Patents

Literature

100 results about "Piperylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

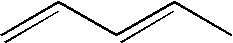

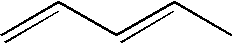

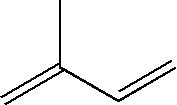

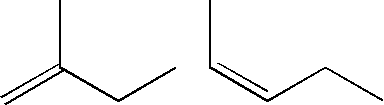

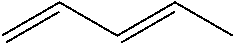

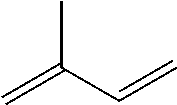

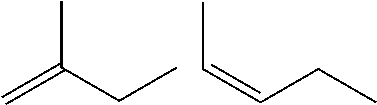

Piperylene is a volatile, flammable hydrocarbon consisting of a five carbon chain with two double bonds. It is obtained as a byproduct of ethylene production from crude oil, combustion of biomass, waste incineration and exhaust gases.

Elastomeric Compositions Comprising Hydrocarbon Polymer Additives

ActiveUS20090186965A1Maintain performanceMaintain rateOther chemical processesPaper coatingElastomerPolymer science

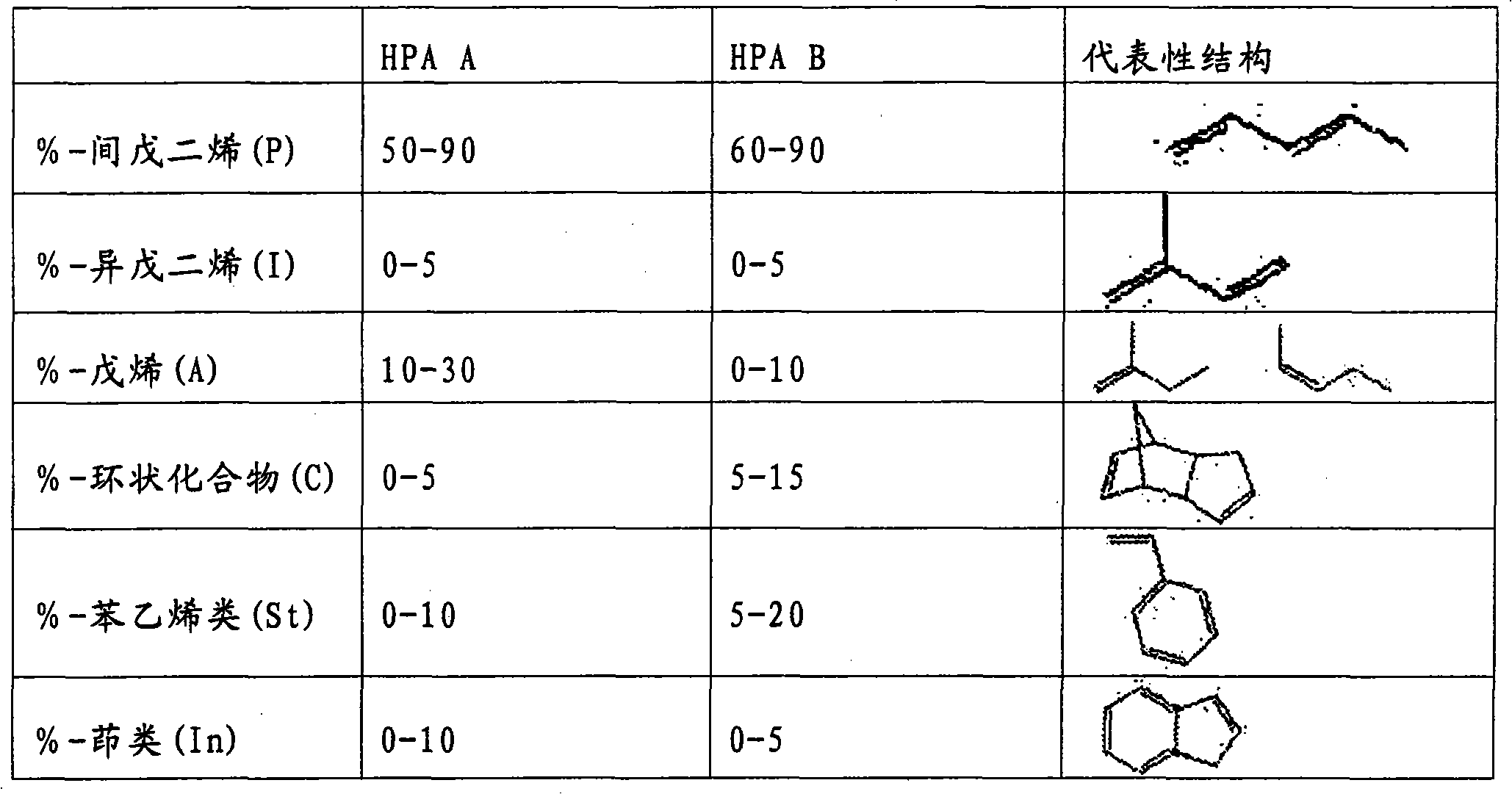

Provided are elastomeric compositions comprising at least one elastomer and a hydrocarbon polymer additive. Preferably the hydrocarbon polymer additive comprises from 60 to 90% piperylene, from 5 to 15% cyclic components, from 5 to 20% styrenic components, up to 5% isoprene, up to 5% indenic components, and up to 10% amylene. Also provided are elastomeric compositions comprising at least one elastomer and a hydrocarbon polymer additive, wherein the hydrocarbon polymer additive has a molecular weight of from 520 to 650 g / mole and a glass transition temperature (Tg) of from 48 to 53° C. The elastomeric compositions are particularly useful in making tires and other cured rubber articles.

