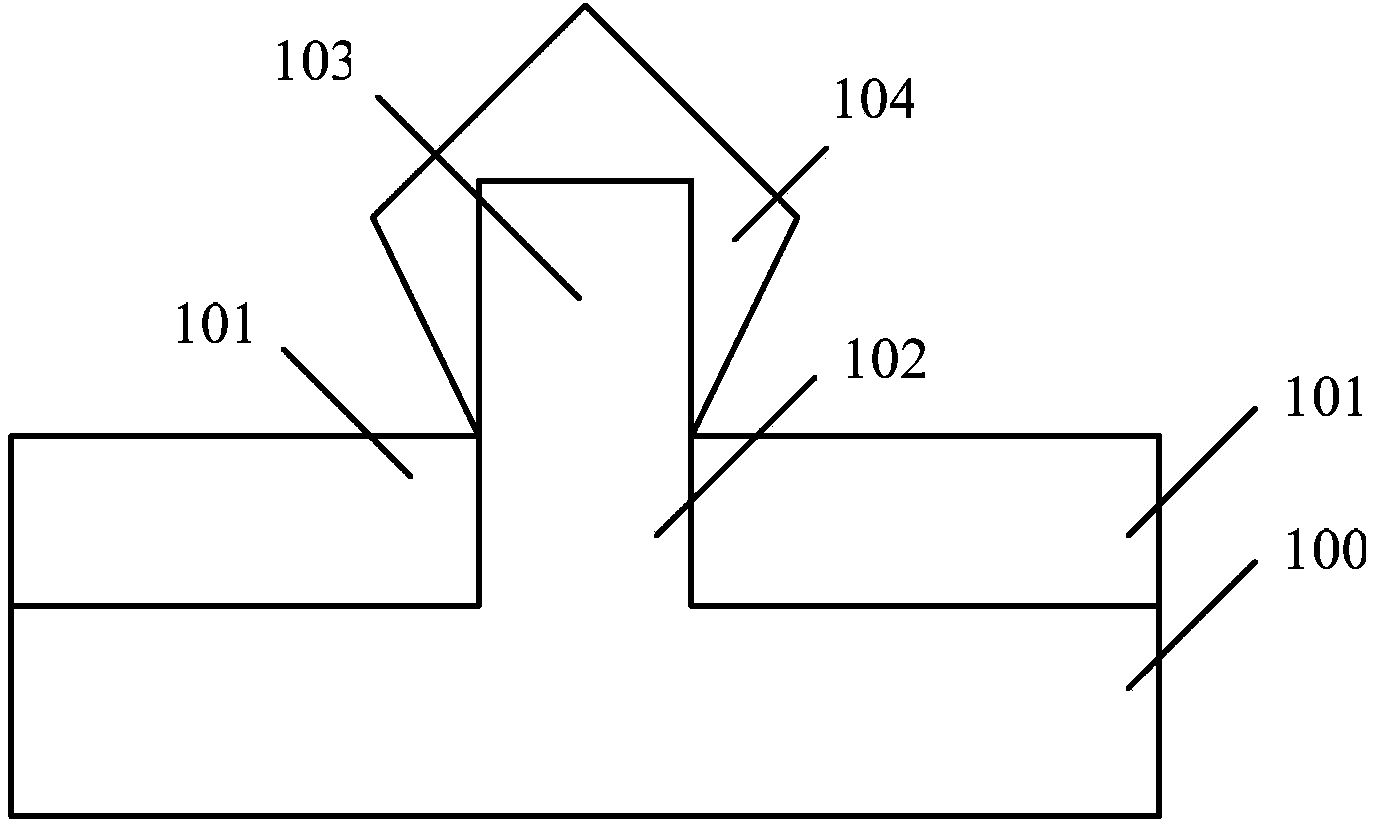

Semiconductor device having saddle fin-shaped channel and method for manufacturing the same

InactiveUS20100164051A1Prevent bridgingImprove manufacturing yieldTransistorSemiconductor/solid-state device detailsIsolation layerEngineering

A semiconductor device includes a semiconductor substrate with an isolation layer formed in the semiconductor substrate to delimit active regions. Recess patterns for gates are defined in the active regions and the isolation layer. Gate patterns are formed in and over the recess patterns for gates, and a gate spacer is formed to cover the gate patterns. The recess patterns for gates have a first depth in the active regions and a second depth, which is greater than the first depth, in the isolation layer. Gaps are created between the gate patterns and upper parts of the recess patterns for gates that are defined in the isolation layer. The gate spacer fills the gaps and protects the gate spacer so as to prevent bridging.

Owner:SK HYNIX INC

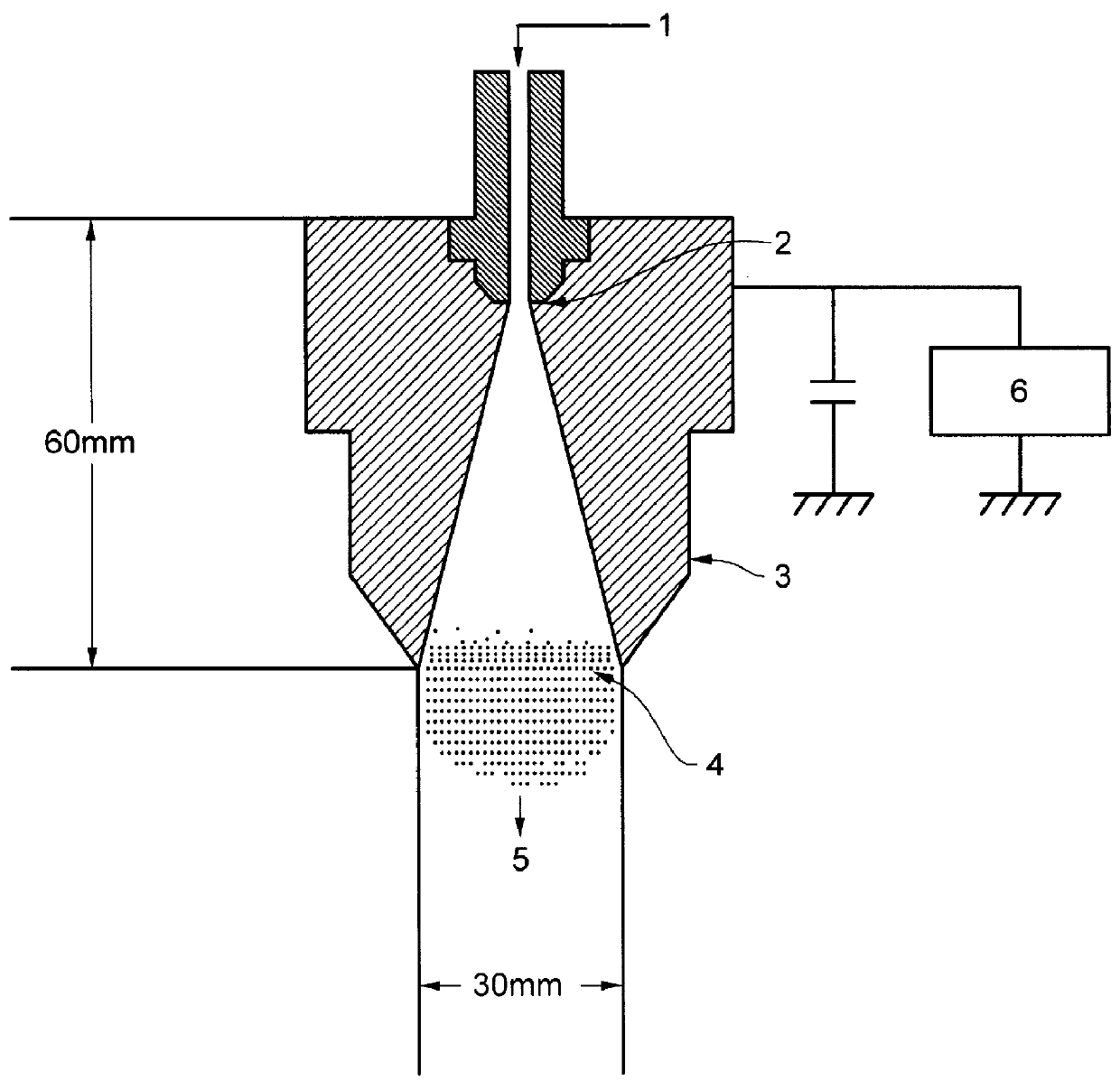

Input dispenser and recorder

ActiveUS20070083293A1Safer mixing of chemicalHigh efficiency in applicationAgricultural machinesAnalogue computers for trafficEngineeringVALVE PORT

An input dispenser / recorder controlled by a computer to dispense a predetermined amount of input or mixture of inputs based on parameters provided by an operator. Specifically, the invention has an inner frame and outer frame associated by load bars connected to the computer. The load bars signal the computer regarding weight change on the inner frame. Associated with the inner frame is at least one major input container having an opening over a conveyor and a valve therebetween controlled by the computer. Associated with the outer frame are minor input containers, each in fluid communication with the conveyor and a flow meter controlled by the computer. The conveyor may be a flighted auger, a belt, or pump and conduit and is also controlled by the computer. The parameters provided by the operator are used by a selected program and the CPU to control the amount and ratio of inputs, speed of conveyor, and mixture thereof.

Owner:APPLEGATE DOUG +2

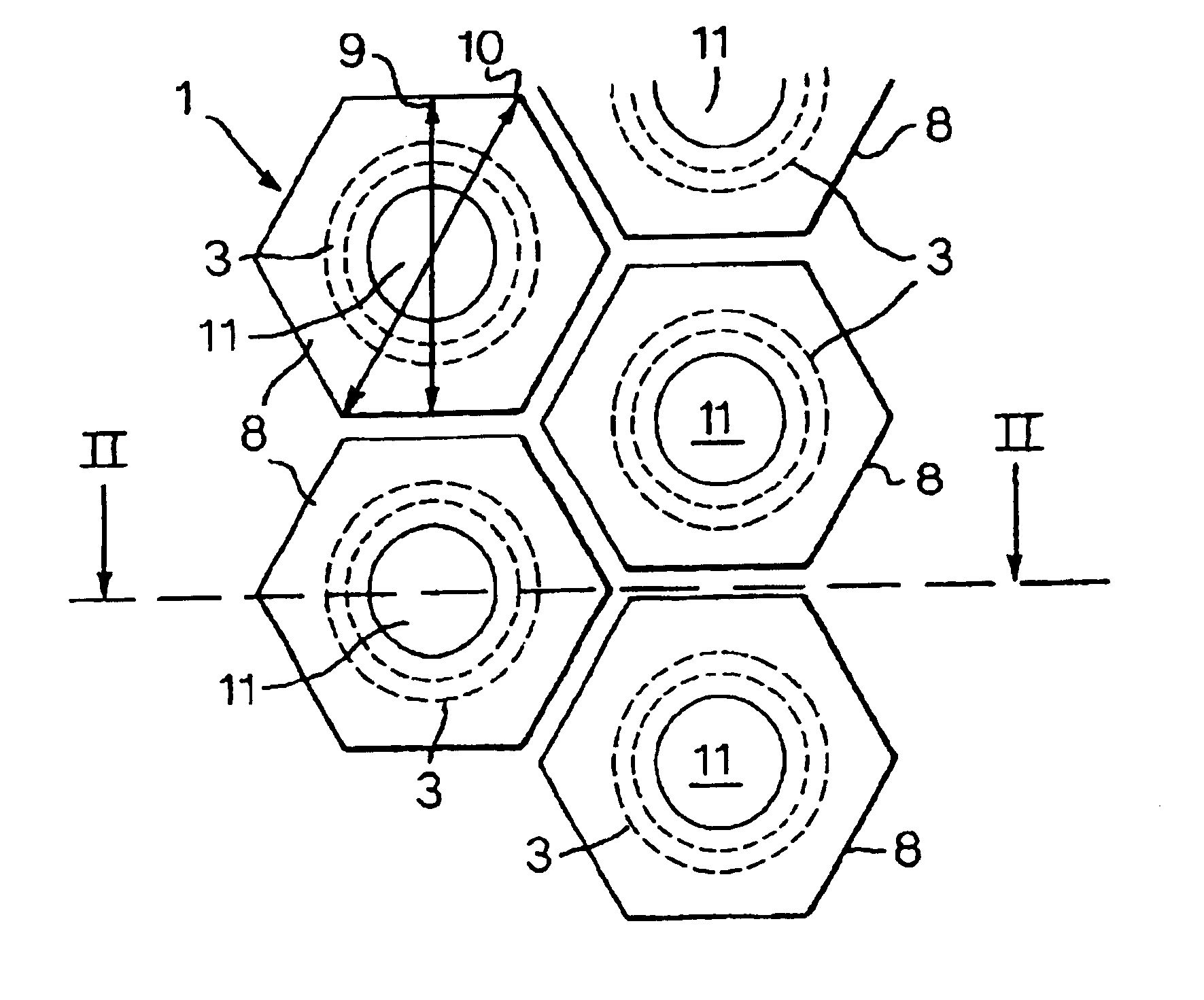

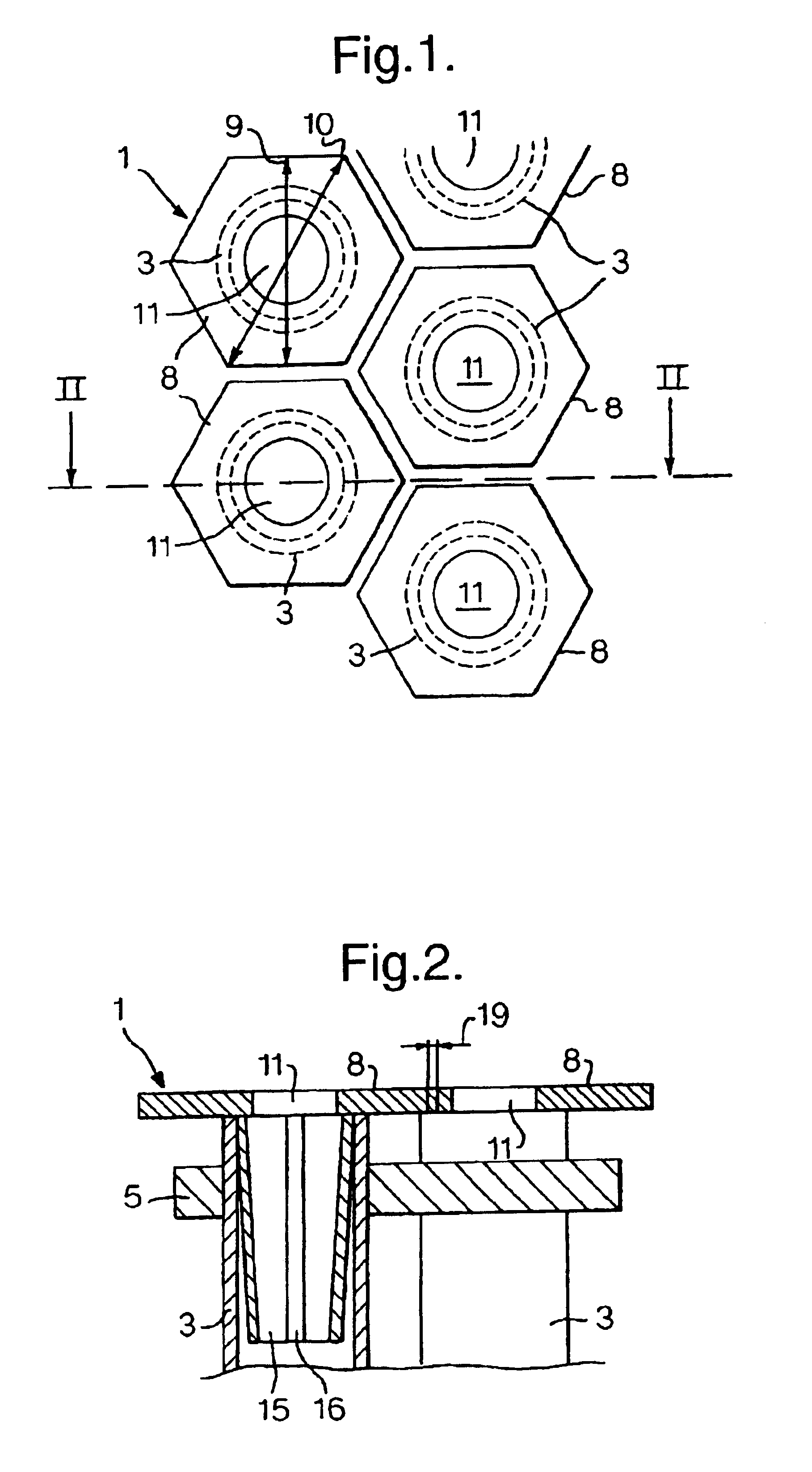

Process for loading a reactor

There is provided a method for loading solid particles into a multi-tube reactor having an upper tube-sheet holding together the upper ends of the multitude of reactor tubes, the method comprising positioning a loading device having a plurality of holes on top of the upper tube-sheet such that the loading device rests on and substantially covers the upper tube-sheet and the holes correspond to the reactor tubes, the loading device comprising a plurality of adjacent polygonal plates, each polygonal plate having from 1 to 30 holes, each hole corresponding to one reactor tube; pouring the particles over the combined polygonal plates covering the tube-sheet; sweeping the particles through the holes in the plates into the respective reactor tubes; removing residual particles and any dust remaining on and between the plates; and removing the loading device.

