Patents

Literature

175results about How to "High conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Highly conductive nano-scaled graphene plate nanocomposites and products

ActiveUS20070158618A1High conductivityHigh bulk electrical conductivityMaterial nanotechnologyConductive materialElectrically conductiveNanometre

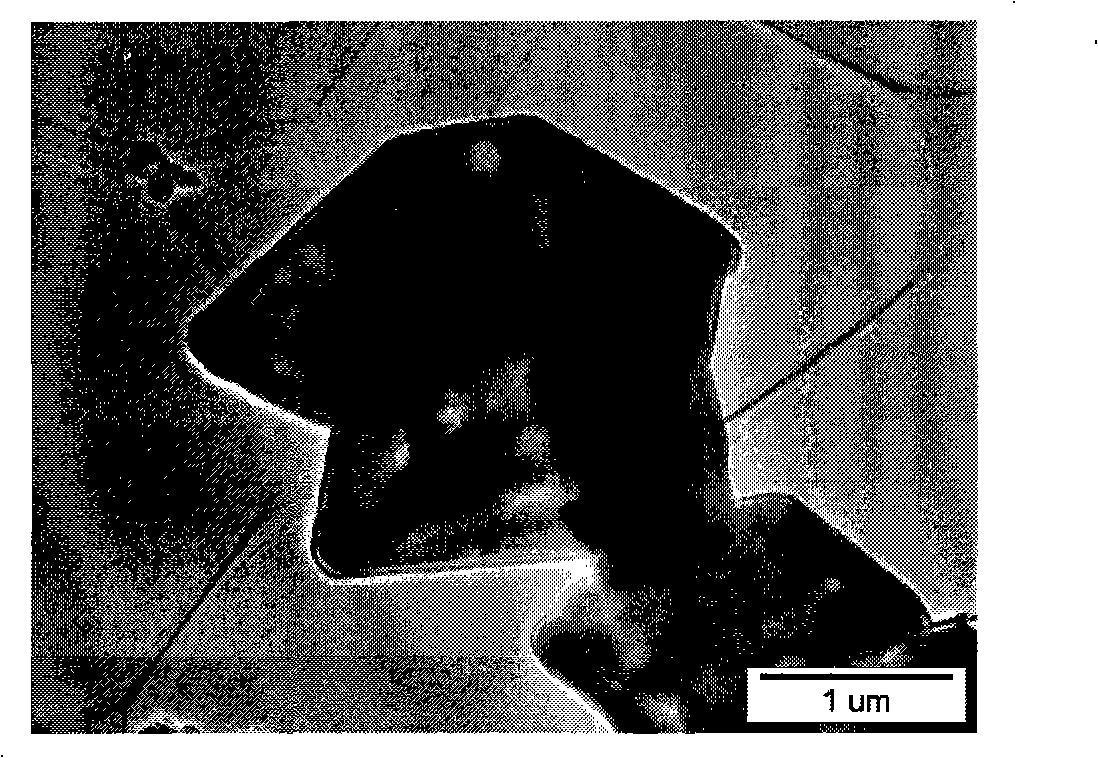

Disclosed is a nano-composite material comprising fully separated nano-scaled graphene platelets (NGPs) dispersed in a matrix material, wherein each of the platelets comprises a sheet of graphite plane or multiple sheets of graphite plane and has a thickness no greater than 100 nm and the platelets have an average length, width, or diameter no greater than 500 nm. The graphene plates are present in an amount no less than 15% by weight based on the total weight of the platelets and the matrix material combined. Typically, the nanocomposite is electrically conductive with a bulk conductivity no less than 10 S / cm and more typically no less than 100 S / cm. Highly conductive NGP nanocomposites are particularly useful for fuel cell flow field plate (bipolar plate) and battery electrode applications. Nanocomposites with high NGP proportions can be used in automotive friction plates and aircraft brake components.

Owner:GLOBAL GRAPHENE GRP INC

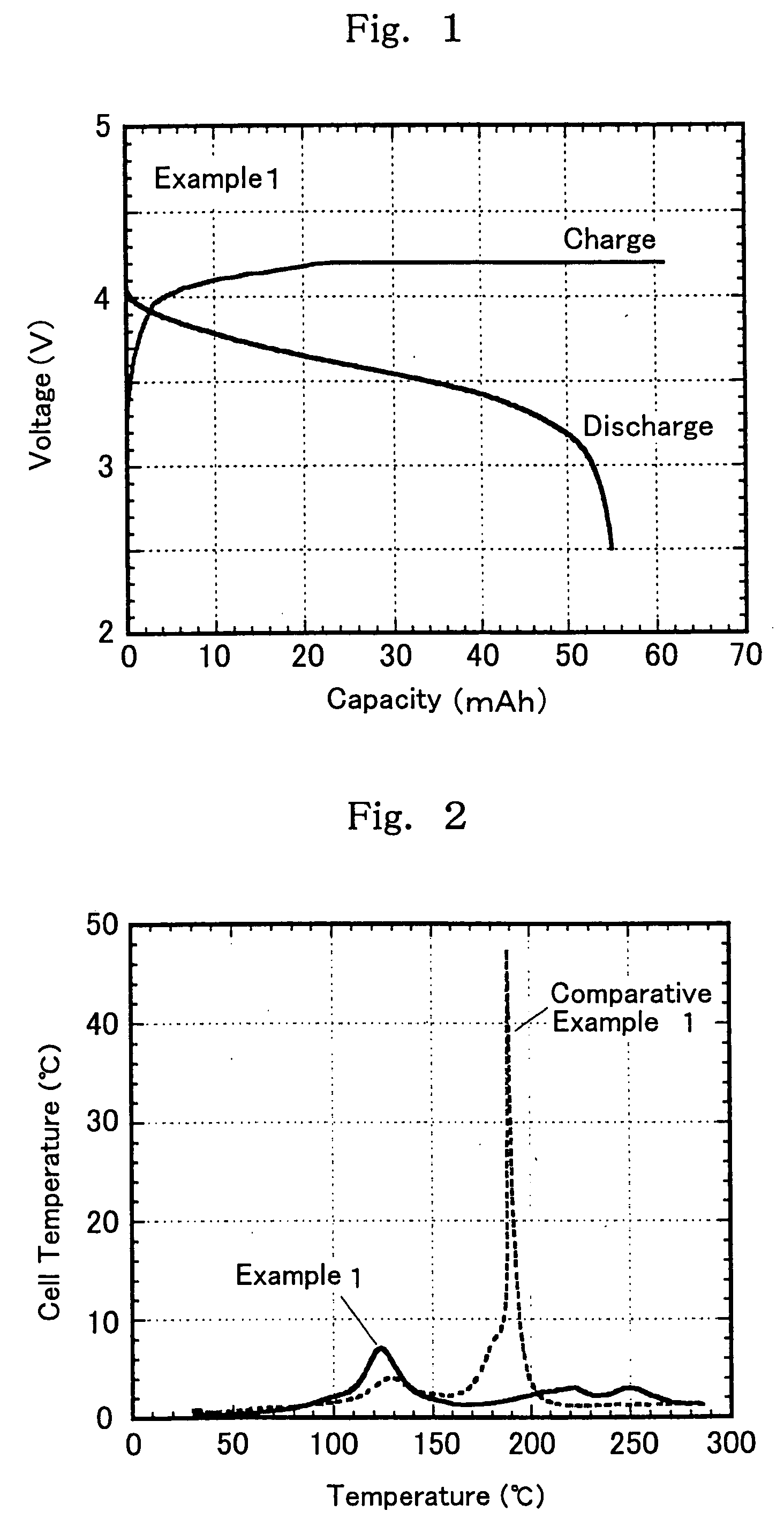

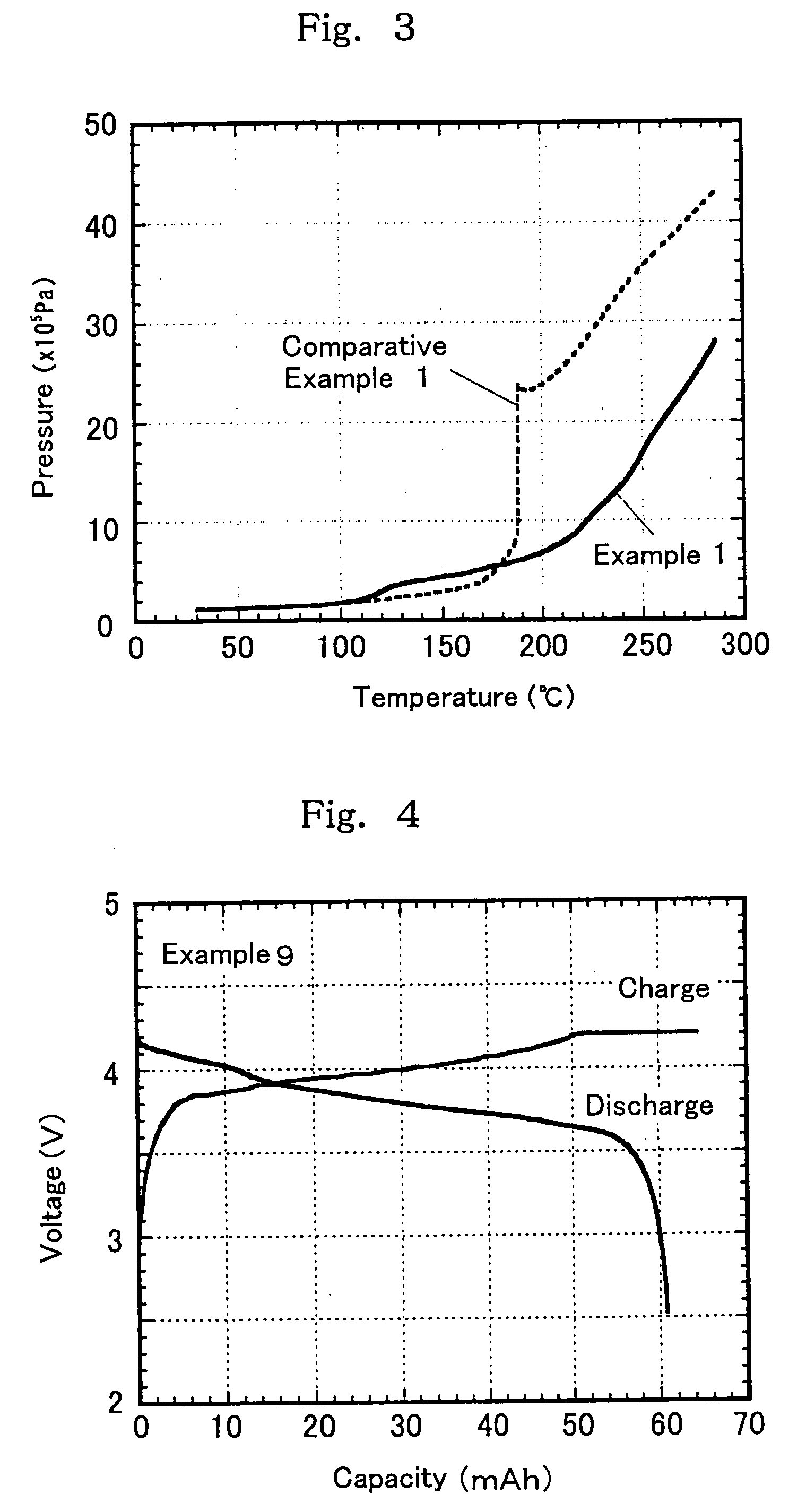

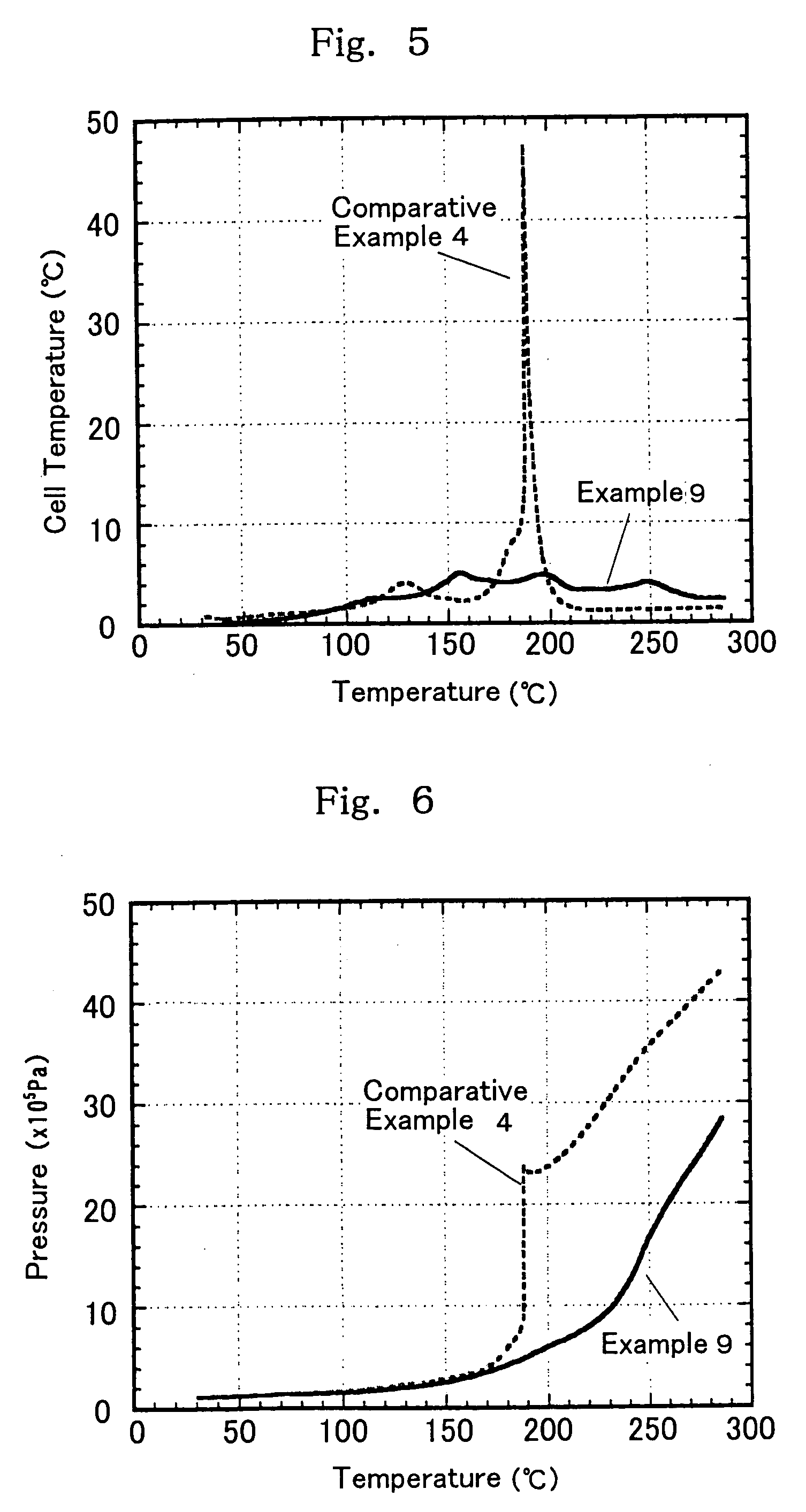

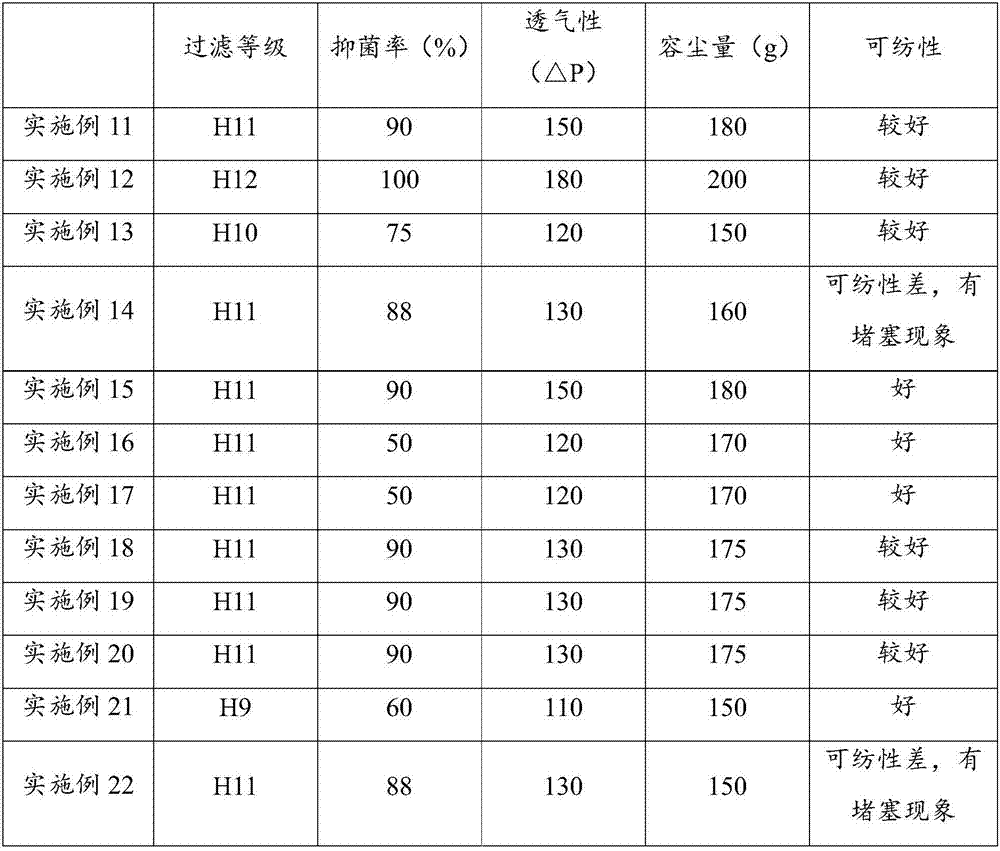

Non-aqueous electrolyte and lithium secondary battery using the same

InactiveUS20060172201A1High conductivityExcellent charge discharge characteristicOrganic electrolyte cellsNegative electrodesSolventCarboxylate

The present invention is directed to a non-aqueous electrolyte for lithium secondary battery, having both flame retardancy (self-extinguishing property) or nonflammability (having no flash point) and high conductivity and being electrochemically stable, and a lithium secondary battery using the non-aqueous electrolyte. Specifically, the non-aqueous electrolyte of the present invention comprises a non-aqueous solvent which comprises (a) at least one phosphate selected from (a1) a chain state phosphate and (a2) a cyclic phosphate as an essential component, and which may contain (b1) a cyclic carboxylate and (b2) a cyclic carbonate. Further, the non-aqueous electrolyte comprises the above non-aqueous solvent which further comprises (c1) a vinylene carbonate compound and / or (c2) a vinylethylene carbonate compound, and at least one compound selected from the group consisting of (d1) a cyclic amide compound, (d2) a cyclic carbamate compound, and (d3) a heterocyclic compound.

Owner:MITSUBISHI CHEM CORP

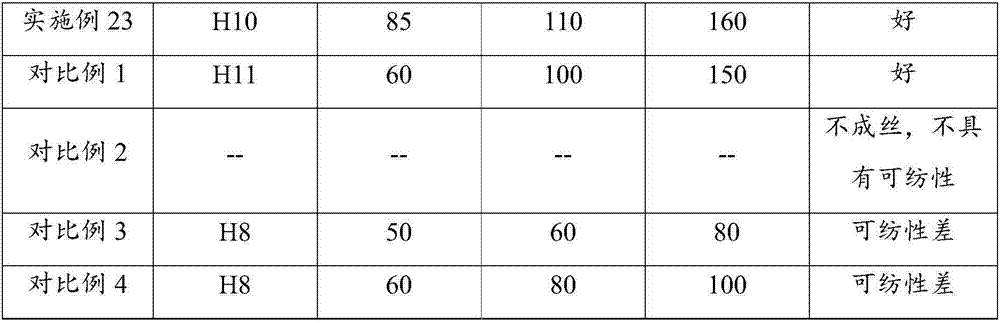

Modified polypropylene master batch, melt-blow cloth, preparation method and application thereof

InactiveCN107286473ALarge specific surface areaHigh conductivityFiltration separationNon-woven fabricsGraphene derivativesAntioxidant

The invention provides a modified polypropylene master batch, melt-blow cloth, a preparation method and an application thereof. The modified polypropylene master batch is mainly produced from, by weight, 77-90% of polypropylene, 5-20% of a graphene material and 1-5% of an additive. The graphene material includes any one or more of graphene, graphene oxide and graphene derivative. The additive includes any one or more of a coupling agent, a dispersant and an antioxidant and preferably includes the coupling agent, the dispersant and the antioxidant. The modified polypropylene master batch, when being used for manufacturing the melt-blow cloth, not only improves antibacterial and electrification property but also increases the filtering efficiency and dust capacity of the melt-blow cloth.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

