Patents

Literature

278results about How to "Prevent crack growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrochemical cell including functionally graded and architectured components and methods

PendingUS20100035152A1Maintain good propertiesEliminate errorsMaterial nanotechnologyMolten spray coatingIonic diffusionHigh rate

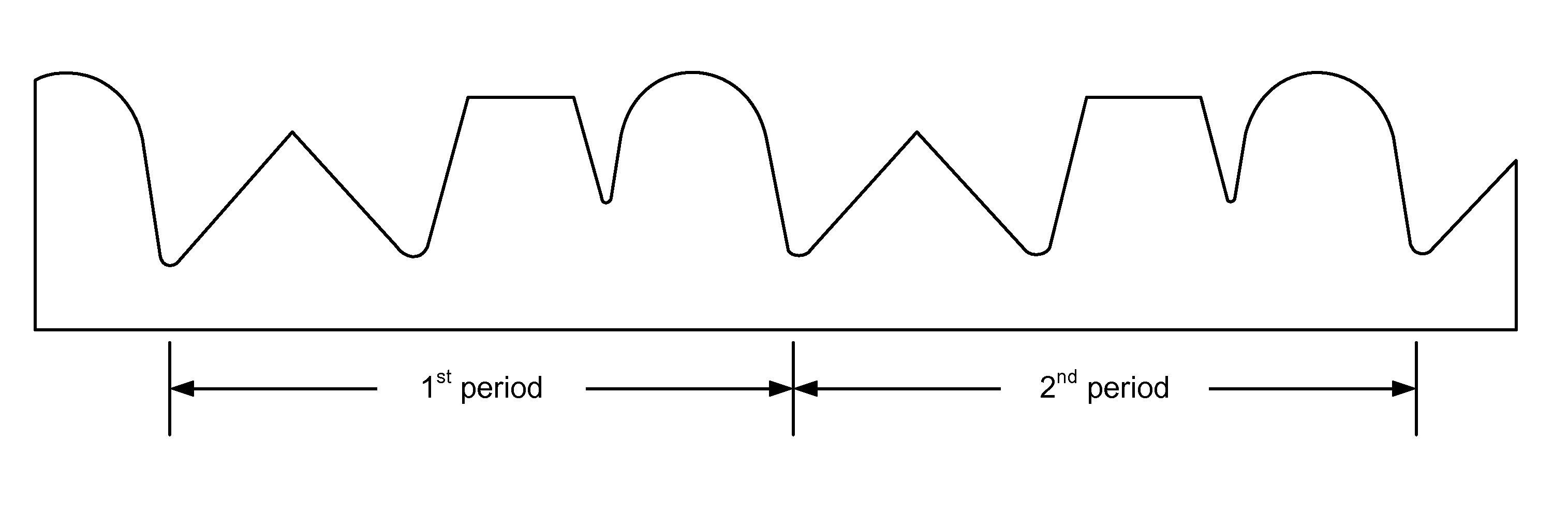

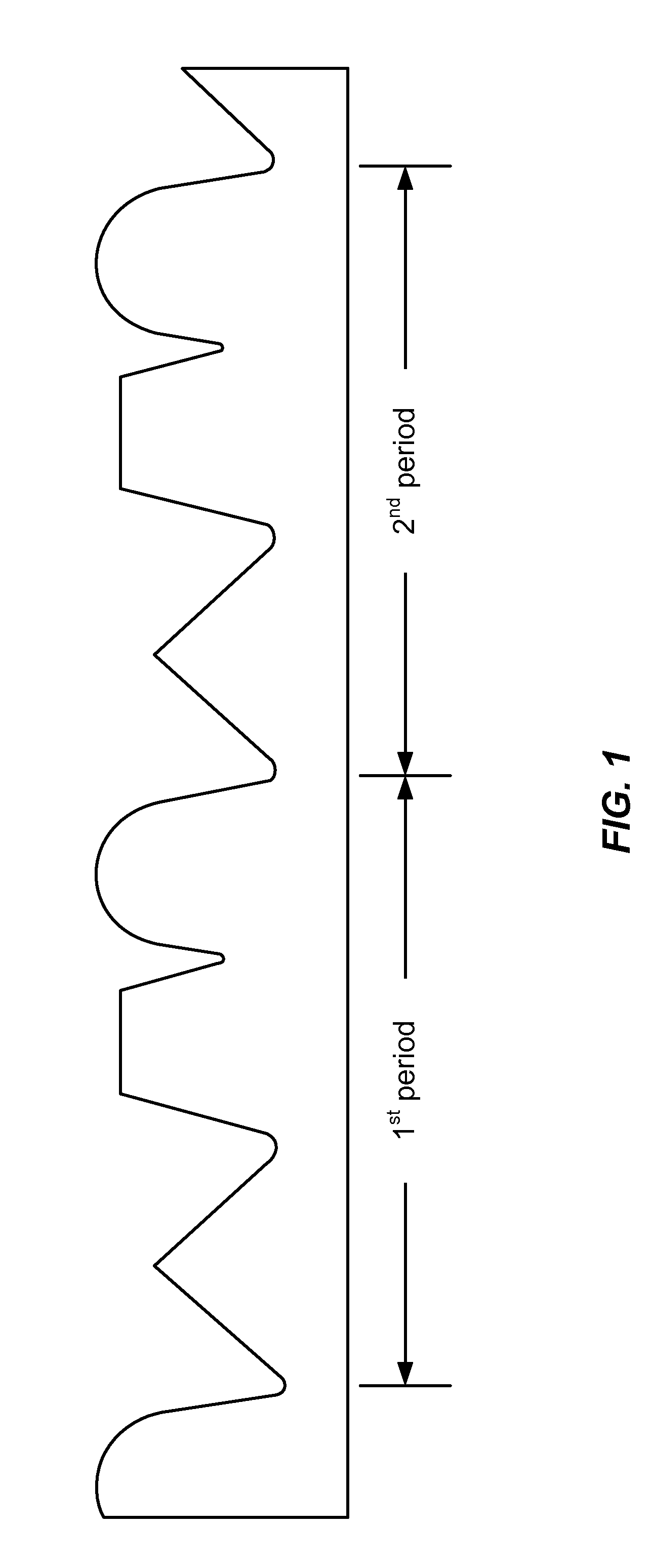

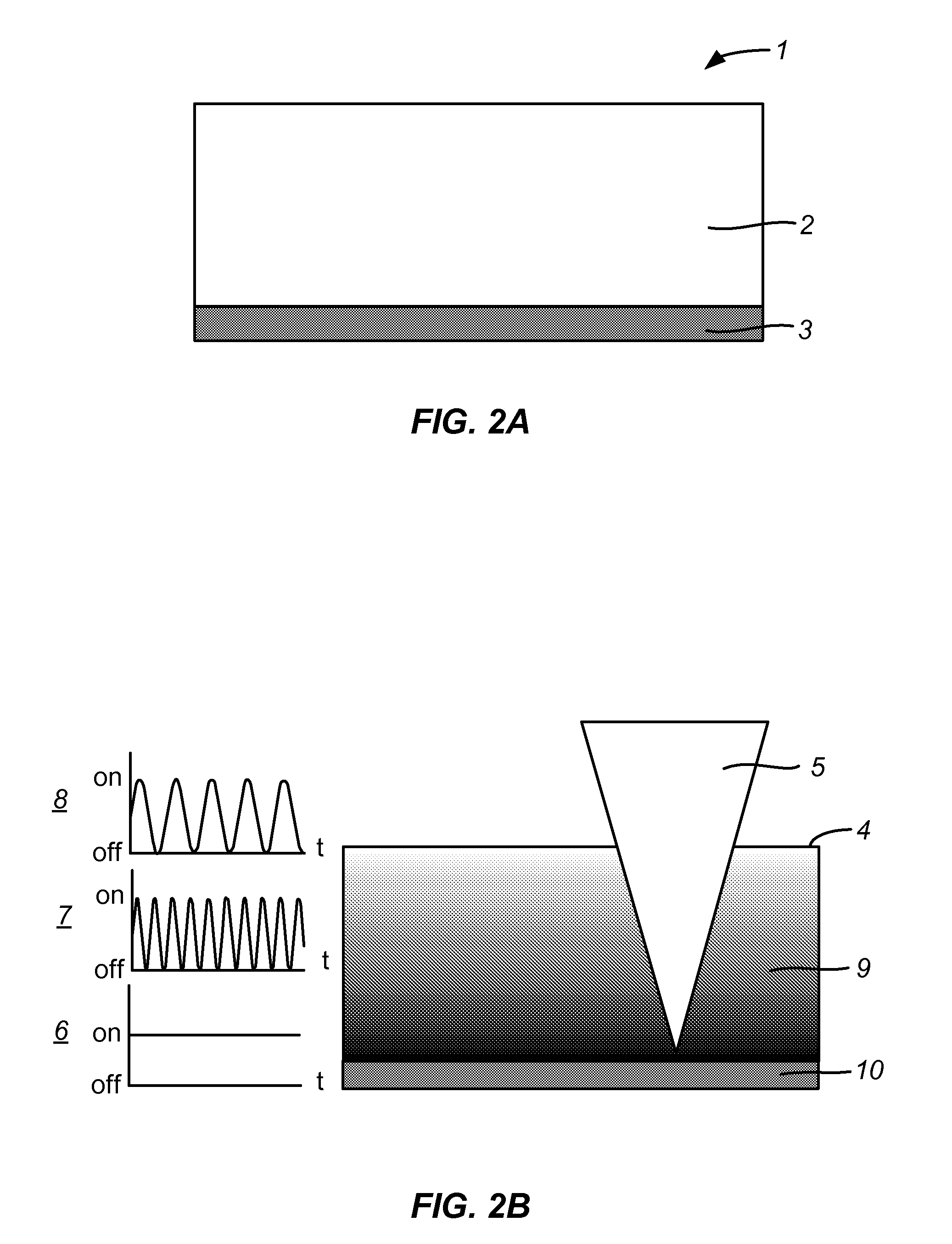

Electrochemical cells or batteries featuring functional gradations, and having desirable, periodic configurations, and methods for making the same. One or more methods, in alone or in combination, are utilized to fabricate components of such electrochemical cells or batteries, which are designed to achieve certain thermal, mechanical, kinetic and spatial characteristics, and their effects, singly and in all possible combinations, on battery performance. The thermal characteristics relate to temperature distribution during charge and discharge processes. The kinetic characteristics relate to rate performance of the cells or batteries such as the ionic diffusion process and electron conduction. The mechanical characteristics relate to lifetime and efficiency of the cells or batteries such as the strength and moduli of the component materials. Finally, the spatial characteristics relate to the energy and power densities, stress and temperature mitigation mechanisms, and diffusion and conduction enhancements. The electrochemical cells or batteries constructed according to the methods presented in this invention are useful for all applications that require high rate performance, high energy / power density, good durability, high safety and long lifetime.