Owner:CLEAN HARBORS CATALYST TECH

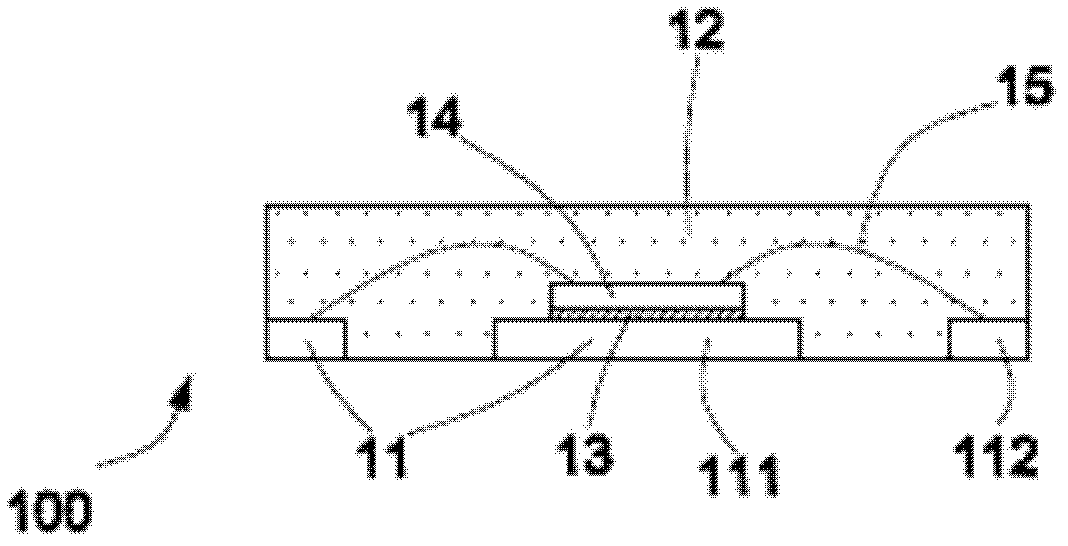

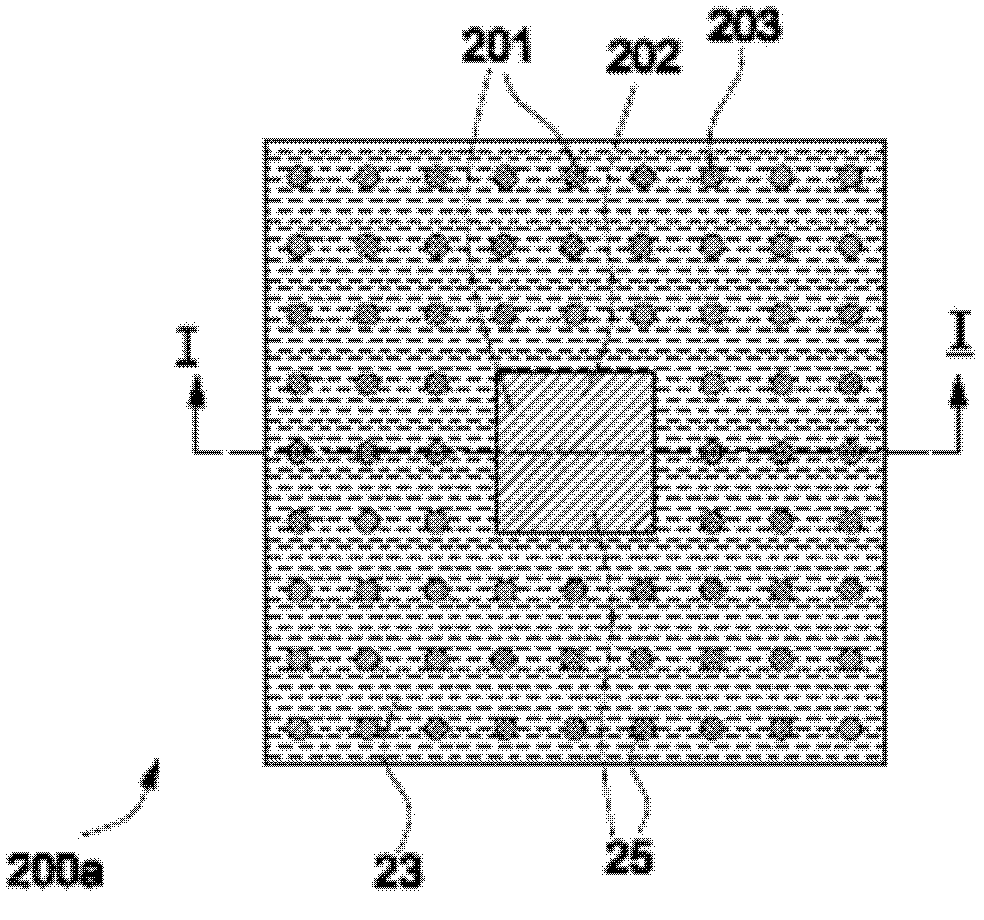

Quad flat non-lead (QFN) package with high density and manufacturing method

InactiveCN102354691AHigh I/O densityPrevent falling offSemiconductor/solid-state device detailsSolid-state devicesFilling materialsMetallic materials

The invention discloses a quad flat non-lead (QFN) package with high density and a manufacturing method. The package comprises a lead frame 201, metal material layers 25, an IC chip 27, insulating filling materials 23, bonding materials 26, metal conductors 28 and plastic package materials 29, wherein the lead frame comprises a chip carrier 202 and a plurality of leads 203 arranged in multiple circles around the chip carrier; the metal material layers are arranged on the upper and lower surfaces of the lead frame; the IC chip is arranged on a metal material layer on the upper surface of the lead frame; the insulating filling materials are arranged below stepped structures 22b of the lead frame; the bonding materials are arranged between the IC chip and the metal material layer on the upper surface of the lead frame; the IC chip is connected to the inner leads of the multiple circles of leads and the upper surface of the chip carrier respectively by the metal conductors; the plastic package materials wrap and seal the IC chip, the bonding materials, the metal conductors, partial regions of the lead frame and partial metal material layers; and the chip carrier and the outer leads exposed out of the bottom surface of a package structure, are provided with raised parts. The package and the manufacturing method have the following beneficial effects: the bottleneck of low I / O quantity is broken through and the package reliability is improved.

