Epoxy resin fullerene composite material and preparation method thereof

A technology of epoxy resin and composite materials, applied in plastic/resin/wax insulators, organic insulators and other directions, can solve the problems affecting the preparation process of composite materials, reduce the insulation performance of epoxy resin, reduce the volume resistivity of the system, etc., to achieve improvement Mechanical and electrical insulation properties, inhibition of crack propagation, and effects of improving insulation aging properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

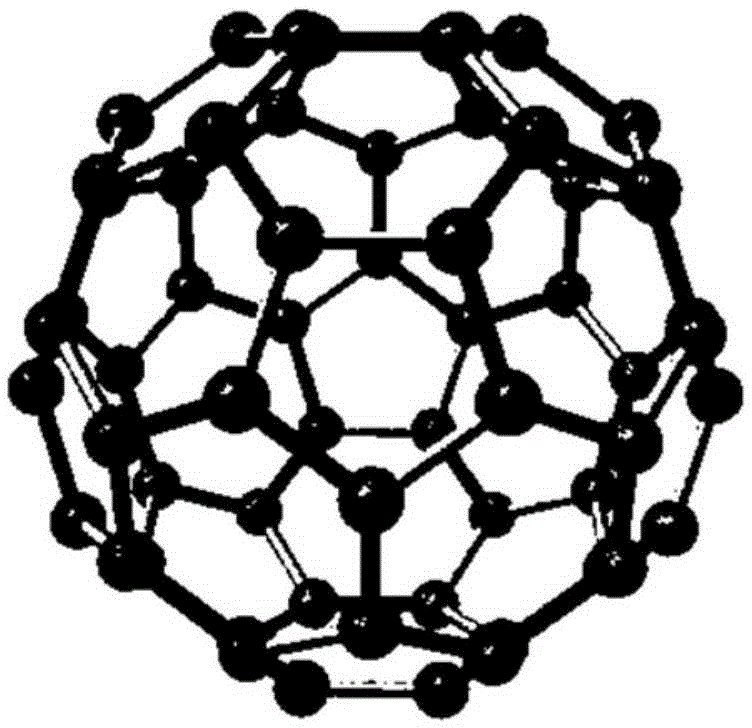

[0046] A kind of epoxy resin fullerene composite material, its raw material comprises fullerene, epoxy resin and curing agent; Described fullerene is C 60 , the epoxy resin is bisphenol A epoxy resin, and the curing agent is an anhydride curing agent HY905. In the epoxy resin fullerene composite material, the mass percentages of fullerene, epoxy resin and curing agent are respectively: 1ppm, 65.8%, and 34.2%.

[0047] In this embodiment, the bisphenol A epoxy resin is purchased from Huntsman Company, and the model is Araldite F; the anhydride curing agent HY905 is purchased from Huntsman Company.

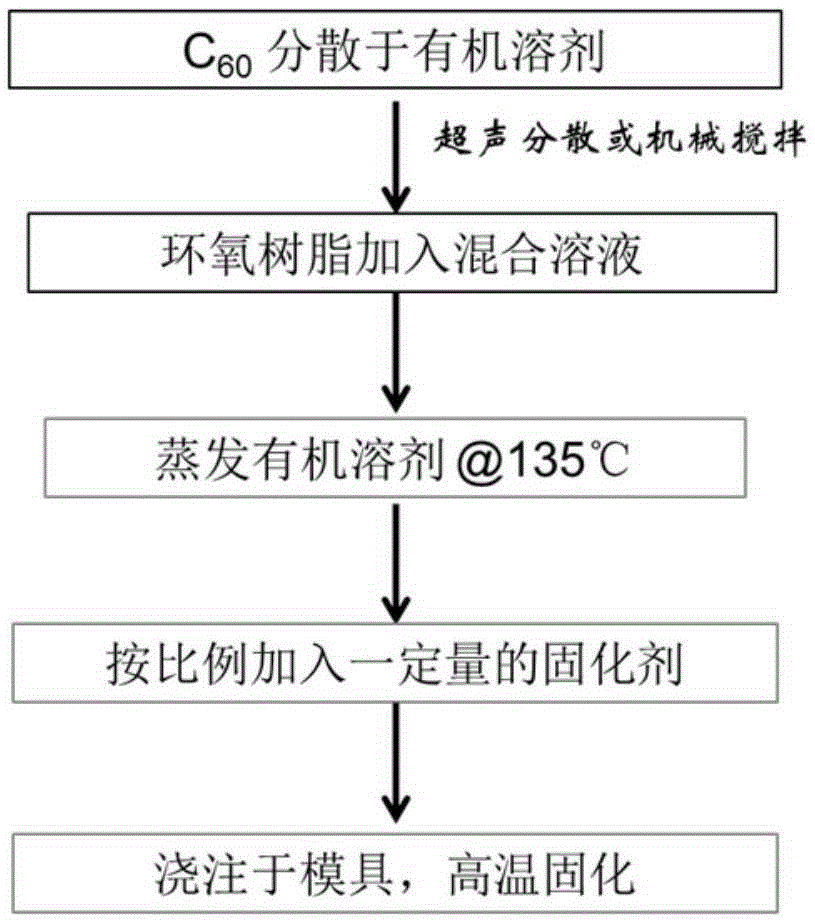

[0048] This embodiment also provides a preparation method of the epoxy resin fullerene composite material, comprising the following steps:

[0049]First, 1 mg of C 60 Add 35mL of toluene for ultrasonic dispersion, the ultrasonic power is 200W, and the time is 30min, to obtain a uniformly dispersed mixed solution. Then take 10mL of the mixed solution and add it to 200g of epoxy re...

Embodiment 2

[0052] A kind of epoxy resin fullerene composite material, its raw material comprises fullerene, epoxy resin and curing agent; Described fullerene is C 60 PC 61 BM, the epoxy resin is novolac epoxy resin, and the curing agent is acid anhydride curing agent T31. In the epoxy resin fullerene composite material, the mass percentages of fullerene, epoxy resin and curing agent are respectively: 10ppm, 71.4%, and 28.6%.

[0053] In this example, the novolac epoxy resin was purchased from Wuxi Bluestar Resin Company, model number F44 (644); the anhydride curing agent T31 was purchased from Wuxi Bluestar Company.

[0054] This embodiment also provides a preparation method of the epoxy resin fullerene composite material, comprising the following steps:

[0055] First, 6.6 mg of PC 61 BM was added into 30mL of xylene for ultrasonic dispersion, the ultrasonic power was 200W, and the time was 30min to obtain a uniformly dispersed mixed solution. Then take 15mL of the mixed solution an...

Embodiment 3

[0058] A kind of epoxy resin fullerene composite material, its raw material comprises fullerene, epoxy resin and curing agent; Described fullerene is C 70 , the epoxy resin is a mixture of bisphenol A epoxy resin and aliphatic epoxy resin, and the curing agent is an anhydride curing agent ER314. In the epoxy resin fullerene composite material, the mass percentages of fullerene, epoxy resin and curing agent are respectively: 100ppm, 64.9%, and 35.1%.

[0059] In this embodiment, the epoxy resin (mixture of bisphenol A epoxy resin and aliphatic epoxy resin) was purchased from Dow Chemical Company of the United States, and the model was ER113; the anhydride curing agent ER314 was purchased from Dow Company of the United States.

[0060] This embodiment also provides a preparation method of the epoxy resin fullerene composite material, comprising the following steps:

[0061] First, 108 mg of C 70 Add 35mL of chloroform for ultrasonic dispersion, the ultrasonic power is 200W, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com