Delaminated hydrotalcite nano-sheet based composite catalyst and preparation method therefor

A composite catalyst and hydrotalcite technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as unrecyclable and difficult to recycle colloidal catalysts , to achieve the effect of improving activity and selectivity, enhancing stability and recyclability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

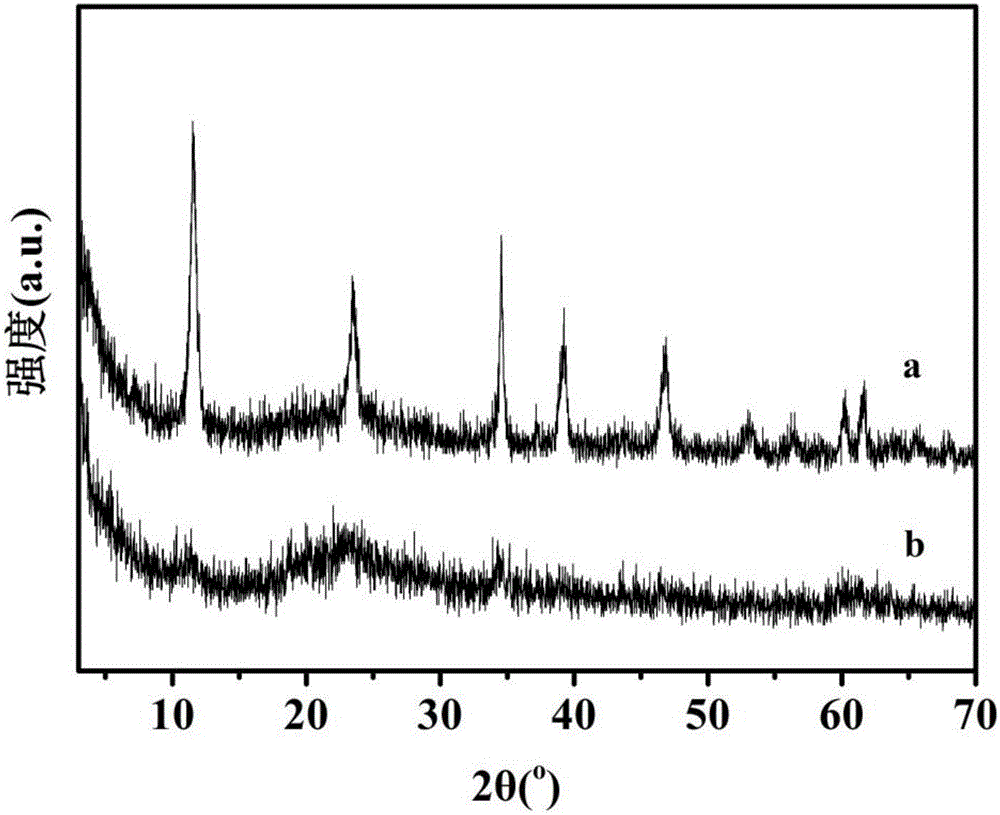

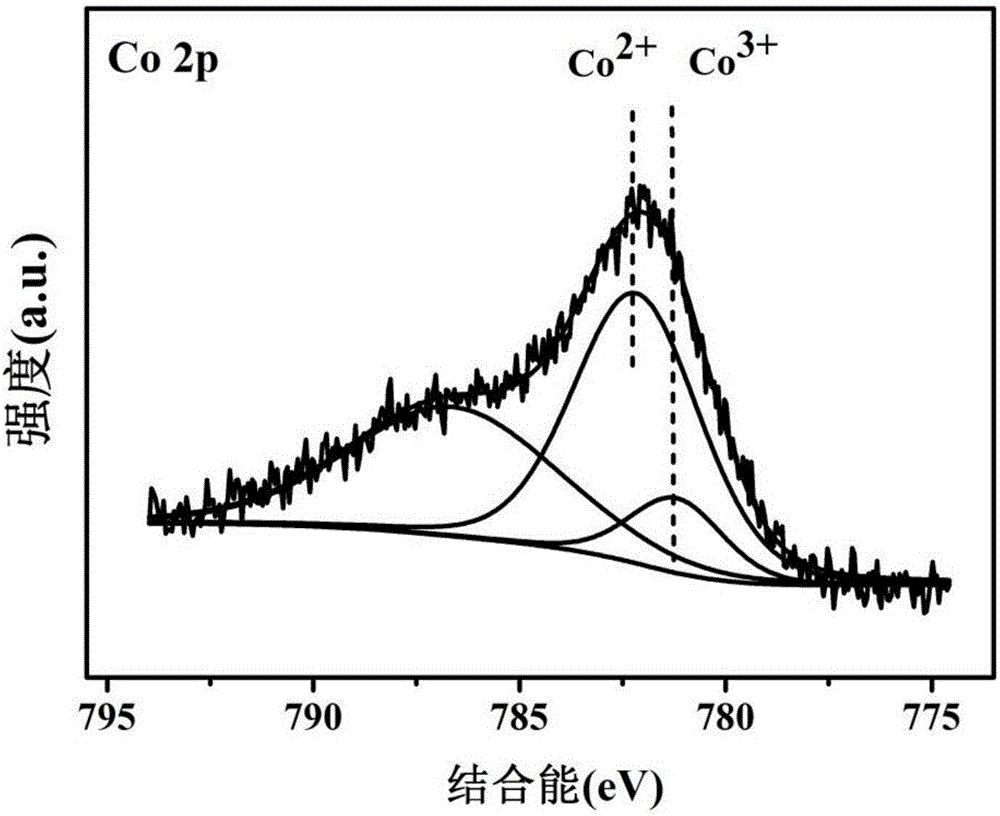

[0038] A. Weigh 0.03mol of Co(NO 3 ) 2 ·6H 2 O, 0.01mol of Al(NO 3 ) 3 9H 2 O and 0.2mol of urea, add 100mL deionized water to dissolve, transfer the solution to a polytetrafluoroethylene reactor, react at 110°C for 12h, centrifuge the supernatant to pH=7 after the reaction, and place it in an oven at 60°C Dry to get CoAl-CO 3 2- - LDHs;

[0039] B. Weigh 0.3g of the above CoAl-CO 3 2- -LDHs in the flask, add 0.2mol NaNO 3 and 300mL of deionized water, and adjust the pH to 5-6 with concentrated nitric acid, and stir for 24 hours under a nitrogen atmosphere. After the reaction, centrifuge until the supernatant has a pH of 7, and fully dry it in a vacuum oven at 60°C to obtain NO 3 - Intercalated LDHs, expressed as CoAl-NO 3 - - LDHs;

[0040] C. Weigh 0.1g of CoAl-NO from step B 3 - -LDHs in the flask, add 100mL formamide, stir for 48h under nitrogen atmosphere, get a clear and transparent colloidal solution, expressed as CoAl-ELDH;

