PPTA paper using aramid nanofiber for self-reinforcement and preparation method thereof

A para-aramid paper and nanofiber technology, applied in special paper, fiber dispersant addition, paper and other directions, can solve the problem of the decline of comprehensive performance of aramid paper, and achieve strong innovation, broad application prospects, large length and diameter Effect of ratio and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

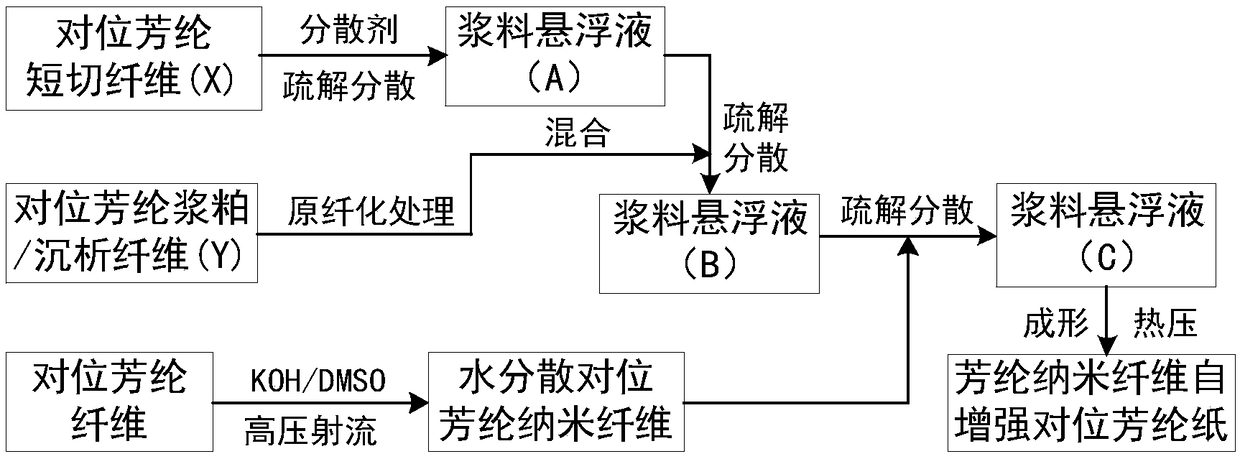

[0041] A method for preparing a self-reinforced para-aramid paper utilizing aramid nanofibers, comprising the following steps:

[0042] Step 1: Disperse the aramid fiber X, that is, the para-aramid chopped fiber, through a standard fiber deflagging machine for 10,000-30,000 r to obtain a slurry suspension A. During the de-flaking, it is necessary to add a fiber with a molecular weight of 3 to 5 million Polyethylene oxide is used as a dispersant, and the dosage is 0.1-0.5% of the absolute dry mass of the aramid fiber X;

[0043] Step 2: Fibrillating one or both of the aramid fiber Y, that is, the para-aramid fibrid fiber and the para-aramid pulp fiber, and adding it to the slurry suspension obtained in step 1 A, using a standard fiber deflagging machine to decompose and disperse for 10000-20000r to prepare a slurry suspension B. The degree of fibrillation treatment is to detect a beating degree of 45-60°SR, and the aramid fiber in the slurry suspension B is X The mass ratio to...

Embodiment 1

[0048] A self-reinforced para-aramid paper using aramid nanofibers, in parts by weight, the components of the aramid paper include: para-aramid fibers: 99 parts, aramid nanofibers: 1 part, The aramid fiber is a mixed system of aramid fiber X and aramid fiber Y, wherein the weight ratio of aramid fiber X and aramid fiber Y is 3:7, and the aramid fiber X is para-aramid Aramid chopped fiber; the aramid fiber Y is a para-aramid fibril;

[0049] Wherein, the aramid fiber nanofiber is made by the following preparation steps:

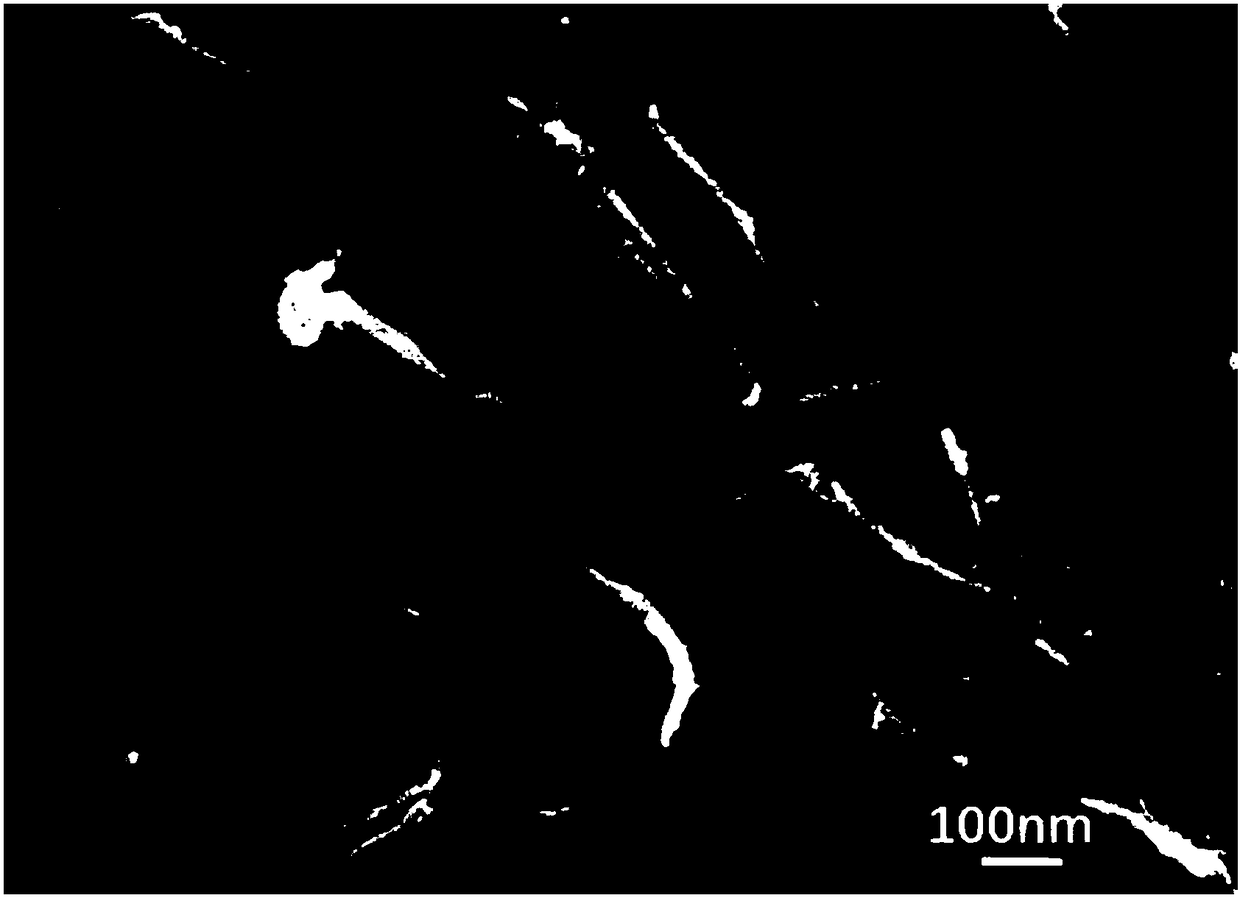

[0050] Step (1): 1.0g para-aramid yarn fiber, 1.5g potassium hydroxide (KOH) and 500ml dimethyl sulfoxide (DMSO) are placed in a container, and stirred at a temperature of 30°C under sealed conditions After 8 days, the aramid nanofiber dispersion liquid dispersed in the KOH / DMSO system was obtained;

[0051] Step (2): The aramid nanofiber dispersion liquid dispersed in the KOH / DMSO system obtained in step (1), under the action of stirring at 600rpm, inject d...