Owner:EXXONMOBIL CHEM PAT INC

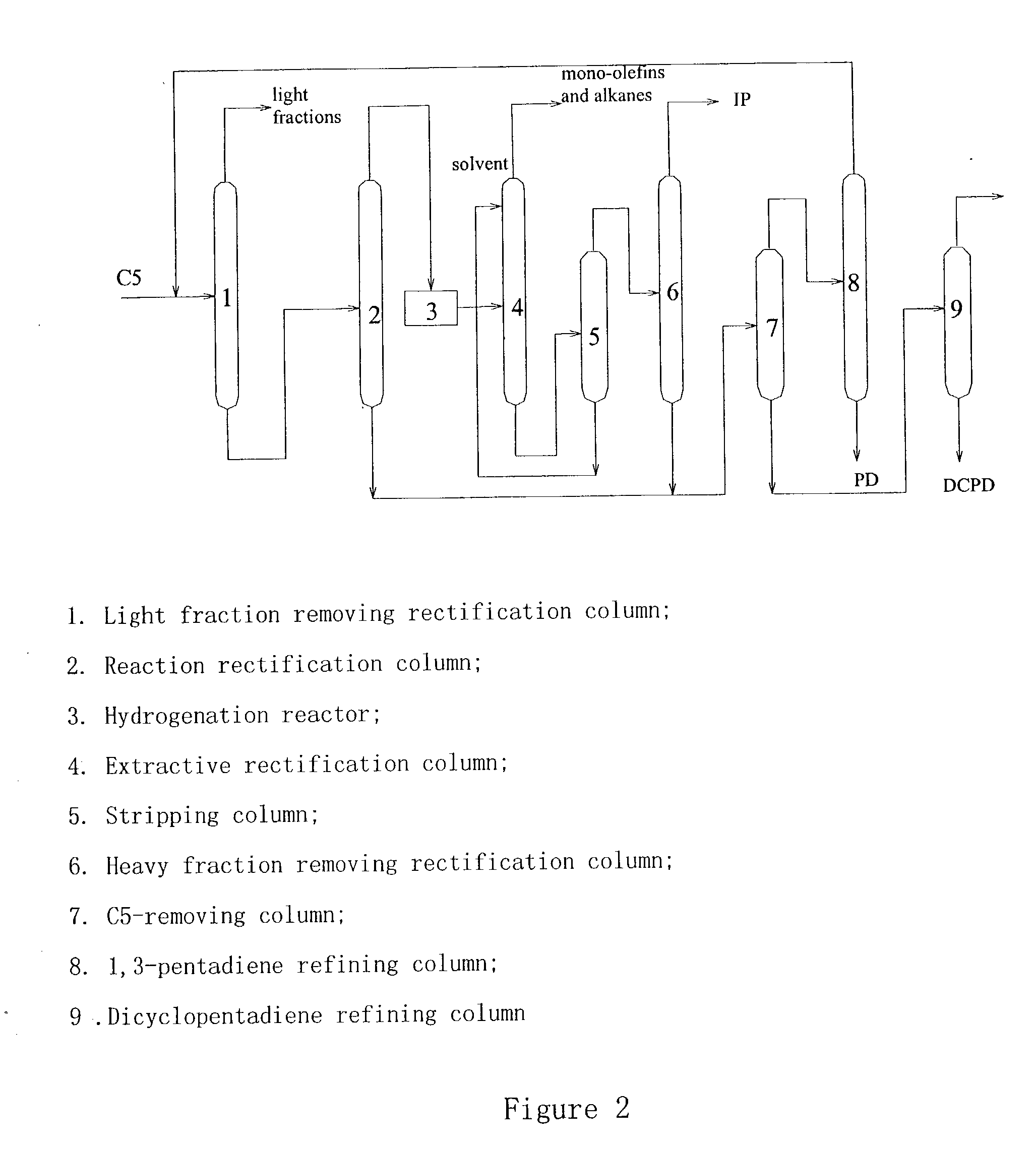

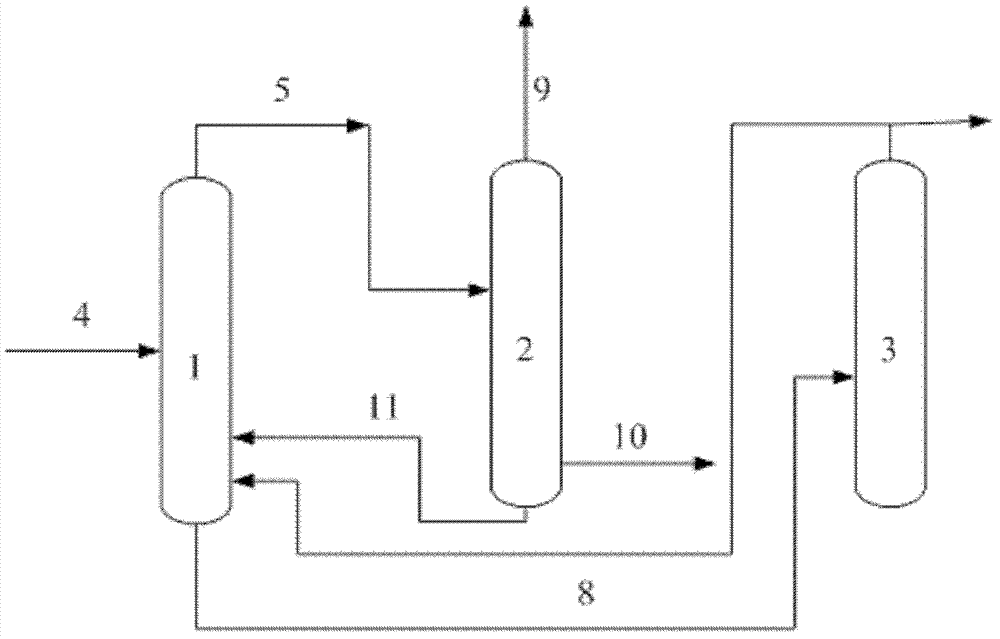

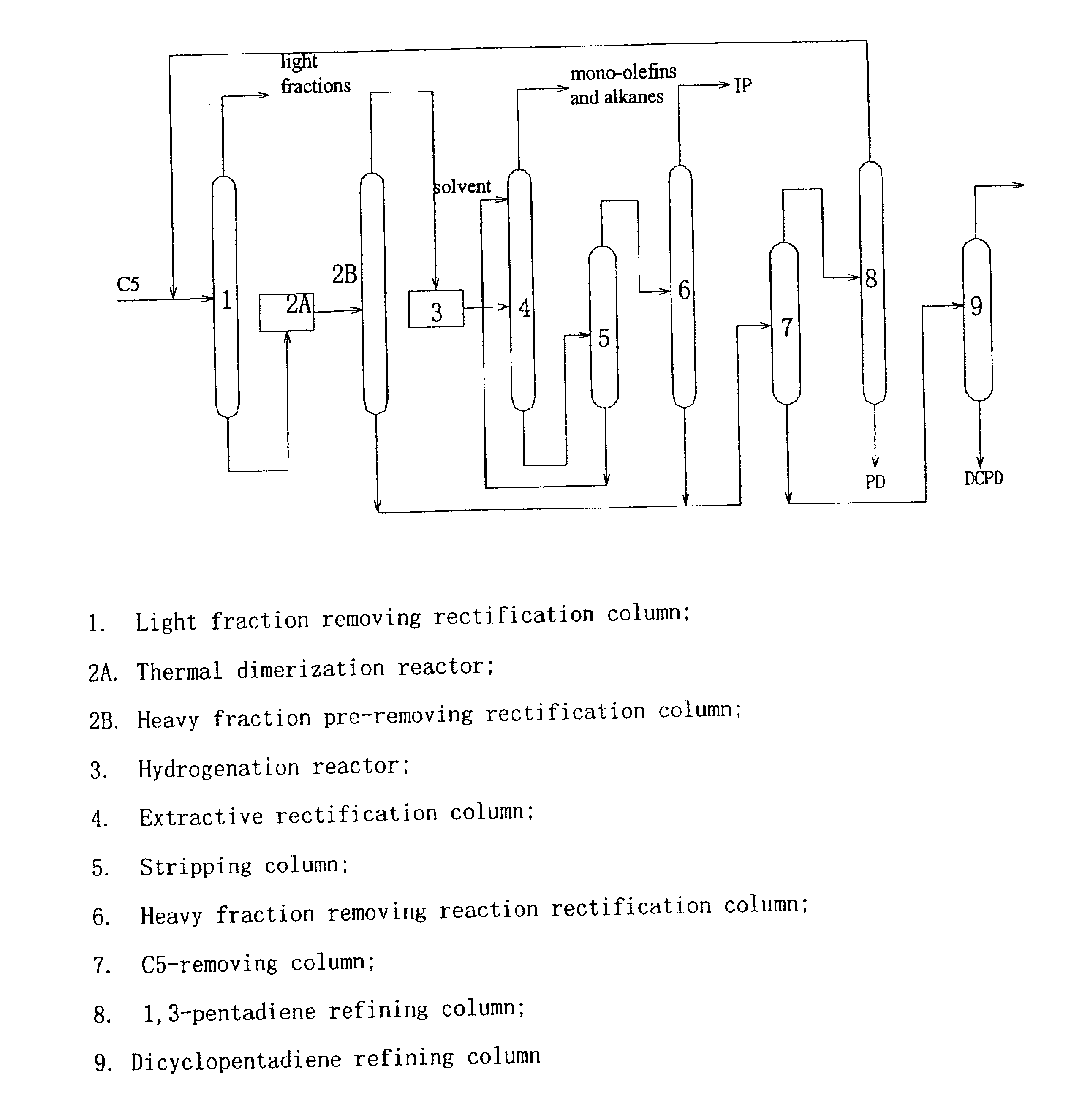

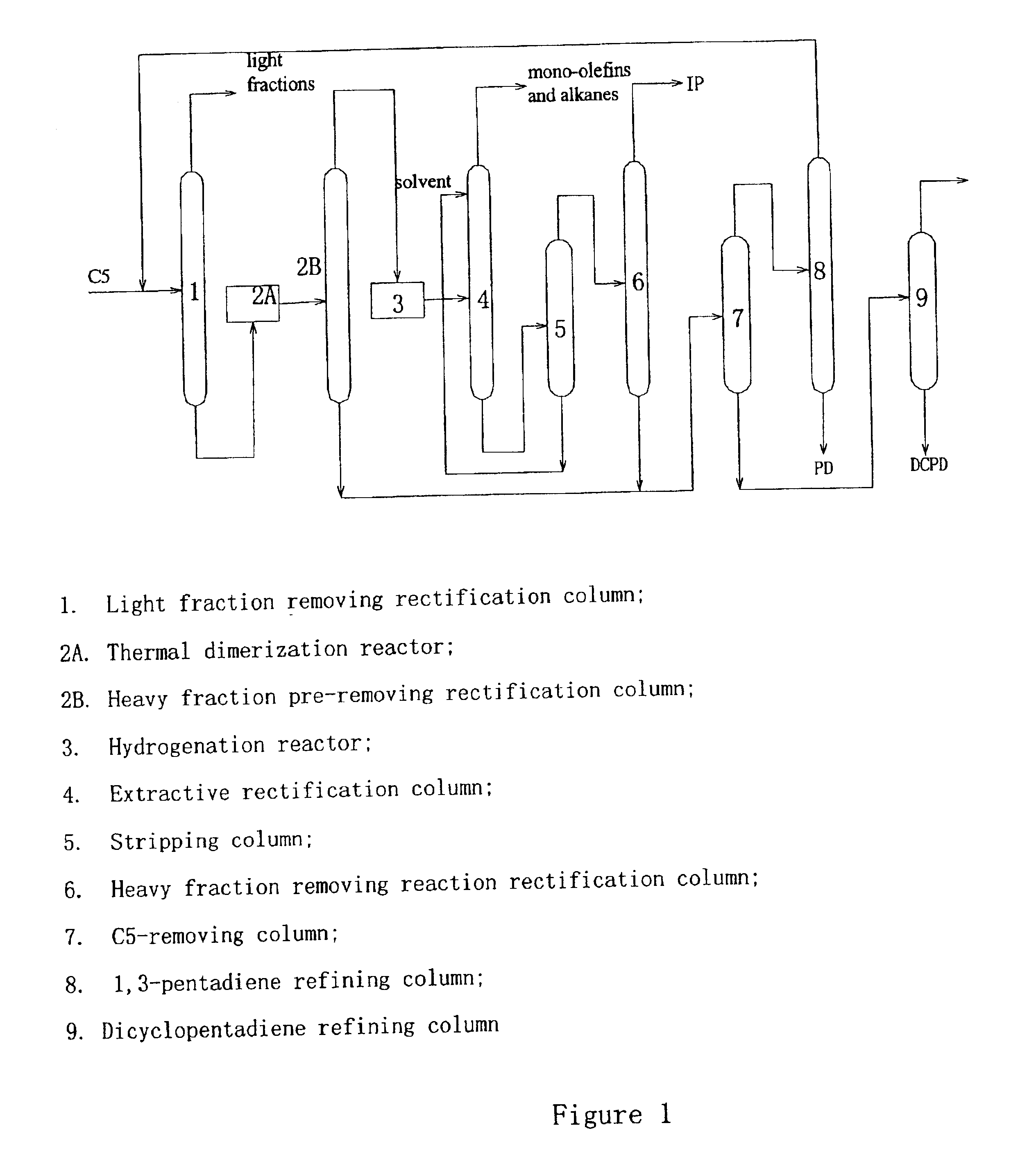

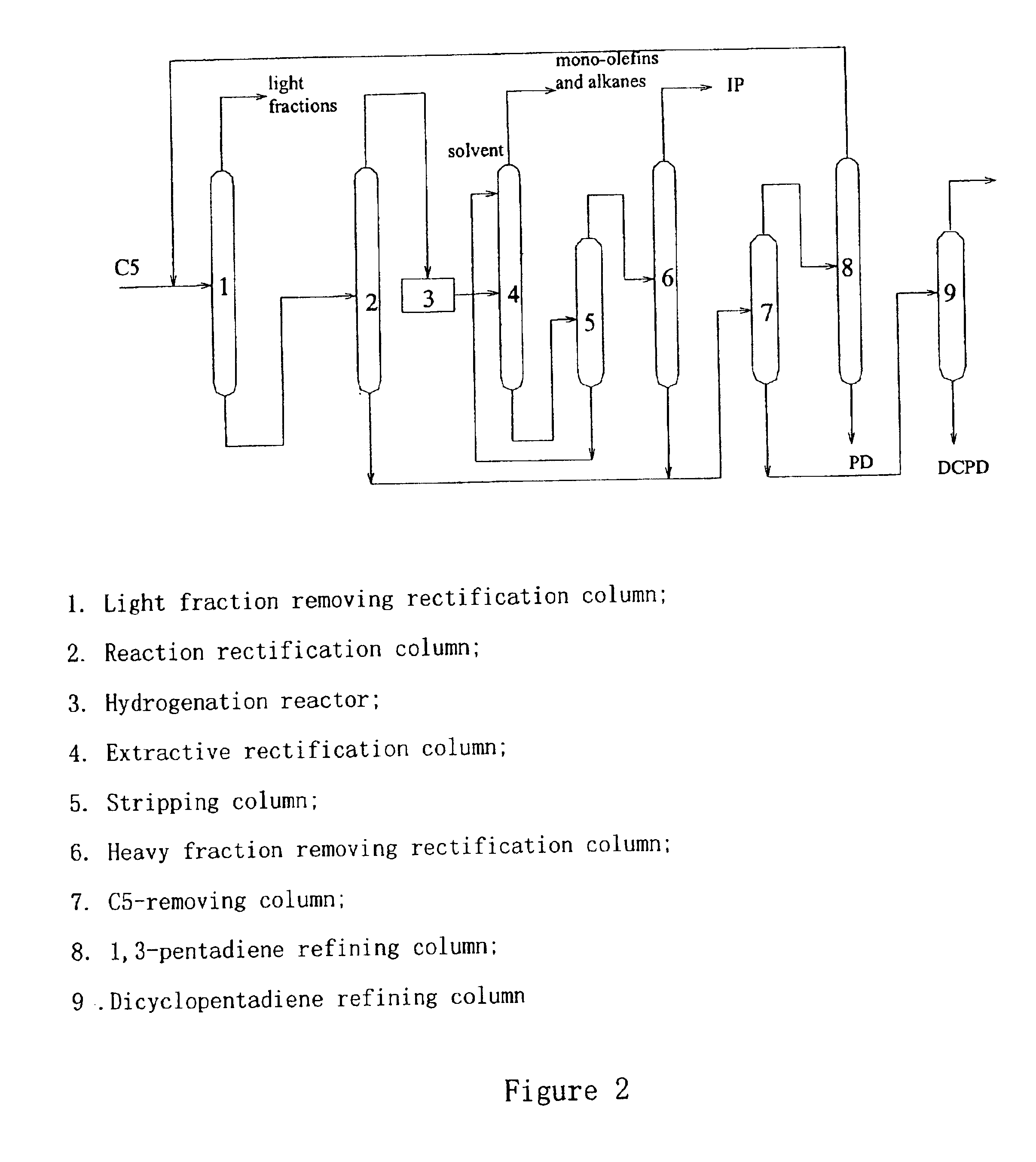

Process for separating C5 cuts obtained from a petroleum cracking process

ActiveUS20030100809A1Improve catalytic performanceHigh activityLiquid hydrocarbon mixtures productionDistillation purification/separationAlkyneSolvent

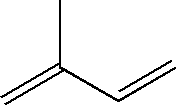

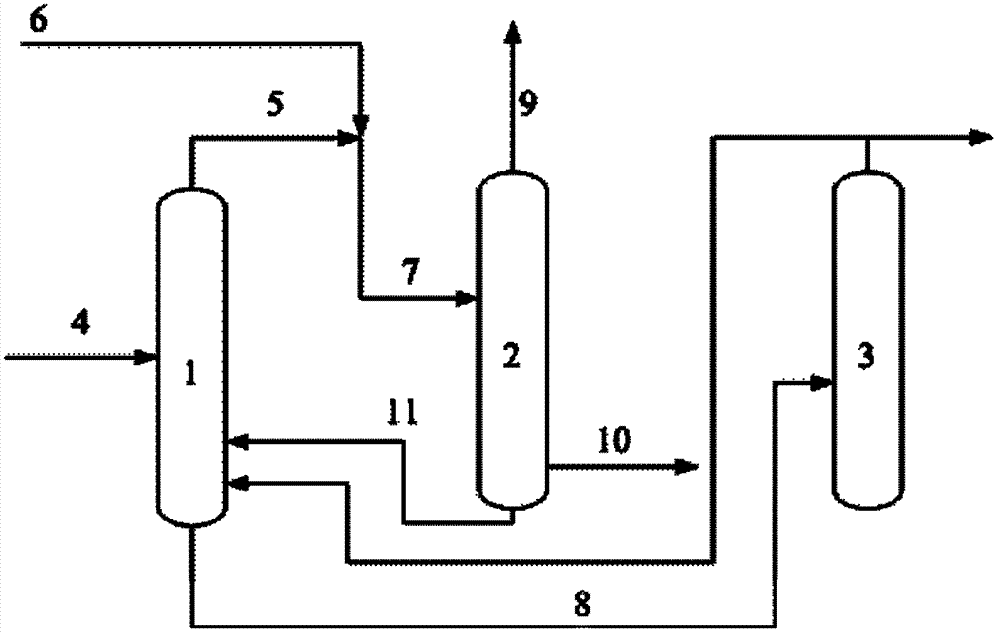

The present invention relates to a process for separating the isoprene, 1,3-pentadiene and dicyclopentadiene from a C5 cuts, comprising dimerization of the cyclopentadiene and selective catalytic hydrogenation. The second extractive rectification step can be omitted, because the alkynes are removed through selective catalytic hydrogenation prior to the extractive rectification. As a result, the solvent-recovering units can be simplified, and thus the process as a whole can be optimized. Correspondingly, the investment and energy consumption, the operation cost, and finally the production cost can be substantially reduced.

Owner:CHINA PETROCHEMICAL CORP +1

Hydrocarbon Polymer Modifiers for Elastomeric Compositions

An elastomeric composition incorporating a hydrocarbon polymer modifier including piperylene, cyclic pentadiene and aromatic components, and having a softening point from 80° C. to 160° C., z-average molecular weight greater than 10,000, and at least 1 mole percent aromatic hydrogen, based on the total moles of hydrogen in the modifier. In a method, the elastomeric composition is processed with a cure package into a composition in the desired shape, which is cured to form the article. The modifier may optionally be immiscible with an elastomer in the composition and / or co-cured with the elastomer or filler in the composition. A tire or tire component may include the elastomeric composition.

Owner:EXXONMOBIL CHEM PAT INC

Elastomeric compositions comprising hydrocarbon polymer additives

ActiveCN101910278AMaintain tire performance parametersGuaranteed performance parametersSpecial tyresElastomerPolymer science

Provided are elastomeric compositions comprising at least one elastomer and a hydrocarbon polymer additive. Preferably the hydrocarbon polymer additive comprises from 60 to 90% piperylene, from 5 to 15% cyclic components, from 5 to 20% styrenic components, up to 5% isoprene, up to 5% indenic components, and up to 10% amylene. Also provided are elastomeric compositions comprising at least one elastomer and a hydrocarbon polymer additive, wherein the hydrocarbon polymer additive has a molecular weight of from 520 to 650 g / mole and a glass transition temperature (Tg) of from 48 to 53 0C. The elastomeric compositions are particularly useful in making tires and other cured rubber articles.

Owner:EXXONMOBIL CHEM PAT INC

Method for preparing pentene

The invention relates to a method for preparing pentene, which comprises the following steps of: (1) mixing a piperylene-rich C-5 fraction and hydrogen and then the mixture being sent to a fixed bed catalytic hydrogenation reactor for a selective catalytic hydrogenation reaction in the presence of a catalyst Pd / Al2O3, wherein the molar feed ratio of hydrogen to diolefin in the material is 1- 3:1, the weight hourly space velocity is 1-8hr<-1>, the reaction pressure is 10-20bar, and the reaction temperature is 30-90 DEG C, and the piperylene contained in the material is converted into 1-pentene and 2-pentene by hydrogenation; (2) by utilizing the difference in boiling point of each component in the hydrogenated material, separating the 1-pentene in a distillation column with the number of theoretical plates of 80-100 at a bottom temperature of 55-80 DEG C, a top temperature of 40-60 DEG C, a reflux ratio of 10 to 30 and a column operating pressure of 2-5bar; and (3) then sending a bottom liquid to a distillation column with the number of theoretical plates of 80-100 to separate the 2-pentene at a bottom temperature of 62-87 DEG C, a top temperature of 47-67 DEG C, a reflux ratio of 10 to 30 and a column operating pressure of 2-5bar. The method provided by the invention has the advantages that 1-pentene and 2-pentene products with the purity of more than 98.5% can be easily produced by hydrogenation and distillation methods.

