Patents

Literature

426results about How to "High breakdown strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

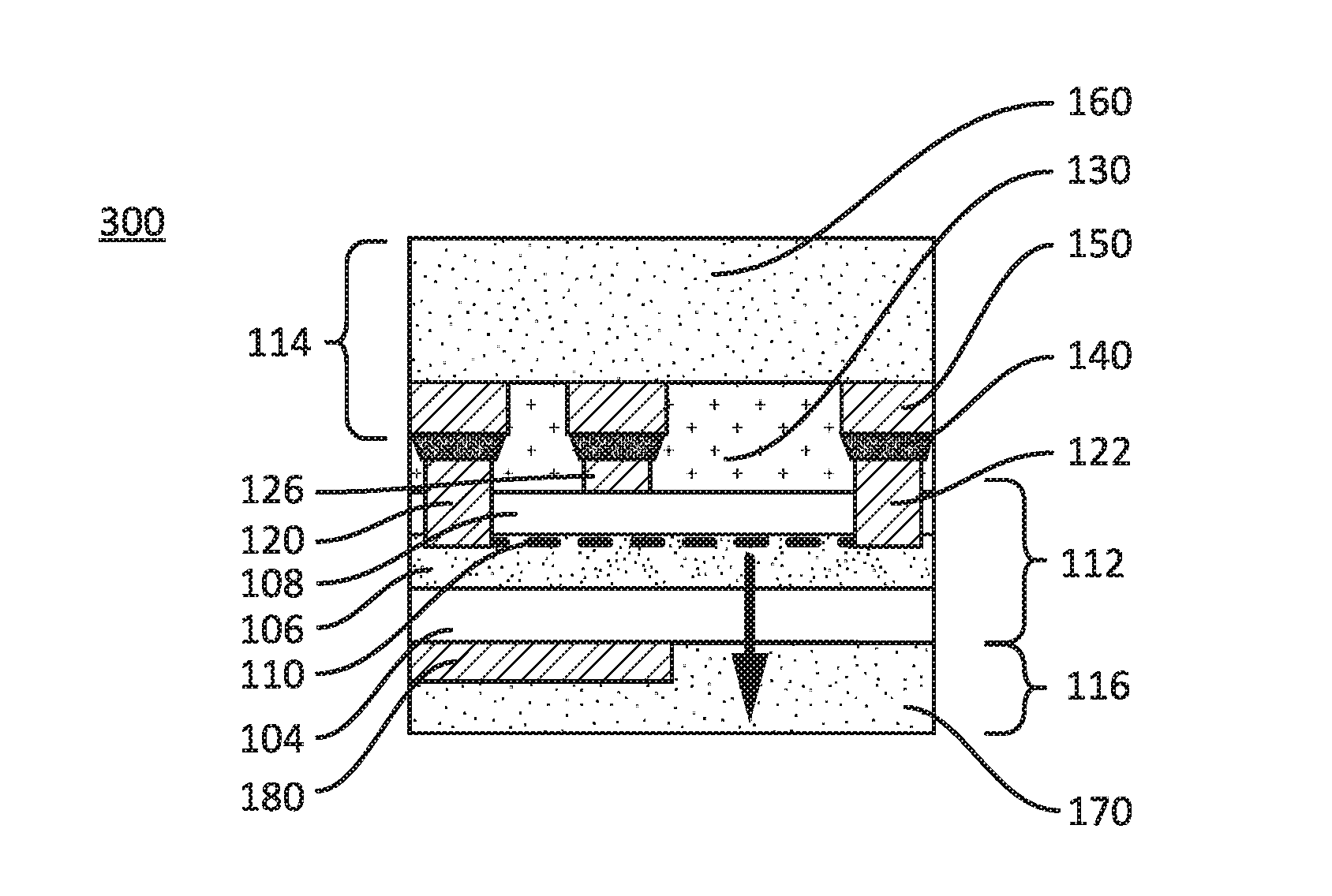

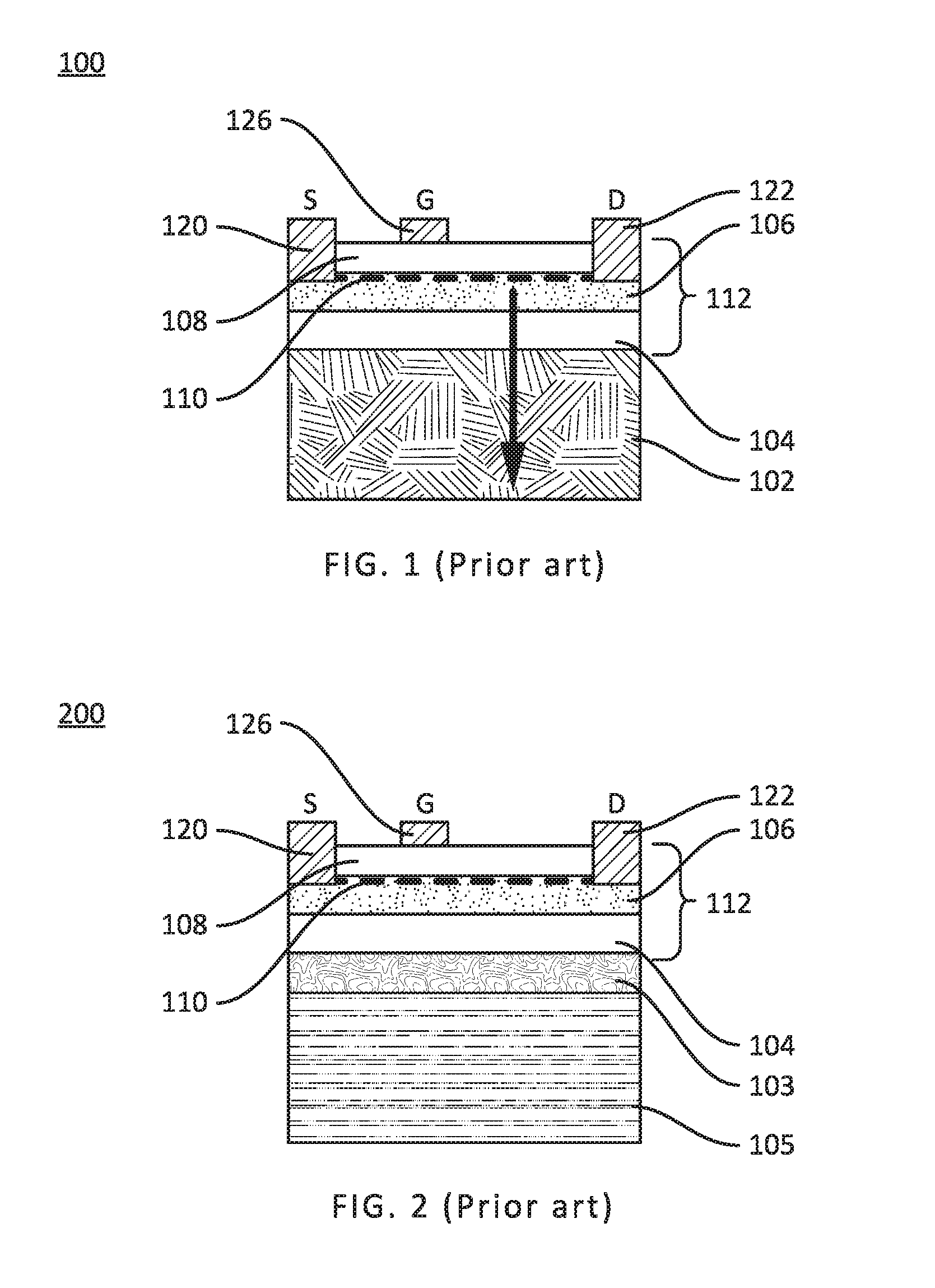

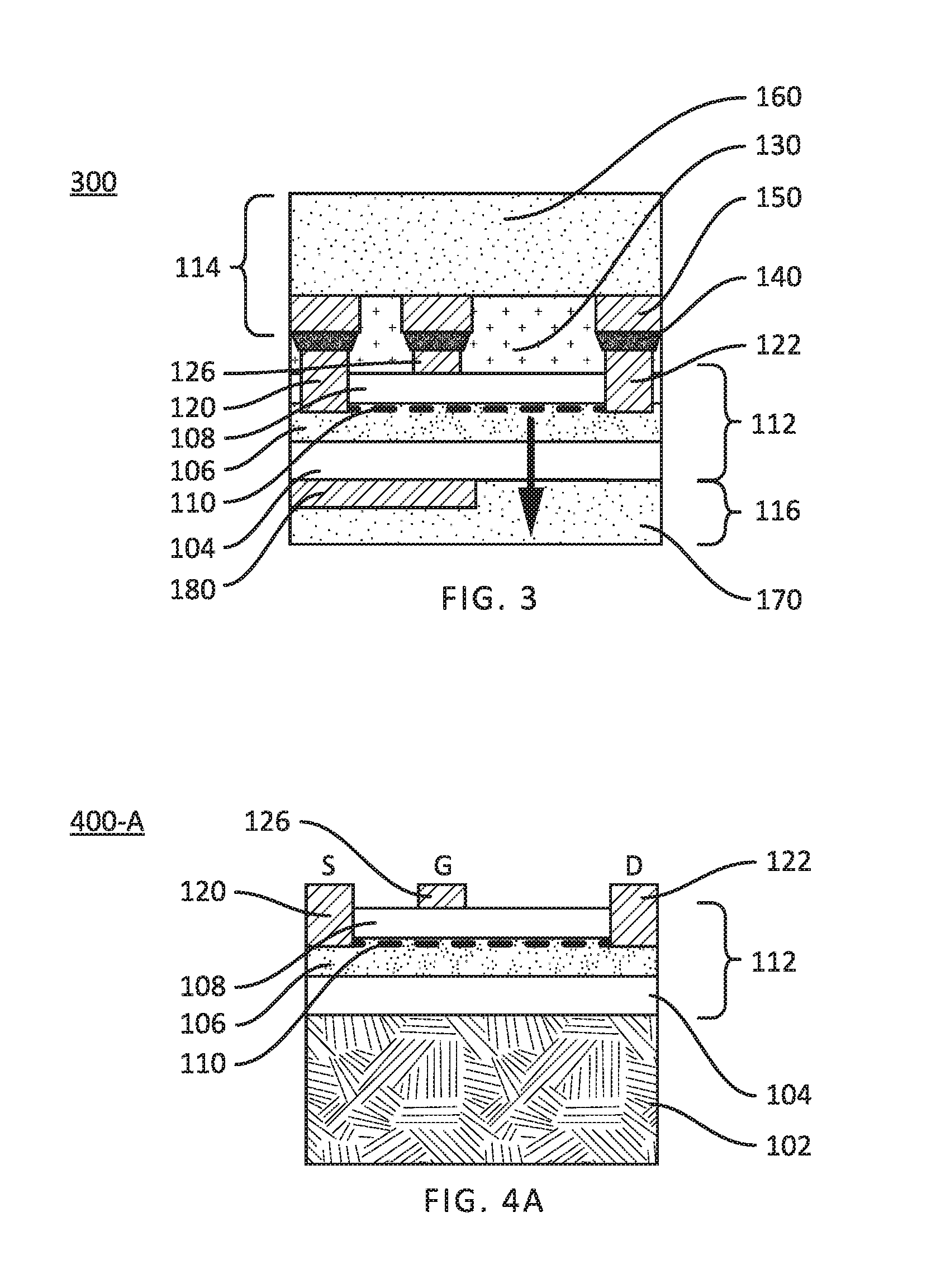

GaN SEMICONDUCTOR DEVICE STRUCTURE AND METHOD OF FABRICATION BY SUBSTRATE REPLACEMENT

ActiveUS20160380090A1Increased vertical breakdown resistanceImprove cooling effectTransistorSemiconductor/solid-state device testing/measurementContact padDevice material

Devices and systems comprising high current / high voltage GaN semiconductor devices are disclosed. A GaN die, comprising a lateral GaN transistor, is sandwiched between an overlying header and an underlying composite thermal dielectric layer. Fabrication comprises providing a conventional GaN device structure fabricated on a low cost silicon substrate (GaN-on-Si die), mechanically and electrically attaching source, drain and gate contact pads of the GaN-on-Si die to corresponding contact areas of conductive tracks of the header, then entirely removing the silicon substrate. The exposed substrate-surface of the epi-layer stack is coated with the composite dielectric thermal layer. Preferably, the header comprises a ceramic dielectric support layer having a CTE matched to the GaN epi-layer stack. The thermal dielectric layer comprises a high dielectric strength thermoplastic polymer and a dielectric filler having a high thermal conductivity. This structure offers improved electrical breakdown resistance and effective thermal dissipation compared to conventional GaN-on-Si device structures.

Owner:GAN SYST

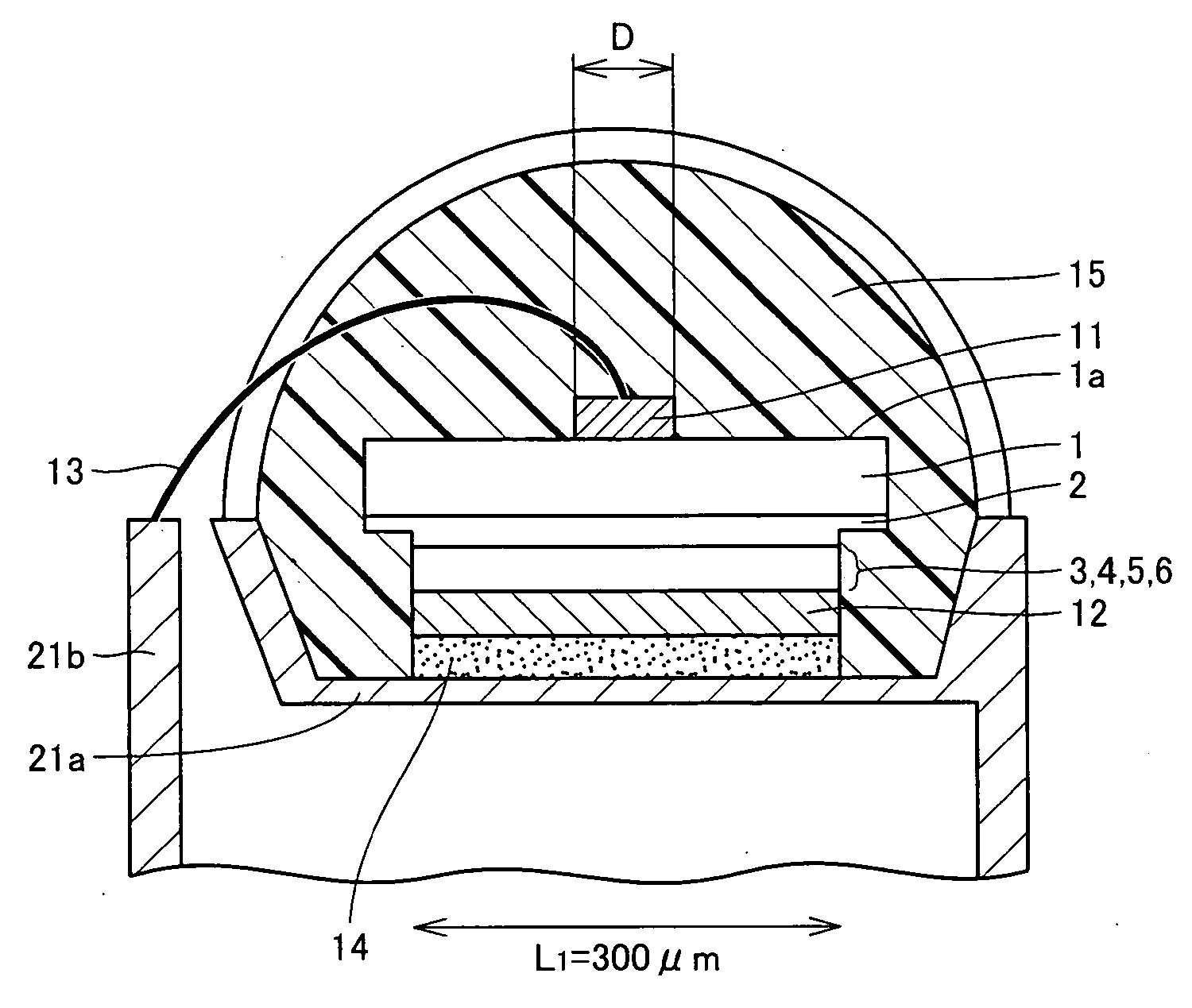

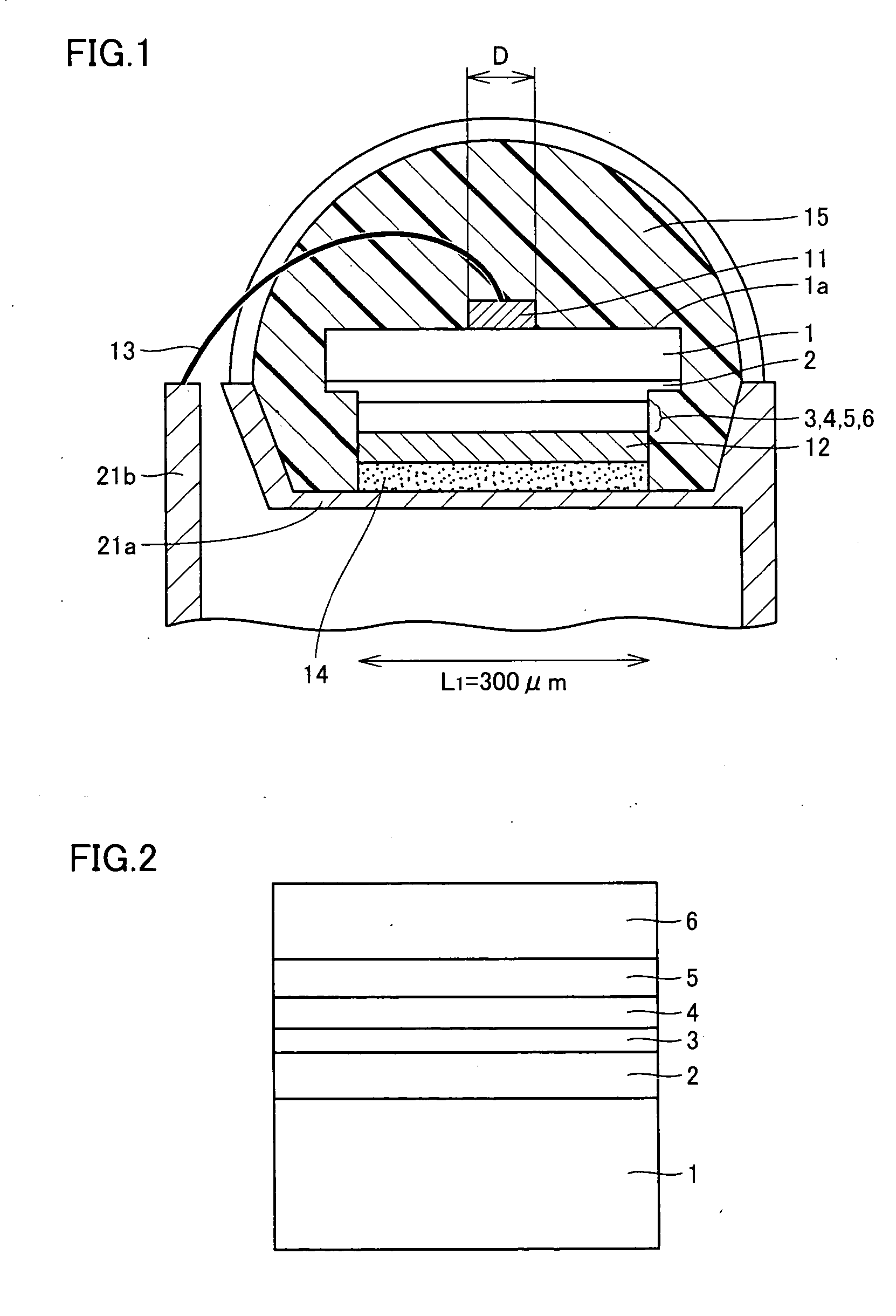

Light emitting apparatus

ActiveUS20050062060A1Easy constructionEasy to makeSolid-state devicesSemiconductor devicesLight emitting deviceLight emission

In order to provide light emitting devices which have simple constructions and thus can be fabricated easily, and can stably provide high light emission efficiencies for a long time period, a light emitting device includes an n-type nitride semiconductor layer at a first main surface side of a nitride semiconductor substrate, a p-type nitride semiconductor layer placed more distantly from the nitride semiconductor substrate than the n-type nitride semiconductor layer at the first main surface side and a light emitting layer placed between the n-type nitride semiconductor layer and the p-type nitride semiconductor layer at the first main surface side. The nitride semiconductor substrate has a resistivity of 0.5 Ω·cm or less and the p-type nitride semiconductor layer side is down-mounted so that light is emitted from the second main surface of the nitride semiconductor substrate at the opposite side from the first main surface.

Owner:SUMITOMO ELECTRIC IND LTD

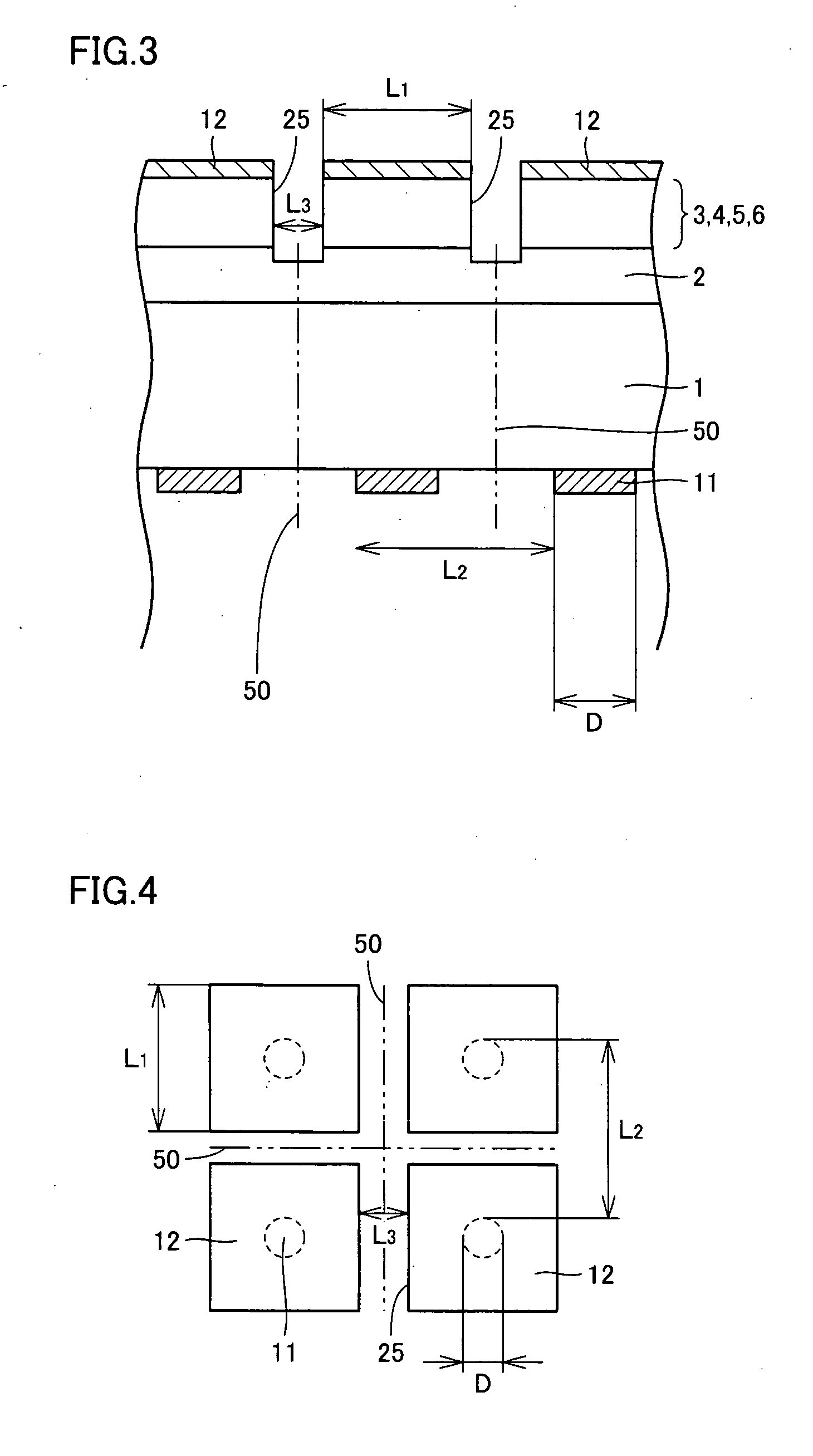

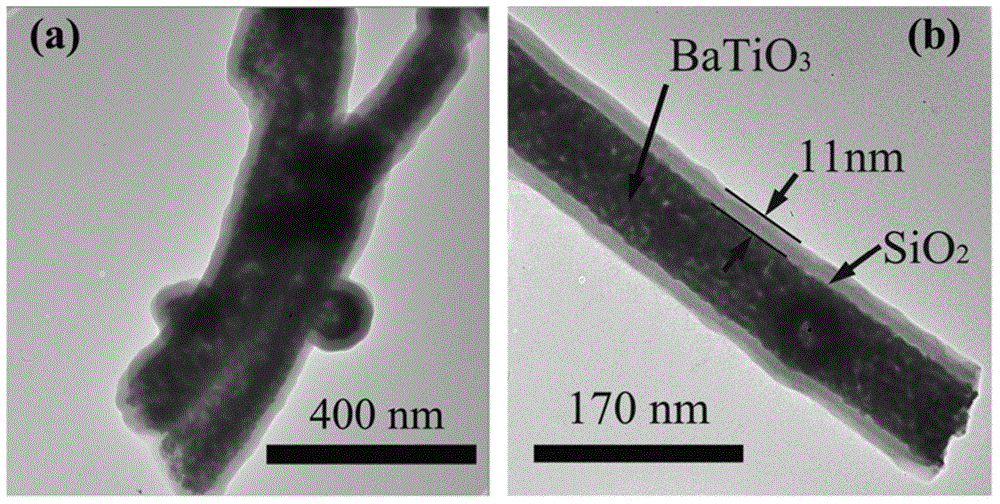

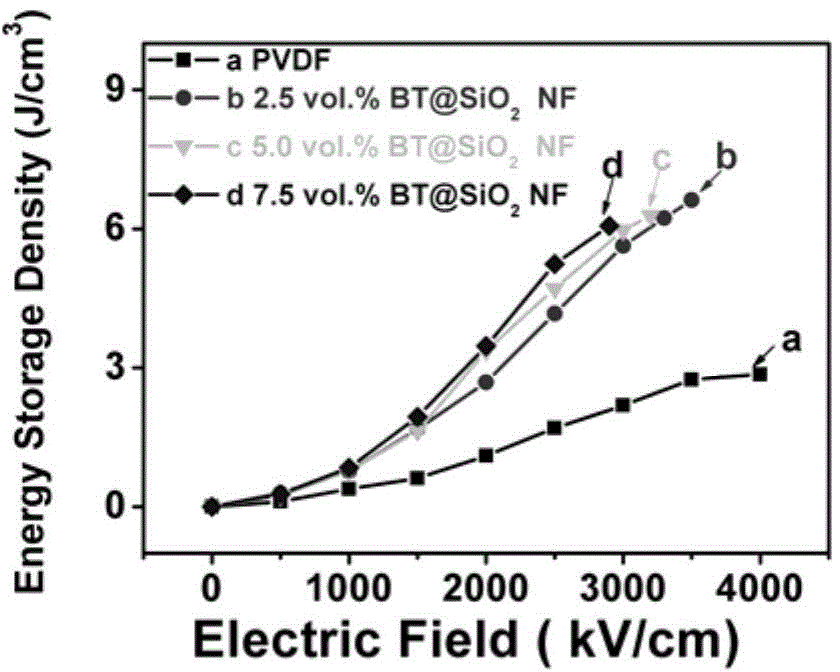

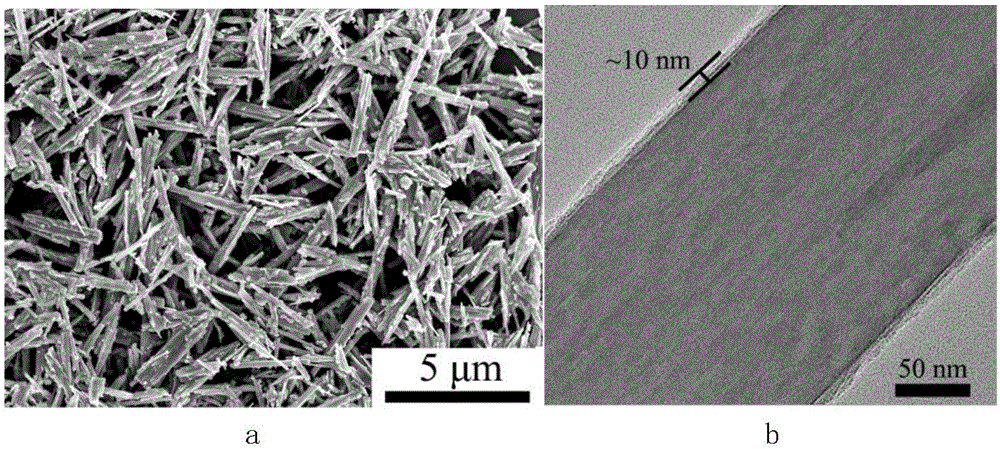

High energy storage density and efficiency polymer composite film and preparation method thereof

The invention relates to a high energy storage density and efficiency polymer composite film and a preparation method thereof. The composite film is composed of a polyvinylidene fluoride matrix and nanofiber with a core-shell structure in the polyvinylidene fluoride matrix, a core layer of the nanofiber with the core-shell structure is ceramic fiber, and the case layer is a silica coating layer. Compared with prior art, the dielectric constant of the composite film can be adjusted by adjusting the content of ceramic fiber, simultaneously, dielectric loss tangent is less than 5%, breakdown field intensity is greater than 2000kV / cm, and energy storage density is 3-7J / cm<3>. The composite film can reduce interfacial polarization generated at a ceramic-compound interface, can increase the energy storage density of PVDF, can be used for capacitor and large power static energy storage materials, has the advantages of simple and practicable operation, low cost, convenience and rapidity, and enables large scale production.

