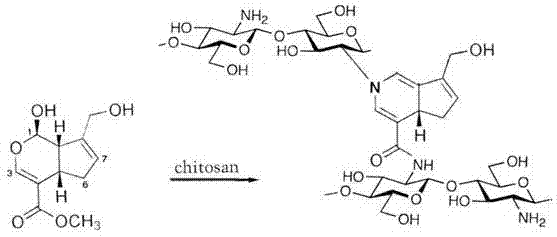

Preparation method of genipin crosslinked chitosan drug-loaded microspheres

A technology of cross-linking chitosan and drug-loaded microspheres, which is applied in the fields of biology, food, and medical engineering. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

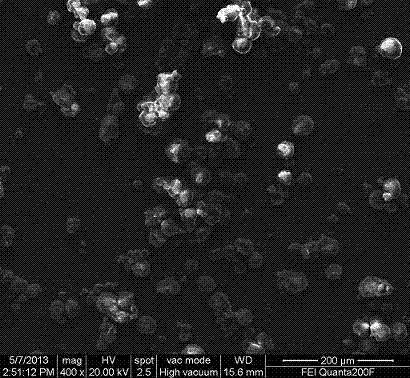

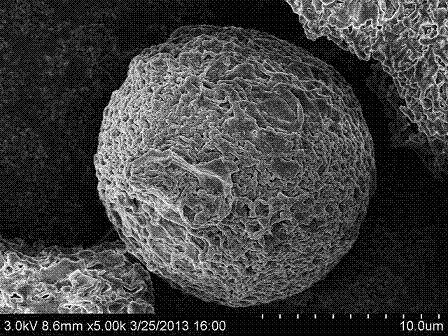

Image

Examples

Embodiment 1

[0022] Example 1. Take 50mL of liquid paraffin in a beaker, add 0.5g each of Tween-80 and Span-80, and stir for 30min at 30°C with a rotation speed of 660r / m to make an oily dispersion. Add 60mg of chitosan to 10mL of 2% acetic acid solution, then add 5mg of rhodiola rosea, after ultrasonic dissolution, add it to the above oil-containing dispersion at a uniform speed, stir for 30min at 30°C, and rotate at 660r / m, then slowly add 6mL of genipin absolute ethanol solution with a ratio of 70:1, and stir at 30°C for 3h at a speed of 660r / m, after standing for 2h, discard the supernatant to obtain the lower layer of sediment for centrifugation , washed three times with petroleum ether, acetone and absolute ethanol respectively. Finally, vacuum-dry at room temperature for 12 hours to obtain the chitosan drug-loaded microspheres of the present invention.

Embodiment 2

[0023] Example 2. Take 100mL of liquid paraffin in a beaker, add 1g each of Tween-80 and Span-80, and stir for 30min at 30°C with a rotation speed of 690r / m to make an oily dispersion. Add 120mg of chitosan to 20mL of acetic acid solution with a concentration of 2%, then add 10mg of salidroside, after ultrasonic dissolution, add it to the above oil-containing dispersion at a uniform speed, stir for 40min at 30°C, and rotate at a speed of 690r / m, then slowly add 12mL of genipin absolute ethanol solution with a ratio of 70:1, and stir at 30°C for 3.5h at a speed of 690r / m, after standing for 2h, discard the supernatant to obtain the lower precipitate Centrifuge and wash three times with petroleum ether, acetone and absolute ethanol respectively. Finally, vacuum-dry at room temperature for 12 hours to obtain the microspheres of the present invention.

Embodiment 3

[0024] Example 3: Take 150mL of liquid paraffin in a beaker, add 1.5mL each of Tween-20 and Span-80, and stir for 30min at 30°C with a rotation speed of 720r / m to make an oily dispersion. Add 180mg chitosan to 30mL acetic acid solution with a concentration of 2%, then add 15mg salidroside, after ultrasonic dissolution, add it to the above-mentioned oil-containing dispersion at a uniform speed, stir at 30°C for 50min, and rotate at a speed of 720r / m, then slowly add 18mL of genipin absolute ethanol solution with a ratio of 70:1, and stir at 30°C for 4h at a speed of 720r / m, after standing for 2h, discard the supernatant to obtain the lower layer of precipitate Centrifuge and wash three times with petroleum ether, acetone and absolute ethanol respectively. Finally, vacuum-dry at room temperature for 12 hours to obtain the microspheres of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com