Patents

Literature

717results about How to "Large aspect ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

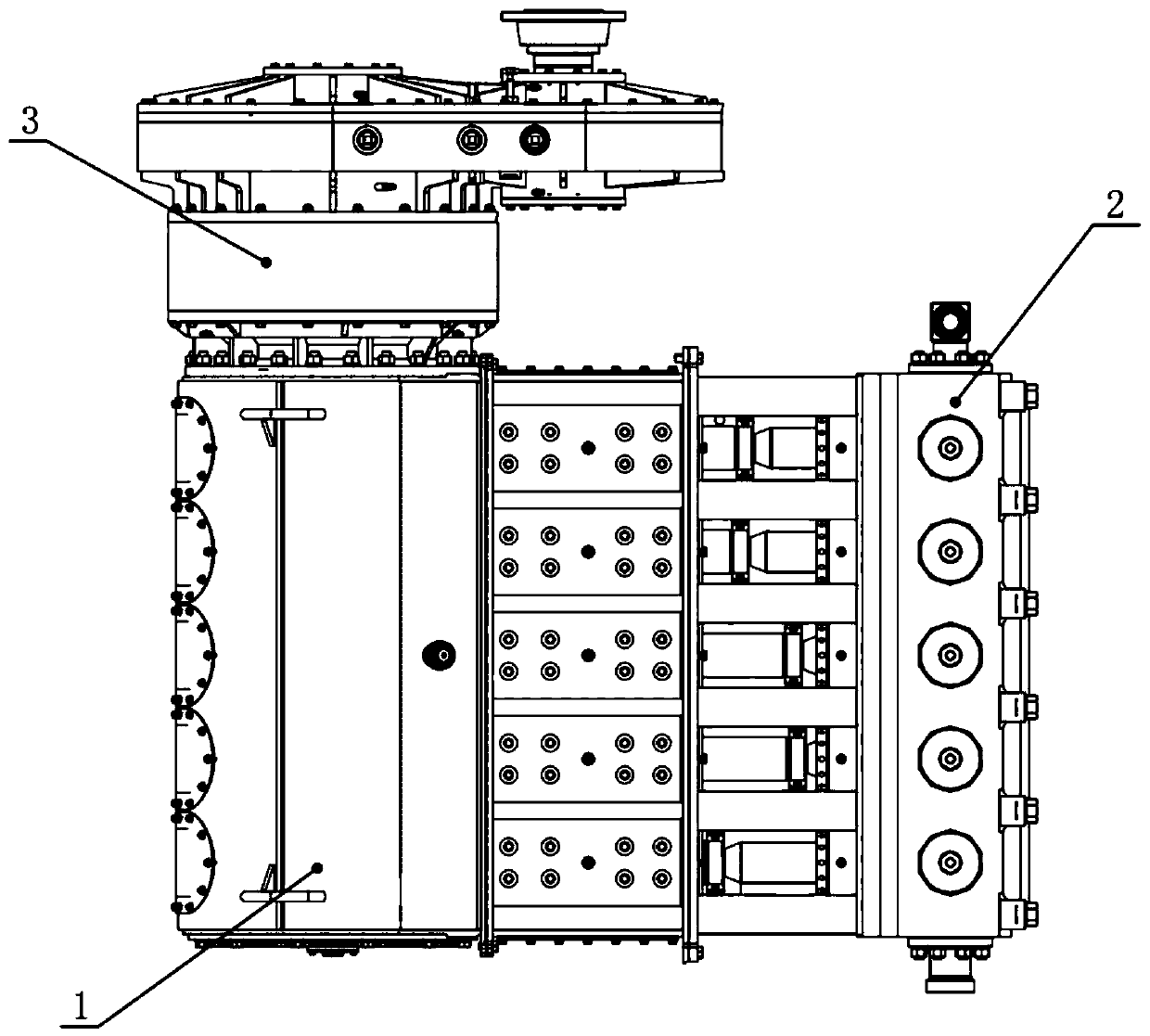

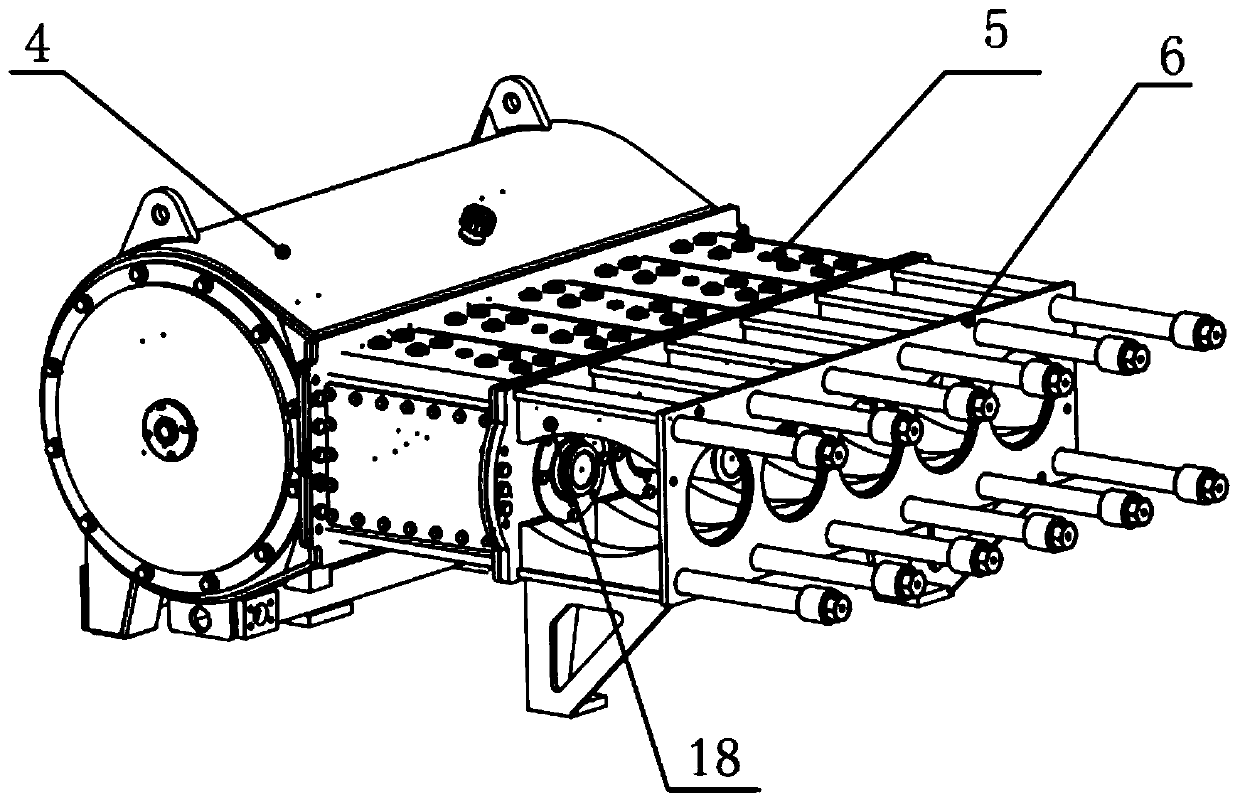

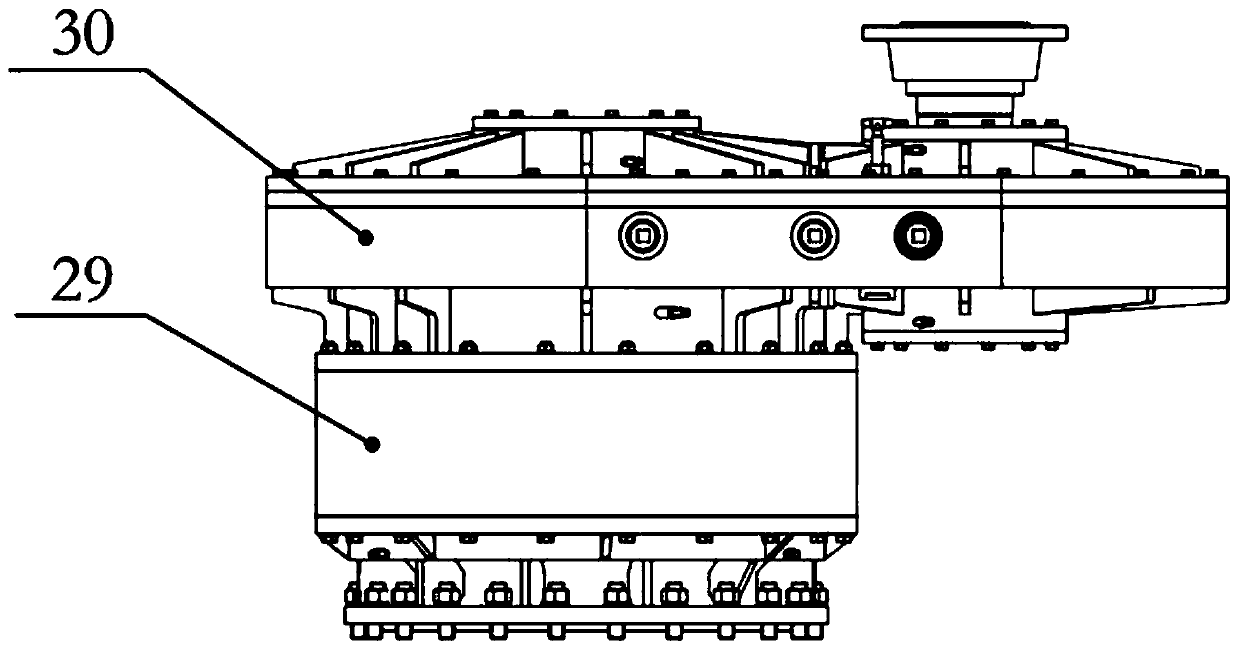

Super-power five-cylinder plunger pump

PendingCN109869294ALess equipmentSave on-site work spaceGearboxesPositive displacement pump componentsElectric driveCentre of rotation

The invention discloses a super-power five-cylinder plunger pump. The super-power five-cylinder plunger pump comprises a power end assembly, a fluid-power end assembly and a reduction box assembly; the power end assembly adopting a sectional type structure design includes a crankshaft box body, a crosshead box body and a space-stop rack, one end of the crosshead box body is connected with the crankshaft box body, and the other end of the crosshead box body is connected with the space-stop rack; the fluid-power end assembly is arranged at one end of the space-stop rack, and the fluid-power endassembly passes through the space-stop rack and the crosshead box body in sequence and is connected with the crankshaft box body through bolts; and the reduction box assembly is connected with the crankshaft box body, a crankshaft in the crankshaft box body is forging alloy steel, the crankshaft includes six shaft necks and five crank threw, each crank throw is arranged between two adjacent shaftnecks, and the distance between the crank threw and the rotating center of the crankshaft is 110mm to 160 mm. The super-power five-cylinder plunger pump has the beneficial effects that the rated inputpower of the super-power five-cylinder plunger pump is 5000 hp, so that the problem that high-power motors cannot be matched with the plunger pumps of corresponding specifications in electric drive fracturing is solved, and the contradictions that the conditions in oil and gas well fields are limited and the matching of fracturing equipment is much is further solved at the same time.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH

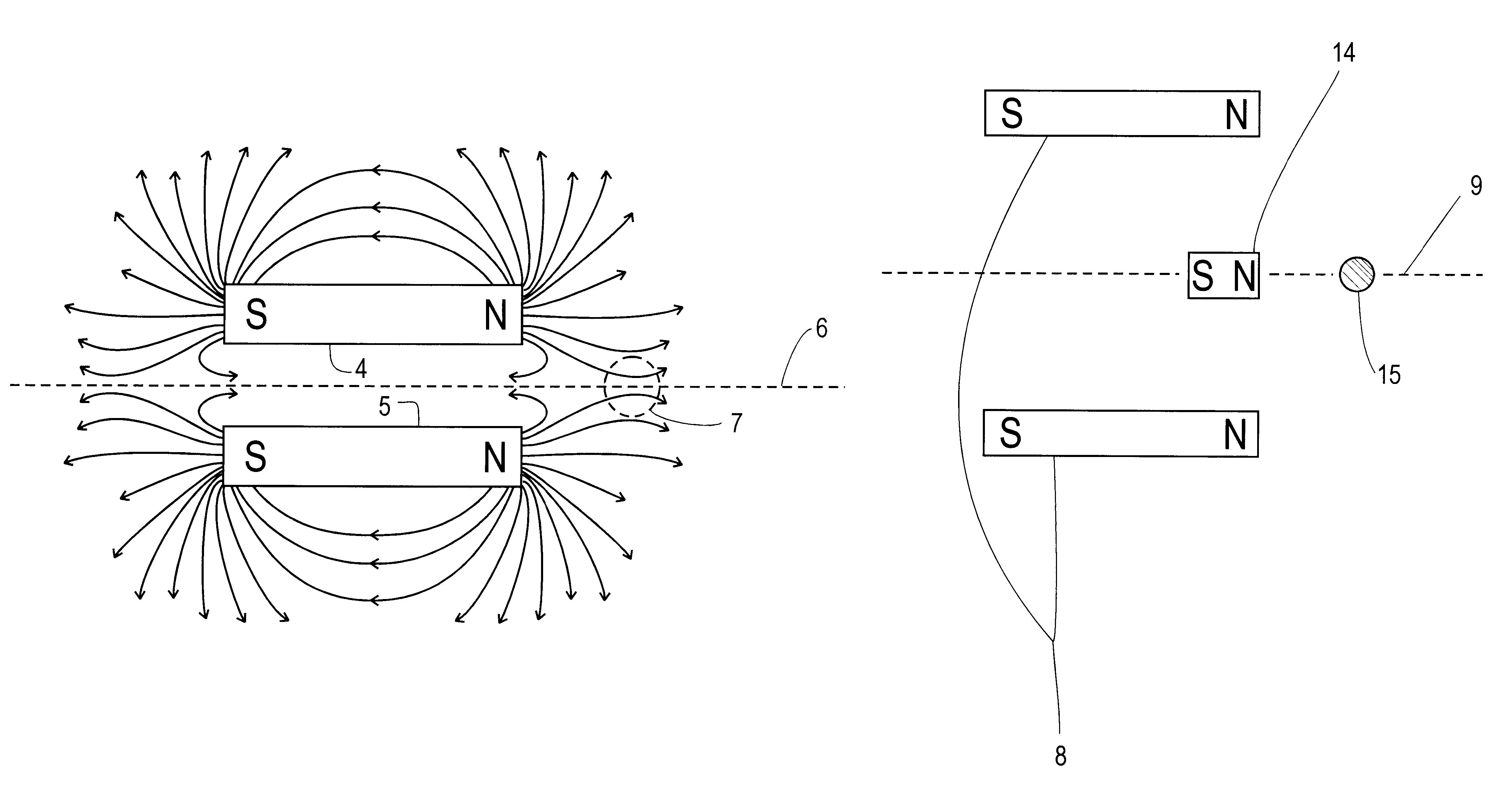

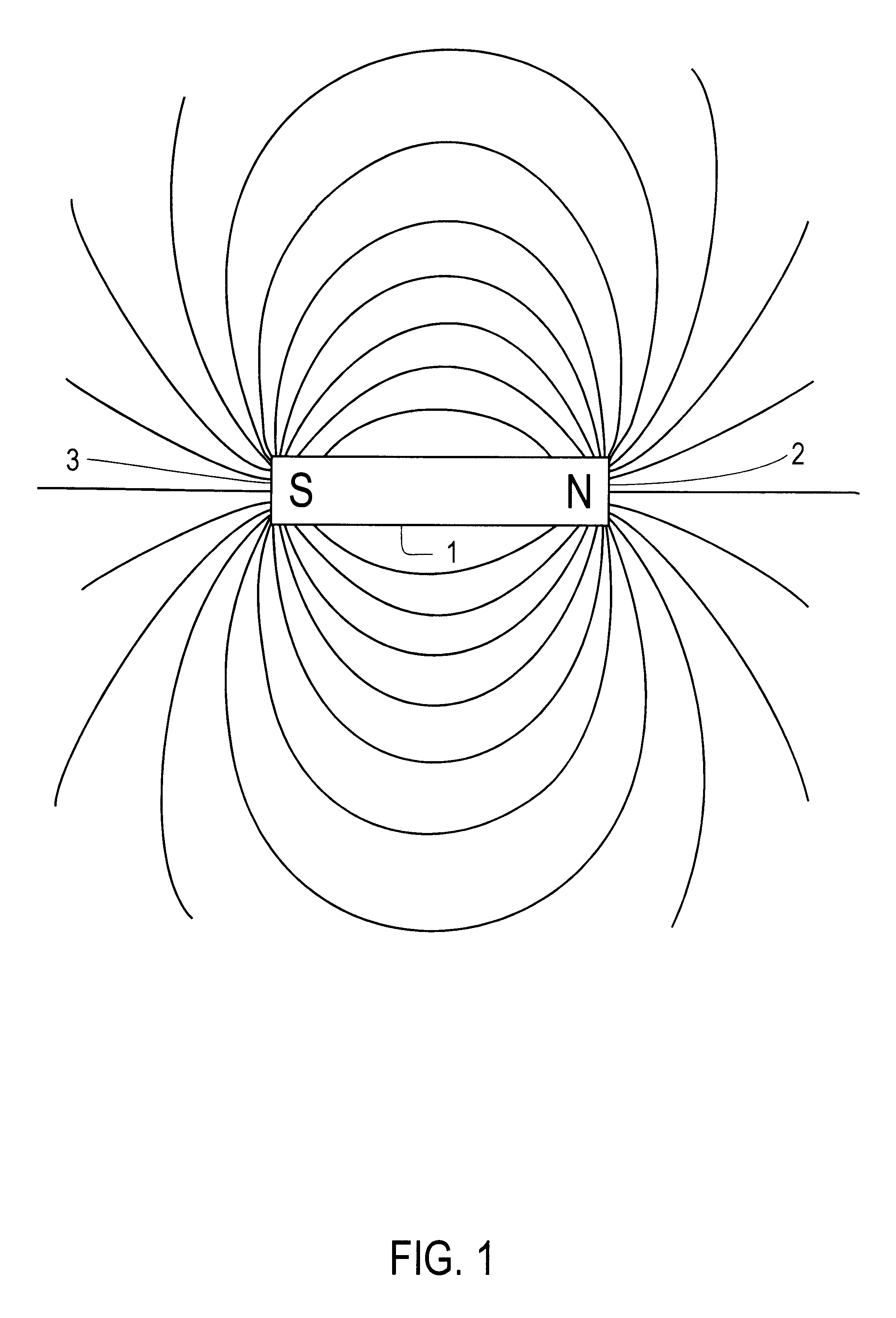

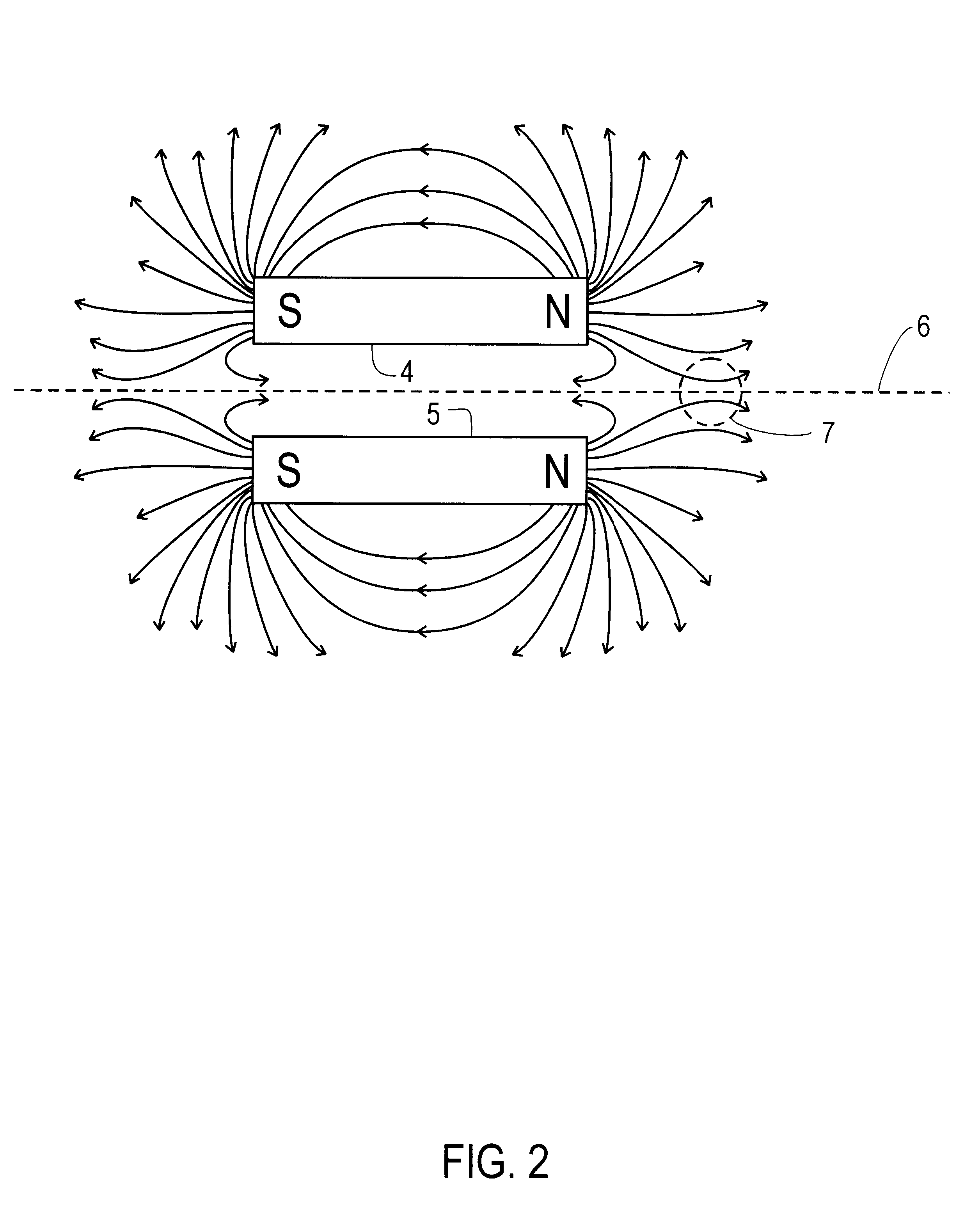

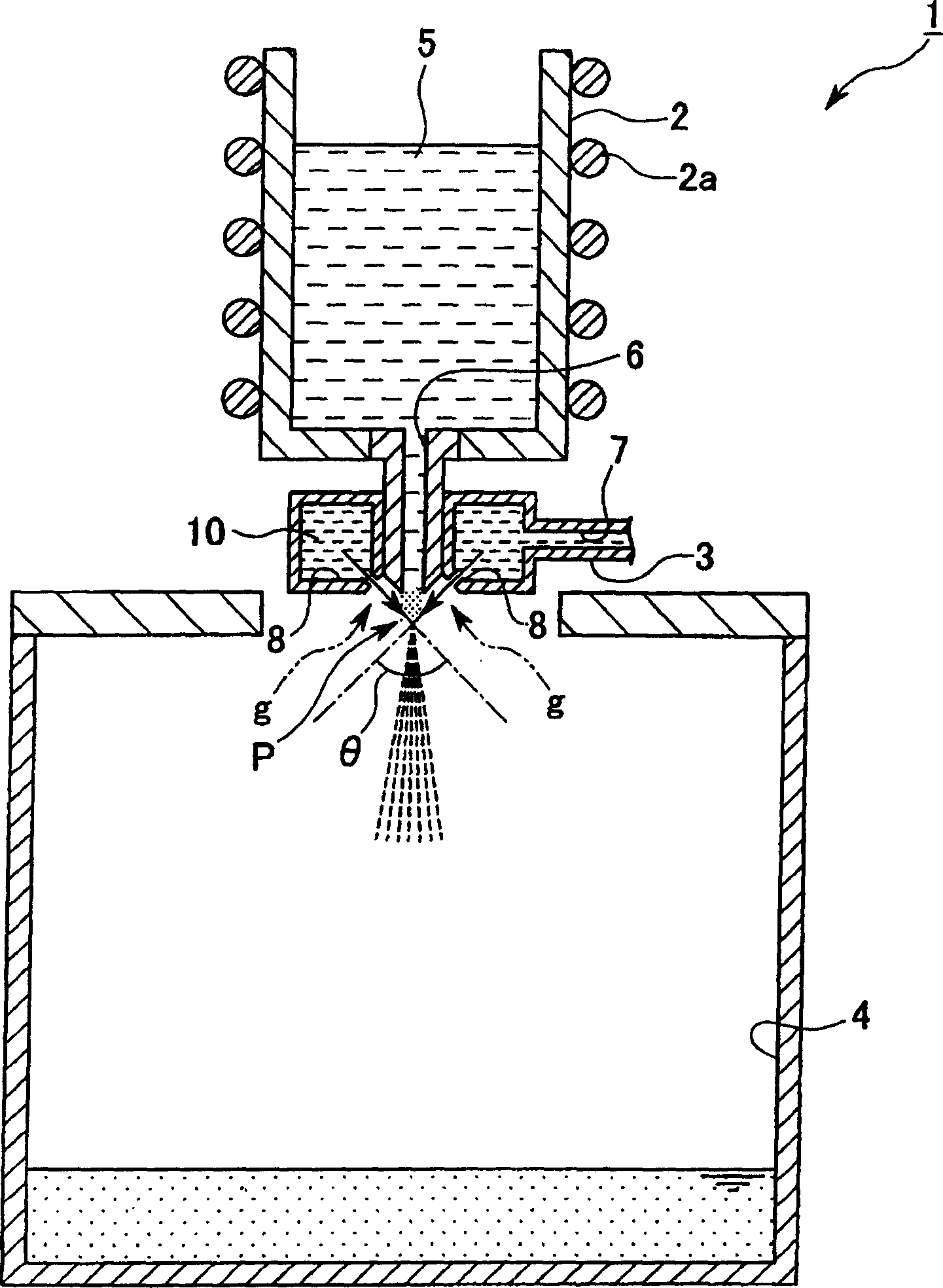

Unilateral magnet having a remote uniform field region for nuclear magnetic resonance

InactiveUS6489872B1Long distanceLarge aspect ratioElectromagnets without armaturesMagnetic materialsUniform fieldNMR - Nuclear magnetic resonance

A unilateral magnet apparatus having a remote uniform field region. The apparatus' uniform remote field region is suitable for a variety of nuclear magnetic resonance applications.