Owner:TONGJI UNIV

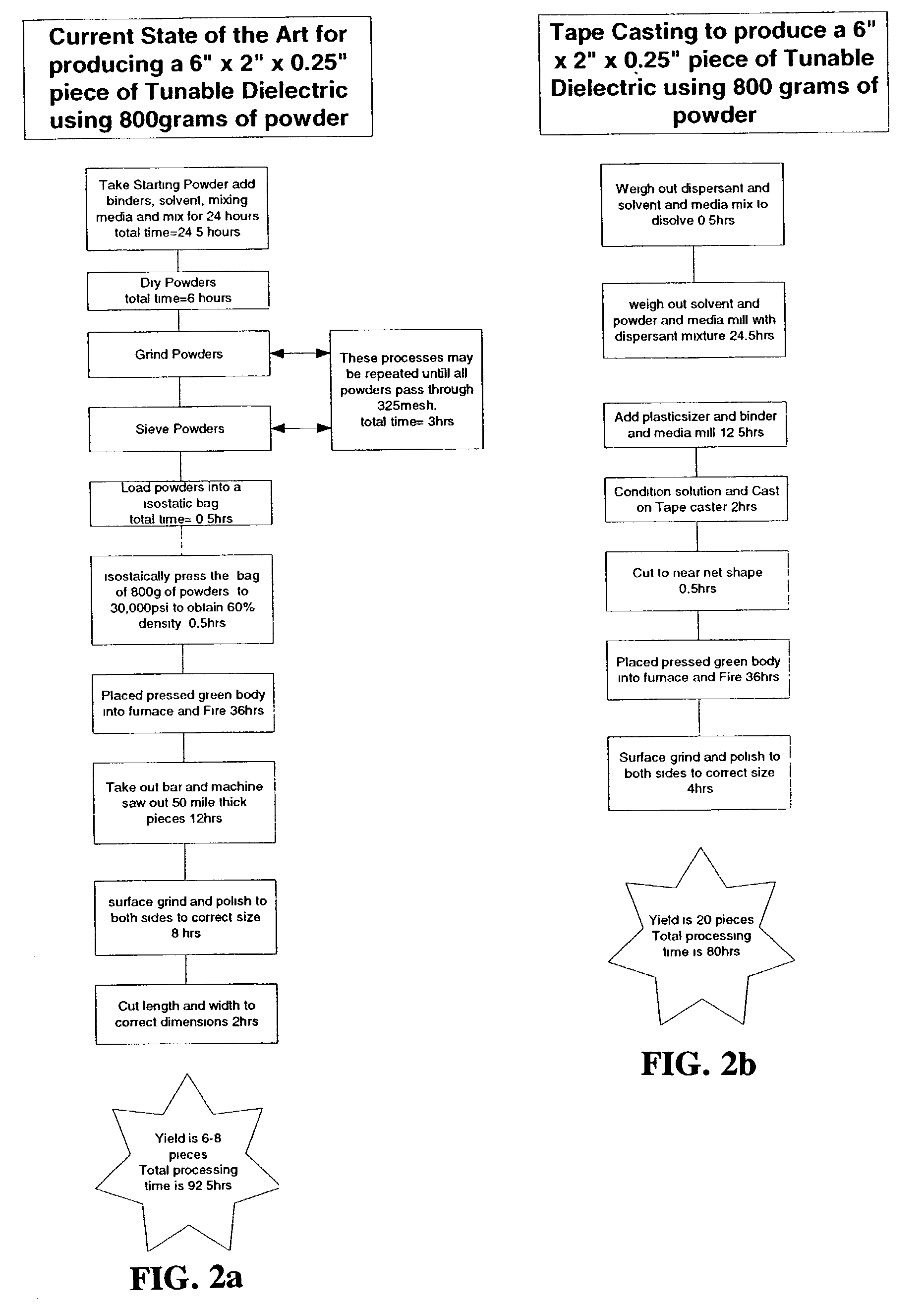

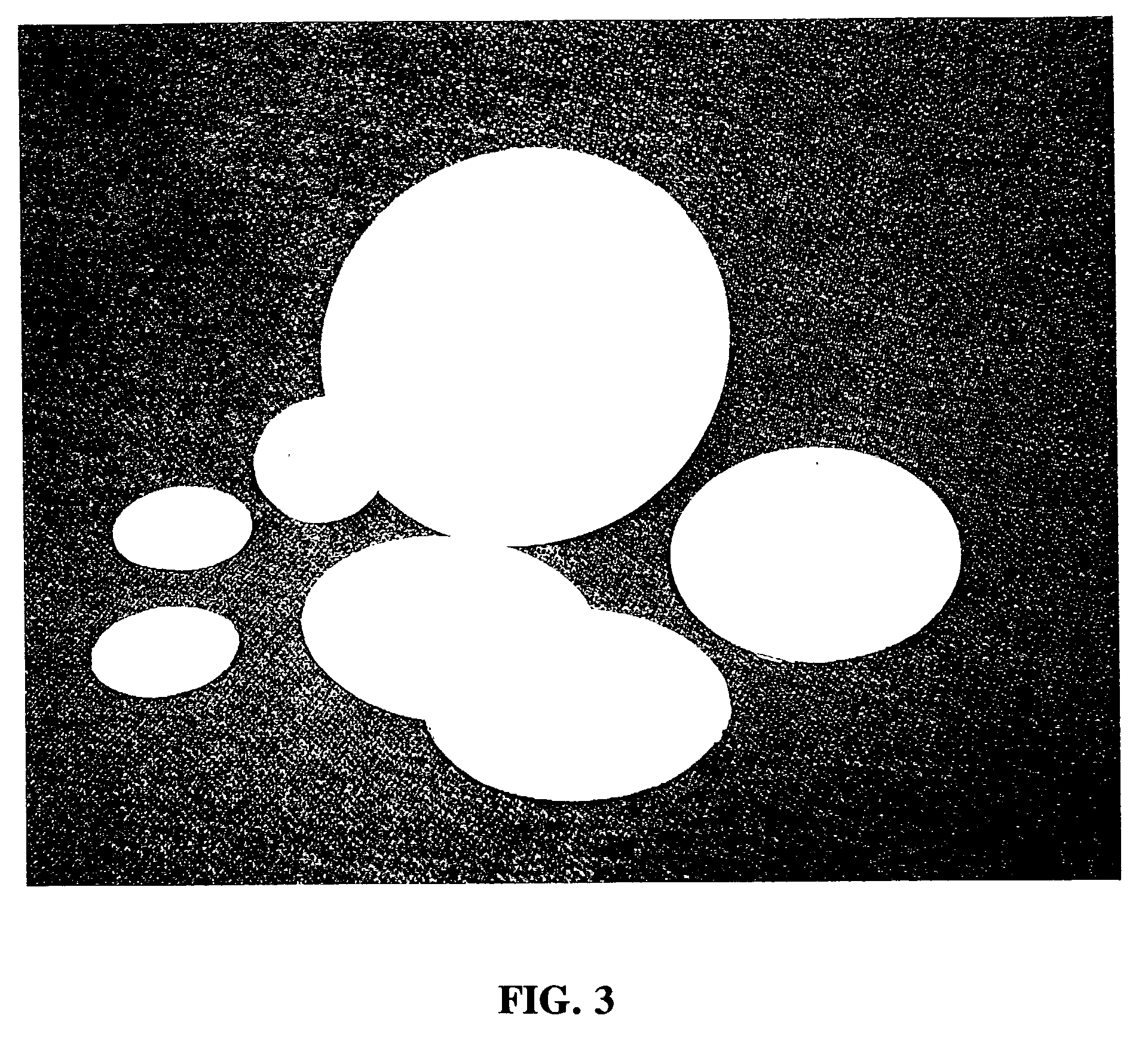

Method for producing low-loss tunable ceramic composites with improved breakdown strengths

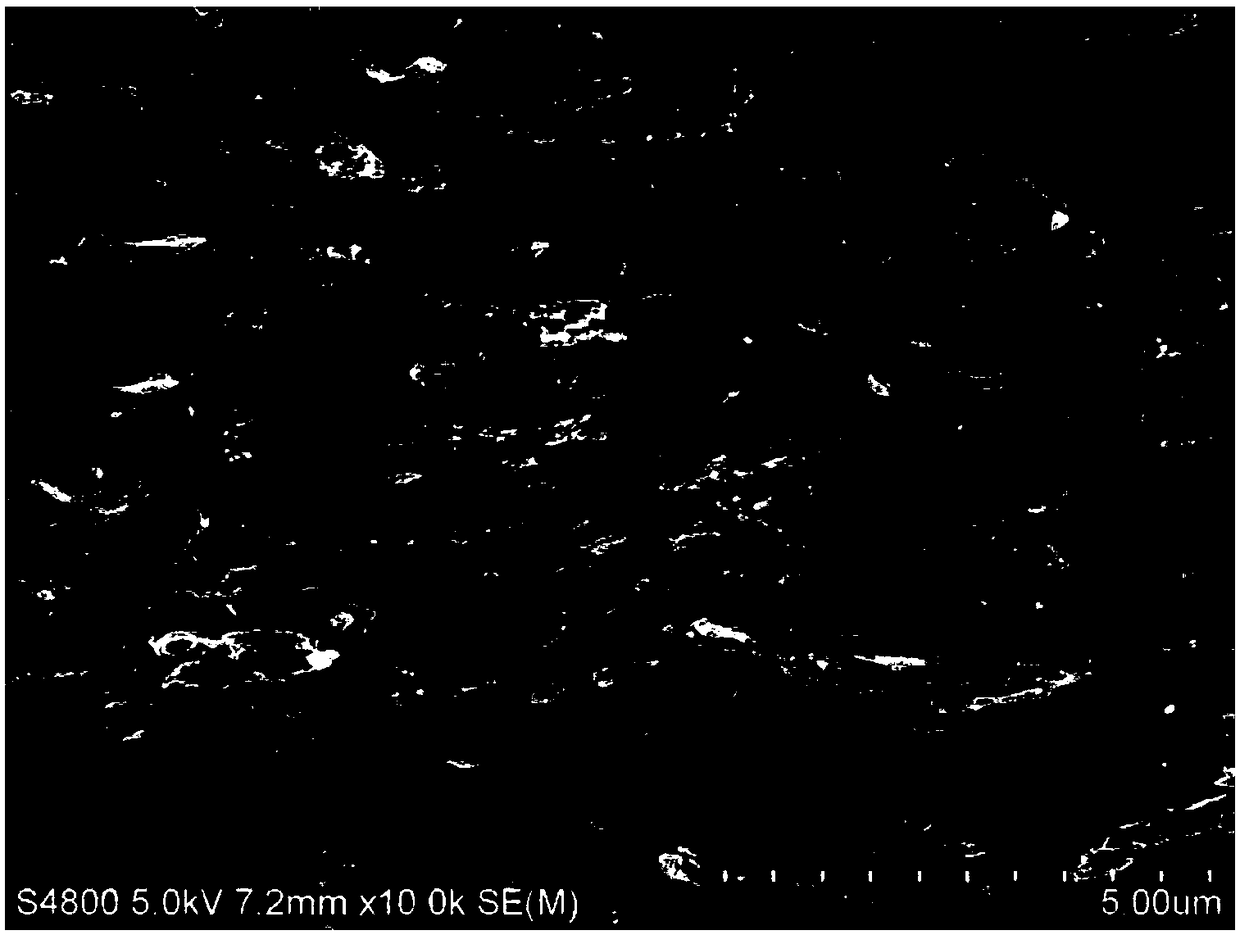

InactiveUS20030119656A1Improved propertyLow cost productionLayered productsFixed capacitor dielectricBreakdown strengthMicrowave

The production of low-loss, tunable composite ceramic materials with improved breakdown strengths is disclosed. The composite materials comprise ferroelectric perovskites such as barium strontium titanate or other ferroelectric perovskites combined with other phases such as low-loss silicate materials and / or other low-loss oxides. The composite materials are produced in sheet or tape form by methods such as tape casting. The composite tapes exhibit favorable tunability, low loss and tailorable dielectric properties, and can be used in various microwave devices.

