Patents

Literature

1503 results about "Dicyclopentadiene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

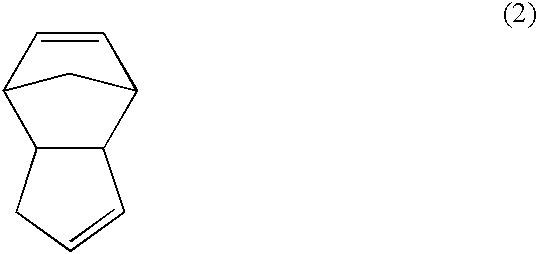

Dicyclopentadiene, abbreviated DCPD, is a chemical compound with formula C₁₀H₁₂. At room temperature, it is a clear light yellow color liquid with an acrid odor. Its energy density is 10,975 Wh/l. Dicyclopentadiene is coproduced in large quantities in the steam cracking of naphtha and gas oils to ethylene. The major use is in resins, particularly, unsaturated polyester resins. It is also used in inks, adhesives, and paints.

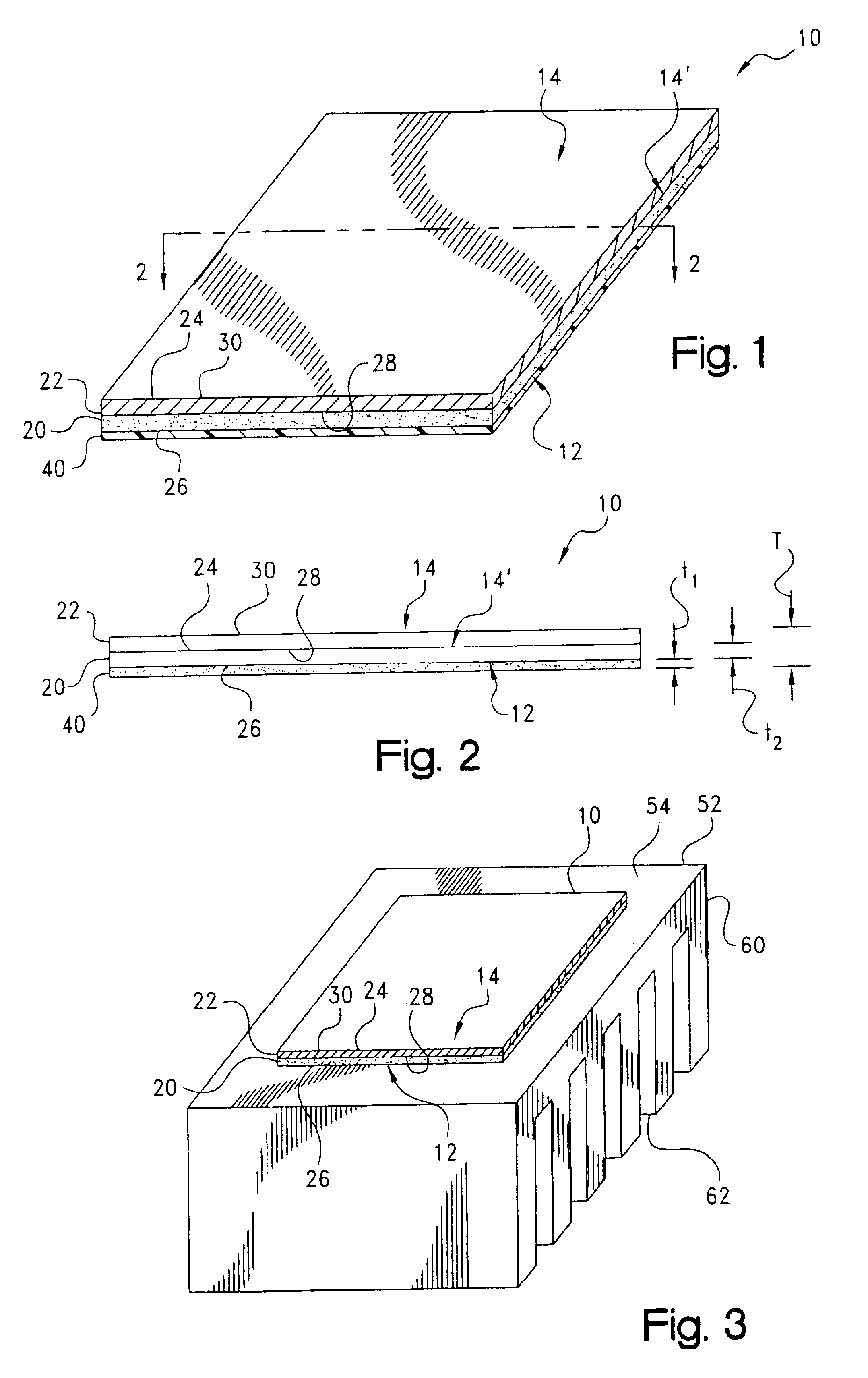

Polymeric composites including dicyclopentadiene and related monomers

InactiveUS6310121B1Group 8/9/10/18 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsFiberMonomer composition

Compositions including fibers, fillers, reinforcing agents or other property-enhancing agents added to a polymeric matrix formed from DCPD monomer or related compounds such as norbornene and norbornadiene are disclosed. The composition has a mechanically forgiving matrix due to the polymer with the inherent strength and other physical properties of the enhancement agent according to the invention. Enhancement agents according to the invention generally include inorganic, organic and metallic substances in a variety of forms.

Owner:CYMETECH

Thermoplastic dicyclopentadiene-base open-ring polymers, hydrogenated derivatives thereof, and processes for the preparation of both

InactiveUS6511756B1Improve efficiencyGood moldabilityPlastic/resin/waxes insulatorsSynthetic resin layered productsThermoplasticDouble bond

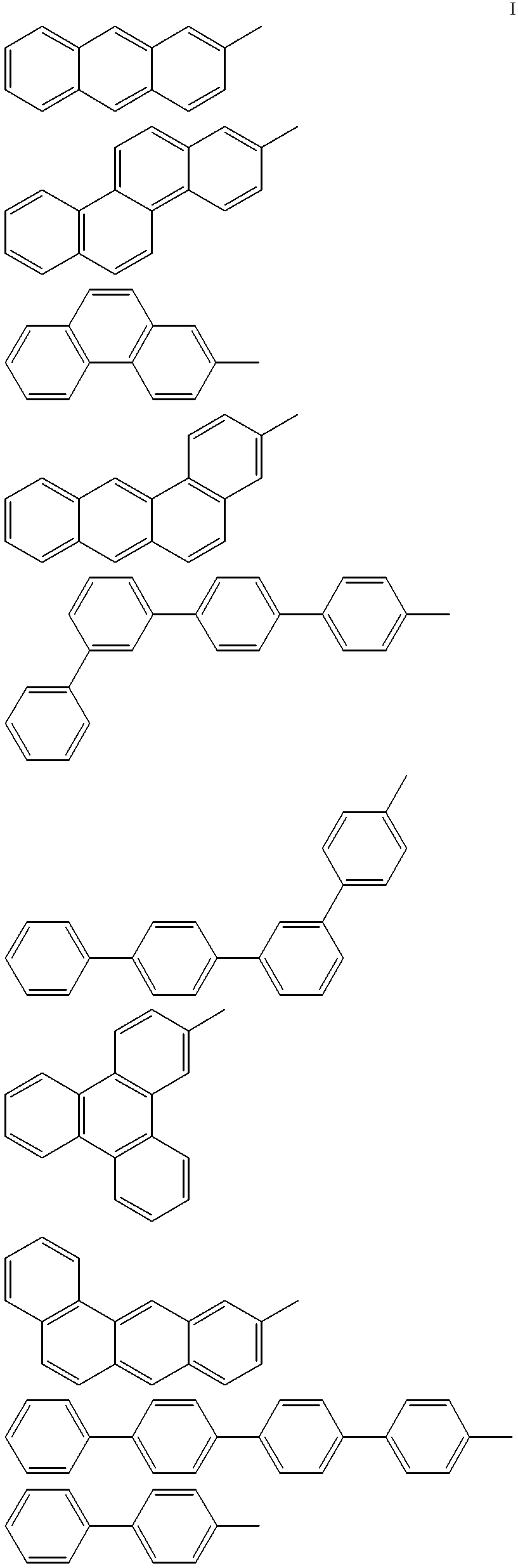

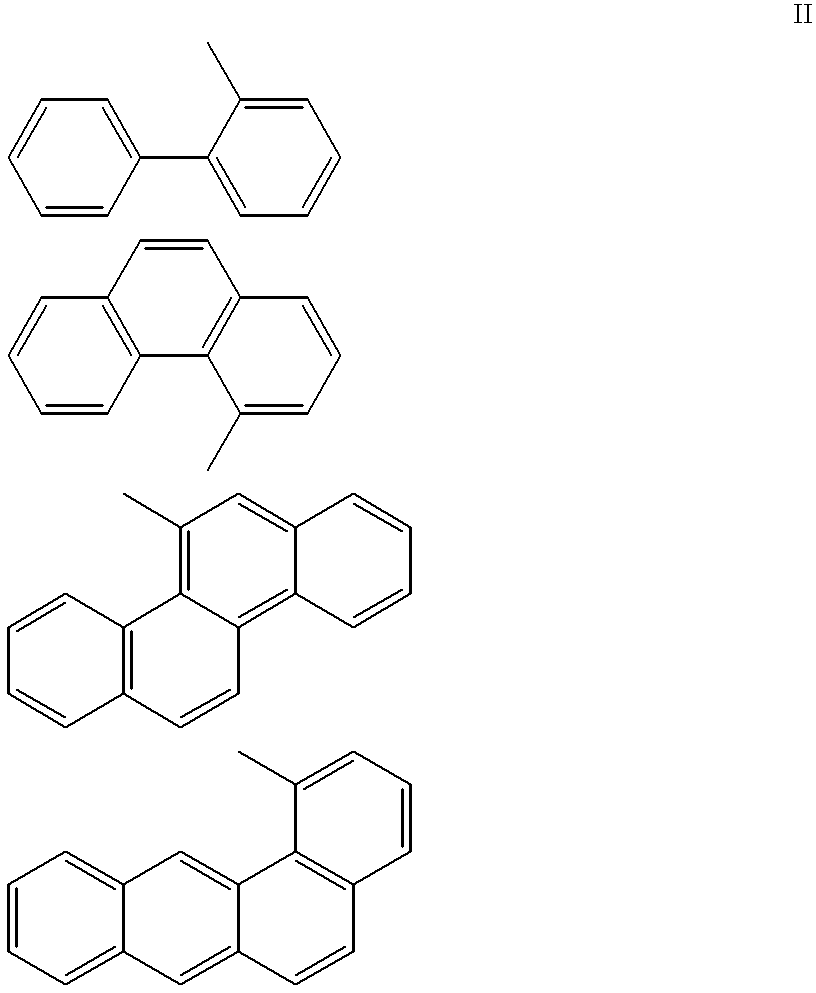

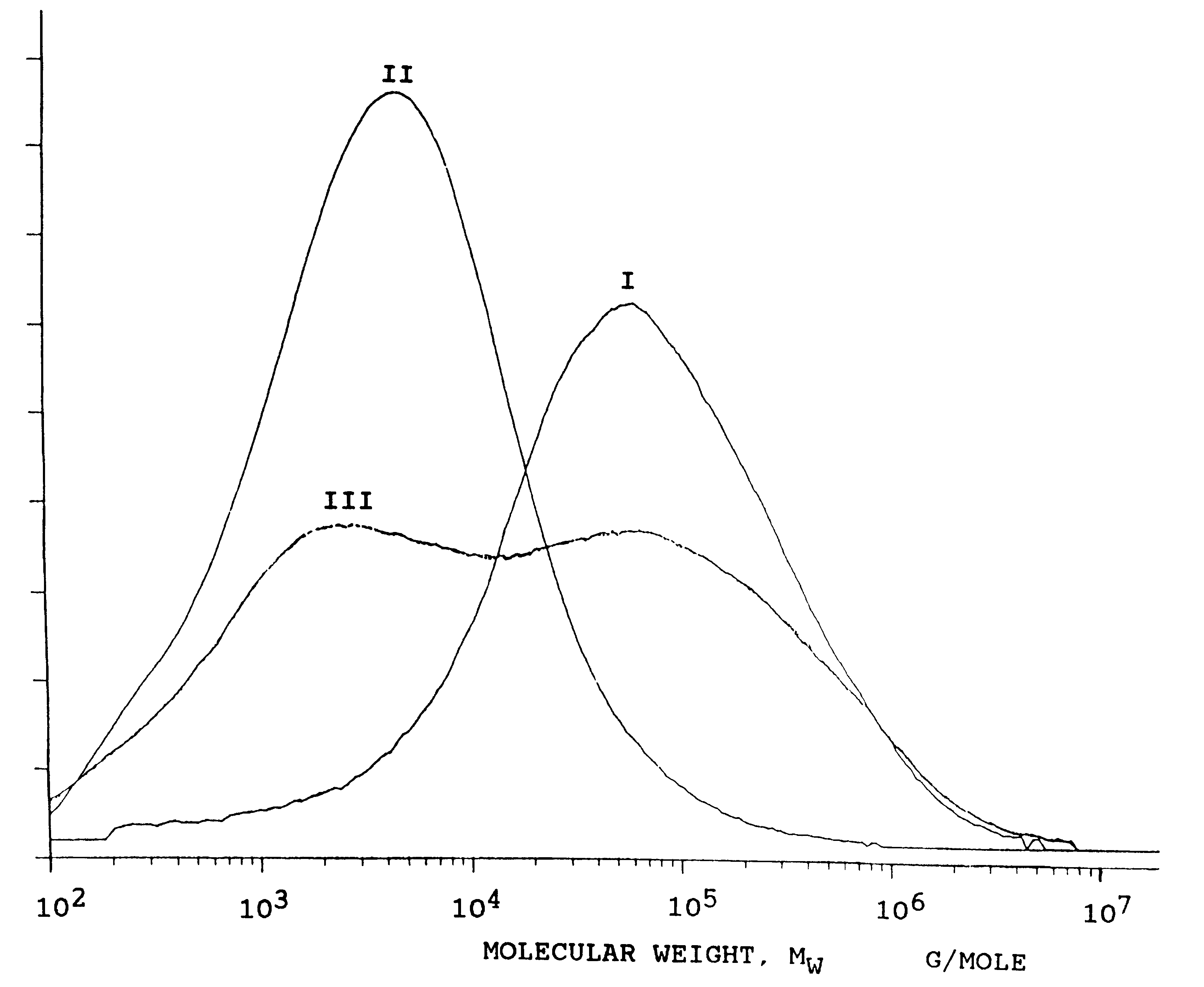

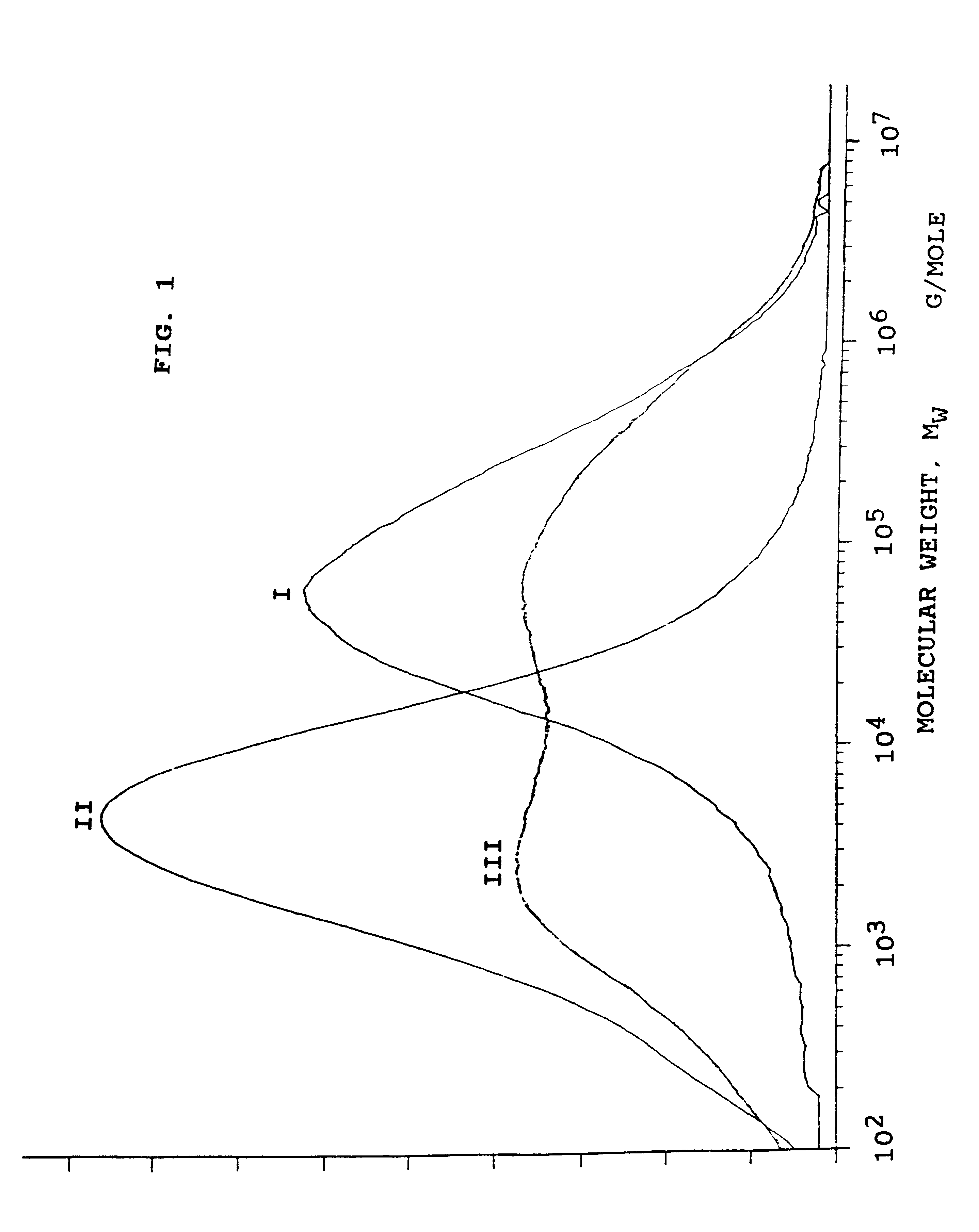

A thermoplastic dicyclopentadiene ring-opening polymer obtained by ring-opening polymerization of a monomer component containing a dicyclopentadiene monomer, characterized in that polycyclic rings which are repeating units of the polymer are bonded in cis-position relative to the carbon-carbon double bond of the main chain of the polymer in 50 mol % or more of the repeating units based on the total repeating units and the content of a low-molecular weight component of 2,000 or less in molecular weight is 10% by weight or less based on the total polymer components, and a hydrogenation product obtained by hydrogenating the carbon-carbon unsaturated bond of the thermoplastic dicyclopentadiene ring-opening polymer.

Owner:ZEON CORP

Nonformaldehyde, nonfuming resorcinolic resins and methods of making and using the same

Methods for preparing formaldehyde-free resorcinol resins are disclosed. The methods generally comprise reacting resorcinol first with dicyclopentadiene and then reacting that mixture with an olefinic compound. The resins produced by this method are also disclosed, as are rubber compositions utilizing the present resins. The resins are characterized as having a free resorcinol content of about 1 wt. % or less, and yielding a suitable softening point when used in rubber applications.