Embodiment 2

[0061] A self-reinforced para-aramid paper using aramid nanofibers, in parts by weight, the components of the aramid paper include: para-aramid fibers: 97 parts, aramid nanofibers: 3 parts, The aramid fiber is a mixed system of aramid fiber X and aramid fiber Y, wherein the weight ratio of aramid fiber X and aramid fiber Y is 3.5:6.5, and the aramid fiber X is para-aramid Aramid chopped fiber; the aramid fiber Y is para-aramid pulp fiber;

[0062] Wherein, the aramid fiber nanofiber is made by the following preparation steps:

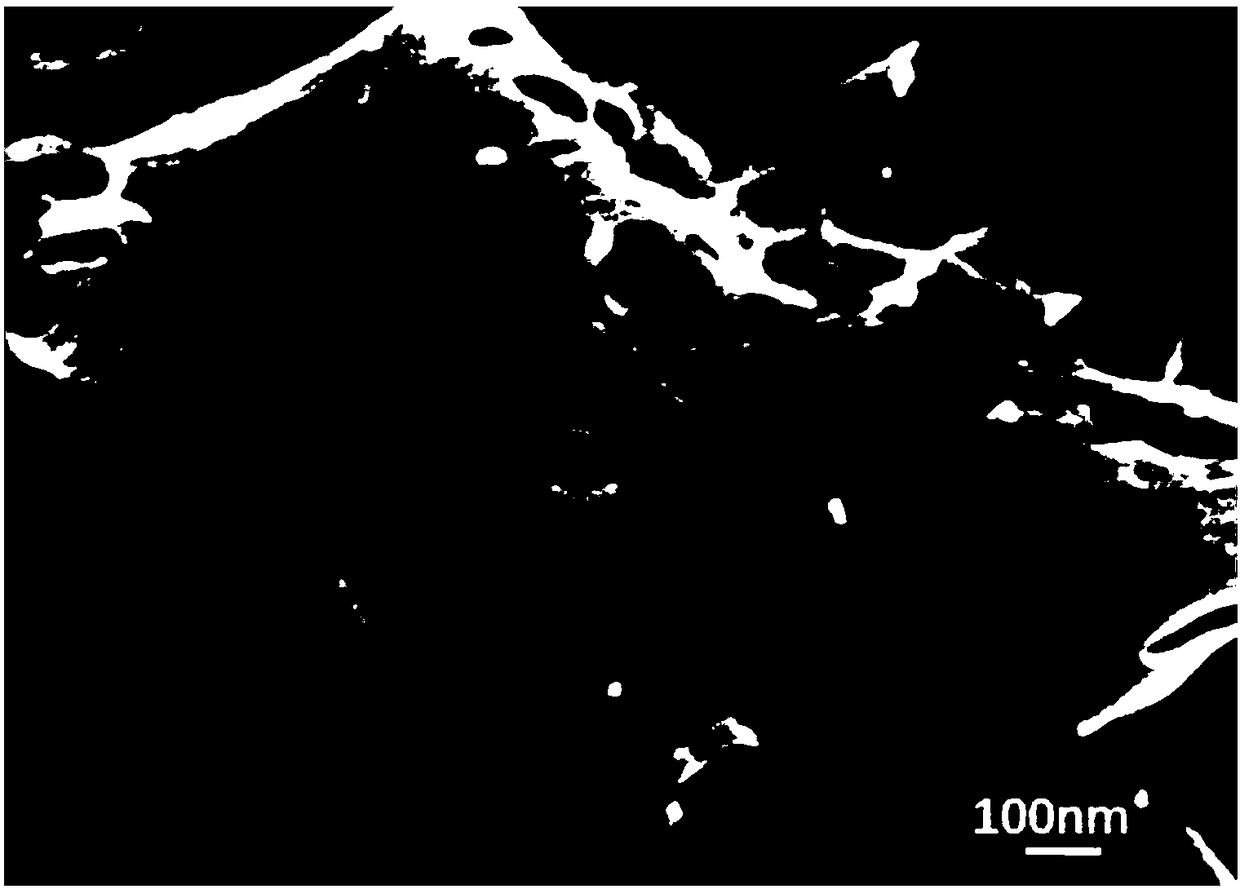

[0063] Step (1): 1.0g of para-aramid chopped fiber, 1.5g of potassium hydroxide (KOH) and 500ml of dimethyl sulfoxide (DMSO) are placed in a container, and stirred at a temperature of 40°C under sealed conditions After 7 days, the aramid nanofiber dispersion liquid dispersed in the KOH / DMSO system was obtained;

[0064] Step (2): The aramid nanofiber dispersion obtained in step (1) dispersed in the KOH / DMSO system is injected with deionized water at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com