Photosensitivity siloxane and hyperbranched polyether polyol-containing photosensitive resin composition used for used for three-dimensional rapid moulding

A technology of hyperbranched polyether and photosensitive resin, which is applied in the field of photosensitive resin, composition and its cured products, can solve the problems of limited improvement of curing speed and mechanical properties of photo-cured three-dimensional rapid prototyping materials, and achieve spherical symmetry Good resistance, good curing performance, and regular structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with embodiment.

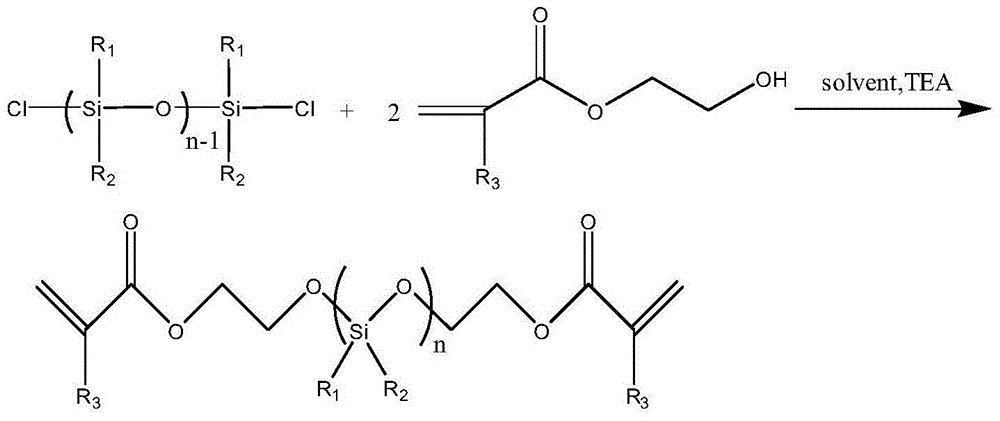

[0058] (1) Preparation of photosensitive siloxane:

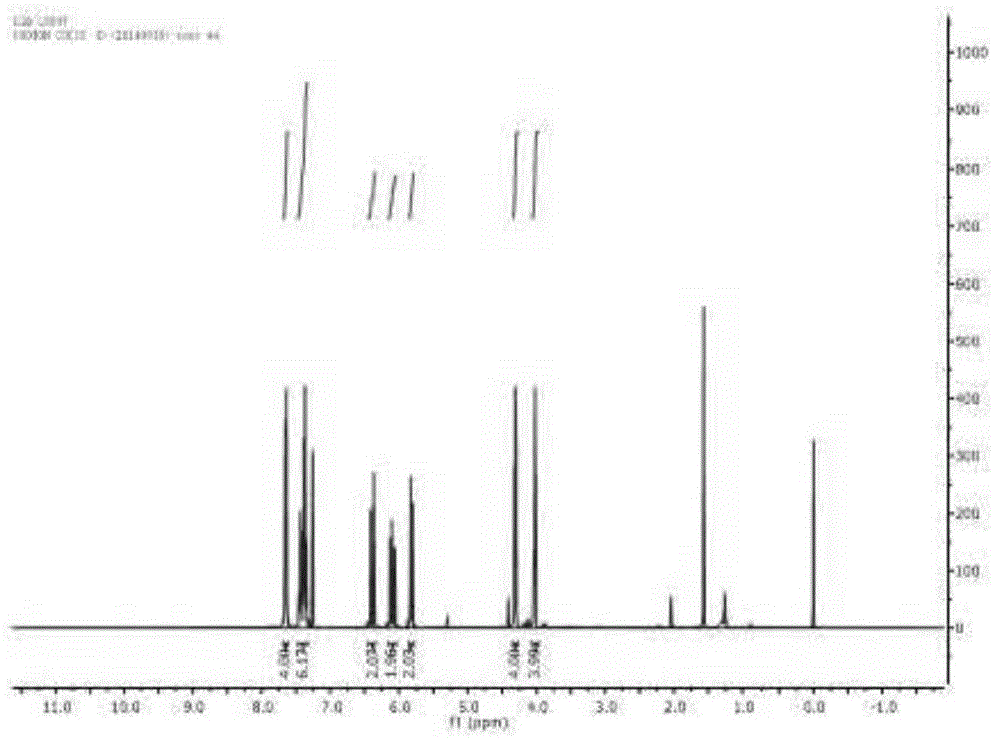

[0059] Under nitrogen protection, 36.4 grams (280 mL) of hydroxyethyl methacrylate and 40 grams of anhydrous triethylamine were dissolved in 500 mL of toluene and stirred, the temperature was lowered to below zero, and 35.42 grams (140 mmL) of diphenyldichlorosilane was dropped Add to the above solution. After the dropwise addition, the temperature was raised, and the mixture was stirred and refluxed for 24 hours. After the reaction was completed, the solution was filtered and the solvent was evaporated to obtain bis[2-(methacryloyloxy)ethoxy]diphenylsilane as an oil. The H NMR spectrum of the compound is figure 1 shown.

[0060] (2) Preparation of hyperbranched polyether polyol (number average molecular weight 1000g / mol):

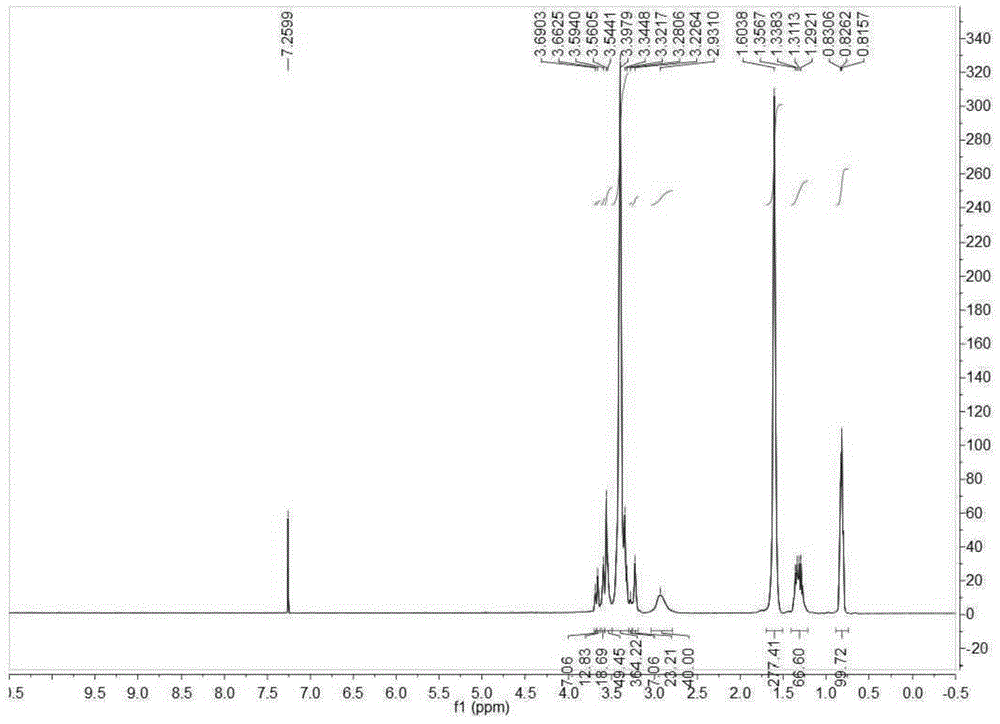

[0061] Under nitrogen protection, 1.28 g (9.6 mmol) of trimethylolpropane was dissolved in 200 mL of dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com