Owner:NXP USA INC

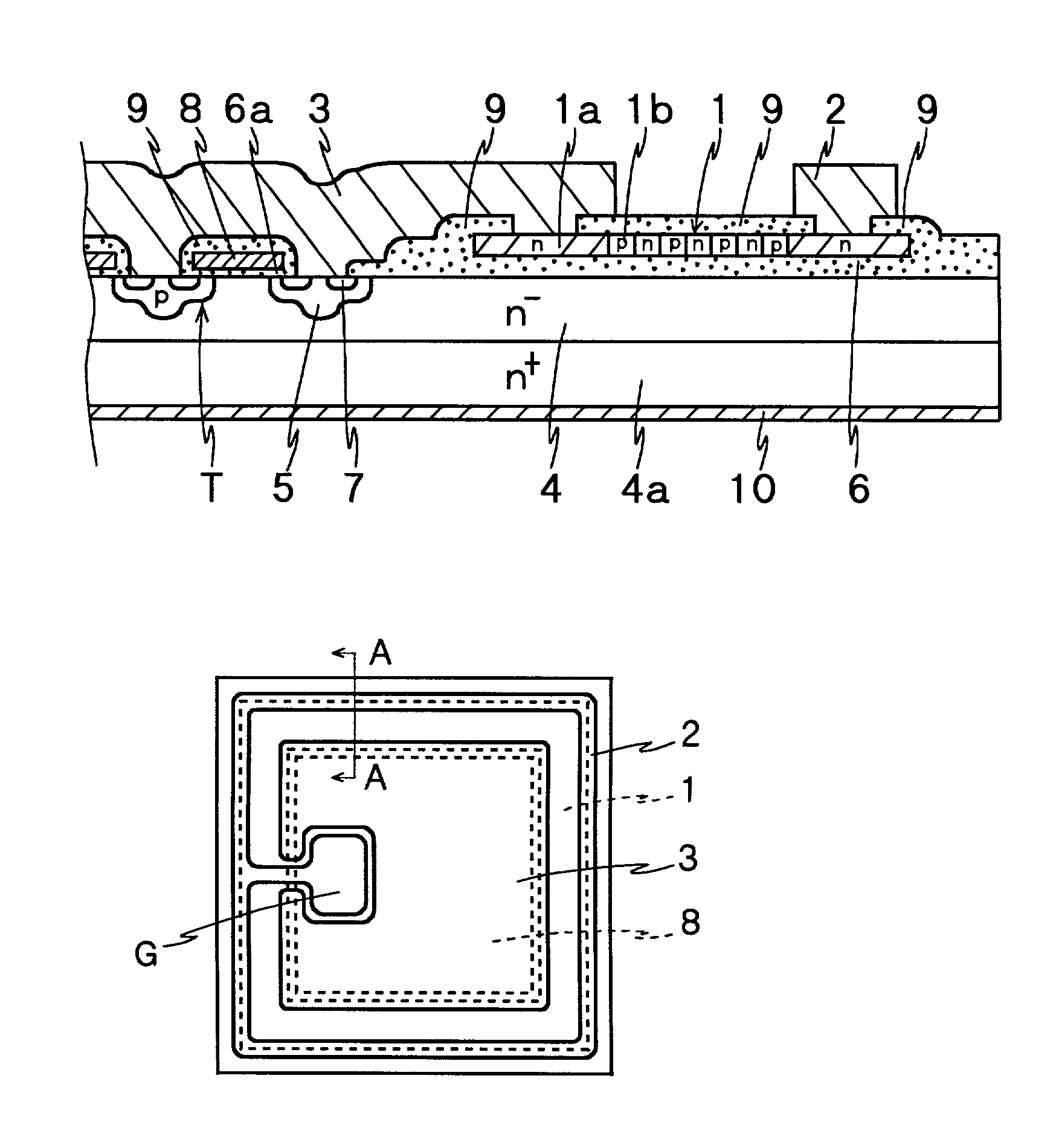

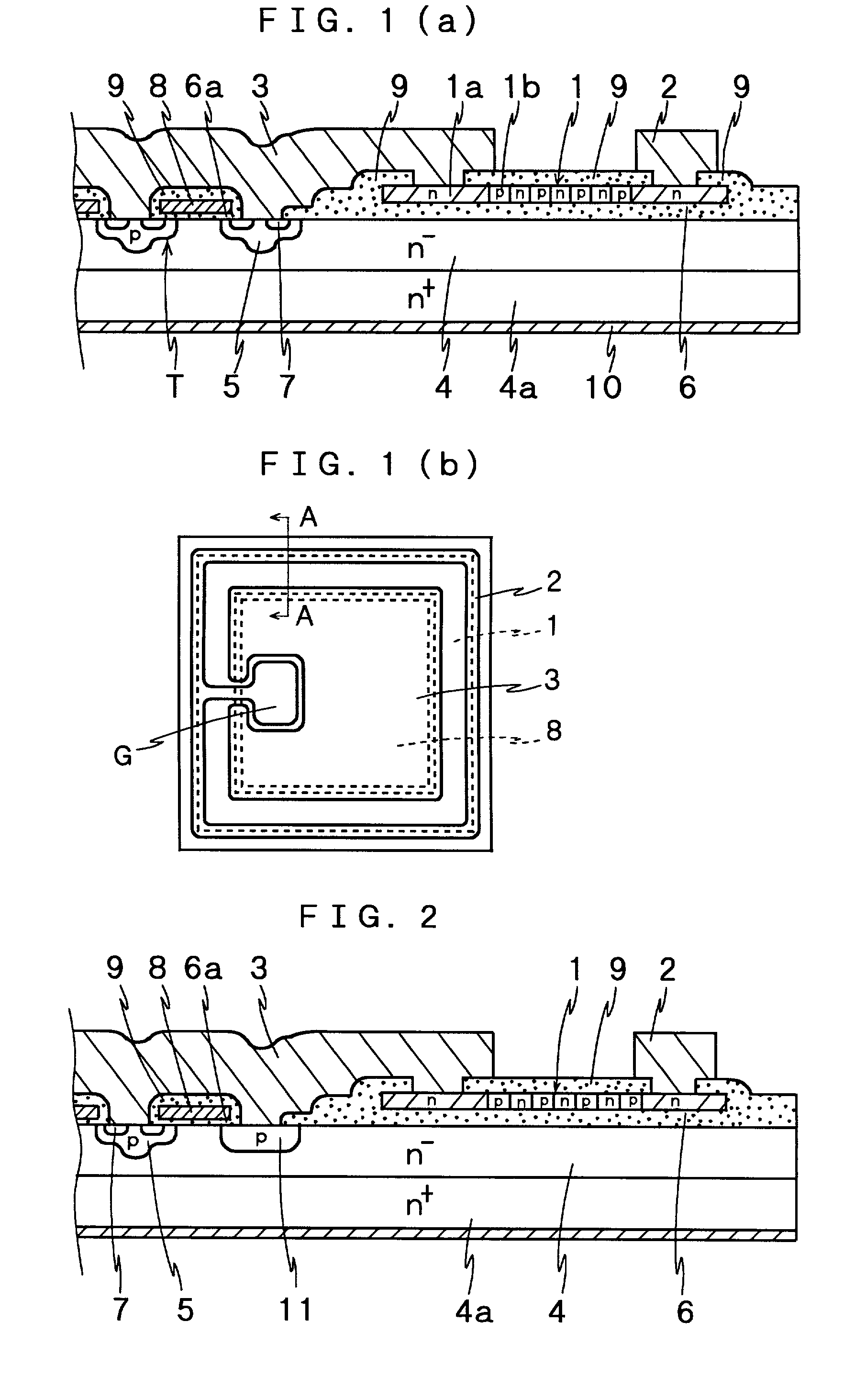

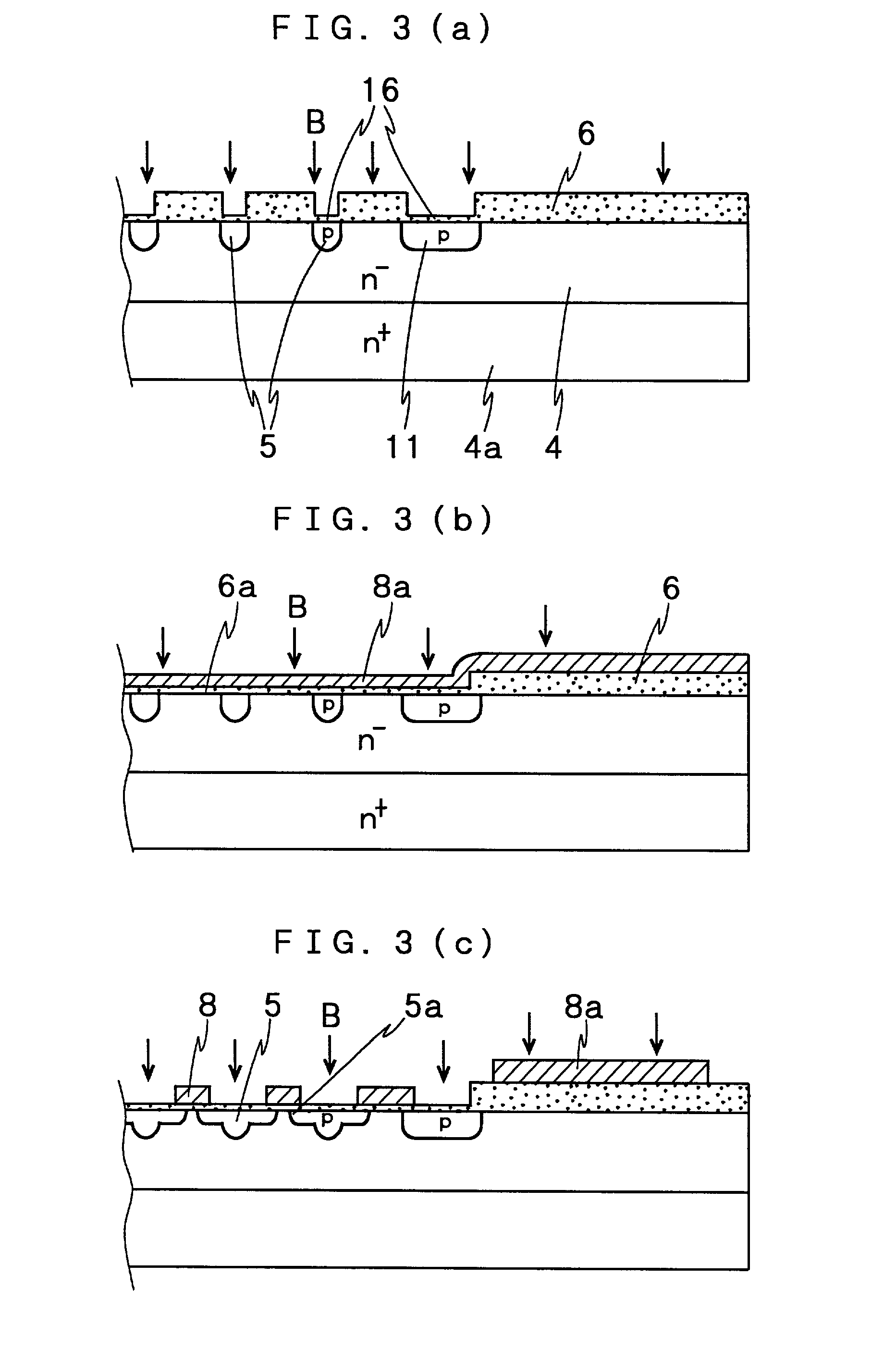

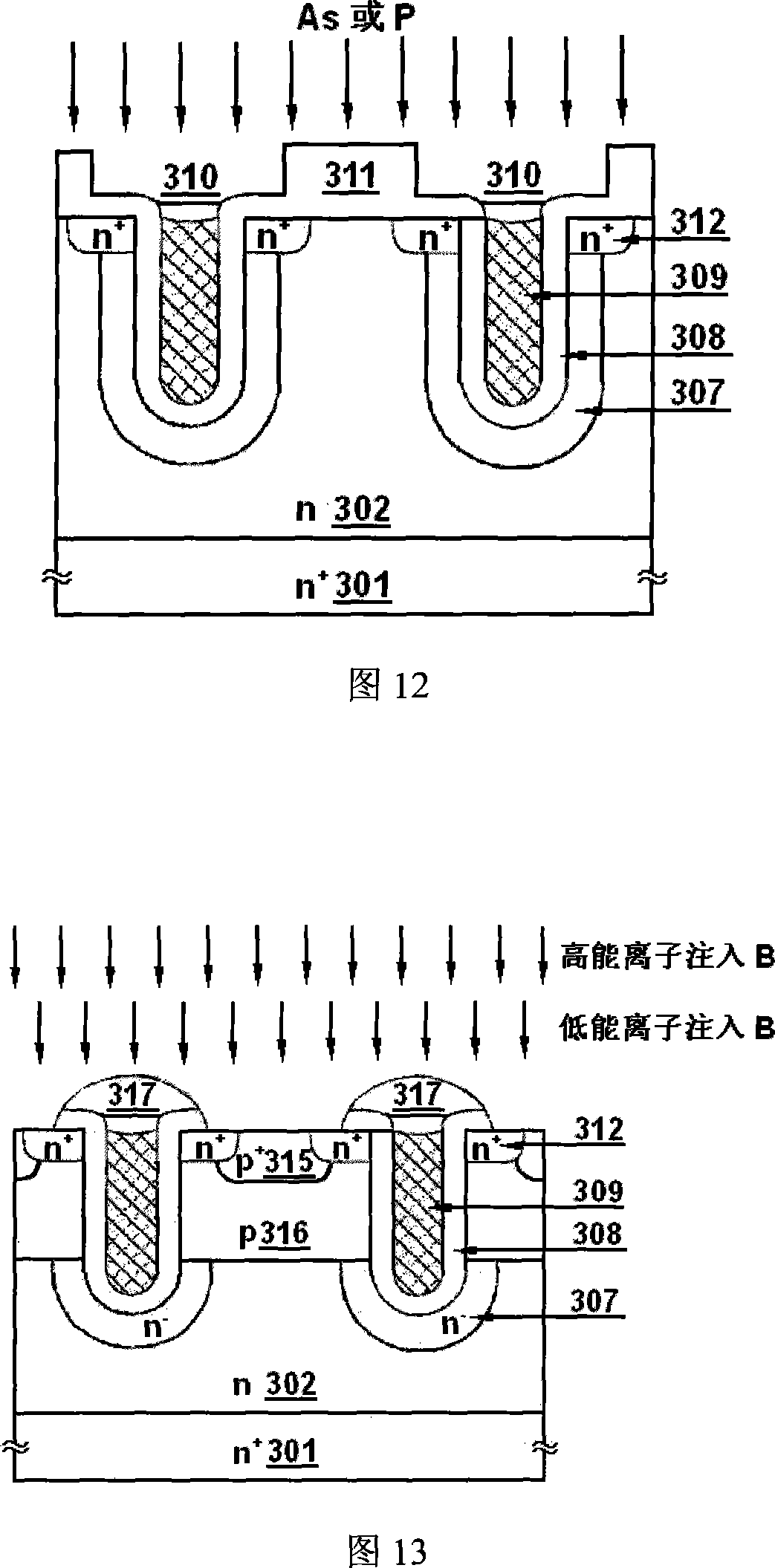

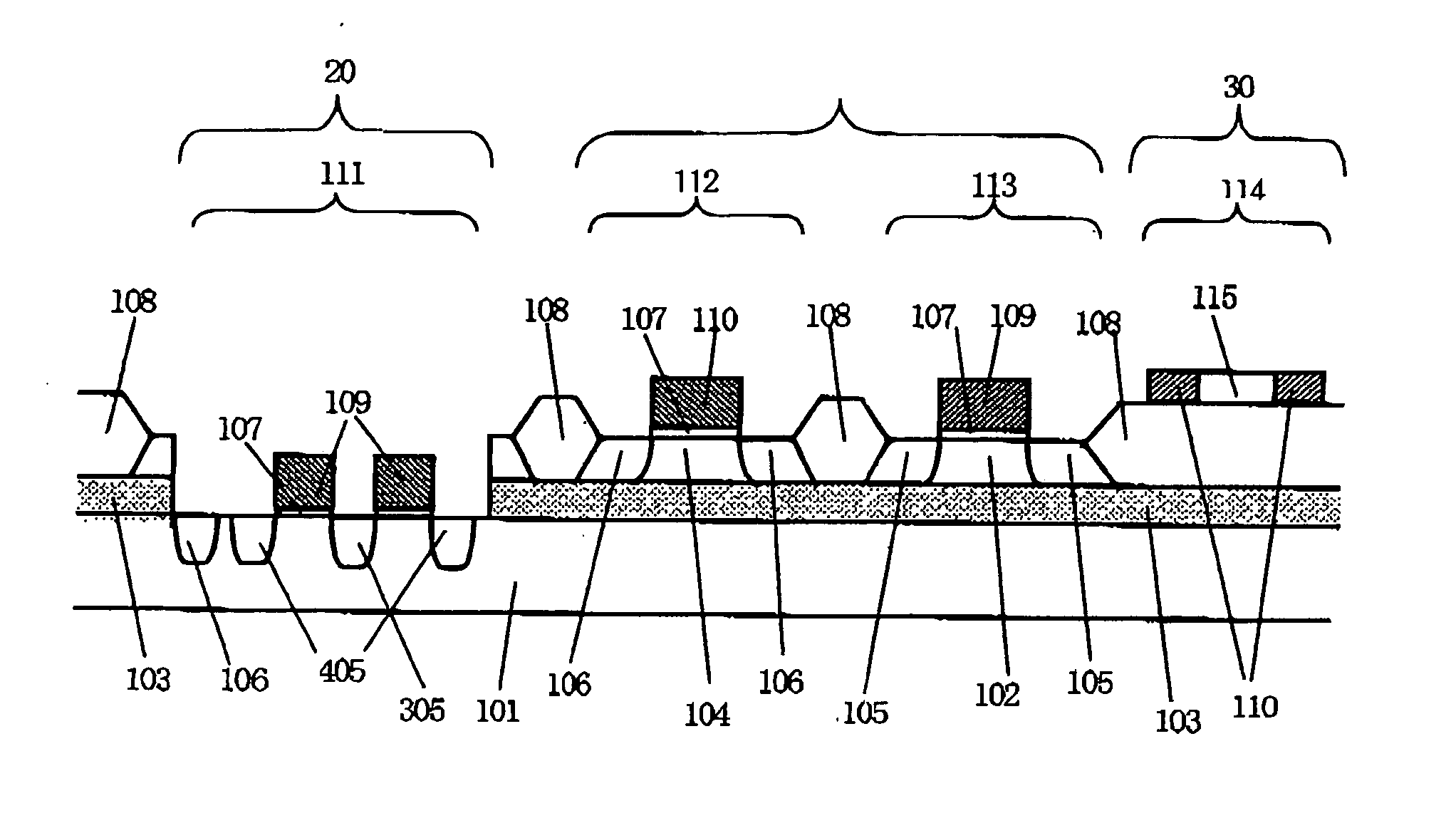

Semiconductor device

InactiveUS6965150B2Reduced series resistanceIncrease joint areaTransistorSemiconductor/solid-state device detailsSemiconductor packageMetal

A plurality of transistor cells (T) are arranged in the semiconductor layer (4). Ring-shaped p-type layers (1b) and n-type layers (1a) composed of polysilicon film are formed alternately on an insulating layer (6) in an outer side than the plurality of transistor cells (T) (the peripheral portion of chip), thereby forming a protective diode (1). The most outer layer of the protective diode (1) is contacted to the gate wiring (2) composed of metal film such as Al, which is formed circularly on the most external layer, and the most inner layer is contacted to the source wiring composed of metal layer, thereby the protective diode is connected between the gate and source of a transistor. As a result of this, the semiconductor device with the protective diode which has the small series resistance, can be formed without enlarging chip area and by using unoccupied space of chip, and realize protection function sufficiently, can be obtained.

Owner:ROHM CO LTD

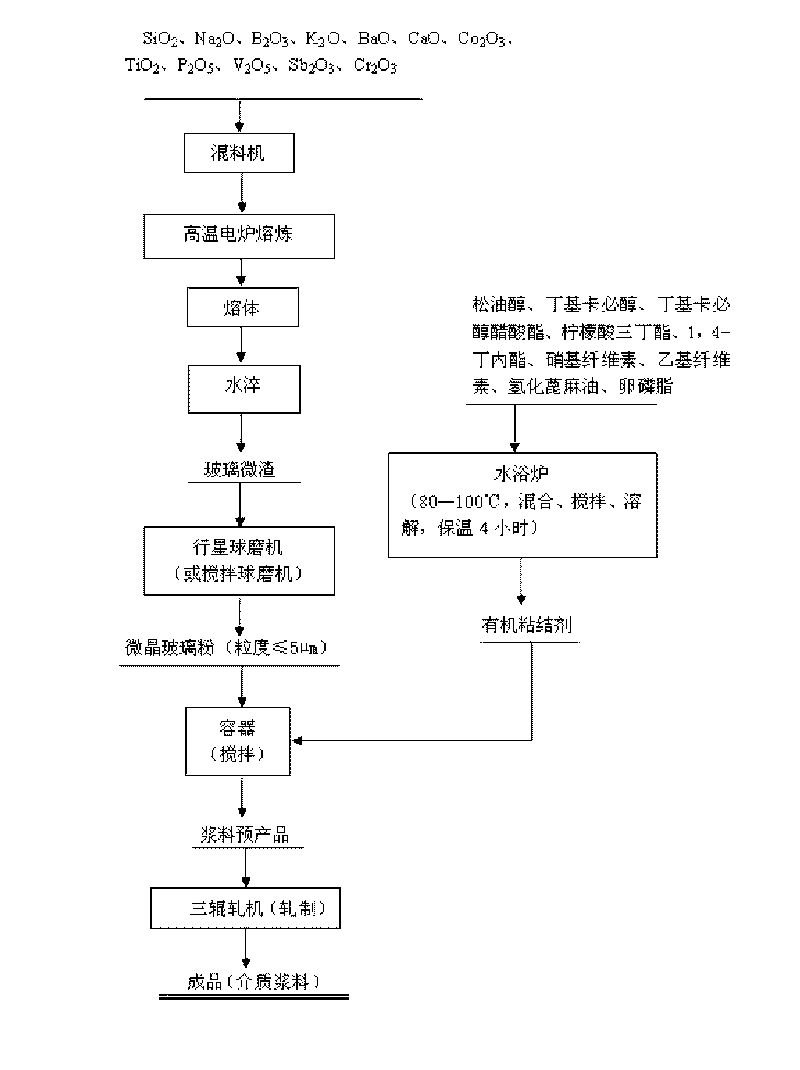

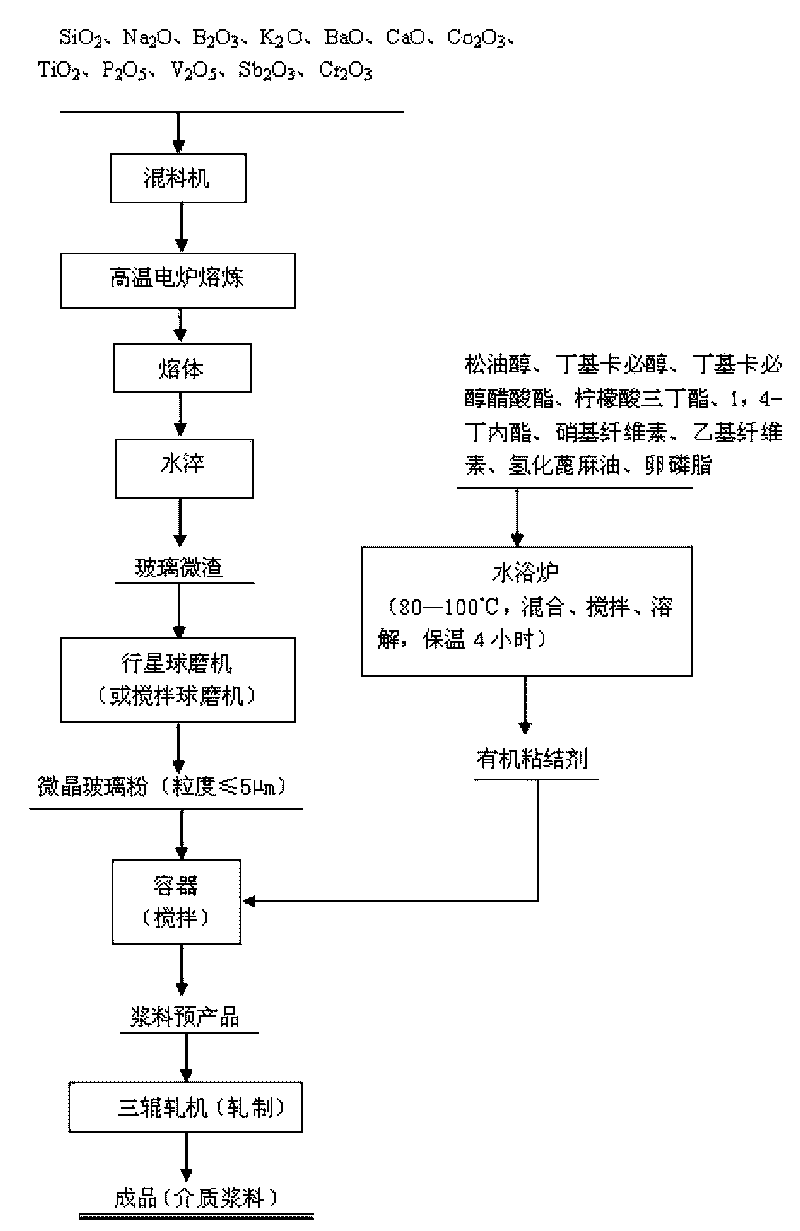

Dielectric paste for metal aluminum substrate thick film circuit and preparation method thereof

InactiveCN101740160AImprove thixotropyGood anti-sinking effectNon-macromolecular adhesive additivesSolid-state devicesDielectricCITRATE ESTER

The invention discloses dielectric paste for a metal aluminum substrate thick film circuit and a preparation method thereof. The invention aims to prepare the dielectric paste matched with a metal aluminum substrate. The dielectric paste is characterized in that SiO2, Na2O, B2O3, K2O, BaO, CaO, Co2O3, TiO2, P2O5, V2O5, Sb2O3 and Cr2O3 are combined to prepare microcrystalline glass powder; and the microcrystalline glass powder and an organic binder which consists of terpinol, butyl carbitol, butyl carbitol acetate, tirbutyl citrate, 1,4-butyrolactone, nitroncellulose, ethyecellulose, hydrogenated castor oil and lecithin are put in a vessel for stirring and rolling by a three-roll roller mill in a weight ratio of the microcrystalline glass powder to the organic binder of 70-90 parts: 30-10 parts so as to prepare the finished product dielectric paste. The dielectric paste is mainly used as the dielectric paste of the thick film circuit formed by being printed on the metal aluminum substrate.

Owner:湖南利德电子浆料股份有限公司

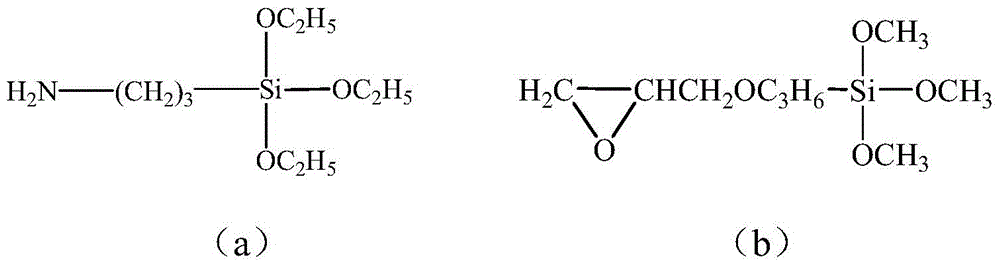

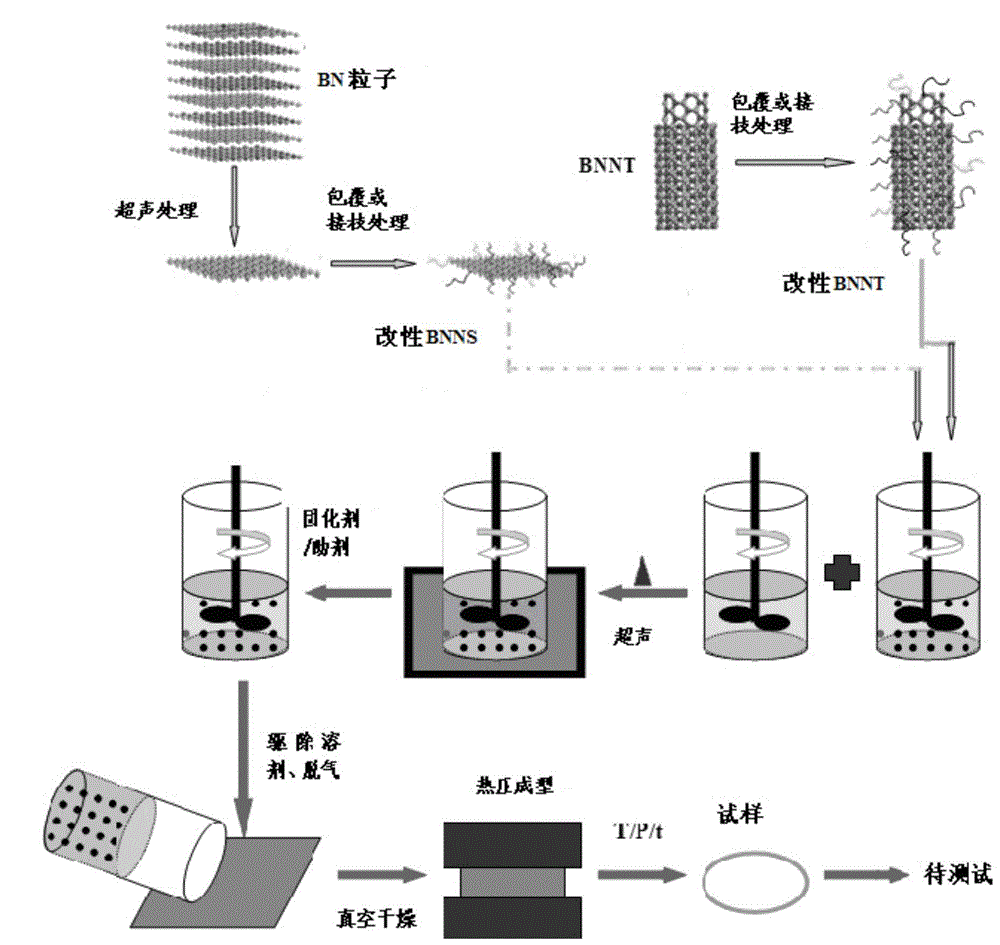

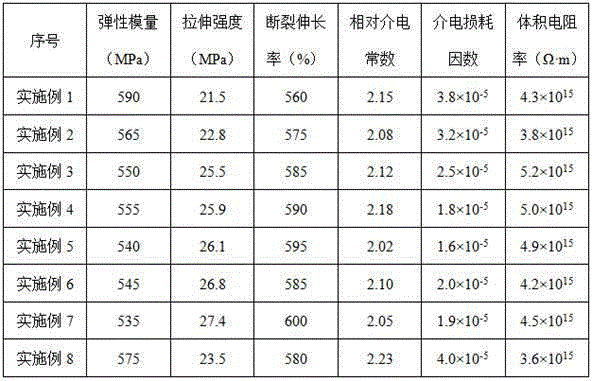

Polymer dielectric medium with low dielectric constant and low loss and preparation method of polymer dielectric medium

InactiveCN103980664AGood dispersionImprove thermal conductivitySynthetic resin layered productsEpoxyHeat conducting

The invention discloses a polymer dielectric medium with low dielectric constant and low loss and a preparation method of the polymer dielectric medium. The polymer dielectric medium comprises the following raw materials: 50-60% of epoxy resin system, and 40-50% of mixed boron nitride nanoparticles, wherein the mixed boron nitride nanoparticle is a mixture of a boron nitride nanotube and a boron nitride nanotube; the epoxy resin system is formed by 100phr of epoxy resin E-51, 85phr of methyl hexahydrophthalic anhydride and 1phr of benzyl dimethylamine in a mixing manner. The thermal breakdown voltage of the polymer dielectric medium is significantly improved by the polymer dielectric material with high heat conductivity and high electric breakdown, the service life is prolonged, the dielectric constant and loss and the heat expansion coefficient are reduced, the mechanical strength and the tenacity are improved, the highest heat conductivity can be up to 5.26W / mK, the volume resistivity is about 1014ohm.cm, the thermal breakdown voltage is about 2-3kV / mm higher than that of the similar heat-conducting polymer dielectric medium, and the dielectric constant and the loss are a little lower than those of pure resin.

Owner:XIAN UNIV OF SCI & TECH

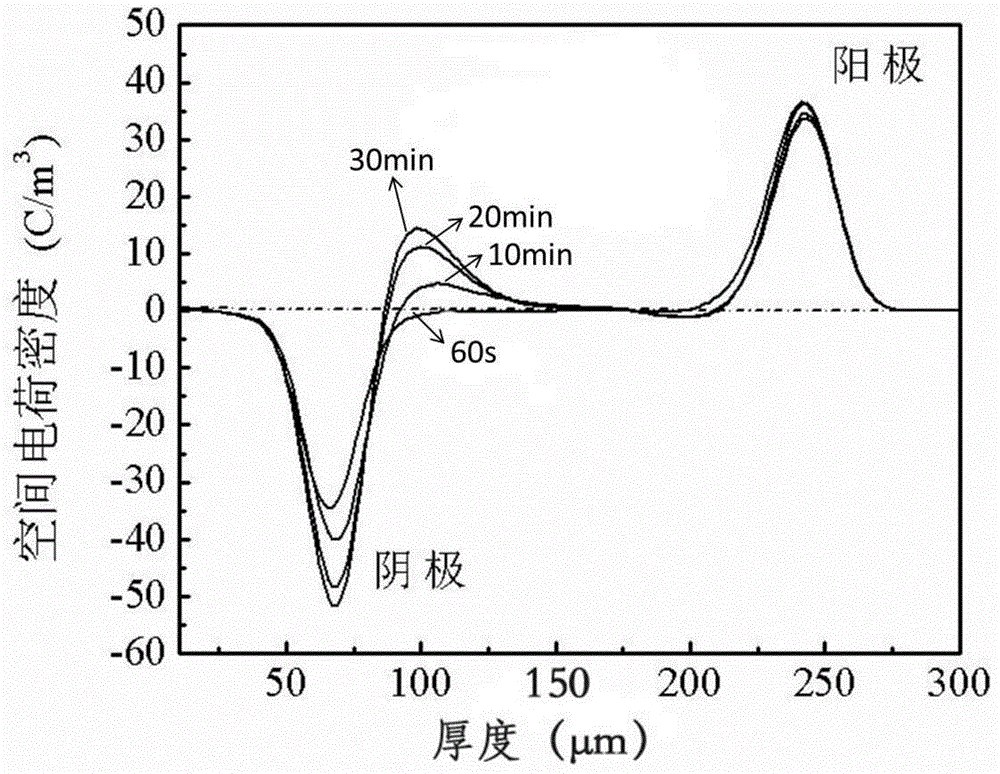

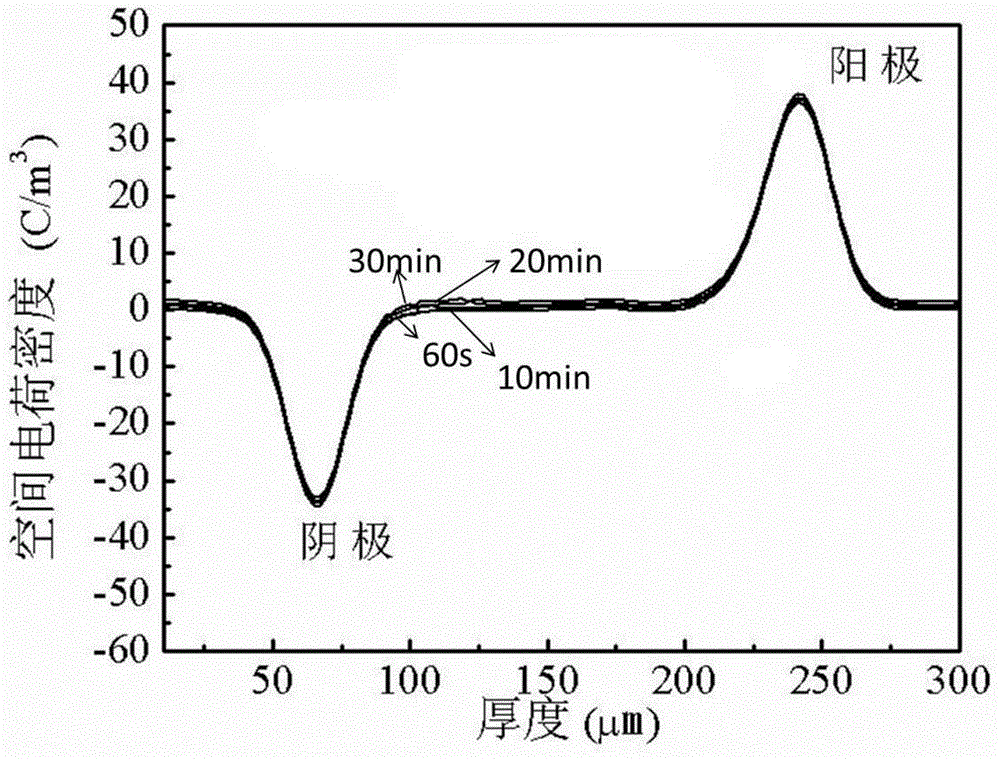

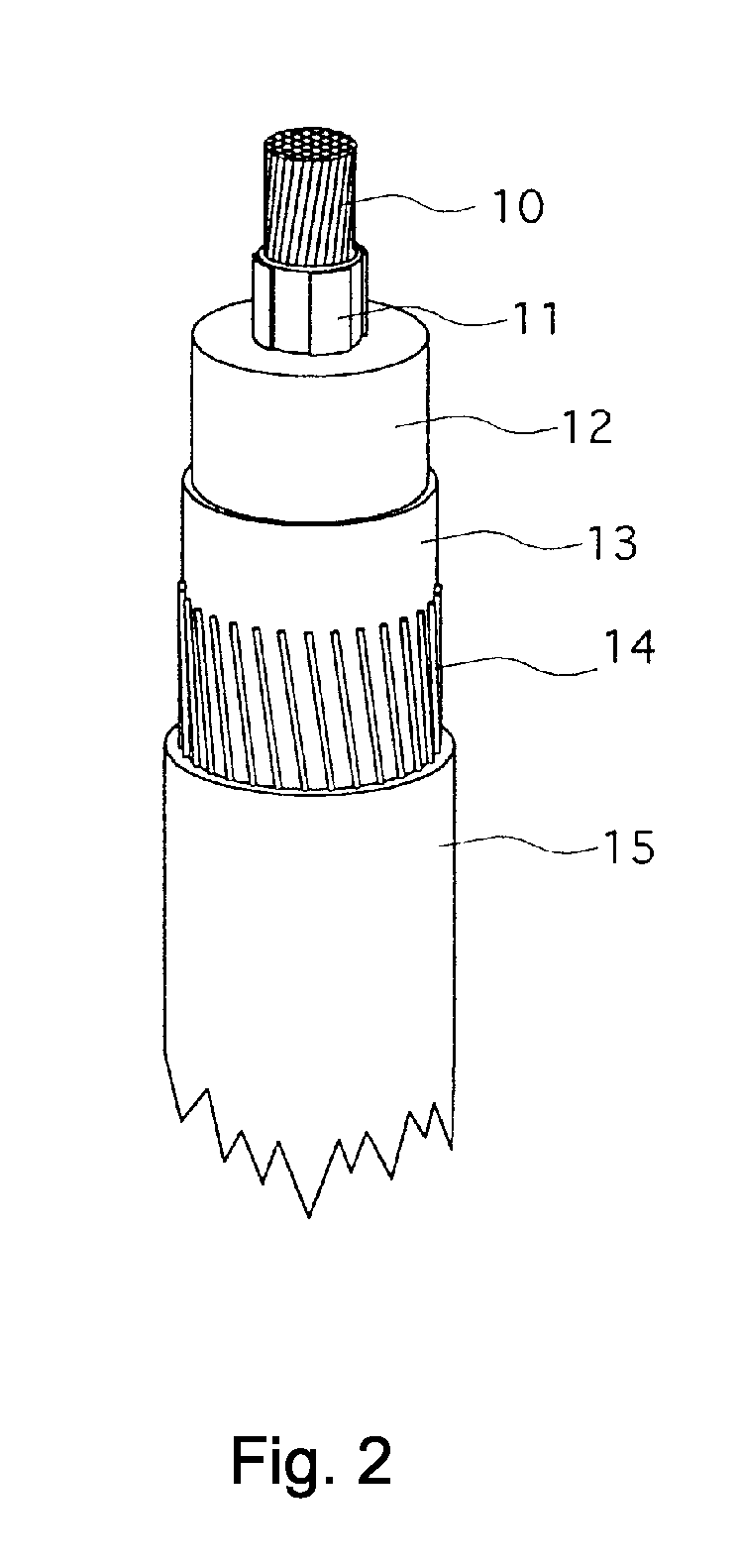

High-voltage direct-current cable material and preparation method thereof

ActiveCN104910495AGood effectAccumulation noPlastic/resin/waxes insulatorsLow-density polyethyleneHigh-voltage direct current