Owner:BEIJING UNIV OF TECH

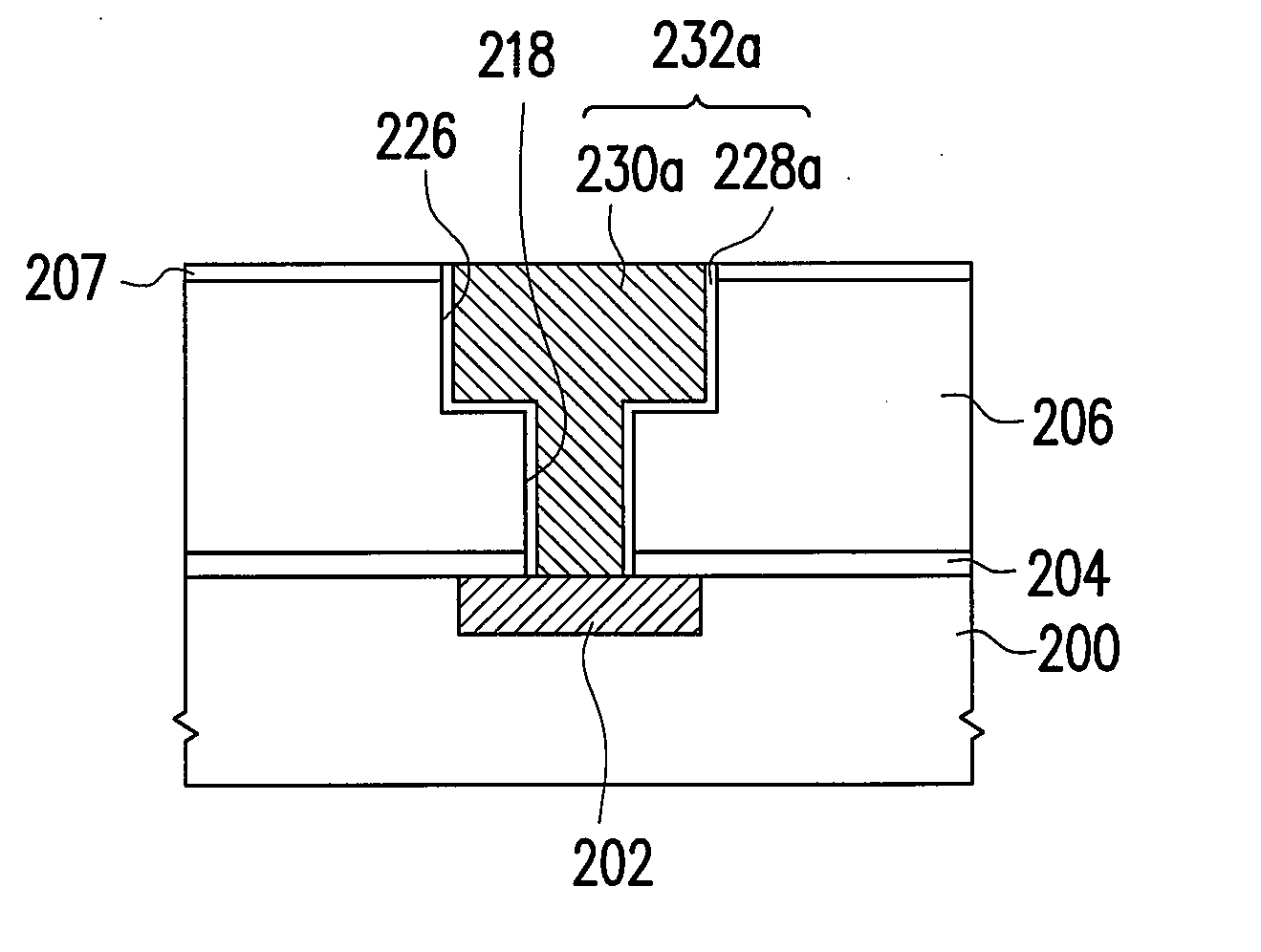

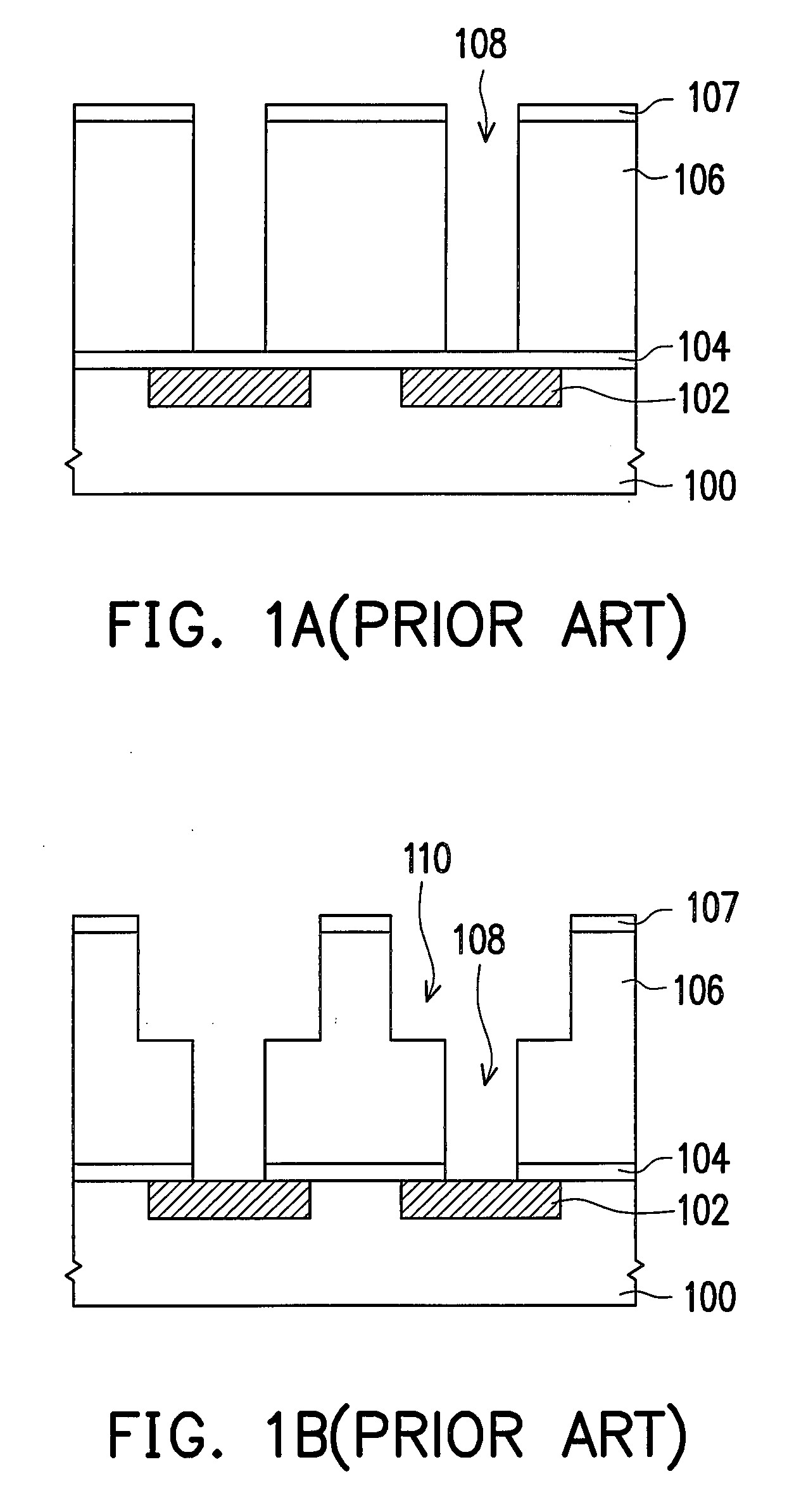

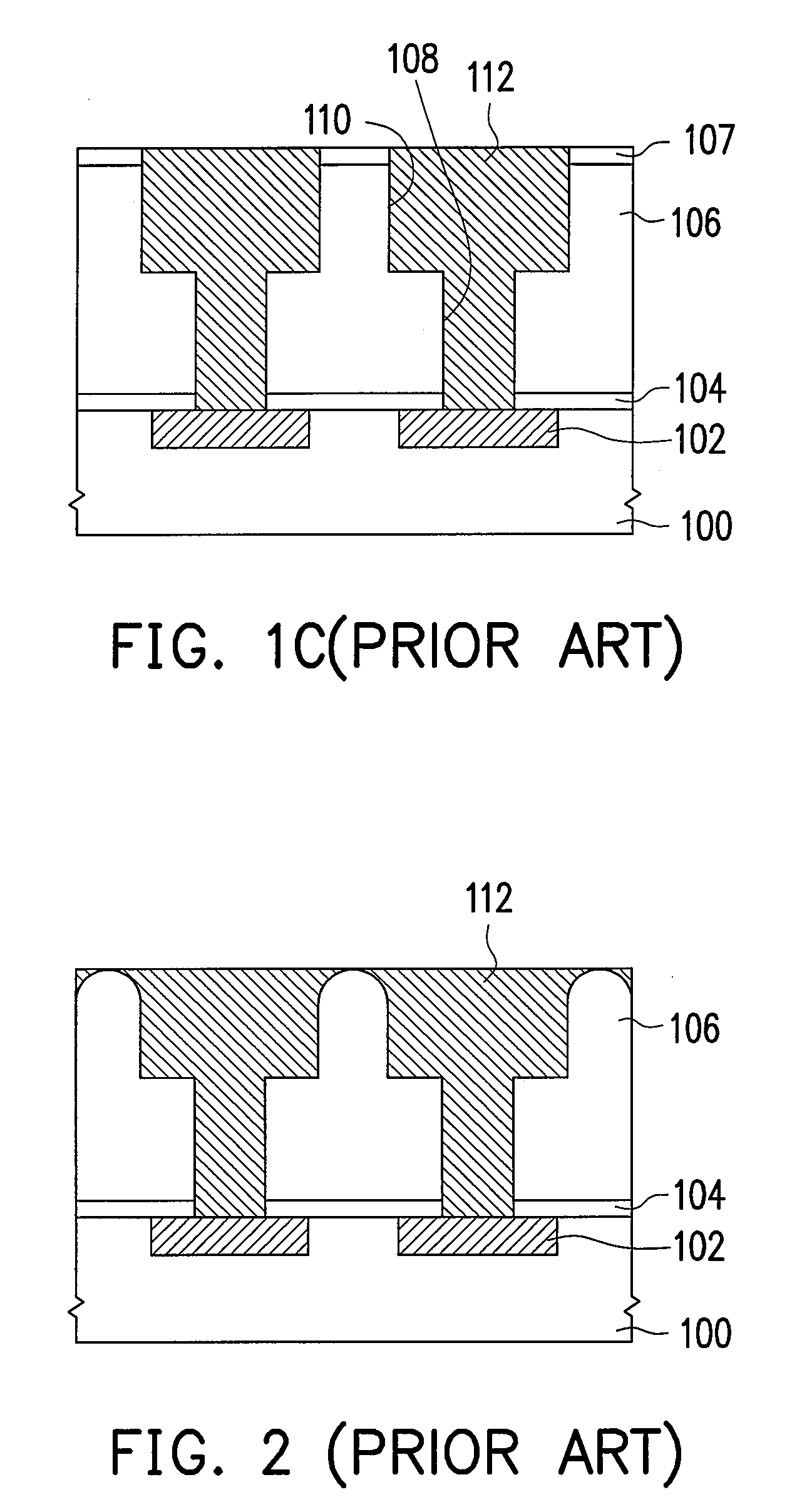

Method of fabricating dual damascene structure

ActiveUS20080171434A1Prevent bridgingAvoid damageSemiconductor/solid-state device manufacturingOptoelectronicsGap filling

A method of fabricating a dual damascene structure is described. A dielectric layer and a metal hard mask layer are sequentially formed on a substrate having thereon a conductive layer and a liner layer. The metal hard mask layer and the dielectric layer are patterned to form a via hole exposing a portion of the liner layer. A gap-filling layer is filled in the via hole, having a height of ¼ to ½ of the depth of the via hole. A trench is formed in the metal hard mask layer and the dielectric layer. The gap-filling layer is removed to expose the portion of the liner layer, which is then removed. A metal layer is formed filling in the via hole and the trench, and then the metal hard mask layer is removed.

