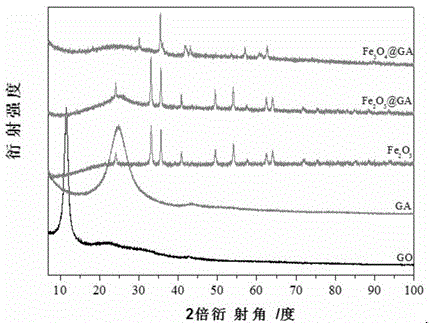

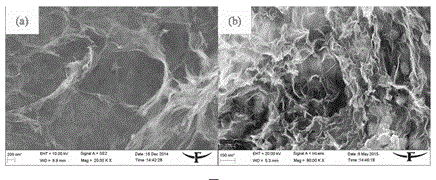

Macroscopic three-dimensional ultralight Fe3O4 doped graphene aerogel composite material and preparation method

A graphene aerogel and composite material technology, which is applied in the field of macroscopic three-dimensional Fe3O4 graphene aerogel ultra-light composite material and preparation, and achieves the effects of mild reaction conditions, simple preparation and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1, pretreatment graphite powder

[0034] At room temperature and under magnetic stirring conditions, add 35 g of graphite powder to 520 mL of a mixed acid solution (1:3) of concentrated nitric acid and concentrated sulfuric acid and stir for 24 hours. Add high-purity water to dilute to 1.5L, and then filter and wash to neutrality (pH = 7) with a glass sand core filter device with a filter membrane pore size of 0.45 μm to obtain a filter cake, and dry the obtained filter cake at 60°C for 2 After a few days, it was ground and processed in batches at 1100°C for 30s to obtain pretreated graphite powder.

[0035] Step 2, preparing graphene oxide solution

[0036] Using the pretreated graphite powder obtained in step 1 as raw material, the graphite oxide solution was prepared by the traditional Hummer method, and then the graphene oxide solution was obtained by ultrasonic stripping, with a concentration of about 4.0 mg / mL.

[0037] Step 3, preparing ferric hydroxide co...

Embodiment 2

[0048] Step one to step three are the same as embodiment 1.

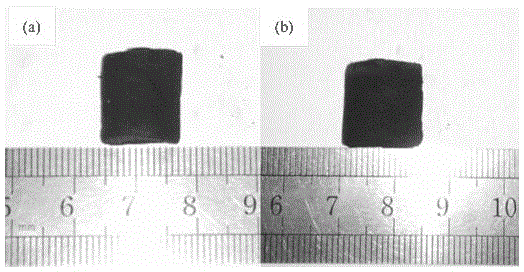

[0049] Step 4, preparation of macroscopic three-dimensional Fe 3 o 4 Graphene airgel ultra-light composite material:

[0050] Fe(OH) 3 The mass ratio with graphene oxide is 1: 1,

[0051] ① Take 15 mL of the graphene oxide solution prepared in step 2 and dilute it with 15 mL of high-purity water, then adjust its pH to 9 with ammonia water under magnetic stirring, and then sonicate for 1 hour to prepare a diluted graphene oxide solution;

[0052] ② At room temperature, the 1.8mLFe(OH) prepared in step 3 3 Add the colloid dropwise to the diluted graphene oxide solution prepared in ①, and stir for 1 hour to make a reaction solution;

[0053] ③ Transfer the reaction solution prepared in ② into a 50mL hydrothermal kettle, and let it stand at 180°C for 24h; then cool the hydrothermal kettle to room temperature to obtain Fe 2 o 3 Graphene hydrogel;

[0054] ④ Fe to be obtained 2 o 3 The graphene hydrogel was move...

Embodiment 3

[0058] Step one to step three are the same as embodiment 1.

[0059] Step 4, preparation of macroscopic three-dimensional Fe 3 o 4 Graphene airgel ultra-light composite material:

[0060] Fe(OH) 3 The mass ratio with graphene oxide is 1.5: 1,

[0061] ① Take 15 mL of the graphene oxide solution prepared in step 2 and dilute it with 15 mL of high-purity water, then adjust its pH to 9 with ammonia water under magnetic stirring, and then sonicate for 1 hour to prepare a diluted graphene oxide solution;

[0062] ② At room temperature, the 2.7mLFe(OH) prepared in step 3 3 Add the colloid dropwise to the diluted graphene oxide solution prepared in ①, and stir for 1h;

[0063] ③ Transfer the reaction solution prepared in ② into a 50mL hydrothermal kettle, and let it stand at 180°C for 24h; then cool the hydrothermal kettle to room temperature to obtain Fe 2 o 3 Graphene hydrogel;

[0064] ④ Fe to be obtained 2 o 3 The graphene hydrogel was moved to ammonia water with a con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com