Method for separating 1-butylene

A technology of butene and absorption tower, applied in the field of separating 1-butene, can solve the problems of high energy consumption and high cost, and achieve the effects of less investment in equipment, low production cost, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

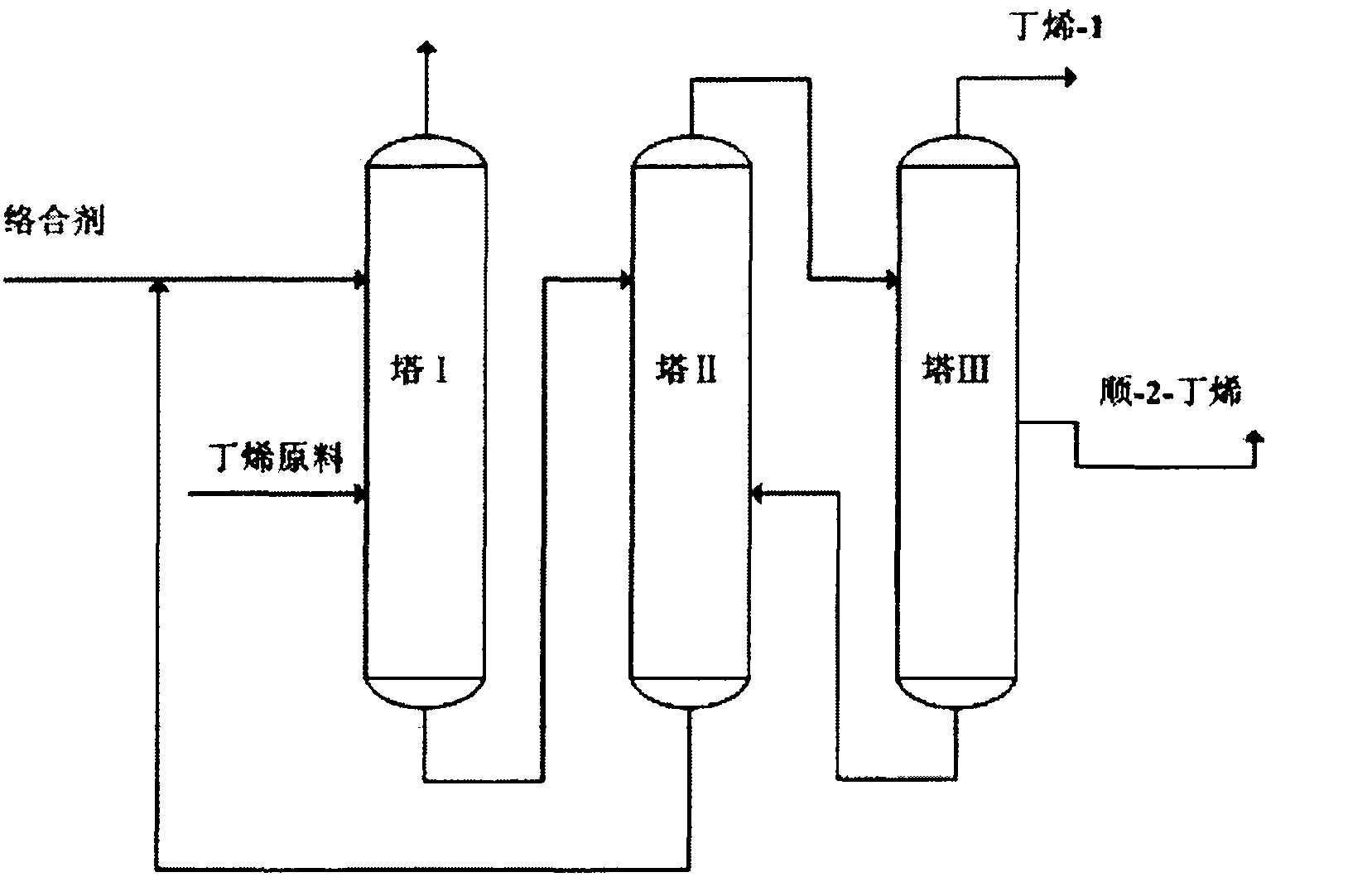

Method used

Image

Examples

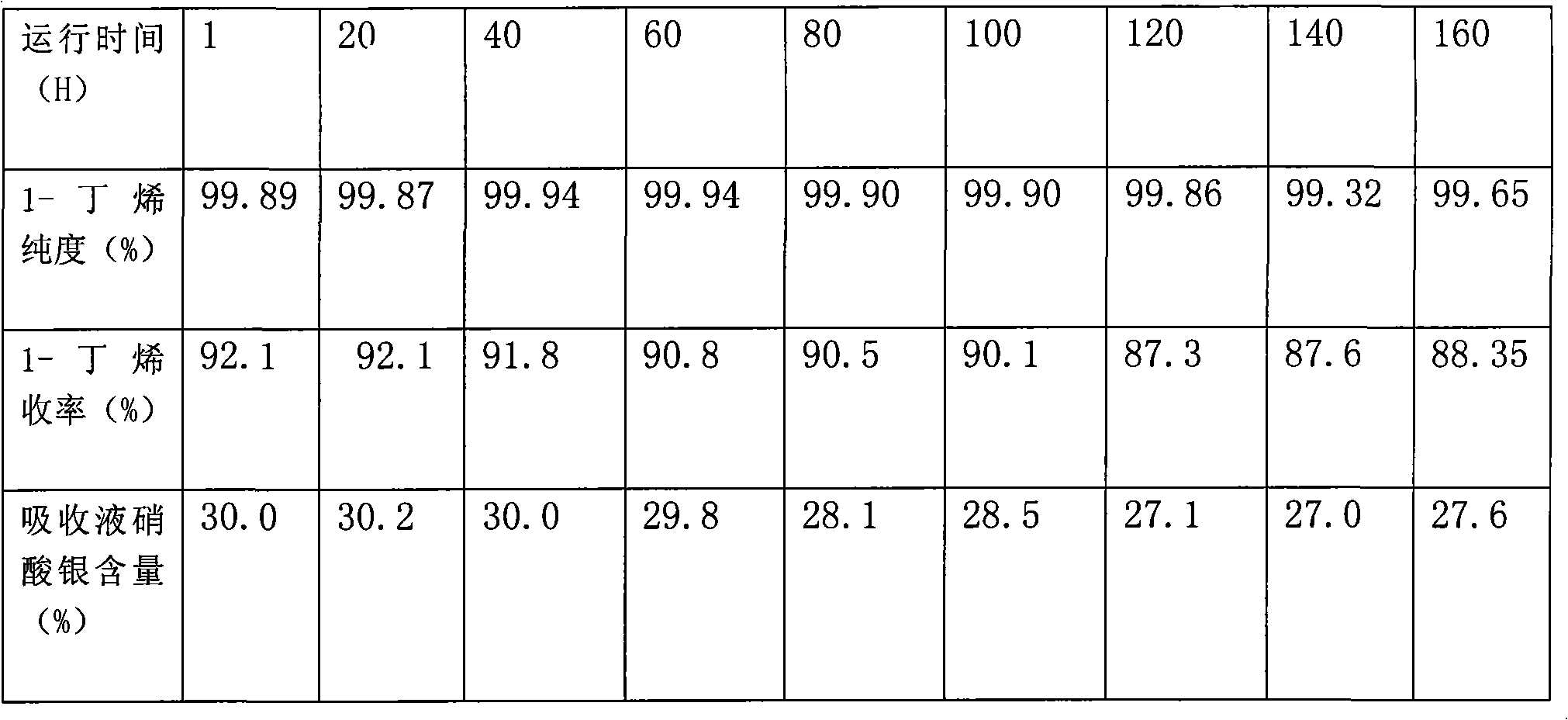

Embodiment 1

[0044] Feed gas (see Table 1 for components and their content) enters the stainless steel packed tower with a tower diameter of 20mm and 29 trays from the bottom of the tower at a flow rate of 1429ml / hr. The absorbing liquid is an aqueous solution of silver nitrate, silver nitrate solution The mass percent concentration is 30%, enters the absorption tower from the top of the tower at a flow rate of 50ml / hr, the temperature in the tower is 26°C, the pressure is 0.1MPa, the tail gas is released from the top of the tower, and the absorption liquid flows out from the tower kettle;

[0045] 60 g / hr of the absorption liquid flowing out from the absorption tower tank is introduced into the upper part of the extraction tank, and 110 g / hr of extractant n-hexane is introduced from the upper part of the extraction tank, the temperature of the extraction tower is 28 ° C, and the pressure is 0.1 MPa;

[0046] The gas analyzed from the extract liquid that flows out from the top of the extrac...