Owner:SUMIKA ELECTRONICS MATERIALS INC USA D B A SUMITOMO CHEM ADVANCED TECH INC

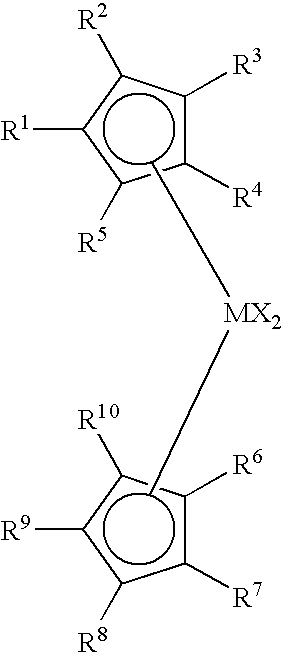

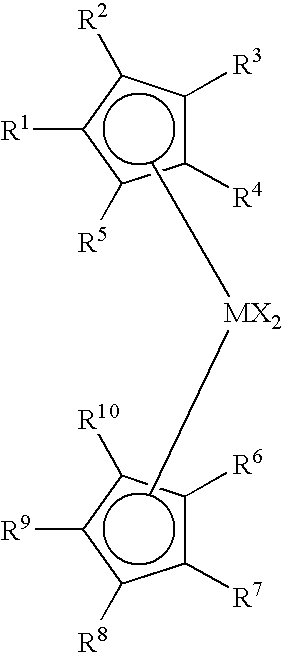

Polymerization process for olefin copolymers using bridged hafnocene compounds

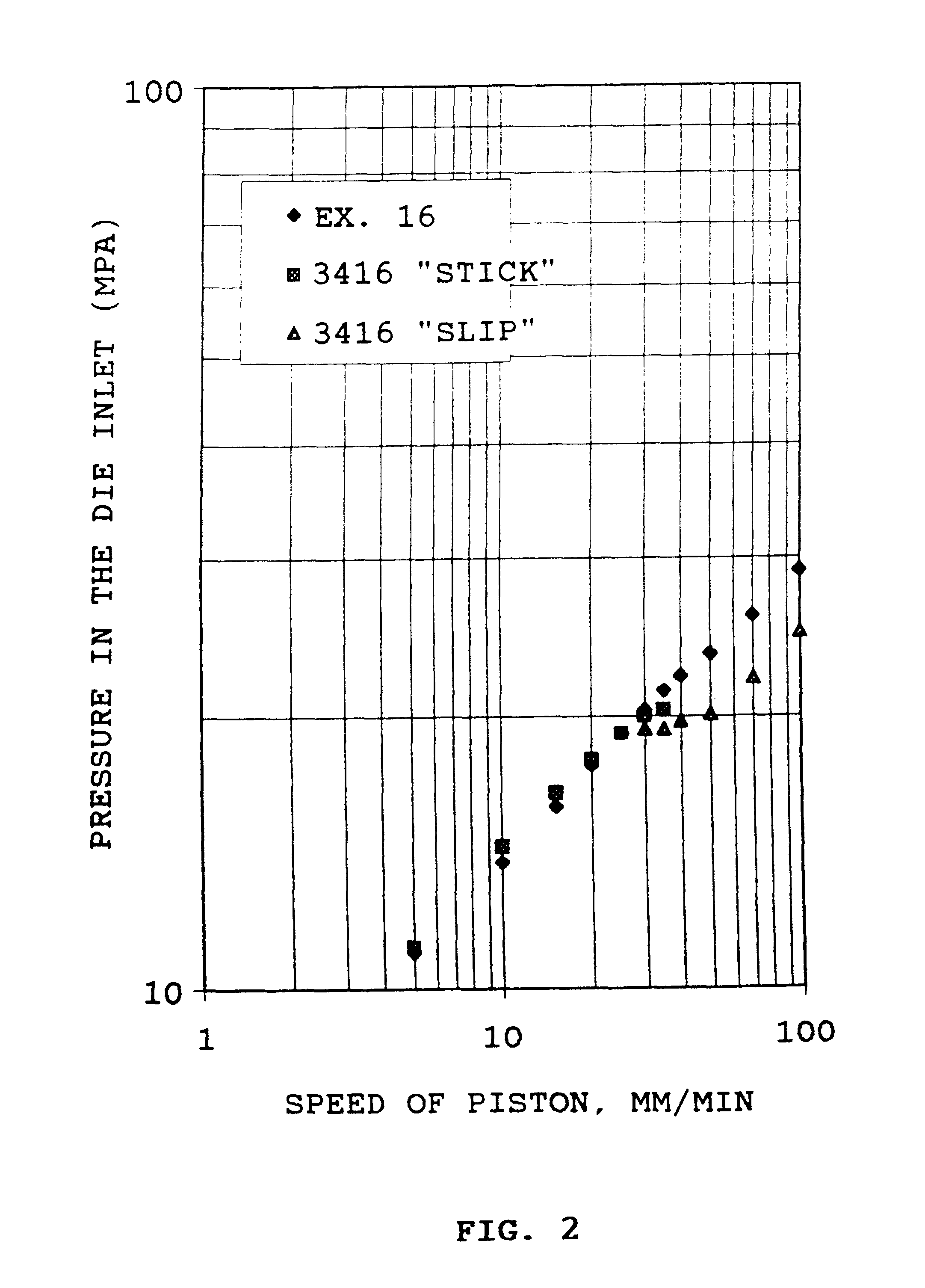

InactiveUS6218488B1High Mooney viscosityIncrease pointsOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationElastomerSide chain

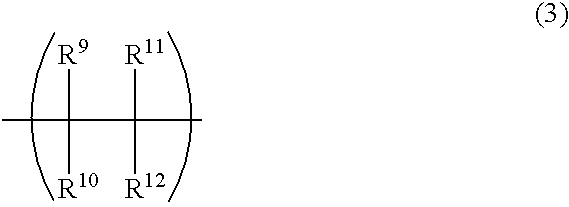

The invention is a polymerization process for ethylene copolymers having a density less than 0.915 comprising contacting ethylene, one or more alpha-olefin monomer, and optionally one or more diene monomer, with a catalyst composition comprising the reaction product of at least one organometallic Group 4 metallocene compound derived from a bridged, fused-ring ligand containing biscyclopentadienyl hafnocene, said bridge being a substituted or unsubstituted carbon or silicon atom connecting the biscyclopentadienyl ligands, and a salt of a Group 13 element anionic complex having halogenated aromatic ligands in an essentially tetrahedral structure wherein the aromatic groups are polycyclic fused or pendant aromatic rings. The process is particularly suitable for the preparation of high comonomer content and high molecular weight ethylene-alpha-olefin plastomers and ethylene-propylene or ethylene-propylene-diene monomer elastomers.

Owner:EXXONMOBIL CHEM PAT INC

Process for producing polyethylenes having a broad molecular weight distribution, and a catalyst system used thereby

InactiveUS6242543B1Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChromium CompoundsEthylene Homopolymers

A process for the polymerization of ethylene and optionally alpha-olefins to form ethylene homopolymer or copolymers having a broad molecular weight distribution, comprising polymerization of 100-80 wt. % of ethylene and 0-20 wt. % of comonomer in the presence of two independent, simultaneously present catalysts A and B, wherein catalyst A, deposited on an inorganic support, comprises chromium in a predominantly oxidant state of 2 and catalyst B comprises a bis-cyclopentadienyl chromium compound reacted with an inorganic support.

Owner:BOREALIS AS

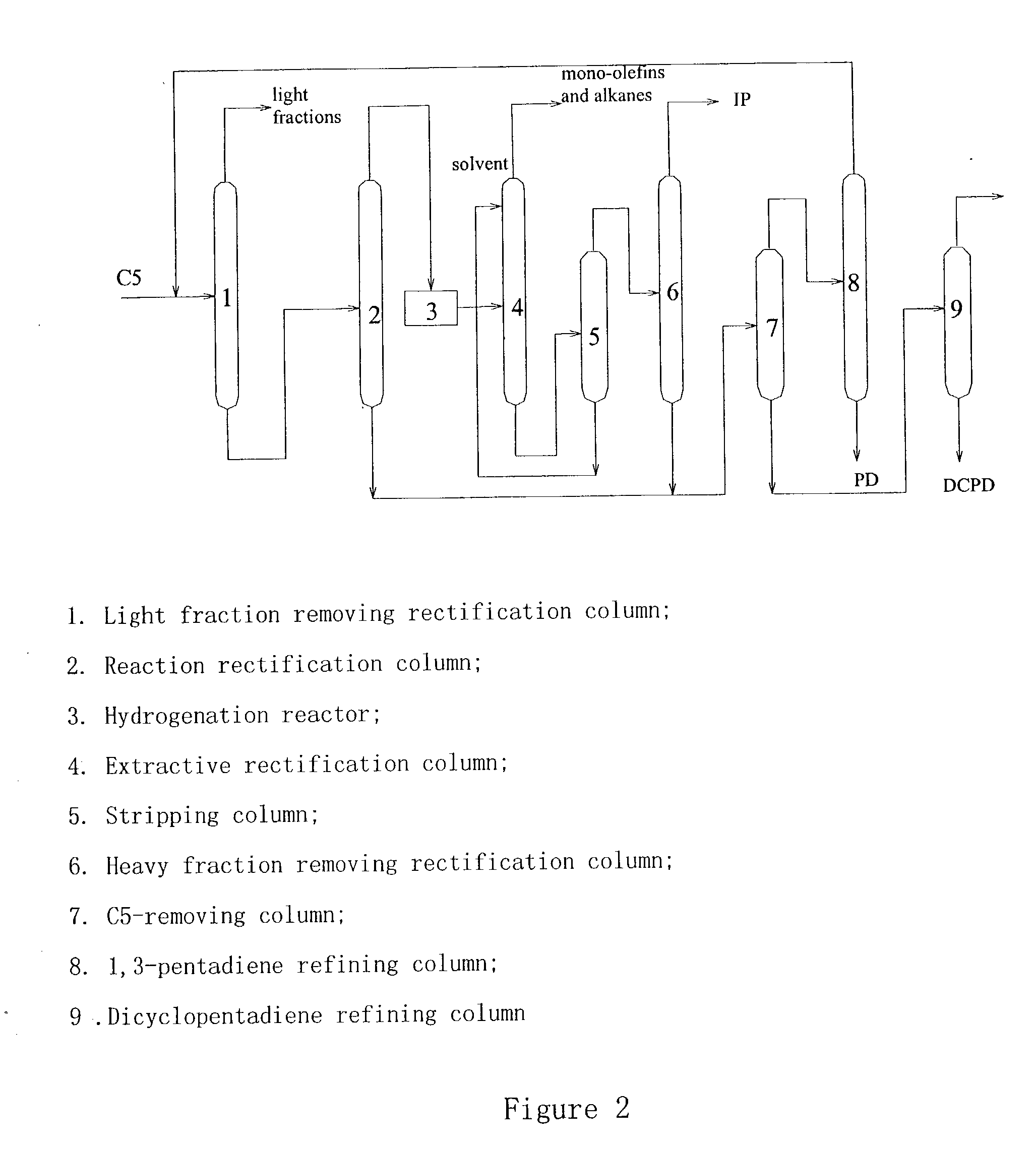

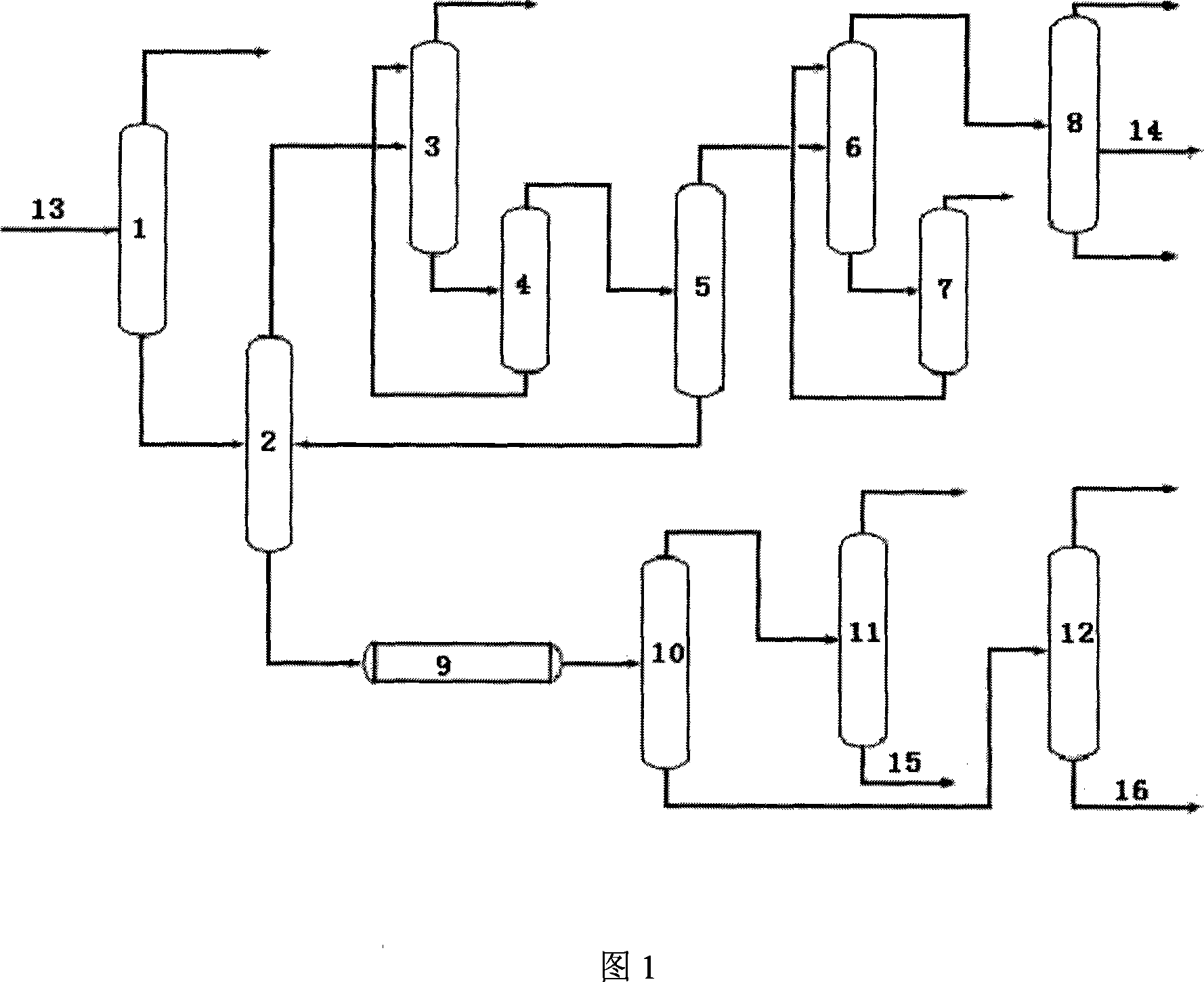

Process for separating C5 cuts obtained from a petroleum cracking process

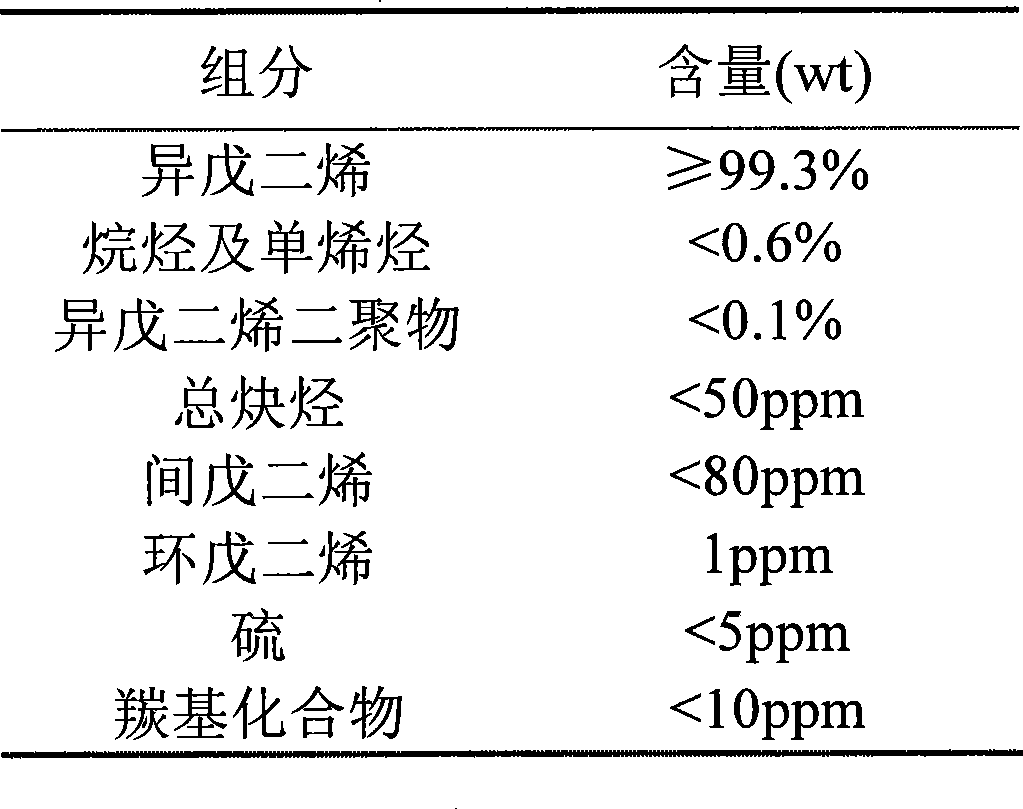

ActiveUS20030100809A1Improve catalytic performanceHigh activityLiquid hydrocarbon mixtures productionDistillation purification/separationAlkyneSolvent

The present invention relates to a process for separating the isoprene, 1,3-pentadiene and dicyclopentadiene from a C5 cuts, comprising dimerization of the cyclopentadiene and selective catalytic hydrogenation. The second extractive rectification step can be omitted, because the alkynes are removed through selective catalytic hydrogenation prior to the extractive rectification. As a result, the solvent-recovering units can be simplified, and thus the process as a whole can be optimized. Correspondingly, the investment and energy consumption, the operation cost, and finally the production cost can be substantially reduced.

