Patents

Literature

1644results about How to "Easy reunion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

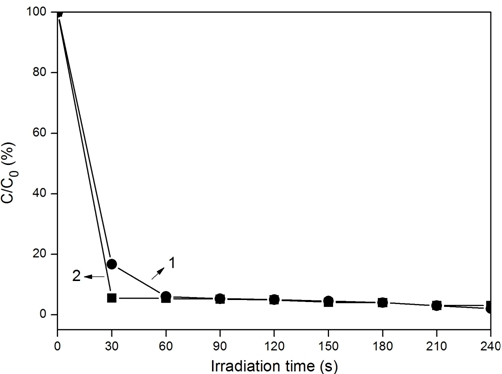

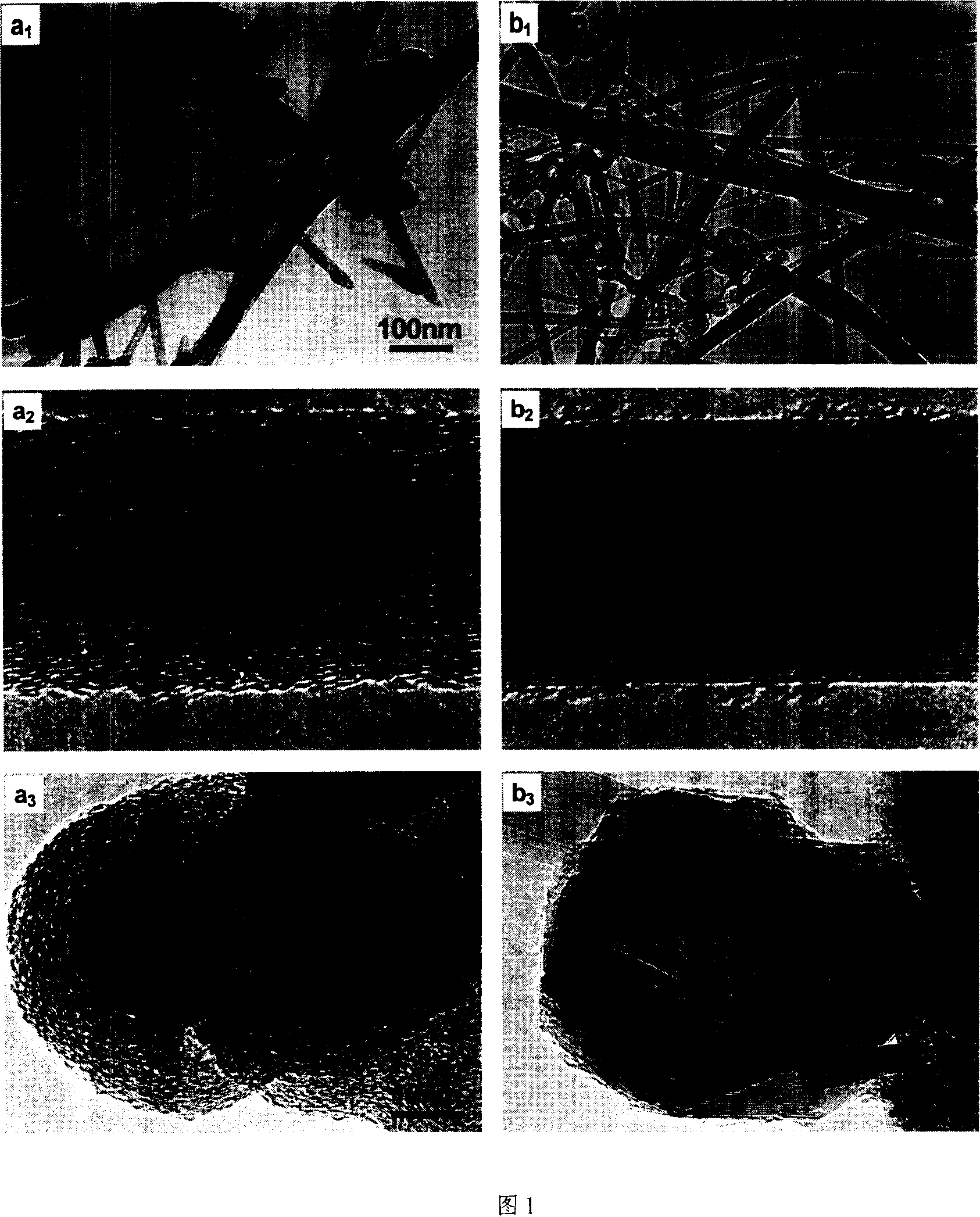

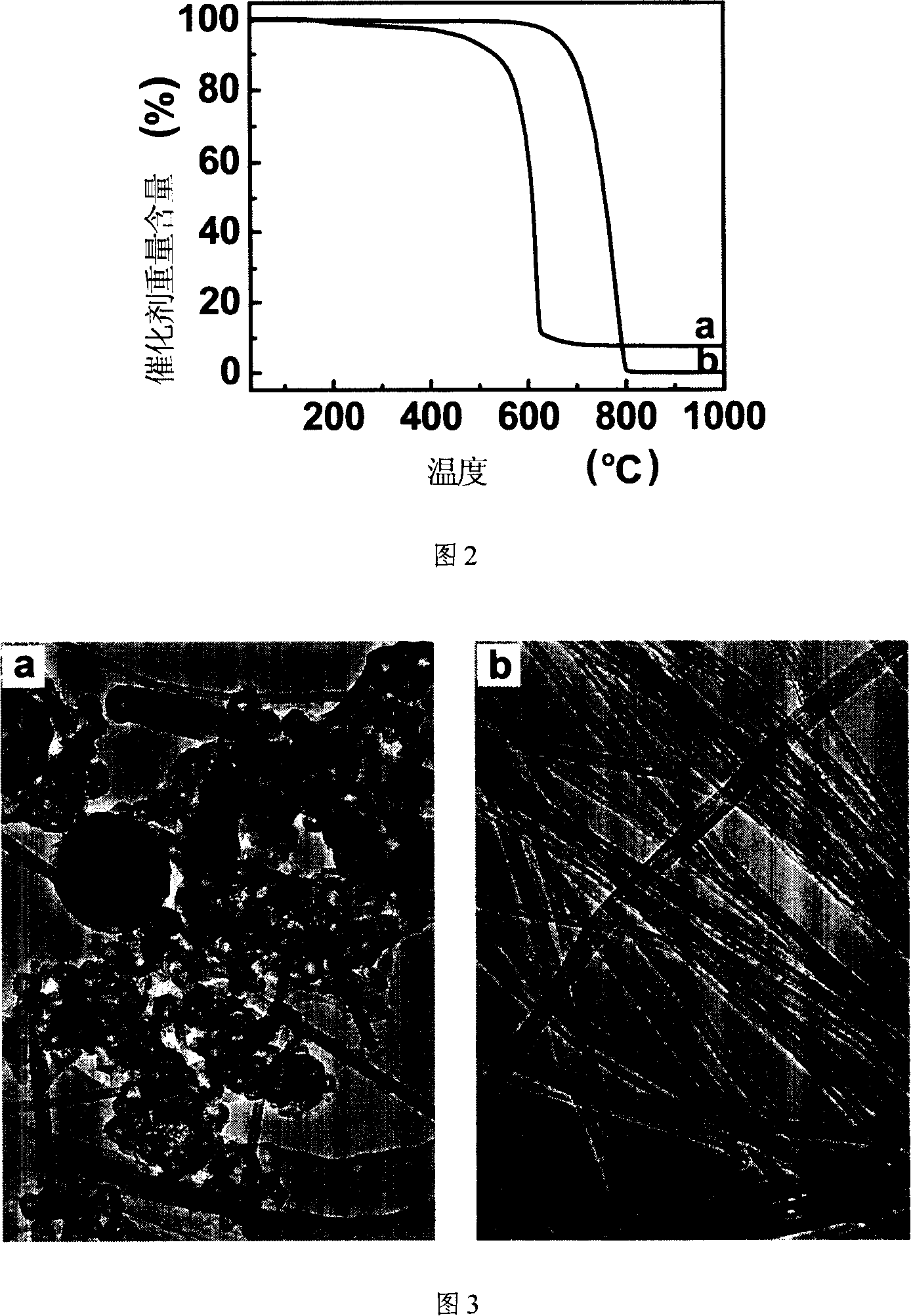

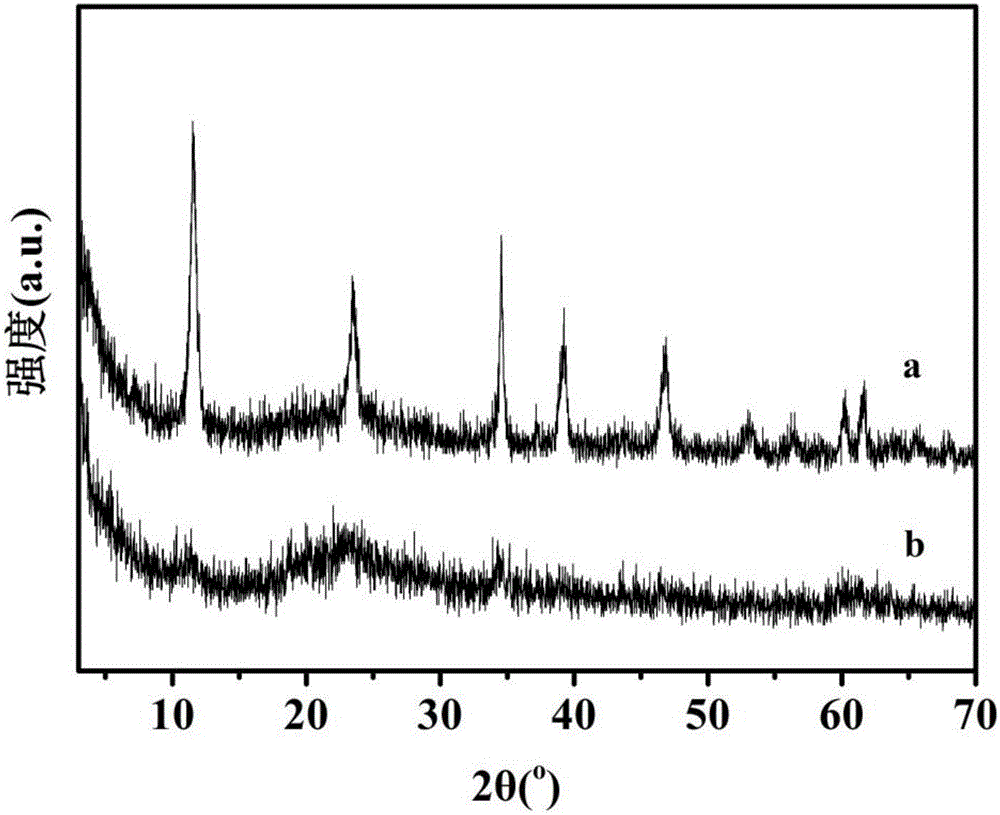

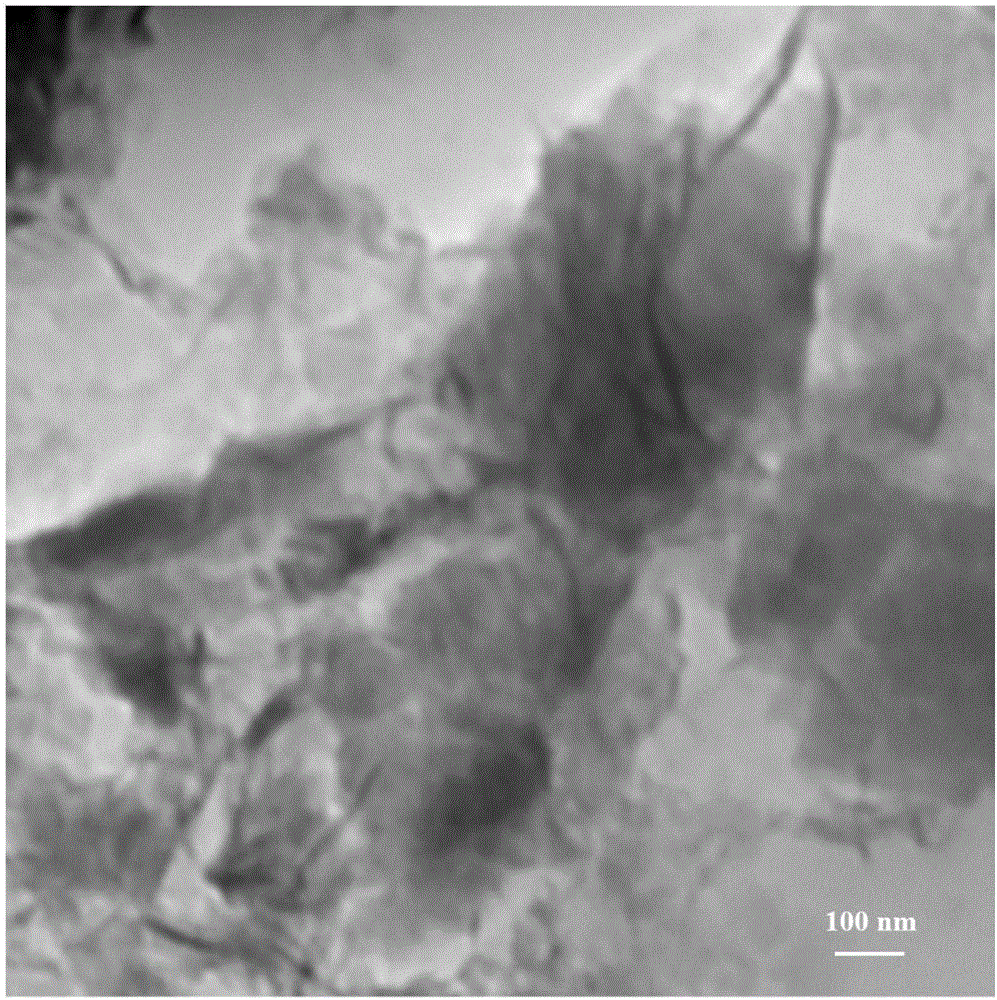

Graphene/silver phosphate composite visible light photocatalyst and preparation method thereof

InactiveCN102631939ALarge specific surface areaEfficient assemblyPhysical/chemical process catalystsWater/sewage treatment by irradiationOrganic dyePhosphoric acid

The invention discloses a high-efficiency graphene / silver phosphate composite visible light photocatalyst and a preparation method thereof, belonging to the technical field of composite materials and environmental management photocatalysis. The preparation method comprises the following steps: dissolving graphene oxide in water, and carrying out ultrasonic treatment to obtain a graphene oxide dispersed liquid; dissolving silver nitrate in deionized water, gradually and dropwisely adding into the graphene oxide dispersed liquid while stirring to obtain a mixed solution, uniformly stirring, and aging; dropwisely adding a prepared disodium hydrogen phosphate or sodium dihydrogen phosphate solution into the graphene oxide-silver nitrate mixed solution, continuing stirring, transferring into a hydrothermal reaction kettle, carrying out hydrothermal reaction, and cooling to room temperature; and washing the reaction product, and carrying out vacuum drying to obtain the visible light photocatalyst. The invention has the advantages of wide material sources and simple preparation process; and the obtained composite material has the advantages of controllable structure and regular pattern, and has high-efficiency degradation effect on organic dyes rhodamine B and methylene blue with certain concentration under the visible light irradiation.

Owner:JIANGSU UNIV

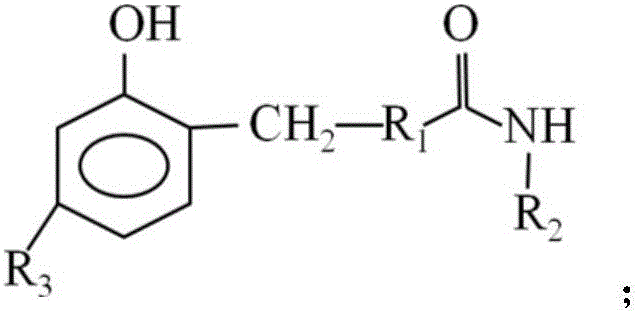

Polymer/graphene anti-static coating, preparation method and application thereof

InactiveCN104449010AEasy reunionSolving Dispersion ProblemsConjugated diene hydrocarbon coatingsPolyurea/polyurethane coatingsStatic performanceCompound system

The invention discloses a polymer / graphene anti-static coating, a preparation method and application thereof. The coating comprises the following constituents by weight percent: 0.01 portions to 0.5 portions of graphene; 0 portion to 10 portions of conductive additive; 90 portions to 100 portions of polymer; and solvent; the preparation method thereof comprises the following steps: completely and uniformly mixing graphene and conductive additive in advance by various manners; preparing a graphene-conductive additive compound system; using the compound system as a base, adding in conductive additive and polymer along with the solvent, completely and uniformly mixing to obtain the coating. Additionally, an anti-static film can be prepared by using different film forming technologies. The polymer / graphene anti-static coating, the preparation method and application thereof effectively solve the problems that graphene in polymer is easy to agglomerate and difficult to be uniformly dispersed in the preparation process of anti-static coating and film; the anti-static performance and mechanical performance of the coating and the film are greatly increased; meanwhile, the preparation technology is easy to be operated; the production is continuous, and the coating and film are suitable for industrial production.

