Patents

Literature

1582results about How to "High reaction conversion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst for preparing low carbon olefin by petroleum hydrocarbon cracking

InactiveCN1504540AImprove cracking capacityHigh reaction conversion rateCatalytic crackingCarbon numberDecomposition

The invention discloses a catalyst for preparing lower carbon number hydrocarbon olefin through petroleum hydrocarbon decomposition, which comprises (catalyst weight as benchmark) 0-70% clay, 5-99% inorganic oxide compound and 1-50% zeolite, wherein the zeolite is 25-100 wt% MFI structure zeolite and 0-75 wt% Y-type zeolite, characterized by that, the MFI structure zeolite contains phosphor and transient metal M. the catalyst can improve the cracking capability for heavy oil macromolecule and conversion rate of reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

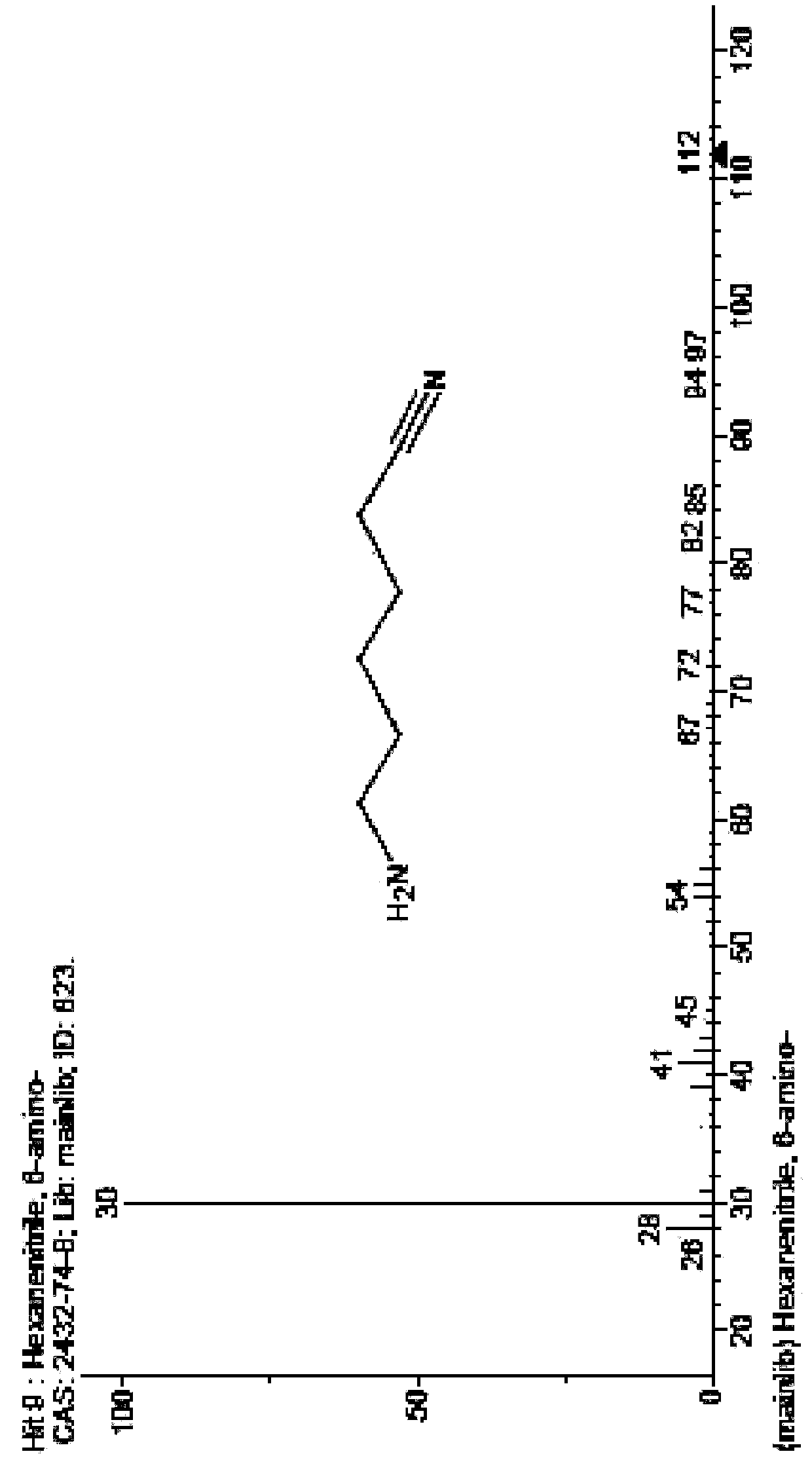

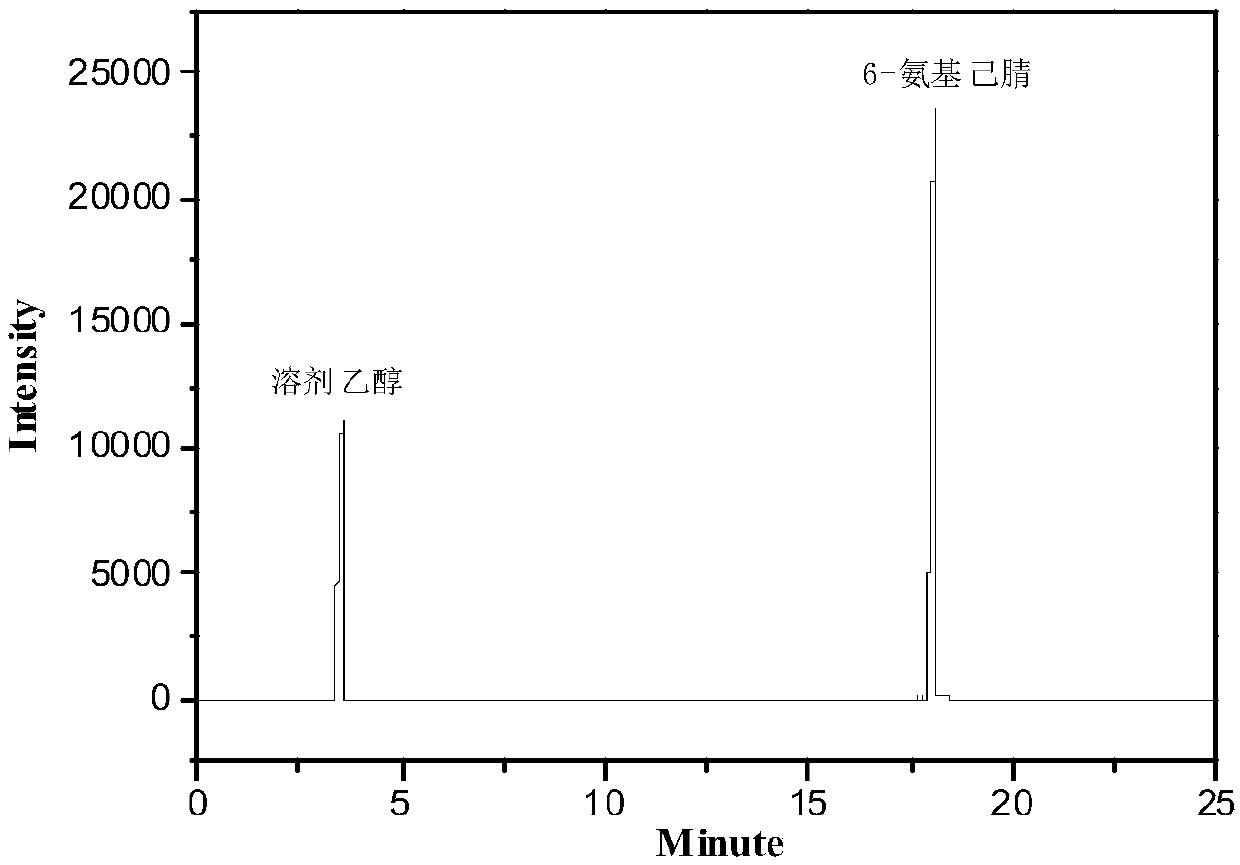

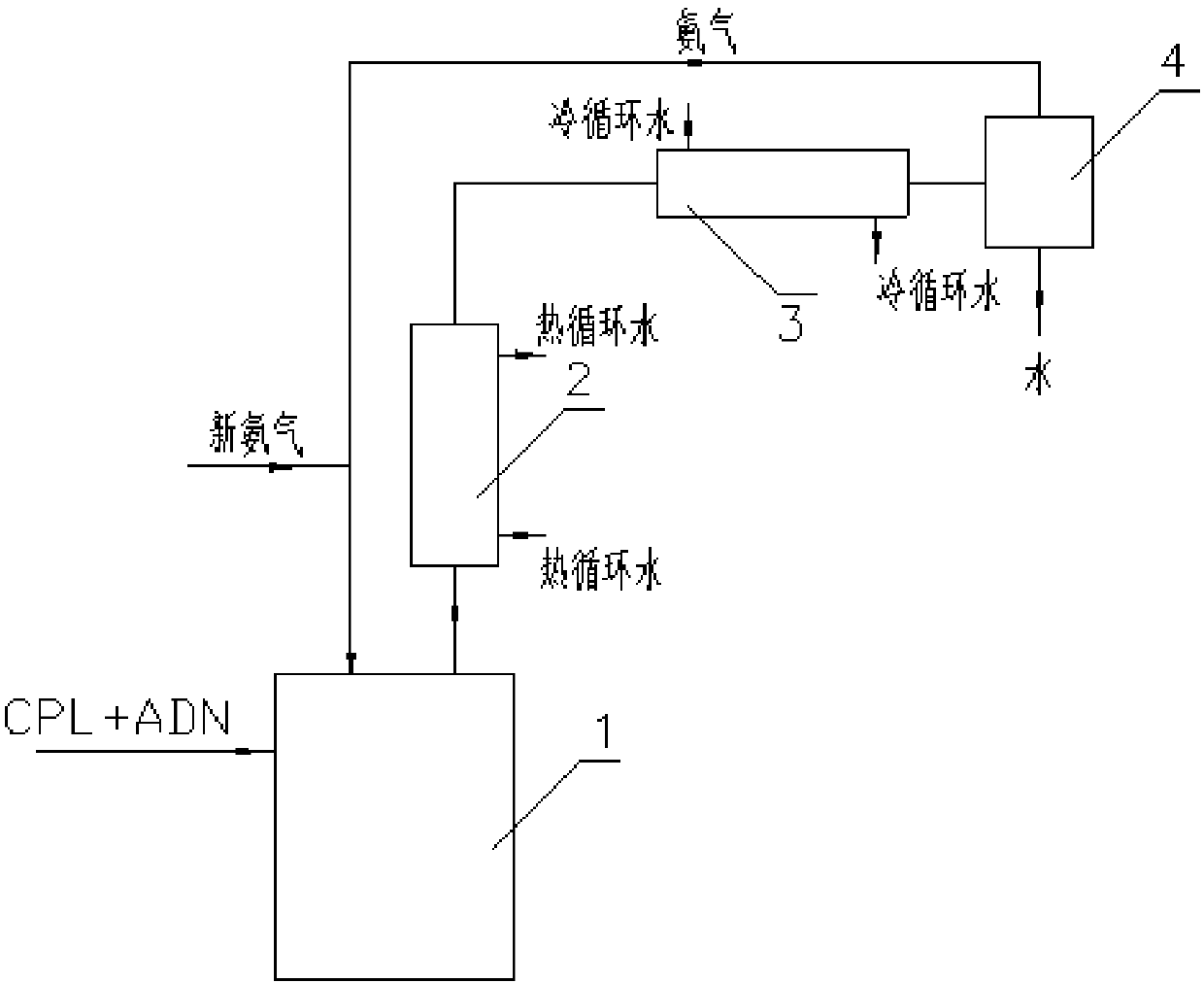

Method and device for preparing 6-amino-capronitrile with caprolactam liquid phase method

InactiveCN107739318AHigh reaction conversion rateGood choicePreparation by carboxylic acid amide dehydrationOrganic solventCaprolactam

The invention provides a method and device for preparing 6-amino-capronitrile from caprolactam by adopting a liquid phase method. In the method for preparing the 6-amino-capronitrile, the caprolactamis taken as a raw material; the method for preparing the 6-amino-capronitrile comprises the following step: S1: mixing the caprolactam, an organic solvent and a catalyst at a certain mass ratio, so asto obtain a mixed solution, adding the mixed solution into a reaction kettle and stirring and heating the mixed solution; S2: when the mixed solution in step S1 reaches certain temperature, introducing ammonia gas into the mixed solution for a reaction; S3, after the reaction in step S2 is ended, rectifying and purifying a reaction product, so as to obtain pure 6-amino-capronitrile. In the methodfor preparing the 6-amino-capronitrile, the caprolactam is taken as the raw material, the reaction conversion rate is comparatively high, and the preparation process is simple.

Owner:CHINA TIANCHEN ENG +1

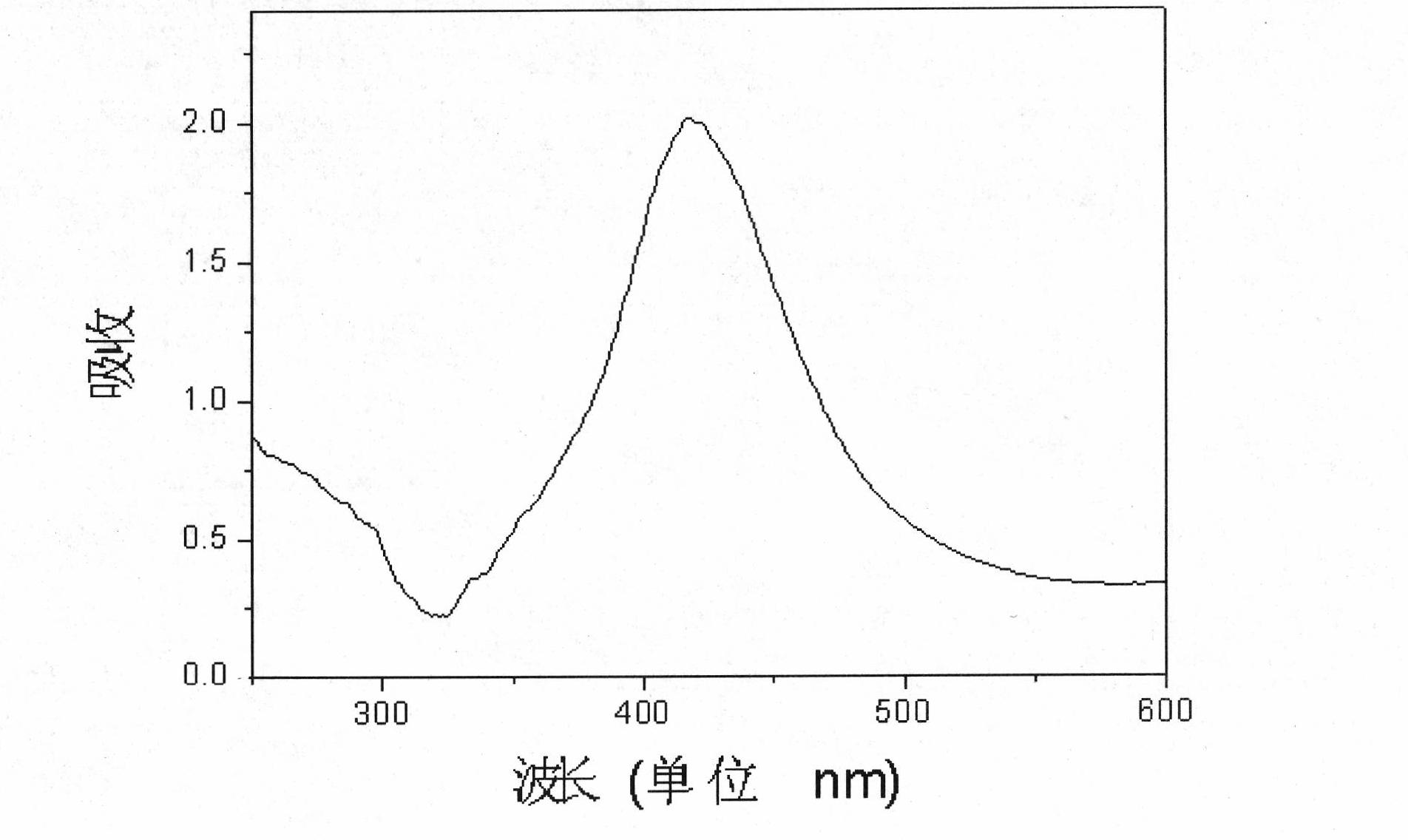

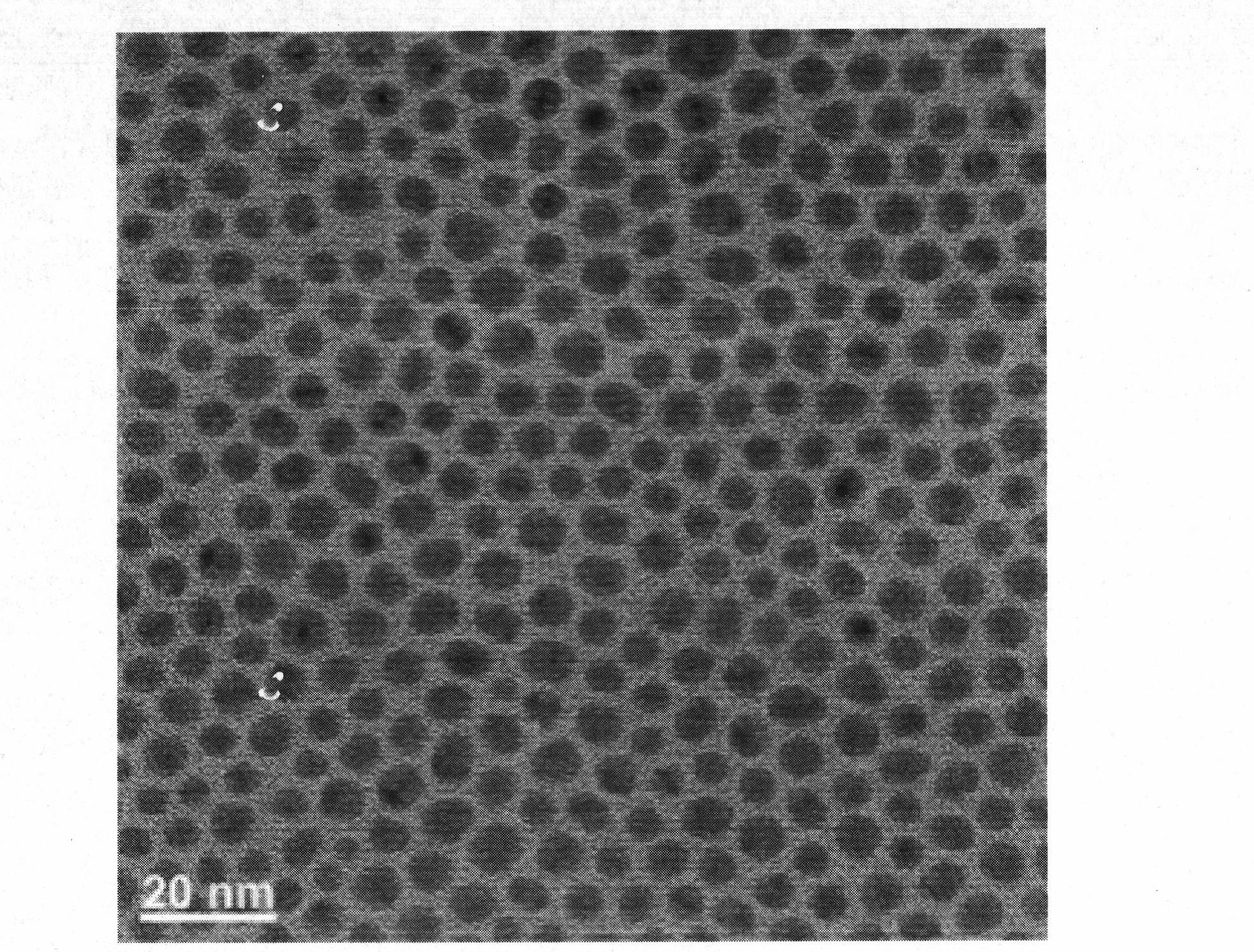

Preparation method of colloid of mono-dispersed silver nano particles and nano silver powder and conductive ink thereof

The invention relates to a preparation method of colloid of mono-dispersed silver nano particles and nano silver powder, and conductive ink prepared on the basis of the nano silver powder. The method comprises the following steps of: dropwise adding a reducing agent solution in a constant-flow manner to the mixed solution of silver salt precursor and a dispersant to obtain a reaction system; after reaction is finished, obtaining the colloid of the mono-dispersed silver nano particles; performing centrifugation on the colloid of the mono-dispersed silver nano particles; cleaning the precipitate with a cleaning agent and drying to obtain the nano silver powder; and mixing the nano silver powder, a terpene alcohol compound solvent and auxiliaries to prepare the conductive ink. The method forpreparing the colloid of mono-dispersed silver nano particles provided by the invention has simple and quick process, high product output, mild preparation conditions, and no need of protection of inert gas. The terpene alcohol compound solvent used for preparing the conductive ink can uniformly disperse the nano silver powder and can maintain long-time stability. The terpene alcohol compound solvent can keep the conductive ink and a substrate in a good spread state.