Owner:CHINA PETROCHEMICAL CORP +1

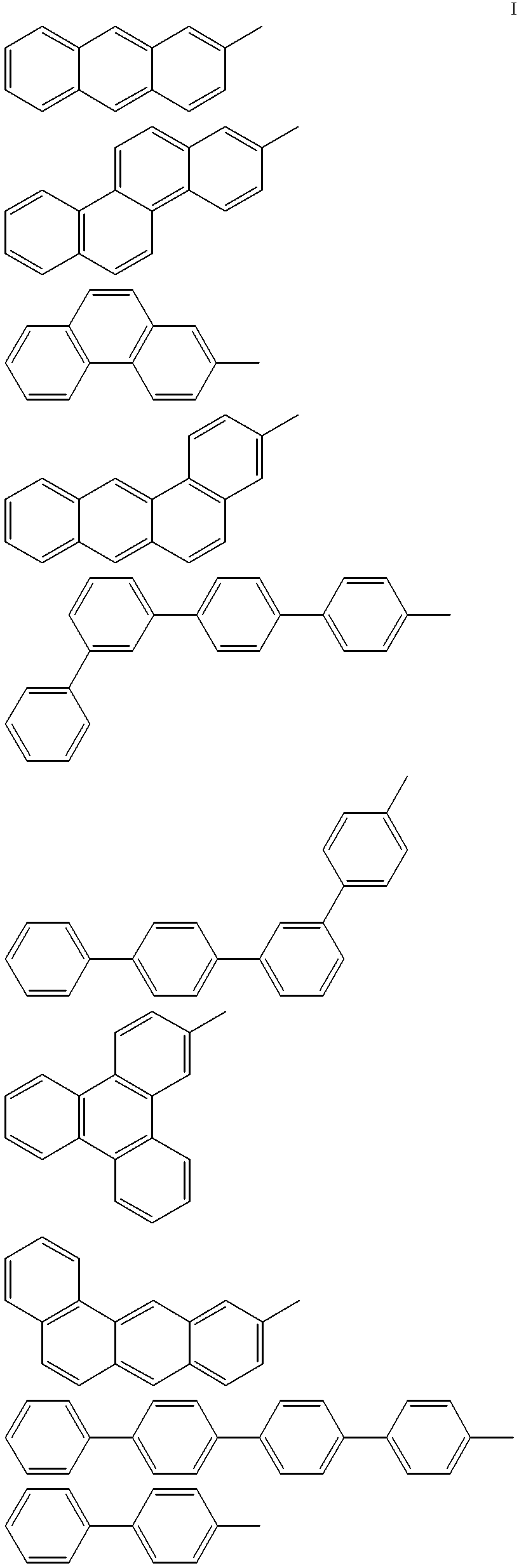

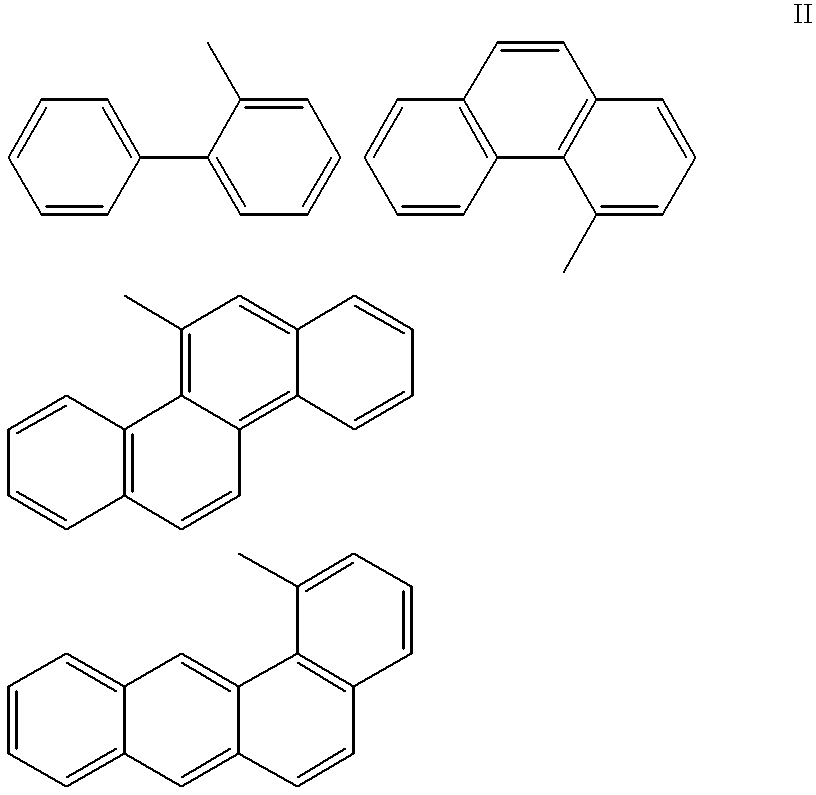

Process to produce low viscosity poly-alpha-olefins

ActiveUS8207390B2Hydrocarbon by hydrogenationHydrocarbons from unsaturated hydrocarbon additionNon-coordinating anionAlpha-olefin

A low viscosity poly(alpha-olefin) (PAO) is produced by contacting one or more C3 to C24 alpha-olefins with an unbridged, substituted bis-cyclopentadienyl transition metal compound, a non-coordinating anion activator, and an alkyl-aluminum compound. The molar ratio of transition metal compound to activator is 10:1 to 0.1:1 and the molar ratio of alkyl aluminum compound to transition metal compound is 1:4 to 4000:1. The transition metal compound has either (a) at least one non-isoolefin substitution on both cyclopentadienyl rings, or (b) at least two substitutions on at least one cyclopentadienyl ring. The PAO is comprised of at least 50 mole % of C3 to C24 alpha-olefins, has a Mw / Mn between 1 and 1.4, and a kinematic viscosity at 100° C. of 20 cSt or less.

Owner:EXXONMOBIL CHEM PAT INC

Composite waterproof plate, ad its manufacturing method and use

InactiveCN1640640AImprove waterproof performanceImprove corrosion resistanceWood working apparatusDomestic articlesPolymer scienceAdhesive

The present invention relates to a composite water-proof material. It is made up by using (by weight portion) 20-70 portions of plant fibre, 10-60 portions of flyash and 5-40 portions of adhesive through the processes of mixing them, die-pressing and polymerization. The described adhesive is formed from maleic anhydride, phthalic anhydride, polyalcohol, styrene or mixture of their homologous compounds, also can include trimeric cyanamide, acrylic acid or rosin and dicyclopentadiene. Its raw material composition also can include 10-40 portions of new and old plastics. Said plate material has strong strength and good water-proof property, so that it has extensive application range.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for producing modified unsaturated polyester resins by low purity technical grade dicyclopentadiene

The present invention relates to a novel method of using industrial dicyclopentadiene of purity of 75 percent to 85 percent to prepare modified unsaturated polyester resin. In the preparation of the resin, the industrial dicyclopentadiene separated from the saturated or unsaturated dicarbonic acid or acidic anhydride and the distilled part of mixed C5 is used as the raw material. After hydrolysis and addition reaction, the diol or polyol of appropriate amount is added. The polymerization and dehydration reaction is done with the influence of acidic catalyst. When the mixture is condensed to the designated acid value, the inhibitor and cross-linking monomer of appropriate amount are added and then stirred to prepare the product. The present invention has the advantage that the cost of resin is lower than the common type unsaturated resin. At the same time, the air-drying performance, heat resistance, volumetric shrinkage rate and other performances are all superior to the common type unsaturated polyester resin. The product can be widely used in the fields of glass steel, mold, plastic clothing, sealing, and adhesive and so on.

Owner:泉州永悦新材料有限公司

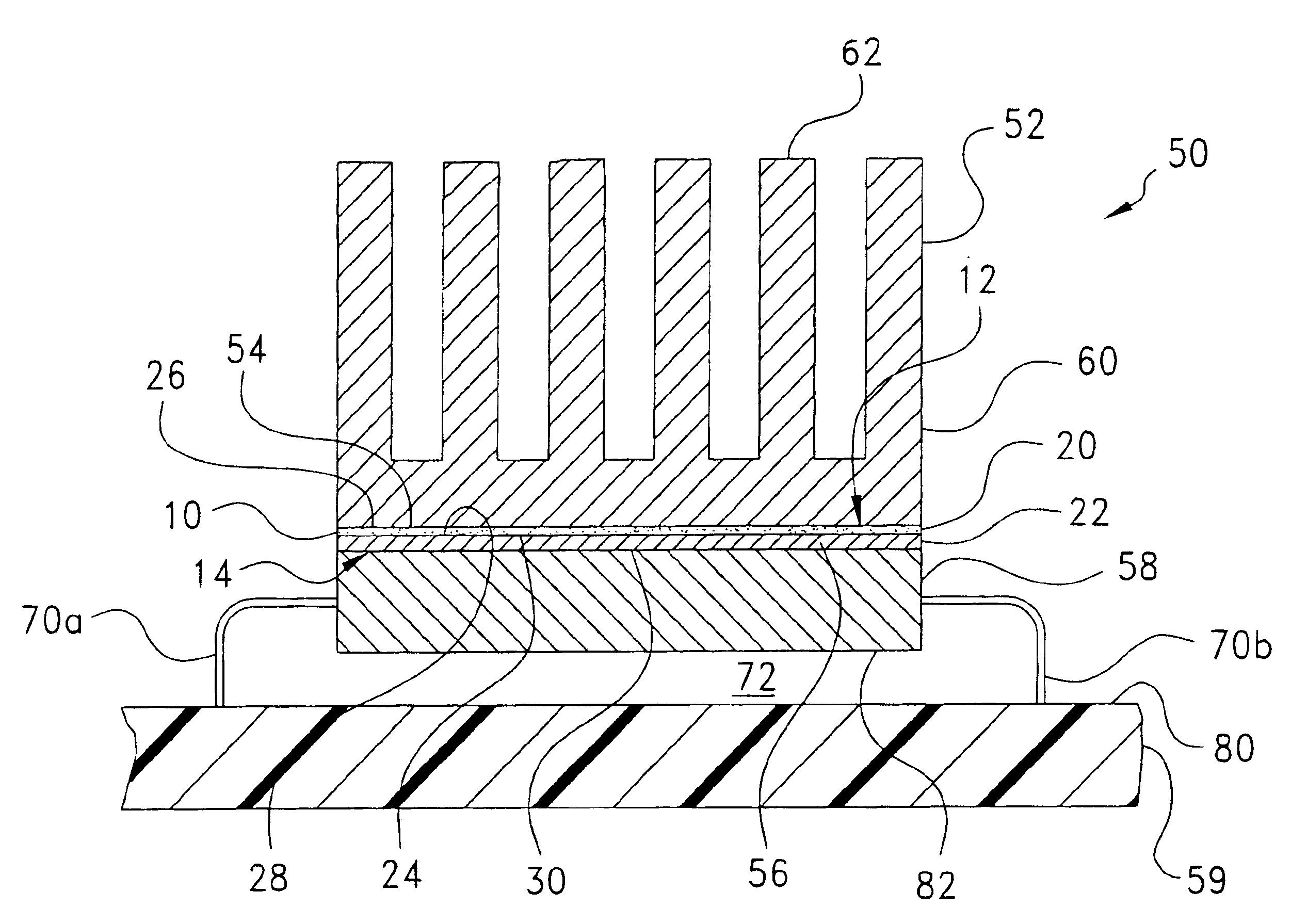

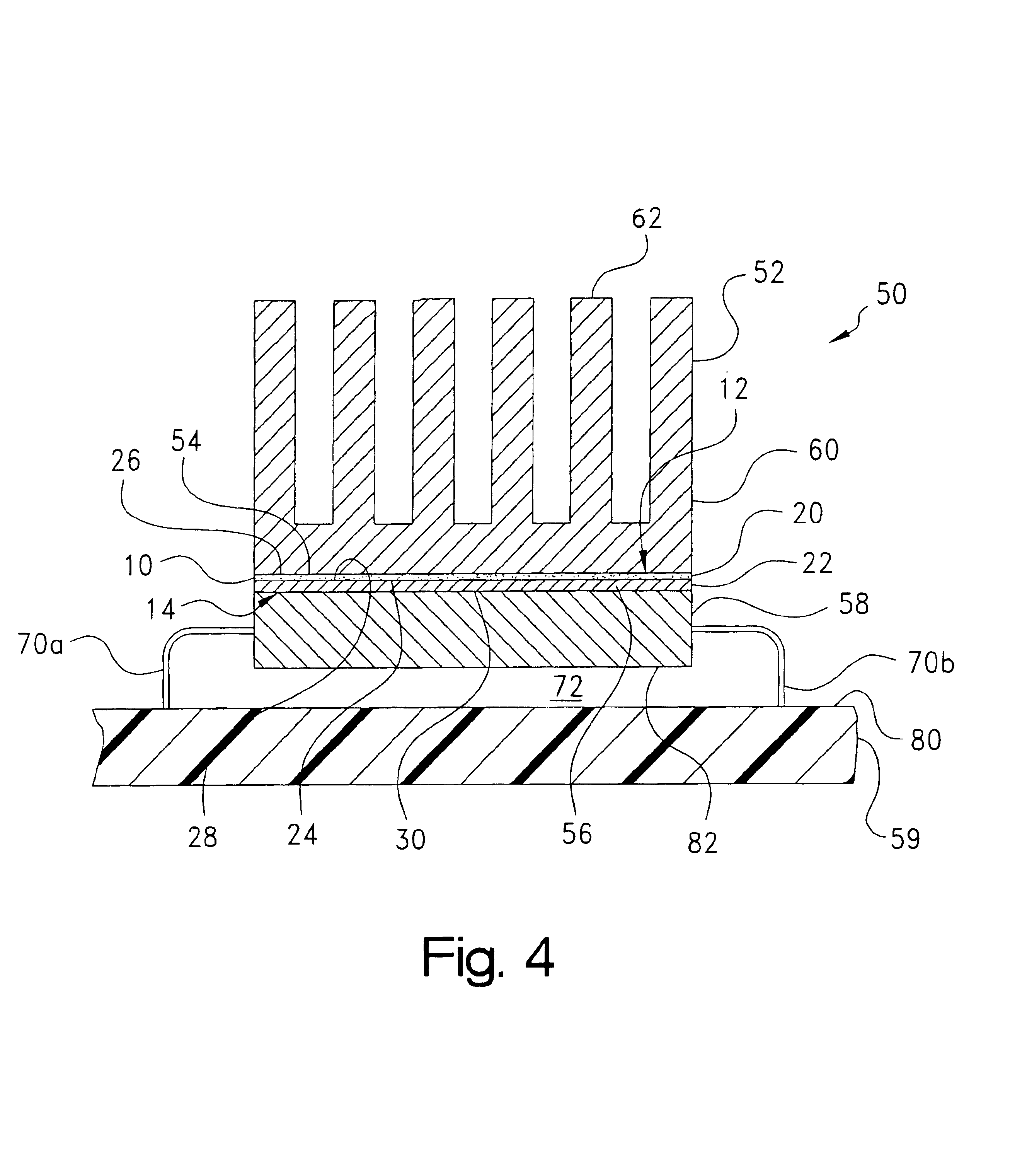

High temperature stable thermal interface material

InactiveUS6956739B2Reduce thermal resistanceImprove performanceSemiconductor/solid-state device detailsSynthetic resin layered productsParticulatesLiquid resin

A thermally-conductive interface interposable intermediate a first heat transfer surface and an opposing second heat transfer surface to provide a thermal pathway therebetween. The interface includes a thermally-conductive compound formed into a layer which is conformable between the first and second heat transfer surface. The compound is an admixture of: (a) a liquid resin constituent; and (b) a particulate filler constituent. The liquid resin constituent may be an ethylene-propylene copolymer (EPM) or a terpolymer (EPDM) of ethylene and propylene and a diene which may be ethylidene norbornene (ENB) or dicyclopentadiene (DCPD).

Owner:PARKER INTANGIBLES LLC

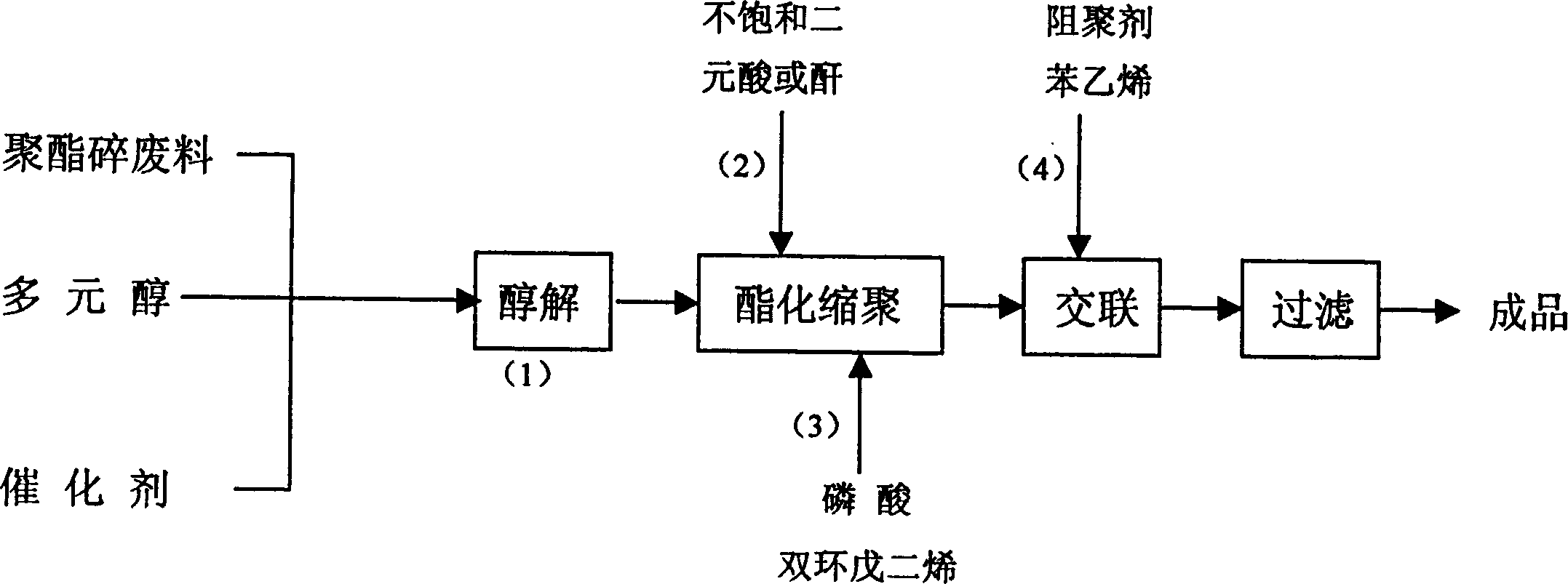

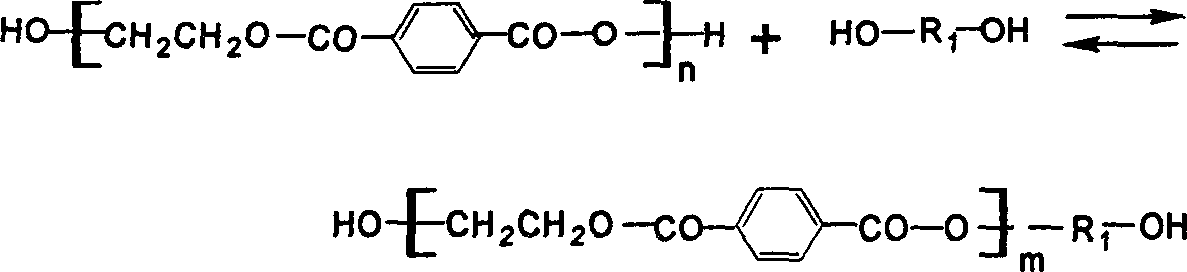

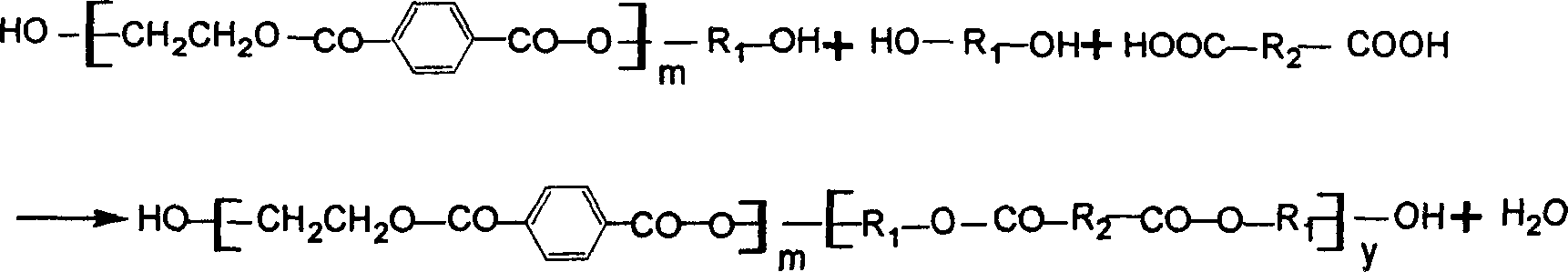

Synthesis of p-phenyl unsaturated polyester resin by using waste polyester material

The invention relates to a method for synthesizing unsaturated phenolic resin with various etherification waste, which includes the four steps: (1) etherification waste and polyhydric alcohol have alcohol sis and ester interchange with catalyst existing; (2)alcohol zed product and unsaturated binary acid or have etherification polycondensation; (3) use dicyclopentadiene (DCPD) to blocking modify in the later period of etherification polycondensation; (4) add into styrene solution for cross linking. The invention has plentiful sources of raw material, low price, decreased pollution and productive cost and energy saving, as well as eliminates the disadvantage of bad dissolubility in styrene .