Owner:SHANGHAI PEARLK CHEM

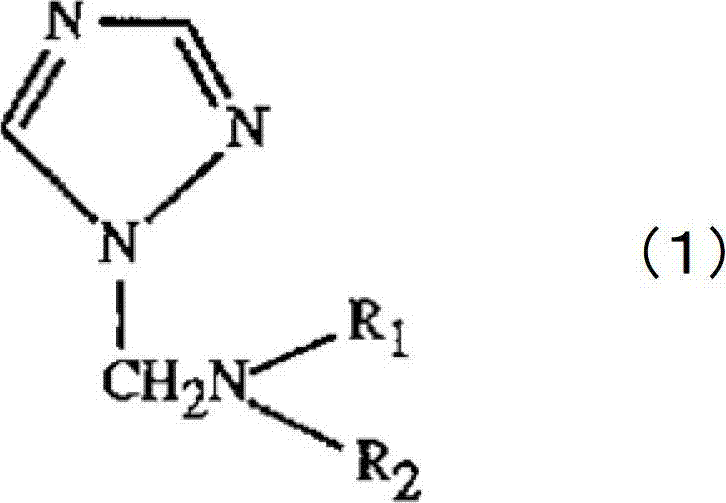

Method for preparing poly-1,3-pentadiene

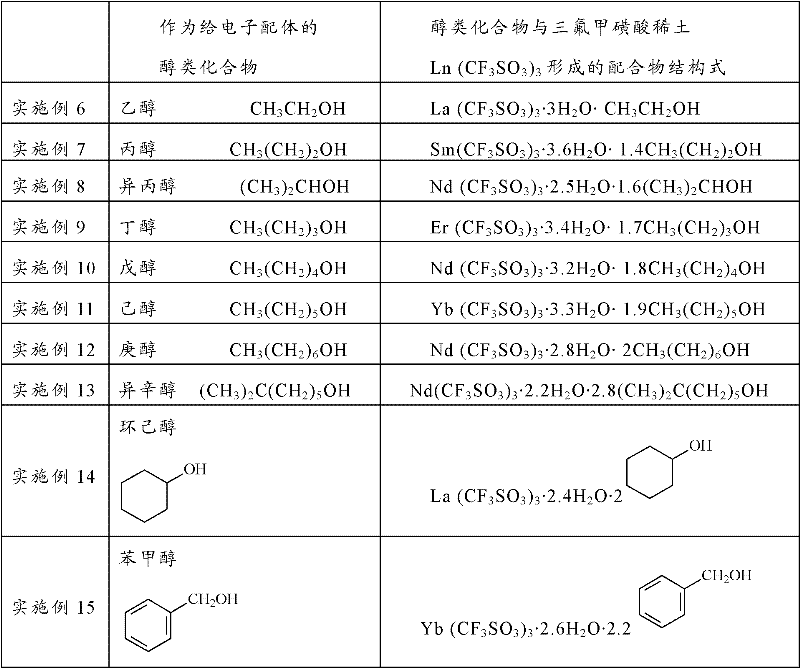

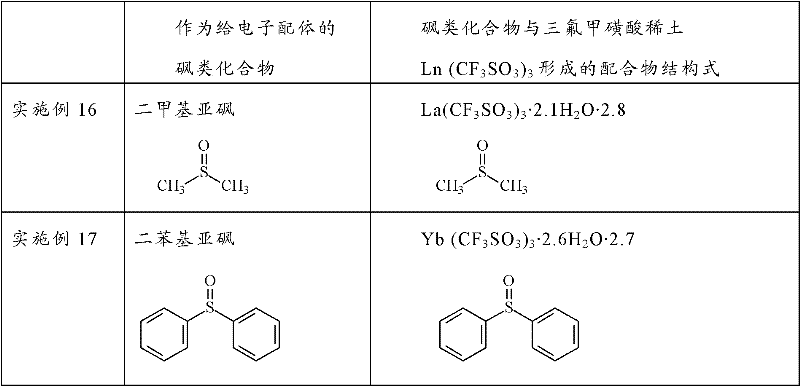

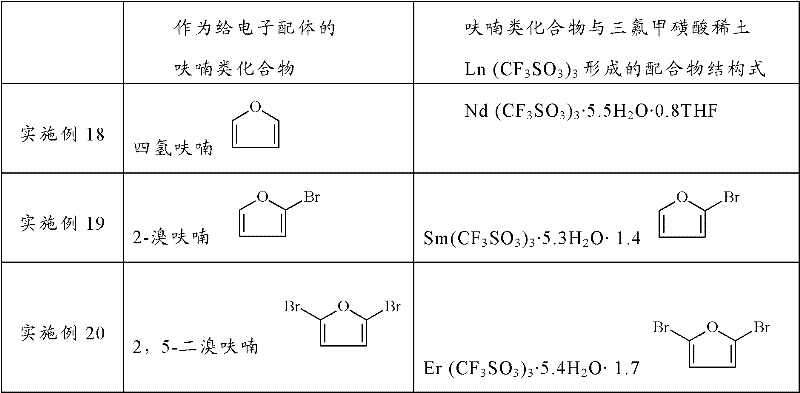

InactiveCN102351970AEliminate corrosionNo corrosionGroup 3/13 element organic compoundsRare-earth elementTriflic acid

The invention provides a catalyst for polymerization of 1,3-pentadiene. The catalyst comprises a trifluoromethanesulfonic acid rare earth complex of which the chemical formula is Ln(CF3SO3)3.xH2O.yL and alkyl aluminum, wherein Ln is a tervalent cation of rare earth element; L is an electron-donating ligand; x is more than 0 and less than or equal to 6; and y is more than or equal to 1 and less than or equal to 4. The molar ratio of the alkyl aluminum to the Ln is (20-60):1. The catalyst can reduce preparation cost and simplify reaction conditions when poly-1,3-pentadiene is prepared; and prepared poly-1,3-pentadiene rubber has good performance. The invention also provides a preparation method for the catalyst for polymerization of the 1,3-pentadiene and a preparation method for the poly-1,3-pentadiene.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI +1

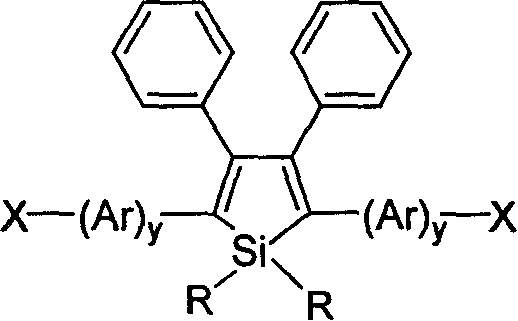

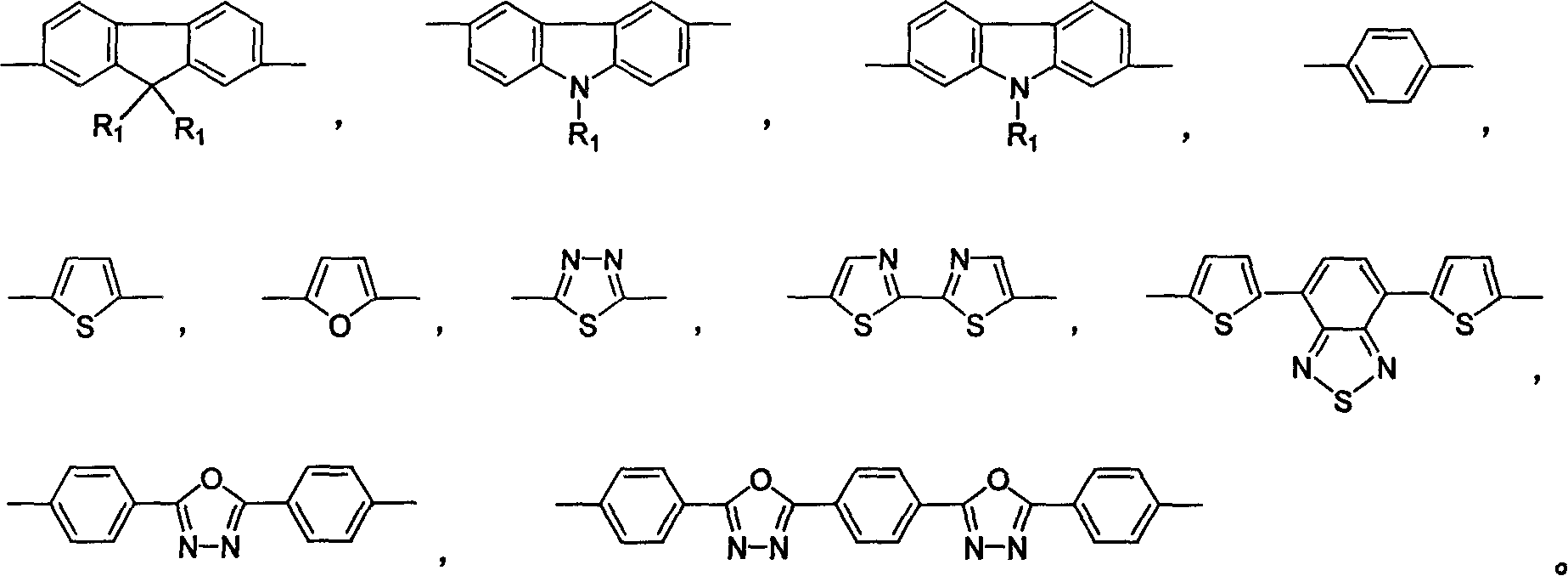

Halogen-sustituted silicon heterocycle pentadiene and production thereof

Halogen-substituted silica heterocycle piperylene and its production are disclosed. The process is carried out by reacting 2,5-dioctyl silica heterocycle piperylene with dihalide compound to obtain the target product. It can be used for compound with multiple chemical structures and polymer luminescent materials containing silica heterocycle piperylene.

Owner:GUANG ZHOU NEW VISION OPTO ELECTRONICS TECH

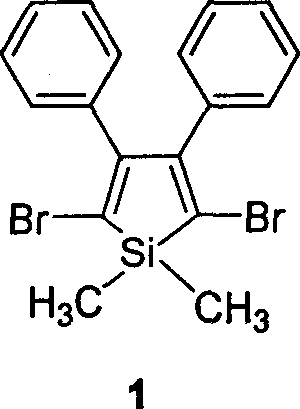

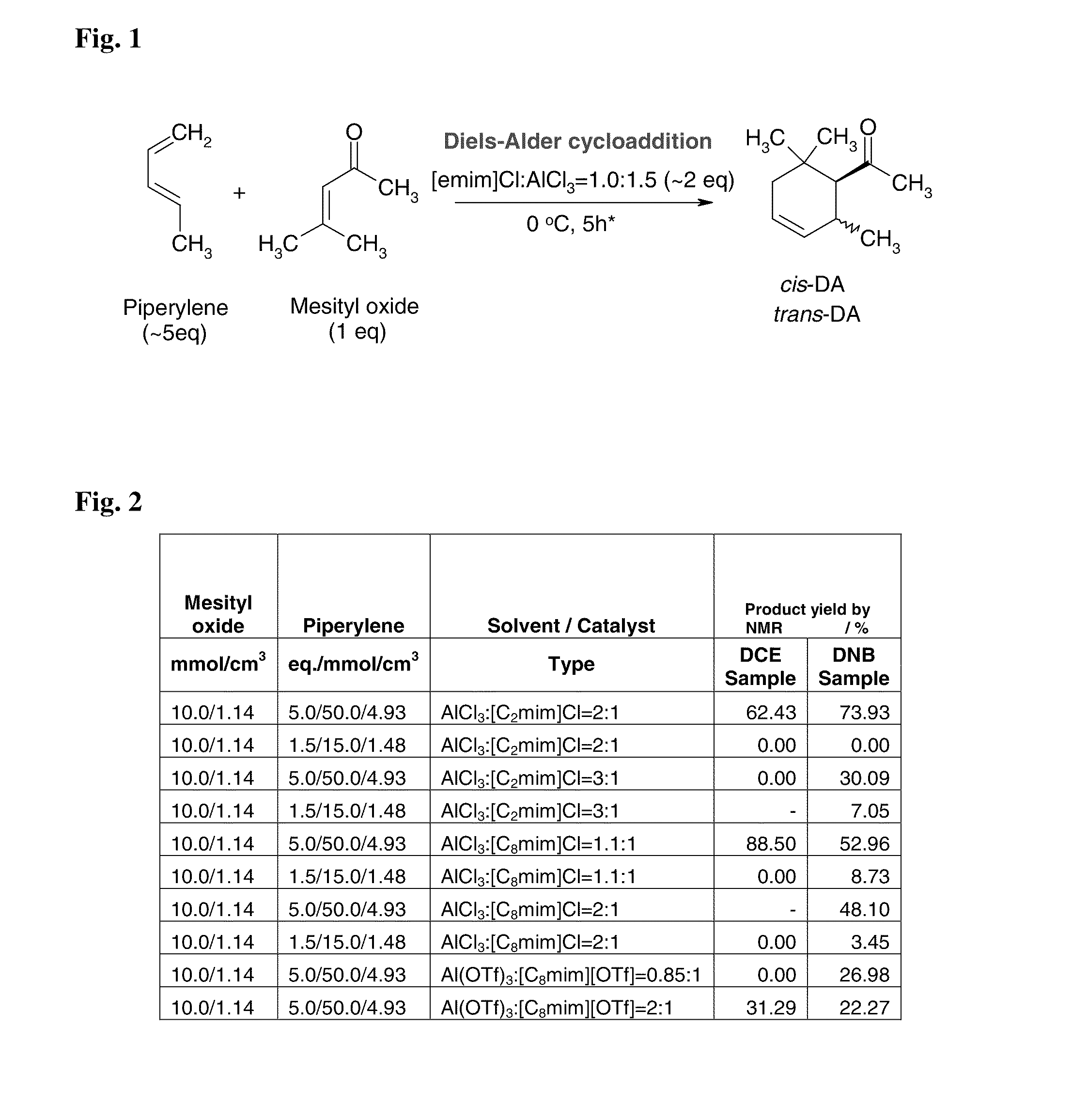

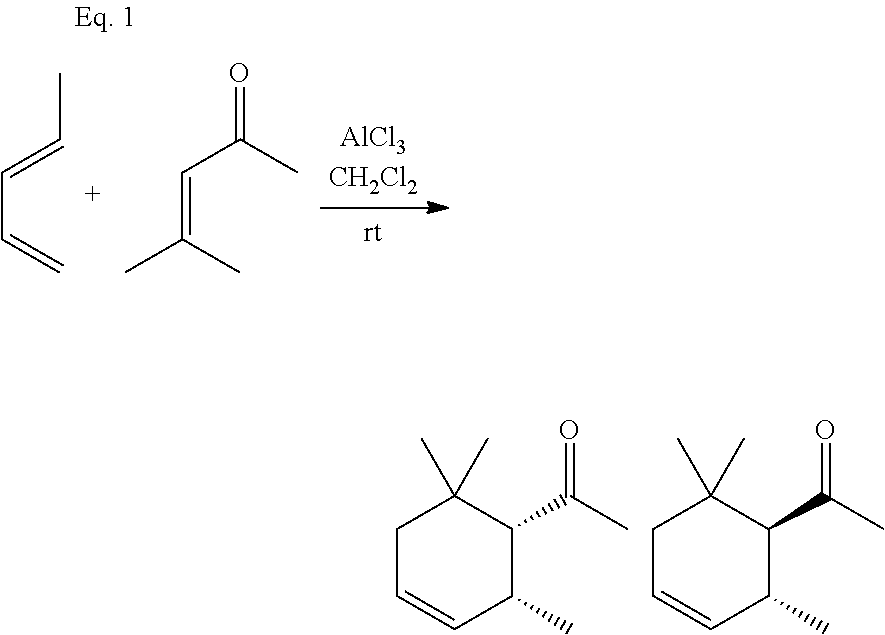

Process for Conducting an Organic Reaction in Ionic Liquids

InactiveUS20110152566A1High yieldSuitable for industrial scaleOrganic compound preparationCarbonyl compound preparationPiperyleneIon

The present disclosure describes processes for producing cyclohexenes using Lewis acidic ionic liquids comprising the steps of providing to a reactor an α,β-unsaturated carbonyl dienophile, providing to the reactor a 1,3-diene, providing a Lewis acidic ionic liquid to the reactor; and reacting the α,β-unsaturated carbonyl dienophile with 1,3-diene to form a substituted cyclohexene product. The α,β-unsaturated carbonyl dienophile can be mesityl oxide, the 1,3-diene can be piperylene; and the Lewis acidic ionic liquid can be AlCl3:[C2mim]Cl; AlCl3:[C8mim]Cl; or mixtures thereof.

