Patents

Literature

250results about "Take-up devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

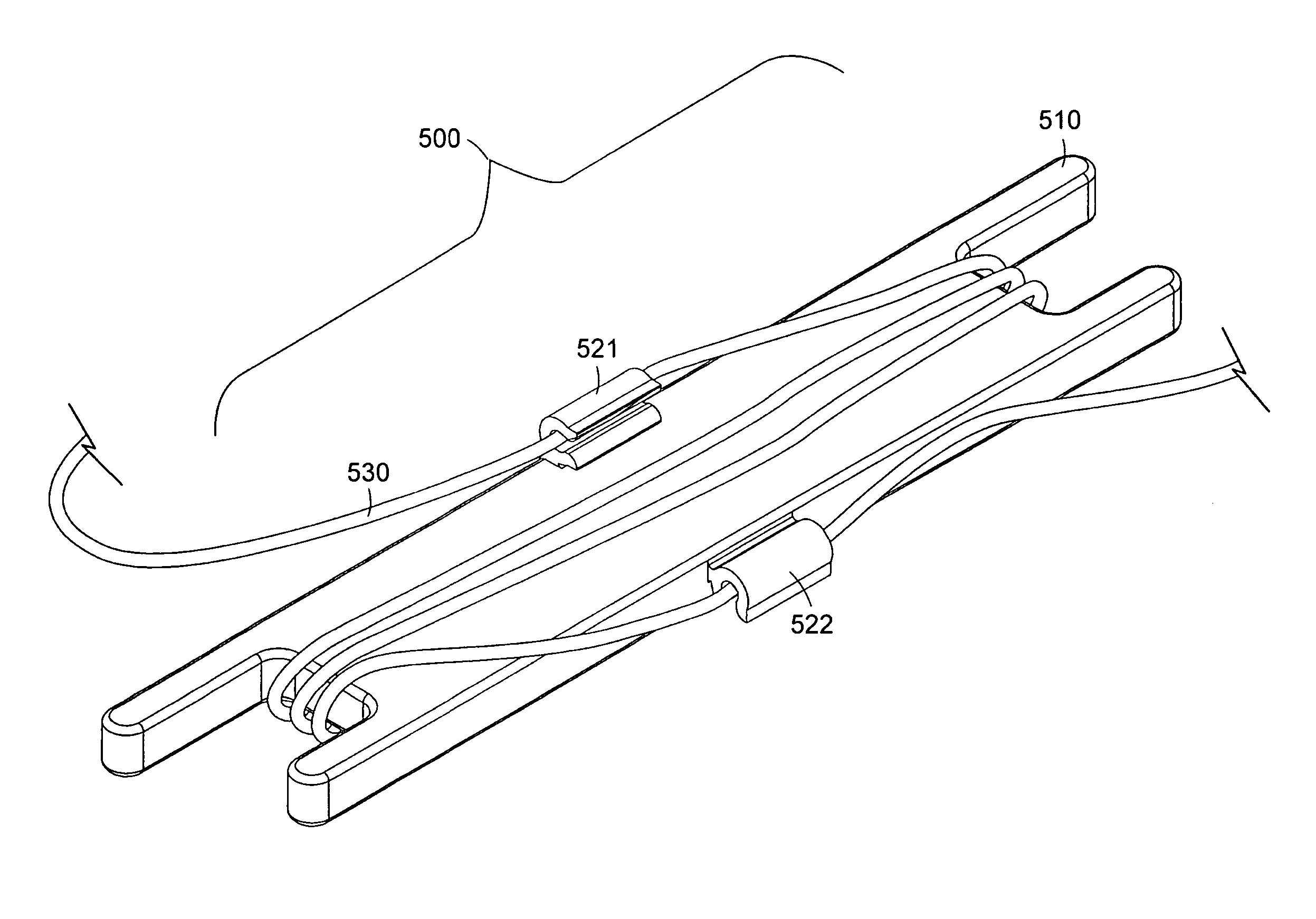

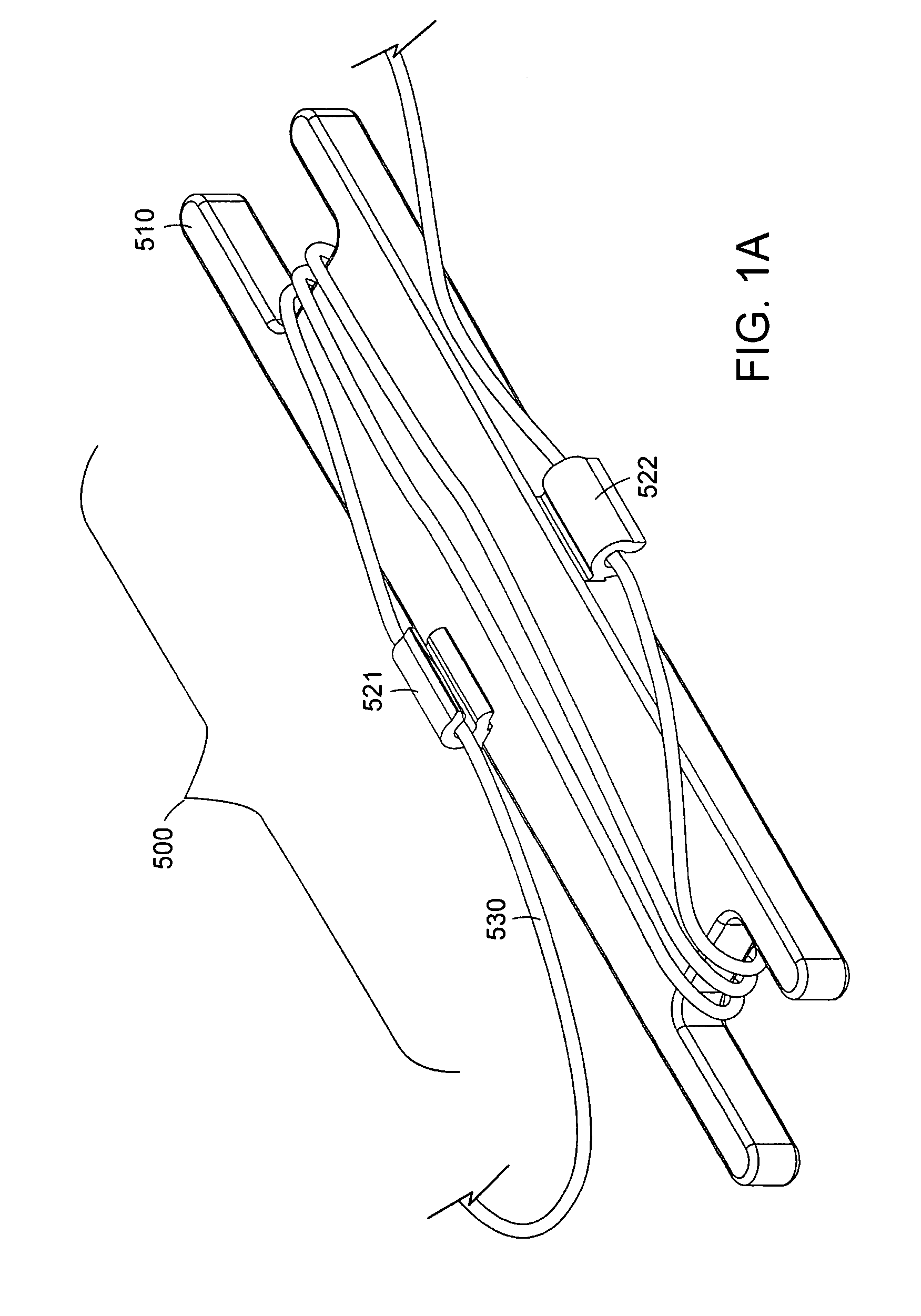

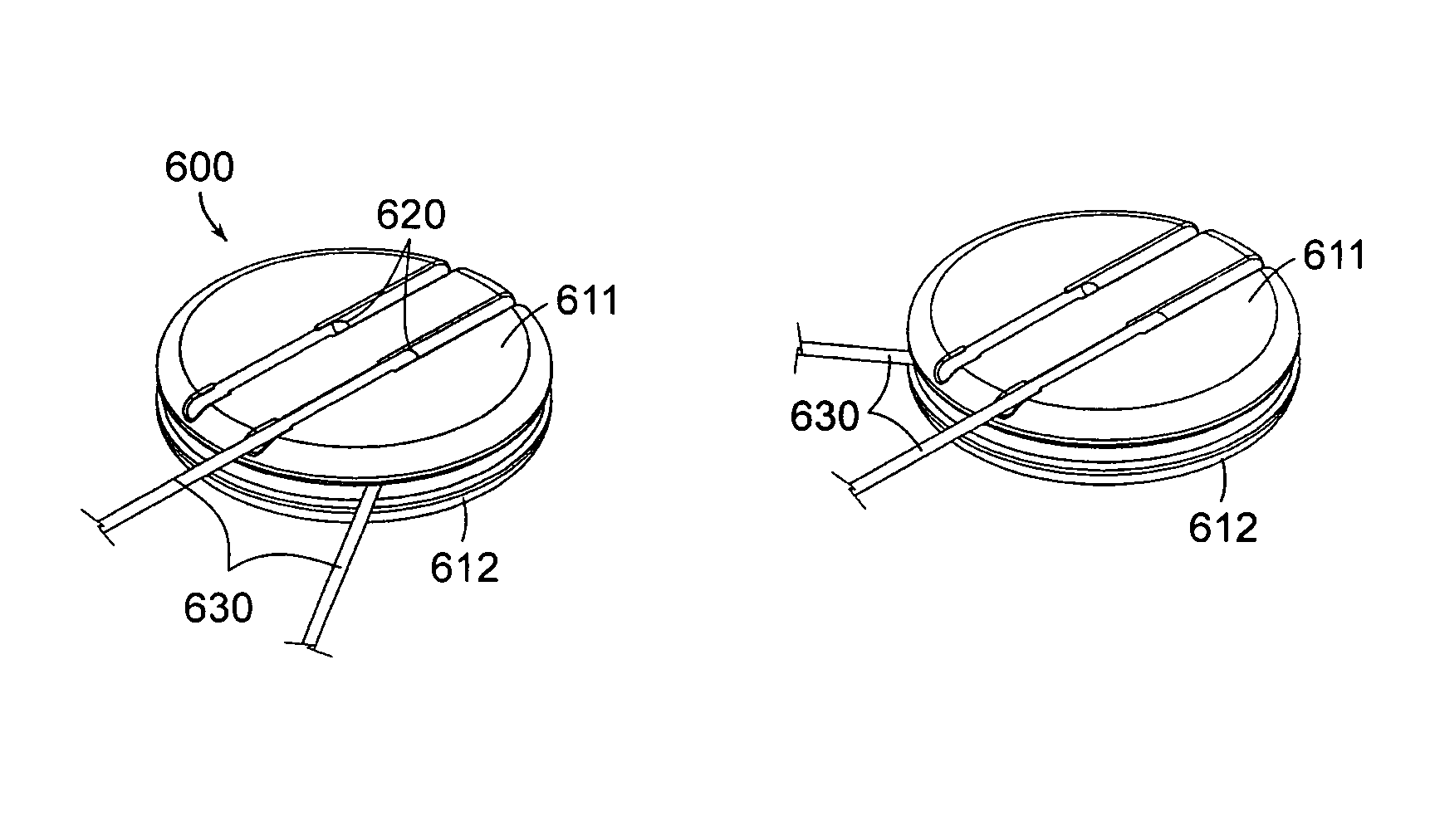

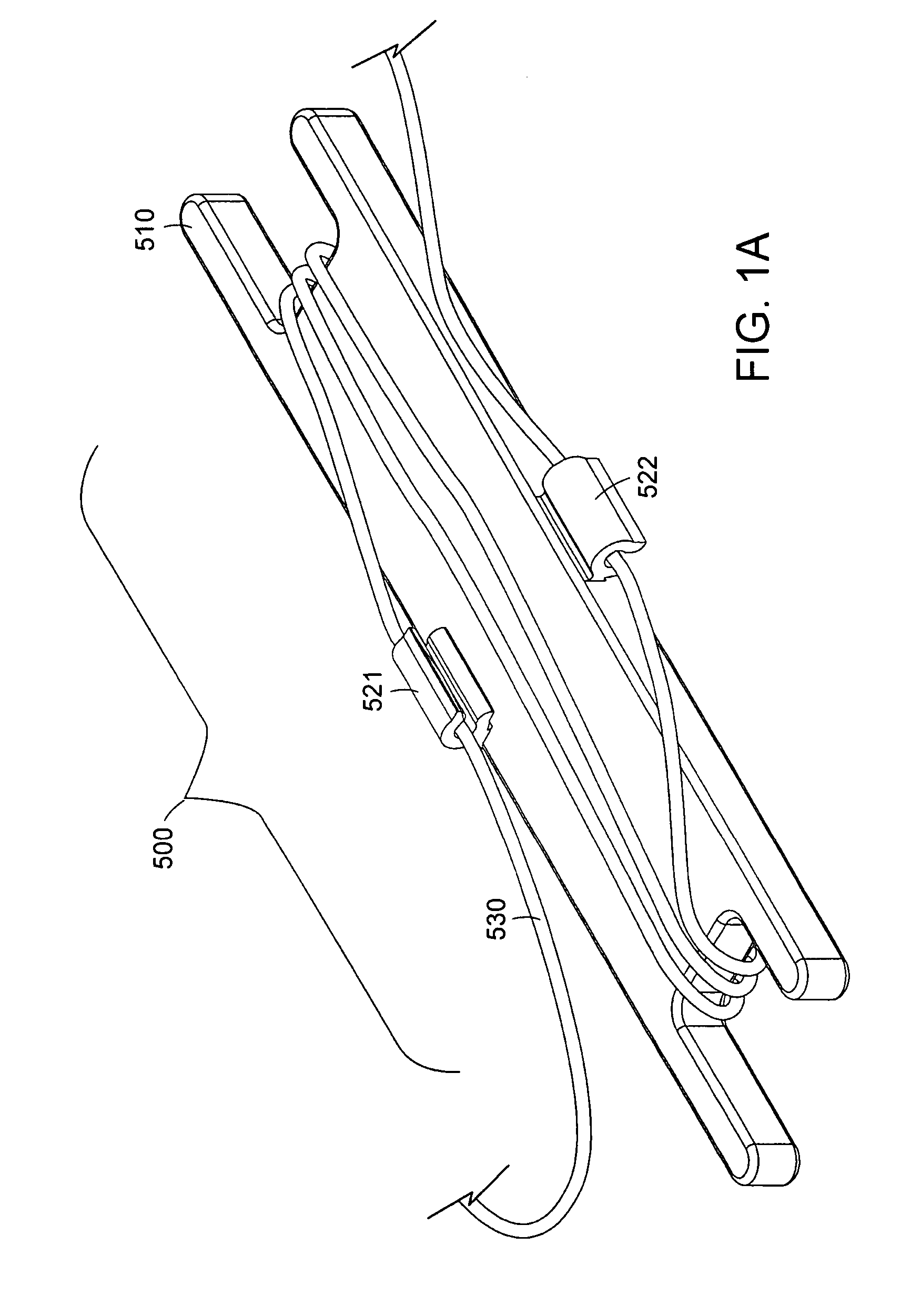

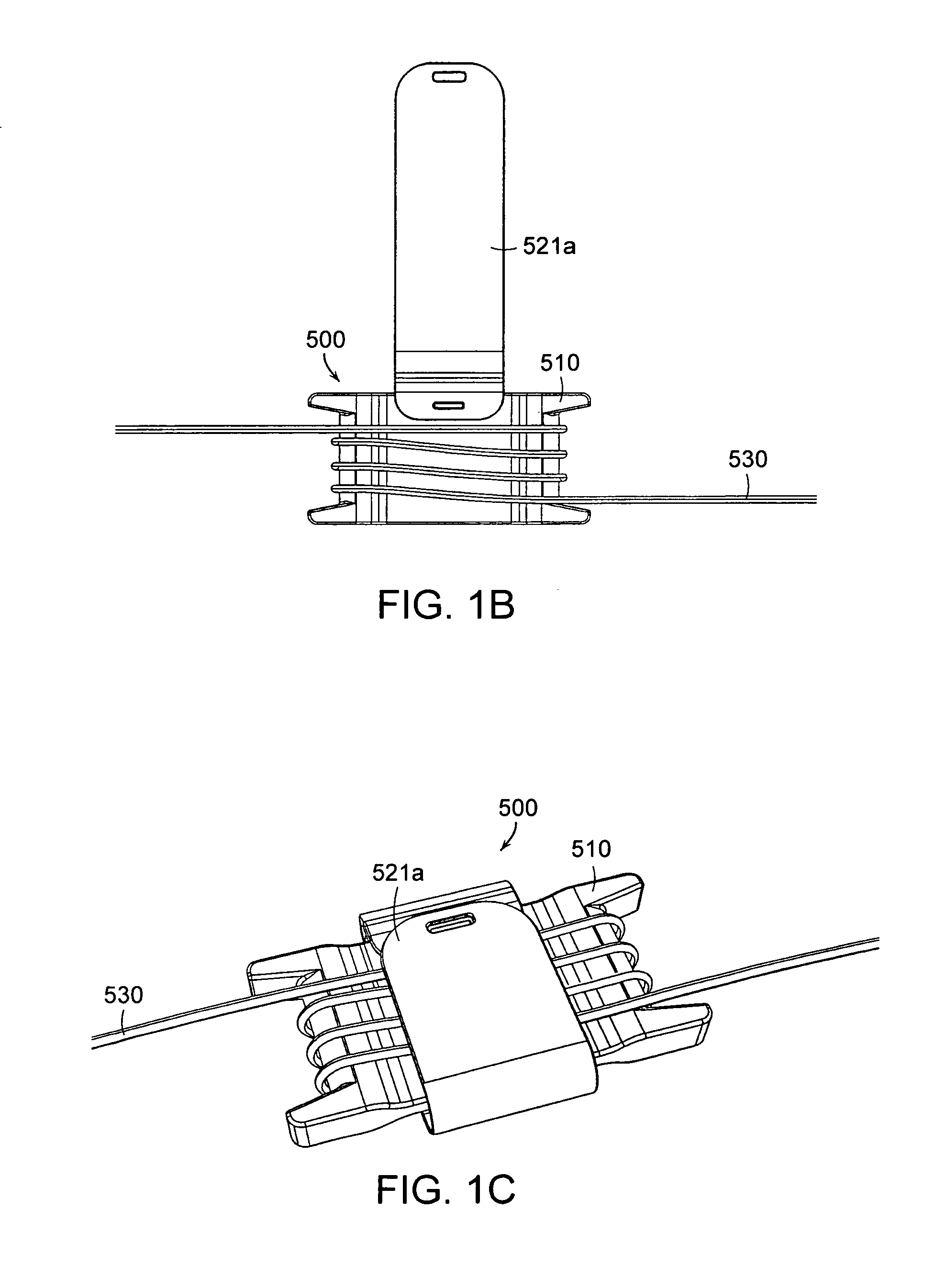

Infusion set improvements

A method and device for adjusting the unstored length of tubing directed to improving the use of infusion sets that deliver fluids to a user. The device includes a storage module and other features for adjusting, storing and securing the length of the tubing. The method of adjusting the length of the tubing to a desired length typically comprises removably attaching the tubing to the adjuster, adjusting the tubing by wrapping the tubing around a hub or post of the adjuster, and fixing the length of the unstored tubing by attaching the tubing to a securing device such as a friction structure or fastener