Owner:UNITED MICROELECTRONICS CORP

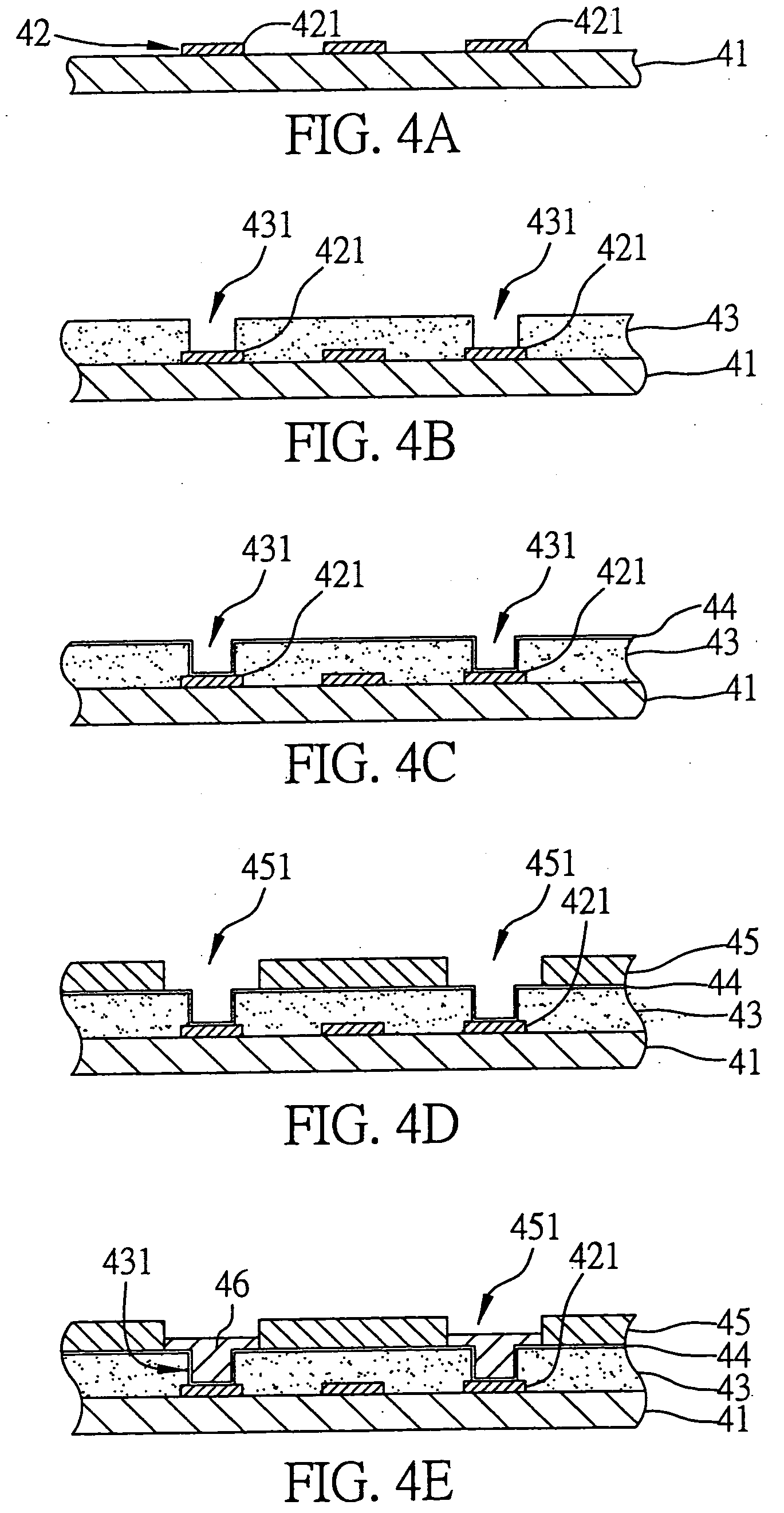

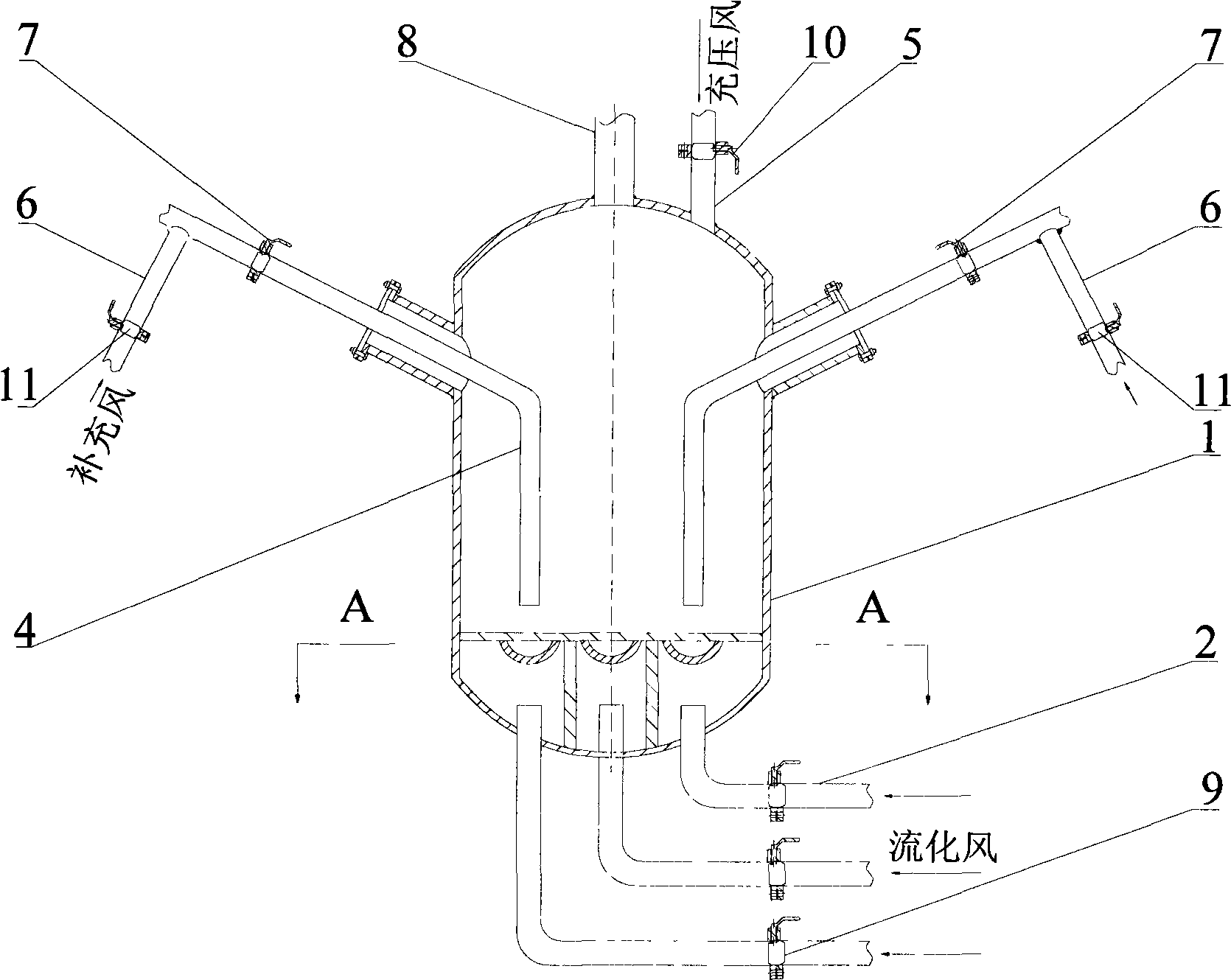

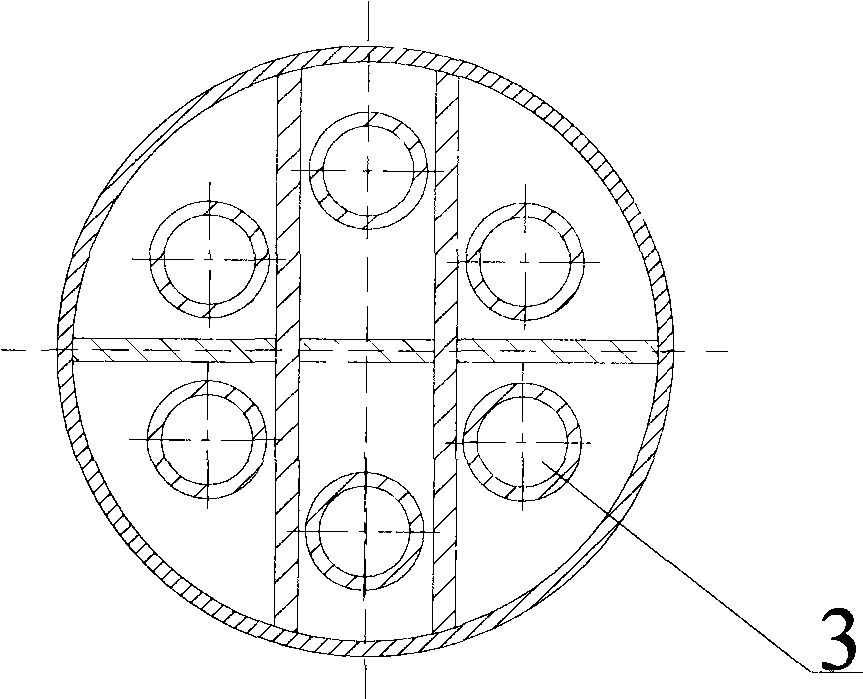

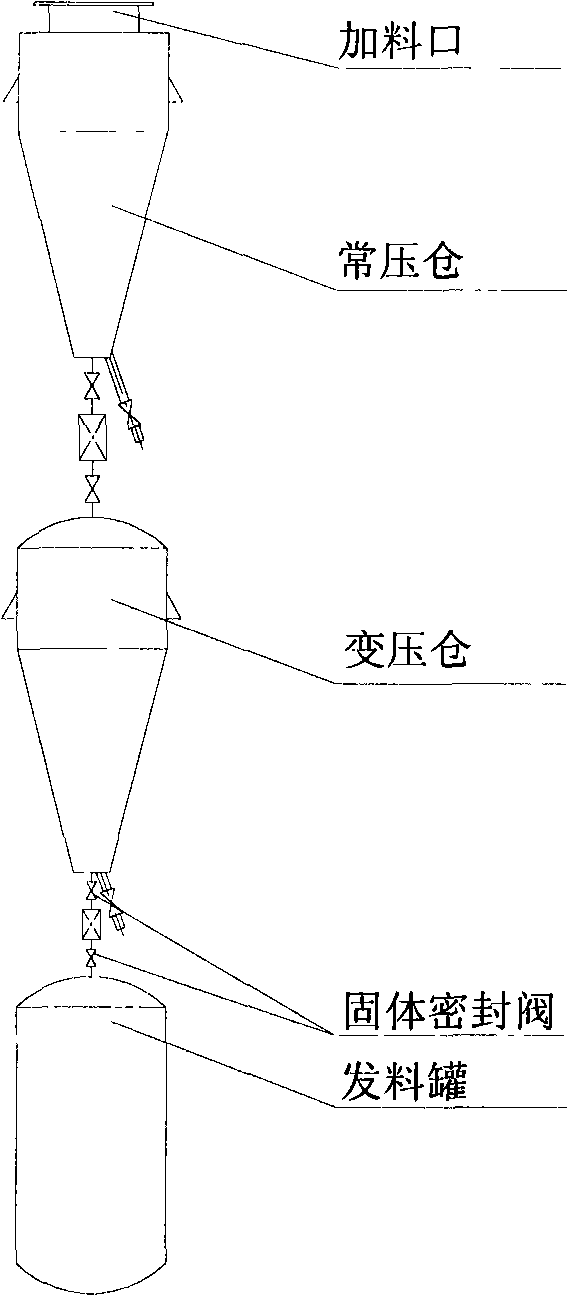

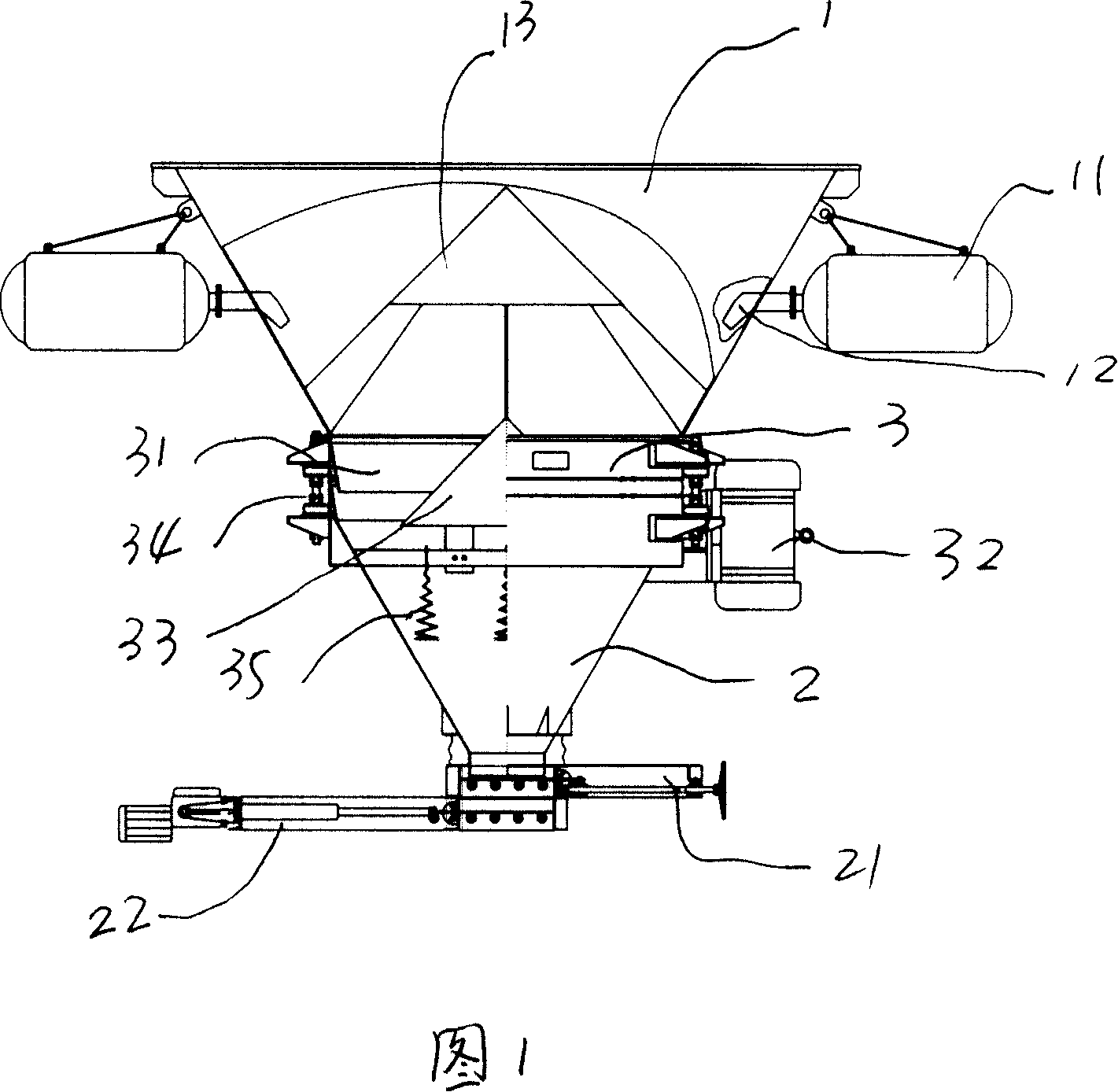

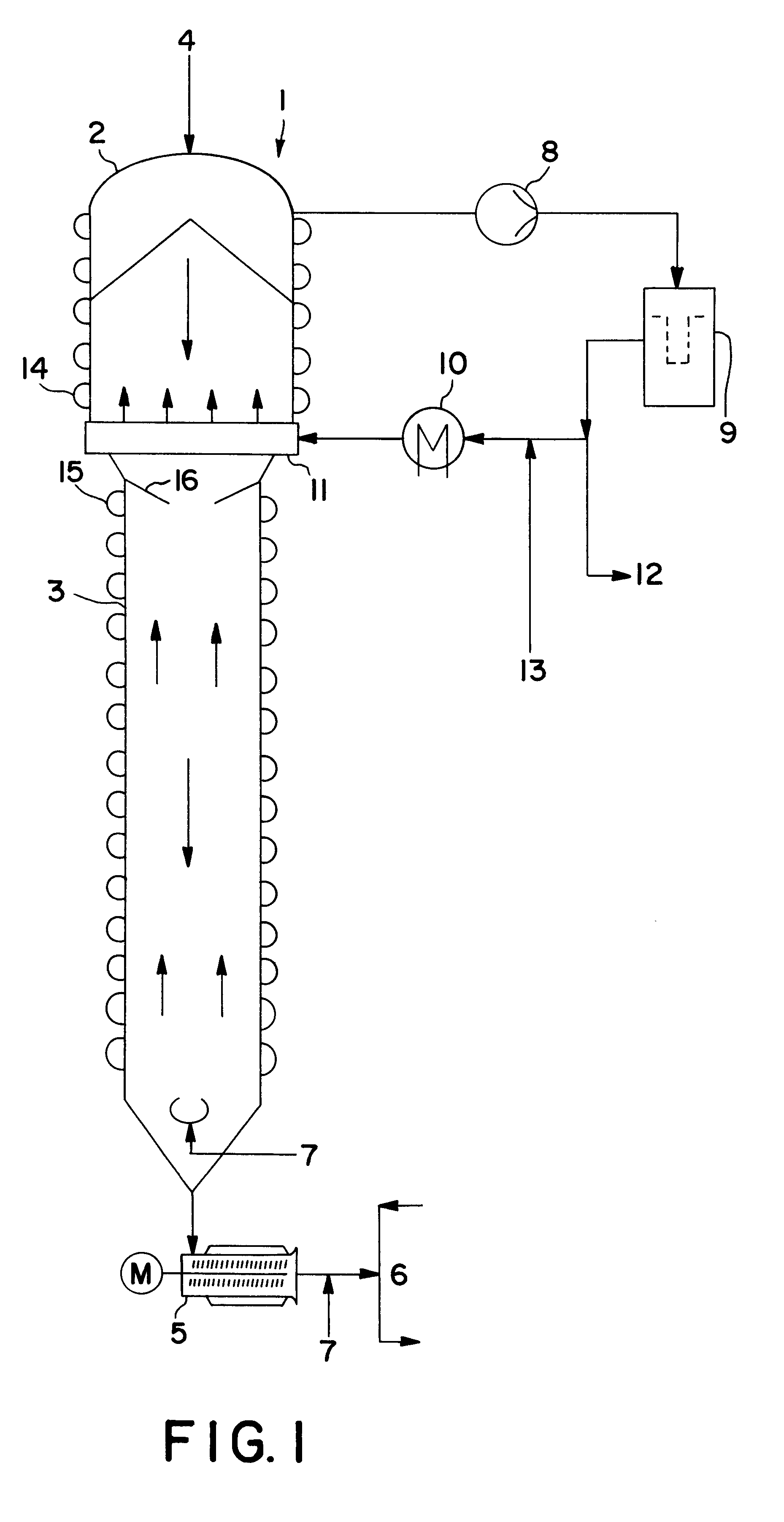

Cylindrical material-issuing tank of a plurality of air distributors and material-issuing tubes and multi-path material-issuing method thereof

InactiveCN101544310AMeet the requirements of variable load operationSimplify multi-channel coal supply systemBulk conveyorsCombined combustion mitigationDistributorMulti path

The invention relates to a cylindrical material-issuing tank of a plurality of air distributors and material-issuing tubes and a multi-path material-issuing method thereof and relates to the pressurization gasification of large-scale dry coal powder and a coal powder delivery system of an IGCC generating technology. The invention adopts the cylindrical material-issuing tank with a plurality of independent air distributors arranged at the bottom of the material-issuing tank, each air distributor corresponds to a path of fluidization air tube and a material-issuing tube to realize the multi-path delivery of coal powder; fluidization air from an air storage tank enters the material-issuing tank from the bottom by each fluidization air tube to fluidize the coal powder on each air distributor, pressurized air is used for maintaining the pressure stability of the material-issuing tank, and supplementary air is used for adjusting a solid-air ration in a delivery tube to ensure the delivery stability. The invention can utilize the material-issuing tank to realize multi-path delivery, effectively simplifies the multi-path delivery system, prevents a conical material-issuing tank from causing a coal powder bridge phenomenon due to continuously reducing flow cross section, effectively lowers the height of the material-issuing tank and improves the space utilization rate of the material-issuing tank.

Owner:SOUTHEAST UNIV

Method for producing terylene pre-tropism continuous yarn by utilizing reclaimed polyester bottle

ActiveCN101144191ALow costReduce energy consumptionMelt spinning methodsSpinning solutions preparationYarnPolyester

The present invention belongs to the fiber producing method field, in particular relates to a method which uses a reclaimed PET bottle to produce the terylene preoriented filament in particular. The present invention mainly solves the problems of the prior art that the cost of raw materials for production is high, the drying efficiency is low, and the uniformity is poor, etc., and provides a method which uses the reclaimed PET bottle to produce the terylene preoriented filament with low cost of the raw materials for production, high drying efficiency, and good uniformity. The present invention has the major steps that the bottle piece of the PET bottle is produced; the bottle piece is continuously crystallized and dried by passing through a pre-crystallizer and a drying tower; the dried bottle piece directly enters a threaded rod extrusion machine, and is melted and extruded by a spinning threaded rod; the molten polyester material is continuously filtrated by a molten mass filter with a big filtering area of one level or two levels, to enter a spinning manifold; a thread line is cooled by passing through a cross air blasting, to wind to form the preoriented filament.

Owner:浙江聚元新材料股份有限公司

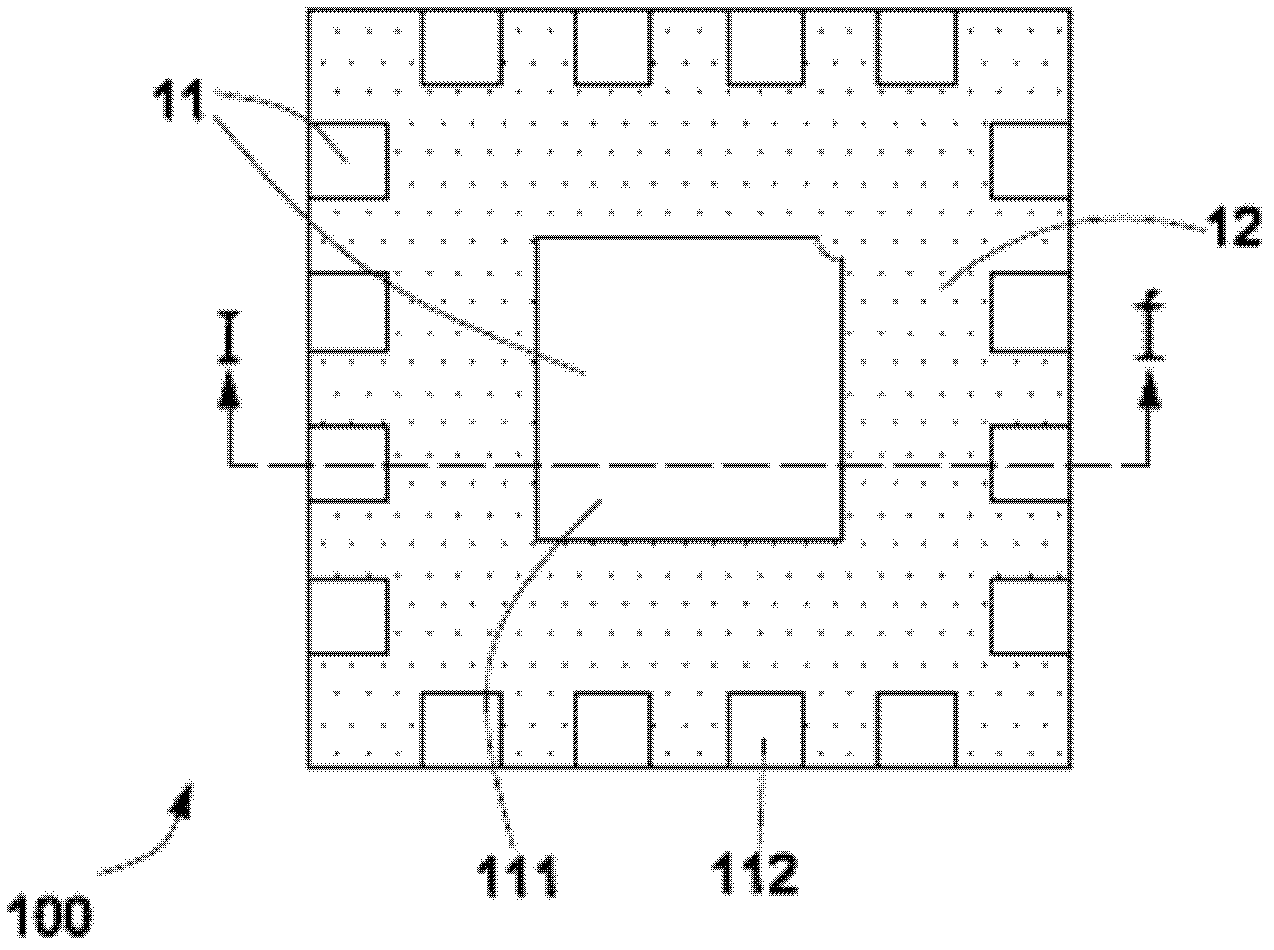

Fine-pitch pillar bump layout structure on chip

InactiveUS20150048499A1Prevent bridgingImprove bindingSemiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

Disclosed is a fine-pitch pillar bump layout structure on chip, comprising a chip, a passivation layer and at least two pillar bumps. Bonding pads of the chip are disposed along an X-axis. Openings of the passivation layer have a first aspect ratio. Pillar bumps are disposed on the bonding pads and each has a pillar body and a solder cap. Each pillar body has a plurality of symmetrical raised blocks disposed on the passivation layer and extended in both directions of Y-axis. The pillar bodies have shrunk bump widths along the X-axis so that a second aspect ratio is at least 1.5 times greater than the first aspect ratio and to partially expose the bonding pads and to make the central points of the pillar bodies be vertically aligned with the central points of the openings of the passivation layer.

