Patents

Literature

233results about How to "Prevent wire breakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

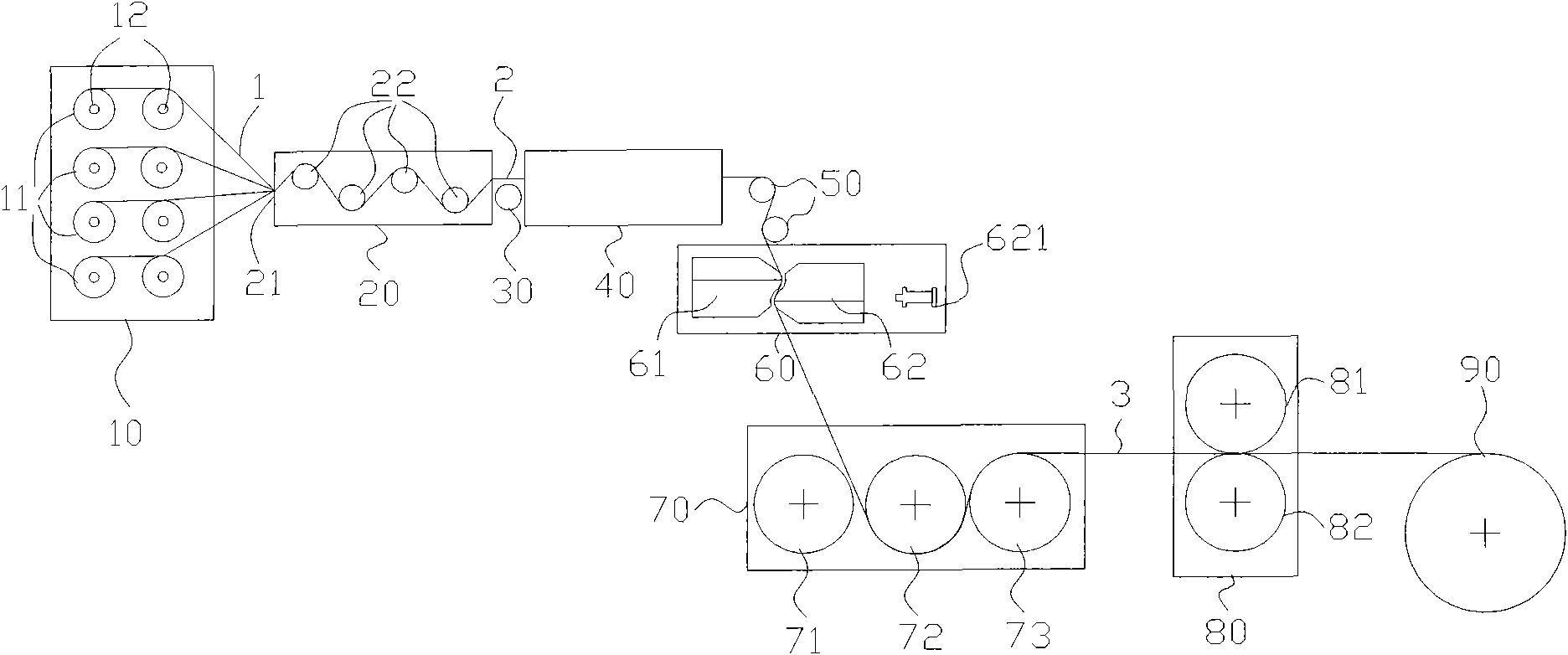

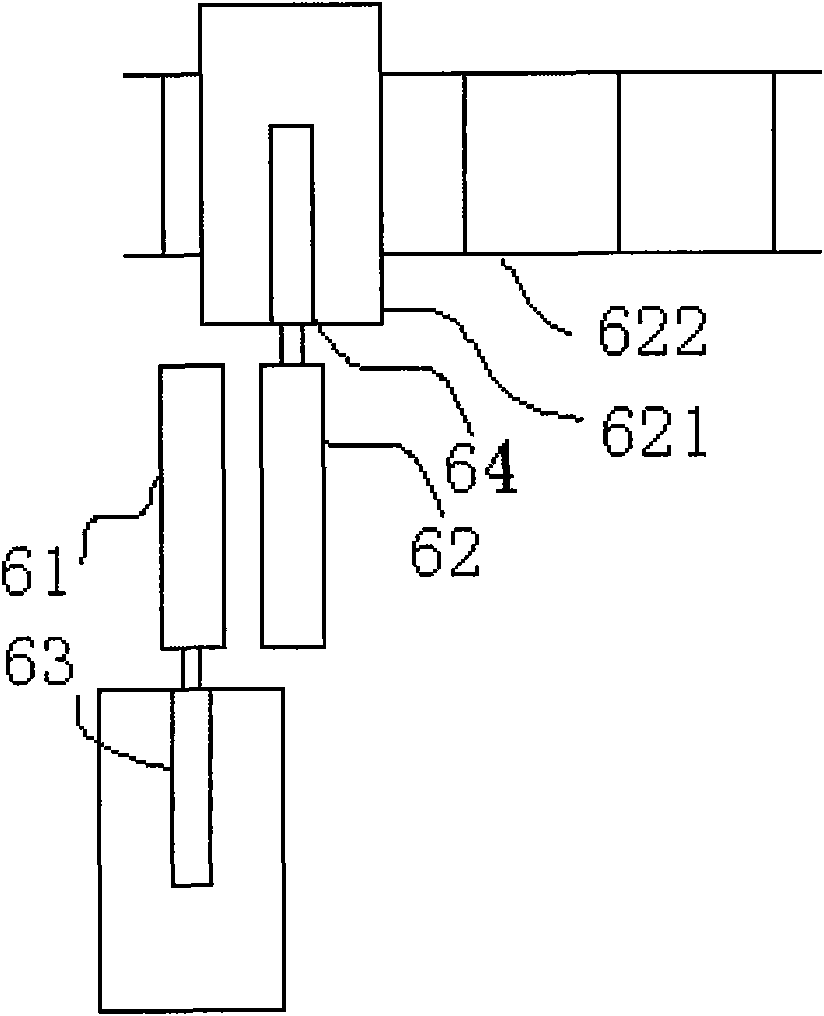

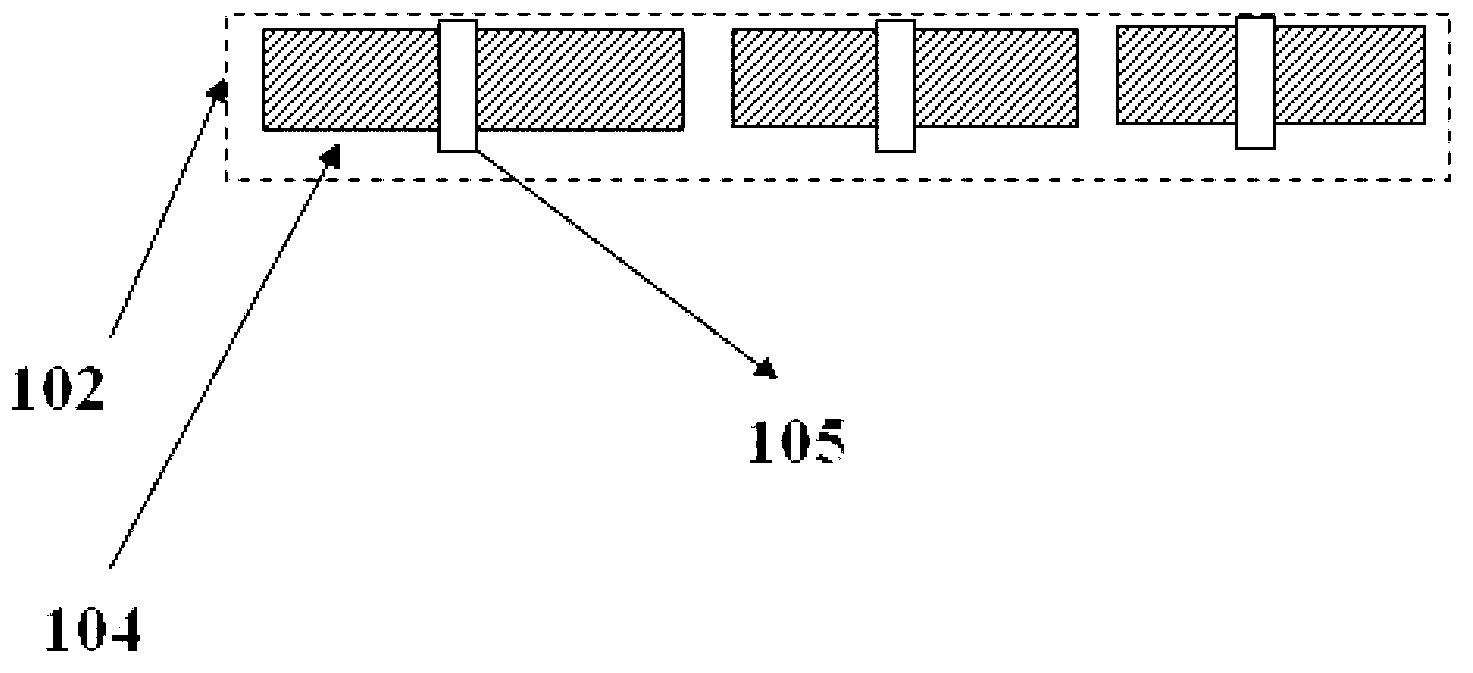

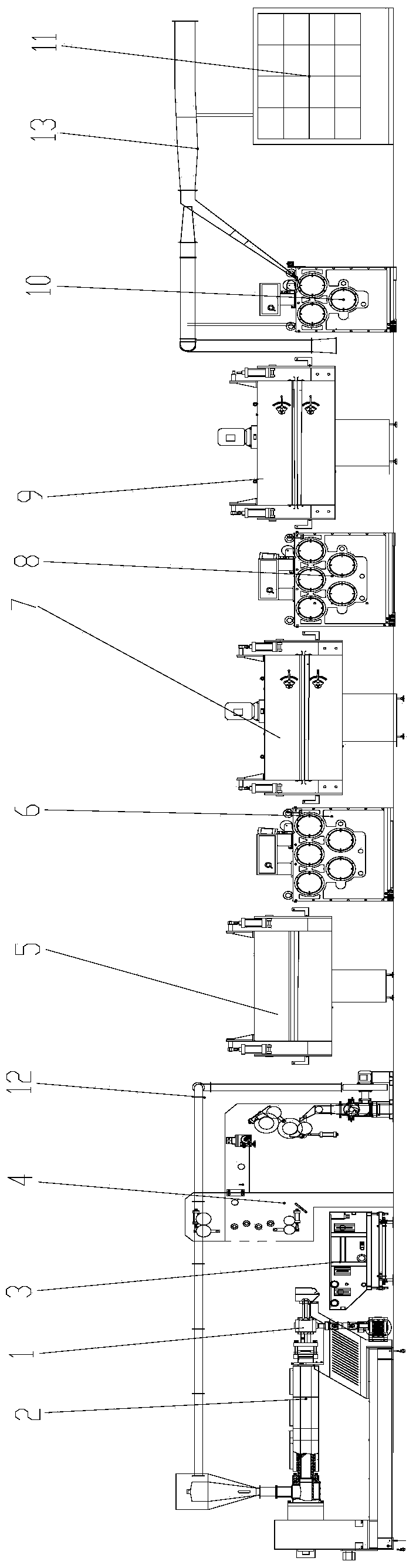

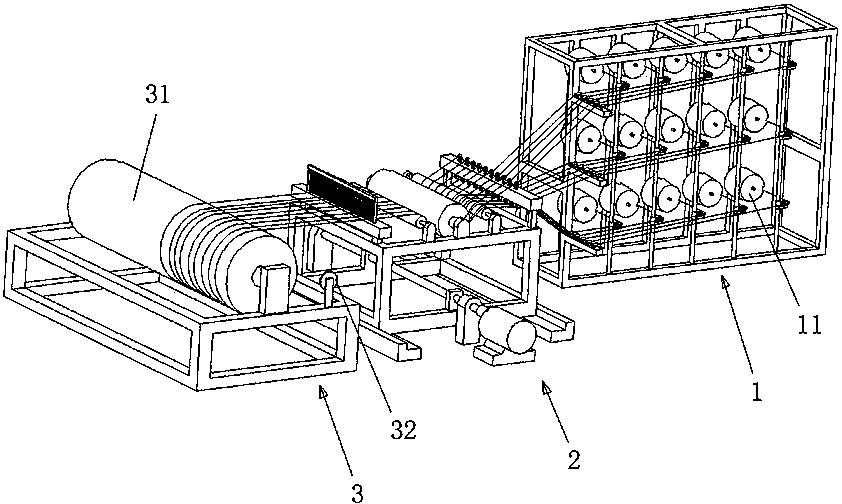

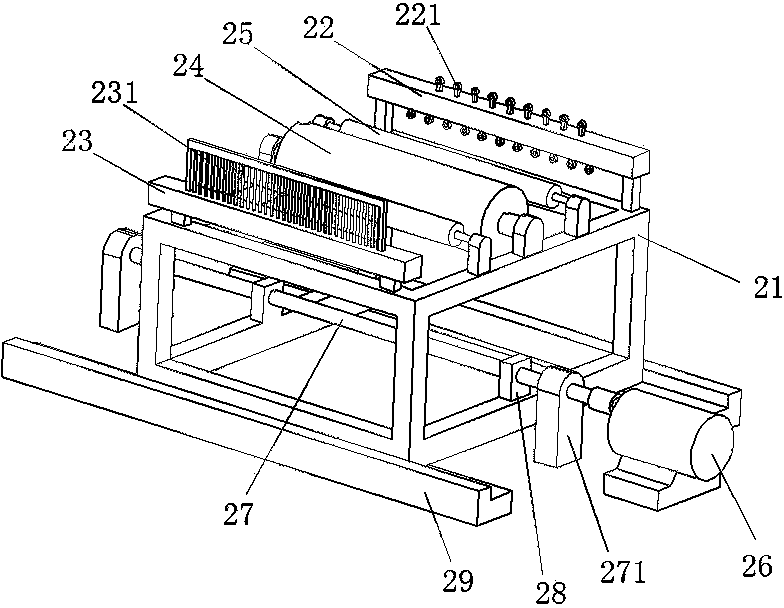

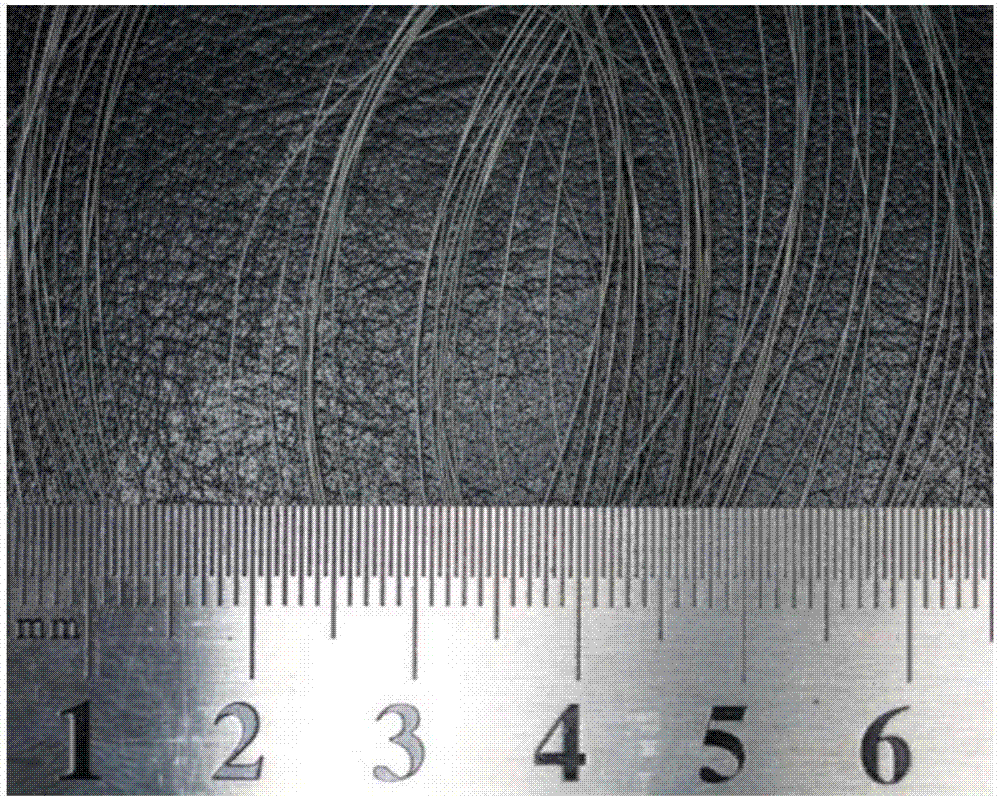

Preparation method of continuous fiber reinforced thermoplastic composite material prepreg and equipment thereof

The invention relates to a preparation method of a continuous fiber reinforced thermoplastic composite material prepreg and equipment thereof. The method comprises the following steps: (a) leading out and unfolding continuous fiber from a creel (10) to pass a tension adjusting device (20) and a static elimination device (30) in sequence, sending the fiber to a preheating oven (40) to preheat, and then passing a tension adjusting device (50); (b) leading a preheated continuous fiber band into a dual-extrusion die head set which can be opened and closed in a staggered manner to presoak; and (c) leading the presoaked continuous fiber band into a soaked rolling roll set (70) to soak, then cooling by a cooling roll-in device (80), and finally leading into a traction rolling device (90) for shaping by winding to obtain the product. Compared with the prior art, the invention significantly improve the dispersion, infiltrating property and operability of the fiber, and obtains the continuous fiber reinforced thermoplastic composite material prepreg which has uniformly dispersed and completely soaked fiber.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