Owner:SAKTI3

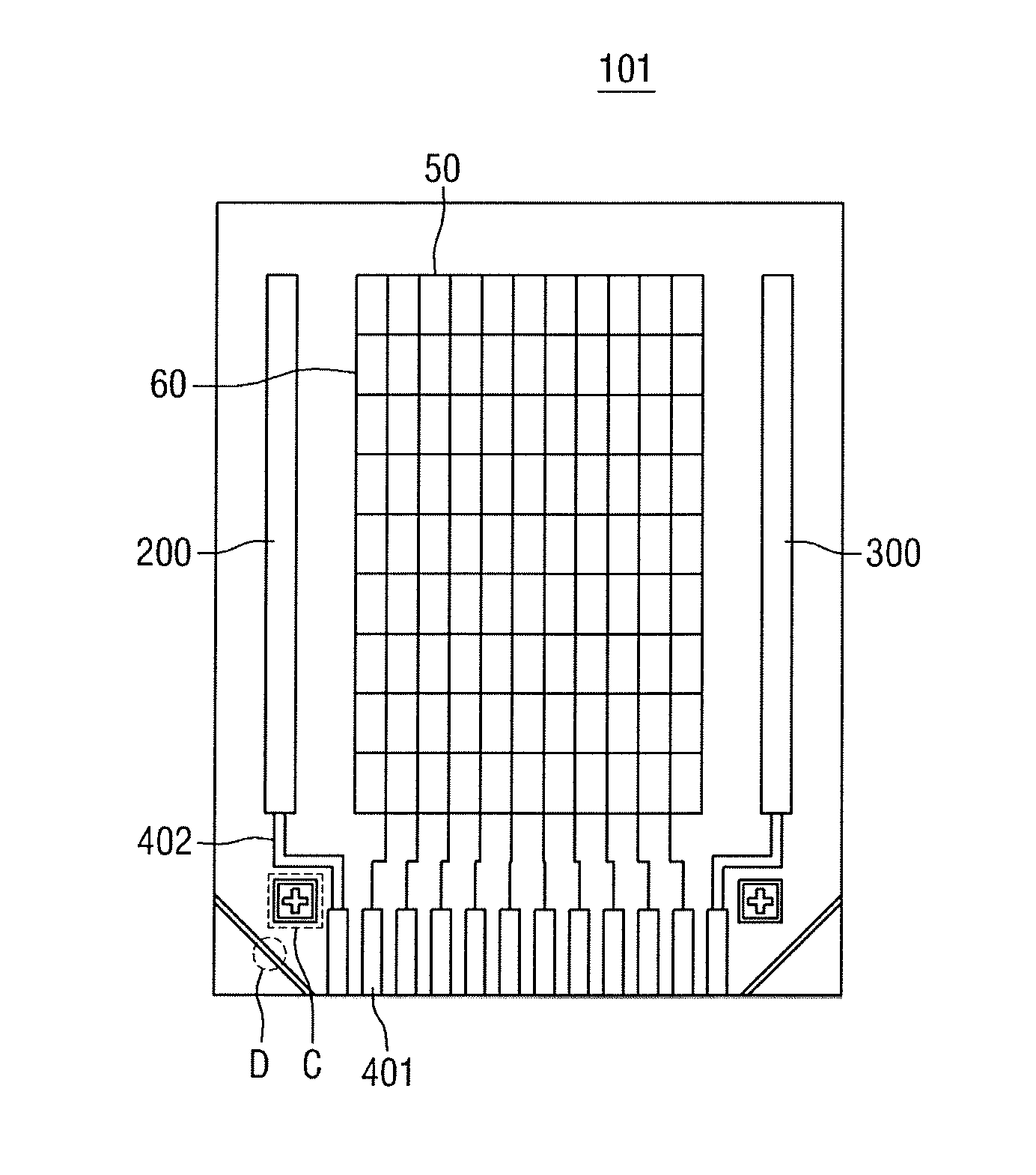

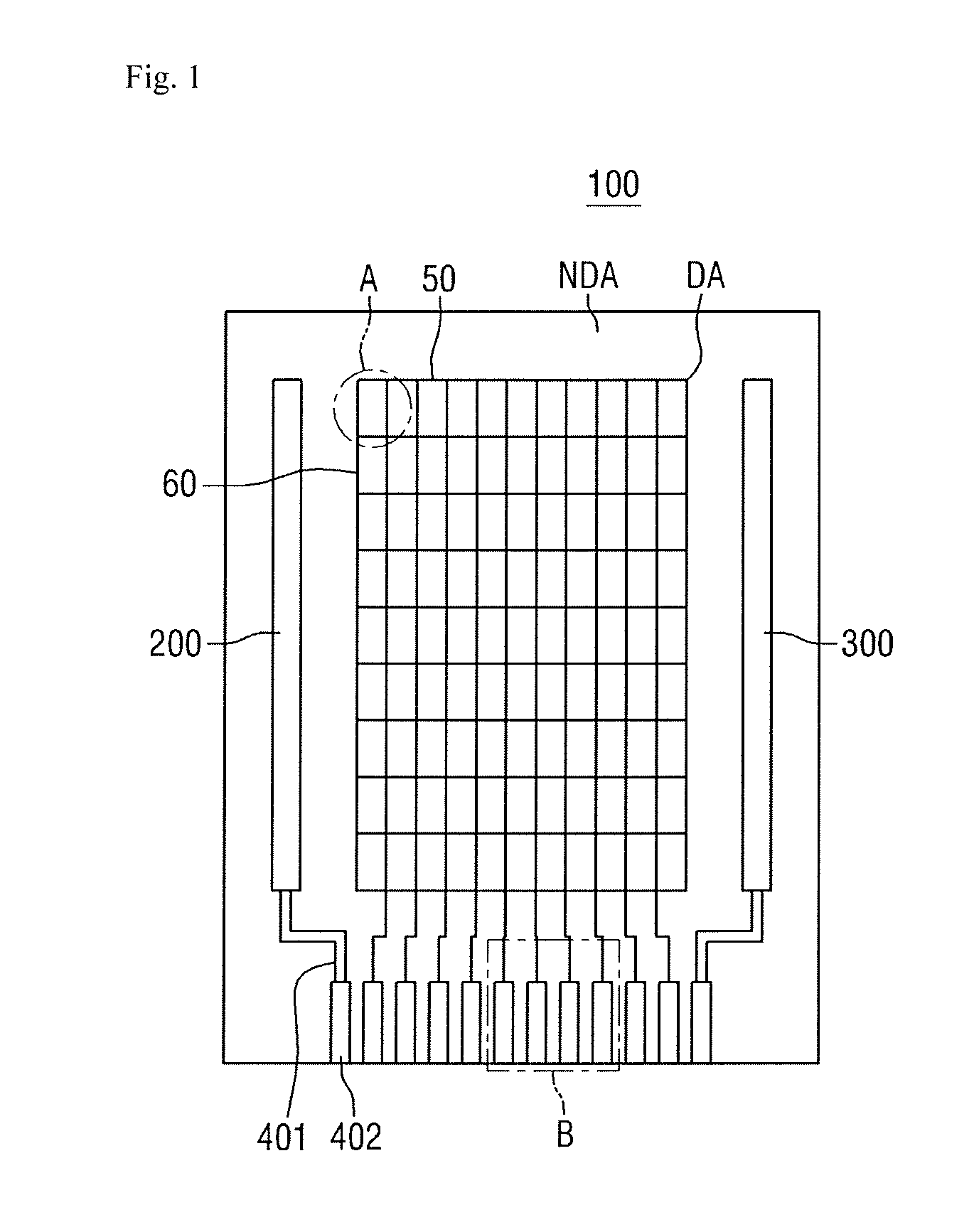

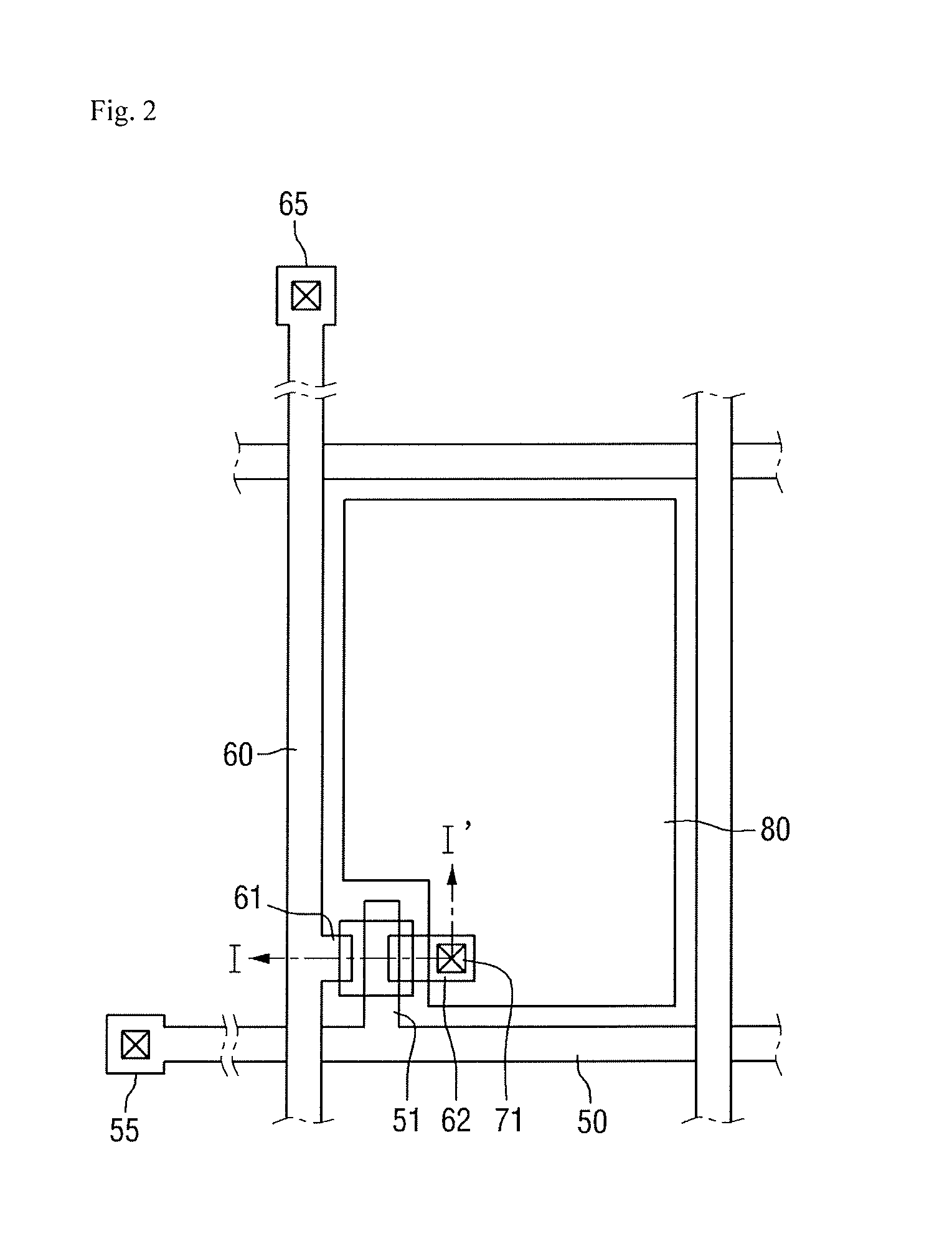

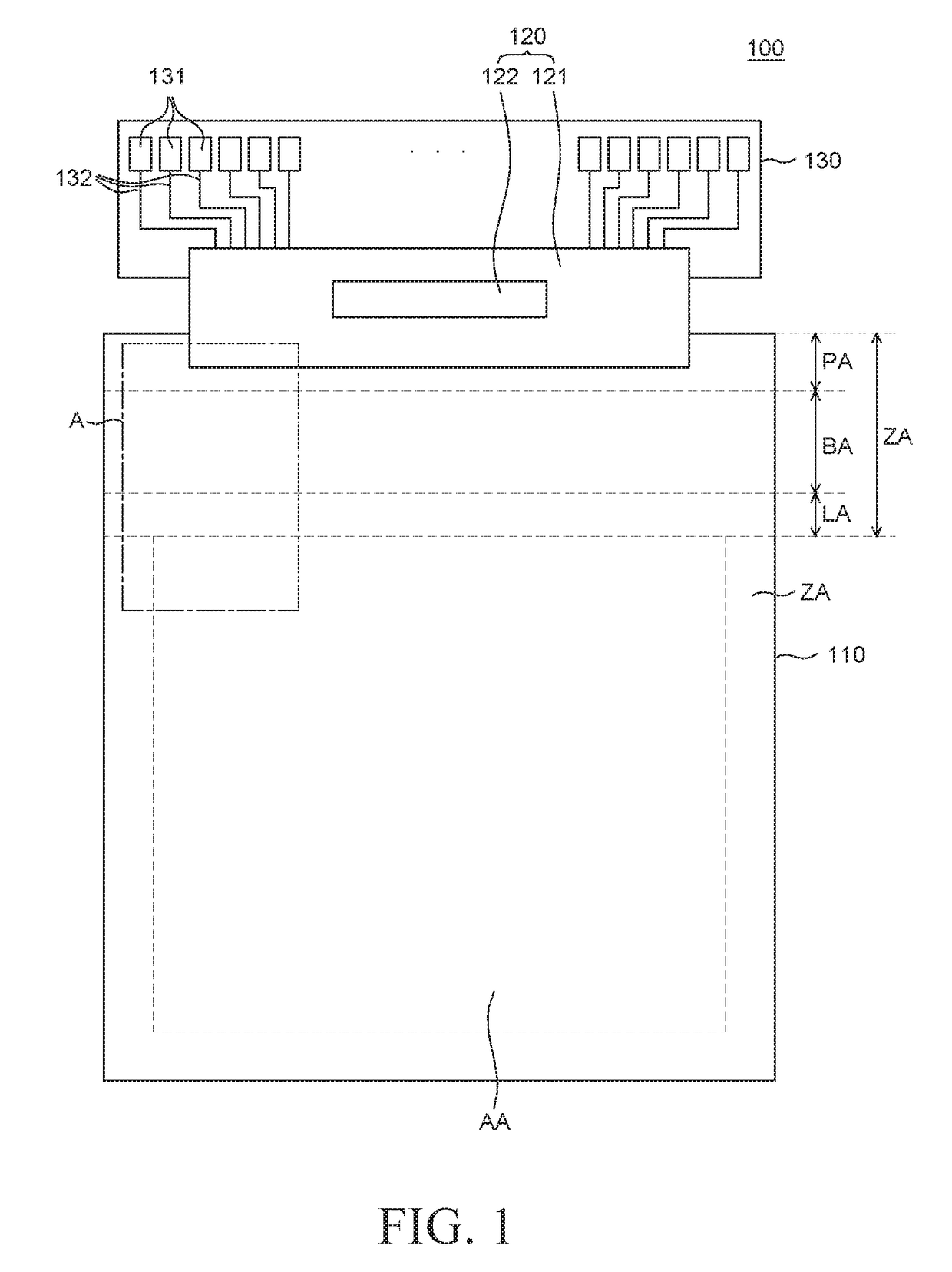

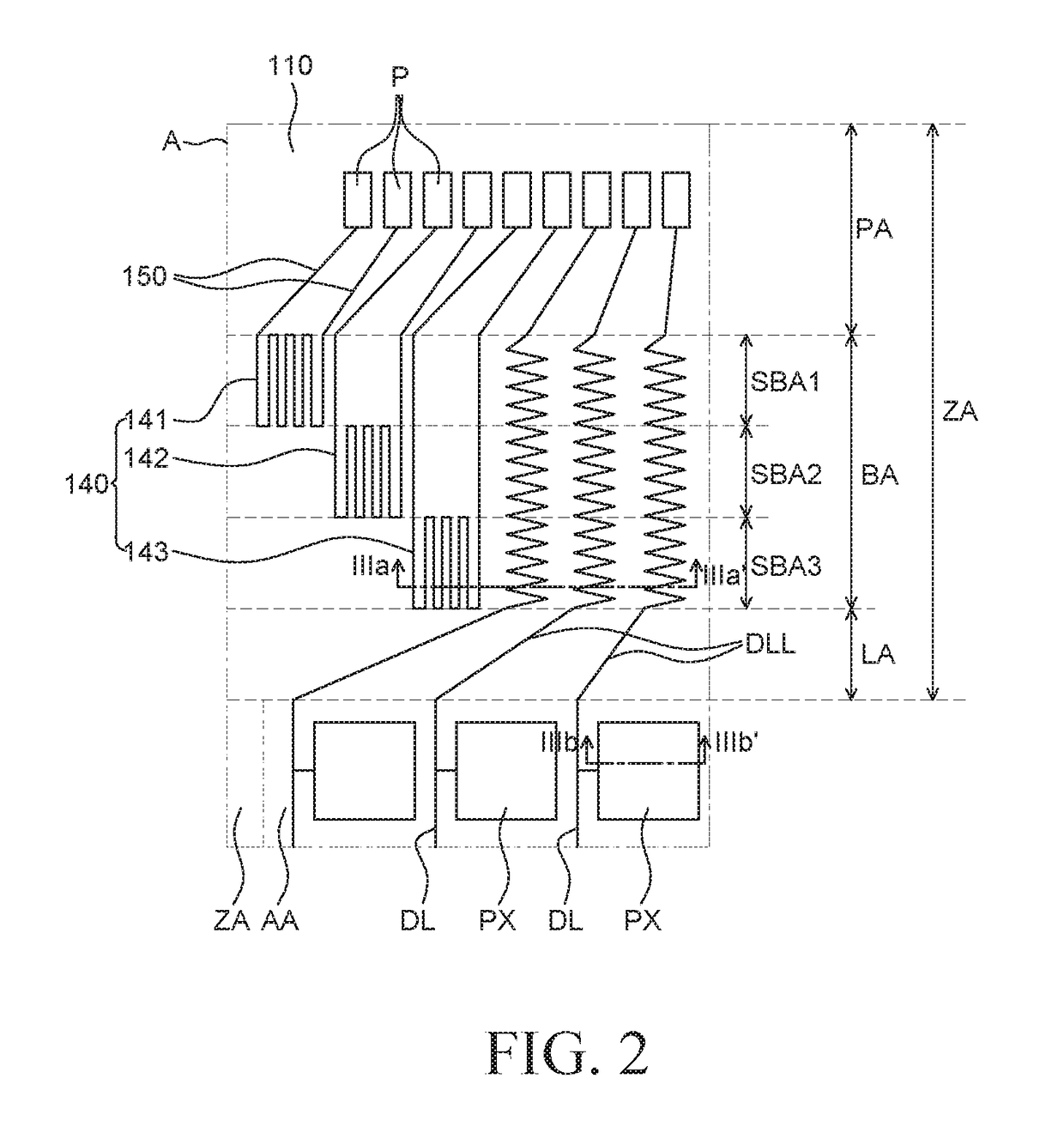

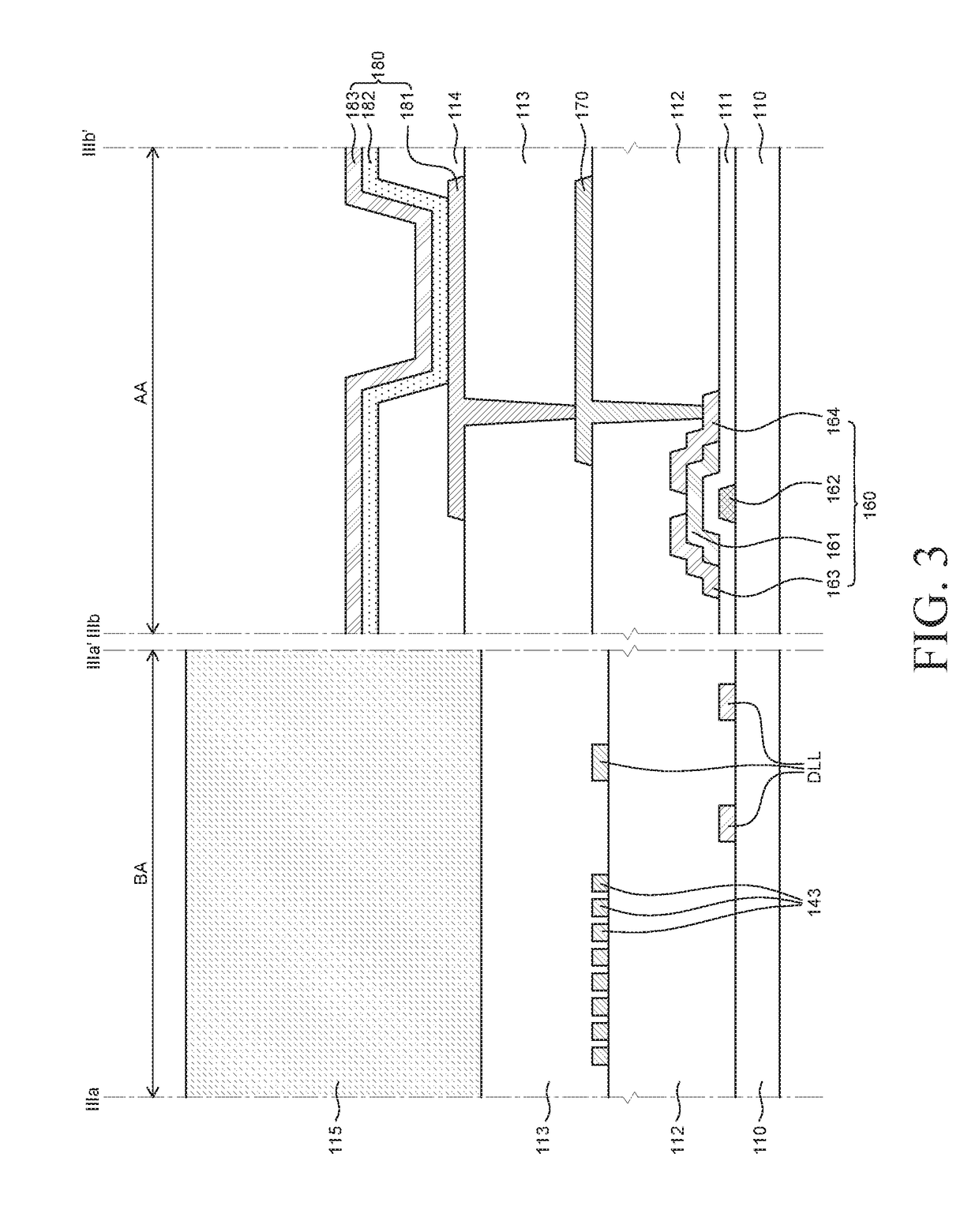

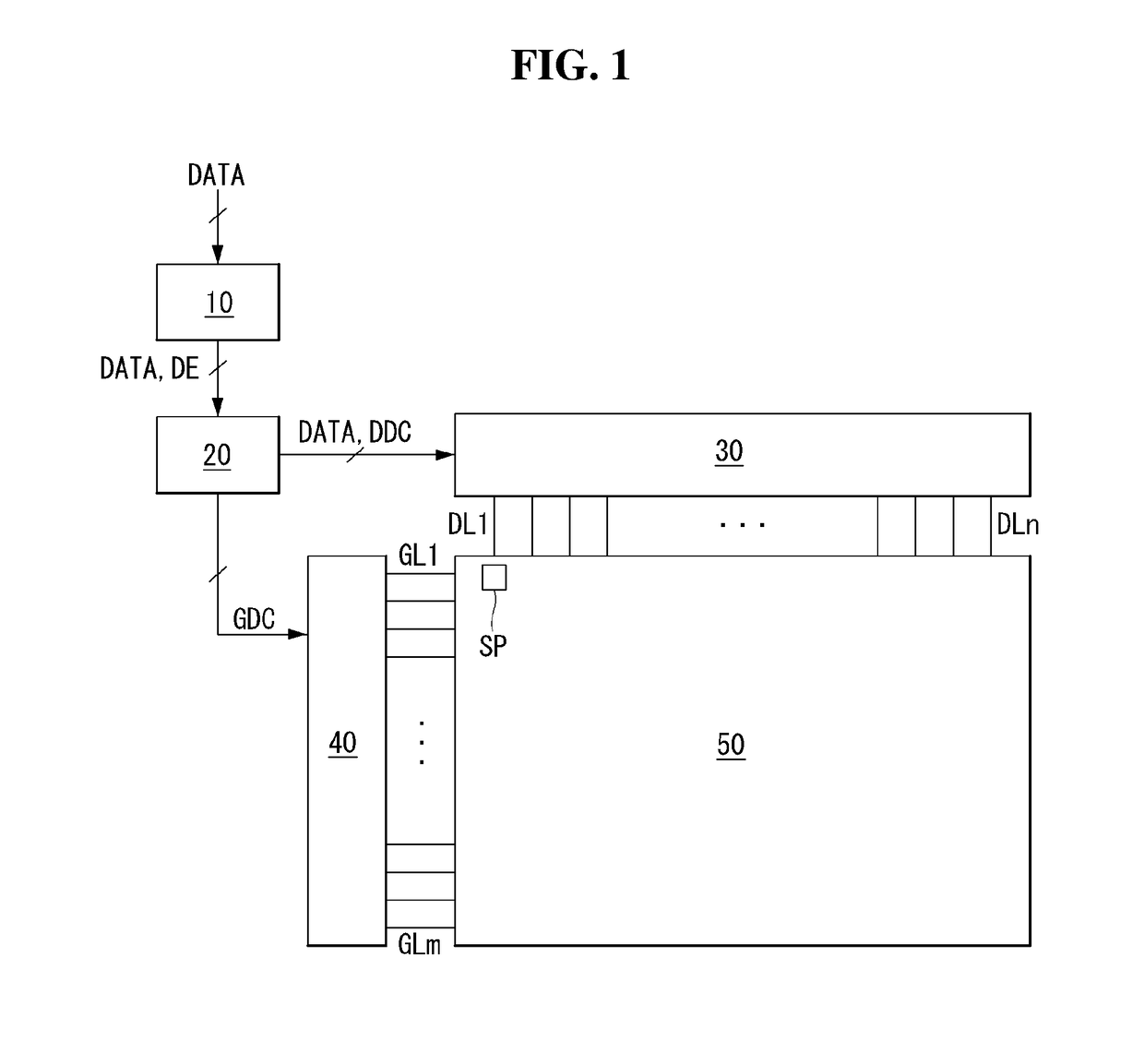

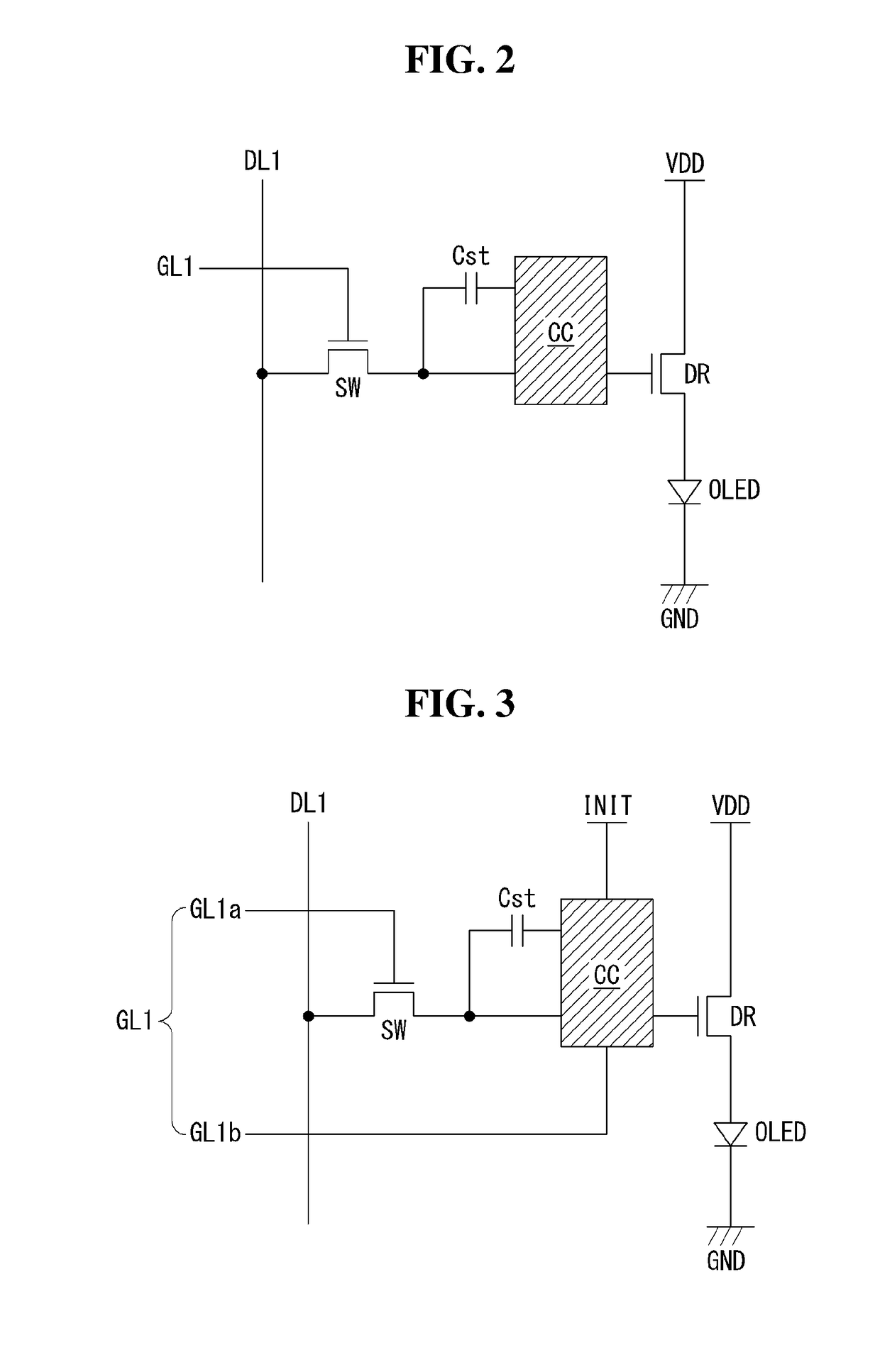

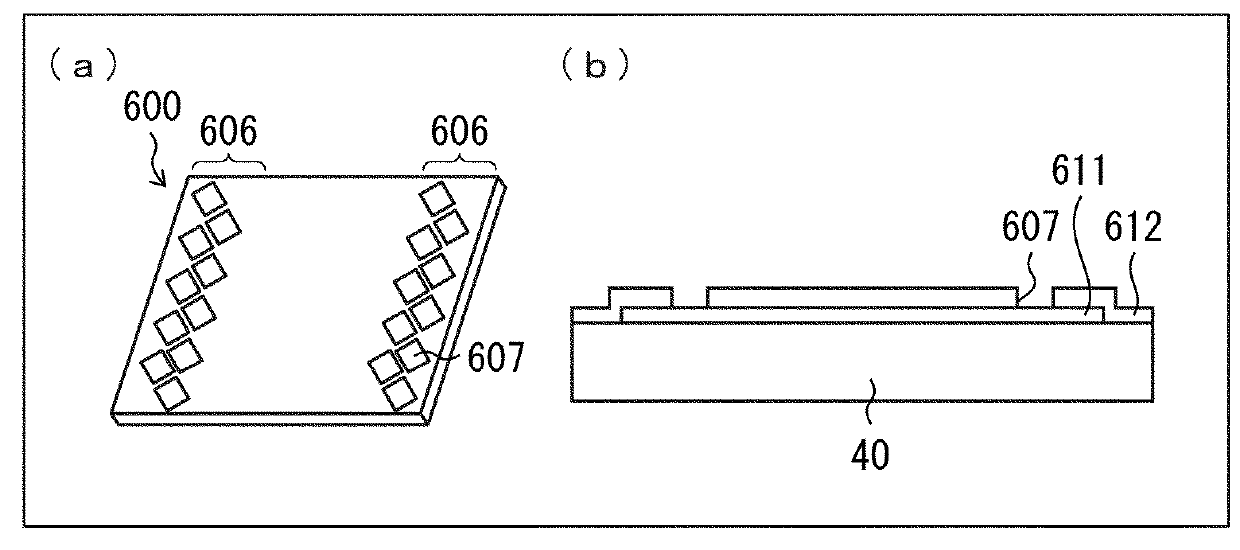

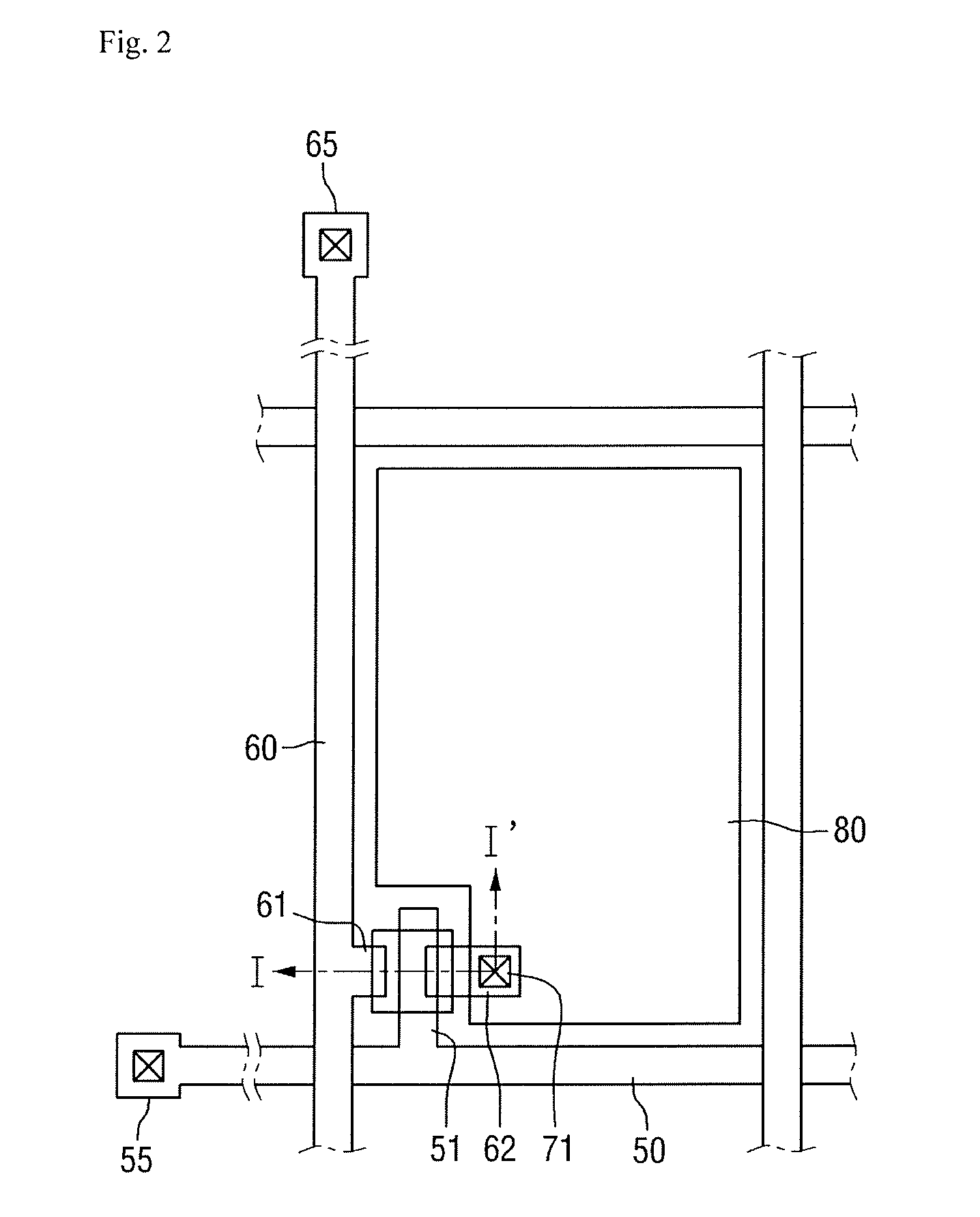

Array substrate and organic light-emitting display including the same

ActiveUS20140367658A1Avoid creatingPreclude creationSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical and Electronics engineering

An array substrate includes a substrate, a barrier layer disposed on the substrate, a buffer layer disposed on the barrier layer, a first insulating layer disposed on the buffer layer, a second insulating layer disposed on the first insulating layer, a plurality of wiring patterns disposed between the first insulating layer and the second insulating layer and / or on the second insulating layer. In addition, the wiring patterns are separated from each other, and extend toward a side of the substrate. The array substrate further includes a recess pattern disposed adjacent the wiring patterns and recessed from a top surface of the second insulating layer to expose at least part of a top surface of the substrate, and an organic insulating layer disposed on the second insulating layer and exposing at least part of a portion of the top surface of the substrate which is exposed by the recess pattern.

Owner:SAMSUNG DISPLAY CO LTD

Flying shear blade and preparation method thereof

InactiveCN101144140AImprove wear resistanceImprove hardenabilityHeat treatment process controlShearing toolsQuenchingImpurity

The present invention discloses a flying shear blade. The component has the weight percentage that C is 0.40-0.70, Si is 0.50-1.20, Mn is 0.20-0.50, Cr is 4.00-6.00, Mo is 0.50-2.00, V is 0.30-1.50, P is less than or equal to 0.02, S is less than or equal to 0.02, and Fe and inevitable impurity are the residual. The present invention provides a manufacture method of electric furnace smelting, and ingot casting; hydrogen removing and annealing treatment, and forging; preliminary heat treatment, rough machining, quenching and tempering heat treatment (primary quenching and high temperature tempering), semi finishing, ultimate heat treatment (secondary quenching, primary low temperature tempering, and secondary low temperature tempering), and fine finishing. By effectively controlling the material texture and the morphology, the quantity, the size and the distribution of carbonide, the quenching temperature and the tempering temperature of the quenching and tempering heat treatment, and the quenching temperature and the tempering temperature of the ultimate heat treatment are controlled, the texture crystal grains are more refined, the carbonide is distributed in a dispersed way, and simultaneously, the thermal stability and the retentivity are remarkably enhanced, thereby being advantageous for improving the operational performance of the blade.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Disk shearing blade and method for manufacturing the same

ActiveCN101177765AImprove wear resistanceHigh strengthShearing machinesFurnace typesHigh intensityWear resistance

A disc scissors blade and its manufacturing method, the composition weight percentage of the material of the disc scissors blade is: C: 0.40-0.70%, Si: 0.50-1.2%, Mn: 0.20-0.50%, Ni: 1.00-1.50% %, Cr: 4.00-6.00%, Mo: 0.50-2.00%, V: 0.30-1.50%, Nb: 0.10-0.80%, P≤0.02%, S≤0.02%. The method introduces an electroslag remelting process into a common manufacturing method of disc shears, and increases the temperature of quenching and tempering heat treatment and final heat treatment. The disc scissors have good wear resistance and deformation resistance, and are suitable for slitting or trimming hot-rolled high-strength thick steel plates. In addition, the disc shear blade of the present invention also has a good use effect on disc shears in other similar working conditions, and can also be applied to disc shears for stripping or edge trimming of cold-rolled strip steel, and also has a promotional effect on non-ferrous metal disc shears. value and application prospects.

Owner:BAOSHAN IRON & STEEL CO LTD +1

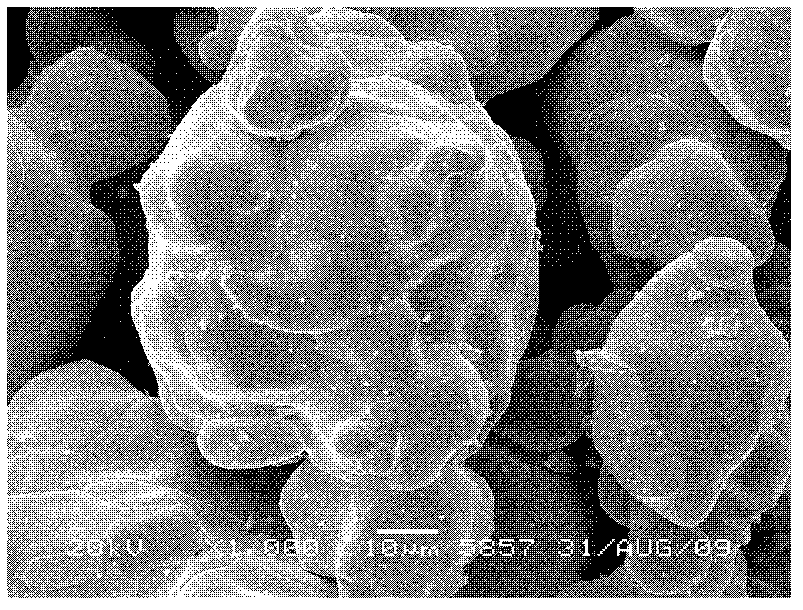

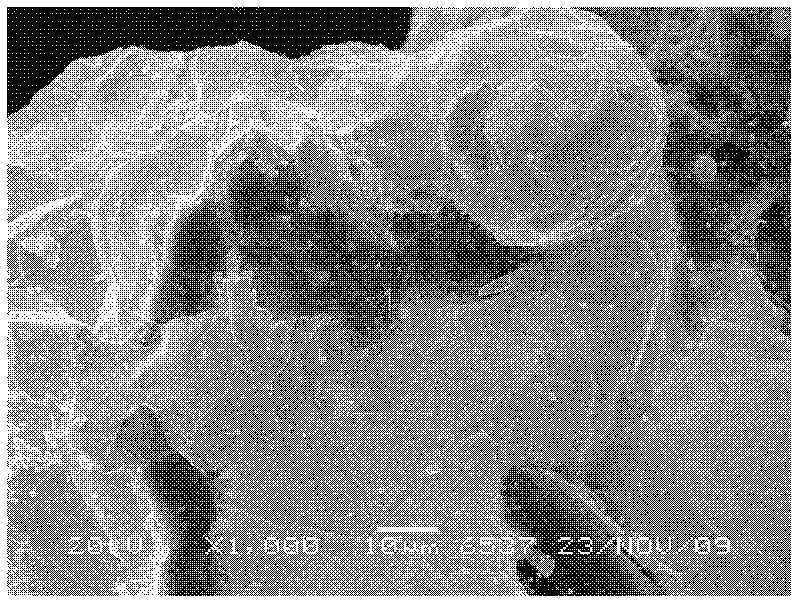

Extra coarse grain WC-Co hard alloy and preparation process thereof

ActiveCN102534344APromote grain growthIncrease the carbon content of tungsten carbideCemented carbideGrain distribution

The invention relates to an extra coarse grain WC-Co hard alloy. The hard alloy comprises 5 to 15 weight percent of Co and the balance of WC, wherein the average grain size of the WC is 6 to 10mu m. A preparation process for the hard alloy comprises the following steps of: pre-ball-milling coarse and fine tungsten carbide to prepare mixed tungsten carbide powder, preparing mixed tungsten carbide powder-cobalt-former mixed powder, pressing, and sintering, wherein the sintering step is divided into a former removing part and a high-temperature sintering part. The average grain size of a metallographic structure of the WC-Co hard alloy prepared by the process is 6mu m or more than 6mu m, the process method is simple and convenient to operate, the prepared hard alloy has a large average grainsize, a narrow grain distribution range, a low thermal expansion coefficient and high heat conductivity, high-temperature wear resistance, transverse rupture strength and rupture toughness, and is suitable for a mining tool and an excavating tool, and the thermal fatigue crack resistance of the alloy is effectively improved.

Owner:HUNAN BOYUN DONGFANG POWDER METALLURGY

Lead-free solder alloy and in-vehicle electronic circuit

ActiveUS20160056570A1Hinders its propagationExcellent temperature cycle characteristicsRelieving strain on wire connectionSoldered/welded conductive connectionsIn vehicleAttachment site

With the increasing density of in-vehicle electronic circuits, not only conventional cracks at bonding interfaces such as between the substrate and the solder attachment site or a component and the solder attachment site but also novel cracking problems of cracks occurring in the Sn matrix in the interior of the bonded solder have appeared. To solve the above problem, a lead-free solder alloy with 1-4 mass % Ag, 0.6-0.8 mass % Cu, 1-5 mass % Sb, 0.01-0.2 mass % Ni and the remainder being Sn is used. A solder alloy, which not only can withstand harsh temperature cycling characteristics from low temperatures of −40° C. to high temperatures of 125° C. but can also withstand external forces that occur when riding up on a curb or colliding with a vehicle in front for long periods, and an in-vehicle electronic circuit device using the solder alloy can thereby be obtained.

Owner:SENJU METAL IND CO LTD

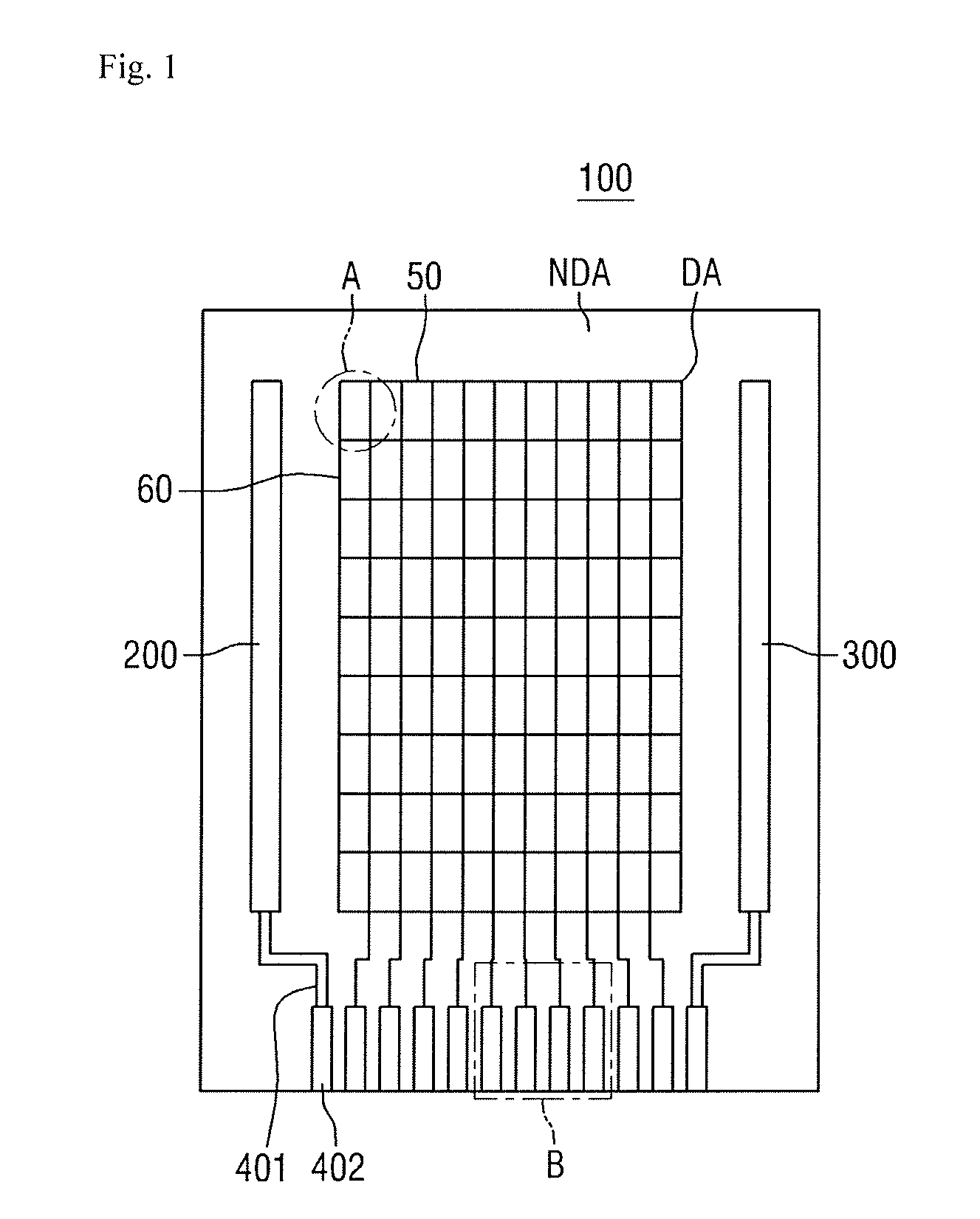

Display device

ActiveUS20190074332A1Reduce border sizeSmall sizeThermometers using electric/magnetic elementsSolid-state devicesDisplay deviceEngineering

Discussed is a display device including a flexible substrate having an active area, a bezel area enclosing the active area, and a bending area defined in at least a part of the active area and the bezel area; and a plurality of bending sensing patterns disposed in the bending area, in which the bending area includes a plurality of sub bending areas and the plurality of bending sensing patterns is disposed in different areas of the plurality of sub bending areas. Therefore, the bending degree of each sub bending area included in the bending area can be independently sensed.

