Rosin-based chelating gemini surfactant and preparation method thereof

A Gemini surface, rosin-based technology, applied in the field of functional green surfactants and its preparation, can solve the problems of unfavorable sustainable development, and achieve the effects of increasing added value, easy biodegradation, and low toxicity of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

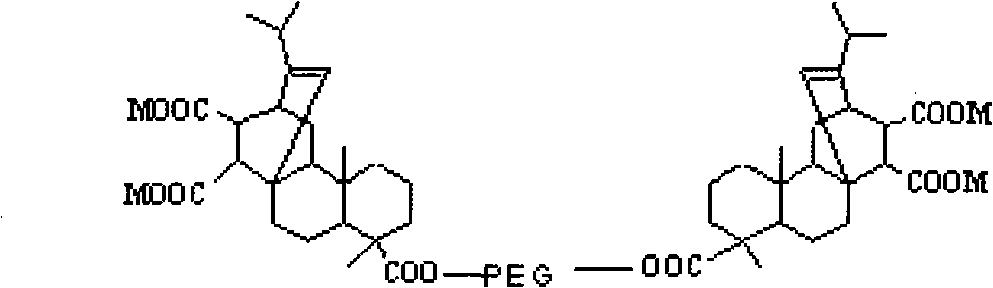

[0022] A kind of rosin-based chelating gemini surfactant, general structural formula is as follows:

[0023]

[0024] In the formula, M is metal ion K or Na, PEG is polyethylene glycol, and the molecular weight of polyethylene glycol is any one of 400, 600, 1000, 2000, 4000.

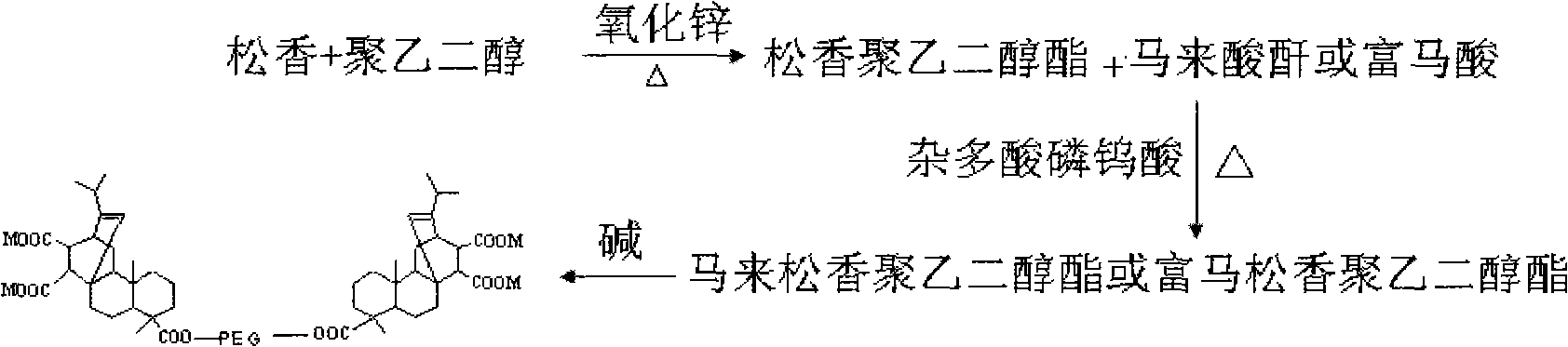

[0025] A method for preparing the rosin-based chelating gemini surfactant, first esterifying rosin with polyethylene glycol, adding the conjugated double bond of rosin through D-A addition, and reacting with an alkali solution to obtain the rosin chelating surfactant , specifically prepared according to the following formula,

[0026]

[0027] The ratio of the amount of rosin to polyethylene glycol is 2: (1-1.1), wherein the preferred ratio is 2: 1, the catalyst consumption is 0.1%-0.2% of the mass of rosin, and the esterification temperature is 230-280°C. The curing time is 6-8 hours.

