Patents

Literature

821 results about "Azeotropic distillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, azeotropic distillation is any of a range of techniques used to break an azeotrope in distillation. In chemical engineering, azeotropic distillation usually refers to the specific technique of adding another component to generate a new, lower-boiling azeotrope that is heterogeneous (e.g. producing two, immiscible liquid phases), such as the example below with the addition of benzene to water and ethanol. This practice of adding an entrainer which forms a separate phase is a specific sub-set of (industrial) azeotropic distillation methods, or combination thereof. In some senses, adding an entrainer is similar to extractive distillation.

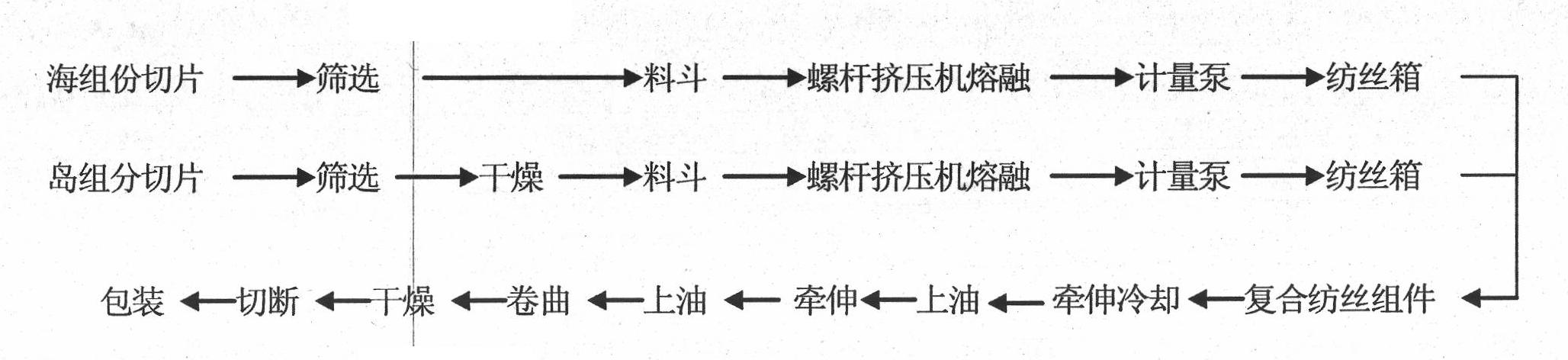

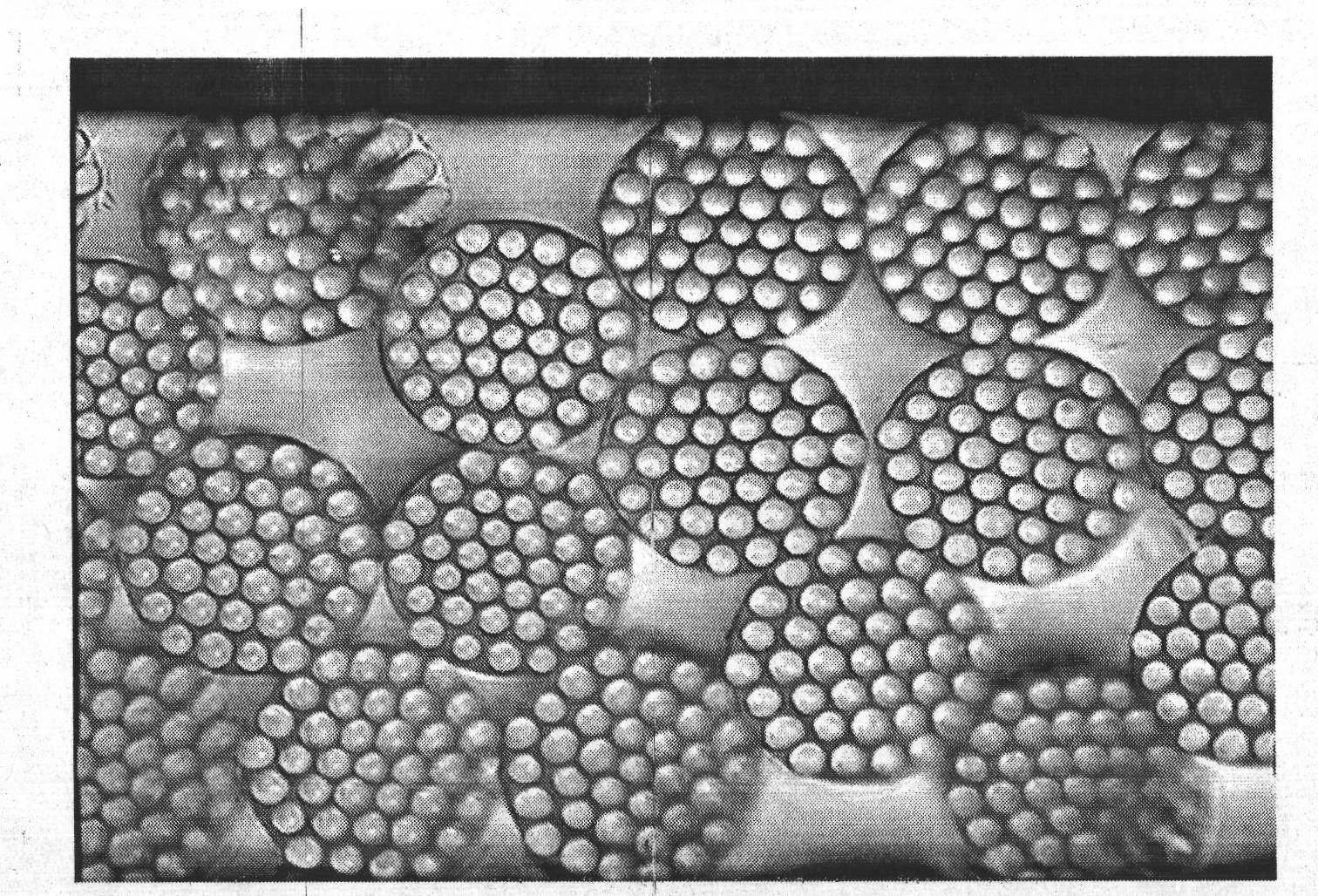

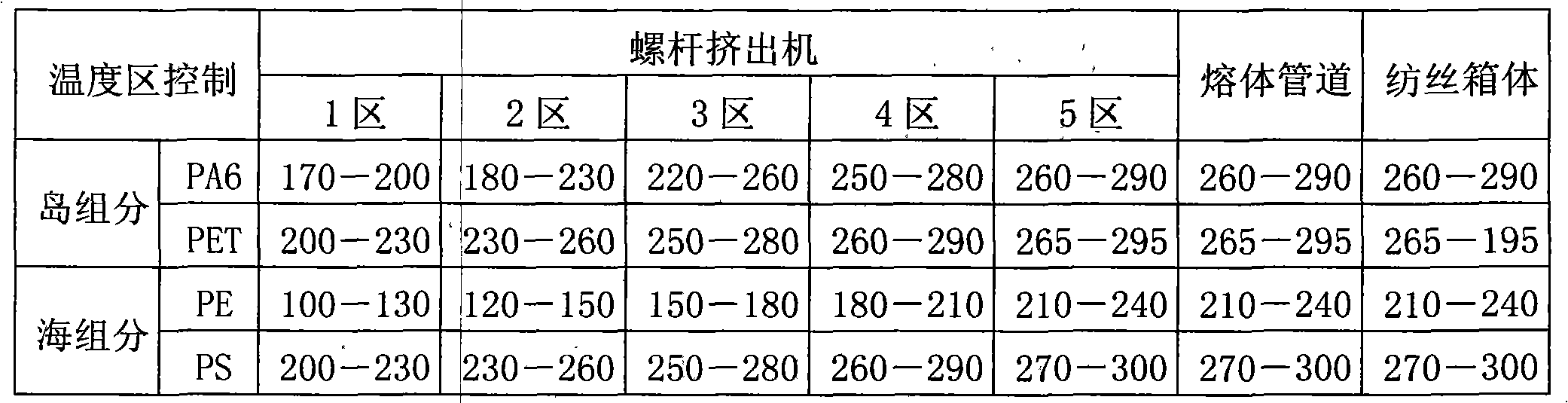

Figured sea-island super-fine fiber, and preparation method thereof and synthetic leather preparing process method using same

ActiveCN102071495AGood mechanical propertiesImprove dyeing effectNew-spun product collectionFilament/thread formingPhospholambanPolyolefin

The invention relates to a figured sea-island super-fine fiber, and a preparation method and a synthetic leather preparing process method using the same, which belong to the technical field of leather and leather manufacture methods. The figured sea-island super-fine fiber is characterized in that the weight percentage ratio of island components of the fiber to sea components of the fiber is 50 percent to 80 percent / 50 percent to 20 percent, wherein the island components are polyamide (PA) 6 or polyethylene terephthalate (PET), and the sea components are polyolefins or phospholamban (PLB) or polyvinyl alcohol (PVOH). The preparation method comprises the steps of slice drying and melting, composite spinning, oiling and falling into a barrel, drafting curling and drying cutting. The synthetic leather preparing method comprises the following steps that: 1. the components are sequentially prepared into a single-layer fiber net, a composite layer fiber net, needle-punched non-woven cloth and needle-punched non-weaving cloth; 2.soakage and coagulation are sequentially carried out on the non-weaving cloth, the non-weaving cloth is washed, so that a synthetic leather impregnated substrate is formed, repeated soaking squeezing, azeotropic distillation and drying are sequentially carried out, so the synthetic leather is obtained. The synthetic leather produced by the invention has the advantages of excellent mechanical performance, excellent dyeing performance, excellent dyefastness, better production controllability, economy and environment protection. Compared with natural leather and products of the natural leather, the synthetic leather has the advantages that use performance such as durability, weatherability, antibacterium mothproofing, dyefastness and the like of products is much superior to that of the natural leather and the products of the natural leather.

Owner:烟台万华超纤股份有限公司

Production method of biodiesel oil using high acid ralue animal and vegetable grease

InactiveCN1556174AAchieve cycleAchieve recyclingBiofuelsLiquid hydrocarbon mixture productionOil and greaseAlcohol

A process for preparing the biological diesel oil from the animal fat or vegetative oil with high acid number includes esterifying by glycerine under existance of strong acid catalyst, distilling in azeotropic solvent for removing water, mixing with methanol, transesterifying reacting to remove glycerine, water washing, and low-temp treating for removing high-smelting-point substances to obtain methyl ester of fatty acid, which is just the biological diesel oil.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