Owner:苏州格瑞丰纳米科技有限公司

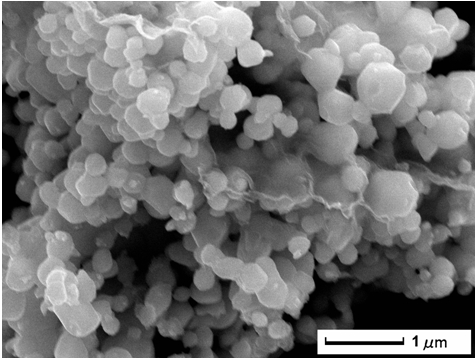

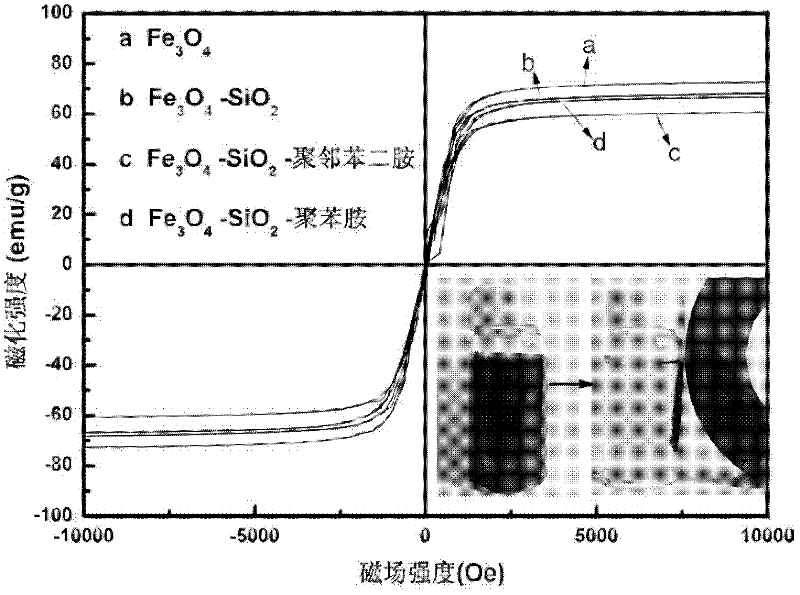

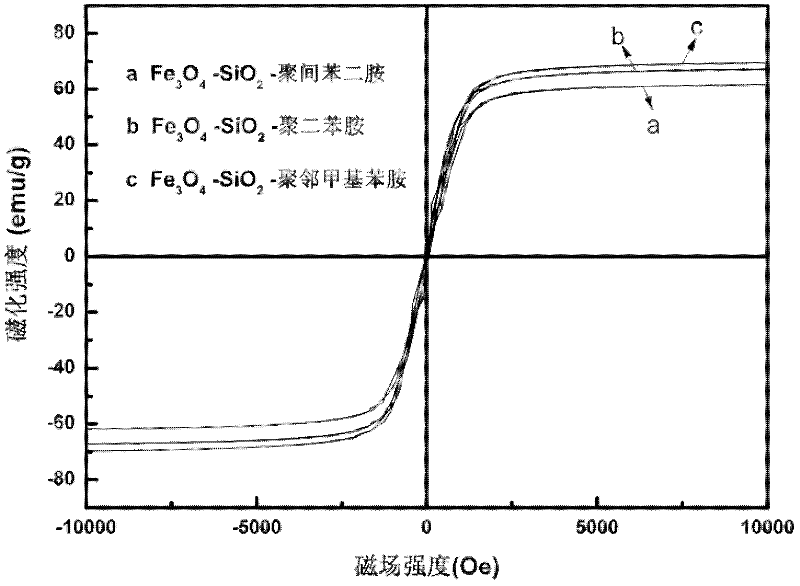

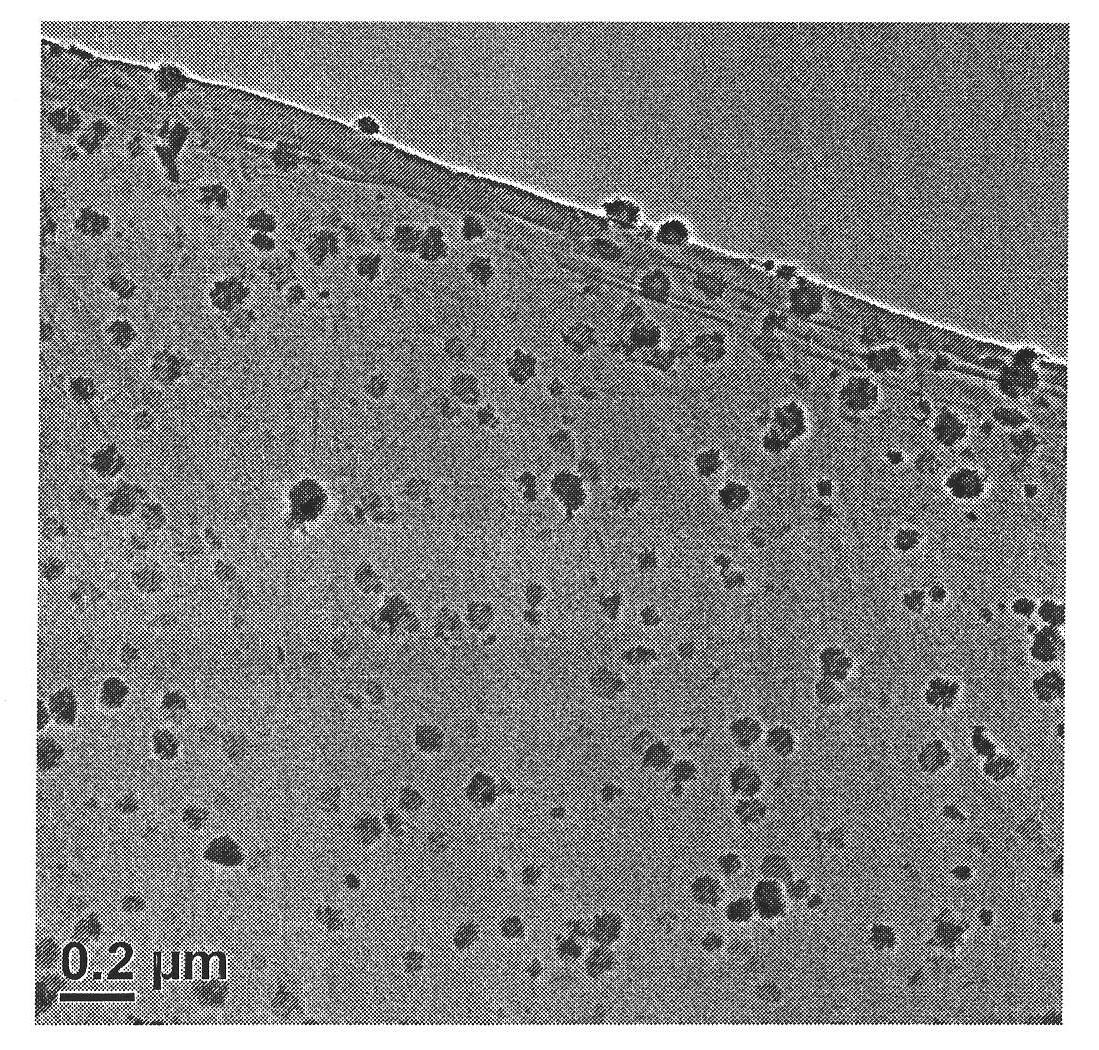

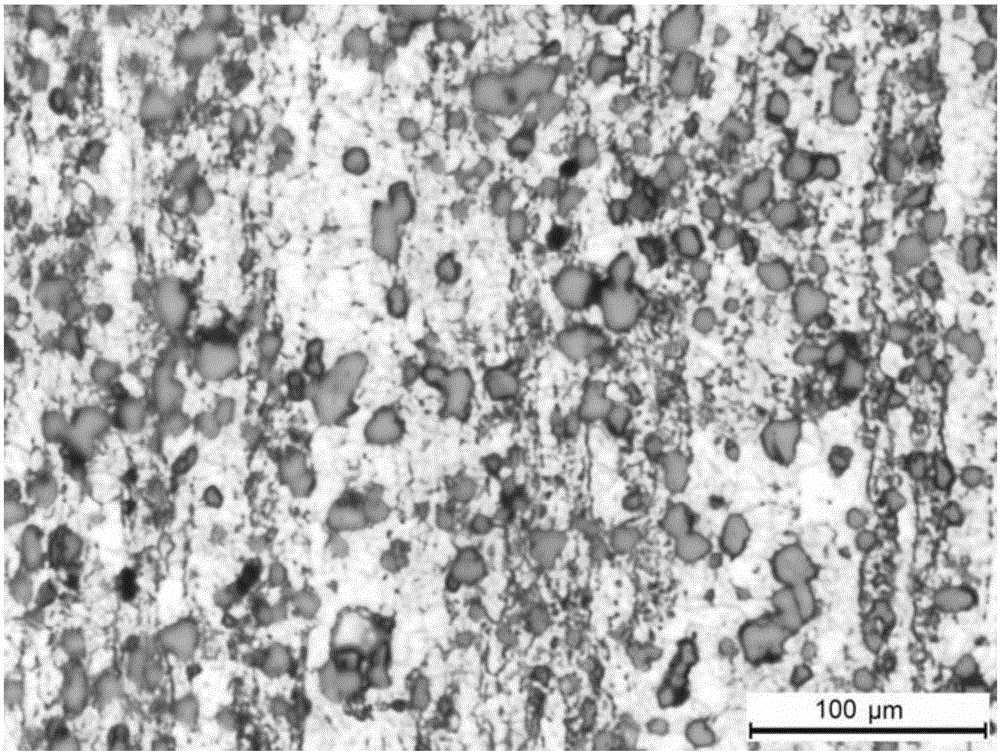

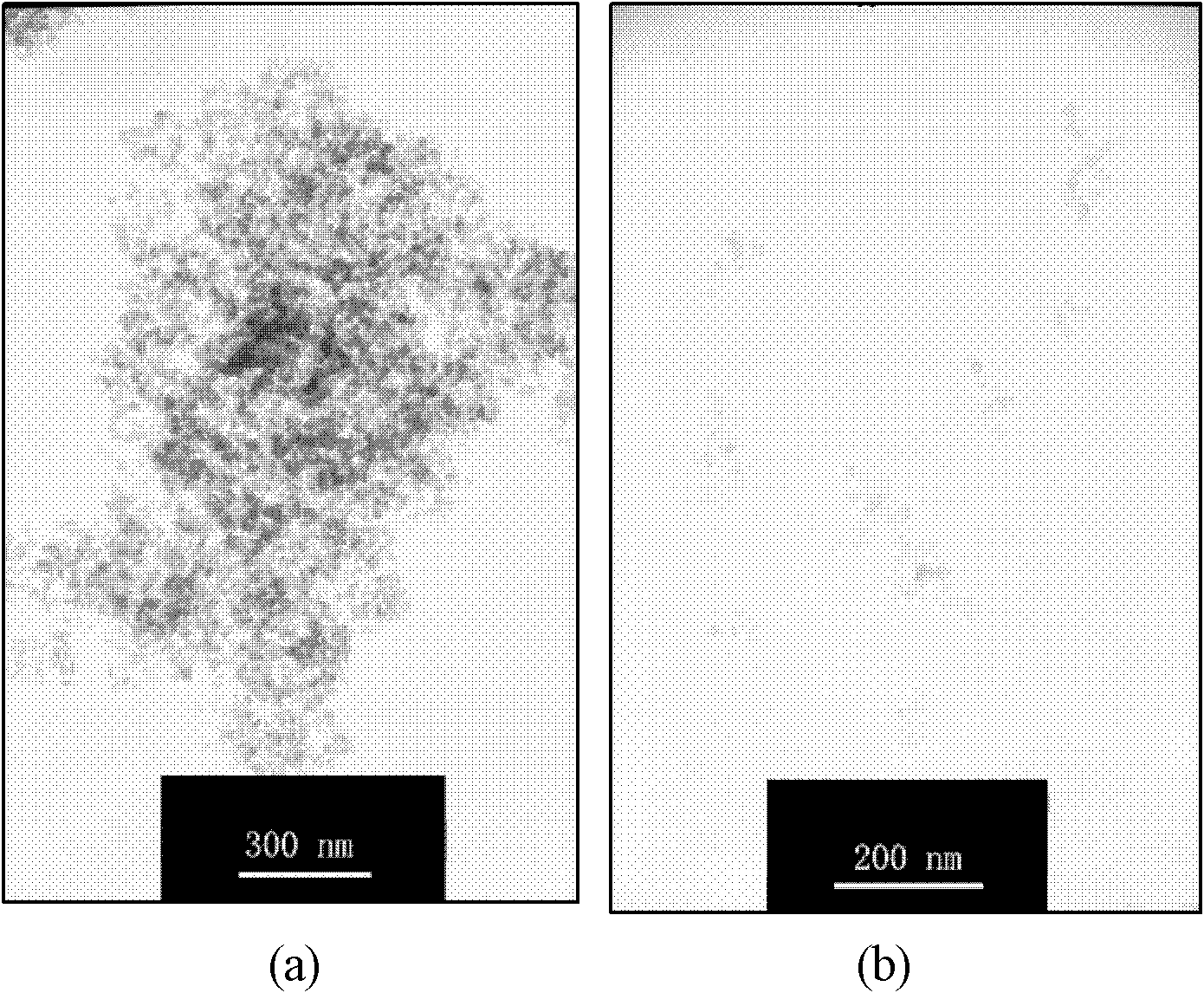

Magnetic submicron composite core-shell particles, and preparation method and application thereof

InactiveCN102360659ALarge specific surface areaGood value for moneyOther chemical processesInorganic material magnetismSewageSolvent

The invention discloses magnetic submicron composite core-shell particles. In the magnetic submicron composite core-shell particles, Fe3O4 particles with the particle size of between 80 and 800nm are taken as a magnetic core, amorphous SiO2 is taken as an immediate shell layer and a substance with heavy metal absorption performance is taken as an outer shell layer. The invention also discloses a preparation method for the magnetic submicron composite core-shell particles. The preparation method comprises the following steps of: preparing the Fe3O4 particles with the particle size of between 80 and 800nm by a solvothermal method and taking the Fe3O4 particles as magnetic cores, performing alkaline hydrolysis of a silicon source reagent on Fe3O4 and dehydrating and condensing hydroxy groups so as to obtain amorphous SiO2 immediate shell layers, and coating the substance with heavy metal absorption performance on obtained submicron spheres under chemical or physical action to obtain the magnetic submicron composite core-shell particles. The submicron material has high performance of absorbing heavy metal ions in the sewage; and the material has stable characteristics, can be magnetically recovered and meets environmental protection requirements, and secondary pollution is avoided.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

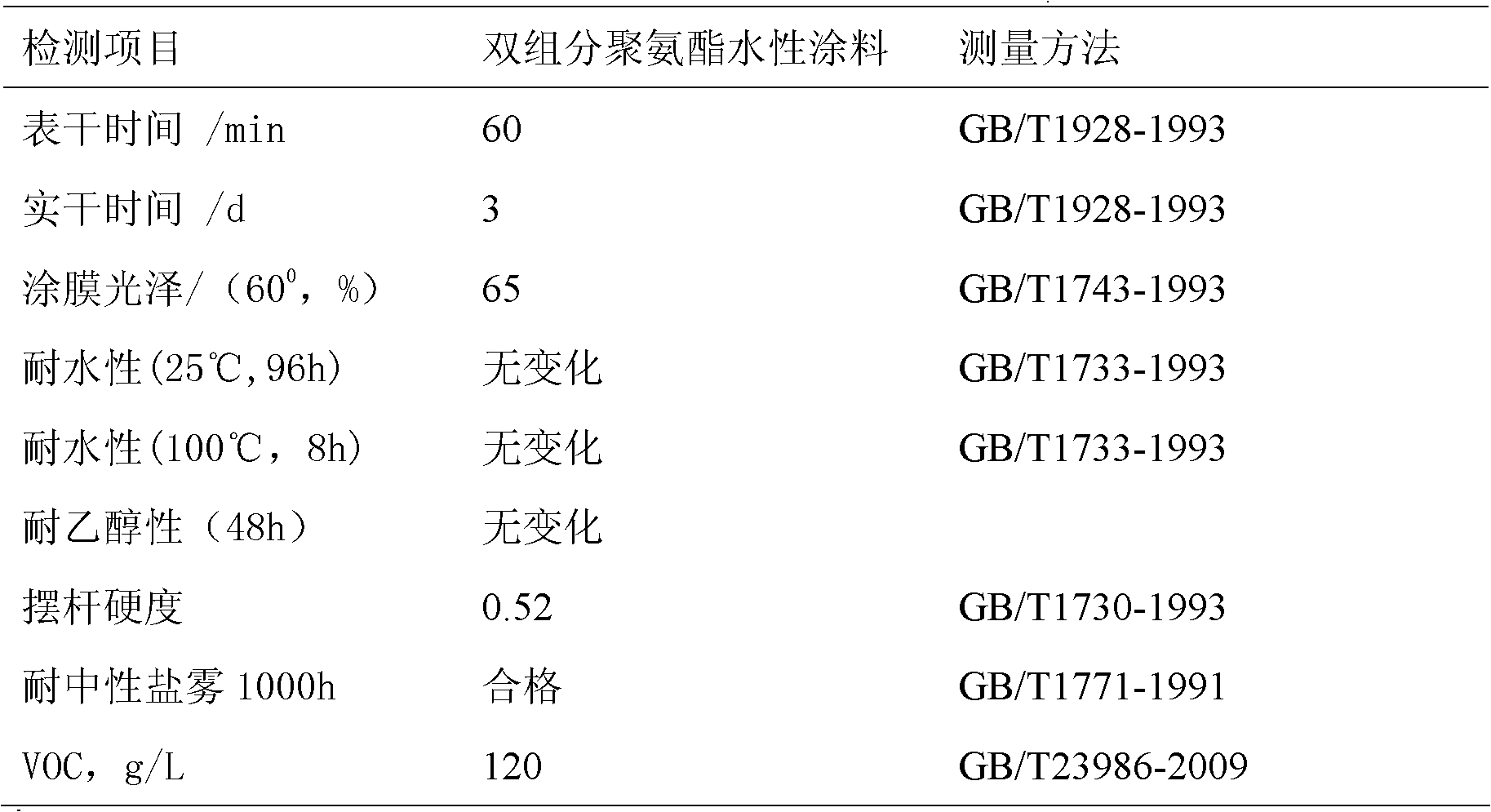

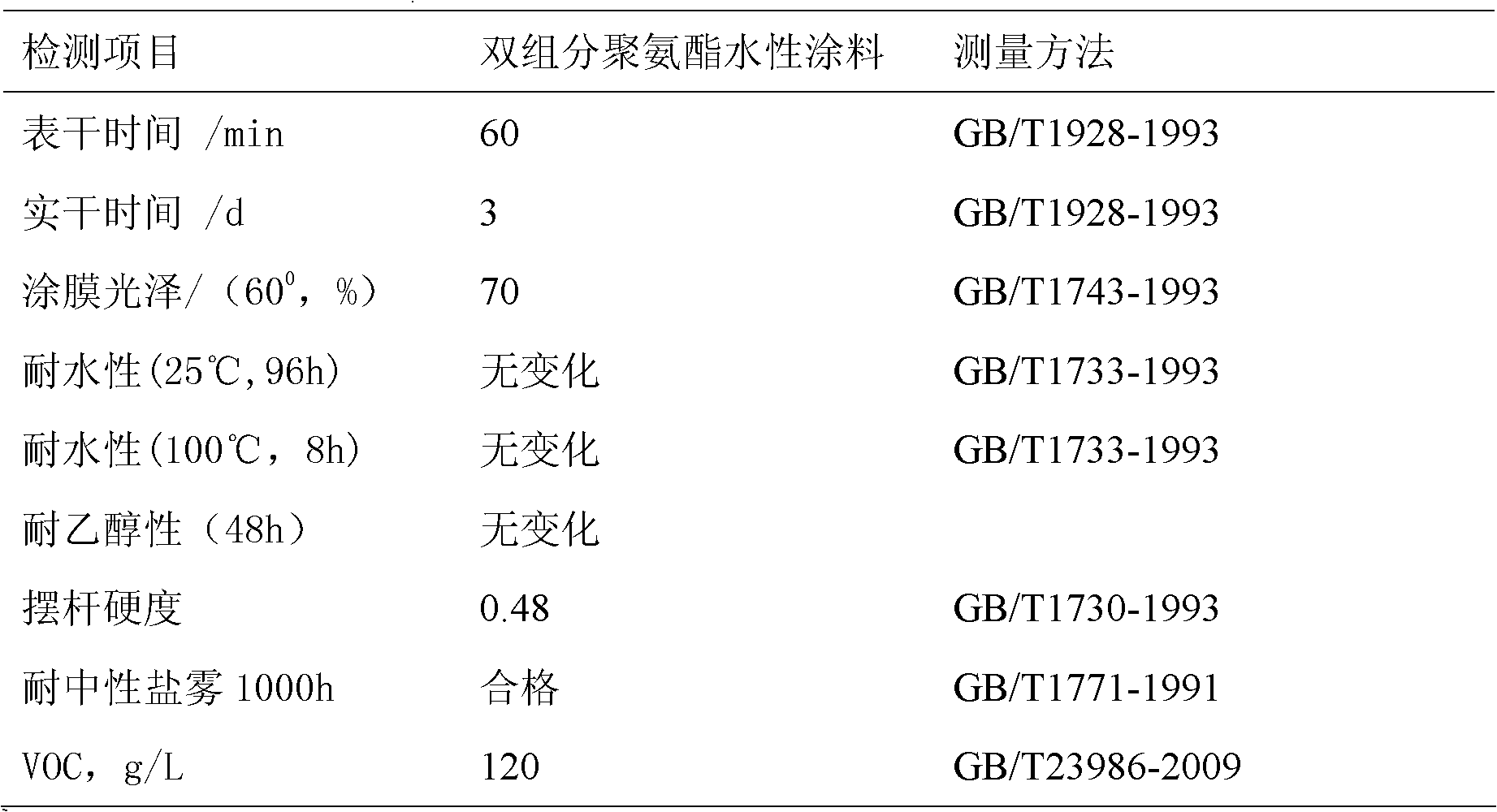

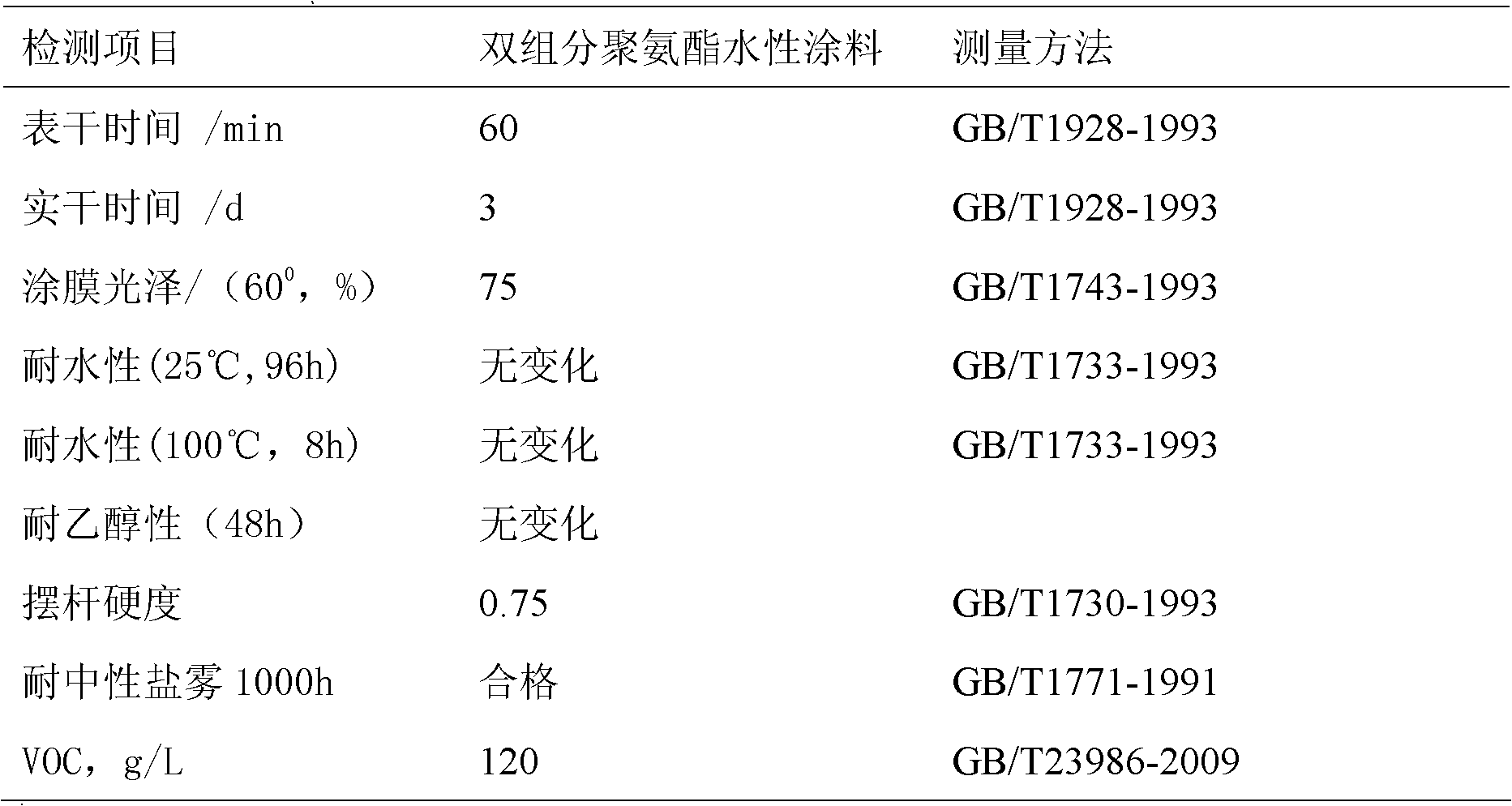

Double-component polyurethane water-based paint

InactiveCN102108246AIncrease roughnessImprove flatnessPolyurea/polyurethane coatingsWater basedPolymer science

The invention provides a double-component polyurethane water-based paint, belonging to the field of organic polymer compounds. The double-component polyurethane water-based paint comprises isocyanate curing agents component A and component B, wherein the molar ratio of OH groups of a polymer in the component A to NCO groups in the component B is 1: (1-2.2); and the component A contains polymer aqueous dispersion and polymer emulsion, wherein the content of OH in the polymer aqueous dispersion is 2.0-5.0% and the grain size of latex in the polymer aqueous dispersion is 10-100nm, the weight of the polymer emulsion is 0.05-16 times that of the polymer aqueous dispersion, the content of OH in the polymer emulsion is 0-2.0%, and the grain size of the latex in the polymer emulsion is 80-500nm. In the invention, the polymer aqueous dispersion which has small average grain size and contains -OH and the polymer emulsion which has large average grain size are compounded, wherein the latex with a large grain size can increase the roughness and unevenness of a film and reduce the gloss of the film, and the emulsion with small particles promotes the latex with the large grain size to aggregate, reduces the lowest film-forming temperature of the film, improves the film-forming capability of the film and decreases the usage amount of a film-forming additive; and the hardness, chemical-resistance and wear-resistance of the film are improved by using two different water-based polymers are used for compounding.

