Patents

Literature

33results about How to "Increase filter pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

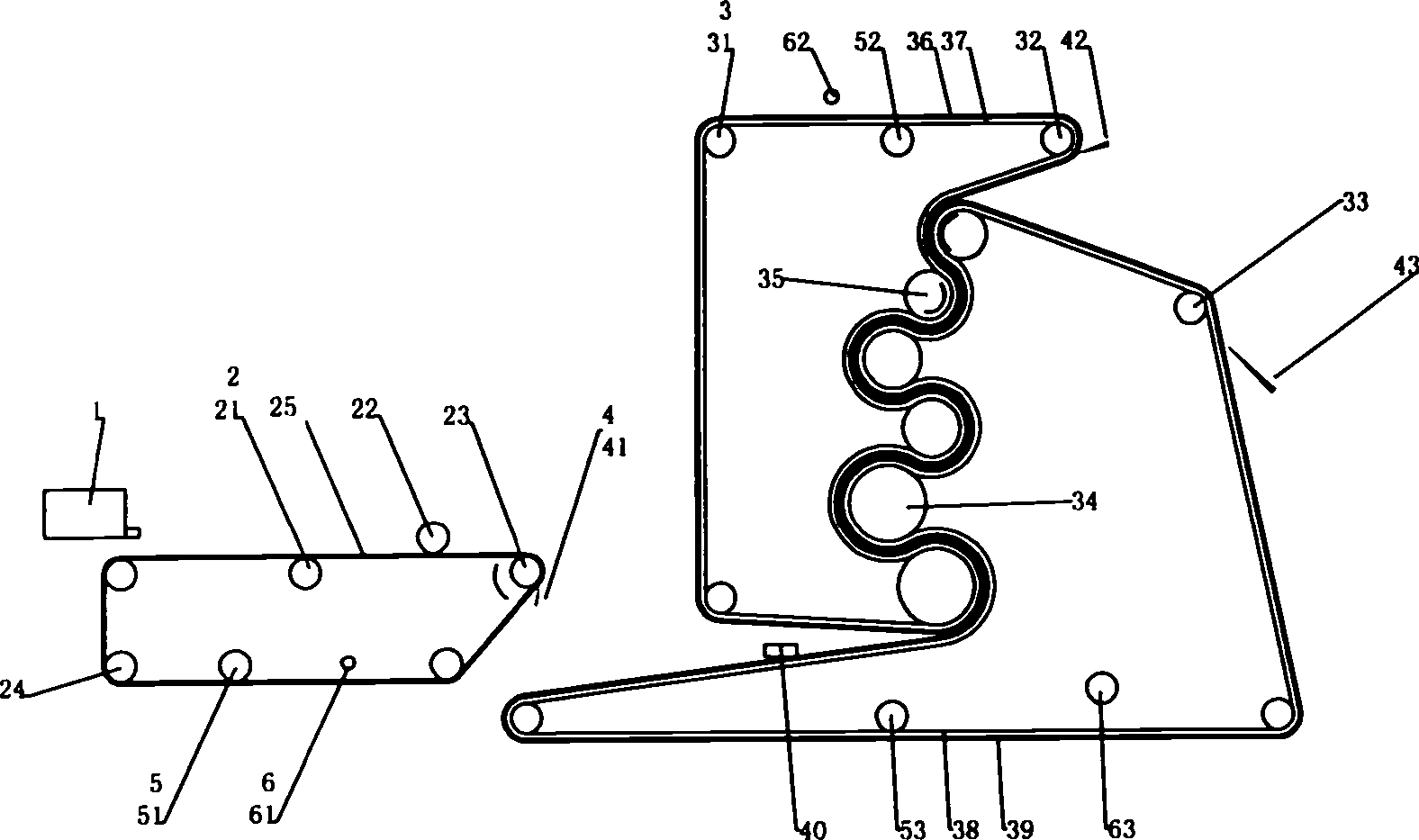

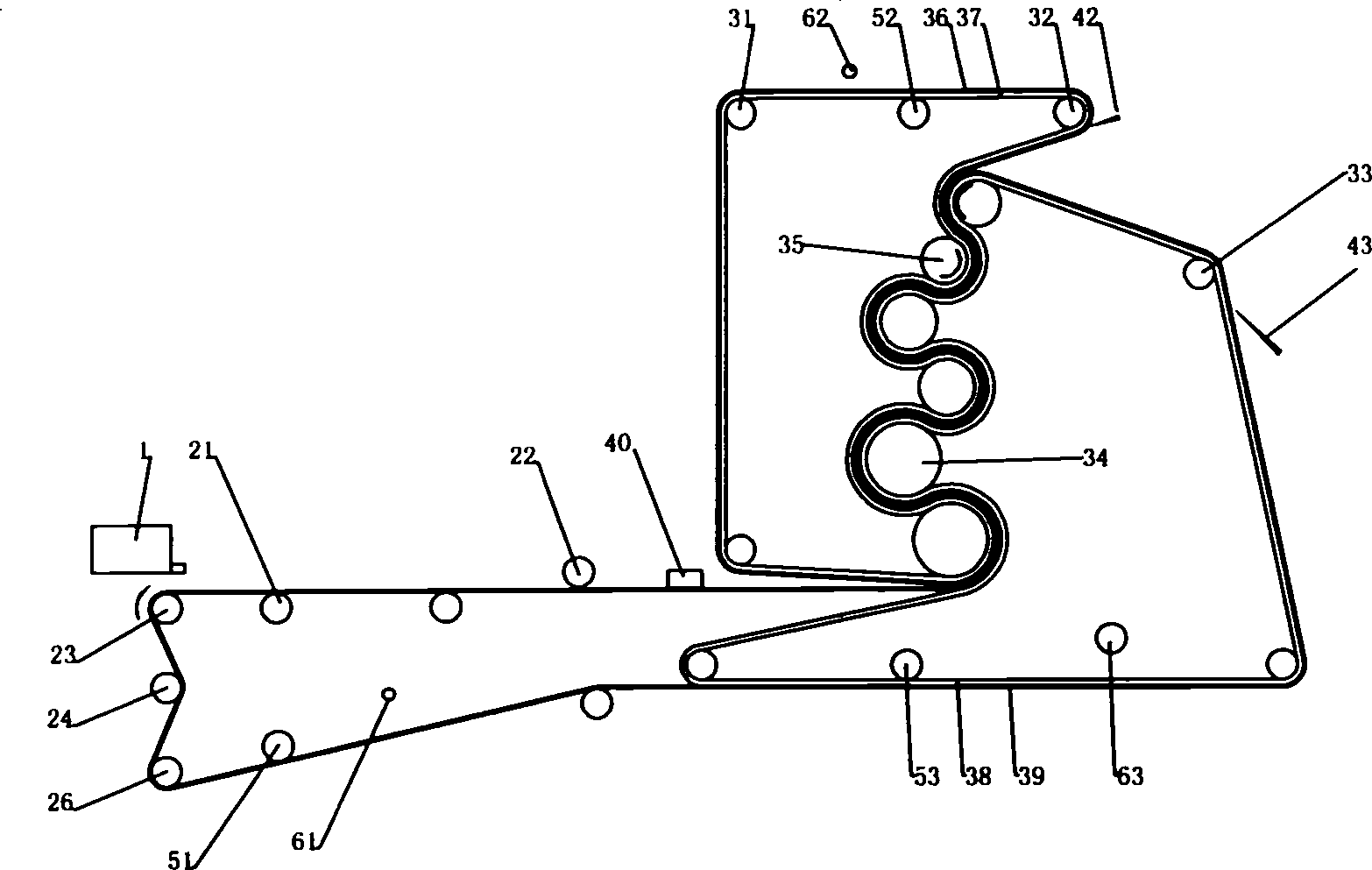

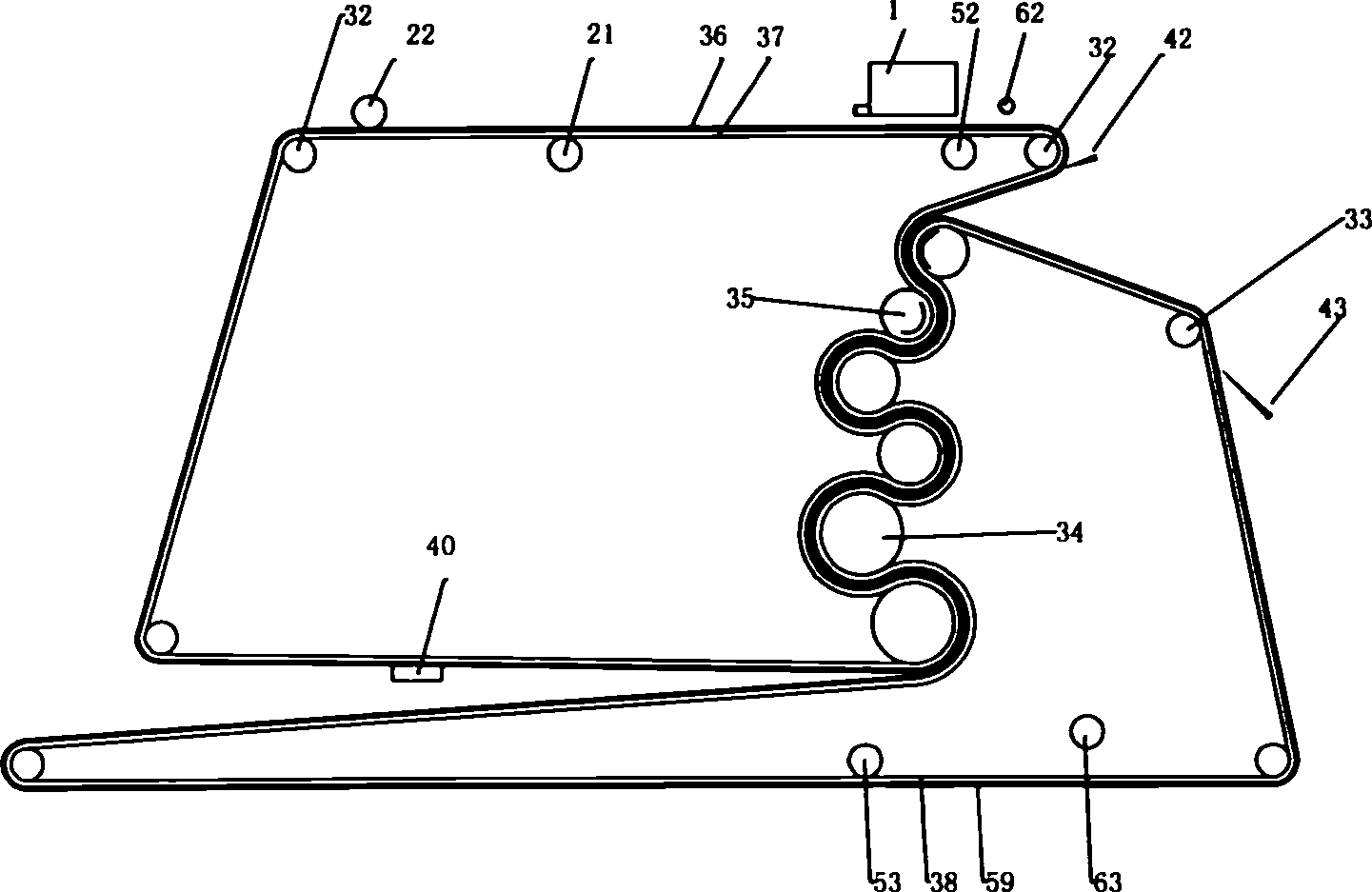

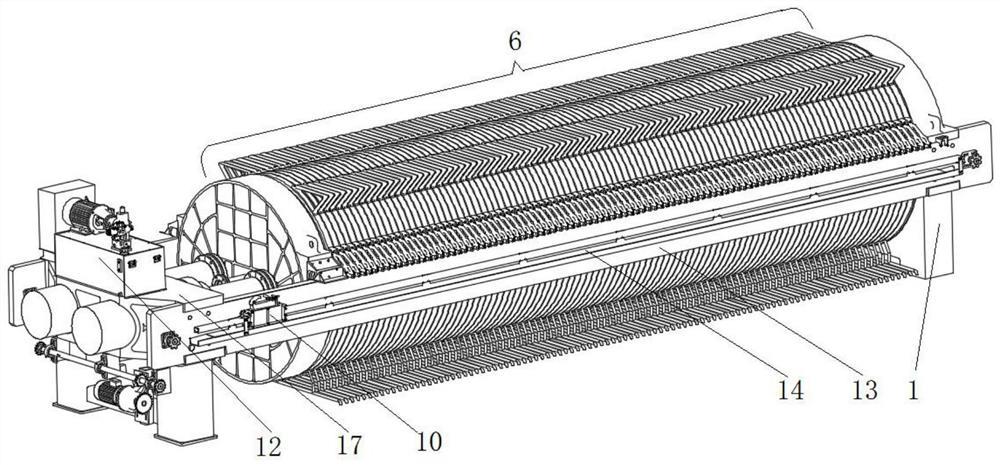

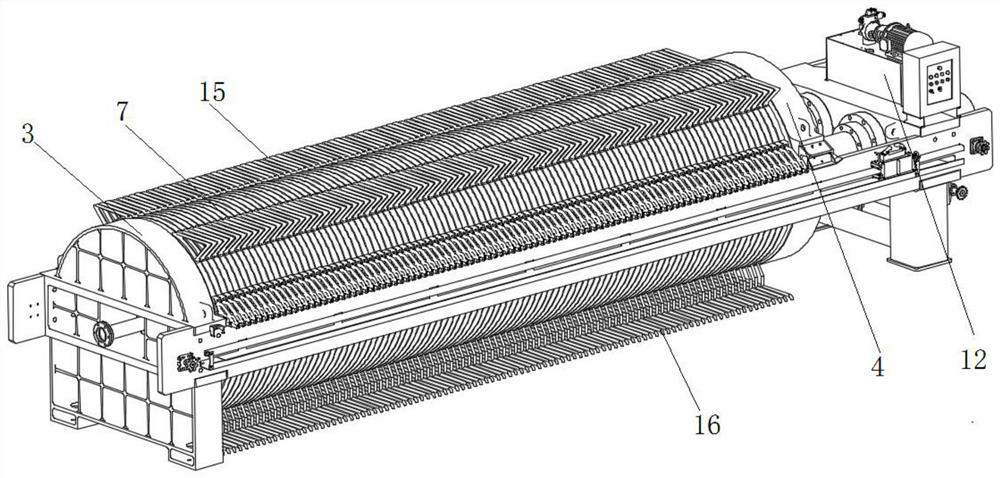

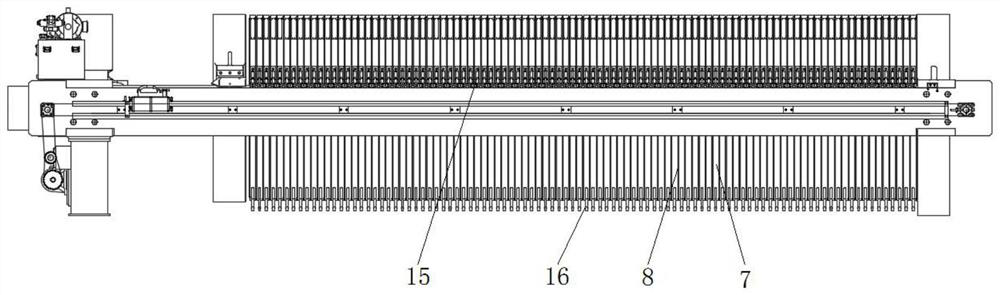

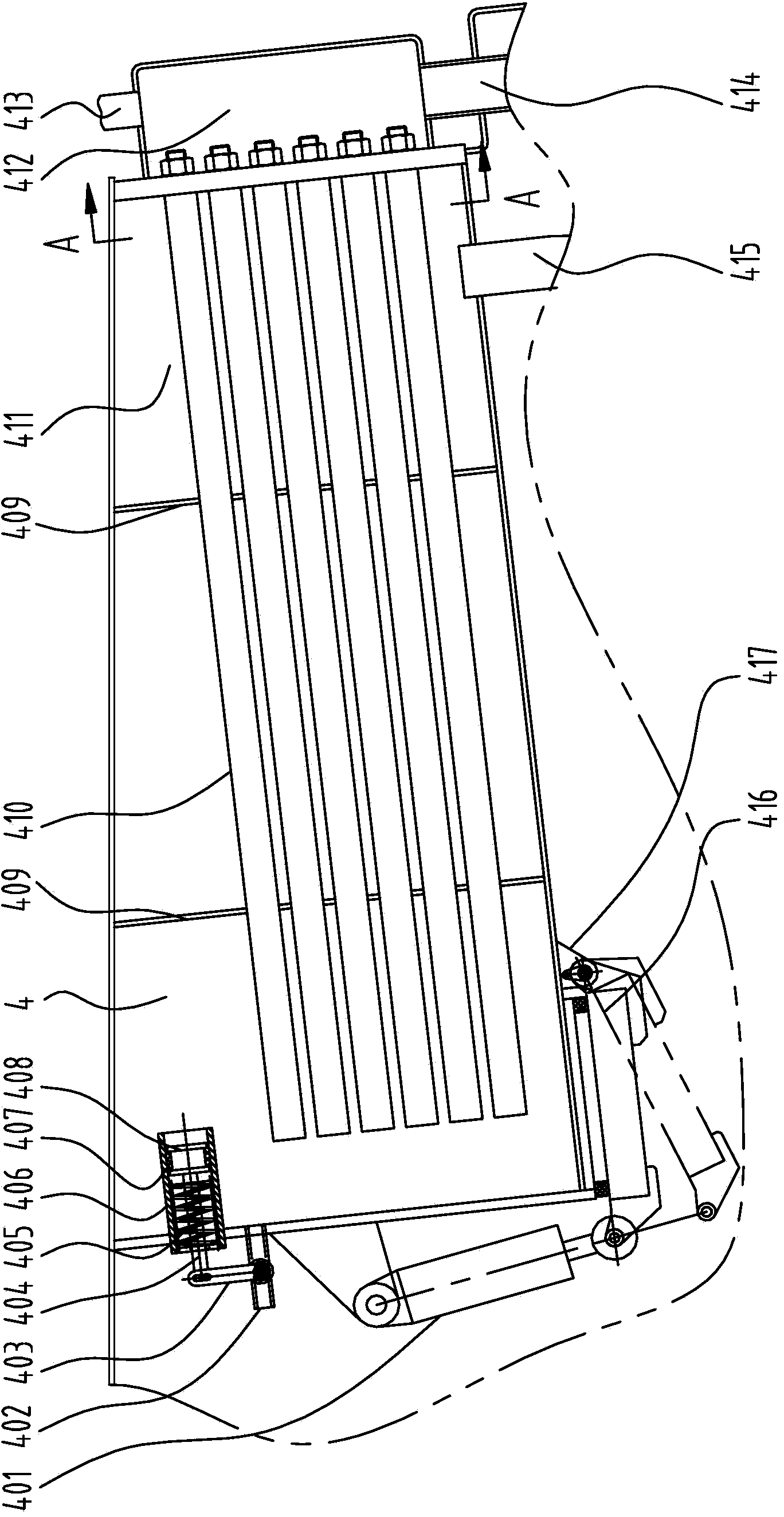

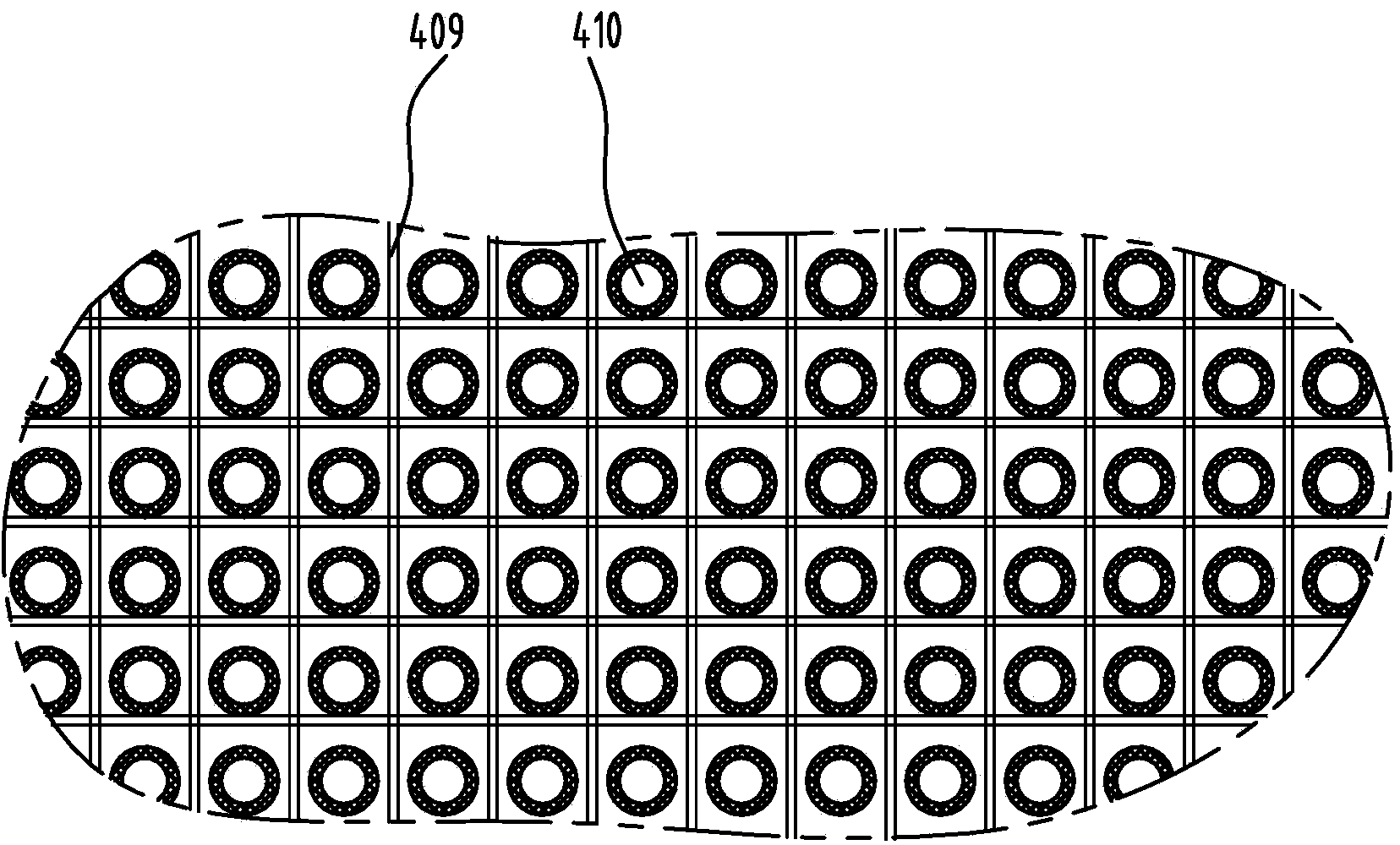

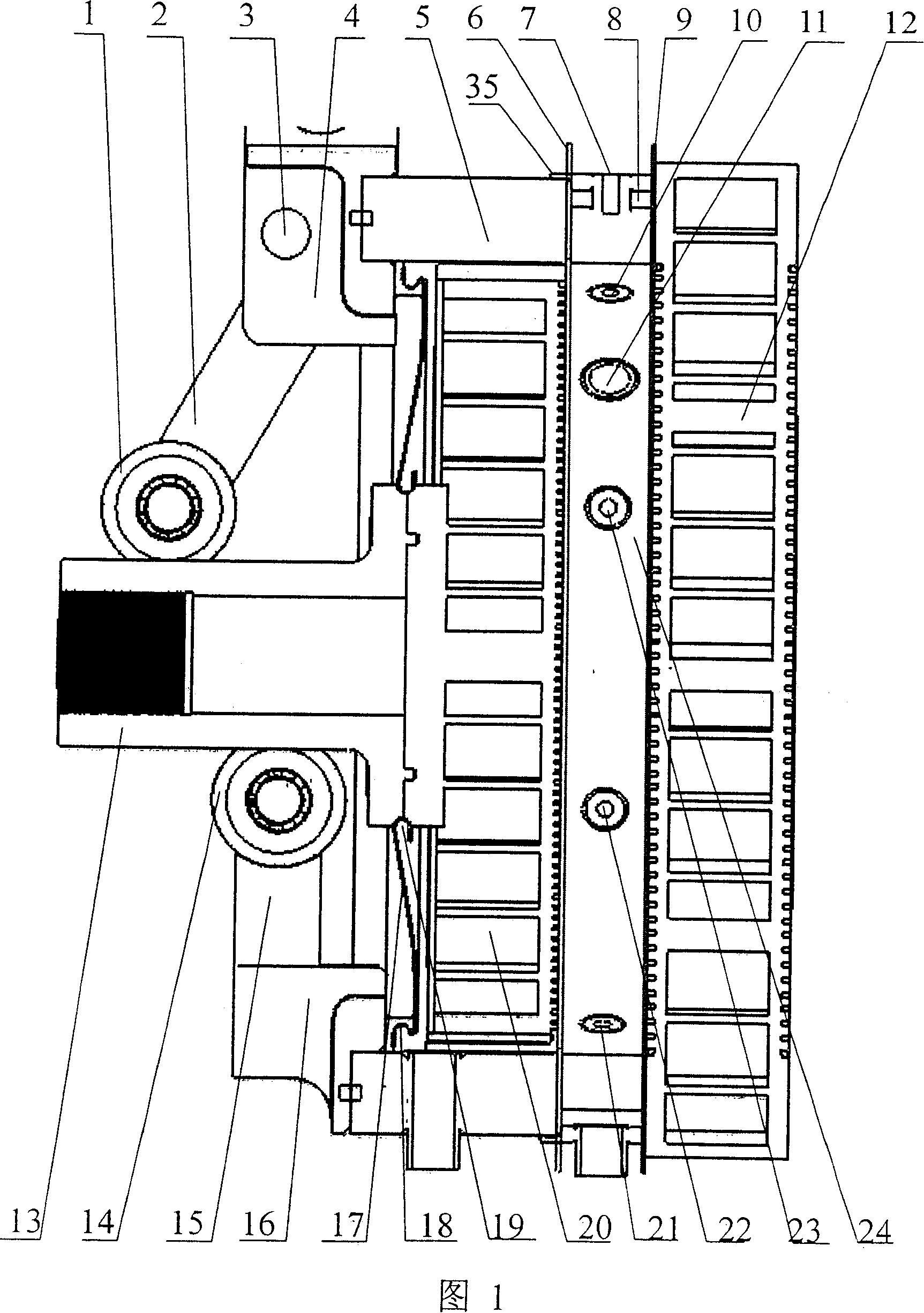

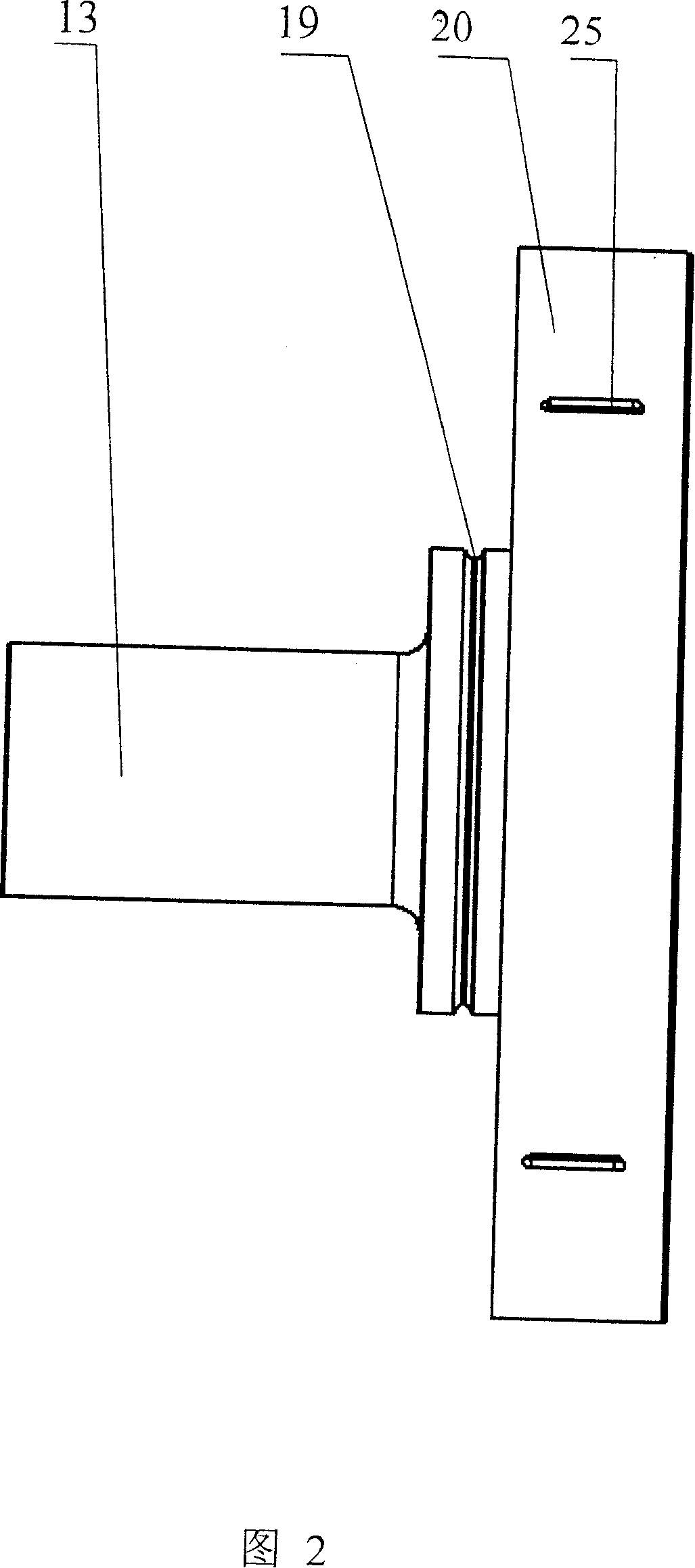

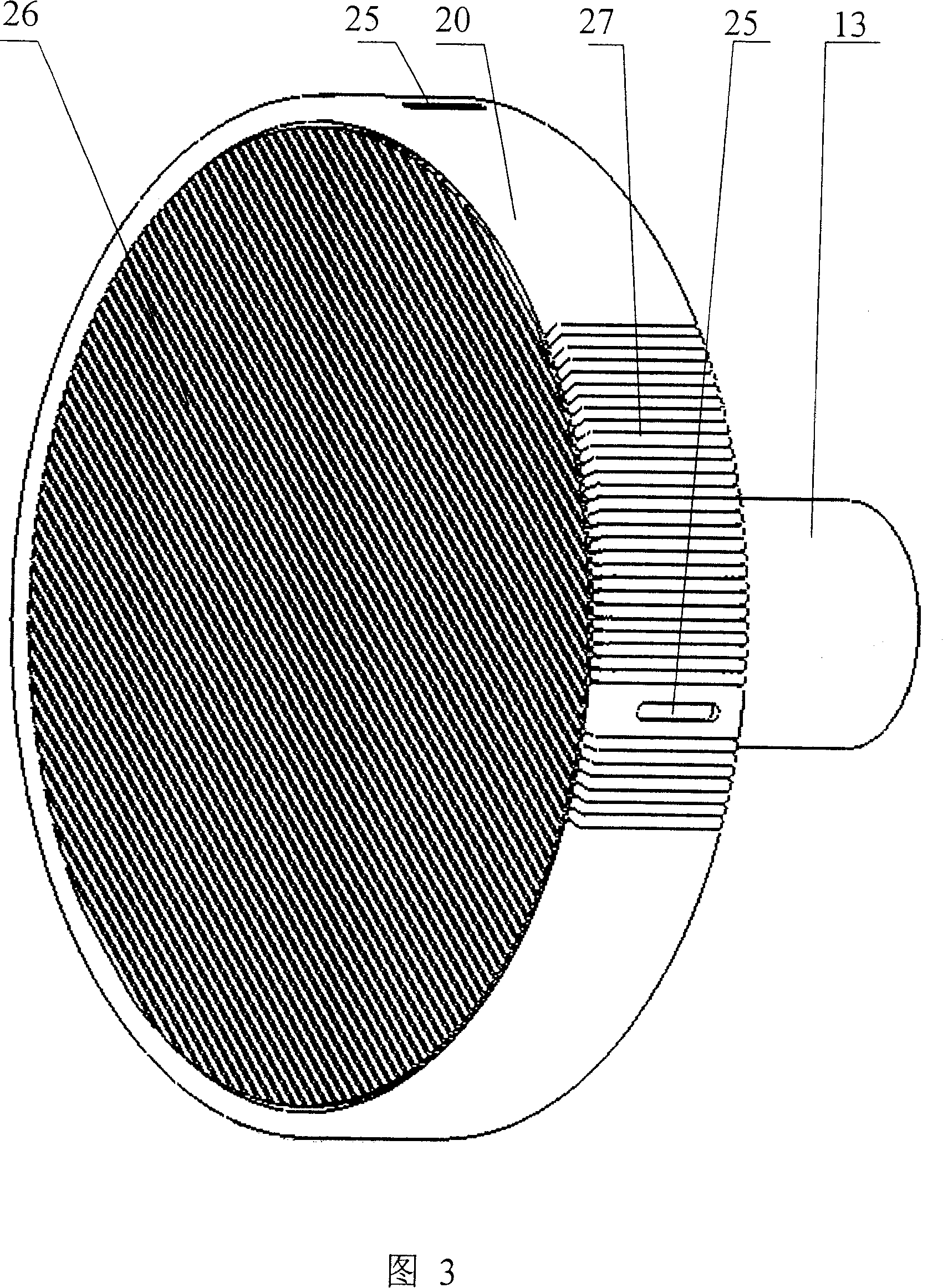

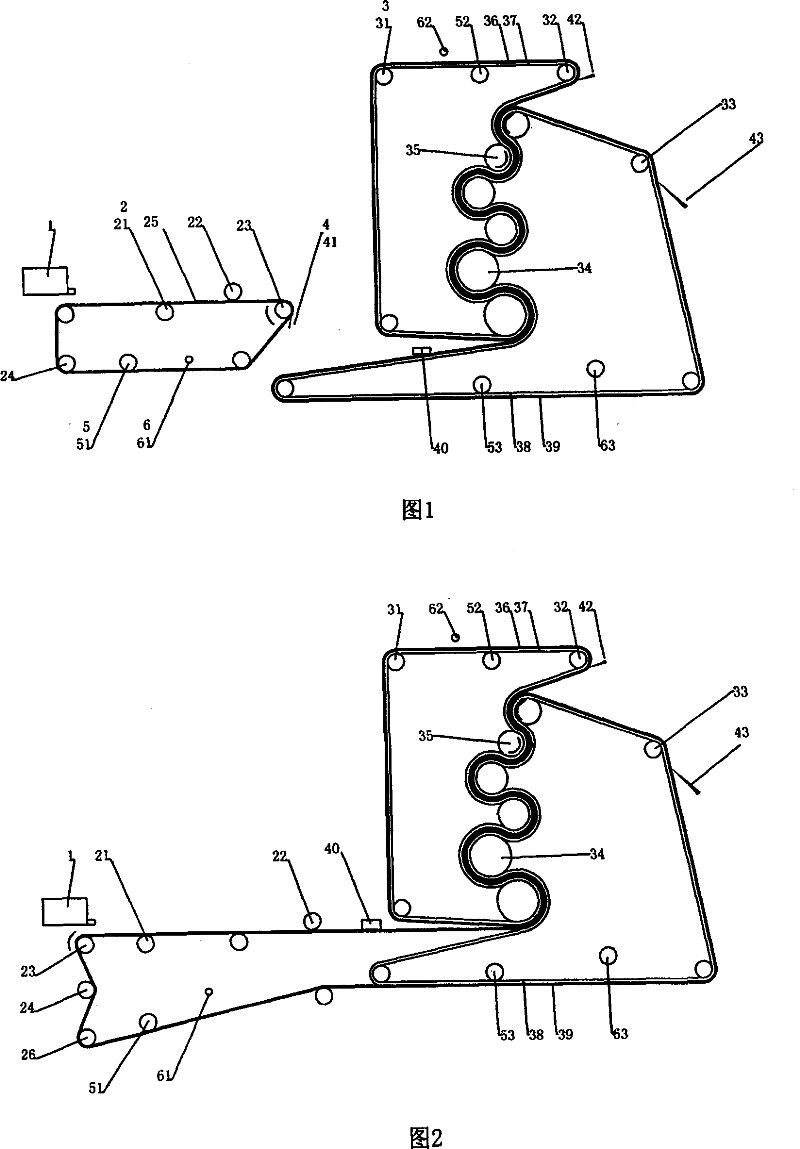

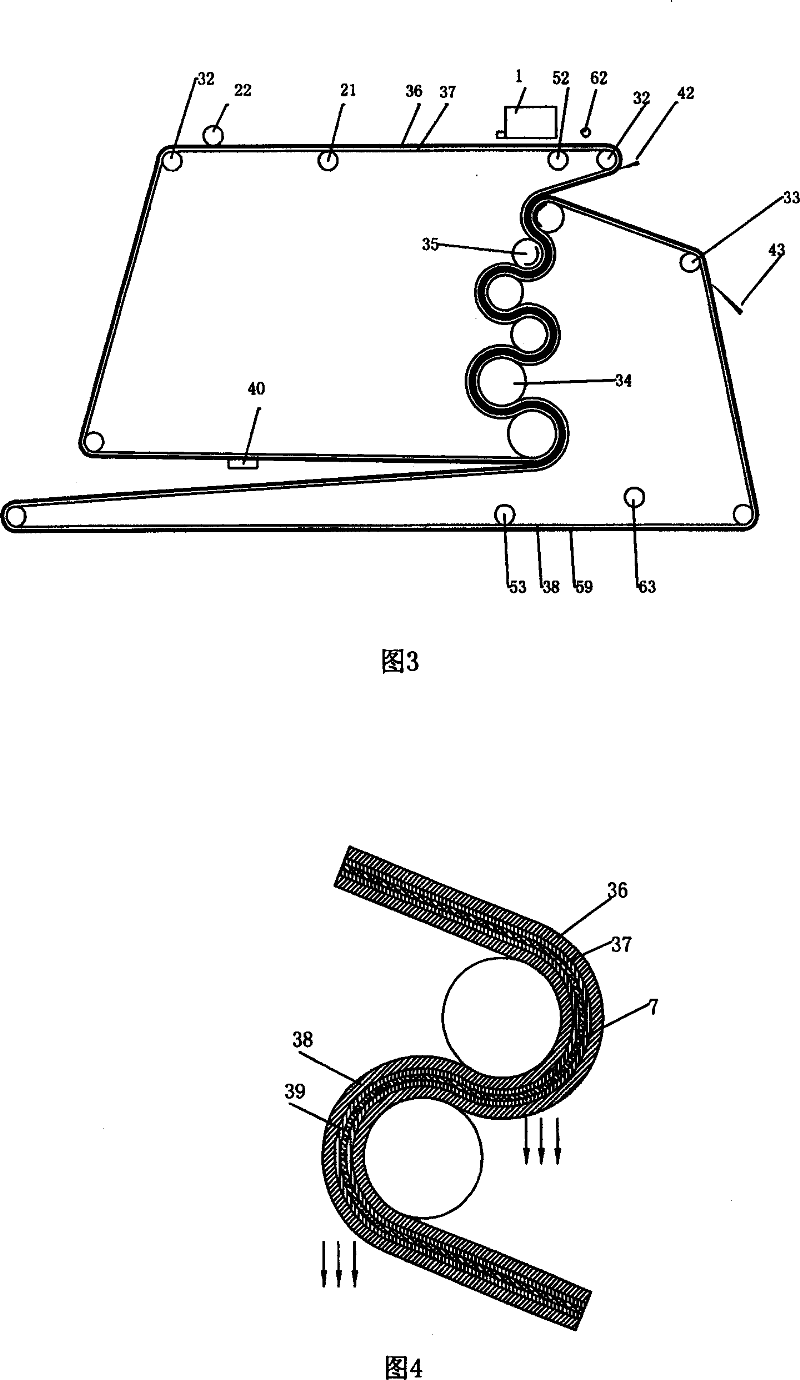

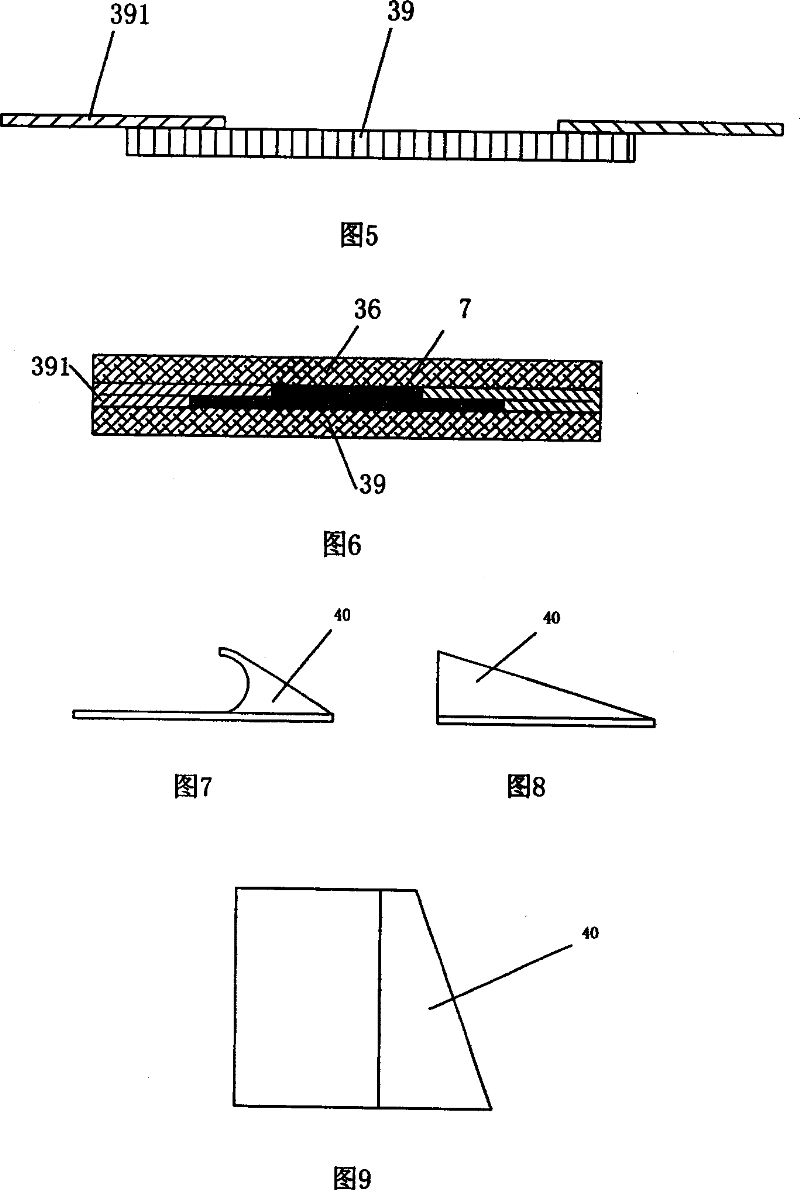

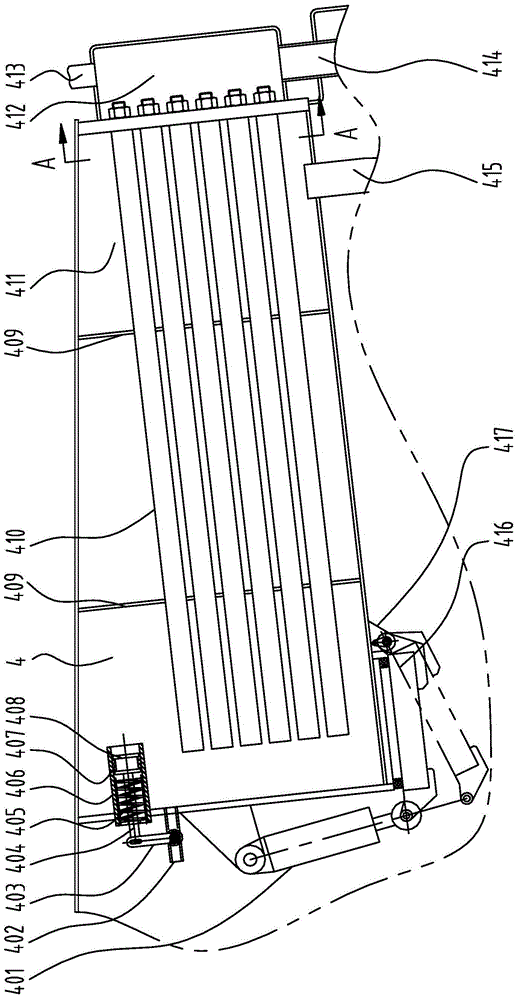

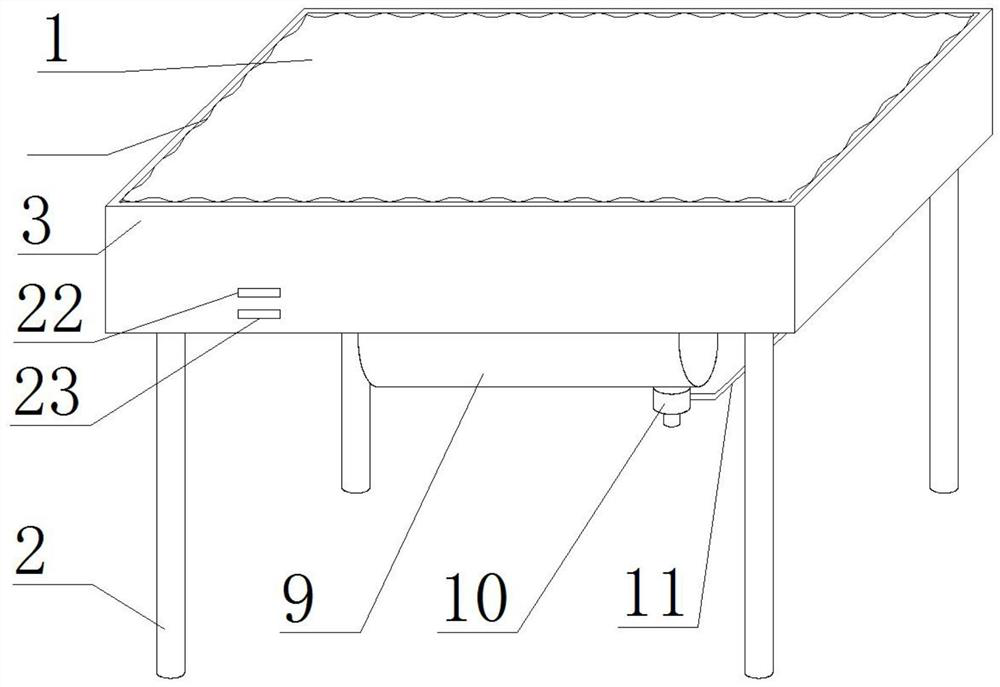

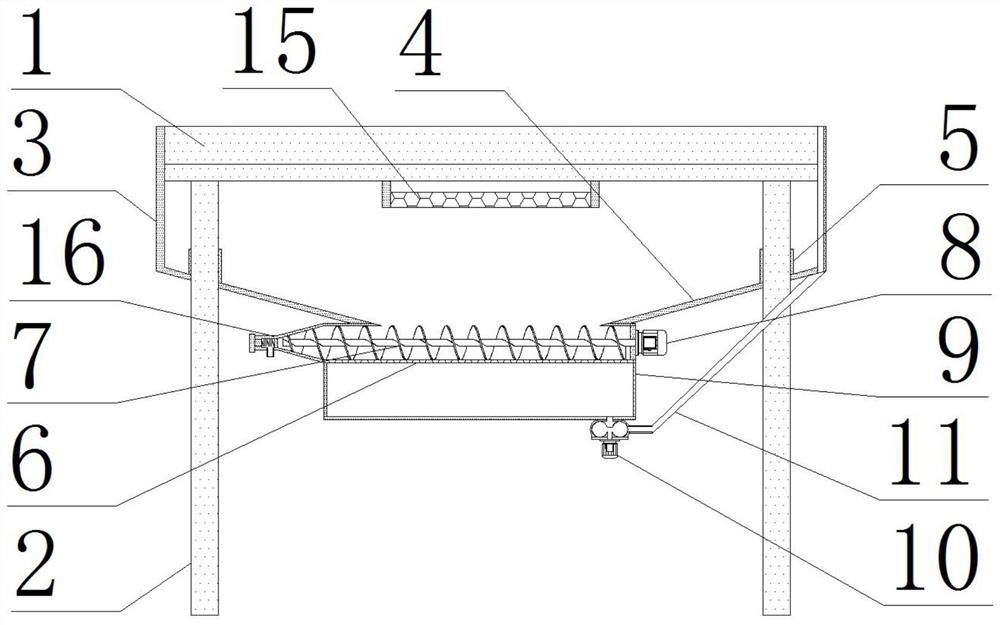

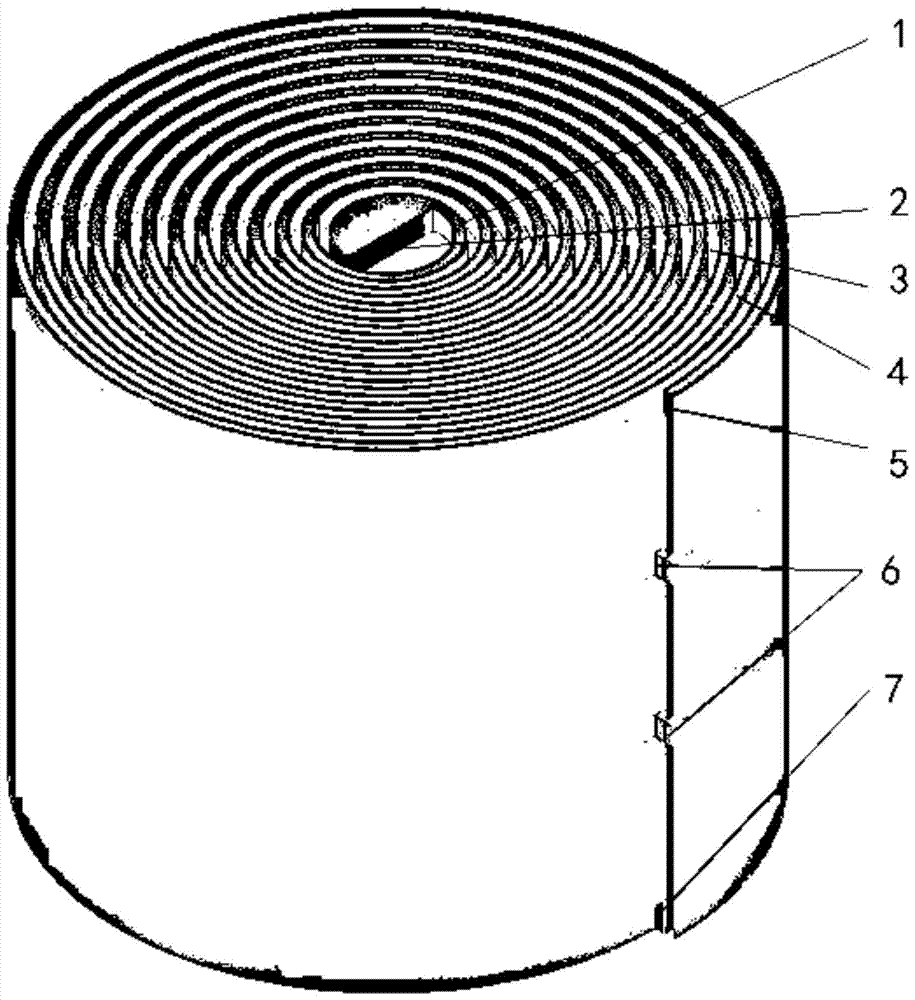

Belt type filter press

ActiveCN1879932AHigh filtration pressureHigh filter pressureMoving filtering element filtersEngineeringFilter press

The invention relates to a belt compress filter for dewatering the micro grains, wherein it is formed by a frame, a driver, a feeding device, a compress area and an auxiliary device; said compress area comprises a compress filtering roller and a filtering belt; the driver comprises a motor and a gear box; the auxiliary device comprises a