The invention provides a high-voltage direct-current cable material and a preparation method thereof. The high-voltage direct-current cable material comprises the following components in parts by mass: 90-100 parts of low-density polyethylene, 0.5-3.5 parts of modified nanometer magnesia, 0.1-0.5 part of molten paraffin, 0.001-0.08 part of an antioxidant and 0.001-2.5 parts of a benzyl compound. The preparation method comprises the following steps: preparing the modified nanometer magnesia by using a drum ball-milling method, premixing the raw materials, and finally pelleting, thereby obtaining the high-voltage direct-current cable material. The high-voltage direct-current cable material provided by the scheme of the invention is excellent in space charge accumulation inhibition property under the condition of 40kV / mm and high in breakdown field strength, and the requirement of high-voltage direct-current cable power transmission of 100kV can be met.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

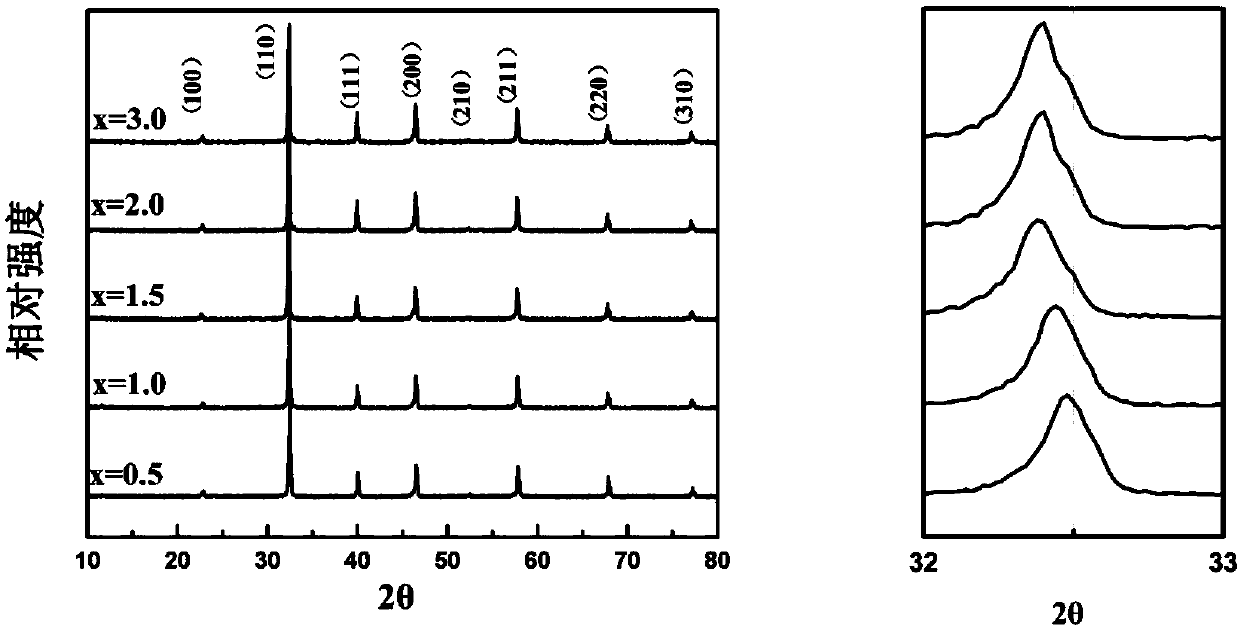

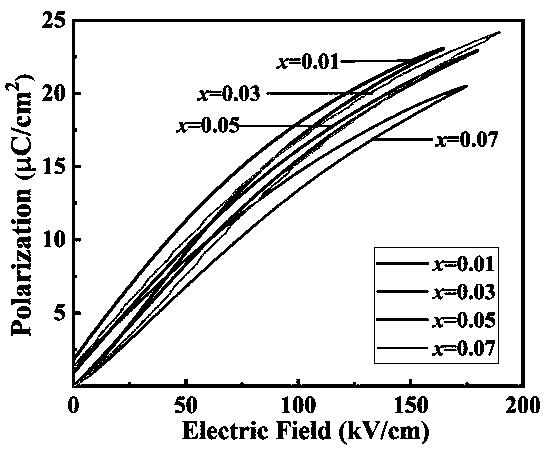

High-energy-storage sodium bismuth titanate-strontium titanate matrix material and preparation method thereof

InactiveCN109574656AImprove energy storage characteristicsHigh breakdown strengthBreakdown strengthStrontium titanate

The invention discloses a high-energy-storage sodium bismuth titanate-strontium titanate matrix material. The chemical formula of the high-energy-storage sodium bismuth titanate-strontium titanate matrix material is 0.5Bi0.5Na0.5TiO3-0.5SrTiO3-x wt%MgO, wherein x=0.5-3.0. A preparation method of the high-energy-storage sodium bismuth titanate-strontium titanate matrix material comprises the following steps of preparing SrCO3, TiO2, Bi2O3, Na2CO3 and MgO by weight ratio according to the chemical formula into a ceramic powder, performing ball milling, drying and pelletizing, and then pressing the ceramic powder in a tablet press into a ceramic blank; rubber-discharging and sintering the ceramic blank inside a muffle furnace to obtain a ceramic sample. The preparation method of the high-energy-storage sodium bismuth titanate-strontium titanate matrix material is simple in preparation process, low in cost and free from pollution; the prepared high-energy-storage sodium bismuth titanate-strontium titanate matrix material achieves a high discharging energy storage density of 1.61-2.17 J / cm3 and a high breakdown strength of 137-226 KV / cm.

Owner:WUHAN UNIV OF TECH

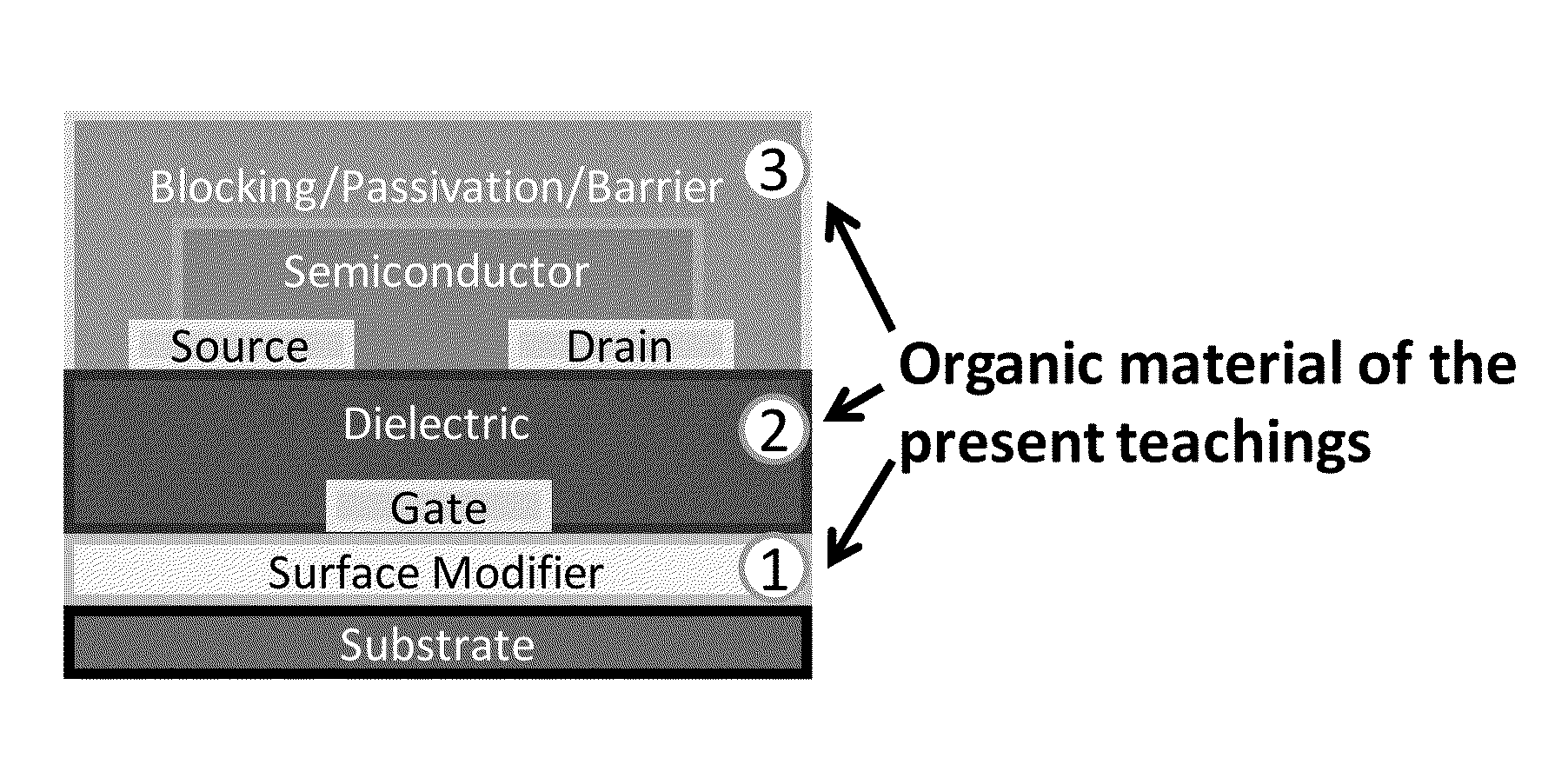

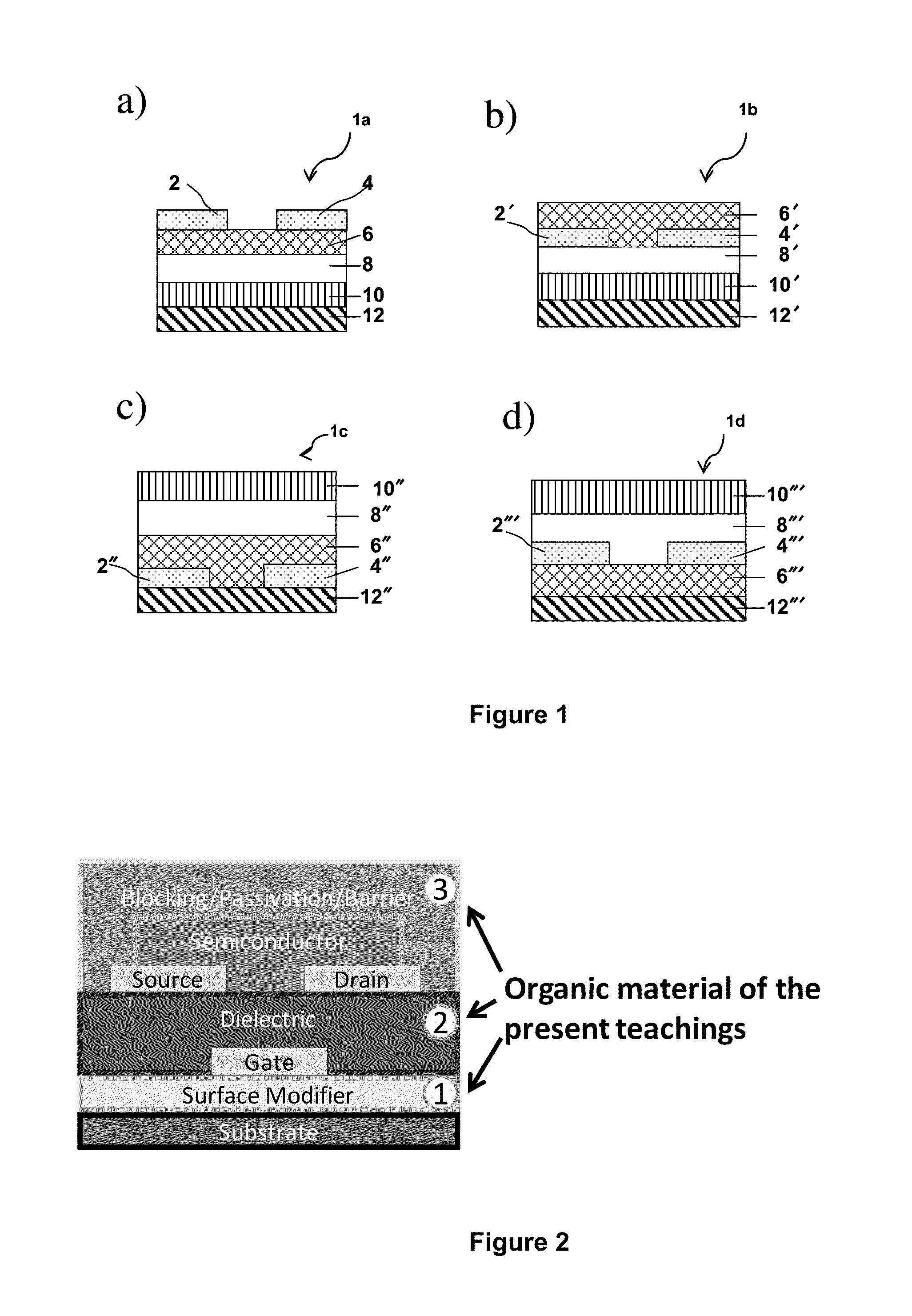

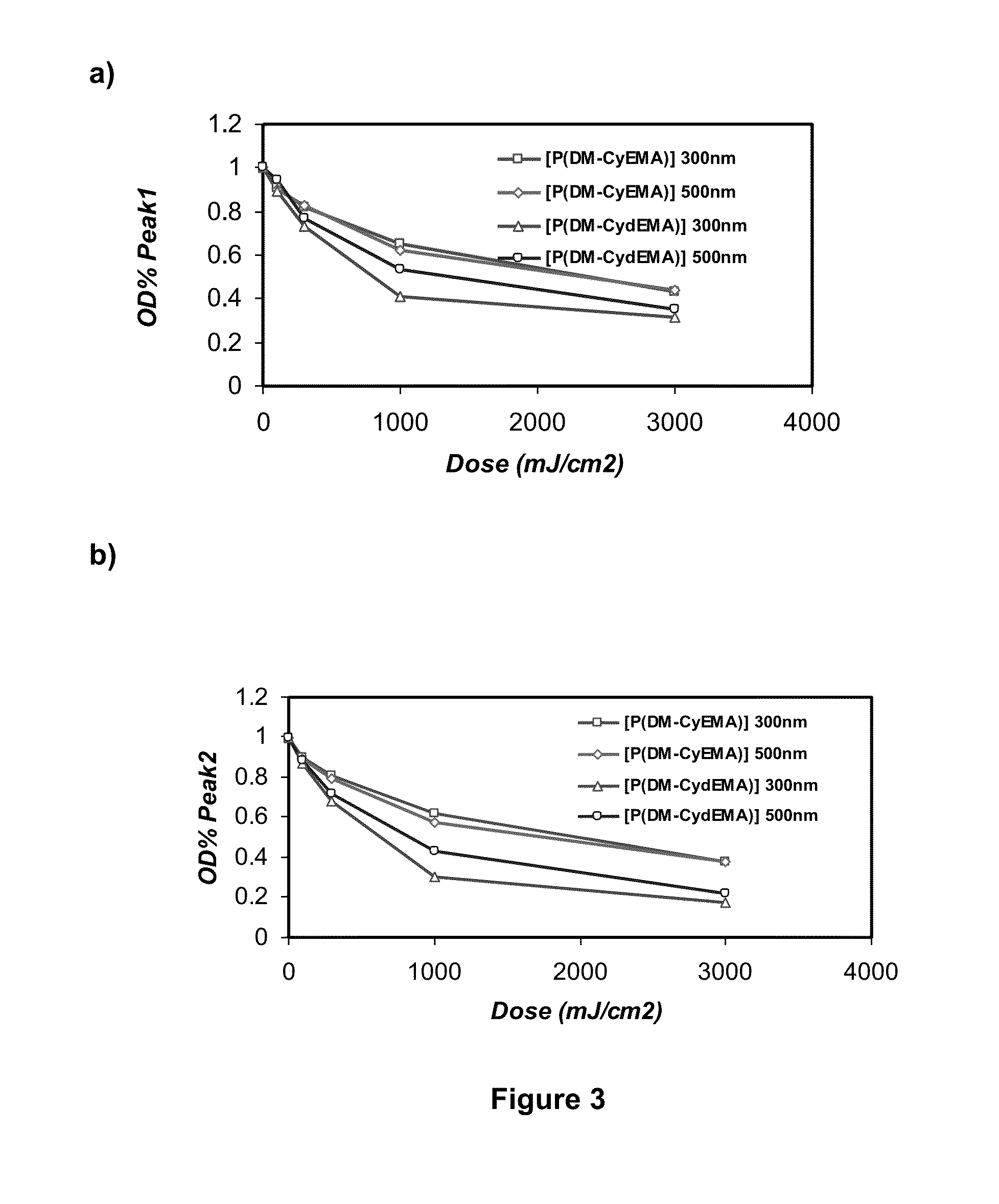

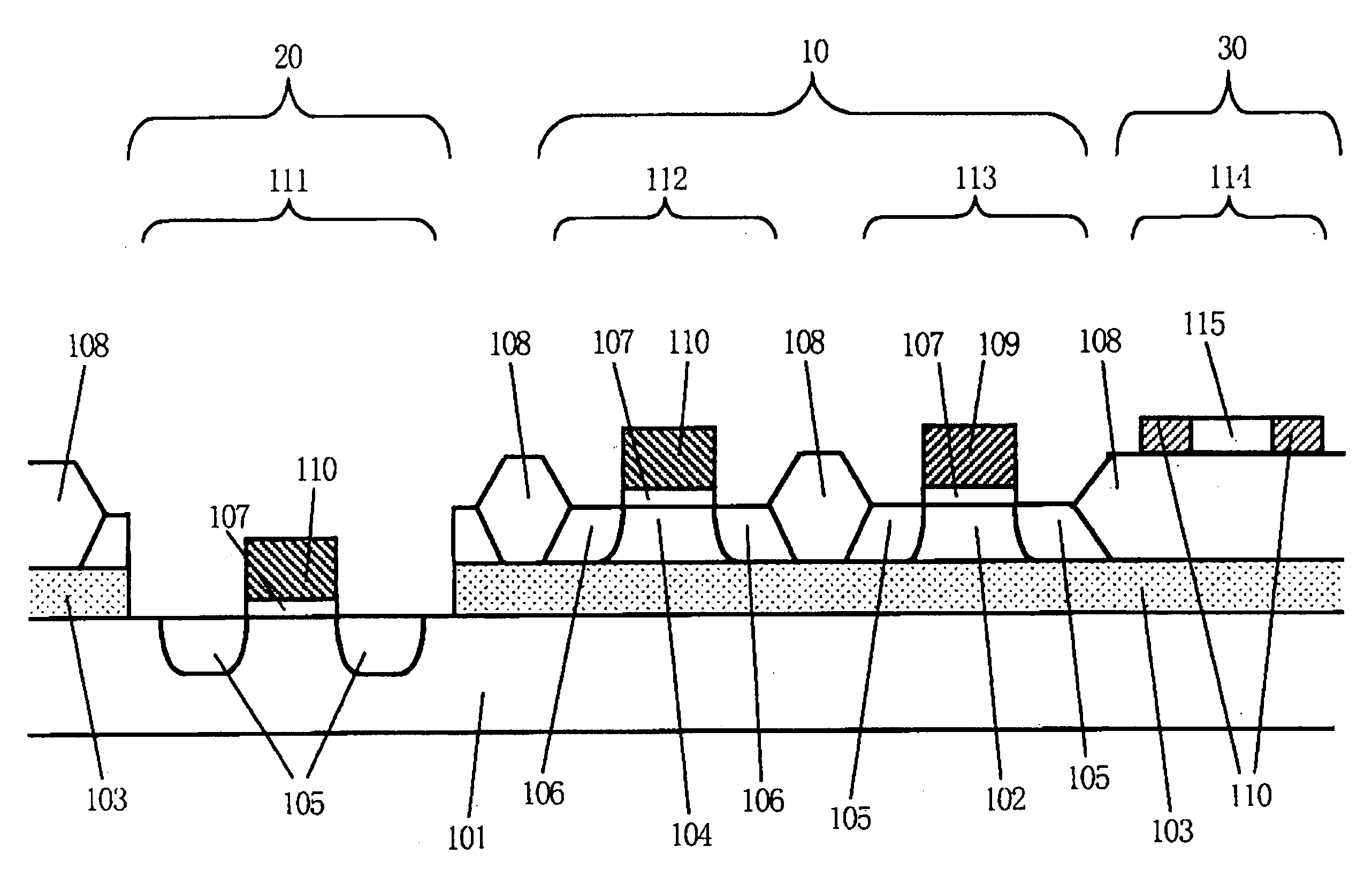

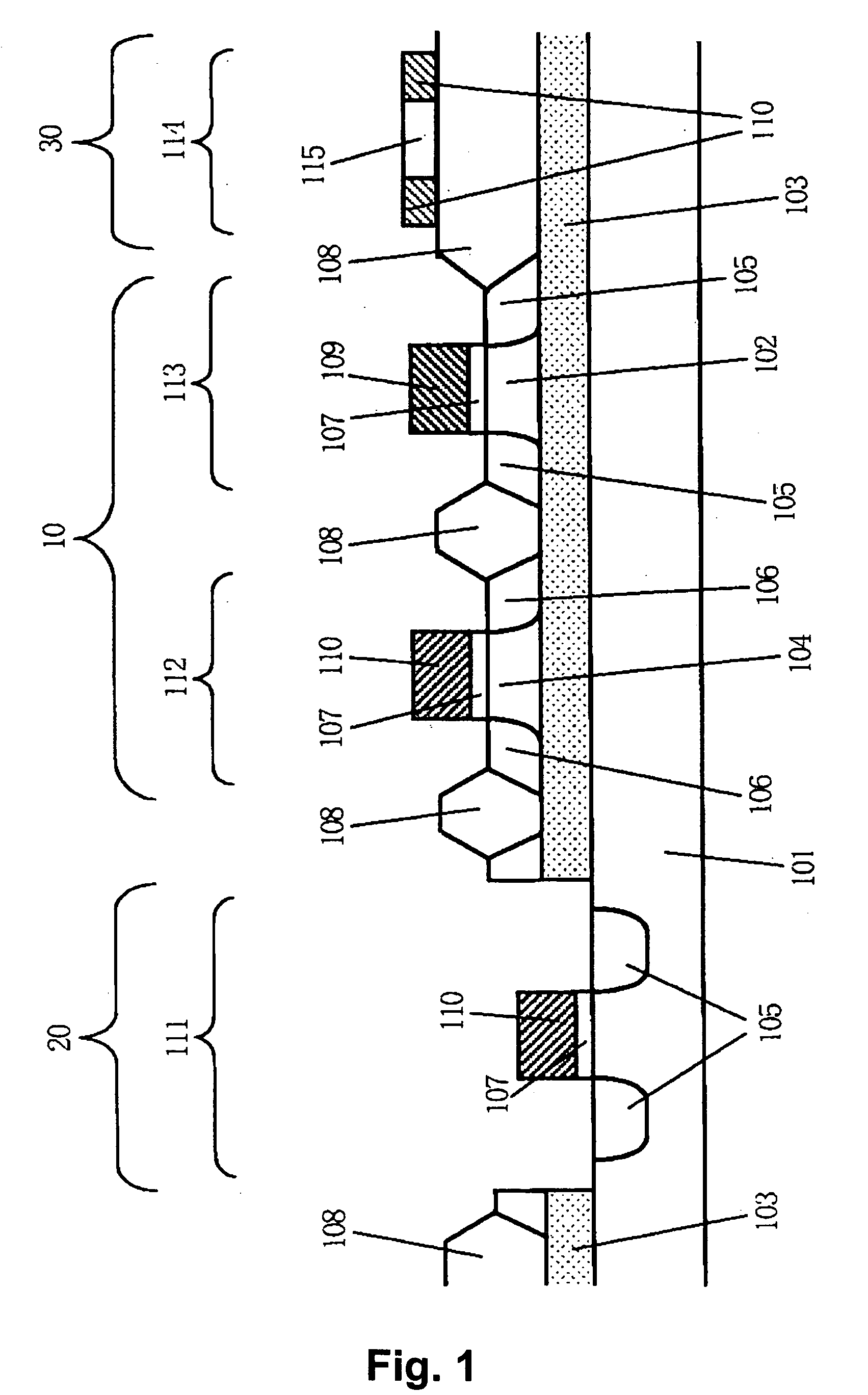

Photocurable Polymeric Materials and Related Electronic Devices

ActiveUS20130200345A1High breakdown strengthIncrease speedSolid-state devicesPhotomechanical apparatusMolecular materialsDielectric layer

Disclosed are photocurable polymers that can be used as active and / or passive organic materials in various electronic, optical, and optoelectronic devices. In some embodiments, the device can include a dielectric layer prepared from such photocurable polymers. In some embodiments, the device can include a passivation layer prepared from the polymers described herein.