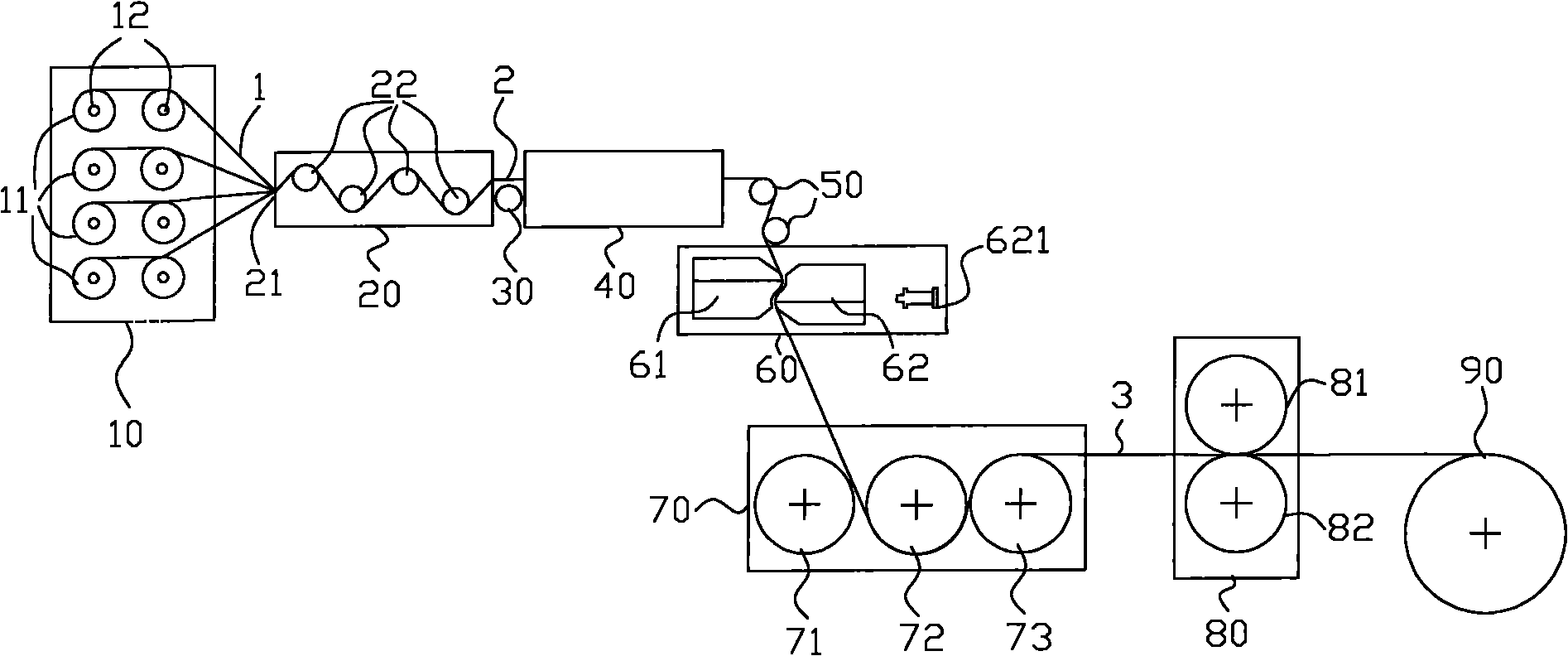

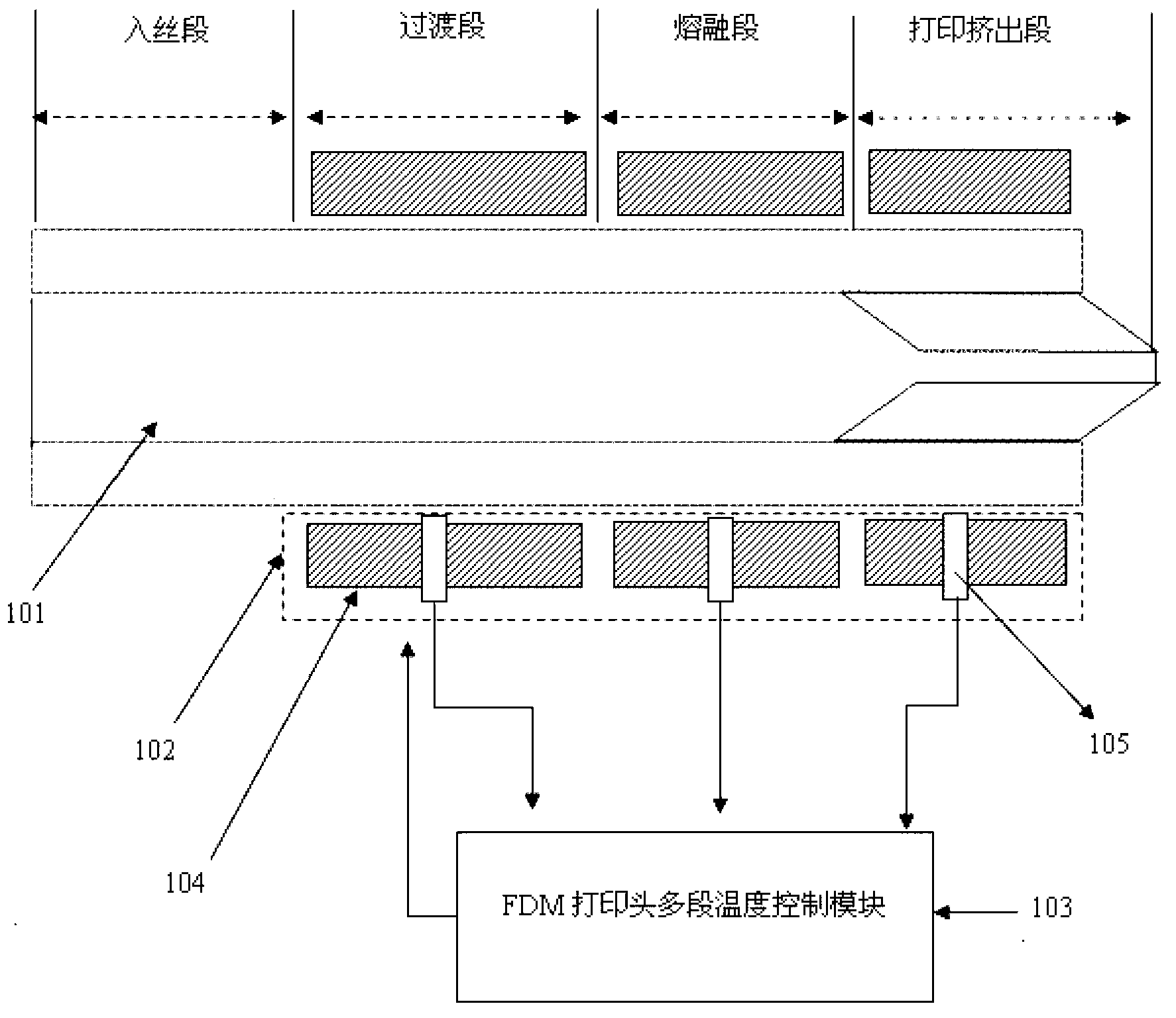

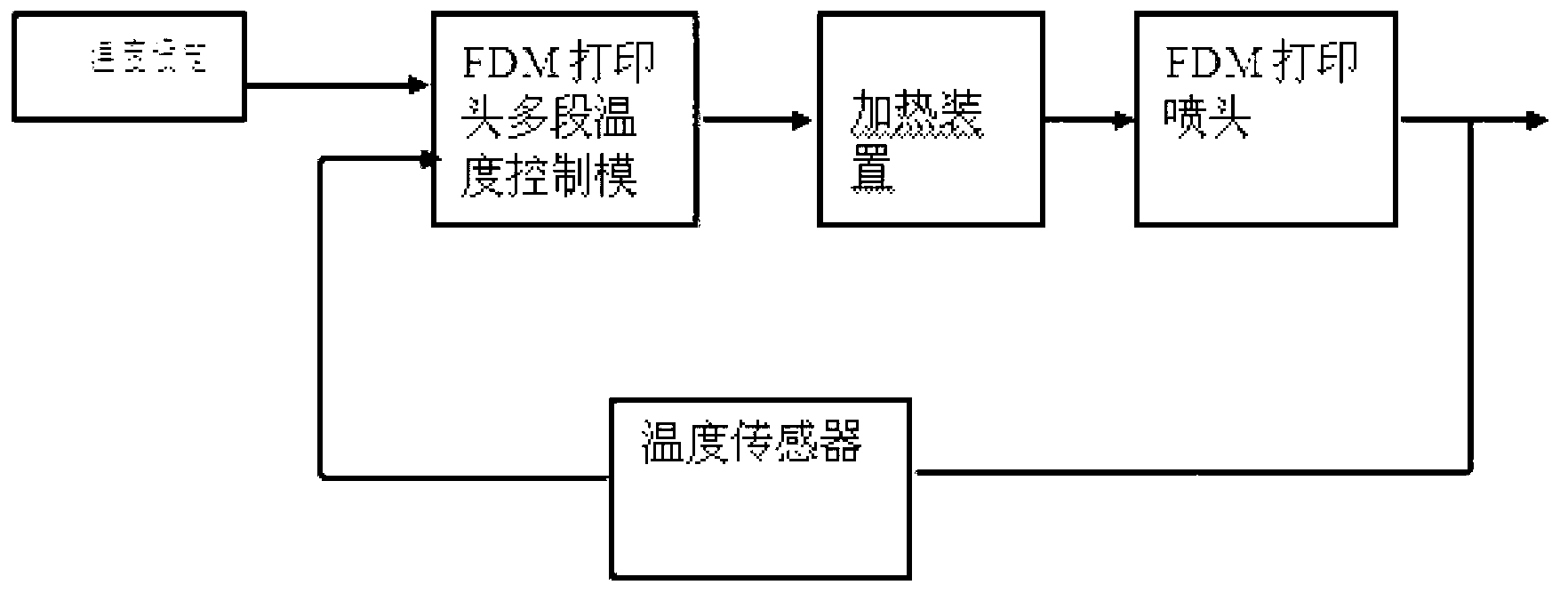

Multistage-temperature-control-based fused deposition modeling (FDM) type 3D printing sprayer and temperature control method

The invention relates to a 3D printing technology, and aims at providing a multistage-temperature-control-based fused deposition modeling (FDM) type 3D printing sprayer and a temperature control method. The multistage-temperature-control-based FDM 3D printing sprayer comprises a printing sprayer body and a heating device arranged at the outer part of the printing sprayer body, and is characterized in that a forming chamber inside the printing sprayer body is divided into four parts of a fuse feeding section, a transition section, a fusion section and a printing and extruding section; the heating device is divided into three sections which are correspondingly arranged at the outer sides of the transition section, the fusion section and the printing and extruding section of the forming chamber, and each section of the heating device comprises an electric heater and a temperature sensor which are independent and is respectively connected with a multistage temperature control module of an FDM type printing sprayer through a signal wire. The multistage-temperature-control-based FDM type 3D printing sprayer is capable of realizing the corresponding gradient control of temperatures of all sections of the printing sprayer and ensuring that an FDM printing material is always kept in a printable state, and can not cause the problems of layer collapse, damage and blockage due to overhigh or overlow temperature due to the adoption of single temperature control; and meanwhile, the blockage and the fracture of a wire of a conventional printing head are avoided, and the quality of formed products is improved.

Owner:ZHEJIANG UNIV

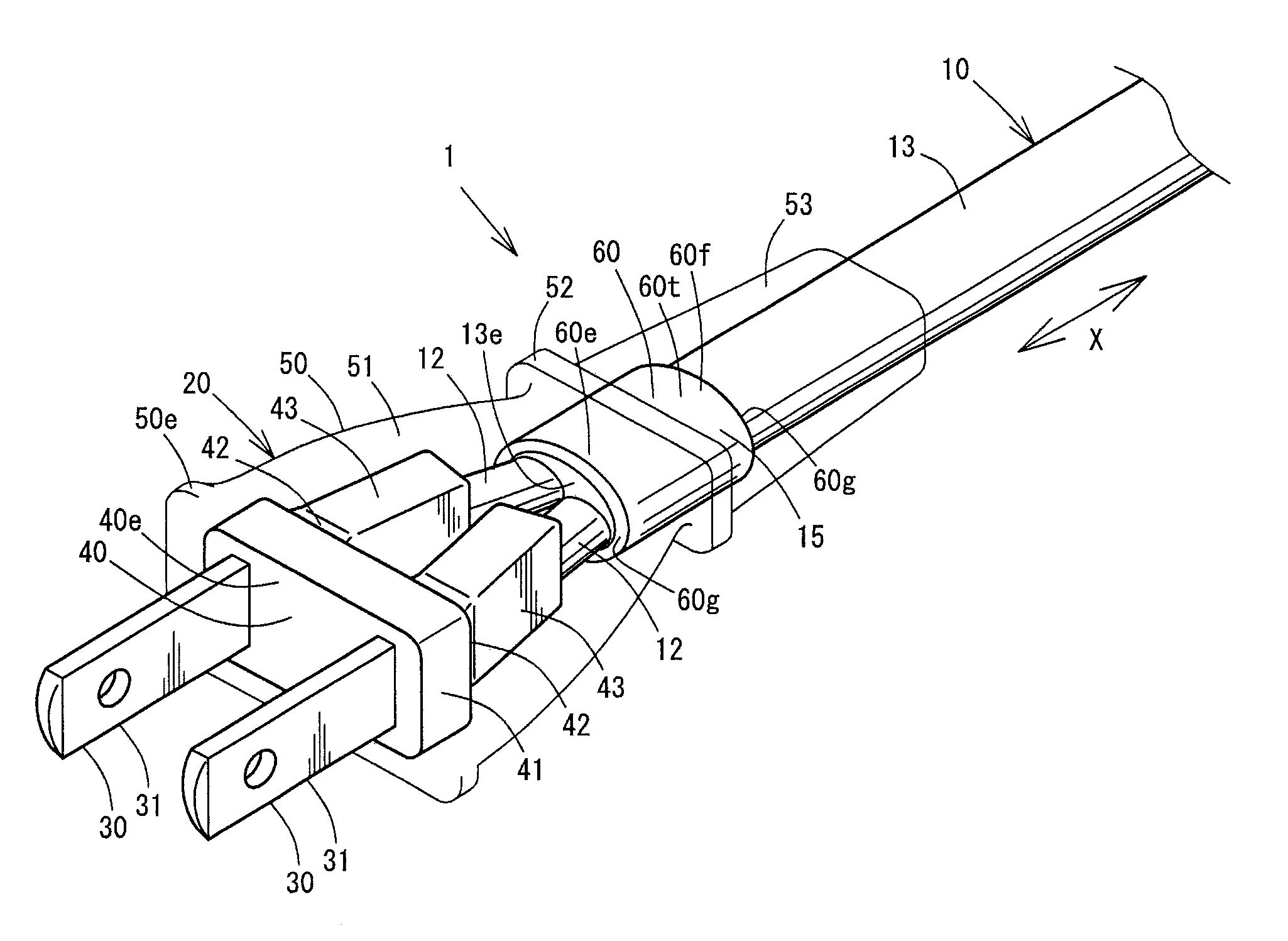

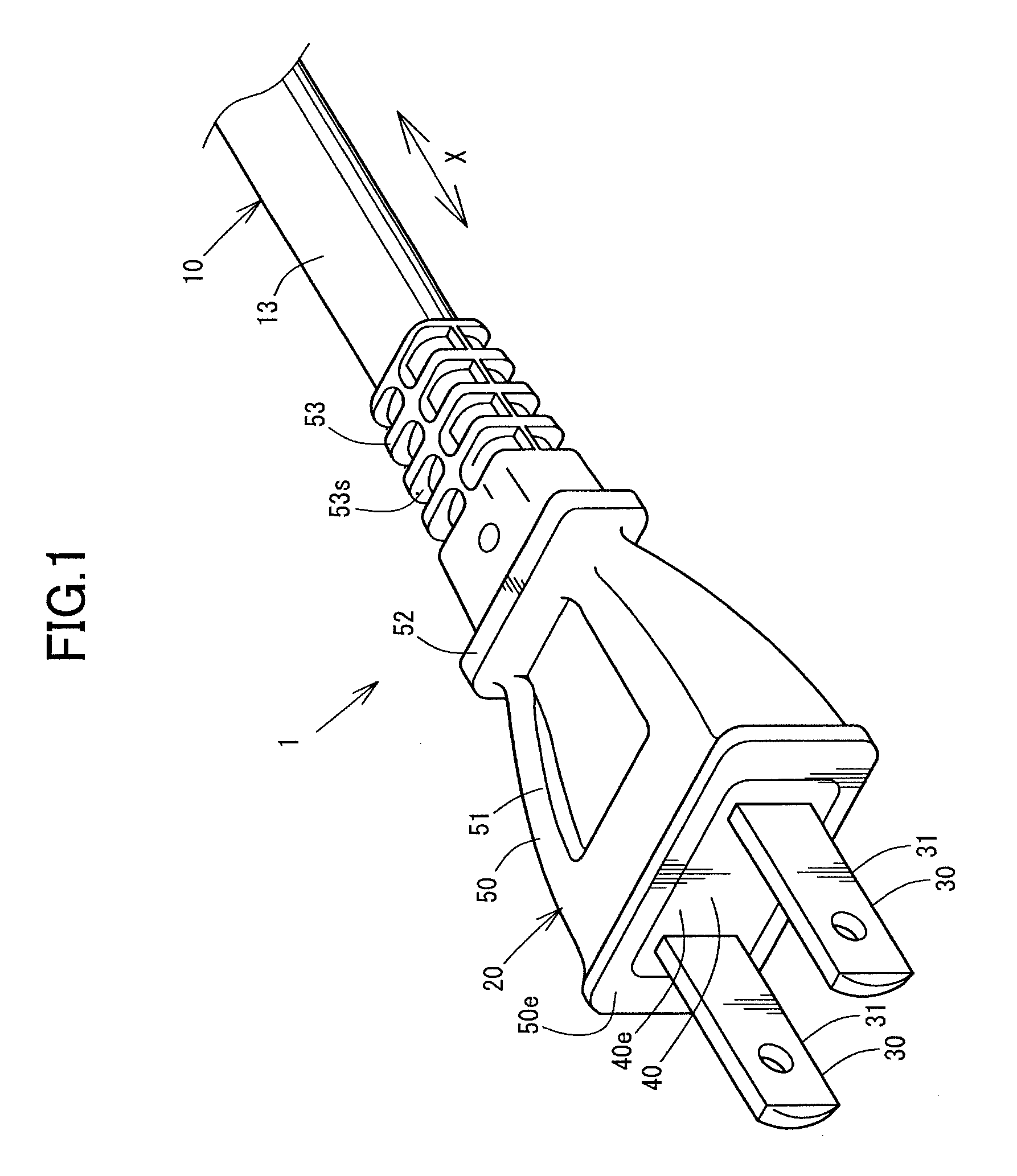

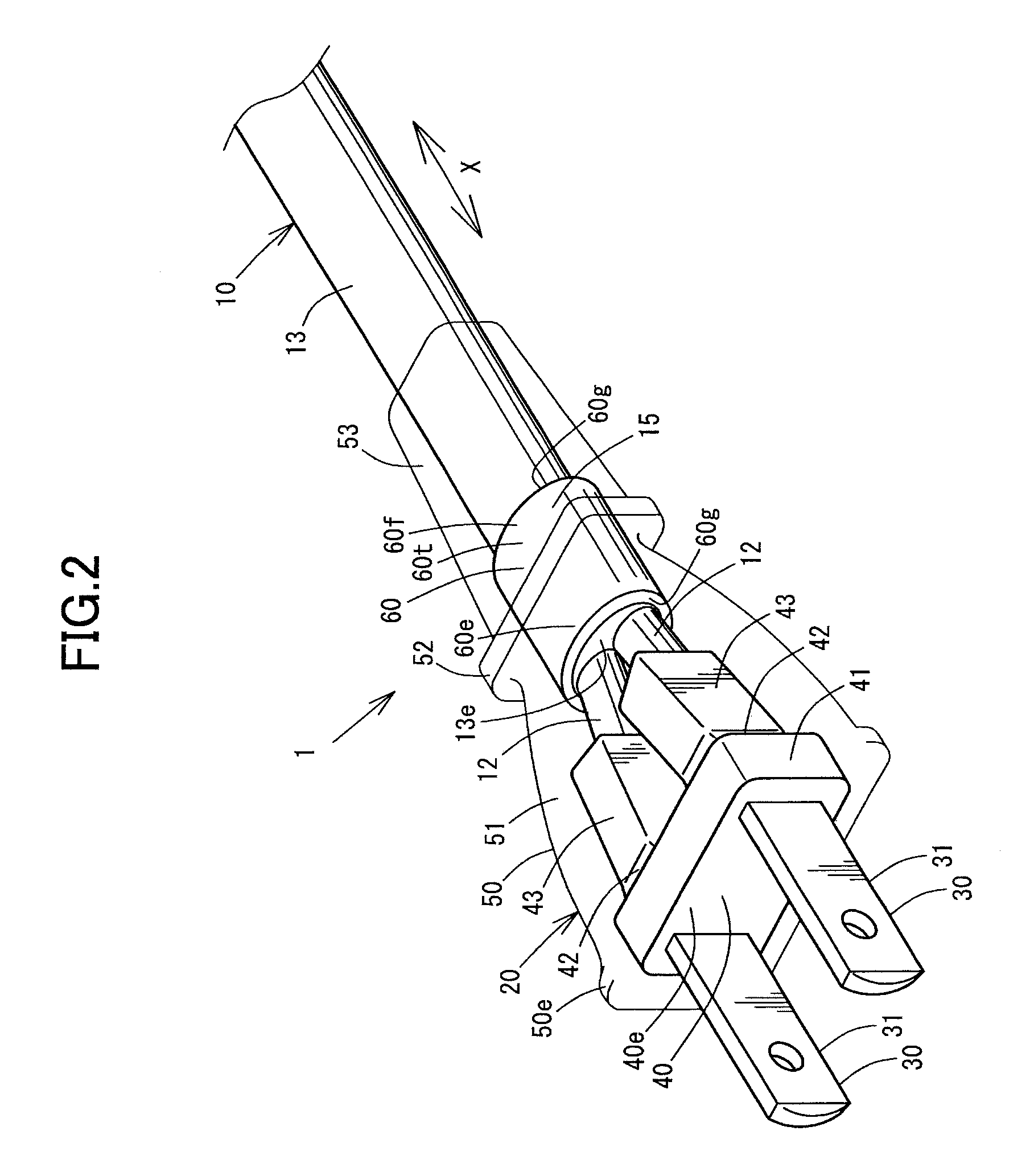

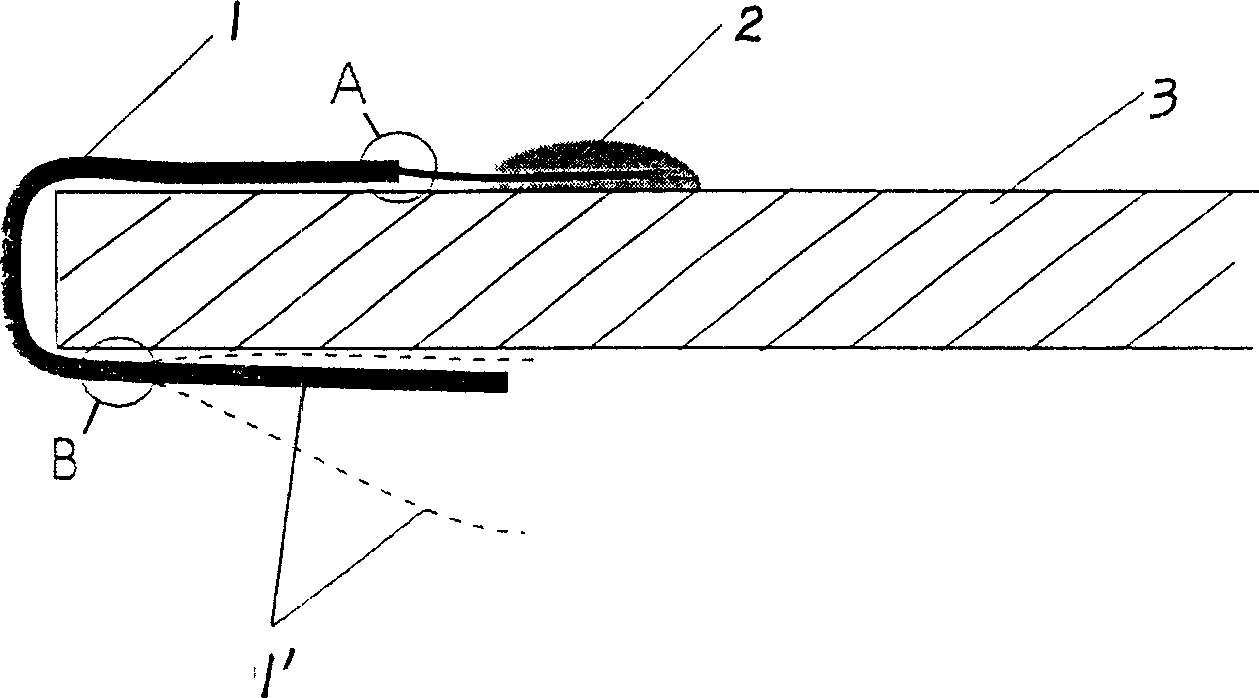

Electrical plug-provided cord

ActiveUS8734178B2Prevent wire breakagePrevent intrusionEngagement/disengagement of coupling partsContact member assembly/disassemblySynthetic resinElectric cables

An electrical plug-provided cord has a cord including lead wires and an outer cover for covering the lead wires, an electrical plug including plug blades connected to the lead wires at a tip of the cord and a plug outer housing for covering a part of the cord and a part of the plug blades from base parts of the plug blades to the outer cover at a tip part of the cord, and a coupling member which surrounds the tip part of the cord in close contact and is coupled to the plug outer housing by thermal welding. The plug outer housing is formed of a synthetic resin. At least an interface of the coupling member with the plug outer housing is formed of a heat-weldable material which is thermally weldable with the plug outer housing.

Owner:FUJI ELECTRIC WIRE INDS

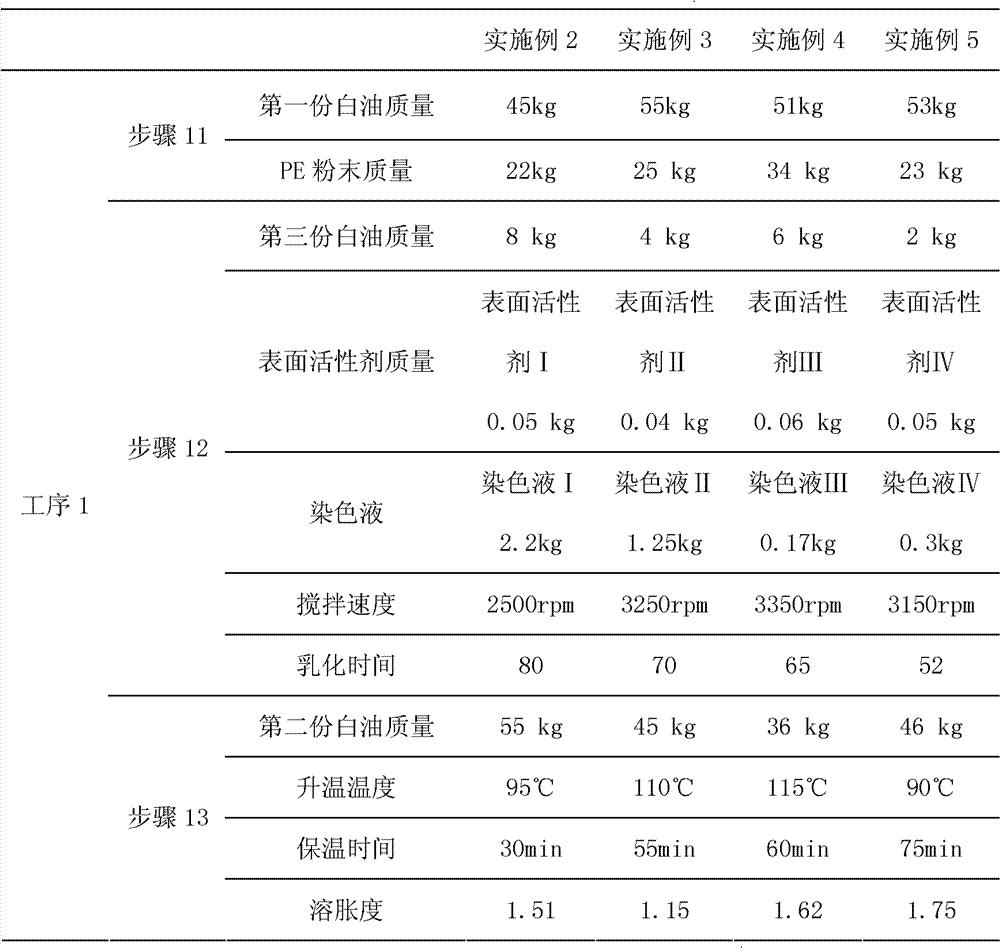

Spinning swelling solution used for preparation of ultra-high molecular weight colored polyethylene fiber and spinning stock solution

ActiveCN102776596AImprove mechanical propertiesEvenly dispersedMonocomponent polyolefin artificial filamentPigment addition to spinning solutionFiberStaining

The invention discloses a spinning swelling solution used for preparation of an ultra-high molecular weight colored polyethylene fiber. The spinning swelling solution comprises, by weight: 10-50% of ultra-high molecular weight polyethylene; a staining solution accounting for 0.01-10% of the weight of the ultra-high molecular weight polyethylene; and spinning solvents. In the invention, first, the staining solution is prepared into a swelling solution, in which the staining solution can be uniformly dispersed. Preparation of the staining solution into a spinning stock solution can be beneficial to uniform dispersion of the staining solution in the spinning stock solution. When using the spinning stock solution for gel spinning, after the spinning stock solution undergoes melting, dispersion, uniform mixing and unwrapping in a twin-screw extruder, the pigment particles in the staining solution can induce crystallization as a nucleating agent and form microcrystals. Extrusion molding of a crystal nucleus-containing spinning melt is in favor of obtaining nascent filaments characterized by low crystallinity and uniform crystal nucleus distribution. Thus, mechanical properties of the ultra-high molecular weight polyethylene fiber can be improved finally.