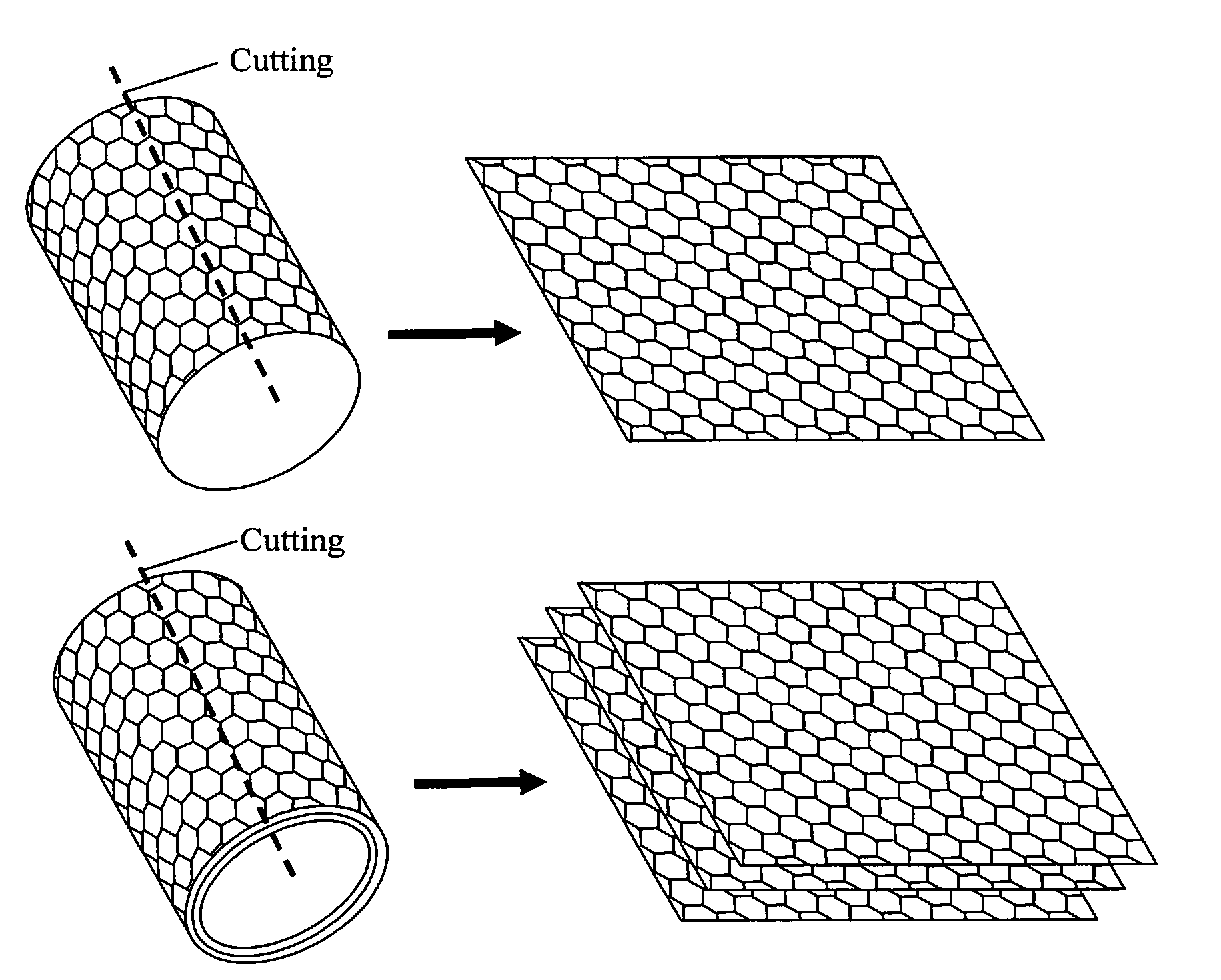

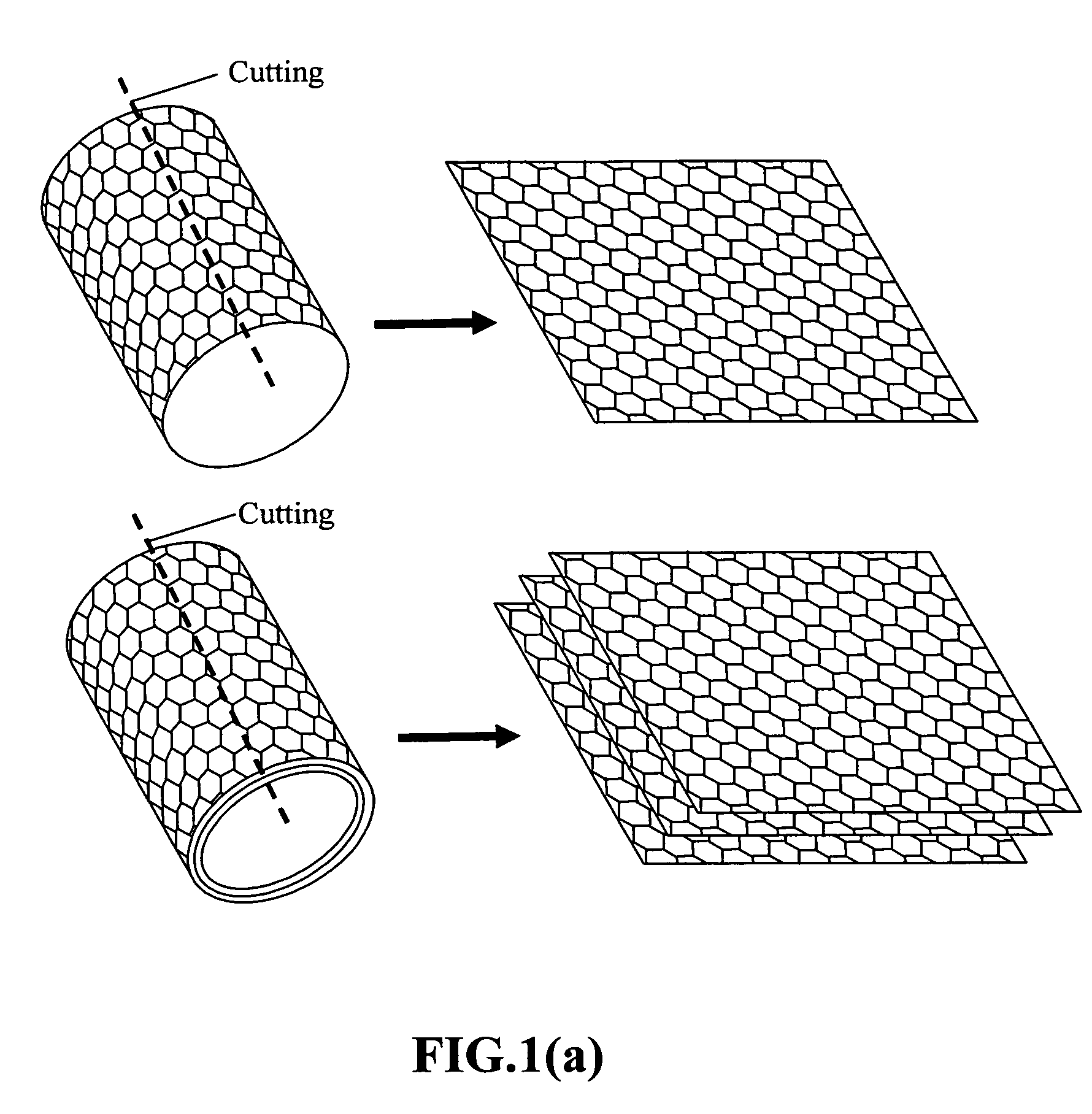

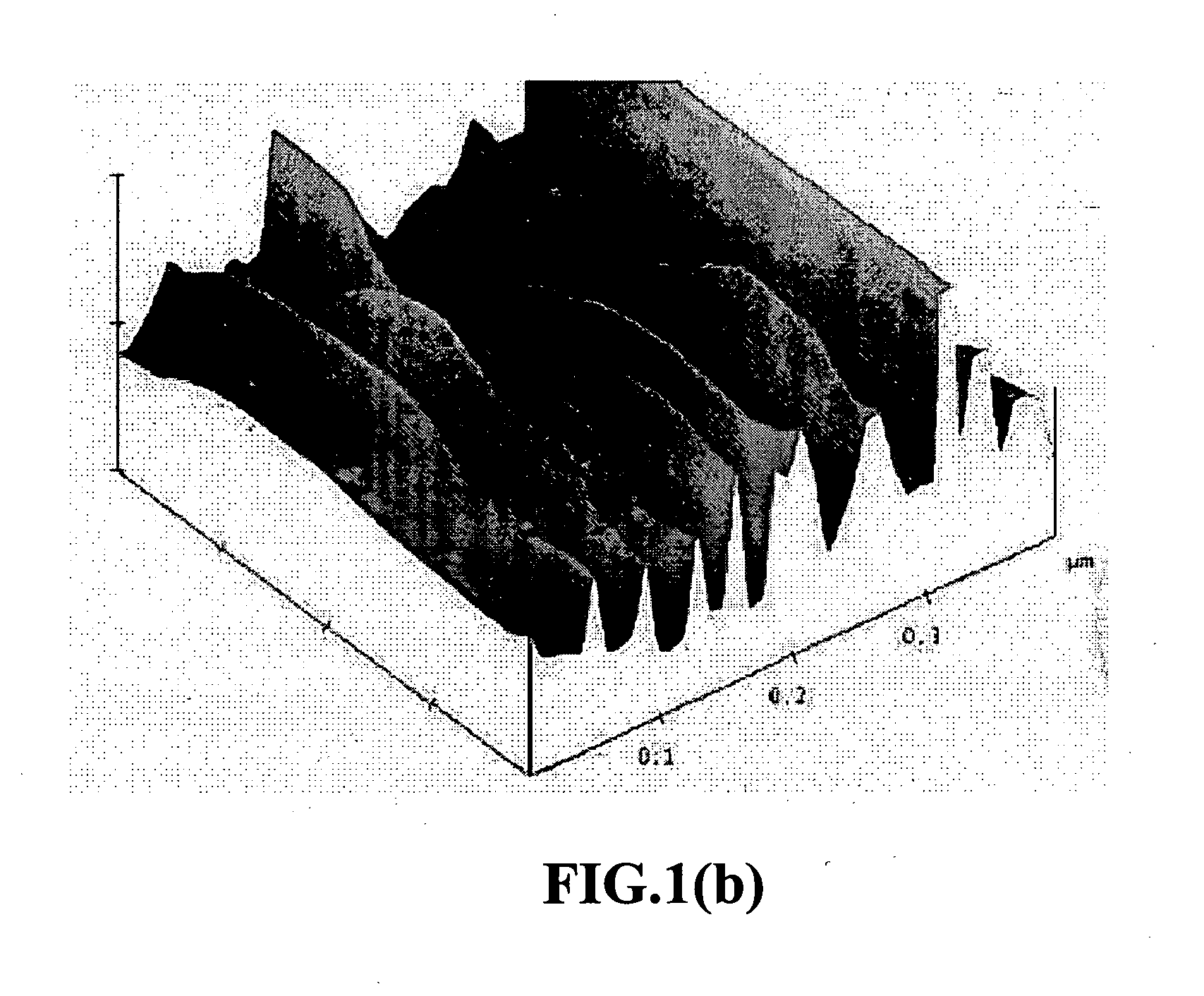

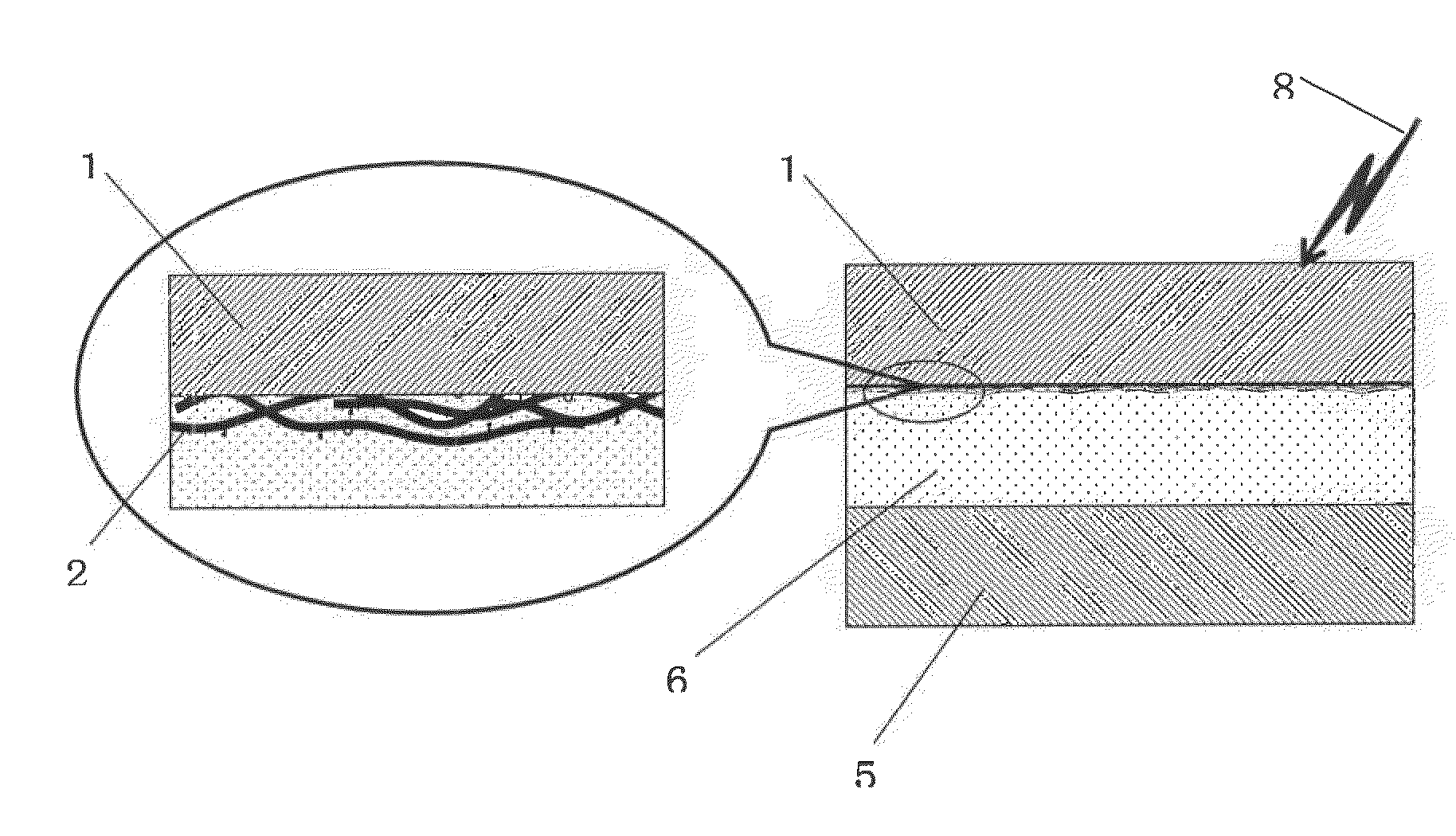

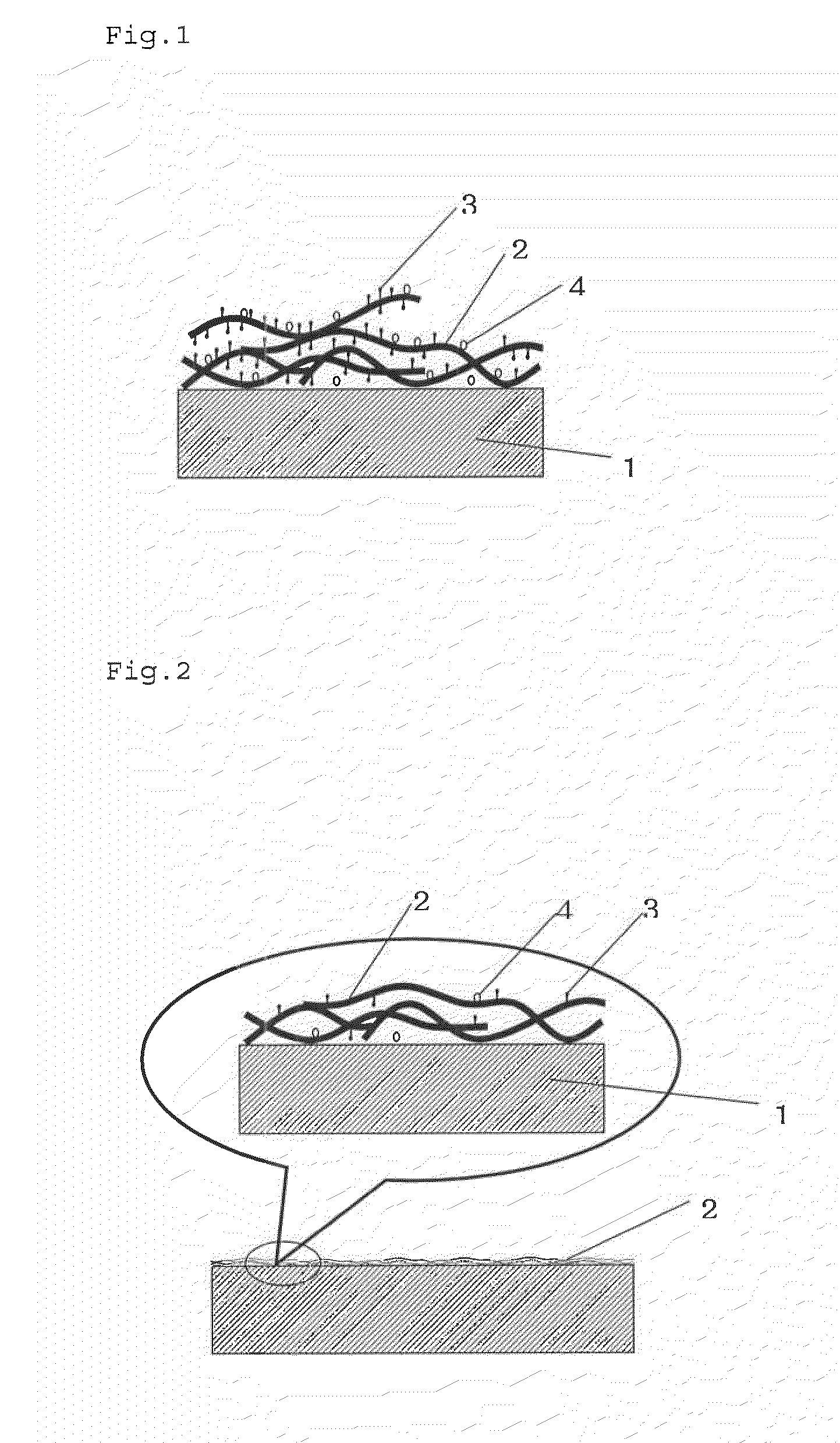

Method for producing carbon nanotube-containing conductor

ActiveUS20100252184A1High conductivityGood conductivityMaterial nanotechnologyDecorative surface effectsCarbon nanotubeLiquid resin

The invention is to provide a method for producing an inexpensive carbon nanotube-containing conductor having high transparency and high conductivity as well as excellent durability. The invention is a method for producing a carbon nanotube-containing conductor having a conductive layer on the surface of an objective substrate, and the method includes the steps of pressing a release substrate having a carbon nanotube network layer, via the carbon nanotube network layer thereon, against a transparent objective substrate coated with an electron beam-curable liquid resin composition to infiltrate the liquid resin composition into the carbon nanotube network layer; irradiating it with electron beams to cure the liquid resin composition; and peeling away the release substrate to obtain an objective substrate having a resin composition layer with carbon nanotubes embedded in the surface thereof. According to the invention, a conductor and a conductive film having high conductivity and transparency as well as excellent strength and durability are obtained.

Owner:MEIJO NANO CARBON

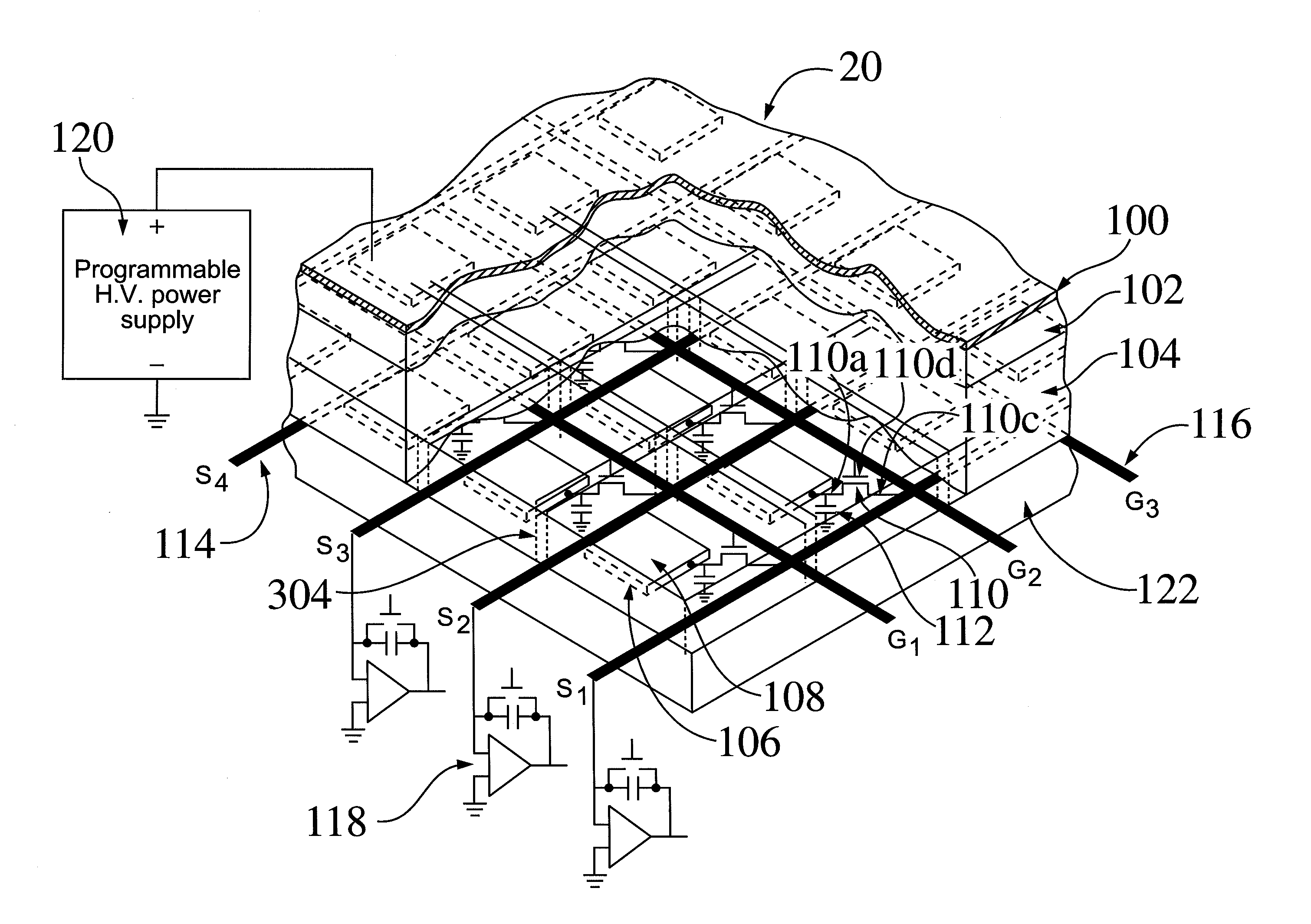

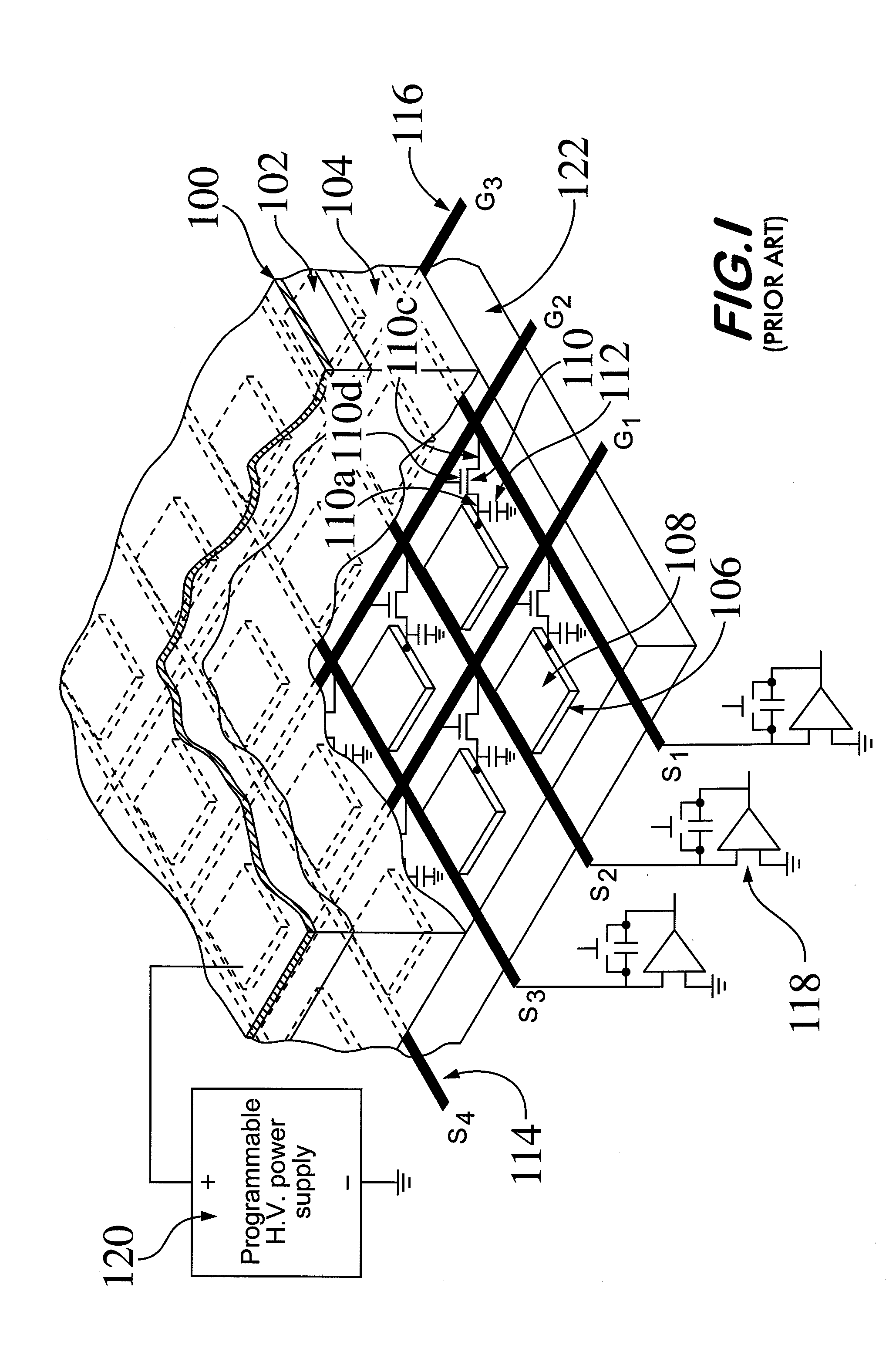

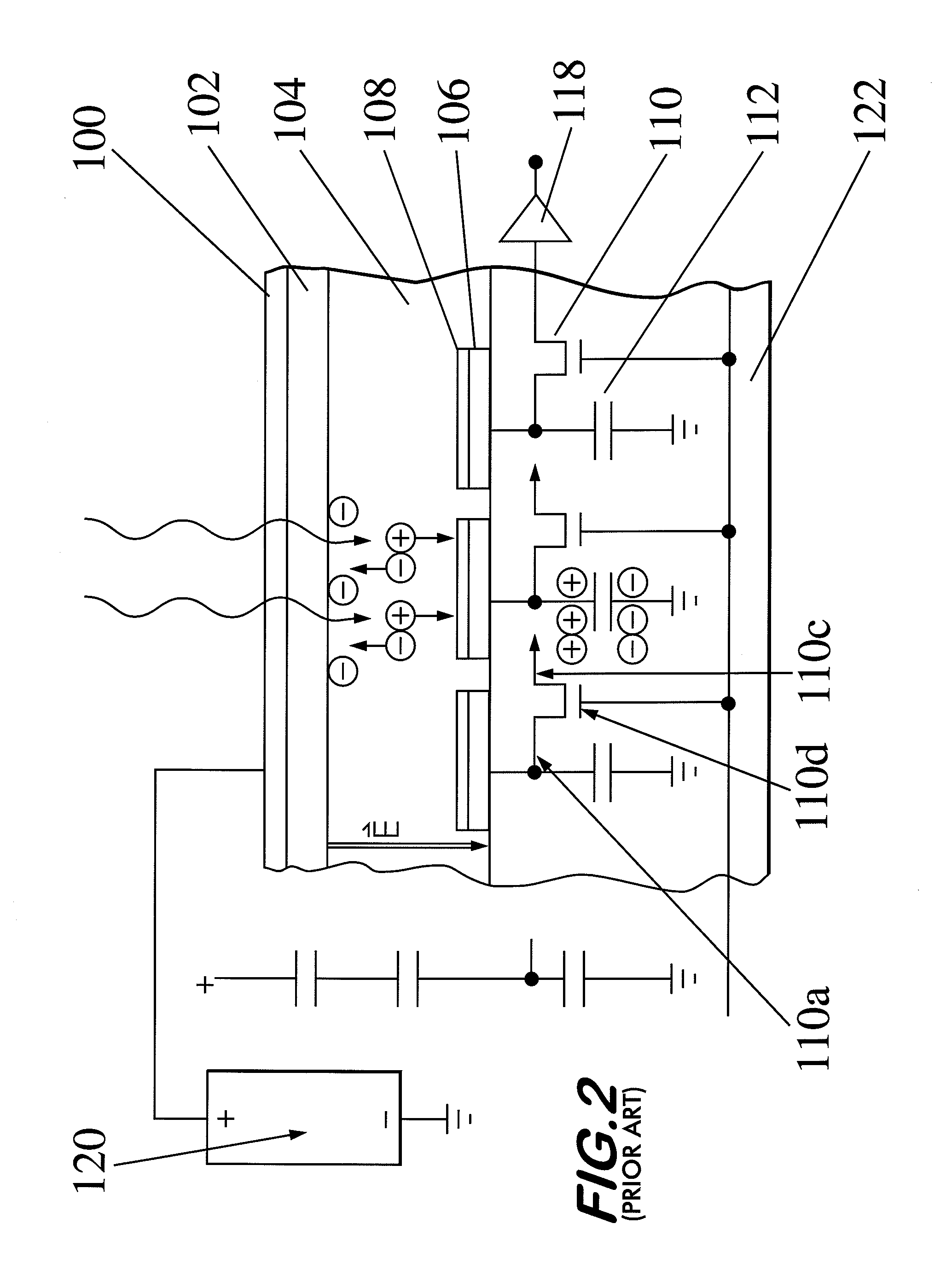

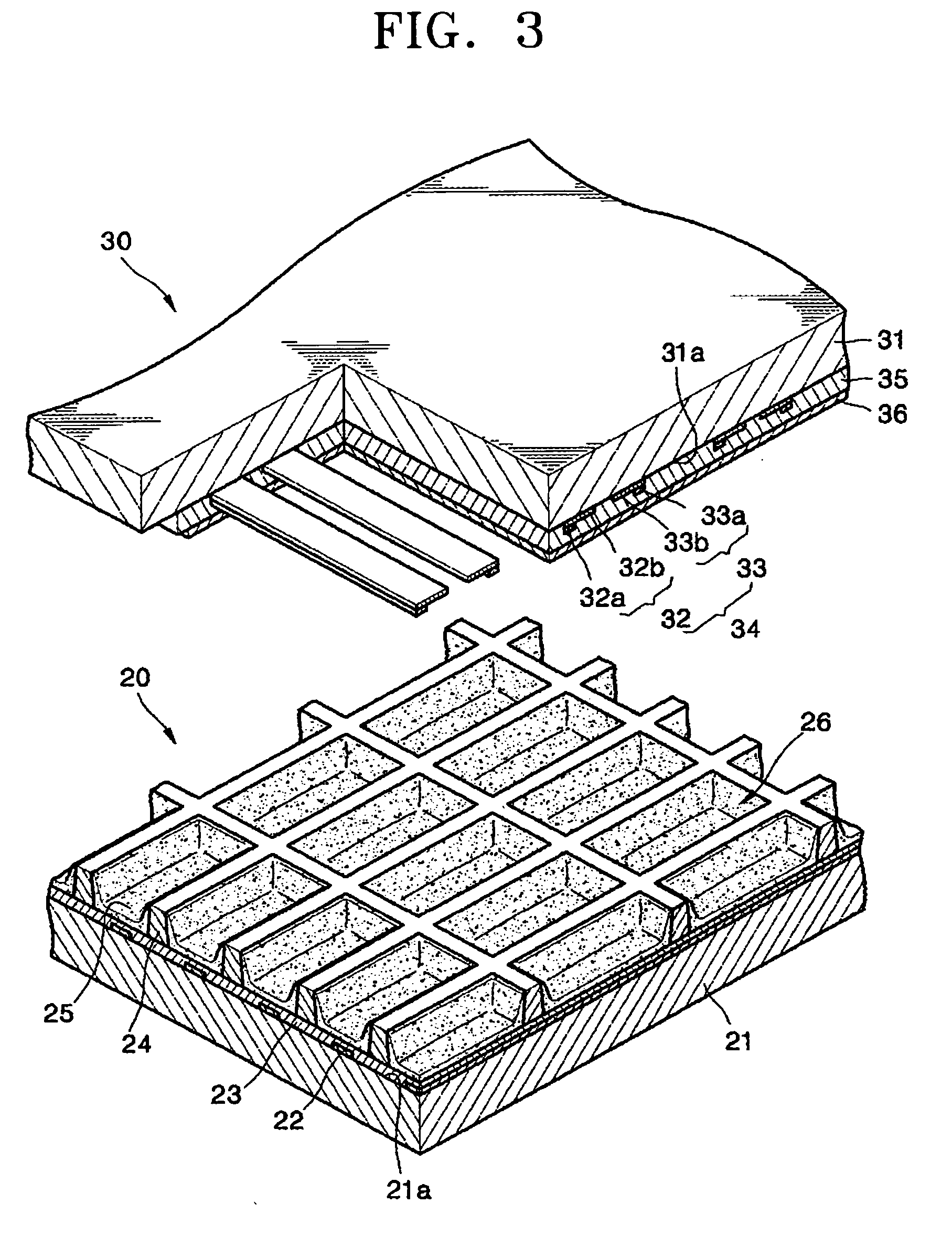

Flat panel X-ray imager with a grid structure

ActiveUS7256402B1High conductivityExtend useful lifeSolid-state devicesMaterial analysis by optical meansPolymerThermal expansion