Owner:DEKA PROD LLP

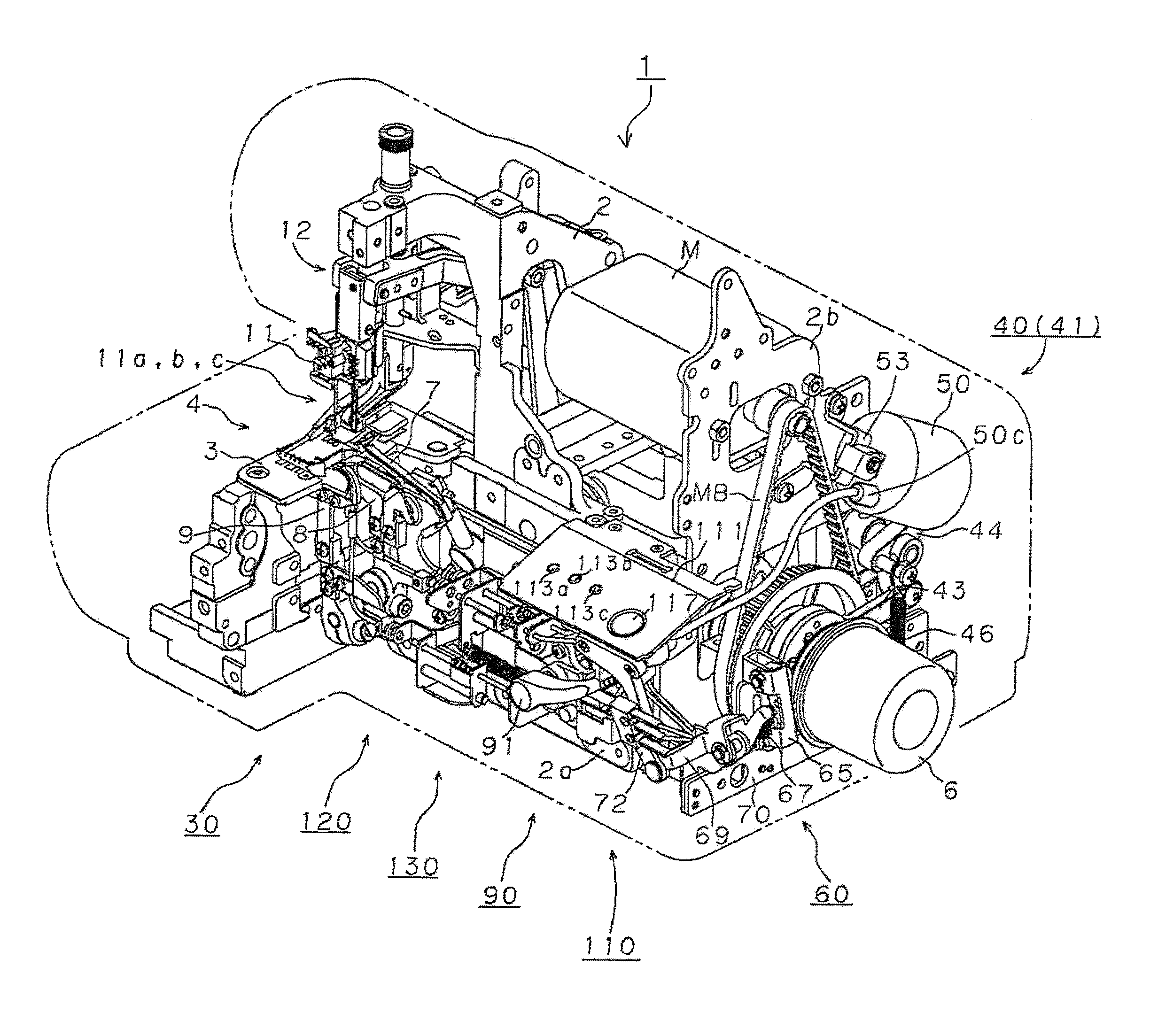

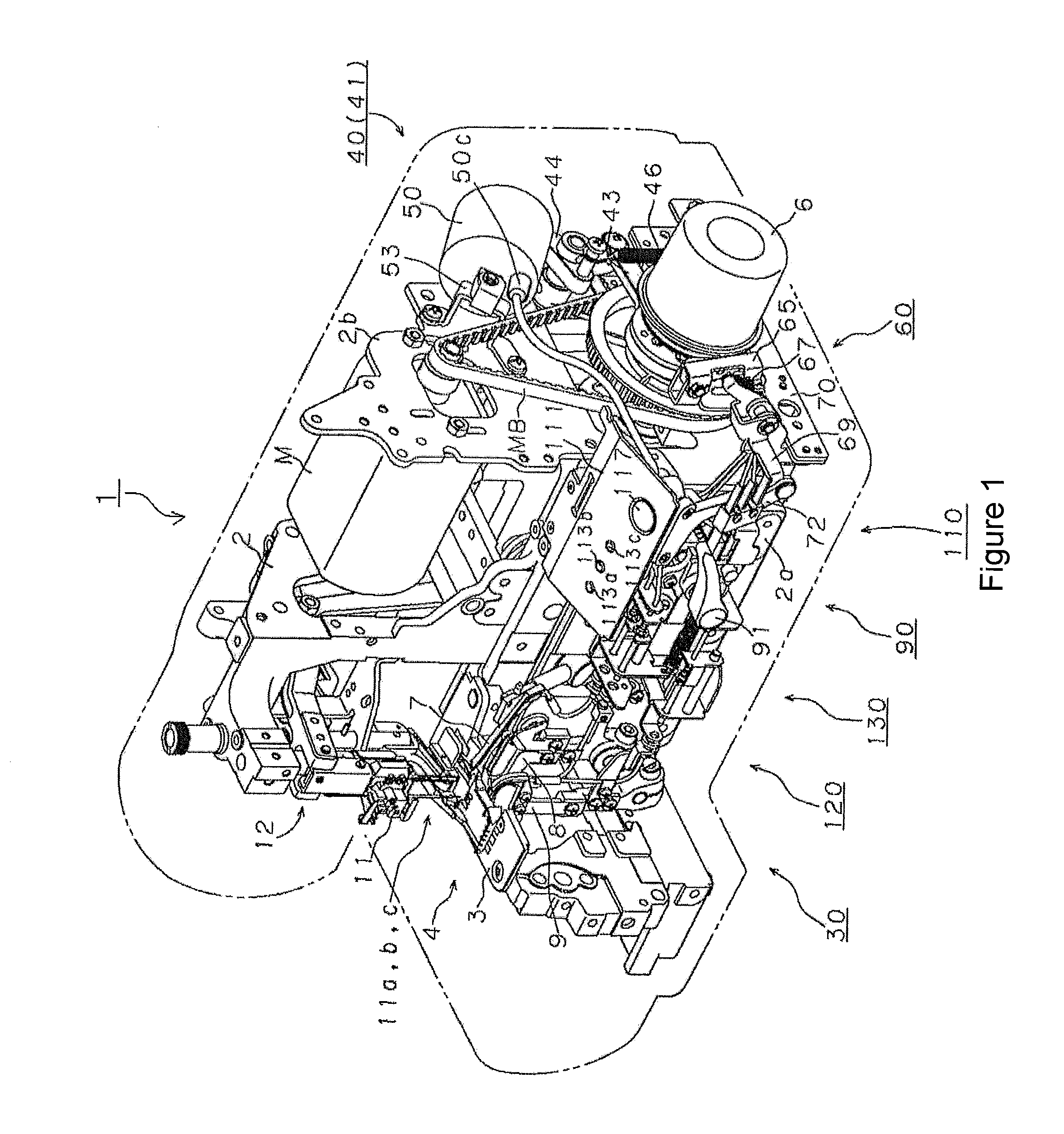

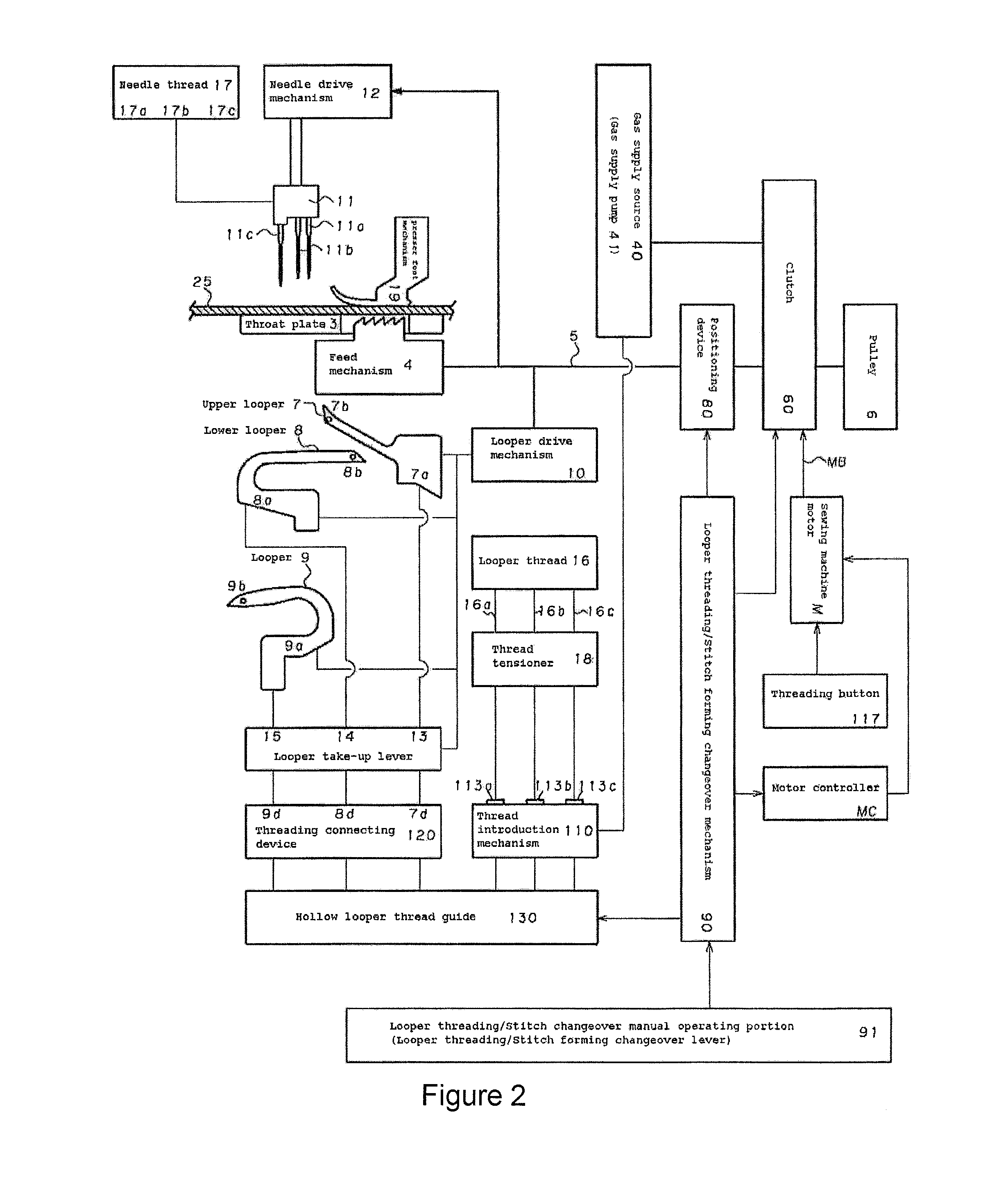

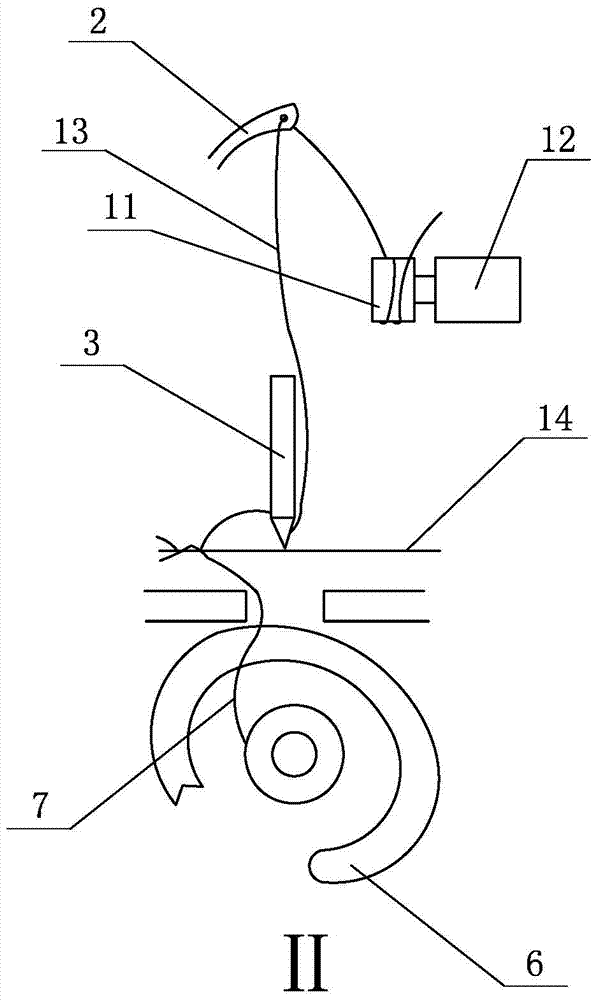

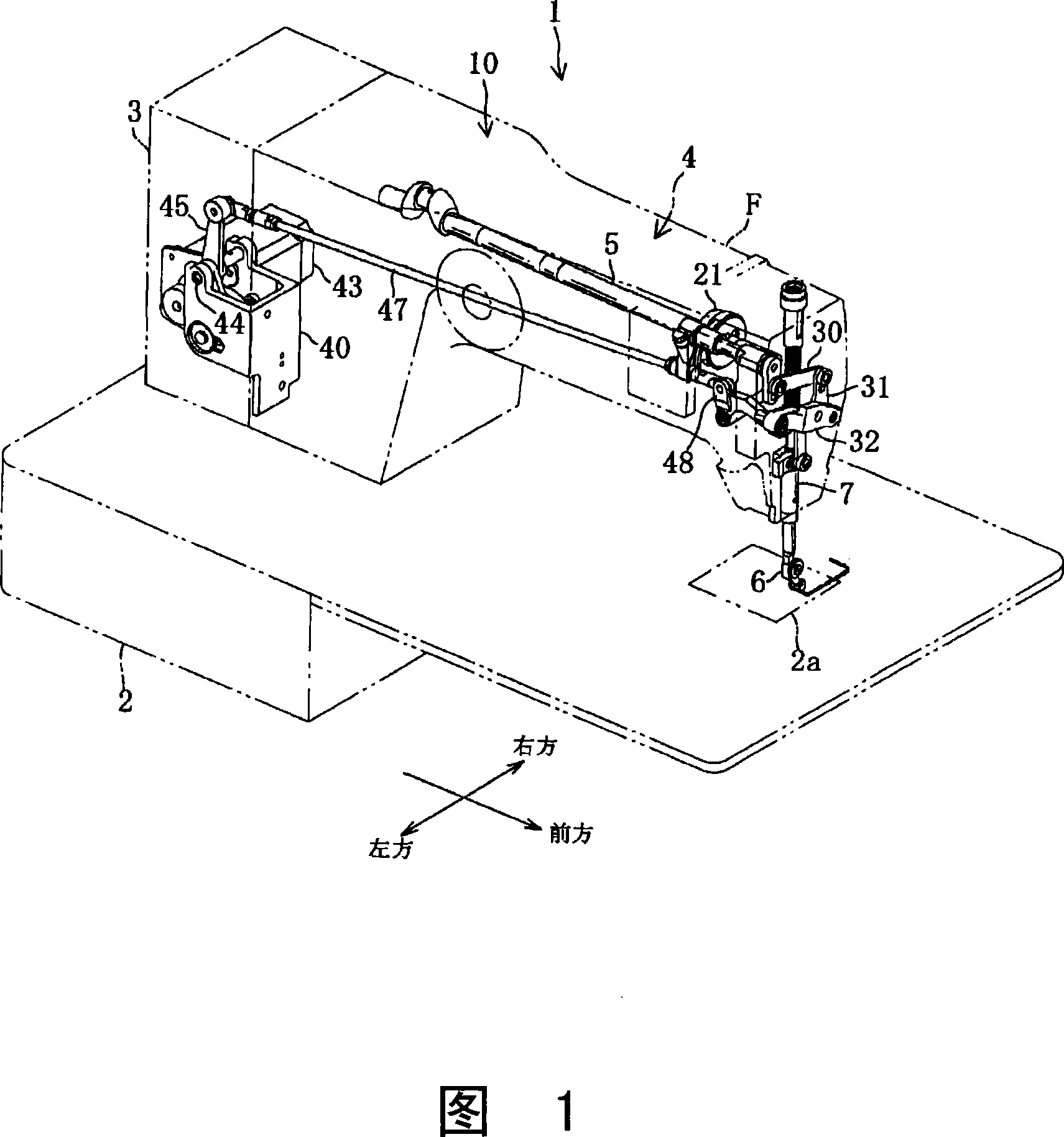

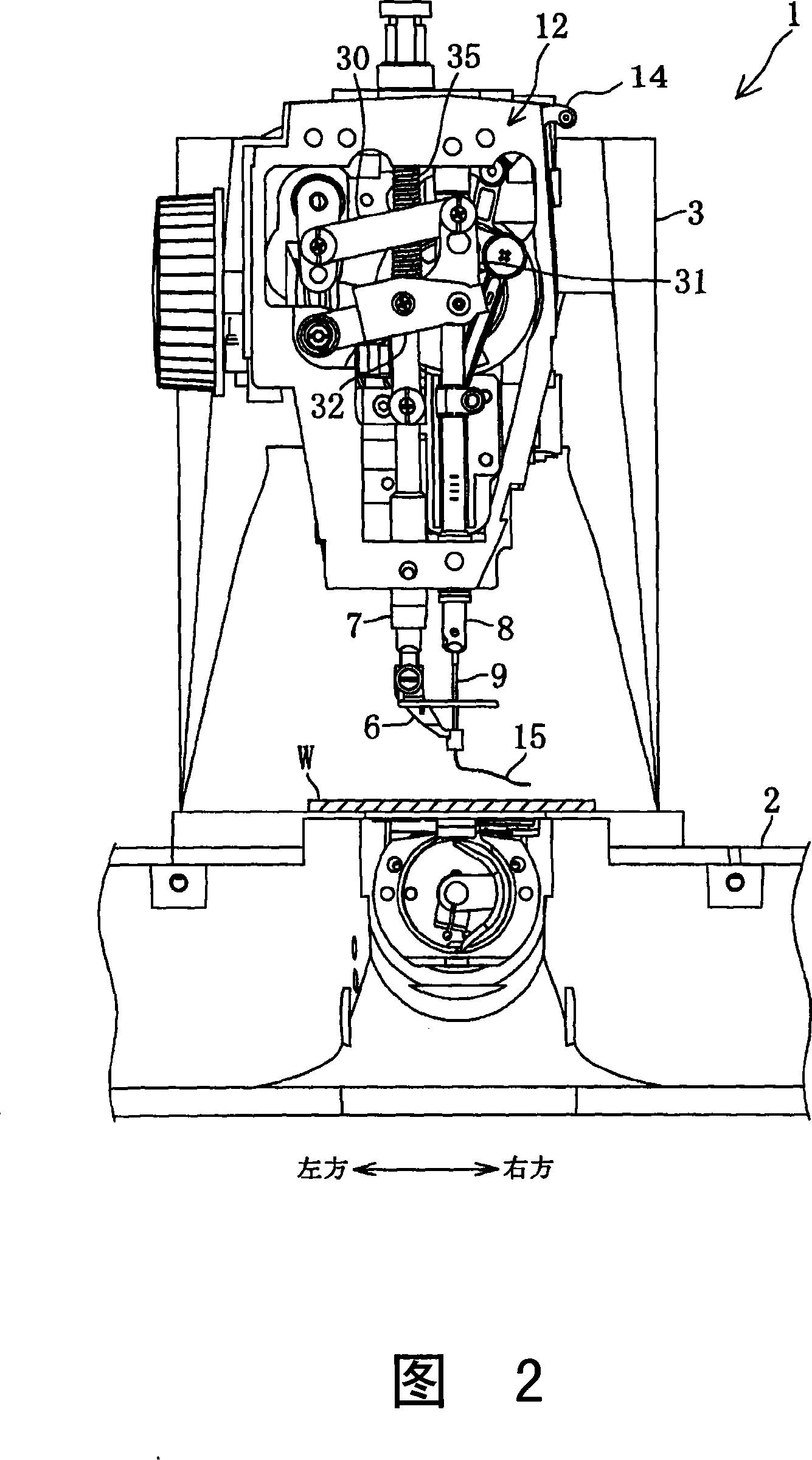

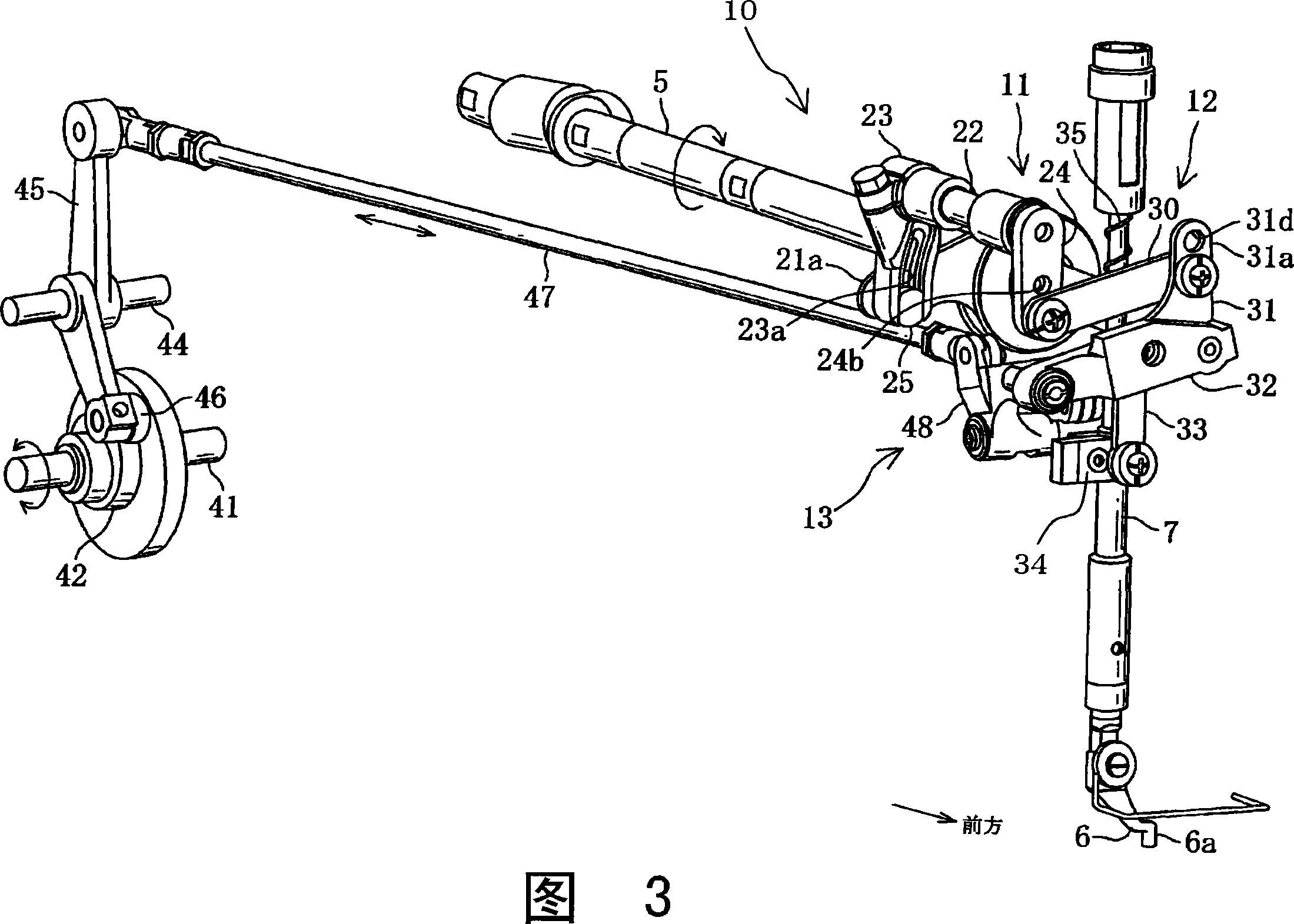

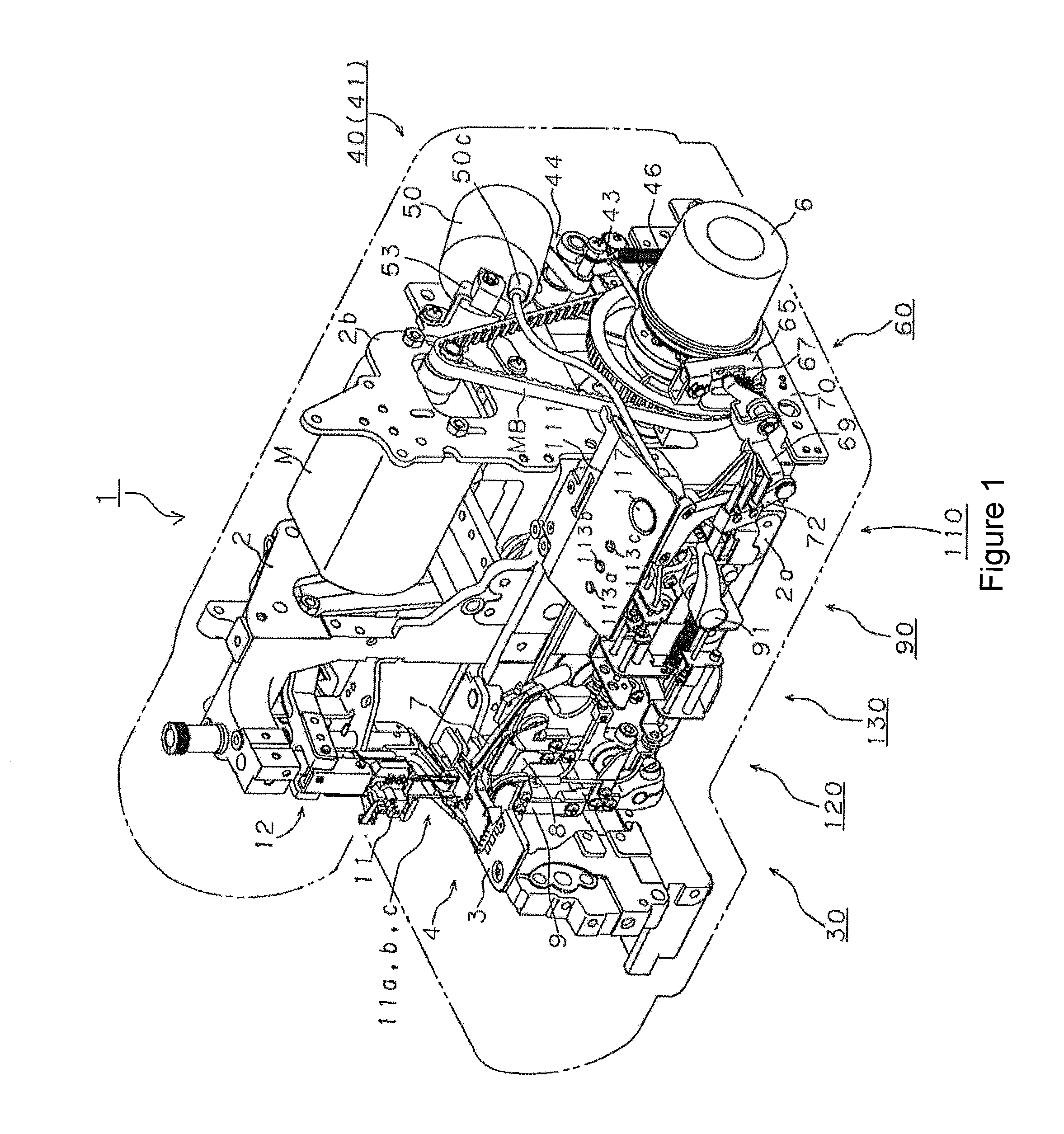

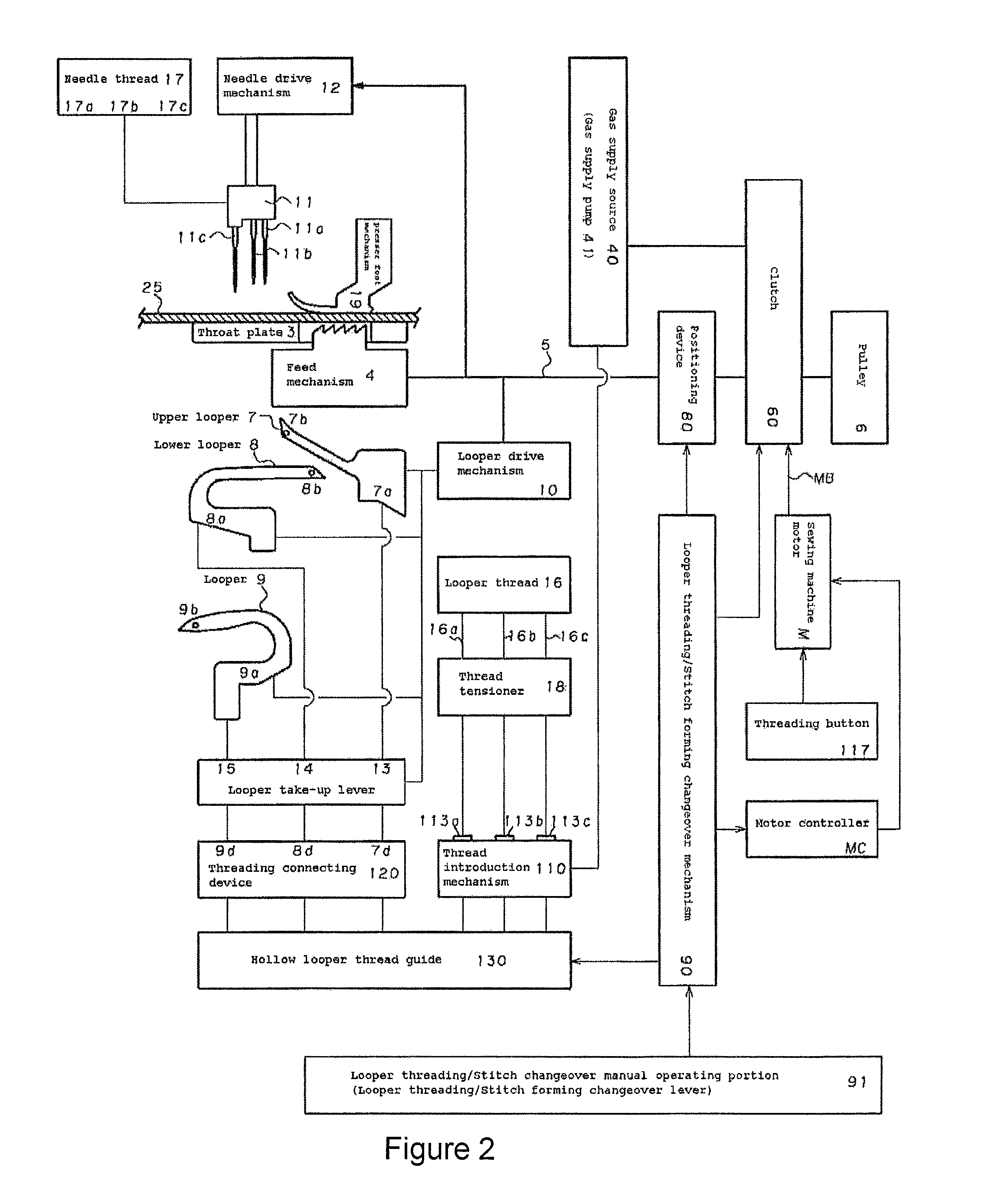

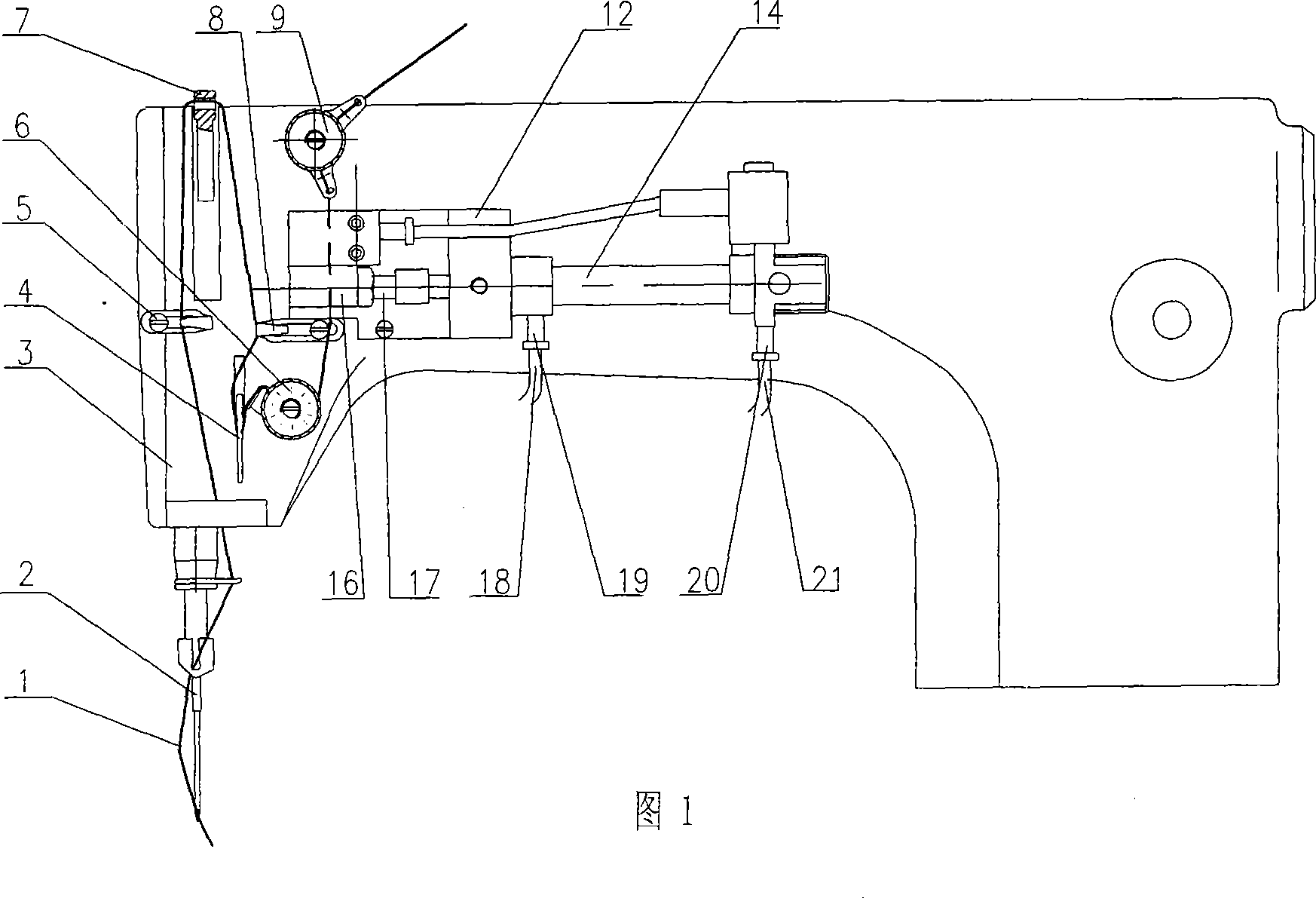

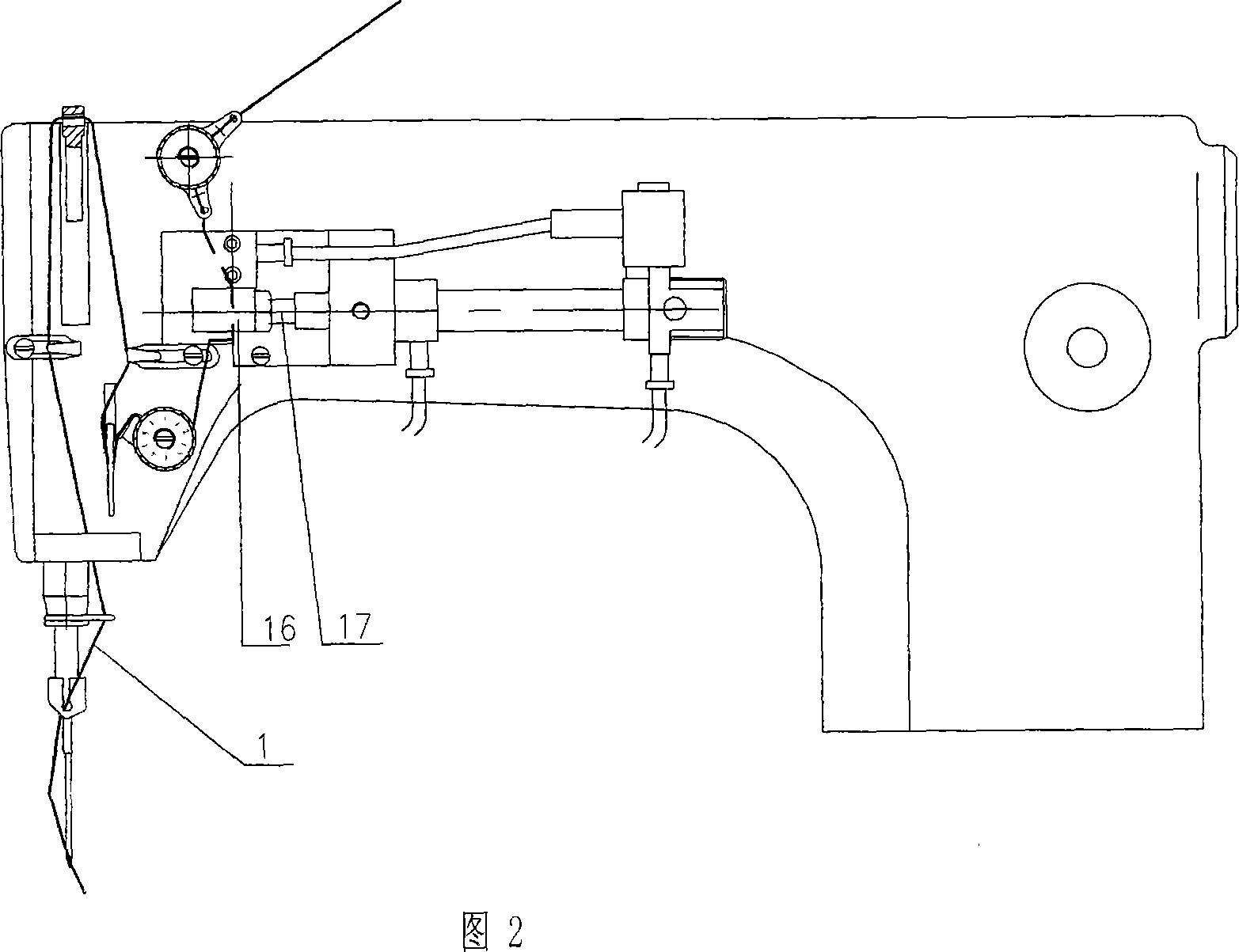

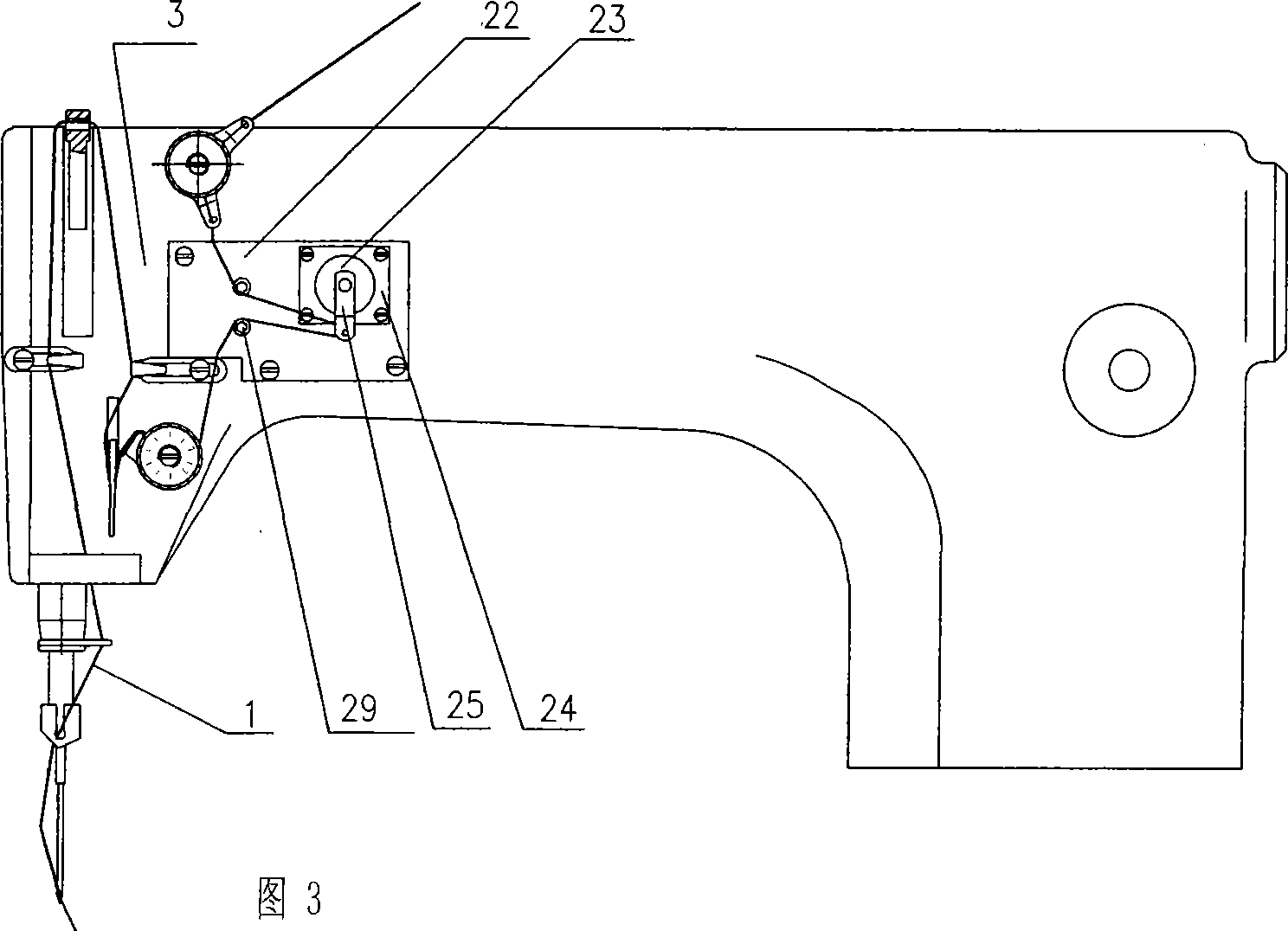

Gas Carrying Threading Device of Sewing Machine

ActiveUS20120210922A1Easy to handleEasy to operateThread-break detectorsNeedle-threading devicesTransmitted powerDrive shaft

Pressurized gas for carrying looper thread by gas is generated by gas supply pump operated by changing over a sewing-machine motor, which drives stitch forming device, looper threading is performed through loopers by one-touch operation. Gas carrying threading device of sewing machine, comprising: looper thread introduction mechanism inserts looper thread guided to loopers; hollow looper thread guide extends from looper thread introduction mechanism to looper thread inlets and has looper thread guide outlets; gas supply pump for performing looper threading by carrying looper thread by gas from looper thread introduction area through hollow looper thread guide to looper thread loop-taker point outlets; clutch for transmitting power from sewing machine motor M to drive shaft which drives stitch forming device including loopers at time of stitch formation or to gas supply pump at time of looper threading.

Owner:SUZUKI MFG CO LTD

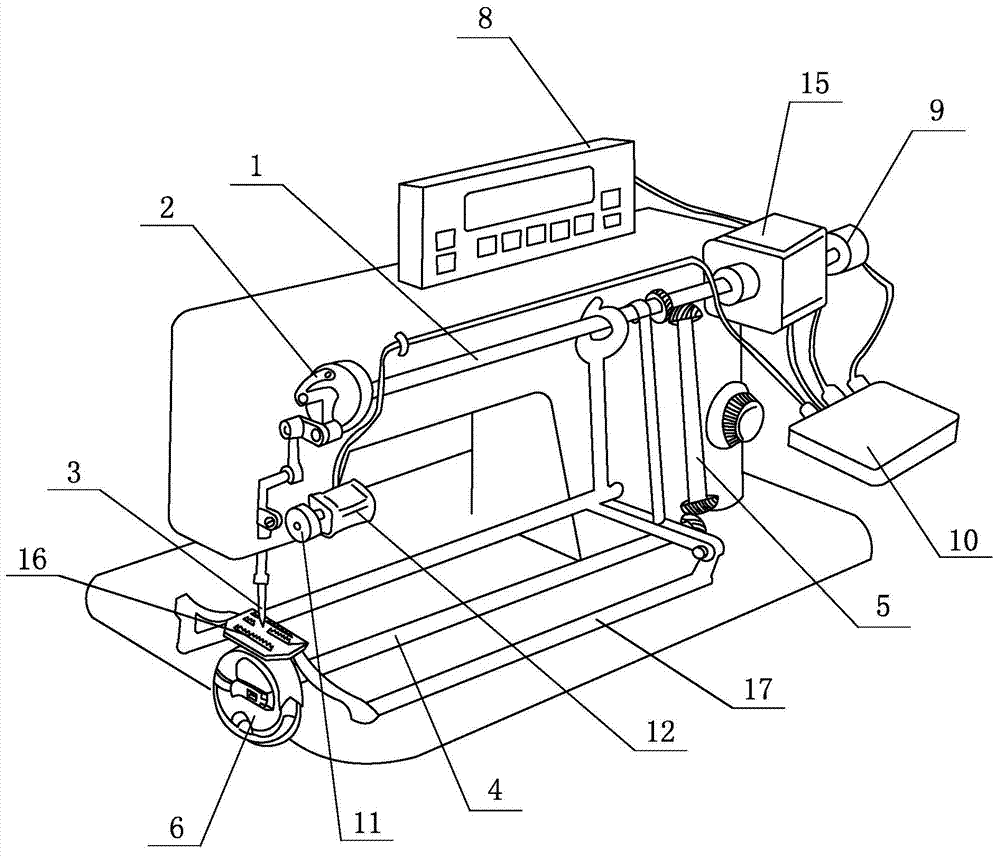

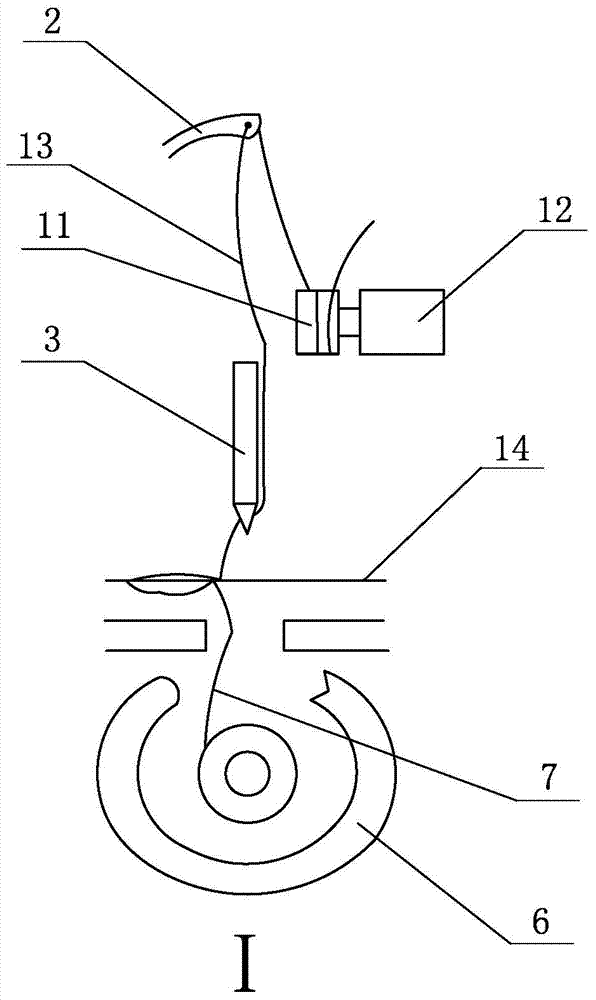

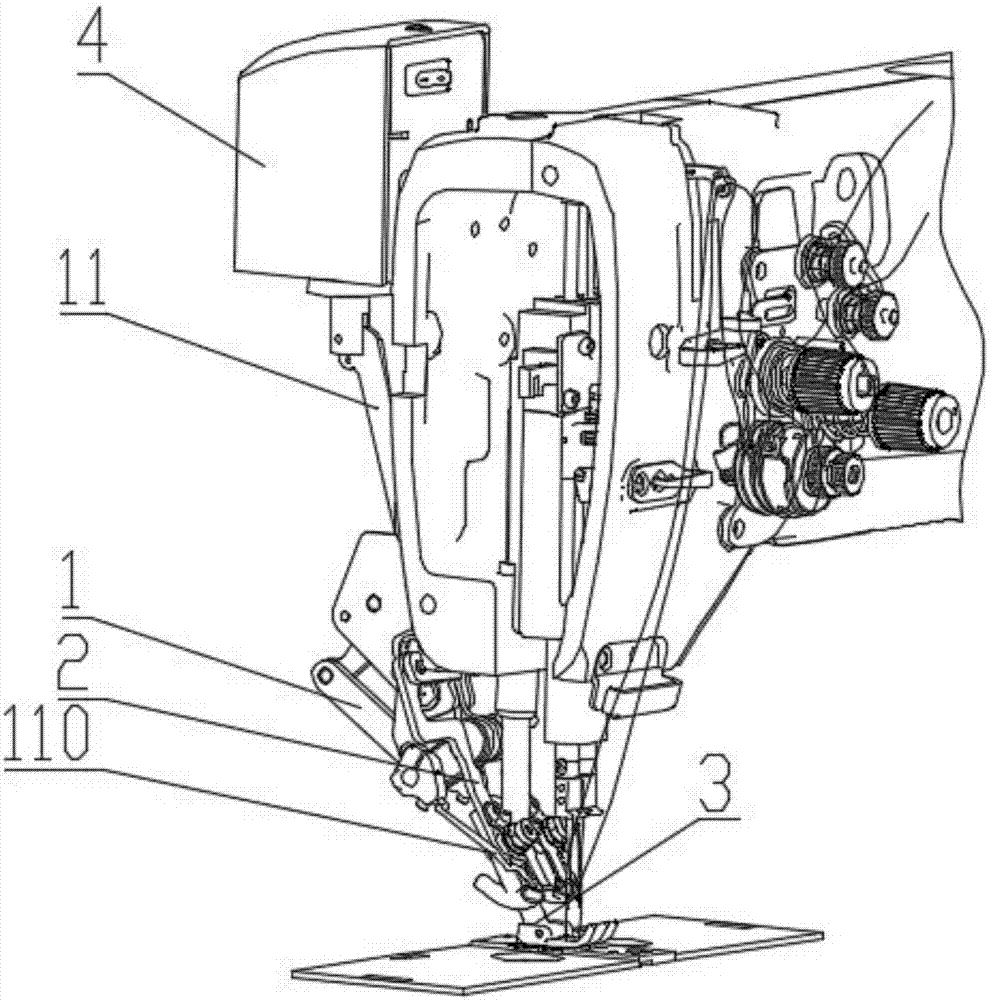

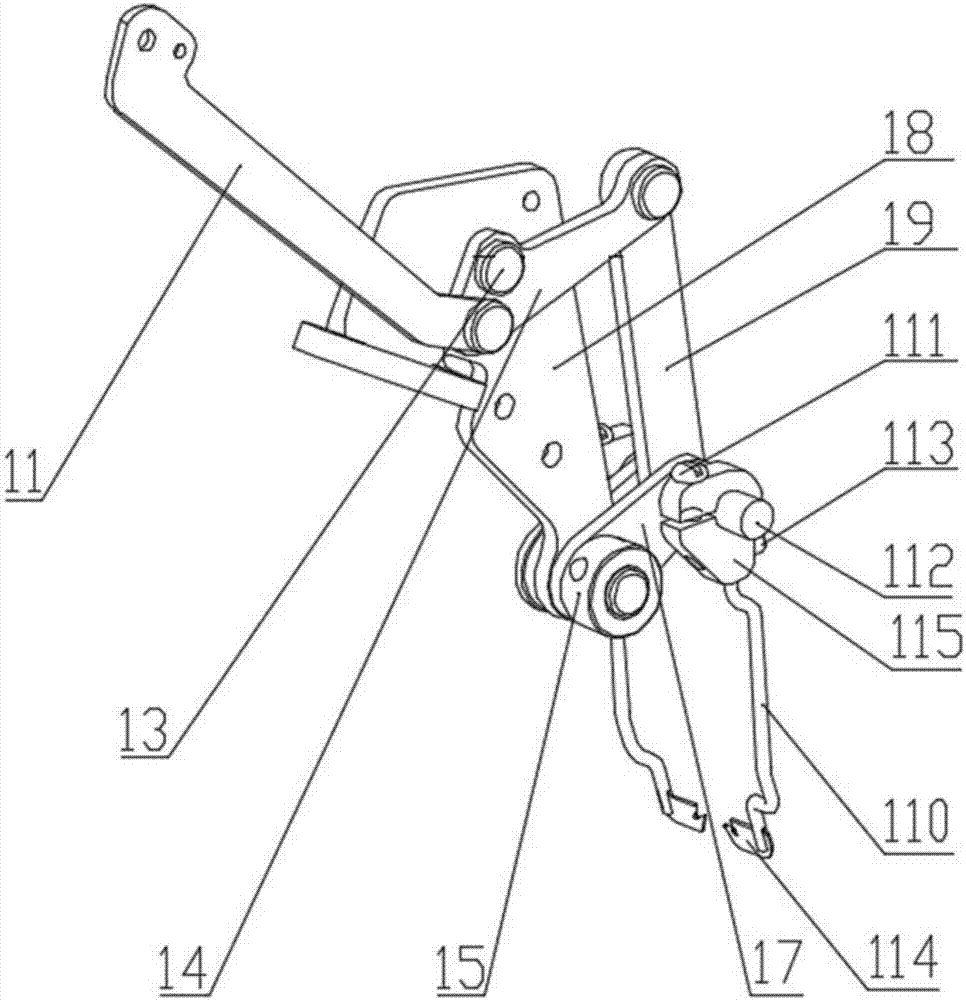

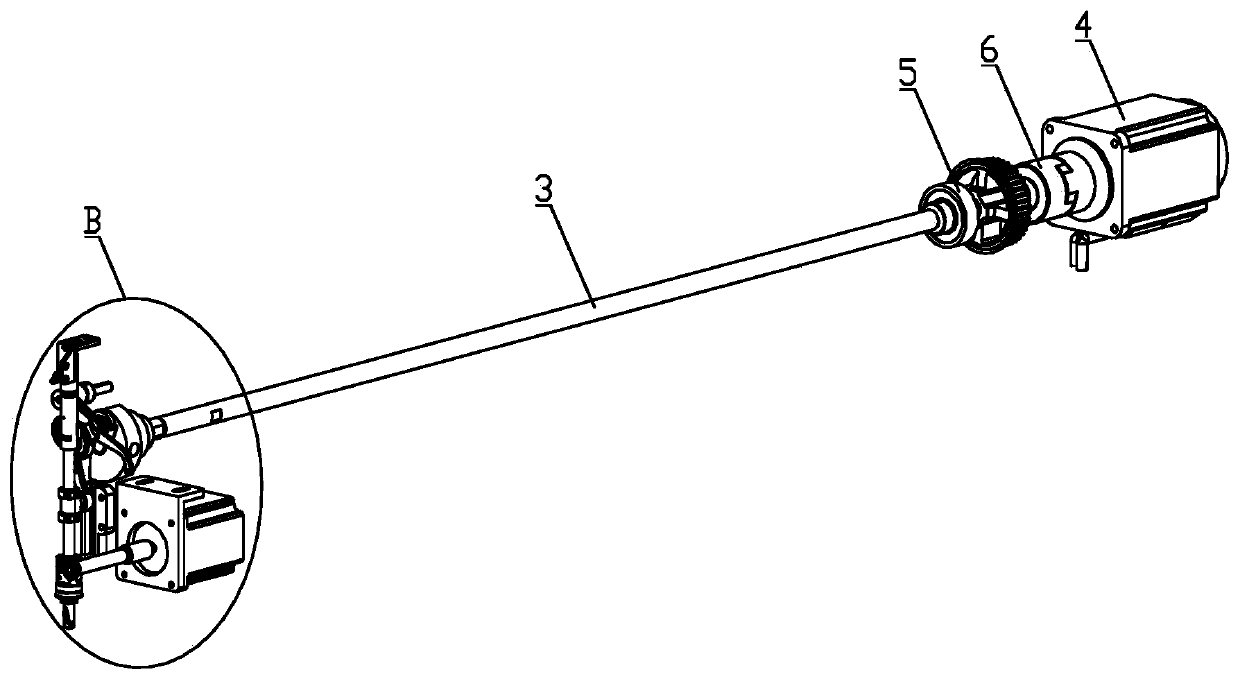

Automatic thread feeding system of sewing machine and control method thereof

InactiveCN104120547AConsistent outputConsistent pitchProgramme-controlled sewing machinesSewing-machine control devicesDrive shaftElectric machinery

The invention discloses an automatic thread feeding system of a sewing machine. The automatic thread feeding system comprises an upper shaft, a lower shaft, a control device, a cloth feeding system and a sewing thread tension adjusting device. One end of the upper shaft is connected with a sewing machine driving mechanism, and the other end of the upper shaft is connected with a thread take-up lever and a sewing needle; one end of the lower shaft is connected with the upper shaft through a transmission shaft, and a rotating shuttle is arranged at the other end of the lower shaft and wound with a sewing bottom thread. The automatic thread feeding system is characterized in that the sewing thread tension adjusting device comprises a rotating body and a stepping motor, the rotating body is connected with an output end of the stepping motor, the sewing machine driving mechanism and a control end of the stepping motor are connected with the control device, the rotating body is wound with a sewing upper thread, and the sewing upper thread penetrates through the thread take-up lever and is connected with the sewing needle. The control method includes the steps of parameter setting, sewing needle sewing, rotating body taking up, cloth moving and rotating body paying off. The sewn stitches are in order, and sewing quality is high.