Owner:BEIJING TONGYIZHONG NEW MATERIAL TECH CORP

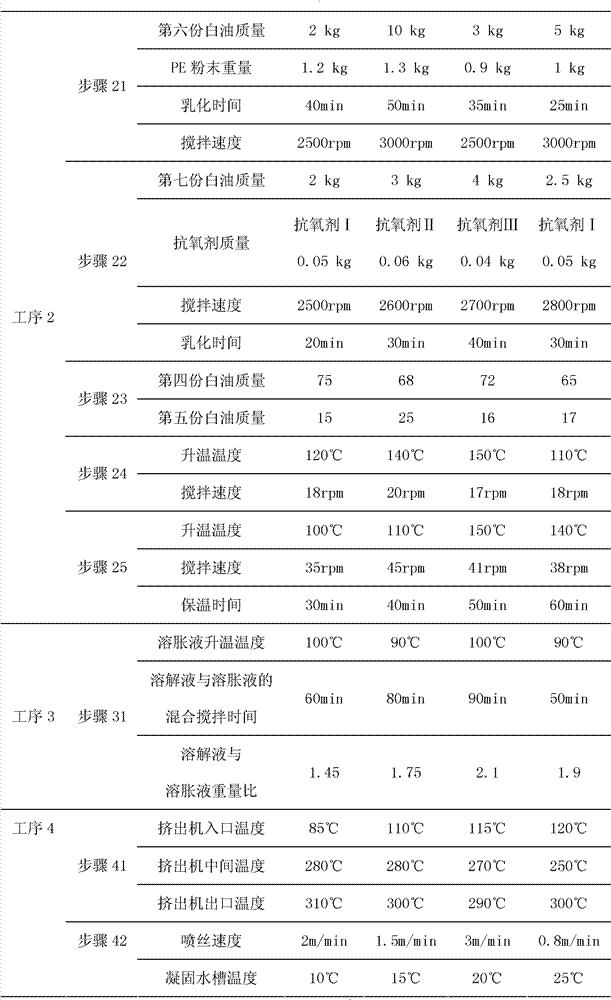

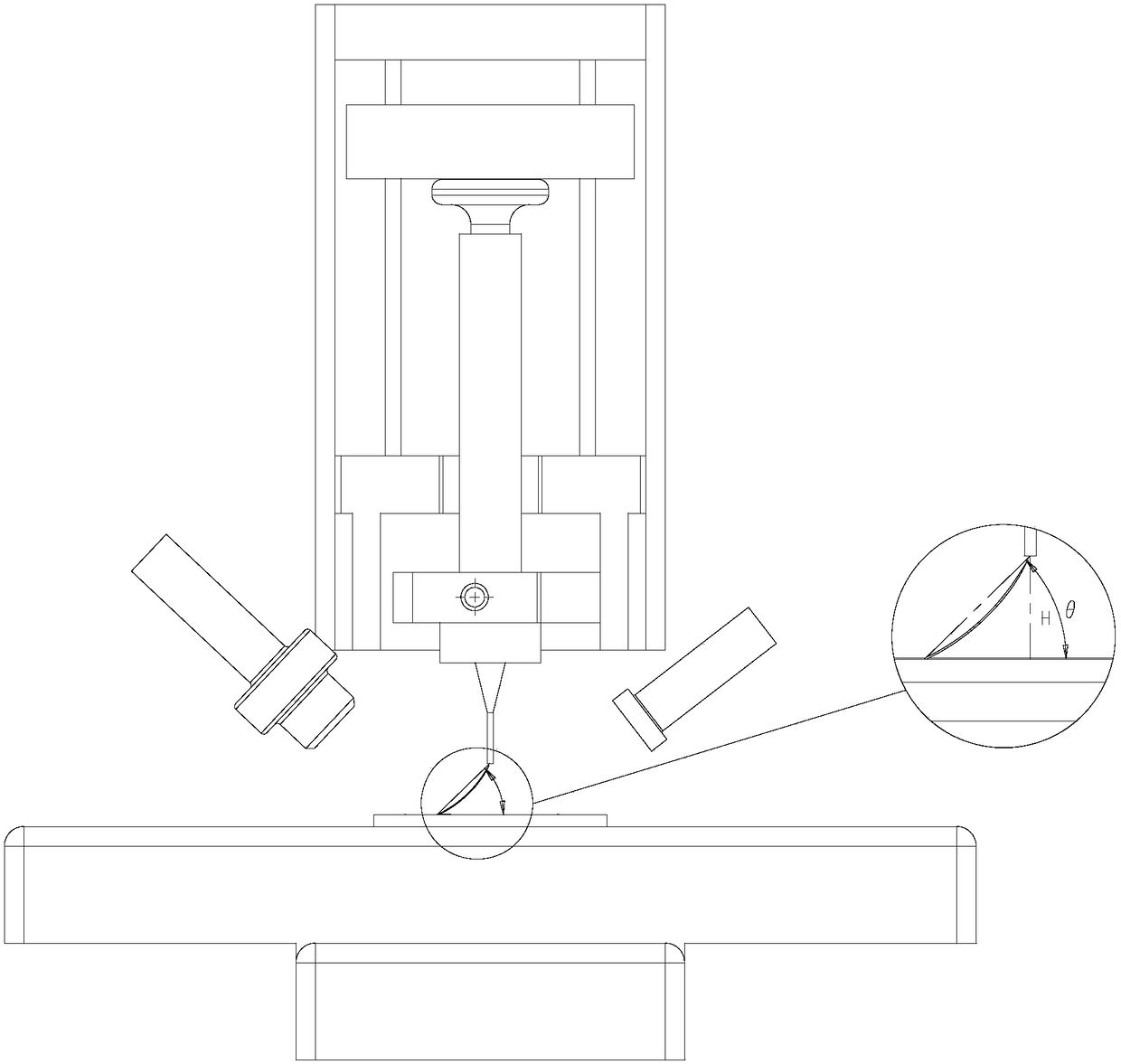

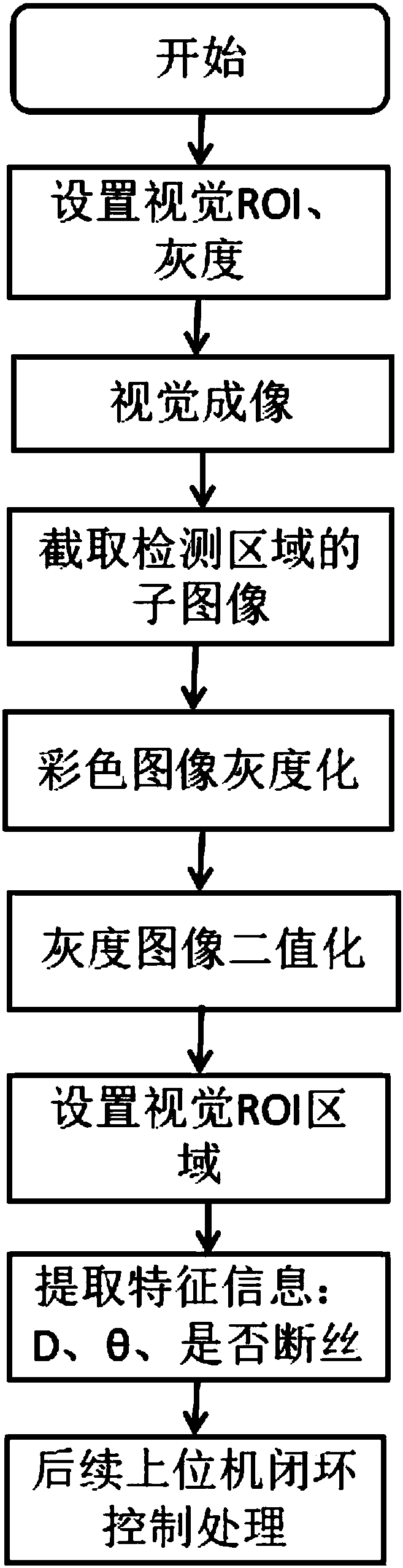

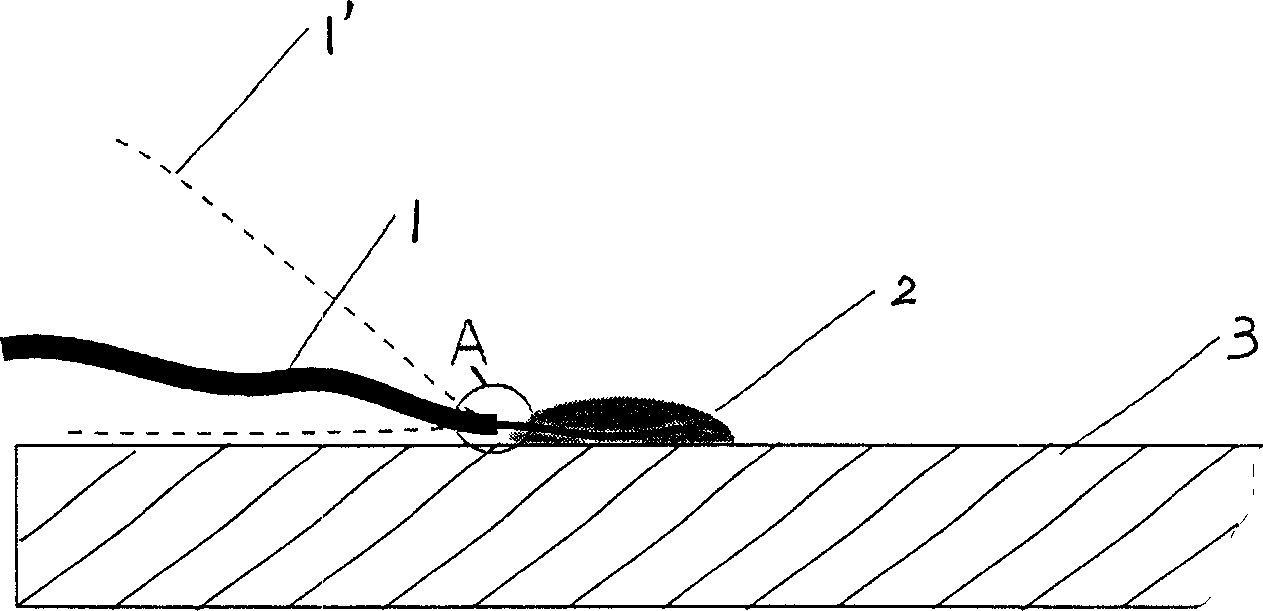

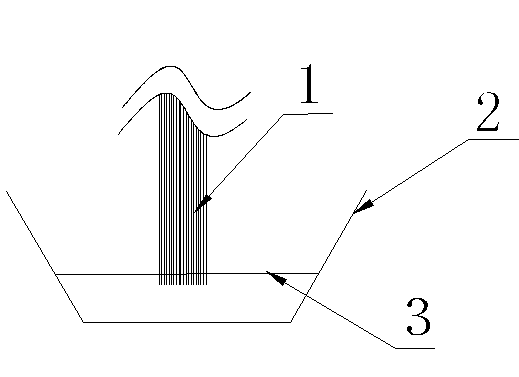

Machine version based online detection and control method of near field electrospinning printing effect

ActiveCN108221068AAddressing vulnerability to distractionsSolve poor printing effectFilament/thread formingInjectorWire drawing

The invention discloses a machine version based online detection and control method of near field electrospinning printing effect. The method includes: grounding a collecting plate of equipment and allowing the tip of an injector to be electrically connected with direct-current high voltage; starting an electrospinning system, and allowing a motion platform to start moving according to a planned path to form a taylor cone at the tip of a spray nozzle; collecting information of wire diameter size, wire drawing state, wire bifurcation and wire fracture in real time during spinning through a vision image collector and performing online feedback and control for different situations; when D and theta exceed the set range, controlling upper computer software through a matching replacement algorithm to control speed and accelerated speed of a traction shaft motor in real time by matching and converting error amount of D or theta with pulse quantity, and fine tuning the distance H from the tipto the collecting plate when D or theta reaches nearby preset value so that the printing effect is gradually close to the parameter range till printing is steady. The method has the advantages of easy implementation, simple operation and stably system operation.

Owner:GUANGDONG UNIV OF TECH

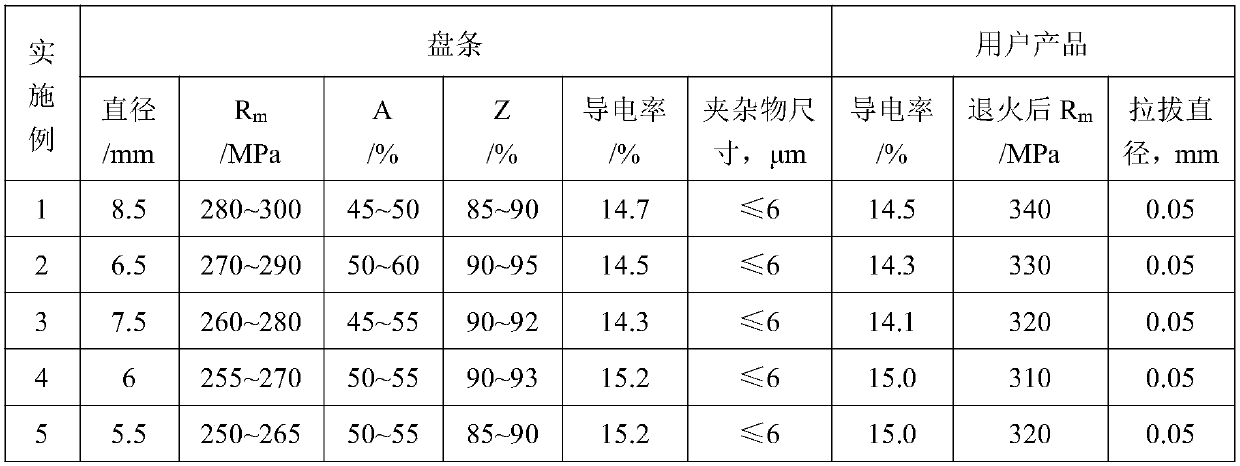

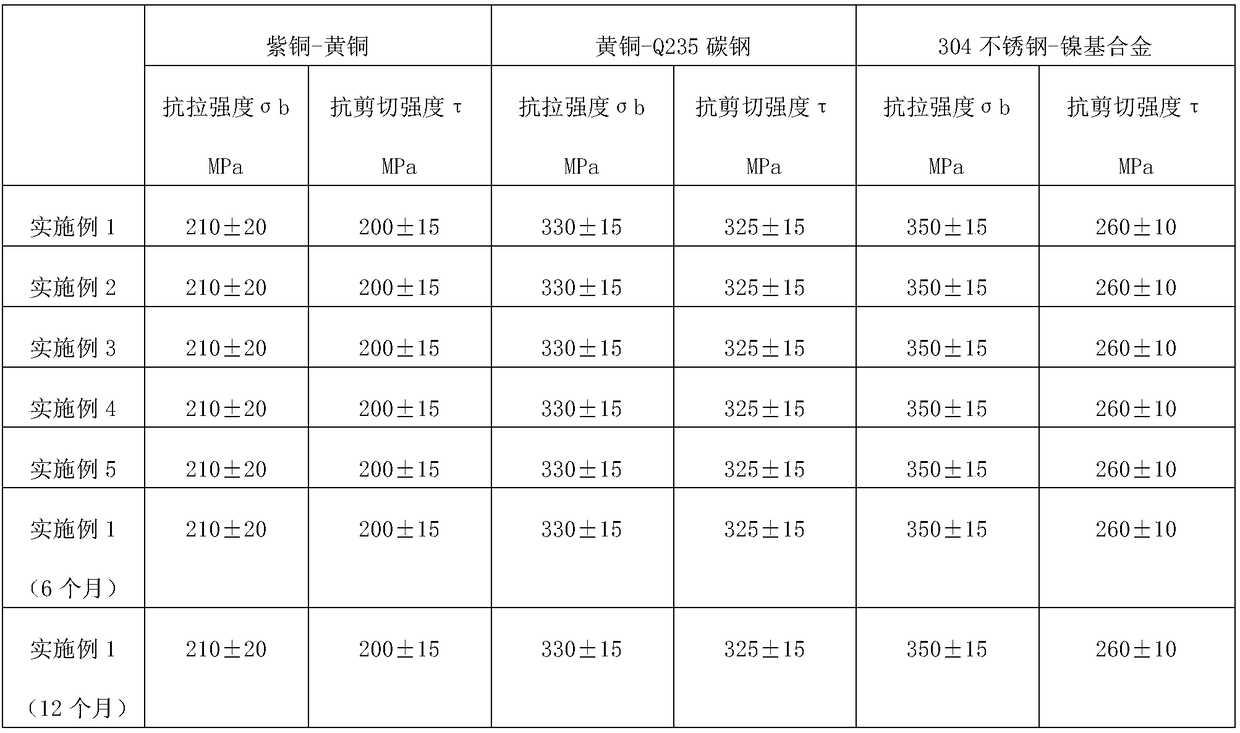

Production method of steel wire rod for very fine copper-clad steel wire

InactiveCN107675068AKeep Steel PureComply with chemical composition requirementsSteelmakingManganese

The invention discloses a production method of a steel wire rod for a very fine copper-clad steel wire. The production method comprises the following steps of a steelmaking procedure and a controlledrolling procedure, wherein the steelmaking procedure comprises the following steps of 1) molten iron pretreatment; 2) converter steelmaking; 3) argon blowing; 4) RH refining: controlling the mass content of carbon in molten steel to be smaller than or equal to 0.003 percent, the mass content of free oxygen to be smaller than or equal to 15ppm and the mass ratio of manganese and sulfur to be Mn / S larger than or equal to 10; and 5) continuous casting; and the controlled rolling procedure comprises the following steps of 6) heating, wherein a temperature of a heating section is 1050-1150 DEG C, atemperature of a heat balance section is 1150 plus / minus 50 DEG C, and a section temperature difference is smaller than or equal to 30 DEG C; 7) roughing; 8) finishing: a temperature of an inlet of afinishing mill is 900 plus / minus 15 DEG C, and a temperature of an inlet of a reducing sizing mill is 890 plus / minus 10 DEG C; and 9) cooling control: controlling cooling on a Stelmor cooling controlline, wherein a laying temperature of a laying machine is 890 plus / minus 10 DEG C, and the average cooling rate is 0.5-1.5 DEG C / s. The steel wire rod produced by the method has especially good colddrawing performance and higher conductivity and meets the requirements for the steel wire rod for the very fine copper-clad steel wire by electronic products including mobile phones.

Owner:武汉钢铁有限公司

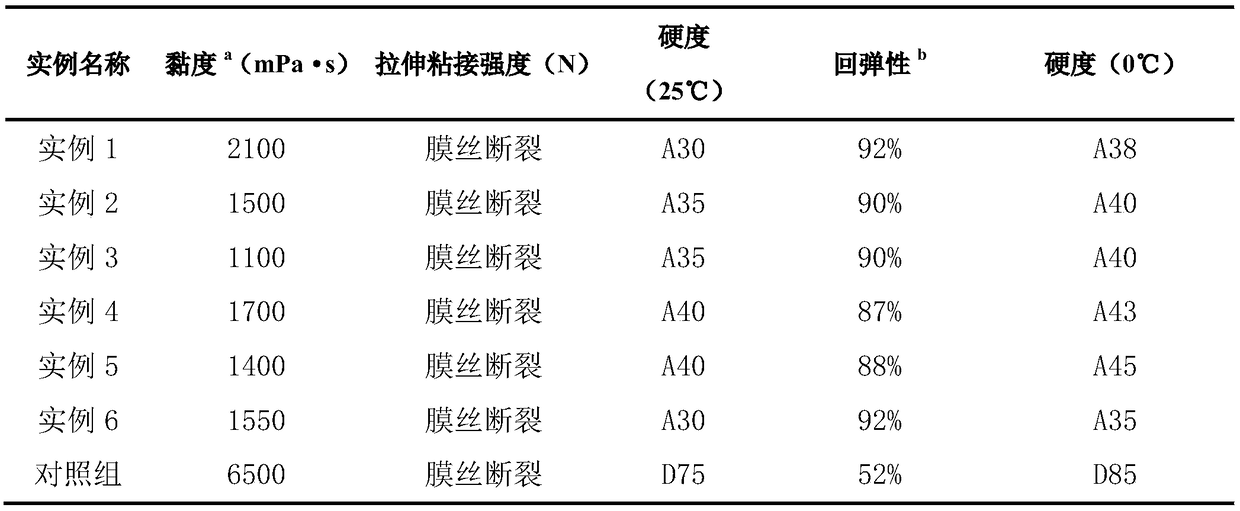

Low-hardness and high-elasticity water treatment membrane component epoxy pouring sealant preparation method and application

The invention discloses a low-hardness and high-elasticity water treatment membrane component epoxy pouring sealant preparation method and application. An epoxy pouring sealant comprises a component Aand a component B, the component A comprises, by weight, 30-70 parts of epoxy resin, 5-20 parts of activated thinners, 10-20 parts of toughening agents, 5-30 parts of fillers and 0.1-3 parts of coupling agents, the component B comprises, by weight, 20-50 parts of polyether amine, 40-70 parts of alicyclic amine and 2-15 parts of curing accelerators, and the weight ration of the component A to thecomponent B is (100:10)-(100:50). By the aid of a 'trinity' toughening modified mode of the flexible toughening agents, the activated toughening thinners and flexible curing agents, the epoxy pouringsealant is characterized of low hardness, high elasticity and stable hardness within wide temperature range, the epoxy pouring sealant has excellent adhesive performance and is low in initial viscosity, high in mold filling speed, simple and convenient to operate and applicable to the fields such as package of water treatment membrane components and flexible package of electronic devices, and theblocking efficiency of the membrane components can be greatly improved.

Owner:浙江航通舟新材料科技股份有限公司

Pressing and stranding method for wire core of aluminum alloy conductor

InactiveCN102163478AStrong enoughTough enoughCable/conductor manufactureElectrical conductorMaterial consumption

The invention relates to a pressing and stranding method for a wire core of an aluminum alloy conductor, which is realized through the following steps: determining the conductor diameter, the conductor cross section and the number of monofilaments of different types and specifications of cables according to requirements of product standard; designing the conductor structure and determining the number of the monofilaments and the diameter of the monofilaments according to the requirements of the standard on the conductor diameter, the section and the number of the monofilaments; designing a mold for stranding each layer of the wire core of the conductor according to the structural requirement of the conductor; and designing the pressing and stranding process for the conductor according to the requirement of the standard on pitch. The pressed and stranded wire core of the aluminum alloy conductor, which is processed by the method, is high in pressing degree and small in conductor diameter, and can reduce the material consumption, reduce the production cost, improve the electrical performances of the conductor and realize energy conservation and high efficiency in transmission.

Owner:ANHUI JOY SENSE CABLE

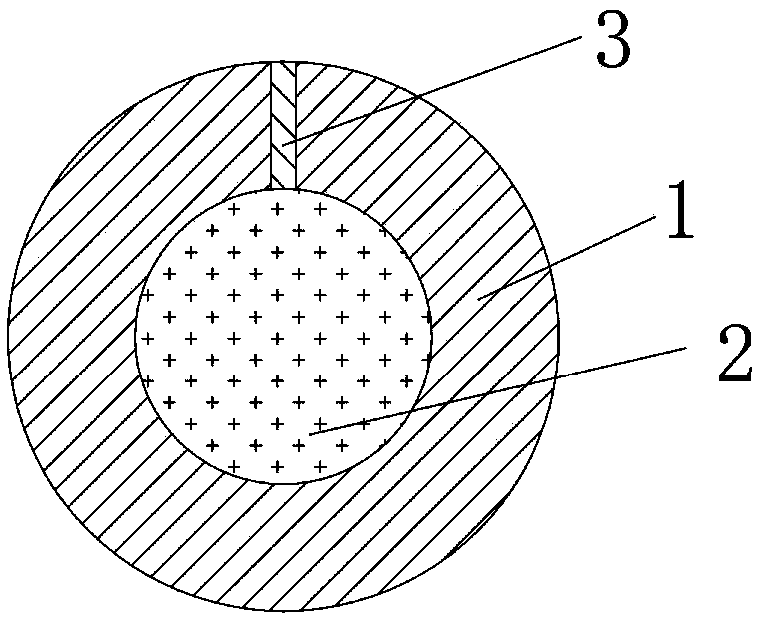

Ultra-extinction memory fiber and preparation method

InactiveCN103628180APrevent wire breakageAvoid the phenomenon of insufficient drapeMelt spinning methodsConjugated synthetic polymer artificial filamentsFiberPolyester

The invention discloses an ultra-extinction memory fiber and a preparation method. The ultra-extinction memory fiber is prepared by a method for differentially distributing titanium dioxide content in a skin-core composite structure. The problems that the conventional complete-extinction fiber has poor ultraviolet resistance, breakage in the weaving process is relatively serious, and clothes produced have a low sagging degree are solved. The ultra-extinction memory fiber adopts the skin-core structure, and has the average titanium dioxide content of more than 3% and high ultraviolet resistance; fabric woven by the ultra-extinction memory fiber is bright in color, comfortable, sagging, stiff and smooth and high in resilience, and has much higher dyeing property and ultraviolet resistance than the conventional polyester and other complete-extinction fibers.