Owner:THE PROCTER & GAMBLE COMPANY

Elastomeric compositions comprising hydrocarbon polymer additives

ActiveUS9062189B2Maintain tire performance parameterMaintain performanceOther chemical processesPaper coatingElastomerPolymer science

Provided are elastomeric compositions comprising at least one elastomer and a hydrocarbon polymer additive. Preferably the hydrocarbon polymer additive comprises from 60 to 90% piperylene, from 5 to 15% cyclic components, from 5 to 20% styrenic components, up to 5% isoprene, up to 5% indenic components, and up to 10% amylene. Also provided are elastomeric compositions comprising at least one elastomer and a hydrocarbon polymer additive, wherein the hydrocarbon polymer additive has a molecular weight of from 520 to 650 g / mole and a glass transition temperature (Tg) of from 48 to 53° C. The elastomeric compositions are particularly useful in making tires and other cured rubber articles.

Owner:EXXONMOBIL CHEM PAT INC

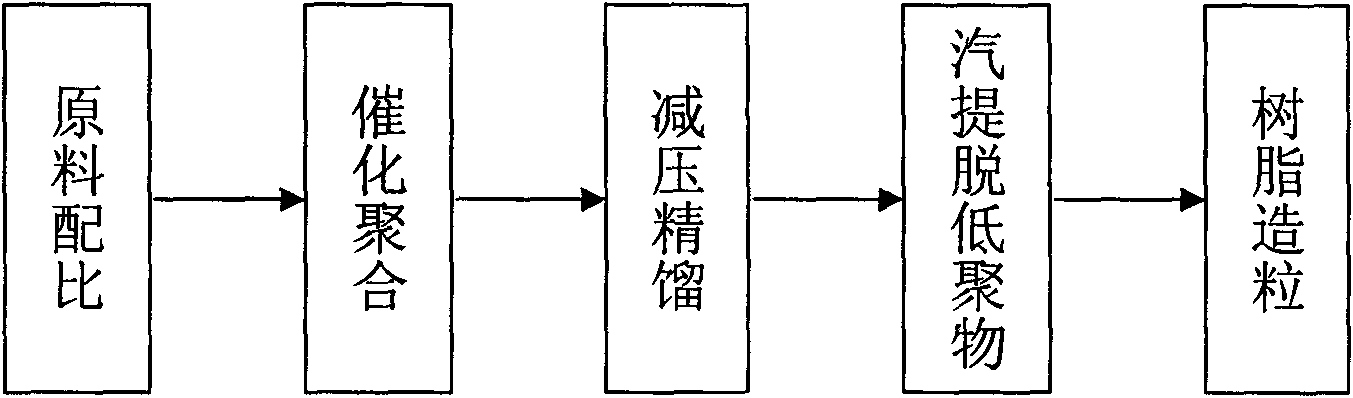

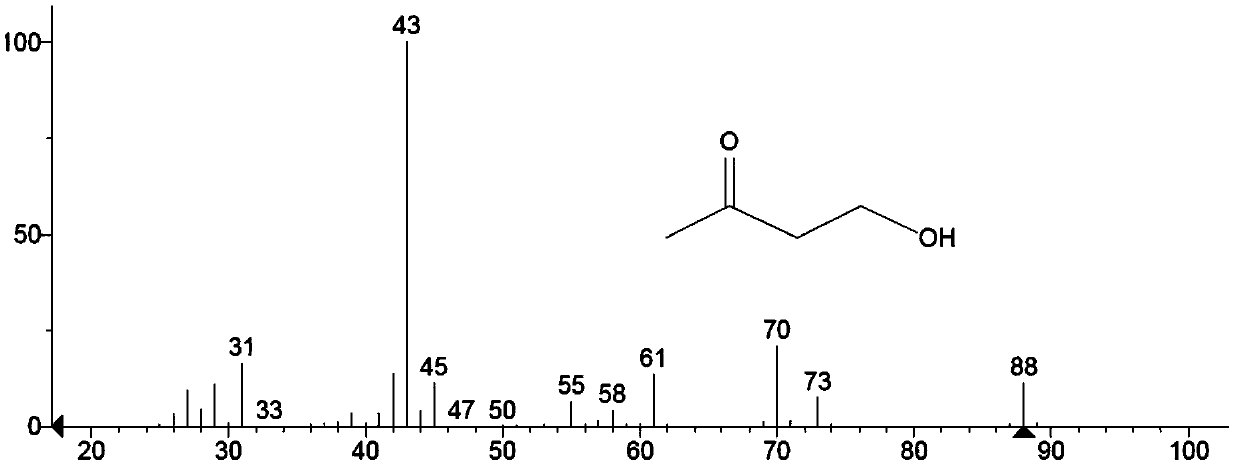

Preparation method of piperylene modified DCPD petroleum resin

The invention relates to a preparation method of piperylene modified DCPD petroleum resin, comprising the following steps: adopting piperylene and dicyclopentadiene (DCPD)as raw materials, adding the raw materials in a reaction kettle with a stirrer, adding anhydrous aluminium trichloride used as catalyst to ensure the raw materials to react at 40-60 DEG C for 3-6h, and obtaining polymer solution; introducing the polymer solution in a vacuum distillation column to remove the solvent; after the distillation, obtaining reaction solvent from the tower top and resin solution form the tower bottom; sending the resin solution to a stripping tower to perform steam distillation and extraction and obtain piperylene modified DCPD petroleum resin. The preparation method has simple operation, the raw material cost of the modified DCPD petroleum resin is lower than that of traditional DCPD resin products so that the modified DCPD petroleum resin has higher economic effect and is applicable to the industrialized production; in addition, the prepared modified DCPD petroleum resin has lighter colour and the colour number is about colour (Fe-Co scale) 5-6; the petroleum resin has better softening point and higher yield and the compatibility between the petroleum resin and EVA resin, rubber or other substances is obviously improved.

Owner:NINGBO YONGHUA RESIN +1

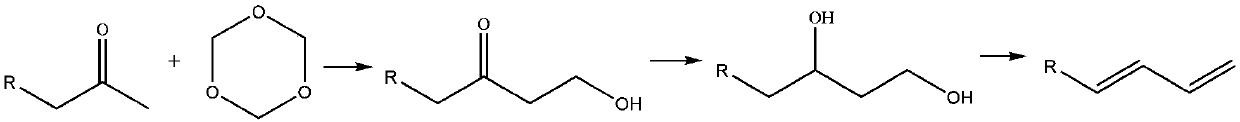

Method for synthesizing diene compounds based on aldehyde-ketone condensation reaction

InactiveCN109678642AEasy to operateMild conditionsOrganic compound preparationMolecular sieve catalystKetonePiperylene

The invention provides a method for synthesizing diene compounds based on an aldehyde-ketone condensation reaction. The method comprises the following steps: firstly, under the action of a condensation catalyst, performing a condensation reaction on ketone compounds and aldehyde compounds to obtain condensation products; then, under the action of a reduction catalyst, performing a reduction reaction on the condensation products obtained in the previous step to obtain reduction products; under the action of a catalyst, performing a dehydration reaction on the reduction products obtained in theprevious step to obtain the diene compounds. According to the method, ketone, aldehyde as well as homologues of ketone and aldehyde which are cheap and easy to obtain can be used as raw materials forsynthesizing the diene compounds such as butadiene, piperylene as well as homologues of butadiene and piperylene, experimental conditions are mild, the operation is simple, and a large-scale synthesisprospect is achieved.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

