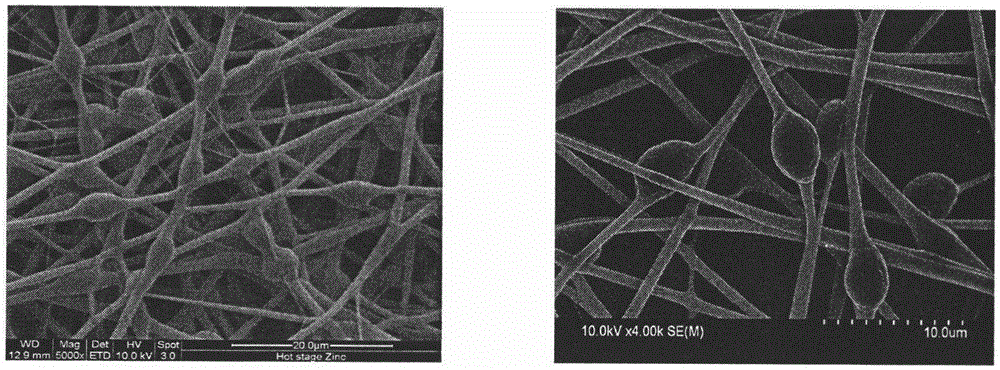

Beaded electrospun nanofiber immobilized saccharomycete and preparation method thereof

A technology for immobilizing yeast and nanofibers, which is applied in the preparation of spinning solution, immobilization on/in organic carriers, fiber processing, etc., which can solve the limitation of enzyme or cell load, difficult product separation, and low product quality. problem, to achieve the effect of rapid response, easy control and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]1) Preparation of electrospinning spinning polymer or macromolecular mixed solution: Weigh polyacrylamide by balance, under nitrogen protection, slowly add mixed solvent ethanol / water volume ratio of 5:7, magnetically stir for 20min, control temperature at 40 °C to make it mix evenly to form a homogeneous solution, and finally configure it into a polyacrylamide mixed solution with a mass concentration of 10wt%;

[0032] 2) Preparation of electrospinning spinning solution containing yeast: Weigh 0.2 g of yeast solid particles, add it to the mixed solution in step 1, and stir magnetically for 20 minutes to fully disperse the yeast cells in the mixed solution, and finally obtain Polyacrylamide electrospinning spinning solution containing yeast;

[0033] 3) Spinning of electrospinning nanofibers with immobilized yeast: Slowly fill the electrospinning spinning solution in step 2 into a plastic syringe with a capacity of 10 mL, and use a self-made electrospinning device to adj...

Embodiment 2

[0036] 1) Preparation of electrospinning polymer or macromolecule mixed solution: weigh polyvinyl alcohol with a balance, under nitrogen protection, slowly add solvent water, magnetically stir for 30min, control the temperature at 100°C to mix evenly, and form a uniform solution , finally configured into a polyvinyl alcohol mixed solution with a mass concentration of 8wt%;

[0037] 2) Preparation of electrospinning spinning solution containing yeast: Weigh 0.1 g of yeast solid particles, add it to the mixed solution in step 1, and stir magnetically for 15 minutes to fully disperse the yeast cells in the mixed solution, and finally obtain Polyvinyl alcohol electrospinning spinning solution containing yeast;

[0038] 3) Spinning of electrospinning nanofiber immobilized yeast: Slowly fill the electrospinning spinning liquid in step 2 into a metal syringe with a capacity of 5mL, and use the purchased electrospinning device to adjust spinning parameters such as spinning Spinning w...

Embodiment 3

[0041] 1) Preparation of electrospinning polymer or macromolecule mixed solution: Weigh polylactic acid with a balance, under nitrogen protection, slowly add solvent dimethyl sulfoxide, magnetically stir for 300min, control the temperature at 45°C to make it evenly mixed, Form a homogeneous solution, and finally configure it into a polylactic acid mixed solution with a mass concentration of 11% by weight;

[0042] 2) Preparation of yeast-containing electrospinning spinning solution: Weigh 0.3 g of yeast solid particles, add it to the mixed solution in step 1, and magnetically stir for 35 minutes to finally obtain the yeast-containing electrospinning spinning solution;

[0043] 3) Spinning of electrospinning nanofibers with immobilized yeast: Slowly fill the electrospinning spinning solution in step 2 into a metal syringe with a capacity of 20 mL, and use a self-made electrospinning device to adjust spinning parameters such as spinning Spinning with a voltage of 12kV, a receivi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com