Owner:FLEXTERRA INC

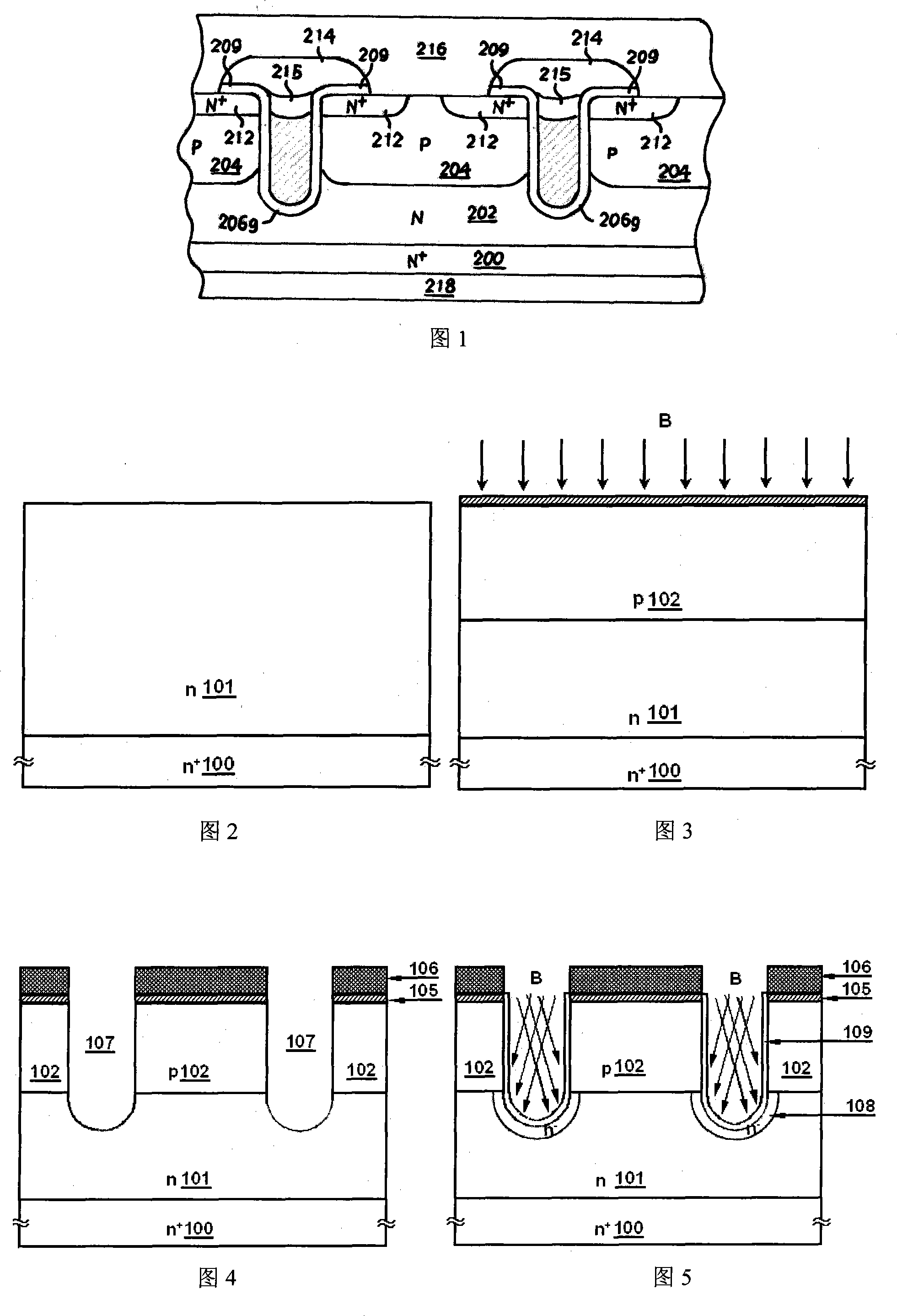

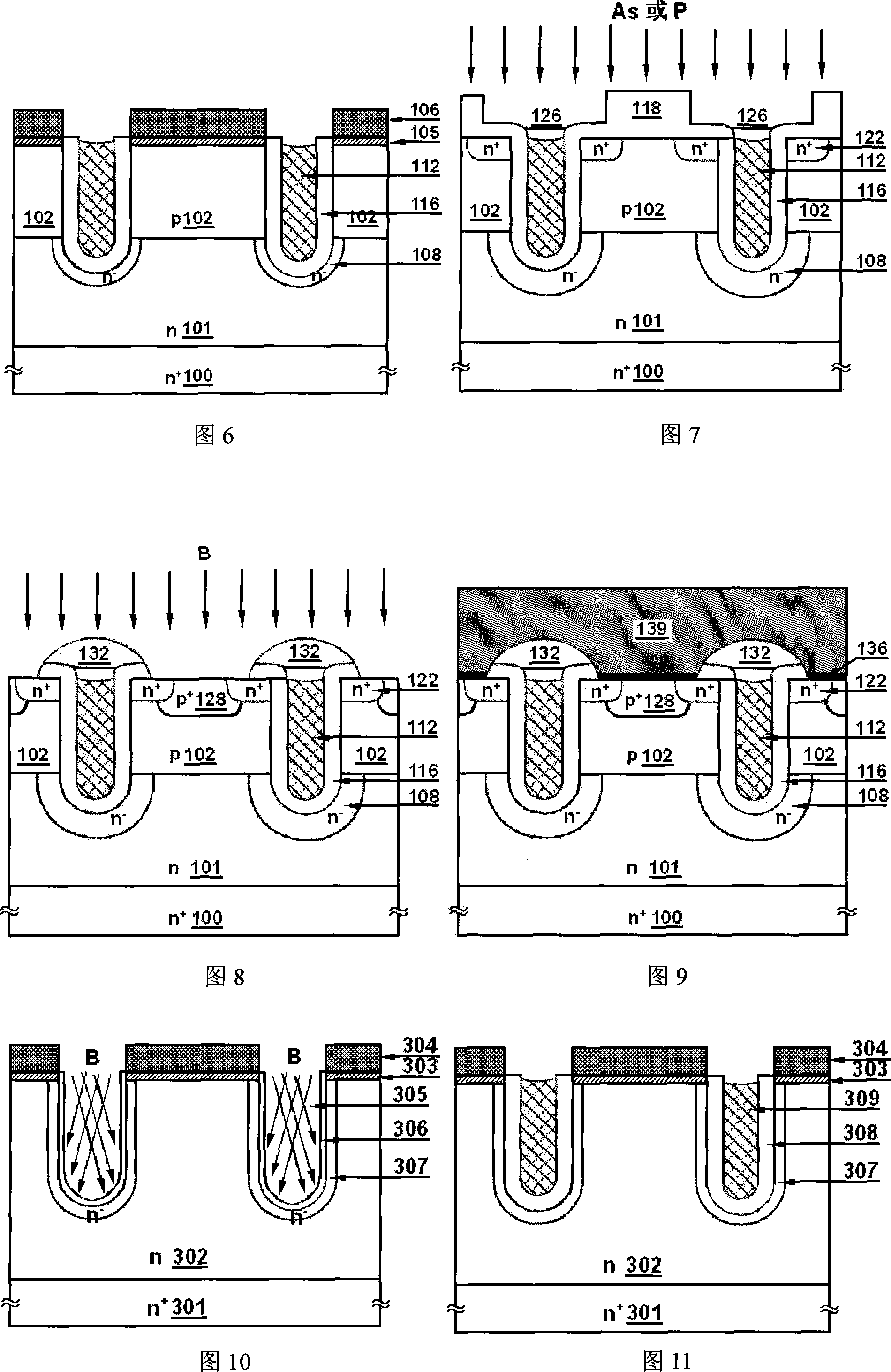

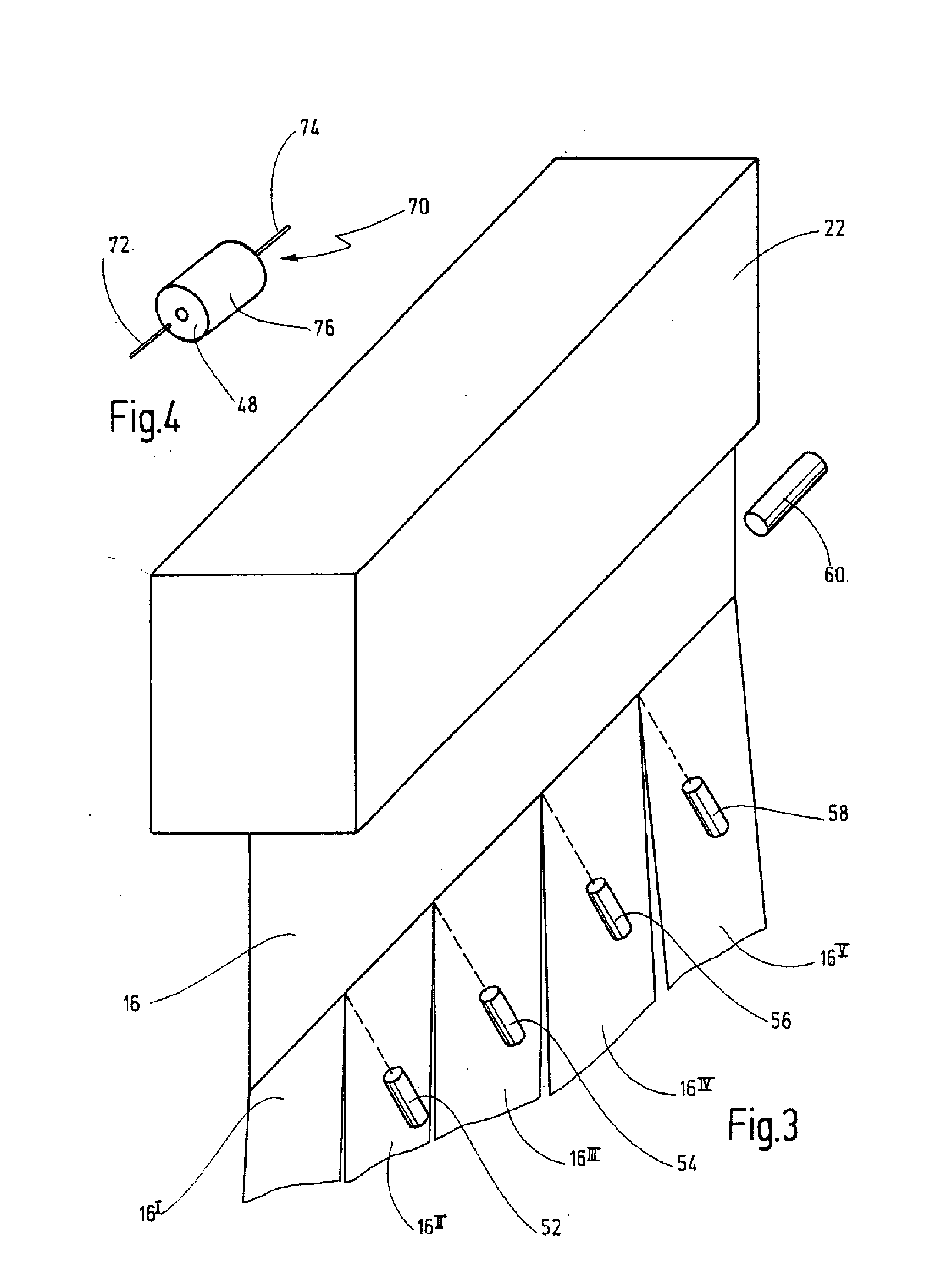

Method for making groove power semiconductor device

InactiveCN101101877AInhibition of channel punch throughReduce electric field strengthSemiconductor/solid-state device manufacturingSemiconductor devicesBreakdown strengthEngineering

The invention is concerned with the manufacture method of the ditch groove power semiconductor device. It is: provides the materials of the basal; forms the first electric transmit epitaxy layer on the basal; forms the second electric transmit zone and the ditch groove inside the epitaxy layer; forms the ebb first electric transmit area and the medium layer with the ditch groove; and then, forms the electric transmit area within the medium layer; forms the first electric transmit source area on the surface of the second electric transmit area; forms the second electric transmit contact area with higher doping PH indicator on the second electric transmit zone surface; forms the passivation layer cap on the top of the ditch groove which must with the medium layer and the electric transmit area; forms the diffusion protecting layer on the surface of the source area and the contact area; finally, forms the structure surface with good electric connection. The invention can control the threshold voltage of the device and improves the breakdown strength of the oxide layer of the device bottom area, and improves its electric connection reliability with no extra cover film printing plate and complex method request.

Owner:HARBIN ENG UNIV

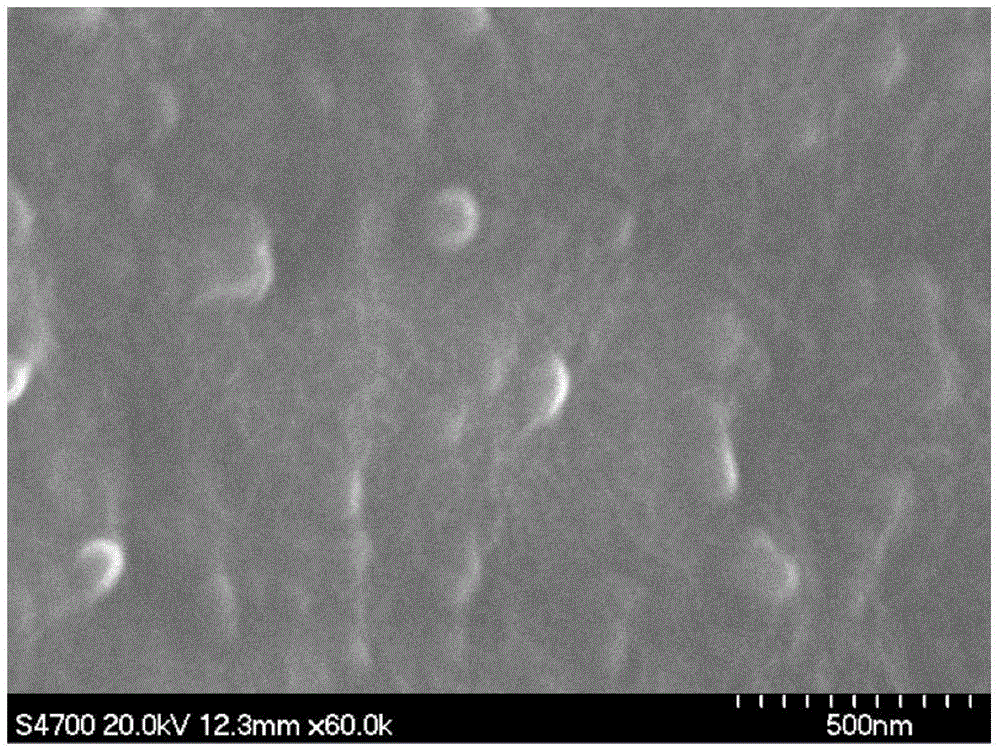

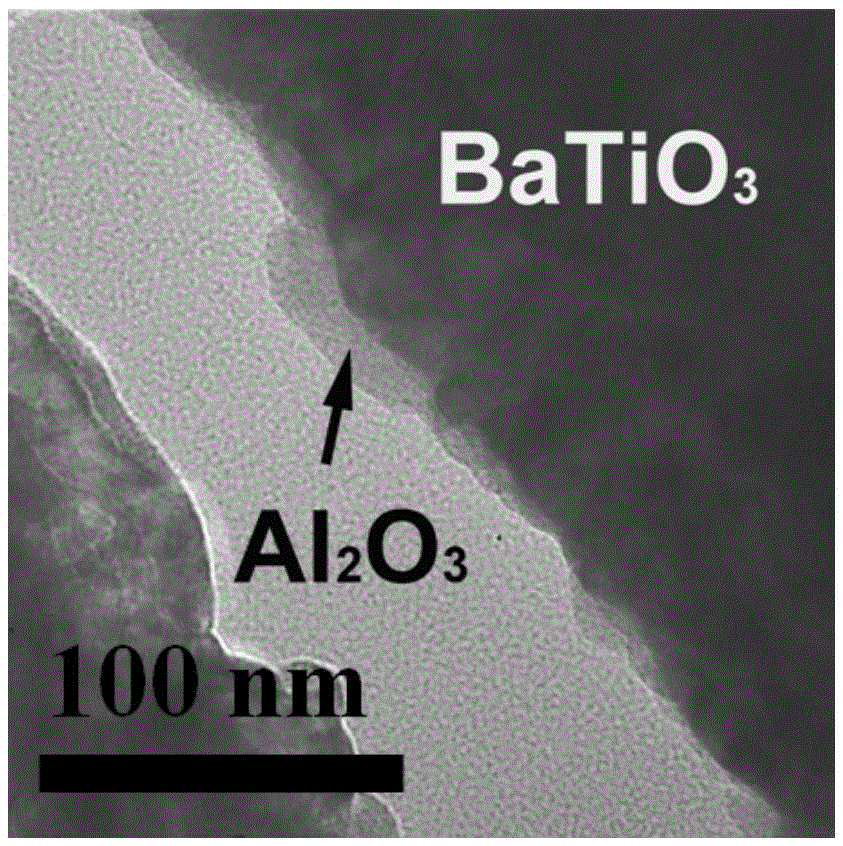

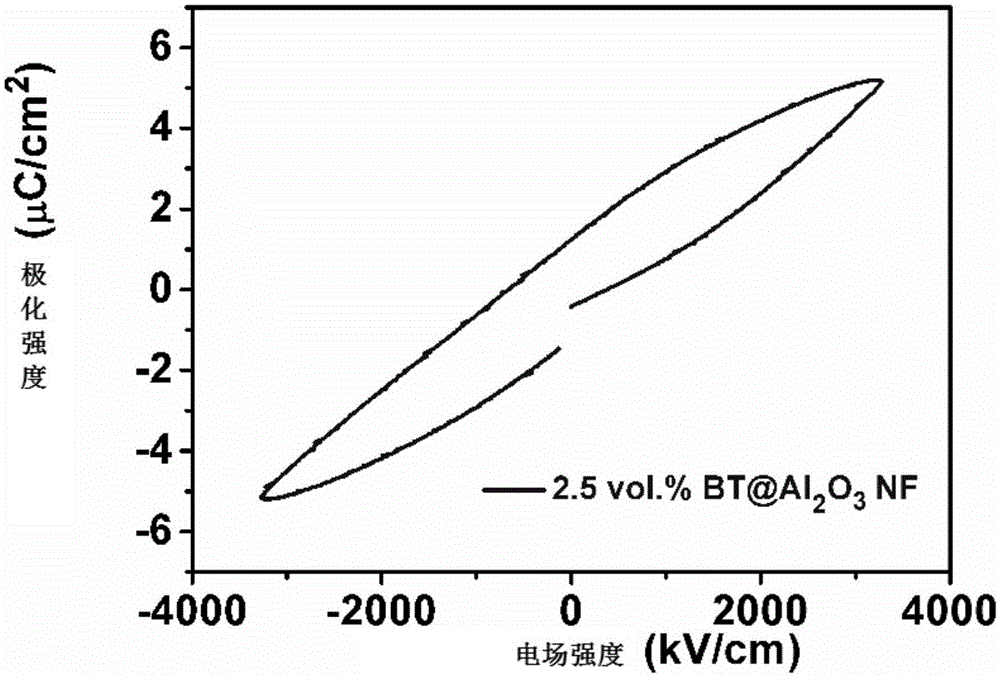

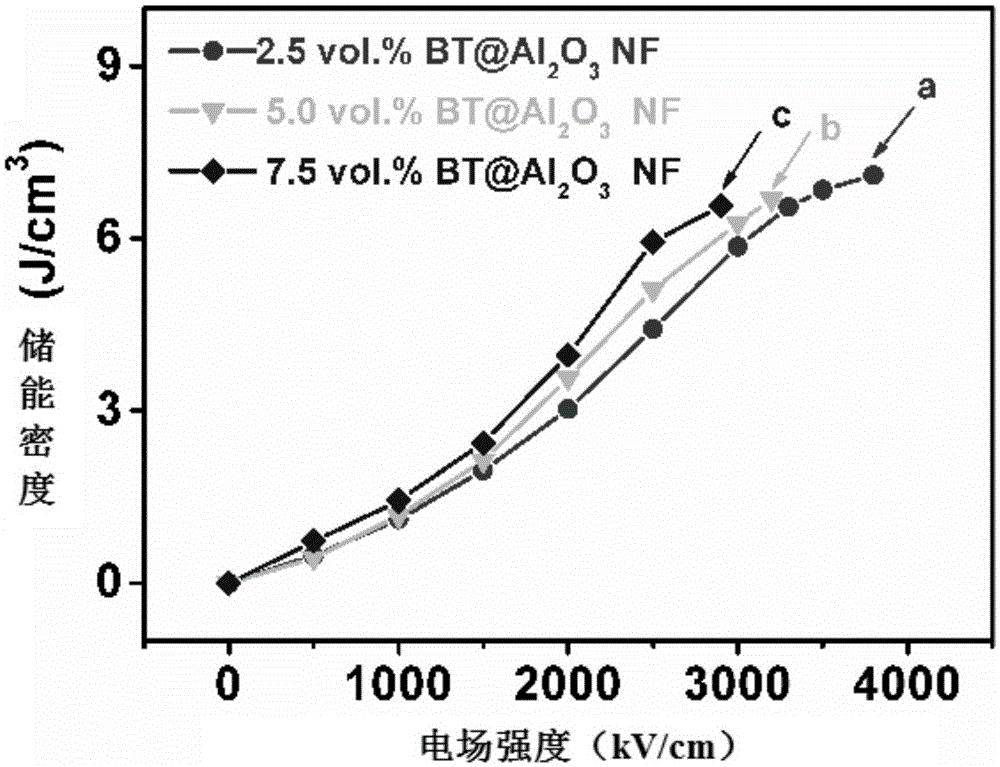

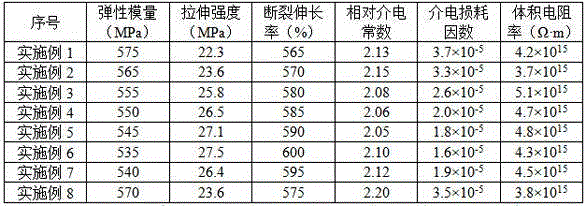

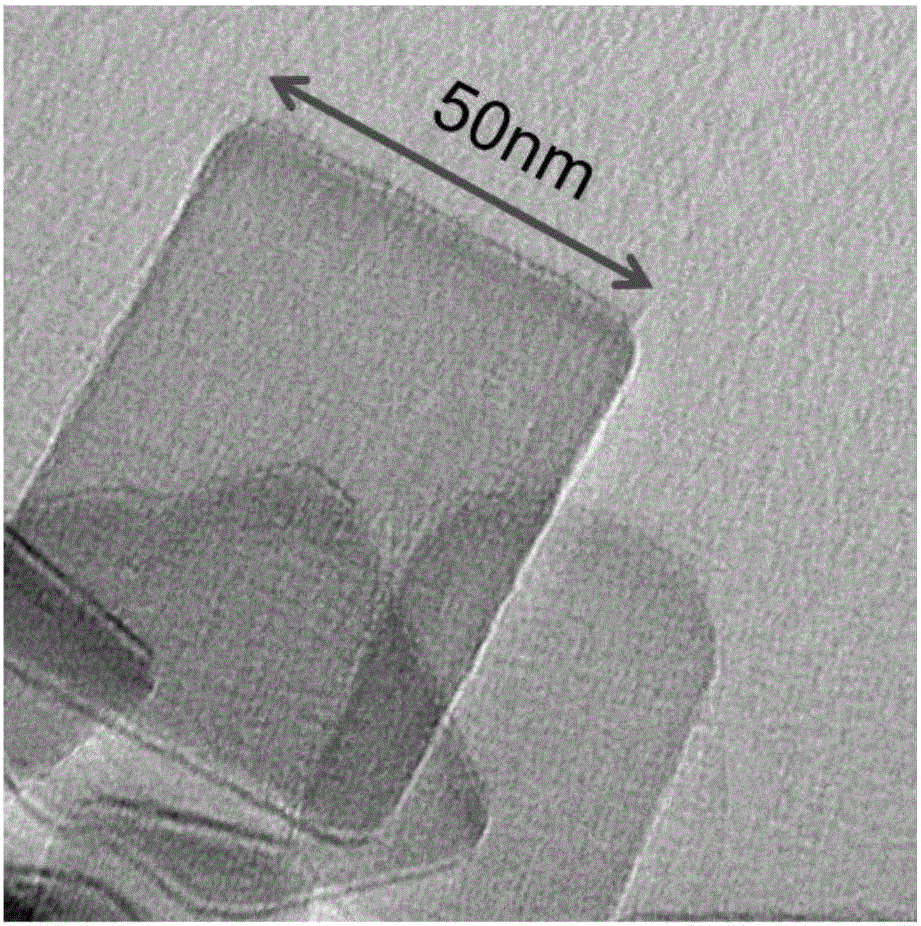

Polymer matrix composite and preparation method thereof

The invention relates to a polymer matrix composite and a preparation method thereof. The composite is a laminated film composed of a polyvinylidene difluoride matrix and a nano-fiber material dispersed in the polyvinylidene difluoride matrix. The nano-fiber material is of a core-shell structure, wherein a core layer is made of a ceramic fiber, and a shell layer is an aluminum oxide coating layer. The polymer matrix composite is prepared through the method comprises the following steps: (1) placing the ceramic fiber in mixed solution of aluminum nitrate, polyvinyl pyrrolidone and ethyl alcohol, and after uniform mixing, obtaining the nano-fiber material through sintering; (2) causing the nano-fiber material to undergo surface modification through a coupling agent, then adding the nano-fiber material into mixture of polyvinylidene difluoride and dimethylformamide, performing uniform mixing, pouring the mixture in a casting film machine to form a film through flow-casting, and performing drying to obtain the laminated film; (4) and causing the laminated film to undergo heating and heat insulation, quenching and drying, and obtaining the polymer matrix laminated film. Compared with the prior art, the polymer matrix composite has the advantages that the laminated film is high in energy density, good in energy storage efficiency, simple in preparation process and low in cost.

