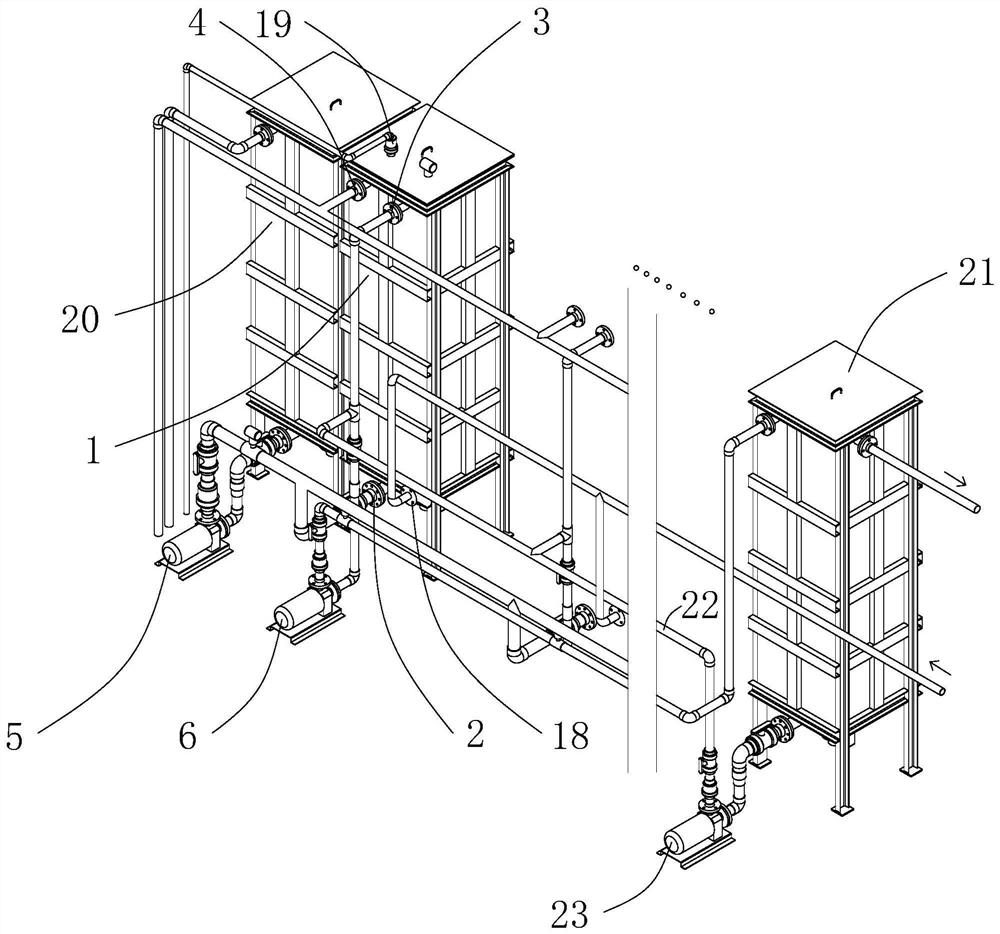

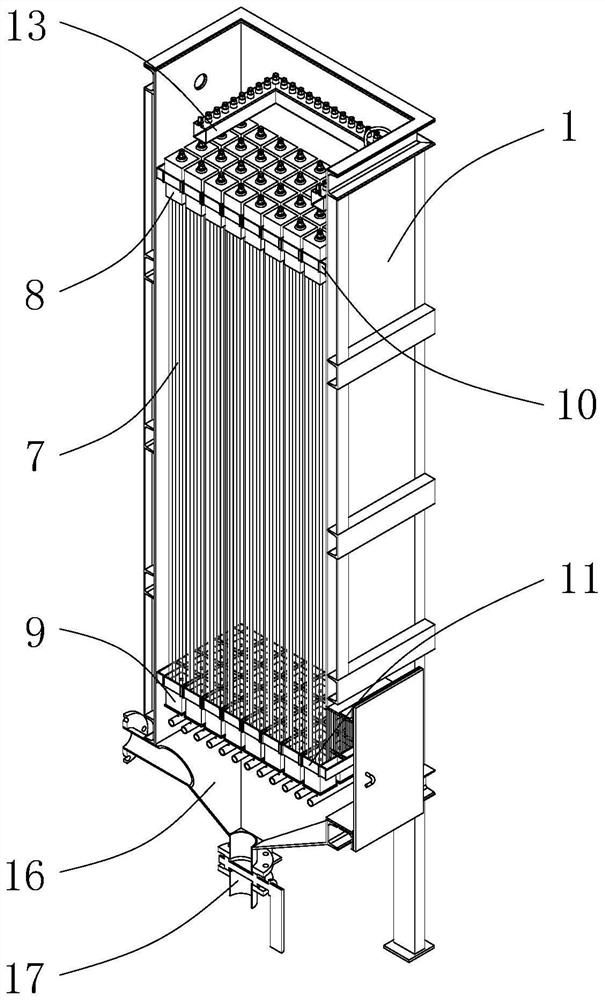

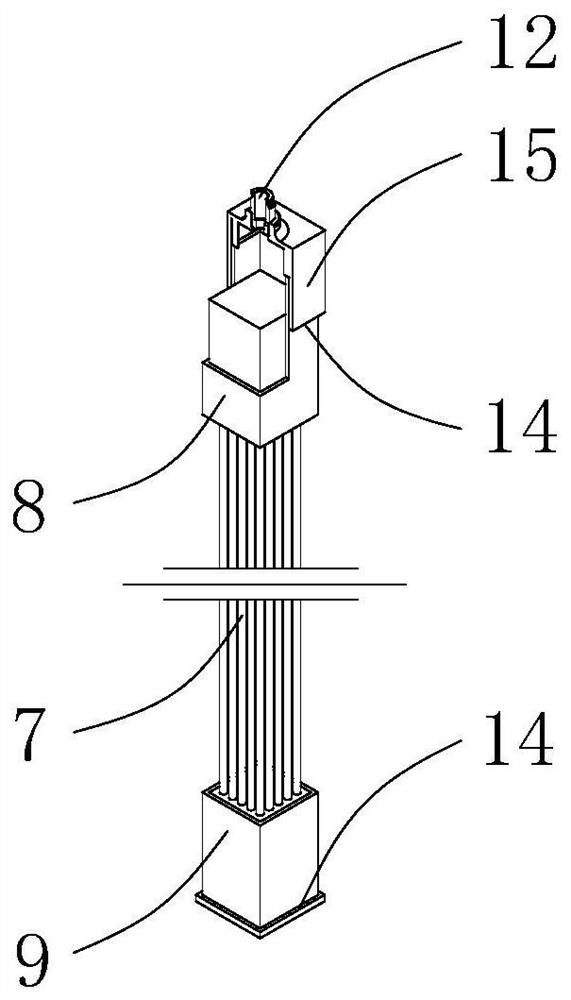

Membrane filtration device

A membrane filtration and membrane tube technology, applied in membrane technology, semi-permeable membrane separation, water/sludge/sewage treatment, etc., can solve the problem of debris fouling, small filtration area of a single membrane column, and low membrane filling efficiency and other problems to achieve the effect of reducing operating costs and reducing aeration volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Example 1: Domestic sewage treatment in a village and town, a closed hollow fiber curtain membrane filter equipment and an A2O integrated equipment at the front end; a single sealed tank 1 is filled with 497 square meters of membrane filaments, and each equipment has five sealed tanks 1 , Fully automatic operation mode. One device can process 1000m of rural domestic sewage per day 3 / sky.

Embodiment 2

[0060] Example 2: A municipal sewage treatment plant uses an external MBR process to upgrade the original A2O process for advanced treatment, transforms the original secondary sedimentation tank into a high-concentration sludge aerobic tank, and uses an external MBR sealed tank 1 The A2O biochemical effluent and secondary sedimentation tank sewage are filtered and concentrated, and the filtered water that passes through the MBR membrane is the treated water that meets the standard. A total of eight closed hollow fiber curtain membrane filtration equipment are used; a single sealed tank 1 is filled with 2121 square meters of membrane filaments, and each equipment has a total of six sealed tanks 1; eight equipments adopt the operation mode of seven openings and one standby, and the daily water output of seven equipments 30000m 3 / sky.

Embodiment 3

[0061] Example 3: A surface water treatment project in a paper mill, three closed-type ultrafiltration hollow fiber curtain membrane filtration equipment, the treated water is used as factory production water; a single sealed tank 1 is filled with 2121 square meters of membrane filaments, and each equipment has a total of six A sealed tank 1; the three equipment adopts the operation mode of two openings and one standby, and the daily water production of the two equipments is 20,000m 3 / sky.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com