Patents

Literature

416results about How to "Strong UV resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

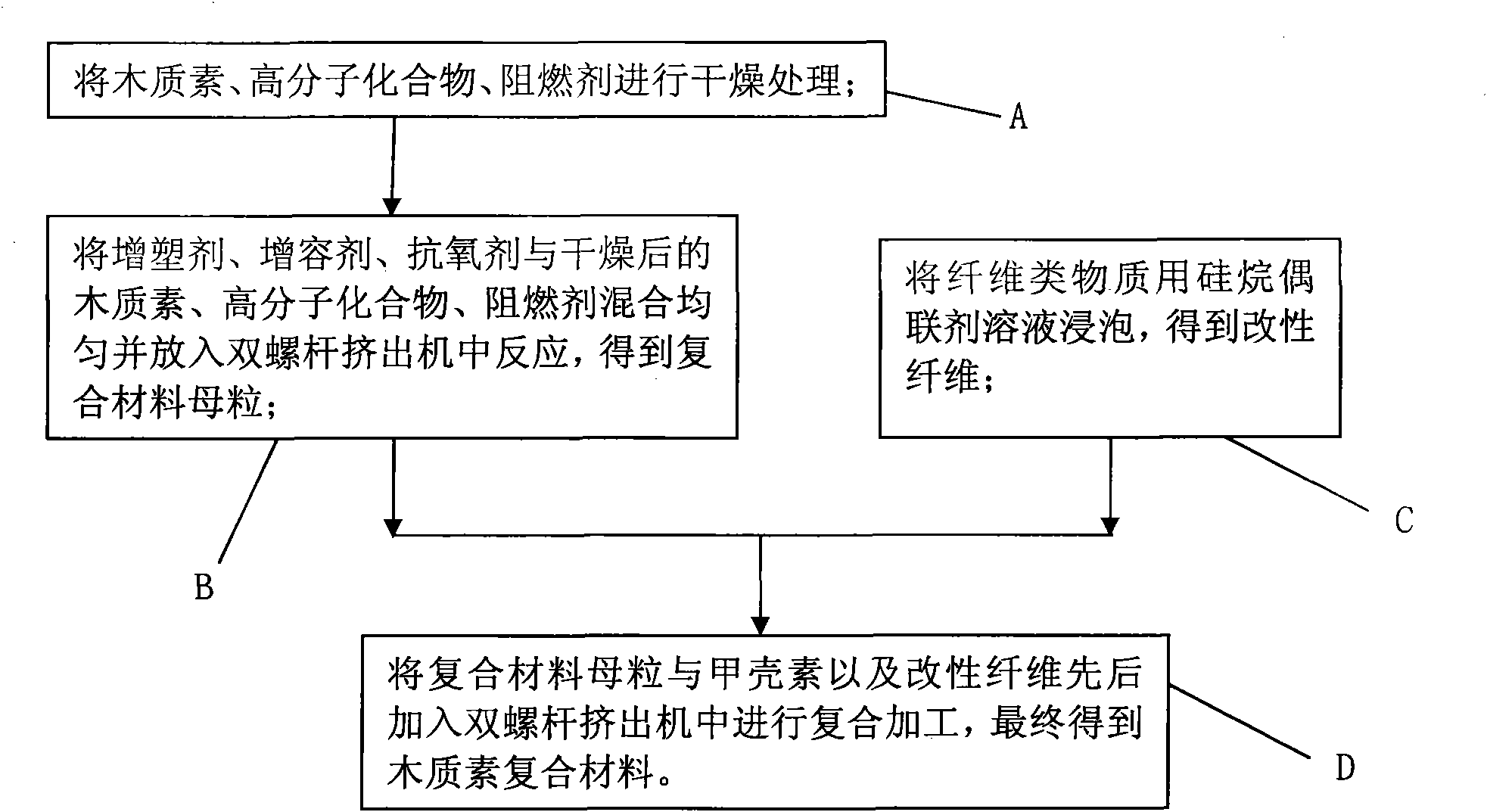

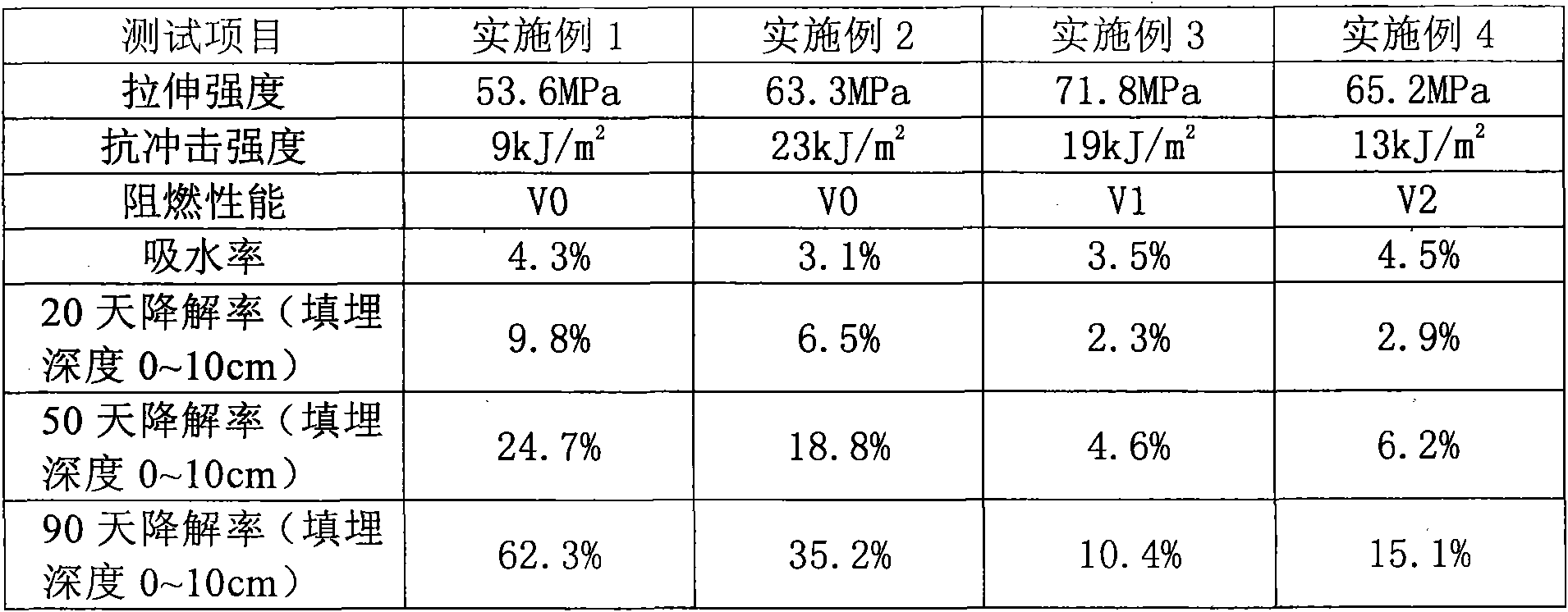

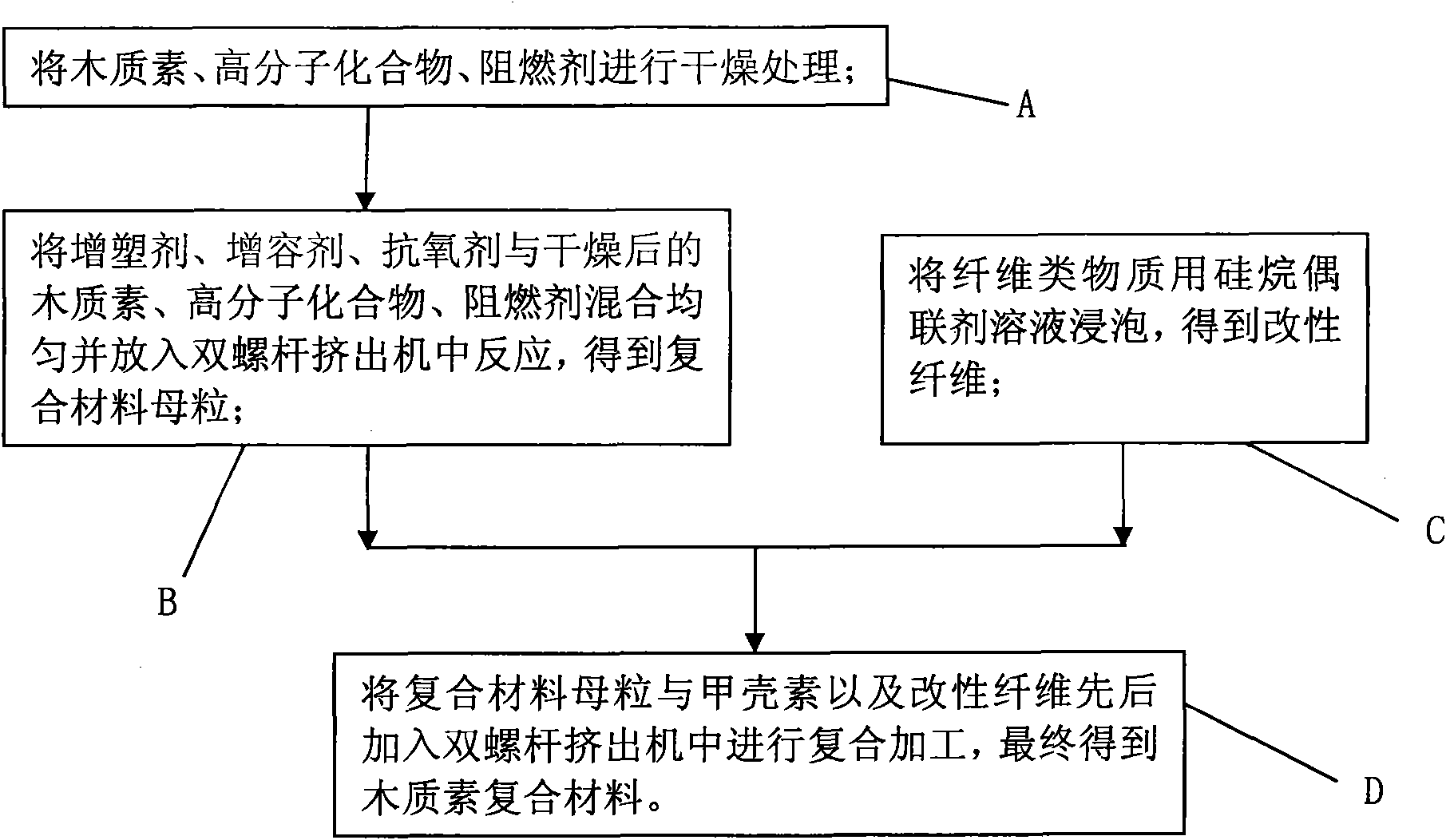

Lignin composite material and preparation method thereof

The invention provides a lignin composite material and a preparation method thereof. The lignin composite material is formed by mixing lignin, a high molecular compound, a fiber substance, chitin, a plasticizer, a compatibilizer, an antioxidant and a flame retardant, wherein the lignin composite material comprises the following components in percentage by weight: 2.5 to 56.4 percent of lignin, 10 to 70.5 percent of high molecular compound, 2.5 to 16.92 percent of flame retardant, 0.5 to 7.52 percent of plasticizer, 0.5 to 9.4 percent of compatibilizer, 0.05 to 1.88 percent of antioxidant, 1 to 10 percent of chitin and 5 to 4 percent of fiber. The composite material is formed by compounding the lignin serving as a base material with at least one high molecular compound and gathering by fusion through a polymer, so the composite material has the advantages of low water absorption, high mechanical performance and degradability.