Owner:TONGJI UNIV

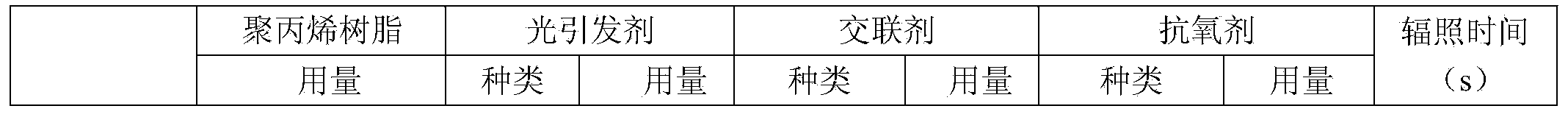

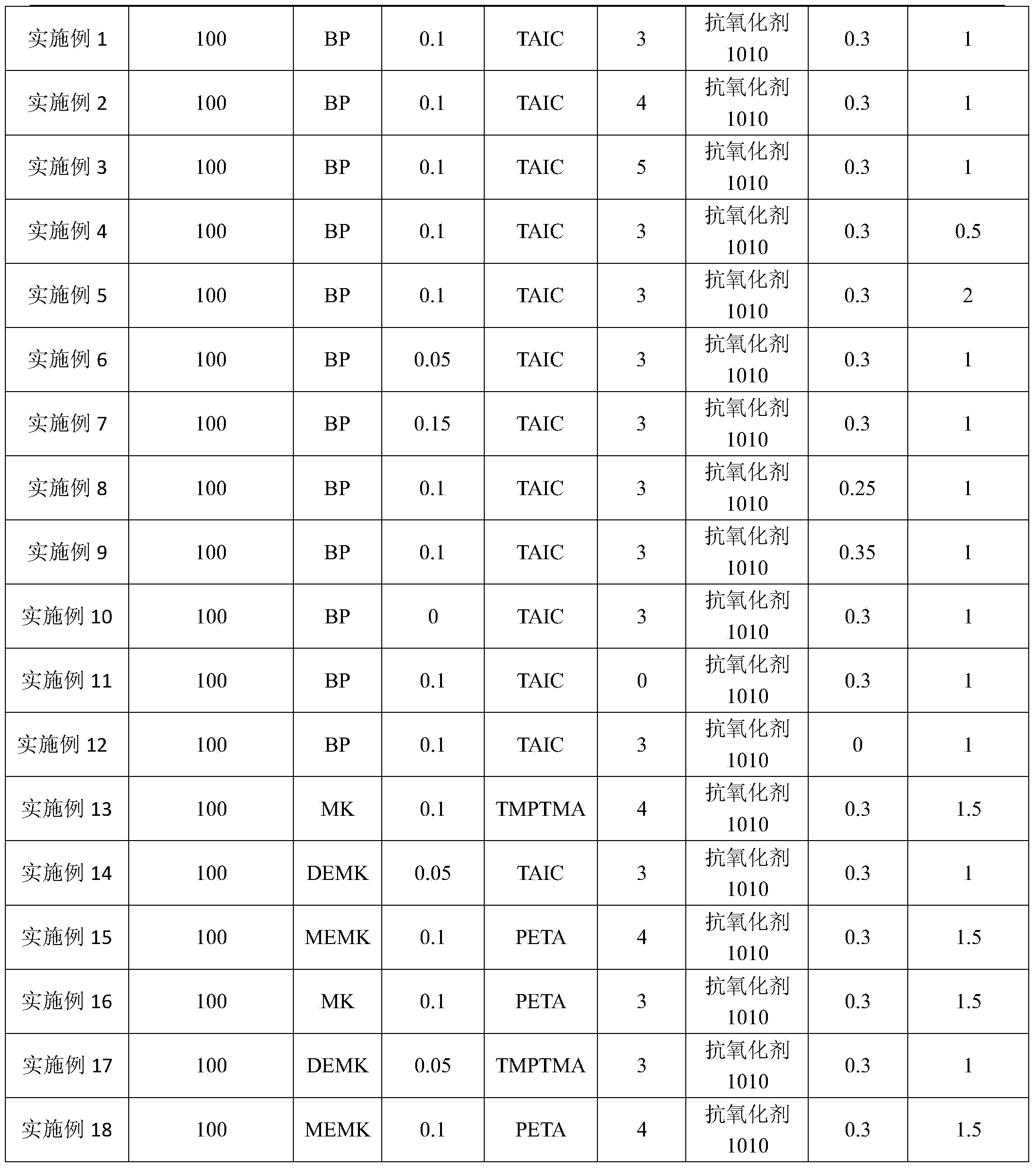

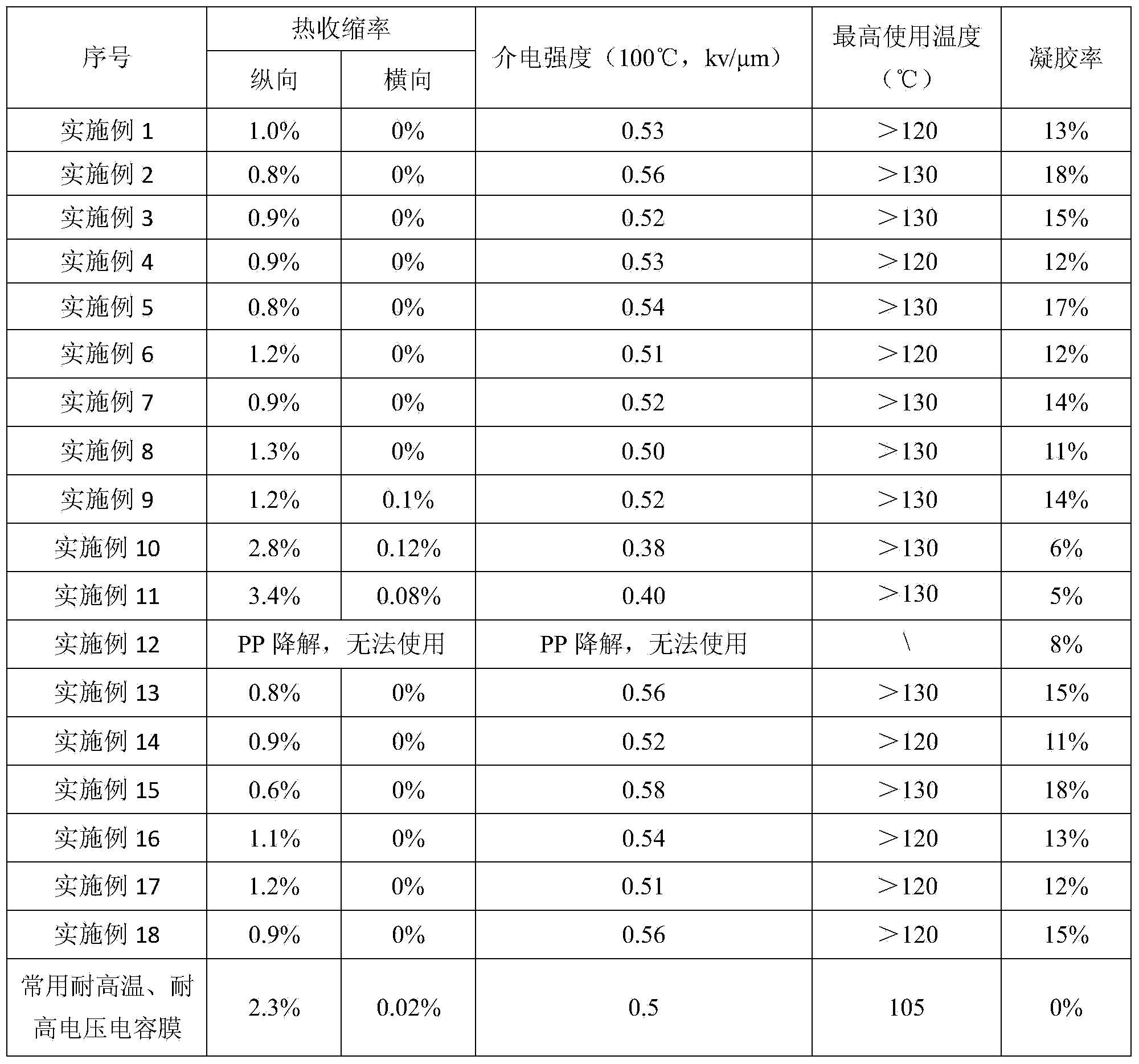

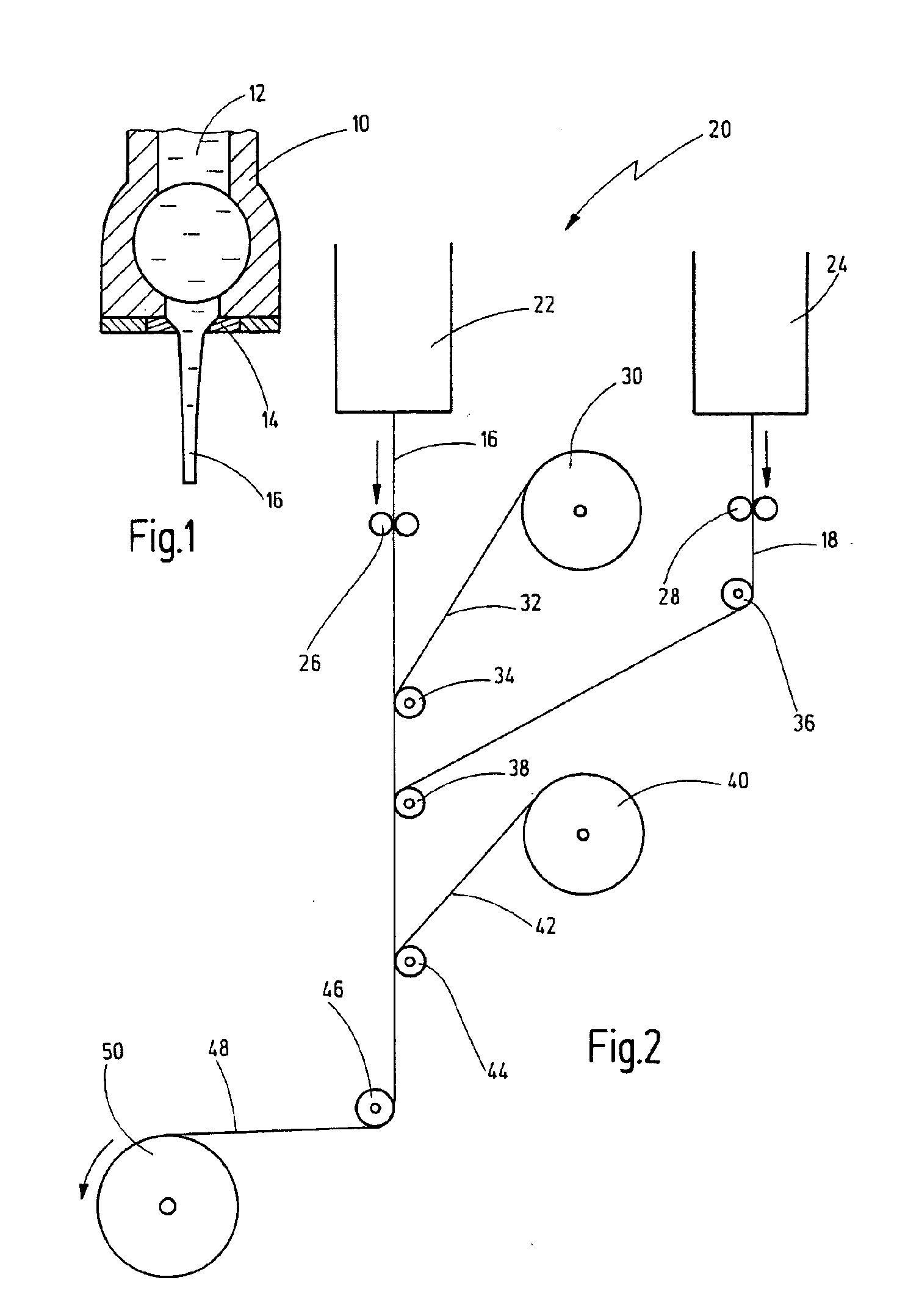

Biaxially-oriented polypropylene capacitance film resisting high temperature and preparation method thereof

ActiveCN103448254AImprove heat resistanceHigh breakdown strengthFlat articlesCapacitanceBreakdown strength

The invention discloses a preparation method of a polypropylene capacitance film. The preparation method comprises the following steps of: (1) preparing a polypropylene material composite from the following components in parts by weight: 100 parts of polypropylene resin, 0.05-0.15 part of a photoinitiator, 3-5 parts of a cross-linking agent and 0.25-0.35 part of a hindered phenol antioxidant; (2) melting, plasticizing and extruding the polypropylene material composite by an extruder; (3) cooling a extruded melt body and casting into a sheet; (4) stretching the cast sheet in two directions into a film by using a bidirectional stretching equipment; (5) performing ultraviolet (UV) irradiation crosslinking on the stretched thin film; and (6) post-treating the irradiated thin film and reeling the thin film in a reeling machine to obtain a finished product. According to the preparation method of the UV crosslinked BOPP (biaxially-oriented polypropylene) capacitance film, the heat resistance and the breakdown strength of the polypropylene capacitance film are remarkably enhanced, the polypropylene capacitance film can meet the development demands of a strong-current capacitor market on advanced insulating thin film materials, and a new path is opened for high performance of the polypropylene capacitance film. Meanwhile the method is simple and easy to realize and has an extremely high industrial application value.

Owner:HUAWEI POLYIMIDE +1

Cellulose/layered boron nitride high-dielectric nano-composite film and preparation method thereof

The invention relates to a cellulose / layered boron nitride high-dielectric nano-composite film and preparation method of the cellulose / layered boron nitride high-dielectric nano-composite film. The cellulose / layered boron nitride high-dielectric nano-composite film has an obvious layered structure and comprises cellulose and boron nitride nanosheet layers uniformly dispersed in the cellulose. Thepreparation comprises the following steps: 1) preparing a boron nitride peeling layer dispersion liquid; 2) preparing a cellulose / boron nitride composite liquid: cooling the boron nitride peeling layer dispersion liquid obtained in the step 1) to below 0 DEG C, adding the cellulose according to the mass ratio of the boron nitride and the cellulose of (5: 95) to (15: 85), rapidly stirring and dissolving, performing centrifugation to remove impurities, thereby obtaining the cellulose / boron nitride composite liquid; 3) carrying out film formation on the prepared cellulose / boron nitride compositeliquid prepared in the step 2) in a coagulation bath to obtain the cellulose / layered boron nitride high-dielectric nano-composite film. The composite material provided by the invention has the layeredstructure and very high dielectric properties and high thermal conductivity (the breakdown voltage reaches 300 to 450 MVm<-1>, and the energy storage density is as high as 4 Jcm<-3> about, the thermal conductivity is about 2Wm<-1>K<-1>), and the cellulose / layered boron nitride high-dielectric nano-composite film has broad application prospects in the field of photovoltaic energy storage materials.

Owner:WUHAN UNIV OF TECH

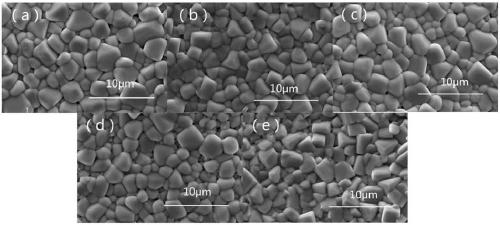

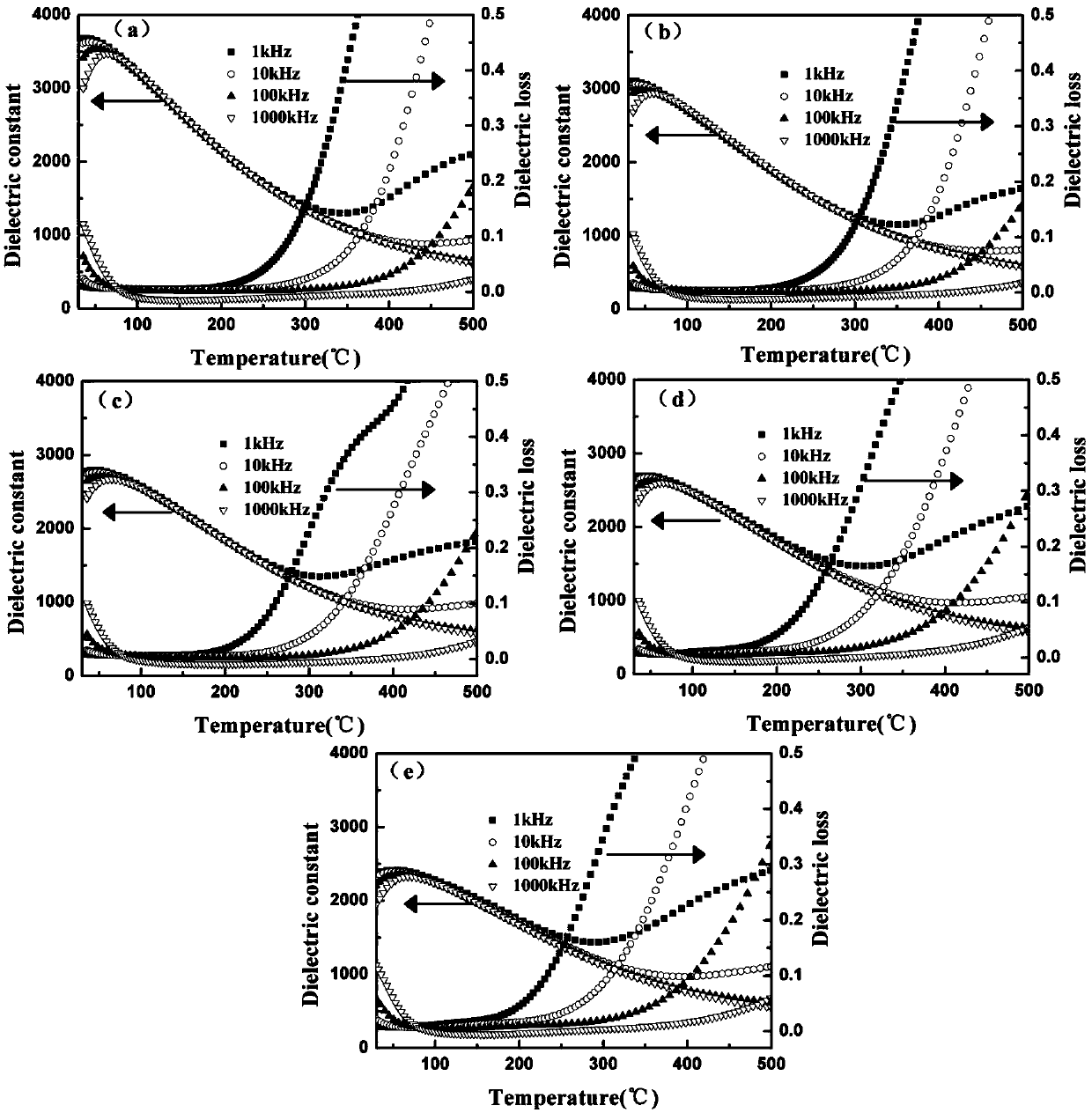

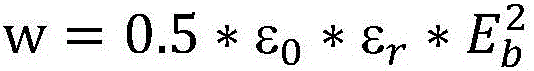

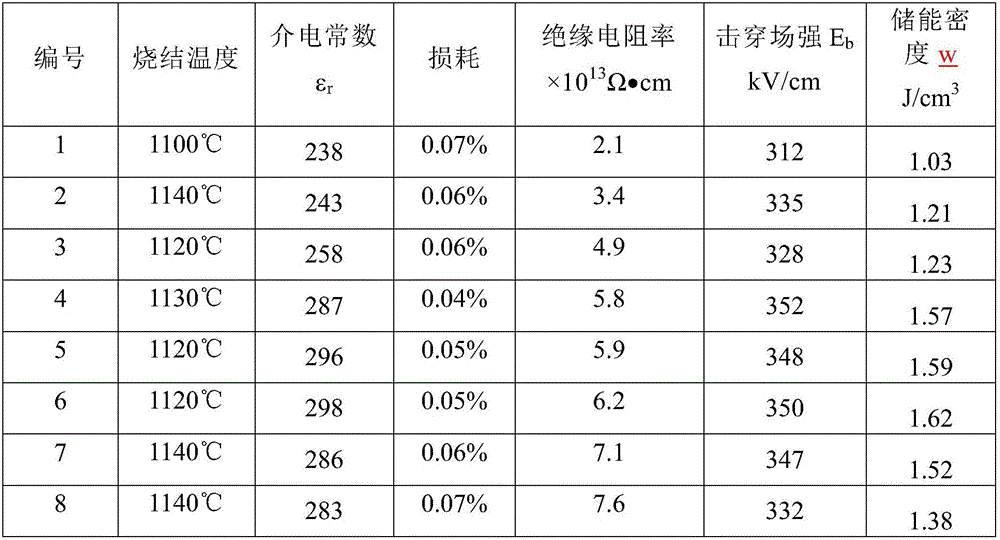

Lead-free high-voltage capacitor dielectric ceramic sintered at medium temperature and preparation method thereof

ActiveCN106631005AHigh dielectric constantHigh breakdown strengthBreakdown strengthHigh voltage capacitors

The invention discloses lead-free high-voltage capacitor dielectric ceramic sintered at medium temperature and a preparation method thereof; the lead-free high-voltage capacitor dielectric ceramic is prepared from, by weight, 100 parts of Sr0.78Ca0.20Ba0.02TiO3, 8-20 parts of Bi2O3.2TiO2, 0.05-0.35 part of MnCO3, 0.05-0.30 part of Co2O3, 0.01-0.08 part of MgTiO3, 0-0.20 part of Al2O3, 0-0.10 PART OF Nb2O5, 0-0.08 part of HfO2, and 1-2 parts of a sintering aid, via the steps of ball milling, drying, grinding and screening. The dielectric constant and insulating resistance of the capacitor dielectric ceramic are adjusted mainly by changing the content of Bi2O3.2TiO2, comprehensive performance of the dielectric ceramic is improved by selecting different doping modifying elements, and the finally prepared dielectric ceramic has high dielectric constant, low loss, high insulating resistance and high breakdown strength. The dielectric ceramic is sintered at medium temperature and free of lead, is suitable for the preparation of high-voltage multilayer ceramic capacitors (MLCC), and has great practical value and market value.

Owner:元六鸿远(苏州)电子科技有限公司

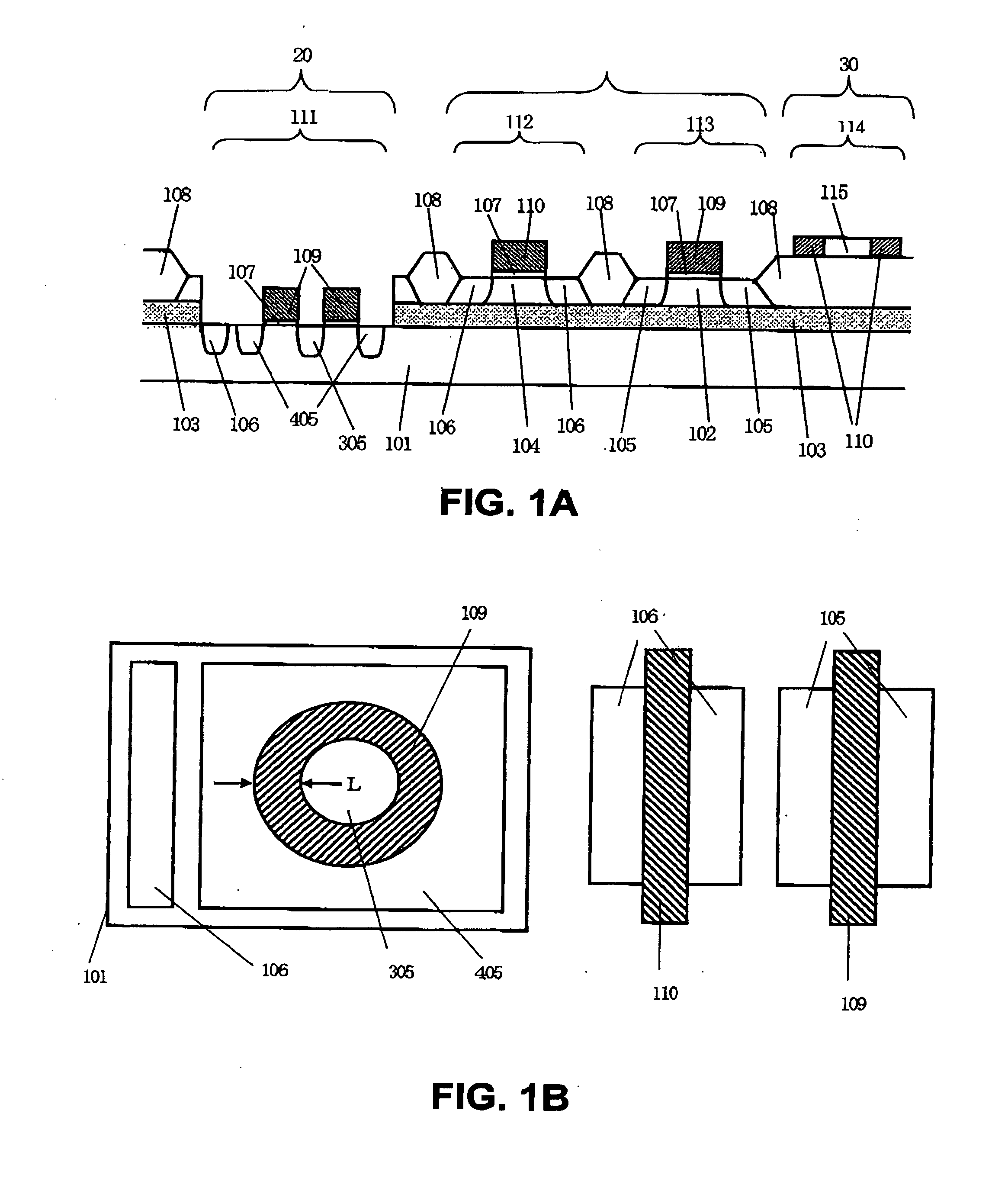

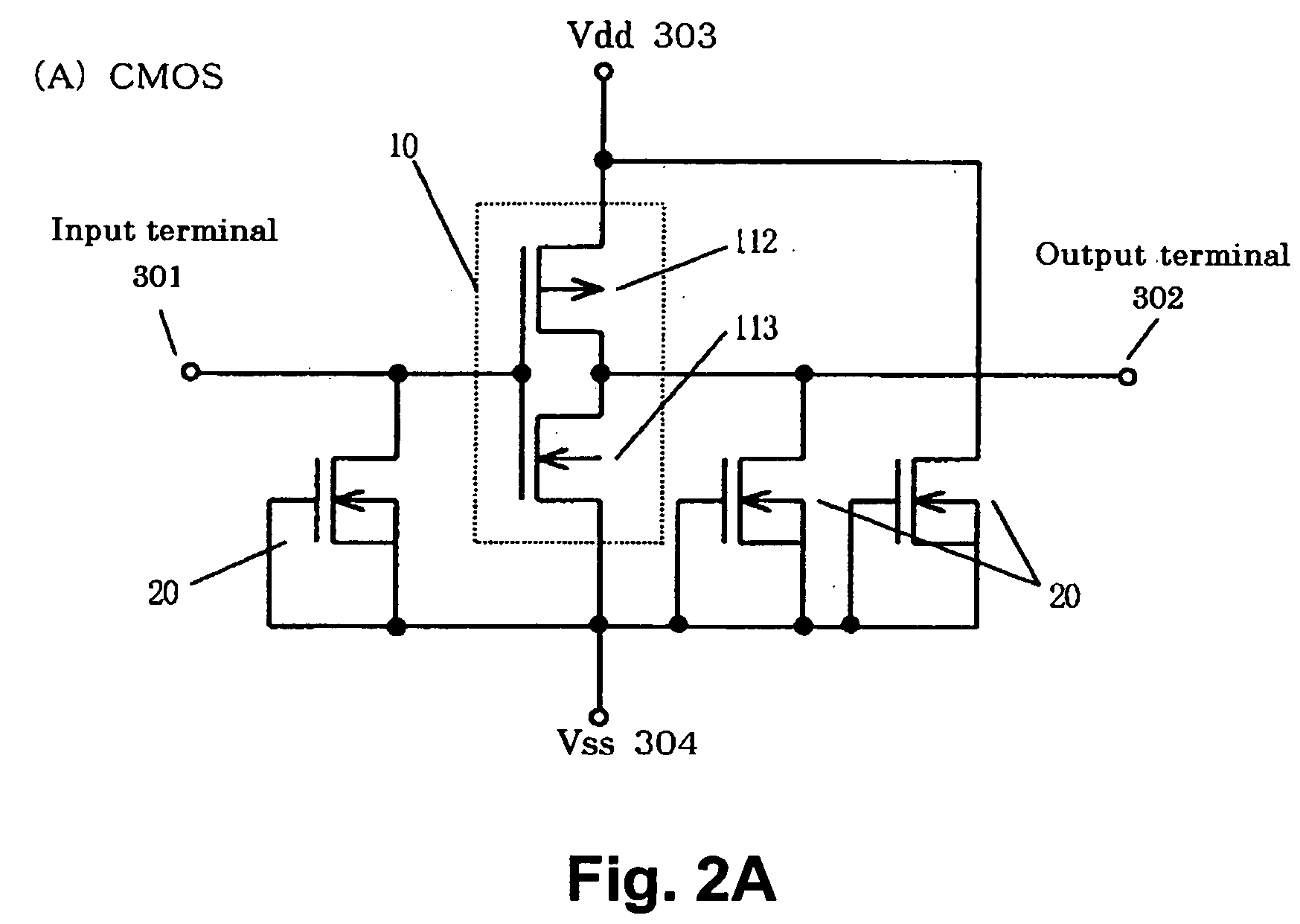

Semiconductor integrated circuit device

InactiveUS20070138558A1High ESD breakdown strengthEasy to controlTransistorSemiconductor/solid-state device detailsBreakdown strengthSoi cmos

In a protection NMOS transistor serving as an ESD input / output protection element formed on a semiconductor support substrate, a drain region of the N-type protection transistor is formed so as to surround the source region, and a minimum distance between the source and the drain is kept constant, which makes it possible to ensure a sufficient ESD breakdown strength and to realize a structure capable of protecting input / output terminal, particularly an output terminal, of the fully depleted SOI CMOS device vulnerable to ESD noise.

