Energy-saving and emission-reducing technique for producing propane epoxide by using hydrogen peroxide epoxidation propylene

A technology for epoxidizing propylene and propylene oxide, which is applied in the chemical industry, organic chemistry, ether separation/purification, etc., can solve the problems of inability to achieve energy saving, not considering energy integration technology, etc., and achieve significant economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

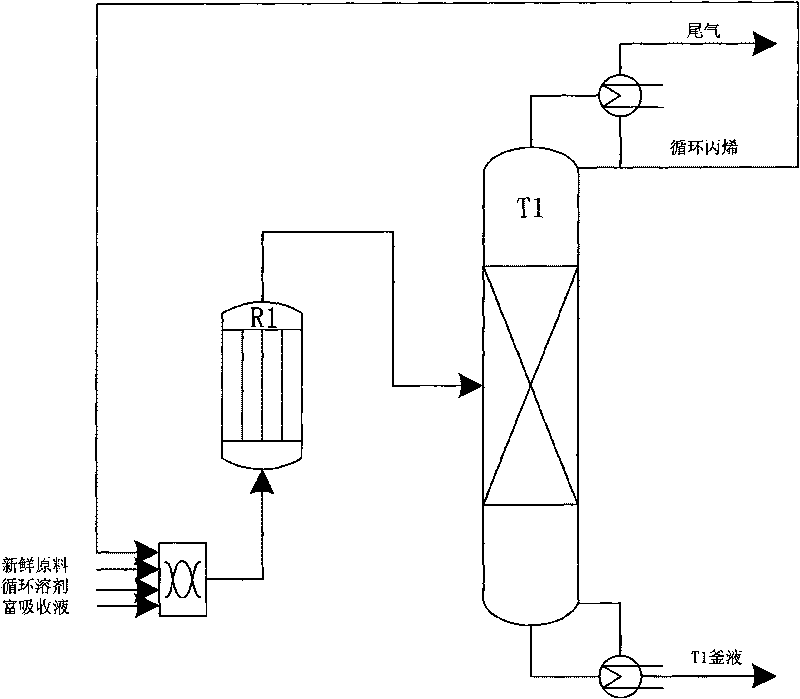

[0027] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings. The technology of the present invention is further described by taking a 100,000-ton PO / year industrial plant as an example.

[0028] like figure 1 As shown, the fresh raw materials flowing into the system are propylene with a mass flow rate of 10.54t / h and 26.86t / h hydrogen peroxide with a mass concentration of 30%. The reaction is carried out in the fixed bed reactor R1, the reaction temperature is 55° C., and the reaction pressure is 20 bar. The reaction product has the composition shown in the table below:

[0029] reaction product

[0030] components

Wt(%)

Acrylic

10.1

[0031] components

Wt(%)

water

10.9

18.2

5.4

Propylene Glycol Monomethyl Ether

0.3

54.7

hydrogen p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com