Owner:SUZHOU HAOJIE MACHINERY ELECTRONICS EQUIP

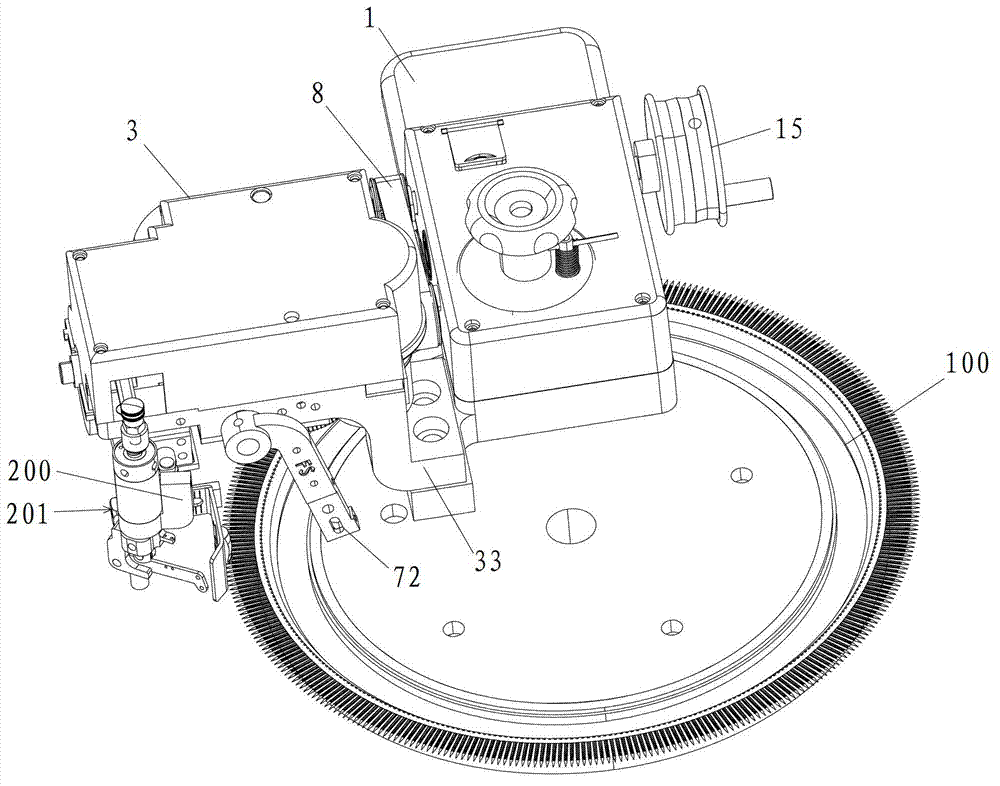

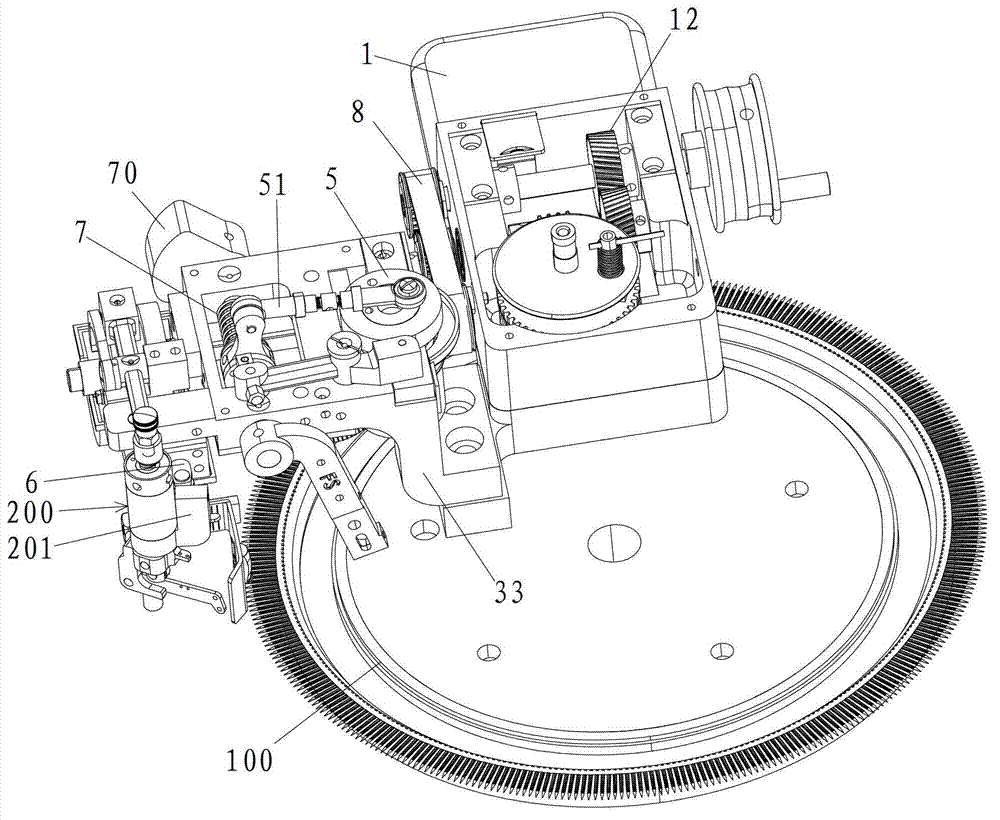

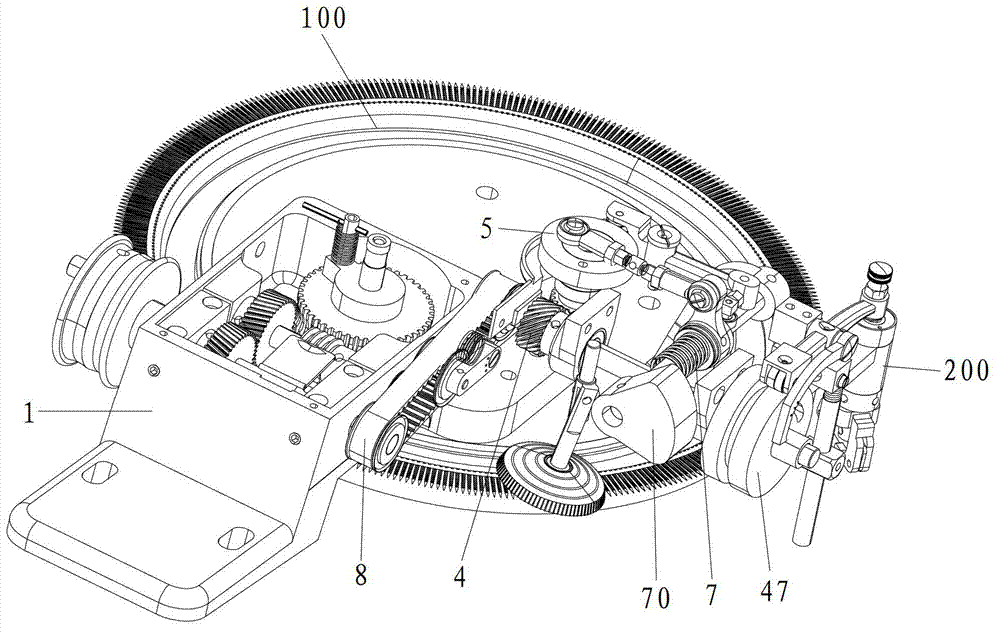

High-efficiency dial linking machine

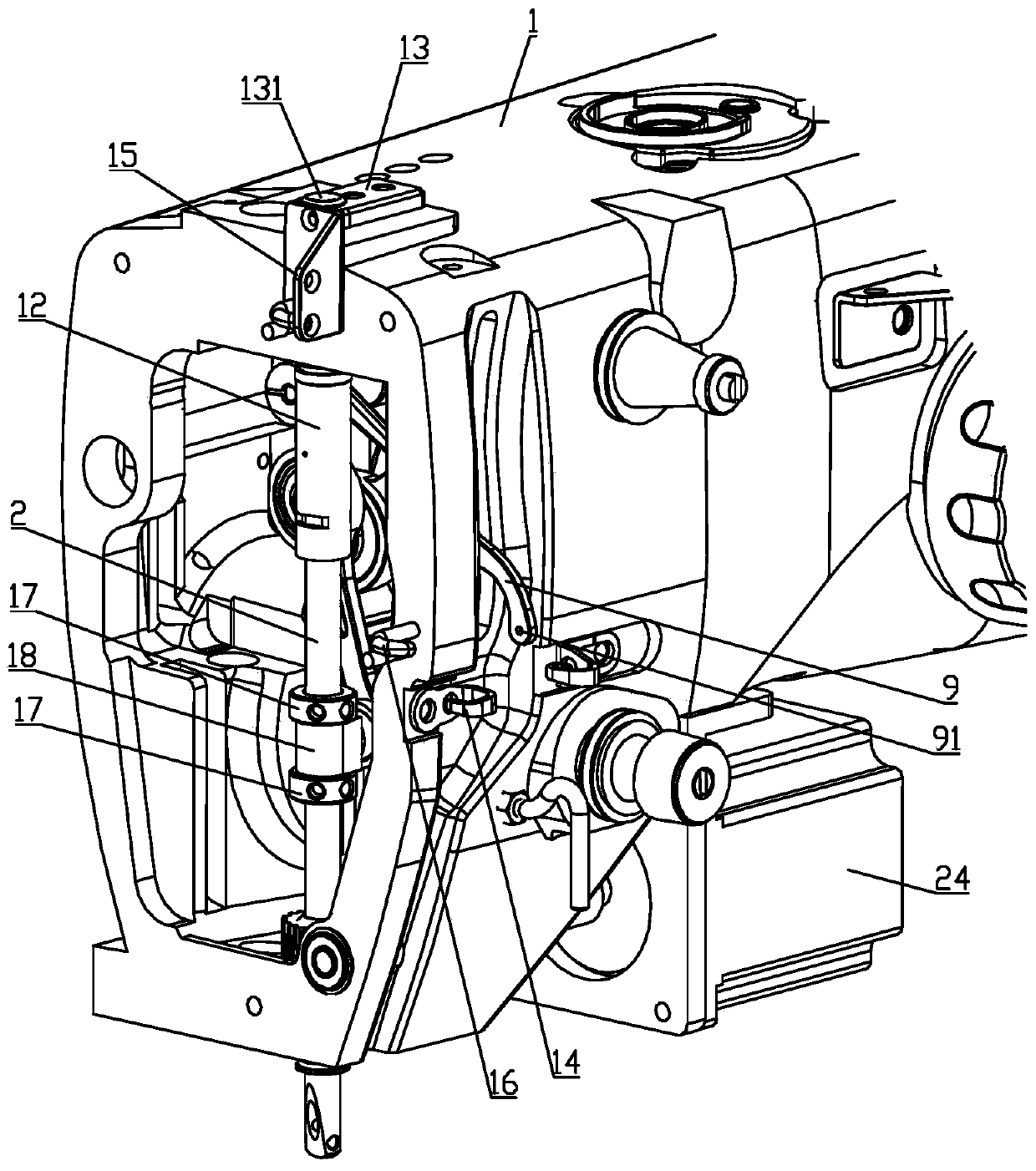

ActiveCN102953234AStable structureGuaranteed uptimeLubrication/cooling devicesSewing-machine control devicesElectric machineryEngineering

The invention discloses a high-efficiency dial linking machine. The high-efficiency dial linking machine comprises a headstock, a speed-regulating unit, a case and a dial; the headstock comprises a box, a box cover, a gear assembly and an adjusting handle, wherein the box cover is mounted on the top of the box, the gear assembly is mounted in the box, the adjusting handle is linked with the gear assembly, and the gear assembly comprises a first gear assembly and a second gear assembly which are respectively provided with a first helical gear and a second helical gear and are engaged with each other; the speed-regulating unit is linked with the gear assembly through a transmission by being matched with a motor; the case comprises a mounting bracket, an upper shield and a lower shield, and the upper shield and the lower shield are jointly formed into an automatic oil filling device; a helical tooth drive unit, a cam drive mechanism linked with the helical tooth drive unit, a striping unit, a push rod drive mechanism and a dividing unit linked with the cam drive mechanism are mounted in the case, wherein the helical tooth drive unit is linked with the gear assembly through a synchronous drive mechanism; and a debuggable counterweight is mounted on the dividing unit. The high-efficiency dial linking machine has the advantages of stable and smooth operation, good sewing quality, long service life and the like.

Owner:东莞市缝神机械设备有限公司

Clamping device for a sewing machine and method

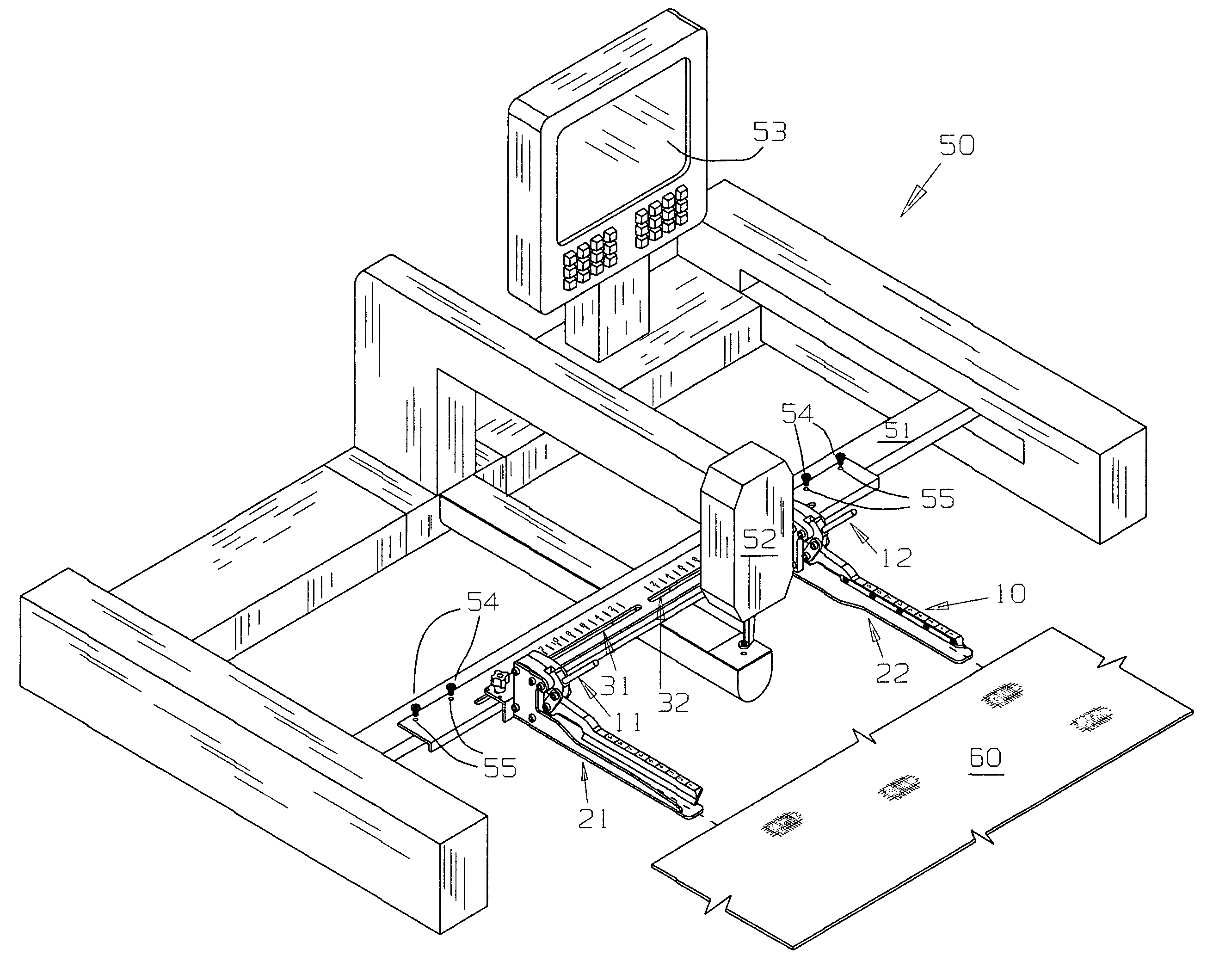

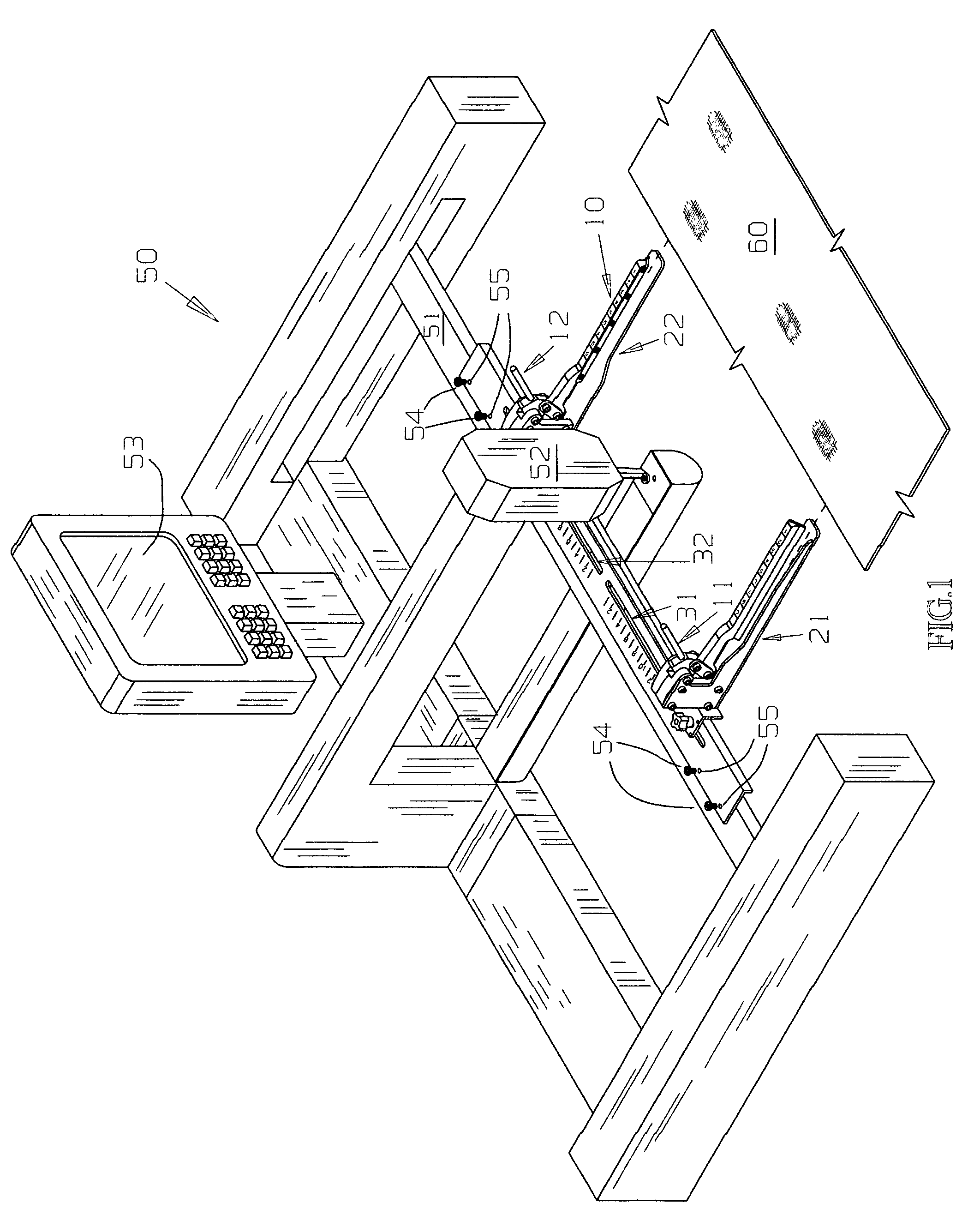

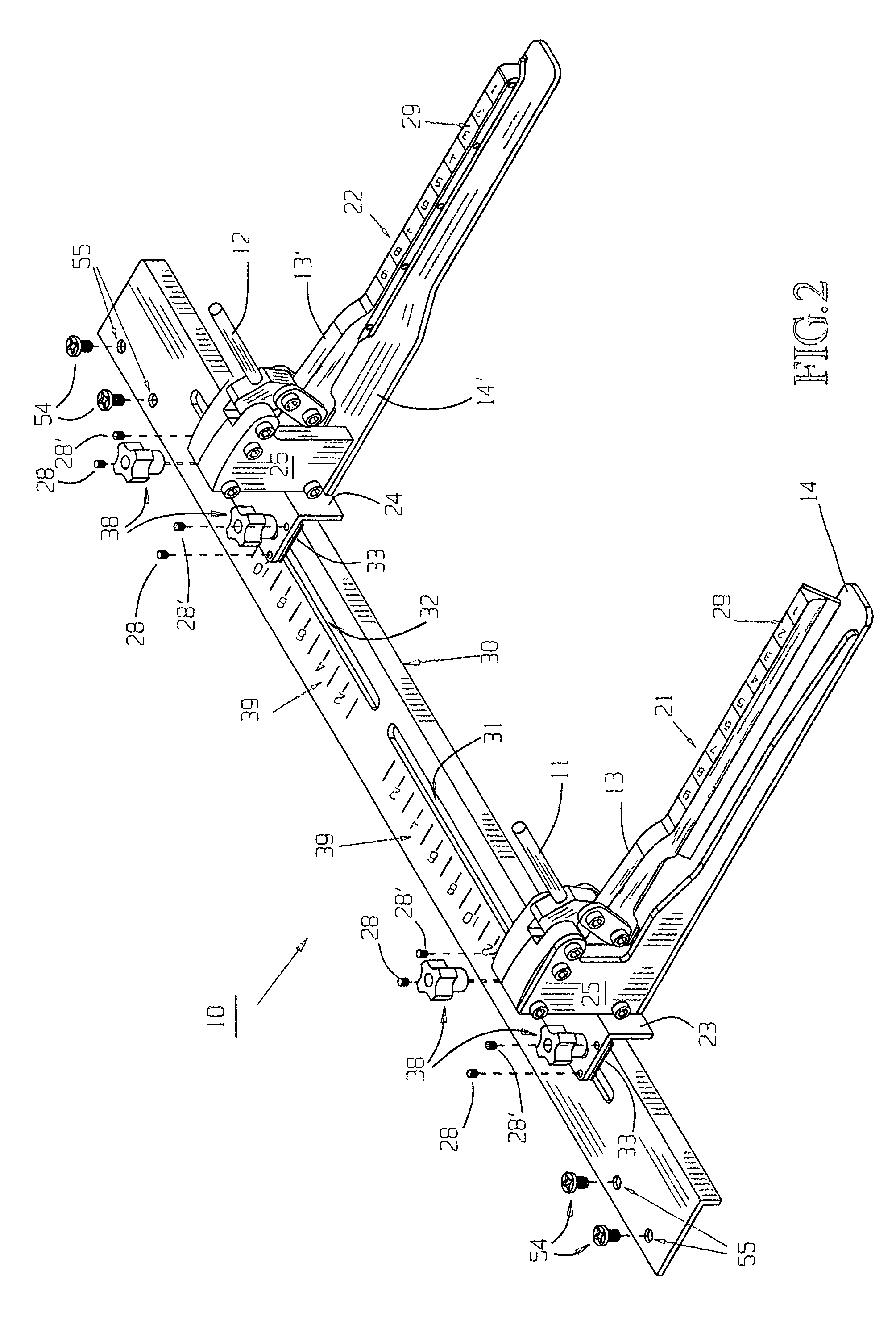

ActiveUS7377222B1Assures speed and efficiencyWork-feeding meansTake-up devicesEngineeringSewing machine

A clamping device and method for a conventional sewing or embroidery machine has a pair of movable arms. Each of the arms includes a fixed section and a movable section for receiving material or item to be embroidered therebetween. A manual lever allows the movable arm to be raised for insertion of the material and a scale on the arm allows the depth of insertion to be easily determined for accurate insertion. Each arm is movable along a slotted mounting plate affixed to the sewing machine proximate the sewing head. The clamping device provides uniform, taut material for accurate, smooth embroidering.

Owner:EFP INC

Infusion set improvements

Owner:DEKA PROD LLP

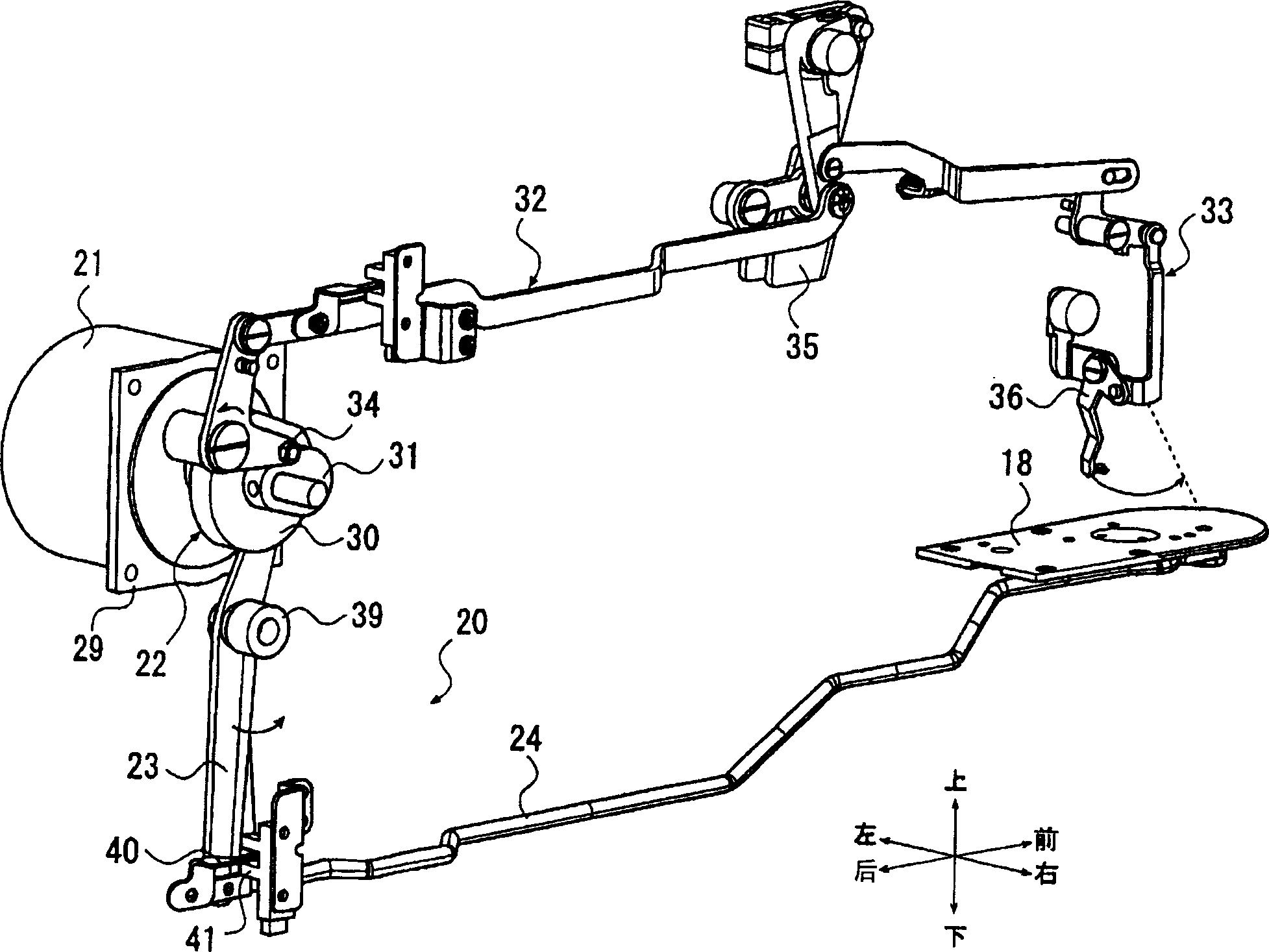

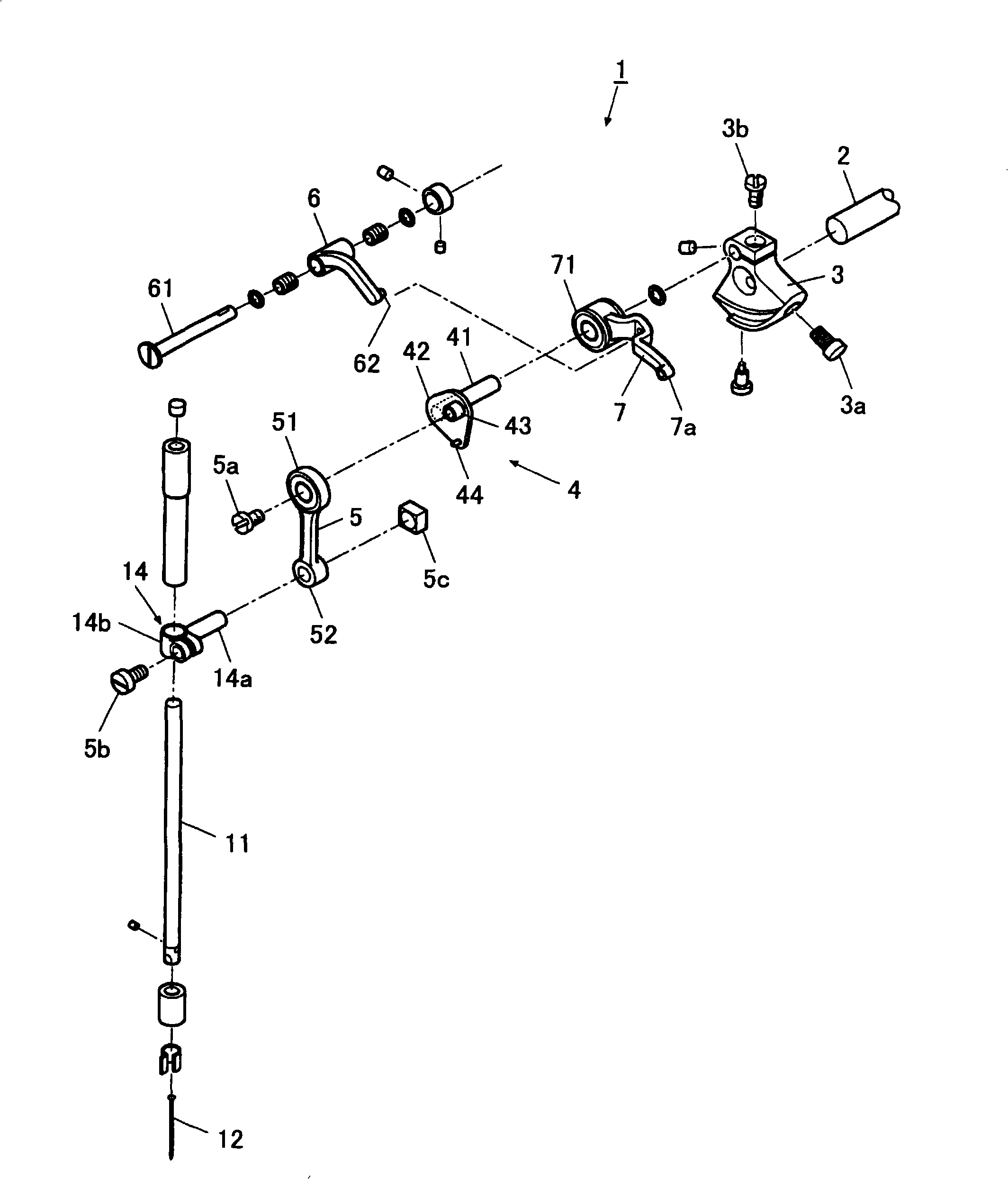

Sewing machine

ActiveCN101135091APrevent disengagementProgramme-controlled sewing machinesWork-feeding meansEngineeringActuator

The invention provides a sewing machine, comprising a pressure foot control part for controlling an actuator of an up-down moving changing mechanism, thereby the moving range of the pressure foot is changed downward during sewing in defined needls from sewing beginning, the up-down moving changing mechanism comprises a pressure foot up-down moving position changing mechanism of the up-down moving pressure foot range changed by the actuator upward-downward and moved with the sewing motion synchronistically upward-downward. By utilizing an up-down moving pressure foot moved in the inferior moving range to press the upper thread end part extended from the needle hole of the needle on the processing cloth, thereby friction impedance is applied. The sewing machine can prevent the upper thread end part running out from the lower side of the processing cloth, utilizes a simple structure without an upper thread crowding mechanism to form thread track from the first needle.

Owner:BROTHER KOGYO KK

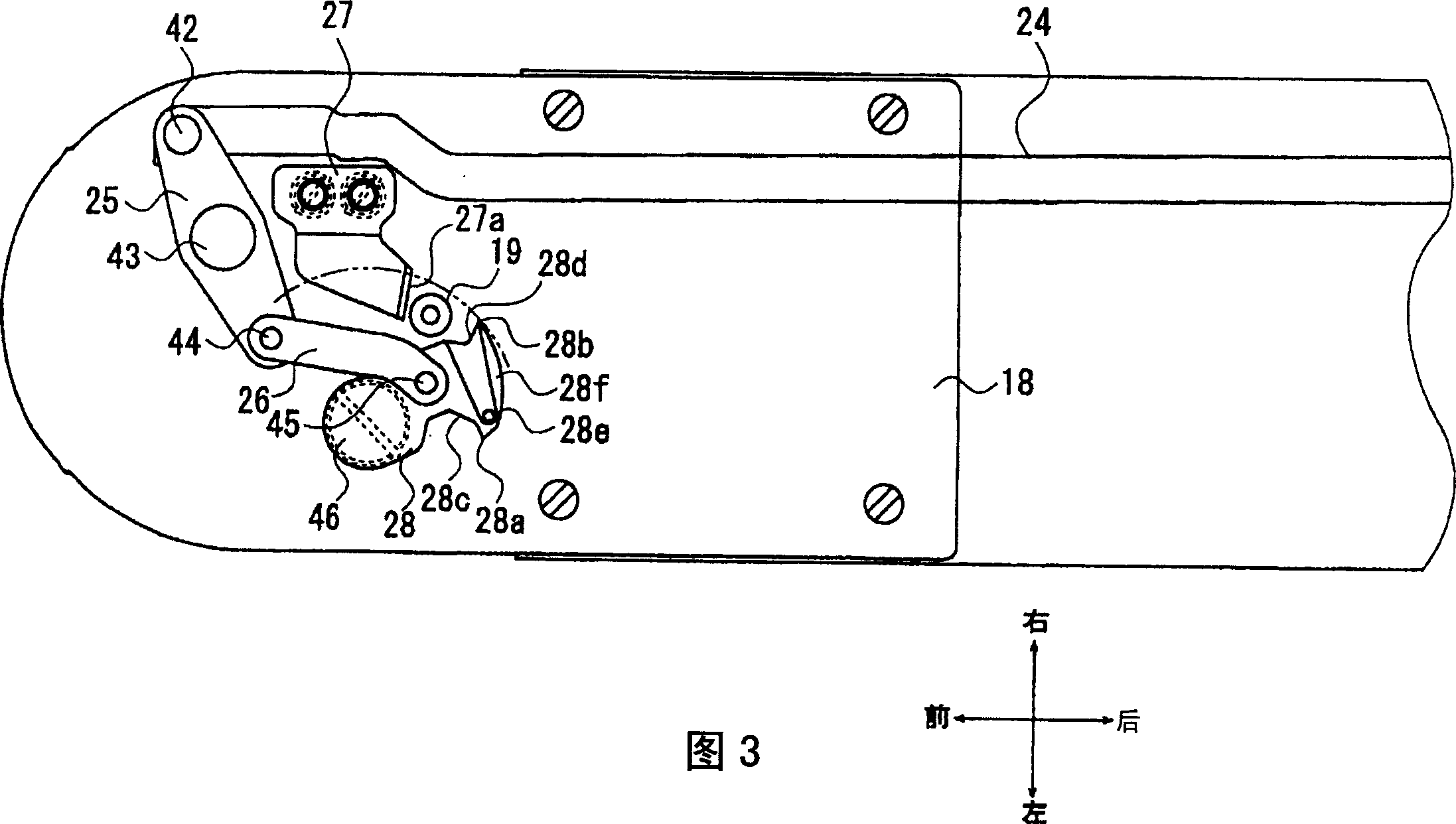

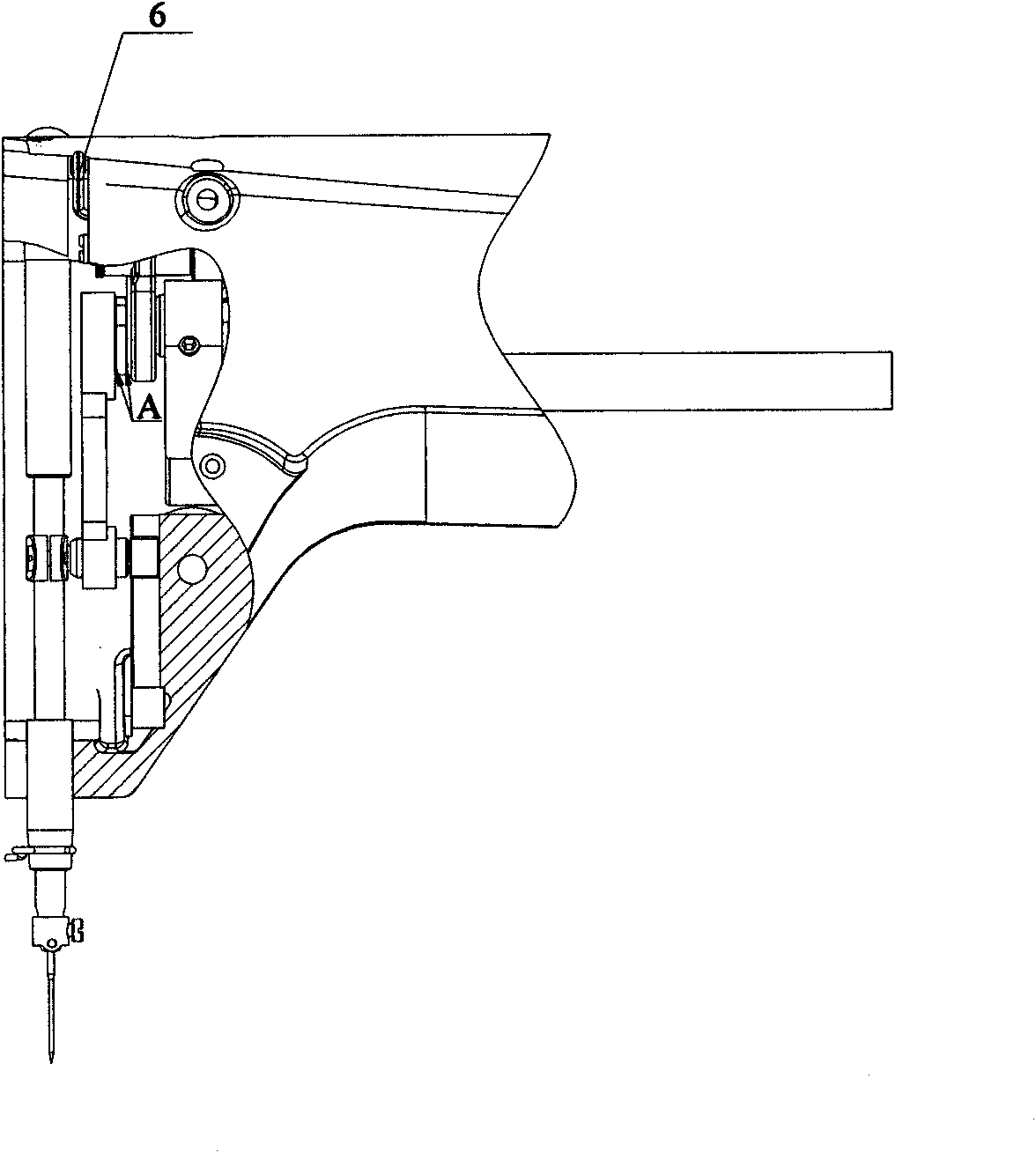

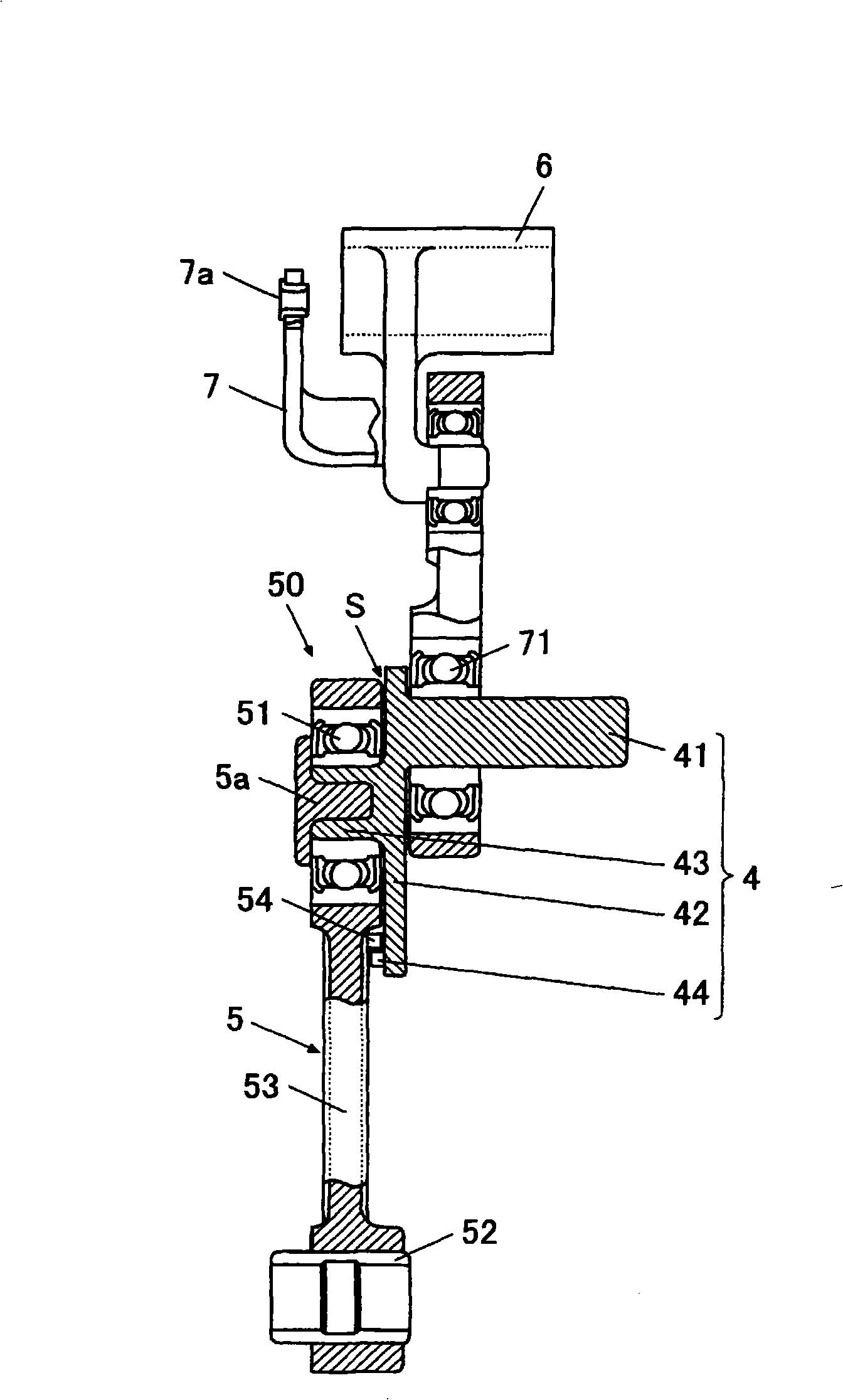

Sewing machine with adjustable needle rod and take-up stroke

InactiveCN103114390ALower purchase costQuick Adjust TransformationTake-up devicesNeedle barsEngineeringCam

The invention relates to a sewing machine with an adjustable needle rod and a take-up stroke. The sewing machine comprises a machine body, a main shaft transmission mechanism, a take-up transmission mechanism, a crank and a needle rod transmission mechanism. The main shaft transmission mechanism comprises a rotary shaft and a bob-weight cam connected with the rotary shaft in a sleeved mode, wherein the rotary shaft is connected with the machine body in a penetrating mode. The take-up transmission mechanism comprises a balance arranged at one side of the bob-weight cam, an eccentric shaft located in a shaft hole and a swinging arm, wherein one end of the swinging arm is in pivot connection with the eccentric shaft, and the other end of the swinging arm is in pivot connection with the balance. One end of the crank penetrates through the balance and is fixed on the bob-weight cam. The needle rod transmission mechanism comprises an eccentric wheel, the needle rod connected with the machine body in a sliding mode and a connecting rod, wherein the eccentric wheel is connected with the other end of the crank in a positioning and sleeved mode, one end of the connecting rod is in pivot connection with the eccentric wheel, and the other end of the connecting rod is in connection with the needle rod. The sewing machine can be adjustably used according to stitching requirements of fabrics with different thicknesses.

