Separation method of piperylene

A separation method and technology of piperylene, applied in the direction of distillation purification/separation, organic chemistry, etc., can solve the problems of low purity of piperylene products, high equipment investment, and large operating costs, so as to improve product purity and reduce Theoretical plate number and reflux ratio, the effect of reducing equipment investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

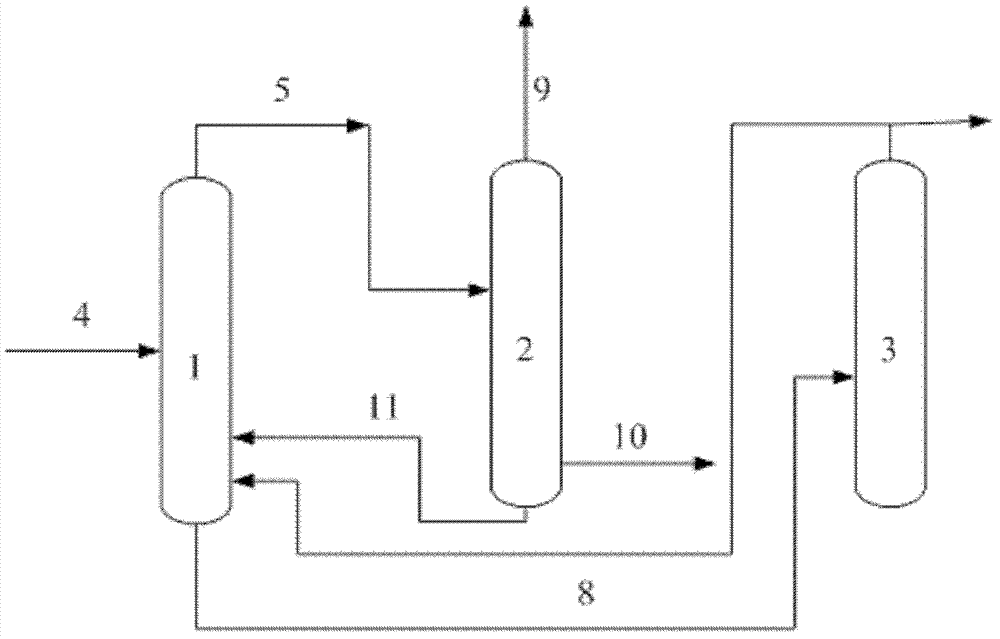

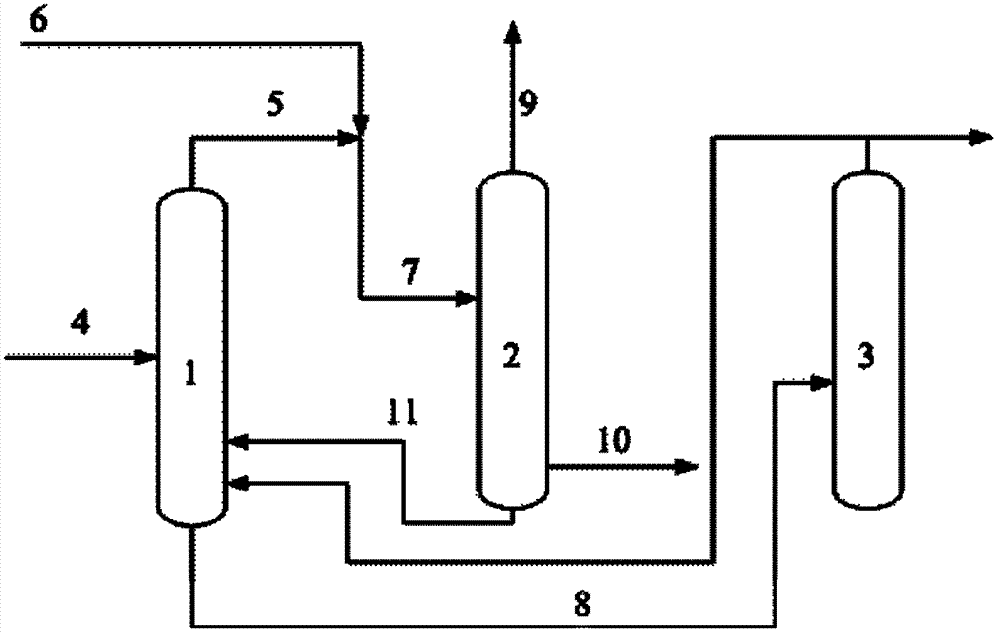

[0033] like figure 2 As shown, the raw material 4 is taken from the pre-de-weighting tower and the de-weighting tower of the C5 separation device of a certain factory, and it is introduced into the decarbonization five-column. The main composition is: n-pentane 0.7 %, cis, trans-2-pentene 1.2%, isoprene 0.7%, cyclopentene 8.7%, piperylene 32.8%, cyclopentadiene 2.9%, dicyclopentadiene 36.3%, carbon six 14.5% %, polymer 2.2%, the flow rate is 13000kg / h. The material is introduced into the five decarburization tower 1, the number of five decarburization towers is 42, feed from 24 plates, the pressure at the top of the tower is 0.12MPa, the temperature at the top of the tower is 47°C, the pressure at the bottom of the tower is 0.14MPa, the temperature at the bottom of the tower is 106°C, The reflux ratio is 1.8. The top extraction 5 is mixed with the azeotropic stream 6, and the flow ratio of the stream 5 and the stream 6 is 0.1, and is introduced into the piperylene column 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com