Owner:POWERTECH TECHNOLOGY +1

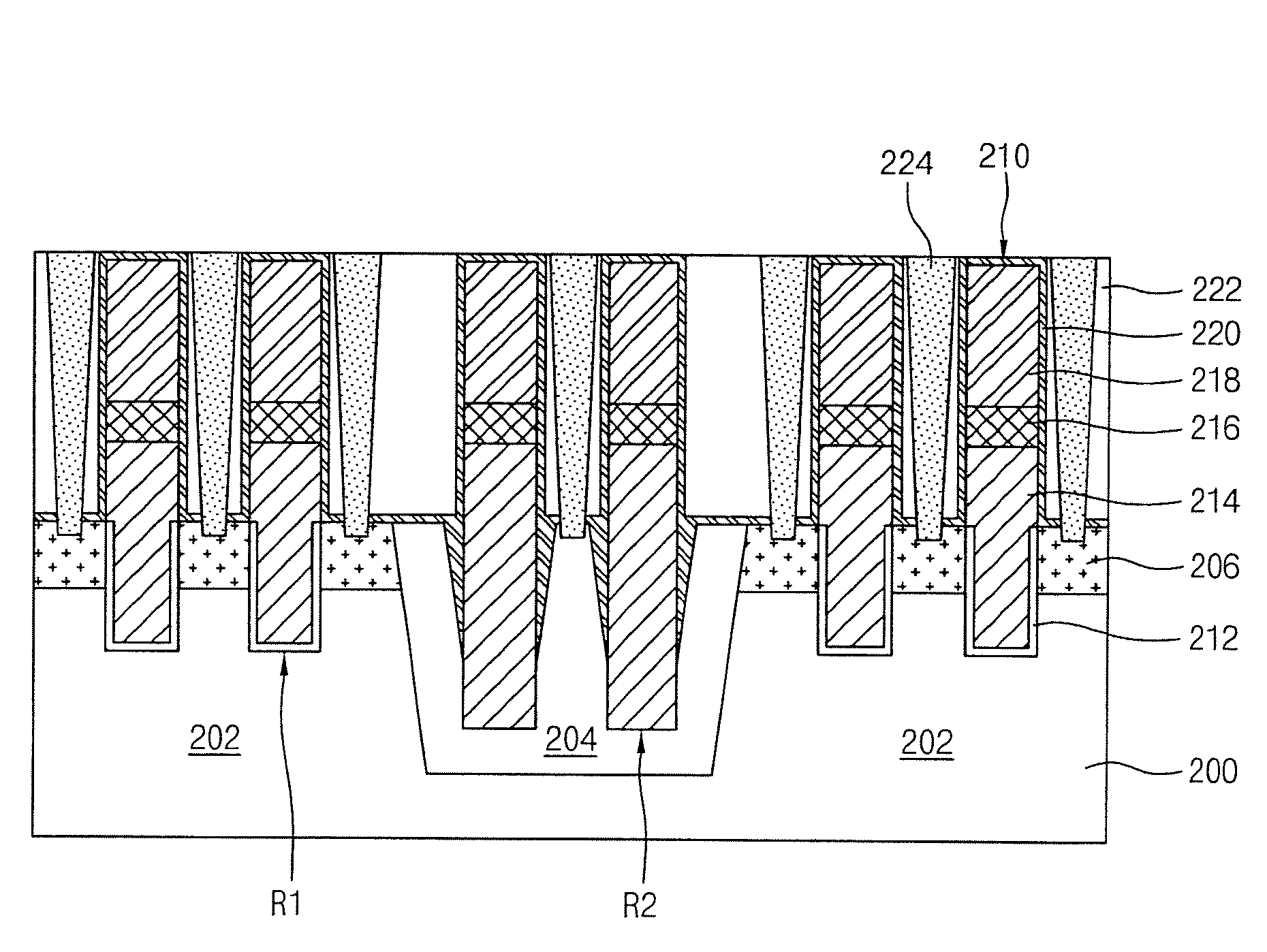

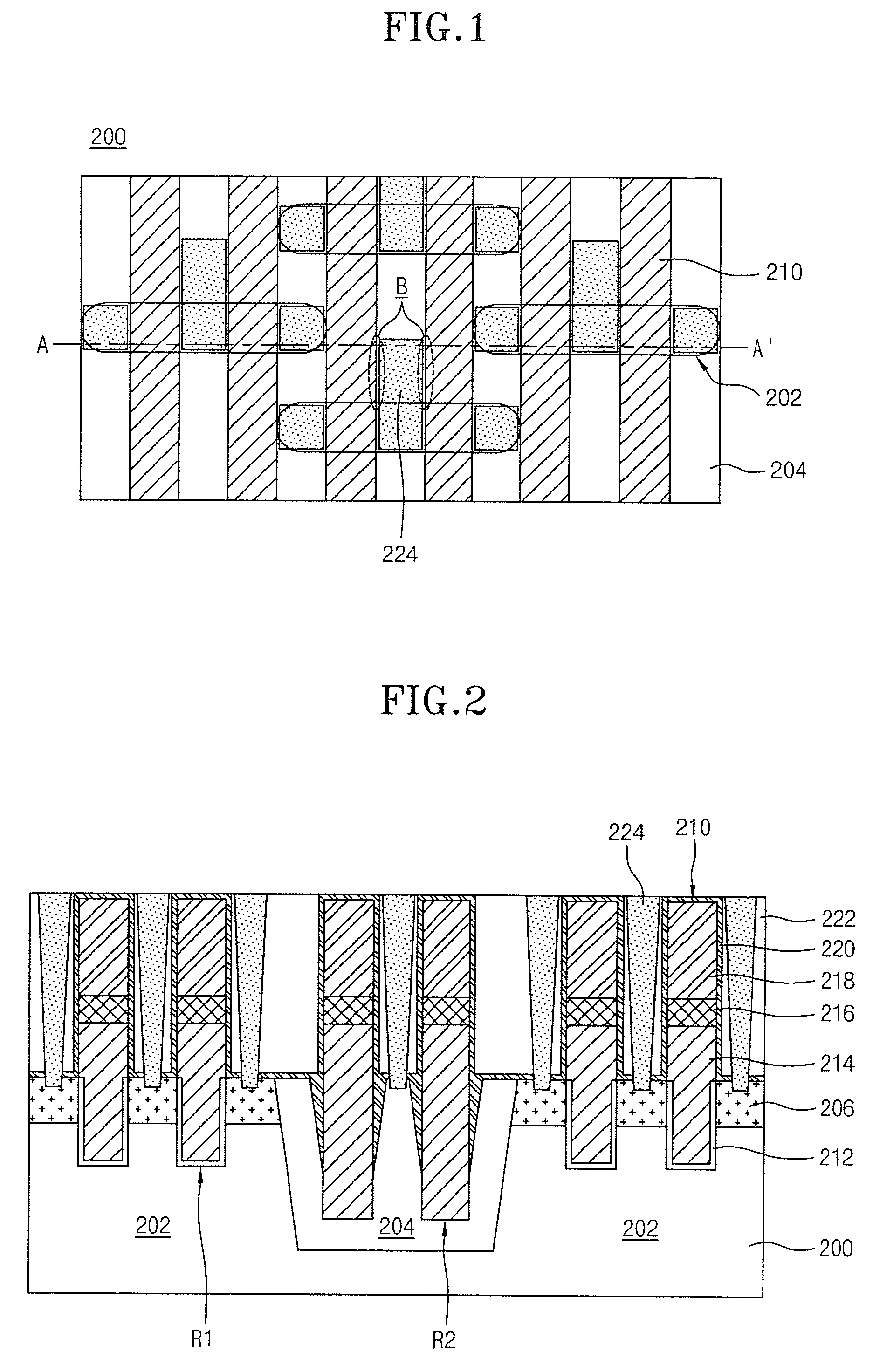

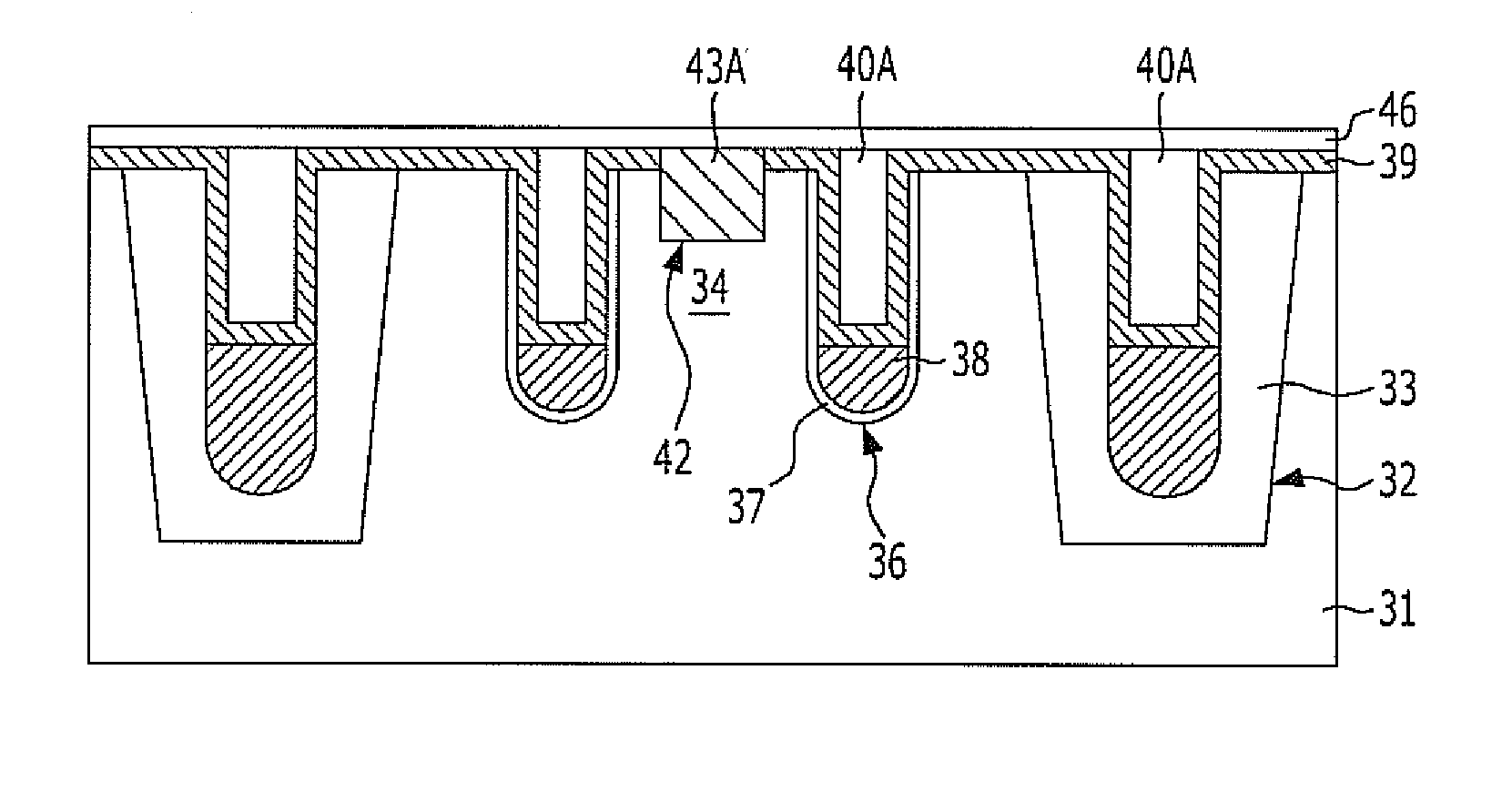

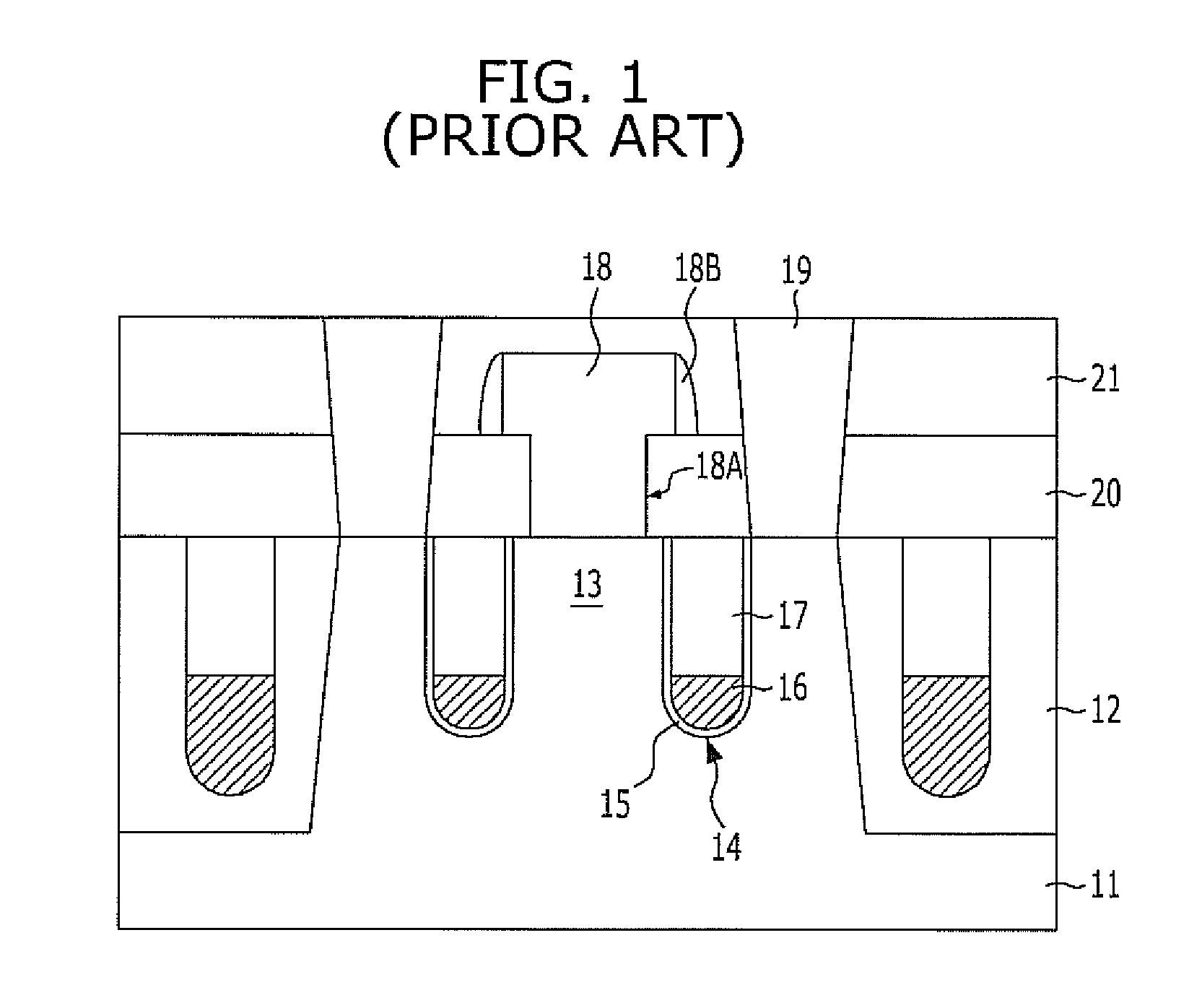

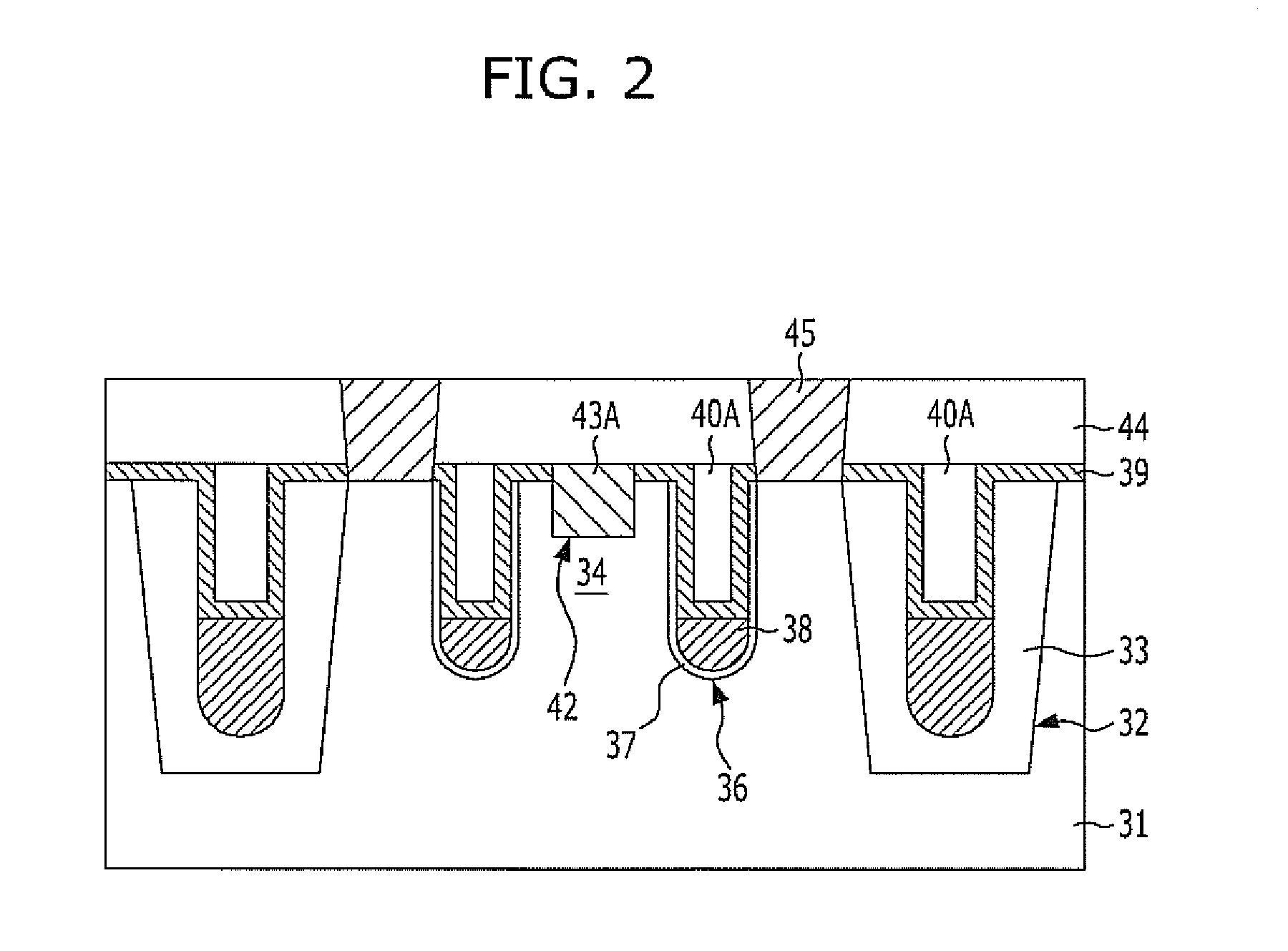

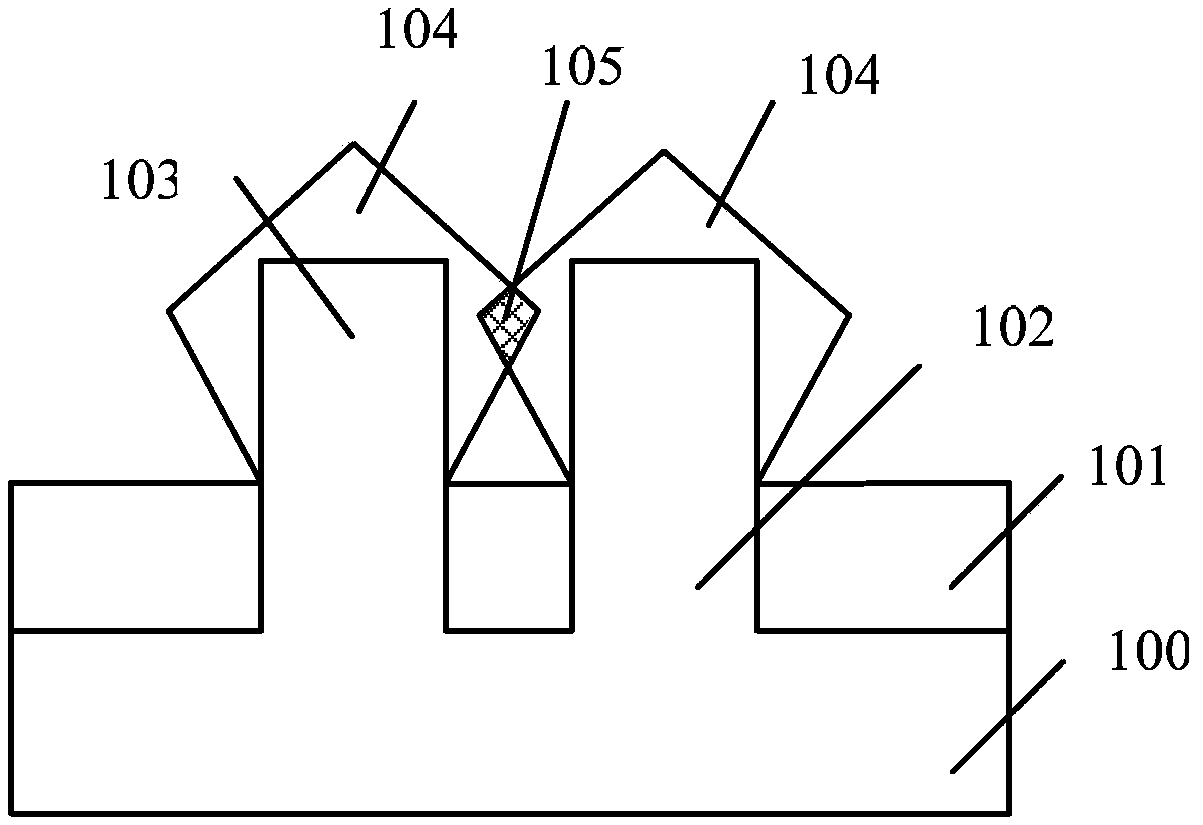

Semiconductor device with buried gates and buried bit lines and method for fabricating the same

InactiveUS20110101450A1Reduce resistancePrevent bridgingSolid-state devicesSemiconductor/solid-state device manufacturingBit lineSemiconductor

A semiconductor device includes: a plurality of first trenches formed inside a plurality of active regions; a plurality of buried gates configured to partially fill insides of the plurality of the first trenches; a plurality of second trenches formed to be extended in a direction crossing the plurality of the buried gates; and a plurality of buried bit lines configured to fill the plurality of the second trenches.

Owner:SK HYNIX INC

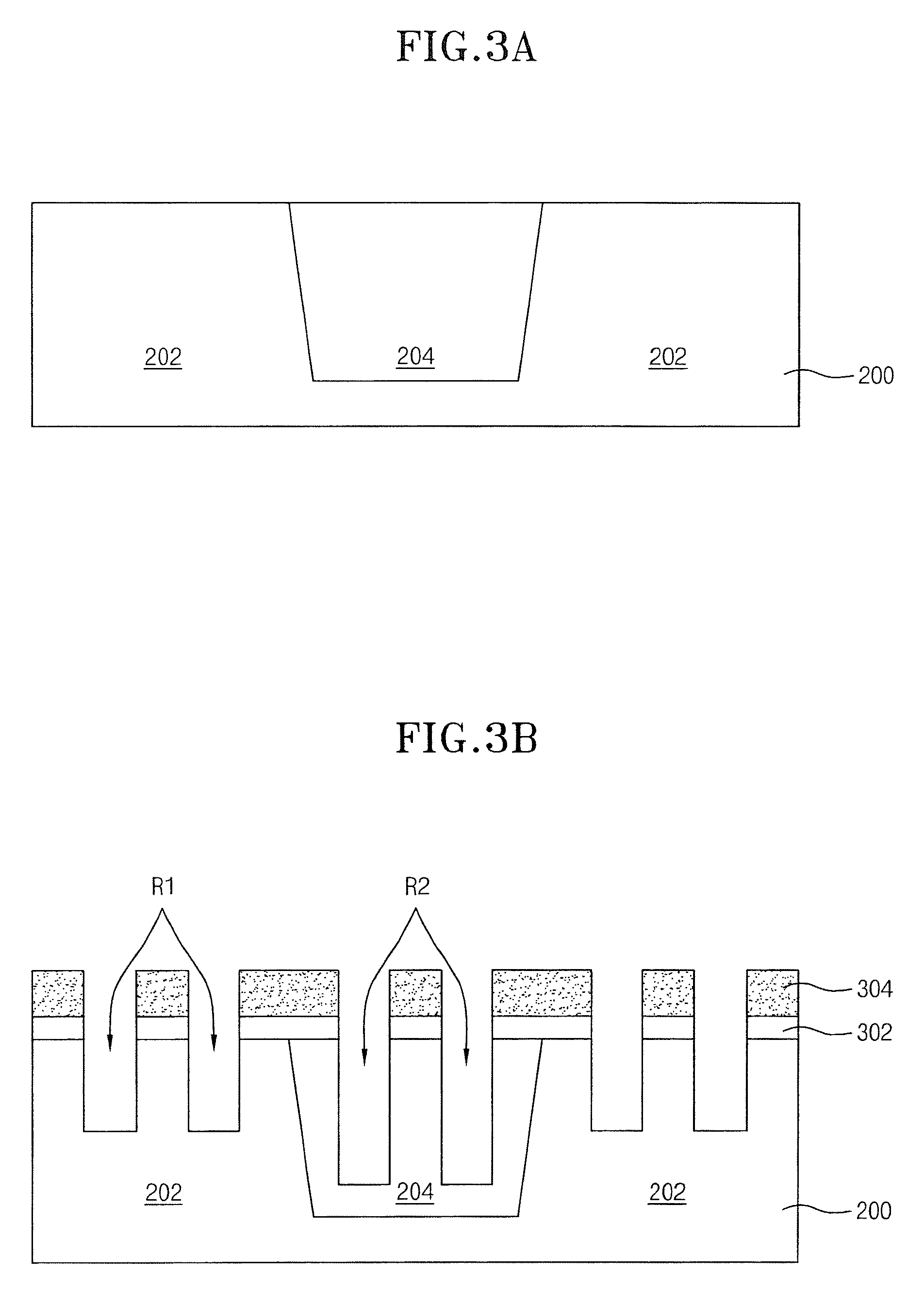

