Method for preparing low-carbon olefin with high selectivity by catalyzing synthesis gas by using heteroatom-doped molecular sieve

A technology of heteroatom molecular sieves and heteroatoms, which is applied in the field of synthesis gas to prepare low-carbon olefins, can solve the problems of low selectivity and low selectivity of product low-carbon olefins, and achieve improved reaction conversion rate, low methane selectivity, and improved selectivity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

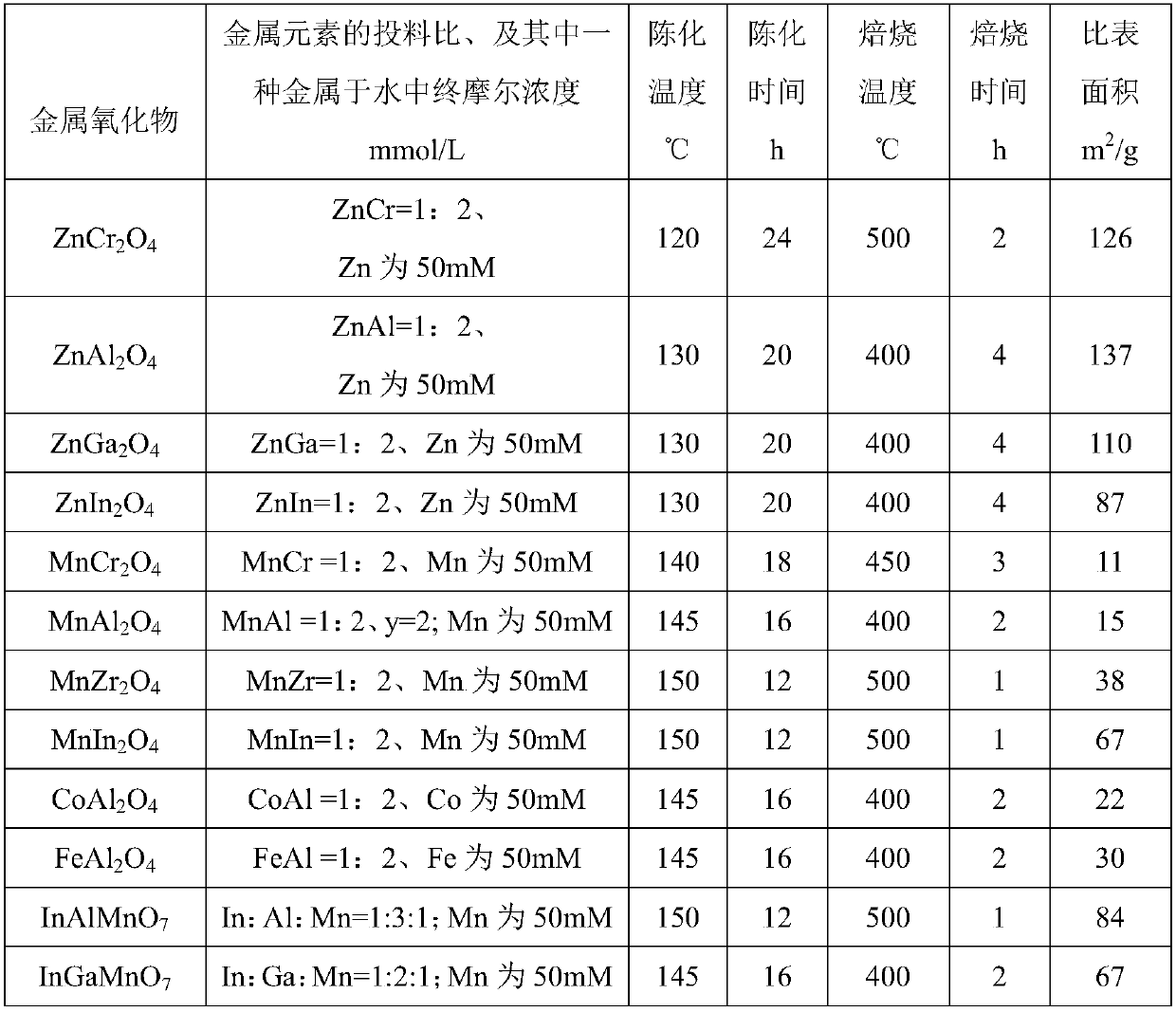

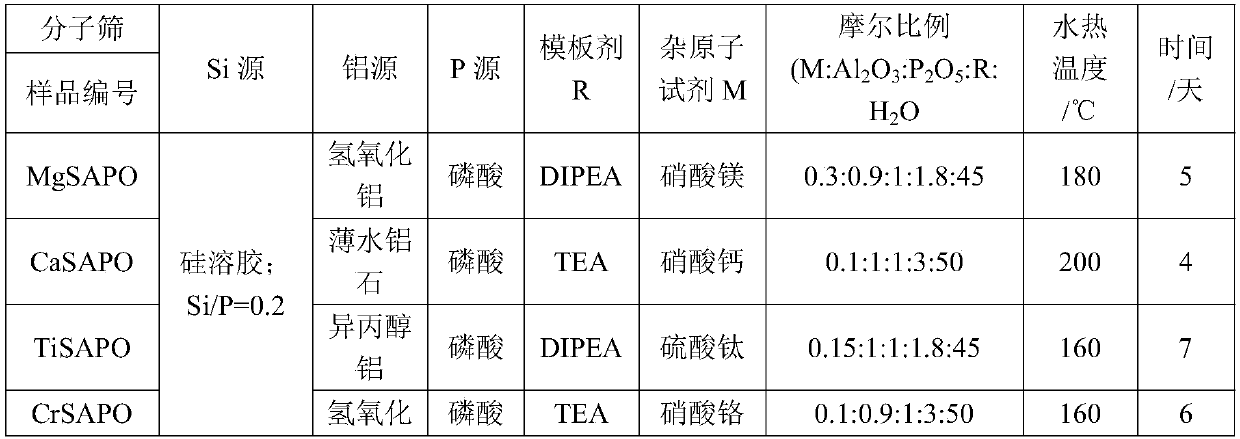

[0027] 1. Preparation of Catalyst Component I

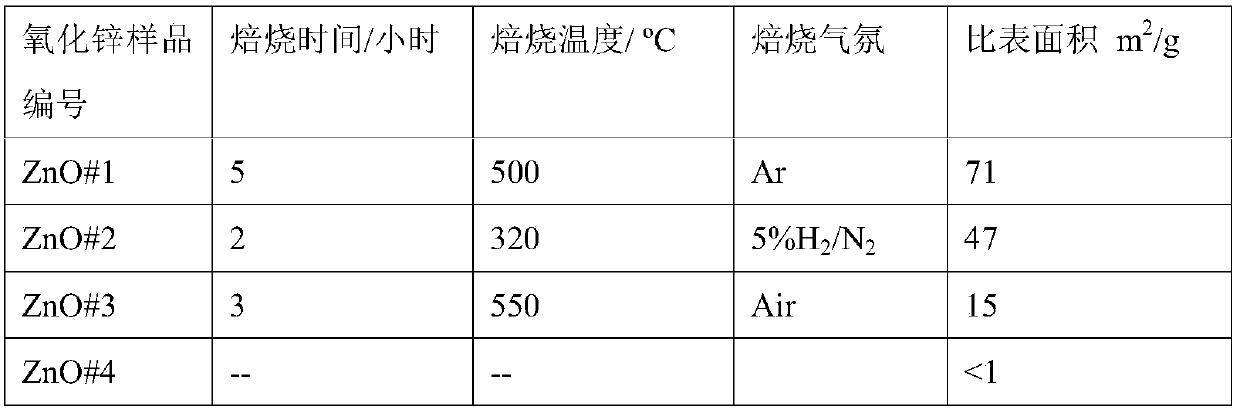

[0028] (1) Synthesis of ZnO materials with high specific surface area by precipitation method:

[0029] (1) Weigh 3 parts, 0.446g (1.5mmol) Zn(NO 3 ) 2 ·6H 2 O in 3 containers, then weigh 0.300g (7.5mmol), 0.480g (12mmol), 0.720g (18mmol) NaOH into the above 3 containers in turn, and then add 30ml of deionized water to the 3 containers In the container, stir at 70°C for more than 0.5h to make the solution evenly mixed, and cool naturally to room temperature. The reaction solution was centrifuged to collect the precipitate after centrifugation, and washed twice with deionized water to obtain the ZnO metal oxide precursor;

[0030] (2) Roasting: After the above-mentioned obtained product is dried in the air, it is calcined in the atmosphere to obtain a ZnO material with a high specific surface area. The atmosphere is inert gas, reducing gas or oxidizing gas; the inert gas is N 2 One or more of , He and Ar; the reducing gas is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com