Owner:KORIN CO LTD

Yarn winding machine

InactiveUS7097129B2Extended time windowEasy alignmentFilament handlingTake-up devicesYarnWinding machine

A yarn winding apparatus for continuously winding yarns to packages. The winding apparatus has a plurality of winding spindles, which are mounted in cantilever fashion for rotation on a movable turret, and which are alternately guided between a winding position for winding the yarns and a doffing position for removing the packages and assembling fresh tubes. To put on the tubes on the winding spindle, a tube slip-on device is provided, which comprises a movable means for guiding the tubes. To make it possible to put on tubes on the winding spindles held in the doffing position even during the progressive movement of the turret, the guide means for slipping on the tubes is movable for a short time or distance synchronously with the winding spindle that is moved by rotation of the turret.

Owner:SAURER GMBH & CO KG

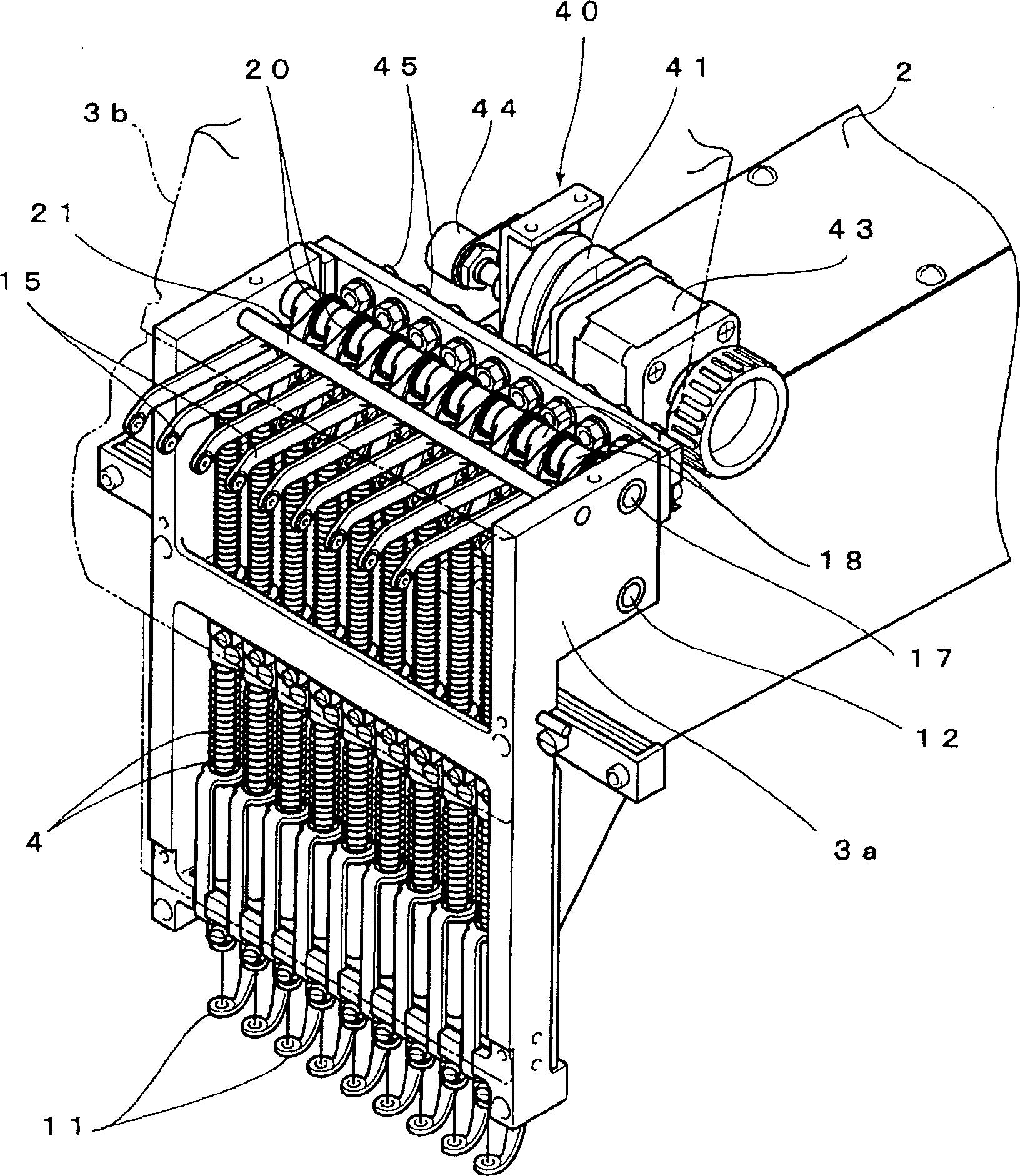

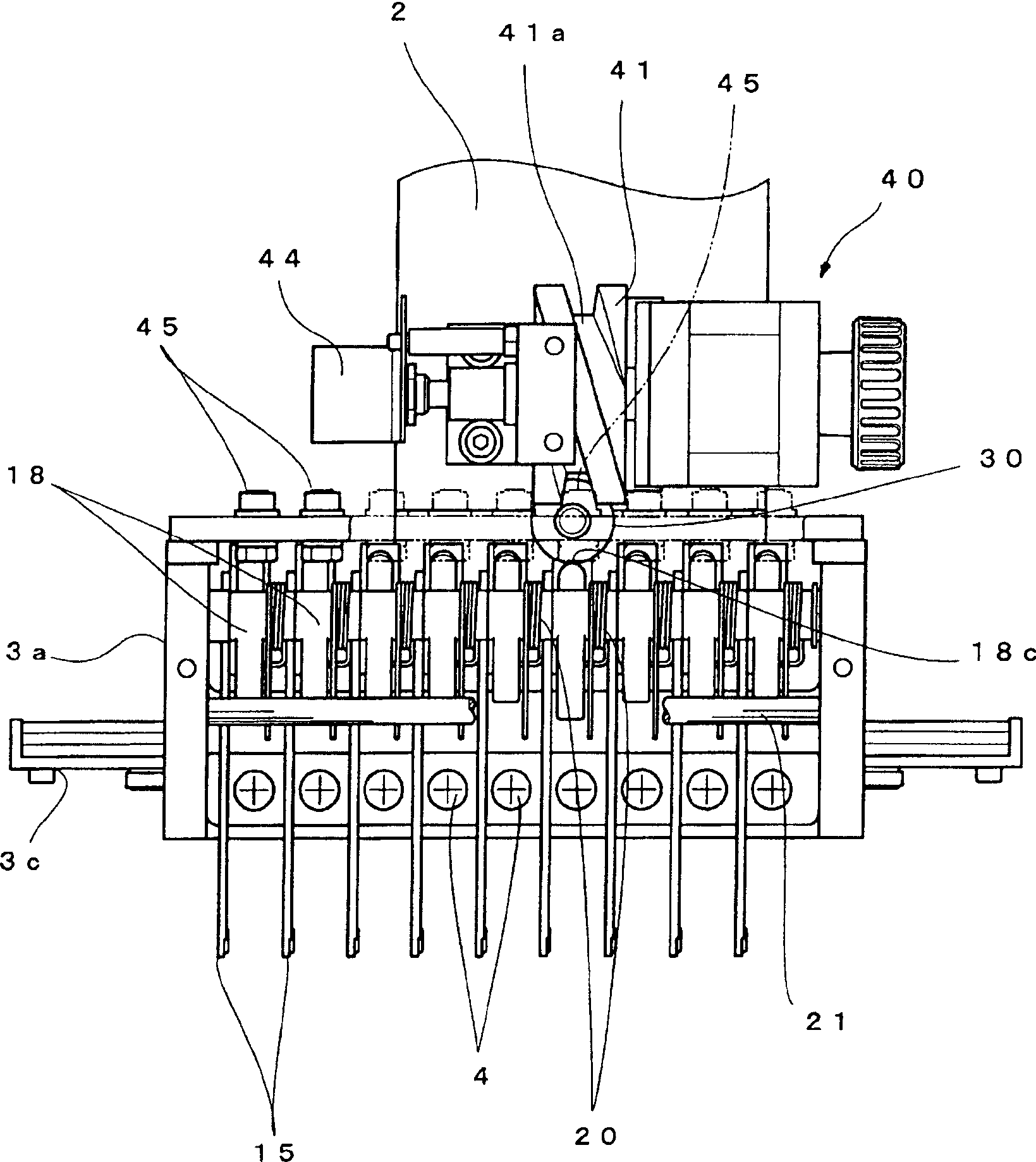

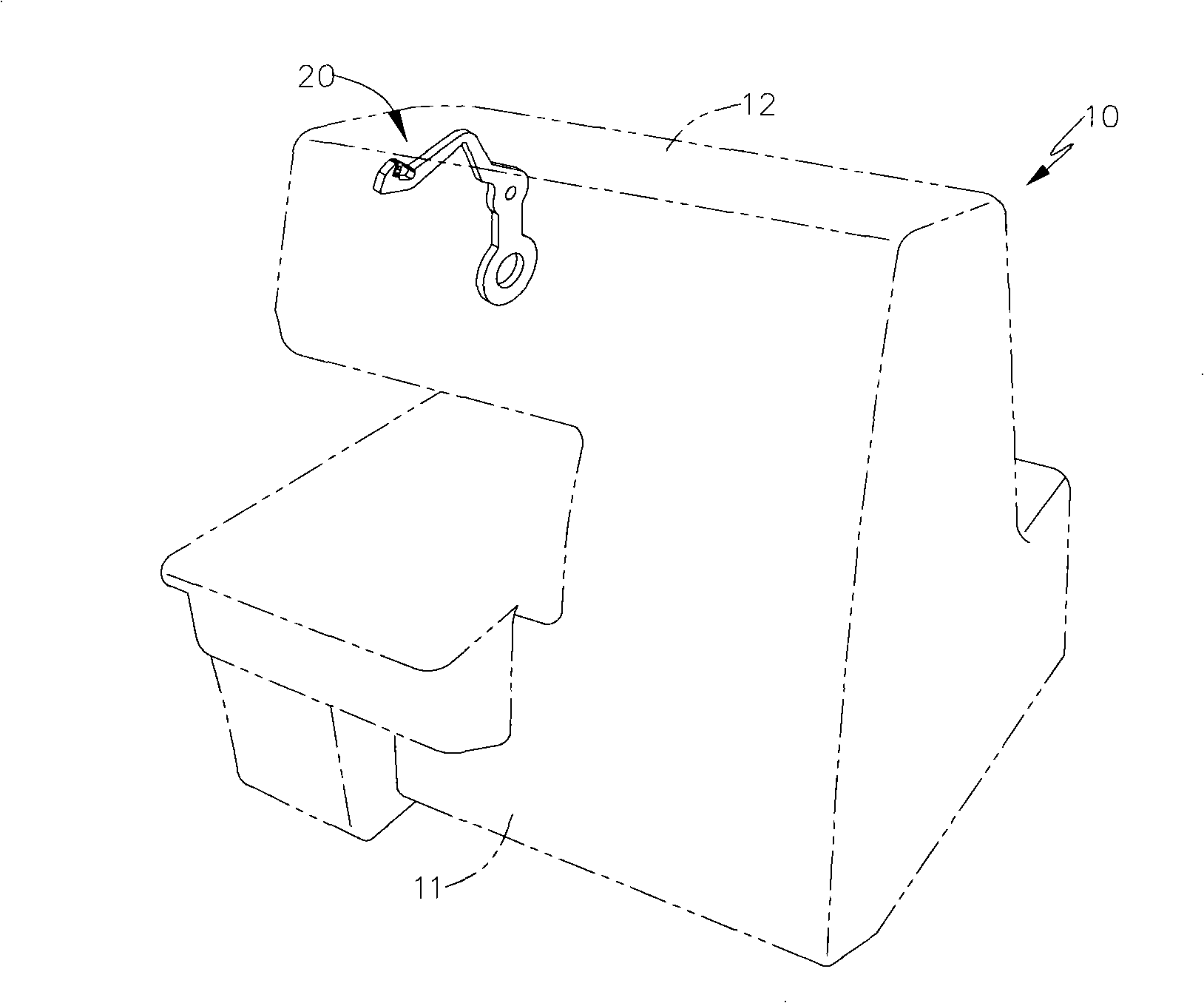

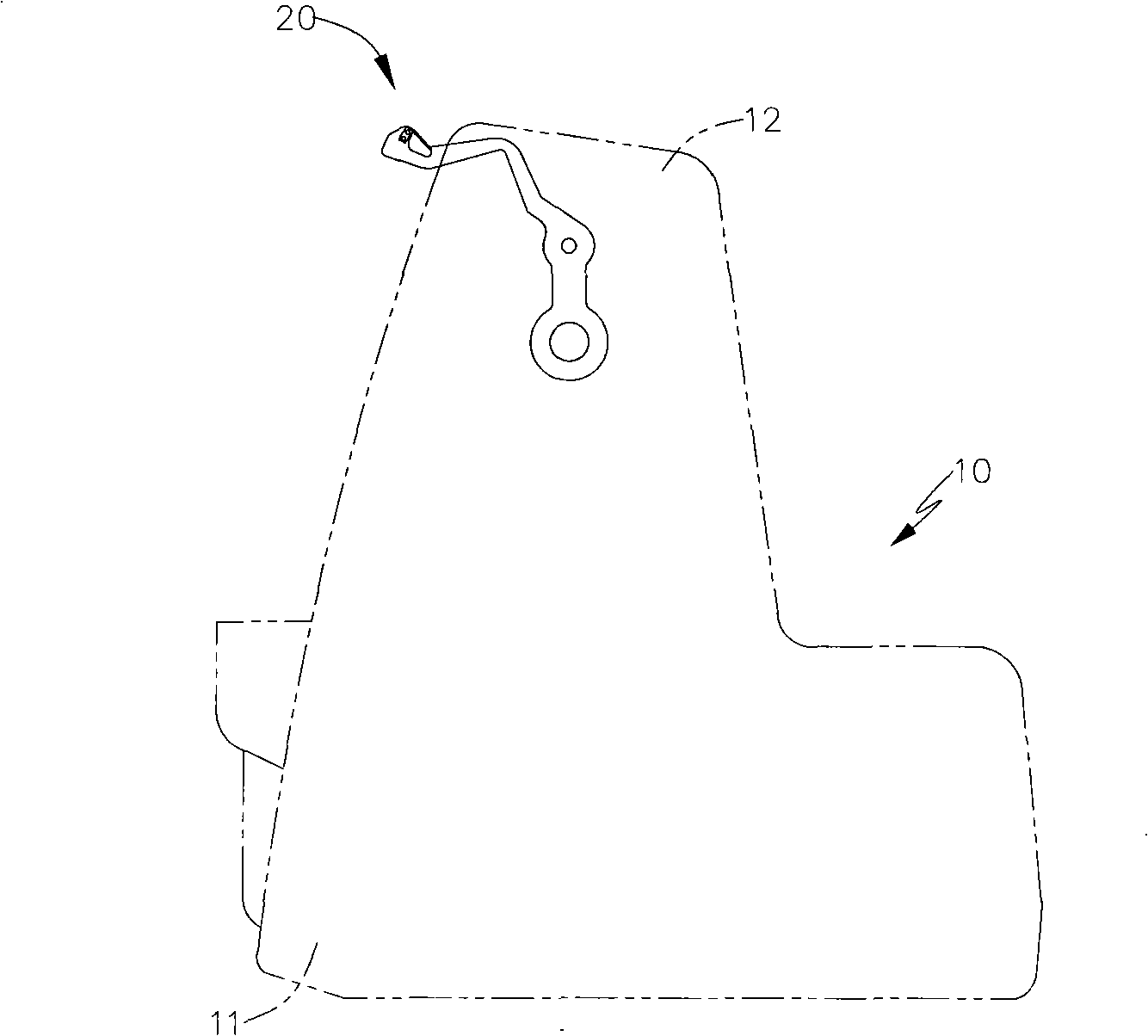

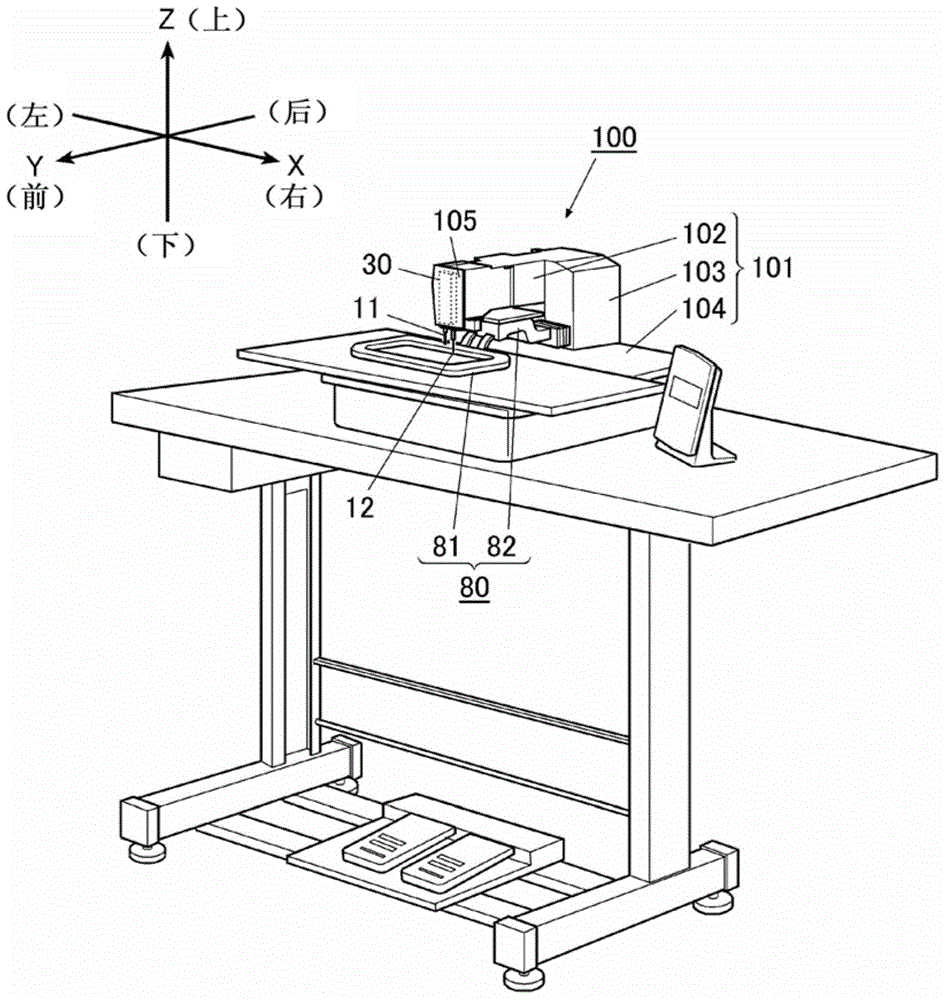

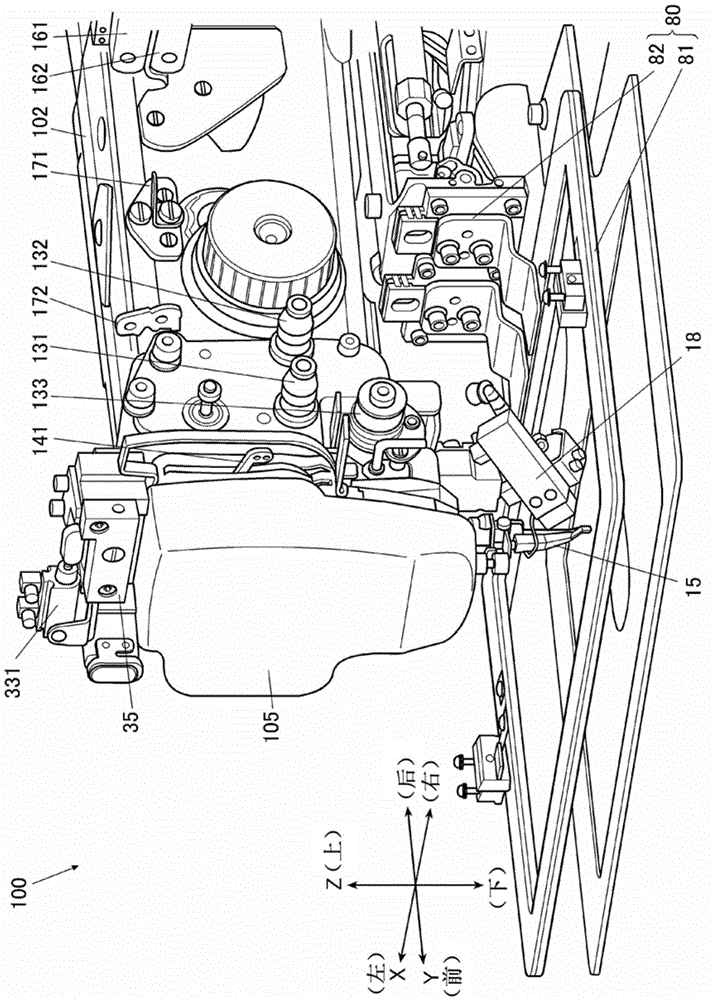

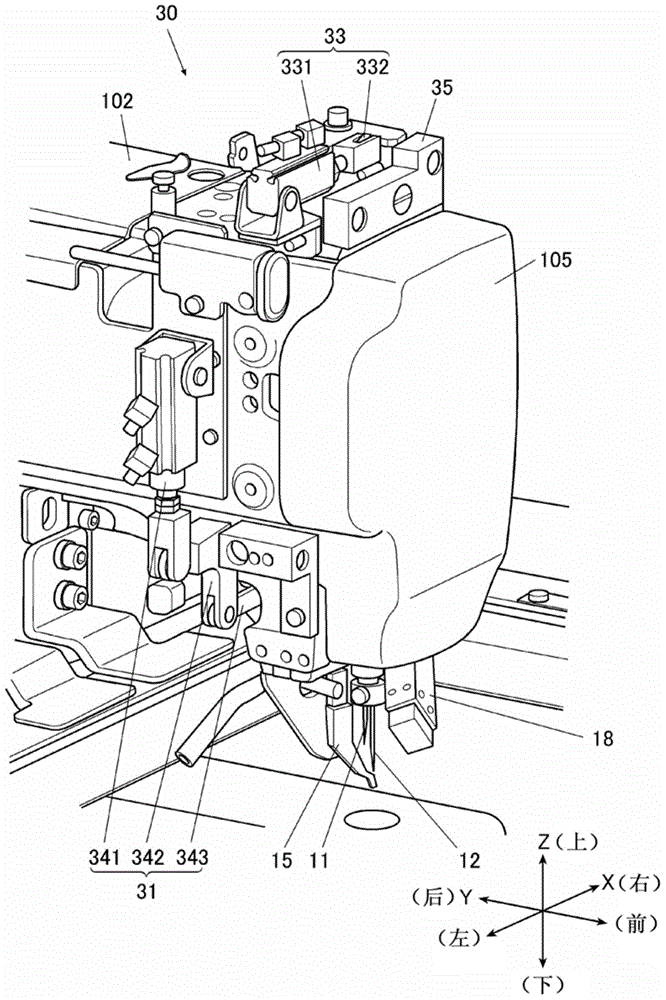

Embroidery machine

An embroidering machine is capable of maintaining an unusing balance on a top dead center surely. An embroidering machine comprises: a holding body supporting plural balances(15) and plural needle rods; a color changing device(40) driving one selected from the balances(15) and the needle rods selectively; and a balance maintaining device permitting driving of the selected balance and maintaining the balance not selected on proper position. The balance maintaining device comprises: a correspondent groove(16c) formed on each balance; a lock lever(18) corresponding to each balance, being capable of shaking and inserting a tip(18b) into the correspondent groove(16c) to maintain the balance on proper position; a spring member(20) supporting the lock lever(18) in a direction that the tip(18b) is inserted into the correspondent groove(16c); and a maintenance release device(18c) shaking the corresponded lock lever(18) to extricate the tip(18b) from the correspondent groove(16c).

Owner:TOKAI IND SEWING MACH CO LTD

Thread take-up lever structure of sewing machine

The invention discloses a thread take-up lever structure of a sewing machine, in particular a thread take-up lever structure which is arranged on the sewing machine and can stop the exiting of stitches, wherein a head end of a thread take-up lever is provided with a C-shaped thread receiving part, the thread receiving part is provided with an opening end, a positioning part is arranged near the opening end for a thread retaining part to fix, one end of the thread retaining part is a fixing part which is positioned on the positioning part, while the other end is an elastic retaining part which extends into the inside of the opening end from the outside of the opening end, the other end of the retaining part is a free end and is pressed against the inner edge of the opening end, the whole retaining part is reliably sealed, and has a state of unidirectional opening and another direction closing to ensure that a sewing thread enters from an outward opening end of the thread receiving part and elastically leaves the position where the opening end is pressed through the free end of the retaining part of the thread retaining part, and the free end automatically rebounds to the position where the opening end is pressed to be immediately closed and non-returned to become a structure used for automatically stopping to prevent the thread breakage after entering the thread receiving part.

Owner:曾贤长

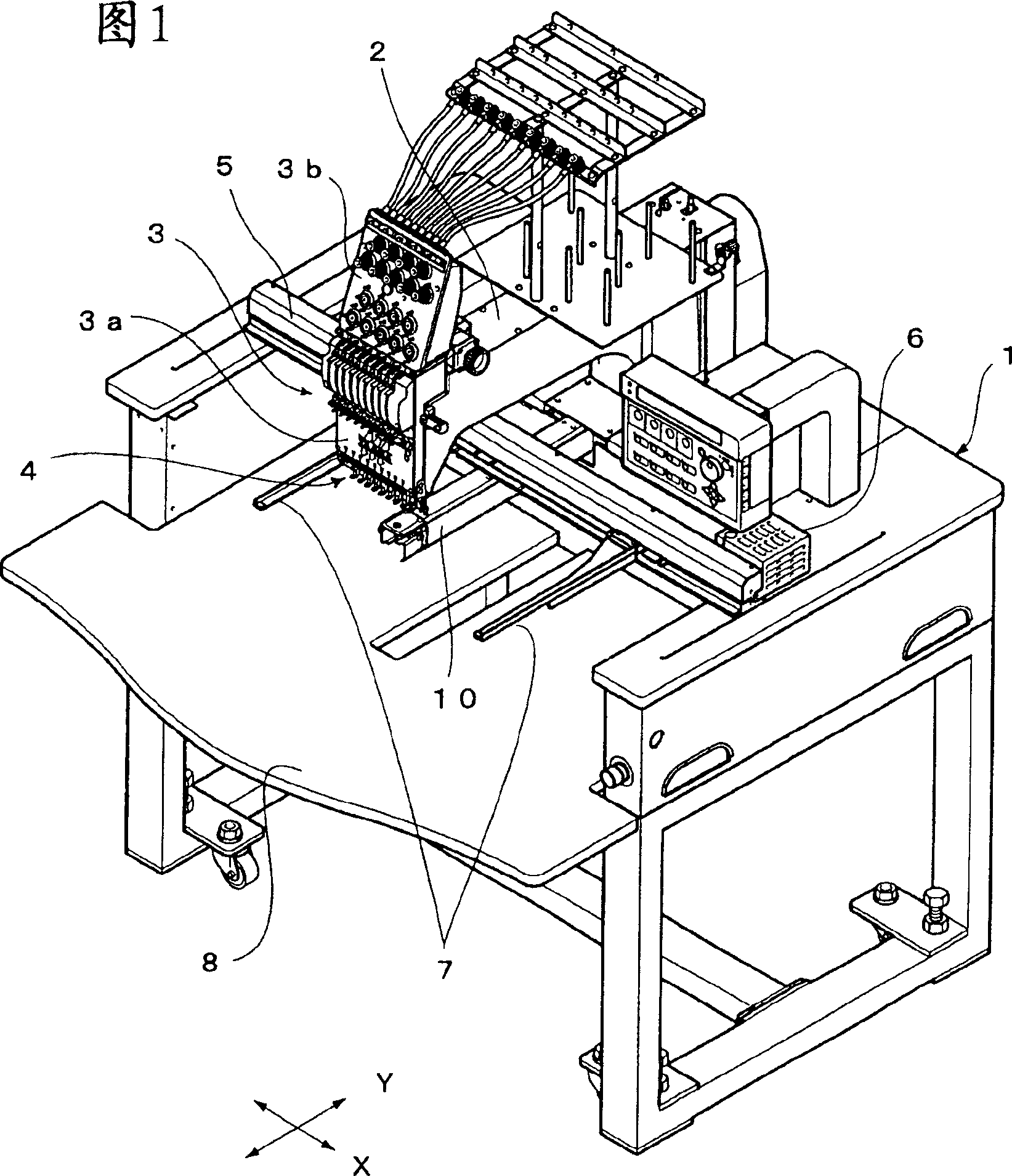

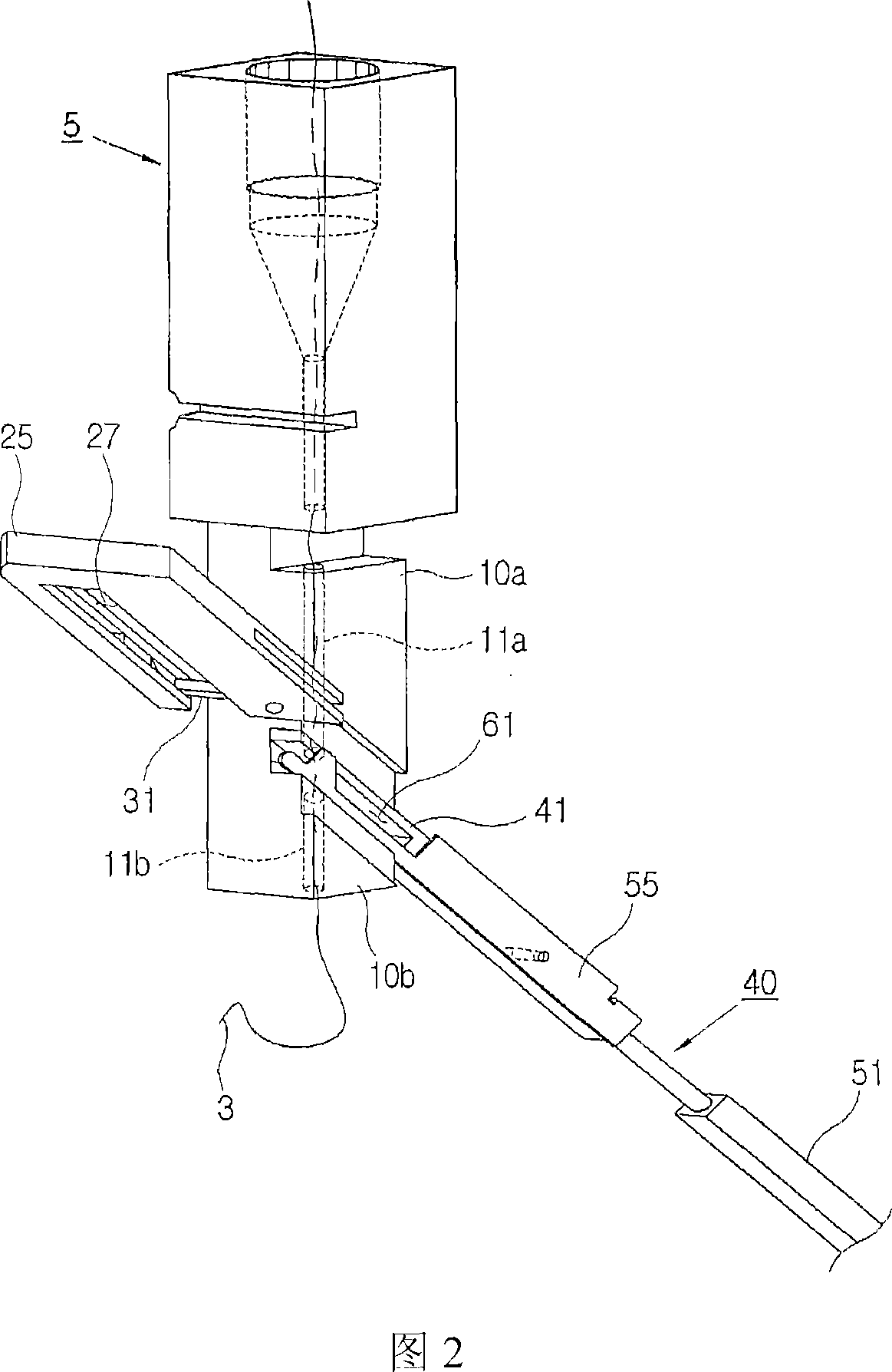

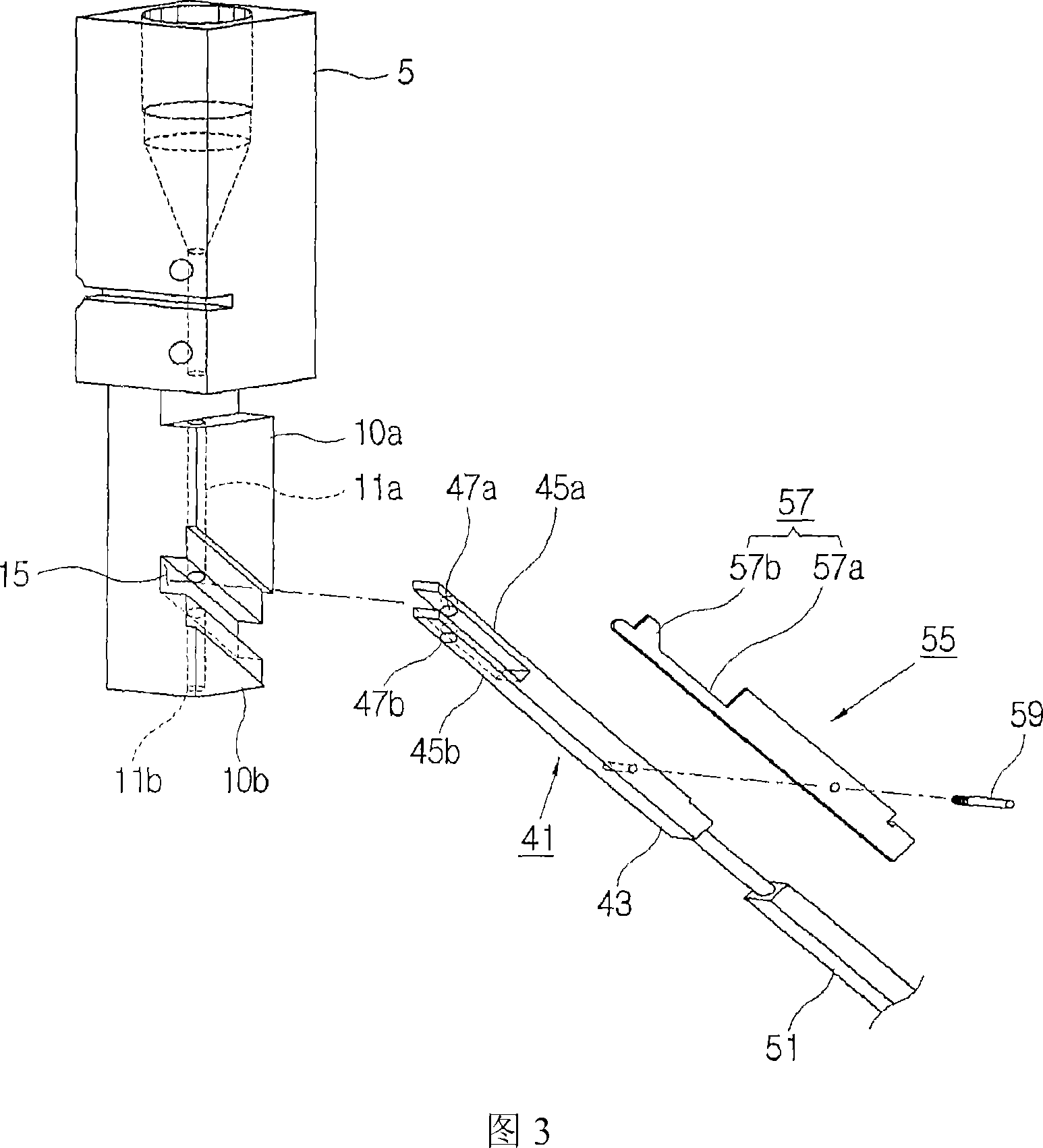

Thread feeding apparatus for an automatic embroidering machine

InactiveCN1997788AAvoid disconnectionTake-up devicesEmbroidering machines apparatusReciprocating motionWaste management

A thread feeding apparatus for an automatic embroidering machine comprises a thread supplying unit to supply one upper thread selected among a plurality of upper threads different in color; a pair of thread guides formed with a thread guiding channel to guide the upper thread supplied from the thread supplying unit, and continuously formed along a thread transferring path of the thread guiding channel, leaving a space portion; a thread take-up unit provided with a thread retainer to retain the upper thread, oscillating between a top dead point and a bottom dead point, and strengthening and releasing the tension of the upper thread; and a thread take-out unit comprising a thread take-out lever to hold and take out the upper thread passing through the space portion, and a thread take-out driver to reciprocate the thread take-out lever to put the upper thread held by the thread take-out lever into the thread retainer. Thus, the present invention provides a thread feeding apparatus for an automatic embroidering machine, which prevents an upper thread from being cut when the upper thread is replaced, and reduces time taken to replace the upper thread, thereby enhancing work efficiency.

