Patents

Literature

340results about How to "Improve filter quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

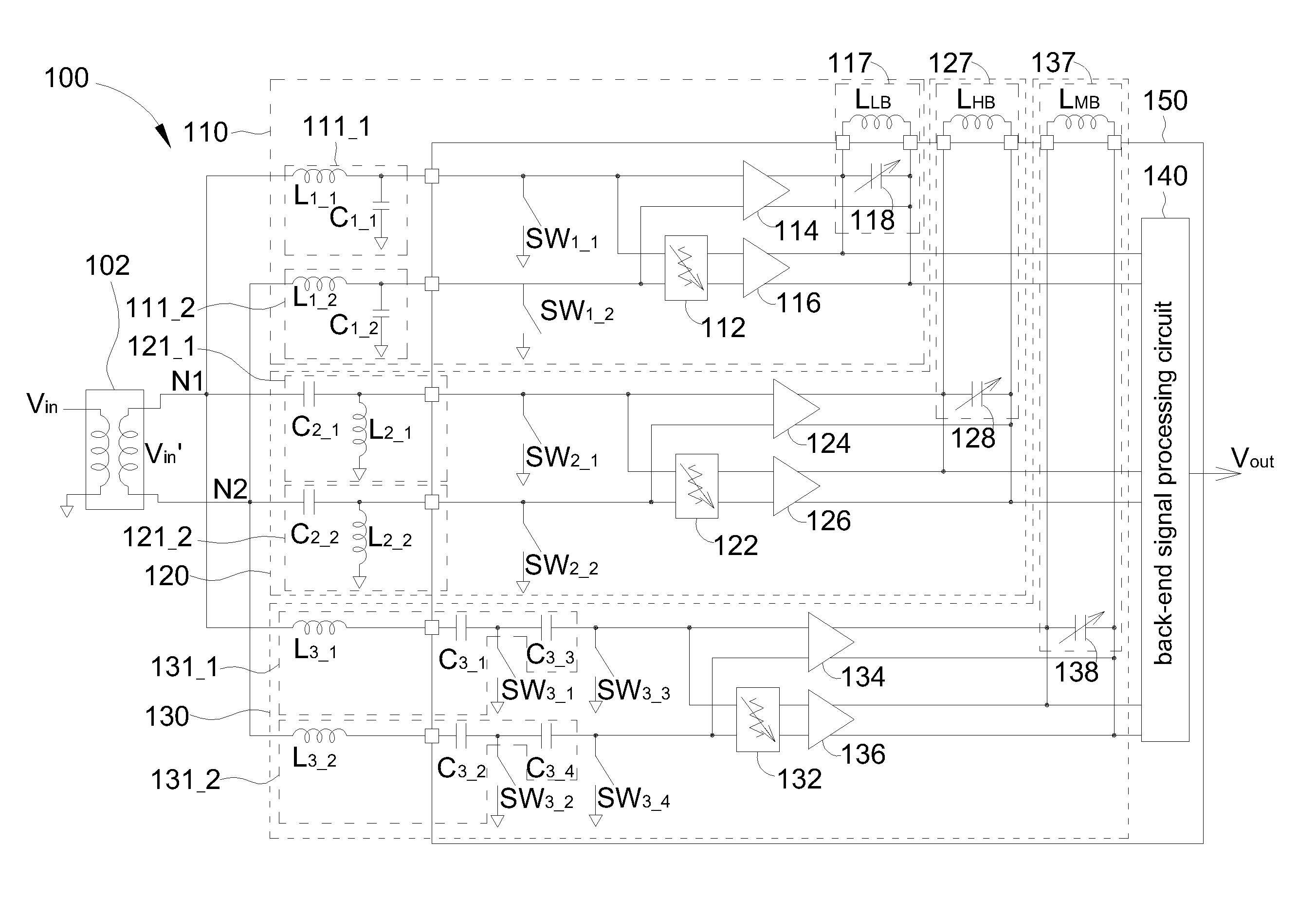

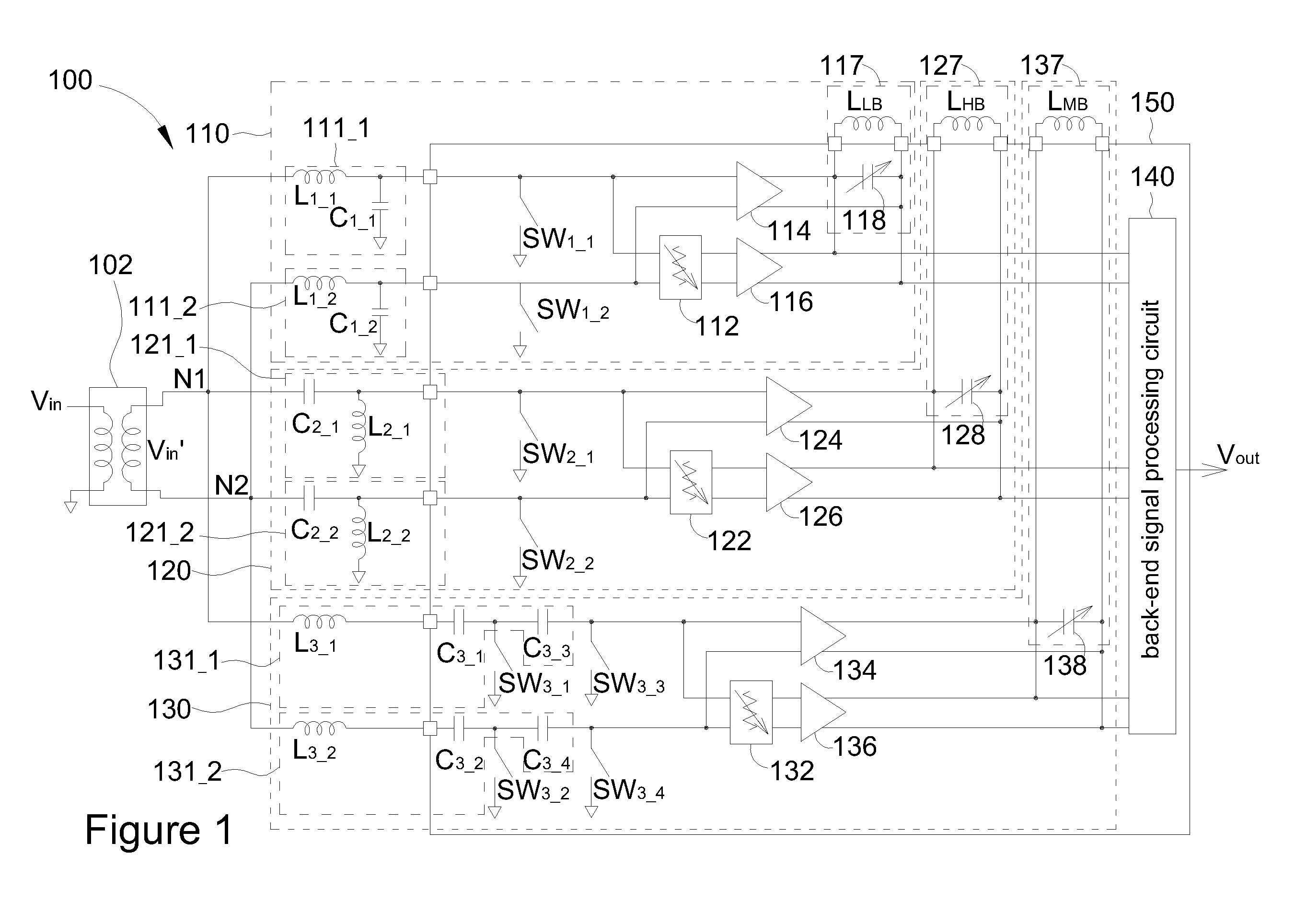

Tuner and Front-end Circuit Thereof

ActiveUS20110051014A1Low production costPreferable filtering qualityTelevision system detailsContinuous tuning detailsCMOSAudio power amplifier

A tuner includes a plurality of paths, and at least one of the paths includes a front-end filter circuit, an amplifier, and a trace filter. The trace filter includes a varactor and an inductor, which are coupled to an output end of the amplifier. Further, the amplifier and the varactor of the tuner are packed in a complementary metal-oxide semiconductor (CMOS) chip.

Owner:MEDIATEK INC

Honey processing process

InactiveCN103549250AHigh purityTargetedFood thermal treatmentMulti-step food processesHeating timeFiltration

The invention relates to a honey processing process. The honey processing process is characterized by comprising the following steps: (1) raw honey inspection; (2) (a) melting, wherein the heating temperature is 45-60 DEG C, and the heating time is 30-60 minutes or 4-8 hours according to the state of raw honey; (b) filtration, namely carrying out pressure filtration in a sealing device at the temperature higher than 40 DEG C so as to remove impurities and larger crystals; (3) vacuum concentration; (4) cooling. According to the honey processing process, the filtration step sequentially comprises rough filtration, fine filtration and refined filtration, wherein the temperature of the fine filtration is higher than that of the rough filtration, and the temperature of the refined filtration is higher than that of the fine filtration. The different processing time can be set according to different states of the raw honey, so that the pertinence is strong, not only can melting quality and the smooth operation of subsequent steps be guaranteed, but also the efficiency is increased, and the unnecessary time waste is reduced; besides, the filtration is performed three times, and the filtering temperatures are different, so that the efficiencies of each filtration process and the whole filtration are increased, and the purity of finished honey is improved.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

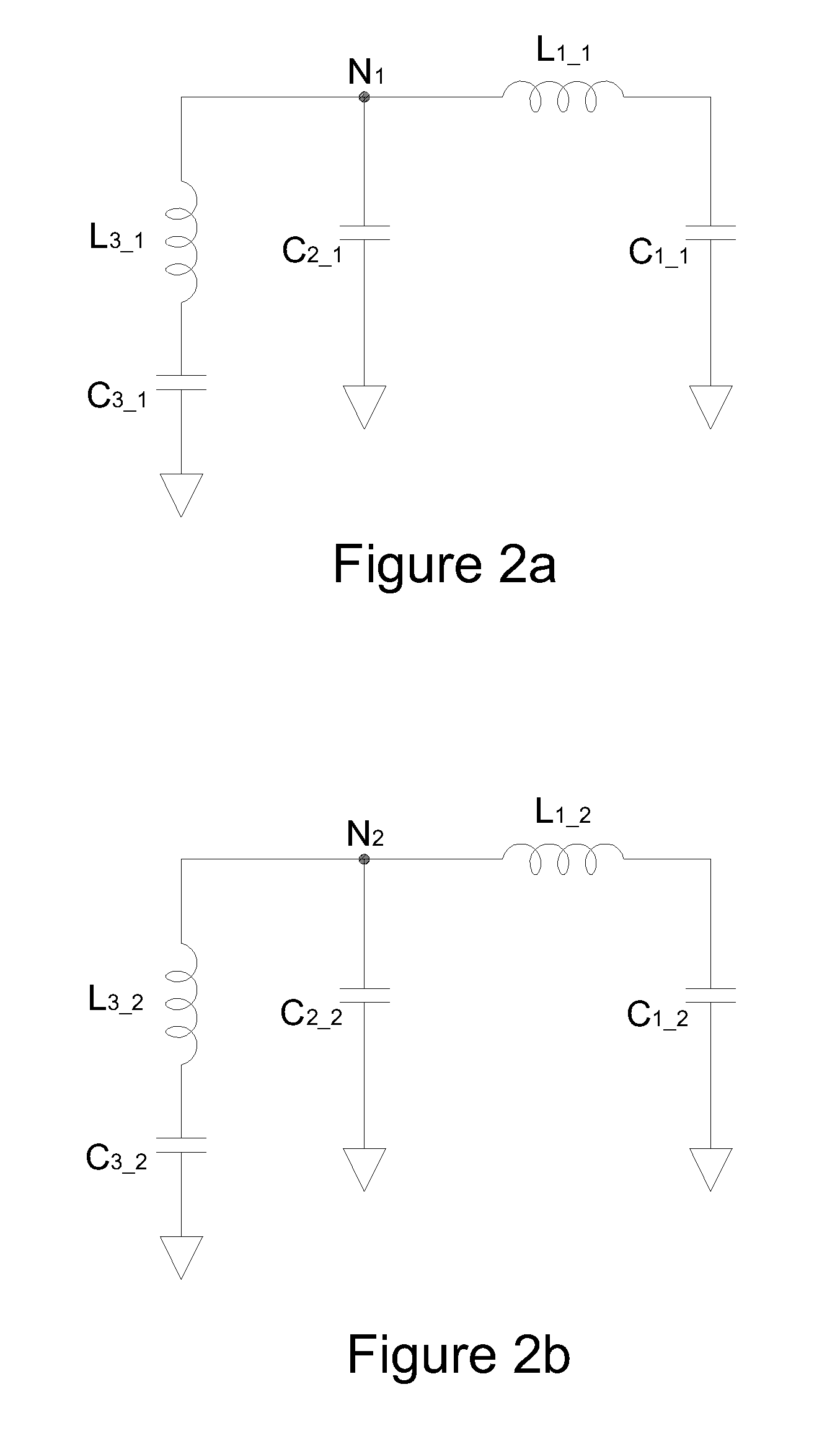

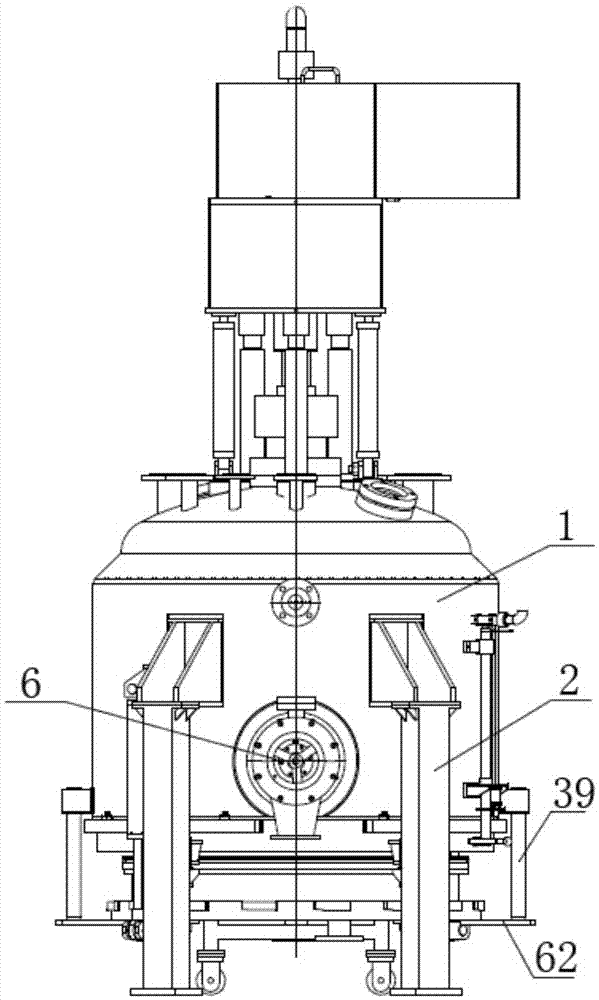

Sump oil vibration filtering device

InactiveCN102600654ASpeed up filteringImprove qualityNon-miscible liquid separationMoving filtering element filtersInlet valveOil quality

The invention relates to a sump oil vibration filtering device, which is characterized in that a vibration filtering plate is vertically arranged in a tank body, an oil output pipe is connected with the bottom of the vibration filtering plate, one end of the oil outlet pipe extends out of the tank body and is provided with an oil discharge valve, a vibration shaft is connected with the top of the vibration filtering plate, an air inlet pipe and an air inlet valve are arranged at the upper part of the tank body, an oil inlet pipe and an oil inlet valve are arranged at the lower part of the tank body, a pollution discharge pipe and a pollution discharge valve are arranged at the bottom of the tank body, the vibration shaft is connected with a vibration pump arranged outside the tank body, the inner layer of the vibration filtering plate is a filter core and a support framework, and the outer layer of the vibration filtering plate is a filtering net. The sump oil vibration filtering device has the advantages that the vibration filtering plate is adopted, the sump oil filtering speed is greatly accelerated, the oil quality is improved, the cleaning speed of a filter is greatly accelerated, the work intensity of cleaning the filter is reduced, the filtering cost is reduced, and the popularization values are realized.

Owner:豆远奎

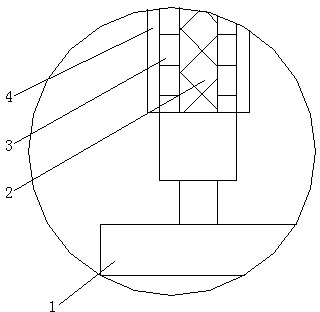

Double-plate type filter without replacing filter screen

The invention provides a double-plate type filter without replacing a filter screen, belonging to the technical field of melt filter equipment, and aiming at solving the problem that when the existing filter is used, the service life of a filter plate is shortened. The double-plate type filter without replacing the filter screen comprises a shell; a rotating shaft is rotatably arranged in the shell in a penetrating way; the peripheral wall of the shell is respectively provided with a feeding hole and a discharge hole; a fixed filter tray is fixedly connected in the shell; the inner circumference wall of the shell is connected with a movable filter tray in a sliding way along the axial direction of the shell; a scraper is fixedly connected in a feeding cavity of the rotating shaft; a cutting edge of the scraper respectively leans against the sides of the fixed filter tray and the movable filter tray; a hold-down mechanism is also arranged in the shell; the circumference wall of the shell is also provided with an impurity discharge hole which is connected with a transmission mechanism. After the double-plate type filter without replacing the filter screen is used, the service lives of the filter trays are prolonged, and the filtering quality and the filtering efficiency are improved.

Owner:ZHEJIANG LEENY TECH

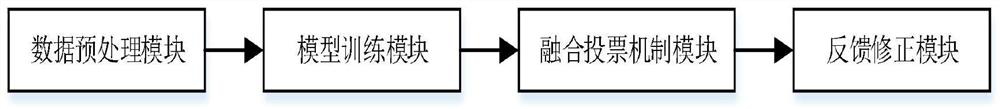

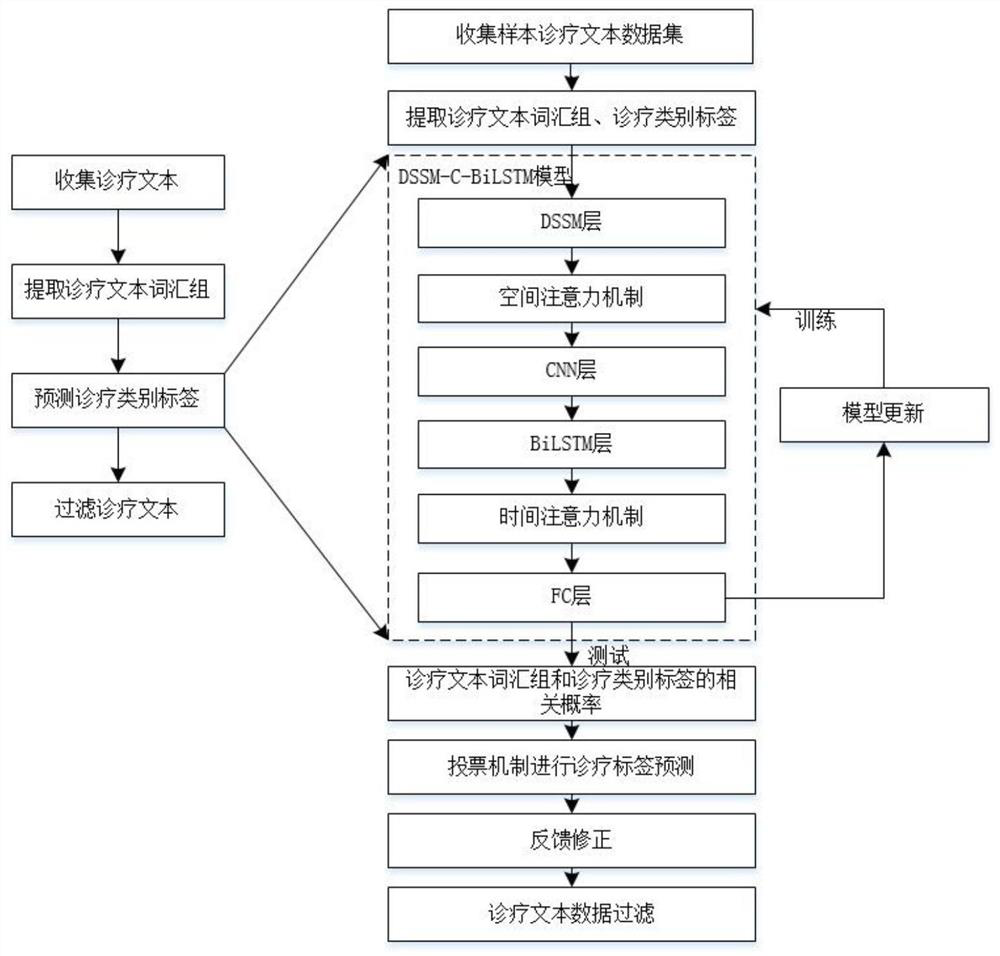

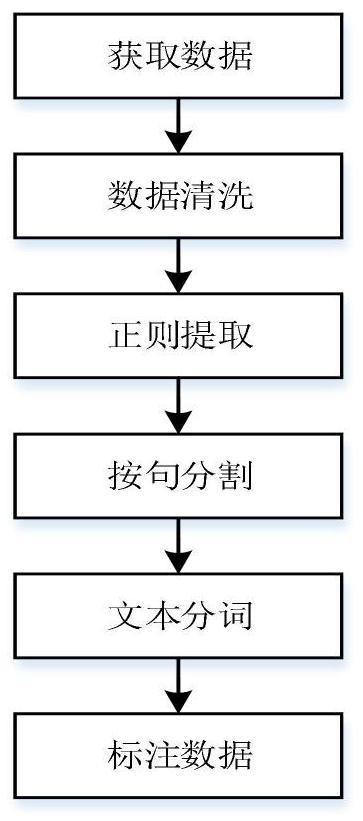

Medical text data-oriented filtering method and system

PendingCN112712118AReduce redundancyEasy to predictCharacter and pattern recognitionNeural architecturesMedical recordData set

The invention provides a medical text data-oriented filtering method, which comprises the following specific steps of: obtaining a medical record data set S which is not labeled with a medical category label, inputting the medical record data set S into a trained DSSM-C-BiLSTM model, outputting a predicted medical category label Label of the data set S, and performing data filtering through the label Label; the DSSM-C-BiLSTM model training process comprises the following steps: (1) collecting a medical record data set A, performing data preprocessing on the medical record data set A to obtain a data set B, and dividing the data set B into a training set and a test set; (2) constructing a DSSM-C-BiLSTM model, inputting a training set of the data set B into the DSSM-C-BiLSTM model for training and learning, and inputting a test set of the data set B into the trained DSSM-C-BiLSTM model to obtain a medical category label probability; and (3) performing model evaluation index calculation according to the predicted medical category label and the real medical category label, and finishing model training when the model evaluation index meets the condition.

Owner:ENJOYOR COMPANY LIMITED

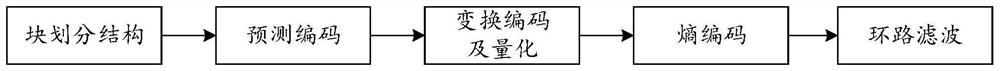

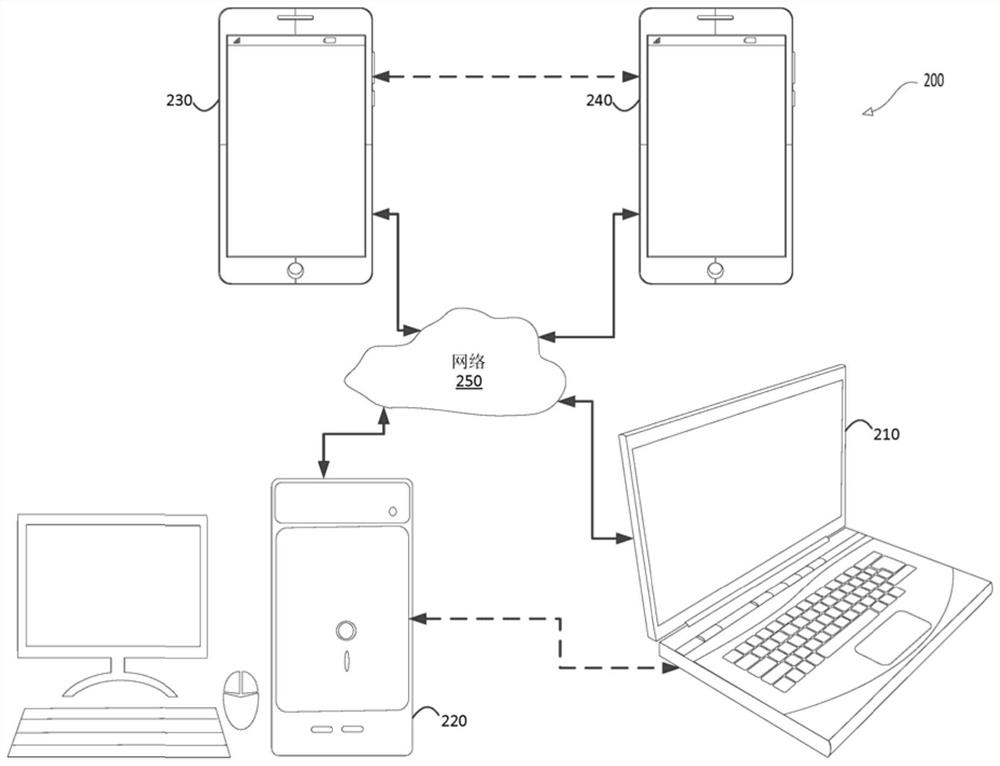

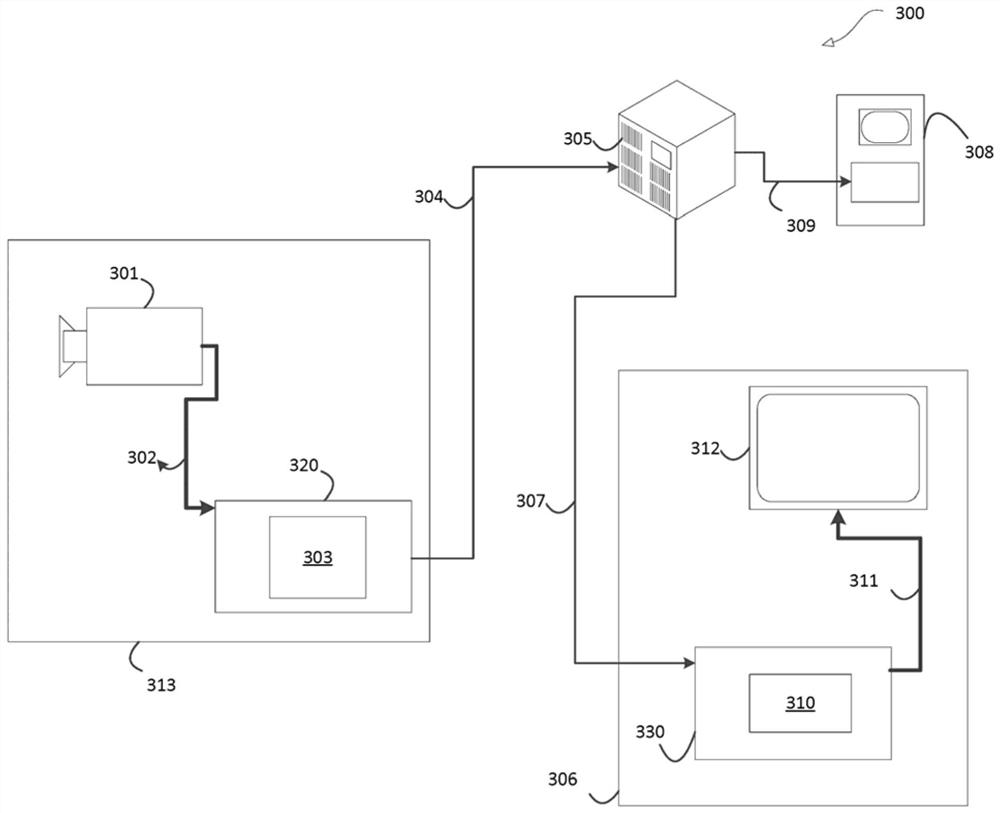

Loop filtering method, device and equipment in video encoding and decoding, and storage medium