A flat panel X-ray imager using an amorphous selenium detector which uses a polymer grid structure within the X-ray conversion layer to form an interface between the X-ray conversion layer and the pixel electrodes. The grid structure provides an additional physical barrier between pixel electrodes that reduces electrical bridging due to crystallization of the amorphous selenium due to temperature increases while also reducing the delamination temperature by providing a good anchor to the selenium, as well as a “cushion” for thermal expansion or contraction of the pixel electrodes. The grid can further include one or more grid electrodes for effecting avalanche-gain within the X-ray conversion layer while minimizing dark current entry into the selenium layer from the pixel electrode.

Owner:VIEWORKS +1

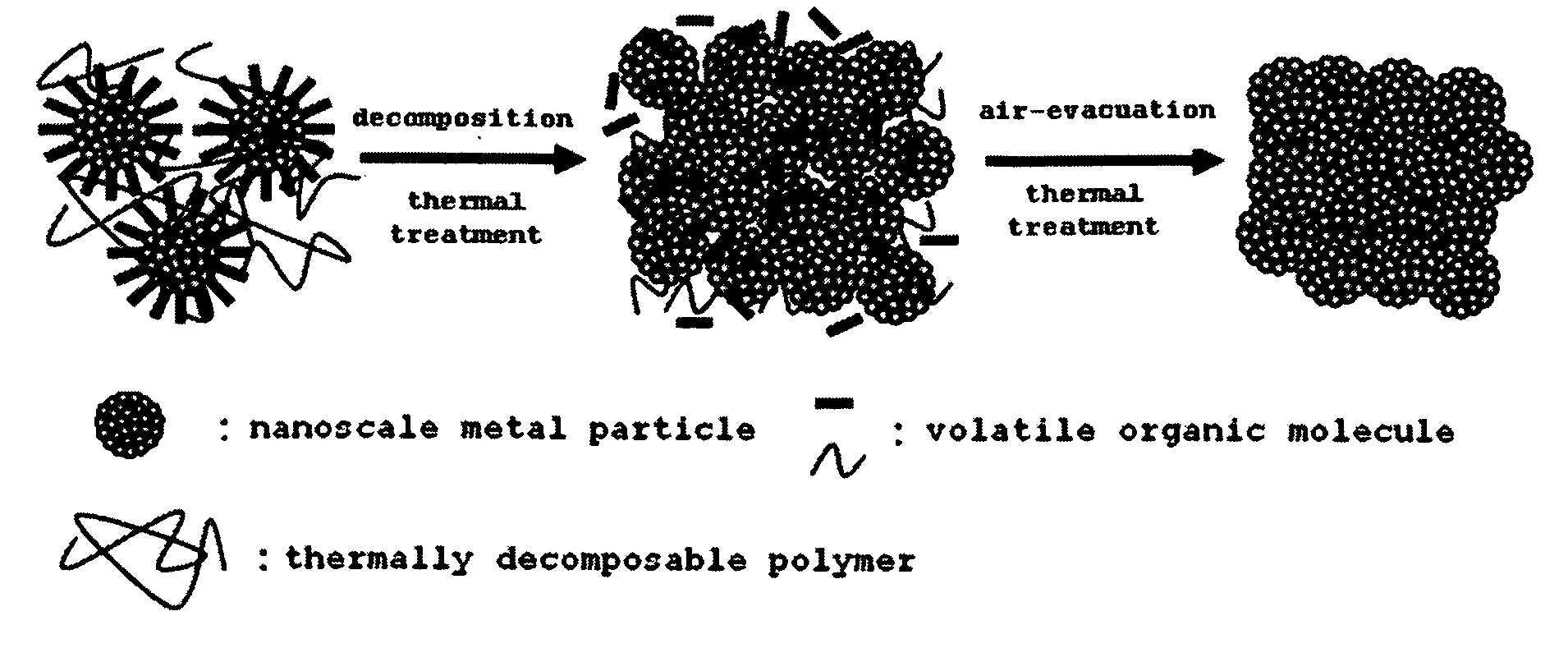

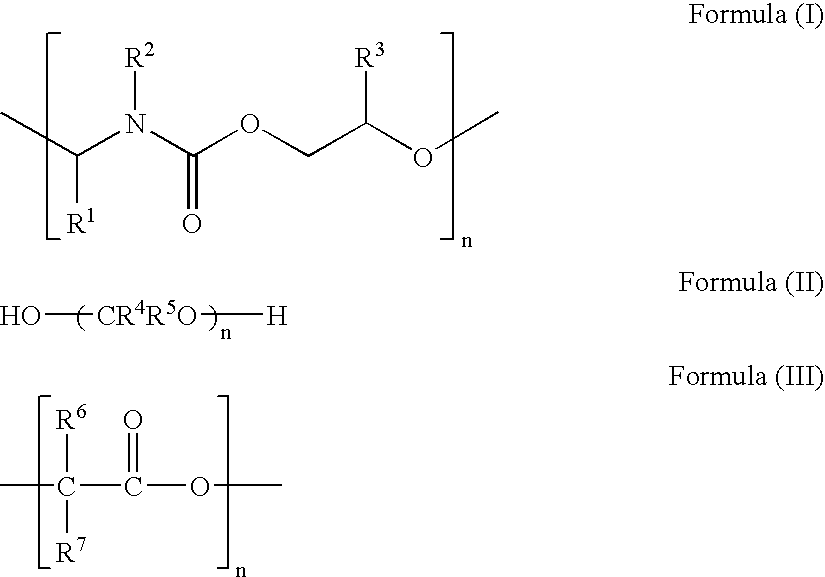

Highly conductive ink composition and method for fabricating a metal conductive pattern

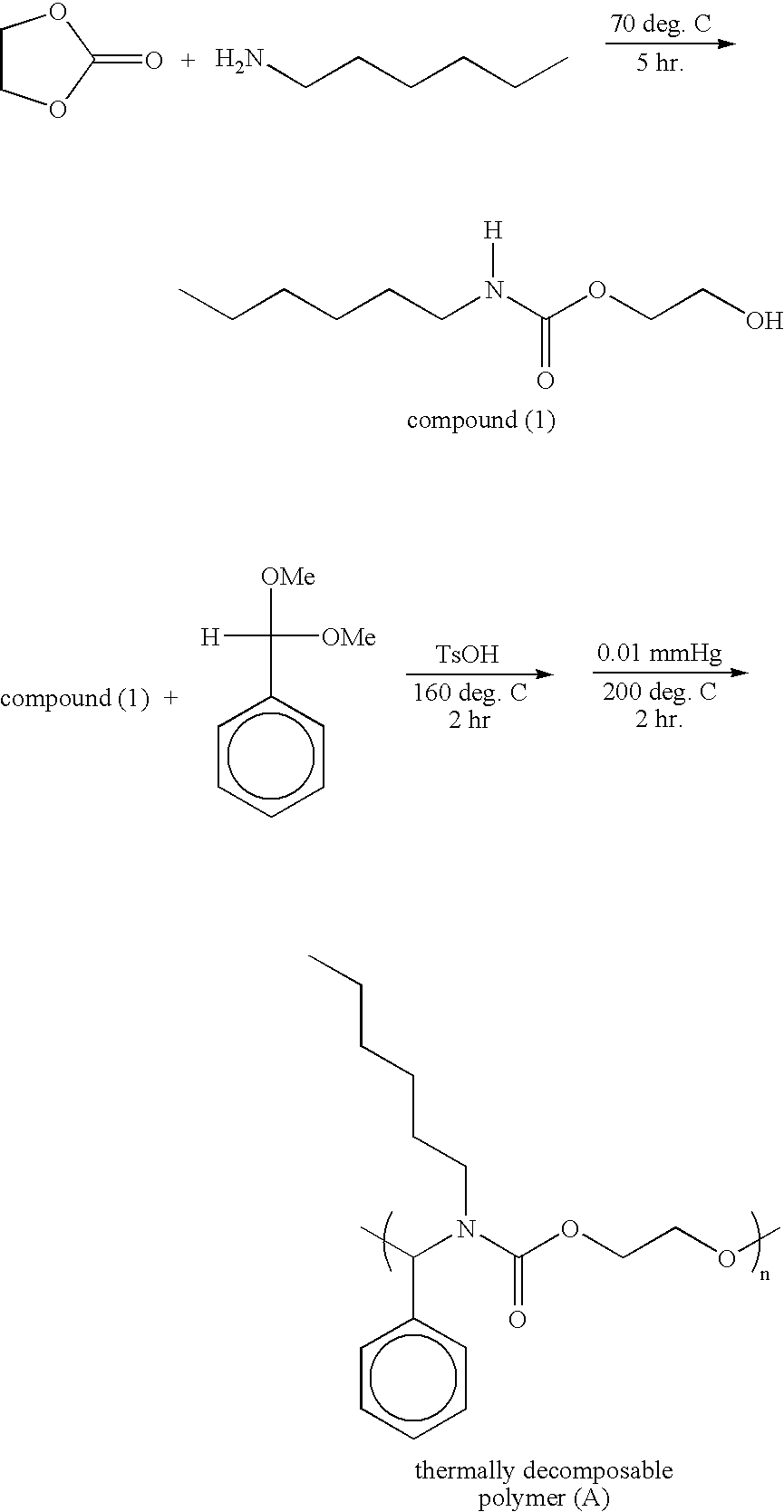

ActiveUS20070154644A1Decrease impactHigh conductivityConductive materialPretreated surfacesDecompositionPolymer chemistry

A viscosity controllable highly conductive ink composition. The highly conductive ink composition comprises an organic solvent, nanoscale metal particles or metallo-organic decomposition compounds, and a thermally decomposable organic polymer. Specifically, since the thermally decomposable polymer can increase the viscosity of the highly conductive ink composition and be removed by subsequent thermal treatment, so as to decrease the impact on conductivity by organic polymer. Therefore, a viscosity-controllable conductive ink composition is obtained.

Owner:IND TECH RES INST

Fountain solution and preparation method thereof

InactiveCN101870213AEasy to keep hydrophilicAdequate dampening capacityPrinting pre-treatmentGermabenPropylene glycol

The invention discloses a fountain solution, which is characterized in that: the fountain solution comprises the following raw materials in percentage by weight: 1 to 15 percent of glycerin, 0.1 to 10 percent of ammonium citrate, 0.1 to 10 percent of malic acid, 0.1 to 5 percent of defoaming agent, 0.1 to 10 percent of wetting agent, 0.1 to 5 percent of bactericide, 1 to 15 percent of L-PCA-Na, 1 to 15 percent of propylene glycol and 1 to 15 percent of sorbierite; and the preparation method comprises the following steps: adding the ammonium citrate, the malic acid, the wetting agent, the L-PCA-Na in a weight percentage ratio, then adding 50 to 80 percent of water, uniformly mixing the materials and the water; and adding the propylene glycol, the sorbierite, the glycerin, the defoaming agent and the bactericide into the obtained mixture and then uniformly stirring the mixture so as to obtain the fountain solution. The fountain solution has the advantages of environmental protection, strong fountain capability, wet non-verbal-visual part, sufficient pH-value buffering, difficult ink emulsification, large electric conductivity, large surface-tension buffering range and easy operating control.

Owner:杜广清

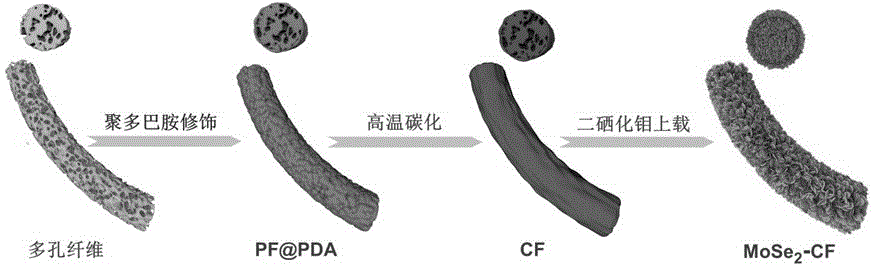

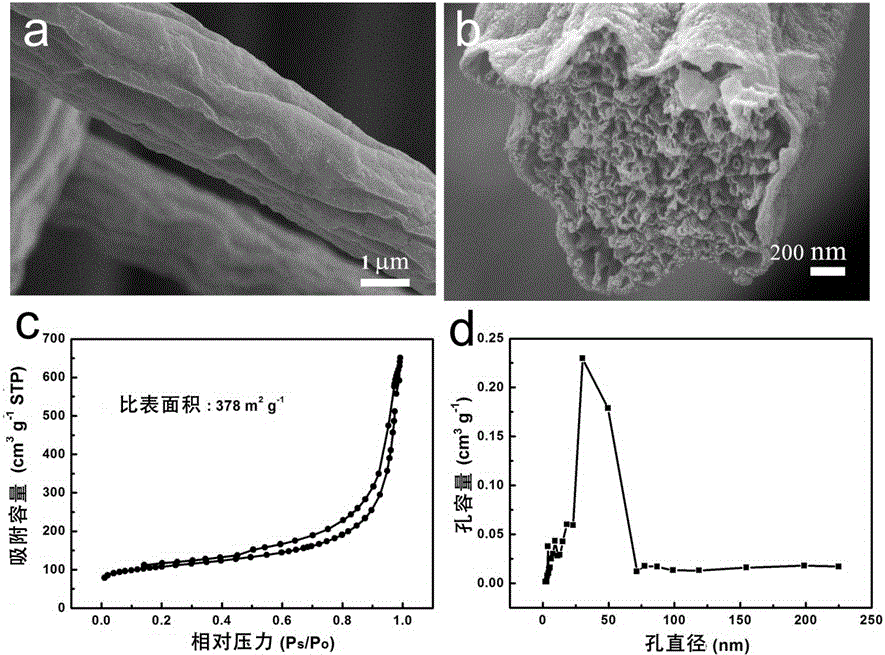

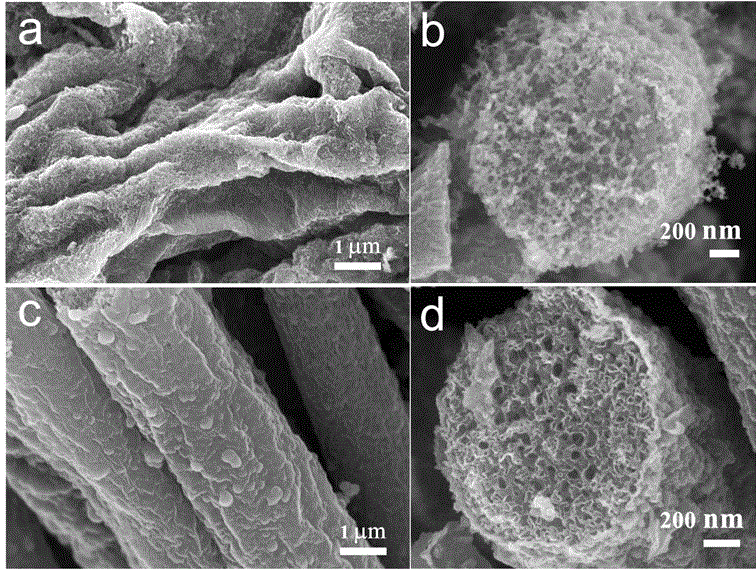

Poly-dopamine based porous carbon fiber/MoSe2 composite material and preparation method thereof

InactiveCN105742074AGentle preparationThe preparation process is environmentally friendlyHybrid capacitor electrodesCell electrodesElectro catalystCarbon fibers

The invention belongs to the technical field of a composite fiber material, in particular relates to a poly-dopamine based porous carbon fiber / MoSe2 nanosheet composite material and a preparation method thereof. The method comprises the following steps of preparing a spinning solution with a spinnable high-polymer material, and preparing to obtain porous fiber with an uniform structure by an electrostatic spinning device; immersing the porous fiber in a dopamine solution, and controlling the thickness of a poly-dopamine cladding layer by adjusting the concentration and the reaction time of the dopamine solution; carrying out high-temperature carbonization to achieve carbonization on the poly-dopamine modified porous fiber material; and uniformly arranging MoSe2 nanosheets on the surface of the porous fiber by a hydrothermal method. The method disclosed by the invention is safe and environment-friendly, and the prepared porous carbon fiber / MoSe2 has the advantages of high active substance content, high specific area, high conductivity, stable physical and chemical performance and the like, and is an ideal electrode material for preparing an active electric catalyst for a hydrogen evolution reaction.