Owner:INBRO

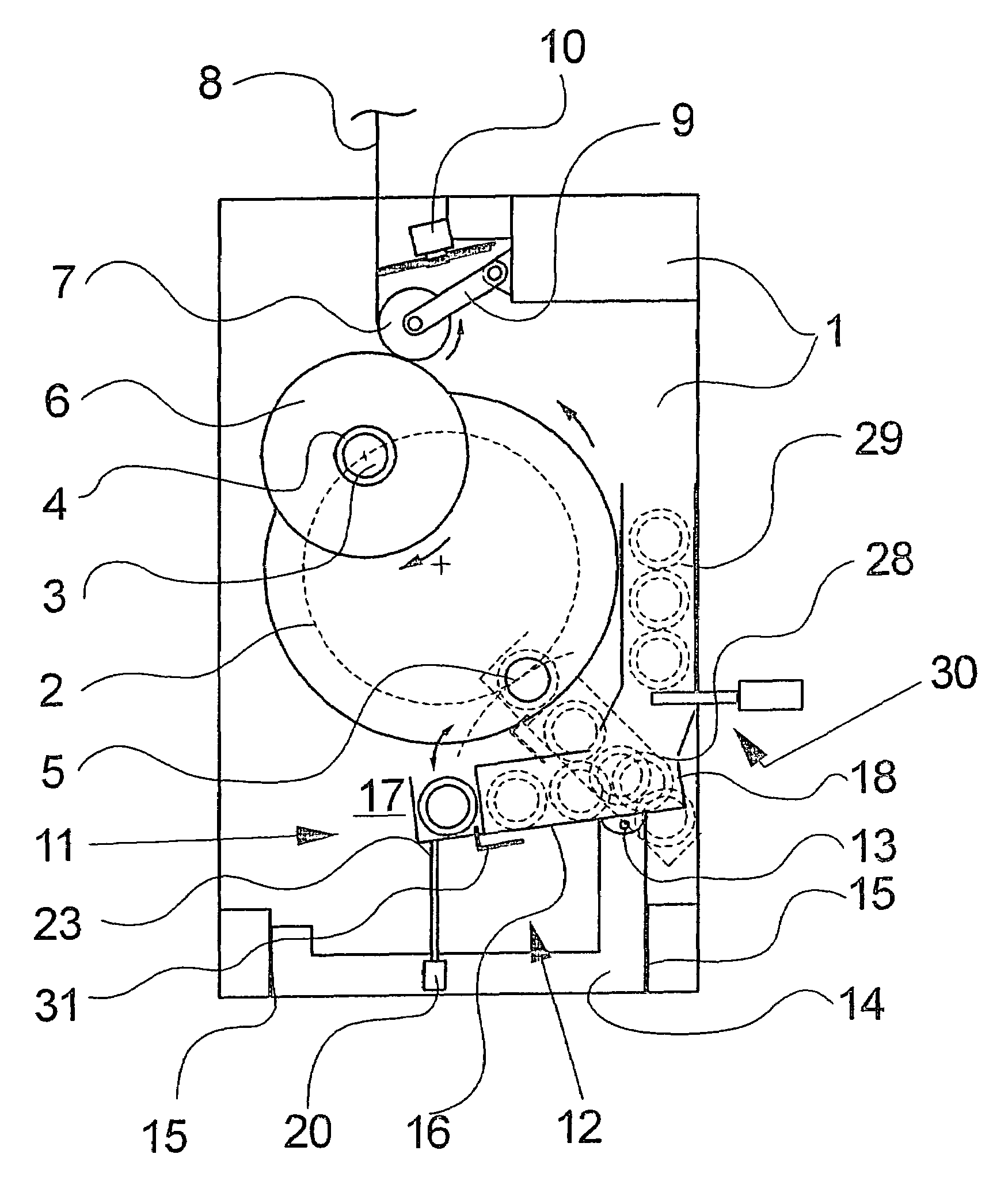

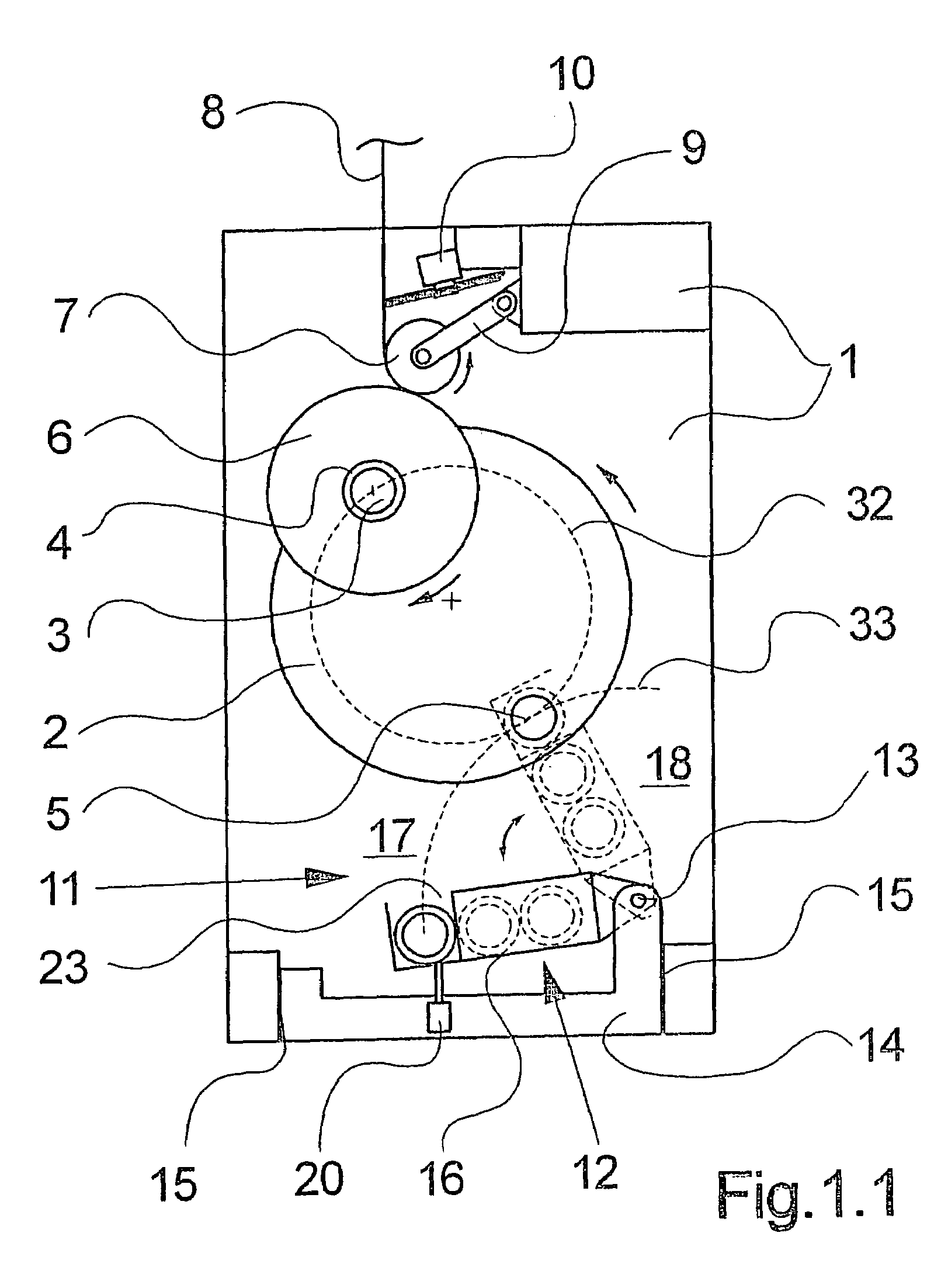

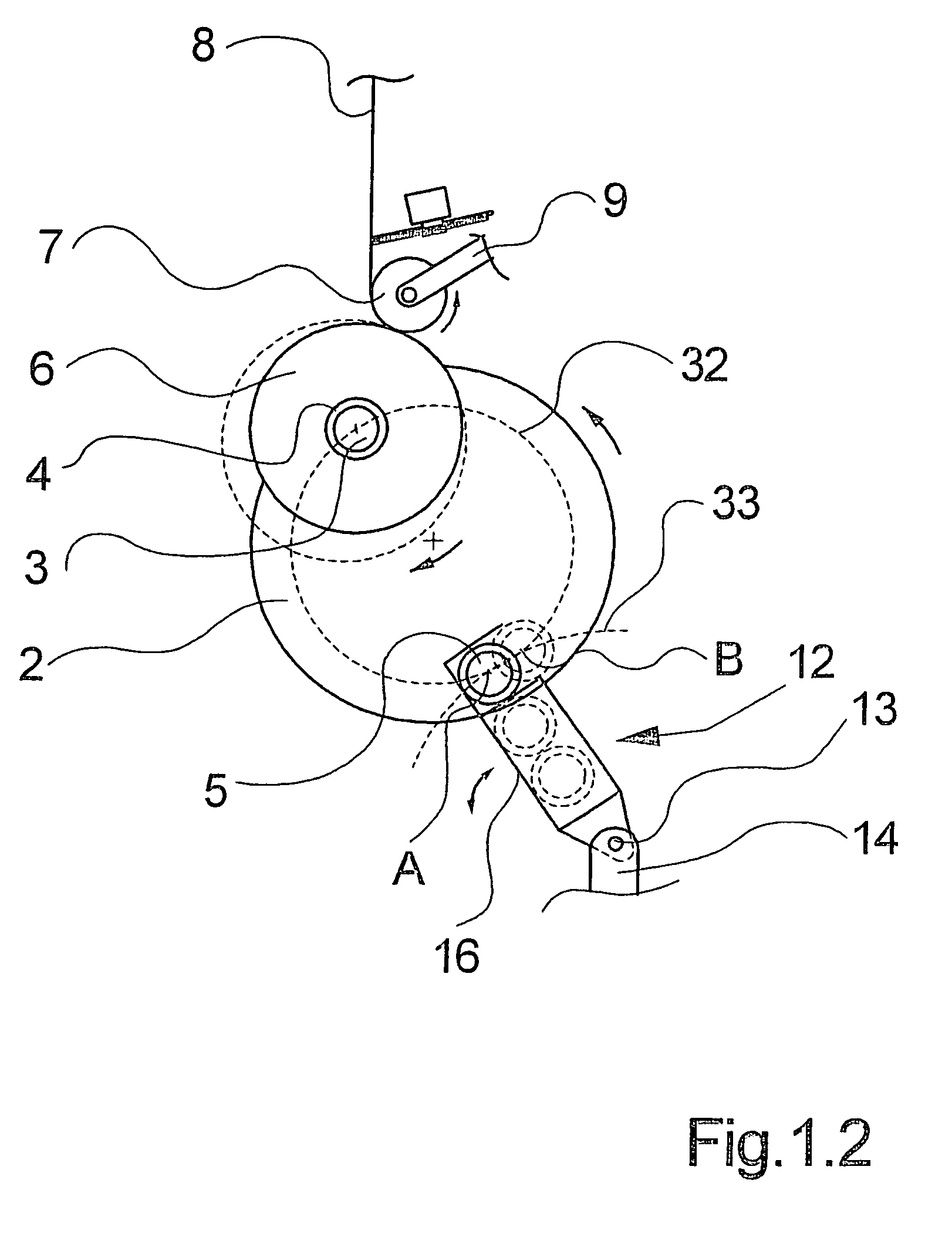

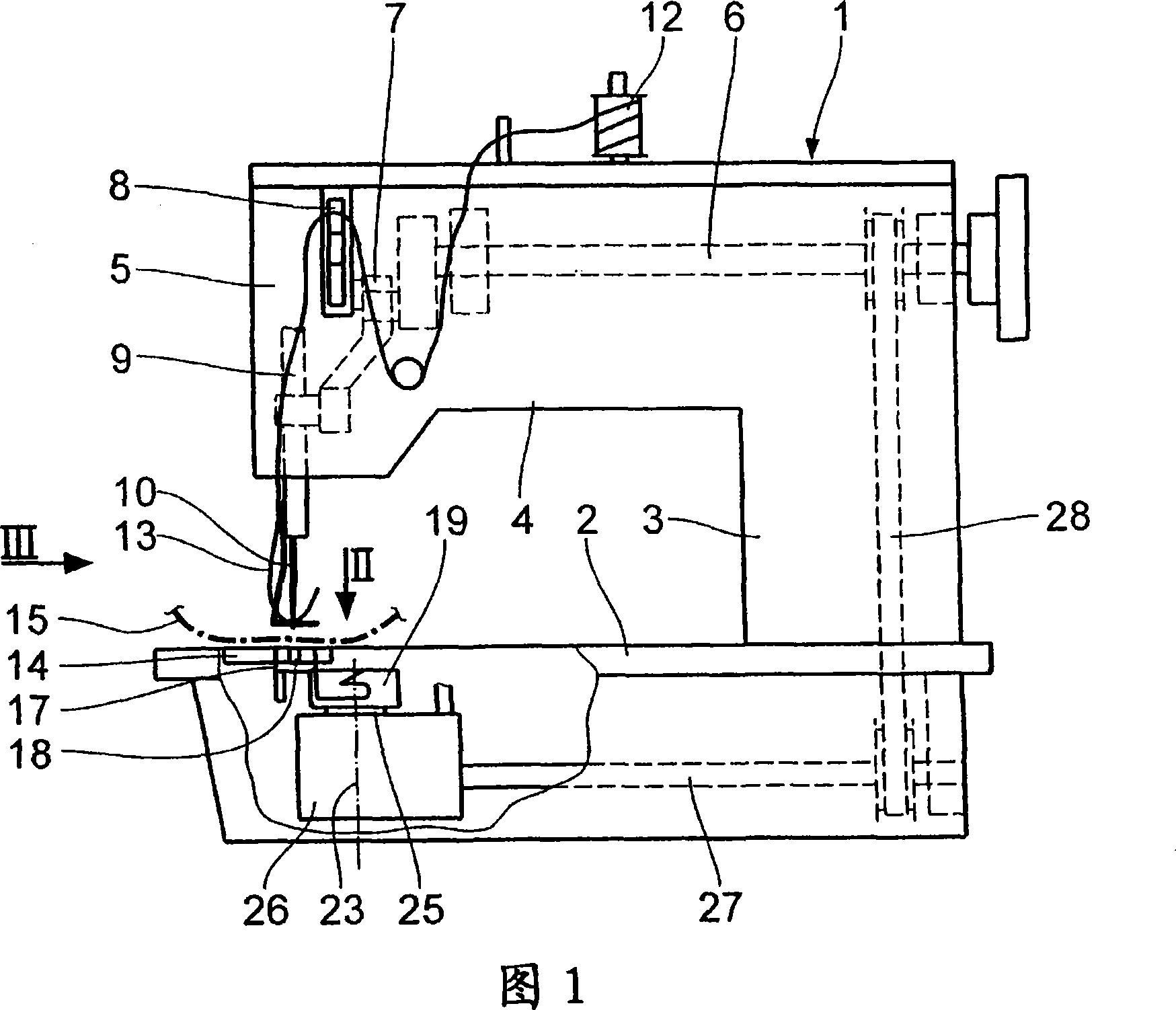

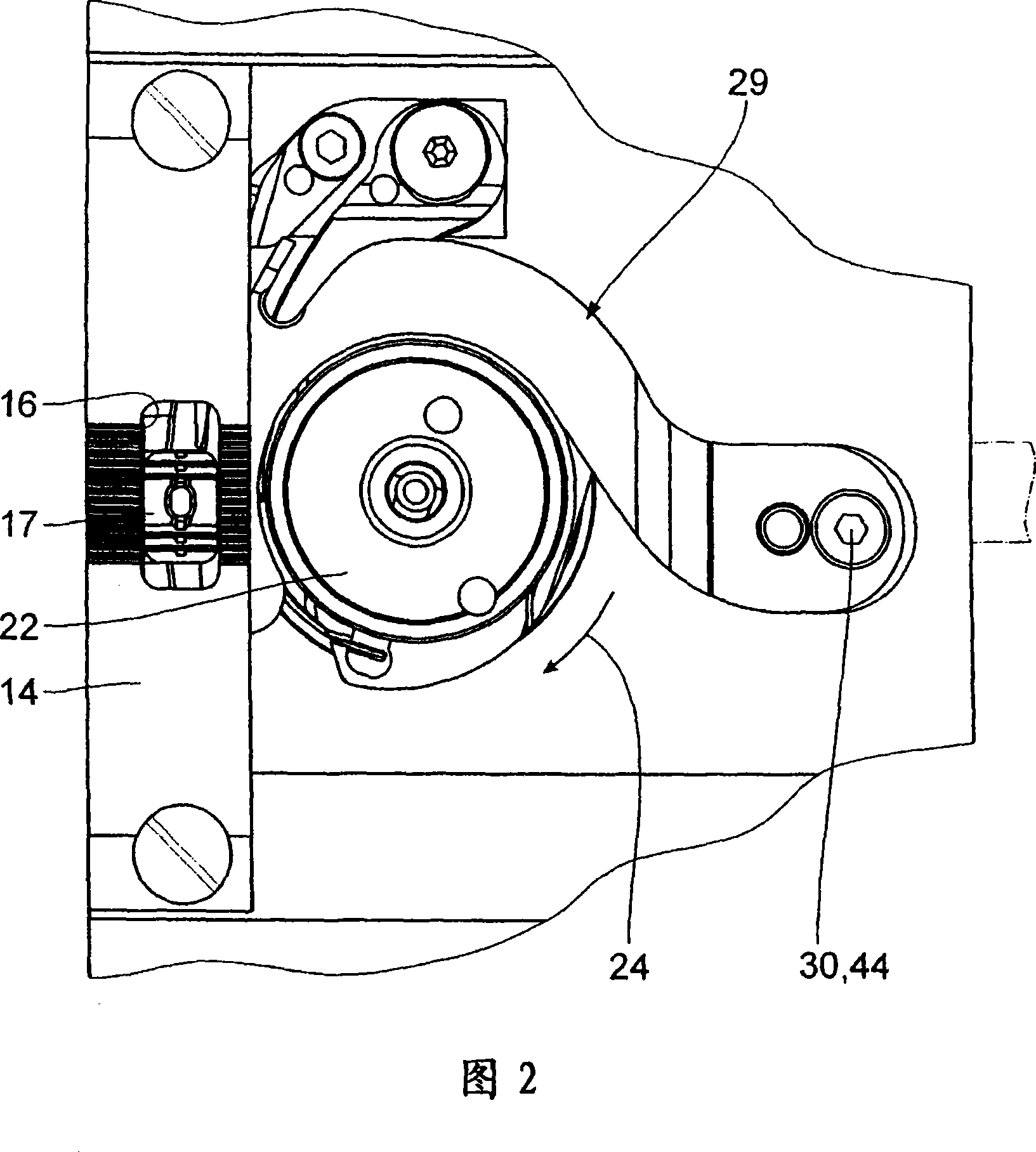

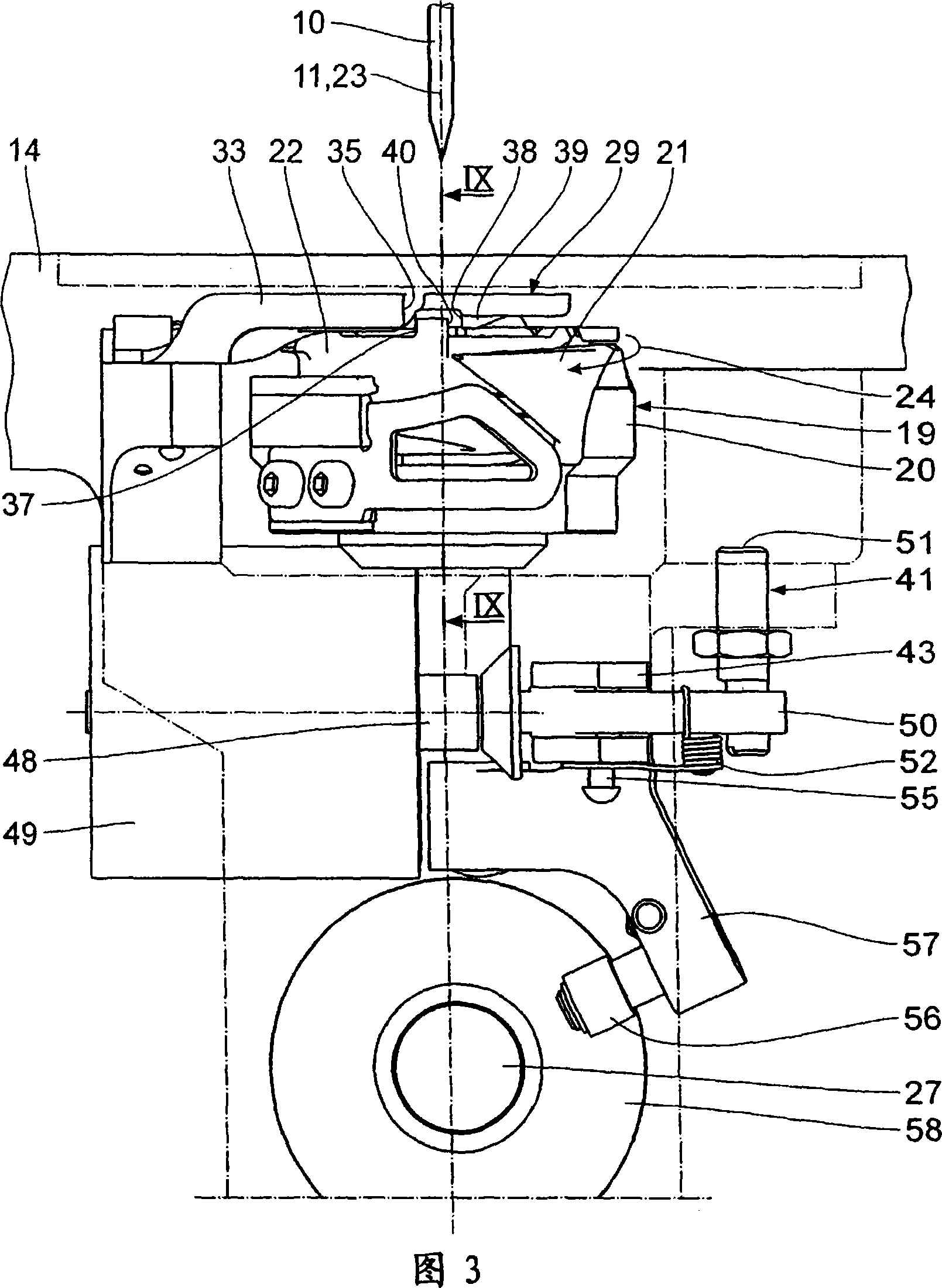

Lock-type chain stitch sewing machine

ActiveCN101058922AGuaranteed absorptionSave spaceNeedle severing devicesTake-up devicesBobbinKnife blades

The lockstitcher is provided with shuttle hook, the shutter hook can revolve around the upright axial cord of the shuttle hook along the rotation direction of the needlework operation process and it composes the shutter body of the bobbin cover which is used to accommodate the supplying source of the shutter thread in the inner part. The knife blade can rotate around the pivot axis of oscillation which is parallel to the axial cord of the shuttle hook between the initial position and take-up position. In the operation process of the needlework, the first rotate-proof stop catch which cooperates with the opposite stop catch of the first bobbin cover avoids the bobbin cover rotating around the axial cord of the shutter hook in the rotation direction. In the opposite direction, the second rotate-proof stop catch which cooperates with the opposite stop catch of the second bobbin cover fixes the bobbin cover. The second rotate-proof stop catch is fixed on the wire-restoring blade. When the shuttle hook rotates along the opposite direction, the location guarantee arrangement in the chucking location fixes the wire-restoring blade on the initial position. At the initial position, the second rotate-proof stop catch cooperates with the opposite catch stop of the second bobbin cover. Therefore it forms the sewing machine which has little critical demand to the whole component room of the line access zone between the bobbin cover and the bearing plate.