ActiveCN111711824AImprove filter qualityRestoring or mitigating varying degrees of quantitative lossDigital video signal modificationNeural architecturesLoop filterAlgorithm

The invention provides a loop filtering method, device and equipment in video encoding and decoding and a storage medium, and relates to the technical field of video encoding and decoding. The methodcomprises the following steps: obtaining a reconstruction frame corresponding to a current frame in a video and residual distribution information, wherein the residual distribution information refersto information influencing or reflecting residual signal data distribution; performing fusion processing on the reconstruction frame and the residual distribution information to obtain fusion data; and performing filtering processing on the fused data through a loop filtering model to obtain a filtered reconstruction frame. According to the invention, the information capable of influencing or reflecting residual signal data distribution is added into input data of a loop filtering model, so the model can better learn the mapping (simulation quantization inverse process) from the quantized residual error to the residual error before quantization, so that quantization losses of different degrees are recovered or relieved, the model can be designed according to factors influencing the codingloss degree, the sensitivity of the loop filtering model to the quantization loss degree is improved, and the filtering quality of the model is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

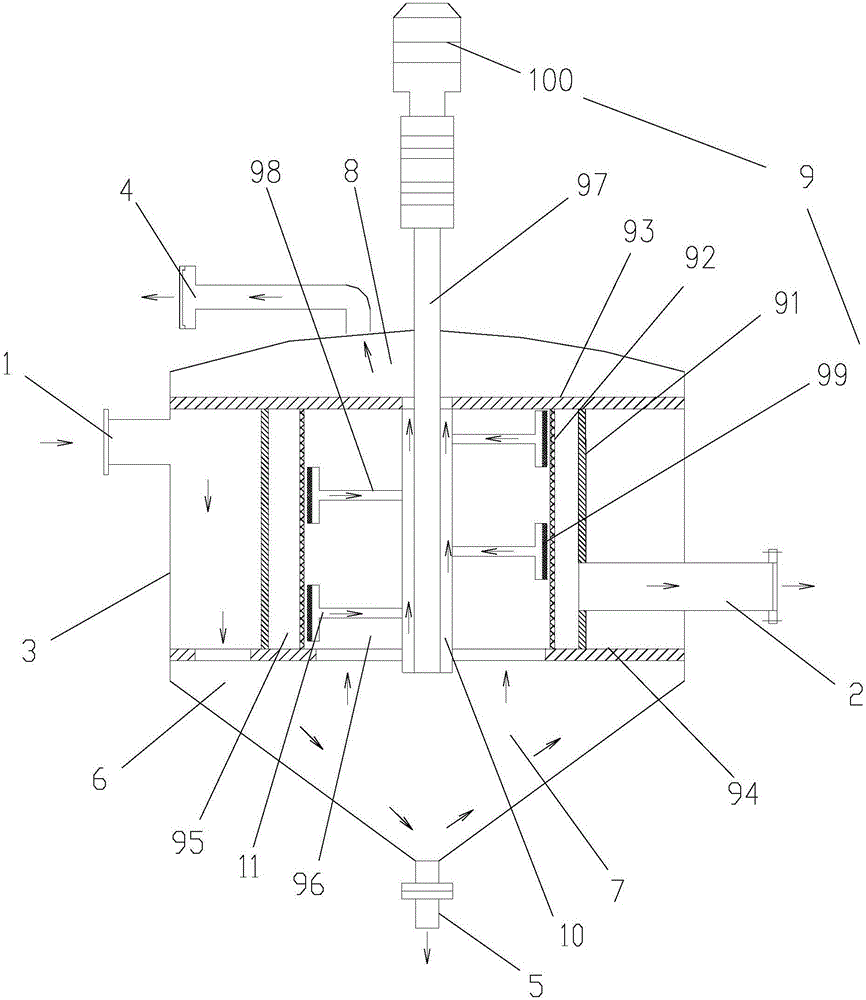

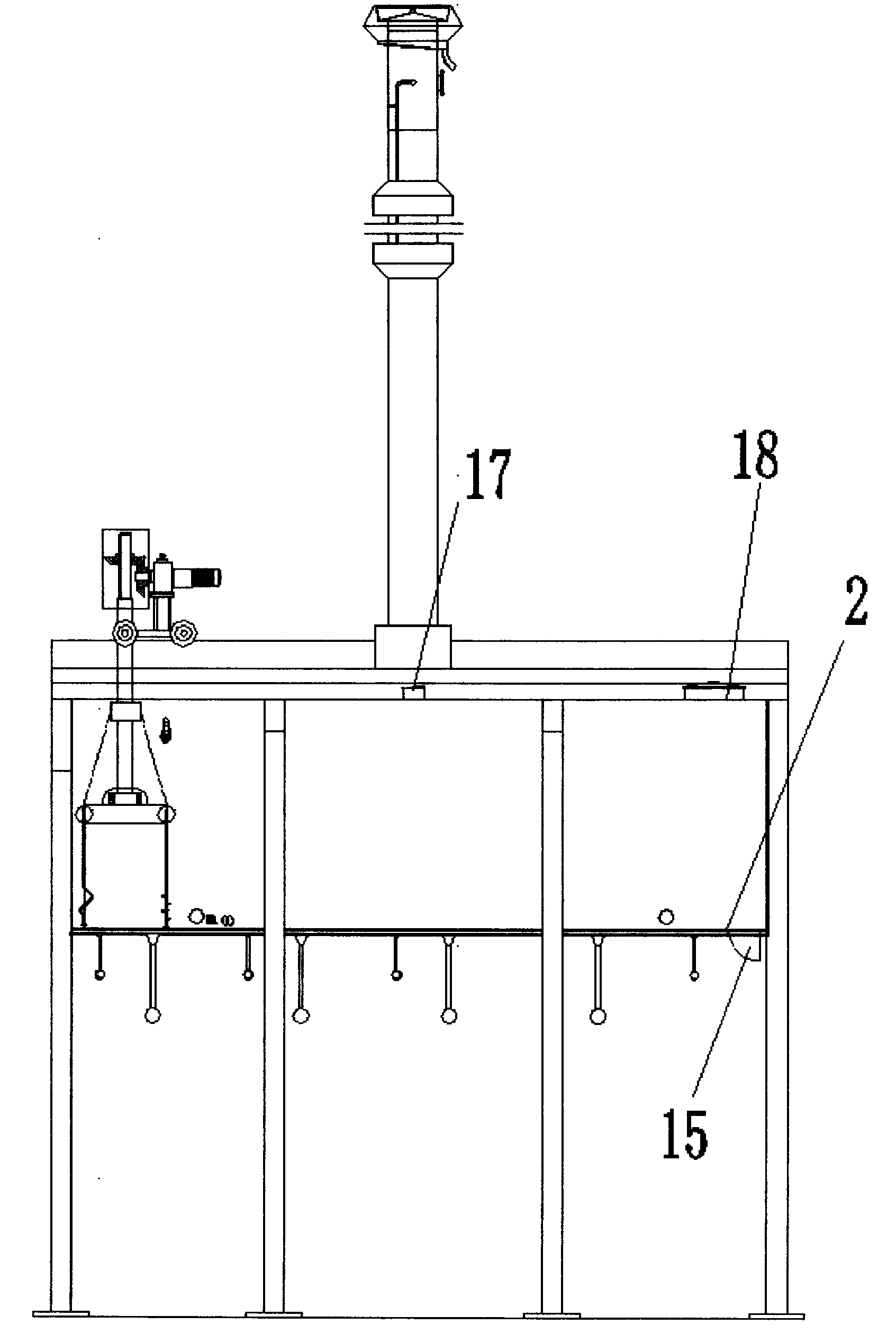

Filtering device for slag-washing water of blast furnace

InactiveCN105709479AImprove filtration efficiencyImprove filter qualityMembrane filtersStationary filtering element filtersSlagFiltration

The invention discloses a filtering device for slag-washing water of a blast furnace, belonging to the technical field of the blast furnace ironmaking. The filtering device for slag-washing water of blast furnace comprises a shell with a water inlet and a water outlet, wherein the water inlet is formed at the lateral upward side of the shell, the water outlet is formed at the lateral down side of the shell, a sewage draining outlet and a slag hole are formed at the top part and the bottom part of the shell respectively, the water inlet and the water outlet are communicated to form a deslagging channel, the slag hole is communicated with the water outlet to form a filtering channel, the slag hole is communicated with the sewage draining outlet to form a back washing channel, a filter is arranged on the filtering channel, and a back washing device is arranged on the back washing channel. The filtering device can separate heavy iron slag particles from slag-washing water by centrifugal rotational flows, and can filter small slag wool and suspended matters by a filter screen. That is to say, the filtering device can realize coarse filtration and fine filtration simultaneously, the filtering efficiency and the filtering quality are improved, the back washing device can realize online full-automatic back washing, the operation is simple and convenient and the operating efficiency is further improved.