Owner:FUDAN UNIV

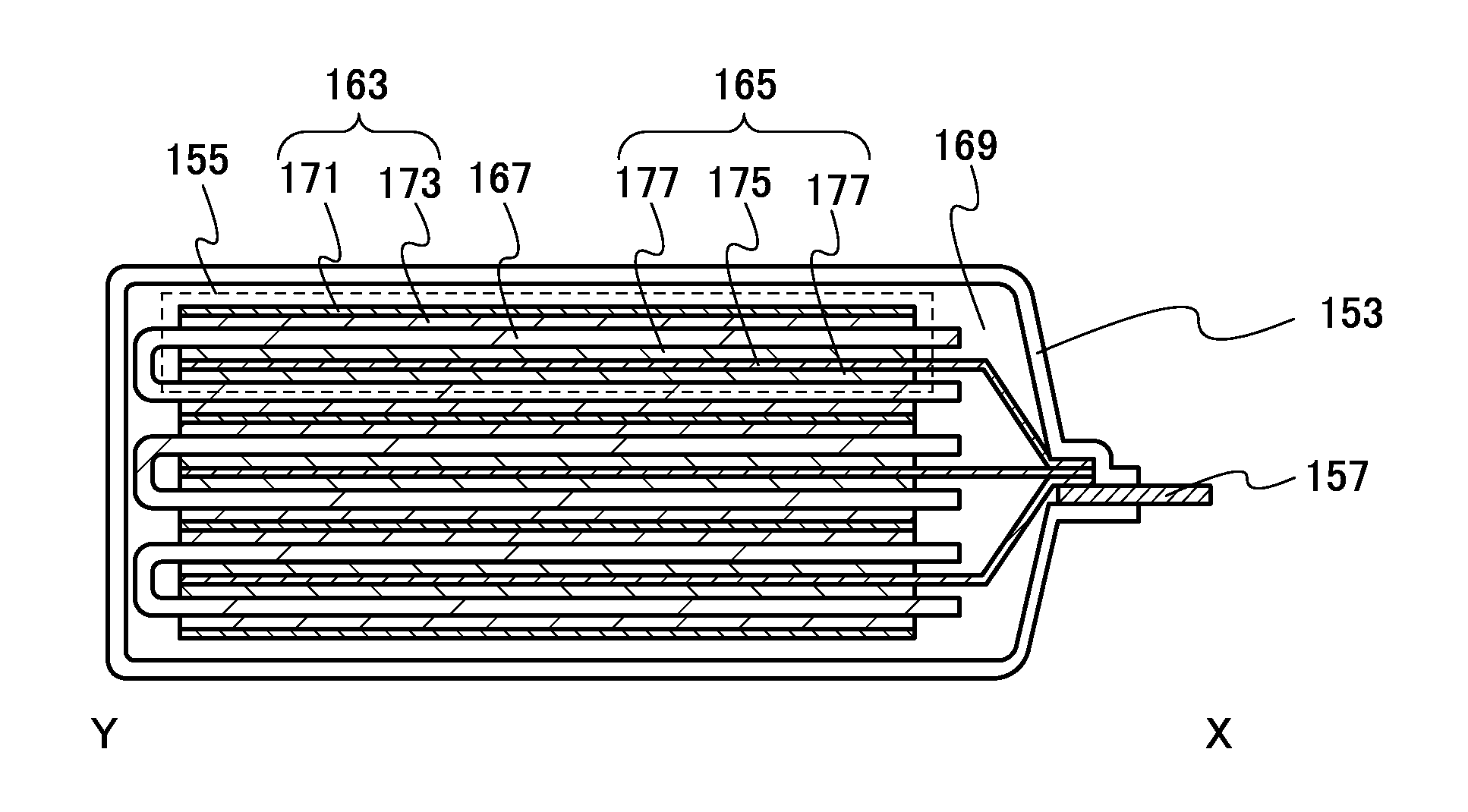

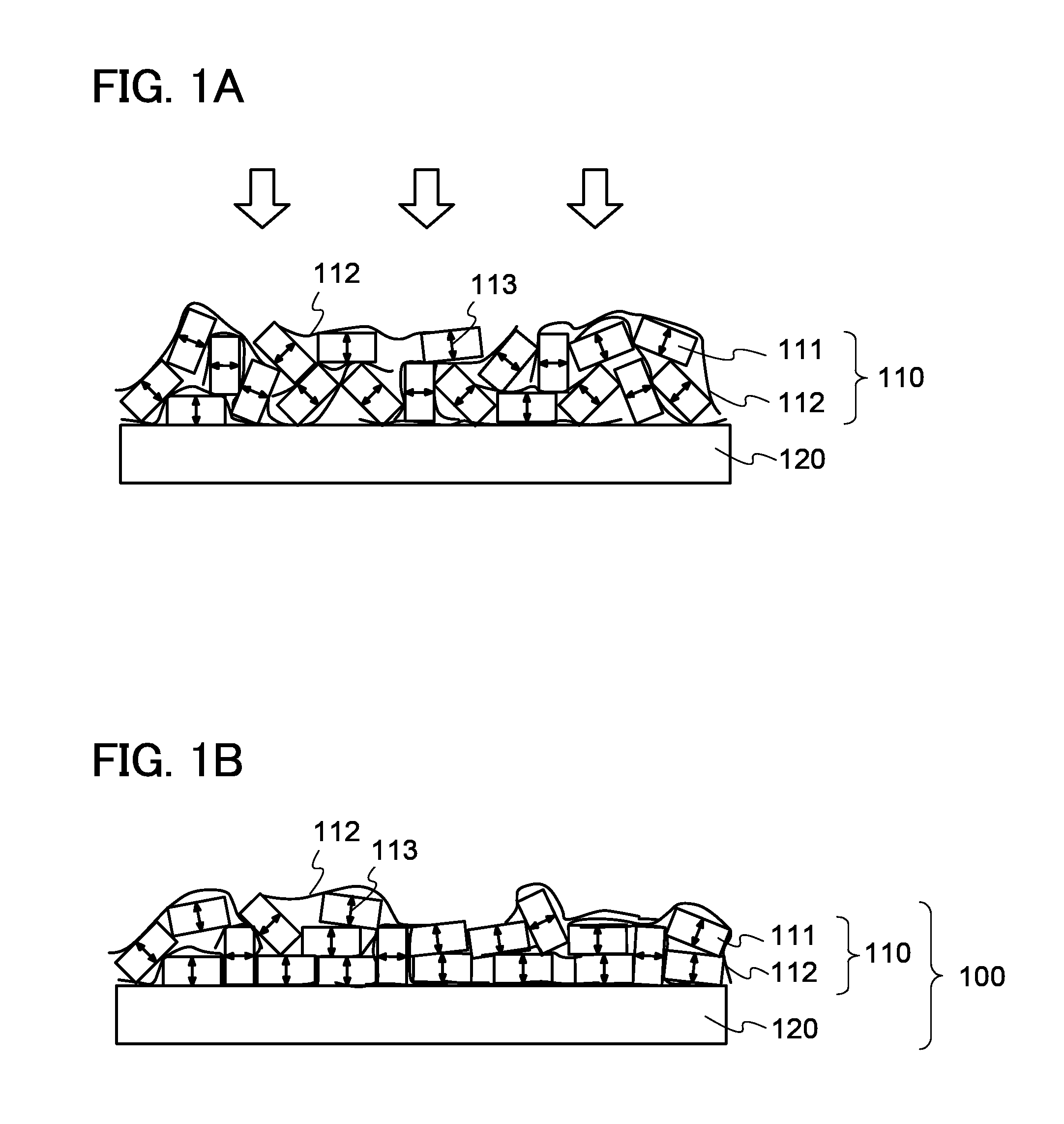

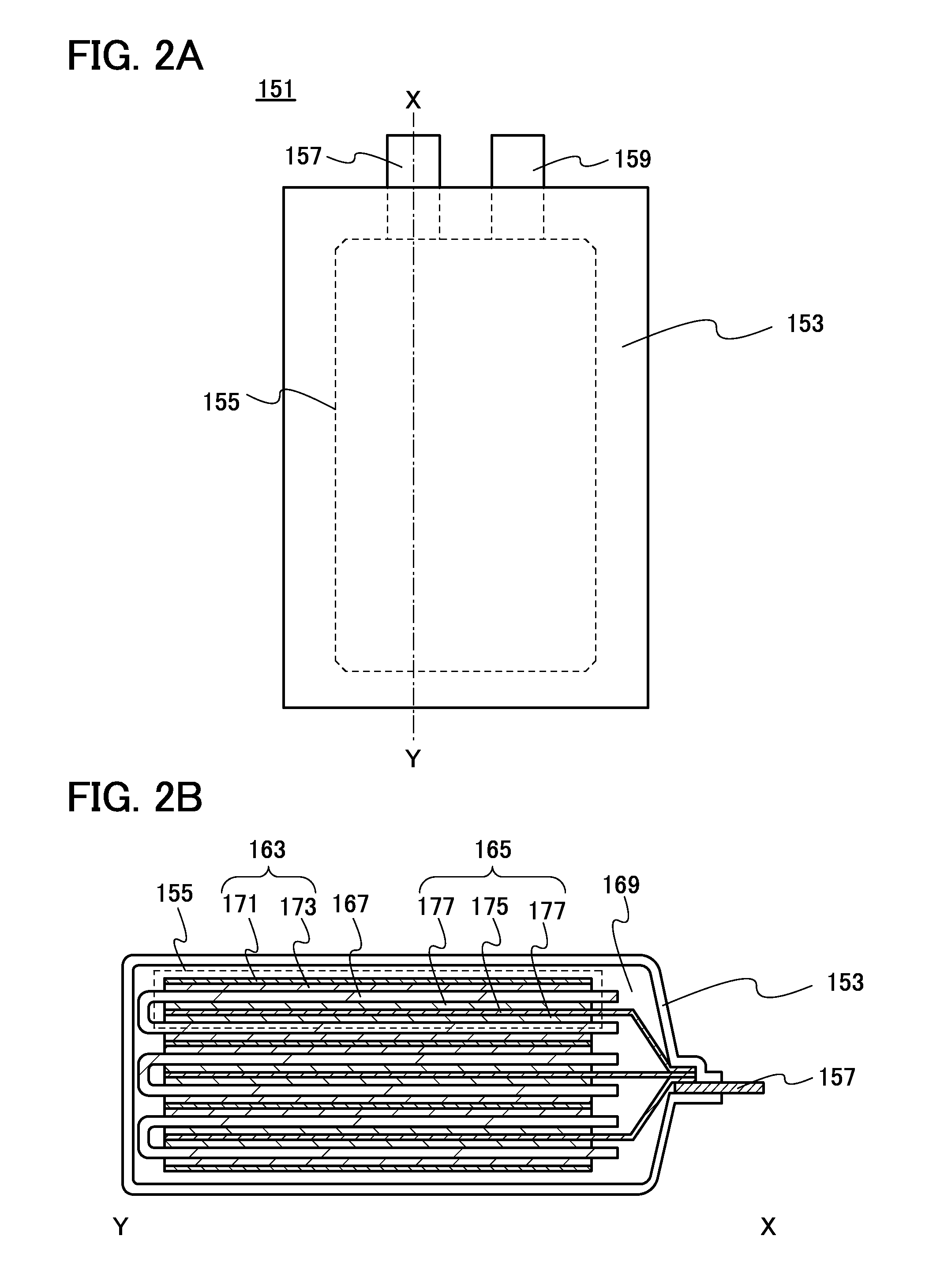

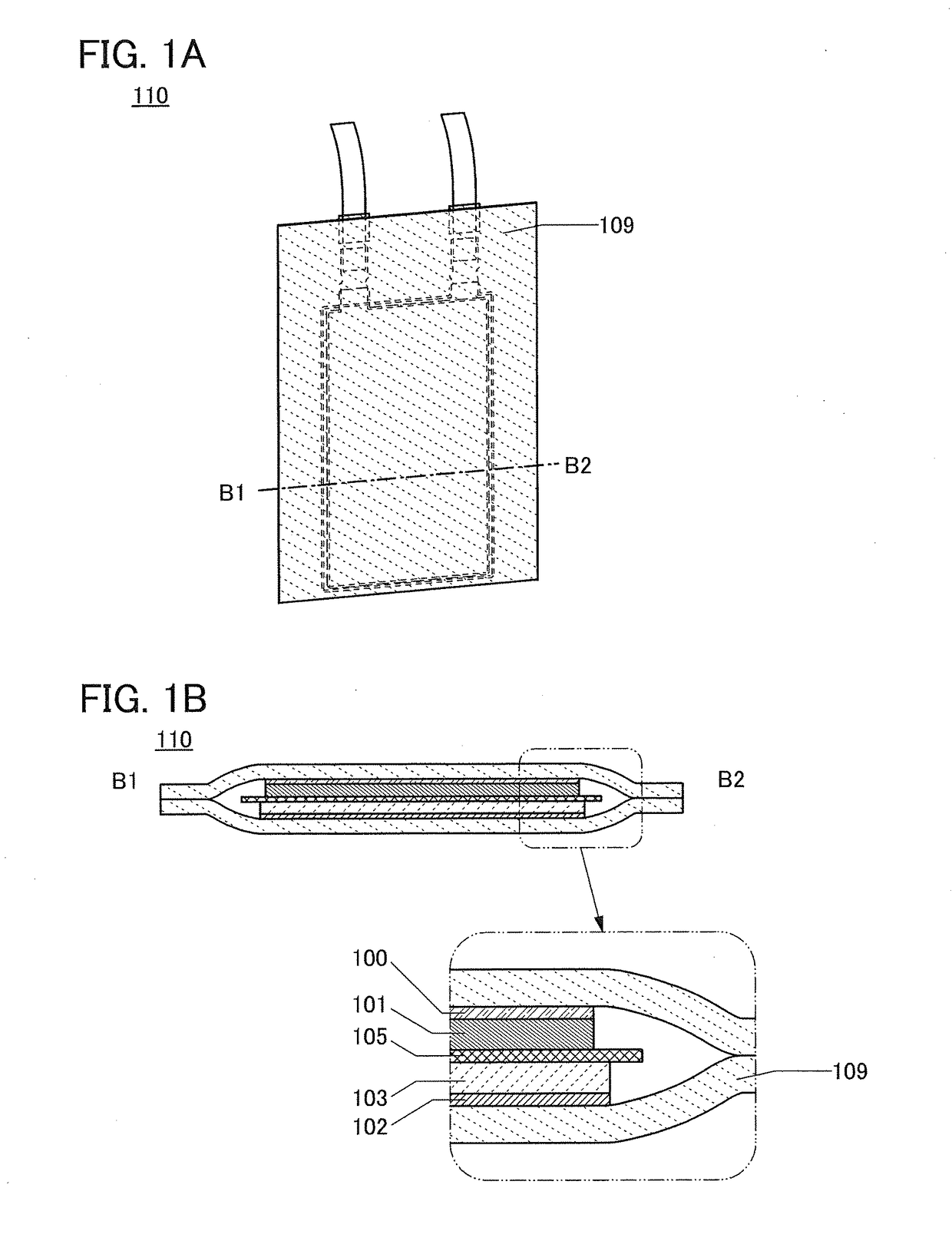

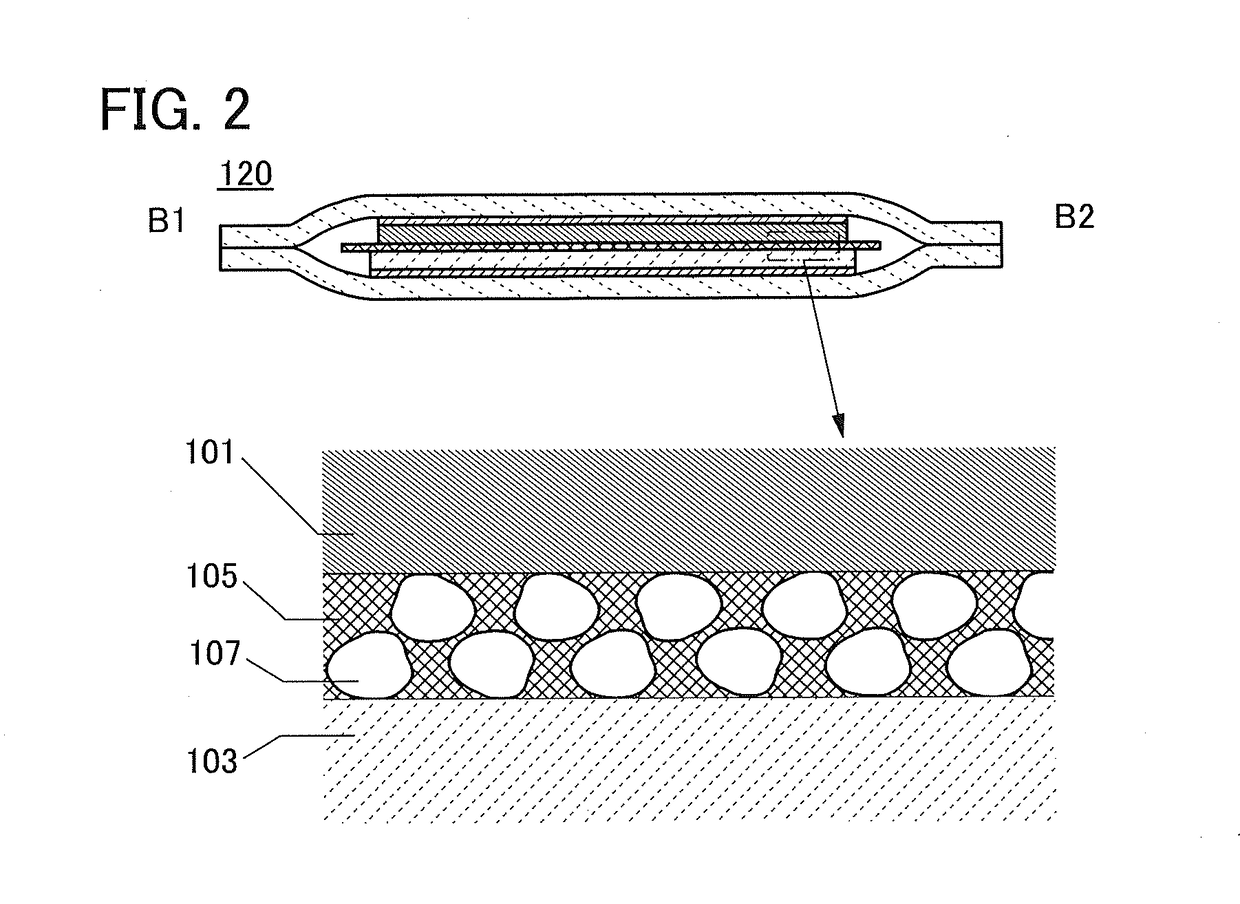

Positive electrode for lithium secondary battery, manufacturing method thereof, and lithium secondary battery

ActiveUS20130065120A1High conductivityReduce proportionMaterial nanotechnologyElectrode rolling/calenderingOlivineComposite oxide

Occlusion and release of lithium ion are likely to one-dimensionally occur in the b-axis direction of a crystal in a lithium-containing composite oxide having an olivine structure. Thus, a positive electrode in which the b-axes of lithium-containing composite oxide single crystals are oriented vertically to a surface of a positive electrode current collector is provided. The lithium-containing composite oxide particles are mixed with graphene oxide and then pressure is applied thereto, whereby the rectangular parallelepiped or substantially rectangular parallelepiped particles are likely to slip. In addition, in the case where the rectangular parallelepiped or substantially rectangular parallelepiped particles whose length in the b-axis direction is shorter than those in the a-axis direction and the c-axis direction are used, when pressure is applied in one direction, the b-axes can be oriented in the one direction.

Owner:SEMICON ENERGY LAB CO LTD

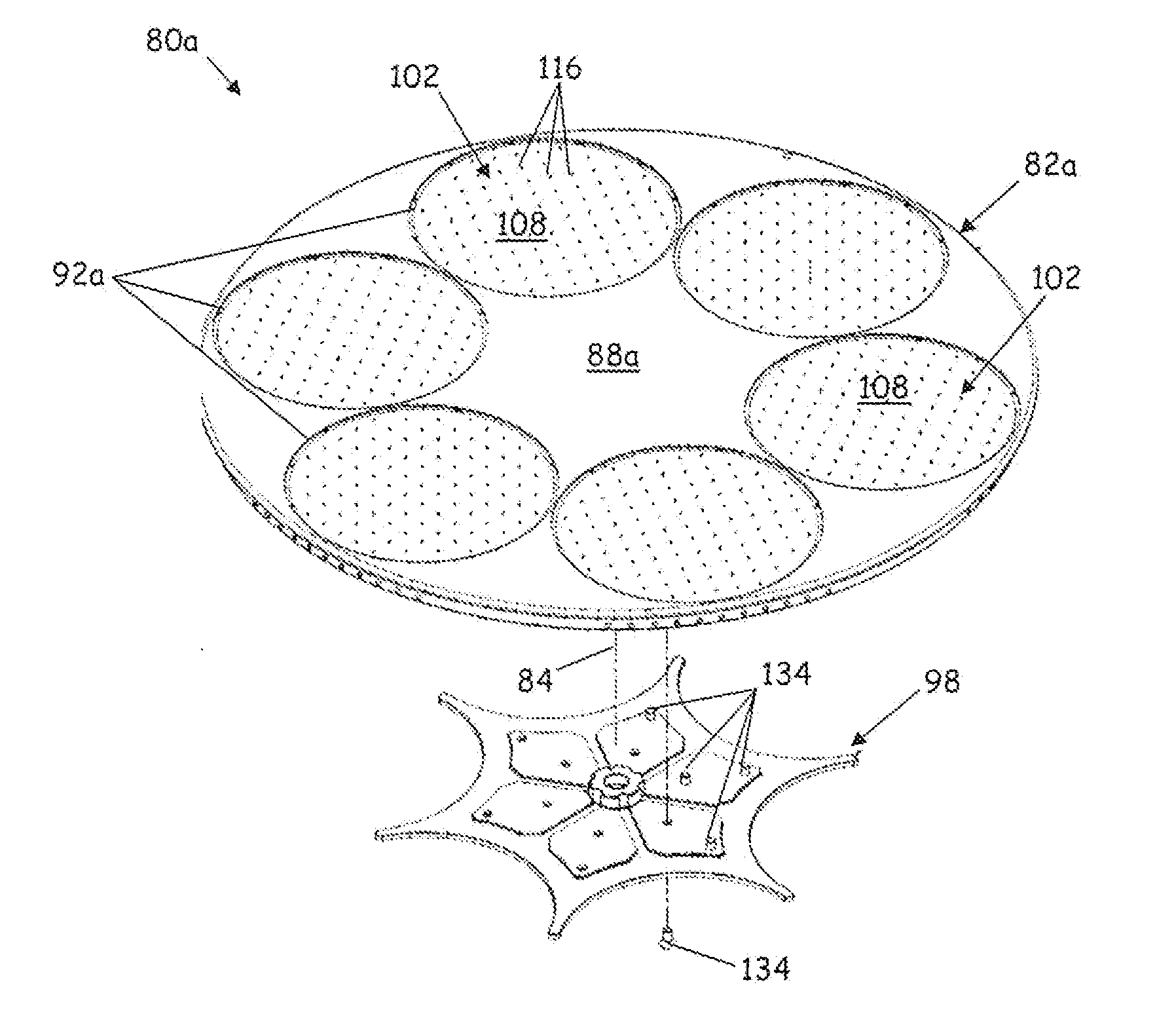

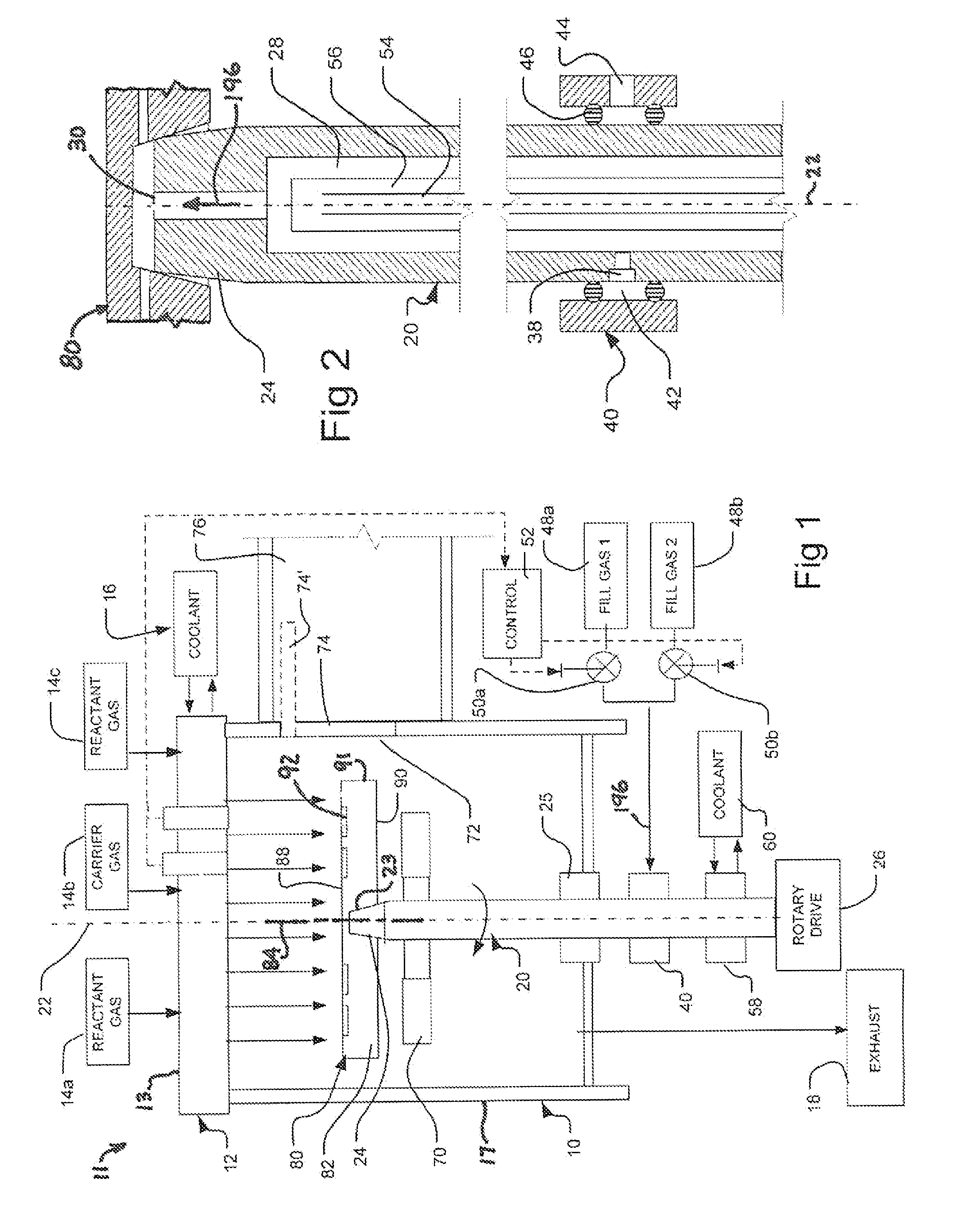

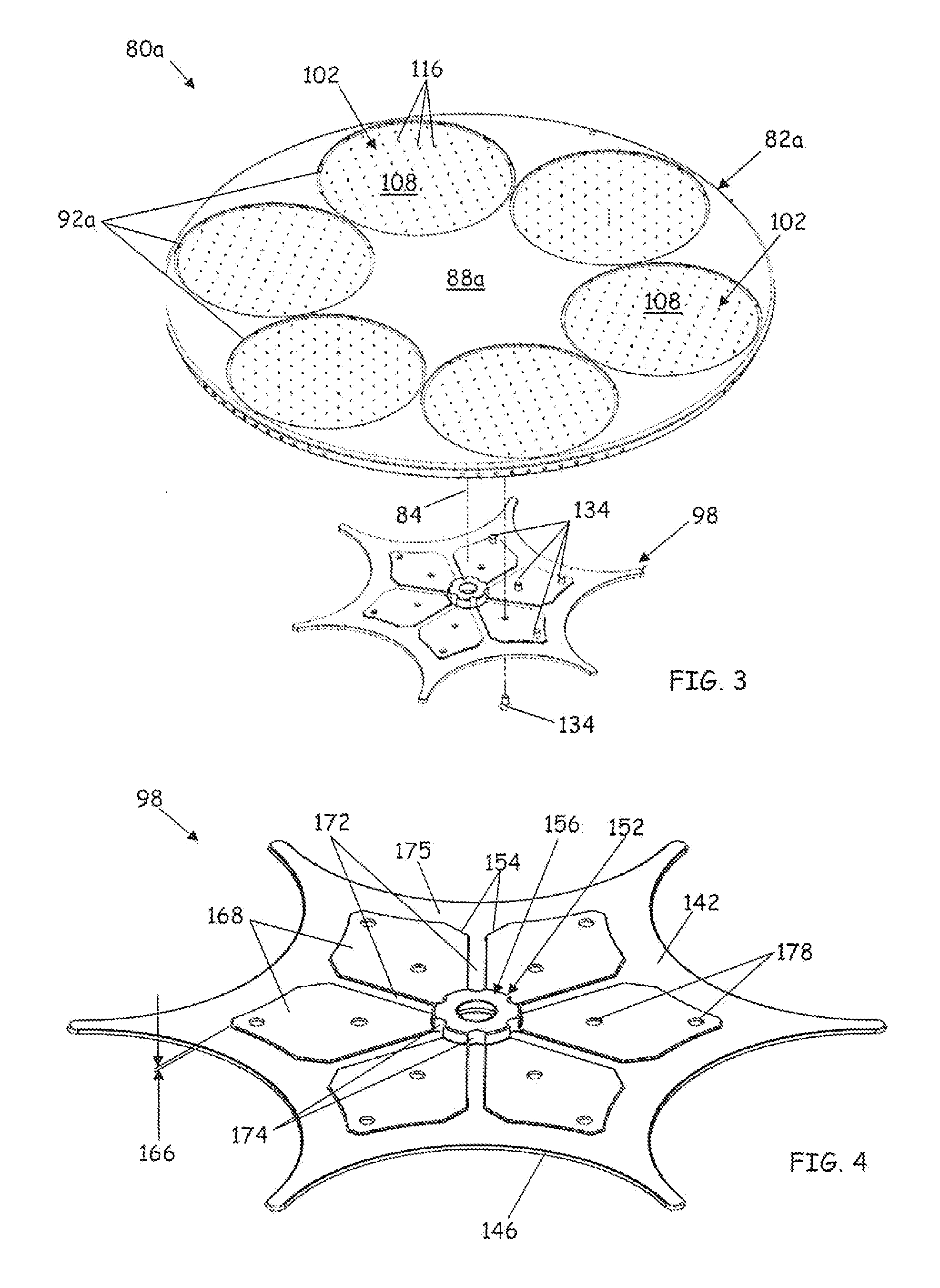

Wafer carrier with temperature distribution control

InactiveUS20140261698A1Enhanced temperature uniformityHigh conductivityPolycrystalline material growthPipeline systemsDistribution controlEngineering

Wafer carrier arranged to hold a plurality wafers and to inject a fill gas into gaps between the wafers and the wafer carrier for enhanced heat transfer and to promote uniform temperature of the wafers. The apparatus is arranged to vary the composition, flow rate, or both of the fill gas so as to counteract undesired patterns of temperature non-uniformity of the wafers. In various embodiments, the wafer carrier utilizes at least one plenum structure contained within the wafer carrier to source a plurality of weep holes for passing a fill gas into the wafer retention pockets of the wafer carrier. The plenum(s) promote the uniformity of the flow, thus providing efficient heat transfer and enhanced uniformity of wafer temperatures.