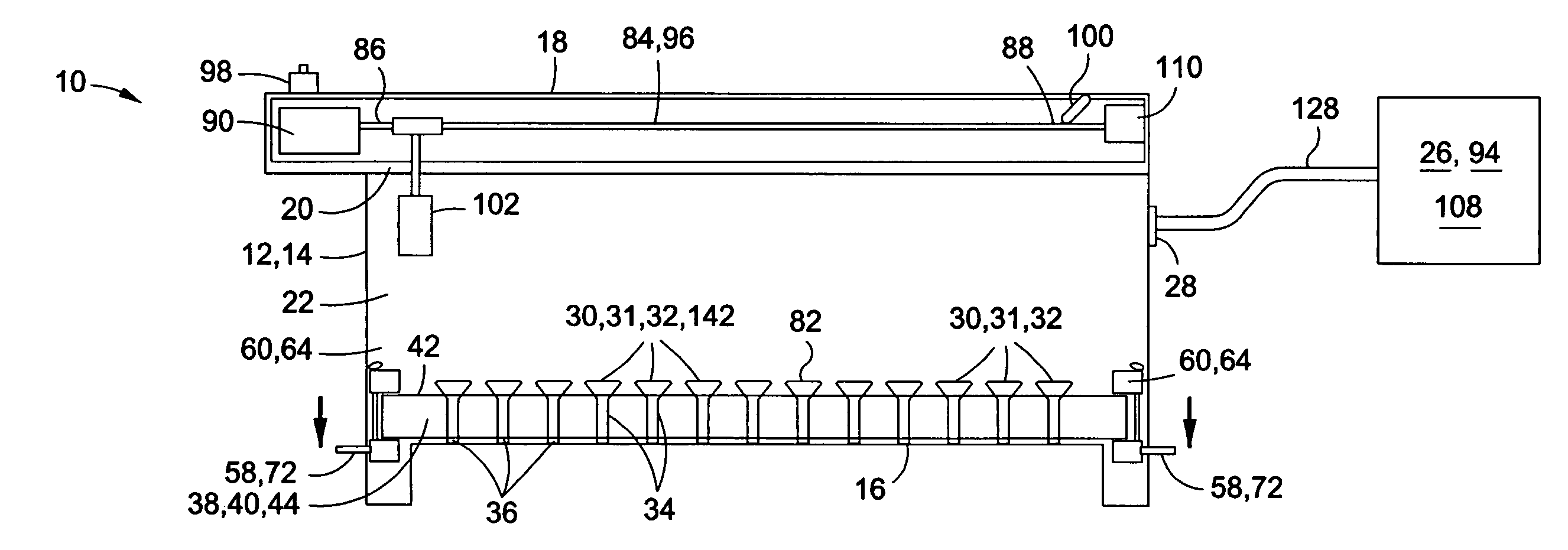

Controlled environment chamber for applying a coating material to a surface of a member

ActiveUS8136475B2Small sizeEasy to controlWire articlesSlide fastenersMechanical engineeringControlled environment chamber

A painting apparatus for applying a coating material to a member surface of a member comprises a housing, at least one slide rail, a rack assembly, a cross beam and a spraying device. The slide rail may be mountable within the housing and may have a plurality of rack positions. The rack assembly is mountable within the housing at one of the rack positions. The rack assembly is configured to support the member such that the member surface is exposed. The cross beam may be coupled to the slide rail. The cross beam is movable along the slide rail and is positionable at the rack positions. The spraying device is mountable on the cross beam and is configured to move along the cross beam while spraying the coating material onto the member surface.

