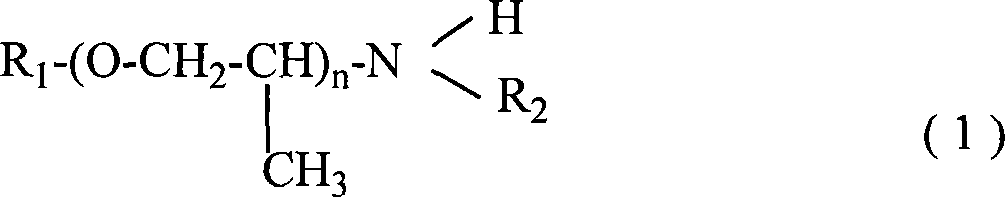

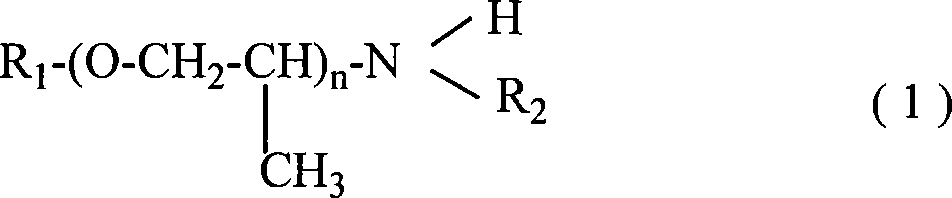

Polyethenoxyamines used as main agent of gasoline detergent and preparation method thereof

A technology of gasoline detergent and polyetheramine, which is applied in the field of polyetheramine and its preparation, can solve the problems of poisonous acrylonitrile as the reaction raw material, difficulty in catalyst preparation, and high investment cost, and achieve improved vehicle driving performance, suitable molecular weight, and low investment. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

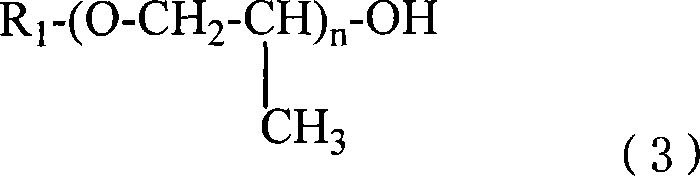

[0047] A) preparation of polyether. 99.2 grams of nonylphenol (chemical structural formula C 9 h 19 C 6 h 4 OH) and 1.5 grams of potassium hydroxide are added to a 1-liter stainless steel reaction kettle, heated to about 110 ° C, dehydrated under vacuum for 0.5 to 1 hour, until no water is distilled, flushed with nitrogen, and then vacuumed, and then The temperature rises to about 140°C, continuously press about 422 grams of propylene oxide into the reactor, control the feed rate of propylene oxide, keep the pressure of the reactor at 0.15-0.6MPa, keep the reaction temperature at 150-180°C, and react in the reactor until the pressure no longer drops. After cooling, pour it into a beaker, add 20 grams of acid activated clay for neutralization and decolorization, and absorb potassium ions, then vacuum filter it with a Buchner funnel. Remove water and volatile matter under the following conditions to obtain polyether products. After chemical analysis, the product polyether h...

Embodiment 2

[0052] A) preparation of polyether. 103g lauryl alcohol (molecular formula C 12 h 25 -OH) and 1.65g of potassium hydroxide are added to a 1-liter stainless steel reaction kettle, heated to about 110°C, dehydrated under vacuum for 0.5 to 1 hour, until no water is distilled, flushed with nitrogen, and then evacuated, and then, Raise the temperature to about 140°C, press 452g of propylene oxide into the reactor, control the feeding speed, keep the pressure of the reactor at 0.15-0.6MPa, keep the reaction temperature at 150-180°C, and react until the pressure in the reactor no longer drops . After cooling, pour it into a beaker, add 24 grams of acidic activated clay for neutralization and decolorization, and absorb potassium ions, then vacuum filter it with a Buchner funnel. Remove water and volatile matter under the following conditions to obtain polyether products. According to chemical analysis, the product polyether has a hydroxyl value of 56.1mgKOH / g and a molecular weight...

Embodiment 3

[0058] A) preparation of polyether. 104g octylphenol (chemical structural formula C 8 h 17 C 6 h 4 OH) and 1.7g of potassium hydroxide are added to a 1-liter stainless steel reaction kettle, heated to about 110°C, dehydrated under vacuum for 0.5 to 1 hour, until no water is distilled, flushed with nitrogen, and then evacuated, and then When the temperature rises to about 140°C, press about 505g of propylene oxide into the reactor, control the feeding speed, keep the pressure of the reactor at 0.15-0.6MPa, keep the reaction temperature at 150-180°C, and react until the pressure in the reactor no longer drops . After cooling, pour it into a beaker, add 27 grams of acid activated clay for neutralization and decolorization, and absorb potassium ions, then vacuum filter it with a Buchner funnel. Remove water and volatile matter under the following conditions to obtain polyether products. After chemical analysis, the product polyether has a hydroxyl value of 47.1mgKOH / g and a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com