Filtering device for slag-washing water of blast furnace

A blast furnace slag flushing water and filtration device technology, applied in the direction of filtration separation, membrane filter, fixed filter element filter, etc., can solve the problem of affecting the filtering effect and service life of the filter, delaying the best time for backwashing, and affecting heat exchange Effect and other issues, to achieve the effect of improving filtration efficiency and quality, simple operation, and improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

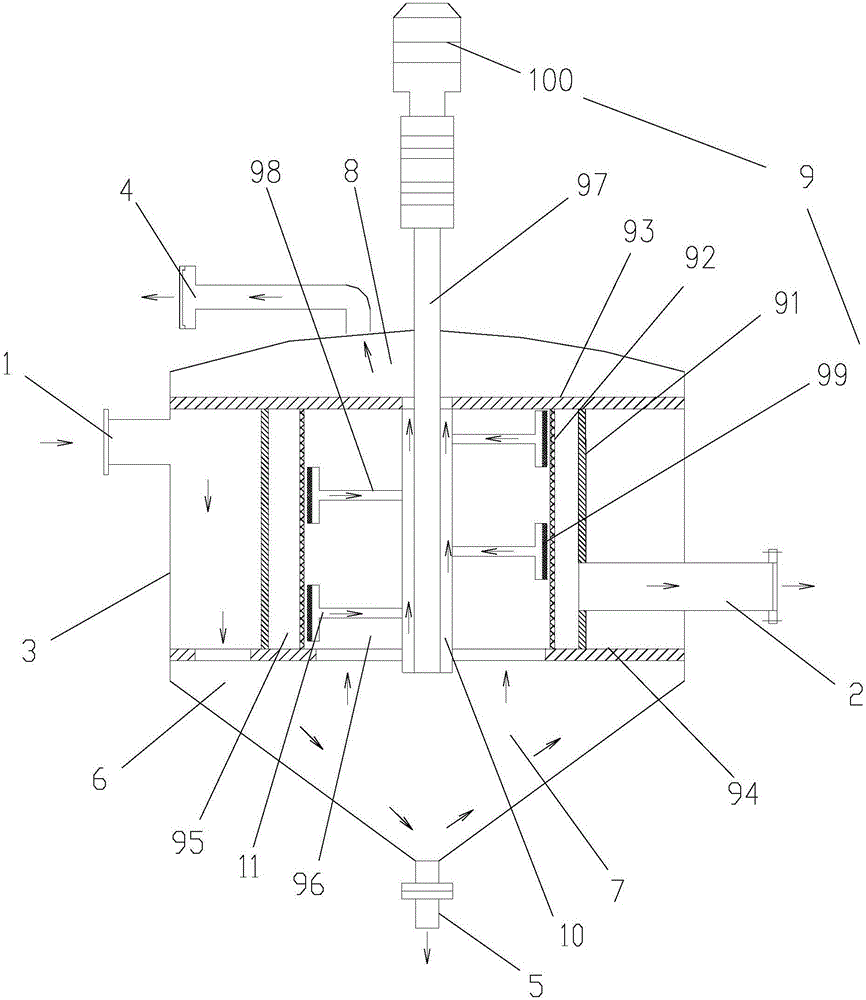

[0019] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

[0020] As shown in the figure, a blast furnace slag flushing water filter device in this embodiment includes a housing 3 with a water inlet 1 and a water outlet 2, the water inlet 1 is arranged on the upper side of the housing, and the water outlet 2 is arranged on the housing Under the side of the side, there is a pressure difference between the water inlet 1 and the water outlet 2, which is convenient for the natural filtration of the slag water under the action of gravity, which is beneficial to reduce energy consumption. The backwash channel is provided with a slag outlet 5 at the bottom of the shell, which is beneficial to discharge the heavier iron slag particles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com