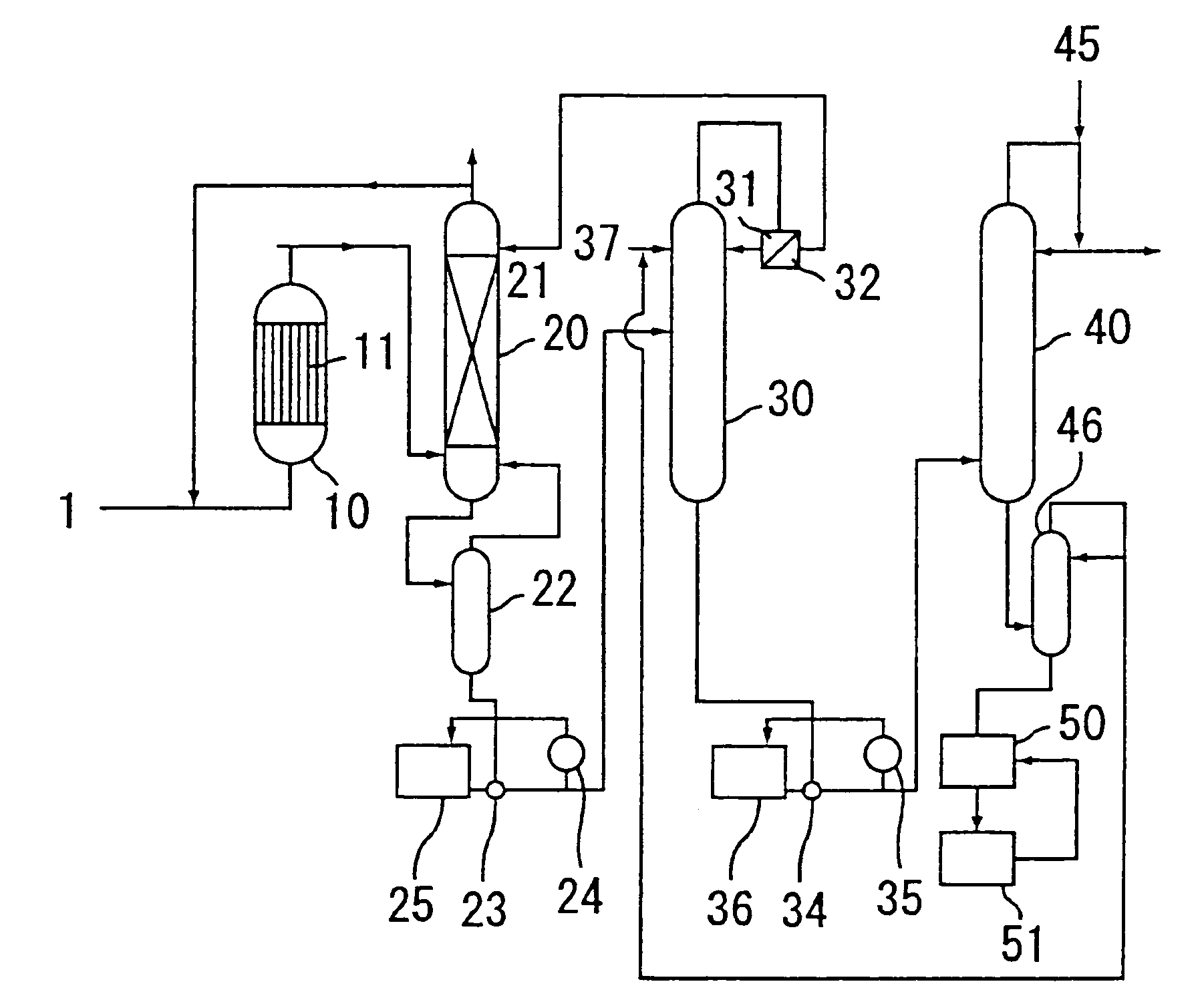

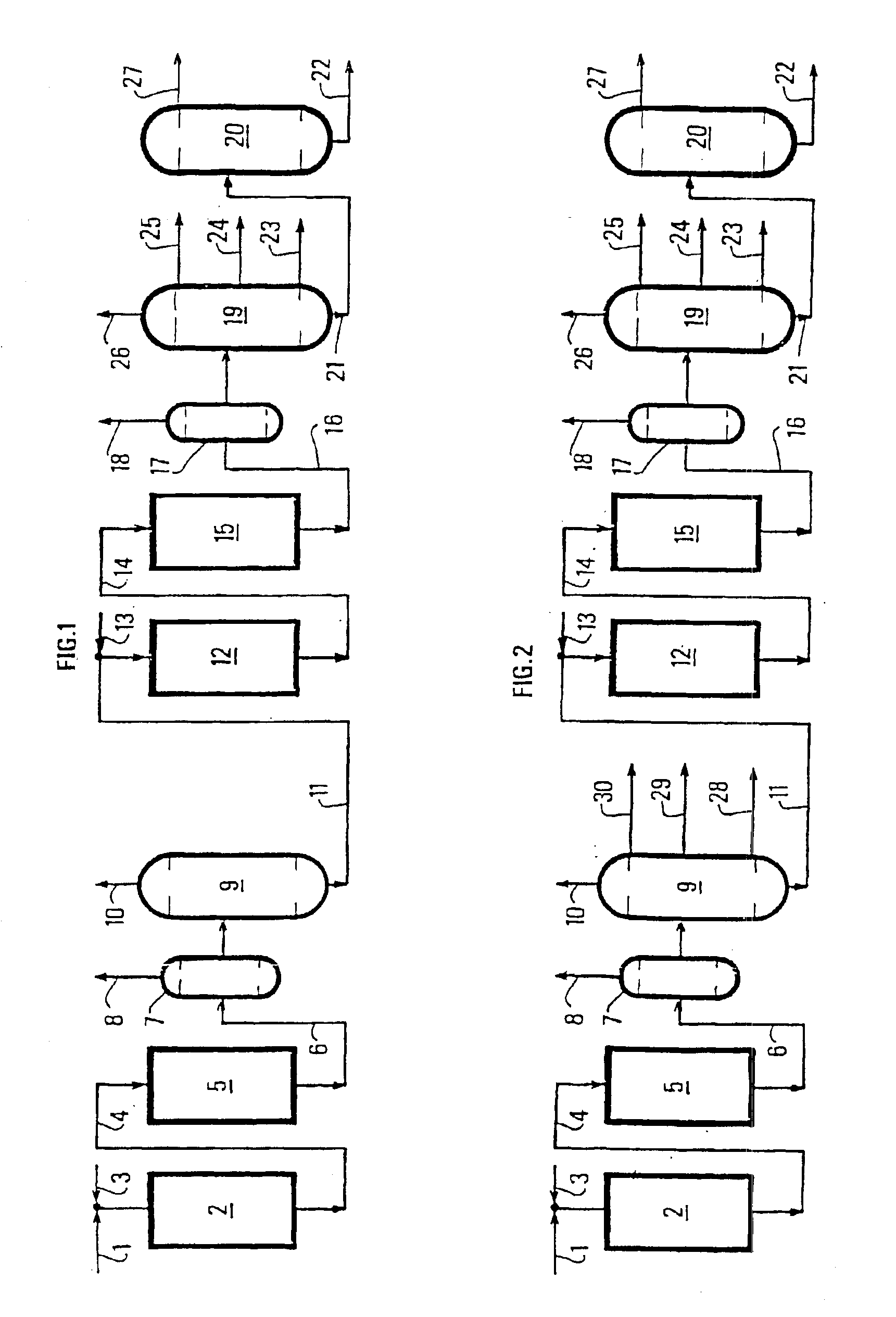

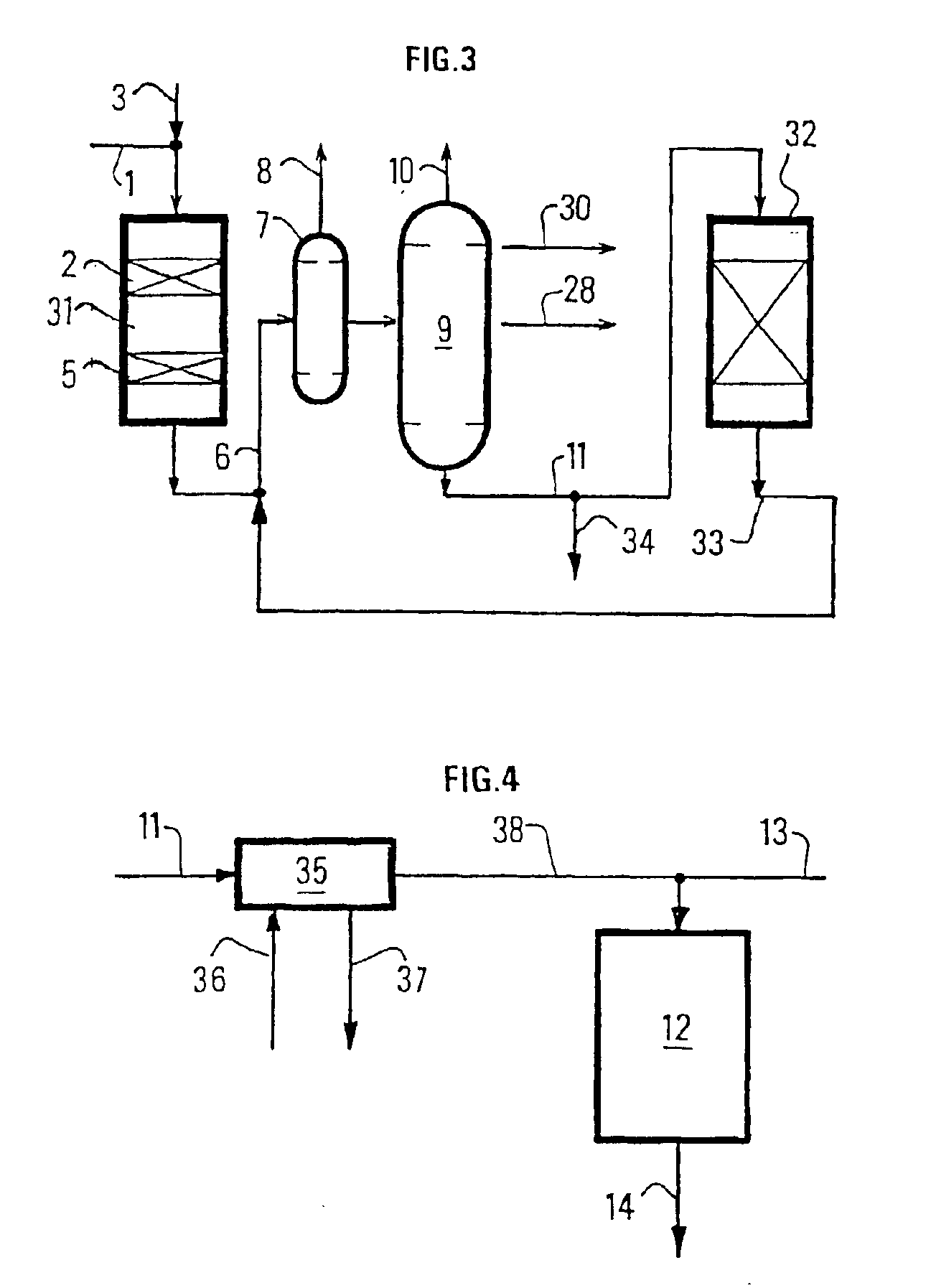

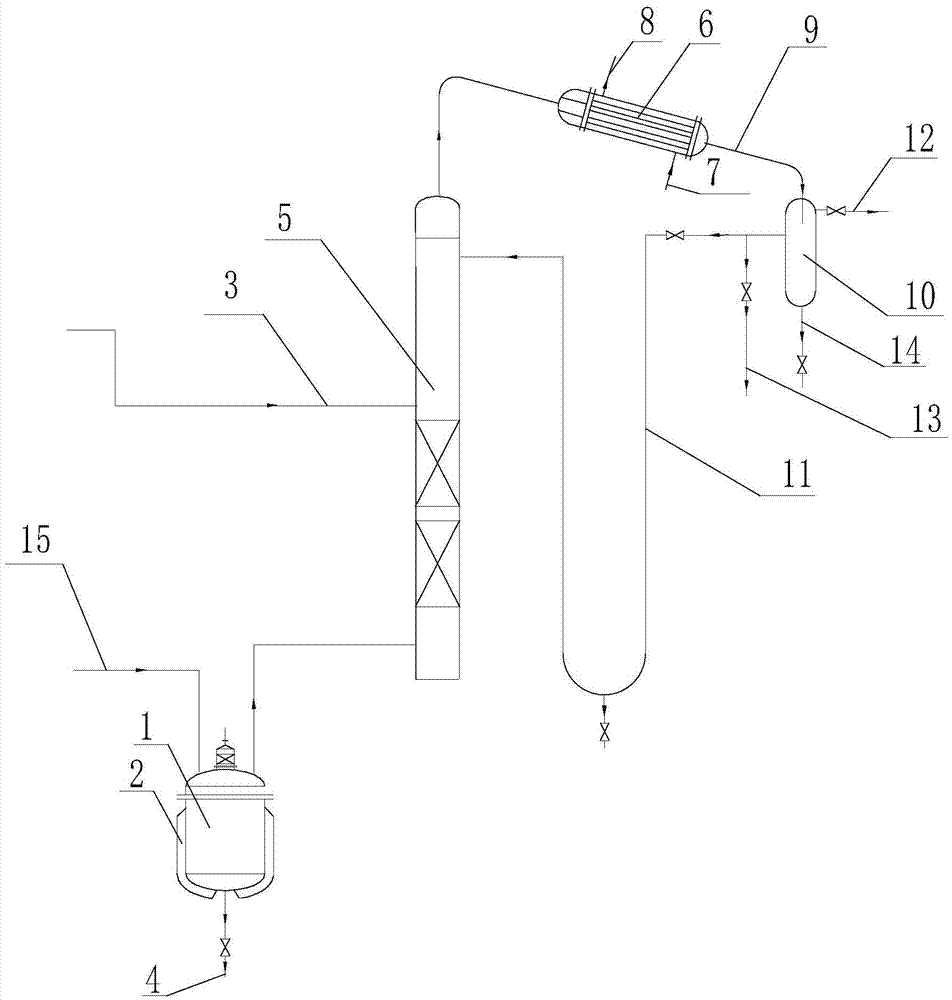

Process for producing aliphatic carboxylic acid

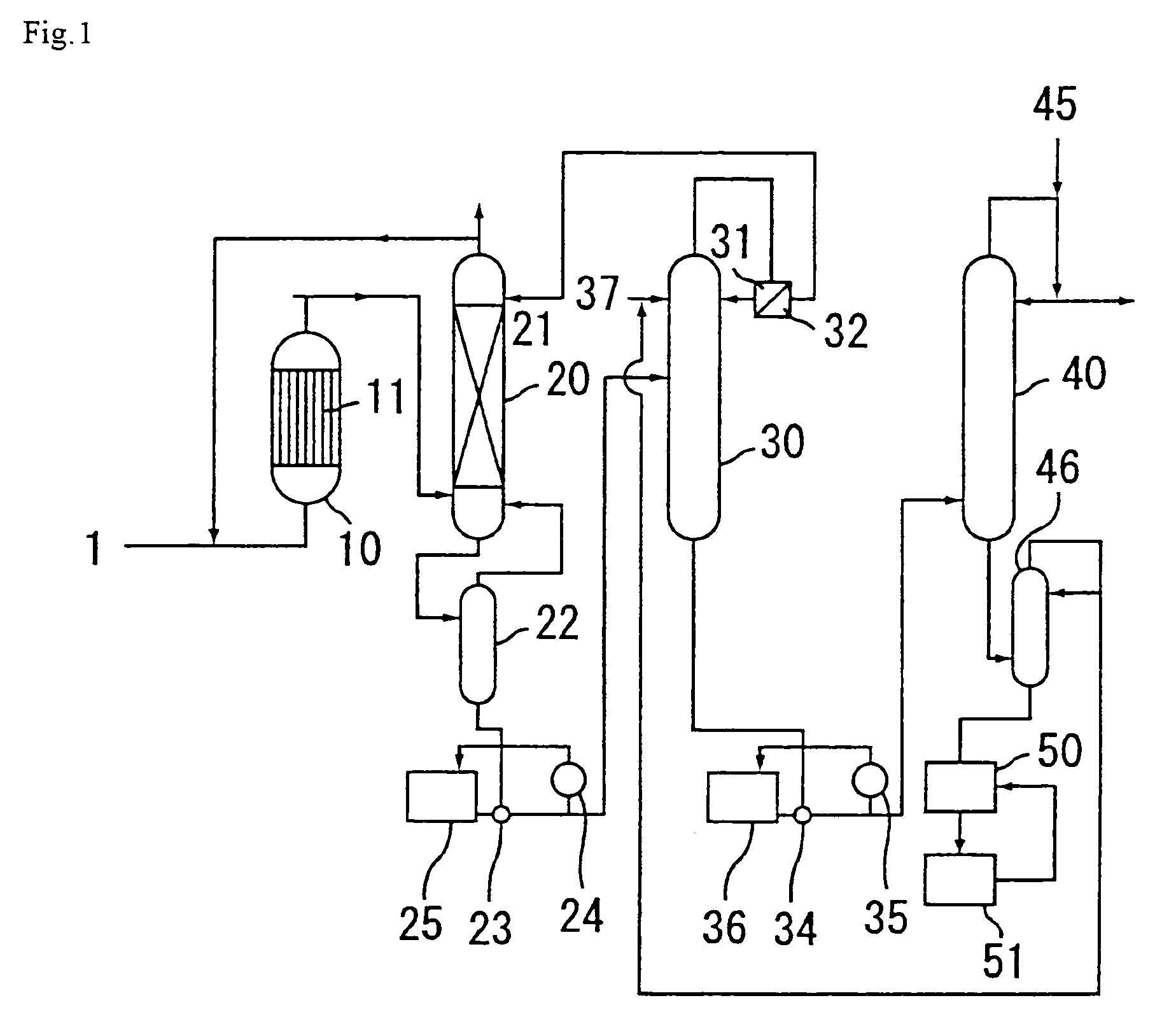

InactiveUS7319168B2Guaranteed uptimeShorten the timeOrganic compound preparationFractional distillationFractionating columnCarboxylic acid

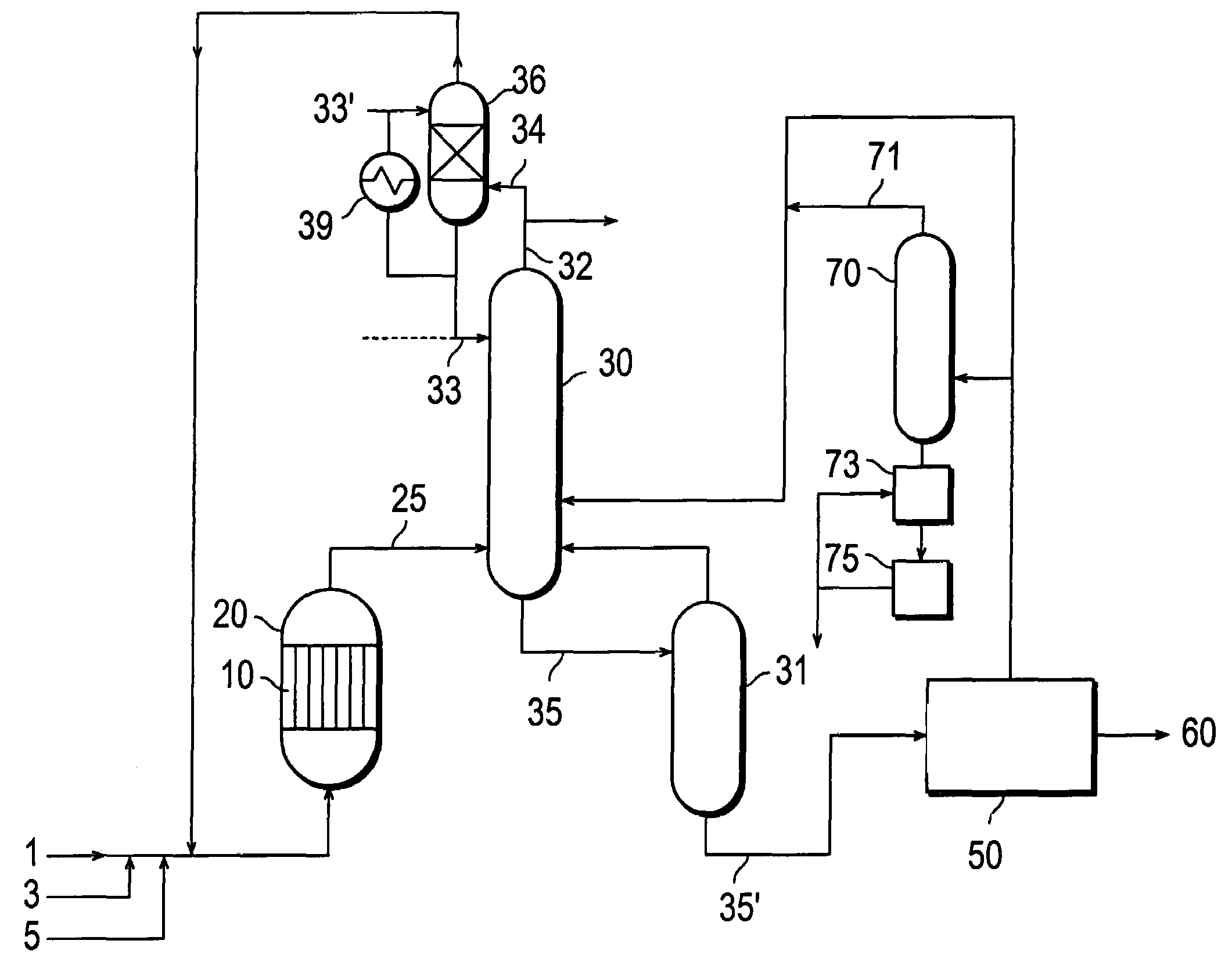

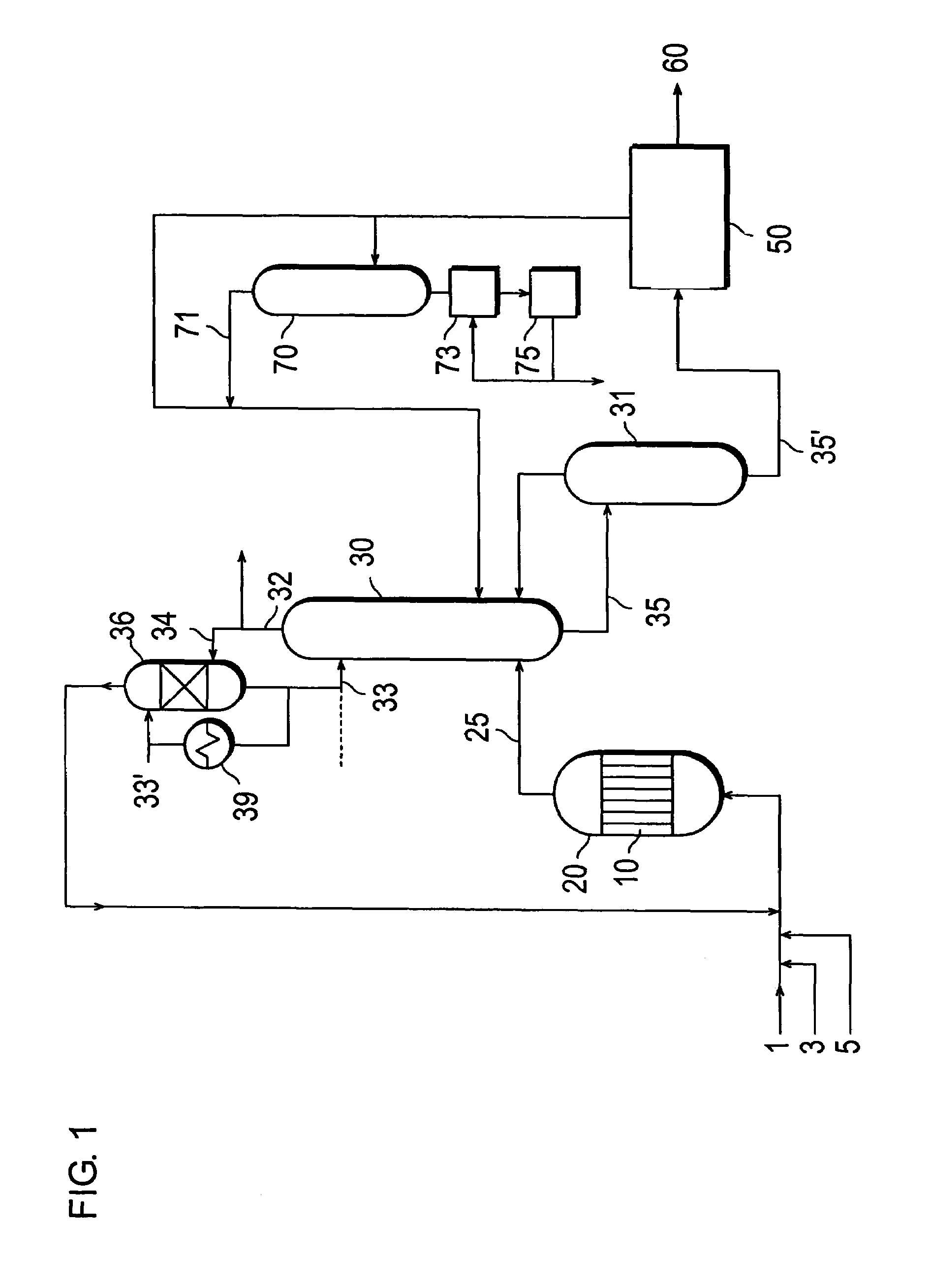

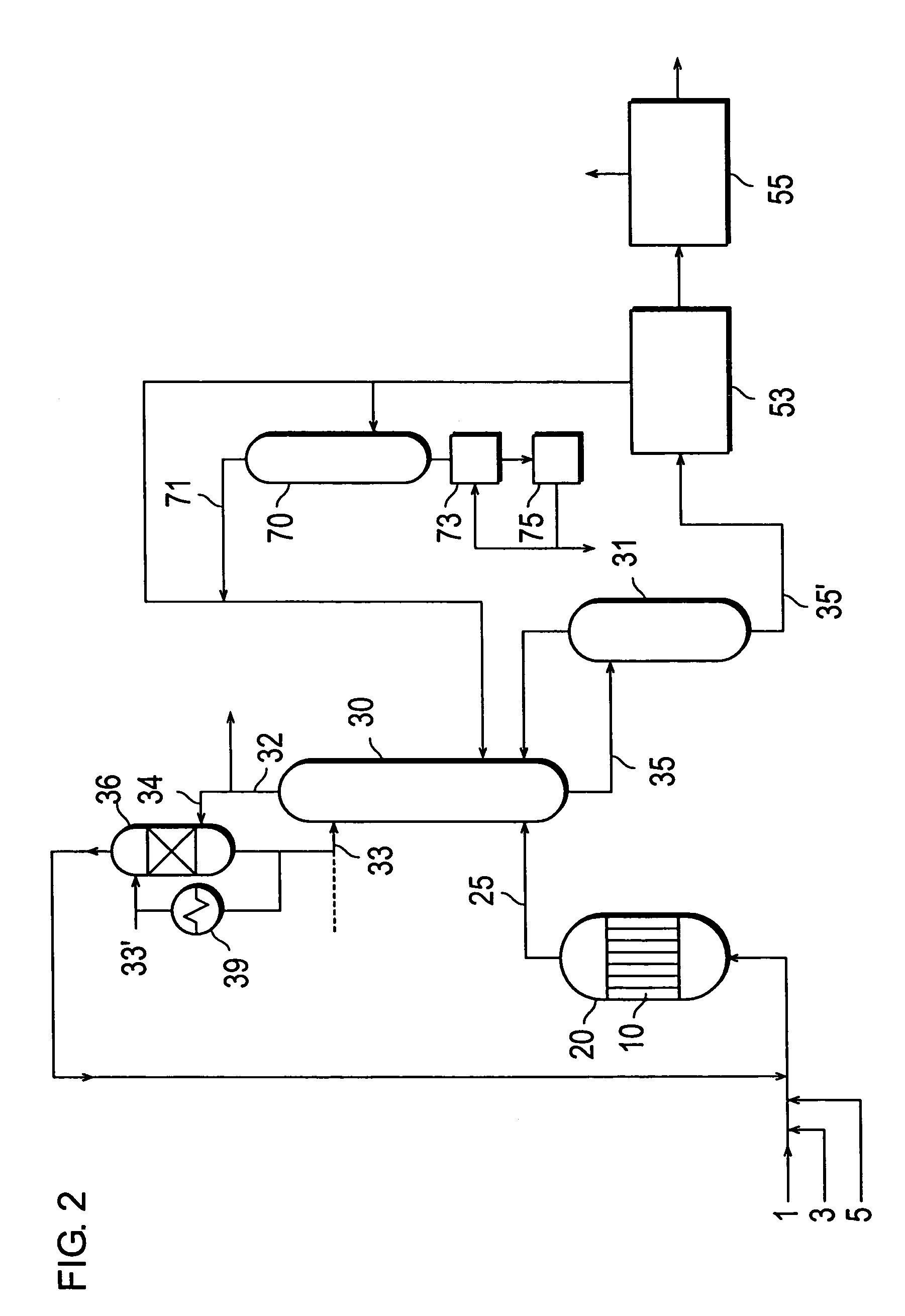

It is an object of the present invention to provide a process for producing aliphatic carboxylic acid, which can stabilize operation of a distillation column upon production of aliphatic carboxylic acid by reducing a water content in an aqueous aliphatic carboxylic acid solution by a distillation column, and can shorten a time during the non-steady state such as at starting up of distillation column operation. The present invention is directed to a process for producing aliphatic carboxylic acid, which comprises an azeotropic distillation step of supplying an aqueous aliphatic carboxylic acid solution and an azeotropic solvent to an azeotropic distillation column to perform distillation, separating an azeotrope containing the azeotropic solvent and water as a distillate, and recovering aliphatic carboxylic acid with a reduced water content as bottom liquid, characterized in that a target value of an amount of the azeotropic solvent to be supplied is set depending on an amount of water in the aqueous aliphatic carboxylic acid solution supplied to the azeotropic distillation column, and the amount of the azeotropic solvent to be supplied is controlled at the target value.

Owner:NIPPON SHOKUBAI CO LTD

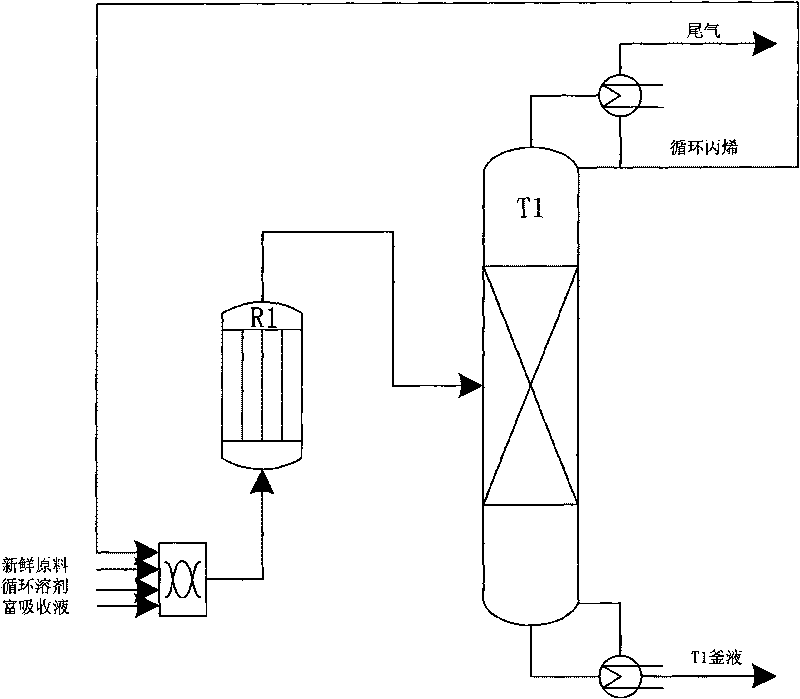

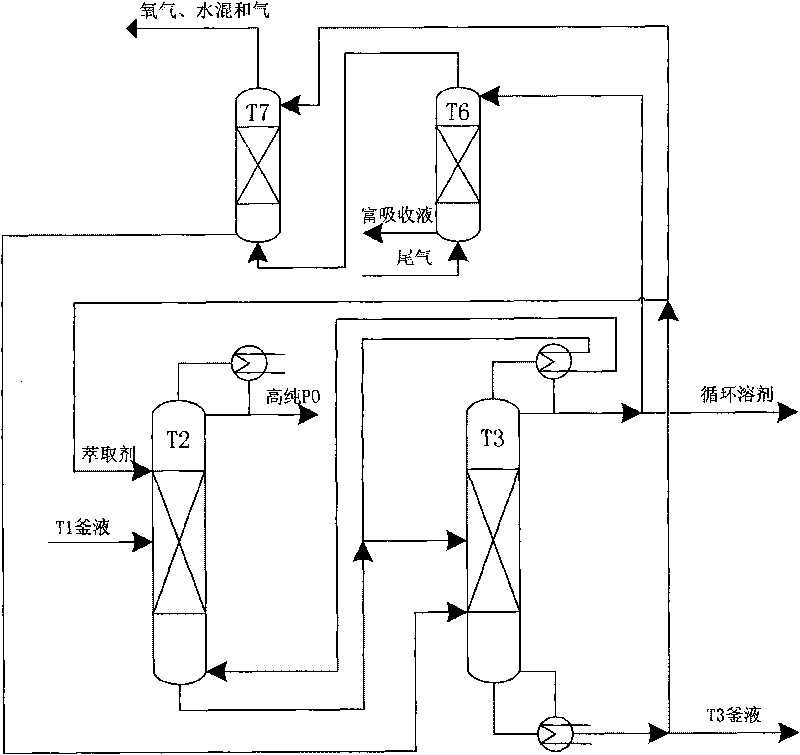

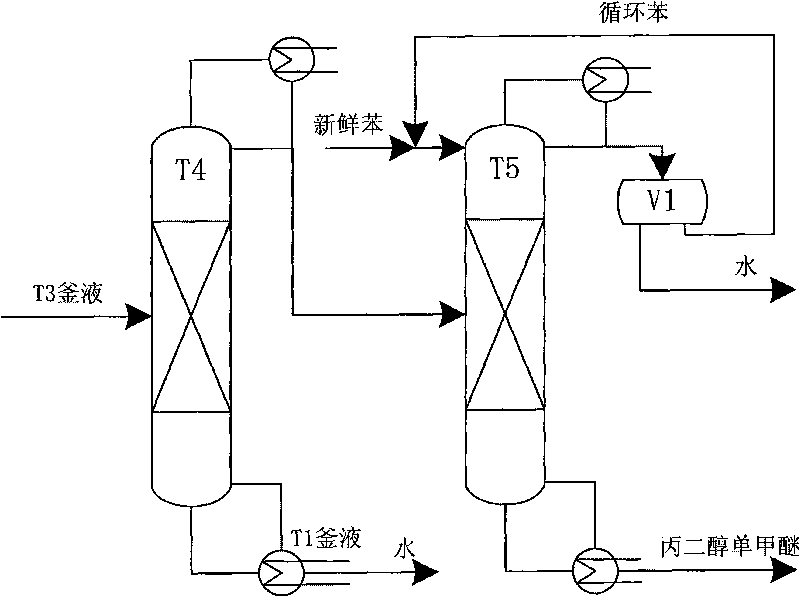

Energy-saving and emission-reducing technique for producing propane epoxide by using hydrogen peroxide epoxidation propylene

InactiveCN101693703ASuitable for industrial productionEther separation/purificationChemical industryThermal energyExtractive distillation

The invention relates to an energy-saving and emission-reducing technique for producing propane epoxide by using hydrogen peroxide epoxidation propylene, belonging to the field of petrochemical technology. The technique comprises a reaction part, a separation part and a tail gas treatment part, and is characterized in that propylene and hydrogen peroxide have an epoxidation reaction through a Ti-Si molecular sieve at medium pressure and low temperature; the propylene and solvent have higher recovery rate, the propane epoxide meeting the requirement of commercial-grade purity can be obtained by extractive distillation, and the joint product of propylene glycol monomethyl ether can be prepared by azeotropic distillation and purification; after part of tail gas is condensed and absorbed and the propylene is recovered, the tail gas reaches the standard and is discharged; extracting agent, absorbing agent and entrainer which are needed by the technique are in closed cycle in the process flow; and medium-pressure operation is adopted by a propylene tower to ensure water-cooling on the top of the tower, and thermal energy can be recovered by multiple-effect rectification and matching of streams. The technique has the effect and the advantage that the new energy-saving and environment-friendly technique for producing the propane epoxide can generate remarkable economic and social benefits.