Owner:CHERY AUTOMOBILE CO LTD

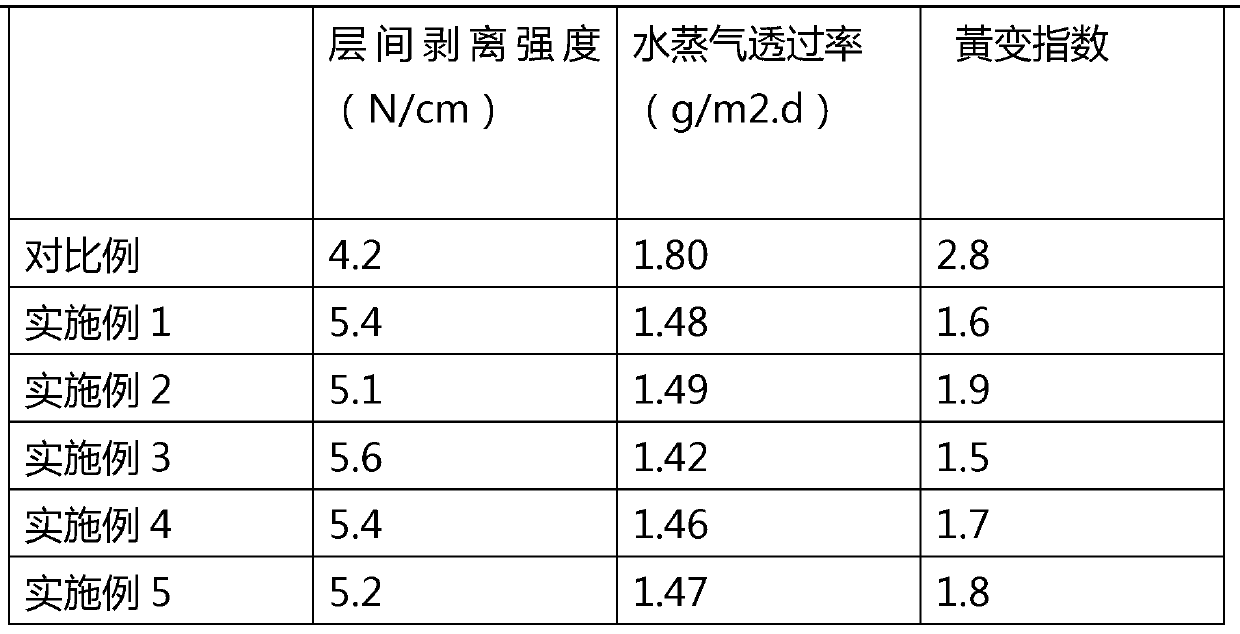

Solar panel back film and manufacturing technology thereof

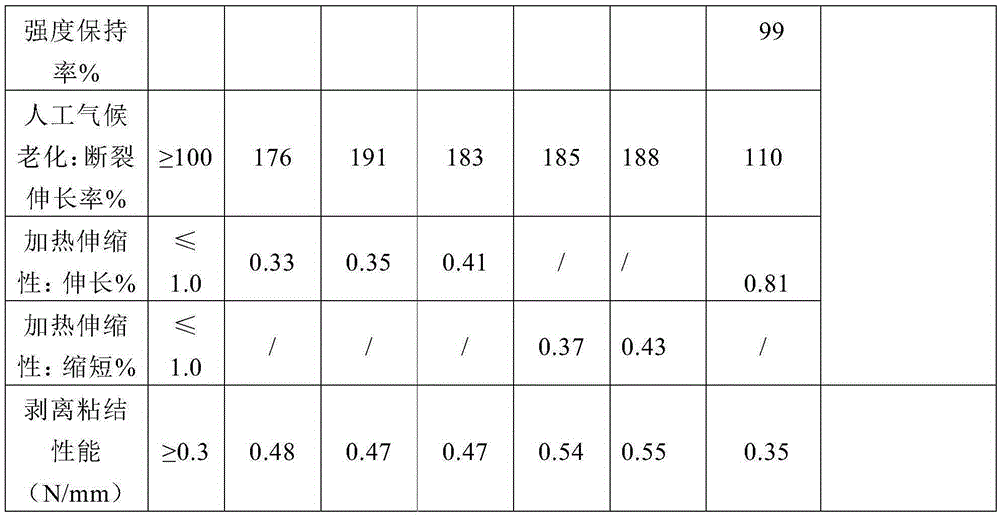

ActiveCN103346182AImprove bindingStrong bonding between layersFinal product manufactureSynthetic resin layered productsPolyesterManufacturing technology

A solar panel back film comprises a PET film matrix with the thickness of 100-350 micrometers. Fluorine-containing polymer coatings of 15-30micrometers cover the two faces of the matrix, and the fluorine-containing polymer coatings are formed by mixing raw material components according to a proportion to obtain mixed emulsion and coating the PET film matrix by the mixed emulsion which is swollen under the temperature between 80 DEG C and 200 DEG C, wherein raw materials of the fluorine-containing polymer coatings comprise, by mass, polyester PET powder, fluorine-containing resin, solvent, a cross-linking agent, padding and ethylene glycol. The polyester PET powder is polyester PET powder with grain size smaller than 25 micrometers, wherein the polyester PET powder is formed by smashing precipitate obtained by dissolving in phenol-carbon tetrachloride mixed solvent. The fluorine-containing resin is fluorine-containing macromolecule resin. The solar panel back film is easy to process, tearing resistant and superior in electrical insulation performance and weather fastness.

Owner:ZHEJIANG VENTURA PHOTOVOLTAIC MATERIALS

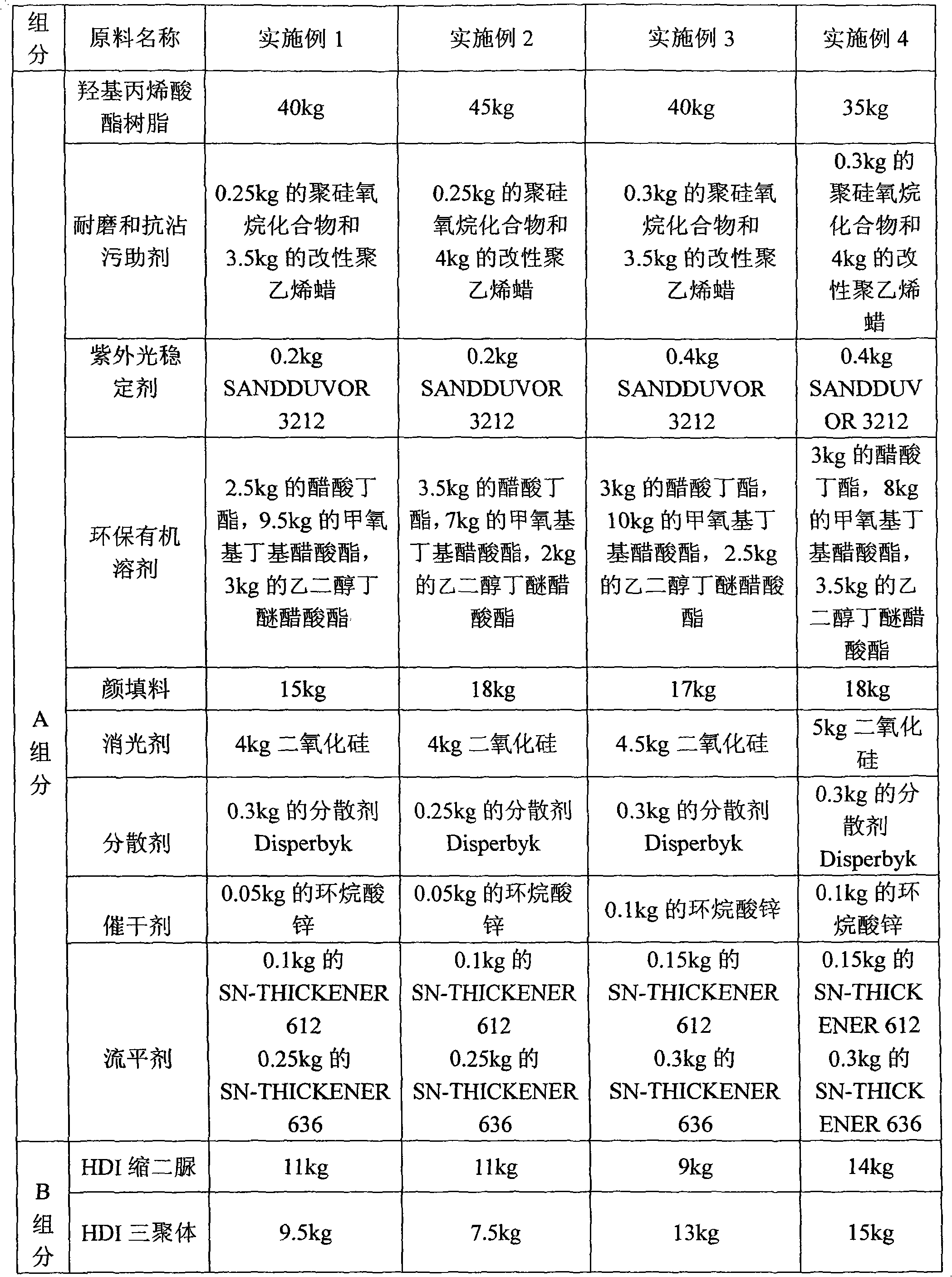

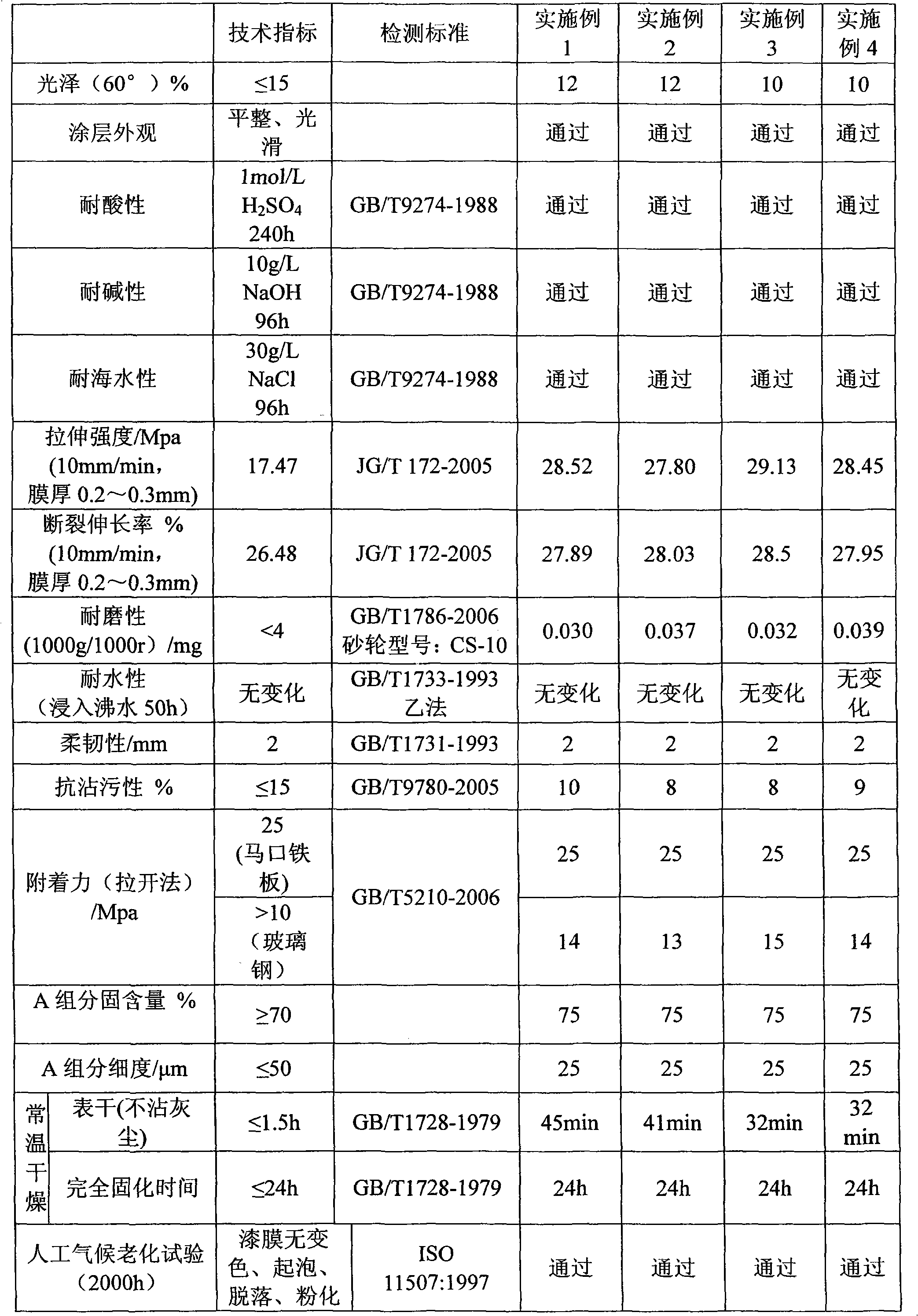

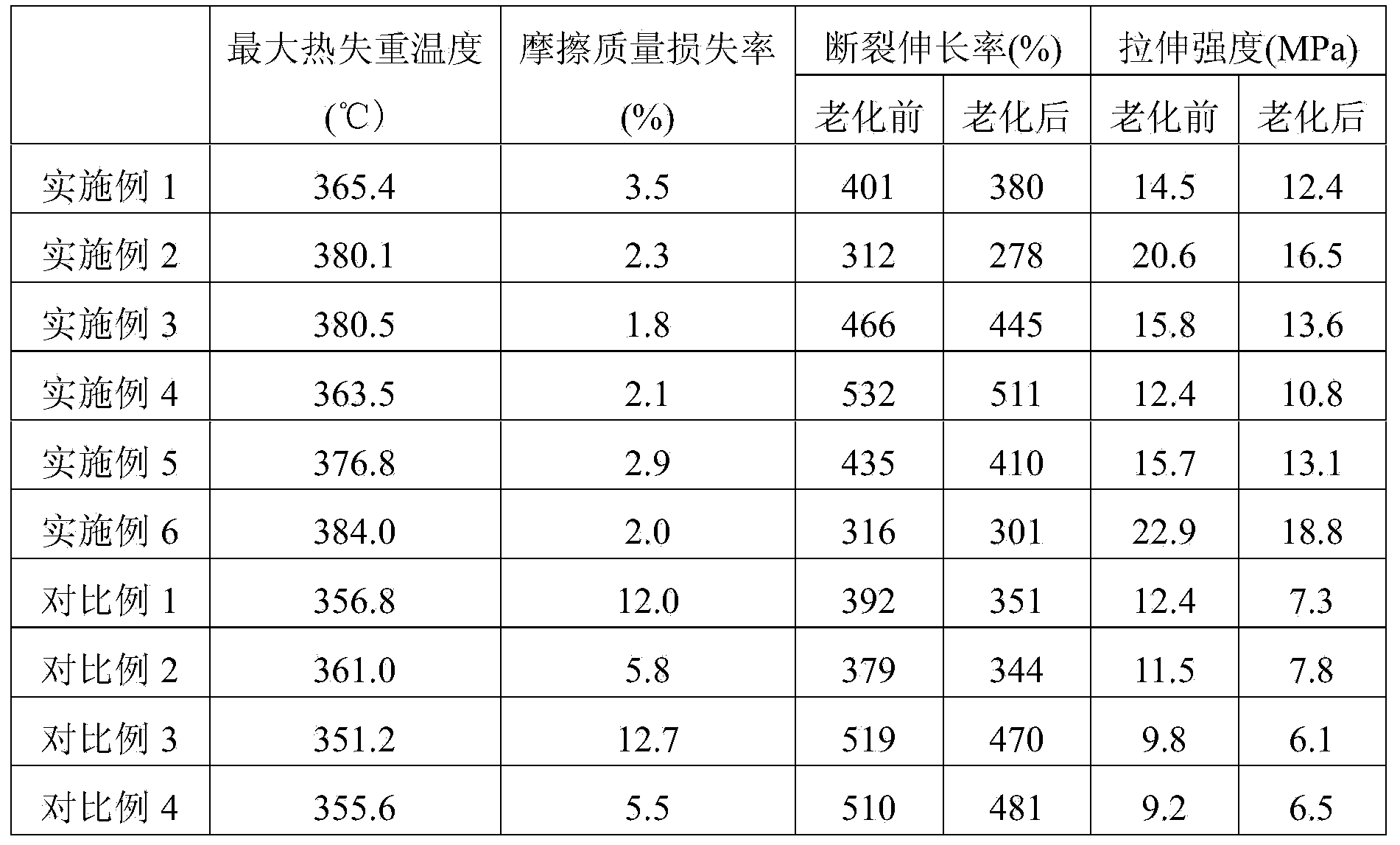

Protective coating for aerogenerator vanes and preparation method thereof

InactiveCN101613564AGood weather resistanceStrong UV resistanceMachines/enginesPolyurea/polyurethane coatingsOrganic solventPliability