Owner:SOUTH CHINA UNIV OF TECH +1

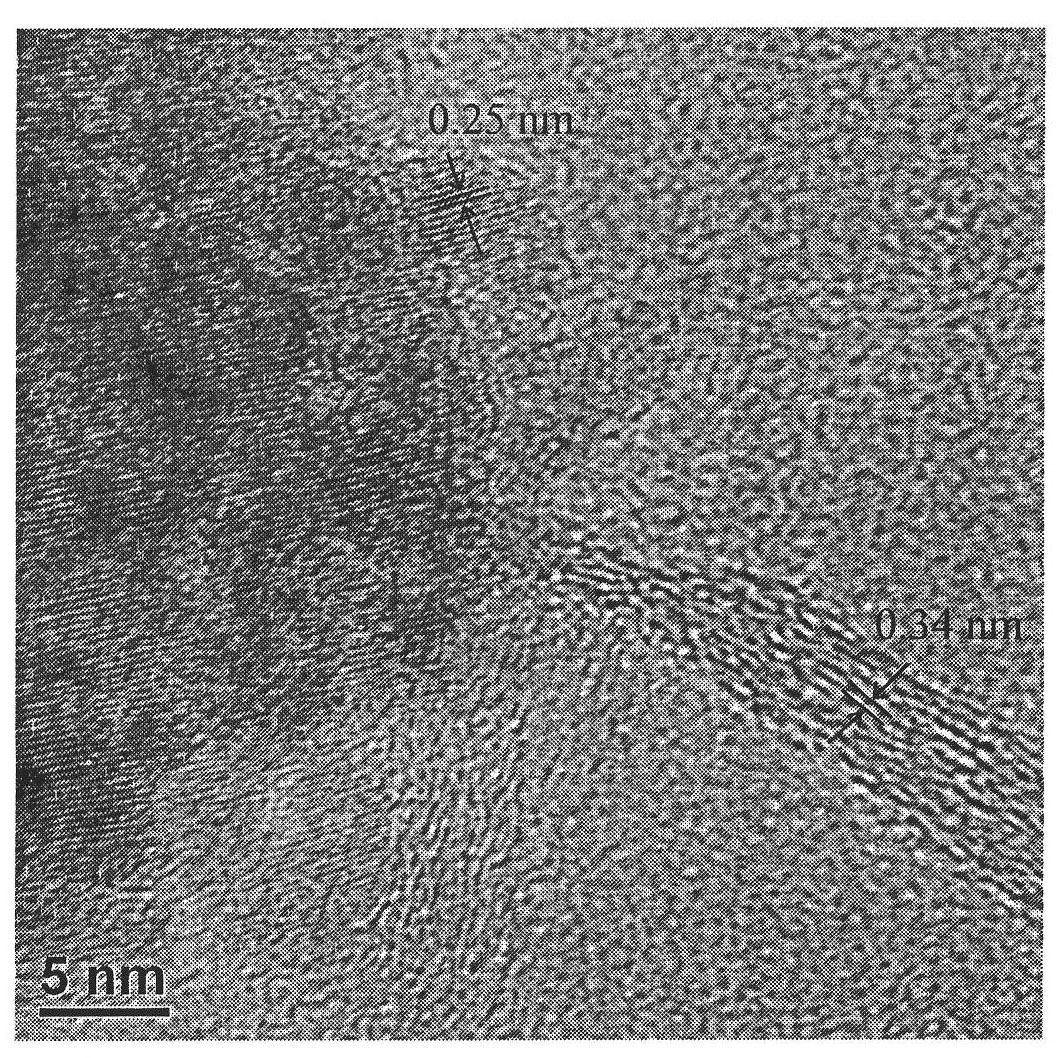

Method for preparing graphene/Fe3O4 composite powder by alcohol thermal method

InactiveCN101837971AEasy to prepareLow requirements for production equipmentFerroso-ferric oxidesAlcoholPolyethylene glycol

The invention relates to a method for preparing graphene / Fe3O4 composite powder by an alcohol thermal method, which comprises the following steps of: (1) weighing oxidated graphite and ferric salt at room temperature, dispersing into a glycol solution, adding polyethylene glycol after dissolving completely, then adding anhydrous sodium acetate, stirring and forming reaction liquid; (2) putting into a reaction kettle, heating to the temperature of 180 to 220 DEG C and reacting for 8 to 16h; and (3) cooling to the room temperature, collecting a product by using a magnet, washing the product by deionized water and drying so as to obtain the graphene / Fe3O4 composite powder. In the invention, the preparation method is simple and is easy for industrialized production; and Fe3O4 in the prepared graphene / Fe3O4 composite powder has pure crystalline phase, little possibility of agglomeration, favorable compounding with graphene and good dispersibility at the surface of the graphene and in the layer of the graphene, and the composite powder has small resistivity and high magnetization intensity.

Owner:DONGHUA UNIV

Technology for preparing organic fuel through directly converting carbon dioxide by using sunlight and photothermal catalyst

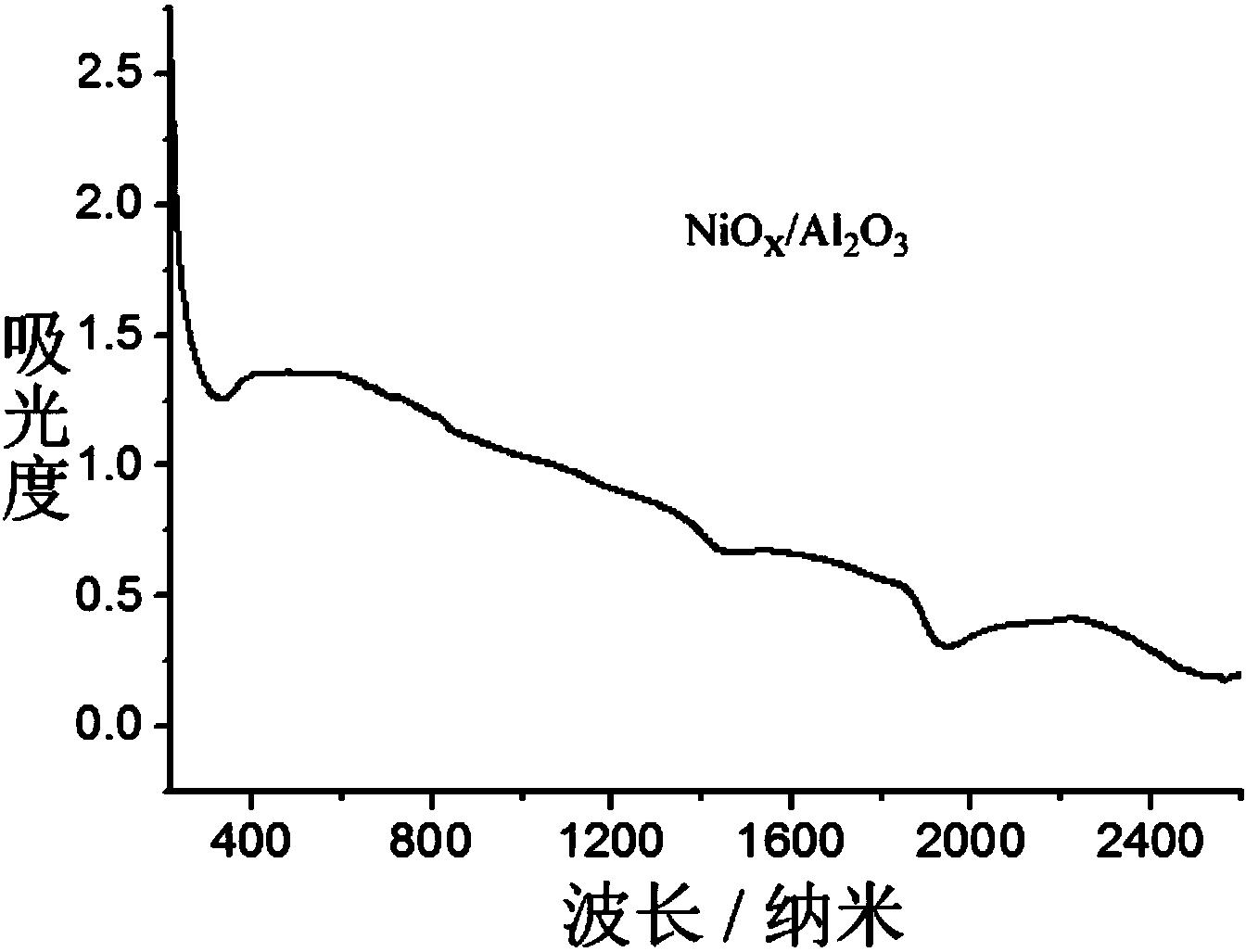

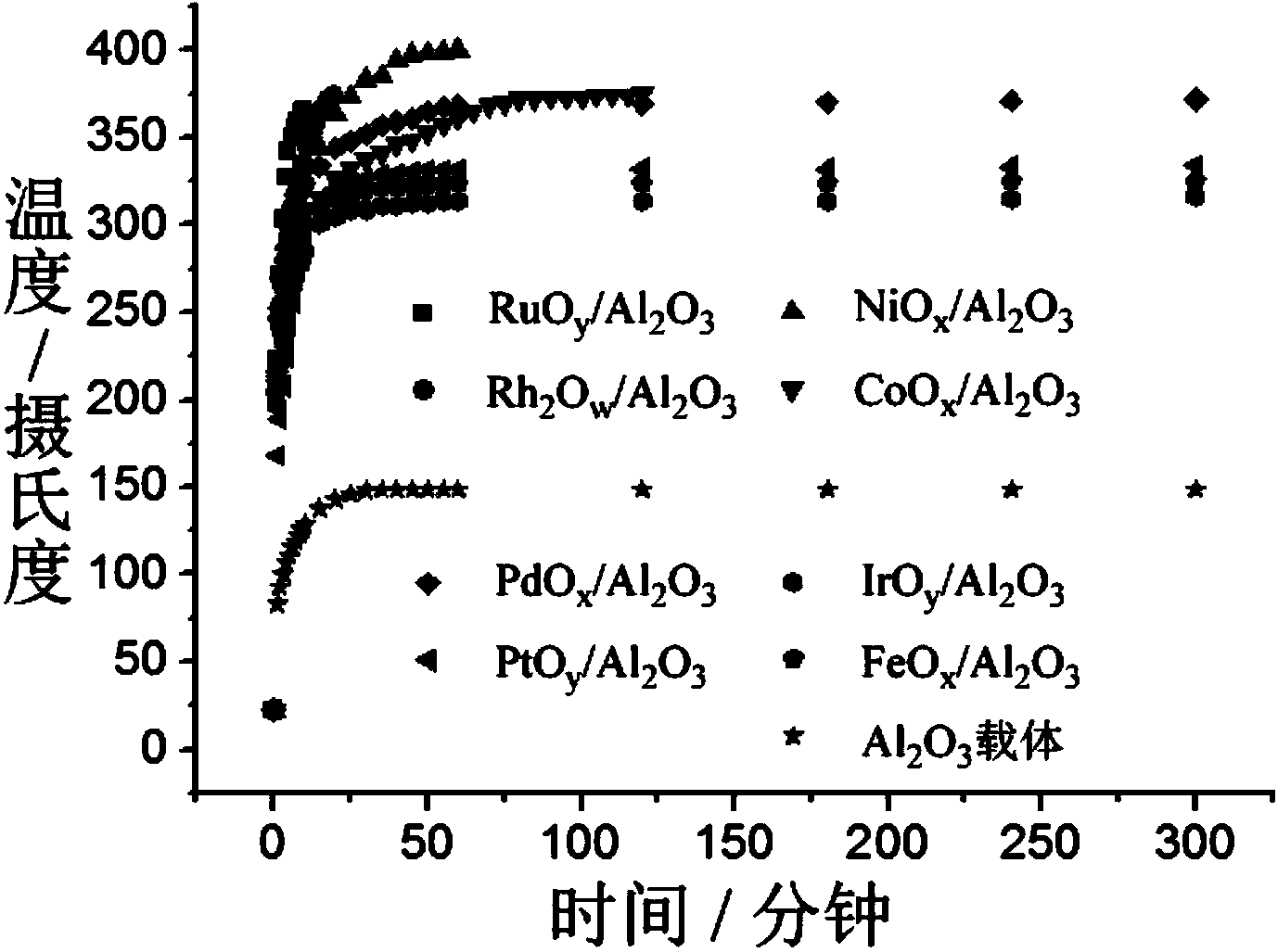

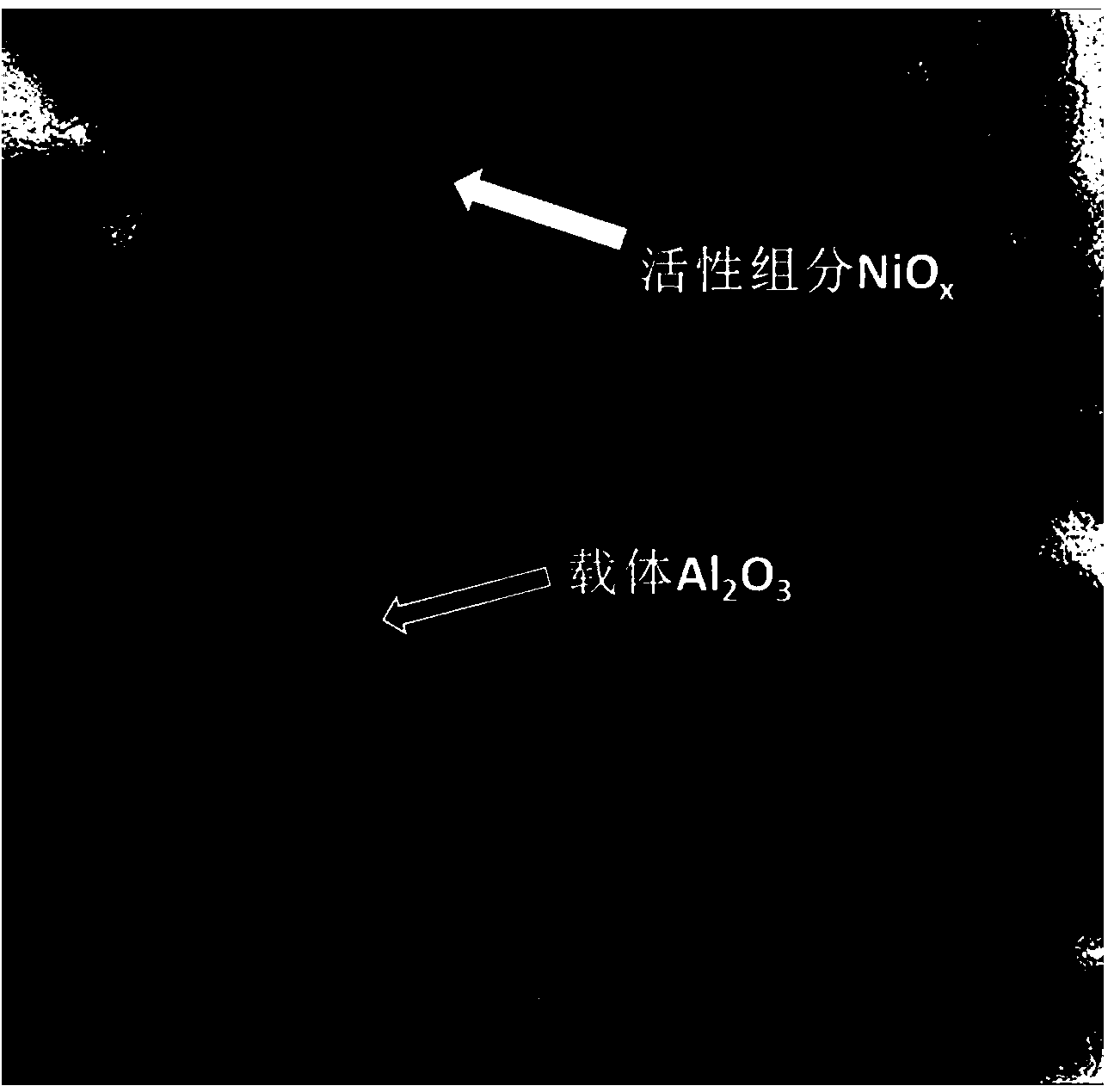

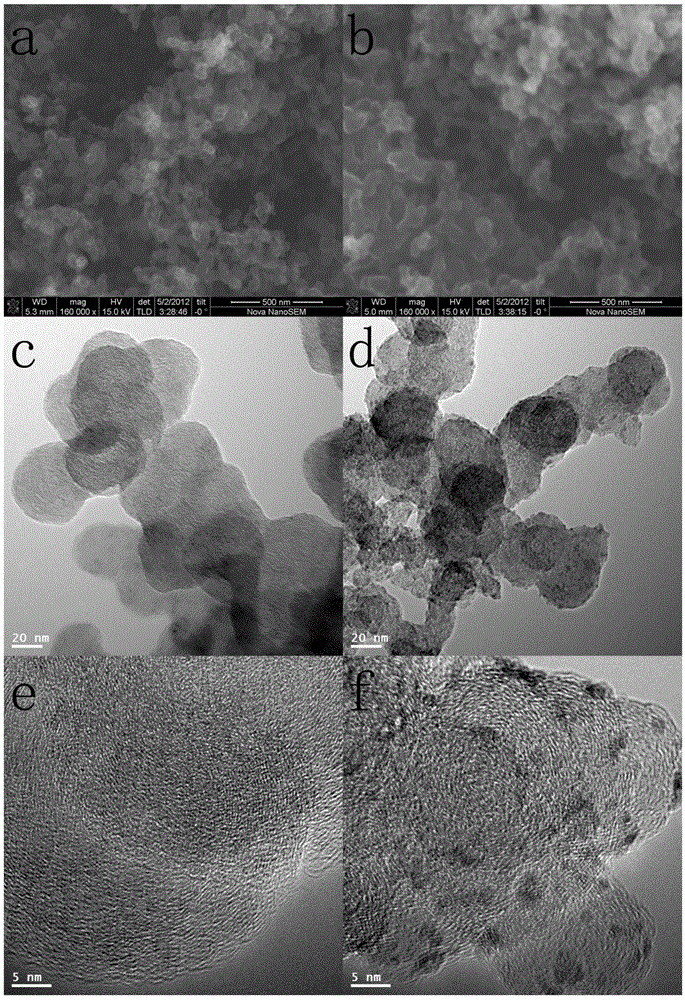

InactiveCN104016825AReduce energy consumptionHigh reactivityHydrocarbon from carbon oxidesOrganic compound preparationSynthesis methodsUltraviolet lights

The invention discloses a technology for preparing organic fuel through directly converting carbon dioxide by using sunlight and a photothermal catalyst. Sunlight is utilized to supply light and heat for the synthesis and catalytic process of the photothermal catalyst, and the photothermal catalyst can simultaneously absorb and utilize ultraviolet light, visible light and infrared light parts in sunlight, so that a phtothermal catalytic reaction is induced to prepare the organic fuel through reducing carbon dioxide by using hydrogen. The photothermal catalyst comprises the following components: an active component which is a 2-30 nano-scale non-stoichiometric oxide belonging to a VIII-family element in a transition family and a carrier material which is an oxide or carbon material with the specific surface area of 30-1000cm<2> / g, alkaline resistance, high heat conductivity or photocatalytic activity. A steeping and in-situ sintering method or photodepositing and in-situ sintering method is used as a synthesis method so that the energy consumption is low, and the photothermal catalyst has high activity and long service life by using a solar-assisted in-situ sintering technology. The technology for preparing organic fuel through directly converting carbon dioxide by using sunlight and the photothermal catalyst is low in energy consumption in the catalytic process, high in organic fuel production efficiency and stable in catalyst activity.