Owner:DALIAN UNIV OF TECH

Flexible method for producing oil bases with a ZSM-48 zeolite

InactiveUS6884339B2Reduce contentImproves UV stabilityTreatment with plural serial cracking stages onlyCoke ovensBase oilAzeotropic distillation

A process for the production of very high quality base oils optionally with simultaneous production of high quality middle distillates comprises the stages for hydrotreatment, preferably hydrocracking, on Y or beta zeolite, and atmospheric distillation. The effluent is subjected to a catalytic dewaxing on the ZSM-48 catalyst. The process then comprises a hydrofinishing stage for hydrogenating the aromatic compounds, preferably on a catalyst that comprises at least one noble metal of group VIII, chlorine and fluorine, and the stages of atmospheric and vacuum distillation. The hydrofinishing stage is conducted at a temperature lower by 20-200° C. than the catalytic dewaxing stage.

Owner:INST FR DU PETROLE

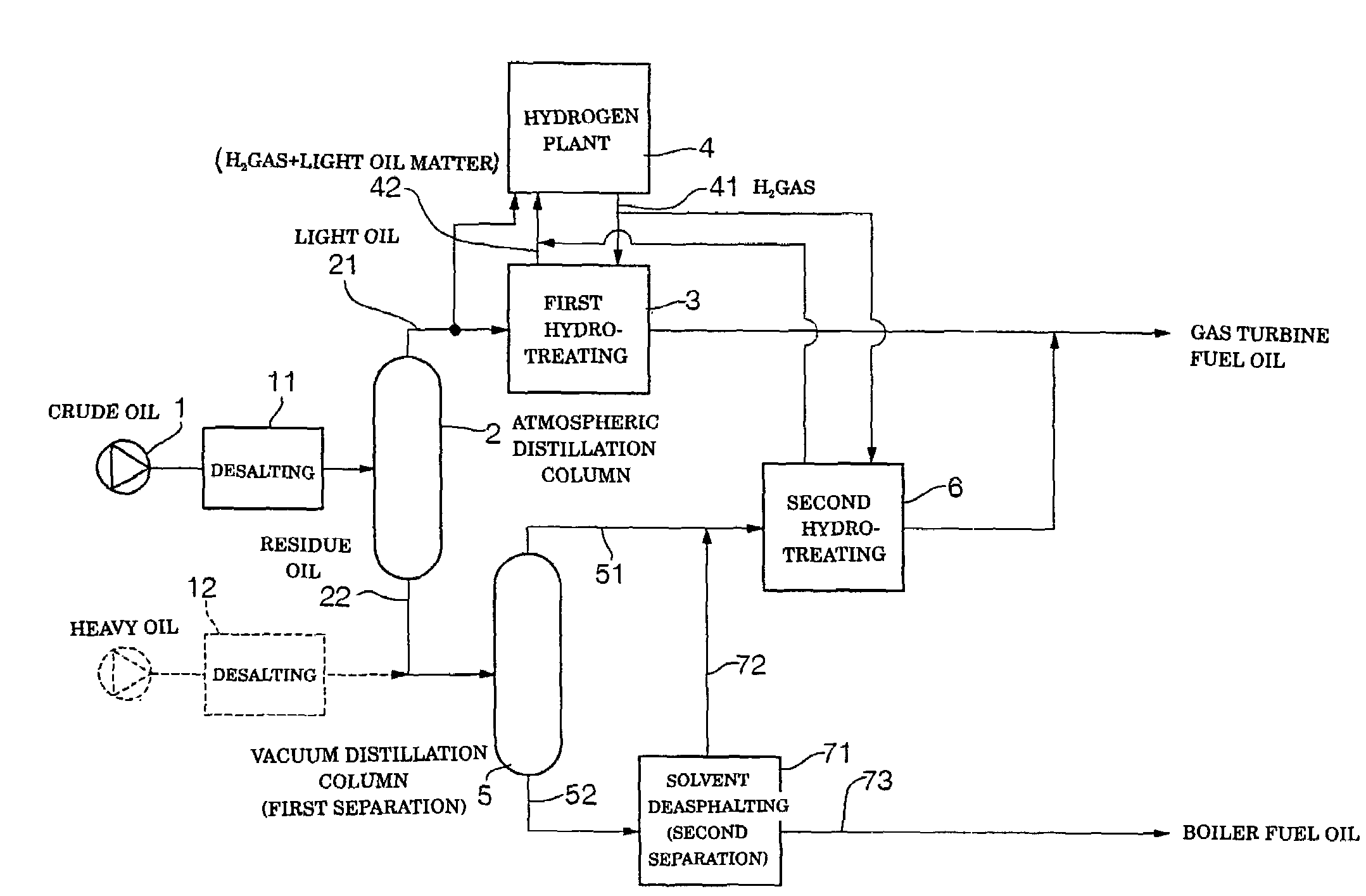

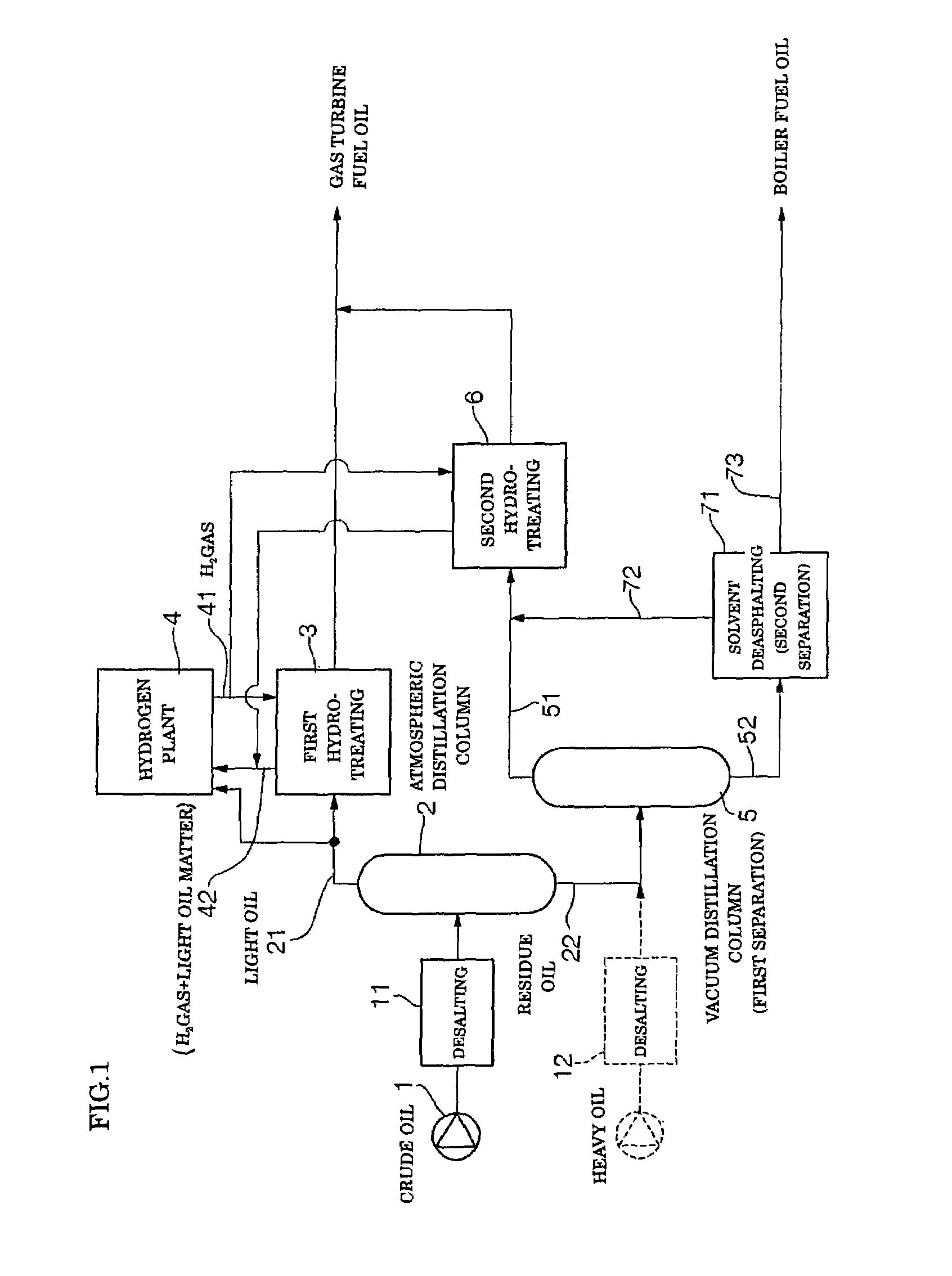

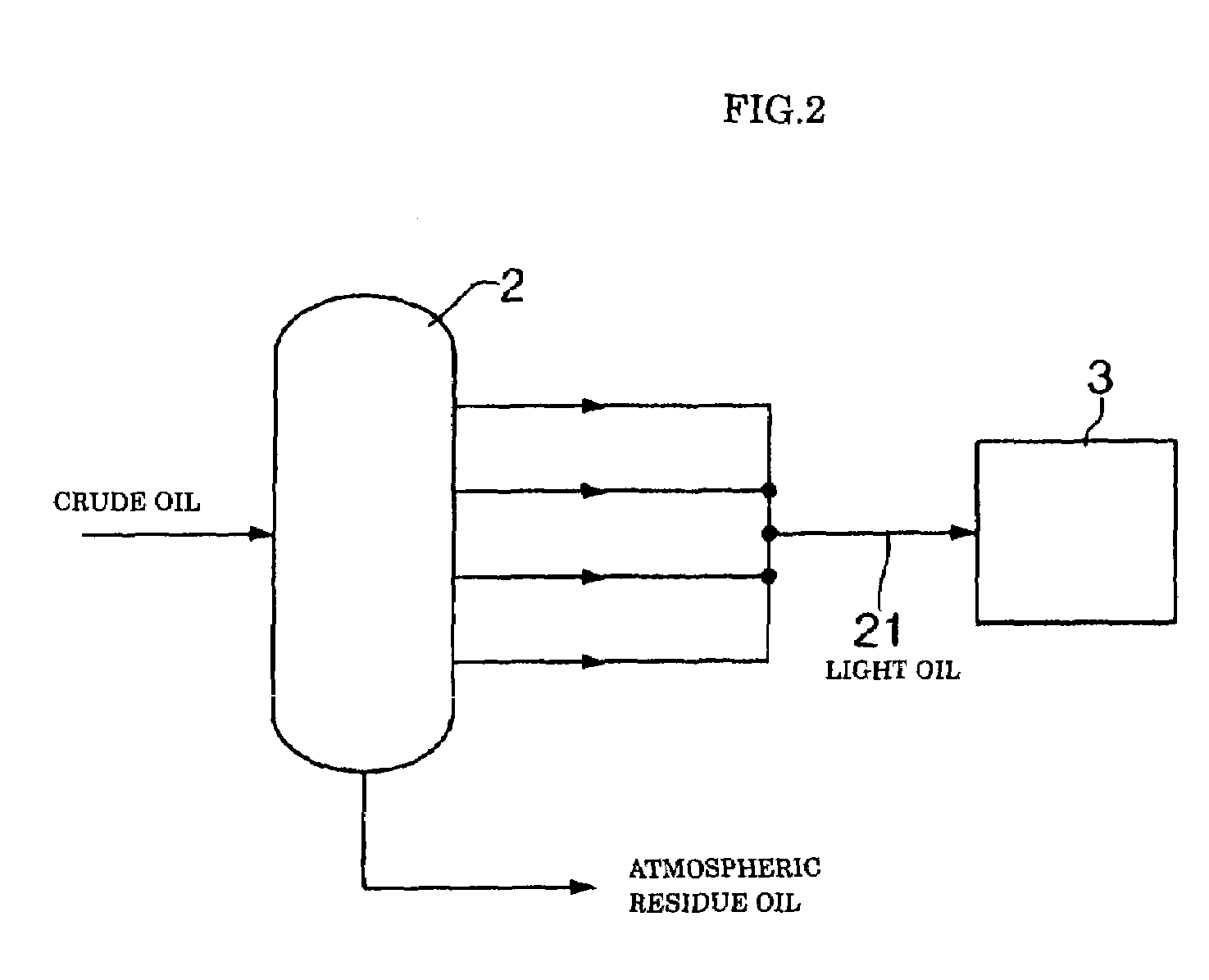

Gas turbine fuel oil and production method thereof and power generation method

InactiveUS7276151B1Carry outImprove efficiencyWorking-up pitch/asphalt/bitumenLiquid carbonaceous fuelsHydrogenFuel oil

Feed oil is subject to atmospheric distillation, to thereby be separated into light oil or light distillate and atmospheric residue oil. The light distillate is catalytically contacted with pressurized hydrogen in the presence of a catalyst, resulting in a first hydrotreating step being executed. In this instance, various fractions of the light distillate produced in the atmospheric distillation are subject to hydrotreating in a lump. The atmospheric residue oil is then separated into a light matter and a heavy matter. The light matter is subject to second hydrotreating in the presence of a catalyst to produce refined oil (light matter), which is mixed with refined oil produced in the first hydrotreating to prepare a mixture. The mixture is used as gas turbine fuel oil.

Owner:JGC CORP

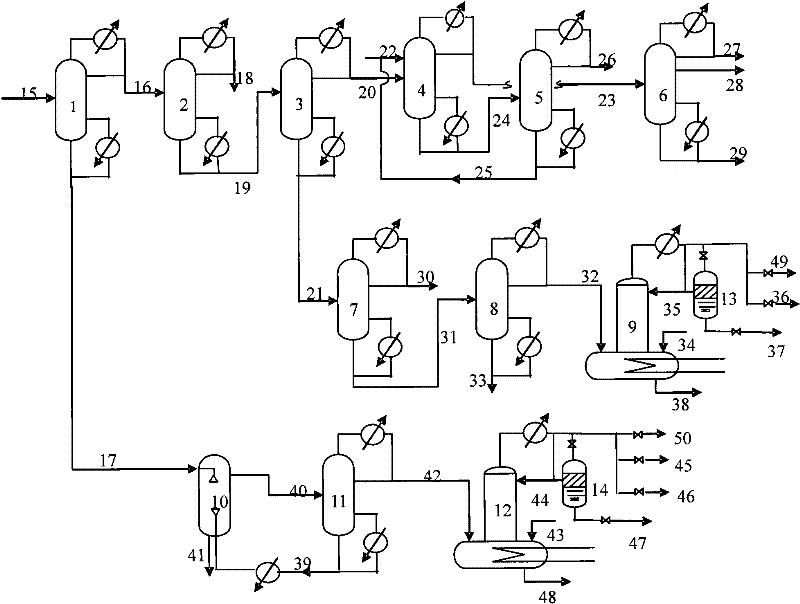

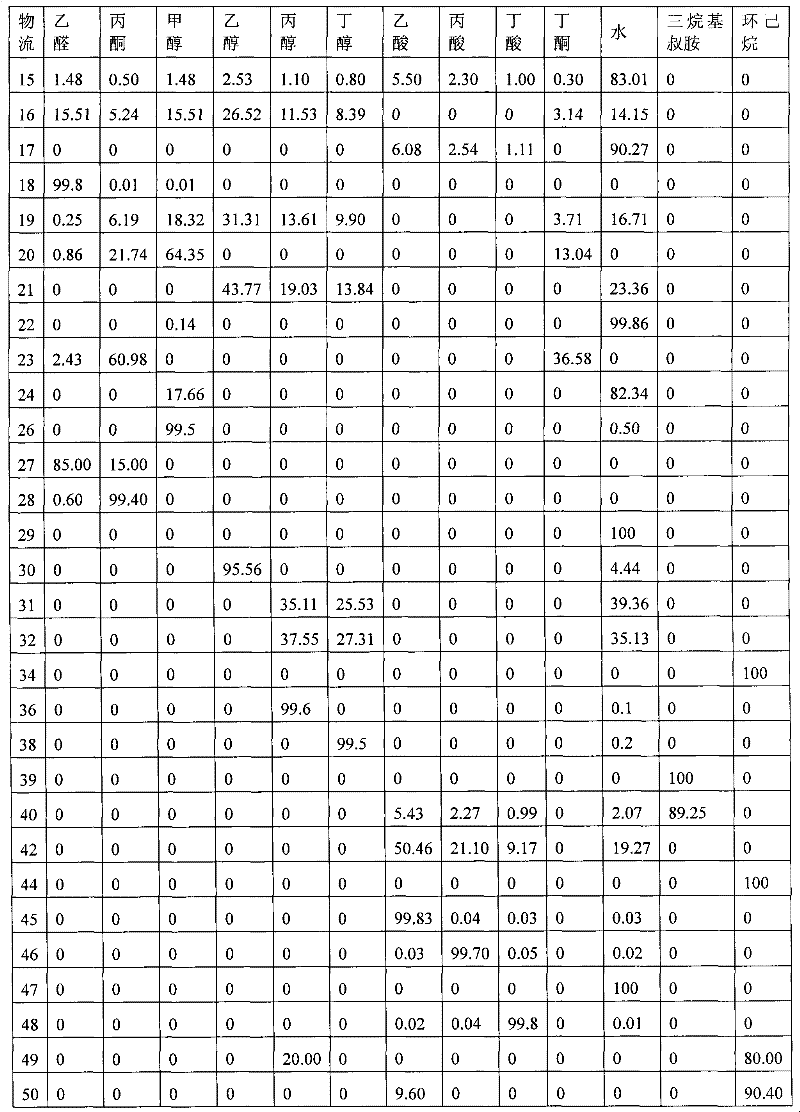

Separating and recovering method for organic oxygen-containing compounds in Fischer-Tropsch synthesis water phase

InactiveCN102442882AReach salesMeet application requirementsOrganic compound preparationHydroxy compound preparationCarboxylic acidOxygen

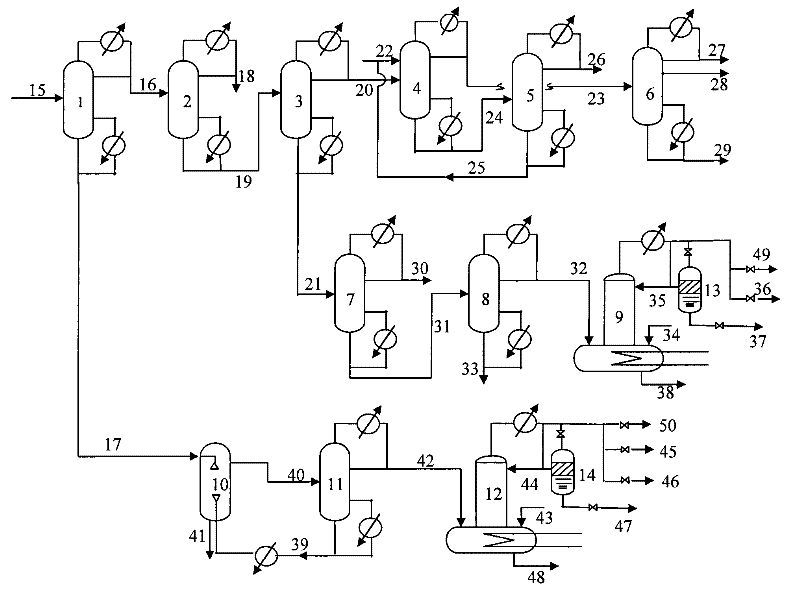

The invention relates to method and equipment system for separating and recovering organic oxygen-containing compounds in a Fischer-Tropsch synthesis water phase. The equipment system is integrated by adopting twelve towers including a mixed acid cutting tower, an acetaldehyde rectifying tower, a methanol / ethanol dividing tower, a methanol extraction rectifying tower, a methanol rectifying tower, an acetaldehyde removing tower, an ethanol tower, a propanol concentration extracting tower, a propanol intermittent azeotropic distillation tower, a carboxylic acid extraction tower, a carboxylic acid intermittent rectifying tower and an extraction agent recovering tower matched with the carboxylic acid extraction tower for use. By applying the method and equipment system disclosed by the invention, more than ten kinds of organic oxygen-containing compounds such as acetaldehyde, acetone, methanol, ethanol, normal propyl alcohol, normal butanol, acetic acid, metacetonic acid, butyric acid, butanone and the like can be separated from raw materials; and the products can respectively reach the industrial purity. The method and equipment provided by the invention are economic, effective and reasonable; and according to the method and equipment, efficiency of Fischer-Tropsch synthesis industrial enterprises can be greatly increased, production cost is reduced and goal of clean production can be achieved.

Owner:SYNFUELS CHINA TECH CO LTD

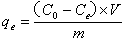

Preparation method of cellulose adsorbent for adsorbing heavy metal cations

InactiveCN103007896AImprove purification effectWide variety of sourcesOther chemical processesWater/sewage treatment by sorptionCelluloseSorbent

The invention discloses a preparation method of a cellulose adsorbent for adsorbing heavy metal cations. The preparation method comprises the following steps: 1) crushing cellulose till the grain diameter is smaller than 80 meshes, putting the cellulose into 15-30% of sodium hydroxide solution, and soaking for 2 hours at 60 DEG C; 2) adding dimethyl sulfoxide, and removing excessive water through azeotropic distillation to obtain a cellulose sol; 3) in the presence of a nitrogen medium, reacting the sol with a diimidazole catalyst and dihydric or polyhydric amine sequentially; and 4) reflowing a reaction product with methylbenzene for 12 hours, filtering, and performing vacuum drying for 12 hours at 50 DEG C to obtain the cellulose adsorbent. The preparation method has the characteristics of mild catalytic reaction conditions, low cost and the like; and the prepared adsorbent is good in effect of adsorbing the heavy metal cations, wide in application range and recyclable.