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

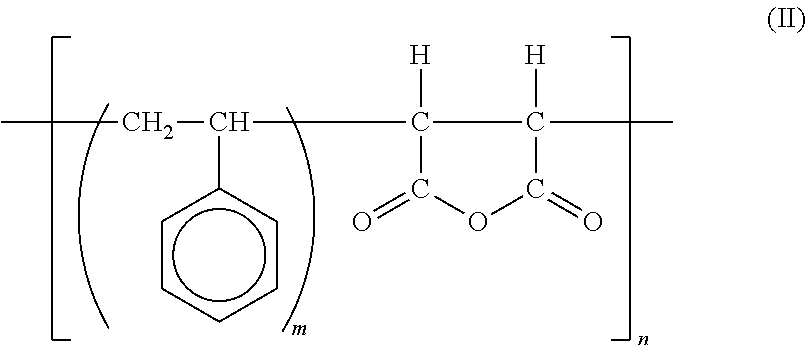

Adhesive tape

InactiveUS20040232563A1Improve abilitiesAvoid crackingSemiconductor/solid-state device detailsSolid-state devicesEpoxyElastic modulus

An adhesive tape comprising a base and, superimposed thereon, an adhesive layer, this adhesive layer comprising an adherent component (A), an epoxy resin (B), a thermally active latent epoxy resin curing agent (C), an energy radiation polymerizable compound (D) and a photopolymerization initiator (E), wherein either or both of the epoxy resin (B) and energy radiation polymerizable compound (D) have a dicyclopentadiene skeleton in its molecule or molecules thereof. The resultant adhesive tape has an adhesive layer which provides reduced water absorption of an adhesive curing product and which enables a lowering of the elastic modulus thereof during thermocompression bonding.

Owner:LINTEC CORP

Method for preparing high-purity cyclopentadiene

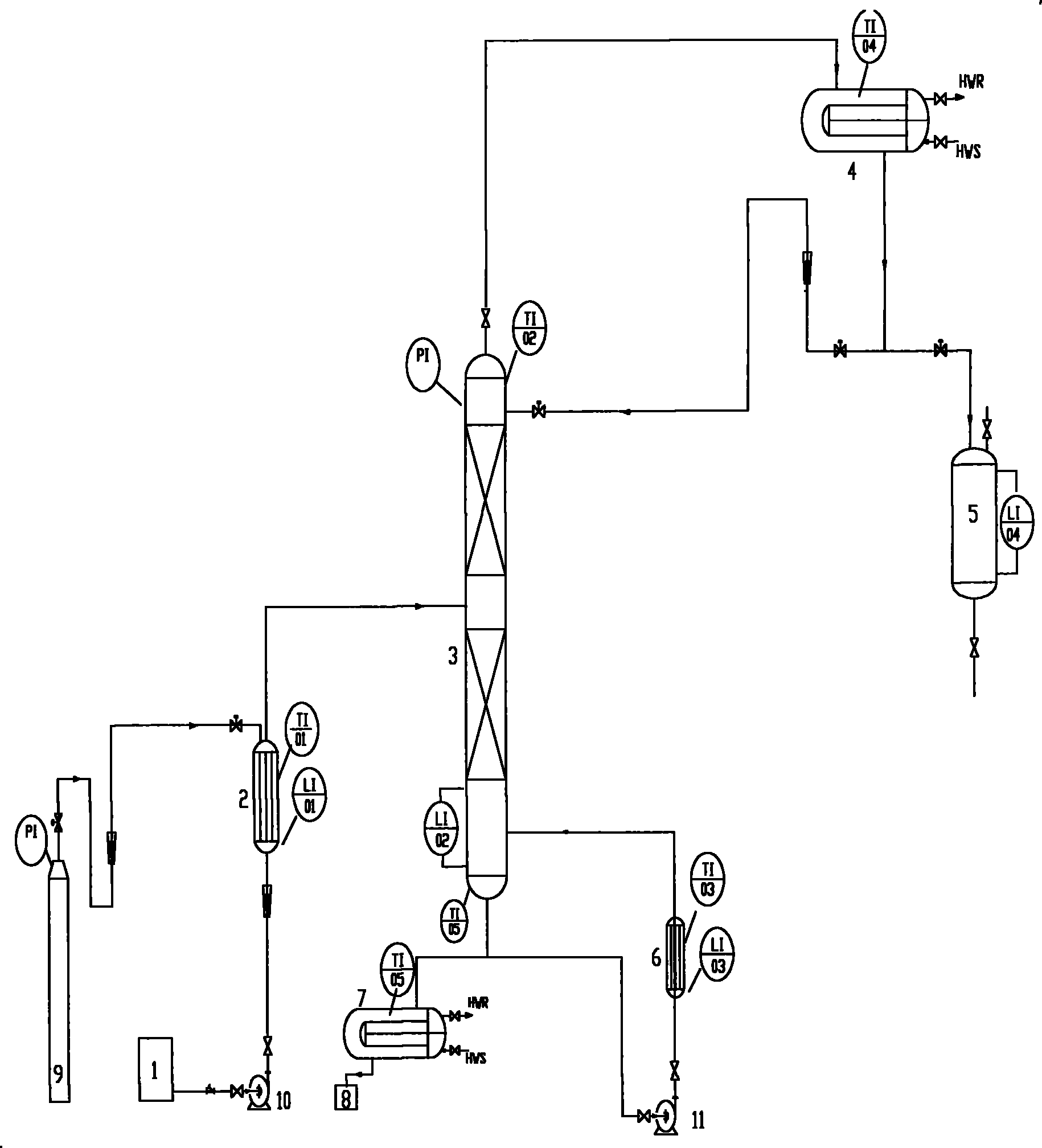

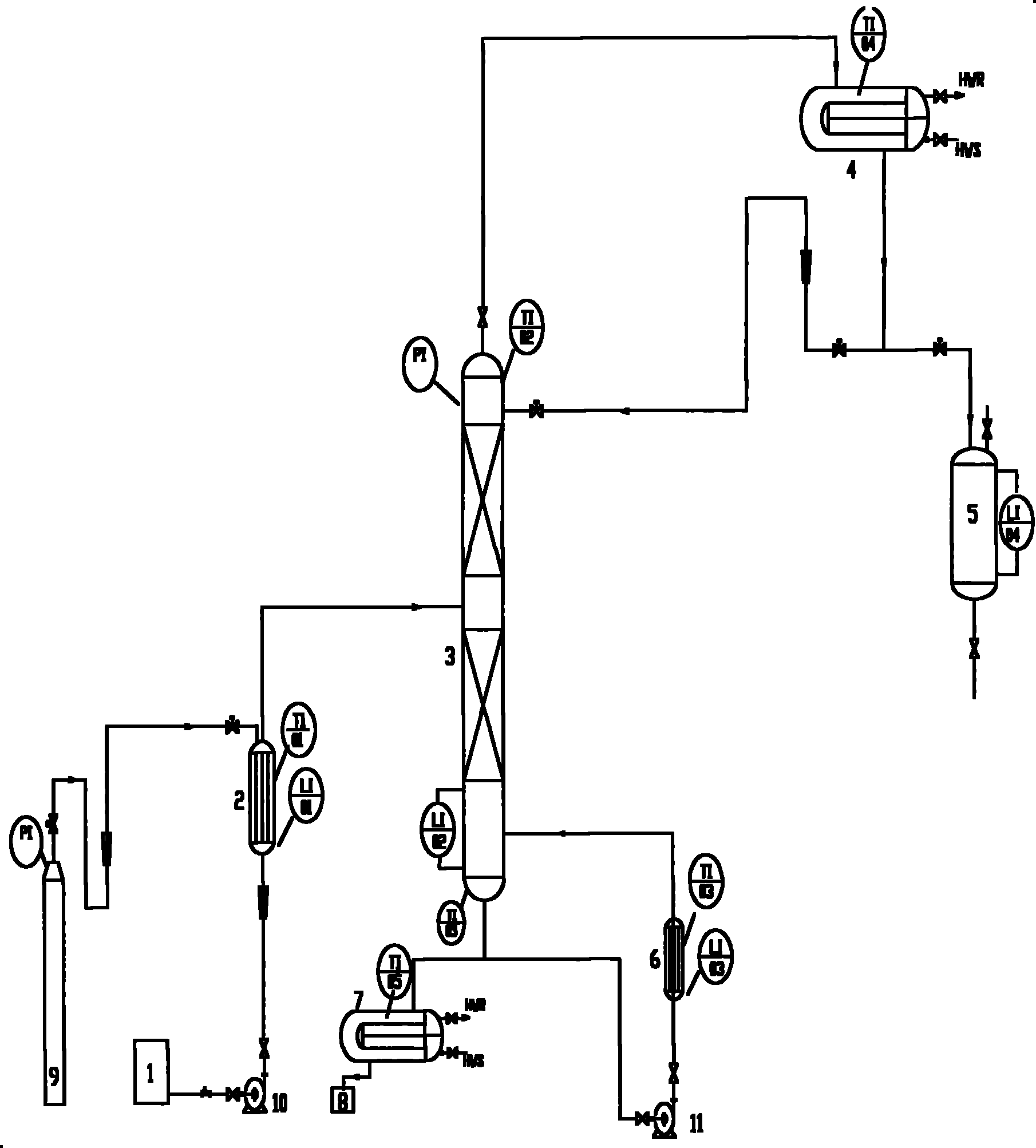

ActiveCN102060649AMild reaction conditionsControllableHydrocarbon by depolymerisationReboilerNitrogen gas

The invention relates to a method for preparing high-purity cyclopentadiene, which comprises the following steps of: heating a thermal decomposer containing purified conduction oil and a composite inhibitor and a rectifying reboiler to a specified temperature; adding dicyclopentadiene serving as a crude product into the thermal decomposer continuously and stably; allowing the depolymerized cyclopentadiene to enter a rectifying column; extracting high-purity cyclopentadiene from a tower top, heating a small amount of dicyclopentadiene and by-products by the reboiler at the tower bottom to rectify the small amount of dicyclopentadiene and by-products again, and recycling kettle liquid. The method has the advantages of simple equipment, high production capacity, little coking and long service life of the conduction oil serving as a raw material and the equipment.

Owner:PETROCHINA CO LTD

A dicyclopentadiene hydrogenation special-purpose catalyzer and its preparing method

InactiveCN101157029AGood dispersionHigh activityMetal/metal-oxides/metal-hydroxide catalystsMolecular sieveUnsaturated hydrocarbon

The invention relates to dicyclopentadiene hydrogenation special catalyst and the preparation method thereof; a catalyst active component is abstracted from Pd or Pt, the percentage content of the weight can be Pd 0.3 to 1.3 percent or Pt 0.5 to 1.2 percent, carriers can be porous inorganic materials of aluminum oxide, silicon oxide, molecular sieves, kaolin, etc. By adopting the novel noble metal colloid method process, the prepared catalyst has the advantages that the grain size of active component particles is concentrated, the dispersion degree is high, the surface area is large, etc., thus the catalyst activity is higher, and the operating pressure of a hydrogenation device can be notably reduced. The preparation method provided by the invention effectively reduces the quantity of noble metals, the catalyst is used for the dicyclopentadiene petroleum resin hydrogenation device with poor color phase in the carbon five fraction, the content of unsaturated hydrocarbon key can be obviously reduced, and the color phase of the resin is improved to be of a water white color.

Owner:CHINA NAT OFFSHORE OIL CORP +1

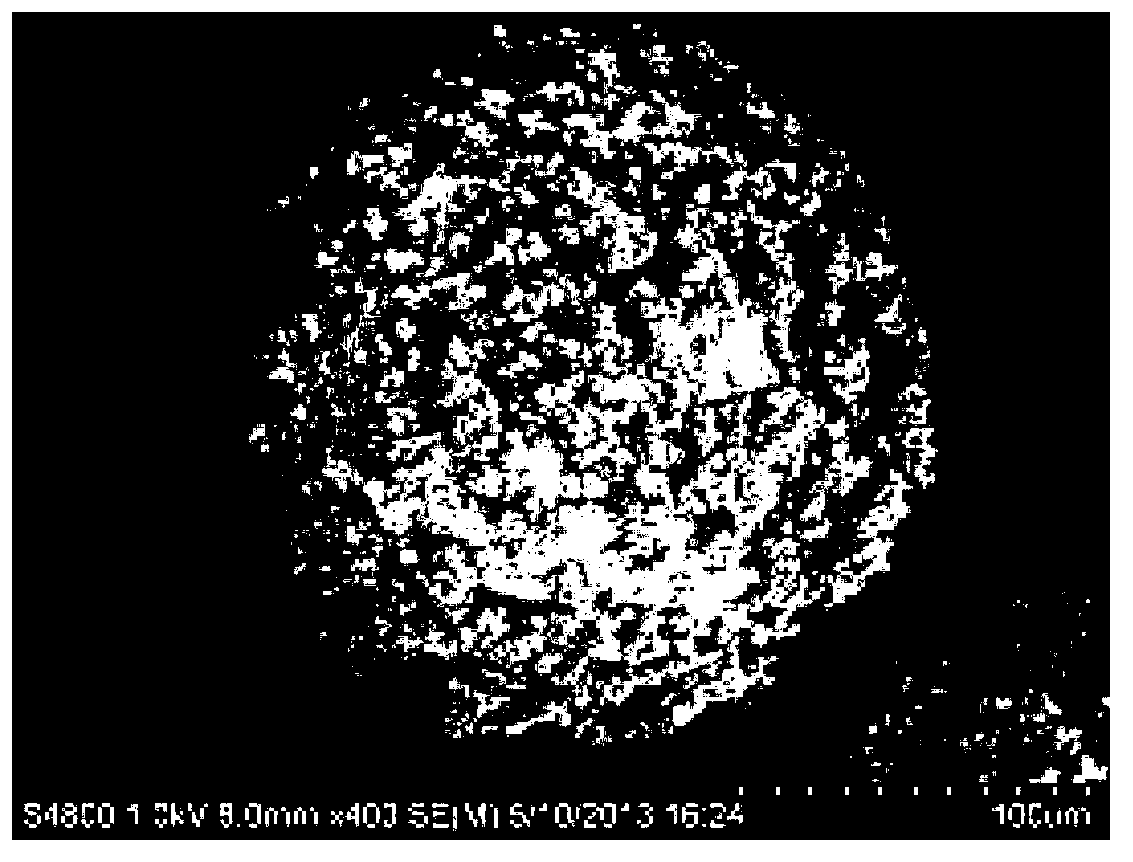

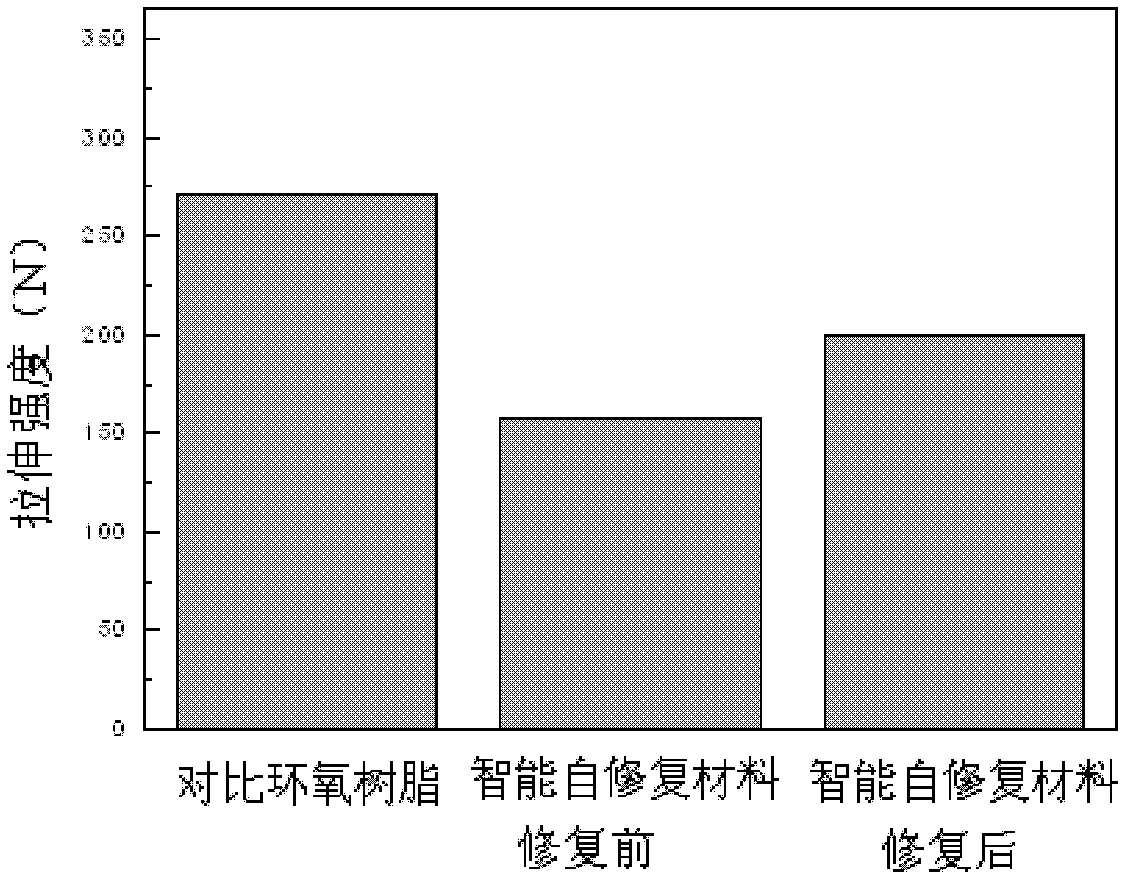

Preparation method of microcapsules for rubber material self-repair

ActiveCN103265736AExpand the scope of researchBroaden the field of applicationMicroballoon preparationMicrocapsule preparationRubber materialPolymer science

The invention relates to a preparation method of microcapsules for rubber material self-healing, belonging to the field of self-repair microcapsules. By adopting an in-situ polymerization method, the wall material urea-formaldehyde resin is coated on the surface of the repair agent core material dicyclopentadiene liquid drop to form microcapsules. An impregnation film spreading method is utilized to compound the microcapsules with natural latex, so that the microcapsules can break and release the repair agent to fill up the cracks and heal the wounds when the rubber substrate is damaged. The invention provides a new technical way for prolonging the service life of the rubber material.