Owner:SHENGHONG GRP CO LTD

Regenerated skin-core structure composite fiber and preparation method thereof

ActiveCN103789873ASolve spinning difficultiesSolve the comfortFilament/thread formingConjugated synthetic polymer artificial filamentsPolyesterPolymer science

The invention discloses a regenerated skin-core structure composite fiber and a preparation method thereof. An intermediate, namely, BHET is prepared by performing a chemical depolymerization reaction on recycled polyester by using a chemical regeneration method, and a core-layer structure is constructed by preparing nano-composite regenerated polyester through an in-situ polymerization method. A core-layer anti-ultraviolet agent is dispersed uniformly by being added at a low temperature, and the content is over 3 percent, so that the phenomena of breakage of the fiber and low overhanging factor of a fabric in a preparation process due to over high content of the anti-ultraviolet agent are avoided. Moreover, a skin-core structure interface contains a small amount of polyether produced by excessive ethylene glycol in a depolymerization process, so that a skin-core polymer can be relatively well combined, and the physical property of the skin-core polymer is relatively higher than that of a purely-regenerated full dull fiber. A fabric woven by using the prepared regenerated skin-core composite fiber is soft, comfortable, pendent, stiff, smooth and high in ultraviolet resistance. The regenerated skin-core structure composite fiber is an optimal fiber suitable for high-quality fashionable clothing, health care and sports clothes.

Owner:SHENGHONG GRP CO LTD

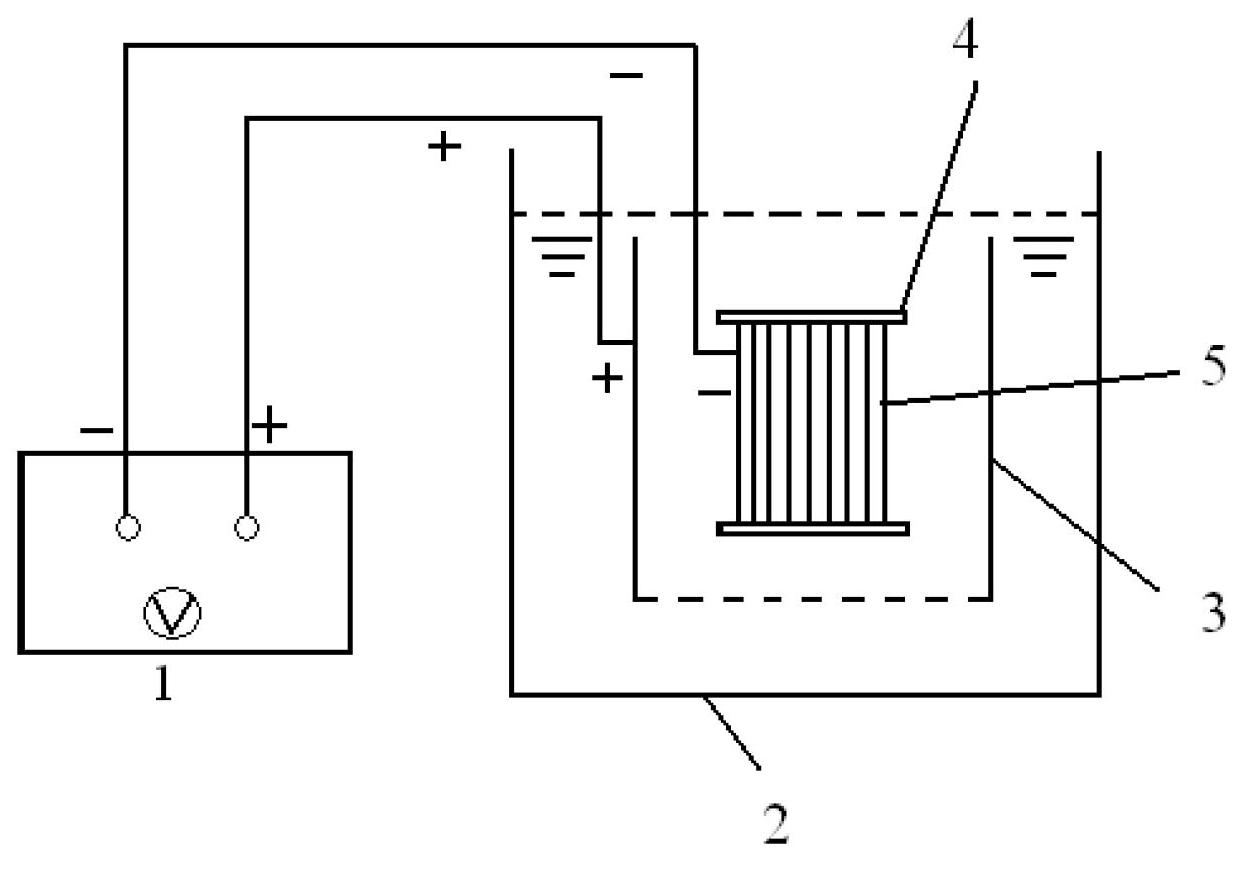

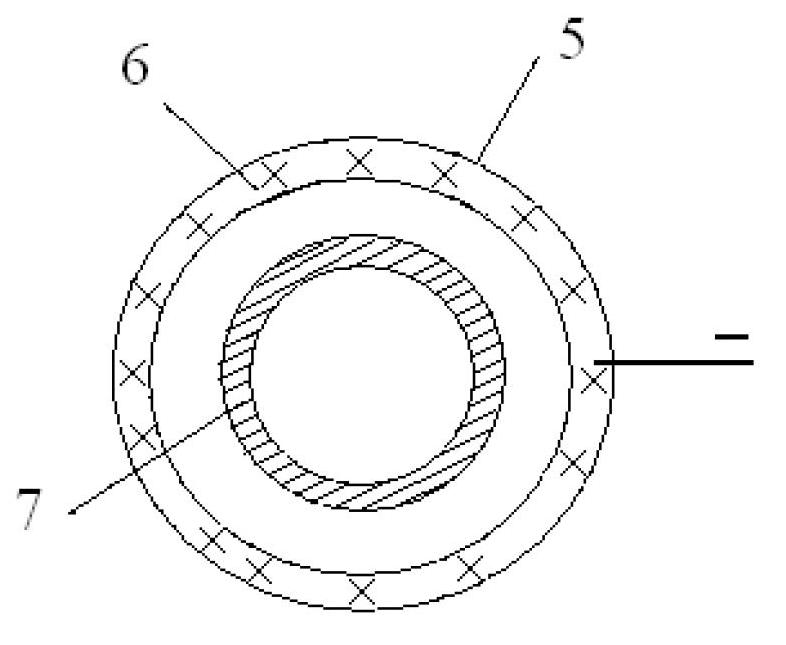

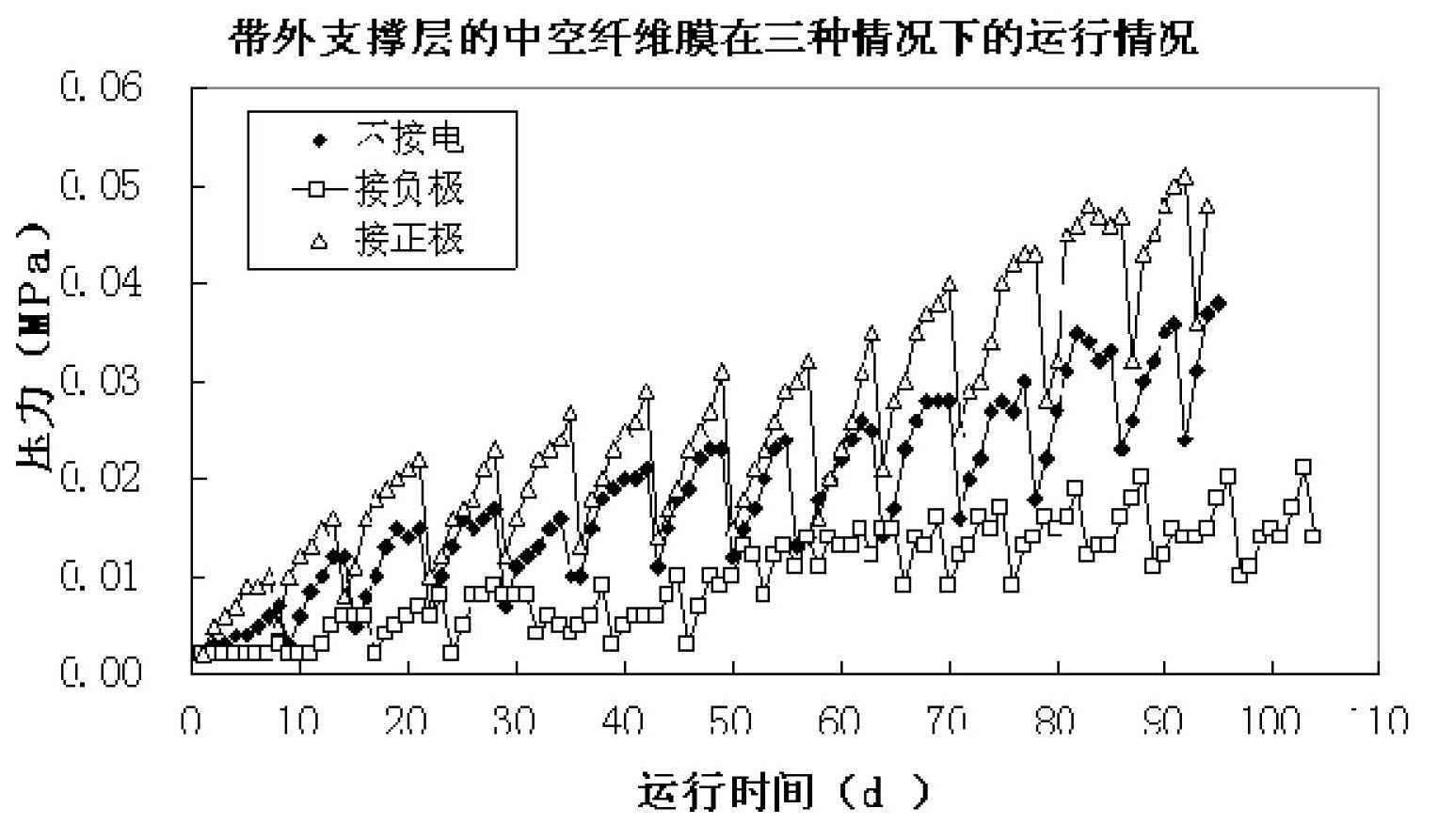

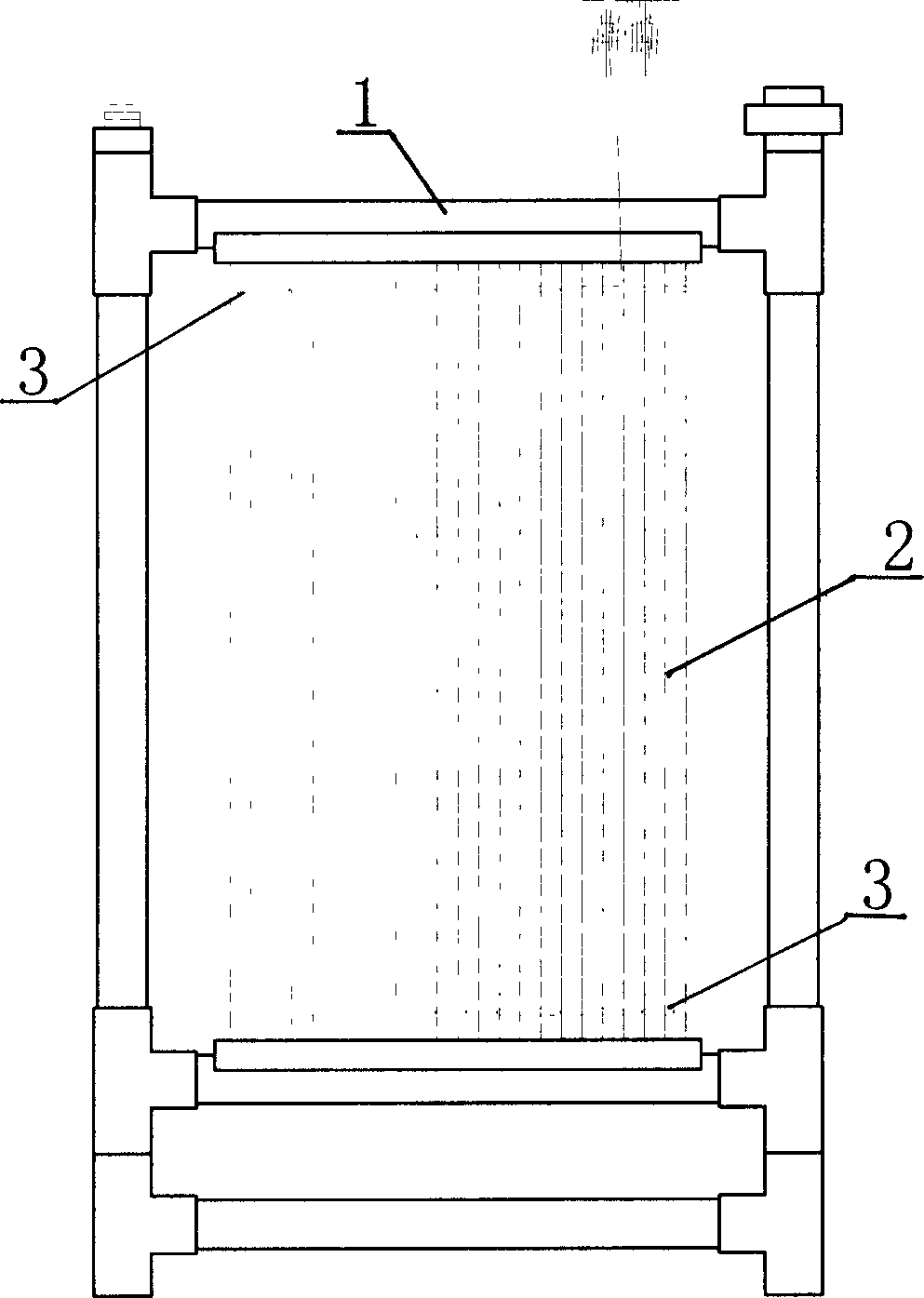

Charged membrane device for water processing and usage method of device

ActiveCN102674542APlay a role in pollutionTo achieve the effect of purifying waterEnergy based wastewater treatmentSustainable biological treatmentElectricityFlocculation

The invention relates to a charged membrane device for water processing. The device comprises a power supply, a membrane group device and a membrane assembly, wherein the membrane group device is groove-shaped, the upper portion and the lower portion of the membrane group device are open and the periphery of the membrane group device is sealed, the membrane assembly is arranged inside the membrane group device, and the outer surface of a hollow fiber membrane wire is coated with a layer of outer tubular supporting layer having a mesh multi-hole structure to form a hollow fiber membrane. When the device is applied in an immersion type membrane separation technology, under the action of current of the power supply, the hollow fiber membrane wire is shielded by the negative electrode of the outer tubular supporting layer, and pollutants with negative electricity can hardly pollute the hollow fiber membrane under the action of electrostatic repulsive force and the flocculation of an electrode dissolution flocculating agent, so that membrane pollution is controlled. The charged membrane device having an anti-pollution function and capable of generating the flocculating agent can control membrane pollution effectively and has the advantages of being high in stain resistance, high in strength of the membrane wire, free of addition of the flocculating agent, capable of purifying waterquality, practical and the like.

Owner:BEIJING ORIGIN WATER FILM TECH

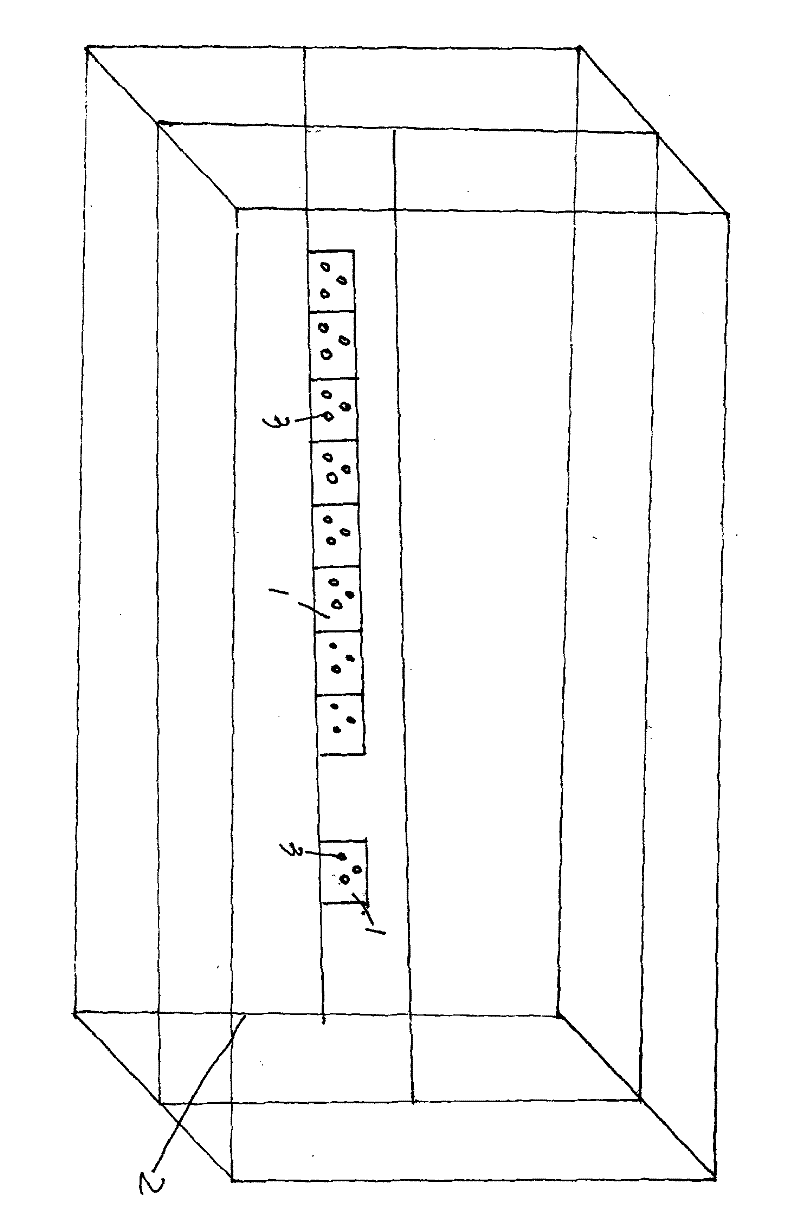

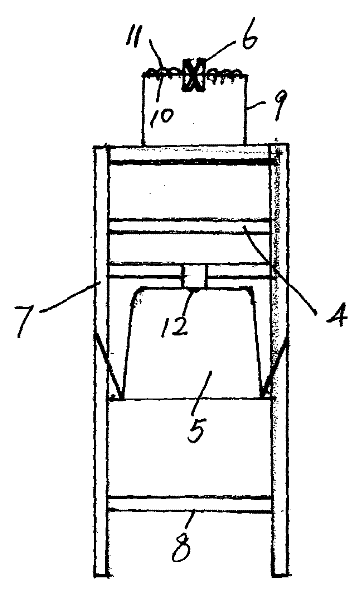

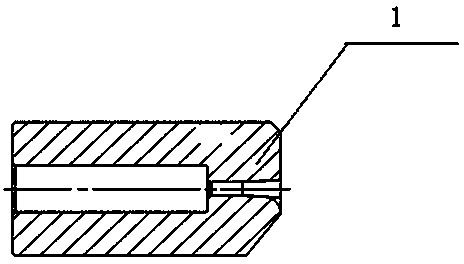

Hollow fiberous-membrane assembly root braiding reinforcing technology

InactiveCN1853763AReduce stressPrevent wire breakageSemi-permeable membranesHollow fibre membraneFiber

A braiding technique for reinforcing the root part of hollow fiber membrane module features that the anticorrosion and hydrophobic cord threads or nylon wires are used to be braided at the adhered positions on the top or bottom sides of hollow fiber membrane module to increase its strength. The number of the braided fibers in a bundle is 10-50 and the number of the braided lines is 1-5.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

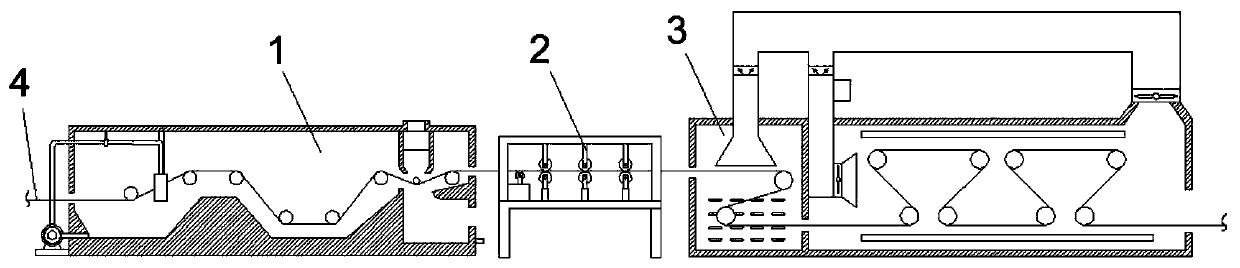

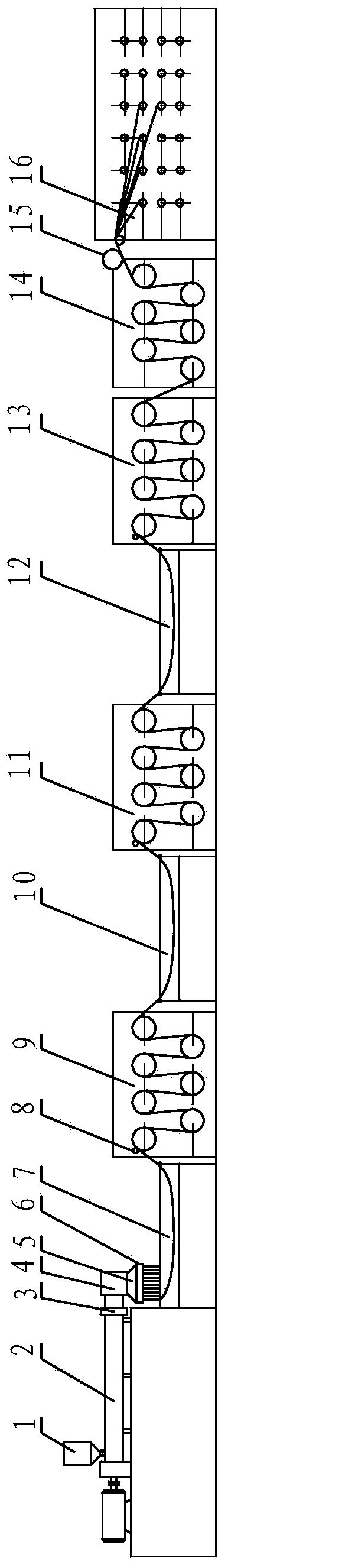

Production technology and production line of high-strength PET (polyethylene terephthalate) flat yarn for freight bag

InactiveCN104233487AHigh strengthAchieve recyclingArtificial thread manufacturing machinesArtificial filament heat treatmentWater bathsYarn

The invention provides a production technology and a production line of a high-strength PET (polyethylene terephthalate) flat yarn for a freight bag. The technology comprises the steps of (1) drying PET raw material, then carrying out pre-crystallization, feeding the product into a screw extruder, and cooling the extruded product by water bath to obtain a diaphragm; (2) drafting: chopping the diaphragm cooled in the step (1) by a chopping device, heating and then carrying out primary drafting; heating again and carrying out secondary drafting; (3) shaping: heating the material obtained by drafting to remove stress, shaping the product by a shaping roller, and then winding to obtain the high-strength PET flat yarn. After the production technology and the production line are adopted, drafting technological parameters are optimized, the problem that the yarn is broken in the drafting process is avoided, and the produced PET flat yarn is high in strength; the process for removing the stress is added, so that the stress generated in the flat yarn drafting process is removed, and the flat yarn fabric is not contracted and deformed due to the existence of stress; a waste PET bottle is also suitable for the production technology and the production line, thus being recovered and utilized.

