Belt type filter press

A belt filter press, frame technology, applied in filtration separation, moving filter element filters, separation methods, etc., can solve the problem that the solid content of the paper deinking sludge outlet is difficult to exceed 40%, and the filtration pressure cannot be increased. There are problems such as the balance point of filtration resistance and the inability of direct comprehensive utilization to achieve the effect of good dehydration efficiency, improved dehydration efficiency and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

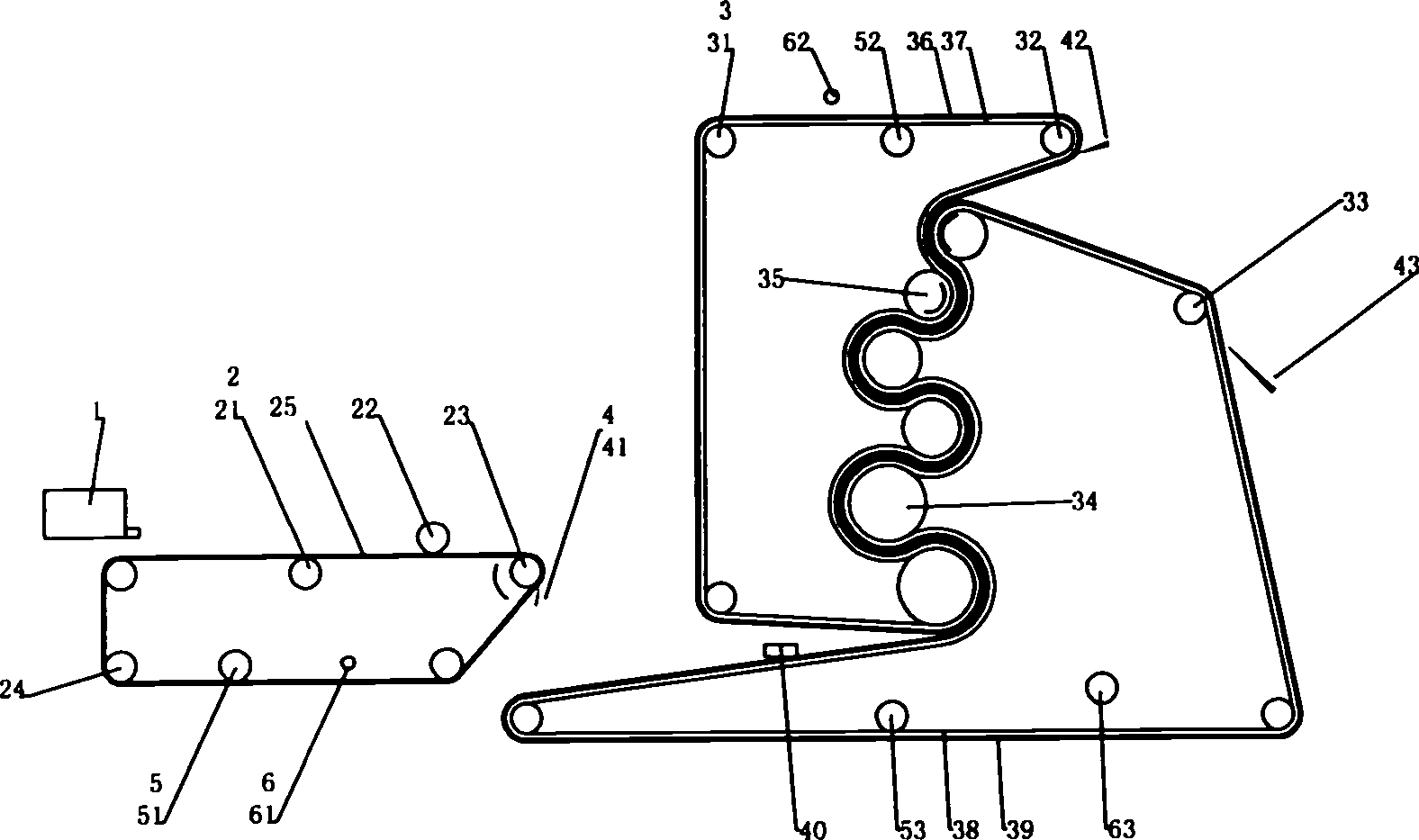

[0037] see figure 1 , the present embodiment belt filter press is provided with gravity and vibration dehydration zone 2, and this filter press mainly is tensioned by frame, driving device, feeding device 1, gravity and vibration dehydration zone 2, squeezing zone 3 and auxiliary device Roller, scraper device 4, water receiving device, deviation correcting device 5, filter belt cleaning device 6. The driving device includes an electric motor and a gearbox. The gravity and vibration dehydration zone 2 is set between the feeding device 1 and the press zone 3, and the scraper device 4 is installed at the junction of the gravity and vibration dehydration zone 2 and the press zone 3, and the separation of the two filter belts of the press zone 3 is also installed. The scraper device 4 and the water receiving device are installed below the gravity and vibration dehydration zone 2 and the filter belt, and the feeding device 1, the gravity and vibration dehydration zone 2 and the pre...

