Method for separating carbon 5 fraction by one-stage extraction and rectification

A technology of extractive rectification and separation method, which is applied in the field of separation of C5 fractions, can solve the problems of complex process and difficult operation, and achieve the effects of simplifying process, reducing operating costs and reducing equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

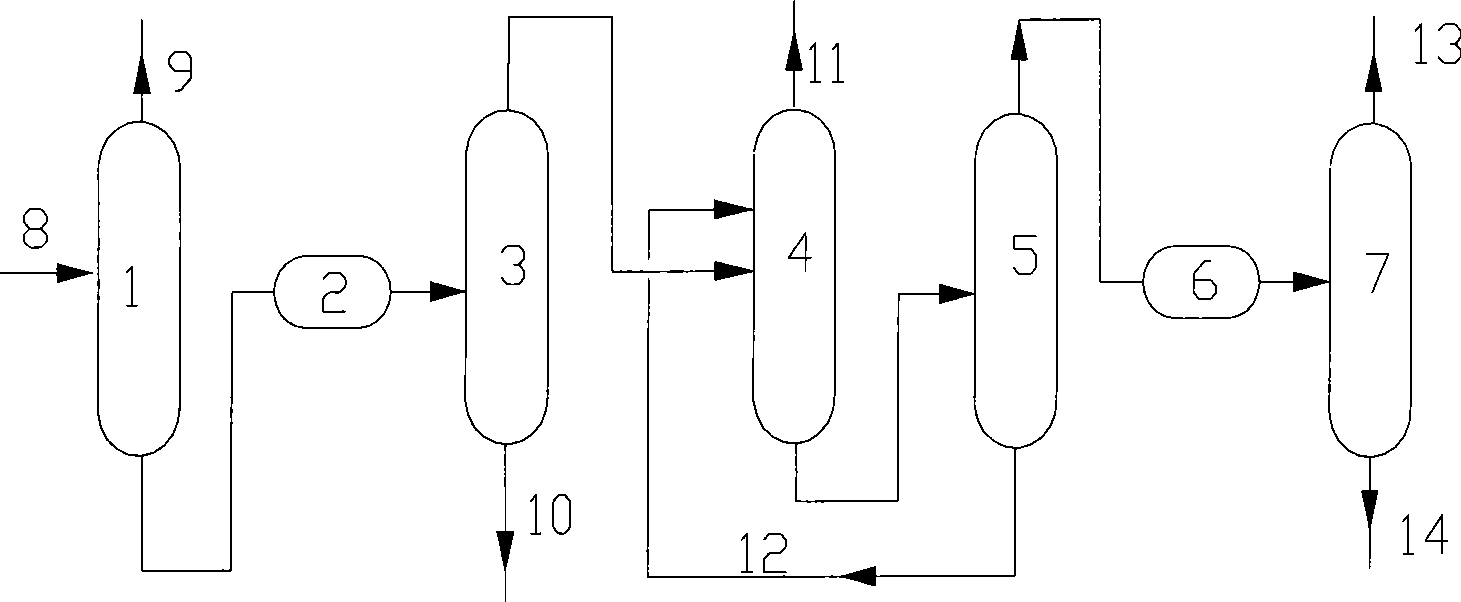

[0037] Refer below figure 1 The method of the present invention is further explained, but the present invention is not limited thereto.

[0038] A method for extracting and rectifying the separation of carbon five fractions of the present invention comprises the following steps:

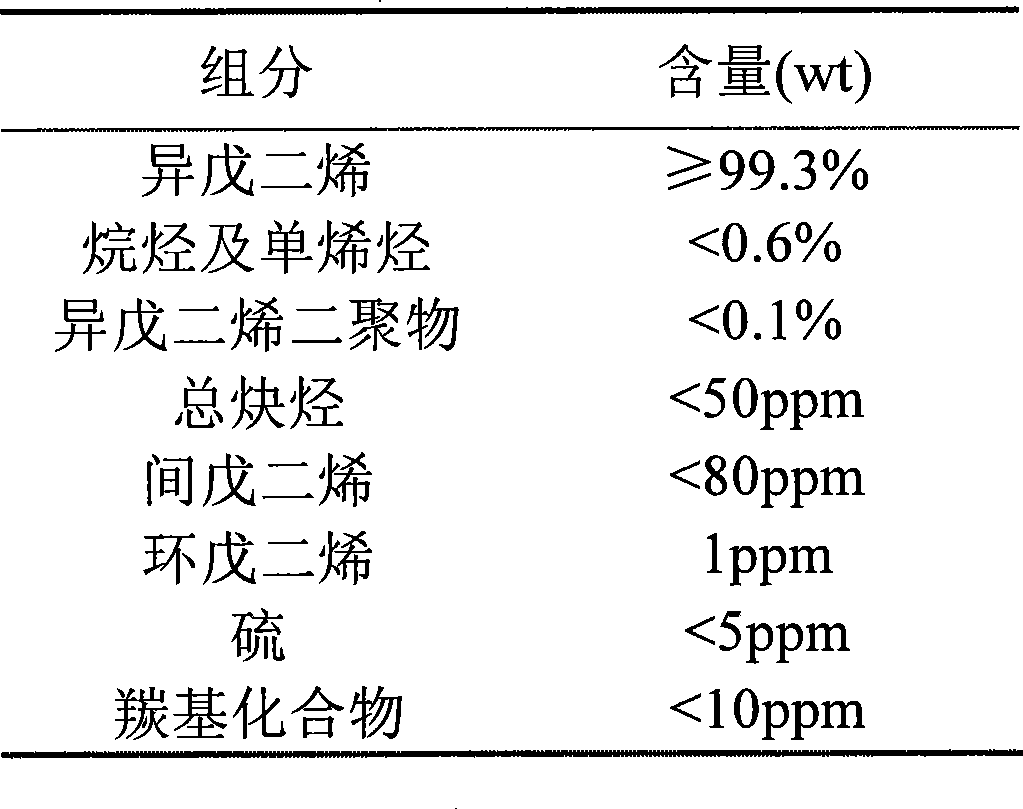

[0039] (1) Light removal: C5 raw material (mainly composed of C4 8.4%, pentane 11.6%, pentene 19.2, alkyne 0.2%, isoprene 21.4%, cyclopentadiene 17.2%, piperylene 13.9%, carbon six 8.1%) enter the light removal tower 1, the theoretical plate number of the light removal tower is 120, the operation reflux ratio is 16, light components 9 such as carbon four, alkynes and isopentane are extracted from the top of the tower, The material in the light removal tower tank is sent to the dimerization reactor 2; the content of isoprene at the top of the light removal tower is controlled to be 1%, 40.6% of carbon four, 24.8% of isopentane, and 0.8% of alkyne, and the alkyne is at the top of the tower The recove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com