Owner:INST OF CHEM CHINESE ACAD OF SCI

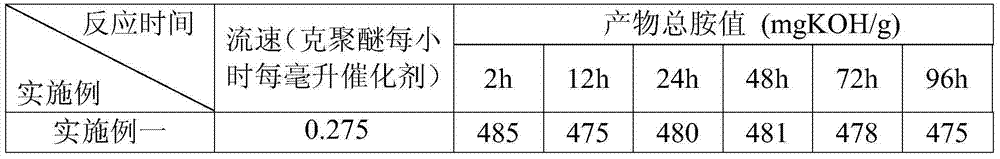

Process of producing small molecular weight polyether amine by continuous method

ActiveCN104119239AReduce the impactThe process steps are simpleOrganic compound preparationAmino-hyroxy compound preparationHydrogenMetal catalyst

The invention relates to a process of producing small molecular weight polyether amine by a continuous method. A continuous method fixed bed process is adopted, polyether, liquid ammonia and hydrogen are used as raw materials, 2-6 reactors which are fixed bed reactors or tubular reactors are connected in series and each reactor is internally filled by a Raney metal catalyst or a supported metal catalyst, respectively; under the reaction condition of certain temperature, pressure and molar proportion, the raw materials are sequentially reacted through the reactors to obtain polyether amine, the molecular weight of which is 100-1000. The process provided by the invention is simple in step. Multiple reactors and a compound catalyst system are adopted, so that the influence of generated water in the reaction to the catalyst efficiency is effectively reduced, and the yield and the conversion ratio of reaction are improved.

Owner:WUXI ACRYL TECH

Hydrocarbon cracking catalyst containing modcfied faujasite

InactiveCN1624079AGood hydrothermal stabilityHigh reaction conversion rateCatalytic crackingHigh resistanceRare earth

A hydrocarbon cracking catalyst containing modified octahedra zeolite is prepared from modified octahedra zeolite, one or moke kinds of other modified zeolite, clay and refractory inorganic oxide through proportional mixing, spray shaping, and washing. Its advantages are high activity and stability, high gasoline output rate, low coke output rate, and high resistance to heavy metal pollution.

Owner:PETROCHINA CO LTD

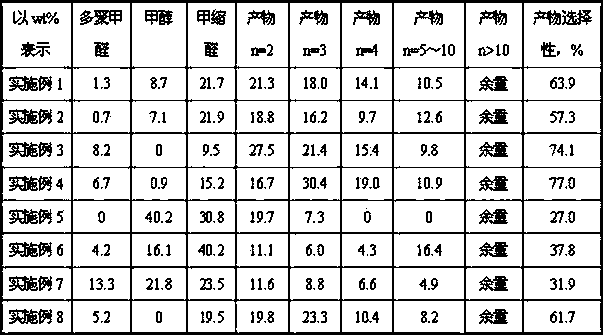

Synthesis method of polyformaldehyde dimethyl ether

InactiveCN102040490AReduce manufacturing costHigh reaction conversion rateOrganic chemistryOrganic compound preparationPolyoxymethylene dimethyl ethersParaformaldehyde

The invention relates to a synthesis method of polyformaldehyde dimethyl ether, which mainly solves the problem that the traditional method for synthesizing the polyformaldehyde dimethyl ether with trioxymethylene as a raw material has higher cost. In the invention, methanol, methylal and paraformaldehyde are used as raw materials, wherein the mass ratio of the methanol to the methylal to the paraformaldehyde is (0-10): (0-10): 1, the using amount of the methanol and the methylal cannot be zero simultaneously; and the raw materials are in contact and react with a catalyst to generate the polyformaldehyde dimethyl ether with a chemical formula of CH3O(CH2O)nCH3 under the condition that the reaction temperature is 70-200 DEG C and the reaction pressure is 0.2-6MPa, wherein the used catalyst is selected from at least one of SO4<2-> / ZrO2, SO4<2-> / Fe2O3, Cl<-> / TiO2, Cl<-> / Fe2O3, SO4<2-> / Al2O3 and S2O8<2-> / ZrO2. The synthesis method provided by the method better solves the problem of the traditional method and can be used in industrial production of the polyformaldehyde dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polyformaldehyde dimethyl ether synthesis method

ActiveCN103664549AReduce manufacturing costHigh product yieldOrganic chemistryOrganic compound preparationPolyoxymethylene dimethyl ethersParaformaldehyde

The invention relates to a polyformaldehyde dimethyl ether synthesis method which mainly solves the problems of difficult catalyst separation, low raw material conversion rate and poor product selectivity in the prior art. The technical scheme of the polyformaldehyde dimethyl ether synthesis method comprises the following steps: by taking methanol, methylal and polyformaldehyde as raw materials, under the conditions that the reaction temperature is 70-200 DEG C and the reaction pressure is 0.2-6 MPa, enabling the raw materials to be in contact with a catalyst, and reacting to generate polyformaldehyde dimethyl ether, wherein the weight ratio of the methanol, the methylal and the polyformaldehyde is (0-10):(0-10):1, and the amounts of the methanol and the methylal can not be 0 at the same time; the amount of the catalyst accounts for 0.1-5.0% of the weight of the raw materials; and the used catalyst comprises the following components in parts by weight: a) 30-80 parts of carrier, which is at least one selected from SBA-15, MCM-41 or MCM-22 molecular sieve, and b) 20-70 parts of solid super-strong acid carried thereon, which is at least one selected from SO4<2-> / ZrO2, SO4<2-> / Fe2O3, Cl<-> / TiO2 or Cl<-> / Fe2O3. Thus, the problems are well solved; and the polyformaldehyde dimethyl ether synthesis method can be used for industrial production of polyformaldehyde dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

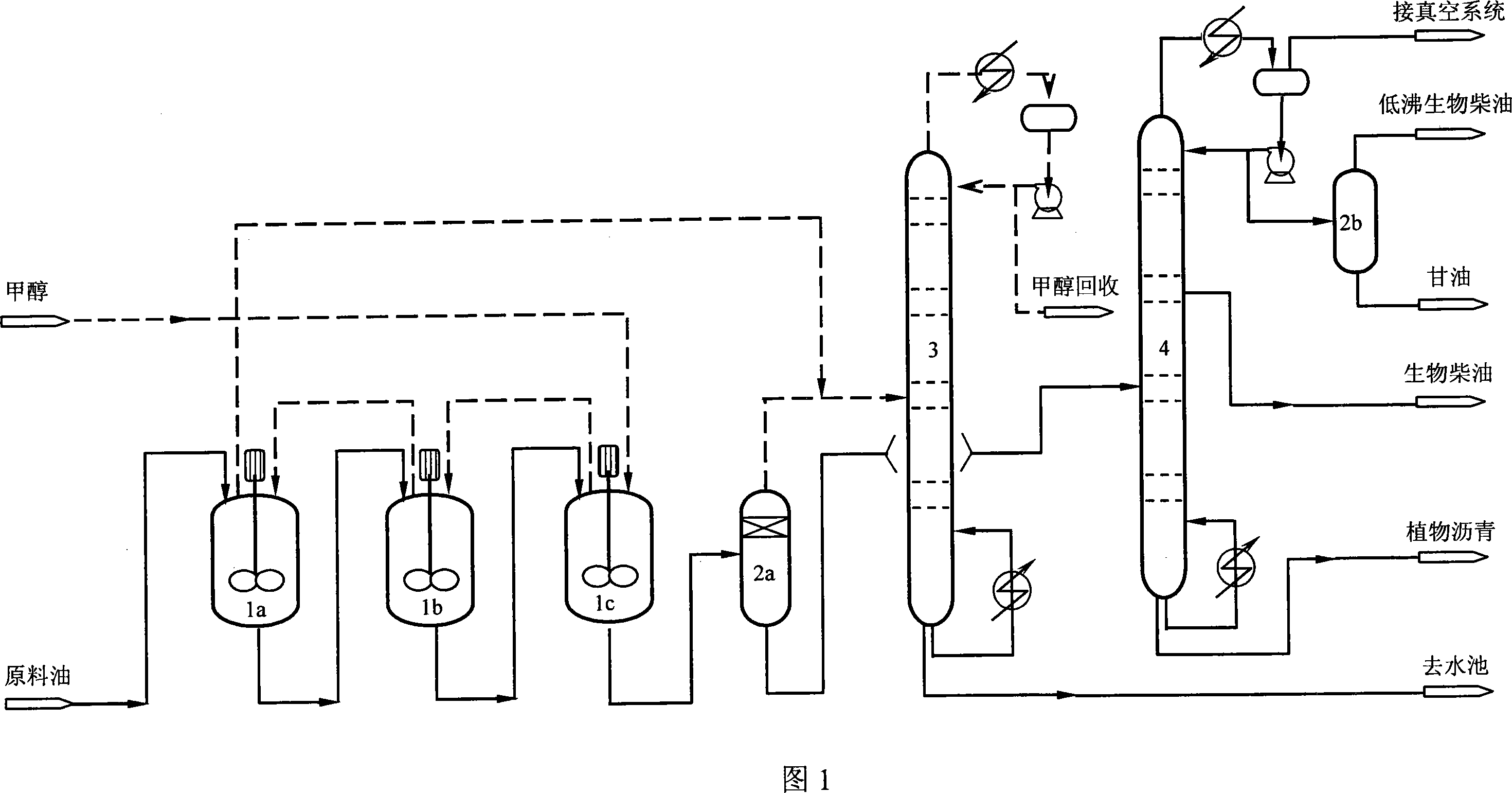

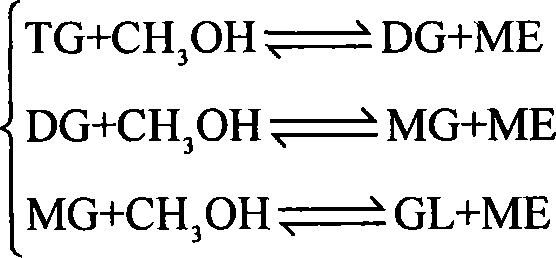

Solid catalysis process of preparing biodiesel oil continuously with high acid value material

InactiveCN101067091AHigh activityLow costPhysical/chemical process catalystsFatty acid esterificationOil and greaseRenewable energy technology

The present invention is solid catalysis process of preparing biodiesel oil continuously with high acid value material, and belongs to the field of grease chemistry and regenerable energy source technology. The process includes following four steps: material pre-treating, reaction, methanol rectifying recovery and vacuum rectification of fatty acid methyl ester; and features the high acid value material, such as acidified oil, waste edible oil, etc. The present invention has the advantages of low material cost, high activity and easy separation of the solid catalyst, high esterification efficiency, high product purity, high yield, less waste, no pollution, etc.

Owner:TSINGHUA UNIV +1

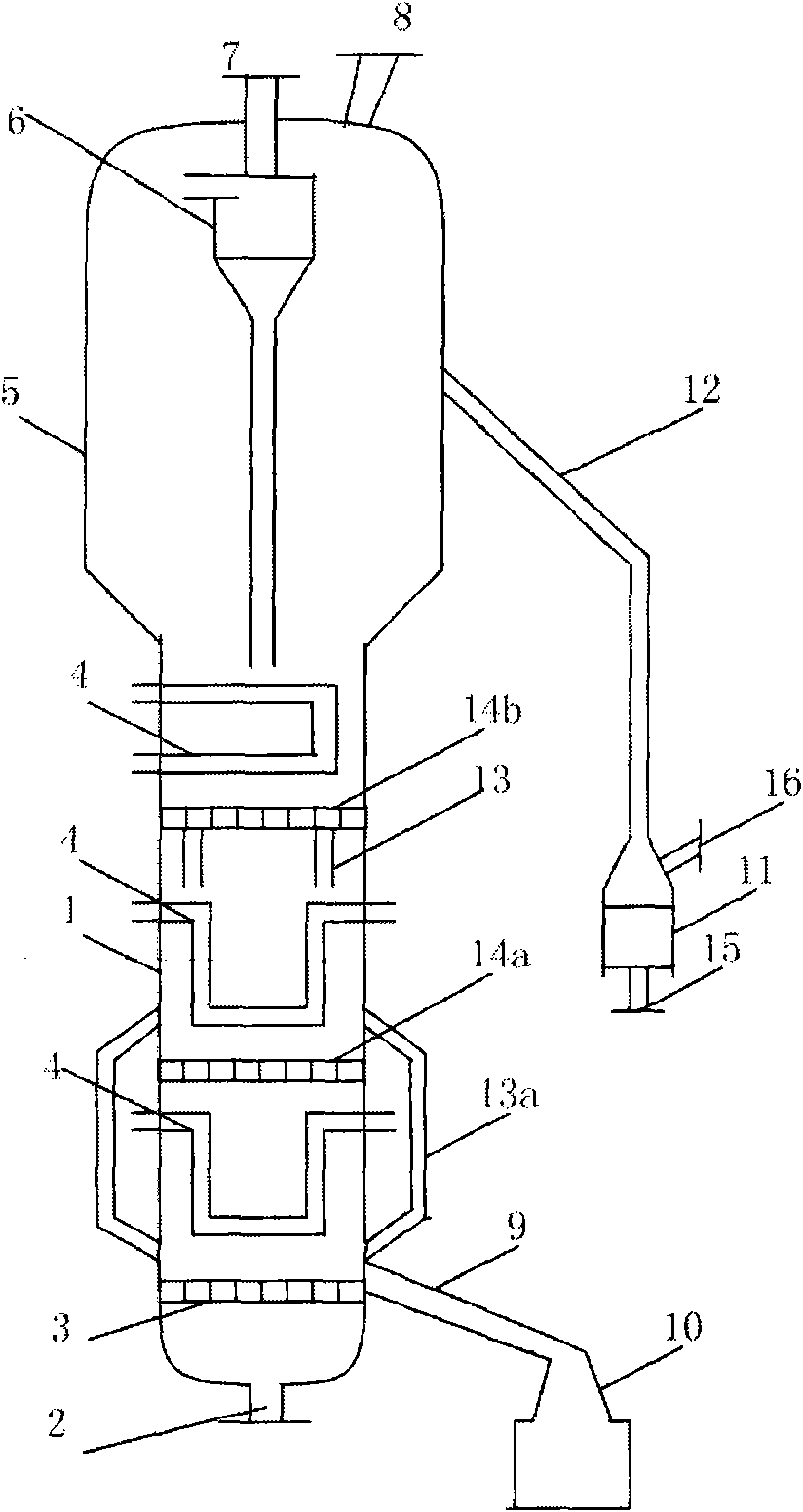

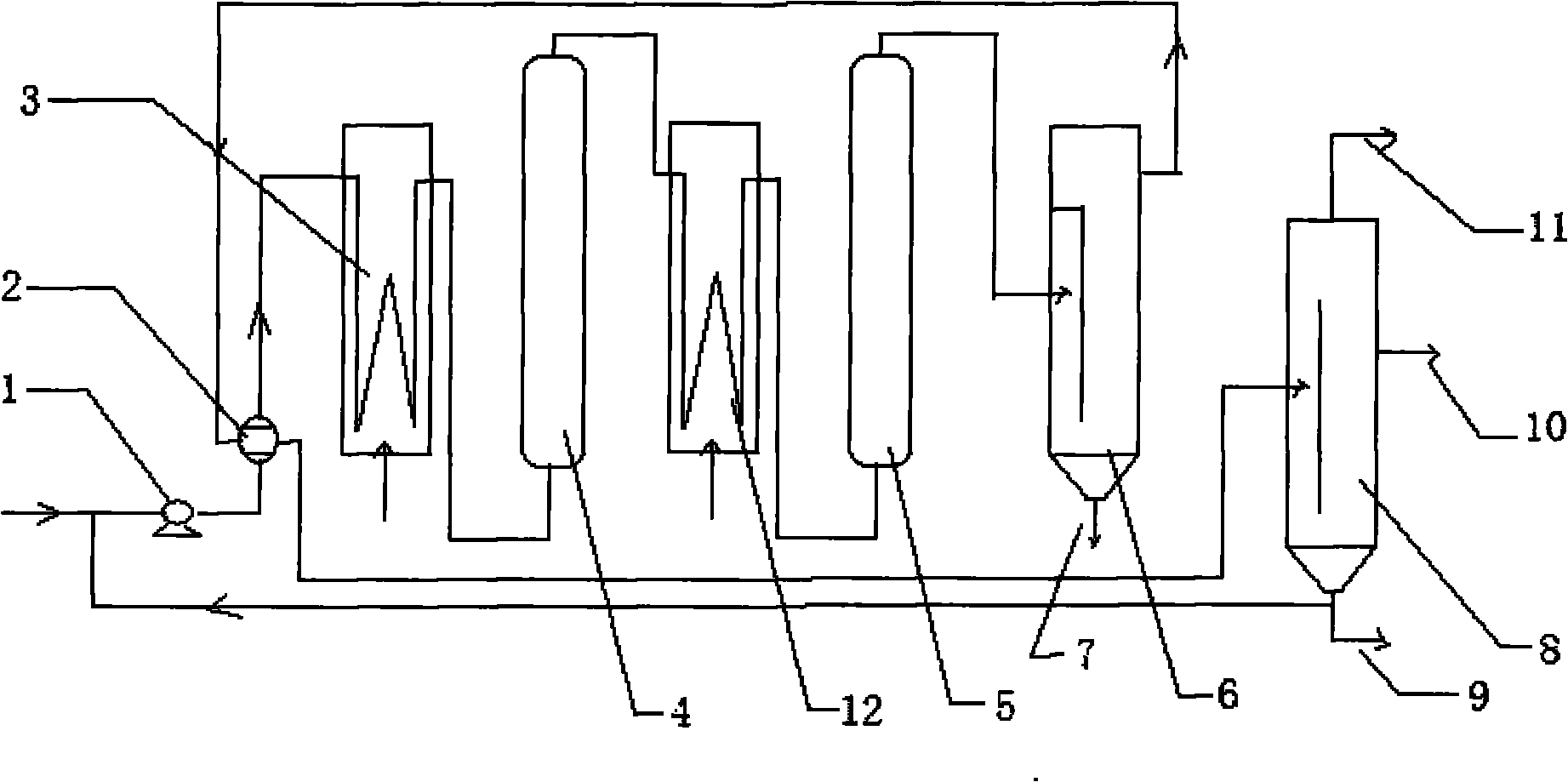

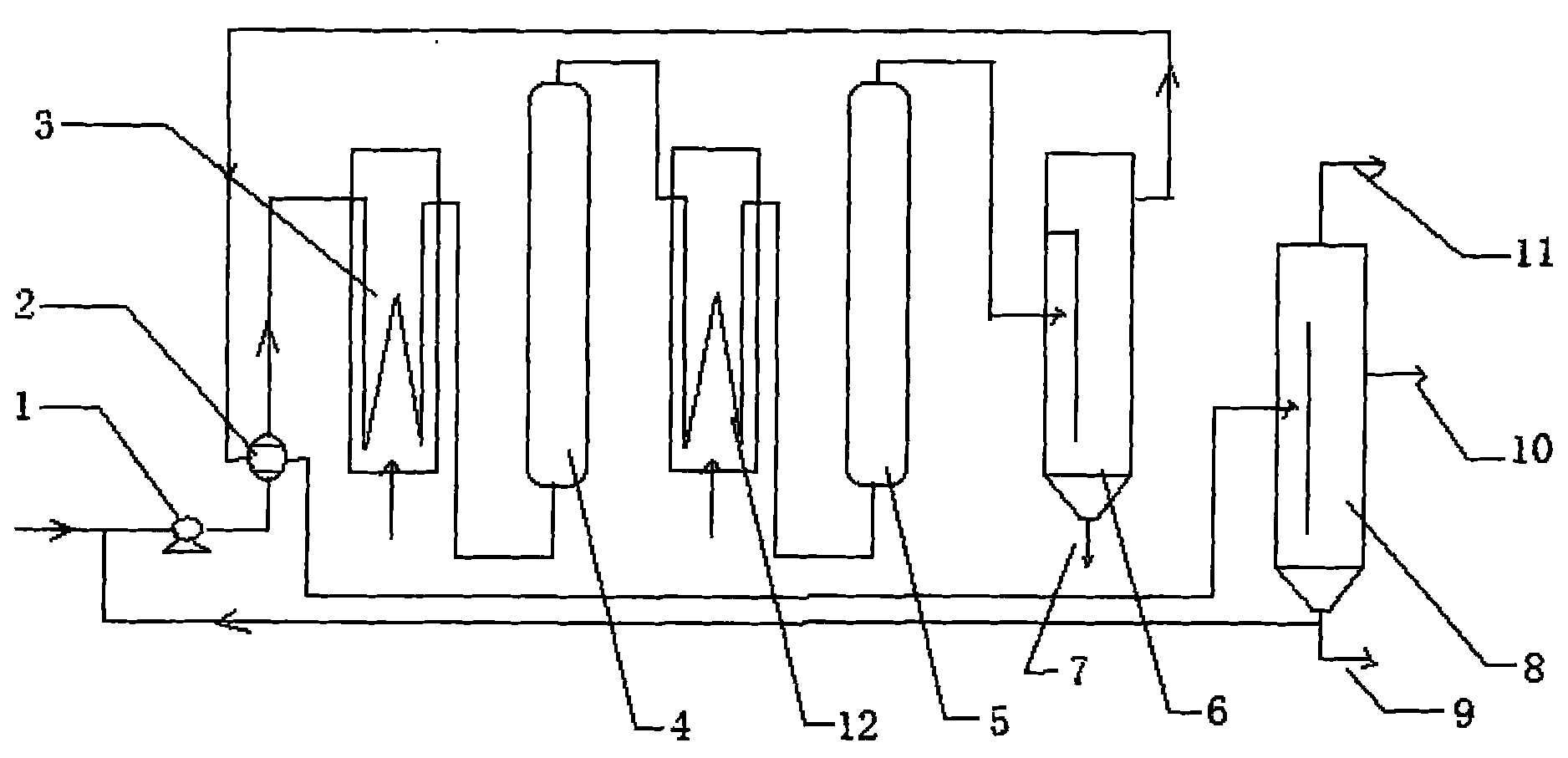

Fluidized bed process and device for preparing methane by synthetic gas

InactiveCN101665395AExpand technical routeRemarkable ability to remove heatHydrocarbon from carbon oxidesChemical/physical processesChemical industryFluidized bed

The invention relates to fluidized bed process and device for preparing methane by a synthetic gas, belonging to the field of chemical industry technologies and equipment. The process comprises the following steps: adding catalyst and diluent into a fluidized bed reaction vessel; heating and reducing the catalyst; charging the synthetic gas into the fluidized bed reaction vessel; charging a cooling medium into a reaction vessel heat exchange component to remove reaction heat; separating to obtain a methane product; and selectively containing the online replacement of the catalyst according tothe service life of the catalyst. The fluidized bed device comprises a reaction vessel simplified body, a raw gas inlet, a gas distributor, a heat exchange component, an expanding section, a cyclone separator, a catalyst feed opening and a gas outlet and selectively comprises a catalyst recovering machine and a gas stripping machine, and the reaction vessel can be divided into at least two stages.The invention has the advantages of good heat removing ability, uniform bed layer temperature, online replacement of the catalyst, high conversion rate and selectivity, long continuous running time of the catalyst, and the like.