The invention relates to a protective coating for aerogenerator vanes and a preparation method thereof, wherein the protective coating has the advantages of excellent ultraviolet radiation resistance, abrasion resistance, stain resistance, corrosion resistance, adhesive force and flexibility. The preparation method uses hydroxyl acrylate resin as a base material of the surface protective coating for the aerogenerator vanes and uses the mixture of HDI biuret and HDI tripolymer as a curing agent. The coating consists of a component A and a component B, wherein the component A comprises the following materials in portion by weight: 10 to 55 portions of the hydroxyl acrylate resin, 1 to 5 portions of abrasion resistant and stain resistant auxiliary agent, 0.2 to 0.4 portion of ultraviolet stabilizer, 10 to 15 portions of environment-friendly organic solvent, 15 to 20 portions of pigments and fillers, 2 to 5 portions of delustering agent, 0.15 to 0.55 portion of dispersing agent, 0.01 to 0.3 portion of drying agent, and 0.25 to 0.55 portion of levelling agent; the component B comprises 1 to 15 portions of the HDI biuret and 1 to 15 portions of the HDI tripolymer; and the mass ratio of the component A to the component B is 2-6:1. When in use, the components A and B are mixed and stirred evenly in proportion, and then the mixture is adjusted to proper viscosity for construction by using a spraying method.

Owner:SOUTHEAST UNIV

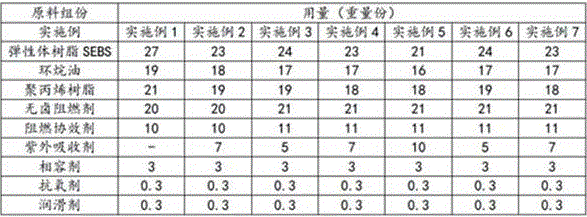

Nano modified polymer-based roof waterproof paint and its production process

InactiveCN1441015AImprove mechanical propertiesImprove barrier propertiesAntifouling/underwater paintsPaints with biocidesUltrasound - actionUltraviolet

The nano modified polymer-based waterproof roof paint incldues polymer emulsion as base material, calcium carbonate, talcum and mica as stuffing, characterized inorganic nano particle and sodium-base montmorillonoid as modifier. The production process includes dispersing the inorganic nano particle as modifier in the base material under the action of ultrasonic wave, adding sodium-base montmorillonid through high speed stirring for inserting compounding; adding stuffing while stirring, grinding and filtering. By means of the composite modification, the paint of the present inventino has excellent mechanical performance and waterproof performance and excellent uvioresistant capacity, and may be used to prolong the service life of roof obviously.

Owner:WUHAN UNIV OF TECH

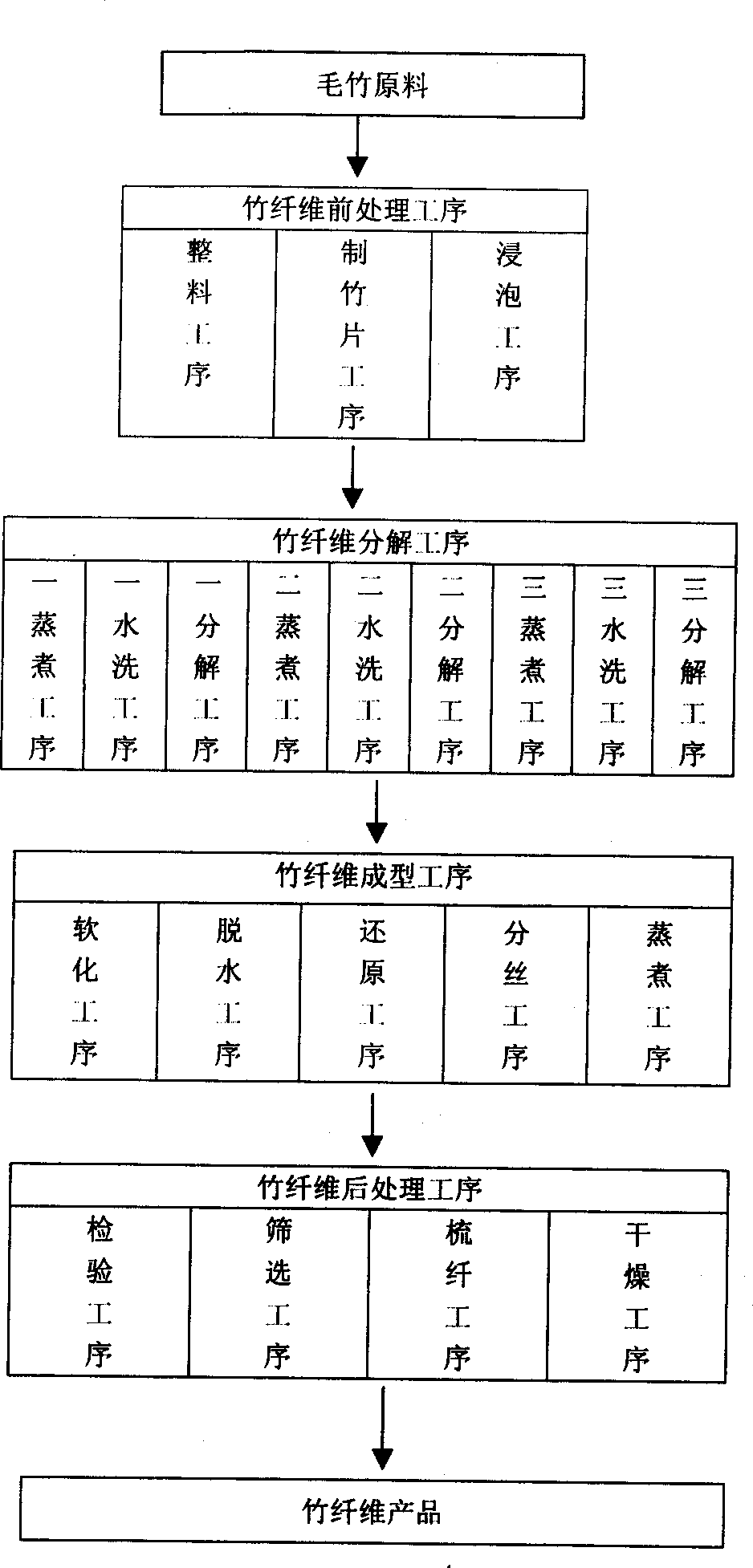

Bamboo fiber and its making process

InactiveCN1375578AGood flexibilityHigh folding resistanceVegetable fibres from other vegetable matterFibrous raw materialsAfter treatmentDecomposition

The present invention uses clustered bamboo as raw material and is aimed at providing a kind of raw material for making shell fabric instead of cotton, chemical fibre, hemp and silk, and its production method incldues the procedures of bamboo fibre pretreatment, bamboo fibre decomposition, bamboo forming and its after treatment, in which it adopts a degumming softening agent made up according to a natural formula, it is neutral in acidity-alkalinity and has no environmental pollution. Said shell fabric made of bamboo fibre is good in flexibility and permeability and is uvioresistant.

Owner:赵子群

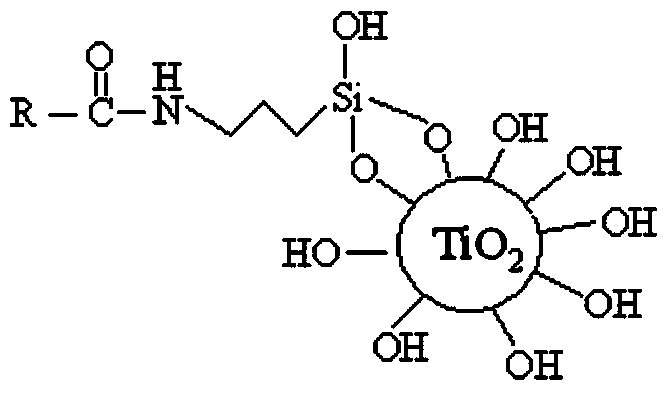

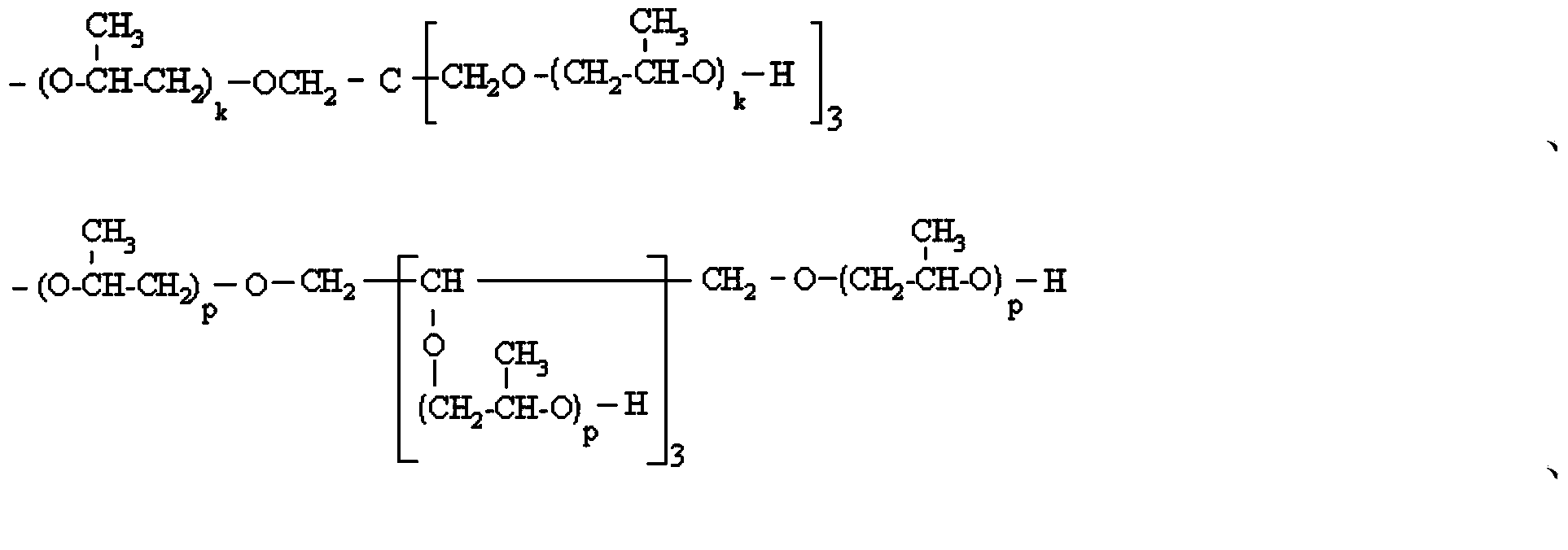

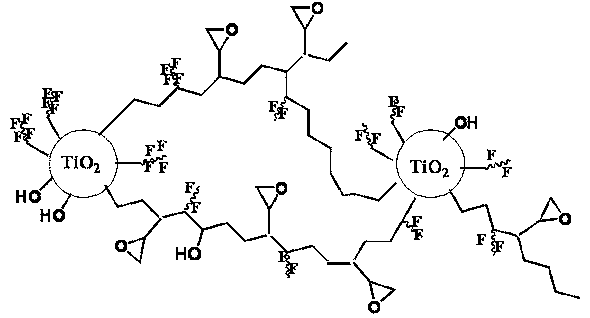

Water-based polyurethane paint containing polyether glycol/nano TiO2 hybrid material

ActiveCN104403548AGood thermal propertiesImprove mechanical propertiesPolyurea/polyurethane coatingsWater basedOrganometallic catalysis

The invention belongs to the technical field of water-based polyurethane paints, and discloses a water-based polyurethane paint containing a polyether glycol / nano TiO2 hybrid material, and a preparation method and application thereof. The paint comprises the following components in parts by mass: 25-75 parts of polyether glycol / nano titanium dioxide hybrid material, 15-65 parts of diisocyanate, 100 parts of polyether glycol, 8-16 parts of polyhydroxy-carboxylic acid, 0.05-0.5 part of organo-metallic catalyst, 0.5-10 parts of crosslinking agent, 6.2-12.4 parts of neutralizer, 1-8 parts of chain extender and 0.2-2.0 parts of defoaming agent. The paint enhances the compatibility between the nano titanium dioxide and polyurethane base, has the advantages of favorable thermal properties, favorable mechanical properties, favorable wear resistance and excellent ultraviolet resistance, and can be widely used in the fields of architectural paints, automobile paints, wood paints, electrodeposition paints, paper conditioning paints, glass fiber paints, electrophoretic paints and the like.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Natural green health care knitwear and its mfg. method

A health-care knitting fabric is made up of hemp fibre, color cotton fibre, bamboo fibre, soybean protein fibre, chitin fibre, and natural wooden pulp fibre through twisting, knitting, boiling, softening, baking and high-pressure ironing.