Owner:CISDI ENG CO LTD

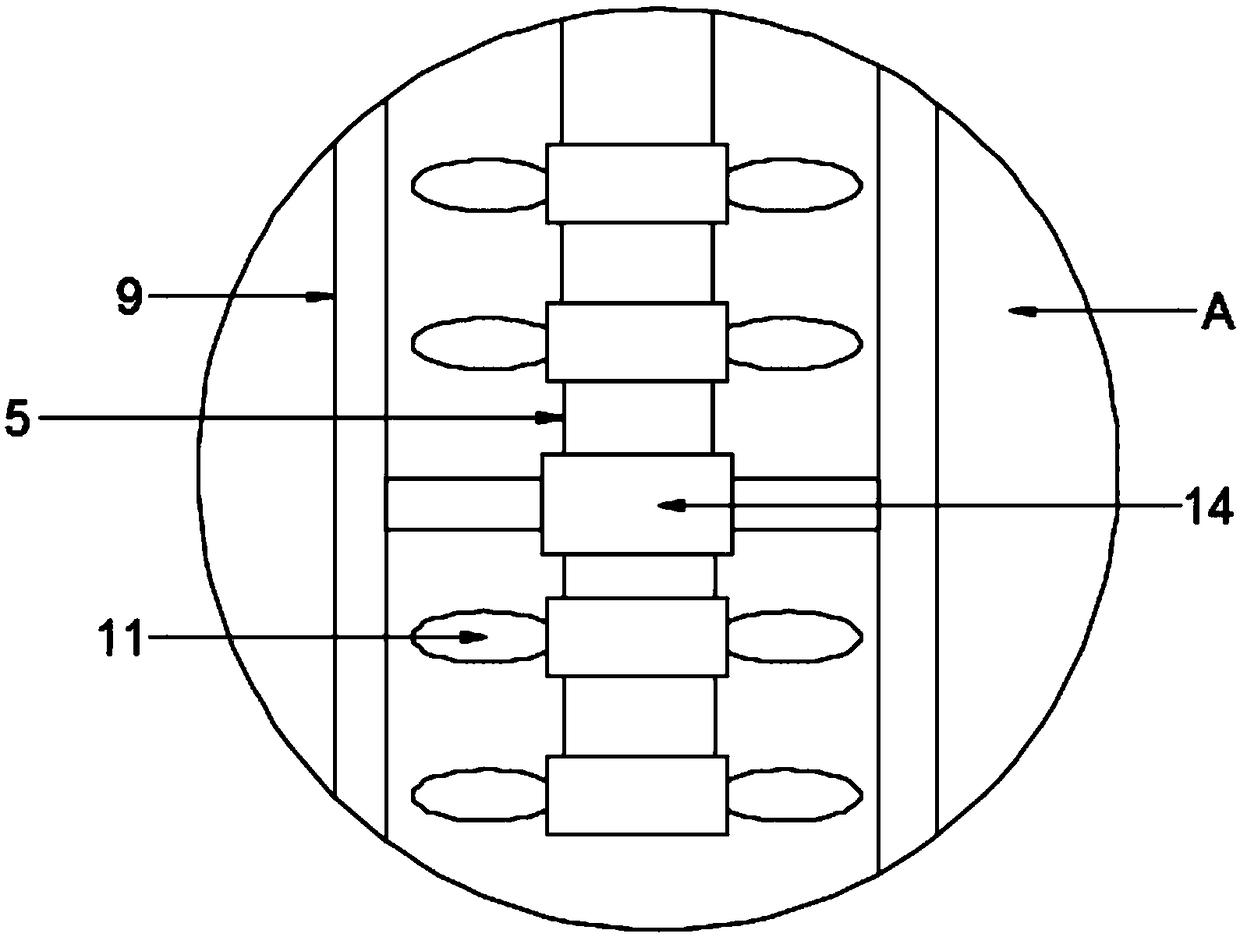

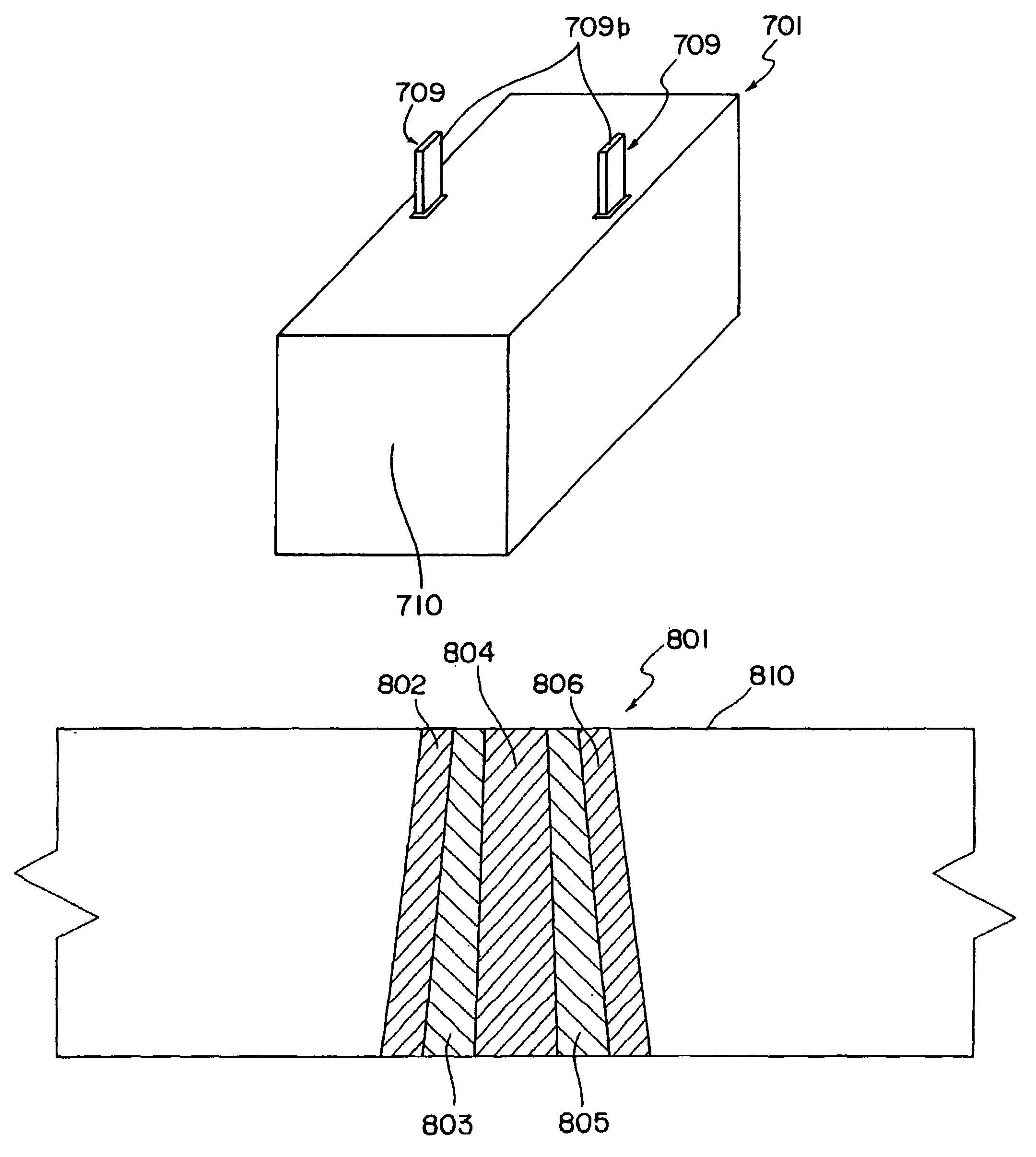

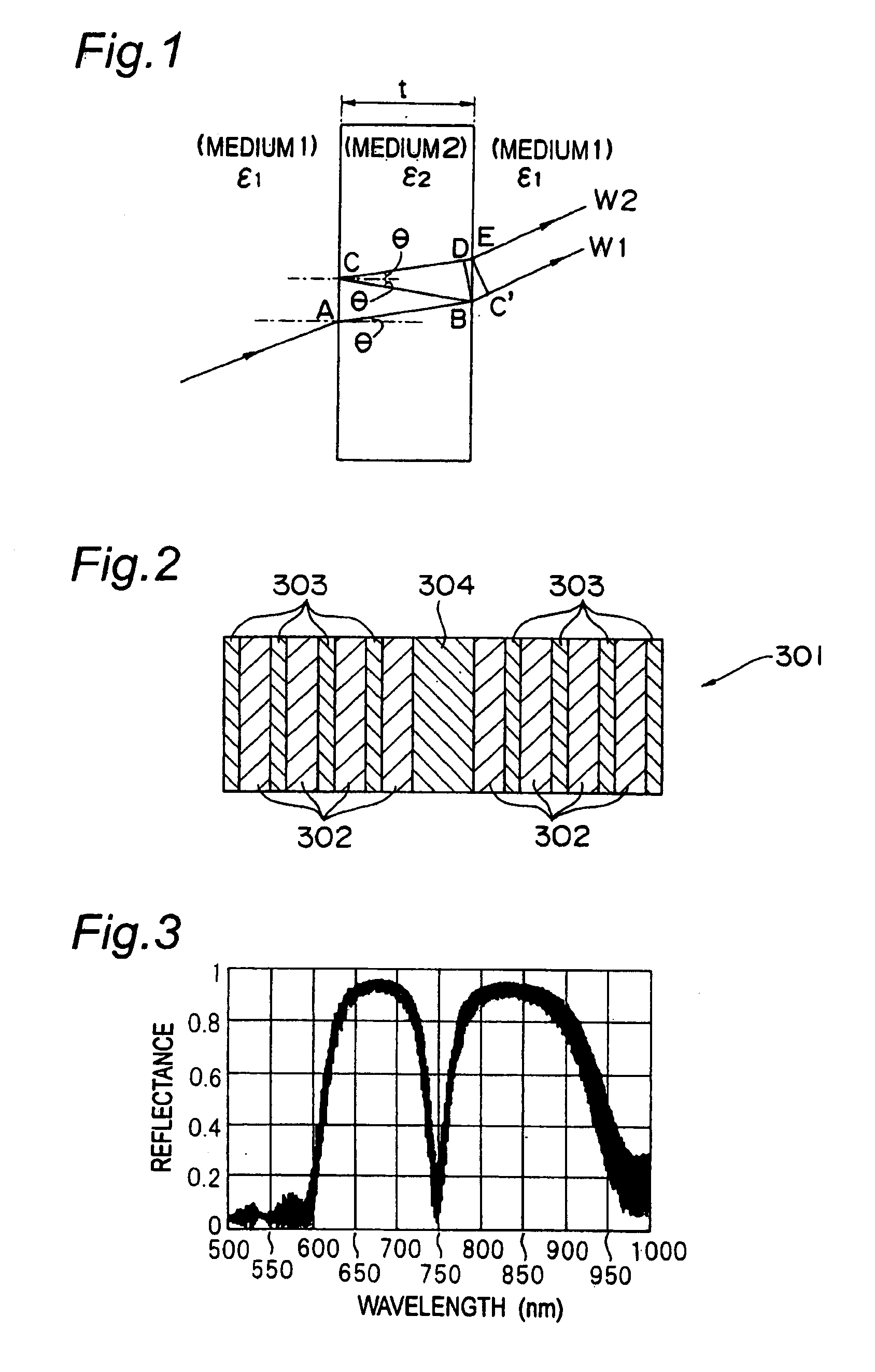

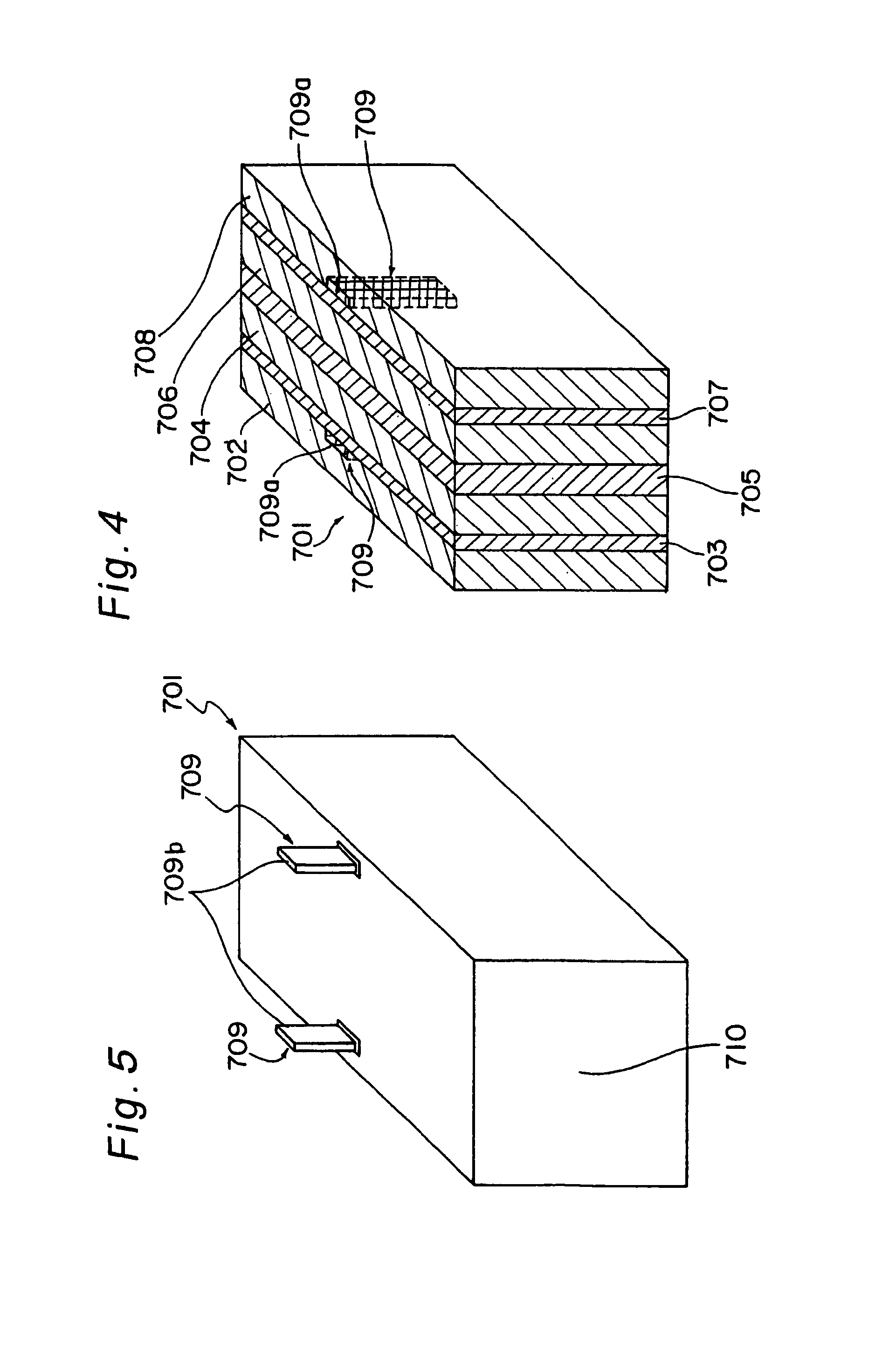

Tunable Magnonic Crystal Device and Filtering Method

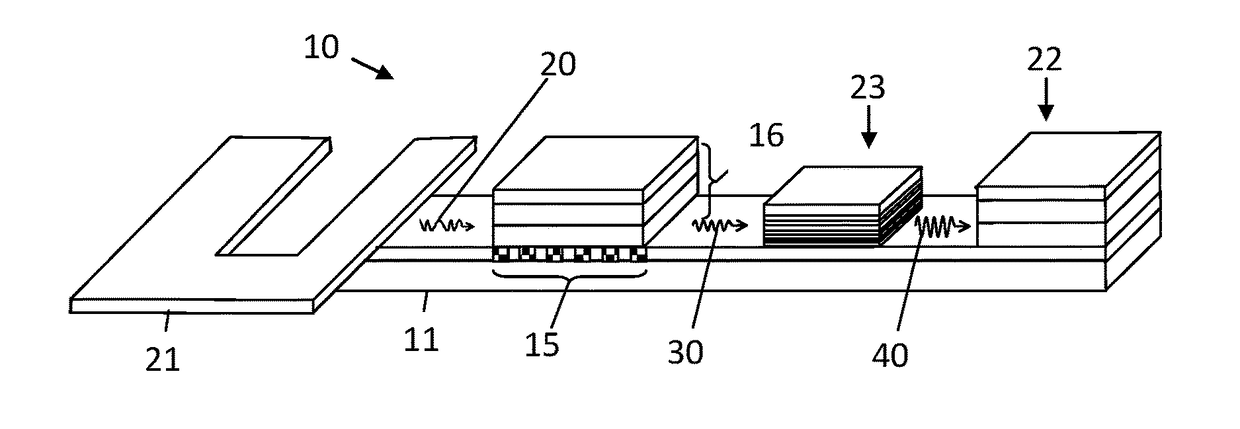

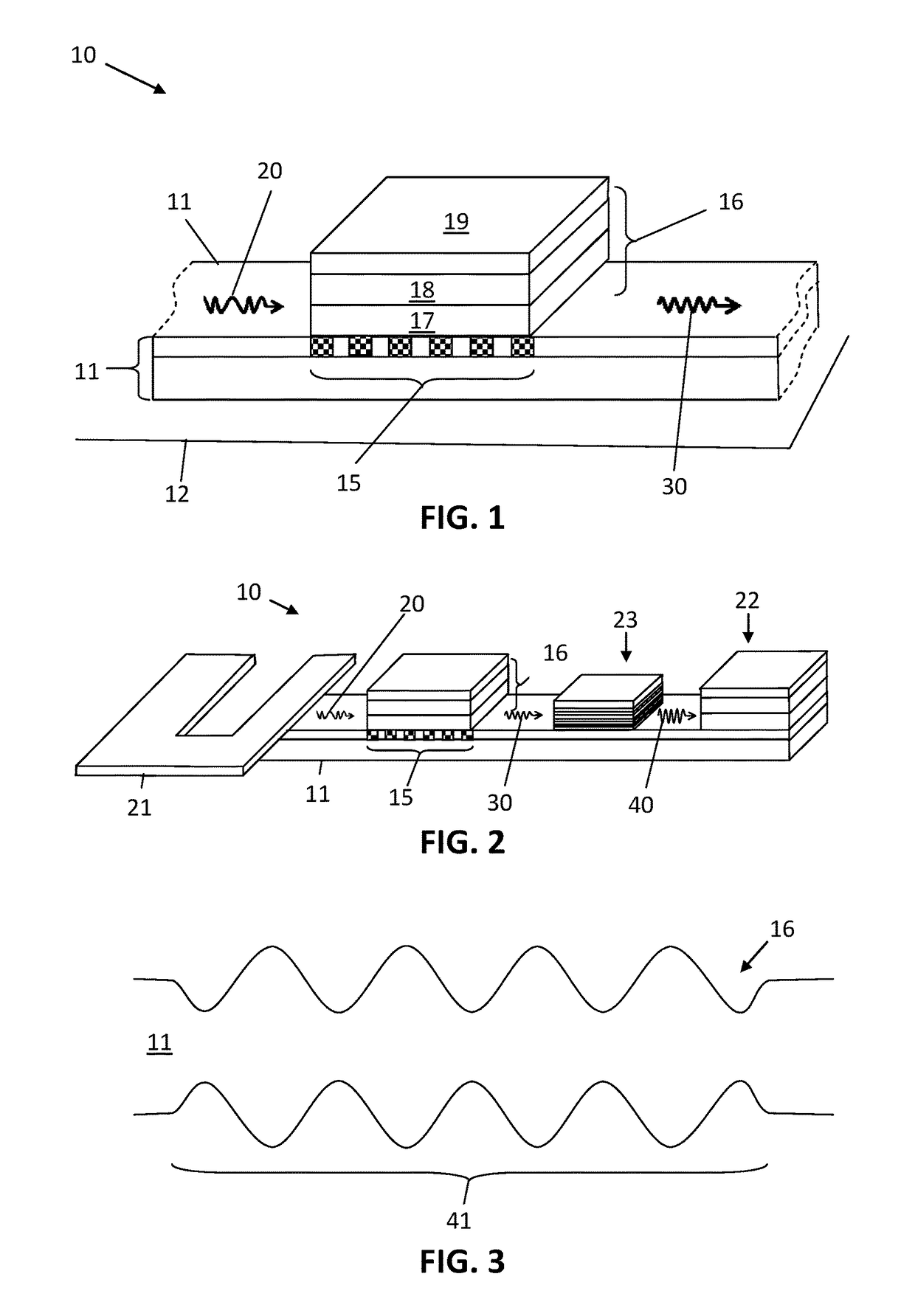

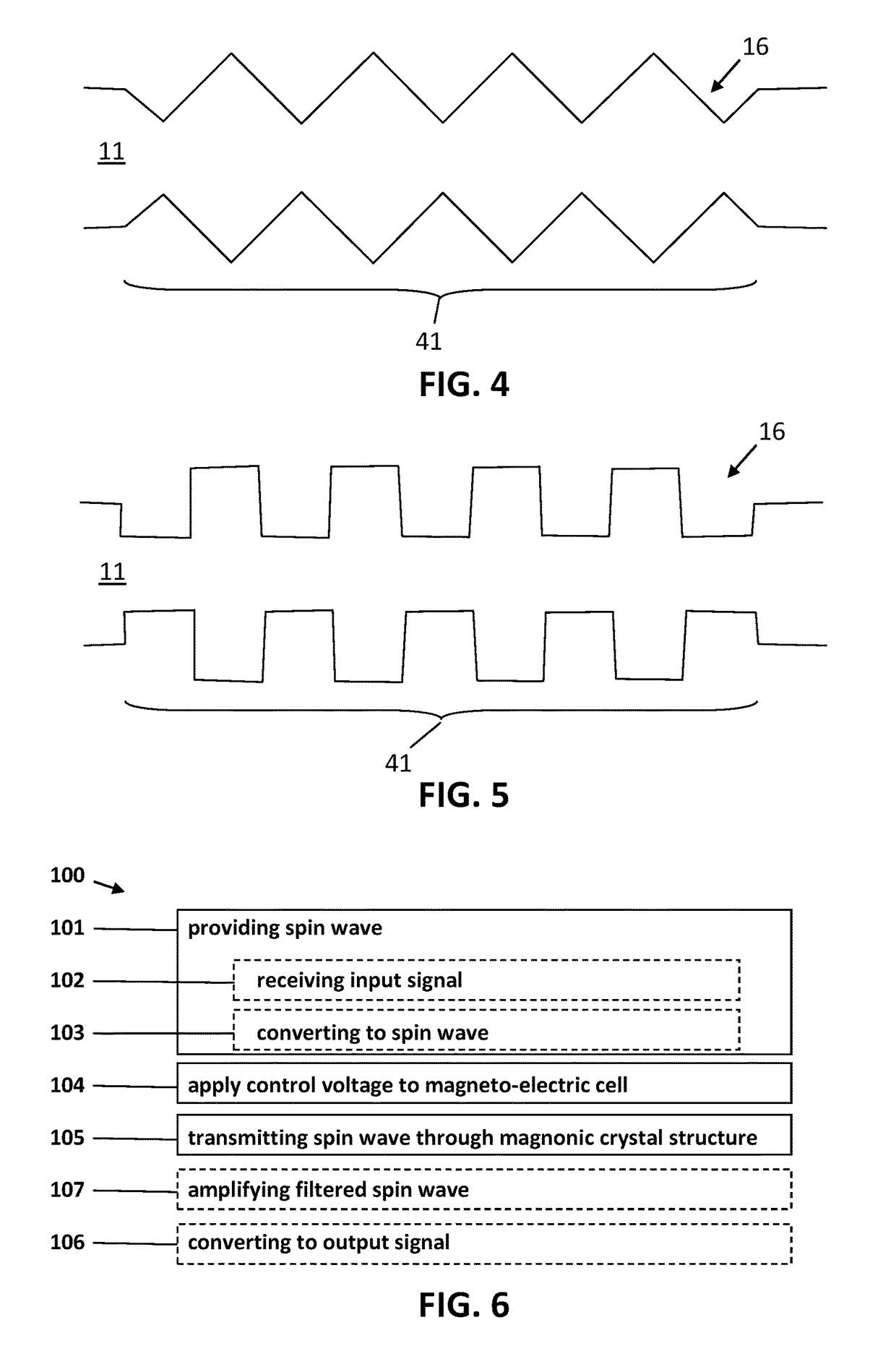

ActiveUS20170346149A1Effective filteringImprove filter qualityNanomagnetismNanoinformaticsElectricityCrystal structure

The present disclosure relates to a tunable magnonic crystal device comprising a spin wave waveguide, a magnonic crystal structure in or on the spin wave waveguide, and a magneto-electric cell operably connected to the magnonic crystal structure. The magnonic crystal structure is adapted for selectively filtering a spin wave spectral component of a spin wave propagating through the spin wave waveguide so as to provide a filtered spin wave. The magneto-electric cell comprises an electrode for receiving a control voltage, and adjusting the control voltage controls a spectral parameter of the spectral component of the spin wave via an interaction, dependent on the control voltage, between the magneto-electric cell and a magnetic property of the magnonic crystal structure.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW) +1

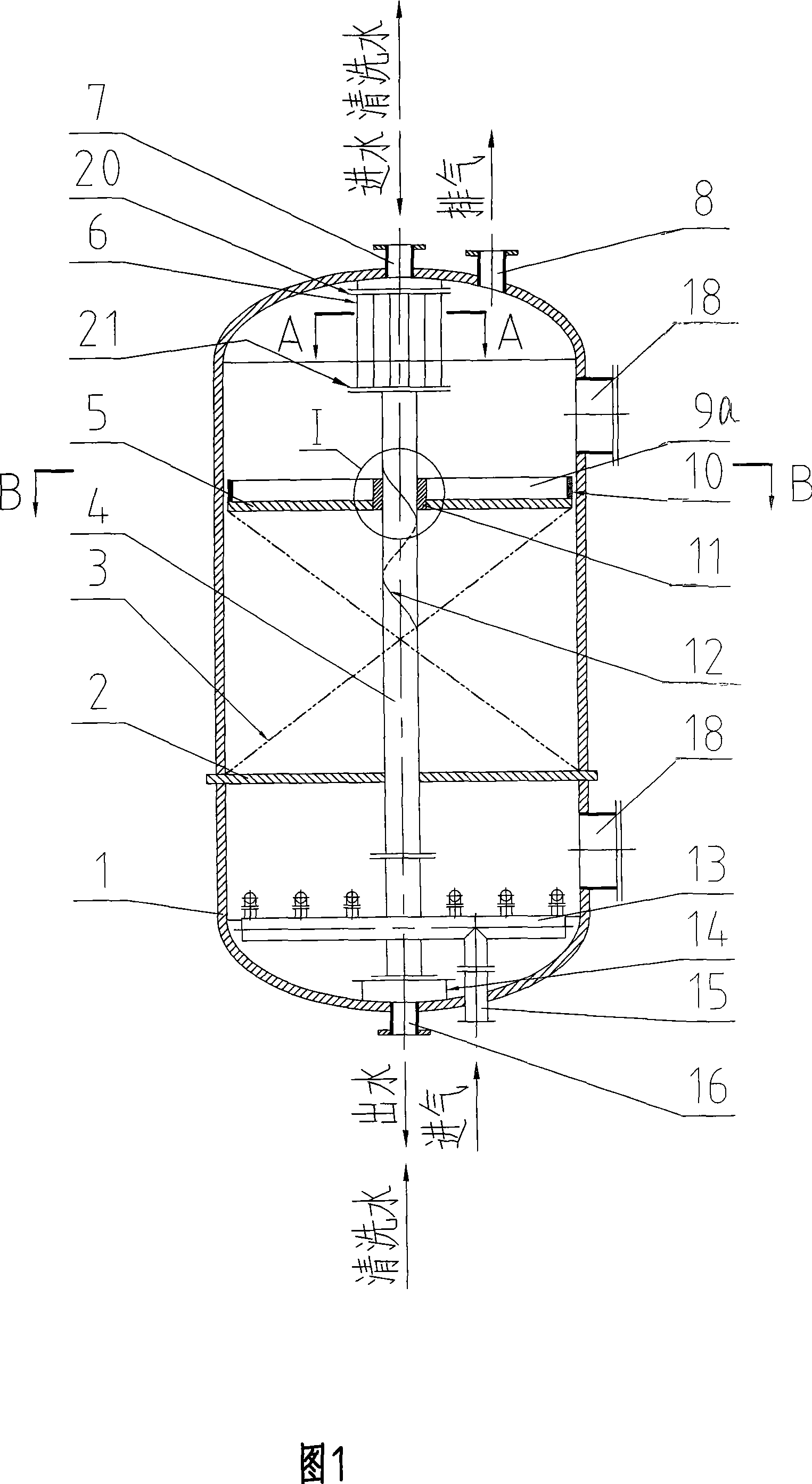

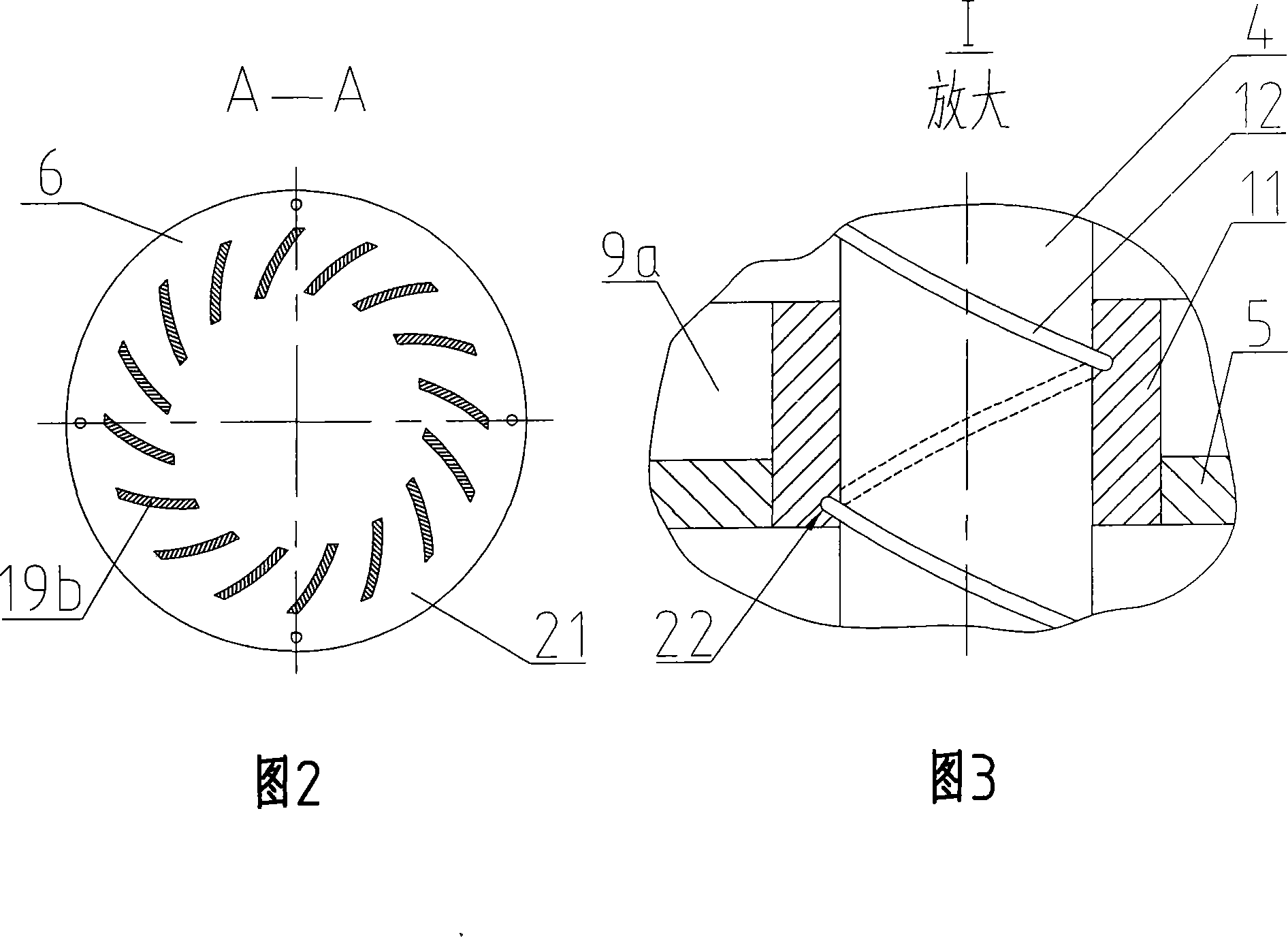

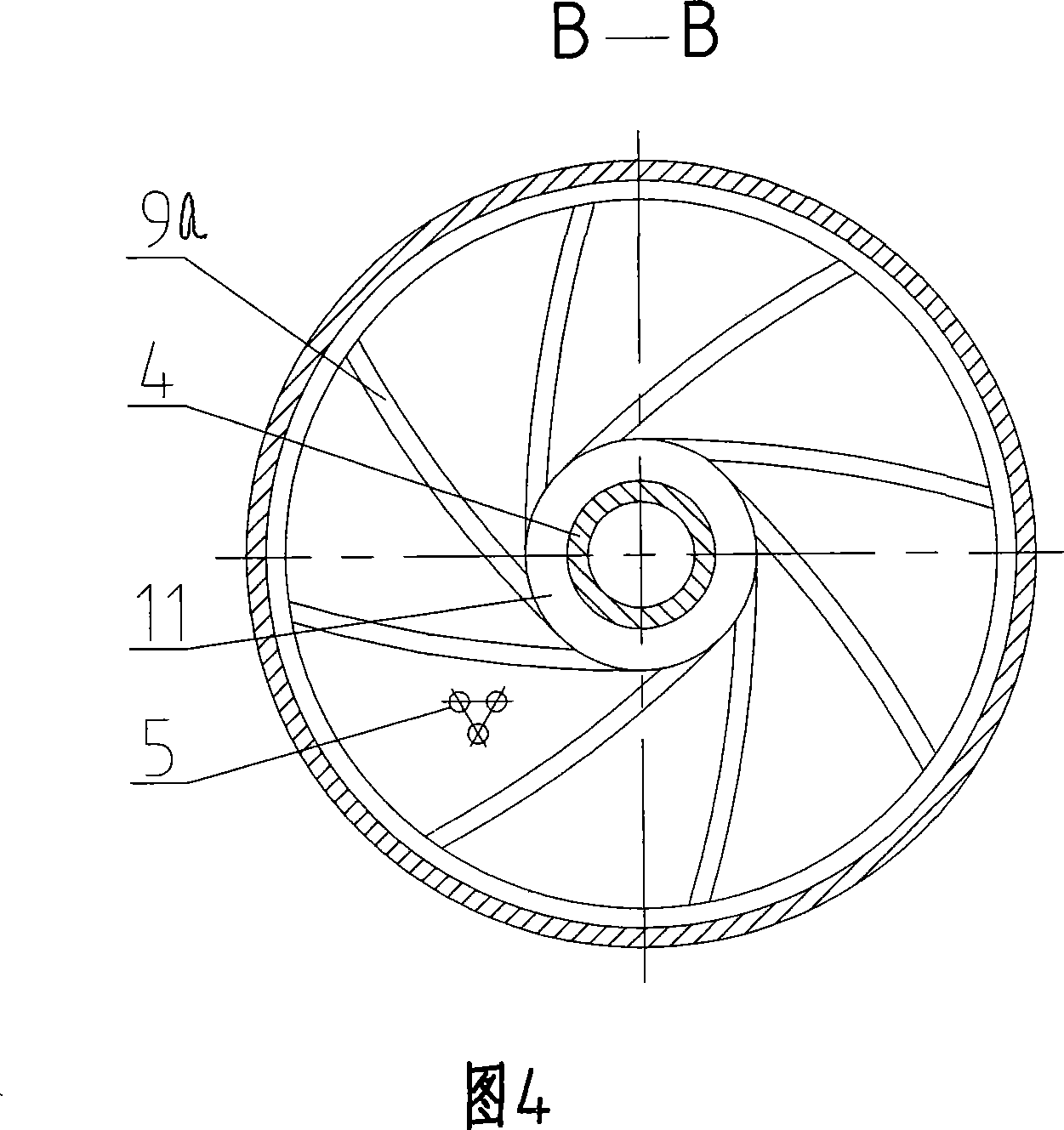

Filter with fiber filter element rotary displacement

InactiveCN101053707ASimple structureConvenient operation and maintenanceLoose filtering material filtersGravity filtersFiberGuide tube

The invention relates to a segregating unit, which is a filter with a rotatable fibre strainer, comprising water inlet / water outlet, air inlet / air outlet and water distribution / water out unit mounted on the tank, air distributing device mounted in the tank, and fibre strainer connected fixedly with the fixed pore plate and moving pore plate and mounted between thereof in the tank. The method is characterized in that: a support guide tube is mounted at the center of the tank and two ends thereof are securely connected with the water distribution / water out unit, a conduit which hitches on the support guide tube and is a helical pair therewith, the moving pore plate which is securely connected with the round plate is securely connected with the conduit, and rotatable fibre strainer composed of plurality of swirl vanes is mounted between the conduit and the round plate. The device has a simple structure, operates and maintains conveniently, and easily realizes large-scale equipment. The device has an advantage of a high filtrating precision, a big area, a large pollution-cutting capability, a long filtrating cycle, a big water-making, a excellent filtrating quality, a and reliable property.

Owner:NORTHEAST DIANLI UNIVERSITY

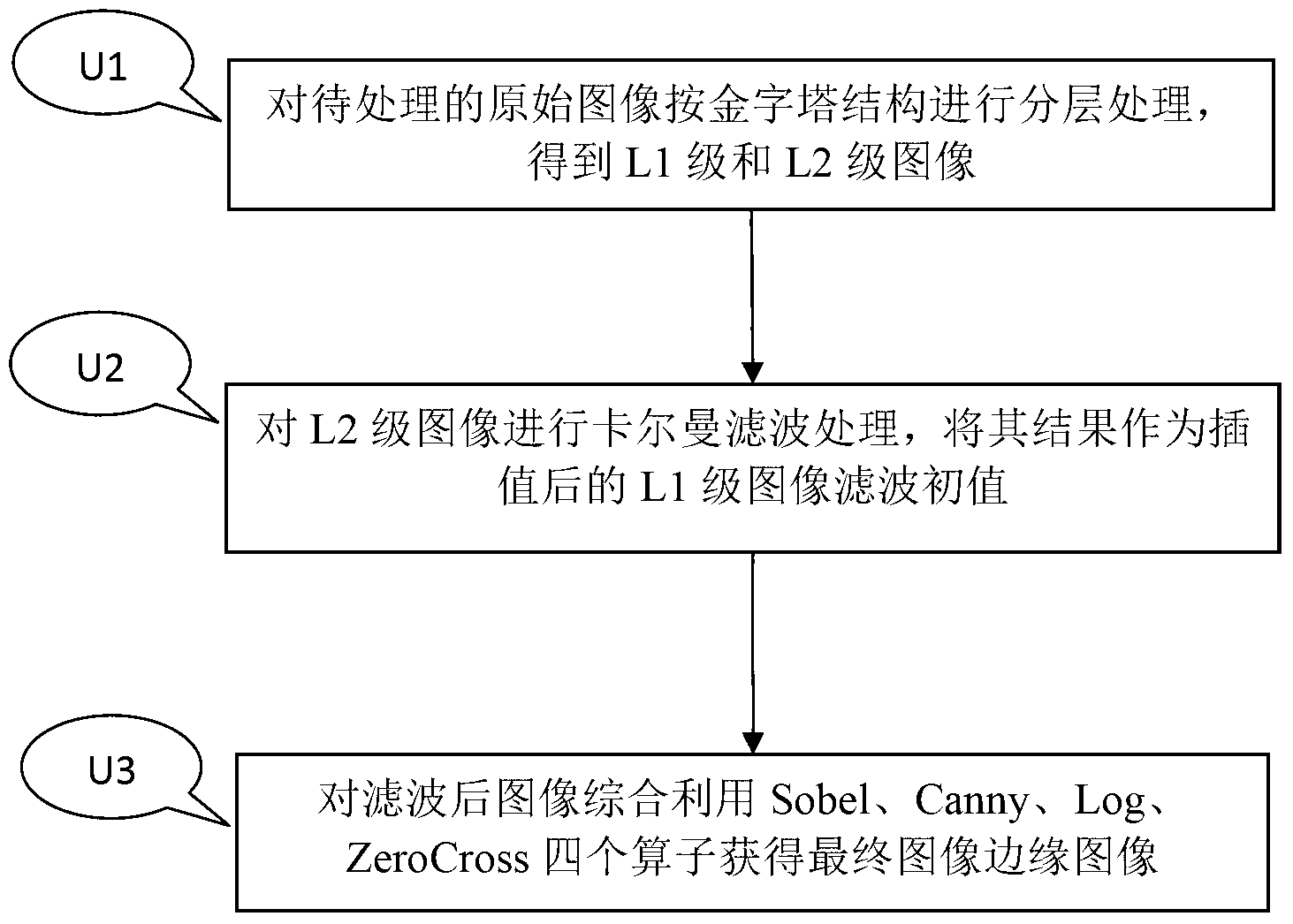

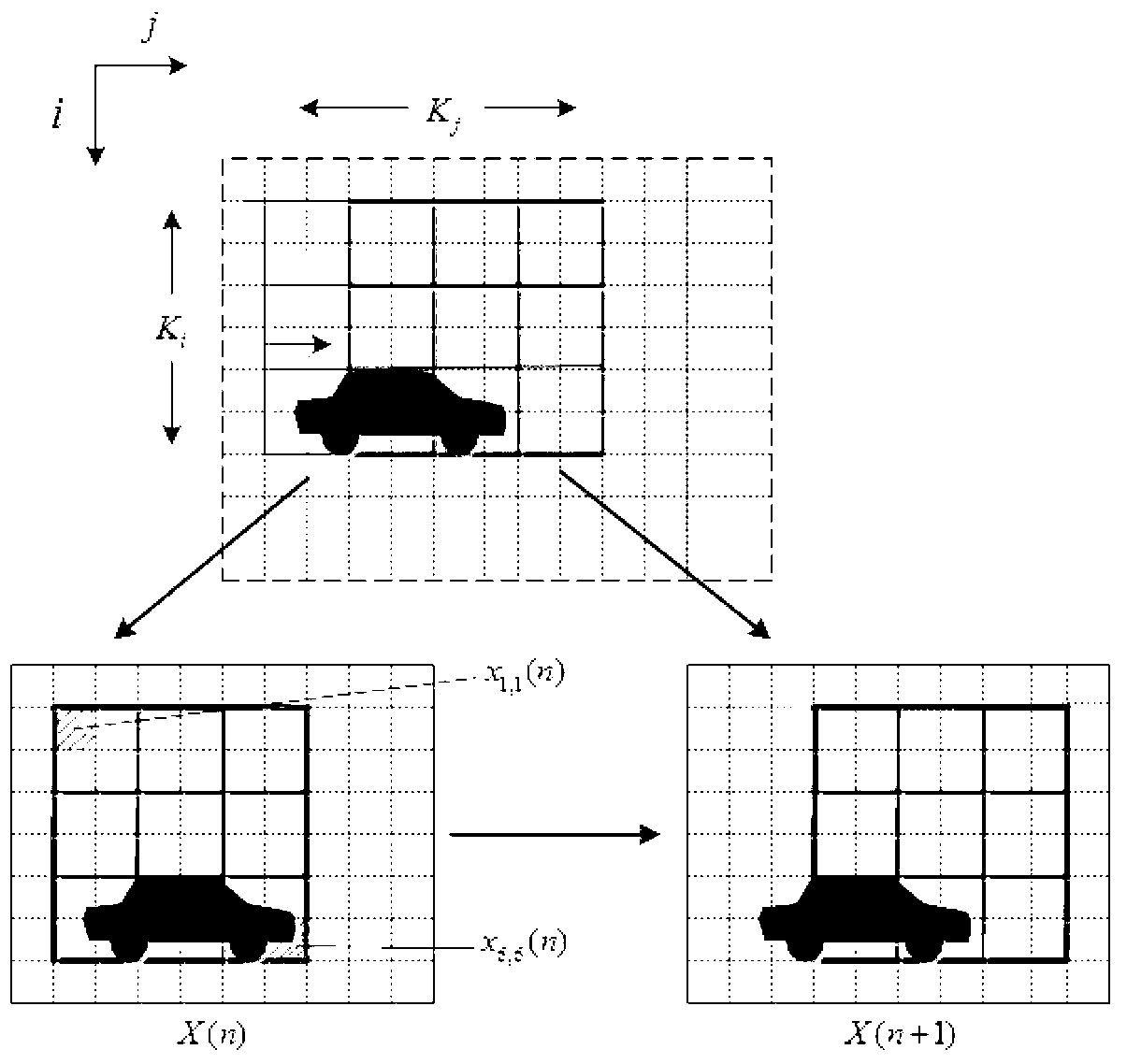

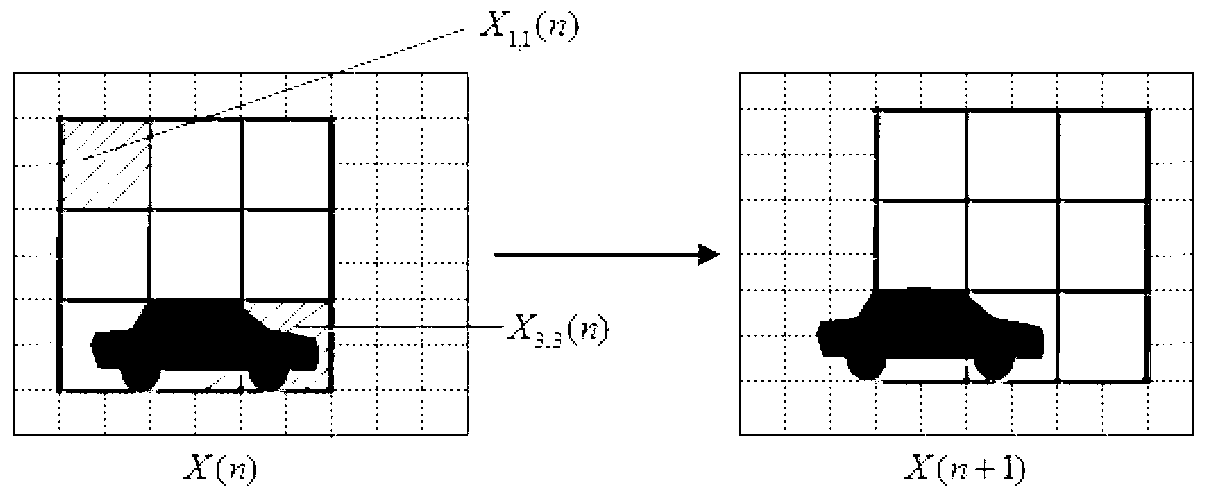

Image edge extraction method based on blocked Kalman filtering

ActiveCN103310461ATotal number of small searchesSmall number of searchesImage enhancementImage analysisSignal-to-noise ratio (imaging)Operand

The invention discloses an image edge extraction method based on blocked Kalman filtering. The image edge extraction method includes the following steps that: (1) original images to be processed are subjected to hierarchical processing according to a pyramid structure; (2) the hierarchical images are subjected to 2D blocked Kalman filtering respectively, the former stage filtering result serves as the original value of the next stage filtering process, and the next stage filtering process includes Kalman filtering for images subjected to full-resolution image interpolation already; and (3) the filtered images are subjected to image edge detection respectively through four operators, namely Sobel, Canny, Log and Zero Cross, and image edge images obtained by the four operators are subjected to OR operation synthesis to obtain the final image edge image. According to the image edge extraction method, hierarchical processing and interpolation calculating are adopted so that the filtering effect of the filtering stage is effectively improved and the operand signal to noise ratio of image edge extraction is improved; and the advantages of the four classical image edge detection operators are fully utilized so that the image edge detection quality is improved.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