Owner:DURKOPP ADLER GMBH

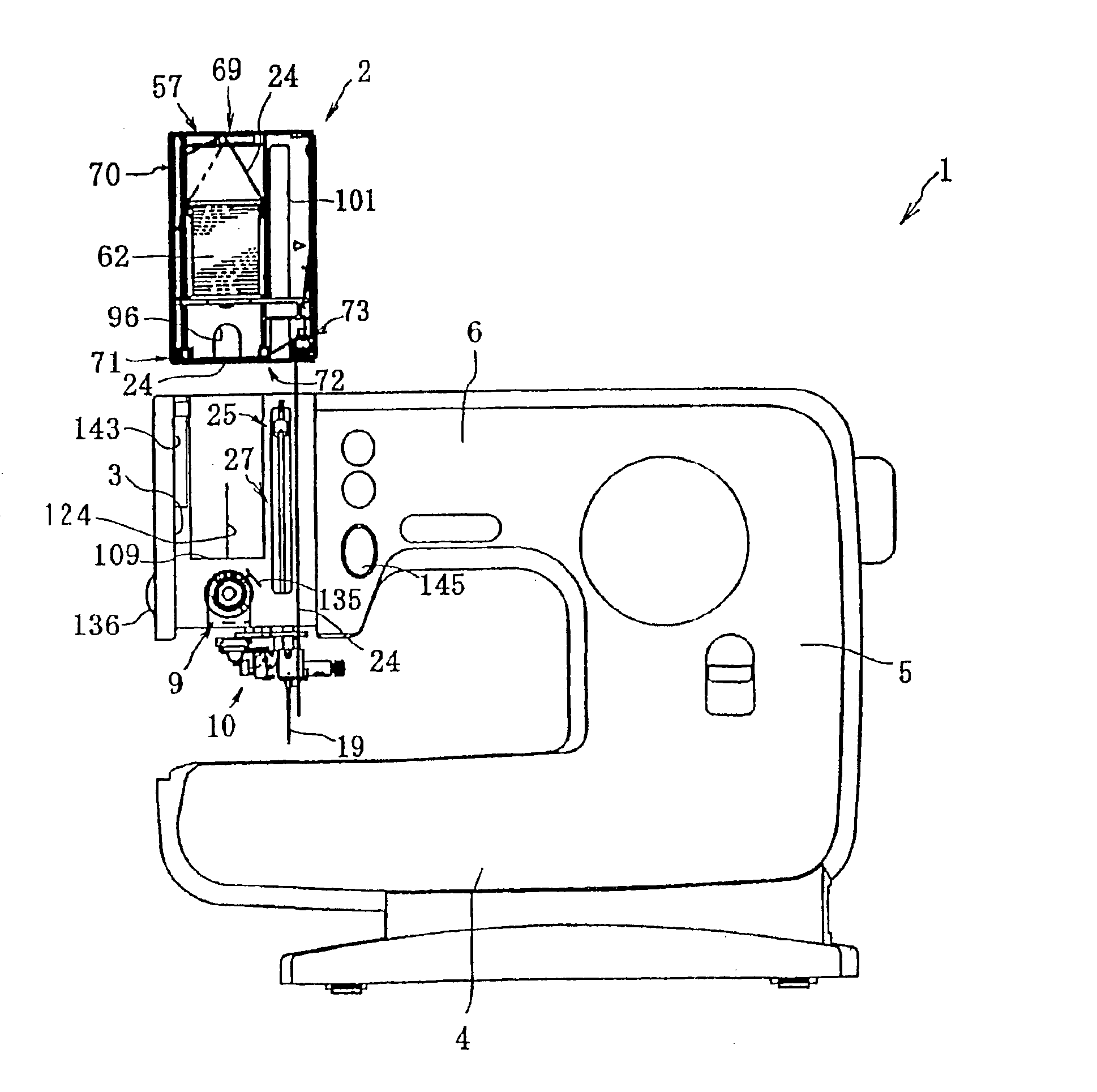

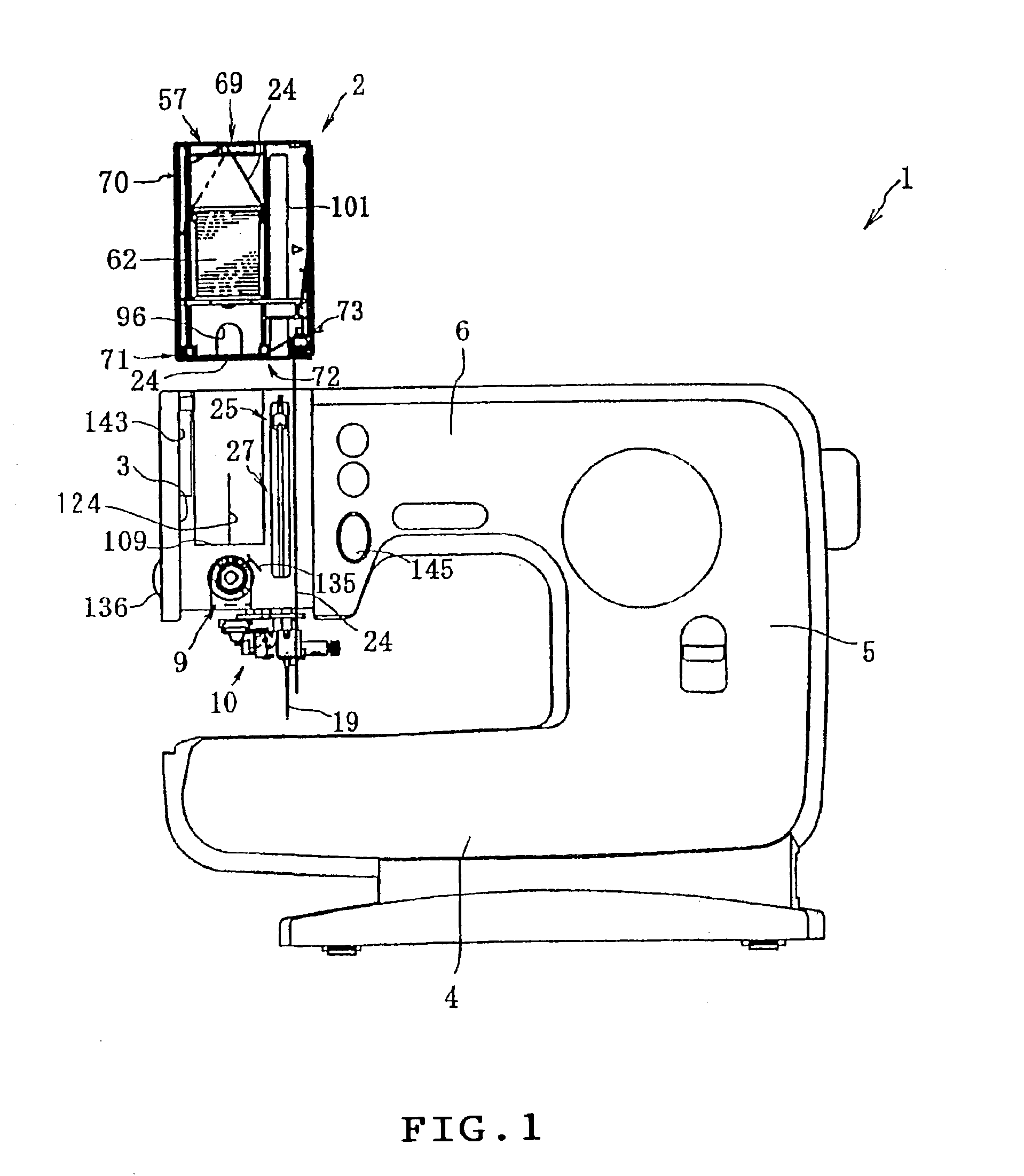

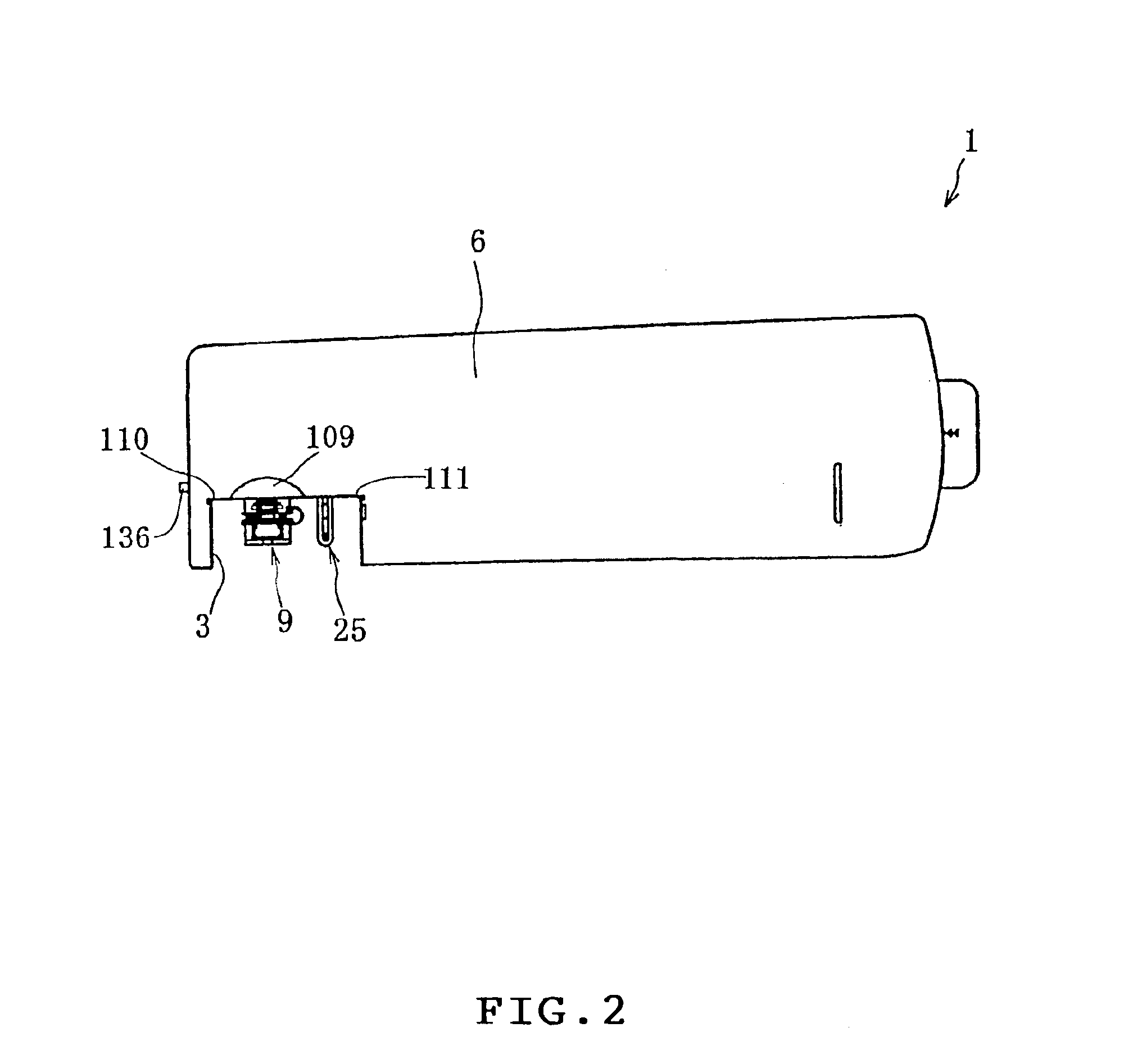

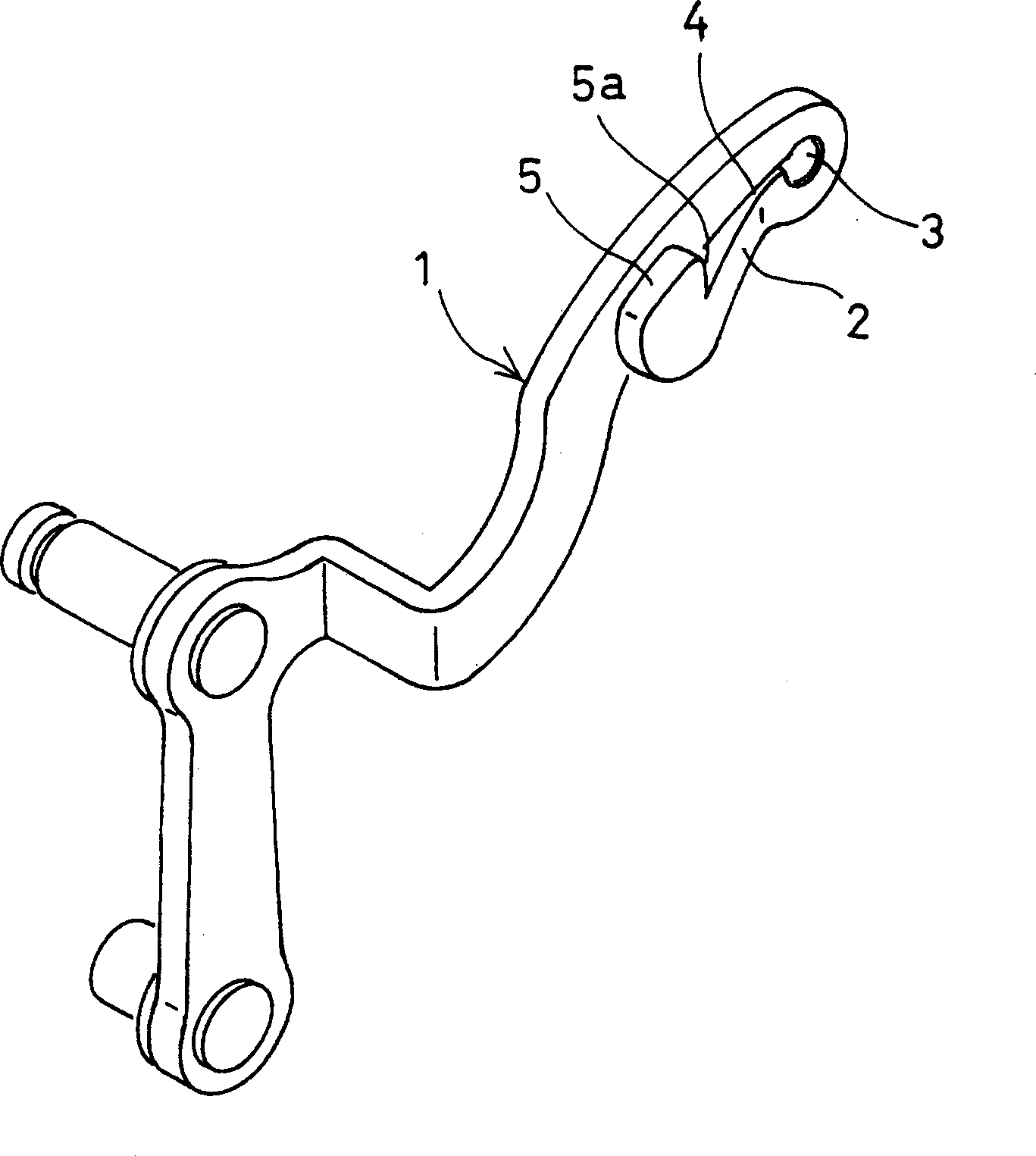

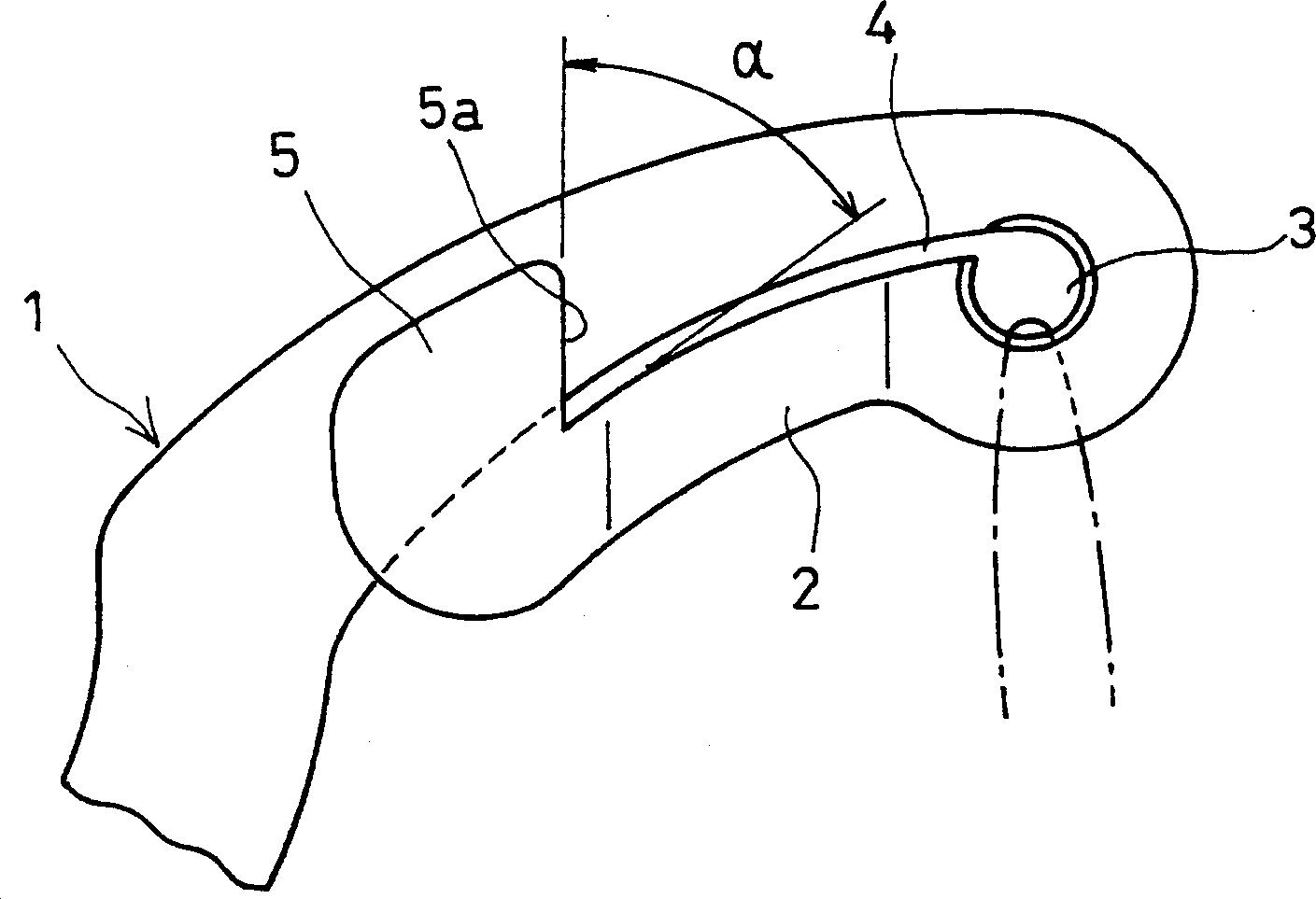

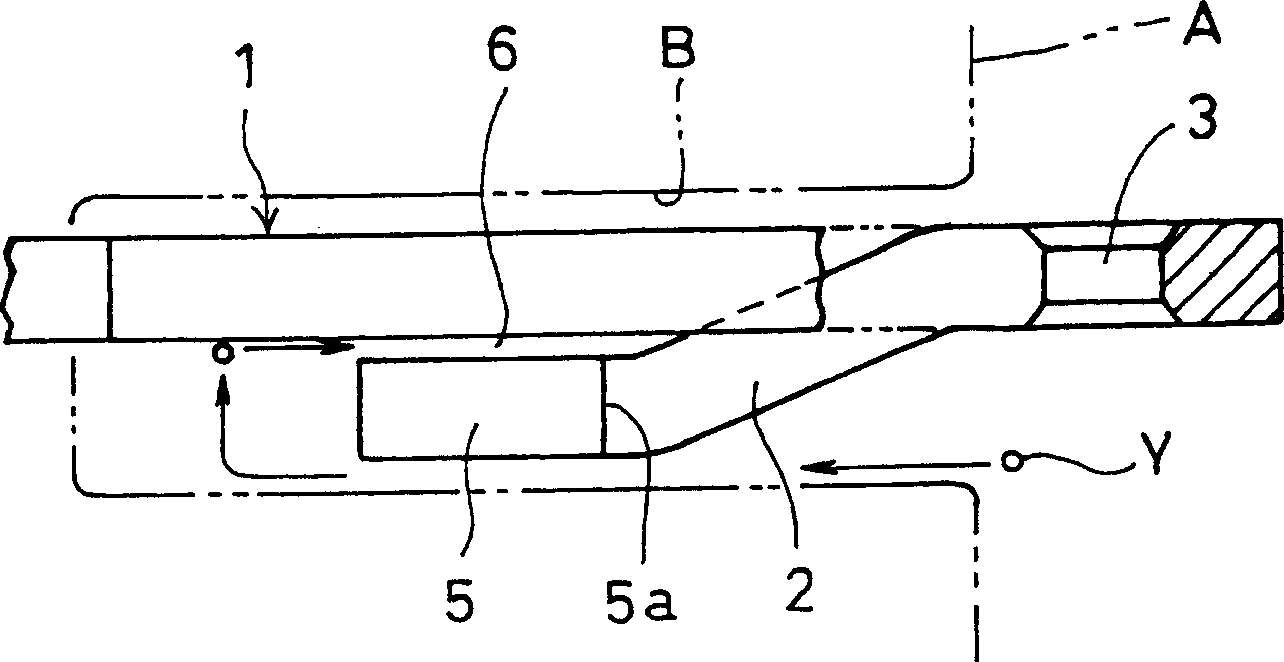

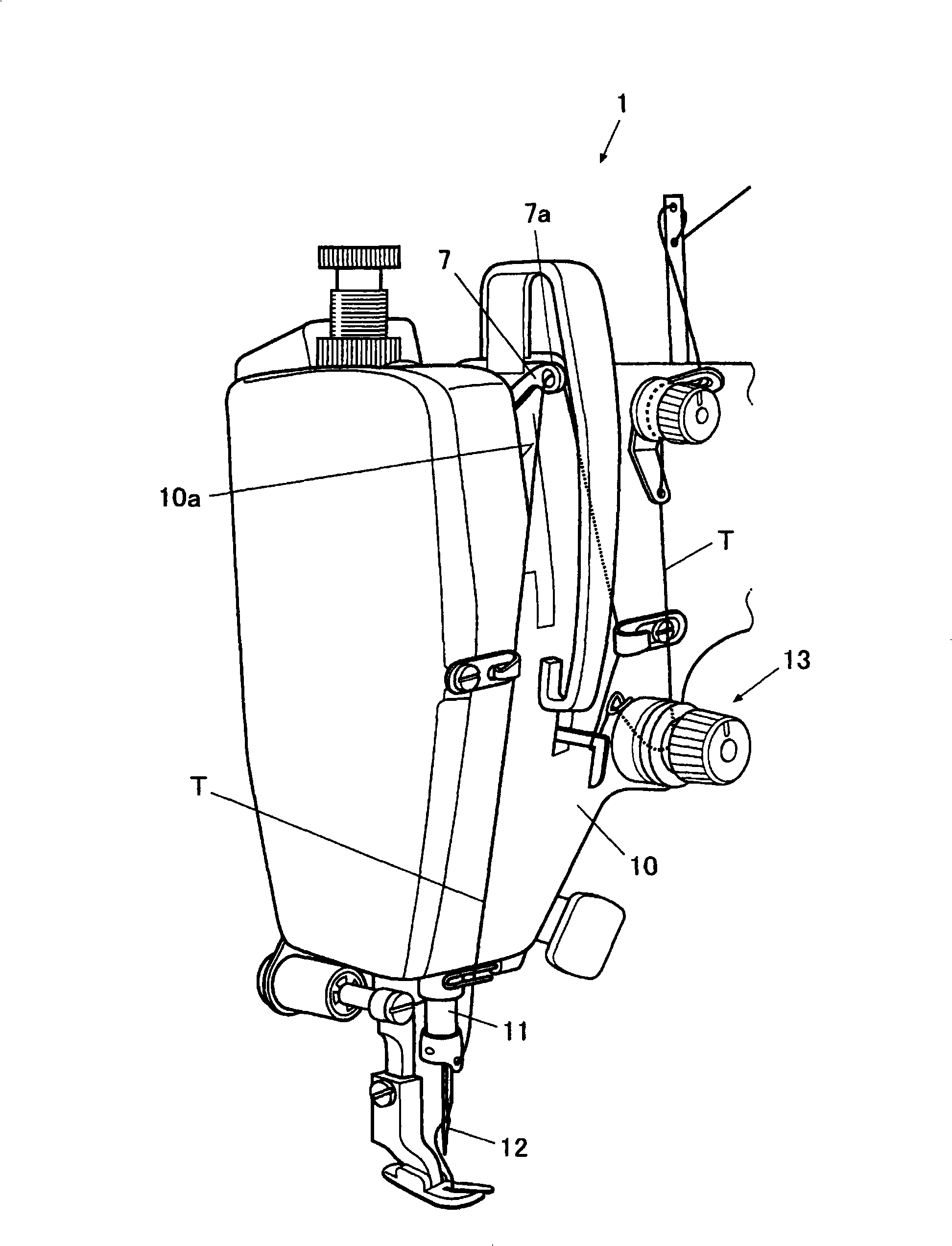

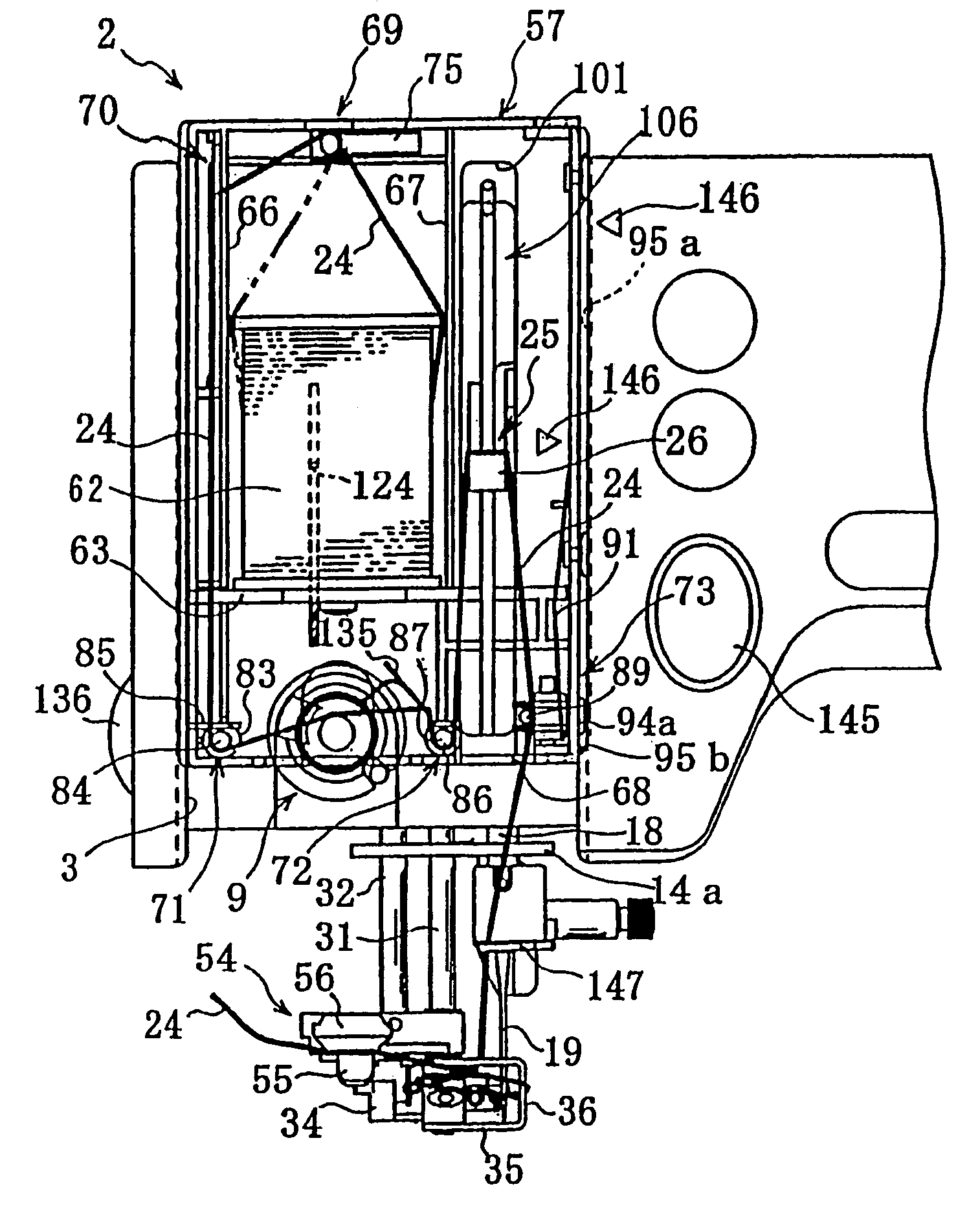

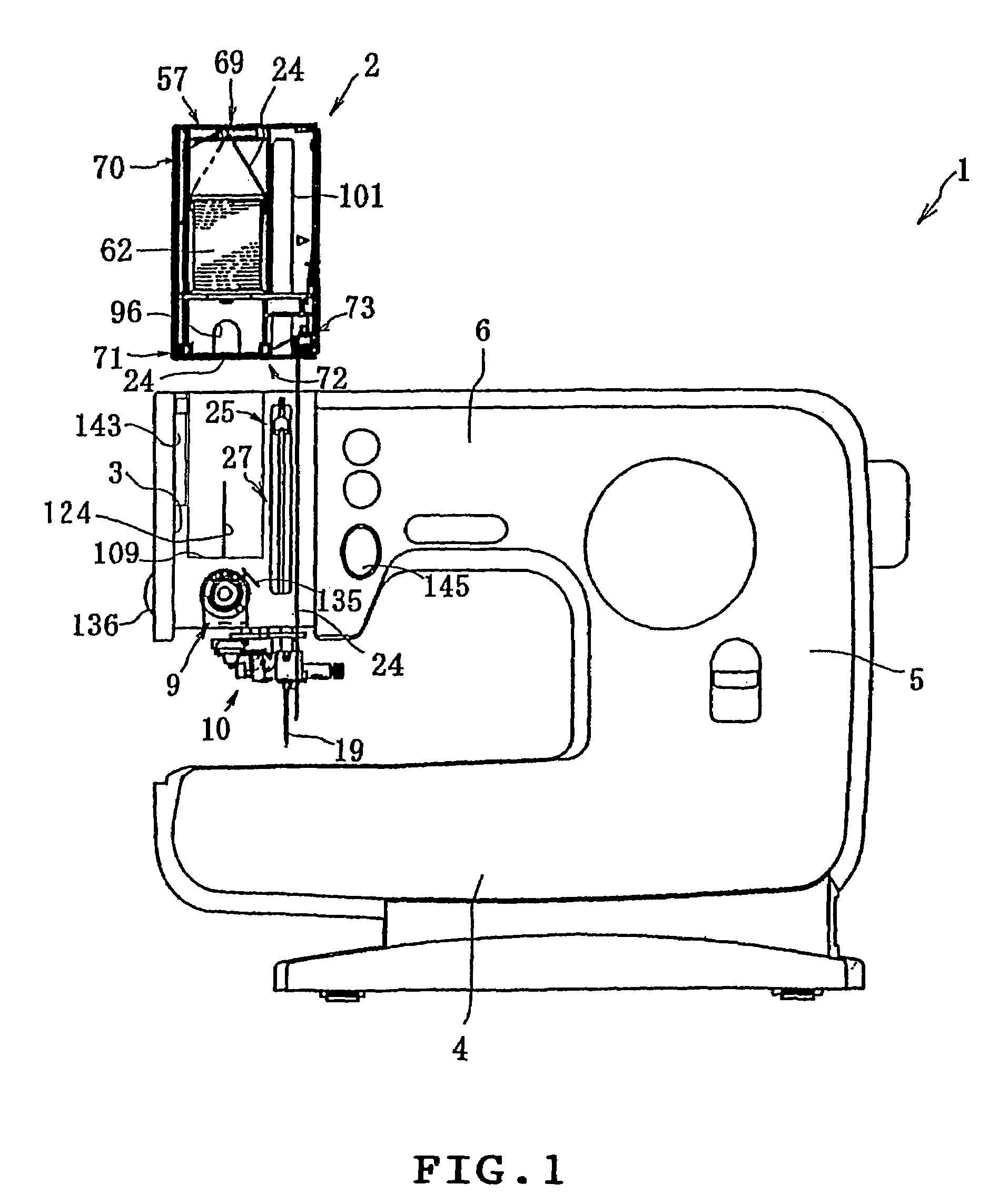

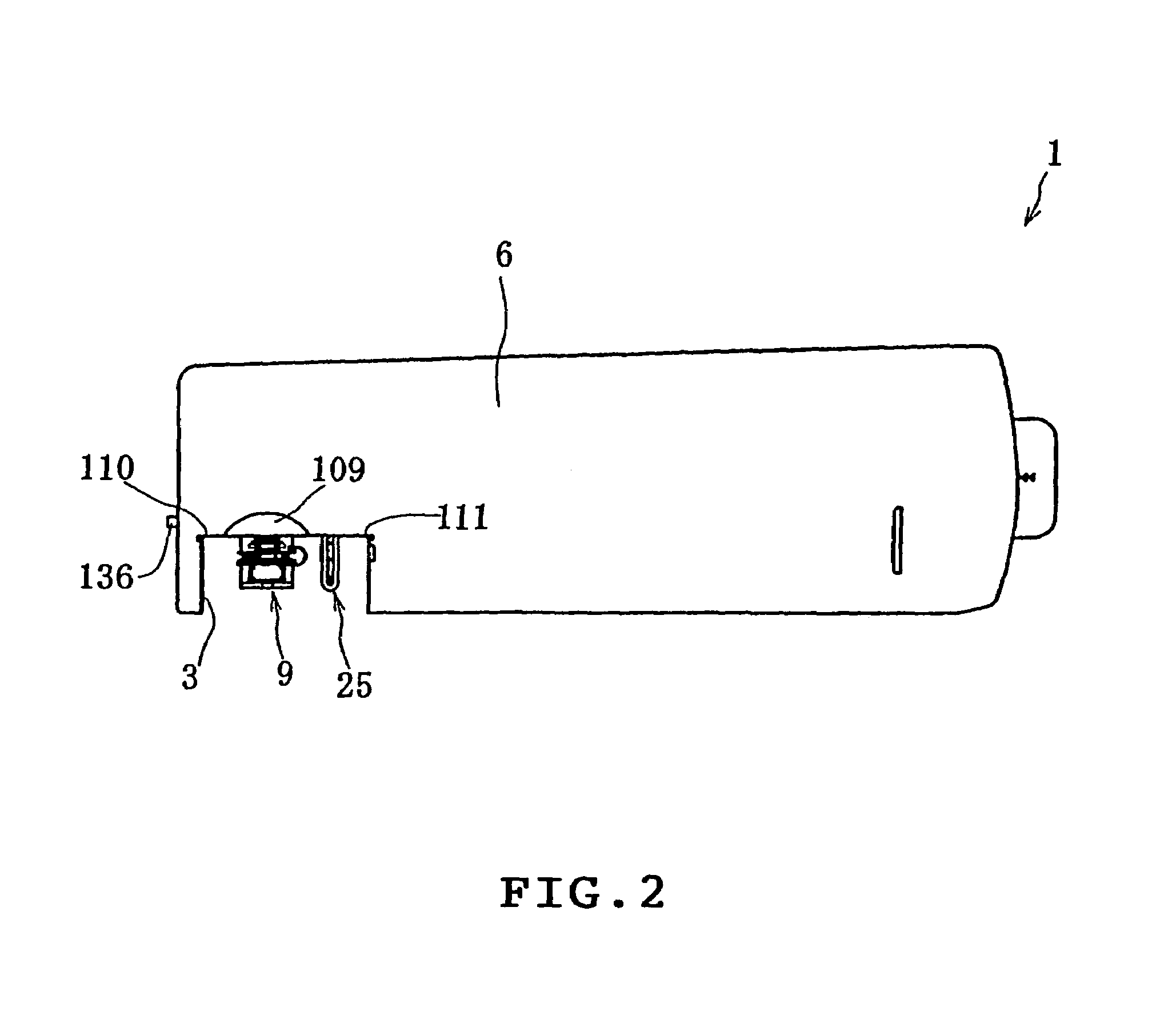

Sewing machine with needle thread cassette and needle thread cassette

InactiveUS6883447B1Improve handlingEasy to operateSewing-machine casingsFilament handlingBobbinEngineering

A sewing machine with a needle thread cassette, wherein a cassette mount (3) is reduced in size. The cassette mount (3) including a thread take-up lever travel region is formed in the form of a vertical groove in the arm head of the sewing machine. A needle thread cassette (2) having a thread bobbin (62) vertically received therein is removably mounted on the cassette mount (3) vertically from above. With a thread take-up lever (25) stopped in a position corresponding to a needle top stop position, the needle thread cassette (2) is mounted on the cassette mount (3), whereby the thread is engaged with the thread guard of the thread take-up lever (25) and a thread tension regulator (9).

Owner:BROTHER KOGYO KK

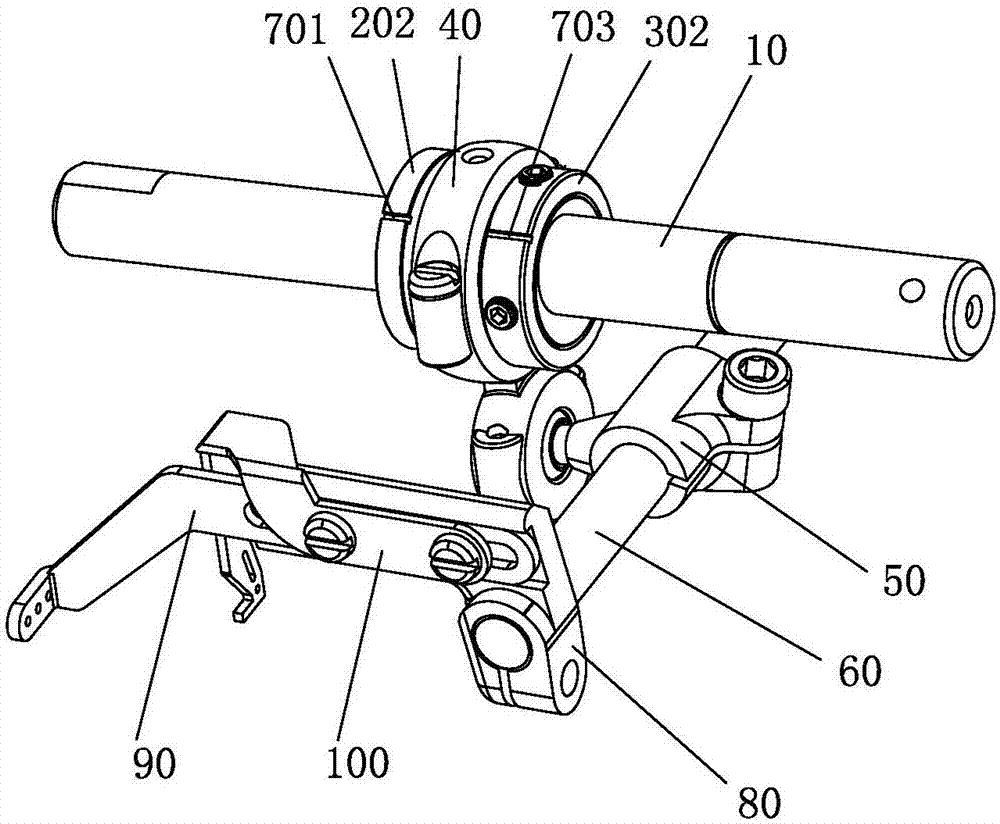

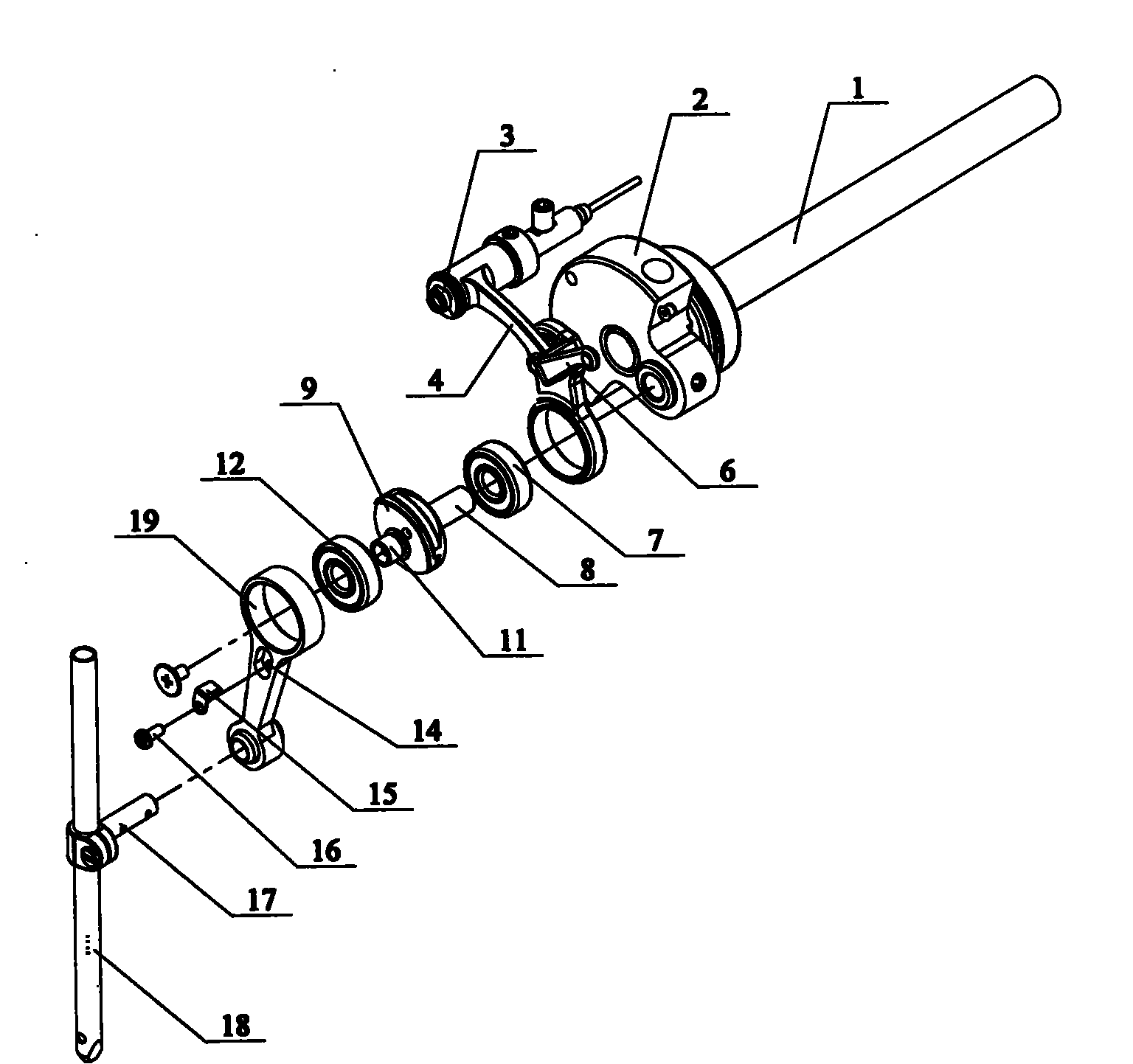

Take-up stroke adjustable structure and sewing machine

ActiveCN107099947AAdjust the tightnessImprove versatilityTake-up devicesVertical motionSewing machine

The invention belongs to the technical field of sewing machines, and relates to a take-up stroke adjustable structure and a sewing machine. The take-up stroke adjustable structure comprises an upper shaft, an eccentric wheel I arranged on the upper shaft in a sleeving mode, and an eccentric wheel II arranged on the eccentric wheel I in a sleeving mode, wherein the eccentric wheel II can rotate on the eccentric wheel I to adjust the eccentricity dimension. A connecting rod is arranged outside the eccentric wheel II in a sleeving mode; the other end of the connecting rod is connected to a crank, and the crank is arranged on a take-up shaft; the upper shaft rotates and drives the eccentric wheel I and the eccentric wheel II to rotate, the eccentric wheel II drives the connecting rod to move vertically, and the vertical motion of the connecting rod is converted into rotary swing of the take-up shaft through the crank. Adjustment of the eccentricity dimension is achieved by arranging the eccentric wheel I and the eccentric wheel II on the upper shaft, so that change of the rotation angle of the take-up shaft is achieved, adjustment of the take-up amount is achieved, the tightness of needle thread is better adjusted, the university of the sewing machine is greatly improved, the use cost is reduced, and stitch optimization is achieved.

Owner:JACK SEWING MASCH CO LTD

Cover stitch sewing machine

ActiveUS7111568B1Avoid skippingAvoid it happening againTake-up devicesLoop takersDouble chainBiomedical engineering

In a cover stitch sewing machine which forms double chain stitch seams, needle threads are pulled out from the needle thread tensioning devices, passing over a thread hanging point on a needle thread pulling-up spring and the needle thread take-up completes drawing-up of the needle threads after needle thread loops of the respective needles are seized by the looper. The sewing material is then fed one feed pitch as the needles are moved down and the needle thread take-up draws out the needle threads, while the needle threads are pulled up at the thread hanging point by the elasticity of the needle thread pulling-up spring, thus preventing slack in the needle threads below the needle thread eyes. The threads which are connected with the needle thread loops, are drawn up by the thread hanging point of the needle thread take-up against the resiliency of the needle thread pulling-up spring.

Owner:SUZUKI MFG CO LTD

Needle thread taking-up lever for sewing machine

Owner:AXE YAMAZAKI

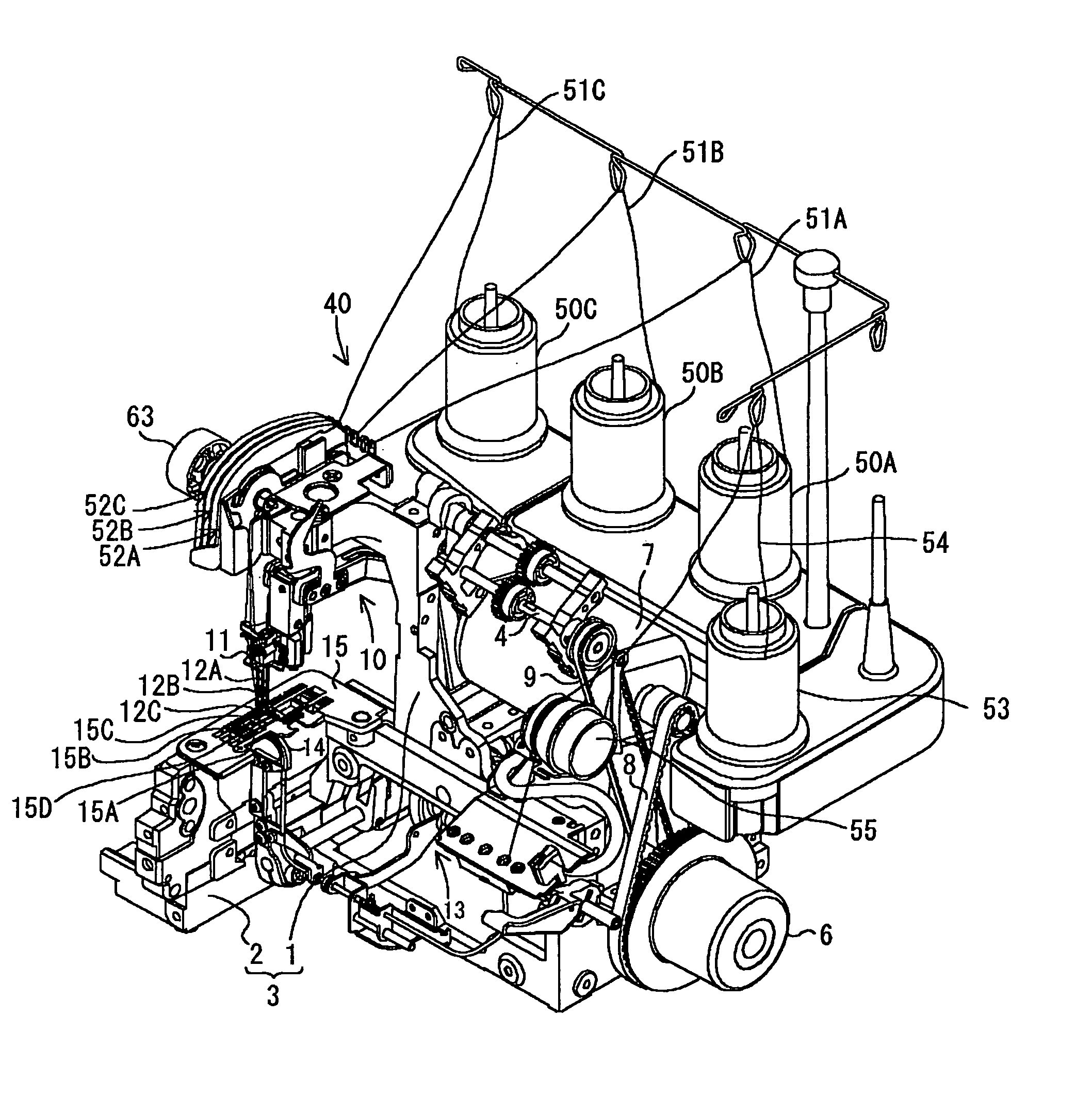

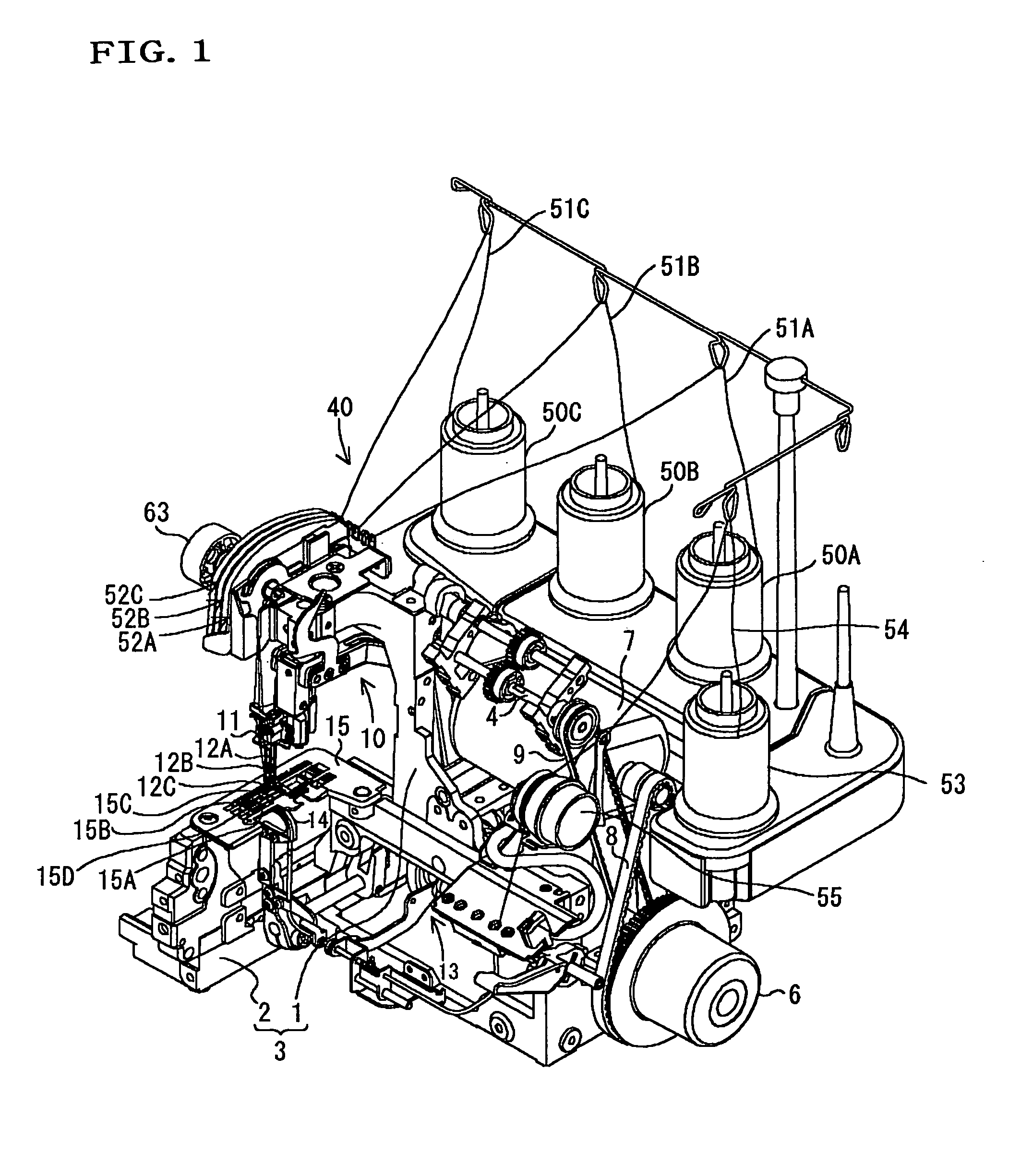

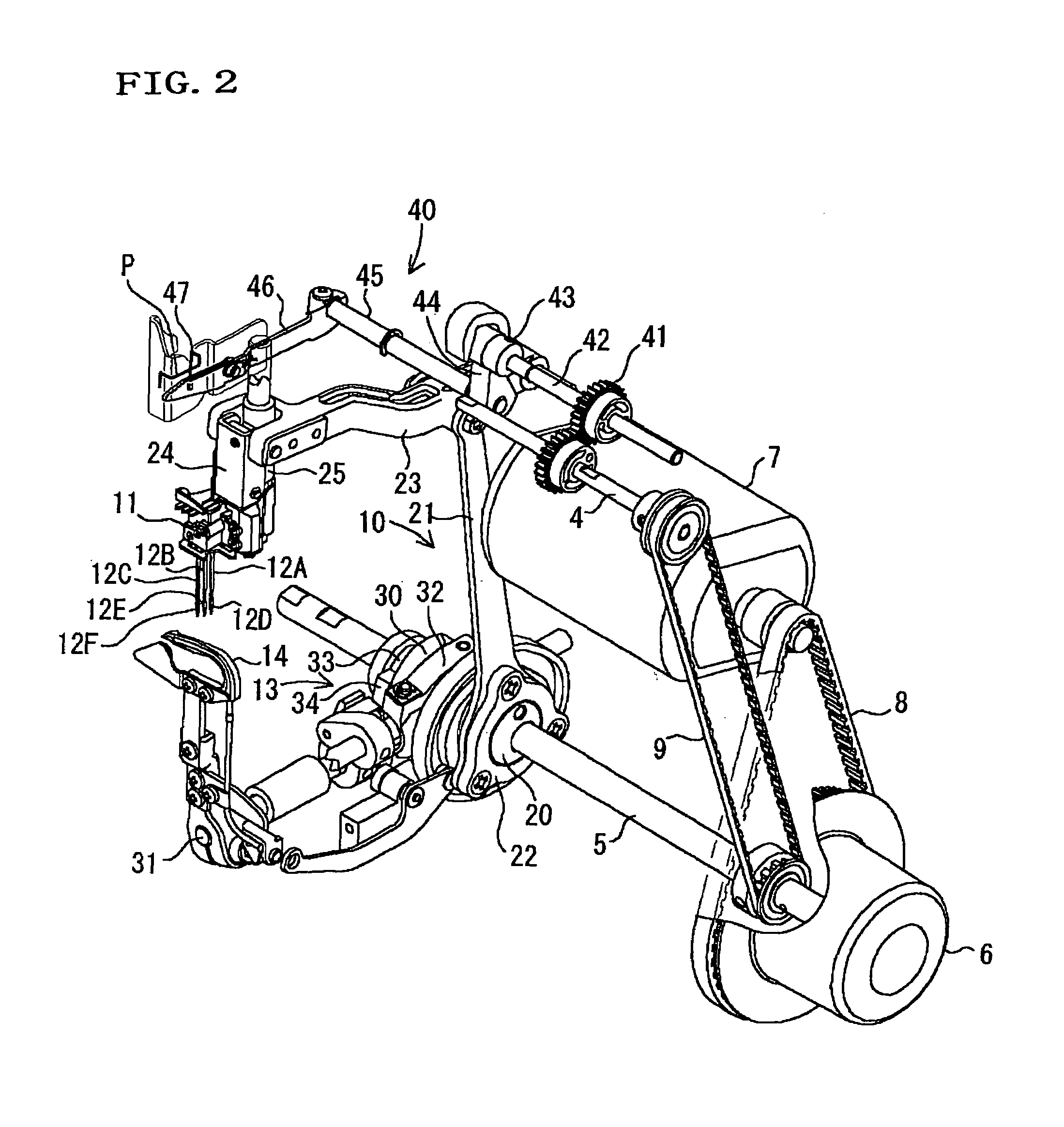

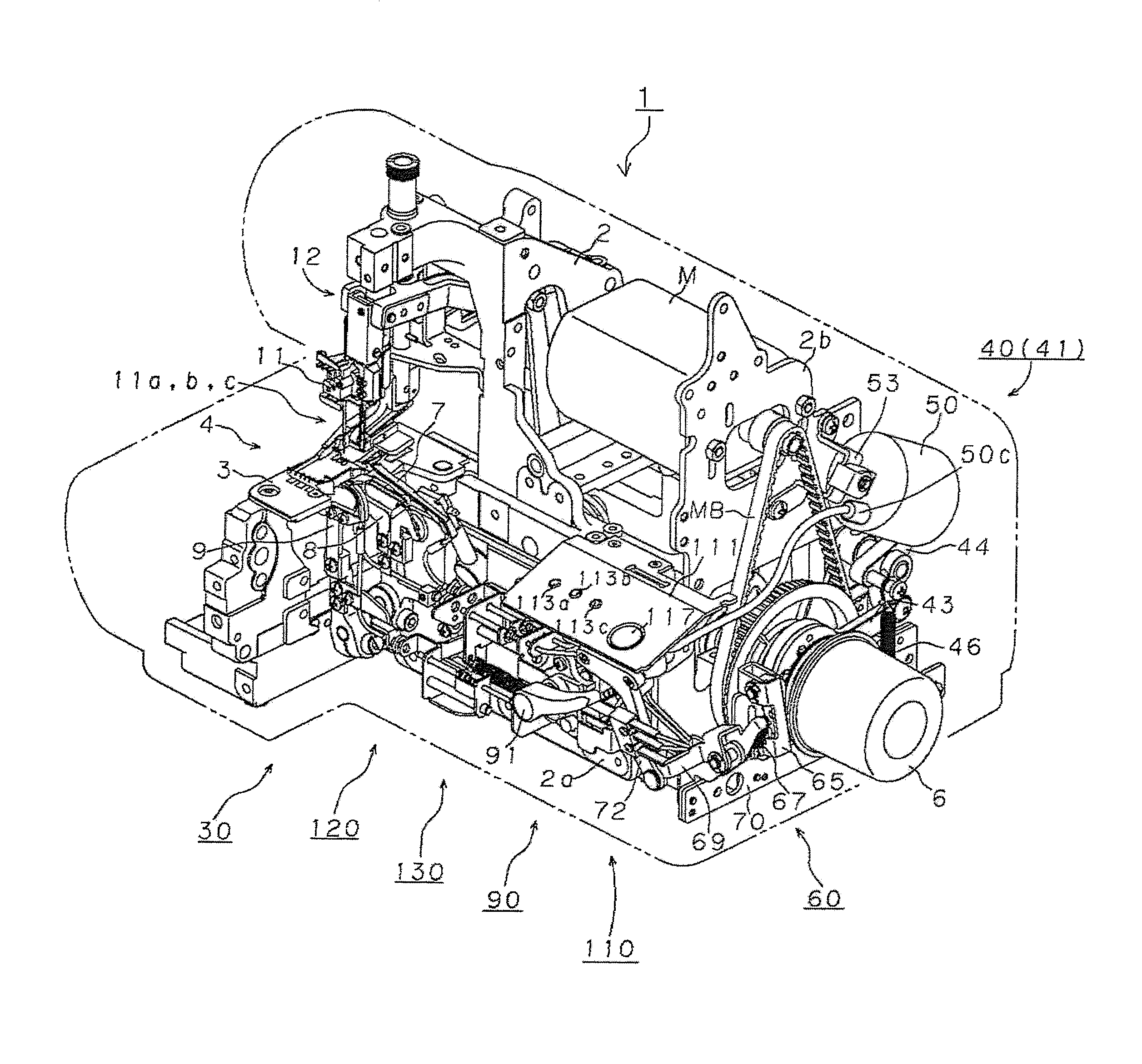

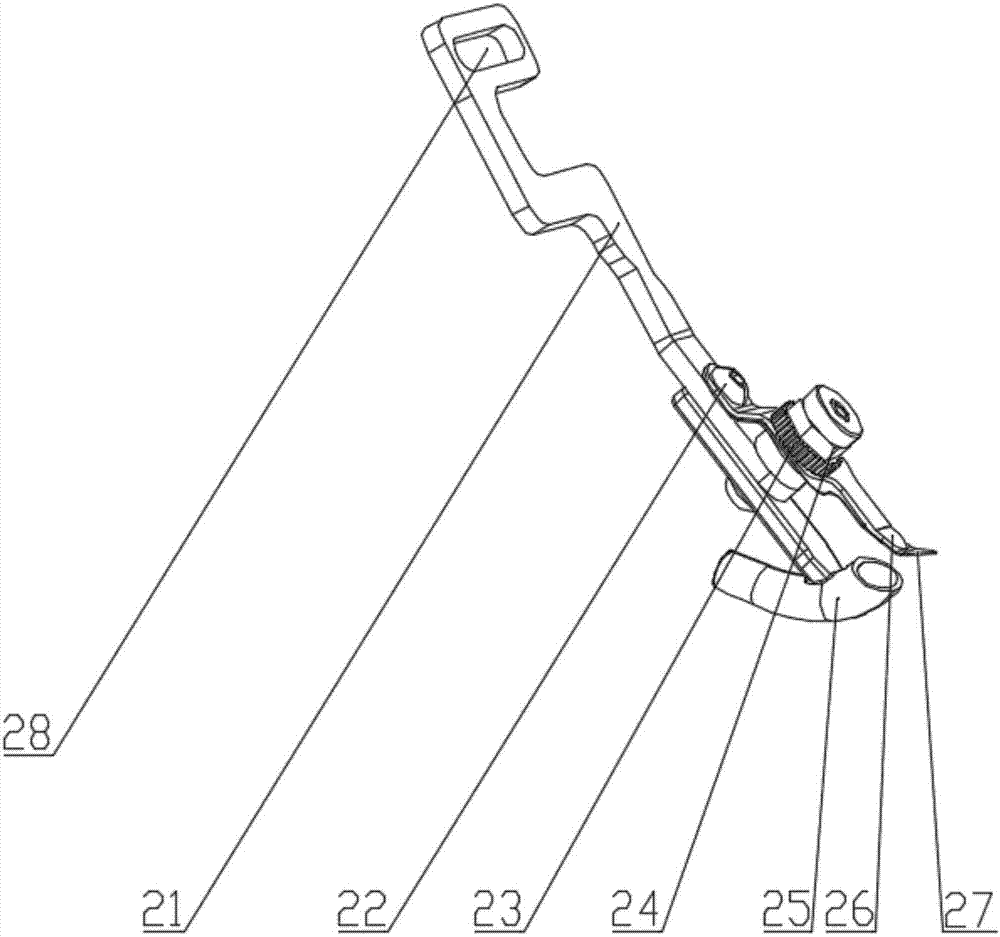

Gas carrying threading device of sewing machine

ActiveUS8925472B2Easy to handleFilament handlingNeedle-threading devicesDrive shaftTransmitted power

Pressurized gas for carrying looper thread by gas is generated by gas supply pump operated by changing over a sewing-machine motor, which drives stitch forming device, looper threading is performed through loopers by one-touch operation. Gas carrying threading device of sewing machine, comprising: looper thread introduction mechanism inserts looper thread guided to loopers; hollow looper thread guide extends from looper thread introduction mechanism to looper thread inlets and has looper thread guide outlets; gas supply pump for performing looper threading by carrying looper thread by gas from looper thread introduction area through hollow looper thread guide to looper thread loop-taker point outlets; clutch for transmitting power from sewing machine motor M to drive shaft which drives stitch forming device including loopers at time of stitch formation or to gas supply pump at time of looper threading.