Owner:王新文

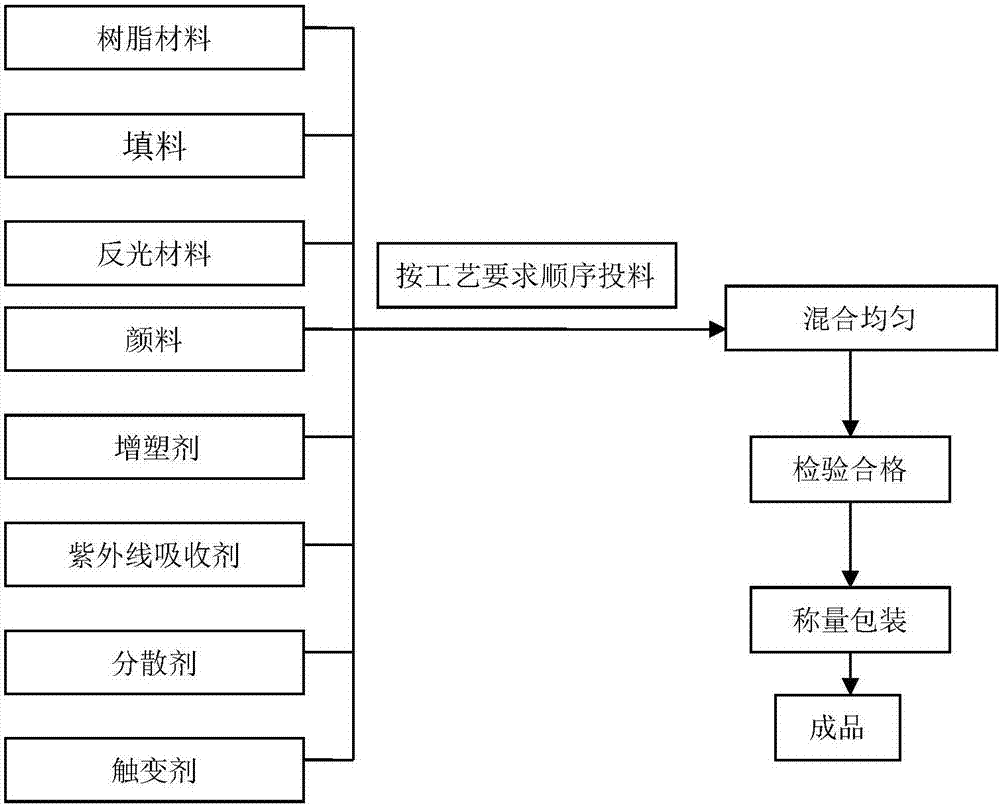

High weather-resistant hot melting reflection type pavement marking paint

InactiveCN106883721AImprove crack resistanceResistant to large temperature difference between day and nightReflecting/signal paintsGlass ballCrack resistance

A hot-melt reflective pavement marking paint with high weather resistance, which is composed of thermoplastic resin, filler, reflective material, pigment and additives, wherein: Among them: thermoplastic resin is C 5 Petroleum resin; the filler is quartz sand and calcium carbonate powder with different particle size distribution; the reflective material is glass beads; the pigment is titanium dioxide or medium chrome yellow; the auxiliary agent is plasticizer, ultraviolet absorber, dispersant, thixotropic agent constitute, of which: The beneficial effect of the invention is that it is suitable for use in high-altitude areas, is resistant to large temperature differences between day and night, has strong anti-ultraviolet rays, and significantly improves the performance of anti-aging and anti-cracking of road marking coatings.

Owner:云南建投建材科技有限责任公司 +1

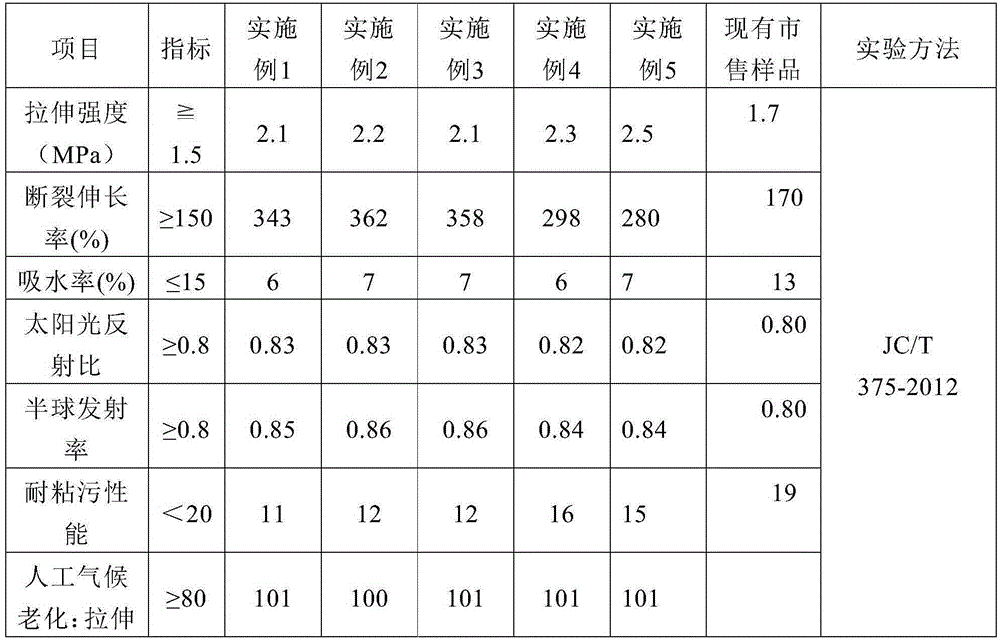

Compound-type metal roof thermal-insulation waterproof coating and preparing method thereof

ActiveCN105331220AEfficient conductionUniform conductionAntifouling/underwater paintsPaints with biocidesThermal insulationHeat conducting

The invention relates to a compound-type metal roof thermal-insulation waterproof coating and a preparing method thereof. The compound-type metal roof thermal-insulation waterproof coating is composed of a surface layer coating and a base layer coating. The surface layer coating is prepared from water, dispersing agents, antifoaming agents, pigment, hollow glass beads, inorganic-thixotropy thickening agents, inorganic filler, silicone-modification acrylic emulsion, acrylic emulsion, film forming assistants, pH value regulation agents, thickening agents and antifreeze agents; the base layer coating is prepared from water, dispersing agents, antifoaming agents, pigment, heat-conducting functional filler, inorganic-thixotropy thickening agents, inorganic filler, acrylic emulsion, pH value regulation agents, thickening agents and antifreeze agents. Compared with the prior art, the problems that bonding of a present waterproof material and a metal base material is not firm, aging is prone to occurrence and the service life is limited are solved, and the compound-type metal roof thermal-insulation waterproof coating has the advantage of integrating water proofing, protection, rust protection and thermal insulation.

Owner:上海北新月皇新材料集团有限公司

Formula and preparation method for ground slipping preventing liquor

ActiveCN104531071AEffective penetrationImprove permeabilityOther chemical processesAcetic acidPotassium carbonate

The invention discloses a formula and preparation method for a ground slipping preventing liquor. The ground slipping preventing liquor is prepared from the following components in percentage by weight: 28% of tartaric acid, 2% of acetic acid, 12% of a surfactant, 0.5% of a defoamer, 9% of sodium chloride, 5% of potassium carbonate, 2% of an emulsifier, 41% of purified water and 0.5% of a corrosion inhibitor. The ground slipping preventing liquor disclosed by the invention is environment-friendly and has a long-time slipping preventing effect.

Owner:SHANGHAI JIADELI NON SLIP PROTECTION TECH

Heavy-anticorrosive epoxy finishing coat and preparation method thereof

ActiveCN103275598AImprove anti-agingEasy to cleanAnti-corrosive paintsEpoxy resin coatingsPolymer scienceFirming agent

The invention relates to heavy-anticorrosive epoxy finishing coat and a preparation method thereof. The heavy-anticorrosive epoxy finishing coat is a double-component system, wherein the component A comprises the following ingredients in parts by weight: 100 parts of hydrogenated bisphenol a expoxy resin, 10-30 parts of epoxy resin TDE 85, 5-20 parts of butyl titanate, 5-20 parts of fluorocarbon-containing silane coupling agent, 10-20 parts of an epoxy-containing silane coupling agent, 10-30 parts of other organic silicone precursor, 0.1-5 parts of a dispersing agent, 0.1-5 parts of a flatting agent, 0.1-5 parts of a defoaming agent, 0.1-2 parts of an accelerant and 50-150 parts of a solvent, and the component B is 30-20 parts by mass of an amine curing agent. The heavy-anticorrosive epoxy finishing coat mainly serves as outdoor heavy-anticorrosive finishing coat and has the advantages of excellent ultraviolet-resistance property, anti-yellowing property, good dispersion stability, excellent acid resistance, alkali resistance and salt-spray corrosion resistance, strong adhesive force, good wear-resisting property, self-cleaning property, room temperature curing, simple and convenient construction and the like.

Owner:STATE GRID CORP OF CHINA +2

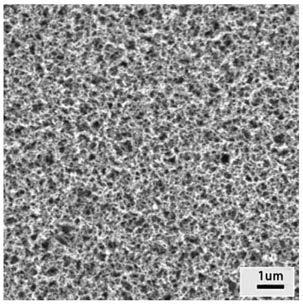

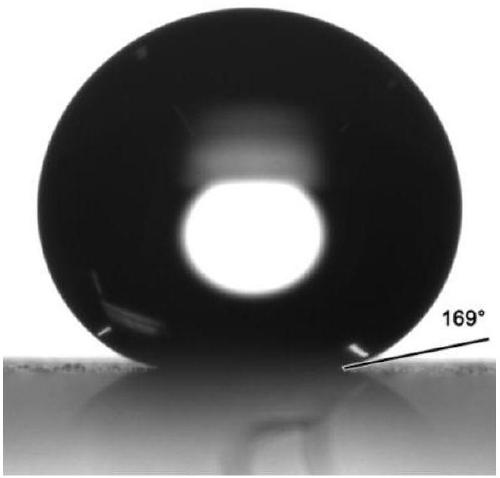

Method of preparing super-hydrophobic coating by compounding waterborne polyurethane and hydrophobic modified inorganic nanoparticles

ActiveCN109370408AHigh transparencyExcellent superhydrophobic propertiesPolyurea/polyurethane coatingsNano structuringRoom temperature

The invention relates to a method of preparing a super-hydrophobic coating by compounding waterborne polyurethane and hydrophobic modified inorganic nanoparticles. The method comprises the following steps: spraying waterborne polyurethane to a substrate; then placing the substrate horizontally for 15-30 minutes; then spraying a hydrophobic modified inorganic nanoparticle dispersion liquid obtainedin the step 2 to a polyurethane film; and drying the film at room temperature; and finally obtaining the waterborne polyurethane and hydrophobic modified inorganic nanoparticle compound coating. Themethod is simple, non-toxic and pollution-free, forms a graded micro / nano structure organically and inorganically, and can be produced on a large scale.