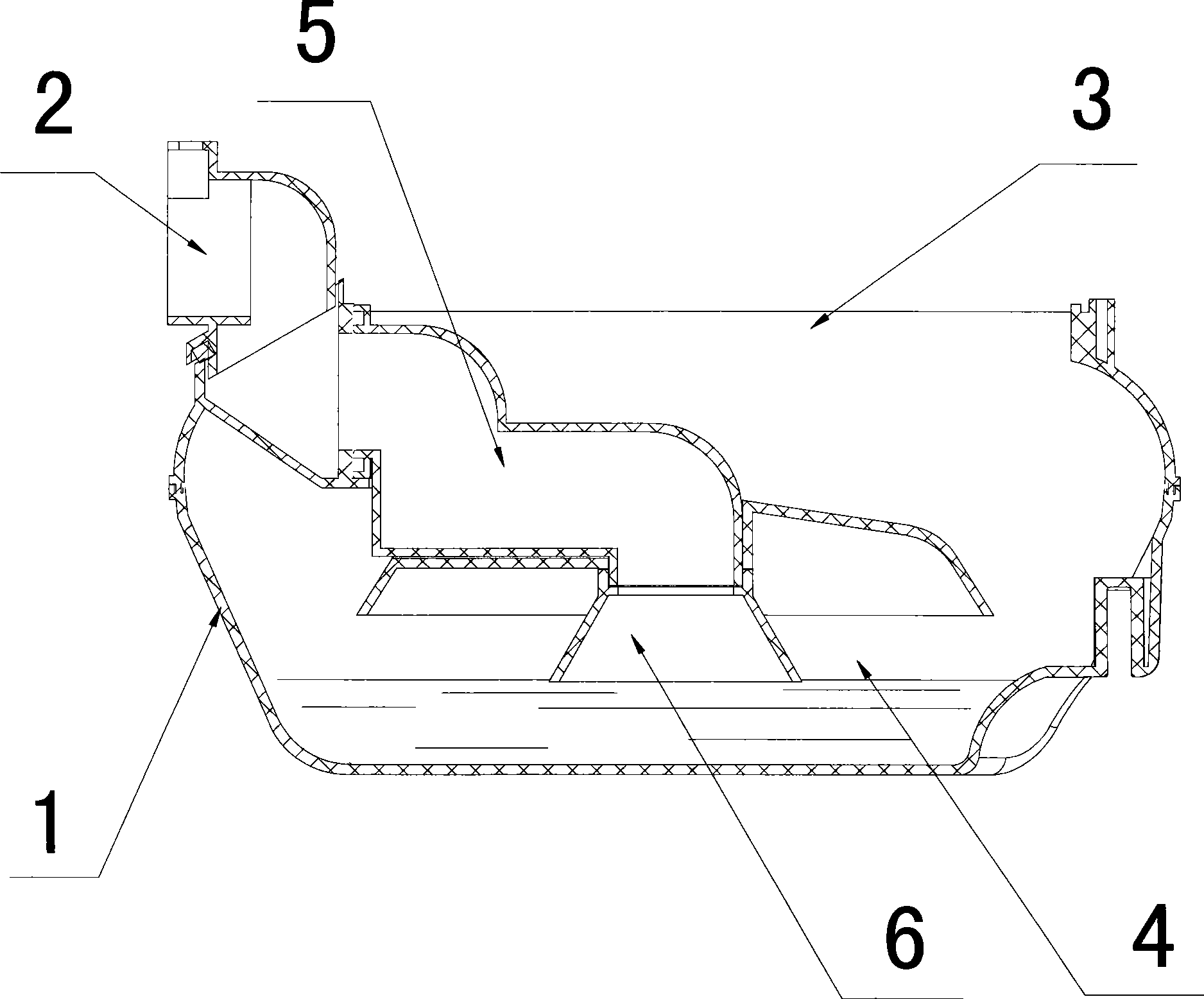

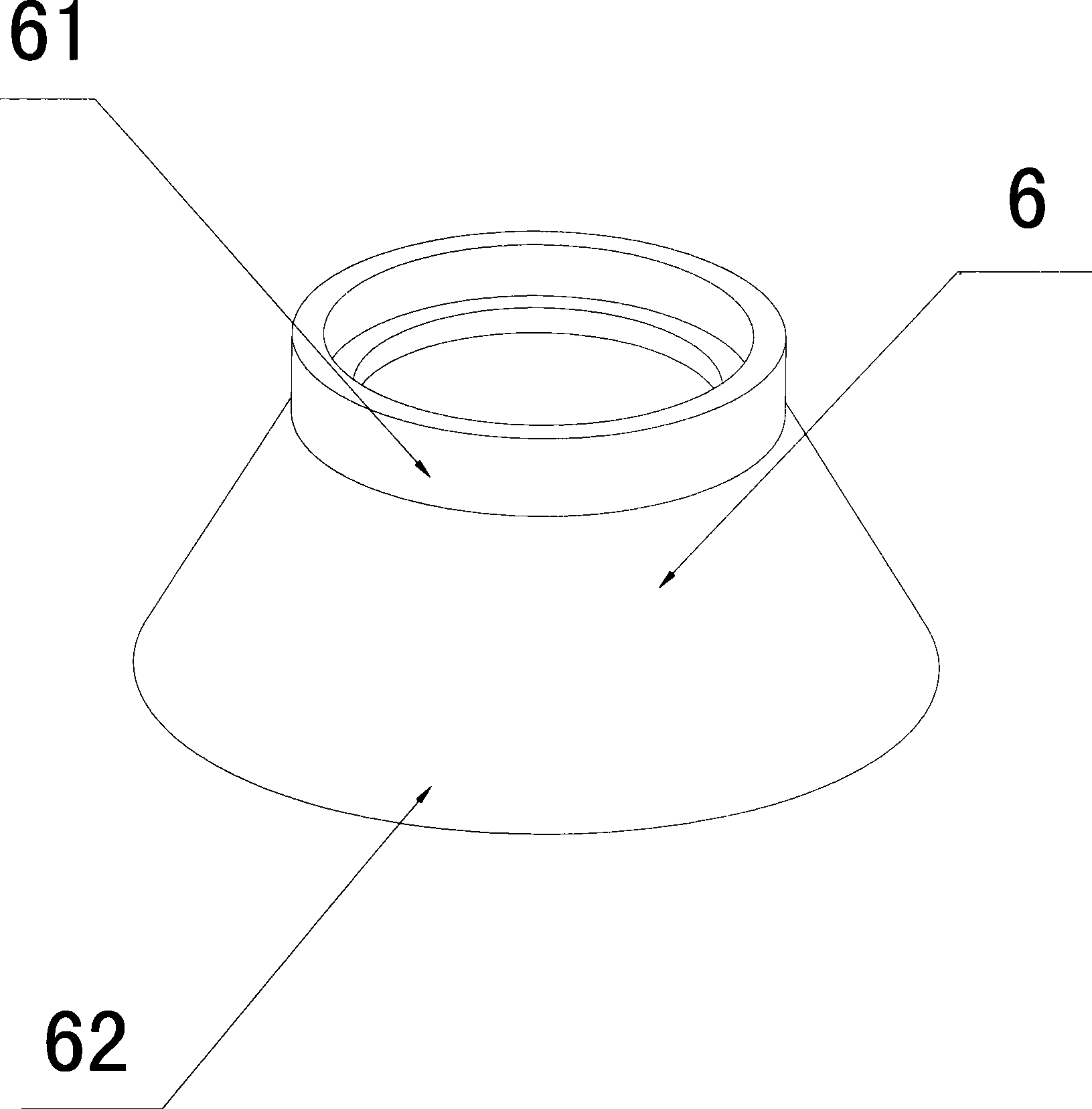

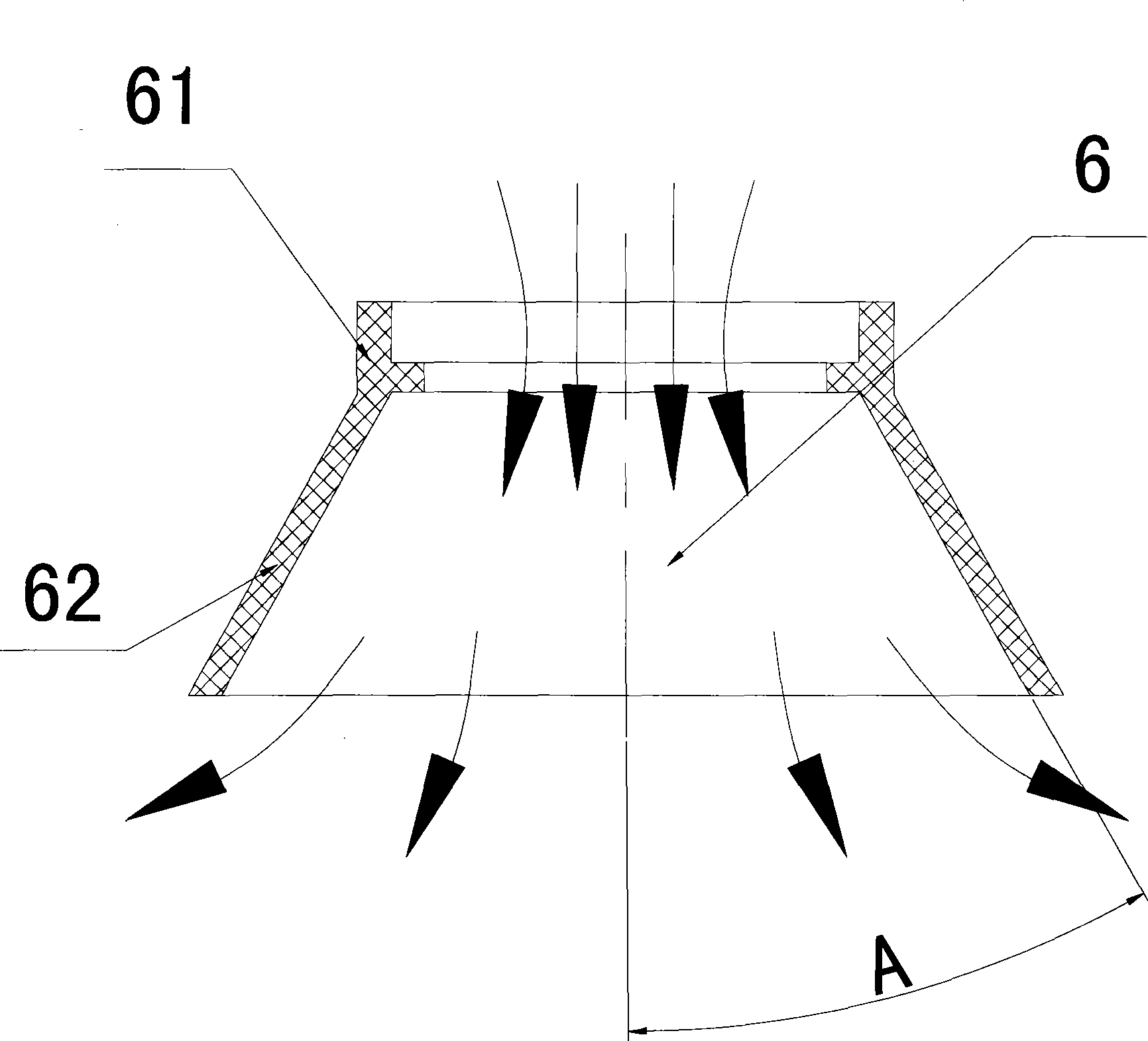

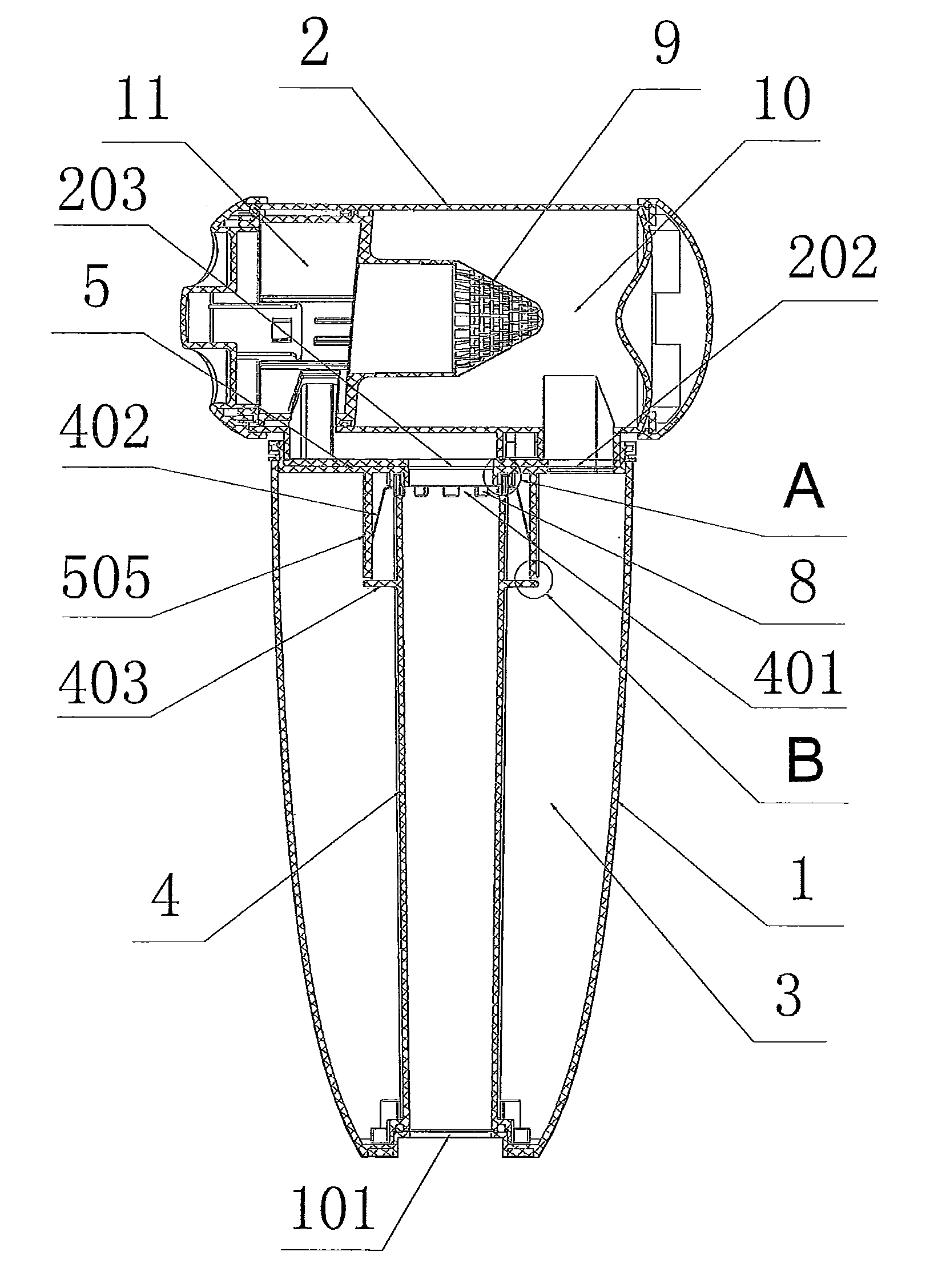

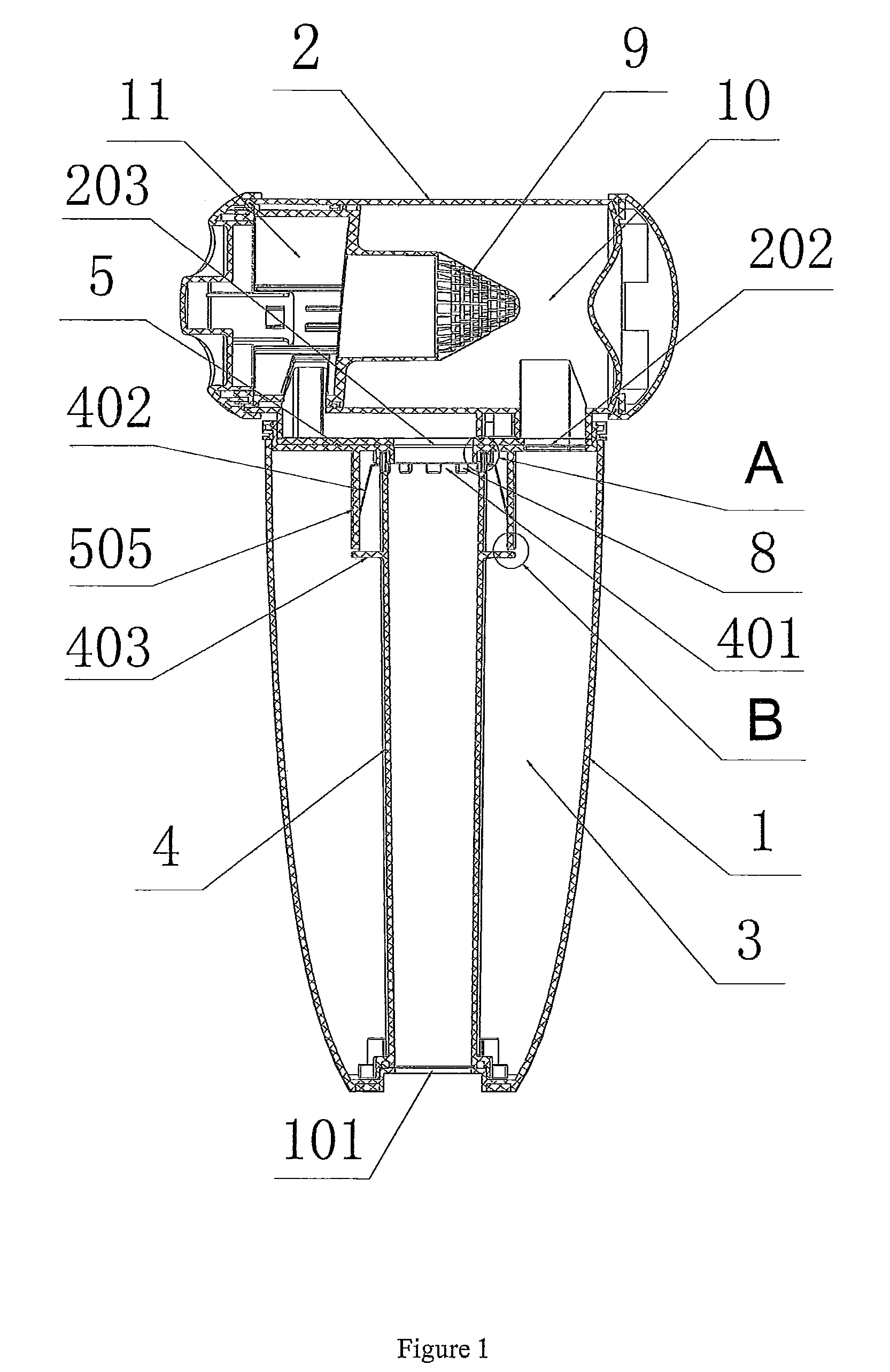

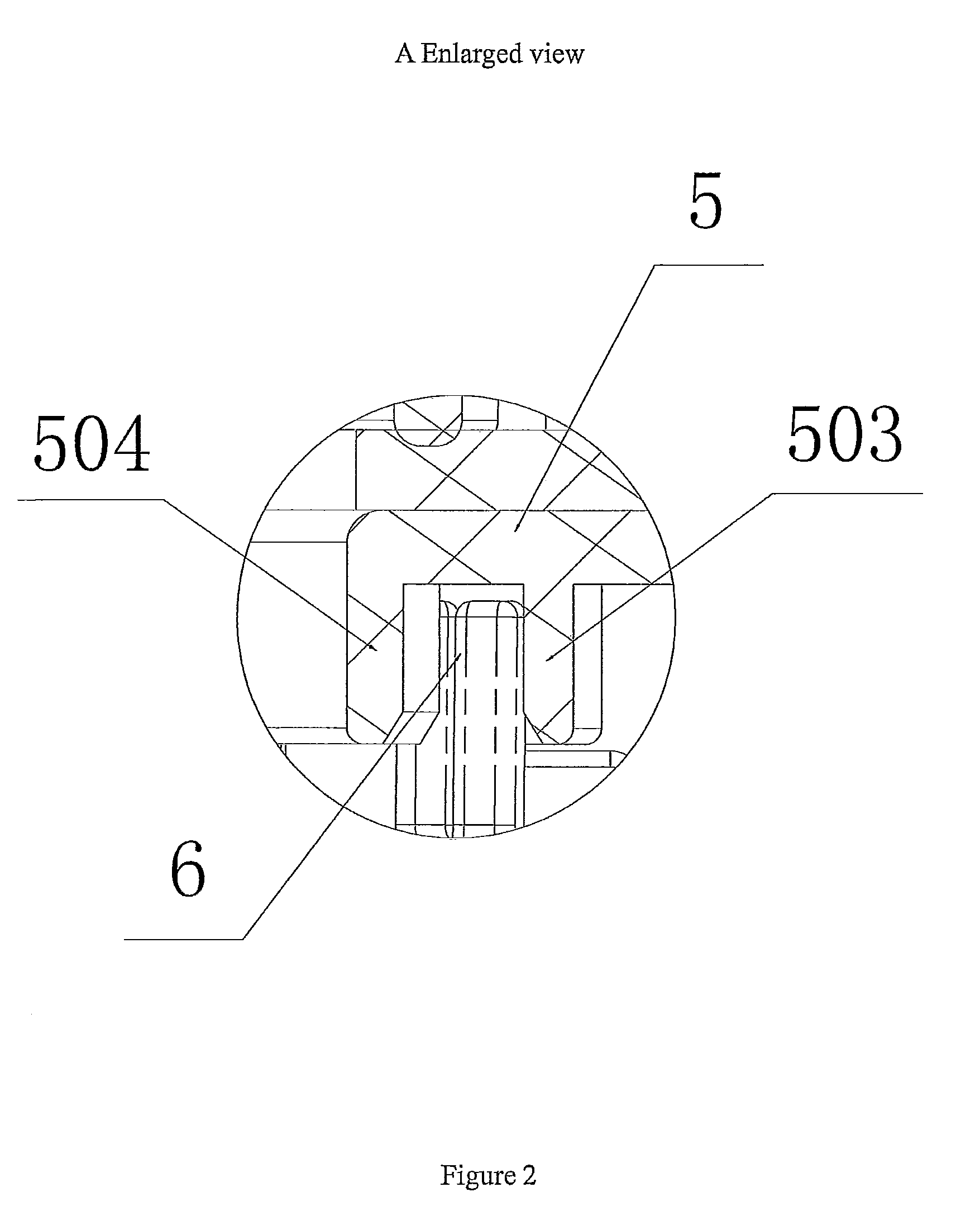

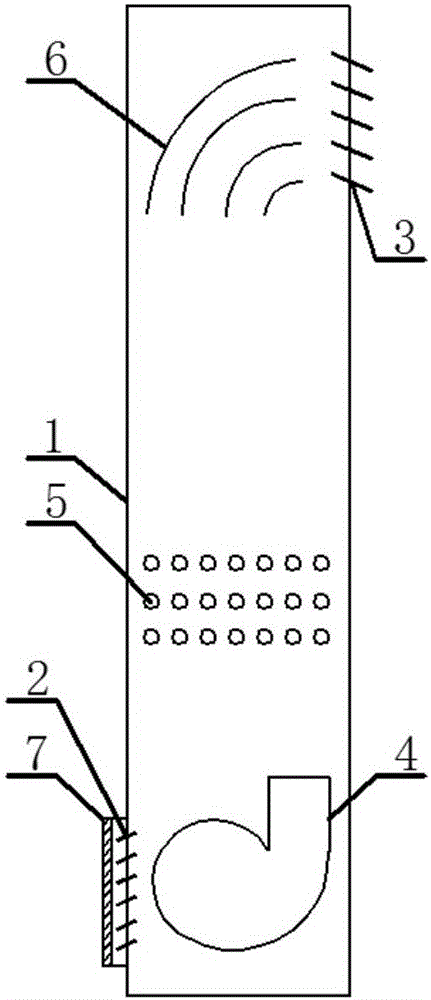

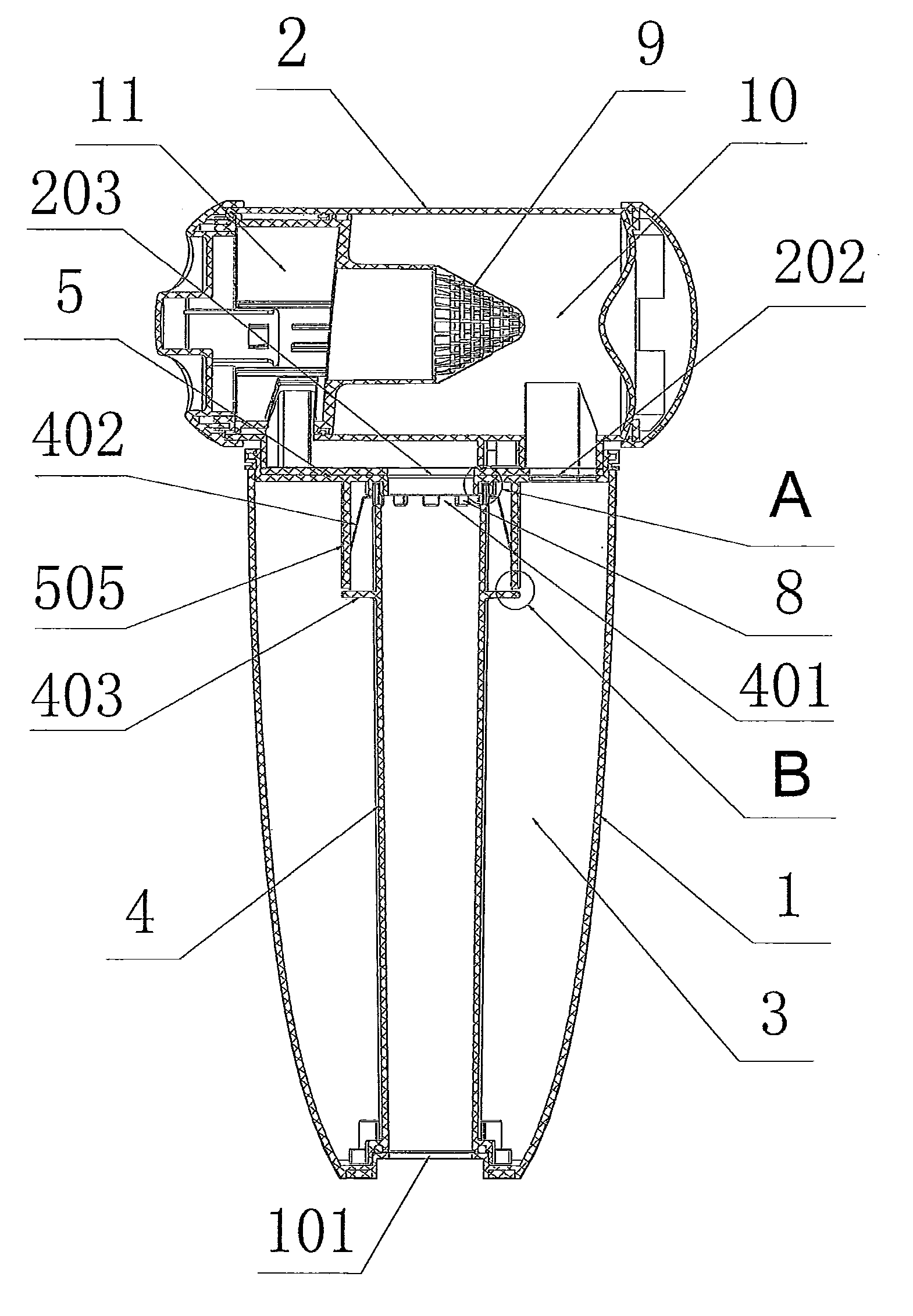

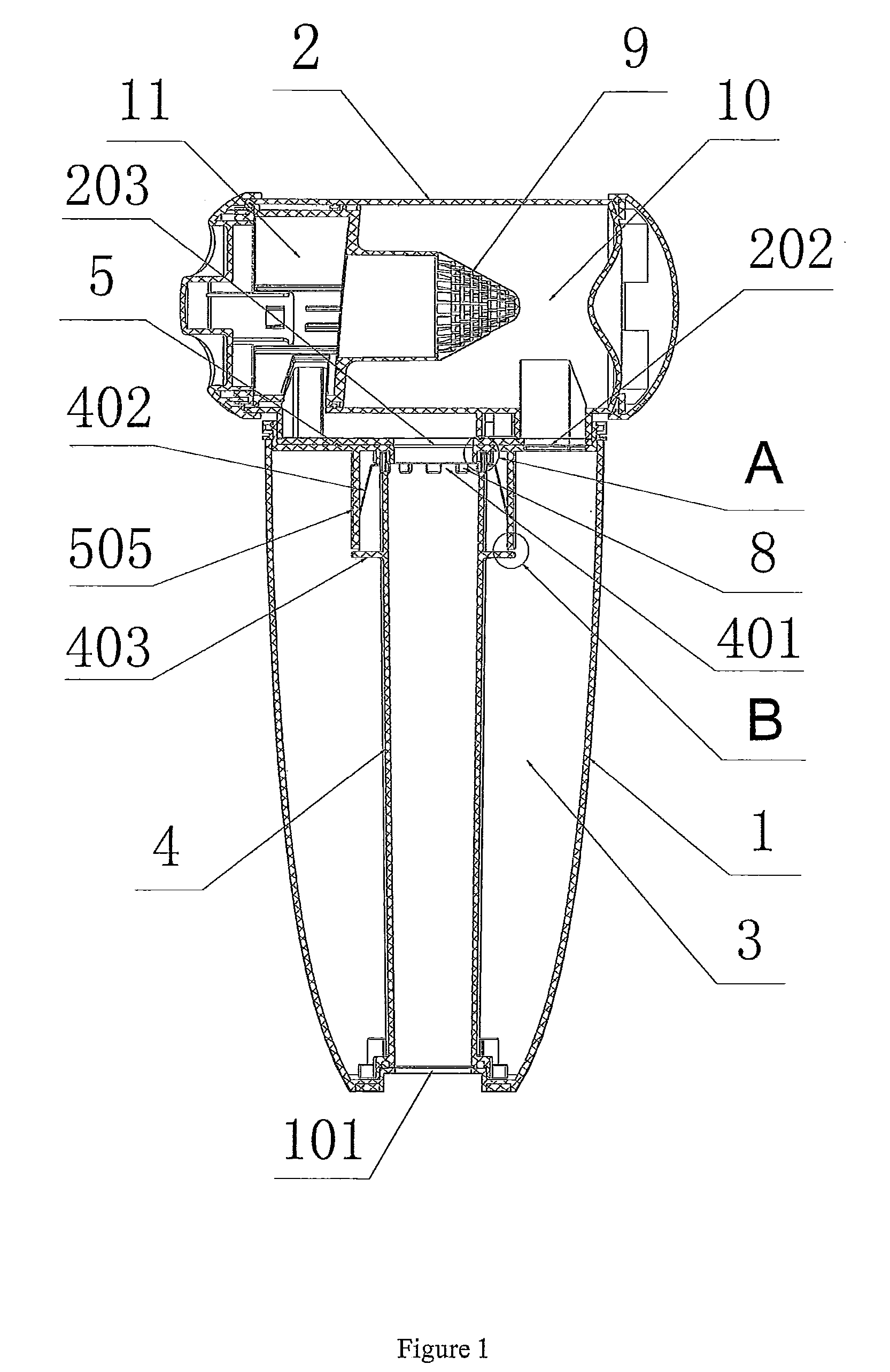

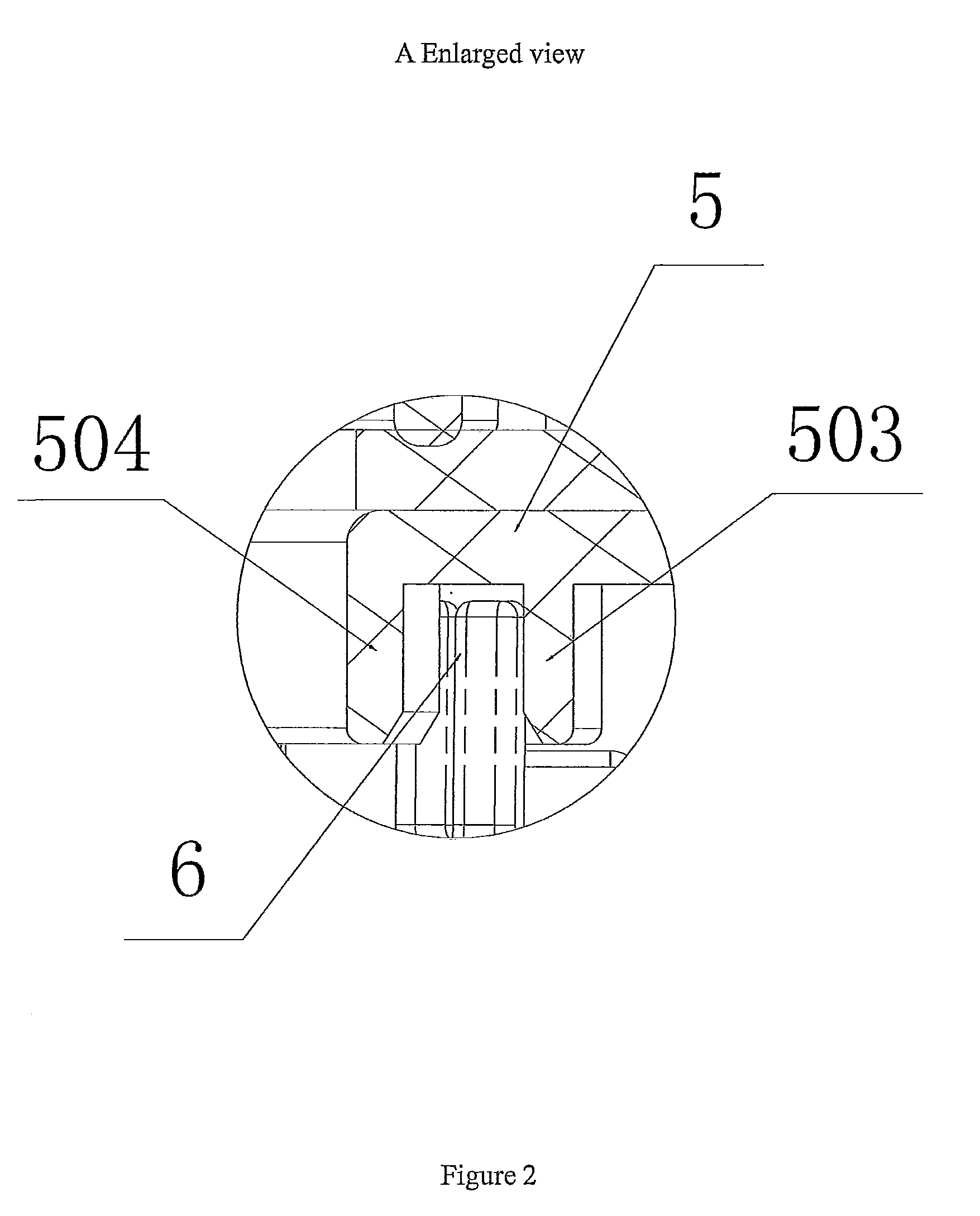

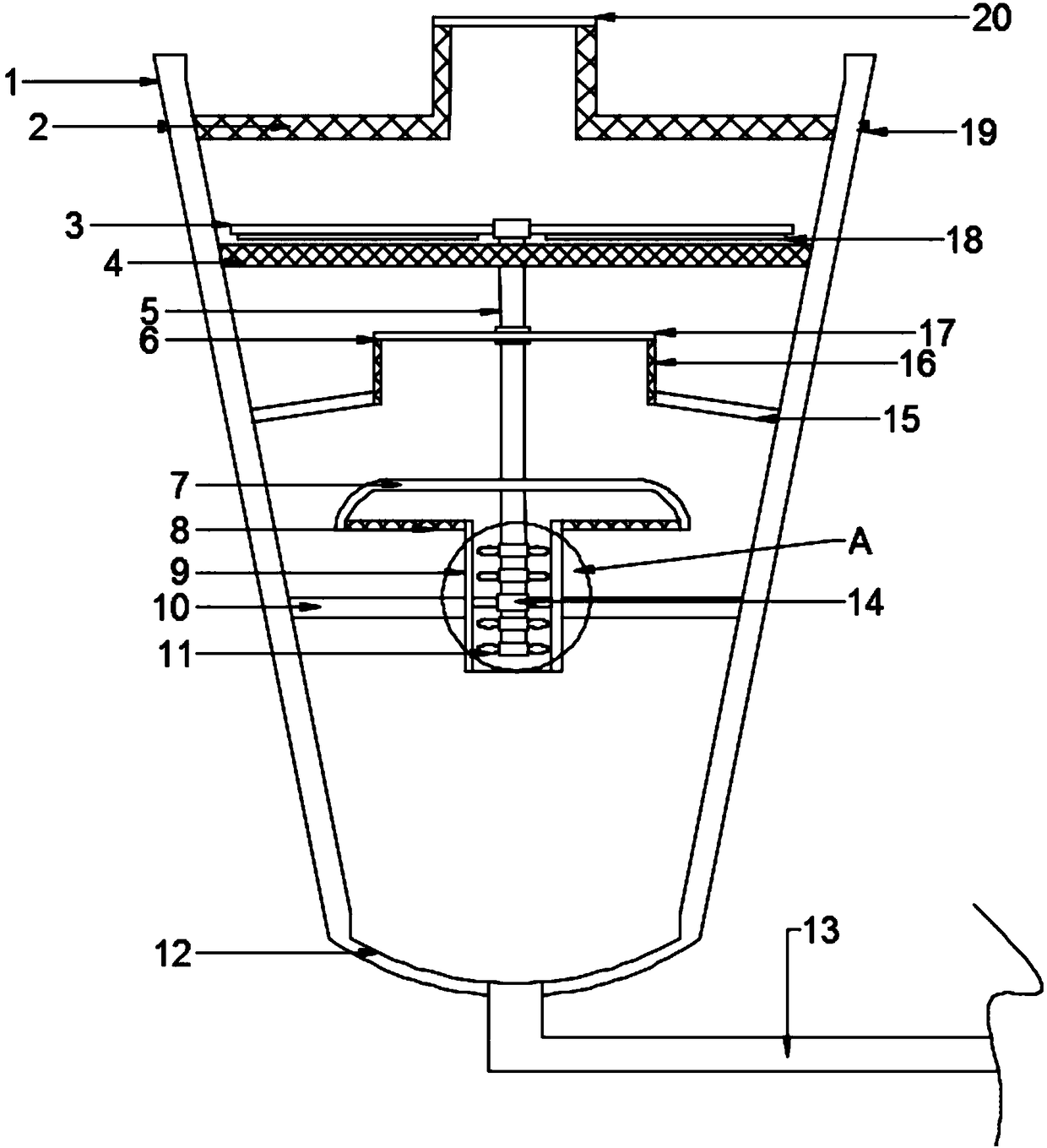

Water filtering and dust removing device of dust collector

The invention discloses a water-filtering dedusting device of a dust catcher, which is mainly featured in that the end of an air inlet pipe in a dust cup is provided with a diffusion element with a downward opening. When the dust catcher catches dust, dusty gas with a certain speed passes through the air inlet pipe and then reaches the diffusion element; under the diffusion effect of the diffusion element, the speed of the dusty air is slowed down, the contact surface with water is enlarged and the contact is more complete, so dust in the dusty air can be filtered by water more completely and the filter quality of the water-filtering dedusting device of the dust catcher can be improved. Meanwhile, the invention also discloses a water-filtering dust catcher. Three baffles arranged in a water-gas separation chamber of the water-filtering dust catcher form a twisted wind channel which can obstruct moist air and change the flowing direction of the moist air after water filtering, and fine grains in the air can be further attached and filtered so as to greatly improve the filtering quality and dedusting effect of the water-filtering dust catcher.

Owner:KINGCLEAN ELECTRIC

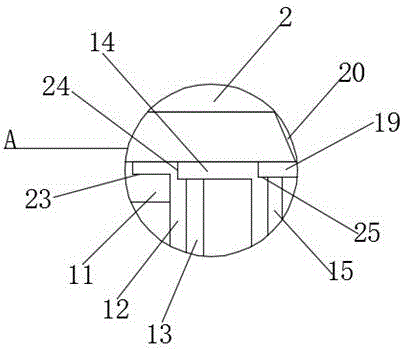

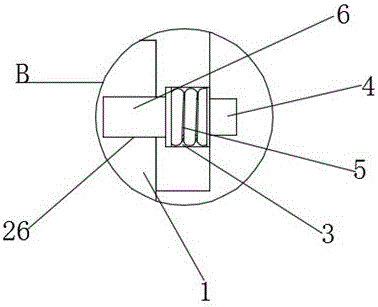

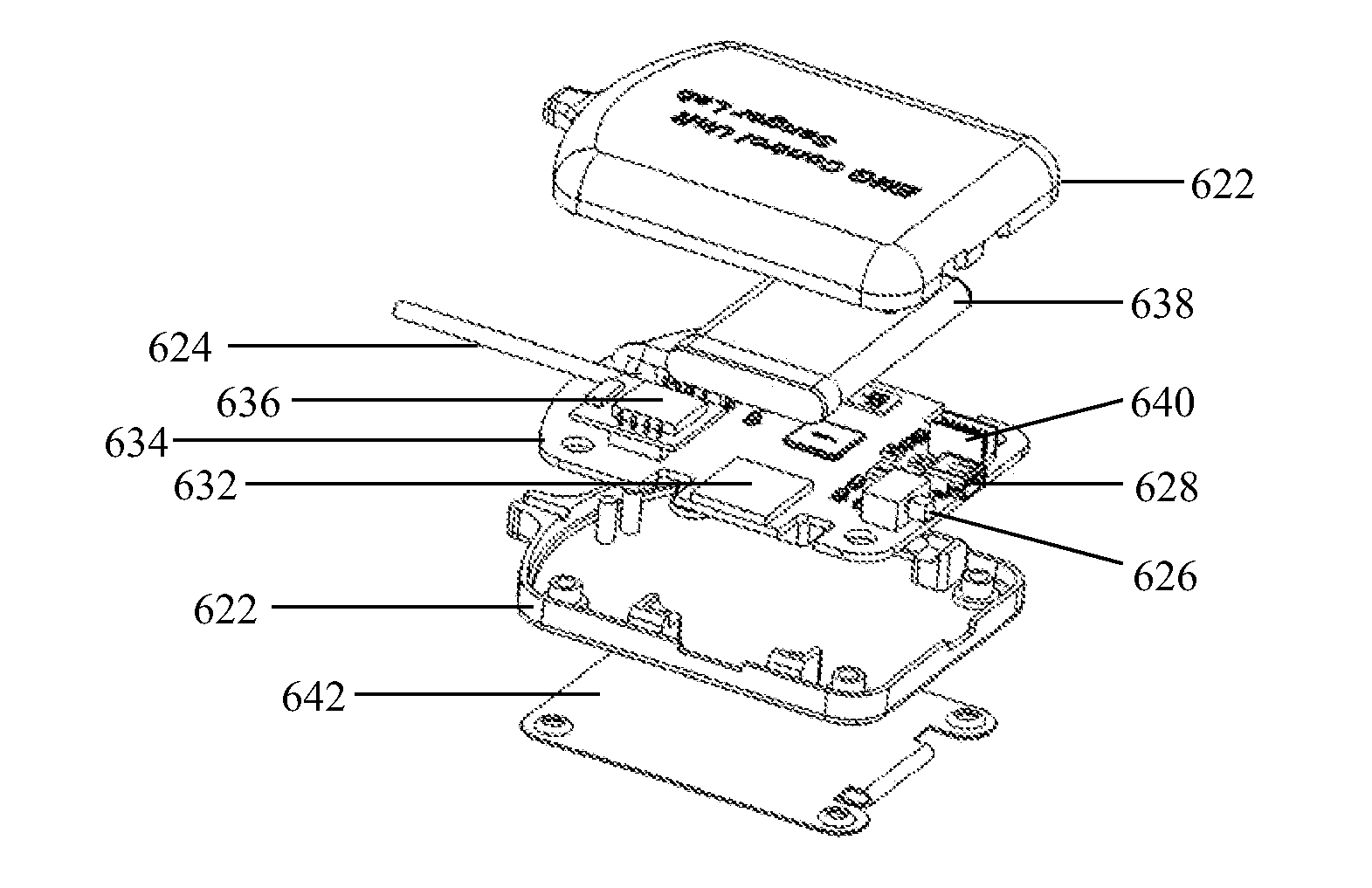

Cyclone separation dust cup and vacuum cleaner using the same

InactiveUS8302253B2Reduce power consumptionCurrent smoothingCleaning filter meansCombination devicesCycloneFilter effect

A cyclone separation dust cup, which includes a cup body and a cyclone tube, the cyclone tube being provided with an air inlet, an ash ejection outlet, and an air exhaust outlet; and the ash ejection outlet communicates with a dust storage cavity in the cup body, the air exhaust outlet with an air outlet positioned on the cup body through an air exhaust pipe, and the dust storage cavity with the air exhaust pipe. The dust storage cavity, by communicating with the air exhaust pipe, enables part of the air current entering the cyclone tube to enter the dust storage cavity in the cup body, thus producing suction in the ash ejection outlet of the cyclone tube that can draw the dust into the dust storage cavity. This enables the impurities with a lighter weight (e.g. hair and downy floc), which cannot fall into the dust storage cavity under gravity, to be inhaled into the dust storage cavity successfully, thus greatly improving the separating and filtering effect of this cyclone separation dust cup.

Owner:SUZHOU KINGCLEAN FLOORCARE

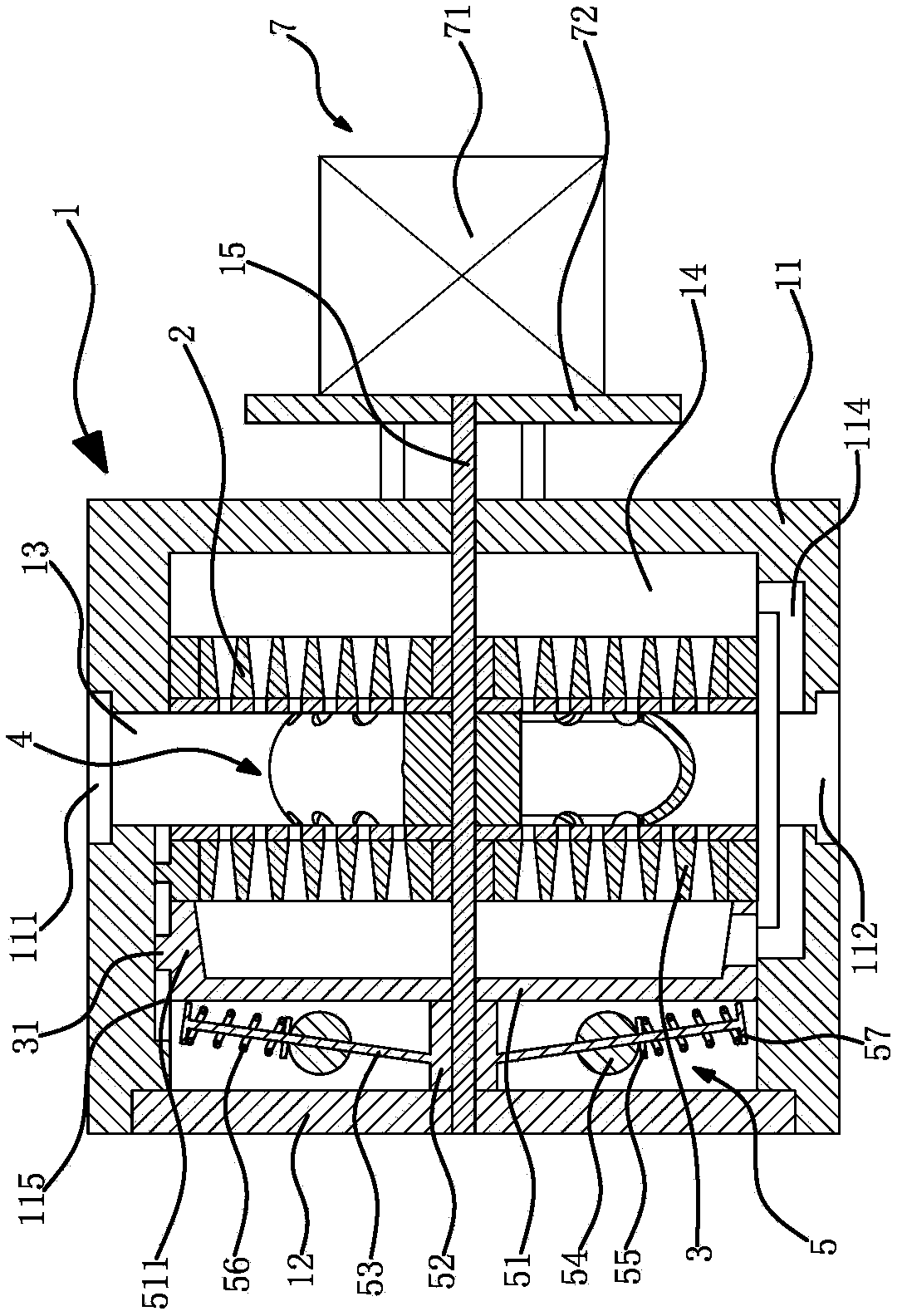

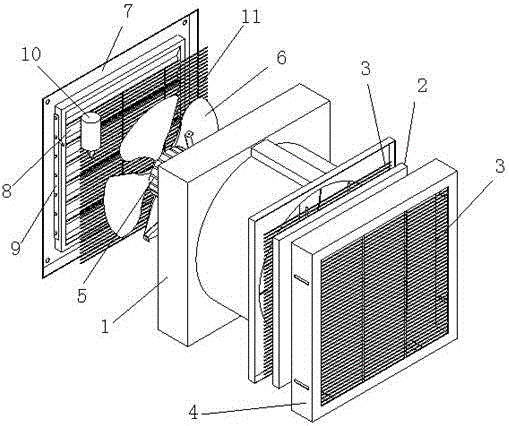

Convection-type heater with air purifying function

InactiveCN105674429AImprove filter qualityImprove filtering effectMechanical apparatusLighting and heating apparatusAir filtrationAir filter

The invention relates to a convection-type heater with an air purifying function. The convection-type heater comprises a casing and is characterized in that an air outlet louver window is arranged on the upper side wall of the casing; an air return louver window is arranged on the lower side wall, opposite to the air outlet louver window, of the casing; a cross-flow fan and an electric heating unit are arranged in the inner cavity of the casing; an air inlet of the cross-flow fan faces the air return louver window, and an air outlet of the cross-flow fan faces the air outlet louver window to form an air inlet / outlet channel structure; the electric heating unit is arranged between the air outlet of the