High energy storage density and efficiency polymer composite film and preparation method thereof

A technology of high energy storage density and composite thin film, which is applied in the field of composite material preparation, can solve problems such as interface polarization, poor flexibility of composite materials, and increased defects, so as to increase the dielectric constant, improve energy storage performance, and increase energy storage density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

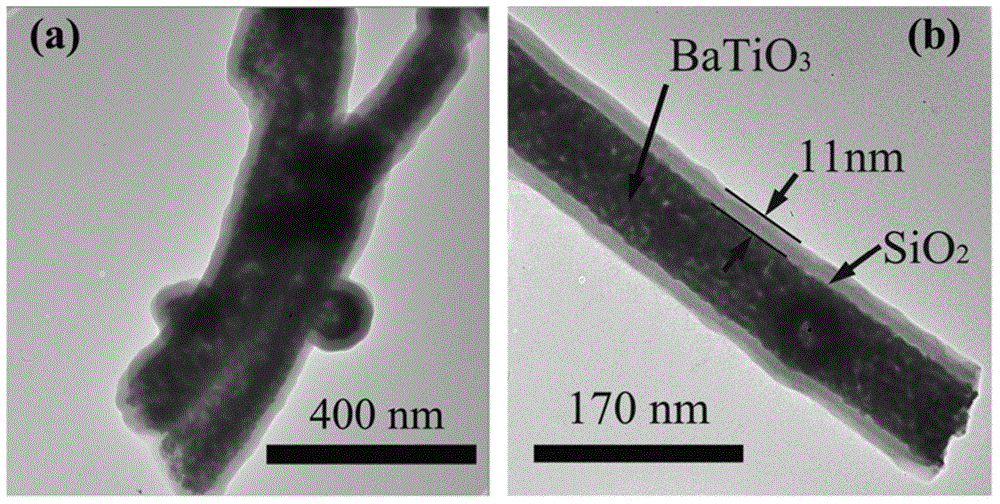

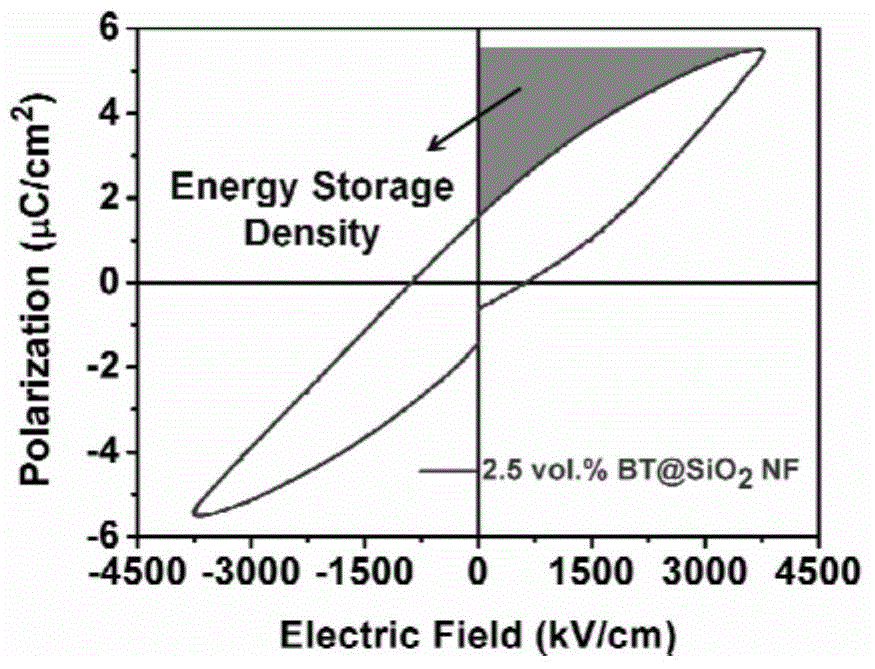

[0026] Preparation of BaTiO by Electrospinning 3 nanofibers, 1.5g BaTiO 3 The nanofibers are placed in a mixed solution of alcohol and ammonia water (the ratio of ammonia water and alcohol is 1:50-1:10), stirred in a water bath at 20-50°C for 1-3 hours, and then mixed with different proportions of ethyl alcohol tetraethyl silicate Ester (TEOS) solution (the ratio of TEOS and alcohol is 1:15-1:4)) is added dropwise from the burette into the beaker, the dropping rate is controlled at 0.025-0.25ml / min and the stirring speed is 50-700r / min, after centrifugation , washed with ethanol, dried, and sintered at 500-700°C for 1-3h to obtain BaTiO with a core-shell structure 3 SiO 2 fiber, the core layer is barium strontium titanate ceramic fiber, and the shell layer is a silica coating layer; the nanofibers with core-shell structure are surface-modified with a coupling agent (3-aminopropyltriethoxysilane), Then the modified BaTiO 3 SiO 2 The fibers were added to the PVDF / DMF mixtur...

Embodiment 2

[0029] The method is the same as above, except that the BaTiO 3 SiO 2 The volume ratio of PVDF and PVDF is 5:95, and PVDF polymer-based composite membrane can be made.

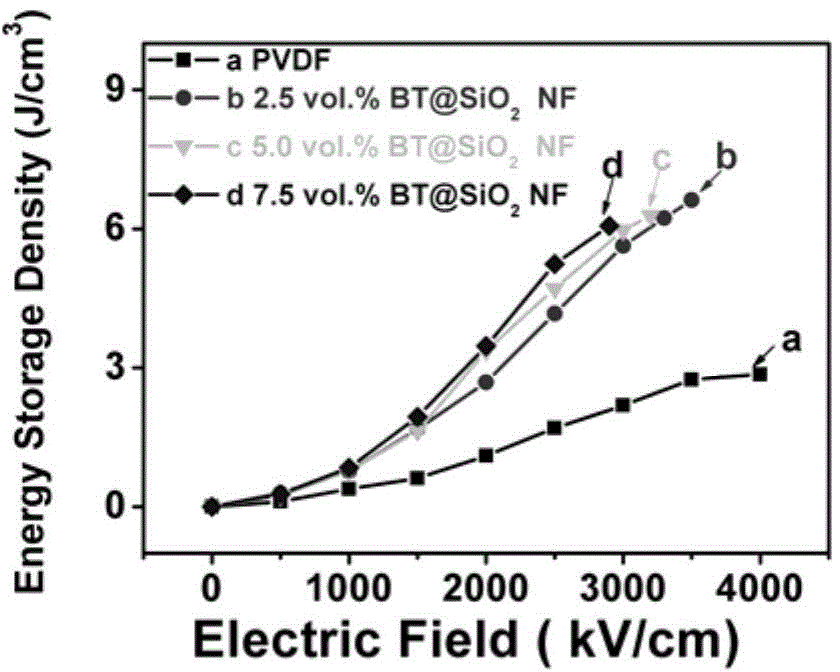

[0030] The energy storage density of the composite film is as image 3 The energy storage density shown is 6.2J / cm 3 .

Embodiment 3

[0032] The method is the same as above, except that the BaTiO 3 SiO 2 The volume ratio of PVDF and PVDF is 7.5:92.5, which can make PVDF polymer matrix composite membrane.

[0033] The energy storage density of the composite film is as image 3 The energy storage density shown is 5.8J / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com