Owner:CHANGZHOU RUNYI MACHINERY MFR

Warping system

The invention relates to the field of textile machinery, in particular to a warping system, which comprises a bobbin creel, a tensioning mechanism and a take-up mechanism, the bobbin creel is provided with a plurality of layers, and cheeses are planted on each layer; the tensioning mechanism comprises a tensioning carriage and rotary parts; the take-up mechanism comprises a spool and a speed and length measurement device; the warping system is characterized in that the tensioning carriage is provided with a reciprocating device, which can drive the tensioning mechanism to move to and fro along the axial direction of the spool. By arranging the reciprocating device, the tensioning mechanism can periodically move to and fro, thus ensuring that the spool can uniformly wind yarns and preventing the problem that the yarns are wound excessively on one end and insufficiently on the other end, meanwhile, because yarn guides and a raddle are arranged at the yarn inlet and yarn outlet of the tensioning carriage, the yarns can be prevented from rubbing the surfaces of the rotary parts to abrade and break when the tensioning mechanism moves to and fro.

Owner:安吉县青云麻纺织厂

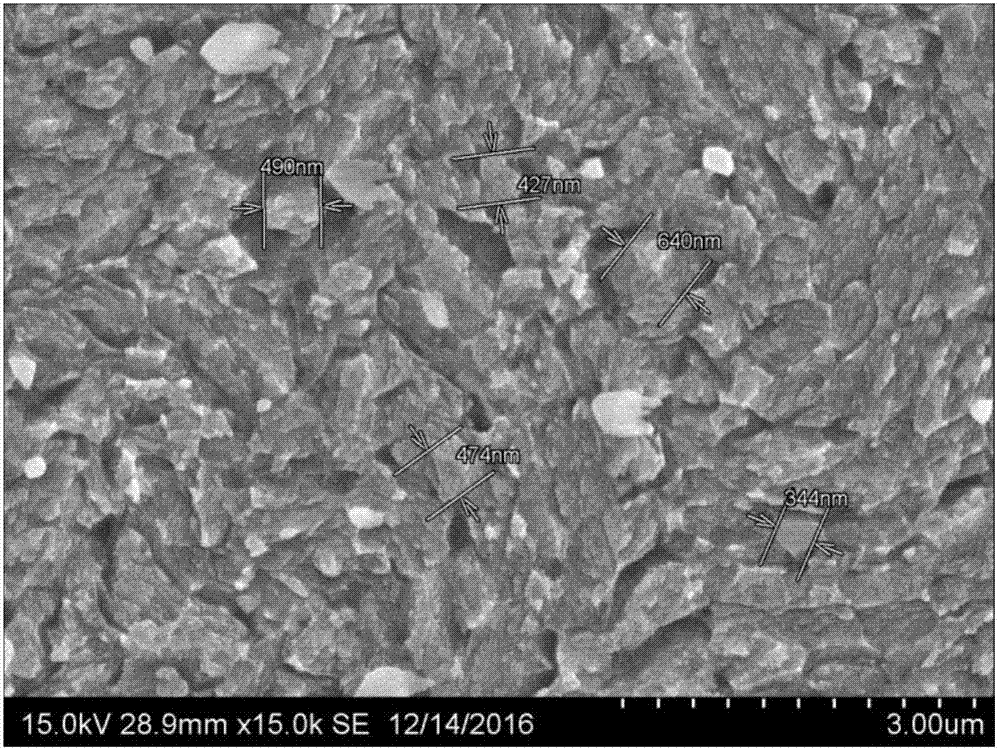

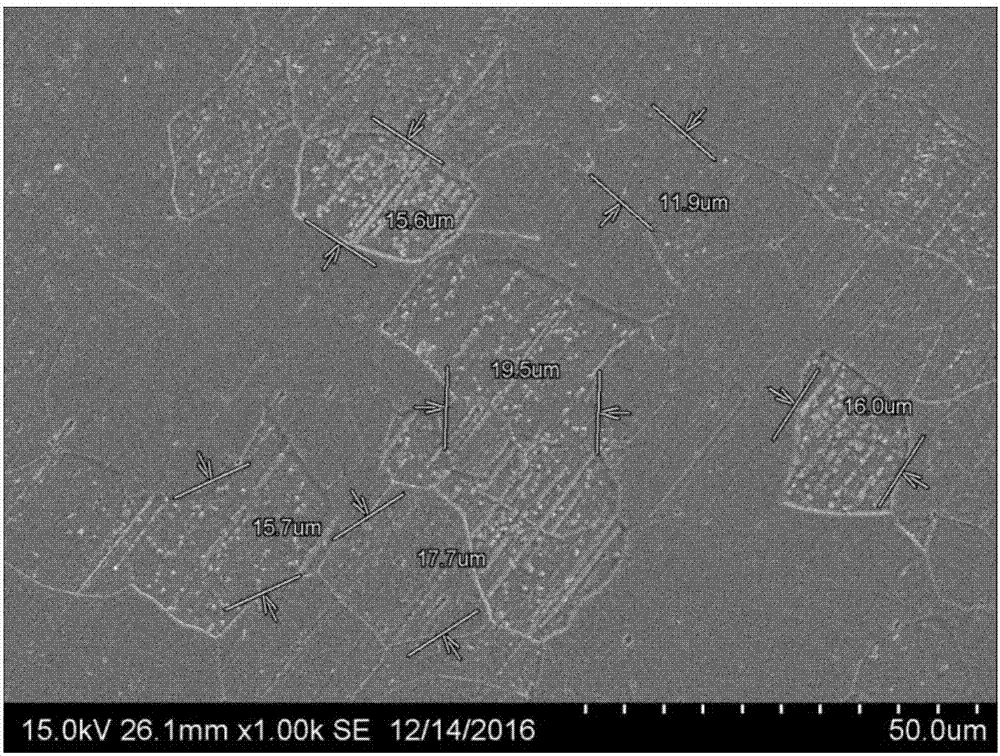

Preparation method of medical biodegradable zinc alloy capillary wire material

The invention provides a preparation method of a medical biodegradable zinc alloy capillary wire material. A medical biodegradable zinc alloy is sequentially subjected to vacuum melting and homogenizing treatment to obtain a zinc alloy cast ingot, then the zinc alloy cast ingot is sequentially subjected to skin turning and extrusion, a zinc alloy coarse bar is obtained and sequentially subjected to rotary swaging and annealing, a fine bar is obtained, the surface of the obtained fine bar is coated with a graphite lubricant coating, then the fine bar is subjected to cold drawing for wire drawing, and the medical biodegradable zinc alloy capillary wire material is obtained, wherein the diameter of the capillary wire material is smaller than 0.1 mm. The preparation method is a compound machining method comprising vacuum melting, thermal extrusion forming, rotary swaging and cold drawing for wire drawing, the purposes of enhancing the material performance and plastification can be achieved through surface lubrication and proper thermal treatment of the special procedures, the microstructure grain fragmentation can reach the nanoscale, the comprehensive mechanical performance is excellent, the surface quality is good, and corrosion resistance, degradation uniformity and degradation speed all meet the clinical application requirements.

Owner:XIAN ADVANCED MEDICAL TECH

Ultra-low carbon steel fine wire drawing method

InactiveCN106311781AAvoid secondary rapid work hardeningPrevent wire breakageFurnace typesHeat treatment furnacesWire rodRapid processing

The invention discloses an ultra-low carbon steel fine wire drawing method, which comprises a first stage of drawing process, a recrystallization annealing process, and a second stage of drawing process. According to the first stage of drawing process, the total deformation is calculated to be 75 percent to 85 percent according to a wire rod axial circle area. The method is applicable to the processing field of products such as copper-clad steel wires and electronic leading wires. The cold plastic deformation is hardly carried out during a second-time rapid processing and hardening process, so that the occurrence of the phenomenon that the tensile strength of middle wires is too high can be effectively avoided, the wire breaking rate can be remarkably reduced, the middle wires are prevented from being processed and hardened excessively, and the die loss is reduced; the finished products i.e. fine wires obtained according to the method provided by the invention can meet the requirement of low tensile strength. The ultra-low carbon steel fine wire drawing method provided by the invention has no special requirement on drawing equipment, is applicable to a common connecting tank drawing machine, and has no need to increase equipment and reformation investment; the diameter of each winding drum can be equal or unequal; and the ultra-low carbon steel fine wire drawing method provided by the invention is applicable to ultra-low carbon steel with the carbon content being not more than 0.05 weight percent, and the raw material steel types are wider.

Owner:XINGTAI IRON & STEEL

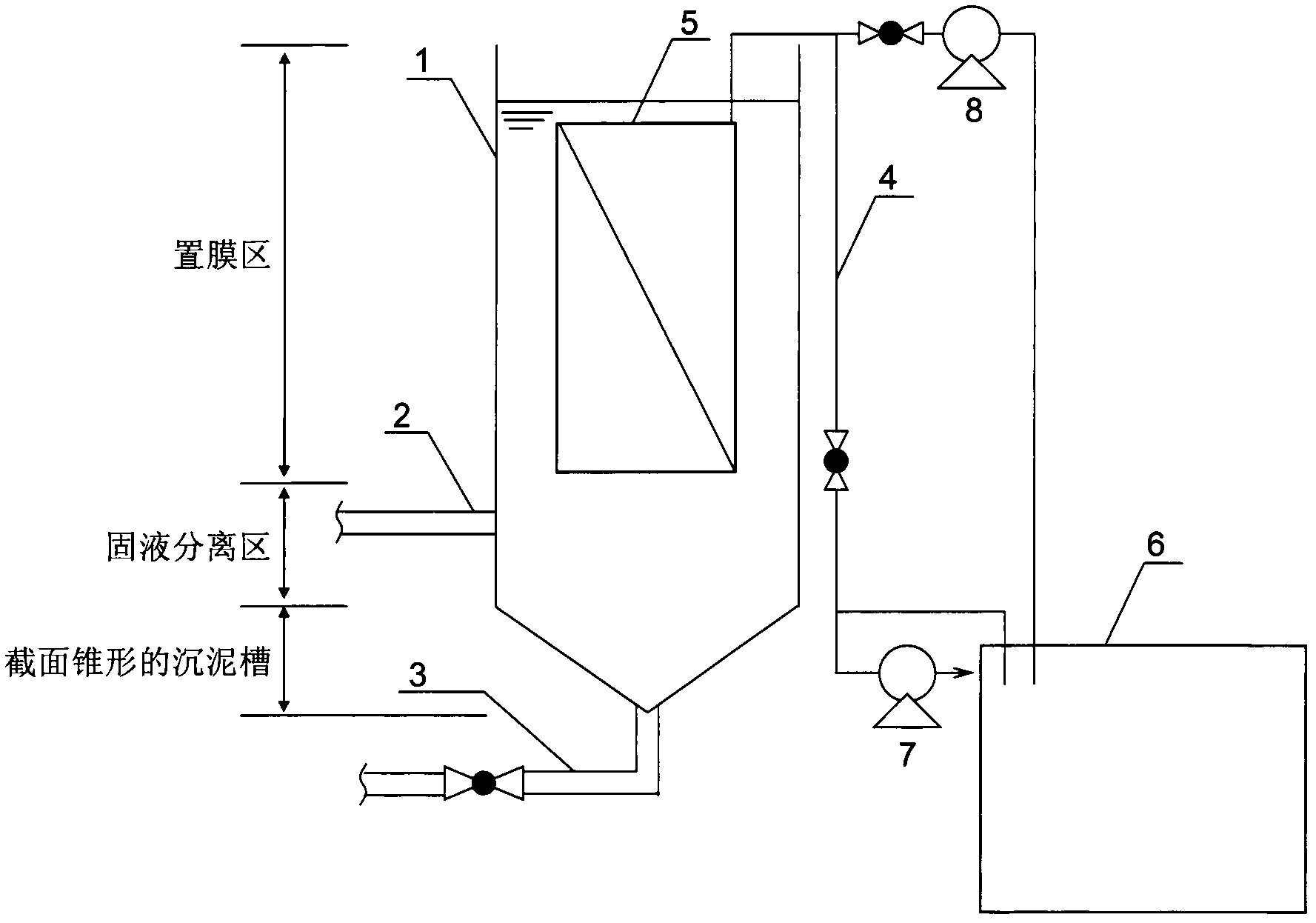

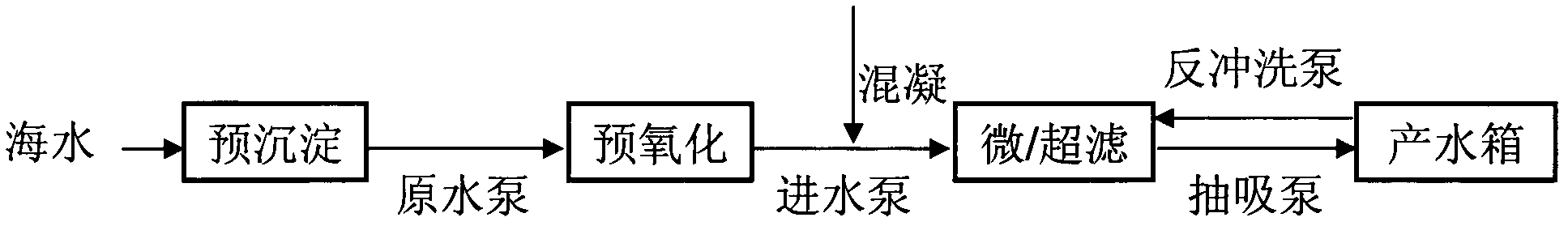

Reverse-osmosis seawater desalination pretreatment method and device for polluted sea areas

InactiveCN103121760AHigh recovery rateControl Membrane FoulingGeneral water supply conservationSeawater treatmentSeawaterPretreatment method

The invention relates to reverse-osmosis seawater desalination pretreatment method and device for polluted sea areas. The technical scheme of the reverse-osmosis seawater desalination pretreatment device includes that a silt precipitation tank with conical section is arranged on the lower portion of a common micro- and ultra-filtration membrane tank body, a solid and liquid separation area is arranged in the middle of the common micro- and ultra-filtration membrane tank, and water is fed from the solid and liquid separation area. By the aid of the structure of the reverse-osmosis desalination pretreatment device, recovery rate of the system can be effectively increased, disturbance on membrane component from water impact is avoided, stability of outlet water quality is guaranteed, energy is saved and consumption is reduced.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

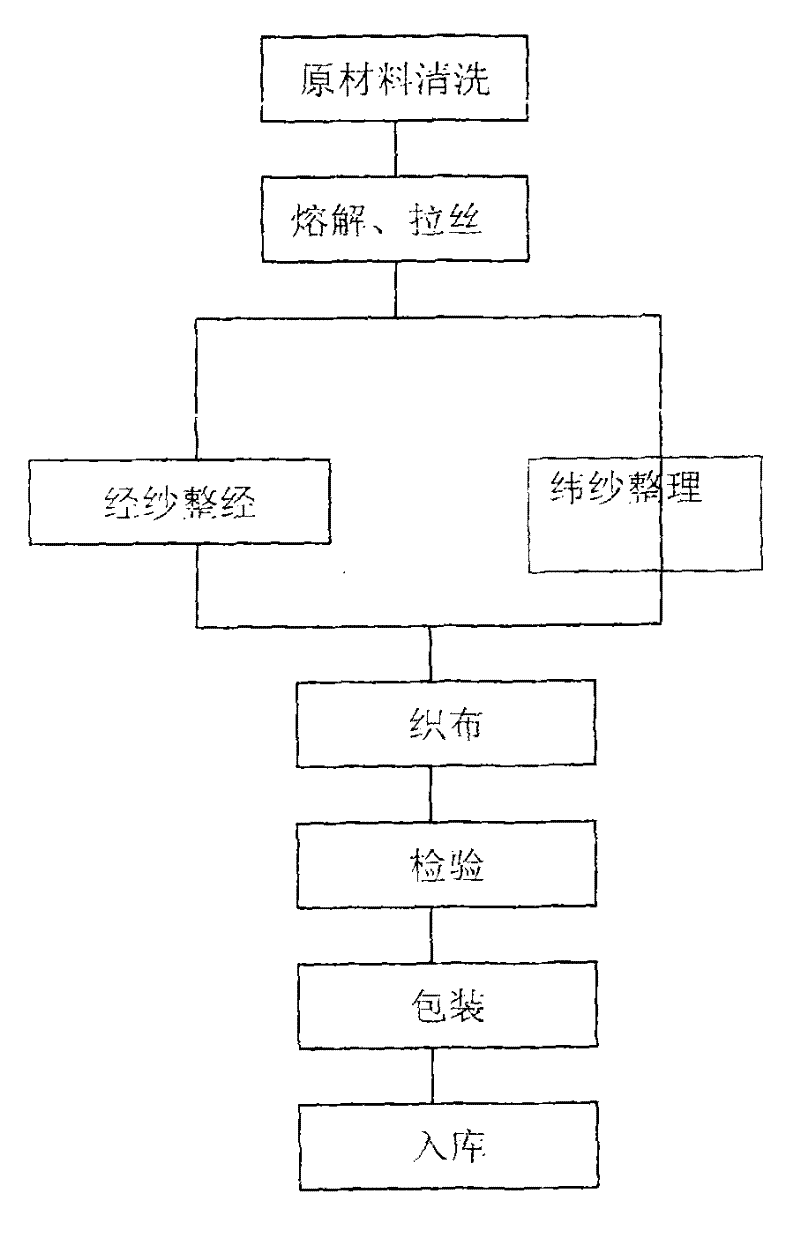

Glass fiber weaving process and special equipment thereof

InactiveCN101748546AAvoid wear and tearAvoid harmLoomsOther manufacturing equipments/toolsFiberGlass fiber

The invention discloses a glass fiber weaving process and special equipment thereof. The technological process is finished through procedures of cleaning, melting, wire drawing, warp yarn warping, weft yarn finishing, weaving, check and warehousing on raw materials. The special equipment is a warping tensioner and a weft yarn introduction device. When the process is adopted to manufacture a glass fabric, procedures of unwinding and twisting are removed from a finishing process of weft yarns, and a stranding procedure is removed from a finishing process of weft yarns so as to enable glass precursor fibers not to generate friction with equipment of unwinding, twisting and stranding, avoid abrasion and hurt to the glass precursor fibers, guarantee the tensile strength of the glass precursor fibers, enhance the product quality and the production efficiency and save the energy consumption and the product cost.

Owner:黄新春

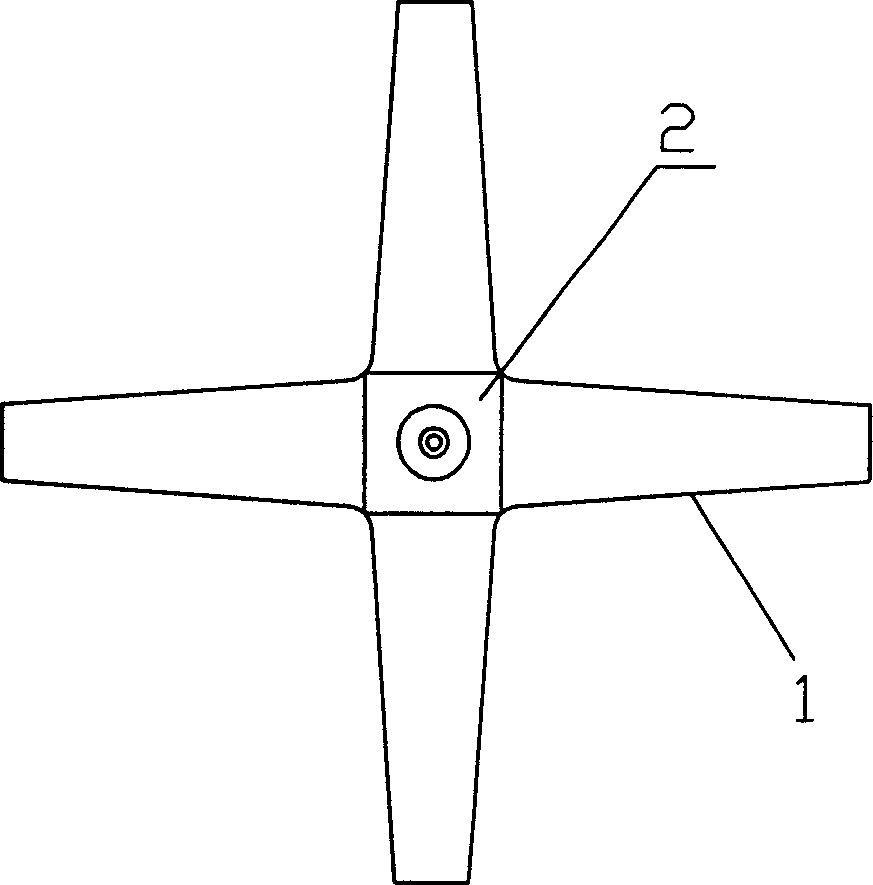

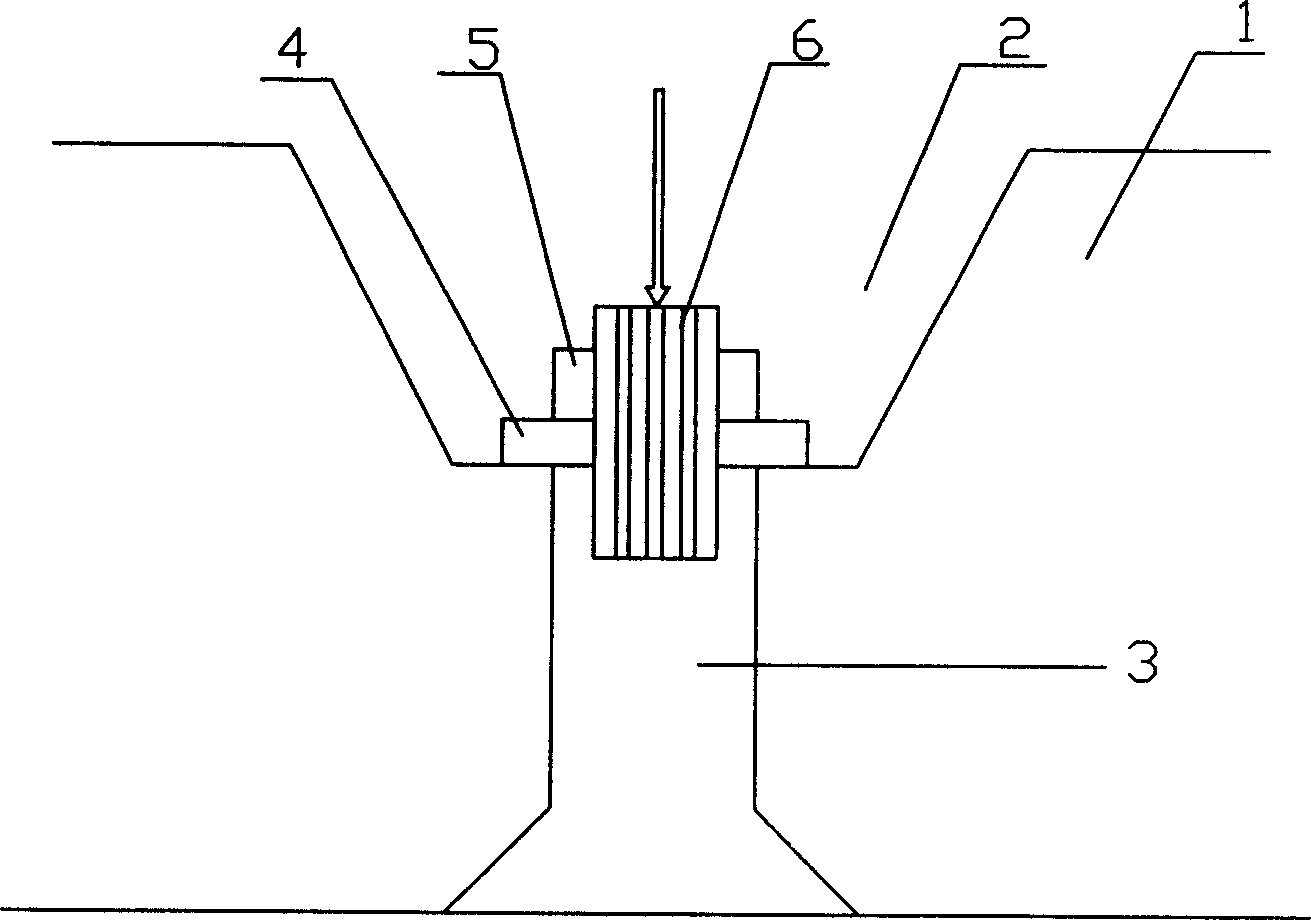

Component for fixing anchor bar/anchor cable head and method for slope stabilization

InactiveCN1621627AMeet management requirementsMeet monitoring requirementsExcavationsBulkheads/pilesEngineeringRock bolt

The present invention discloses one kind of anchor bolt / cable head fixing member and the method of using the member in protecting slope, and aims at providing one kind of fixing member with high bearing capacity and less possibility of generating crack and capable of being re-stretched for slope protection. The anchor bolt / cable head fixing member includes rood beam, backing plate, anchor screw and anchor nut; and features that the rood beam has notched part in the bottom, the backing plate is embedded into the notched part, and the stepped anchor nut is inserted into the hole in the backing plate center. When it is used in slope fixing, the anchor bolt / cable is penetrated through the anchor screw before the anchor screw is screwed into the anchor nut for stretching and the anchor nut is turned to regulate tension.