Owner:LG DISPLAY CO LTD

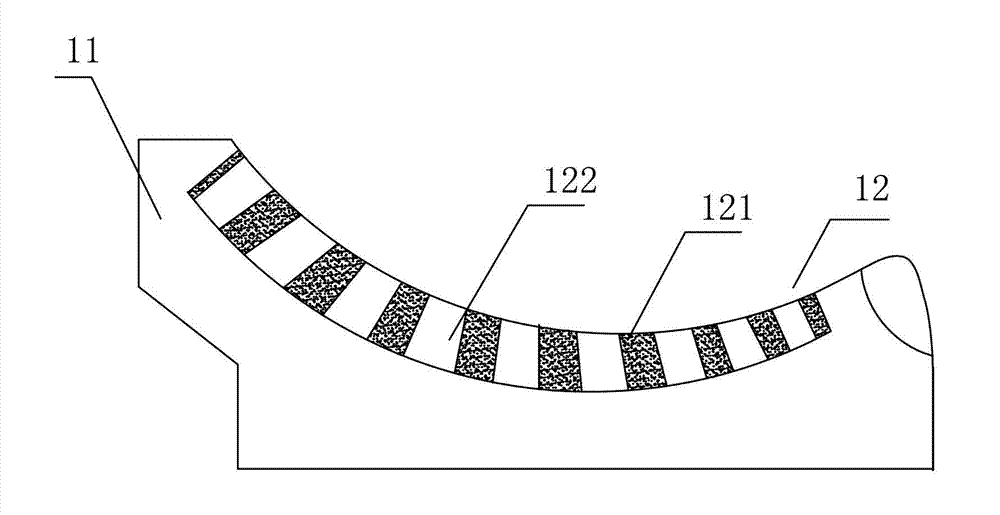

Multi-coating cutting tool deposited in periodicity and preparation method thereof

ActiveCN101690978AAntioxidantHigh temperature stabilityLayered productsTurning toolsOxidation resistantHardness

The invention discloses a multi-coating cutting tool deposited in periodicity and a preparation method thereof. The multi-coating cutting tool comprises a cutting tool matrix and a coating deposited on the cutting tool matrix; the coating comprises a composite coating which is a multiple periodic coating taking TiN layer to TiSiN layer to TiAlSiN layer to TiSiN layer as one period. The multi-coating cutting tool prepared through simple process, conventional equipment and low manufacturing cost has high rigidity, high strength, excellent high-temperature oxidation resistance and high-temperature stability; and the coating and matrix have favorable bonding strength.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

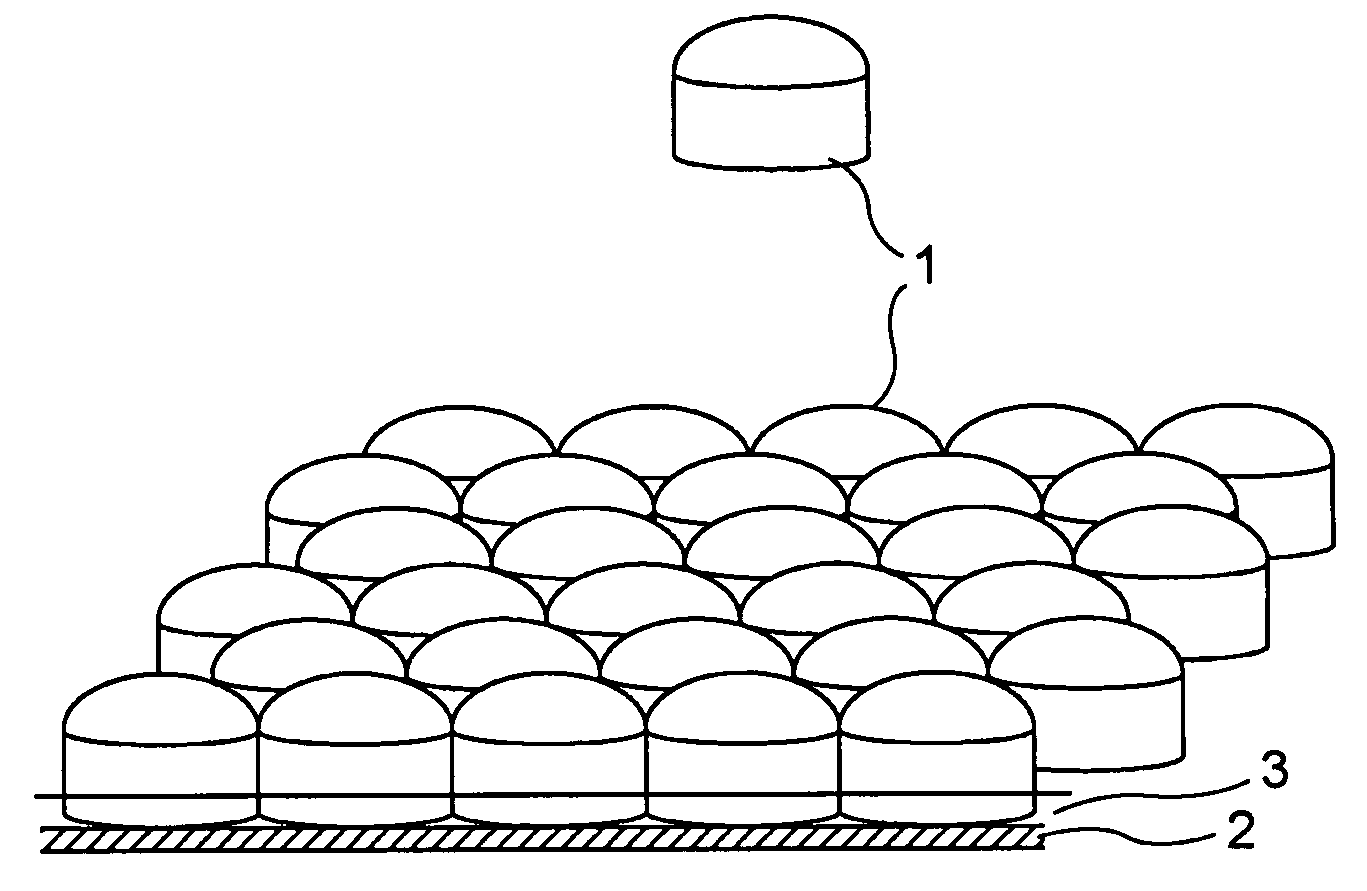

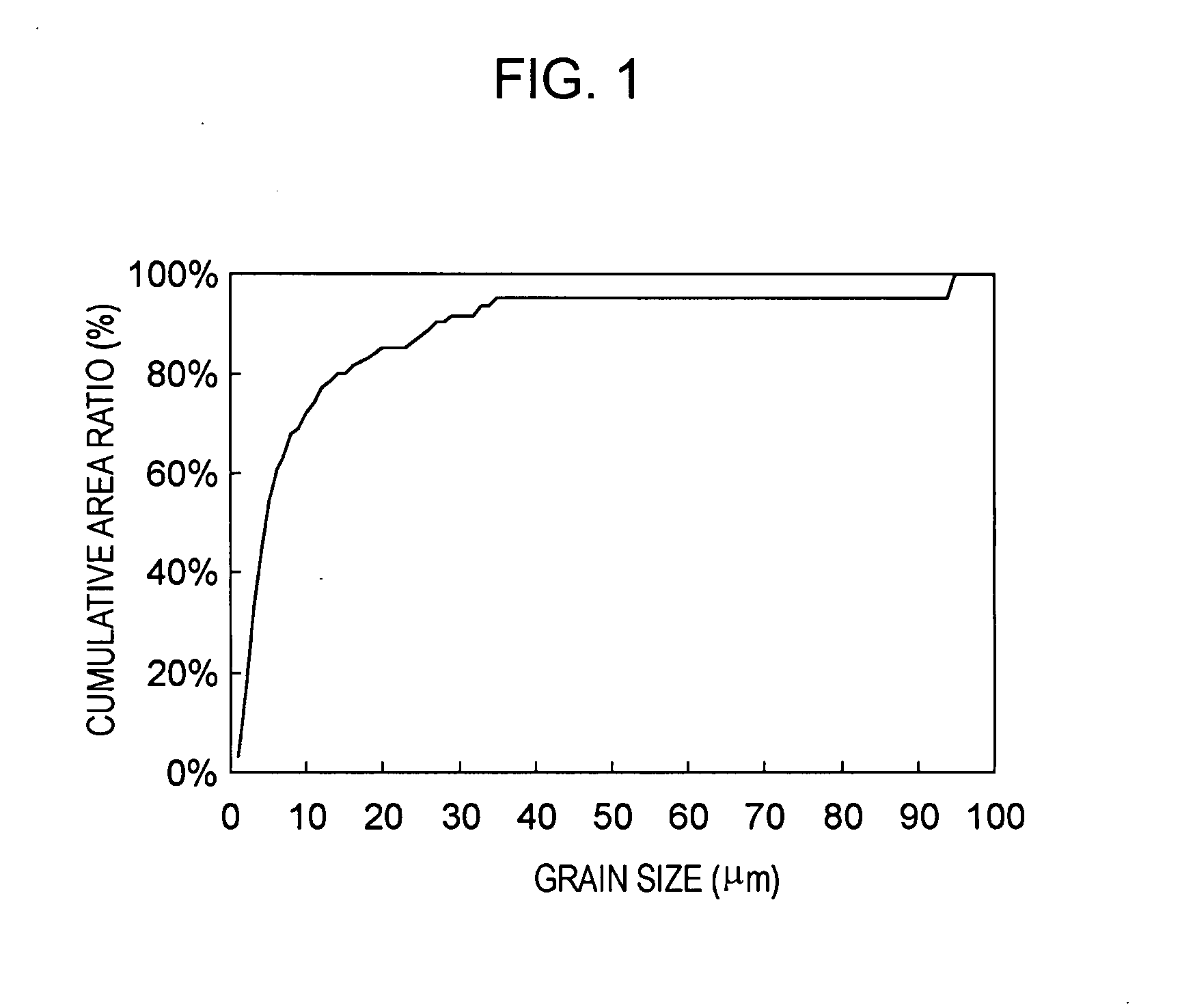

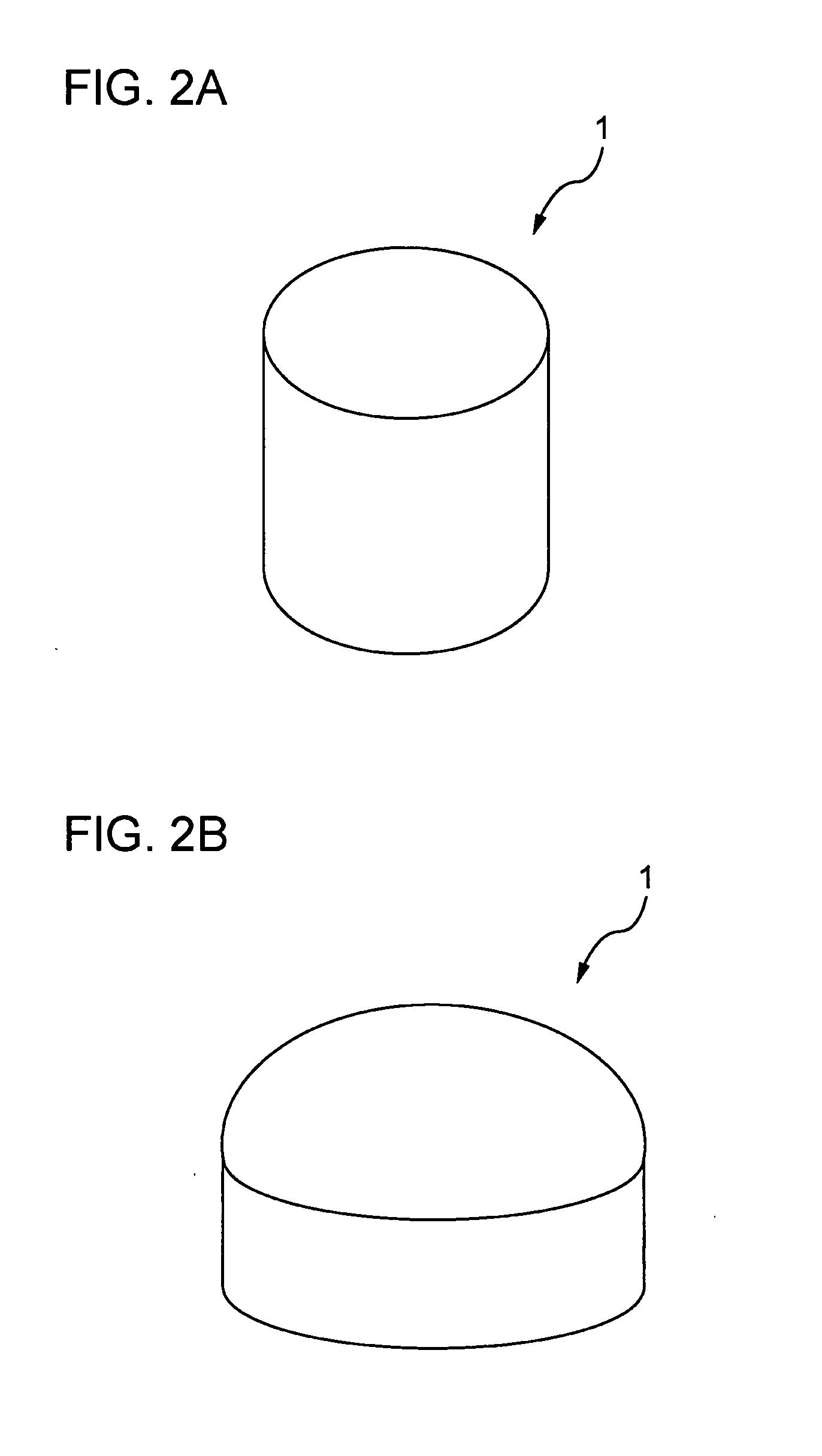

Boron carbide sintered body and protective member

The compressive strength of a boron carbide sintered compact is improved by controlling crystals of the boron carbide to a polycrystalline structure having a grain size distribution in which coarse crystals with a grain size of 20 μm or more and fine crystals with a grain size of 10 μm or less are mixed in an appropriate ratio. Furthermore, a protective member having an improved compressive strength can be provided using the boron carbide sintered compact having a polycrystalline structure in which coarse crystals and fine crystals are mixed in an appropriate ratio or a boron carbide sintered compact containing graphite and silicon carbide.

Owner:KYOCERA CORP

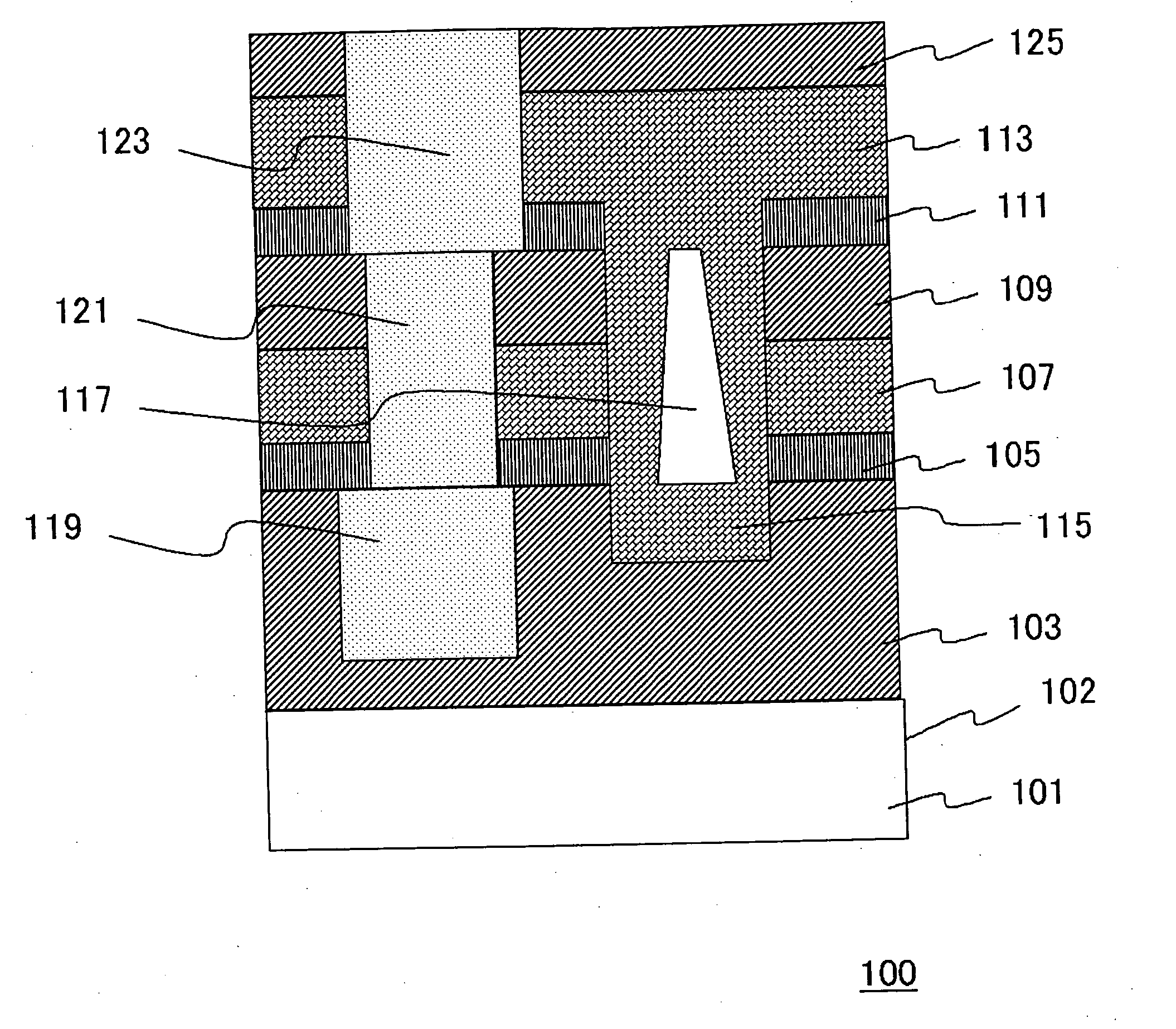

Semiconductor device

ActiveUS20060038297A1Propagation of crack can be suppressedSeparationSemiconductor/solid-state device detailsSolid-state devicesDevice materialSilicon

Propagation of a crack in a semiconductor device is to be suppressed, thus to protect an element forming region. An interface reinforcing film is provided so as to cover a sidewall of a concave portion that penetrates a SiCN film and a SiOC film formed on a silicon substrate. The interface reinforcing film is integrally and continuously formed with another SiOC film, and includes an air gap.

Owner:RENESAS ELECTRONICS CORP

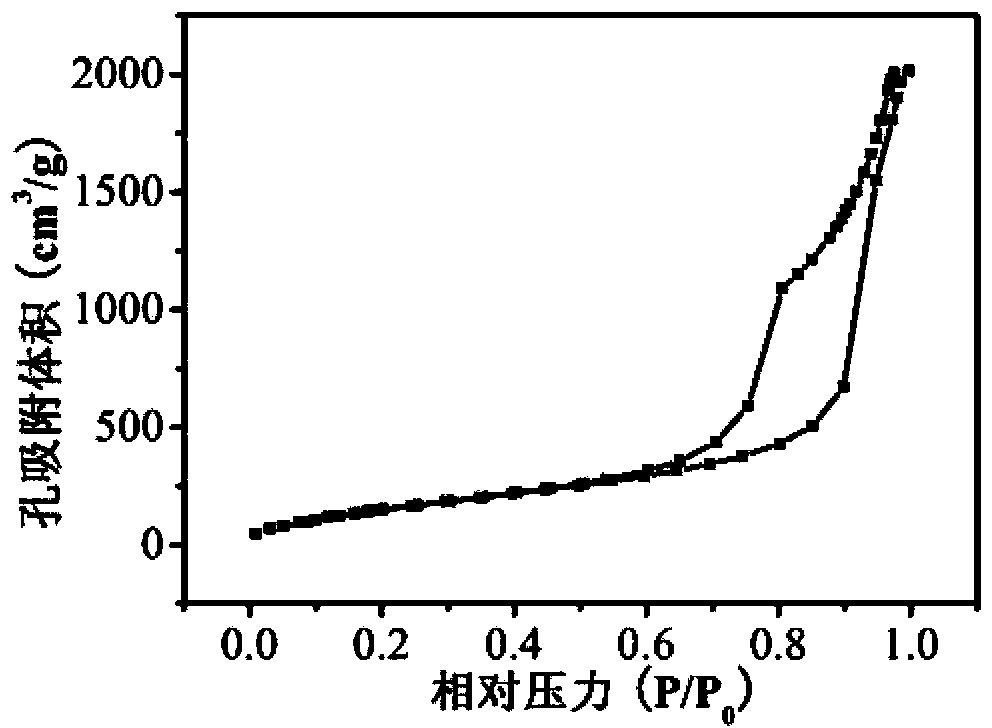

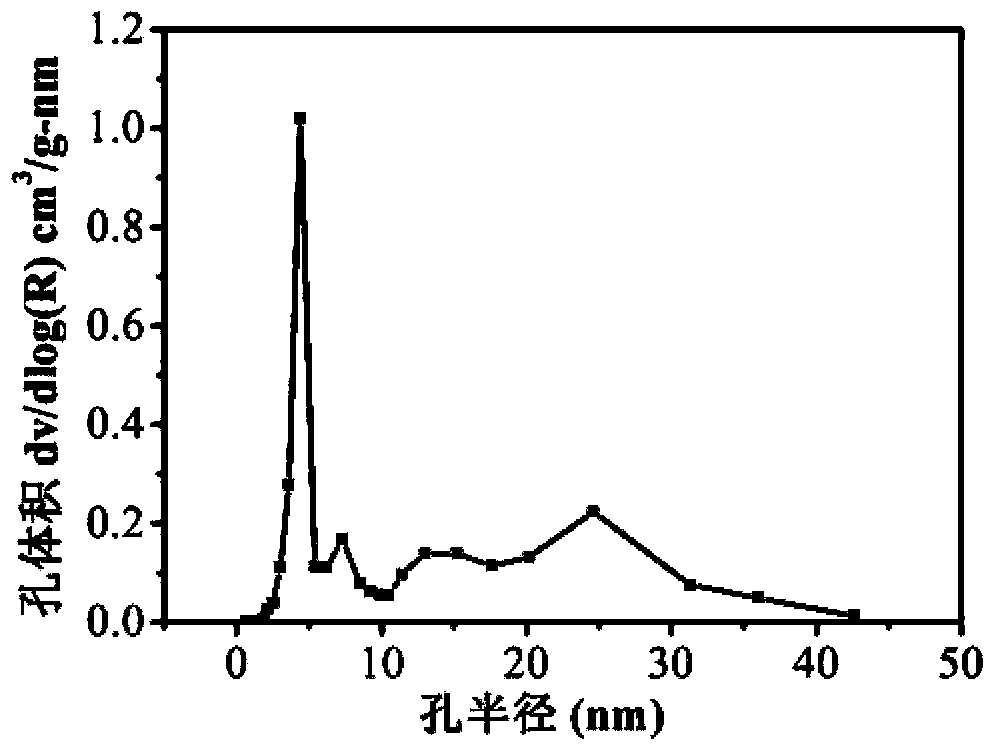

Preparation method for glass fiber-reinforced water glass-based silica composite aerogel

The invention provides a preparation method for a glass fiber-reinforced water glass-based silica composite aerogel, which relates to a silica aerogel. The preparation method comprises the following steps: mixing methoxysilane with a water glass solution and water and allowing methoxysilane to be hydrolyzed in water to obtain solution A; then adding a strongly acidic styrene resin for ion exchange, carrying out pumping filtration to obtain a solution with a pH value of 2 to 3, adding a glass fiber having undergone heat treatment into the solution obtained after pumping filtration and adding ammonia water to adjust a pH value to 8 to 8.5 so as to obtain a fiber compounded silica sol; transferring the fiber compounded silica sol to a container for standing so as to obtain a composite silica hydrogel; and then immersing the composite silica hydrogel in an absolute ethyl alcohol solution for aging and alcoholization of the gel, immersing the wet gel obtained after alcoholization in a mixed solution of trimethylchlorosilane, absolute ethyl alcohol and hexane, carrying out surface modification and drying the modified gel so as to obtain the glass fiber-reinforced water glass-based silica composite aerogel. The preparation method provided by the invention has the advantages of low cost, simple process, a short production period, a controllable product shape and capacity of realizing continuous production.

Owner:XIAMEN UNIV

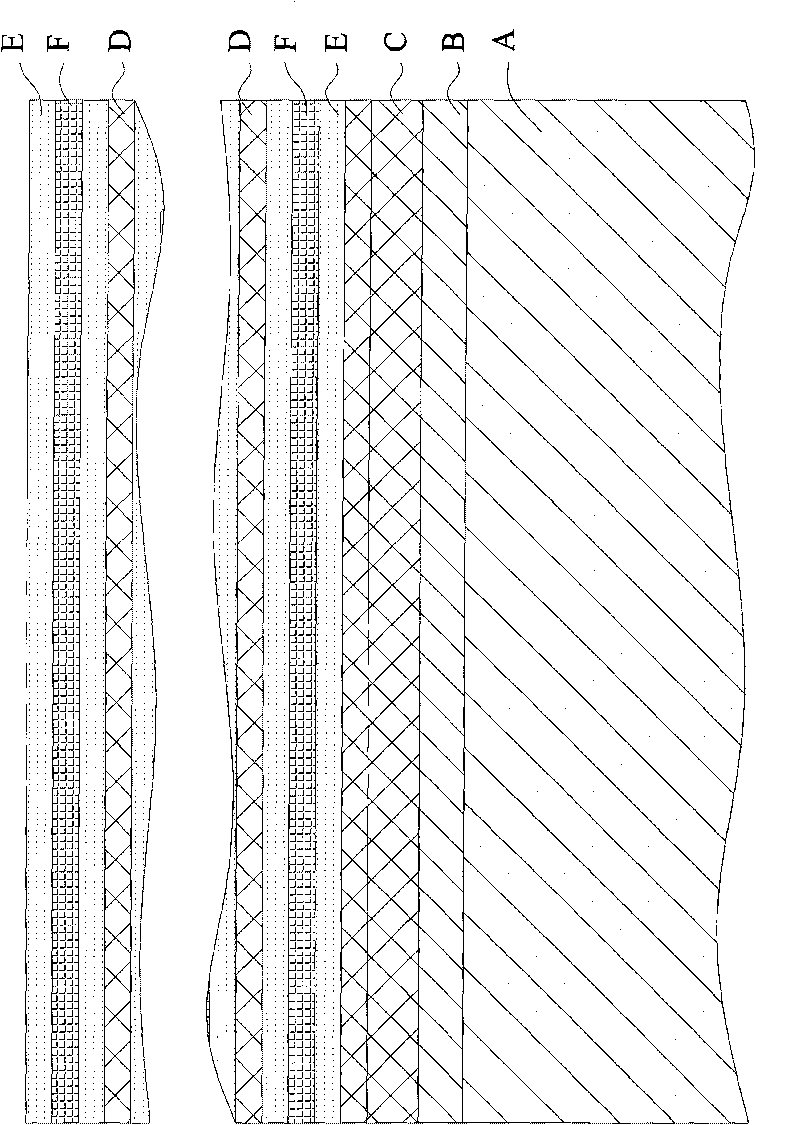

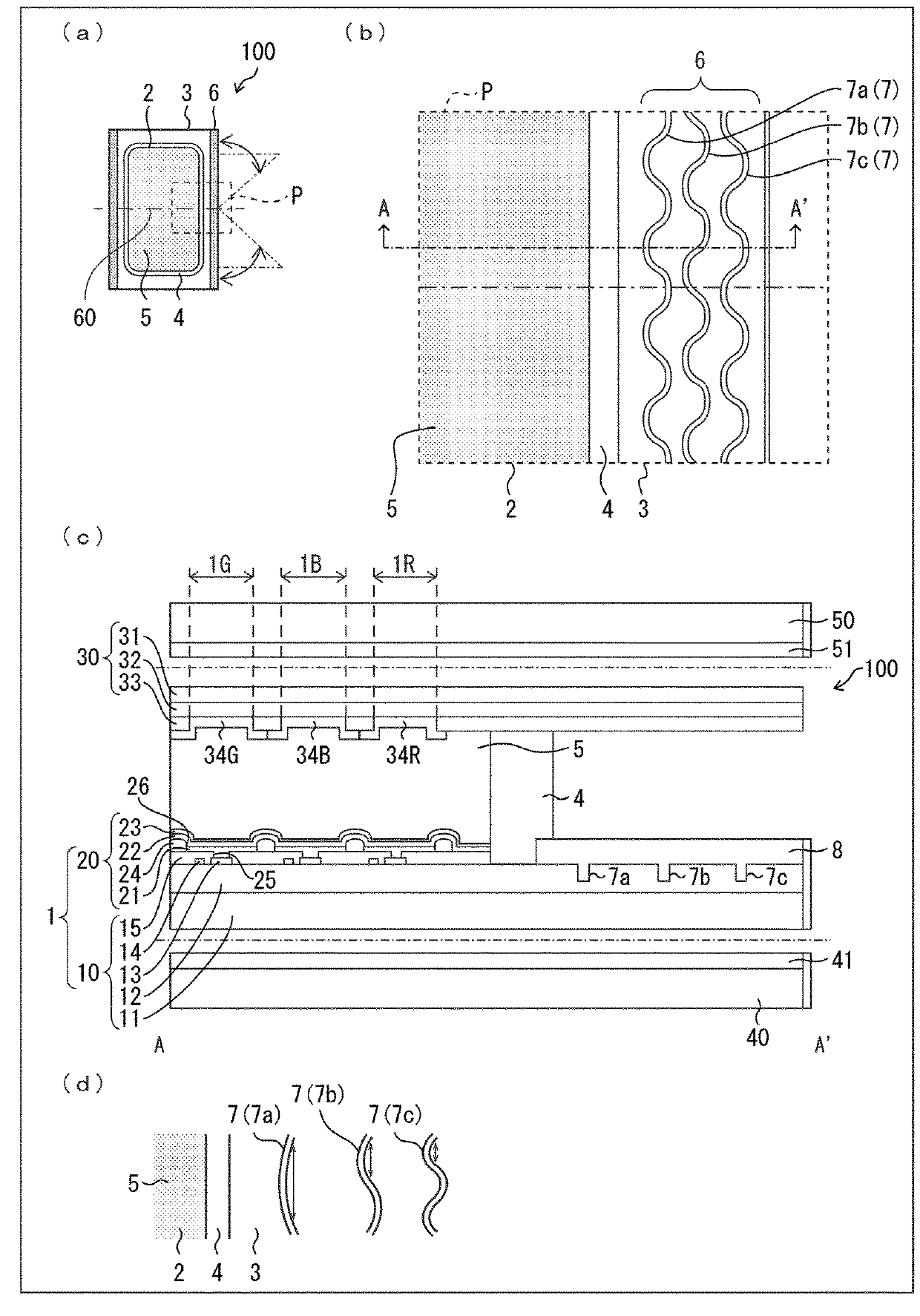

Display device and method for manufacturing the same

InactiveUS20170162822A1Extend the lifespanImprove reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay devicePhysics

A display device and a method for manufacturing the same are disclosed. The display device includes a substrate including a display area having a plurality of subpixels and a bezel area around the display area; at least one insulating layer on the substrate and having a via hole which suppresses propagation of cracks in the bezel area.

Owner:LG DISPLAY CO LTD

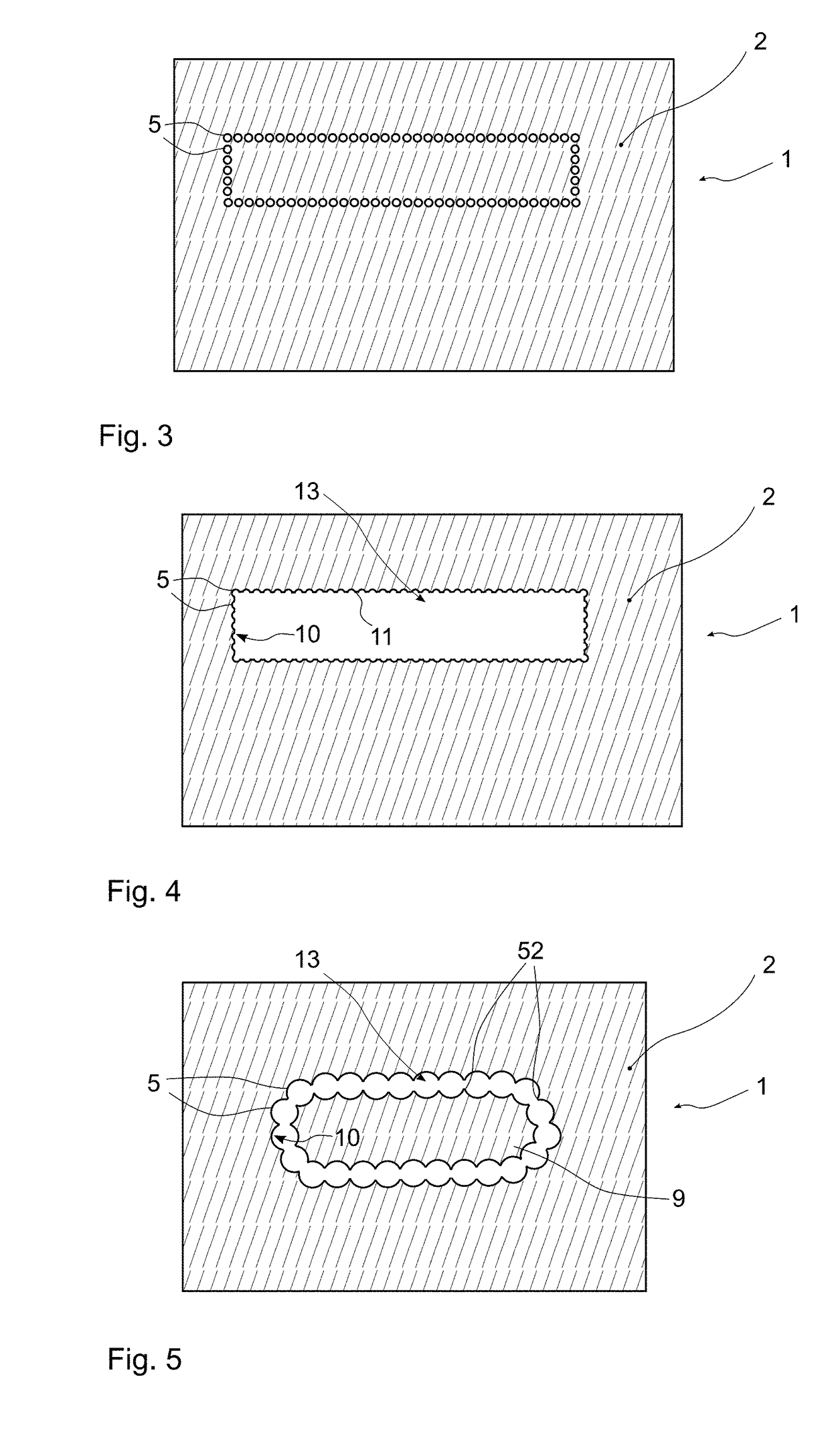

Structured plate-like glass element and process for the production thereof

ActiveUS20180215647A1Difficult to etchSuitable structureSemiconductor/solid-state device manufacturingGlass severing apparatusEngineeringMechanical engineering

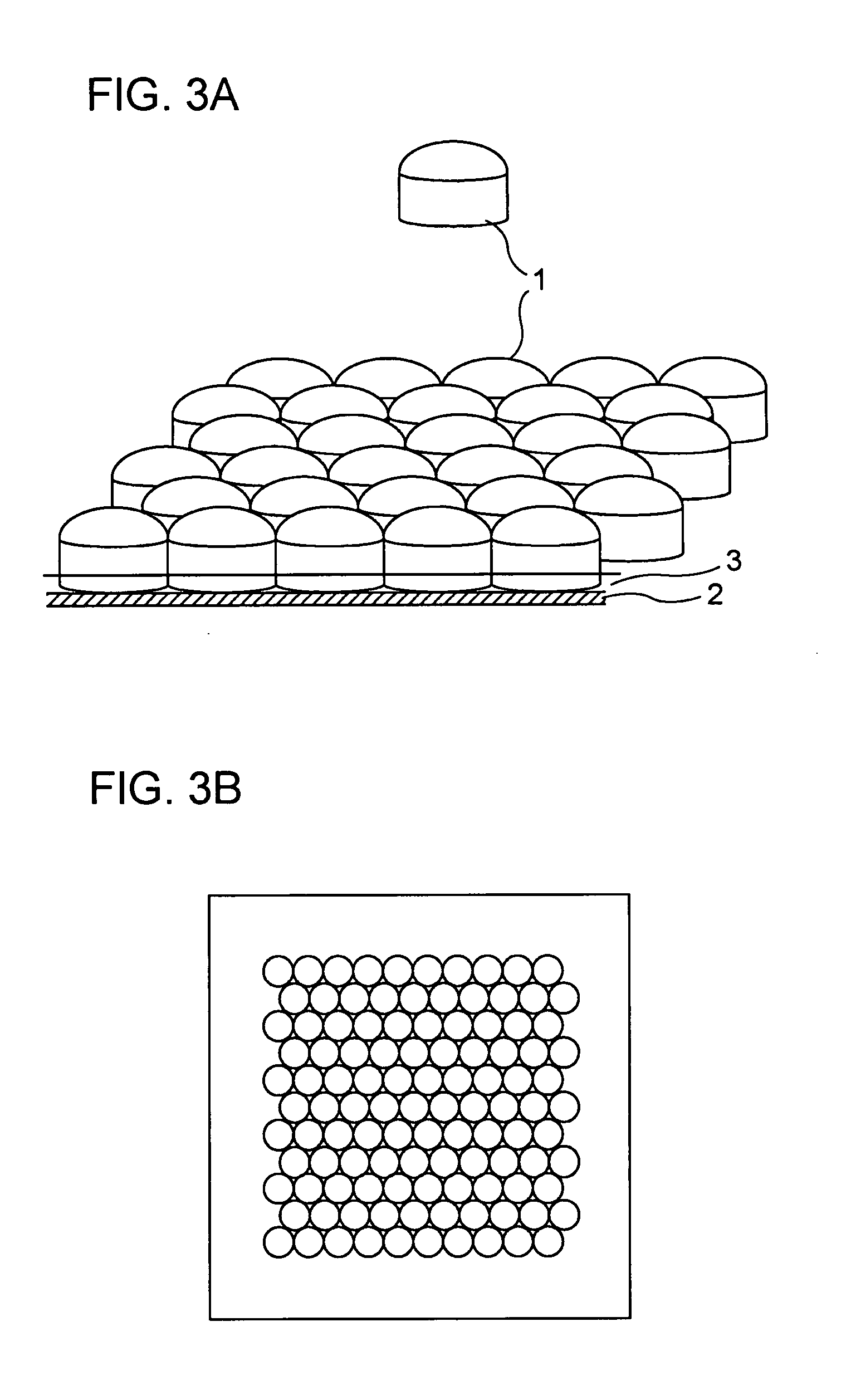

A plate-like glass element including a pair of opposite side faces and at least one channel introduced into the glass of the glass element. The at least one channel joins the side faces and opens into the side faces. The at least one channel has a rounded wall and a transverse dimension of less than 100 μm. The at least one channel extends in a longitudinal direction that runs transverse to the side faces. The rounded wall of the at least one channel has a plurality of rounded, substantially hemispherical depressions.