tension roller, a scrape device, a water collector, a corrector, and a filter belt washer. The invention is characterized in that: the back of filter belt is lined with steel compress belt; the compress filtering rollers are compacted arranged. The invention can improve the filter pressure of compress filter to improve the balance point between the filter pressure and the filter resistance, to overcome the defects of present technique, while it can improve the dewatering efficiency and the yield.

Owner:ZHEJIANG HUAZHANG TECH

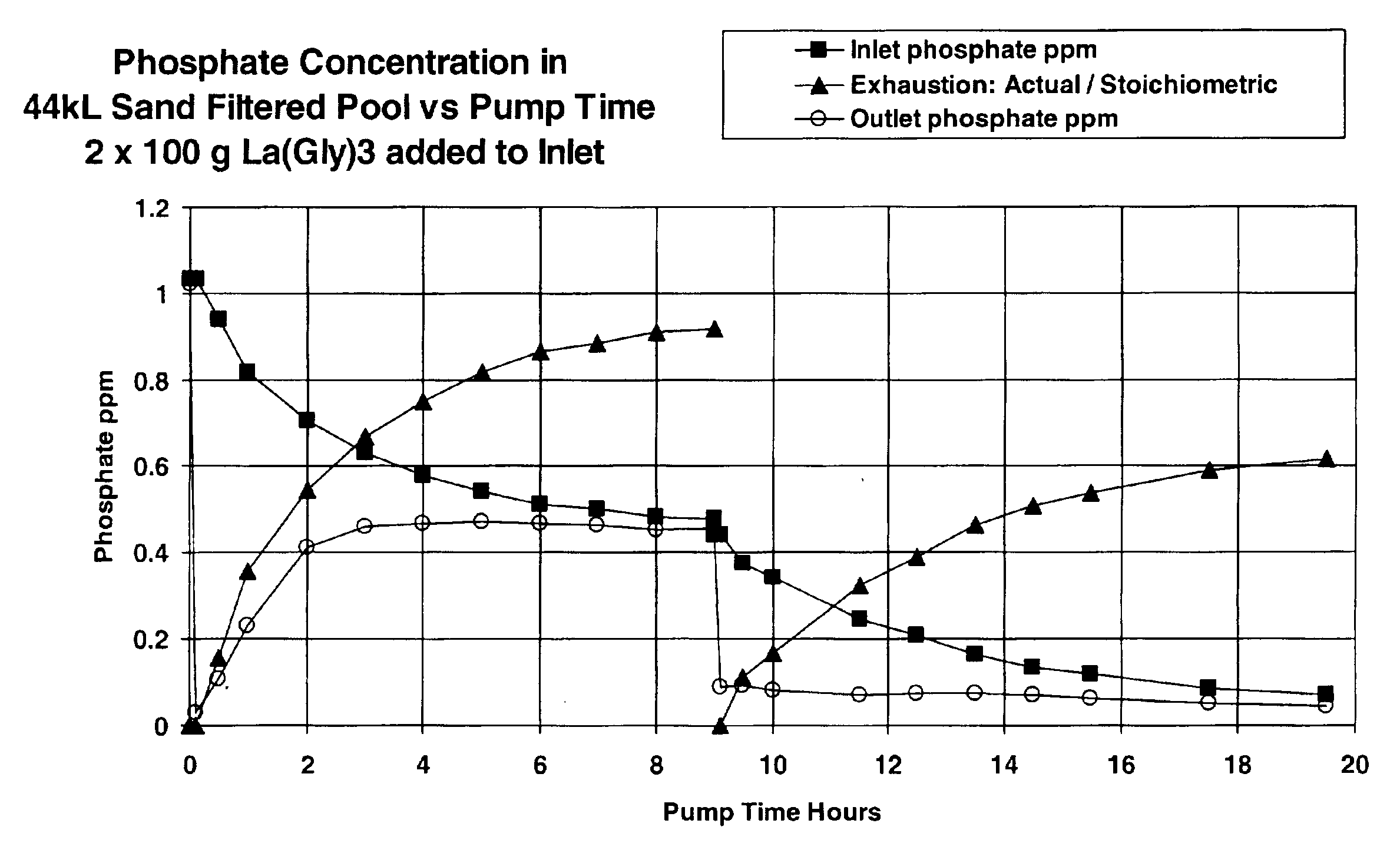

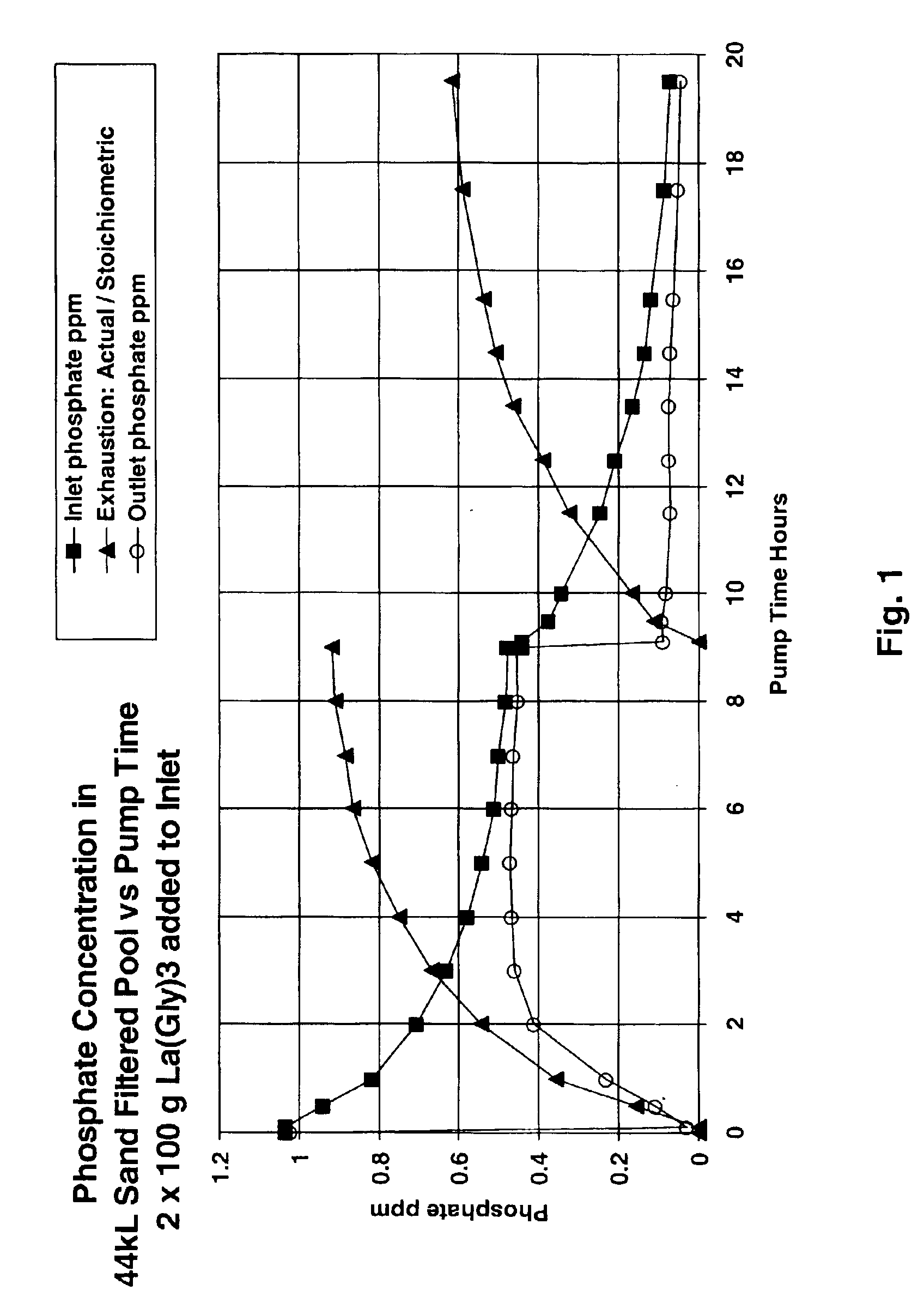

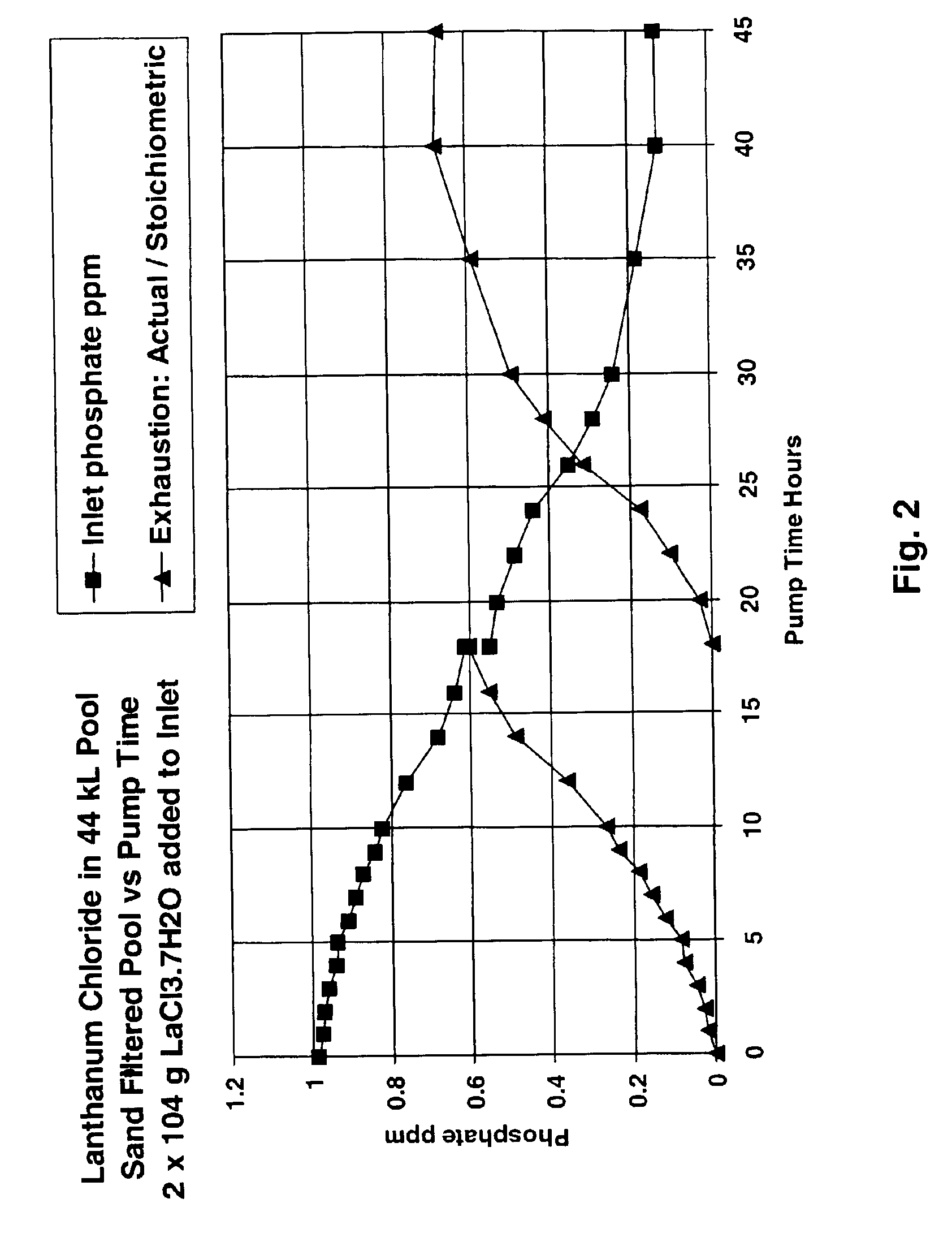

Removal of phosphate from water

InactiveUS6846432B2Increase filter pressureSatisfied with the resultWater contaminantsScale removal and water softeningPhosphateCarboxylic salt

Methods and compositions for removing phosphate from swimming pool waters are disclosed. The compositions include both soluble and substantially insoluble lanthanide carboxylates, preferred examples being lanthanum glycolate and lactate. The methods include the addition of the lanthanide compounds to the bulk of the pool water, but preferably involve the loading of the pool filter with the composition and the circulation of pool water through the filter to effect the removal of dissolved phosphate in the water.