Owner:MINNAN NORMAL UNIV

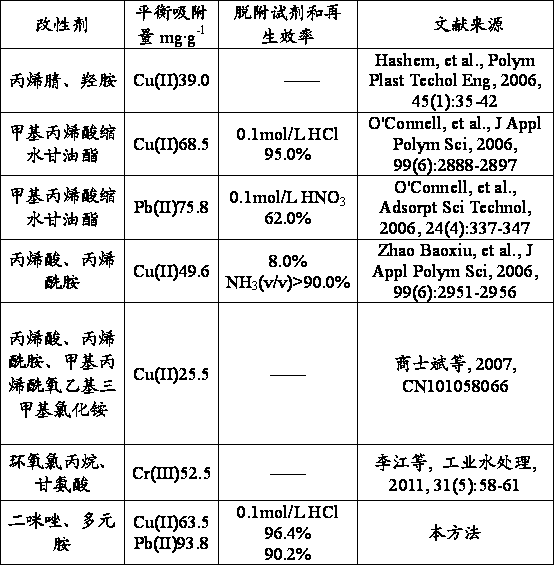

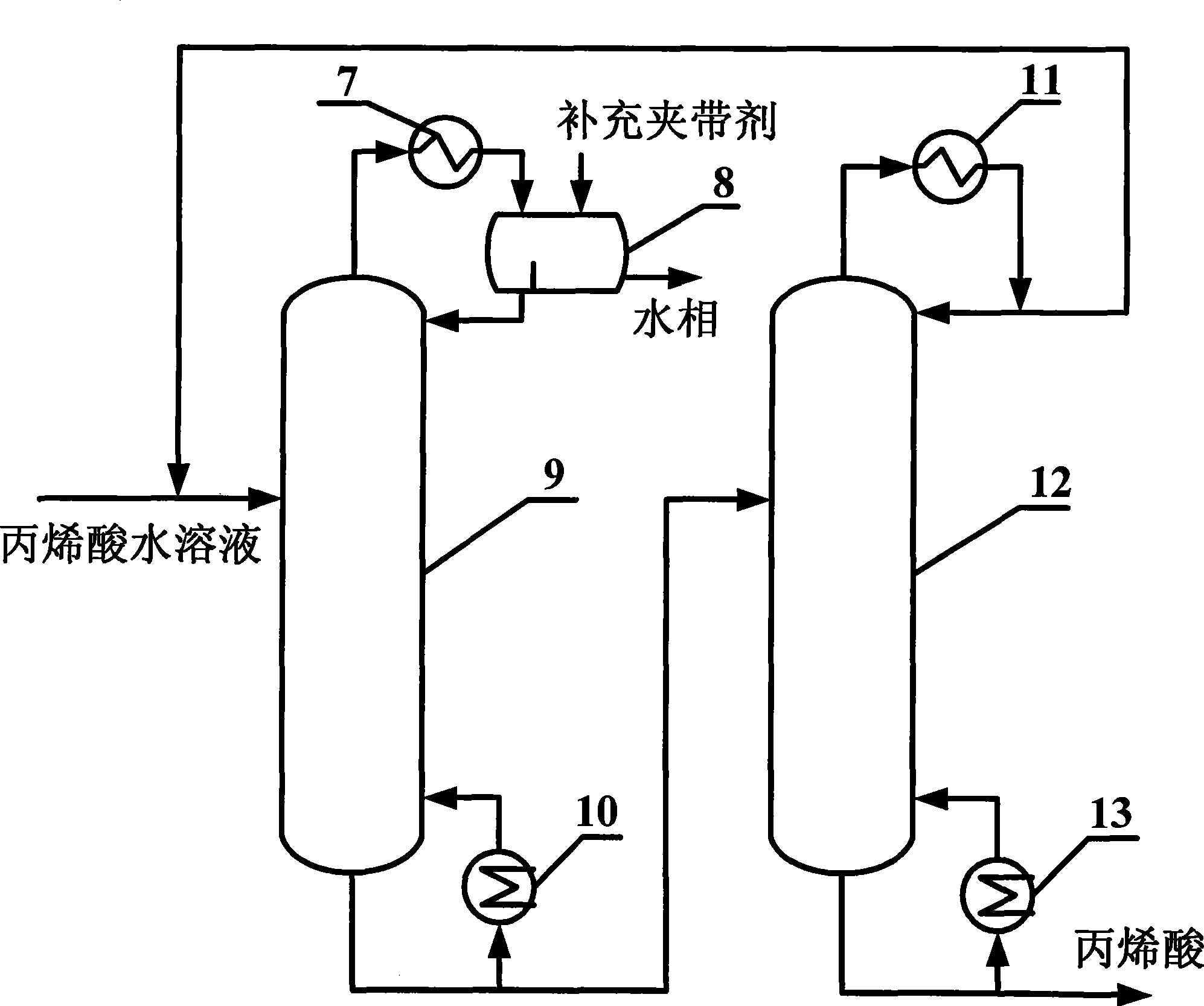

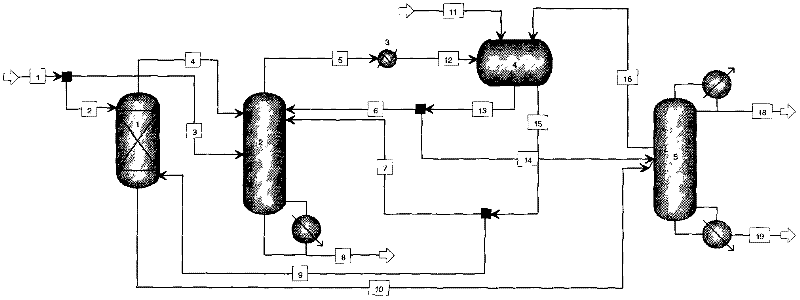

Acrylic purification process and apparatus of bulkhead azeotropy rectification column

InactiveCN101367720AReduce energy consumptionLess investmentCarboxylic compound separation/purificationAzeotropic distillationAcetic acidAqueous solution

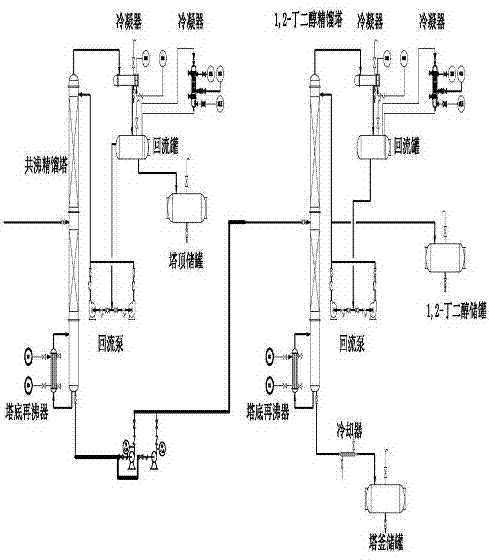

The invention relates to a novel azeotropic distillation process method and a device thereof, in particular to a process method which use a septal azeotropic distillation column to produce acrylic acid, and a device thereof. The septal azeotropic distillation column is achieved by arranging a septal wall in the azeotropic distillation column in the vertical direction from the upper part to the bottom of the column, and the right side of the septal wall is sealed, and the azeotropic distillation column is divided into four areas. The acrylic acid solution containing the impurity of acetic acid enters into the column from the bottom of the rectification part (I); wherein, light components (water and acetic acid) and entrainer form azeotrope to be steamed out of the top of the column, and then the steam on the top of the column is condensed and treated by the phase separation; wherein, the organic phase (entrainer) reflows; the water phase (containing water and acetic acid) is exhaused out of the system; the material flow on the side rectification part (III) reflows to the feeding pipeline to be recycled; the acrylic acid product with the mass fraction of more than 99 percent can be obtained at the bottom of the public stripping part. With the invention, the dehydration of acrylic acid, the remove of acetic acid and the recycle of entrainer can be finished in the same column, thus the cost of the equipment and energy consumption are reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

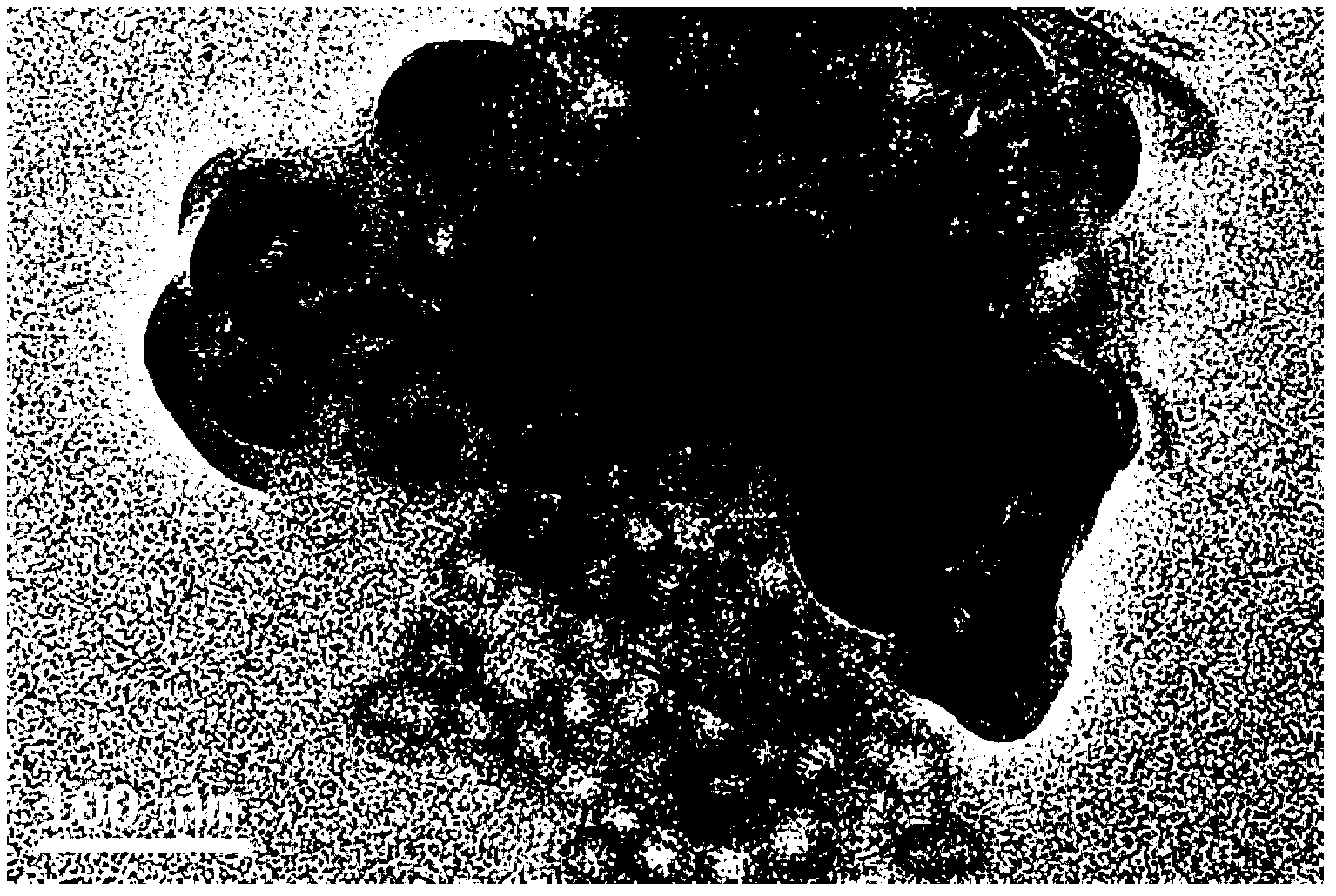

Preparation method for hollow nano metal

InactiveCN103231069AReduce sizeControl shapeMicroballoon preparationMicrocapsule preparationSurface-active agentsAzeotropic distillation

The invention relates to a preparation method for hollow nano metal, which comprises the following steps: a), reducing agent is dissolved into deionized water firstly, then is mixed with organic solvent and surface active agent, and stirring is performed for preparing microemulsion; b), water inside a system is evaporated through azeotropic distillation till the solution is clear and colorless, and at the moment, and the reducing agent is coated with the surface active agent and exist in the system in a state of monodispersed nano particles; c), metallic compound is added into the system after getting complexing through complexant, and metal is obtained through the reduction of the metallic compound on the surface of the reducing agent; and d), centrifugal separation is performed on the system after reduction reaction, precipitation is taken, and the hollow nano metal can be obtained through centrifugation after water washing. A micro-emulsion method is utilized for preparing the hollow nano metal in an assisting manner, and since the reducing agent is used as a hard template, the size and the appearance of the hollow nano metal can be effectively controlled. The prepared hollow nano metal has excellent monodispersity and is uniform in size.

Owner:CHANGZHOU UNIV

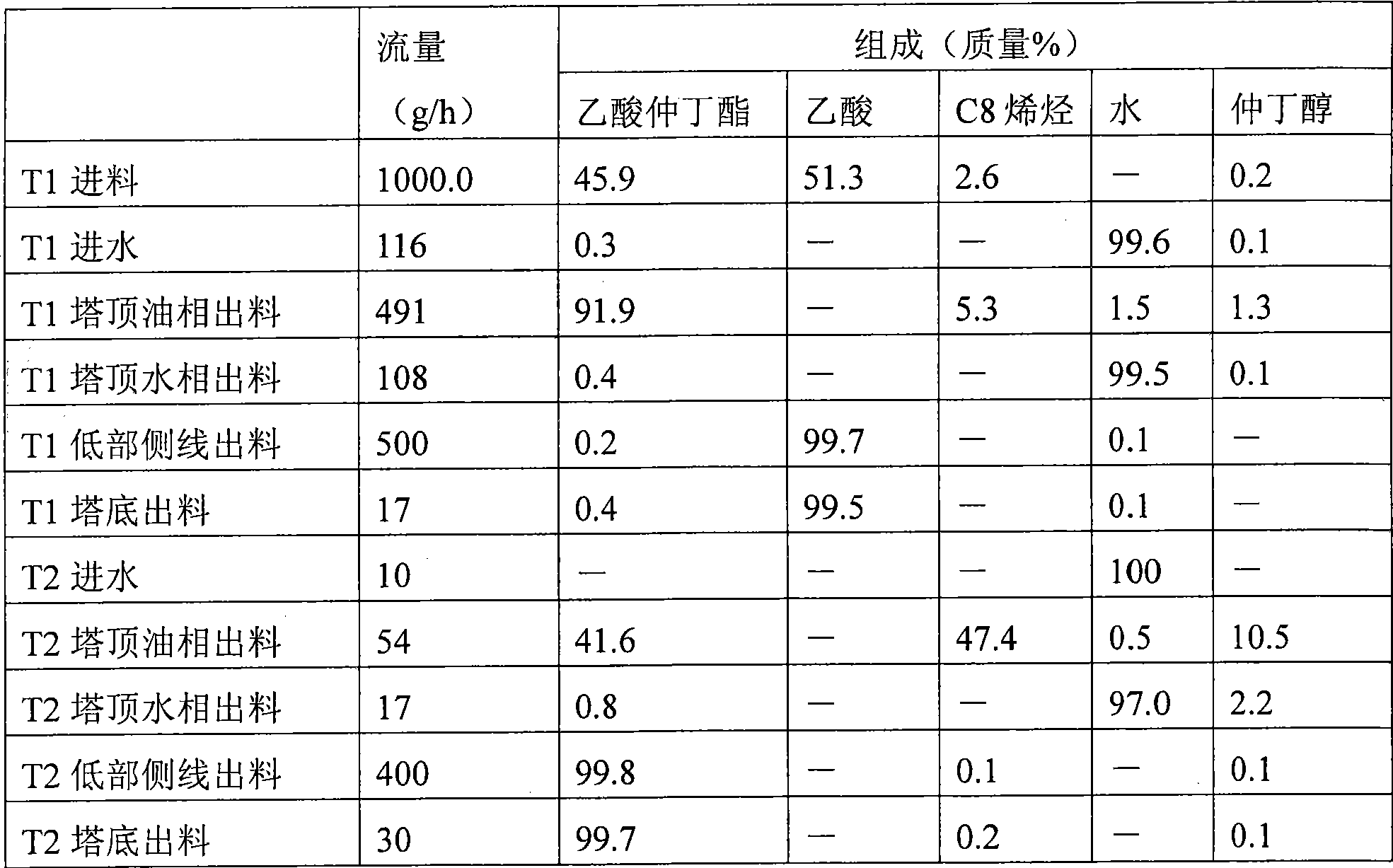

Method for separating acetic acid and sec-butyl acetate from reaction products

ActiveCN101481307AReduce energy consumptionLess investmentOrganic compound preparationCarboxylic acid esters preparationSec-Butyl acetateOil phase

The invention provides a method for separating acetic acid and sec-butyl acetate from reaction products for preparing the sec-butyl acetate. The reaction products contain the sec-butyl acetate, the acetic acid and C8 alkene. The method comprises the following steps: under operating condition of azeotropic distillation, allowing water and the reaction products to enter a first azeotrope tower for azeotropic distillation, obtaining an azeotrope from the tower top, and obtaining the acetic acid from the tower bottom; performing oil-water separation on the obtained azeotrope after condensation to obtain an aqueous phase product and an oil-phase product containing the C8 alkene and the sec-butyl acetate; and under the operating condition of azeotropic distillation, allowing the water and the obtained oil-phase product to enter a second azeotrope tower for azeotropic distillation, obtaining the azeotrope from the tower top, and obtaining the acetic acid from the tower bottom. The method can help obtain the high-purity sec-butyl acetate product by separating the reaction products, and recover the high-purity acetic acid; and the method has simple operation process, low energy consumption and lower investment in the whole device.

Owner:HUNAN RUIYUAN PETROCHEM

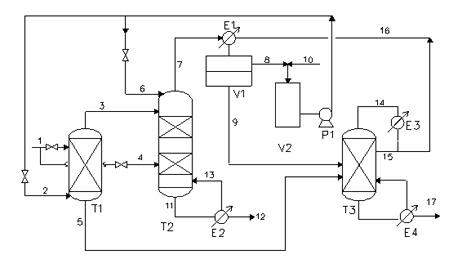

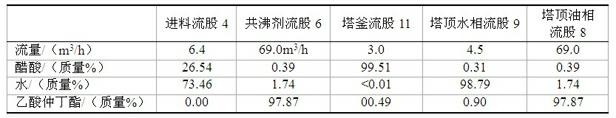

Method for recovering dilute acetic acid by virtue of extraction-azeotropic distillation of sec-butyl acetate

InactiveCN102153458AGood value for moneyReduce lossCarboxylic compound separation/purificationPhysical chemistryEthylic acid

The invention relates to a method for recovering dilute acetic acid by virtue of extraction-azeotropic distillation of sec-butyl acetate. In the method, the sec-butyl acetate is an extractant of an extraction tower and an entrainer of an azeotropic distillation tower. The method is characterized in that a part of dilute acetic acid is fed into the top of a filler extraction tower, a small portion of tower top reflux liquid of the azeotropic distillation tower is used as the extratant to be fed to the bottom of the extraction tower, and is subjected to room temperature counter current contact extraction together with the dilute acetic acid; an extraction phase containing the sec-butyl acetate, acetic acid and little water is obtained on the top of the extraction tower; raffinate water containing trace acetic acid is obtained at a tower kettle, and enters into a solvent recovering tower; and the extraction phase in the extraction tower is fed to the upper half part of the azeotropic distillation tower for further concentration, and the other part of sec-butyl acetate is fed to the tower top of the azeotropic distillation tower. The method has the characteristic of high separation efficiency; and the recovery of the acetic acid is more than 95%, and the content of the acetic acid in waste water is below 0.5%. By using the method, the defects of large reflux ratio, high energy consumption and the like which are caused by using a rectification method are directly overcome, and the production capability of dilute acetic acid recovery is enlarged.

Owner:FUZHOU UNIV

Preparation of good quality benemicin

ActiveCN101486716AReduce dosageAvoid changeAntibacterial agentsOrganic chemistrySodium bicarbonateSide chain

The invention discloses a preparation method of high-quality rifampicin, solving the problem that the traditional preparation method has the defects such as unfavorable product quality and high cost; the preparation method comprises the operational steps: S-BA liquid is salified by alkalescence sodium bicarbonate during a salification reaction; S is separated out by acetate acid before a cyclization reaction; then, dihydroxy is added for a reaction to obtain oxazine; after the reaction is finished, DMF is recovered by a molecular distillation method and then dissolved by other hydrophilic solvents; oxazine is separated out by an elutriation method; after a hydrolysis reaction and a condensation reaction are finished, an azeotropic distillation method is adopted to recover un-reacted side chains; pH is adjusted and temperature is lowered so that crystals are separated to obtain the crude products of rifampicin; and then the crude products are refined to obtain the high-quality rifampicin. Compared with the existing preparation technique, the preparation method significantly improves the product purity, reduces the production cost, controls the overall quantity of impurities to be lower than 1.5 percent, reduces two thirds of the general consumption of raw materials and more than a half of the usage of 1-methyl-4-aminopyrazine which is a valuable raw material, and eliminates the environmental pollution caused by strong acid and alkali.