Owner:TSINGHUA UNIV

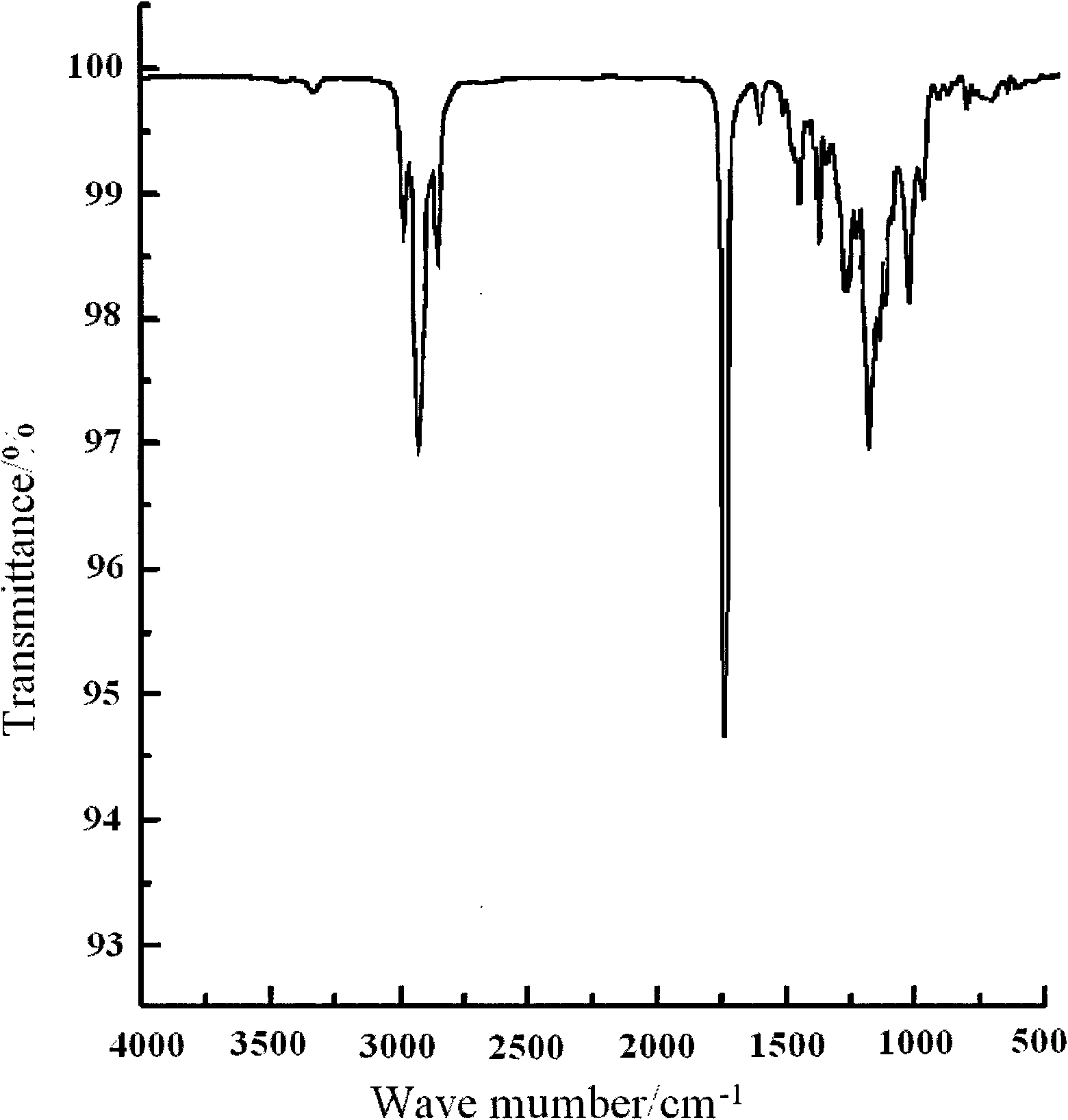

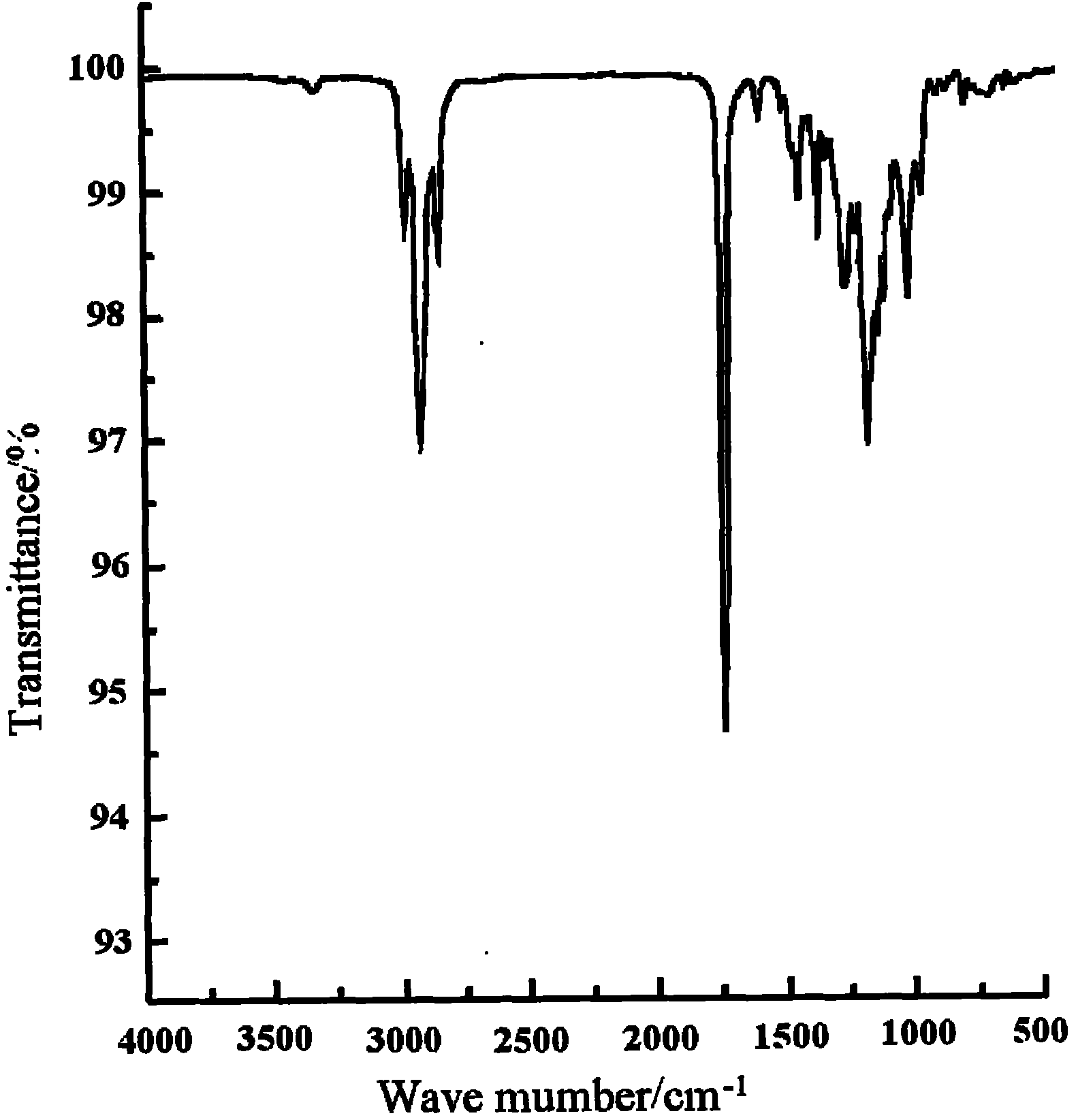

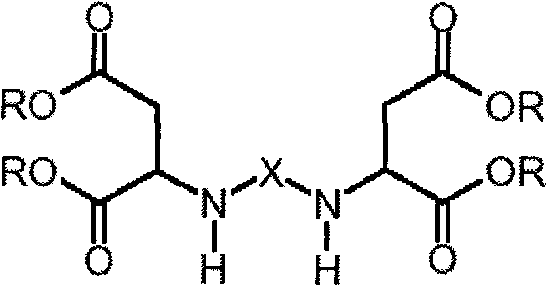

Method for preparing novel polyaspartic ester and application thereof

InactiveCN101817924AHigh reaction conversion rateShort reaction timePolyurea/polyurethane coatingsPolyasparticDicarboxylic acid

The invention discloses a method for preparing novel polyaspartic ester, in particular a method for preparing a component for slow reaction type polyurea paints. The method comprises the following concrete steps of: 1) performing a catalytic reaction of dicarboxylic ester and primary amine to obtain a Michael additive product; and 2) adding epoxy resin into the product obtained in the step 1) to obtain the novel polyaspartic ester after reaction. The method for preparing the novel polyaspartic ester shortens the reaction time, improves the reaction conversion ratio, and conveniently realizes industrial preparation. Due to the adoption of the method, the problems of low conversion ratio in short time, long synthesis time, failure of timely delivery, difficult industrial production or low product performance after solidification in the prior art are solved. The novel polyaspartic ester has high tensile strength and high elongation rate.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

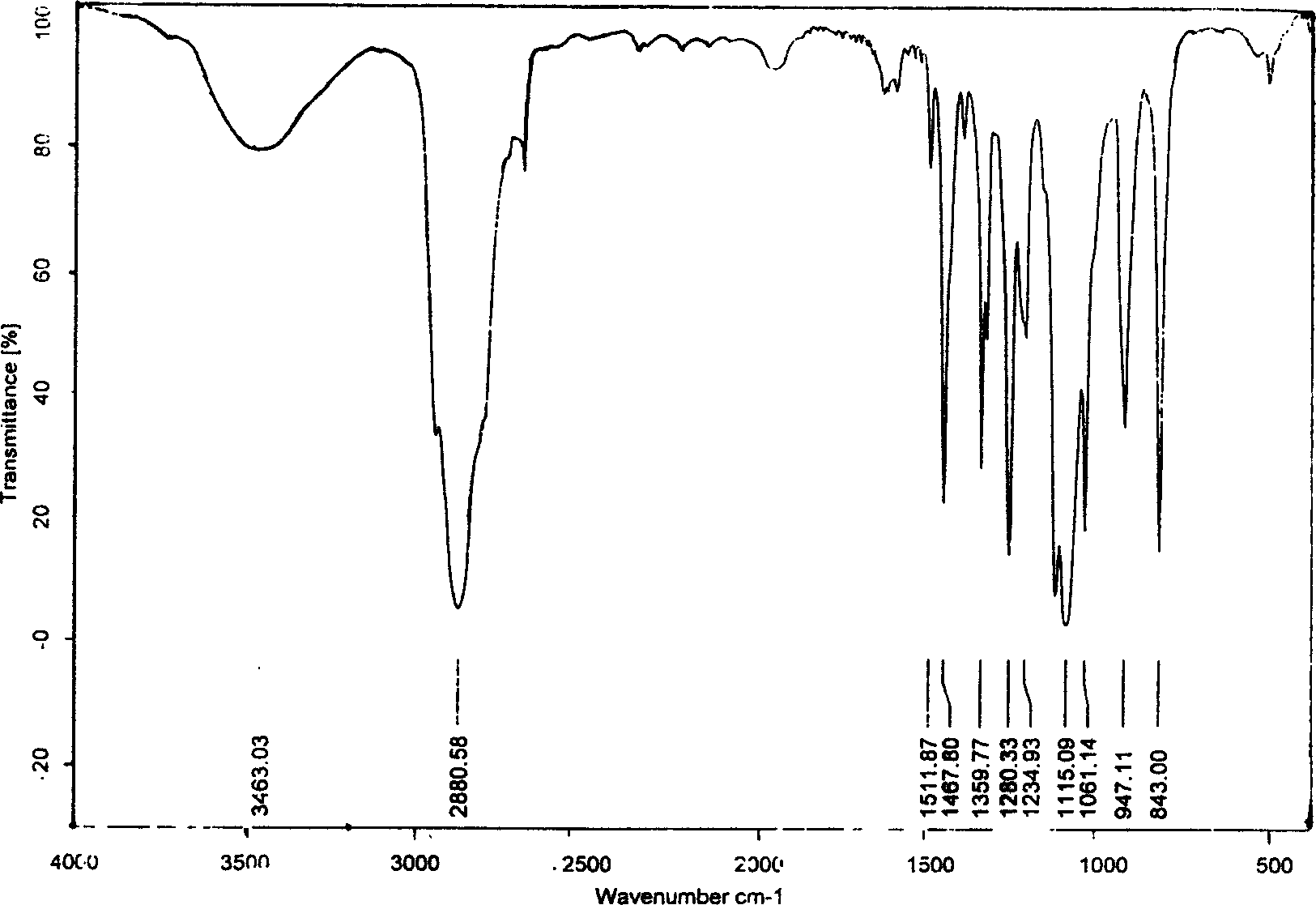

Room-temperature self-crosslinking water-soluble polyurethane acrylic resin and preparation method and application thereof

InactiveCN101544738ALow viscosityImprove conversion ratePolyureas/polyurethane adhesivesInksPolymer scienceAcrylic resin

The invention discloses a room-temperature self-crosslinking water-soluble polyurethane acrylic resin and a preparation method and an application thereof. The preparation method adopts an in-situ emulsion polymerization method and improves the prior preparation method, introduces tetramethyl benzene dimethylene diisocyanate or 2, 4 methyl cyclohexyl diisocyanate, and dipropylene glycol or neopentyl glycol functioning as chain extendor in raw materials, thereby lowering the viscosity of polyurethane prepolymer, and achieving the purpose of performing the synthetic reaction without organic solvent; oil-soluble evocating agent and water-soluble evocating agent are adopted to together evocate radical copolymerization so that oil-soluble monomer and water-soluble monomer can more effectively perform the radical copolymerization, thereby improving the reaction conversion rate. In addition, the combination of the two evocating agents also leads emulsion in the reaction to keep stable without easily jellifying and layering. The resin can be used for preparing plastics, aluminum foil package compound gel, paper-plastics compound gel, water color ink, water oil polish, water wooden ware paint or water plastic paint.

Owner:SUN YAT SEN UNIV

Synthetic method for polyoxymethylene dimethyl ether

ActiveCN103880614AEvenly distributedHigh adsorption potentialOrganic chemistryOrganic compound preparationActivated carbonReaction temperature

The invention relates to a synthetic method for polyoxymethylene dimethyl ether, and mainly overcomes the problem of relatively high cost in a conventional method for synthesizing polyoxymethylene dimethyl ether by using trioxymethylene as a raw material. The synthetic method takes use of methanol, methylal and paraformaldehyde as raw materials, wherein a mass ratio of methanol to methylal to paraformaldehyde is 0-10 : 0-10 : 1; and the usage amount of methanol and methylal is not zero at the same time; and the raw materials are contacted with a catalyst under a reaction pressure of 0.2-6 MPa to produce polyoxymethylene dimethyl ether (CH3O(CH2O)nCH3), wherein the used catalyst is selected from activated carbon. By adopting the above technical solution, the problem is overcome relatively well; and the synthetic method can be used for industrial production of polyoxymethylene dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