Owner:TIANJIN UNIV

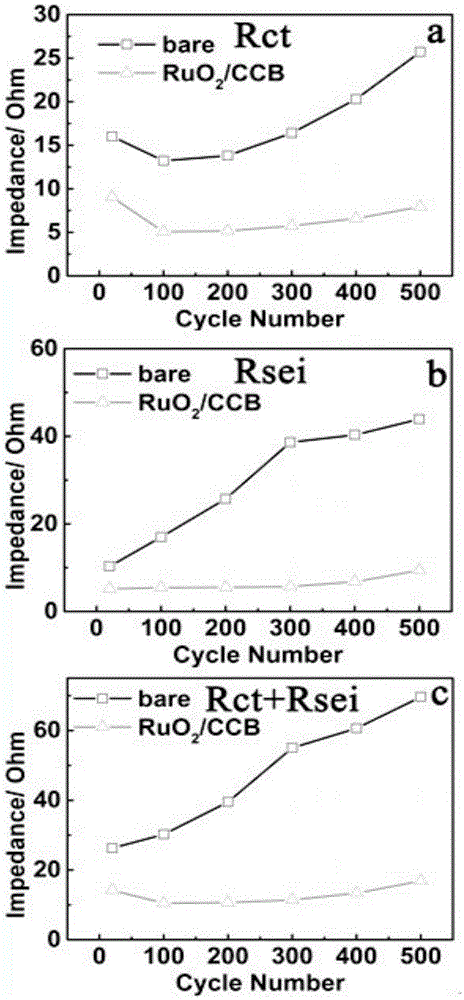

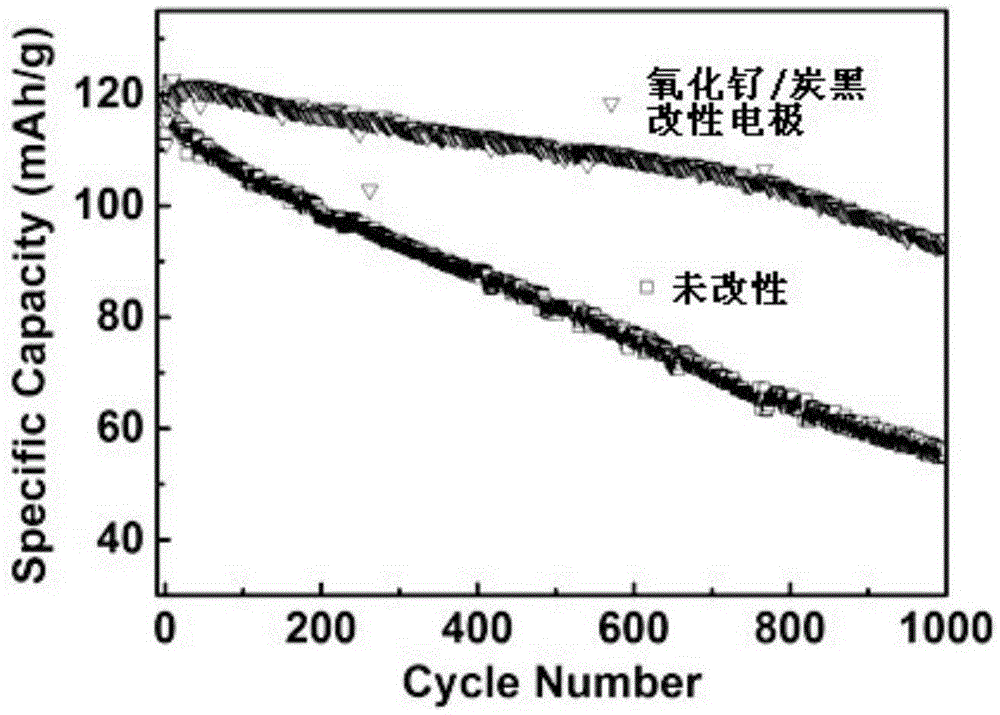

Method for modifying positive electrode of lithium ion battery by adding metal oxide/carbon composite material

ActiveCN105390700AEvenly dispersedAchieve electrode modificationCell electrodesCarbon compositesSodium-ion battery

The invention discloses a method for modifying a positive electrode of a lithium ion battery by adding a metal oxide / carbon composite material, and belongs to the technical field of secondary lithium ion batteries. The modification method comprises: mechanically mixing a positive electrode active material of the lithium ion battery with an electrode additive, wherein the electrode additive is the composite material and consists of two parts of a conductive carbon material carrier and a metal oxide load. The electrode additive can reduce the rate of increment of impedance of the positive electrode of the lithium ion battery along with charging / discharging cycle, thereby achieving the purpose of improving the cycle performance of the lithium ion battery.

Owner:HARBIN INST OF TECH

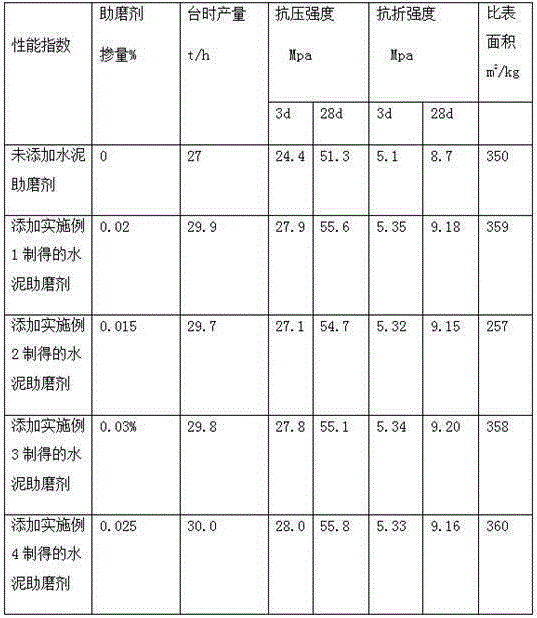

Cement grinding aid and preparation method thereof

The invention relates to a cement grinding aid, in particular to a cement grinding aid and a preparation method thereof. The cement grinding aid is prepared from, by weight, 13-18 parts of polymeric polylol, 8-12 parts of tri-isopropanolamine, 12-15 parts of polyol ether, 15-20 parts of ethanediol, 25-30 parts of triethanolamine, 15-18 parts of molasses, 13-15 parts of lignin, 0.03-0.06 part of sodium chloride, 0.5-1 part of silane coupling agents and 40-45 parts of water. By means of the obtained cement grinding aid, in the cement production process, the phenomena of clinker fine particle aggregation and ball pasting can be effectively improved, mobility of clinker particles is enhanced, thereby the pulverization effect of grinding media in a grinding machine for materials is enhanced, grinding efficiency can be improved by 15-20%, the cement machine-hour yield is increased, electricity consumption is greatly lowered, production cost is lowered, in addition, strength of cement at different ages can be remarkably improved, and flowability of the cement is improved.

Owner:内蒙古同佳技术发展有限公司

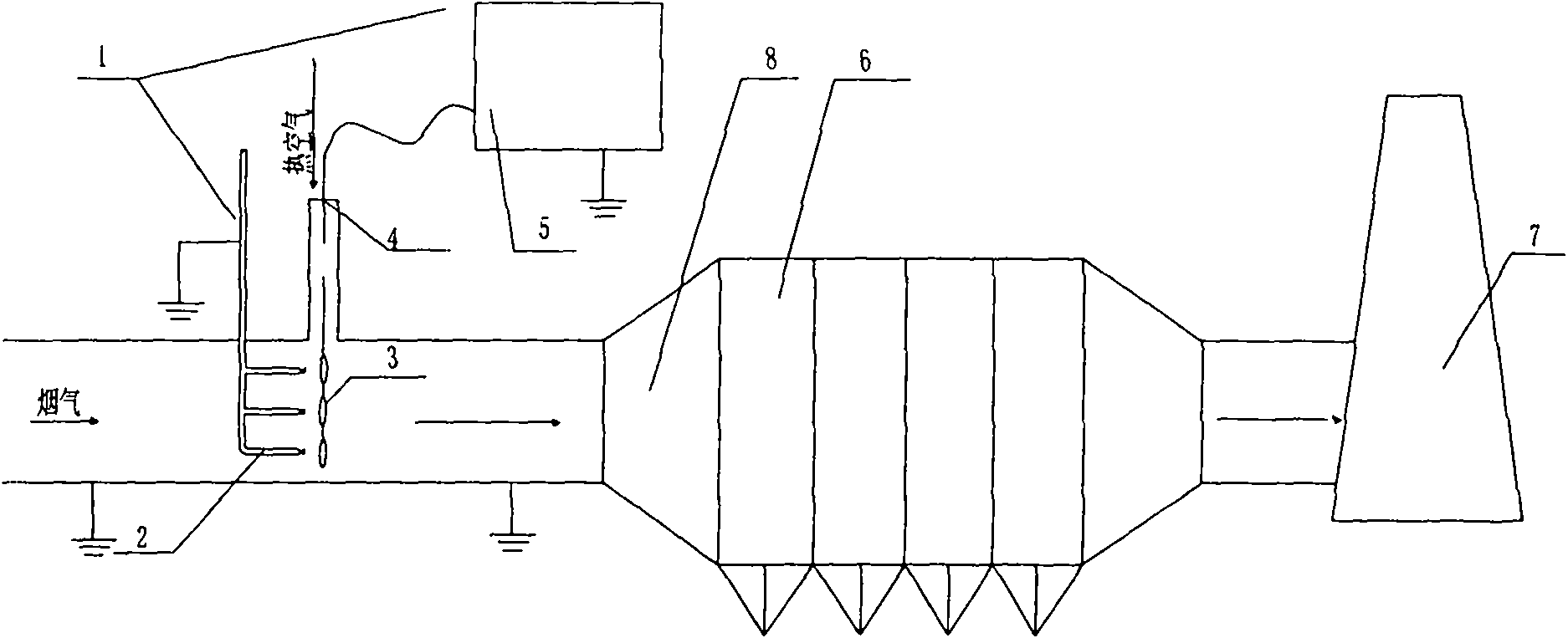

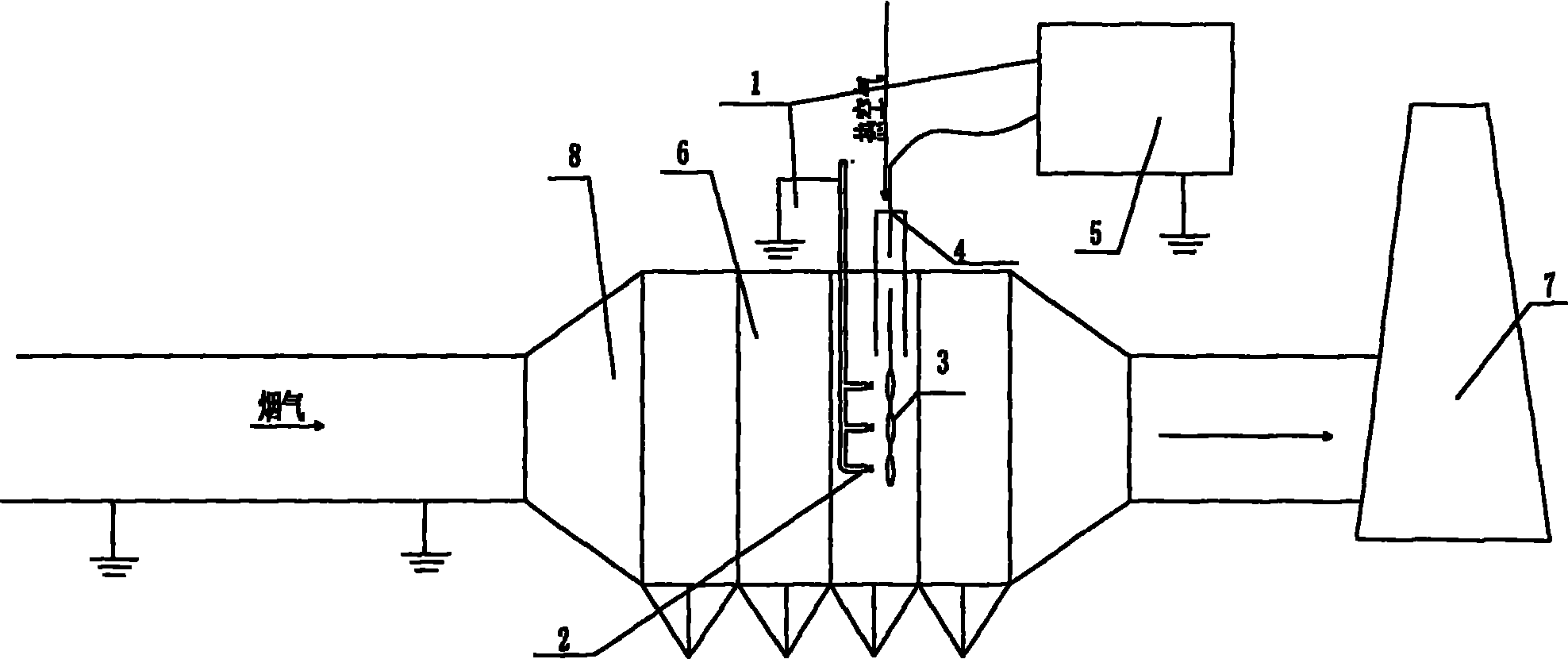

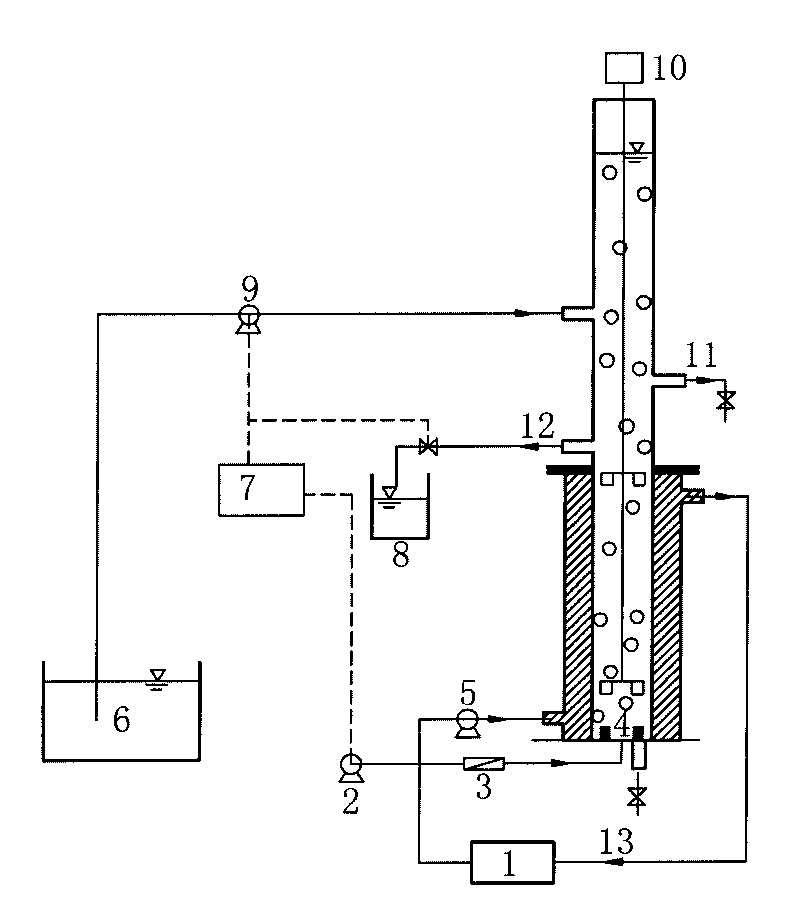

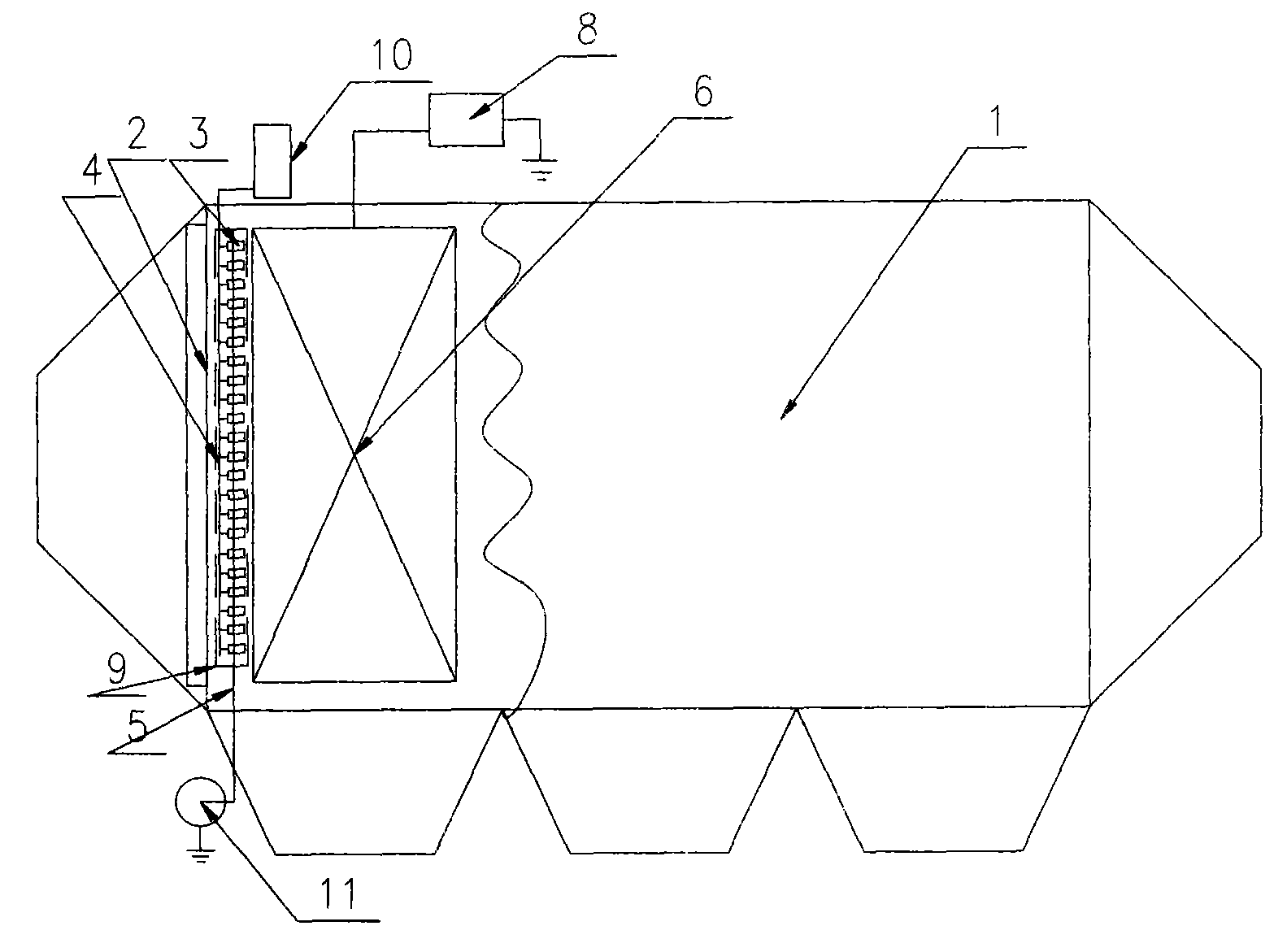

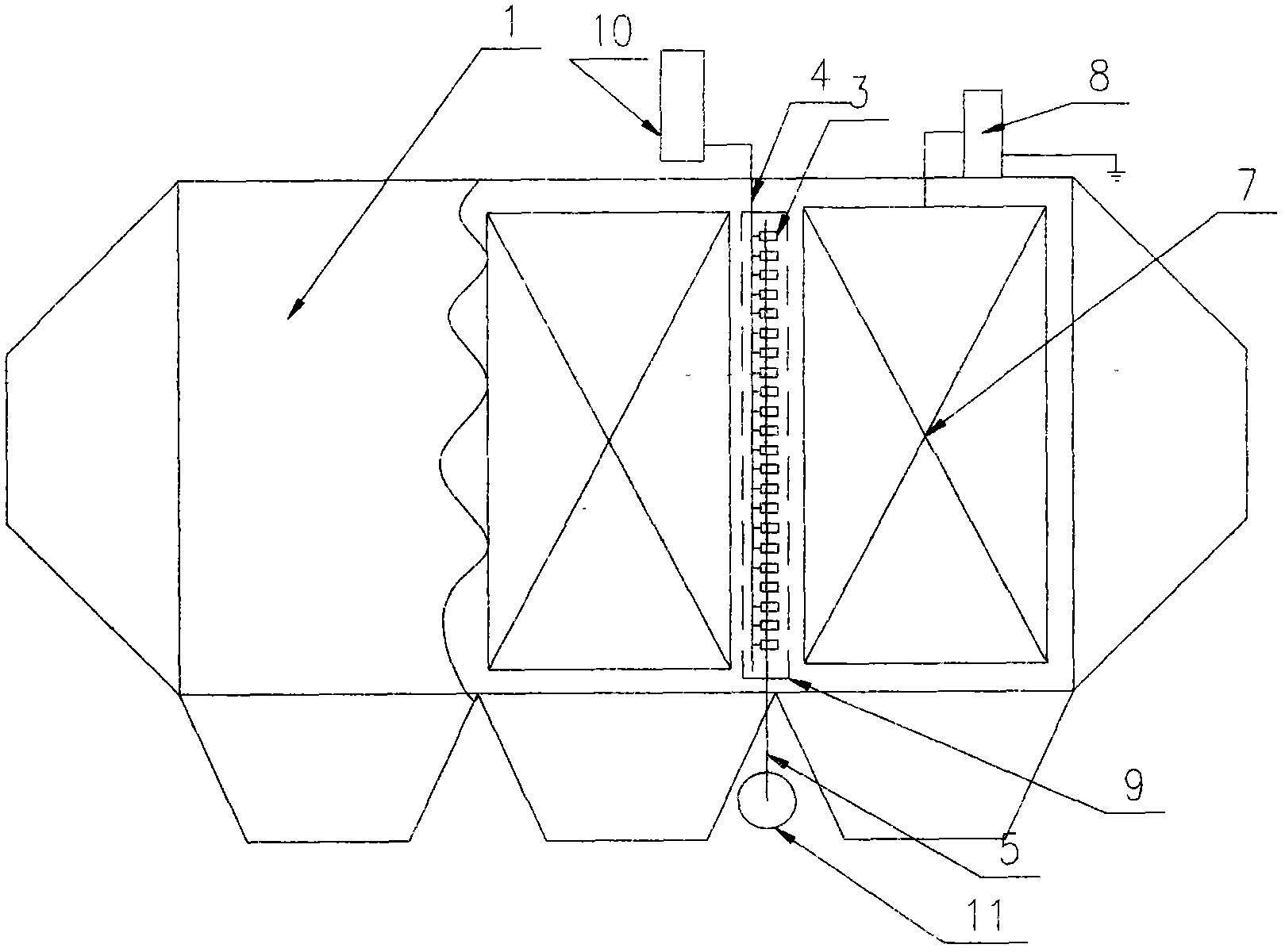

Synergistic spray charging and electrostatic dust collecting method and device

InactiveCN102145316AIncreased viscosityPromote reunionElectrostatic separationElectrostatic precipitatorDust particles

The invention relates to a synergistic spray charging and electrostatic dust collecting method by which a water spray charging device is combined with an electrostatic dust collector, flue gas is conditioned by using water spray, agglomeration of dust particles is promoted and the charging characteristic of the dust particles is improved through charging drops containing an agglomerating agent, thus the dust collection efficiency of the electrostatic dust collector is increased, the fine dust collecting efficiency is higher than 90 percent, and the concentration of smoke dust at an outlet is lower than 50 milligrams per cubic meter. The invention also discloses a synergistic spray charging and electrostatic dust collecting device which comprises the electrostatic dust collector and the water spray charging device, wherein the electrostatic dust collector is arranged on a flue; and the water spray charging device is arranged on a flue in front of an inlet of the electrostatic dust collector, or on a gradually expanded section of the inlet or on a position of a bottom second-stage or third-stage electric field in the electrostatic dust collector. The water spray charging device comprises a dual-fluid atomizing nozzle and a corona ring, wherein the dual-fluid atomizing nozzle is arranged at the front part of the corona ring, an insulator is arranged outside the upper end of the corona ring, and the corona ring is connected with a high-voltage power supply through a wire. The synergistic spray charging and electrostatic dust collecting device has a simple structure, low cost and high dust collecting efficiency.