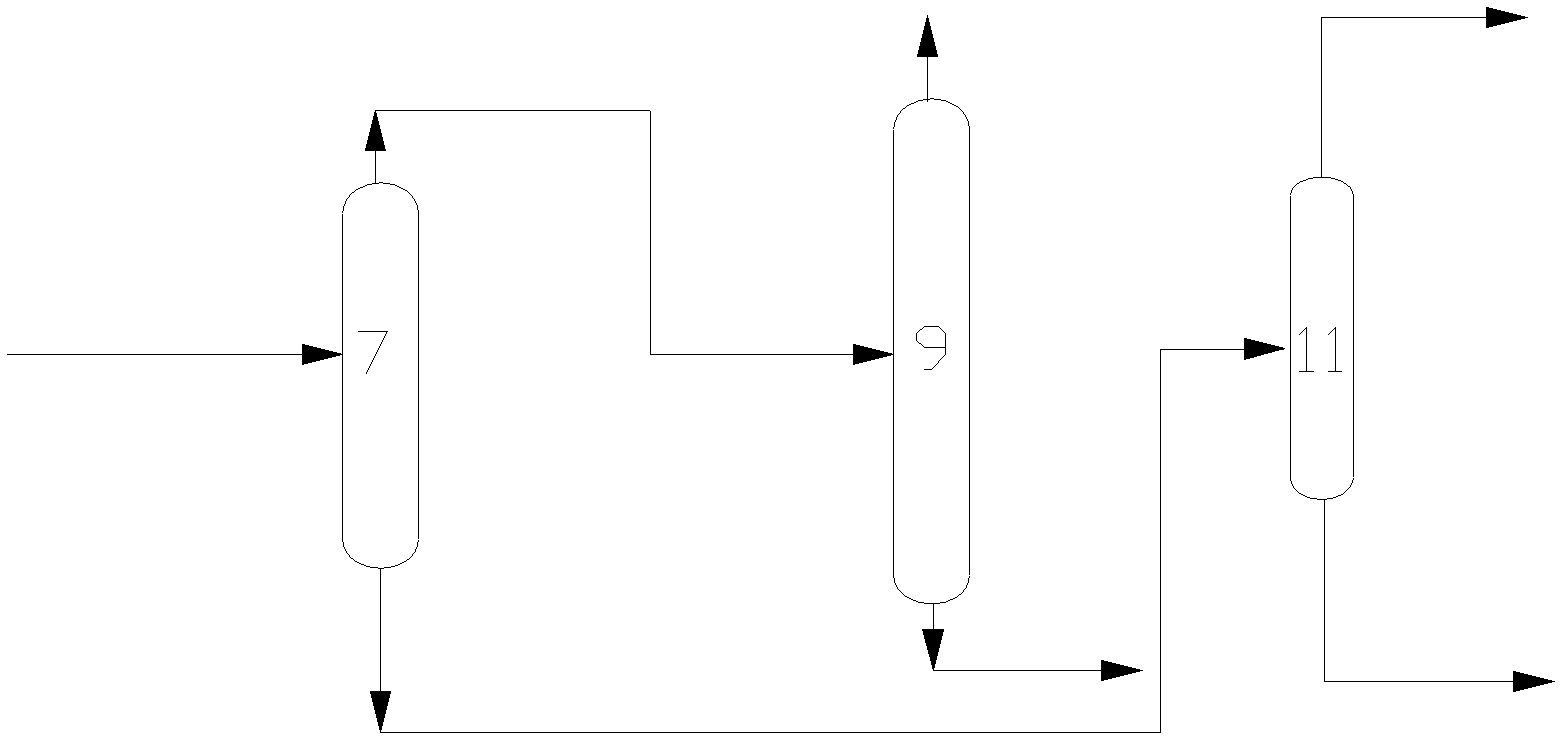

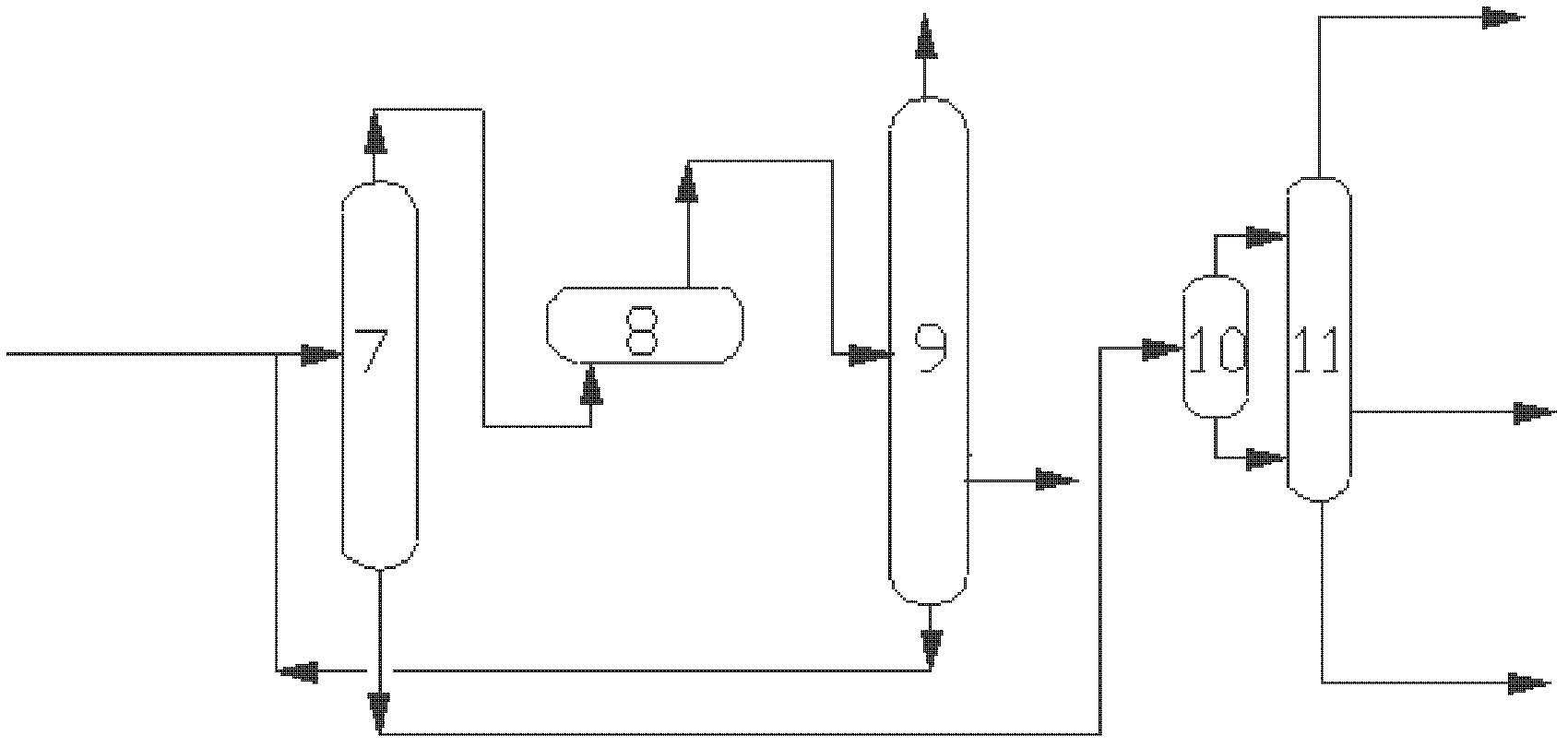

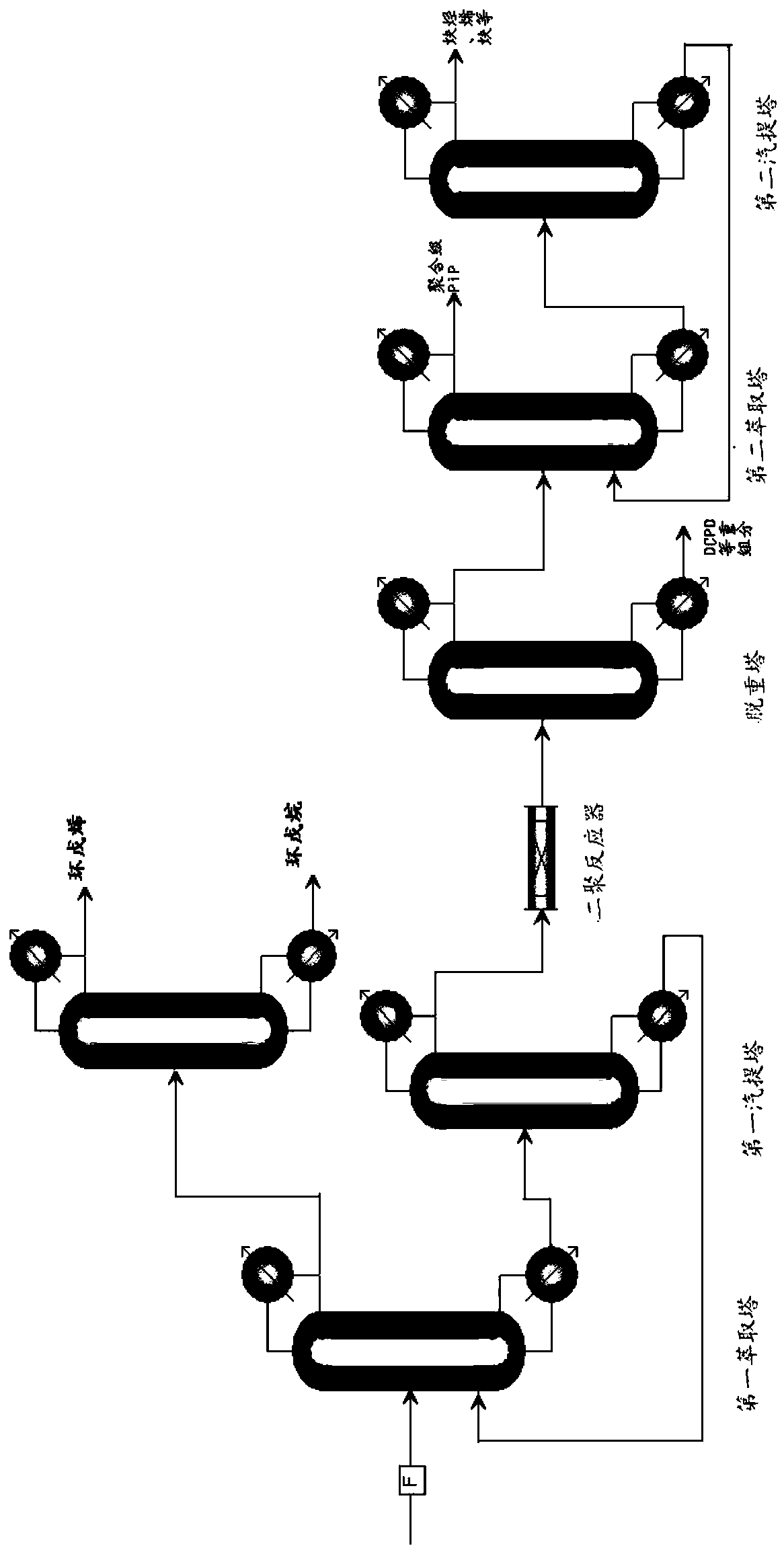

Separation system and separation method for piperylene and dicyclopentadiene

ActiveCN103183579AReduce refluxHigh yieldDistillation purification/separationHydrocarbons from unsaturated hydrocarbon additionGas phaseEconomic benefits

The invention discloses a separation method and a separation system for piperylene and dicyclopentadiene. The system comprises a C5 boil-up tower, a piperylene tower and a dicyclopentadiene tower and is characterized in that a second dimerization reactor is arranged between the C5 boil-up tower and the piperylene tower and a double-ring feeding flash vaporization vessel is arranged before the dicyclopentadiene tower. The separation method comprises the following steps: (1) allowing a C5 fraction having undergone removal of light components to enter into the middle part of the C5 boil-up tower and a tower-top materiel flow to enter into the second dimerization reactor, delivering a reacted material to the piperylene tower, carrying out gas-phase side-draw at the lower part of the piperylene tower so as to recover a piperylene product and returning a material obtained at the bottom of the piperylene tower to a C5 removing tower as a feed; and (2) recovering a material from the bottom of the C5 boil-up tower, allowing the material to enter into the flash vaporization vessel, allowing material flows obtained at the top and the bottom of the flash vaporization vessel to respectively enter into the upper part and the lower part of the dicyclopentadiene tower and carrying out side-draw at the dicyclopentadiene tower to recover a dicyclopentadiene product. With the system and the method provided by the invention, the purity and the color of piperylene and dicyclopentadiene can be improved, and economic benefits of equipment are enhanced.

Owner:CHINA PETROCHEMICAL CORP +1

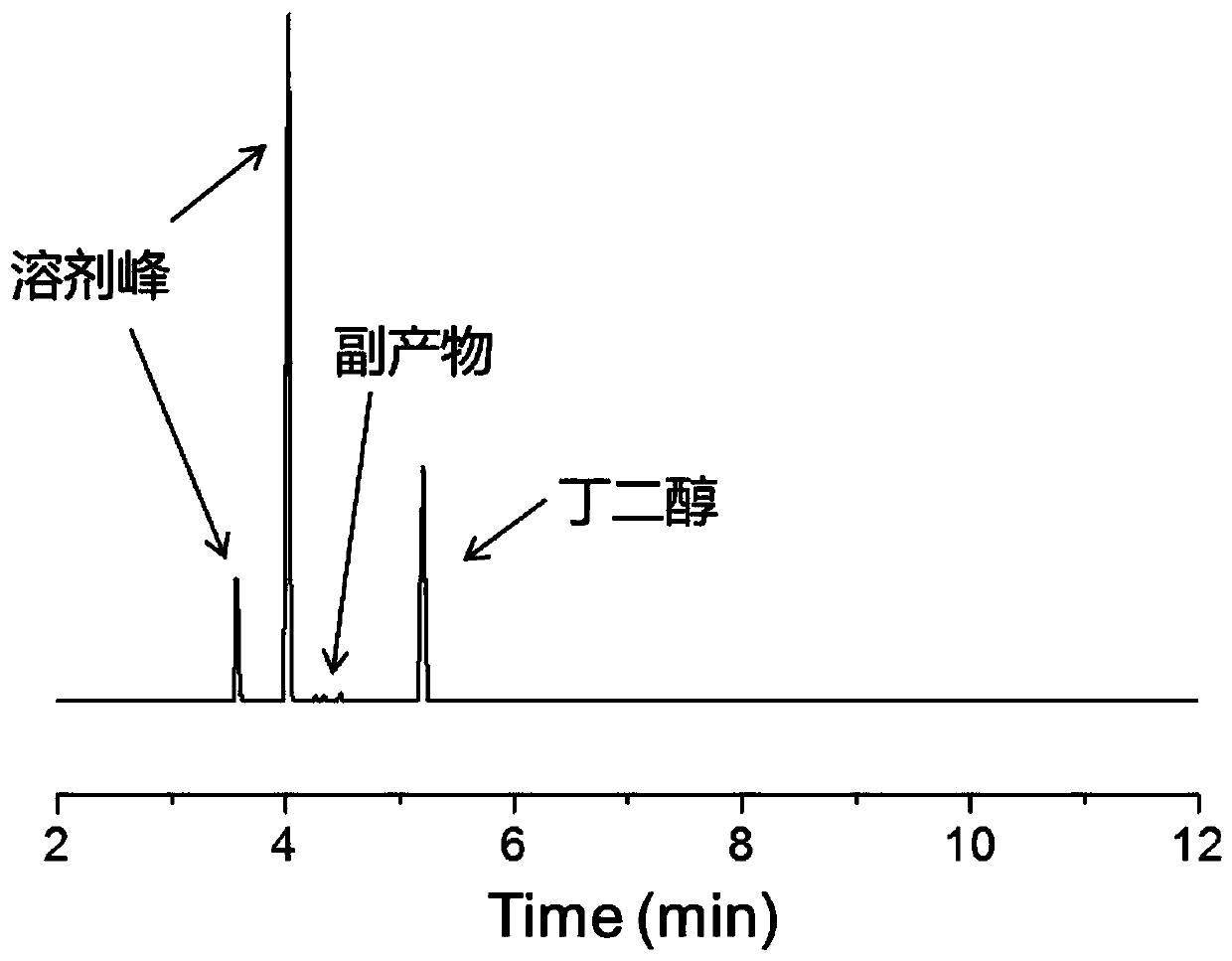

Catalytic dehydration of alcohols and ethers over a ternary mixed oxide

InactiveUS20130072696A1Organic compound preparationHeterogenous catalyst chemical elementsMixed oxideAlcohol

A ternary V—Ti—P mixed oxide is shown to catalytically dehydrate 2-methyl-tetrahydrofuran in high conversion to give piperylene, in good yield. Volatile products collected from this reaction contain piperylene in concentrations as high as 80 percent by weight. Dehydration of glycerol to acrolein in high conversion and moderate selectivity is also demonstrated. The catalyst is also shown to dehydrate other alcohols and ether substrates. The catalyst is resistant to deactivation and maintains activity between runs.

Owner:EASTMAN CHEM CO

Separation method of piperylene

ActiveCN103086822AReduce the number of theoretical boardsReduce the reflux ratioDistillation purification/separation2-Methyl-2-buteneFlow ratio

The invention discloses a piperylene separation method. According to the invention, piperylene is separated through azeotropic rectification. An azeotropic material flow is introduced into a fed material of a piperylene tower. The azeotropic material flow comprises n-pentane and 2-methyl-2-butene. Flow ratio of the azeotropic material flow to a C5 removing tower top recovered material flow is 0.01-1. The two are mixed and are delivered into the piperylene tower. With the method provided by the invention, piperylene product purity is improved, equipment investment is reduced, and operation cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