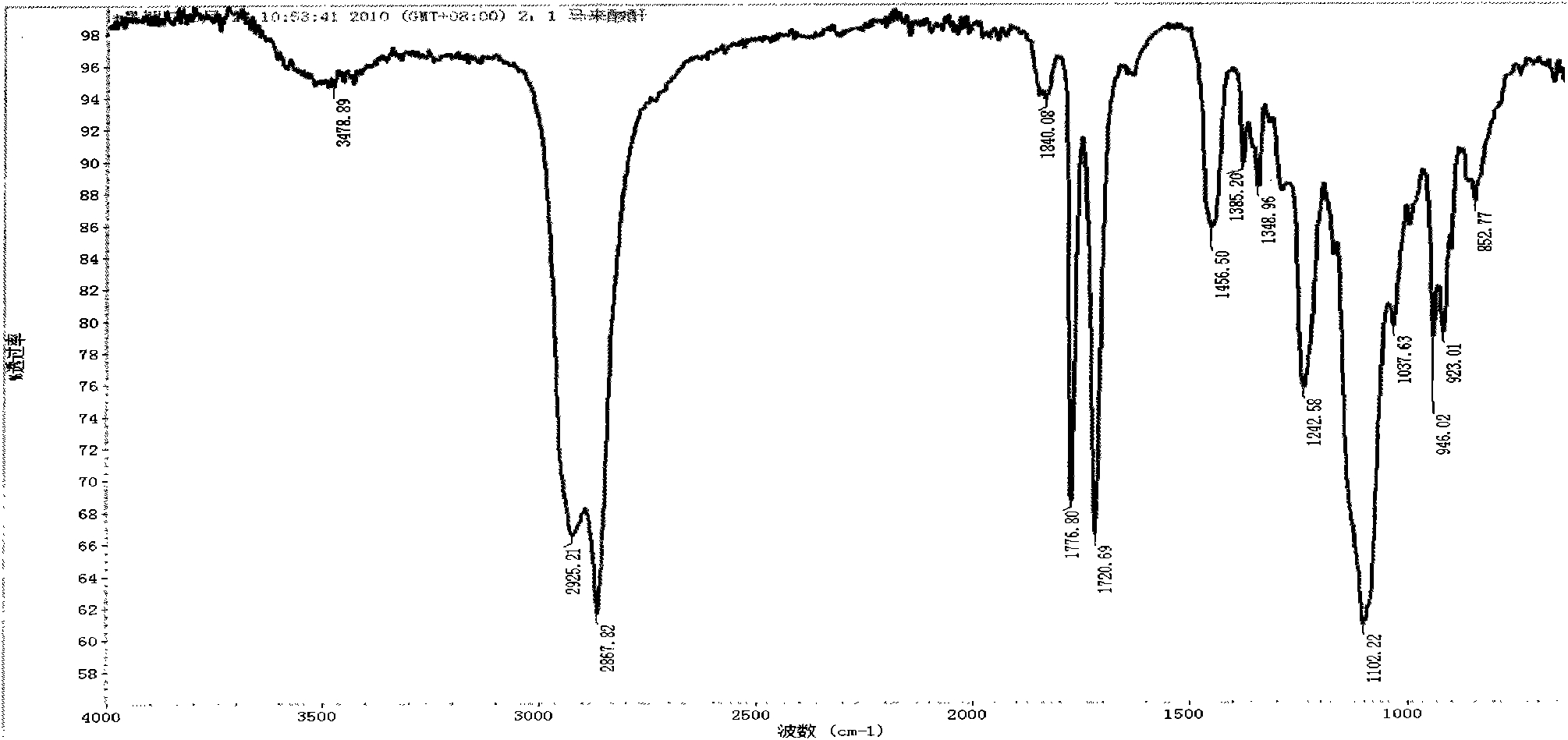

[0028] The reaction process is controlled by measuring the acid value of the reactant. When the acid value of ...

Embodiment 2

[0032] A kind of preparation method of rosin base chelating surfactant, synthesis comprises the following steps:

[0033] Respectively take rosin and Polyethylene Glycol 400 with a molar ratio of 2:1 and pour them into a 500ml four-neck flask, then add an appropriate amount of zinc oxide (the amount of zinc oxide accounts for about 0.1-0.2% of the rosin quality) as a catalyst, Heat to 250°C to make it fully react, and when the acid value drops to about 10, the reaction is basically completed, then cool down.

[0034] Cool rosin polyethylene glycol ester to 220°C, add maleic anhydride (mass ratio of maleic anhydride to rosin = 1:5), the catalyst is heteropolyphosphotungstic acid, and the catalyst dosage is 0.1%-0.2% of the mass of rosin , React at 220°C for 5h, cool down to about 120°C and pour out the product.

[0035] Take 50g of maleic rosin polyethylene glycol ester and put it in a 250ml four-necked flask, slowly add 30% NaOH solution dropwise at room temperature while sti...

Embodiment 3

[0039] Synthetic technique is similar to embodiment 2, and rosin double bond D-A addition raw material can replace maleic anhydride with fumaric acid, and the mass ratio of its rosin and fumaric acid is (4-5): 1, for example can choose 4: 1, 4.2:1, 4.4:1, 4.6:1, 4.8:1, 5:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com