Owner:SHANDONG UNIV

Graphene-based heat conduction silica gel phase change composite material and preparation method thereof

ActiveCN105348797AEasy reunionImprove thermal conductivityHeat-exchange elementsCarbon nanotubePhase change

The invention provides a graphene-based heat conduction silica gel phase change composite material comprising silicon substrate and heat conduction phase change material dispersed in the silicon substrate. The heat conduction phase change material comprises heat conductive filler and microencapsulation phase change material, and the heat conductive filler is selected from one or more of graphene, alumina powder, aluminium nitride powder and carbon nanotube. The composite material adds the heat conductive filler into silica gel, and can form a complete heat conduction access in the silica gel, so that the thermal conductivity of the composite material is improved. Moreover, the microencapsulation phase change material is added into the silica gel, the latent heat of the composite silica gel material is improved, and a part of heat can be stored as heat conduction. Meanwhile, the heat conduction is effective as the synergism of heat conduction silica gel and phase change material.

Owner:NINGBO GRAPHENE INNOVATION CENT CO LTD

Preparation method for aesthetic resin for improving affinity of aluminum powder pigment

ActiveCN102372904AGood dispersionIncrease speedPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsDispersityOrganic solvent

The present invention relates to a preparation method for an aesthetic resin for improving affinity of an aluminum powder pigment. According to the method, an organic solvent and an aluminum powder pigment are stirred at a middle-low speed in a stirring machine, and are added with a coupling agent; the resulting mixture is transferred to a high-speed mixer to carry out a treatment; the pretreatedaluminum powder pigment, a compatibilizer, and a plastic substrate are uniformly mixed in the high-speed mixer, and are extruded and pelletized to obtain the aluminum powder pigment master batch; finally, according to the requirement of the metal effect, the aluminum powder pigment master batch is added to various corresponding plastic substrates according to a certain ratio; after high-speed mixing, a double screw extrusion process is adopted to prepare the spray-free aesthetic resin with the special metal effect. The phenomenon of aluminum powder pigment shedding from the plastic substrate is easily generated after the aluminum powder pigment is added to the plastic substrate, and is extruded and pelletized. With the present invention, the shedding phenomenon of the aluminum powder pigment can be effectively improved, such that the dispersity of the aluminum powder pigment during the injection molding is improved, the cases of easy agglomeration and accumulation of the aluminum powder pigment are avoided, a technical support is provided for replace of the traditional paint spraying scheme by the green and environmental protection aesthetic resin.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

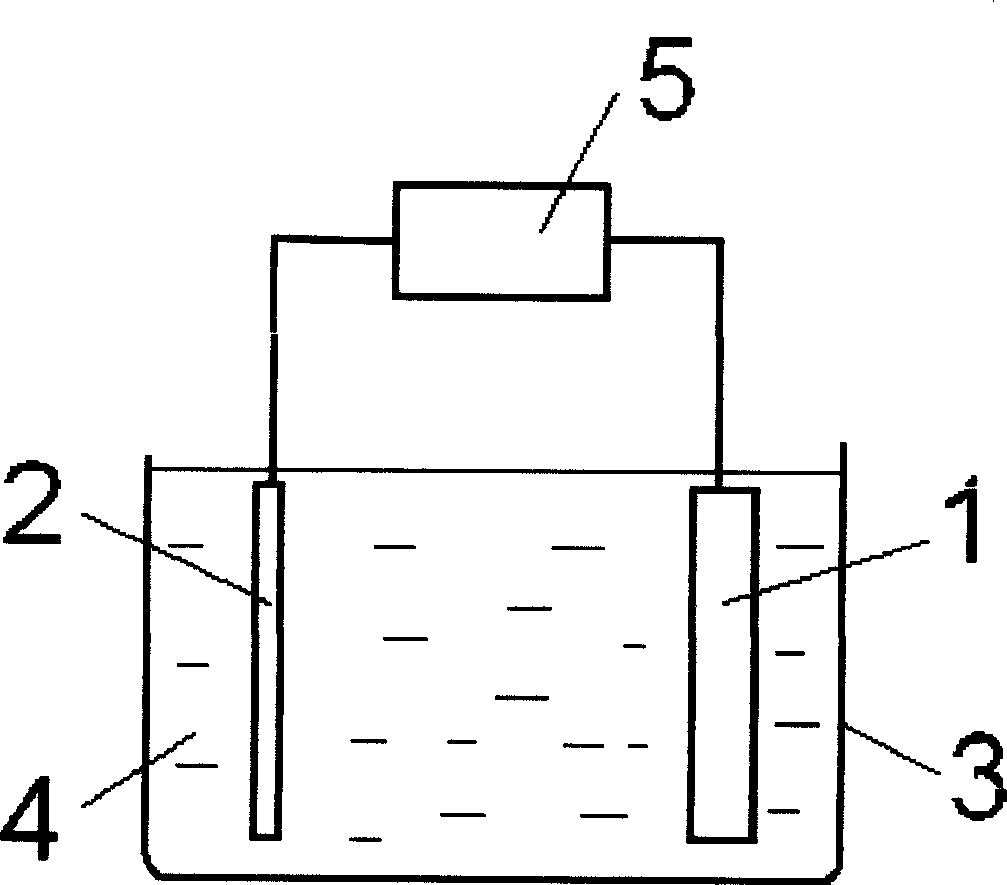

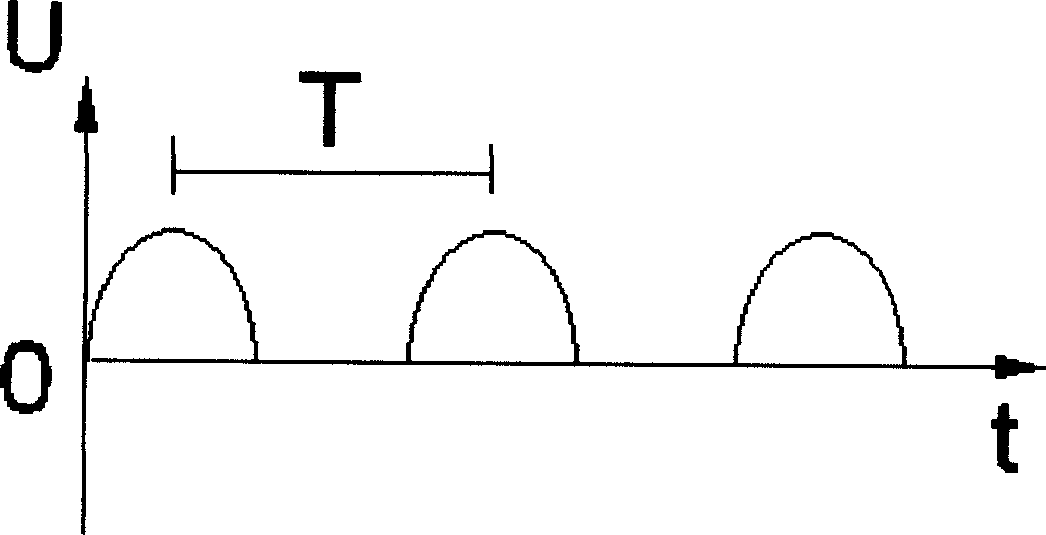

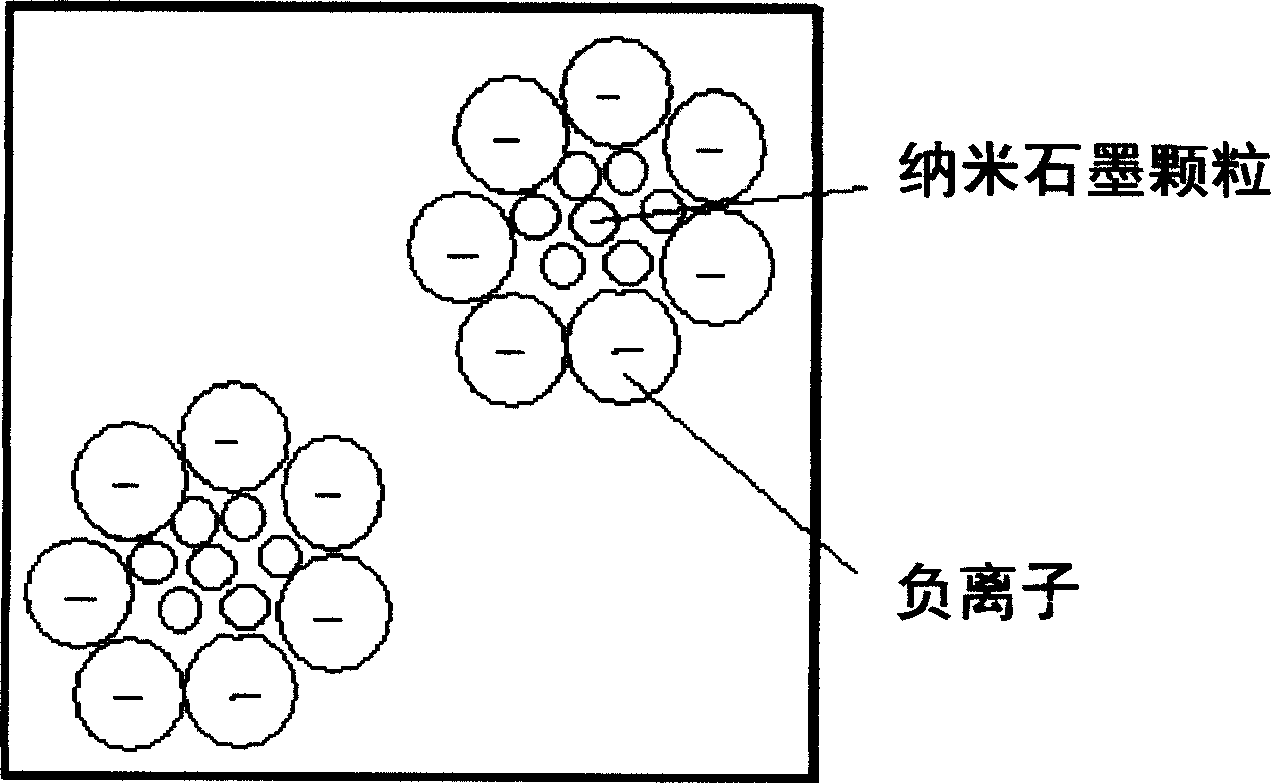

Preparation of nano graphite carbon colloidal SOL by pulse electrode process

InactiveCN1579932ASimple processReduce manufacturing costElectrolysis componentsVolumetric Mass DensityPulse period

The invention discloses a method to produce nanometer graphite sol. It supplies a system which includes highly pure graphite as anode, inert materials as cathode and electrolytical aqueous solution. There is an impulsing power source to connect the anode and cathode. The pulse period of the power source is 0.05-0.5 second, effective voltage 2-10V (3-5V is prelatered) and effective amphere density 15-75A (25-35 is prelatered). The efficiency of this invention is higher than common direct-current electrode method. The produced nanometer graphite sol is stable and disperses so it can produce nanometer graphite powder whose diameter is under 15nm.

Owner:华农纳米科技(天津)有限公司

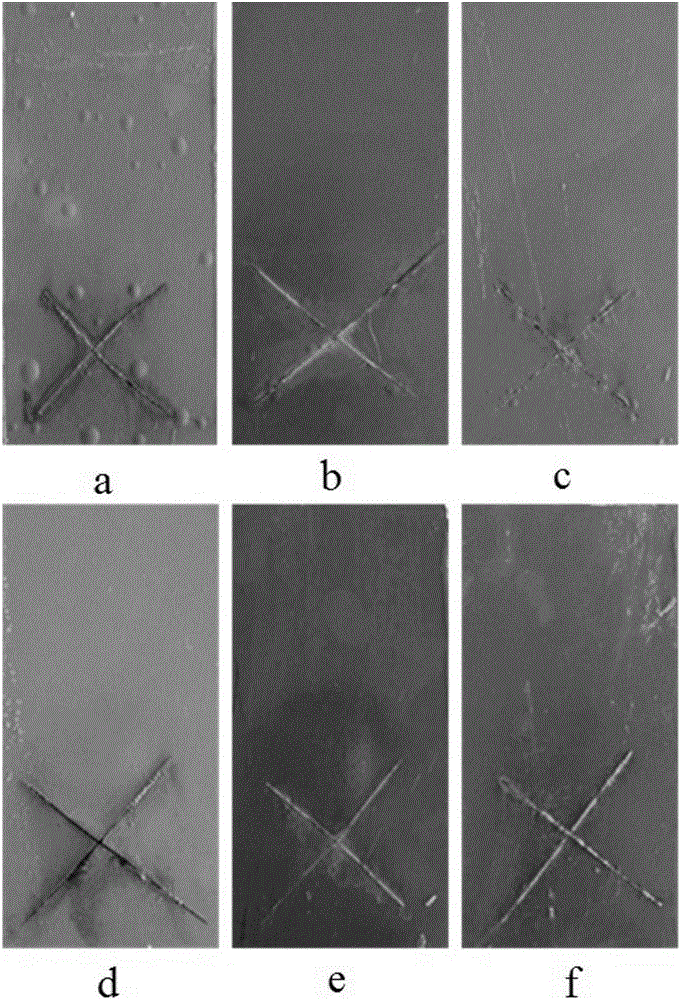

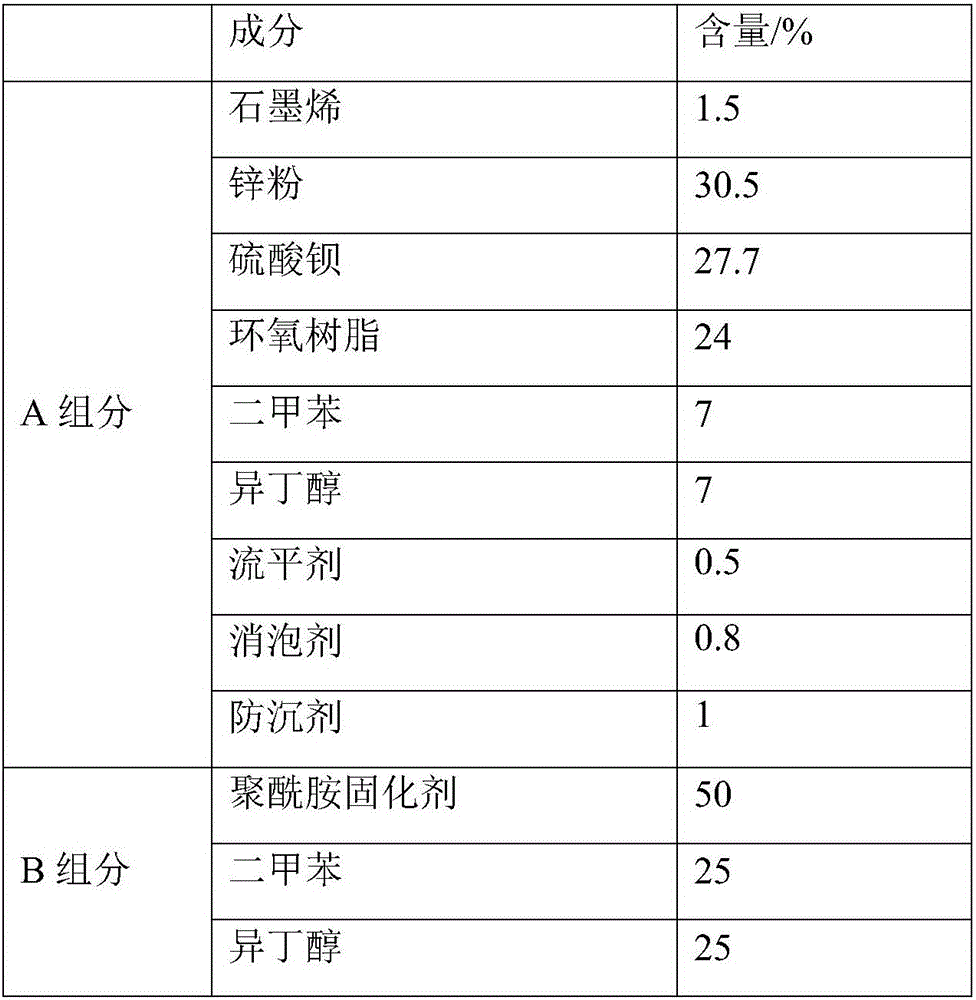

Graphene anticorrosive coating and preparation method thereof

ActiveCN106189719AEasy reunionSolving Dispersion ProblemsAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyamide

The invention provides a graphene anticorrosive coating and a preparation method thereof. The graphene anticorrosive coating is prepared from a component A and a component B, wherein in percentage by weight, the component A comprises 20%-30% of epoxy resin, 1%-3% of graphene, 0.5%-2% of a dispersing agent, 15%-25% of talcum powder, 10%-20% of zinc powder and 1%-5% of aluminum paste, and the component B comprises 30%-50% of cashew nut shell oil phenolic amide and 10%-30% of polyamide. The graphene anticorrosive coating provided by the invention is safe and environment-friendly, is moderate in cost, simple and convenient in process, stable in storage, excellent in adhesive force on base materials such as steel, iron and the like, excellent in mechanical performance such as flexibility, wear resistance performance and the like, and prominent in protective effects in chemical media such as an acid, an alkali, a salt and the like, shows excellent protective performance such as high and low temperature resistance, high salinity resistance and the like in a condition of a simulation marine environment experiment, and can be applied as primer for an anticorrosive coating in ocean engineering with various steel and iron materials.

Owner:HUNAN AEROSPACE SANFENG SCI & TECH CO LTD

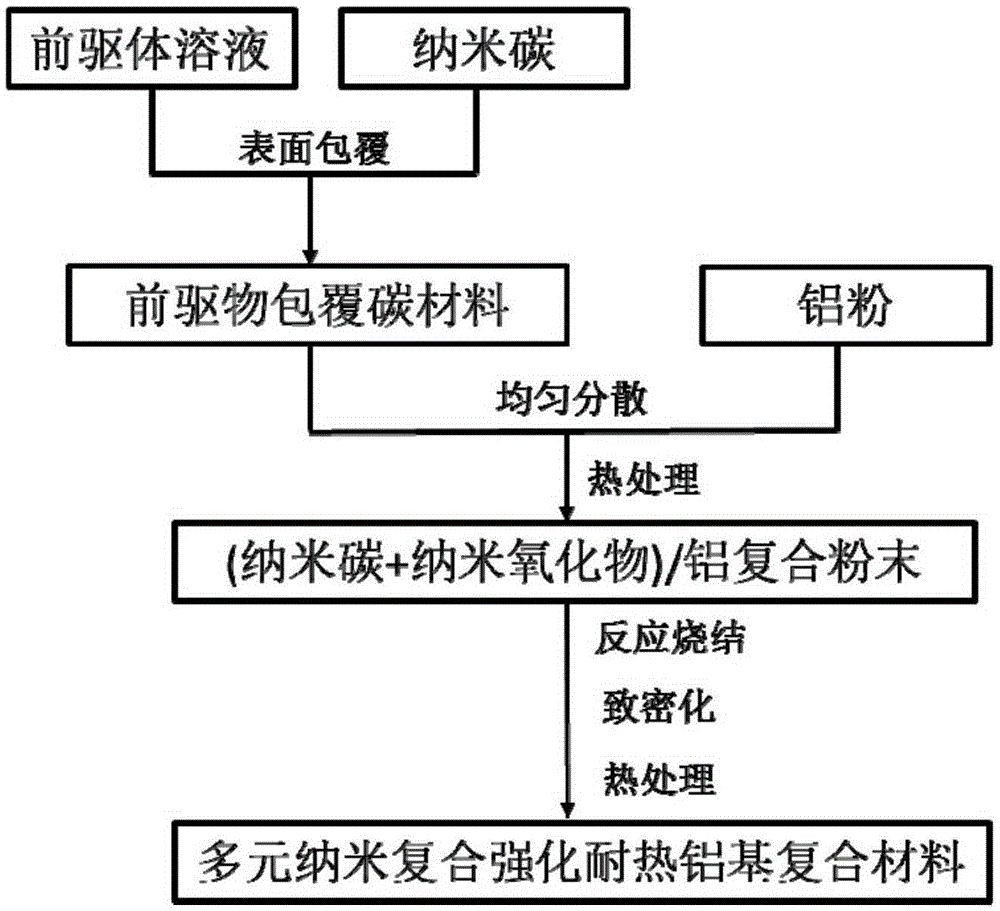

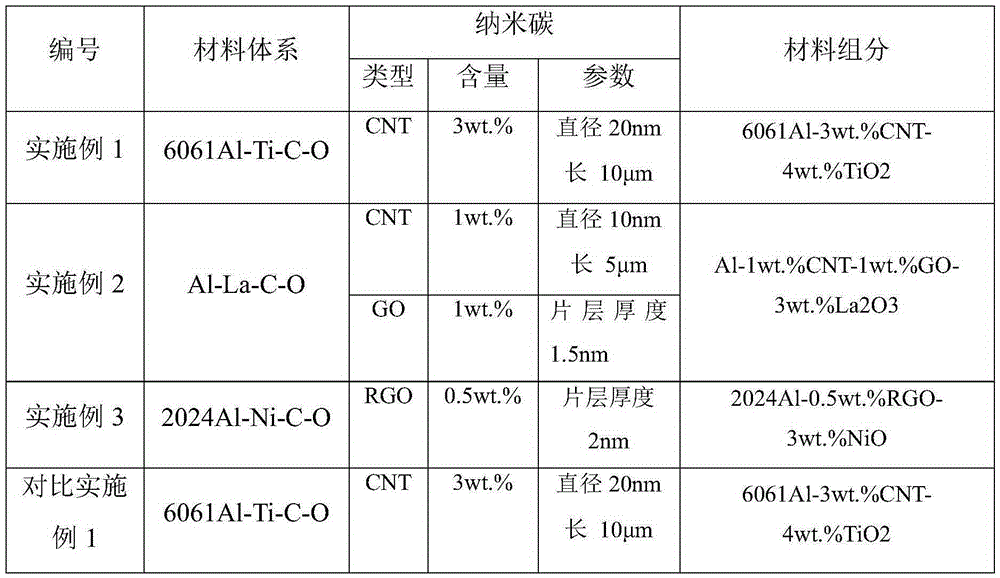

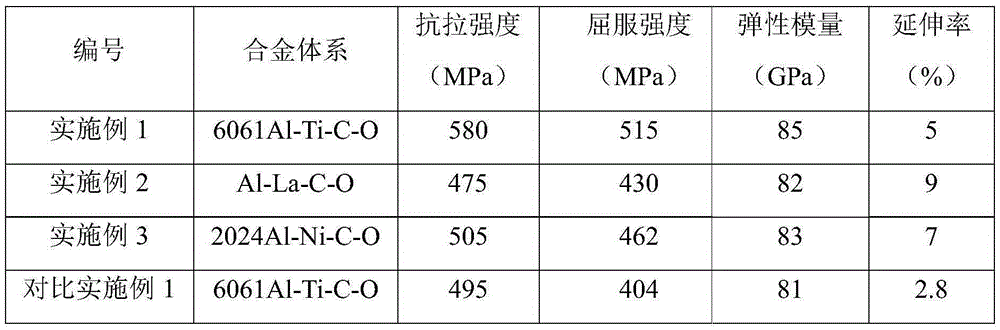

Preparing method of multielement nanometer composite strengthening thermal-resisting aluminum matrix composite