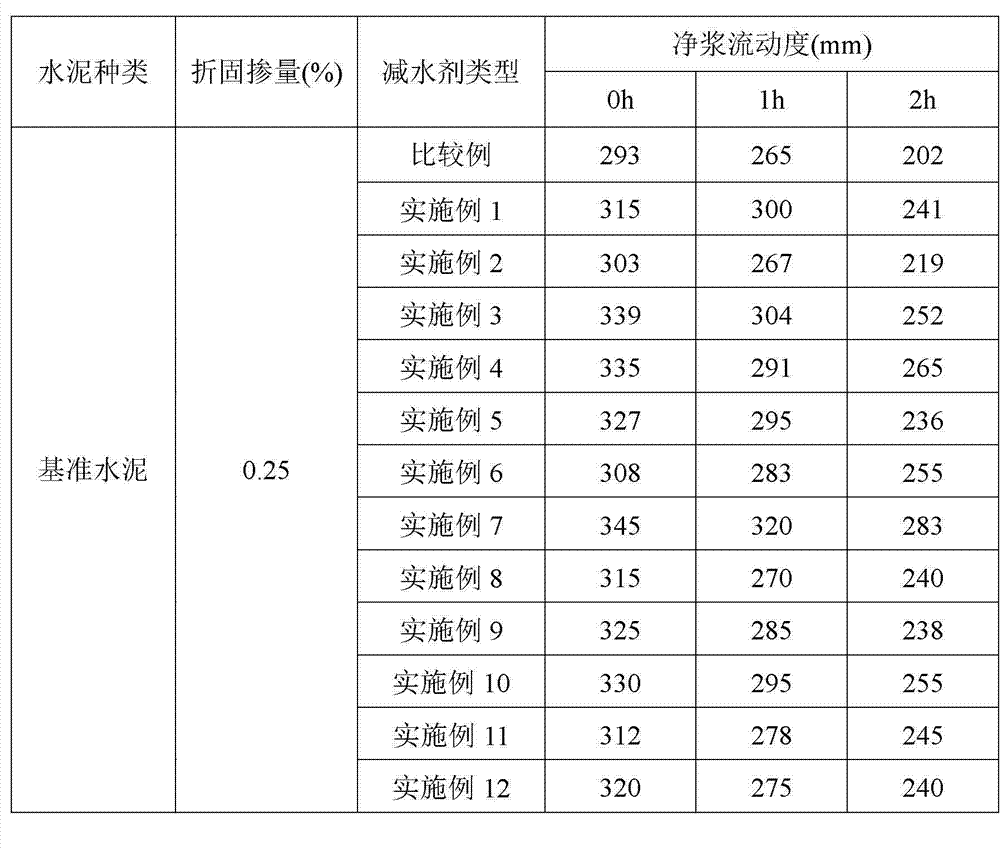

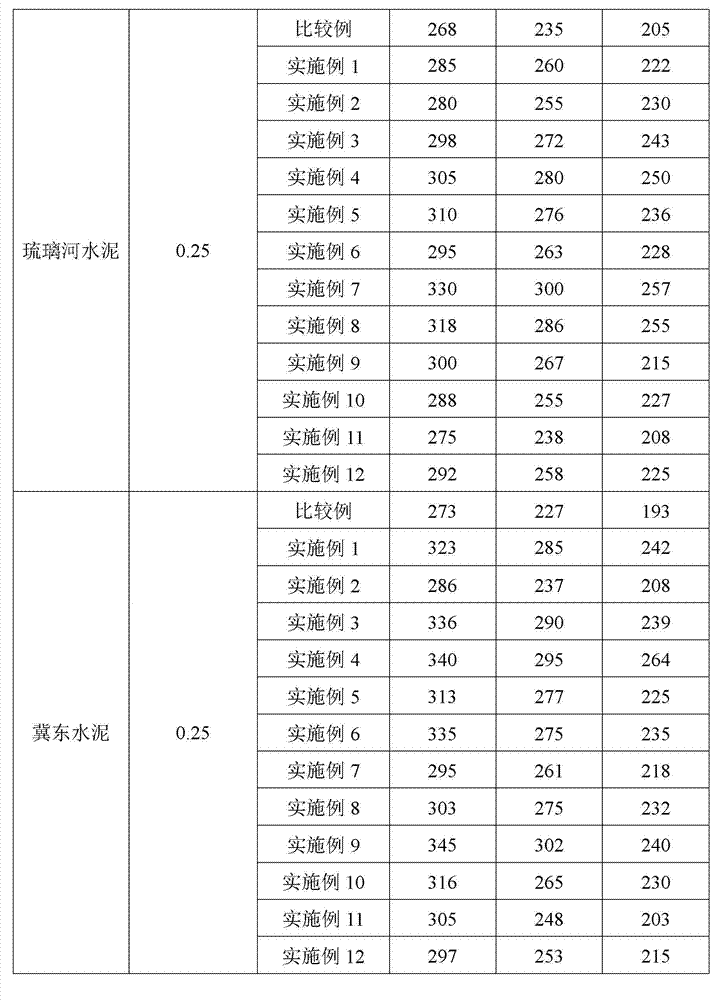

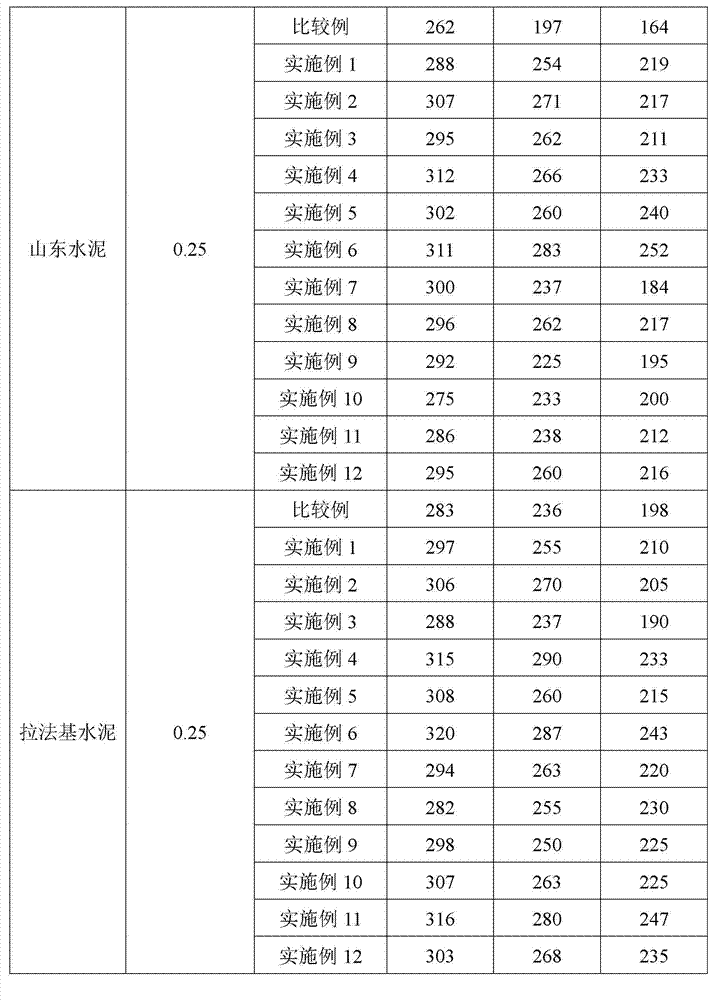

Preparation method of polyester type pure solid polycarboxylic acid high-performance water reducing agent

ActiveCN103012694AReduce shipping costsMarket competitiveness and application prospects are goodSolventControllability

The invention discloses a preparation method of a polyester type pure solid polycarboxylic acid high-performance water reducing agent, belonging to the field of water reducing agents. According to the invention, by taking a (methyl) acrylic acid monomer and a polyethylene glycol compound as reactants, a polymerizable macromonomer is prepared through esterification reaction under the effect of a catalyst, and the polymerizable macromonomer conducts a free radical bulk polymerization reaction with an unsaturated carboxylic acid monomer and a chain transfer agent under the effect of an initiator in an environment without any solvent to obtain the polyester type pure solid polycarboxylic acid high-performance water reducing agent. The method disclosed by the invention has strong process controllability, high degree of polymerization and low cost and prevents environmental pollution; a completely anhydrous polyester type pure solid polycarboxylic acid high-performance water reducing agent is prepared through esterification reaction and bulk polymerization, which has neat cement paste liquidity and holding ability, cement adaptability and concrete application performance similar to a traditional solution method; meanwhile, since the polymer product is an anhydrous pure solid, a solution with any concentration can be prepared according to actual needs; and without the after-treatment processes such as heating and drying, solvent separation and the like, the transportation is more convenient, and good market competitiveness and application prospects are realized.

Owner:BEIJING UNIV OF TECH

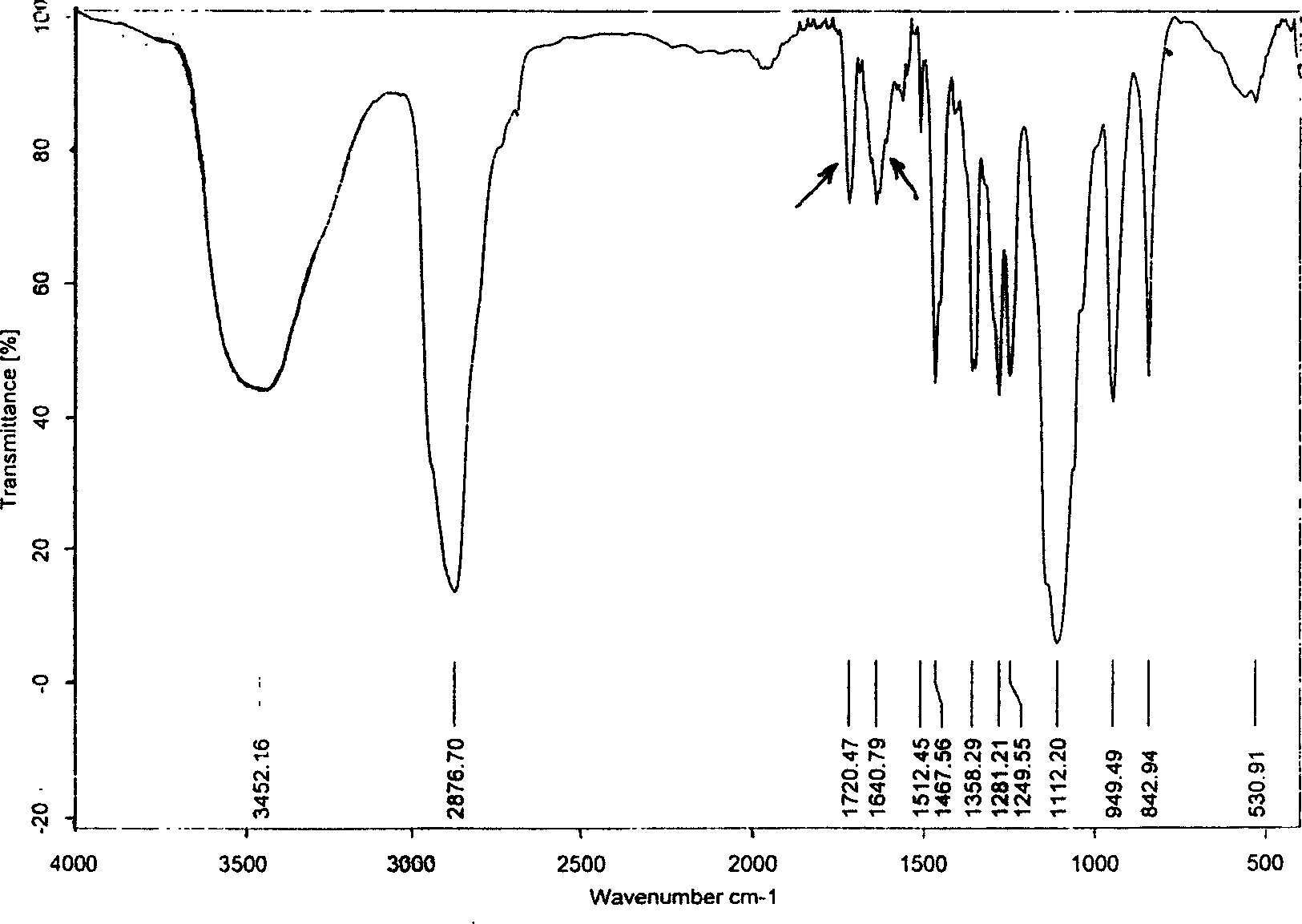

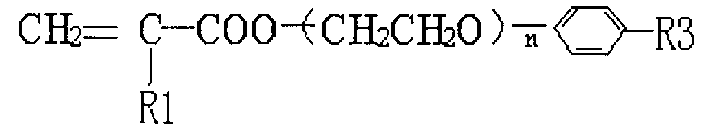

Lissapol N(methyl) propenoic acid ester and its preparation and use

InactiveCN1511859AMild reaction conditionsEasy to industrializeOther chemical processesTransportation and packagingMethacrylateAlkylphenol

The present invention relates to the preparation and use of alkylphenol ethoxylate (methyl) acrylic ester. The preparation is preferably a ester exchange reaction process including azeotropic dewatering of the mixture of alkylphenol ethoxylate and acrylic ester or methyl acrylic ester in the presence of azeotropic solvent and polymerization inhibitor, ester exchange reaction in the presence of catalyst, separating and recovering azeotropic solvent and acrylic ester or methyl acrylic ester to obtain alkylphenol ethoxylate (methyl) acrylic ester. The technological process is simple and has no polymerization of the material in the reactor and separating tower, good product appearance and alkylphenol ethoxylate converting rate up to 80-95 %.

Owner:SINOPEC QILU CO

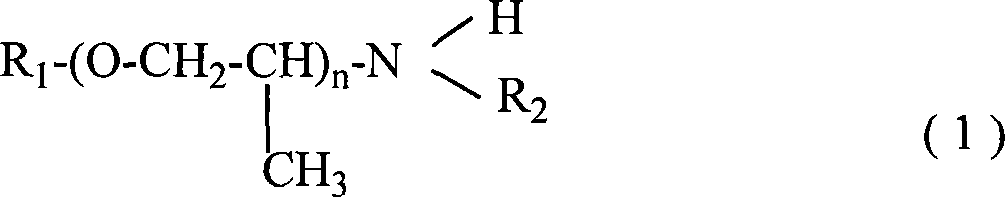

Polyethenoxyamines used as main agent of gasoline detergent and preparation method thereof

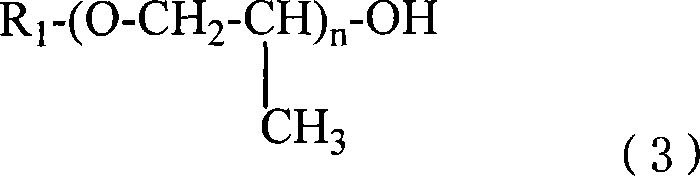

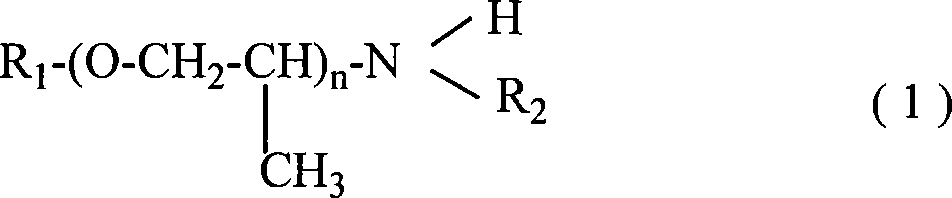

InactiveCN101225332AUnique chemical structureEasy to cleanOrganic chemistryLiquid carbonaceous fuelsCombustion chamberHydrogen

The invention relates to a polyetheramine used as the major component of gasoline detergent and the preparation method, which can be indicated by a general formula (1), in the formula (1), n is the repeated unit of the polyether segmer and the value is between 9 to 34; R1 is any one of the alkyl (C4 to C20), nonyl phenyl, octyl phenyl, dodecyl phenyl, pentadecyl phenyl, dinonyl phenyl and 2,6-di-tert-butyl-p-methylphenyl; R2 is any one of the hydrogen, methyl, ethyl, isopropyl or butyl. The preparation method comprises two steps: the preparation of polyether and the preparation of polyetheramine by the polyether with hydro-ammonification in a batch tank reactor. The polyetheramine used as the major component of gasoline detergent can be used as the major component of gasoline detergent and has the advantages of inhibiting carbon accumulation in the intake system and the combustion chamber of gasoline engine.

Owner:金浦新材料股份有限公司

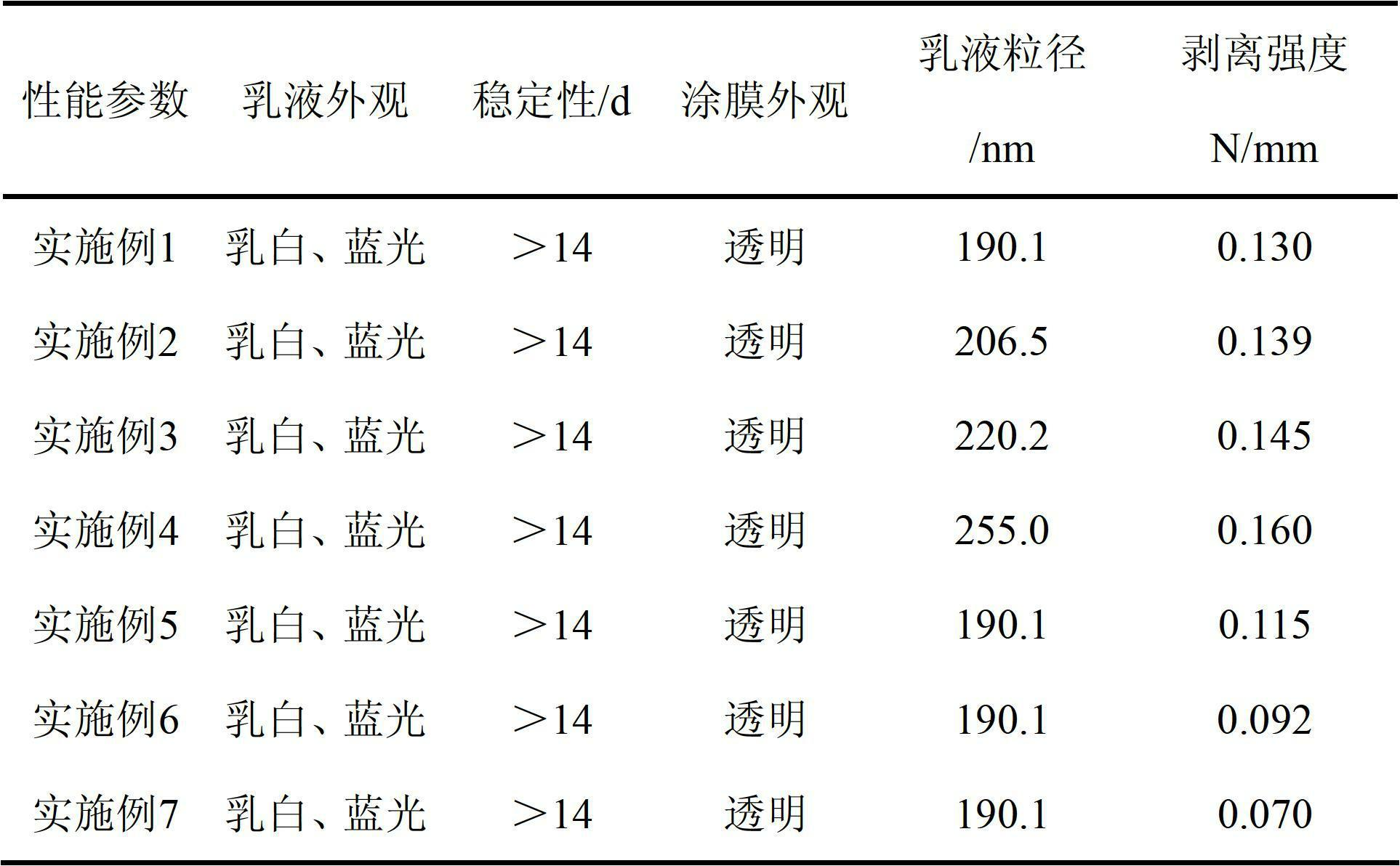

Preparation method of water-borne long-chain acrylate separant

InactiveCN102675527ARaw materials are easy to getSimple processCoatingsUltrasonic emulsificationSilicon

The invention discloses a preparation method of a water-borne long-chain acrylate separant. The method comprises the following steps: (1) adding a monomer, an emulsifying agent and the initiator into deionized water, pre-emulsifying at a constant temperature between 40 and 50 DEG C for 20 to 40 minutes to obtain a pre-emulsion; (2) performing ultrasonic emulsification on the pre-emulsion obtained in the step (1) to obtain a fine emulsion; and (3) pouring the fine emulsion obtained in the step (2) into a reactor, and reacting at a constant temperature between 75 and 85 DEG C for 6 to 7 hours to obtain the water-borne long-chain acrylate separant. According to the method, the crylic acid long-chain alkyl ester has strong hydrophobicity and the function of assisting emulsion, and other assistant emulsions are not added. The water-borne separant prepared by using the method has no silicon, low transfer possibility, good stability, high transformation rate and excellent separation effect. Furthermore, the water-borne separant has the advantages that raw materials are easy to prepare, the preparation process is simple, VOC (volatile organic compounds) emission amount is extremely low and environmental-friendliness effect is achieved.

Owner:SOUTH CHINA UNIV OF TECH

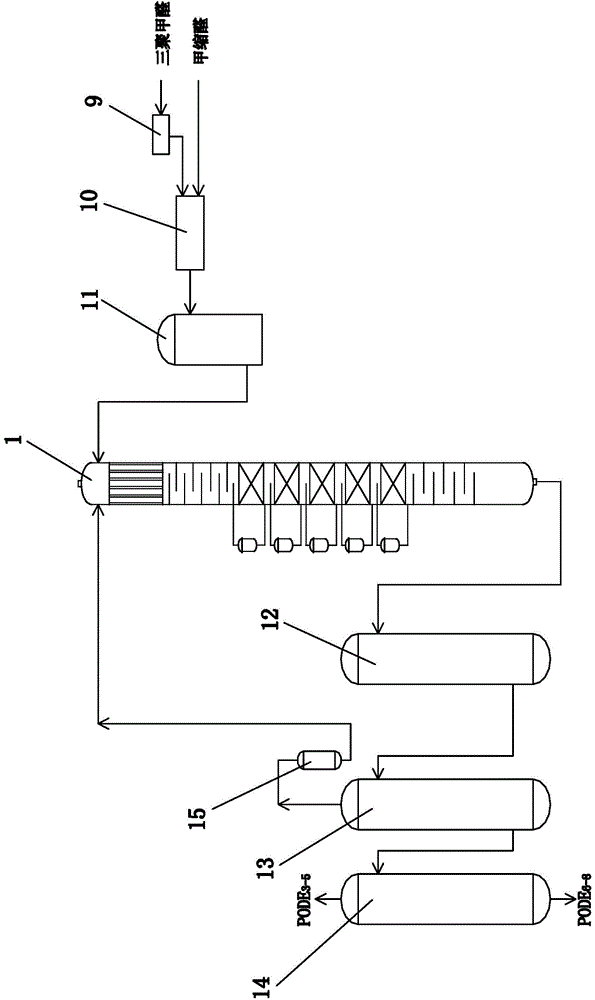

Method for preparing polymethoxy dimethyl ether through reaction and rectification of fixed bed

ActiveCN104355973AHigh catalytic activityEasy to separateOrganic chemistryOrganic compound preparationMolecular sieveTower

The invention discloses a method for preparing polymethoxy dimethyl ether through reaction and rectification of a fixed bed. The method comprises the following steps: (1) preheating trioxymethylene, uniformly mixing the preheated trioxymethylene and methylal, and feeding the trioxymethylene and the methylal which are uniformly mixed into a fixed bed reactor for an etherification reaction; (2) feeding materials after the etherification reaction into a reaction rectifying tower for the reaction and the rectification, and discharging PODE2-8 from the tower bottom of the reaction rectifying tower; (3) transporting the PODE2-8 to a dewatering tower loaded with a 3A molecular sieve for dehydration, then transporting the dehydrated PODE2-8 into a first refining tower, transporting materials which are discharged from the tower bottom of the first refining tower into a second refining tower, discharging PODE3-5 from the tower top of the second refining tower, and discharging PODE6-8 from the tower bottom of the second refining tower. When the method disclosed by the invention is used for preparing the PODE3-8, the yield of the polymethoxy dimethyl ether can reach 95%, wherein the products of the PODE3-8 can reach 80%-95%, and after refinement, the PODE3-5 of which the quality purity reaches 99.9% can be obtained.

