Epoxy resin based on 2,5-furandicarboxylic acid, preparation method and application thereof

A technology of furandicarboxylic acid and epoxy resin, which is applied in the direction of epoxy resin glue, epoxy resin coating, adhesive type, etc., to achieve the effects of simple operation, less pollution and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Under the protection of nitrogen, 100 parts by weight of 2,5-furandicarboxylic acid, 1000 parts by weight of epichlorohydrin and 10 parts by weight of tetrabutylammonium bromide were fully mixed, reacted at 100°C for 1.5h, and then cooled to 30°C. 80 parts by weight of sodium hydroxide and 160 parts by weight of deionized water were added to form a reaction system, and the reaction was continued for 3 hours. After the reaction system was lowered to the ambient temperature of 25°C, 150 parts by weight of deionized water was added each time for washing for a total of 3 times, and then the solvent was removed with a rotary evaporator, and vacuum-dried at 50°C for 12 hours to obtain a compound based on 2,5-furan 165 parts by weight of the epoxy resin of formic acid.

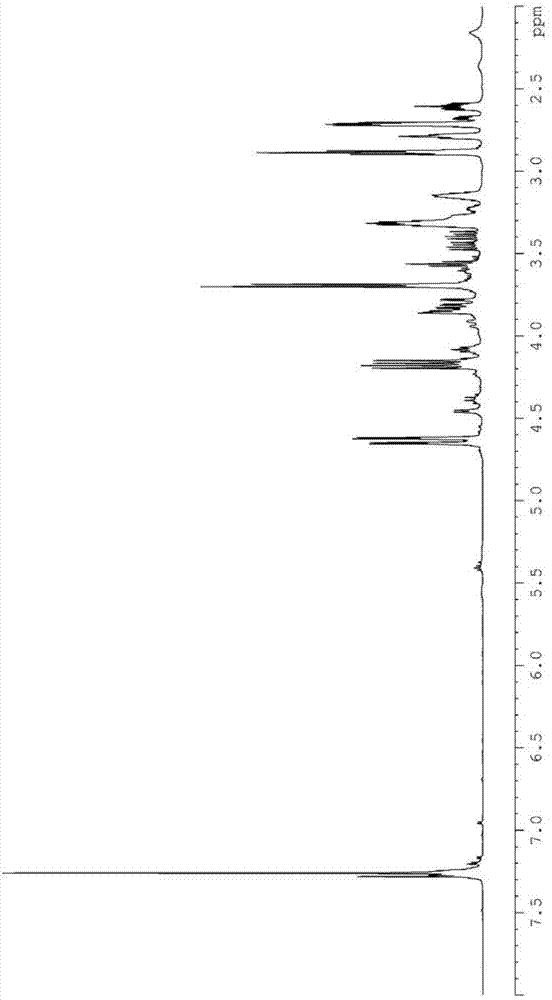

[0042] The epoxy resin based on 2,5-furandicarboxylic acid prepared above is characterized by structure, and the hydrogen nuclear magnetic resonance spectrum is as follows: figure 1 shown.

[0043]The epoxy ...

Embodiment 2

[0048] Under the protection of nitrogen, 100 parts by weight of 2,5-furandicarboxylic acid, 900 parts by weight of epichlorohydrin and 20 parts by weight of tetrabutylammonium bromide were fully mixed, reacted at 140°C for 2.5h, and then cooled to 60°C. 80 parts by weight of sodium hydroxide and 160 parts by weight of deionized water were added to form a reaction system, and the reaction was continued for 5 hours. After the reaction system was lowered to the ambient temperature of 20°C, 150 parts by weight of deionized water was added each time for washing for a total of 3 times, and then the solvent was removed with a rotary evaporator, and vacuum-dried at 50°C for 12 hours to obtain a compound based on 2,5-furan 159 parts by weight of the epoxy resin of formic acid.

[0049] The above-prepared epoxy resin based on 2,5-furandicarboxylic acid was characterized structurally, and the hydrogen nuclear magnetic resonance spectrum and figure 1 Basically the same.

[0050] The epo...

Embodiment 3

[0055] Under the protection of nitrogen, 100 parts by weight of 2,5-furandicarboxylic acid, 200 parts by weight of epichlorohydrin and 2 parts by weight of tetrabutylammonium bromide were fully mixed, reacted at 110°C for 0.5h, and then cooled to 40°C, 80 parts by weight of sodium hydroxide and 160 parts by weight of deionized water were added to form a reaction system, and the reaction was continued for 5 hours. After the reaction system was lowered to the ambient temperature of 25°C, 150 parts by weight of deionized water was added each time for washing for a total of 3 times, and then the solvent was removed with a rotary evaporator, and vacuum-dried at 50°C for 12 hours to obtain a compound based on 2,5-furan 110 parts by weight of epoxy resin of formic acid.

[0056] The above-prepared epoxy resin based on 2,5-furandicarboxylic acid was characterized structurally, and the hydrogen nuclear magnetic resonance spectrum and figure 1 Basically the same.

[0057] The epoxy va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com