Owner:NEW MEXICO RESONANCE

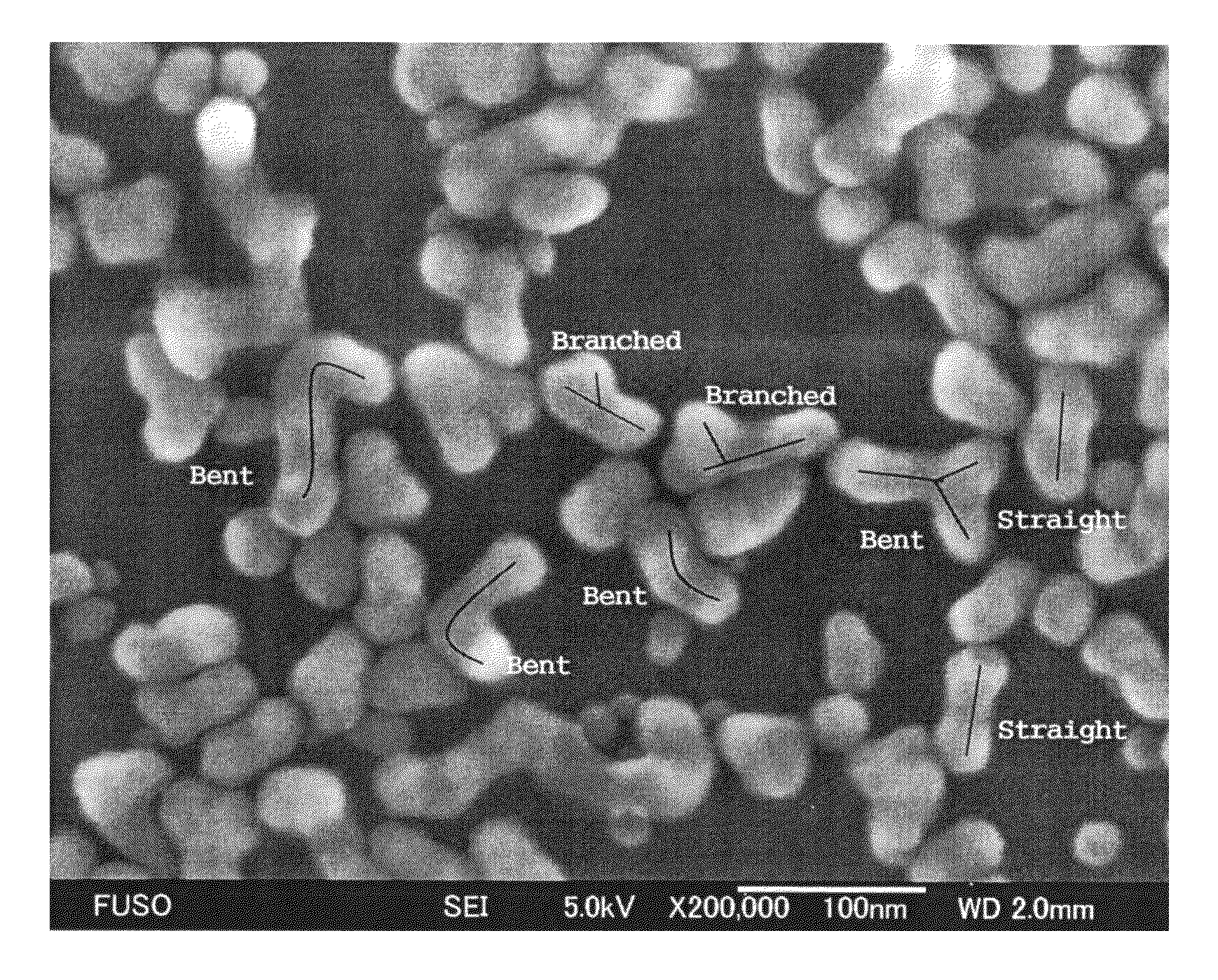

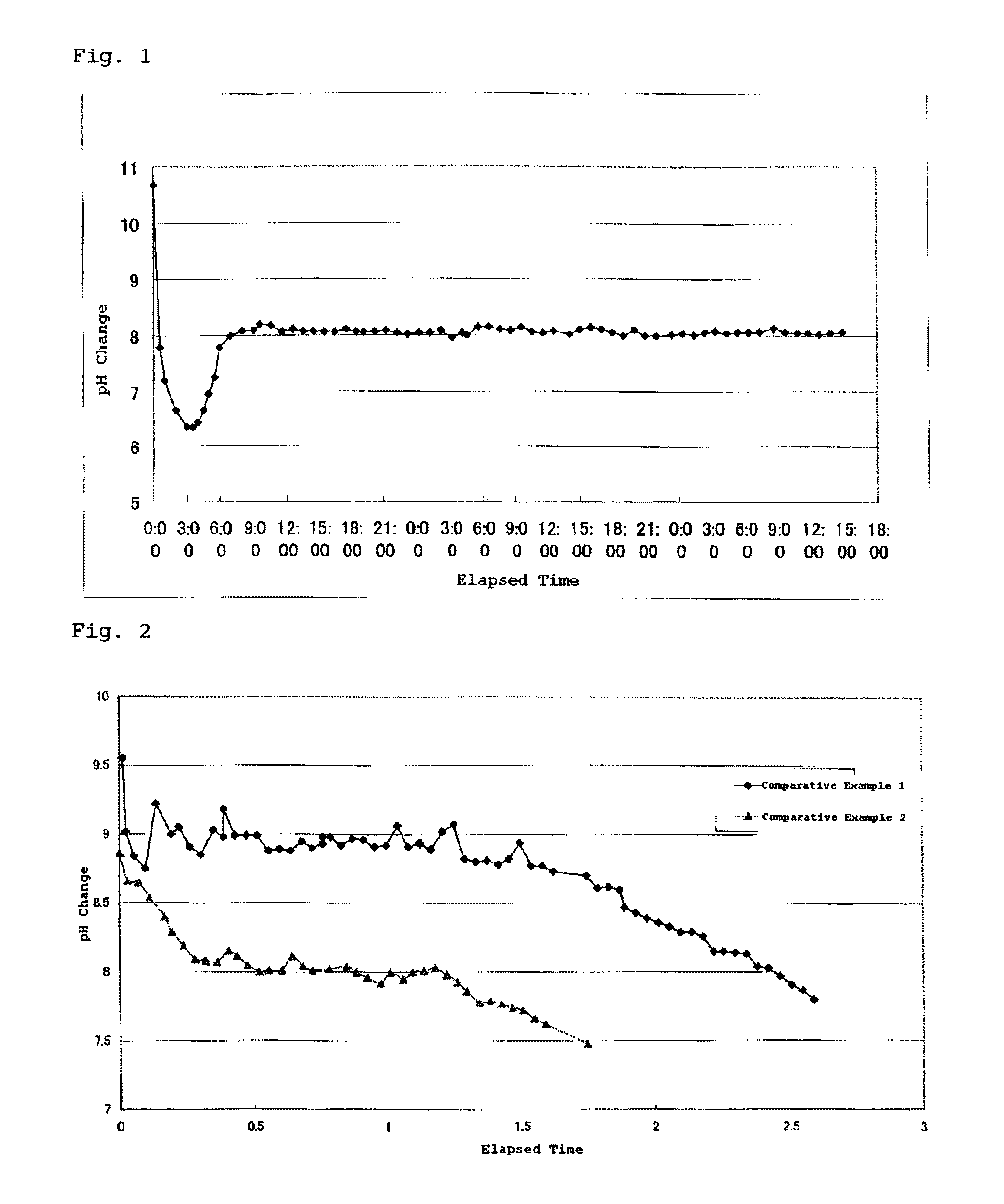

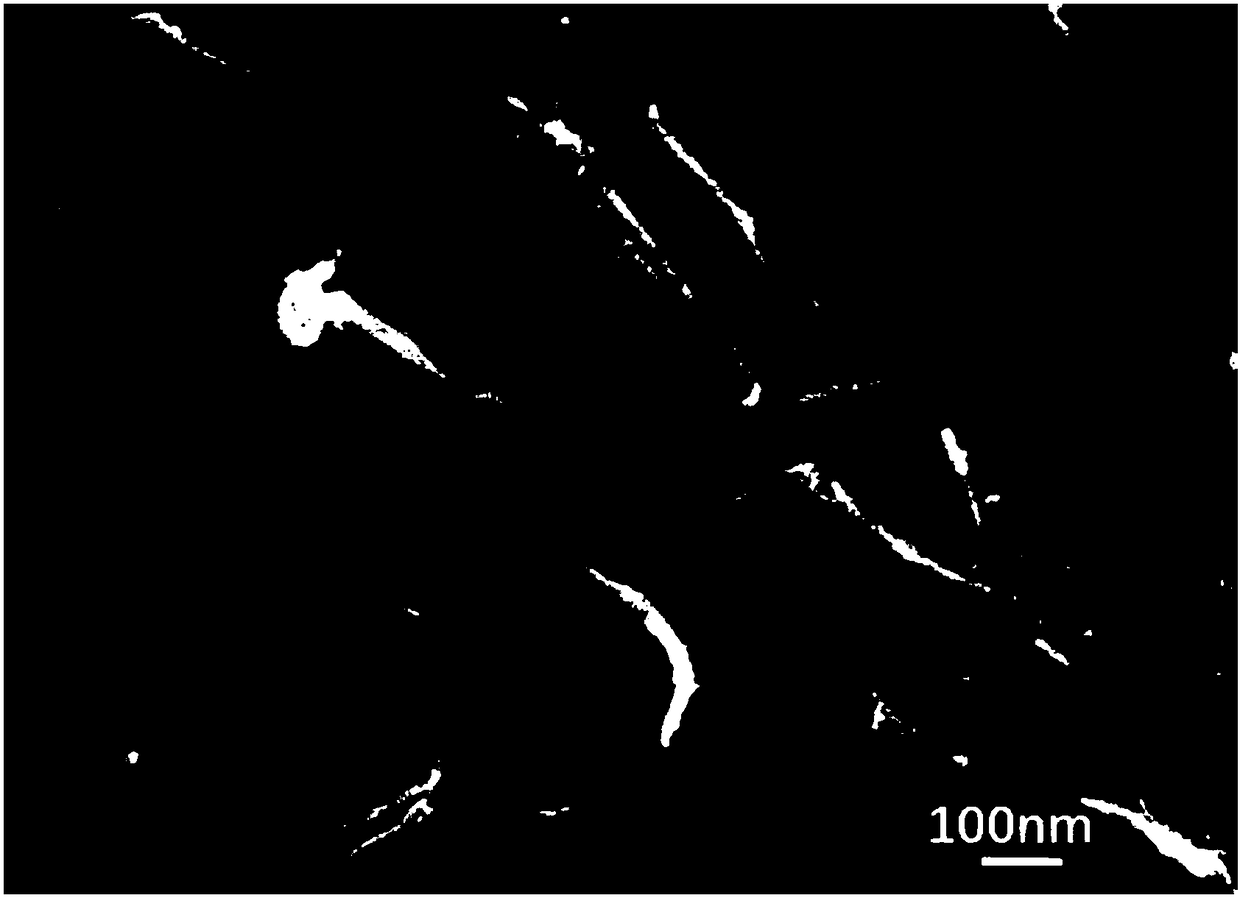

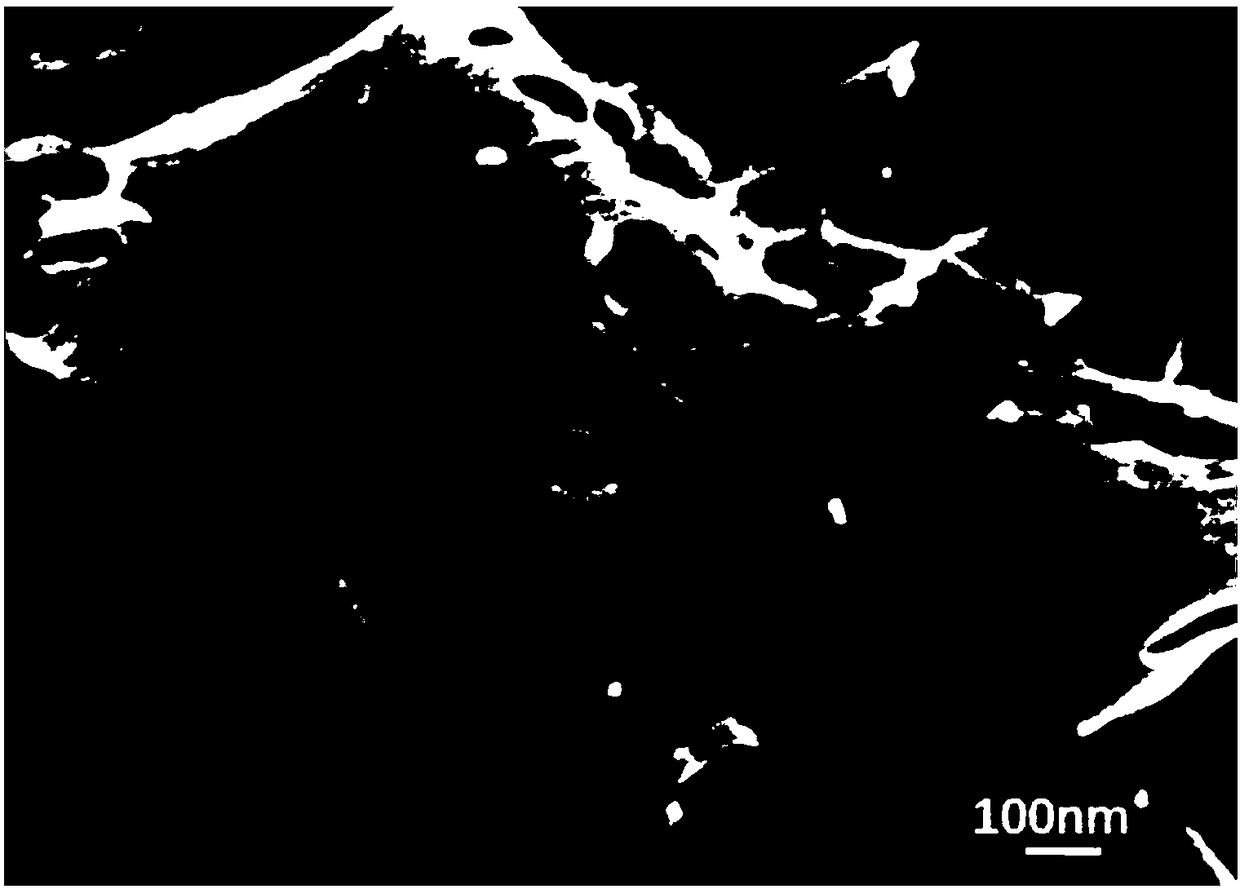

Colloidal silica containing silica secondary particles having bent structure and/or branched structure, and method for producing same

ActiveUS8529787B2Improve polishing rateLarge aspect ratioSilicaOther chemical processesColloidal silicaColloid

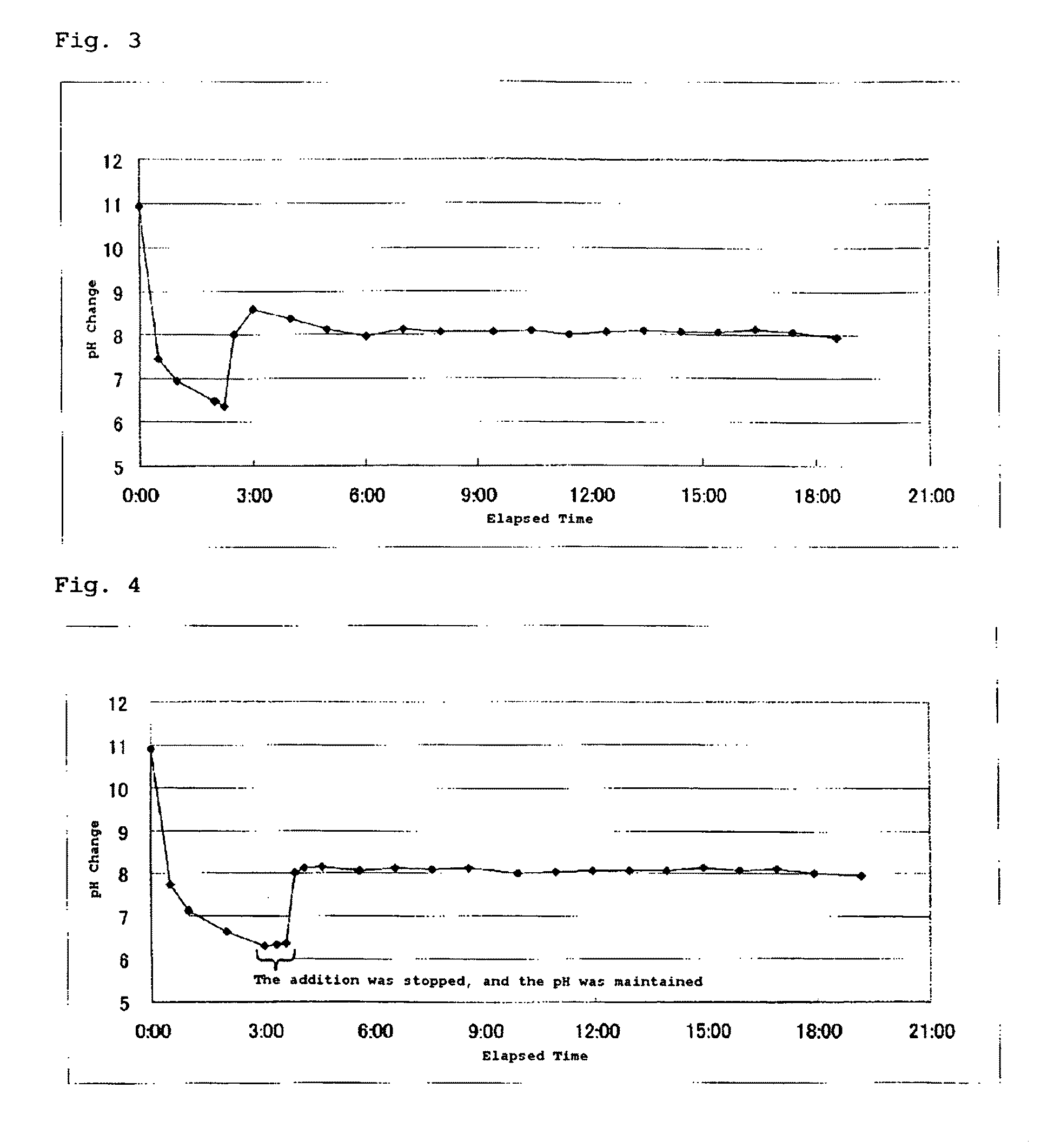

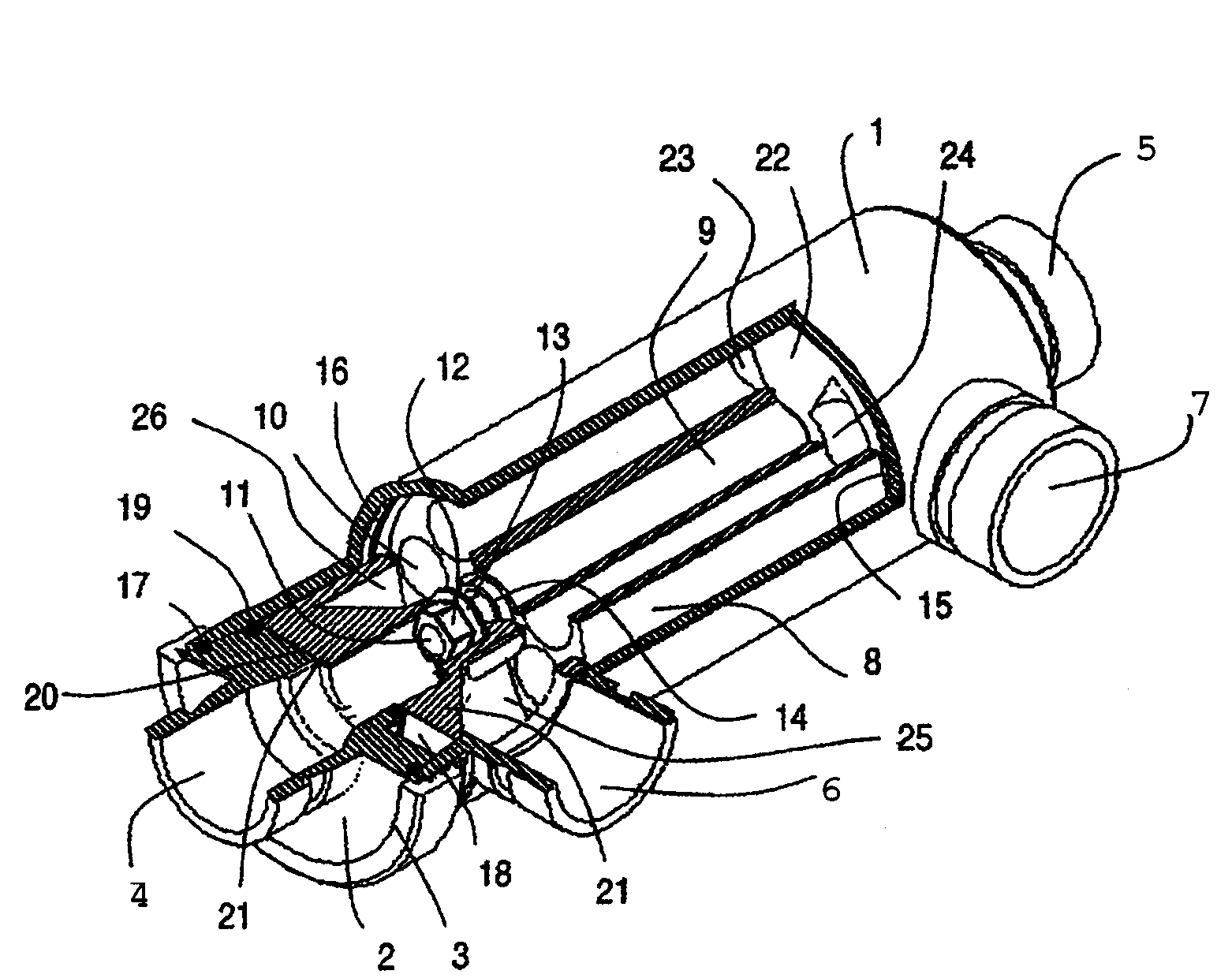

This invention provides a dense, high-purity colloidal silica containing silica secondary particles having a branched and / or bent structure, and a production method thereof. Specifically, this invention provides a method for producing a colloidal silica, comprising the steps of 1) preparing a mother liquid containing an alkali catalyst and water, and having a pH of 9 to 12; and 2) adding a hydrolysis liquid obtained by hydrolysis of an alkyl silicate to the mother liquid, wherein the step of adding the hydrolysis liquid to the mother liquid sequentially comprises A) step 1 of adding the hydrolysis liquid until the pH of the resulting liquid mixture becomes less than 7; B) step 2 of adding an aqueous alkali solution until the pH of the liquid mixture becomes 7 or more; and C) step 3 of adding the hydrolysis liquid while maintaining the pH of the liquid mixture at 7 or more, and a colloidal silica containing silica secondary particles having a branched and / or bent structure, obtained by this method.