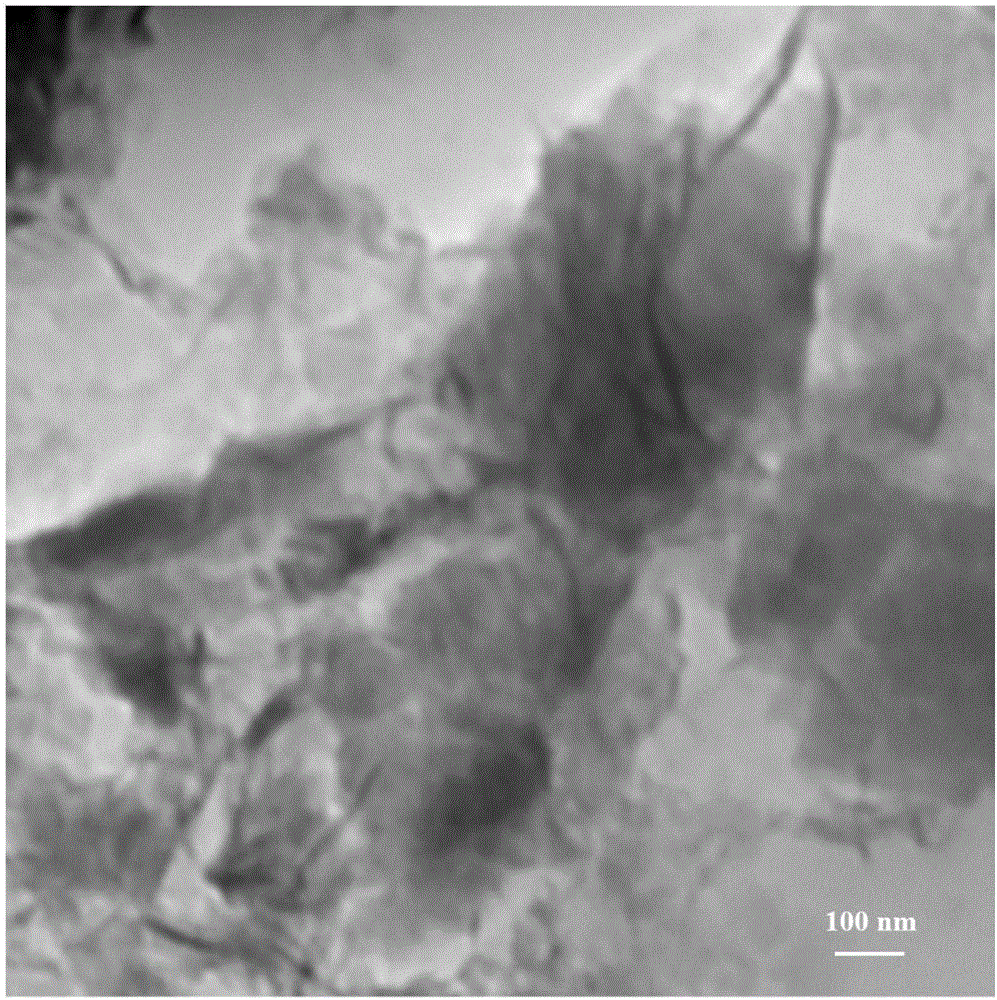

[0041] D. Weigh 0.03g GO a...

Embodiment 2

[0044] A. with embodiment 1;

[0045] B. Weigh 0.3g of the above CoAl-CO 3 2- -LDHs in the flask, add 0.2mol Na 2 SO 4 and 300mL deionized water, and adjust the pH=5~6 with concentrated sulfuric acid, stir for 24h under nitrogen atmosphere, centrifuge after the reaction until the supernatant pH=7, fully dry in a vacuum oven at 60°C to obtain SO 4 2- Intercalated LDHs, expressed as CoAl-SO 4 2- - LDHs;

[0046] C. Weigh 0.1g of CoAl-SO from Step B 4 2- -LDHs in a 500mL flask, add 100mL N,N-dimethylformamide, ultrasonication for 2h, to obtain a clear and transparent colloidal solution, expressed as CoAl-ELDH;

[0047] D. Weigh 0.05g MgO and disperse it in 100mL of sodium lauryl sulfate aqueous solution with a concentration of 0.25g / L, and ultrasonically disperse it for 30min to obtain a uniformly dispersed MgO slurry;

[0048]E. Add the MgO slurry in step D dropwise to the colloid solution in step C at a rate of 2 mL / min. After the dropwise addition, use deionized wate...

Embodiment 3

[0050] A. with embodiment 1;

[0051] B. Weigh 0.3g of the above CoAl-CO 3 2- -LDHs in a 500mL flask, add 0.1mol sodium dodecyl sulfate and 300mL deionized water, stir for 24h under nitrogen atmosphere, centrifuge after the reaction, and fully dry in a vacuum oven at 60°C to obtain dodecylsulfuric acid Sodium-intercalated LDHs, expressed as CoAl-SDS-LDHs;

[0052] C. Weigh 0.1g of CoAl-SDS-LDHs from step B into a flask, add 100mL of n-butanol, and stir for 12h under a nitrogen atmosphere to obtain a clear and transparent colloidal solution, expressed as CoAl-ELDH;

[0053] D. Weigh 0.05g HAP and disperse it in 100mL of sodium lauryl sulfate aqueous solution with a concentration of 0.25g / L, and ultrasonically disperse for 30min to obtain a uniformly dispersed HAP slurry;

[0054] E. Add the HAP slurry in step D dropwise to the colloid solution in step C at a rate of 2 mL / min. After the dropwise addition, use deionized water to centrifuge and wash the precipitate several time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com