Owner:BEIJING UNIV OF CHEM TECH

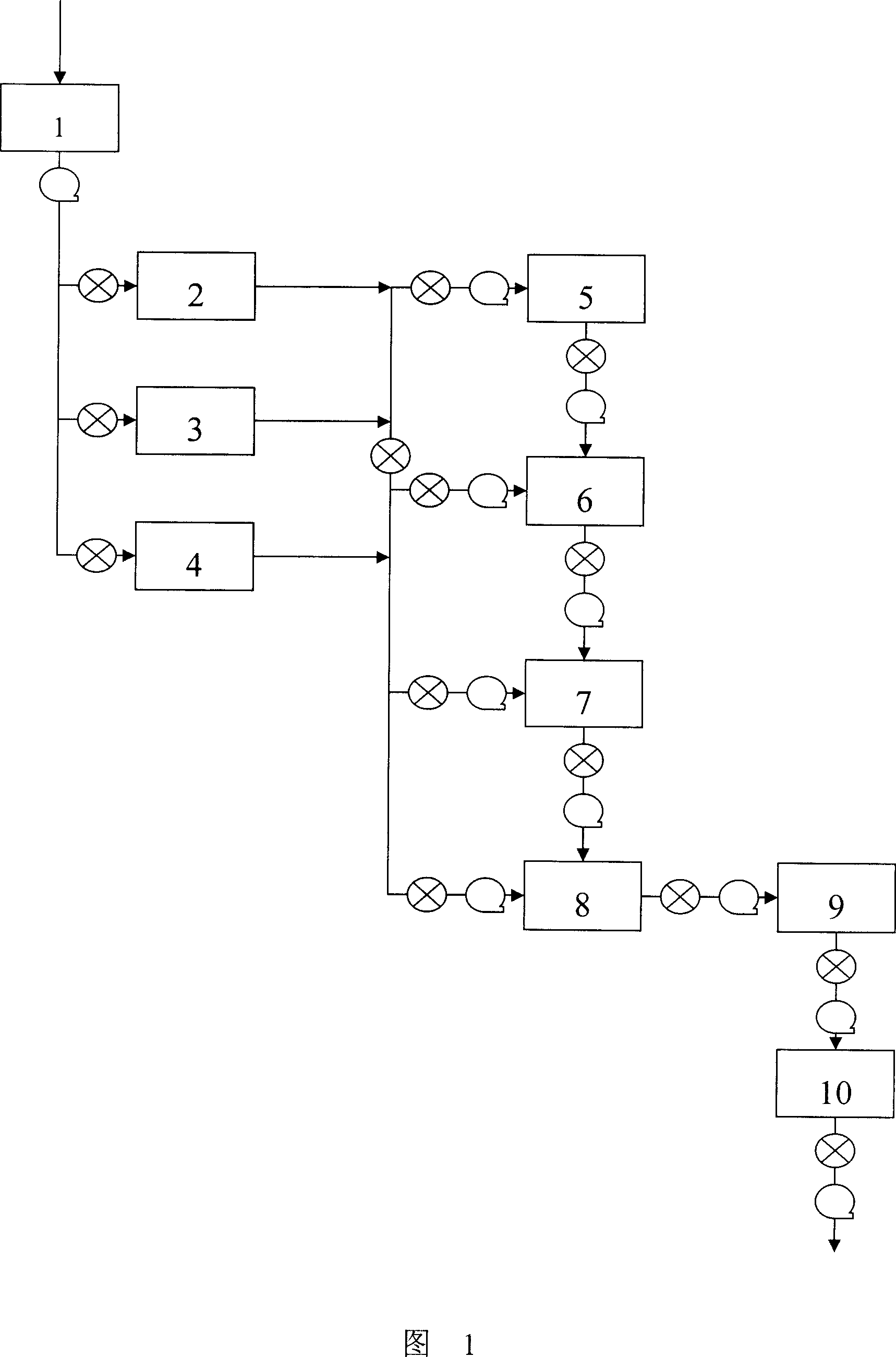

Process for producting petruleum resin by hot polymerizing

InactiveCN100999564ASolve the difficulty of not being able to produce low-color petroleum resinRetention timePetroleum resin

The present invention relates to hot polymerization process of producing petroleum resin, especially with C9 fraction as the side product of ethylene production. The C9 fraction material is first cut into three fraction sections including styrene resin oil, dicyclopentadiene resin oil and indene resin oil; and the three fraction sections are added into hot polymerization reaction kettle according to the requirement of the product for polymerizing, with the hot polymerization reaction kettle comprising four serially connected kettles with separate regulation on temperature, pressure, material retention time and other parameters. The product obtained through polymerization in the four serially connected kettles is distilled to eliminate solvent so as to obtain the petroleum resin product.

Owner:天津天大天海化工新技术有限公司 +1

High temperature olefin polymerization process

InactiveUS6291609B1Superior molecular weight and activity capabilityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationReaction temperatureHafnium

Owner:EXXONMOBIL CHEM PAT INC

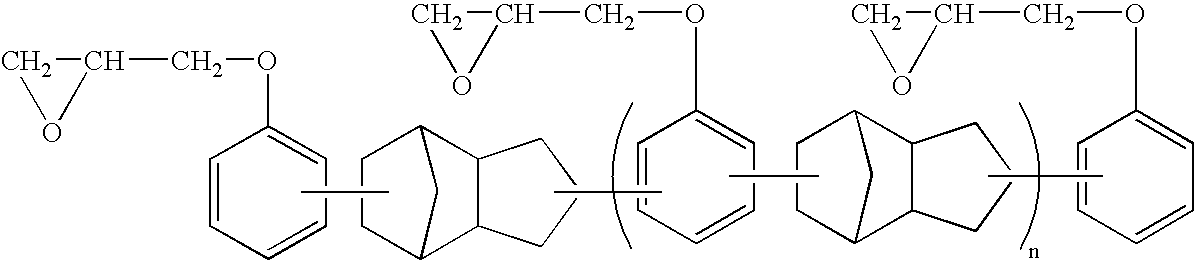

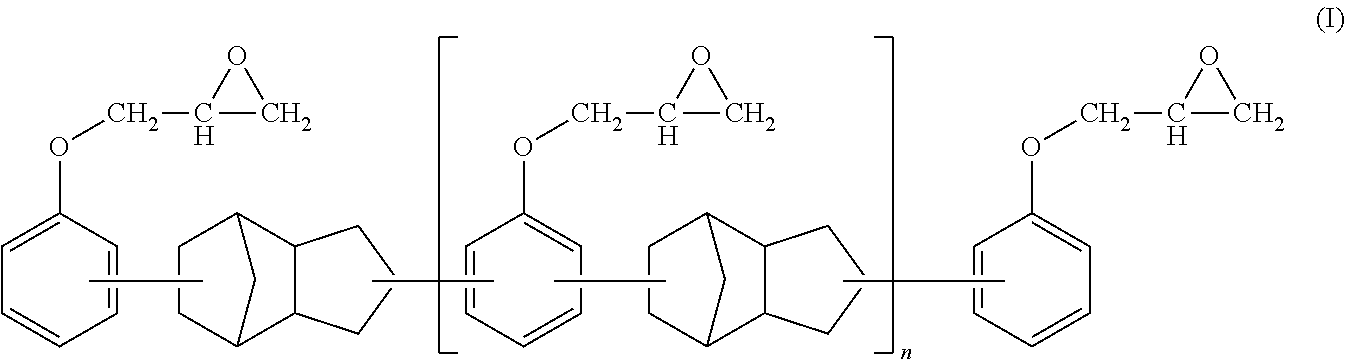

Resine Composition For Printed Circuit Board And Composite Substrate And Copper Laminates Using The Same

InactiveUS20090004484A1Desirable formabilityDesirable processibilitySynthetic resin layered productsElectrical equipmentEpoxyComposite substrate

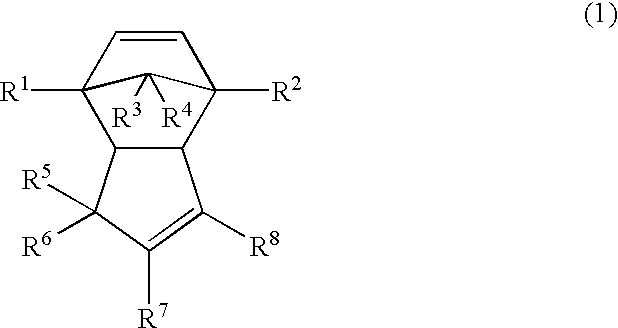

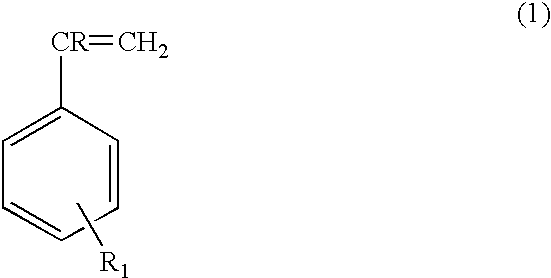

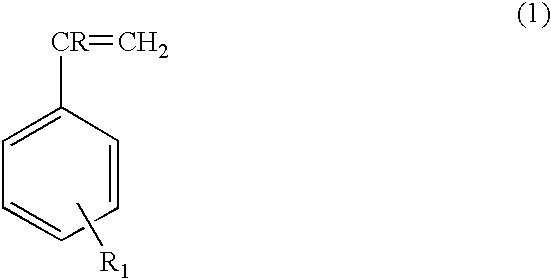

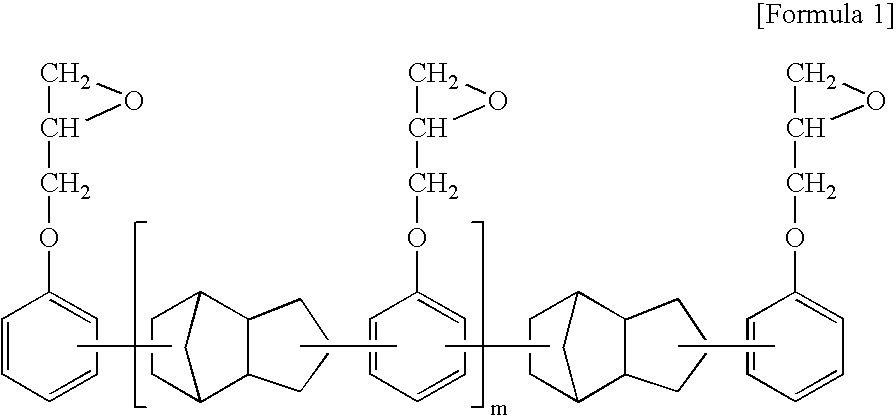

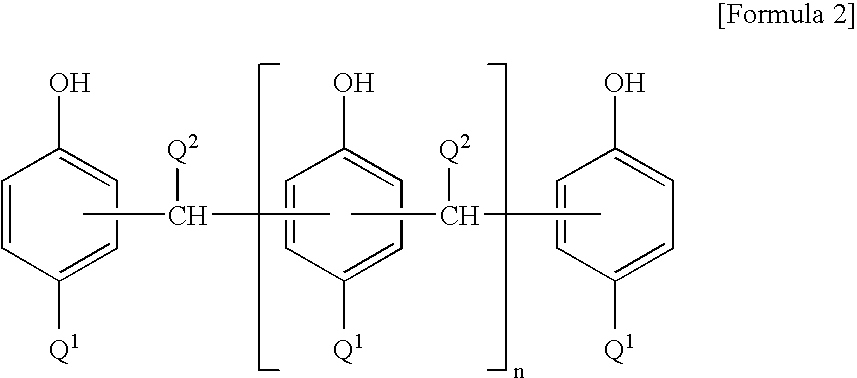

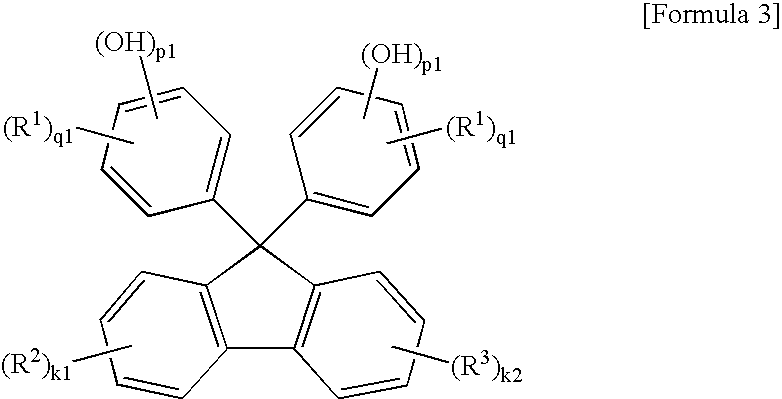

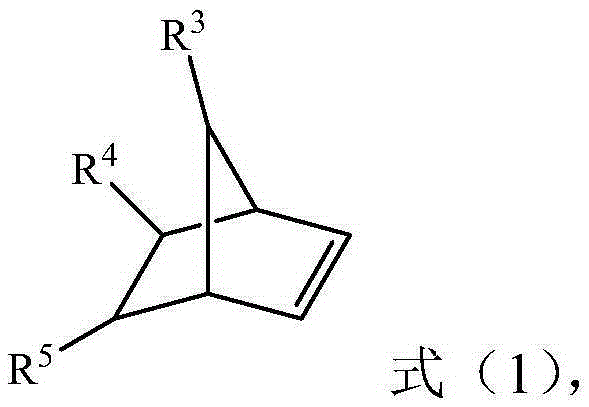

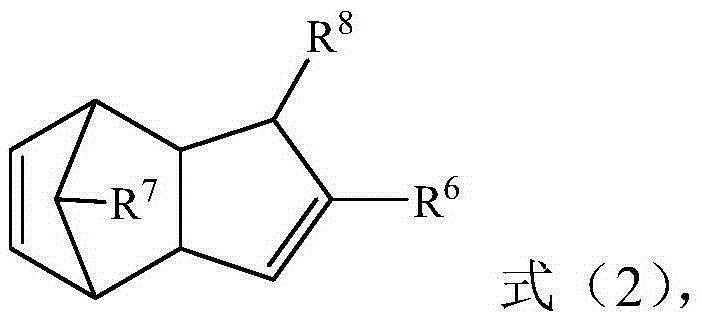

Disclosed is a resin composition for a PCB, the composition including: (a) a polyphenylene ether resin modified via a redistribution reaction of polyphenylene ether in the presence of 9,9-bis(hydroxyaryl)fluorene or 9,10-dihydro-9-oxa-10-(dihydroxyaryl)-10-phosphaphenanthrene 10-oxide; (b) a dicyclopentadiene epoxy resin represented by Formula 1; and (c) an alkylphenol aldehyde novolak curing agent represented by Formula 2, wherein, when the polyphenylene ether resin is modified via a redistribution reaction of the polyphenylene ether in the presence of 9,9-bis(hydroxyaryl)fluorene, the composition further includes (d) a brominated epoxy resin. Also, a composite substrate and a copper laminate using the same are disclosed.

