Pressure filter

A technology of filter press and filter screen, which is applied in the field of pressure filtration machinery, can solve the problems of not too high filtration pressure, failure to obtain filter cake, unsatisfactory filtration effect, etc., and achieve the effects of saving labor, increasing filtration pressure, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

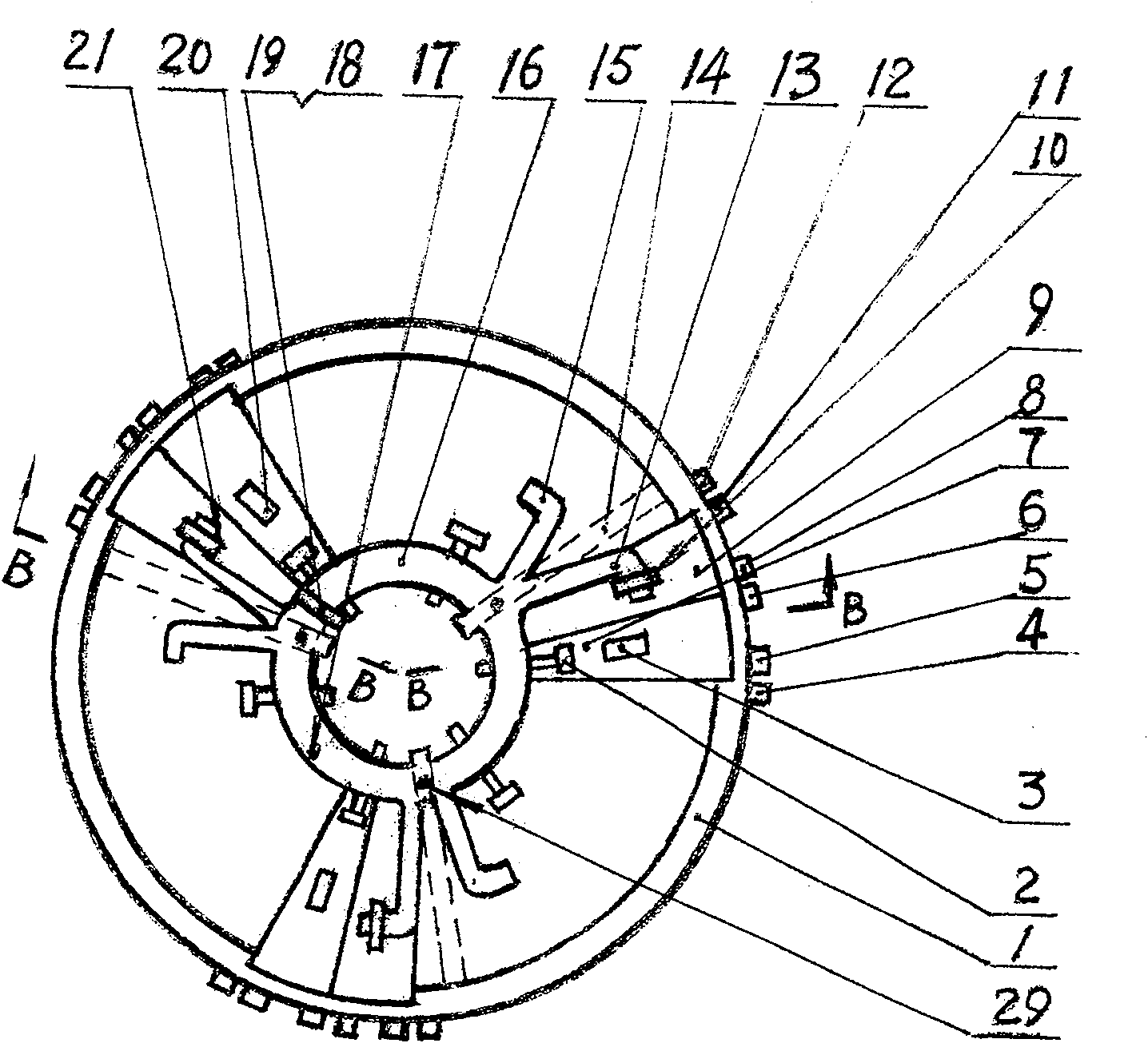

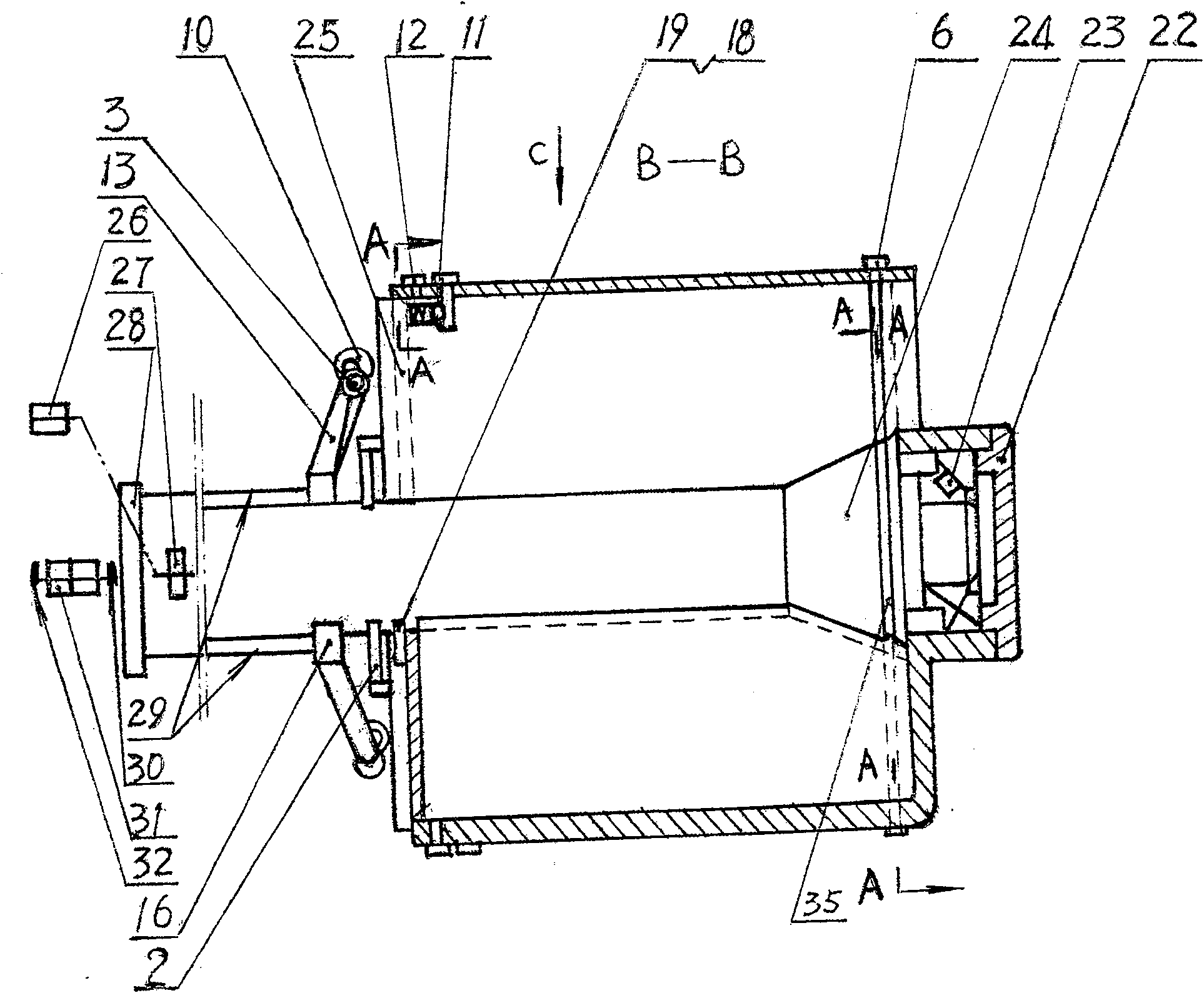

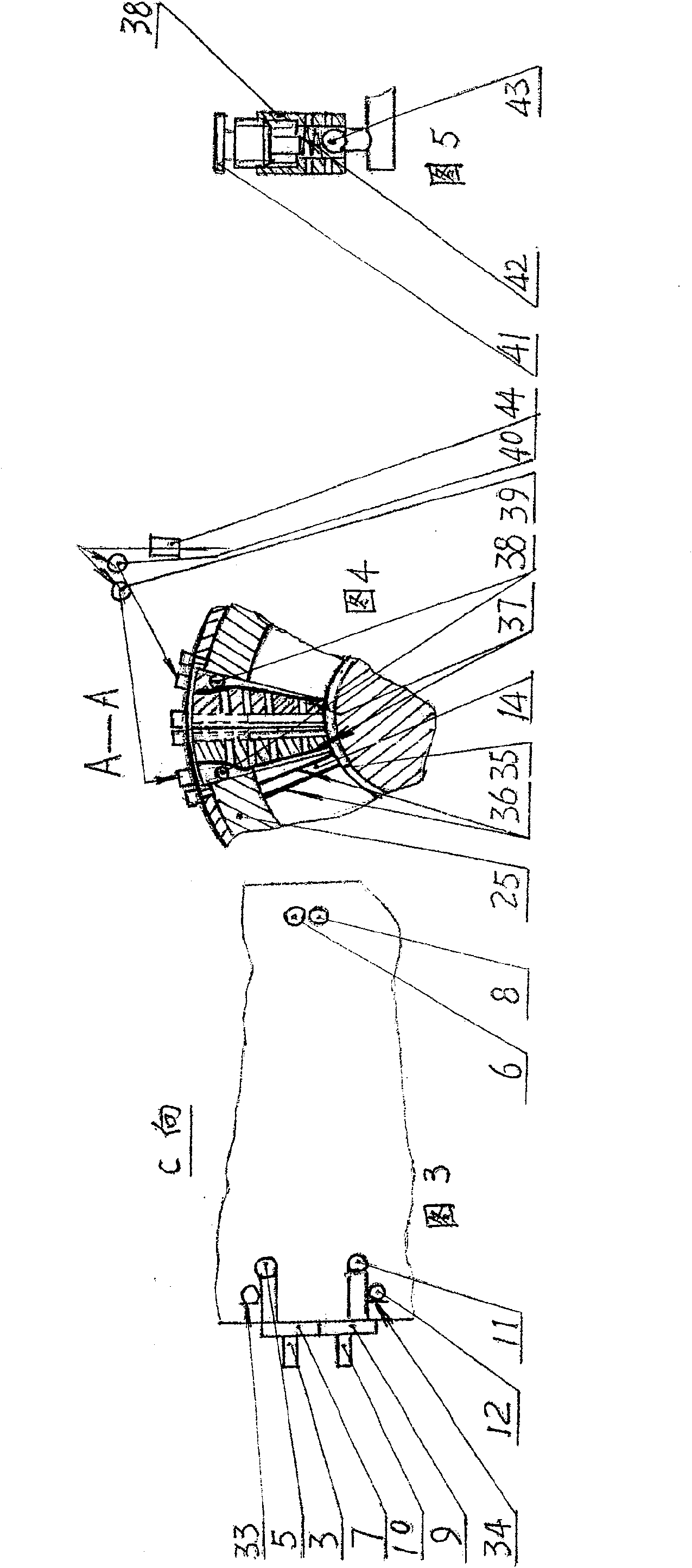

[0014] The present invention will be further described below in conjunction with accompanying drawing, appended figure 1 , 2 , 3, 4, 5, 7:

[0015] Close the main switch 1HK, press the pump 44 to switch PQA, the PC is powered, 2D drives the pump 44, the filtrate is fed through the left valve 39, the right valve 40, the left pipe 11, the right pipe 5, and the left and right pressure limit The valve 38 enters the left and right filter chambers: press the start button QA, RQC to get electricity, 1D starts, drives the electro-hydraulic stepping motor 26 to rotate clockwise, passes through the coupling 27, drives the shaft 24 and the rotating plate 14 to rotate accordingly; The left filter chamber surrounded by the cylinder 1, the left partition 9, the rotating plate 14, and the cover plate 25 gradually shrinks. After the filtrate is compressed and filtered, the filter cake remains in the left filter chamber, and the filtrate passes through the partition screen 37 , Rotating plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com