Owner:薛荔 +1

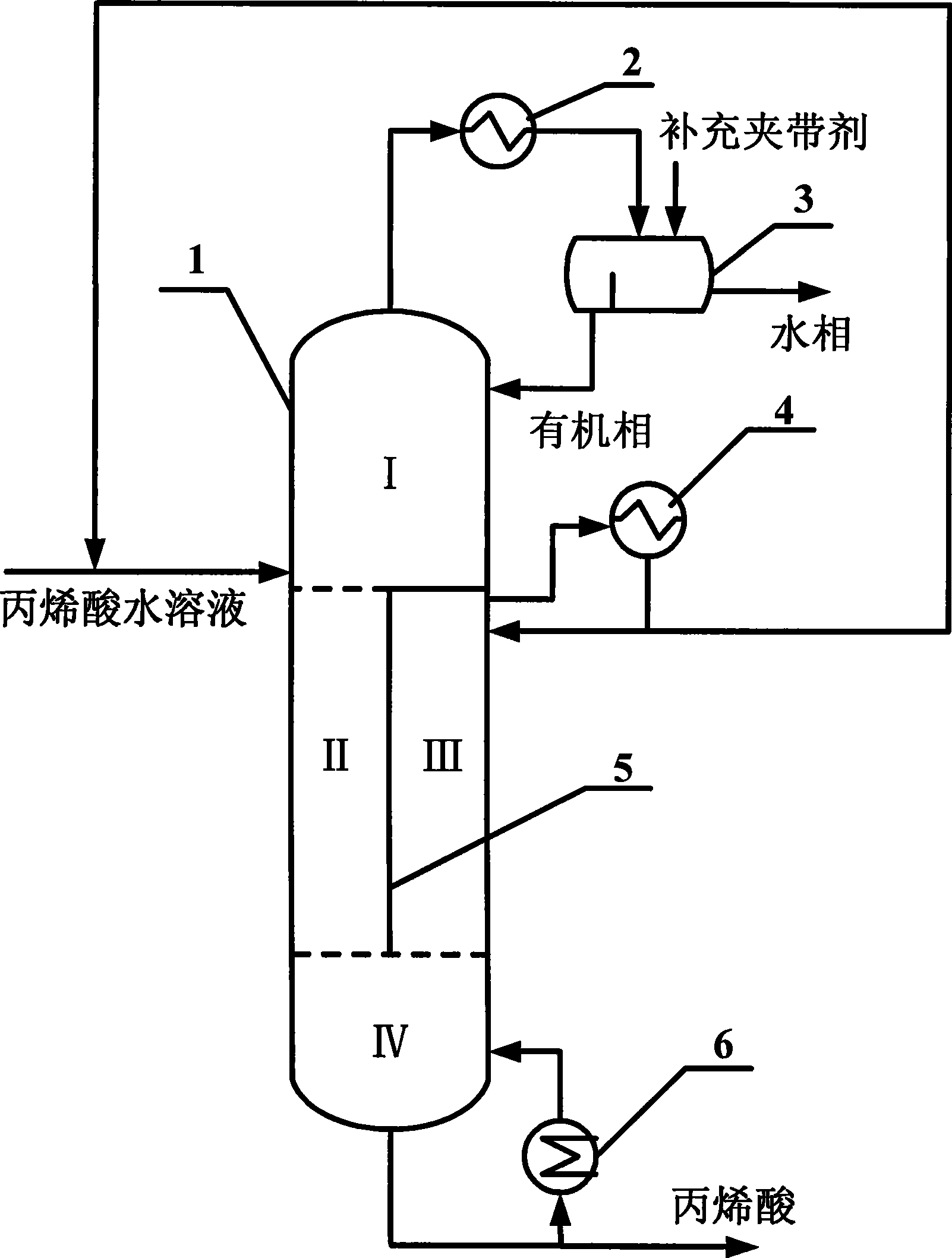

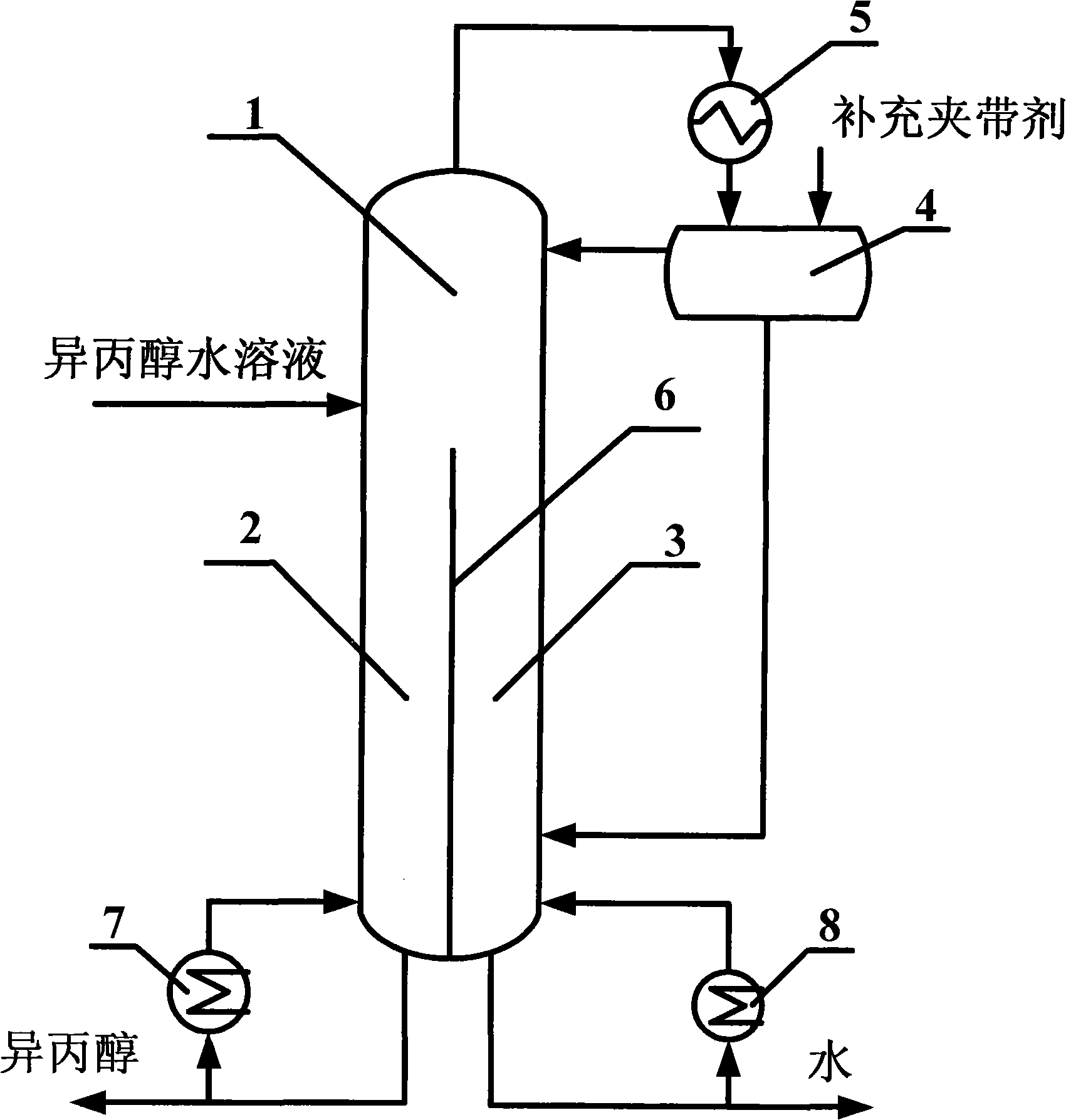

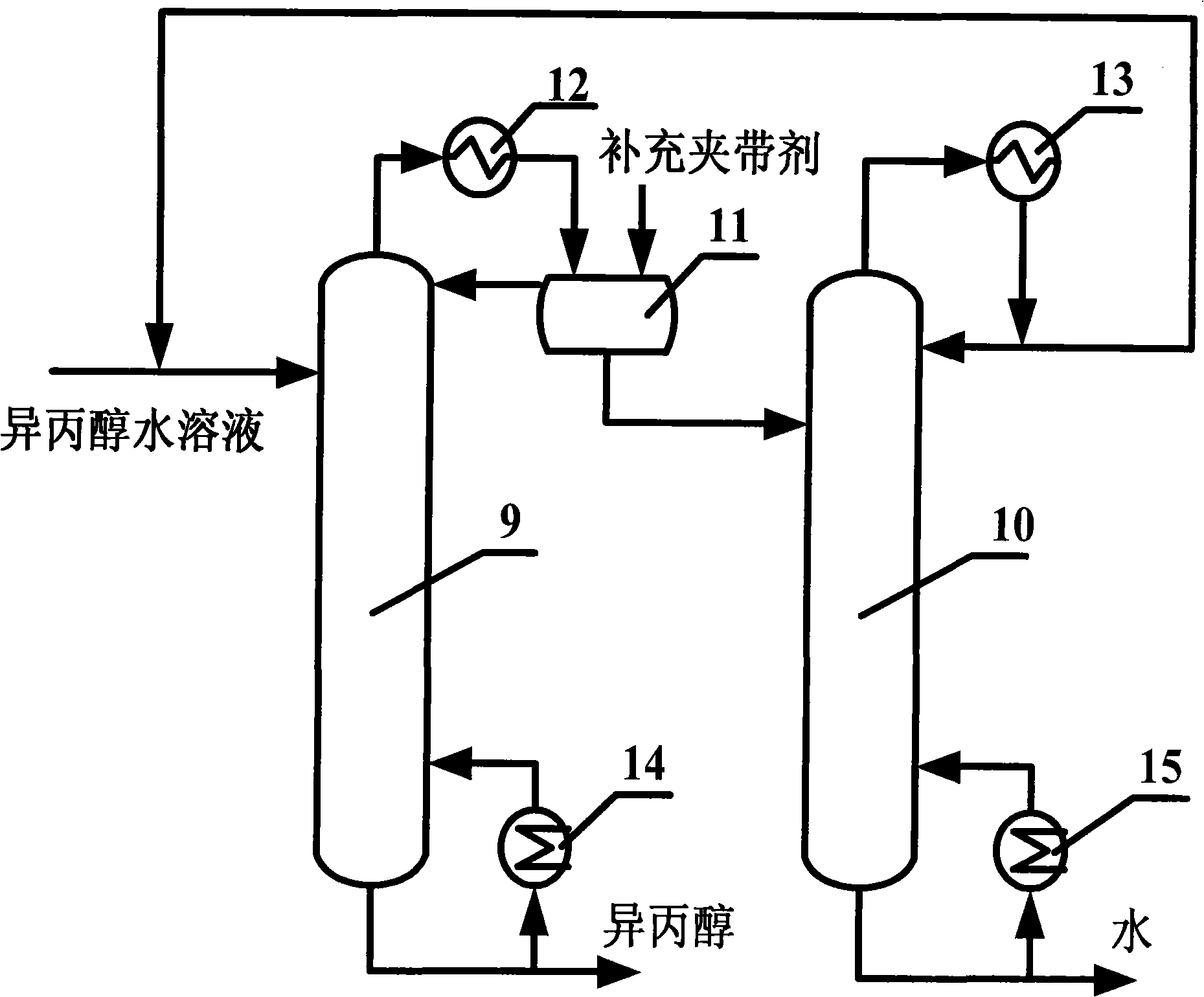

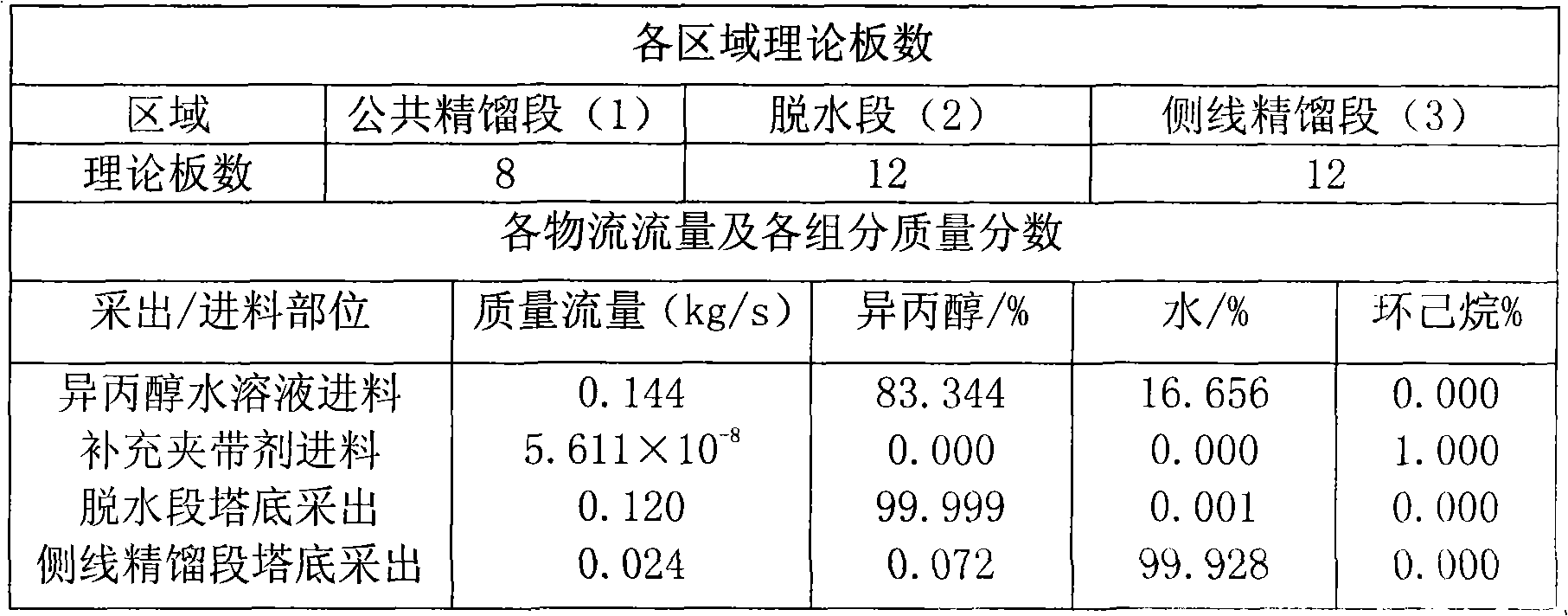

Technological process and device for separating isopropanol water solution

InactiveCN101333150ALess investmentHigh purityOrganic compound preparationHydroxy compound preparationPhase splitterAqueous solution

The invention relates to a novel azeotropic distillation technical method and a device, particularly to a technical method and a device using a bulkhead azeotropic distillation column to produce anhydrous isopropanol. The invention enables the separation between isopropanol and water, as well as the recovery of entrainer to be integrated into the same distillation column. The bulkhead azeotropic distillation column refers to a piece of bulkhead (6) which is arranged in the vertical direction inside the conventional distillation column and extended from the upper part of the distillation column to the bottom part of the distillation column; the total height of the bulkhead (6) is less than that of the distillation column; the bottom of the bulkhead is closed; the bulkhead (6) divides the distillation column into three parts: a public distillation segment (1), a dehydration segment (2) and a lateral line distillation segment (3). The isopropanol aqueous solution which needs to be separated enters into the distillation column from the lower part of the public distillation segment (1) and get the high-purity isopropanol from the bottom of the dehydration segment (2); the , ternary azeotrope is steamed out from the top of the distillation column; the steam at the top of the distillation column is condensed through a condenser (5) and then enters into a phase splitter (4) to be divided into light and heavy two-phase liquid; the light phase (entrainer) flows back, while the heavy phase enters into the lower part of the lateral line distillation segment (3) to get the water containing a small amount of isopropanol at the bottom of the lateral line distillation segment (3).

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Process for preparing carboxylic esters

InactiveUS6916950B2Increased space-time yieldPreparation rom asymmetrical anhydridesOrganic compound preparationLiquid mediumAlcohol

Carboxylic esters are prepared by a process, which comprises reacting dicarboxylic or polycarboxylic acids or their anhydrides with alcohols in a liquid medium with the concomitant removal of water formed by the esterification reaction by azeotropic distillation together with the alcohol in the medium, wherein the amount of liquid removed from the reaction medium by azeotropic distillation is replaced in whole or in part with the alcohol.

Owner:OXENO OLEFINCHEMIE GMBH

A kind of dilute acetic acid recovery method combining extraction and azeotropic distillation

InactiveCN102267889AReduce energy consumptionReduce contentChemical recyclingCarboxylic compound separation/purificationAcetic acidAlcohol

The invention relates to a method for recovering dilute acetic acid by combining extraction and azeotropic rectification. The method first carries out liquid-liquid extraction on part of the acetic acid-water component to be separated, the extractant is injected into the bottom of the extraction tower, and is extracted by countercurrent contact with dilute acetic acid to obtain the top component (extract phase) comprising acetic acid and the extractant and meet environmental protection requirements. The waste water (raffinate phase) is discharged; then, the extract phase and another part of dilute acetic acid enter the azeotropic rectification tower to carry out azeotropic rectification. Azeotrope of boiling agent and water. The azeotropic agent and water achieve liquid-liquid separation in the phase separator, the organic phase returns to the azeotropic rectification tower as an azeotropic agent and returns to the extraction tower for use as an extraction agent, and the water phase enters the azeotropic agent recovery tower or is discharged. The extractant and entrainer used in the present invention are the mixture of alkyl acetate and corresponding alcohol. The extraction technology reduces the water content entering the azeotropic distillation, thereby reducing the amount of the entrainer and saving the heating steam flow of the azeotropic distillation column, so as to reduce the amount of the azeotrope and the energy consumption of the device.

Owner:EAST CHINA UNIV OF SCI & TECH

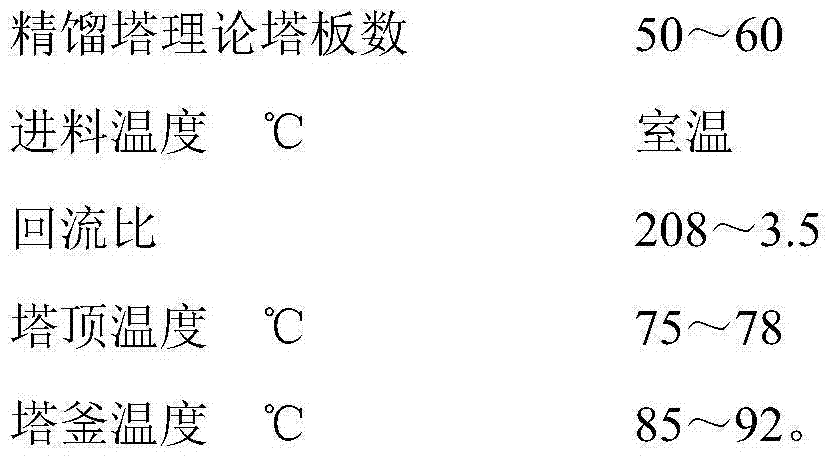

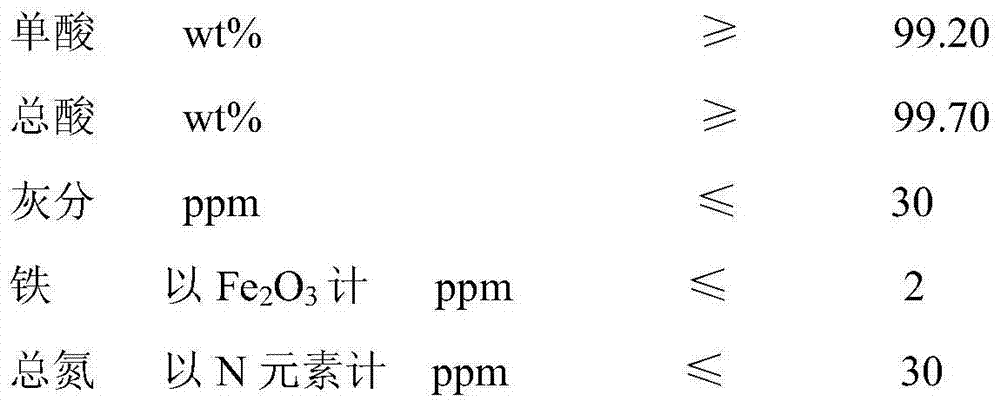

Method for refining long-carbon chain dicarboxylic acid

ActiveCN104496793AMeet the technical requirements of useLess investmentCarboxylic compound separation/purificationEngineeringCarboxylic acid

The invention relates to a method for refining long-carbon chain dicarboxylic acid. A long-chain dicarboxylic acid crude product prepared by a fermentation method is used as a raw material, acetic acid is used as a solvent, and the refining and purification are performed by recrystallization treatment. The method comprises the process steps of bleaching filtration, cooling crystallization, centrifugal separation, centrifugal material washing, secondary centrifugation and drying, and is characterized in that a. the long-chain dicarboxylic acid crude product to be refined does not need to be dried; b. the acetic acid solvent is recycled by an azeotropic distillation method, and isopropyl acetate is used as an azeotropic dehydrating agent; and c. the isopropyl acetate is used as a centrifugal material washing solvent for replacing the acetic acid. The purification method of the long-carbon chain dicarboxylic acid provided by the invention has the advantages of distillation equipment investment conservation, low operating power consumption, good product color, high purity, high refining yield and low production cost, the long-carbon chain dicarboxylic acid to be refined does not need to be dried and dehydrated, and the acetic acid solvent is completely recyclable. The quality of the refined product can meet the technical requirements of use of condensed monomer raw materials used by synthesis of high polymer materials.