Owner:THE BOEING CO

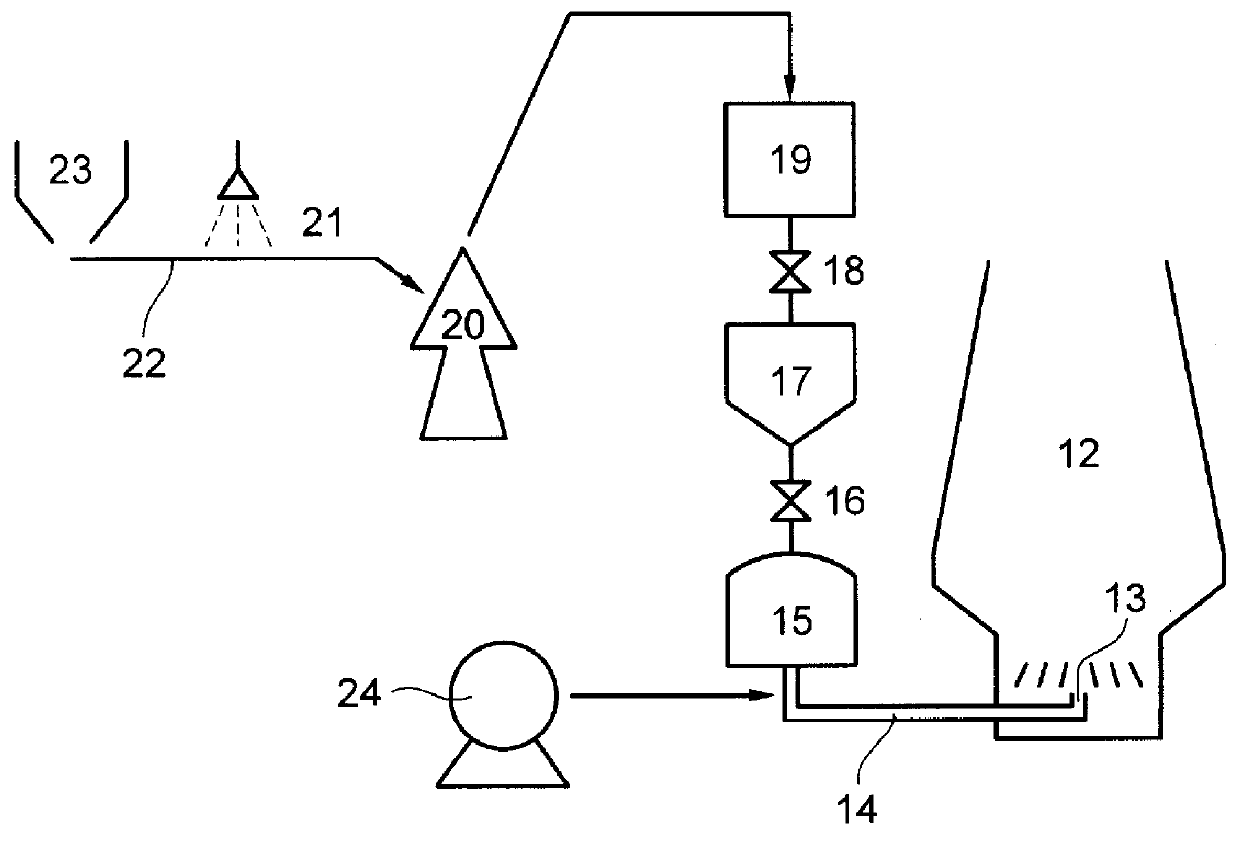

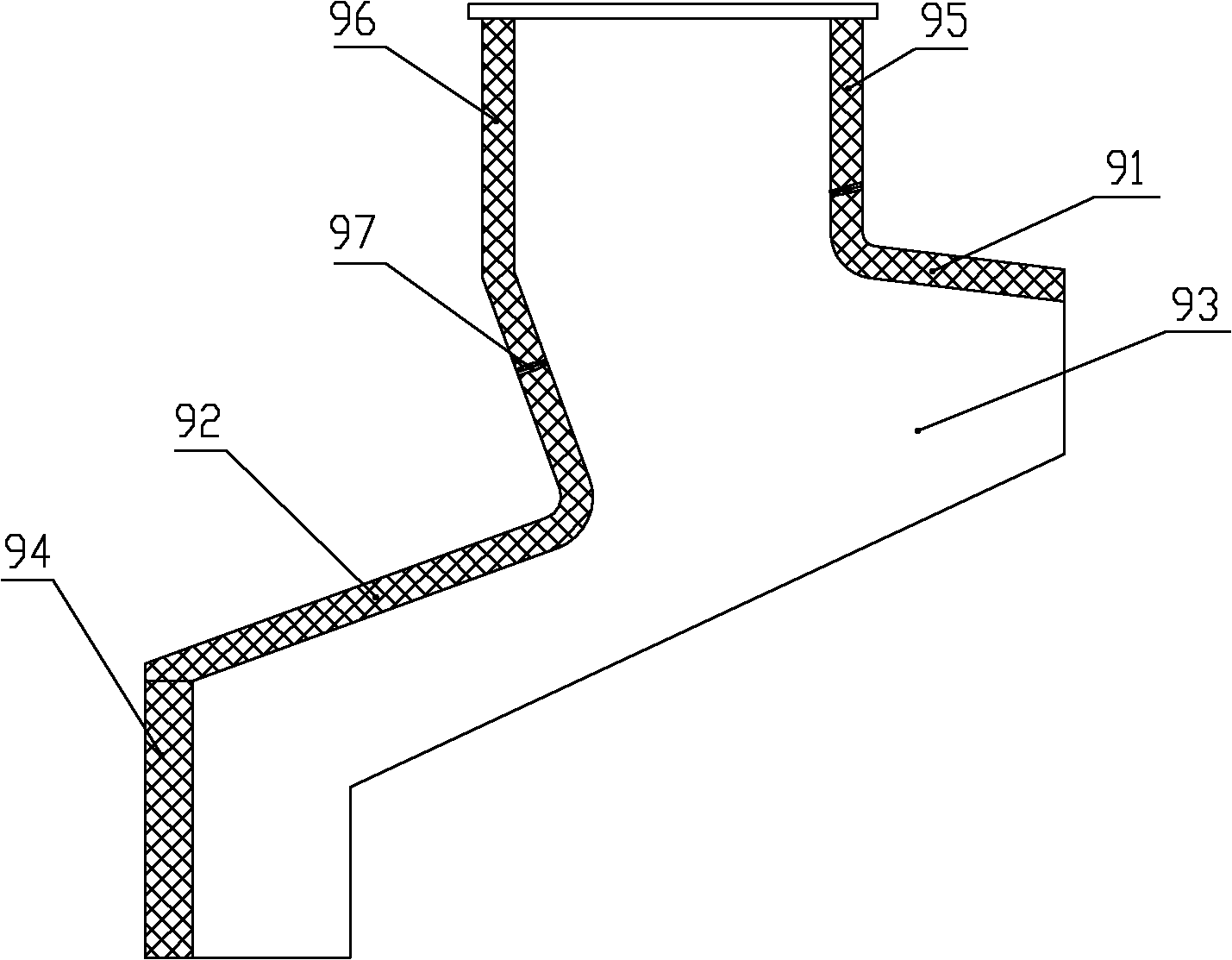

Clay vibrating bunker

InactiveCN101148215AGuarantee unimpededPrevent bridgingLarge containersLoading/unloadingBunkerEngineering

The clay vibrating bin includes one upper cone, one lower cone, one vibrating unit set in between the upper cone and the lower cone. The upper cone has one air gun with nozzle in the inner wall, and the lower cone has one hand valve and one electric valve in the lower part. The clay vibrating bin has fluent and homogeneous material feeding and easy cleaning.

Owner:JIANGSU WANLI MACHINERY

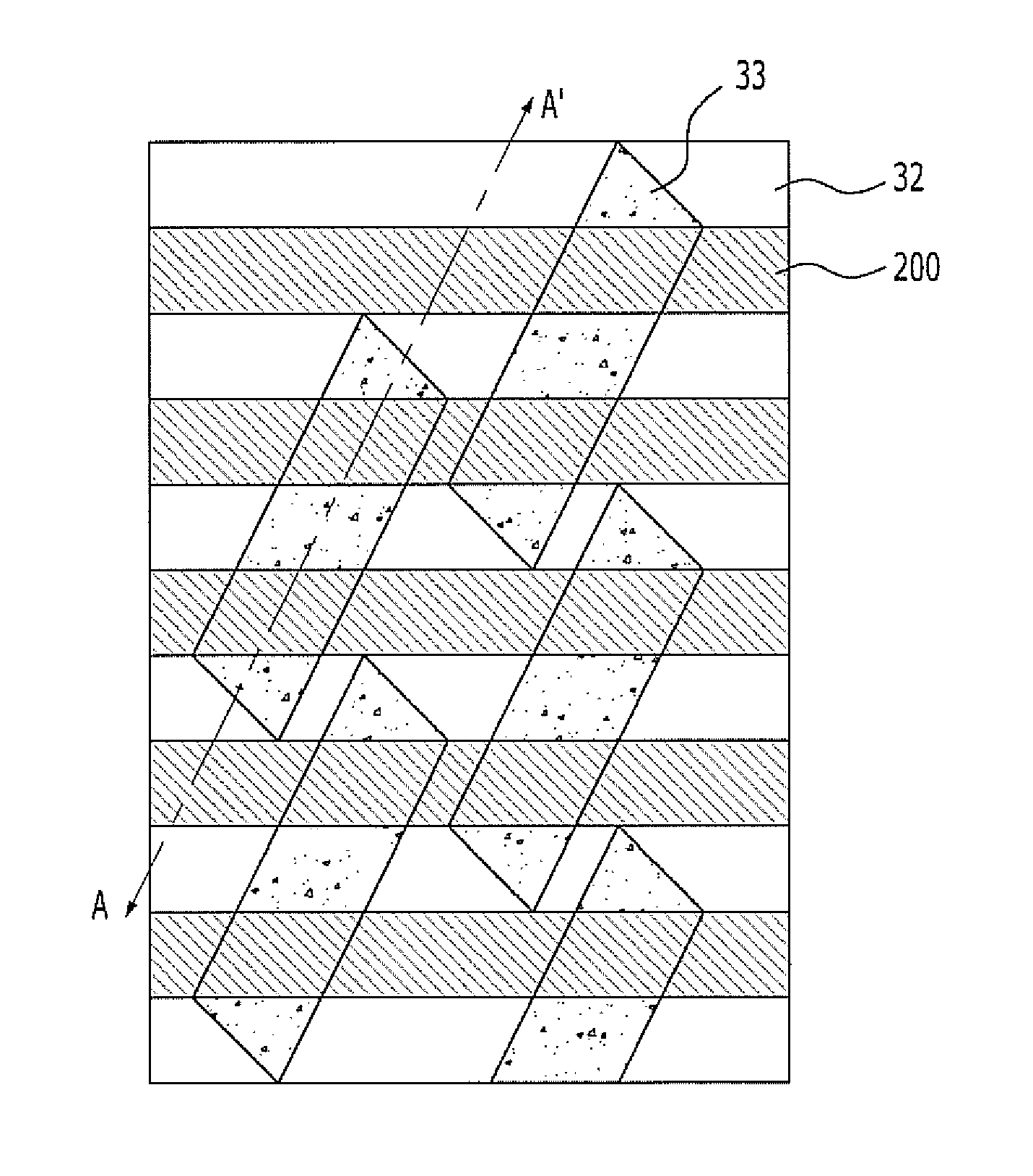

Semiconductor device and method for fabricating the same

ActiveUS20120001346A1Prevent bridgingSemiconductor/solid-state device detailsSolid-state devicesBit lineContact pad

A semiconductor device includes a word line, a bit line crossing the word line, an active region arranged in an oblique direction at the word line and the bit line, and a contact pad contacting the active region, where the contact pad extends in the oblique direction.

Owner:SK HYNIX INC

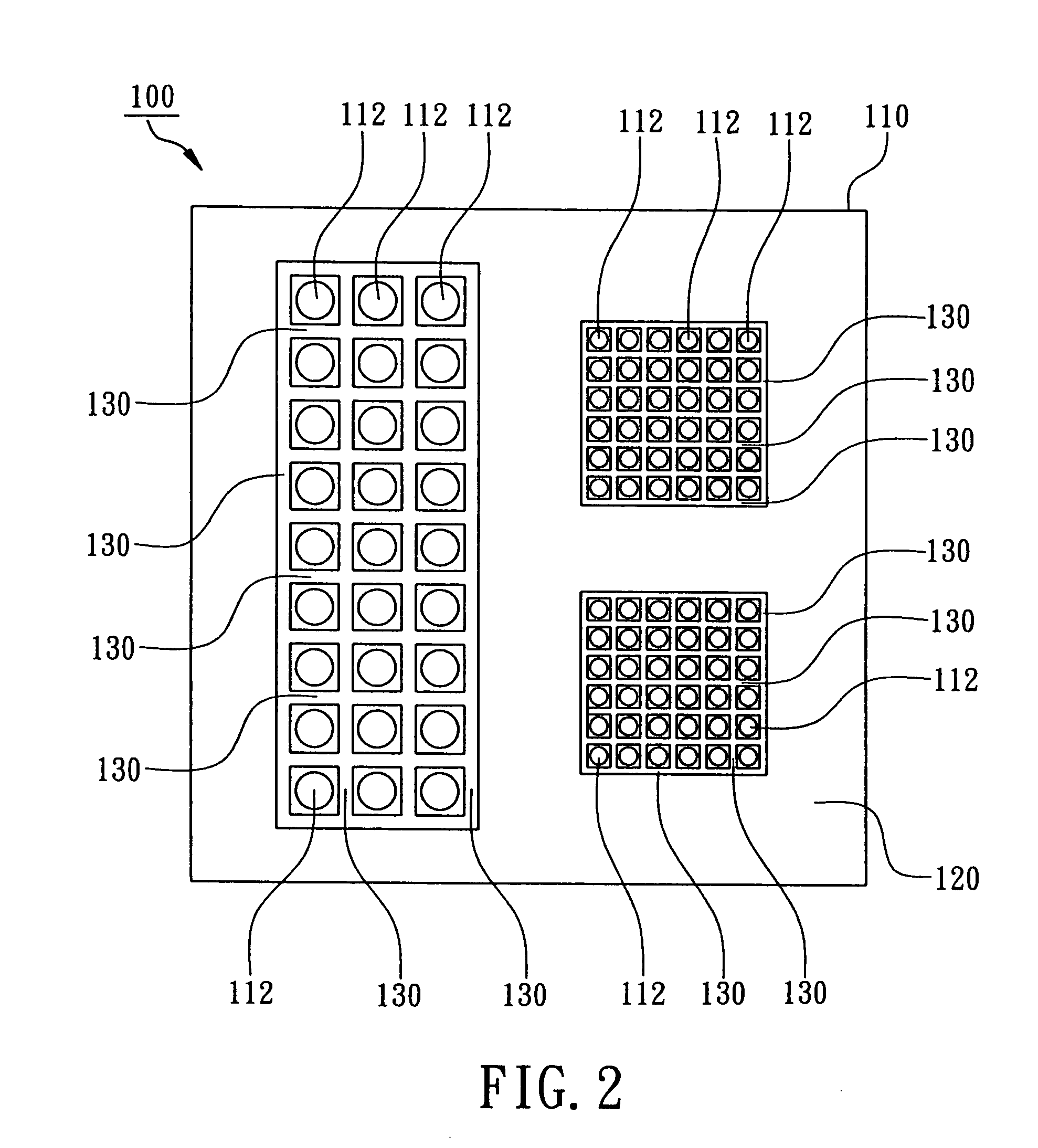

Mesh shaped dam mounted on a substrate

ActiveUS7180181B2Prevent bridgingPrinted circuit assemblingSecond resist patternSolder maskContact pad

A substrate is provided for carrying at least a semiconductor device. The substrate mainly includes a carrier body, a plurality of contact pads, a solder mask and a plurality of dams of a mesh. The contact pads are disposed on a surface of the carrier body and each has a bonding surface exposed out of the solder mask for connecting with the external terminals of the semiconductor device. The dams are disposed above the surface of the carrier body. The dams protrude from and located between the bonding surfaces of the contact pads to prevent solder paste, flux or the external terminals of the semiconductor device from bridging.