Owner:SCHOTT AG

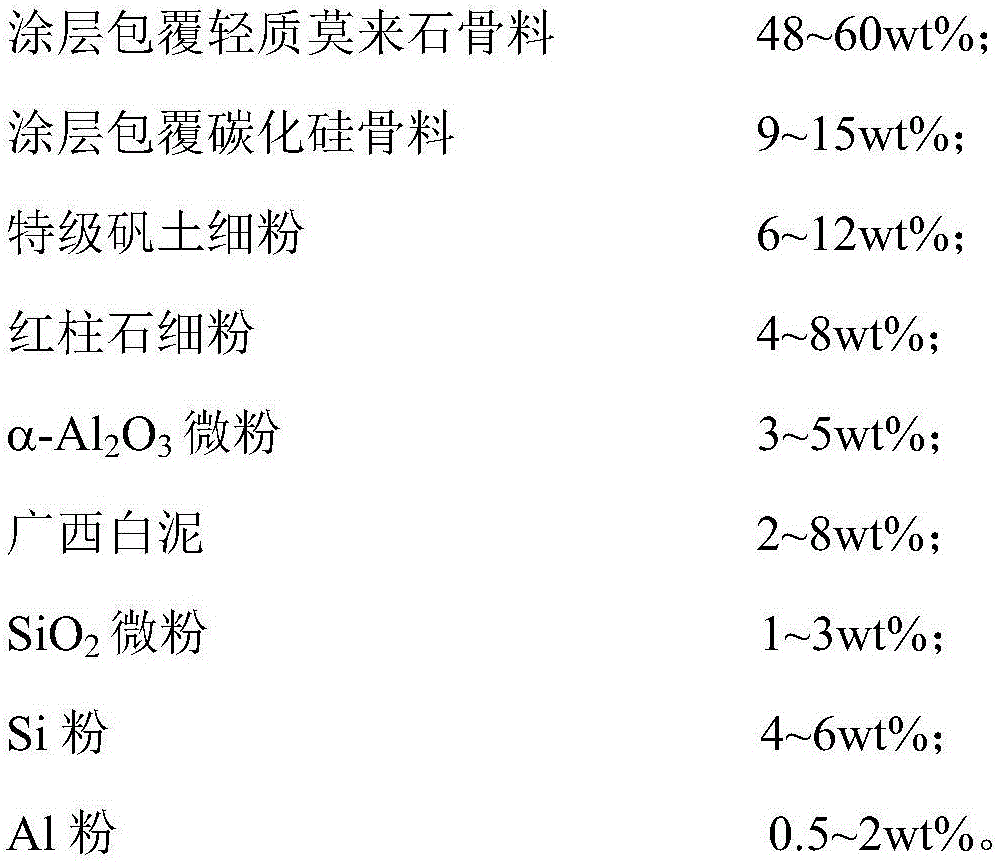

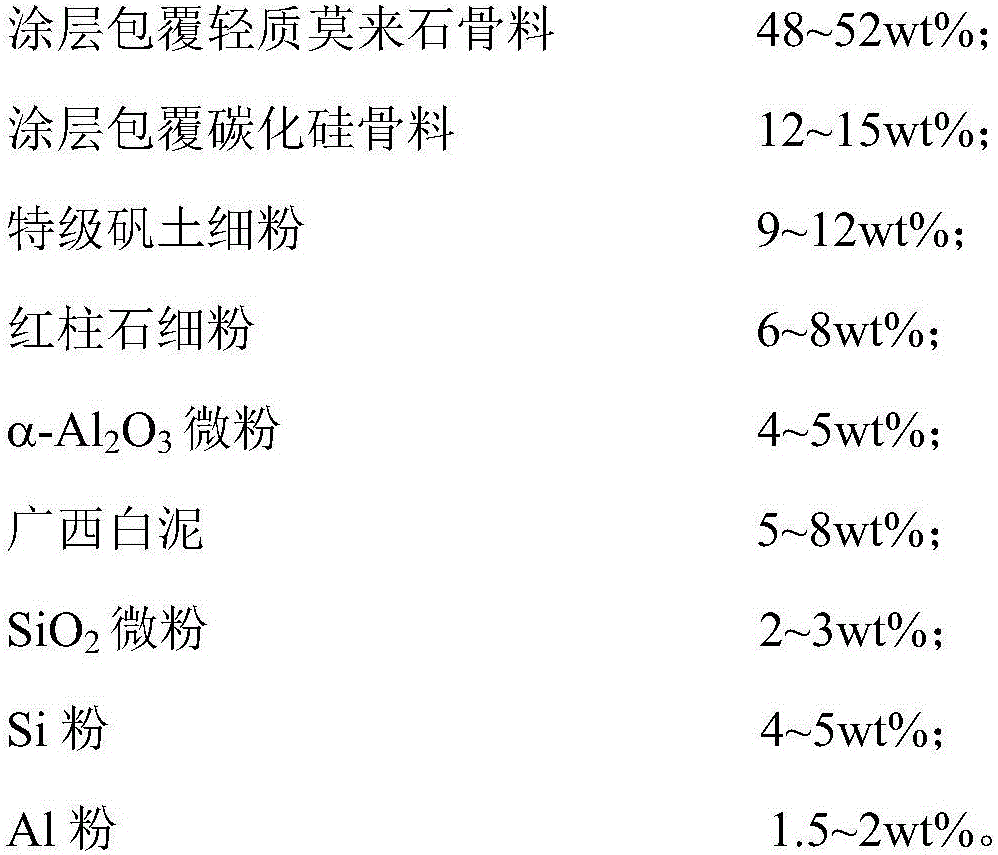

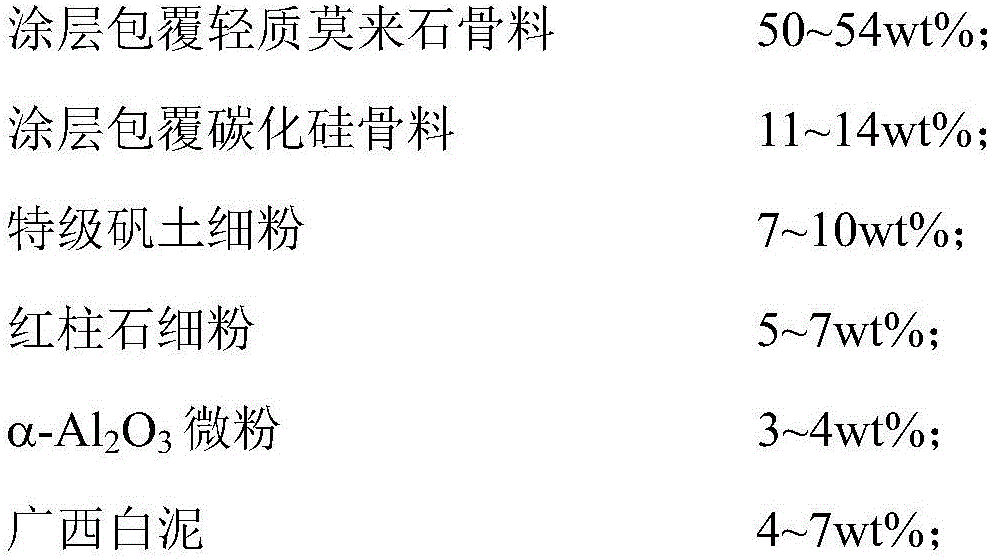

Mullite silicon carbide complex-phase fireproof material and preparation method thereof

The invention relates to a mullite silicon carbide complex-phase fireproof material and a preparation method thereof. The mullite silicon carbide complex-phase fireproof material is characterized in that 48-60wt% of coating cladding mullite light aggregate, 9-15wt% of coating cladding silicon carbide aggregate, 6-12wt% of top-grade bauxite fine powder, 4-8wt% of andalusite fine powder, 3-5wt% of alpha-Al2O3 micro powder, 4-8wt% of Guangxi white clay, 1-3wt% of SiO2 micro powder, 4-6wt% of Si powder and 0.5-2wt% of Al powder are used as raw materials. The preparation method comprises the following steps of firstly mixing two kinds of the aggregate in the raw materials, adding a bonding agent, then performing mixed refining on the mixed aggregate, the bonding agent and other raw materials, performing material trapping, performing compression moulding, performing drying, and performing baking under the condition of 1250-1400 DEG C so as to obtain the mullite silicon carbide complex-phase fireproof material. The mullite silicon carbide complex-phase fireproof material prepared by the preparation method disclosed by the invention has the excellent characteristics of being low in heat conduction coefficients, good in erosion resistance, and high in intensity.

Owner:WUHAN UNIV OF SCI & TECH

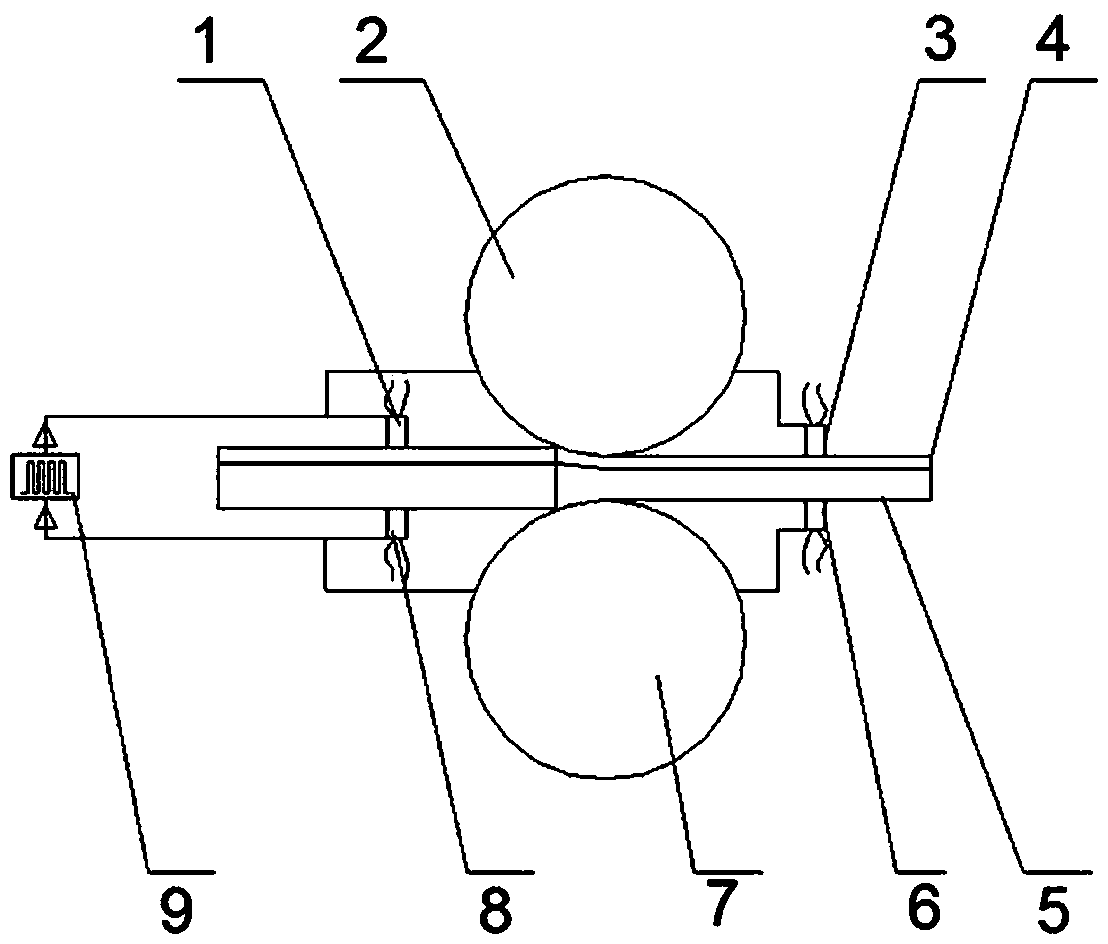

Rolling method for applying pulse current to metal composite plate

InactiveCN108356075AReduce deformation resistanceReduce the critical reduction rateAuxillary arrangementsMetal rolling arrangementsPower flowClosed loop

The invention belongs to the technical field of double-metal composite material rolling, and in particular, relates to a method for improving forming performances of a double-metal composite plate through adding pulse current in a rolling process. The method comprises main steps of treatment of coating layer metal and base layer metal before rolling, communication of the pulse current on a metal plate and rolling through startup of a rolling mill. The rolling method of the double-metal composite material is to apply the pulse current to double metal in the rolling process; and positive and negative output ends of a pulse power supply are connected with an electric brush to form a closed loop. The method has the following beneficial effects: the plasticity of the double-metal plate is improved; the rolling force is reduced; the edge cracking of the composite plate is inhibited; the element dispersion of the coating layer and base layer metal is promoted; the energy barrier is overcome;the metal atom dispersion efficiency is improved; the bonding strength is improved; and the rolling productivity is improved.

Owner:TAIYUAN UNIV OF TECH

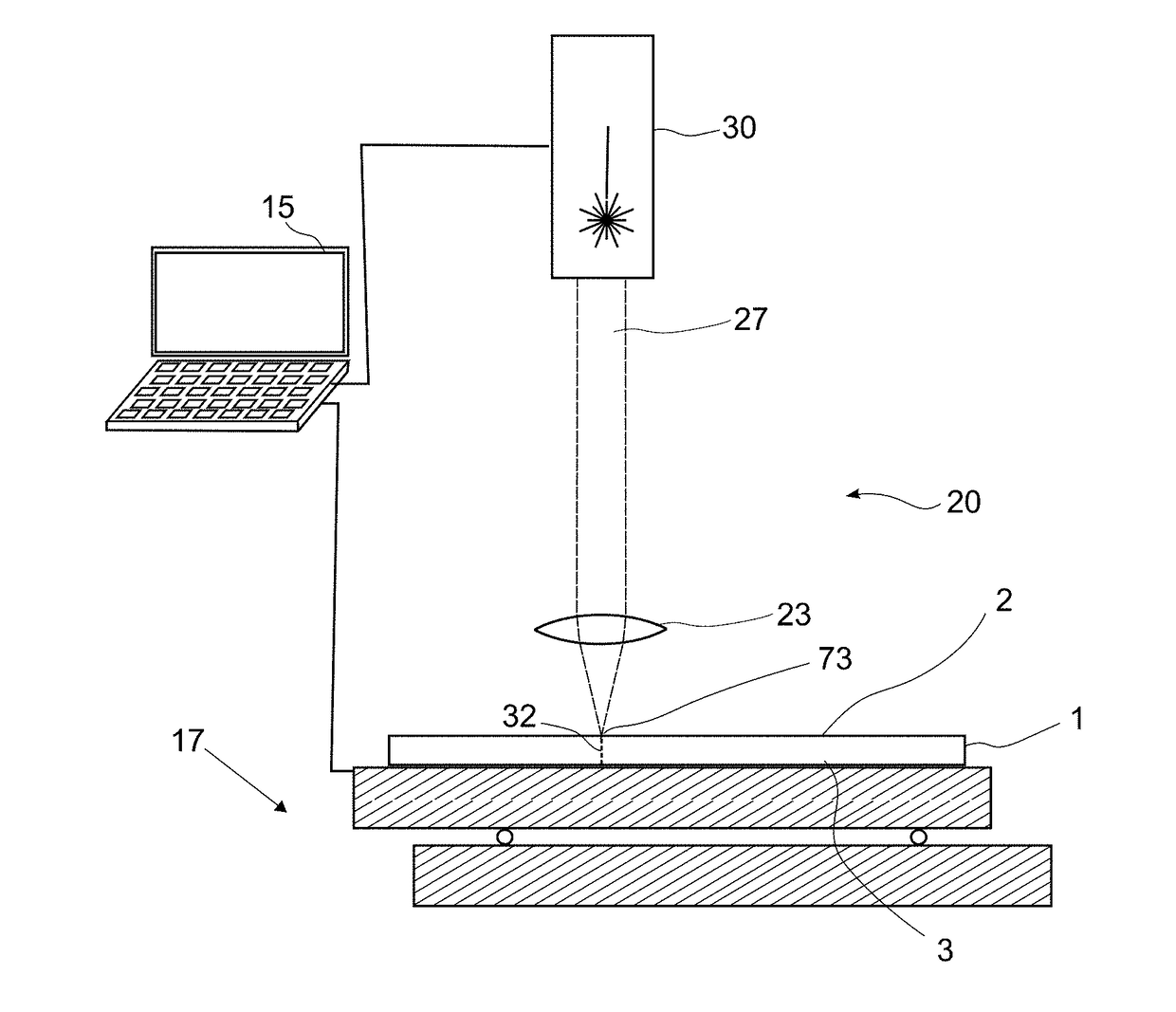

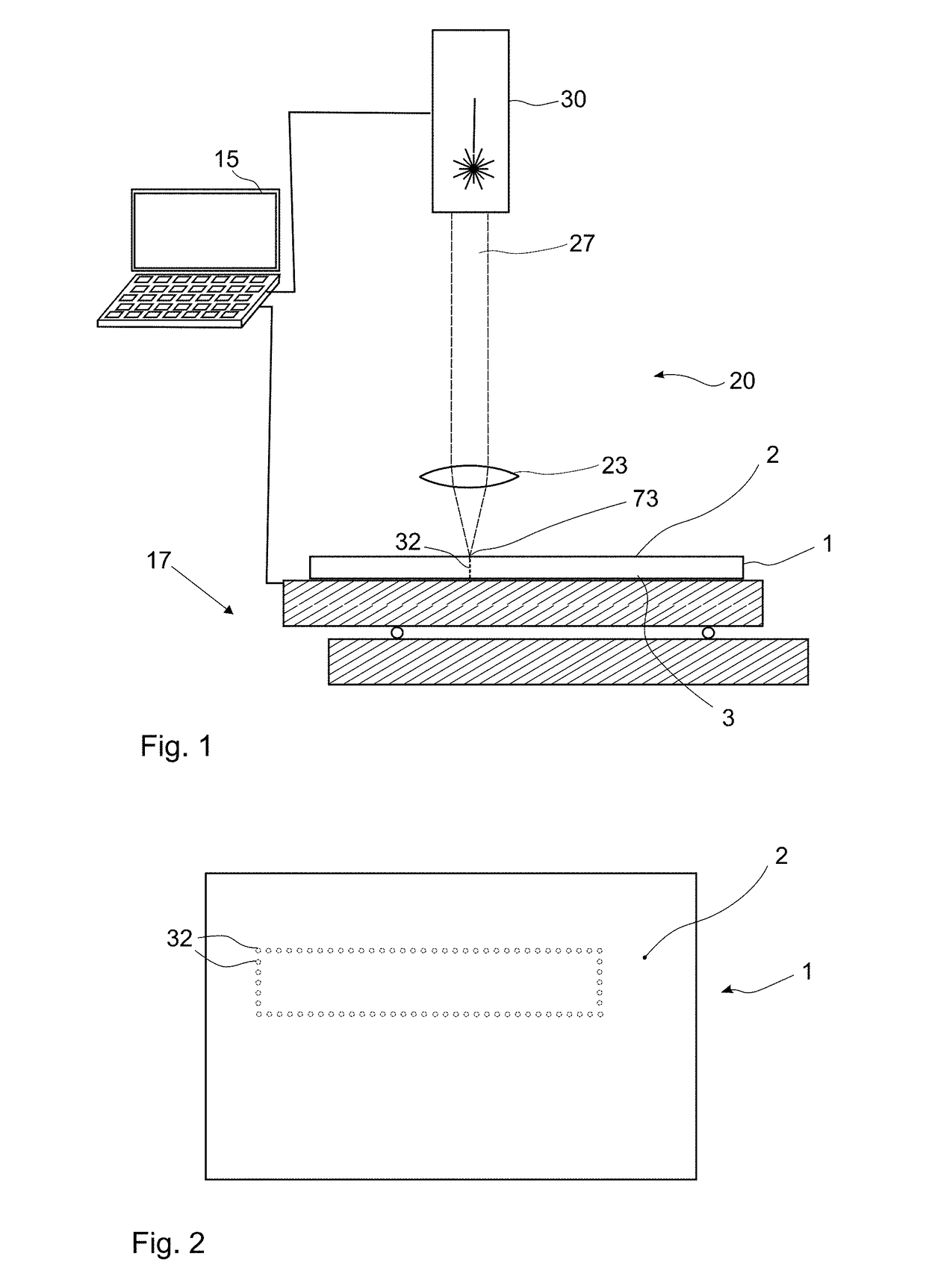

Laser peeling method of gallium nitride-based epitaxial film

InactiveCN101555627AReduce shockReduce shock wave stressPolycrystalline material growthAfter-treatment detailsShock waveInterface layer

The invention discloses a laser peeling method of a gallium nitride-based epitaxial film, comprising the following steps: a plurality of layers of gallium nitride-based epitaxial films grow on a sapphire substrate; the layers of gallium nitride-based epitaxial films are isolated by a scribing groove to form a gallium nitride-based unit component; the scribing groove scribes through till the surface of the sapphire substrate; protection materials are filled in the scribing groove; a metal layer is used as an interface layer, the gallium nitride-based epitaxial film is connected to the high heat-conducting and electricity-conducting substrate; laser facula is shaped so that the facula projected at the interface position of the sapphire substrate and the gallium nitride-based epitaxial film is processed to be a graphical facula array which can effectively reduce and restrain the stress of laser shock wave; and by adopting the graphical facula array which irradiates at the interface position of the sapphire substrate and the gallium through the sapphire, the gallium at the interface position is decomposed so that the gallium nitride-based epitaxial film is peeled off the sapphire substrate. The method realizes laser peeling with low damage, greatly reduces the damage of the gallium nitride-based epitaxial film and improves the good product rate of chips.