Owner:HEBEI UNIV OF TECH

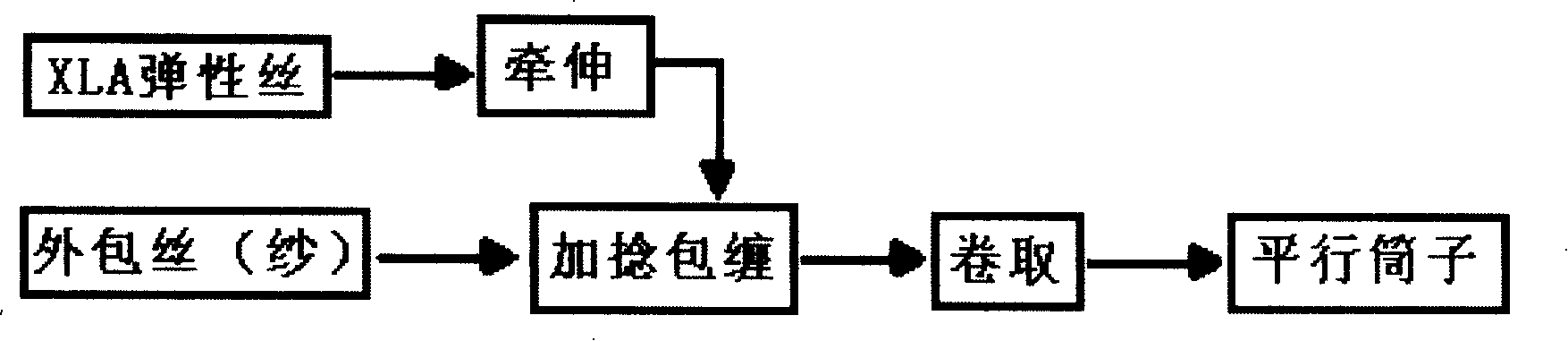

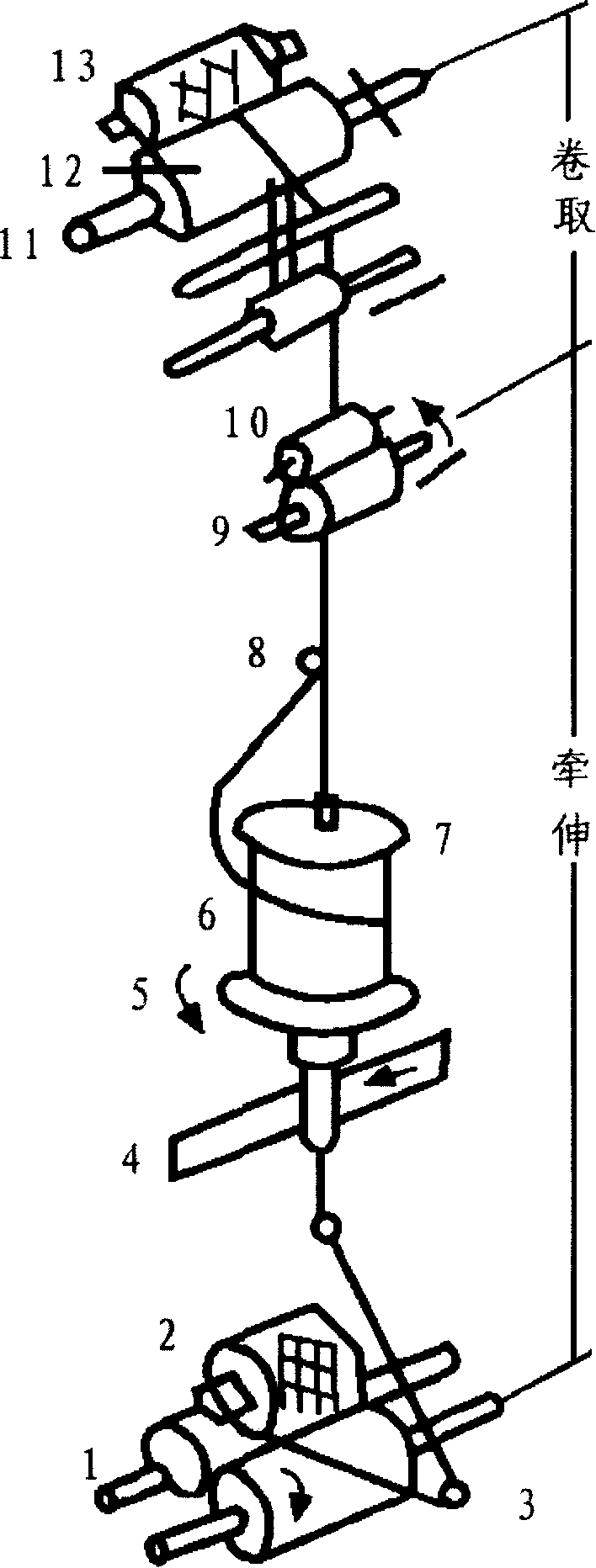

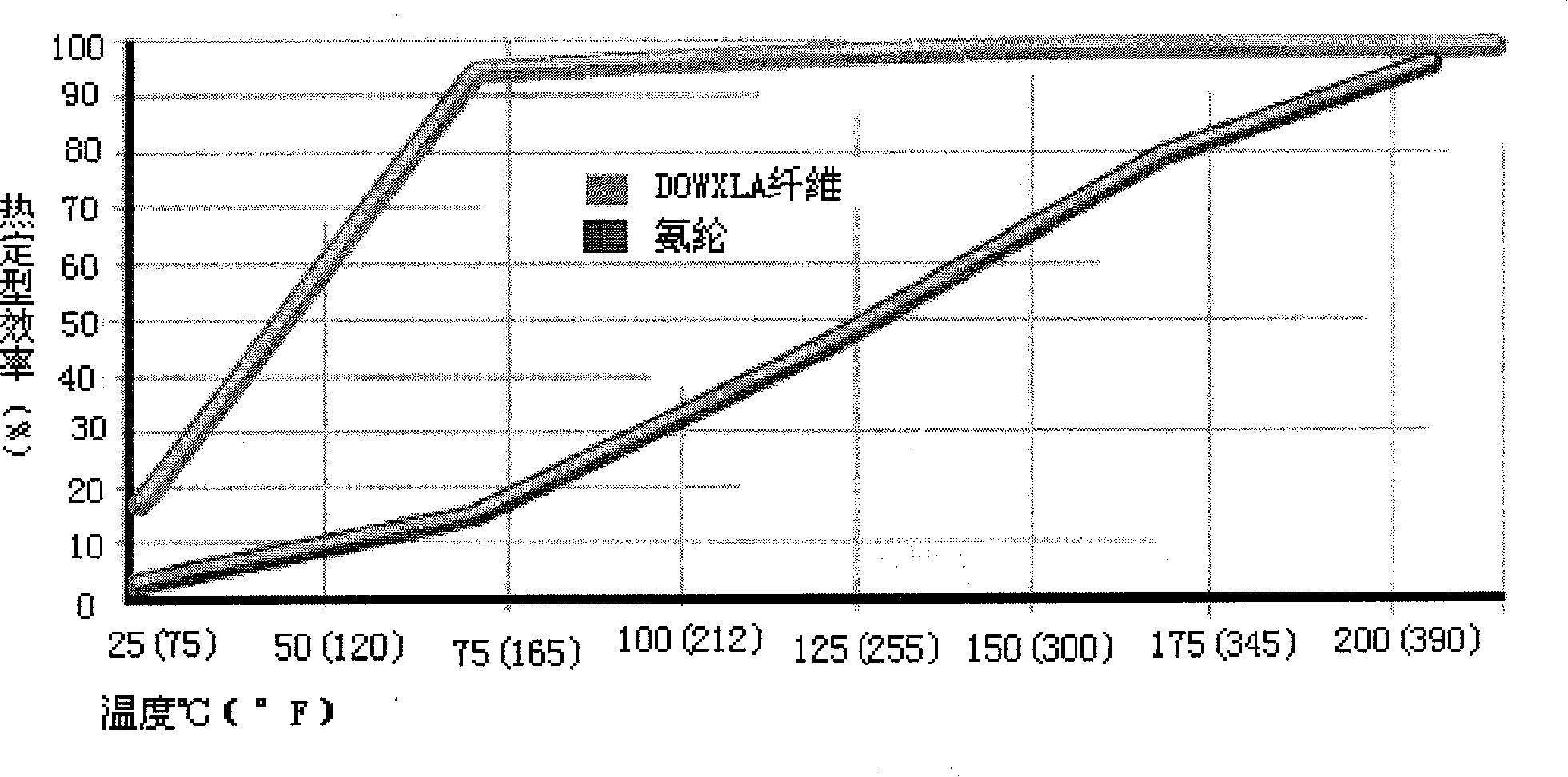

Manufacturing process for low-temperature shaped elastic coating yarn

InactiveCN101200825AImprove physicsGood chemical propertiesHeating/cooling textile fabricsYarnYarnPolyolefin

The invention discloses a low temperature setting elastic coating wire manufacturing process, in particular relates to a coating manufacturing process which implements the low temperature setting on polyolefin elastic filament fiber. The technological process of the invention is mainly divided into four parts of elastic wire feeding, tensile covering, relaxation coiling and the last lower temperature setting of textile. In every process step, specific process conditions are selected. Especially when the low temperature setting condition is selected, such as 60 or 70 DEG C, the setting of the elastic long fiber textile can be realized. At the same time, proper traction force, traction multiple, coating twist, winding speed, etc. are matched in the coating wire manufacturing process. The invention has the advantage that wearing fabrics with high quality can be produced under the effective energy saving condition. Fabric strength, heat setting property, etc. are well guaranteed. And the operation is more convenient. The invention can be widely applied to the preparation process of various high-grade fabrics.

Owner:ZHEJIANG SCI-TECH UNIV +1

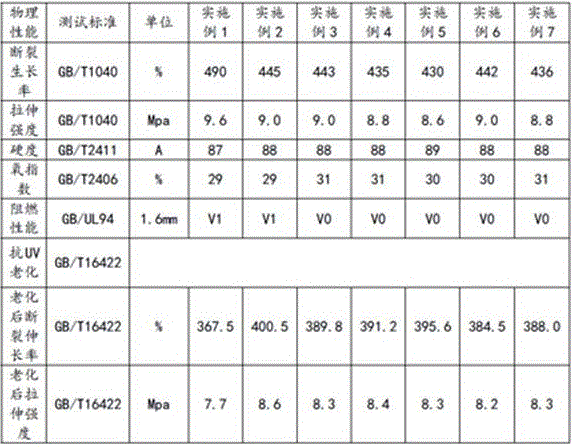

Ultraviolet-resistant halogen-free flame-retardant thermoplastic elastomer TPE material and preparation method thereof

The invention relates to an ultraviolet-resistant halogen-free flame-retardant thermoplastic elastomer TPE material and a preparation method thereof. The ultraviolet-resistant halogen-free flame-retardant thermoplastic elastomer TPE material contains the following components in parts by weight: 15-35 parts of elastomer resin SEBS, 10-25 parts of naphthenic oil, 10-25 parts of polypropylene resin, 1-10 parts of ultraviolet absorbent, 10-30 parts of halogen-free synergist, 10-20 parts of flame retardant synergist, 1-5 parts of compatilizer, 0.2-1 part of antioxidant and 0.3-2 parts of lubricant. The ultraviolet-resistant halogen-free flame-retardant thermoplastic elastomer TPE material prepared by the invention has good ultraviolet resistance, generates low smoke in burning and can reach V0 flame-retardant level. The ultraviolet-resistant halogen-free flame-retardant thermoplastic elastomer TPE material does not contain harmful heavy metals, halogen and chemical substances endangering human health and natural environment, can be repeatedly recycled and is suitable for the fields of outdoor sports and wires and cables and the like.

Owner:苏州安鸿泰新材料有限公司

Coating composition for solar cell backboards and solar cell backboards which are coated by coating composition

InactiveCN107236378AHigh efficiencyHigh temperature resistantFireproof paintsAntifouling/underwater paintsPolyethylene terephthalateWeather resistance

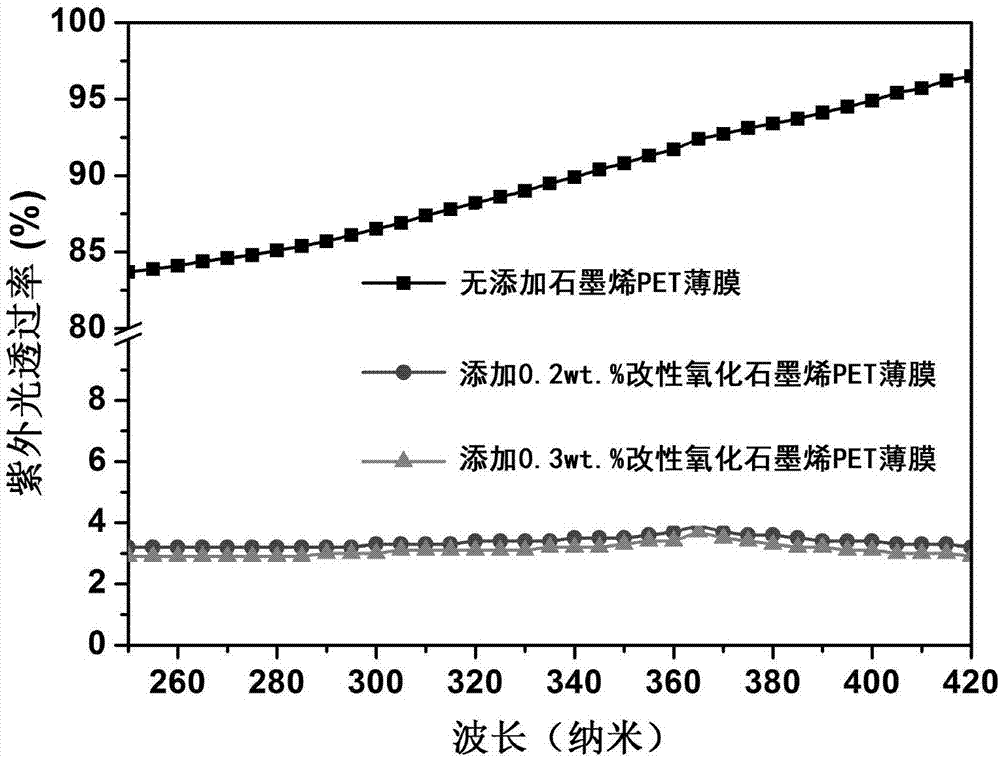

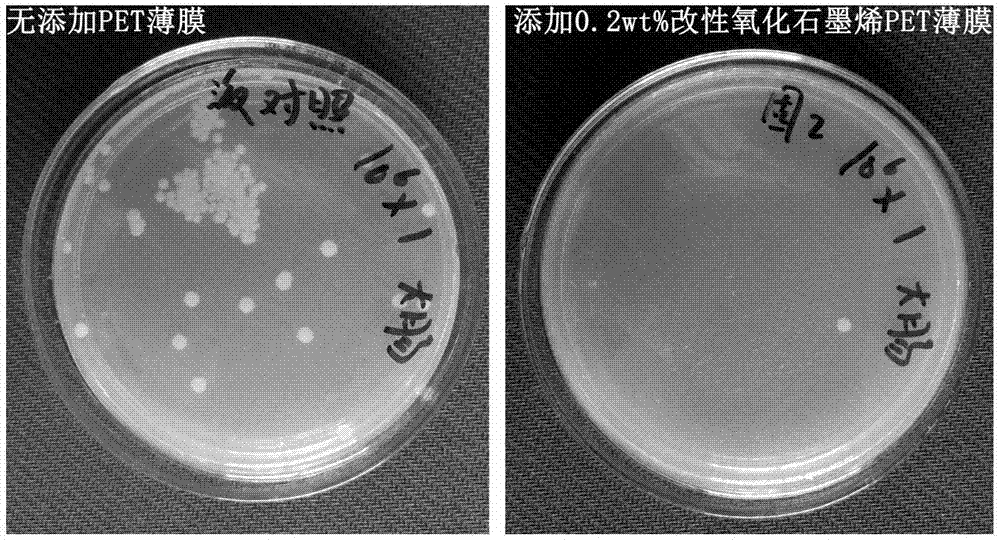

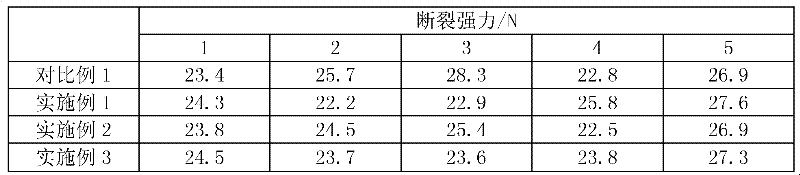

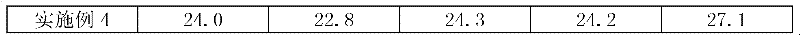

The invention provides a coating composition for solar cell backboards and the solar cell backboards which are coated by the coating composition. The coating composition comprises the following components: a graphene-like filler, resin, titanium dioxide, a solvent, a curing agent, and an auxiliary agent. A preparation method of the solar cell backboards which are coated by the coating composition comprises the following steps: a graphene-like filler and PET (polyethylene terephthalate) slices are uniformly mixed, and then mixing, extruding, rotation-drum sizing and biaxial stretching are successively performed, so that the solar cell backboards are obtained; surfaces of the solar cell backboards are treated to produce low-temperature plasma, and the coating composition coats the surfaces of the solar cell backboards; and drying solidification is performed, so that the solar cell backboards which are coated by the coating composition are obtained. According to the invention, by using graphene as an additive of the coating composition of the solar cell backboards, the solar cell backboards which are coated by the coating composition have the advantages of good mechanical performance, good ultraviolet resistance (aging resistance and weather resistance are enhanced), good heat conductivity (rapid heat dissipation, high-temperature resistance, high safety, improved cell efficiency and service life and the like) and the like, and an extensive application in all kinds of environmental climates.