Owner:山东广通新材料有限公司

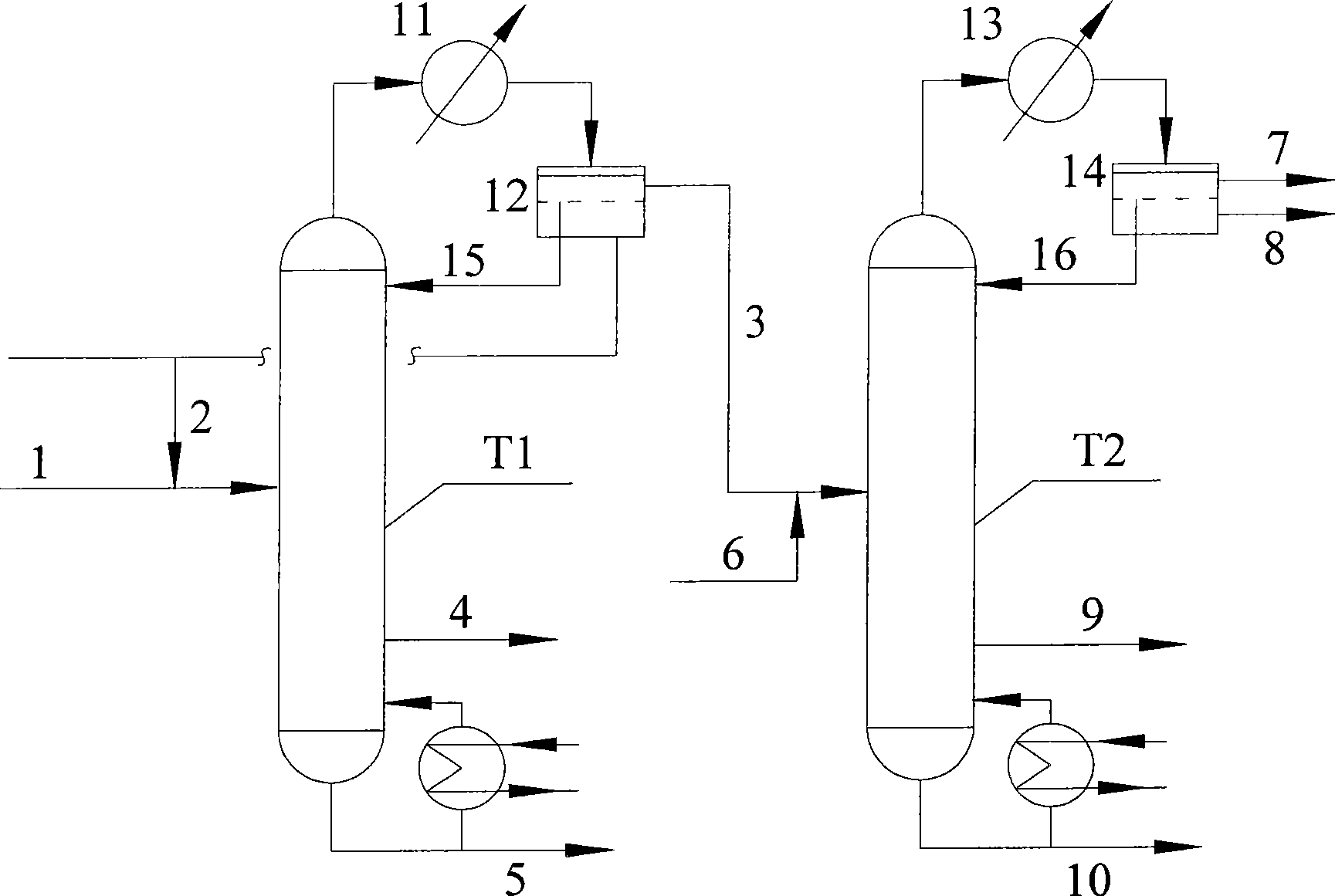

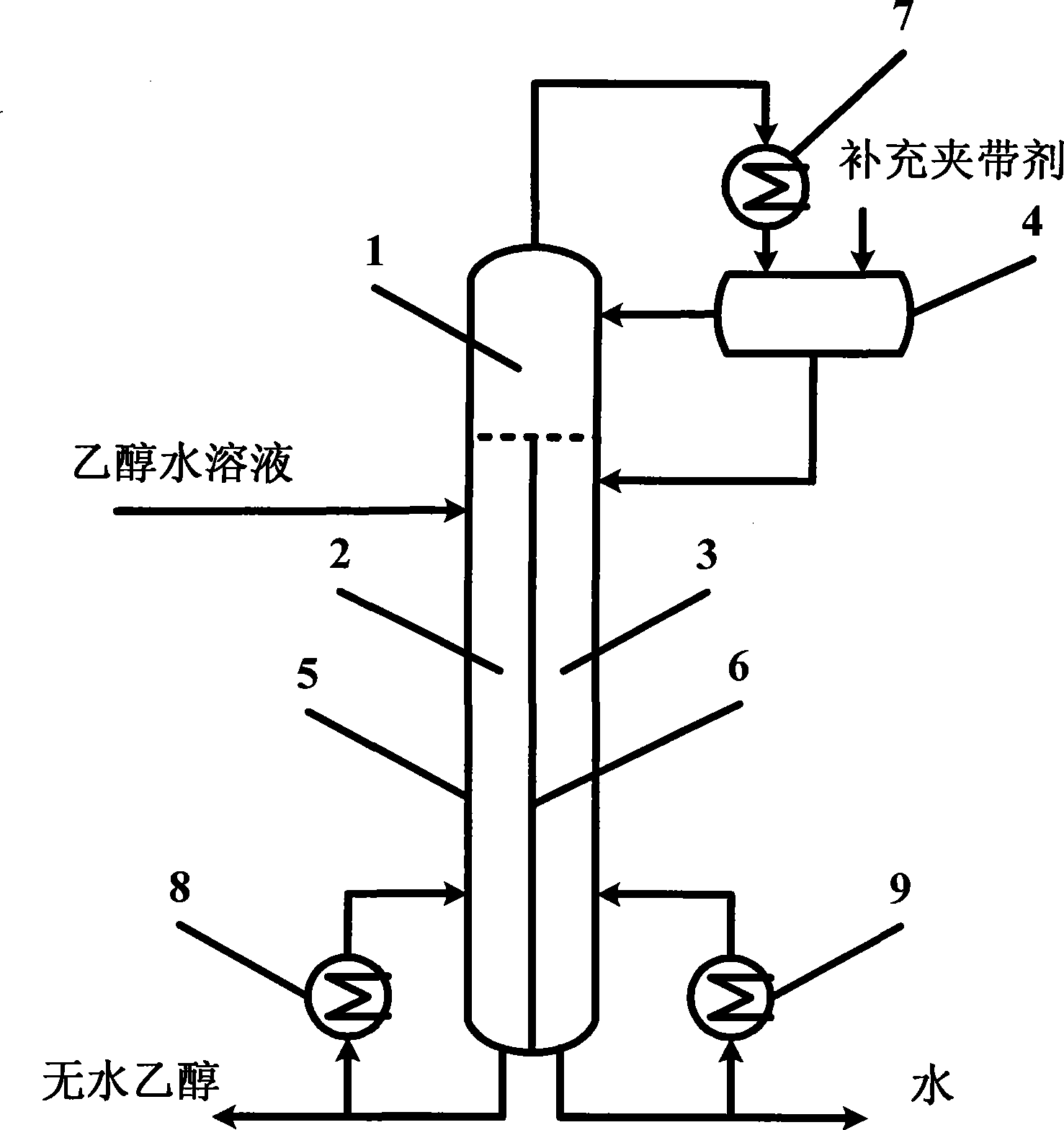

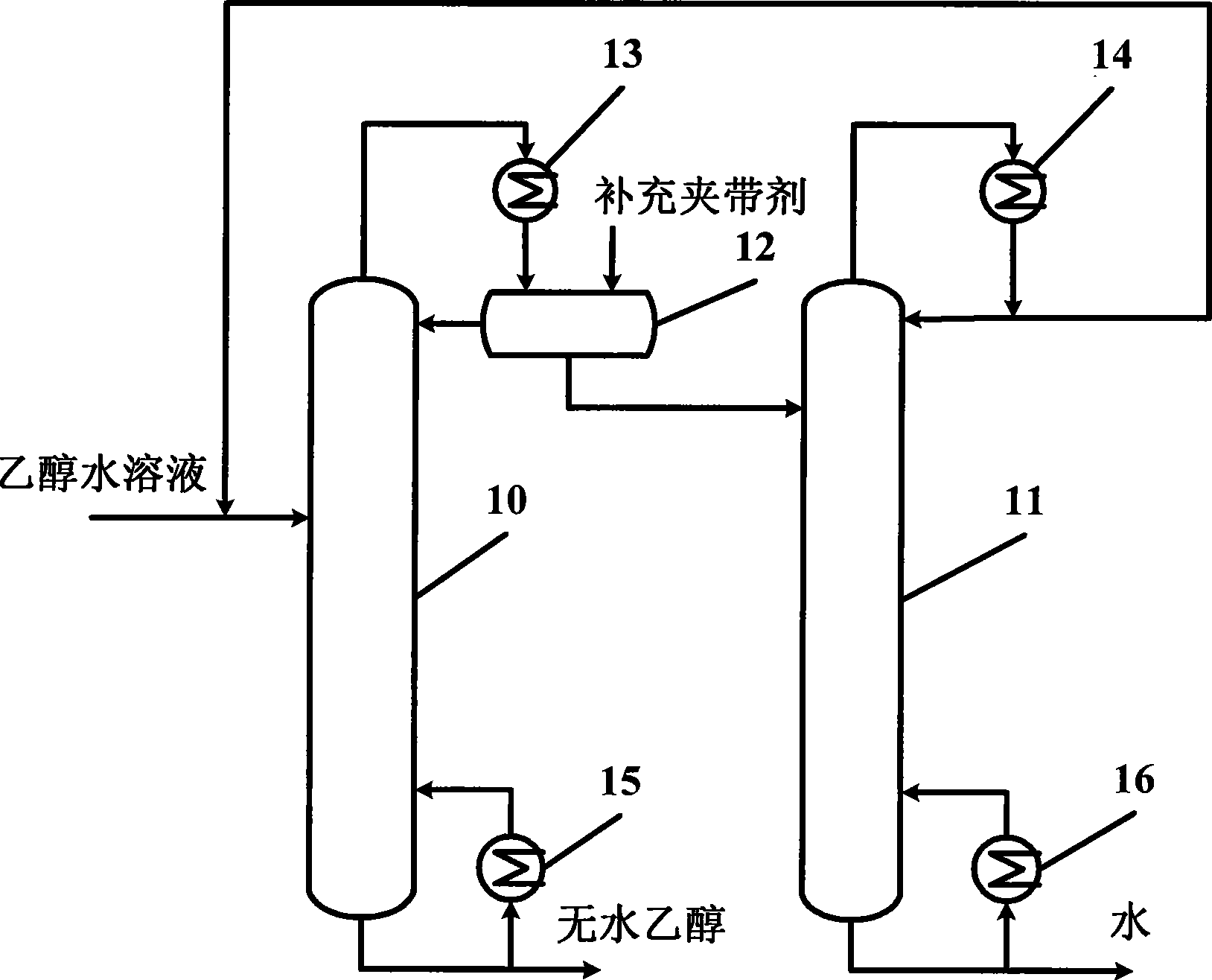

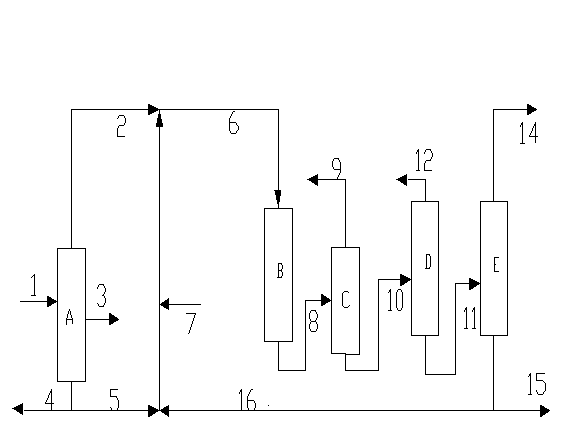

Process and apparatus for preparing absolute ethyl alcohol

InactiveCN101367710ALess investmentSimplify the conventional azeotropic distillation processOrganic compound preparationHydroxy compound preparationAlcoholPhase splitter

The invention relates to a novel azeotropic distillation process method and a device thereof, in particular to a process method which use a septal azeotropic distillation column (5) to produce absolute alcohol, and a device thereof. The septal azeotropic distillation column (5) is achieved by arranging a septal wall (6) in the azeotropic distillation column in the vertical direction, and the septal wall (6) divides the space of the azeotropic distillation column into three areas with different functions; a public distillation part (1), a dehydration part (2) and a side stripper part (3). The alcohol solution to be separated is filled to the azeotropic distillation column from the upper part of the dehydration part (2), and the absolute alcohol is obtained at the bottom of the dehydration part (2); ternary azeotrope is steamed out of the top of the column, and condensed by a condenser (7) and then splitted into light phase solution and heavy phase solution in a phase splitter; the light phase solution (entrainer) reflows and the heavy phase solution is the feed stock in the side stripper part (3), and little water containing alcohol is obtained at the bottom of the side stripper part (3). The device and the process method of the invention can produce the absolute alcohol, and can simplify the process, reduce the energy consumption and the cost of the divices.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

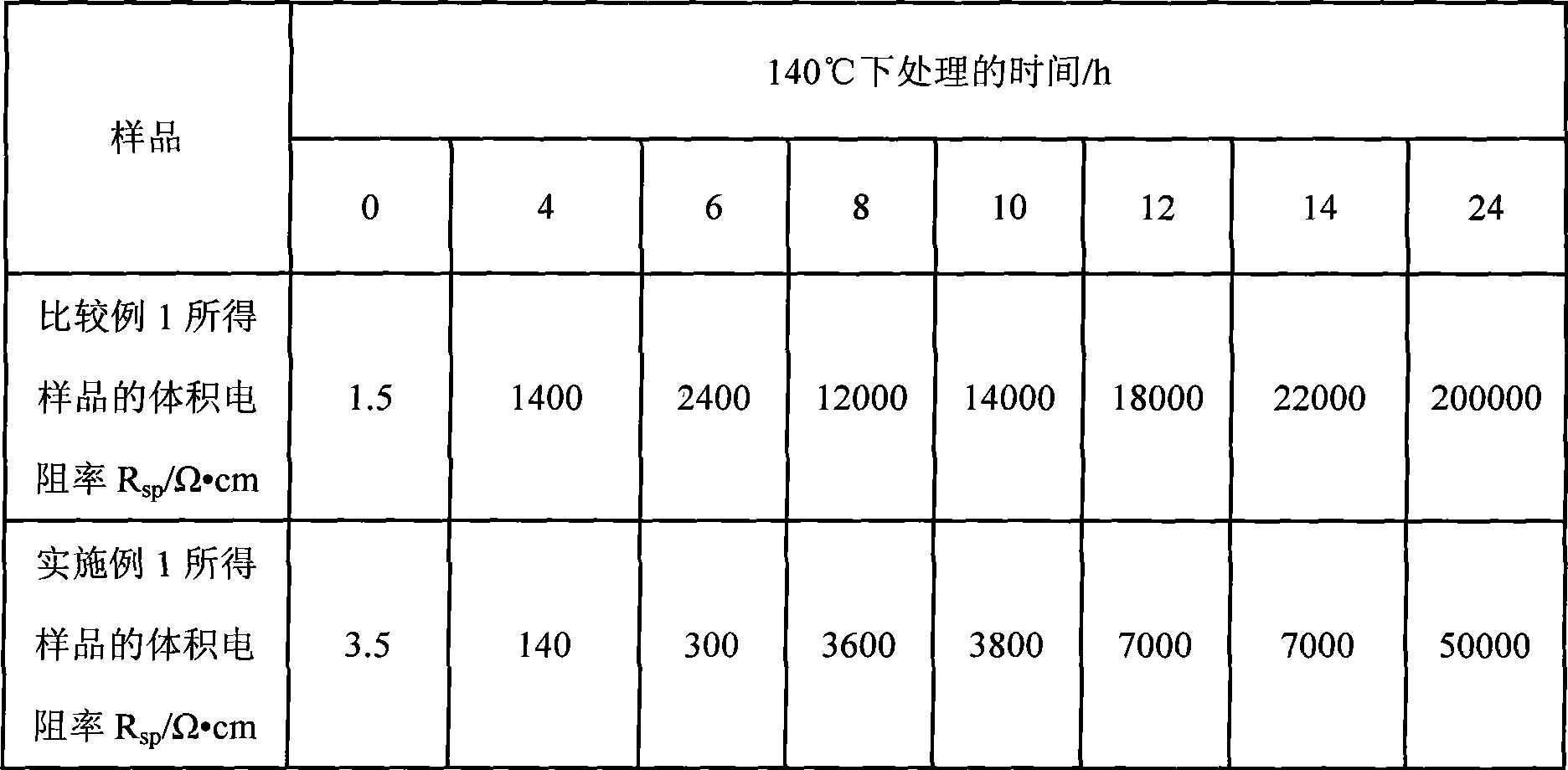

Method for improving conductive heat stability of polyaniline/inorganic nano conductive composite material

ActiveCN101376712AImprove electrical conductivity and thermal stabilityReduce clumpingOrganic conductorsThermal stabilityAzeotropic distillation

The invention discloses a method for improving the conductive thermal stability of a polyaniline / inorganic nano-conductive composite material, which comprises the following steps: a proton acid doped polyaniline / inorganic nano-conductive composite material filter cake is firstly prepared, then the obtained filter cake is carried out the azeotropic distillation treatment, water in the filter cake is removed, and the proton acid doped polyaniline / inorganic nano-conductive composite material is simultaneously transferred into an organic phase. The method easily prepares the proton acid doped polyaniline / inorganic nano-conductive composite material organic dispersion liquid with the excellent dispersion through the azeotropic distillation dehydration and the phase transfer process, thereby reducing the clustering phenomenon of the composite material, improving the dispersion of the composite material in the organic phase and improving the conductive thermal stability of the nano-conductive composite material.

Owner:溧阳常大技术转移中心有限公司

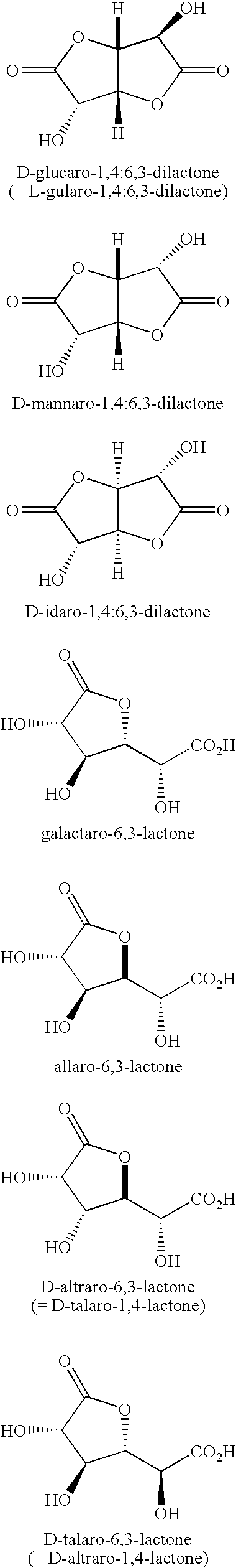

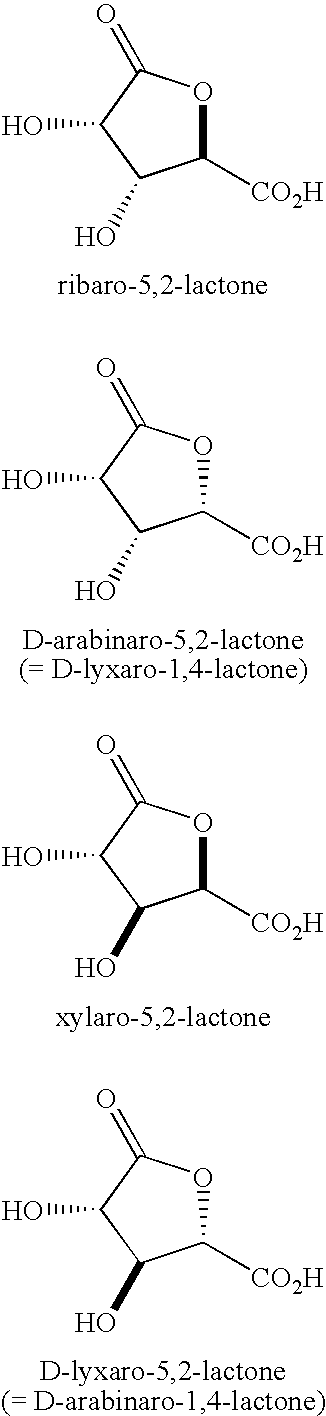

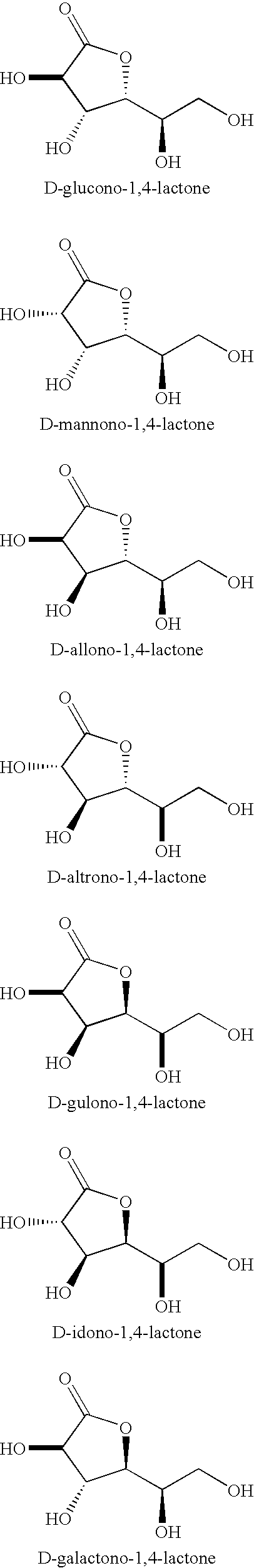

Synthesis of aldonolactones, aldarolactones, and aldarodilactones using azeotropic distillation

Processes for making lactones and dilactones from aldaric acids, aldonic acids, and their corresponding salts by dehydrative cyclization and azeotropic distillation. The processes can be carried out in the presence of water because water is removed by azeotropic distillation.