Owner:李炳奇

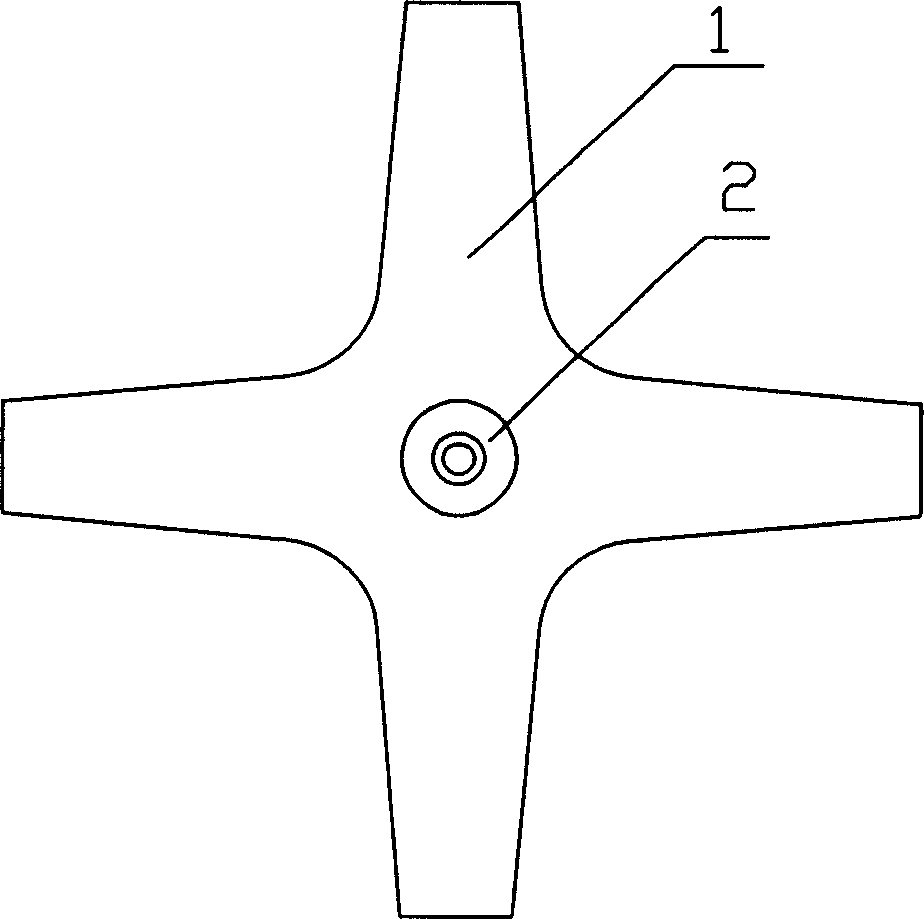

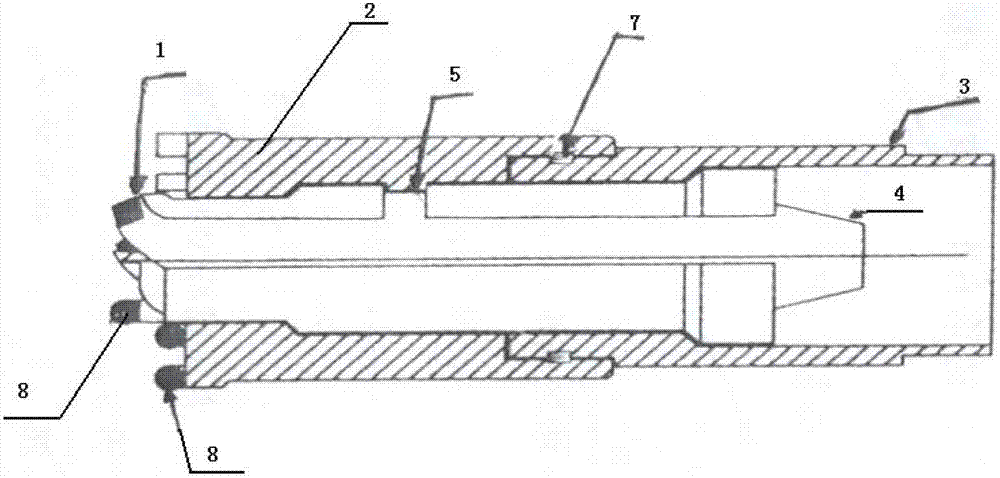

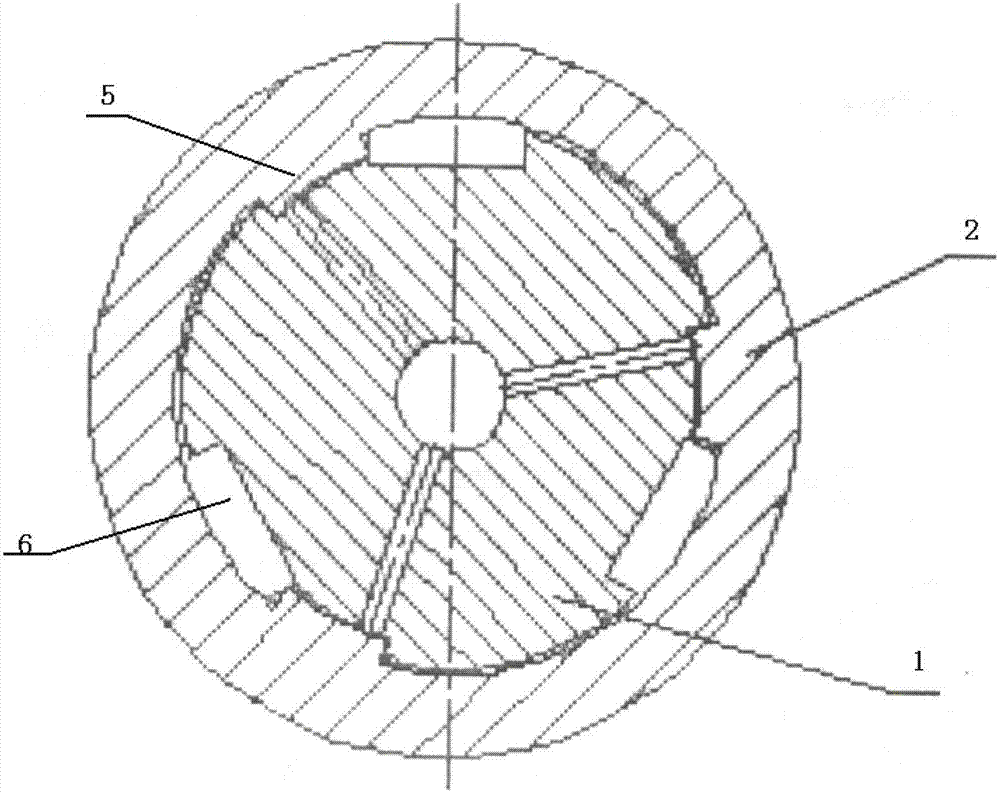

Diamond compact annular concentric simultaneous casing drilling bit and working method thereof

InactiveCN103114812AImprove drilling efficiencyImprove coaxialityDrill bitsDrilling rodsPetroleum engineeringRock breaking

The invention relates to a diamond compact annular concentric simultaneous casing drilling bit. The diamond compact annular concentric simultaneous casing drilling bit comprises a center drilling bit, a casing drilling bit and a casing shoe. The center drilling bit is connected with a drilling rod through a drilling rod connector, and the casing shoe is in threaded connection with a casing pipe. The casing drilling bit and the casing shoe are sleeved on the center drilling bit, and the drilling bit end surface of the casing drilling bit is flush with the drilling bit end of the center drilling bit in a stamping mode. The center drilling bit and the casing drilling bit are in a bonding structure, and the center drilling bit rotates around the axis in a unidirectional and limiting mode in the casing drilling bit. The casing drilling bit and the casing shoe are connected in a relative rotation mode around the axis through a sleeved installation method. According to the diamond compact annular concentric simultaneous casing drilling bit, the advantage of efficient rock breaking is fully used, in the process of efficient rock breaking and pushing of the center drilling bit, the casing drilling bit is also efficiently pushed, stratum pushing can be assisted, besides, the center drilling bit and the wall of a drill hole can be protected, coaxiality of the two-step drilling bits is good, guiding and righting supplement each other, bending of the drill hole can not be caused, efficiency of stratum hole drilling can be improved, and service life of the whole drilling tool can be prolonged.

Owner:SHANDONG TOPS DIAMOND BIT CO LTD

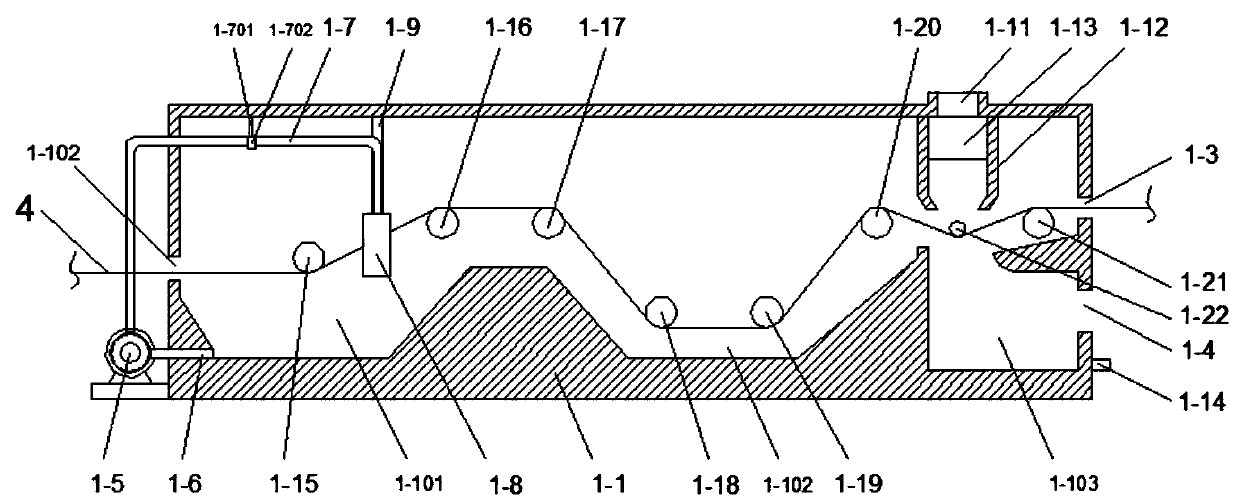

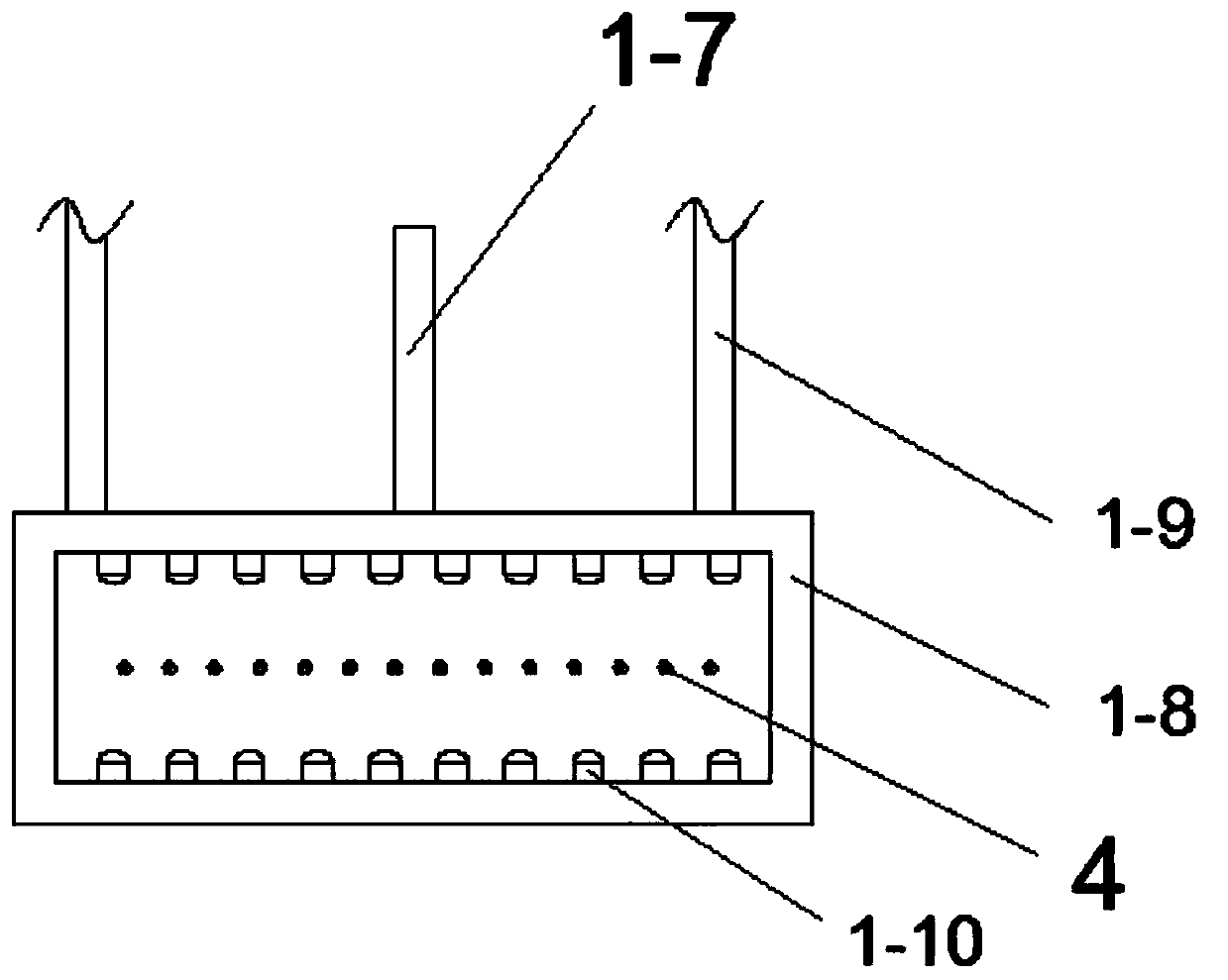

Special production tooling for high-strength carbon fiber

ActiveCN109972329AReasonable structural designFunctionalSucessive textile treatmentsTextile treatment machine arrangementsFiber bundleCarbon fibers

The invention provides a special production tooling for a high-strength carbon fiber. The special production tooling comprises sizing equipment, an opening and shaping device, a drying device and a carbon fiber bundle, wherein the sizing equipment comprises a sizing shell, a pre-spraying pump, a spraying pipe, a spraying pipe bracket, spray headers, an air inlet pipe, an air curtain machine, a waste liquid draining pipe, a first sizing roller, a second sizing roller, a third sizing roller, a first dipping roller, a second dipping roller, a fourth sizing roller, a fifth sizing roller and a positioning roller; the opening and shaping device comprises a workbench, a boss, guide roller brackets, guide rollers, a frame, paired roller brackets, upper paired rollers, hydraulic rods and lower paired rollers; the drying device comprises a drying shell, a partition plate, preheating section rollers, drying section rollers, heating pipes, a return air draught fan, a main air pipe, a preheating air pipe, a circulating air pipe, a fresh air pipe, a circulating draught fan and air valves. The special production tooling for the high-strength carbon fiber has the advantages that the carbon fiber bundle can be standardized, specialized and integrated, high-standard production requirements can be met, and the phenomenon that the carbon fiber bundle is disordered and broken is avoided systematically, and the system stability is strong.