Owner:ABLIC INC

Rare earth electrode slurry of rare earth thick film circuit based on metal plate and its preparation technology

ActiveCN1909748AIntermolecular bonding strength and improved manufacturabilitySolid combinationOhmic-resistance electrodesNon-conductive material with dispersed conductive materialSolid phasesYttrium

The invention relates to a rare-earth electrode slurry of rare-earth circuit, based on the metal base board and a relative production, wherein it is characterized in that: said slurry is formed by solid material and organic solvent carrier, while their mass ratio is 70-90:30-10; the solid component comprises: silver, palladium, and yttrium composite power and micro-crystal glass powder, while their mass percentage is 99.4-94:0.6-6; said composite power is formed by silver, palladium, and yttrium powders at the ratio as 0.6-10:99-82:0.4-8; said micro-crystal glass is the one in SiO2-Al2O3-CaO-B2O3-Bi2O3-La2O3 group. And the production comprises: (1), preparing rare-earth micro-crystal glass powder; (2), preparing silver, palladium, and yttrium composite powder; (3), preparing organic solvent carrier; (4), mixing material in three-dimension and rolling with three rollers; (5), preparing the rare-earth slurry; (6), bottling. The invention is environment friendly and better humidity compatibility.

Owner:GUANGDONGSHENG YUCHEN ELECTRONICS & TECH CO LTD

Capacitor and method of making same

ActiveUS20110317329A1High breakdown strengthIncrease energy densityLamination ancillary operationsFixed capacitor dielectricAlkali metal oxideOverflow downdraw method

A capacitor having a dielectric consisting of a glass layer with an alkali metal oxide content of at most 2 wt % and a thickness of at most 50 μm is provided. The capacitor includes at least two metal layers which are separated by the glass layer. The glass layer is preferably produced by a down-draw method or by an overflow down-draw fusion method.

Owner:SCHOTT AG

Special insulating material for electrical equipment and preparation method for special insulating material

InactiveCN105348739AGood compatibilityGood dispersionPlastic/resin/waxes insulatorsEpoxyPower equipment

The invention discloses a special insulating material for electrical equipment and a preparation method for the special insulating material. The special insulating material for the electrical equipment comprises the following components in parts by weight: 90-100 parts of epoxy resin, 15-25 parts of methyl vinyl silicone rubber, 20-25 parts of fluorosilicon resin, 15-20 parts of polytetrafluoroethylene, 10-15 parts of glass fiber, 15-20 parts of nano inorganic powders, 0.2-1 part of butyl titanate, 20-40 parts of distilled water, 1-6 parts of a compatilizer, 1-5 parts of a flame retardant, 0.3-1.2 parts of an antioxidant and 1-10 parts of a crosslinking agent. The special insulating material for the electrical equipment prepared by the invention can inhibit the space charge accumulation in the cable insulating material, improve the anti-aging property, the anti-flashover property and the anti-acidic and alkaline water-resistent property of the material, has good mechanical properties, electrical property and thermal property, and is excellent in comprehensive properties.

Owner:国网河南唐河县供电公司

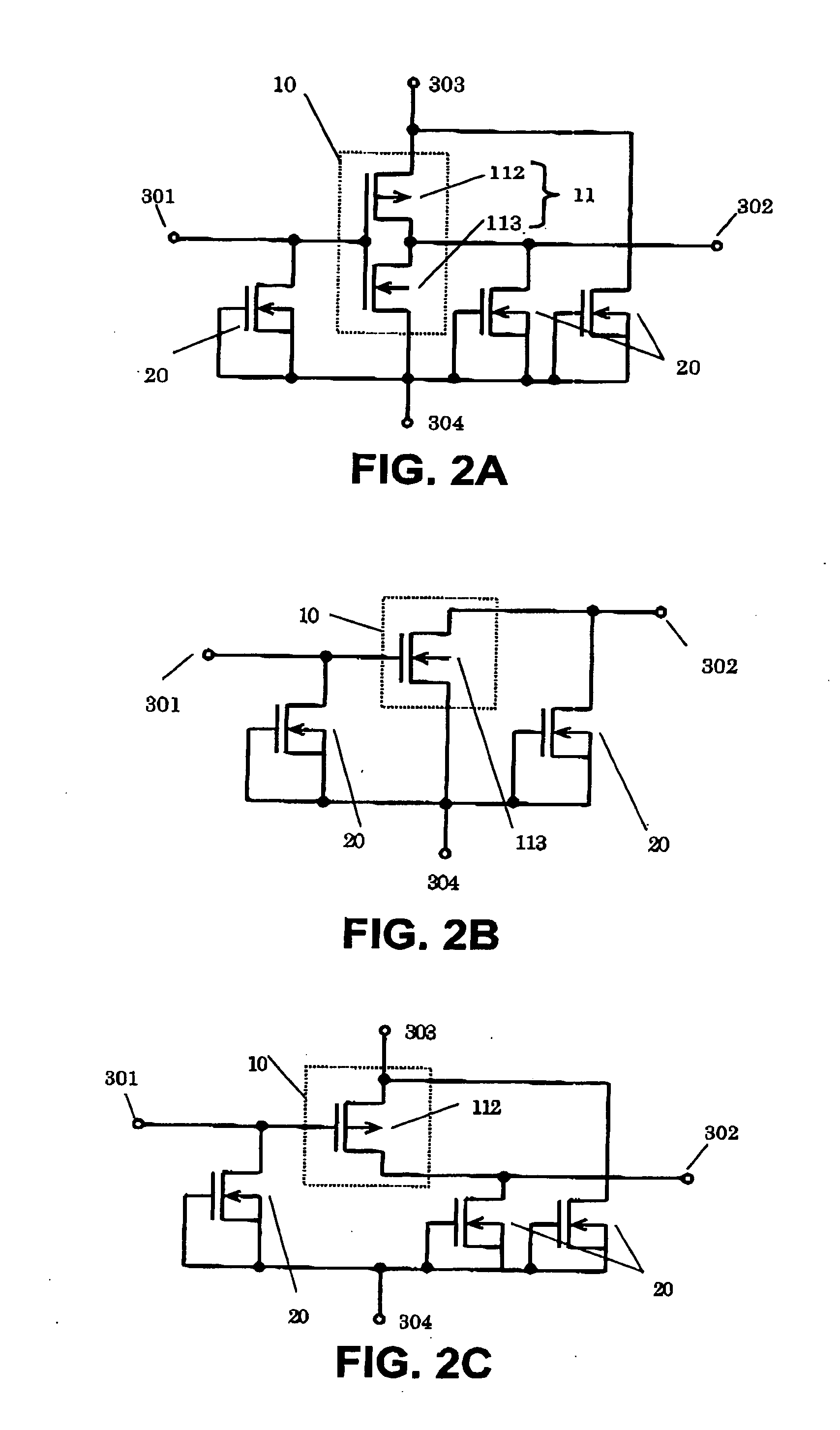

Semiconductor integrated circuit device

InactiveUS20060022274A1Reduce leakage currentReduction of gate lengthTransistorSemiconductor/solid-state device detailsCMOSBreakdown strength

Provided is a structure in which a gate electrode of an MMOS transistor of a fully depleted SOT CMOS circuit formed on a semiconductor thin film has an N-type conductivity, while a gate electrode of an protection NMOS transistor as an ESD input / output protection element formed on a semiconductor support substrate has a P-type conductivity, making it possible to protect input / output terminals, especially, an output terminal of a fully depleted SOI CMOS device, which is weak against ESD noise, while ensuring a sufficient ESD breakdown strength.

Owner:SEIKO INSTR INC

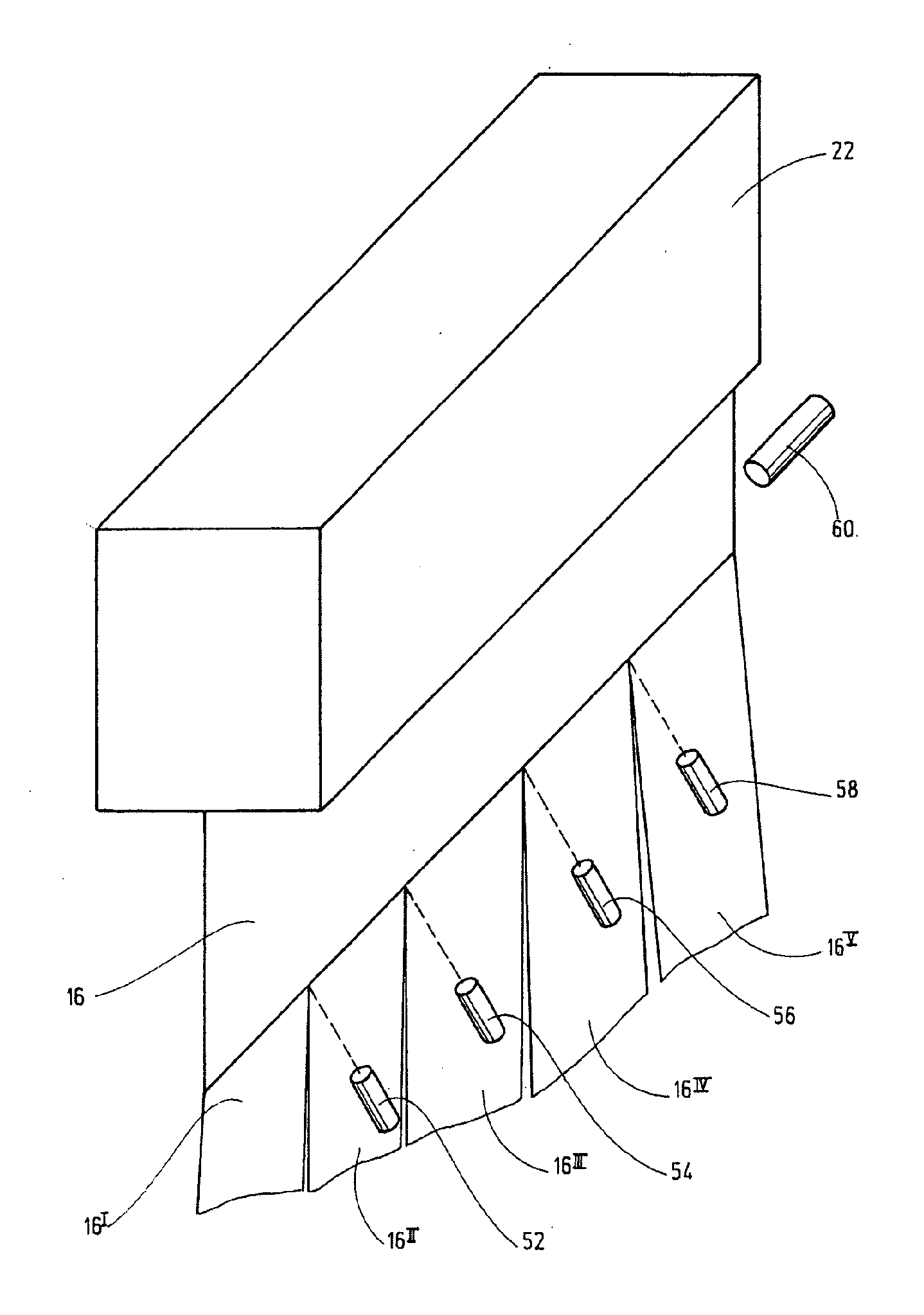

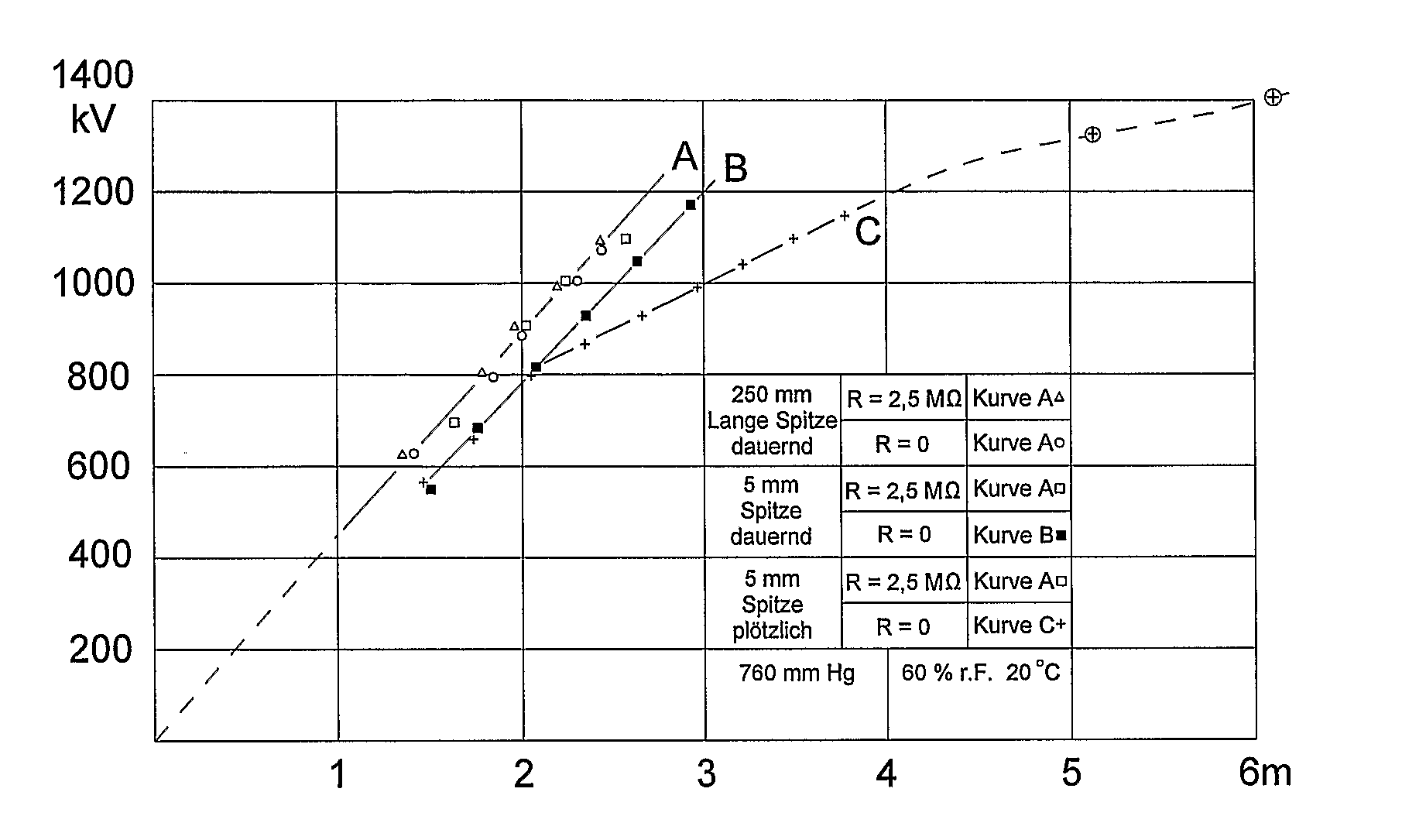

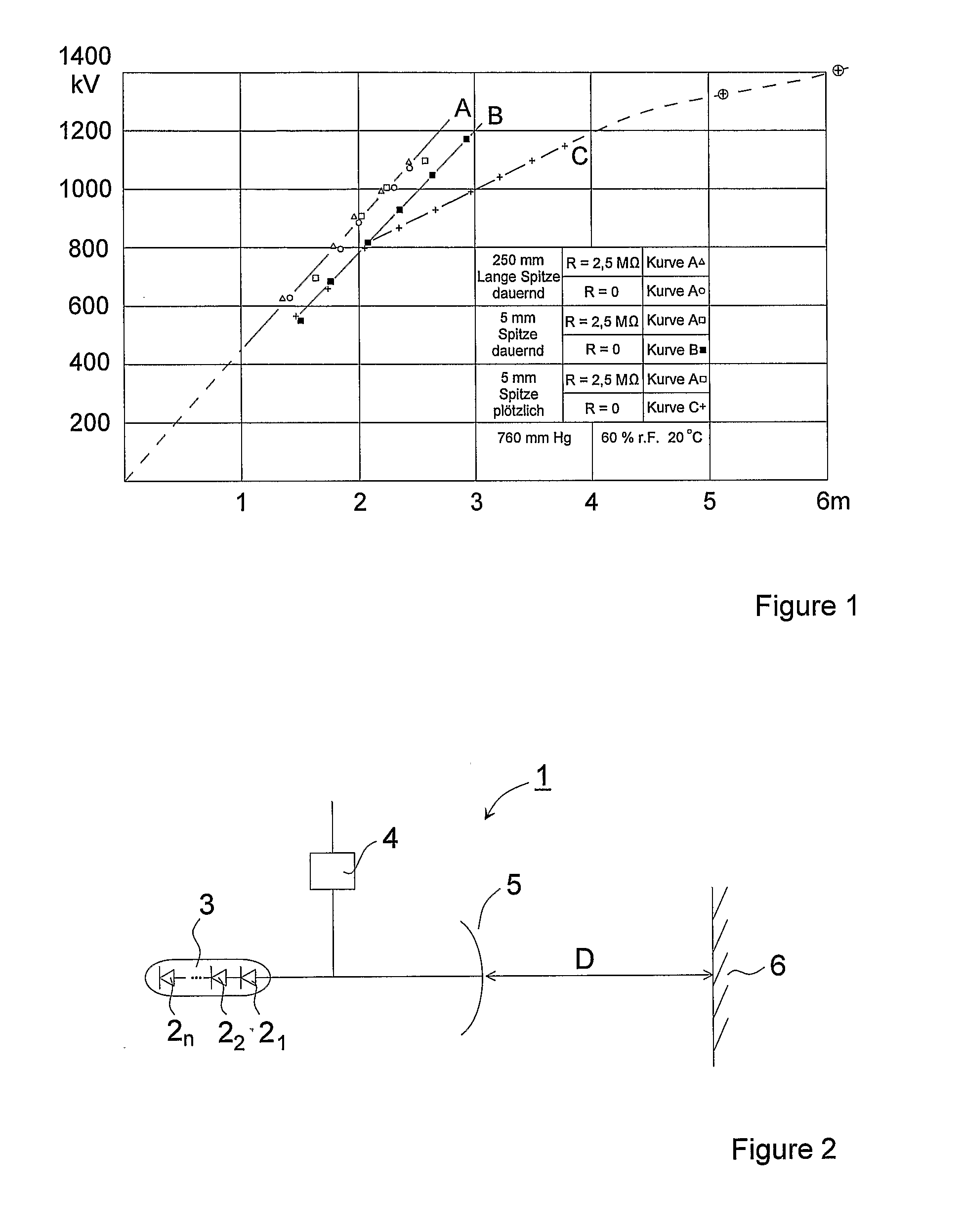

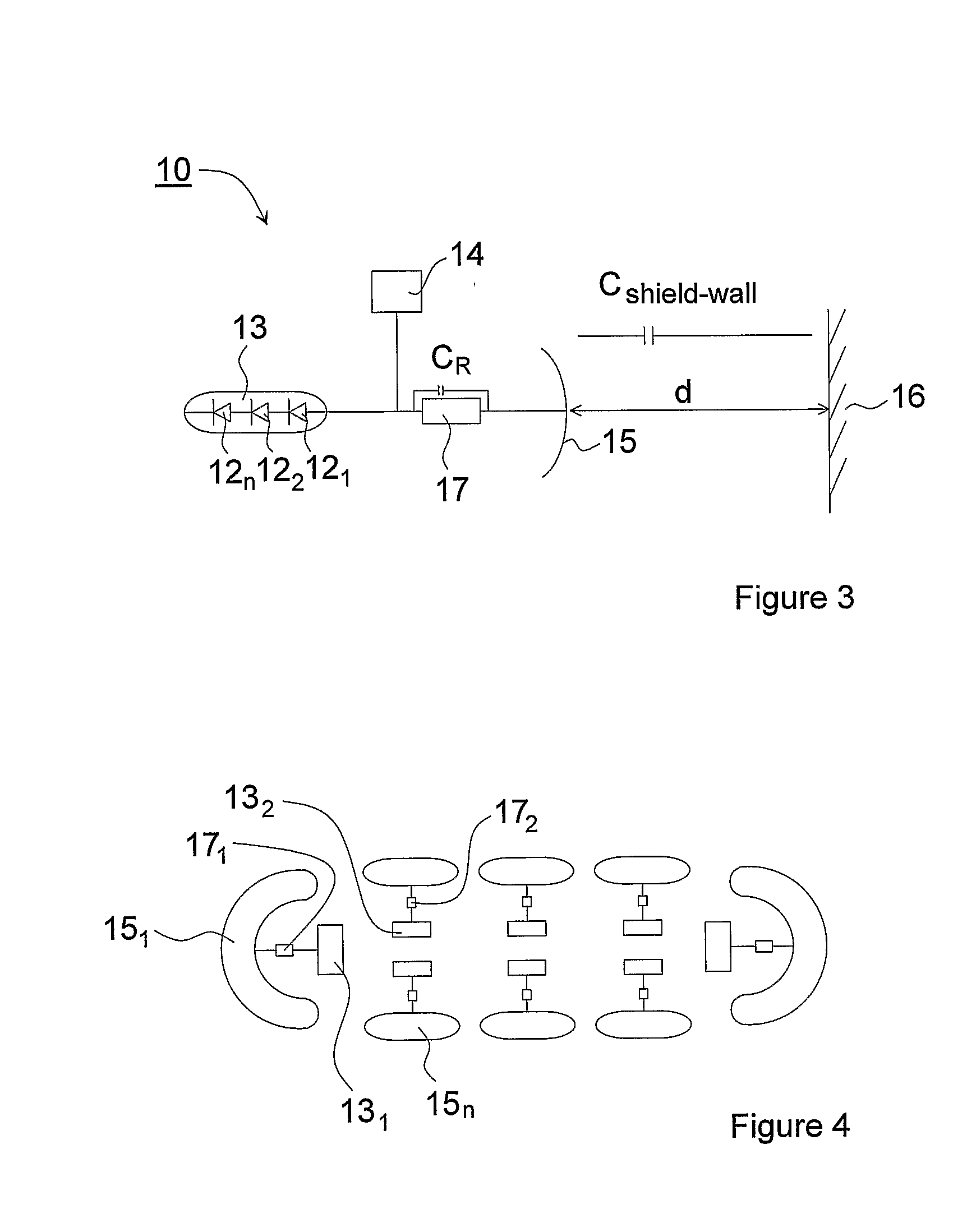

High voltage valve group with increased breakdown strength

InactiveUS20090266605A1Improved high voltage structureImprove securityOverhead installationElectric power transfer ac networkBreakdown strengthEngineering

A high voltage assembly including a valve group and a shield connected to the valve group. A resistor is connected between the shield and the valve group The assembly provides an increased breakdown strength and DC withstand level.