Owner:DOOSAN CORP

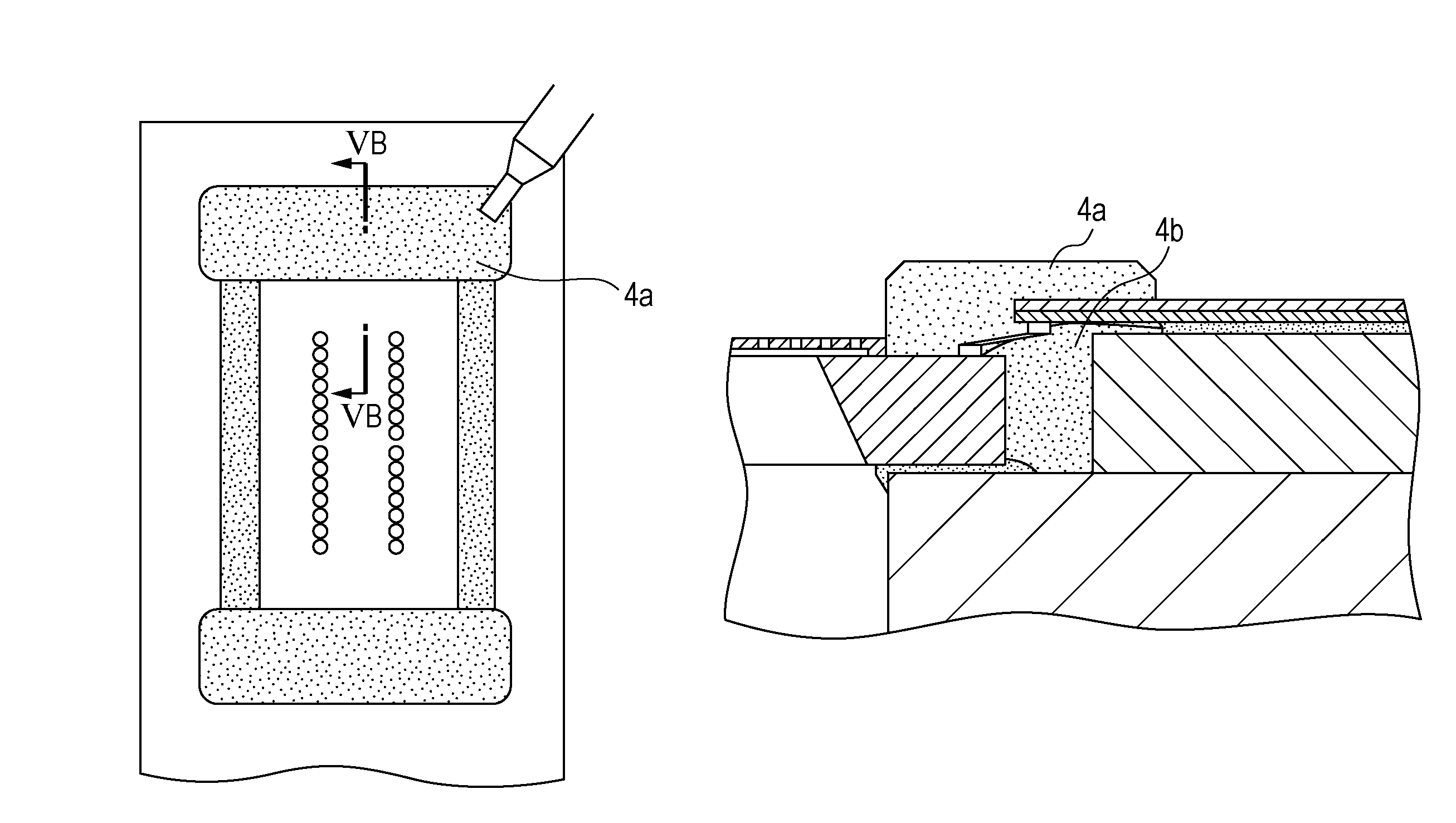

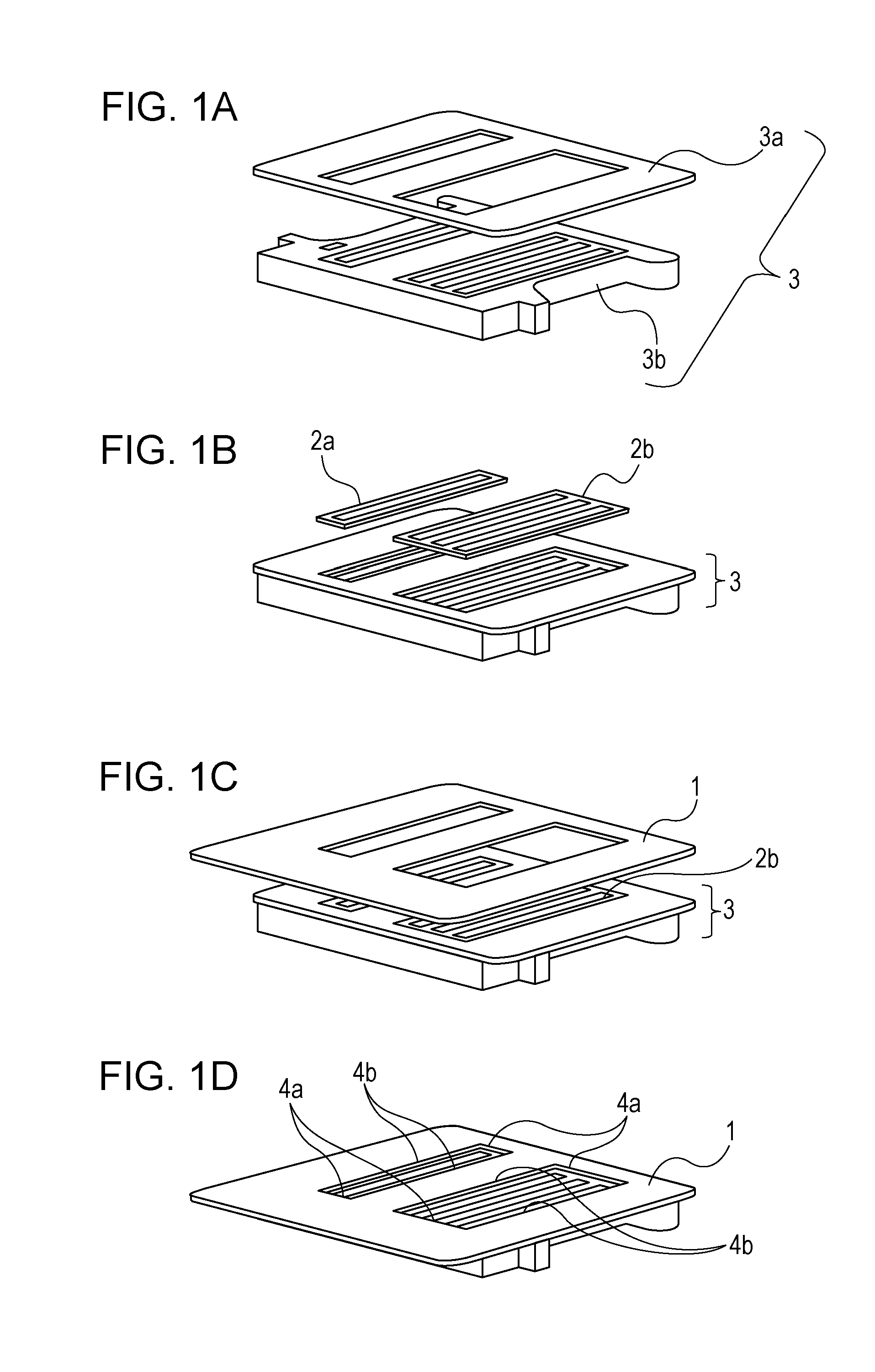

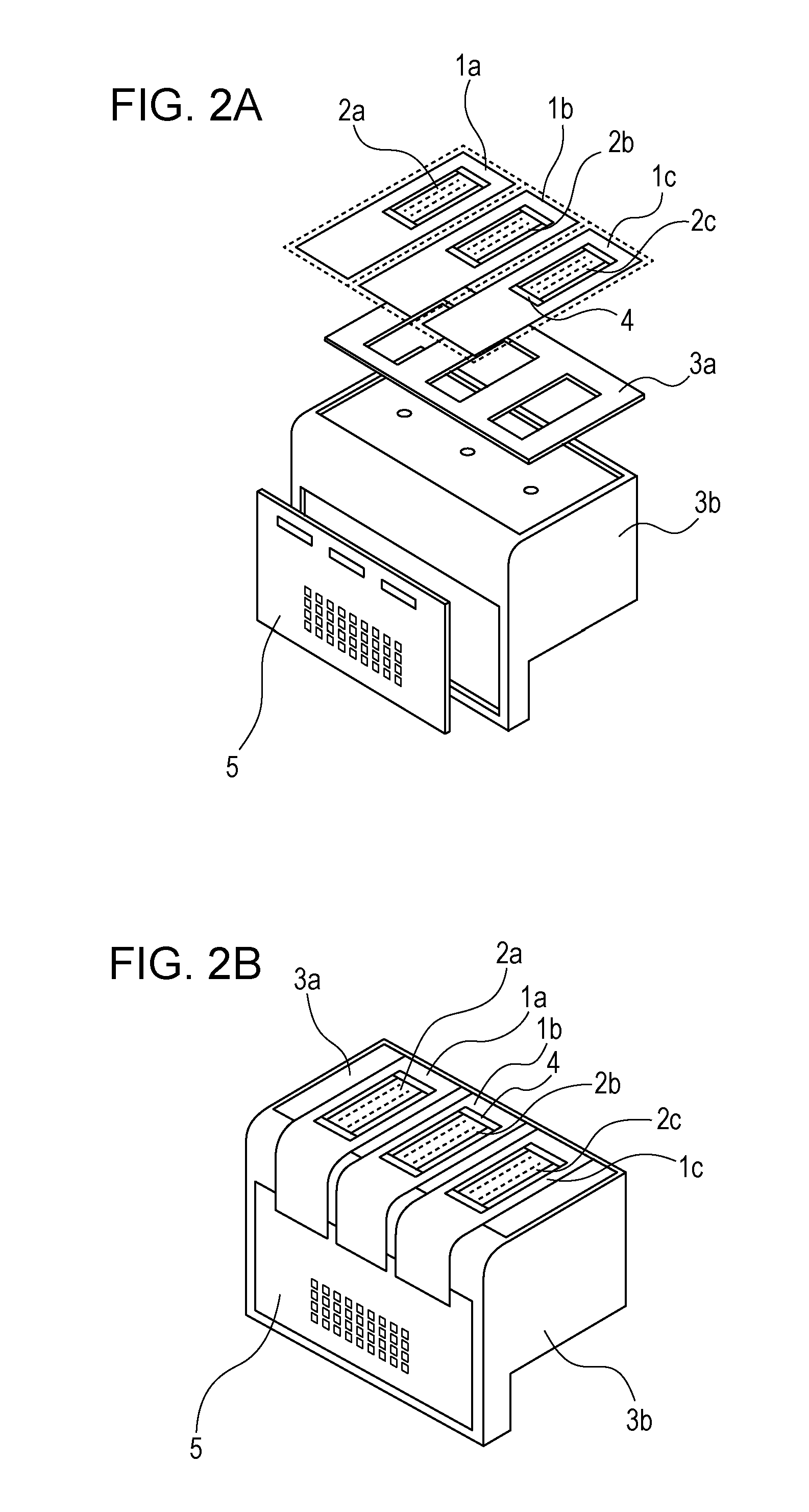

Sealant, inkjet recording head using sealant, and method for manufacturing the same

ActiveUS8876257B2Adjustable viscositySuitable for useLine/current collector detailsPrintingCationic polymerizationSealant

A sealant contains a dicyclopentadiene type epoxy resin represented by formula 1 below, a hydrogenated bisphenol A epoxy resin, and a photo-induced cationic polymerization initiator, in which the content of the dicyclopentadiene type epoxy resin is 15 to 40 parts by mass relative to 100 parts by mass of the total mass of epoxy resins contained in the sealant.where n represents an integer of 0 to 2.

Owner:CANON KK

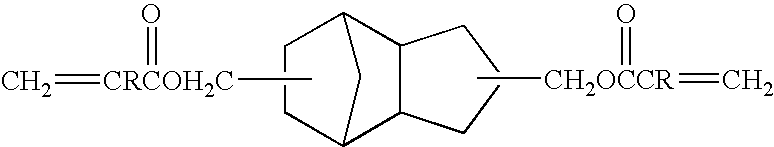

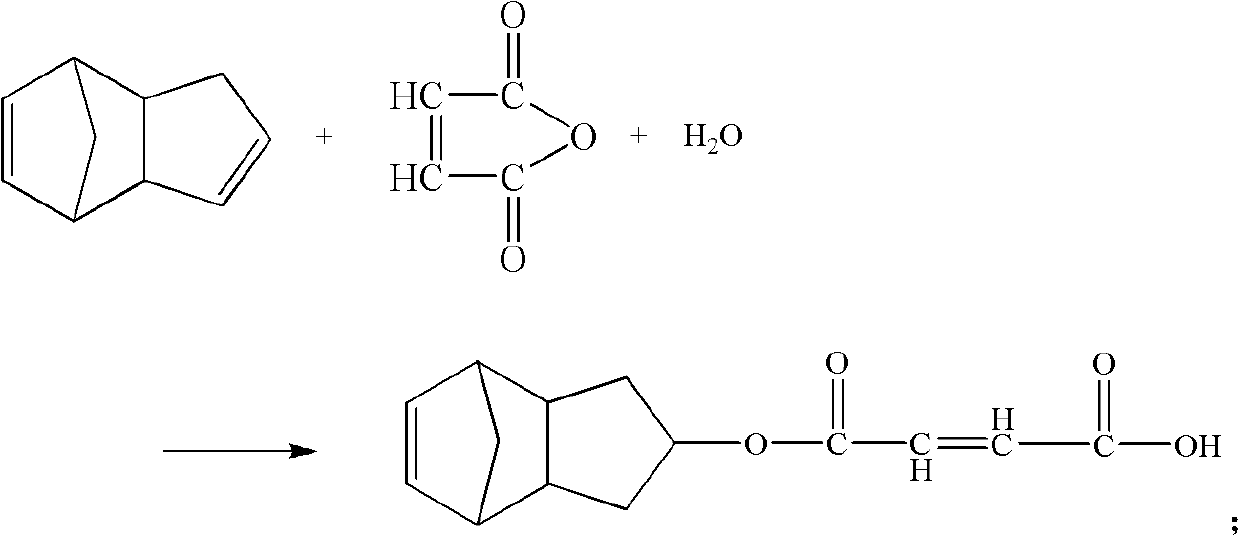

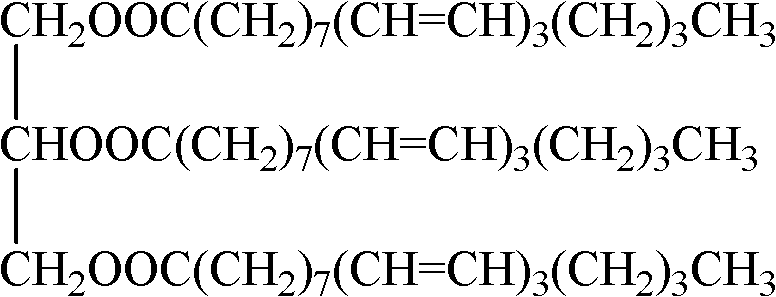

Dicyclopentadiene type unsaturated polyester modified by tung oil, and preparation method and application thereof

InactiveCN102115534AEasy to operateImprove product qualityPlastic/resin/waxes insulatorsOther chemical processesAlcoholAcid value

The invention discloses a dicyclopentadiene type unsaturated polyester modified by tung oil, and a preparation method and application thereof. The method comprises the following steps: reacting raw materials maleic anhydride and dicyclopentadiene under the action of a catalyst to obtain dicyclopentadiene semi-maleate; adding dihydric alcohol, dibasic acid and polymerization inhibitor, and heatingto 190-210 DEG C for dehydration and esterification; when the acid value reaches 50-120 mg KOH / g, cooling to 120-180 DEG C, adding a certain amount of tung oil, and heating to 200-210 DEG C to continue the reaction; and after the acid value reaches 20-35 mg KOH / g under the action of esterification, cooling to 100-120 DEG C, diluting with styrene dissolved with a small amount of polymerization inhibitor, and uniformly dispersing to obtain the product. The dicyclopentadiene type unsaturated polyester modified by tung oil according to the method has the advantages of favorable air-drying property, aging resistance, biodegradability and the like. The product is suitable to be used as an unsaturated polyester paint for corrosion protection, insulation and binding.