The invention provides a preparing method of a multielement nanometer composite strengthening thermal-resisting aluminum matrix composite. The surface of nanocarbon is coated with a metal ion precursor in advance, the nanocarbon is evenly scattered in aluminum powder, the precursor is converted into oxide through thermal treatment, reactive sintering and densifying treatment are carried out on the obtained composite powder, and the multielement nanometer strengthening aluminum matrix composite is obtained. The nanocarbon has the high specific surface area, the feature size of the nanocarbon is far larger than that of the nanometer oxide, and therefore a proper amount of nanometer oxide can be loaded and evenly led into the aluminum powder, metallic oxide, carbide, an intermetallic compound and other multielement nanometer strengthening phases are generated through the in-situ reaction, and the tissue stability and the thermal resistance of the aluminum matrix composite are improved coordinately. The method achieves the purposes of even leading of high-volume-content multielement nanometer strengthening phases and the space occupation control, and the conventional powder metallurgy technology can be adopted for preparing the multielement nanometer composite strengthening thermal-resisting aluminum matrix composite.

Owner:SHANGHAI JIAO TONG UNIV

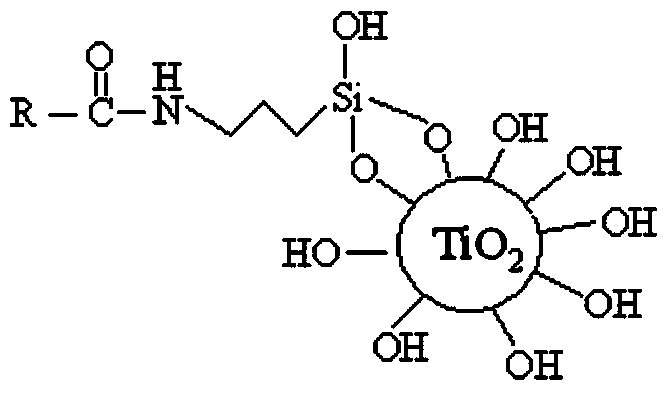

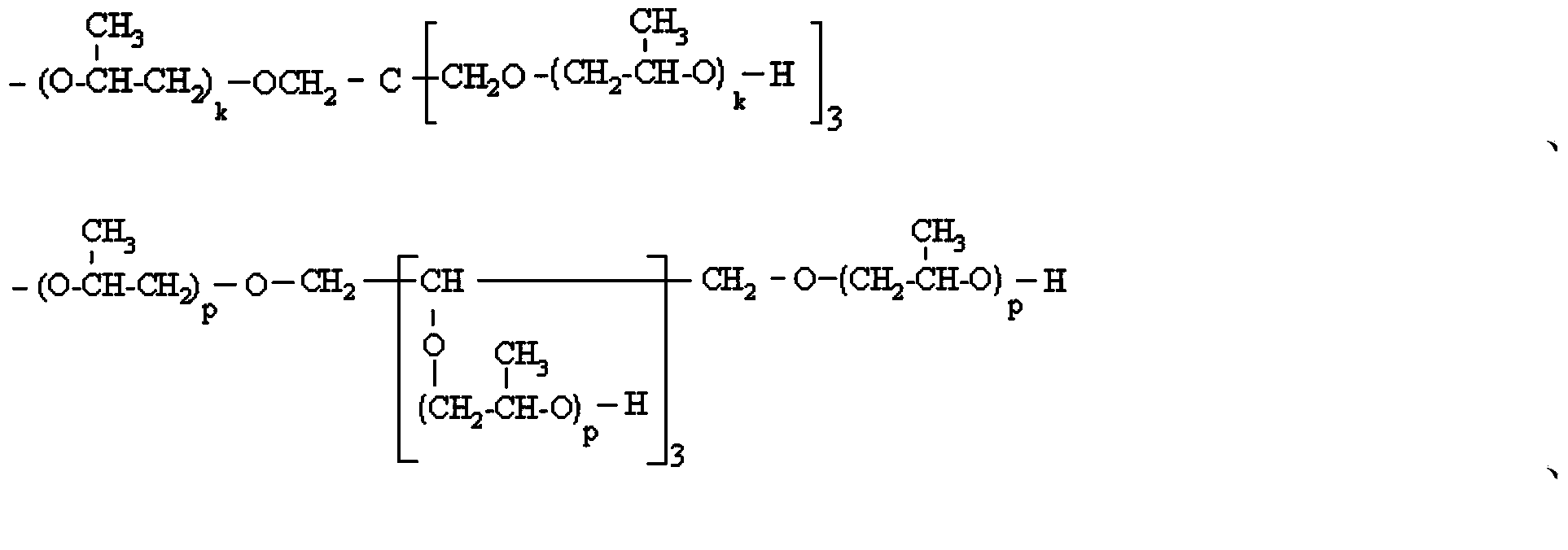

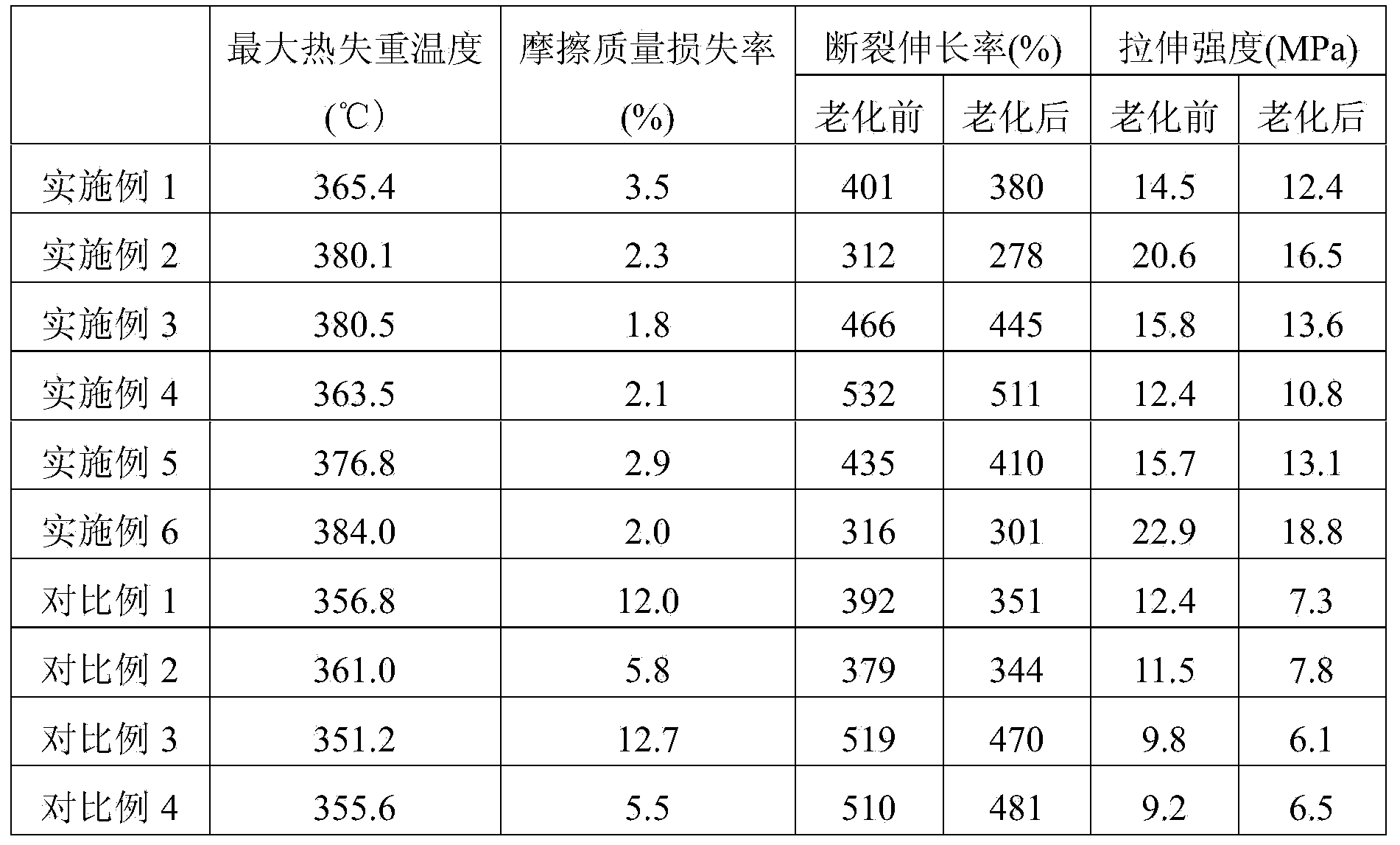

Water-based polyurethane paint containing polyether glycol/nano TiO2 hybrid material

ActiveCN104403548AGood thermal propertiesImprove mechanical propertiesPolyurea/polyurethane coatingsWater basedOrganometallic catalysis

The invention belongs to the technical field of water-based polyurethane paints, and discloses a water-based polyurethane paint containing a polyether glycol / nano TiO2 hybrid material, and a preparation method and application thereof. The paint comprises the following components in parts by mass: 25-75 parts of polyether glycol / nano titanium dioxide hybrid material, 15-65 parts of diisocyanate, 100 parts of polyether glycol, 8-16 parts of polyhydroxy-carboxylic acid, 0.05-0.5 part of organo-metallic catalyst, 0.5-10 parts of crosslinking agent, 6.2-12.4 parts of neutralizer, 1-8 parts of chain extender and 0.2-2.0 parts of defoaming agent. The paint enhances the compatibility between the nano titanium dioxide and polyurethane base, has the advantages of favorable thermal properties, favorable mechanical properties, favorable wear resistance and excellent ultraviolet resistance, and can be widely used in the fields of architectural paints, automobile paints, wood paints, electrodeposition paints, paper conditioning paints, glass fiber paints, electrophoretic paints and the like.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Method for purifying nano carbon fiber of multi-wall carbon nano-tube

InactiveCN101130431AImproves Structural IntegrityImprove the degree of graphitizationPolycrystalline material growthSingle crystal growth detailsFiberPurification methods

The invention discloses a purifying technique of metal catalyst and carbon nanometer particle in the original sample of multi-wall carbon nanometer pipe / nanometer carbon fiber, which comprises the following steps: doing high-temperature graphitizing disposal (1800-3000 deg. c) for original multi-wall carbon nanometer pipe / nanometer carbon fiber to remove high-temperature effumable impurity, for example metal catalyst; eliminating the defect in the multi-wall nanometer carbon pipe; dispersing the graphitized carbon nanometer pipe / nanometer carbon fiber with different carbon structures evenly through dispersant solution under ultrasound; making different carbon structure form discrete phase; filtering to remove discrete carbon nanometer particle in the sample; obtaining high-purity product. The method has advantages of simple operation, high purify, easy manufacturing and so on.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Silicon carbide particle reinforcement aluminum-based composite for train brake disc and preparation method

Disclosed are a silicon carbide particle reinforcement aluminum-based composite for a train brake disc and a preparation method. The composite includes the following components of, by mass percentage, 15-25% of SiC particles, 18-24% of Si, 0.6-3.5% of Mg, 0.15-0.35% of Zr, 0.12-0.45% of Sc, and the balance Al and unavoidable impurities. According to the preparation method, SiC, Mg, Si, Zr and Sc with the particle size being 10-15 [mu]m are added into molten aluminum in the form of intermediate alloy, SiC with the particle size being 15-25 [mu]m is added into the molten aluminum in the form of particles, and thus the silicon carbide particle reinforcement aluminum-based composite is obtained. The SiC thin particles are added in the form of Mg-SiC, so that the problems of uniform dispersing difficulty of silicon carbide particles in a matrix and poor interface bonding are effectively solved, the particle reinforcement effect is fully played, and the toughness of alloy is improved. Meanwhile, transitional element zirconium and rare earth element scandium are added to replace titanium fine grains, the roughness and heat resistance of the aluminum-based composite are remarkably improved, and occurrence of heat fatigue cracks is restrained. In addition, the added rare earth scandium has a good modification effect on the interfacial compatibility of the silicon carbide particles and aluminum alloy.

Owner:湖南中南智造新材料协同创新有限公司

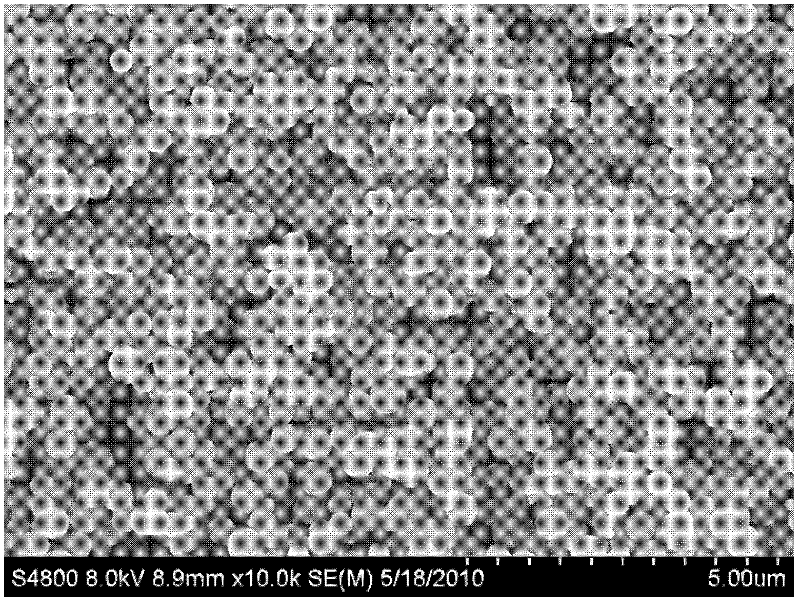

Nano antibacterial powdered paint and its micro-suspension one-step preparation therefor

InactiveCN1844270ALittle pollutionEasy reunionAntifouling/underwater paintsPaints with biocidesUltrasonic dispersionOrganic polymer

The invention relates to a manufacturing domain of nanopowder composite, especially to a nano antibacterial powder coating and one-step manufacturing method of microsuspension. The nano antibacterial powder coating consists of water, mixture monomer, pigment, surface processing agent, nanometre-sized inorganic antiseptic particle and auxiliary agent. The method comprises dispersing components such as water and suspending disperser by ultra-audio wave, then performing dispersion by high-shear emulsifier to prepare the predispersion; afterwards, adding the other components into polymerization kettle according to priority, after agitation and heating, adding the said predispersion at one time, reacting at a constant temperature, then cooling, discharge, centrifugally dewatering and drying to obtain the product. The invention solves the problems that the nanoparticles are easy to aggregate inside the organic polymer existed in present technology and the manufacturing engineering of the traditional powder coating is difficult, and has advantages that the process flow is short, the equipment investment is low, and can save working hours and energy resource, is of no dust pollution, the prepared powder coating particles is of regular shape, and has better levelling property in application.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

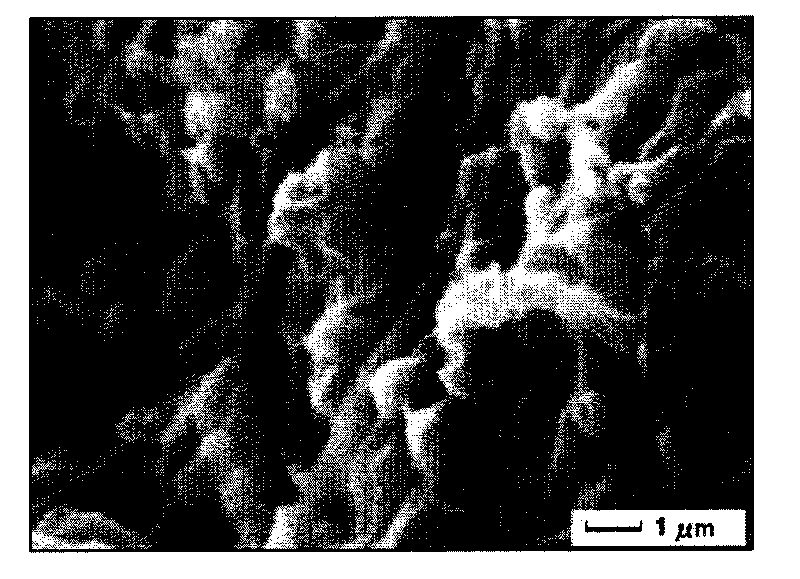

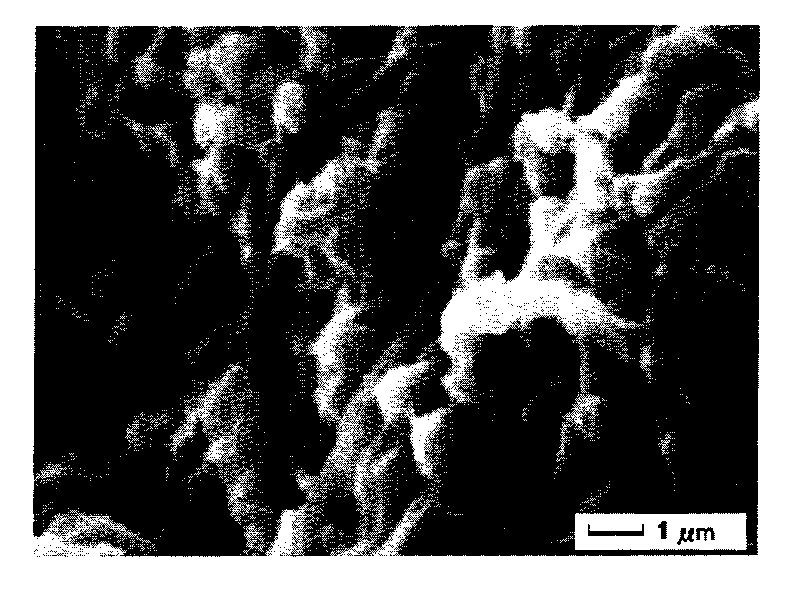

Method for culturing aerobic granular sludge for treating biological nutrients in municipal sewage

InactiveCN101759289APromote formationChange surface propertiesSustainable biological treatmentBiological water/sewage treatmentNutrientChemistry

The invention relates to a method for culturing aerobic granular sludge for treating biological nutrients in municipal sewage, which comprises two reaction stages: (1) flocculent activated sludge is added in a sequencing batch reactor (SBR) as seed sludge, the domestic sewage is fed in the SBR which automatically operates according to the mode of water inlet-aeration-hypoxia-secondary aeration-precipitation-drainage, activated carbon powder and Mg2+ are added in the domestic sewage in the fourth day or fifth day after culturing, 10-20 days are needed in the stage, and the aerobic granular sludge with organism-removing and synchronous denitrifying capability can be obtained after 30-60 cycles; and (2) the SBR automatically operates according to the mode of water inlet-anaerobic mixing-aeration-precipitation-drainage-standing, 10-15 days are needed in the stage, and the aerobic granular sludge with high-efficient and synchronous denitrifying phosphorus-removing capability can be obtained after 20-45 cycles. In the invention, the culture time of the synchronous denitrifying phosphorus-removing aerobic granular sludge is shortened to 20-35 days, while in the prior art, 60-120 days are required generally.