Owner:北京百年初心科技有限公司

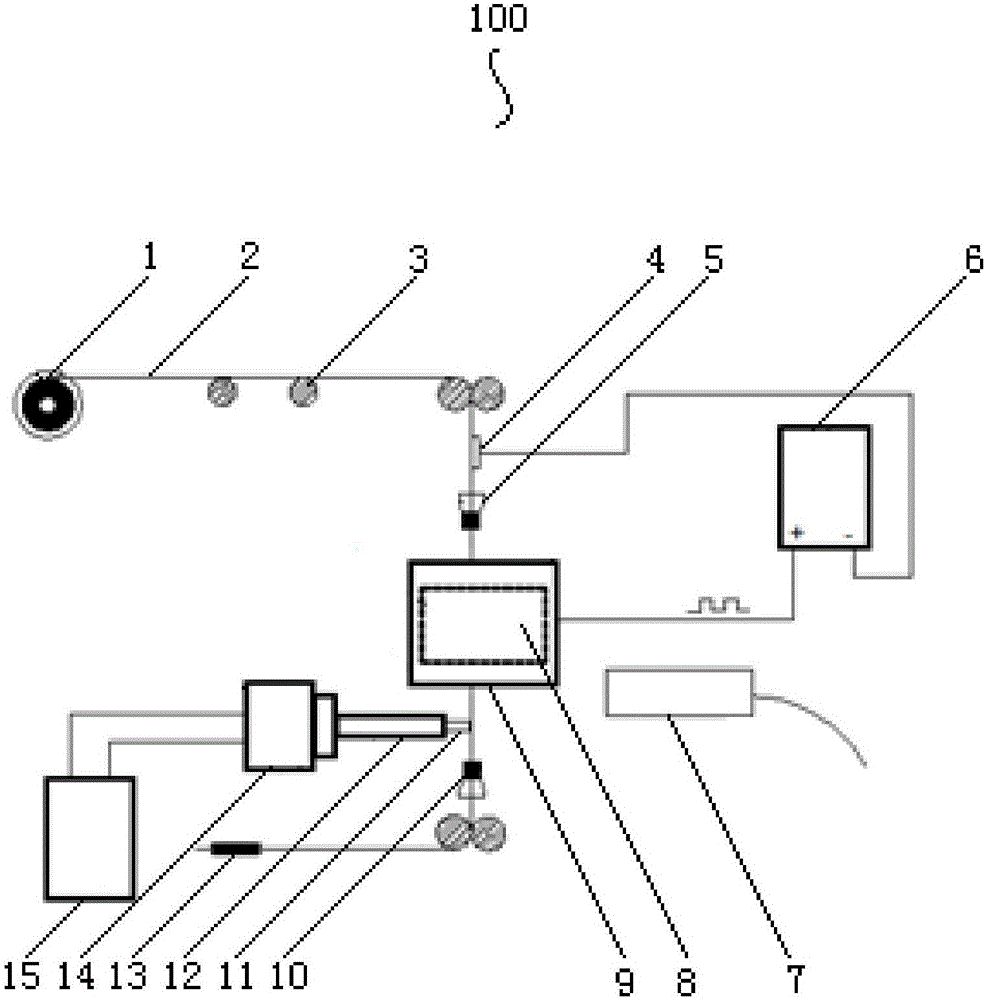

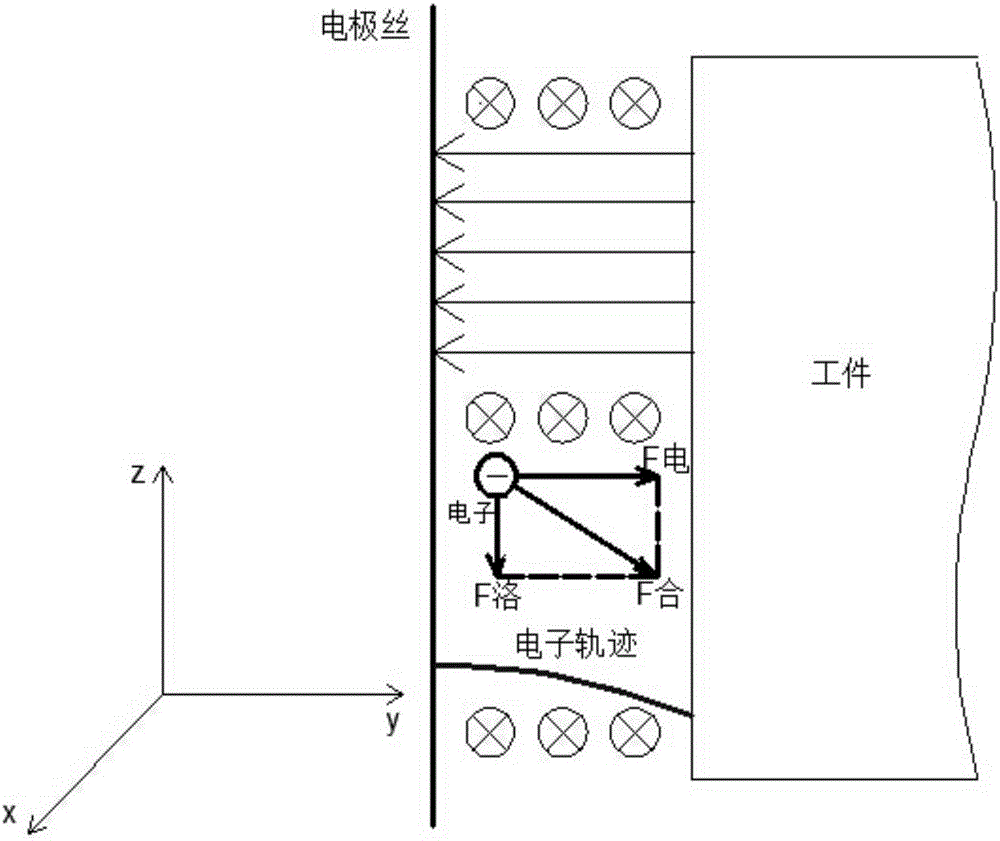

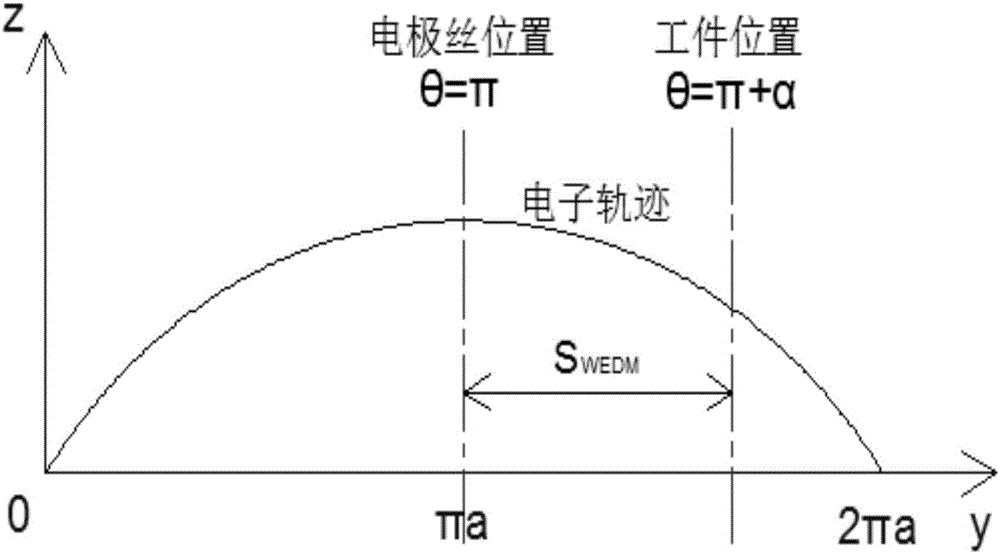

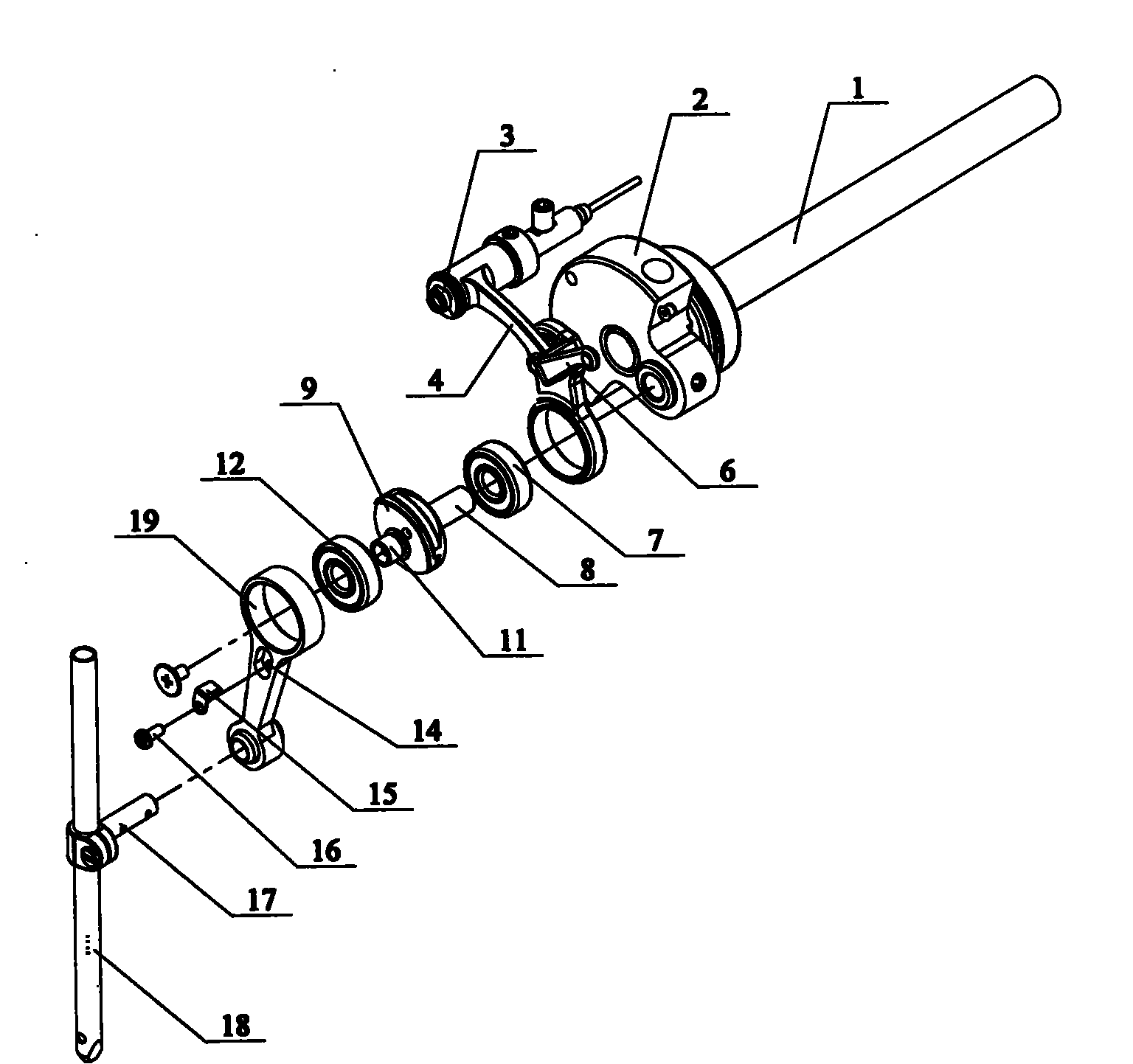

An ultrasound and magnetic field-assisted wire cut electrical discharge machining method and device

InactiveCN106607628AReal-time grasp of processing stabilityIncrease radiusPulse power supplyElectron

The invention provides an ultrasound and magnetic field-assisted wire cut electrical discharge machining method. A magnetic field is utilized to make electrons in a discharge channel generated between an electrode wire and a workpiece perform curvilinear motion, so that the radius of the discharge channel is increased and the smoothness of the surface of the machined workpiece is improved; ultrasound waves are adopted to make corrosion removing particles generated by wire cut electrical discharge machining perform horizontal reciprocating vibration and be discharged by the action of ultrasound vibration, so that the machining speed is increased. The invention also provides an ultrasound and magnetic field-assisted wire cut electrical discharge machining device comprising a workbench, an electrode wire device, a pulse power source, an ultrasound generator and a magnetic field device, wherein the electrode wire device has a wire storage drum, a plurality of guide rollers and a guide device; the negative electrode of the pulse power source is connected to the electrode wire via a conductive block and the positive electrode is connected to a workpiece; the ultrasound generator comprises an ultrasound generating unit, an ultrasound transducer, an amplitude-change pole and a tool rod; the magnetic field device comprises two permanent magnets installed on the two sides of the workpiece symmetrically and used for providing a magnetic field.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Method for machining stainless steel singe dual-lug support plate nut

The invention relates to a method for machining a stainless steel singe dual-lug support plate nut. The method includes the steps of the step A, machining a cold heading mould, the step B, trimming, the step C, tapping and the step D, shell nosing, wherein the step A includes the step A1 of primary heading and the step A2 of final heading. The method is advanced, easy to adopt, and capable of ensuring malleability and flowability of materials; the percent of pass of riveting of machined parts can reach 100%, and the parts can meet assembling requirements.

Owner:JIANGXI HONGDU AVIATION IND GRP

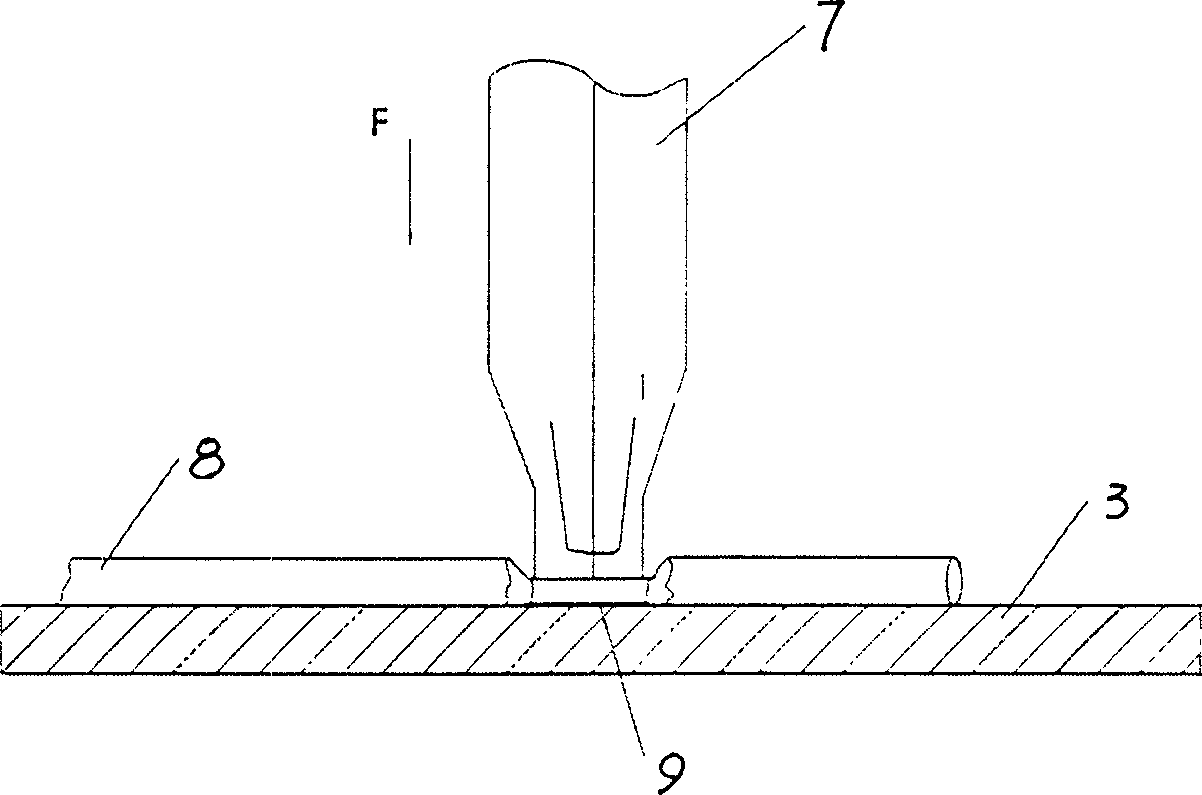

Method for improving fine enamelled wire spot welding strengh in spot welding

InactiveCN1589093AInhibit sheddingPrevent wire breakagePrinted circuit assemblingPrinted circuit aspectsWire rodStress point

Owner:MORNSUN GUANGZHOU SCI & TECH

Ultrafiltration membrane bundle and processing method thereof

InactiveCN103252168AReduce impactPrevent wire breakageUltrafiltrationUltrafiltrationMembrane configuration

The invention relates to an ultrafiltration membrane bundle and a processing method thereof. A hollow ultrafiltration membrane bundle comprises hollow ultrafiltration membranes, wherein one end of each hollow ultrafiltration membrane, as well as the hollow ultrafiltration membranes are fixedly connected; the hollow part of the other end of each hollow ultrafiltration membrane is in a tail end closed form; and the hollow ultrafiltration membranes are mutually dispersed. The processing method comprises the following steps of: cutting one end of each hollow ultrafiltration membrane tidily and encapsulating the ends by using glue or devices; and cutting the other end of each hollow ultrafiltration membrane tidily, soaking the other ends into glue, and cutting tidily along the glue climbing position of the outer wall after the glue is solidified, wherein the hollow ultrafiltration membranes are dispersed naturally and a hollow hole of each hollow ultrafiltration membrane is plugged completely by the glue. The ultrafiltration membrane bundle and the processing method thereof have the advantages of convenience for cleaning, long life, stable operation, simple method, convenience for operation, high production efficiency and suitability for large-scale industrialized production.

Owner:HANGZHOU CREFLUX MEMBRANE TECH

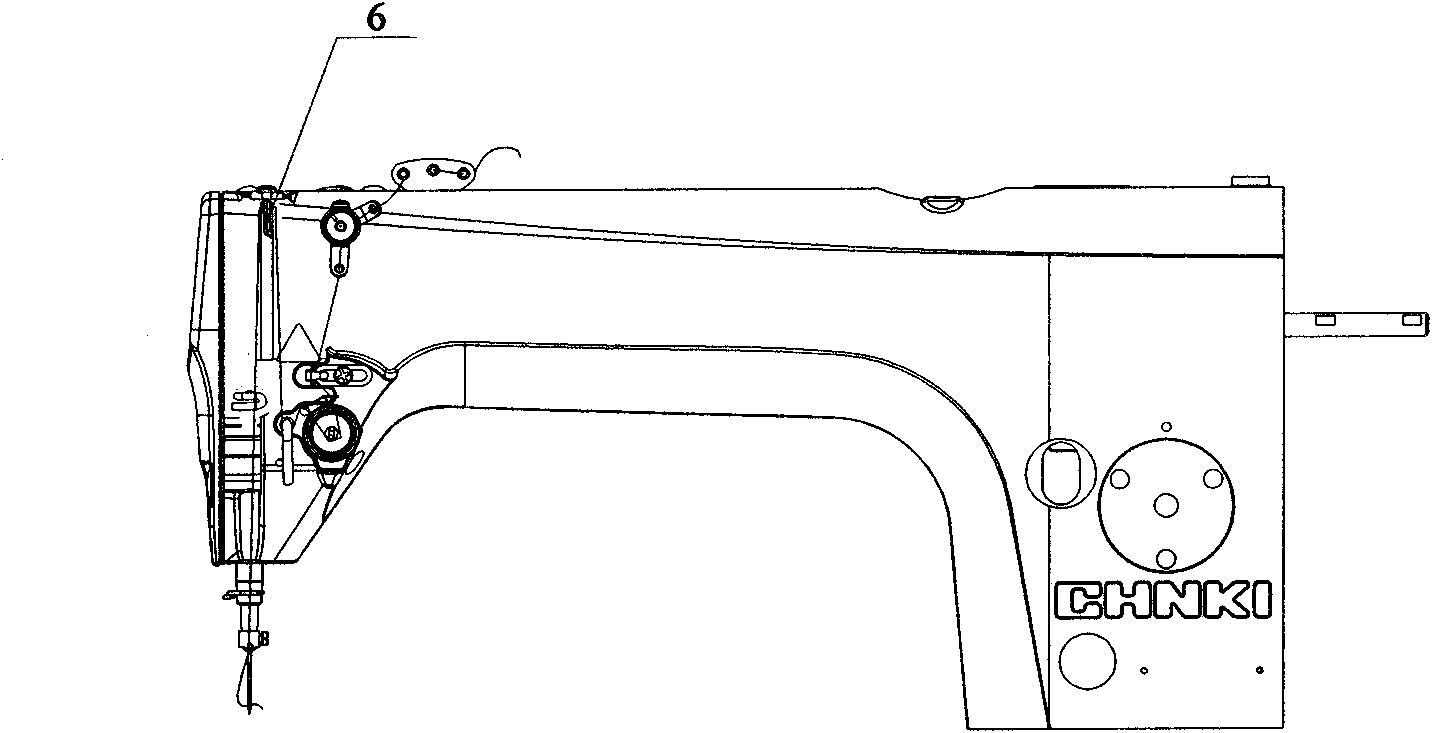

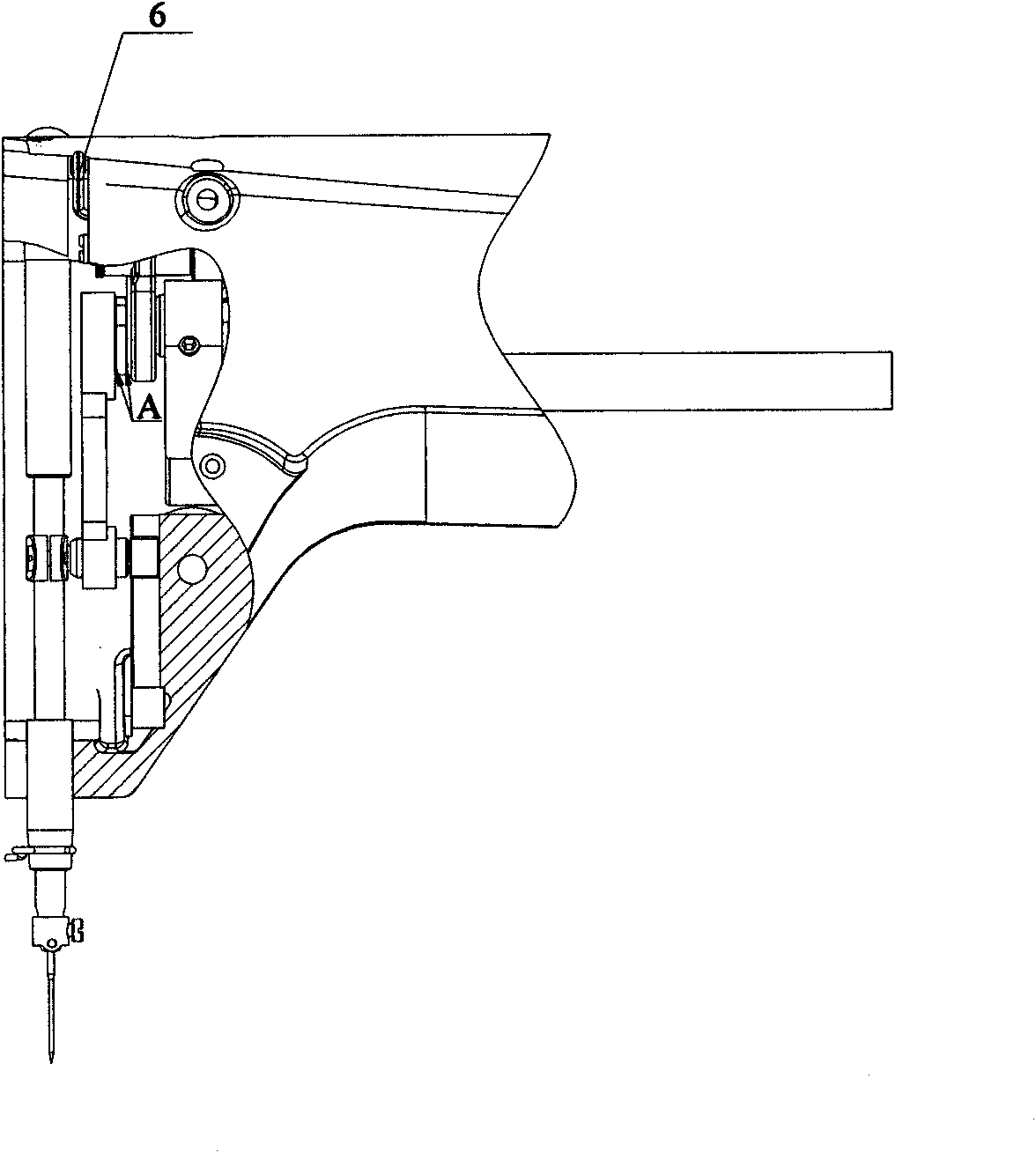

Anti-coiling mechanism of sewing machine

ActiveCN102182018AAvoid entanglementPrevent wire breakageNeedle severing devicesTake-up devicesEngineeringSewing machine

The invention discloses an anti-coiling mechanism of a sewing machine. The mechanism comprises a needle rod connecting rod and a thread take-up lever which are arranged on a left rotation shaft and a right rotation shaft at the left end and the right end of a crank, wherein the crank comprises a round disc, a left rotation shaft and a right rotation shaft; the left rotation shaft and the right rotation shaft are eccentrically arranged on the round disc; the needle rod connecting rod and the thread take-up lever are sleeved on the left rotation shaft and the right rotation shaft through a bearing respectively; a sheath extending rightwards is arranged along the outer peripheral face of the right end face of the round disc; an arc convex block extending leftwards is arranged along the outerperipheral face of the left end face of the round disc; an arc through groove is formed along the peripheral direction of the disc on the convex block; and a rightwards convex blade is arranged on the needle rod connecting rod. When the crank rotates one circle, the blade passes through the arc through groove. When broken threads are wound on the outer peripheral face of the crank, along with therotation of the crank, the blade passes through the arc through groove on the crank and cuts off the broken threads wound on the outer peripheral face of the crank, so that the phenomenon that the broken threads are wound in a clearance between the left end face of the round disc and the right end face of the needle rod connecting rod is avoided.

Owner:四川精上缝纫机有限公司

Method for producing flat filament by using PET (Polyethylene Terephthalate)

ActiveCN103726126AImprove melt strengthImprove toughnessMonocomponent polyesters artificial filamentArtifical filament manufactureWater bathsPolyethylene terephthalate

The invention discloses a method for producing a flat filament by using PET (Polyethylene Terephthalate). The method is characterized by comprising the following steps: (1) drying PET particles, then, hot melting and blending the dried PET particles with a toughening agent, an anti-hydrolysing agent, an antioxidant and a nucleating agent in a screw extruder, extruding and forming a primary flat filament; and (2) carrying out water bath cooling, drafting for the first time, carrying out primary water bath, drafting for the second time, carrying out secondary water bath, drafting for the third time, carrying out drawing and heat shaping, cooling, and finally, rolling to obtain the PET flat filament. Compared with the prior art, the method has the advantages that a proper draw ratio is adopted in a PET melt extrusion process to ensure that the PET sufficiently reacts with auxiliaries, so that the melt strength and toughness of PET are improved, and the drafting performance of the flat filament is improved; and proper temperature, drawing speed and multiplying power as well as multiple heating and drafting are adopted, so that the PET drafting orientation is benefited, the proper PET crystallinity is controlled, the filament breakage is avoided, and the tensile strength of the produced PET flat filament is up to over 50MPa.