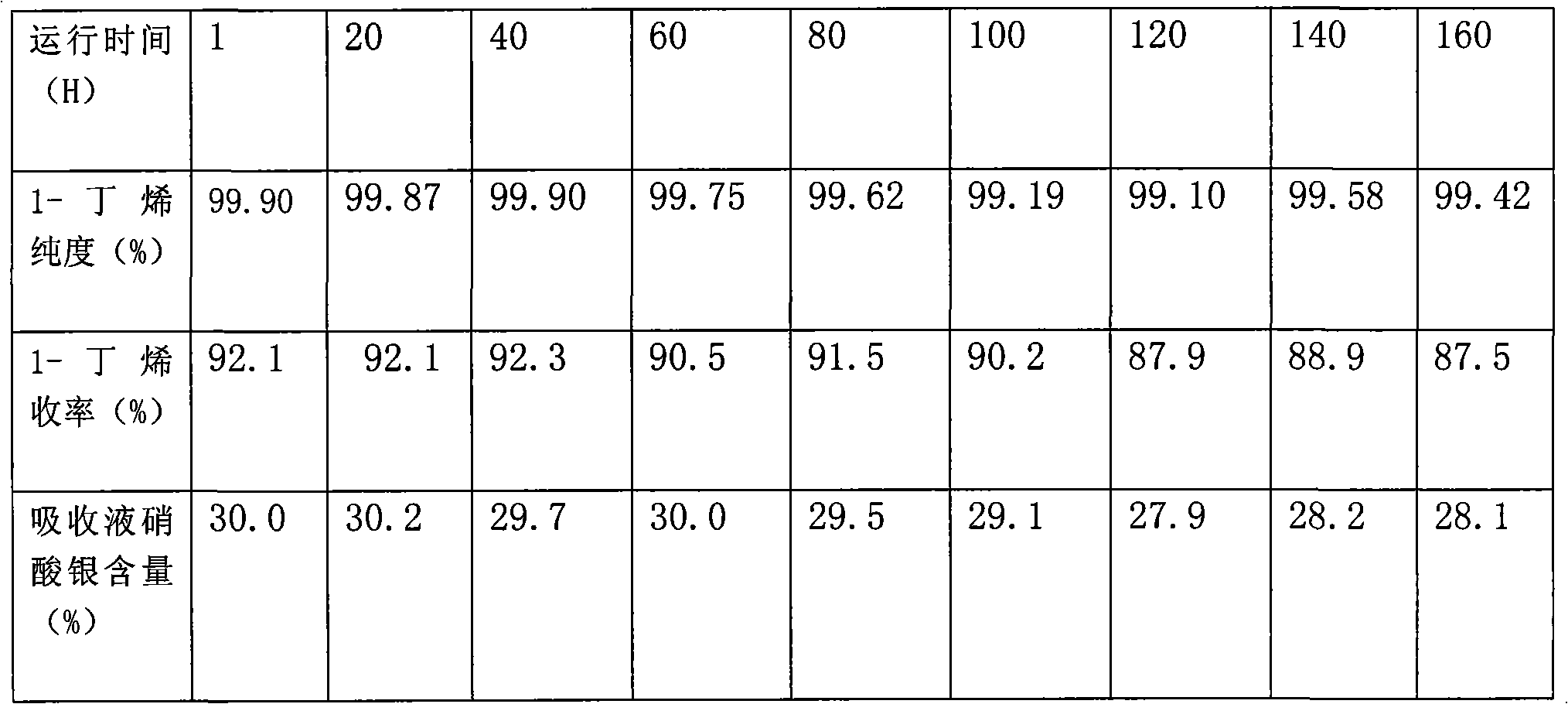

Embodiment 2

[0049] Feed gas (see Table 1 for components and their content) enters the stainless steel packed tower with a tower diameter of 20mm and 29 trays from the bottom of the tower at a flow rate of 1429ml / hr. The absorbing liquid is an aqueous solution of silver nitrate, silver nitrate solution The mass percent concentration is 30%, enters the absorption tower from the top of the tower at a flow rate of 50ml / hr, the temperature in the tower is 26°C, the pressure is 0.1MPa, the tail gas is released from the top of the tower, and the absorption liquid flows out from the tower kettle;

[0050] 60 g / hr of the absorption liquid flowing out from the absorption tower tank is introduced into the upper part of the extraction tank, and 60 g / hr of extractant n-heptane is introduced from the upper part of the extraction tank, the temperature of the extraction tower is 28 ° C, and the pressure is 0.1 MPa;

[0051] The gas analyzed from the extract liquid that flows out from the top of the extrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com