cross-flow fan and the air outlet louver window to form a convection-type circulating hot air structure; an air filtering layer is arranged at the air return louver window to form a convection-type heater structure with the air purifying function. According to the convection-type heater with the air purifying function, the problems of poor air purification effect and low heating efficiency in the prior art can be solved; the convection-type heater with the air purifying function has the prominent beneficial effects that the air purifying effect is good, the heating efficiency is high, and particularly, the quality and the effect on filtering organic substances, such as bacteria, ozone and formaldehyde, are good.

Owner:GUANGZHOU DESIGN INST

Cyclone separation dust cup and vacuum cleaner using the same

InactiveUS20100251508A1Reduce power consumptionCurrent smoothingCleaning filter meansCombination devicesCycloneCyclonic separation

The present invention discloses a cyclone separation dust cup, which includes a cup body and a cyclone tube, the cyclone tube being provided with an air inlet, an ash ejection outlet, and an air exhaust outlet; and the ash ejection outlet communicates with a dust storage cavity in the cup body, the air exhaust outlet with an air outlet positioned on the cup body through an air exhaust pipe, and the dust storage cavity with the air exhaust pipe. The present invention, with the dust storage cavity communicating with the air exhaust pipe, enables part of the air current entering the cyclone tube to enter the dust storage cavity in the cup body, thus producing suction in the ash ejection outlet of the cyclone tube that can inhale the dust into the dust storage cavity. This makes the impurities with lighter weight (e.g. hair and downy floc), which cannot fall into the dust storage cavity under gravity, be inhaled into the dust storage cavity successfully, thus greatly improving the separating and filtering effect of this cyclone separation dust cup.

Owner:SUZHOU KINGCLEAN FLOORCARE

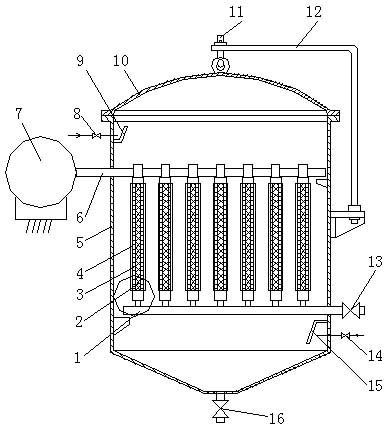

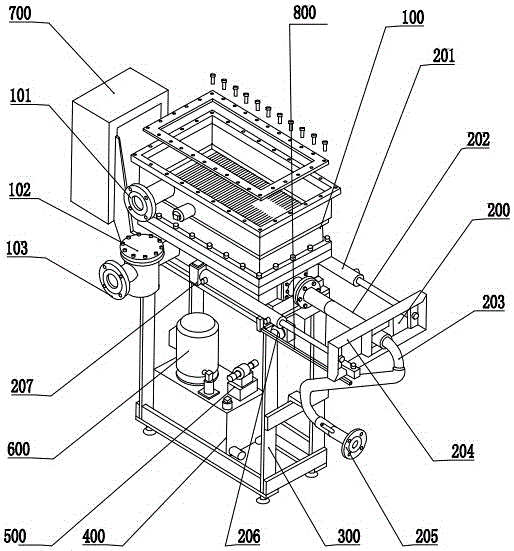

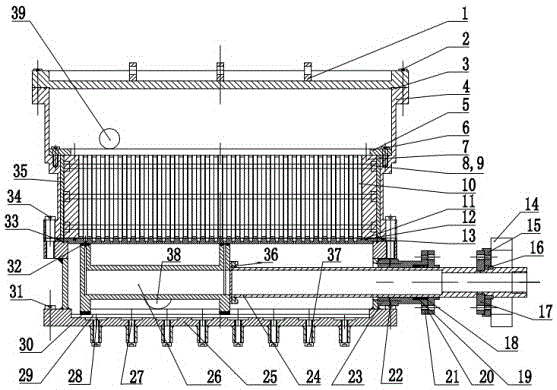

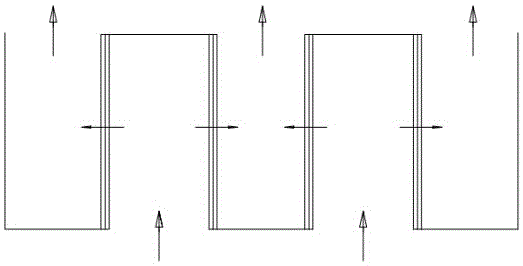

Automatic back-washing plate frame filter

ActiveCN105126402ASave human effortReduce energy consumptionFiltration separationFiltrationStructural engineering

The invention discloses an automatic back-washing plate frame filter which comprises a main engine, a back-washing device and a plate frame filter rack, wherein the main engine comprises an upper body cover plate, a filter element body, an intermediate plate and a base in sequence from top to bottom; the filter element body is divided into a clear liquid tank positioned at the upper part and a filter element tank positioned at the lower part; a plurality of filter element filter plates are arranged in the filter element tank at uniform intervals; intervals of front and back adjacent filter element filter plates are formed into filter seams, the lower ends of the front filter seams are in sealed connection with the plate surface of the intermediate plate, the upper ends of the front filter seams are communicated with the clear liquid tank, the lower ends of the back filter seams are communicated with a to-be-filtered liquid through hole in the intermediate plate, and the upper ends of the back filter seams are sealed, so as to form a staggered connection structure; a piston cavity structure is formed by the intermediate plate and the base; a back-washing device is arranged in the piston cavity, and comprises a piston, a hydraulic device connected with the piston and a back washing outlet; the piston and the plate surface of the intermediate plate are connected in a sliding and sealed manner; a back-washing inlet corresponding to the to-be-filtered liquid through hole in position is formed in the piston. According to the automatic back-washing plate frame filter, automatic back-washing can be realized in the use process, and the filtration quality is high.