Owner:NANTONG QIANGSHENG PHOTOVOLATIC TECH

Insect baculovirus pesticides in dosage form of water dispersible granule and preparation

ActiveCN101278680AReduce pollutionSolution to short lifeBiocideAnimal repellantsWater dispersibleVirus

The invention relates to a water dispersion granula preparation formulation of an insect baculovirus pesticide and a preparation thereof, which is a solid water dispersion granula preparation formulation and comprises 10-500 billion PIB / g of the insect baculovirus raw powder and accessory agents, the accessory agents comprise vector, dispersant, wetting agent, disintegrant, light protective agent and bond. The proportion of weight portion of every component is as follows: 1 to 50 portions of the insect baculovirus raw powder, 1 to 70 portions of the vector, 1 to 20 portions of the dispersant, 0 to 20 portions of the wetting agent, 1 to 20 portions of the disintegrant, 0.5 to 20 portions of the light protective agent and 1 to 20 portions of the bond. The preparation method is that the insect baculovirus raw powder and the accessory agents are mixed by certain proportion to be crushed by airflow for granulating and drying to obtain the water dispersion granula preparation formulation of the insect baculovirus pesticide which can be used separately and also can be used by combing with chemical pesticide. The water dispersion granula preparation formulation of the insect baculovirus pesticide has the advantages of little pollution caused by producing and processing process, long shelf life, stable product quality, good dispersibility, easy storage, convenient transportation, extremely low dosage and high virus content, which has significant meaning for preventing and curing insects in agriculture and forestry.

Owner:INST OF ZOOLOGY CHINESE ACAD OF SCI +2

Filter nonwoven fabric capable of releasing negative ions

ActiveCN102517802AImprove mechanical propertiesStrong UV resistanceZinc oxides/hydroxidesNanotechnologyFiltrationNonwoven fabric

The invention discloses a filter nonwoven fabric capable of releasing negative ions, which is prepared by electrostatic spinning. A spinning solution comprises the following components in percentages by weight: 55-70% of isopropanol, 10-20% of deionized water, 10-15% of poly(ethylene-co-vinyl alcohol), 3-10% of carbon fiber, 2-10% of nanometer zinc oxide, and 3-10% of negative ion nanopowder. The negative ion nanopowder comprises 10-100nm tourmaline, opal and magnesium oxide, and a weight ratio of tourmaline to opal to magnesium oxide is (3-10):1:1. Compared with the prior art, the inventive nonwoven fabric has good anti-bacterial and anti-ultraviolet effects, and can long-term release negative ions beneficial for human health, under the premise of maintaining good mechanical properties, and has wide application prospects in the field of water filtration treatment.

Owner:薛毓敏

Synthetic fiber paper containing basalt fiber and chemical fiber and its preparation method

ActiveCN1948615AImprove high temperature resistanceImprove mechanical propertiesInorganic fibres/flakesTemperature resistanceBasalt fiber

The invention belongs to the field of composing fiber paper. It relates to composing non-woven paper, especially relates to a kind of fiber paper made by wet method with basaltic fiber, aramid fiber and polyphenylene sulfide fiber. The composing fiber paper has much strongpoint including well mechanical property, good high-temperature resistance, acid resistance, alkali resistance, strength uvioresistant property, low hygroscopic, better environment bearing property, good insulativity, good high-temperature filterability, radio resistance and good wave-passing property. Therefore, the composing fiber paper is applicable for military engineering and civil fields including aerospace, military engineering, vehicle and ship building and architecture.

Owner:LONGPONT

Ultra-extinction memory fiber and preparation method

InactiveCN103628180APrevent wire breakageAvoid the phenomenon of insufficient drapeMelt spinning methodsConjugated synthetic polymer artificial filamentsFiberPolyester

The invention discloses an ultra-extinction memory fiber and a preparation method. The ultra-extinction memory fiber is prepared by a method for differentially distributing titanium dioxide content in a skin-core composite structure. The problems that the conventional complete-extinction fiber has poor ultraviolet resistance, breakage in the weaving process is relatively serious, and clothes produced have a low sagging degree are solved. The ultra-extinction memory fiber adopts the skin-core structure, and has the average titanium dioxide content of more than 3% and high ultraviolet resistance; fabric woven by the ultra-extinction memory fiber is bright in color, comfortable, sagging, stiff and smooth and high in resilience, and has much higher dyeing property and ultraviolet resistance than the conventional polyester and other complete-extinction fibers.

Owner:SHENGHONG GRP CO LTD

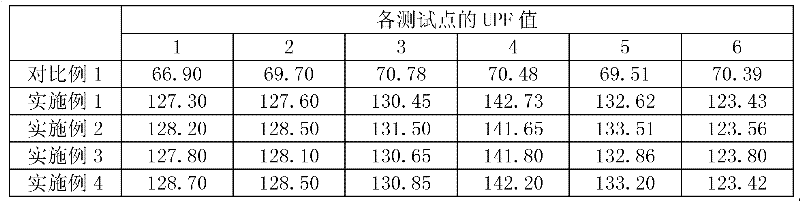

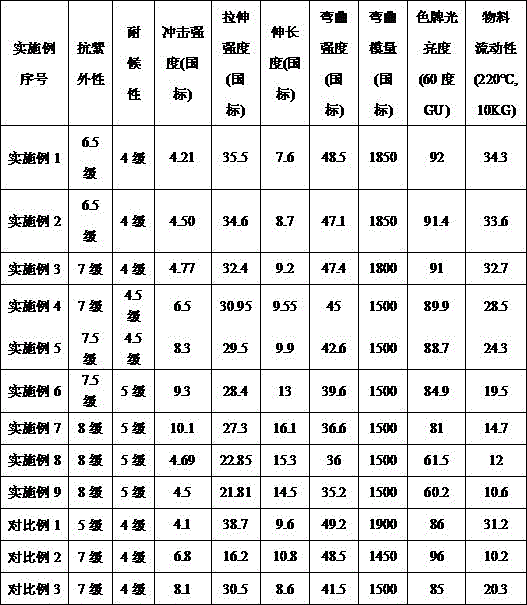

Uvioresistant weather fastness ASA resin, co-extrusion plastic product, thin film and product

InactiveCN106188927AImproved UV and weather resistanceHigh UV and weather resistanceSynthetic resin layered productsSurface finishRoom temperature

The invention relates to an uvioresistant weather fastness ASA resin, a co-extrusion plastic product, a plastic thin film and a plastic product, wherein the uvioresistant weather fastness ASA resin comprises the following components according to weight percentage: 28%-96% of acrylonitrile-styrol copolymer, 3%-70% of polyacrylic core-shell copolymer, and 0.1%-5% of assistant. The uvioresistant weather fastness ASA resin is poly-blended with SAN through the polyacrylic core-shell copolymer (PBA-MMA), so that the weather fastness and low-temperature or room-temperature shock resistance of the ASA resin are remarkably improved, and the other physical properties of the ASA resin are not affected. The ASA resin has an excellent property of ultraviolet resistance as well as weather fastness, is easy to process, is further excellent in surface cleanness, keeps excellent rigidity, and is widely applied to various co-extrusion plastic products and thin films.

Owner:SHENZHEN YICAIHONGXIANG NEW MATERIALS TECH CO LTD

Organosilicon coating agent and preparation method thereof

InactiveCN106398523AStrong UV resistanceImprove antioxidant capacityCoatingsChemical reactionUltraviolet

The invention provides an organosilicon coating agent and a preparation method thereof. According to the invention, an organosilicon material is used as a basic raw material which is allowed to have a film forming function through a normal-temperature chemical reaction; an organosilicon material film is allowed to be firmly bonded with the surface of an object in virtue of the action of an adhesion promoter and a diluent, so the effect of long-lasting anti-adhesion effect is obtained; meanwhile, the organosilicon coating agent provided by the invention has good ultraviolet resistance and antioxidation capability and is suitable for brush coating of an external surface. The organosilicon coating agent can be applied onto the surfaces of decorative coatings and exterior coatings; after curing, the organosilicon coating agent has good adhesion, is hard to fall, enables the surfaces of the coatings to be bright and smooth and shows excellent anti-adhesion effect; with the organosilicon coating agent, advertisement labels cannot be firmly bonded on the surfaces of the coatings and can be easily taken off, and marks written on the surfaces of the coatings by marking pens can be directly erased without solvent or water; and the organosilicon coating agent has long-lasting anti-adhesion effect and presents good anti-adhesion effect after having been coated on the surfaces for one year.

Owner:湖北新四海化工股份有限公司

Light diffusion PMMA-MABS composite material and preparation method thereof

The invention discloses a light diffusion PMMA-MABS composite material and a preparation method thereof. The composite material comprises PMMA resin, MABS resin, compatilizer, light diffusant, stabilizing agent, ultraviolet ray absorber, and auxiliary agents. The preparation method comprises the following steps: baking MABS and PMMA, then mixing PMMA resin, MABS resin, auxiliary agents and other raw materials in proportion, melting and mixing through a double screw extruder at a temperature of 160-230 DEG C, cooling the extruded strips through a circulating water tank to normal temperature, carrying out air drying on the cooled extruded strips, and carrying out granulation. The prepared composite material product has high light transmittance, strong ultraviolet resistance, good dimensional stability and heat stability, and can be widely applied in inner-illuminated billboards, resin window glass, light diffusion plates for display devices, cold light source light diffusion plates and the like.

Owner:句容市育达实业投资有限公司

Liquid crystal electrolyte solution for dye-sensitized nano film solar battery

InactiveCN101694813AImprove efficiencyImprove conductivityLight-sensitive devicesSolid-state devicesUltravioletElectrochemistry

The invention discloses a liquid crystal electrolyte solution for a dye-sensitized nano film solar battery, which is formed from components 1 and 2 or components 1, 2 and 6 as main components by compounding or not compounding one or several components in other four components, wherein the component 1 is liquid crystal electrolyte; the component 2 is an oxidation-reduction pair with good electrochemical reversibility; the component 3 is a dark current inhibitor; the component 4 is a hetero-atom containing compound acting with positive ions in the electrolyte solution; the component 5 is a hetero-atom containing compound acting with I2 in the electrolyte solution; the component 6 is an organic solvent or an ionic liquid; and the component 7 is a compound for improving the ultraviolet performance of the battery. The liquid crystal electrolyte solution has the advantages of higher electrical conductivity, good electrochemical reversibility, good low-temperature stability, stronger ultraviolet resistance, efficiency improvement of the solar battery, life prolonging of the solar battery, stable performance, no environmental pollution and the like.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

