Chitosan pellet/microsac and prepn. thereof

A technology of chitosan microspheres and chitosan solutions, which is applied in the fields of medical engineering and bioengineering, can solve the problems of low mechanical strength of chitosan microspheres/microcapsules, and achieve low mechanical strength and reduce activity loss , The effect of improving the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Chitosan was dissolved in 0.2mol / L acetic acid solution to prepare a 2% (w / v) solution, 50mL of liquid paraffin was added to the reactor, 0.5mL of Span80 and 1mL of Tween80 were added, stirred for 10 minutes, and the rotating speed was 1500 rpm Minutes, after adding the 10mL chitosan solution prepared above, continue to stir and disperse for 30 minutes with the same rotating speed, then add 40mL of ammonium sulfate solution with a concentration of 50% (w / v), continue to stir for 1 hour and then stop. Centrifuge, pour out the upper liquid, separate the chitosan microspheres precipitated by ammonium sulfate in the lower layer, wash the precipitates with pure water, petroleum ether, and absolute ethanol in turn, and dry them in vacuum at room temperature to obtain the chitosan microspheres of the present invention. ball.

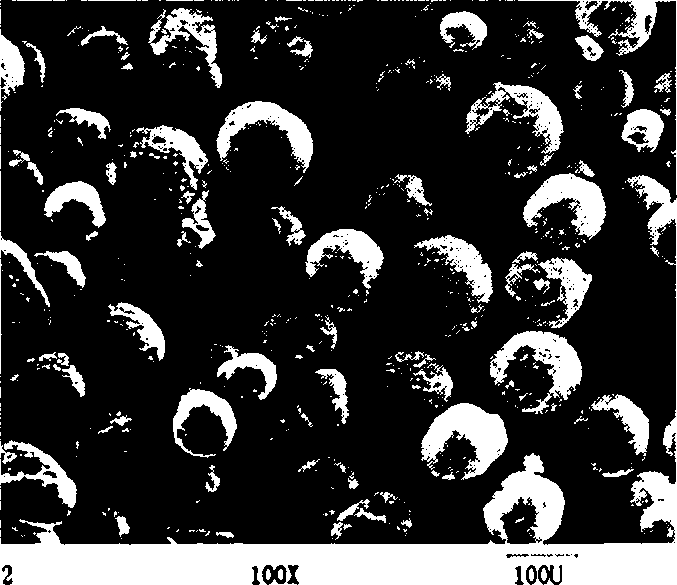

[0035] Its surface morphology is as figure 1 and figure 2 As shown in the scanning electron microscope picture, it can be seen that the chitosan micr...

Embodiment 2

[0037]Dissolve chitosan in 0.25mol / L acetic acid solution to prepare a 5% (w / v) solution, take 50mL peanut oil and add it to the reactor, add 0.5mL Span60 and 1mL Tween60, stir for 5 minutes, and the rotating speed is 2000 rpm After adding the above-mentioned chitosan solution of 10mL, continue to stir after 60 minutes with the same rotating speed, add the ammonium sulfate solution 100mL that concentration is 30% (w / v), stop after continuing to stir for 2 hours. Centrifuge, pour out the upper liquid, separate the chitosan microspheres precipitated by ammonium sulfate in the lower layer, wash the precipitates with pure water, petroleum ether, and absolute ethanol in turn, and dry them in vacuum at room temperature to obtain the chitosan microspheres of the present invention. ball.

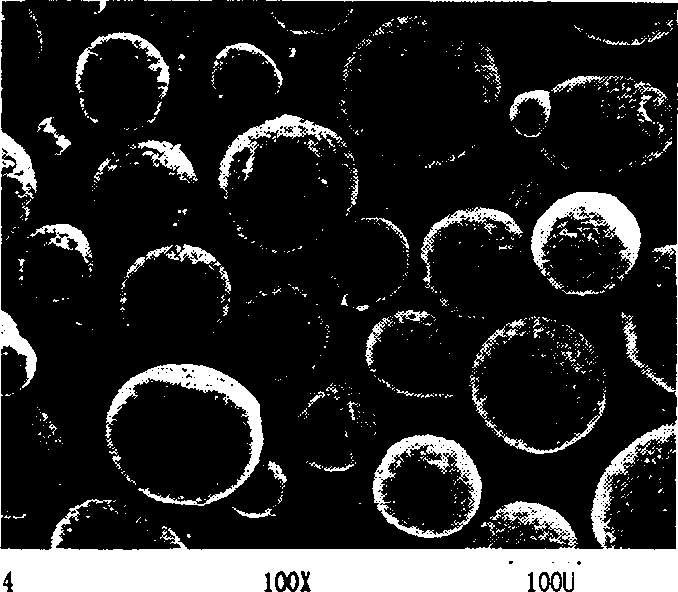

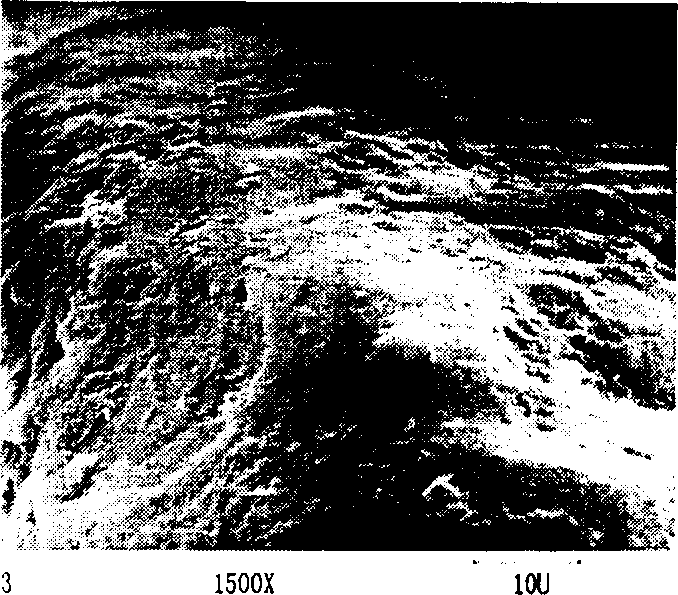

[0038] Its surface morphology is as image 3 and Figure 4 As shown in the scanning electron micrograph, it can be seen that the chitosan microspheres have a porous surface, a particle size of 154...

Embodiment 3

[0040] Chitosan was dissolved in 0.25mol / L acetic acid solution to prepare a 4% (w / v) solution, 50mL corn oil was added to the reactor, 1mL Tween65 was added, stirred for 20 minutes, and the rotating speed was 500 rpm; After 2.5mL of the chitosan solution prepared above, continue to stir with the same rotating speed for 40 minutes, add concentration and be 50mL of ammonium sulfate solution of 65% (w / v), stop after continuing to stir for 3 hours. Centrifuge, pour out the upper liquid, separate the chitosan microspheres precipitated by ammonium sulfate in the lower layer, wash the precipitates with pure water, petroleum ether, and absolute ethanol in turn, and dry them in vacuum at room temperature to obtain the chitosan microspheres of the present invention. ball.

[0041] The cross-section of the microsphere is shown in Figure 5 As shown, it can be seen that its internal structure is dense and it is a solid ball.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com