Owner:JIUJIANG HENGSHENG CHEM FIBER

Cleaning agent filter device convenient for dismounting

InactiveCN106390562AImprove filtration efficiency and filtration qualityEasy to install and removeStationary filtering element filtersEngineeringCleaning agent

The invention discloses a cleaning agent filter device convenient for dismounting. The cleaning agent filter device comprises a machine barrel; a barrel cover is arranged at the top end of the machine barrel ; a mounting chamber is formed in the bottom end of each of two ends of the barrel cover; a pull rod is arranged in each of the mounting chambers; the surface of the pull rod is connected with a spring in a sleeving manner; a fixed rod is arranged at one end of the pull rod ; a mounting rack is arranged at the top of the barrel cover; a motor is arranged in the mounting rack; a liquid inlet pipe is arranged on the surface of the barrel cover on one side of the mounting rack; a rotating shaft of the motor is connected with a stirring rod through a coupler. According to the cleaning agent filter device, the mounting rack, the motor, the coupler, the stirring rod, a rotating seat, a first collection box, a first filtering plate, a second collection box, a second filtering plate, a first connecting pipe, a liquid collecting box, a through hole and a bearing are arranged and are utilized cooperatively to achieve the effects of stirring a used cleaning agent, improving the filtering efficiency and the filtering quality of the used cleaning agent and preventing silt from blocking a filtering hole.

Owner:WUXI JINWU AUX AGENT FACTORY CO LTD

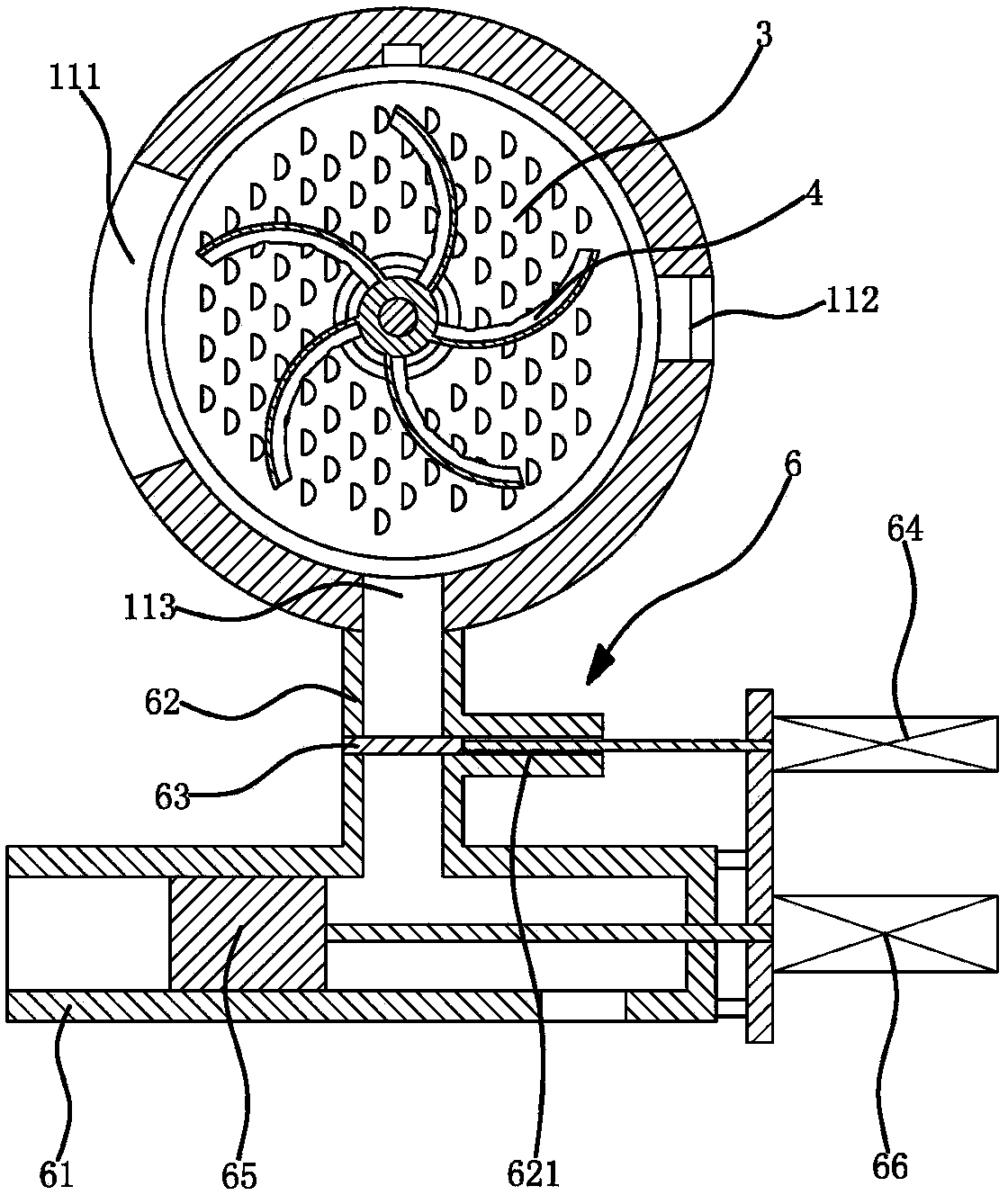

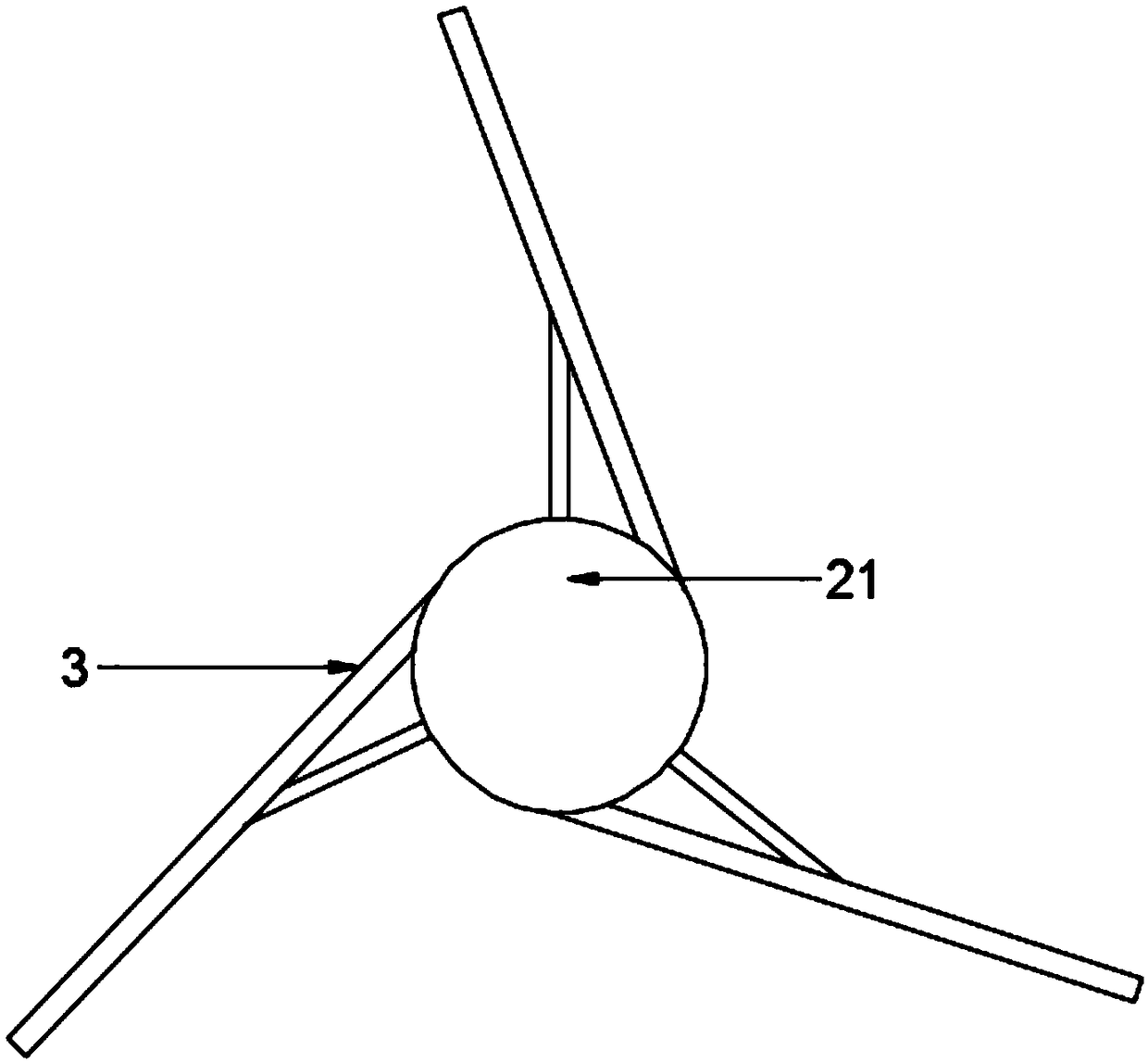

Water guiding box for environment-friendly sewage treatment tank

ActiveCN108854196AEasy to handleGuaranteed filtering effectStationary filtering element filtersImpellerEngineering

The invention discloses a water guiding box for an environment-friendly sewage treatment tank. The water guiding box comprises a water guiding box body, a first filter screen, a filter frame and a separation plate, wherein the water guiding box body is in a circular truncated cone shape with a large upper end diameter and a small lower end diameter, the first filter screen is fixed on the top of the water guiding box body by virtue of an installation pin, the filter frame is fixed inside the water guiding box body, the filter frame consists of an annular fixed plate, a fourth filter screen anda top plate, a water through pipe is fixed on the center of the separation plate in a penetrating manner, the upper end of the water through pipe is provided with a filter cover, a rotating shaft isinserted inside the through water pipe, the rotating shaft is provided with impellers which are distributed in an array manner in the through water pipe, the top of the rotating shaft is fixedly provided with a rotating column, the periphery of the rotating column is provided with three clearing rods which are circularly distributed in an array manner. According to the water guiding box for the environment-friendly sewage treatment tank, by virtue of four-time filtering of the first filter screen, the second filter screen, the fourth filter screen and the third filter screen, the domestic sewage filter effect is good, the filter quality is high, the water guiding box is uneasy to block, and the subsequent sewage treatment is facilitated.

Owner:徐州虹源环保科技有限公司

Dielectric filter

InactiveUS7057479B2Easy to manufactureImprove accuracyResonatorsConductive materialsDielectric permittivity

A dielectric filter is provided with a dielectric multilayer structure formed by layering two or more dielectric layers which have different relative permittivities, at least one feeding electrode formed between any dielectric layers or formed inside of any dielectric layers of the dielectric multilayer structure, and a shield portion that covers the outer surface of the dielectric multilayer structure and is made of a conductive material placed so as to fit on the outer surface without any gap.

Owner:PANASONIC CORP

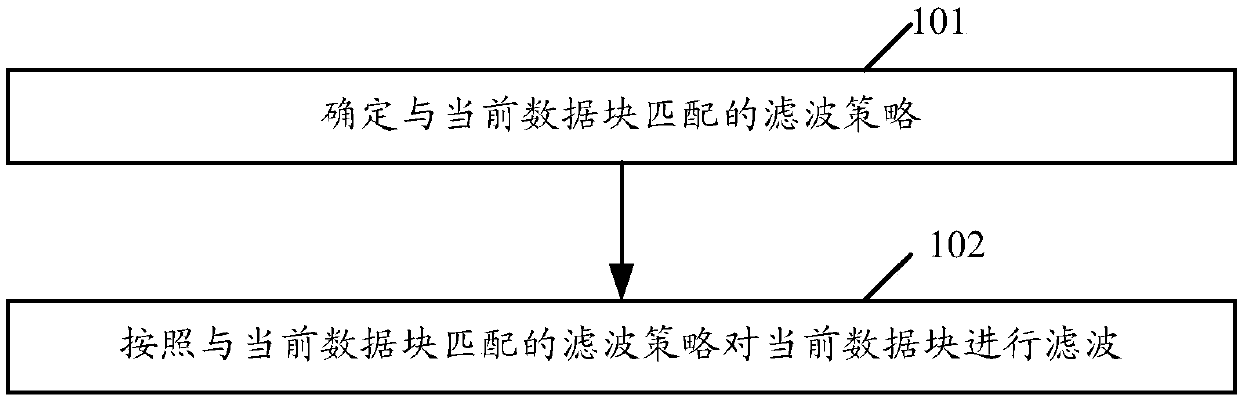

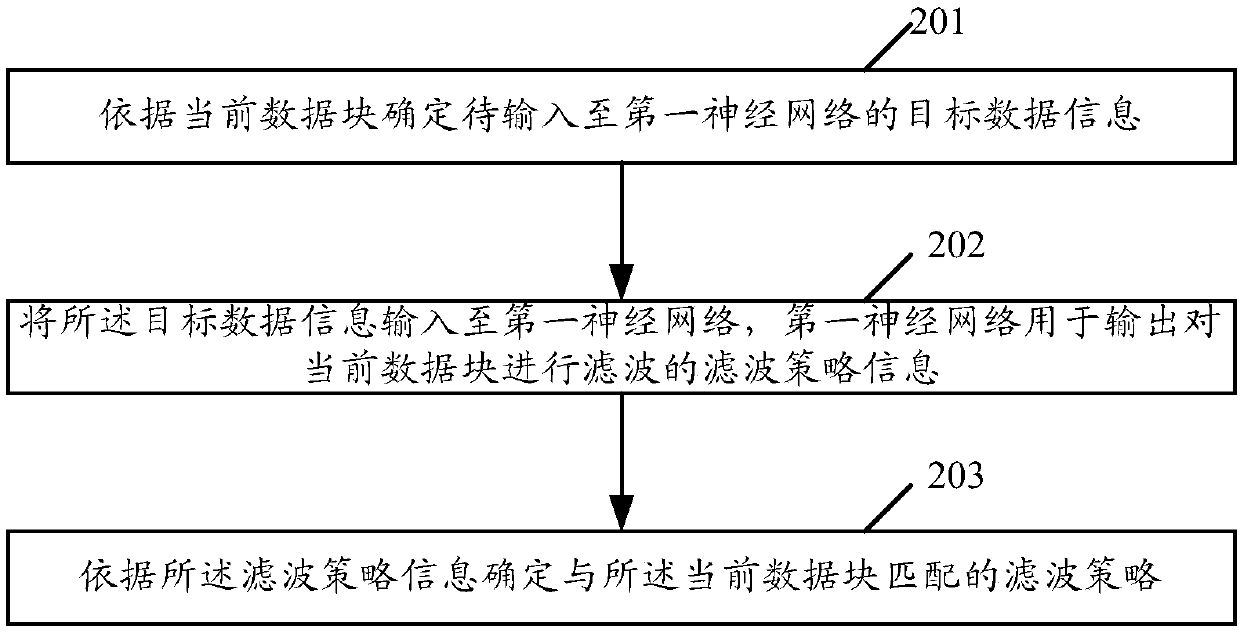

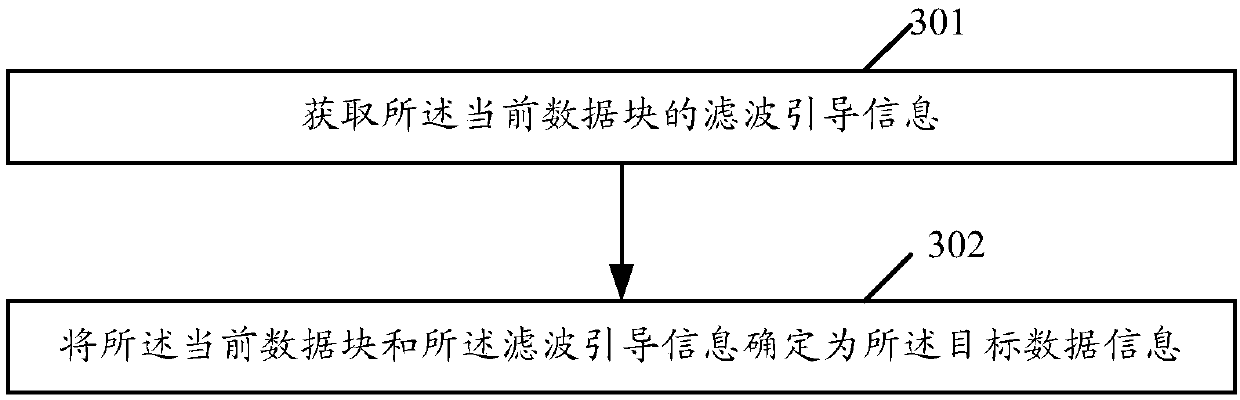

Filtering method and device

ActiveCN110971915AAchieve de-distortionAvoid visual effectsDigital video signal modificationPattern recognitionComputer graphics (images)

The invention provides a filtering method and device. According to the application, a matched filtering strategy is determined for a data block in distorted video data regardless of an encoding end ora decoding end, and then the data block is filtered according to the filtering strategy matched with the data block, so that distortion of the distorted video data is removed, and visual impairment or false images caused by distortion are prevented.

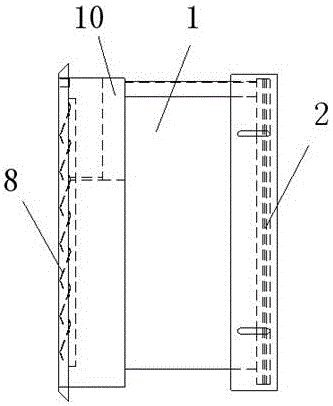

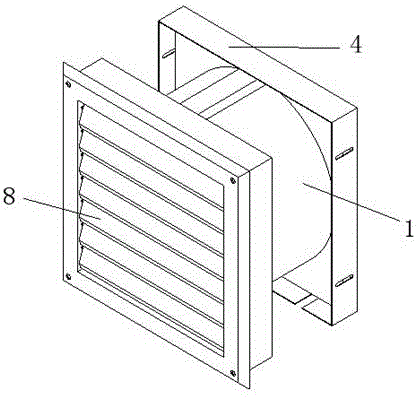

Louver with air filtering cotton

InactiveCN105781368AImplement hierarchical filteringImprove filter qualityDispersed particle filtrationLighting and heating apparatusPush and pullAir filtration

The invention discloses a louver with air filtering cotton.The louver comprises a case, a motor cavity, an air incoming cavity and an air outgoing cavity are formed in the case, the air incoming cavity and the air outgoing cavity are positioned on two sides of the motor cavity respectively, a main motor is arranged in the motor cavity, a blade is arranged in the air incoming cavity and connected with the main motor, a filtering component is arranged in the air outgoing cavity, and a fixing frame for fixing the filtering component is arranged on the air outgoing cavity; the filtering component comprises the air filtering cotton and two first stainless steel meshes, the air filtering cotton is sandwiched between the first stainless steel meshes, a controller and a standby power source are arranged on the case, and a push-and-pull motor is connected with both the controller and the standby power source.When being used for indoor air inducing, the louver can induce outside air after being filtered into a room, and quality of gas induced into the room is improved.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LIANYUNGANG POWER SUPPLY CO +1