Owner:ZHEJIANG WANKAI NEW MATERIAL

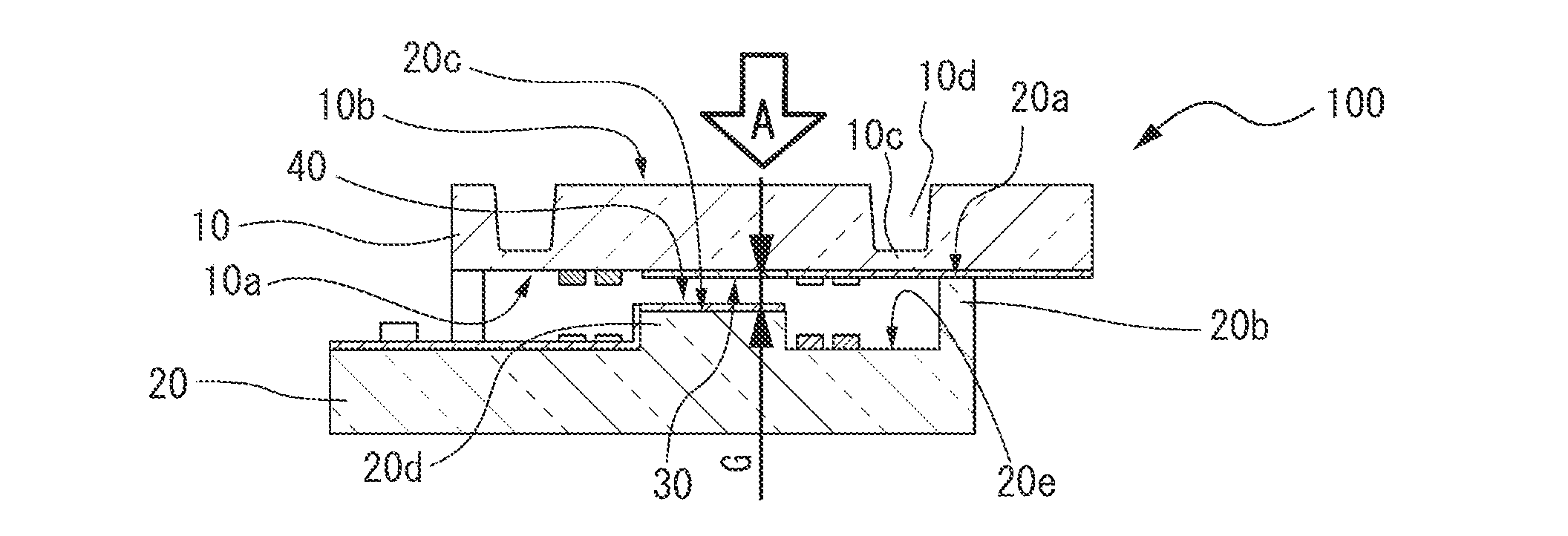

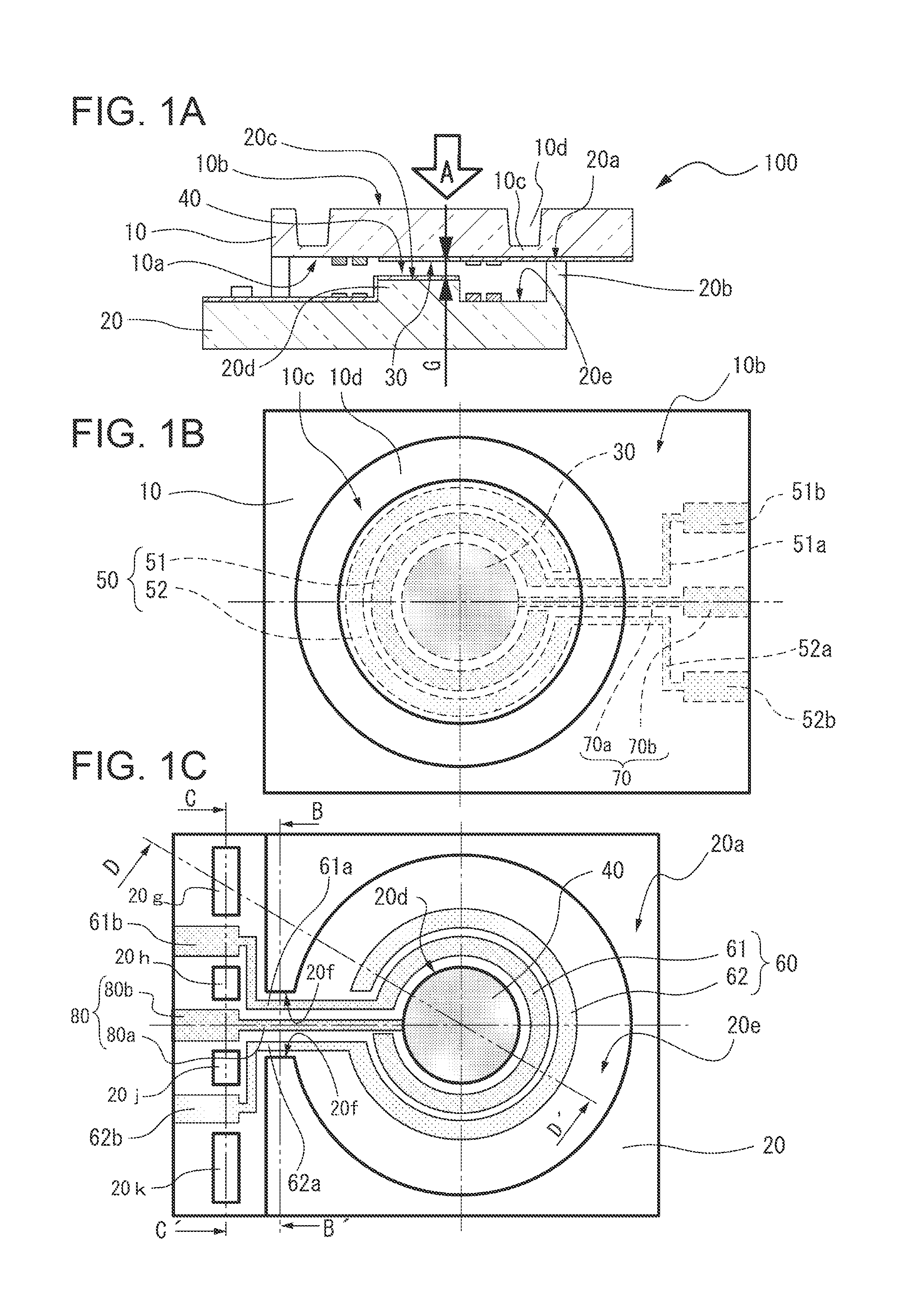

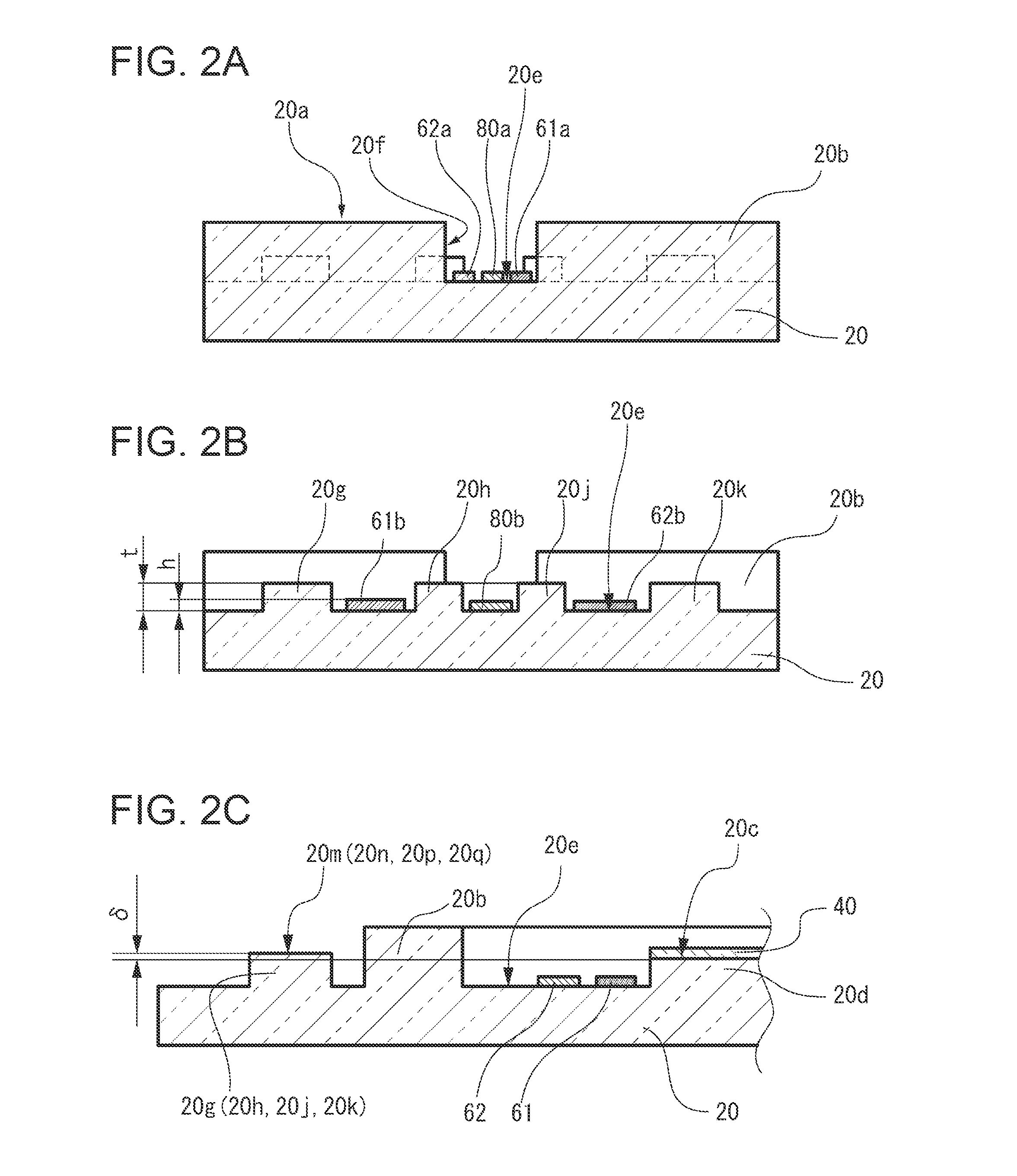

Wavelength tunable interference filter, method of manufacturing wavelength tunable interference filter, optical apparatus, and optical component

ActiveUS20140092478A1Avoid damagePrevent wire breakageOptical articlesOptical elementsOptical instrumentLight filter

A wavelength tunable interference filter, an optical apparatus, and an optical component include a first substrate, which includes a first optical film and a first driving electrode, and a second substrate, which includes a support portion that supports the first substrate, a second optical film, and a second driving electrode. The second substrate includes an external connection electrode extending to an outer side of the support portion, and includes an electrode forming surface on which the external connection electrode is disposed. A plurality of protruding portions protruding from the electrode forming surface are formed so as to be arrayed in a direction crossing the extending direction of the external connection electrode.

Owner:SEIKO EPSON CORP

Flux-cored silver filler metal with good liquidity

InactiveCN109202331AGood moisture absorptionImprove liquidityWelding/cutting media/materialsSoldering mediaTetrafluoroborateMetasilicate

The present invention provides a flux-cored silver filler metal with good liquidity, belonging to the technical field of braze welding materials. The flux-cored silver filler metal comprises brazing flux powder and a sliver brazing filler metal strap coated with the brazing flux powder, the sliver brazing filler metal strap is Bag30CuZnSn, the mass ratio of each component in the brazing flux powder comprises: 30-35% of K3BF6, 2-5% of potassium fluoride, 20-25% of boric acid, 30-32% of boric oxide, 2-6% of sodium carbonate, 0.5-1.5% of potassium metasilicate, and the balance being KBF4. The ratio of the sodium carbonate and the sodium carbonate is 4:1, and the mass of the brazing flux powder is 15-30% of the total mass. In the invention, the brazing flux powder reduces the fluoride and adds the sodium carbonate, the sodium carbonate, the potassium tetrafluoroborate and the KBF4 so as to improve the moisture absorption of the brazing flux powder, improve the liquidity of the brazing flux powder, have an effect on lubrication of the brazing flux powder in the flux-cored silver filler metal drawing process and achieve the smooth diameter reduction of the flux-cored silver filler metal.

Owner:JIANGSU UNIV OF SCI & TECH +1

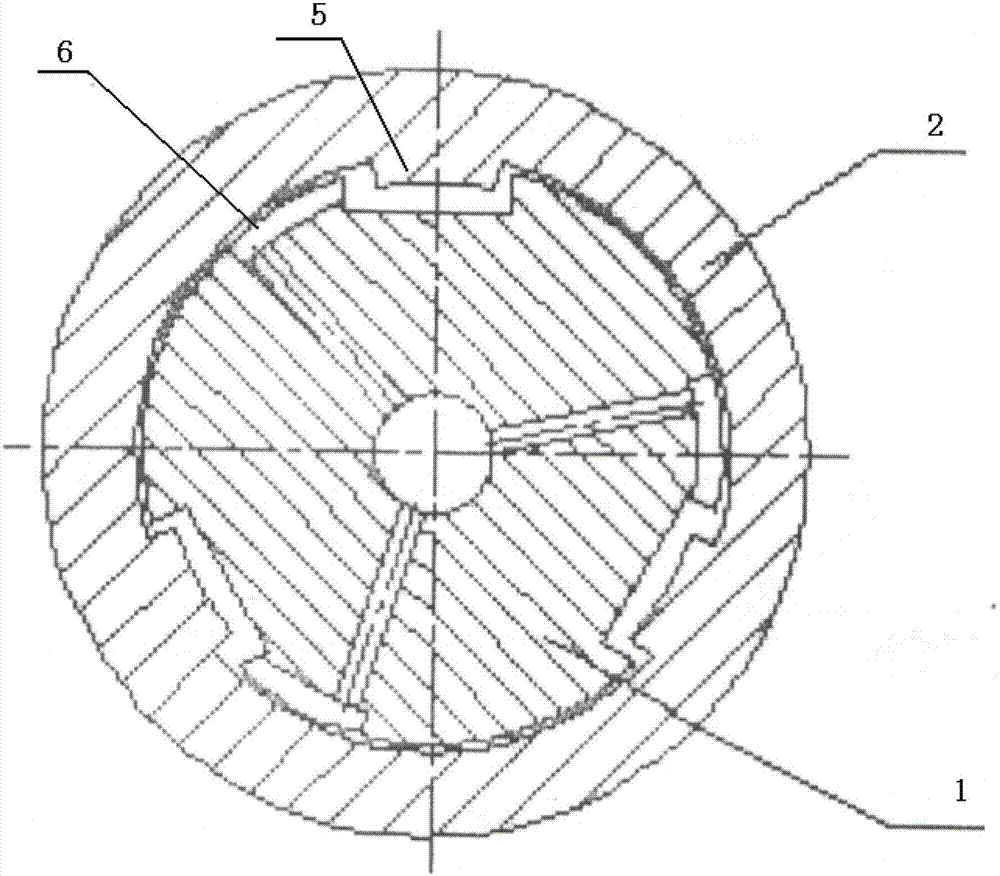

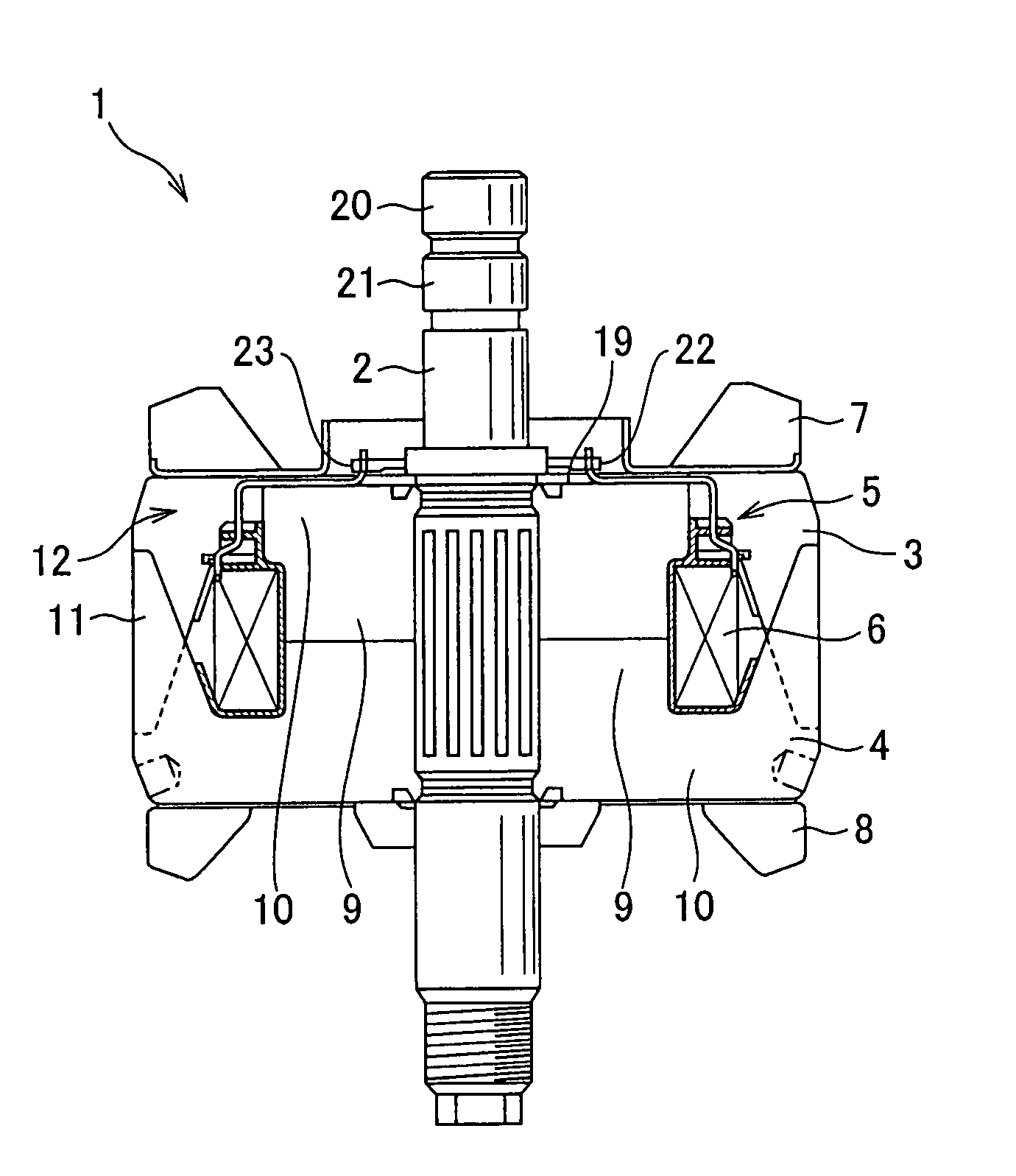

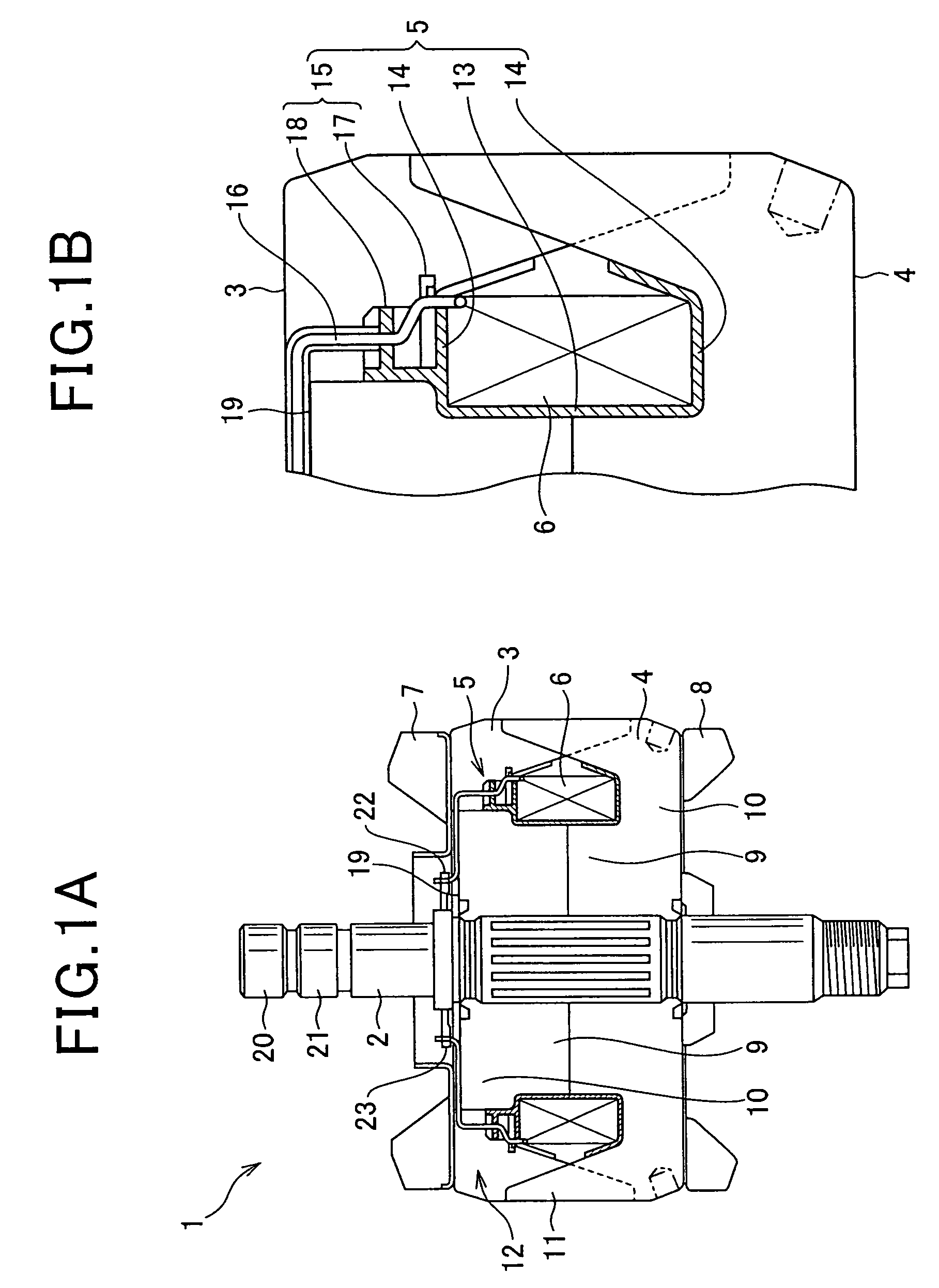

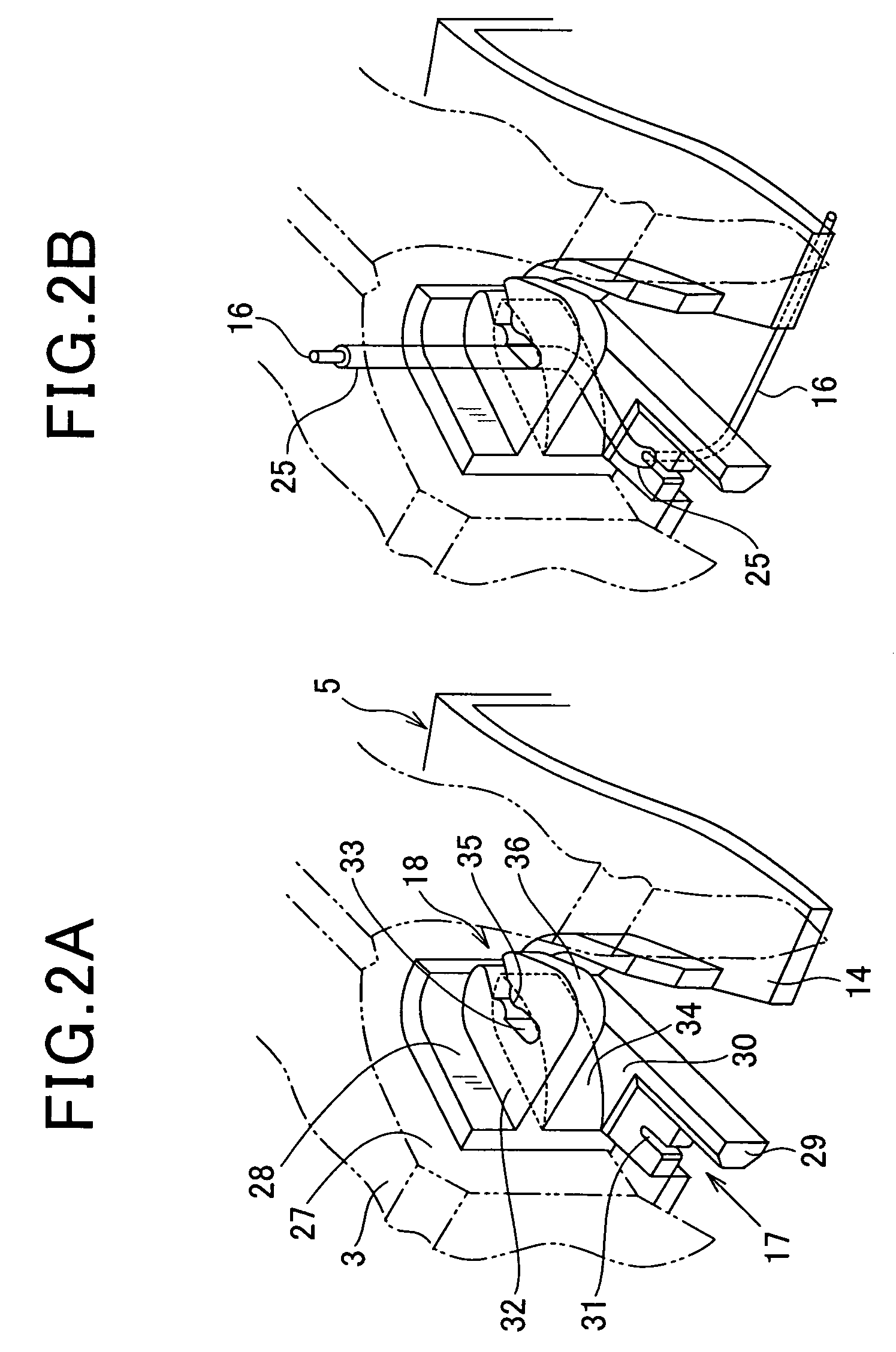

Rotor for rotating electrical machine and method of manufacturing same

ActiveUS7956507B2Easily and reliably hooked (or held)Prevent wire breakageSynchronous generatorsWindingsBobbinField coil

In a rotor for a rotating electrical machine, a flange of an insulating bobbin is formed with a first hook portion and a second hook portion. The first hook portion directs a lead of a field coil both against the winding direction of the field coil and radially inward. The first hook portion has a first groove in which is hooked a proximal portion of the lead. The second hook portion directs the lead axially outward. The second hook portion has a second groove which has an open end on a radially inner periphery of the second hook portion, a closed end positioned radially outward of the open end, and a neck between the open and closed ends. The second hook portion has an intermediate portion of the lead hooked in the second groove between the neck and closed end of the second groove.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com