Owner:NATURAL CHEM

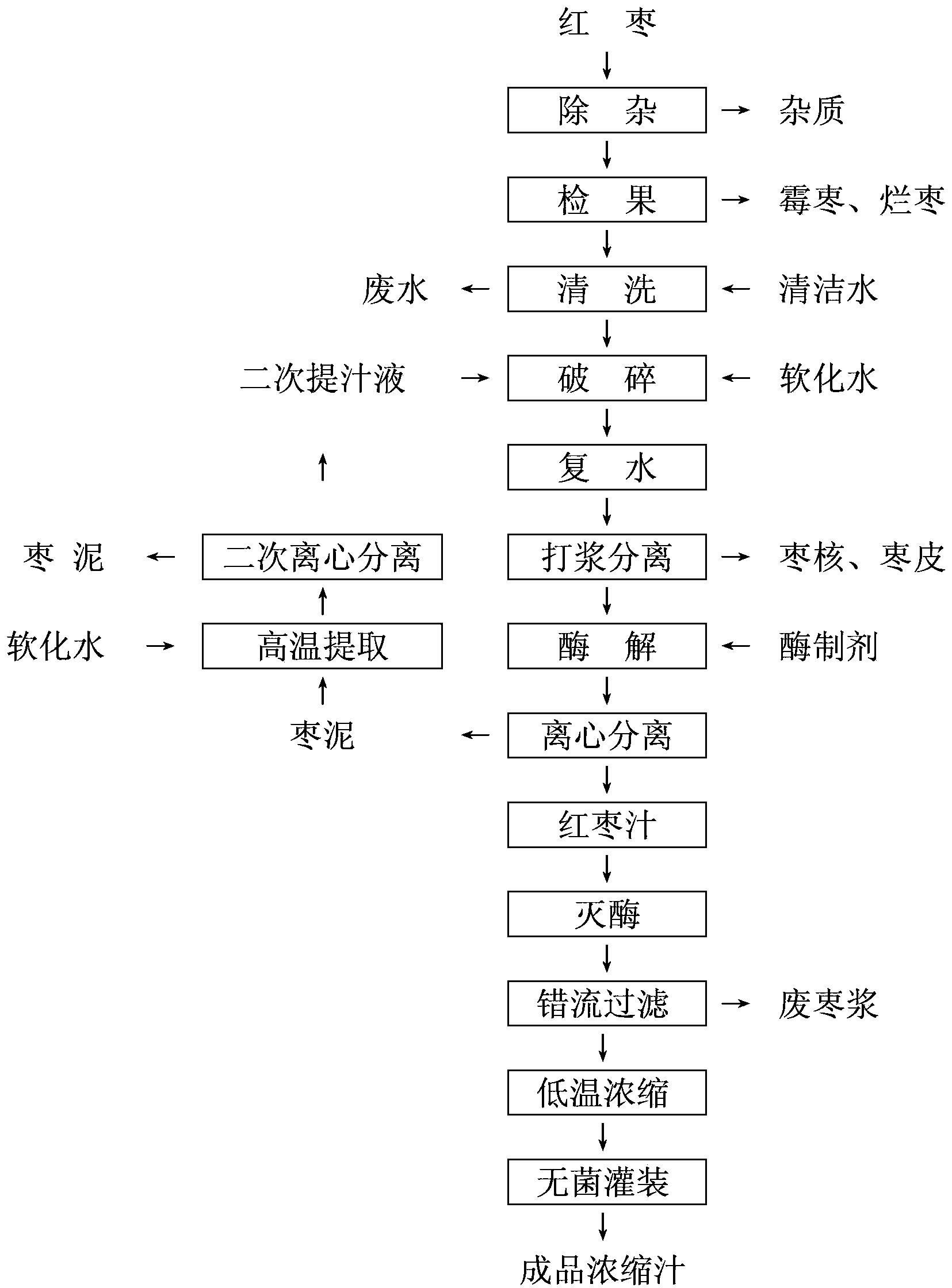

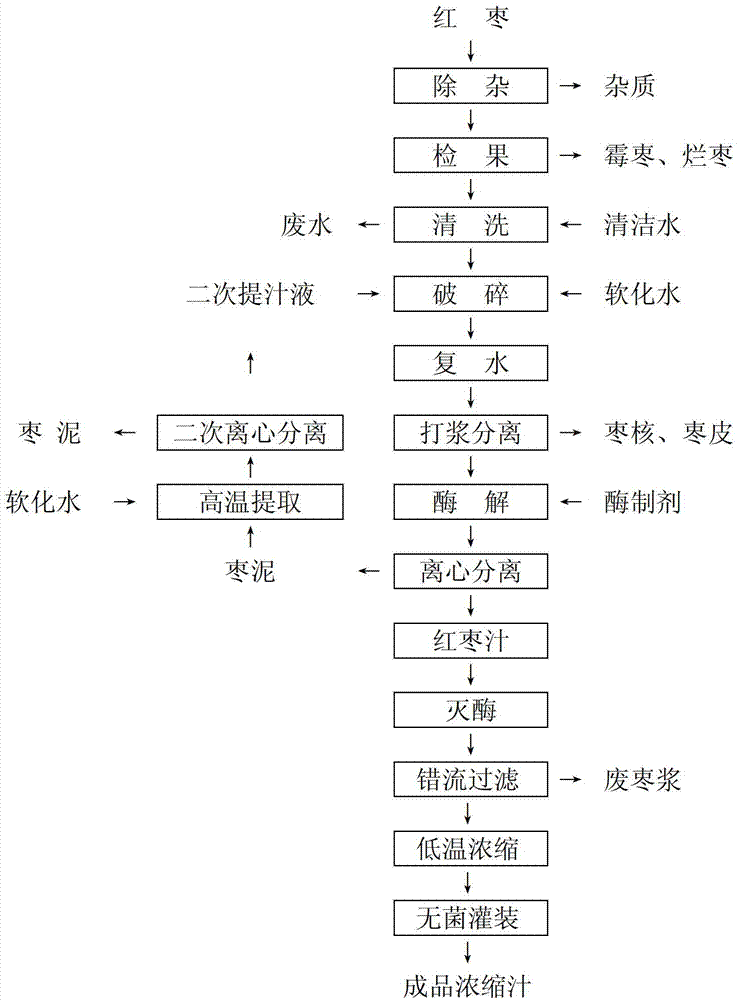

Production technology of red date concentrated clear juice

ActiveCN103519260AAdd flavorKeep the aromaFood thermal treatmentFood preparationAdditive ingredientCross-flow filtration

The invention relates to a production technology of red date concentrated clear juice, which comprises the following steps: impurity removal, fruit check and cleaning; breaking and rehydration; pulping and separation; enzymolysis; centrifugal separation; enzyme deactivation; high-temperature extraction; secondary centrifugal separation; cross flow filtration; vacuum low-temperature concentration; and sterile filling. The production technology provided by the invention has the advantages that with the red dates as the raw materials and by adopting a two-step breaking process, the breaking effect is improved, and the extraction rate of the raw materials is improved; by adopting the low-temperature rehydration process, the bright color, pure flavor and high content of nutritional ingredients of the date juice are guaranteed; by adopting the high-temperature extraction process, the physiologically-active substances in the red dates can be extracted to the greatest degree; since the high-temperature extracted juice returns to the rehydration section, the utilization rate of the raw materials is improved; and by adopting the cross flow filtration, the product has bright color and rich date aroma and is the best raw material for the deep processing of red dates. The production technology provided by the invention is reliable in the production technique of the domestic advanced level, fills up the blank of the key processing technology in domestic red date juice production, is a national initiative and meets the industrial production need.

Owner:CHINA LIGHT IND INT ENG CO LTD

Polyester polymerization catalyst and method for producing polyester using the same

ActiveUS20110178265A1Improve catalytic stabilityHigh activityTitanium organic compoundsMonocomponent polyesters artificial filamentPolyesterMannitol

Provided are a polyester polymerization catalyst with which the generation of foreign materials caused by the catalyst or mold pollution at the time of molding are reduced and polyesters having remarkably superior thermal stability and color tone can be obtained.Provided is a polyester polymerization catalyst produced by the reaction of a titanium compound and a mannitol in a molar ratio of titanium atom to mannitol of from 1:1 to 1:3. A method for producing a polyester employs the polyester polymerization catalyst.

Owner:TORAY IND INC

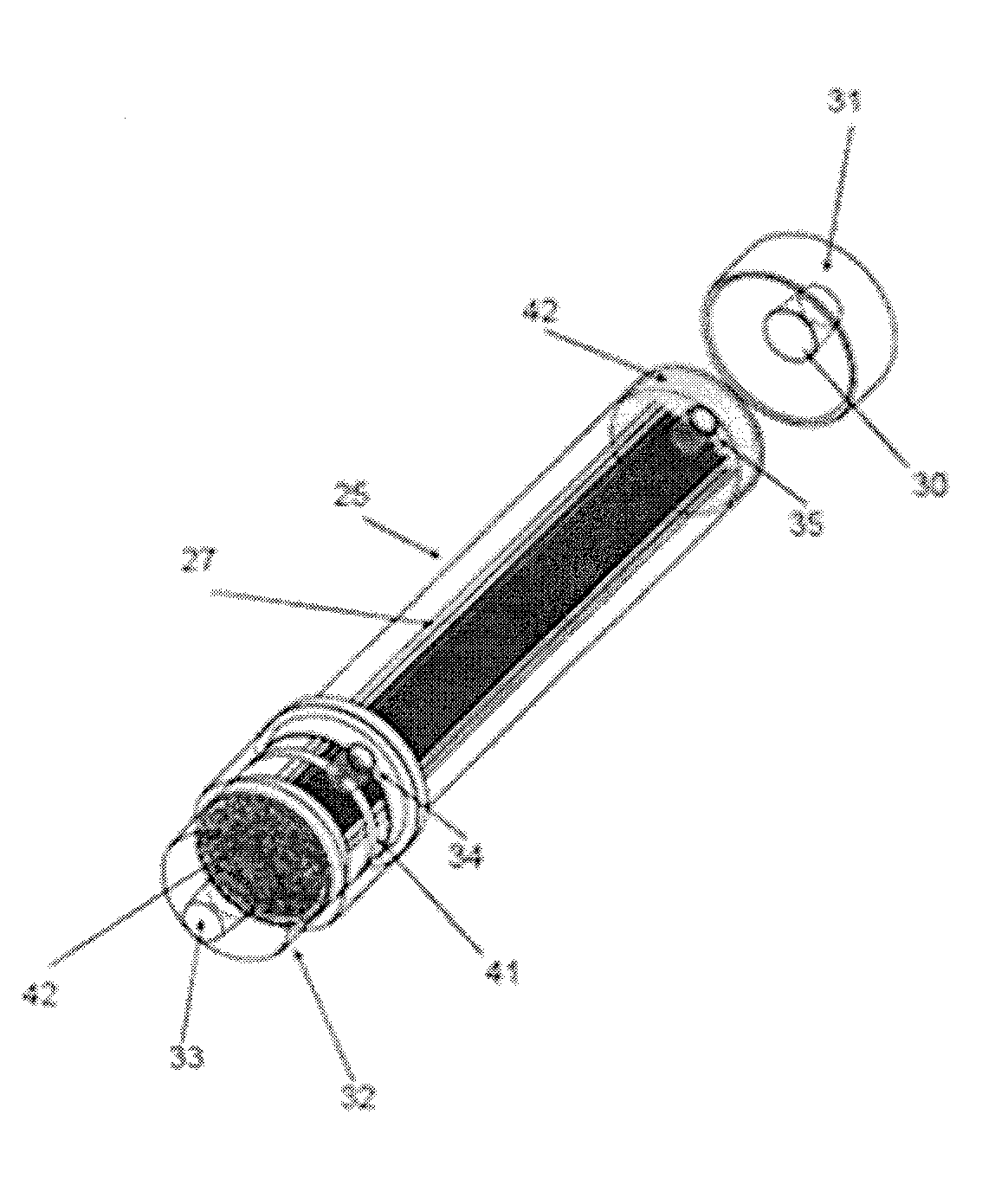

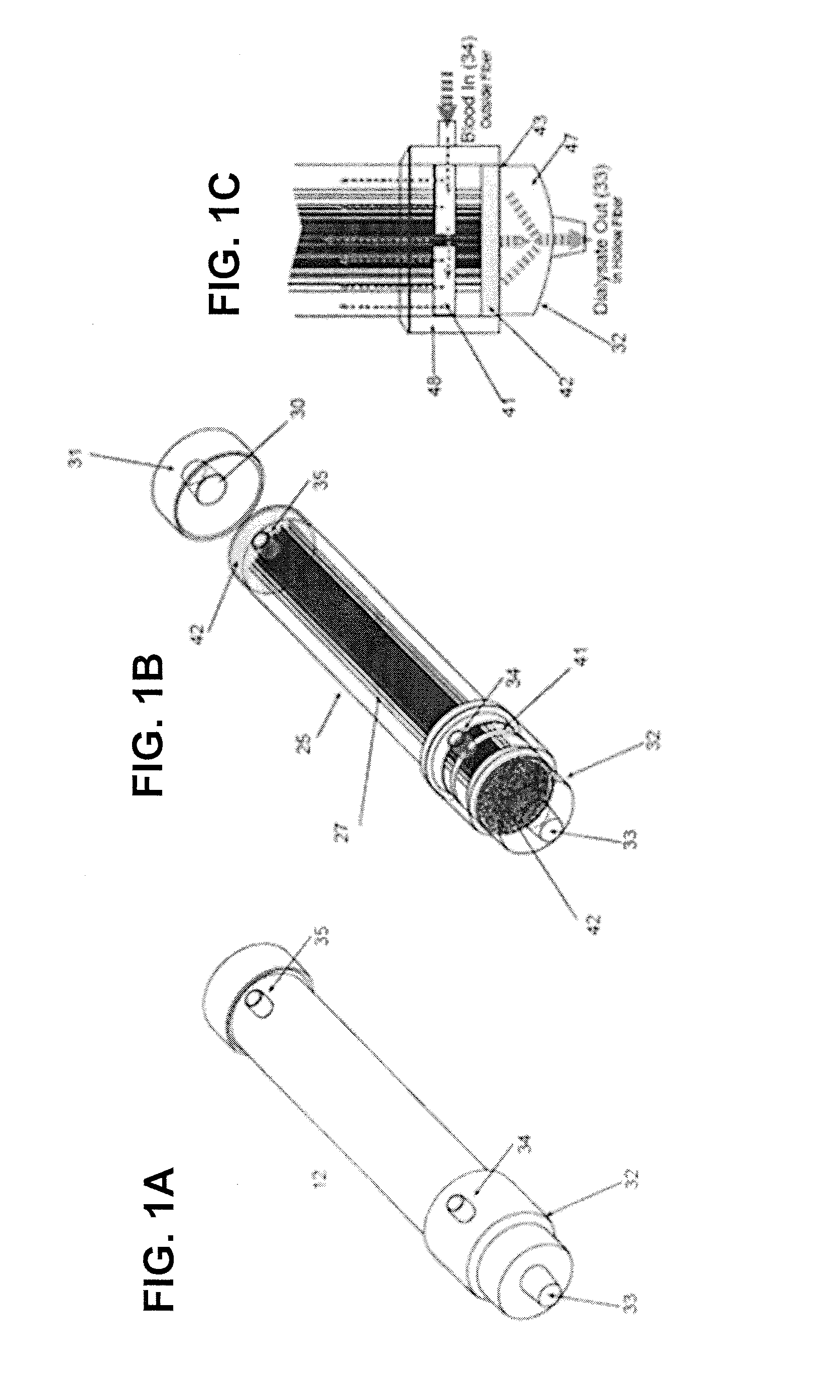

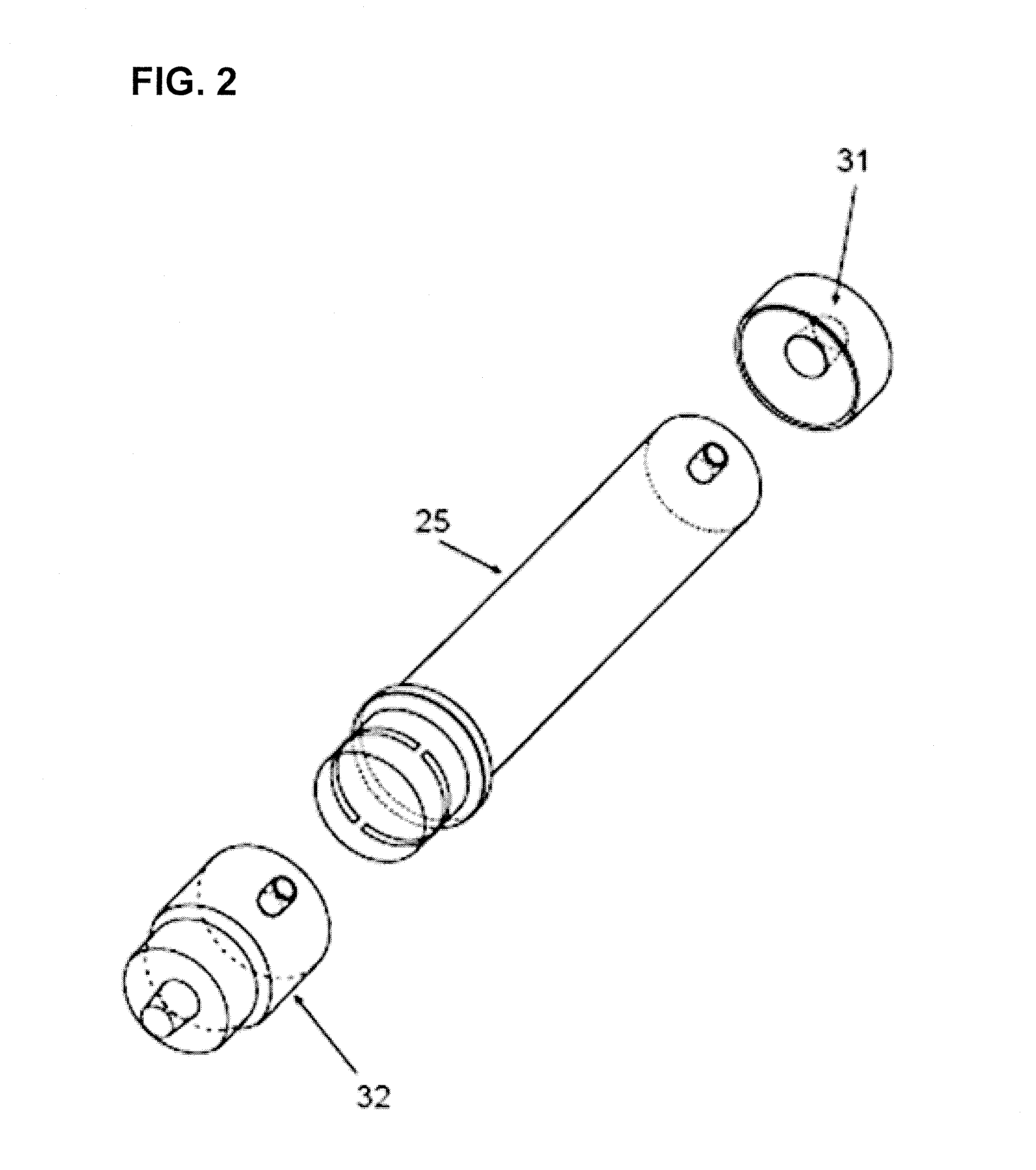

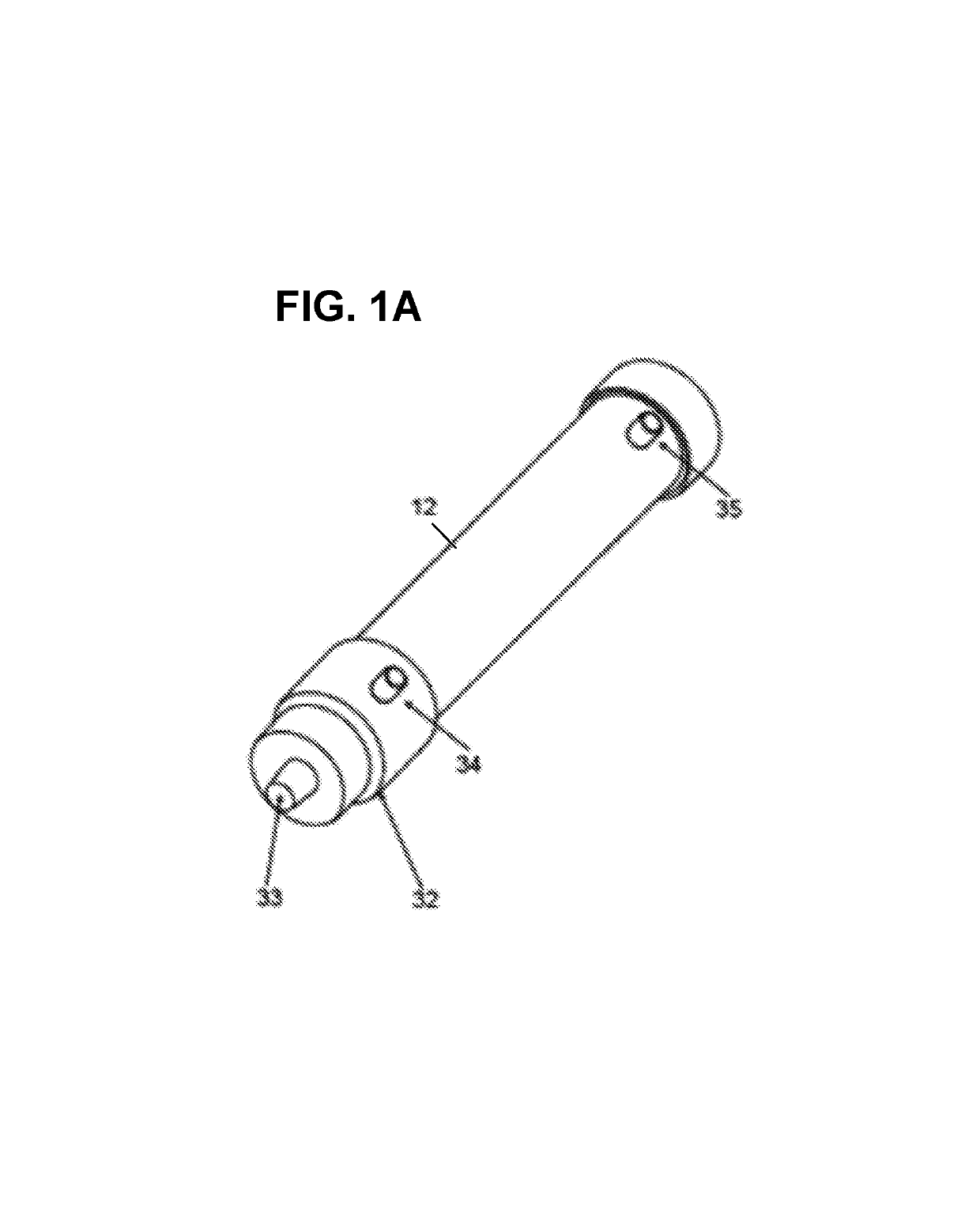

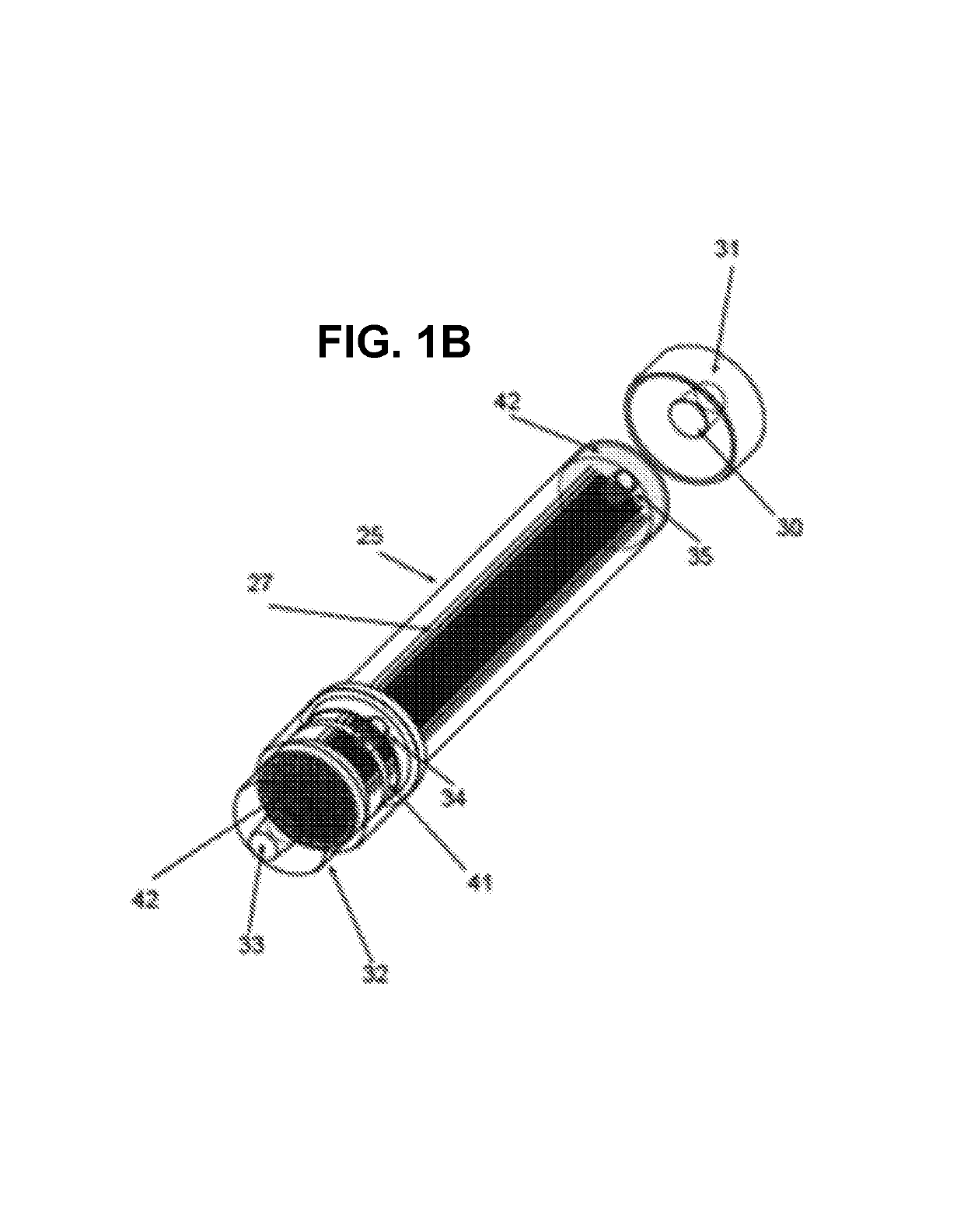

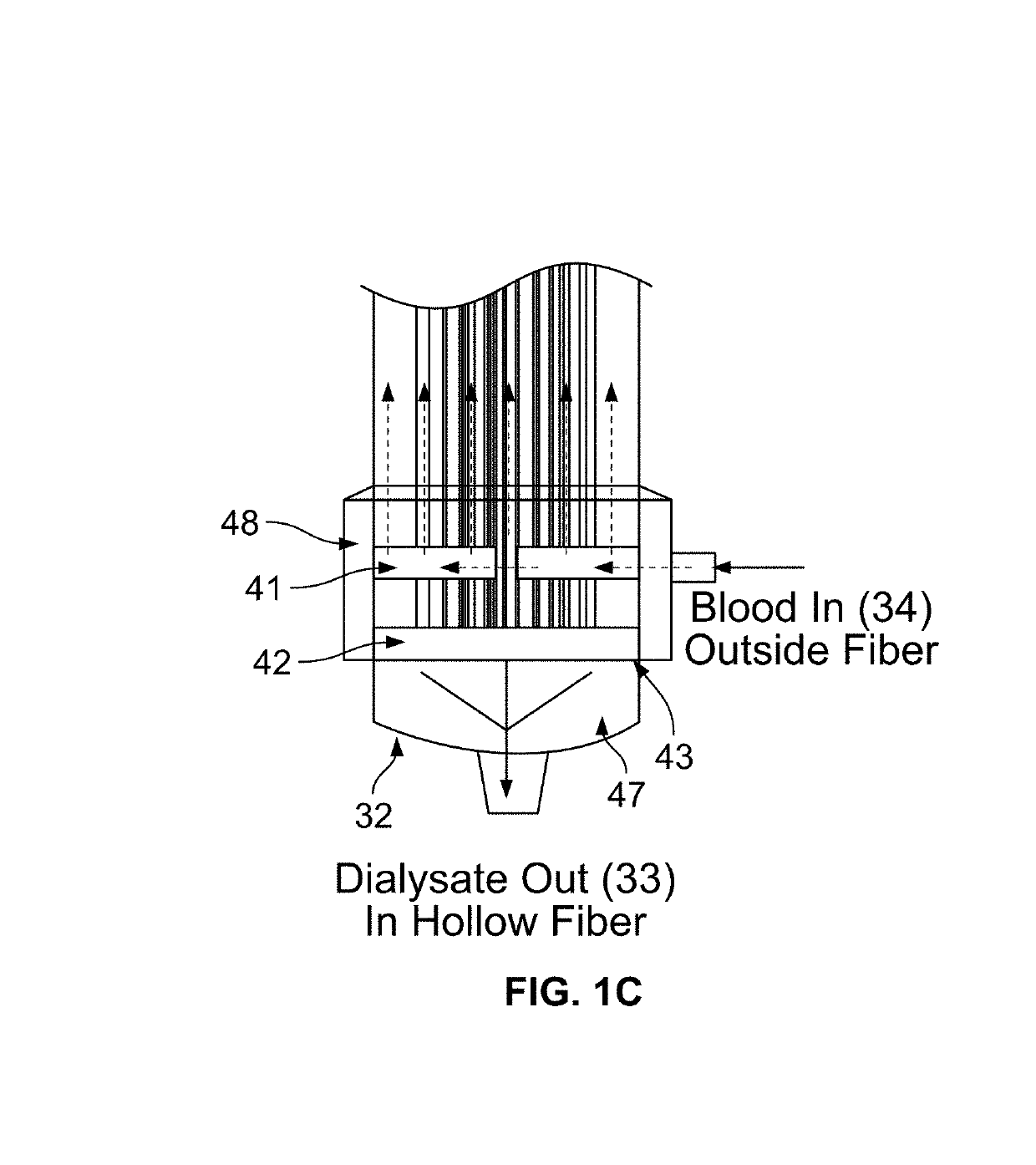

Cartridges and systems for outside-in flow in membrane-based therapies

ActiveUS20160375188A1Increase pressureReduces and even eliminates needMembranesHaemofiltrationDiagnostic Radiology ModalityBlood treatments

Embodiments of the invention pertain to cartridges, systems and methods for performing hemodialysis and related extracorporeal blood treatment modalities and therapies, in which blood flows in the inter fiber space and dialysate flows in the lumens of hollow fibers. Appropriate connectors and fitting orientations may be provided. There may be provided orbital distributors, fanning of fibers, and features to promote uniformity of fiber spacing in the fiber bundle. Orbital distributors may contain contoured surfaces, flow redirectors, non-uniform-conductance flow elements, through-wall distributors, and other features. There may be subdivision of the fiber bundle into two groups of fibers with separate control fluid to each group. Appropriate systems may be provided for various therapies. Flow past the fibers may be parallel, transverse or other configuration. These various features may enable long-term application to all dialysis and ultrafiltration related therapies, and also to other therapies and to applications including implantables, portables and wearables.