Owner:SUZHOU NANOJOIN PHOTONICS

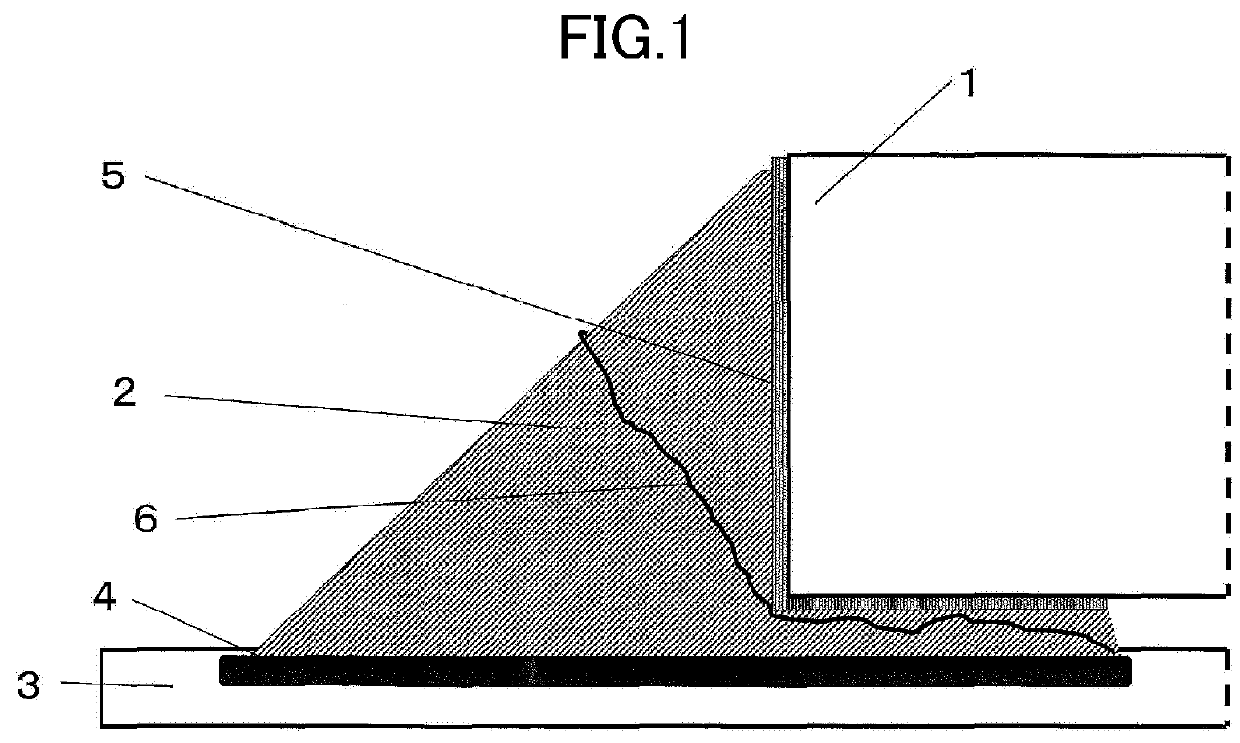

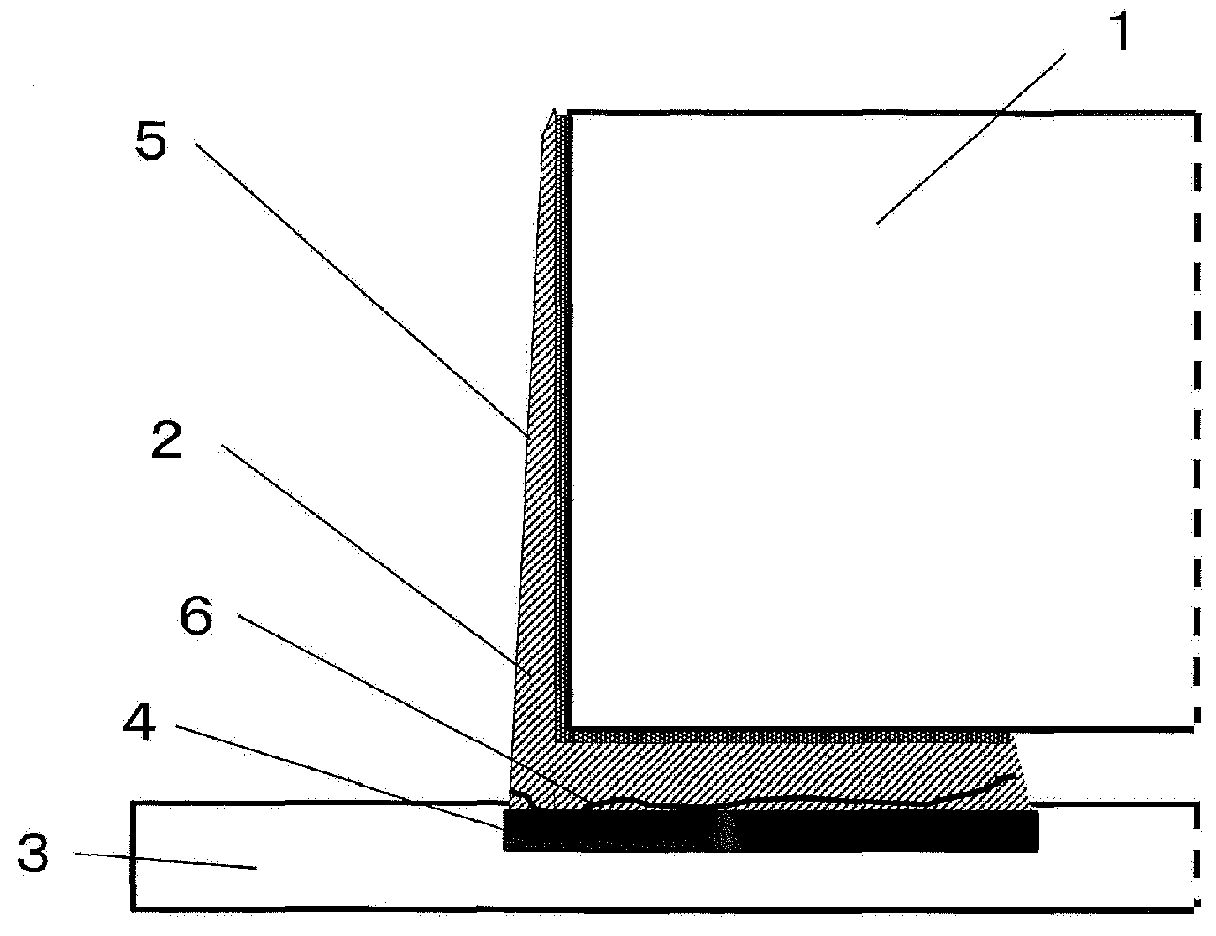

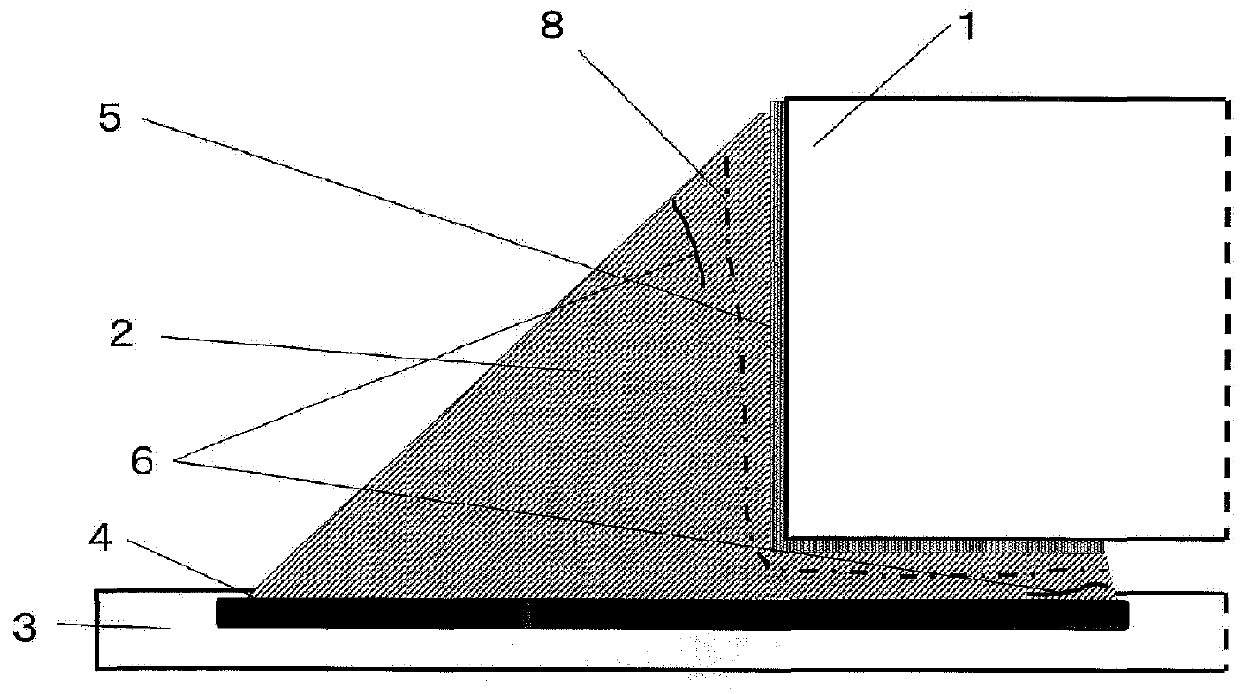

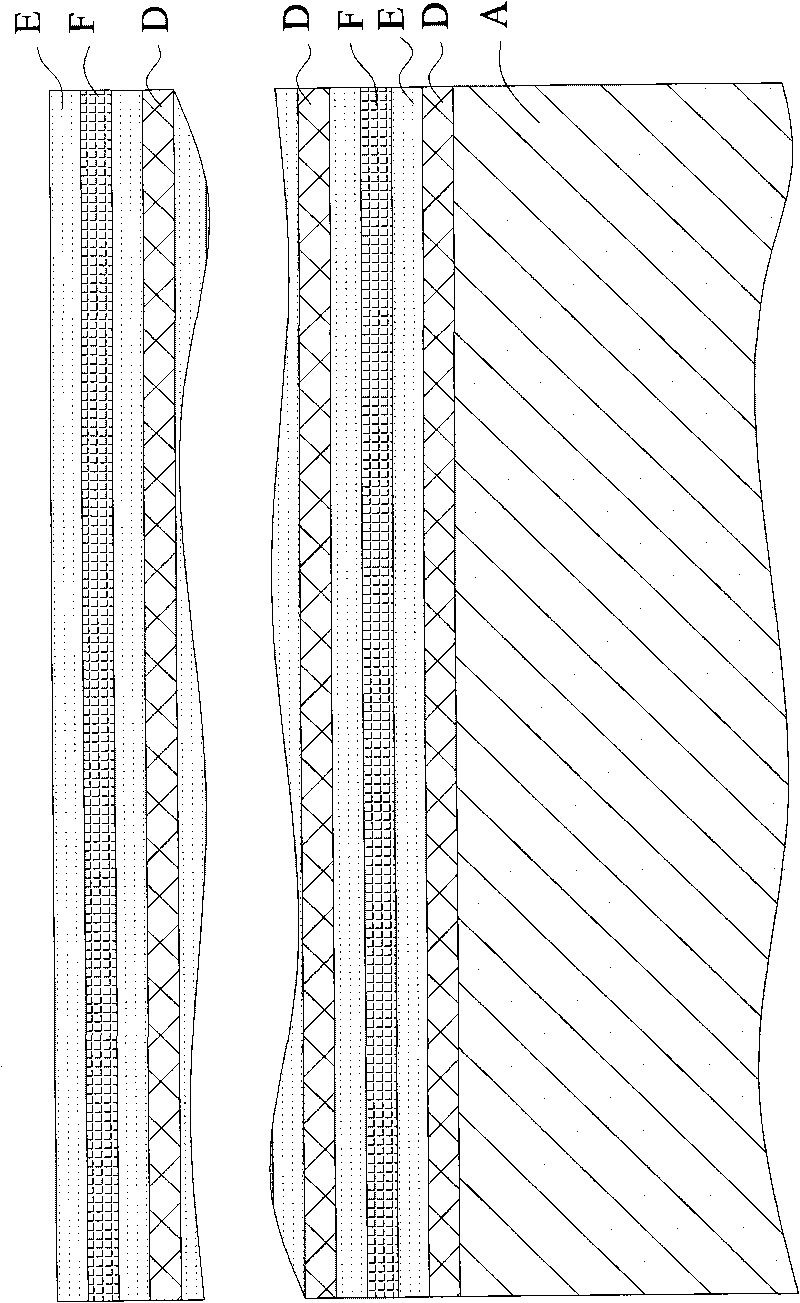

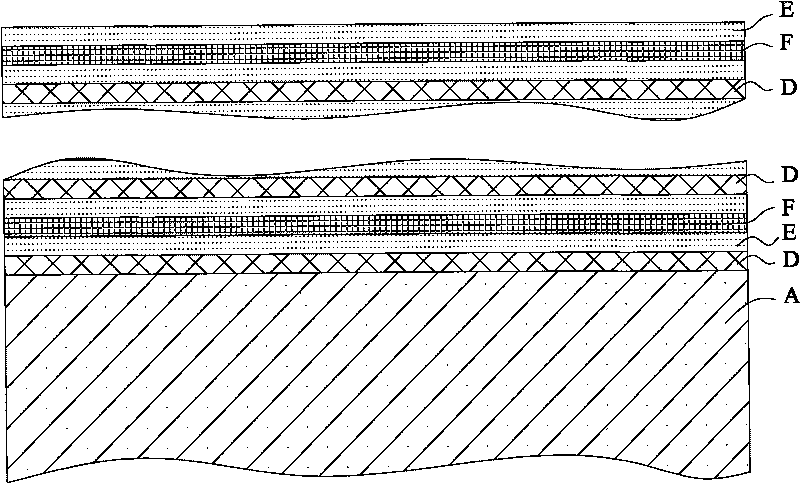

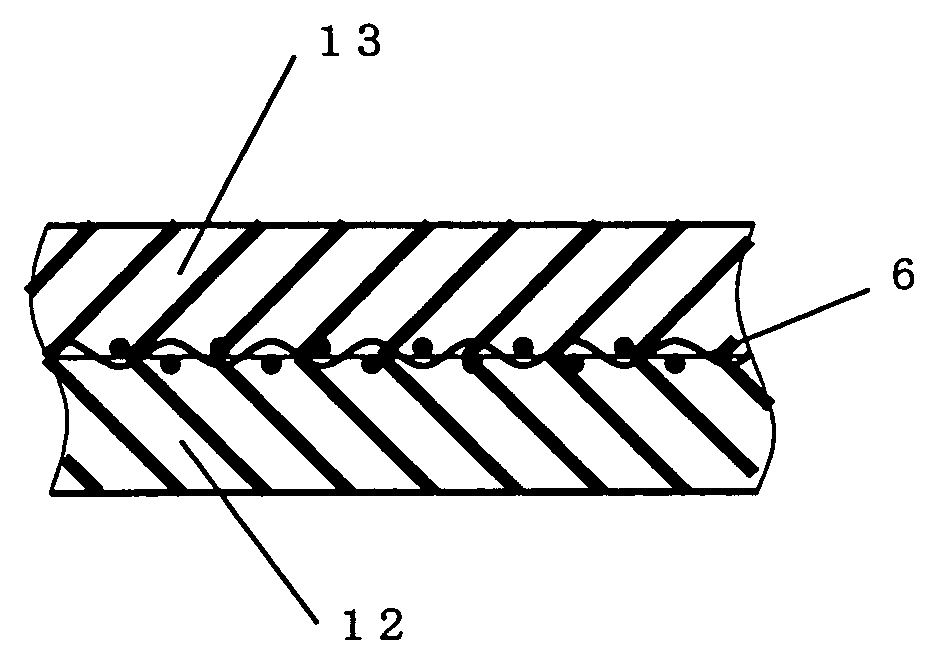

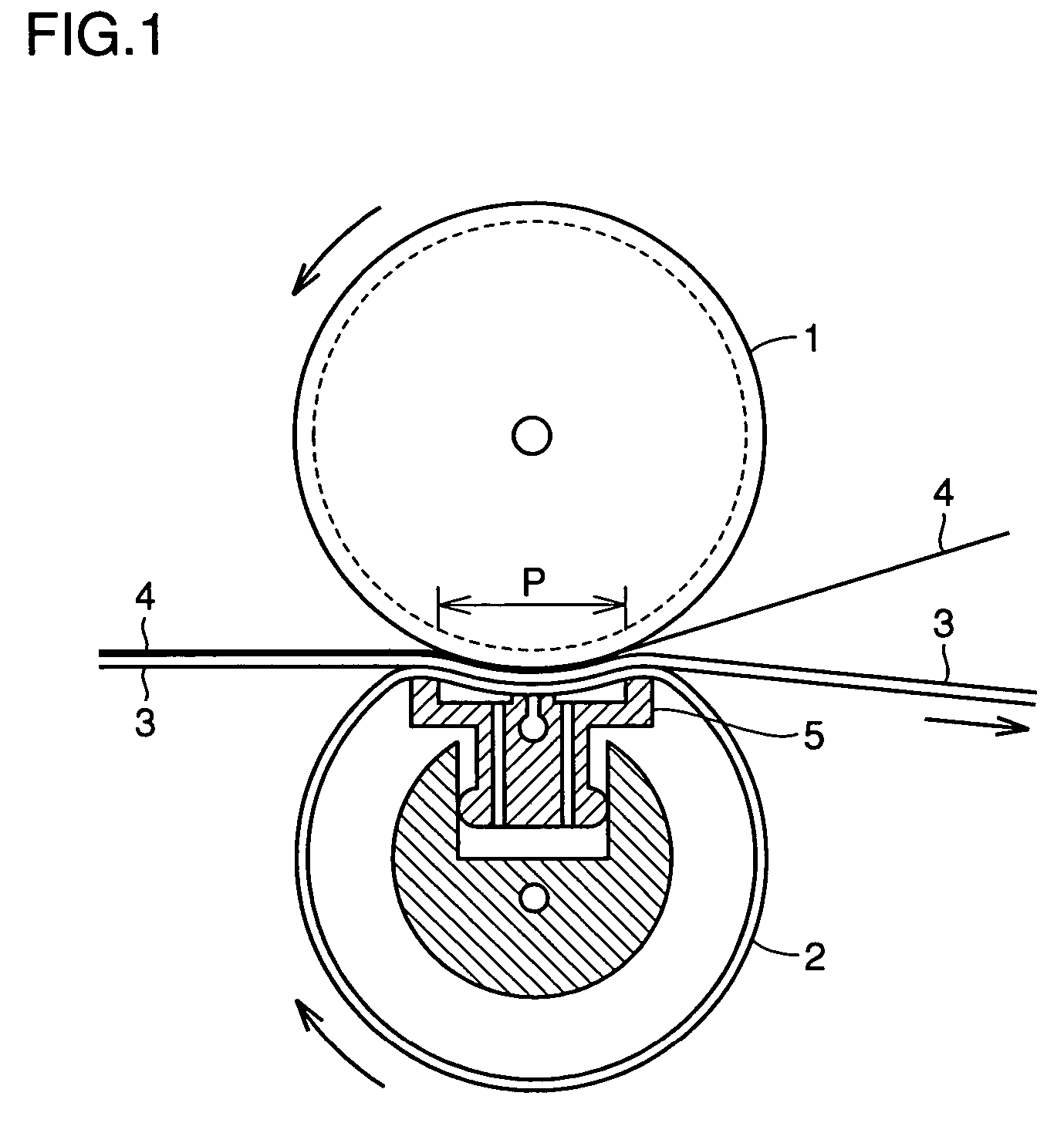

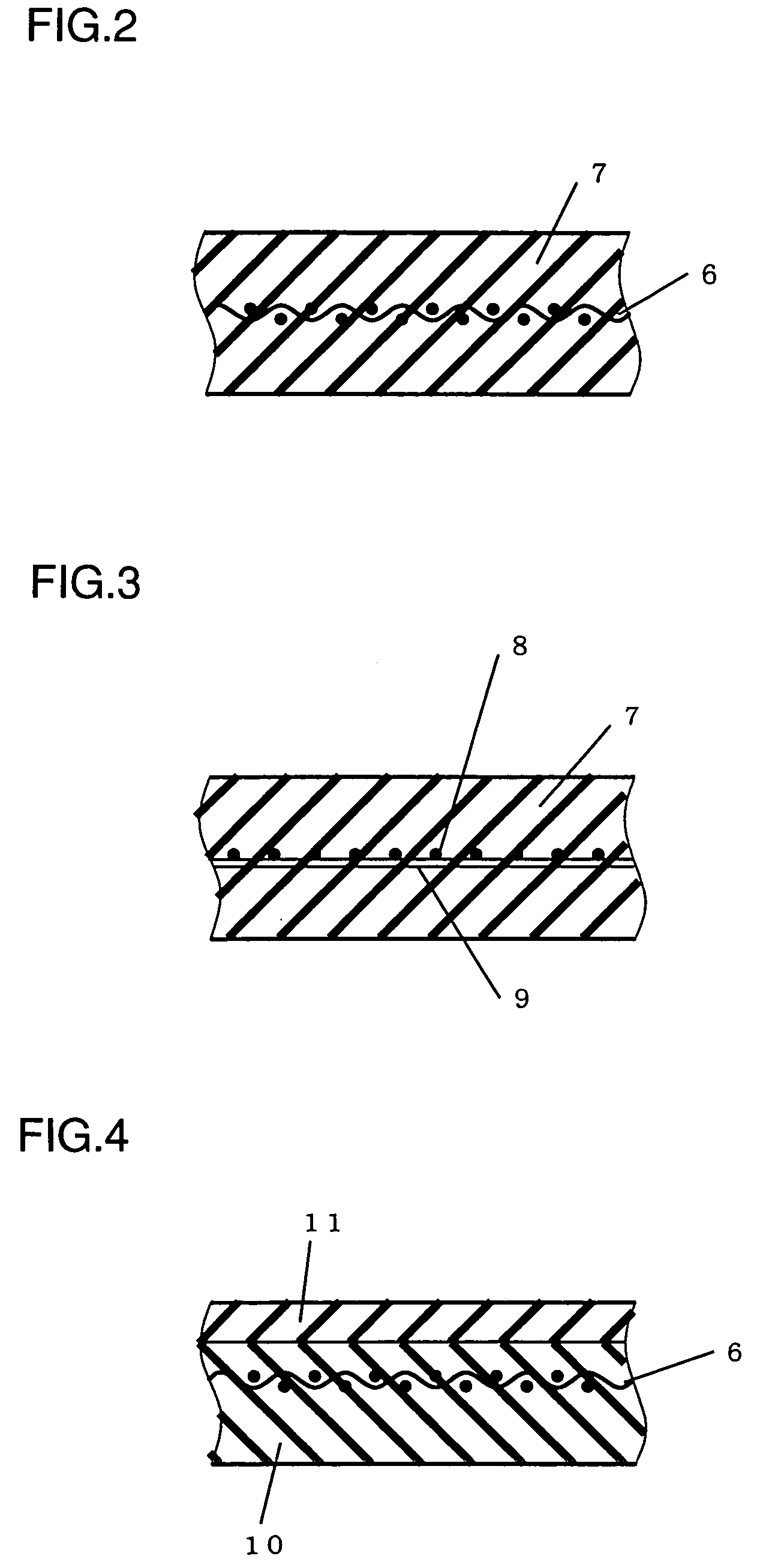

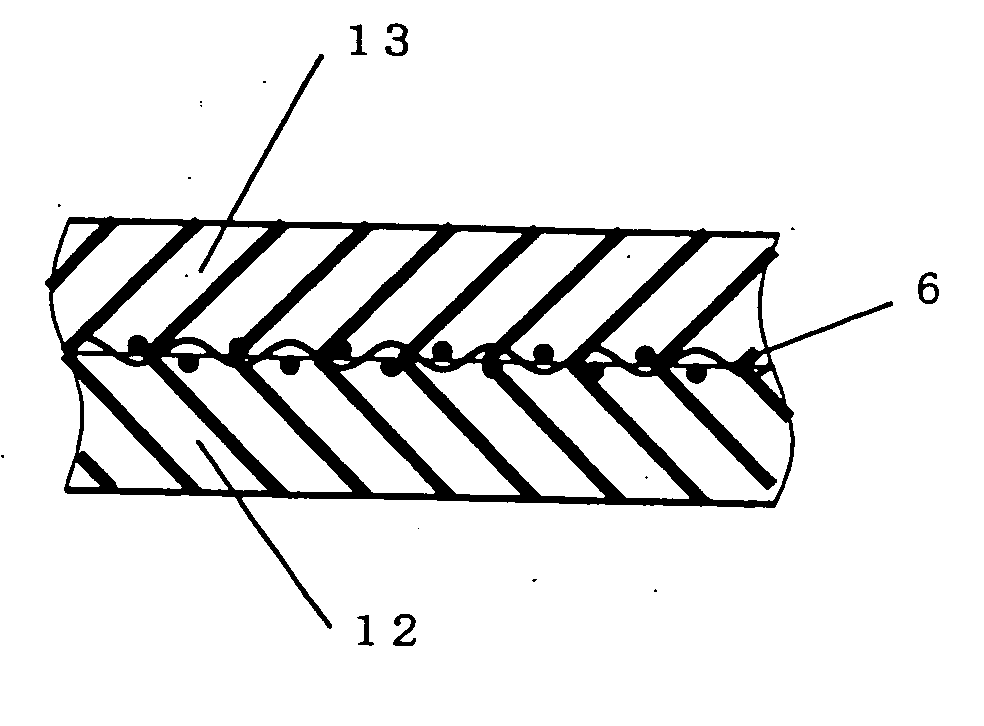

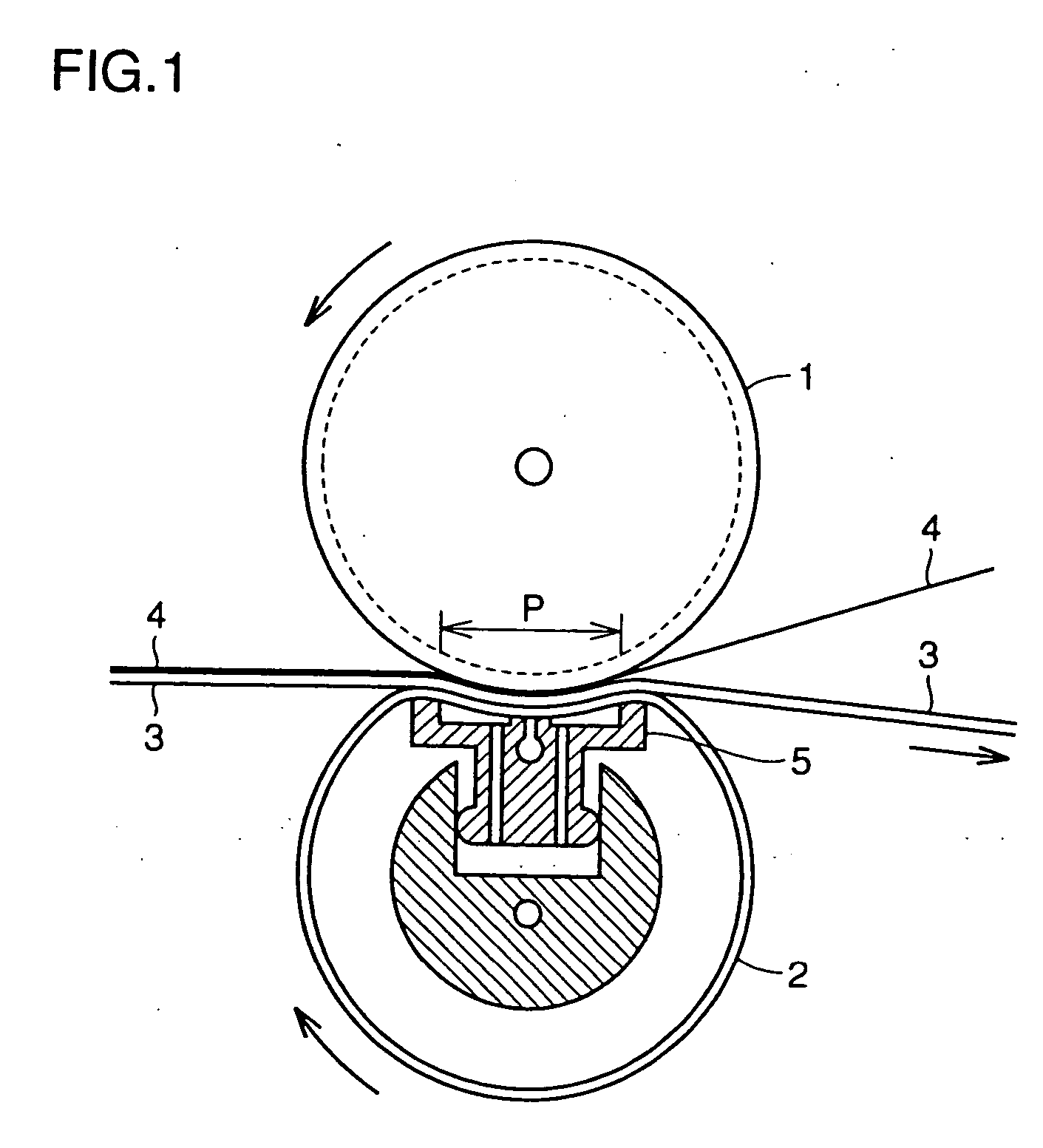

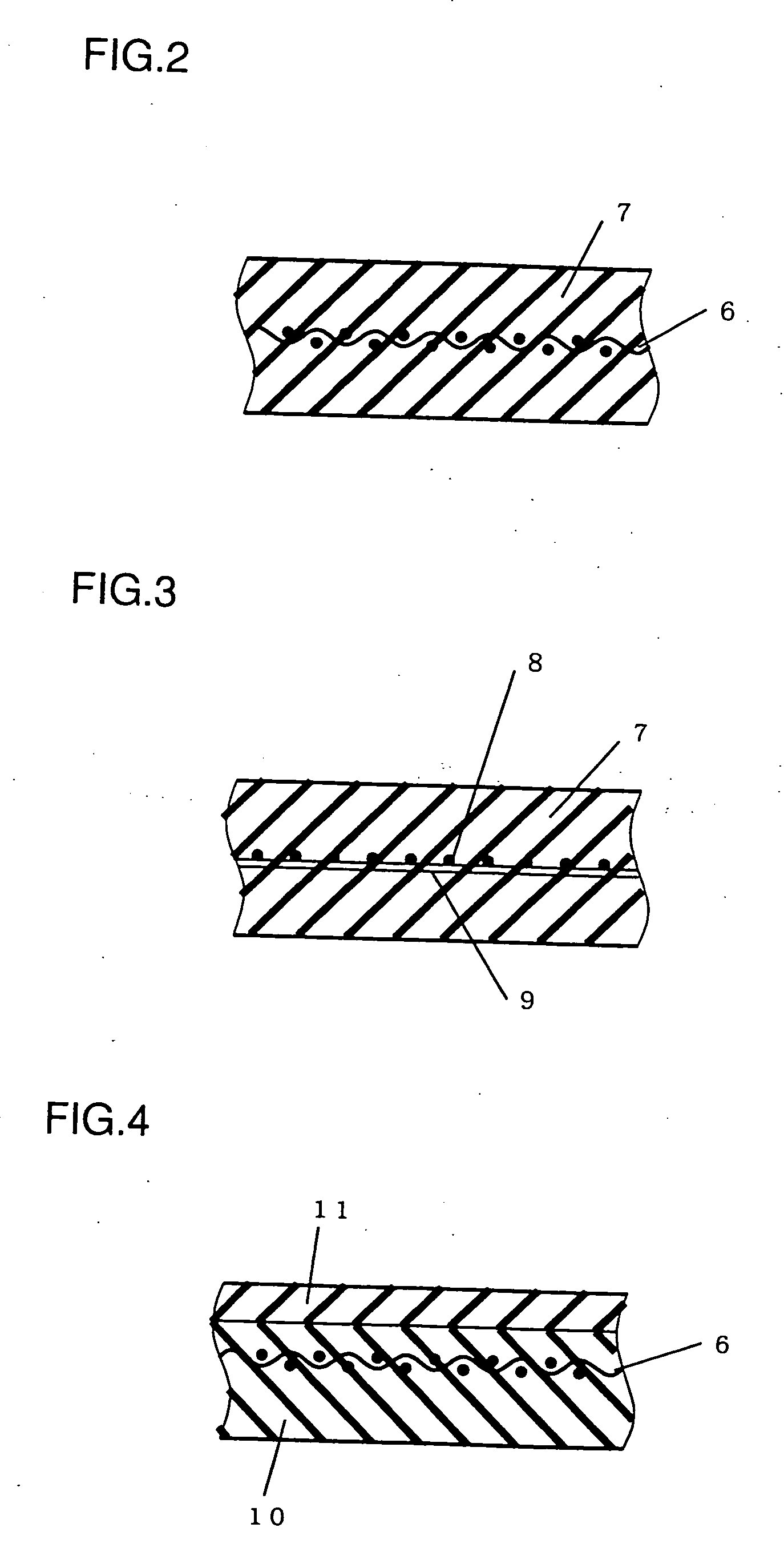

Belt for papermarking and process for producing papermaking belt

InactiveUS7090747B2Prevent crack growthAvoid stratificationLiquid surface applicatorsSynthetic resin layered productsPulp and paper industryPrepolymer

A papermaking belt which prevents cracking and inhibits crack growth which includes a reinforcing substrate embedded in a thermosetting polyurethane layer so that the reinforcing substrate and the thermosetting polyurethane layer are integrated with each other and the outer peripheral surface and the inner peripheral surface of the belt are formed by polyurethane layers, the polyurethane layer forming the outer peripheral surface being made of a composition containing a urethane prepolymer having isocyanate groups on its ends and a hardener containing dimethylthiotoluenediamine.

Owner:YAMAUCHI CORP

Flexible electronic device and method for manufacturing flexible electronic device

InactiveUS20180165996A1Prevent crack growthFinal product manufactureElectroluminescent light sourcesFlexible electronicsEngineering