Owner:XIAN SHANGHUA TECH DEV CO LTD

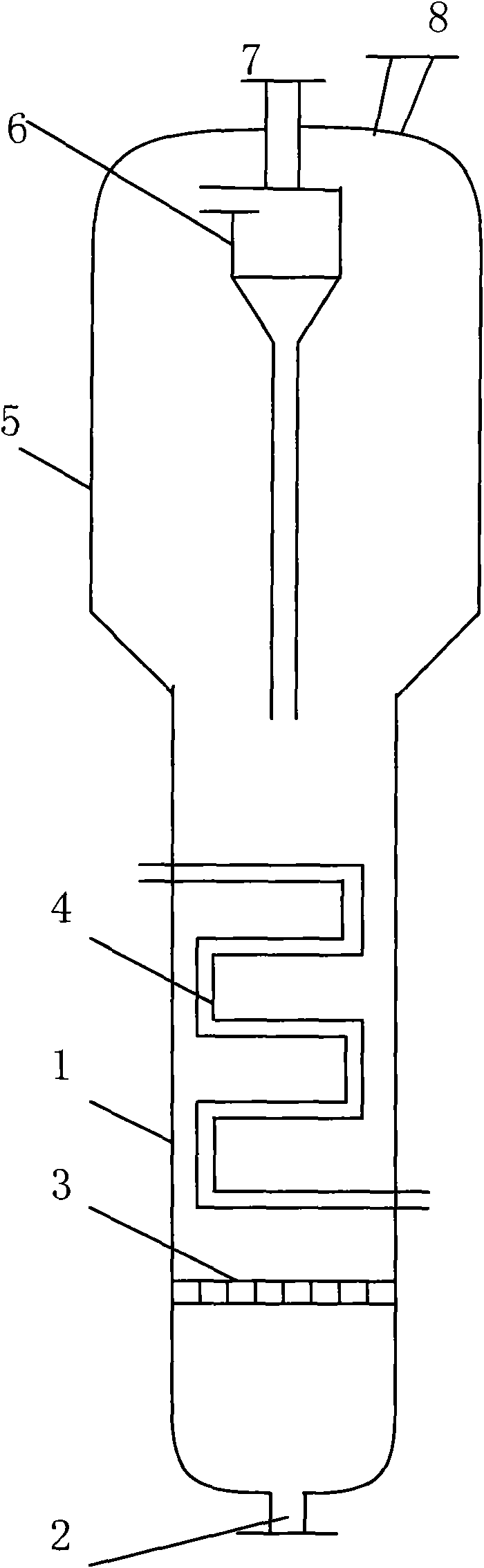

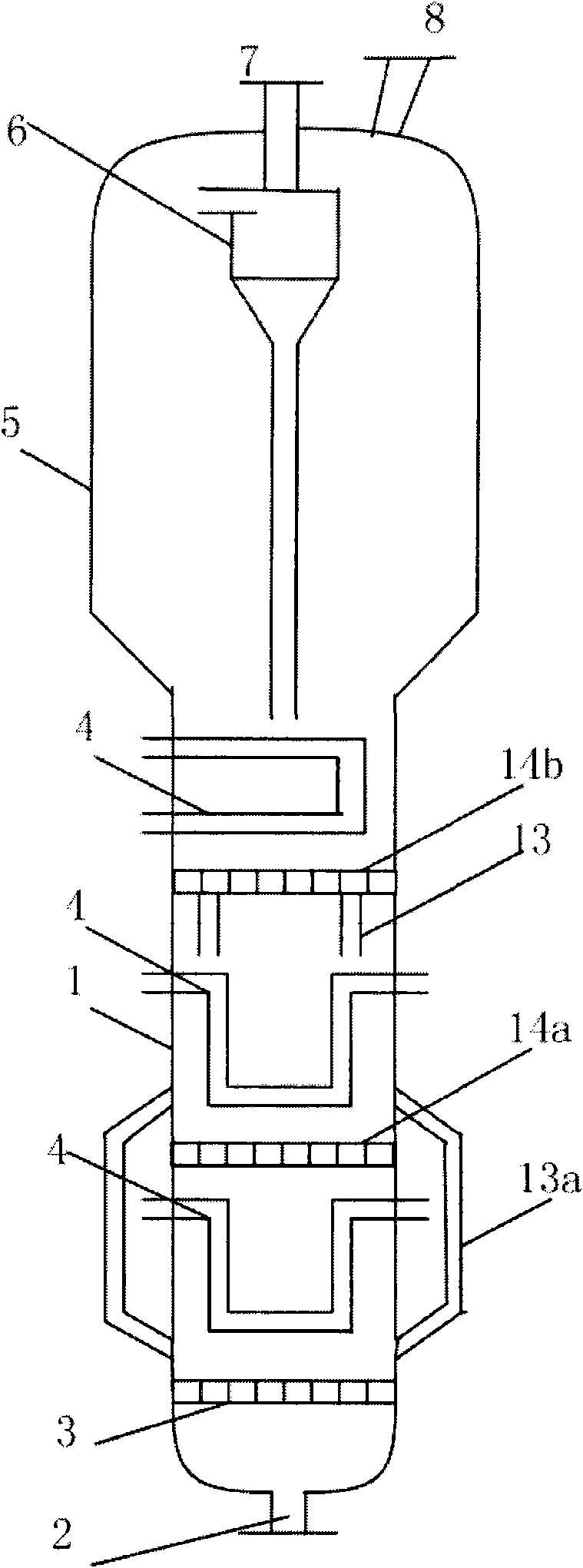

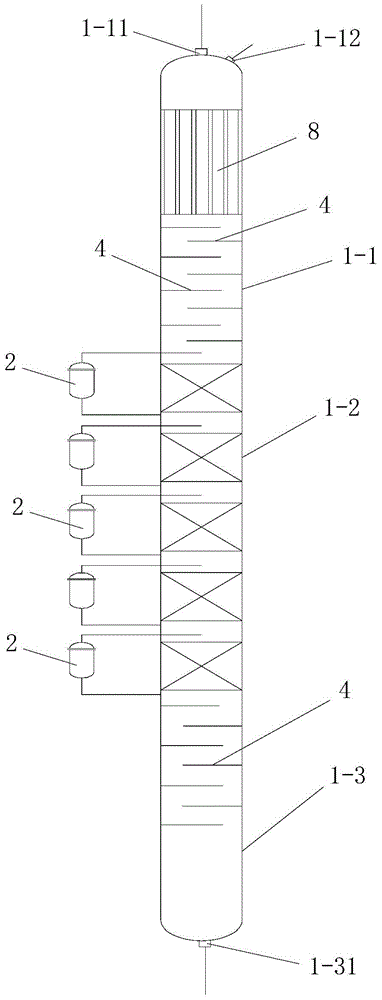

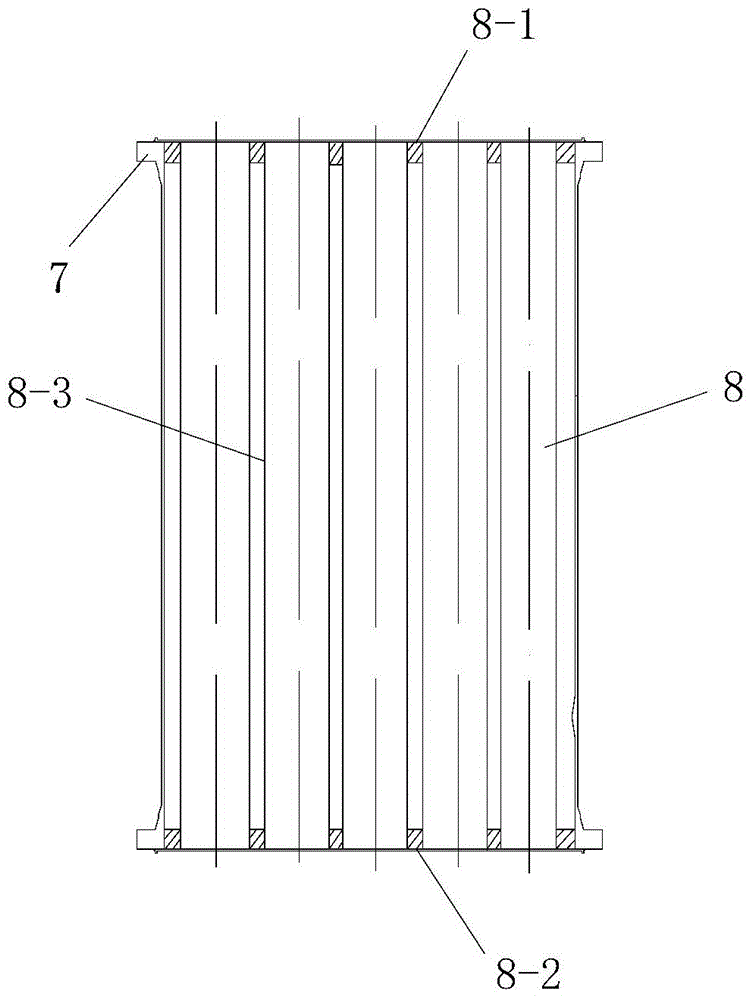

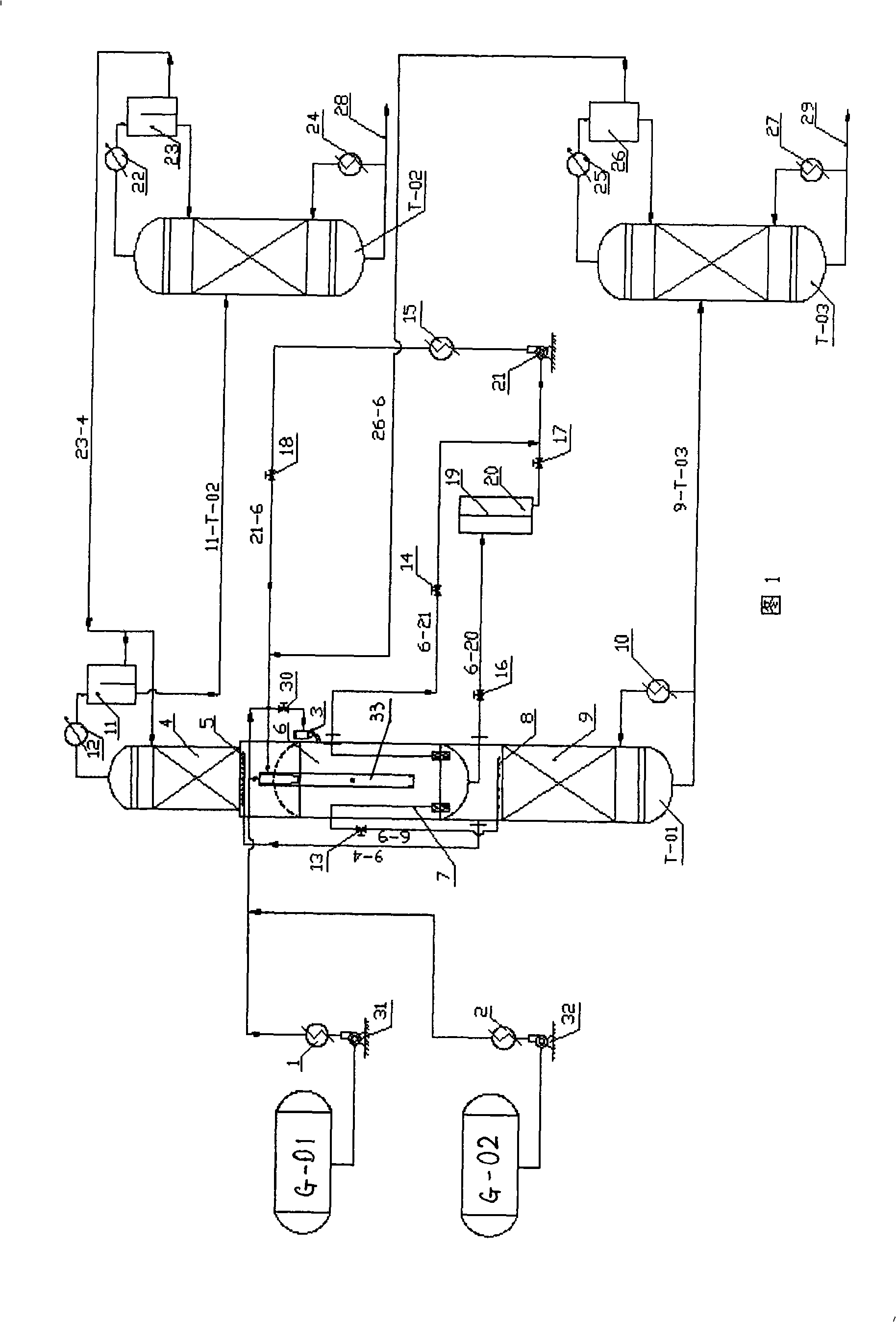

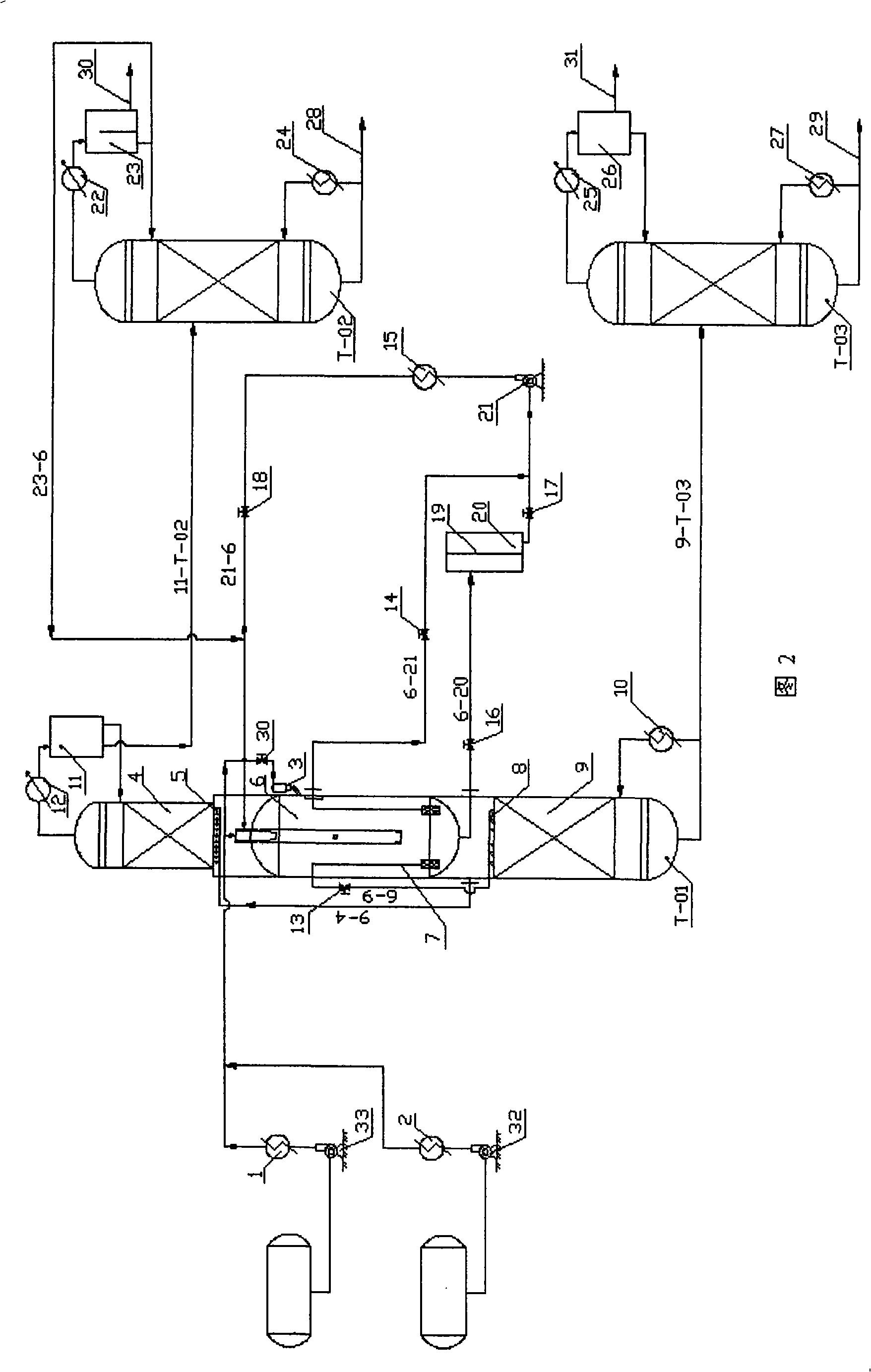

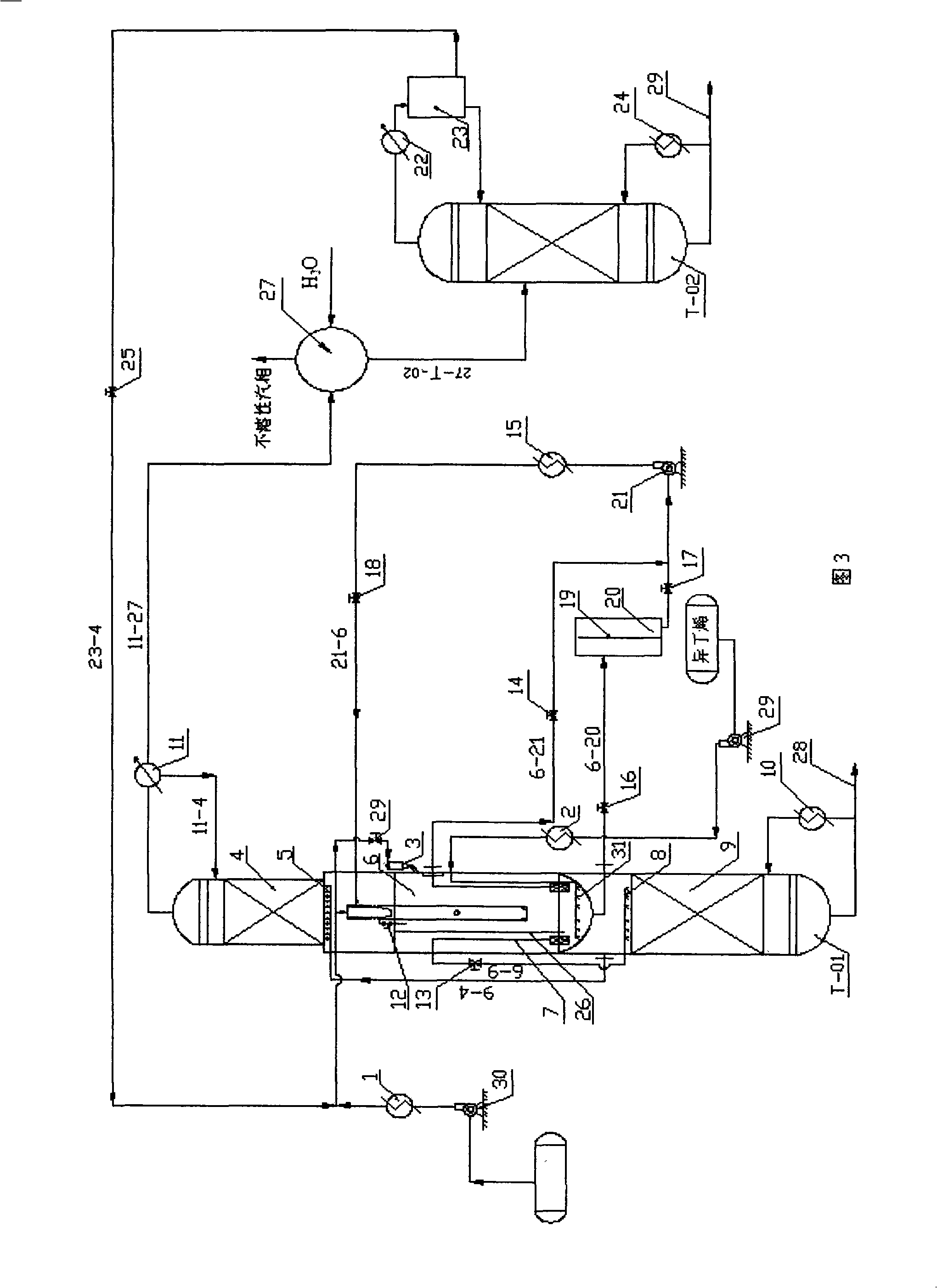

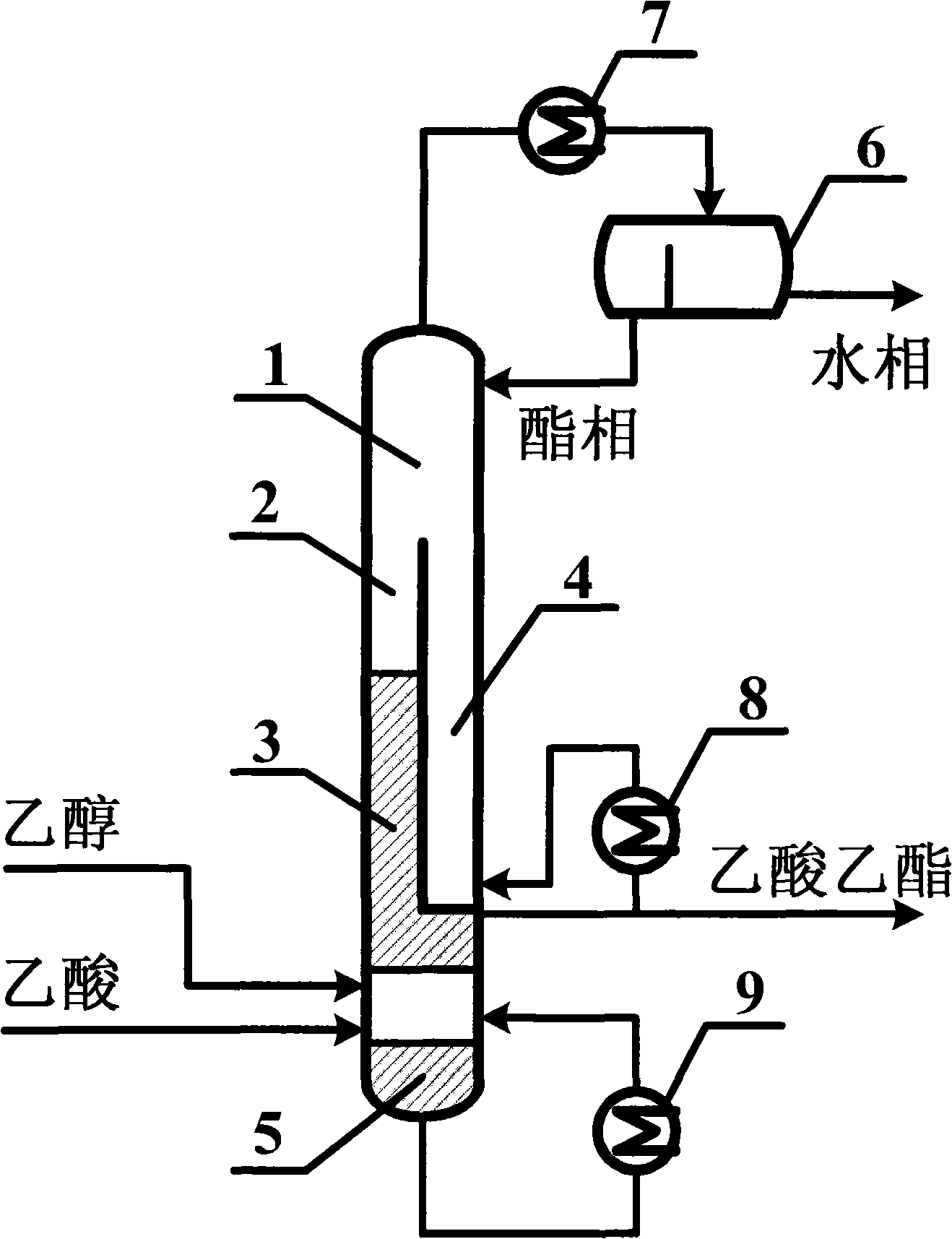

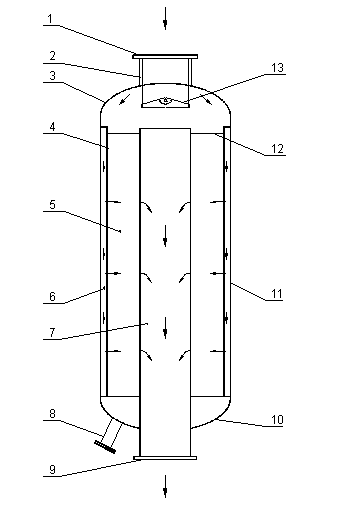

Catalytic reaction, rectification integrated technique and special-purpose equipment

InactiveCN101254444AIncrease production capacityHigh reaction conversion rateOrganic compound preparationCarboxylic acid esters preparationAlcoholEther

A catalytic reaction / rectification integrated process is provided, which includes: reaction raw materials are pre-heated and then mixed with catalysts; the resulting mixture is fed into a jet mixing reaction section 6 of a catalytic reaction / rectification integrated tower through a feed port, wherein the jet mixing reaction section 6 is a kettle-like reactor in the middle of the catalytic reaction / rectification integrated tower T-01; after the reaction raw materials are pressurized by a centrifugal pump, a subsonic or transonic jet mixer 33 inside the jet mixing reaction section 6 jets the reaction raw materials at a high speed into the jet mixing reaction section 6 and performs high-efficiency mixing of solid and liquid phases inside the jet mixing reaction section 6, thereby enhancing the heat and the mass transfer efficiencies during the process; the reaction mixture is directly separated and purified inside the catalytic reaction / rectification integrated tower. Therefore, the catalytic reaction / rectification integrated process has high conversion rate and production capacity and low energy consumption and production cost. The process is used for esterification, alcohol synthesis from alkenes and water, and the ether synthesis from alkenes and alcohols. A special catalytic reaction / rectification integrated tower is also provided.

Owner:NANJING UNIV

Modified octahedral zeolite

InactiveCN1209288CGood hydrothermal stabilityHigh reaction conversion rateCatalytic crackingFaujasite aluminosilicate zeoliteAmmonium compoundsFiltration

A modified faujasite is obtained by exchanging the faujasite with a phosphorus compound and an ammonium compound, and then introducing a rare earth solution into the exchange slurry for further reaction, filtering, washing, and roasting with water vapor. Mix the zeolite component, clay and the precursor of the high-temperature-resistant inorganic oxide uniformly in a certain proportion, spray molding, and washing. The prepared catalyst has good activity and stability, high gasoline yield, low coke yield, and heavy oil Strong cracking ability and heavy metal pollution resistance.

Owner:PETROCHINA CO LTD

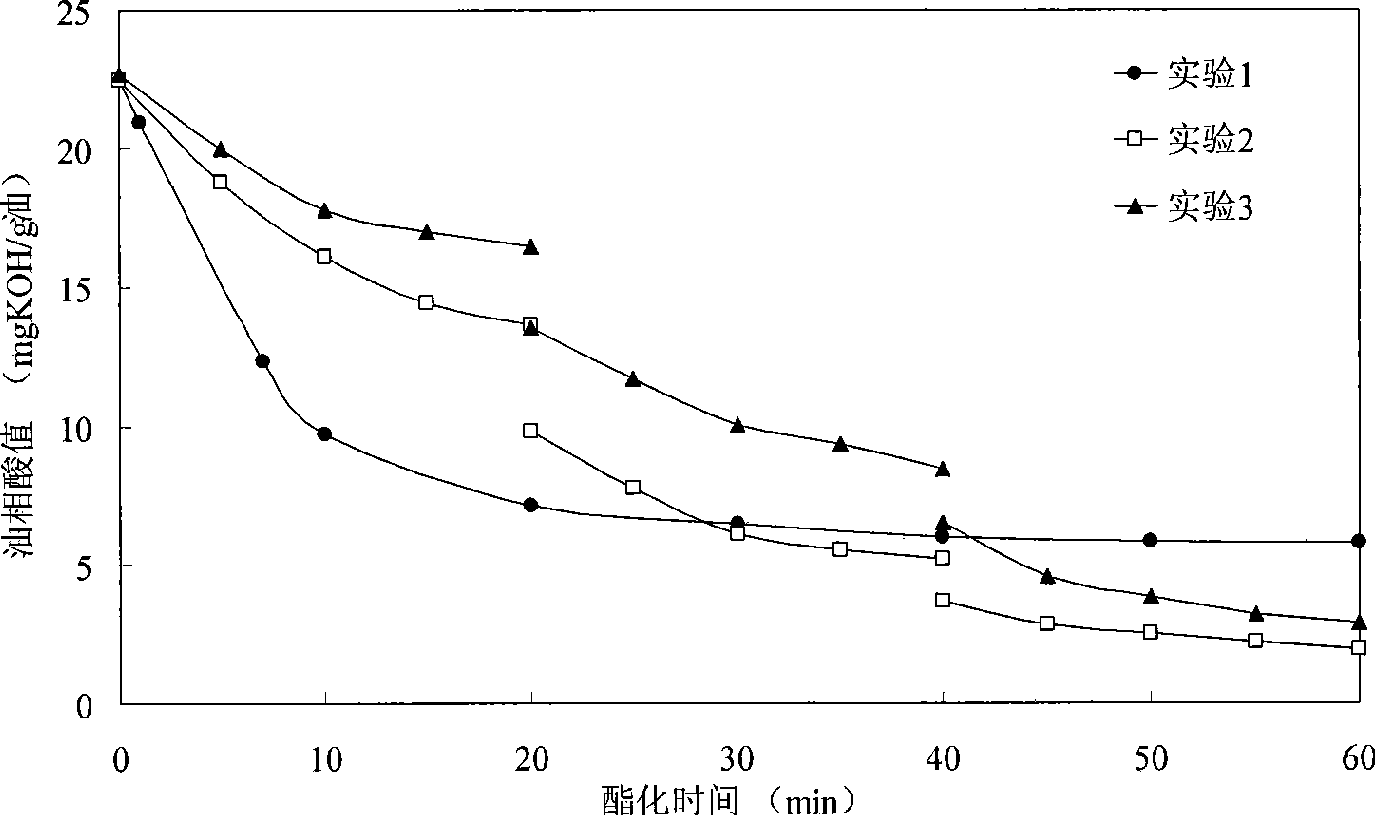

Inorganic nano composite anti-doodling resin and preparation method thereof

ActiveCN104558447AEasy to modifyGood weather resistanceAntifouling/underwater paintsPaints with biocidesRadical polymerizationWeather resistance

The invention discloses an inorganic nano composite anti-doodling resin and a preparation method thereof. Silane-coupling-agent-modified inorganic nanoparticles, fluorine-containing acrylate monomer, alkyl acrylate monomer and hydroxyalkyl acrylate monomer are subjected to free-radical polymerization reaction to obtain the inorganic nano composite anti-doodling resin. The film formed by the inorganic nano composite anti-doodling resin has the advantages of excellent weather resistance, excellent scratch resistance, excellent chemical corrosion resistance, excellent ultraviolet resistance, excellent wear resistance, low surface energy, excellent pollution resistance and excellent anti-doodling performance, thereby implementing the long-term anti-doodling action. The invention relates to the field of an anti-doodling resin and a preparation method thereof.

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

Synthetic method of cyclosulphate

InactiveCN110386916AHigh reaction conversion rateImpurities increaseOrganic chemistrySecondary cellsCatalytic oxidationOrganic layer