Owner:NOVAFLUX INC

Cartridges and systems for outside-in flow in membrane-based therapies

ActiveUS10426884B2Increase pressureReduces and even eliminates needMembranesOther blood circulation devicesDiagnostic Radiology ModalityBlood treatments

Embodiments of the invention pertain to cartridges, systems and methods for performing hemodialysis and related extracorporeal blood treatment modalities and therapies, in which blood flows in the inter fiber space and dialysate flows in the lumens of hollow fibers. Appropriate connectors and fitting orientations may be provided. There may be provided orbital distributors, fanning of fibers, and features to promote uniformity of fiber spacing in the fiber bundle. Orbital distributors may contain contoured surfaces, flow redirectors, non-uniform-conductance flow elements, through-wall distributors, and other features. There may be subdivision of the fiber bundle into two groups of fibers with separate control fluid to each group. Appropriate systems may be provided for various therapies. Flow past the fibers may be parallel, transverse or other configuration. These various features may enable long-term application to all dialysis and ultrafiltration related therapies, and also to other therapies and to applications including implantables, portables and wearables.

Owner:NOVAFLUX INC

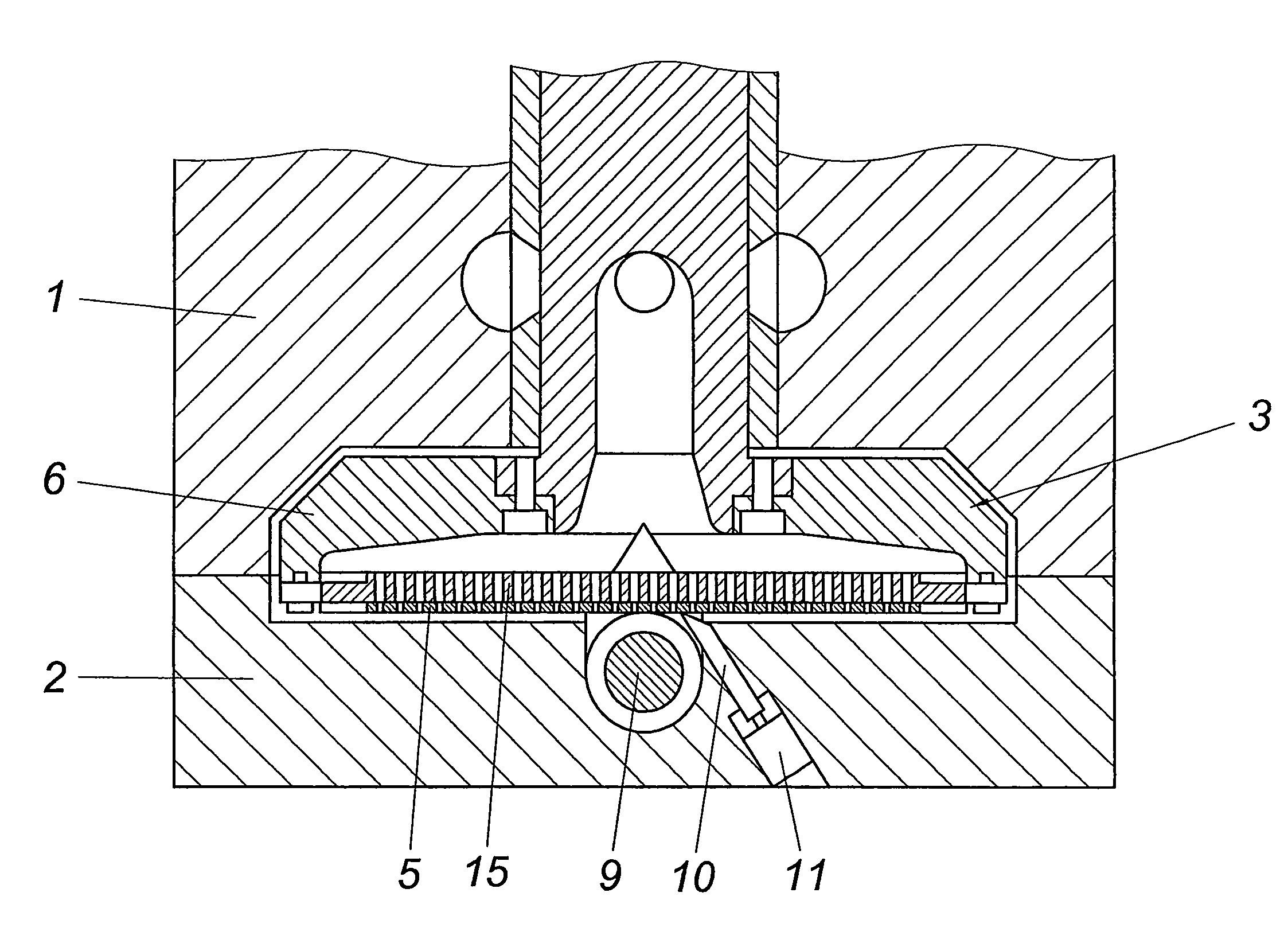

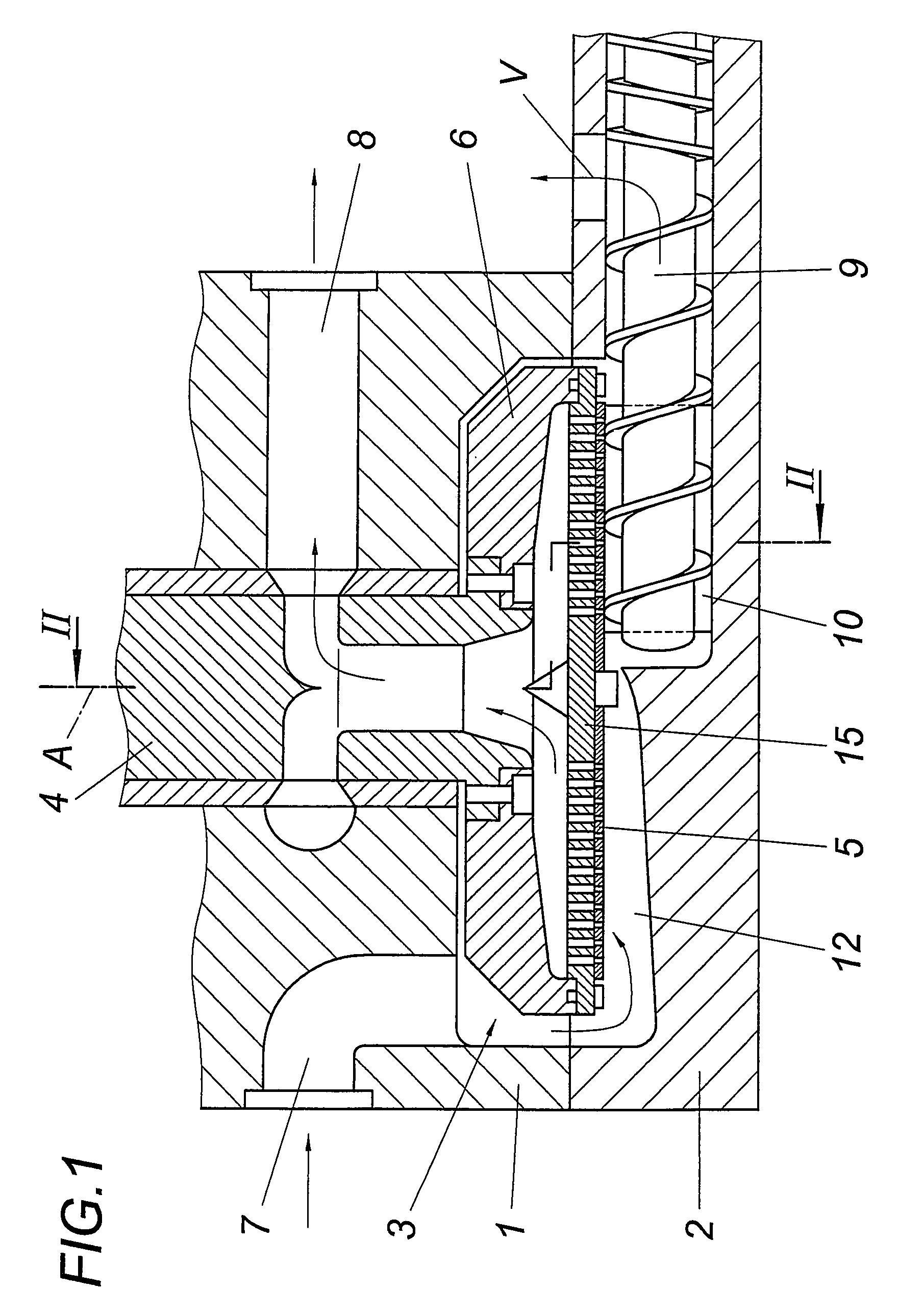

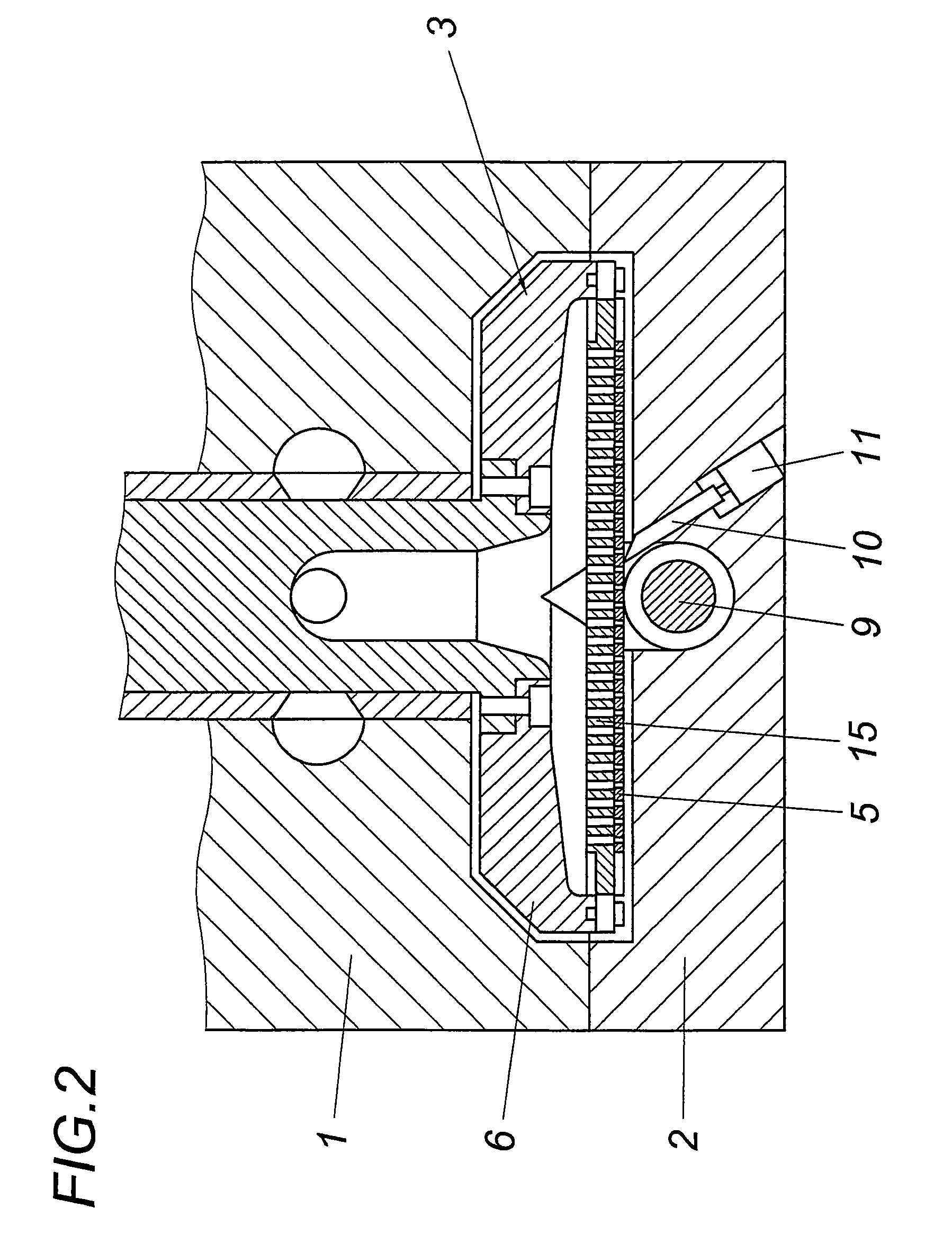

Apparatus for the continuous filtering of impurities from a flowable compound

ActiveUS7820039B2Rapid and smooth exchangeDismounted easilyWater/sewage treatment by centrifugal separationPlastic recyclingRotational axisEngineering

The invention relates to an apparatus for the continuous filtering of impurities from a flowable compound, especially a plastic melt, comprising a filter insert (3) in the form of a hollow rotary body which is held to rotate about its rotational axis (A) relative to a housing (1, 2) and is flowed through by the flowable compound and which is arranged in a flow conduit of the housing (1, 2) between a feed conduit (7) for the compound to be filtered and a discharge conduit (8) for the filtered compound, and a discharge apparatus for impurities held back by the filter, which apparatus comprises a feed screw (9) cooperating with the filter insert (3). In order to provide advantageous constructional conditions it is proposed that the filter insert (3) comprises a disk-like filter (5) which is arranged on the face side of the rotary body and is coaxial to the rotational axis (A).

Owner:SCHULZ KATHARINA

Filter press

InactiveCN1843557AGood airtightnessIncrease filter pressureMoving filtering element filtersMoving framePiston

The invention relates to a pressure filter, which comprises a single straining chamber device formed by a fixing filter plate, a multifunctional straining chamber ring, a moving frame and a movable filter plate. Wherein, the fixing filter plate has a liquid inlet and a filtrate outlet and a ring to fix the sealing surface of filter plate straining chamber; the surface of fixing filter plate has liquid discharge grooves; the fixed filter plate straining chamber sealing surface and the straining chamber sealing surface of multifunctional straining chamber ring clamp the fixed filter plate filter cloth; another straining chamber sealing surface of multifunctional straining chamber ring and the sealing surface of moving frame fix the filter cloth of movable filter plate; the moving frame via the hydraulic system compresses the moving frame, the multifunctional straining chamber ring and fixing filter plate; the fixing filter plate, multifunctional straining chamber ring and the moving frame form the straining chamber; the movable filter plate can make piston movement inside the straining chamber; the side wall of multifunctional filter chamber ring has a feeding inlet; the surface and side surface of movable filter plate have liquid discharge grooves, while the back surface has guide rod; the hydraulic system via the guide rod pushes the movable filter plate forwards or backwards inside the straining chamber.