Owner:杨国靖

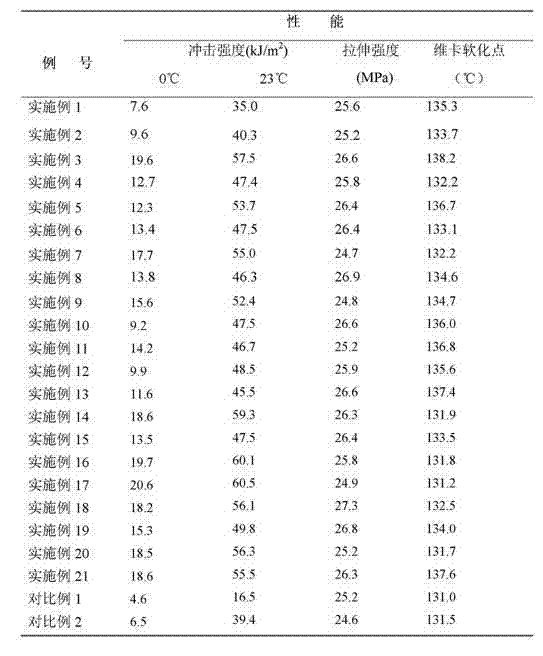

Random-copolymerization polypropylene toughening modified material and preparation method thereof

The invention discloses a random-copolymerization polypropylene toughening modified material which is formed by carrying out melt blending modification on the following components in parts by weight: 100 parts of random-copolymerization polypropylene, 0-15 parts of polypropylene homopolymer, 5-20 parts of ethylene copolymer, 2.5-12 parts of modifying master batch and 0.1-0.4 part of antioxidant. The tensile strength of the material is 24.7-27.3MPa, the notch impact strength at 23 DEG C is 35.0-60.5 kJ / m<2>, the notch impact strength at 0 DEG C is 7.6-20.6 kJ / m<2>, and the Vicat softening point is 131.2-138.2 DEG C. The invention also discloses a preparation method of the random-copolymerization polypropylene toughening modified material. The random-copolymerization polypropylene toughening modified material disclosed by the invention has favorable rigidity / toughness balance performance and heat resistance, can be widely used in the industries of construction materials, furniture, automobiles, electric appliances, electronics, electric appliances and the like, and can be used for preparing various profiles, tubes, films, sheets, plates, injection molding parts and the like. Besides, the preparation method is simple, can shorten the molding processing time, and can also lower the energy consumption and the production cost, thereby having high practicality.

Owner:SICHUAN UNIV

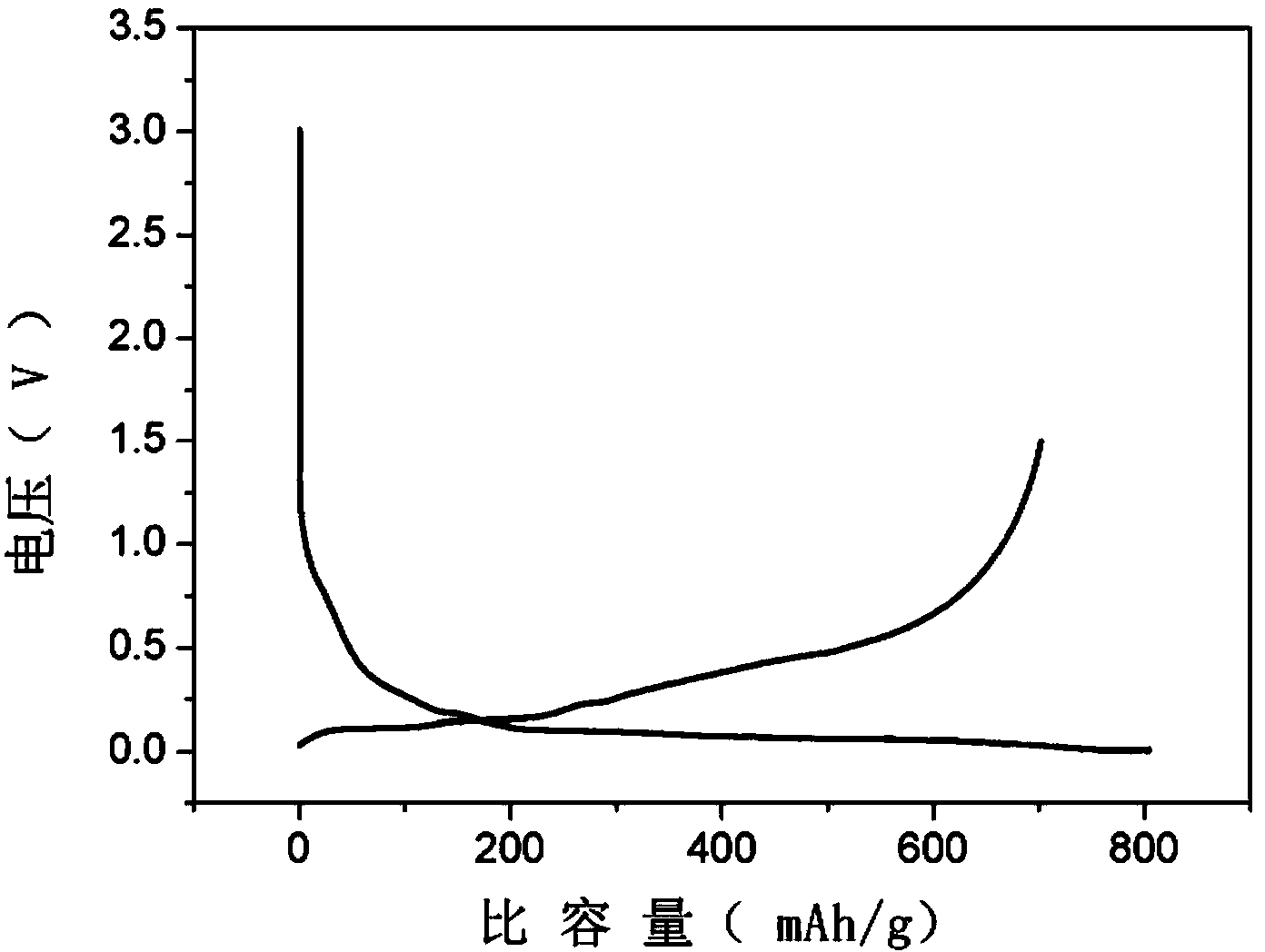

Graphite silicon-based composite anode material and preparation method thereof

InactiveCN104362307ASmall granularityHigh specific surface energyCell electrodesSecondary cellsCarbon compositesHigh carbon

The invention relates to a graphite silicon-based composite anode material for a lithium ion battery and a preparation method thereof. The graphite silicon-based composite anode material comprises a nano-silicon cracked carbon composite material, graphite and a carbon material coating layer. The preparation method comprises the following steps: firstly, nano-silicon is obtained by a high-energy wet mechanical milling method; secondly, nano-silicon and a polymer with high carbon residue are compounded by dispersion polymerization so as to form a polymer / nano-silicon composite microsphere emulsion with nano-silicon inlaid in polymeric microspheres; thirdly, the microsphere emulsion and graphite are compounded; and finally, solid-phase coating is carried out by the use of an organic carbon source, and heat treatment is conducted to obtain the graphite silicon-based composite anode material for a lithium ion battery. By the above method, the problem that nano-silicon is liable to agglomeration, especially agglomeration of nano-silicon from a liquid disperse state to a dry state, due to low granularity and high specific surface energy is solved. The anode material has characteristics of high specific capacity (greater than 550mAh / g), high initial charge discharge efficiency (greater than 80%) and high conductivity.

Owner:南京毕汉特威高分子材料有限公司

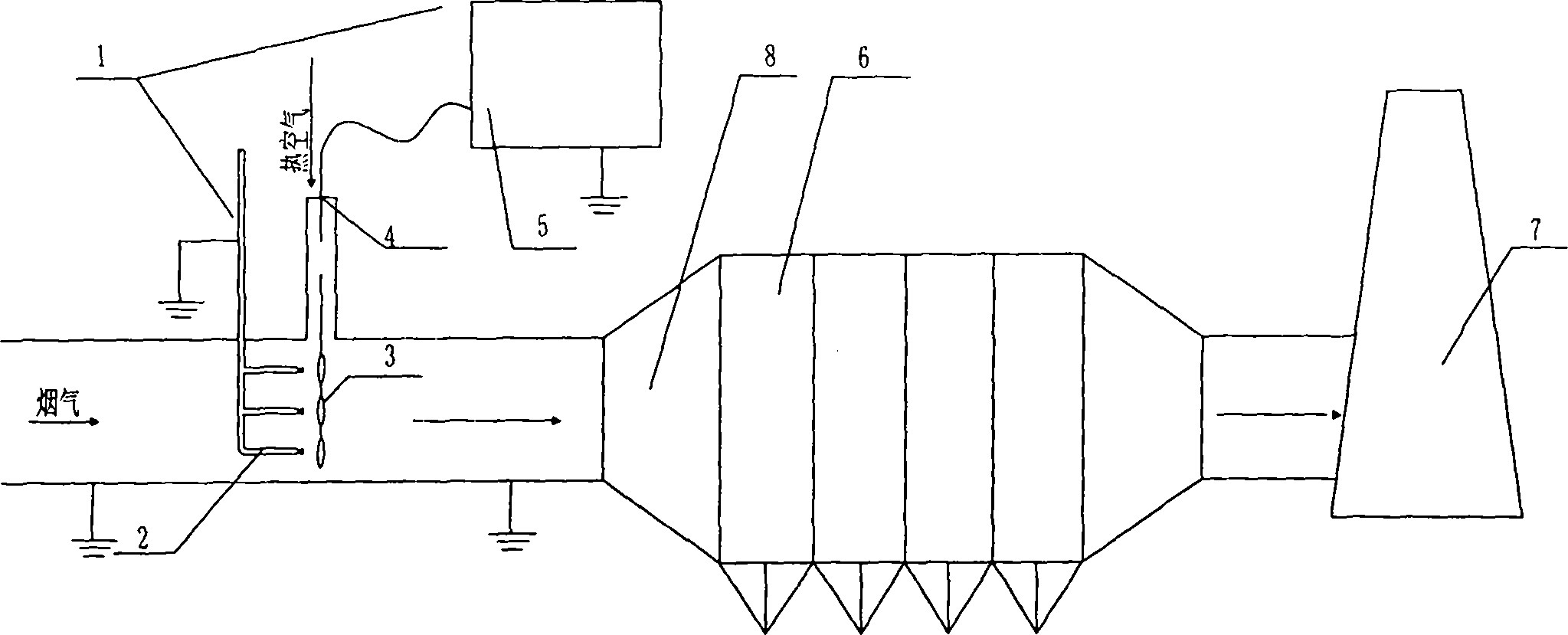

Method for capturing PM2.5 fine particles through water mist charged coagulation for electric precipitation

InactiveCN104324805AIncrease viscosityPromote coagulation and reunionExternal electric electrostatic seperatorSpray nozzleElectric field

The invention relates to a method for capturing PM2.5 fine particles through water mist charged coagulation for electric precipitation. The method comprises an electrostatic precipitation part and a liquid atomization part. Atomized liquid droplets are subjected to corona charge in an electric field; the droplets are charged; the charged droplets collide with the fine particles; the fine particles are agglomerated through coagulation; and charges are transferred on the fine particles, thereby improving charging performances of the particles and effectively increasing removal efficiency of the fine particles. The invention also provides a device for capturing the PM2.5 fine particles through water mist charged coagulation for electric precipitation. The device comprises an electrostatic precipitation part and a double-fluid jet atomization part. The double-fluid jet atomization part comprises a gas supply pipeline, a water supply pipeline and a plurality of nozzles. The device is small in occupied area, simple in structure and steady to operate; and the removal efficiency of the fine particles can reach over 95%.

Owner:SHIJIAZHUANG HULIN ENVIRONMENTAL PROTECTION EQUIP

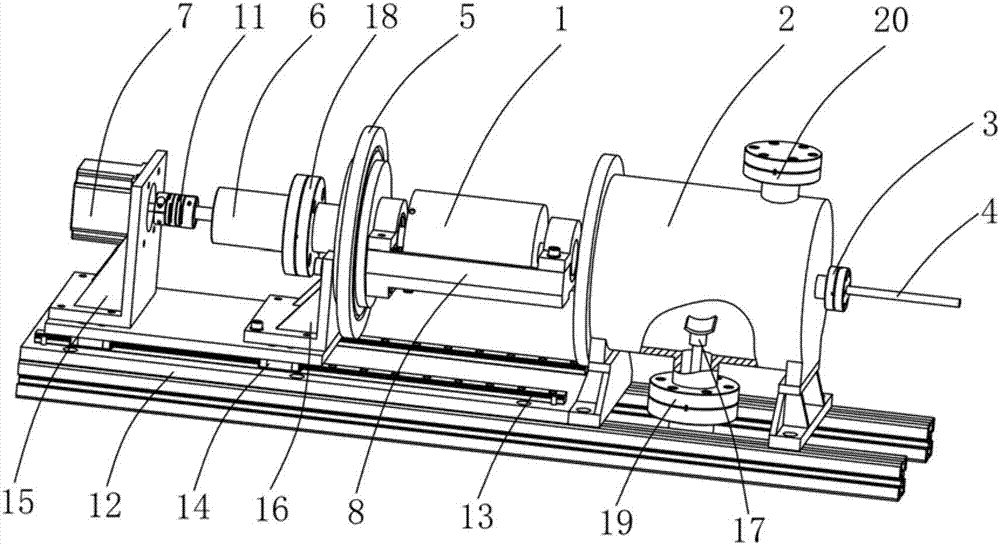

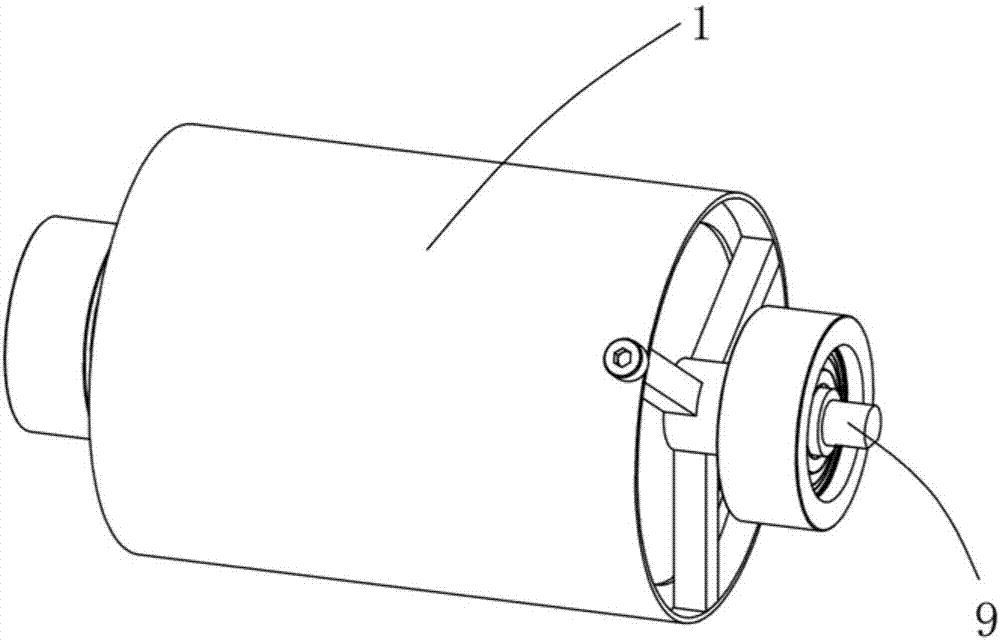

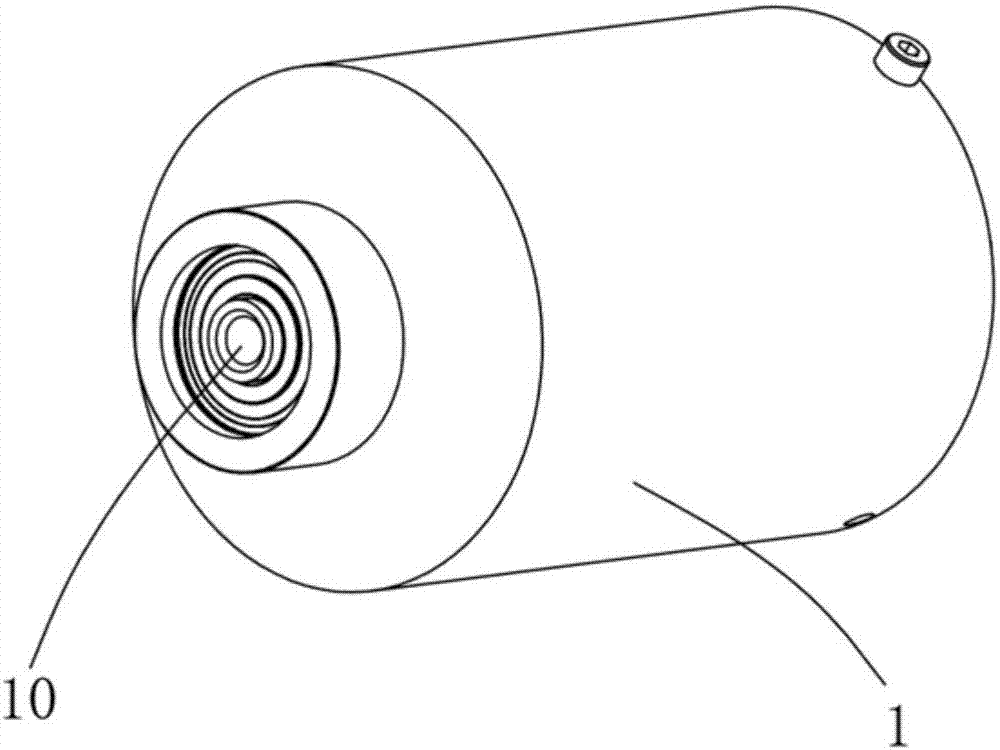

Powder-coated atomic layer deposition device

ActiveCN107502873AFully coveredCoated evenlyChemical vapor deposition coatingRotation methodEngineering

The invention discloses a powder-coated atomic layer deposition device. The powder-coated atomic layer deposition device comprises a powder container and a reaction cavity, wherein an inlet source hole is formed in one end of the reaction cavity; a gas inlet tube used for inputting reaction gas or carrier gas is arranged in the inlet source hole in a sealing mode; a cavity door is arranged at the other end of the reaction cavity; the powder container is arranged inside the cavity door; under driving of a power device, rotation can be realized; a gas inlet is formed in the powder container; the gas inlet tube enters an inner cavity of the powder container through the gas inlet; an ultrasonic vibrating rod is arranged inside the reaction cavity; and after the powder container enters the reaction cavity through a guide device, the outer side wall of the powder container is in contact with the ultrasonic vibrating rod. According to the powder-coated atomic layer deposition device disclosed by the invention, a rotary method is combined with an ultrasonic vibrating method, contact possibility of powder and reaction gas can be increased by rotation, and powder agglomeration can be relieved by energy generated by vibrations, so that powder is dispersed, and a uniform and compact film is finally coated on the surface of the powder.

