A method for preparing water-dispersed aramid nanofibers by using recycled para-aramid paper

A para-aramid paper and nanofiber technology, applied in fiber raw materials, recycling technology, fiber raw material processing, etc., can solve the problems of high energy consumption in mechanical processing, poor uniformity of aramid fiber, unfavorable recycling treatment, etc., to achieve High added value, excellent heat resistance, and large aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

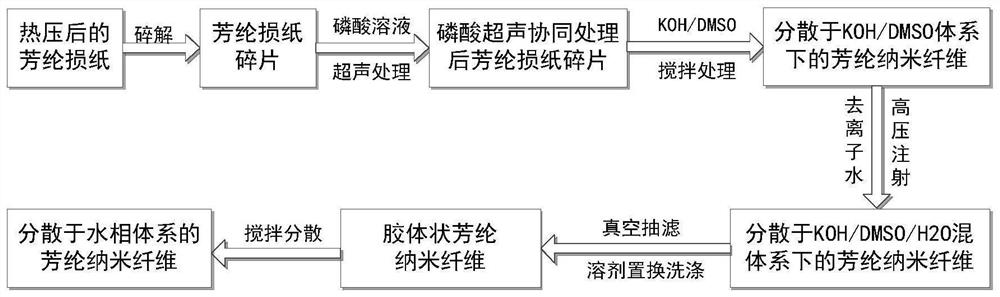

Method used

Image

Examples

Embodiment 1

[0047] In this embodiment, a method for preparing water-dispersed aramid nanofibers by using recycled para-aramid paper, the specific preparation steps are as follows:

[0048] (1) The raw materials include aramid chopped fibers and para-aramid pulp fibers, and undergo the following hot pressing conditions: line pressure 30kN / m, hot pressing temperature 220°C, hot pressing roll speed 1.5m / min, hot pressing times The aramid fiber paper that has been hot-pressed once is crushed by a hydropulper with a mass concentration of 1.5% when crushed, and the obtained broken aramid paper fragments have a specification length of 1 to 3 cm;

[0049] (2) Put the aramid broken paper fragments obtained in step (1) in 10% phosphoric acid solution, adjust the pulp mass concentration to 1.5%, and use ultrasonic treatment, the ultrasonic conditions are: power 300W, ultrasonic time is 80min, and the ultrasonic is finished Afterwards, it was washed and dried with deionized water;

[0050] (3) 0.5 g...

Embodiment 2

[0056] In this embodiment, a method for preparing water-dispersed aramid nanofibers by using recycled para-aramid paper, the specific preparation steps are as follows:

[0057] (1) The raw materials include aramid chopped fibers and para-aramid fibrids, and undergo the following hot pressing conditions: line pressure 50kN / m, hot pressing temperature 230°C, hot pressing roll speed 2.0m / min, hot pressing times The aramid paper that has been hot-pressed twice is crushed with a hydropulper, the mass concentration is 2.5% when crushed, and the length of the obtained broken aramid paper fragments is 1-3 cm;

[0058] (2) Place the aramid broken paper fragments obtained in step (1) in 15% phosphoric acid solution, adjust the pulp mass concentration to 2.5%, and use ultrasonic treatment, the ultrasonic conditions are: power 500W, ultrasonic time is 70min, and the ultrasonic is finished Afterwards, it was washed and dried with deionized water;

[0059] (3) 0.7g of aramid broken paper f...

Embodiment 3

[0065] In this embodiment, a method for preparing water-dispersed aramid nanofibers by using recycled para-aramid paper, the specific preparation steps are as follows:

[0066] (1) The raw materials include aramid chopped fibers, para-aramid pulp fibers and para-aramid fibrids, and undergo the following hot-pressing conditions: line pressure 80kN / m, hot-pressing temperature 240°C, hot-pressing roll speed The aramid paper that has been hot-pressed at 3.0 m / min and the number of times of hot pressing twice is crushed by a hydropulper, and the mass concentration is 3.5%.

[0067] (2) Place the aramid broken paper fragments obtained in step (1) in 20% phosphoric acid solution, adjust the pulp mass concentration to 3.5%, and use ultrasonic treatment. The ultrasonic conditions are: power 700W, ultrasonic time 60min, and the ultrasonic is finished Afterwards, it was washed and dried with deionized water;

[0068] (3) 1.0 g of aramid broken paper fragments, potassium hydroxide (KOH) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com