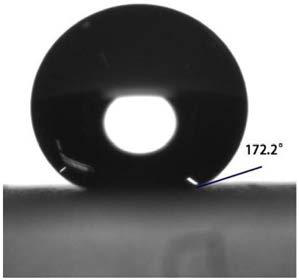

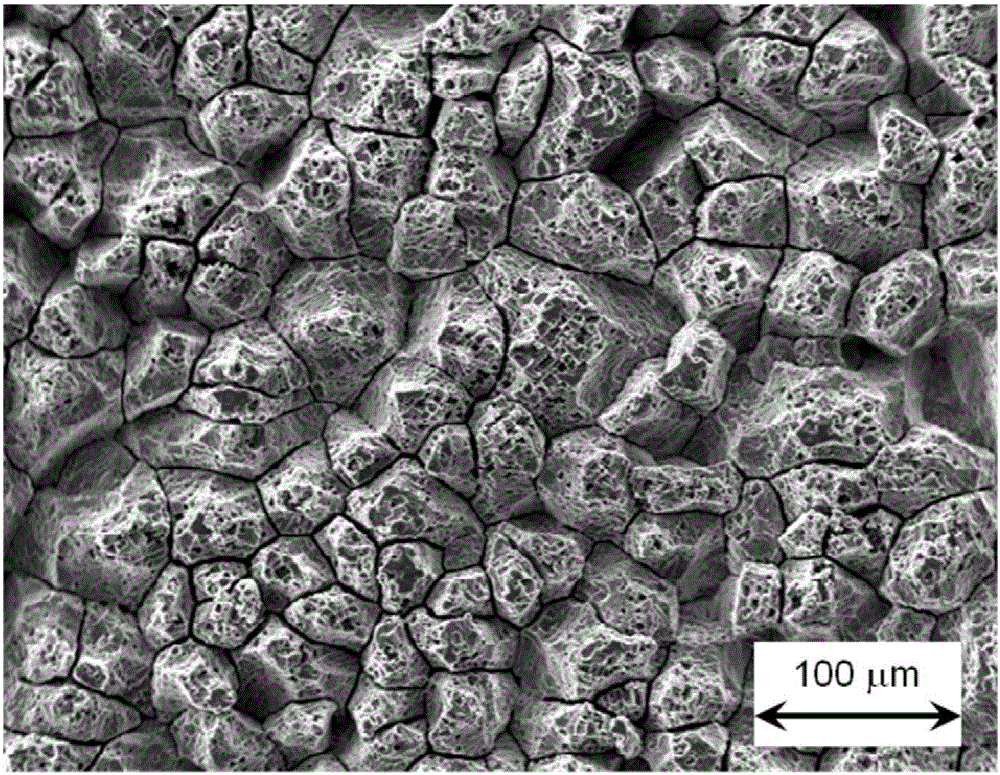

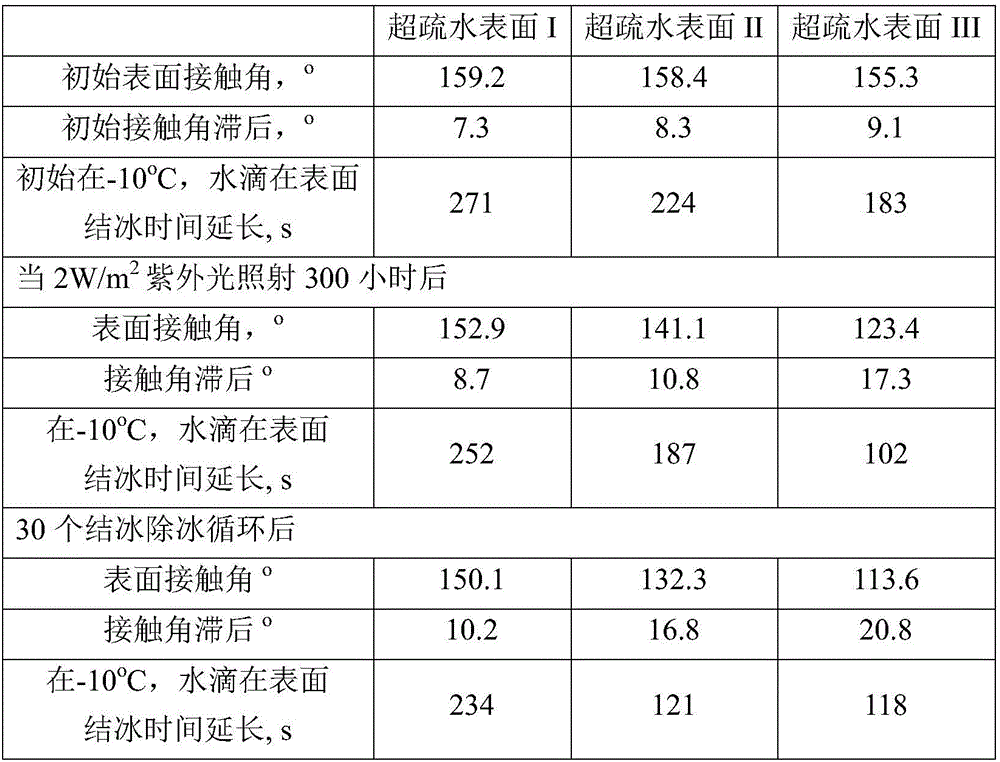

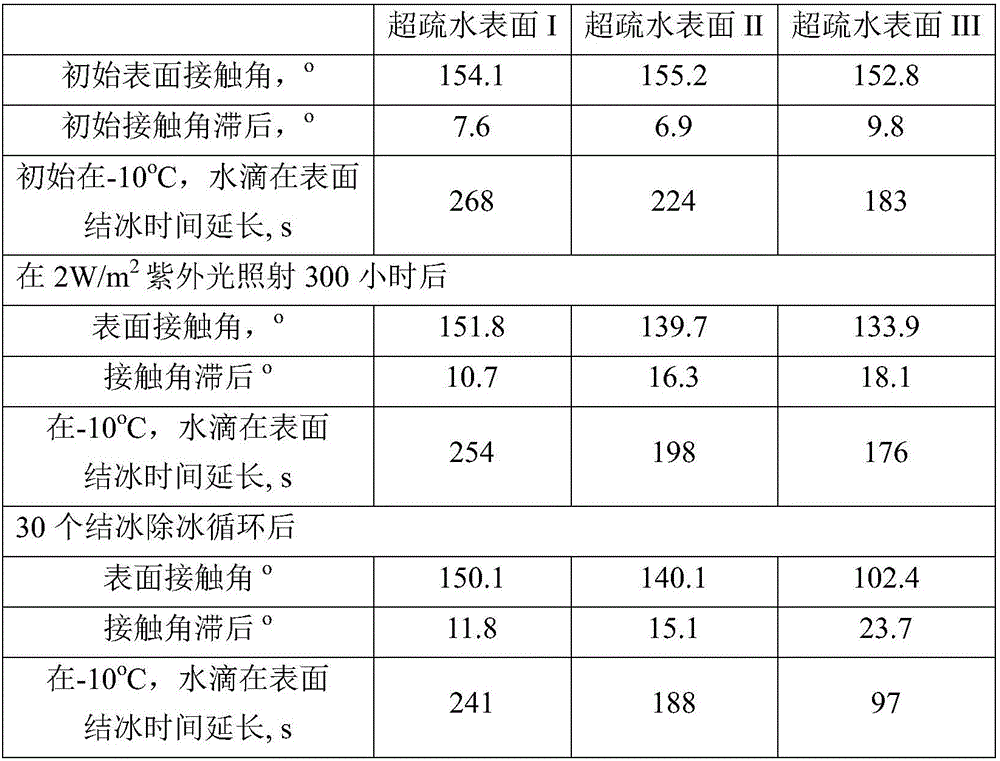

Super-hydrophobic material and preparation method thereof

InactiveCN106752462AAchieve hydrophobicityAchieving UV resistanceCoatingsUltraviolet resistanceCoating

The invention discloses a super-hydrophobic material which comprises a substrate and a coating layer, wherein the coating layer comprises the following ingredients in parts by weight: 65-78 parts of resin and 8-16 parts of nano-particles. The invention also provides a preparation method of the super-hydrophobic material. The super-hydrophobic material prepared by the preparation method provided by the invention has the advantages that the ultraviolet resistance is strong, the material is wear-resisting, the freezing time on the surface can be effectively prolonged, etc.; meanwhile, the service life of the super-hydrophobic material is prolonged, and the super-hydrophobic material has wide market prospect.

Owner:THE SECOND RES INST OF CIVIL AVIATION ADMINISTRATION OF CHINA

Flash paint and its manufacturing method

A flash paint including oil and water ones is prepared from acrylic acid series, nacreous powder, golden powder and solvent through proportional mixing and stirring. Its advantages are high ultraviolet and ageing resistance and weatherability, high adhesion, not decolouring and low cost.

Owner:广州市黄埔区宏泰建筑材料厂

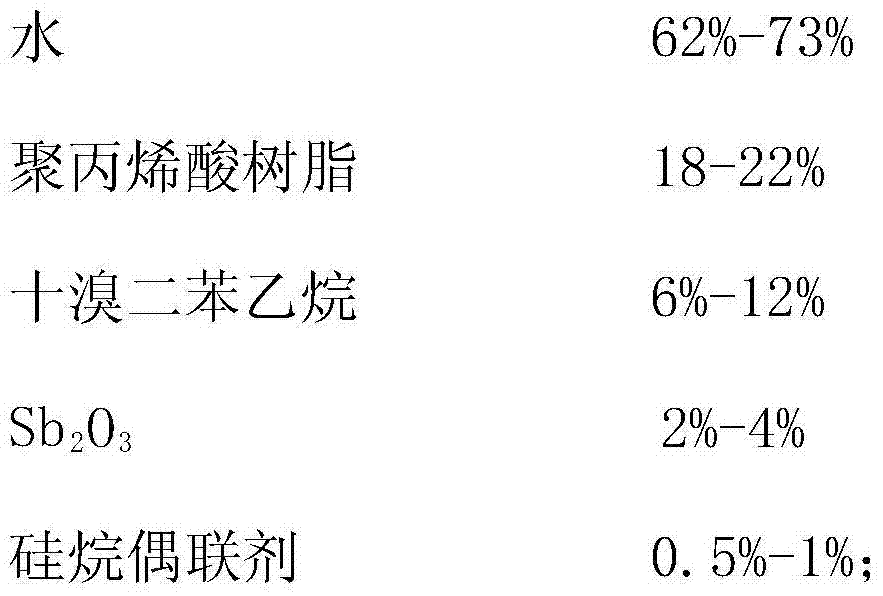

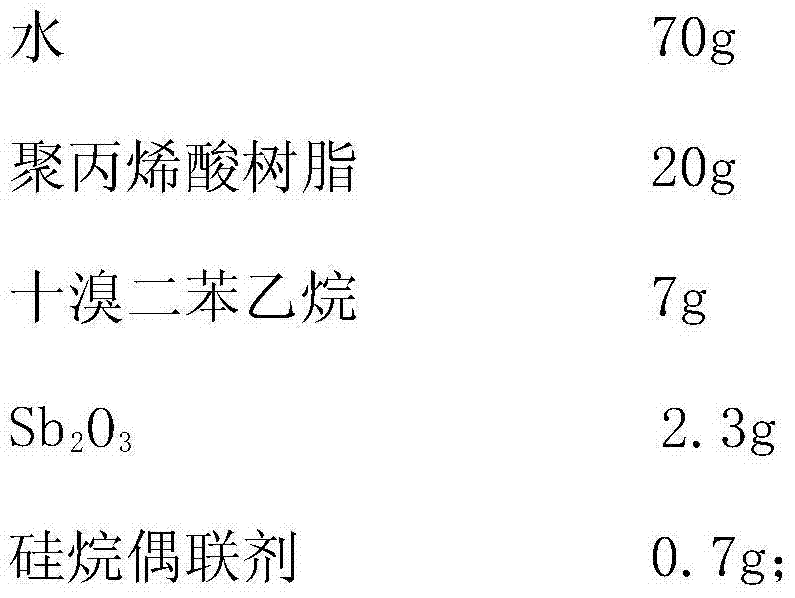

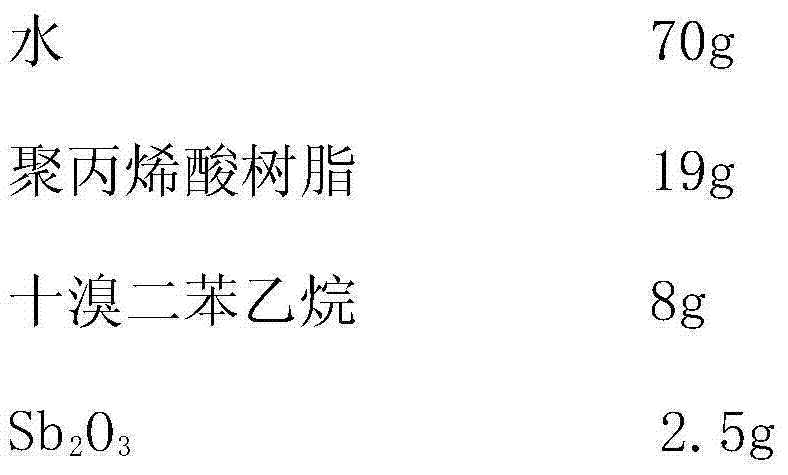

Preparation method of flame retardant PP (polypropylene) non-woven fabric

The invention relates to a preparation method of flame retardant PP (polypropylene) non-woven fabric. The non-woven base fabric obtained by a melt blowing method is subjected to flame retardant finishing. The preparation method comprises the following steps: preparing flame retardant slurry from the following components in percentage by mass: 62 to 73 percent of water, 18 to 22 percent of polyacrylic acid, 6 to 12 percent of decabromodiphenylethane, 2 to 4 percent of Sb2O3 and 0.5 to 1 percent of a silane coupling agent; pouring the flame retardant slurry into a slurry barrel with a stirring device, making the non-woven base fabric pass through a pressure roller and a slurry feeding roller, and transferring the slurry in a slurry groove to the base fabric through a screen frame by using the slurry feeding roller; placing the base fabric which is coated with the slurry between two rubber pressure rollers of a roller press for extruding to remove excessive slurry; finally, drying the base fabric to obtain the flame retardant non-woven fabric. The preparation method is simple in process, convenient to operate, and environmental friendly; the selected decabromodiphenylethane is a high-efficiency brominated flame retardant, and has the characteristics of high bromine content, high thermal stability, low toxicity and the like; meanwhile, the decabromodiphenylethane and the added Sb2O3 have a synergistic flame retardant effect, so that the prepared non-woven fabric has a good flame retardant effect.

