Solvent-based nano silicon oxide concentrated pulp and preparation method thereof

A nano-silica and concentrated slurry technology, applied in the nano field, can solve the problems of large consumption of siloxane raw materials, good dispersion of concentrated slurry, complicated process, etc., and achieves low environmental pollution, storage stability, and high solid content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

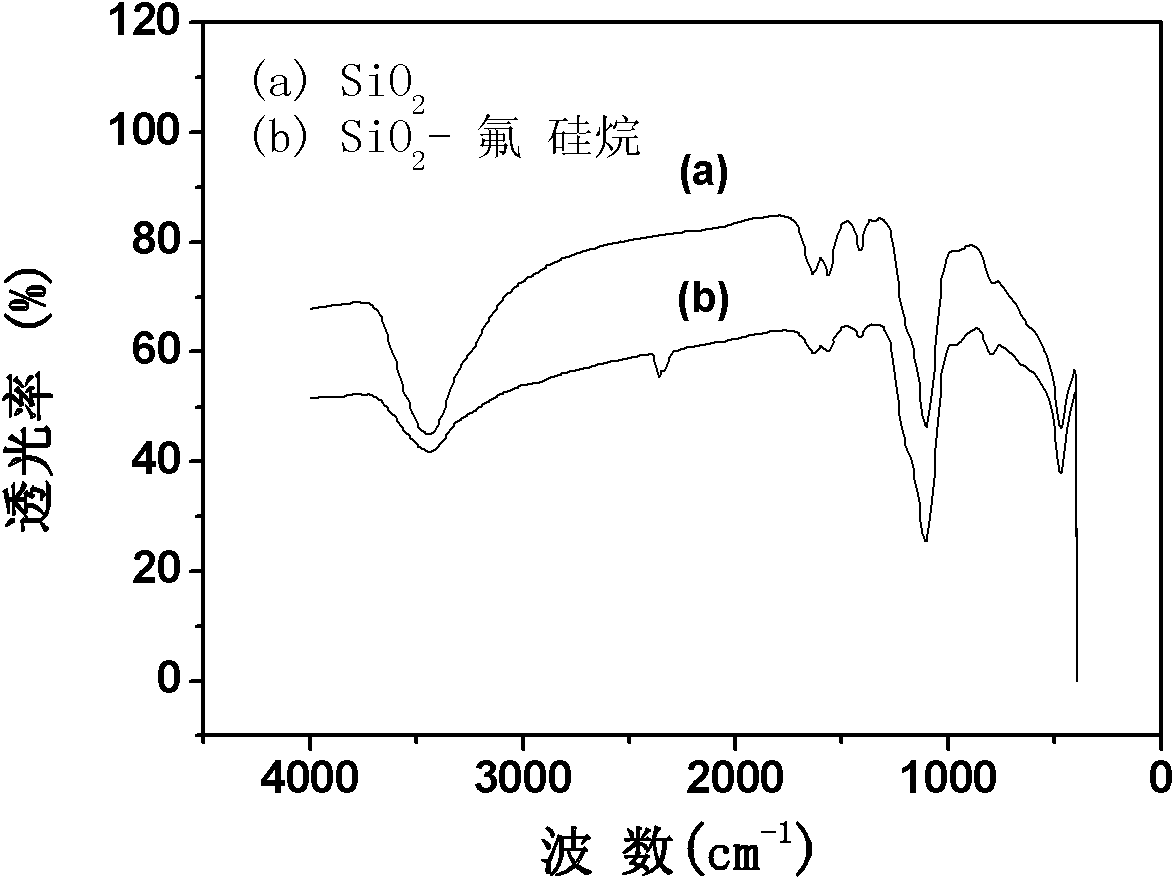

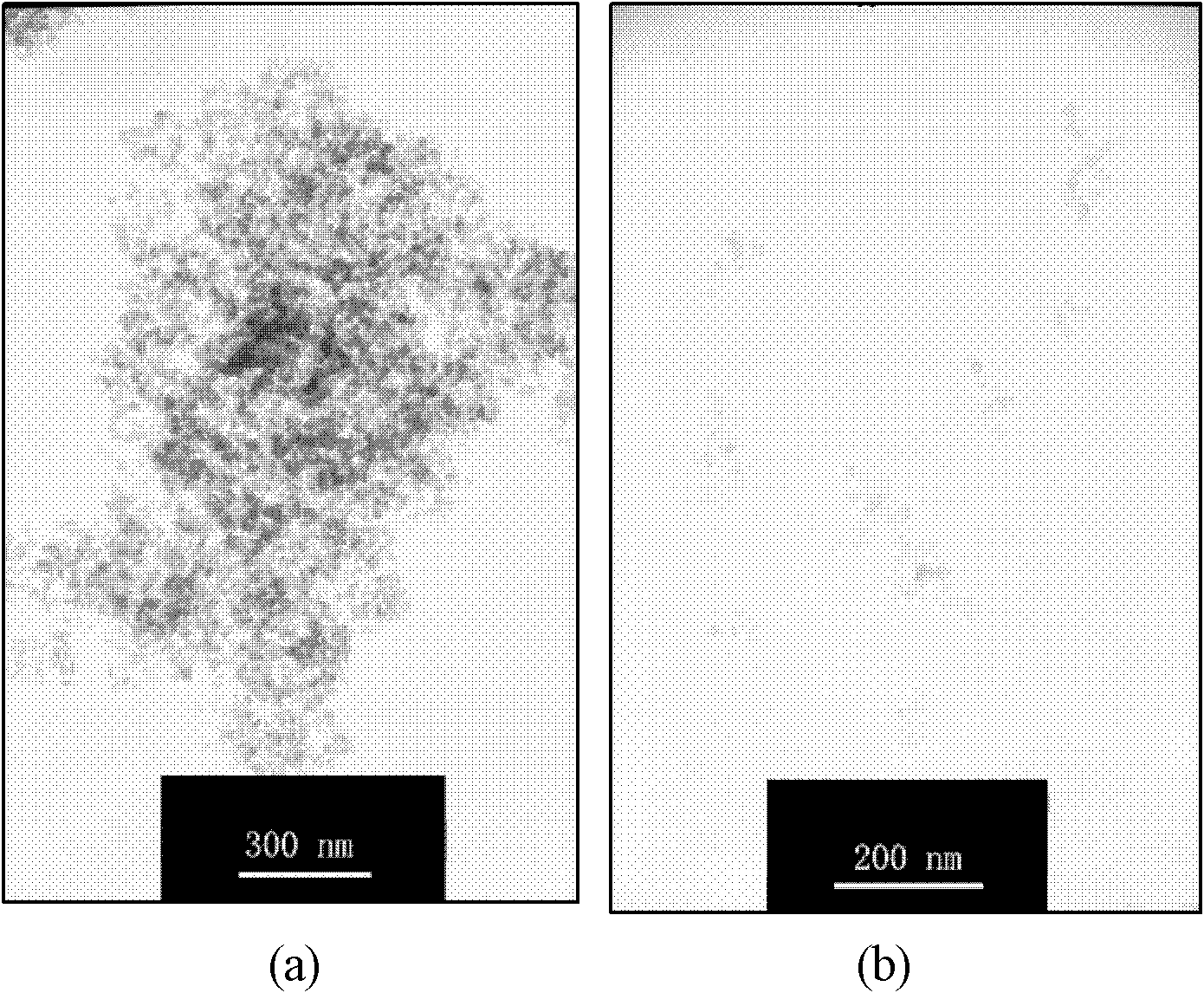

[0029] In this example, fluorosilane (this example is heptadecafluorodecyltrimethoxysilane) modified nano-SiO 2 The specific process of the concentrated slurry is as follows:

[0030]First prepare mixed solution, its component mass ratio is fluorosilane coupling agent: water: isopropanol=1: 15: 1, mixed solution is hydrolyzed in the hydrochloric acid solution of pH=6, and hydrolysis product is fluorosilanol; Solution quality 30% nano-SiO 2 (in this embodiment, nano-SiO 2 The average particle size is 20nm), heated at 60°C for 2h under stirring conditions, dried at 40°C, and ground into fluorosilane grafted modified nano-SiO 2 powder, in which fluorosilane: nano-SiO 2 The mass ratio is 0.15:1, and the powder is fluorosilane-modified nano-SiO 2 Powder: dispersant = 1:1 Add dispersant BYK110, disperse at 1200rpm, after confirming complete dissolution, modify nano-SiO with fluorosilane according to mass ratio 2 Powder: organic solvent = 1:3 Add organic solvent (methoxypropyl a...

Embodiment 2

[0032] In this embodiment, fluorosilane (this embodiment is trifluoropropylmethyldimethoxysilane) modified nano-SiO 2 The specific process of the concentrated slurry is as follows:

[0033] First prepare mixed solution, its component mass ratio is fluorosilane coupling agent: water: isopropanol=1: 12: 1, mixed solution is hydrolyzed in the hydrochloric acid solution of pH=5, and hydrolysis product is fluorosilanol; Solution quality 15% nano-SiO 2 (in this embodiment, nano-SiO 2 The average particle size is 20nm), heated at 80°C for 1h under stirring conditions, dried at 40°C, and ground into fluorosilane graft-modified nano-SiO 2 powder, in which fluorosilane: nano-SiO 2 The mass ratio is 0.15:1, and the powder is fluorosilane-modified nano-SiO 2 Powder: dispersant = 1: 1.2 Add dispersant BYK-P104S, disperse at 900rpm, confirm complete dissolution, modify nano-SiO with fluorosilane according to mass ratio 2 Powder: organic solvent = 1: 2 Add organic solvent (propylene gly...

Embodiment 3

[0035] In this embodiment, fluorosilane (this embodiment is trifluoropropyltrimethoxysilane) modified nano-SiO 2 The specific process of the concentrated slurry is as follows:

[0036] First prepare the mixed solution, its component mass ratio is fluorosilane coupling agent: water: isopropanol=1:15:1, the mixed solution is hydrolyzed in the hydrochloric acid solution of pH=4.5, and the hydrolyzate is fluorosilanol; 20% nano-SiO by solution mass 2 (in this embodiment, nano-SiO 2 The average particle size is 20nm), heated at 100°C for 0.5h under stirring conditions, dried at 30°C, and ground into fluorosilane graft-modified nano-SiO 2 powder, in which fluorosilane: nano-SiO 2 The mass ratio is 0.15:1, and the powder is fluorosilane-modified nano-SiO 2 Powder: dispersant = 1: 2 Add dispersant EFKA5065, disperse at 1500rpm, after confirming complete dissolution, modify nano-SiO with fluorosilane according to mass ratio 2 Powder: organic solvent = 1:5 Add organic solvent (n-bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com