A kind of preparation method of spinel lithium titanate

A spinel-type lithium titanate technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of high irreversible capacity of carbon materials, poor material rate performance, and voltage hysteresis of carbon materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

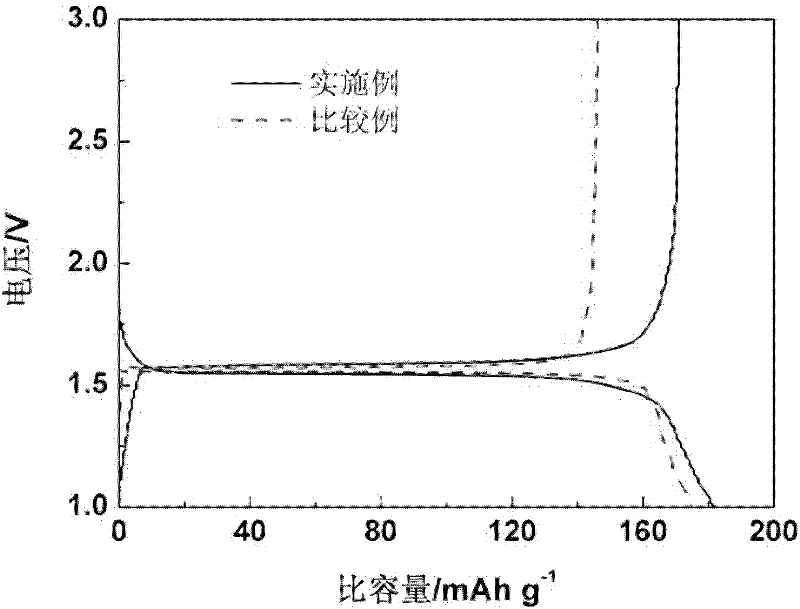

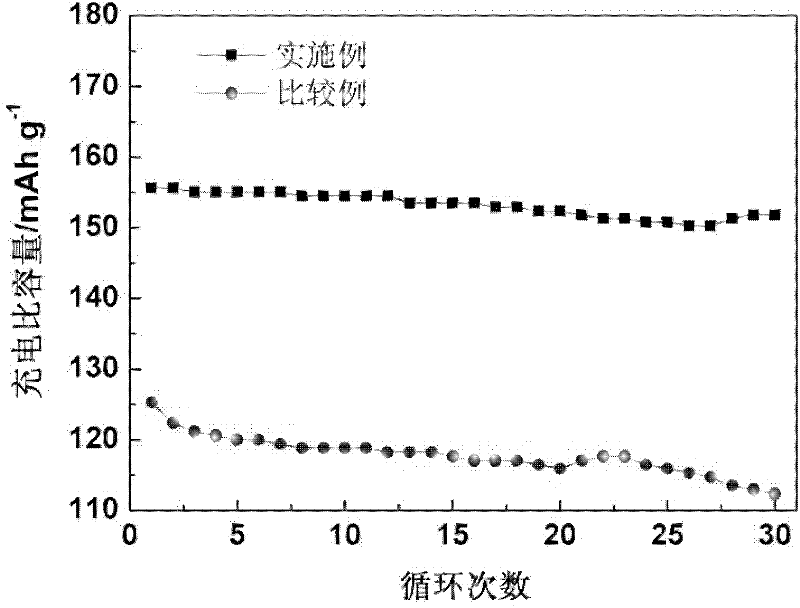

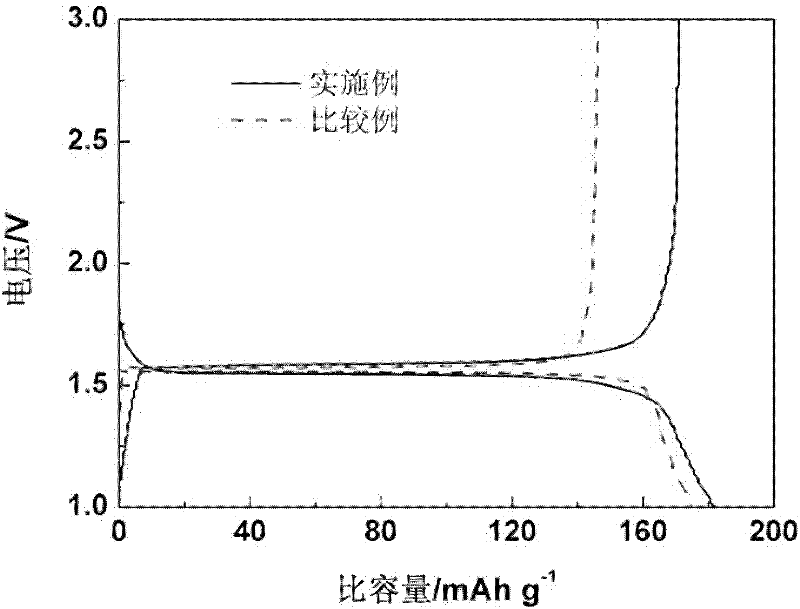

Examples

Embodiment 1

[0020] A method for surfactant-assisted solid-phase synthesis of lithium titanate, comprising the following steps:

[0021] Step A, put n Li : n Ti = 0.86 Li 2 CO 3 , Anatase TiO 2 , and polyethylene glycol that is 1 times the quality of lithium titanate finally prepared is dispersed in absolute ethanol (m 乙醇 :m 原料 =1.7) Ball milling for 12h;

[0022] Step B, placing the precursor obtained by ball milling in step A and drying it in an oven for 12 hours, the temperature in the oven is 80°C;

[0023] Step C, transfer the dry product dried in step B to a muffle furnace for pre-calcination for 6 hours to obtain a pre-calcined product, and the pre-calcined temperature is 500°C;

[0024] Step D. Grinding the calcined product obtained in step C for 20 minutes, pressing it into tablets, and then transferring it to a muffle furnace for calcination for 8-24 hours at a calcination temperature of 800° C.;

[0025] Step E. After calcination, the calcined product is taken out until ...

Embodiment 2

[0027] A method for surfactant-assisted solid-phase synthesis of lithium titanate, comprising the following steps:

[0028] Step A, put n Li : n Ti CH = 0.84 3 COOLi·2H 2 O, rutile TiO 2 , and polyvinyl alcohol that is 1 times the quality of the lithium titanate finally prepared is dispersed in absolute ethanol (m 乙醇 :m 原料 =2.0) Ball milling for 8h;