Owner:EI DU PONT DE NEMOURS & CO

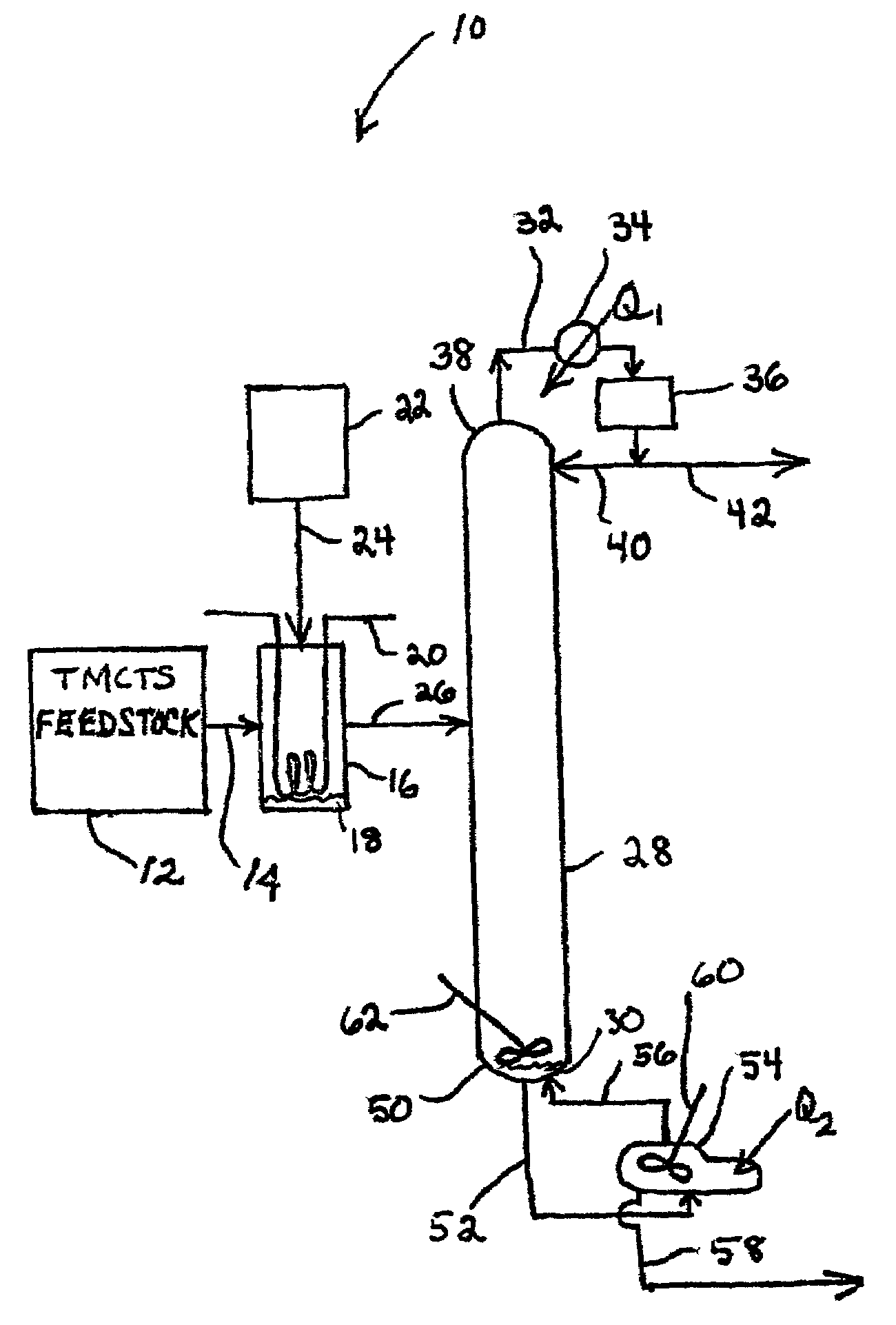

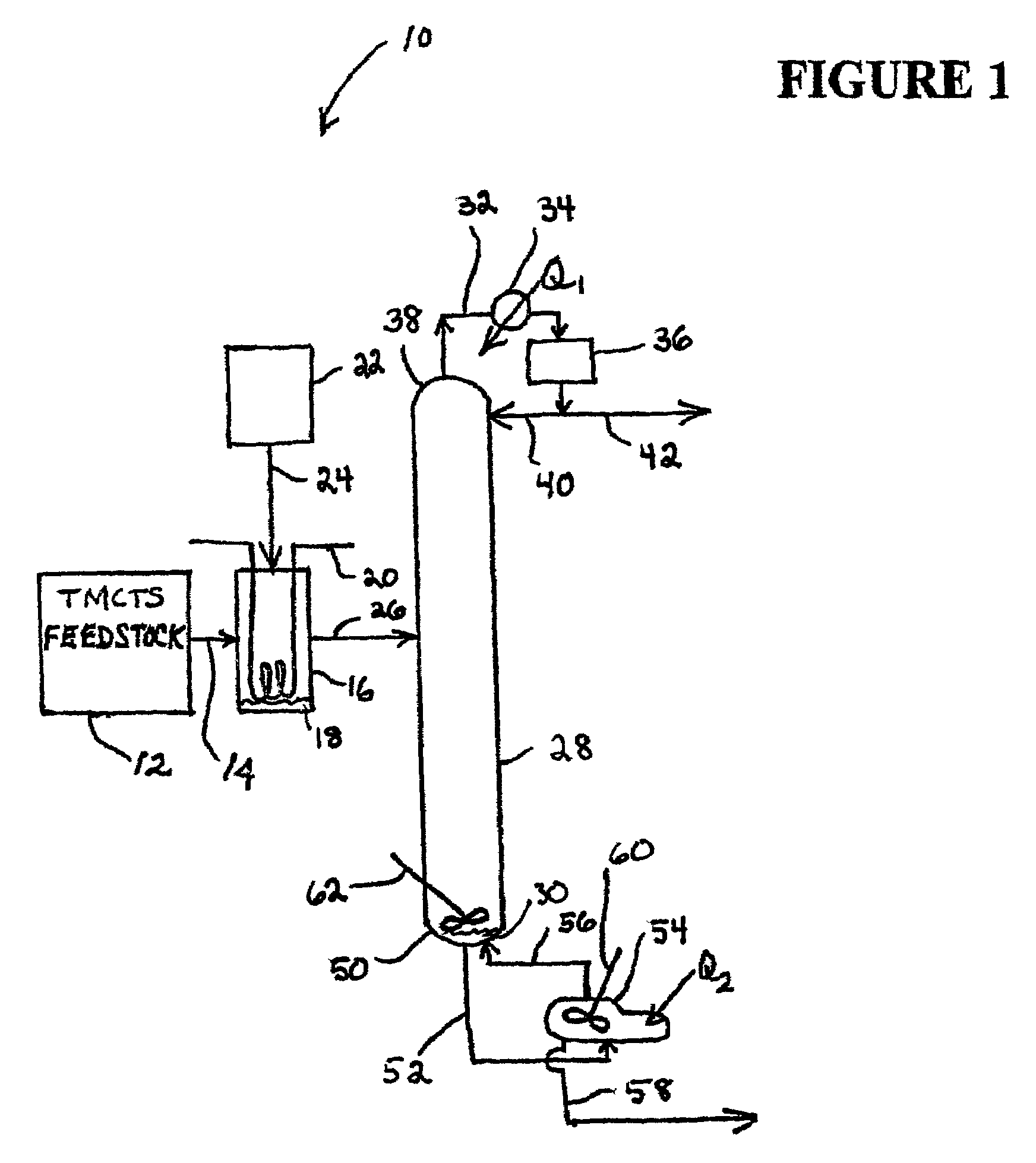

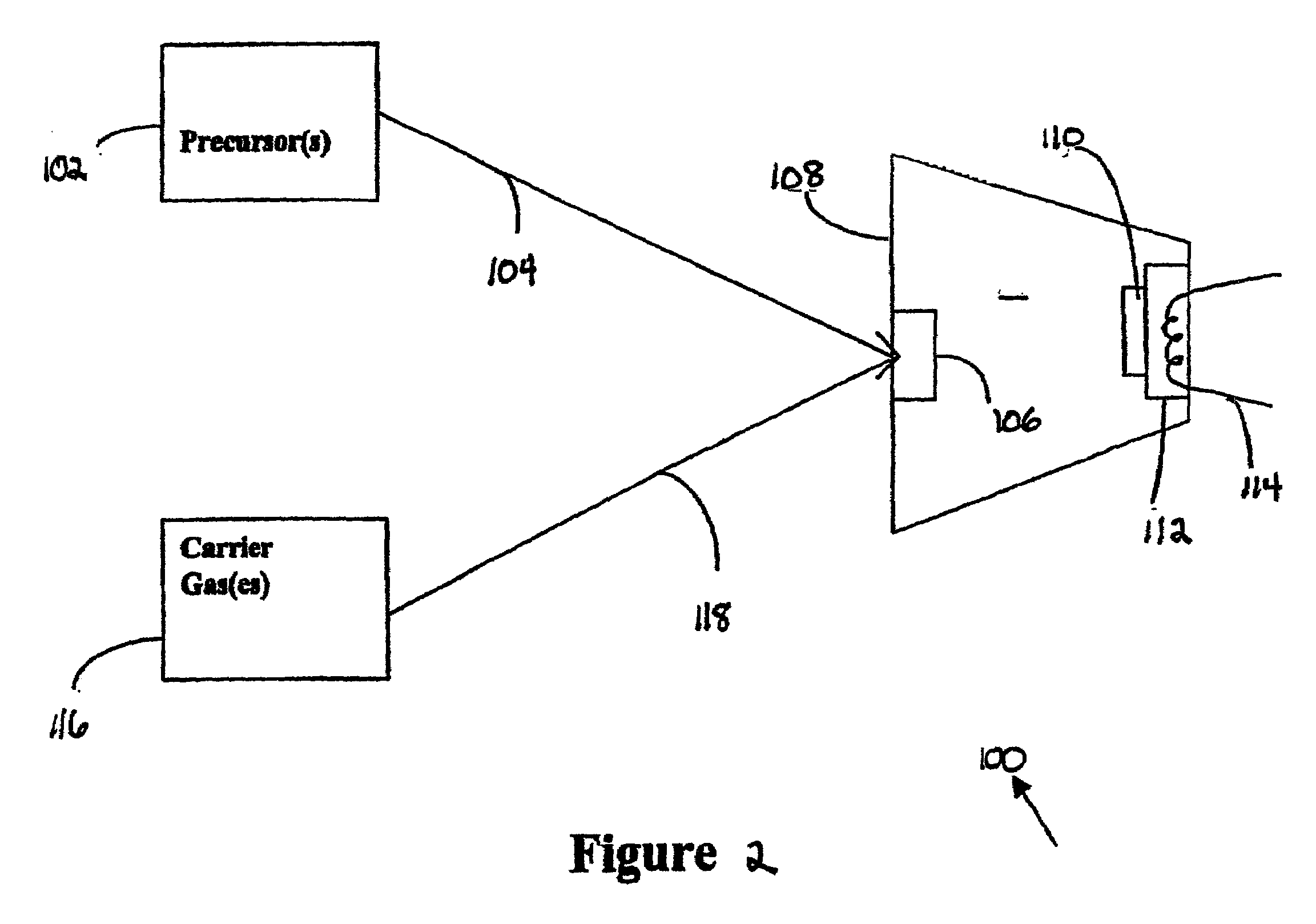

Method for removal of impurities in cyclic siloxanes useful as precursors for low dielectric constant thin films

InactiveUS7108771B2Silicon organic compoundsOrganic compound preparationAzeotropic distillationImpurity

A process for reducing the level(s) of water and / or other impurities from cyclosiloxanes by either azeotropic distillation, or by contacting the cyclosiloxane compositions with an adsorbent bed material. The purified cyclosiloxane material is useful for forming low-dielectric constant thin films having dielectric constants of less than 3.0, more preferably 2.8 to 2.0.

Owner:ENTEGRIS INC

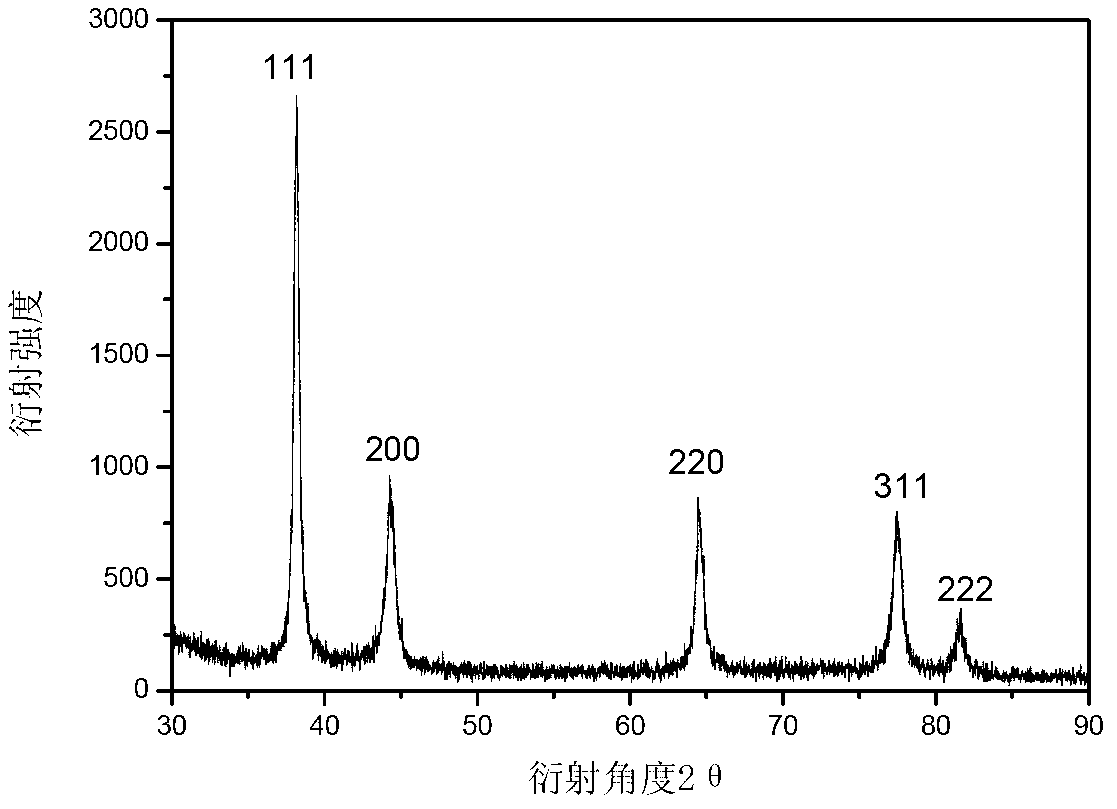

Preparation method of supported nickel catalyst

InactiveCN101733106AOrganic reductionHydrocarbon by hydrogenationSupercritical dryingNickel catalyst

The invention discloses a preparation method of a supported nickel catalyst, which comprises the following steps of: reacting soluble nickel salt solution and a precipitator to obtain a green precipitate, wherein the precipitator is mixed solution of sodium silicate and sodium carbonate, the Na<+> concentration is 0.1-1 mol / L, the amount of the sodium silicate is calculated according to the content of SiO2 in a carrier, and the amount of the sodium carbonate is 10-30 percent more than that of nickel nitrate based on a stoichiometric ratio; washing the precipitate by distilled water and carrying out supercritical drying or azeotropic distillation drying to obtain a supported nickel catalyst precursor; roasting the supported nickel catalyst precursor for 2-5 hours under N2 atmosphere at 200-600 DEG C, changing the N2 atmosphere into H2 atmosphere, and reducing the supported nickel catalyst precursor for 2-4 hours under H2 atmosphere at 300-550 DEG C to obtain the supported nickel catalyst with the surface area of high active metal nickel. The surface area of the obtained catalyst is 250-450m<2> / g, the average aperture is 4-16nm, and the pore volume is 1.0 -1.9cm<3> / g. The surface area of the active metal nickel of the obtained catalyst is 40-70m<2> / g. The catalyst prepared by using the method can be used for catalyzing hydrogenation of a benzene ring.

Owner:NANJING UNIV

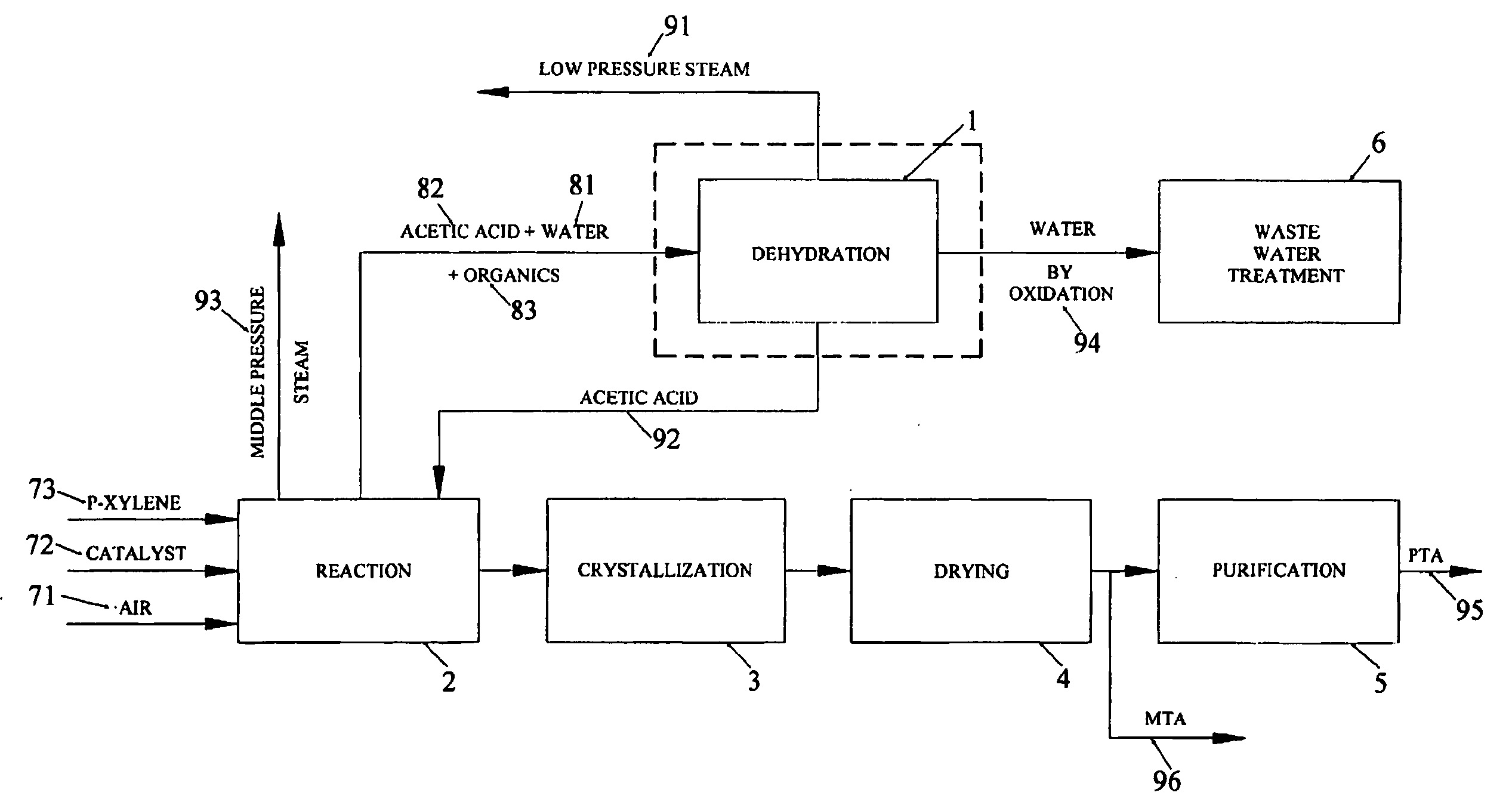

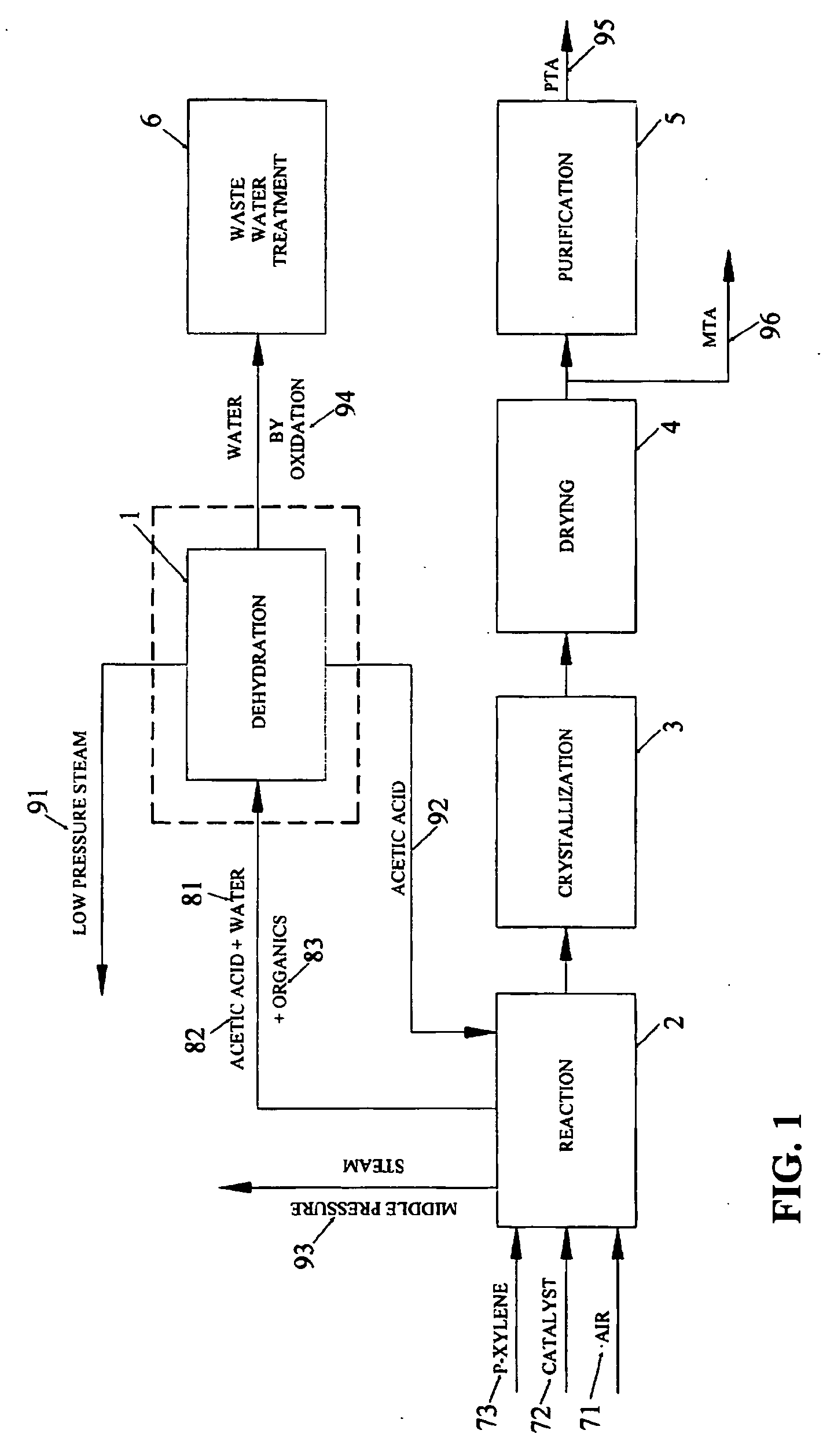

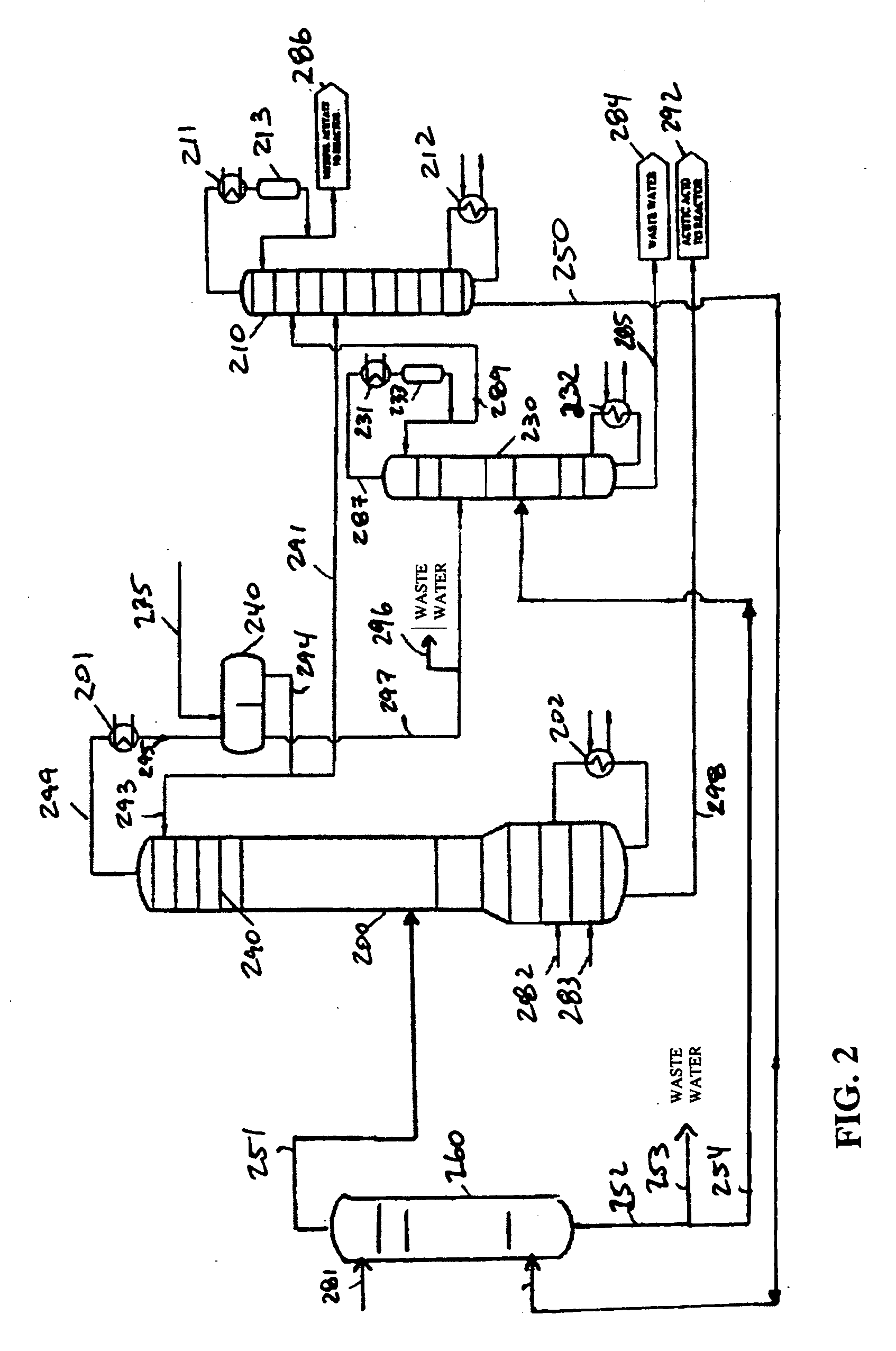

System and method for acetic acid dehydration

InactiveUS20070068792A1OptimizationOrganic compounds purification/separation/stabilisationOrganic compound preparationAcetic acidSteam condensation

Disclosed is a distillation system and method for recovering acetic acid from a feed stream containing acetic acid and water stream generated during terephthalic acid production. The invention includes a liquid-liquid extraction column and a dehydration distillation column utilizing azeotropic distillation or conventional to recover the acetic acid. The liquid-liquid extraction column is installed upstream from the dehydration distillation column. The liquid-liquid extraction column produces an extract of an extraction solvent and acetic acid which is sent to the dehydration distillation column to separate the extraction solvent and acetic acid. The dehydration distillation column may be used with or without a condenser system to recover the energy. The condenser system is a steam generator that condenses the vapor into a concentrated acetic acid stream while generating a low pressure steam. Any remaining acetic acid in water is sent to a waste water recycling facility.

