Asphalt modifier and industrial production method and application thereof

An asphalt modifier and modifier technology, applied in the field of asphalt modifiers, can solve problems such as inability to be widely promoted and affect the atmospheric environment, and achieve the effects of improving structural stability and fire resistance, low input cost, and promoting bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] In this example, the prepared asphalt modifier is uniformly mixed with modified sulfur and red mud particles, the particle size of the red mud particles is ≤0.1mm and its weight is 200g; Modified sulfur prepared by adding olefin modifiers and sulfur modification additives in the medium, the mass purity of the sulfur is above 99% and its weight is 1000g, and the olefin modifiers are dimerized Cyclopentadiene and its addition amount is 40g, and described sulfur modification addition is nanoscale FeCl 2 particles, the nanoscale FeCl 2 The weight of the granules is 70 g.

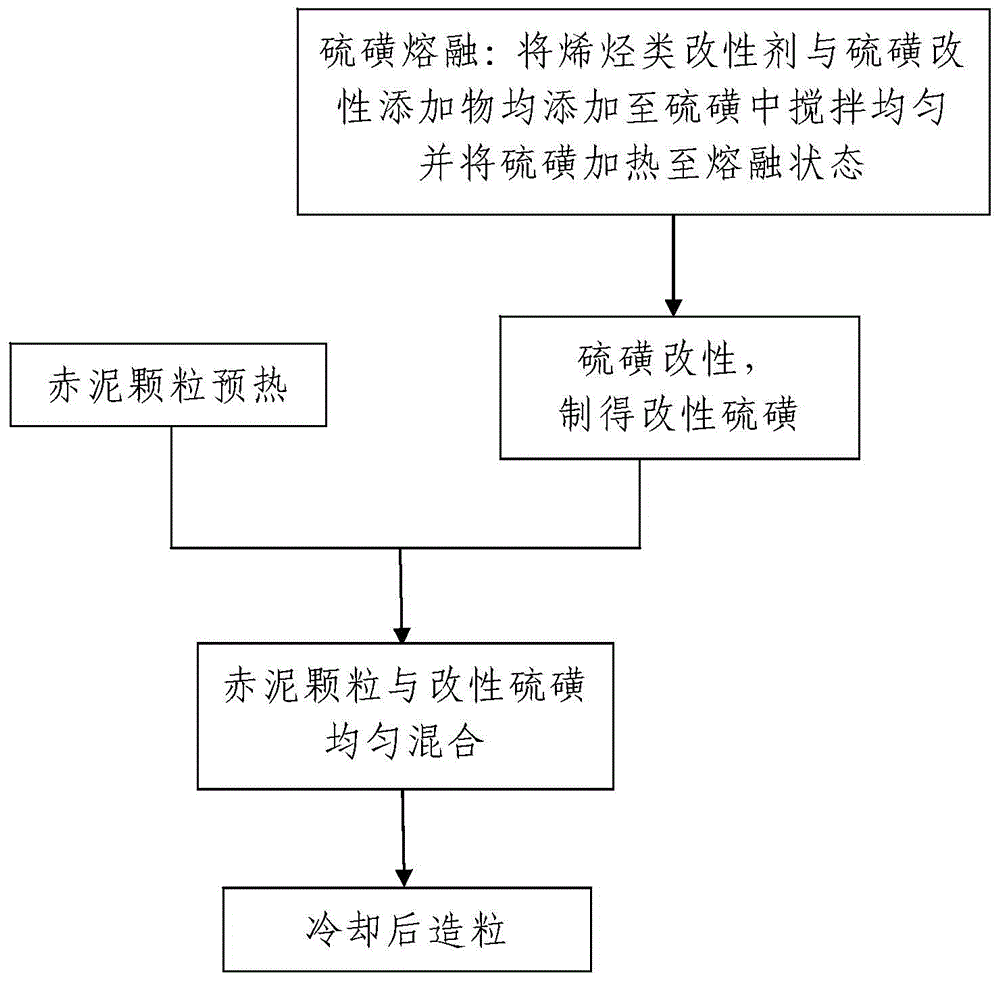

[0074] In the present embodiment, when asphalt modifier is produced, comprise the following steps:

[0075] Step 1, preparation of modified sulfur, the process is as follows:

[0076] Step 101, sulfur melting: according to the designed ratio, add the olefin modifier and the sulfur modification additive to the sulfur and stir evenly to obtain a sulfur mixture; then use heating equipment to heat the sulf...

Embodiment 2

[0108] In this embodiment, the asphalt modifier produced is the same as that in Embodiment 1.

[0109] In this embodiment, the industrial production method of the asphalt modifier used is the same as that in Embodiment 1.

[0110] In this embodiment, when applying the asphalt modifier produced, the difference from Example 1 is that when mixing in step II, after the preheated asphalt modifier and mineral aggregate are mixed uniformly, Obtain an intermediate mixture; then add the preheated base asphalt into the intermediate mixture and mix evenly to obtain modified asphalt concrete. When mixing the asphalt modifier and mineral aggregate, the temperature of the mixture composed of the asphalt modifier and mineral aggregate is lower than 150°C; when adding the preheated base asphalt into the intermediate mixture for mixing , the temperature of the mixture composed of the preheated base asphalt and the intermediate mixture is lower than 150°C.

[0111] In this embodiment, when th...

Embodiment 3

[0149] In this example, the prepared bitumen modifier is different from Example 1 in that: the weight of the red mud particles is 150g; the olefin modifier is low-density polyethylene and its addition amount is 30g, so The sulfur modified additive is nano CuSO 4 particles, the nanoscale CuSO 4 The weight of the granules is 60 g.

[0150] During actual preparation, the olefin modifier may be one or both of low-density polyethylene, hot-melt polyurethane, dicyclopentadiene and cyclopentadiene.

[0151] In this example, the remaining components and proportions of the prepared asphalt modifier are the same as those in Example 1.

[0152] In this example, the production method of the asphalt modifier is different from Example 1 in that: when sulfur is melted in step 101, heating equipment is used to heat the sulfur mixture at a temperature of 135°C until Heat the sulfur to a molten state; when performing sulfur modification in step 102, use the heating equipment and continue hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com