Owner:蒋卓冰

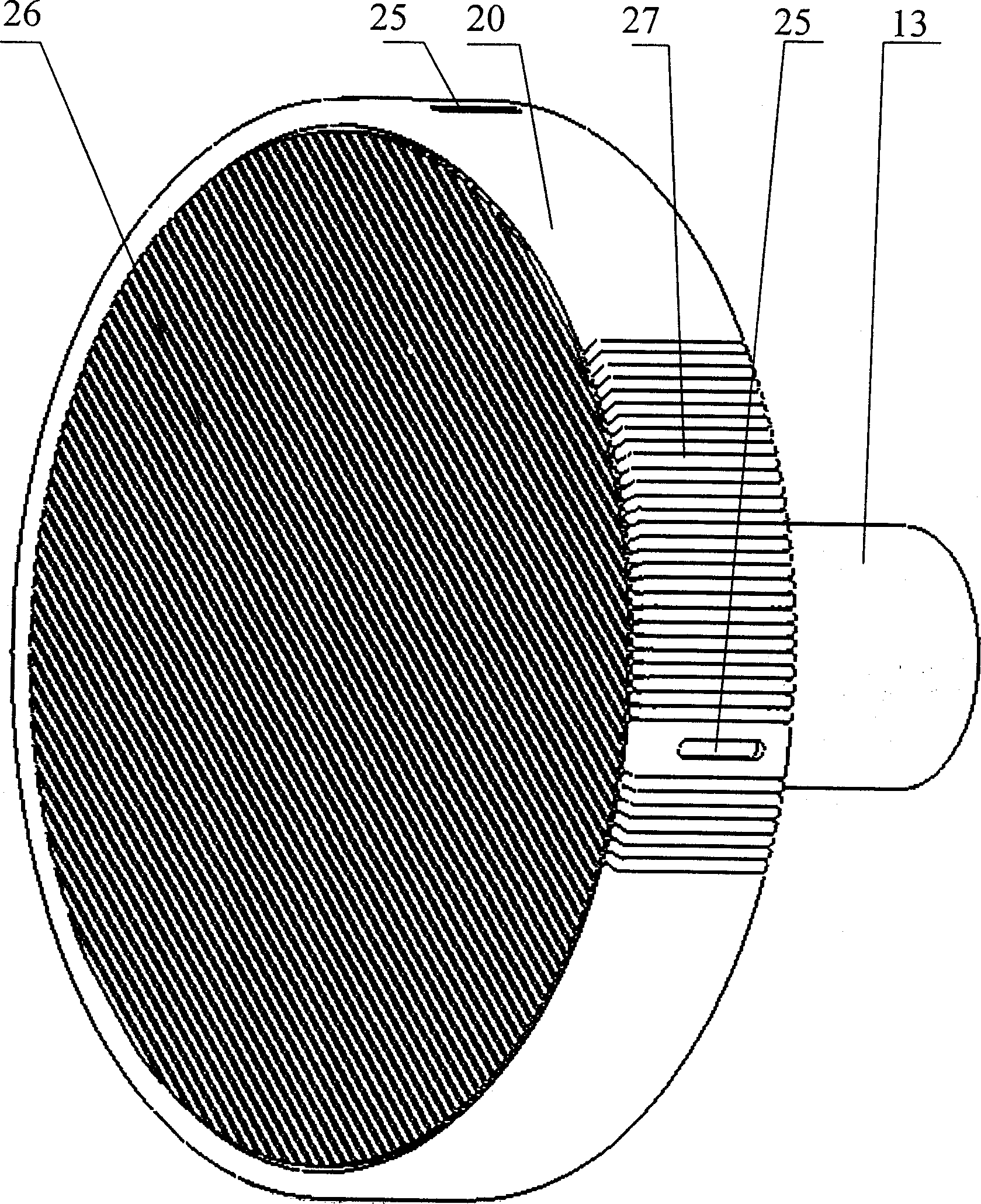

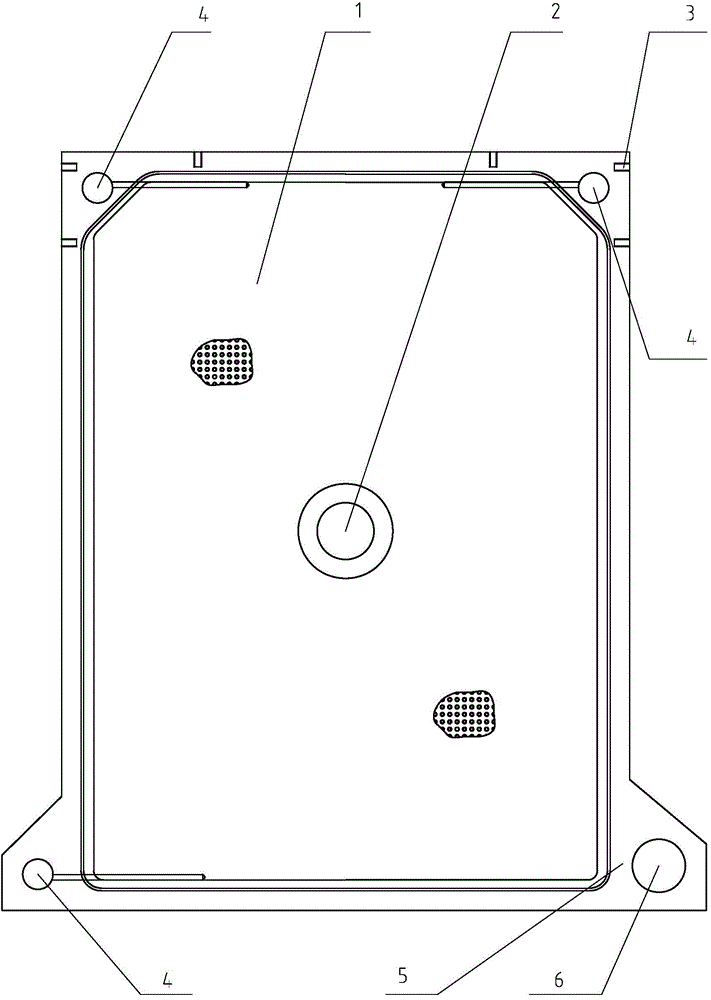

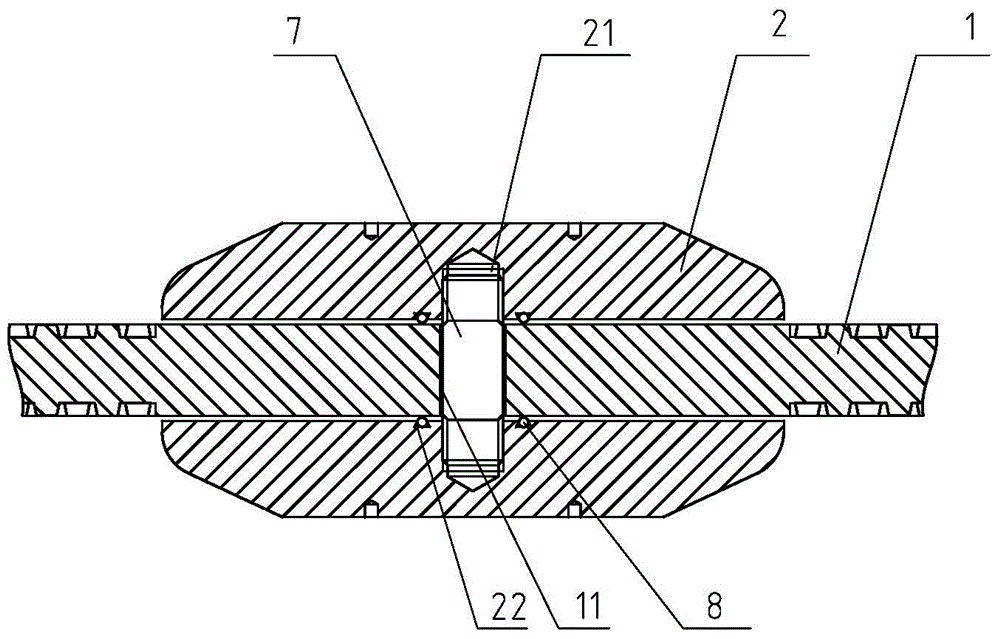

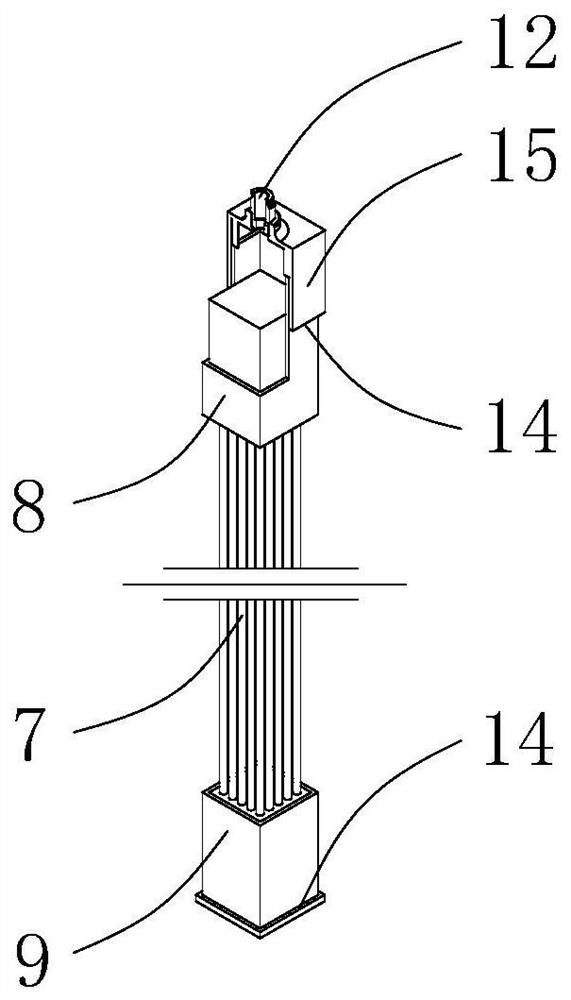

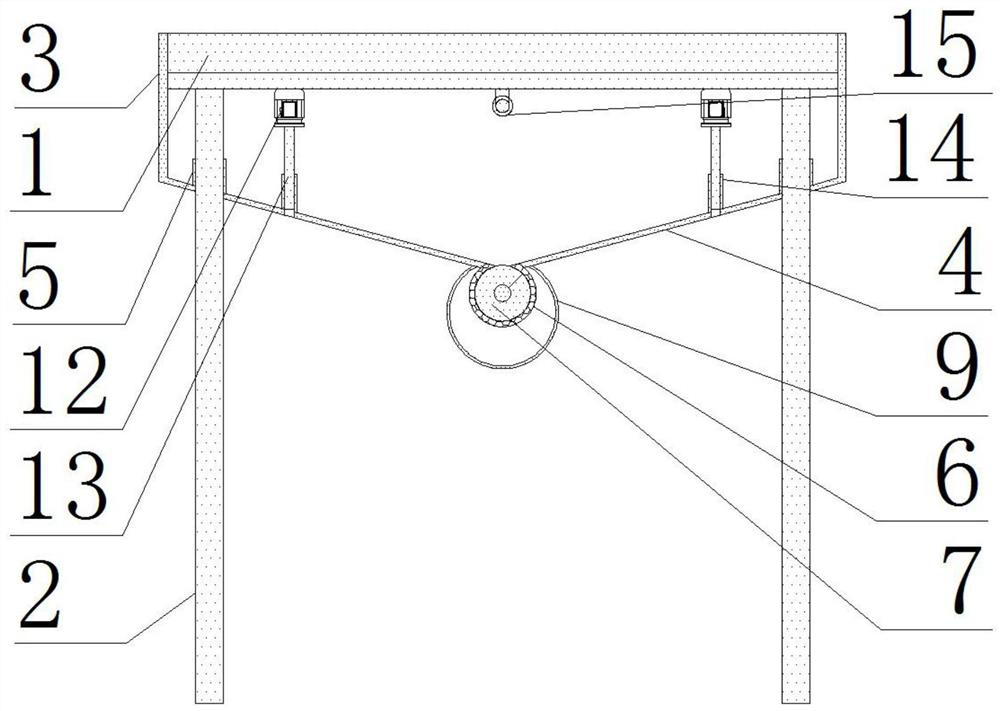

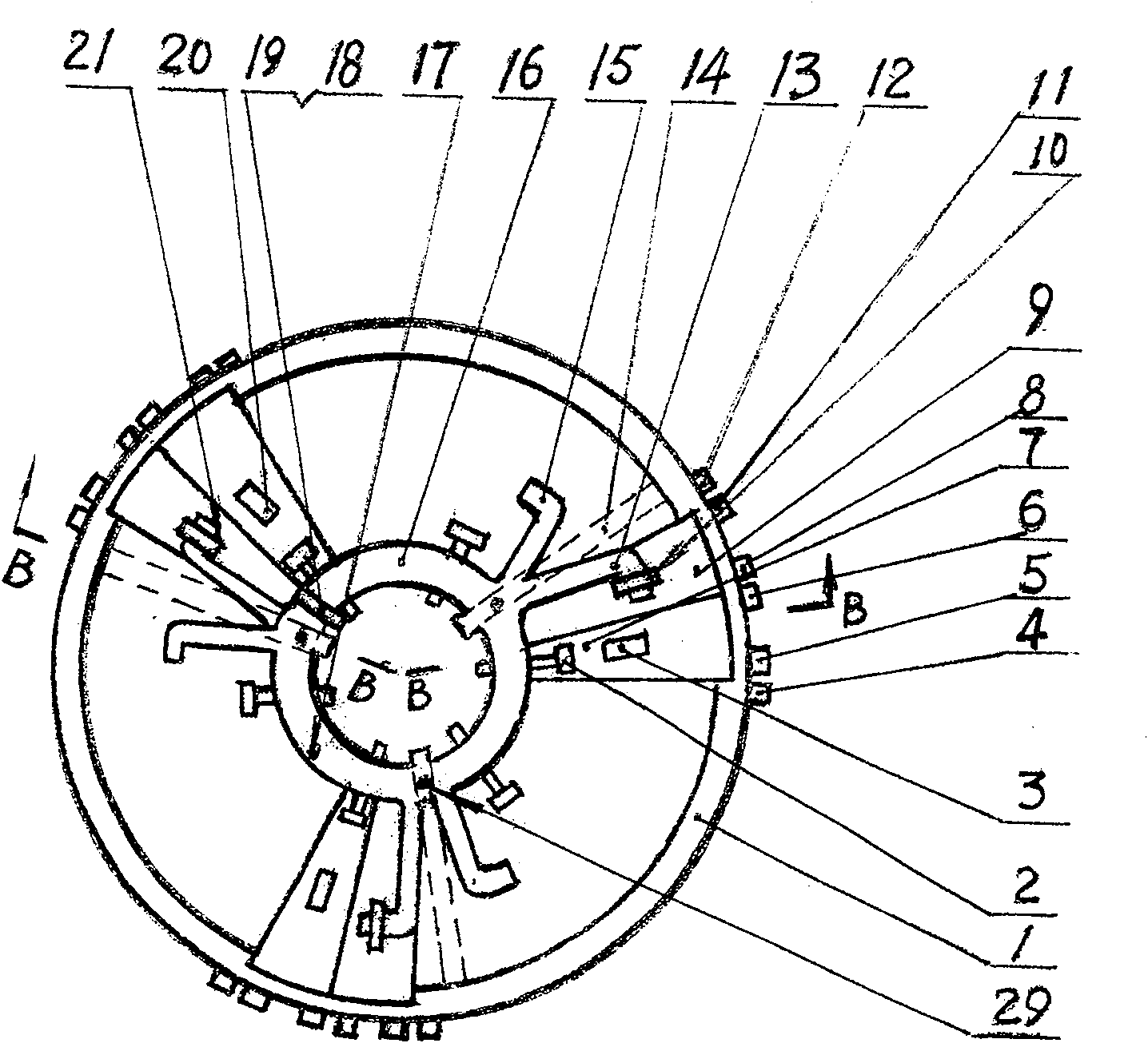

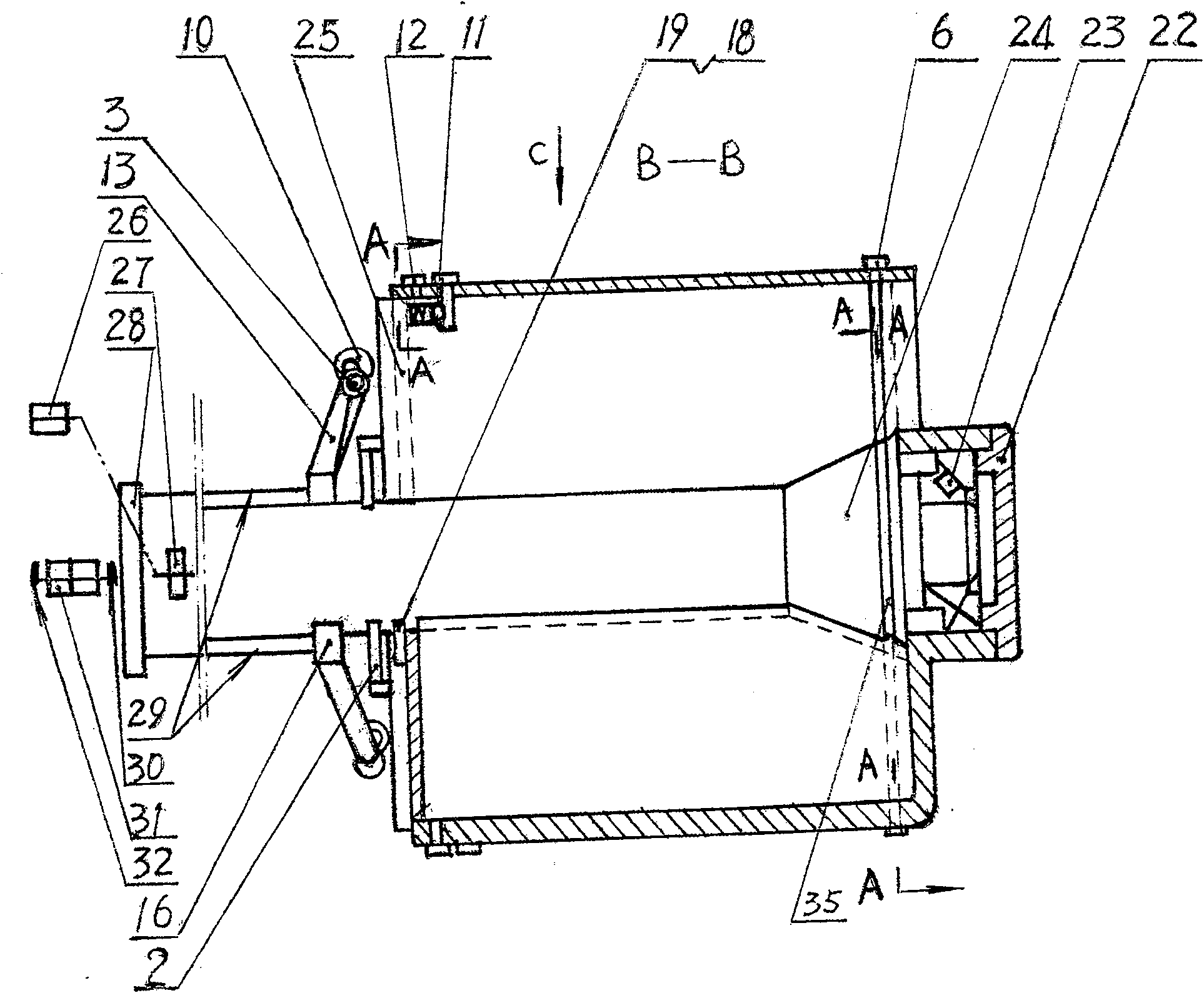

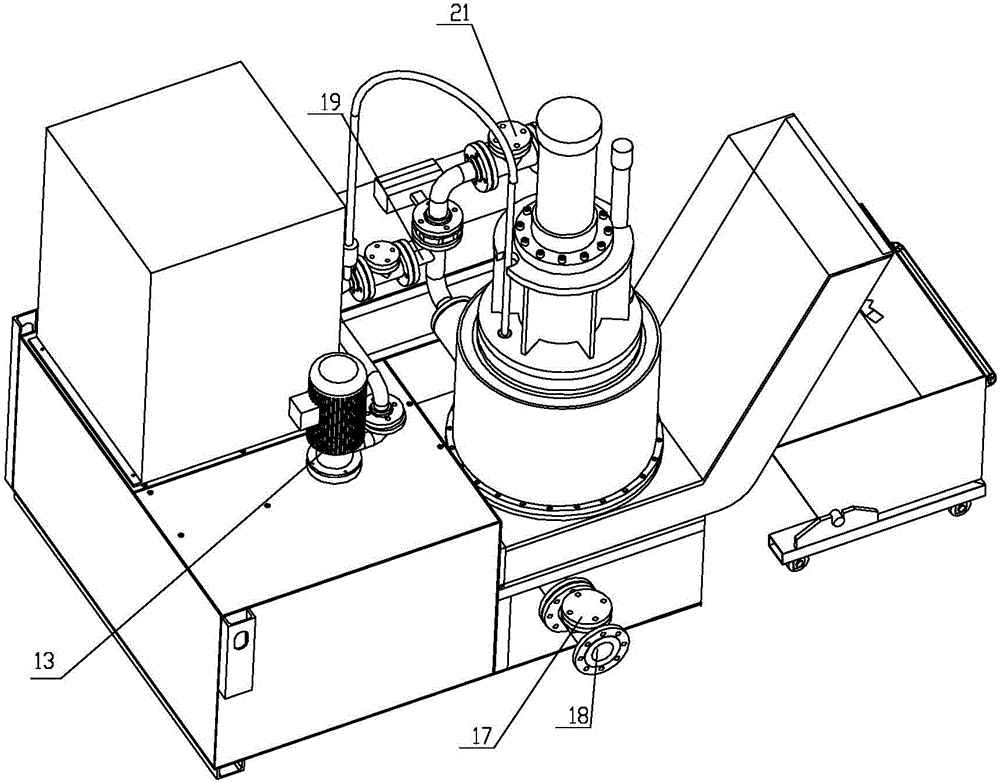

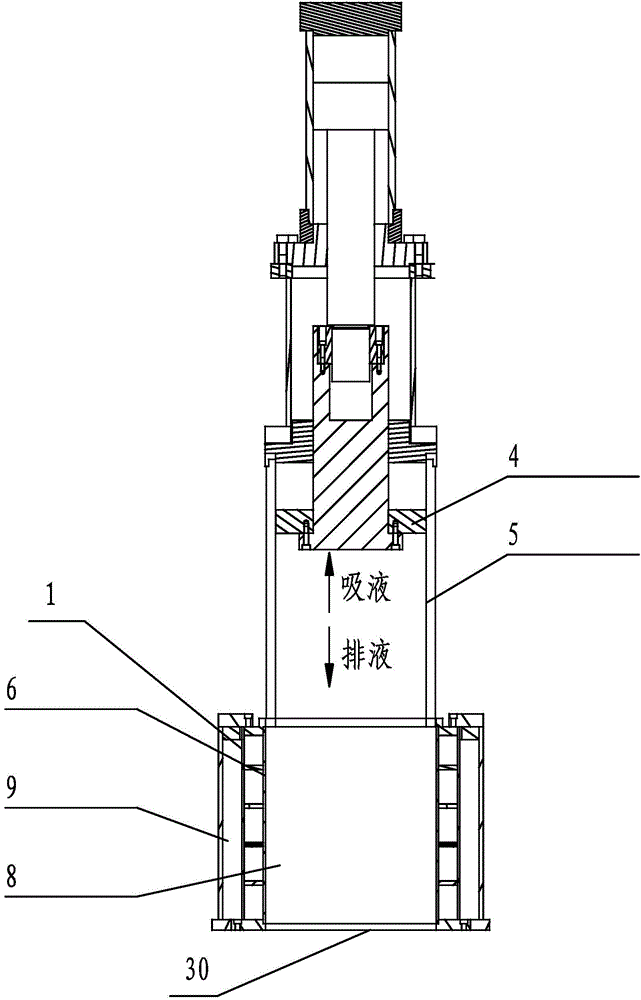

Large circular plate high-pressure automatic filter press

PendingCN112206555AIncrease productionGuaranteed tightnessFiltration separationAutomatic controlControl system

The invention discloses a large circular plate high-pressure automatic filter press, which relates to the field of environmental protection equipment and mainly comprises a rack part, a filtering part, a hydraulic system, an automatic plate pulling device and an electrical control system. The single-machine yield is increased by adopting large-area circular filter pressing plates, and meanwhile, the sealing surface is used for ensuring the sealing property of each filter chamber during filter pressing, so that the phenomenon of slurry leakage between the filter plates during high-pressure filter pressing is effectively avoided. Meanwhile, double oil cylinders are horizontally arranged side by side, so that the space is saved, and the filtering pressure can be effectively improved; a mode of simultaneously feeding slurry from two ends is also adopted, so that the filter pressing time is further shortened, and the filtering efficiency is improved. Besides, the automatic filter press provided by the invention is integrally designed and manufactured by machine, electricity and liquid, can realize automatic control of various processes such as filter plate pressing, filtering, squeezing, filter plate loosening, discharging and the like, and is high in practicability.

Owner:广东增盛机械科技有限公司

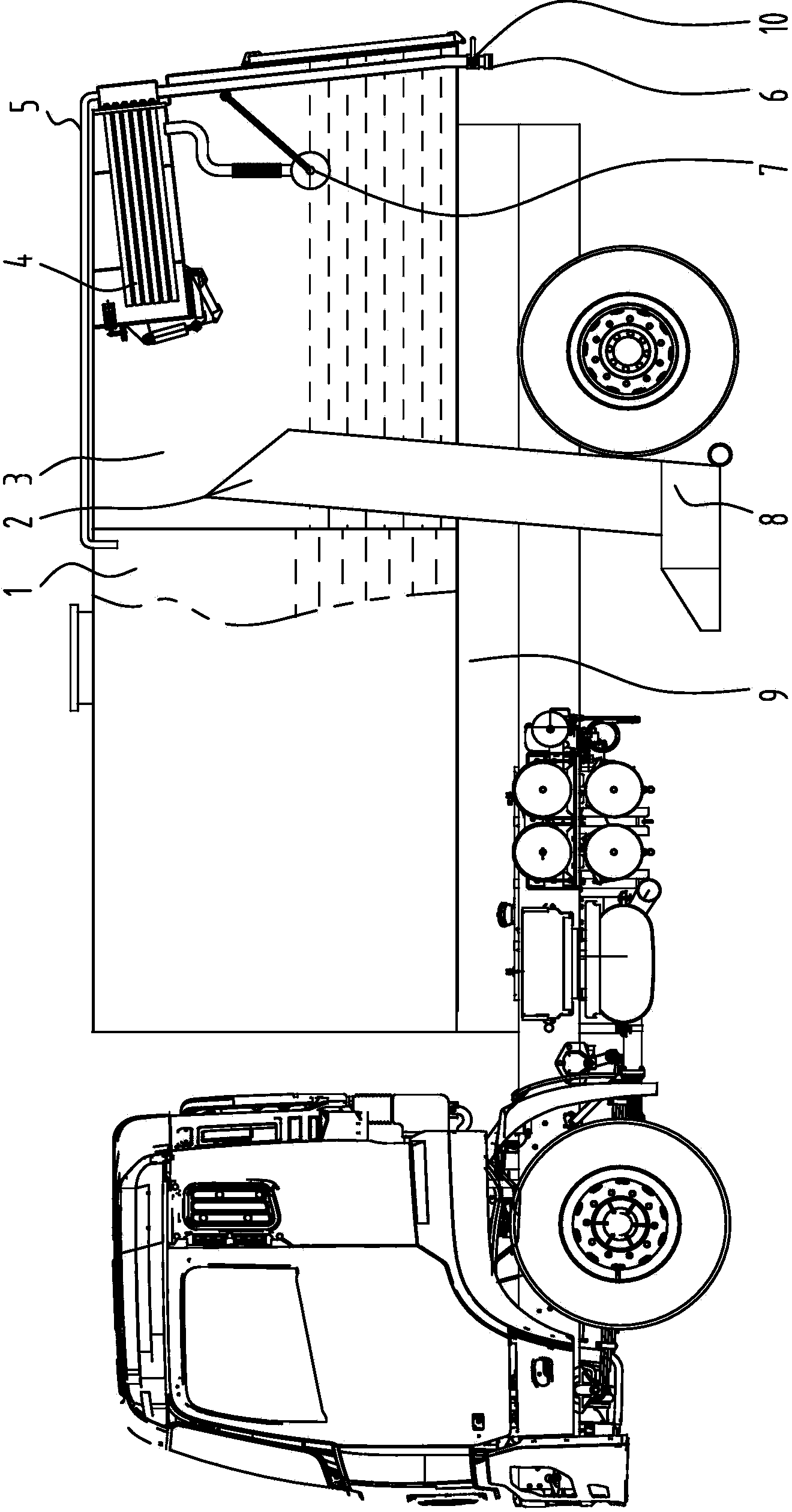

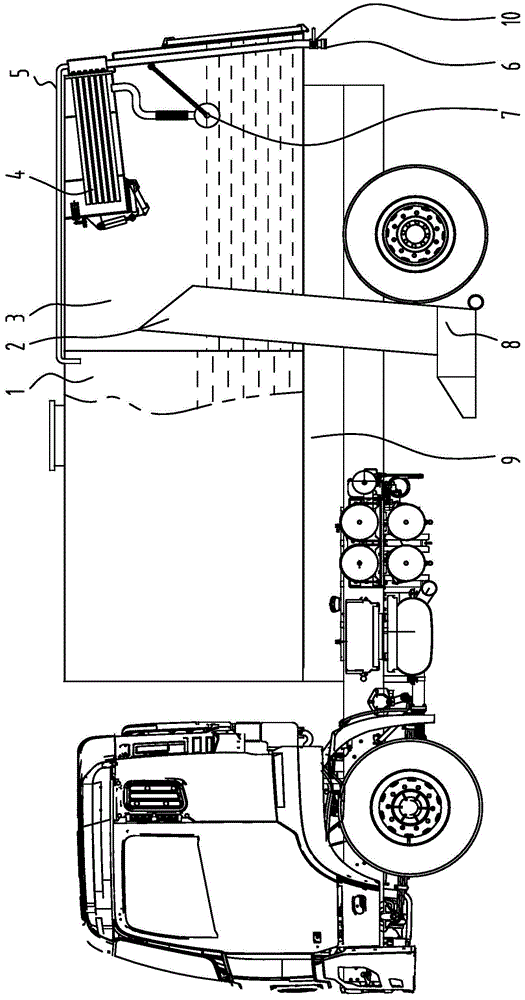

Road cleaning sweeper truck with sewage recovery and reutilization function

InactiveCN103821098ASolve the problem of taking up too much spaceSolve difficult puzzles to controlSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisSewageTruck

The invention relates to a road cleaning sweeper truck with a sewage recovery and reutilization function. The sweeper truck comprises a truck body and a clean water tank, wherein the clean water tank and a sewage tank are separated by a retaining plate, and are respectively and fixedly arranged on a chassis, a suction pipe penetrates through the chassis and extends into the sewage tank, the bottom of the suction pipe is connected with a suction nozzle for cleaning, a polymer sintering membrane filter is arranged at the top end in the sewage tank, a sewage pump is arranged in the sewage tank, and is connected with the polymer sintering membrane filter through a pipeline, a filtering water outlet pipe extends to an opening at the top of the clean water tank along the outer edge of the sewage tank by passing through the polymer sintering membrane filter, a backwashing pipe is connected with the polymer sintering membrane filter, and the opening of the backwashing pipe is provided with a backwashing valve. The sweeper truck has the advantages that the space structure of the sewage tank of the sweeper truck is sufficiently utilized by the horizontal type polymer sintering membrane, the problem of overlarge occupation space when the polymer sintering membrane filter is vertically arranged is solved, the filtering flow quantity of the polymer sintering membrane is approximate to the constant flow quantity in the specific application, and the filtering pressure in the sewage cavity is increased; the problems of overhigh initial flow quantity and difficult control over constant flow quantity are solved.

Owner:XIAMEN UNIV OF TECH

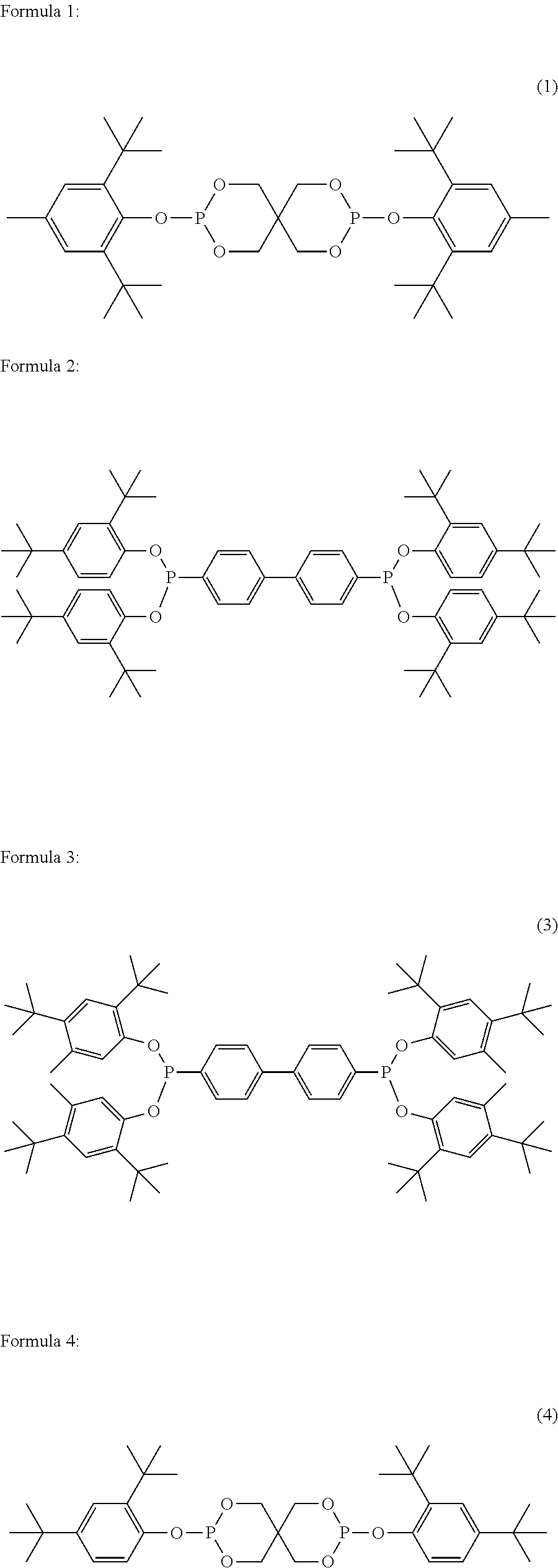

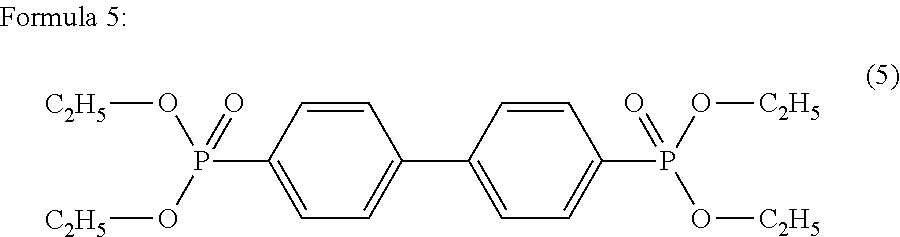

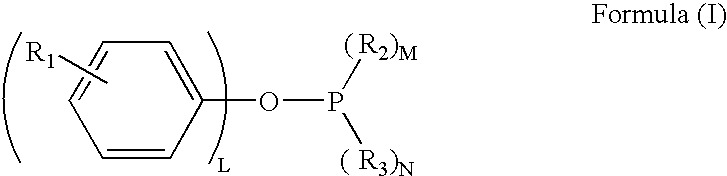

Polyester production method, polyester composition, and polyester fiber

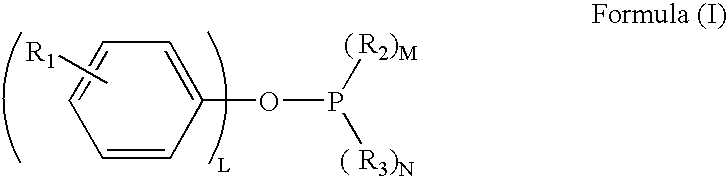

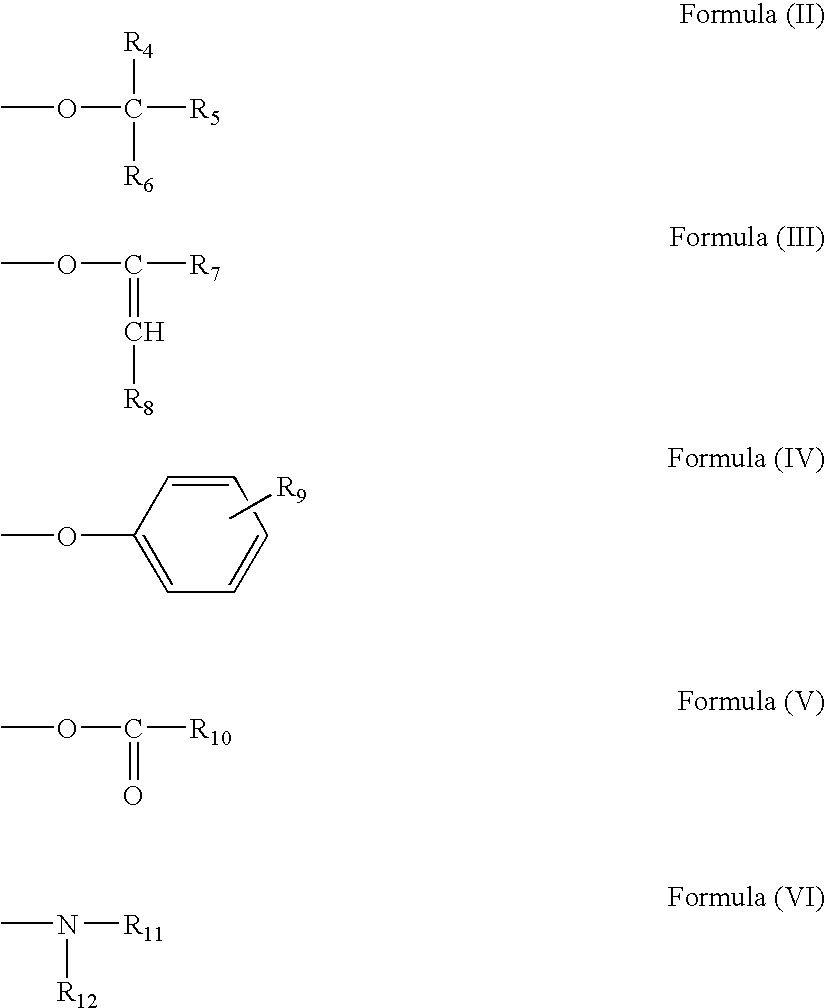

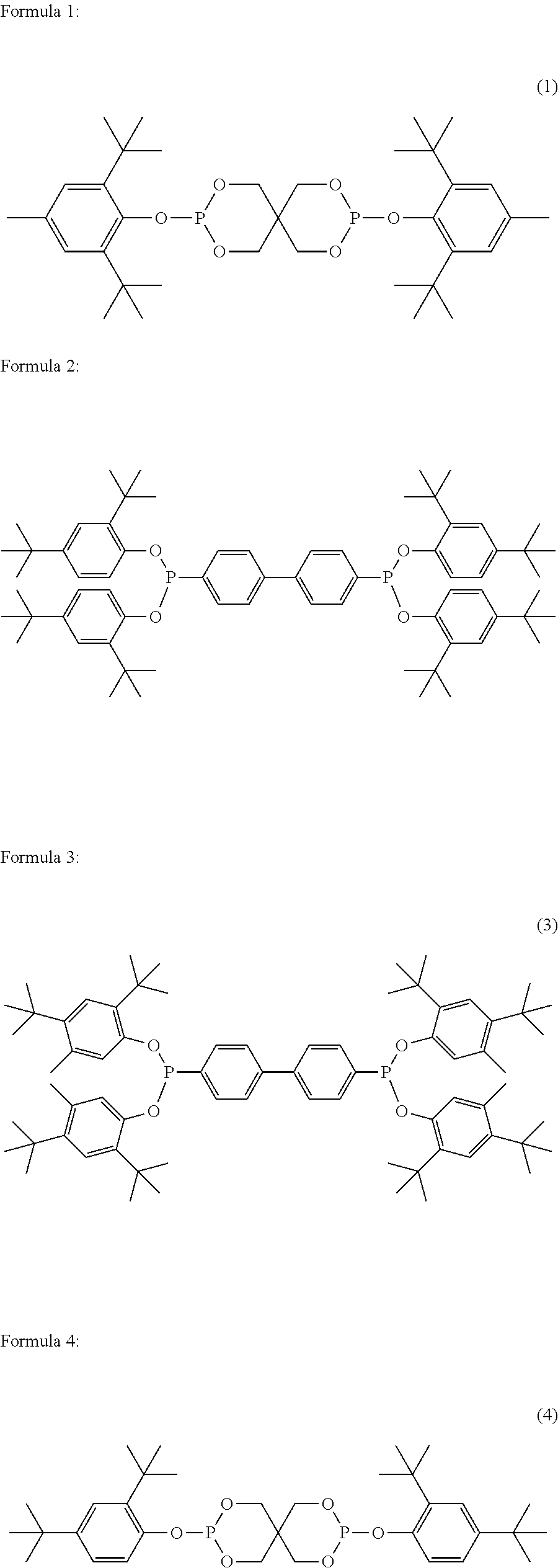

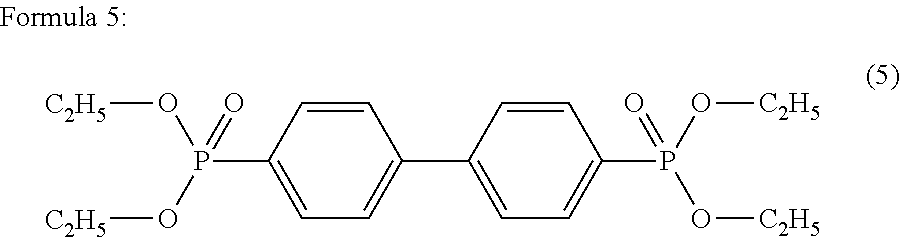

In a polyester production method, a titanium compound having a radical selected from a carbonyl group, a carboxyl group, or an ester group, and a phosphorous compound having a structure illustrated in Formula (I), are addedThis yields a polyester composition which does not exhibit increased filter pressure when forming, which has excellent filament and film forming properties, and which has a polymer color tone superb to that of conventional products.

Owner:TORAY IND INC

Filter plate of filter press

InactiveCN104083911AHigh strengthAvoid deformationFiltration separationCompressive strengthFilter press

The invention discloses a filter plate of a filter press and relates to the field of solid-liquid separation, aiming at solving the technical problem that a plate-and-frame filter plate is low in compressive strength in the prior art. A feeding channel and a liquid outlet are formed in the filter plate; bosses are formed in the front surface and the rear surface of the filter plate; the bosses are detachably connected with the filter plate. The filter plate is applied to a plate-and-frame filter press.

Owner:浙江金鸟压滤机有限公司

Production technology of red date concentrated clear juice

ActiveCN103519260BAdd flavorKeep the aromaFood thermal treatmentFood preparationAdditive ingredientCross-flow filtration

The invention relates to a production technology of red date concentrated clear juice, which comprises the following steps: impurity removal, fruit check and cleaning; breaking and rehydration; pulping and separation; enzymolysis; centrifugal separation; enzyme deactivation; high-temperature extraction; secondary centrifugal separation; cross flow filtration; vacuum low-temperature concentration; and sterile filling. The production technology provided by the invention has the advantages that with the red dates as the raw materials and by adopting a two-step breaking process, the breaking effect is improved, and the extraction rate of the raw materials is improved; by adopting the low-temperature rehydration process, the bright color, pure flavor and high content of nutritional ingredients of the date juice are guaranteed; by adopting the high-temperature extraction process, the physiologically-active substances in the red dates can be extracted to the greatest degree; since the high-temperature extracted juice returns to the rehydration section, the utilization rate of the raw materials is improved; and by adopting the cross flow filtration, the product has bright color and rich date aroma and is the best raw material for the deep processing of red dates. The production technology provided by the invention is reliable in the production technique of the domestic advanced level, fills up the blank of the key processing technology in domestic red date juice production, is a national initiative and meets the industrial production need.