Owner:VEECO INSTR

Conductive printing ink composite for printing of wireless radio frequency identification devices (RFID)

Owner:溧阳常大技术转移中心有限公司

Conductive oxide film, display device, and method for forming conductive oxide film

ActiveUS20140063368A1High conductivityHigh transmittanceConductive layers on insulating-supportsZinc oxides/hydroxidesHigh transmittanceOptoelectronics

One embodiment of the present invention provides a conductive oxide film having high conductivity and high transmittance of visible light. The conductive oxide film having high conductivity and high transmittance of visible light can be obtained by forming a conductive oxide film at a high substrate temperature in the film formation and subjecting the conductive oxide film to nitrogen annealing treatment. The conductive oxide film has a crystal structure in which c-axes are aligned in a direction perpendicular to a surface of the film.

Owner:SEMICON ENERGY LAB CO LTD

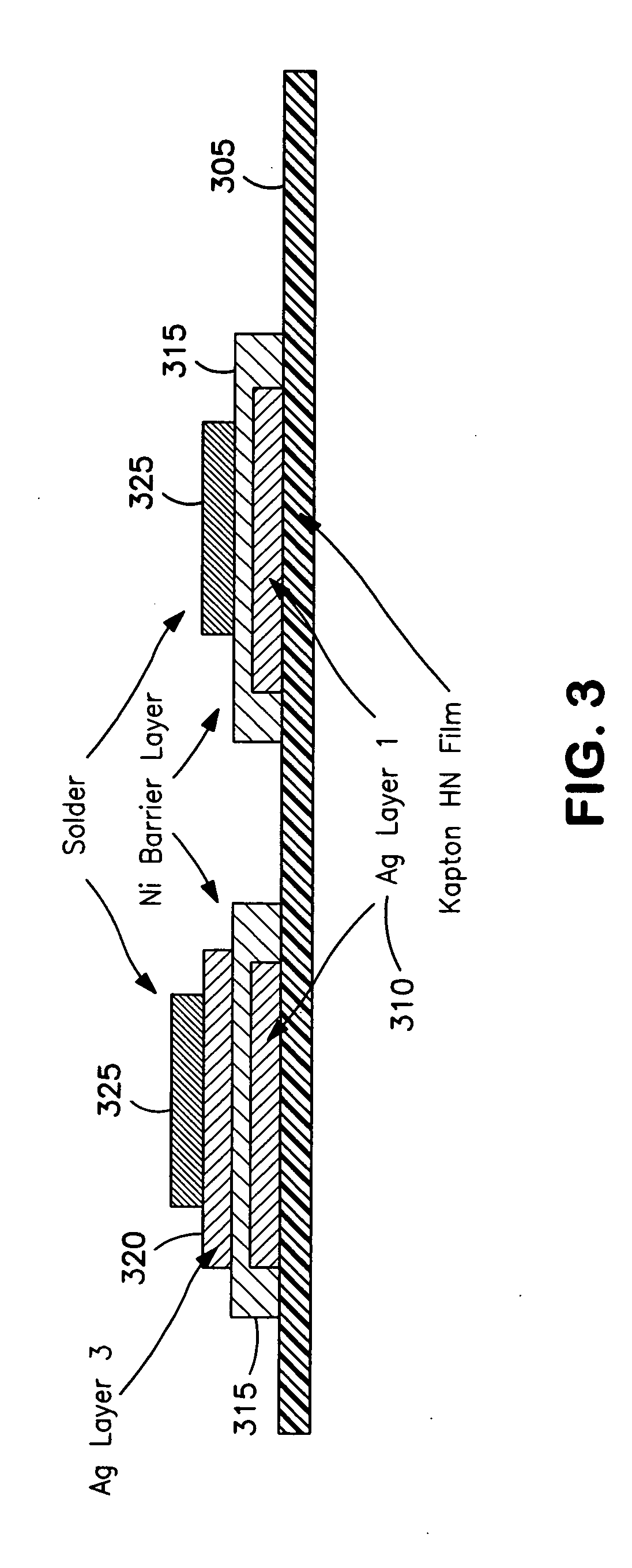

Solderable pads utilizing nickel and silver nanoparticle ink jet inks

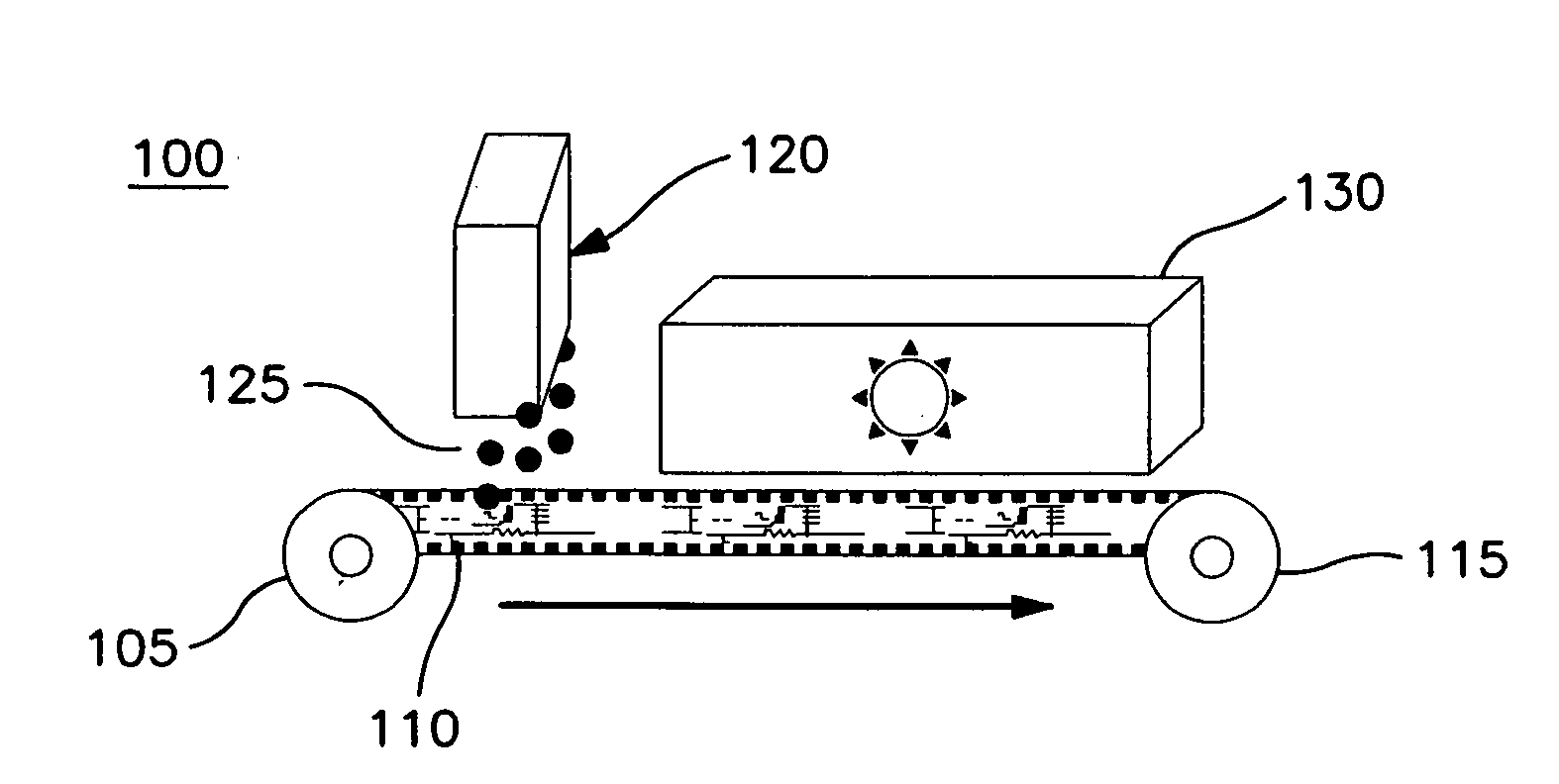

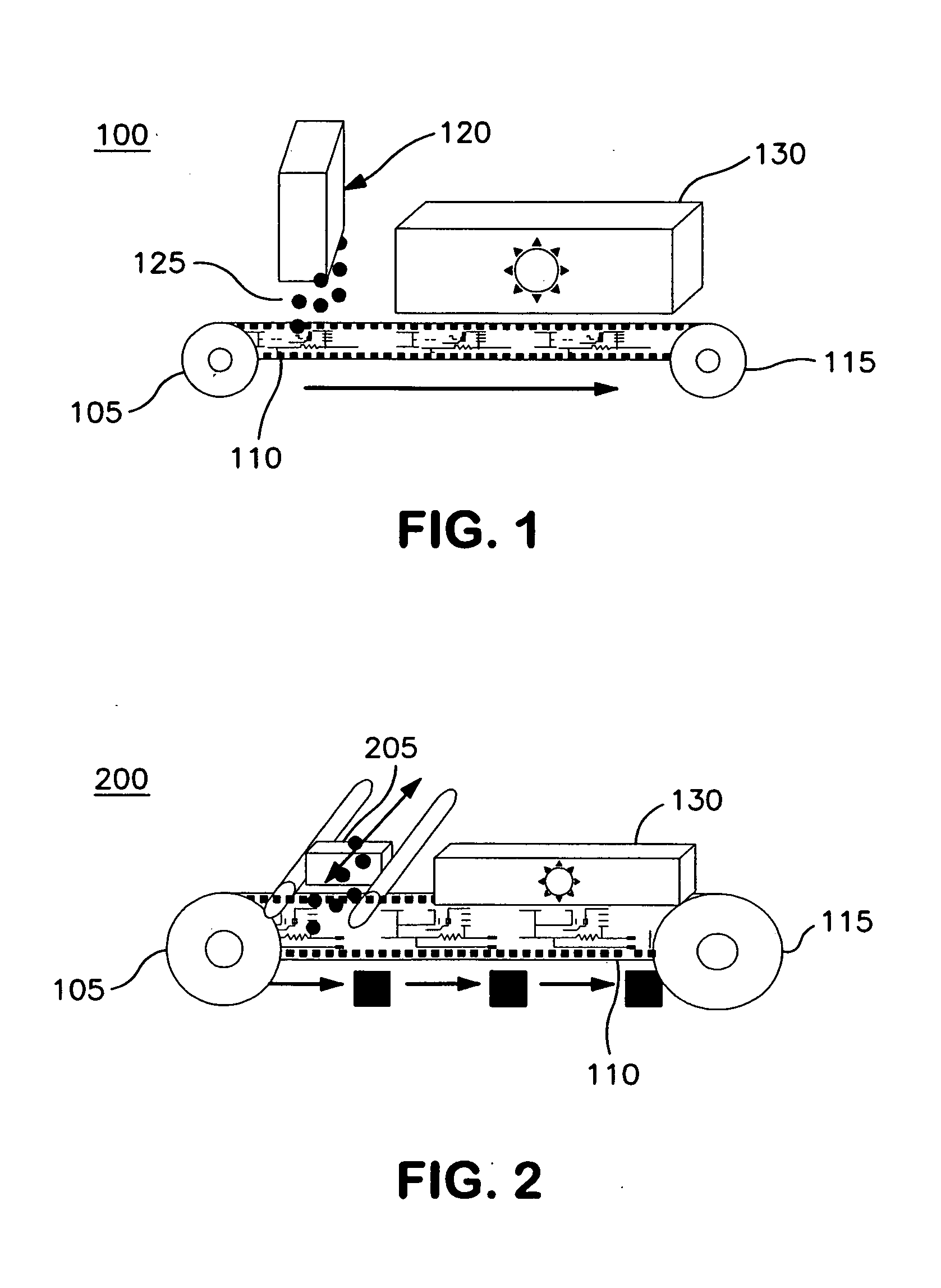

InactiveUS20070281099A1High conductivityLow conductivityPrinted circuit aspectsPretreated surfacesNanometreEngineering

A system and a method are provided for ink-jet printing a solderable conductive pad onto a substrate. The system comprises at least one print head and a curing station for curing an ink deposited onto the substrate. The system is configured to: deposit at least a first layer of a first ink onto the substrate; cure the first layer of the first ink; deposit at least an intermediate layer of a second ink on top of the cured first layer of the first ink; cure the intermediate layer of the second ink; deposit at least a last layer of the first ink on top of the cured intermediate layer of the second ink; and cure the last layer of the first ink. The first ink has a relatively high conductivity. The second ink has a relatively low conductivity. The first layer, the intermediate layer, and the last layer may be arranged such that when solder is applied to the last layer, the solder is prevented from leaching through to the first layer.

Owner:CABOT CORP

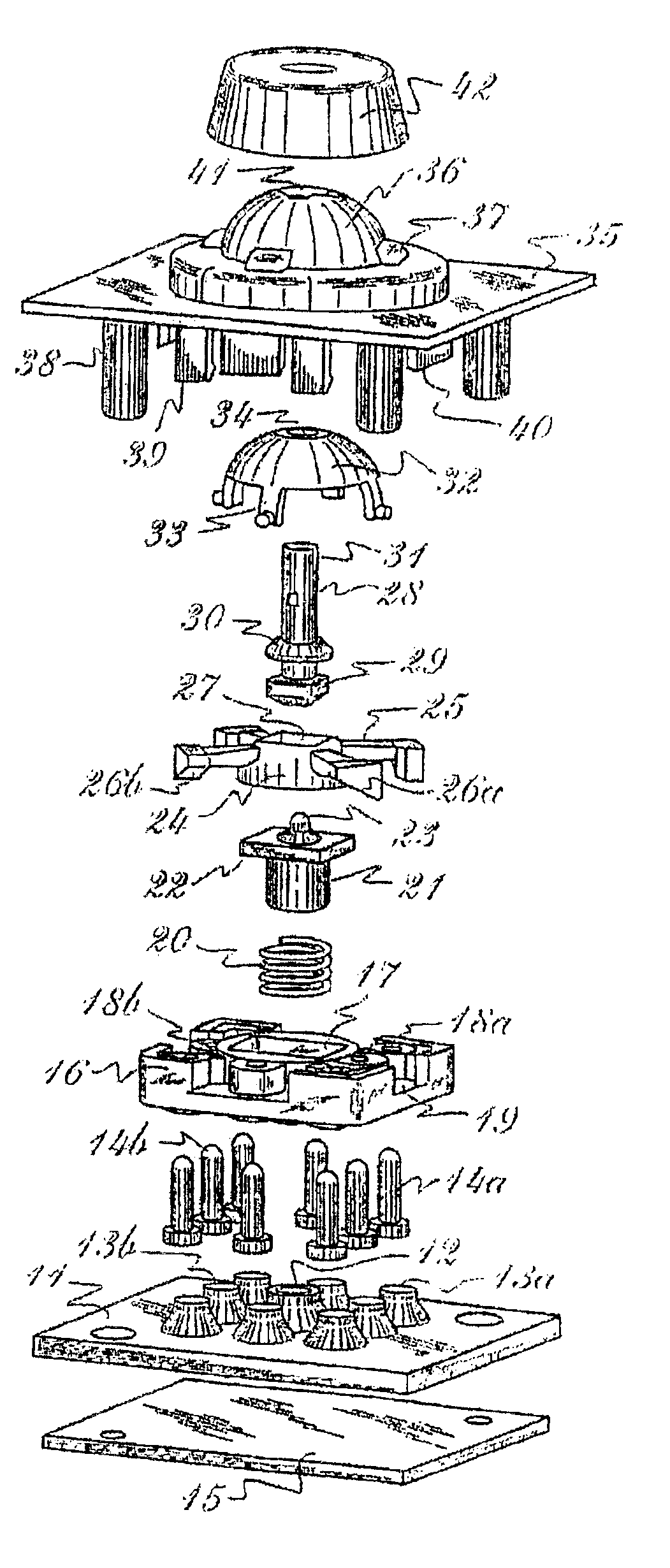

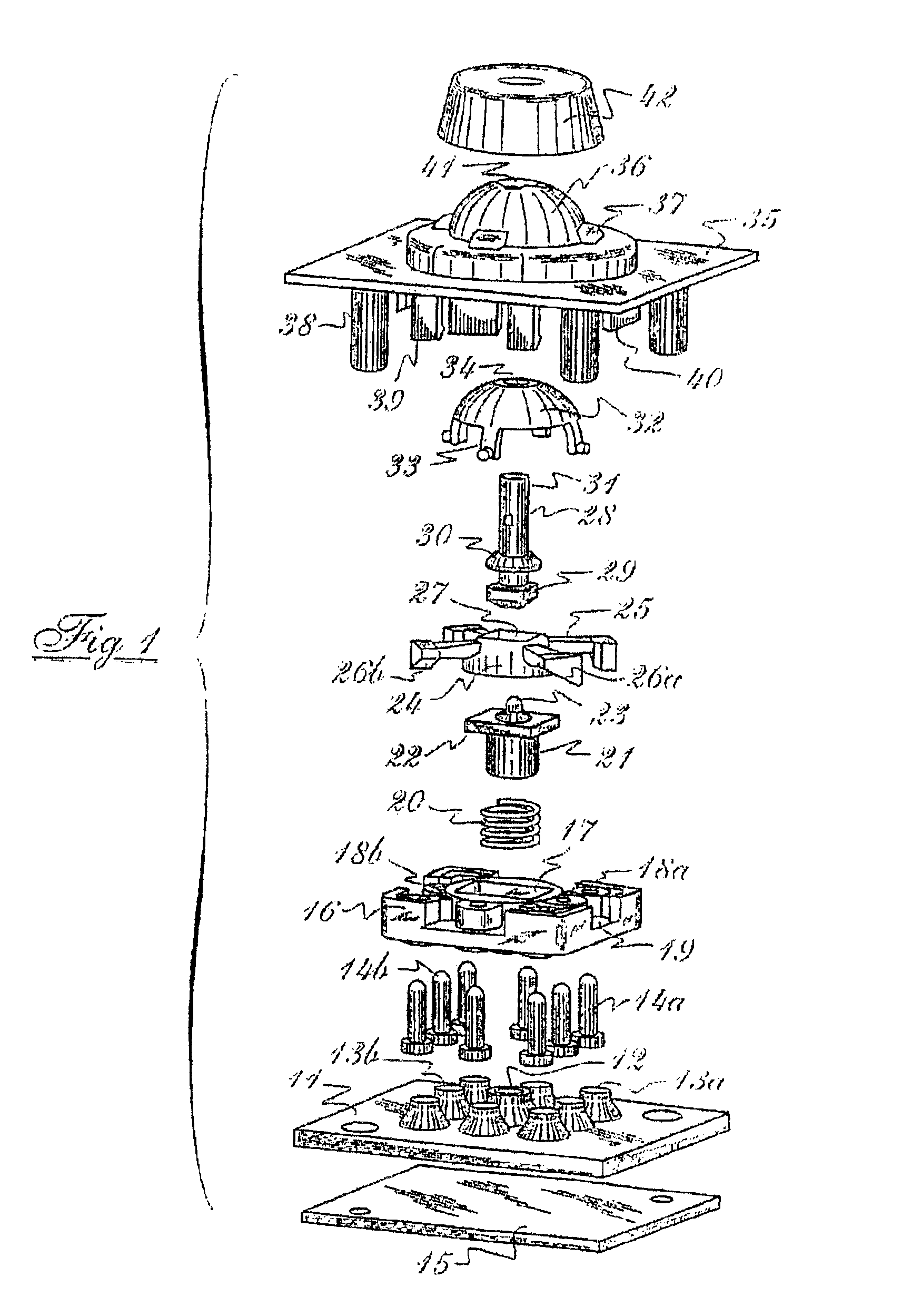

Electric membrane switch with seven contact positions

InactiveUS6897391B2Facilitate reliable connectionHigh conductivityManual control with multiple controlled membersContact surface shape/structureElectricityMembrane switch

An electric switch of mechanical structure and functioning, and with electric contacts by means of membranes, suitable for optionally arranging seven different control signals by means of other such contact positions selectively induced by a single button means, four of these positions are differentiated when a slight rolling movement is carried out on said button means in any of four opposite directions and 90° equidistant from each other, a fifth contact position in its clockwise axial rotation, the sixth position by means of its counter-clockwise rotation, and a last contact position by means of a linear pulsating movement.

Owner:LEAR CORP

Separation method utilizing polyallylamine ligands

InactiveUS20110065900A1High conductivityCation exchanger materialsPeptide/protein ingredientsIonAmount of substance

The present invention relates to a method for removing at least one negatively charged substance from an aqueous liquid by contacting the liquid with a separation matrix comprising a plurality of polyallylamine ligands, comprising binding said negatively charged substance to said ligands under conditions where the ionic strength of the aqueous liquid applied to the chromatography resin ≧0.25 M NaCl.

Owner:GE HEALTHCARE BIO SCI CORP

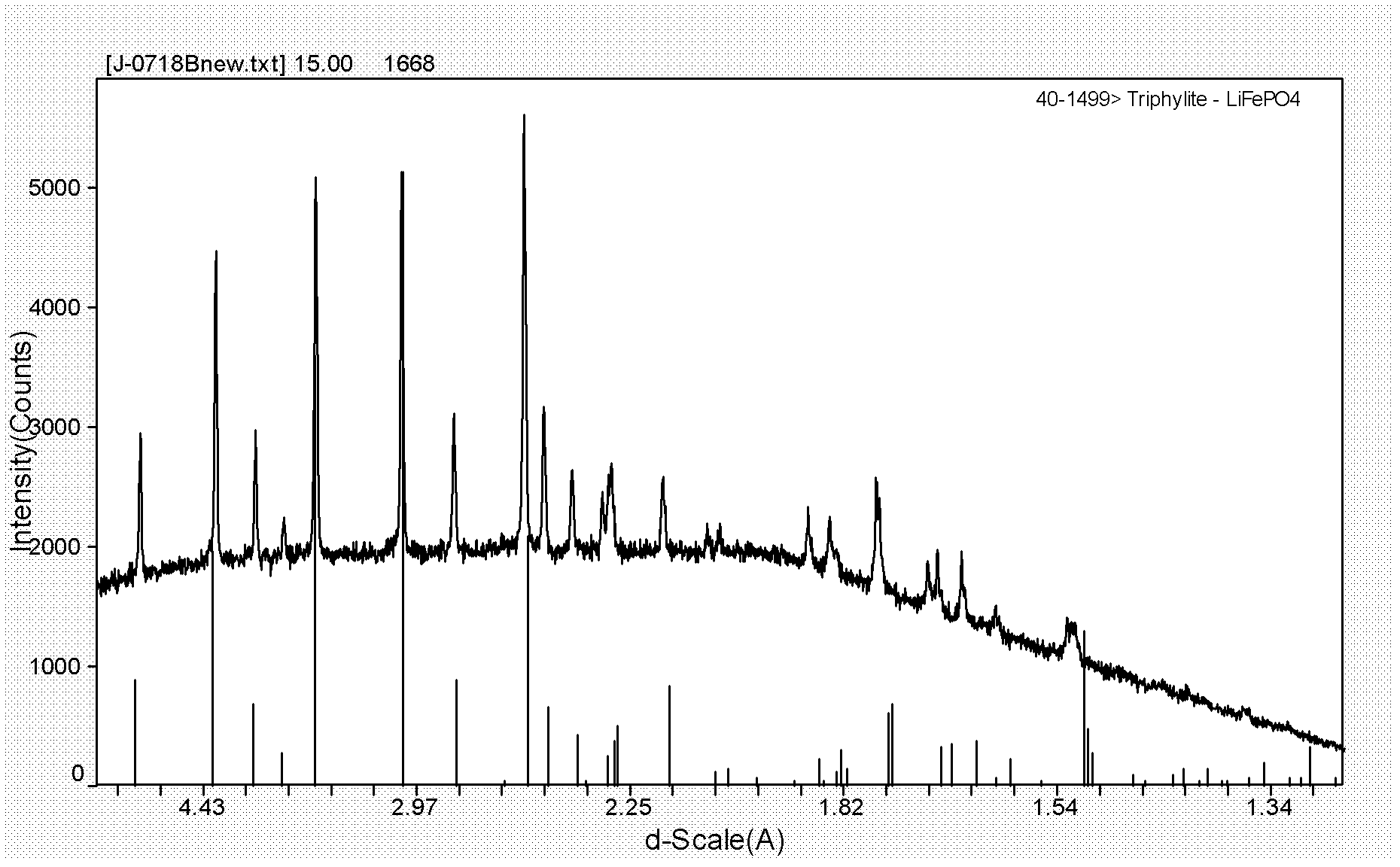

Method for uniformly and controllably coating conducting carbon layer at surface of LiFePO4 granule surface

InactiveCN101333650AUniform thicknessHigh conductivityCell electrodesChemical vapor deposition coatingCarbon filmCarbon source

The invention relates to a method for coating an even and controllable deposit carbon layer on the surface of LiFePO4 particles serving as lithium ion battery cathode materials for increasing the LiFePO4 conductivity. The method adopts the concrete preparation processes that: LiFePO4 powders are placed in a constant temperature zone of a chemical vapor deposition furnace, then the air in the furnace is fully discharged for inputting inert gases, after the temperature rises to the set level, a carbon source gas is input for covering a conductivity carbon film on the surface of the LiFePO4 particles evenly, the LiFePO4 coated with the carbon film has excellent conductivity which is increased by five orders of magnitude compared with the condition before coating. The chemical vapor deposition temperature ranges from 580 to 720DEG C, the deposition time is from 1 to 10 hours, and the volume percent of the carbon source gas is between 1 and 20 percent, and a sample deposited with carbon is cooled to the room temperature with a natural furnace and is then taken out. The method can cover the conductivity carbon film on the surface of each LiFePO4 particle evenly for increasing the conductivity of LiFePO4, and the thickness of the conductivity carbon film can be accurately controlled in the range of 2 to 50 nanometers through adjusting parameters (deposition temperature, deposition time and carbon source gas volume percent) of the chemical vapor deposition process.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