Embodiment 2

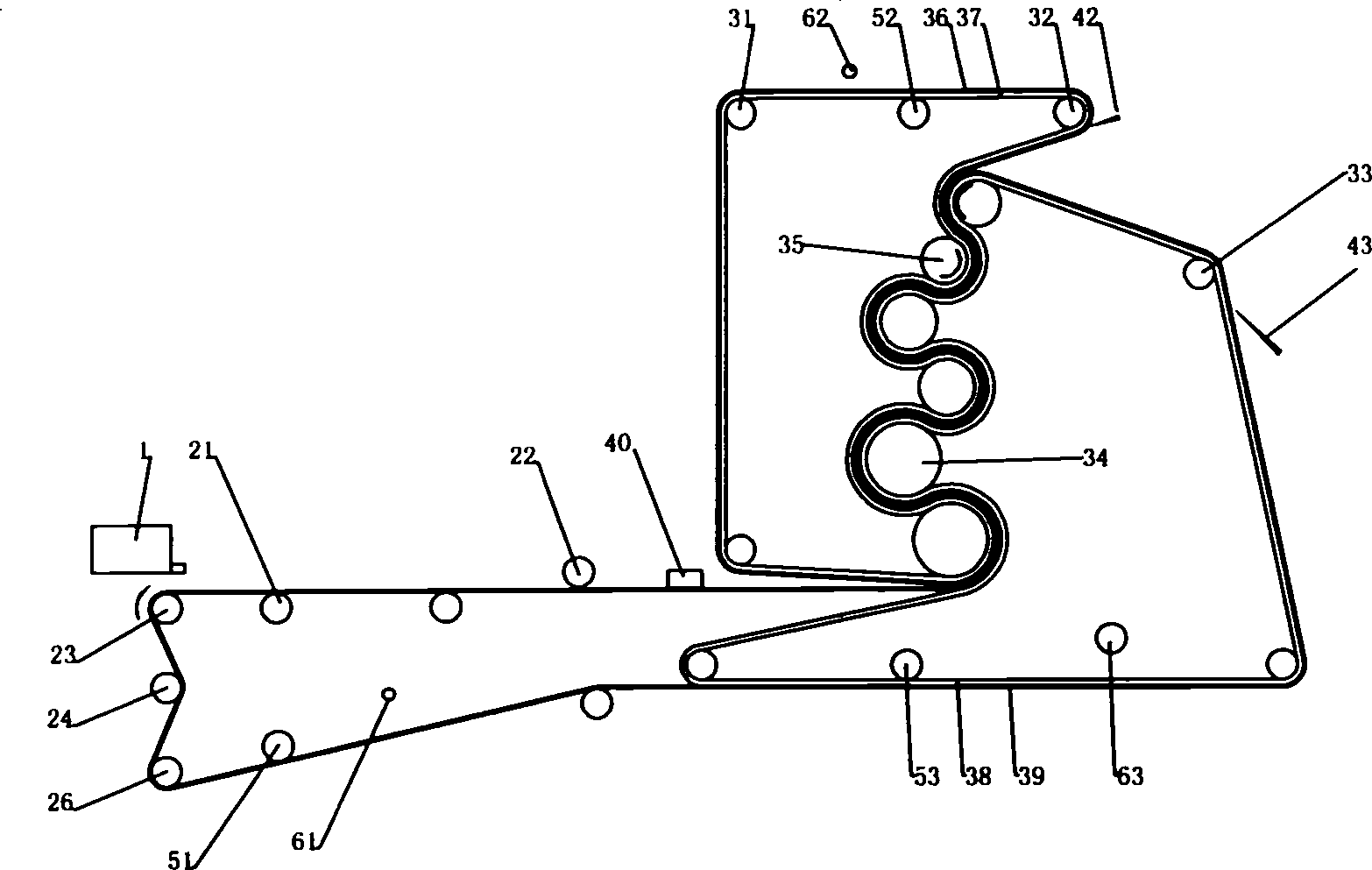

[0043] see figure 2 , in order to reduce the number of sheets of filter belts and reduce the replacement times of filter belts, the gravity of the belt filter press and the filter belt in the vibration dehydration zone 2 and the lower filter belt 39 in the press zone 3 are combined together. The lower filter belt 39 is wrapped around the vibrating roller 21, the driving roller 23, the tension roller 26, two pressure-increasing zone guide filter belt rollers 31, the lower filter belt tension roller 33, and two drive rollers in the gravity and vibration dehydration zone. Roller 35 and four filter press rolls 34, guide filter belt roll 24 is contained in the filter belt outside between drive roll 23 and tension roll 26. In this embodiment, the filter belt in the gravity and vibration dehydration zone 2 and the lower filter belt 39 of the press zone 3 are combined, and the gravity and vibration dehydration zone 2 does not need a material scraper 41 to the squeeze zone 3. Other s...