The invention discloses a synthetic method of cyclosulphate. A peroxysulfate solution is pre-synthesized through sulfuric acid and hydrogen peroxide, then under existence of an organic solvent, a metal inorganic compound and a catalyst, the peroxysulfate solution is dropwise added to generate a catalytic oxidation reaction with cyclosulfite, after the reaction is completed, salt residue is filtered out, still standing for layering is conducted, an organic layer is taken to be distilled, concentrated and purified, and a cyclosulphate high-quality product is obtained. According to the syntheticmethod of the cyclosulphate, the cheap sulfuric acid and hydrogen peroxide are used as the raw materials, the peroxysulfate solution is prepared to conduct catalytic oxidation on the cyclosulfite, onthe one hand, the reaction is mild, control is easy, and the reaction conversion rate is high; on the other hand, the evaporation capacity of water is small, energy consumption is low, generated wastewater is less, and a synthetic process is more environmentally friendly; and the prepared cyclosulphate is few in impurity, high in purity and wide in market prospect.

Owner:CHANGSHU CHANGJI CHEM

Method for preparing 5-hydroxymethylfurfural by taking glucose as raw material

ActiveCN101628902AHigh reaction conversion and selectivityAvoid side effectsOrganic chemistryBulk chemical productionChemistrySupercritical carbon dioxide

The invention discloses a method for preparing 5-hydroxymethylfurfural by taking glucose as a raw material, which comprises the steps of: mixing the glucose with water according to the mass ratio of 1: 3-10, loading the mixture into a high-pressure reactor, sealing the high-pressure reactor, increasing the reaction temperature to be between 120 and 250 DEG C, injecting liquid carbon dioxide into the reactor, and controlling the pressure to be between 10 and 25MPa; performing the separation of carbon dioxide and a product on supercritical carbon dioxide with the product dissolved therein through a separator during the reaction, and controlling the separation pressure to be between 5 and 8MPa and the separation temperature to be between 25 and 70 DEG C; and discharging the product from the bottom of the separator, and obtaining a 5-hydroxymethylfurfural product through drying, dehydration and crystallization. The method has the advantages of high selectivity of the 5-hydroxymethylfurfural, continuous production, high product content, green and environment-friendly process, and easy industrialized production.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

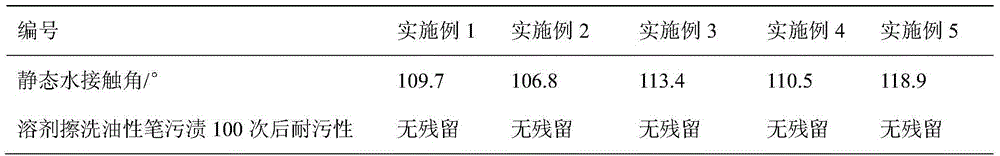

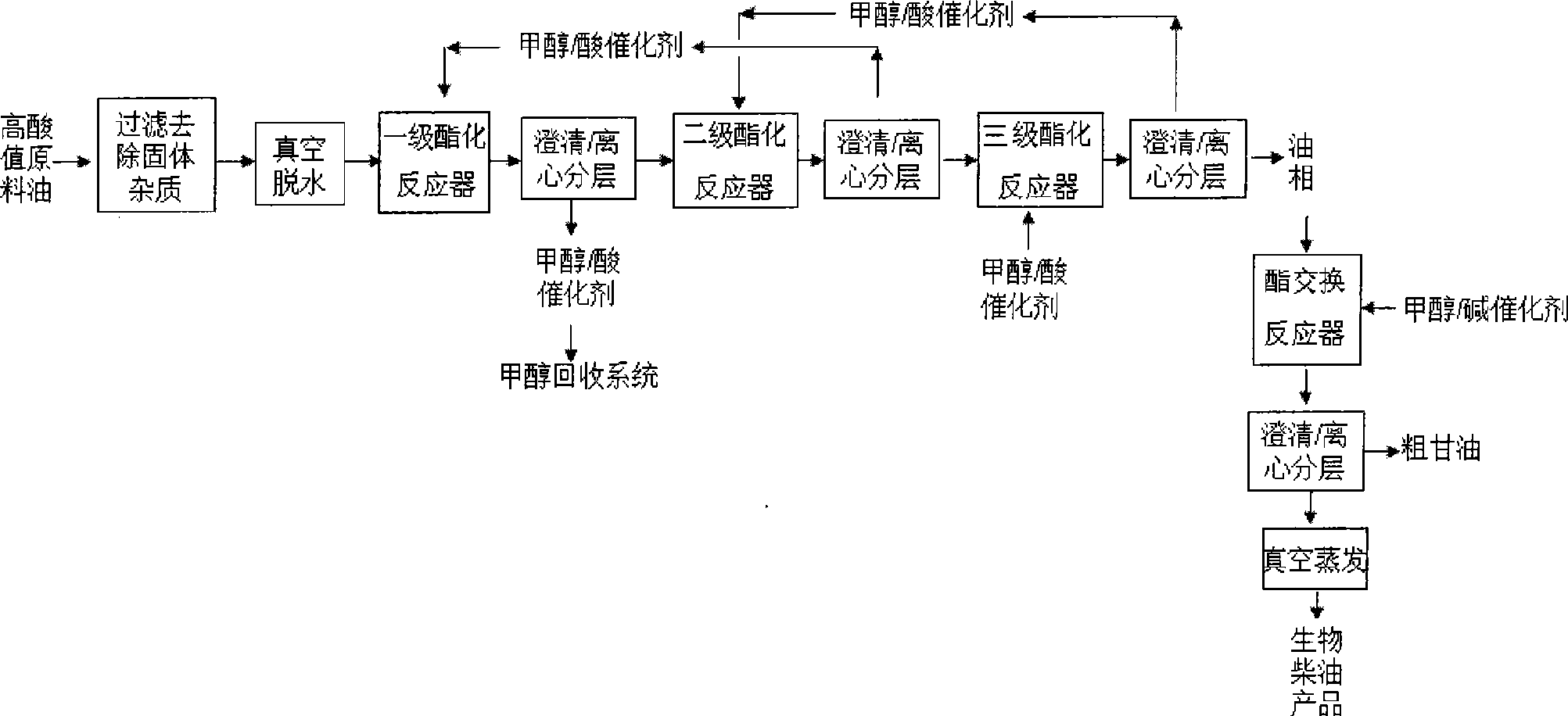

Method for preparing biodiesel by utilizing stratified and graded esterified deacidification of high acid value oil

InactiveCN101445742AHigh reaction conversion rateNot easy to carbonizeBiofuelsLiquid hydrocarbon mixture productionOil and greaseFiltration

The invention provides a method utilizing high acid value oil as raw material for preparing biodiesel. Various animal and vegetable oil, the acid value of which is larger than 3.0mg KOH / g oil, oilstock, soapstock and acidic oil in a vegetable oil refining process, various food waste oil (restaurant waste oil, hogwash oil, trench waste oil, and the like) and various waste animal oil in industrial processing (waste animal oil in leather processing, waste animal oil in slaughtering process, and the like) are used as raw materials to obtain biodiesel products by filtration for removing solid impurities, vacuum dehydration, stratified graded acid catalytic esterification, alkali catalytic transesterification and vacuum distillation. The method utilizing the high acid value oil as the raw material for preparing the biodiesel has the beneficial effect that the production process can be applied to raw materials with different acid values to produce biodiesel products with high purity by changing the operational series of the stratified graded acid catalytic esterification reaction and has the advantages of simple process, low energy consumption, high conversion rate and small device. And continuous production can be realized.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of sofosbuvir intermediate

ActiveCN104151352AEnvironmental protection and green patentsEnvironmental Protection and Green LiteratureGroup 5/15 element organic compoundsKetone solventsKinetic resolution

The invention discloses a preparation method of a sofosbuvir intermediate, which comprises the following step: in an anhydrous non-protonic solvent, carrying out dynamic kinetic resolution on a compound disclosed as Formula (II) under the action of an organic alkali and / or inorganic alkali to prepare a compound disclosed as Formula (I), wherein the non-protonic solvent is one or more of ester solvent, ketone solvent and ether solvent, the organic alkali and / or inorganic alkali account / accounts for 0.1-10 wt% of the compound disclosed as Formula (II), the temperature of the dynamic kinetic resolution is 10-30 DEG C, and the time of the dynamic kinetic resolution is 5-10 hours. The preparation method has the advantages of high conversion rate, high product purity and low cost, and is environment-friendly.