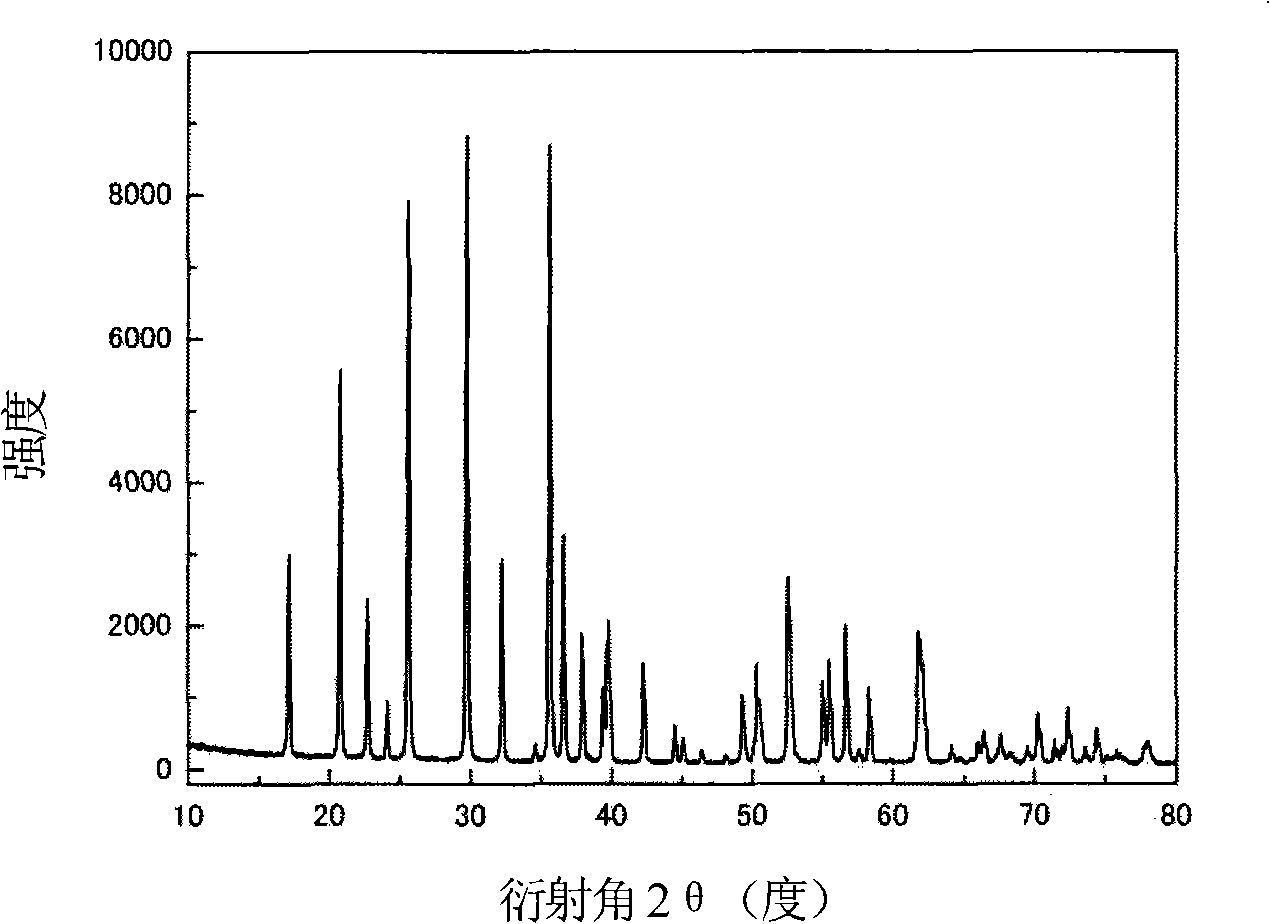

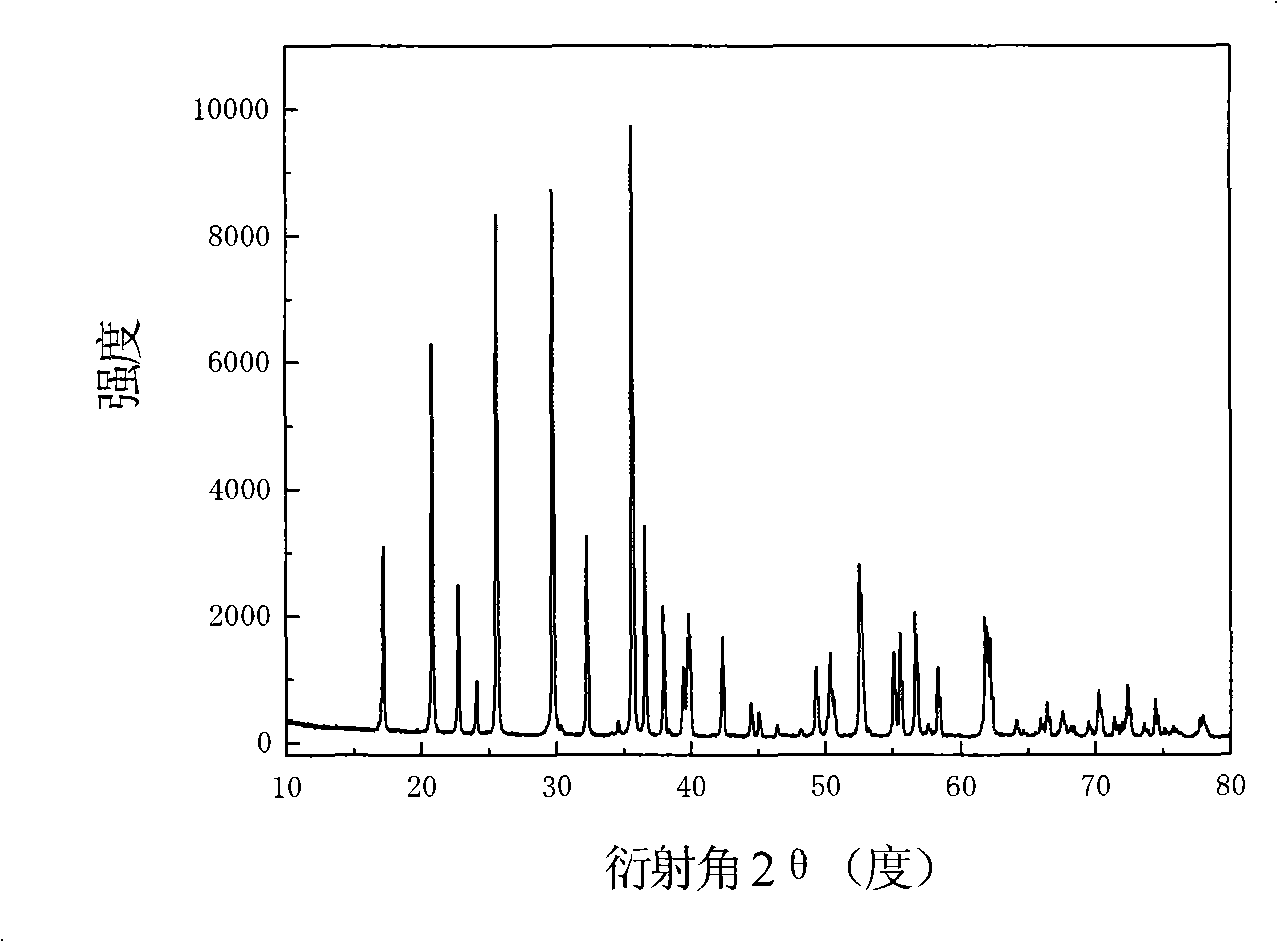

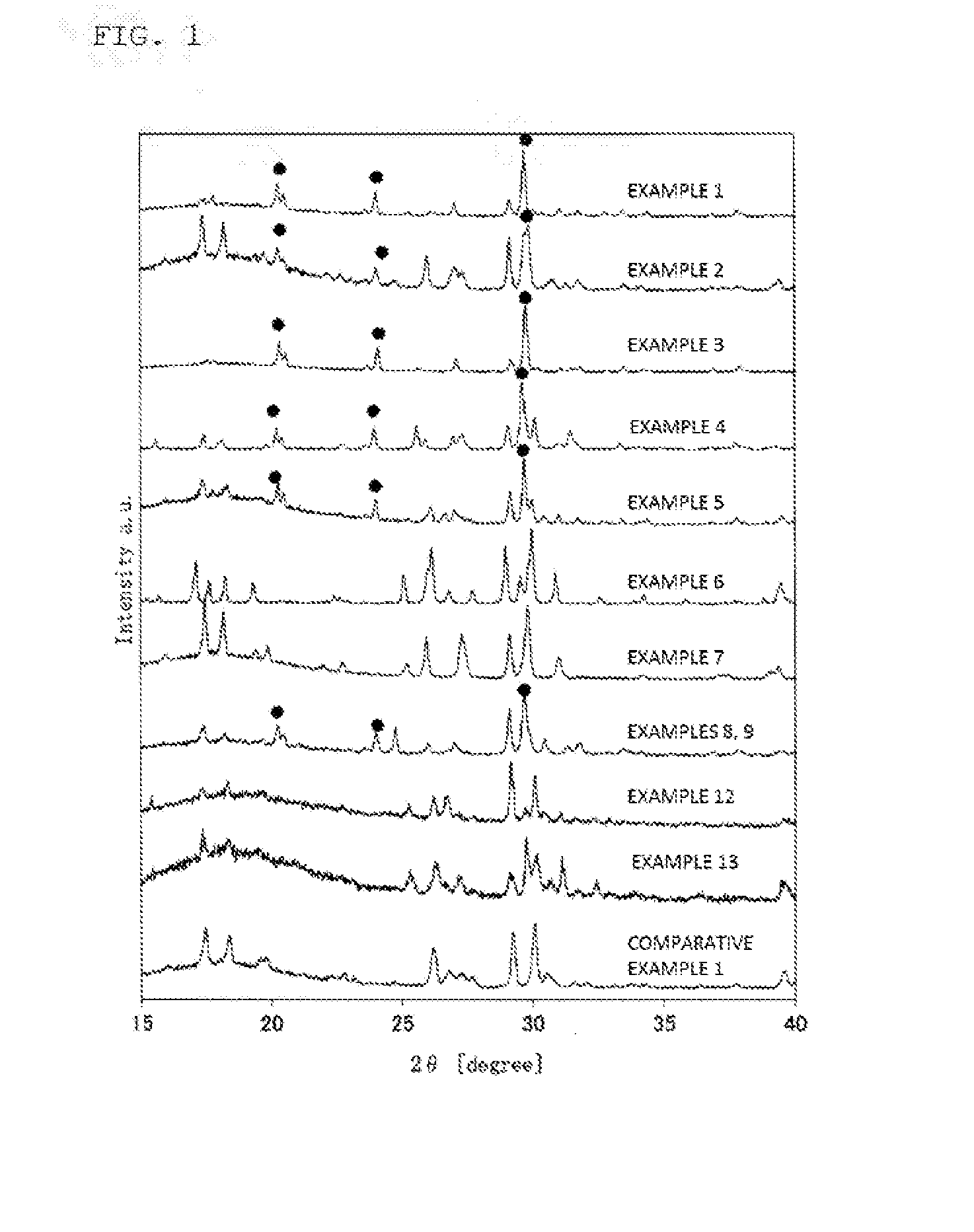

Crystalline solid electrolyte and production method therefor

ActiveUS20160164136A1High chemical stabilityHigh conductivitySolid electrolytesFinal product manufactureSolventElectrolyte

Provided is a novel crystalline solid electrolyte which can be used as a dispersion medium when slurrying polar solvents such as NMP, acetone, and DMF, and for which a decrease in conductivity when the crystalline solid electrolyte is immersed in said solvents can be suppressed. Proposed is a crystalline solid electrolyte represented by Compositional Formula: LixSiyPzSaHaw (here, Ha includes one or two or more of Br, Cl, I, and F, and 2.4<(x−y) / (y+z)<3.3), in which the content of S is 55 to 73% by mass, the content of Si is 2 to 11% by mass, and the content of a Ha element is 0.02% by mass or more.

Owner:MITSUI MINING & SMELTING CO LTD

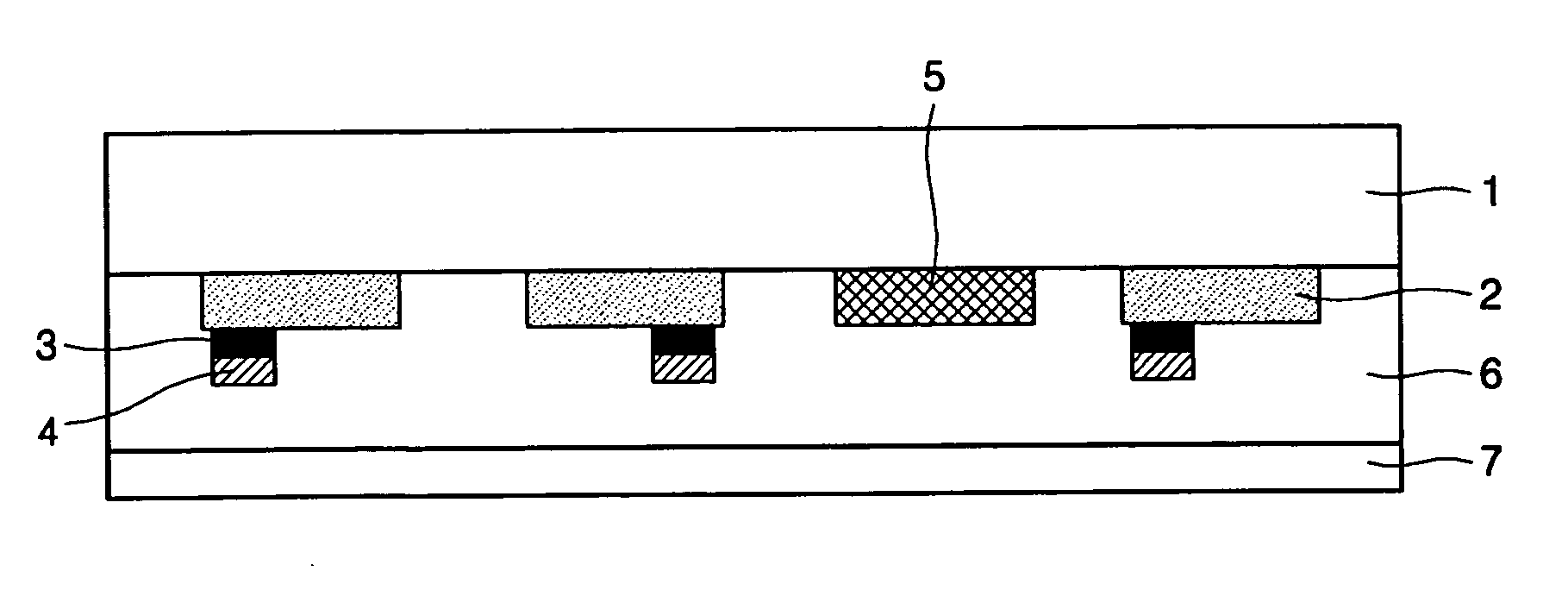

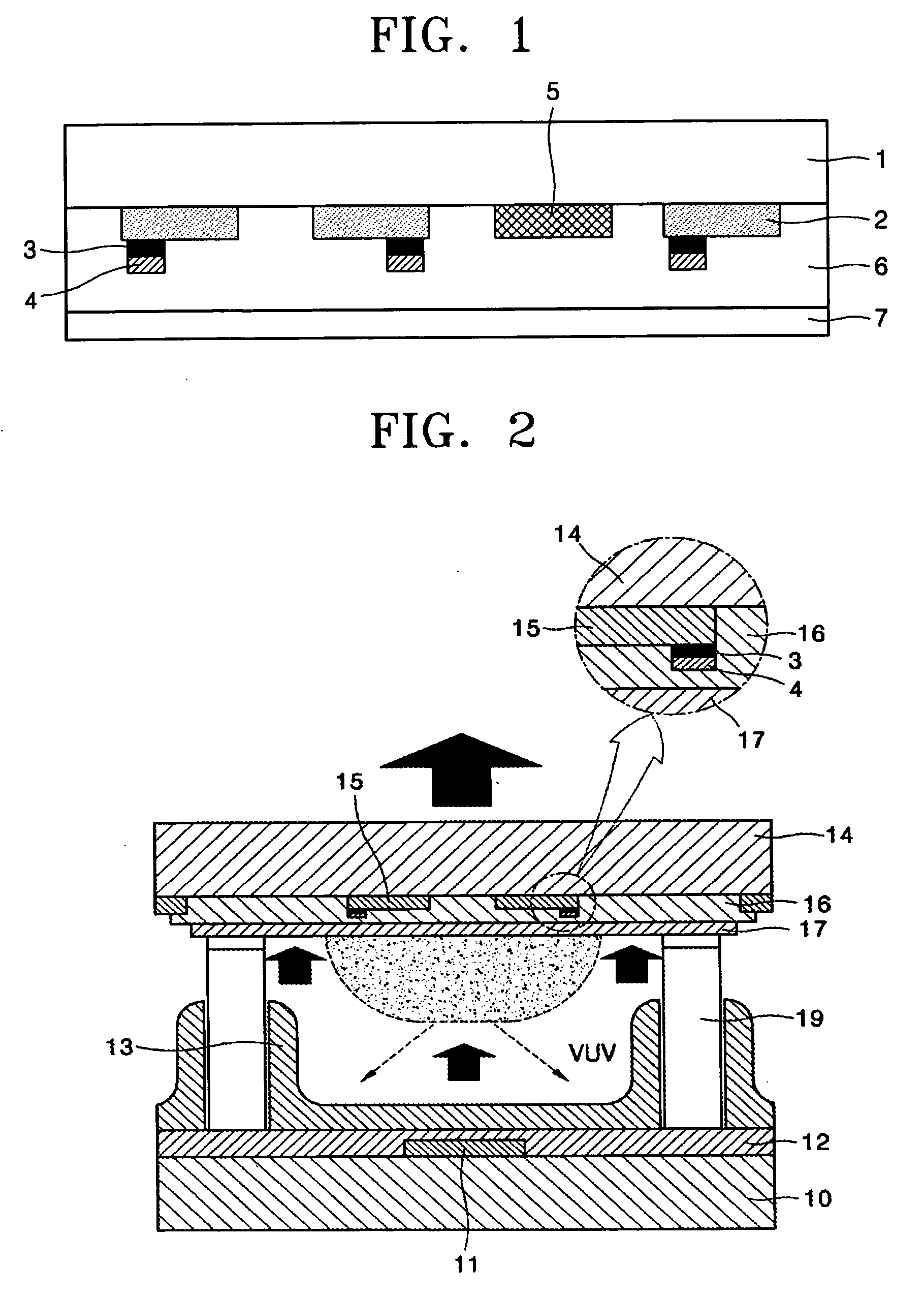

Photosensitive paste composition, PDP electrode manufactured using the composition, and PDP including the PDP electrode

InactiveUS20060164011A1High degree of blacknessHigh conductivityAddress electrodesDomestic stoves or rangesVoltageHigh conductivity

A plasma display panel (PDP) electrode contains a superconductor and an inorganic binder. A photosensitive paste composition for manufacturing the PDP electrode contains a superconductor, an inorganic binder, and a photosensitive vehicle. In the photosensitive paste composition, a superconductor with excellent conductivity is used as a black pigment, so that the discharge voltage is low, the resistance is uniform, and a difference in brightness between electrodes is minimized in double layer bus electrodes manufactured using the composition. In addition, single layer bus electrodes with high conductivity and degree of blackness can be manufactured using the photosensitive composition. With the use of the plasma display panel electrode, the improved plasma display panel is provided.

Owner:SAMSUNG SDI CO LTD

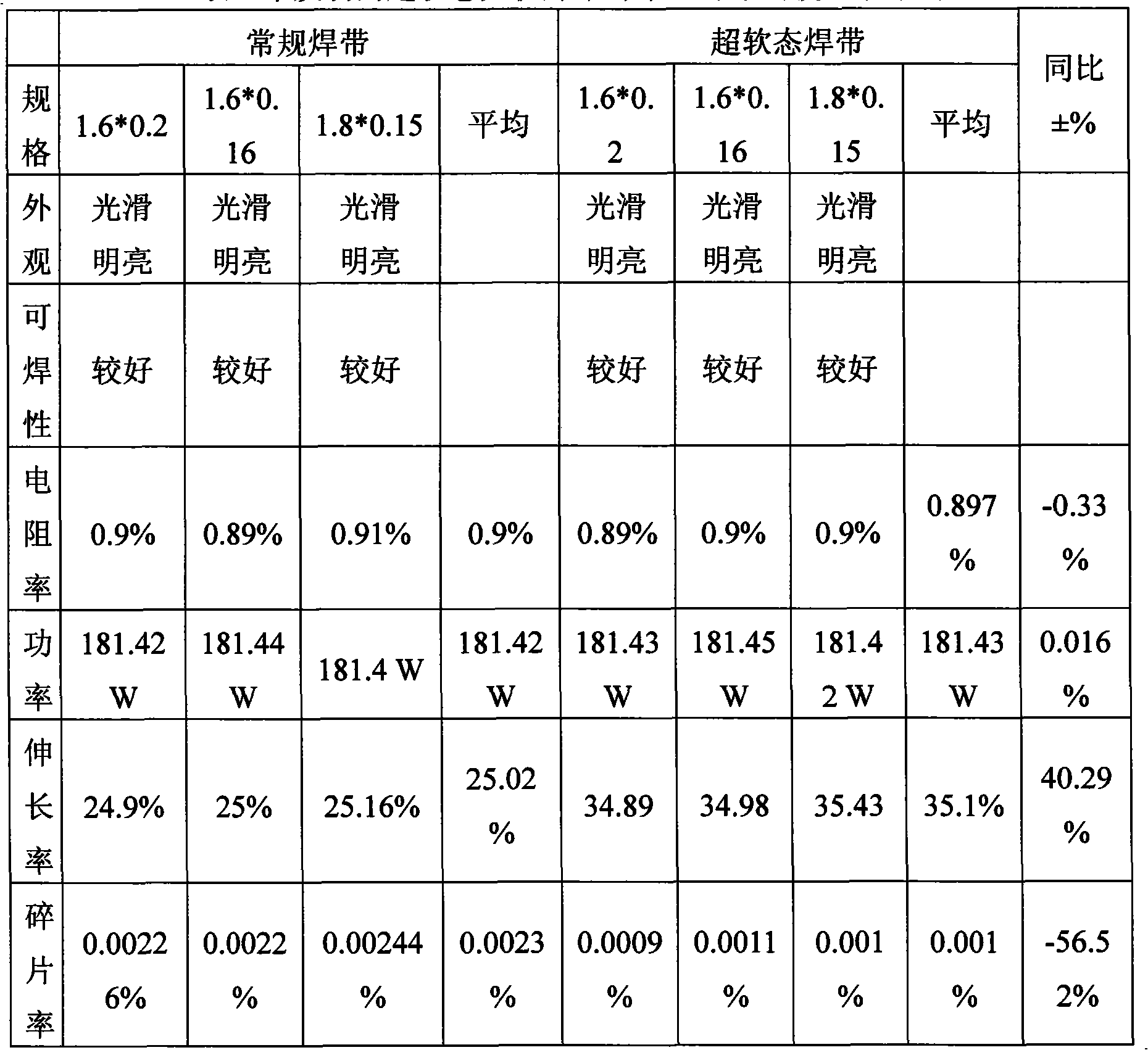

Manufacturing method of ultra-soft state photovoltaic welding belt

InactiveCN101621090AStrong weldabilityHigh conductivityFinal product manufactureSemiconductor devicesSolderabilityMegasonic cleaning

The invention discloses a manufacturing method of an ultra-soft state photovoltaic welding belt. The method comprises the following steps: oxygen-free copper wires are firstly planished and are annealed in a continuous pipe mode; clear water is then used for carrying out ultrasonic cleaning on the annealed oxygen-free copper wires; copper belts are then soaked by a welding flux and are led to a tin furnace for plating tin, and an automatic speed-regulating draught fan is finally arranged at an outlet of the tin furnace; after coming out from the tin furnace, the copper belts plated with tin firstly pass through the draught fan, and then pass through an automatic capstan and an automatic wire-rewinding machine for hanging, and a finished product of the welding belt is formed. The invention adopts a continuous working procedure so that material loss is reduced, labor capacity is increased, and meanwhile, strong weldability and high conductivity of the welding belt are ensured. Compared with a conventional photovoltaic welding belt manufactured by a traditional method, the tensile stretch is increased by 40%, and the fragmentation rate in the process of welding is greatly reduced.