Owner:SUZUKI MFG CO LTD

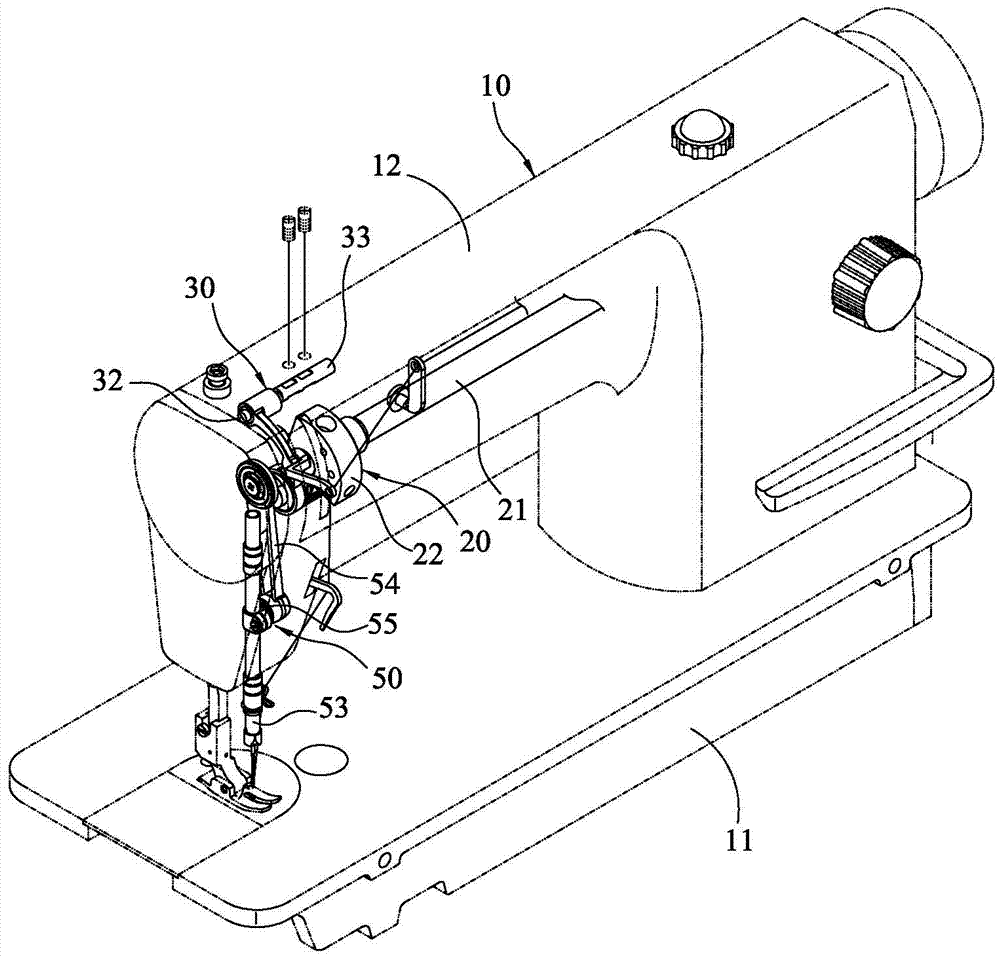

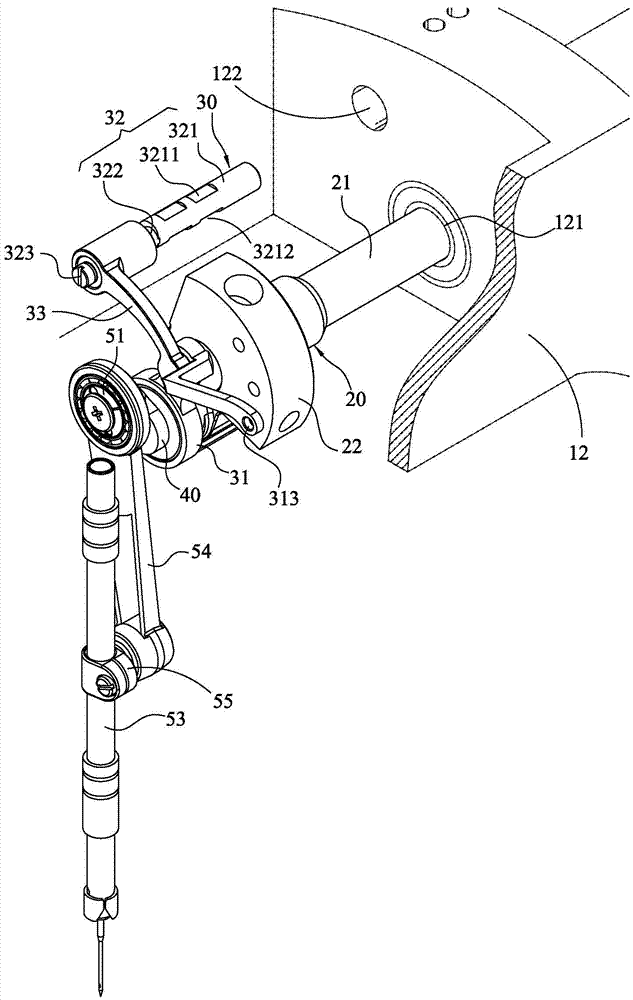

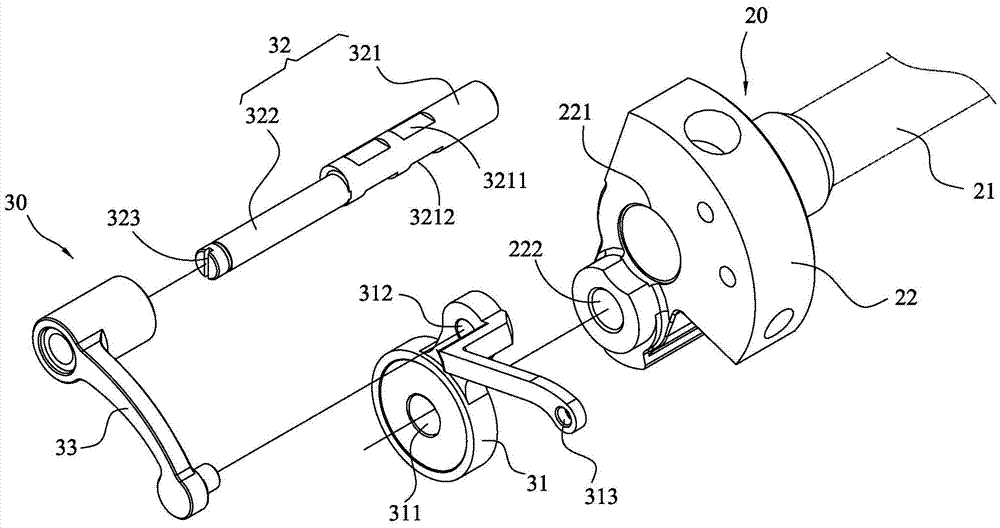

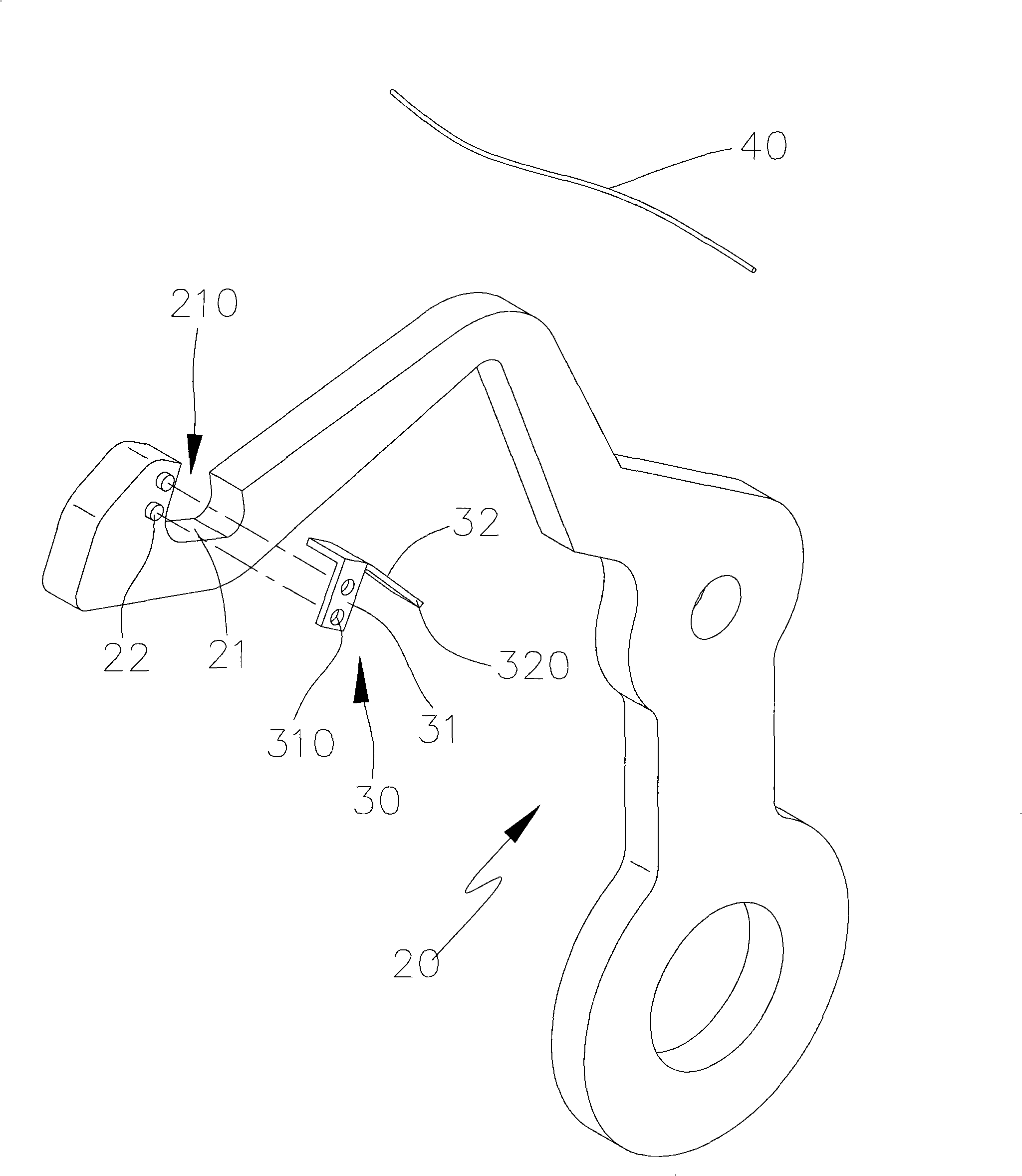

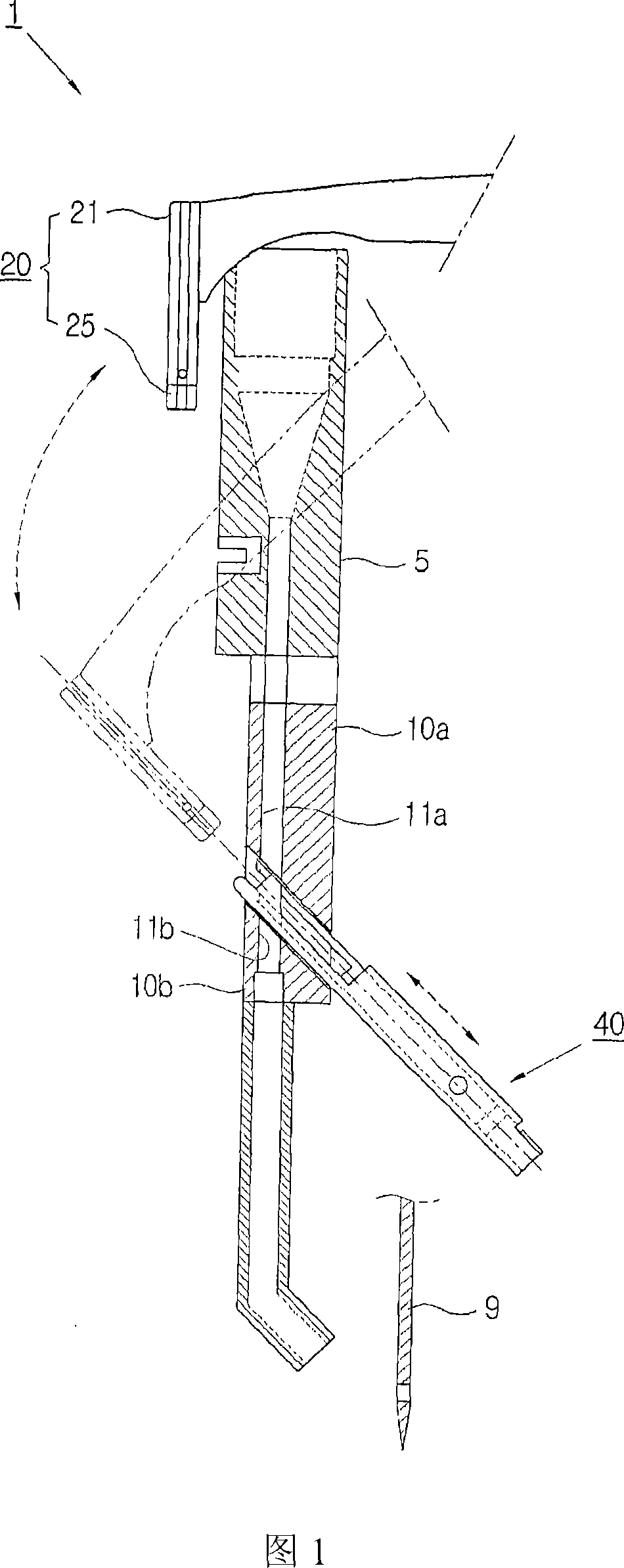

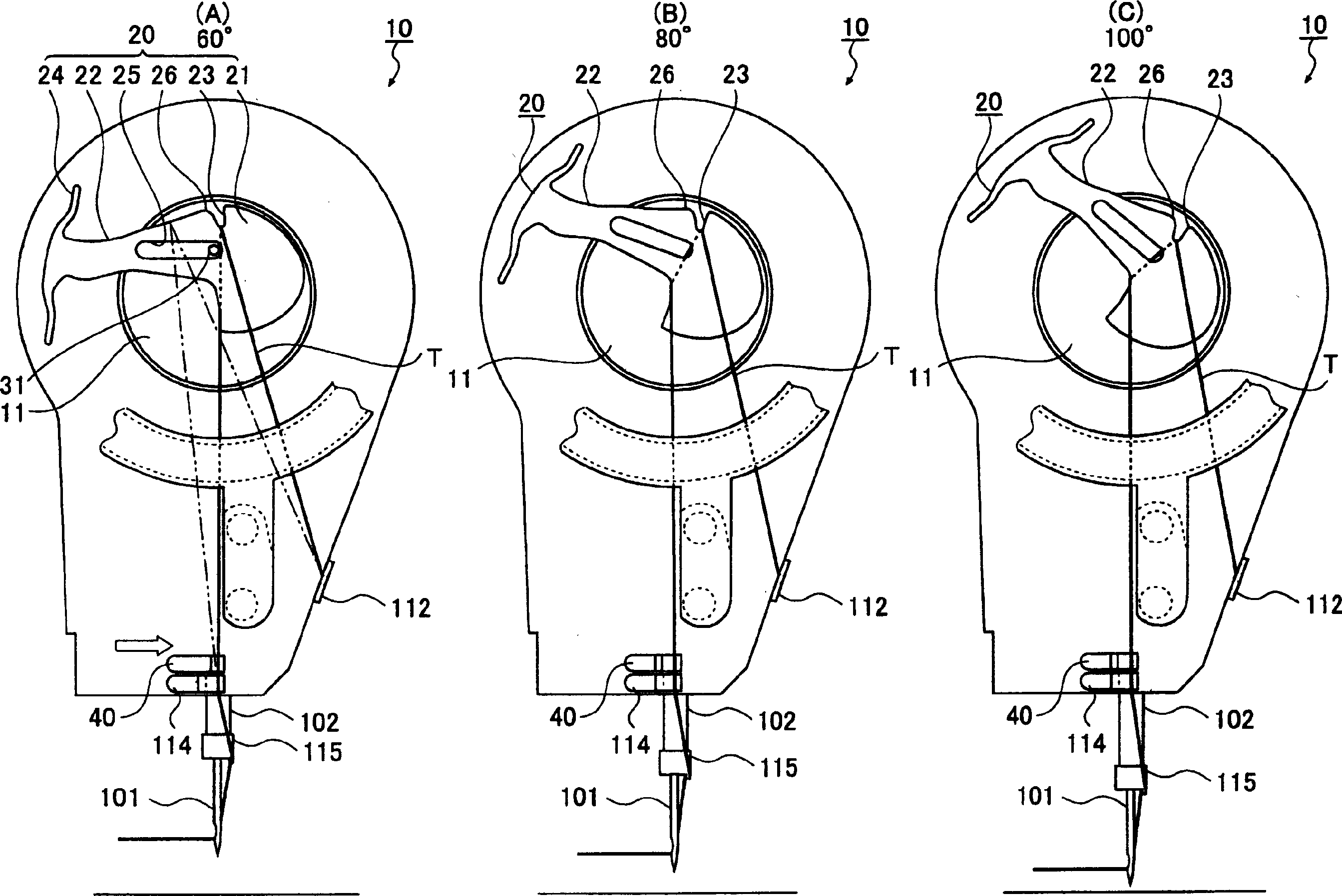

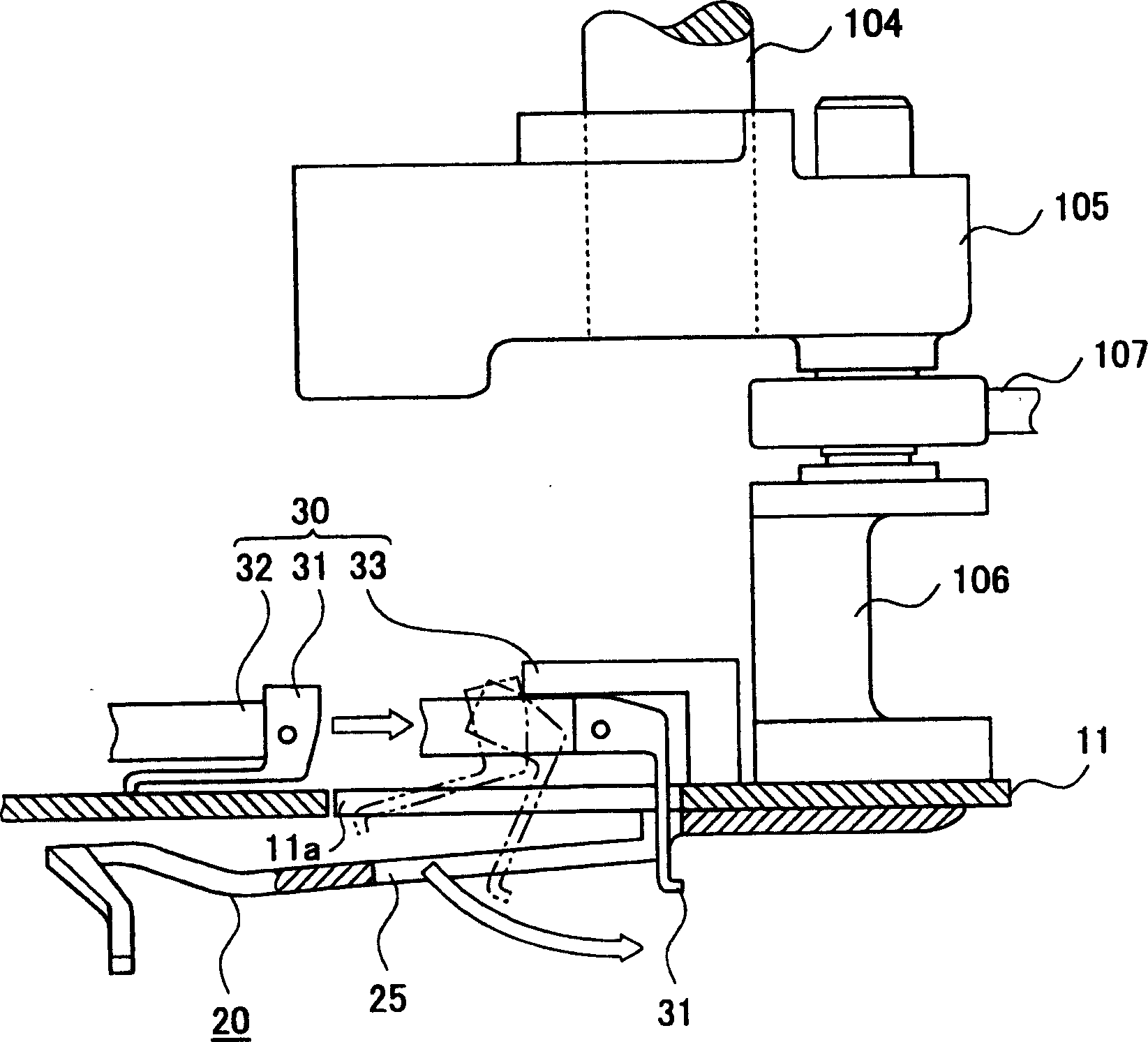

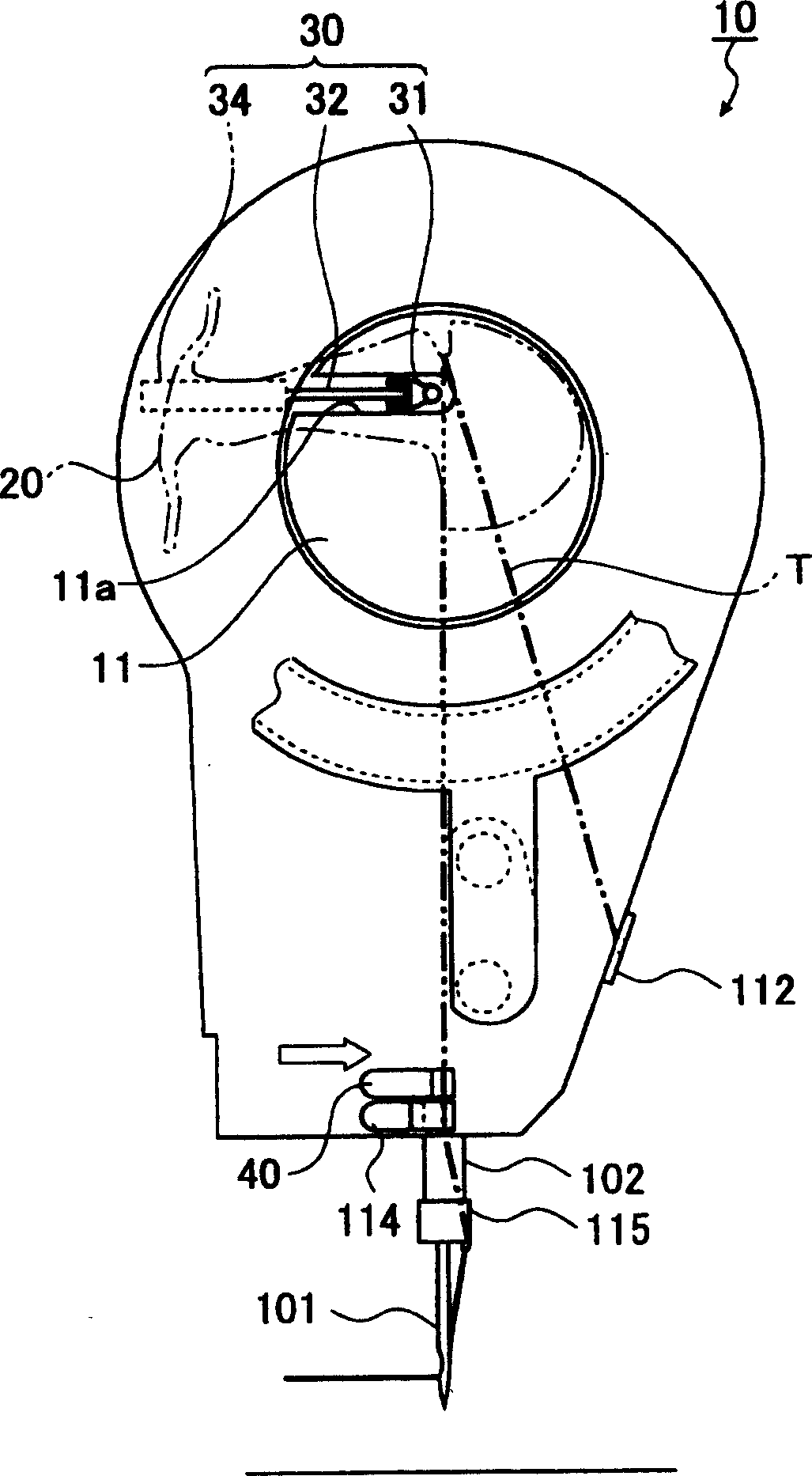

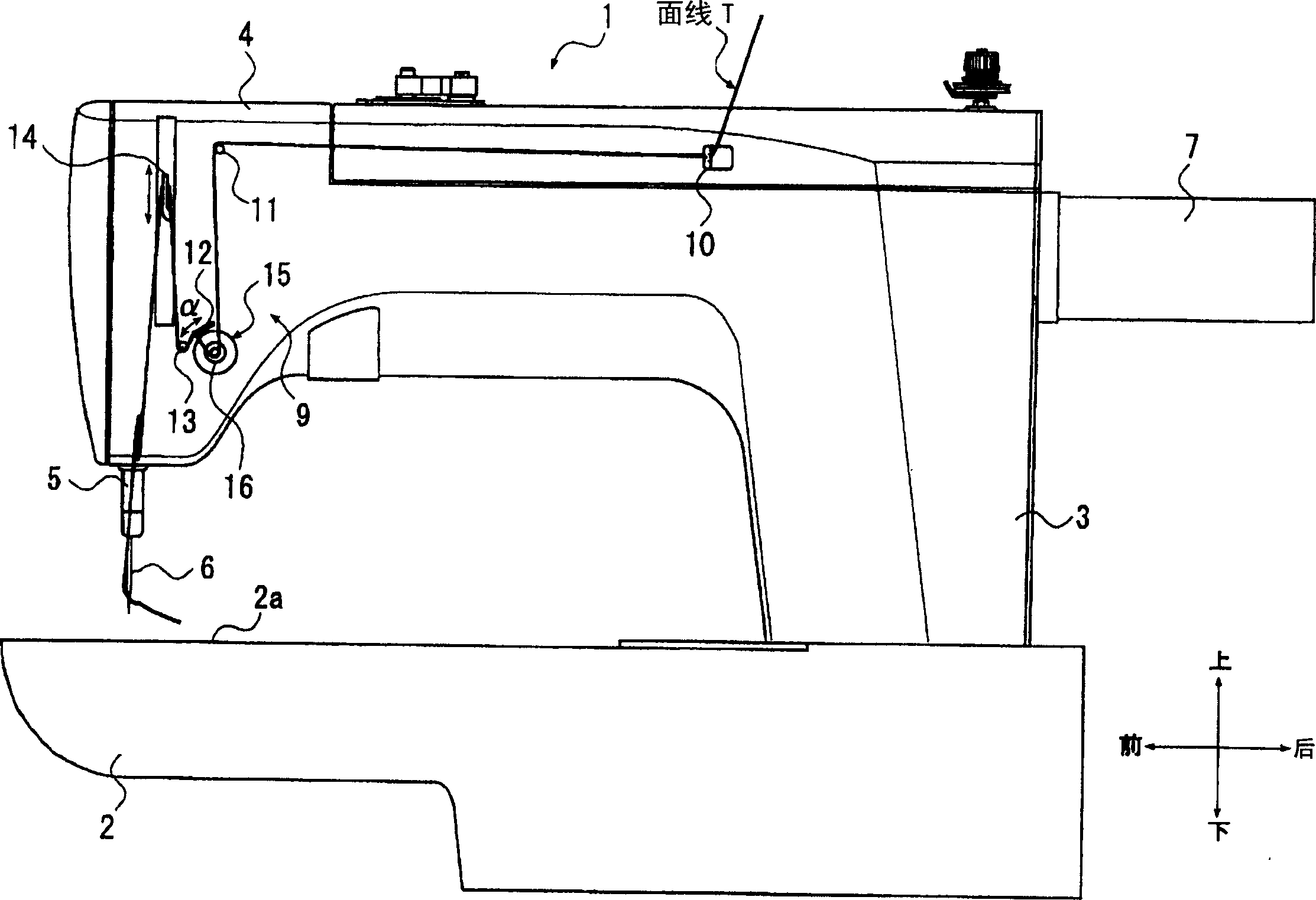

Sewing machine

InactiveCN1607285APrevent movementAbundant supplyProgramme-controlled sewing machinesSewing-machine control devicesSewing needleBiomedical engineering

PROBLEM TO BE SOLVED: To suppress the dropping of a needle thread from a sewing needle at the time of the starting of sewing. SOLUTION: This sewing machine 10 is equipped with a rotary needle thread take up member 20 which is arranged on the upstream side of the sewing needle 101 on a thread needle pathway, and at the same time, imparts a tension which periodically changes by the same cycle as the vertical movement of the sewing needle 101 to the needle thread. The rotary needle thread take up member 20 is equipped with a base section 21 which becomes the pivot side, and an arm section 22 which makes the needle thread T reciprocate in the longitudinal direction by rotating as it remains spanned with the needle thread T. A recess section 23 in which the needle thread T drops from the needle take up upper dead point position 26 of the needle thread T is provided on the arm section 22. The rotary needle thread take up member 20 is constituted by having a needle thread position changing means 30 which moves the needle thread T to the recess section 23 before a first stitch is formed. COPYRIGHT: (C)2005,JPO&NCIPI

Owner:JUKI CORP

Two-needle sewing machine

ActiveCN107574590AAvoid pollutionNeedle severing devicesTake-up devicesNeedle positionBiomedical engineering

The invention discloses a two-needle sewing machine, which comprises a clamping component (2) capable of adjusting position according to a needle position so as to clamp a sewing thread end and a linehooking component (1) capable of adjusting position according to the needle position and matching with the clamping component (2) to clamp the sewing thread end. The two-needle sewing machine furthercomprises a line cutter (33) for cutting off the sewing thread end. The line hooking component and the clamping component in the two-needle sewing machine can adjust position according to the sewingmachine; the sewing thread end can be hooked and clamped at different needle positions, and then the sewing thread end is cut off through the line cutter, thus the sewing thread end of the two-needlesewing machine is sheared and shortened, and the appearance of the bird's nest is avoided.