Owner:CHEMVON BIOTECH CO LTD

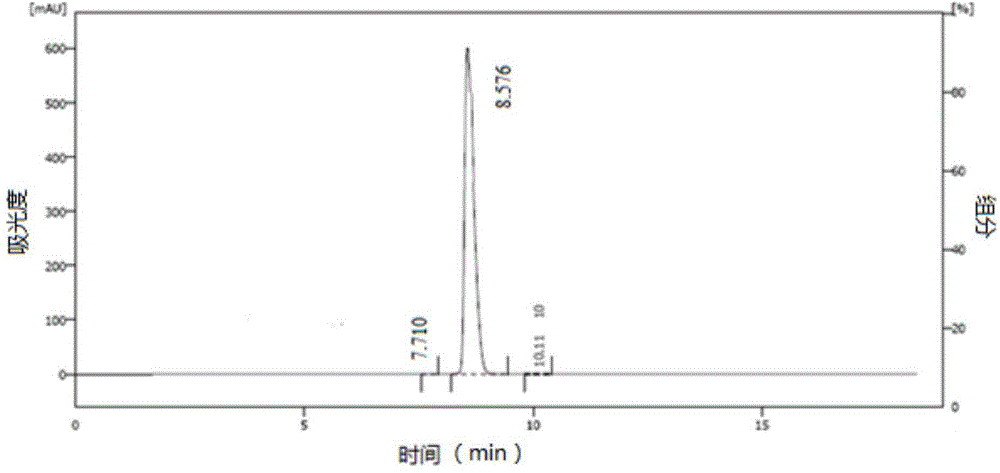

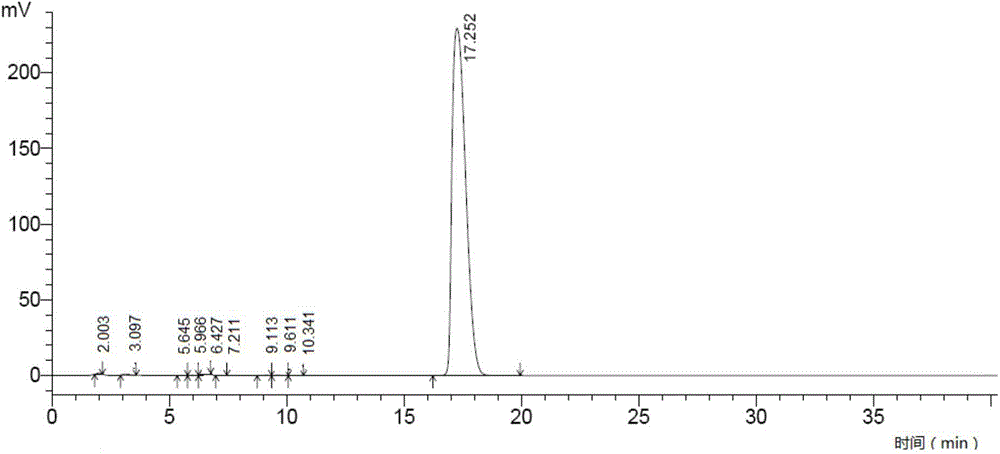

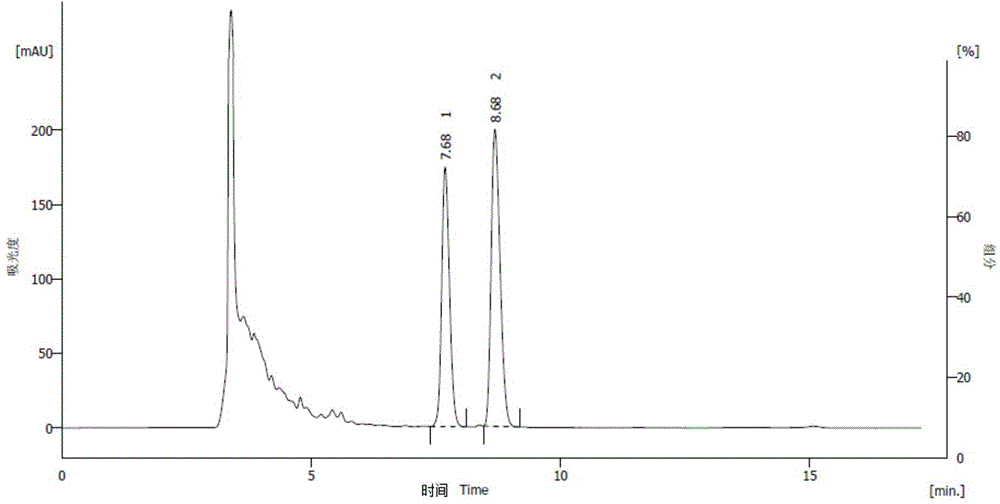

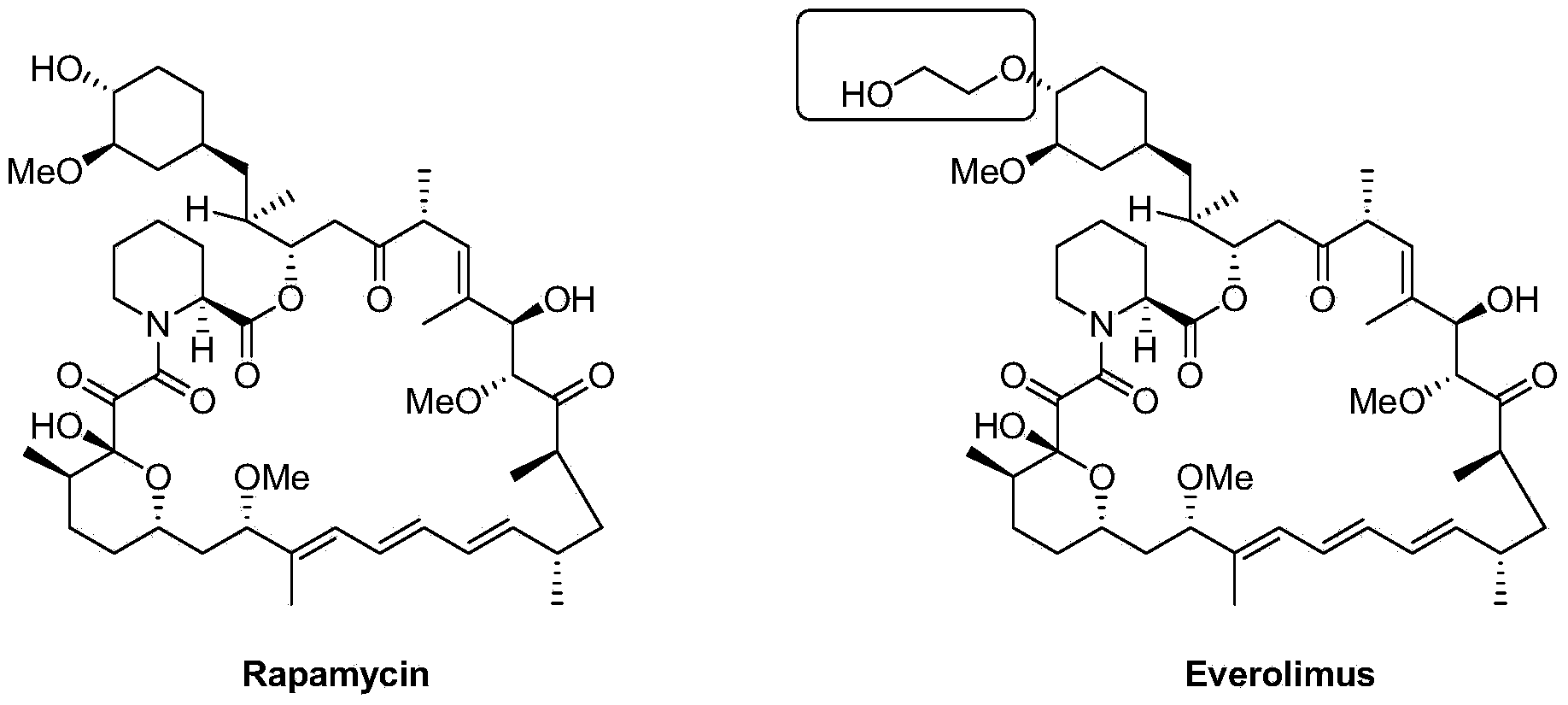

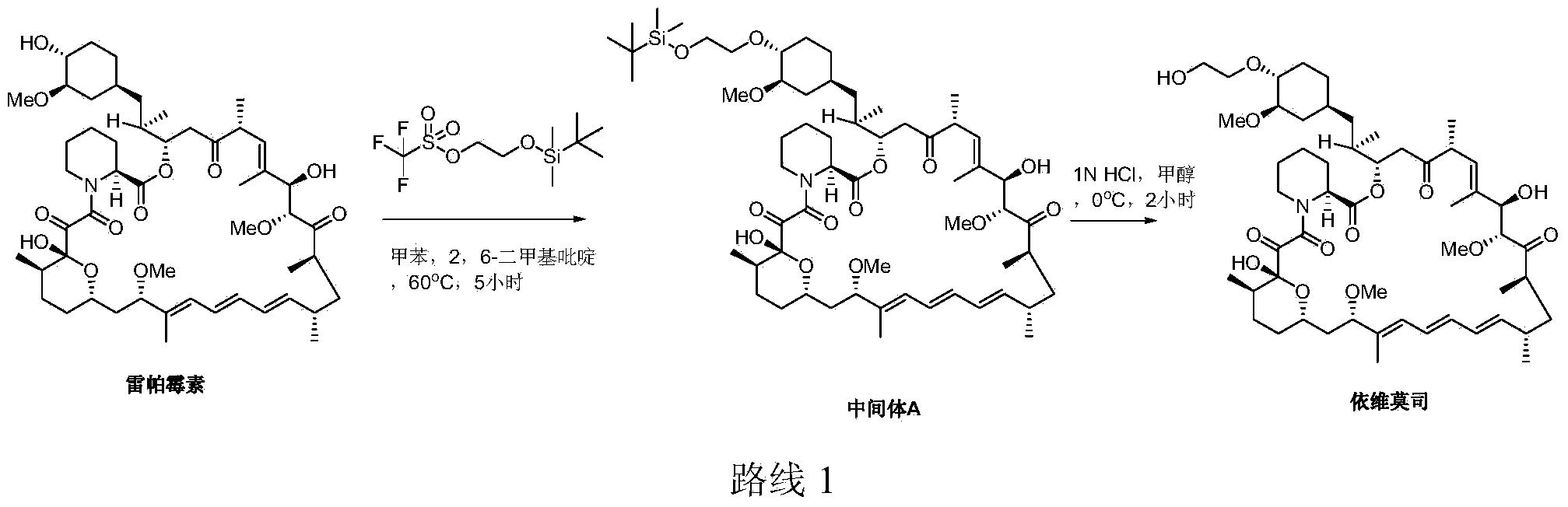

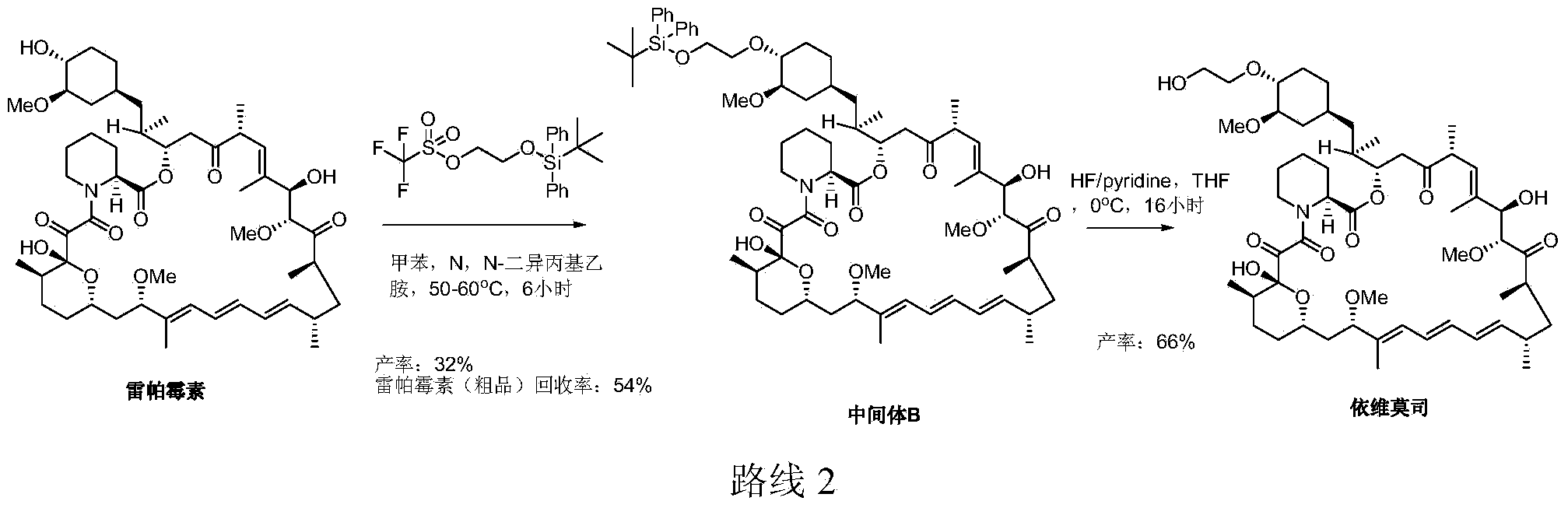

Preparation technology for everolimus

The invention provides a preparation technology for everolimus. The preparation method comprises the two steps of: 1) reacting sirolimus with 2-(tert-butyldiMethylsilyloxy) ethyl trifluoromethane sulfonate in the presence of proper solvent and organic base, to obtain an intermediate A; 2) reacting the intermediate A with inorganic acid in an organic solvent to obtain everolimus, wherein the organic base used in the step 1) is selected from large-steric hindrance or non-nucleophilic bases such as triethylamine, N,N-diisopropylethylamine, 1,8-diazabicycloundec-7-ene or N-methylmorpholine, acid used in the step 2) is hydrochloric acid, sulfuric acid or phosphoric acid. According to the technology, the total yield in the two steps and the purity of a final product are greatly improved as compared with those reported by the existing literature, the process route is short, the reaction conditions are mild, and the reaction result is also stable and reliable.

Owner:SHANGHAI INST OF PHARMA IND CO LTD +1

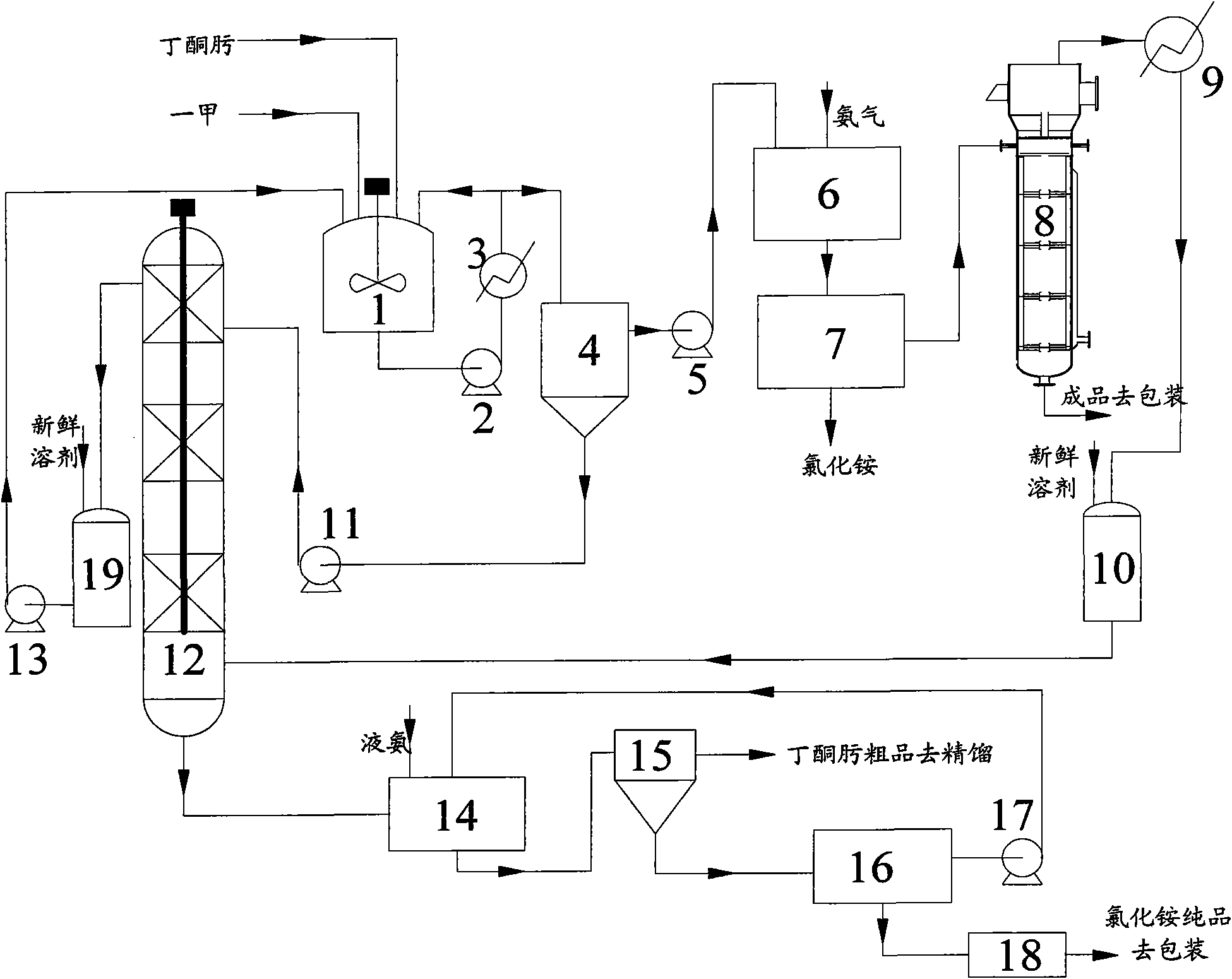

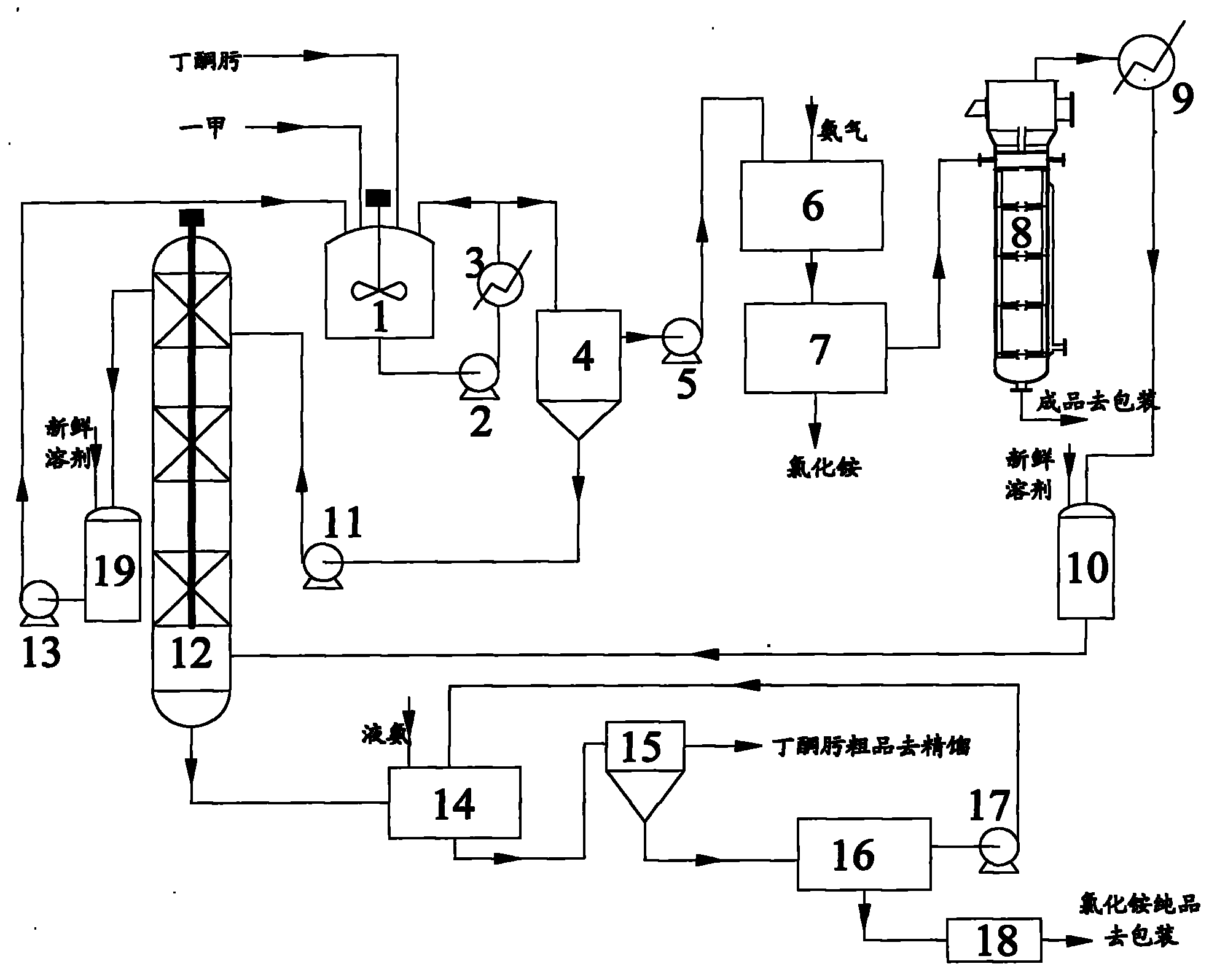

Preparation method of methyl tris-methylethylketoxime silane

ActiveCN102079753ANothing producedNo pollution in the processGroup 4/14 element organic compoundsSilanesMethyltrichlorosilane

The invention discloses a preparation method of methyl tris-methylethylketoxime silane, comprising the following steps of: a, respectively and continuously pumping monomethyl trichlorosilane, diacetylmonoxime and a solvent No. 120 into a kettle type stirring reactor by a feeding pump via a flowmeter, circulating one part of discharged reaction materials to the kettle type reactor, and recovering the other part of discharged reaction materials, precipitating and separating the recovered materials through a two-phase separator for demixing to obtain a solvent, as well as crude products of methyl tris-methylethylketoxime silane, unreacted diacetylmonoxime and a little included diacetylmonoxime hydrochloride in the upper layer, and a diacetylmonoxime hydrochloride precipitate in the lower layer; and b, neutralizing the crude products in the upper layer with ammonia gas in a neutralizer to obtain solid ammonium chloride, filtering, distilling a filtered crude solution through a film evaporator, and circulating the distilled solvent to an extraction tower for use, wherein a finished product of the high-purity methyl tris-methylethylketoxime silane can be obtained at the bottom in the film evaporator. The method can be used for realizing the continuous production of the methyl tris-methylethylketoxime silane and has the advantages of high reaction conversion rate, high product recover rate and no pollution to the environment, wherein the obtained product yield reaches 95% and the content of the methyl tris-methylethylketoxime silane exceeds 97%.