Owner:AMT INT INC

Method for preparing silicon dioxide aerogel powder

The invention discloses a method for preparing preparing silicon dioxide aerogel powder, which comprises the following steps: adding acid into sodium silicate solution to make a pH value equal to 3 to 6; adding a chemical drying control agent into mixture and standing to form gel; after the gel is sufficiently aged, adding an azeotropic distillation organic solvent into the gel to distill to form a primary dried product; and drying the primary dried product to form silicon dioxide aerogel powder. The method uses the common commercial sodium silicate as the raw material to prepare the silicon dioxide aerogel powder and has the advantages that the raw material is easily obtained; the normal pressure is used for preparation; the chemical drying control agent is adopted to prolong the gelation time to promote uniformity of the gel structure; an azeotropic distillation drying process is adopted to control a stress level when the solvent is dried; a pore volume and a specific surface area of the silicon dioxide aerogel are controlled; the pore volume reaches 1.2 to 3.0ml / g; the specific surface area reaches 300m2 / g to 800m2 / g; and compared with the normal pressure drying, the drying time is shortened and the like. The organic solvent is easy to realize recycling. And the production process is simple and the production cost is low.

Owner:FUJIAN NORMAL UNIV

Wear-resisting ceramic coating for non-stick cookware and preparation method thereof

The invention discloses a wear-resisting ceramic coating for non-stick cookware and a preparation method thereof. The coating is composed of a component A and a component B, wherein the weight ratio of the component A to the component B is (2.8-3.2): (1.8-2.0); the component A is composed of silicon dioxide sol, aluminum oxide sol, zirconium oxide sol, water soluble polyester modified epoxy resin, ultrafine aluminum oxide powder processed by azeotropic distillation method, black iron oxides, ultrafine spherical ceramic powder, isopropyl alcohol, deionized water, hydroxyethyl cellulose acetate butyrate and fluorosilicon oil; and the component B is composed of methyl triethoxysilane, amino dimethyldiethoxylsilane, dimethyl dimethoxy silicane, isopropyl alcohol and alcohol. The preparation method comprises the following steps of: mixing the component A and the component B of the coating in a weight ratio of (2.8-3.2): (1.8-2.0); and hermetically stirring and curing the obtained mixture for at least 3 hours under the conditions of 35 DEG C and 800-1000 rpm, thereby obtaining the coating. According to the invention, through carrying out polycondensation reaction on metal oxide colloids and polysiloxane, the bonding strength of a film forming matter is improved.

Owner:JIANGMEN ANNUOTE COOKING UTENSILS MFG

Technological method for purifying 1,4-butanediol and co-producing tetrahydrofuran

ActiveCN103044198AReduce lossesFlexible adjustment of outputOrganic compound preparationHydroxy compound preparationPtru catalystIon exchange

The invention discloses a technological method for purifying 1,4-butanediol and co-producing tetrahydrofuran. The technological method comprises the following steps: a raw 1,4-butanediol material flow containing 2-(4-hydroxyl butoxy) tetrahydrofuran enters a 1,4-butanediol refining tower, and a 1,4-butanediol product is produced at the side line of the refining tower; and material flows rich in the 1,4-butanediol at the top and bottom of the refining tower enter a tetrahydrofuran reactor, dehydration cyclization is continuously carried out for producing the tetrahydrofuran through a palladium carried sulfonating ion exchange resin catalyst in the presence of hydrogen; after reaction, a raw tetrahydrofuran material flow enters a gas-liquid separator, a gas phase flow is reused or is discharged, and a liquid phase enters an azeotropic distillation tower; and azeotrope of tetrahydrofuran and water is obtained at the tower top and is separated to obtain the tetrahydrofuran product, liquid at the tower bottom enters a dehydration tower, and a material flow at the tower bottom returns to the tetrahydrofuran reactor. According to the technological method, the tetrahydrofuran with the high selectivity is produced while the 1,4-butanediol product with the high purity is separated out, the seperation problem of the 2-(4'-hydroxyl butoxy) tetrahydrofuran in the 1,4-butanediol product flow is solved, and the production cost is greatly reduced; and the technological method is suitable for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for production of acrylic acid

ActiveUS7183428B2Improve absorption rateOrganic compound preparationCarboxylic preparation from carbon monoxide reactionHigh concentrationAbsorption column

A method for producing acrylic acid by using an acrylic acid-containing solution of high concentration without azeotropic distillation is provided. This method of producing acrylic acid comprises introducing an acrylic acid-containing gas obtained by catalytic gas phase oxidation reaction into an absorption column and supplying the acrylic acid-containing solution to crystallization step thereby separating the solution into acrylic acid and residual mother liquid, and distilling at least part of the residual mother liquid and circulating the distillate obtained by the distillation to the absorption column.

Owner:NIPPON SHOKUBAI CO LTD

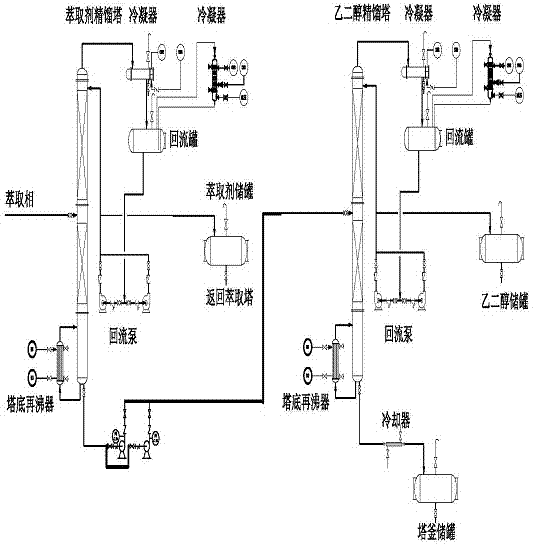

Novel method for separating mixture of ethylene glycol and 1, 2-butanediol by adopting azeotropic distillation and extraction coupling technologies

InactiveCN103772148AImprove versatilityImprove operational stabilityOrganic compound preparationHydroxy compound preparationHigh concentrationPolyol

The invention provides a novel method for separating a mixture of ethylene glycol and 1, 2-butanediol by adopting azeotropic distillation and extraction coupling technologies. The method adopts continuous azeotropic distillation and extraction coupling separation technologies to separate an azeotropic mixture of ethylene glycol and 1, 2-butanediol; an entrainer and an extraction agent are selected through ASPEN modeling and simulation, and rectification and extraction conditions are determined preliminarily; a polyatomic alcohol mixed solution and the entrainer enter a rectification tower, and azeotropic liquid of ethylene glycol and the entrainer is obtained at the tower top, and 1,2-butanediol with high concentration is obtained at a tower kettle; the extraction agent is not dissolved into the entrainer but can be mutually dissolved with ethylene glycol; the extraction agent is added into the azeotropic liquid at the tower top for extraction, and the entrainer can be recovered; a mixture of ethylene glycol and the extraction agent is rectified under normal pressure or reduced pressure, so as to obtain the ethylene glycol product, and the extraction agent is recovered for cyclic utilization.

Owner:JILIN INST OF CHEM TECH

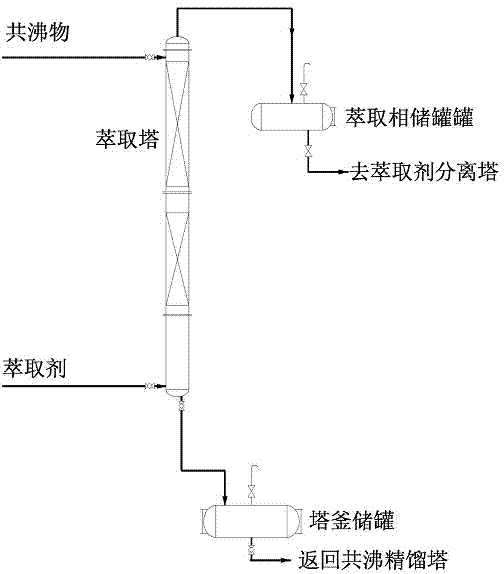

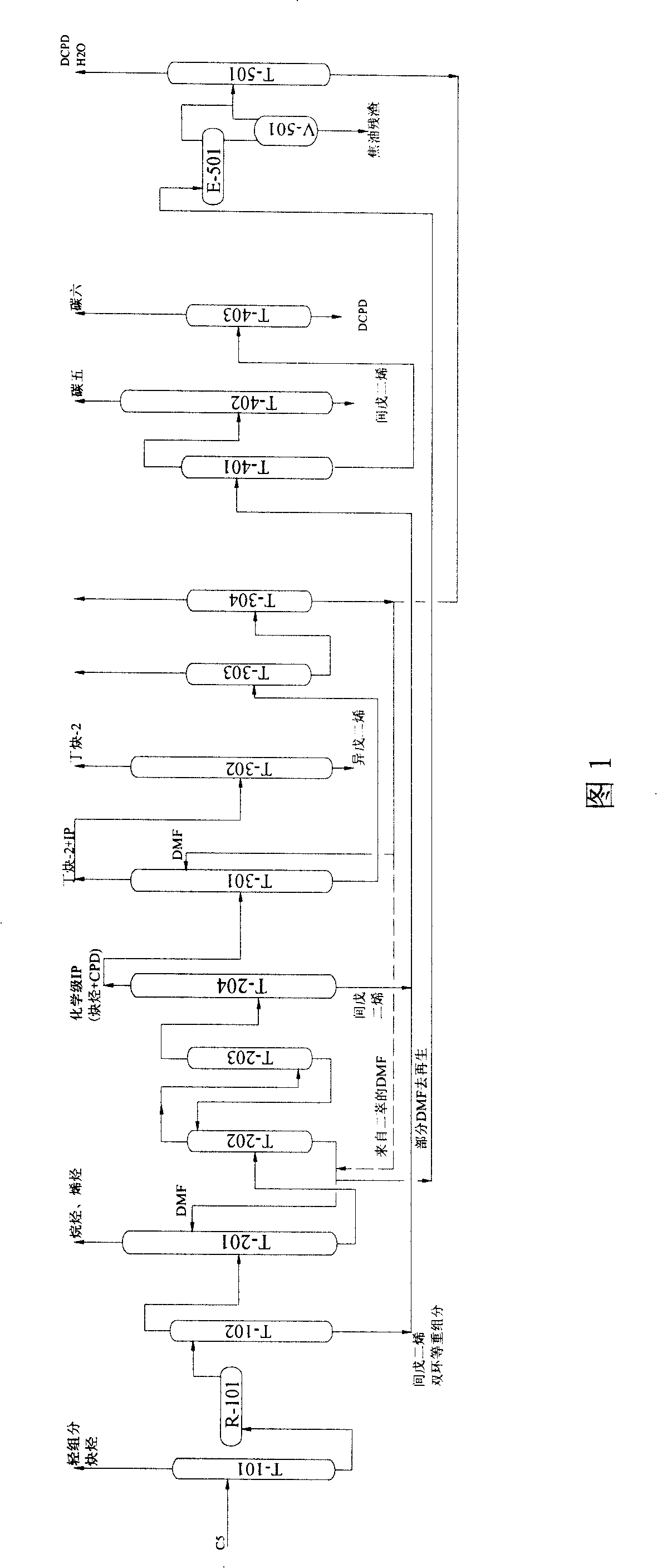

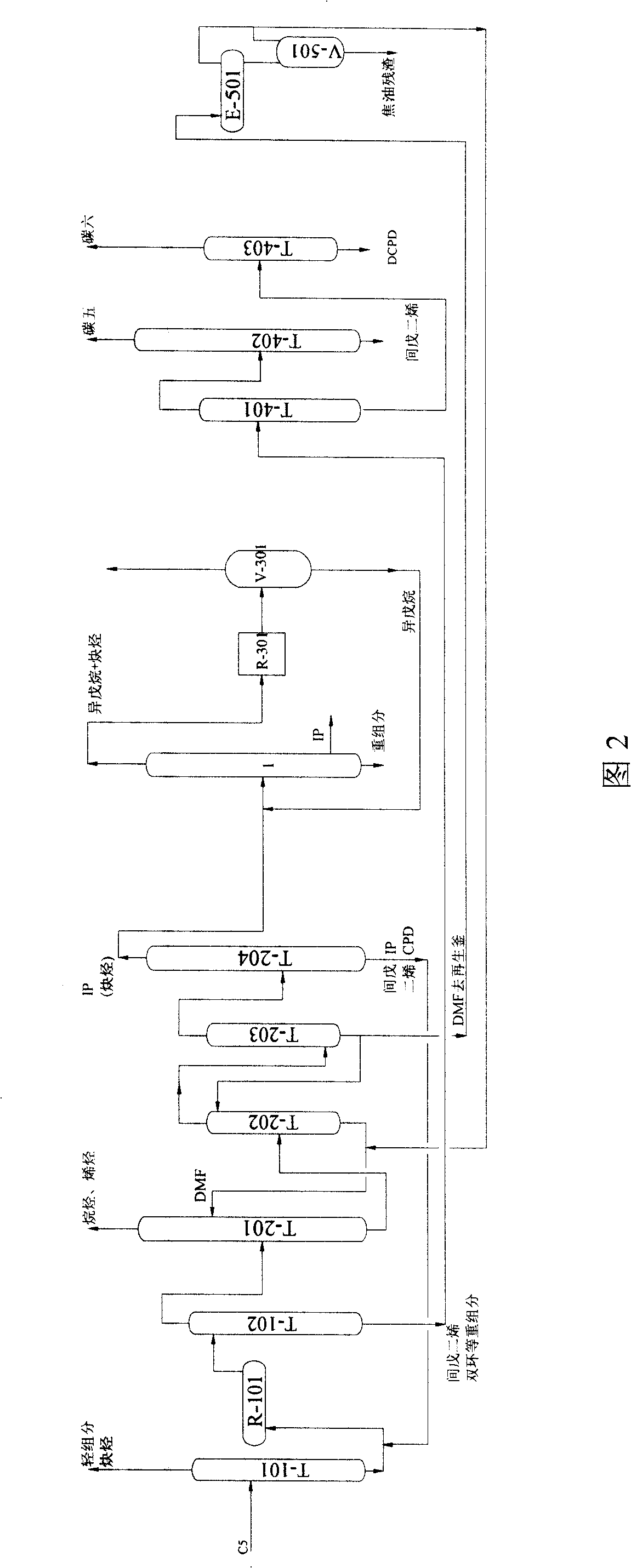

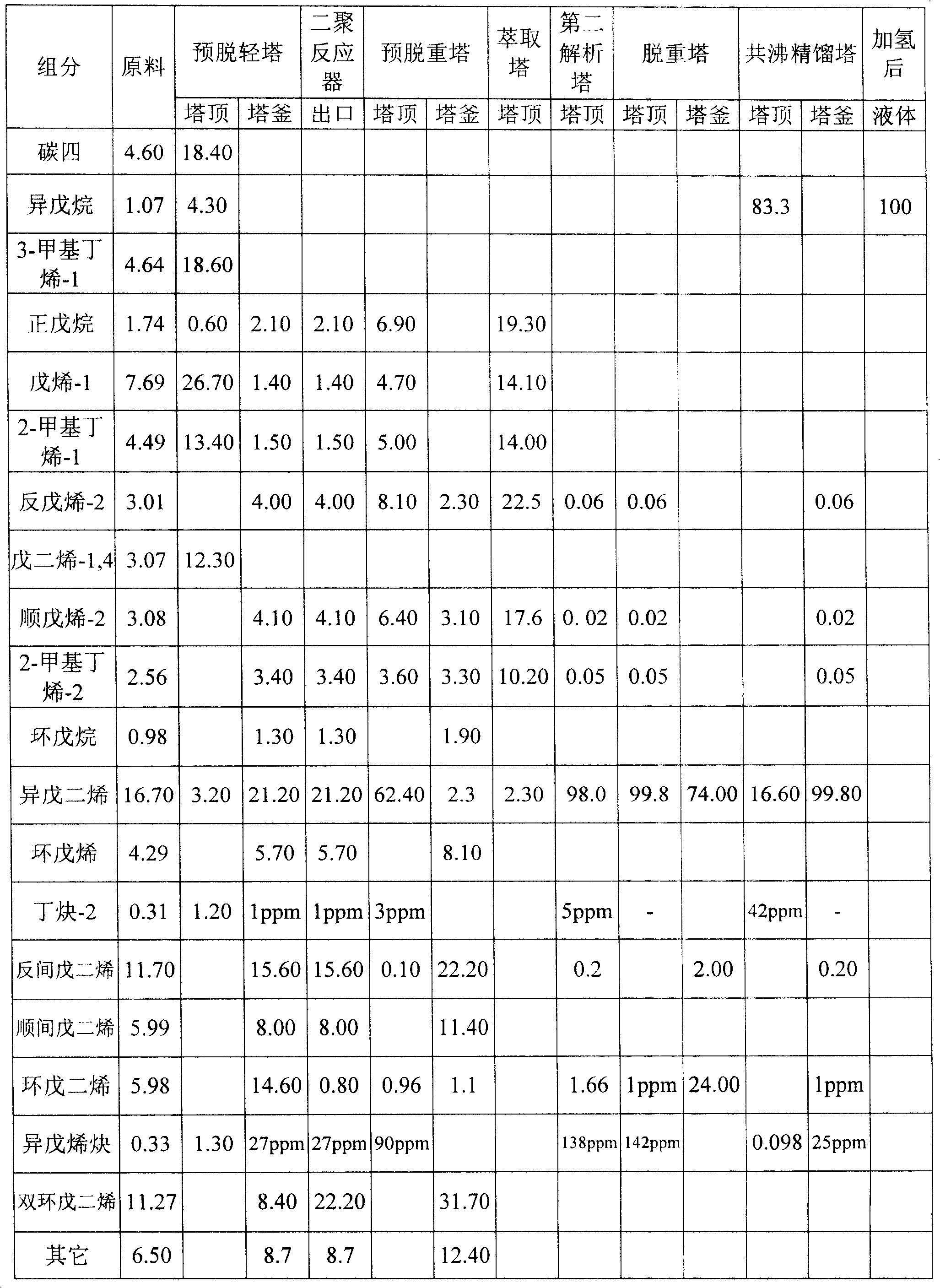

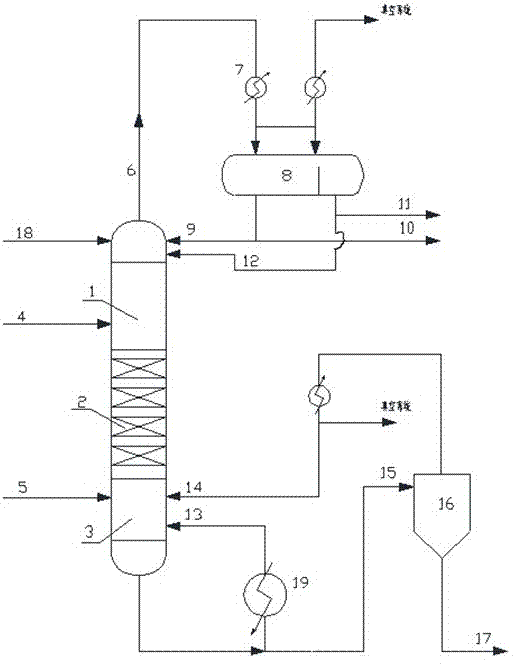

Method for one-section abstraction distillation separation cracking carbon 5-cut fraction

The invention relates to a section of extracting, rectifying, separating and cracking 5 carbon stream which belongs to the technical field of separating 5 carbon stream, and provides a method of a section extracting, rectifying, separating and cracking 5 carbon stream in order to solve the problems of a second extraction unit in the existing carbonium 5 separation process, such as high energy consumption, complex operation, harsh operation demand and big extraction solvent loss, etc.; the method adopts distillation method to remove isoprene and uses an azeotropy distillation method to remove alkyne; a polymerization grade isoprene product is obtained with no need of two times extraction and the second extraction unit and a solvent refining tower are omitted. The method of a section extracting, rectifying, separating and cracking 5 carbon stream is simple in operation, easy in operation and low in production cost; the energy consumption of the polymerization grade isoprene product unit of the invention is about 20 percent of the existing second extraction unit in the same treating load of the raw material; m-pentadiene is produced from a pre-deheavy tower kettle and does not enter an extraction and distillation unit; the throughput of the extraction and distillation tower, an absorption tower and a de-heavy tower is reduced by 50 percent with the energy consumption being reduced by 50 percent correspondingly, and construction cost and production cost are reduced largely. .

Owner:CHINA PETROLEUM & CHEM CORP +1

Reactive distillation method for producing methyl methacrylate

InactiveCN103193640ASimple processOrganic compound preparationChemical industryDecompositionReactive distillation

The invention relates to a reactive distillation method for producing methyl methacrylate. The method comprises steps of synthesizing the methyl methacrylate in a rectifying column; separating a target product from raw materials through azeotropic distillation while reacting, thereby obtaining an organic phase which does not contain methacrylic acid and is rich in methyl methacrylate from a column top and obtaining a solution which contains a great quantity of methacrylic acid from a column bottom; connecting a film evaporator with the column bottom in series; and further concentrating the heavy components of the column bottom so as to reduce the consumption of the methacrylic acid. An azeotropic distillation technology is utilized to separate the methyl methacrylate from acid; a whole rectifying system is integrated and coupled; one reacting and rectifying column is used to realize reacting and rectifying; tasks such as esterification, raw material and product separation and heavy component decomposition which need to be completed by a plurality of columns are completed at the same time; the organic phase which does not contain methacrylic acid and is rich in methyl methacrylate is obtained from the column top; and an original complicated technology is simplified.

Owner:FUYANG JINGLUE CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com