Owner:ABB POWER GRIDS SWITZERLAND AG +1

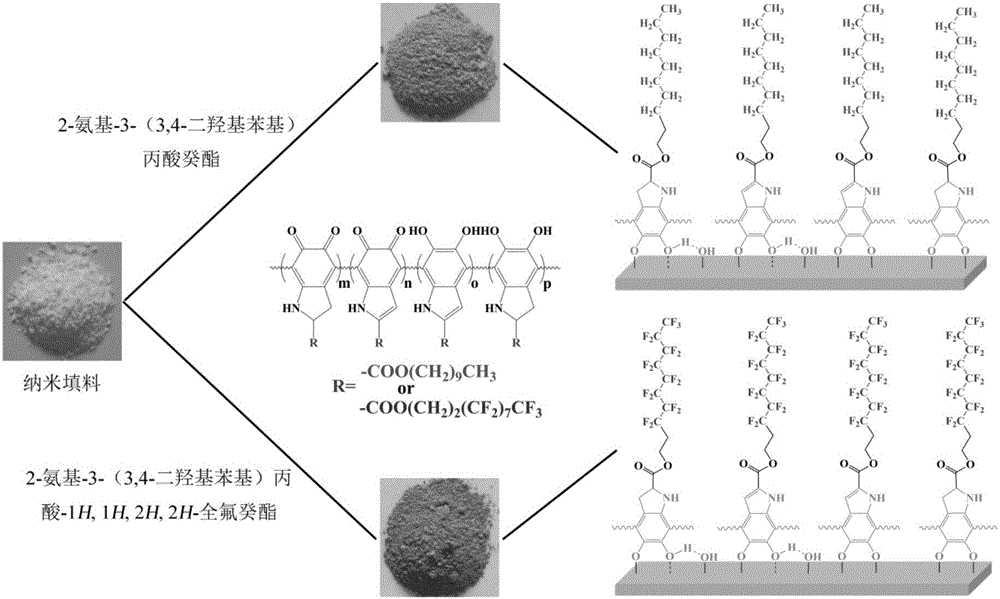

High-energy density polymer composite dielectric and preparation method thereof

The invention discloses a high-energy density polymer composite dielectric and a preparation method thereof. The composite dielectric comprises, by mass, 55-97.5% of a fluorine-containing ferroelectric polymer matrix and 45-2.5% of a dopamine modified high-dielectric constant nanofiller. The preparation method comprises solution blending, film casting and hot press molding. High-dielectric constant nanoparticles are grafted and modified with dopamine having a long chain structure, and the dopamine having a long chain structure improves the dispersion of the high-dielectric constant nanoparticles, has good compatibility with the fluorine-containing ferroelectric polymer matrix and enhances the interface combination force between the polymer matrix and the high-dielectric constant nanoparticle filler. The high-energy density polymer composite dielectric prepared in the invention has the characteristics of light weight, good flexibility and high energy density, and is suitable for producing high-energy density capacitors, embedded capacitors, field effect transistors and other advanced electronic and electric devices.

Owner:SHANGHAI JIAO TONG UNIV

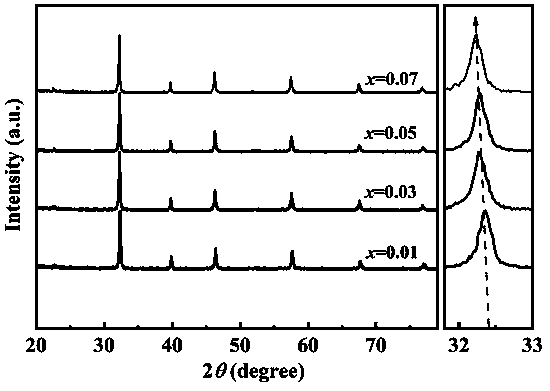

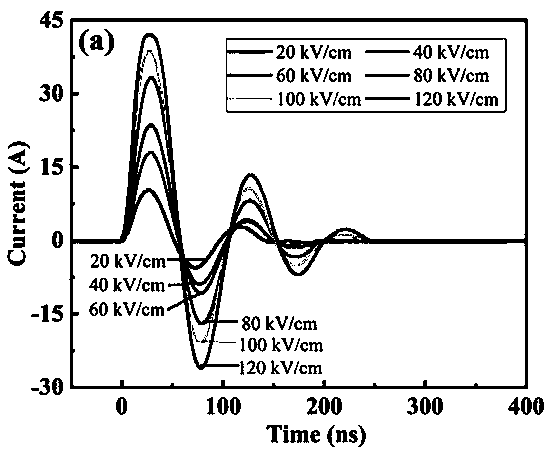

Sn-doped high-entropy perovskite oxide ceramic material with high power density, and preparation method thereof

ActiveCN111039672AHigh breakdown strengthGrowth inhibitionFixed capacitor dielectricOxide ceramicFree energies

The invention discloses a Sn-doped high-entropy perovskite oxide ceramic material with high power density. The preparation method of the material comprises the following steps: taking Na2CO3, Bi2O3, BaCO3, SrCO3, CaCO3, TiO2 and SnO2 as raw materials according to a chemical formula (Na0.2Bi0.2Ba0.2Sr0.2Ca0.2)Ti[1-x]Sn[x]O3, carrying out wet ball-milling mixing on the powder, pre-firing the dried powder at 900 DEG C for 2 hours, carrying out secondary ball-milling, sieving and molding, and finally sintering at 1250 DEG C for 2 hours to obtain the single-phase high-entropy perovskite oxide ceramic material. According to the invention, the high-entropy ceramic material prepared by the invention is simple in preparation process and low in manufacturing cost, the discharge energy storage density can reach 1.74 J / cm<3> and the power density can reach 51.4 MW / cm<3> by selecting a proper x value, and a new lead-free energy storage material matrix is provided.

Owner:SHAANXI UNIV OF SCI & TECH

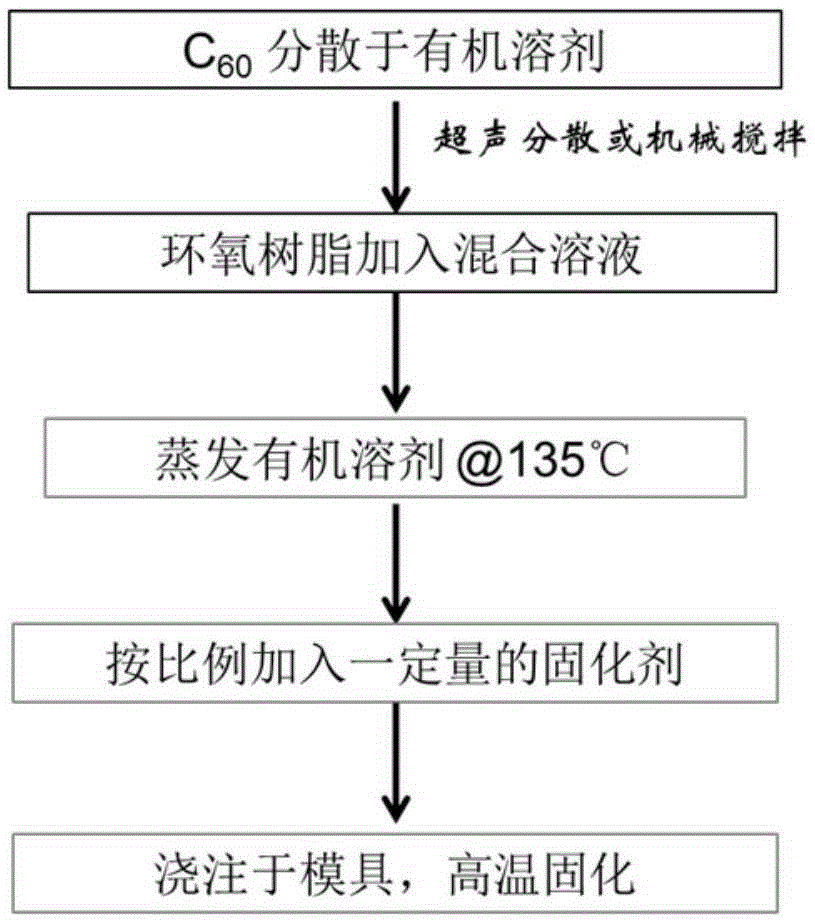

Epoxy resin fullerene composite material and preparation method thereof

The invention relates to an epoxy resin fullerene composite material and a preparation method thereof. The materials of the epoxy resin fullerene composite material include fullerene, epoxy resin and a curing agent. The epoxy resin fullerene composite material has the advantages of remarkably increasing the volume resistivity and breakdown voltage of a polymer matrix, inhibiting the injection of space charges, decreasing dielectric constant and loss, and improving the electrical aging property of the epoxy resin, and moreover, the mechanical strength and toughness of the epoxy resin are also increased to a certain degree.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Extra-high-voltage heat-resistant insulating material and preparation method thereof

The invention belongs to the technical field of electrical equipment and particularly relates to an extra-high-voltage heat-resistant insulating material and a preparation method thereof. The extra-high-voltage heat-resistant insulating material comprises components in parts by weight as follows: 80-100 parts of epoxy resin, 15-30 parts of polytetrafluoroethylene, 2-6 parts of nano-silica, 0.1-1 part of butyl titanate, 10-50 parts of distilled water, 2-10 parts of a mixture of nano silicon carbide, nano boron nitride and nano titanium dioxide, 5-15 parts of a diluent, 2-5 parts of a compatilizer, 0.2-2 parts of an antioxidant and 2-8 parts of a cross-linking agent. The prepared extra-high-voltage heat-resistant insulating material can effectively inhibit space charge accumulation in cable insulation materials and has good mechanical properties, electrical properties, thermal properties and physical properties and excellent comprehensive properties.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY

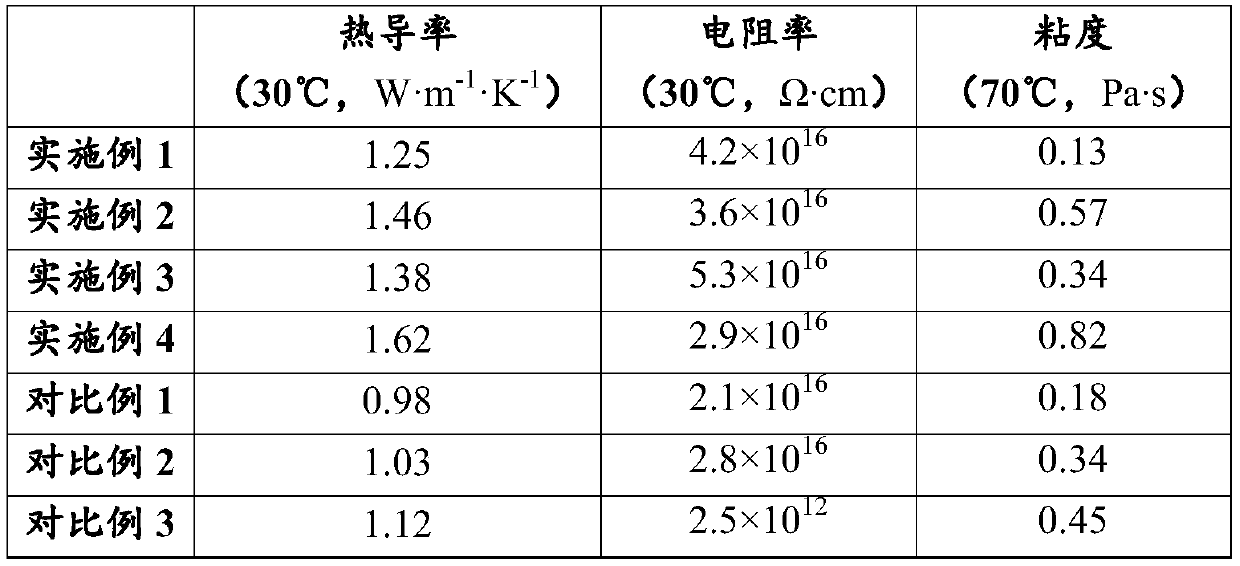

Epoxy resin thermally conductive insulating material and preparation method thereof

ActiveCN110016205AImprove thermal conductivityFunction increasePlastic/resin/waxes insulatorsHeat-exchange elementsEpoxyOmega

The invention belongs to the technical field of thermally conductive and insulating materials, and particularly relates to an epoxy resin thermally conductive insulating material and a preparation method thereof. The material includes an epoxy resin basic material, inorganic filler and a curing agent, wherein the inorganic filler is composed of fillers of three different particle sizes. The epoxyresin thermally conductive insulating material has excellent thermal conductivity and insulation performance only through selection of the ratio of three different particle size grading of the inorganic filler, the ratio of the use amount of the filler of different particle sizes and the particle sizes, and no surface-modified inorganic filler is needed, so that the material cost is reduced, and the preparation method of the material is simpler. The thermal conductivity of the material can reach 1.25 W.m<-1>.K<-1> at 30 DEG C, the highest thermal conductivity can reach 1.62 W.m<-1>.K<-1>, theresistivity of the material is 2.9x10<16> omega.cm or above below 30 DEG C, and application requirements of power electronic transformers, saturation resistors and other high insulation scenes can bemet fully.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

Aluminium oxide ceramic substrate and preparation method for same

The invention provides a preparation method for an aluminium oxide ceramic substrate, and a ceramic substrate prepared by the method. The preparation method comprises the following steps that: a first sintering aid and a second sintering aid are added in a ceramic substrate powder; the first sintering aid is the glassy-state powder of XCaO.YMgO.ZSiO2, X is not less than 0.1 and not greater than 0.4, Y is not less than 0.1 and not greater than 0.4, Z is not less than 0.5 and not greater than 0.7, and the sum of X, Y and Z is 1, wherein X: Y: Z is a mass ratio; the second sintering aid is BaO; and the mode of stacking a ceramic substrate blank and a burning-isolating plate interlayer coated with nanometre aluminium oxide powder on the surface together, then placing the ceramic substrate blank and the burning-isolating plate interlayer in a sintering furnace, and sintering is adopted, wherein the prepared aluminium oxide ceramic substrate is high in volume density, good in surface smoothness and high in anti-breakdown strength.

Owner:BYD CO LTD

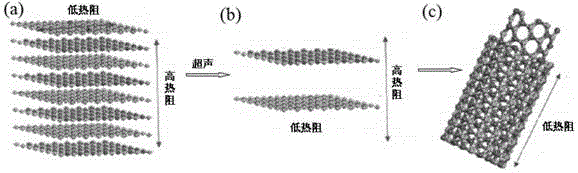

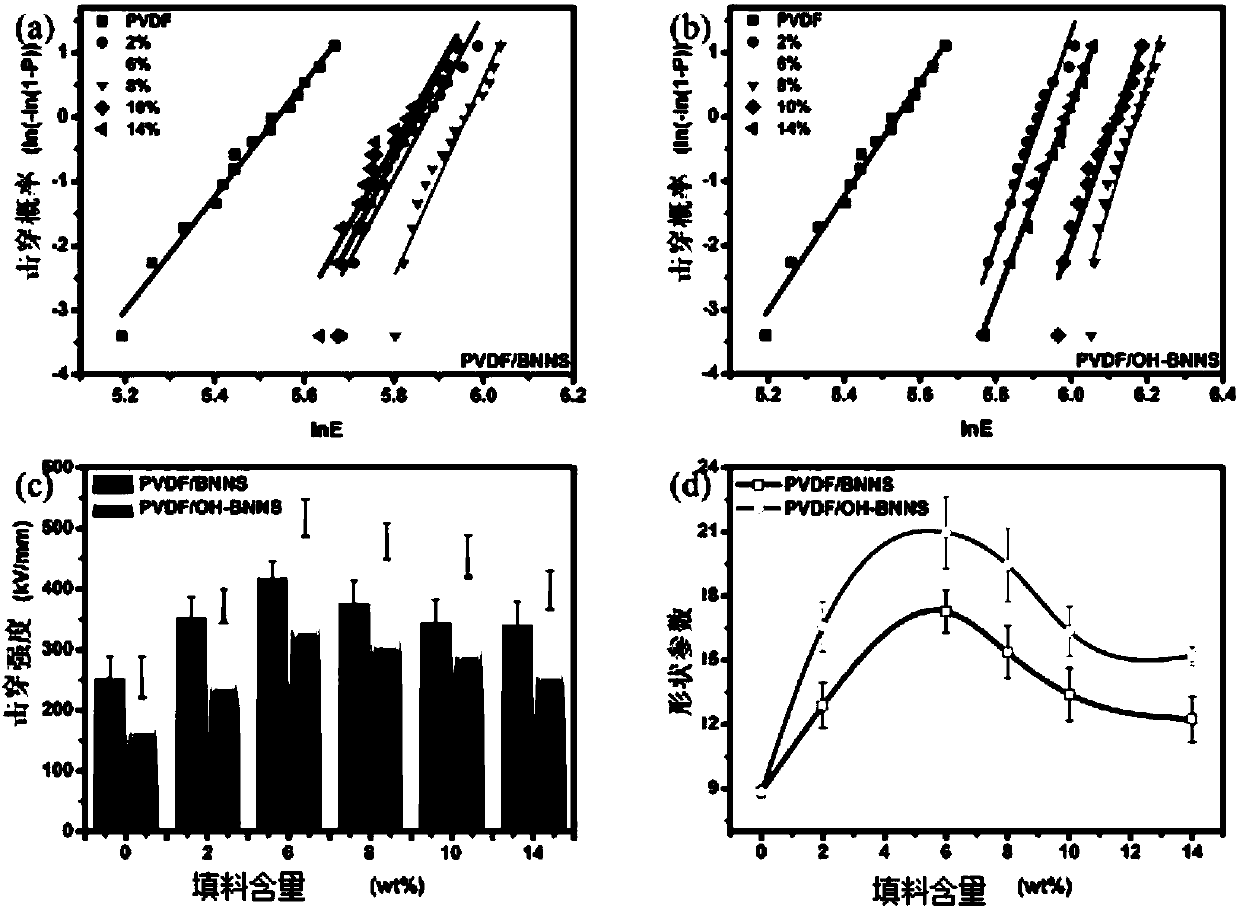

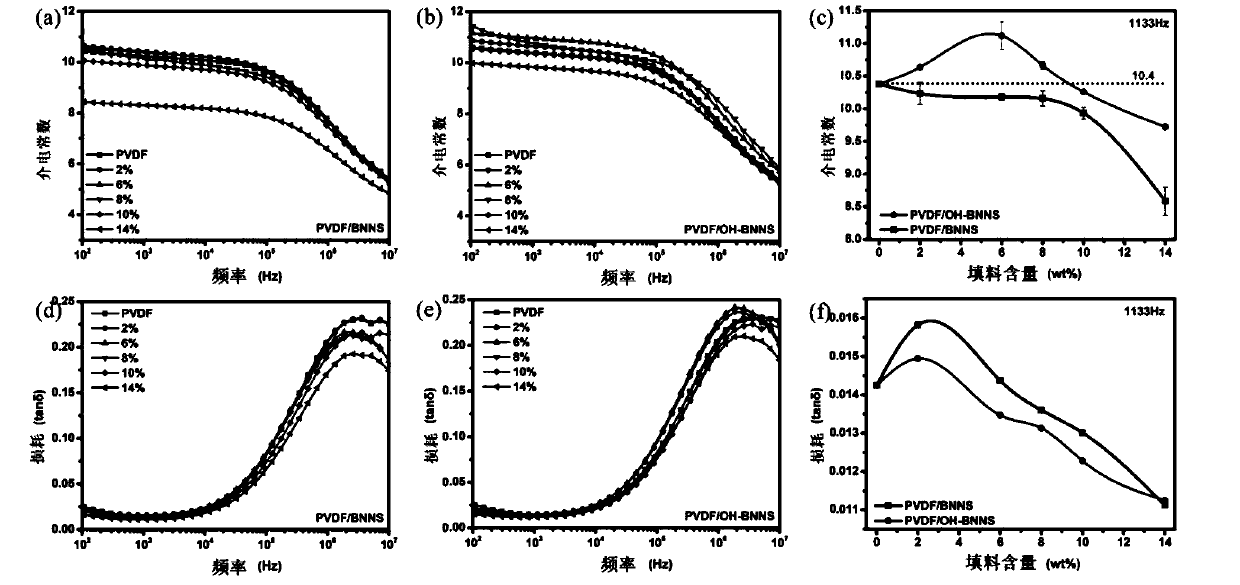

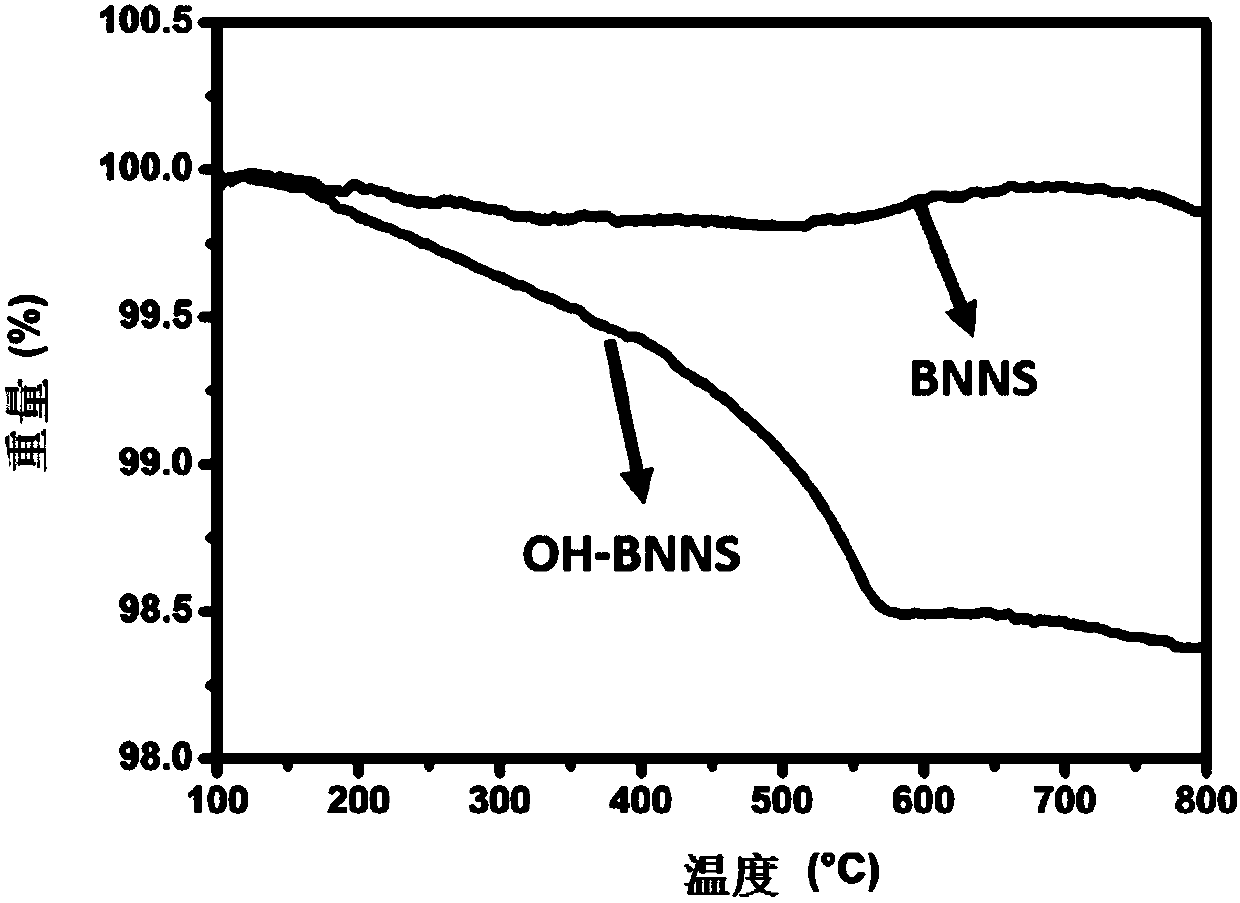

Method for improving breakdown strength and energy storage density of polymer

ActiveCN107903441AEasy to operateLow equipment requirementsHeat-exchange elementsBreakdown strengthHexagonal boron nitride

The invention relates to the technical field of energy storage materials, and in particular relates to a method for improving the breakdown strength and energy storage density of a polymer. The methodfor improving the breakdown strength and energy storage density of the polymer comprises the following steps: adding 2-14 parts by weight of hydroxylated hexagonal boron nitride to 100 parts by weight of the polymer. The modified product of BNNSs (hexagonal boron nitride nanosheets) provided by the invention has better dispersion effects in the polymer, so that the agglomeration tendency of the BNNSs in the polymer is greatly weakened, and the method is very beneficial for the improvement of the breakdown strength and energy storage density of a composite capacitor.

Owner:SICHUAN UNIV

Polypropylene for film capacitor, polypropylene sheet for film capacitor, method for producing the same, and uses of the same

ActiveUS20120010318A1Small thermal shrinkage ratioHigh breakdown voltageThin/thick film capacitorFixed capacitor dielectricFilm capacitorPolypropylene

A polypropylene for a film capacitor or a polypropylene sheet for a film capacitor which exhibits excellent stretchability when stretched into a film and provides a film having high breakdown voltage and small thermal shrinkage ratio, and which is suitable for a polypropylene film for a film capacitor and a film capacitor comprising the film.The polypropylene for a film capacitor of the present invention is obtained by irradiating a propylene homopolymer with a radiation with an absorbed dose of 0.1 to 500 kGy, the propylene homopolymer having (1) a melt flow rate (MFR) within a range of 1 to 10 g / 10 min as determined at 230° C. under a load of 2.16 kg in accordance with ASTM D1238, (2) an isotactic pentad fraction (mmmm fraction) of not less than 94% as determined using 13C-NMR, (3) an ash amount of not more than 30 ppm as obtained by completely burning the propylene homopolymer in air, and (4) a chlorine amount of not more than 10 ppm as determined by ion chromatography.

Owner:PRIME POLYMER CO LTD

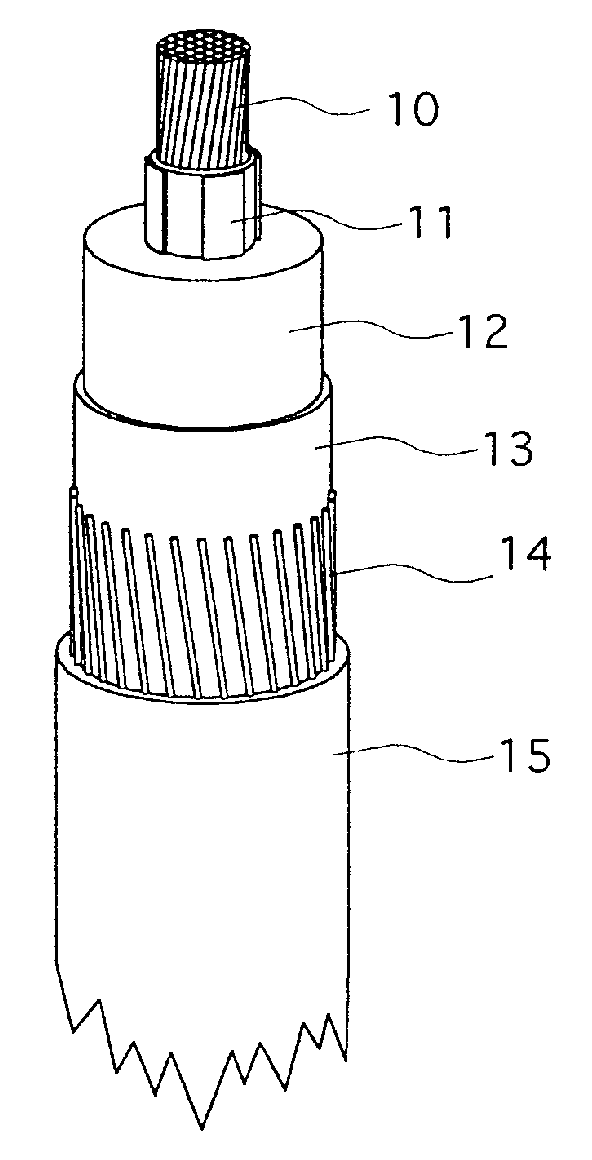

Method for providing an insulated electric high voltage DC cable or a high voltage DC termination or joint

ActiveUS8398803B2Stable and consistent dielectric propertyHigh and consistent electric strengthPlastic/resin/waxes insulatorsSynthetic resin layered productsEngineeringInsulation system

Owner:NKT HV CABLES AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com