Owner:湖北新蓝天新材料股份有限公司

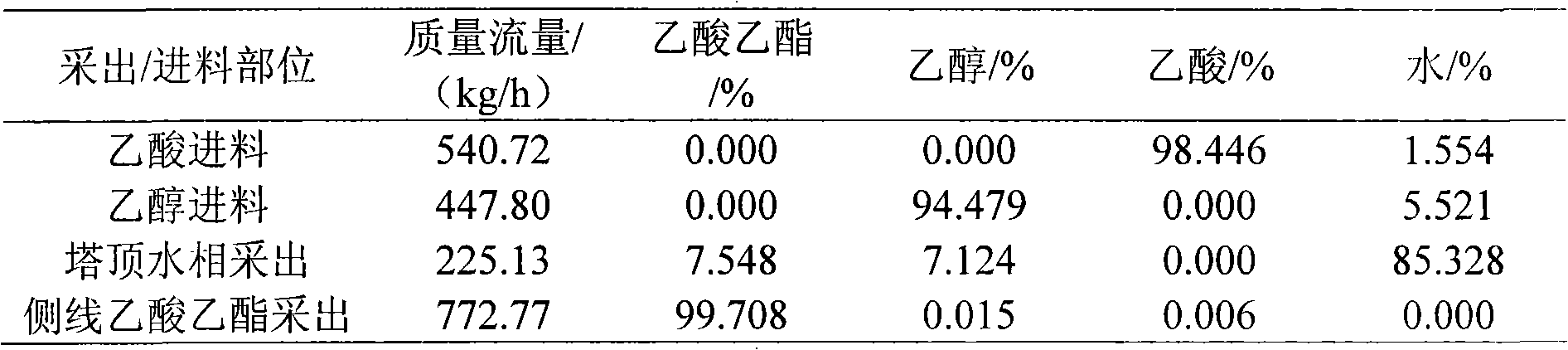

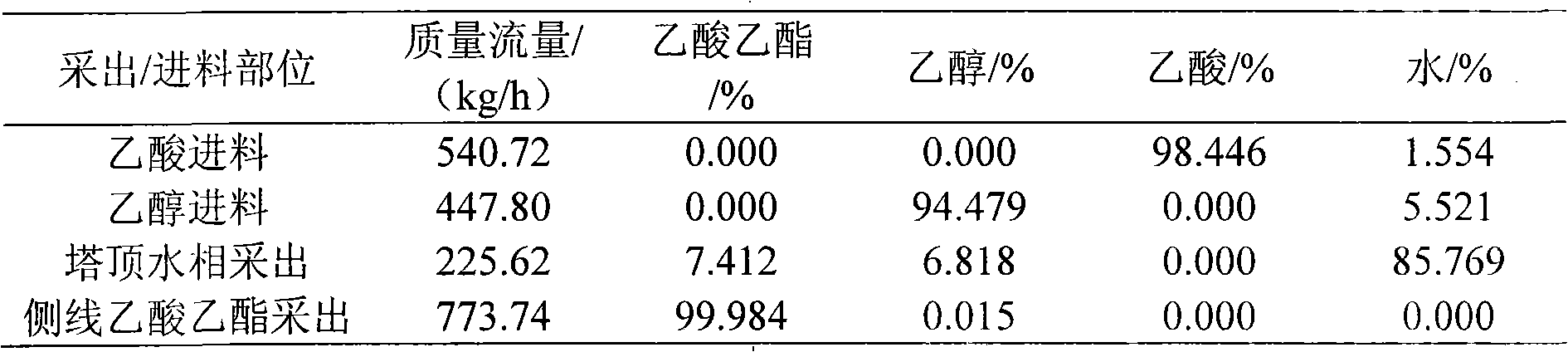

Ethyl acetate synthetic process and apparatus thereof

InactiveCN101357887AHigh puritySimplify the routine reactive distillation processOrganic compound preparationCarboxylic acid esters preparationAcetic acidGas phase

The invention discloses a technological method for synthesizing ethyl acetate by using reactive rectifying bulkhead tower and a device thereof. The reactive rectifying bulkhead tower is provided with a piece of bulkhead along the vertical direction in the conventional rectifying tower, and the bottom of the right side of the bulkhead is closed. The whole tower is divided into five zones. Ethanol and acetate which are taken as raw materials are put into the tower from the top space of a tower kettle, and carry out esterification to generate ethyl acetate under the action of a catalyst of acidic cation exchange resin in the reaction section and at the lower part of the tower kettle. After the condensation and phase separation of the gas phase at the top of the tower, water phase is discharged from the system, and ester phase is driven into the top of the tower as reflux. Ethyl acetate with high purity is obtained at the bottom of the siding stripping section, and the bottom of the tower has no discharging material. The method gives a full play of the advantages of the bulkhead tower and reaction rectifying, which can cause the esterification and the product purification to be realized in the same tower and can reduce equipment investment and energy consumption effectively.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

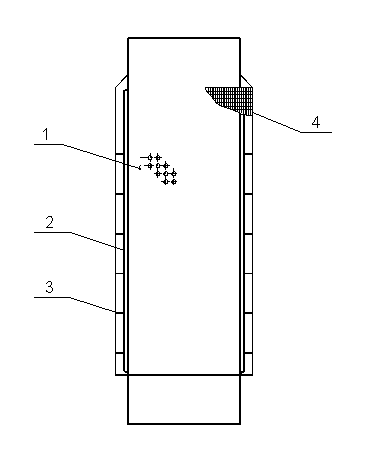

Radial fixed bed reactor for oxy-dehydrogenation of butylene

InactiveCN103071429ABalanced utilizationSimple structureHydrocarbonsChemical/physical processesPorositySingle stage

The invention relates to a radial fixed bed reactor for oxy-dehydrogenation of butylene. The radial fixed bed reactor mainly solves the problems that the pressure drop of the reactor is high, fluid distribution is nonuniform, a raw material conversion rate is low, and product selectivity is low in the prior art. The radial fixed bed reactor adopts a centripetal Z-shaped structure and is a cylindrical vessel with a catalyst bed; a feed port is located at the top of the reactor; a discharge port is located at the bottom of the reactor; a gas predistributor with a conical single-stage baffle is arranged at the feed port; the catalyst bed consists of a fan-shaped barrel distributor located at an outer ring and a porous wall barrel located at an inner ring; a catalyst is filled in the catalyst bed; a cover plate sealing structure is arranged at the top of the catalyst; the fan-shaped barrel distributor can be in a porosity-variable or Johnson screen structural form; and the porous wall barrel at the inner ring consists of an inner layer center porous barrel, an intermediate layer punched plate and an outer layer screen. The radial fixed bed reactor solves the problems better and can be used for industrial production of preparing butadiene through the oxy-dehydrogenation of butylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Microalgae high-pressure continuous tower-type liquefying process

InactiveCN102071038AHigh reaction conversion rateHigh recovery rateLiquid hydrocarbon mixture productionGas phaseSnow melting

The invention provides a microalgae high-pressure continuous tower-type liquefying process, which comprises the following steps of: pressurizing microalgae-containing suspension by using a high-pressure pump, making the suspension flow through a heat exchanger to exchange heat with liquefied liquid, heating to be between 180 and 250 DEG C according to a certain heating curve by using a heating furnace, and preserving heat in a gelatinizing tower for certain time to make solid biomass changed into flowable slurry; quickly heating gelatinized liquid to be between 270 and 350 DEG C at a certain heating rate by using a secondary heating furnace, and adding into a liquefying tower for hydrothermal liquefying to prepare a liquid fuel; separating coke slurry from a hydrothermal liquefying product by using a high-pressure settling tank, discharging the coke slurry from a coke slurry outlet, and making liquefied gas liquid pass through the top of the high-pressure settling tank, exchange heat with the microalgae suspension through the heat exchanger and flow into a three-phase separator; separating the liquefied gas liquid into a water phase, an oil phase and a gas phase in the three-phase separator, circulating and discharging the water phase by connecting the water phase with the high-pressure pump and a discharging port from the lower part of the three-phase separator, concentrating to prepare a foliar fertilizer, biological gasoline or a snow-melting agent and the like, discharging the oil phase from a biological oil outlet in the middle of the three-phase separator to obtain a product, and discharging the gas phase from a tail gas outlet on the top of the three-phase separator to serve as a fuel; and discharging the solid-phase coke slurry to serve as an activated carbon material or a fuel.

Owner:田原宇

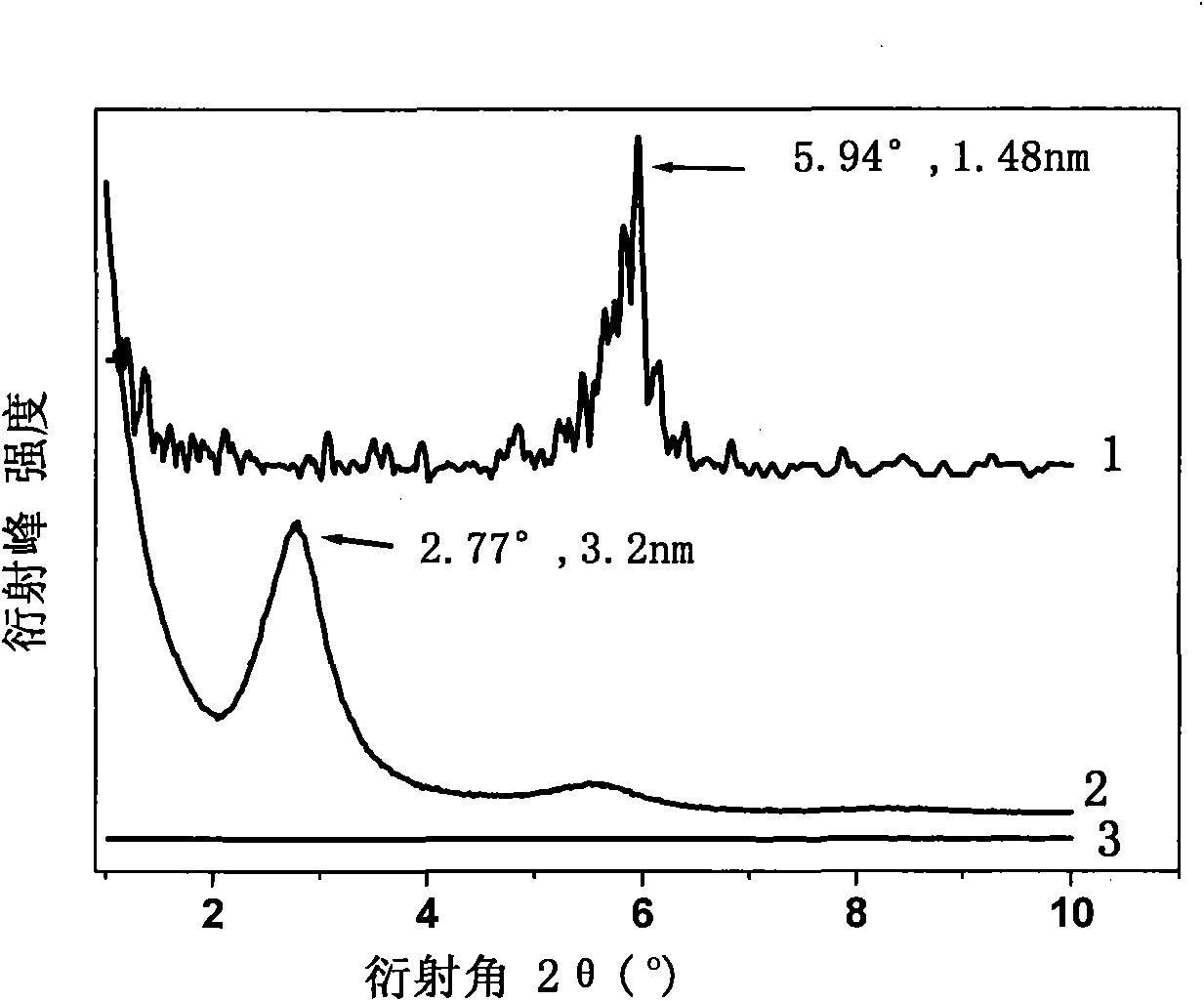

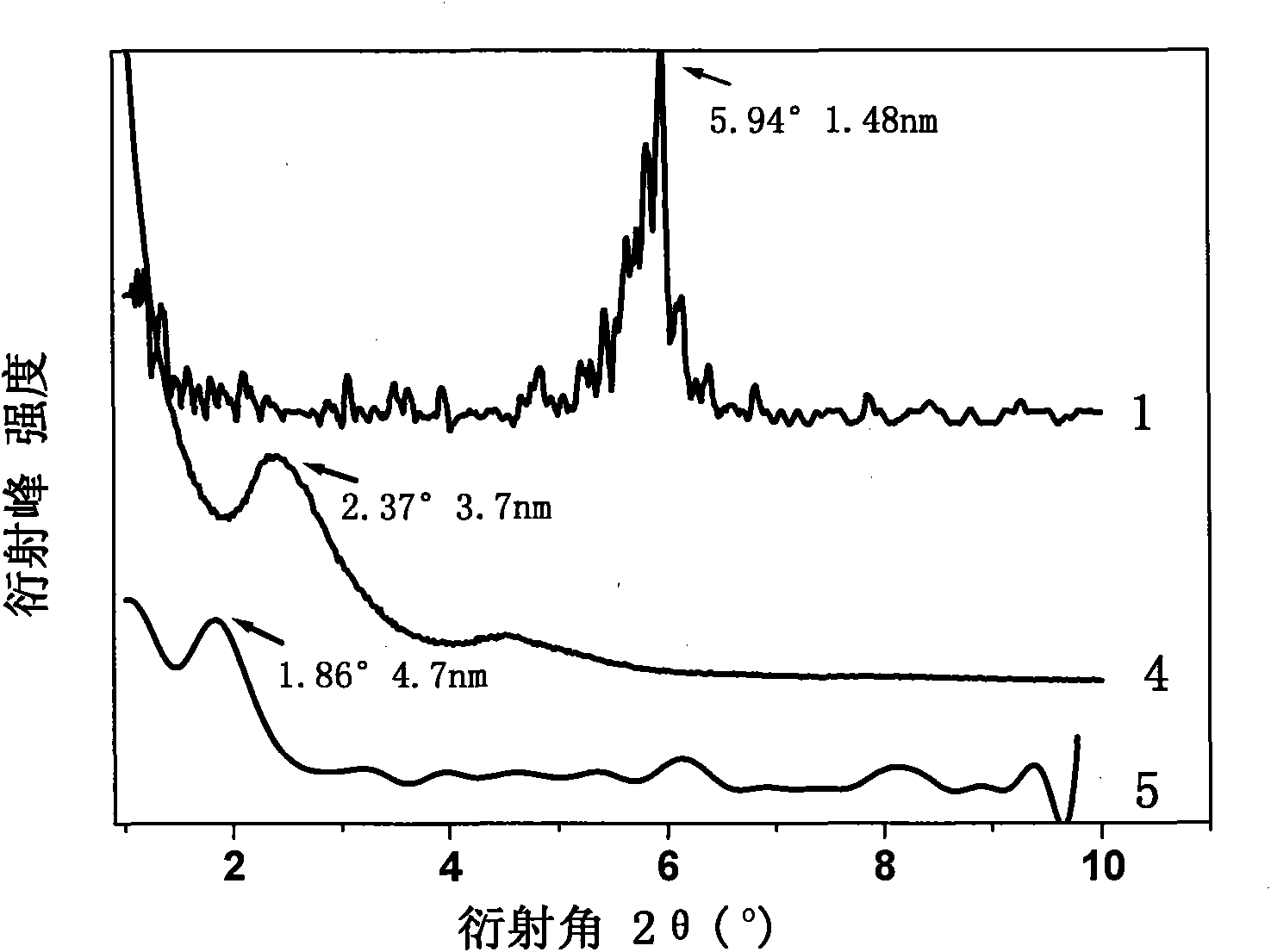

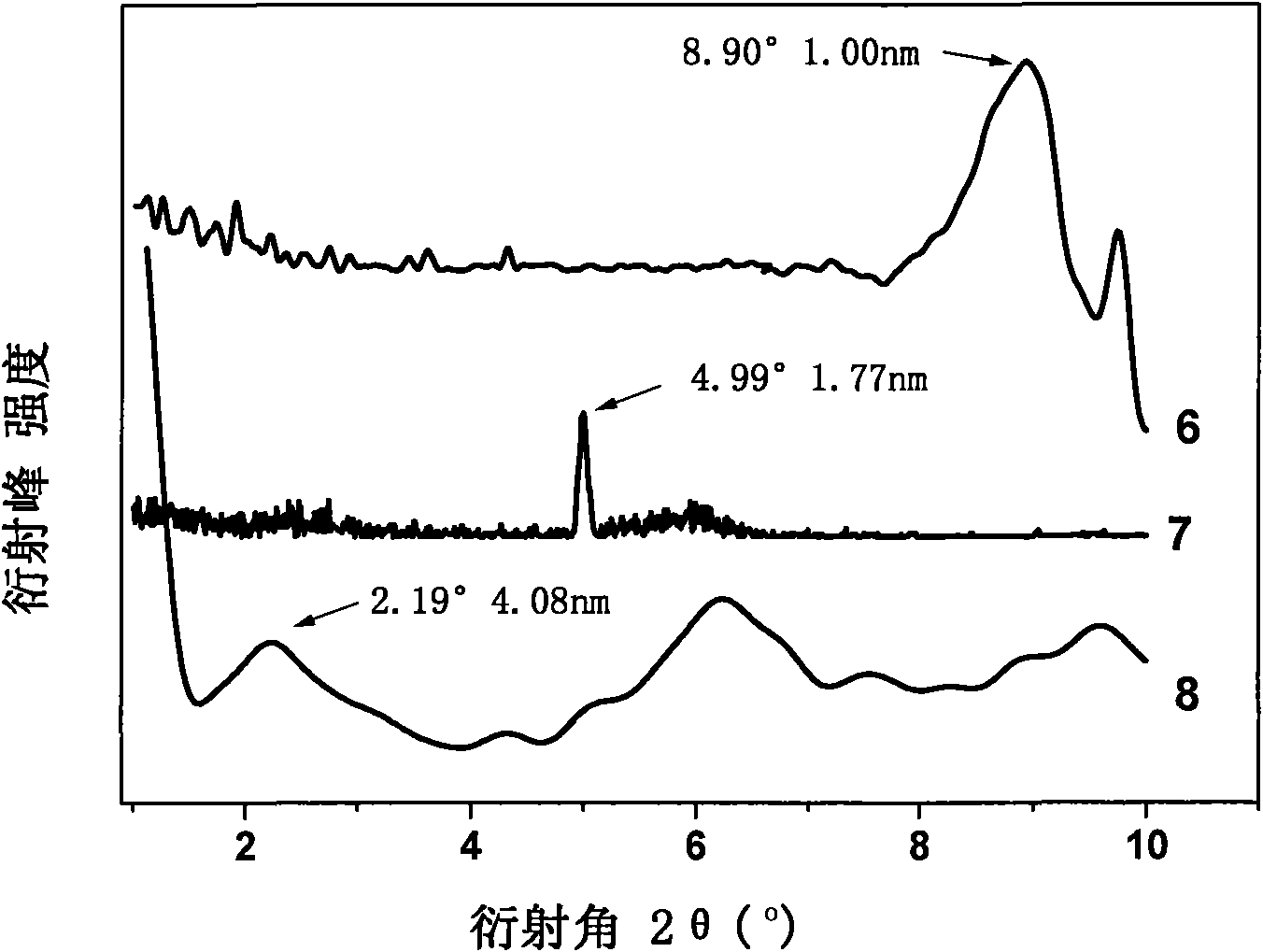

Methods for preparing quaternary phosphonium salt ionic liquid pillaring-modified montmorillonite and polymer/montmorillonite nanocomposite

InactiveCN101979444AGood physical and chemical stabilityGreen chemical reagents are goodFibre treatmentCoatingsPhosphonium saltEngineering plastic

The invention relates to the field of polymer / montmorillonite nanocomposites, and discloses methods for preparing quaternary phosphonium salt ionic liquid pillaring-modified montmorillonite and the polymer / montmorillonite nanocomposite. The method for preparing the polymer / montmorillonite nanocomposite comprises the steps of performing pillaring-modification on montmorillonite by using quaternaryphosphonium salt ionic liquid and then intercalating the quaternary phosphonium salt ionic liquid pillaring-modified montmorillonite and a polymer or a polymeric monomer. In the methods, the montmorillonite is pillaring-modified directly by the quaternary phosphonium salt ionic liquid without water and any other solvent, and the ionic liquid can be recycled; the methods are simple, convenient to operate and environmentally-friendly, reduces the cost and saves energy consumption; and the quaternary phosphonium salt ionic liquid has more stable chemical properties and higher thermal stability, greatly improves the mechanical properties of the polymer material, can be applied to engineering plastics and heat-resisting polymers, and greatly expands the application range of the montmorillonite.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com