Owner:SHARP KK

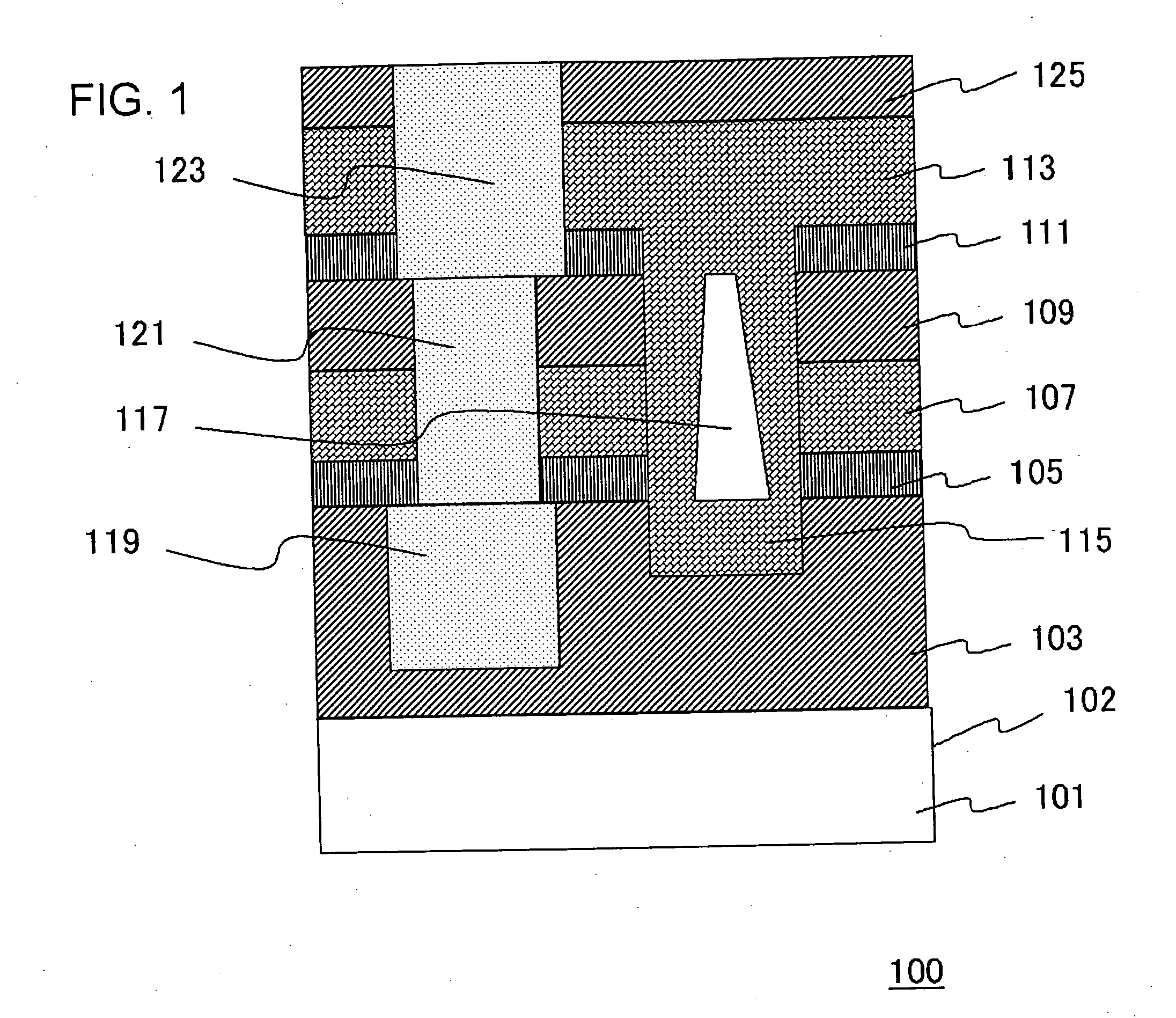

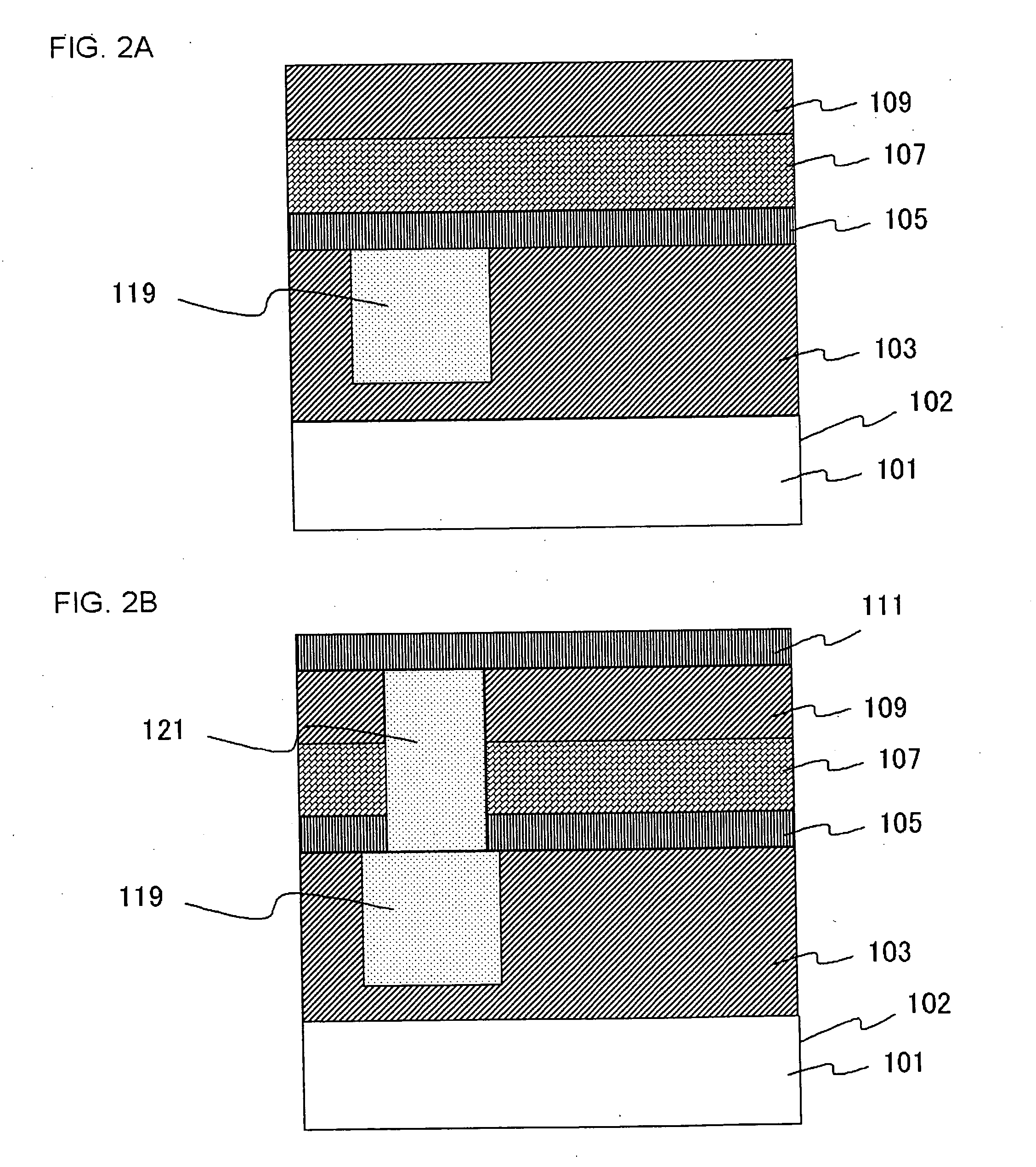

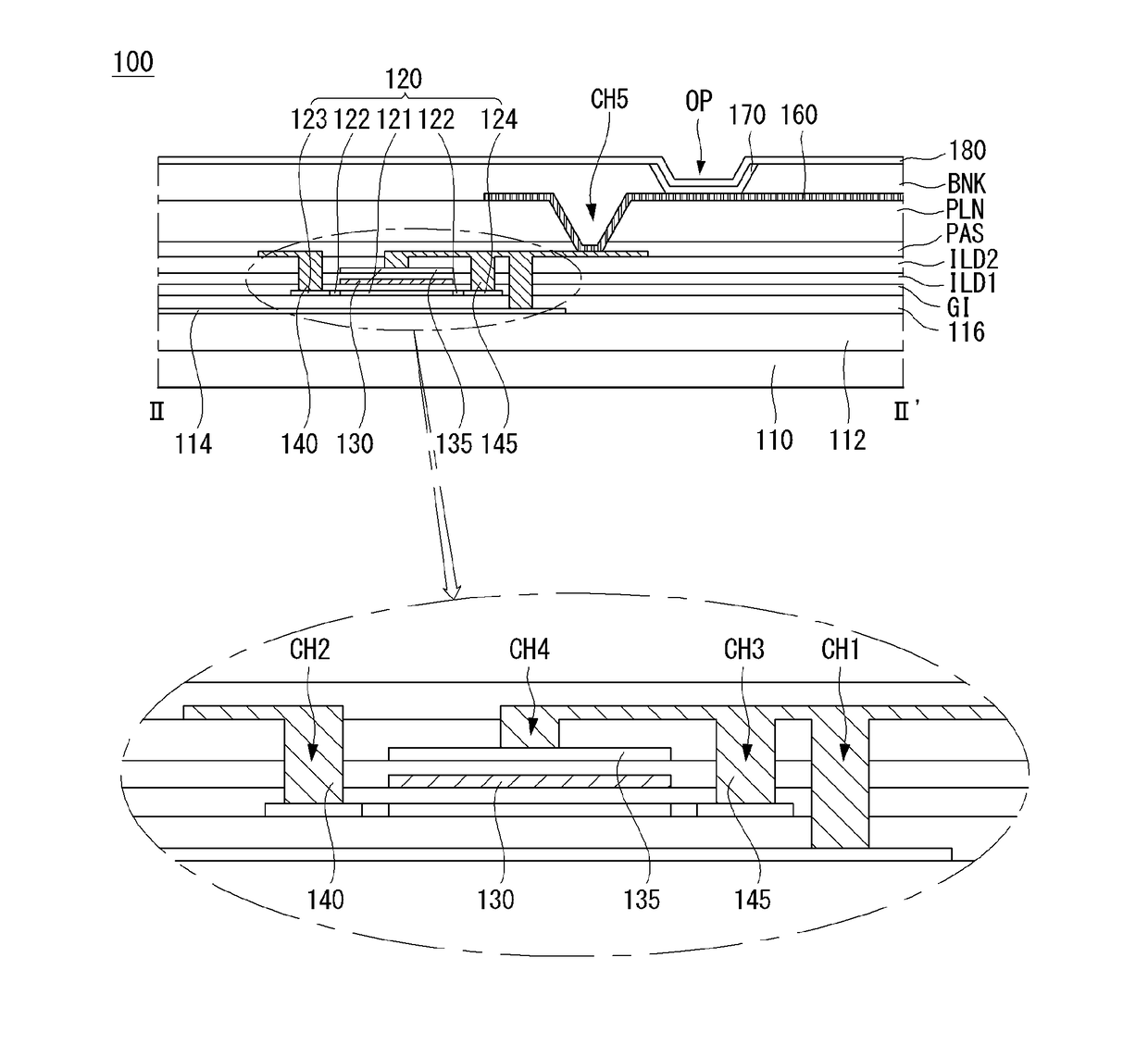

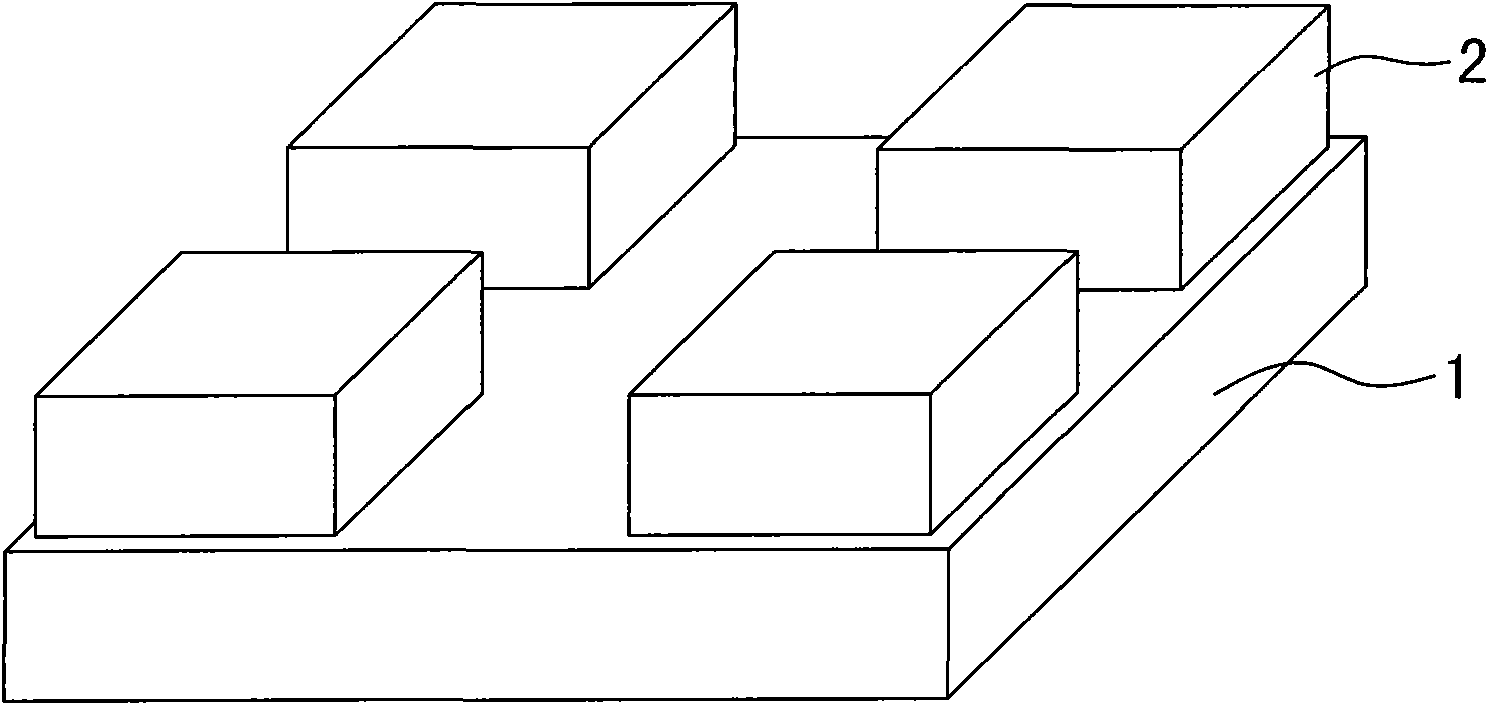

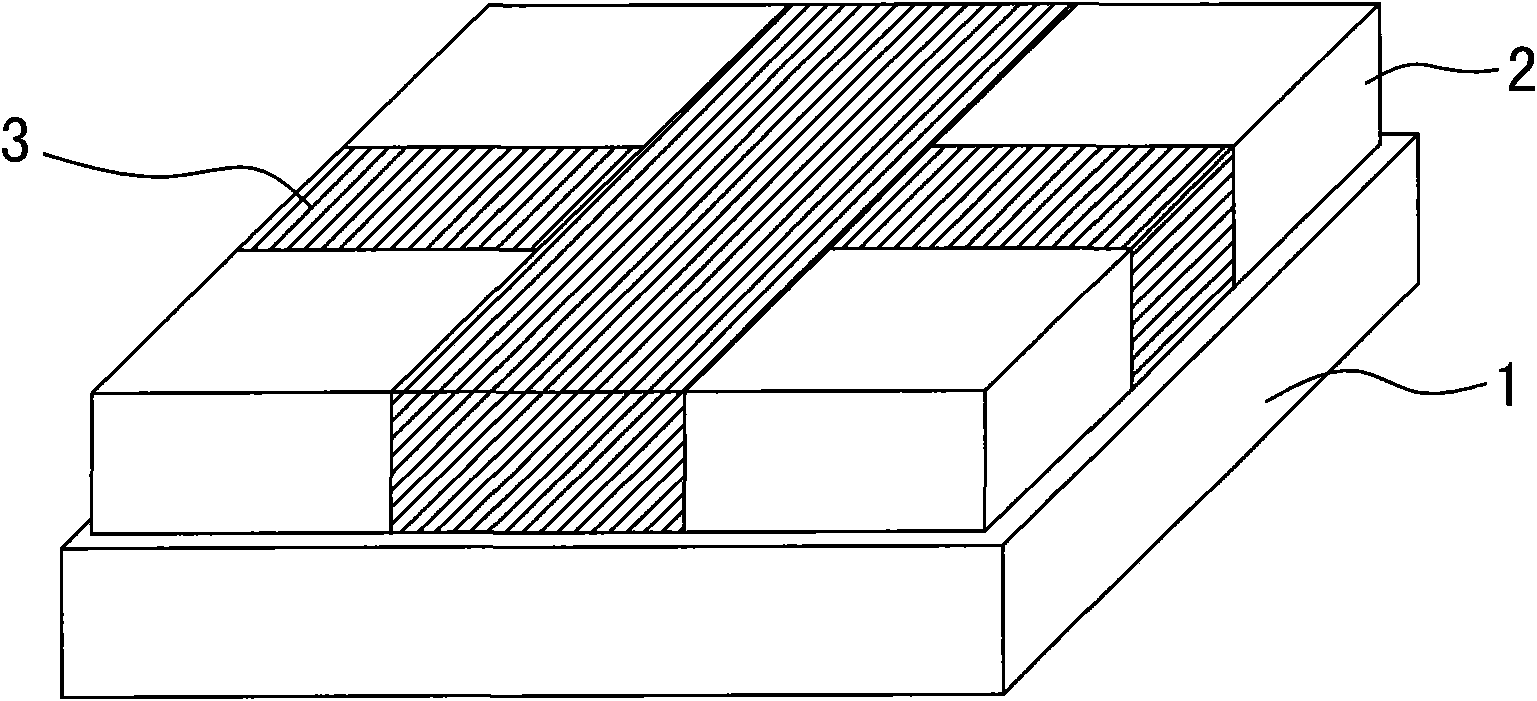

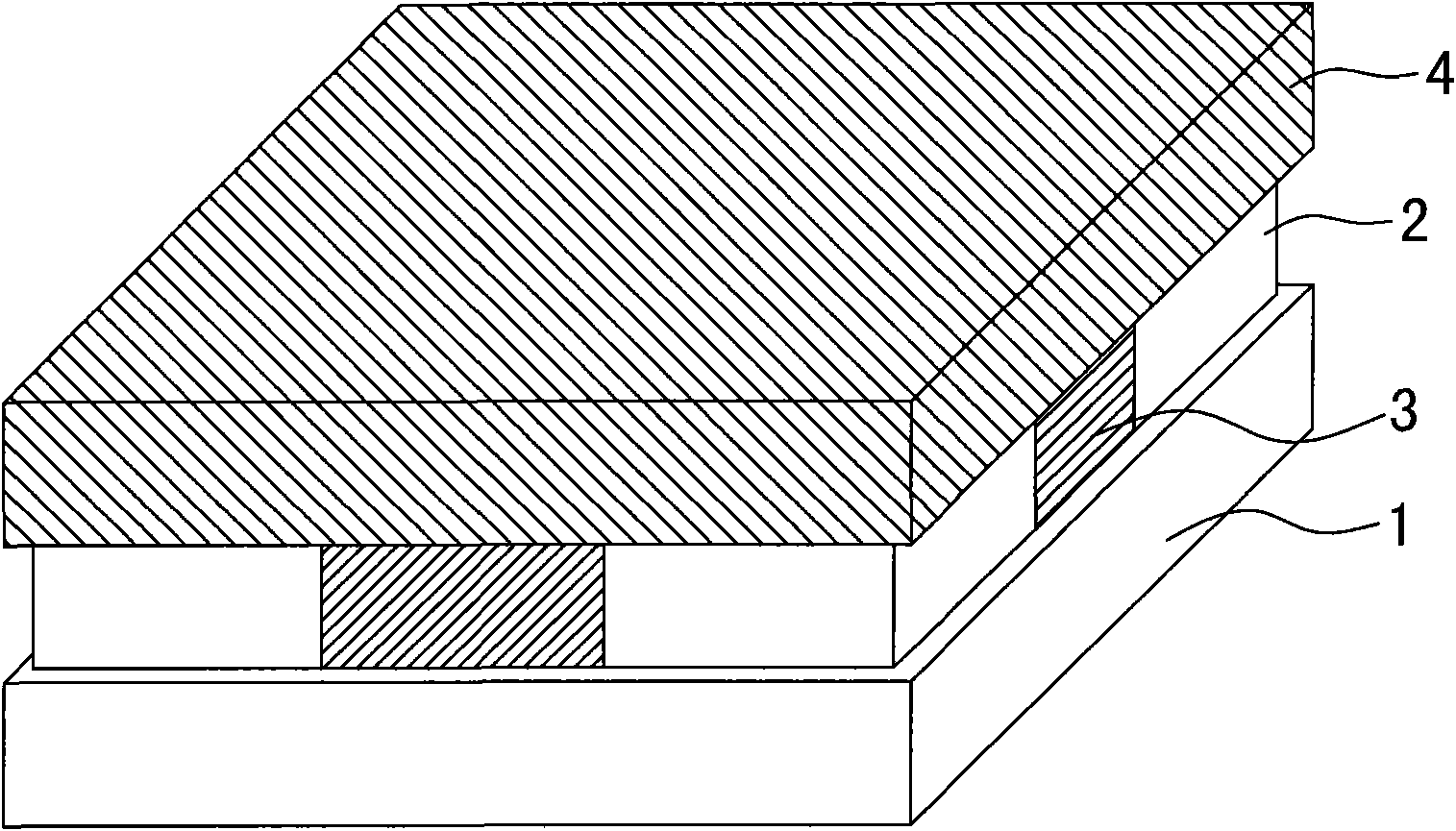

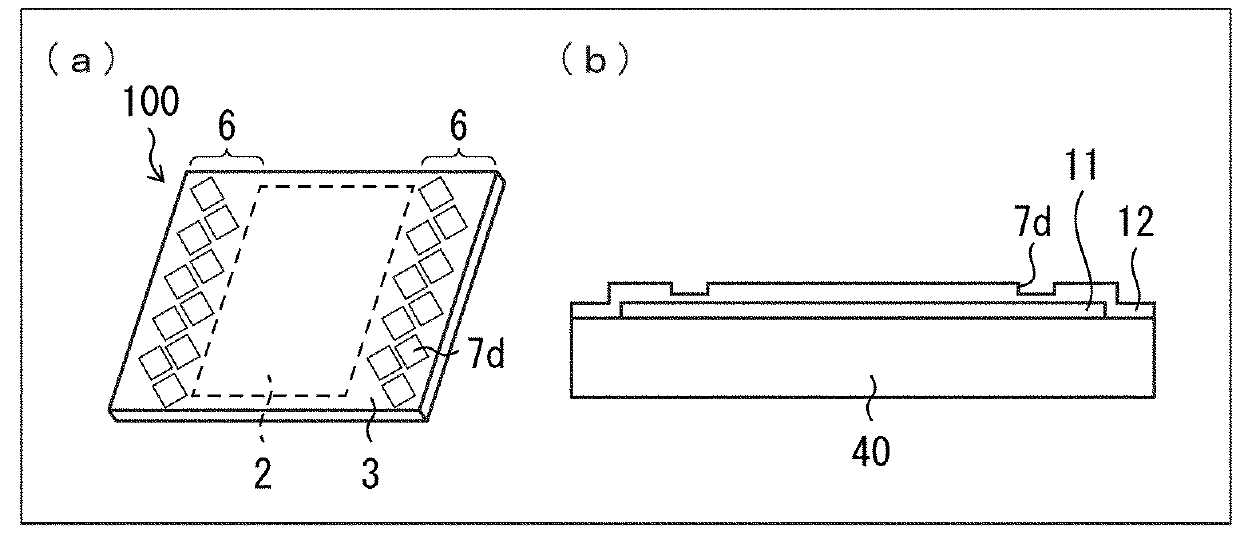

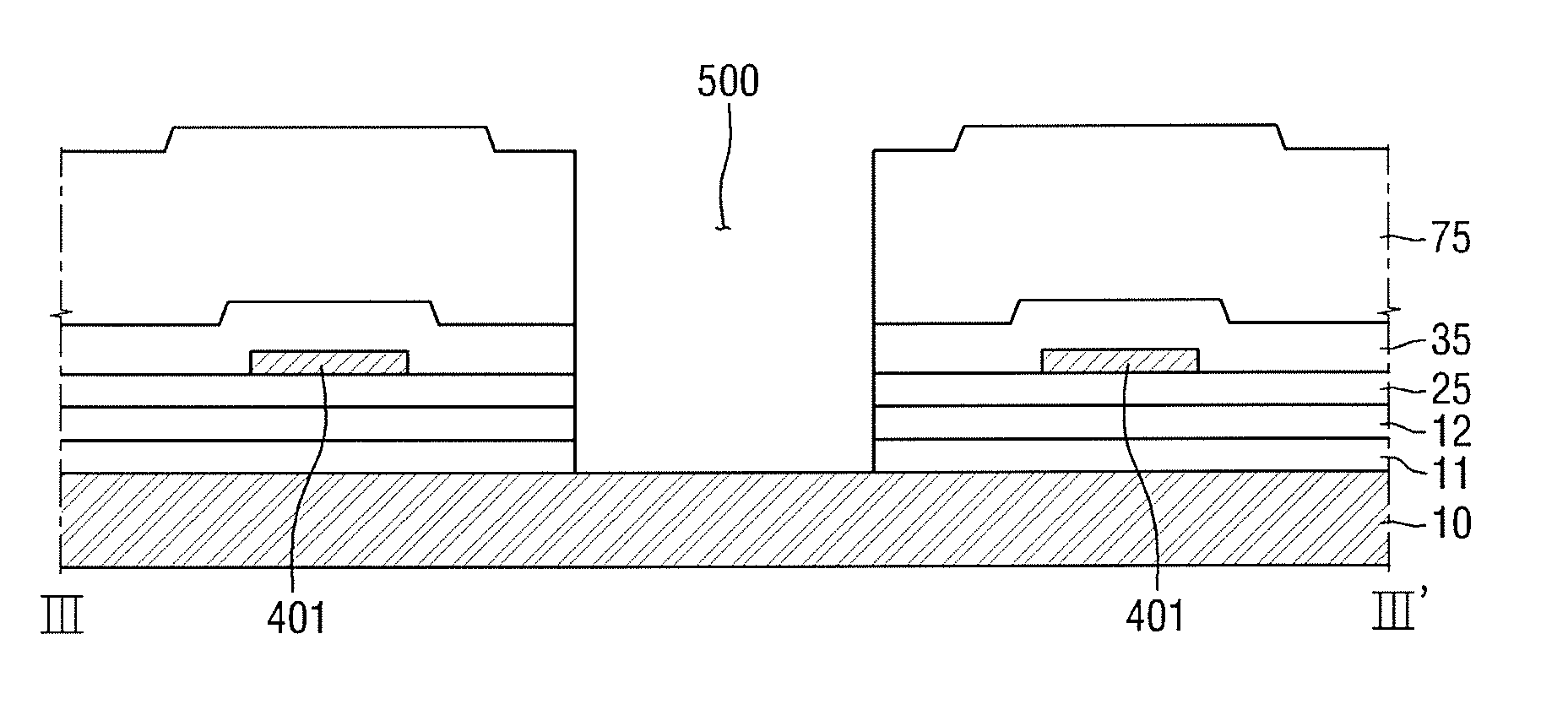

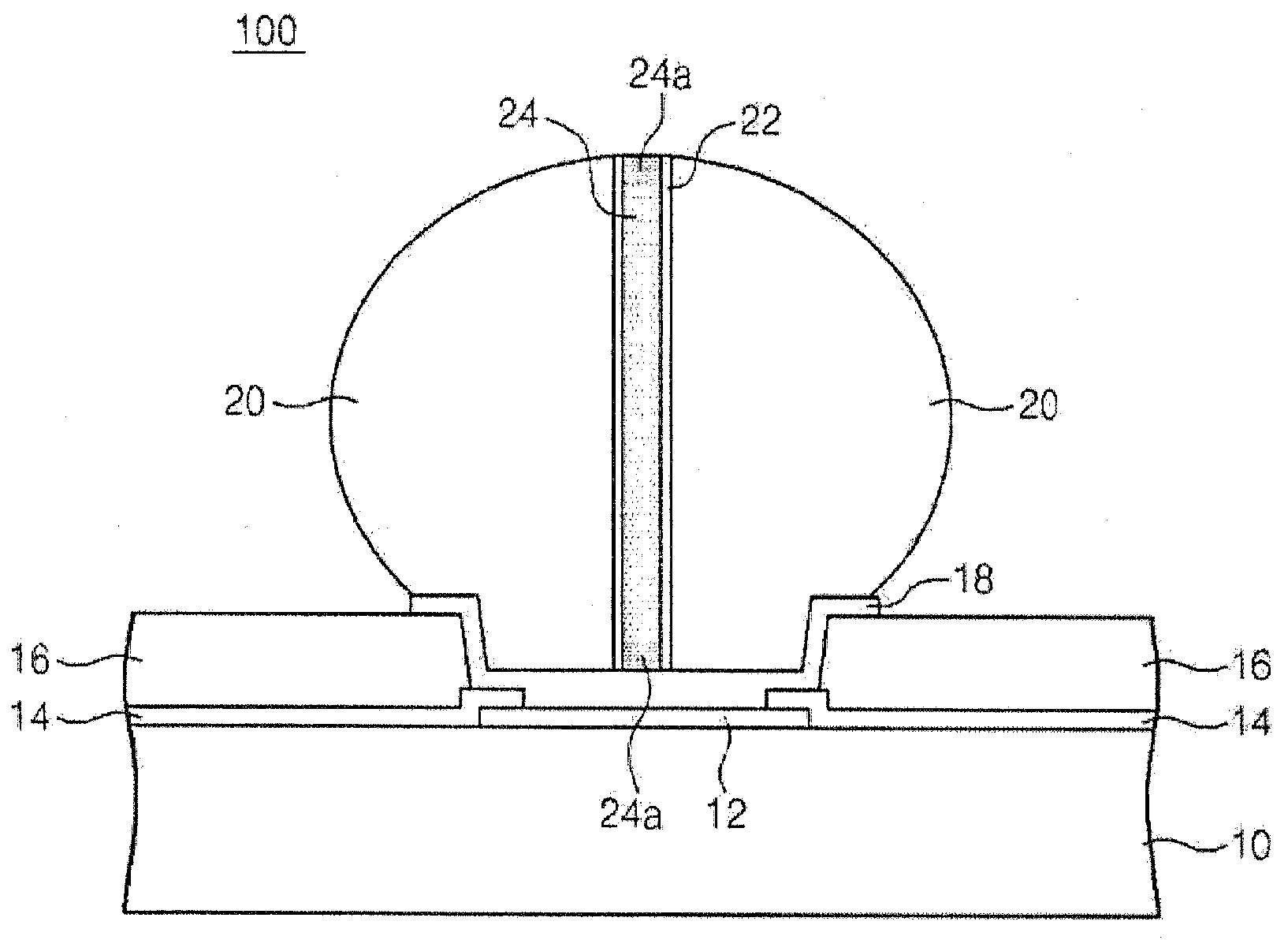

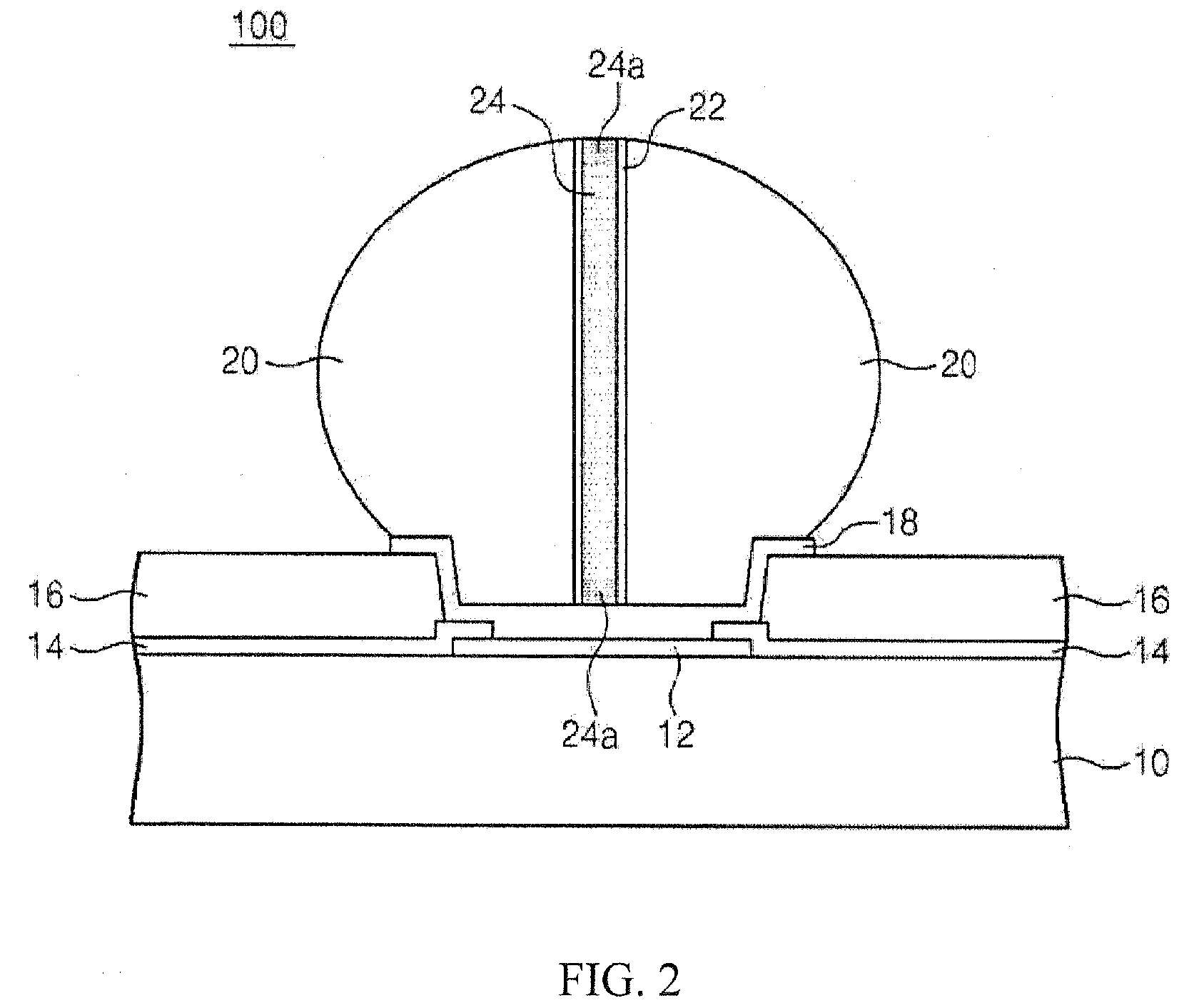

Array substrate and organic light-emitting display including the same

ActiveUS9472507B2Preclude creationPrevent crack growthSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical and Electronics engineering

An array substrate includes a substrate, a barrier layer disposed on the substrate, a buffer layer disposed on the barrier layer, a first insulating layer disposed on the buffer layer, a second insulating layer disposed on the first insulating layer, a plurality of wiring patterns disposed between the first insulating layer and the second insulating layer and / or on the second insulating layer. In addition, the wiring patterns are separated from each other, and extend toward a side of the substrate. The array substrate further includes a recess pattern disposed adjacent the wiring patterns and recessed from a top surface of the second insulating layer to expose at least part of a top surface of the substrate, and an organic insulating layer disposed on the second insulating layer and exposing at least part of a portion of the top surface of the substrate which is exposed by the recess pattern.