Owner:FUSO CHEM

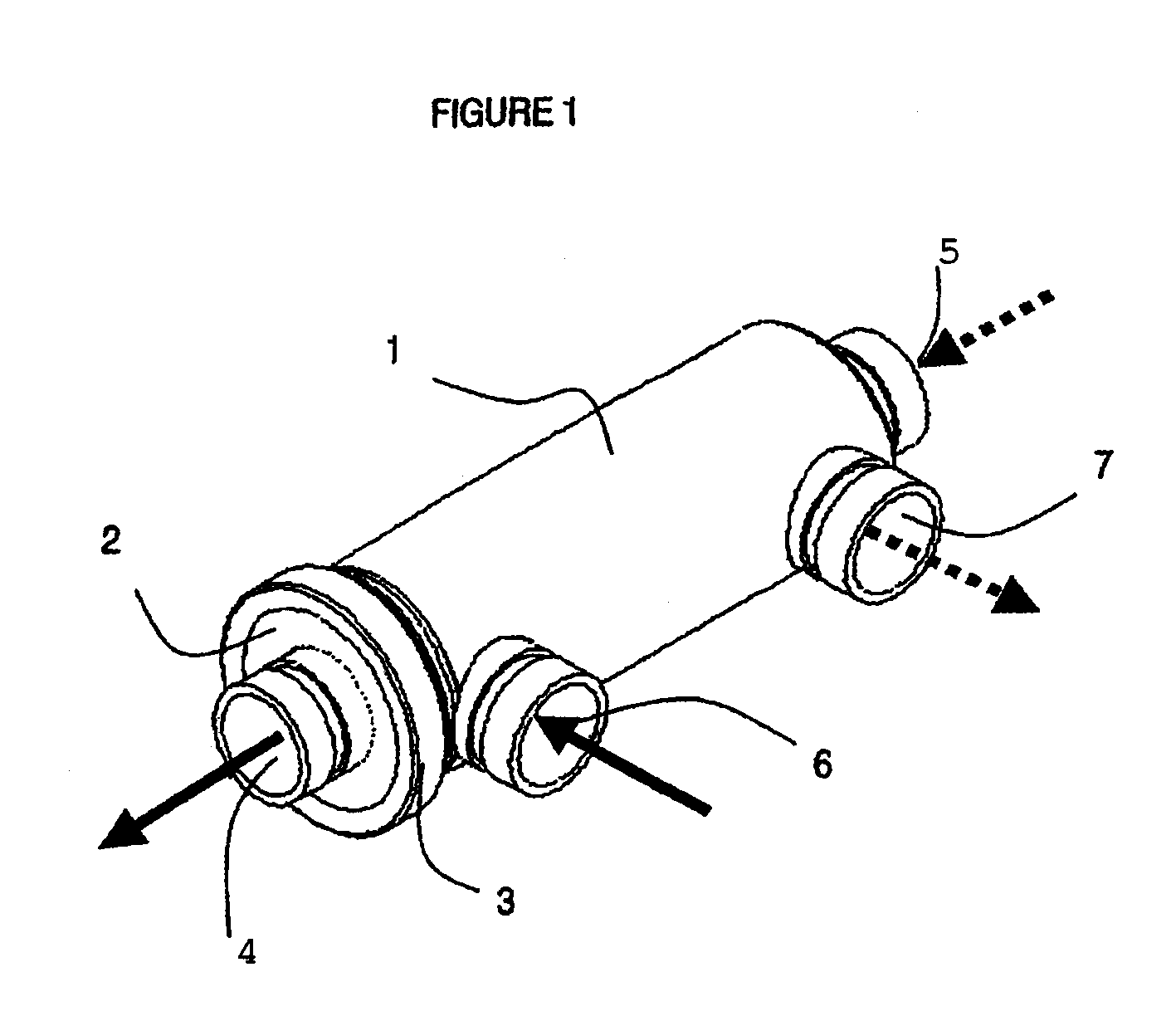

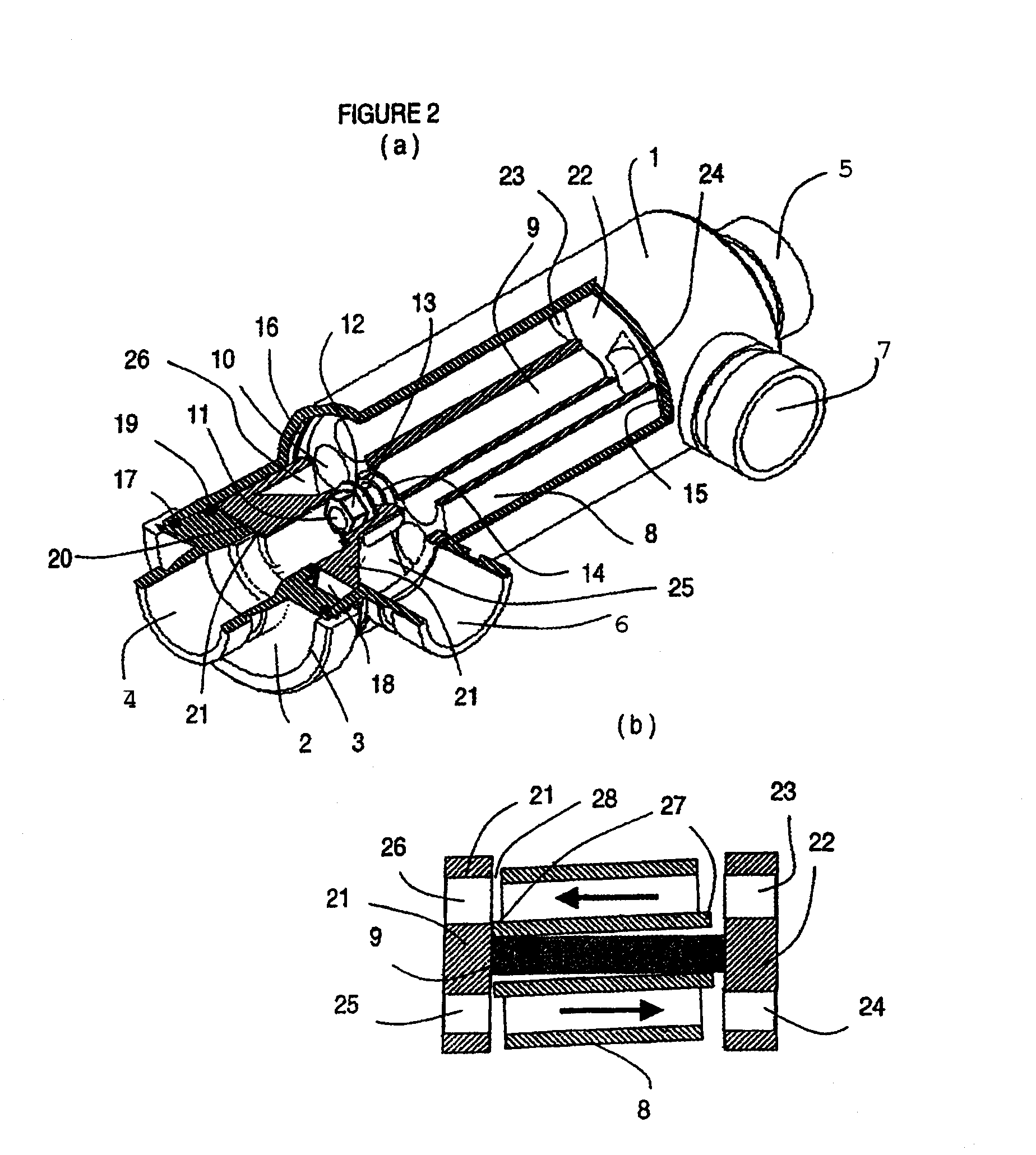

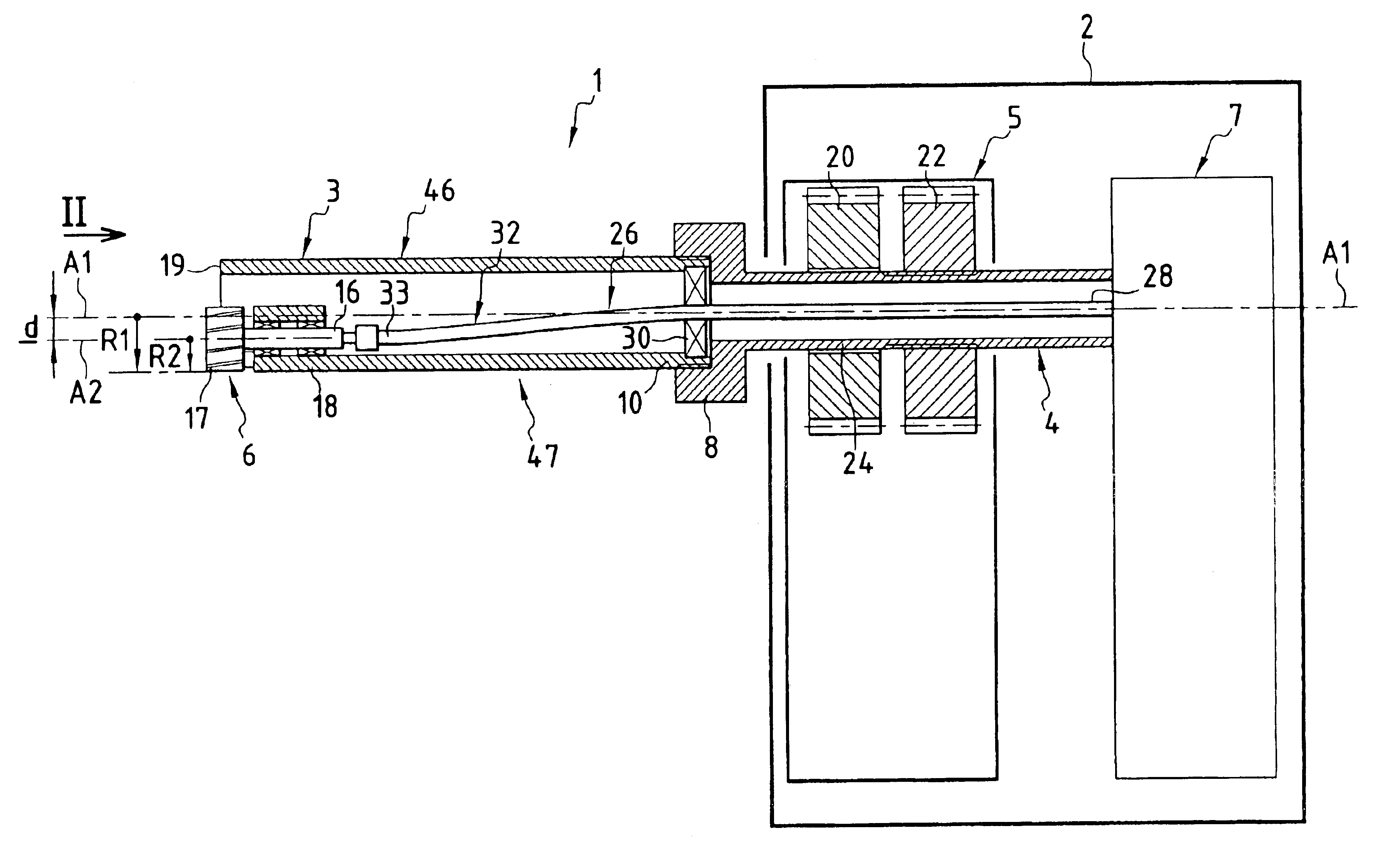

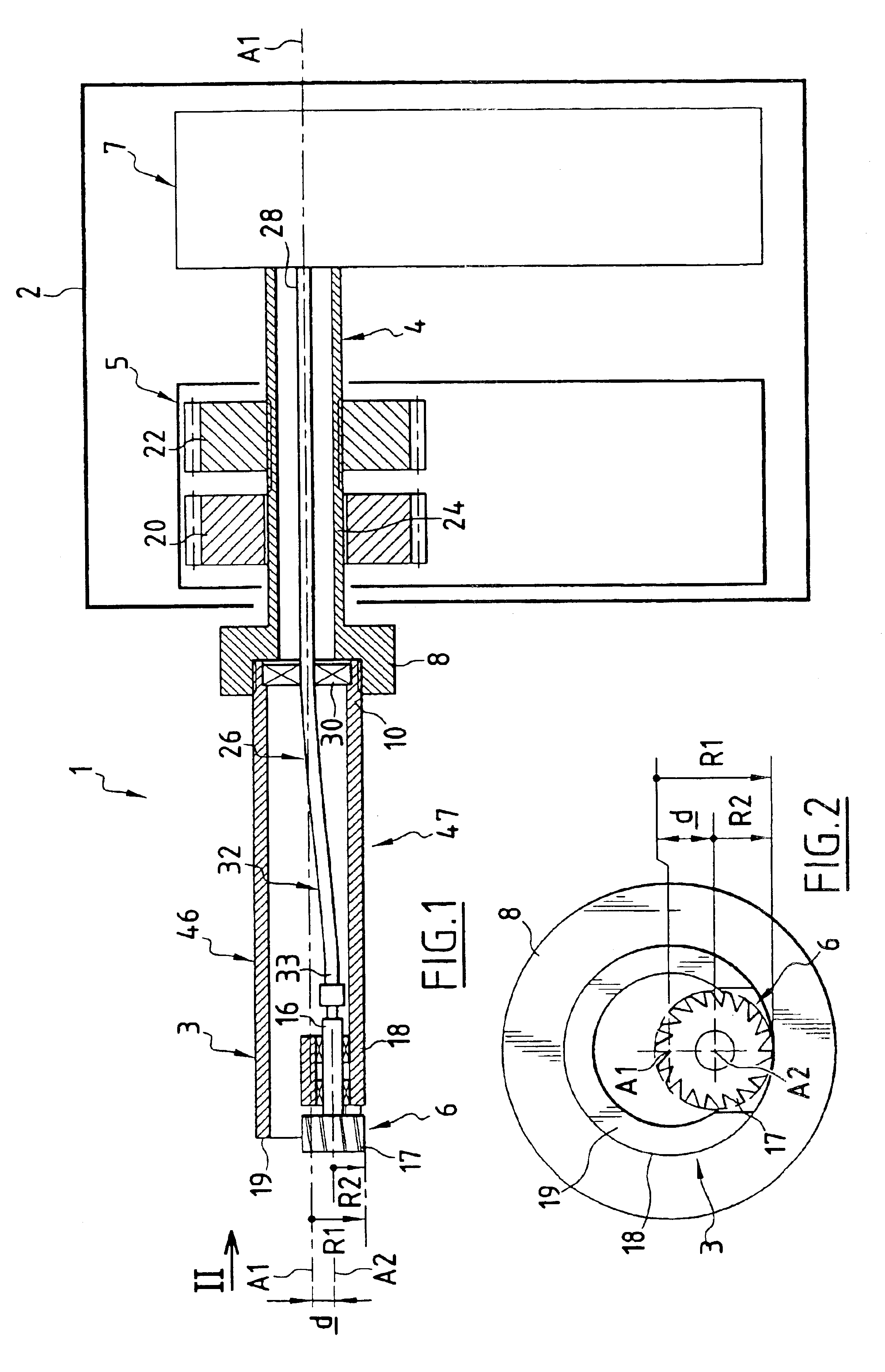

Pressure exchanger

ActiveUS7306437B2Increase capacityIncrease momentumRotary/oscillating piston combinations for elastic fluidsGeneral water supply conservationCavitationMomentum

Owner:ISOBARIC STRATEGIES INC

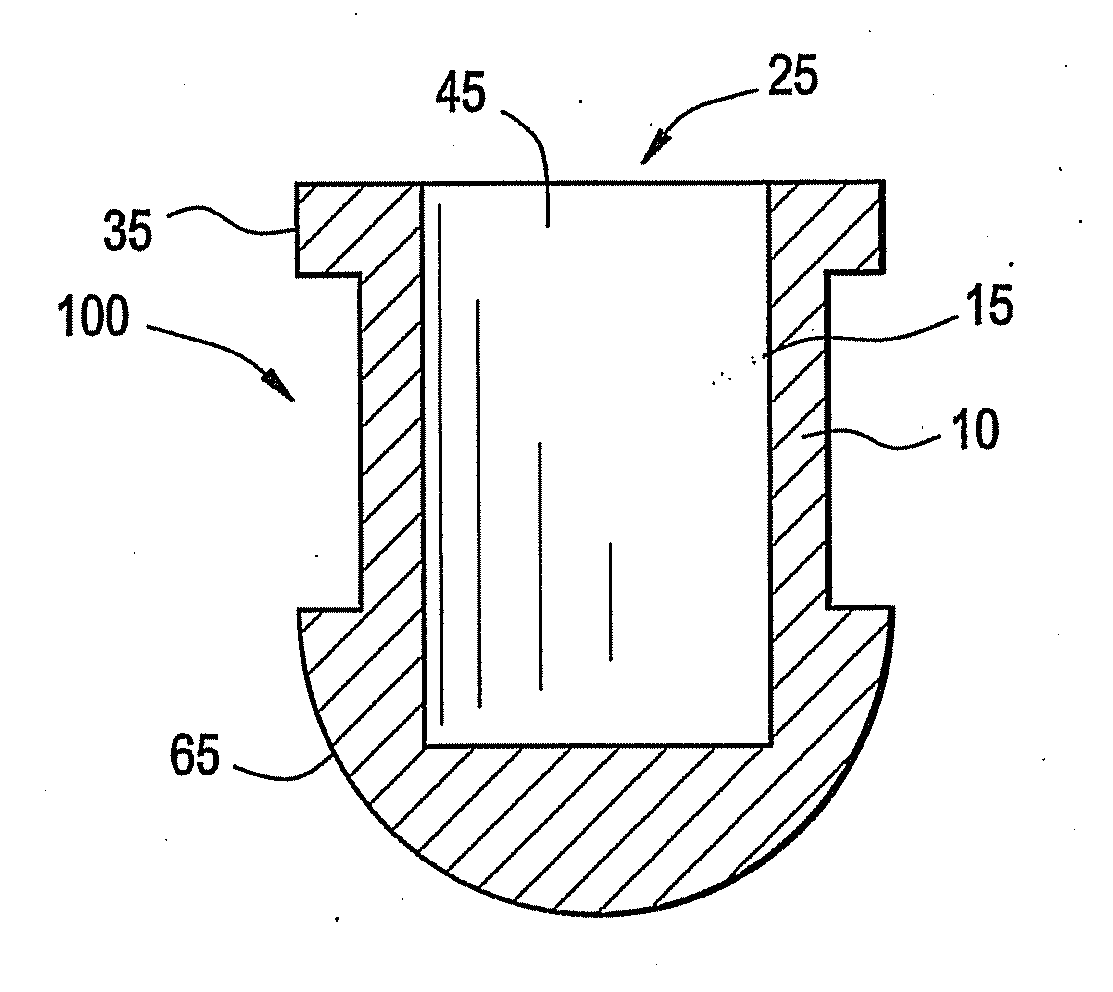

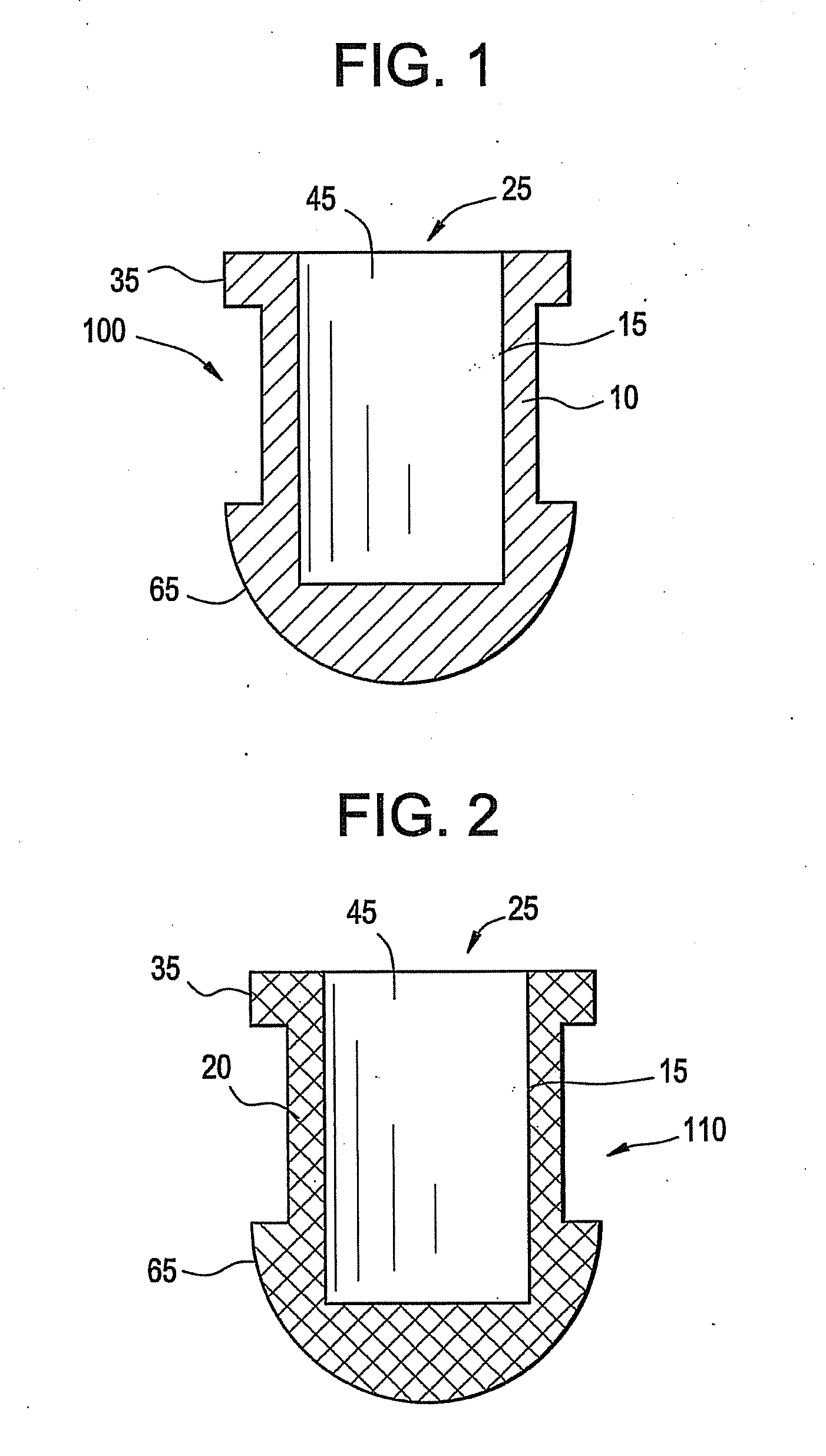

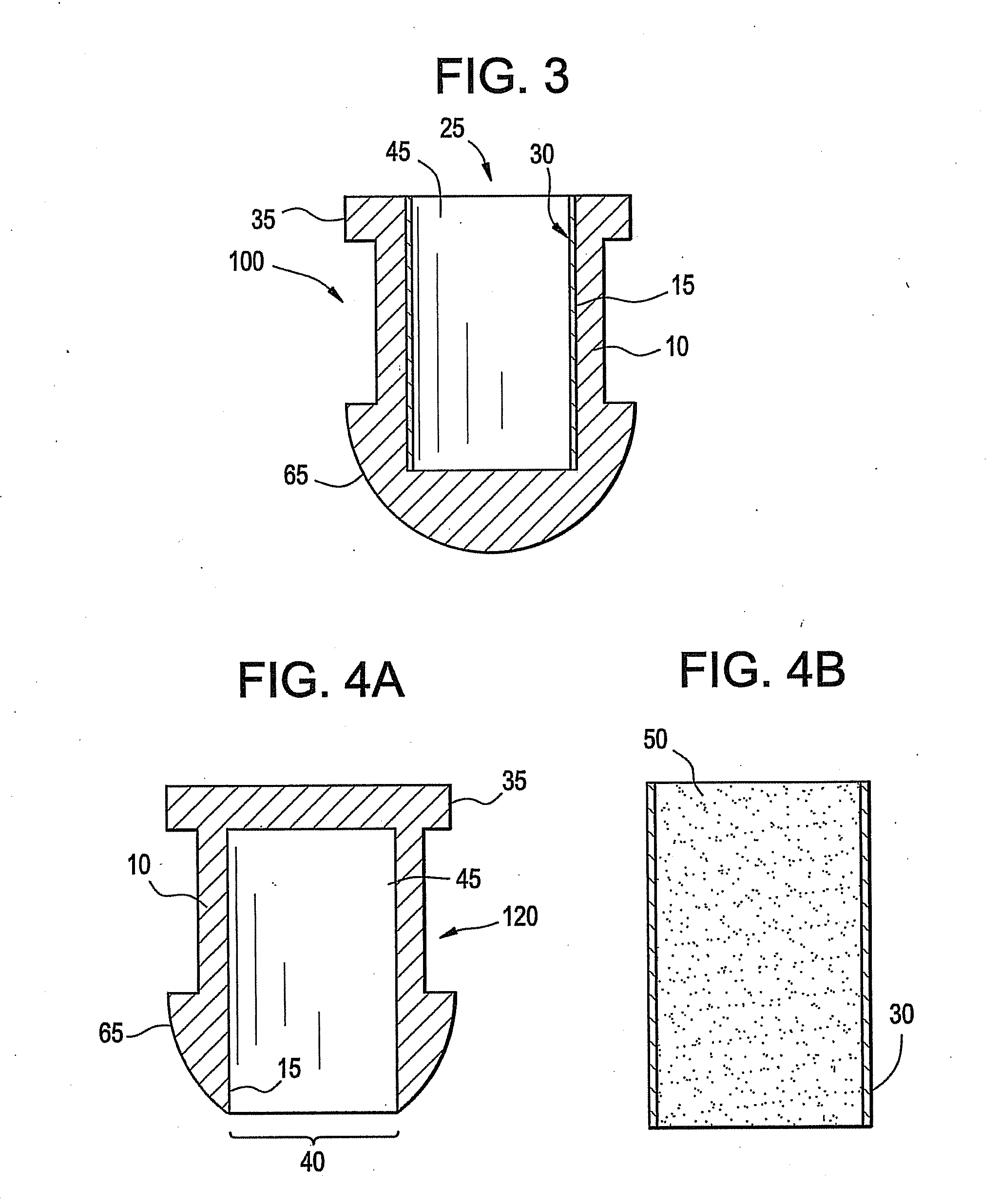

Biocompatible wire battery

ActiveUS20130034760A1Reliable and stable powerEasy to useFinal product manufactureSmall-sized cells cases/jacketsActive componentElectrochemistry

A rechargeable electrochemical battery in the form of a single or multi-stranded wire assembly may be utilized as a power source for any number of implantable or non-implantable medical devices. As the wire form battery may be scaled to micro size, it may be utilized to power medical devices that were traditionally non-active devices, but which may be enhanced with active components. The wire form battery may be cut to size for a particular application which provides the same open circuit voltage regardless of how the wire is ultimately configured and the length of the wire utilized. Although the battery is in wire form, various arrangements of the components within the battery are also possible.