Owner:无锡市耀普科技有限公司

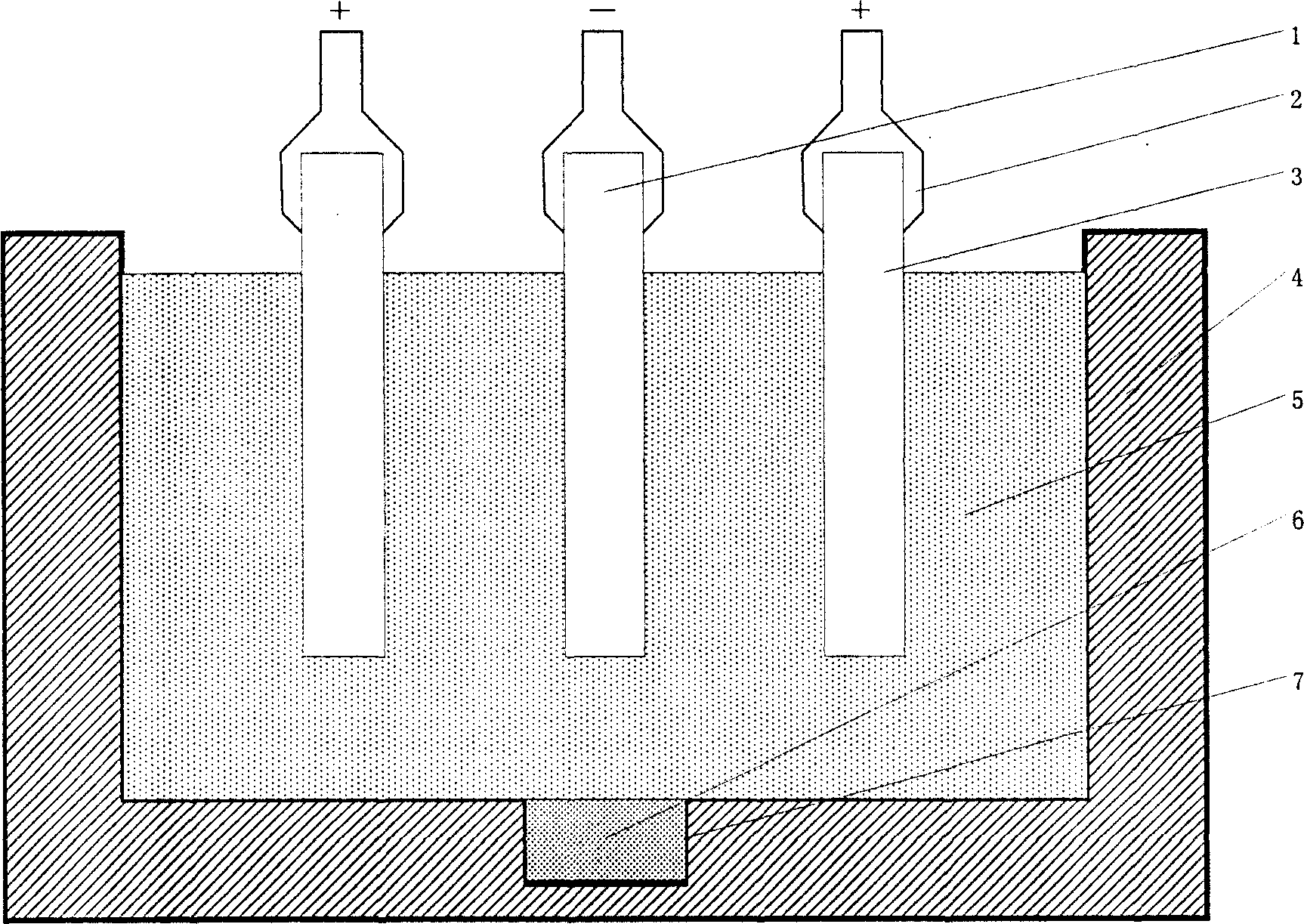

Production of aluminium by low-temperature electrolytic process and special aluminium electrolytic tank thereof

InactiveCN1673418AHigh conductivityImprove solubility and dissolution rateAluminum electrolysisAluminium oxide

The present invention belongs to the field of non-ferrous metal material, and is especially low temperature aluminum producing process and special aluminum electrolyzing bath. The present invention features the low temperature aluminum electrolyzing process at 700-850 deg.c in molten potassium cryolite salt system with alumina as material. The aluminum electrolyzing bath consists of cathode, wires, anode, electrolytic bath, electrolyte and aluminum liquid collecting tank. The present invention uses molten potassium cryolite salt system as electrolyte with high electric conductivity, great alumina dissolubility and great alumina dissolving rate to overcome the demerits of low temperature aluminum electrolysis. The low temperature aluminum electrolysis creates the condition for using inertial material. The present invention can realize high current efficiency, low power consumption and low cost.

Owner:UNIV OF SCI & TECH BEIJING

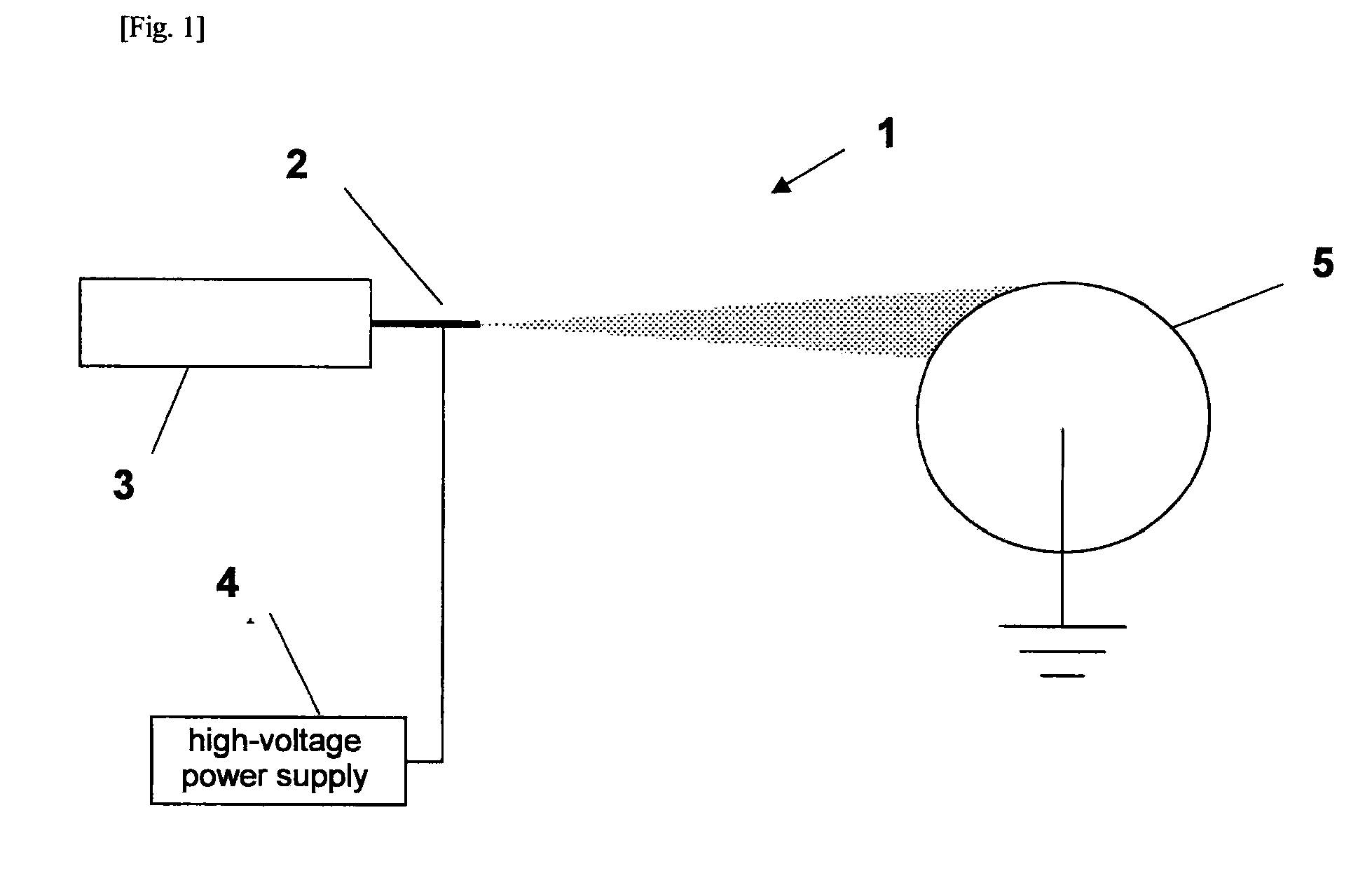

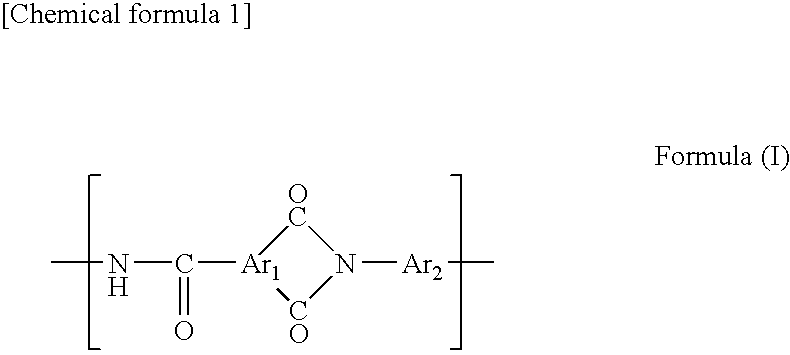

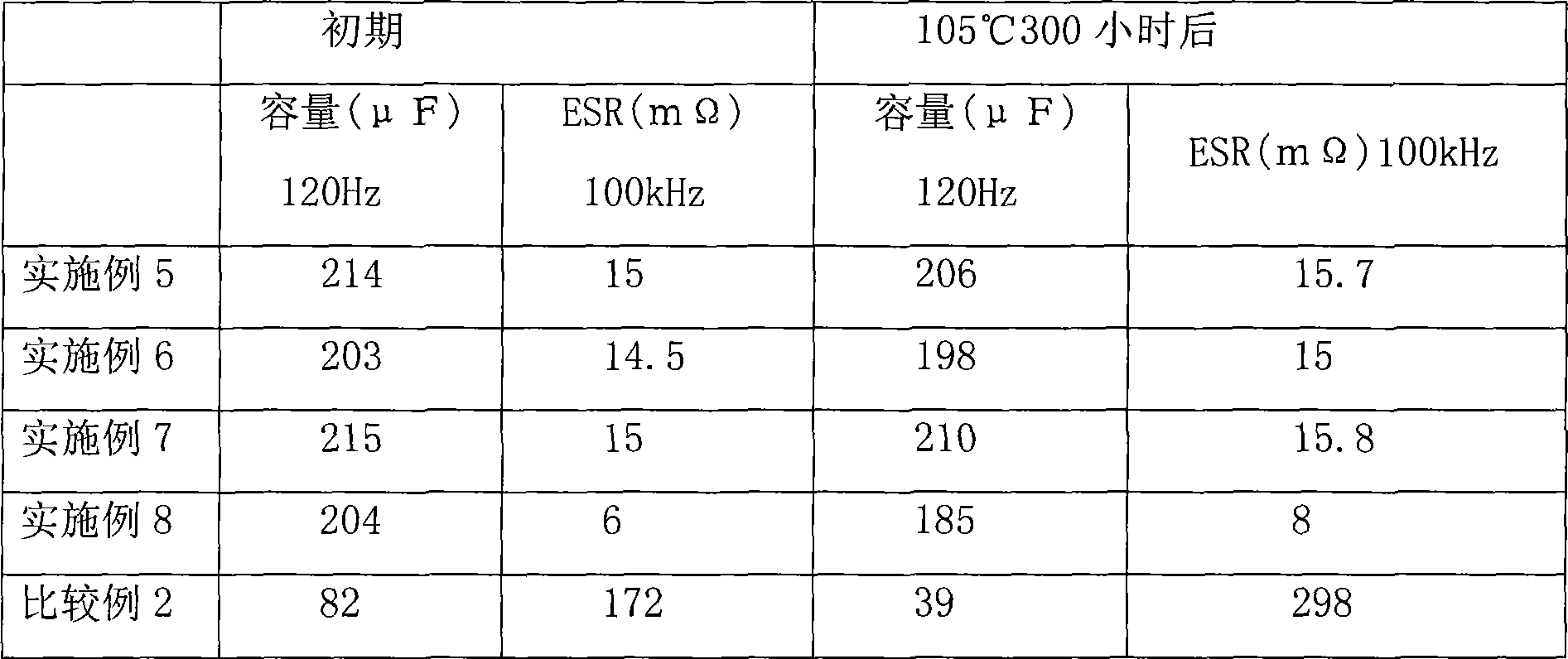

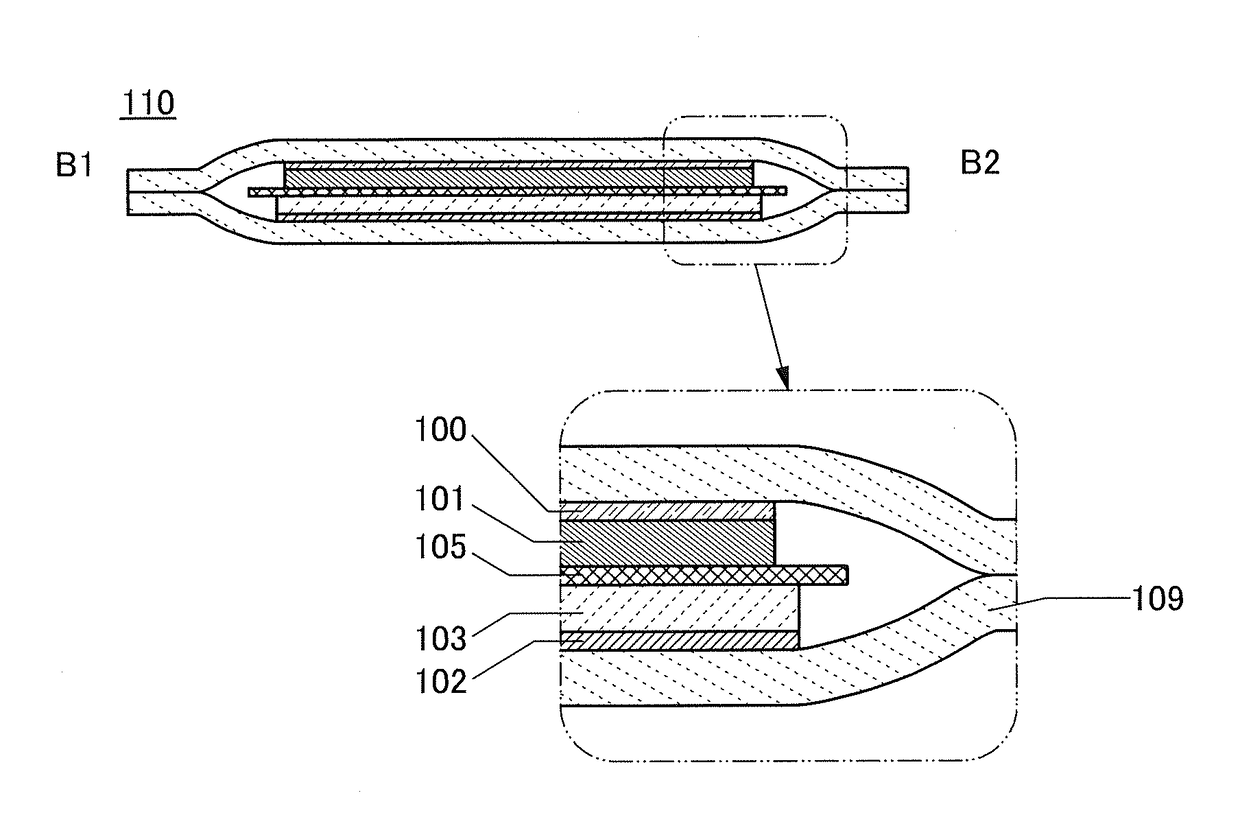

Polyamide imide fiber, non-woven fabric composed of the fiber, process for manufacture of the non-woven fabric, and separator for electronic component

ActiveUS20100151333A1Excellent heat resistance and mechanical strengthHigh conductivityElectric discharge heatingFinal product manufactureWoven fabricHeat processing

The present invention provides a fiber having a nano-order fiber diameter, which is produced by without a process of dehydration and cyclization by a heat treatment after fiber spinning and has excellent heat resistance and mechanical strength, and a non-woven fabric composed of the fiber, and discloses the polyamide-imide fiber and the non-woven fabric having an average fiber diameter of from 0.001 μm to 1 μm and also discloses the process for producing threrof. The present invention also provides a separator for an electronic component which has a high conductivity and a small separator thickness and is improved in safety during reflow soldering or short-circuiting, and discloses the separator composed of a non-woven fabric obtained by an electro-spinning method.

Owner:TOYO TOYOBO CO LTD

Tin titanium carbide granule reinforced copper base composite material and its preparation method

The invented composite material consists of wild phase of Ti2SnC granule and copper base with percentage of volume as 5-50%. The preparing procedures are as follows. The Ti2SnC granule and Cu powder are mixed evenly by use of physical and mechanical method. Then, under condition of vacuum or in protection of inert gases, the sinter of hot pressing or sinter of isostatic pressing in temperature at750-900 deg.C, pressure at 20-50 MPa and agglomeration time as 0.5-2 hr. carries out to obtain the composite material. The prepared composite material possesses the synthetical capabilities of high intensity, high electrical conductivity, high temperature resistant and self lubricating.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for electroplating zinc-nickel alloy through neodymium iron boron magnet ionic liquid

InactiveCN102828210AAvoid hydrogen evolution reactionHigh conductivityCorrosion resistantNeodymium iron boron

The invention relates to a method for electroplating zinc-nickel alloy through neodymium iron boron magnet ionic liquid. According to the method, a neodymium iron boron magnet treated before electroplating is used as a cathode, zinc is used as an anode, the ionic liquid containing additives is used as electroplating liquid, under the magnetic stirring condition, the temperature, the current intensity and the electroplating time are controlled for implementing the zinc-nickel alloy electroplating process on the neodymium iron boron magnet, and then, bright dipping, passivation and aging treatment are carried out. The method has the advantages that the plating liquid cost is low, the synthesis is simple, the operation temperature is low, the hydrogen evolution reaction is avoided, the obtained plating layer is bright and compact, the combination of a base body and the plating layer subjected to passivation treatment after plating is firm, and the corrosion resistance performance is good.

Owner:TAIYUAN UNIV OF TECH

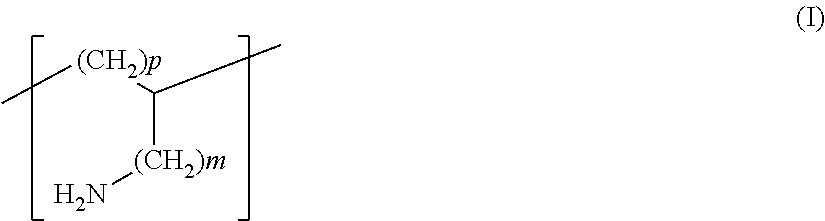

Conductive polymer composition, solid electrolyte and solid electrolyte capacitor using the conductive polymer

InactiveCN101486838AHigh conductivityGood stabilityCapacitor electrolytes/absorbentsOrganic conductorsEtherAcrylic acid

An electroconductive high molecule compound contains electroconductive high molecules, polyanion and ether compounds. The electroconductive high molecules are polypyrrole and derivates thereof, polythiophene and derivates thereof, polyaniline and derivates thereof, polyacetaldehyde and derivates thereof, poly(1, 2-ethenylidene thiofuran) and derivates thereof, poly(vinyl carbazole) and derivates thereof, and the copolymer of all the compounds. The formula of the ether compounds is shown as formula I, R2-(O-R1)n-R3 (in the formula I, at least one of R2 or R3 is one of ethylene, vinyl ether, acrylamide, acrylic acid, vinyl alcohol and alcohols that can all be replaced arbitrarily, and n is an integer between 1 and 20). In the solid electrolyte layers of a solid electrolytic capacitor, at least one layer contains electroconductive high molecules, polyanion and ether compound that has one functional group of ethylene, vinyl ether, acrylamide, acrylic acid, vinyl alcohol and alcohols that can all be replaced arbitrarily. Therefore, the capacitor has excellent electric volumetric properties and high temperature stability.

Owner:ZHENGZHOU TAIDA ELECTRONICS MATERIAL TECH +1

Graphene Compound, Method for Forming Graphene Compound, and Power Storage Device

ActiveUS20180019462A1Prevent internal short circuitHigh conductivitySolid electrolytesElectrode thermal treatmentPower storageCarboxylic group

A material that can be used in a wide temperature range and a manufacturing method thereof are provided. A graphene compound has a substituted or unsubstituted chain group. The chain group has one or more ester groups or carboxyl groups and contains a Si atom. The chain group is bonded to a graphene layer through the Si atom. A method for forming a graphene compound includes a step of stirring graphene oxide and a Lewis base and a step of mixing a silicon compound having one or more ester groups or carboxyl groups into the mixed solution and stirring the obtained mixed solution. The Lewis base is butylamine, pentylamine, hexylamine, diethylamine, dipropylamine, dibutylamine, triethylamine, tripropylamine, or pyridine.

Owner:SEMICON ENERGY LAB CO LTD

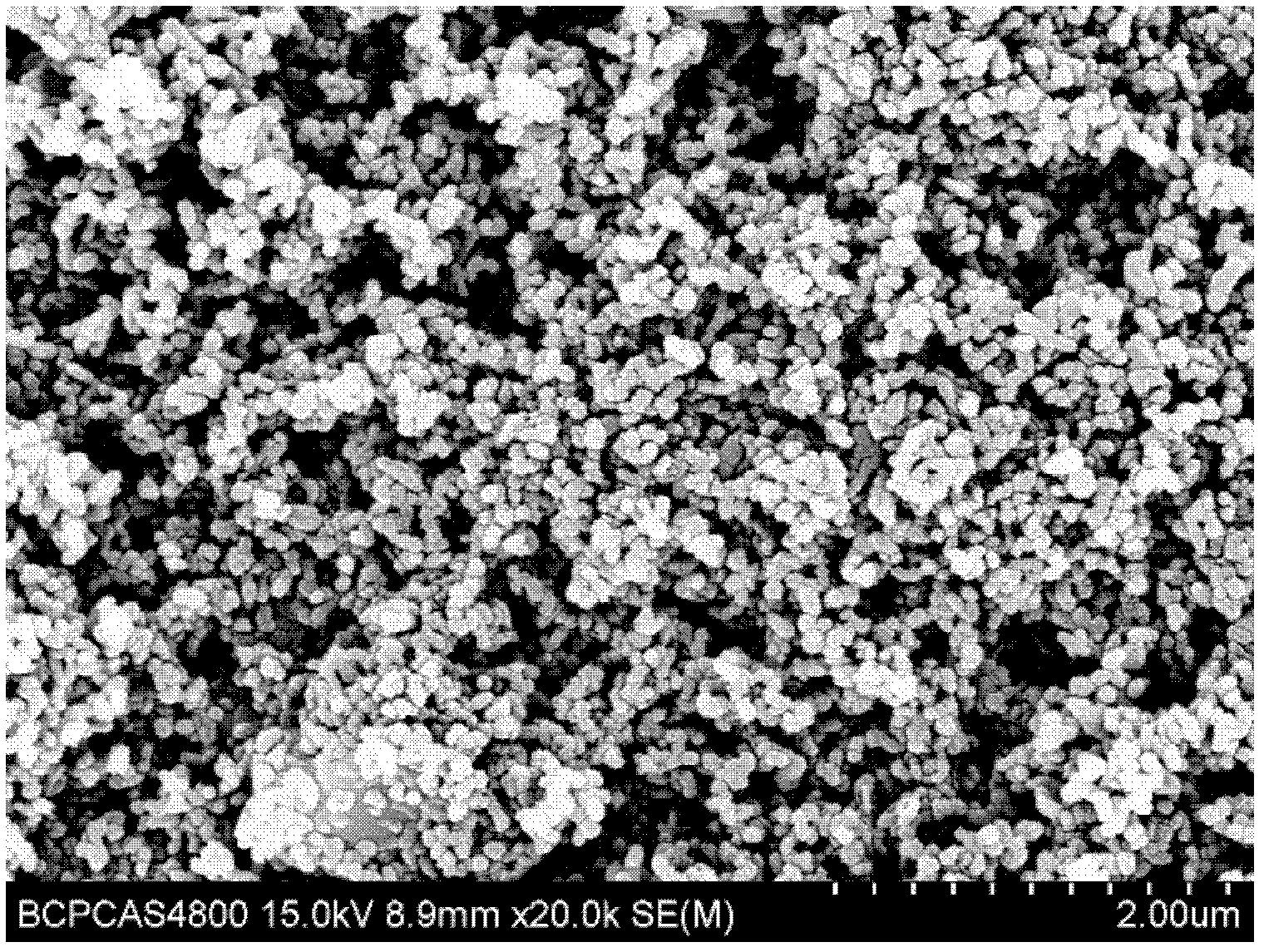

Preparation method for LiFePO4 (lithium iron phosphate) superfine powder serving as power battery anode materials

InactiveCN102522551AHigh conductivityReduce difficultyCell electrodesPhosphorus compoundsCarbon coatingOrganic solvent

The invention discloses a preparation method for LiFePO4 (lithium iron phosphate) superfine powder serving as power battery anode materials, which includes the steps: firstly, preparing LiFePO4 tiny crystalline particles with ferrous salt, phosphoric acid, lithium hydroxide and organic solvent through a hydrothermal method; and then performing carbon coating in a CaC2 (calcium carbide)-CCl4 (carbon tetrachloride) reaction system to obtain cotton-shaped nanoscale lithium iron phosphate powder. Therefore, the electric conductivity and the diffusion rate of Li+ (lithium-ion) of the lithium iron phosphate are increased, difficulty in using the superfine lithium iron phosphate to manufacture a battery is decreased, the lithium iron phosphate is more widely applied, and the charge-discharge performances of the lithium battery are improved.