Owner:SAMSUNG DISPLAY CO LTD

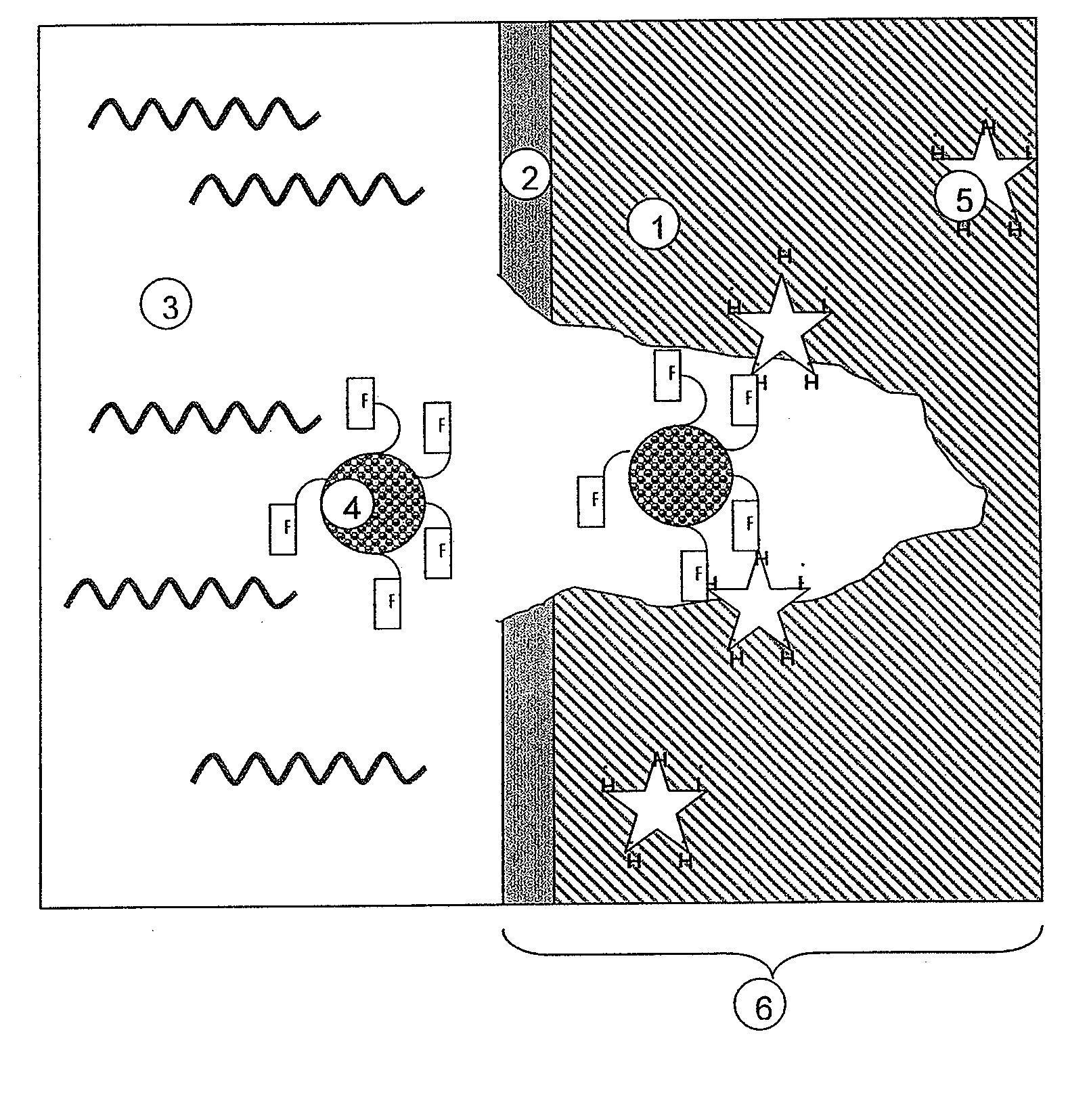

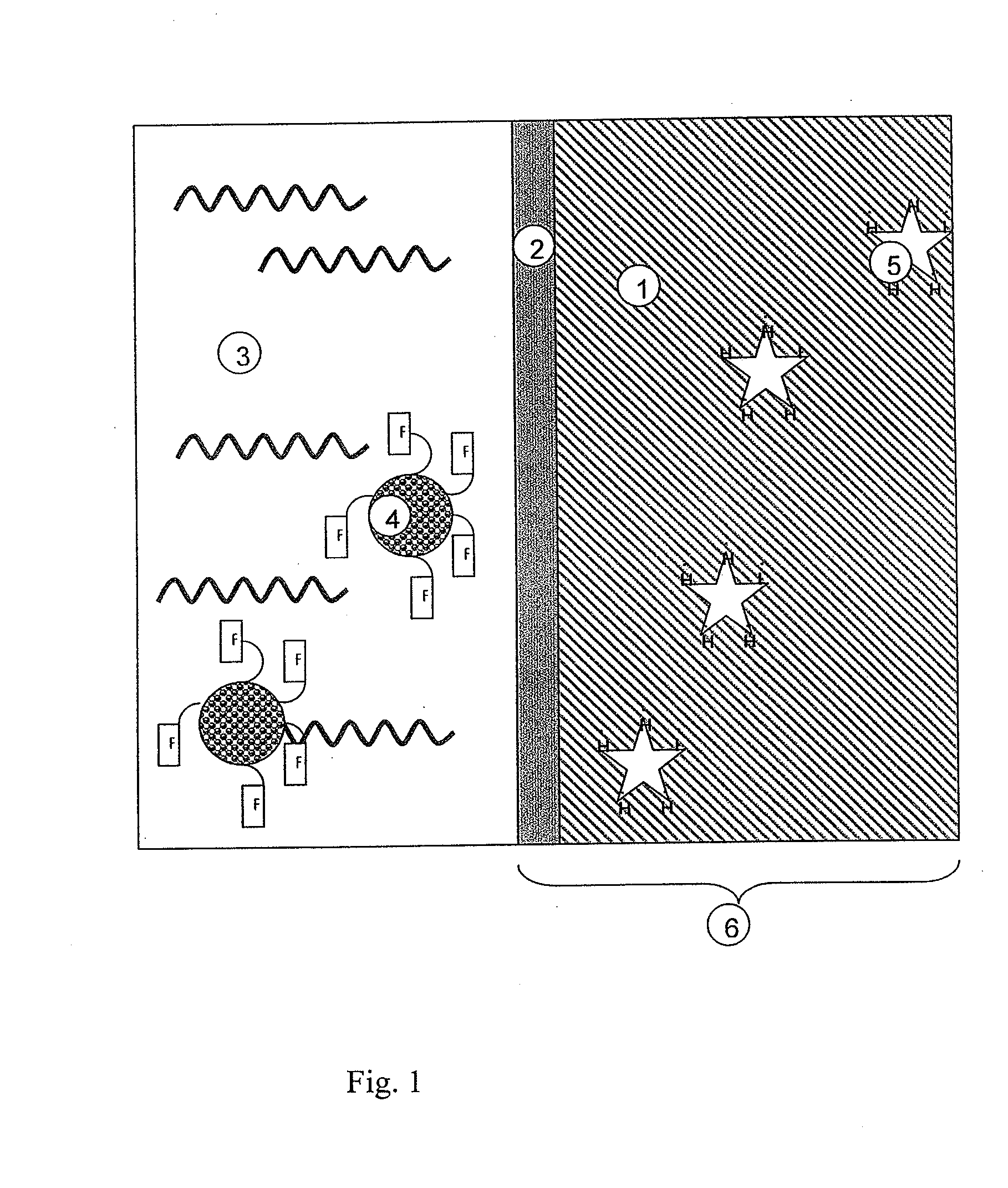

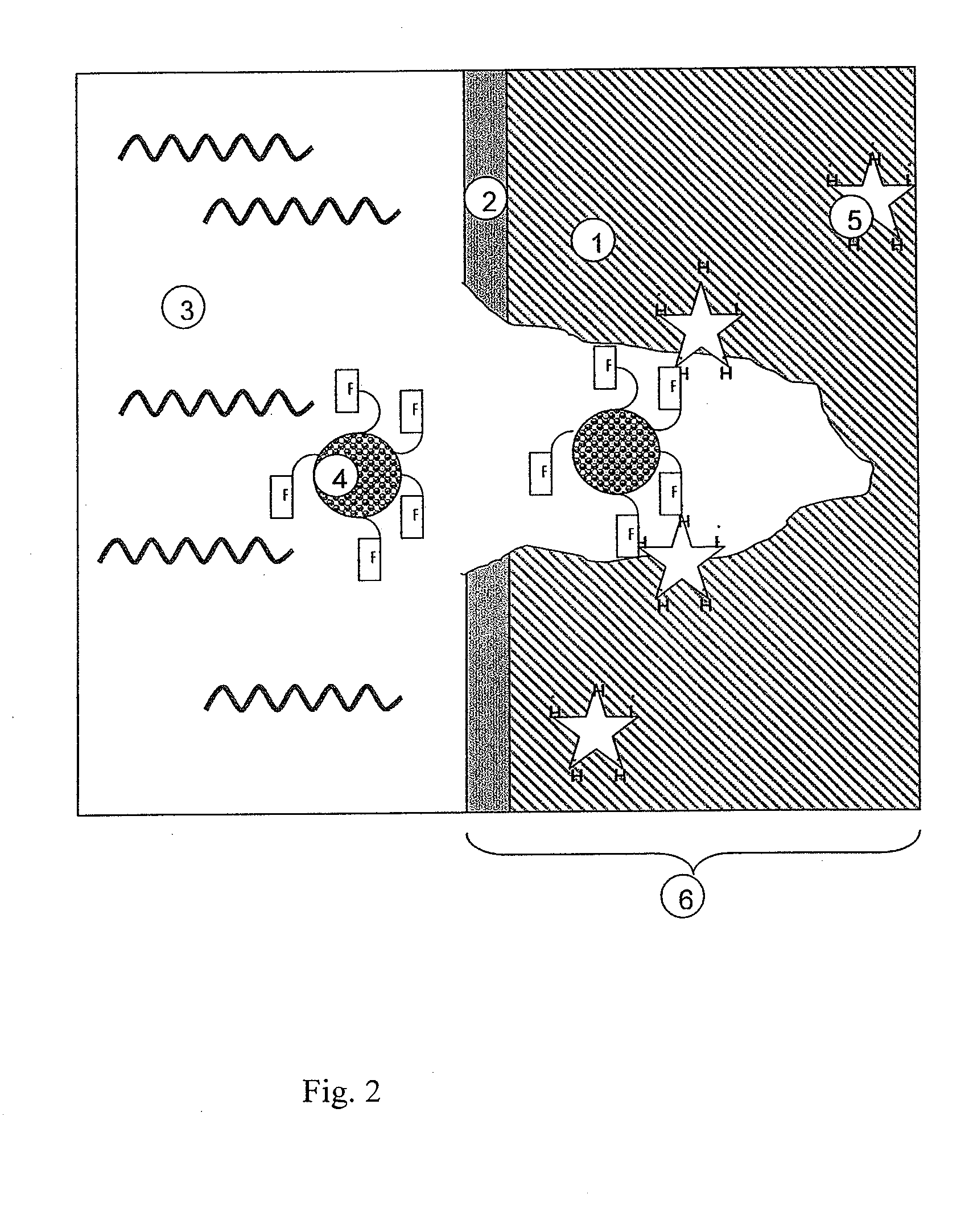

Self-healing elastomer system

A self-healing elastomer system is provided. The system includes an elastomer that has a surface and a core. The elastomer has an elastomer matrix. The elastomer matrix has first functional groups covalently bonded in the interior. A liquid phase borders on the surface of the elastomer. The liquid phase contains an additive. The first functional groups and the additive are chosen so that, in the case of damage to the elastomer, the first functional groups that come into contact with the liquid phase enter into a reaction. The invention also concerns methods for producing and using the self-healing elastomer system and suitable elastomers.

Owner:CARL FREUDENBERG KG

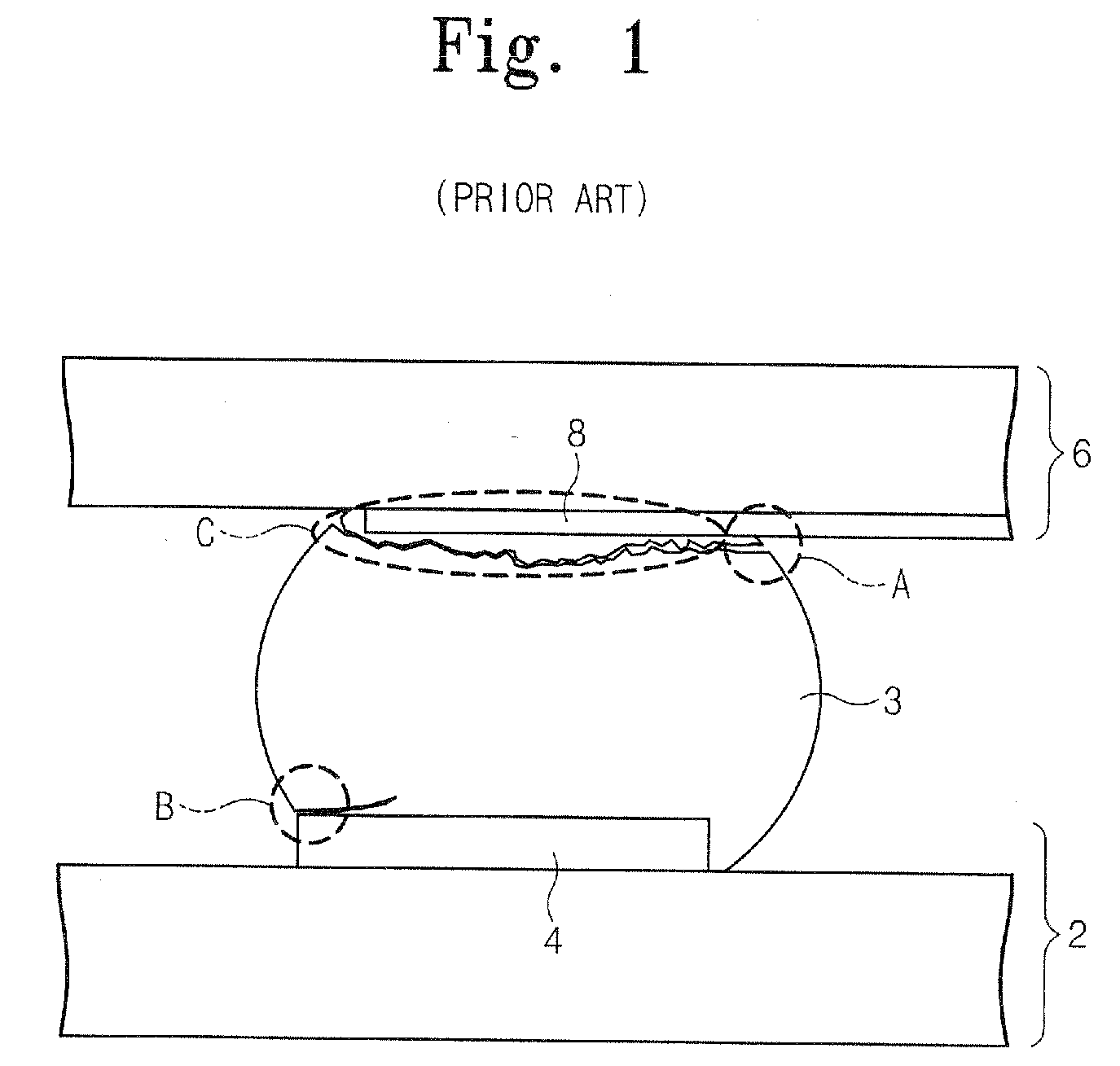

Semiconductor package and fabricating method thereof

InactiveUS20080224308A1Suppresses propagation of crackRestoring resistance characteristic of connectionSemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor package

Provided is a semiconductor device including a substrate, an electrode pad disposed on the substrate, an external terminal disposed on the electrode pad, a container extended from the electrode pad into the external terminal, and a conductive liquid disposed inside the container. The conductive liquid solidifies when exposed to air. When a crack forms in the external terminal, the container suppresses propagation of the crack. Further, if the crack breaches the container, the conductive liquid fills the crack, thereby minimizing further crack propagation and recovering the resistance characteristics of the external terminal prior to the crack formation. A method of forming a semiconductor device including a container having a conductive liquid is also provided.

Owner:SAMSUNG ELECTRONICS CO LTD

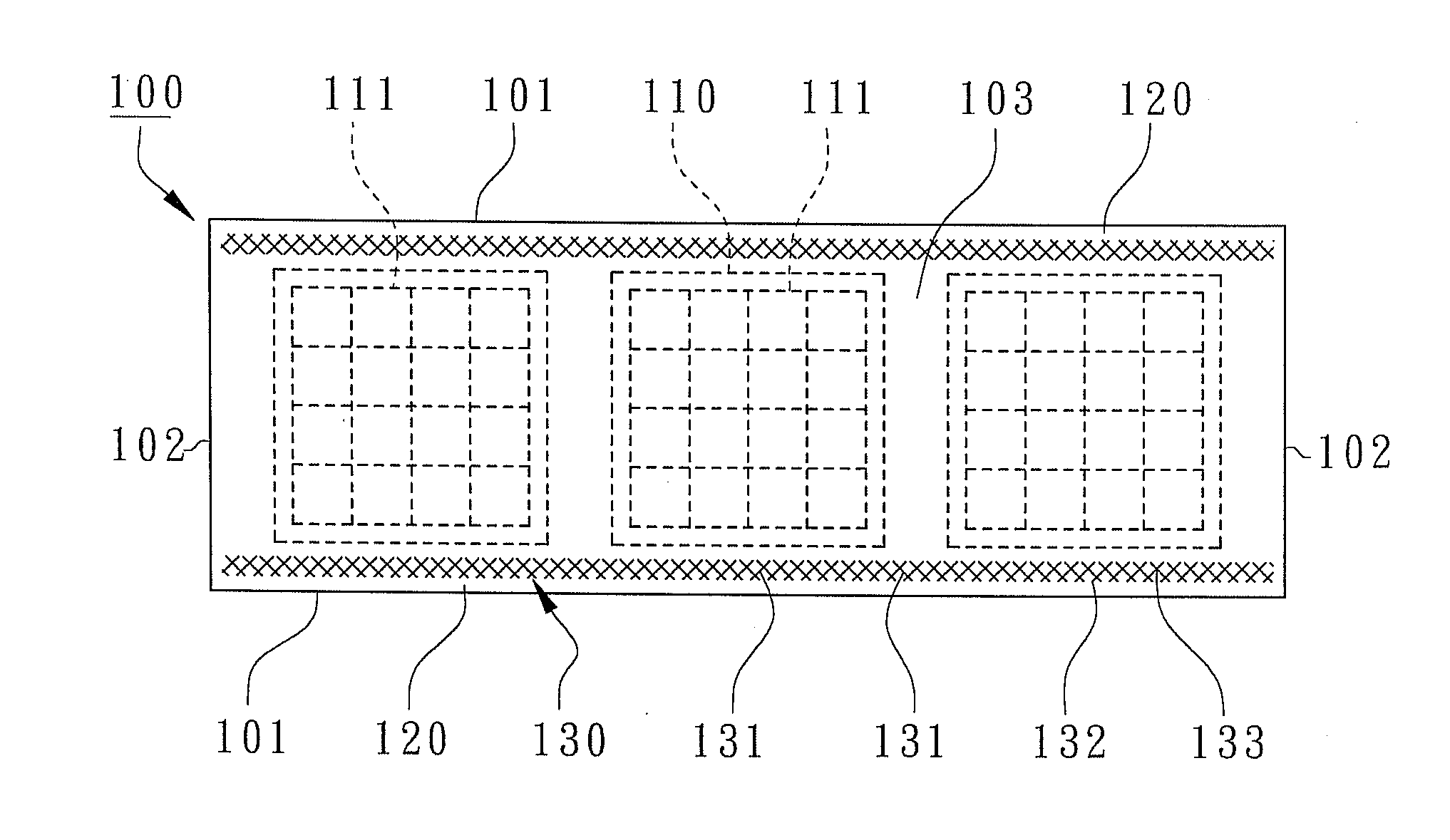

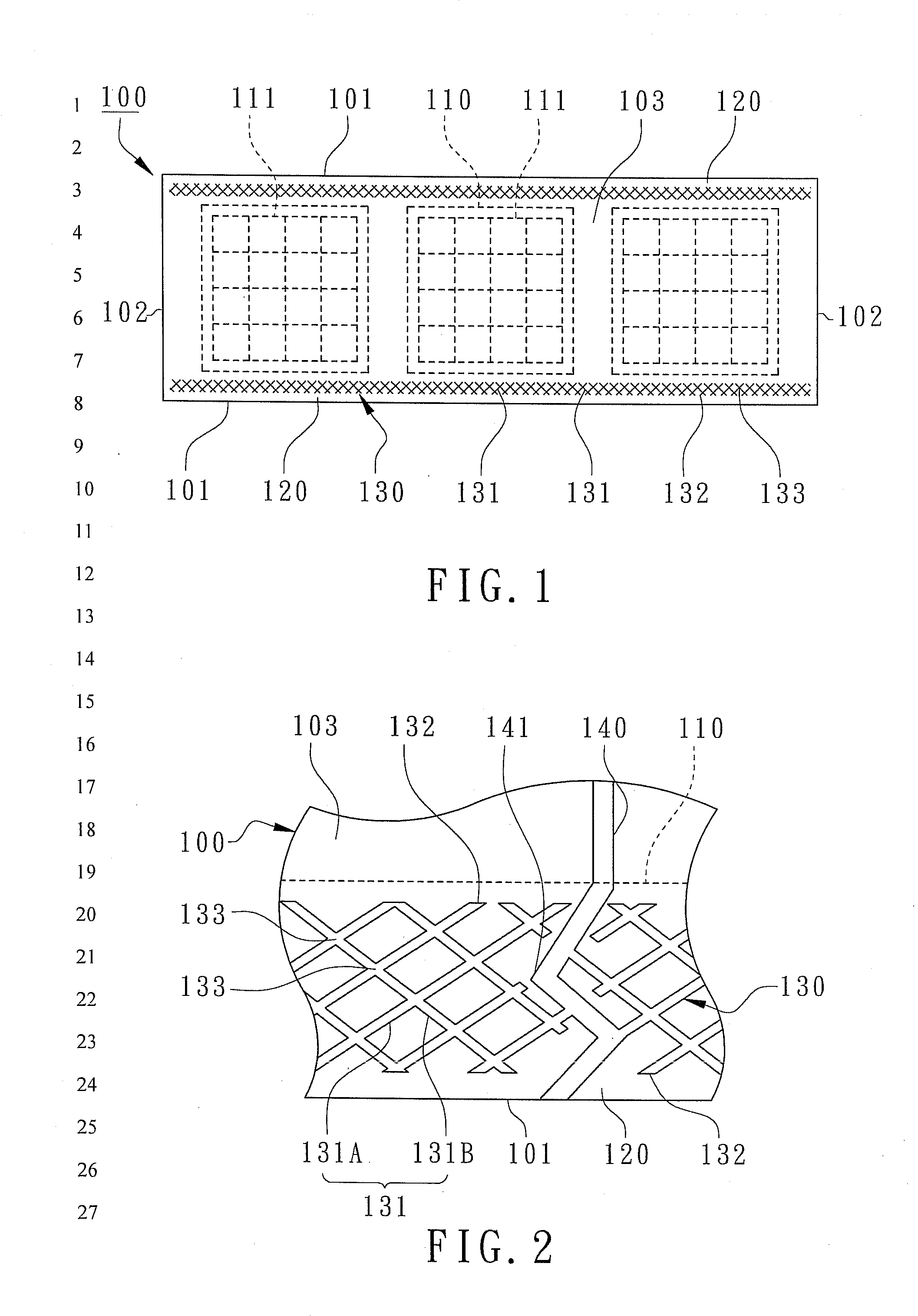

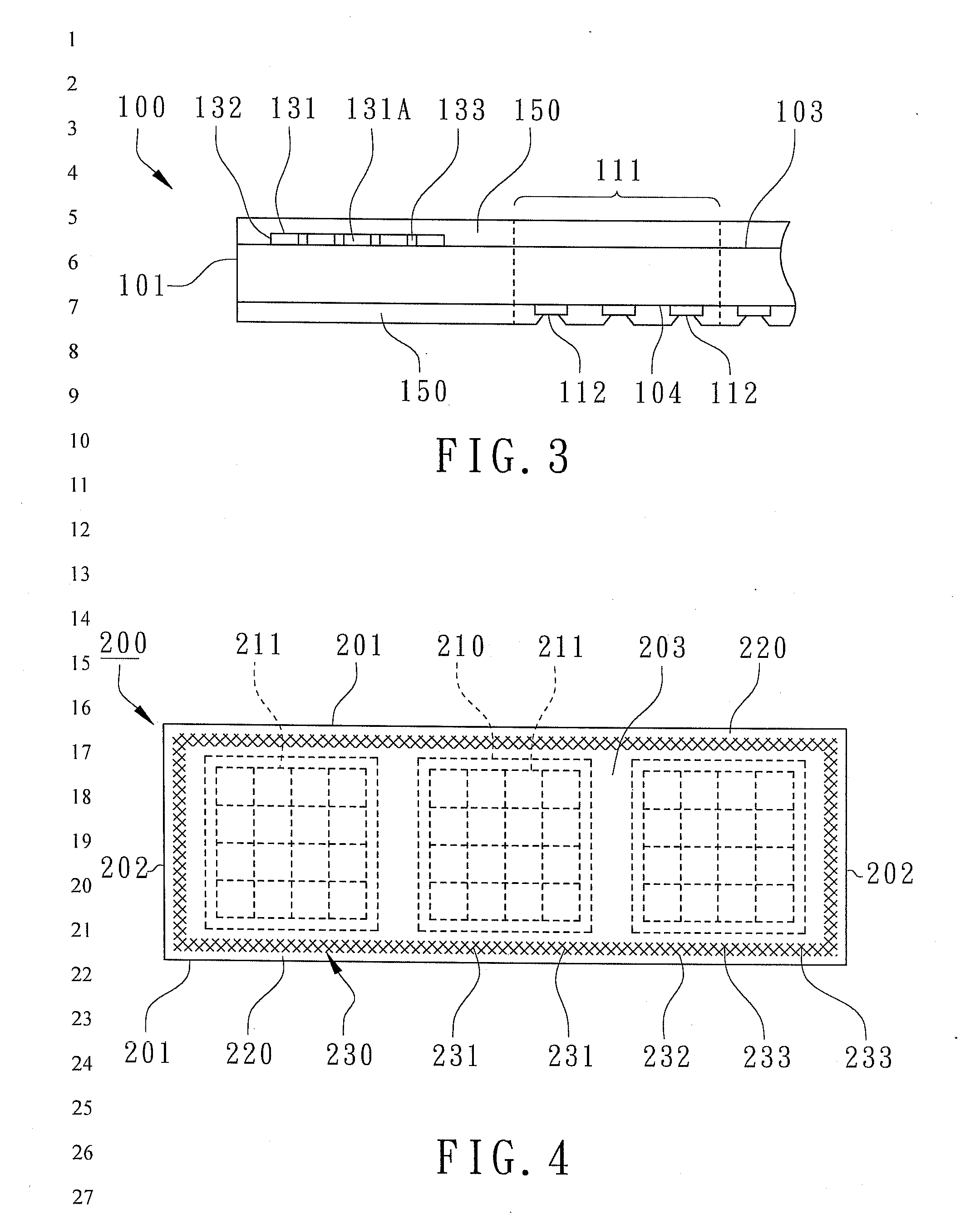

Substrate strip for semiconductor packages

InactiveUS20090224395A1Retard crack growthImprove stress distributionSemiconductor/solid-state device detailsSolid-state devicesShell moldingSemiconductor package

A substrate strip for semiconductor packages to slow the crack growth, primarily comprises a molding area and two side rails. The molding area includes a plurality of packaging units. The side rails are located outside the molding area and include two opposing longer sides of the substrate strip. A metal mesh is disposed on the side rails. The metal mesh consists of a plurality of crisscrossed wires having a plurality of isolated wire terminals at one edge of the metal mesh. Accordingly, crack growth is slowed by the specific metal mesh without damaging the packaging units. In one embodiment, the metal mesh is without boundary wires connecting to the isolated wire terminals to enhance the resistance to crack growth.