Owner:JOHNSON & JOHNSON VISION CARE INC

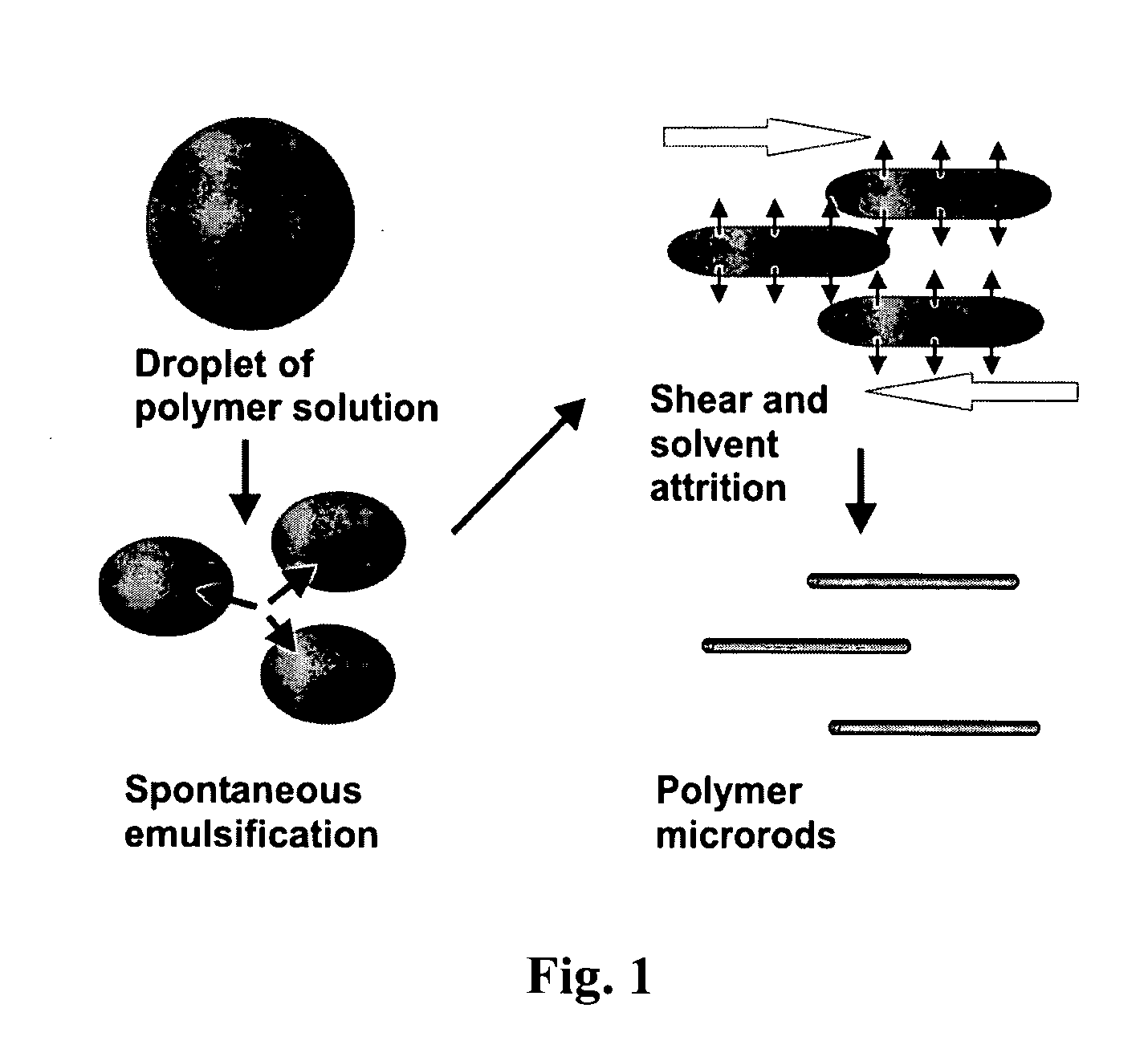

Process for preparing microrods using liquid-liquid dispersion

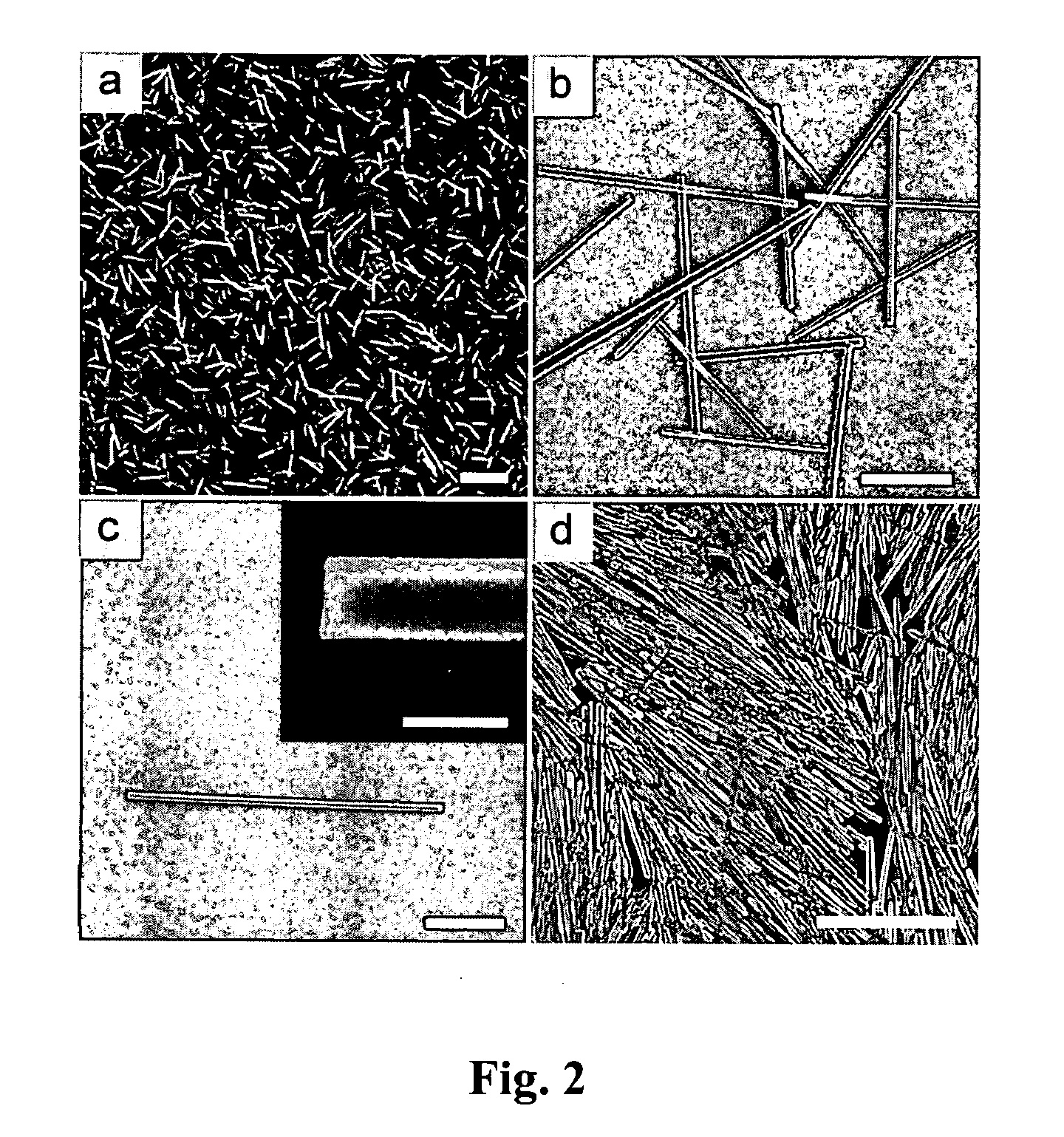

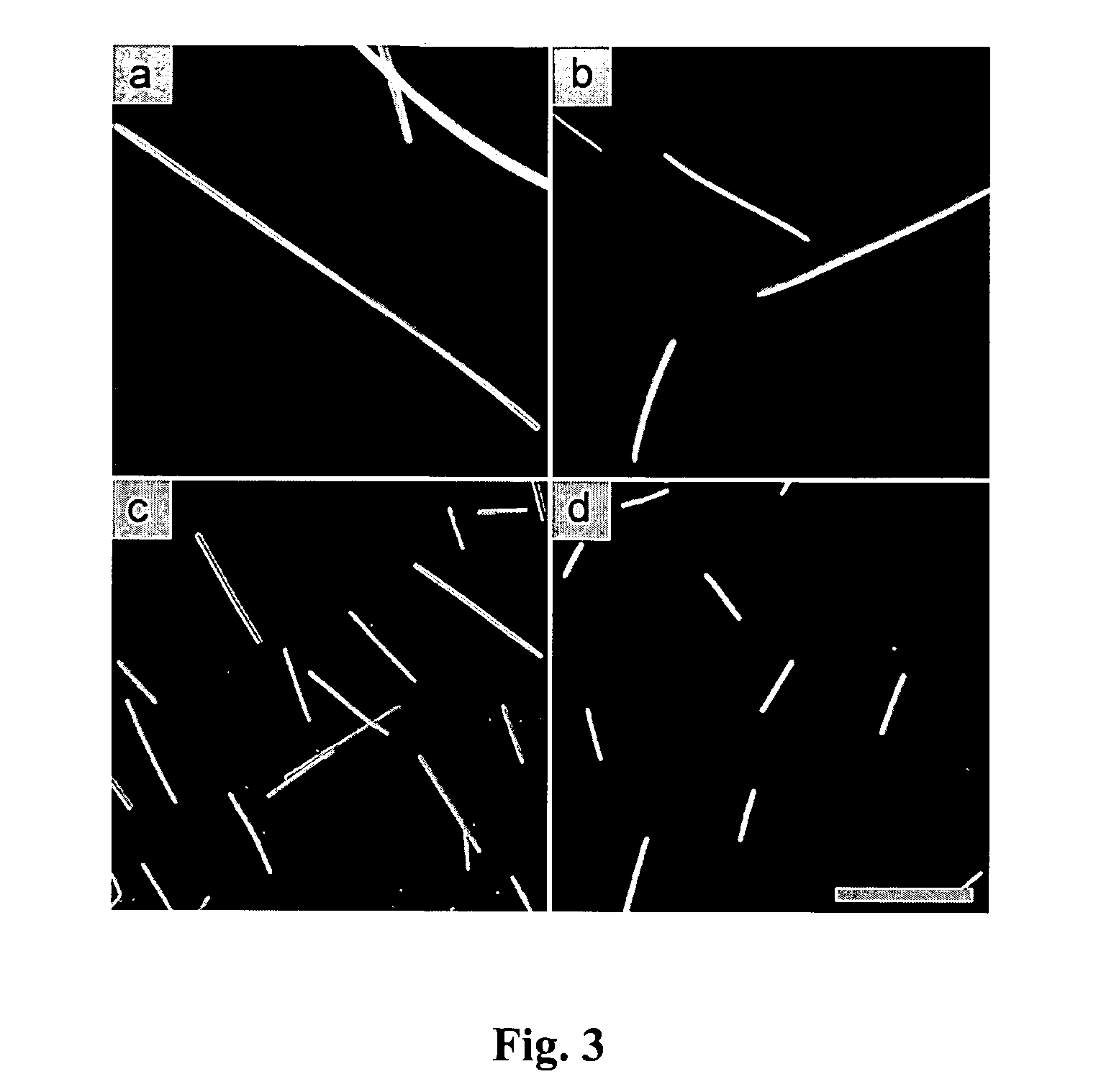

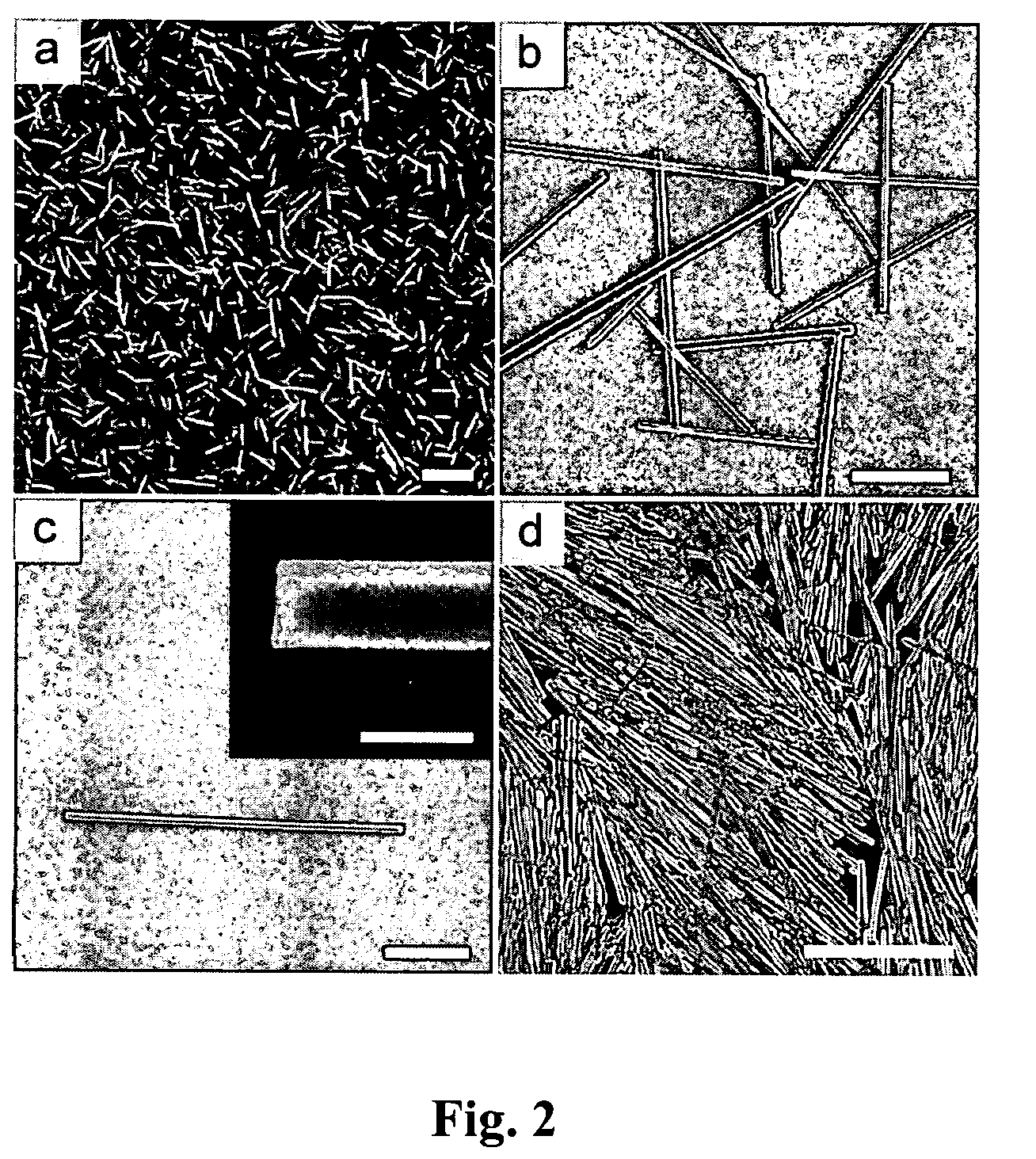

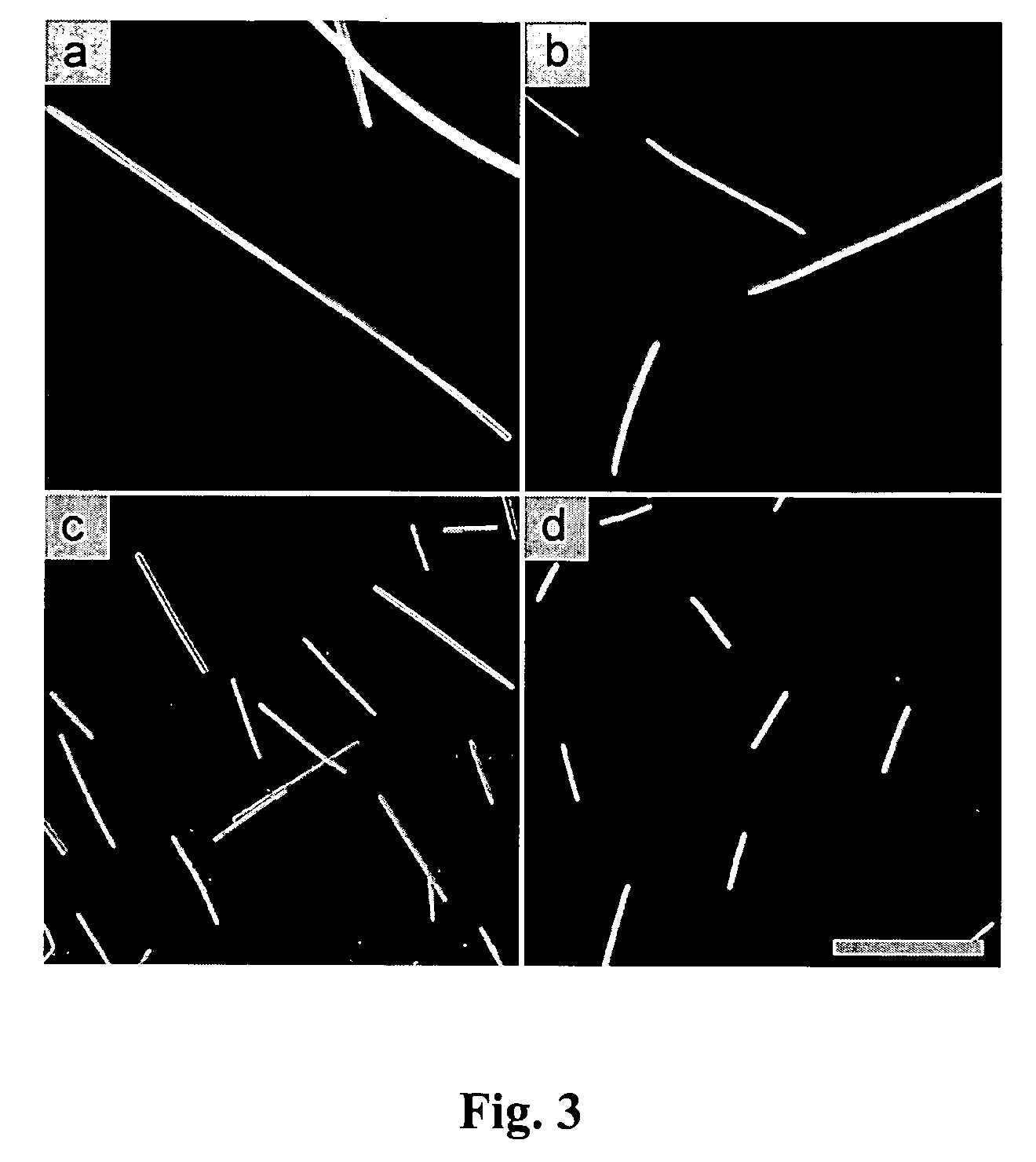

ActiveUS20060063882A1Large aspect ratioSimple methodBiocideOrganic active ingredientsPolymer scienceDispersed media

The invention provides a method for forming polymer microrods, the method including the steps of providing a polymer solution comprising a polymer dissolved in a first solvent; providing a dispersion medium comprising a second solvent, wherein the first solvent and the second solvent are miscible or partially soluble in each other, and wherein the polymer is insoluble in the second solvent; adding the polymer solution to the dispersion medium to form a dispersed phase of polymer solution droplets within the dispersion medium; and introducing a shear stress to the dispersion medium and dispersed polymer solution droplets for a time and at a shear rate sufficient to elongate the polymer solution droplets to form microrods and solidify the microrods by attrition of the polymer solvent into the dispersion medium.

Owner:NORTH CAROLINA STATE UNIV

Degradable compound biomaterial membrane for medical purpose

InactiveCN1994476AHigh porosityLarge specific surface areaAbsorbent padsBandagesFiberElectrospinning

The invention relates to a method for preparing composite biological medical material used to avoid adhering organisms, wherein said film is formed by two layers; the layer used as base material is formed by degradable composite macromolecule polylactic acid, glycolic acid, or their copolymer, treated by static spin technique, to make film fiber into nanometer level; then coats one layer of degradable natural macromolecule chitose or relative derivant on the base film, to be treated to obtain the degradable composite biological medical film; and the invention can add different amounts of medical elasticizer between two layers to adjust the degrade speed. The invention can improve immunity with haemostasis function, etc.

Owner:BEIJING HUASHI BENQUAN TECH

Medical anti-sticking membrane and preparation method thereof

The invention provides a medical anti-sticking membrane and a preparation method thereof. The anti-sticking membrane comprises a nanometer frame and hydrosol attached thereon. The hydrosol is internally packed with one or several kinds of styptic medicament or / and anti-sticking medicament. The invention also provides a preparation method of the anti-sticking membrane, comprising the following steps of: preparing electro-spinning solution, styptic medicament and / or anti-sticking medicament-containing hydrosol solution and crosslinker solution; receiving static spinning with the crosslinker solution to obtain the nanometer frame; printing the styptic medicament and / or anti-sticking medicament-containing hydrosol solution onto the nanometer frame by an ink-jet printer, and solidifying the hydrosol solution to obtain the anti-sticking membrane. The anti-sticking membrane has good capability and biological compatibility, and nontoxicity as well as nonirritant, can be completely degraded and absorbed, is compounded with controllably released styptic medicament or / and anti-sticking medicament, has controllable degrading time and speed, and conquers defects of the prior art.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

Preparation method of cellulose nano-fiber/polylactic acid composite membrane

InactiveCN103387688AUniform diameter distributionReduce hydrogen bondingPaper material treatmentFiberChemical treatment

The invention provides a preparation method of a cellulose nano-fiber / polylactic acid composite membrane. The preparation method comprises the following steps of: (1) treating raw materials; (2) performing chemical treatment; (3) performing mechanical treatment; (4) preparing a nano cellulose membrane; (5) preparing a nano cellulose / polylactic acid composite membrane material by using a mixing and dissolving method or an immersion method. The preparation method has the advantages that lignin and most of hemicellulose are removed by using a chemical method, and under a water wet swelling condition, water fills the positions in which most of the hemicellulose and the lignin are removed, so that the hydrogen bond acting force among fibrillae is reduced; then lignocellulose nano fibrillae with uniform morphological sizes and mesh gangles are prepared by adopting mechanical treatment. The nano celluloses prepared by grinding for 30 minutes and homogenizing are small in diameter size and are uniformly distributed, the diameters of the nano fibrillae is 15-50nm, and the length-diameter ratio is high and reaches 1200. The cellulose nano-fiber / polylactic acid composite membrane can be used as a substitute and the like for a flexible display, electronic paper, a solar battery, a flexible circuit and a glass substrate.

Owner:NANJING FORESTRY UNIV

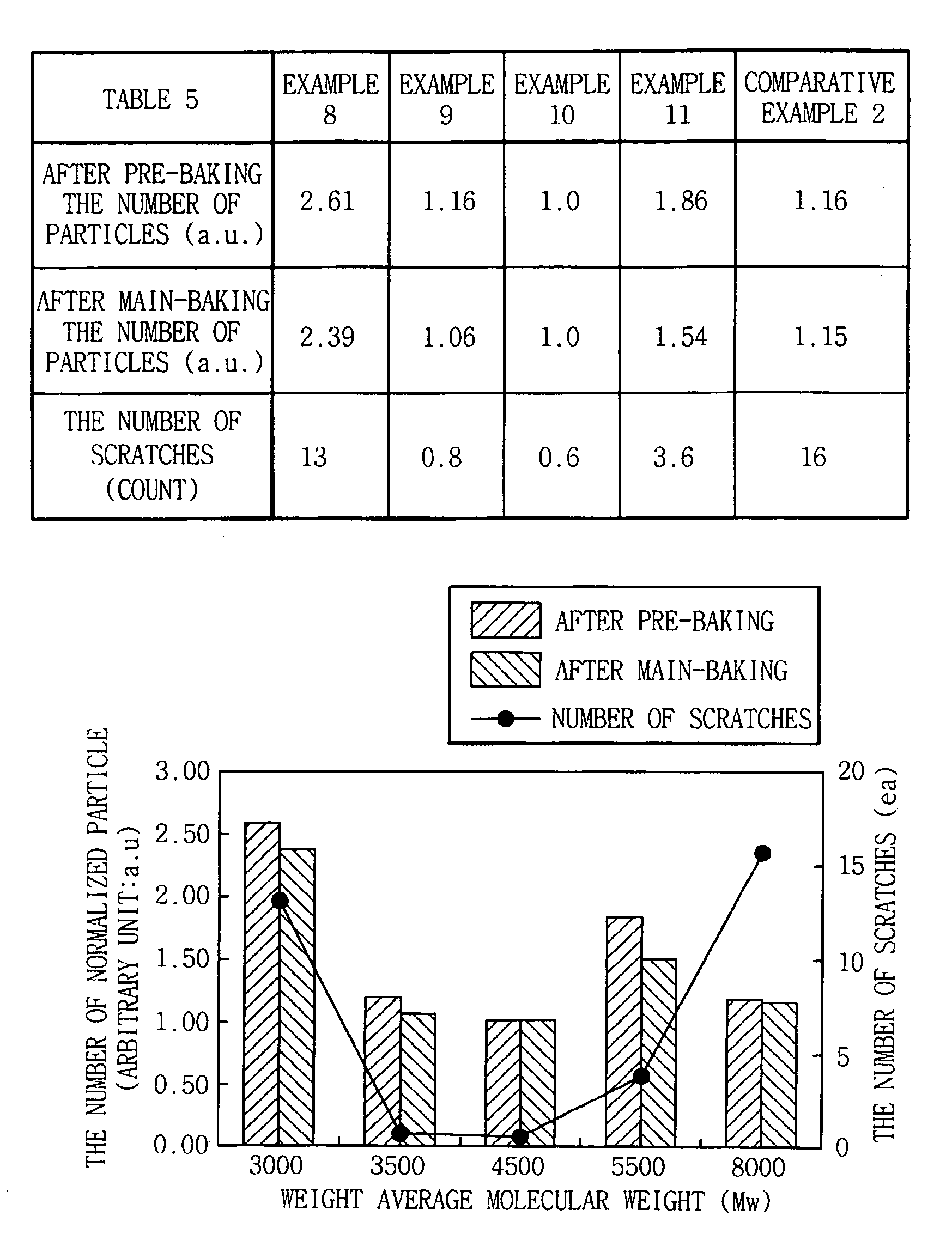

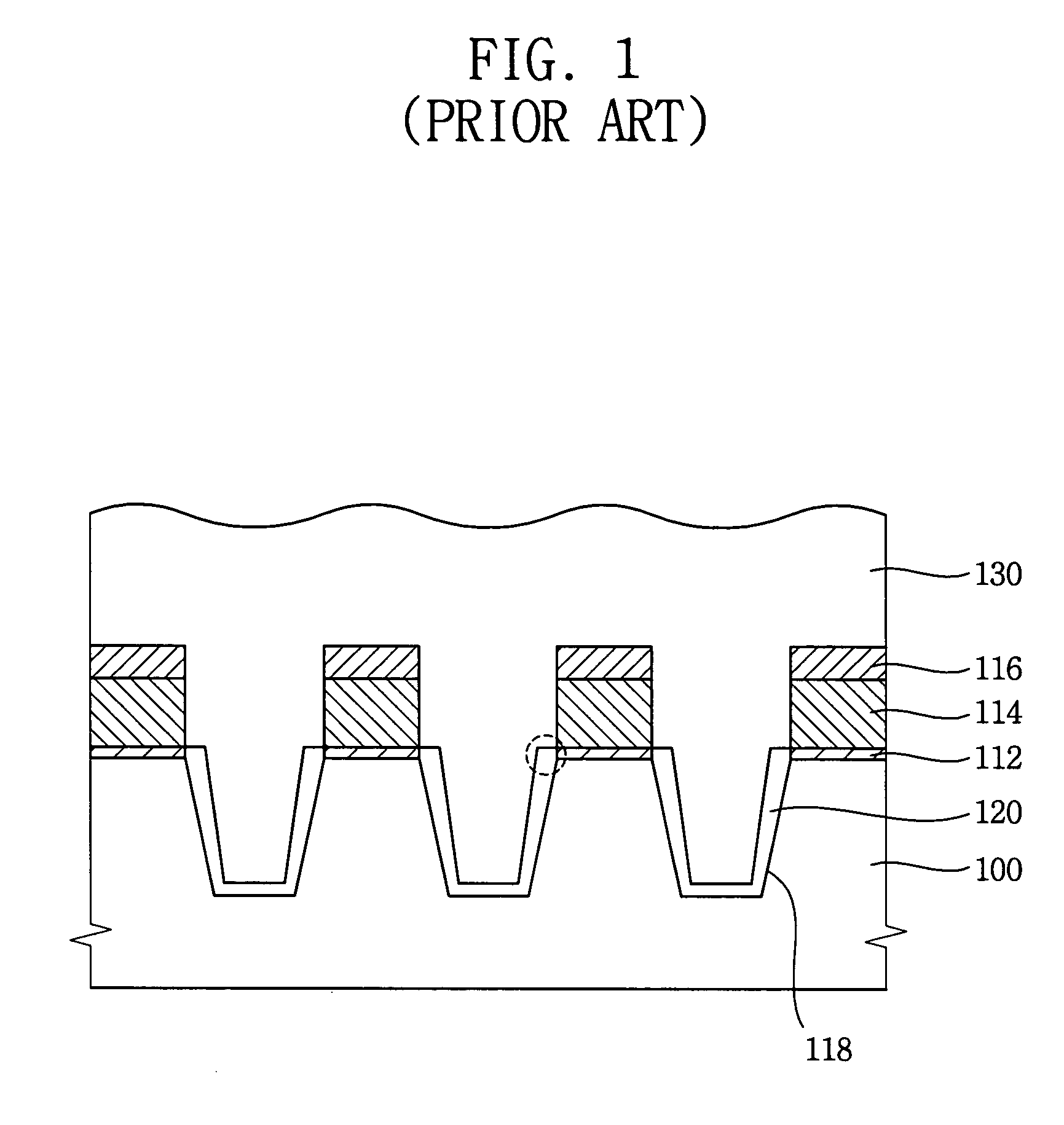

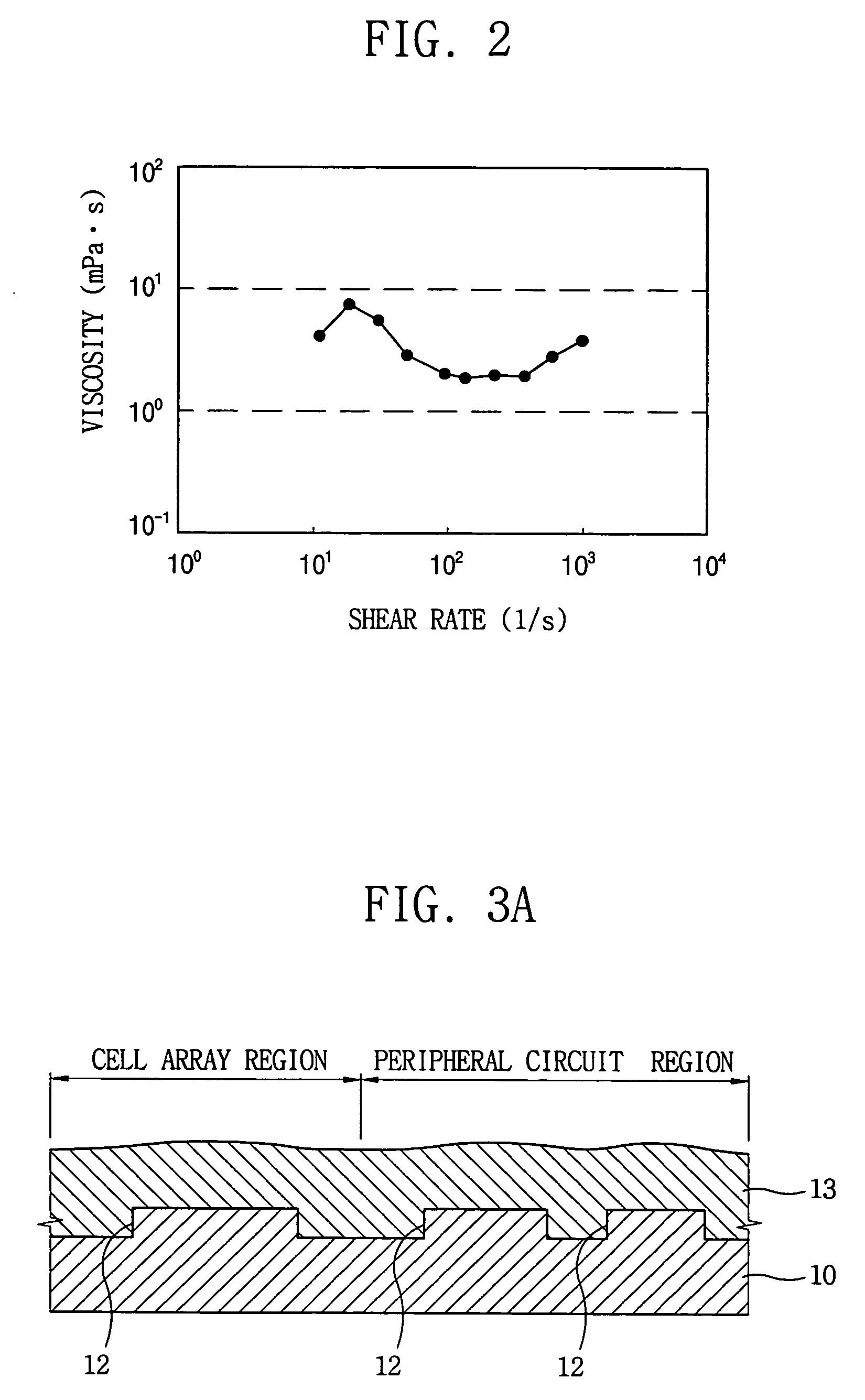

Spin-on glass composition and method of forming silicon oxide layer in semiconductor manufacturing process using the same

InactiveUS7270886B2High bulk densityLarge aspect ratioLayered productsSolid-state devicesPolysilazaneSilicon oxide

A spin-on glass (SOG) composition and a method of forming a silicon oxide layer utilizing the SOG composition are disclosed. The method includes coating on a semiconductor substrate having a surface discontinuity, an SOG composition containing polysilazane having a compound of the formula —(SiH2NH)n— wherein n represents a positive integer, a weight average molecular weight within the range of about 3,300 to 3,700 to form a planar SOG layer. The SOG layer is converted to a silicon oxide layer with a planar surface by curing the SOG layer. Also disclosed is a semiconductor device made by the method.

Owner:SAMSUNG ELECTRONICS CO LTD

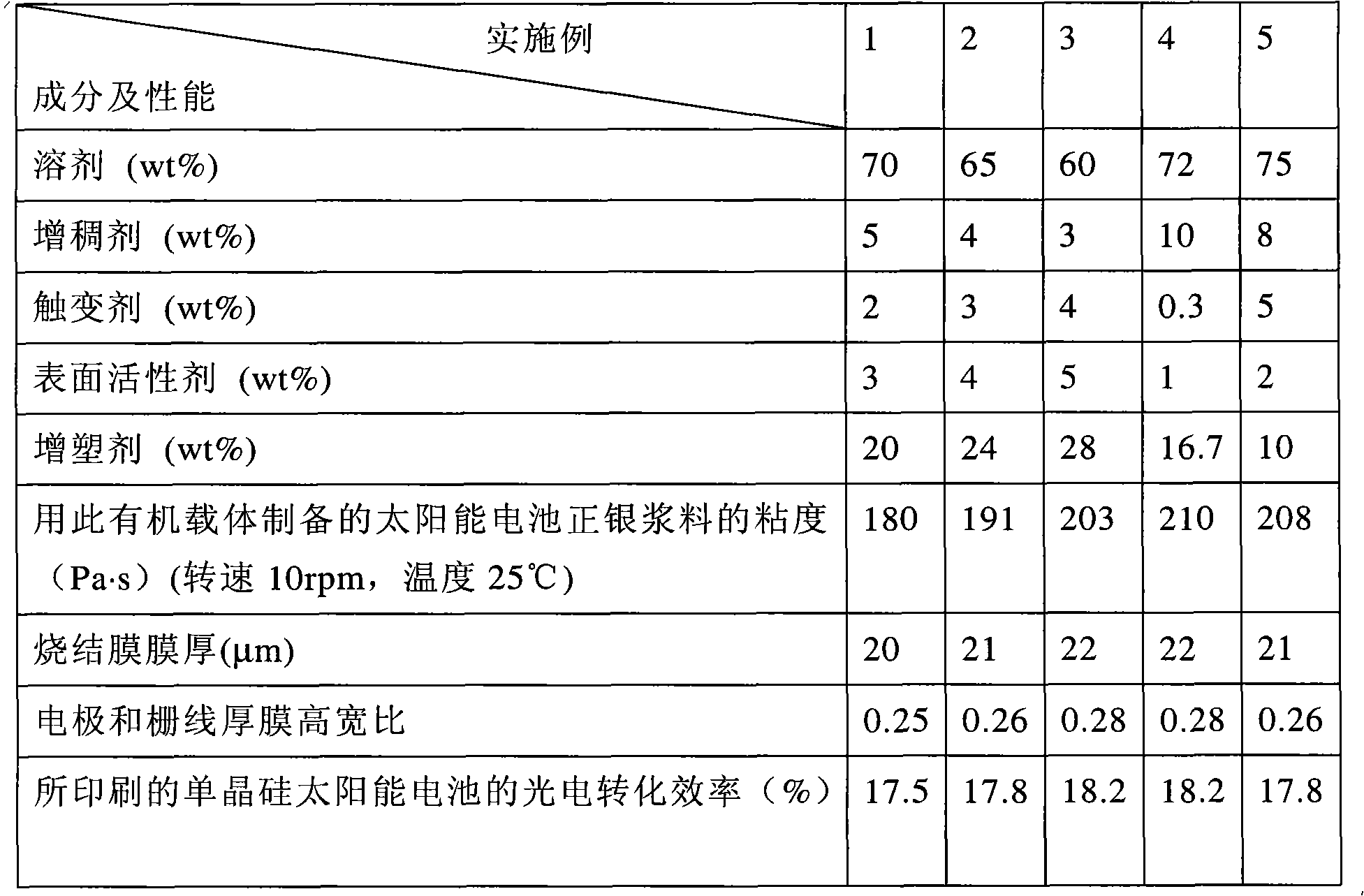

Organic carrier for silver paste and preparation method thereof as well as silver paste containing organic carrier and solar cell manufactured from silver paste

InactiveCN102136308AModerate viscositySuitable ThixotropyNon-conductive material with dispersed conductive materialSemiconductor devicesSolventChemical stability

The invention discloses an organic carrier for conductive silver paste applied to a front face electrode and a grid line of a solar cell, a preparation method of the organic carrier, silver paste containing the organic carrier and a solar cell manufactured from the silver paste. The organic carrier comprises the following components in percentage by weight: 60-75 percent of solvent, 1-10 percent of thickener, 0.3-5 percent of thixotropic agent, 1-5 percent of surfactant and 10-30 percent of plasticizer. The preparation method of the organic carrier comprises the following steps of: weighing various raw materials; adding various aids into a solvent respectively; and heating and stirring until the aids are dissolved completely. The organic carrier has proper viscosity and a simple preparation process. Paste prepared from the organic carrier has proper viscosity, fineness, leveling property, thixotropy and chemical stability. After the paste is subjected to screen printing and sintering on a cell substrate, the thicknesses of a front face electrode and a grid line thick film of a cell panel can be over 20 micros, and the prepared electrode and the grid line thick film can obtain a higher height-width ratio.