Owner:CHINA LIGHT IND INT ENG CO LTD

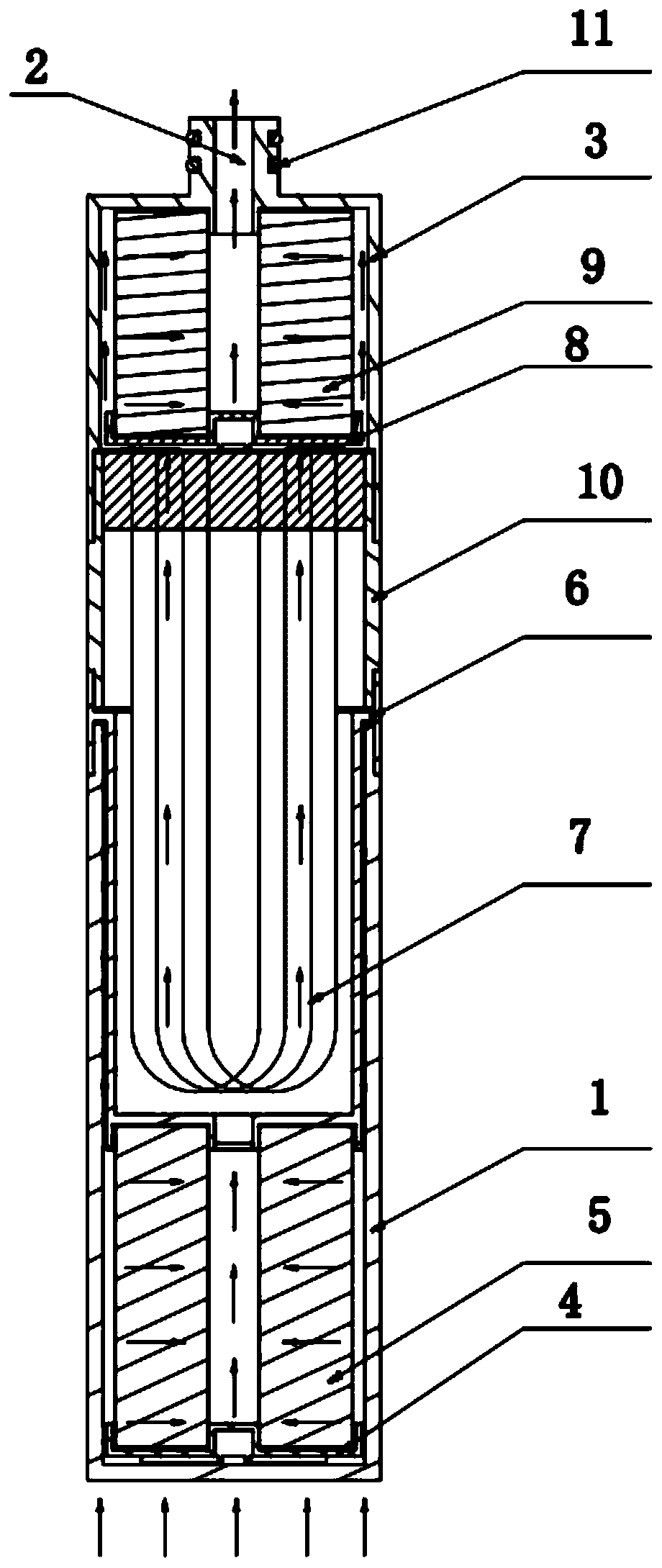

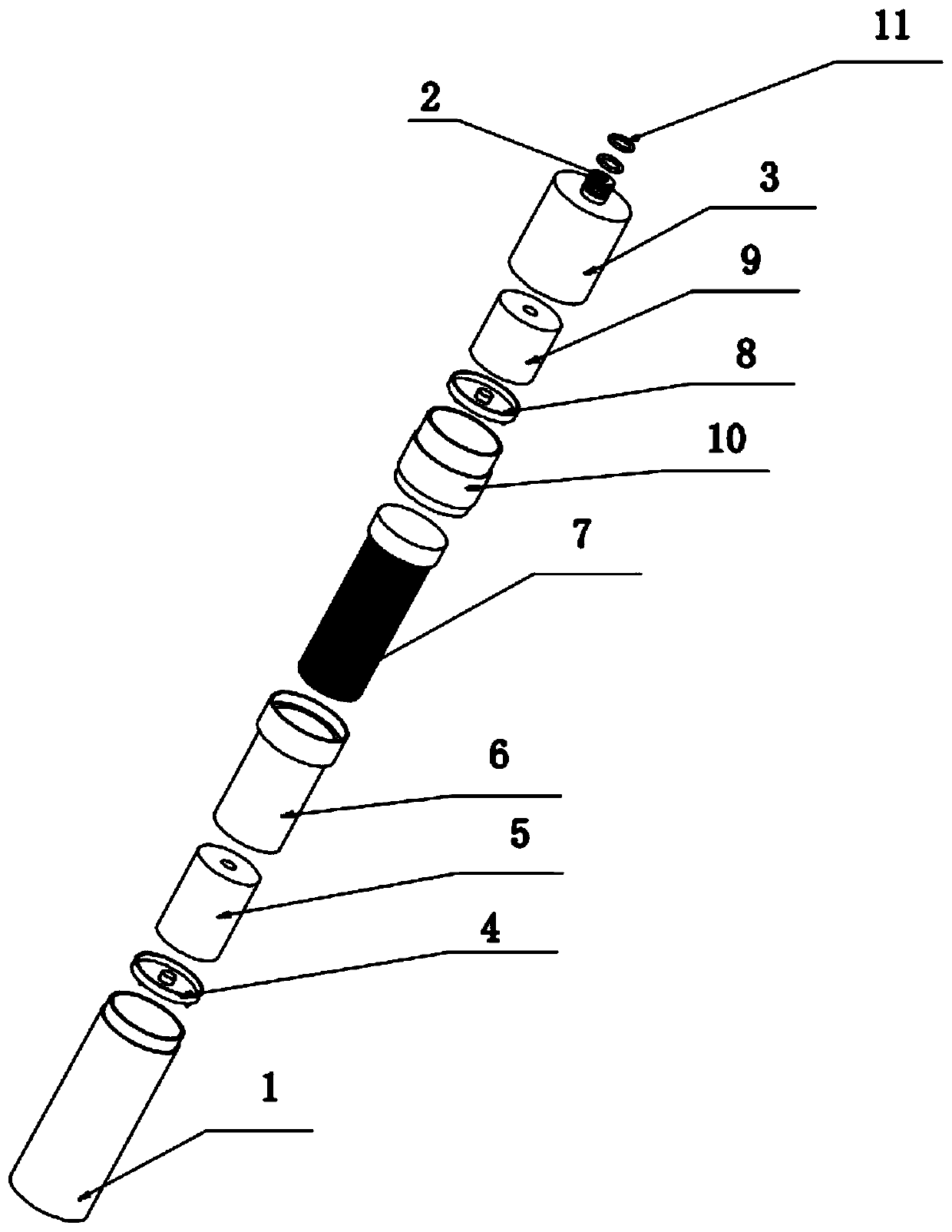

Personal water purifying device

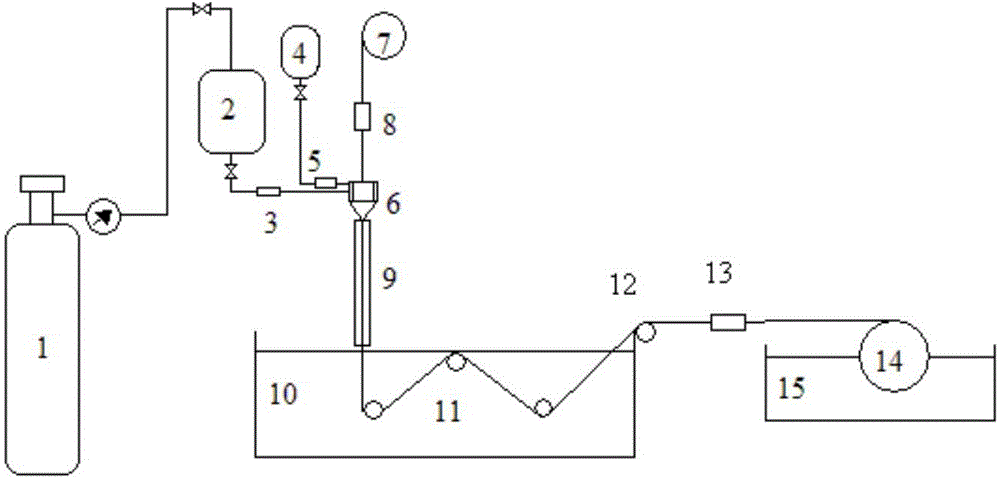

PendingCN106315898ATo achieve the purpose of drinking directlyImprove filtering effectTreatment involving filtrationMultistage water/sewage treatmentPeristaltic pumpTap water

The invention discloses a personal water purifying device, which comprises a water purifying device body and is characterized in that the water purifying device body comprises a peristaltic pump module, a primary filtering module, a secondary filtering module and a tertiary filtering module in sequential connection. By adopting the technical scheme, the personal water purifying device has the beneficial effects that tertiary filtering mode is used; the filtering effect is good; the goal of direct drinking of producing water is realized; a hand-operated peristaltic pump is used; the continuous water inlet and water producing can be realized; the filtering driving pressure is provided for municipal pipeline tap water, so that the effective multistage filtering becomes feasible; the modular design is used; the filtering modules are connected through screw threads; any module can be simply and conveniently replaced; the whole service life of the device is effectively prolonged.

Owner:XIAMEN ZHONGZHAN RENEWABLE RESOURCES TECH

Filter press

InactiveCN100376307CAdaptableImprove airtightnessMoving filtering element filtersDevice formEngineering

The invention relates to a pressure filter, which comprises a single straining chamber device formed by a fixing filter plate, a multifunctional straining chamber ring, a moving frame and a movable filter plate. Wherein, the fixing filter plate has a liquid inlet and a filtrate outlet and a ring to fix the sealing surface of filter plate straining chamber; the surface of fixing filter plate has liquid discharge grooves; the fixed filter plate straining chamber sealing surface and the straining chamber sealing surface of multifunctional straining chamber ring clamp the fixed filter plate filter cloth; another straining chamber sealing surface of multifunctional straining chamber ring and the sealing surface of moving frame fix the filter cloth of movable filter plate; the moving frame via the hydraulic system compresses the moving frame, the multifunctional straining chamber ring and fixing filter plate; the fixing filter plate, multifunctional straining chamber ring and the moving frame form the straining chamber; the movable filter plate can make piston movement inside the straining chamber; the side wall of multifunctional filter chamber ring has a feeding inlet; the surface and side surface of movable filter plate have liquid discharge grooves, while the back surface has guide rod; the hydraulic system via the guide rod pushes the movable filter plate forwards or backwards inside the straining chamber.

Owner:蒋卓冰

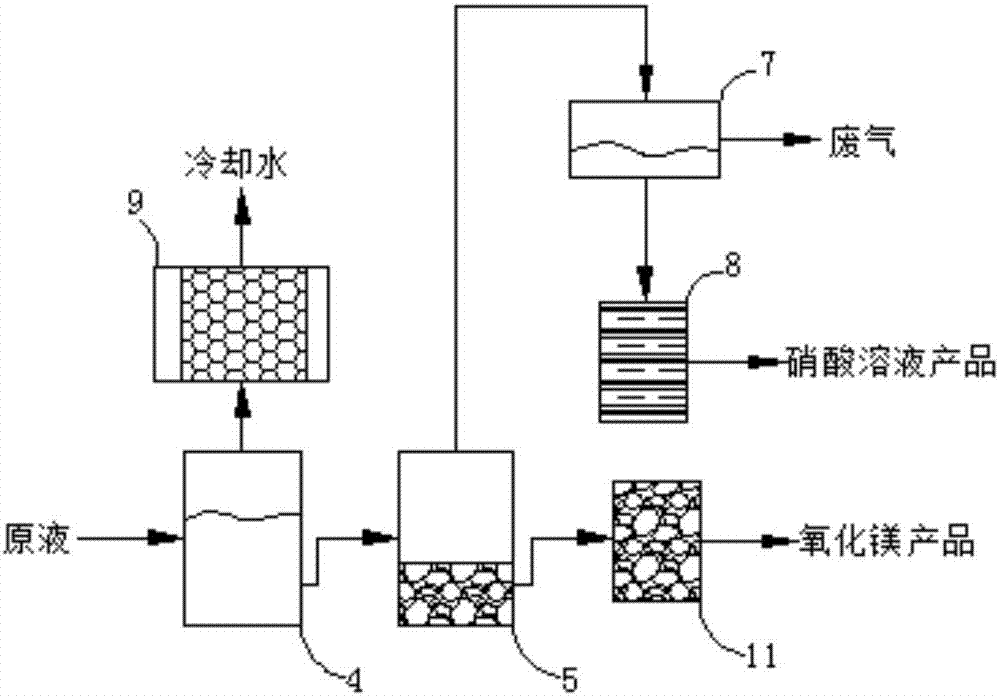

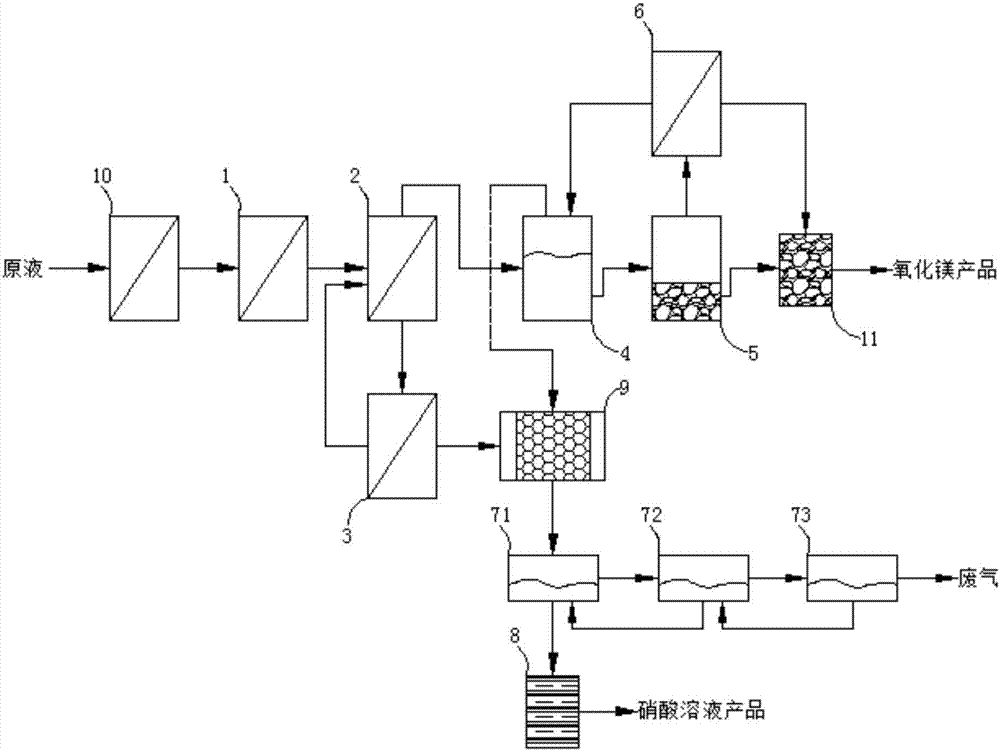

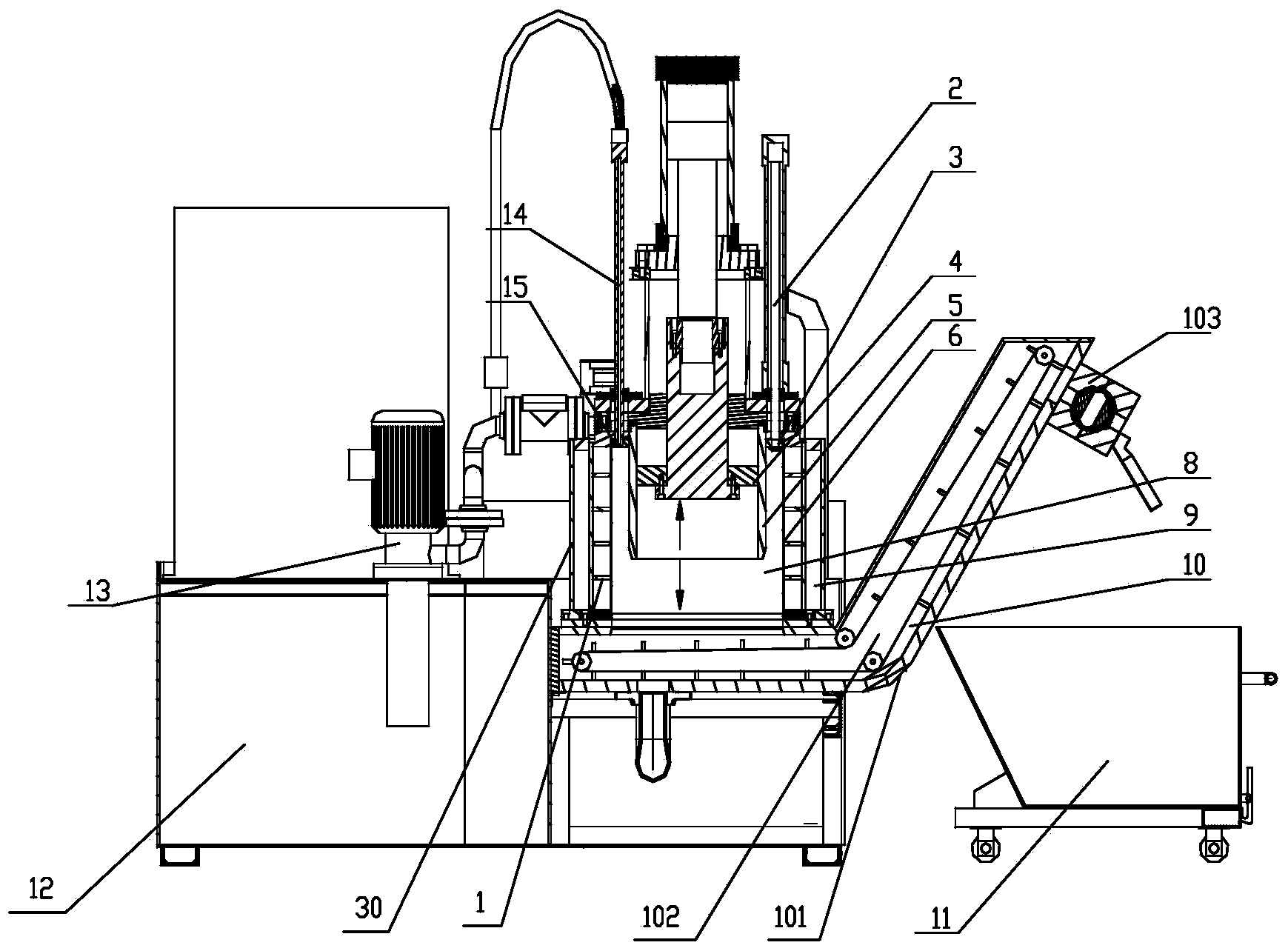

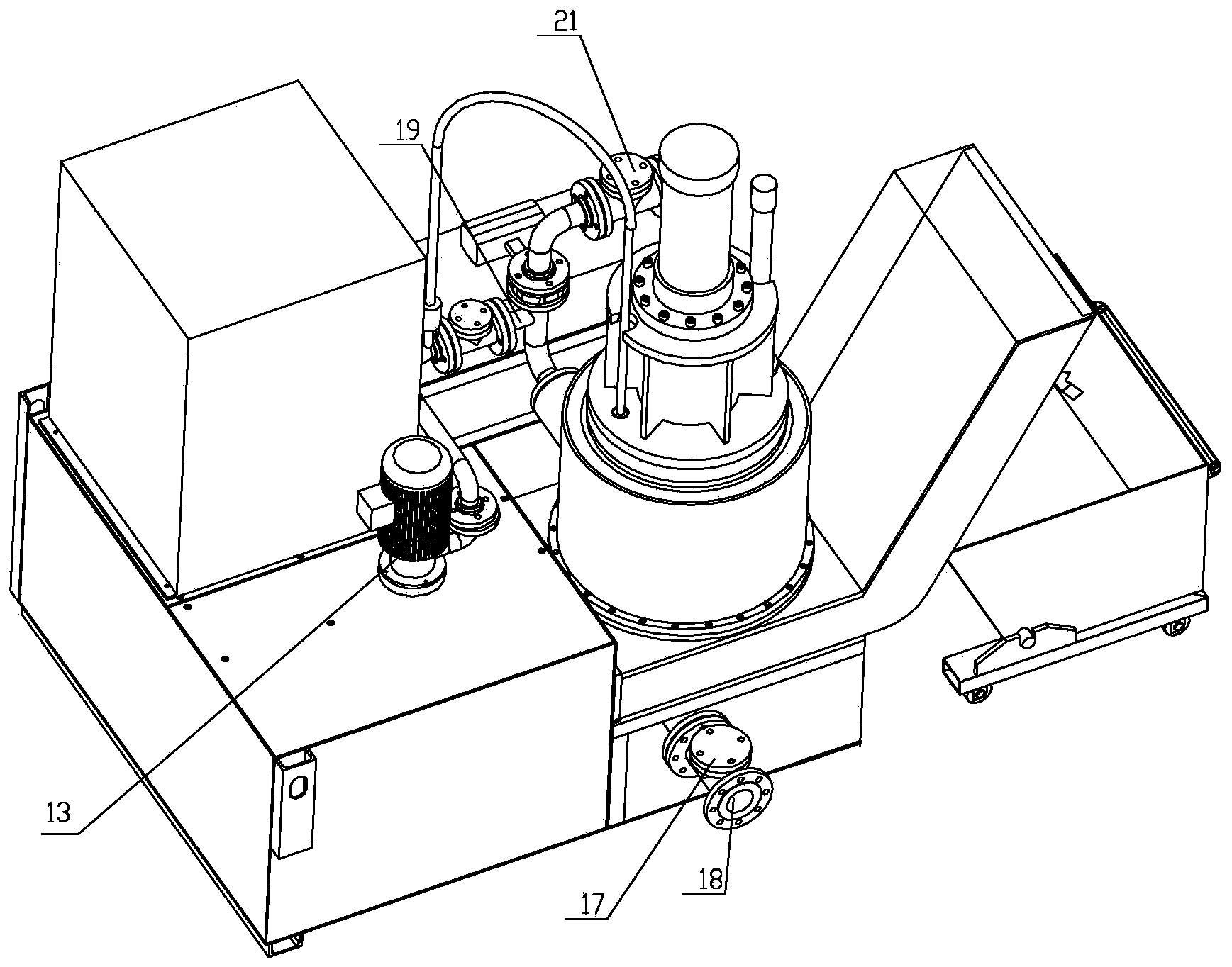

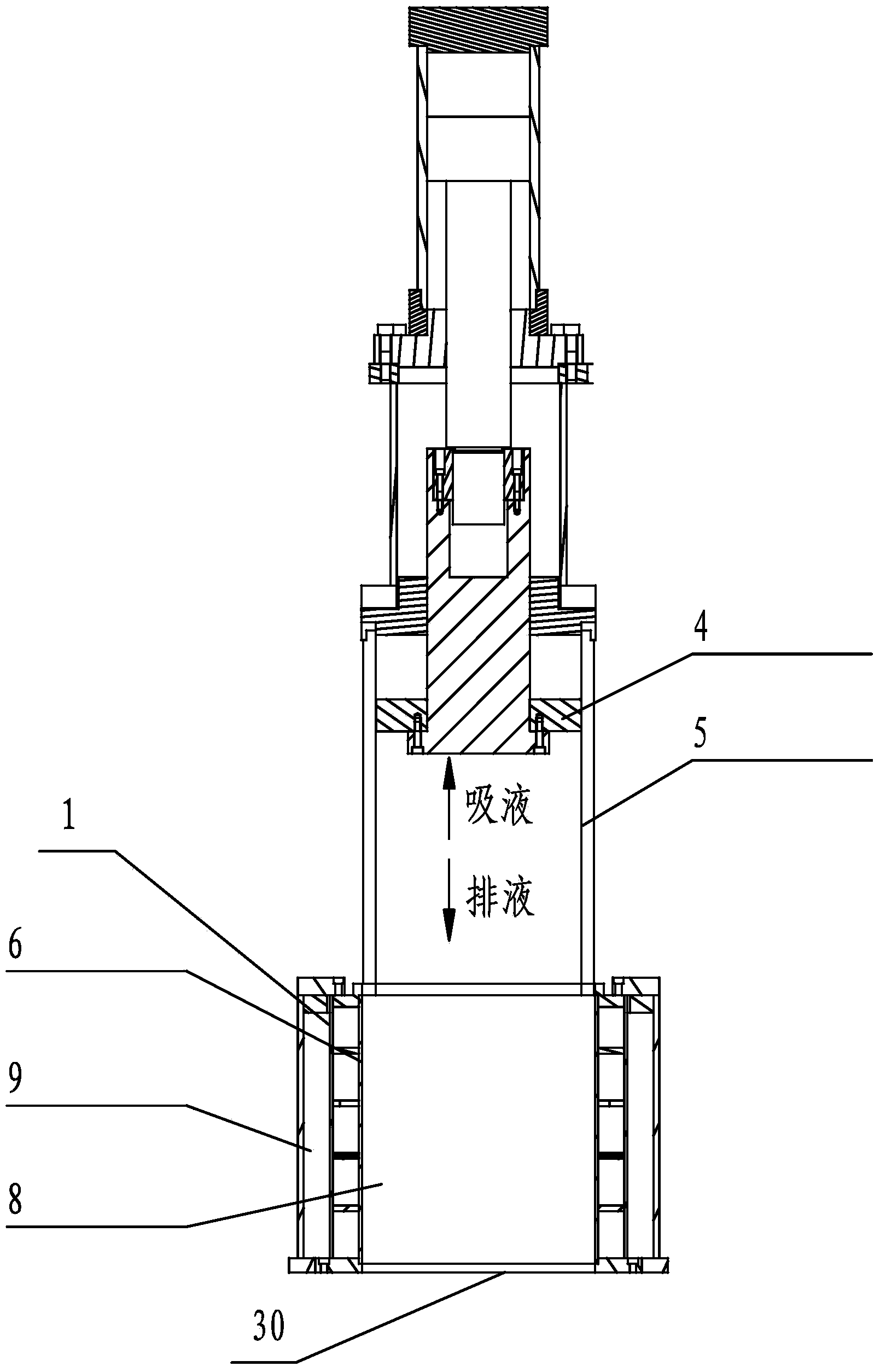

Equipment and method for dissolving nitrate solution

PendingCN107459021ASimple structureReduce energy consumptionNickel oxides/hydroxidesMagnesiaNitrate saltsFiltration

The invention discloses equipment for dissolving a nitrate solution. Nitrate comprises nitrate ions and metal ions. The nitrate liquor is dissolved by the equipment to obtain a nitric acid solution and metallic oxides. The equipment comprises a concentration device, a calcination device and an absorption device. The concentration device is used for concentrating stock solutions, the calcination device is used for calcinating second concentrated solutions, and the absorption device is used for absorbing nitric acid in acid gases. The concentration device comprises a first filter, a second filter and an evaporation and concentration device. The ratio of filtration media of the first filter to the molecular weight is larger than or equal to interception rate of 1000 substances which is larger than or equal to 99%. The ratio of filtration media of the second filter to the molecular weight is larger than or equal to the interception rate of 100 substances which is larger than or equal to 99%. A first filtrate outlet of the first filter is communicated with a liquid inlet of the second filter. A first concentrated-solution outlet of the second filter is communicated with a liquid inlet of the evaporation and concentration device. A second concentrated-solution outlet of the evaporation and concentration device is communicated with a liquid inlet of the calcination device. An acid-gas outlet of the evaporation and concentration device is communicated with a gas inlet of the absorption device.

Owner:SICHUAN SIDANENG ENVIRONMENTAL PROTECTION TECH CO LTD

Solid-liquid mixture filter device

InactiveCN103949101ANo wearNo vacuumStationary filtering element filtersChemical industryWater filter

The invention discloses a solid-liquid mixture filter device. The solid-liquid mixture filter device comprises a tank, a cylinder jacket, a piston, a filter medium and a solid discharging device, wherein the bottom of the tank is communicated with the solid discharging device; the filter medium is arranged in the tank; the space in the tank is partitioned into two parts of a filter cavity and a liquid purification cavity; the filter cavity is communicated with the liquid purification cavity through filter holes in the filter medium; a liquid inlet pipe provided with a liquid inlet one-way valve is communicated with the filter cavity; a liquid outlet pipe provided with a liquid outlet one-way valve is arranged on the outer wall of the tank and is communicated with the filter purification cavity; the cylinder jacket is communicated with the filter cavity; the piston is inserted into the cylinder jacket. The solid-liquid mixture filter device is reasonable in structure, convenient to operate, high in filter precision, high in efficiency, low in energy consumption, free from pollution, and low in using cost and maintenance cost, and is applicable to water filter, oil filter and mineral purification and filter, and can be widely applied to filtering of solid-liquid mixtures in water treatment industry, food chemical industry, industrial mining industry, machining industry and the like.

Owner:于洪峰

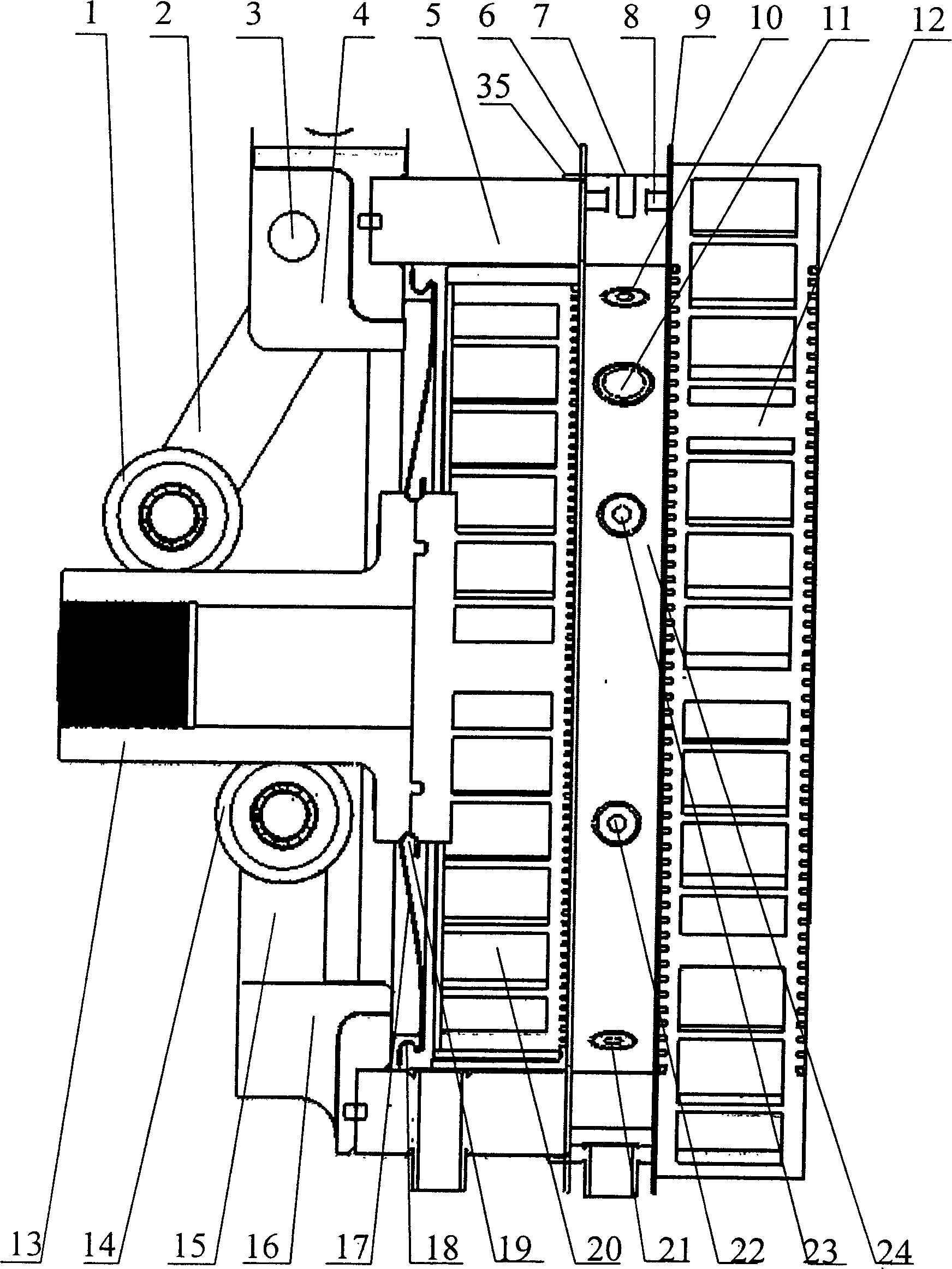

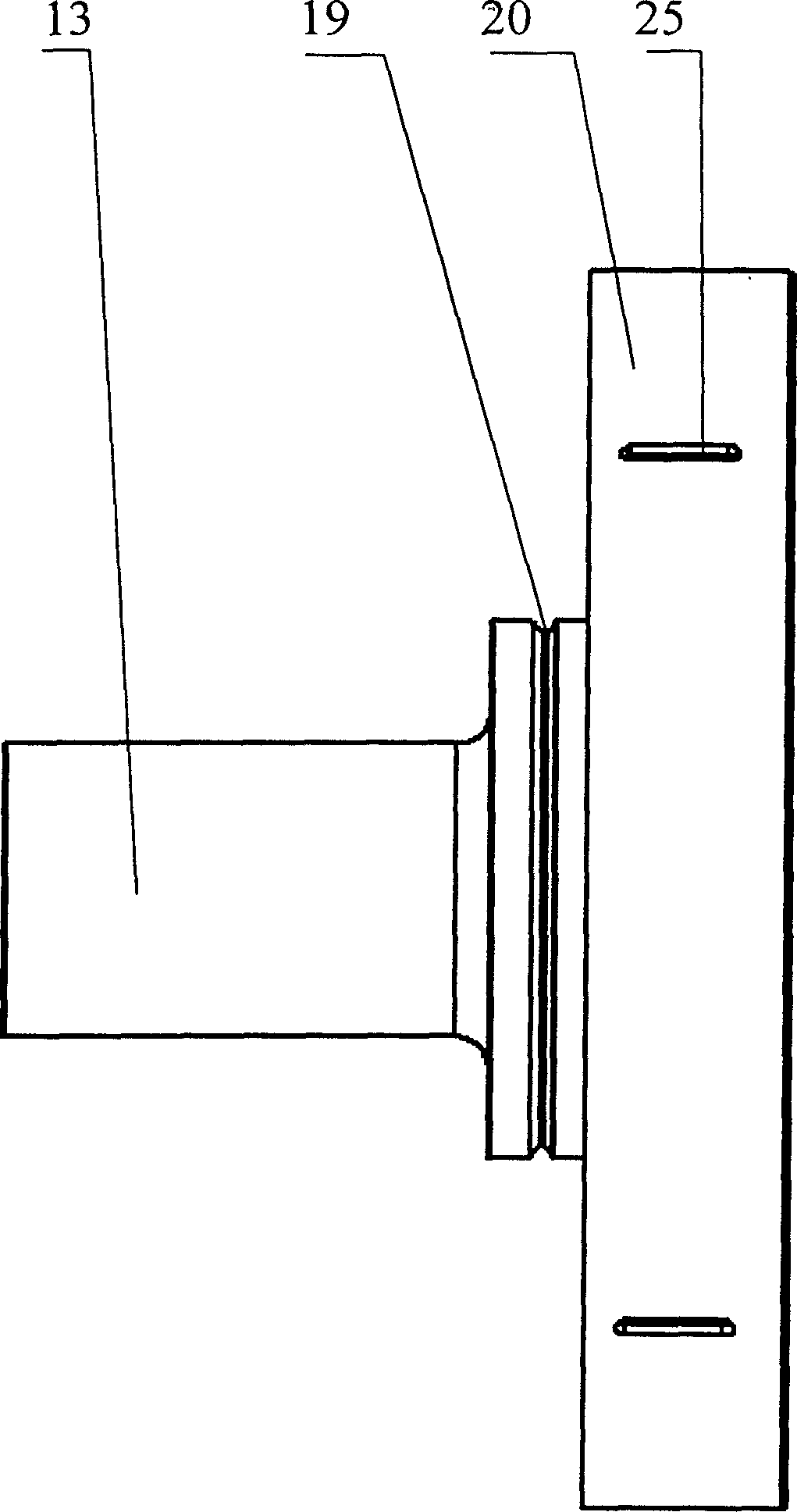

Belt type filter press

ActiveCN100355481CHigh filtration pressureHigh filter pressureMoving filtering element filtersEngineeringFilter press

The invention relates to a belt compress filter for dewatering the micro grains, wherein it is formed by a frame, a driver, a feeding device, a compress area and an auxiliary device; said compress area comprises a compress filtering roller and a filtering belt; the driver comprises a motor and a gear box; the auxiliary device comprises a tension roller, a scrape device, a water collector, a corrector, and a filter belt washer. The invention is characterized in that: the back of filter belt is lined with steel compress belt; the compress filtering rollers are compacted arranged. The invention can improve the filter pressure of compress filter to improve the balance point between the filter pressure and the filter resistance, to overcome the defects of present technique, while it can improve the dewatering efficiency and the yield.

