Poly-dopamine based porous carbon fiber/MoSe2 composite material and preparation method thereof

A technology of porous carbon fiber and molybdenum diselenide, which is used in hybrid capacitor electrodes, electrical components, battery electrodes, etc., can solve the problems of single structure and difficult to meet practical applications, and achieves easy operation, prevents agglomeration, and mild preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment includes the following steps:

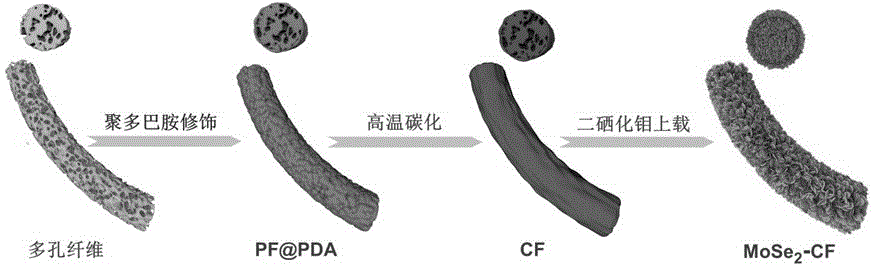

[0044] (1) Polystyrene PS was dissolved in DMF to prepare a spinning solution, and PS porous fibers were prepared by electrospinning technology absorbed by ethanol;

[0045] (2) Put the PS porous fiber in the dopamine solution for 4 hours to obtain the coating layer of polydopamine;

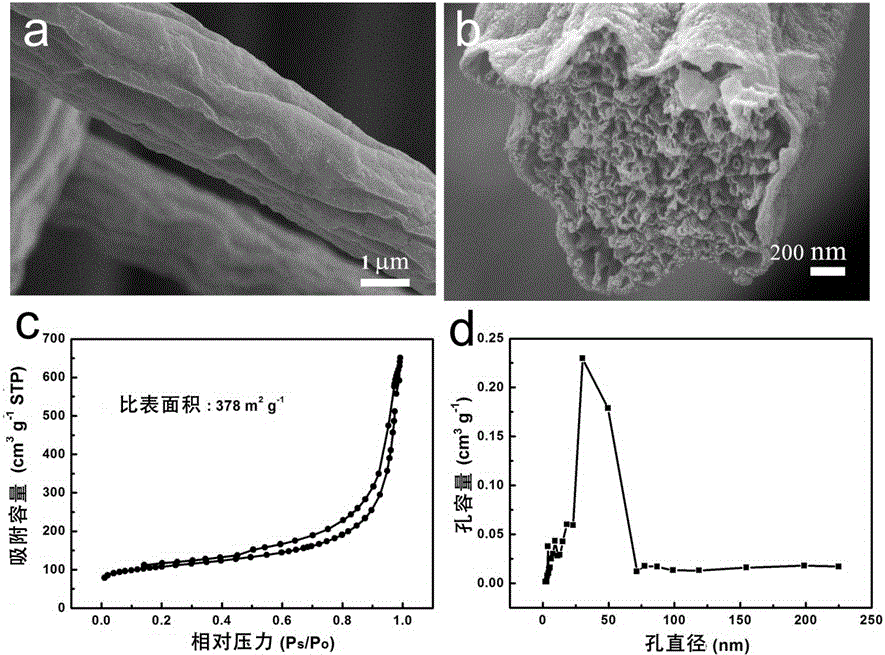

[0046] (3) Carbonize the polydopamine-modified PS porous fiber at high temperature to obtain a carbon fiber material with a porous structure, denoted as 4-CF;

[0047] (4) Soak 4-CF in concentrated acid solution for 5-6 hours for acidification, then wash with deionized water repeatedly for 3-5 times, dry for later use;

[0048] (5) Add selenium elemental substance into hydrazine hydrate (3mg / mL), heat and dissolve for later use;

[0049] (6) Put 20mg of carbon fiber, 1mL of selenium-containing elemental hydrazine hydrate solution and 4.76mg of sodium molybdate into the solvent, transfer to a hydrothermal kettle, and conduct a hydrothermal r...

Embodiment 2

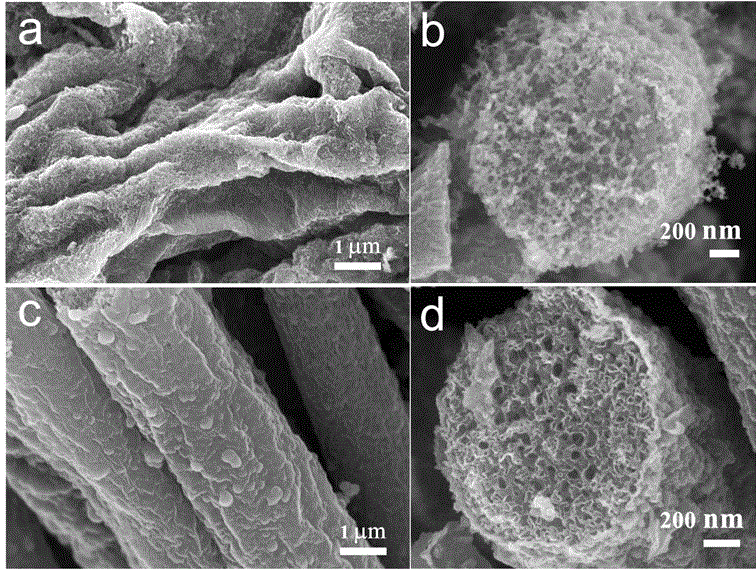

[0052] The dopamine soaking time in Example 1 is changed to 2h, and the rest are the same as in Example 1. The finally obtained carbon fiber is recorded as 2-CF. Since the coated polydopamine layer is too thin, the porous structure of the fiber is destroyed after high-temperature calcination. See attached image 3 .

Embodiment 3

[0054] The dopamine immersion time in embodiment 1 is changed into 6h, and all the other are the same as embodiment 1, and the carbon fiber finally obtained is denoted as 6-CF, and too much polydopamine cladding layer then makes polydopamine aggregate appear on the fiber surface, see attached image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com