Embodiment 3

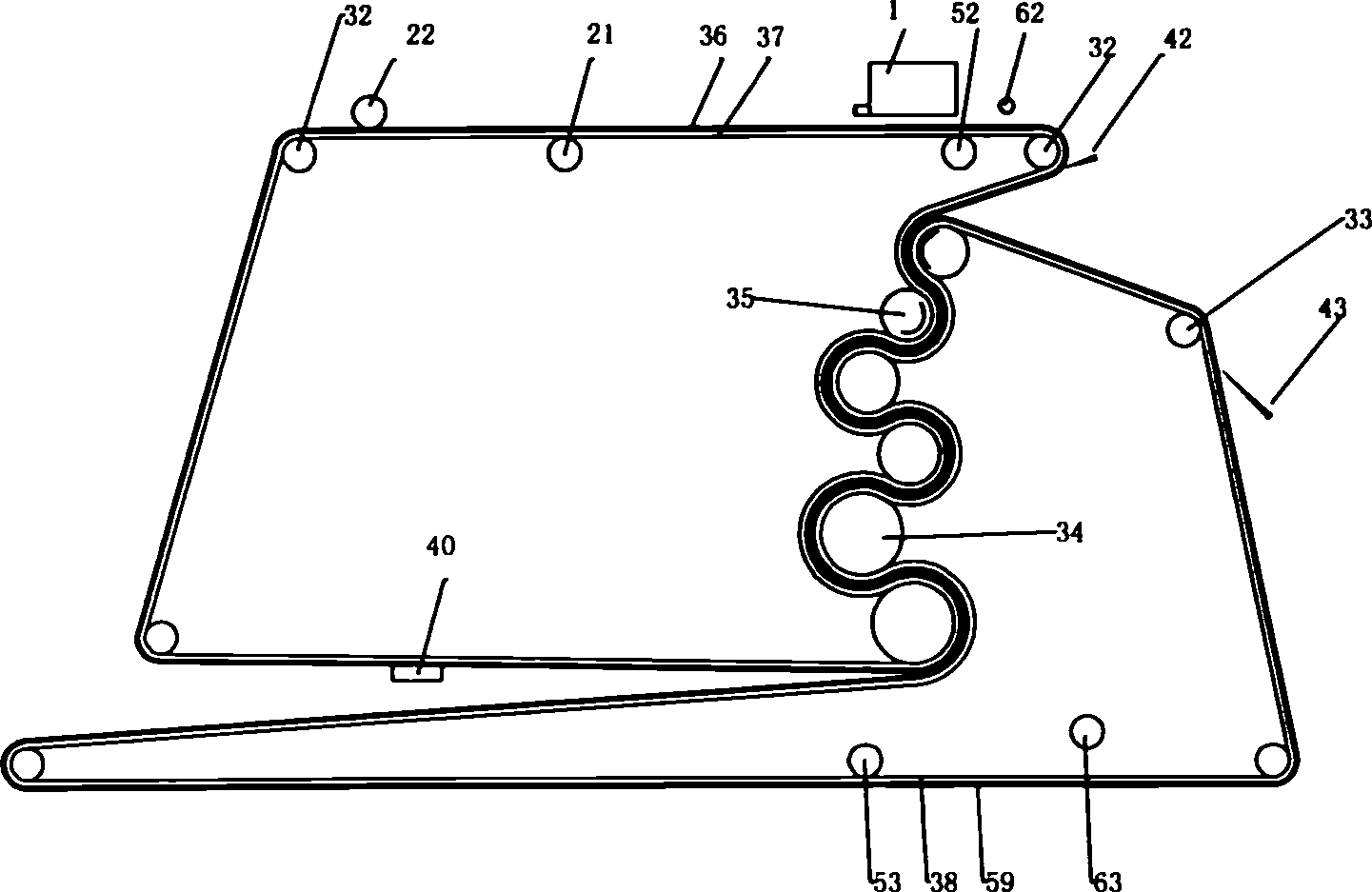

[0046] see image 3 , this embodiment has lengthened the length of upper filter belt 36, utilizes the return filter belt of upper filter belt 36 of press zone 3 as gravity and vibration dehydration zone, under the same situation of dehydration effect, has reduced investment. The upper filter belt 36 of the belt filter press is wrapped around two upper filter belt tension rollers 32, vibrating rollers 21, two drive rollers 35 and four filter press rollers 34. The both sides of the upper filter belt 36 of this embodiment have hemming, and the filter belt flanging device 40 is contained in the both sides of the upper filter belt 36. Before entering the filter press roller 34 in the pressure gradually increasing zone 3, the soft edges on both sides of the upper filter belt 36 are automatically turned downwards with the help of the edger 40 to wrap the dehydrated material on the upper and lower filter belts Between 36 and 39. Other structures and operating procedures of this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com