Owner:ZHEJIANG HUAZHANG TECH

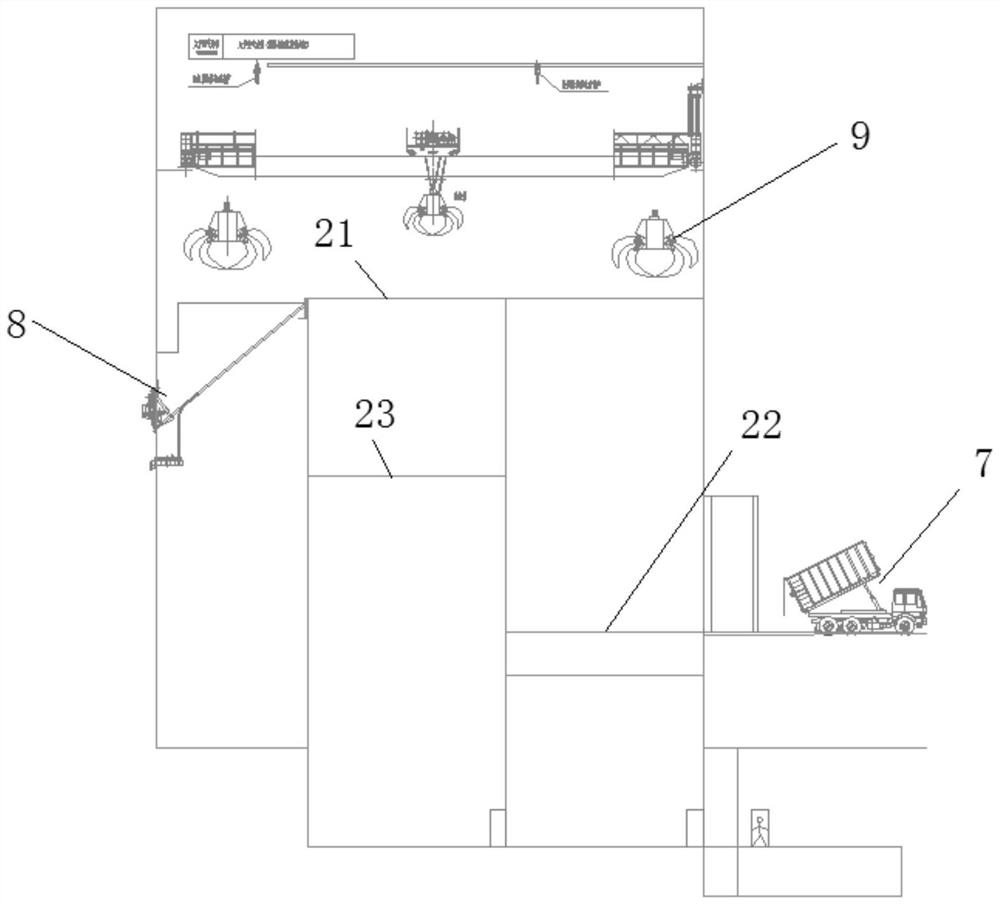

Garbage storage warehouse

PendingCN112443846AIncrease effective storage capacityIncrease filter pressureWaste collection and transferRefuse receptaclesAir volumeDust control

The invention relates to a garbage storage warehouse. The garbage storage warehouse comprises a storage warehouse bin, wherein a plurality of partition plates are arranged in the storage warehouse binand divide the storage warehouse bin into a plurality of partition cabins with openings in the upper portions, the partition cabins are divided into an unloading cabin, a circulation cabin, a fermentation cabin and a feeding cabin, and the feeding cabin and the circulation cabin are both adjacent to the unloading cabin. Compared with the prior art, the effective storage capacity of the garbage warehouse is improved, the fermentable (especially anaerobic fermentation) time of garbage can be prolonged, the average prolonged time is 30%, the filter pressing pressure of leachate of the garbage isimproved, the standing leachate time is prolonged, and more leachate is generated, so that the water content of the garbage before entering a furnace is reduced, the waste incineration heat value andthe power generation capacity are improved, the air volume is reduced, the loads of fan equipment and dust removal, deacidification and denitration equipment are reduced, and the equipment investmentis reduced.

Owner:SHANGHAI INSTALLATION ENG GRP

A road cleaning and sweeping vehicle with sewage recycling and recycling

InactiveCN103821098BSolve the problem of taking up too much spaceSolve difficult puzzles to controlSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisSpatial structureSewage

The invention relates to a road cleaning sweeper truck with a sewage recovery and reutilization function. The sweeper truck comprises a truck body and a clean water tank, wherein the clean water tank and a sewage tank are separated by a retaining plate, and are respectively and fixedly arranged on a chassis, a suction pipe penetrates through the chassis and extends into the sewage tank, the bottom of the suction pipe is connected with a suction nozzle for cleaning, a polymer sintering membrane filter is arranged at the top end in the sewage tank, a sewage pump is arranged in the sewage tank, and is connected with the polymer sintering membrane filter through a pipeline, a filtering water outlet pipe extends to an opening at the top of the clean water tank along the outer edge of the sewage tank by passing through the polymer sintering membrane filter, a backwashing pipe is connected with the polymer sintering membrane filter, and the opening of the backwashing pipe is provided with a backwashing valve. The sweeper truck has the advantages that the space structure of the sewage tank of the sweeper truck is sufficiently utilized by the horizontal type polymer sintering membrane, the problem of overlarge occupation space when the polymer sintering membrane filter is vertically arranged is solved, the filtering flow quantity of the polymer sintering membrane is approximate to the constant flow quantity in the specific application, and the filtering pressure in the sewage cavity is increased; the problems of overhigh initial flow quantity and difficult control over constant flow quantity are solved.

Owner:XIAMEN UNIV OF TECH

Faucet filter element structure

InactiveCN109824162AImprove corrosion resistanceEffective take outWater contaminantsMultistage water/sewage treatmentSolventImpurity

The invention discloses a faucet filter element structure. The faucet filter element structure adopts a PE sintering filter element as a main shell, and the PE sintering filter element can bear high filter pressure, is nontoxic and tasteless, and has good corrosion resistance to an acid-base solvent; an inner filter element material adopts multiple combination modes, and multiple effects that large particle impurities and tiny particles can be effectively taken out, chlorine, organic impurities, colors and peculiar smells in raw water are removed, bacterium breeding is effectively inhibited, viruses are effectively removed, and water scales are prevented from generating are achieved; the faucet filter element structure is high in filtering capacity and is also completely excellent in adsorption capacity, and water after filtering is clean and safe, and can be directly drunk.

Owner:叶丹

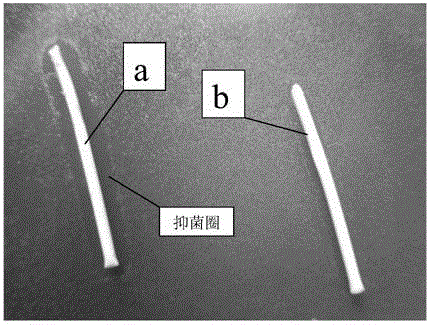

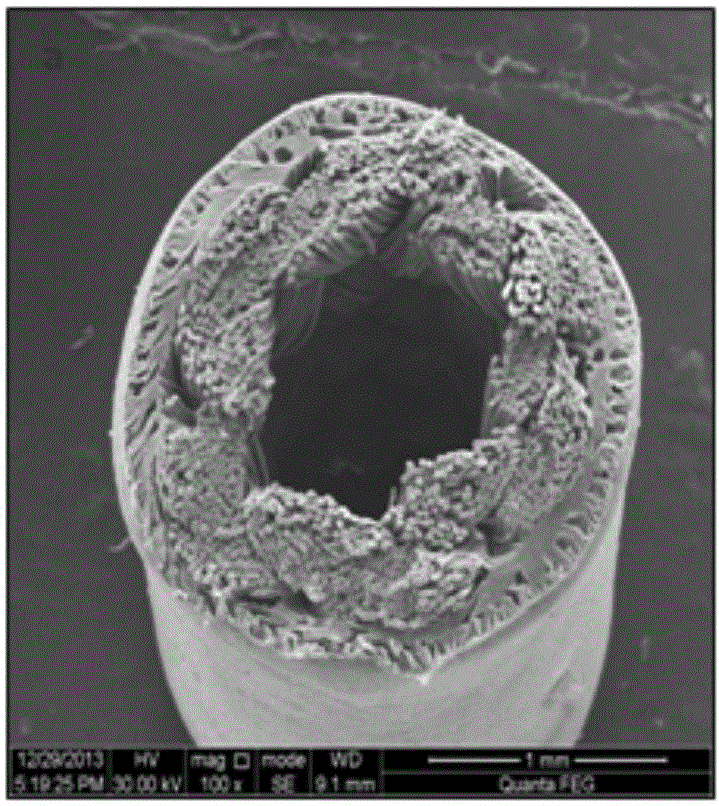

A kind of preparation method of pvc hollow fiber membrane with bacteriostasis

ActiveCN103933867BReduce manufacturing costImprove mechanical propertiesSemi-permeable membranesPolyesterPolymer science

The invention provides a preparation method of a PVC (polyvinyl chloride) hollow fiber film with antibacterial performance. The preparation method comprises the following steps: under an ultrasonic condition, dissolving and dispersing silver nanoparticles in a solvent for dissolving polyvinyl chloride; adding polyvinyl chloride, a pore-forming agent and Tween-80 into a spinning pot with a solvent and stirring under a sealing condition; vacuumizing, standing and defoaming; filtering out impurities to obtain a film casting solution; injecting the film casting solution into a spinneret by a metering pump and simultaneously introducing polyester yarn threads into the spinneret by traction, allowing the polyester yarn threads to flow out together with the film casting solution, and evenly applying the film casting liquid to the outer surfaces of the polyester yarn threads of a support layer; and performing a phase inversion process in a coagulating bath, thereby obtaining the reinforced hollow fiber film with antibacterial performance. The hollow fiber film has the characteristics of bacteria inhibiting capability, high strength, high flux and low price.

Owner:HARBIN ENG UNIV

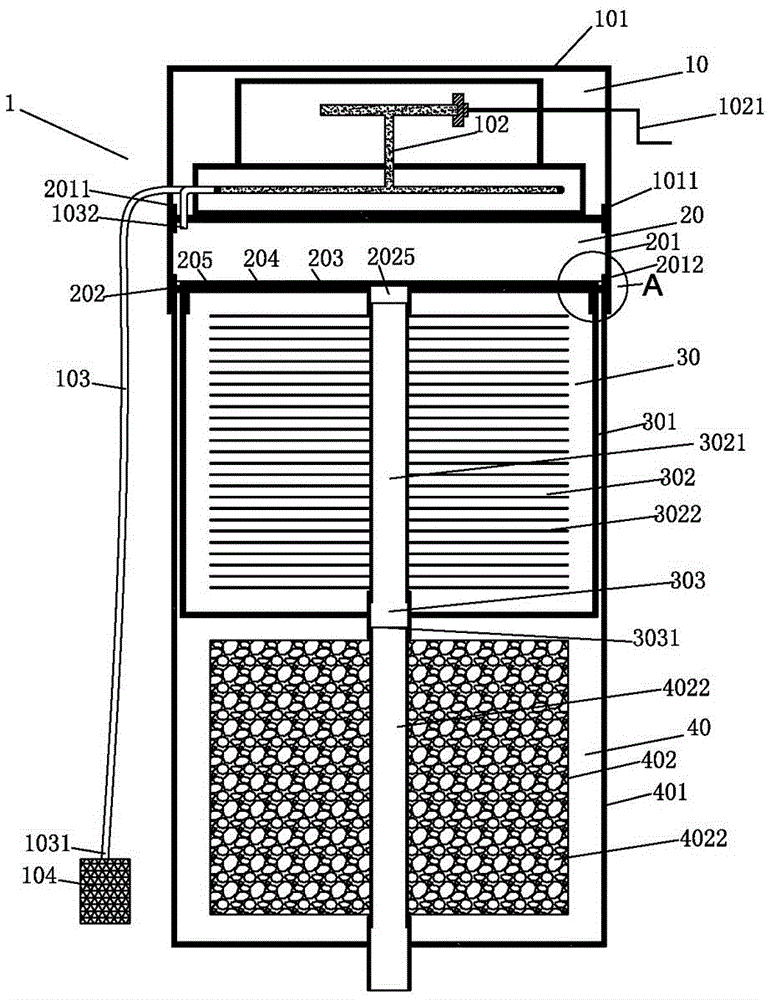

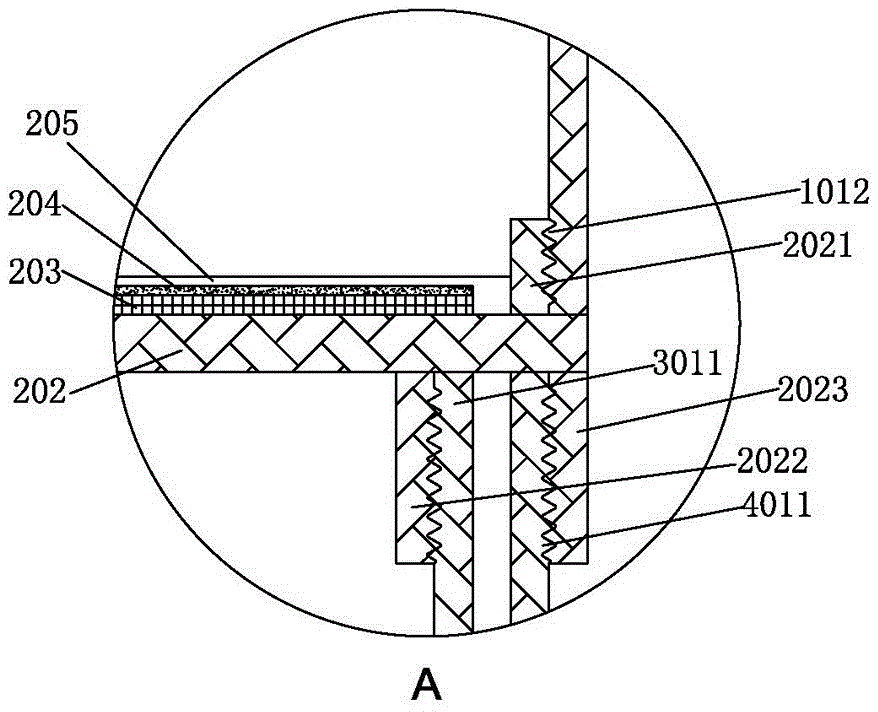

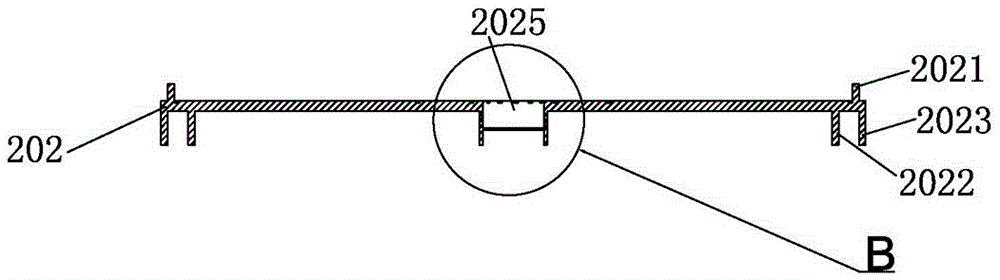

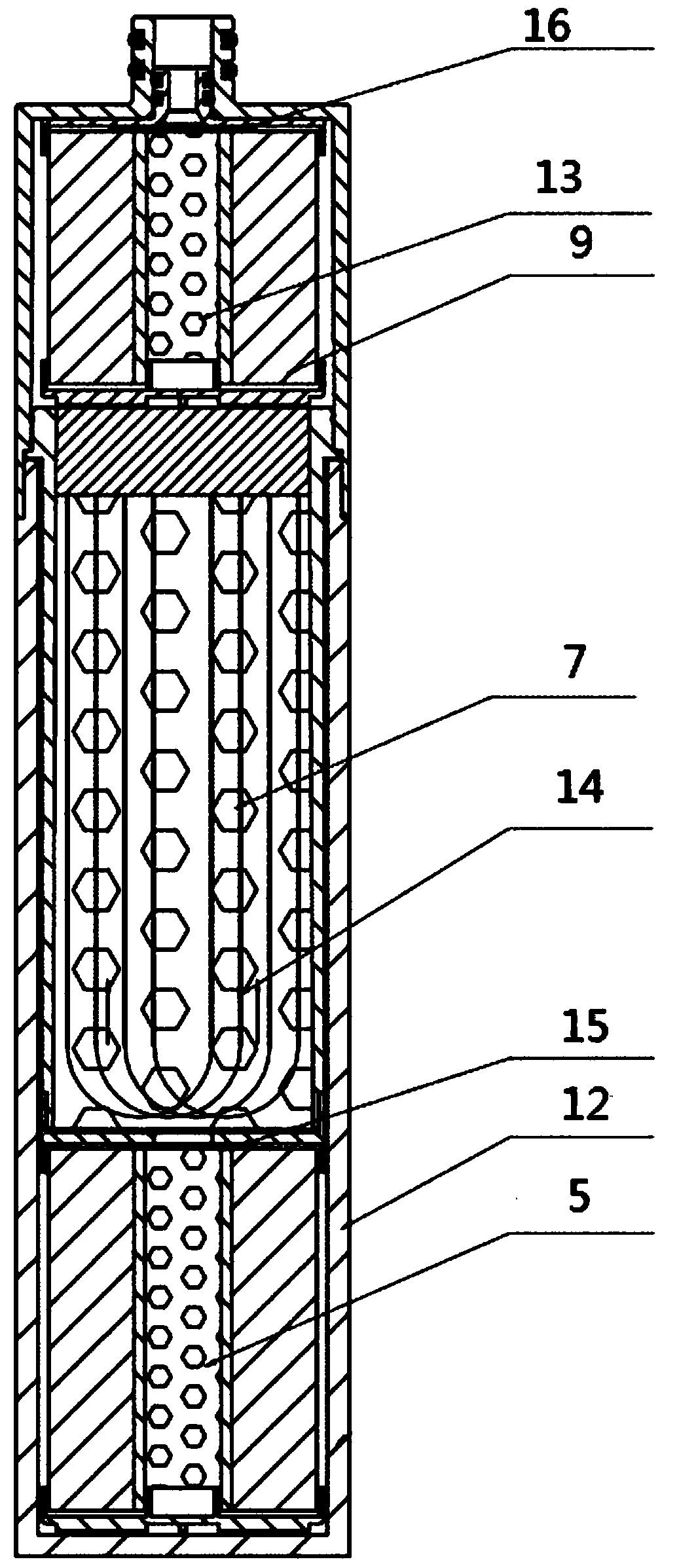

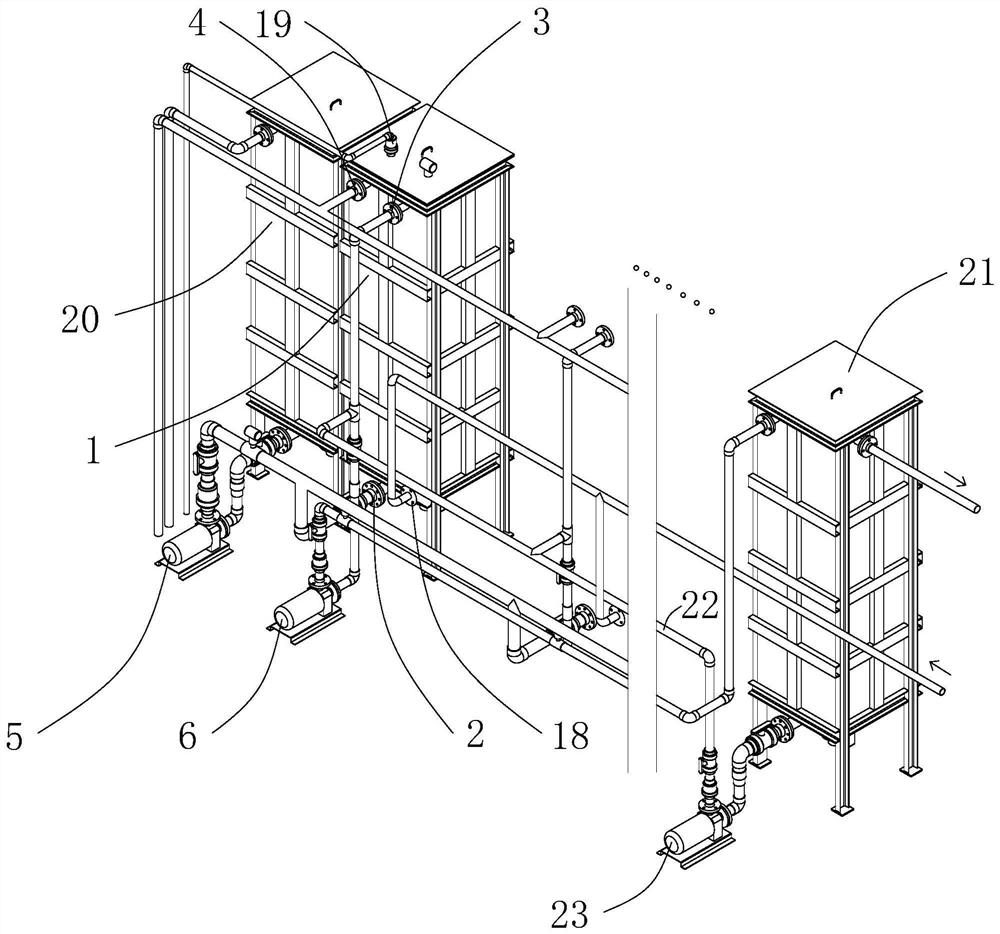

Membrane filtration device

PendingCN112263914AIncrease filter pressureIncrease membrane fluxSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFiltrationWater production

The membrane filtration device comprises a sealing tank, a water inlet, a first water production port, a concentrated water port, a water inlet pump, a water production pump and an immersed curtain type membrane assembly, wherein the water inlet, the first water production port and the concentrated water port are formed in the sealing tank; the water inlet pump is communicated with the water inlet; the immersed curtain type membrane assembly comprises a membrane tow, an upper membrane tube, a lower membrane tube, an upper mounting bracket, a lower mounting bracket, a second water production port formed in the upper membrane tube and / or the lower membrane tube, and a water collector communicated with the first water production port and the second water production port respectively; the upper mounting bracket and the lower mounting bracket are fixedly connected into the sealed tank, wherein at least one of the upper membrane tube and the lower membrane tube is a movable membrane tube, the movable membrane tube is movably connected with the corresponding mounting bracket, a limiting piece for preventing the movable membrane tube and the corresponding mounting bracket from completely separating is arranged on the movable membrane tube, and the limiting piece is positioned on one side, away from the membrane tow, of the corresponding mounting bracket. According to the membrane filtration device, the membrane flux is relatively high; sundries can be prevented from accumulating at the end of the film curtain, and the system operation stability is good.

Owner:苏州富淼膜科技有限公司

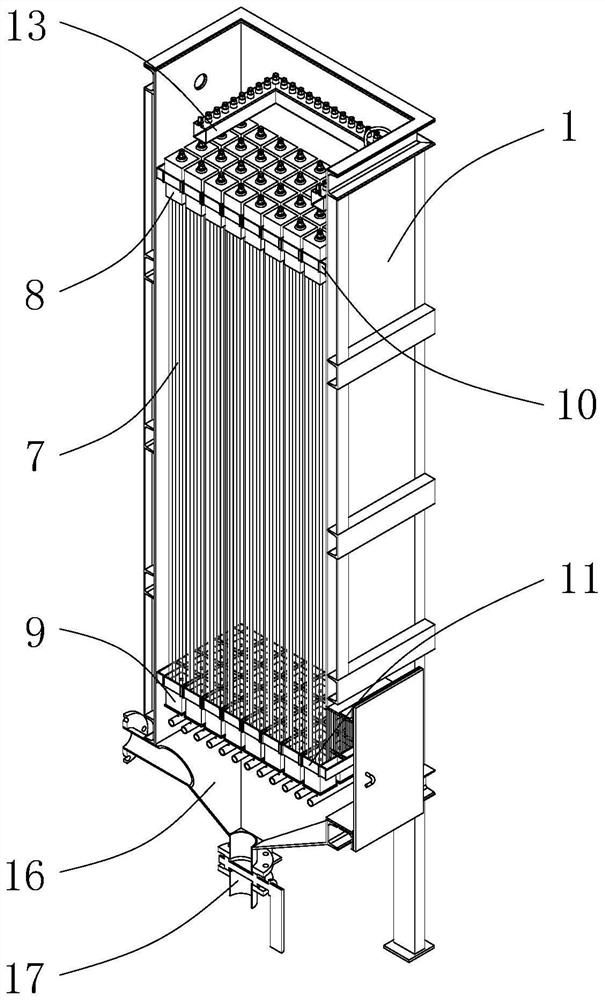

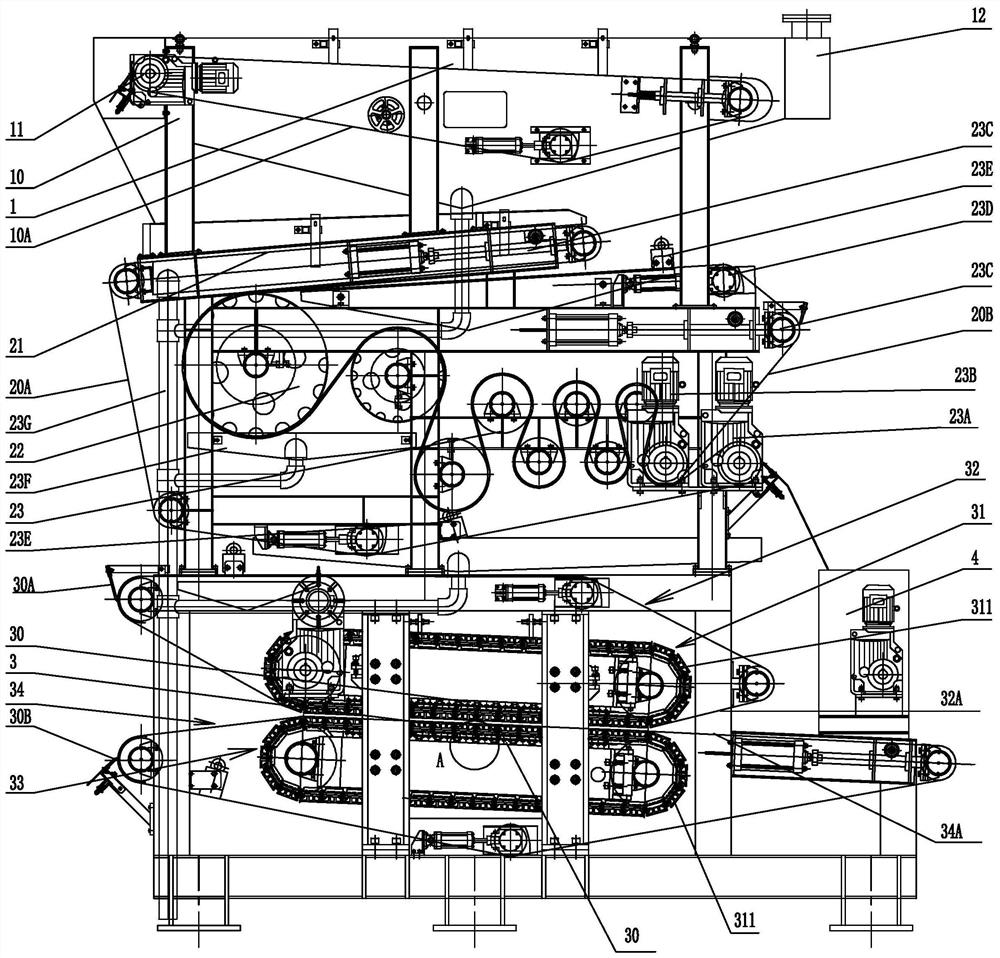

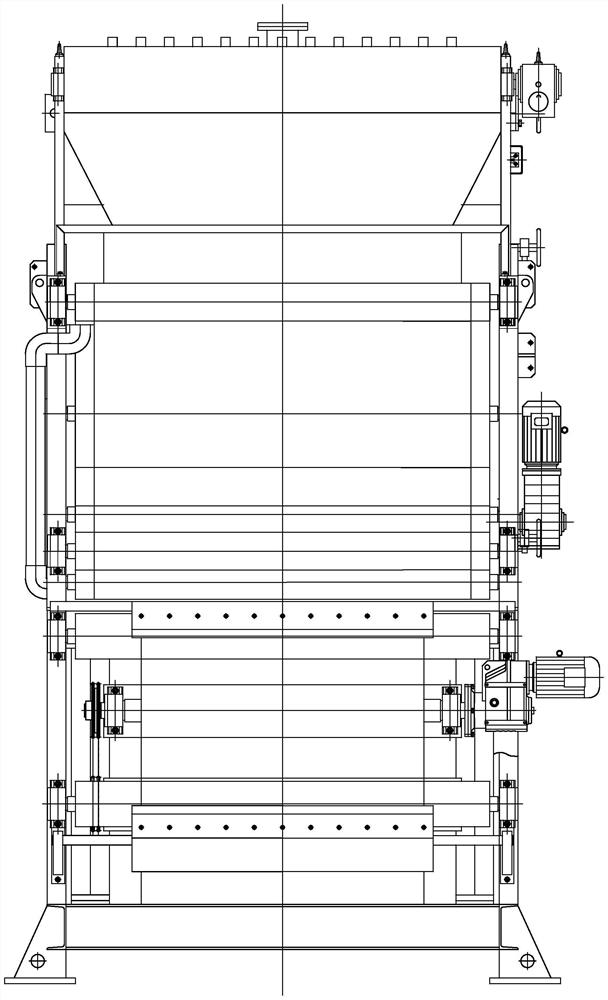

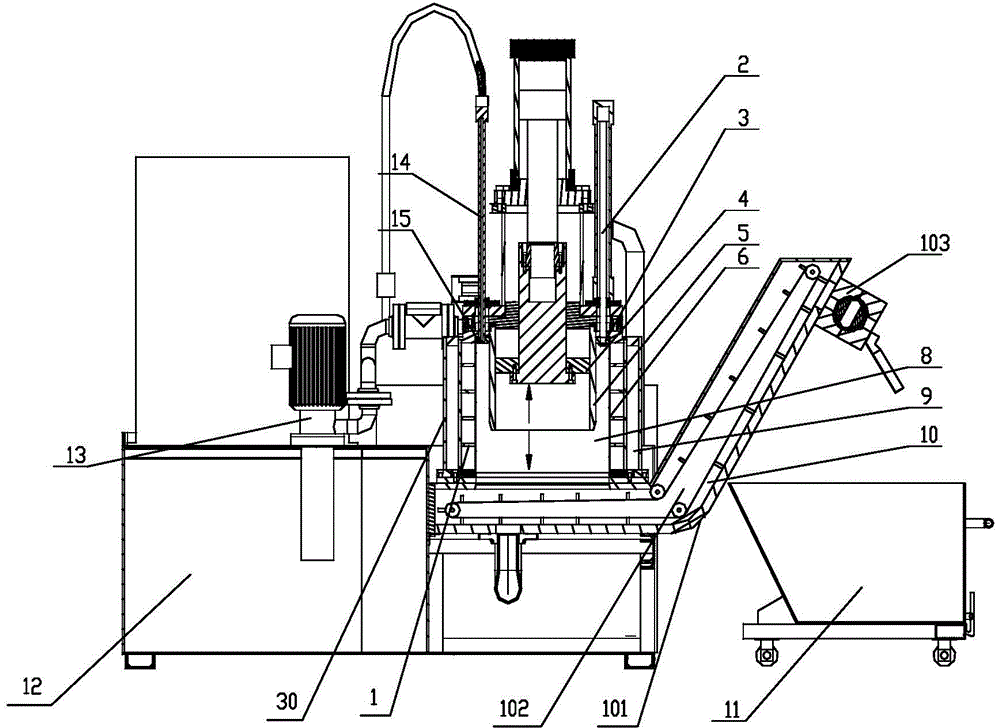

High-pressure filter press

PendingCN113018952AIncrease filter pressureImprove high pressure adaptabilitySludge treatmentWaste water treatment from plant processingEngineeringFilter press

The invention discloses a high-pressure filter press. The high-pressure filter press comprises a belt type filter-pressing dehydration section and a crawler belt high-pressure dehydration section which are mounted on a rack from top to bottom, wherein the belt type filter-pressing dehydration section comprises a gravity dehydration section, a low-pressure dehydration section and a medium-pressure dehydration section with pressures sequentially increased from top to bottom; and a mixing stirrer is arranged between a discharge port of the medium-pressure dehydration section and a feed port of the crawler belt high-pressure dehydration section. According to the high-pressure filter press, filtering pressure is greatly increased, the maximum filtering pressure is increased to 5 MPa from 0.6 MPa, and the filtering effect which is not lower than the filtering effect of a high-pressure diaphragm plate-and-frame filter press is achieved; the mixing stirrer is mounted at the feeding position of the crawler belt high-pressure dehydration section, and a filter aid or a treated backflow material is added into a material having been subjected to medium-pressure dehydration according to the characteristics of the material, so the high-pressure adaptability of the material is improved, and continuous high-pressure filtration dehydration is realized; and a crawler belt ring in the crawler belt high-pressure dehydration section is provided with a sealing strip and a water retaining flange, so a nail bearing is not corroded by a filtrate, and service life is greatly prolonged.