Owner:湖南威能新材料科技有限公司

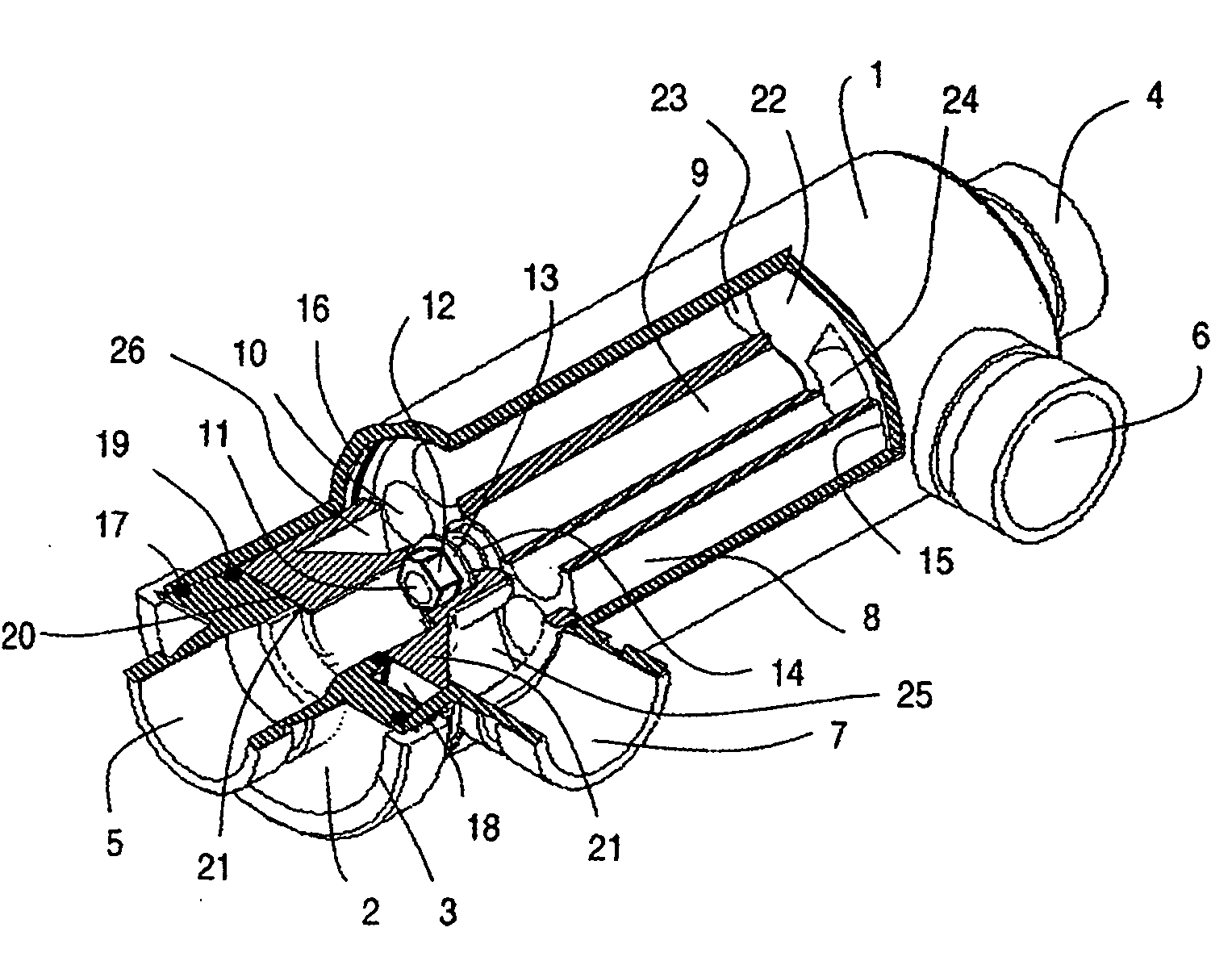

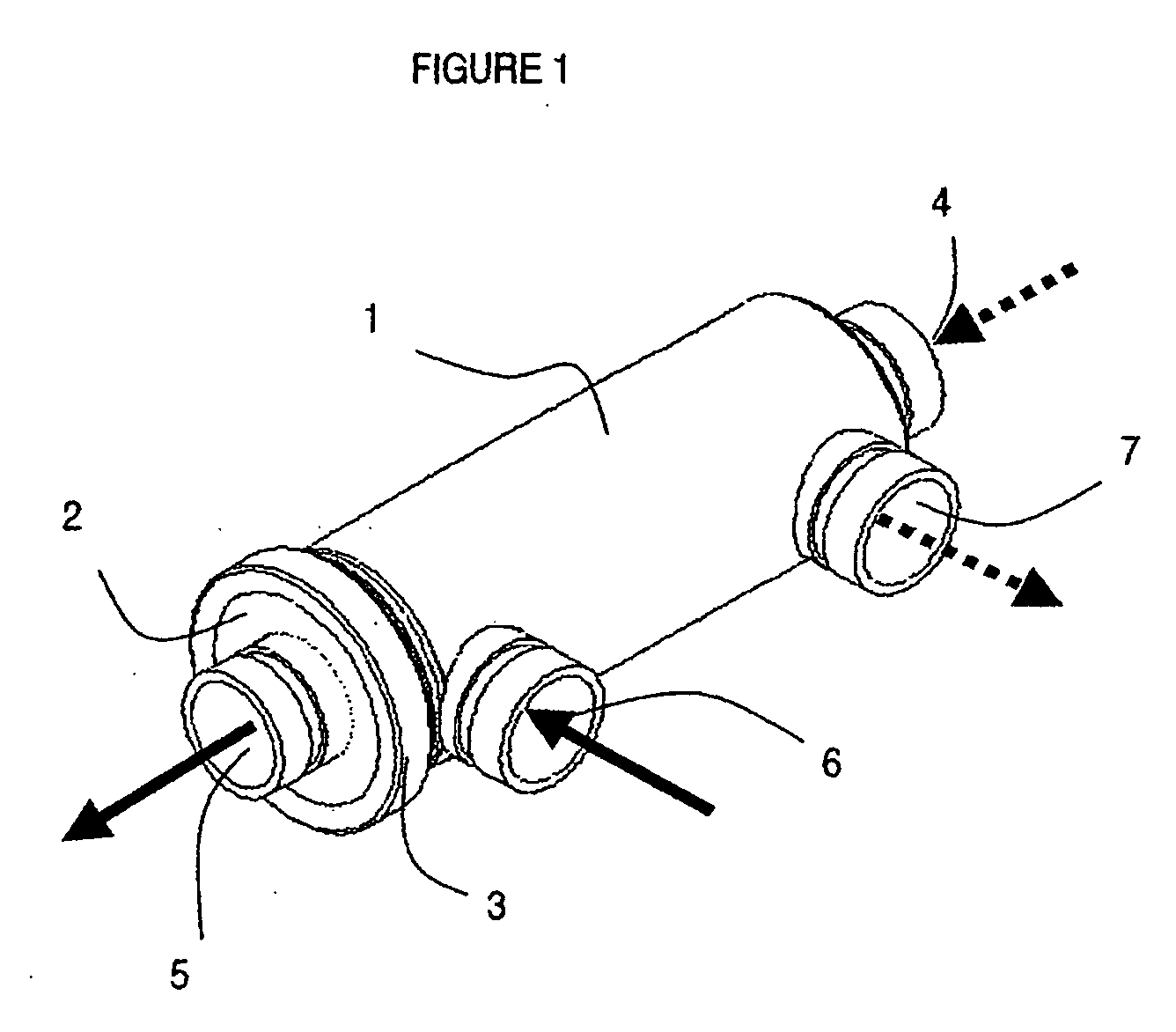

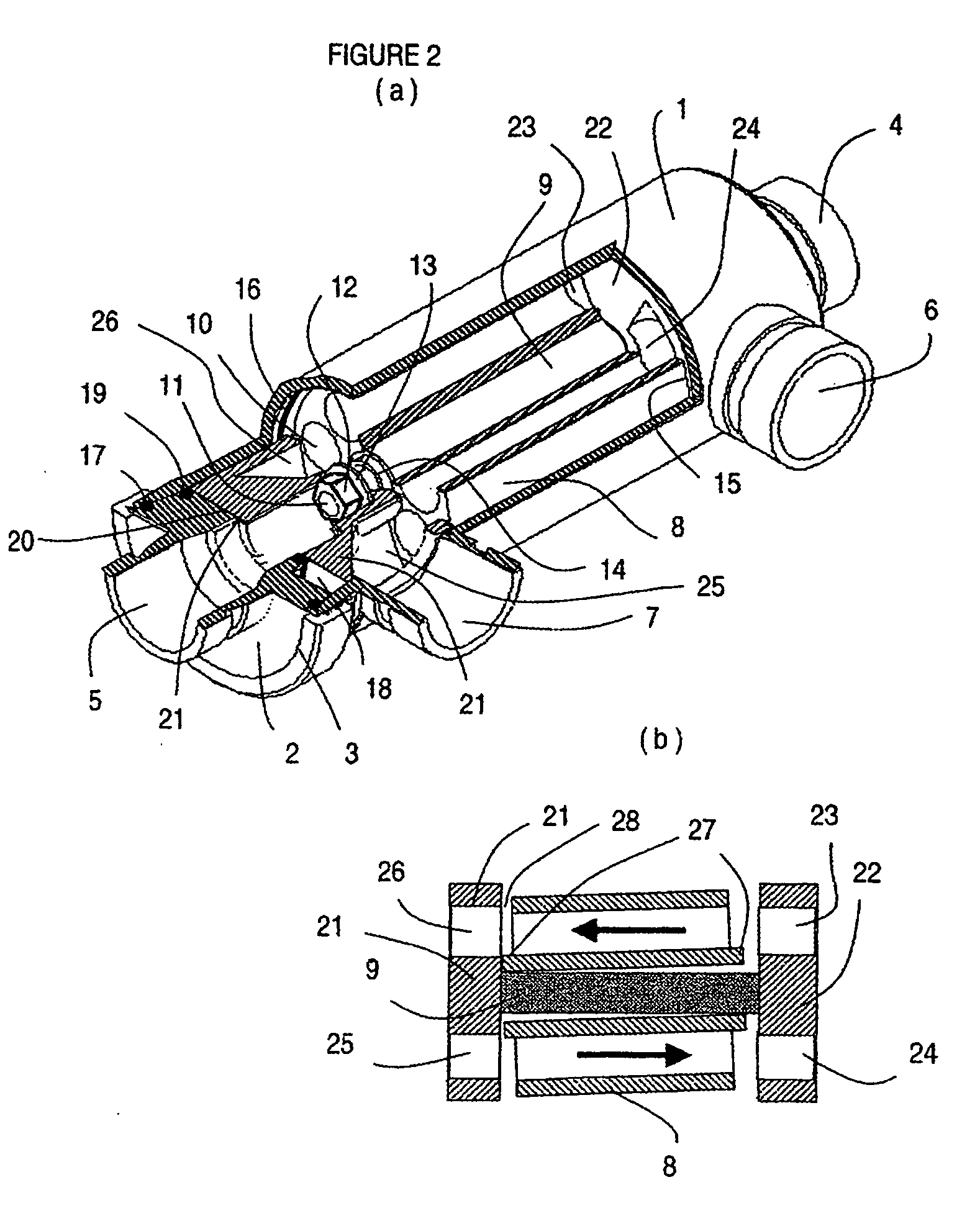

Pressure exchanger

ActiveUS20060032808A1Improve flow capacityIncrease momentumRotary/oscillating piston combinations for elastic fluidsGeneral water supply conservationCavitationMomentum

A pressure exchanger for transferring pressure energy from a relatively high-pressure fluid stream to another relatively low-pressure fluid stream is provided. A ducted rotor is positioned on a central axle between two end covers inside a pressure vessel with a coaxial inlet and outlet pair that is in communication with a pair of low pressure ports having inclination forming an inlet tangential velocity vector in the direction of rotor rotation and an outlet tangential velocity vector in opposite direction imparting a rotational momentum on rotor. A pair of high-pressure ports is adapted for flow without inclination and imparts no momentum to rotor and flow can be varied without impacting the rotor's RPM. The end covers have a sloped surface following a flat sealing area that increases the clearance in the direction of rotation causing increased outflow during depressurization and lower duct pressure before duct is exposed to low pressure port and furthermore causing increased inflow during the pressurization phase before duct is exposed to the high pressure port, which will dissipate pressure energy as opposed to producing cavitation or pressure waves with result wear and noise.

Owner:ISOBARIC STRATEGIES INC

Noncrystalline soft magnetic alloy powder and dust core, electricwale absorber using the same

ActiveCN1487536AExcellent soft magnetic propertiesSpeed up coolingInorganic material magnetismCores/yokesMetallurgyAmorphous phase

Provided is amorphous soft magnetic alloy powder which has high saturation magnetization and low core loss and which is almost spherical and manufactured by water atomization method, and to provide a green compact core and radio wave absorber using the same. This amorphous soft magnetic alloy powder is formed substantially spherical by the water atomization method. The powder mainly consists of Fe and contains at least P, C and B, and is formed of amorphous soft magnetic alloy powder consisting of an amorphous phase with a temperature interval DeltaTx of the supercooled liquid of >= 20K. A green compact core is formed by solidifying the granulated mixture of this amorphous soft magnetic alloy powder, insulator and lubricant. The radio wave absorber is formed by mixing the amorphous soft magnetic alloy powder the particles of which is flattened and insulator.

Owner:ALPS ALPINE CO LTD

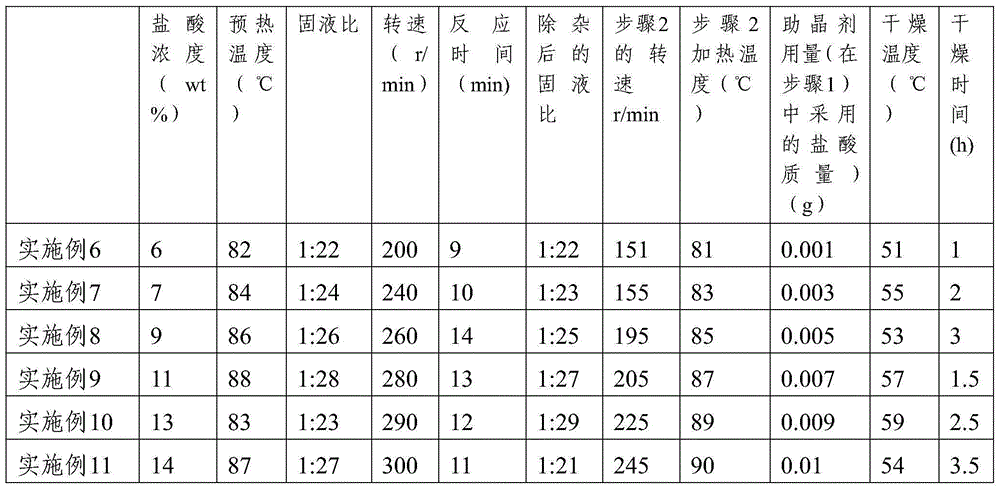

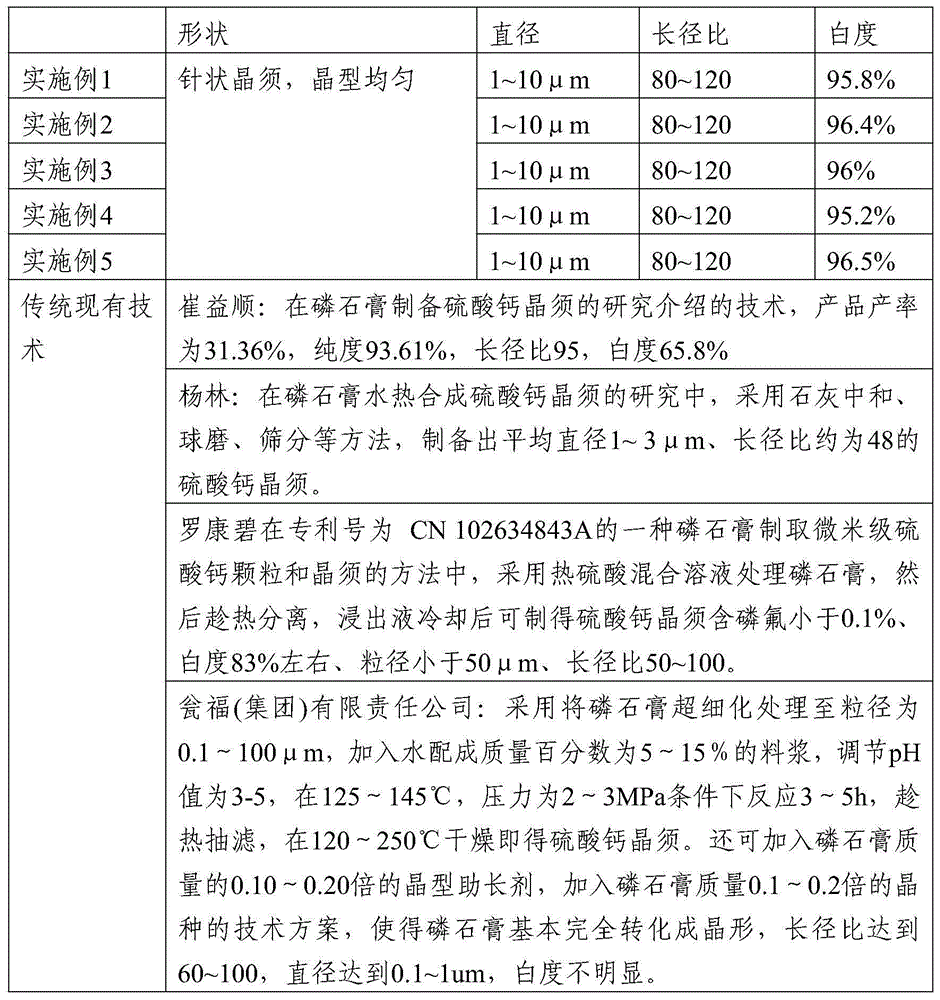

Method for preparing calcium sulfate dihydrate crystal whisker from phosphorus gypsum

InactiveCN104005086ANot to be wastedReduce generation influence ratePolycrystalline material growthFrom normal temperature solutionsProduction rateSulfate

The present invention relates to the technical field of chemical raw material preparation, and particularly to a method for preparing calcium sulfate dihydrate crystal whisker from phosphorus gypsum. The method comprises the following steps: preparing calcium sulfate dihydrate without impurities, preparing a crystal whisker, washing, and drying to obtain the calcium sulfate dihydrate crystal whisker. By preheating hydrochloric acid and matching the hydrochloric acid with phosphorus gypsum at a certain ratio at a constant temperature, the reaction can proceed and the materials is not wasted, the impurities contained in the phosphorus gypsum can be properly removed maximatily, the impact rate of impurities on the generation of calcium sulfate dihydrate crystal whisker is decreased, the content of calcium sulfate component is increased, the production rate of calcium sulfate dihydrate crystal whisker is improved and the production costs of calcium sulfate dihydrate crystal whisker prepared by comprehensively utilizing phosphorus gypsum are reduced.