Owner:ADVANCED SEMICON ENG INC

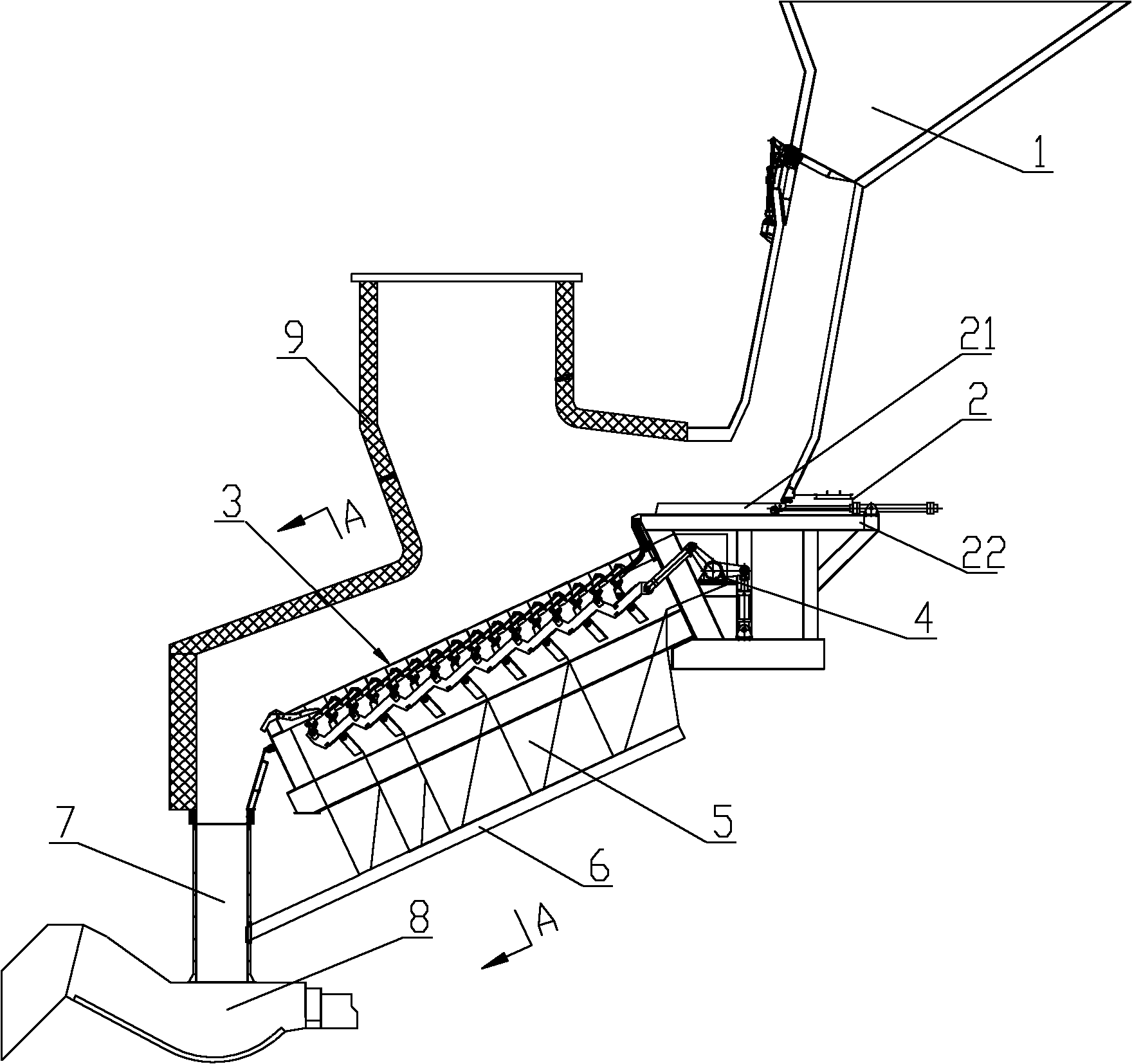

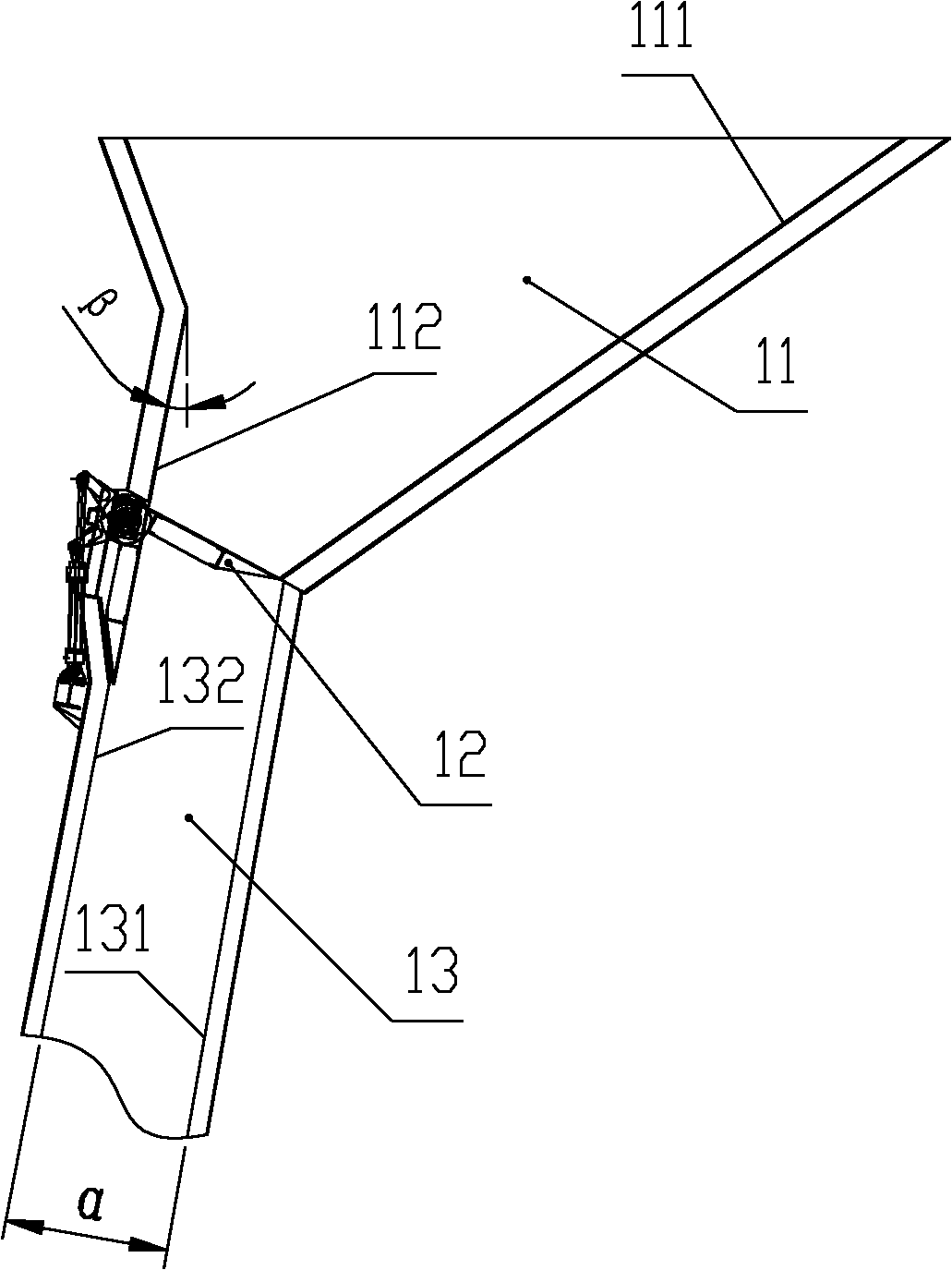

Reciprocating inverse-pushing type garbage incinerator

The invention discloses a reciprocating inverse-pushing type garbage incinerator which comprises a hearth wall body, a hopper device arranged on an upper port of the hearth wall body, a residue falling groove arranged at a lower port of the hearth wall body and a residue discharging machine positioned below the residue falling groove, wherein a reciprocating inverse-pushing type fire grate is arranged in the hearth wall body, a primary air chamber and an ash discharging device are sequentially arranged below the fire grate, a closed rotating shaft fire grate drive device is arranged below thefeeding device; the fire grate comprises a fire grate frame, a plurality of fixed beams used for supporting and fixing fire grate sheets, and a plurality of movable beams used for driving movable fire grate sheets; the fixed beams and the movable beams are arranged on the fire grate frame at intervals laterally, the corresponding fixed fire grate sheets and the movable fire grate sheets are arranged and overlapped at intervals laterally, the fire grate is inclined downwards along the advancing direction of rubbish, the fire grate is divided into 2-6 lines of fire grate units along the direction vertical to the advancing direction of rubbish, and the movable beam of each line of fire grate units is driven by the corresponding primary closed rotating shaft drive device through a movable beam frame. The reciprocating inverse-pushing type garbage incinerator ensures that the rubbish can be effectively conveyed, stirred, loosened, crushed and fully combusted in a process of incinerating the rubbish, and has the advantages of good sealing property, and no air and ash leakage and dropping and permeating phenomena.

Owner:SHENZHEN DINGZHU ENVIRONMENTAL PROTECTION TECH

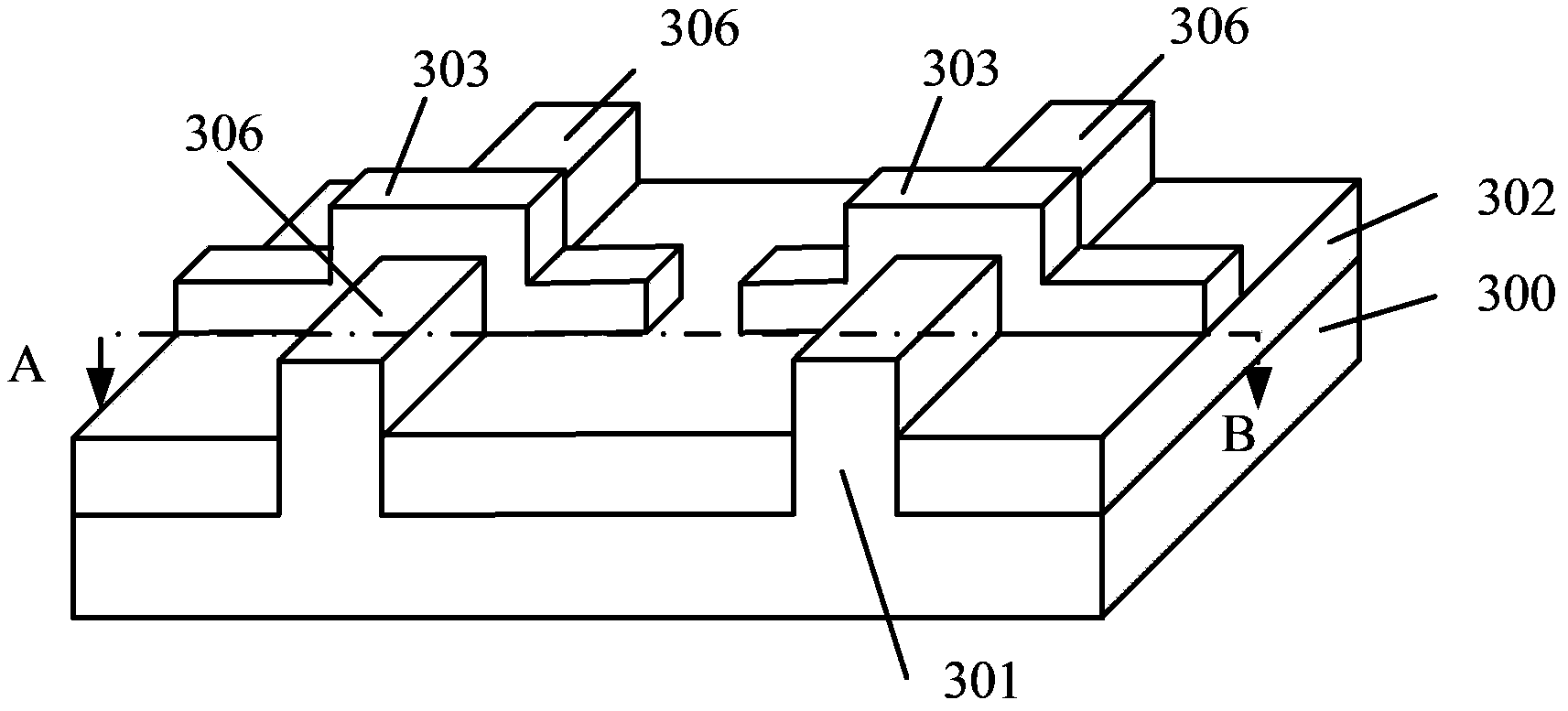

Forming method of fin field effect transistor

ActiveCN104078355AIncrease spacingPrevent bridgingSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringField-effect transistor

The invention discloses a forming method of a fin field effect transistor. The forming method comprises the steps of providing a semiconductor substrate which is provided with at least two adjacent convex fin parts, a grid electrode structure crossing top and side wall surfaces of the fin parts and source / drain areas located in the fin parts on the two sides of the grid electrode structure, performing selective epitaxy on the source / drain areas to form semiconductor layers which cover partial side wall and top surfaces of the fin parts, forming a sacrificial layer covering the surfaces of the semiconductor substrate, the fin parts and the semiconductor layers, etching back the sacrificial layer, exposing partial surfaces of the semiconductor layers, forming mask layers on the exposed surfaces of the semiconductor layers, and etching to remove partial edges of the sacrificial layer and the semiconductor layers by taking the mask layers as masks, wherein the semiconductor layers located above the tops of the fin parts are provided with bulges, and the semiconductor layers located on the two sides of the fin parts are provided with edges. The forming method can effectively avoid bridging of embedded sources / drains of the connected fin parts, and can improve the stability of a device.

Owner:SEMICON MFG INT (SHANGHAI) CORP

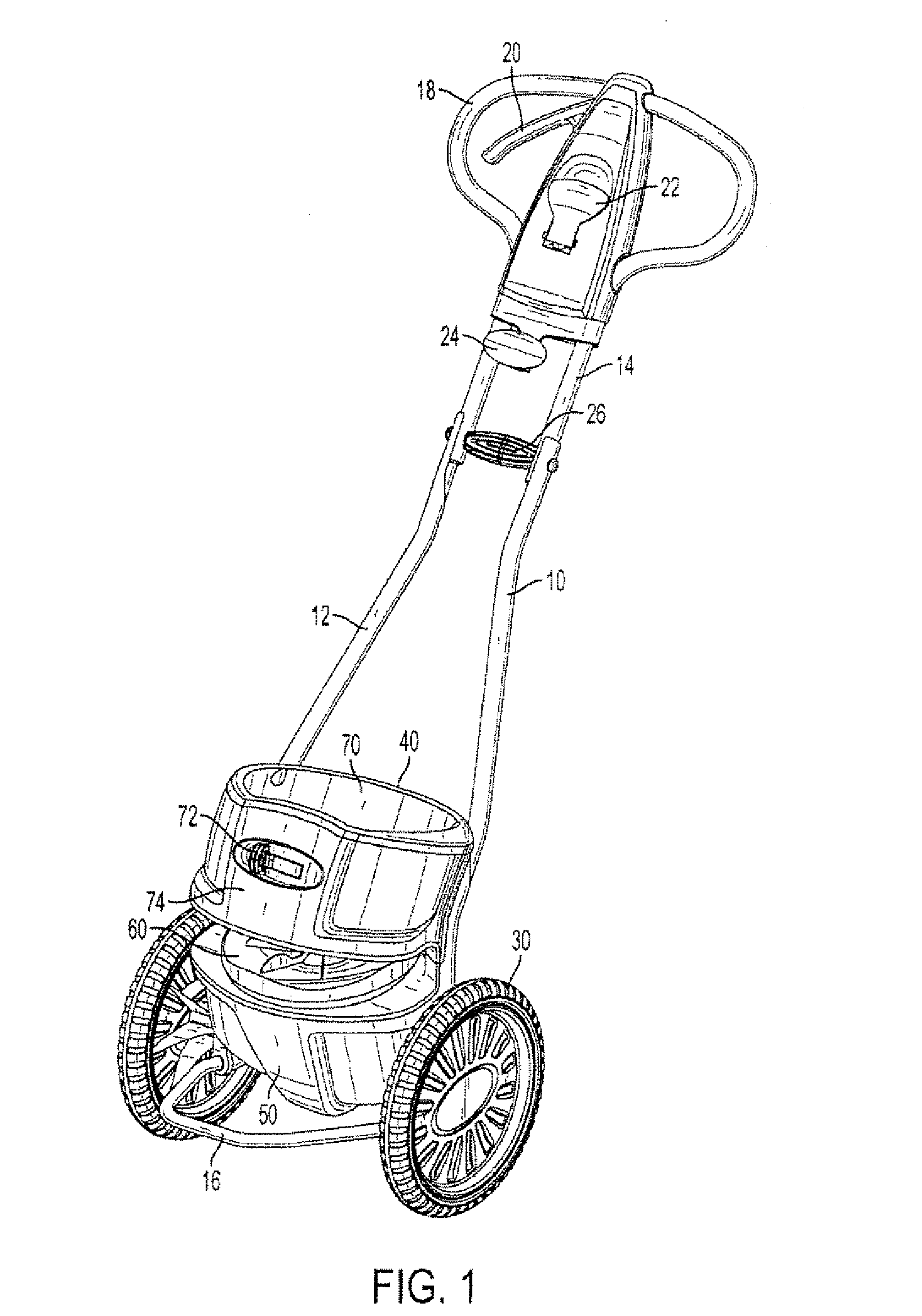

Cartridge spreader system

ActiveUS20090277979A1Promote activationEasy to moveWatering devicesFertiliser distributersEngineeringBiological activation

The cartridge spreader system includes a mobile cartridge spreader with a cartridge station configured to engage a cartridge and includes a locking controller for locking the cartridge securely into the cartridge station. The cartridge station includes an activator mechanism for activating and deactivating an engaged cartridge. The cartridge spreader includes an activation controller for activating and deactivating the cartridge. Activation of the cartridge allows the granular product contained in the cartridge to flow out of the container, through a granular chute on the cartridge station, and onto a granular product launcher which launches or impels the granular product over terrain or other surface. When the cartridge is deactivated, the flow path is sealed stopping the flow of granular product. The cartridge itself includes a fitment that engages with the cartridge station. The cartridge fitment includes an appropriately sized metering gate.

Owner:OMS INVESTMENTS INC

Semiconductor package with encapsulated passive component

ActiveUS7268437B2Prevent bridgingEasy to fillPrinted circuit assemblingFinal product manufactureSolder maskSemiconductor package

A semiconductor package with an encapsulated passive component mainly includes at least a substrate having a surface, a passive component and a molding compound. A plurality of SMD pads (Solder Mask Defined pads) and a solder mask are formed on the surface of the substrate. Each SMD pad has an exposed sidewall portion exposed out of the solder mask. A blocking bar is formed between the exposed sidewall portions of the SMD pads. There is at least a flowing channel formed between the blocking bar and the exposed sidewall portions. The passive component is mounted on the surface of the substrate and connected to the SMD pads, the flowing channel is located under the passive component. It is advantageous to fill the molding compound into the flowing channel.

Owner:ADVANCED SEMICON ENG INC

Continuous polyamide extraction process

A process for continuous extraction of polyamide particles in an essentially vertical extraction column using an aqueous extractant comprises using an extraction column that is divided into two zones and performing an extraction with a recirculating 15-40% strength by weight aqueous epsi-caprolactam solution in the first zone and then with countercurrent water at a from 5 to 40° C. lower temperature in the second zone. The process provides for economical extraction of polyamides with a low level of monomers and oligomers.

Owner:BASF AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com