Owner:POWERTECH TECHNOLOGY

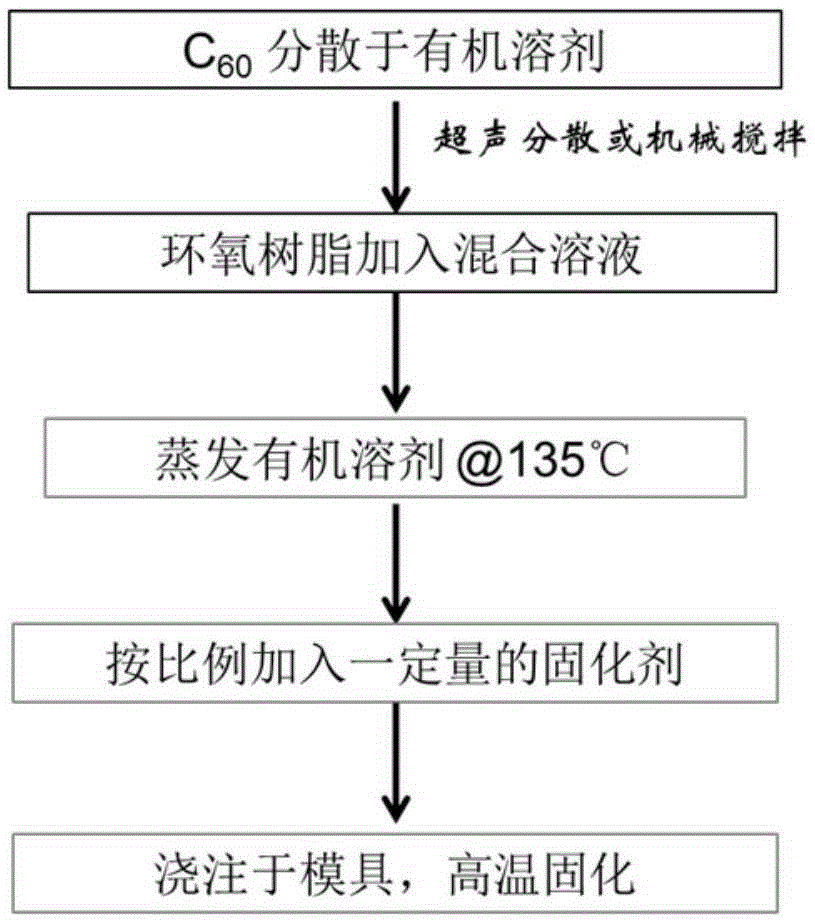

Epoxy resin fullerene composite material and preparation method thereof

The invention relates to an epoxy resin fullerene composite material and a preparation method thereof. The materials of the epoxy resin fullerene composite material include fullerene, epoxy resin and a curing agent. The epoxy resin fullerene composite material has the advantages of remarkably increasing the volume resistivity and breakdown voltage of a polymer matrix, inhibiting the injection of space charges, decreasing dielectric constant and loss, and improving the electrical aging property of the epoxy resin, and moreover, the mechanical strength and toughness of the epoxy resin are also increased to a certain degree.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Papermaking belt and method of manufacturing papermaking belt

InactiveUS20060191658A1Prevent crack growthAvoid stratificationLiquid surface applicatorsPaper/cardboardPulp and paper industryPrepolymer

Owner:YAMAUCHI CORP

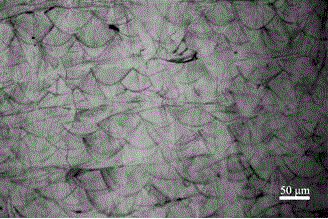

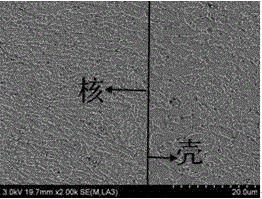

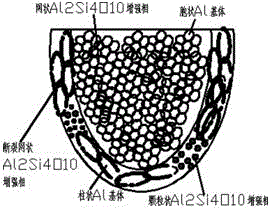

Aluminum-based in-situ composite material formed based on laser 3D printing and preparation method of aluminum-based in-situ composite material

ActiveCN105328186AGood comprehensive mechanical propertiesImprove the overall mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyLaser printingAluminium

The invention belongs to the technical field of particle-reinforced aluminum-based in-situ composite materials and discloses an aluminum-based in-situ composite material formed based on laser 3D printing and a preparation method of the aluminum-based in-situ composite material. The preparation method includes the steps that a mixture of Al-Si-Mg alloy powder and Al2O3 powder is prepared; the mixture is ball-milled through an intermittent ball-milling process; a three-dimensional CAD model established through a workpiece is subjected to layered slicing treatment; laser beams are adopted for scanning the laid powder line by line to form a two-dimensional section of the workpiece; and the steps are repeated till the workpiece is machined, and the aluminum-based in-situ composite material with an Al2Si4O10 reinforced element scattered on an Al matrix is formed. The operation method is easy and convenient to carry out, Al-Si-Mg alloy and Al2O3 generate the Al2Si4O10 reinforced phase in situ under the effect of high-energy lasers in the laser forming process, the interface wettability is improved, and then the interface strength of the composite material is enhanced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

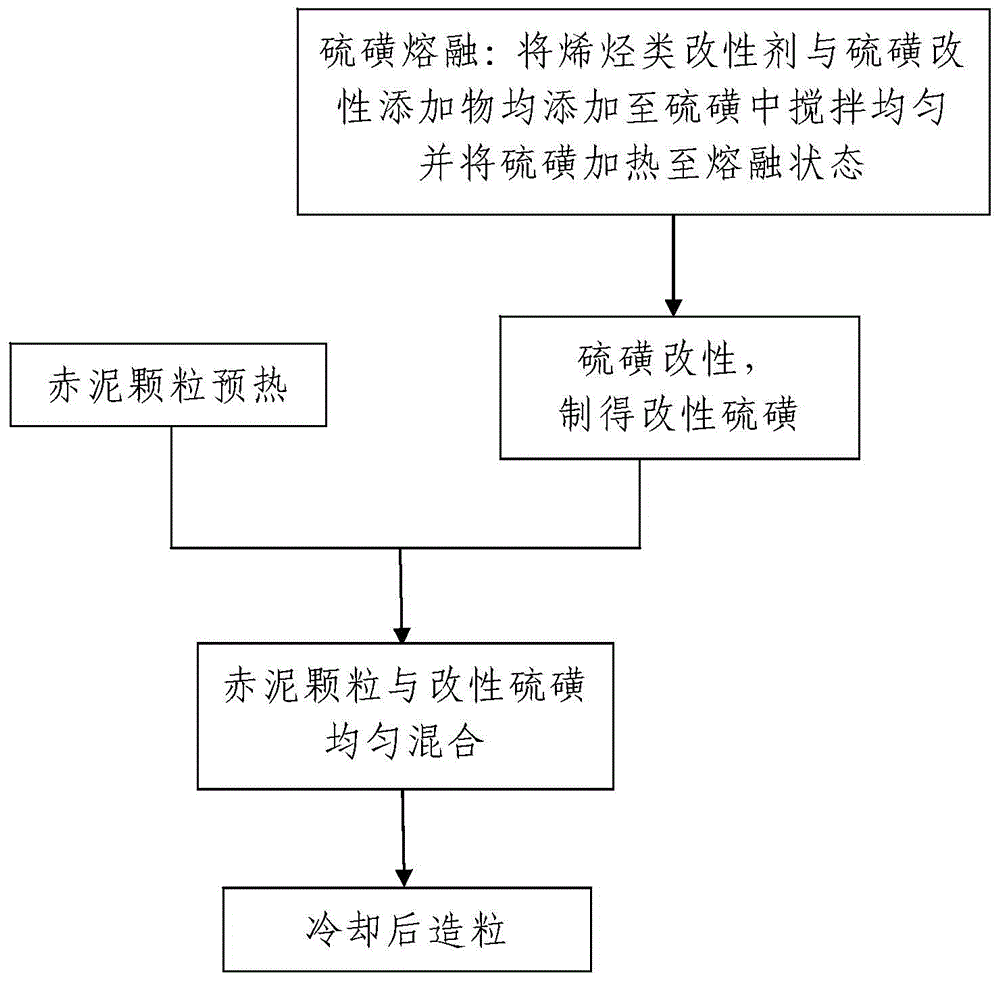

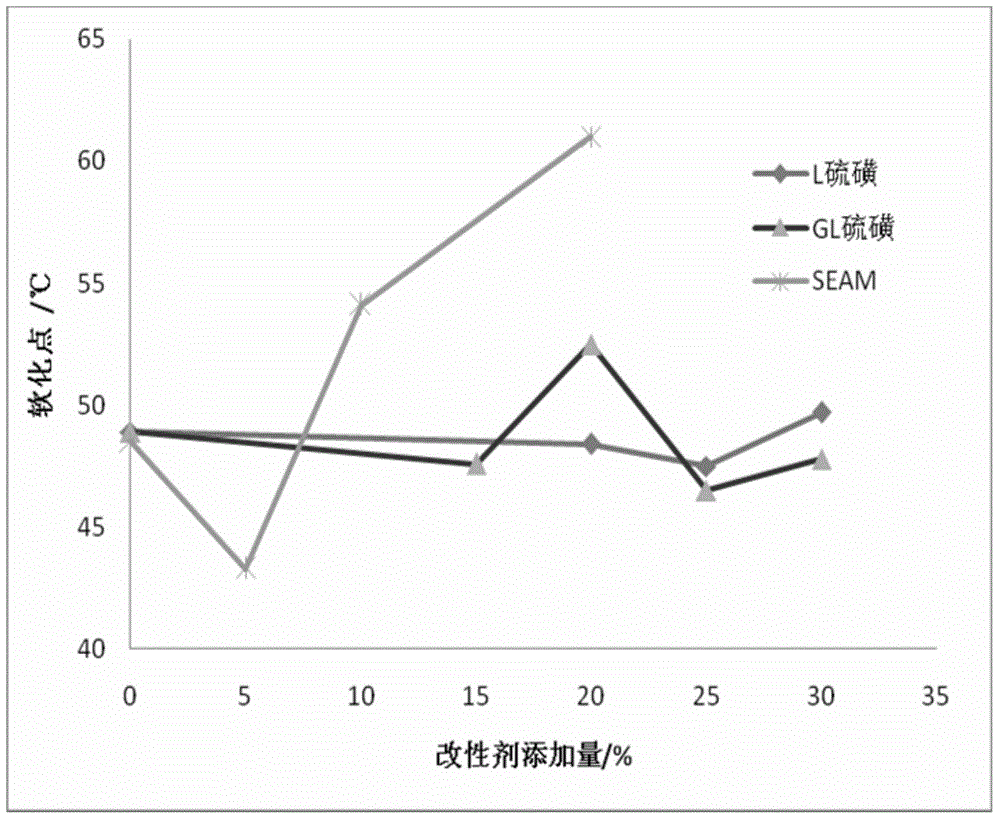

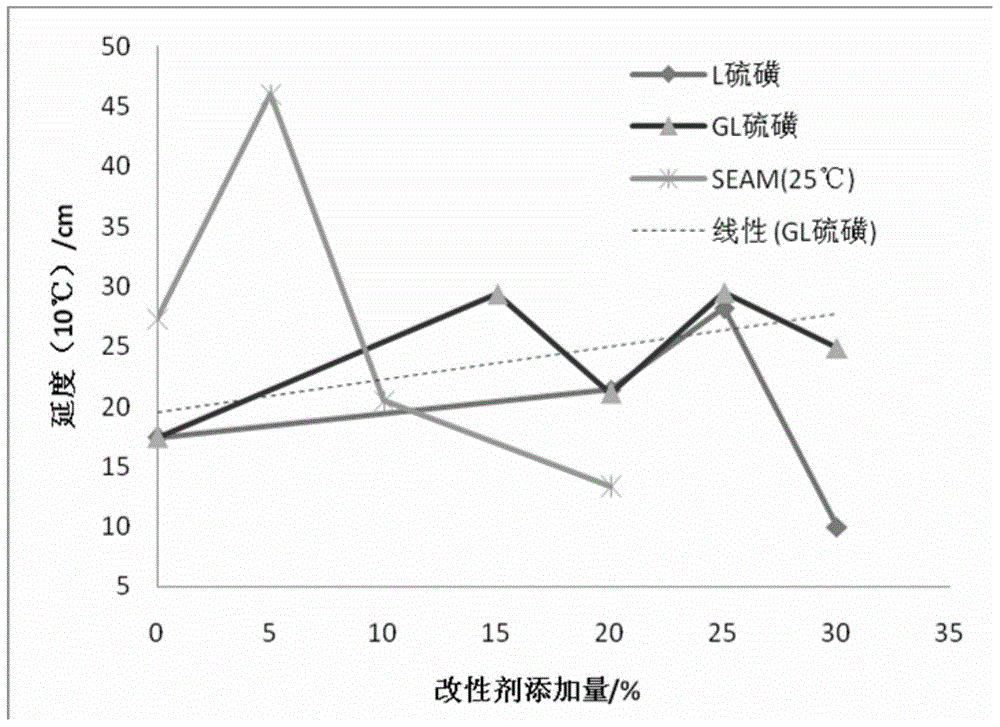

Asphalt modifier and industrial production method and application thereof

The invention discloses an asphalt modifier and an industrial production method and application thereof. The asphalt modifier is prepared by uniformly mixing modified sulfur and red mud particles. The industrial production method comprises the following steps: 1, preparing the modified sulfur, namely performing sulfur fusion and sulfur modification; and 2, adding the red mud particles. In the industrial production method, the modified sulfur is prepared in a way that an olefin modifier and a sulfur modification additive are added into sulfur for modifying sulfur; a weight ratio of the olefin modifier to sulfur is 2-6:100, and a weight ratio of the red mud particles to the sulfur is 10-30:100. The application process of the asphalt modifier comprises the following steps: I, preheating raw materials; and II, mixing, namely mixing the preheated asphalt modifier, mineral aggregate and matrix asphalt. The asphalt modifier adopted in the production method is simple in production process, low in construction cost, incombustible, safe to use and excellent in performance, the amount of discharged atmospheric pollutants in the production and application process is small, comprehensive performance of the modified asphalt concrete is excellent, and industrial waste red mud can be effectively utilized.

Owner:XIAN UNIV OF SCI & TECH

Boron carbide sintered body and protective member

InactiveUS20070203012A1High compressive strengthSuppressing propagation of crackGranularityBoron carbide

The compressive strength of a boron carbide sintered compact is improved by controlling crystals of the boron carbide to a polycrystalline structure having a grain size distribution in which coarse crystals with a grain size of 20 μm or more and fine crystals with a grain size of 10 μm or less are mixed in an appropriate ratio. Furthermore, a protective member having an improved compressive strength can be provided using the boron carbide sintered compact having a polycrystalline structure in which coarse crystals and fine crystals are mixed in an appropriate ratio or a boron carbide sintered compact containing graphite and silicon carbide.

Owner:KYOCERA CORP

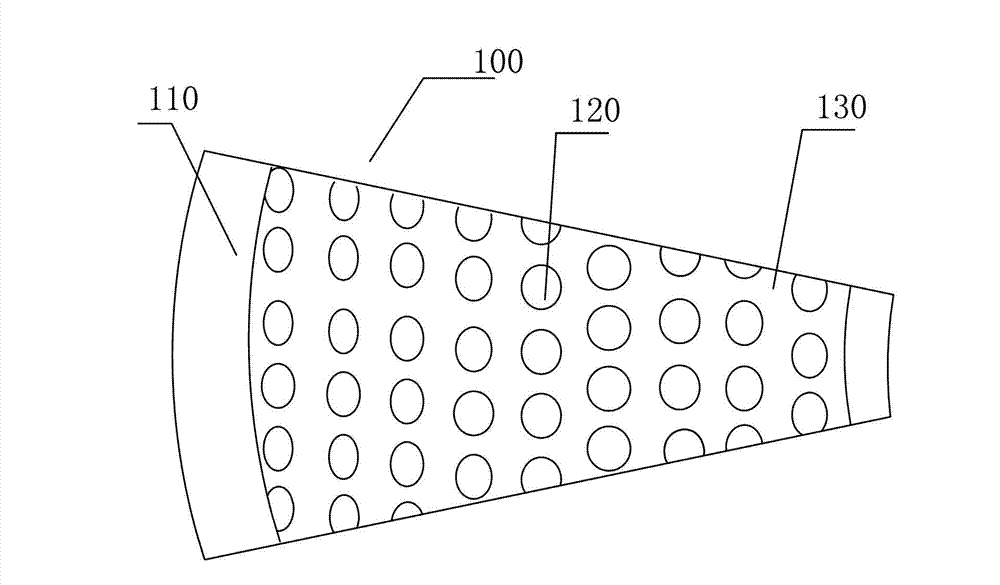

Lost foam casting type composite wear-resistant component and casting method thereof

ActiveCN103203428AAnti-wear self-protectionEvenly distributedFoundry mouldsFoundry coresWear resistantCasting types

The invention discloses a lost foam casting type composite wear-resistant component and a casting method of the lost foam casting type composite wear-resistant component. The wear-resistant component comprises a metallic substrate part and a working layer part, wherein the metallic substrate part is provided with concave part; the working layer part, the metallic substrate part are cast into a whole and the working layer part is filled into the concave part; reinforced particles are uniformly distributed on the working layer part; and the reinforced particles are wrapped with molten metal which flows around the reinforced particles during integrated casting and then is solidified, so as to be fixed on the working layer part. The composite wear-resistant component has wear-resistant and self-protective effects, and is capable of preventing possible cracks from expanding in a ceramic working layer; therefore, the wear resistance is improved, and the service life is prolonged. Compared with cast-in type reinforced particles, the reinforced particles disclosed by the invention have higher yield, are hardly influenced by the casting temperature and speed; simultaneously, the reinforced particles are distributed more uniform in the metal substrate; in addition, the casting method is simple to operate, short in production period and low in cost, and materials can be saved.

Owner:BEIJING POWER EQUIP GRP

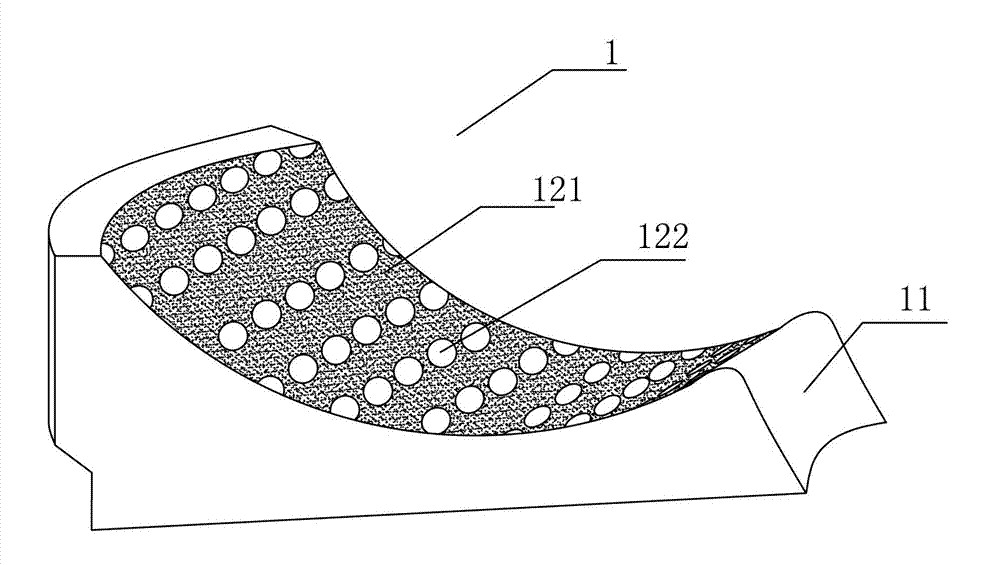

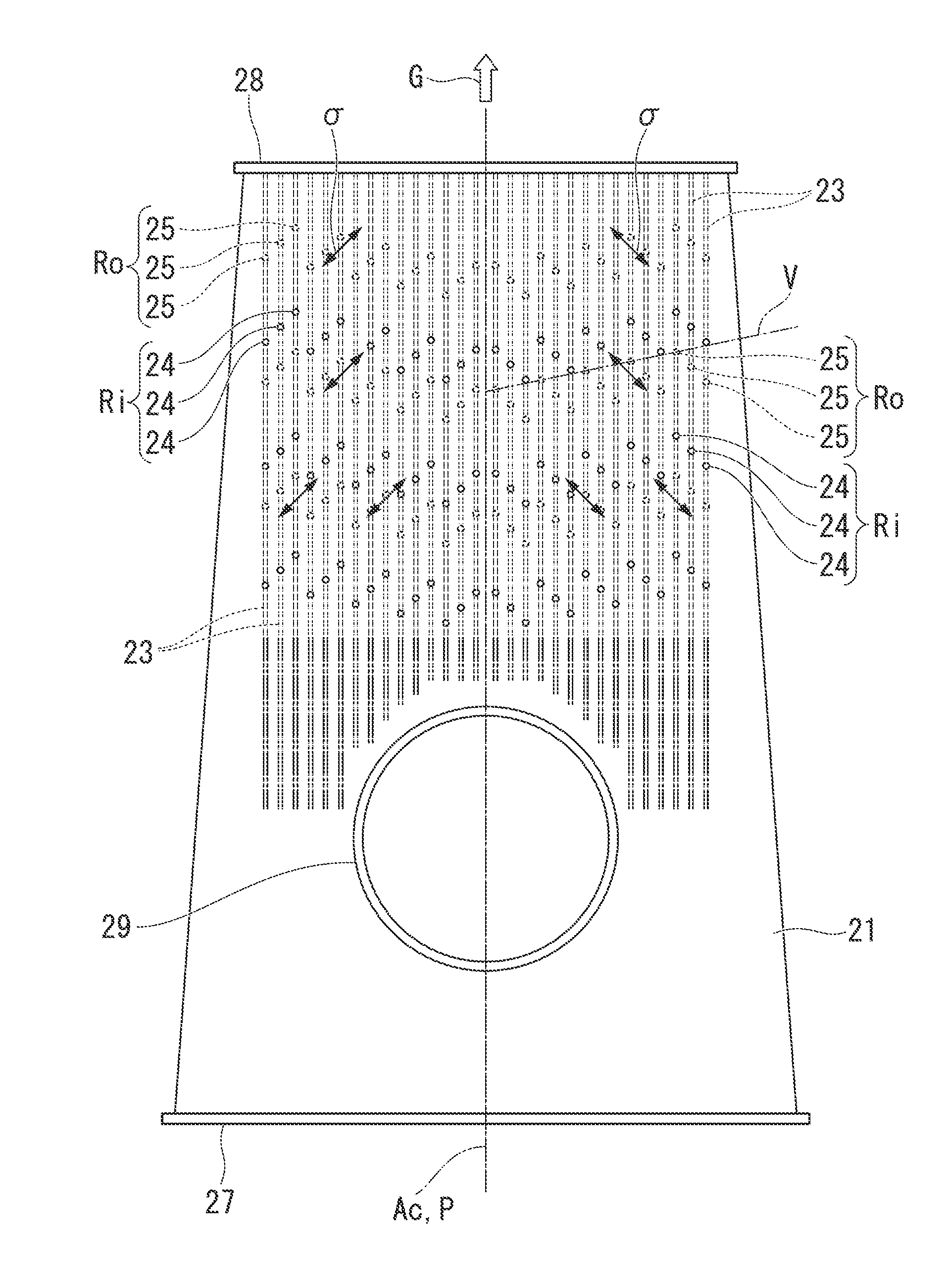

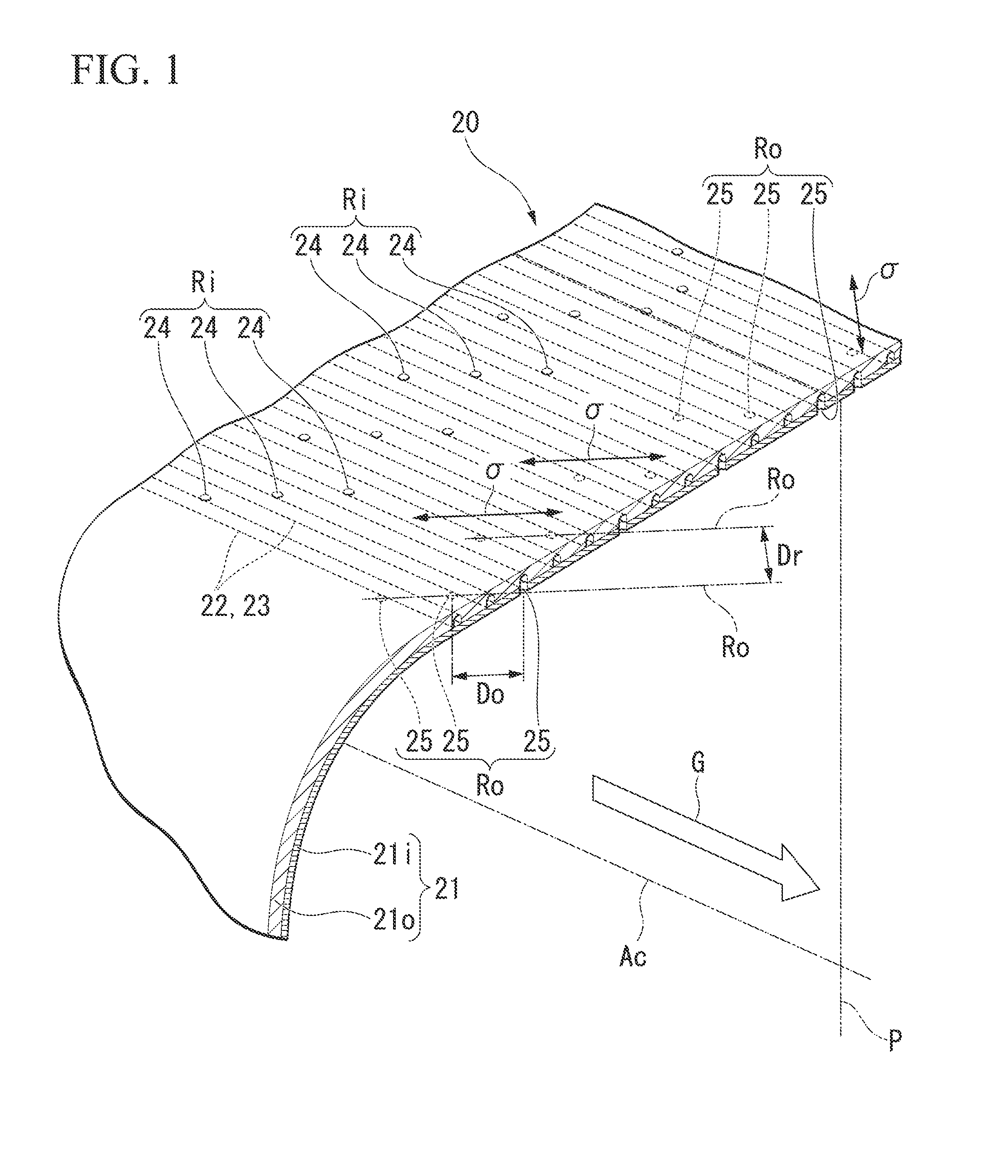

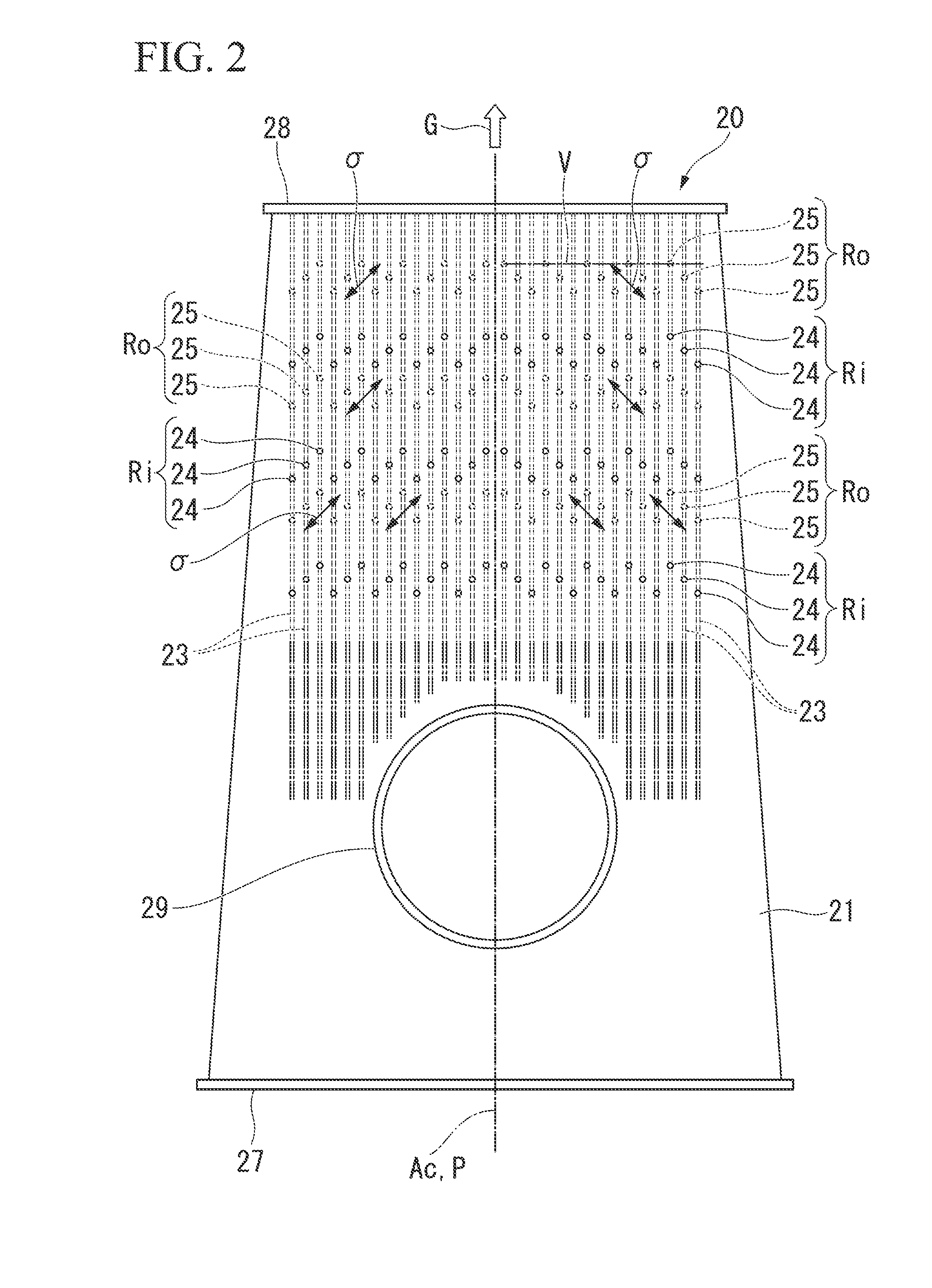

Transition piece of combustor, and gas turbine having the same

ActiveUS20140144147A1Improve cooling effectPrevent crack growthContinuous combustion chamberEngine manufactureCombustorTurbine

A transition piece of a combustor that sends high temperature combustion gas to a turbine includes a cylindrical body wall and cooling air passages. The passages are formed in the body wall so as to extend in an axial direction thereof, and each of the passages has cooling air inlet ports opened at an outer circumferential surface of the transition piece and cooling air outlet ports opened at an inner circumferential surface of the transition piece. The cooling air outlet ports form a plurality of lines in a direction oblique with respect to the axial direction of the body wall. A first distance between a first line of the cooling air outlet ports and a second line of the cooling air outlet ports adjacent to the first line is larger than a second distance between the cooling air outlet ports adjacent to each other.

Owner:MITSUBISHI POWER LTD

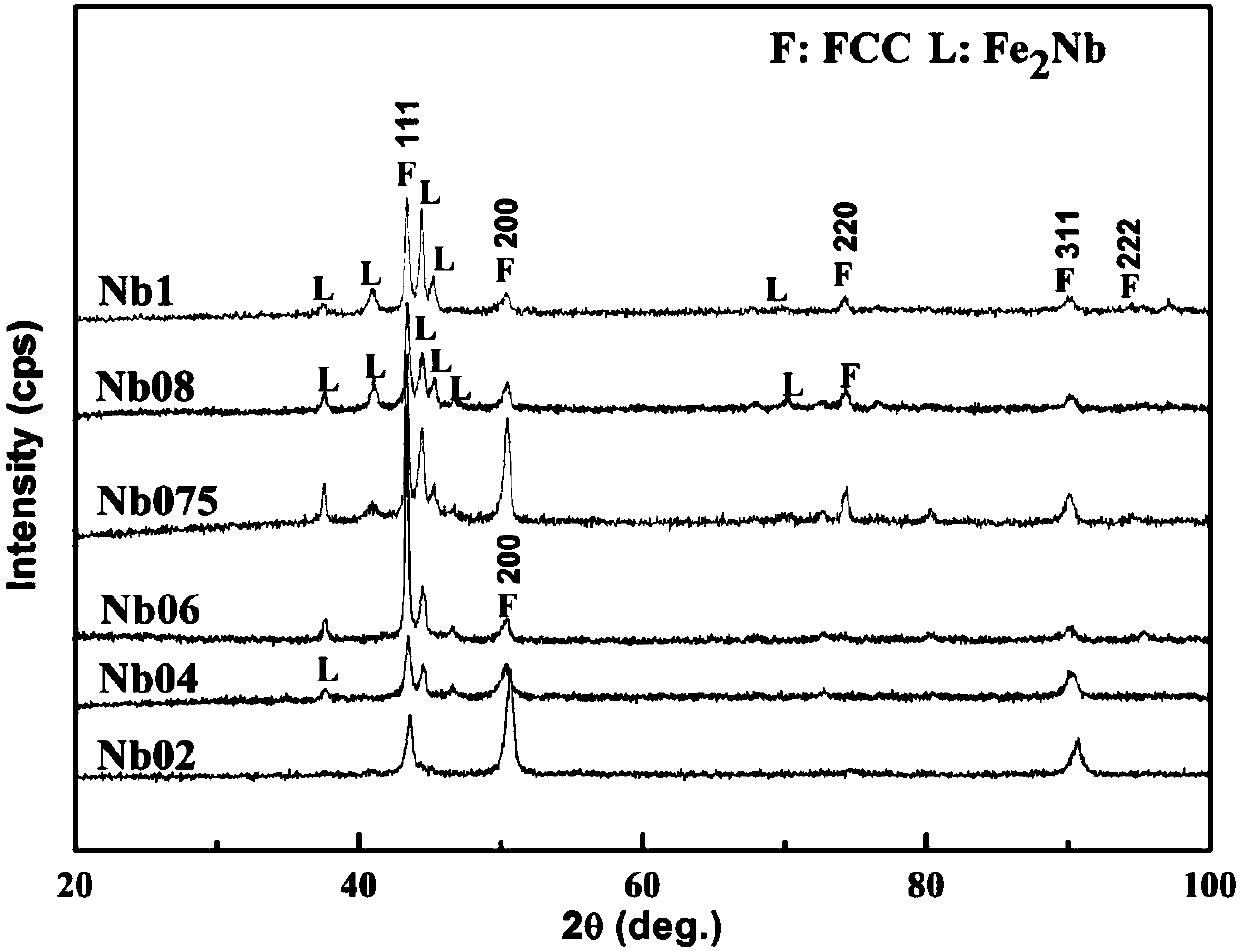

CoFexNiyV0.5Nbz high-entropy alloy and preparation method thereof

The invention discloses a CoFexNiyV0.5Nbz high-entropy alloy and a preparation method thereof. The CoFexNiyV0.5Nbz high-entropy alloy consists of the following elements in molar percentage: 1:x:y:0.5:z, wherein x is greater than or equal to 1.0 and smaller than or equal to 2.0, y is greater than or equal to 0 and smaller than or equal to 2.0, z is greater than or equal to 0 and smaller than or equal to 1.0. The preparation method for the CoFexNiyV0.5Nbz high-entropy alloy comprises the following specific steps of: ultrasonically cleaning; batching; and smelting the high-entropy alloy. A microstructure of a hard Laves phase is dispersed and distributed in a soft FCC solid solution, the structure generally has good wear resistance, the hard phase achieves the effect of strengthening the alloy, and a soft phase achieves the effect of preventing cracks from expanding. According to the results, the alloy with a eutectic component and a hypereutectic component shows the most outstanding wearresistance and relatively high hardness.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com