Owner:GUIZHOU KAILIN GRP CO LTD

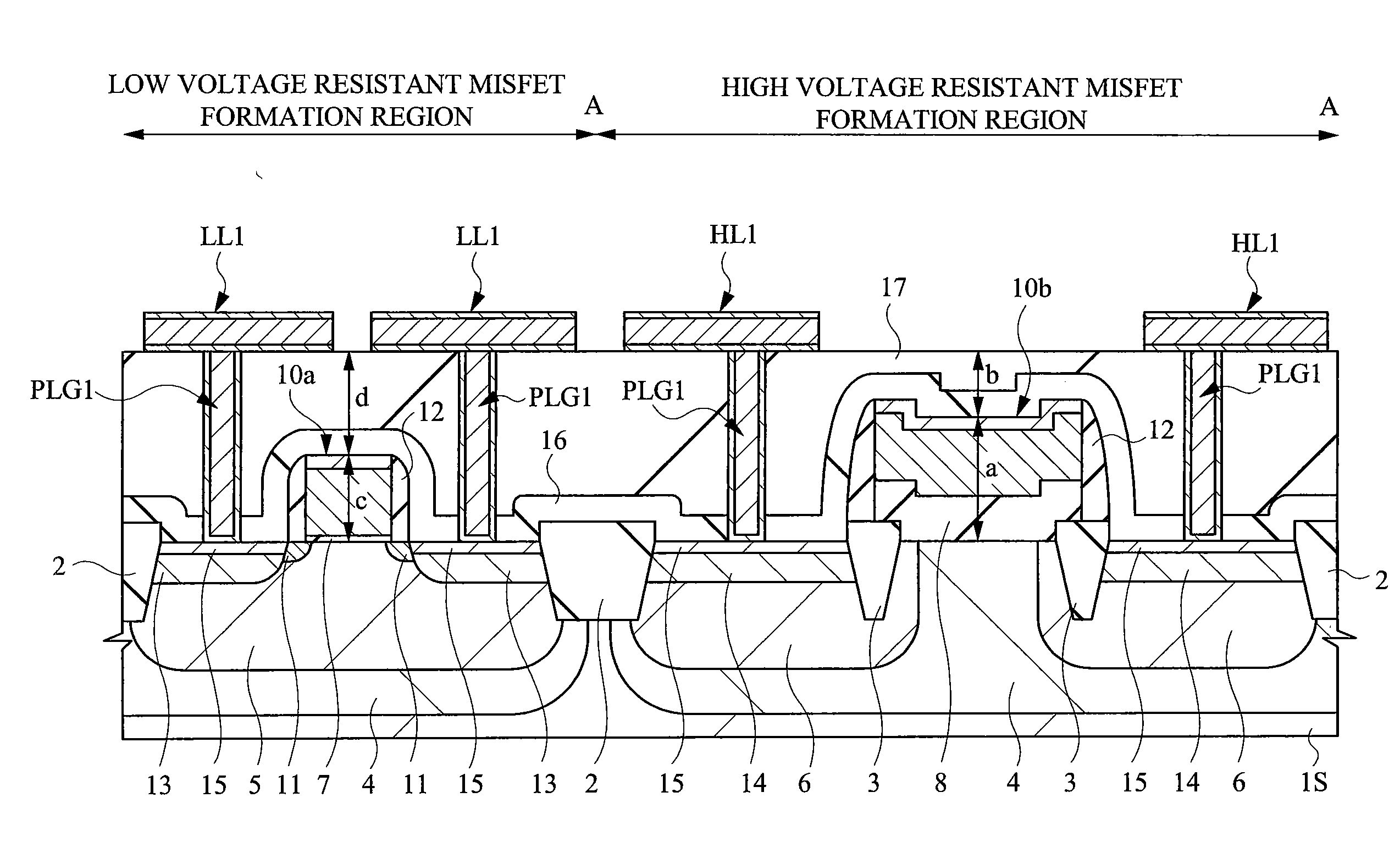

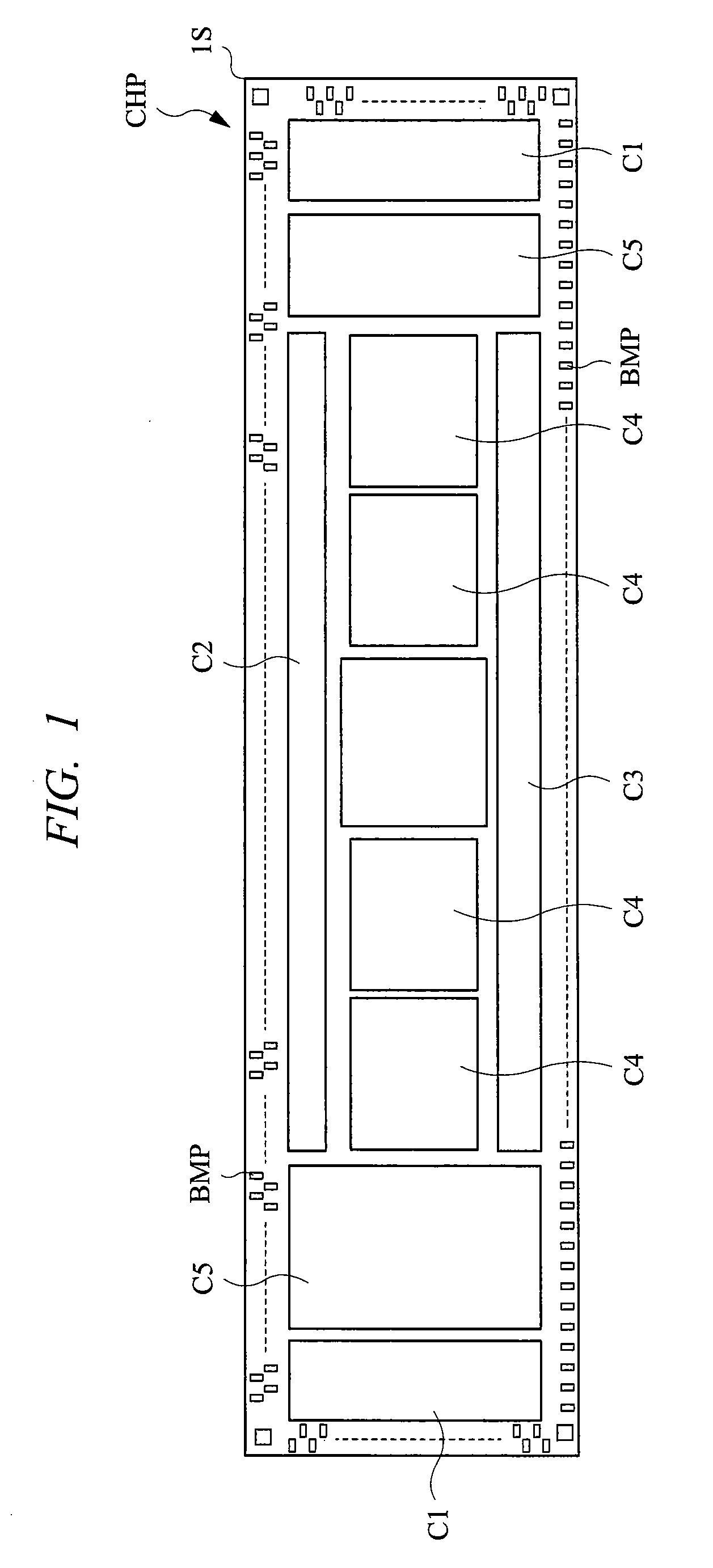

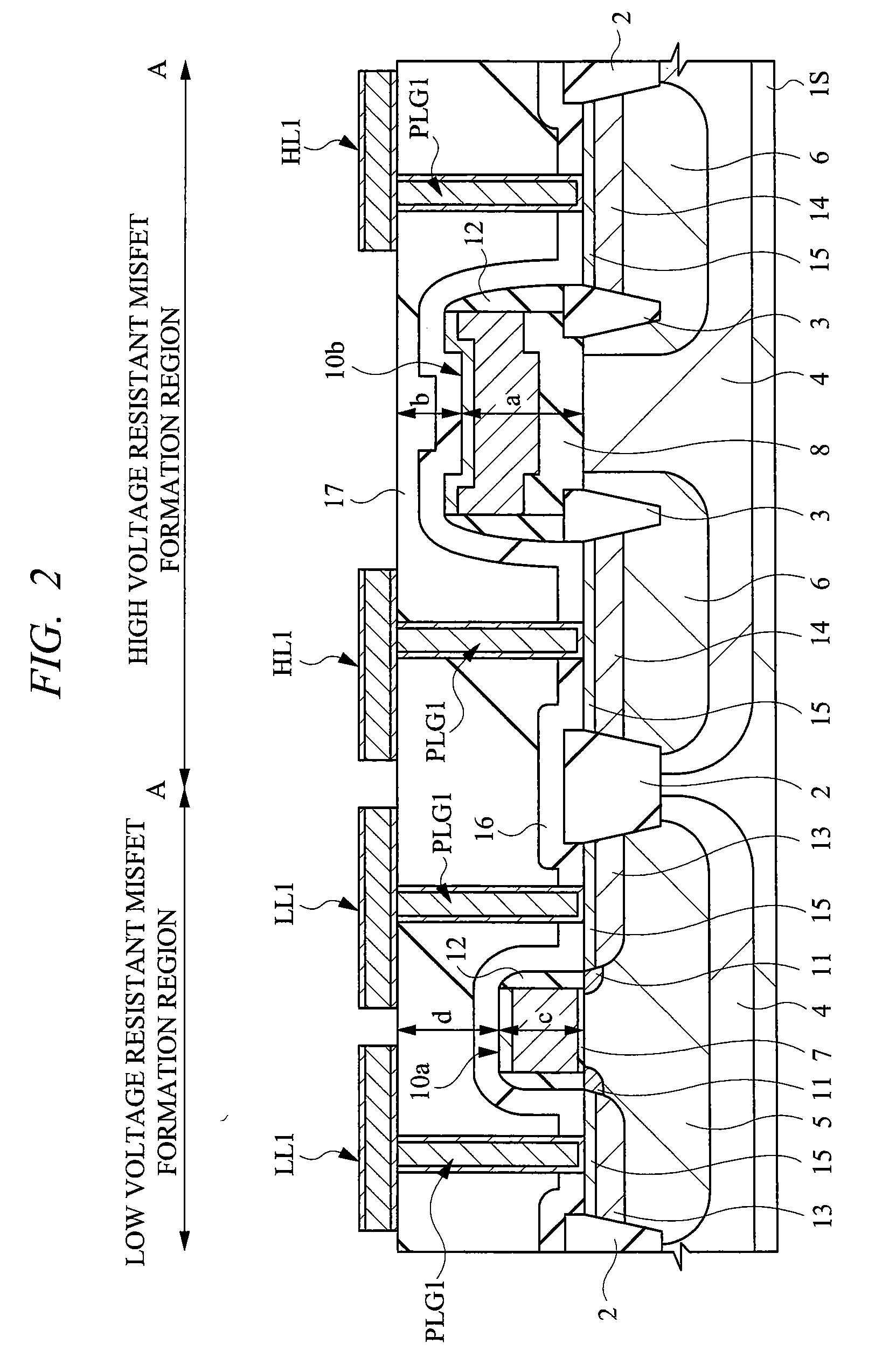

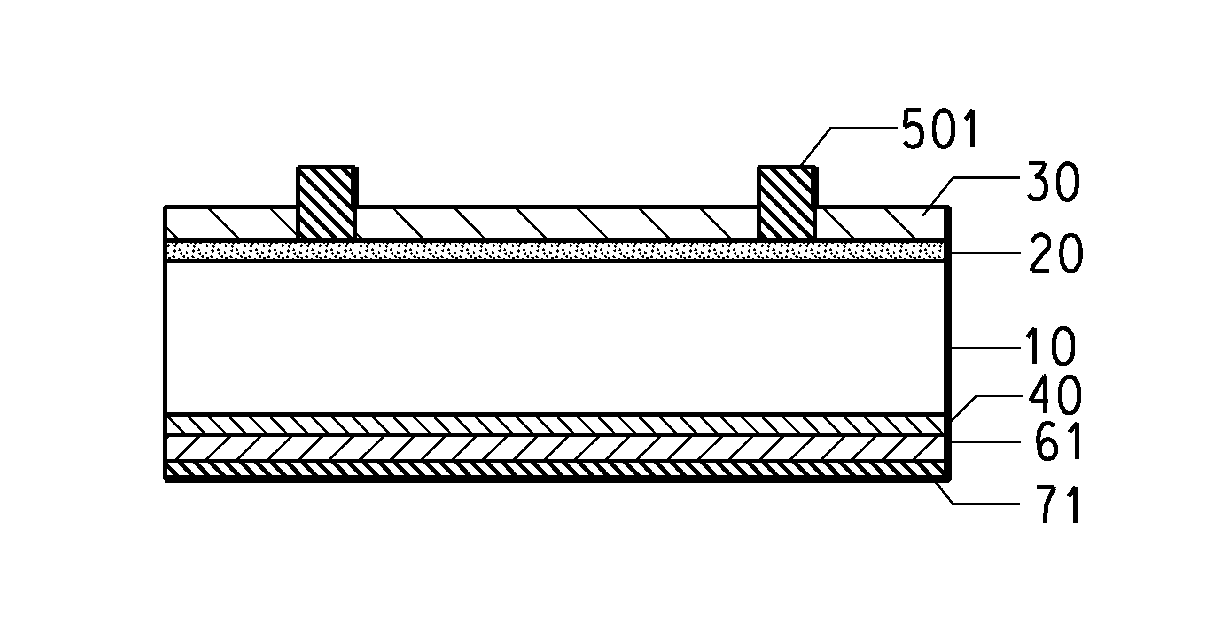

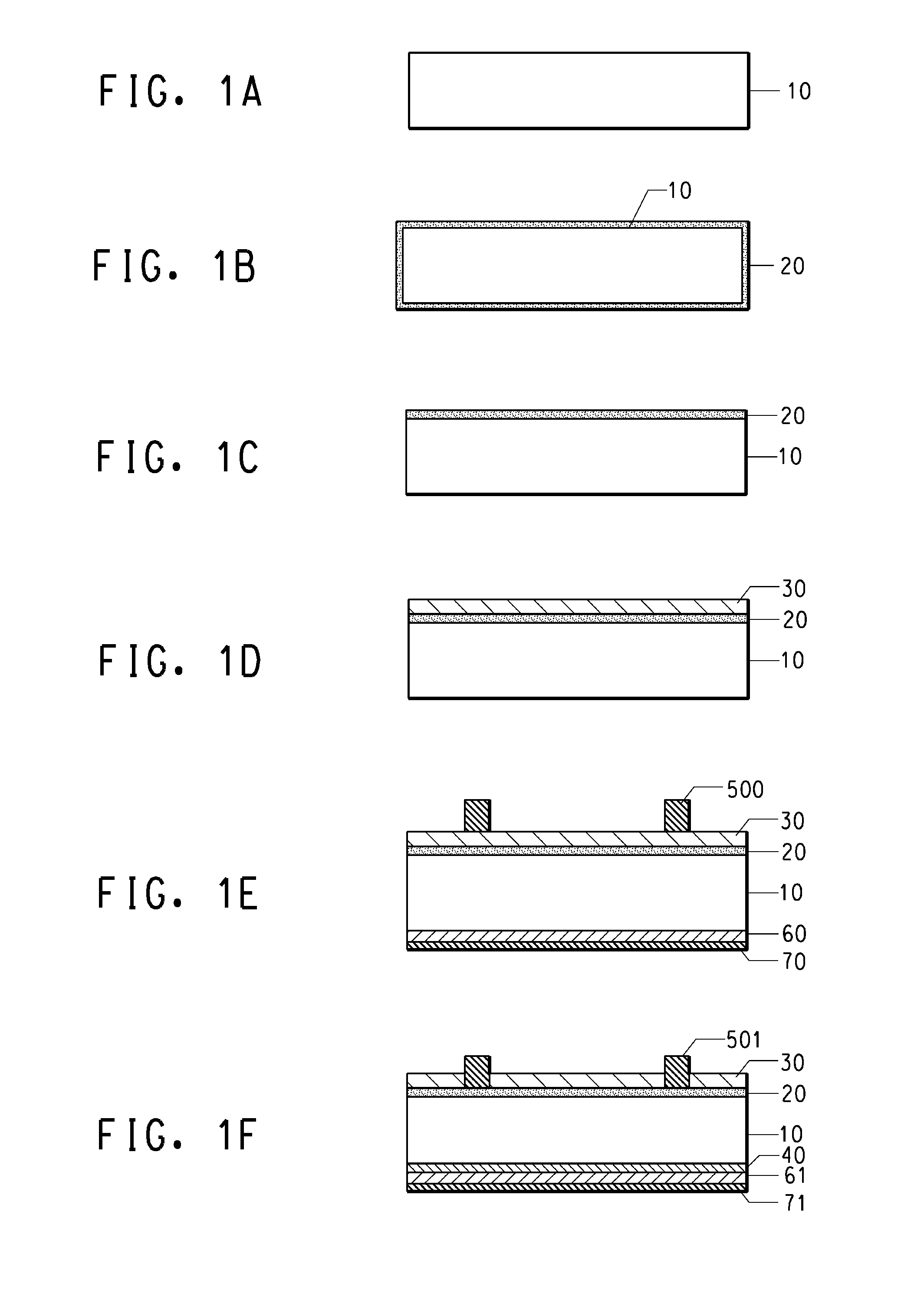

Semiconductor device and method of manufacturing the same

ActiveUS20080303968A1Lower resistanceReduce the overall diameterTransistorSemiconductor/solid-state device detailsDevice materialEngineering

In an LCD driver, in a high voltage resistant MISFET, end portions of a gate electrode run onto electric field relaxing insulation regions. Wires to become source wires or drain wires are formed on an interlayer insulation film of the first layer over the high voltage resistant MISFET. At this moment, when a distance from an interface between a semiconductor substrate and a gate insulation film to an upper portion of the gate electrode is defined as “a”, and a distance from the upper portion of the gate electrode to an upper portion of the interlayer insulation film on which the wires are formed is defined as “b”, a relation of a>b is established. In such a high voltage resistant MISFET structured in this manner, the wires are arranged so as not to be overlapped planarly with the gate electrode of the high voltage resistant MISFET.

Owner:RENESAS ELECTRONICS CORP

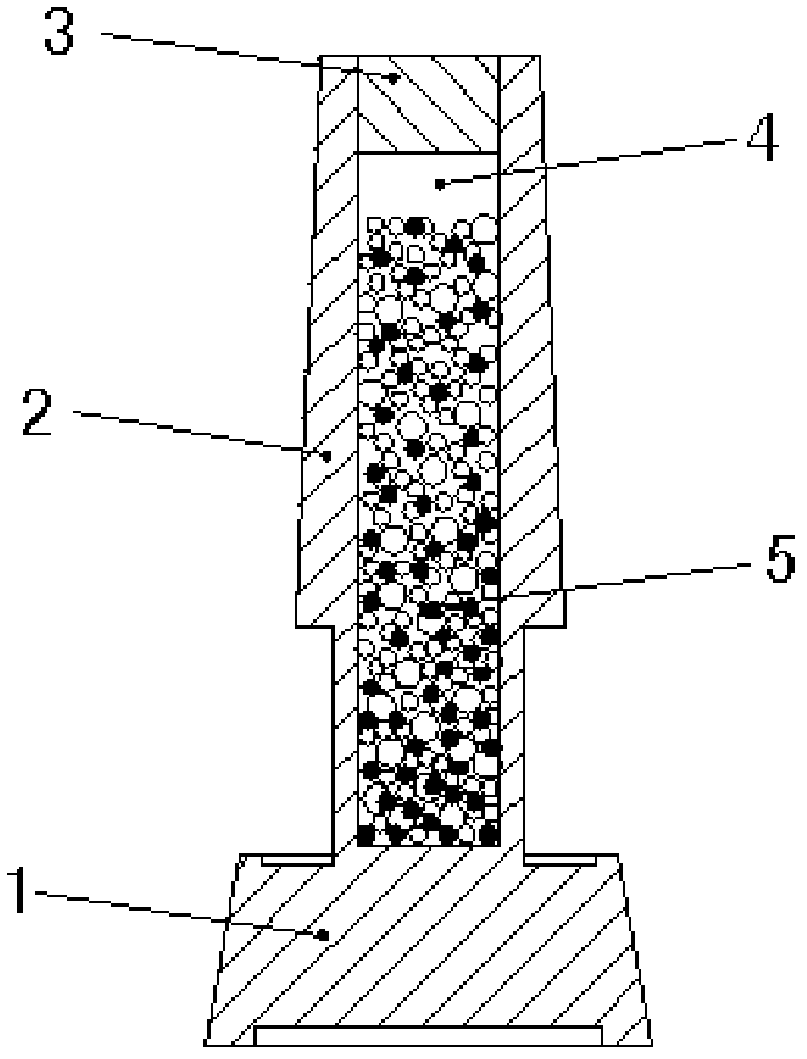

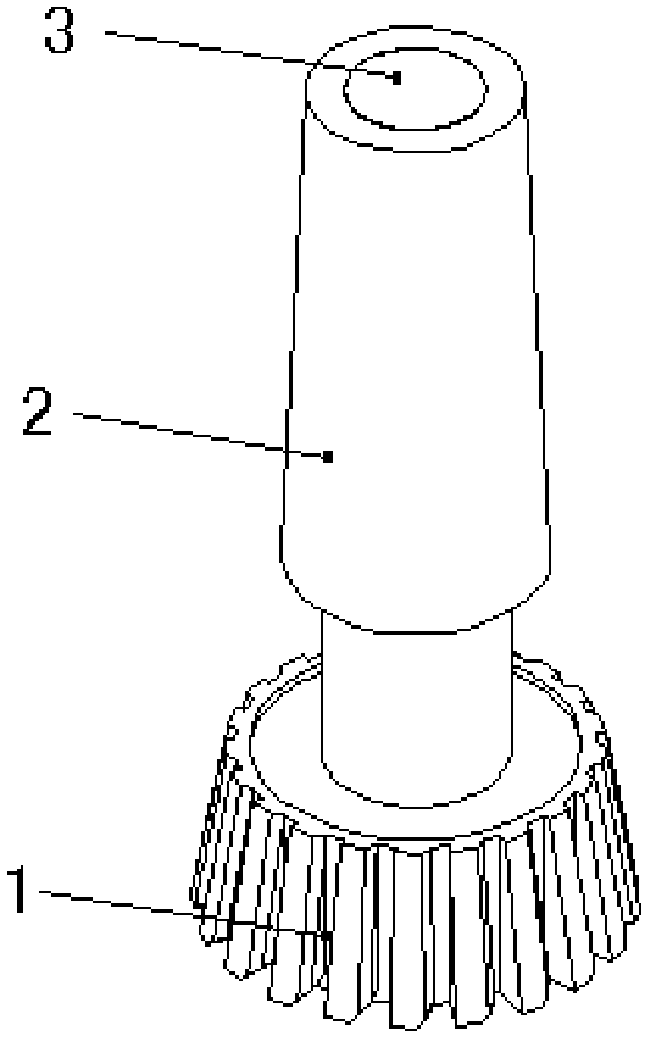

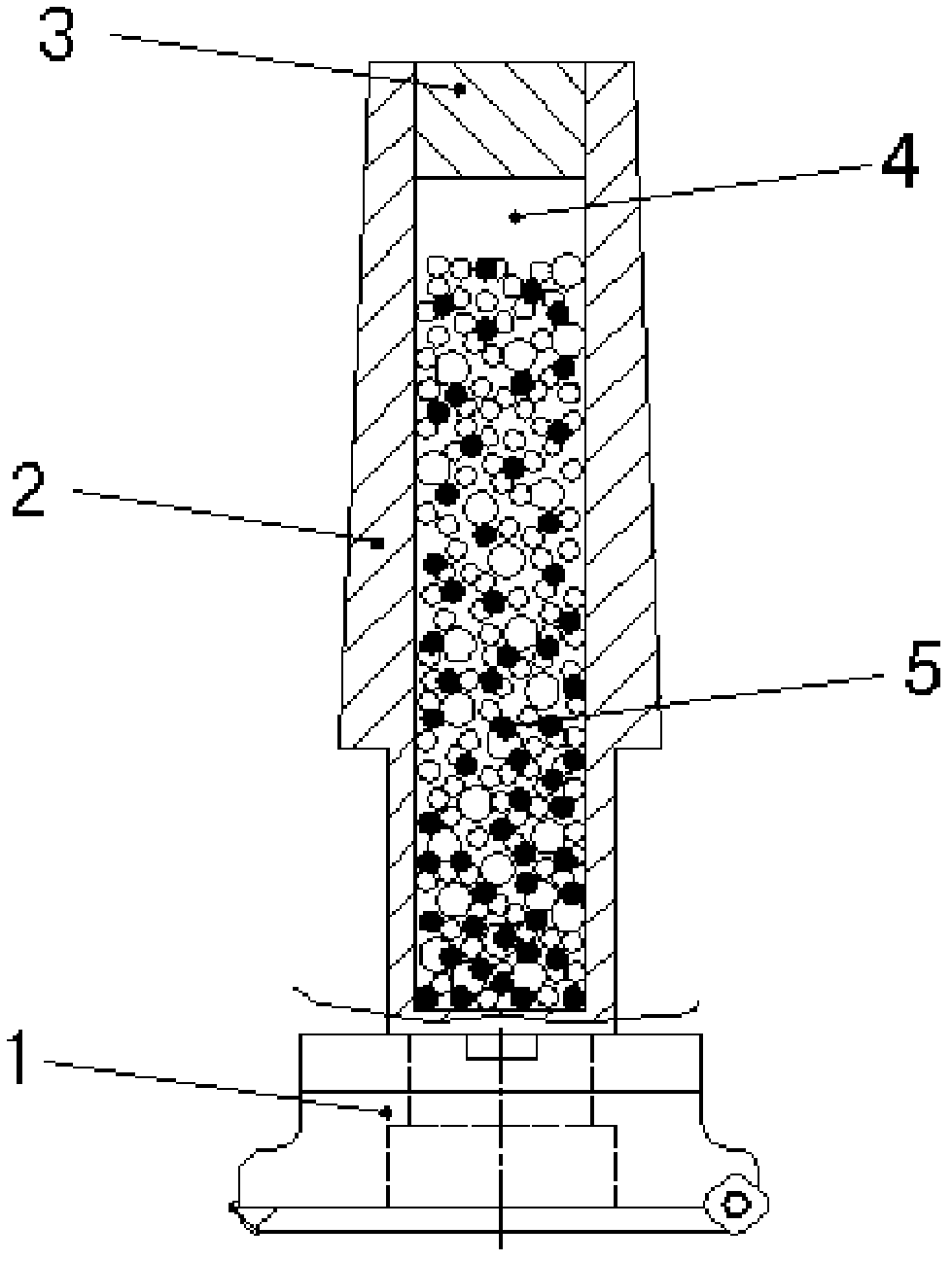

A damping and vibration-reducing tool rod

InactiveCN102275086ALow costLarge aspect ratioMaintainance and safety accessoriesEngineeringMachining process

The invention relates to a damping and vibration reduction cutter rod. The knife rod includes: a knife handle (2) and a cutter head (1) arranged at the lower end of the knife handle (2), and a cylindrical cavity (4) is coaxially arranged in the knife handle (2). Damping particles (5) are sealed and filled in the cylindrical cavity (4). The present invention has the advantages that: 1) the anti-vibration cutter of the particle damping and vibration-reduction system is used in the vibration-damping cutter bar, which can realize a large length-to-diameter ratio at a relatively low cost, making the processing process simpler and more efficient. high. 2) The vibration-damping tool holder of the present invention can improve the machining precision of the tool and prolong the life of the tool. 3) At the same time, in mechanical processing, the use of vibration-damping tools can improve the quality of surface processing and greatly improve work efficiency, especially in boring tools, using this vibration-damping tool bar to bore and cut deep holes, improve the quality of the inner surface and speed up boring Cutting speed will help a lot.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +3

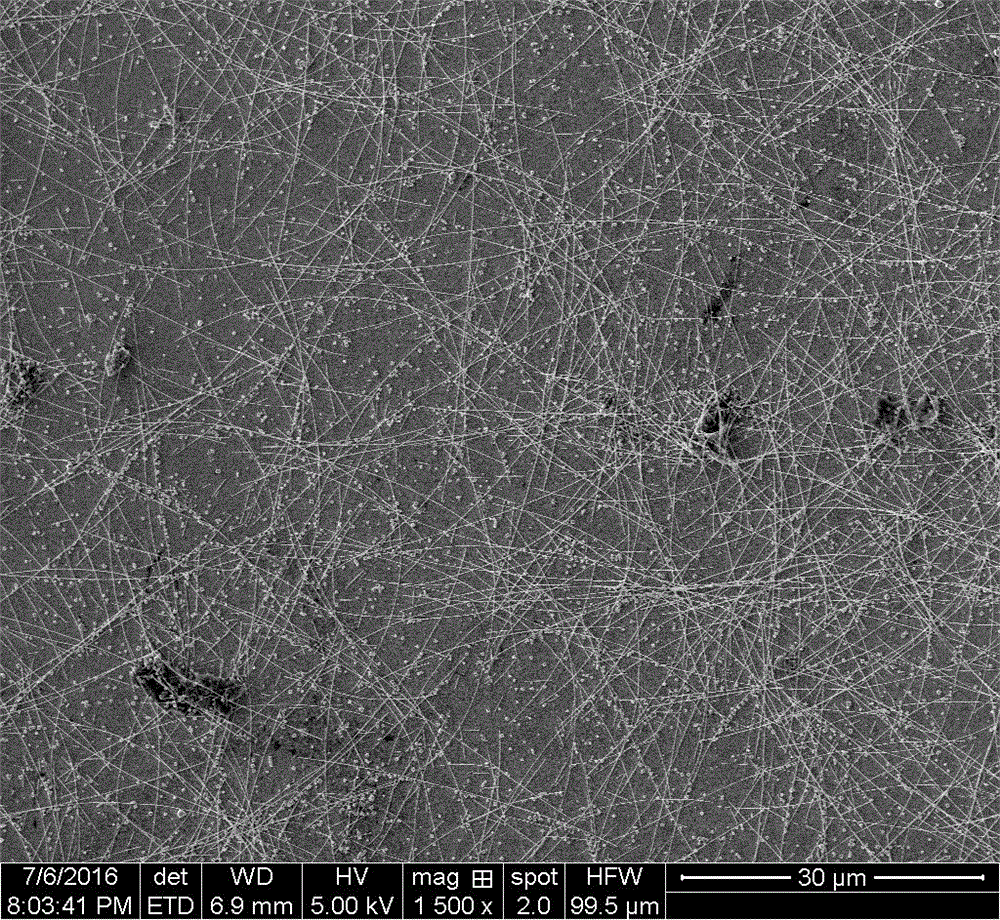

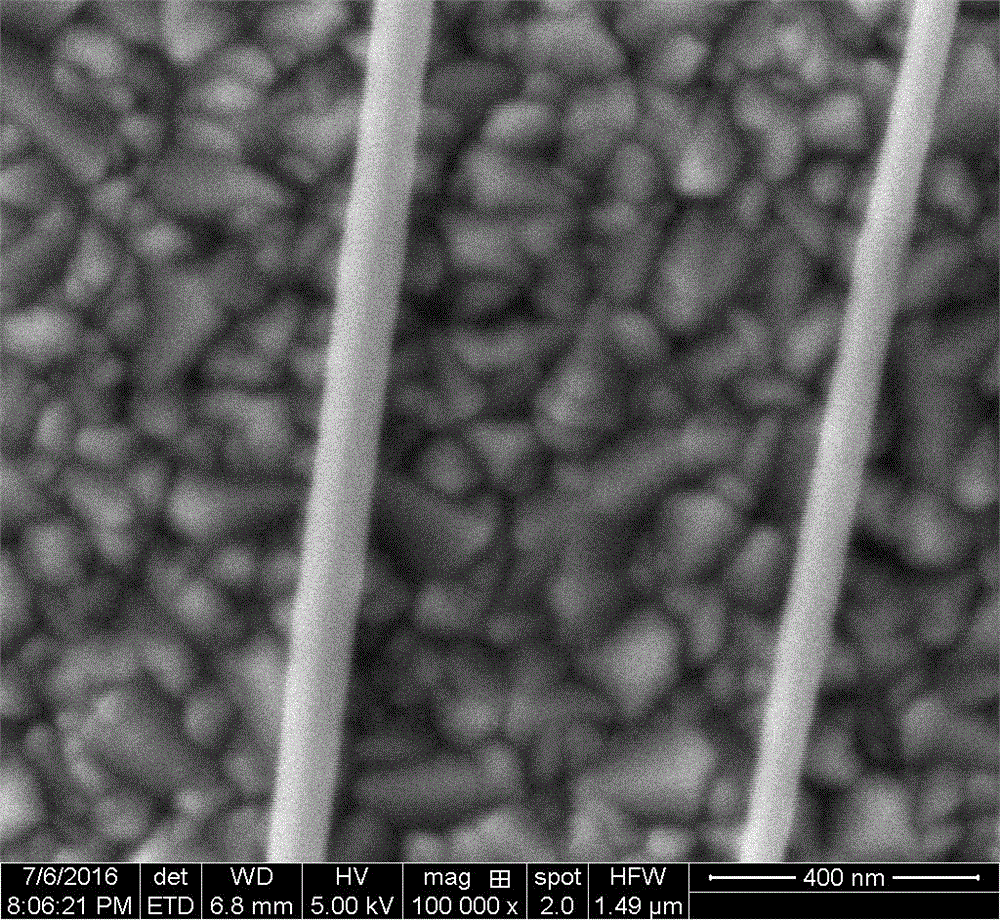

Method for preparing ultra-long silver nanowires through trace-salt-assisted polyol method

InactiveCN106238749AGood dispersionImprove uniformityMaterial nanotechnologyTransportation and packagingRoom temperatureDiameter ratio

The invention discloses a method for preparing ultra-long silver nanowires through a trace-salt-assisted polyol method. The method includes the following steps that firstly, FeCl3 is added into an ethylene glycol (EG) solution; secondly, polyvinylpyrrolidone (PVP) is added into the FeCl3 / EG solution and heated and stirred; thirdly, AgNO3 is dissolved in the EG solution; fourthly, AgNO3 is added into the mixture obtained in the second step and heated and stirred; fifthly, the solution prepared in the third step is gradually added into the solution prepared in the fourth step dropwise and reacts for 0.2-5 h, room temperature cooling and centrifugal cleaning are conducted, and the silver nanowires high in length-diameter ratio can be obtained. The method is easy to operate, good in repeatability and stability and capable of being used for mass production.

Owner:UNIV OF JINAN

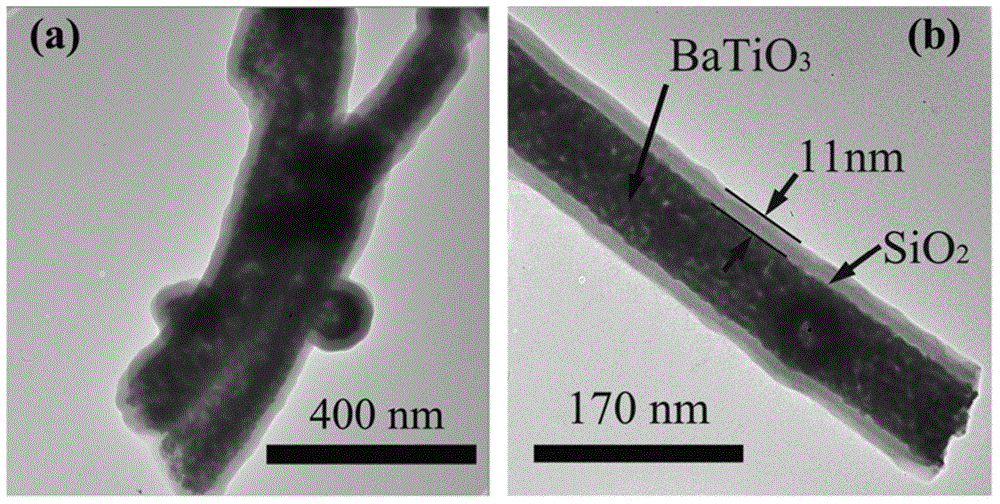

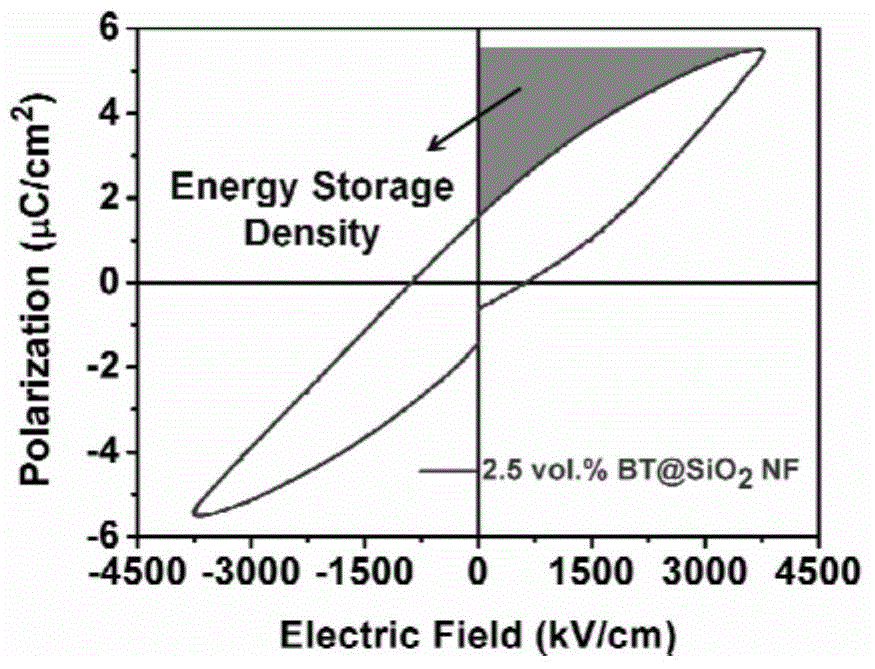

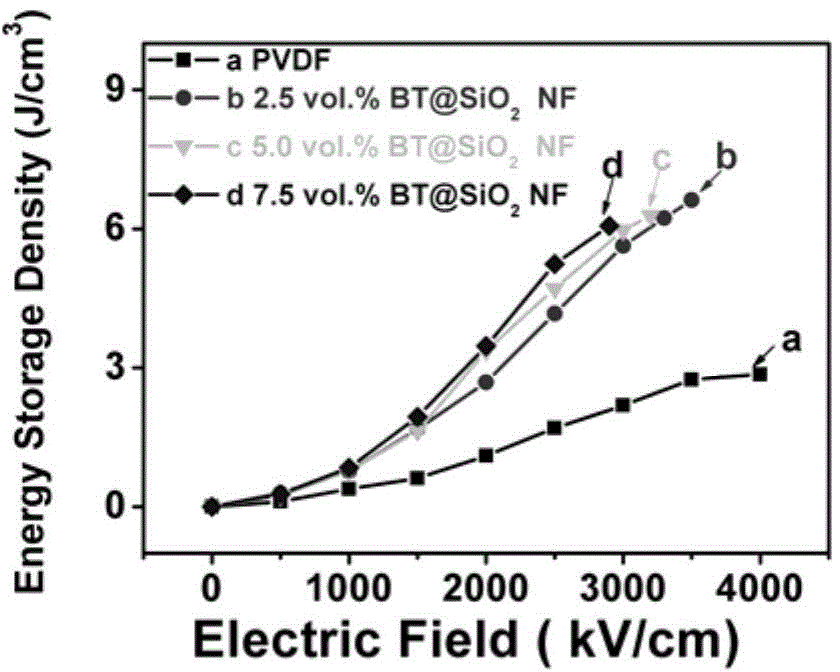

High energy storage density and efficiency polymer composite film and preparation method thereof

The invention relates to a high energy storage density and efficiency polymer composite film and a preparation method thereof. The composite film is composed of a polyvinylidene fluoride matrix and nanofiber with a core-shell structure in the polyvinylidene fluoride matrix, a core layer of the nanofiber with the core-shell structure is ceramic fiber, and the case layer is a silica coating layer. Compared with prior art, the dielectric constant of the composite film can be adjusted by adjusting the content of ceramic fiber, simultaneously, dielectric loss tangent is less than 5%, breakdown field intensity is greater than 2000kV / cm, and energy storage density is 3-7J / cm<3>. The composite film can reduce interfacial polarization generated at a ceramic-compound interface, can increase the energy storage density of PVDF, can be used for capacitor and large power static energy storage materials, has the advantages of simple and practicable operation, low cost, convenience and rapidity, and enables large scale production.

