Water-based polyurethane paint containing polyether glycol/nano TiO2 hybrid material

A polyether polyol, water-based polyurethane technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problem of difficulty in improving the compatibility of nano-titanium dioxide and polyurethane, achieve excellent UV resistance, improve compatibility, Reduce the effect of aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

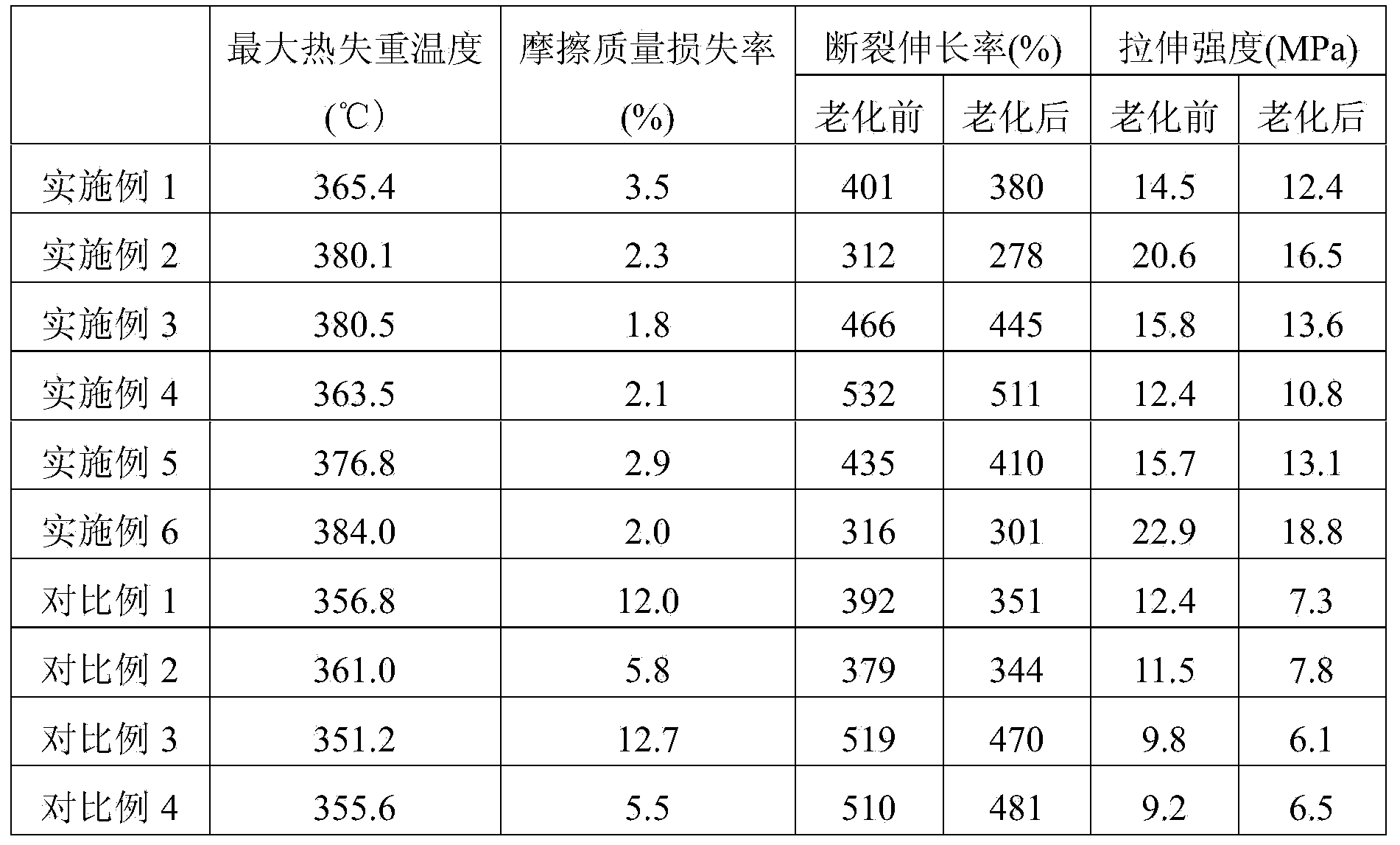

Examples

Embodiment 1

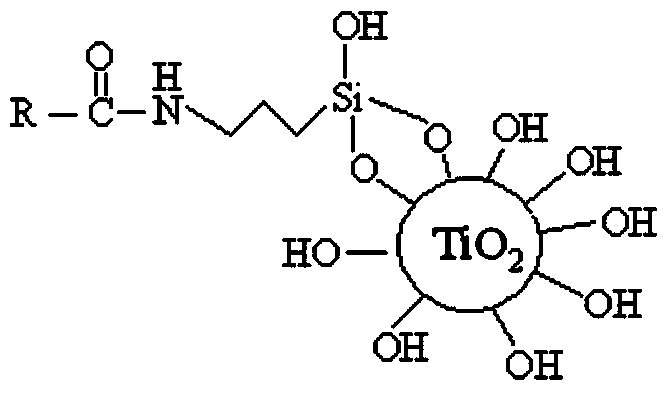

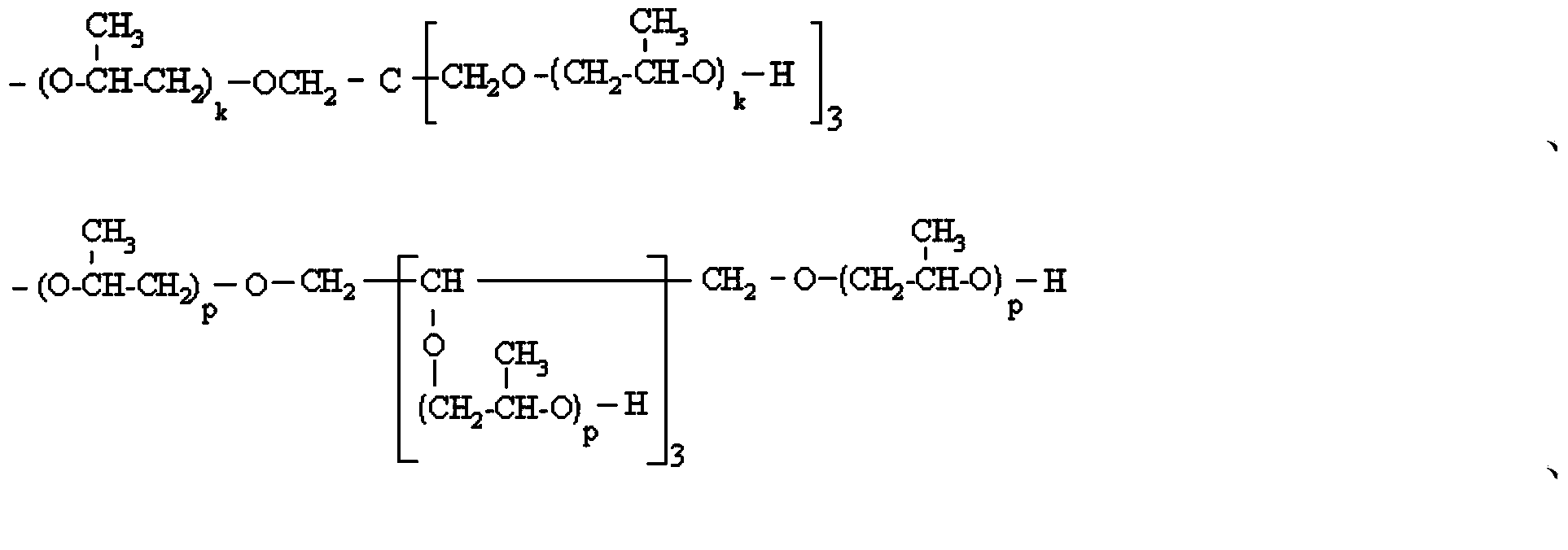

[0057] (1) Preparation of polyoxypropylene ether triol N330 / nano titanium dioxide hybrid material

[0058] a. Under the protection of nitrogen, add 10g of 3-isocyanatopropyltrimethoxysilane to 146g of polyoxypropylene ether triol N330, 0.5g of stannous octoate, and stir and react at 70°C for 6h to obtain a polymer A .

[0059] b. Disperse 10 g of nano-titanium dioxide in 100 g of toluene and sonicate for 0.5 h to obtain a nano-titanium dioxide dispersion.

[0060] c. 16g of polymer A, 11g of nano-titanium dioxide dispersion, 1g of distilled water, and 100g of toluene were stirred and reacted at 60°C for 6 hours, and then rotary evaporated at 70°C to remove toluene and water to obtain polyoxypropylene ether trihydric alcohol N330 / Nano-titanium dioxide hybrid materials.

[0061] (2) Preparation of water-based polyurethane coatings containing polyoxypropylene ether triol N330 / nano-titanium dioxide hybrid materials

[0062] 25g of polyoxypropylene ether triol N330 / nano-titaniu...

Embodiment 2

[0064] (1) Preparation of polyoxypropylene ether triol JH-3030 / nano titanium dioxide hybrid material

[0065] a. Under the protection of nitrogen, add 10g of 3-isocyanatopropyltrimethoxysilane to 146g of polyoxypropylene ether trihydric alcohol JH-3030, 0.05g of dibutyltin dilaurate, and stir at 75°C for 4h. Polymer A was obtained.