Owner:IRICO

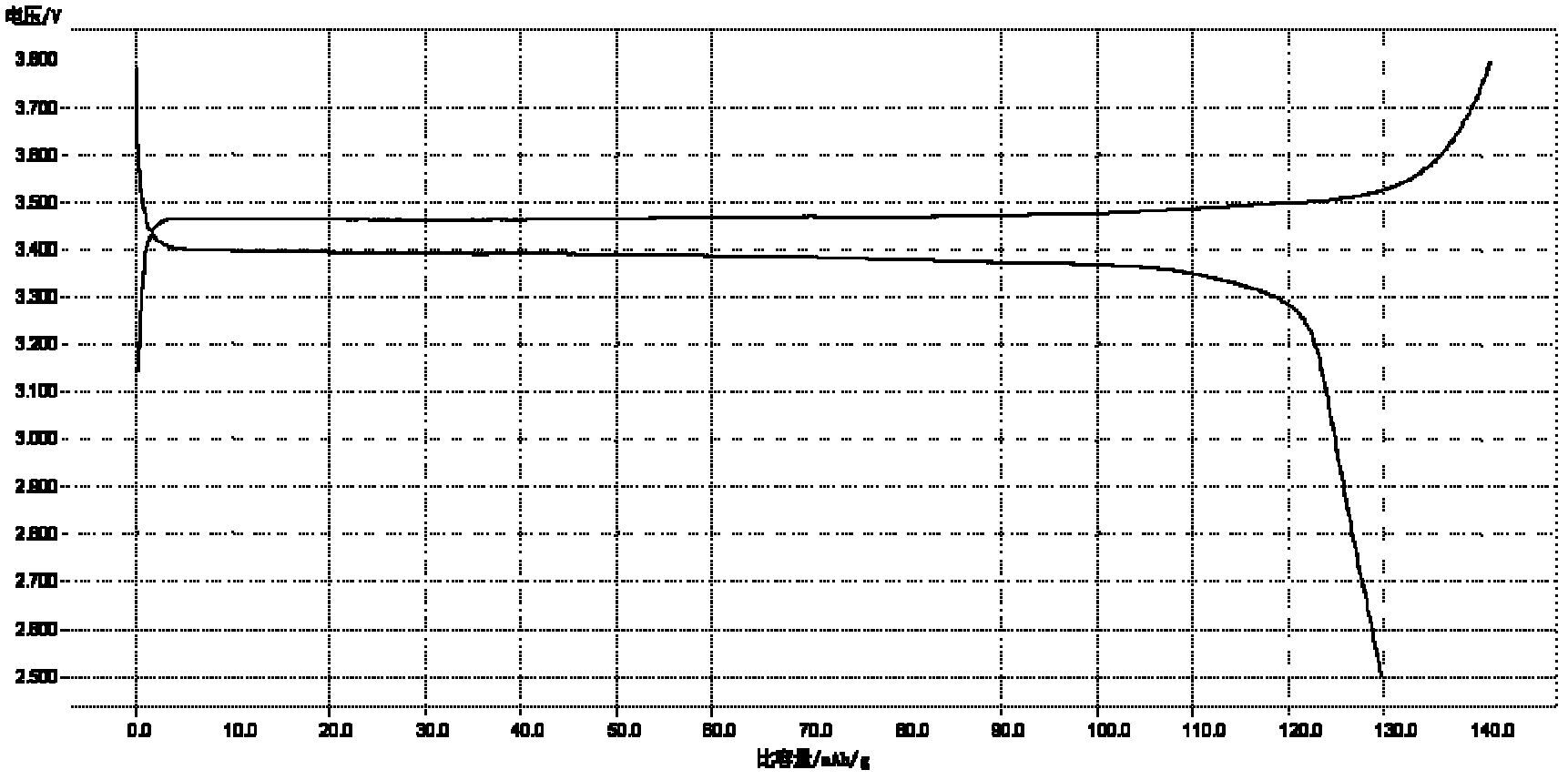

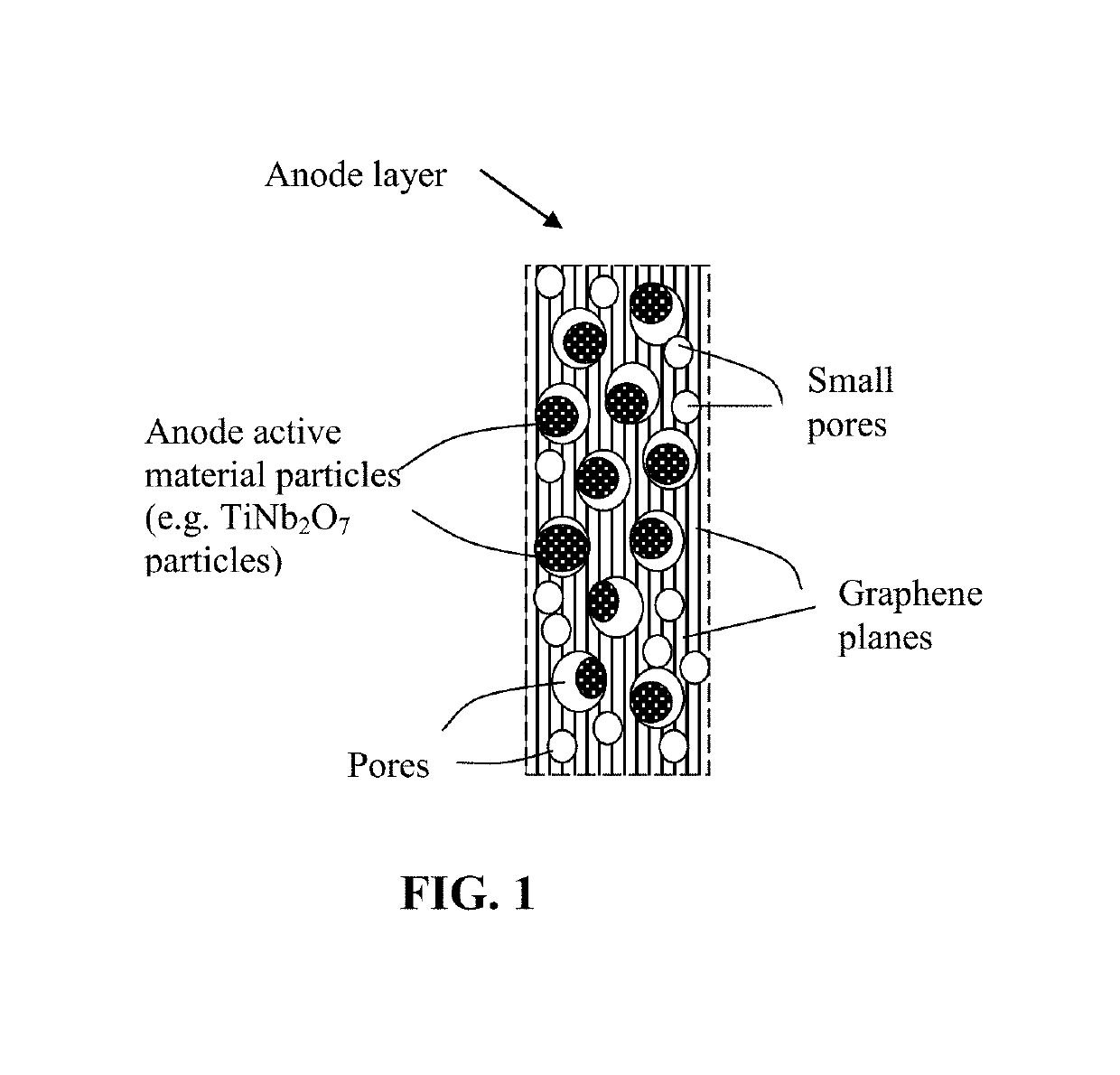

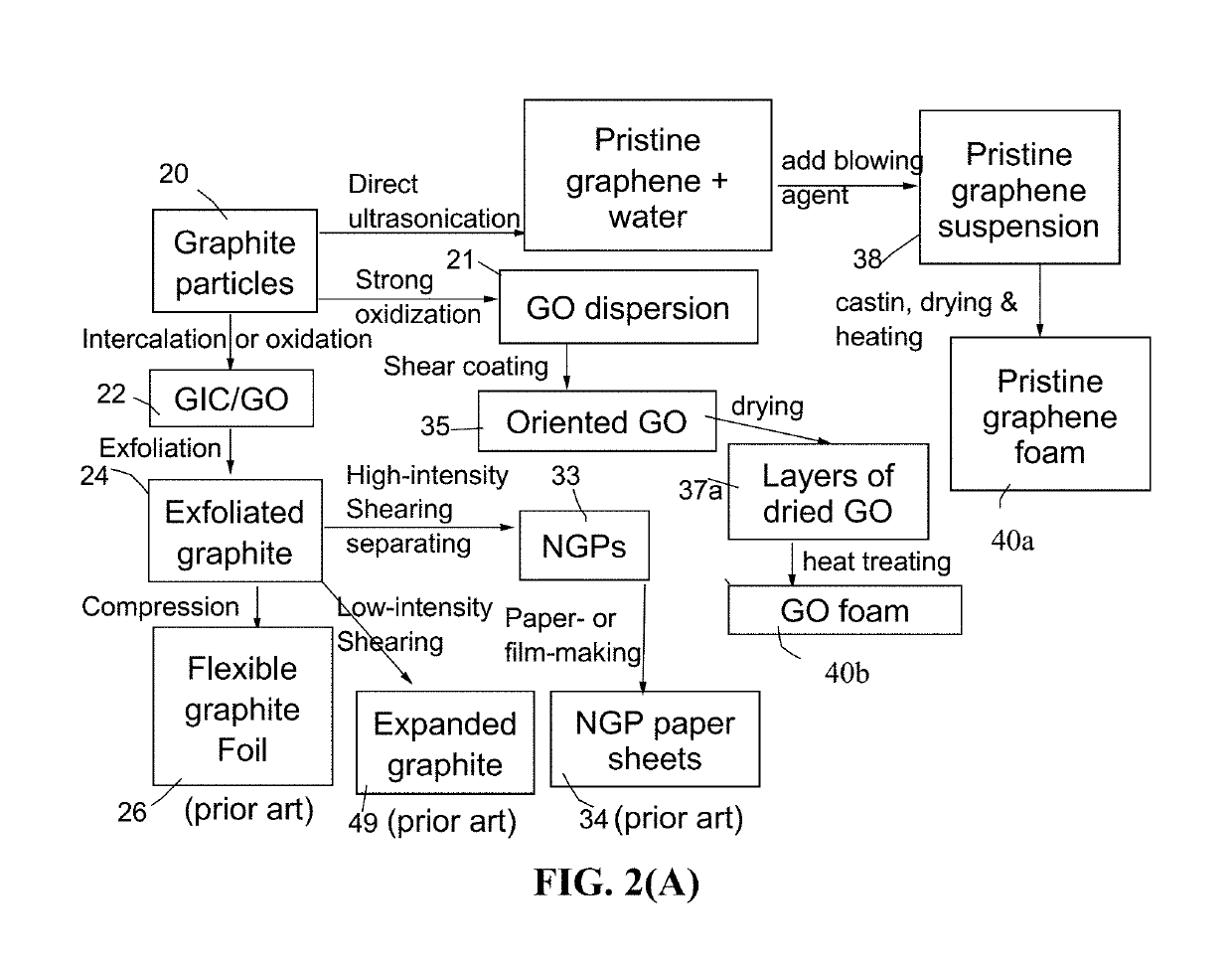

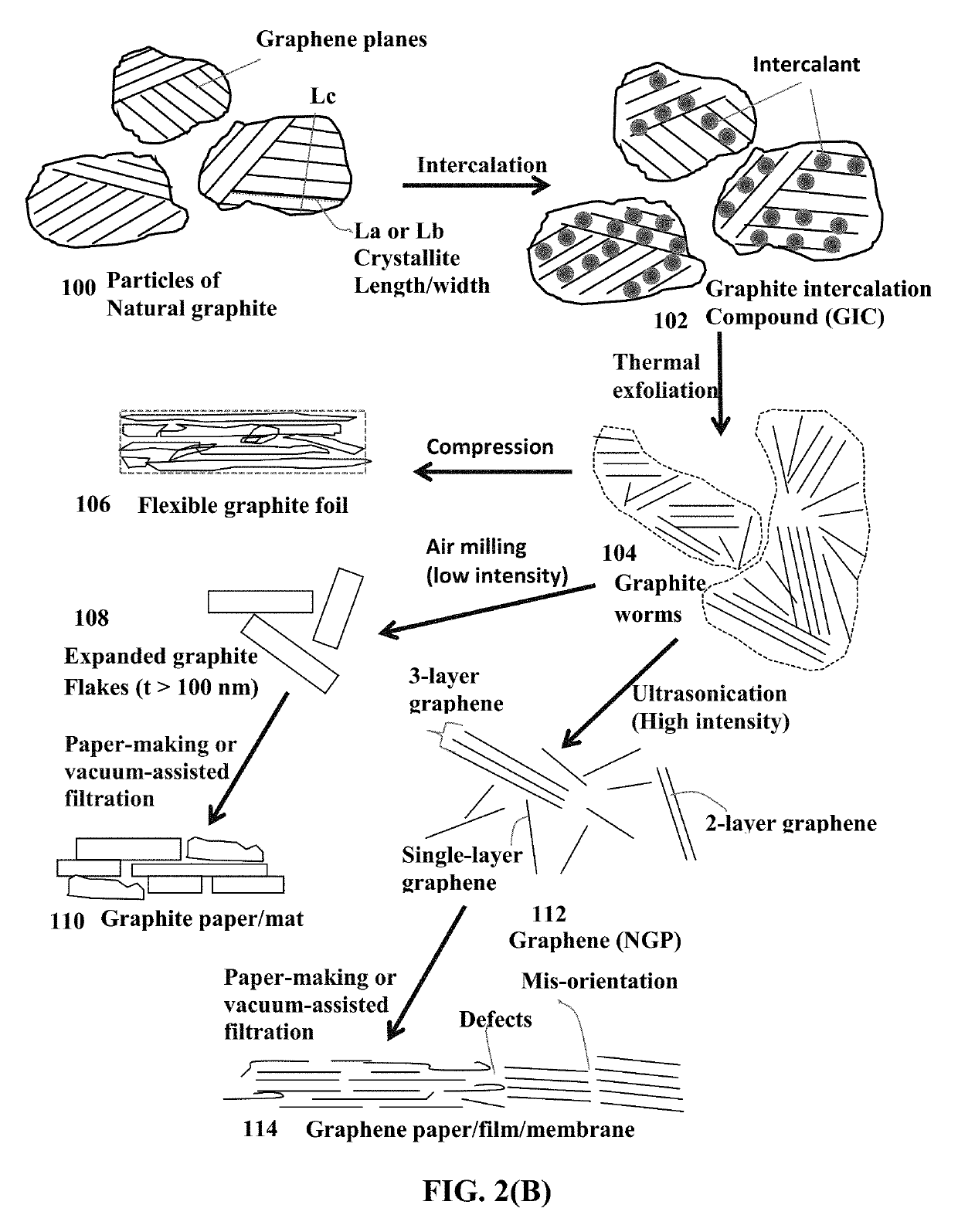

Graphene Foam-Protected Niobium-Based Composite Metal Oxide Anode Active Materials for Lithium Batteries

PendingUS20190165363A1High conductivityLarge electrode thicknessMolybdeum compoundsSingle layer grapheneSpecific gravityGraphene foam

A lithium-ion battery anode layer, comprising an anode active material embedded in pores of a solid graphene foam composed of multiple pores and pore walls, wherein (a) the pore walls contain a pristine graphene or a non-pristine graphene material; (b) the anode active material contains particles of a niobium-containing composite metal oxide and is in an amount from 0.5% to 99% by weight based on the total weight of the graphene foam and the anode active material combined, and (c) the multiple pores are lodged with particles of the anode active material. Preferably, the solid graphene foam has a density from 0.01 to 1.7 g / cm3, a specific surface area from 50 to 2,000 m2 / g, a thermal conductivity of at least 100 W / mK per unit of specific gravity, and / or an electrical conductivity no less than 1,000 S / cm per unit of specific gravity.

Owner:GLOBAL GRAPHENE GRP INC

Preparation method of mineral graphene reinforced ultra-high molecular weight polyethylene double-resistant pipe

The invention relates to a preparation method of a mineral graphene reinforced ultra-high molecular weight polyethylene double-resistant pipe. The pipe is prepared from the following raw materials: 100 parts of ultra-high molecular weight polyethylene, 2-5 parts of nano-graphene sheets, 5-10 parts of a coupling agent, 0.1-1 part of a foaming agent, 0.1-1 part of a compatibilizer, 1-2 parts of a lubricating agent, 6-10 parts of a halogen-free flame retardant, 3-6 parts of an antistatic agent, 2-4 parts of a flow modifier, 1-3 parts of a nucleating agent, and the like; the graphene reinforced ultra-high molecular weight polyethylene double-resistant pipe is prepared by the processes of extruding, sizing, and the like. According to the preparation method, nano-graphene, the antistatic agent and the flame retardant are dispersed into ultra-high molecular weight polyethylene resin medium gaps by means of the coupling agent, the compatibilizer, the flow modifier, the lubricating agent, the nucleating agent, and the like; the nano-graphene sheets have significant synergistic flame retardation after being compounded with the flame retardant, and can reduce the resistivity of the pipe after being compounded with the antistatic agent. The prepared pipe has the characteristics of being light in weight, high in strength, flame-retardant, antistatic, and the like, thus being used in the operating environments such as coal mines, downhole and mines in which a great deal of gas exists.

Owner:JIUJIANG UNIVERSITY

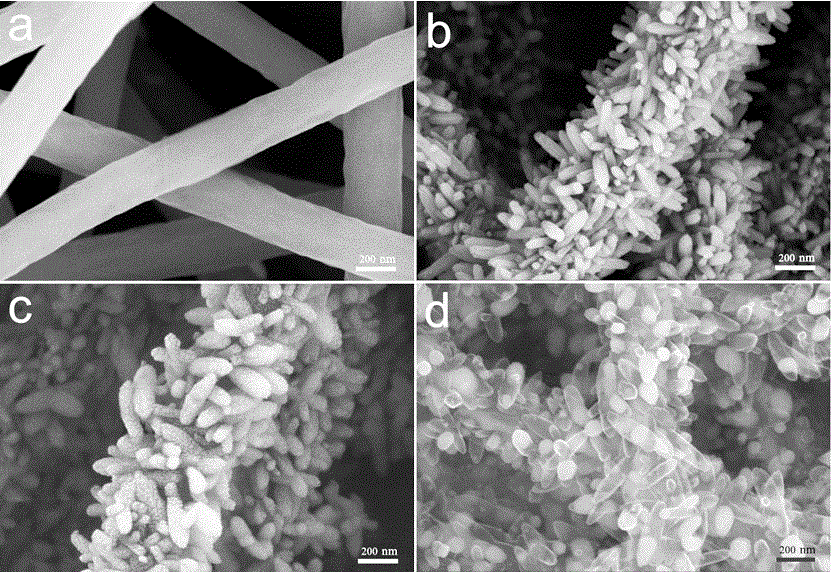

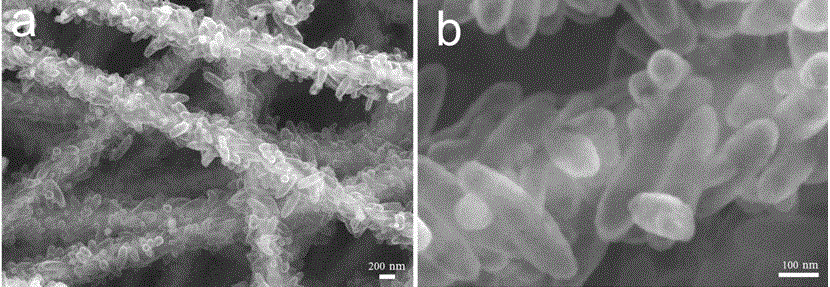

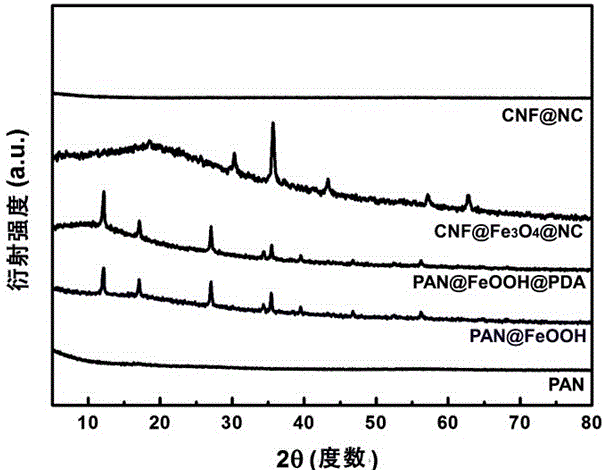

Pure carbon fiber material adopting 'vesical string' structure and preparation method of pure carbon fiber material

InactiveCN105734725ALarge specific surface areaHigh porosityMaterial nanotechnologyElectroconductive/antistatic filament manufactureFiberCarbon fibers

The invention belongs to the technical field of nano-fiber materials, in particular to a pure carbon fiber material adopting a 'vesical string' structure and a preparation method of the pure carbon fiber material. The preparation method comprises the following steps: preparing a spinning solution from a spinnable polymer material, and preparing nanofibers of uniform structures with an electrostatic spinning device; uploading iron oxide hydroxide cambiform nanorods on the surfaces of the nanofibers uniformly via a water bath or hydrothermal method; soaking an iron oxide hydroxide-modified fiber membrane in a dopamine solution, and controlling the thickness of a polydopamine coating layer by adjusting the concentration of the dopamine solution and the reaction time; carrying out high-temperature carbonization treatment, so as to realize fiber carbonization, and conversion of iron oxide hydroxide to ferroferric oxide as well as polydopamine to a N-doped carbon material; removing ferroferric oxide via soaking in an acid solution. The preparation method is safe and environmentally friendly; the prepared pure carbon fiber material is high in nitrogen content, specific surface area and electric conductivity, and stable in physical and chemical properties, so as to be an ideal electrode material for production of new energy devices such as a supercapacitor.

Owner:FUDAN UNIV

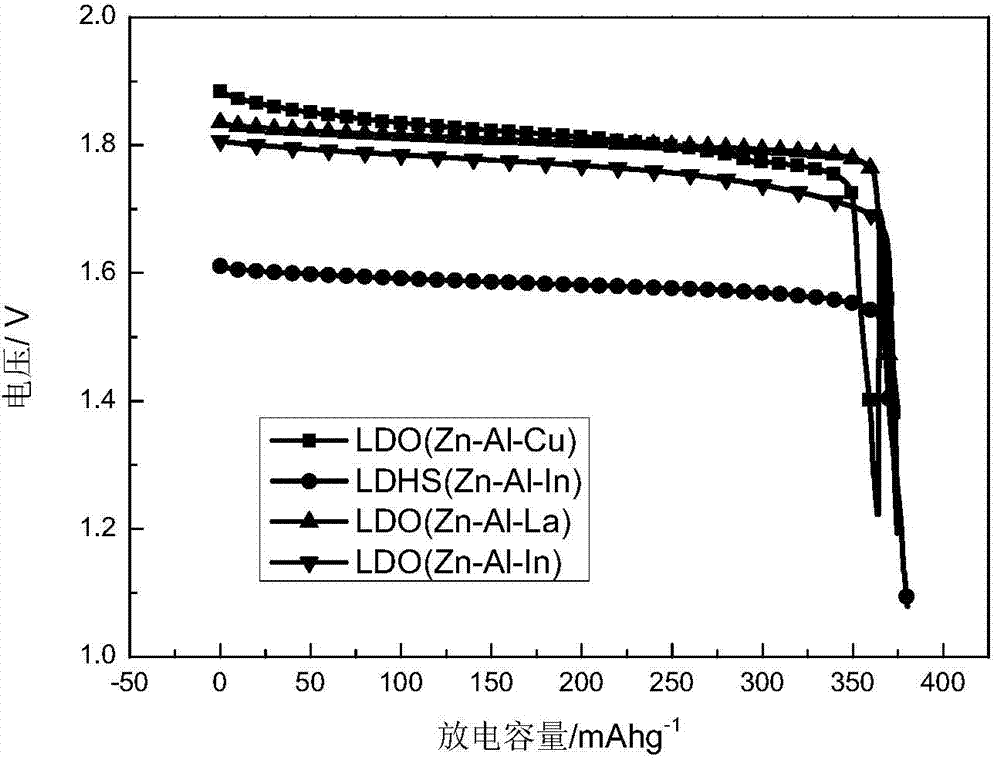

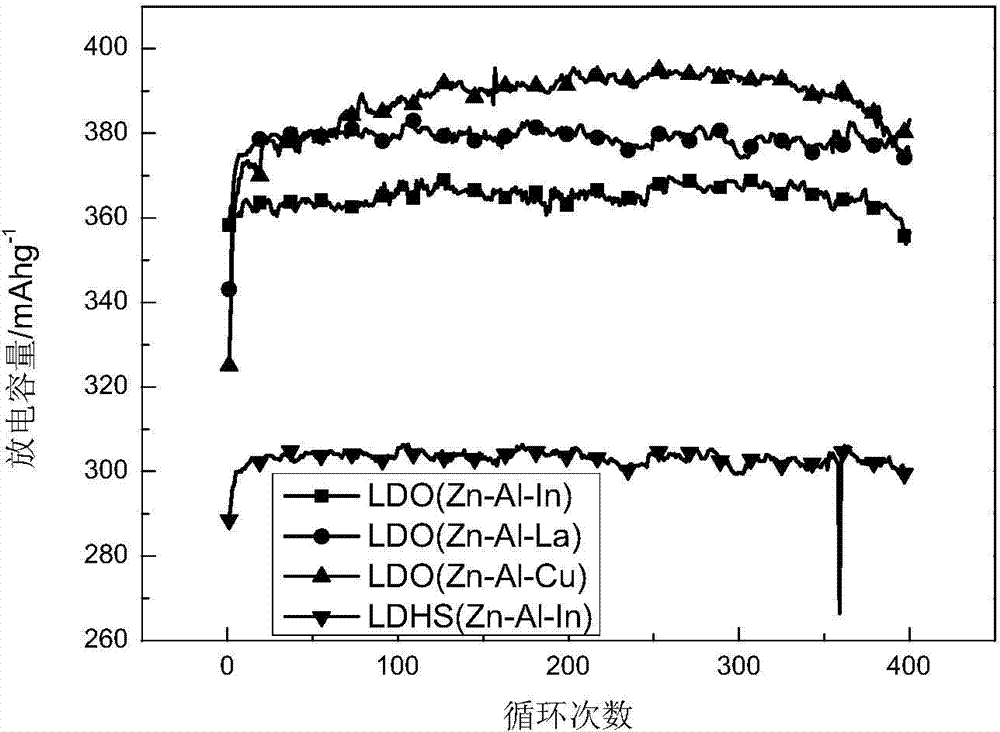

Application of zinc-based ternary layered composite oxide to zinc-nickel battery electrode material

InactiveCN103579588ASpeed up electron conductionHigh conductivityAlkaline accumulator electrodesDivalent metalComposite oxide

The invention discloses an application of a zinc-based ternary layered composite oxide to a zinc-nickel battery electrode material. The zinc-based ternary layered composite oxide is obtained by calcining carbonate type ternary zinc-based hydrotalcite; the ternary zinc-based hydrotalcite is prepared from zinc nitrate and two selected from divalent metal oxides and trivalent metal nitrates without the zinc nitrate. The zinc-based ternary layered composite oxide is used as an active substance so that the deformation of a zinc cathode is weakened, the dissolution of the active substance of the zinc cathode is inhibited, the reversibility of a zinc-nickel battery electrode is improved and the service life of the zinc-nickel battery electrode is prolonged.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com