Owner:TONGJI UNIV

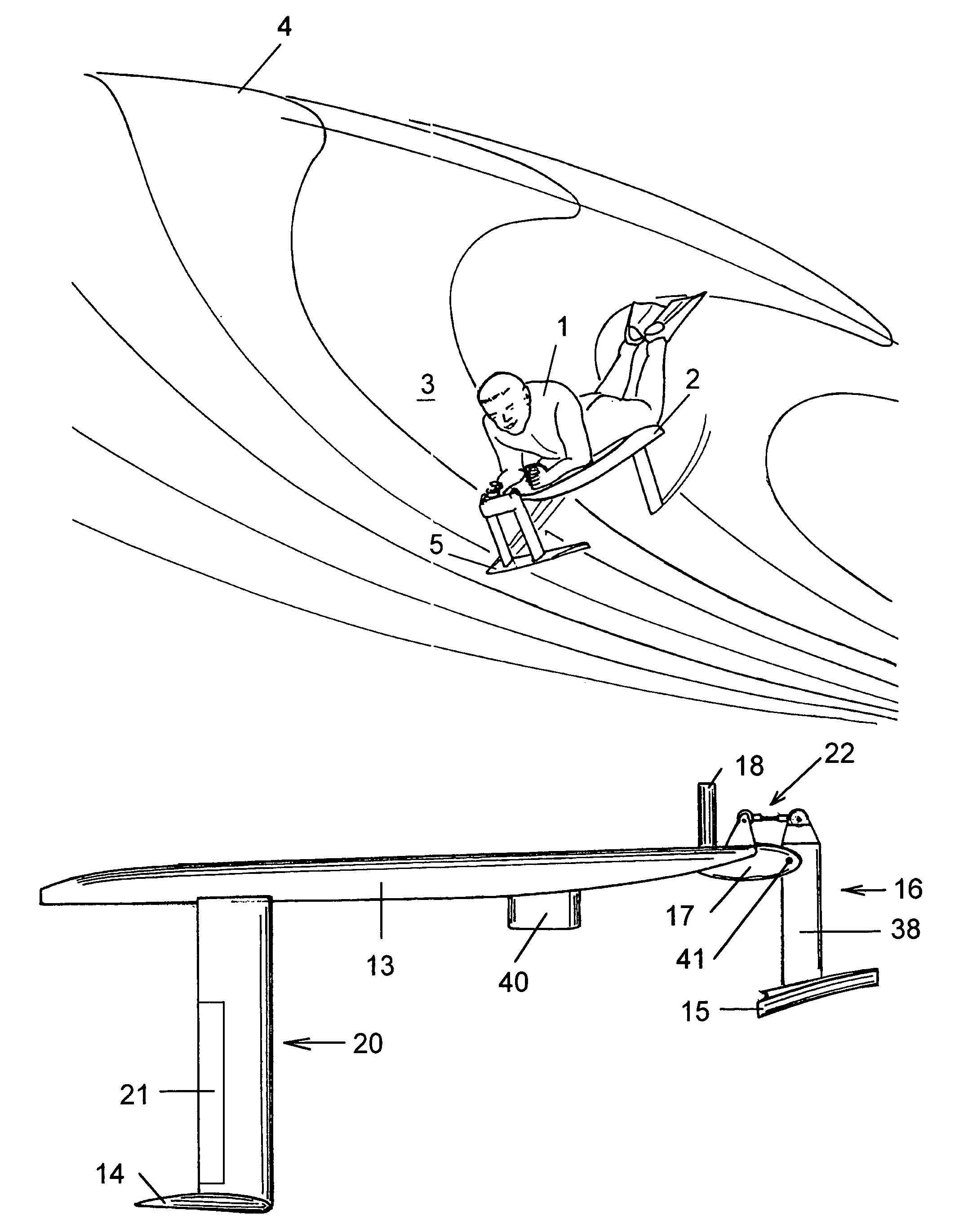

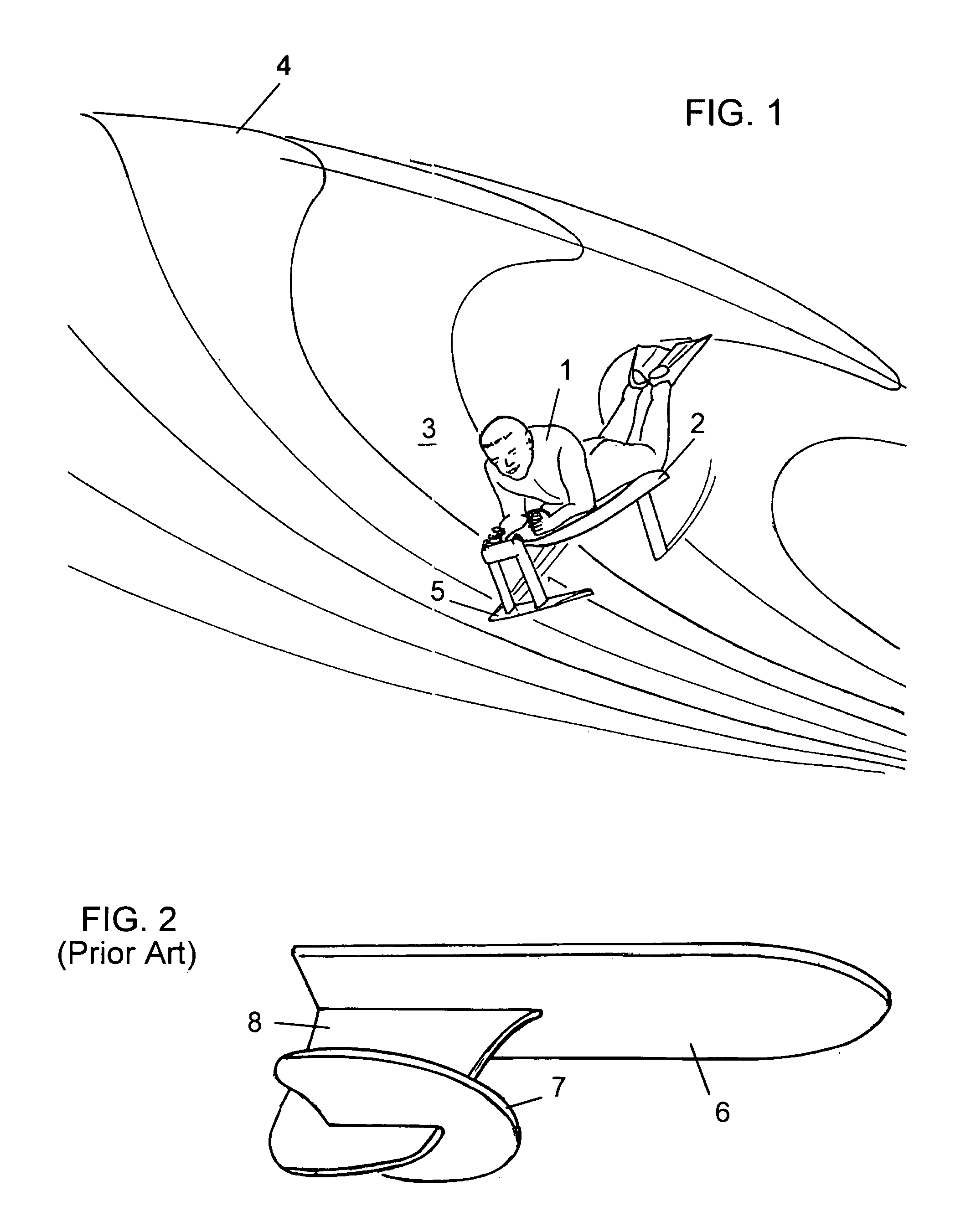

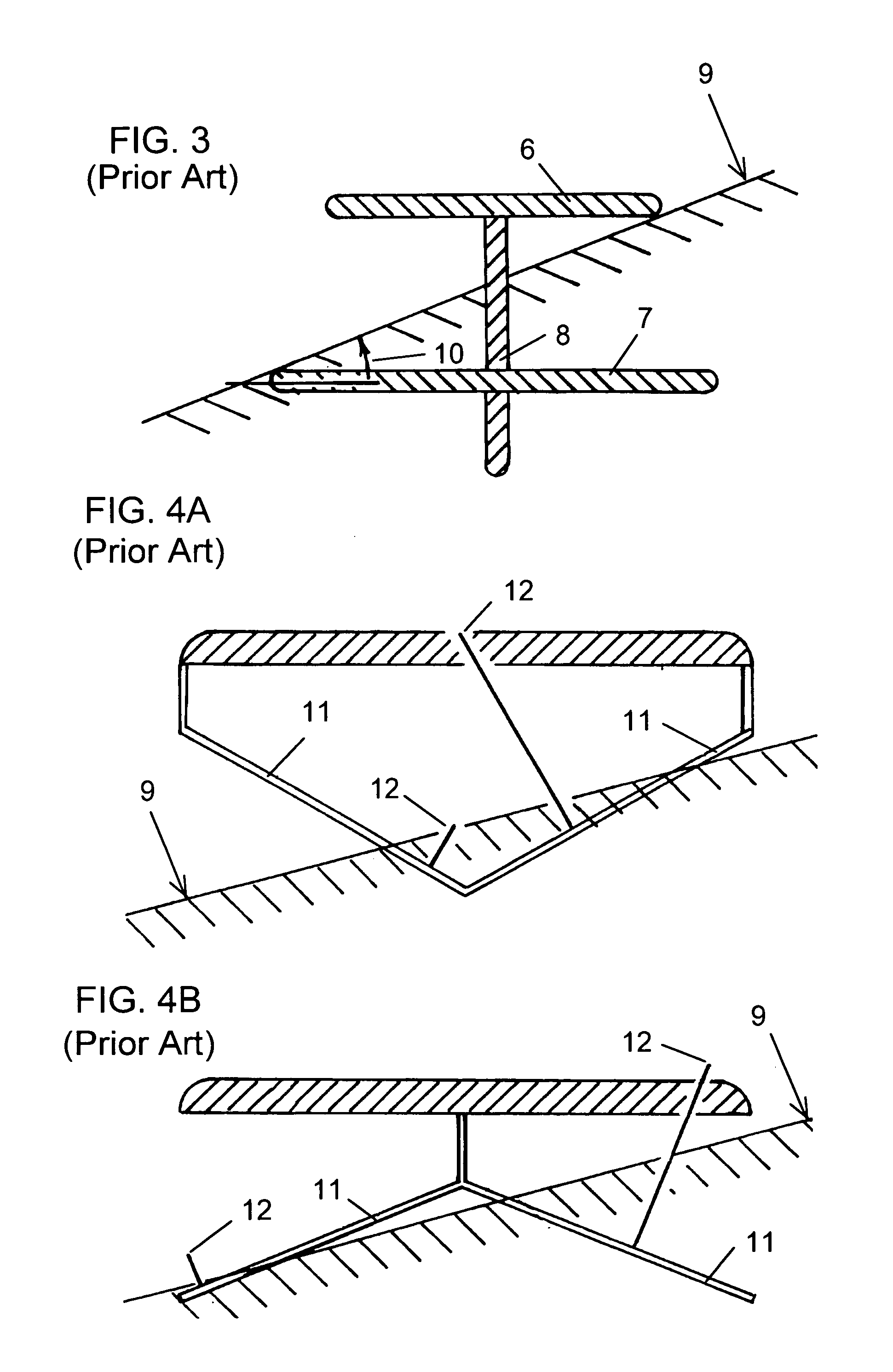

Hydrofoil surfing board

InactiveUS7144285B1Easy to operateIncrease speedWater sport boardsSnowboardsEngineeringTrailing edge

A wave riding surfing board with a pair of transversely oriented hydrofoils, each attached to respective front and rear struts, for supporting a surfer in a prone or kneeling position. In operation, the front canard hydrofoil is arranged for piercing the surface of the water and partially supporting the weight of the rider and the board, while the fully submerged rear hydrofoil is arranged for supporting the remaining 90–100 percent of the weight. The rigging angle of the front canard hydrofoil can be adjusted. The surfing board can be maneuvered by banking the board. In a preferred embodiment, a pair of control handles and a control mechanism give rider a control over the front canard hydrofoil and the flap surfaces on the trailing edge of the rear strut to enable precision maneuvering.

Owner:HENDRICKS TAREAH JOHN

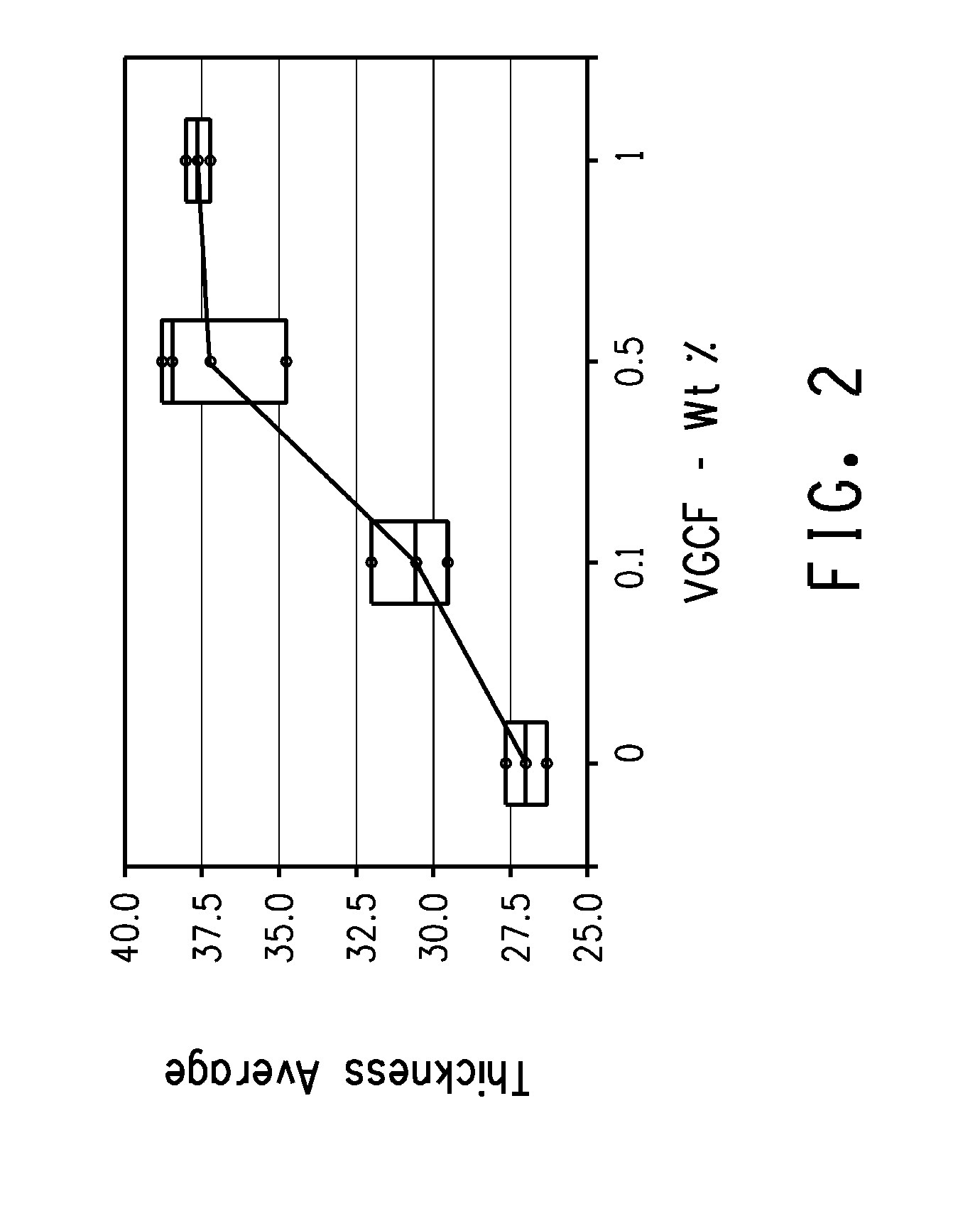

Conductive paste for solar cell electrode

InactiveUS20100294353A1High light conversion efficiencyIncrease light receiving areaSemiconductor/solid-state device manufacturingInksConductive pasteCarbon fibers

An electrode formed on the light-receiving side of photovoltaic cell, comprising conductive component, glass binder, and carbon fiber or metal fiber. By including a carbon fiber and a metal fiber, an electrode having a high aspect ratio can be formed, and improvement of optical conversion efficiency through an increase in light-receiving area can be expected.

Owner:EI DU PONT DE NEMOURS & CO

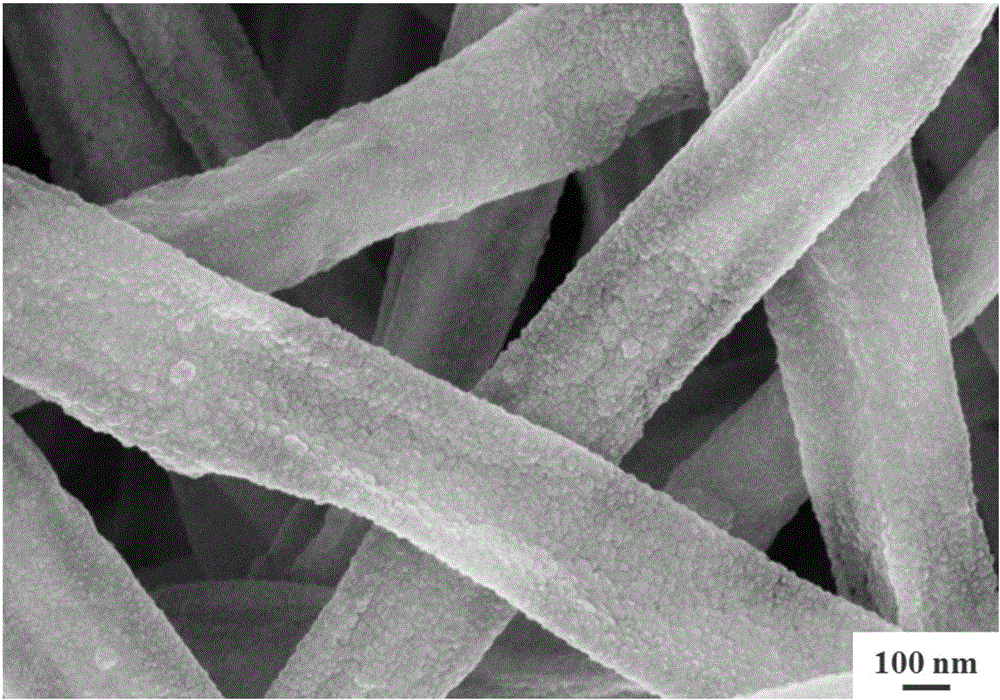

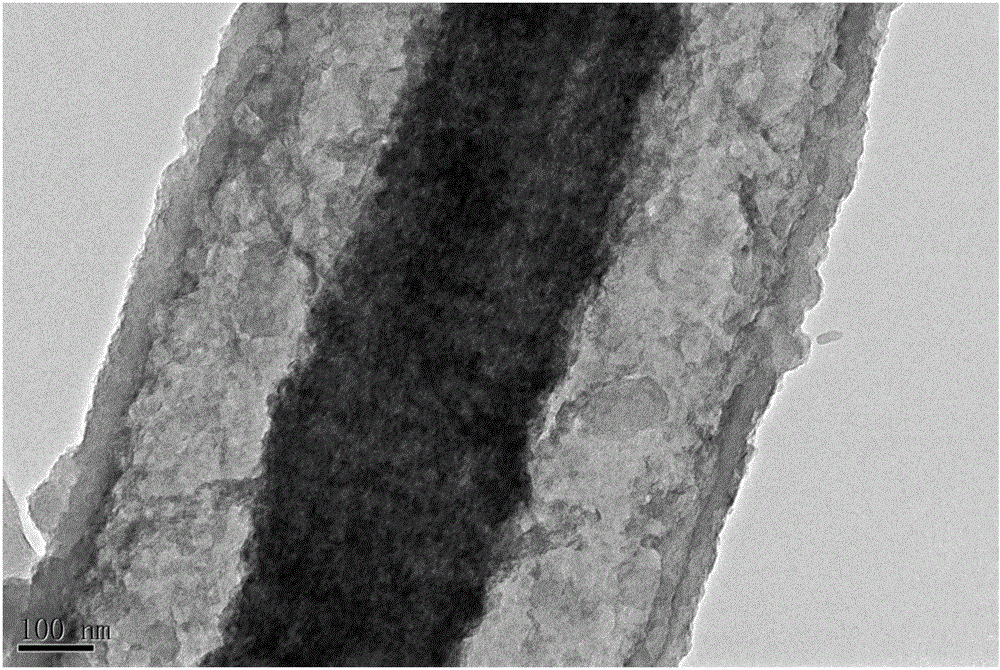

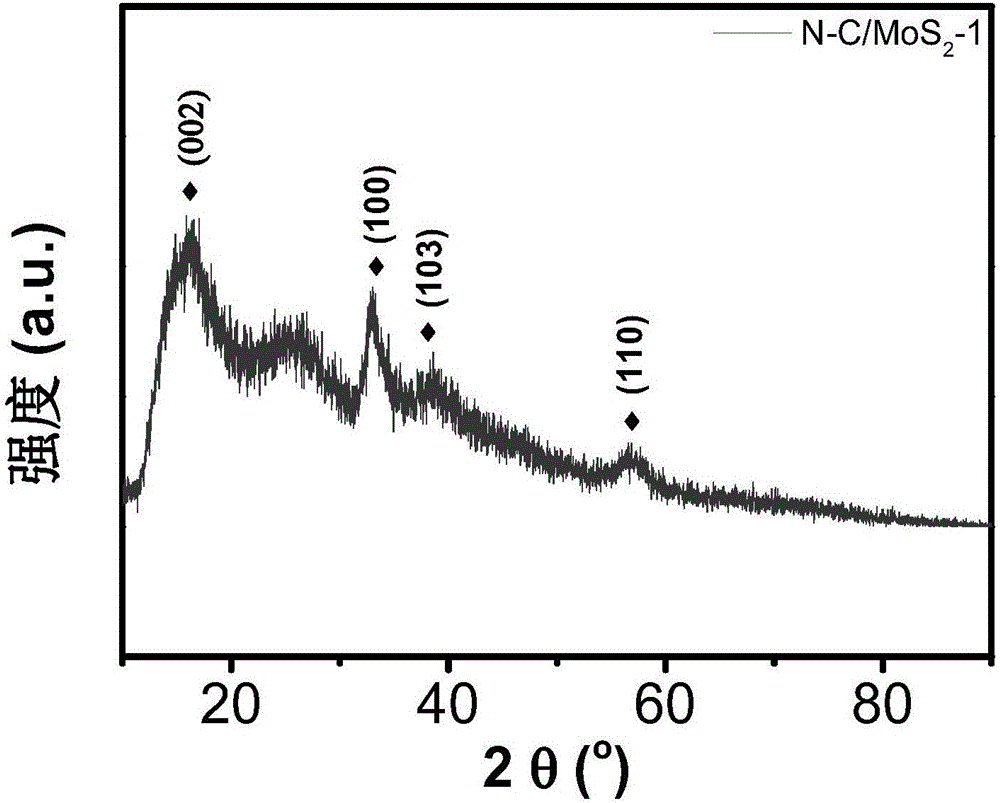

Molybdenum disulfide/nitrogen-doped carbon nanofiber composite material and preparation method and application thereof

ActiveCN106450181AHigh specific capacityImprove cycle stabilityCell electrodesSecondary cellsFiberIn situ polymerization

The invention relates to a molybdenum disulfide / nitrogen-doped carbon nanofiber composite material and a preparation method and an application thereof. The composite material is of a pipe sleeving structure, a molybdenum disulfide fiber core is arranged in the composite material and a nitrogen-doped carbon nanofiber shell is arranged outside the composite material; and a gap is arranged between the molybdenum disulfide fiber core and the nitrogen-doped carbon nanofiber shell. The preparation method comprises the steps of dissolving ammonium thiomolybdate and polymethyl methacrylate into a solvent and carrying out electrostatic spinning to obtain a polymethyl methacrylate / ammonium thiomolybdate nanofiber; carrying out drying and surface treatment, immersing the nanofiber into a pyrrole / hydrochloric acid solution, dropwise adding a ferric chloride / hydrochloric acid solution and carrying out in-situ polymerization to obtain the fiber coated with polypyrrole on the surface; and washing and drying the fiber, carrying out high-temperature reduction under the condition of taking an argon / hydrogen mixed gas as a protective atmosphere and then carrying out high-temperature carbonization under an argon condition. The composite material has high specific capacity and good cycle stability, and can be used as an efficient and safe novel negative electrode material of a lithium-ion battery.