Owner:康觉

Polyester polymerization catalyst and method for producing polyester using the same

ActiveUS8816041B2Good colorImprove stabilityTitanium organic compoundsMetal/metal-oxides/metal-hydroxide catalystsForeign matterPolyester

Provided are a polyester polymerization catalyst with which the generation of foreign materials caused by the catalyst or mold pollution at the time of molding are reduced and polyesters having remarkably superior thermal stability and color tone can be obtained.Provided is a polyester polymerization catalyst produced by the reaction of a titanium compound and a mannitol in a molar ratio of titanium atom to mannitol of from 1:1 to 1:3. A method for producing a polyester employs the polyester polymerization catalyst.

Owner:TORAY IND INC

Integrated cutting table for live pig slaughtering

InactiveCN112934806AEasy to split jobsPrevent fallingClimate change adaptationLavatory sanitoryPork meatAgricultural engineering

The invention provides an integrated cutting table for live pig slaughtering. The integrated cutting table comprises a table top, a support and a clamping cover, wherein the table top is mounted at the top of the support, the clamping cover sleeves the outer side of the table top, inclined planes are welded to the bottom of the clamping cover, a spacer bush is welded to the inclined planes, a water tank is welded to the bottom of the inclined planes, a filter cylinder is welded to the inner wall of the water tank, a spiral plate is clamped to the inner side of the filter cylinder, and a motor I is mounted on one side of the water tank through bolts. According to the integrated cutting table for live pig slaughtering, water can be prevented from falling onto the ground, cleanliness and sanitation of the ground are guaranteed, the situation that carrying and moving of live pigs are affected by the clamping cover can be avoided, a live pig cutting operation is facilitated, contact between the corners of the table top and the clamping covers is reduced, cleaning is convenient, cleaning water can be recycled, water is saved, the interior of the filter cylinder and the interior of a conical opening can be cleaned up and disinfected, the inner side of the integrated cutting table can be kept clean and sanitary, bacterium breeding can be prevented, and the integrated cutting table is suitable for pork cutting in live pig slaughtering.

Owner:戚文芝

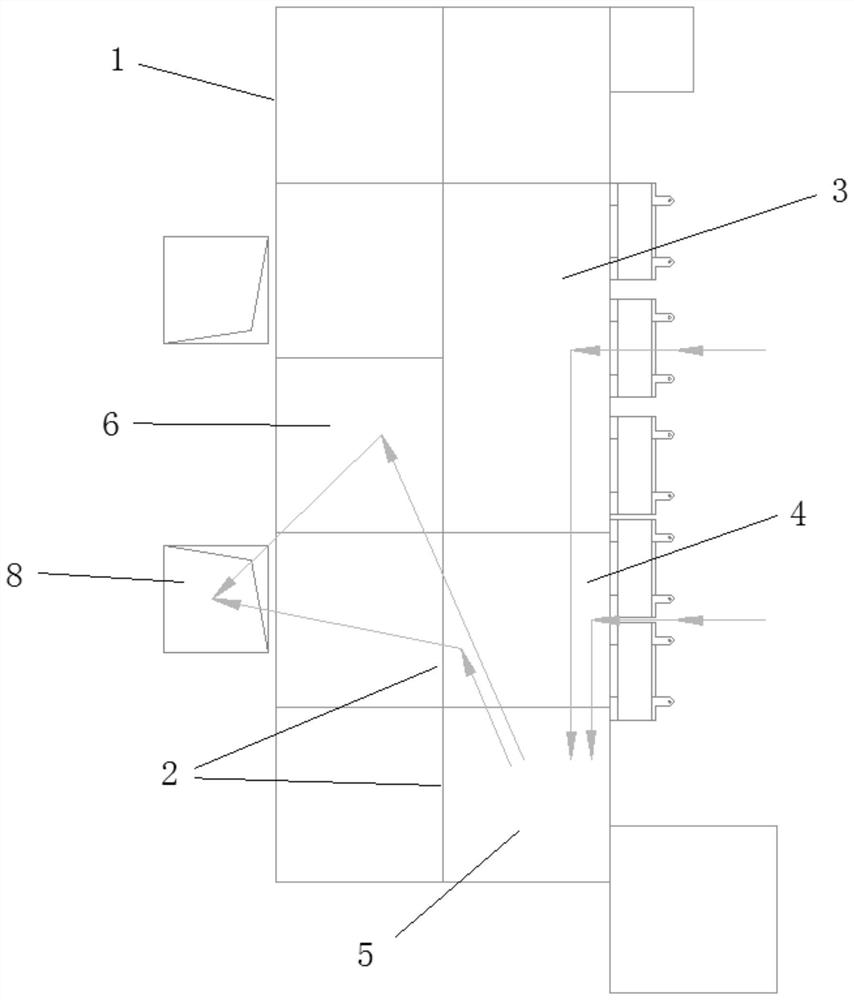

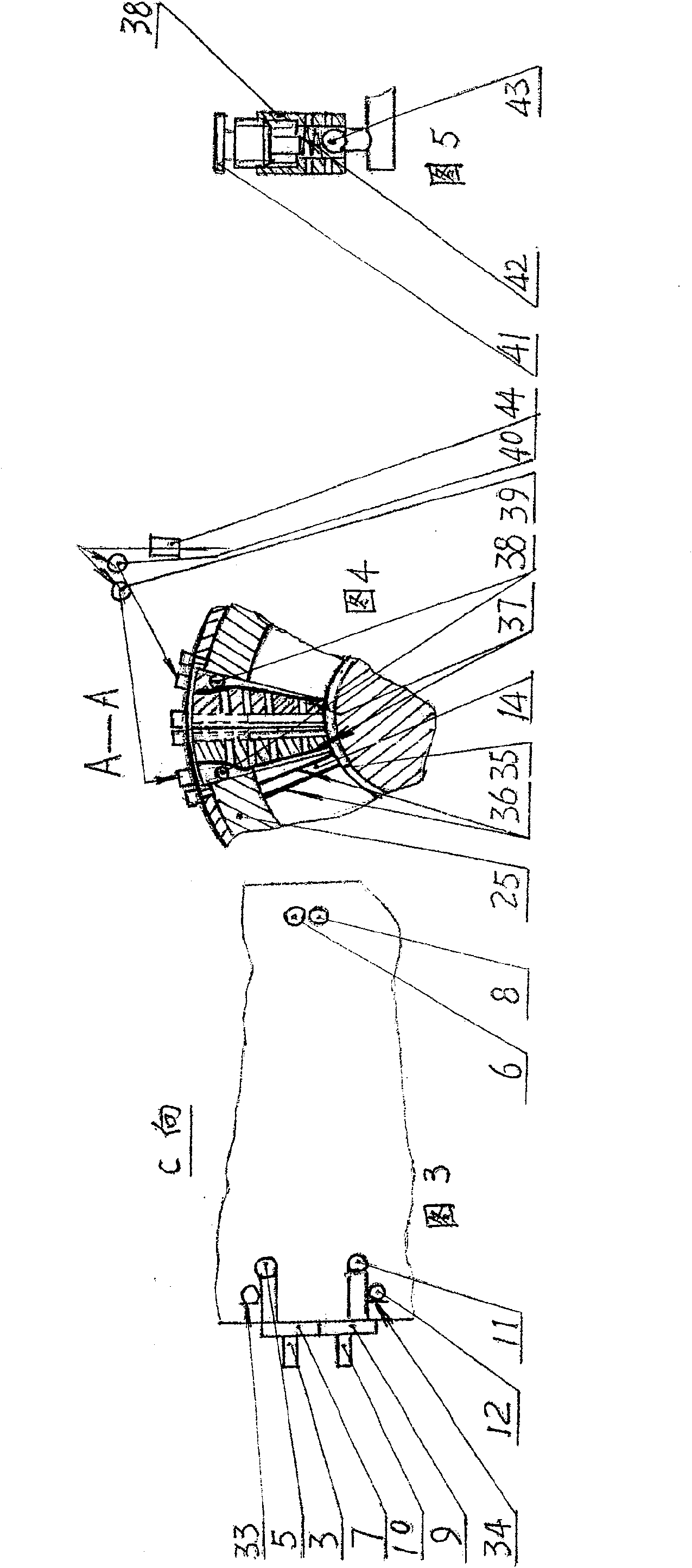

Pressure filter

InactiveCN100551484CImprove drynessImprove filter qualityFiltration separationClockwiseGastric tube feeding

The invention relates to a pressure filter machine, which is an improvement on the filter press. The invention provides a filter press which not only works continuously and automatically, but also can increase the filtration pressure and is convenient for vehicle-mounted movement. The present invention has a cylinder (1), has shaft (24) in its center, and rotating plate (14) is arranged on the shaft and rotates clockwise and anticlockwise alternately with the shaft at the same angle, left dividing plate (9), right dividing plate ( 7) It can move up and down, and the filtered filter cake can be moved from the partition to be emptied into fan-shaped holes, and discharged from the cylinder (1), and the filtrate passes through the rotating plate filter (36) and the rotating plate (14). The clapboard filter screen (37) on the clapboard, the sump (35), the left drain pipe (8), and the right drain pipe (6) are discharged; the filtrate is discharged by the pump (44) through the feed left valve ( 39), the feed right valve (40), the feed left pipe (11) feed right pipe (5), and the pressure limiting valve (38) enters the filter chamber. The present invention can continuously and automatically perform pressure filtration. In addition to the pump pressure of the original technology, the filtration pressure also increases due to the rotation of the rotating plate (14) to reduce the volume of the filter chamber, thereby saving labor, reducing labor intensity and improving automation. In addition, it also improves the filtration efficiency and filtration quality.

Owner:张新强

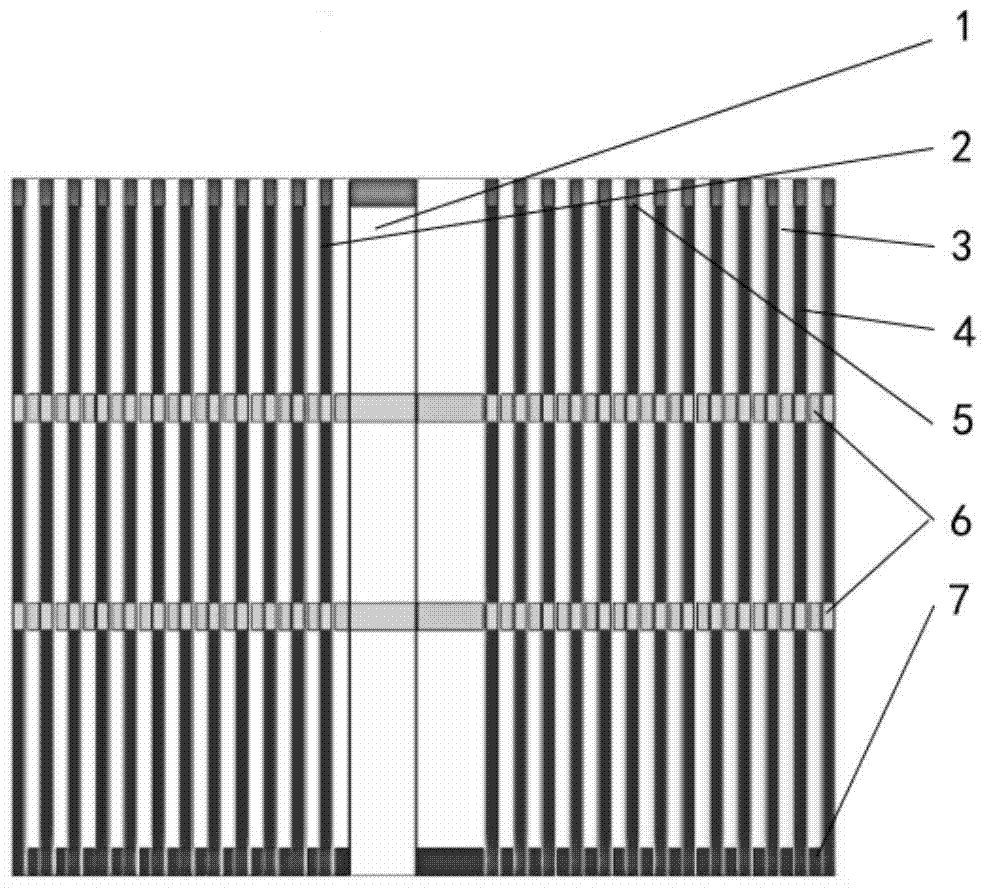

High-throughput anti-pollution microporous filter and filtering method thereof

ActiveCN105413275BMaintain self-cleaning abilityLarge filter areaStationary filtering element filtersHigh fluxFilter material

The invention discloses a high-flux anti-pollution microporus filter and a filtering method thereof. The filter comprises an inner side filtering membrane, an outer side filtering membrane, clear water channels, unfiltered water channels, seal strips for the unfiltered water channels, filtering membrane supports and seal strips for the clear water channels. A filter element of the filter is a spiral structure formed by rolling and machining the inner side filtering membrane and the outer side filtering membrane, the multiple filtering membrane supports are inlaid between the two filtering materials, and the seal strips for the unfiltered water channel and the seal strips for the clear water channels are installed on the upper edge and the lower edge of the filter element in a spaced mode respectively and have the function of stopping unfiltered water from entering an upper clear water region and the function of stopping filtered clear water from back flowing to a lower unfiltered region respectively. According to the high-flux anti-pollution microporus filter and the filtering method thereof, the pollution resisting effect is good, the service life is long, and the filtering capacity per unit volume is large.

Owner:江苏铁军软件科技有限公司

A solid-liquid mixture filter device

InactiveCN103949101BNo wearNo vacuumStationary filtering element filtersChemical industryWater filter

The invention discloses a solid-liquid mixture filter device. The solid-liquid mixture filter device comprises a tank, a cylinder jacket, a piston, a filter medium and a solid discharging device, wherein the bottom of the tank is communicated with the solid discharging device; the filter medium is arranged in the tank; the space in the tank is partitioned into two parts of a filter cavity and a liquid purification cavity; the filter cavity is communicated with the liquid purification cavity through filter holes in the filter medium; a liquid inlet pipe provided with a liquid inlet one-way valve is communicated with the filter cavity; a liquid outlet pipe provided with a liquid outlet one-way valve is arranged on the outer wall of the tank and is communicated with the filter purification cavity; the cylinder jacket is communicated with the filter cavity; the piston is inserted into the cylinder jacket. The solid-liquid mixture filter device is reasonable in structure, convenient to operate, high in filter precision, high in efficiency, low in energy consumption, free from pollution, and low in using cost and maintenance cost, and is applicable to water filter, oil filter and mineral purification and filter, and can be widely applied to filtering of solid-liquid mixtures in water treatment industry, food chemical industry, industrial mining industry, machining industry and the like.

Owner:于洪峰

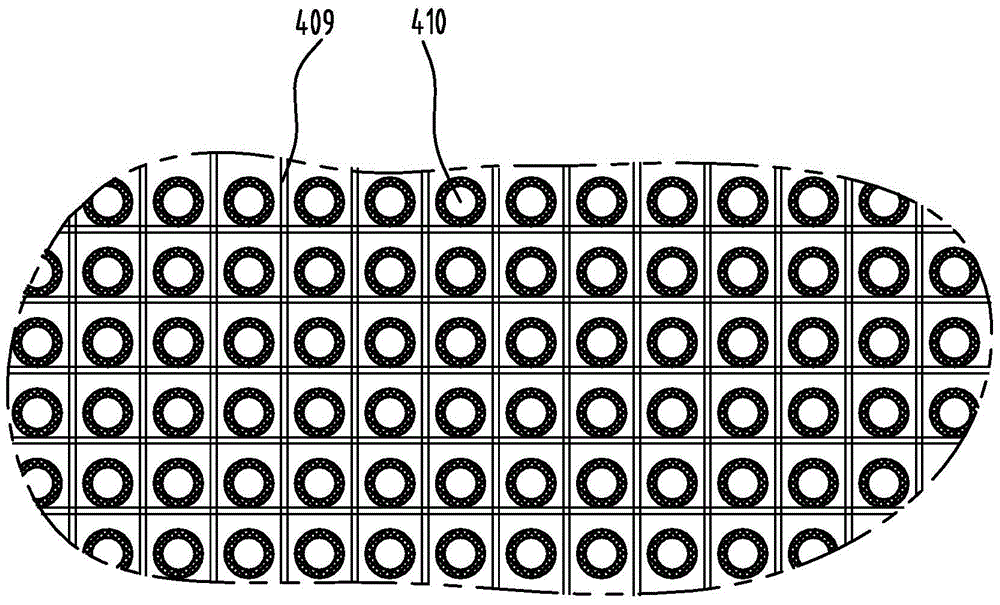

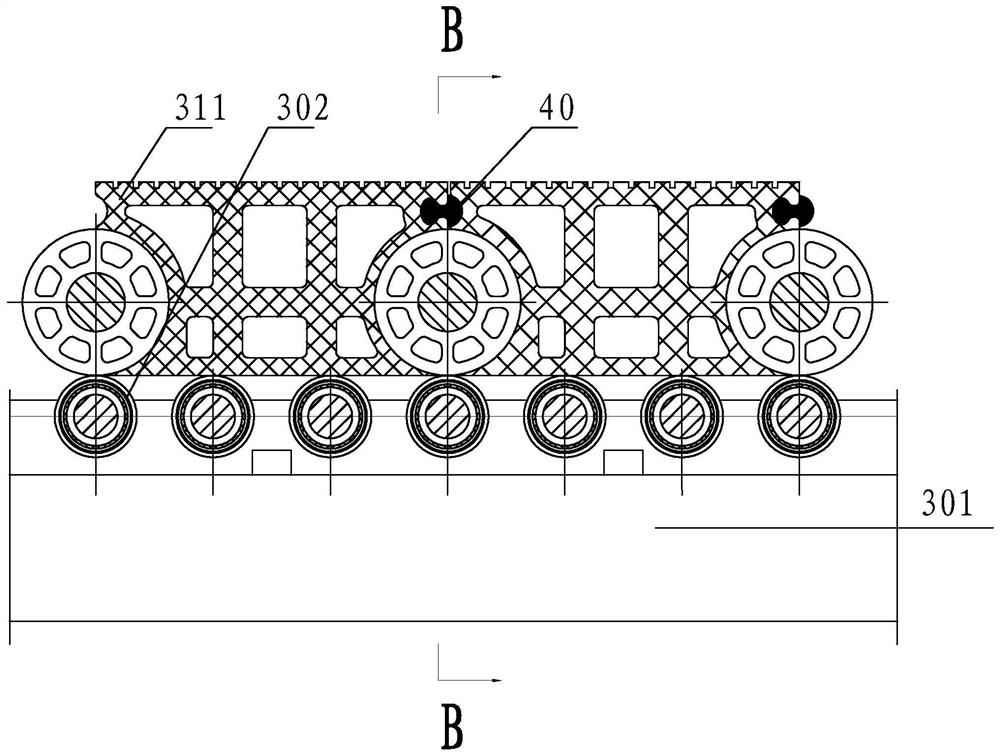

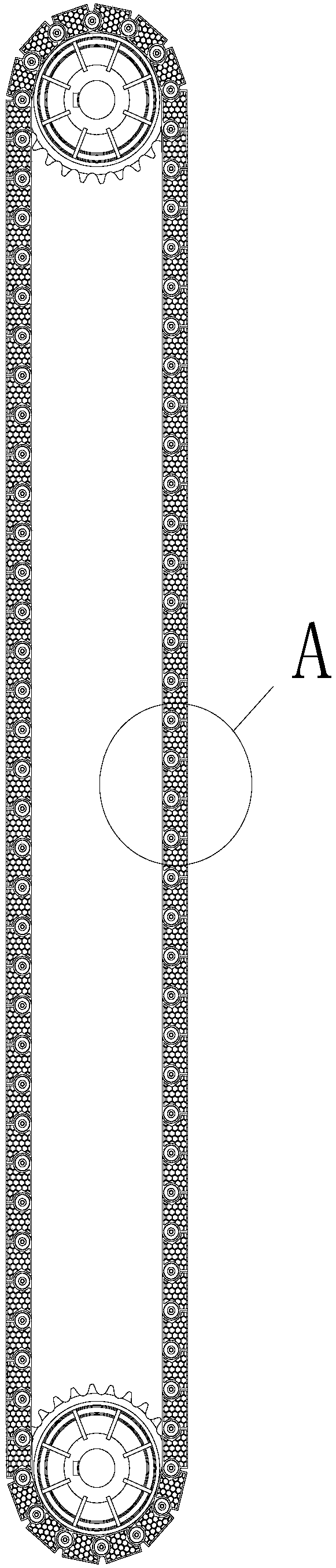

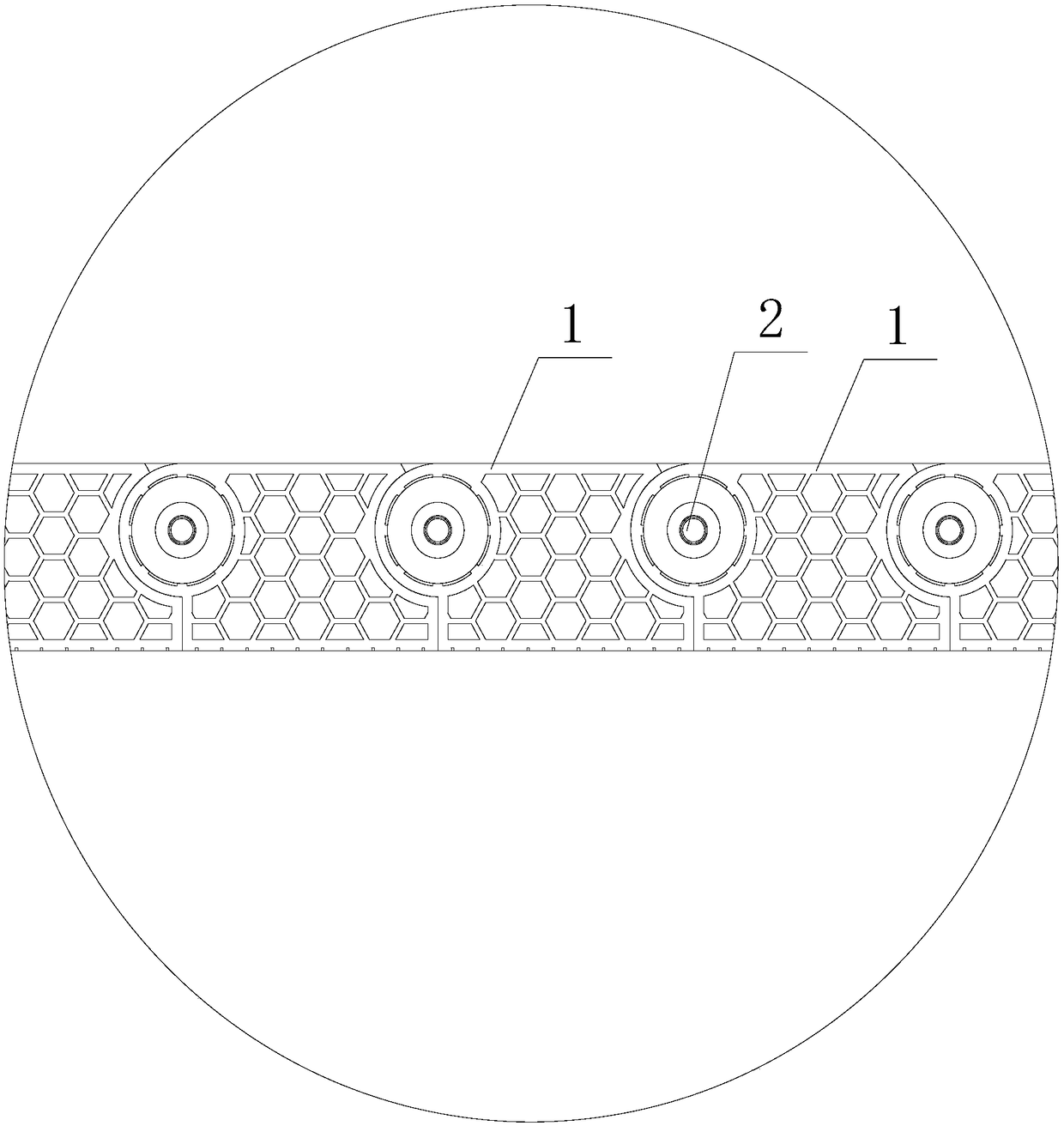

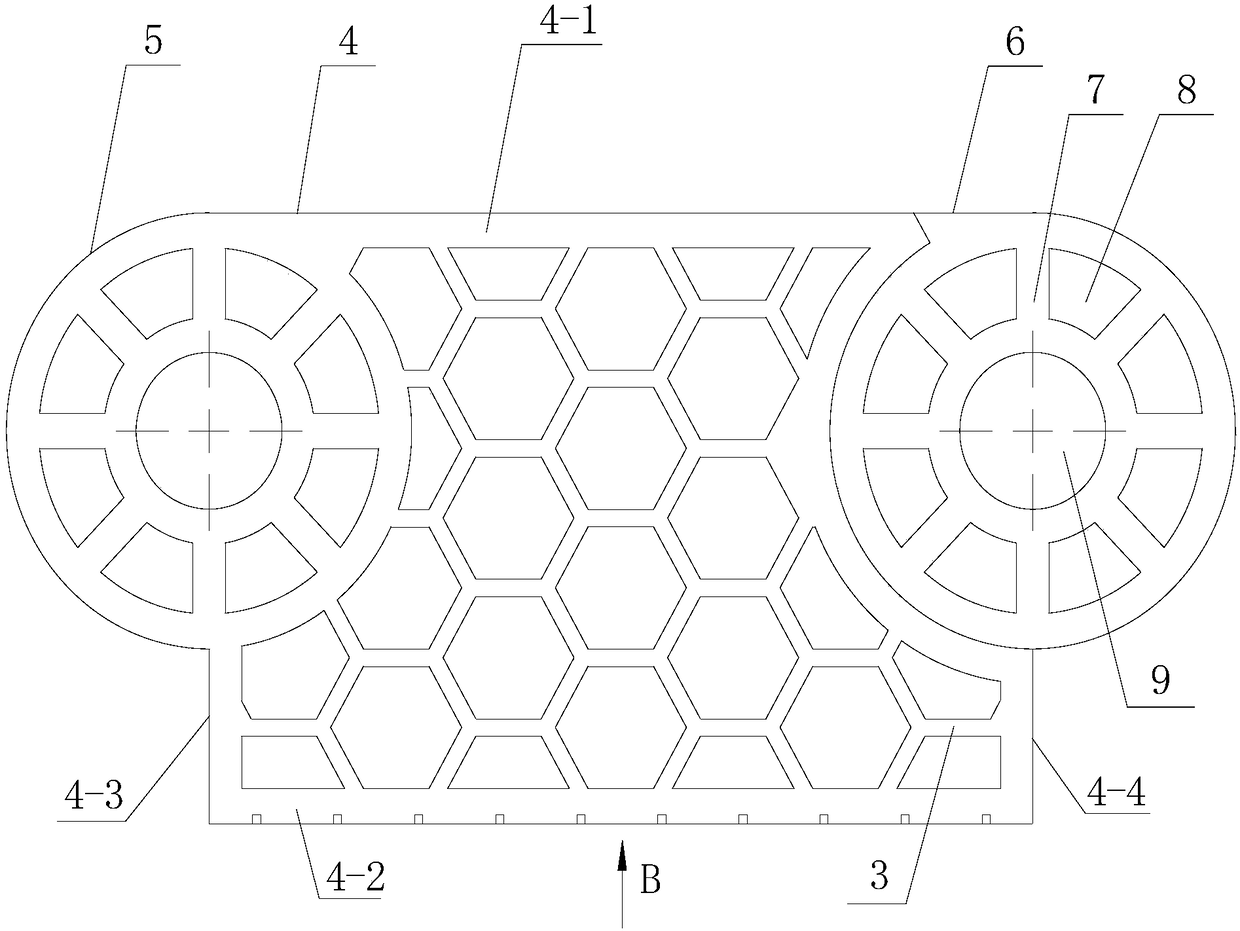

Filter press track for belt sludge dewatering equipment

ActiveCN106237693BReduce weightGuaranteed stiffnessSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesFiltrationPulp and paper industry

The invention discloses a press filtration crawler belt used for belt-type sludge dehydration equipment. The press filtration crawler belt comprises several chain links, the chain links are connected in order to form a cyclic enclosed structure, and a central part of the chain link is cellular inner ribs. According to the invention, the central part of the chain link is designed as a cellular structure, rigidity of the chain link is guaranteed, the weight of the press filtration crawler belt is greatly mitigated, a structure is easily moved, press filtration time is prolonged, and the press filtration pressure is increased. The test proves that compared with the belt-type press filtration equipment with a traditional structure, the belt-type sludge dehydration equipment can increase the continuous press filtration time by 5-10 times, and the press filtration pressure is increased by 1-2 times. The power energy consumption is relatively reduced due to the light structure, and compared with the belt-type press filtration equipment, the power saving rate is saved by 10-50%.

Owner:广东宝福嘉环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com