Owner:JACK SEWING MASCH CO LTD

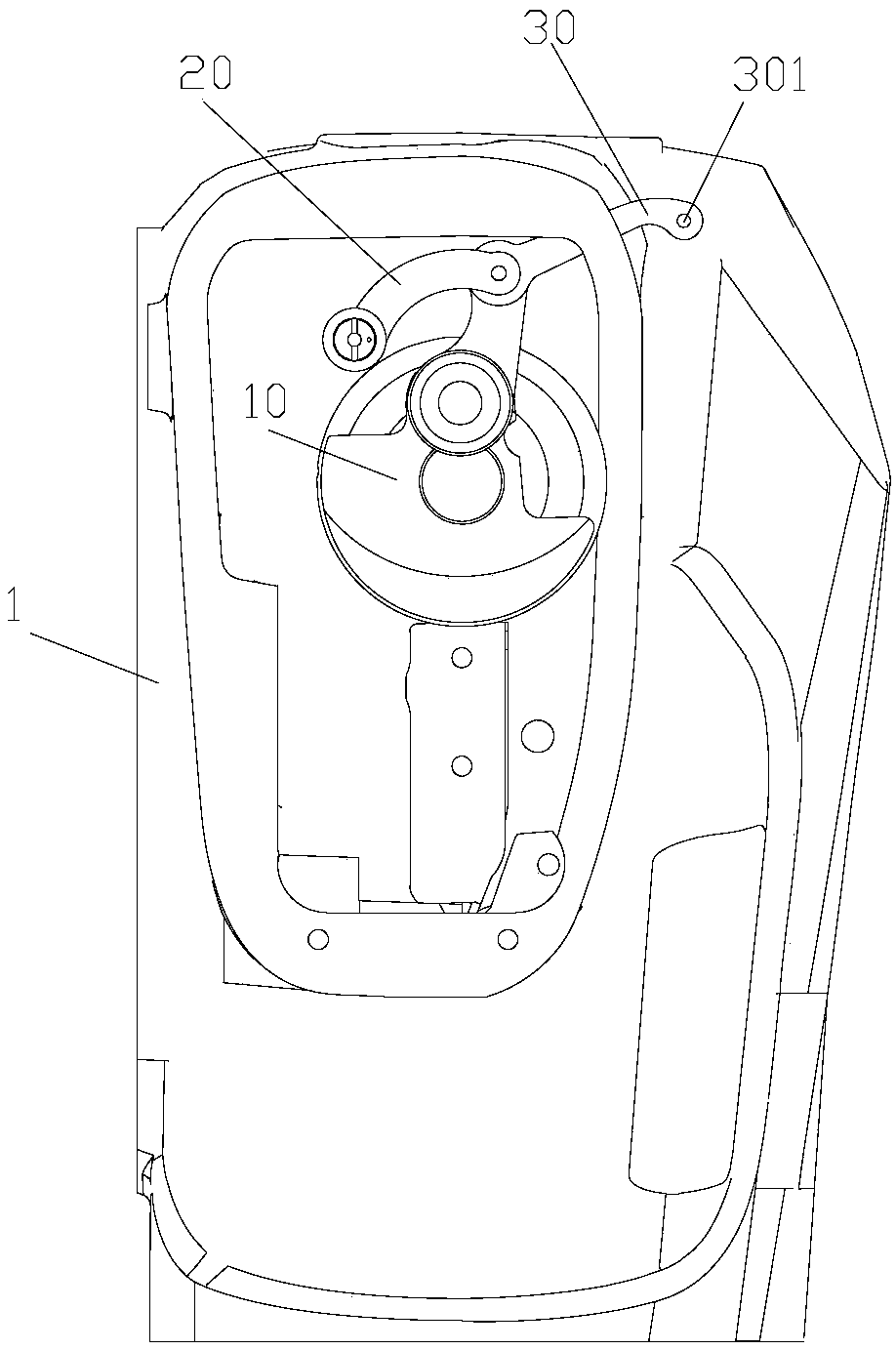

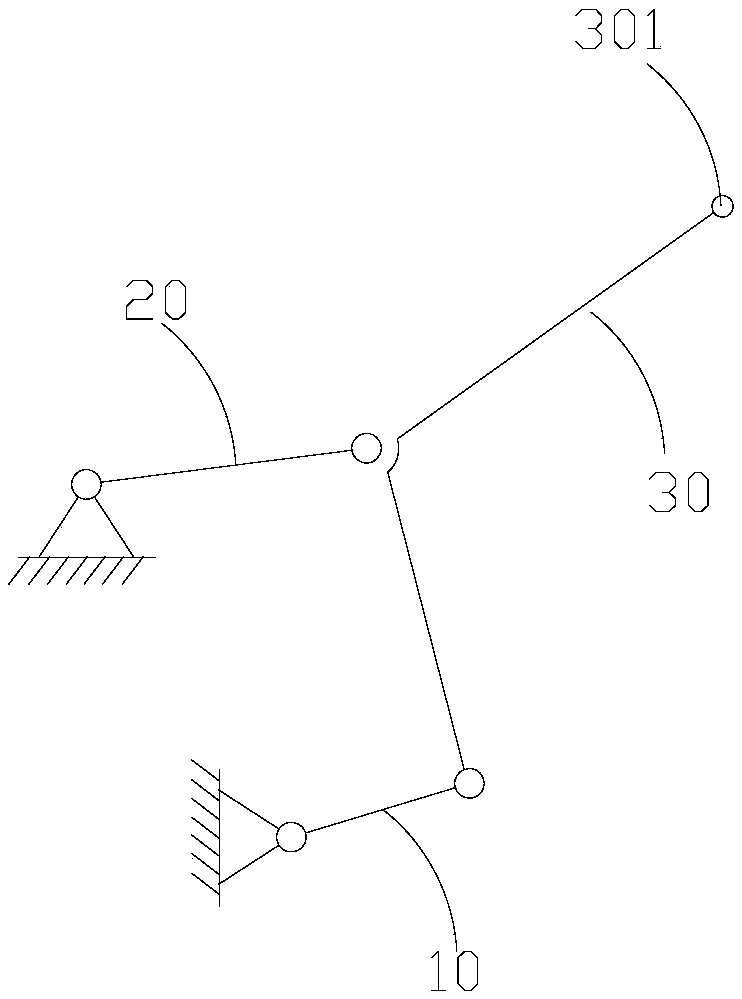

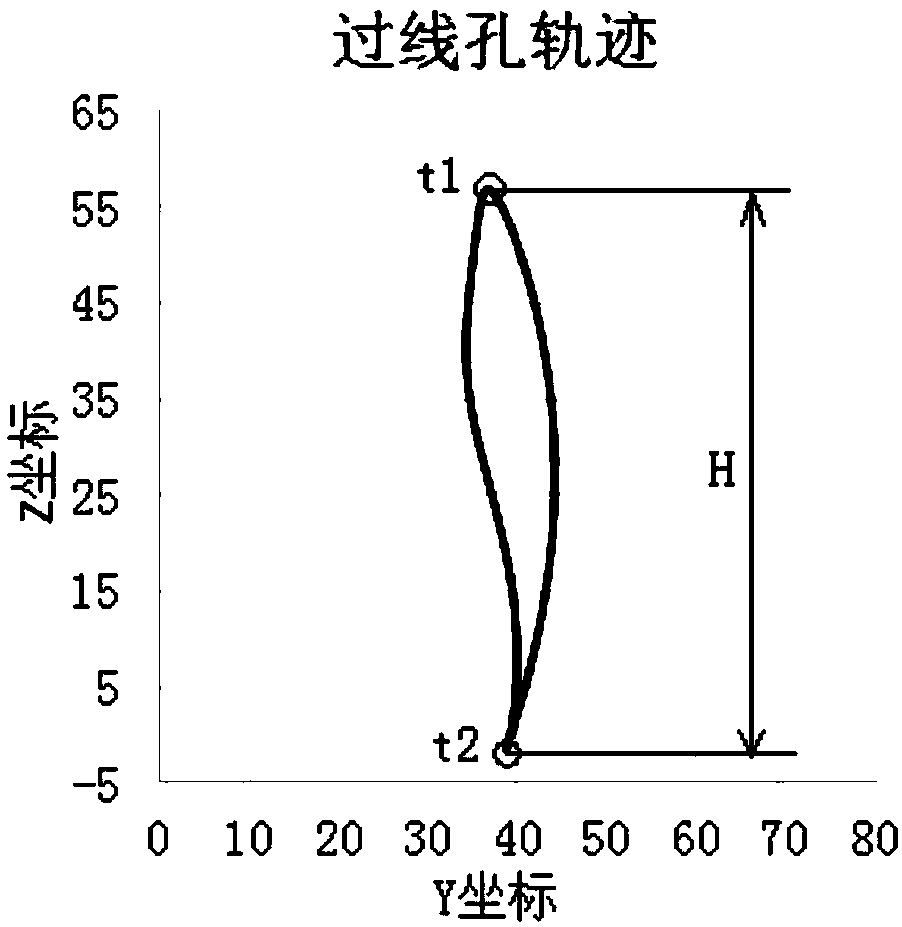

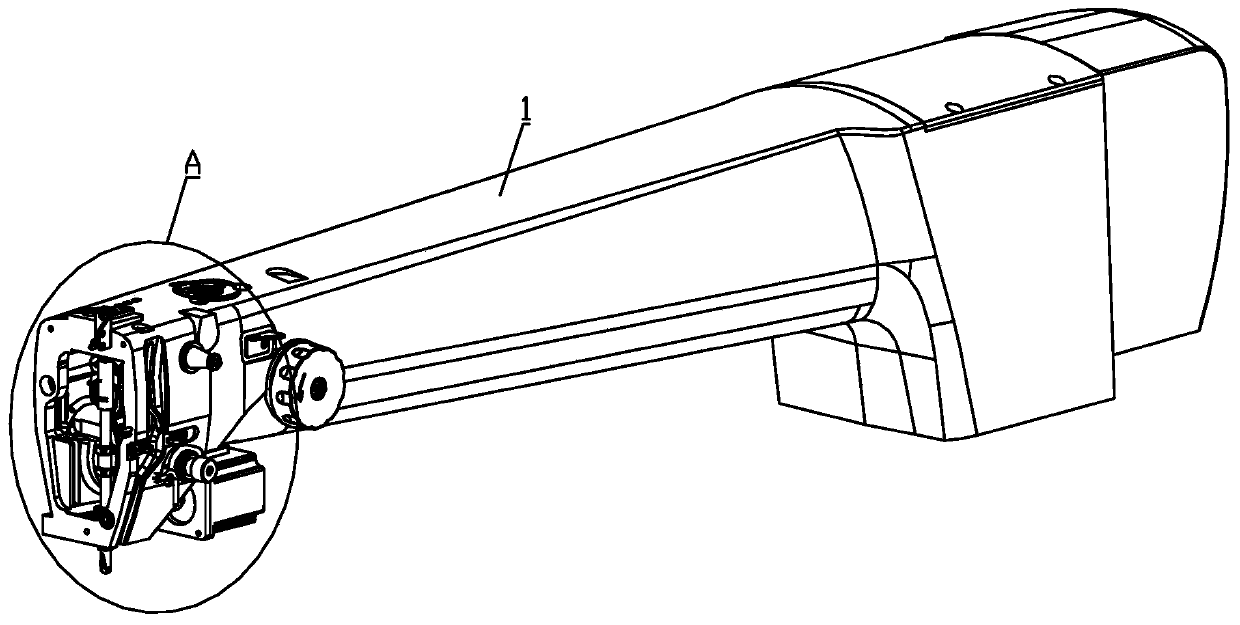

Thread take-up mechanism for sewing machine and sewing machine

InactiveCN109402885AChange the stroke of the upper holeChange swingTake-up devicesSewing machineEngineering

The invention provides a thread take-up mechanism for a sewing machine and the sewing machine. The thread take-up mechanism comprises a thread take-up rod, a connecting rod assembly and a fixedly arranged driving member, wherein the thread take-up rod is a bent member, the bent portion of the bent member is rotationally arranged, one end of the thread take-up rod is provided with a thread guide hole, one end of the connecting rod assembly is connected with the driving member, the other end of the connecting rod assembly is connected with the other end of the thread take-up rod, the driving member drives the connecting rod assembly to reciprocate between two states, the thread guide hole of the thread take-up rod is located at the lowest point in the first state, and the thread guide hole of the thread take-up rod is located at the highest point in the second state. The thread take-up mechanism for the sewing machine and the sewing machine have the advantages that by changing the swinging scope of the driving member, the stroke of the thread guide hole in the thread take-up rod can be changed, or the thread take-up moment is changed when the stroke of the thread guide hole in the thread take-up rod does not change, so that the thread take-up mechanism adapts to sewing of sewing materials of different thicknesses, and the amount of thread take-up can be adjusted according to different rotating shuttles.

Owner:JACK SEWING MASCH CO LTD

Needle bar rotating type template machine

The invention relates to the technical field of sewers, in particular to a needle bar rotating type template machine. The needle bar rotating type template machine comprises a needle bar, wherein an upper shaft, a thread picking assembly and a cloth needling assembly are arranged on one side of the needle bar, the thread picking assembly and the cloth needling assembly are both arranged on the upper shaft, the upper shaft is driven by a first power part to rotate and drives the thread picking assembly and the cloth needling assembly to synchronously execute the thread picking action and the cloth needling action. The thread picking assembly and the cloth needling assembly are arranged on the same upper shaft and both located on one side of the needle bar, so that the height of a machine heat is not required to be increased because of the thread picking assembly, and the needle bar rotating type template machine has the advantage of being simple in structure. Besides, the thread pickingassembly and the cloth needling assembly perform coaxial output, so that the stable and good synchronous relation can be kept between the thread picking assembly and the cloth needling assembly, theproblem of trouble in adjustment of the synchronous relation between the thread picking assembly and the cloth needling assembly is solved, and the reliability and stability of action of the assemblies are better.

Owner:BULLMER ELECTROMECHANICAL TECH

Sewing machines

InactiveCN1439758AStable residual lengthQuality improvementProgramme-controlled sewing machinesSewing-machine casingsBobbinEngineering

The patent relates to a sewing machine 1 in which a needle thread loop 101 is formed by the co-operation of a needle 6 and a semi-rotating shuttle to perform lock stitch. This sewing machine 1 includes a needle thread take-up lever 14 for taking up the needle thread loop 101, a main shaft motor 7 for driving the needle 6 and the needle thread take-up lever 14, a fixed knife 27 fixed in the vicinity of the semi-rotating shuttle, a movable knife 28 capable of freely approaching and separating from the fixed knife 27, a pulse motor 21 for driving the movable knife 28, and a control device 8 for controlling the pulse motor 21 and the main shaft motor 7. The movable knife 28 is stopped immediately before the movable knife 28 meets the fixed knife 27 at the final stitch under the control of the control device 8, and then the needle thread take-up lever 14 is raised and stopped. After that, the movable knife 28 is moved to cut the needle thread and the bobbin thread with the fixed knife 27. The sewing machine is capable of stabilize the so-called remaining length of a needle thread without lengthening the time required for cutting the needle thread.

Owner:JUKI CORP

Trapping device of computerized seam plaining machine

InactiveCN101046037AReduce in quantityImprove aestheticsNeedle severing devicesTensioning devicesTrappingEngineering

The present invention belongs to the field of sewing machine technology, and is especially one kind of trapping device of computerized seam plaining machine. The trapping device includes a holding frame, a small trapping nut, a trapping unit, a right string, a take-up lever, a string, a left string, a needle and a sewing machine head. It features one string grip beside the trapping unit, and the string grip includes a string gripping head and its drive unit to drive the string gripping head to move left and right. The string from the small trapping nut passes through the string gripping head to the trapping unit. The present invention can reach stitch in good look.

Owner:JACK SEWING MASCH CO LTD

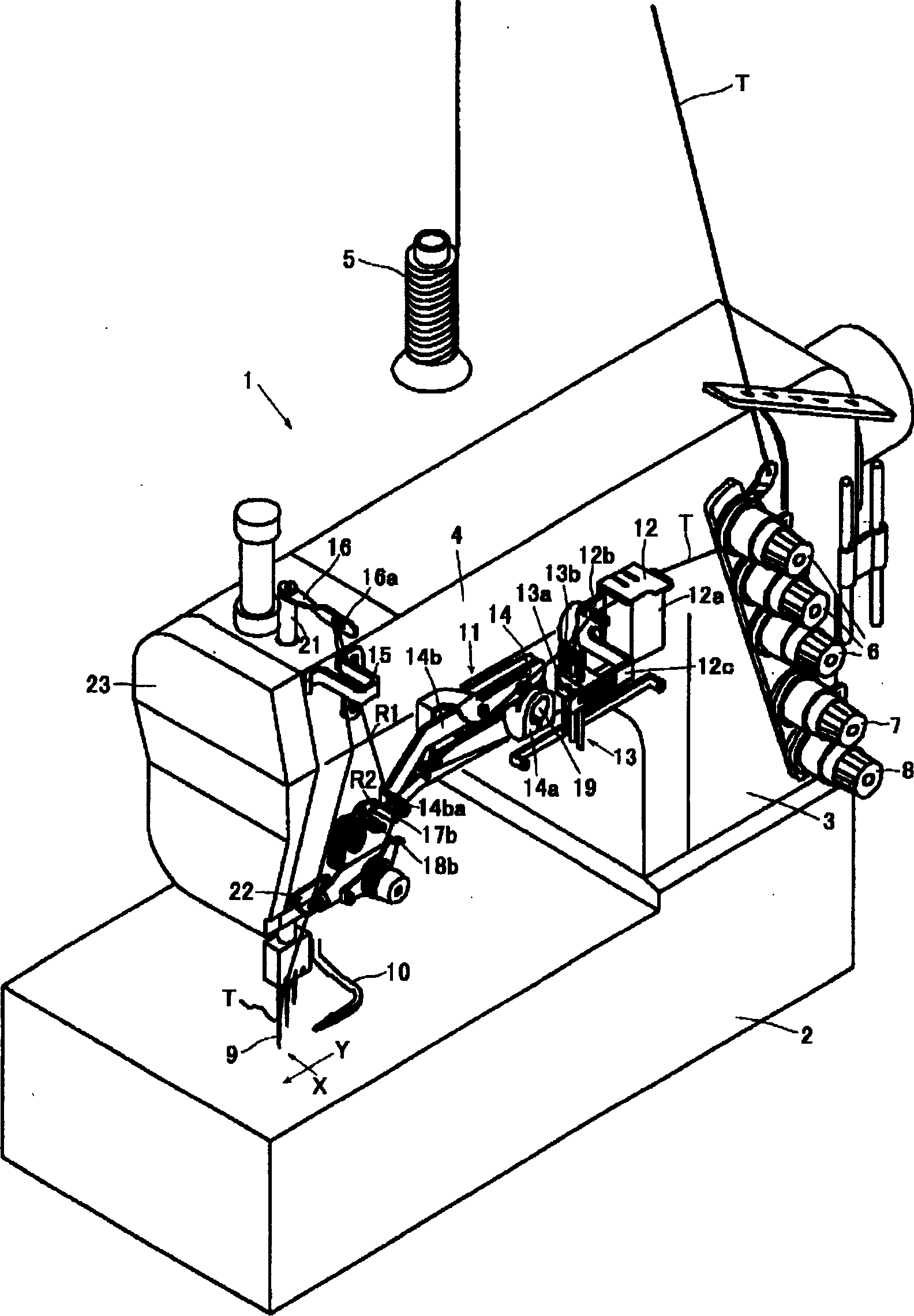

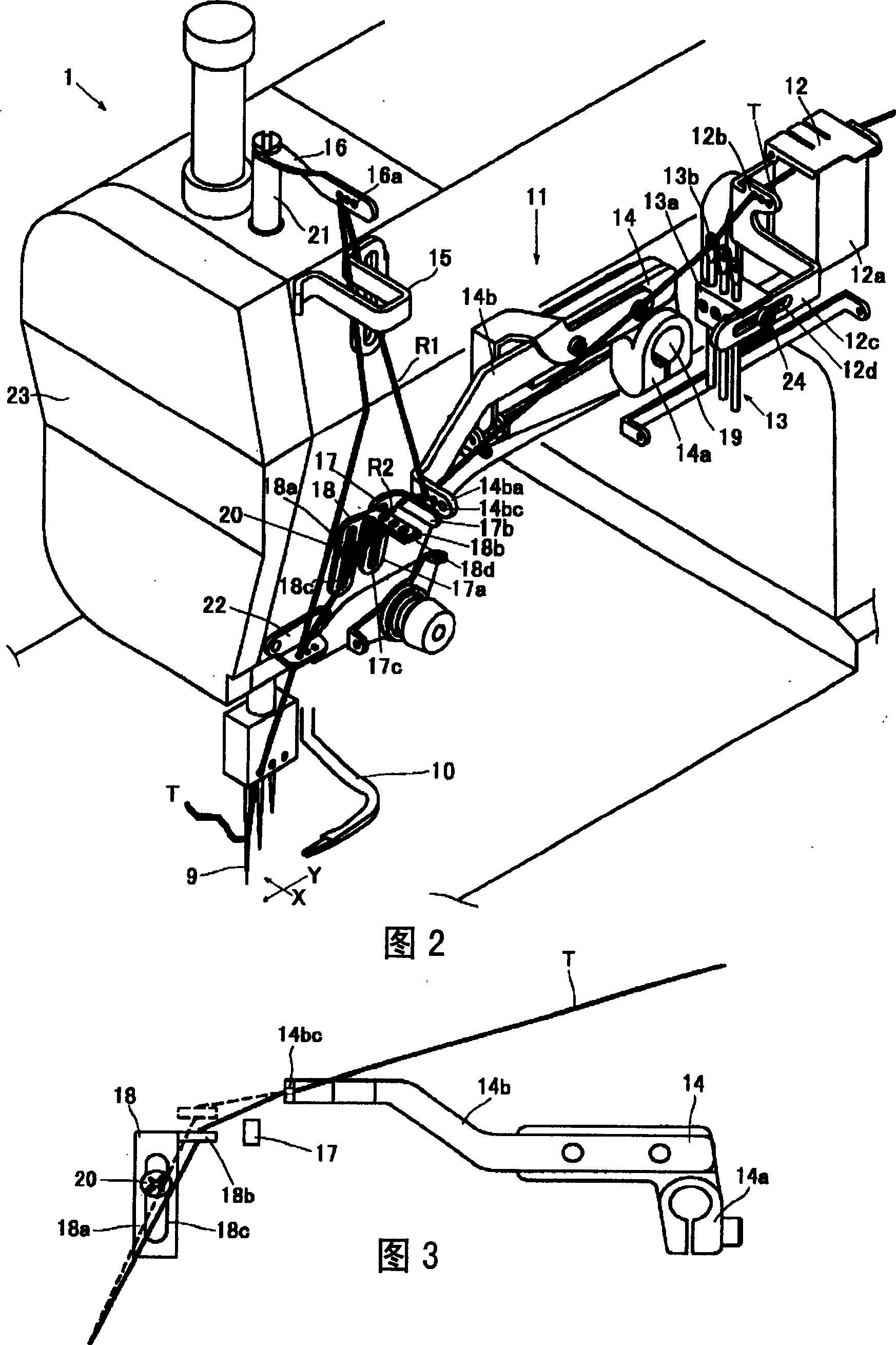

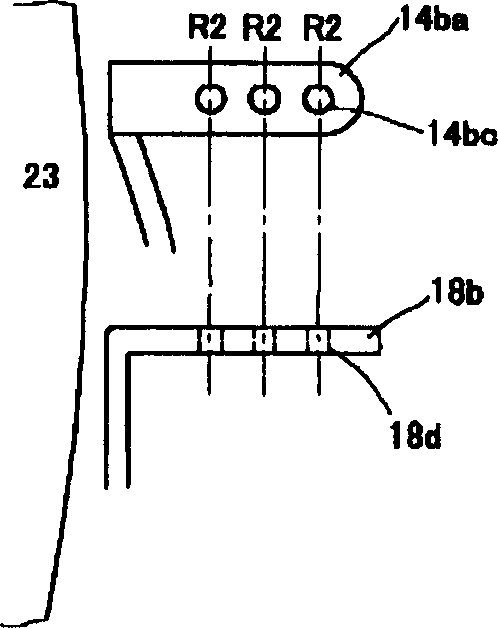

Take-up device for sewing machine

Provided is a thread feeding device of a sewing machine capable of selecting optimum thread-reeling-out control. In the thread feeding device of the sewing machine capable of selecting a first thread path R1 reaching a needle 9 through a swinging thread take-up lever 14 and a needle-bar take-up lever 16 from a bobbin 5 and a second thread path R2 reaching the needle 9 through the swinging take-up lever 14 from the bobbin 5, there is provided a swinging take-up lever thread receiver 17 arranged at the position separated from a thread-reeling hole 14bc of the swinging take-up lever 14 to the needle side, and a needle thread T selecting the second thread path is disposed can be engaged with the receiver 14.

Owner:JUKI CORP

Anti-coiling mechanism of sewing machine

ActiveCN102182018AAvoid entanglementPrevent wire breakageNeedle severing devicesTake-up devicesEngineeringSewing machine

The invention discloses an anti-coiling mechanism of a sewing machine. The mechanism comprises a needle rod connecting rod and a thread take-up lever which are arranged on a left rotation shaft and a right rotation shaft at the left end and the right end of a crank, wherein the crank comprises a round disc, a left rotation shaft and a right rotation shaft; the left rotation shaft and the right rotation shaft are eccentrically arranged on the round disc; the needle rod connecting rod and the thread take-up lever are sleeved on the left rotation shaft and the right rotation shaft through a bearing respectively; a sheath extending rightwards is arranged along the outer peripheral face of the right end face of the round disc; an arc convex block extending leftwards is arranged along the outerperipheral face of the left end face of the round disc; an arc through groove is formed along the peripheral direction of the disc on the convex block; and a rightwards convex blade is arranged on the needle rod connecting rod. When the crank rotates one circle, the blade passes through the arc through groove. When broken threads are wound on the outer peripheral face of the crank, along with therotation of the crank, the blade passes through the arc through groove on the crank and cuts off the broken threads wound on the outer peripheral face of the crank, so that the phenomenon that the broken threads are wound in a clearance between the left end face of the round disc and the right end face of the needle rod connecting rod is avoided.

Owner:四川精上缝纫机有限公司

Sewing machine

The invention provides a sewing machine preventing the suture curling to the needle bar crankshaft and the connection portion between the needle bar crankshafts and preventing the burning of the connection portion in advance. The sewing machine has an upper shaft, a balance weight, a needle bar crankshaft, a needle bar crankshaft bar, a libra crankshaft and a libra. The needle bar crankshaft has a first convex portion projecting to the side of needle bar crankshaft bar. The needle bar crankshaft bar has a second convex portion projecting to the side of the needle bar crankshaft. The front endportion of the second convex portion projects more to the side of the needle bar crankshaft compared with the front end portion of the first convex portion. The distance from the rotation center of the connection portion of the needle bar crankshaft bar and the needle bar crankshaft to the second convex portion is short than the distance between the rotation center and the first convex portion.

Owner:JUKI CORP

Sewing machine

InactiveUS6981459B2Operation efficiency can be improvedSimple engagementSewing-machine casingsFilament handlingBobbinEngineering

A sewing machine includes a thread take-up lever and a thread tension regulator each disposed along a predetermined needle thread passage from a thread bobbin to a needle, an arm having a front face, and a movable controller disposed in the front of the arm so as to be movable at least within a predetermined range. The movable controller does not protrude out of the front face of the arm when moved in the predetermined range. The needle thread is engaged with at least one of the thread take-up lever and the thread tension regulator when the movable controller is moved within the predetermined range while the needle thread has been drawn from the thread bobbin near to the needle substantially along the predetermined needle thread passage.

Owner:BROTHER KOGYO KK

Sewing machine

ActiveCN104005188AReduce foulingImprove reliabilitySewing-machine control devicesTensioning devicesSewing needleBiomedical engineering

The invention provides a sewing machine which can make needle poles smoothly switched. The sewing machine comprises two needle poles respectively maintaining a sewing needle on the lower end part; a needle pole base supporting the needle poles in a vertically moving way; a sewing needle vertical movement mechanism exerting vertical movemention motion on each needle pole through a needle pole retaining part; needle pole stopping mechanisms respectively arranged relative to each needle pole and switching between a needle pole retaining state realized through the needle pole base and a needle pole retaining state realized through the needle pole retaining part; a stopping selecting mechanism inputting two retaining state switches according to each needle pole stopping mechanism; and a switch driving mechanism selecting an applied needle pole during a sewing process through the needle pole base. The needle pole base can make the two needle poles supported on a sewing machine frame in a way that the lower end parts of the two needle poles swing. Swing motion is exerted on the needle pole base through a switch of driving mechanism. One needle pole is thus selected from the two needle pole for a sewing purpose.

Owner:JUKI CORP

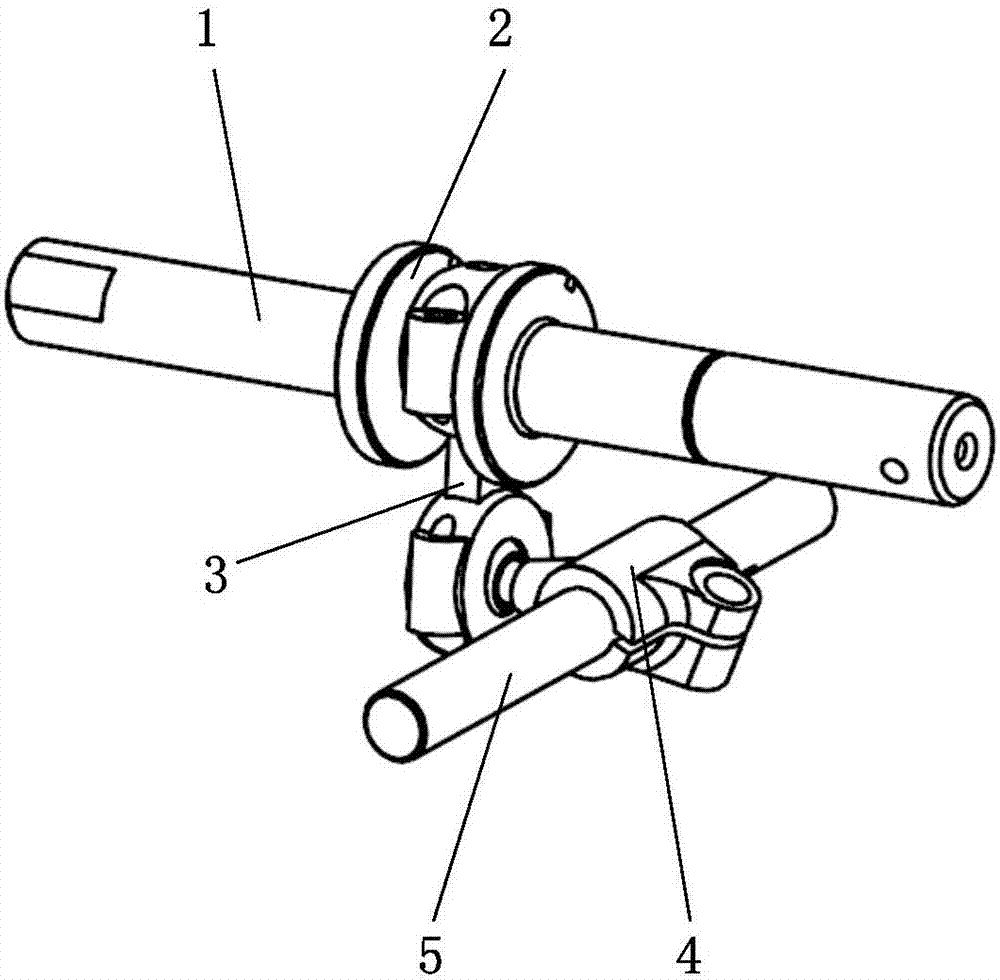

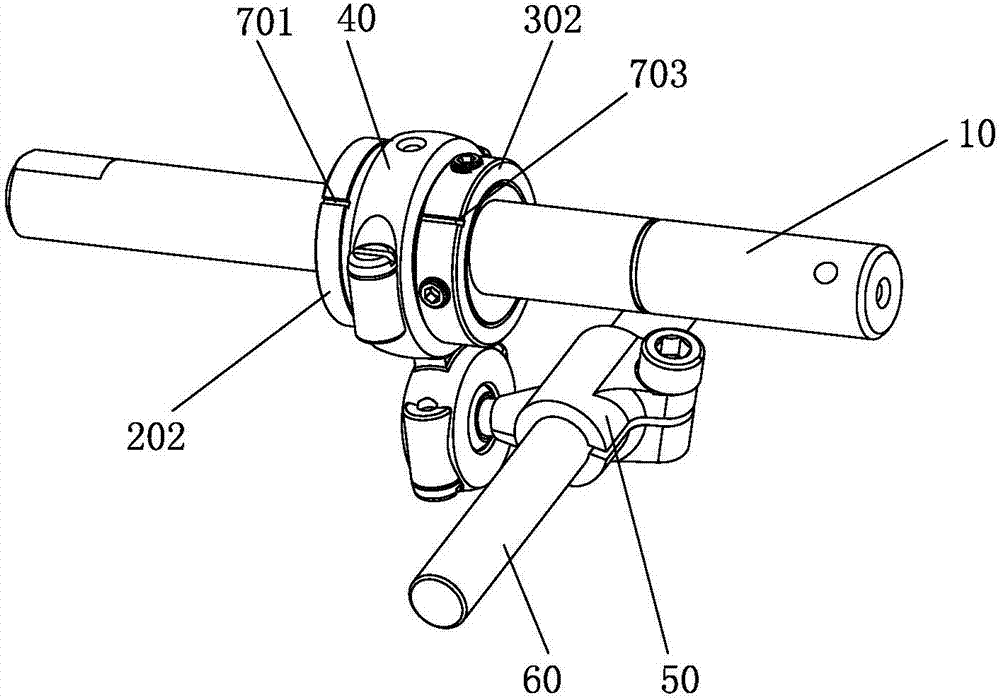

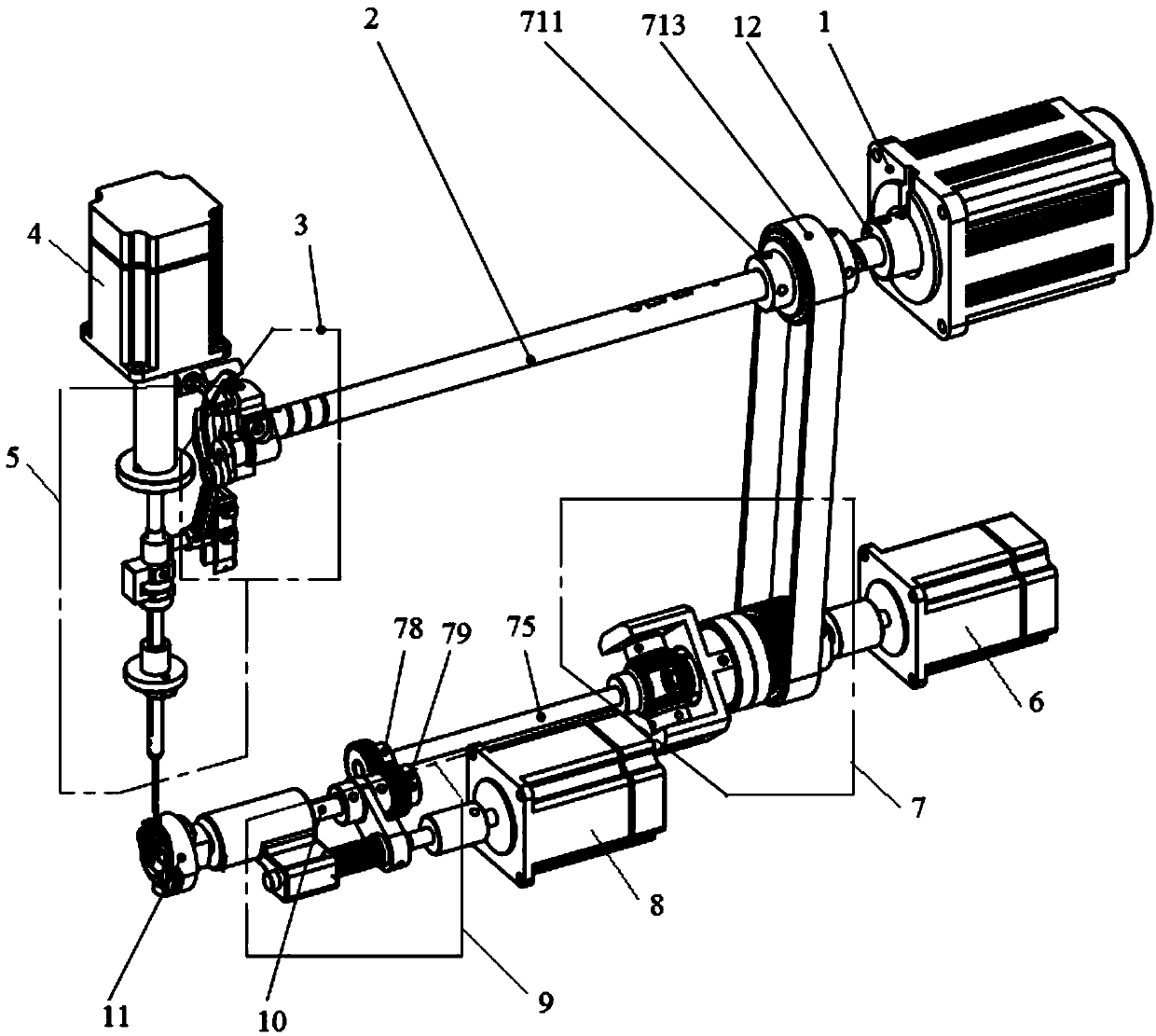

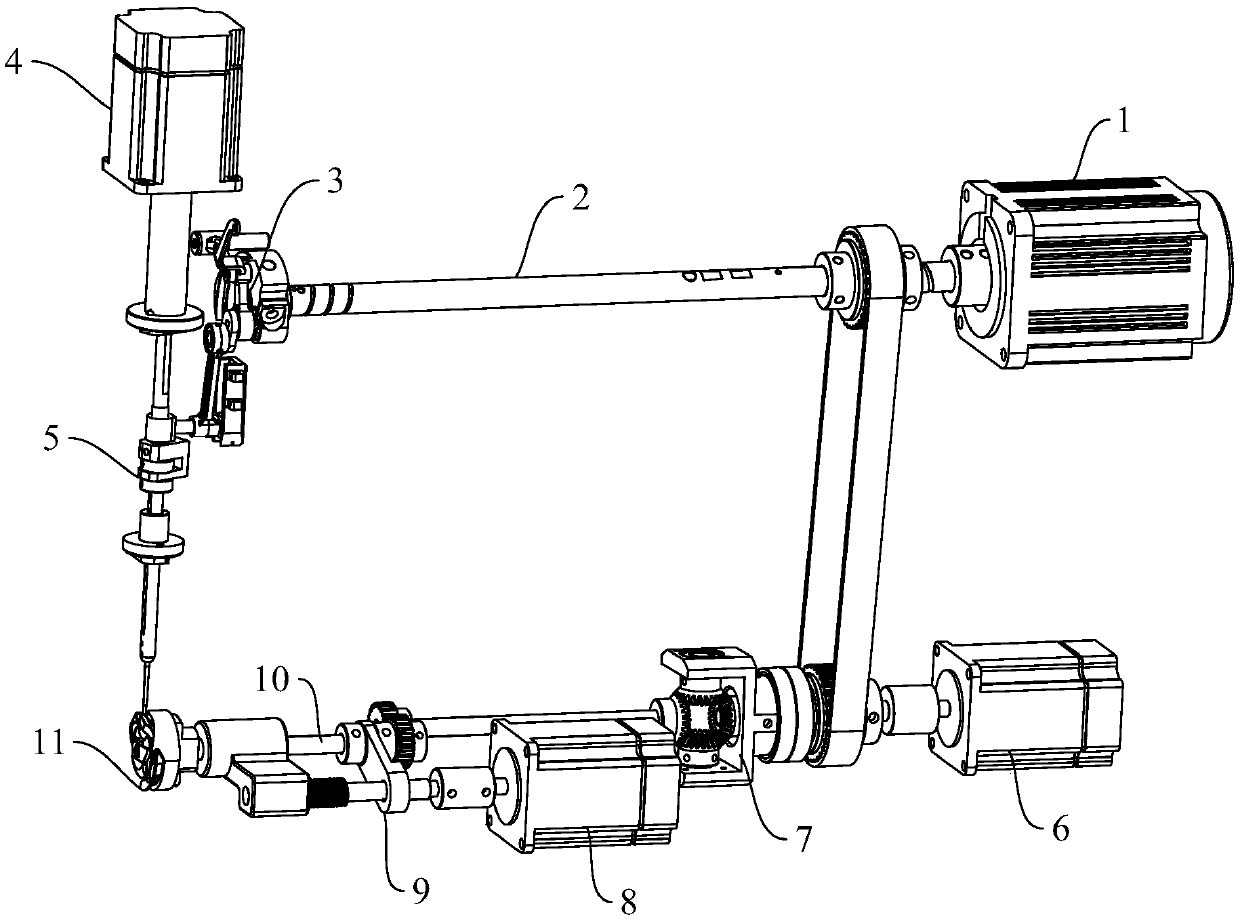

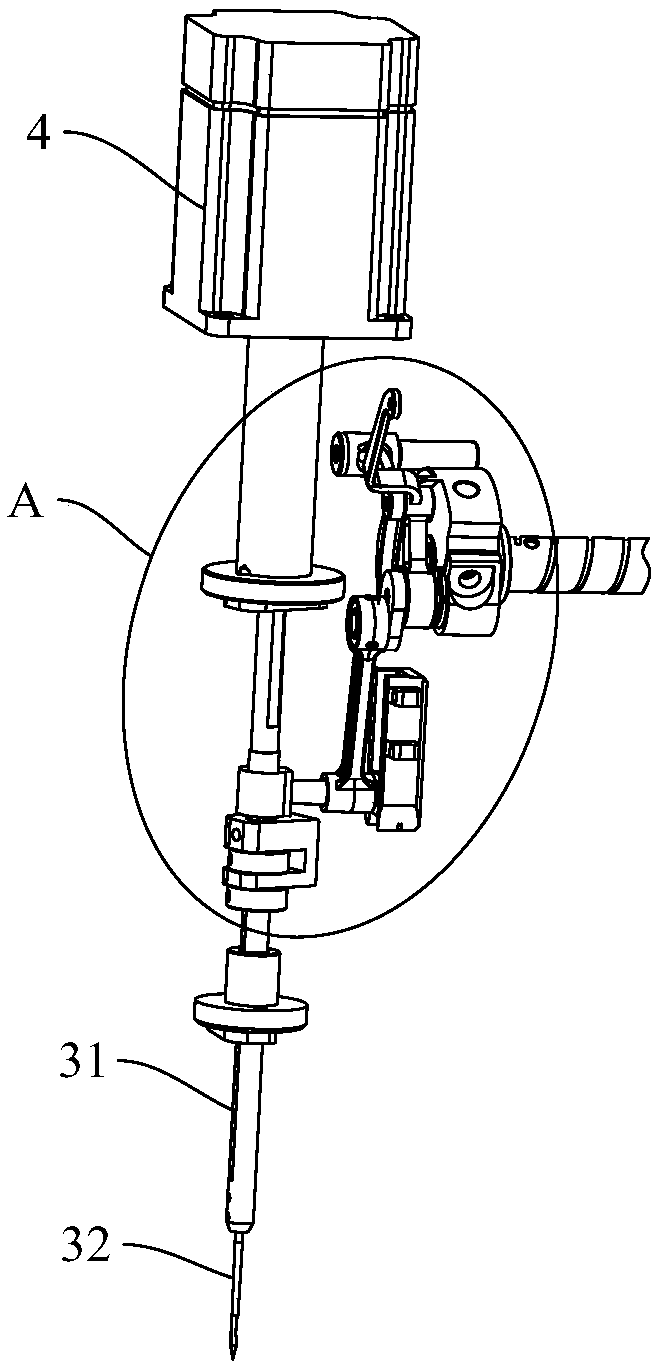

Needle and shuttle cooperation automatic adjustment mechanism and sewing machine

ActiveCN111118758ARealize automatic adjustmentImprove debugging efficiencyTake-up devicesNeedle barsElectric machineryControl theory

The present invention provides a needle and shuttle cooperation automatic adjustment mechanism. The needle and shuttle cooperation automatic adjustment mechanism comprises a main motor, an upper shaft, a needle driving and thread take-up assembly with a needle rod and a frame needle, a lower shaft, a rotating shuttle, a needle rod height adjustment driving source, a rotating shuttle angle adjustment driving source, a rotating shuttle position adjustment driving source, a needle rod height adjustment mechanism connected between the needle rod height adjustment driving source and the needle rod,a rotating shuttle angle adjustment mechanism connected between the rotating shuttle angle adjustment driving source and the lower shaft, and a rotating shuttle position adjustment mechanism connected between the rotating shuttle position adjustment driving source and the lower shaft, wherein the needle rod height adjustment driving source drives the needle rod to move in the vertical direction through the needle rod height adjusting mechanism; the rotating shuttle angle adjustment driving source drives the lower shaft to rotate around the self axis through the rotating shuttle angle adjusting mechanism; and the rotating shuttle position adjustment driving source drives the lower shaft to move in the self axial direction through the rotating shuttle position adjusting mechanism. The height of the needle rod, the angle of the rotating shuttle and the left-right position of the rotating shuttle can be automatically adjusted, so that the debugging efficiency and the debugging accuracy ofneedle and shuttle cooperation are improved.

Owner:BULLMER ELECTROMECHANICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com