Owner:JIANGSU SHENGFANG NANO MATERIAL TECH CO LTD

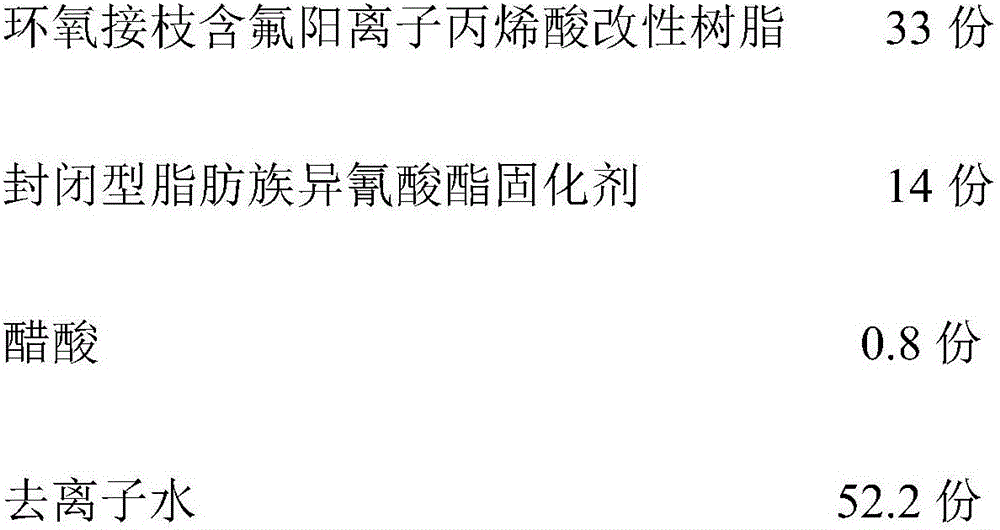

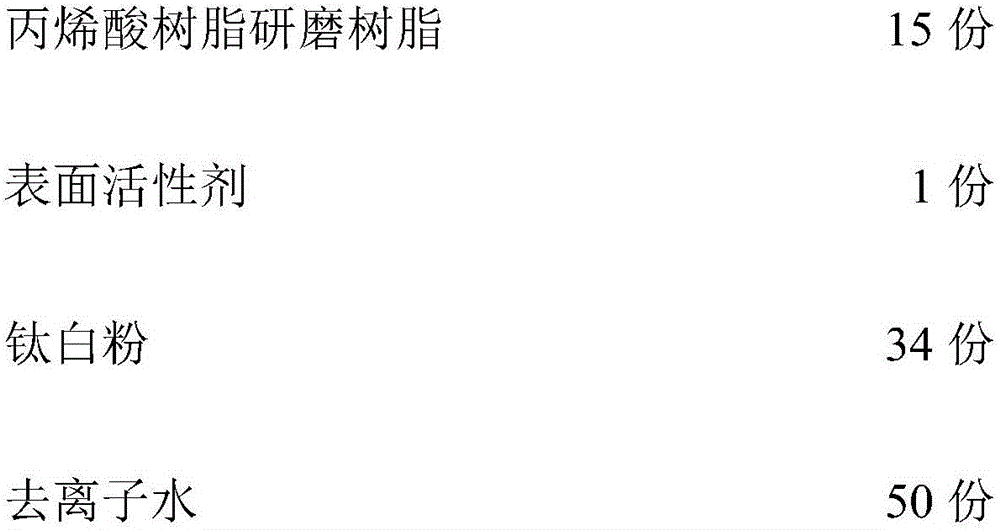

Electrophoretic paint with high weather resistance and better spring coverage and preparation method thereof

InactiveCN106318001AGood alkali resistanceGood weather resistanceAnti-corrosive paintsPaints for electrolytic applicationsEpoxyWeather resistance

The invention relates to electrophoretic paint with high weather resistance and better spring coverage and a preparation method thereof. The electrophoretic paint is prepared by high weather resistance acrylic acid modified emulsion and weather-resistant color paste according to the ratio of 8:1, the high weather resistance acrylic acid modified emulsion is obtained by reacting 33-39 parts of epoxy grafted fluoride cation acrylic modified resin, 2-3 parts of microgel, 14-16 parts of sealing, 0.8-1 part of neutralizer and 44-52.2 parts of deionized water; the weather-resistant color paste is prepared by mixing and grinding 15-18 parts of acrylic acid grinding resin, 1-2 parts of surfactant, 42-50 parts of deionized water and 34-38 parts of pigment filler. According to the painting, the coating appearance is flat and bright, the yellowing resistance is good, and the coating has excellent mechanical property, bath stability, weather resistance, corrosion resistance and spring coverage.

Owner:HAOLISEN COATING SHANGHAI

Waterborne highlight environment-friendly toughened glass ink and preparation method thereof

The invention belongs to waterborne highlight environment-friendly toughened glass ink and a preparation method thereof. The toughened glass ink is prepared from, by weight, 8-30 parts of inorganic pigments, 30-78 parts of a low-melting-point frit, 10-55 parts of ink abrasive oil, 0-2 parts of a wetting dispersant, 0-1 part of a defoamer, 0-2 parts of a flatting agent and a 0-2 parts of a solid additive. The glass ink is low in melting point, good in weather fastness, good in brightness and high in artistic appreciation; the low-melting-point frit is low in melting temperature and power saving, service life of the device can be effectively prolonged, and oxide is less volatile; the low-melting-pint frit does not contain Pb, Cr<6+>, Cd and Bi, cost of the ink can be effectively reduced, and harmful Pb, Cd and Cr<6+> are not contained; a Te element is introduced in the low-melting-point frit which can reduce the melting temperature, low-temperature viscosity of the frit is effectively reduced, and high covering power and anti-ultraviolet linear capacity of the glass are achieved.

Owner:郑州市亚美凯新材料有限公司

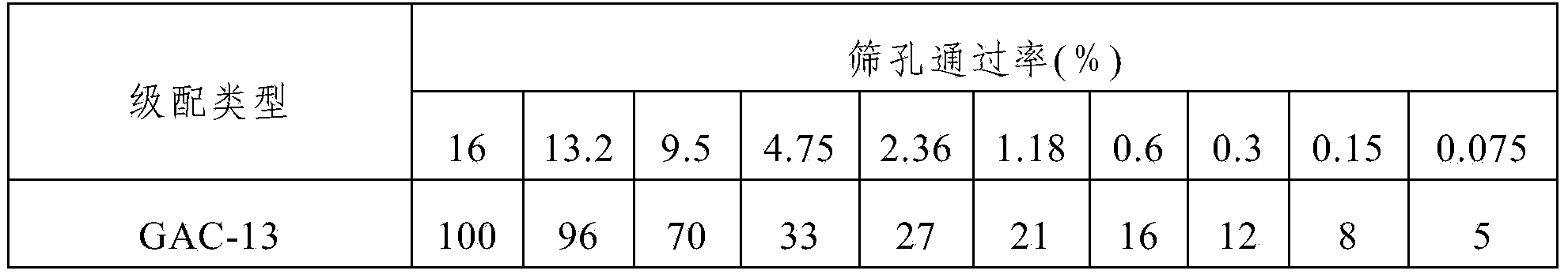

Sericite-modified bituminous concrete

ActiveCN103553443AEmission reductionReduce emission concentrationClimate change adaptationSericiteBituminous concrete

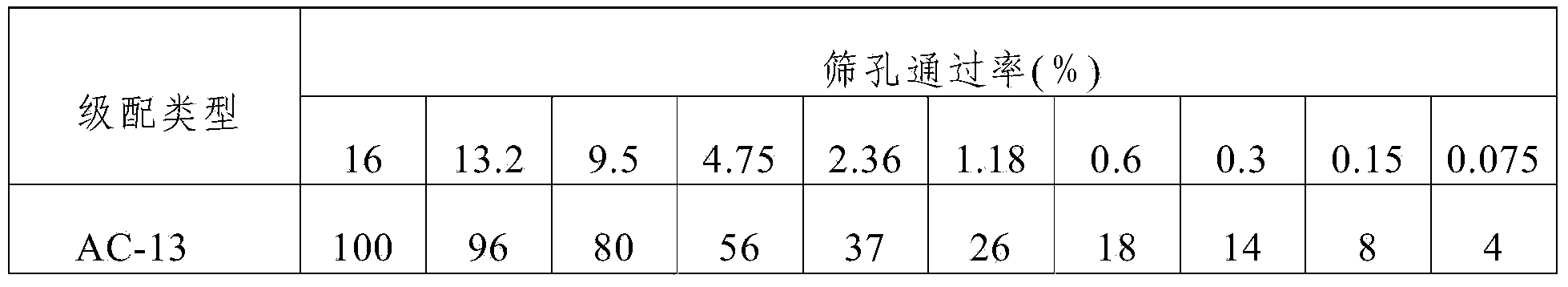

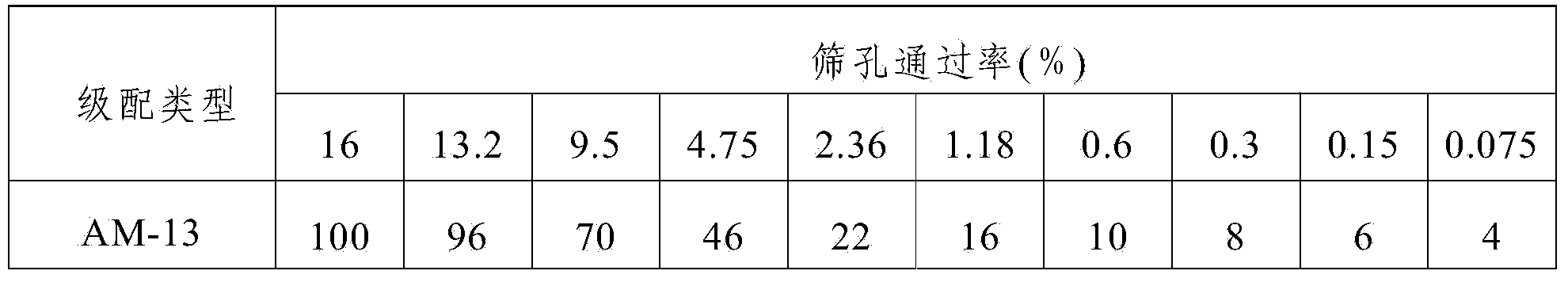

The invention provides sericite-modified bituminous concrete. The sericite-modified bituminous concrete is prepared from the following raw materials in parts by weight: 100 parts of mineral aggregate, 4-7 parts of asphalt, 0.5-2 parts of sericite powder, and 0.1-4 parts of coupling agent, wherein the coupling agent is a silane coupling agent, a titanate coupling agent or an aluminate coupling agent; the aggregate grading type of the mineral aggregate is GAC-13, AC-13, AM-13, SMA-13, OGFC-13 or superpave. The sericite-modified bituminous concrete provided by the invention is hot mixed asphaltic concrete; the emission of poisonous gases in the blending and paving processes of the bituminous concrete can be significantly reduced; emission of asphalt fume is greatly reduced; the sericite-modified bituminous concrete is non-toxic, free of corrosion, good in stability, wide in application and applicable to large-scale popularization; no secondary pollution is caused.

Owner:CHANGAN UNIV

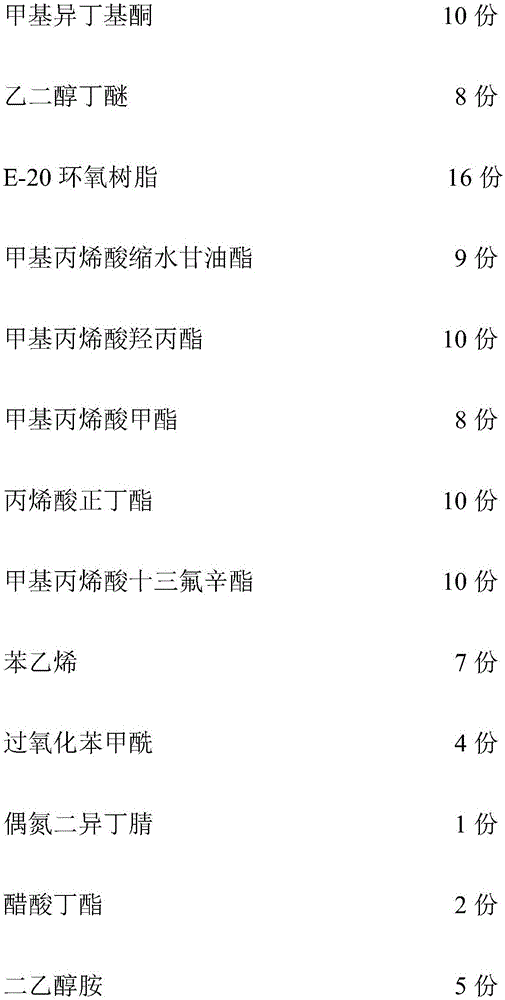

Paint special for curtain coating

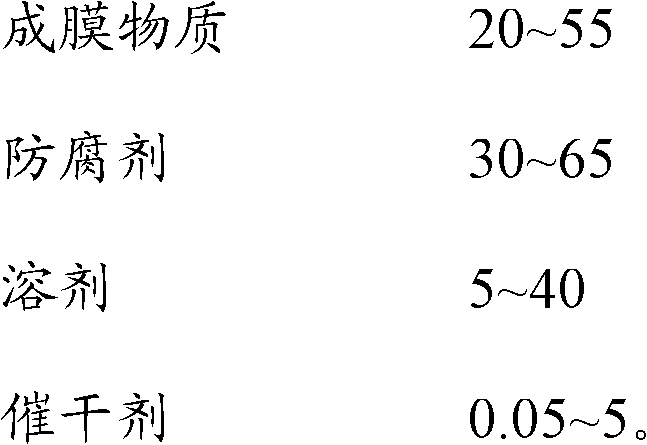

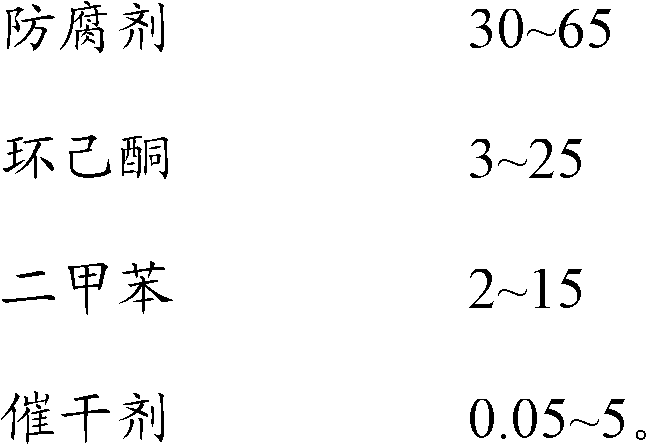

InactiveCN102417782AIncrease dosageEasy to dryAnti-corrosive paintsEpoxy resin coatingsCyclohexanoneEpoxy

The invention relates to paint special for curtain coating, which comprises the following components in part by weight: 20-55 parts of film forming substance, 30-65 parts of preservative, 5-40 parts of solvent and 0.05-5 parts of drier. Compared with the prior art, the paint special for the curtain coating has the characteristics that: (1) the dryness of a coating is enhanced by reducing the content of epoxy ester resin and increasing the dosage of the drier; (2) in a coating solvent, cyclohexanone is added into dimethylbenzene, so that the volatilization speed is adjustable; and the volatilization speed of a coating solvent system and the dryness of the coating can be adjusted; (3) the paint has excellent corrosion resistance; and (4) the paint has high insulating performance, temperature change resistance and ultraviolet resistance, and is suitable for the curtain coating and outdoor conditions.

Owner:TIANCHANG JULONG TRAVEL PAINT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com