Owner:DONGHUA UNIV

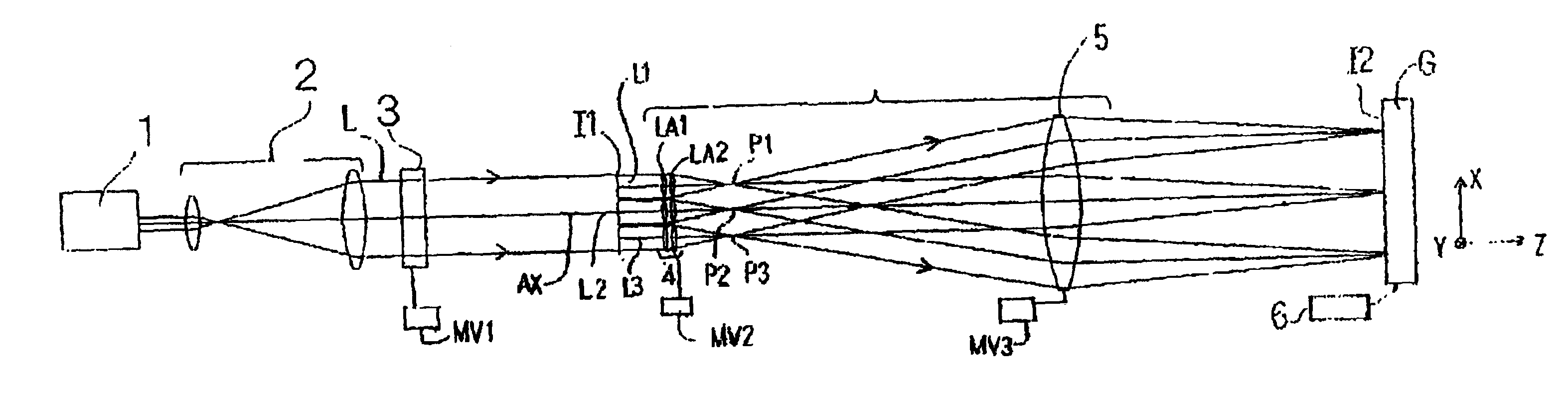

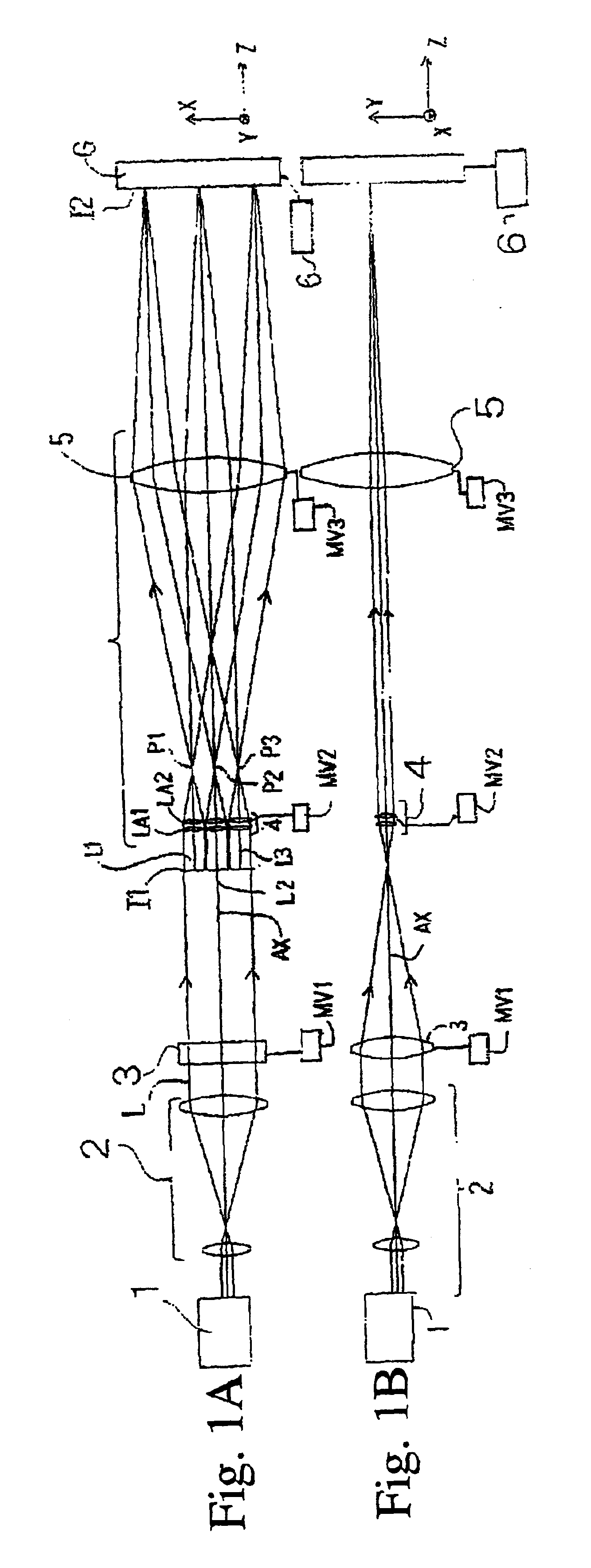

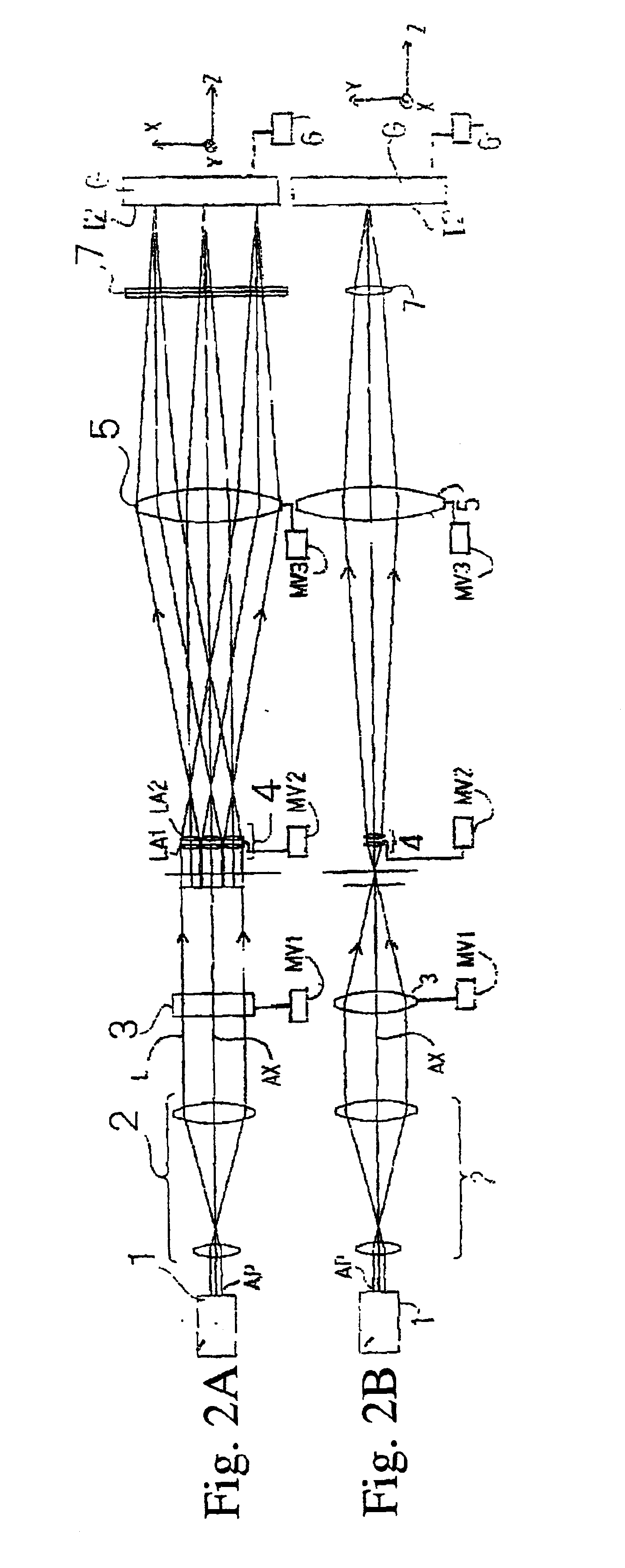

Illumination optical system and laser processor having the same

InactiveUS6894839B2Superior image formationImprove light uniformityPhotomechanical exposure apparatusMicrolithography exposure apparatusBeam expanderLine width

An illumination optical system has superior image formation capabilities, and can radiate a linear beam with excellent illumination uniformity and a narrow line width having a large aspect ratio; the illumination optical system comprises an afocal beam expander system which expands an beam illuminated from a laser light source; a linear beam-forming lens system having at least refractive power in a second direction which is substantially at a right angle to at least a first direction, the linear beam-forming lens system converting the beam, illuminated from said beam expander system, to a linear beam having its long side in said first direction; a lens array section having a plurality of element lenses, arranged along said first direction; and a condenser optical system which illuminates a processed face by reconnecting images of said linear beam from each of said element lenses thereon.

Owner:IHI CORP

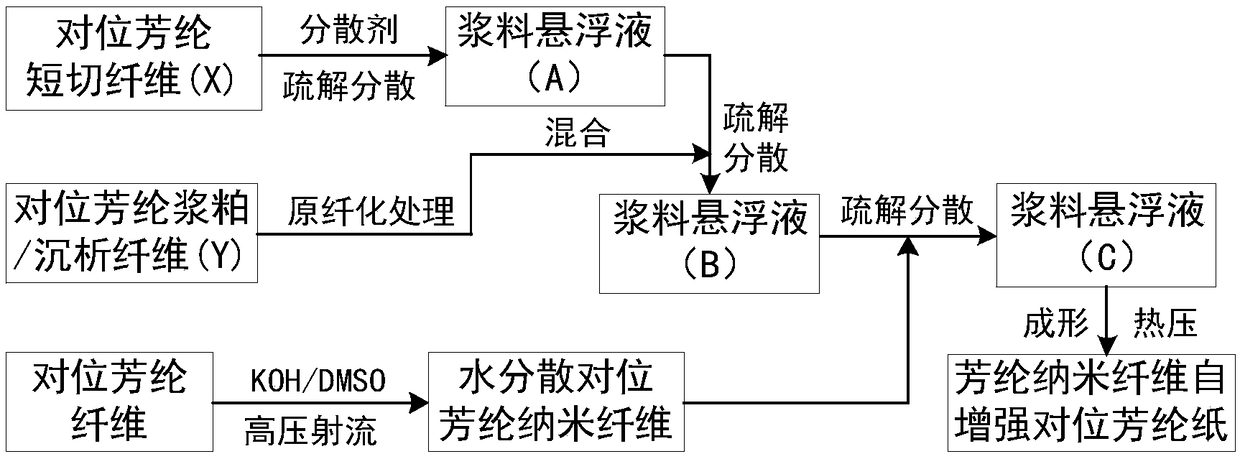

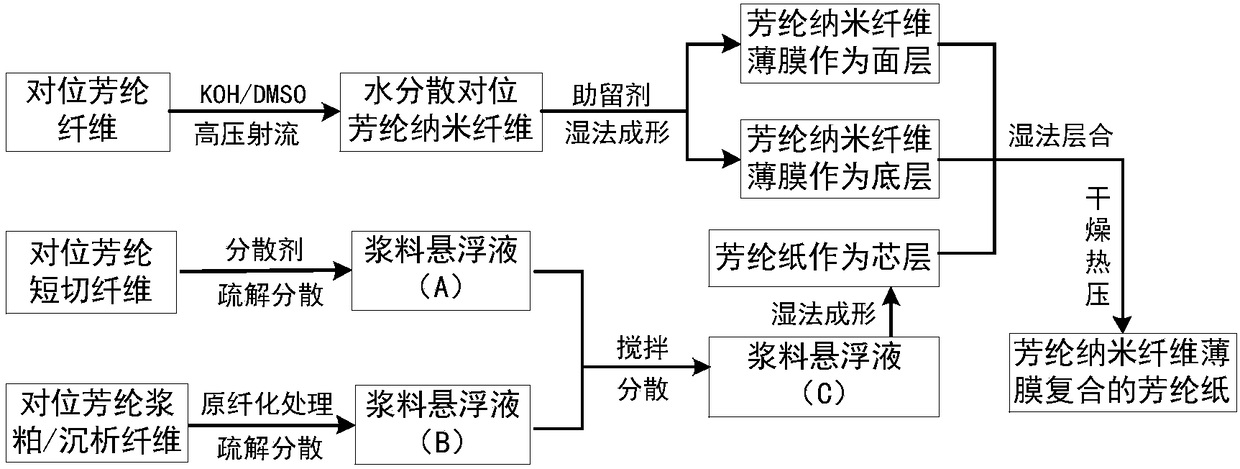

PPTA paper using aramid nanofiber for self-reinforcement and preparation method thereof

ActiveCN108265566AUnique nanoscale structureLarge aspect ratioSpecial paperPaper/cardboardNano structuringHigh surface

The invention discloses a PPTA paper using aramid nanofiber for self-reinforcement and a preparation method thereof. The preparation method includes: utilizing para-aramid paper nanofiber with the advantages of special nano-structure, small fiber diameter, large length-diameter ratio, high surface activity, excellent heat resistance and the like as the self-reinforcement material of para-aramid paper, conducting mixing, defibering and dispersion on aramid chopped fiber, pulp or fibrid and aramid nanofiber to make a uniform suspension, carrying out papermaking shaping, squeezing and drying, andfurther performing hot-pressing on a hot press to obtain aramid paper. The introduced aramid nanofiber enables nanoscale aramid fiber and an aramid nanofilm formed thereby to reach the good interfacefilling, coating and enhancement effects, provides more binding sites for the combination of components, at the same time reduces the pores and holes between components, significantly improves the bonding strength between the aramid paper components, and greatly enhances the mechanical and insulation properties.

Owner:SHAANXI UNIV OF SCI & TECH

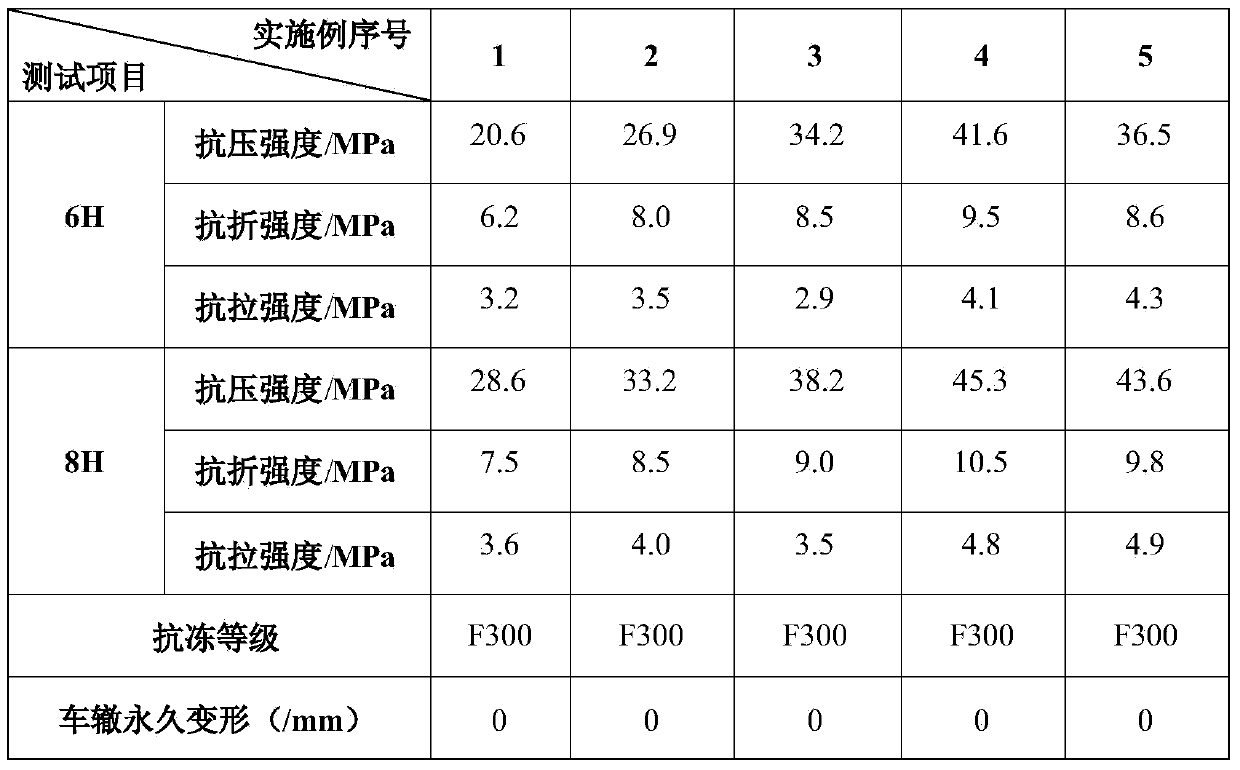

Concrete pavement material for heavy traffic roads and preparation method thereof

ActiveCN104193221AElastic modulus controllableHigh modulus of elasticitySolid waste managementMass ratioWaste rubber

The invention relates to a concrete pavement material for heavy traffic roads and a preparation method thereof. The material is composed of a component A, a component B and a component C in a mass ratio of 1:(0.2-0.6):(4-8). The component A comprises the following components in parts by mass: 40-80 parts of epoxy resin, 0-20 parts of epoxy reactive diluent, 10-50 parts of elastic modifier, 0.2 part of defoaming agent and 0.2 part of dispersing agent. The component B comprises the following components in parts by mass: 100 parts of curing agent, 0-10 parts of curing accelerator and 1 part of coupling agent. The component C comprises the following components in parts by volume: 100 parts of fine stone, 30-300 parts of fine sand, 130-800 parts of waste rubber particle, 50-100 parts of waste rubber powder and 10-20 parts of crystal whisker. Compared with the prior art, the concrete pavement material for heavy traffic roads has the advantages of high strength, favorable durability, favorable roadability, energy saving, environment friendliness and the like, and is convenient for construction.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

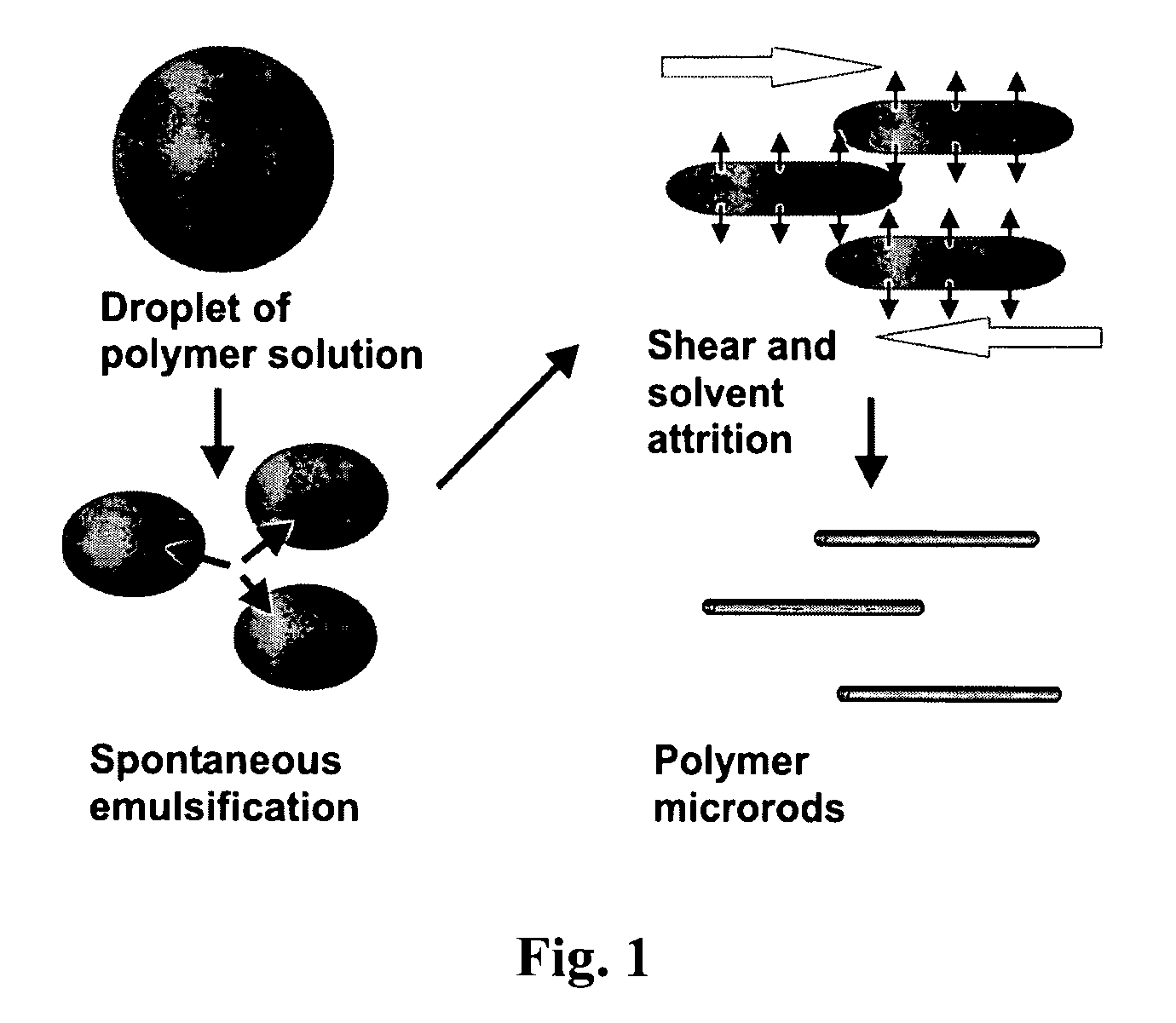

Process for preparing microrods using liquid-liquid dispersion

ActiveUS7323540B2Simple methodLarge aspect ratioOrganic active ingredientsBiocideShear stressPolymer science

The invention provides a method for forming polymer microrods, the method including the steps of providing a polymer solution comprising a polymer dissolved in a first solvent; providing a dispersion medium comprising a second solvent, wherein the first solvent and the second solvent are miscible or partially soluble in each other, and wherein the polymer is insoluble in the second solvent; adding the polymer solution to the dispersion medium to form a dispersed phase of polymer solution droplets within the dispersion medium; and introducing a shear stress to the dispersion medium and dispersed polymer solution droplets for a time and at a shear rate sufficient to elongate the polymer solution droplets to form microrods and solidify the microrods by attrition of the polymer solvent into the dispersion medium.

Owner:NORTH CAROLINA STATE UNIV

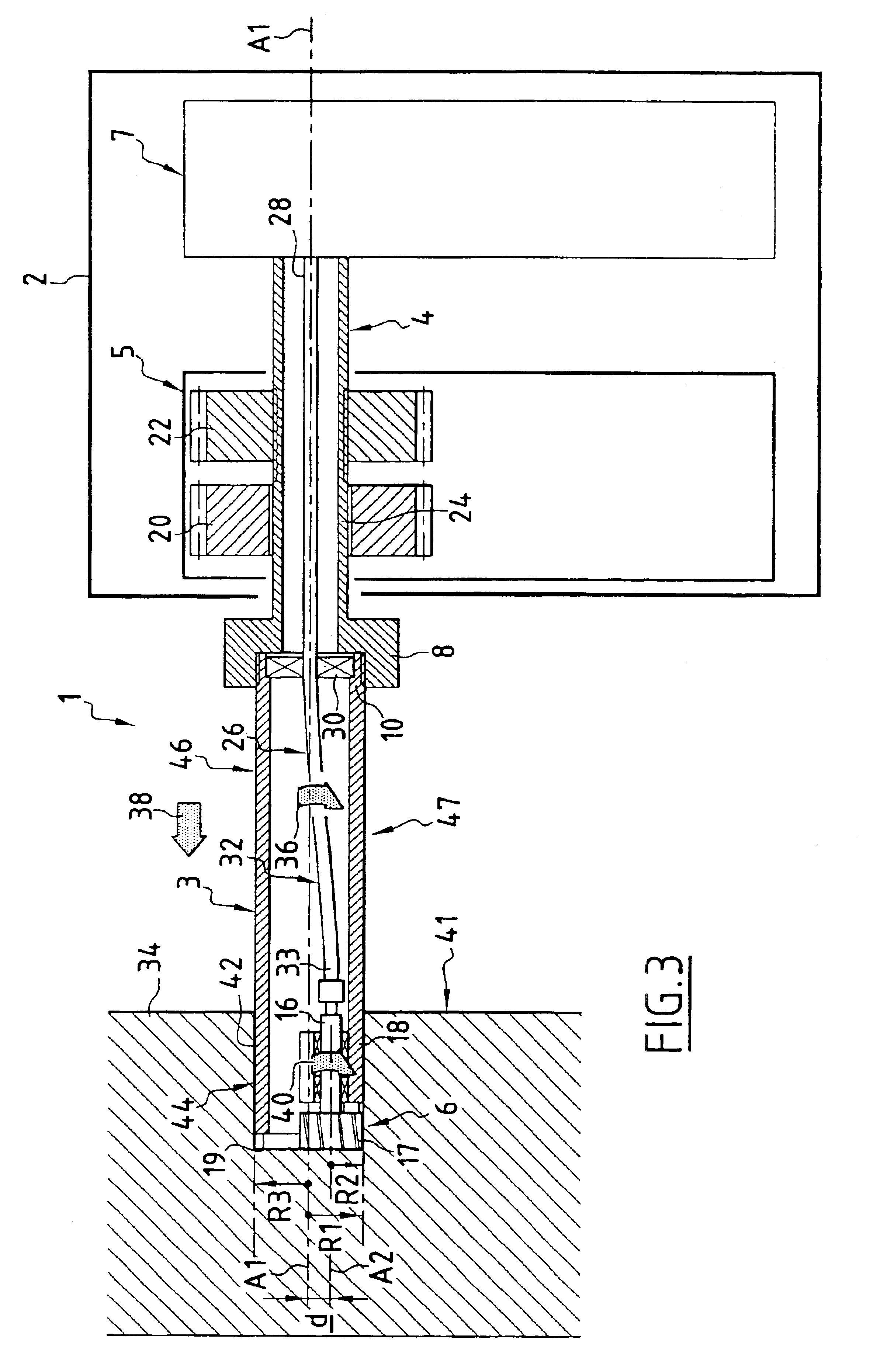

Tool, a machine, and a method for orbitally drilling an orifice

The tool comprises firstly a cutter support for being driven in rotation about a first axis of rotation that is to coincide with the axis of the orifice, and a cutter rotatably mounted on the cutter support to rotate about a second axis of rotation parallel to the first axis of rotation and spaced apart therefrom by a non-zero offset distance. A front segment of the cutter support has maximum radial extent relative to the first axis of rotation that is less than or equal to the radius of the orifice to enable the front segment to penetrate into the orifice during drilling. The tool is particularly applicable to drilling machines used in the aviation industry.

Owner:APEX BRANDS

Aramid paper compounded with aramid nanometer fiber thin film and preparation method thereof

ActiveCN108316056AUnique nanoscale structureLarge aspect ratioSpecial paperSynthetic resin layered productsSurface layerPapermaking

The invention discloses an aramid paper compounded with an aramid nanometer fiber thin film and a preparation method thereof. The aramid paper is compounded by a surface layer, a core layer and a bottom layer through a wet type papermaking laminating method, wherein the ratio of the surface layer to the core layer to the bottom layer is (5 to 20):(60 to 90):(5 to 20) in parts by weight of absolutedry fiber; the surface layer and the bottom layer respectively adopt aramid nanometer films which are prepared from aramid nanometer fibers; the core layer adopts the aramid paper which is prepared from one of aramid chopped fibers and aramid pulp fibers or aramid precipitated fibers. The aramid paper has the advantages that because of excellent strength property and dense thin film structure ofthe aramid nanometer fiber film, more bonding sites are provided for bonding with the fiber components of the aramid paper, and the larger pores can be filled and coated; the comprehensive property ofthe final product is greatly improved, and the aramid paper is favorably widened to the high-end application field.

Owner:SHAANXI UNIV OF SCI & TECH

Long carbon fiber enhanced high-heat-conductivity polymer composite and preparation method thereof

ActiveCN102477182AEnhancement effect is goodImprove continuityHeat-exchange elementsMasterbatchCarbon fibers

The invention discloses a long carbon fiber enhanced high-heat-conductivity polymer composite, which is made of, by weight, from 10 to 80 parts of long carbon fiber enhanced thermoplastic resin masterbatch and from 20 to 90 parts of heat-conducting masterbatch by means of mixing. The long carbon fiber enhanced thermoplastic resin masterbatch is made of from 30 to 80 parts of first thermoplastic resin, from 20 to 70 parts of continuous long carbon fibers, from 0.5 to 2 parts of first coupling agent, from 0.3 to 0.5 part of first antioxidant and from 0.5 to 1 part of first processing aid by means of pultrusion. The heat-conducting masterbatch is made of from 30 to 80 parts of second thermoplastic resin, from 20 to 70 parts of heat-conducting agent, from 0.5 to 2 parts of second coupling agent, from 0.3 to 0.5 part of second antioxidant and from 0.5 to 1 part of second processing aid by means of traditional extrusion process. The long carbon fiber enhanced high-heat-conductivity polymer composite has excellent heat conductivity and mechanical property, and continuity of a heat-conducting network can be effectively improved by means of the long carbon fibers.

Owner:上海事升新材料有限公司

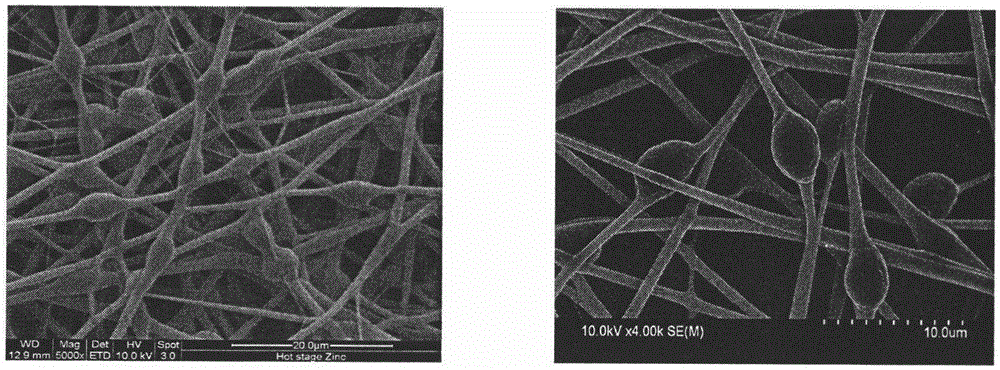

Beaded electrospun nanofiber immobilized saccharomycete and preparation method thereof

InactiveCN105802950AReduce lossesExperiment operation is simpleFilament/thread formingOn/in organic carrierPorositySpinning

The invention relates to beaded electrospun nanofiber immobilized saccharomycete and a preparation method thereof. Nanofiber comprises electrospun polymer or macromolecules, a solvent and a saccharomycete; prepared mixed solution is placed in an injector and is spun with an electrospinning instrument, microorganisms are introduced into the nanofiber by dispersion of the saccharomycete in a spinning solution, the advantages of the nanofiber such as high specific area, high porosity, large length-diameter ratio and bulkiness and porousness are combined, in-situ immobilization is achieved for saccharomycete cells, an active organic / microorganism composite is obtained, and a function similar to a multi-enzyme bioreactor is enabled. A product and preparation method of the invention have the advantages such as high processing efficiency, high reacting speed, ease of control, high antifouling capacity, continuous reusability, and ease of product separation. The beaded electrospun nanofiber immobilized saccharomycete is applicable to the fields such as biological catalysis, filtering and adsorption, drug delivery and tissue engineering.

Owner:TIANJIN POLYTECHNIC UNIV

Sintered alumina-based ceramics and process for producing same

Alumina-based ceramics are thermally stable because of their high melting point and excellent materials in wear resistant properties and chemical stability. However, they contradictly have such a problem that fracture toughness is low, and its improvement is desired. The present invention provides such sintered alumina-based ceramics and their production process that have rendered to grow alumina grains anisotropically and fracture simultaneously attain high flexural strength and fracture toughness by sintering the formed mixture comprising Al2O3, 0.05-2.5 mol % of VA metal oxide and 0.01-4 mol % SiO2, relative to Al2O3, respectively.

Owner:NGK SPARK PLUG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com