Owner:山东中洋新创复合材料有限公司

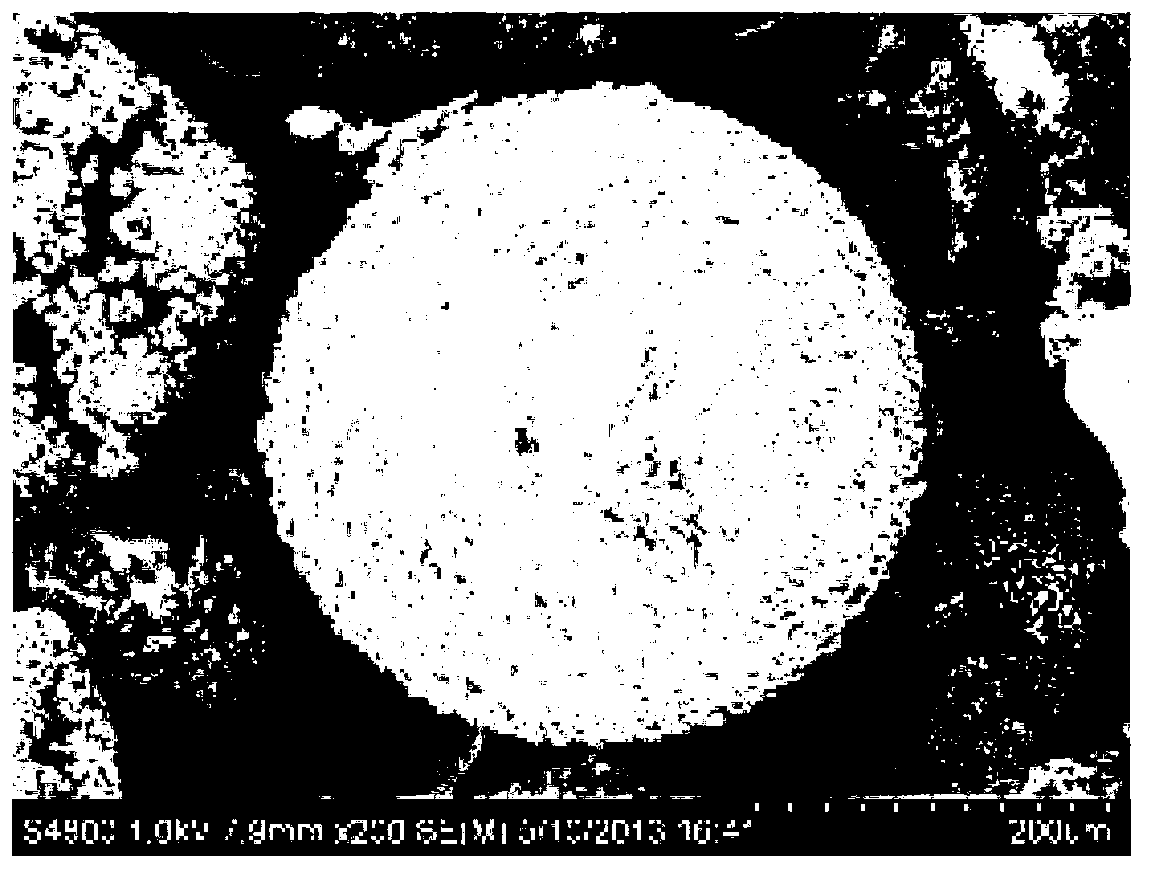

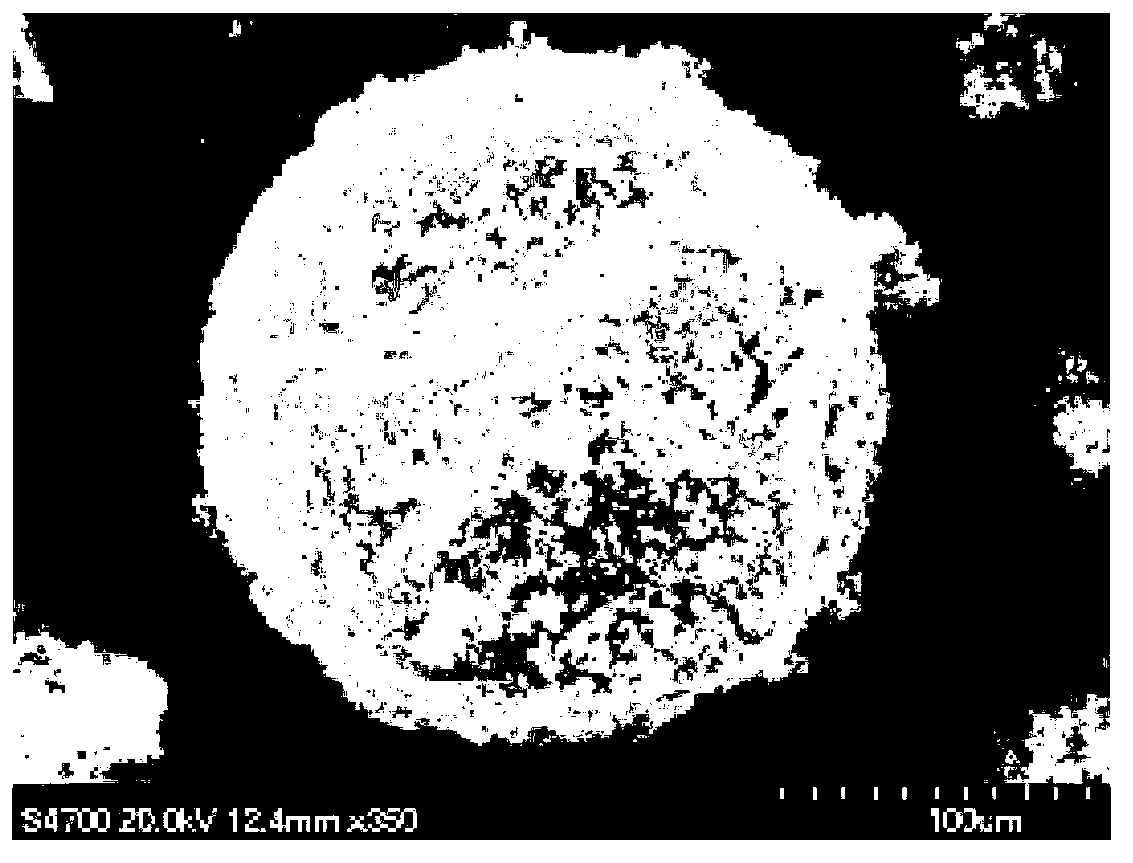

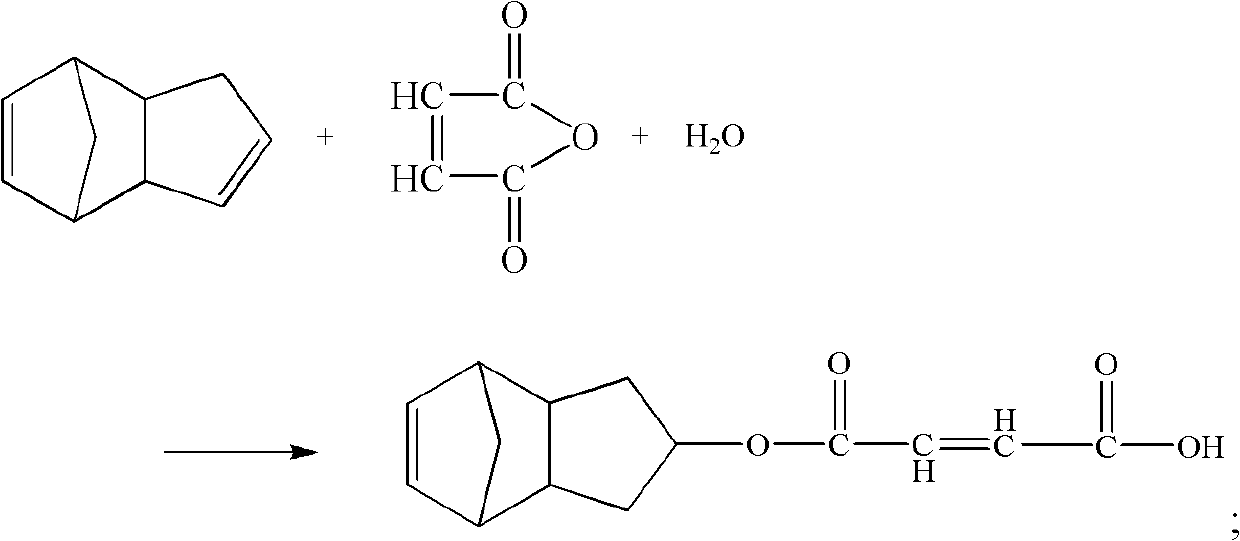

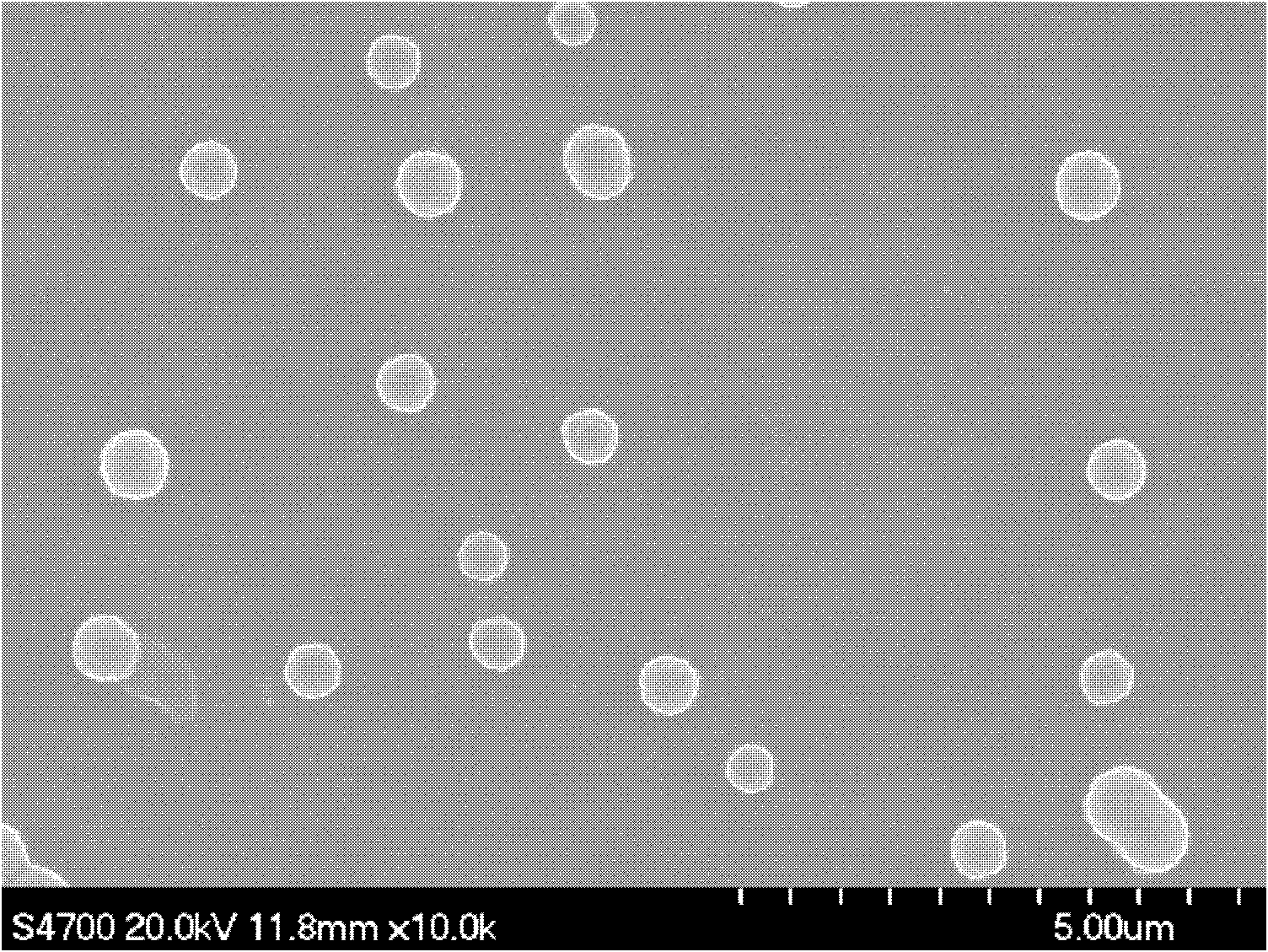

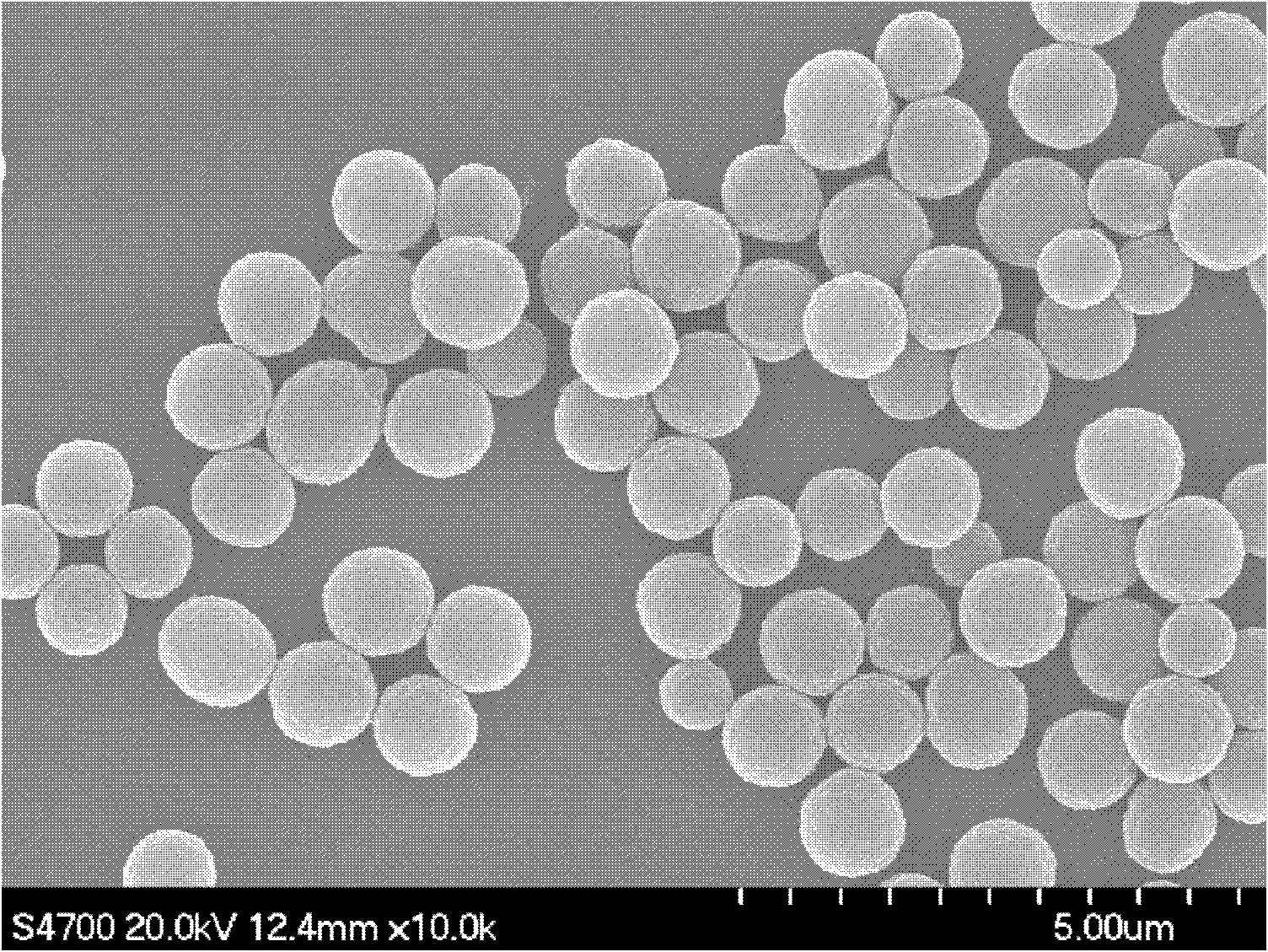

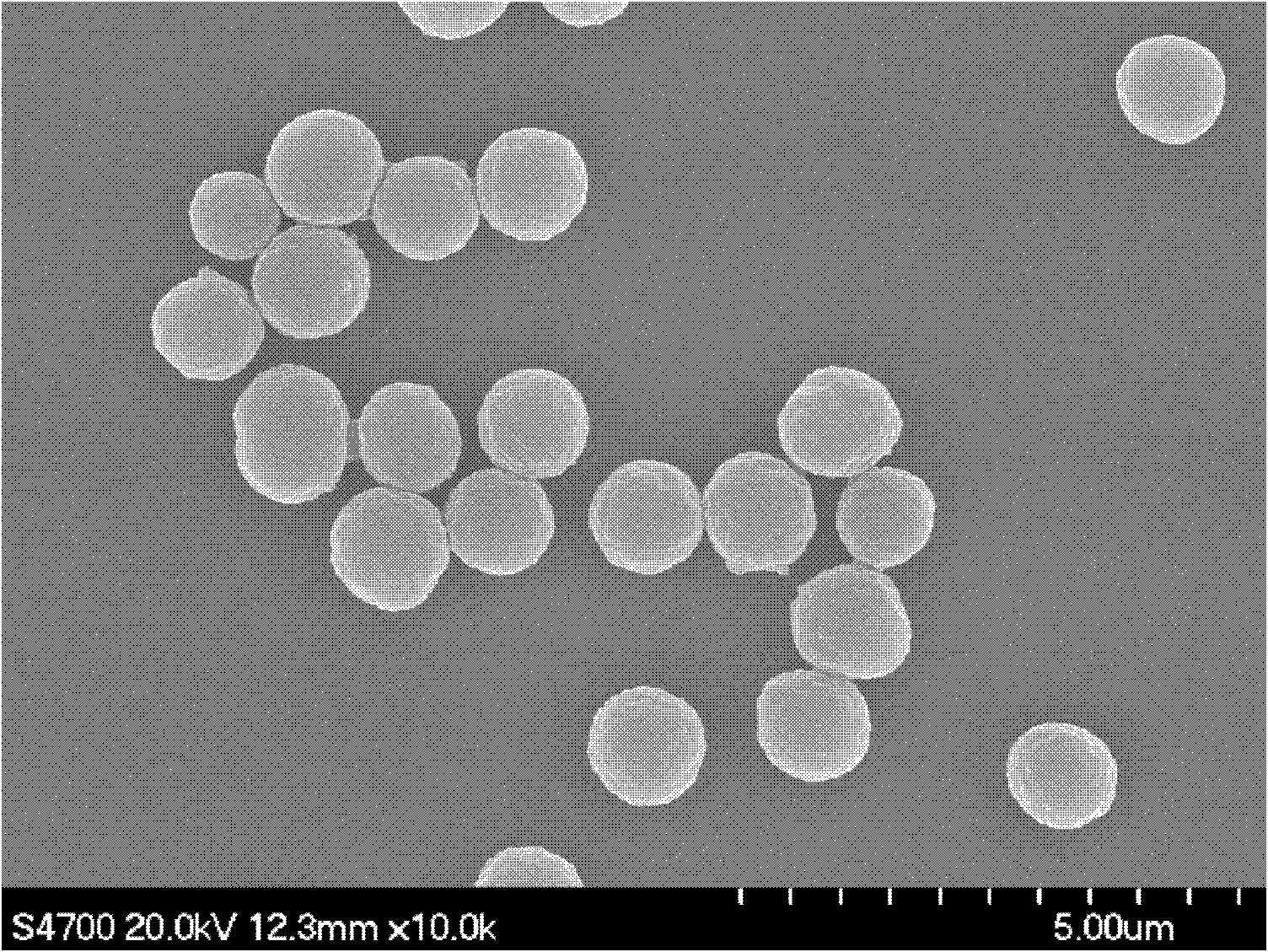

Novel method for performing copolymerization reaction of dicyclopentadiene and maleic anhydride

The invention discloses a novel method for performing a copolymerization reaction of dicyclopentadiene and maleic anhydride, and belongs to the technical field of copolymers. The method comprises the following steps of: under the protection of nitrogen, adding monomers and an initiator into an organic medium and dissolving, reacting for 2 to 12h at the temperature of between 60 and 90 DEG C to obtain a self-stabilizing dispersion system of monodisperse microspheres of an alternating copolymer, and performing centrifugal separation, and drying to obtain a white solid of the dicyclopentadiene / maleic anhydride alternating copolymer, wherein the reaction monomers are the dicyclopentadiene and the maleic anhydride, and the molar ratio of the two monomers is 5:1-1:5; the medium is a mixed solvent of organic acid alkyl ester and organic alkane, and the organic acid alkyl ester accounts for 30 to 70 volume percent of the mixed solvent; and a chemical structure is that: R1 is a hydrogen atom, C1-C5 alkyl, phenyl or benzyl, and R2 is C1-C5 alkyl. A stabilizer and a costabilizer are not required to be added, the reaction system is simple, and a product is easy to separate; and polymer microspheres have smooth and clean surfaces, uniform particle sizes, controllable appearances, and high dispersibility.

Owner:BEIJING UNIV OF CHEM TECH

Application of organosilane, polyolefin in-kettle alloy and preparation method thereof

The invention provides an application of organosilane, a polyolefin in-kettle alloy and a preparation method thereof. The preparation method for the polyolefin in-kettle alloy comprises the following steps: enabling a first olefin monomer to carry out first polymerization reaction in the presence of a catalyst; introducing a second olefin monomer into a polymerization reaction system to carry out second polymerization reaction, wherein the first olefin monomer is different from the second olefin monomer; first polymerization reaction and / or second polymerization reaction is carried out in the presence of organosilane with a general formula of R1mSiXn(OR2)k; R1 is C2-C20 alkyl and a R1 terminal comprises alpha-olefin double bonds, a norborneol alkenyl group, a cycloolefin group or a dicyclopentadiene group; X is halogen; R2 is a C1-C20 linear chain, a branched chain or isomerized alkyl; m is an integer number from 1 to 3; n is an integer number from 1 to 3; k is an integer number from 0 to 2; and m+n+k is equal to 4. Cross-linking degree of a rubber phase in the polyolefin in-kettle alloy obtained from the preparation method is relatively high, and the polyolefin in-kettle alloy has relatively high toughness and relatively low tensile breaking strength.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

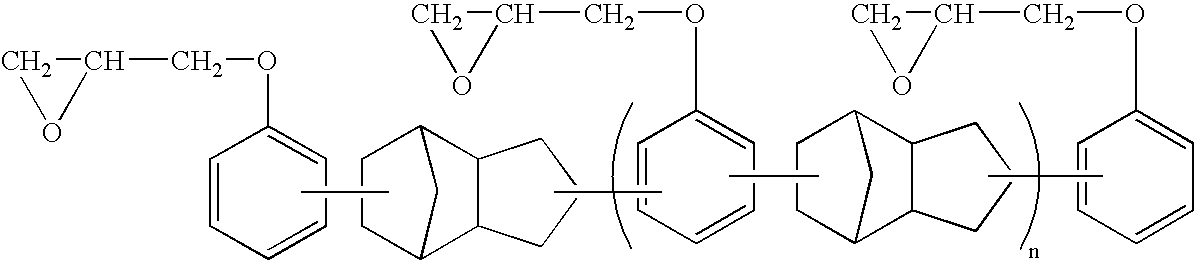

A kind of toughened epoxy resin composition containing dicyclopentadiene alicyclic structure

ActiveCN102286139AReduce the three-dimensional cross-linked structureGuaranteed performanceAccelerantMoisture

The invention relates to a toughened epoxy resin composition containing a dicyclopentadiene ester ring structure and a preparation method thereof. The composition comprises 100 parts of epoxy resin, 25 to 50 parts of acid anhydride curing agent, 10 to 25 parts of dicyclopentadiene, and 0.5 to 5 parts of accelerants. By introducing the dicyclopentadiene ester ring structure, the toughness of the epoxy resin is improved. Meanwhile, because of the dicyclopentadiene ester ring structure, the cured epoxy resin has low water absorption, good air dried property and waterproof and moisture-proof performance.