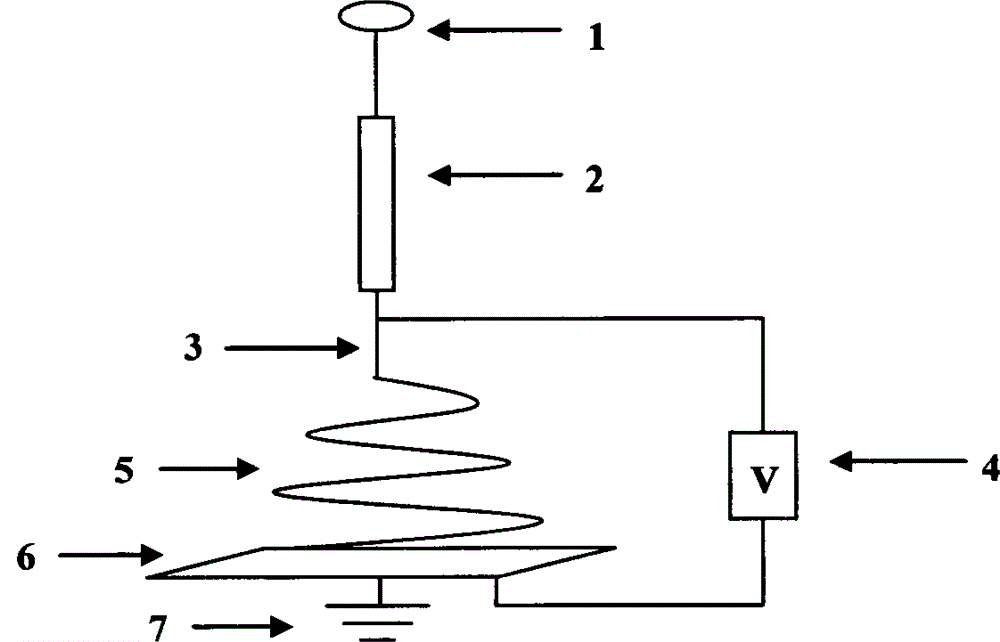

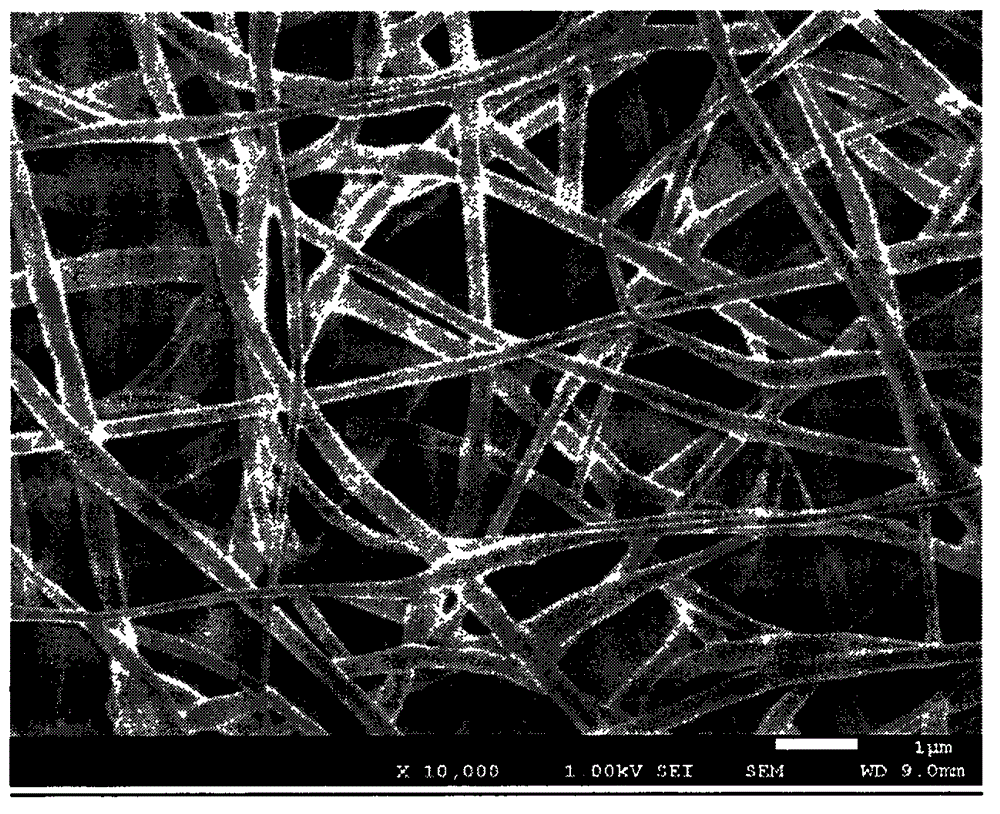

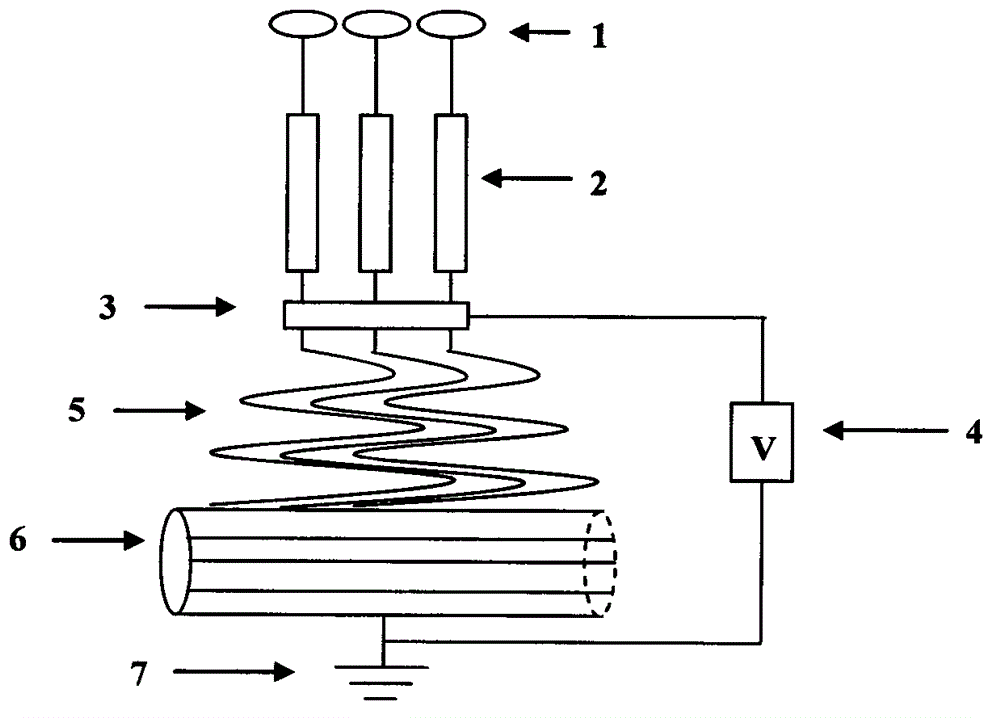

Trans-rubber fiber material, preparation method and applications thereof

InactiveCN103911766AControl diameterControl speedNew-spun product collectionFilament/thread formingFiberPorosity

The invention provides a trans-rubber fiber material. The trans-rubber is selected from one or more of trans-1, 4-polyisoprene, trans-1, 4-polybutadiene, trans-1, 4-butadiene-isoprene copolymerization rubber, trans-1, 4-butadiene-piperylene copolymerization rubber, trans-1, 4-polydiolefin rubber alloy and trans-1, 4-alkadiene homopolymer and / or homopolymer epoxidation or chlorination modified derivatives and derivatives. The diameter of the trans-rubber is in a range of 100nm to 10 microns. The invention further provides a preparation method and applications of the trans-rubber fiber material. The trans-rubber fiber material has the advantages of being fine in diameter, low in weight, large in specific surface area, large in porosity, small in mass-to-volume ratio, capable of maintaining good fiber morphology after being put for a period and free of fiber dissolving and deformation of other fibers in the prior art.

Owner:QINGDAO UNIV OF SCI & TECH

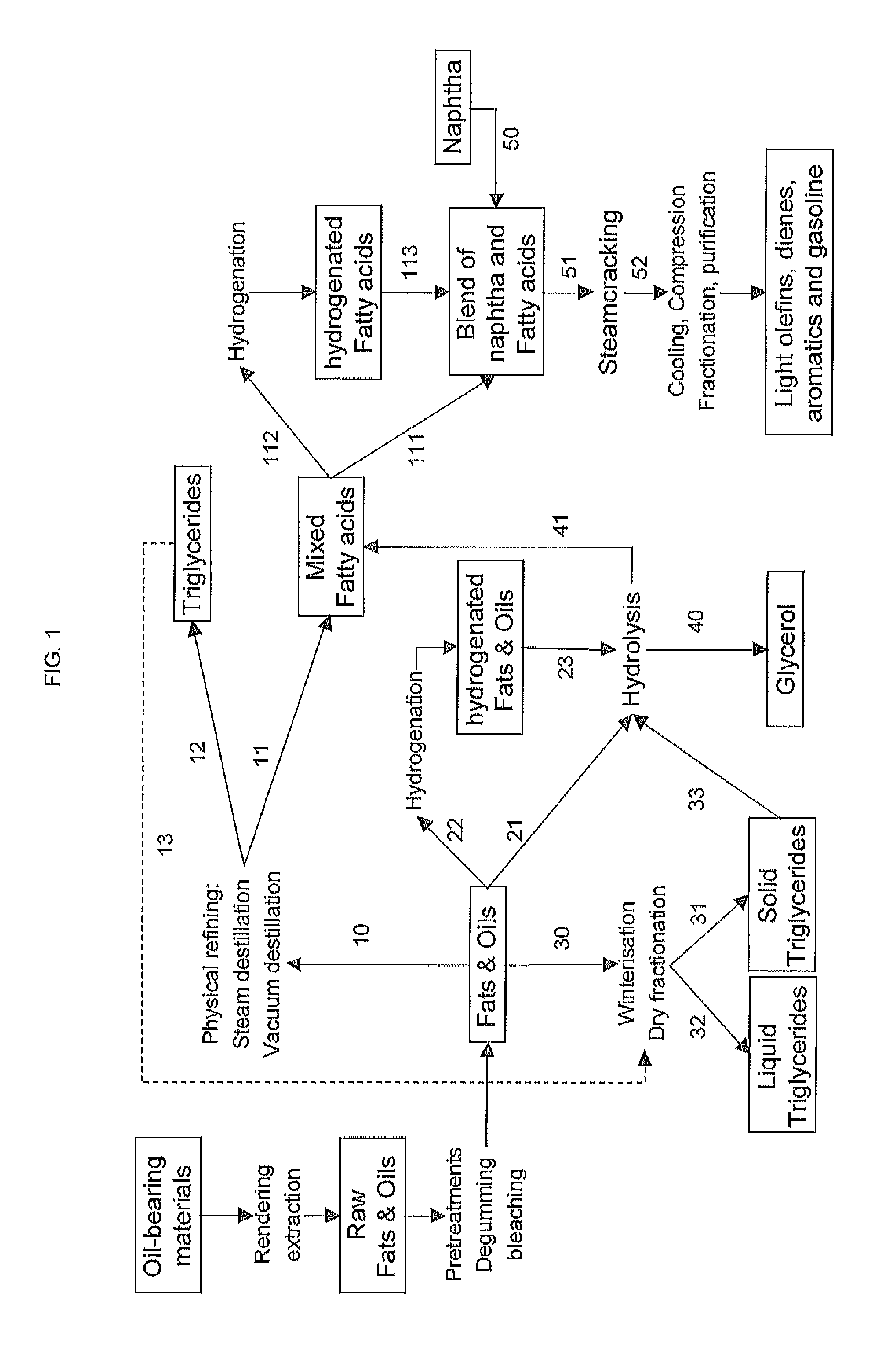

Use of free fatty acids produced from bio-sourced oils & fats as the feedstock for a steamcracker

InactiveUS20120142982A1Fatty acid chemical modificationLiquid carbonaceous fuelsGasolineTG - Triglyceride

Use of fatty acids produced from a complex mixture of natural occurring oils & fats and / or of triglycerides deriving from said complex mixture as the feedstock of a steamcracker, by mixing the fatty acids with steam in a steam / feedstock ratio of at least 0.2 kg per kg, a coil outlet temperature of at least 700° C. and an coil outlet pressure of at least 1.2 bara in order to obtain cracking products including bio-ethylene, bio-propylene, bio-butadiene, bio-isoprene, bio-cyclopentadiene and bio-piperylenes, bio-benzene, bio-toluene, bio-xylene and bio-gasoline.

Owner:TOTAL RES & TECH FELUY

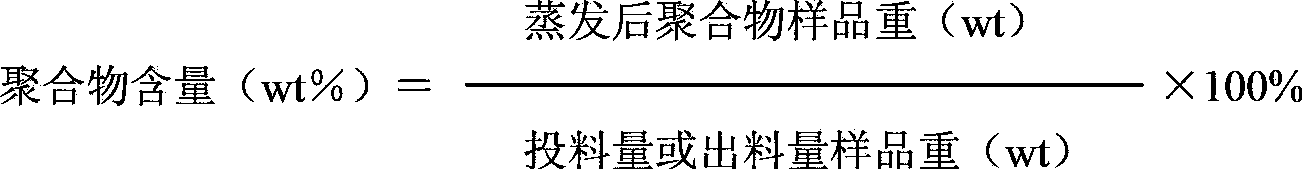

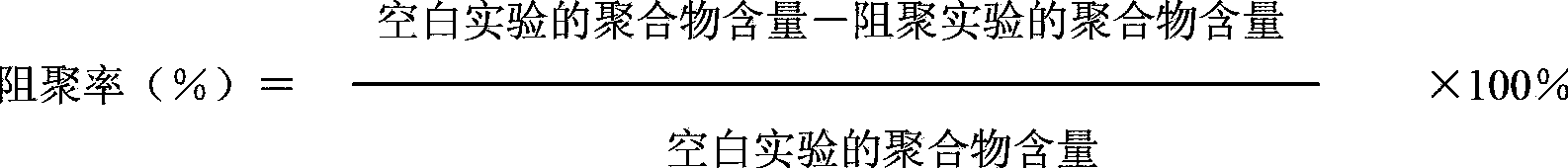

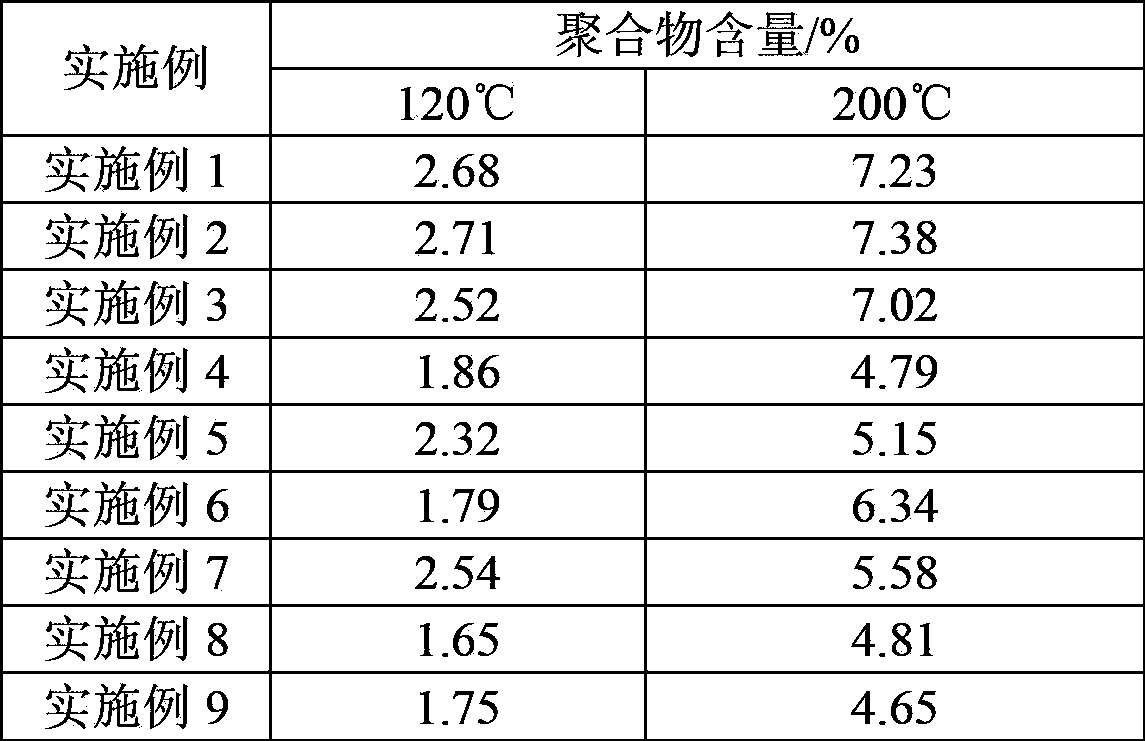

C5 diolefin auto-agglutination or copolymerization inhibition method

ActiveCN103896711AGood inhibition effectHydrocarbon purification/separationHydrocarbonsAgglutinationDiethylhydroxylamine

The invention relates to a C5 diolefin auto-agglutination or copolymerization inhibition method in C5 fraction separation process of petroleum, a polymerization inhibitor is added into a C5 fraction material, the polymerization inhibitor in the C5 fraction material is maintained at a certain amount, the polymerization inhibitor comprises component A N, N-diethylhydroxylamine, component B N,N'-di-sec-butyl-1,4-phenylenediamine and component C succinimide, the weight ratio of component A to component B to component C is (0.1-3):1-3 :0.1-3, and taking the total amount of the component A, component B and component C as a reference, the polymerization inhibitor in the C5 fraction material is maintained at the amount of 20-600ppm; the polymerization inhibitor used in the method is good in polymerization inhibition effect and good in versatility, a big difference in the boiling point between each component and solvent and isoprene, cyclopentadiene (or dicyclopentadiene), piperylene and other diolefins in C5 fraction is existed, so that the components and solvents can be separated in the separation process without further increase of a separation process.