[0066] b. Disperse 10 g of nano-titanium dioxide in 100 g of toluene and sonicate for 1 hour to obtain a nano-titanium dioxide dispersion.

[0067] c. 50g of polymer A, 30g of nano-titanium dioxide dispersion, 4g of distilled water, and 200g of toluene were stirred and reacted at 70°C for 6 hours, and then rotary evaporated at 70°C to remove toluene and water to obtain polyoxypropylene ether trihydric alcohol JH- 3030 / nano titanium dioxide hybrid material.

[0068] (2) Preparation of water-based polyurethane coating containing polyoxypropylene ether triol JH-3030 / nano titanium dioxide hybrid material

[0069] 75g polyoxypropylene ether triol JH...

Embodiment 3

[0071] (1) Preparation of polyoxypropylene ether triol MN-3050 / nano titanium dioxide hybrid material

[0072] a. Under the protection of nitrogen, add 10g of 3-isocyanatopropyltrimethoxysilane to 146g of polyoxypropylene ether triol MN-3050, 0.3g of lead octoate, and stir at 80°C for 4h to obtain polymer A.

[0073] b. Disperse 10 g of nano-titanium dioxide in 100 g of toluene and sonicate for 2 hours to obtain a nano-titanium dioxide dispersion.

[0074] c. 32g of polymer A, 22g of nano-titanium dioxide dispersion, 2g of distilled water, and 150g of toluene were stirred and reacted at 60°C for 8 hours, and then rotary evaporated at 70°C to remove toluene and water to obtain polyoxypropylene ether trihydric alcohol MN- 3050 / nano titanium dioxide hybrid material.

[0075] (2) Preparation of waterborne polyurethane coatings containing polyoxypropylene ether triol MN-3050 / nano-titanium dioxide hybrid materials

[0076] 50g of polyoxypropylene ether triol MN-3050 / nano-titanium d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com