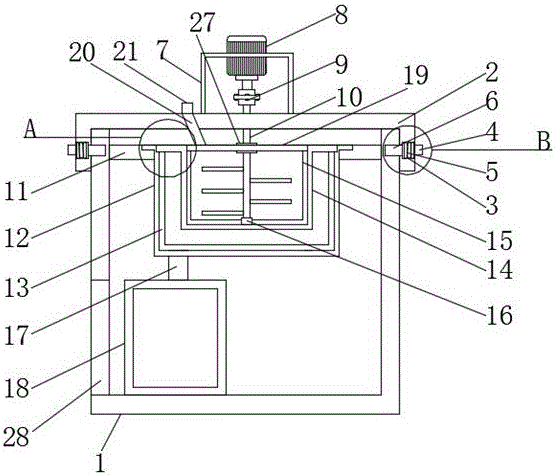

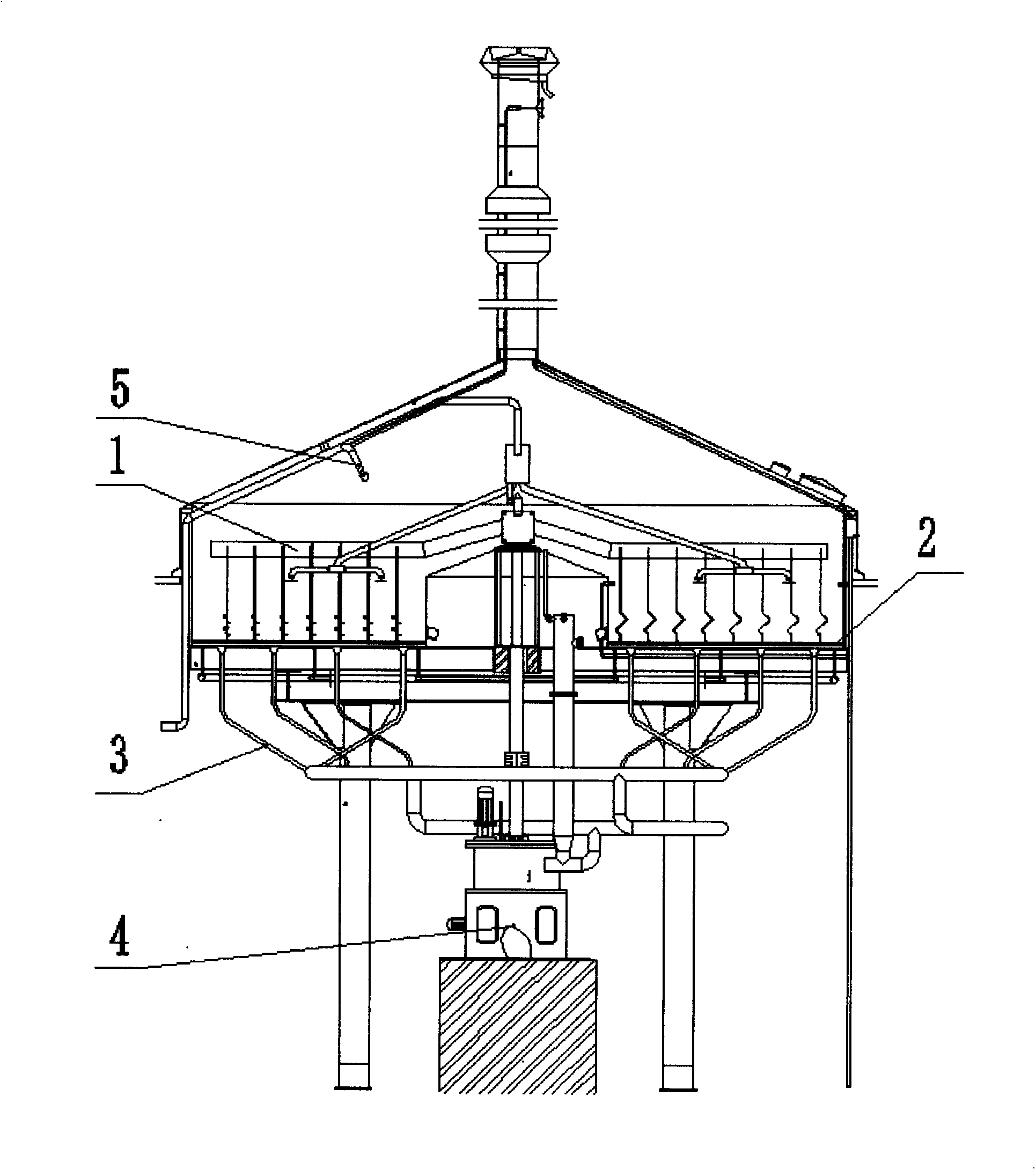

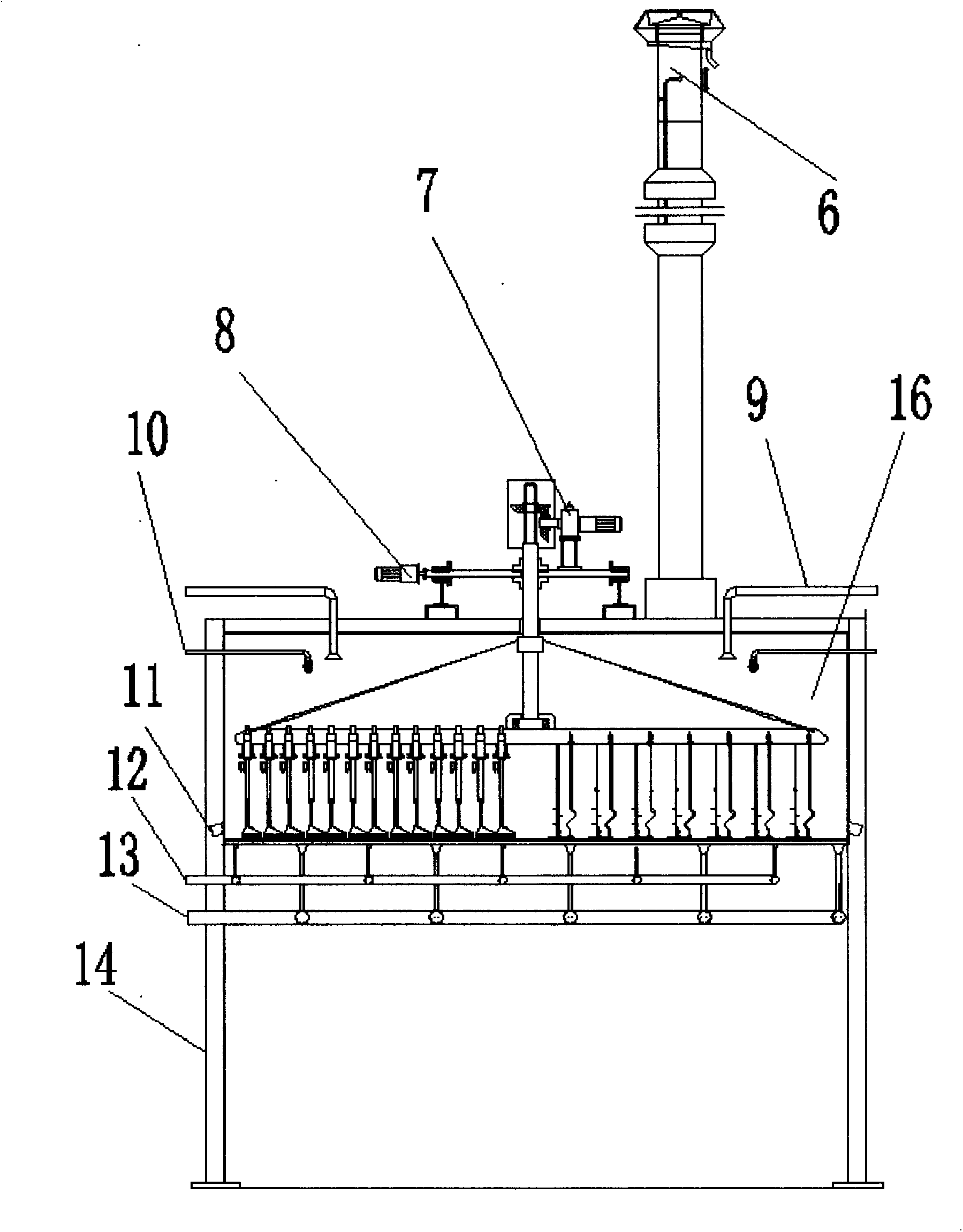

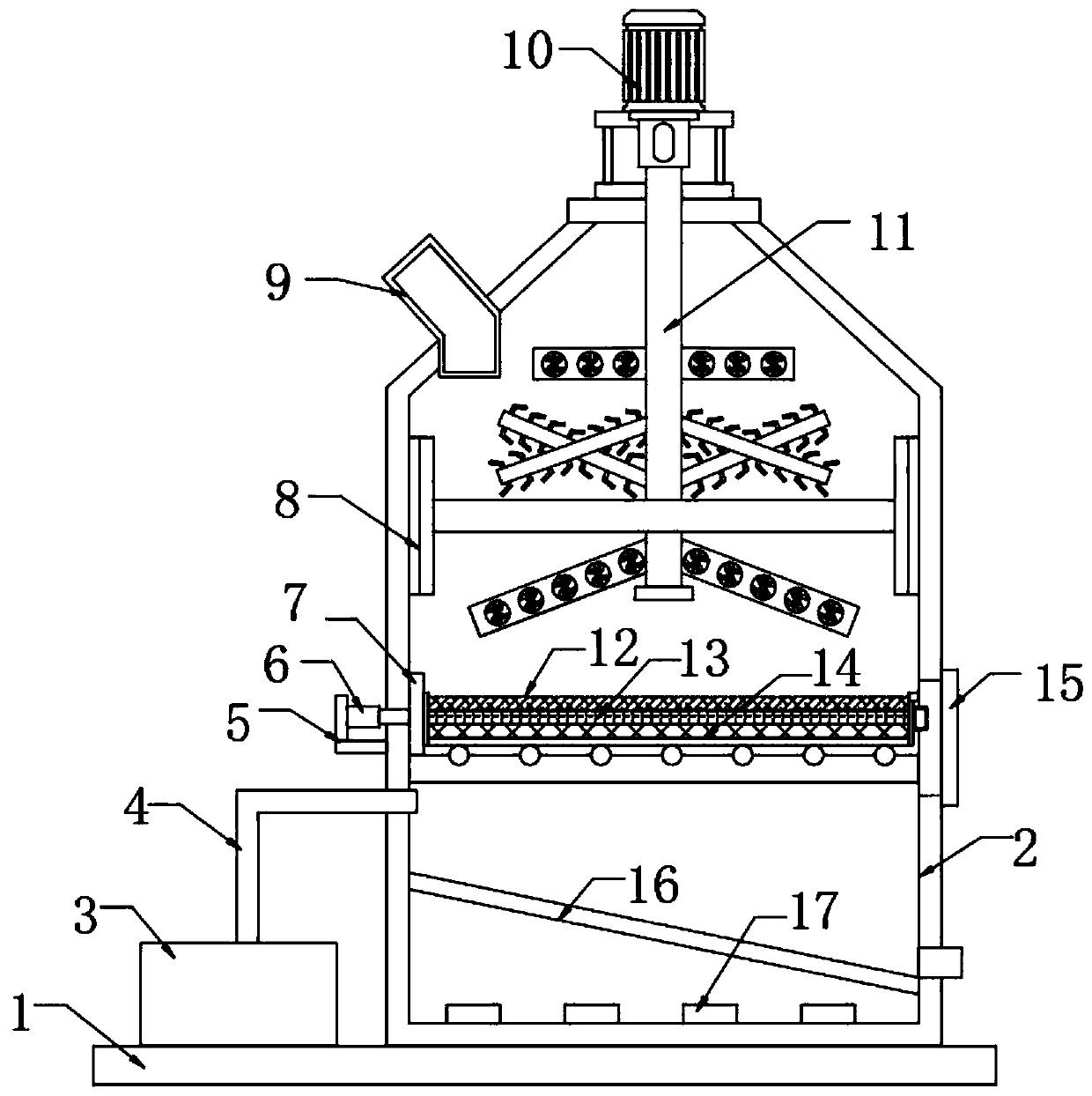

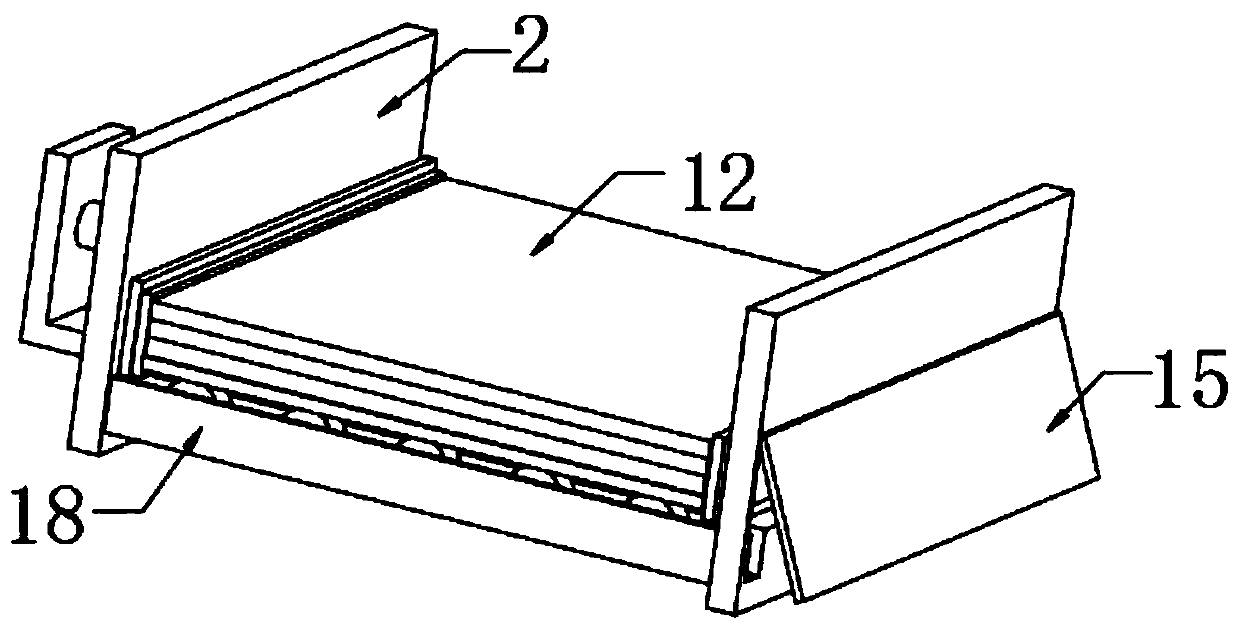

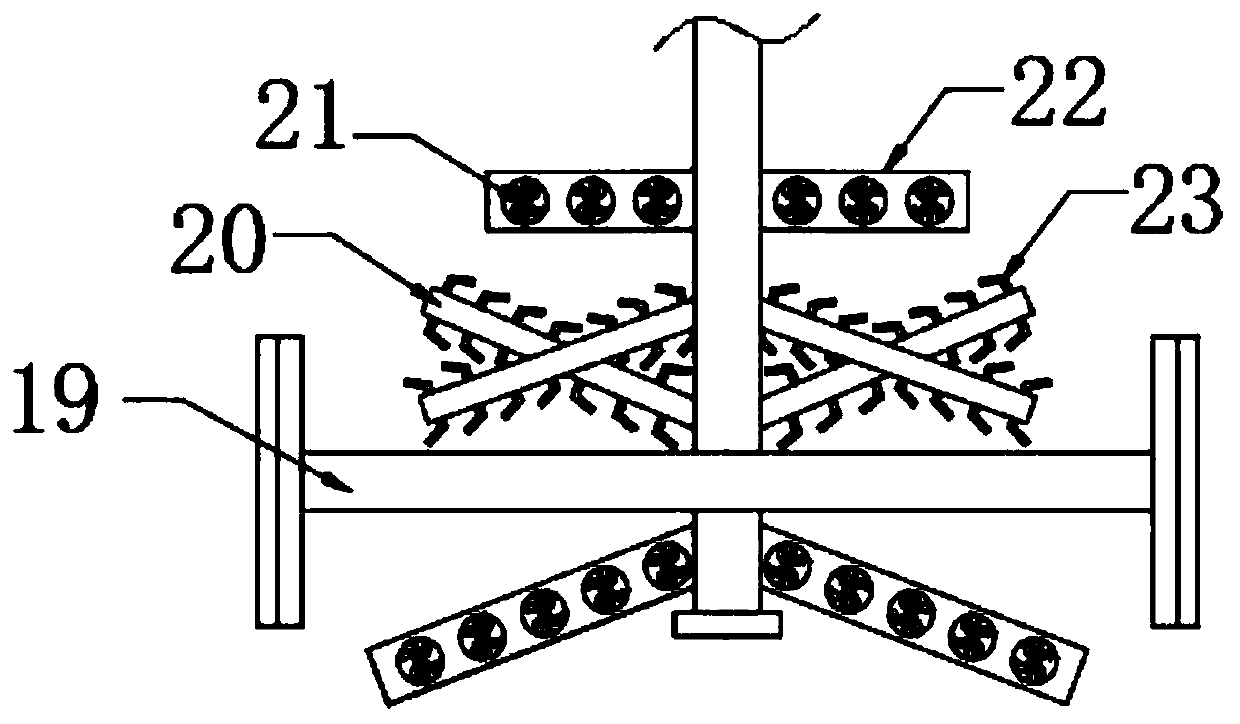

Square filtering tank for beer saccharification filtering system

The invention discloses a square filtering tank for a beer saccharification filtering system, and relates to a filtering system special for beer saccharification. The square filtering tank comprises a filtering plate, an exhaust barrel, a vinasse discharging lifting device, a vinasse raking reciprocating device, a tank washing water inlet, a washing water inlet, supporting legs, a mash inlet, a backwashing water inlet and a wheat juice outlet, wherein the exhaust barrel is fixed at the top of a tank body; the vinasse discharging lifting device and the vinasse raking reciprocating device are arranged on the tank body in a sliding manner and are both connected with a large vinasse raking arm in the tank body; the tank washing water inlet is also formed in the tank body; the washing water inlet is formed in the side surface of the tank body; the mash inlet is formed below the washing water inlet; the filtering plate is arranged in the tank body; a vinasse discharging door is arranged on the filtering plate; the backwashing water inlet and the wheat juice outlet are formed in the lower end of the tank body. According to the square filtering tank for the beer saccharification filtering system, the linear speeds of raking cutters in the tank during vinasse raking are consistent, so that the original concentration of the collected wheat juice at different positions after mash is filtered is the same, and the pure flavor of wheat juice is guaranteed.

Owner:青岛啤酒工程有限公司

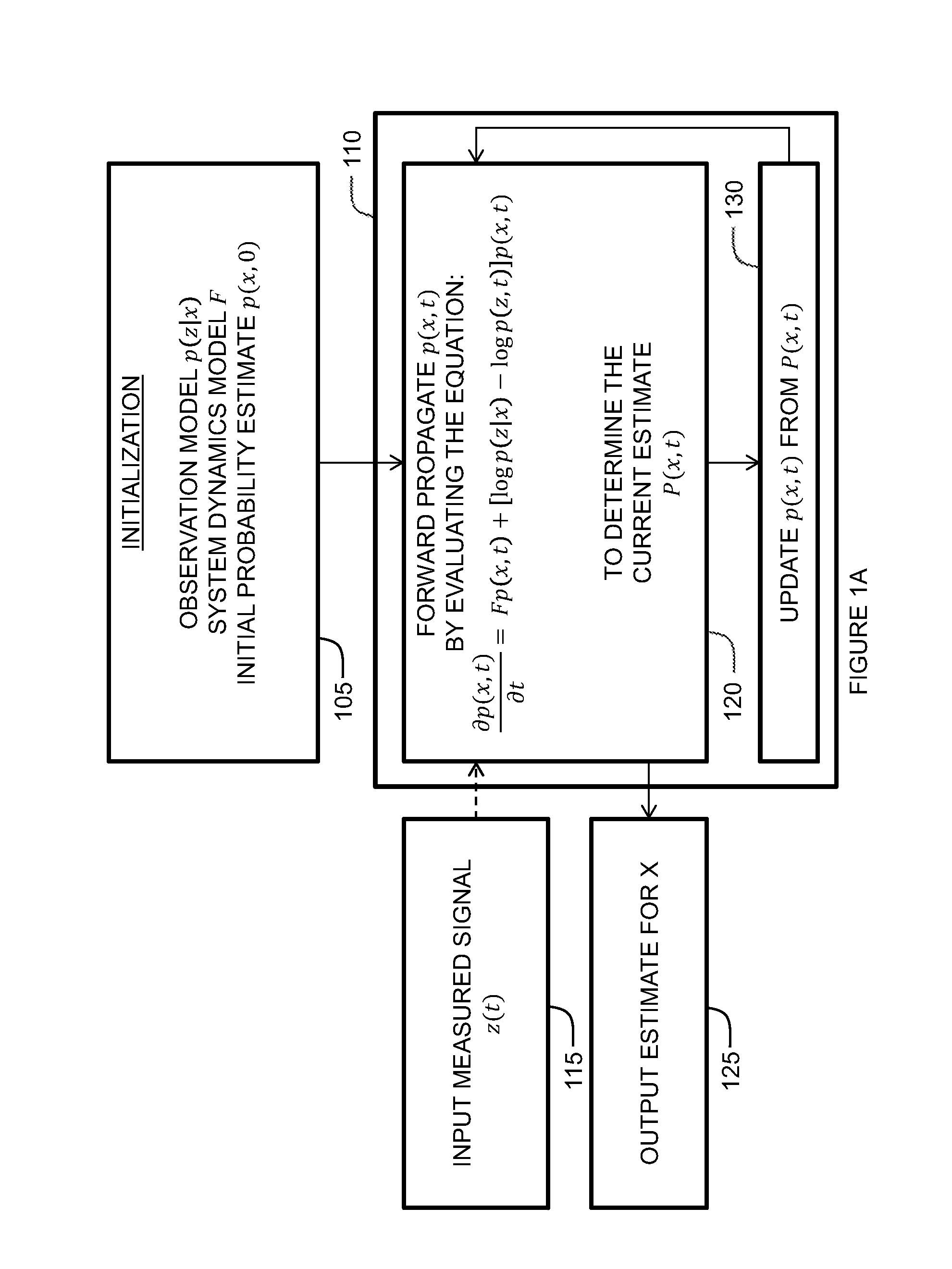

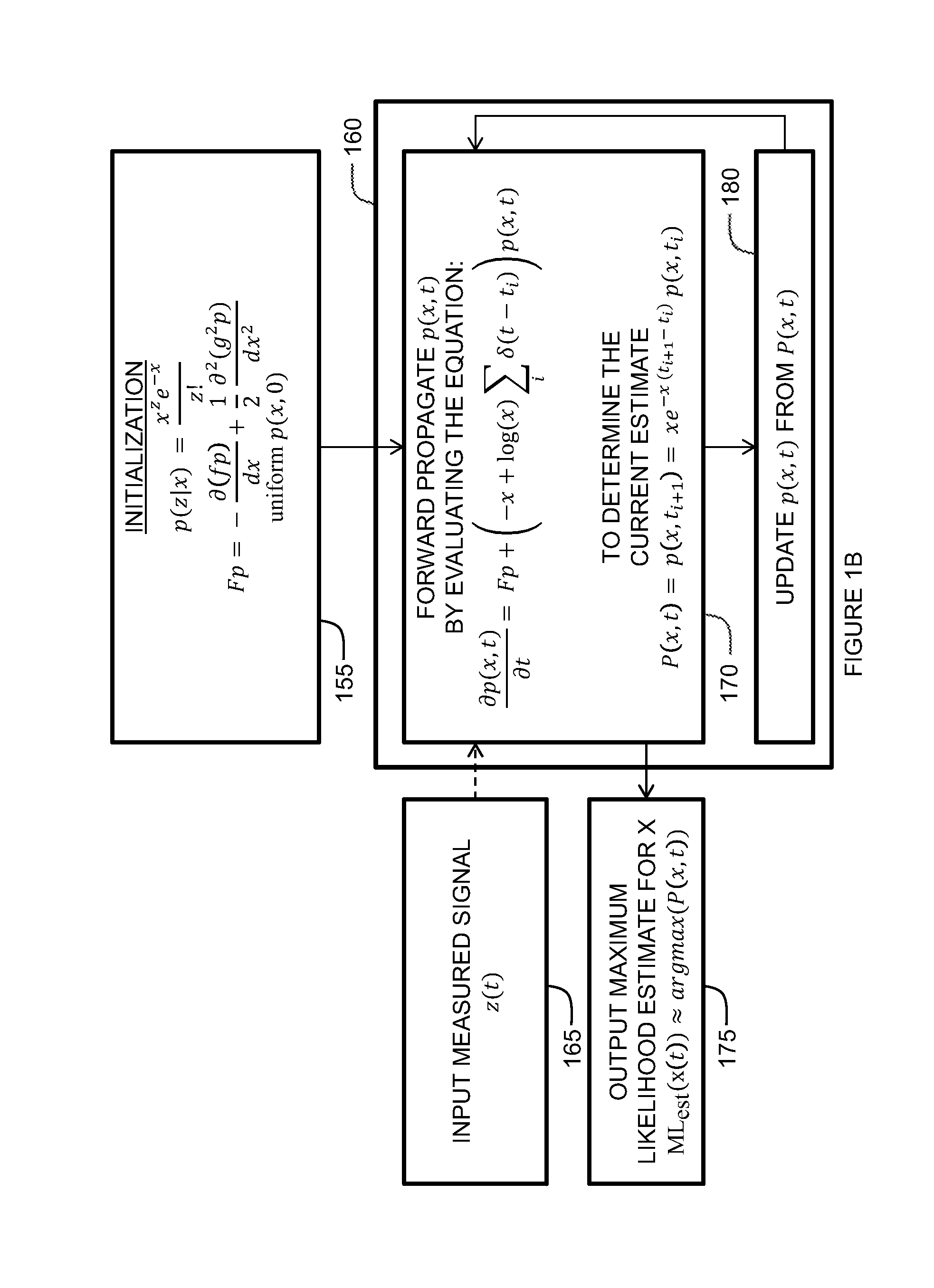

Systems, Methods, and Uses of a Bayes-Optimal Nonlinear Filtering Algorithm

ActiveUS20160007871A1Encouraging increased muscle usageImprove accuracyElectromyographyMedical automated diagnosisNonlinear filterLinear filter

A stochastic Bayesian non-linear filtering system and method that improves the filtering of noisy signals by providing efficiency, power, speed, and flexibility. The filter only requires the likelihood function p(observation|state) to determine the system state and works in various measurement models. This allows for the processing of noisy signals to be used in real time, such as in a biofeedback device that senses noisy surface electromyography muscle electrical activity, filters the sensed signal using the nonlinear filtering method, and provides vibrations based on the muscular activity.

Owner:GSACORE LLC

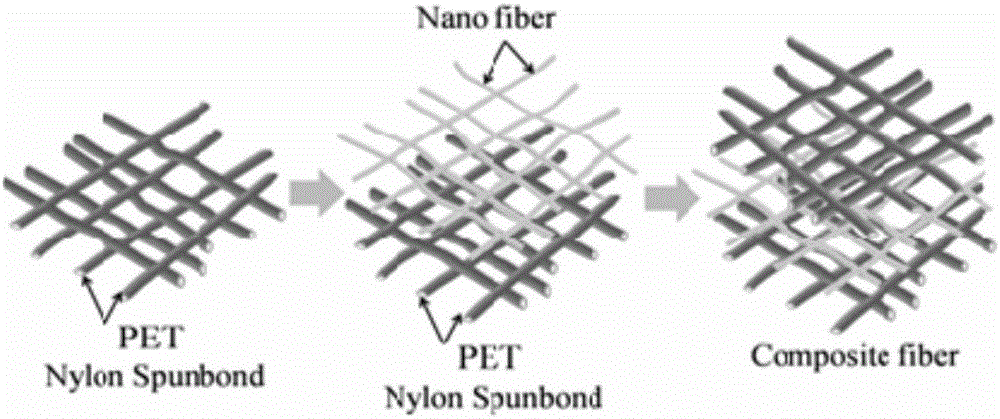

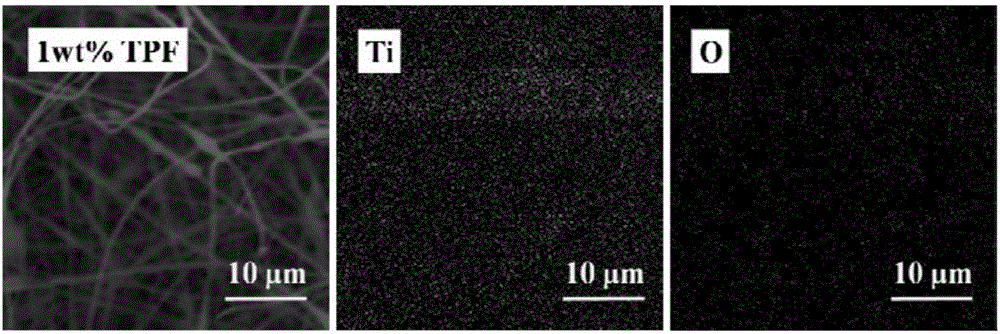

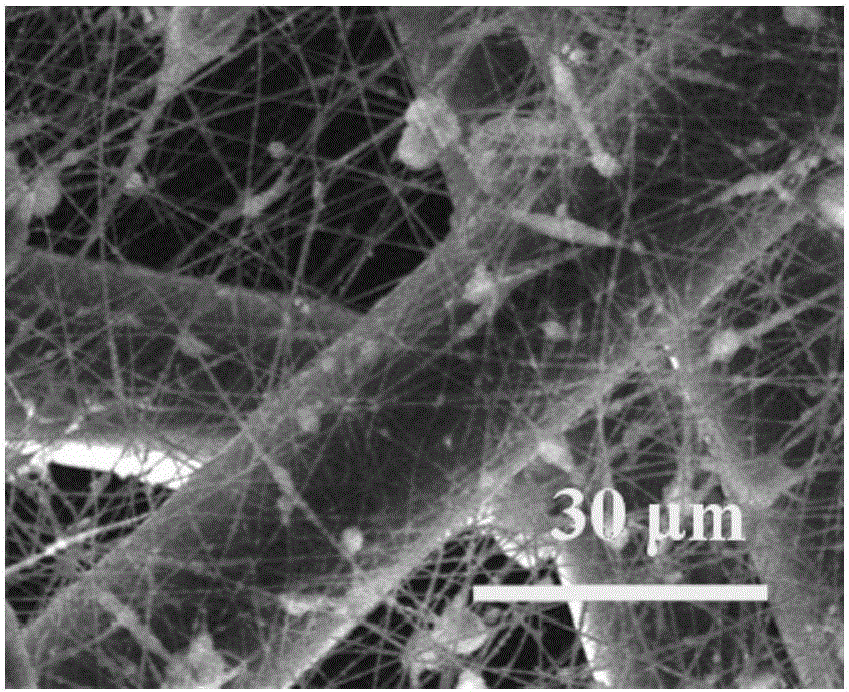

Composite nanometer photocatalyst electrospun fiber filtering material and preparation method thereof

InactiveCN106178686AImprove chargeabilityLow penetration efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationPolymer solutionPolyethylene terephtalate

The invention discloses a composite nanometer photocatalyst electrospun fiber filtering material and a preparation method thereof, and relates to a fiber filtering material. The composite nanometer photocatalyst electrospun fiber filtering material is provided with a carrier, and the carrier is coated with a layer of photocatalyst fibers. The preparation method comprises the following steps: 1) mixing polyacrylonitrile and dimethylacetamide, and heating the mixture to obtain a polymer solution; 2) mixing the polymer solution prepared in the step 1) with a titanium dioxide solution, and heating the mixture to obtain a photocatalyst composition solution; 3) placing the photocatalyst composition solution prepared in the step 2) into an injector of an automatic sample introduction device, and jetting titanium-containing photocatalyst fibers through an electrostatic spinning device; 4) placing poly-p-phthalic acid fibers on a collector, directly electrically-spinning the photocatalyst composition solution on the poly-p-phthalic acid fibers, overlapping a layer of poly-p-phthalic acid fibers to form a sandwich structure, and performing hot pressing to obtain the composite nanometer photocatalyst electrospun fiber filtering material. The composite nanometer photocatalyst electrospun fiber filtering material has contribution to enhancement of the particle filtering effect and improvement on the treatment performance of volatile organic matters.

Owner:AF&C ENVIRONMENTAL TECH XIAMEN

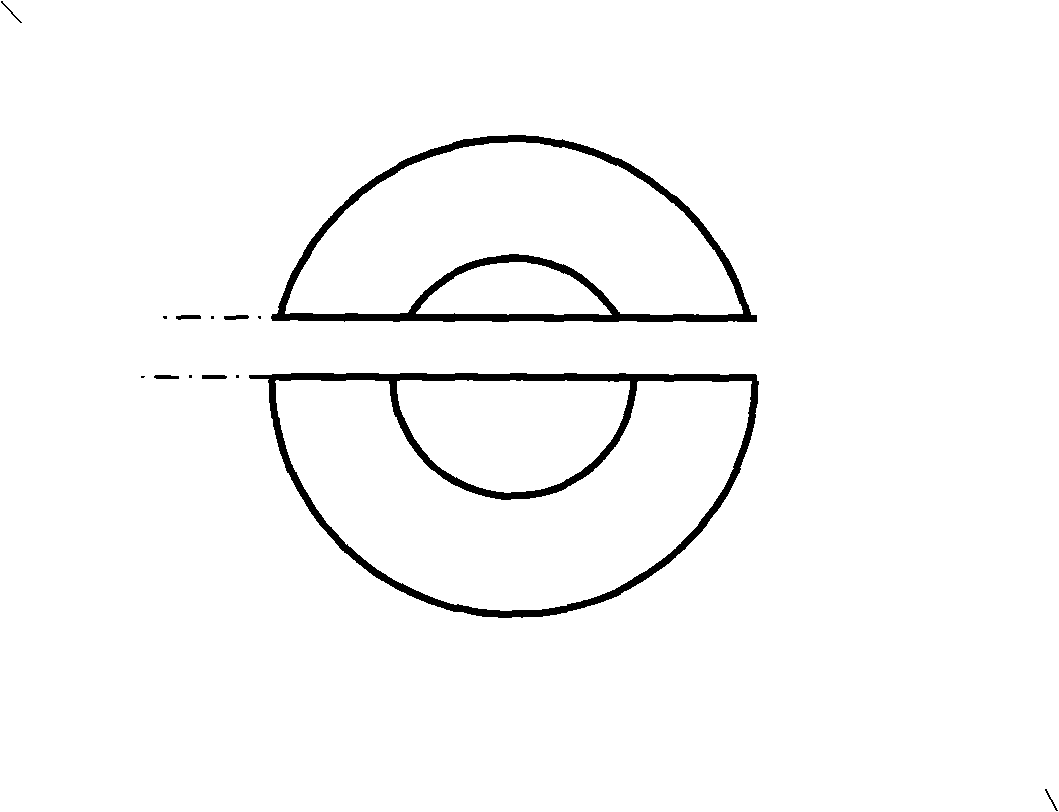

Technique for preparing returnable bottle piece spinning hollow fiber

InactiveCN101270504AGuaranteed uptimeEfficient removalFilament/thread formingFilament-forming treatmentFiberEngineering

The invention relates to a manufacture technique for spinning hollow fiber by recycling bottle chips. The method is characterized in that the manufacture steps includes filtering bottle chip, drying bottom chip, melting with high temperature, screw rod extrusion, spraying silk spray plate, cooling and oiling, shaping and winding, balancing, stretching, deforming, network and finished product. The silk spraying holes of the adopted silk spray plate are combined by ''C''-shaped holes arranged in a concentric circle, and the numbers of the ''C''-shaped holes are the same as that of special-shaped fiber singles to lead the section shape of the special-shaped fiber sprayed by the silk spray plate and formed by a subsequence working procedure to be ''C''-shaped; a bottle chip drying tower the upper part of which adopts a variable diameter form and the inside is added three rectangle cones; a melt filter device is a three grade vertical filter. The invention is used very broadly.

Owner:邹军

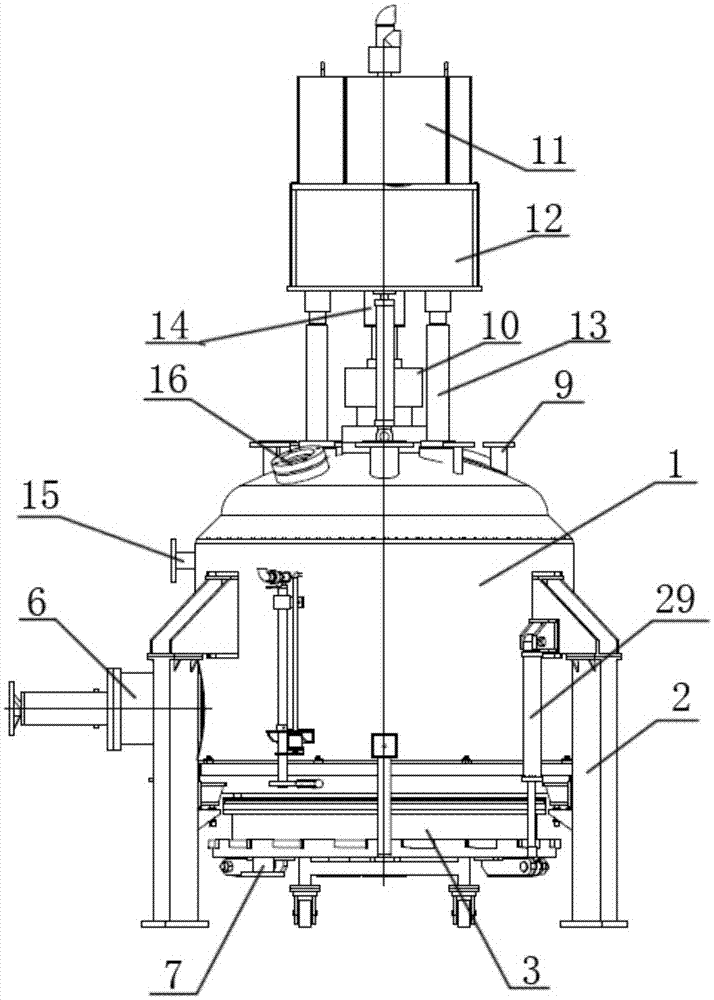

Liquid cosmetic semi-finished product filtering device

InactiveCN110917920AImprove mixing efficiencyReduce filter qualityDispersed particle filtrationRotary stirring mixersElectric machineryChemistry

The invention belongs to the technical field of filtering devices, particularly relates to a liquid cosmetic semi-finished product filtering device, and provides the liquid cosmetic semi-finished product filtering device for solving the problem of poor stirring effect, the liquid cosmetic semi-finished product filtering device comprises a bottom plate, a filtering box is arranged on the outer wallof the top of the bottom plate, an L-shaped fixing plate is arranged on the outer wall of one side of the filtering box, and a motor is arranged on the outer wall of the top of the filtering box; andan output shaft of the motor is connected with a rotating rod through a coupler, a stirring frame is arranged on the outer wall of one side of the rotating rod, and stirring blades distributed at equal intervals are connected to the inner wall of the stirring frame through bearings. According to the liquid cosmetic semi-finished product filtering device, an X-shaped stirring rod, crushing cutters, the stirring frame and the stirring blades are arranged, the crushing cutters distributed at equal intervals are installed on the outer wall of the X-shaped stirring rod, the X-shaped stirring rod can stir layers with different water levels during stirring, the stirring effect is good, the crushing cutters can crush caked cosmetics, and the stirring effect is good. In addition, the stirring blades can rotate under the flowing of liquid during stirring, so that the mixing efficiency of cosmetics is improved.