Owner:PETROCHINA CO LTD

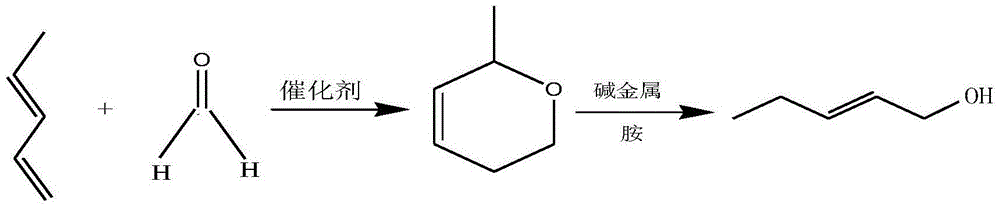

Preparation method of Fe/Mo-Al2O3 catalyst and method of synthesizing leaf alcohol by virtue of piperylene

ActiveCN104689824AEasy to prepareMild process conditionsMetal/metal-oxides/metal-hydroxide catalystsPreparation by hydrolysisSolventMethyl group

The invention relates to a preparation method of a Fe / Mo-Al2O3 catalyst and a method of synthesizing leaf alcohol by virtue of piperylene. The method comprises the following steps: with Fe / Mo as the active component, gamma-Al2O3 as a carrier and formaldehyde or acetaldehyde as a solvent, under the conditions of heating and stirring, catalytically synthesizing 2-methyl-5,6-dihydropyran; and converting 2-methyl-5,6-dihydropyran into the leaf alcohol under the catalysis of alkali metal and amine. According to the method disclosed by the invention, Fe / Mo-Al2O3 is firstly adopted as a catalyst for synthesizing 2-methyl-5,6-dihydropyran through piperylene; according to the process for catalyzed synthesis of 2-methyl-5,6-dihydropyran, conditions are mild, and the equipment requirements are low; Diels-Alder reaction is carried out on piperylene under the action of the catalyst without changing the catalyst; 2-methyl-5,6-dihydropyran, serving as a synthetic intermediate, is subjected to reaction under the catalysis of alkali metal and amine to easily produce leaf alcohol serving as a target product, and purity and yield are high.

Owner:TIANJIN UNIV

Process for separating C5 cuts obtained from a petroleum cracking process

ActiveUS6958426B2Improve catalytic performanceHigh activityDistillation purification/separationLiquid hydrocarbon mixtures productionAlkyneSolvent

The present invention relates to a process for separating the isoprene, 1,3-pentadiene and dicyclopentadiene from a C5 cuts, comprising dimerization of the cyclopentadiene and selective catalytic hydrogenation. The second extractive rectification step can be omitted, because the alkynes are removed through selective catalytic hydrogenation prior to the extractive rectification. As a result, the solvent-recovering units can be simplified, and thus the process as a whole can be optimized. Correspondingly, the investment and energy consumption, the operation cost, and finally the production cost can be substantially reduced.

Owner:CHINA PETROCHEMICAL CORP +1

Hydrocarbon polymer modifiers for elastomeric compositions

An elastomeric composition incorporating a hydrocarbon polymer modifier including piperylene, cyclic pentadiene and aromatic components, and having a softening point from 80° C. to 160° C., z-average molecular weight greater than 10,000, and at least 1 mole percent aromatic hydrogen, based on the total moles of hydrogen in the modifier. In a method, the elastomeric composition is processed with a cure package into a composition in the desired shape, which is cured to form the article. The modifier may optionally be immiscible with an elastomer in the composition and / or co-cured with the elastomer or filler in the composition. A tire or tire component may include the elastomeric composition.

Owner:EXXONMOBIL CHEM PAT INC

Catalytic dehydration of alcohols and ethers over a ternary mixed oxide

A ternary V—Ti—P mixed oxide is shown to catalytically dehydrate 2-methyl-tetrahydrofuran in high conversion to give piperylene, in good yield. Volatile products collected from this reaction contain piperylene in concentrations as high as 80 percent by weight. Dehydration of glycerol to acrolein in high conversion and moderate selectivity is also demonstrated. The catalyst is also shown to dehydrate other alcohols and ether substrates. The catalyst is resistant to deactivation and maintains activity between runs.

Owner:EASTMAN CHEM CO

Catalytic system for synthesizing piperylene petroleum resin and preparation method for piperylene petroleum resin

Owner:NINGBO JINHAI CHENGUANG CHEM

Acid modification C5 petroleum resin and molecular weight controllable preparation method thereof

The invention discloses an acid modification C5 petroleum resin and a molecular weight controllable preparation. The preparation method comprises the following steps that a decyclization C5 compound,piperylene, recycled piperylene, monoolefine, styrene, styrene derivatives thereof and other substances are accurately weighed according to the certain proportional relation and dissolved into solventnaphtha, then, the mixture is added into a cold polymerization reaction kettle and stirred to be uniform, the polymerization reaction temperature is controlled to be 45-80 DEG C, the reaction time iscontrolled within 0.5-4 h, and basic resin is prepared after polymerization; finally, a final acid modification petroleum resin product is obtained through the grafting technology performed on the basic resin. By blending the contents of material components in reaction materials, the molecular weight of the basic resin is regulated, then, on the basis of the grafting technology, accordingly, themolecular weight of petroleum resin can be controlled finally, and the regulating range is wide.

Owner:安徽同心新材料科技有限公司

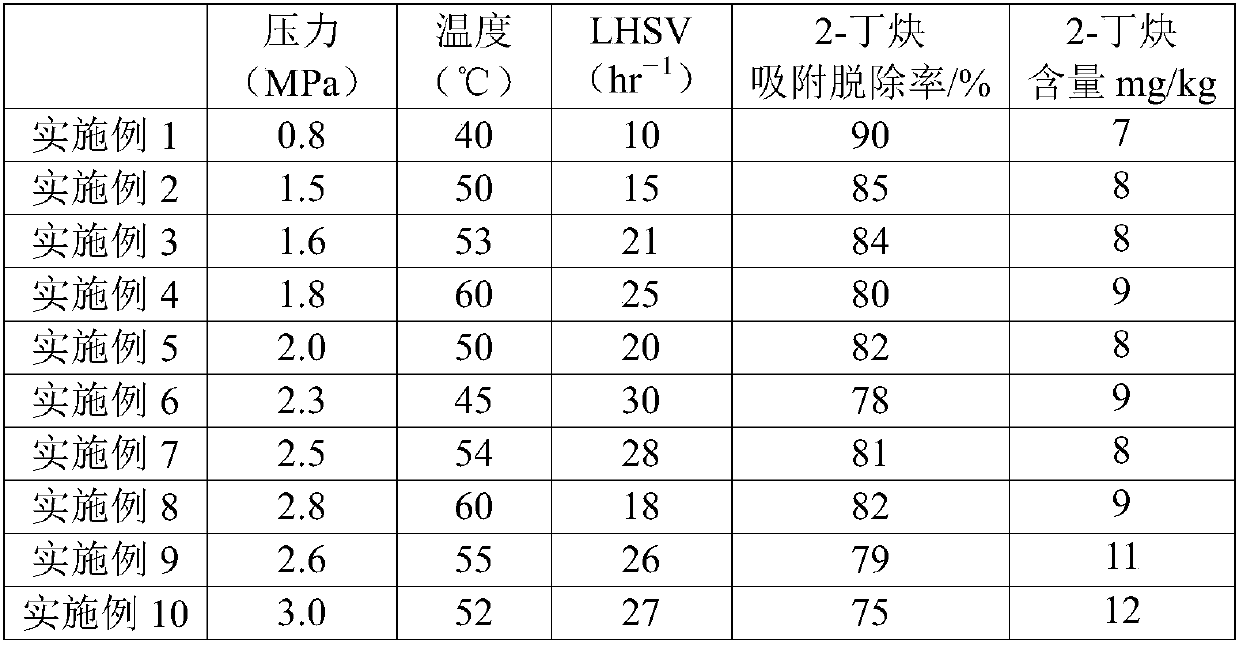

High-purity piperylene preparation method

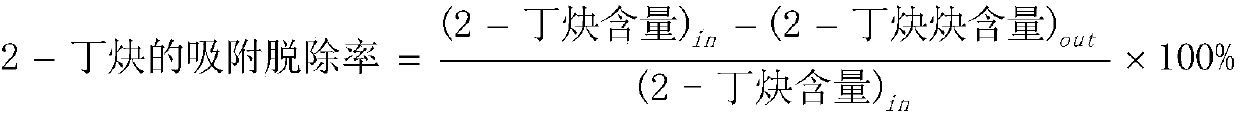

InactiveCN109721454ANo pollution in the processHigh adsorption selectivityHydrocarbonsAdsorption purification/separationPiperyleneRaw material

The invention discloses a high-purity piperylene preparation method, wherein isoprene and cyclopentadiene are removed from C5 distillate, the obtained C5 distillate is used as a raw material, and treatment is performed through adsorption and extraction rectification to obtain the high-purity piperylene. With the method of the present invention, a small of difficultly-removed cyclopentadiene and 2-butyne can be effectively removed from piperylene; the process is simple and effective; and with the method, the high-purity piperylene with the cyclopentadiene content of less than 50 ppm and the 2-butyne content of less than 20 ppm can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

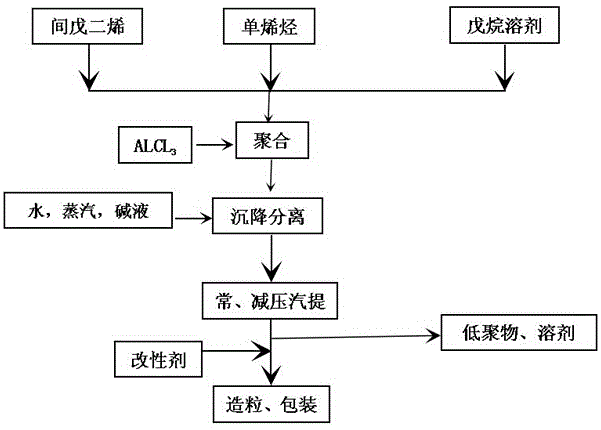

Method for improving performance of petroleum resin product

InactiveCN104673045AImprove performanceGood weather resistanceCoatingsPetroleum productCationic polymerization

The invention discloses a method for improving the performance of a petroleum resin product. The method comprises the steps of performing cationic polymerization to obtain a polymerization solution by using pentane as a solvent, aluminium trichloride as a solvent and monoolefine and piperylene as raw materials; performing alkali washing and water washing to inactivate the catalyst and remove the catalyst and other impurities; then performing normal and reduced pressure steam stripping to remove the pentane solvent and oligomers; and adding a modifier, then granulating and packaging, wherein the modifier is polyisobutene maleic anhydride. By adopting the method for improving the performance of the petroleum resin product, the weather tolerance, pollution resistance, levelling property, adhesion and the like of the product obtained by adding the maleic anhydride modifier in the process of serving as a hot-melt traffic coating are better than those of a traffic coating without the modifier.

Owner:新疆天利石化控股集团有限公司

Nonwoven web with improved adhesion and reduced dust formation

InactiveUS20050064186A1Improve adhesionConjugated synthetic polymer artificial filamentsNon-woven fabricsFiberPolyolefin

Making suitable nonwoven webs requires good adhesion between the binder and the absorbent material. The present invention relates to a nonwoven web having improved adhesion based on tackifiers present in the binder. Optionally, the binder with tackifier may also contain an adhesion promoter, usually grafted polyolefins, and an enhancement agent, usually inactive inorganic compounds in powder form. The web comprises from about 5 to about 25% by weight binder fiber and from about 75 to 95% by weight absorbent. The absorbent may be a natural absorbent or a super absorbent polymer or a combination of these. The binder fiber contains less than about 40% by weight tackifier. Tackifier is selected from the class of rosin, rosin esters, terpene based, piperylene based, and hydrocarbon based compounds.

