High-throughput anti-pollution microporous filter and filtering method thereof

A technology of microporous filter and microporous filtration membrane, which is applied in chemical instruments and methods, fixed filter element filters, filtration and separation, etc. It can achieve the effect of large water flux, easy automatic process production, and large filtration capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

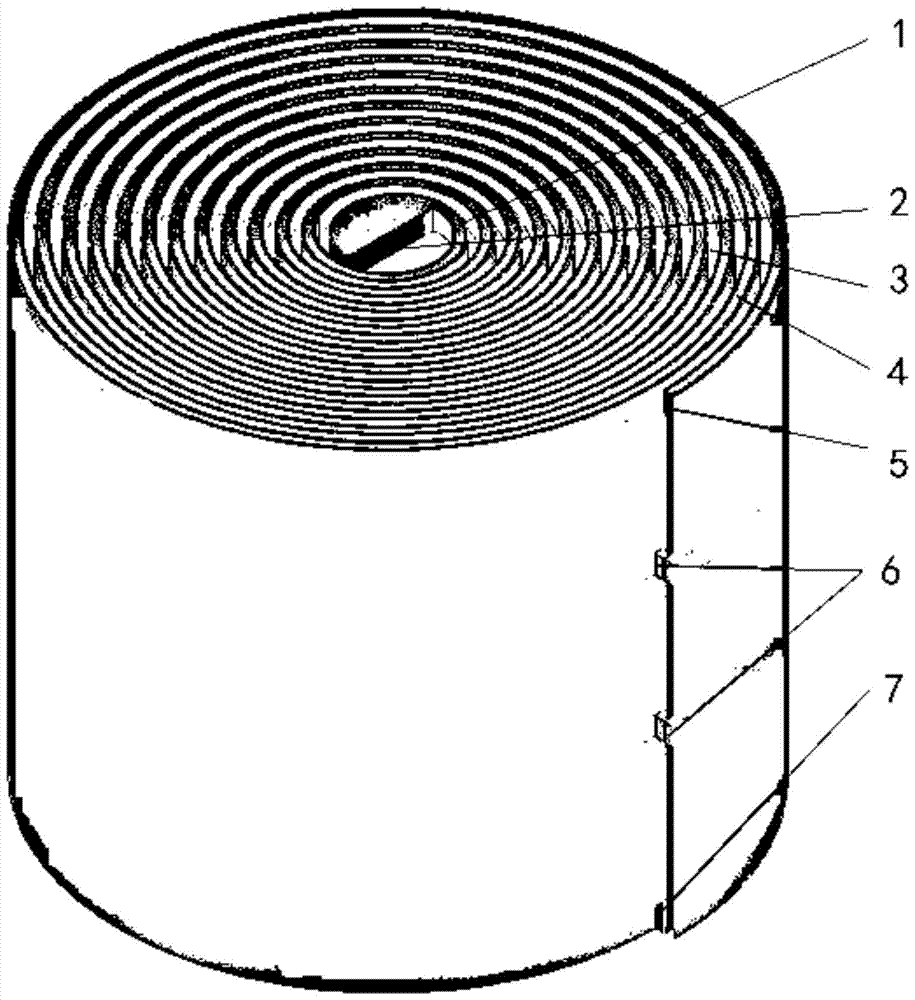

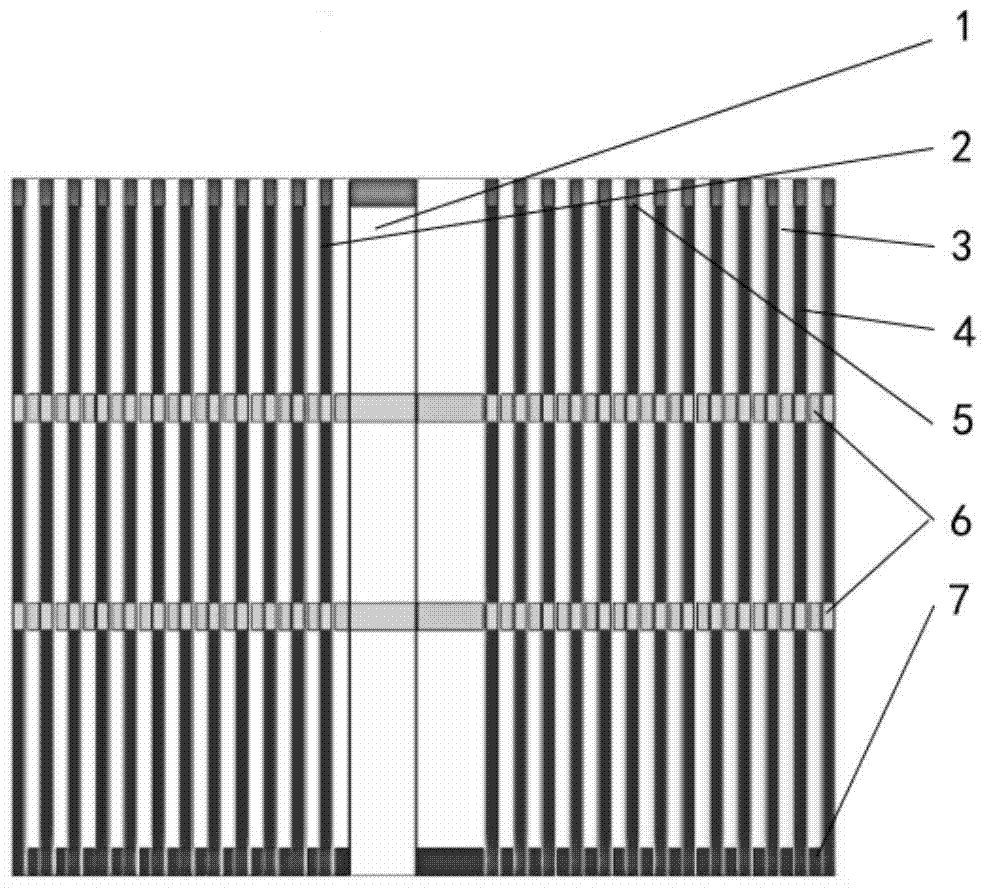

[0039] see figure 1 , the present invention discloses a schematic structural view of Example 1 of a high-throughput anti-pollution microporous filter, the filter includes an inner filter membrane 1, an outer filter membrane 2, a clean water channel 3, an unfiltered water channel 4, and an unfiltered water channel 4. Water channel sealing strip 5, filter membrane support 6, clean water channel sealing strip 7.

[0040] see figure 1 , figure 2, the spiral plate filter core is processed by rolling up two microporous filter membranes, the inner filter membrane 1 and the outer filter membrane 2, and several filter membrane supports 6 are embedded between the two microporous filter membranes for Keep the distance between the two microporous filter membranes, and at the same time have the effect of reinforcing the filter core; on the top of the filter core, an unfiltered water channel sealing strip 5 is installed to prevent unfiltered water from entering the upper water purificati...

Embodiment 2

[0046] The difference between this embodiment and Embodiment 1 is that in this embodiment, two layers of microporous filtration membranes are rolled together to form two channels, one for unfiltered water and one for filtered water; unfiltered water The way of inflow is one of the following two ways, the first way: unfiltered water enters from the outside of the filter, the second way: unfiltered water enters from the center of the filter.

[0047] The first method: the unfiltered water first enters the middle of the two layers of microporous filter membranes from the secondary outer side at a relatively high flow rate, and the water flows back out from the bottom after flowing to the bottom, forming a vortex flow between the lower part of the filter and the middle of the filter layer, so that When the filter layer exits, a large tangential scour force is formed, which is beneficial to remove the sediment on the filter surface, and the space under the filter is also conducive t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com