[0029] Step B, placing the precursor obtained by ball milling in step A and drying it in an oven for 12 hours, the temperature in the oven is 80°C;

[0030] Step C, transfer the dry product dried in step B to a muffle furnace for pre-calcination for 6 hours to obtain a pre-calcined product, and the pre-calcined temperature is 500°C;

[0031] Step D. Grinding the calcined product obtained in step C for 20 minutes, pressing it into tablets, and then transferring it to a muffle furnace for calcination for 8-24 hours at a calcination temperature of 800° C.;

[0032] Step E: After calcination, the calcined product is taken out...

Embodiment 3

[0034] A method for surfactant-assisted solid-phase synthesis of lithium titanate, comprising the following steps:

[0035] Step A, put n Li : n Ti = 0.86 Li 2 CO 3 , Anatase TiO 2 , and polyvinylpyrrolidone that is 1.2 times the quality of lithium titanate finally prepared is dispersed in absolute ethanol (m 乙醇 :m 原料 =2.5) Ball milling for 10h;

[0036] Step B, placing the precursor obtained by ball milling in step A and drying it in an oven for 12 hours, the temperature in the oven is 80°C;

[0037] Step C, transfer the dry product dried in step B to a muffle furnace for pre-calcination for 6 hours to obtain a pre-calcined product, and the pre-calcined temperature is 500°C;

[0038] Step D. Grinding the calcined product obtained in step C for 20 minutes, pressing it into tablets, and then transferring it to a muffle furnace for calcination for 8-24 hours at a calcination temperature of 800° C.;

[0039]Step E: After calcination, the calcined product is taken out unti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com