Owner:INVISTA NORTH AMERICA R L

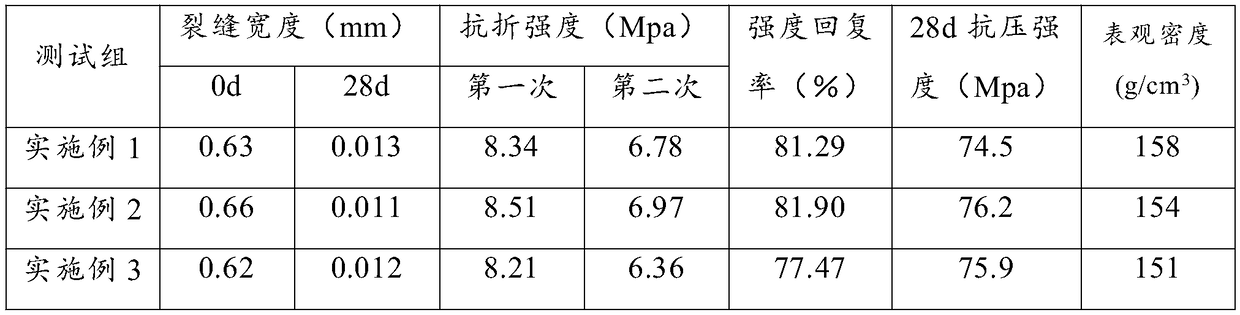

High-strength self-healing concrete

The invention provides high-strength self-healing concrete, the high-strength self-healing concrete is prepared from the following raw materials in parts by weight: 100-120 parts of Portland cement, 30-50 parts of water, 10-20 parts of carbon dioxide foaming agents, 20-30 parts of dispersing agents, 55-65 parts of aggregates, 20-30 parts of microbial composites, 20-30 parts of modified fiber compound, 1-3 parts of phenol antioxidants, 1-3 parts of octadecanoic acid and 4-8 parts of modified piperylene petroleum resin, the high-strength self-healing concrete has the advantages that through specific proportions and a specific preparation method, fracture strength and compressive strength are improved to a certain extent, the self-healing capability of the concrete is enhanced, repair time ofthe concrete is prolonged, high durability and compactness are realized, and the strength reversion rate of the repaired concrete is high; in view of the embodiment and proportions, components of thehigh-strength self-healing concrete have synergistic effects, the fracture strength and the compressive strength of the concrete are decreased obviously when some components are replaced, and the reversion rate is reduced obviously.

Owner:KUNMING SHUNHONG CEMENT PIPE PROD

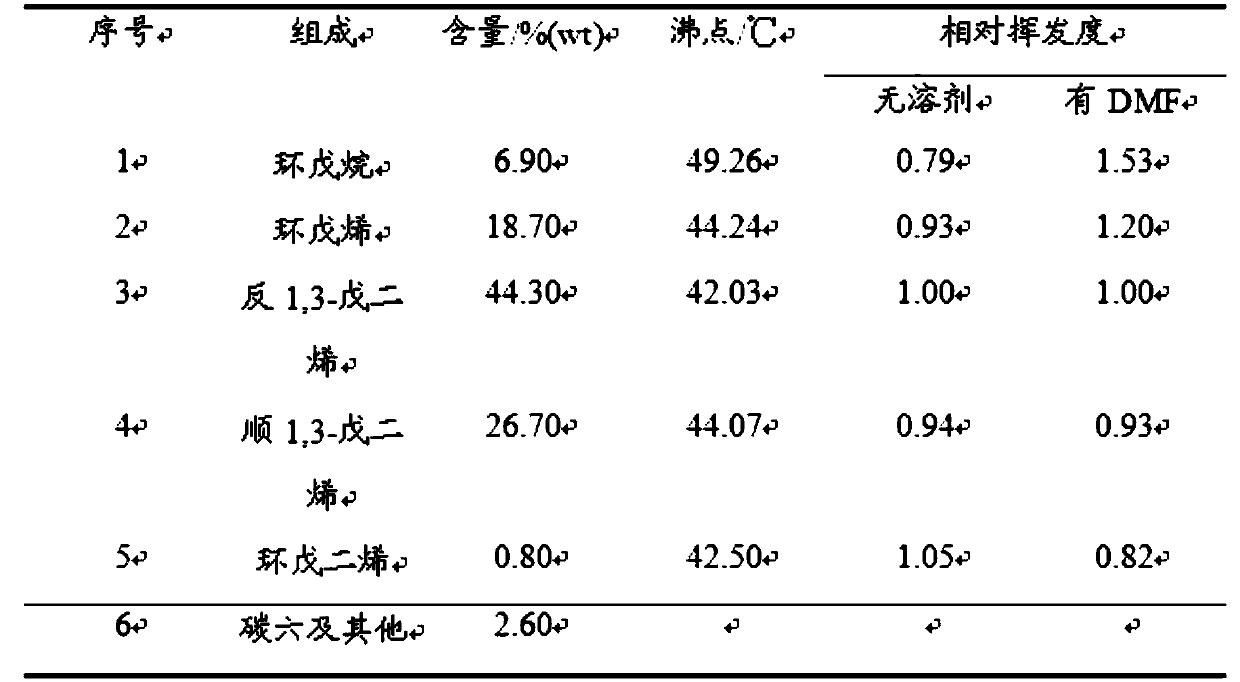

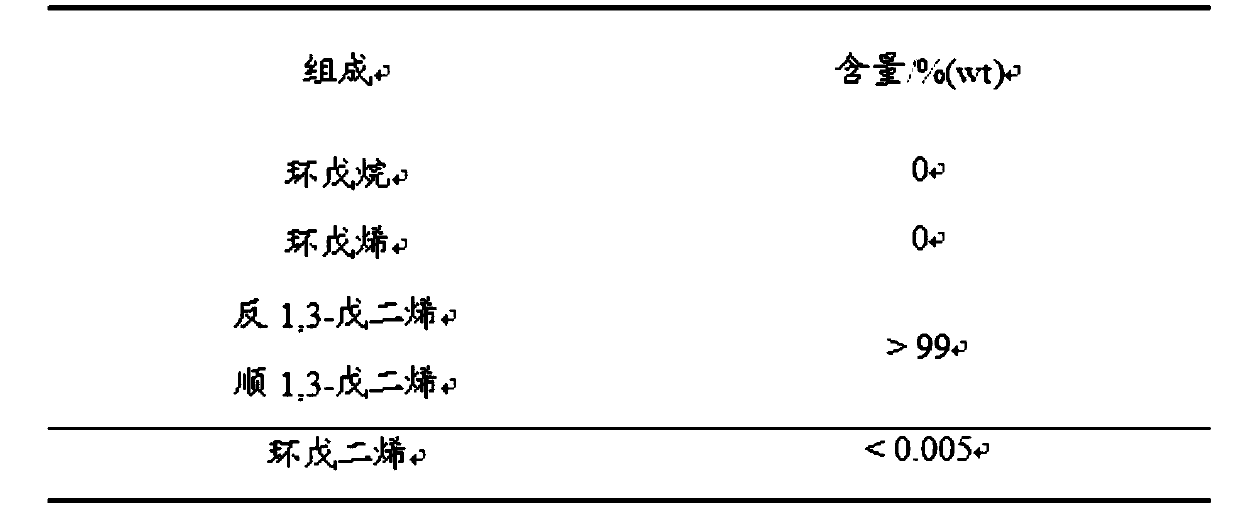

Method for preparing polymer-grade piperylene

ActiveCN105585412ASolve problems that are hard to separateReduce energy consumptionDistillation purification/separationCyclopenteneExtractive distillation

The invention discloses a method for preparing polymer-grade piperylene. The method mainly comprises the following processes: 1) crude piperylene obtained by separation of a C5 fraction which is a byproduct of petroleum cracking for preparation of ethylene enters a first extractive distillation column to undergo extractive distillation, mixed materials rich in cyclopentene and cyclopentane are obtained at the top of the column, and materials rich in piperylene and an extraction agent are obtained at the bottom of the column; 2) the materials at the bottom of the column in the step 1) enter a first stripping column to remove a solvent, an extraction agent is obtained at the bottom of the column, and the extraction agent returns back to a first extraction column for recycling; 3) materials at the top of the column in the step 2) enter a dipolymer reactor to undergo a polymerization reaction, a dimerization reaction liquid enters a heavies removing column to undergo refining, heavy components such as dicyclopentadiene and the like are obtained at the bottom of the column, and materials rich in piperylene are obtained at the top of the column; 4) the materials at the top of the column in the step 3) enter a second extractive distillation column to undergo secondary extractive distillation, and a polymer-grade piperylene product is obtained at the top of the column; and 5) the materials at the bottom of the column in the step 4) enter a secondary stripping column to recover a solvent, an extraction agent is obtained at the bottom of the column, and the extraction agent returns back to a secondary extraction column for recycling.

Owner:CHINA PETROLEUM & CHEM CORP +1

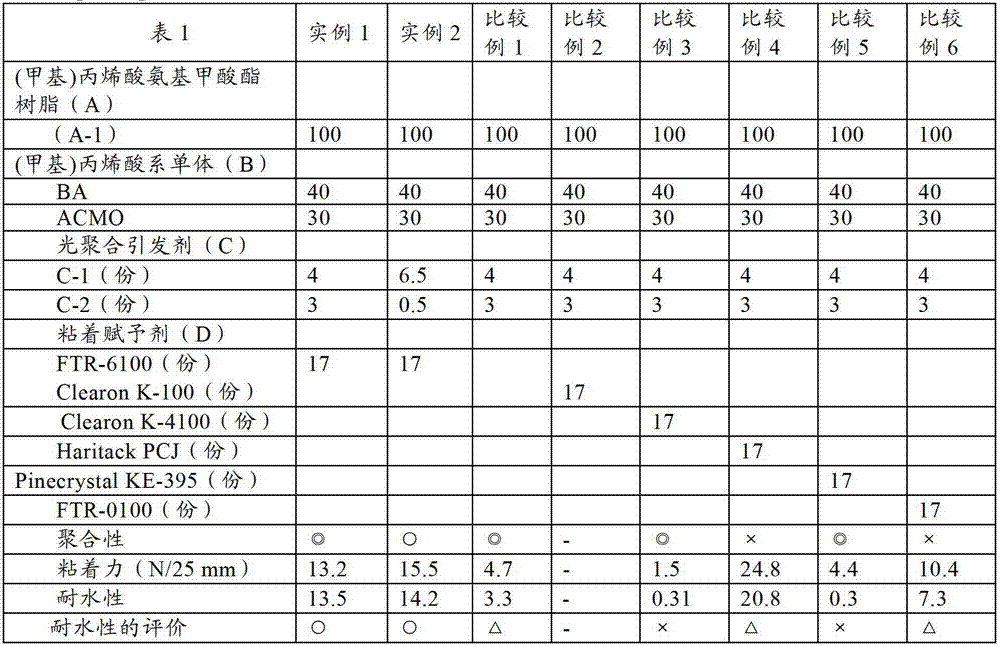

Resin composition for ultraviolet curable adhesive and adhesive

ActiveCN102994036APromote aggregationEasy to manufacturePolyureas/polyurethane adhesivesPiperyleneChemistry

The invention provides a resin composition for an ultraviolet curable adhesive and an adhesive. The resin composition contains a urethane(meth)acrylate resin (A) which is obtained by reaction of a polyol (a), a polyisocyanate (b) and a (meth)acrylic compound (c) containing a hydroxyl group, a (meth)acrylic monomer (B), a photopolymerization initiator (C) and an adhesion imparting agent (D), wherein the adhesion imparting agent (D) is obtained by reaction of more than one unsaturated aromatic compound (d-1) selected the group consisting of a styrene, an alpha-methyl styrene, a vinyl toluene, an indene and an isopropenyl toluene, and more than one unsaturated aliphatic compound (d-2) selected from a group consisting of an isobutylene, an butadiene, an isoprene, an piperylene and an dicyclopentadiene.

Owner:DIC CORP

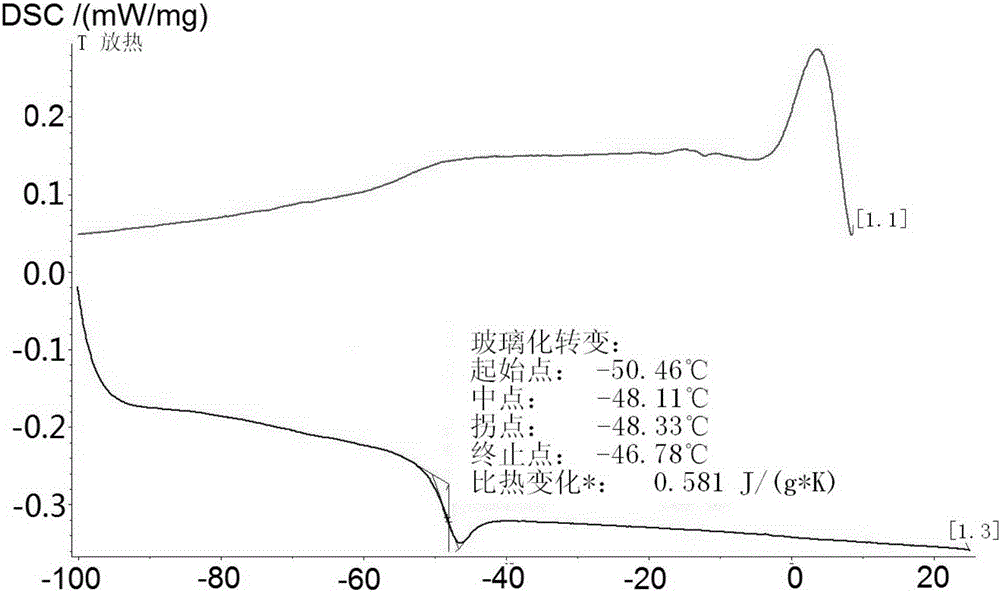

Preparation method of butadiene/1,3-pentadiene random copolymer

InactiveCN106478881AWide molecular weight rangeAdjustable microstructureReaction rateReaction temperature

The invention belongs to the technical field of polymer synthesis, and specifically discloses a preparation method of a butadiene / 1,3-pentadiene random copolymer. According to the preparation method, in the absence of water and oxygen, an organic alkali metal initiator is adopted, a randomization additive is added, butadiene and 1,3-pentadiene carry out copolymerization reactions to obtain the butadiene / 1,3-pentadiene random copolymer, the mass ratio of butadiene to 1,3-pentadiene is 1:9-6:4, the reaction temperature is 0 to 100 DEG C, and the reaction time is 1 to 24 hours. The results show that the prepared butadiene / 1,3-pentadiene random copolymer has the advantages of controllable molecular weight, adjustable molecular weight distribution, high randomization degree, controllable microscopic polymer structure, low glass-transition temperature (Tg=-70 to -40 DEG C), quick reaction rate, and high monomer conversion rate (100%).

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com