Owner:周晶晶

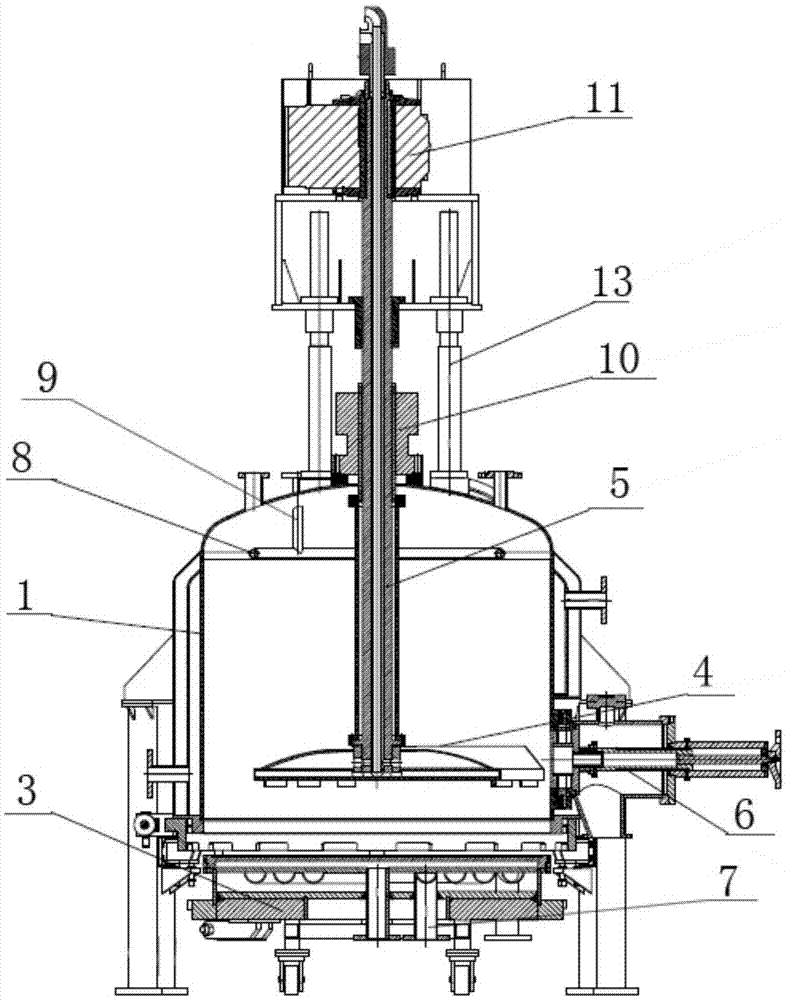

Three-in-one kettle structure

InactiveCN105435502AImprove filtration efficiency and qualityImprove heat transfer coefficientMembrane filtersStationary filtering element filtersFiltrationWater source

The invention provides a three-in-one kettle structure. According to the three-in-one kettle structure, internal cleaning and material slurry washing can be realized in a container, when materials are dried, the turning distance is short, the crystal destruction is less, the agglomeration is difficult, and the heat transfer coefficient is high. The three-in-one kettle structure comprises a kettle body, wherein a plurality of vertically arranged support legs are arranged on the outer side of the kettle body, a lower end cover is arranged just below the bottom end surface of the kettle body, a stirring blade is arranged in the kettle body, a stirring shaft penetrates through the top of the kettle body and then is fixedly connected to the center of the stirring blade, and a discharging mechanism is arranged on the middle lower part of the kettle body. The three-in-one kettle structure is characterized in that a suction filtration opening is formed in the lower end cover which is a filter heating chassis, a spray device is arranged on the upper part of an inner cavity of the kettle body, the spray device is externally connected with an external water source through a connecting pipe, a sealing device is arranged between the stirring shaft and the top of the kettle body, a stirring motor is externally connected to the top of the stirring shaft, and the stirring motor is supported on a motor base.

Owner:MIYOU GROUP

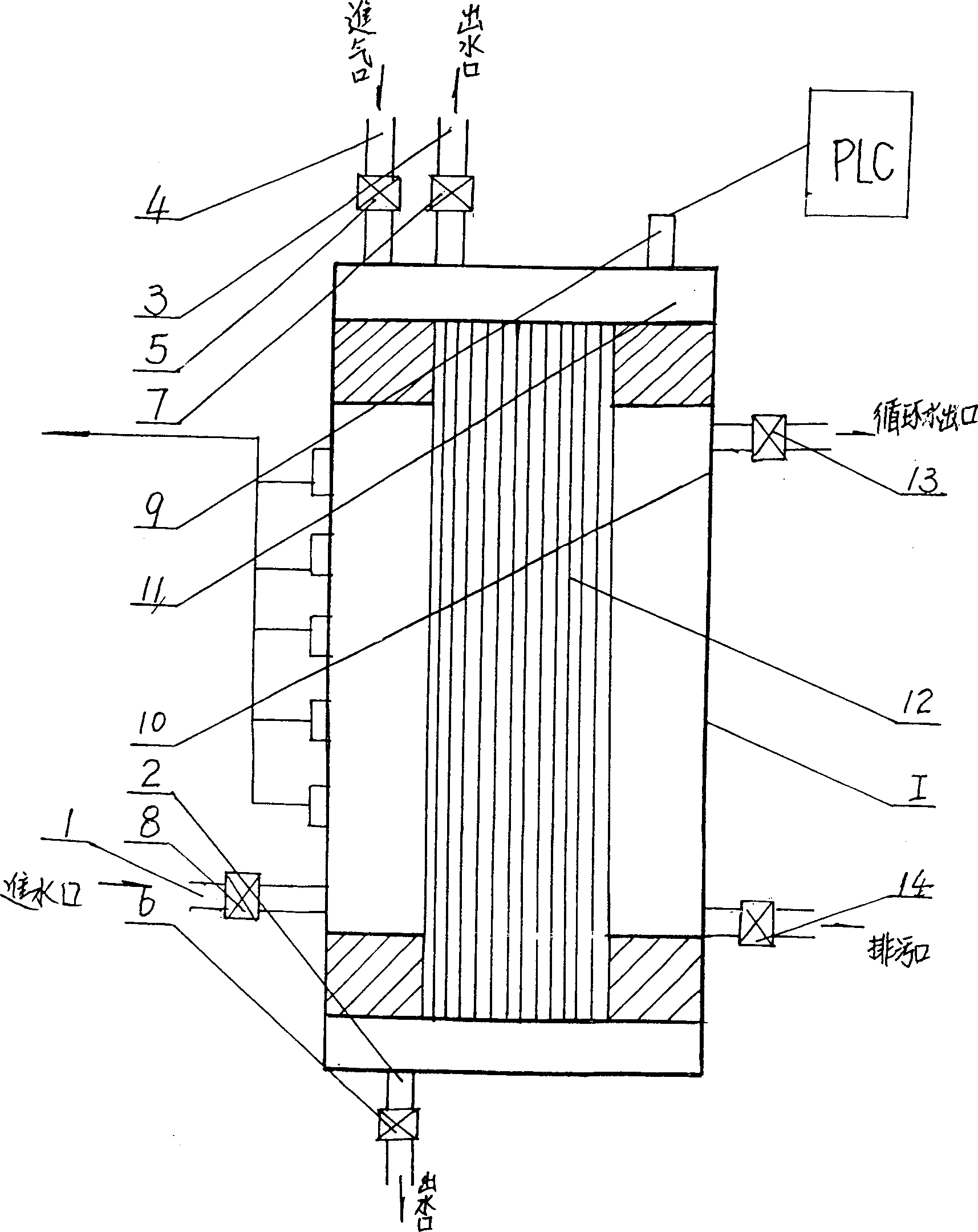

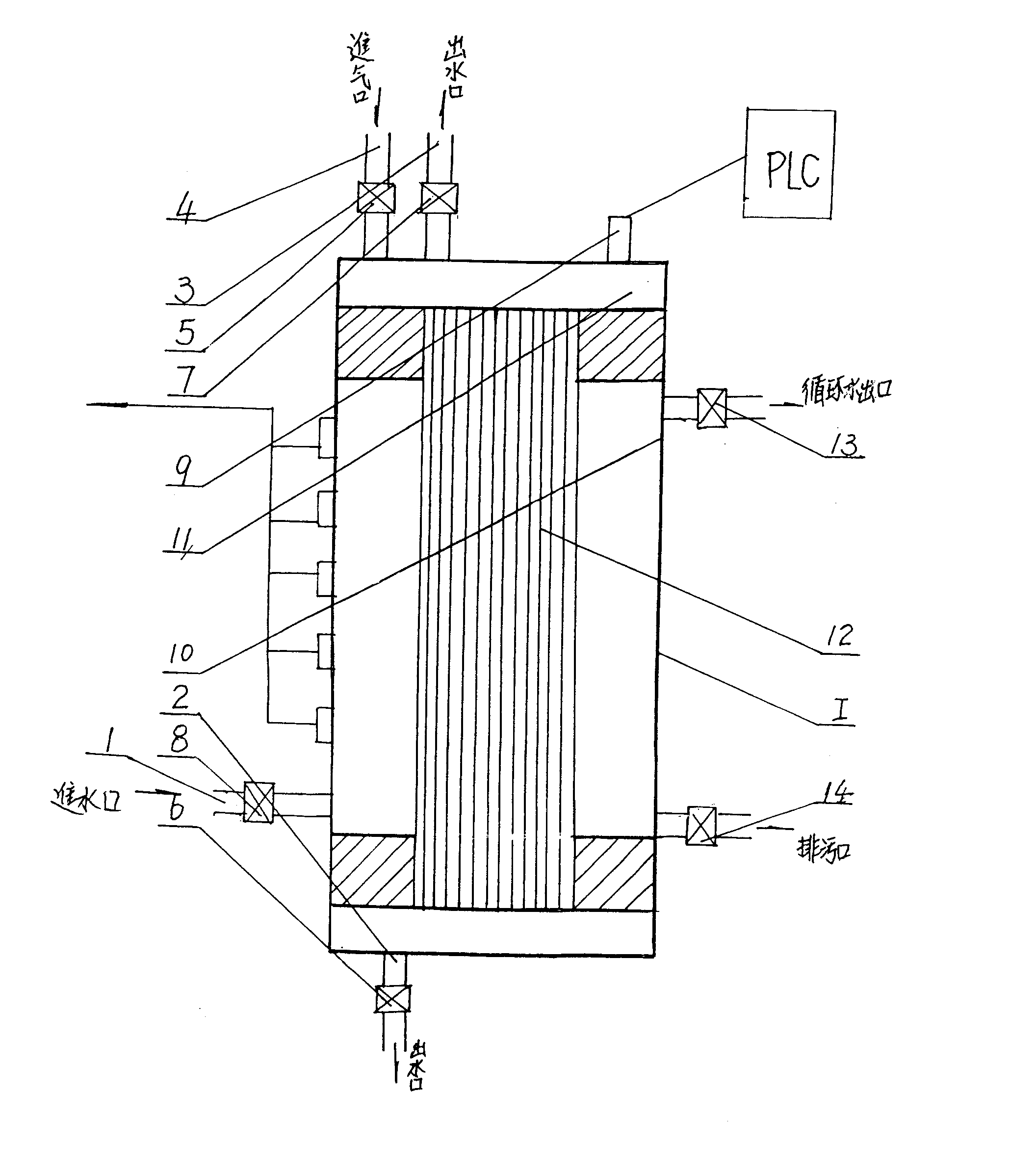

Automatic on line detecting device of hollow fiber separating membrane

InactiveCN1479101ATimely monitoring of integrityImprove filter qualityWater/sewage treatment bu osmosis/dialysisMaterial analysisFiberHollow fibre membrane

An automatic on-line tester for detecting the integrity of the separating hollow fibre membrane is disclosed. A pressure sensor is fixed on the separating membrane module and connected to PLC control system. The perssure air is pumped in the separating membrane module untile all water in it is discharged. The pressures at different time are measured. Their pressure difference can be used to judge the membrane integrity. When said pressure difference is greater than 5Kpa, the membrane must be exchanged. Its advantages are high correctness and efficiency and low cost.

Owner:天津泰达新水源科技开发有限公司

Filter used for producing nano-coating

InactiveCN107433070AAvoid cloggingPrevent splashFiltration circuitsStationary filtering element filtersHelical bladeFilter effect

The invention provides a filter used for producing a nano-coating. The filter comprises a filter body and a filter cover, the filter body includes a main shaft, a filtering module and a filter screen, the filtering module is concentrically and detachably arranged in the filter body, the cooperating filter screen is arranged in the filtering module, the filter screen is uniformly provided with a plurality of through holes, and a feeding opening communicating with the inner chamber of the filter body is arranged at the upper end of the filter cover; and a discharging opening and an electric heating tube communicating with the interlayer of the filter body are arranged at the lower end of the filter body. The nano-material rapidly moves under the driving of helical blades, and is filtered by the filter screen, and a wall scraping device drives a scraper to rotate in order to momentarily clean the material on the inner wall of the filter body, so adherence to the wall is reduced, and the filtering efficiency and the filtering quality are improved; and the heating tube is used to heat in order to make the coating keep a high temperature and not form large blocks, and then the heated material is filtered by the filter screen, so the filtering effect is effectively enhanced, and the obstruction phenomenon is less likely to occur.

Owner:NINGBO DUNCOTEK NEW MATERIAL CO LTD

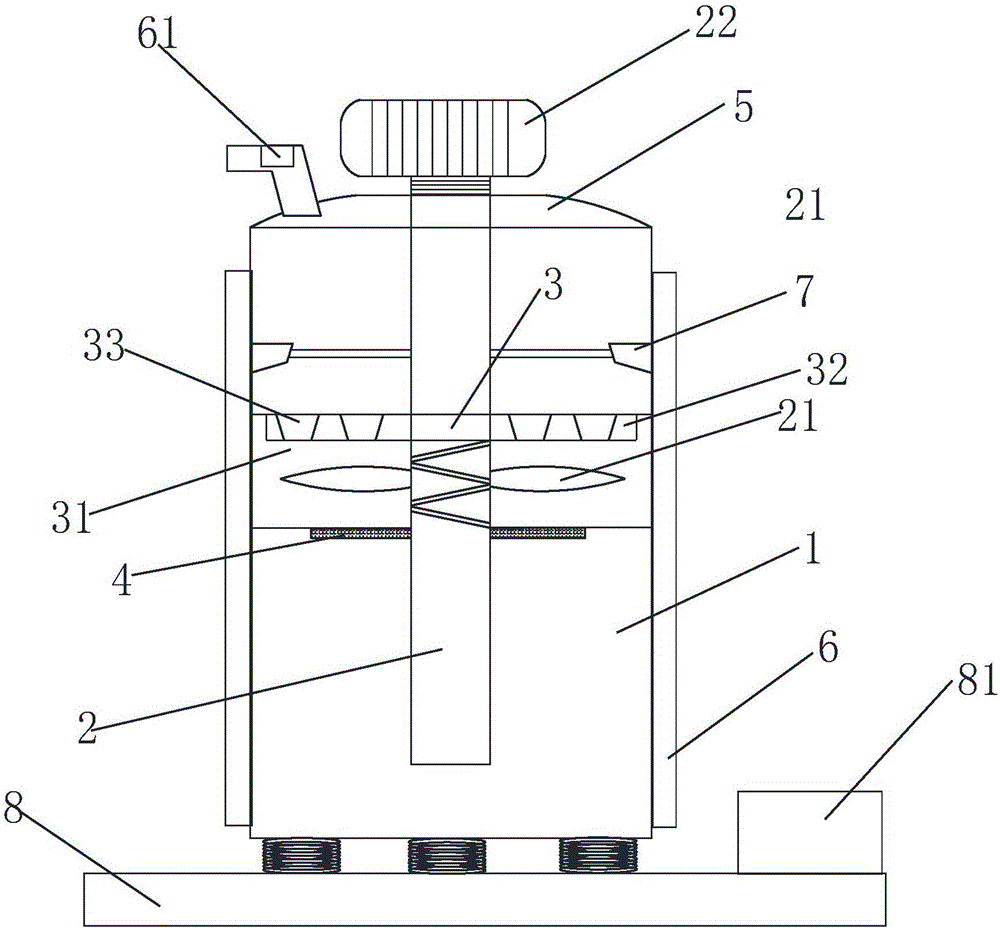

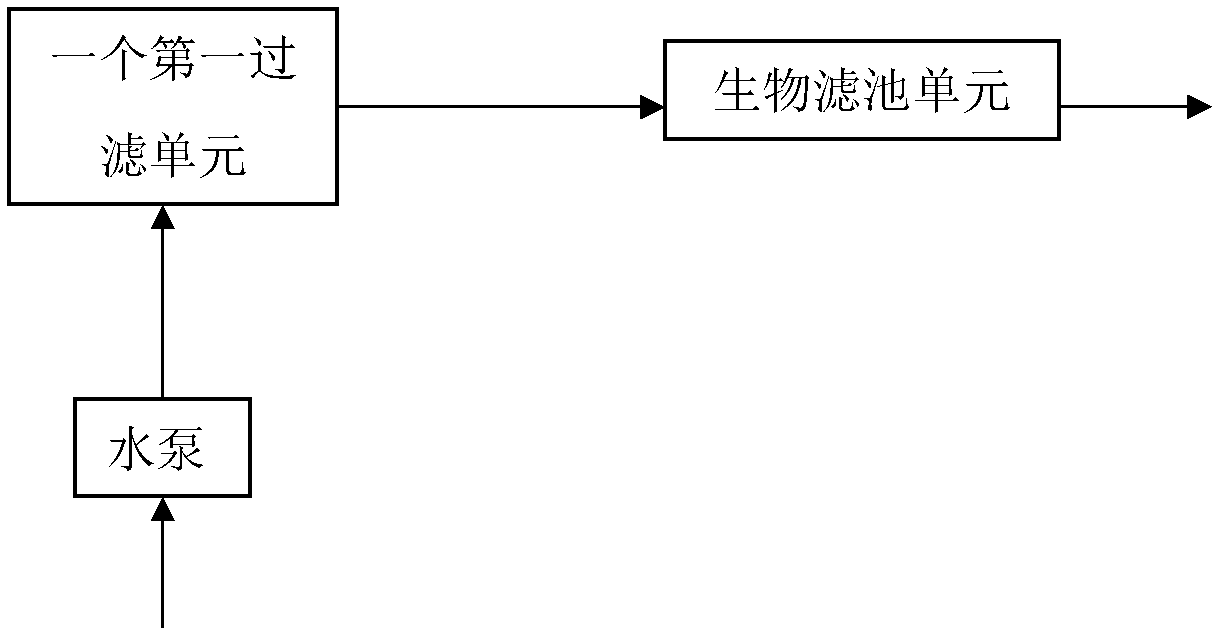

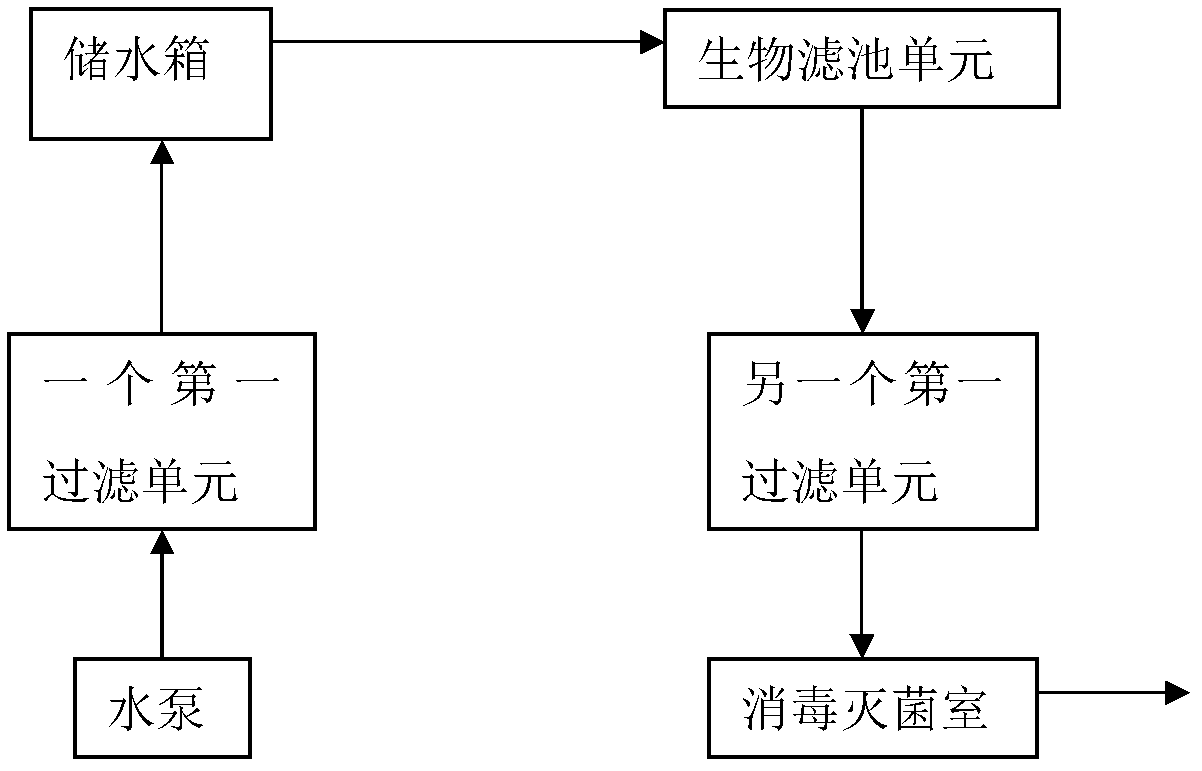

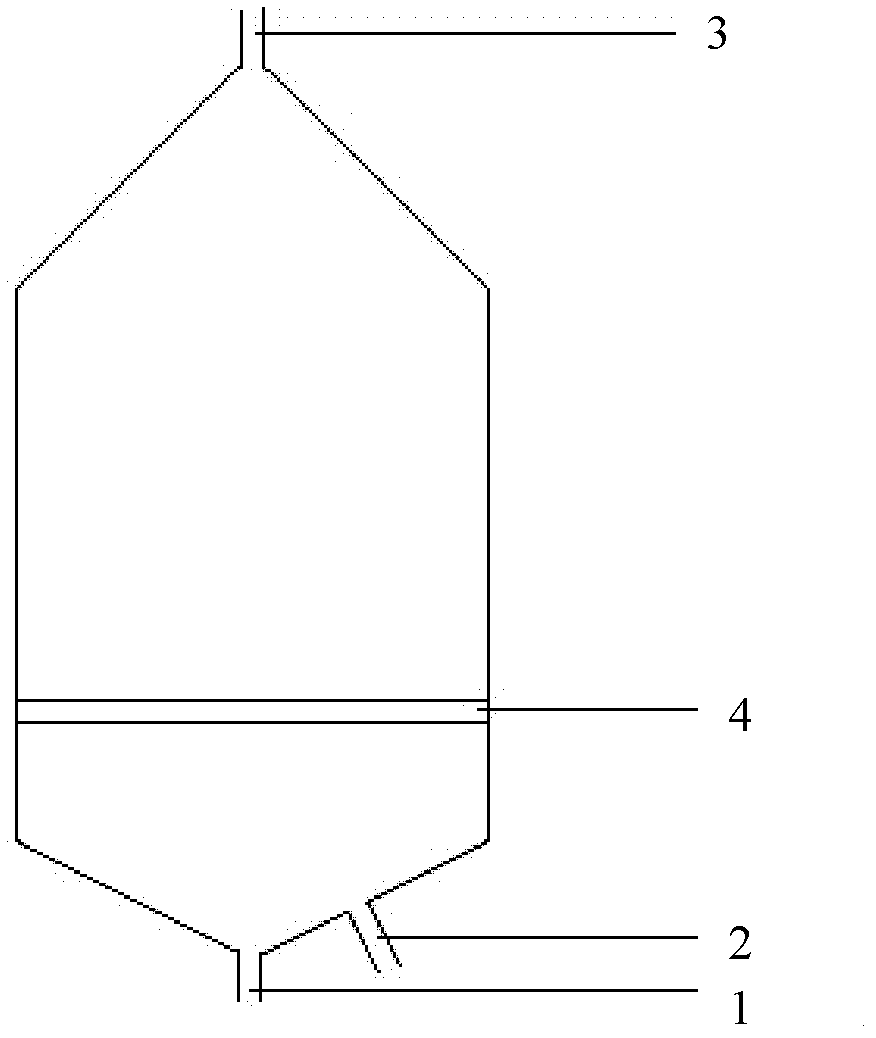

Sewage disposal system

ActiveCN102849890AAvoid cloggingAvoid damageMultistage water/sewage treatmentSludgeBiological filter

The invention discloses a sewage disposal system. The sewage disposal system comprises a water pump, a second filtering unit and at least a first filtering unit, wherein the first filtering unit is gravity automatic backwashing filtering unit; the second filtering unit is biological filter unit; the gravity automatic backwashing filtering unit comprises a cavity having a water inlet, a sludge outlet and a water outlet, and a filtering plate; the water inlet and sludge outlet are located under the filtering plate; the water outlet is positioned above the filtering plate; one of the first filtering unit is in flow connection with the water pump through the water inlet, and in flow connection with the biological filter unit through the water outlet; and the filtering plate comprises a 2-5 mm thick filtering layer formed by bonding silica sand and / or film covered silica sand through binder and curing. The inventive system has good sewage disposal effect, and can be widely applied in sewage treatment field.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

Environment-friendly and efficient production method of high-purity silver nitrate

PendingCN111732120AImprove filtration efficiency and filtration qualityHigh product purityFiltration circuitsSilve compoundsNitric oxideNitrogen oxides

The invention discloses an environment-friendly and efficient production method of high-purity silver nitrate. The method includes steps of: firstly, performing a reaction on a silver ingot with nitric acid to obtain a silver nitrate solution; purifying the silver nitrate solution, and sequentially carrying out efficient evaporation under reduced pressure, efficient crystallization, solid-liquid separation, drying, crushing and packaging operations. According to the method, a finished product of 1150-1210 kg of high-purity silver nitrate crystals can be produced from the time when 800-850 kg of silver ingots enter a production line for 22-22.5 hours; hydrogen peroxide is used for absorbing nitric oxide into nitric acid for cyclic utilization; after impurities are removed through the impurity removing agent, filtration is conducted through combination of the negative-pressure filter element and the positive-pressure filter element, efficient solid-liquid separation of silver nitrate isachieved through a suction filtration mode of combination of the pneumatic diaphragm pump and vacuum negative pressure after efficient reduced-pressure evaporation; compared with the prior art, the production method of high-purity silver nitrate has the advantages of being environmentally friendly, efficient, low in cost and high in quality.

Owner:中船重工黄冈贵金属有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com