Owner:北京蓝星清洗有限公司

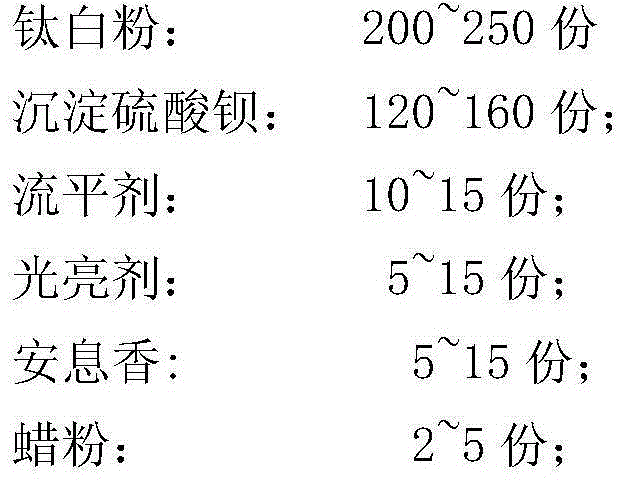

Self-healing epoxy powdery coating containing microcapsule and preparation method thereof

InactiveCN105038502AAvoid breakingPrevent peelingPowdery paintsEpoxy resin coatingsSelf-healingEpoxy

The present invention discloses a self-healing epoxy powdery coating containing microcapsule. The self-healing epoxy powdery coating containing microcapsule consists of the following components by weight: 5-15 parts of microcrack self-healing capsule, 2-4 parts of a Grubbs catalyst and 89-93 parts of epoxy powder resin matrix. The capsule wall of the self-healing microcapsule is theurea-formaldehyde resin prepared from urea and 37% formaldehyde solution in molar ratio of 0.5-0.6:1, and the capsule core is dicyclopentadiene by blending and high pressure electrostatic spraying. The housing capsule wall of the microcapsule is urea-formaldehyde resin; and the mass ratio of the inner capsule core to capsule wall is 5:1. When the coating cracks, the microcapsule ruptures, and dicyclopentadiene rapidly penetrates into the crazing and the met Grubbs catalyst to produce cross-linking, in order to achieve the purpose of repair. The invention prolongs the service life of the powdery coating and is applicable to novel industrial production.

Owner:南通南京大学材料工程技术研究院

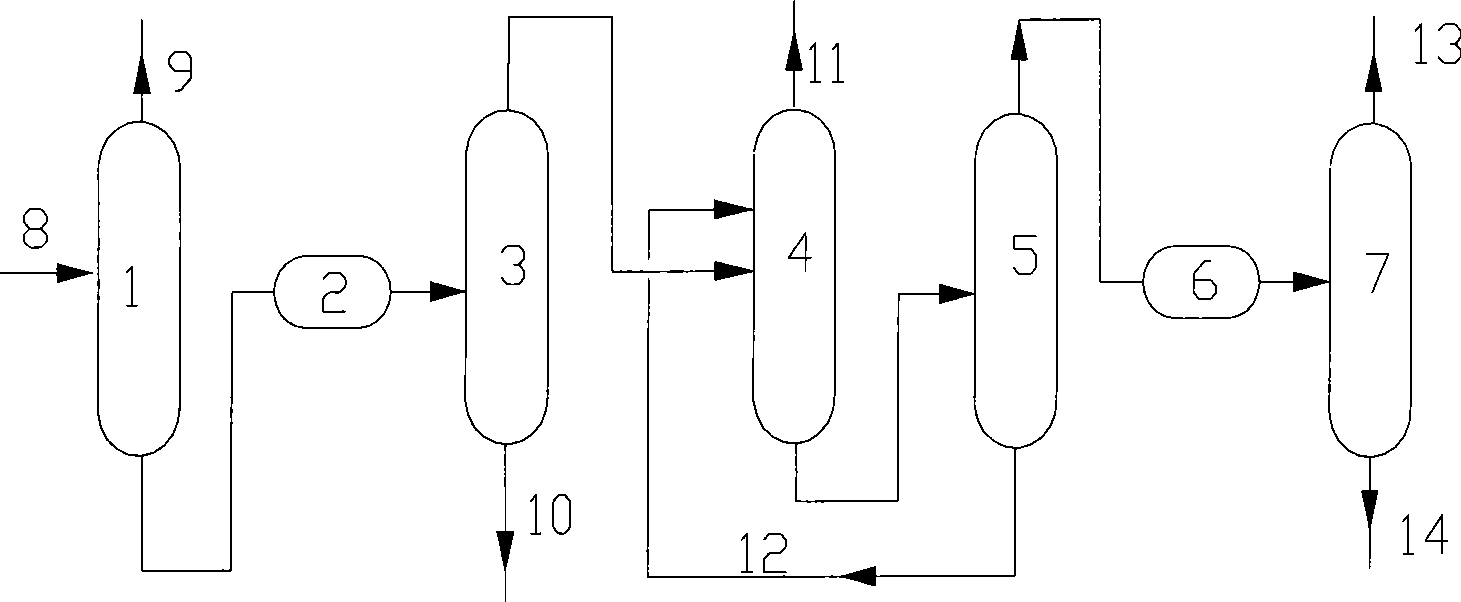

Method for separating carbon 5 fraction by one-stage extraction and rectification

ActiveCN101450885AReduce in quantityLess investmentDistillation purification/separationHydrocarbonsAlkyneSolvent

The invention discloses a method for the one-section extraction separation and cracking of C5 distillate. The method comprises the following steps: cracking C5 raw materials to separate light components such as C4 and acetylene hydrocarbons in a lightness removing tower; making the raw materials in a lightness removing tower kettle to react in a dipolymer reactor so as to make cyclopentadiene be dimerized into dicyclopentadiene; removing heavy components of reaction products in a weight removing tower so as to obtain material stream containing isoprene at the tower top; carrying out extraction and rectification in an extraction and rectification tower, and collecting the reaction products at a tower kettle and sending the reaction products into a stripping tower; separating isoprene with solvent in the stripping tower, collecting the isoprene at the tower top and sending the isoprene into the dipolymer reactor, and making cyclopentadiene be dimerized into dicyclopentadiene; and finally introducing the reaction products into an isoprene treating tower for refinement so as to obtain a polymer grade isoprene product. The method has the advantages of short flow, low energy consumption, low construction and operating cost, high product quality, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Epoxy resin composition, and prepreg and printed circuit board using the same

InactiveUS20120024580A1Excellent dielectric propertiesLow dielectric constantPrinted circuit aspectsPrinted circuit manufactureEpoxySilanes

Disclosed is an epoxy resin composition for printed circuit board, which includes (A) an epoxy resin comprising a dicyclopentadiene type epoxy resin; (B) a copolymer of styrene and maleic anhydride as a curing agent; (C) a curing accelerator; (D) an optional silane dispersing agent; (E) an optional phosphorous-containing flame retardant; (F) an optional toughening agent; and (G) an optional inorganic filler.

Owner:TAIWAN POWDER TECH CO LTD

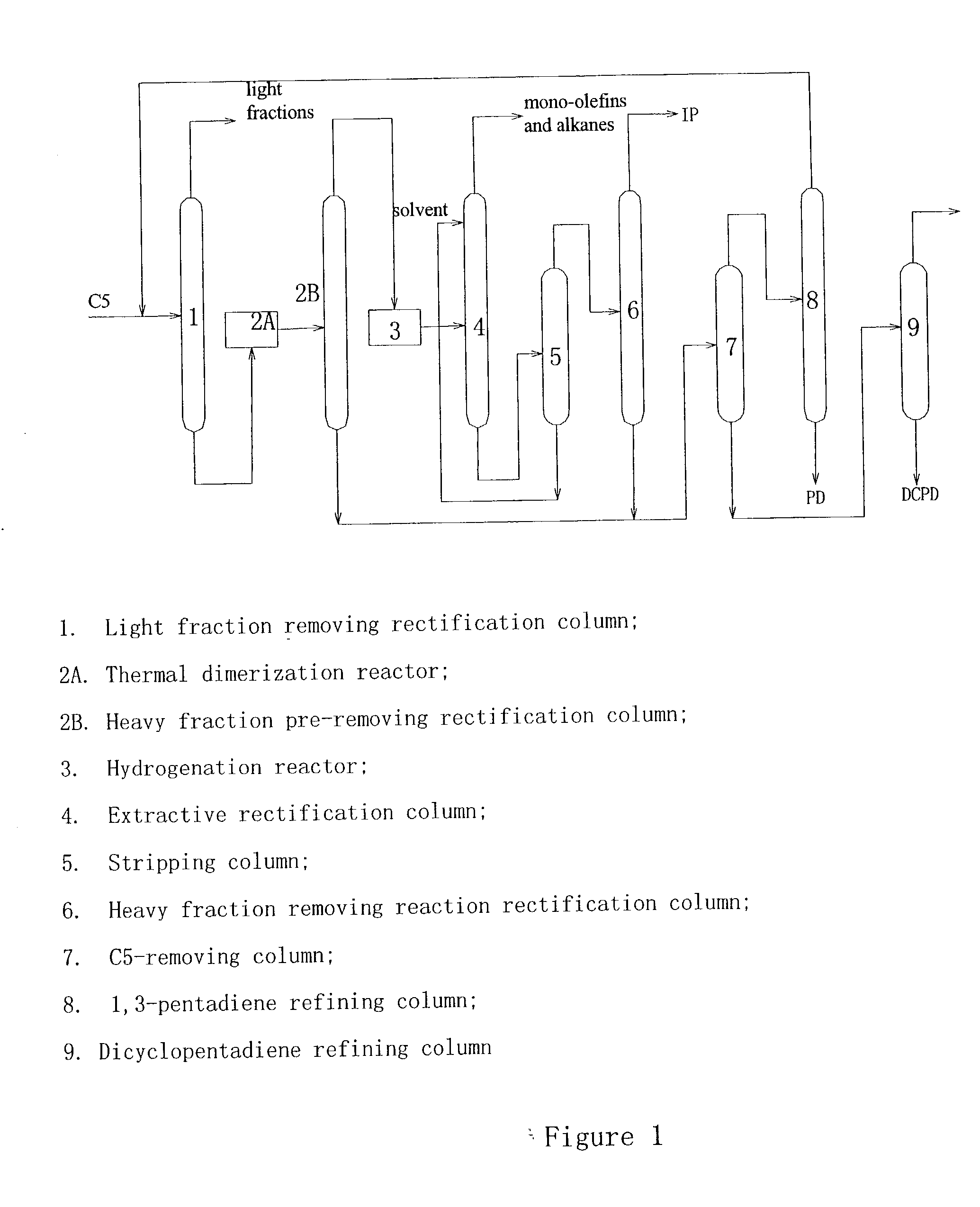

Separation method of diene hydrocarbon in five fractions of petroleum cracked carbon

ActiveCN101108782AImprove conversion rateReduced temperature control requirementsDistillation purification/separationHydrocarbonsPetroleumIsoprene

The invention relates to a separation method of the diolefin in the petroleum cracking C5 fraction, which mainly solves the problems that the cracking C5 fraction in the past technology generates the dicyclopentadiene via the thermal dimerization reactor, the isoprene does self-polymerization and does copolymerization with the cyclopentadiene to cause great loss of the isoprene and the cyclopentadiene, at the same time the dicyclopentadiene has low product purity and low utilization value. The invention better solves the problem through the technical proposal that the isoprene in the C5 fraction is separated with the cyclopentadiene and the cyclopentadiene enters the thermal dimerization reactor to generate the dicyclopentadiene and separate with the m-pentadiene, which can be used in the industrial production of the diolefin separation in the cracking C5 fraction.

Owner:CHINA PETROCHEMICAL CORP +1

Hydrogenation catalyst for preparing dicyclopentadiene hydrogenated petroleum resin

A hydrogenation catalyst for preparing dicyclopentadiene hydrogenant petroleum resin by dicyclopentadiene petroleum resin. The active components of the resin are Pd and Pt. The contents of Pd and Pt are 0.1í½ 1.0wtúÑ and 0.05í½0.5wtúÑ, respectively. The carrier of the catalyst is ª†-Al2O3, the specific surface are is 150í½250m2 / g, the volume is 0.5í½0.9ml / g. Hydrogenant resin prepared from dicyclopentadiene petroleum resin through the catalyst has a lowered content of unsaturated hydrocarbon bonds, and the color of the resin is improved to water-white.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

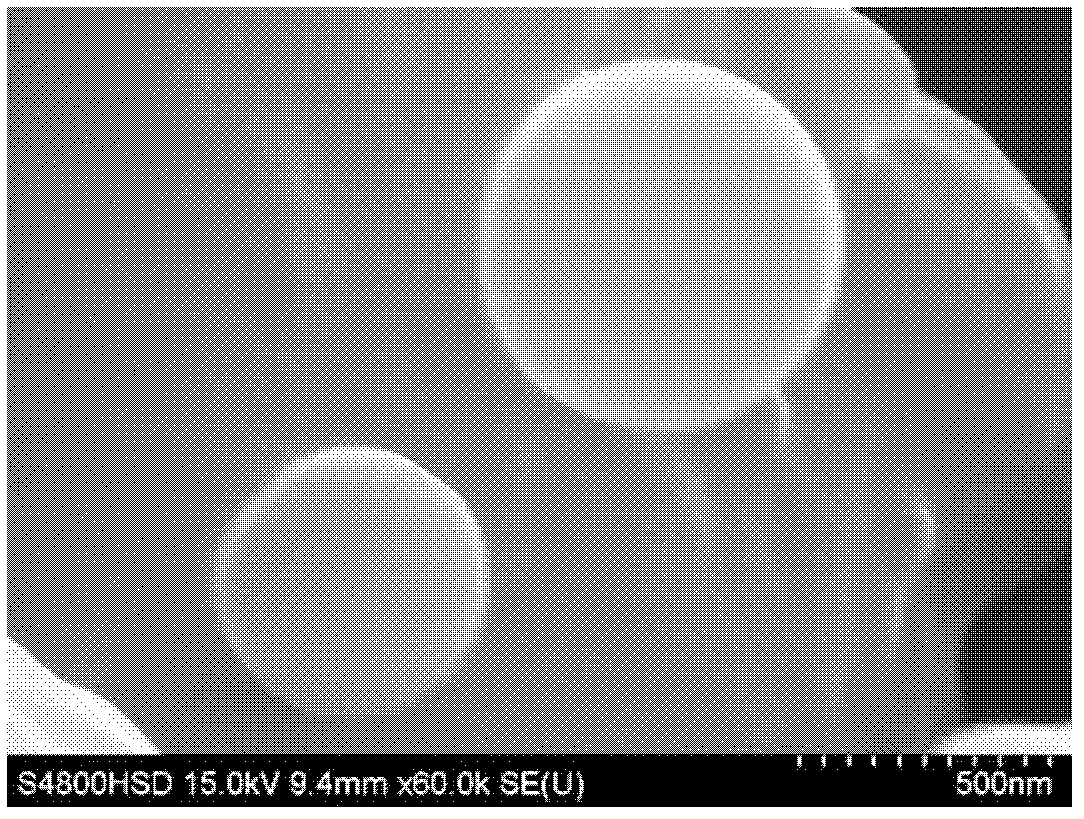

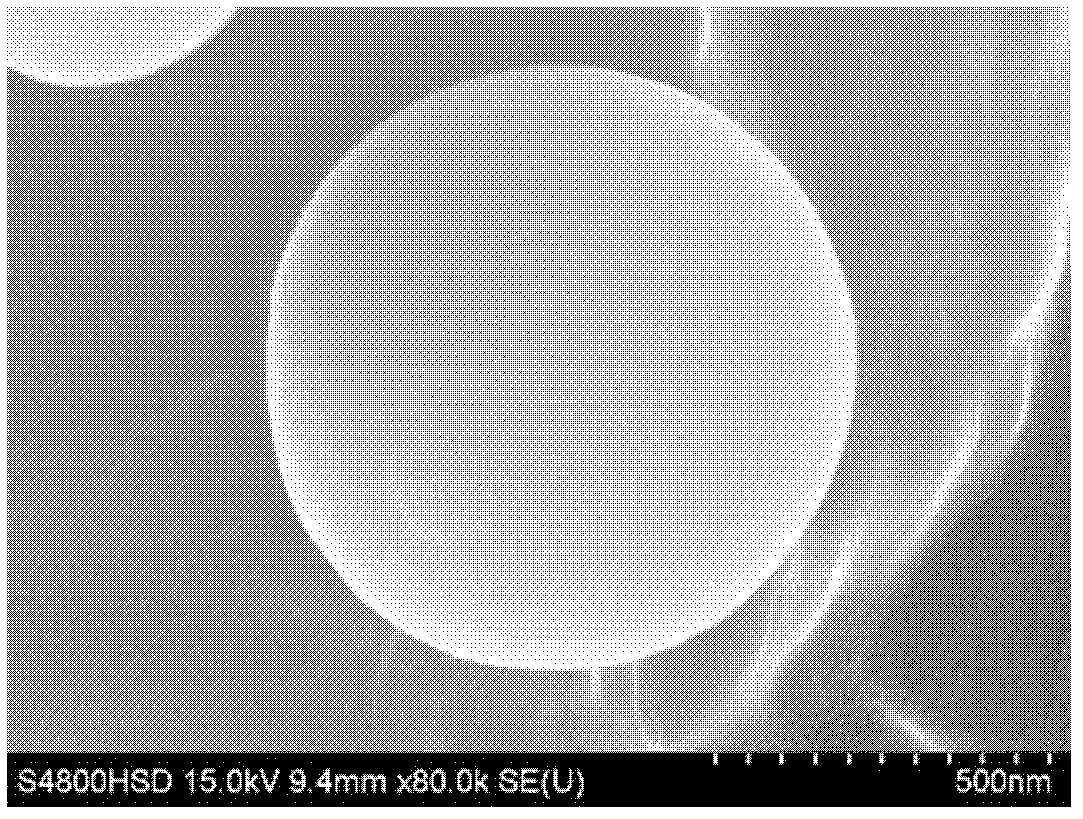

Urea resin wrapped dicyclopentadiene nanometer microcapsule, and synthetic method and application thereof

InactiveCN102492174AEasy to prepareEasy to operateMicroballoon preparationMicrocapsule preparationRepair materialPrepolymer

The invention discloses a urea resin wrapped dicyclopentadiene nanometer microcapsule, and a synthetic method and application thereof, and relates to a self-repair material, and a synthetic method and application thereof. The urea resin wrapped dicyclopentadiene nanometer microcapsule is a nanometer spherical granule prepared from urea resin used as a wall shell, and dicyclopentadiene used as a core material. The method comprises the following steps of: adding urea and a formaldehyde solution into a reactor, stirring uniformly, adding resorcinol and NH4Cl, regulating a pH value, and heating and reacting to obtain a prepolymer; and adding a sodium dodecyl benzene sulfonate solution into the dicyclopentadiene and the prepolymer, mixing the dicyclopentadiene and the prepolymer, regulating the pH value until the solution is acidic, heating, cooling the obtained suspension, washing, filtering and drying to obtain the urea resin wrapped dicyclopentadiene nanometer microcapsule. The self-repair efficiency of the nanometer microcapsule is over 60 percent, the preparation method is simple and easy to operate, and the yield is between 80 and 85 percent. The urea resin wrapped dicyclopentadiene nanometer microcapsule can be used for composite materials of aerospace.

Owner:HARBIN INST OF TECH

Process for producing high purity dicyclo pentylene

InactiveCN1781887AHigh selectivityHydrocarbonsHydrocarbon by depolymerisationReaction rateAcid substances

The present invention provides a technological process of producing high purity dicyclopentadiene (DCPD) with petroleum cracking C5 fraction as main material. The process includes the following steps: 1. dimerizing C5 fraction and eliminating light components to obtain coarse DCPD; 2. catalytically depolymerizing the coarse DCPD at 100-200 deg.c in the presence of inorganic carrier supported acid catalyst to obtain high purity CPD; and 3. dimerizing CPD and eliminating light components to obtain high purity DCPD. The present invention is a low temperature catalytic depolymerizing process with low scaling, and effectively raised depolymerizing reaction rate and depolymerizing reaction selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com