Owner:HUST WUXI RES INST

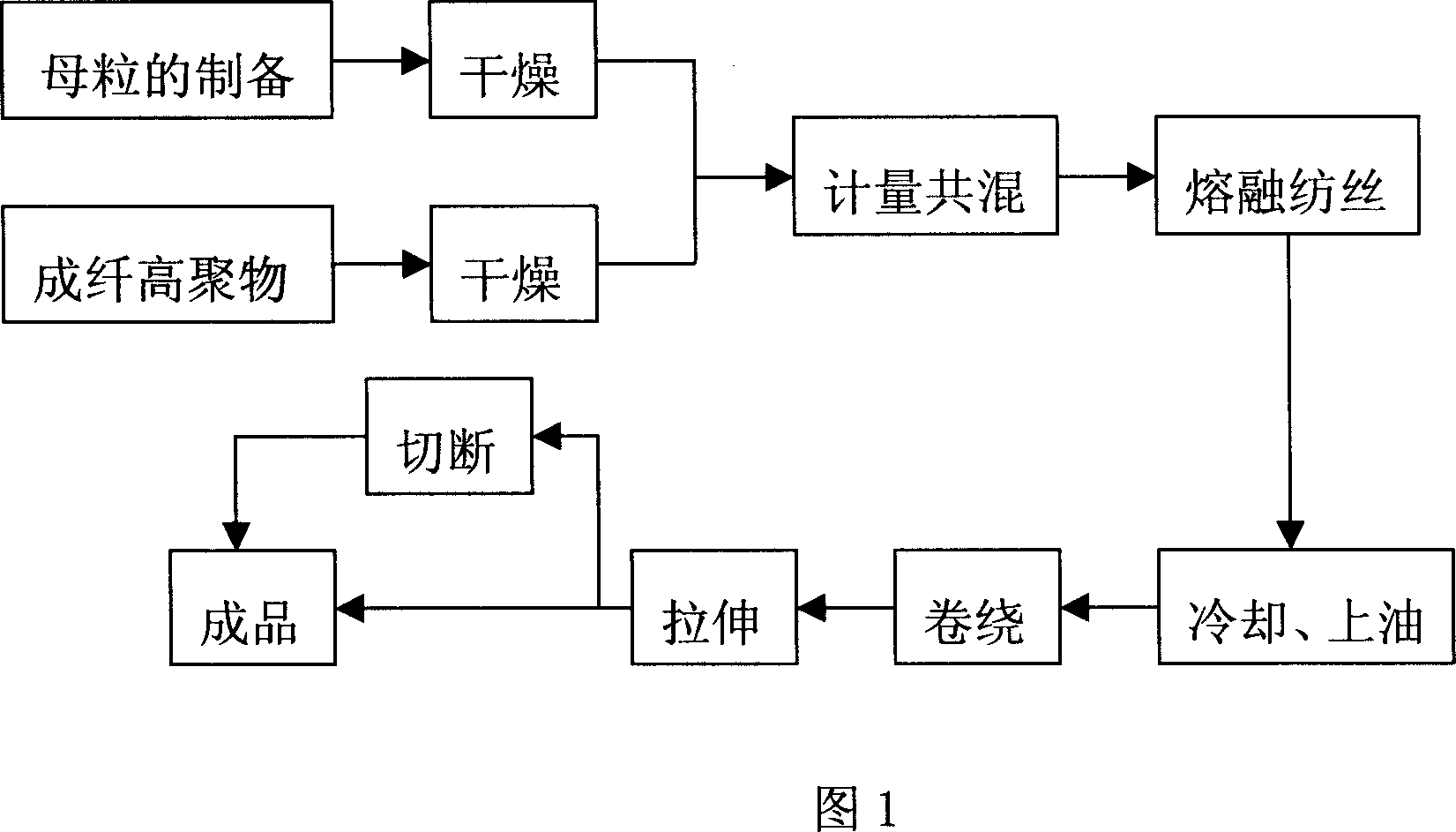

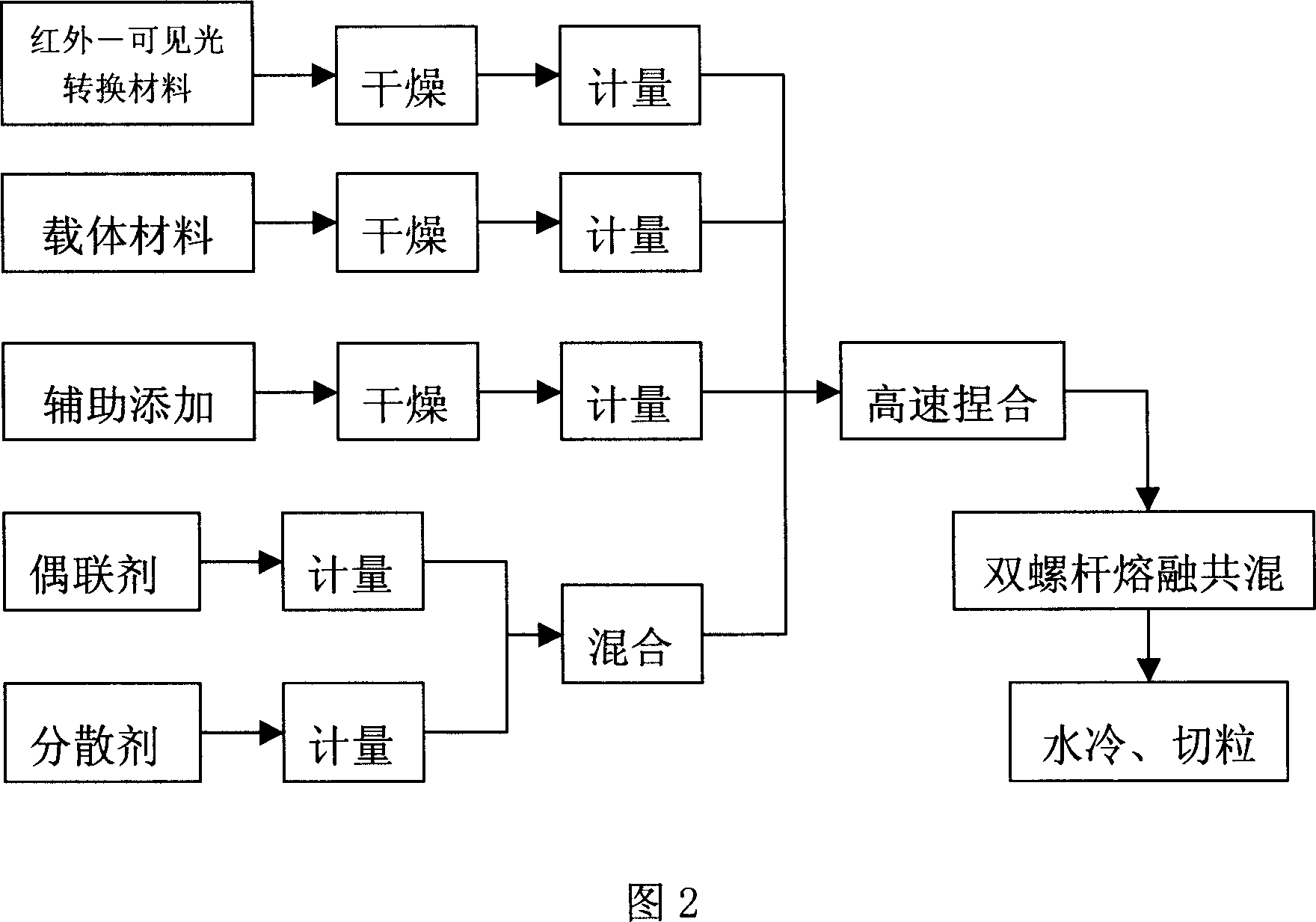

Infrared anti-false fiber and its production method and use

InactiveCN1966785AHigh processing technology requirementsImprove concealmentLight effect designsMonocomponent polypropylene artificial filamentFiberOptoelectronics

The infrared camouflage fiber is composed of infrared and visible light fertile material 1-15%, fiber-forming high polymer 64-98%, coupling agent 0.1-3%, disperser 0.1-3%, and auxiliary additive 1-4%. It includes the following manufacturing procedures: 1) the preparation of infrared camouflage base, 2) preparation of spinning material. 3) Spinning and extension. It can be applied to trade marks, packing of name brands, certificates, bills, banking cards, stamps or invoices. It has good false proof and concealing effect, and long endurance.

Owner:DONGHUA UNIV

Delaminated hydrotalcite nano-sheet based composite catalyst and preparation method therefor

ActiveCN106693945AEasy reunionSolving activityMetal/metal-oxides/metal-hydroxide catalystsDivalent metalHydrotalcite

The invention provides a delaminated hydrotalcite nano-sheet based composite catalyst and a preparation method therefor. The preparation method for the catalyst comprises the steps of introducing cationic active ingredients into a hydrotalcite laminate to form a precursor with a layered structure, then, carrying out swelling to enable the laminate to be delaminated into 1 to 10 layers, carrying out compounding on obtained hydrotalcite nano-sheets and a support with a special surface structure or electron features, and carrying out washing and drying, thereby obtaining the M1M2-ELDH / S catalyst, wherein M1 represents a divalent metal cation for forming a hydrotalcite structure, M2 represents a trivalent metal cation for forming the hydrotalcite structure, ELDH represents a delaminated hydrotalcite nano-sheet, and S represents the support. The catalyst has the characteristics that the variety and ratio of the active ingredients are adjustable; after the laminate is delaminated into 1 to 10 layers, an active center is exposed to the maximum, and the stability and cycle use performance of the catalyst can be improved after the active center is compounded with the support; and the hydrotalcite laminate and the support with the special surface structure and the electron features generate an interaction, so that the activity and selectivity of the catalyst are further improved.

Owner:BEIJING UNIV OF CHEM TECH

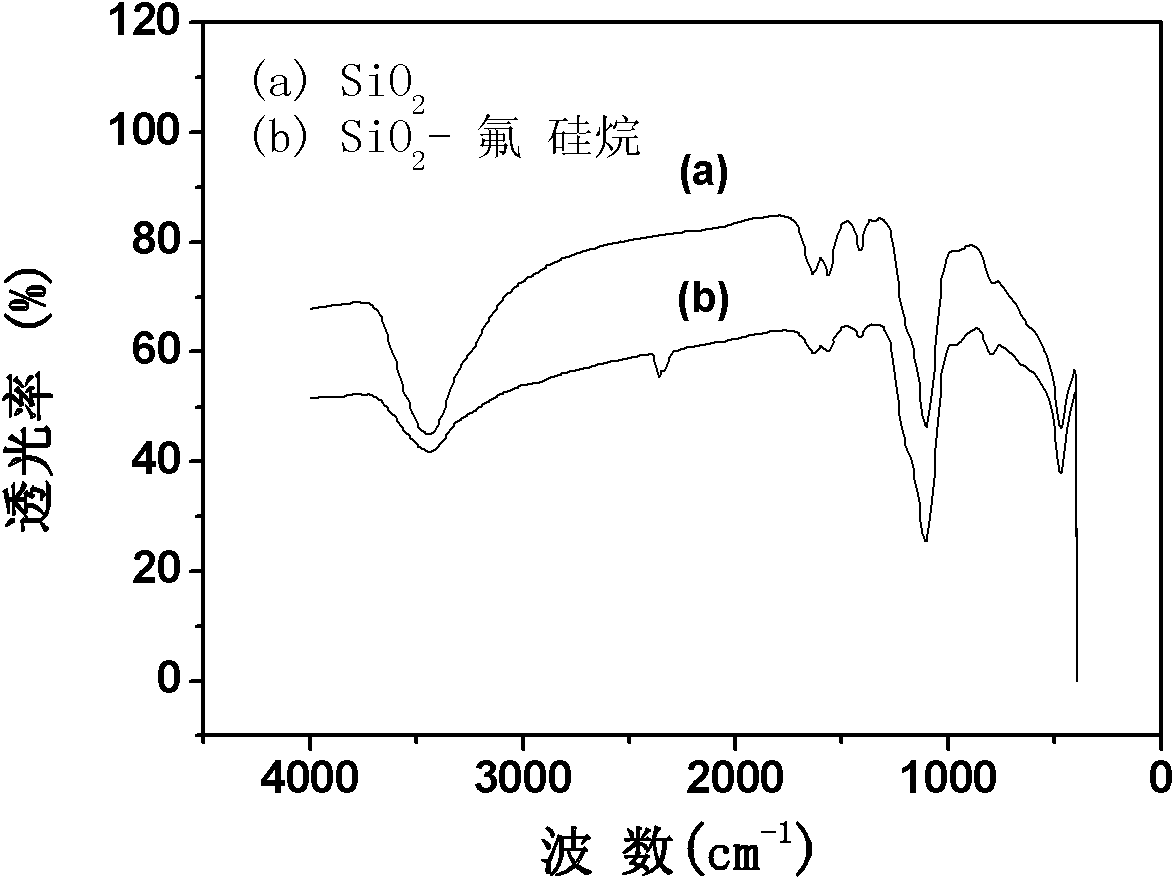

Solvent-based nano silicon oxide concentrated pulp and preparation method thereof

ActiveCN102408757AEasy to useEasy to manufacturePigment treatment with organosilicon compoundsNano siliconAdhesive

The invention relates to the nanotechnology, and specifically relates to a solvent-based nano silicon oxide concentrated pulp and a preparation method thereof. The concentrated pulp comprises the following raw materials in percentage by mass: 10-30% of fluorosilane modified nano SiO2, 20-50% of dispersant and the balance of solvent. The preparation method comprises the following steps: dissolving the SiO2 in a mixed solution of fluorosilane coupling agent, water and isopropanol, then heating and stirring under subacid conditions, and drying before grinding into fluorosilane modified nano SiO2 powder; mixing the fluorosilane modified nano SiO2 powder with the dispersant according to a mass ratio of 1:(0.2-2), and then dispersing at 800-2000rpm; and after ensuring that the raw materials are completely dissolved, adding the solvent according to the fluorosilane modified nano SiO2 powder / solvent mass ratio of 1:(1.5-5), carrying out ball milling for 4-8 hours, and discharging to obtain the fluorosilane modified nano SiO2 concentrated pulp. The invention solves the problems of high raw material consumption, complicated process and the like in the prior art; and the concentrated pulp has good dispersibility, high storage stability, high solid content and low viscosity, thereby being applicable to multiple fields such as paint, ink, ceramic, rubber, adhesive and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

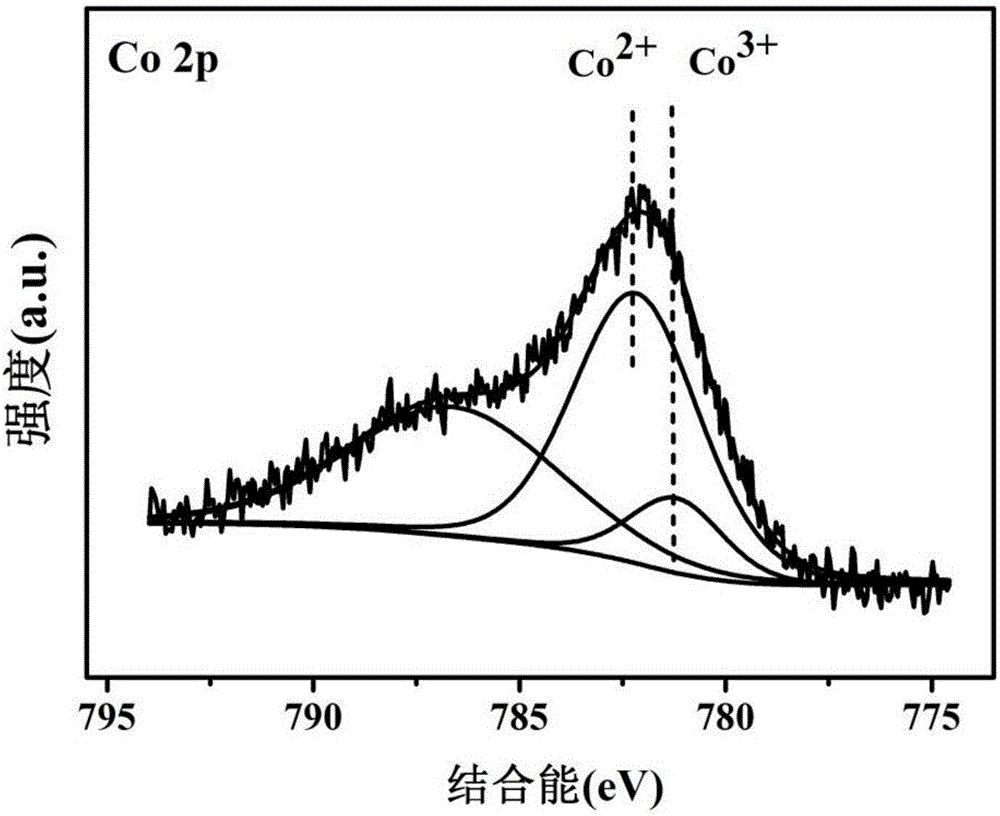

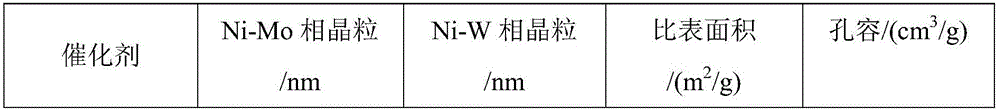

Preparation method of bulk-phase hydrofining catalyst

ActiveCN106513006AExcellent hydrodesulfurization performanceReduce utilizationHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsActive phaseSulfur containing

The invention relates to a preparation method of a bulk-phase hydrofining catalyst. The method comprises steps as follows: an Ni-containing compound and deionized water are mixed and pre-dispersed in an ultrasonic environment, a Mo-containing compound is added, an Ni-Mo fine grain structure is formed by adjusting the ultrasonic frequency and in combination with a surfactant and ammonia water, a W-containing compound and a complexing agent are added for a hydrothermal reaction, spray drying and roasting are performed, and active component powder is obtained; an active component and aluminum hydroxide dry glue are mixed, kneaded and extruded, and the catalyst is obtained through drying and roasting. According to the catalyst prepared with the method, grains of active phases are fine, grains of different active phases are uniformly dispersed, the utilization rate of active metal is high, the catalyst has an excellent pore structure property, the removal efficiency of complicated sulfur-containing compounds in inferior diesel oil is improved, hydrogen consumption is reduced, and the use cost of the catalyst is reduced.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Preparation for catalyst of Nano titanium dioxide, and method for treating ozonized water of catalysis

InactiveCN1695796AEasy reunionEasy to recycleCatalyst activation/preparationWater/sewage treatment by oxidationHYDROSOLSilica gel

A process for preparing the nano-TiO2 catalyst includes slowly dissolving tetrabutyl titanate in absolute alcohol, immersing the granular activated carbon or active Al2O3 or white silica gel or molecular sieve or zeolite in it, oscillating for 5-48 hrs, filtering, and drying or ageing. It can be used to treat water by making it, ozone and water to be treated in contact for 1-50 min.

Owner:HARBIN INST OF TECH

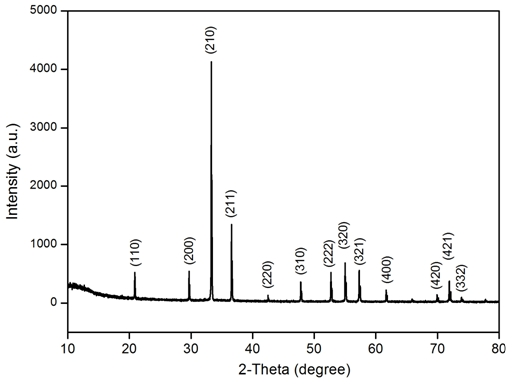

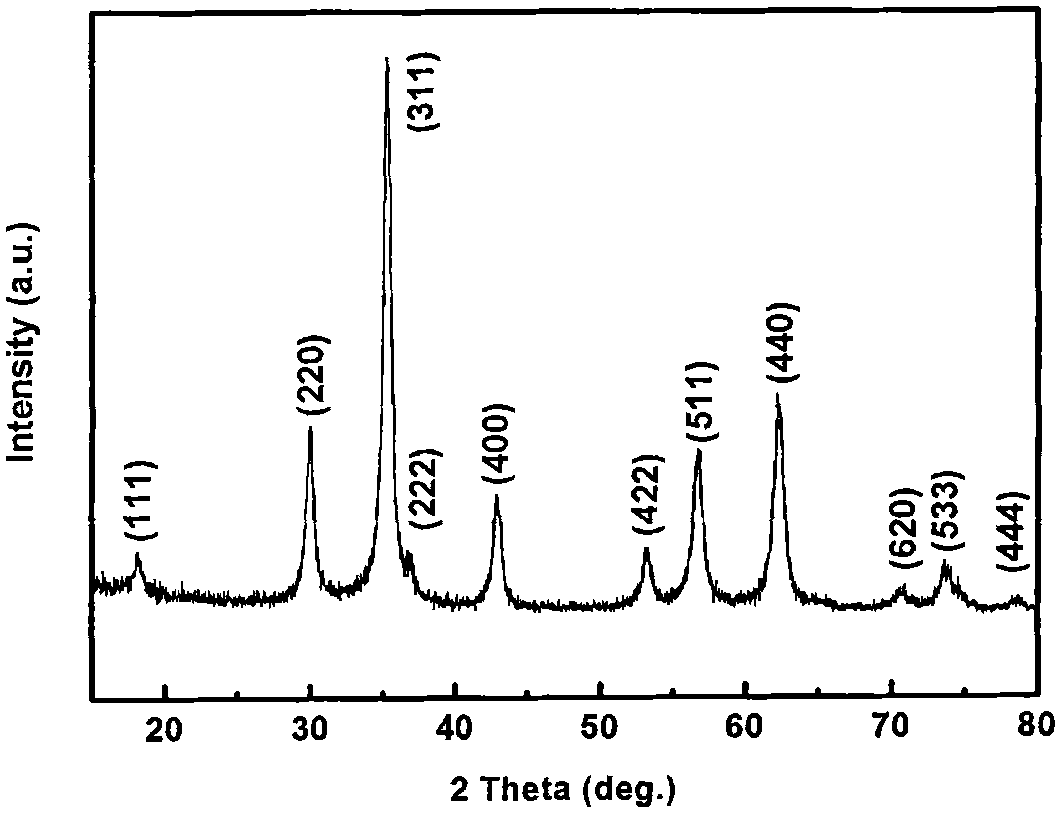

A kind of preparation method of spinel lithium titanate

InactiveCN102299313AStable structureHigh discharge specific capacityCell electrodesBall millCalcination

The present invention relates to the preparation method of lithium ion battery electrode material, especially relates to a kind of preparation method of spinel type lithium titanate; In the present invention firstly disperses surfactant, lithium source, titanium source in absolute ethanol and ball mills to obtain the precursor and then drying, calcining, grinding, tableting, calcining, regrinding and other treatments on the precursor, and finally obtain the spinel-type lithium titanate; the present invention uses a surfactant as a dispersant to make The raw materials are mixed more uniformly and dispersed better, and lithium titanate materials with small and uniform particle size and good electrochemical performance can be synthesized at lower calcination temperature and shorter calcination time; High, synthetic materials have good dispersion performance, small particle size, simple process, high production efficiency, environmental friendliness, and easy large-scale production.

Owner:MCNAIR TECH

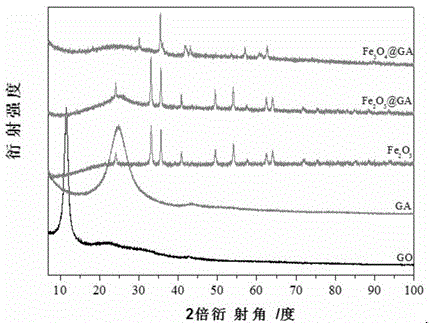

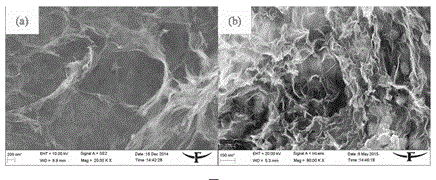

Macroscopic three-dimensional ultralight Fe3O4 doped graphene aerogel composite material and preparation method

The invention belongs to the technical field of functional materials and relates to a macroscopic three-dimensional ultralight Fe3O4 doped graphene aerogel composite material and a preparation method. According to the preparation method, firstly, expanded graphite powder is taken as a raw material, graphene oxide is prepared with an improved Hummers method, and ferric trichloride is thermally hydrolyzed to prepare ferric hydroxide colloid; secondly, the ferric hydroxide colloid is dropwise added into a graphene oxide solution, and a hydrothermal reduction reaction is performed to obtain Fe3O4 doped graphene aerogel; and finally, hydrothermal treatment by ammonia water and vacuum freeze-drying are performed to obtain the macroscopic three-dimensional ultralight Fe3O4 doped graphene aerogel composite material. In percentage by weight, the Fe3O4 content is 0-65% and the balance is graphene aerogel. The synthetic method for the Fe3O4 doped graphene aerogel composite material is simple, feasible, easy to control, small in specific gravity, large in surface area and outstanding in porous characteristic, and can be used in the fields of sewage treatment, stealth, biological medicines, new energy, electronic materials and the like.

Owner:ZHENGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com